Spraying type evaporator

An evaporator and spray-type technology, applied in the field of spray-type evaporators, can solve problems such as difficulty in liquid separation, reduced operating efficiency of the evaporator, unsatisfactory distribution effect, etc. The effect of thermal temperature difference and heat exchange efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

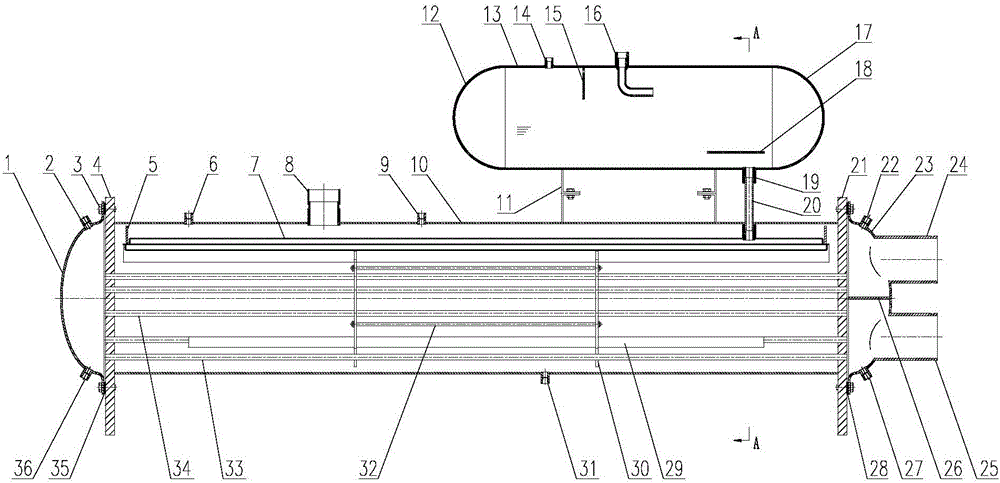

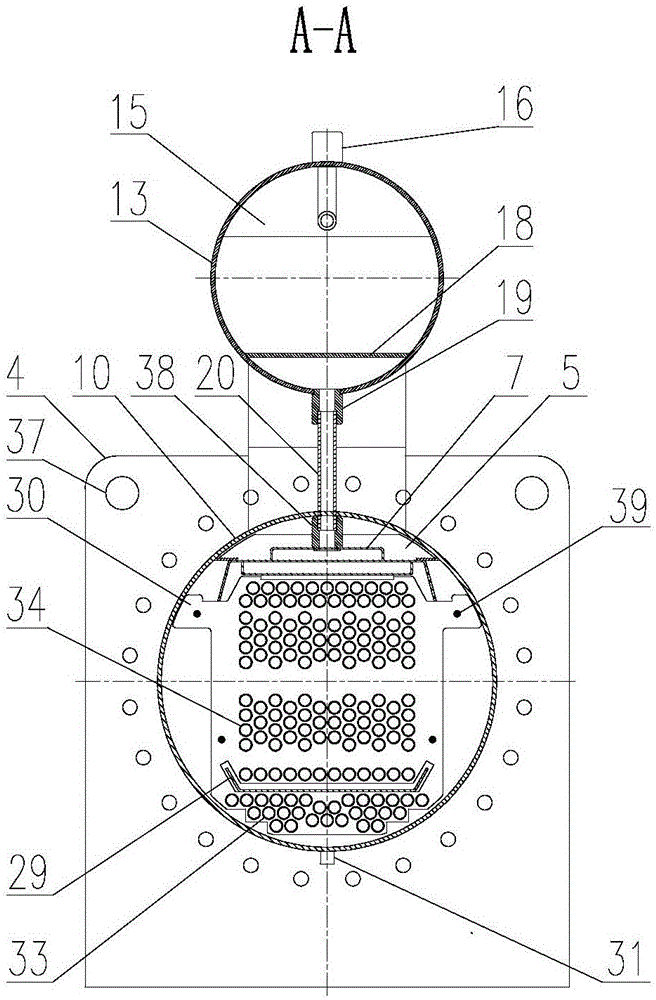

[0030] Example 1: A spray evaporator, such as figure 1 As shown: it includes a heat exchanger and a gas-liquid separator. The gas-liquid separator is fixedly connected to the heat exchanger through a connecting bracket 11 and communicated with the inner space of the heat exchanger through a connecting pipe 20 .

[0031] The gas-liquid separator includes a housing 13, a liquid inlet connecting pipe 16 arranged on the upper part of the housing 13, a gas return connecting pipe 14 and a joint seat 19 arranged at the bottom of the housing 13:

[0032] The two ends of the shell 13 are respectively sealed by the first head 12 and the second head 17, the liquid inlet connecting pipe 16 is a curved pipe, one end protrudes from the shell 13 to receive refrigerant, and the other end extends into the shell 13 inside, and bend to the opposite direction of the air return port connection 14; between the liquid inlet connection 16 and the air return port connection 14, a partition 15 matchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com