Device for uniformly distributing liquid by using dry evaporator and use method thereof

A dry evaporator and liquid separation technology, applied in the direction of evaporator/condenser, heat exchanger shell, refrigeration and liquefaction, etc., can solve the problems of reduced heat transfer performance, uneconomical, high processing cost, improve energy efficiency and Heat transfer performance, easy production and installation, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

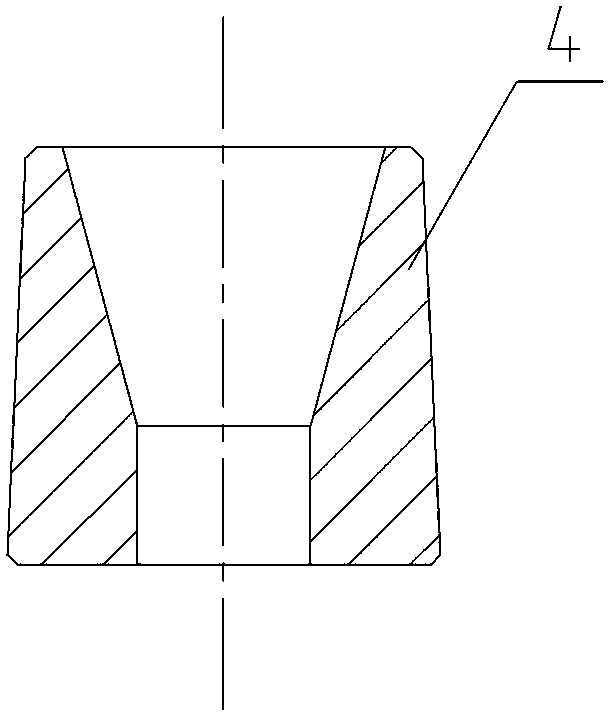

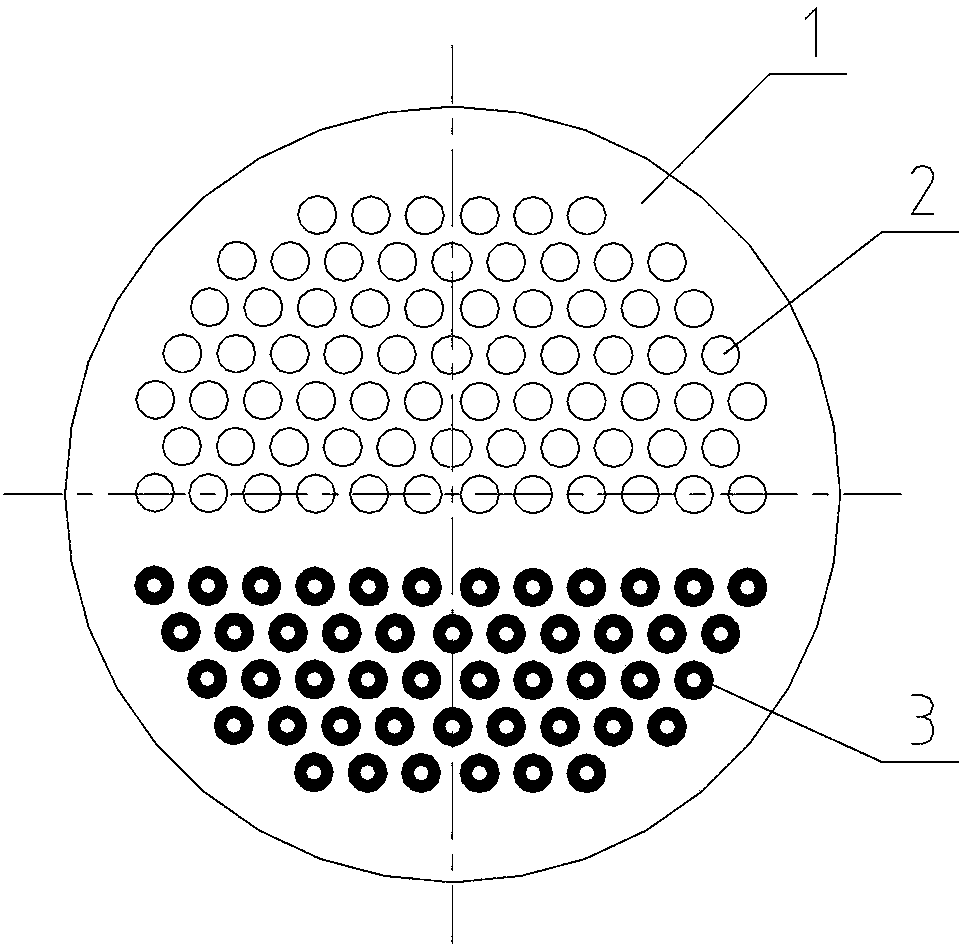

[0014] This embodiment is a dry-type evaporator liquid distribution and uniform distribution device used in the process of refrigeration and air conditioning. It is composed of a liquid distribution uniform distribution device 4 and associated tube sheets 1 and evaporator tube bundles 2. The liquid separation Distributor 4 is an upper, smaller, lower, and large circular platform with a basin-shaped conical hole and a connected cylindrical hole inside the axial section. The height of the cone is 12mm, the outer diameter of the small end of the cone is φ12.3mm, and the cone angle of the cone is 2.5°; the taper angle of the basin-shaped conical hole is 15°, the diameter of the cylindrical hole is φ4mm, and the depth is 4mm. figure 1 , 2 The given structure is installed, wherein: insert the small end of the liquid distributor 4 into the first process of the split tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com