Method for manufacturing tobacco sheet taking substrate as carrier through dry paper making method

A technology for dry papermaking and tobacco sheet, which is applied in the preparation of tobacco, tobacco, and applications, can solve the problems of high drying energy consumption, insufficient stretching resistance, large investment scale, etc. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

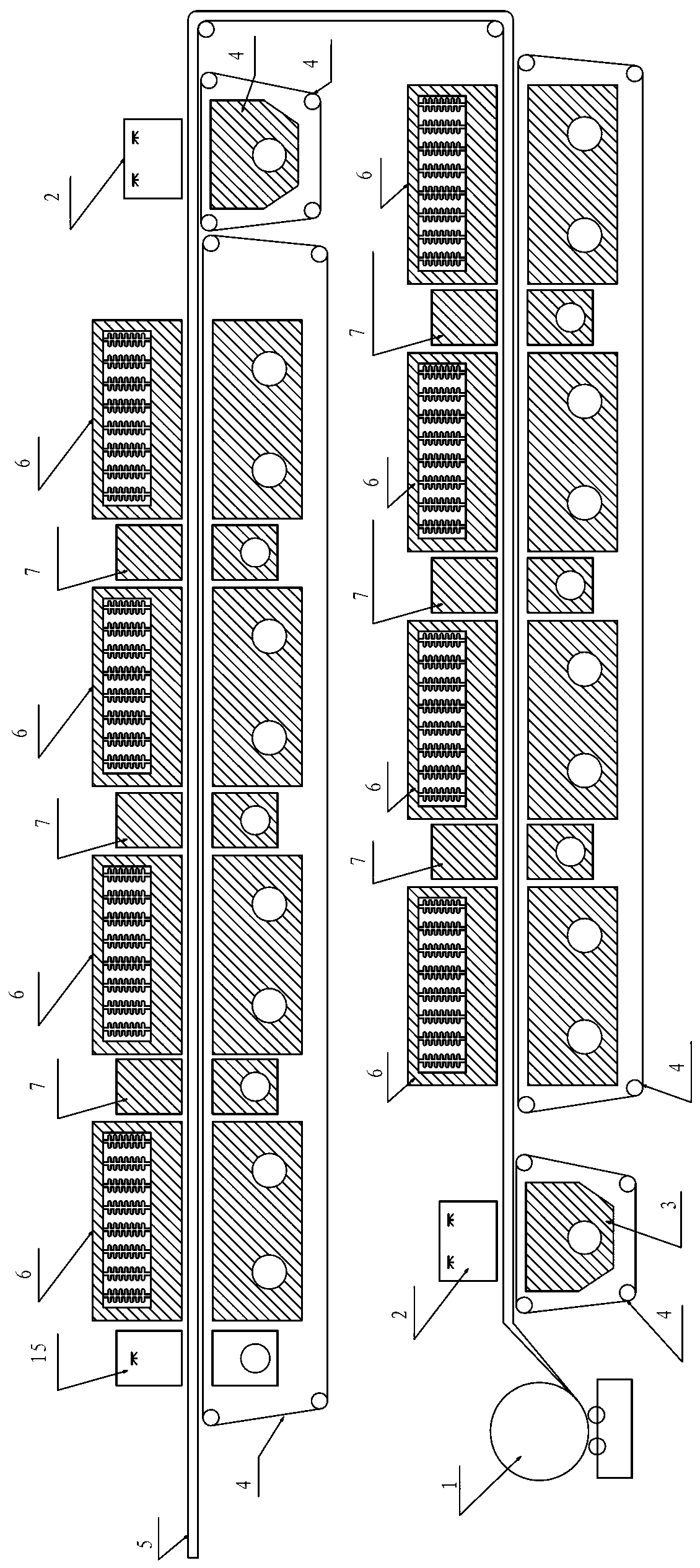

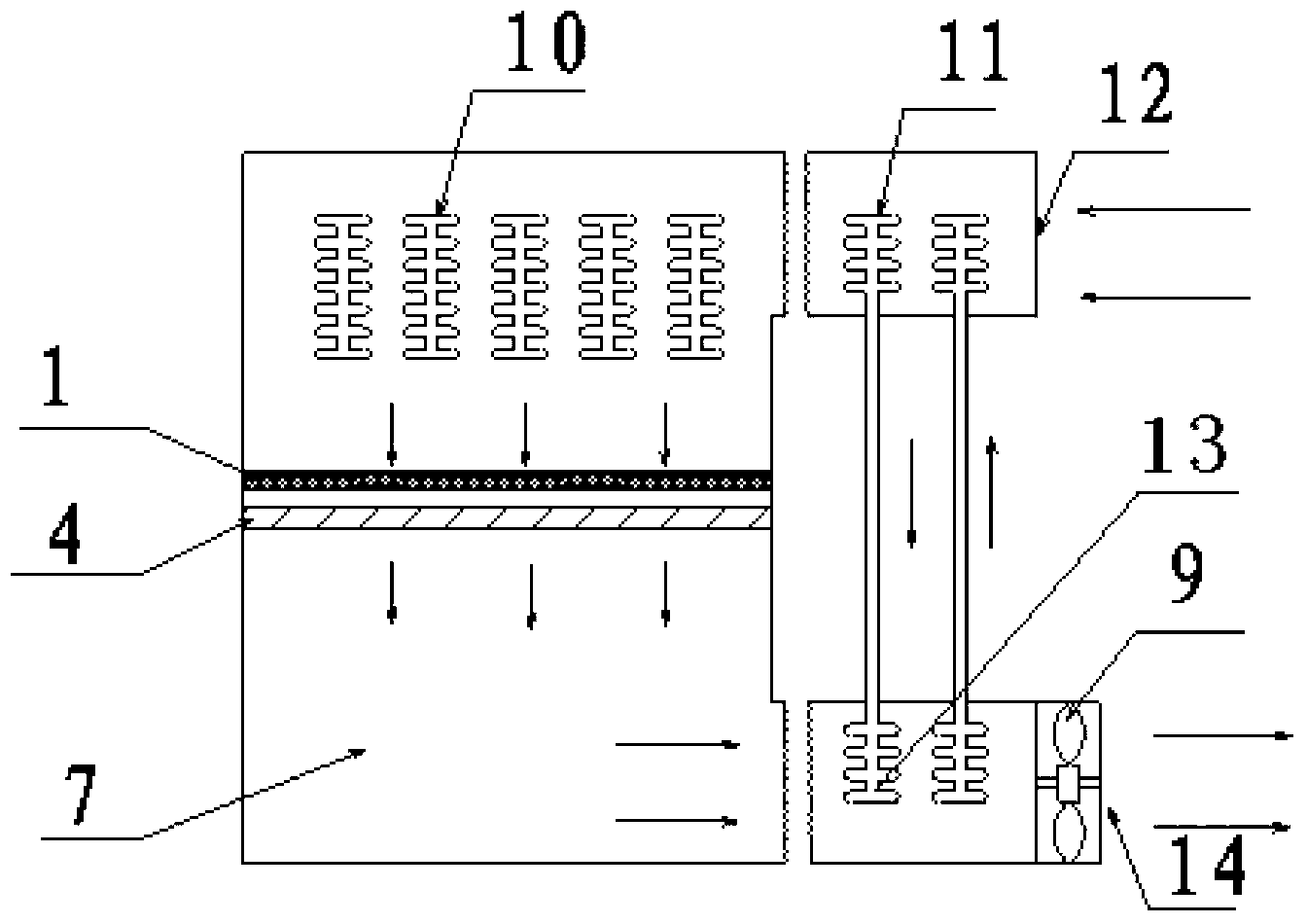

Embodiment 1

[0093]After the wood pulp paddle board is crushed and defibrated into short fibers, it is stored in the storage tank. The length of a single fiber is 2-8mm. While removing the static electricity, the negative pressure generated by the vacuum box 28 makes the fibers form a fluffy, disorderly and staggered short thin layer on the forming wire 26 through the air-laid method. Then spray the glue to the surface of the substrate. When spraying, use the compressed air to fully atomize the liquid containing the adhesive, spray it on the surface of the substrate, and at the same time suck the negative pressure on the back of the sprayed surface. 2% of the mass (the mass ratio of the adhesive is: chitosan 70%, carboxymethyl starch 15%, cyclodextrin 10%, carboxymethyl cellulose 5%), the substrate sprayed with glue is transported to the oven Drying, and then spray glue on the other side using the same process as above. The amount of adhesive sprayed accounts for 2% of the weight of the dr...

Embodiment 2

[0095] After the bamboo pulp paddle is defibrated into single fibers, it is stored in a storage tank with a fiber length of 2 mm to 5 mm. 10% of tobacco powder (fragments) is mixed into the storage tank, and the metering air is sent to the forming head box 25. While the static electricity is removed by the antistatic rope 27 and / or the antistatic net 29, the negative pressure generated by the vacuum box 28 makes the fibers form a fluffy and disorderly staggered short fiber thin film on the forming net 26 through the air-laid method. layer, and then spray the glue. When spraying, use compressed air to fully atomize the glue and spray it on the surface of the substrate. At the same time, negative pressure is sucked on the back of the sprayed surface. % (the mass ratio of the adhesive is: chitosan 50%, pullulan starch 20%, dextrin 10%, carboxymethyl cellulose 5%, glucomannan 15%), substrates sprayed with glue Dry in an oven, then spray glue on the other side of the substrate. The...

Embodiment 3

[0097] After the wood pulp board is defibrated into single fibers, it is stored in the storage tank, and 10% short tobacco stem fibers and 10% tobacco powder (fragments) are added to the storage tank at the same time. The fiber length is 2mm-5mm, and the metering The wind is sent to the forming head box 25, and while the antistatic effect is removed by the antistatic rope 27 and / or antistatic net 29, the negative pressure generated by the vacuum box 28 makes the fibers form fluffy on the forming net 26 through the air-laid method. Disorderly stacked non-structural strength substrates, and then spray a composite adhesive material liquid mixed with a material liquid that improves the quality of paper-based absorption. When spraying, use compressed air to fully atomize the composite material liquid and spray it on the surface of the substrate. Negative pressure suction on the back of the sprayed surface, the spraying amount of the adhesive accounted for 3% of the weight of the dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com