Patents

Literature

442results about How to "Improve wear performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

Prostheses

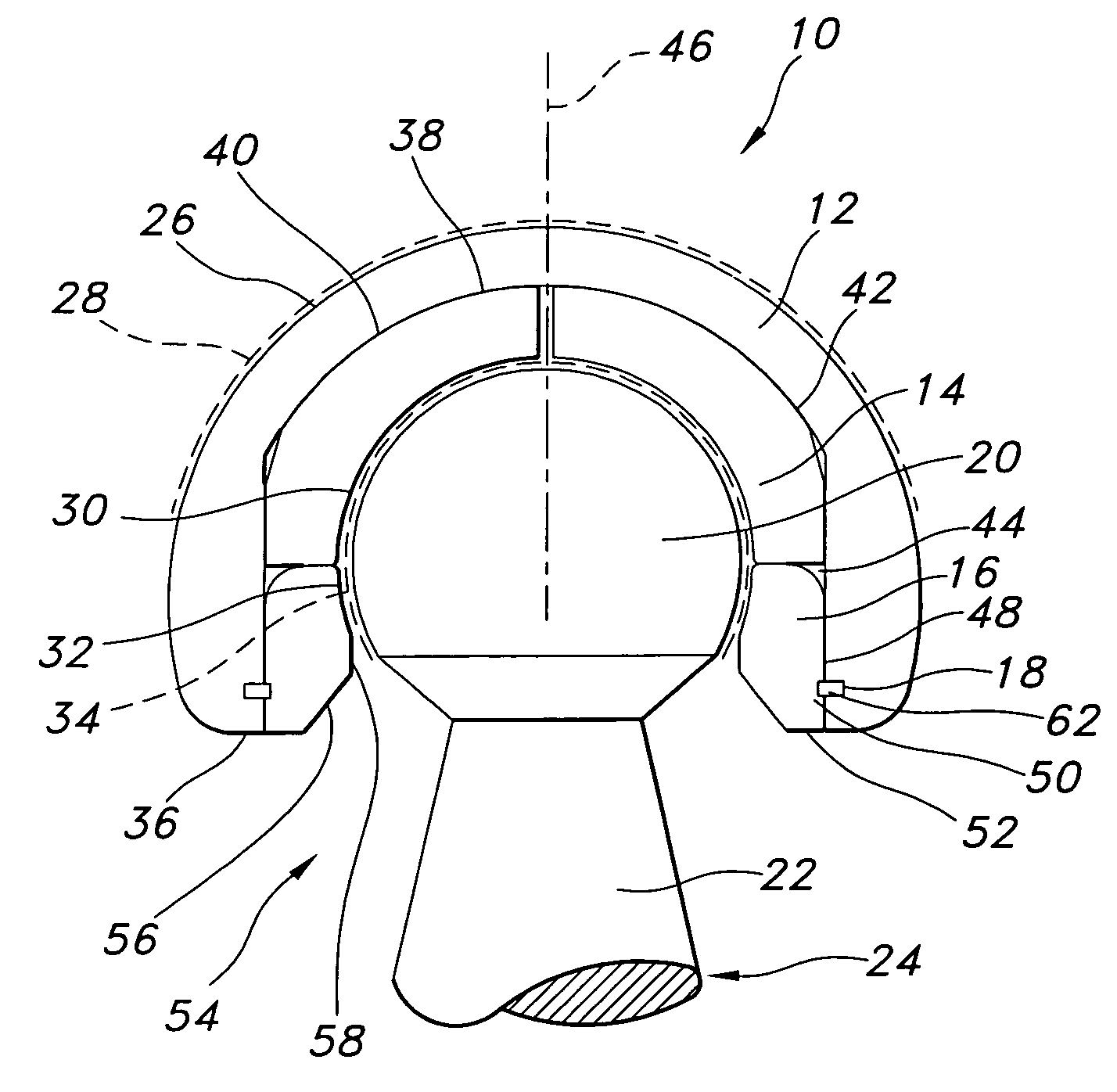

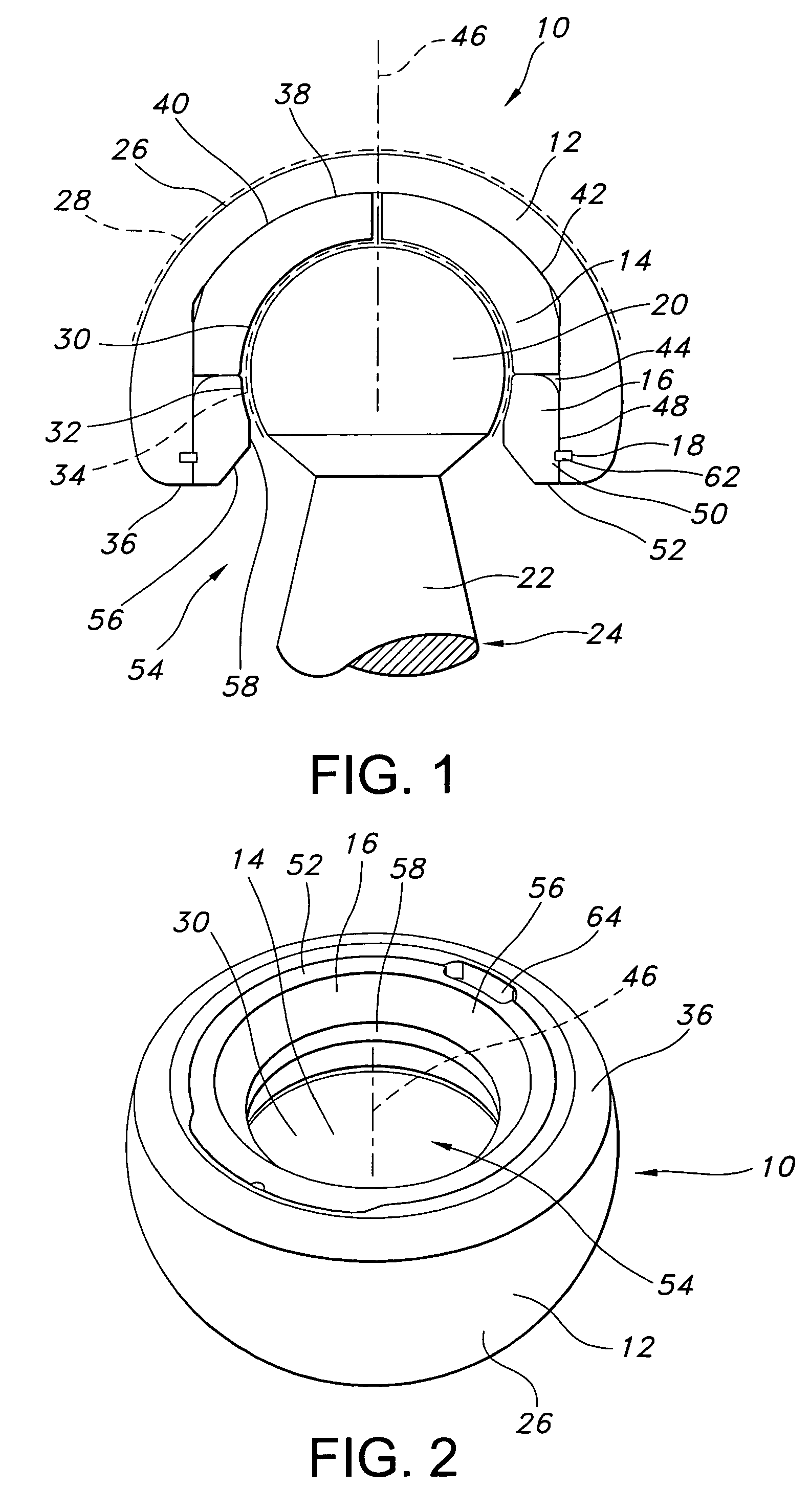

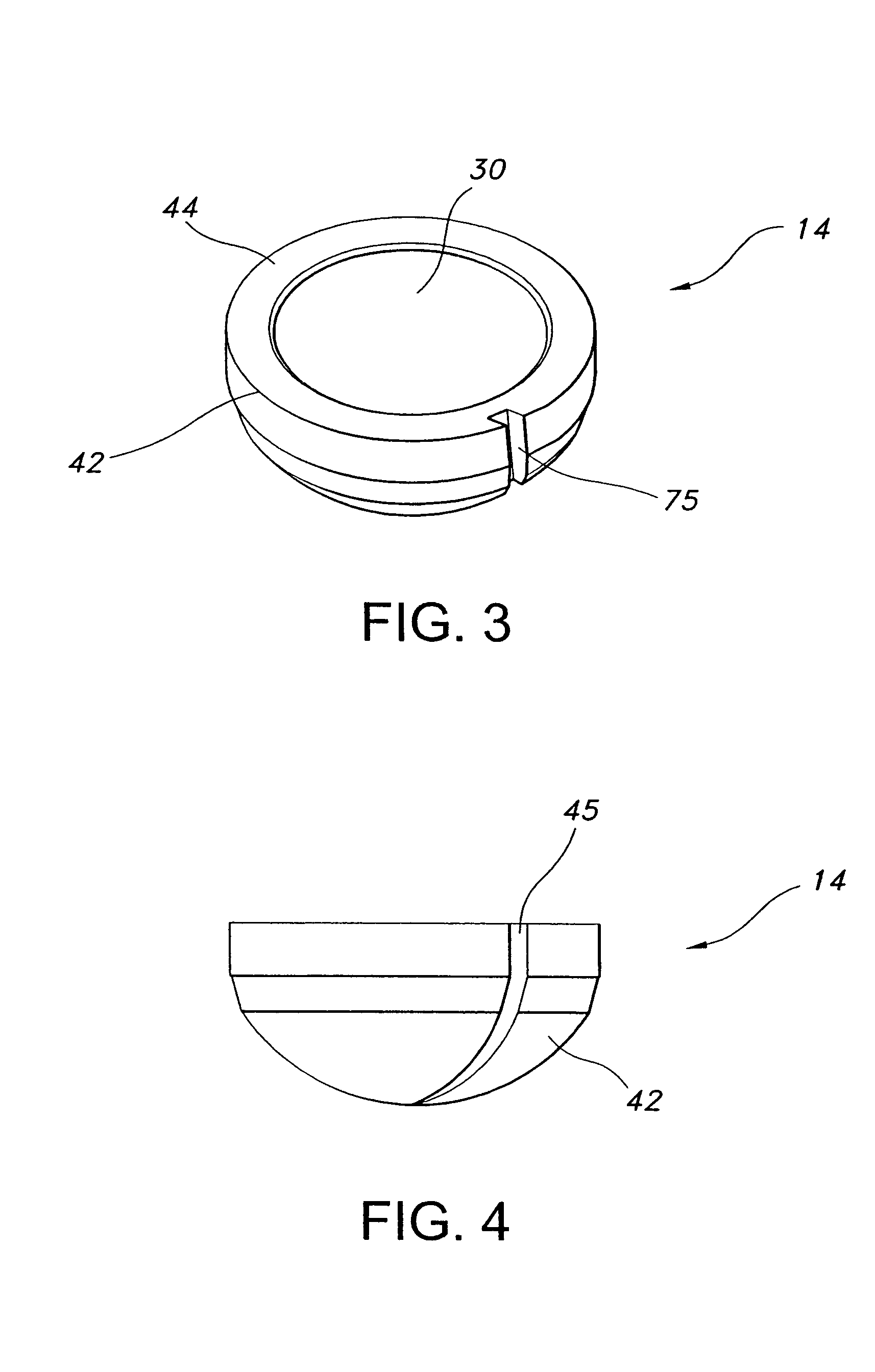

InactiveUS6986792B2Reduce wearIncreasing or at least not compromising ability of the shell/linerJoint implantsFemoral headsFemoral stemWear resistance

Bipolar prostheses which include various structures and other techniques for optimizing material wear and mechanical strength properties. Such prostheses feature, for example, improved resistance to polyethylene wear while also reducing potential for dislocation of the femoral stem from the prosthesis. Such techniques and structures include varying wear resistance and mechanical strength treatment in various components of the prostheses or portions of those components as desired to improve, accentuate or optimize wear performance and dislocation reduction, locking ring structural features, structures for retaining locking rings in the bipolar prosthesis shell, and structures for limiting or reducing movement or rotation of locking rings and liners in bipolar prosthesis shells.

Owner:SMITH & NEPHEW INC

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Radar invisible coating

InactiveCN101440250APromote absorptionLow densityPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationMicrosphere

The invention discloses a radar wave stealth coating with good radar wave-absorbing performance, light mass and thermal insulation function, and a production method thereof. The coating comprises a film-forming substance, an absorbent, an external additive and a solvent. The coating is characterized in that the radar wave absorbent is hollow microspheres covered with magnetic conductive metal films. The coating absorbent has good performance, light mass and good thermal insulation. The components by weight percentage comprise the following: 16.25 to 74.40 percent of film forming substance, 25.60 to 83.80 percent of absorbent, 1 to 20 percent of additive, and 10 to 150 percent of solvent. The coating is applied to the field of radar wave absorption, for example, the coating is used for various weapons, camouflage nets and, protection suits and so on.

Owner:崔悦

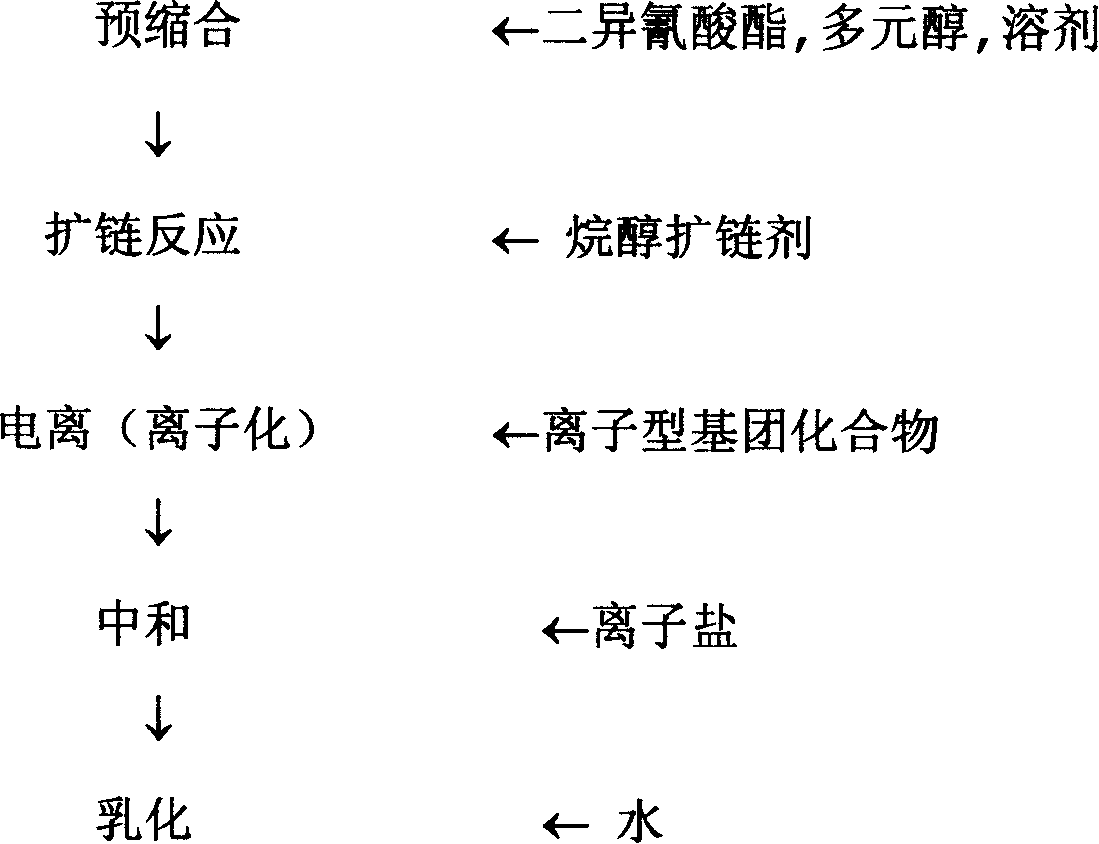

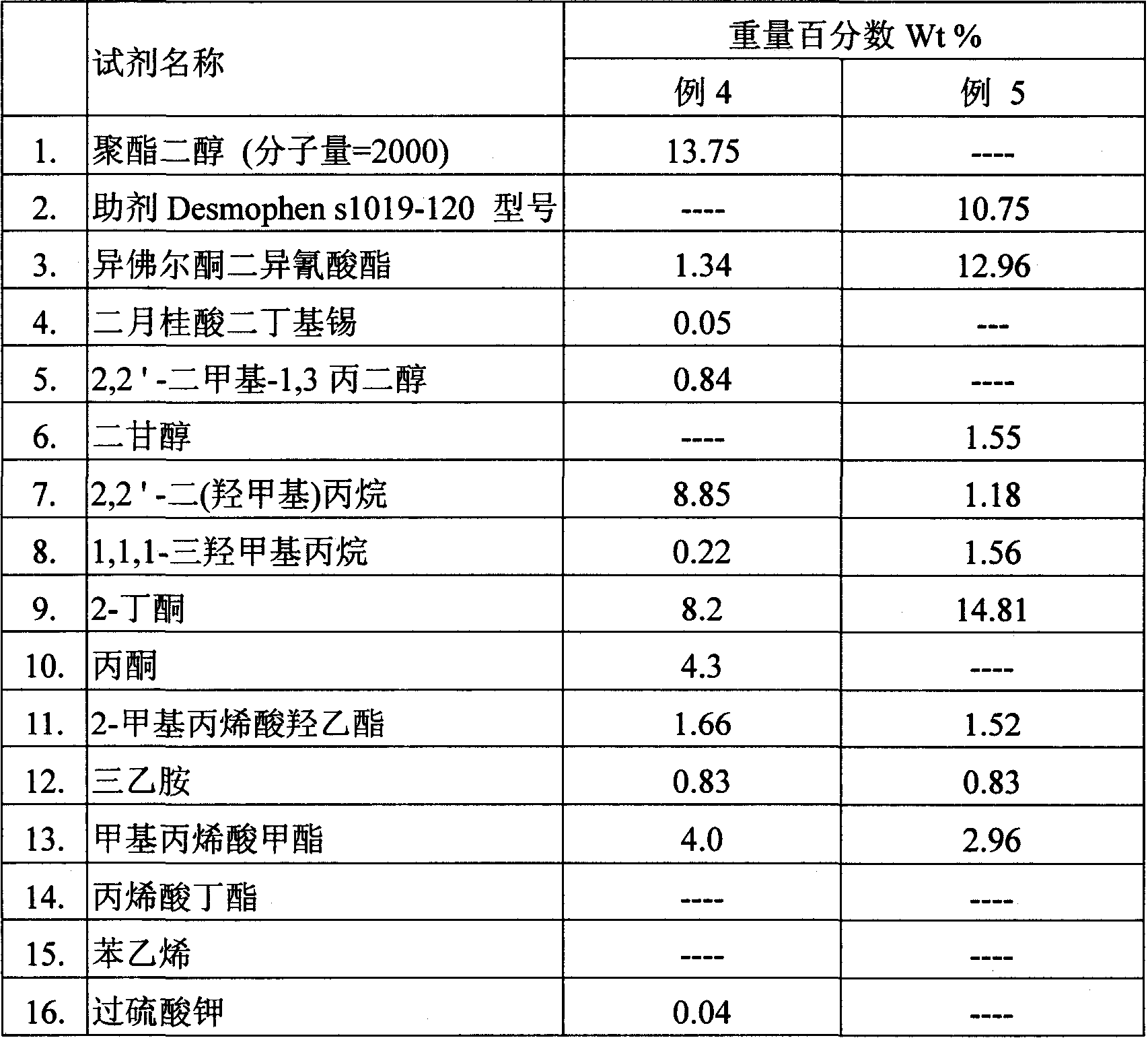

Polyurethane-acrylic ester composite emulsion and preparation method thereof

InactiveCN101165075AWide range of applicationsImprove water resistanceCoatingsCross-linkMethacrylate

The present invention provides one kind of polyurethane-acrylate composite emulsion and its preparation process. The preparation process includes preparing water soluble polyurethane seed emulsion, and adding methacrylate and cross-linking agent to the seed emulsion to prepare interpenetrating polymer network polyurethane-acrylate composite emulsion. The polyurethane-acrylate composite emulsion contains solid material in 20-60 wt%, and has particle diameter of 10-100 nm. The preparation process is simple, and the prepared polyurethane-acrylate composite emulsion has high quality, especially excellent water resistance, heat resistance, chemical resistance and wear resistance, and wide application range.

Owner:HONG KONG PRODUCTIVITY COUNCIL

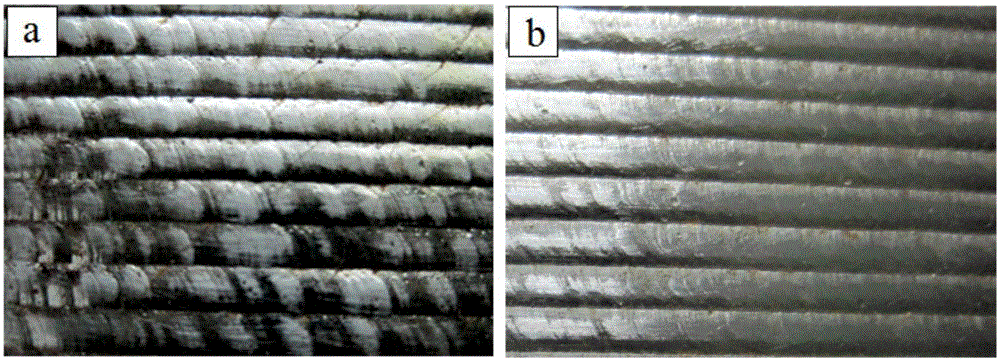

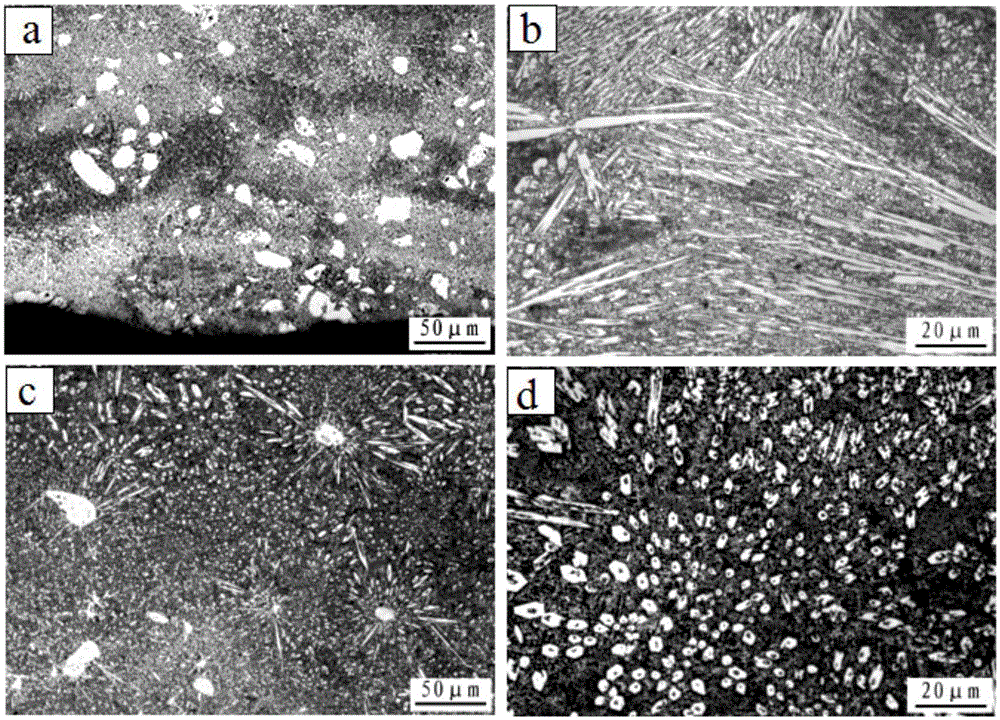

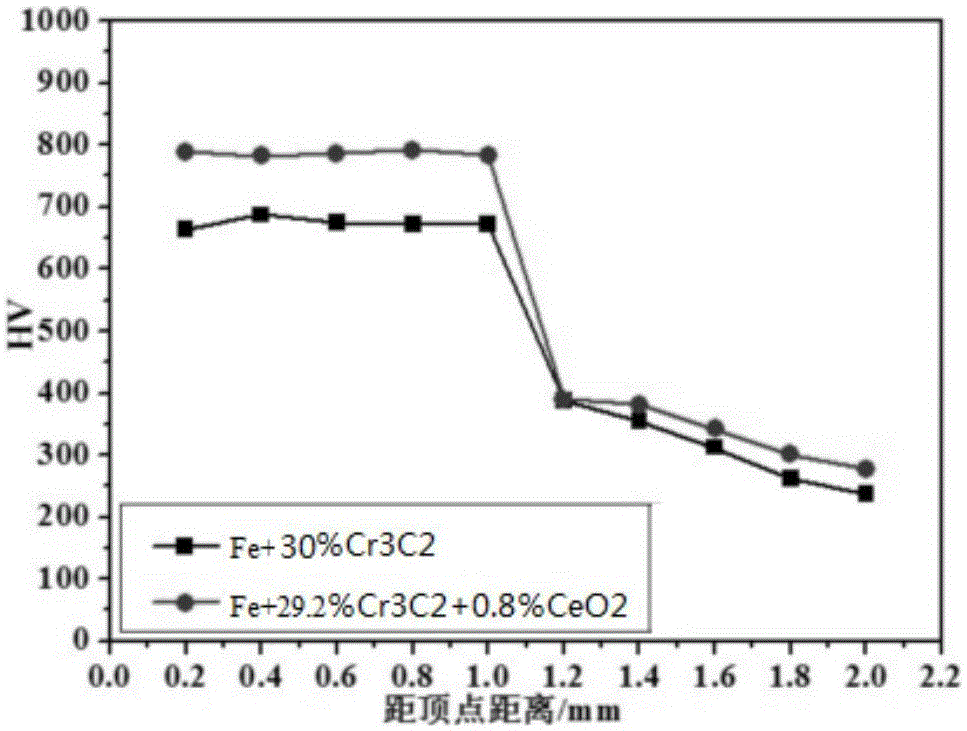

Iron-based Cr3C2 laser-cladding coating added with CeO2 and preparation method of coating

ActiveCN105112909AHigh hardnessImprove wear resistanceMetallic material coating processesAlloyHardness

The invention discloses an iron-based Cr3C2 laser-cladding coating added with CeO2 and a preparation method of the coating, and belongs to the technical field of surface modification. The coating is prepared by uniformly mixing the following components in percentage by mass for laser-cladding: 65-73% of iron-based self-fluxing alloy powder, 26.5-34% of Cr3C2 alloy powder and 0.5-1% of CeO2 powder. The preparation method comprises the following steps: powder preparation; uniform mixing and drying; preparation and post-treatment of the coating. Through adoption the technical scheme, the rigidity, abrasion resistance and high-temperature oxidation resistance of the coating can be improved; besides, the forming quality and cladding property of the coating can be remarkably improved to inhibit and eliminate bubbles and cracks.

Owner:ANHUI MA STEEL SURFACE TECH CO LTD

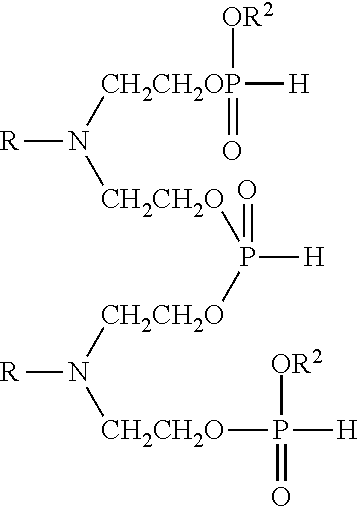

Polymeric Phosphorus Esters for Lubricant Applications

A lubricant composition of an oil of lubricating viscosity and a polymeric phosphorus ester comprising the condensation product of a monomeric phosphorus acid or an ester thereof with a diol having two hydroxy groups separated by a chain of 4 to about 100 atoms exhibits good volatility, corrosion, wear, and / or seal performance in lubrication of a transmission.

Owner:THE LUBRIZOL CORP

Polymeric compositions containing nanotubes

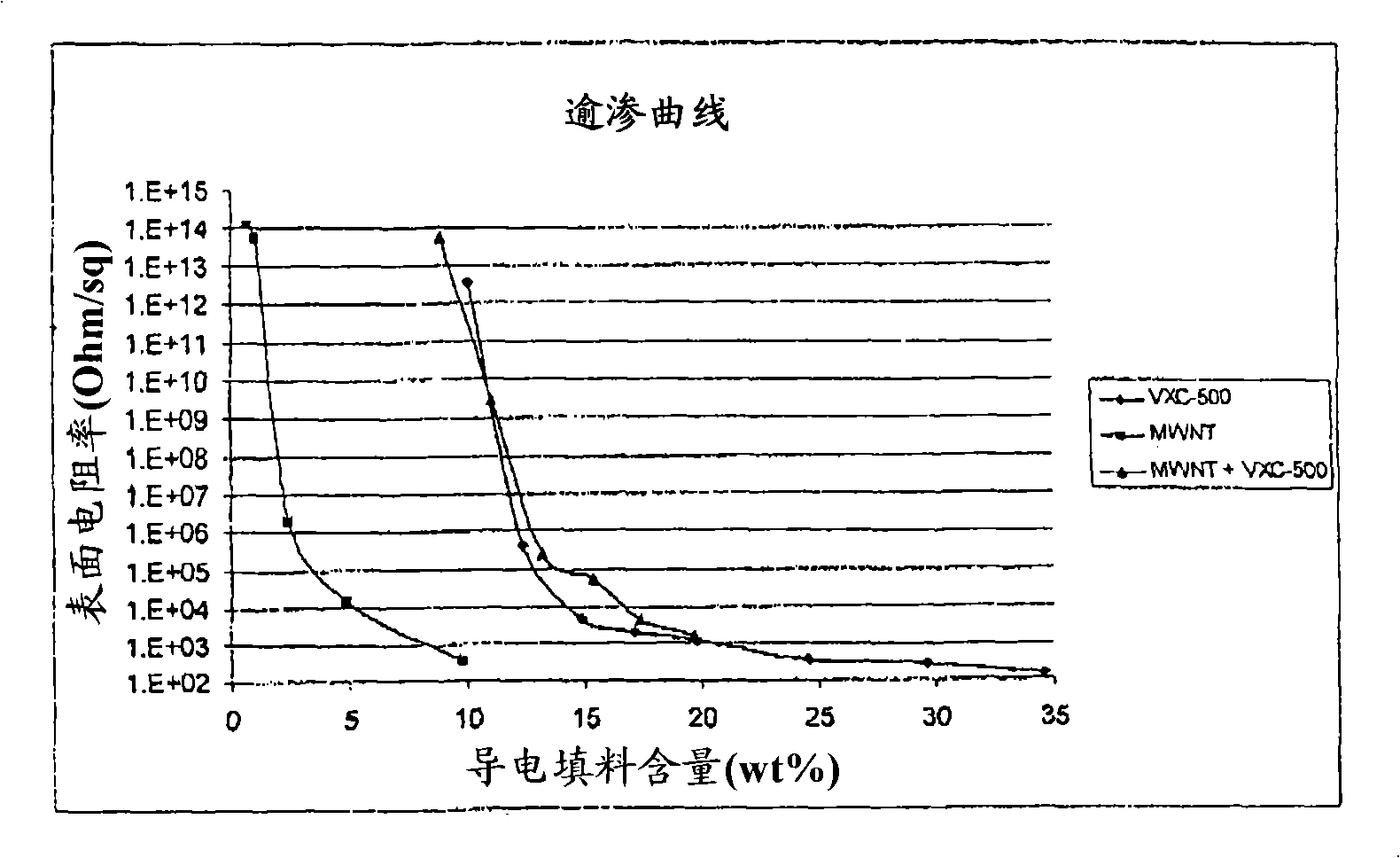

InactiveCN101283027AHigh conductivity rangeImprove smoothnessMaterial nanotechnologyNon-conductive material with dispersed conductive materialPolymer sciencePolymer chemistry

A polymeric composition containing at least one polymer and carbon nanotubes is described. The polymeric composition can have carbon nanotubes that are multi-wall carbon nanotubes and / or single-wall carbon nanotubes. The compositions can also contain carbon black. Also described are various articles made from the polymeric compositions including cables and other articles.

Owner:CABOT CORP

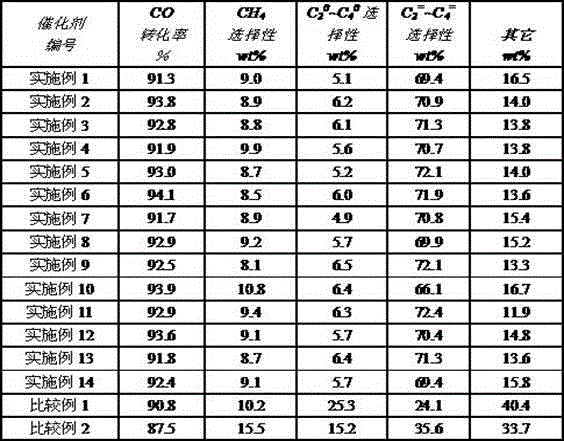

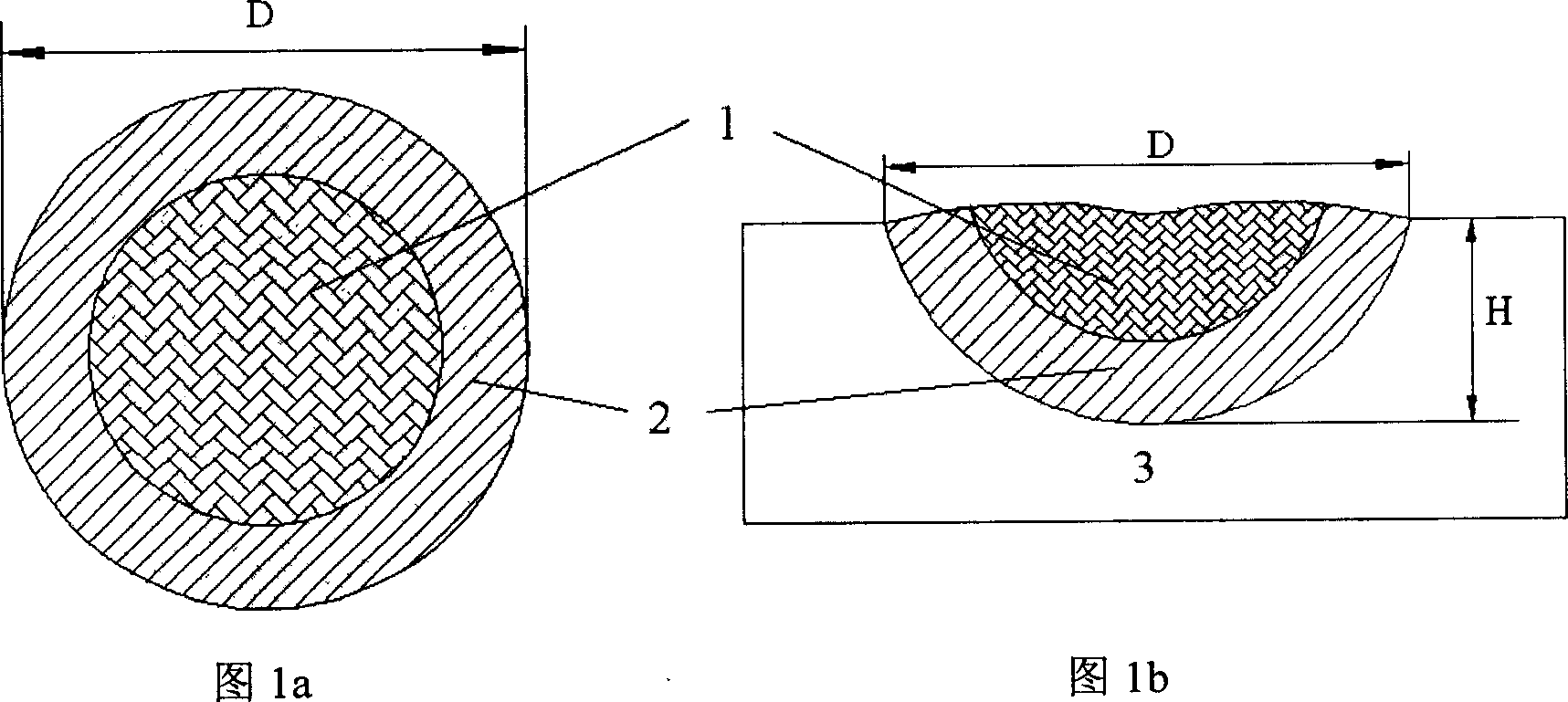

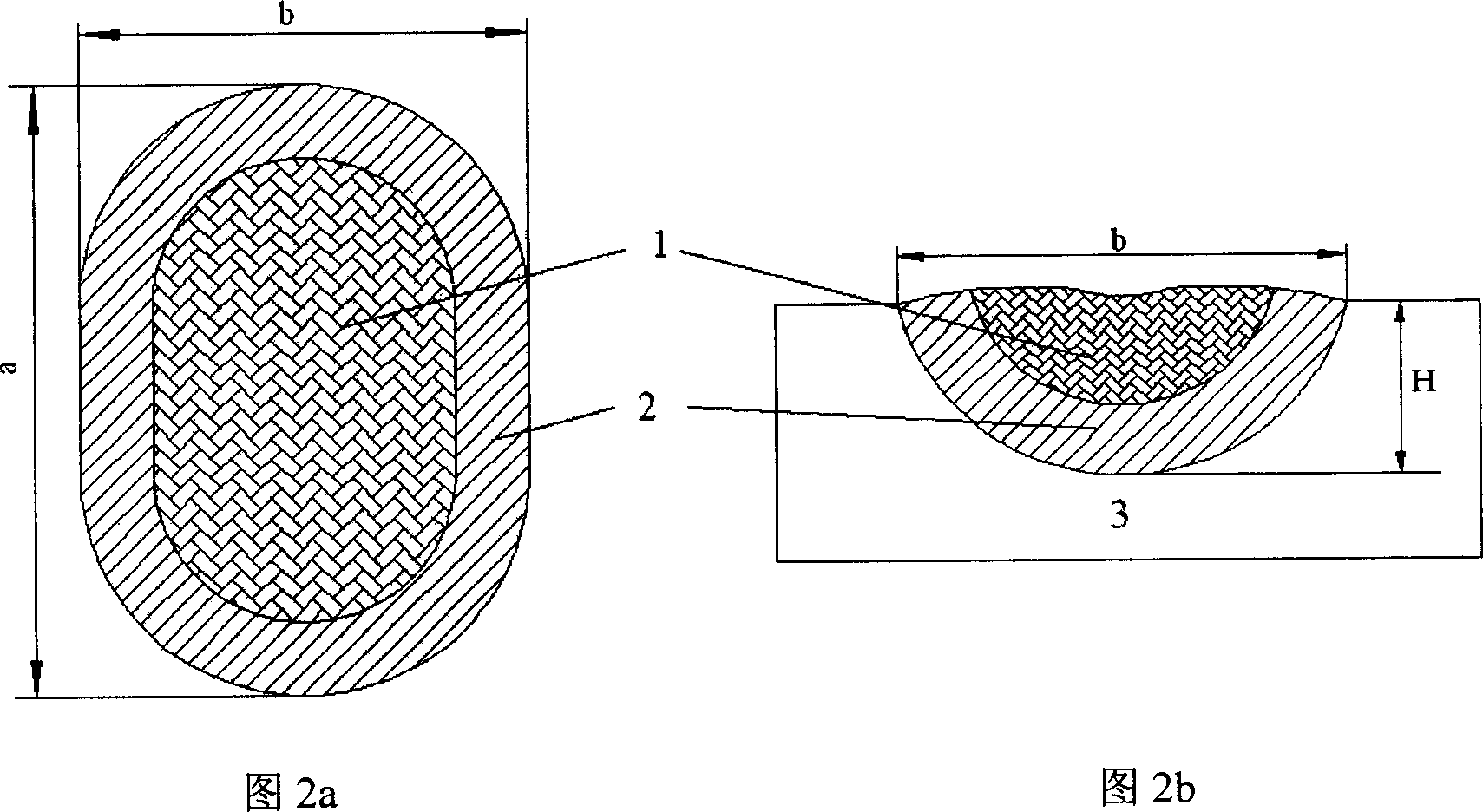

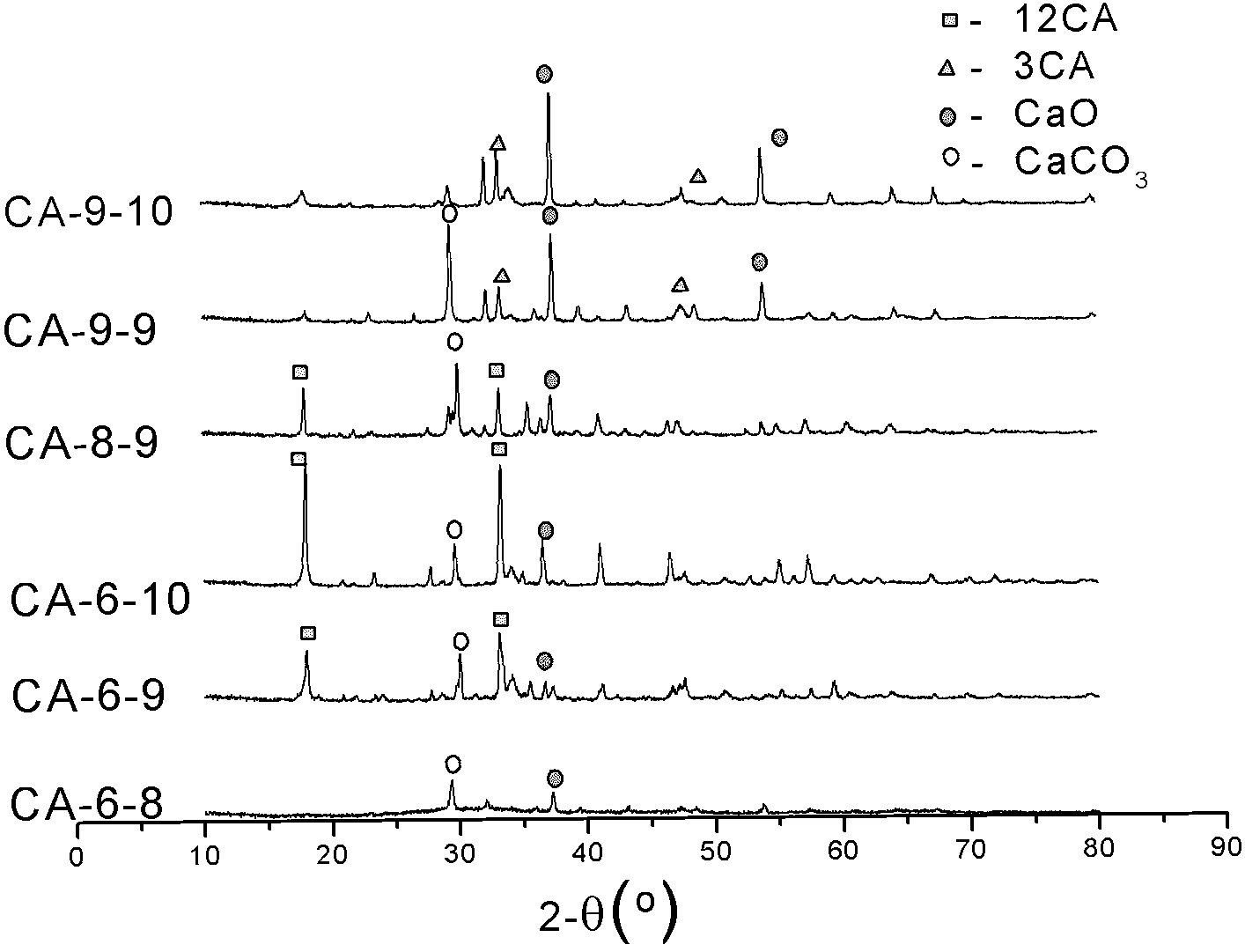

Catalyst for directly preparing low-carbon olefin from microspherical synthesis gas, as well as preparation method thereof

ActiveCN104549296AImprove wear performanceReduce wear rateHydrocarbon from carbon oxidesLiquid hydrocarbon mixture productionSyngasFluidized bed

The invention relates to a catalyst for directly preparing a low-carbon olefin from a microspherical synthesis gas, and is mainly used for solving the problems that the existing co-precipitation Fischer-Tropsch catalyst preparation technology comprises the following steps: firstly co-precipitating and then pulping and spray-forming, so that the slurry is substantially a non-homogenous body dispersed by adopting a physical method, the finial catalyst finished product is uneven and the hydrocarbon products on the catalyst are widely distributed. The problems are well solved by adopting the technical scheme that the preparation method comprises the following steps: firstly precipitating a part of components, then carrying out peptization on the obtained precipitates by using the salt solution of non-precipitated components to obtain chemically evenly dispersed sol, then spray-drying the sol, and then roasting at high temperature. The preparation method can be used for industrial production for a catalyst for synthesizing the low-carbon olefin from the synthesis gas. The catalyst is applicable to but not limited to such reactors as a fluidized bed and a slurry-state bed in which catalyst grains are required to be distributed according to the certain distribution rule.

Owner:CHINA PETROLEUM & CHEM CORP +1

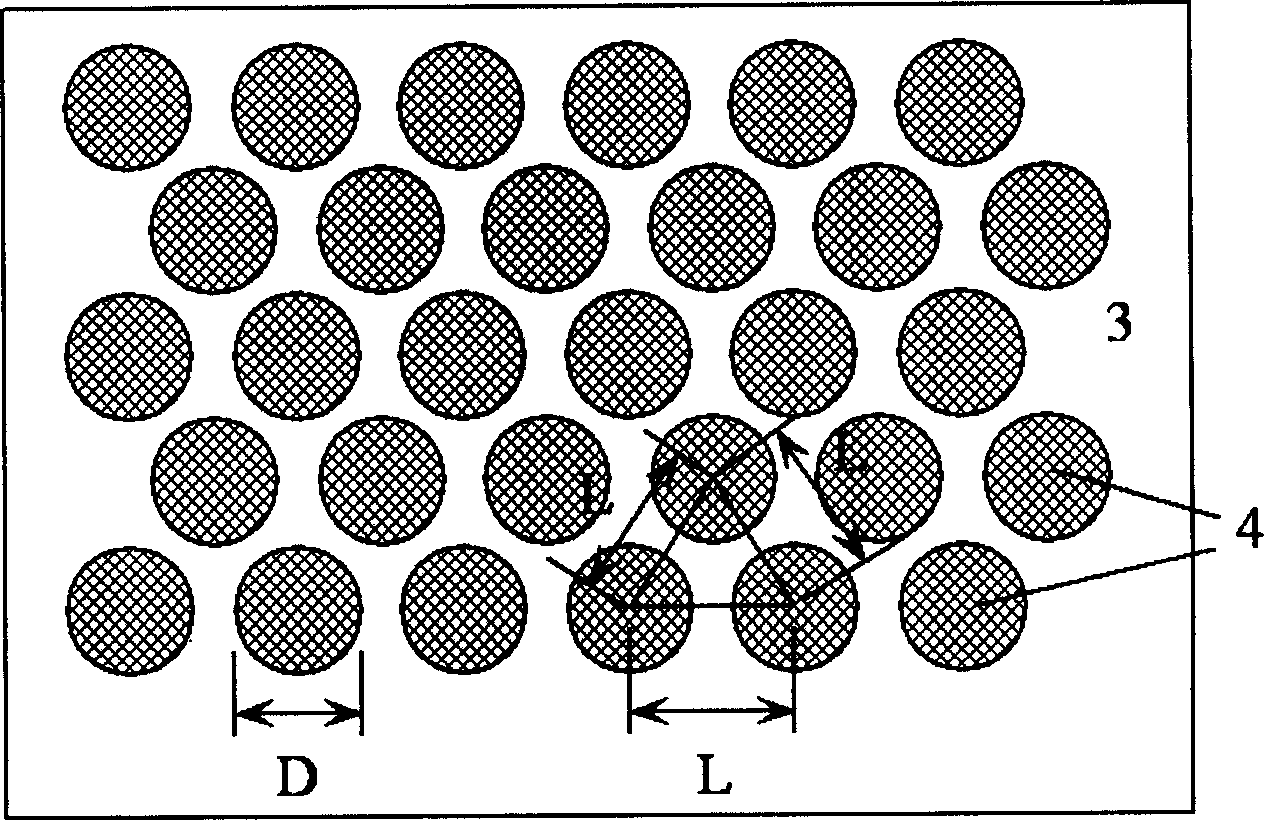

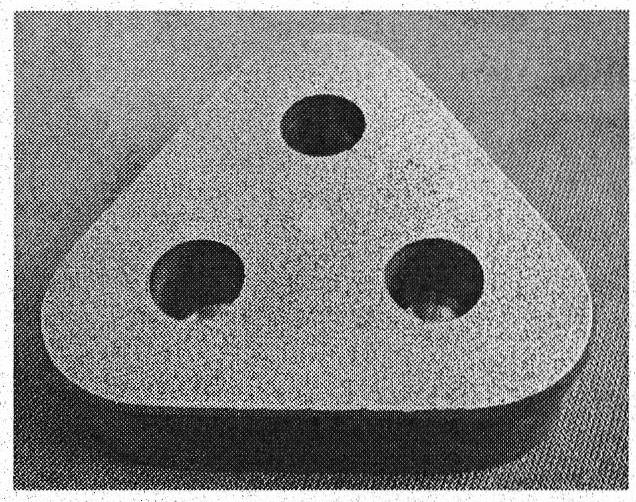

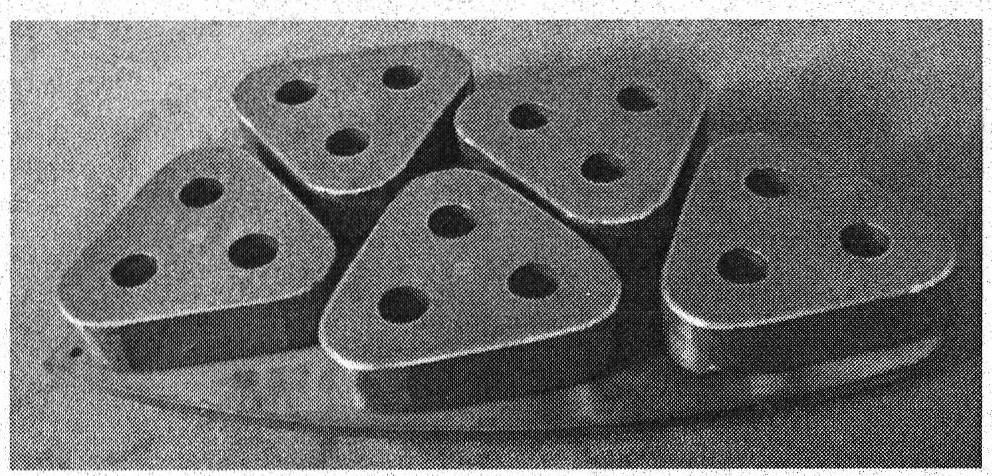

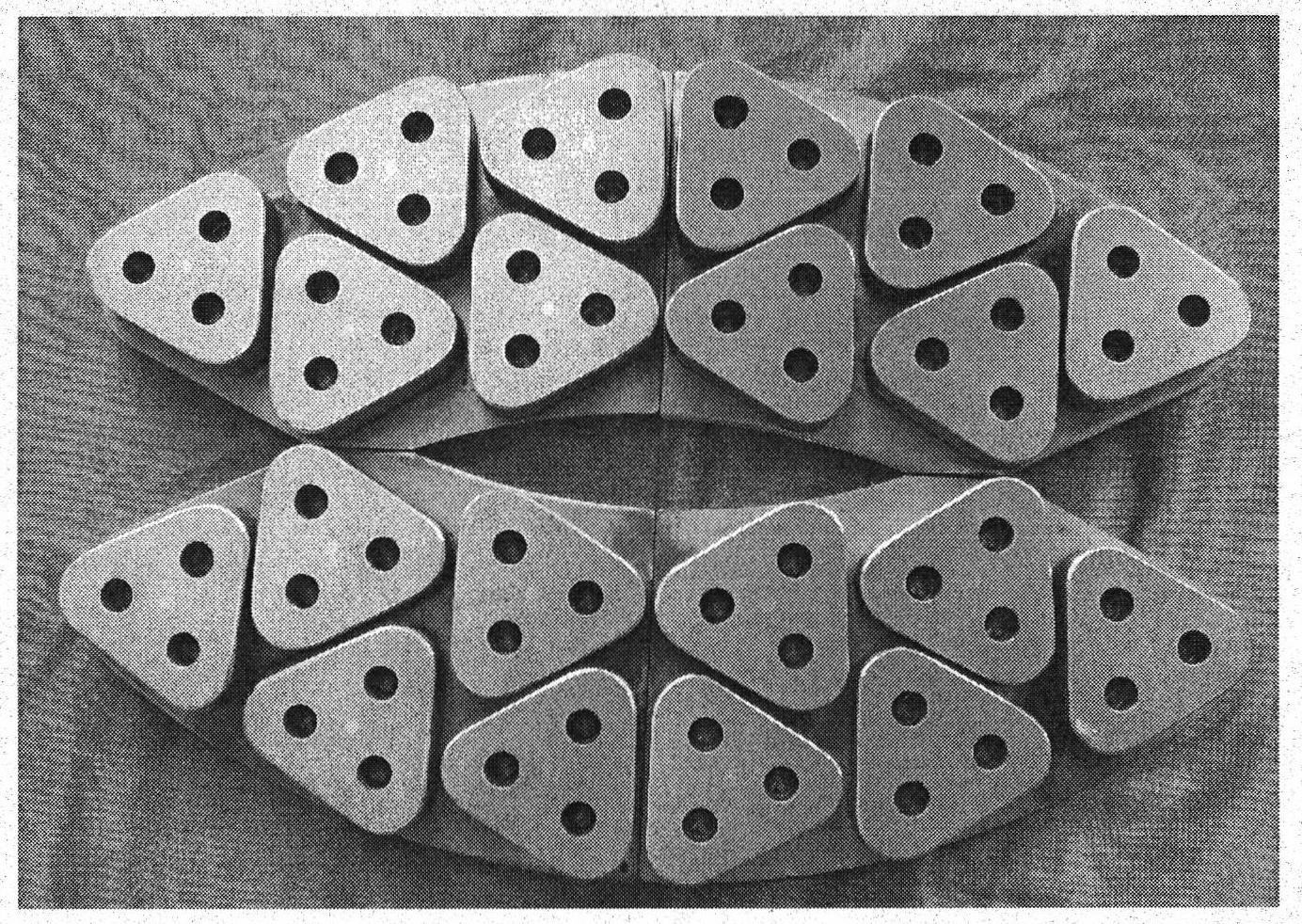

Distribution type laser spot alloying method

InactiveCN1831195AImprove wear performanceOvercoming temper softening problemsMetallic material coating processesLaser beam welding apparatusDepth enhancementAlloy

The invention relates to a distributed laser point-shaped alloying method that uses the small-hole effect caused by high power density laser effect to form mixing liquid bath by metal base and high performance alloy power sent by powder sending machine, the alloying point would be formed in the following rapid concreting. Controlling the laser beam processing point to point to form alloying points on the surface of the material, the distributed laser depth enhancement would be realized. The invention optimizes the alloying points and the distributing state to improve abrasion resistance of the surface, and the useful life of the component would be improved.

Owner:TSINGHUA UNIV

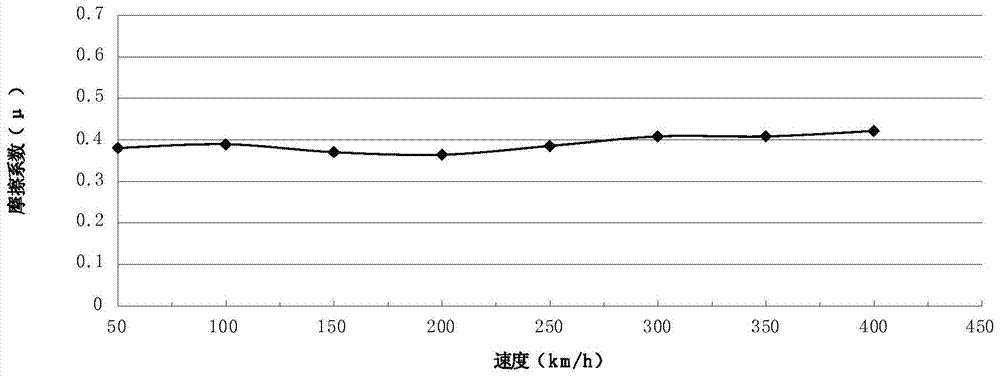

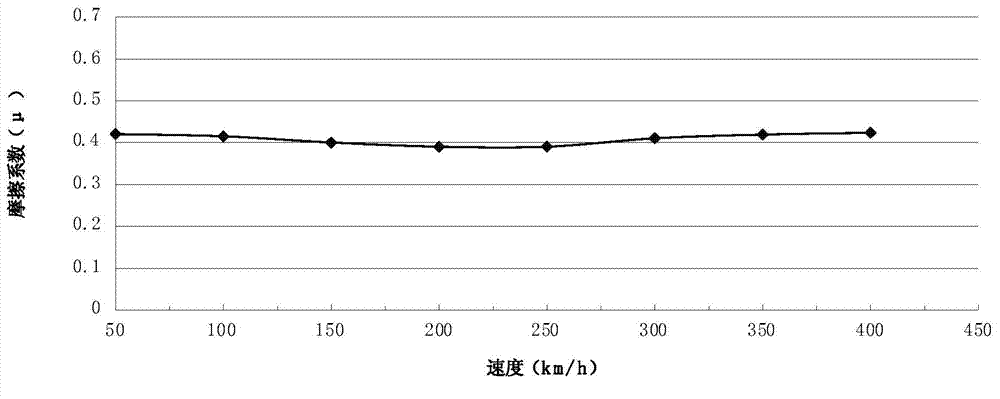

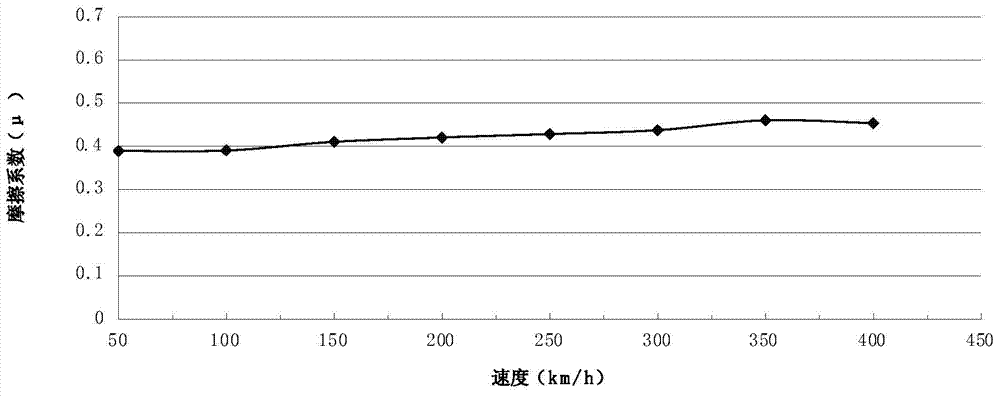

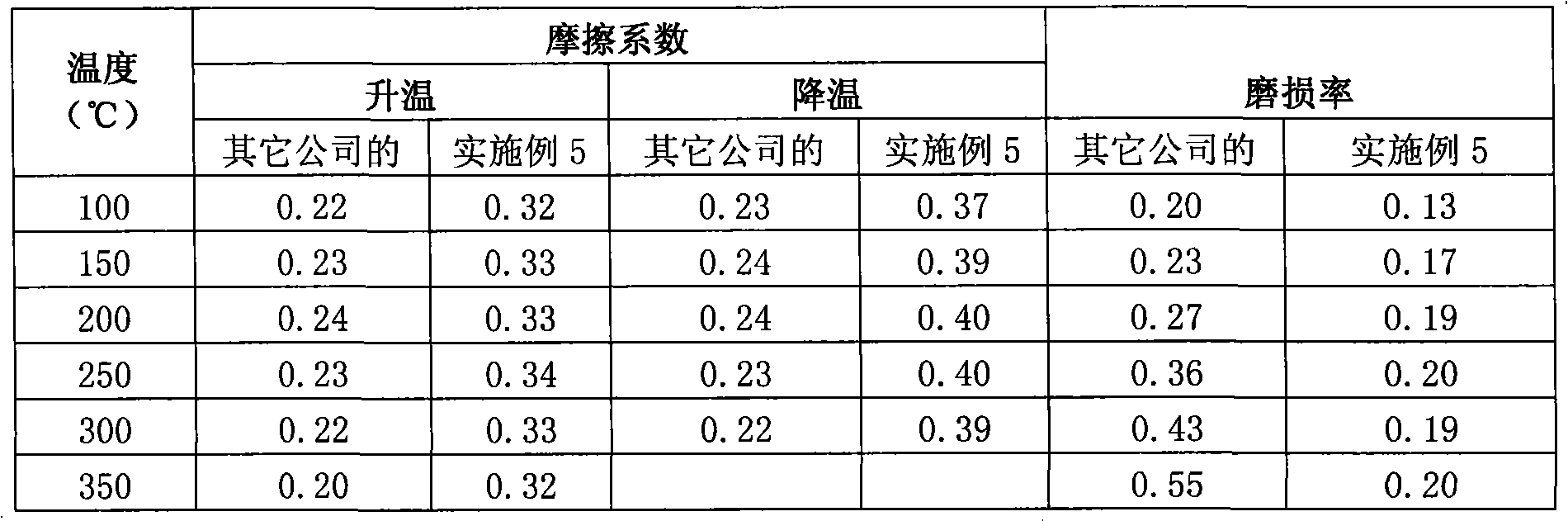

Ceramic/metallic double continuous phase composite material brake pad and preparation method thereof

The invention relates to the field of friction materials for braking of high-speed trains, in particular to a ceramic / metallic double continuous phase composite material brake pad and a preparation method thereof. The brake pad comprises the following components in percentage by weight: 15 to 40 percent of foam silicon carbide ceramics, 10 to 30 percent of friction element and 75 to 30 percent ofmetal. The method comprises the following steps of: preparing the silicon carbide foam ceramics having a three-dimensional network structure by employing a technology combining polymer pyrolysis withcontrollable infiltration reaction sintering; selecting a proper friction element and filling in mesh holes of the foam ceramics; and injecting melt copper alloy into a framework of the foam ceramicsby utilizing an extrusion casting method to obtain the ceramic / metallic double continuous phase composite material brake pad. The composite material brake pad can be paired with a 28CrMoV forged steel brake disc, has the characteristics of proper and stable friction coefficient, low wear rate, high heat resistance, high thermal or mechanical damage resistance, good process performance, low manufacturing cost, long service life and the like, completely meets the brake requirement of a high-speed train at a speed of 200 to 300km / h, and has good competitive advantage on the brake requirement of a high-speed train at the speed of 350km / h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

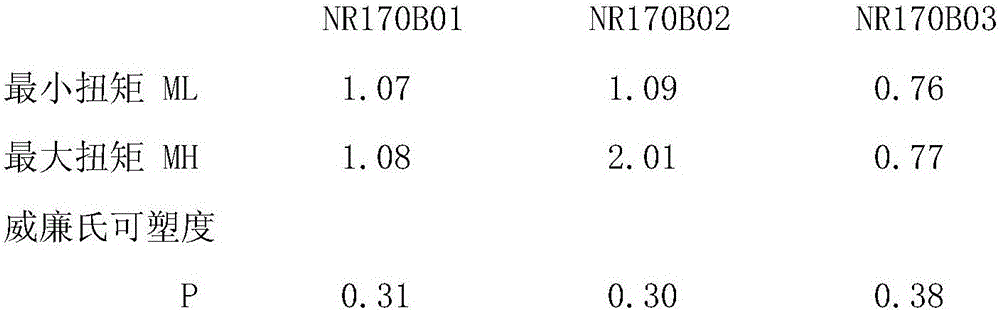

Tire tread rubber composition and preparation method

ActiveCN102634077AImprove tire wear performanceReduce tire rolling resistanceSpecial tyresRolling resistance optimizationWaxCarbon black

The invention relates to the technical field of rubber, in particular relates to a tire tread rubber composition and a preparation method. The tire tread rubber composition is characterized by taking 100 parts of natural rubber as reference, also comprising 5-10 parts of liquid butadiene rubber, 40-55 parts of carbon black, 5-15 parts of white carbon black, 2.5-3.0 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of silane coupling agent, 1-3 parts of N-(1, 3-dimethylbutyl)-N'-phenyl-p-phenylenediamine anti-aging agent, 1-2 parts of 2, 2, 4-trimethyl-1, 2-dihydroquinoline polymer anti-aging agent, 1-2 pats of protective wax, 1-1.5 parts of sulphur, 1.0-1.5 parts of vulcanization accelerator, and 0.1-0.3 parts of anti-scorching agent in part by weight. In the tire tread rubber composition, the tire wear property can be increased, the tire rolling resistance can be lowered, the tire slippery property is improved, and the comprehensive use property of the tire can be enhanced.

Owner:TRIANGLE TIRE

Modification method for improving surface nano indentation property of material

ActiveCN103422098AHigh fatigueImprove fatigue lifeSolid state diffusion coatingHigh densityDislocation

The invention discloses a modification method for improving the surface nano indentation property of a material. The modification method combines three technologies of mechanical shot blasting, surface alloying and laser shock peening effectively, parts realize the surface nanocrystallization and alloying modification through shot blasting and pack aluminization, and the surfaces of the parts are subjected to laser shock peening complex treatment. The sequence of the technologies improves the surface nano uniformity of the material greatly, and shortens the diffusion time; meanwhile, the high-ductility deformation of the material is caused, and high-amplitude residual compressive stress is applied on the surface of the material, and the surface of the material is subjected to high-density dislocation. The parts prepared by the peening method have a good nano indentation property, high abrasive resistance, high corrosion stability and high temperature oxidation resistance, and the fatigue lives of the parts at the normal temperature and high temperature are prolonged greatly.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Copper-based powder dispersion ceramic as well as preparation method and application thereof

InactiveCN103667772AStrong impact pressureHigh mechanical strengthBraking membersCopperUltimate tensile strength

The invention relates to copper-based powder dispersion ceramic as well as a preparation method and application thereof, and relates to the field of ceramic materials. The copper-based powder dispersion ceramic is prepared from an anti-abrasion constituent element as one of the raw materials, wherein the anti-abrasion constituent element comprises the following components by mass percent of all the raw materials: 1-5 percent of diamond powder and 1-5 percent of titanium diboride powder. The copper-based powder dispersion ceramic is high in impact pressure resistance, high in mechanical intensity, high in friction and abrasion resistance, long in service life, high in heat dissipation property and heat recovery property, high in high-temperature and low-temperature resistance, high in acid, alkaline, oil, water and the like corrosion resistance and the like.

Owner:刘伟

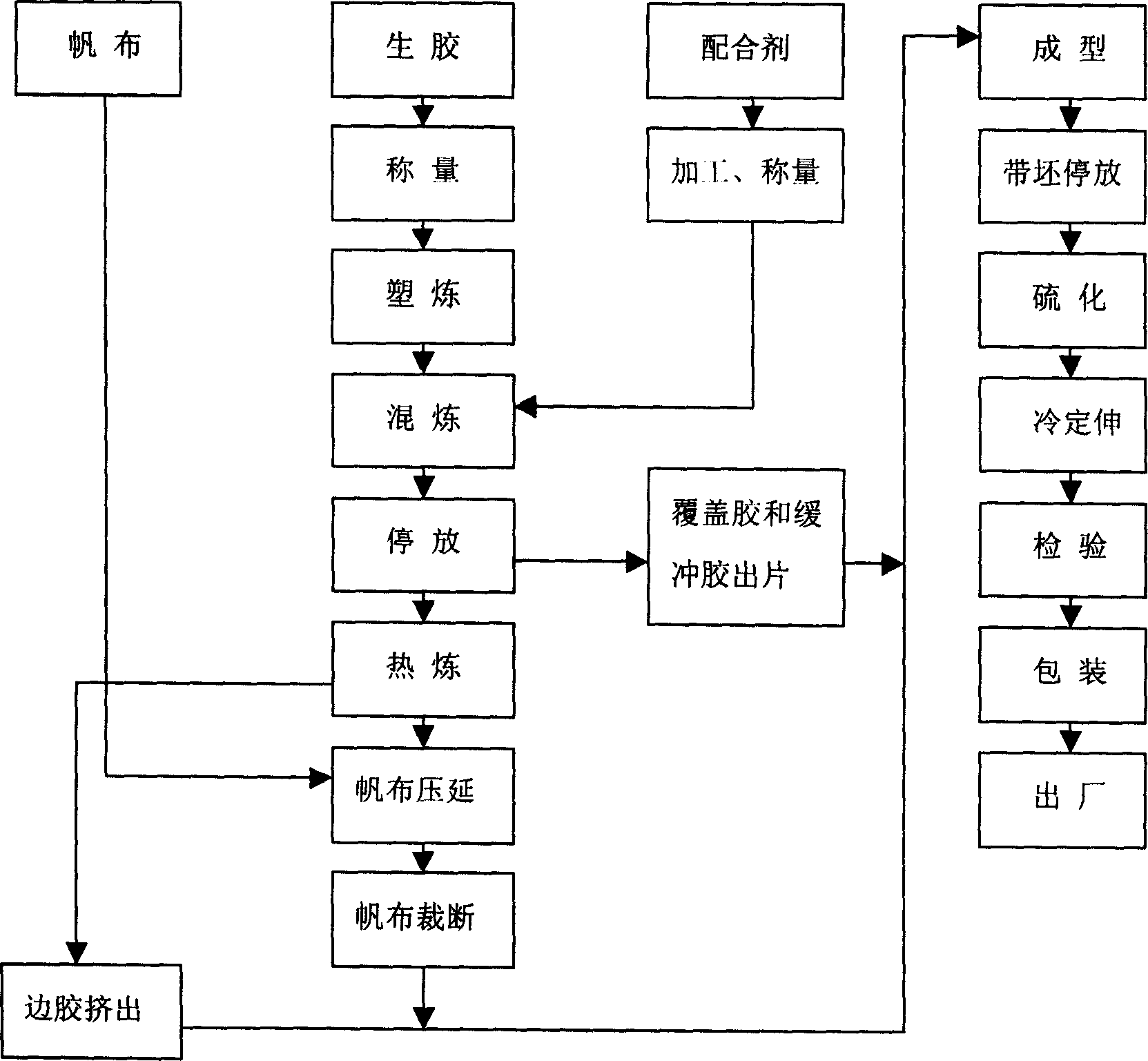

Impact resistance high wearing-proof conveyer belt

An anti-impact and anti-wear conveying belt features that the rubber layer covered on its surface is proportionally prepared from natural rubber, synthetic rubber, sulfur, zinc oxide, stearic acid, promoter, reinforcing agent, softening agent and anti-ageing agent.

Owner:阳江市北山胶化有限公司

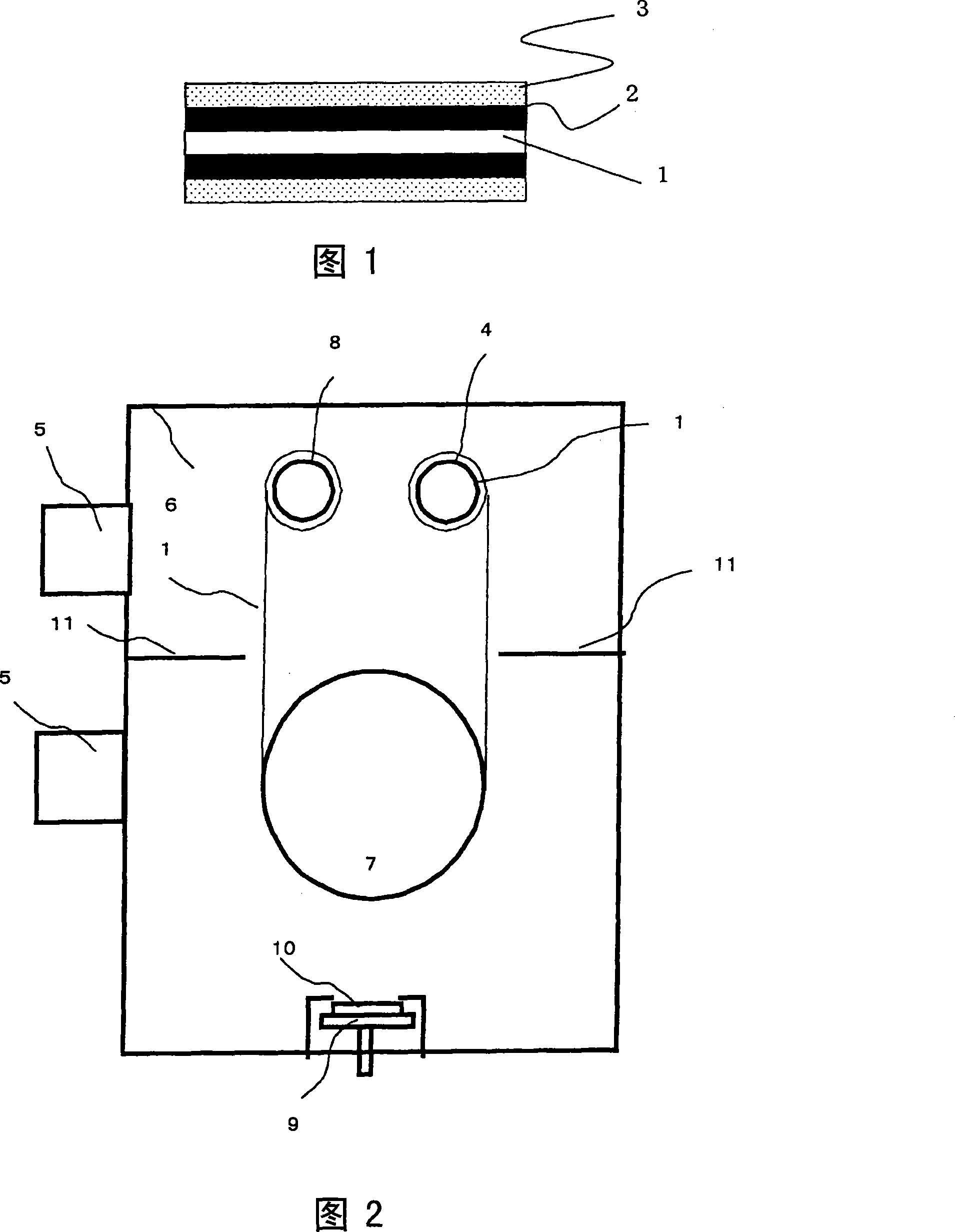

Heat-resisting shading sheet, manufacturing method thereof, and diaphragm and light quantity adjusting device using the same

InactiveCN101191843AHigh reflectivity reductionImprove wear performanceSynthetic resin layered productsVacuum evaporation coatingHeat resistanceSurface roughness

The present invention provides a heat-resistant light-shielding sheet, its manufacturing method, and an aperture or light amount adjusting device using the same. Used for optical instrument parts such as the aperture blades of the aperture device for adjustment, and has excellent light resistance, heat resistance, sliding properties, low gloss, and electrical conductivity. The heat-resistant light-shielding sheet is characterized by comprising a resin sheet substrate (A) having a heat resistance of 200° C. or higher, and Ni with a thickness of 50 nm or more formed by sputtering on one or both surfaces of the resin sheet substrate (A). The metalloid film (B), the Ni-based oxide film (C) with low reflectivity formed by sputtering on the Ni-based metal film (B), and the surface roughness is 0.1-0.7 μm (arithmetic mean height Ra).

Owner:SUMITOMO METAL MINING CO LTD

Environment-friendly stemming and preparation method thereof

The invention provides an environment-friendly stemming and a preparation method thereof. The environment-friendly stemming is prepared from, by mass, 15-40% of aluminum containing aggregates, 2-15% of coke, 1-5% of graphite, 10-25% of silicon carbide, 5-20% of ferro-silicon nitride, 5-20% of aluminum containing fine powder, 5-15% of clay, 2-8 parts of sericite, 2-6% of high-temperature pitch, 2-15% of an expanding agent and a binding agent accounting for the total mass of the other materials by 15-30%, wherein thermoplastic phenolic resin serves as the binding agent. The environment-friendly stemming and the preparation method thereof have advantages that toxic gases are avoided, a furnace front operation environment is improved, environmental friendliness, low raw material consumption, high hardening speed and short sintering time are realized, opening performance and slag iron erosion resistance of the anhydrous stemming are improved, resistance of the anhydrous stemming to flushing and abrasion of high-temperature molten iron is enhanced, and quality stability of the anhydrous stemming is improved.

Owner:ZHENGZHOU SAIWO TECH CO LTD

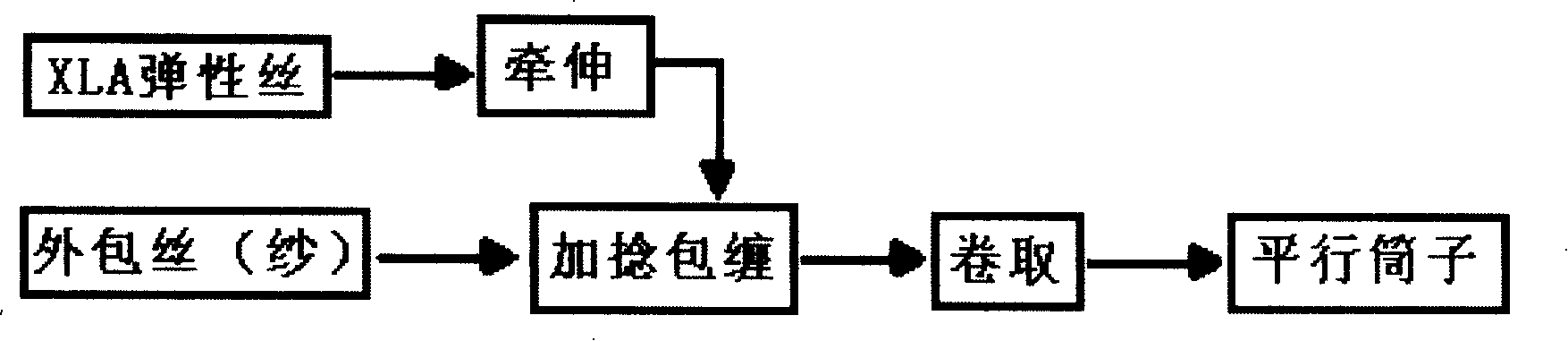

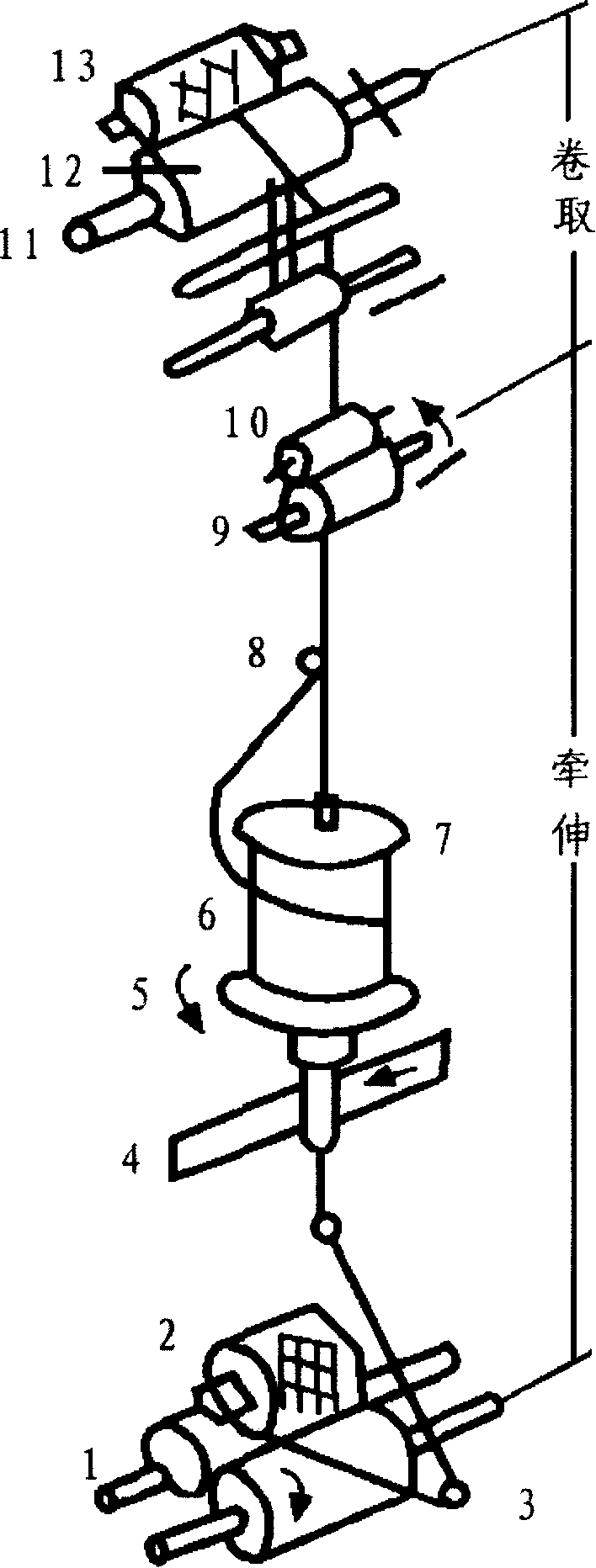

Manufacturing process for low-temperature shaped elastic coating yarn

InactiveCN101200825AImprove physicsGood chemical propertiesHeating/cooling textile fabricsYarnYarnPolyolefin

The invention discloses a low temperature setting elastic coating wire manufacturing process, in particular relates to a coating manufacturing process which implements the low temperature setting on polyolefin elastic filament fiber. The technological process of the invention is mainly divided into four parts of elastic wire feeding, tensile covering, relaxation coiling and the last lower temperature setting of textile. In every process step, specific process conditions are selected. Especially when the low temperature setting condition is selected, such as 60 or 70 DEG C, the setting of the elastic long fiber textile can be realized. At the same time, proper traction force, traction multiple, coating twist, winding speed, etc. are matched in the coating wire manufacturing process. The invention has the advantage that wearing fabrics with high quality can be produced under the effective energy saving condition. Fabric strength, heat setting property, etc. are well guaranteed. And the operation is more convenient. The invention can be widely applied to the preparation process of various high-grade fabrics.

Owner:ZHEJIANG SCI-TECH UNIV +1

Multielement silane coupling agent-modified phenolic resin base combined disc brake pad and preparation method thereof

ActiveCN105801014AImprove physical propertiesGood chemical propertiesFriction liningCarbon fibersSilanes

The invention provides a multielement silane coupling agent-modified phenolic resin base combined disc brake pad and a preparation method thereof, and relates to the technical field of automobile parts.The brake pad is prepared from, by mass, 4-7% of organosilicone-modified phenolic resin, 2-4% of polyacrylonitrile carbon fibers, 2-4% of aramid pulp, 10-34% of potassium titanate lamellae, 5-18% of steel fibers, 2-6% of glass fibers, 3-10% of natural flake graphite, 3-10% of granulated coke, 0.5-1.5% of silicon dioxide, 25-40% of barite and 2.5-10% of a multielement silane coupling agent.The disc brake pad has the advantages of being good in interfacial compatibility, stable in friction coefficient and product quality, excellent in wear resistance and anti-noise performance and the like; besides, a material modification process and a mixing process are integrated in the preparation method of the disc brake pad, so that production efficiency is high, modification cost is lowered, and the process is simple.

Owner:SHANDONG GOLD PHOENIX

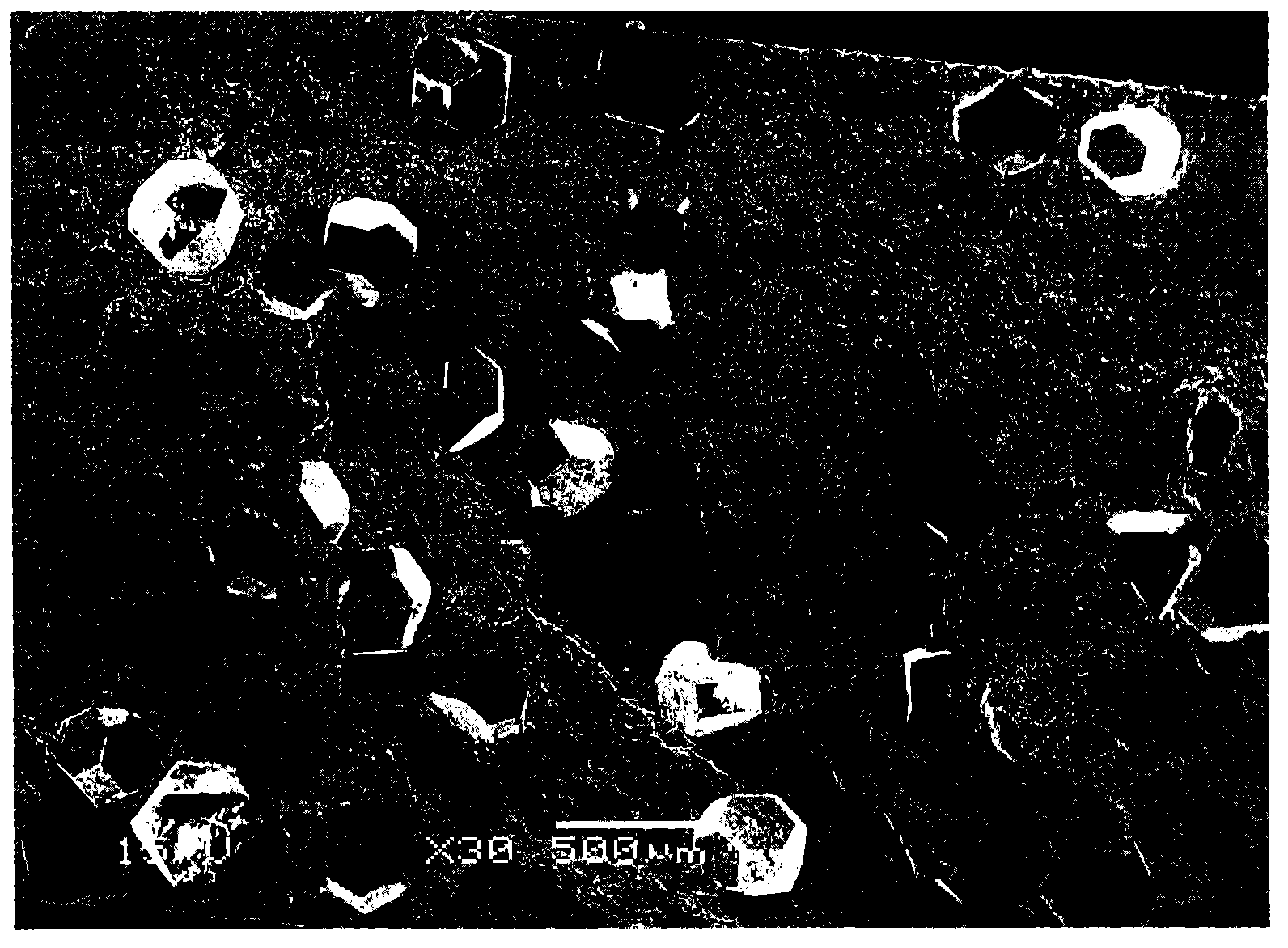

Rare earth prealloyed powder and preparation method thereof

The invention relates to rare earth prealloyed powder which is obtained by water atomization. The powder comprises the following components in percentage by weight: 36-45wt% of Cu, 5-8wt% of Sn, 5-8wt% of Ni, 0.5-1.5wt% of Ce, 8-12wt% of Co and 26-43wt% of Fe. According to the rare earth prealloyed powder provided by the invention, the sintering temperature is 740-800 DEG C, the bending strength is grater than 1000MPa, the utilization ratio of diamond reaches over 50%, the service life of the product is improved by over 30%, and the sharpness of the product is improved by over 20%. The rare earth prealloyed powder provided by the invention is wide in application range, and can be widely applied to granite cutting saw webs of various specifications.

Owner:JIANGSU FENGTAI TOOLS

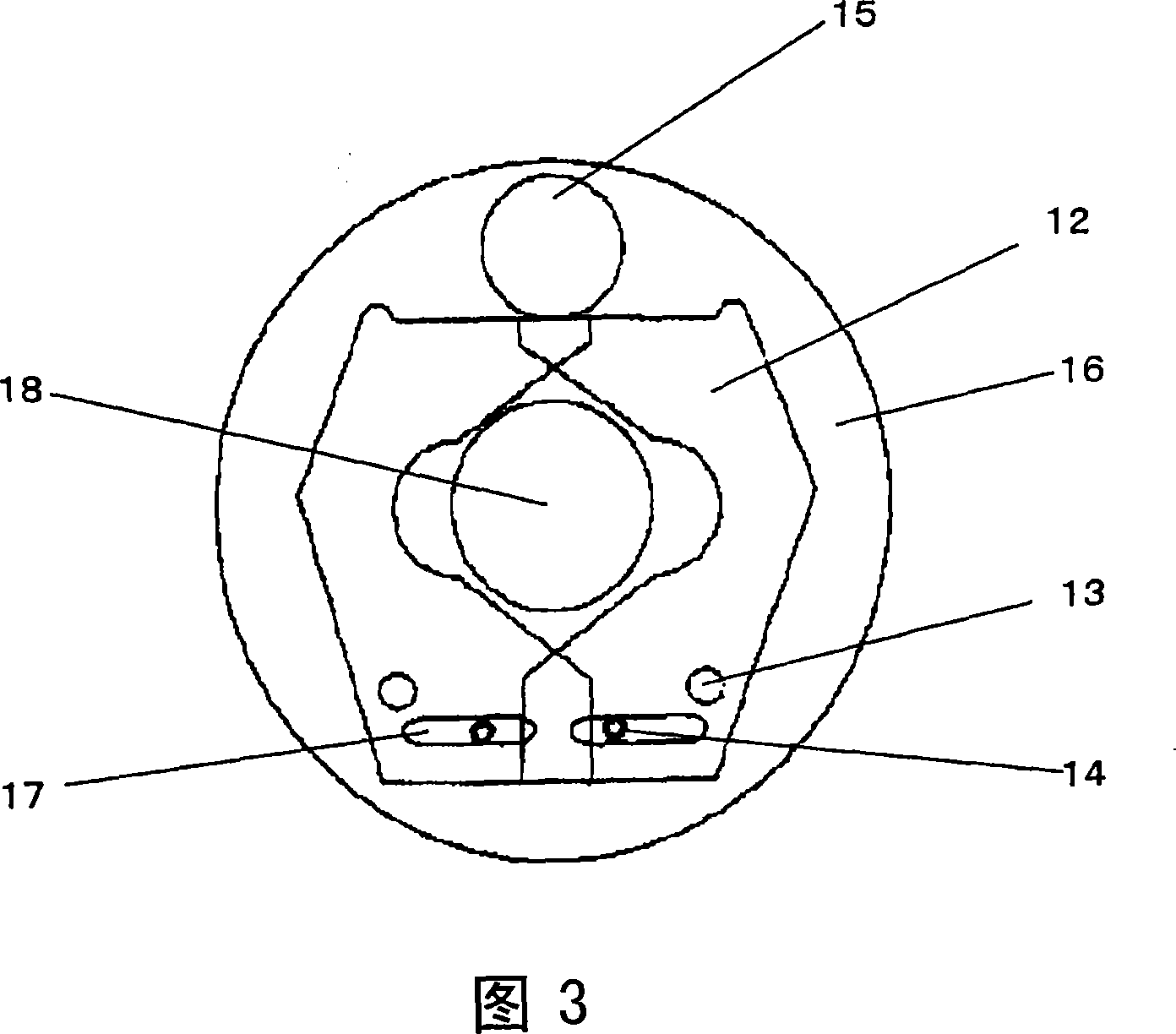

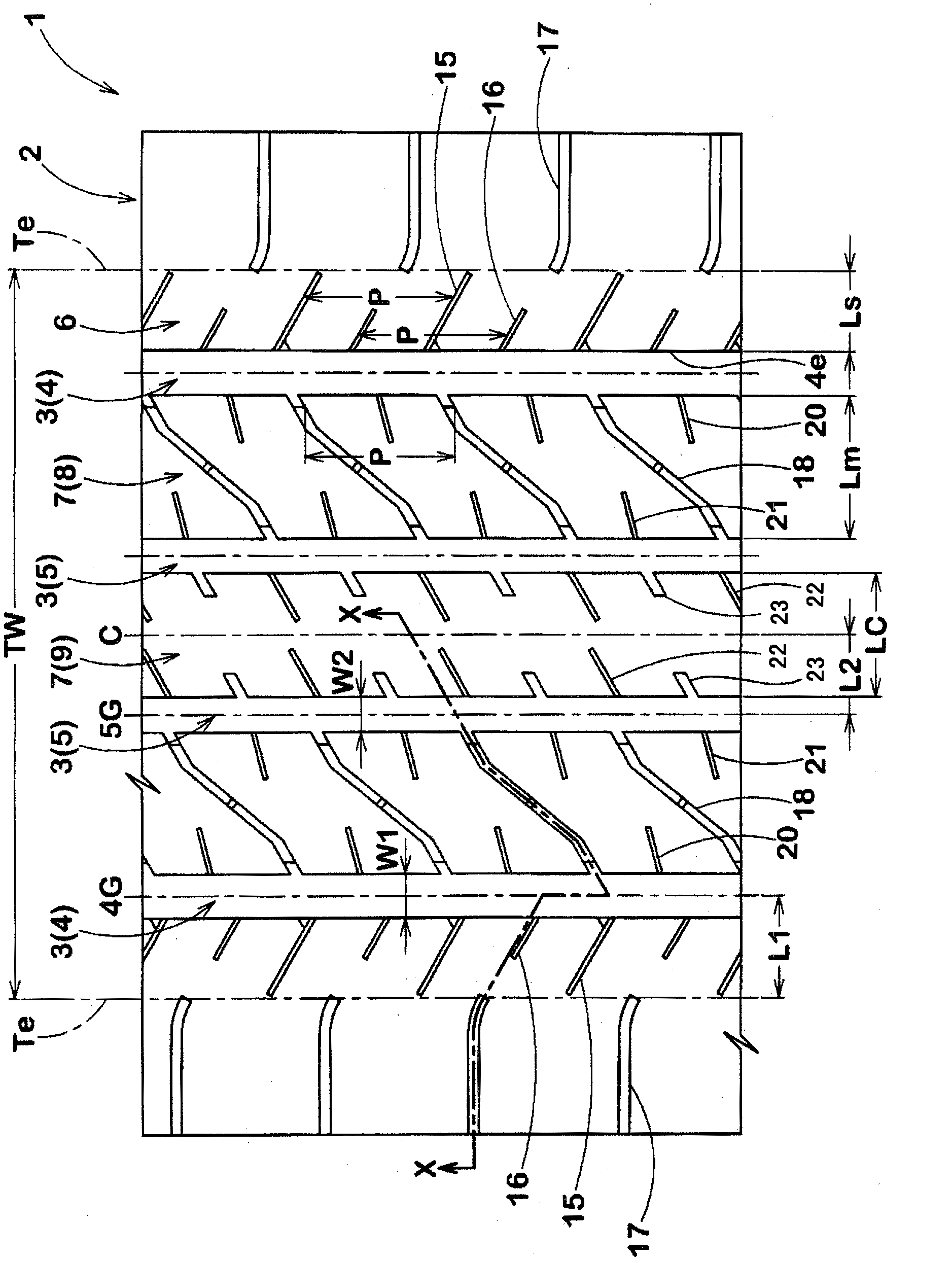

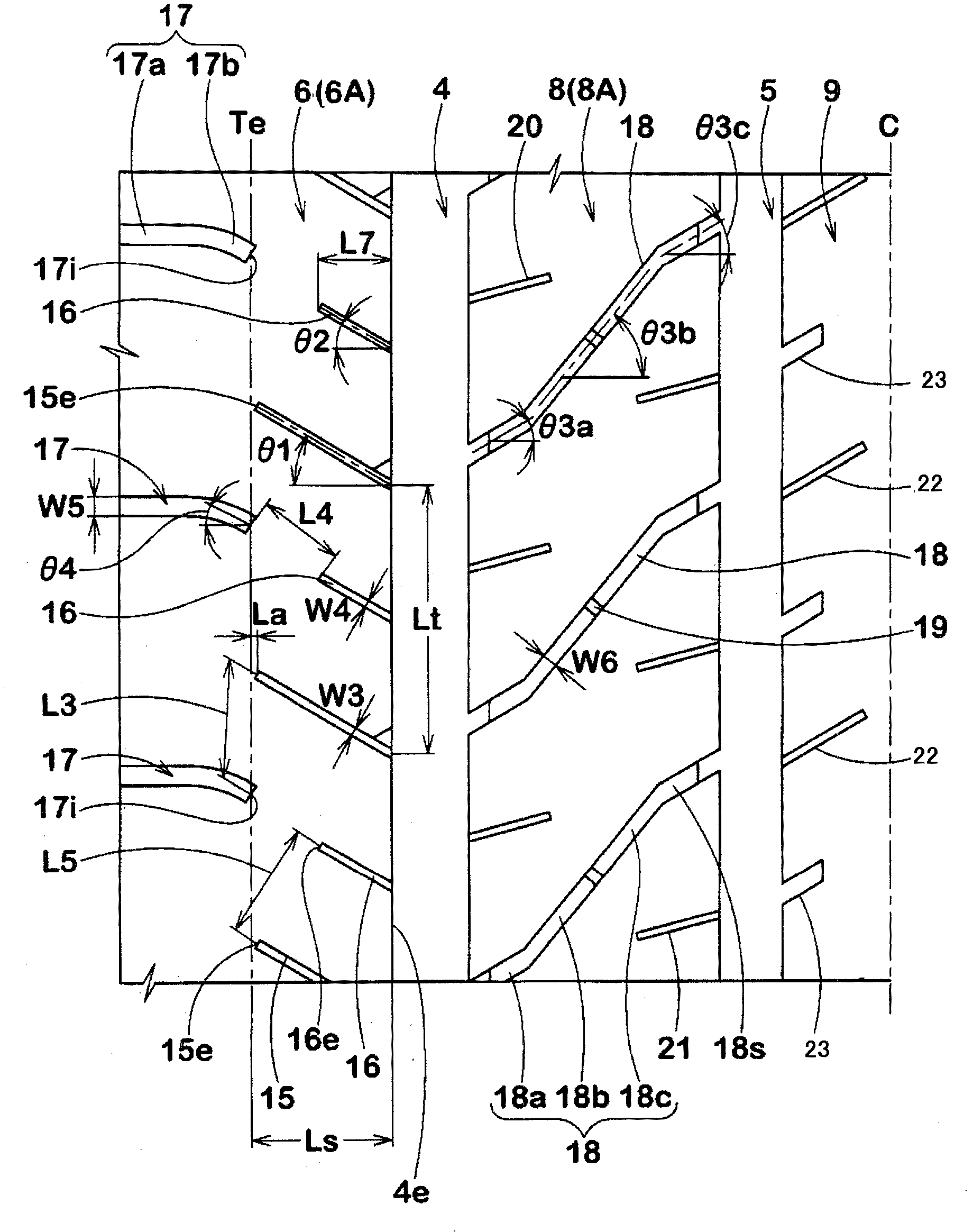

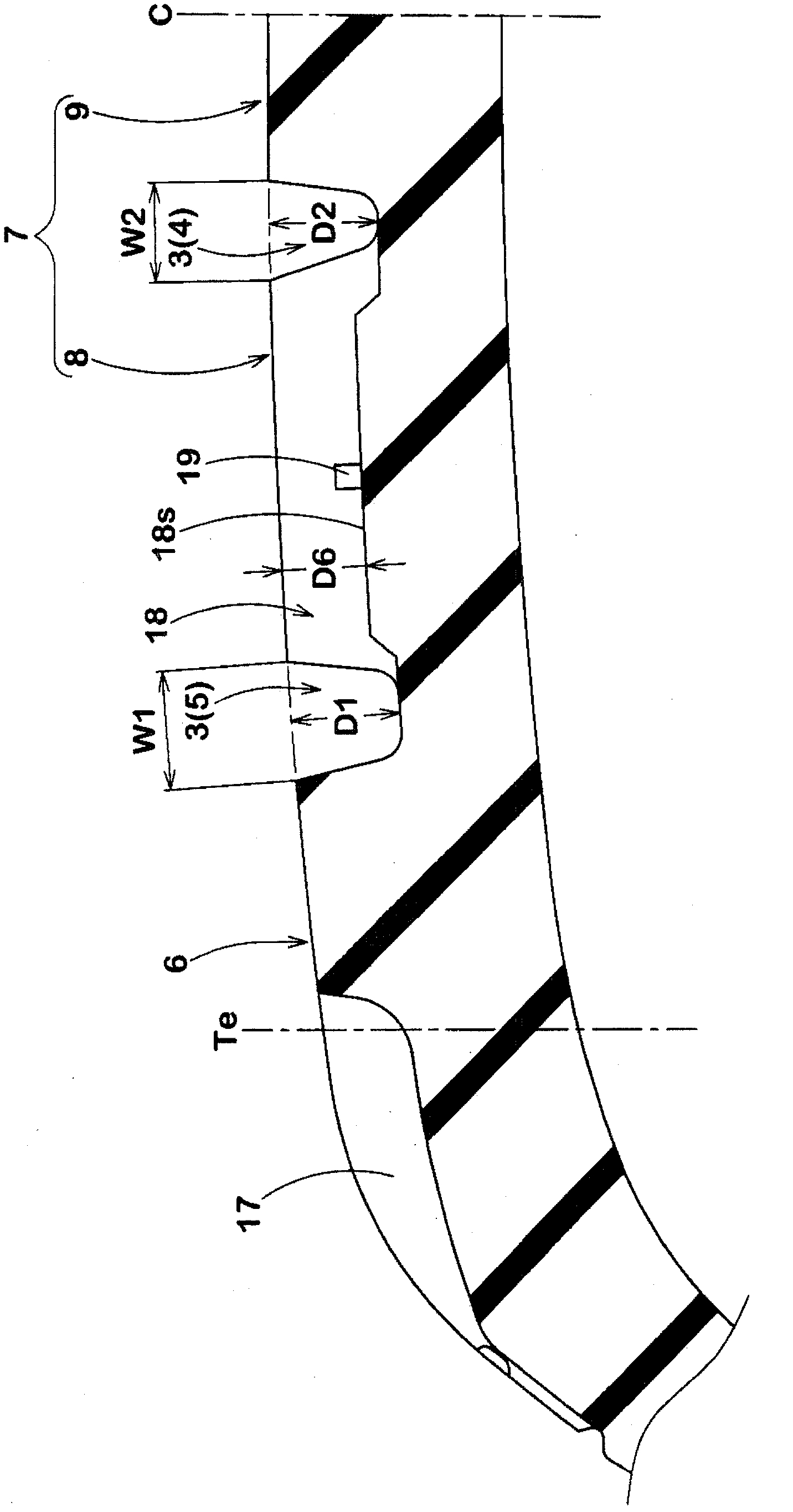

Inflation tire

InactiveCN102649389AImprove impactImprove rigidityTyre tread bands/patternsRoad surfaceWear resistance

The invention discloses an inflation tire, which can be used to maintain the sideslipping performance, the performance on wet road surfaces of the vehicle, and to improve the heal-and-toe wear resistance performance of the vehicle. The inflation tire (1) is provided with a plurality of grooves(3) of a pair of tire shoulder main grooves(4). A land part width (Ls) of a tire shoulder land part(6) is 10 to 15% of a tire surface grounding width (TW). The tire shoulder land part (6) is provided with a first tire shoulder horizontal groove (15), which extends from the part close to the tire surface grounding end (Te),and is inclined at an angle of 10 to 35 degrees relative to the tire shaft; a second tire shoulder horizontal groove (16), which is inclined from the part between the first tire shoulder horizontal grooves (15, 15) at an angle of 10 to 35 degrees towards the axial direction of the tire, and can form a terminal on the tire shaft more close to the inner side than the first tire shoulder horizontal groove(15); a third tire shoulder horizontal groove (17), which is inclined from the outer side of the tire surface grounding end (Te) of the tire shaft towards the inner side of the tire shaft, and can form a terminal close to the tire surface grounding end(Te).

Owner:SUMITOMO RUBBER IND LTD

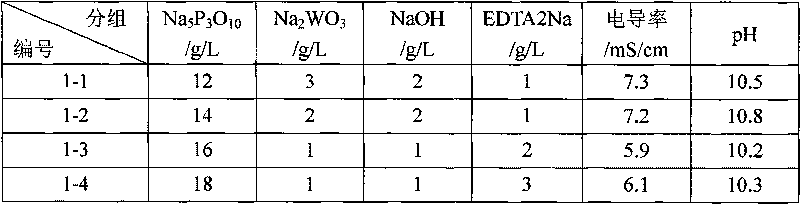

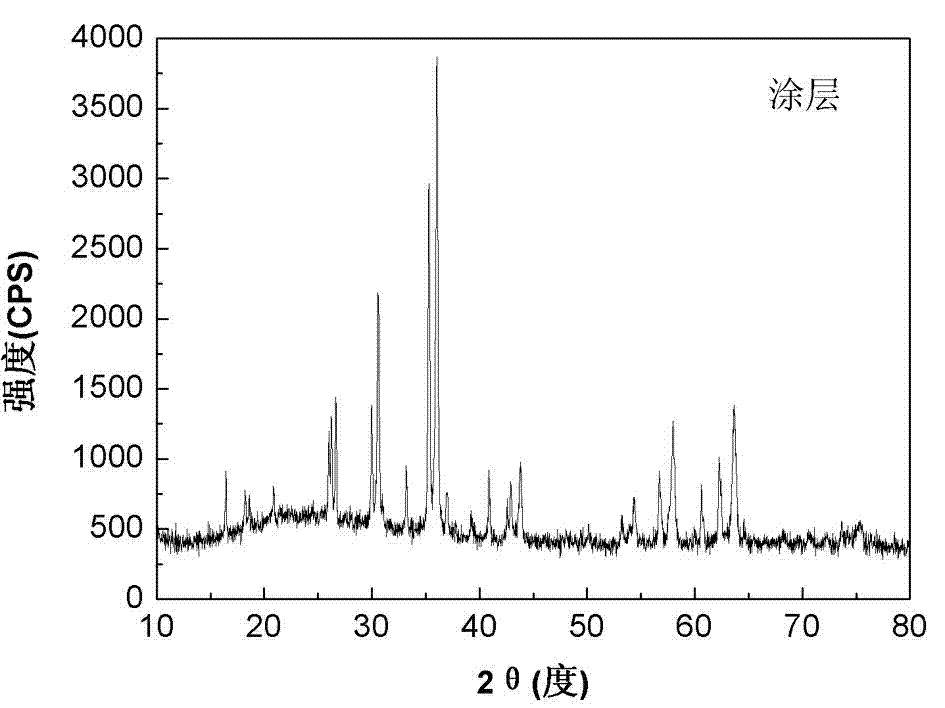

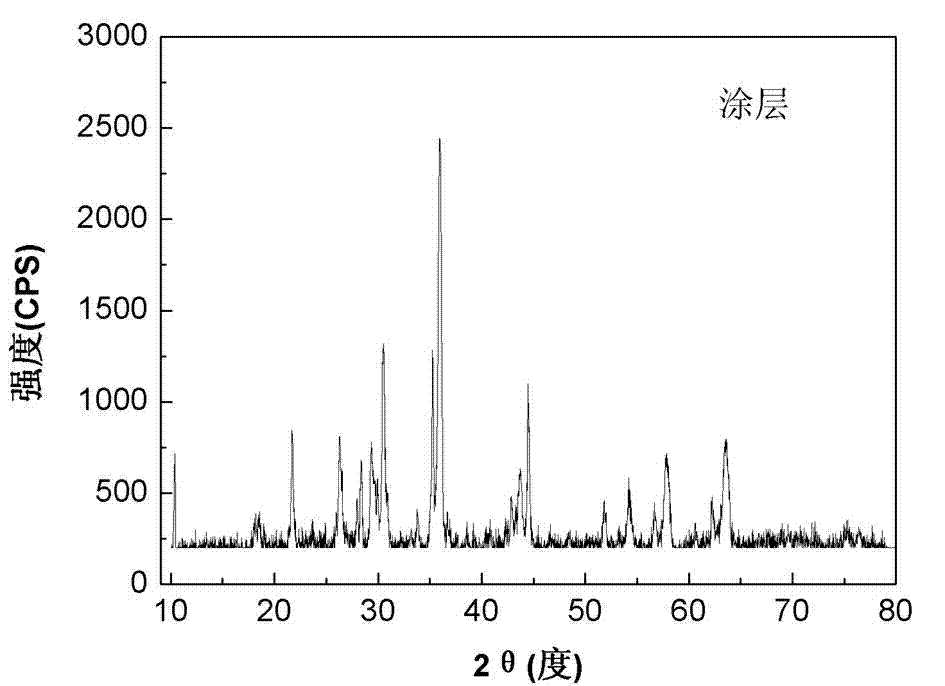

Electrolyte and technology for preparing ceramic coating formed by plasma micro-arc oxidation on zirconium alloy surface

InactiveCN101713091AExtended service lifeImprove wear resistanceSurface reaction electrolytic coatingAlkalinityMicro arc oxidation

The invention discloses an electrolyte and technology for preparing a ceramic coating formed by plasma micro-arc oxidation on a zirconium alloy surface. The technology comprises the following steps: (1) preparing the electrolyte; (2) treating the zirconium alloy surface; and (3) carrying out the micro-arc oxidation technology. The invention has the advantages that the electrolyte is water solution of various compounds, can provide a micro-arc discharge center, and has proper acidity and alkalinity, good ionic conductivity and chemical stability; the solutes of the electrolyte have wide source and low price; the treatment of the zirconium alloy surface has low requirement, and the micro-arc oxidation technology is simple and convenient in control; the ceramic coating formed by micro-arc oxidization has larger thickness, and by adjusting the formula of the electrolyte and the conditions of the micro-arc oxidation technology, the thickness of the ceramic coating can be controlled in a range of 30-80 micrometers; and the ceramic coating has good wear resistance and corrosion resistance.

Owner:INNER MONGOLIA UNIV OF TECH +1

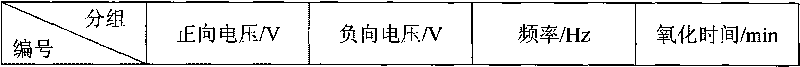

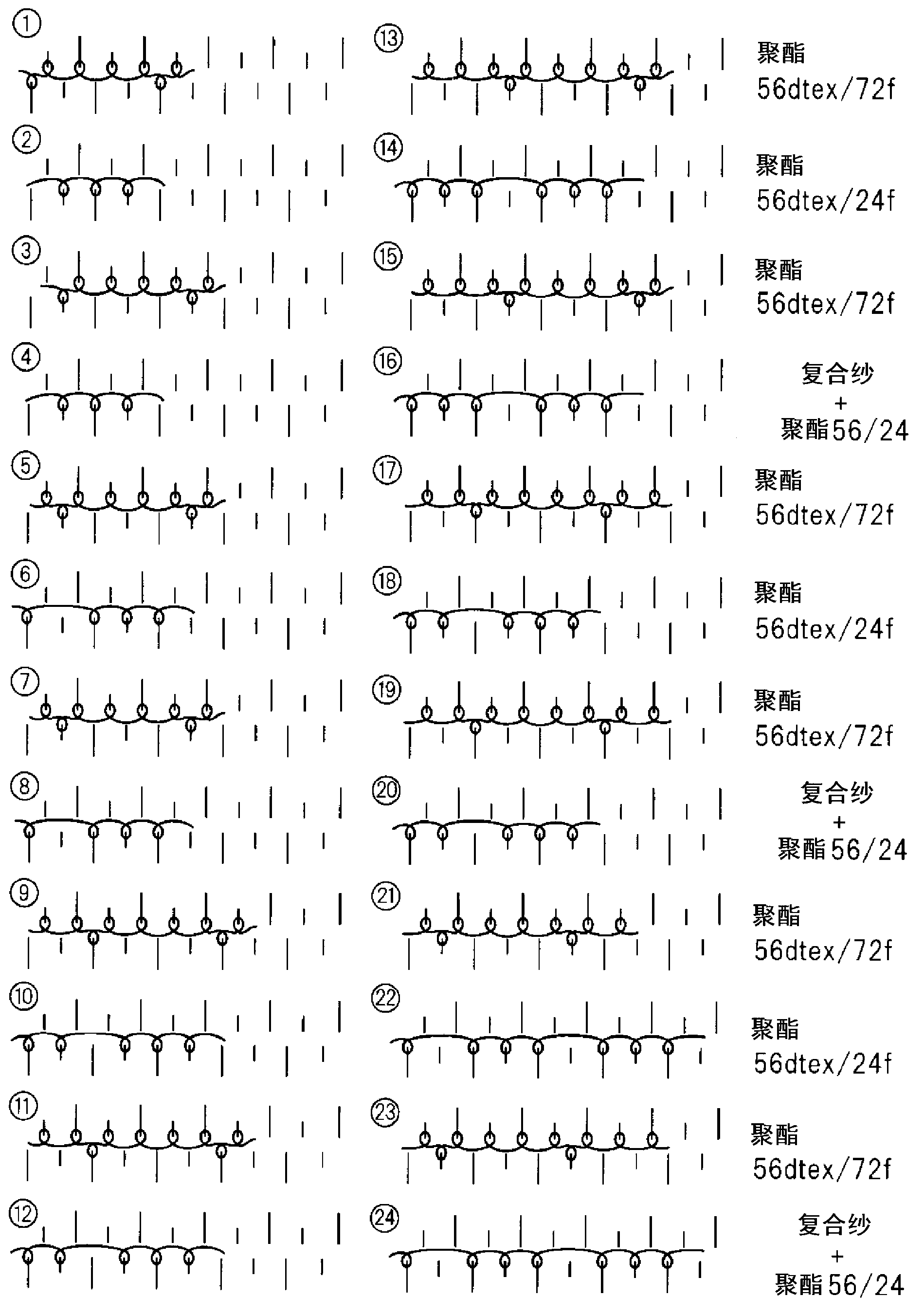

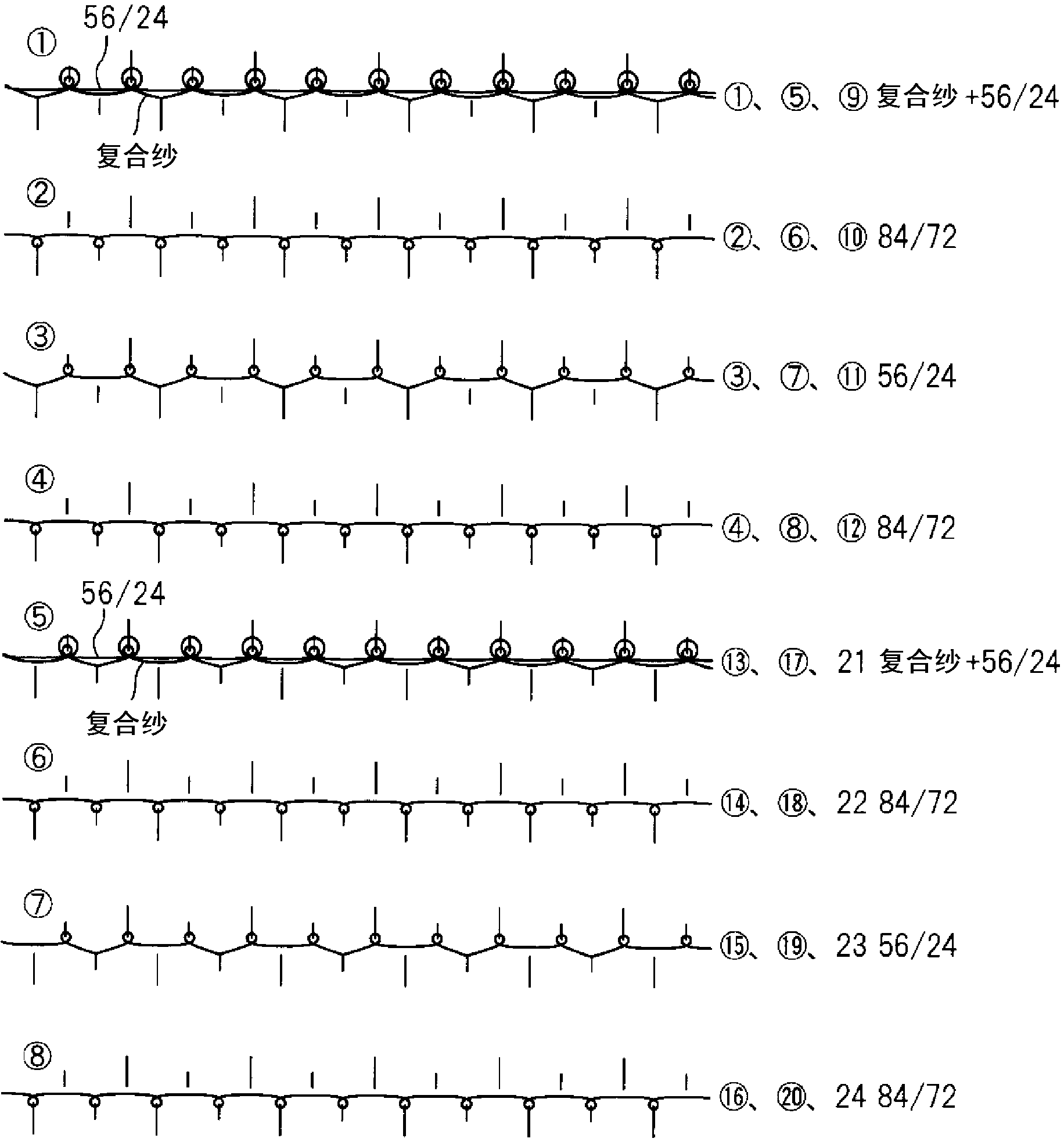

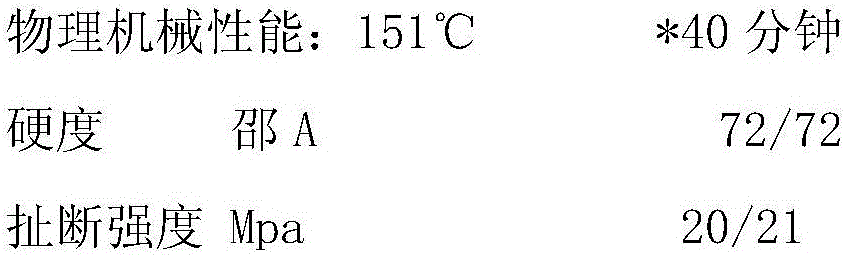

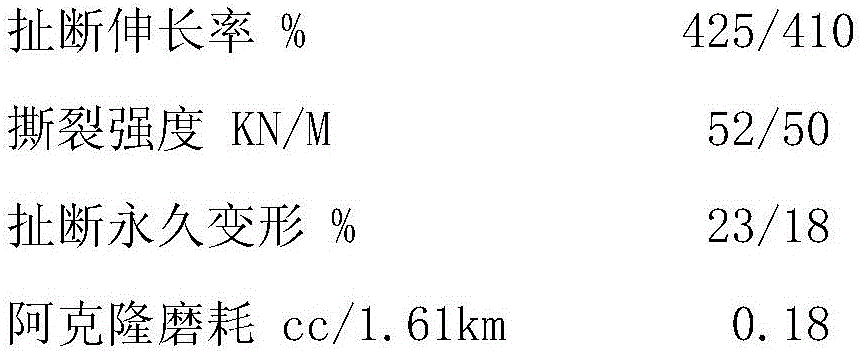

Multilayered knitted fabric

ActiveCN103154344AFeel goodImprove wear performanceOrnamental textile articlesWarp knittingCellulosePerspiration

The knitted fabric of the present invention is knitted fabric which is not stuffy and is comfortable during insensible perspiration or slight perspiration, which even after considerable perspiration due to exercise, etc., does not make the wearer feel sticky, wet, or cold because of the sweat, and which has a satisfactory texture and excellent wear resistance. The knitted fabric comprises 5-25 wt.% cellulosic long fibers and 75-95 wt.% synthetic fibers, and is characterized in that in at least one surface A thereof, the proportion of the area occupied by the cellulosic long fibers to the overall area of the knitted fabric in the region of the knitted fabric which ranges to a depth of 0.13 mm is 0.2-15% and that the surface A to which moisture was imparted in an amount of 200 g / m2 has a degree of coldness to the touch of 180-330 W / m2 C.

Owner:ASAHI KASEI KK

Rubber composition and application thereof

ActiveCN105778179AGood physical and mechanical propertiesGood workmanshipBuilding insulationsPolymer scienceAdjuvant

The invention relates to a rubber composition. The rubber composition is prepared from the ingredients in parts by mass: 80-120 parts of crude rubber, 1-5 parts of peroxide initiator, 2-15 parts of bridging agent, 0.1-1 part of free-radical absorption and release regulator and reinforcing and anti-aging agents, wherein the crude rubber comprises any one to any three of polybutadiene rubber, natural rubber and styrene-butadiene rubber and accounts for 70 percent or more of mass of the crude rubber. According to the rubber composition and the application thereof, a formula of the rubber composition and adjuvants for product cross-linking and the like is provided, so that the requirements of a technical scheme for representatives, i.e., tires, shoe materials and wear resisting plates on good properties and good industrial adaptability effect can be met; cost and environmentally-friendliness can be taken into account simultaneously.

Owner:NANJING SIKAI RUBBER & PLASTIC PROD CO LTD

Infrared radiation coating suitable for metal matrix and preparation method

InactiveCN102786820AReduced TEC gapImprove thermal shock resistanceCoatingsAl powderDefoaming Agents

The invention discloses an infrared radiation coating suitable for a metal matrix and a preparation method, a mass ratio of a component A to a component B is 80-120%, wherein the component A comprises the following raw materials by mass percentage: 30-90% of transitional metal oxides infrared radiation powder, 2-20% of inorganic bind additive, 0-30% of silicon carbide, 0-30% of corundum, 0-20% of zirconia, 0-20% of Ni powder, 0-20% of Zn powder, 0-20% of Al powder, 0-1% of carbon powder and 0-10% of sodium fluosilicate; the component B comprises the following raw materials by mass percentage: 60-95% of sodium silicate, 0-35% of water, 0-3% of dispersant, 0-1% of thickener, 0-1% of defoamer and 0-1% of leveling agent. After drying and solidifying the coating, the surface of the formed coating is compact, the infrared radiation coating has excellent infrared radiation performance and high temperature stability, and can firmly bonded with the metal matrix.

Owner:WUHAN UNIV OF TECH

Corrosion resistant low noise semi-metallic brake pad

ActiveCN101555916AImprove heat resistanceGood instantaneous high temperature resistanceFriction liningLow noiseFiber

A corrosion resistant low noise semi-metallic brake pad comprises the following components according to weight percentages: 2-4% of nitrile rubber buna, 3-5% of tyre powder, 3-5% of expandable graphite, 9-13% of phenolic resin, 10-15% of stainless steel chopped fibre, 4-7% of red copper fibre, 2-3% of cashew nut oil friction powder, 3-5% of graphite particle, 7-10% of superfine ferric oxide powder, 3-5% of diatomite, 7-12% of acicular wollastonite fibre, 10-15% of barite, 3-5% of chromite, 4-8% of sepiolite fibre, 0.2-0.5% of zinc stearate, 2-3% of zirconite, 3-5% of boron nitride and 2-3% of supramoly; the brake pad has the characteristics of corrosion resistant performance, high frictional coefficient, satisfactory high temperature and thermal decay resistant performance, long service life, and the like. After the brake pad is used, the car brake is sensitive, the braking is stable and brake noise is low, and the brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

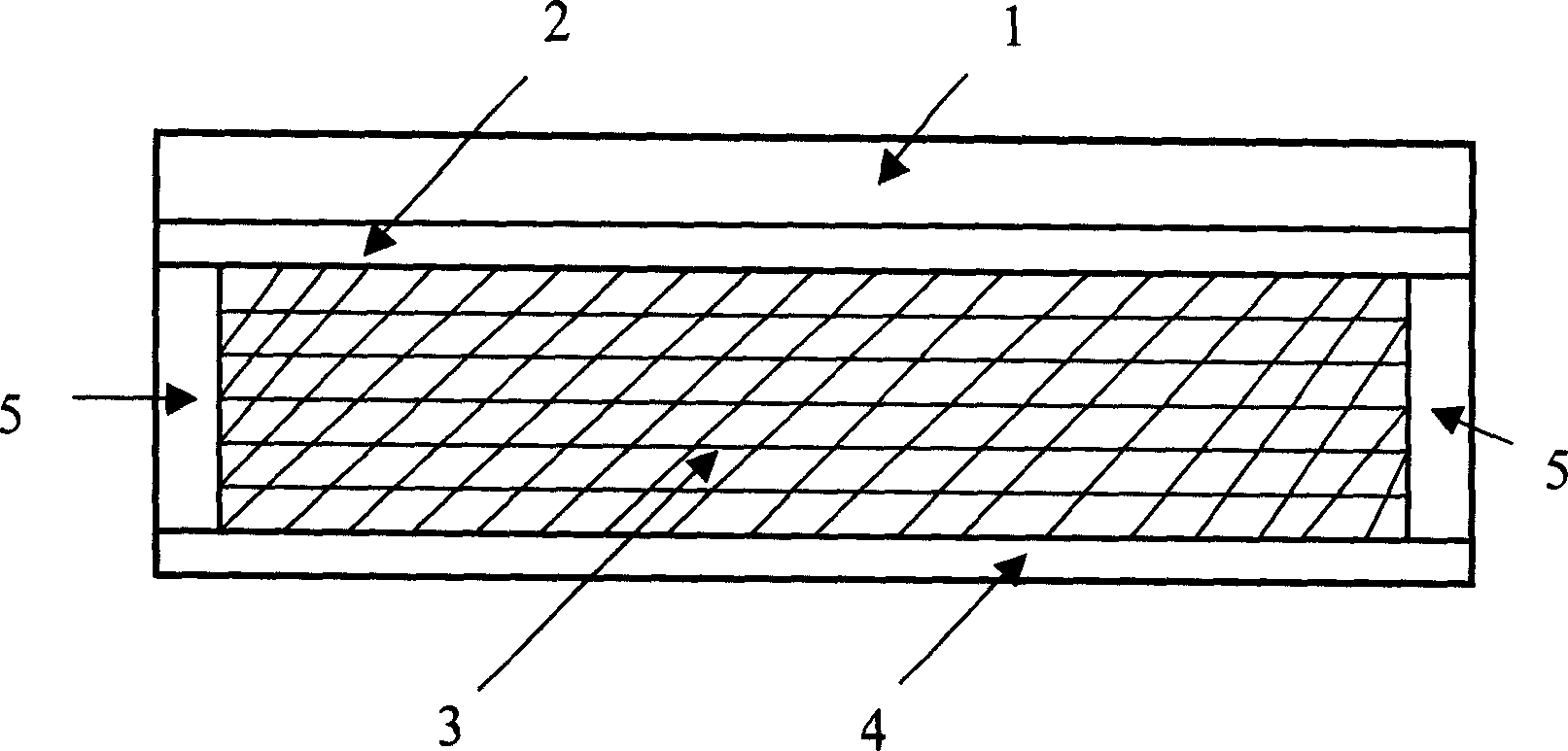

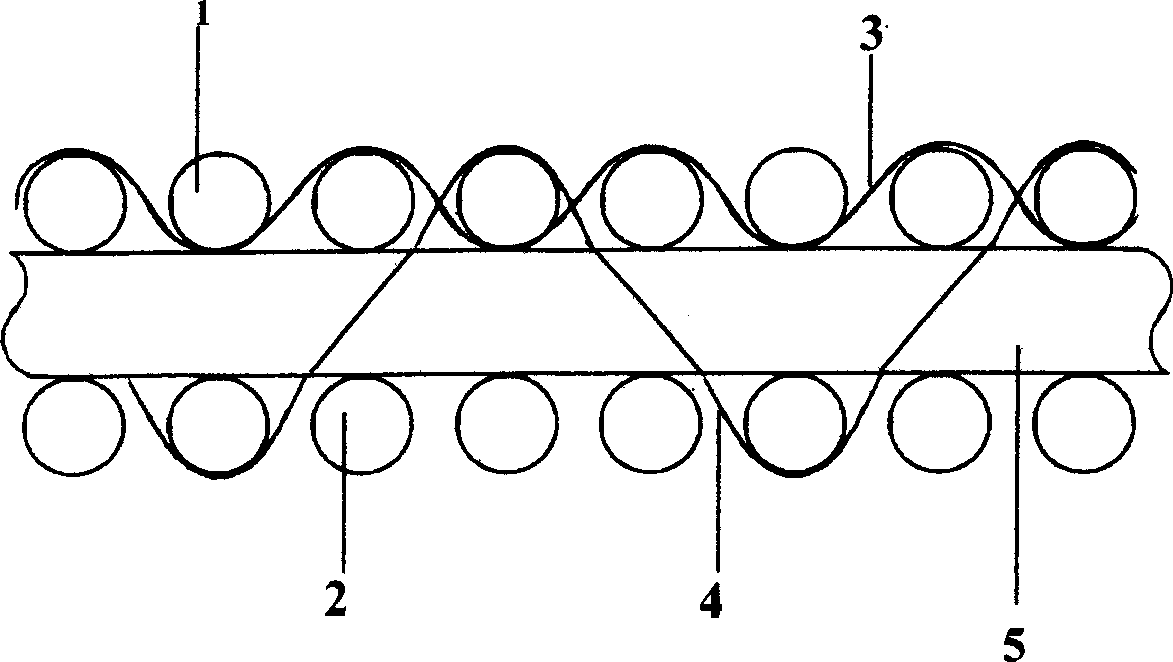

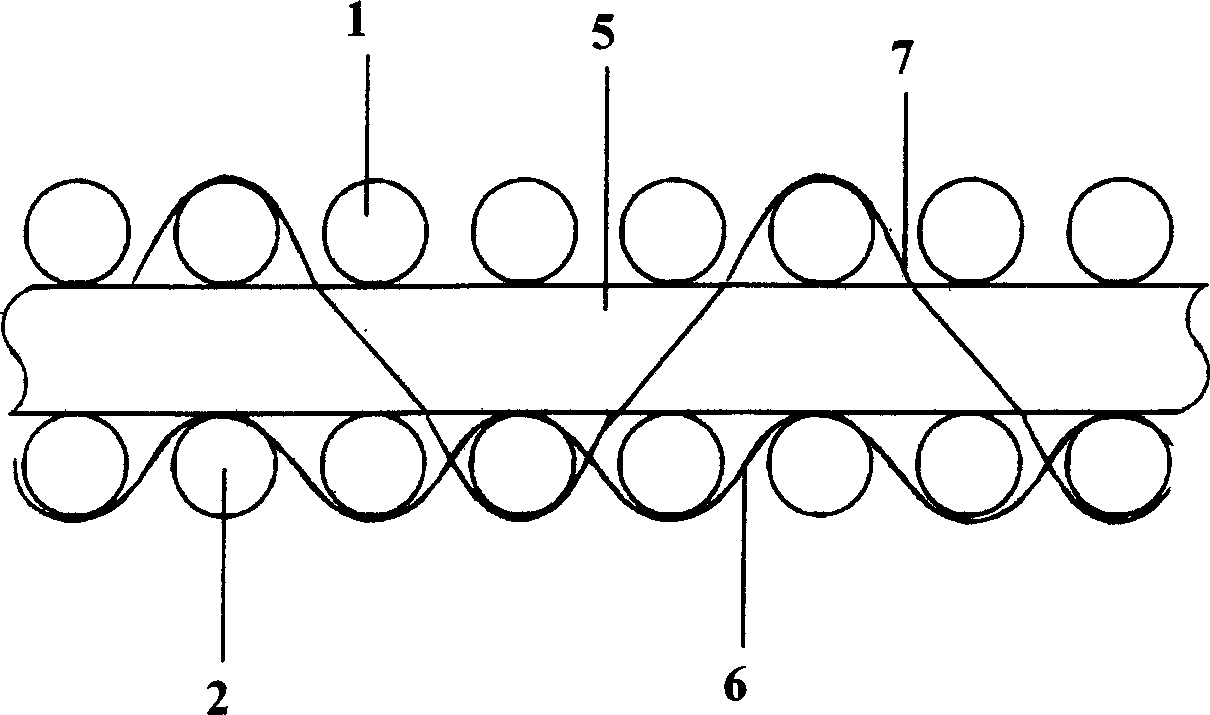

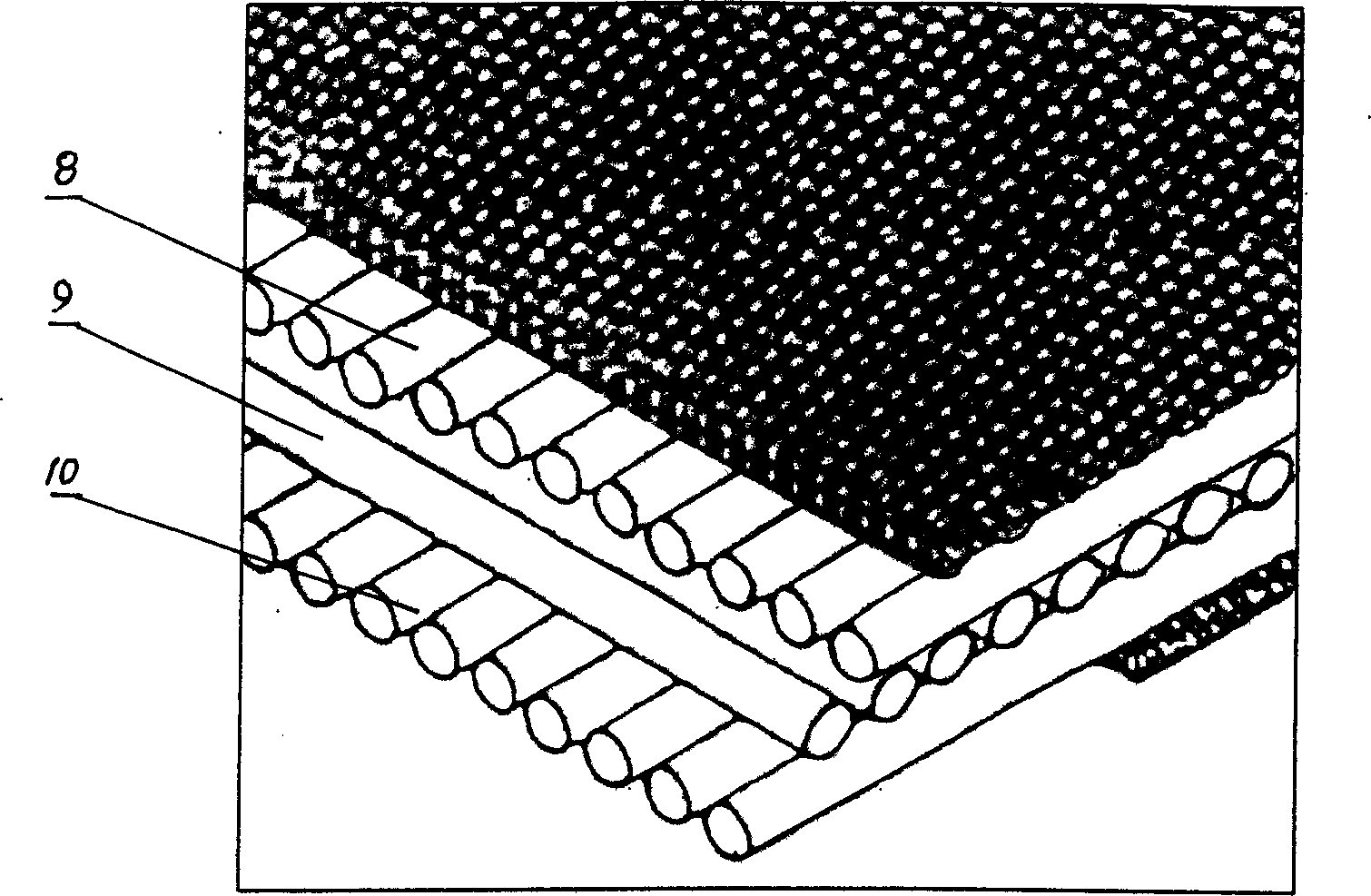

Three-layer non-mixed bottom net papermaking press felt

ActiveCN1793498AImprove wear performanceImprove wear resistancePaper-making machinesYarnSoluble fiber

The invention discloses multilayer bottom mesh paper making felt with non interlaced warp and weft. It is formed by stabbing fiber web at the side of the bottom web. It is added weft layer as middle layer, used Vienna yarn as upper and lower layer fabric weft and warp connecting line. The bottom web is stabbed and washed to form three layers with non interlaced warp and weft after soluble fiber yarn hydrolyzing. It has good gas and water permeability, flattening, and wear, compression, cockle resilience.

Owner:SICHUAN VANOV TECH FABRIC

Thermoplastic elastomer foam material and preparation method thereof

The invention relates to the technical field of a foam material, in particular to a thermoplastic elastomer foam material and a preparation method thereof. The thermoplastic elastomer foam material consists of following raw materials in parts by weight: 20 to 30 parts of styrene-ethylene butylene-styrene (SEBS), 20 to 30 parts of white mineral oil, 25 to 35 parts of calcium carbonate, 3 to 8 parts of ethylene vinyl acetate (EVA), 1 to 5 parts of polyolefin elastomer (POE) and 0.1 to 0.5 parts of zinc stearate. Multiple raw materials such as calcium carbonate, EVA and POE are selected to be matched with the SEBS to use, so that the prepared foam material is not only low in cost and good in abradability and compression deformation, but also other physical indexes such as hardness, elasticity and the like are improved. The preparation method is simple in process and low in cost.

Owner:东莞市鑫塑源塑胶科技有限公司

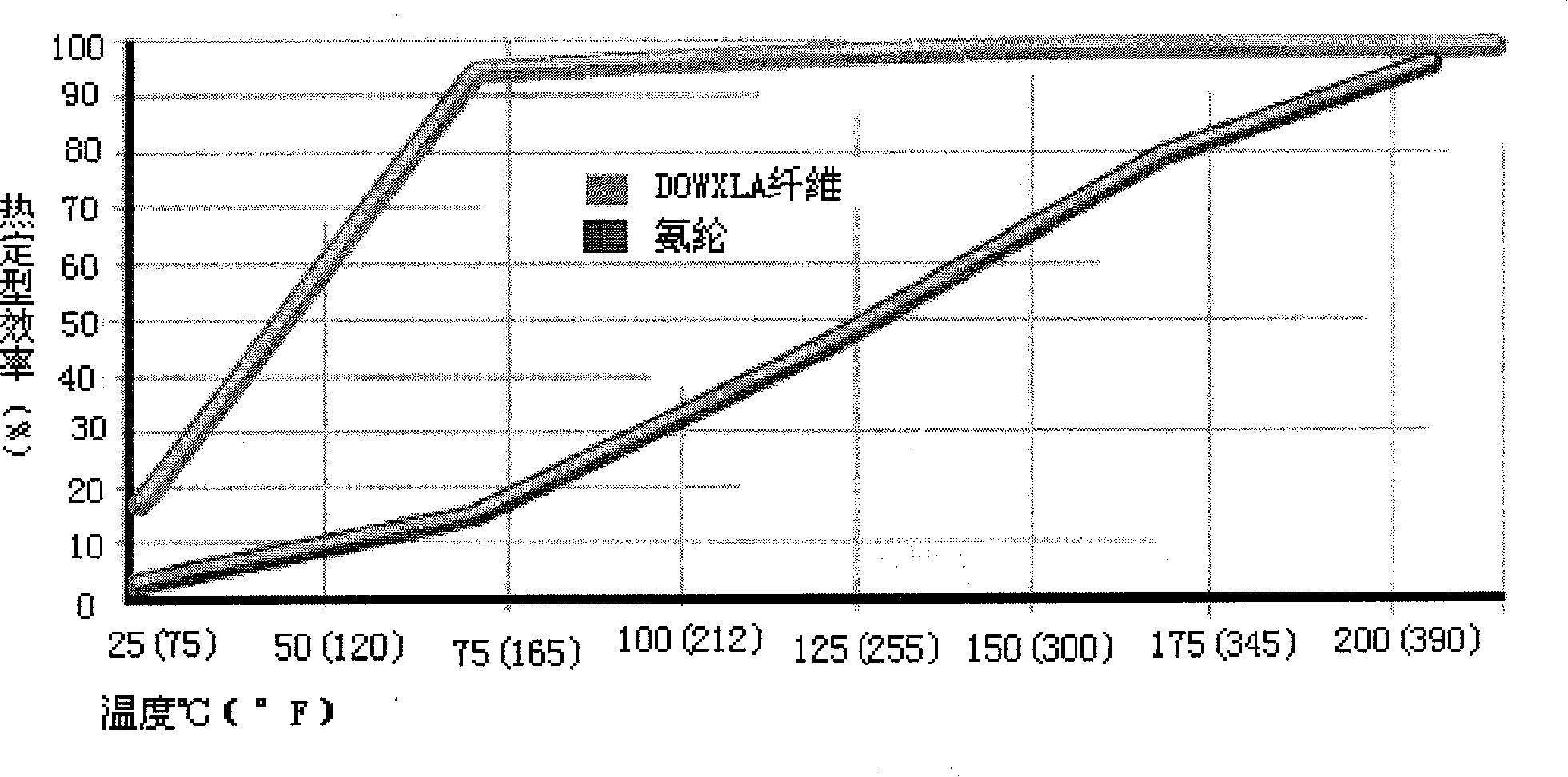

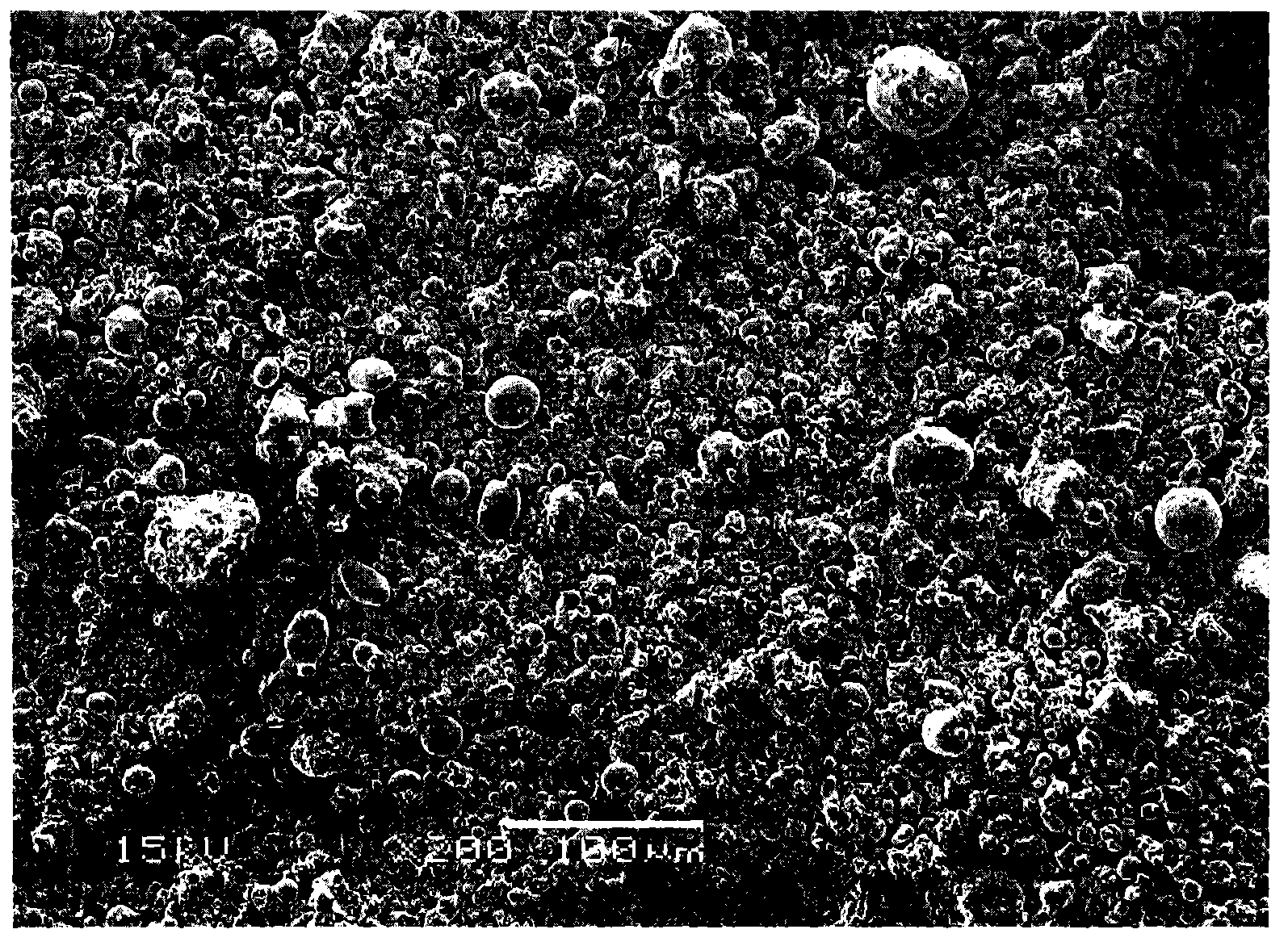

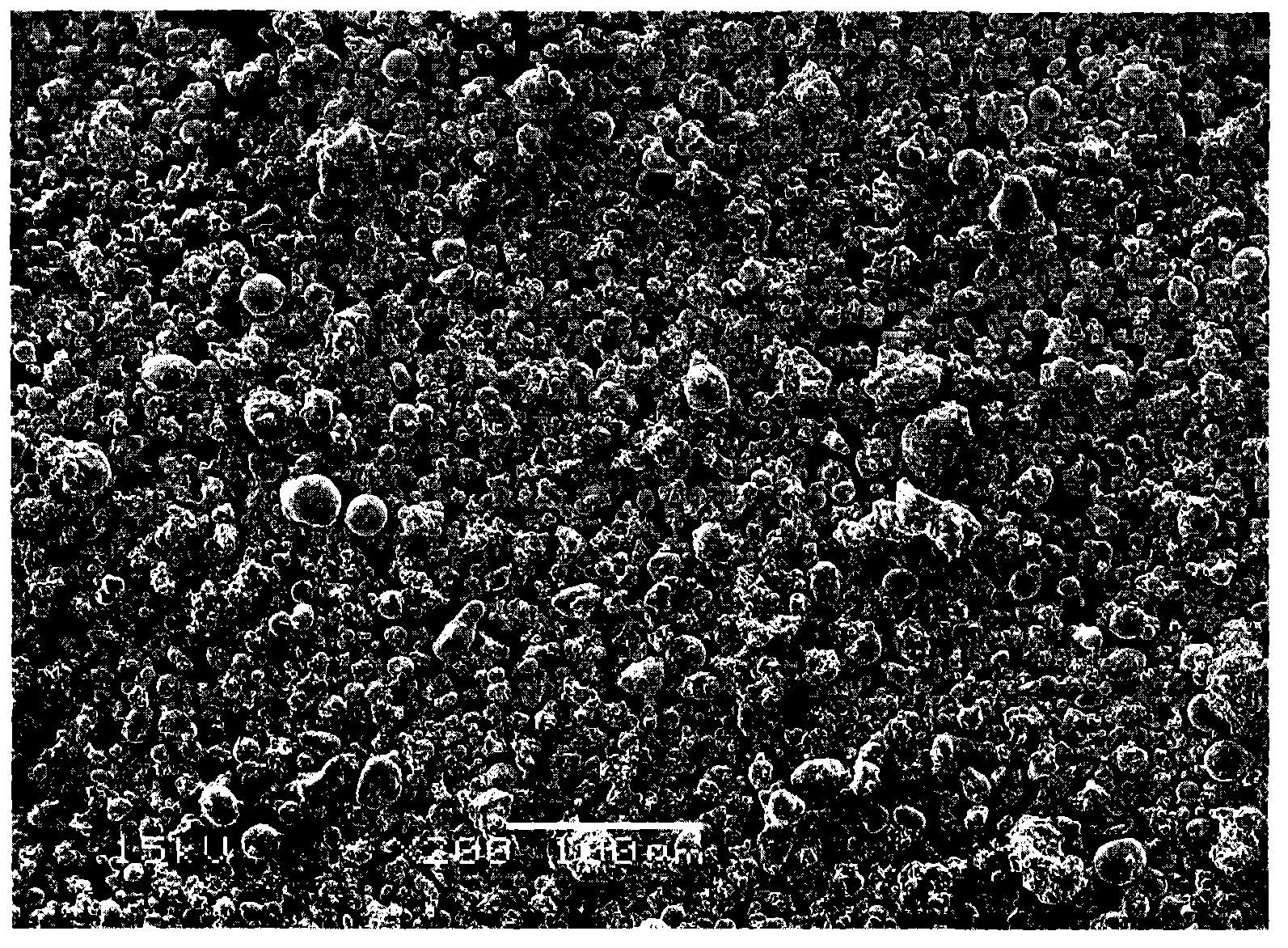

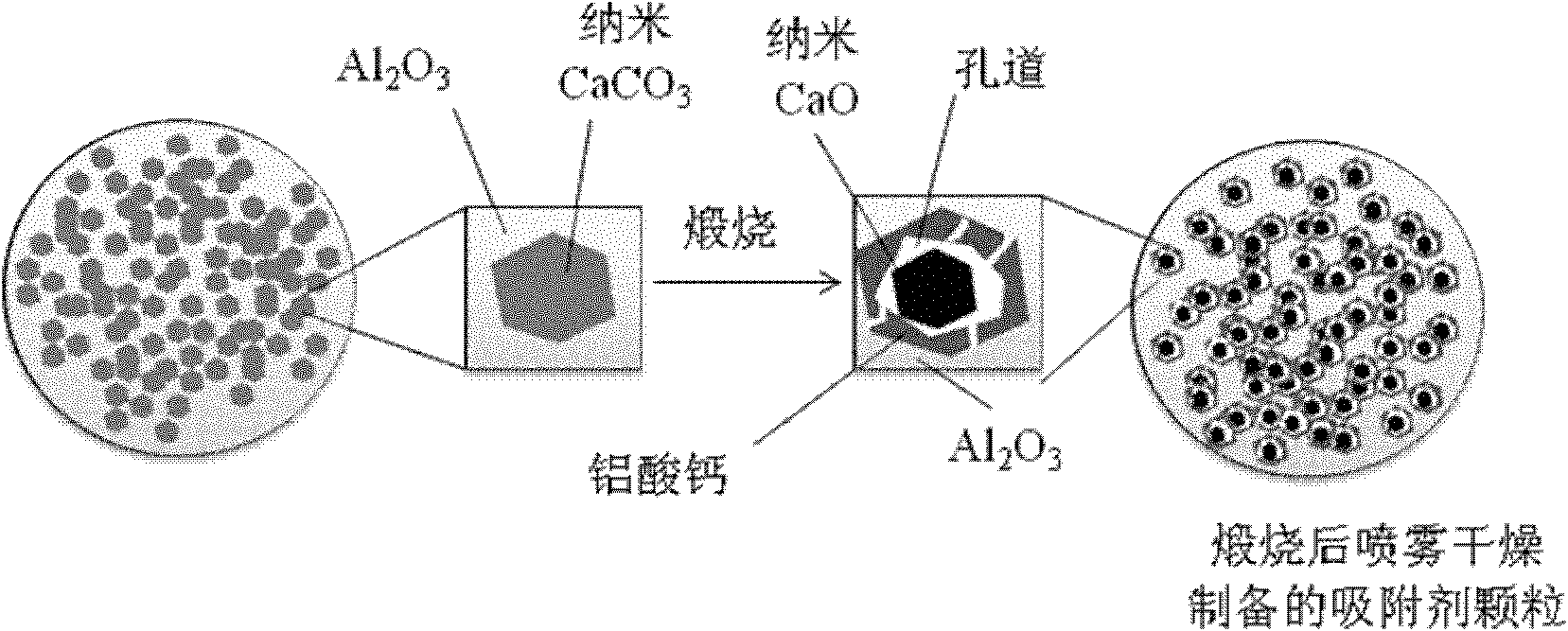

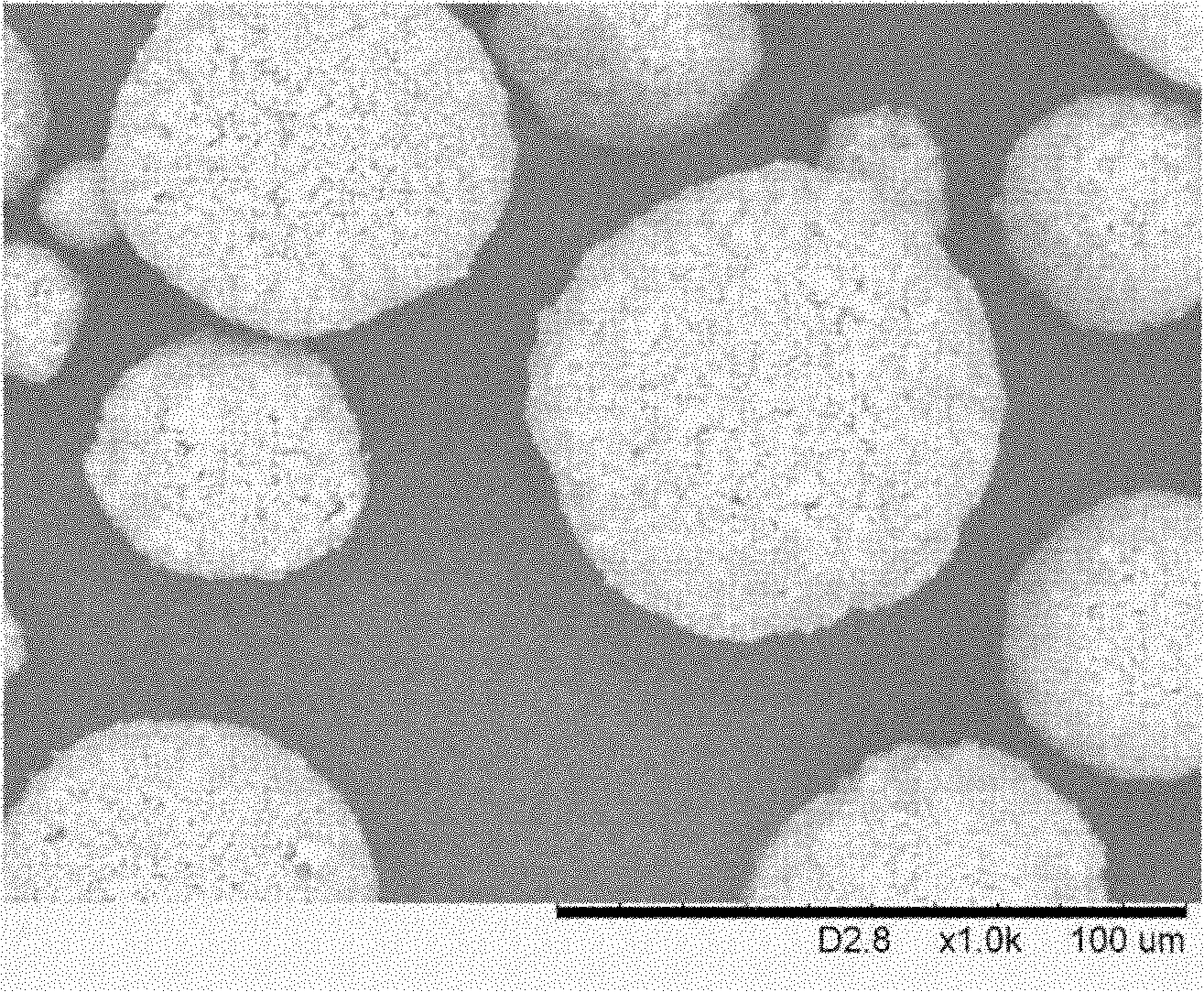

Method for preparing wear-resistant nano calcium oxide-based carbon dioxide reaction adsorbent

ActiveCN101961638ASmall particlesImprove wear performanceGas treatmentOther chemical processesSteam reformingSorbent

The invention discloses a method for preparing a wear-resistant nano calcium oxide-based carbon dioxide (CO2) reaction adsorbent. The method comprises the following steps of: dispersing calcium carbonate (CaCO3) particles in water; adding aluminasol; stirring until pulp is well distributed; spraying and pelleting to obtain microspherical particles with particle diameter of 20 to 250 mu m; and calcining the microspheric particles to obtain the spherical wear-resistant nano calcium oxide-based CO2 reaction adsorbent. The wear strength of the wear-resistant nano calcium oxide-based CO2 reaction adsorbent can be improved by the method; and the method can be widely applied to industrial processes of removing the CO2 from industrial smoke, removing the CO2 by a reaction, a new adsorption strengthening methane steam reforming hydrogen production process and the like.

Owner:ZHEJIANG UNIV

Invisible coating material and preparation method thereof

ActiveCN103013256AImprove absorbing performanceLow areal densityCoatingsAcrylic resinCarbon nanotube

The invention discloses an invisible coating material and a preparation method thereof. The invisible coating material comprises a component A and a component B in a weight ratio of (10-15): 1, wherein the component A is prepared from the following raw materials in weight percentage: 40-60% of hydroxyl acrylic resin, 10-15% of carbon nanotube, 5-10% of ceramic powder, 5-8% of vacuum glass microbead, 1-5% of siloxane coupling agent, 1-10% of nano-sized barium sulphate, 1-10% of nano-sized titanium dioxide and 5-10% of dimethylbenzene and butyl acetate mixture; and the component B is prepared from the following raw material in weight percentage: 100% of biuret. The invention provides the invisible coating material with good invisible effect, high wave-absorbing capacity, small surface density, light weight and high bonding strength and the preparation method thereof.

Owner:山东孚日宣威新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com