Patents

Literature

488results about How to "High fatigue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

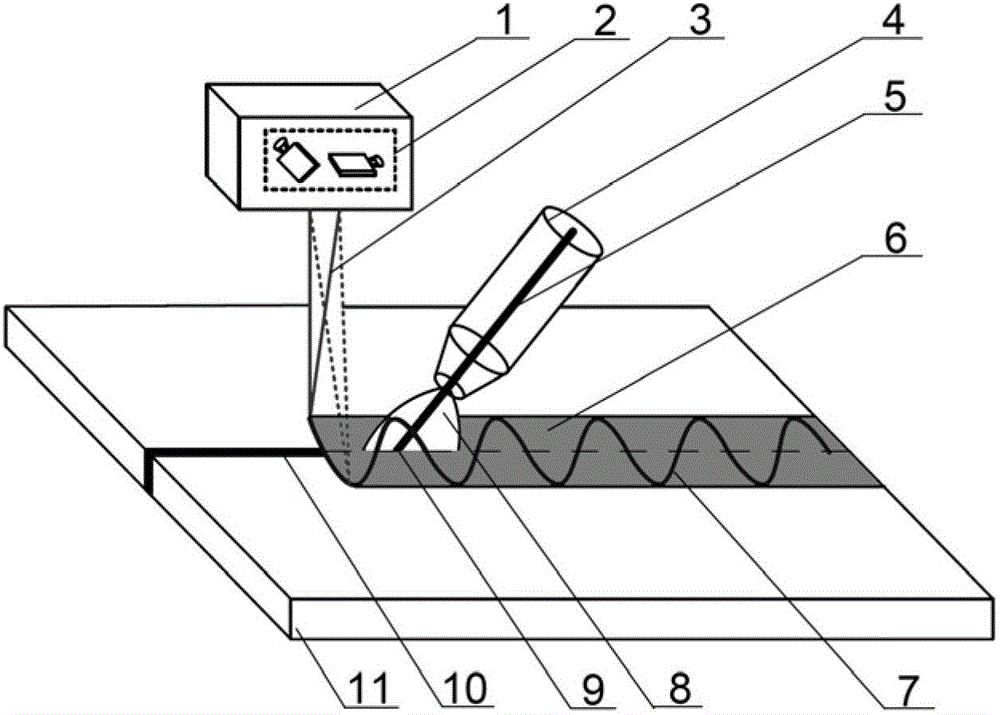

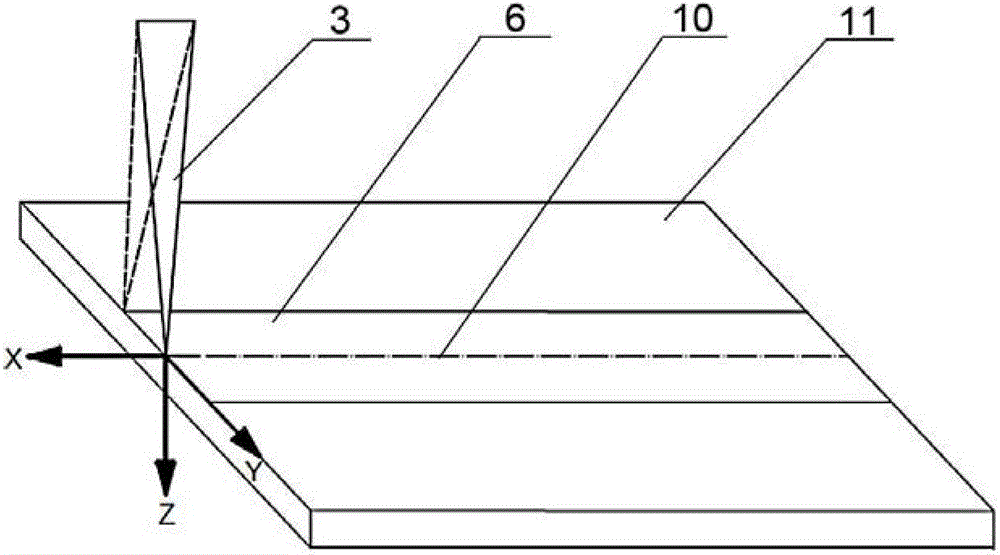

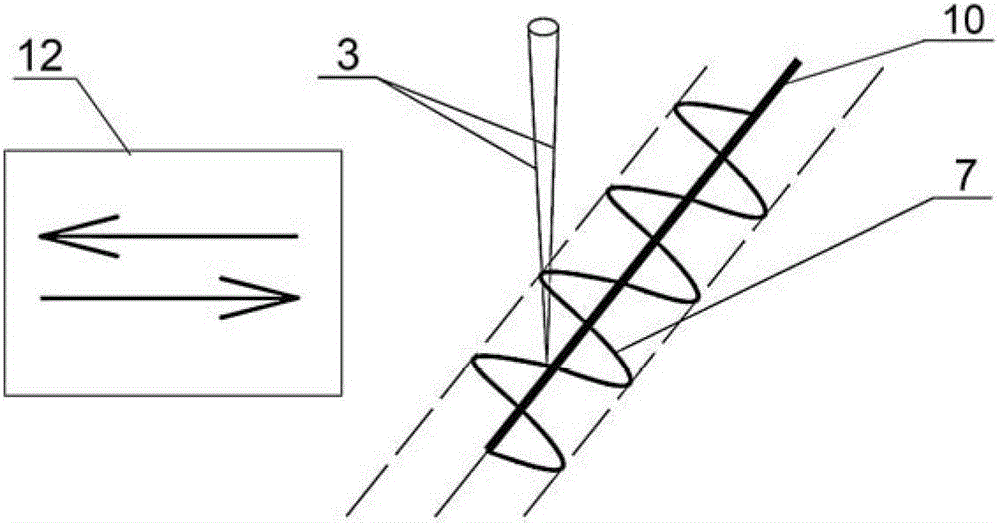

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

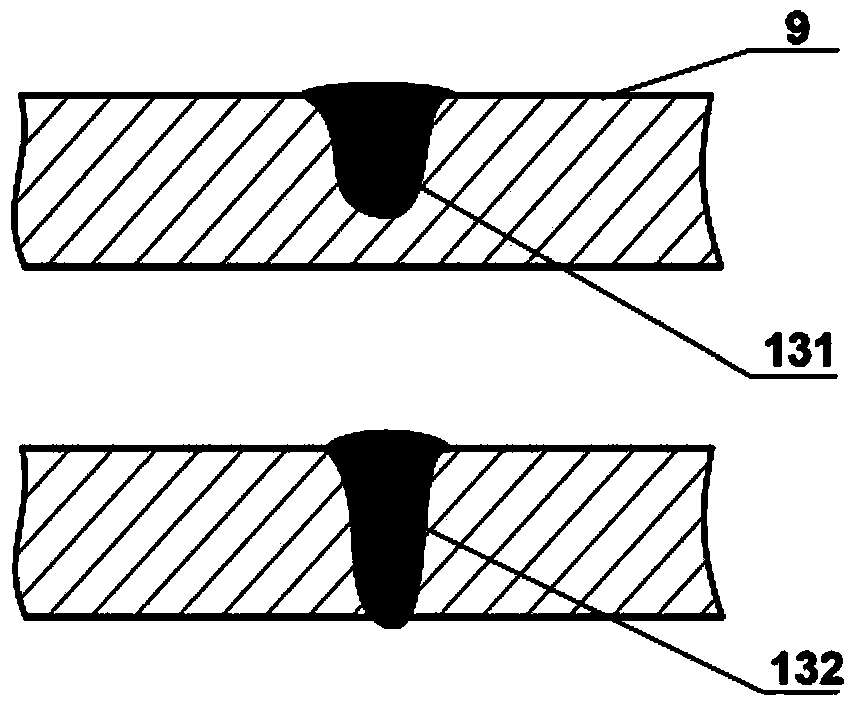

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

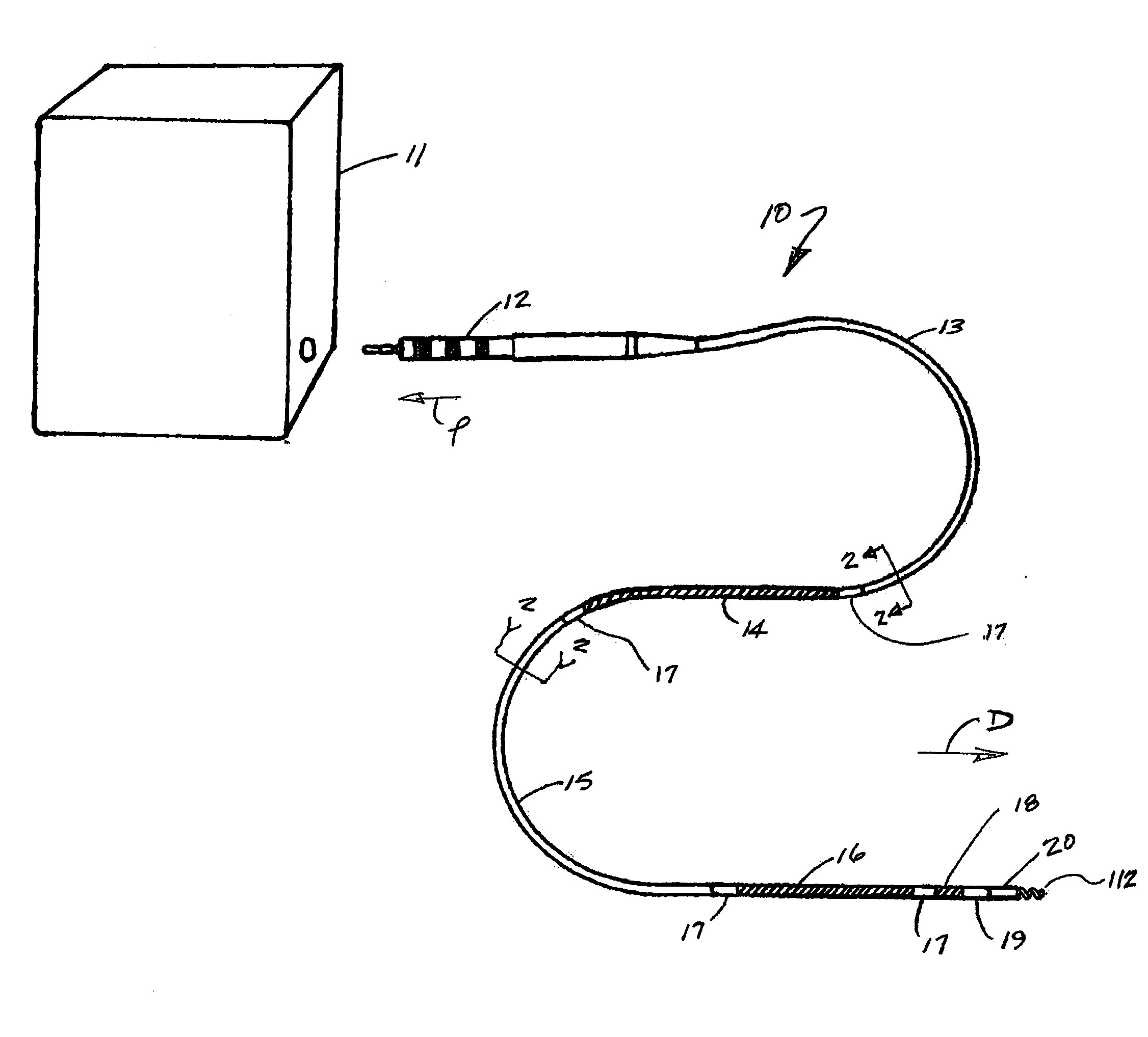

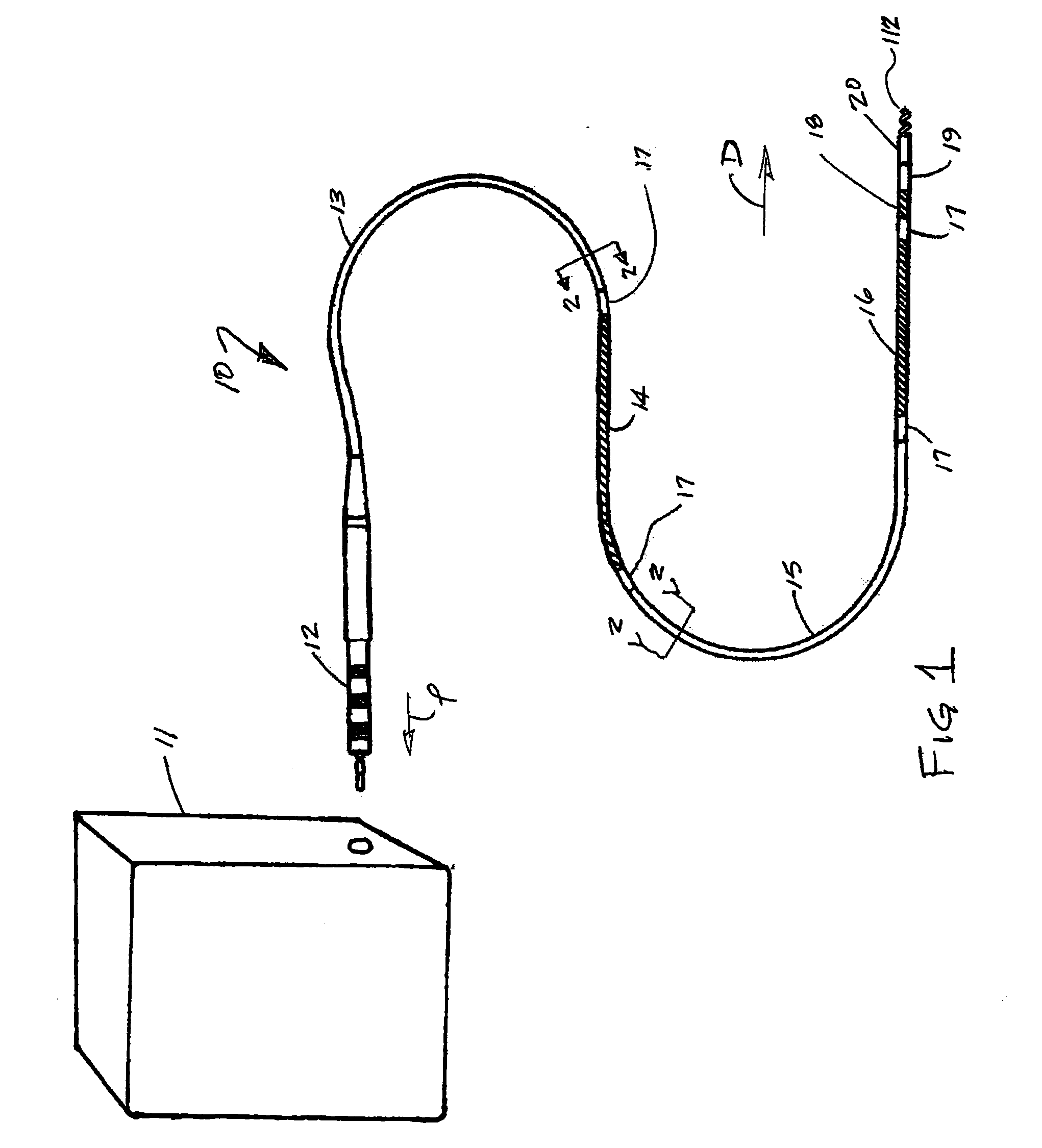

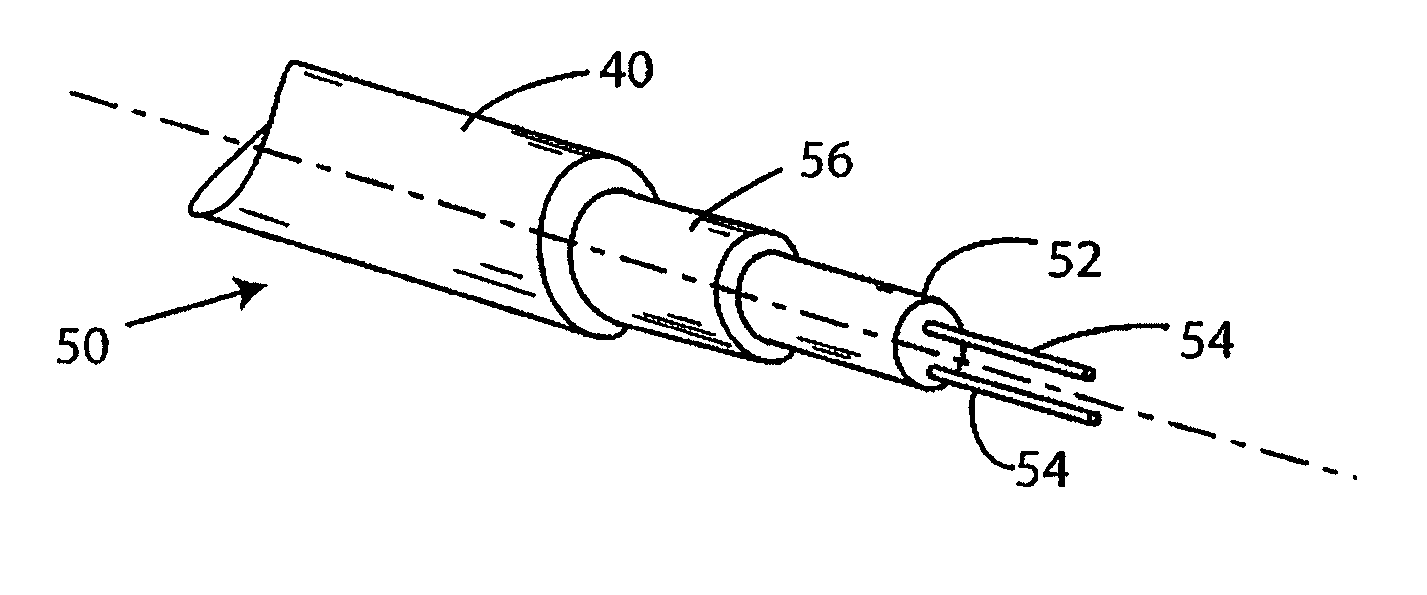

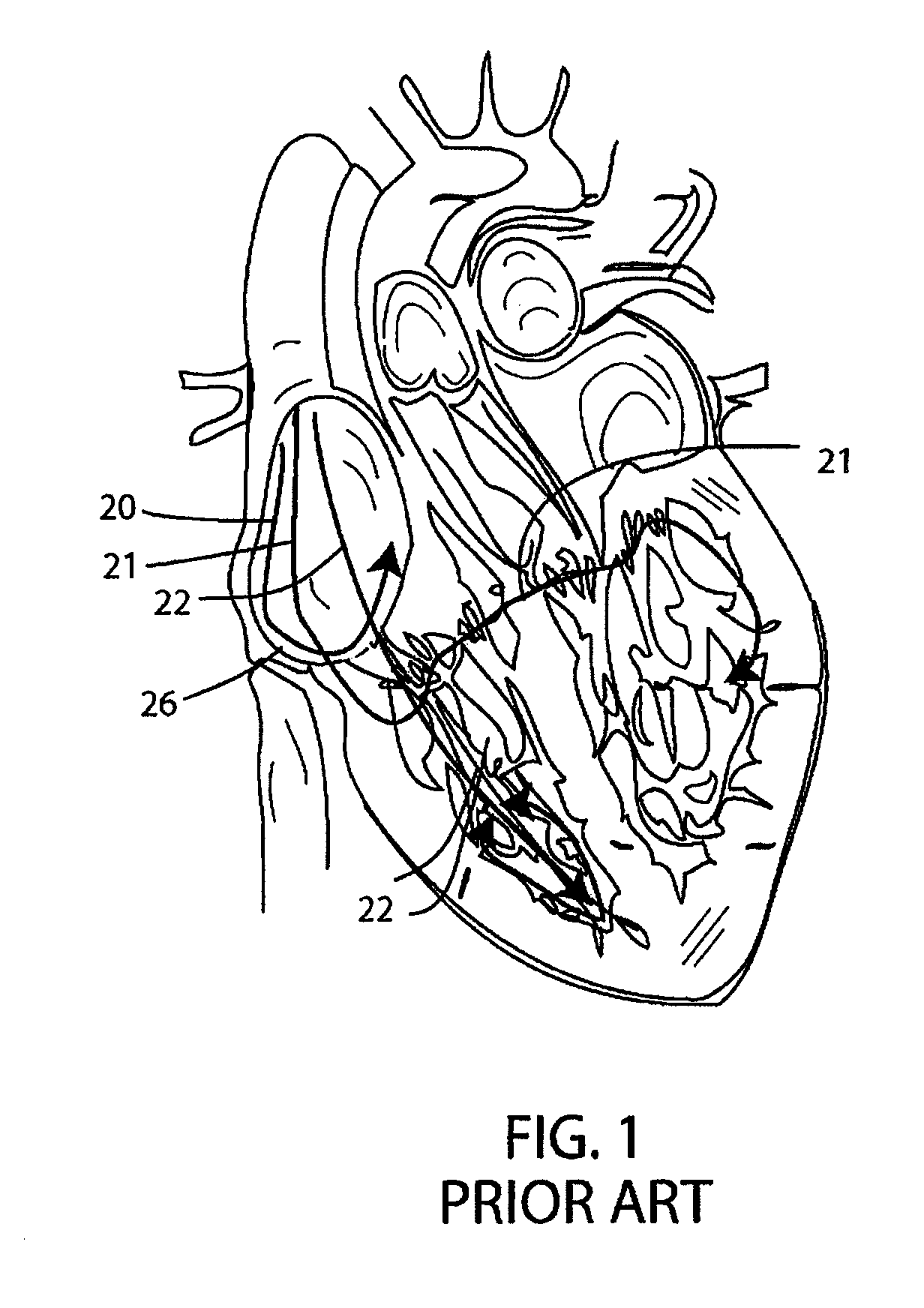

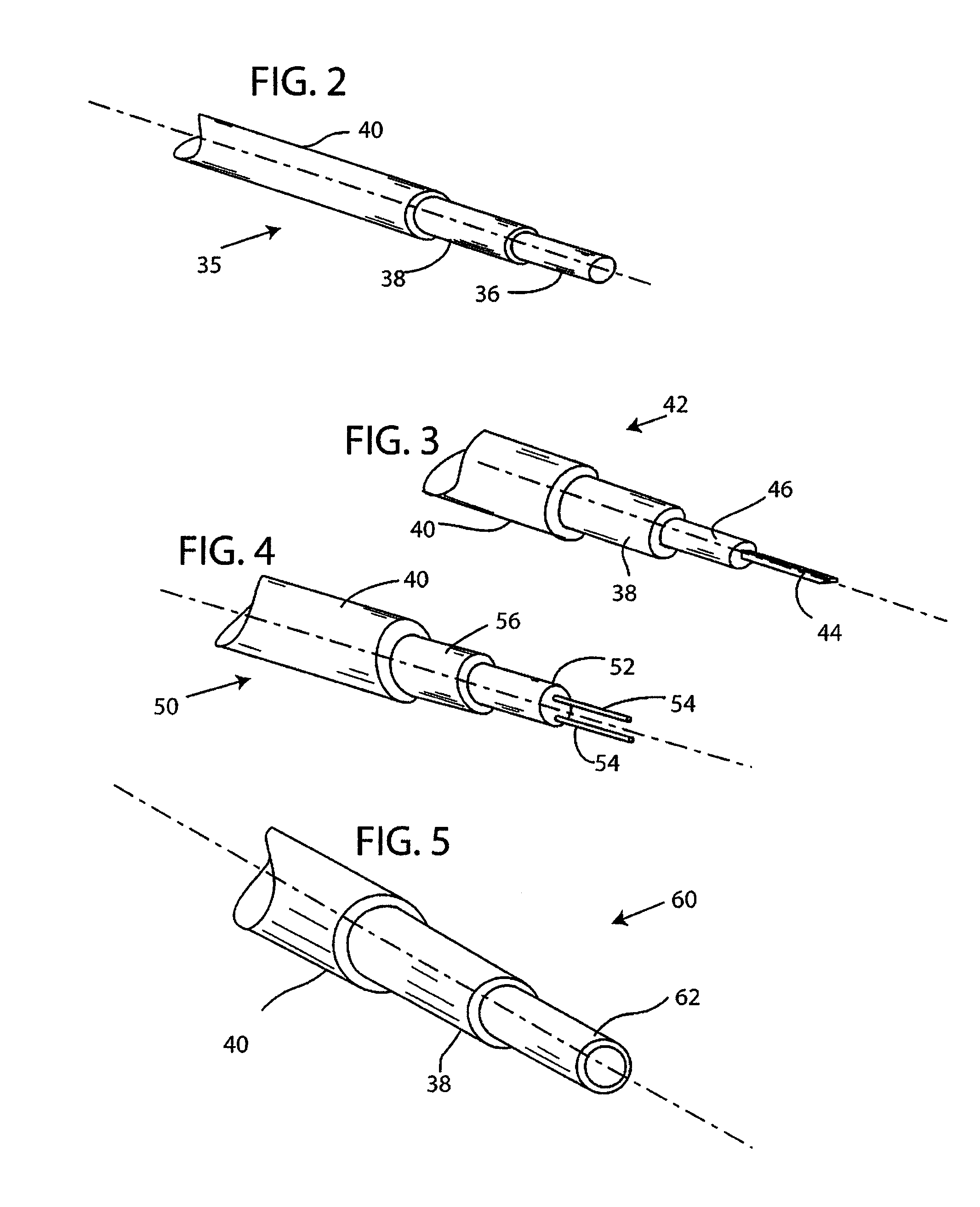

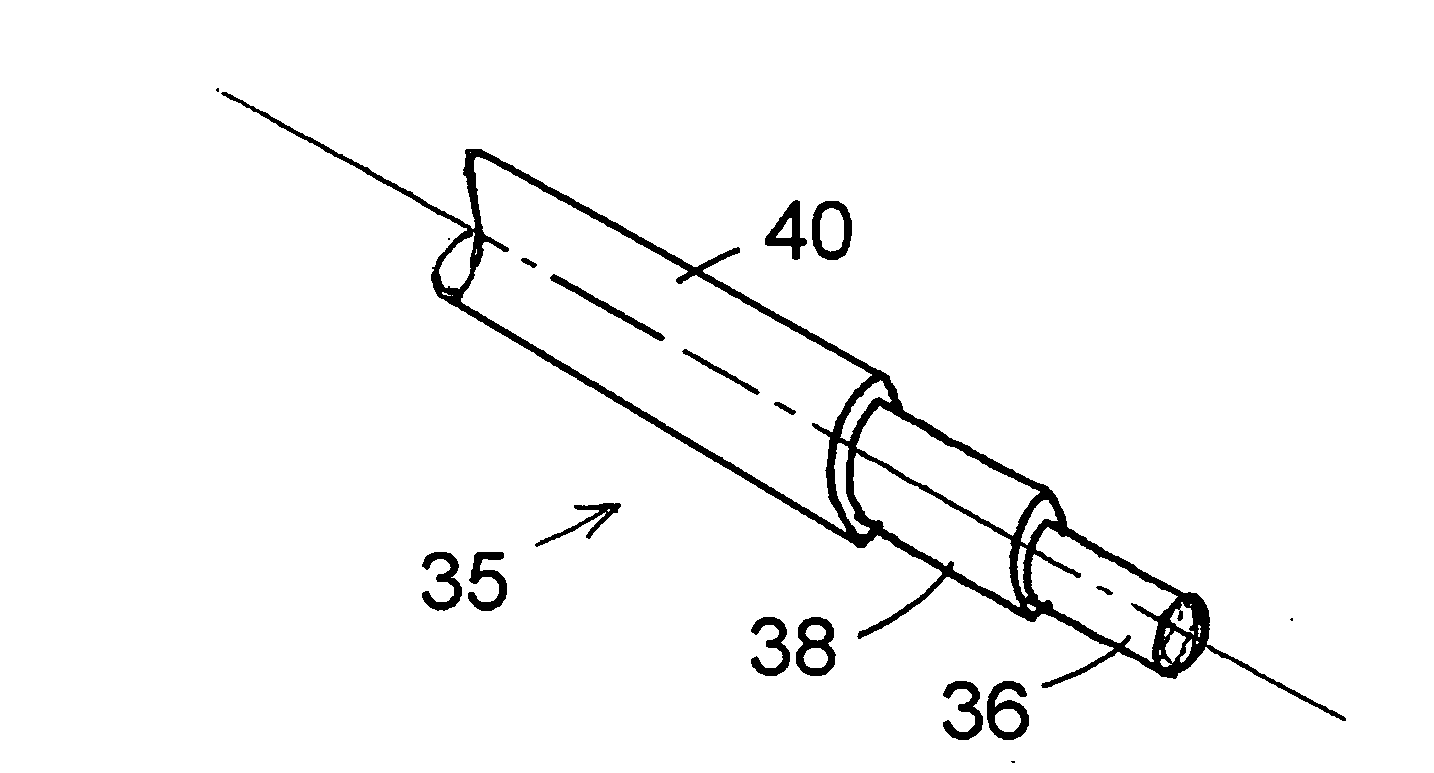

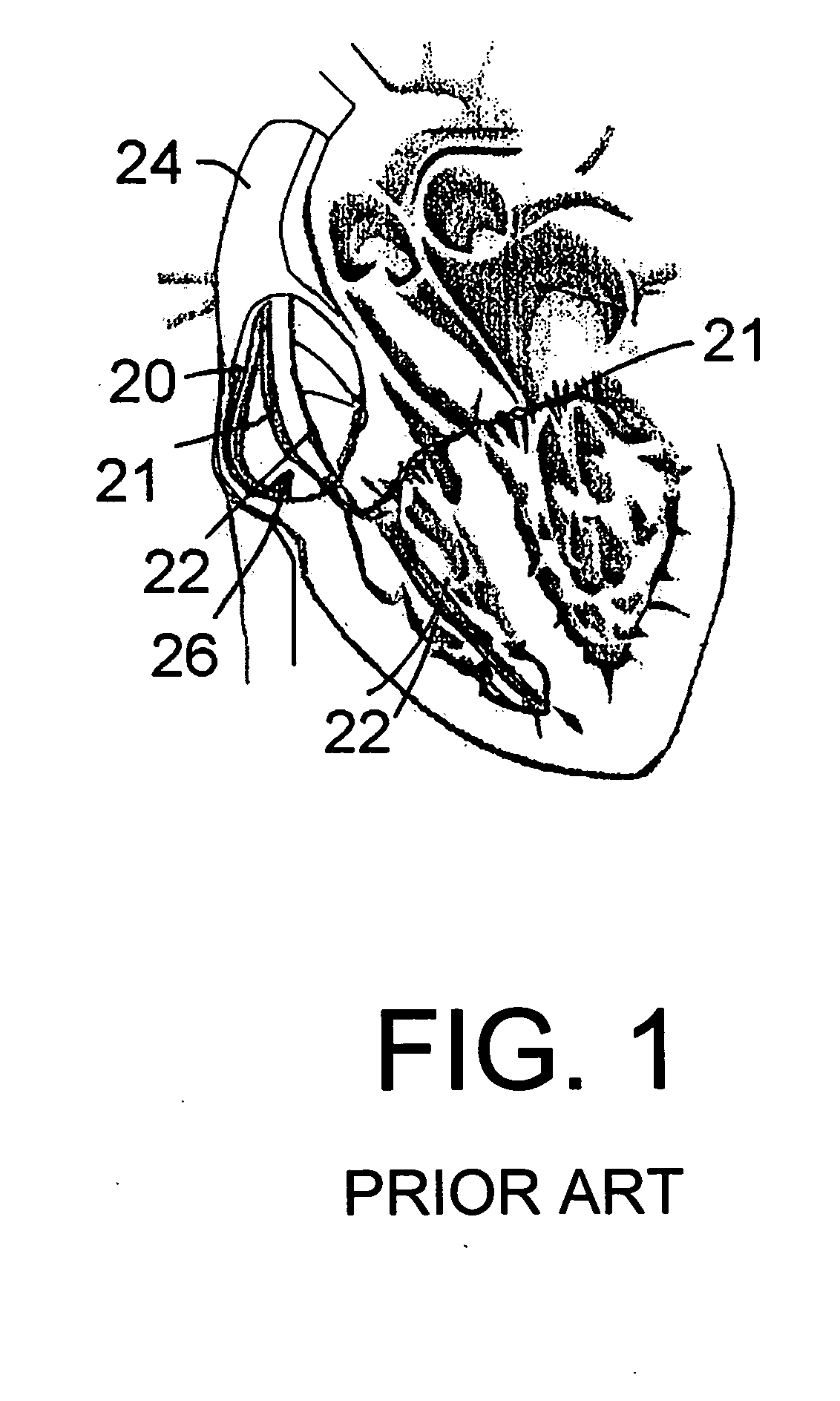

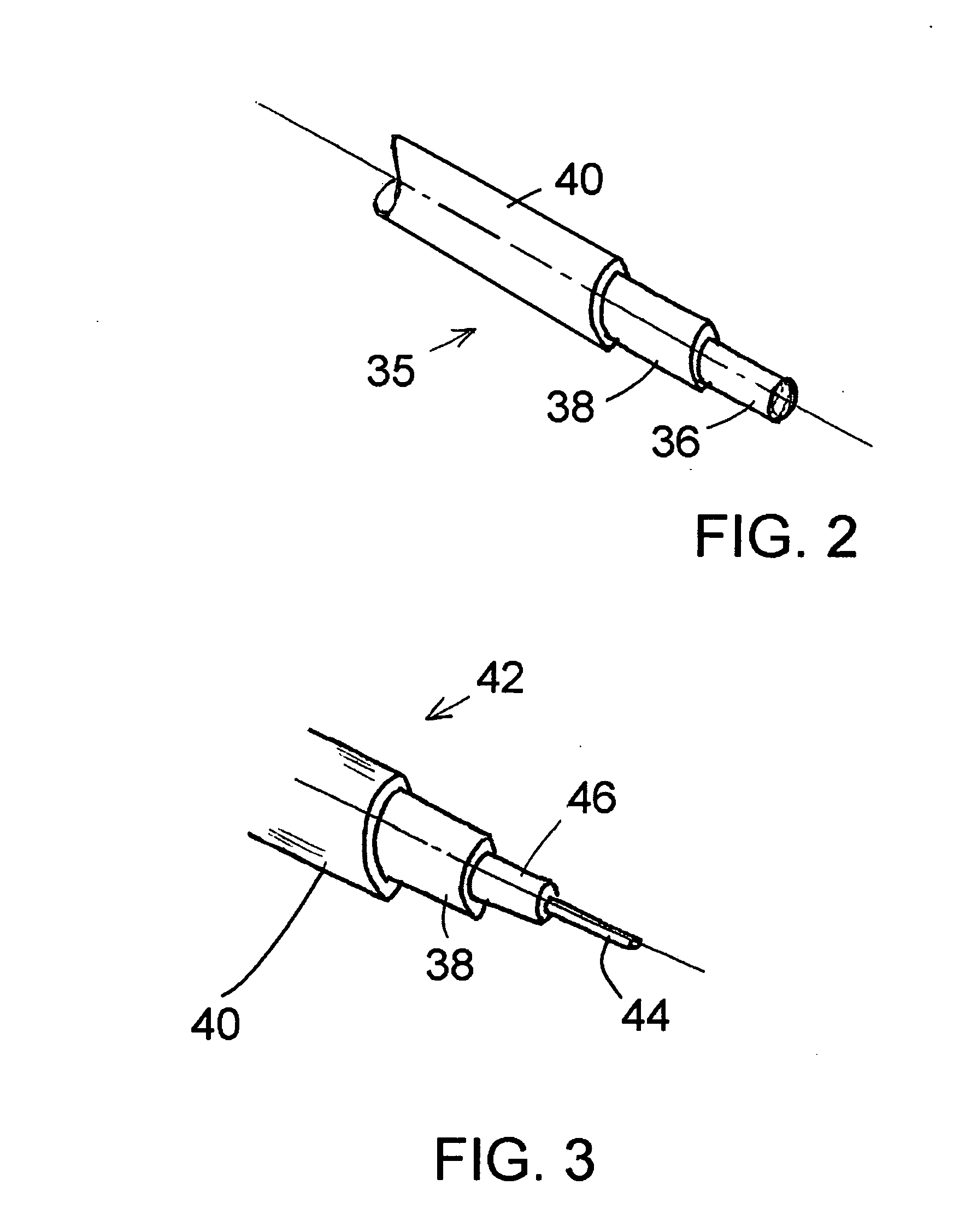

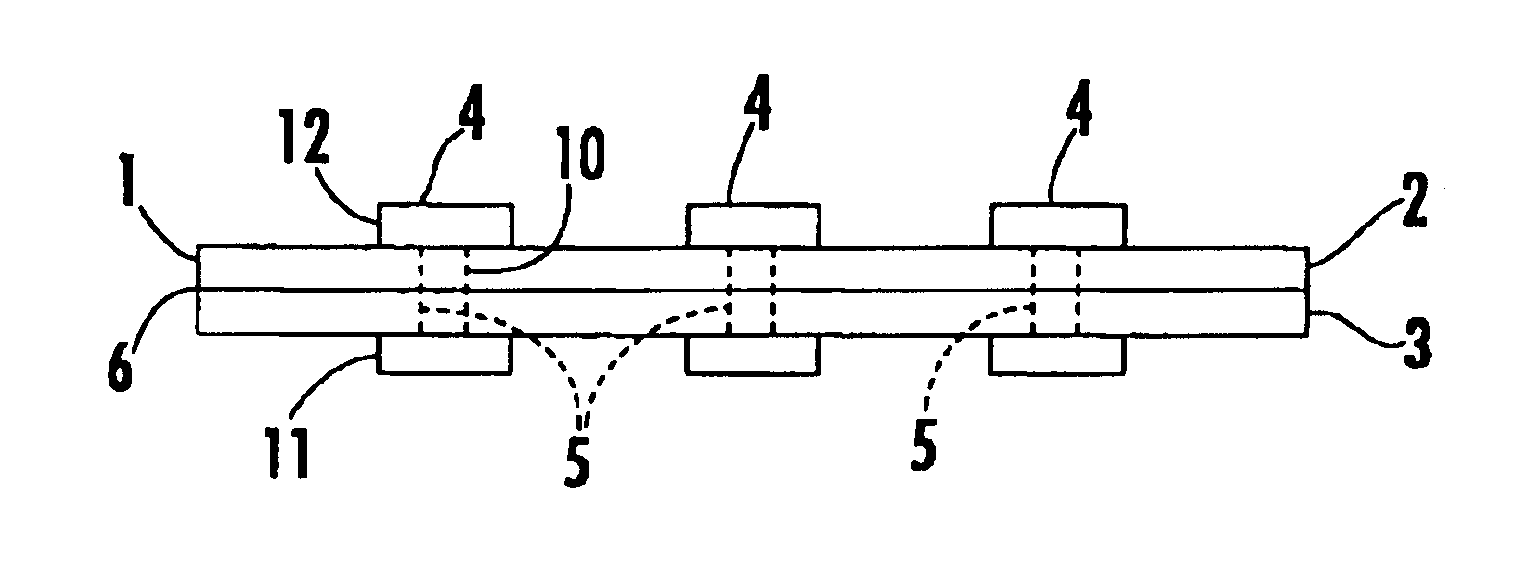

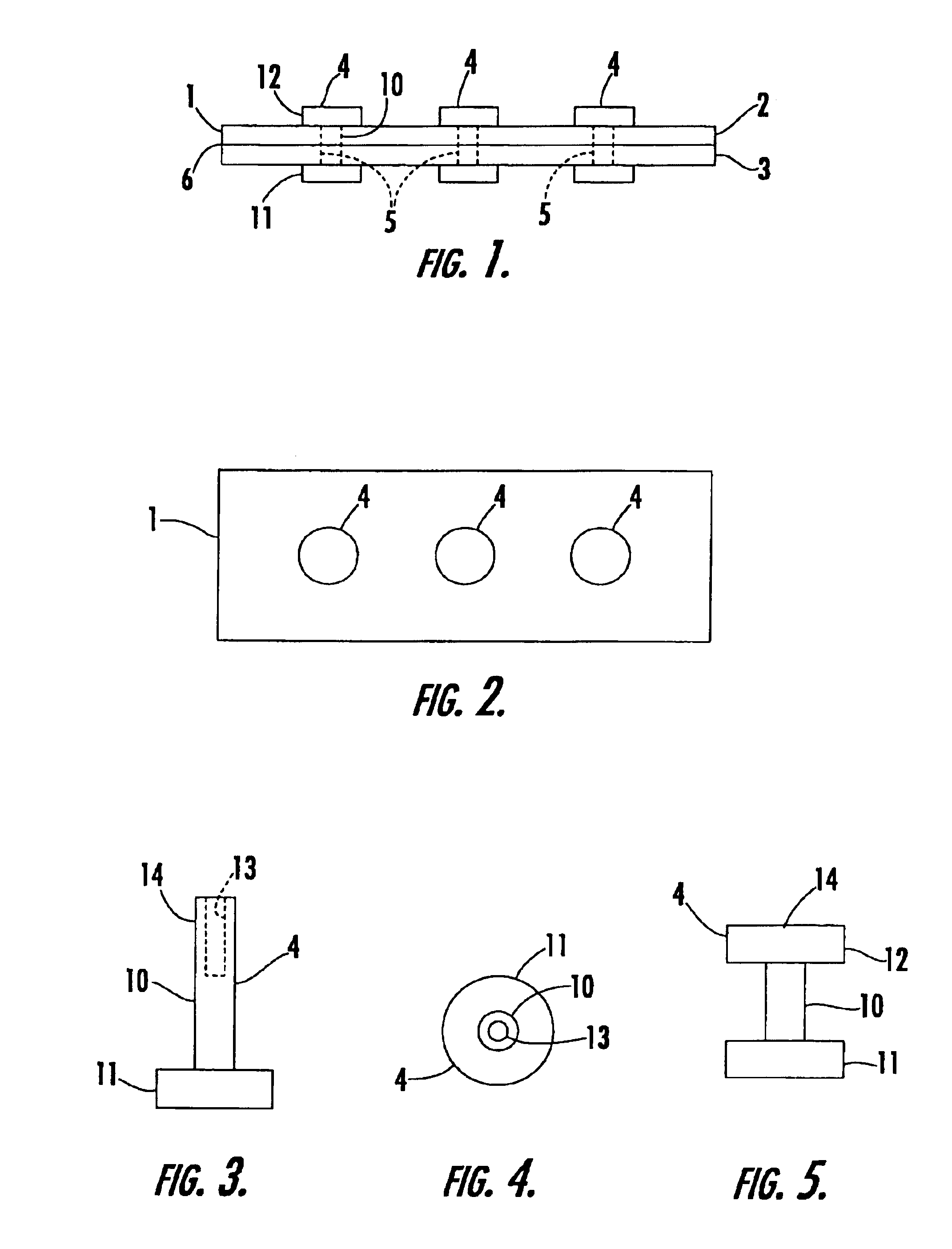

Implantable lead

ActiveUS20100137928A1Good flexibility , fatigue resistance and flex lifeImprove reliabilityContact member manufacturingInternal electrodesTissue damageDefibrillation

Owner:WL GORE & ASSOC INC

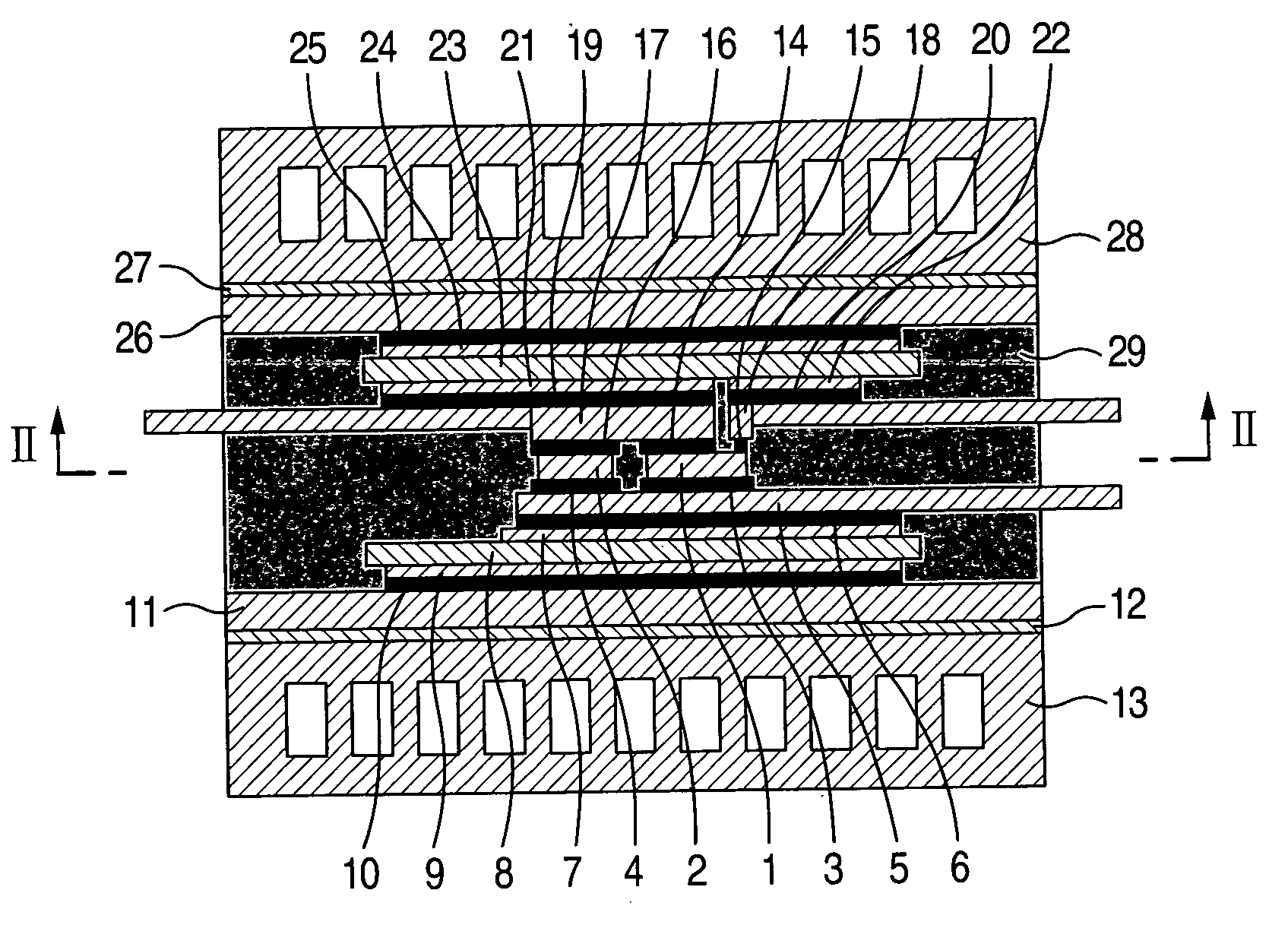

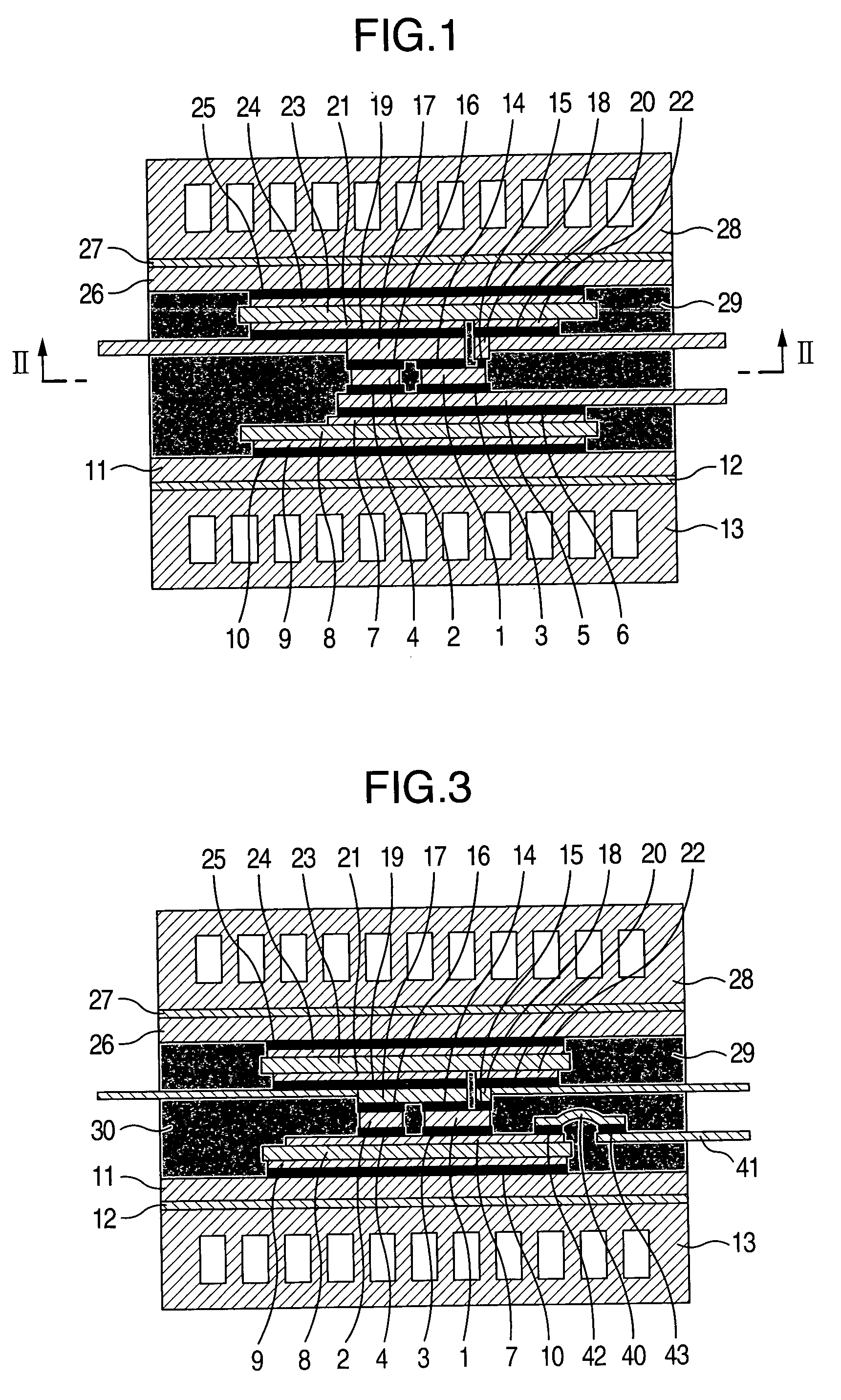

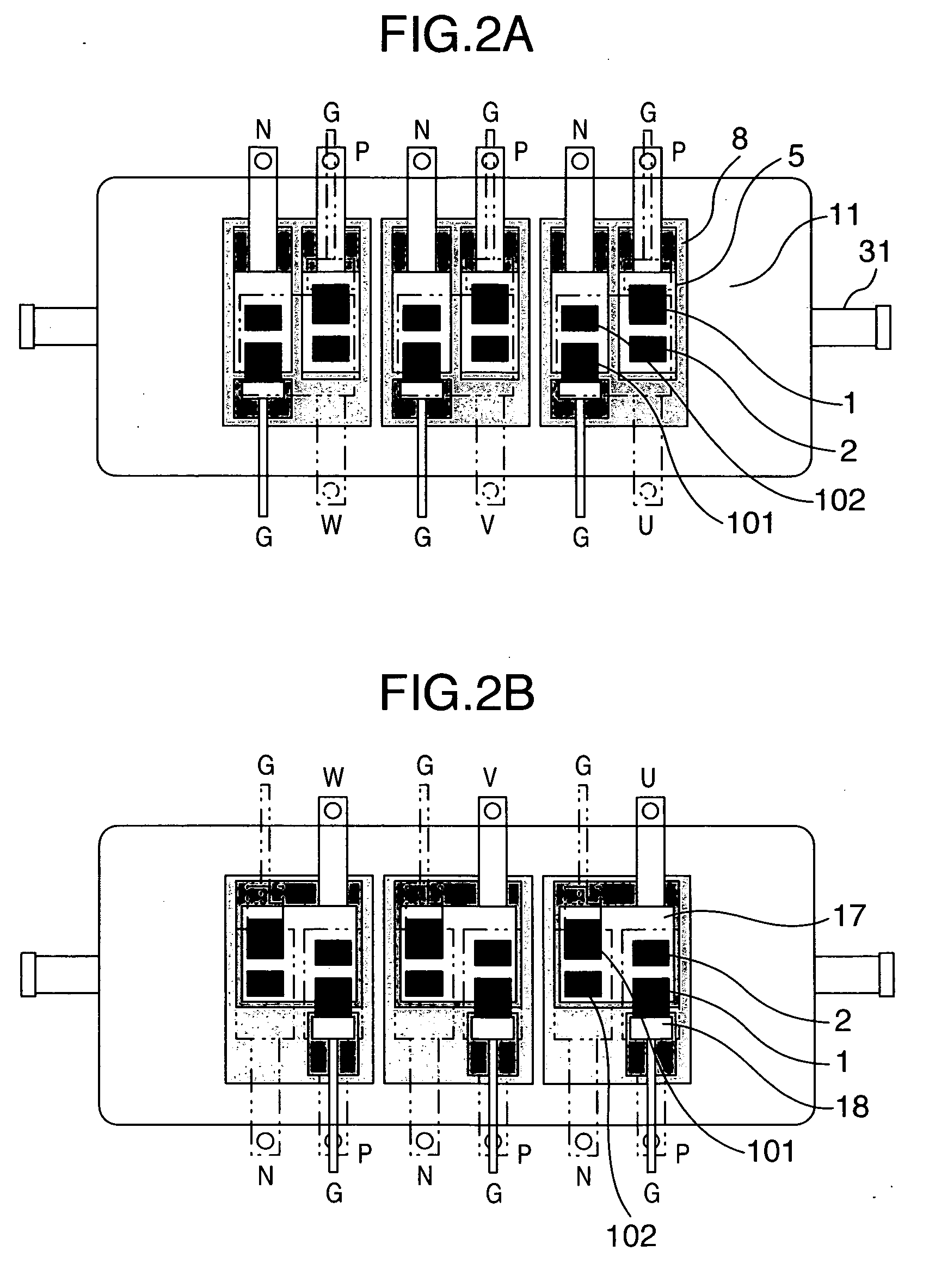

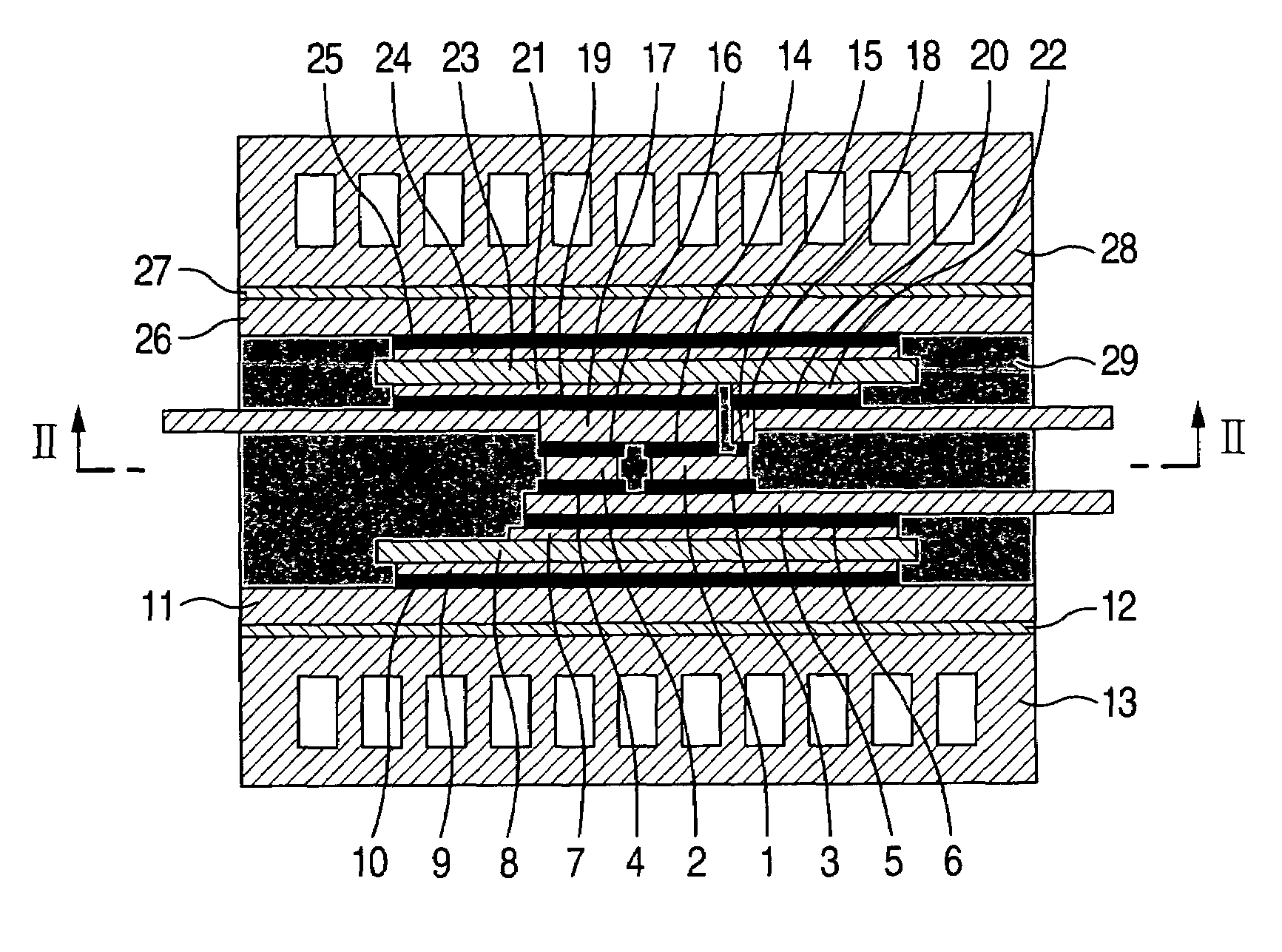

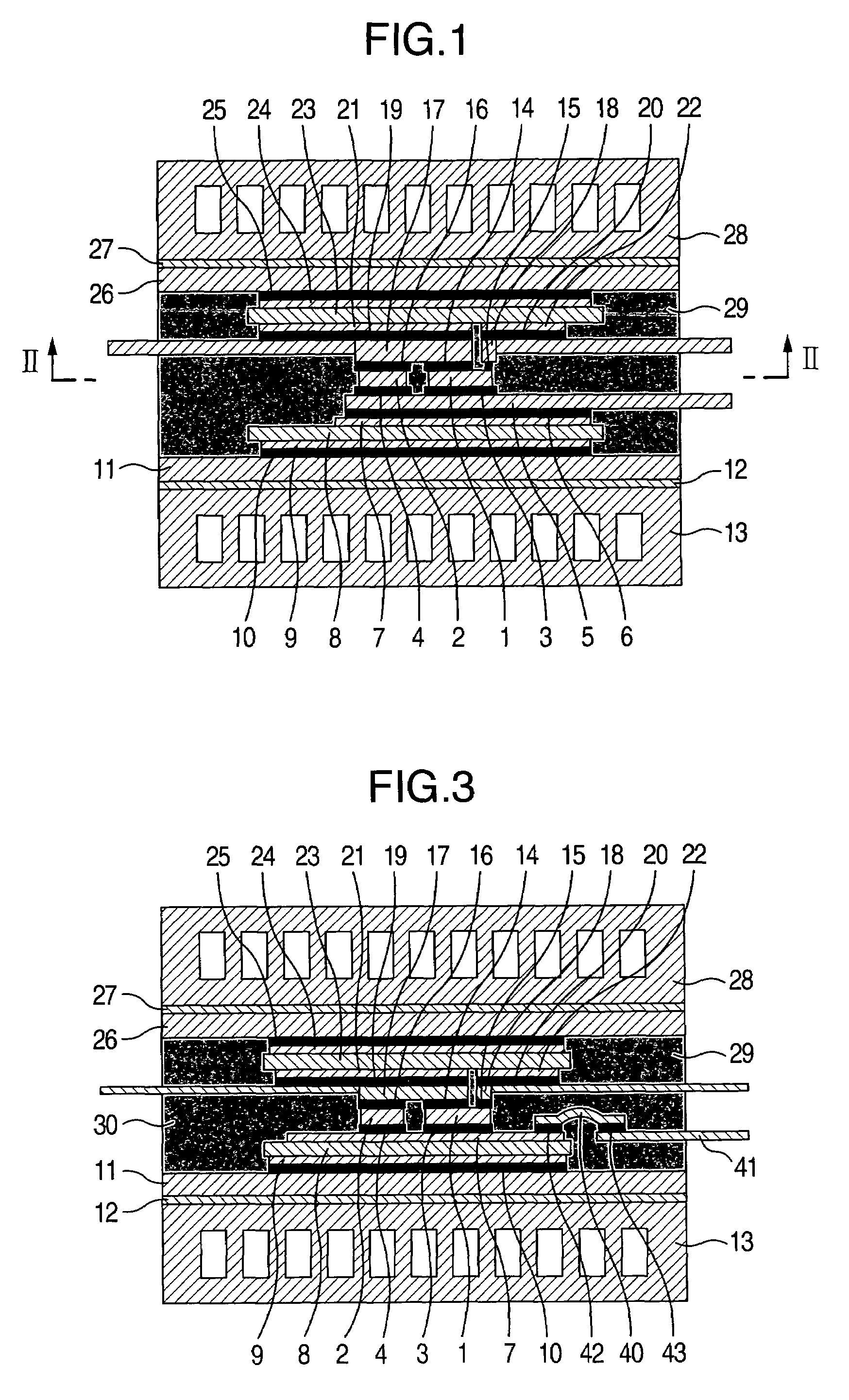

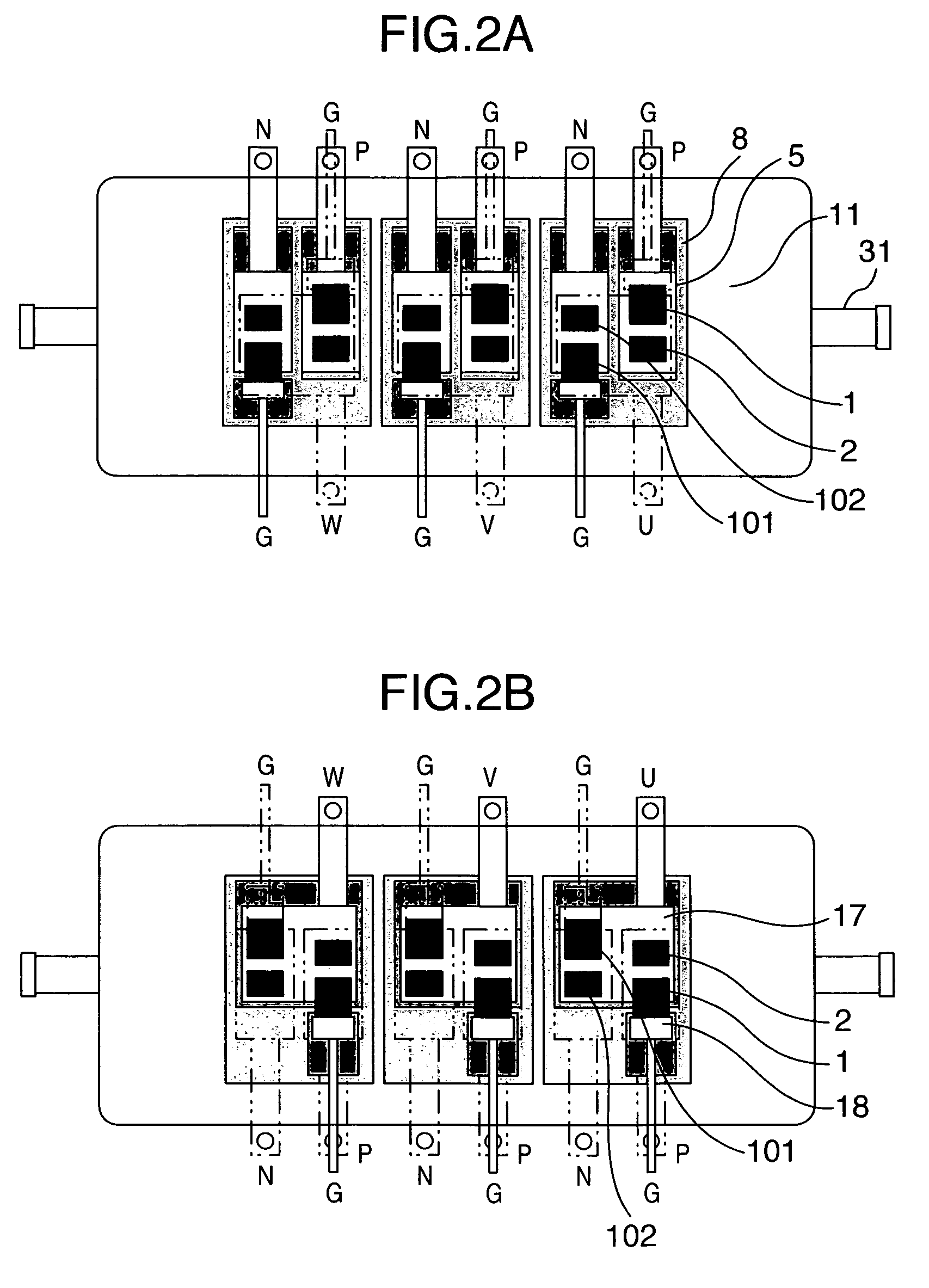

Power semiconductor module

InactiveUS20070216013A1Minimize powerIncreased reliability against thermal fatigueSemiconductor/solid-state device detailsSolid-state devicesMetallic foilThermal fatigue

A power semiconductor module having an increased reliability against thermal fatigue includes a power semiconductor element, a lower-side electrode connected to the lower side of the element, a first insulating substrate connected to the upper side of the lower-side electrode and having metallic foils bonded on both surfaces thereof, an upper-side electrode connected to the upper side of the power semiconductor element, a second insulating substrate connected to the upper side of the upper-side electrode and having metallic foils bonded on both surfaces thereof, a first heat spreader connected to the lower side of the first insulating substrate, and a second heat spreader connected to the upper side of the second insulating substrate. The power semiconductor element and the first and second insulating substrates are sealed with a resin.

Owner:HITACHI LTD

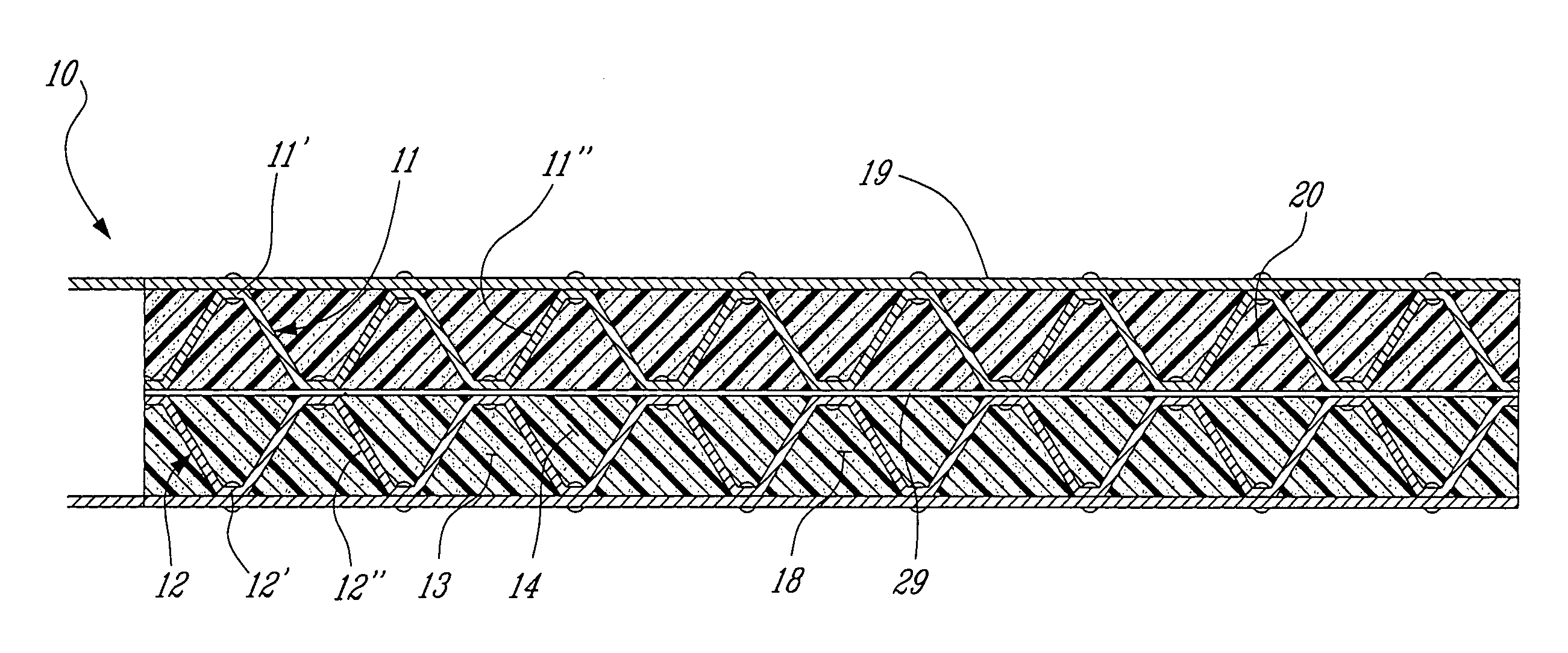

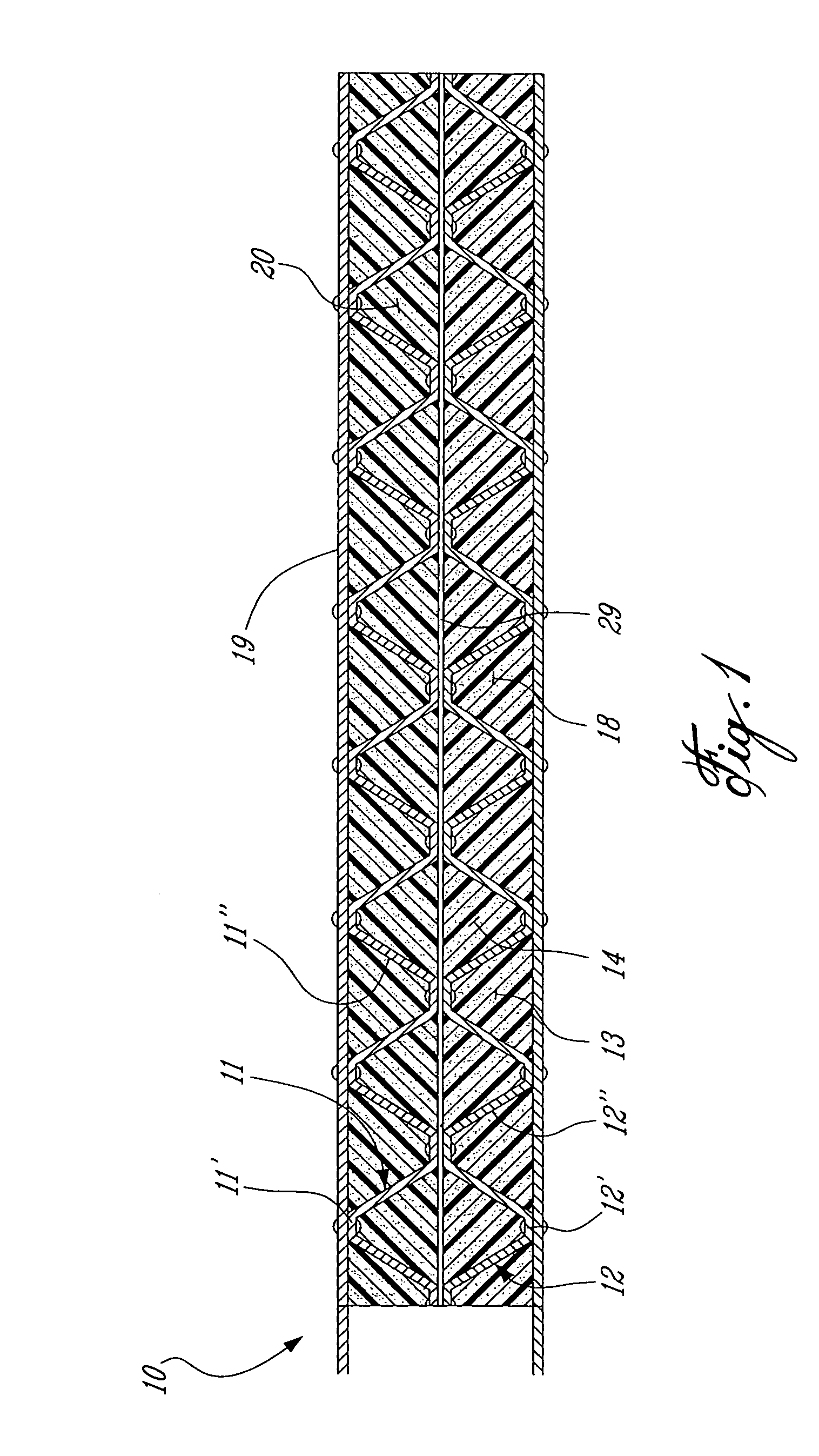

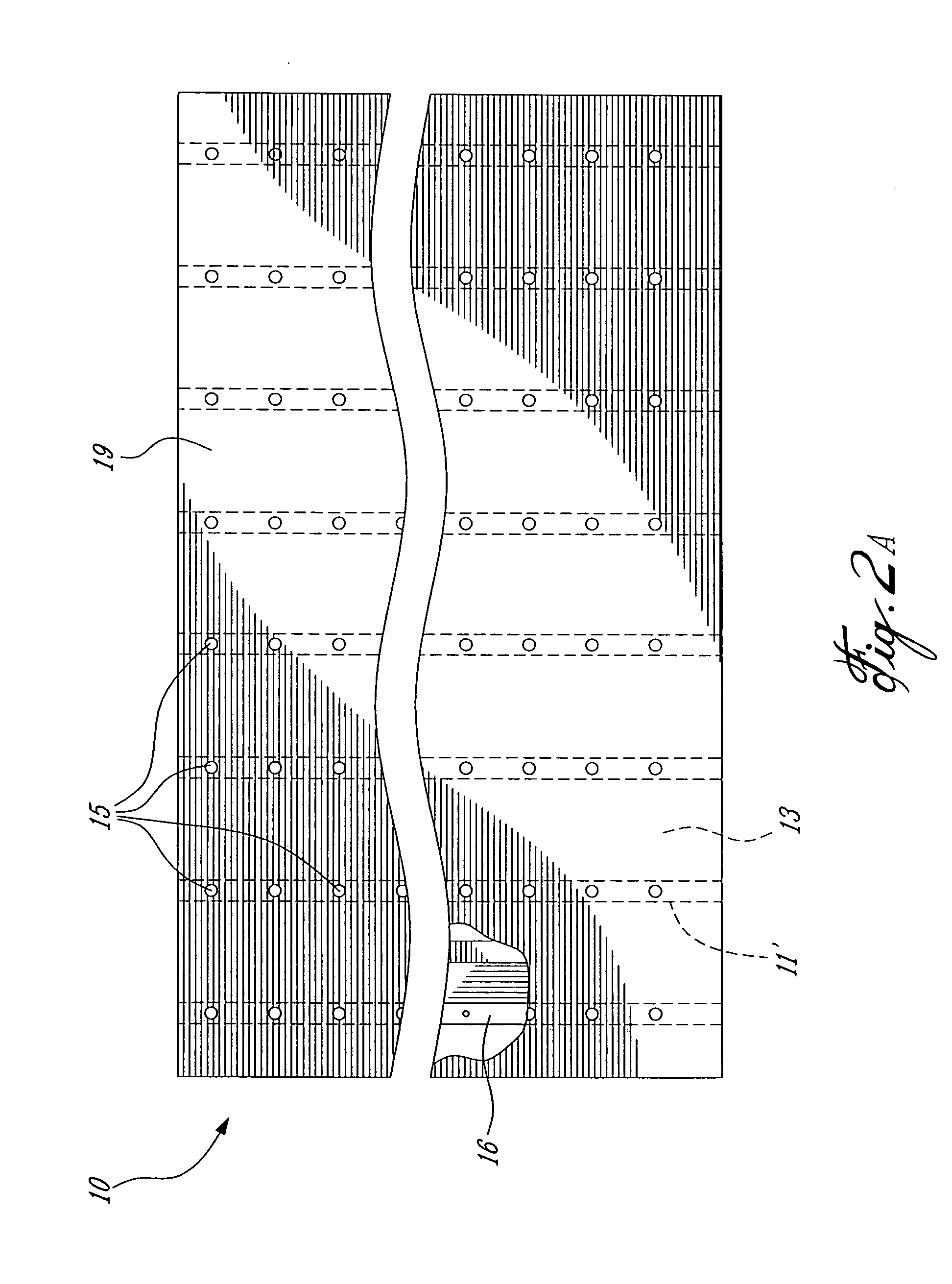

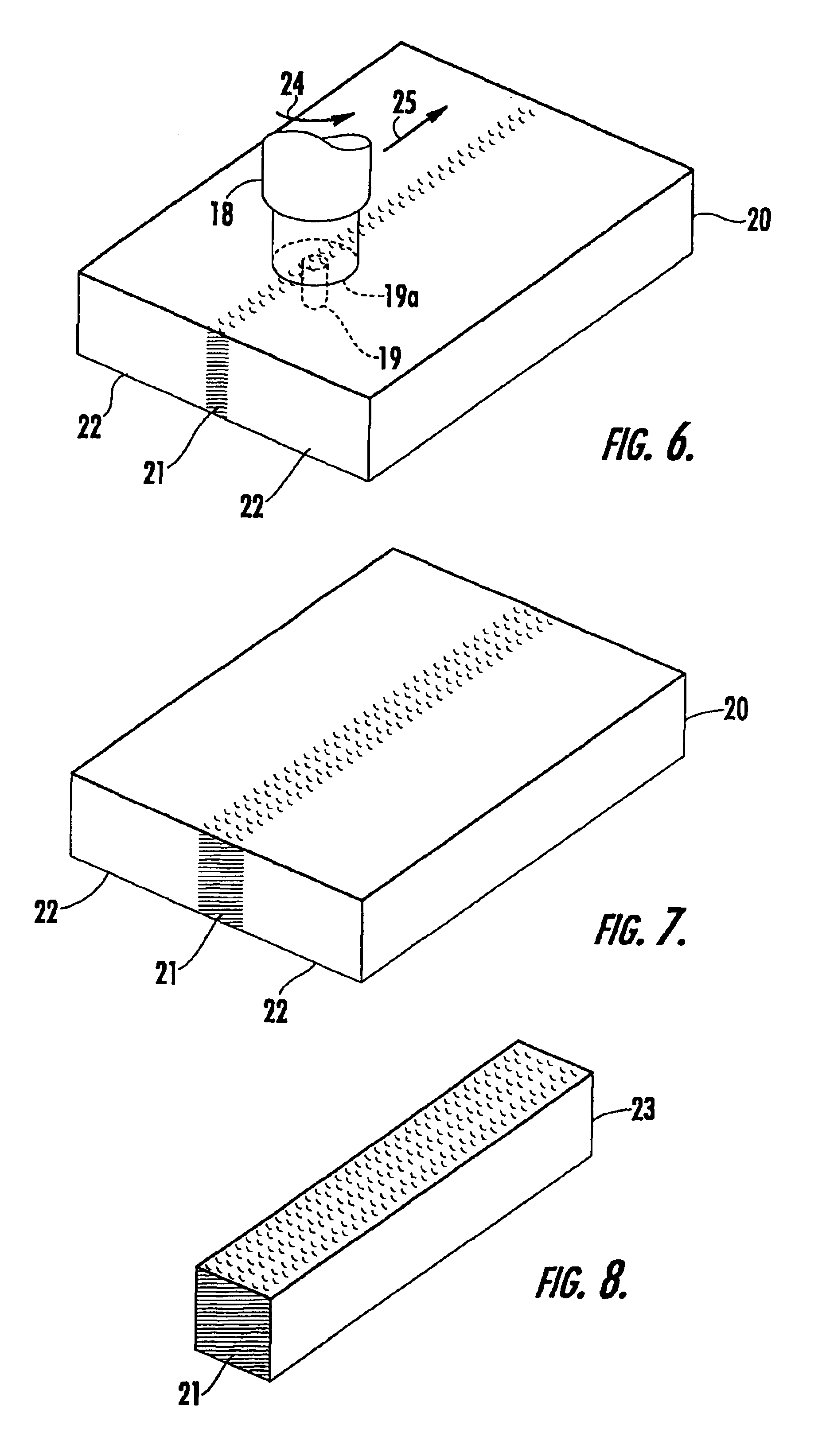

Fiber reinforced thermoplastic composite panel

InactiveUS20080078038A1Increased durabilityHigh fatigueSynthetic resin layered productsBridge structural detailsGlass fiberFilling materials

A fiber reinforced thermoplastic composite panel is described. One use of the panel is to construct bridge decks although the panel may have several other uses. It comprises two flat plates formed of commingled glass fiber reinforced polypropylene secured in spaced parallel relationship to a core. The core is formed by either two corrugated sheets interconnected together along connecting ridge sections or else by a plurality of elongated FRP channel members disposed transversely between the flat plates. The corrugated sheets or channel members form hollow core spaces between the two flat plates and the core material and these hollow spaces are filled with a filler material to add stability to the panel. Both the flat plates and the core material are formed of commingled glass fiber reinforced polypropylene (FRP).

Owner:BORAZGHI HOSSEIN

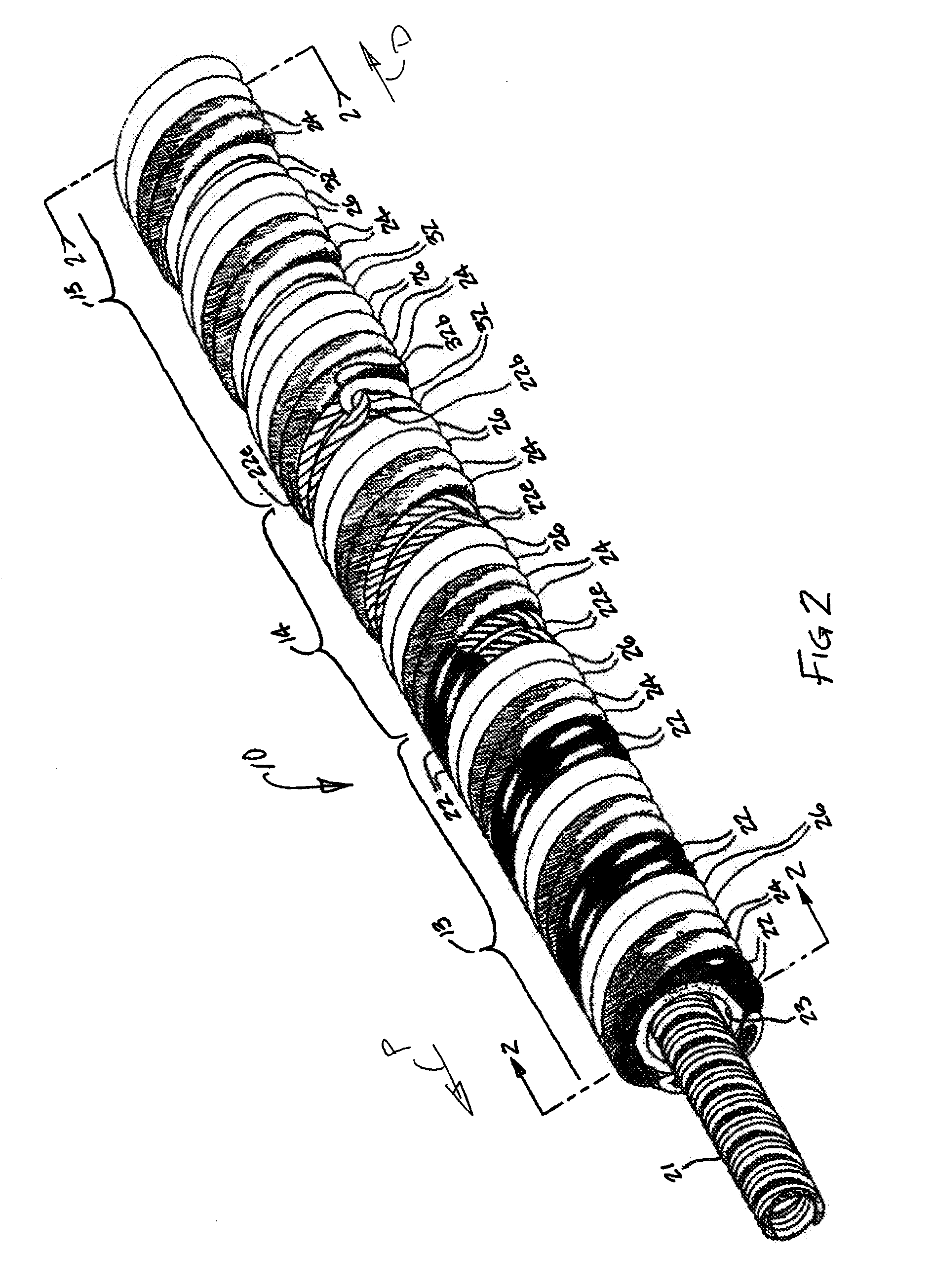

Durable fine wire lead for therapeutic electrostimulation and sensing

InactiveUS20130041447A1Increase flexibilitySmall diameterContact member manufacturingTransvascular endocardial electrodesElectrical conductorCardiac pacemaker

A cardiac pacemaker, other CRT device or neurostimulator has one or more fine wire leads. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal buffer cladding, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The buffered fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar leads can include several conductors side by side within a glass / silica fiber, or can be concentric metal coatings in a structure including several fiber layers. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

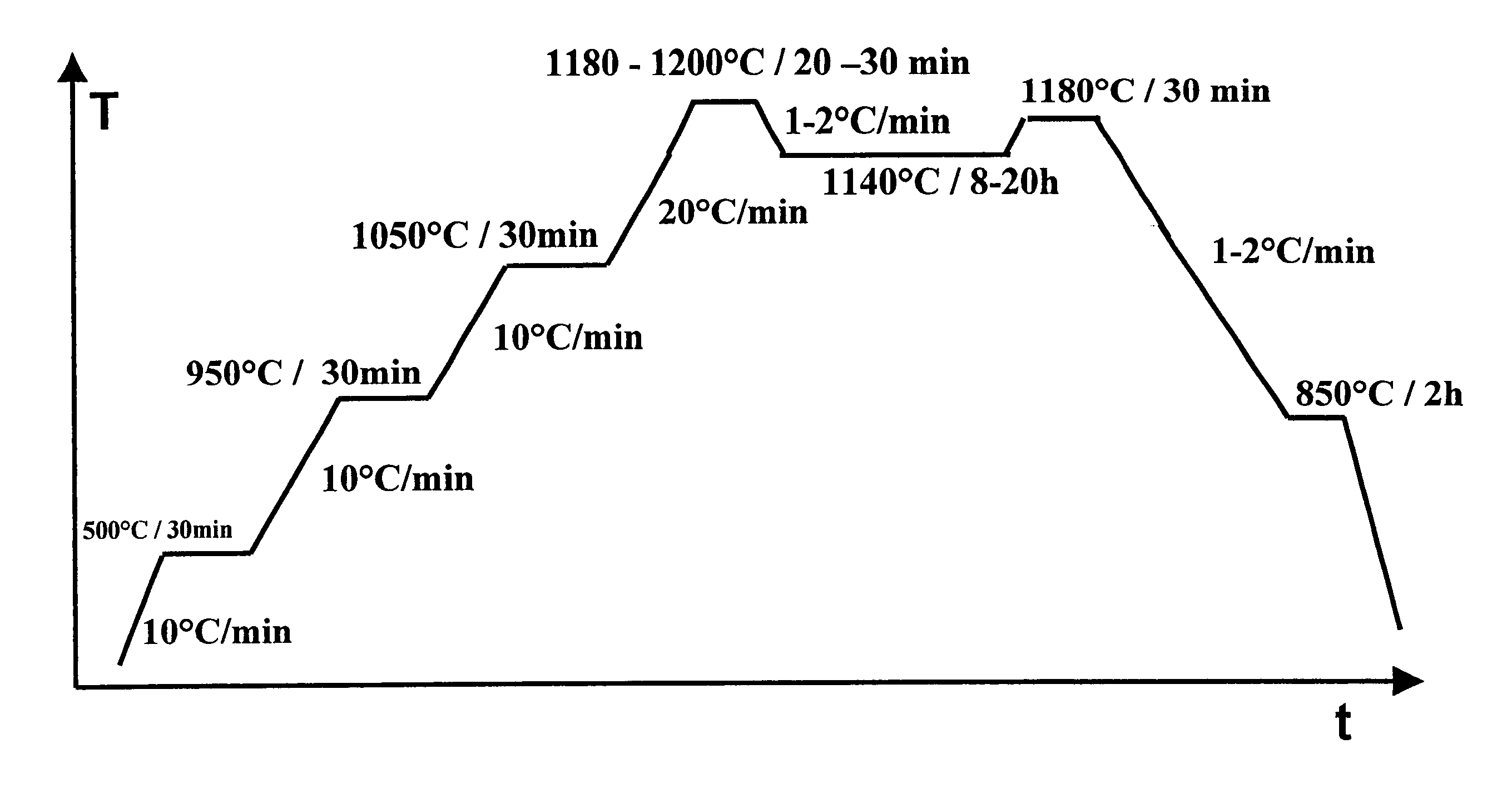

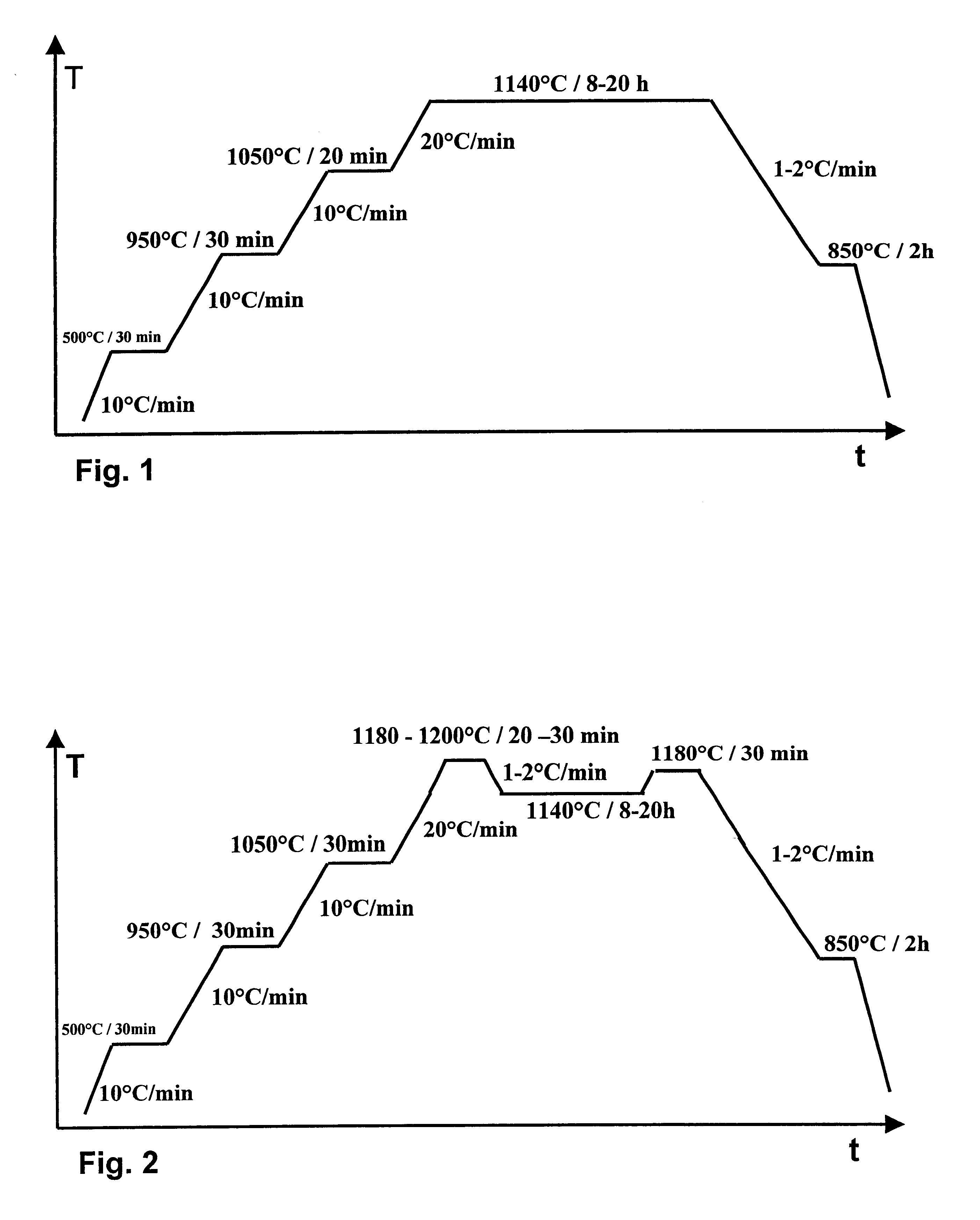

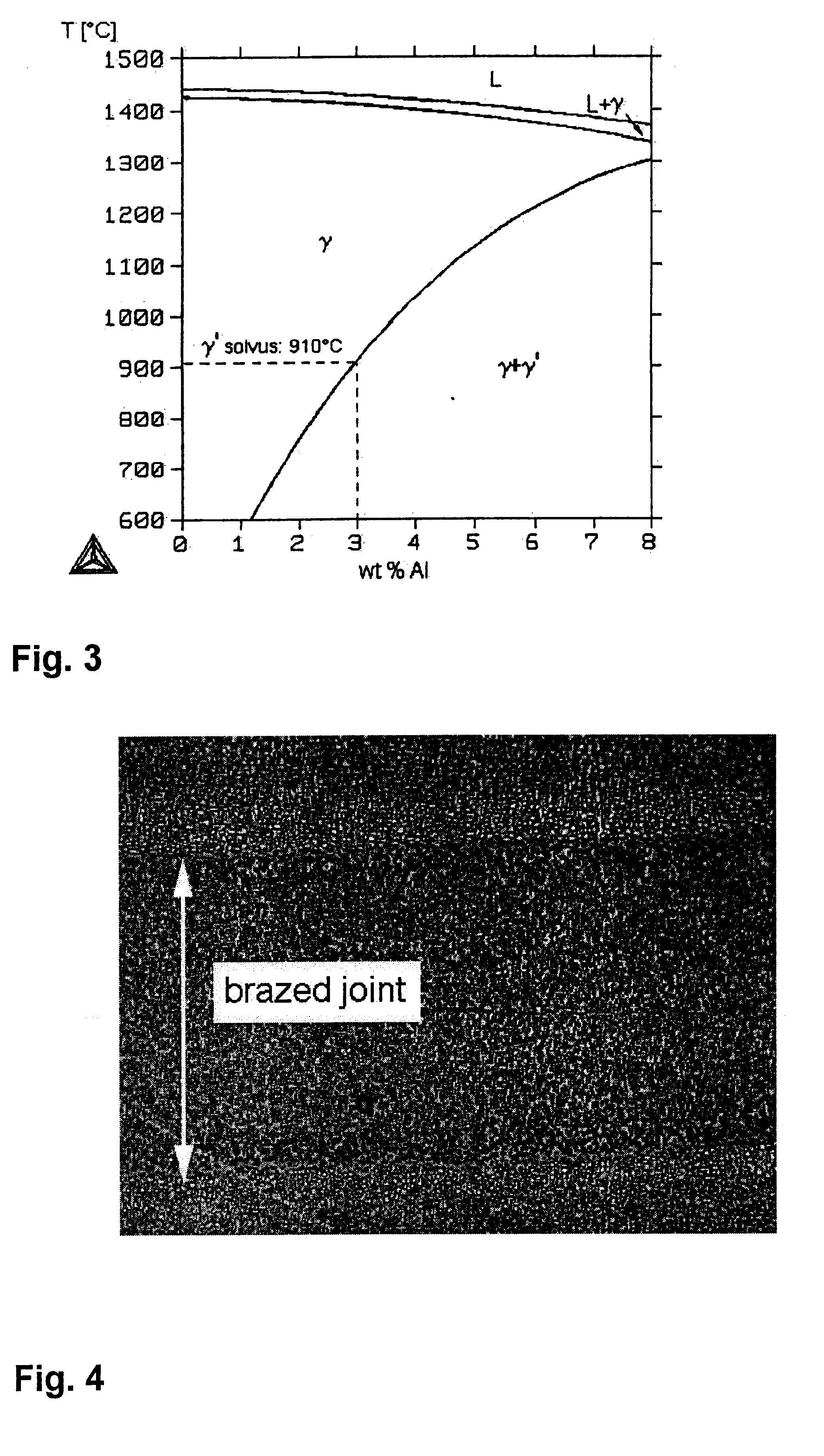

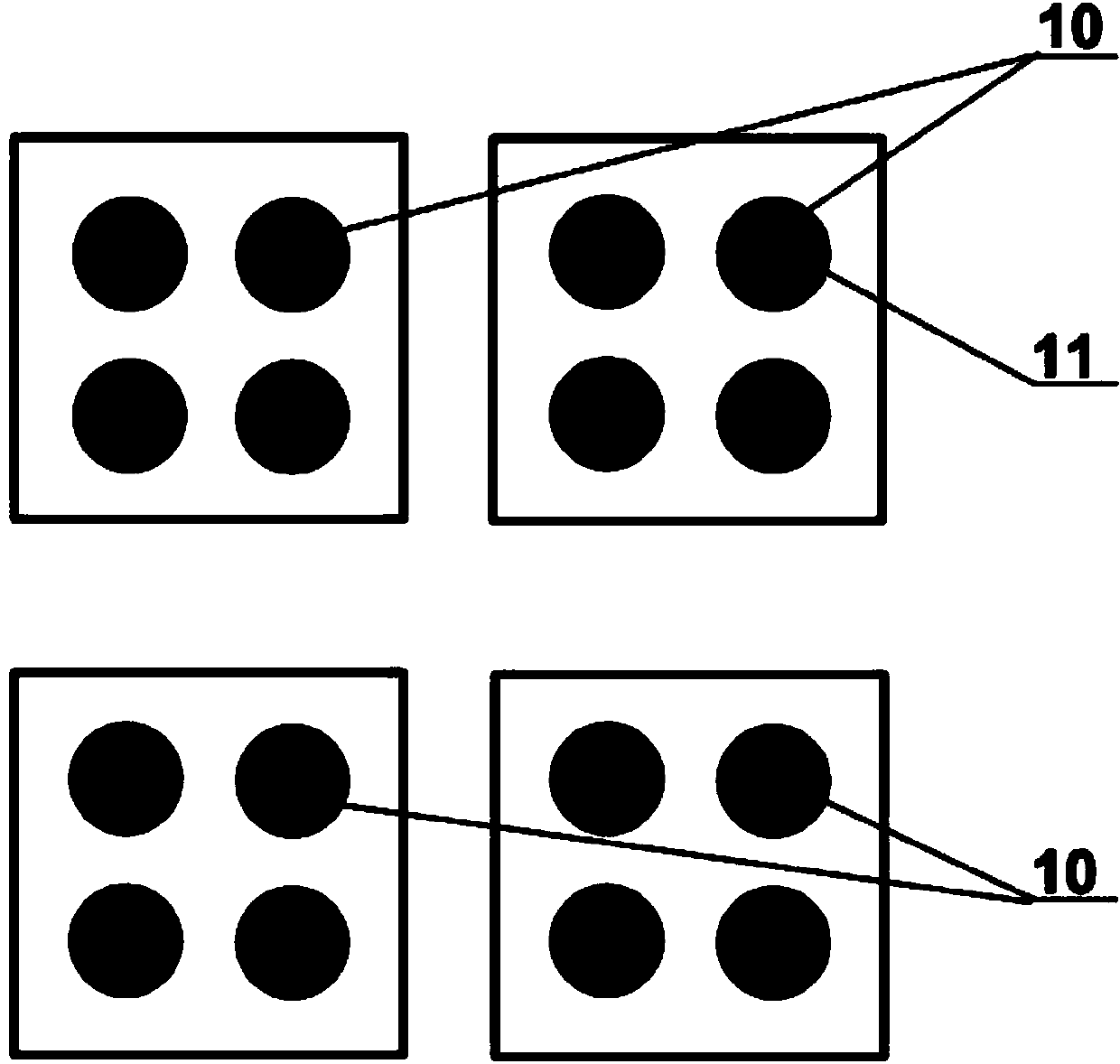

Method for isothermal brazing of single crystal components

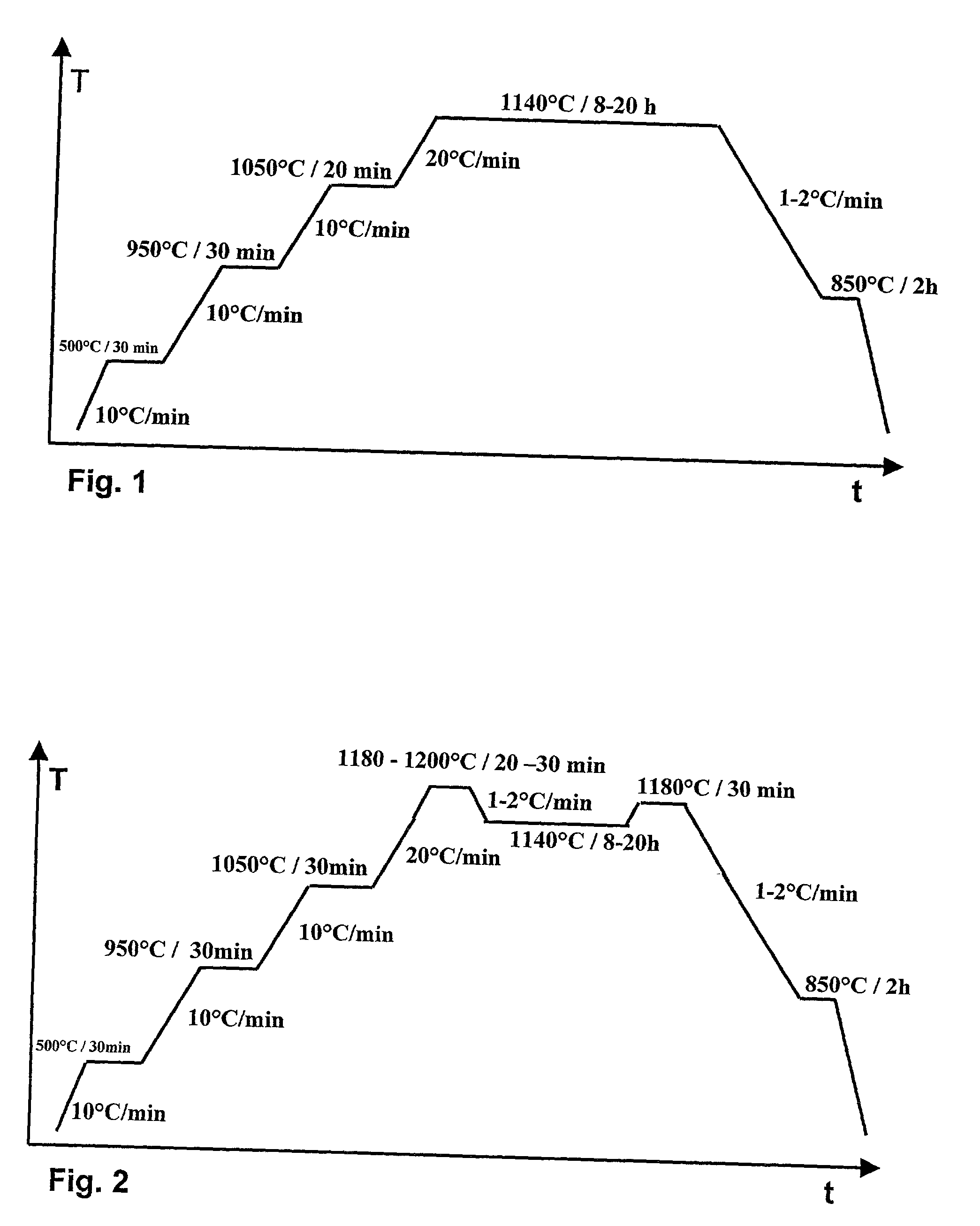

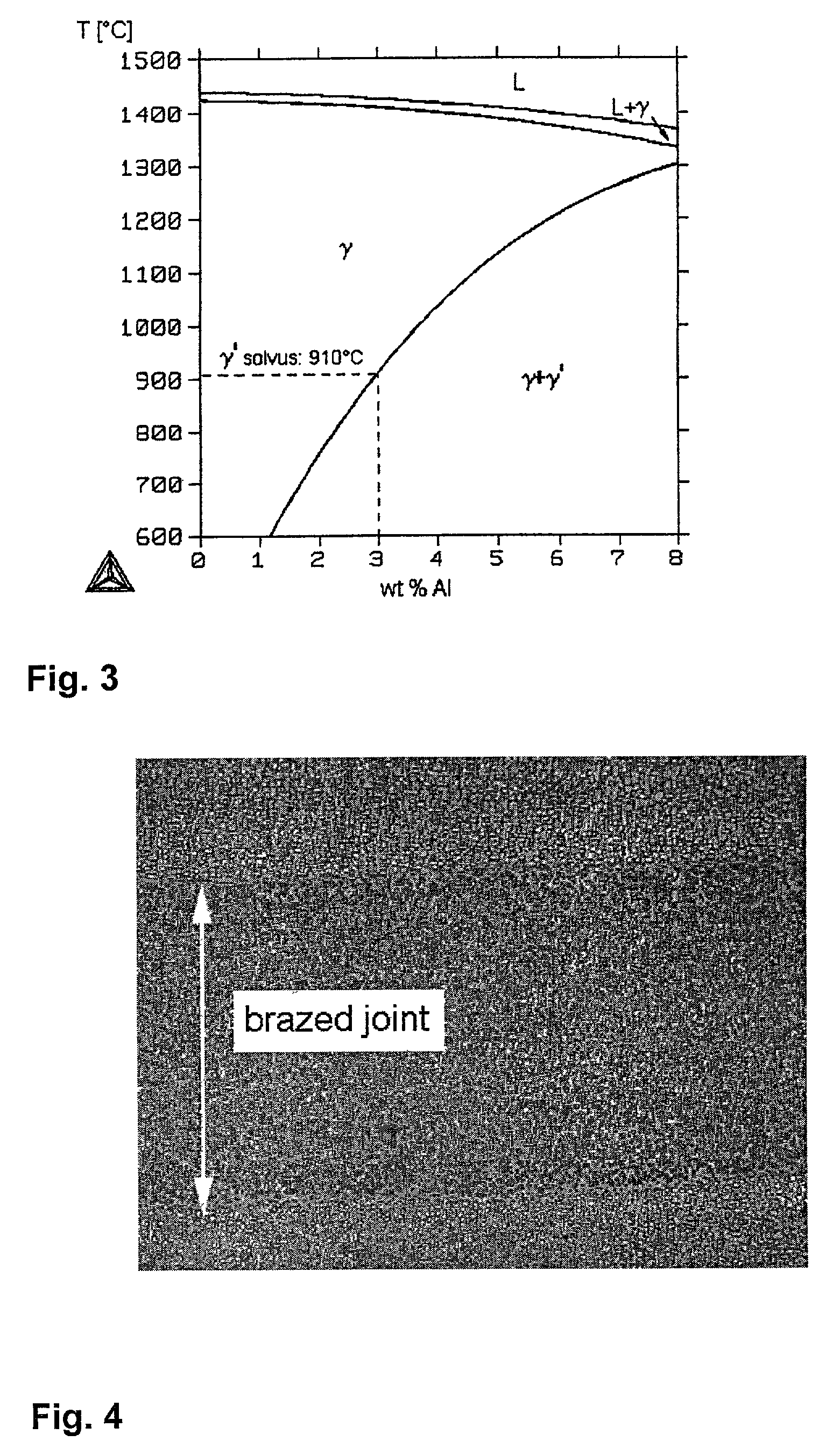

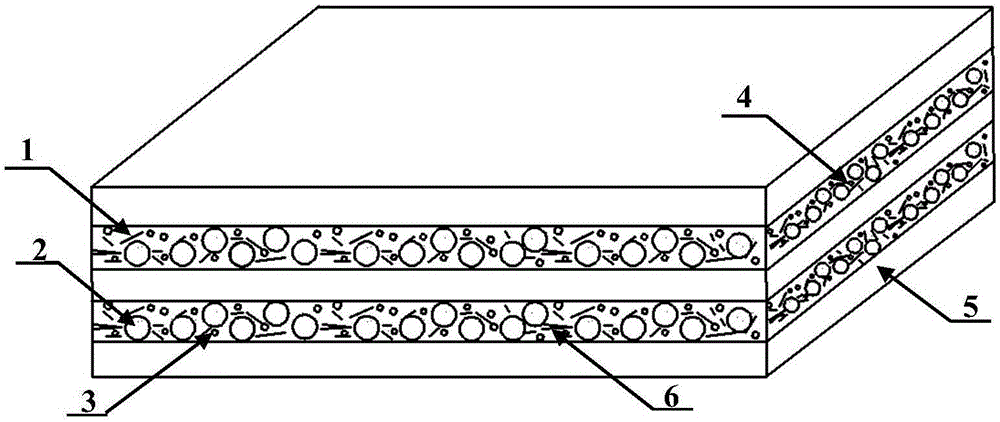

InactiveUS6629368B2High fatigueSolution value is not highPolycrystalline material growthAfter-treatment detailsSingle crystalMechanical property

A process of brazing cracks and gaps in a single crystal article which takes places isothermally under the following conditions: the temperature of the isothermal solidification is between TLiqidus, Braze+5*(wt-%BBraze) and (Tsolidus, base material-70*(wt-%BBraze)), while (wt-%B*wt-%Cr) is between 15 and 40 and (Tsolv.gamma', base material-TLiqidus, Braze) is above 140° C. This results in an homogeneous gamma / gamma'-microstructure of the isothermal solidified, brazed joint with mechanical properties similar to those of the base material.

Owner:ANSALDO ENERGIA IP UK LTD

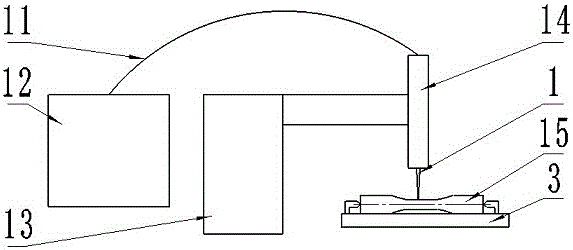

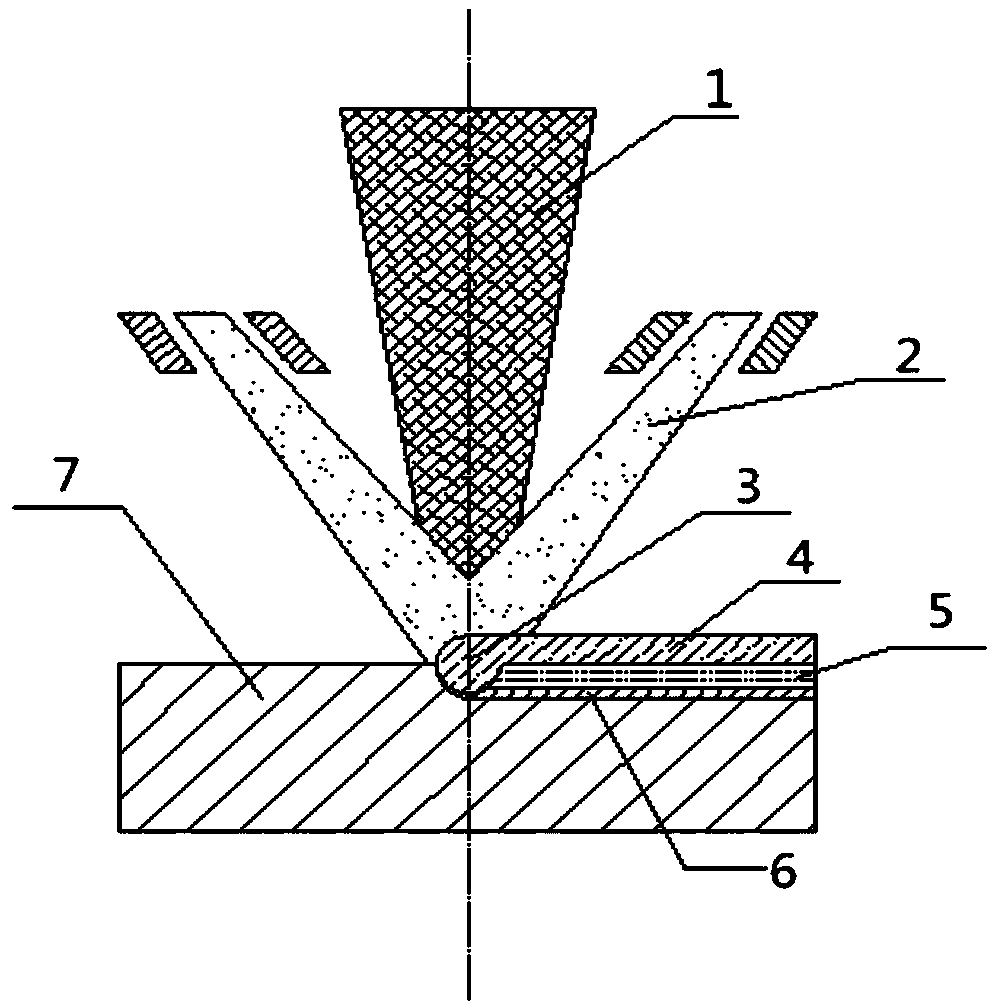

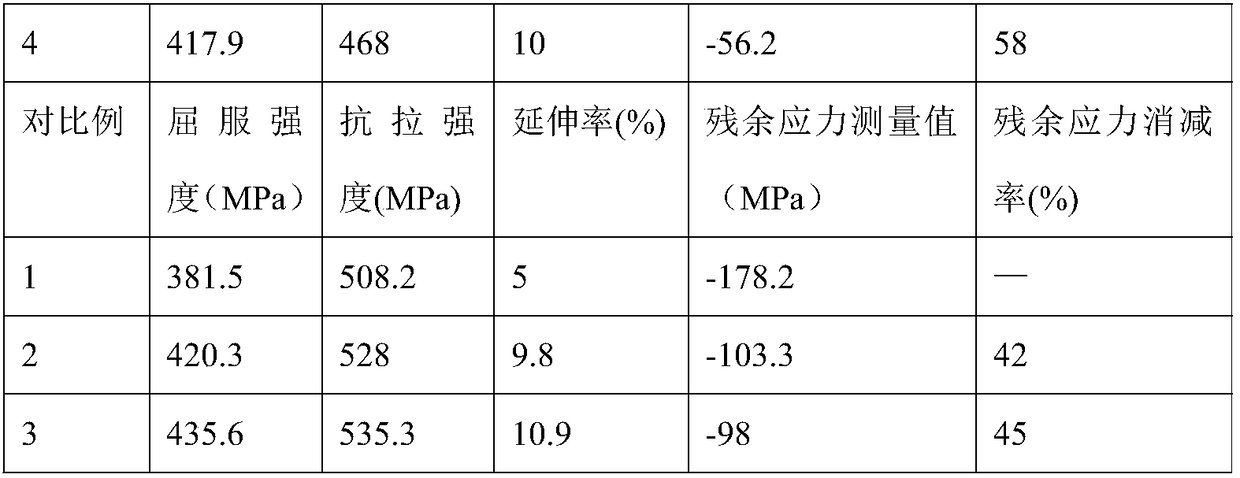

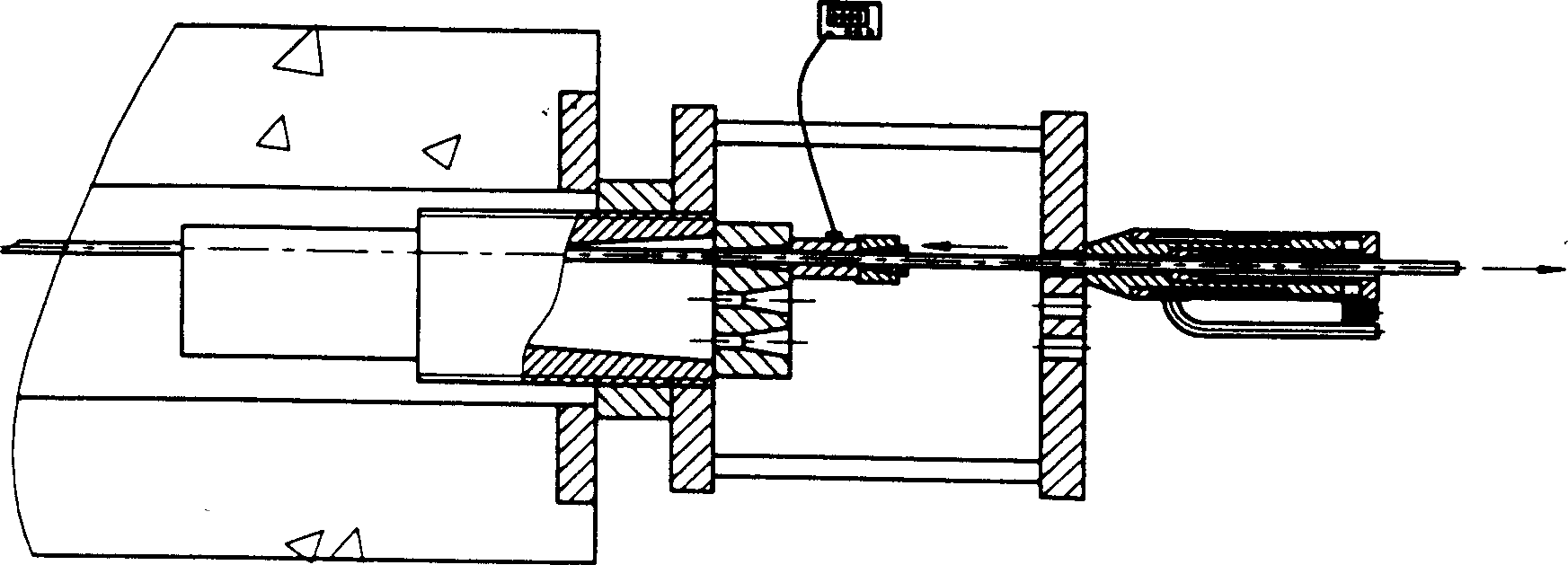

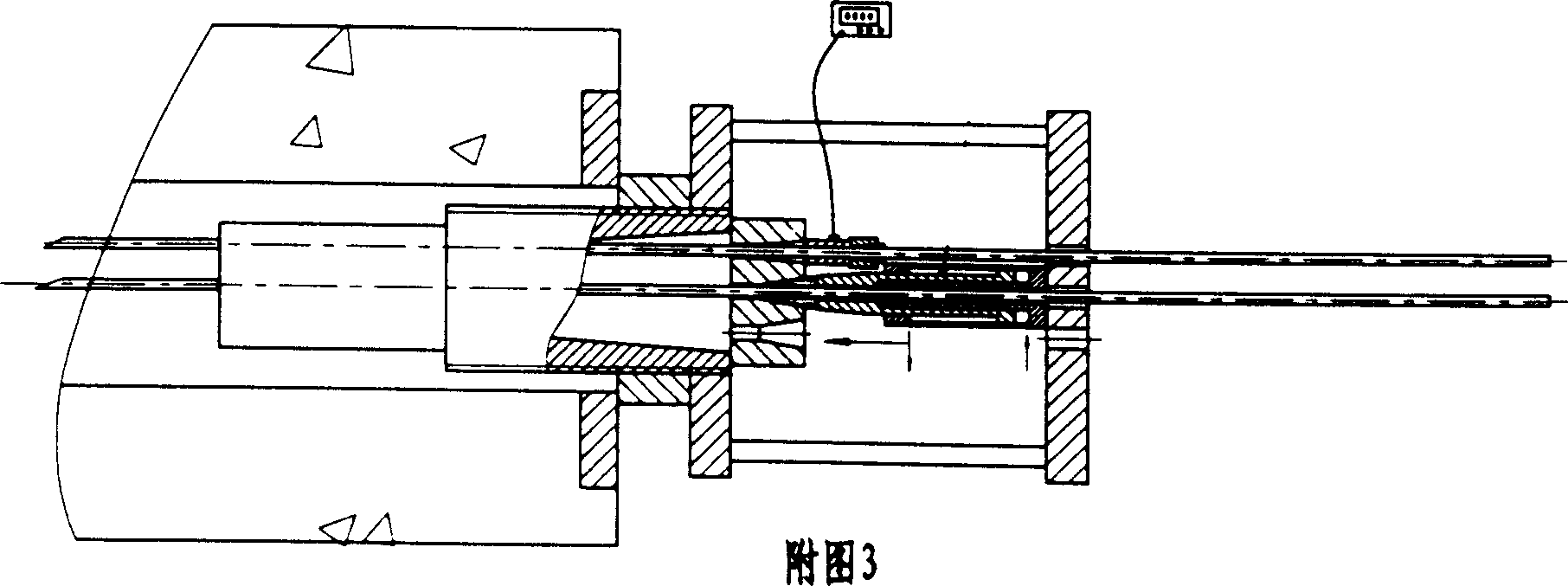

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

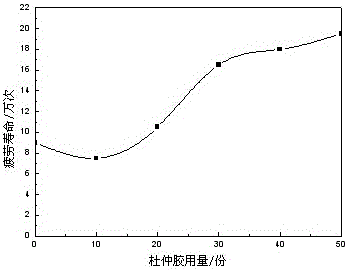

Natural and fatigue-resistant gutta-percha vulcanized rubber and preparation method thereof

InactiveCN105801925AThe ingredients of the formula are reasonableImprove fatigue resistanceRubber materialPolymer science

The invention provides natural and fatigue-resistant gutta-percha vulcanized rubber and a preparation method thereof and relates to rubber and a preparation method thereof. The natural and fatigue-resistant gutta-percha vulcanized rubber is prepared from components in parts by weight as follows: 10-100 / 0-90 parts of the gutta-percha / blend rubber, 4-8 parts of an active agent, 1-4 parts of an anti-aging agent, 30-80 parts of reinforcing filler, 1-6 parts of a vulcanizing agent, 1-4 parts of a vulcanization accelerator, 0-10 parts of a softening agent and other auxiliaries. The preparation method of the fatigue-resistant gutta-percha / blend rubber vulcanized rubber comprises the following technological steps: A, plastication and mixing; B, remilling and vulcanization. The fatigue-resistant gutta-percha / blend rubber vulcanized rubber has reasonable components in the formula and higher anti-fatigue performance. The vulcanized rubber material prepared with the method has good anti-fatigue performance and long service life, can be widely applied to tires, triangular belts, synchronous belts, conveying belts and shock-reducing rubber products and has higher popularization and application value.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

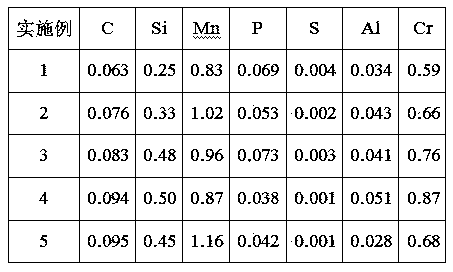

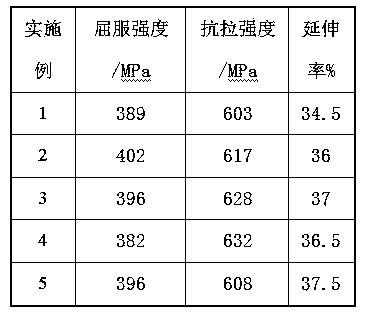

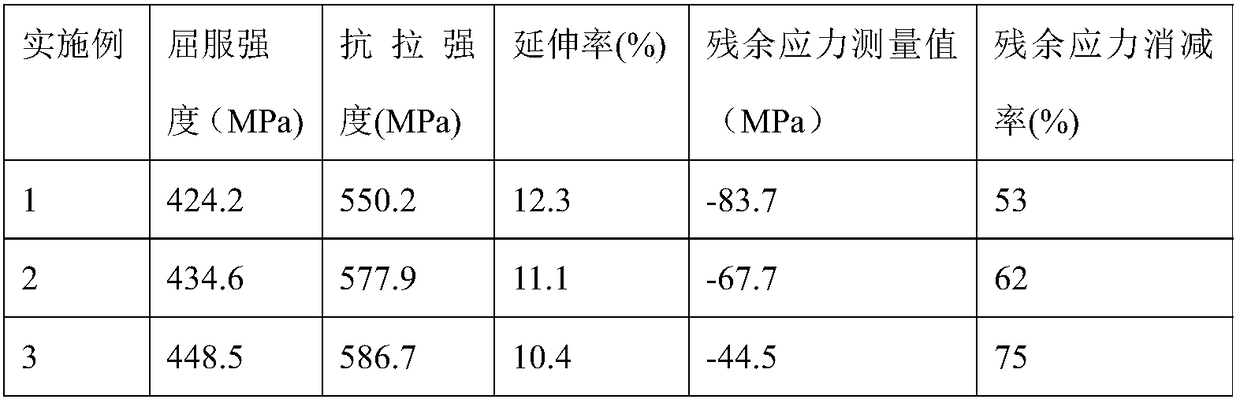

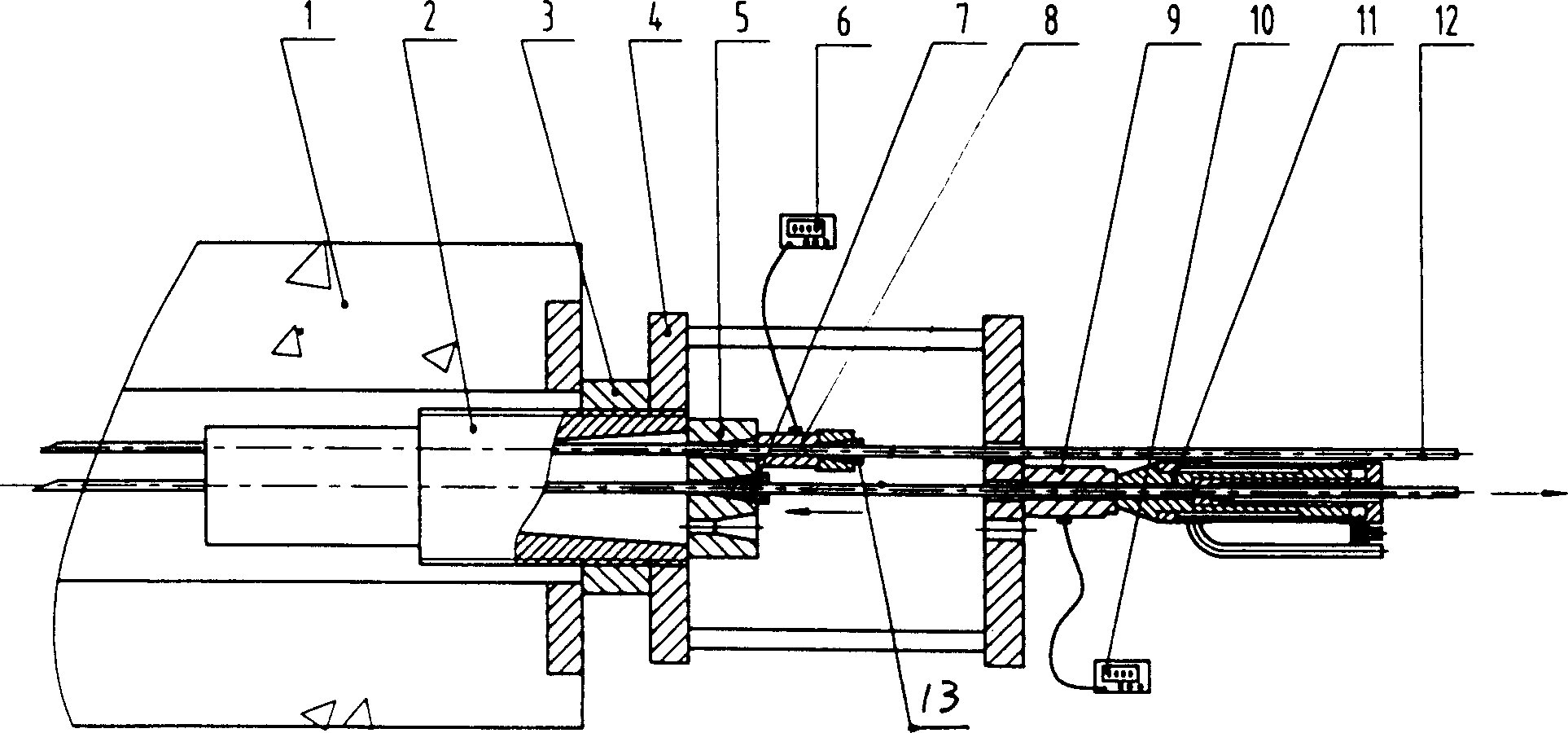

600 MPa-level thick-specification hot rolling spoke steel and manufacturing method thereof

The invention provides 600 MPa-level thick-specification hot rolling spoke steel and a manufacturing method thereof. The spoke steel comprises the following chemical constituents in mass percent: 0.06-0.12% of C, 0.20-0.60% of Si, 0.80-1.20% of Mn, 0.02-0.06% of Alt, 0.50-1.00% of Cr, 0.03-0.08% of P, smaller than or equal to 0.005% of S, smaller than or equal to 0.006% of N, and the balance of Fe and inevitable impurities. In the manufacturing method of the spoke steel, the billet heating temperature is 1,150-1,250 DEG C, and the finish rolling temperature is 760-840 DEG C; after rolling, a conventional cooling technology is used to cool the steel at a cooling rate of 20-100 DEG C per second to 350 DEG C below, and then the steel is reeled. The steel plate is good in processability and fatigue performance, and free of Nb, V, Mo, Ni and other elements, so as to save the production cost. The steel plate provided by the invention can be widely applied to the spoke production of steel wheels of commercial vehicles.

Owner:SHANDONG IRON & STEEL CO LTD

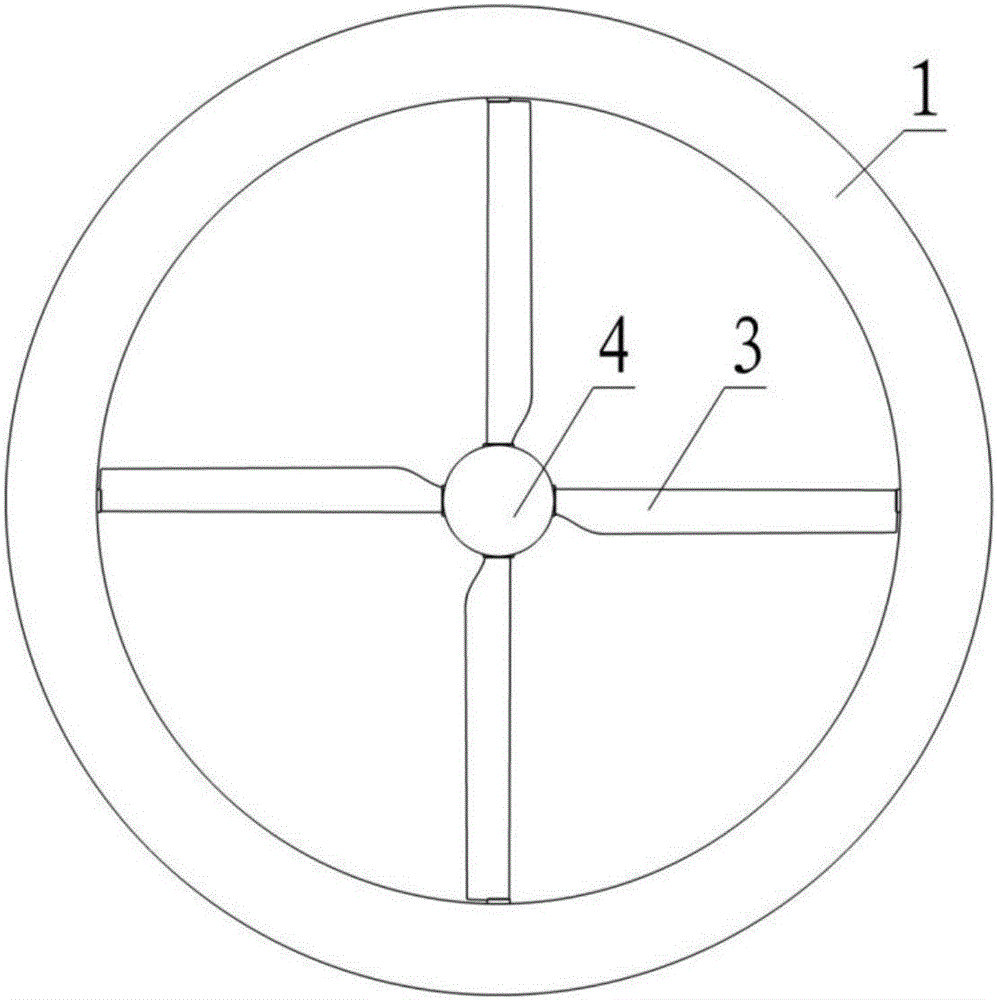

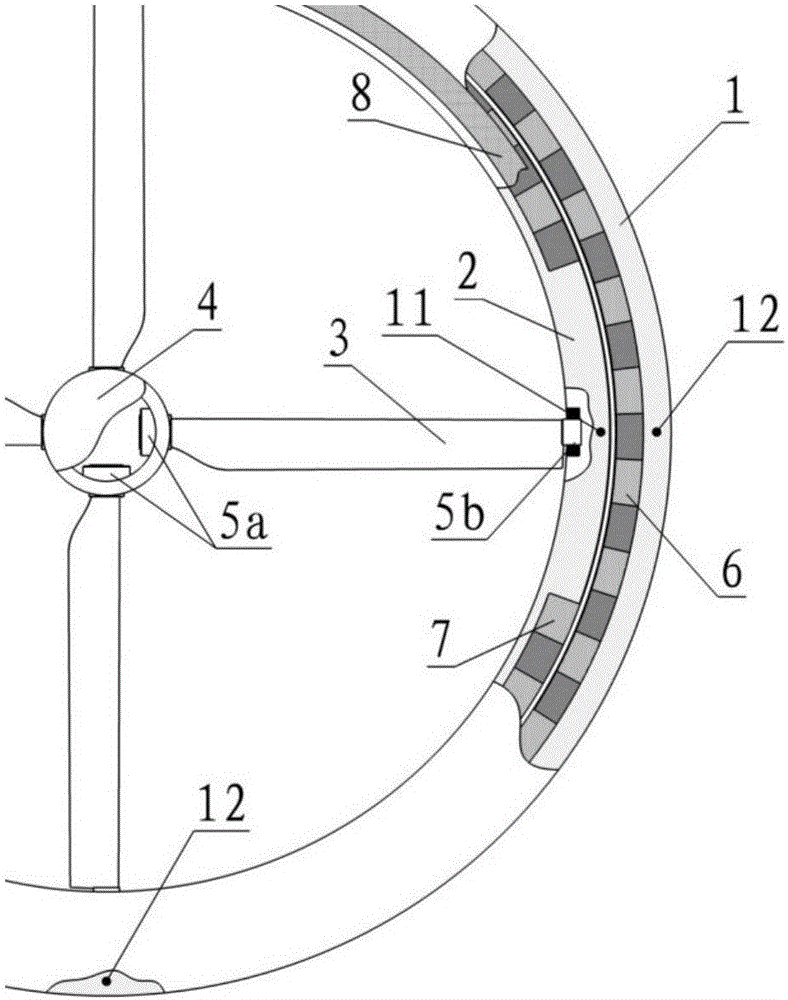

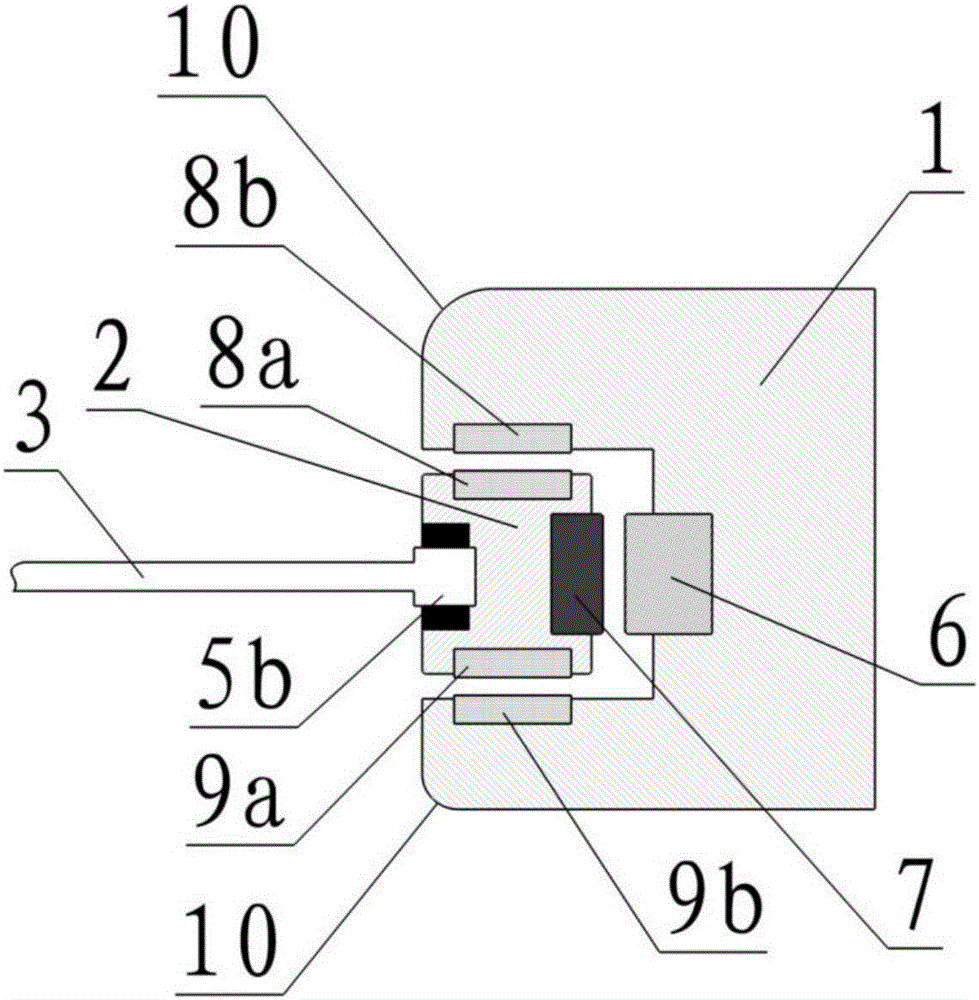

Magnetic levitation rotor wing system and helicopter with same

ActiveCN106516127AEffective consideration of strengthEffectively consider the lift effectPropellersPower plant constructionAviationPropeller

The invention relates to a magnetic levitation rotor wing system and a helicopter with the same and the field of aviation, in particular to the technical field of rotor wings. The magnetic levitation rotor wing system comprises a rotor wing ring (2) and a rail ring (1), wherein the rotor wing ring (2) is connected with a rotor wing propeller point, and the rail ring (1) provides magnetic suspension force for the rotor wing ring (2). Magnetic suspension force provided by the rail ring (1) includes a driving device capable of driving blades to rotate and a suspension device capable of enabling the propeller point to suspend. A first deflection driving mechanism is arranged on the root portions of the blades of the rotor wing so that first deflection angles of the root portions of the blades can be provided, and a second deflection driving mechanism is arranged on the rotor wing ring (2) so that second deflection angles of the points of the blades can be provided. According to the magnetic levitation rotor wing system and the helicopter with the same, only an outside rail ring is needed to drive the rotor wing ring, and the blades are connected by a central connecting component; and the requirement of independent variable pitch of the rotor wing is guaranteed, partial load of the blades is counteracted with one another through the central connecting component, integrality of the rotor wing ring is increased, and working reliability of improved.

Owner:CHINA HELICOPTER RES & DEV INST

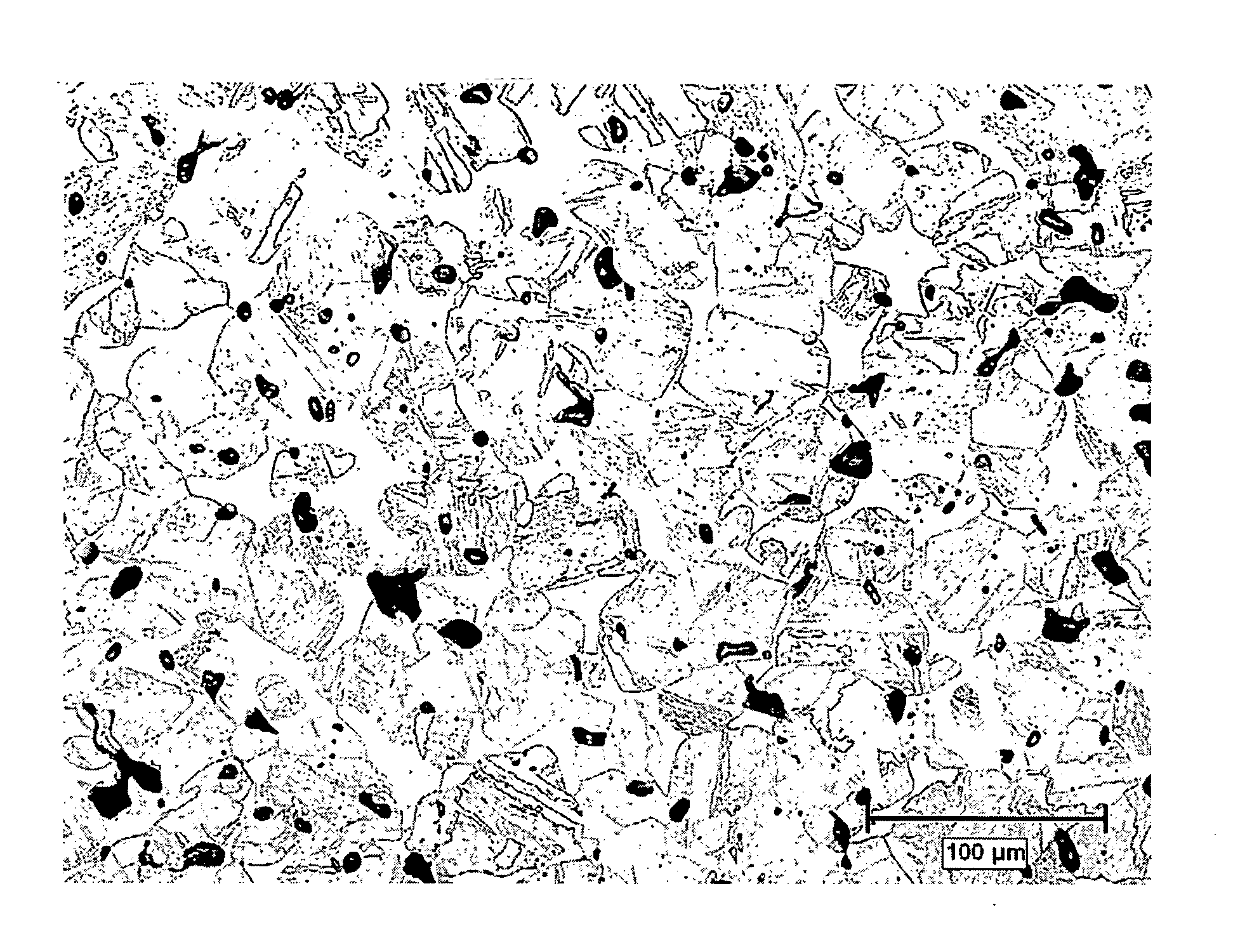

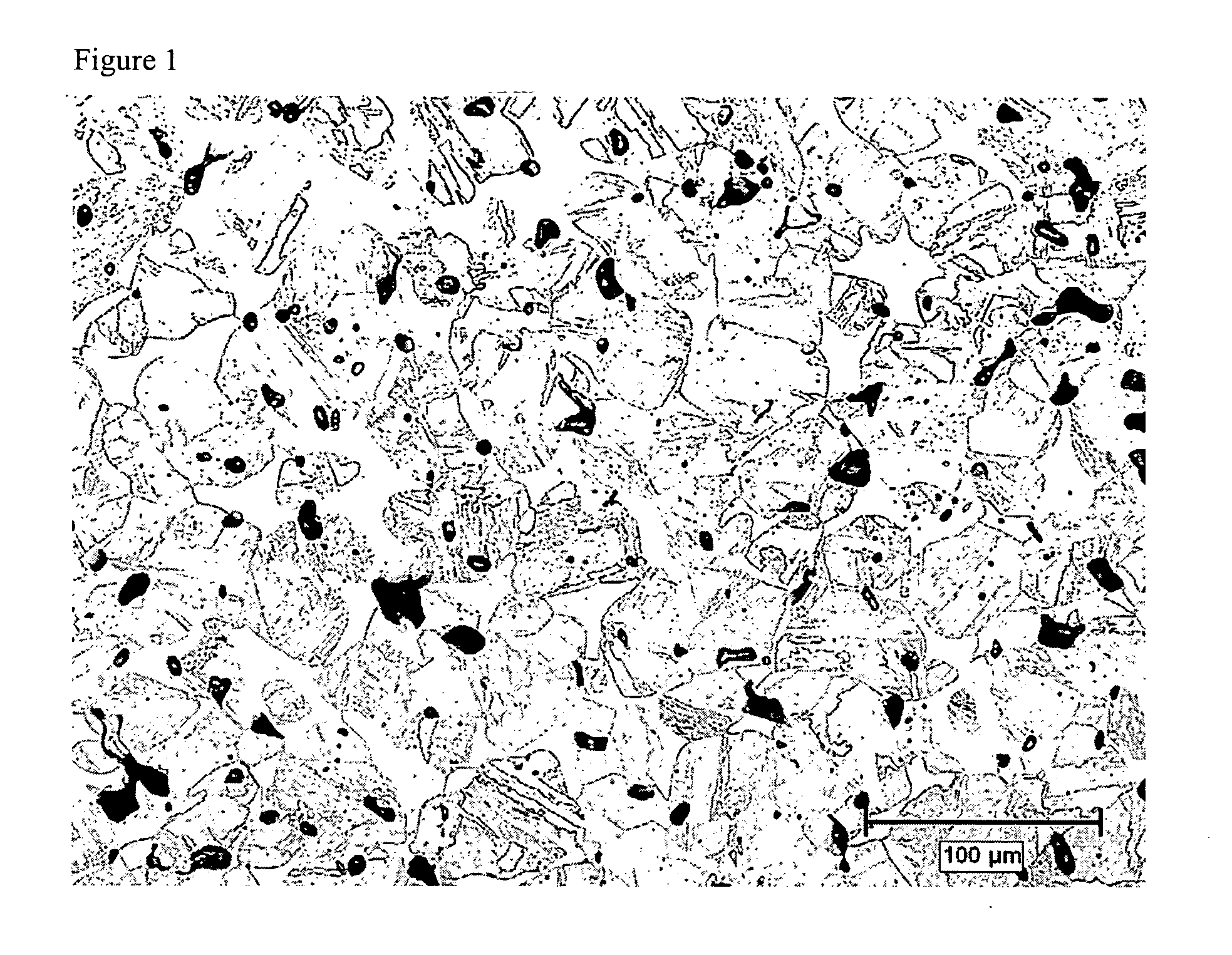

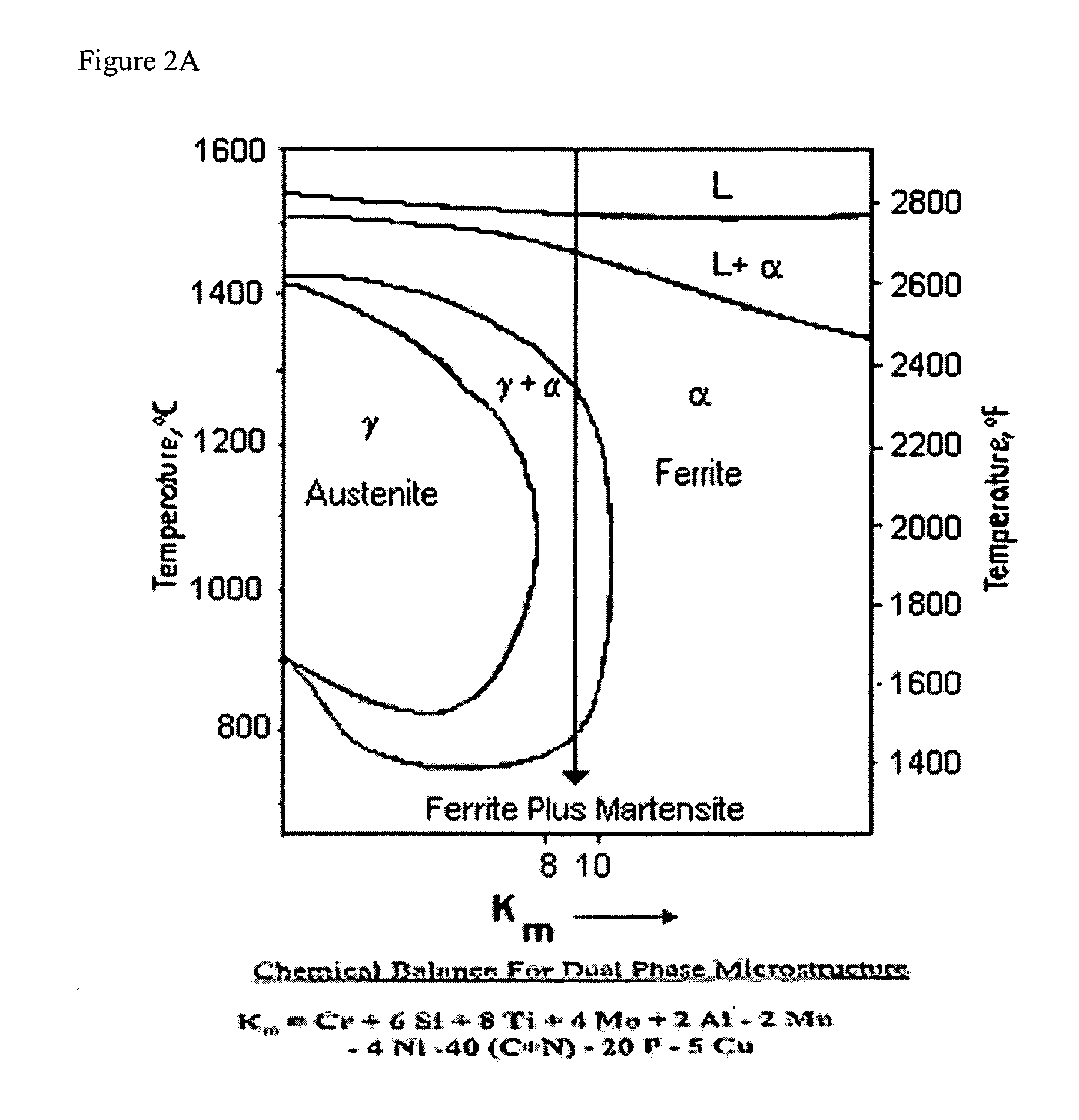

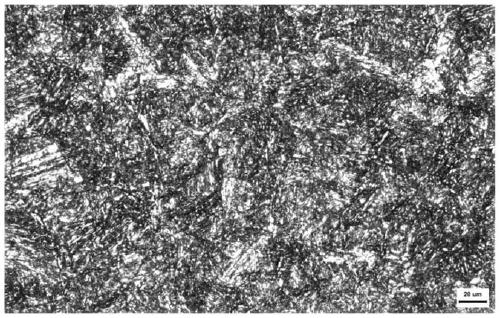

Corrosion resistant metallurgical powder compositions, methods, and compacted articles

InactiveUS20060285989A1High impact strengthStay malleableTransportation and packagingMetal-working apparatusAlloyHardness

Provided are corrosion resistant metallurgical powder compositions, corrosion resistant compacted articles prepared from metallurgical powder compositions, and methods of preparing the same. Corrosion resistant metallurgical powder compositions include as a major component, an iron-based powder and, as a minor component, alloy additives that include chromium, and carbon. Upon compaction and sintering, the iron-based powder and alloy additives form a dual phase alloy system. The dual phase alloy system is denoted by an admixed martensite and ferrite microstructure. This unique microstructure results in beneficial physical properties, such as for example, high strength, hardness, and ductility, impact energy, and fatigue endurance, while maintaining resistance to corrosion.

Owner:HOEGANNES

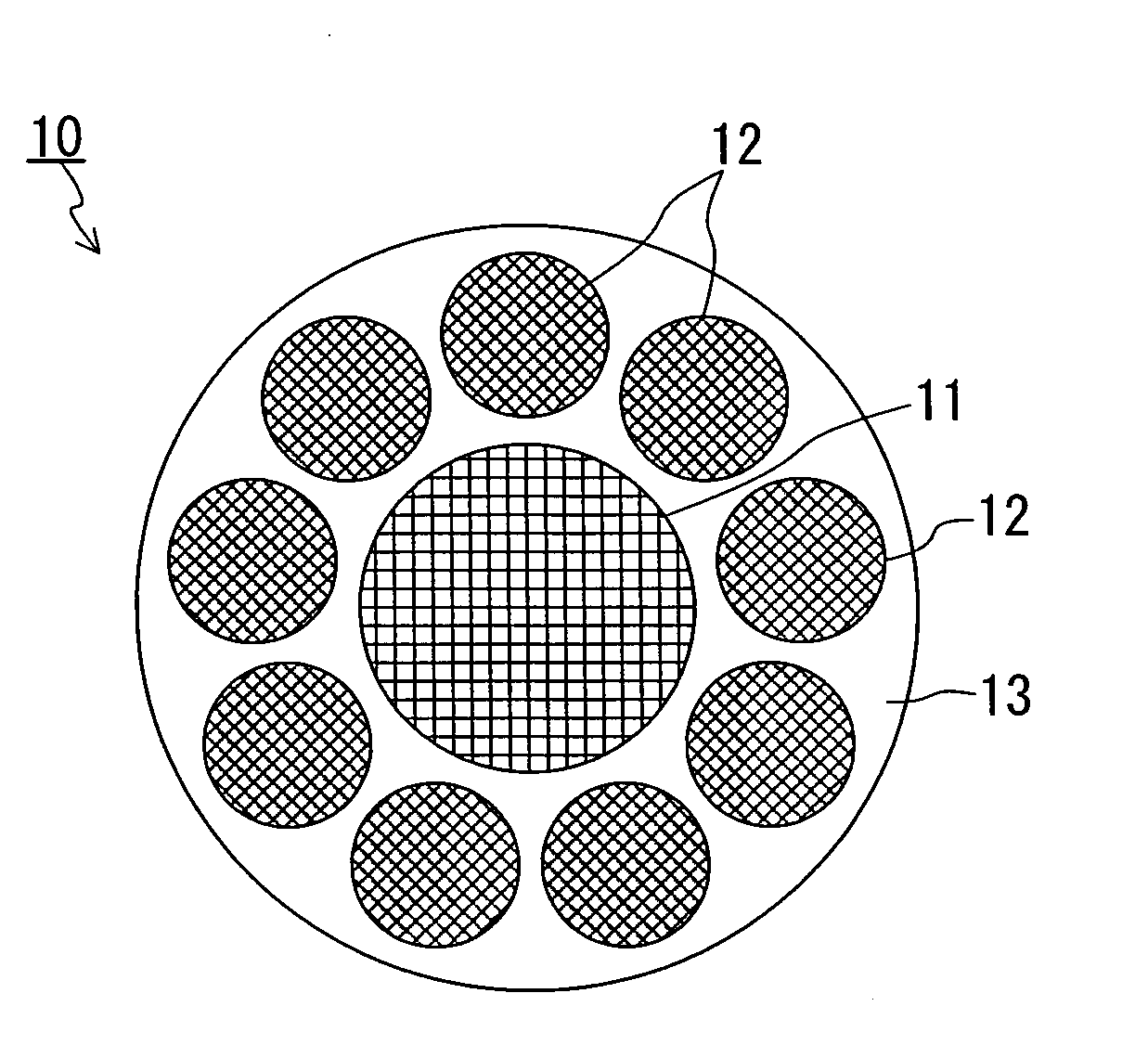

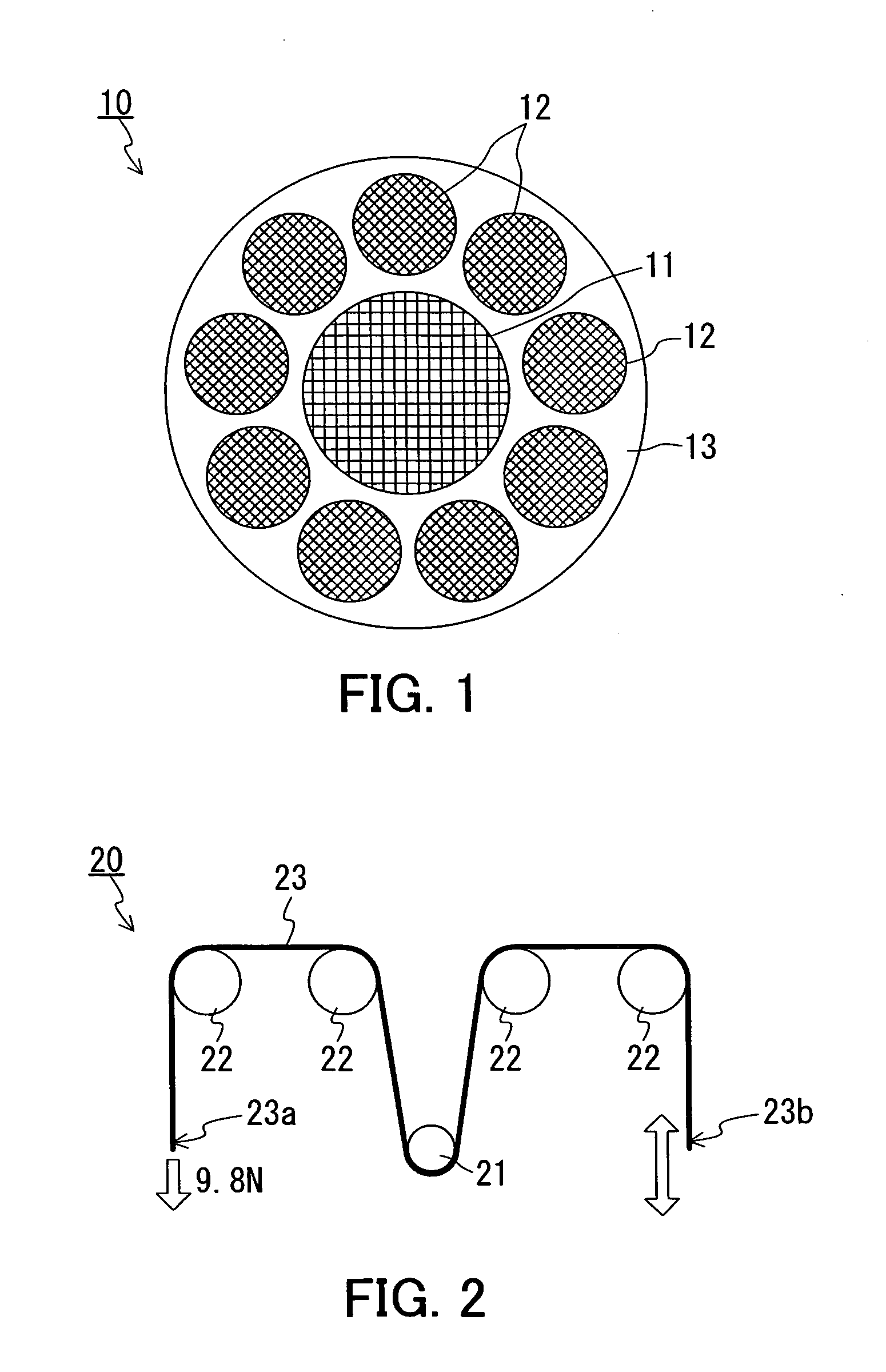

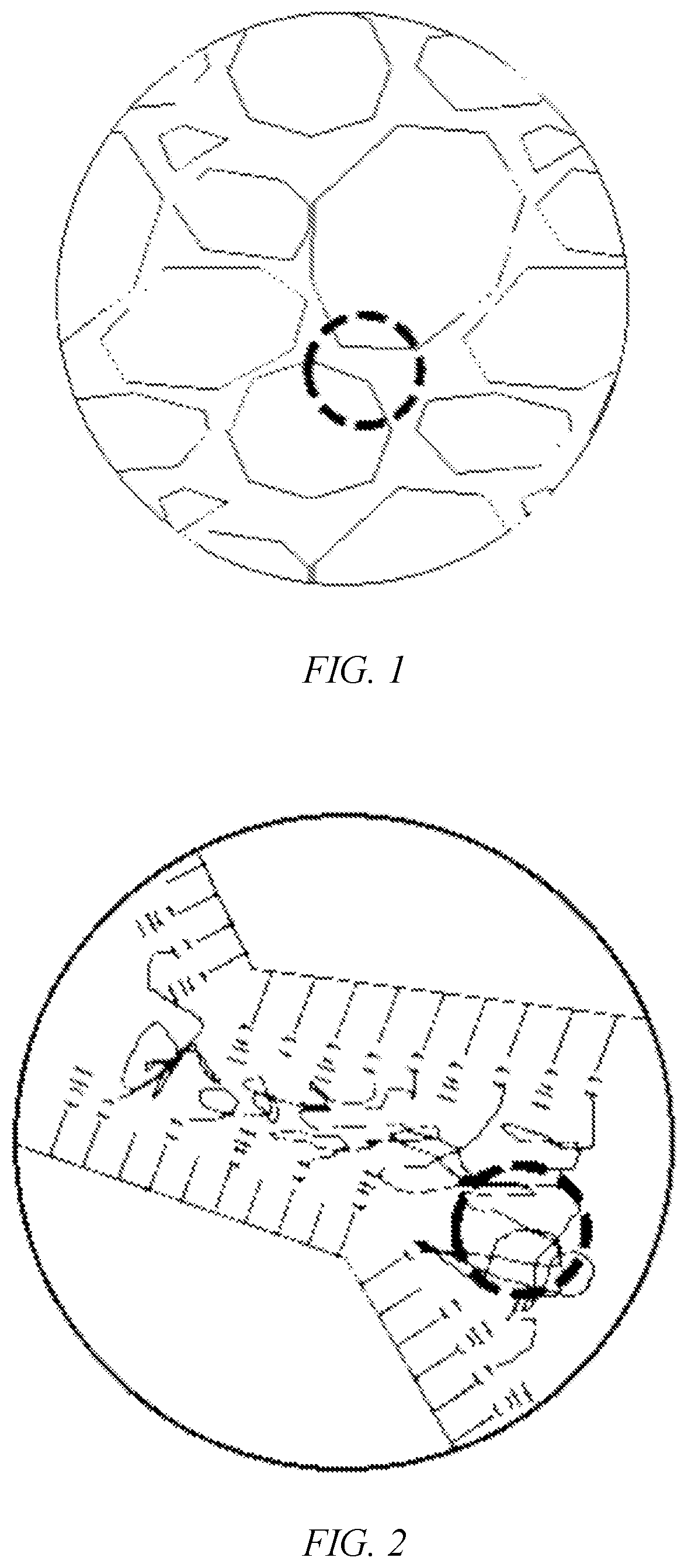

Reinforcing cord for rubber reinforcement and rubber product including the same

A reinforcing cord for rubber reinforcement of the present invention includes reinforcing fibers. The reinforcing fibers include polyarylate fibers 11 and a plurality of outer strands 12 that are arranged around the polyarylate fibers 11. The plurality of outer strands 12 include fibers other than polyarylate fibers. The use of this reinforcing cord for rubber reinforcement makes it possible to obtain a reinforcing cord for rubber reinforcement having high strength, elasticity, and bending fatigue resistance, and a rubber product including the same.

Owner:NIPPON SHEET GLASS CO LTD

Power semiconductor module

InactiveUS7671465B2Increased reliability against thermal fatigueMinimize powerSemiconductor/solid-state device detailsSolid-state devicesMetallic foilThermal fatigue

Owner:HITACHI LTD

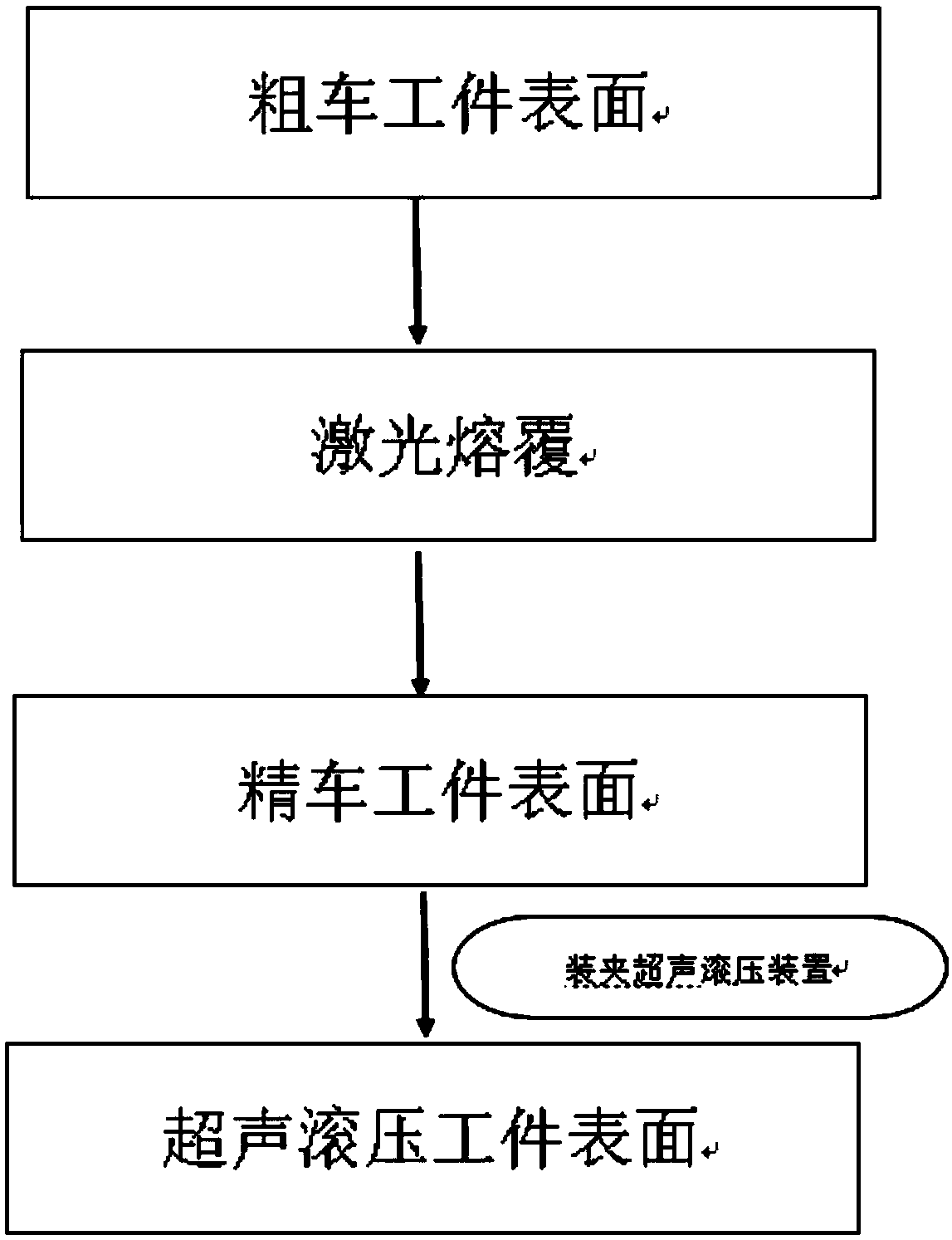

Ultrasonic rolling recombination laser remelting method for improving fatigue property of welded joint

InactiveCN106283038AReduce frictionReduce roughnessMetallic material coating processesSurface layerMaterials processing

The invention relates to an ultrasonic rolling recombination laser remelting method for improving the fatigue property of a welded joint, and belongs to the field of material processing and surface strengthening. The method comprises the following steps: first, the surface modification of the welded joint is performed according to the laser remelting technology, and then ultrasonic surface rolling treatment is performed. Compared with a pure ultrasonic surface rolling processing method, the ultrasonic rolling recombination laser remelting method has the advantages that not only can surface nanocrystallization and ultra-low roughness of the welded joint be realized, but also the welded joint structure can be improved, welding defects can be eliminated, and the depth of a modified surface layer can be deepened, so that the fatigue strength of the welded joint is greatly improved.

Owner:JILIN UNIV

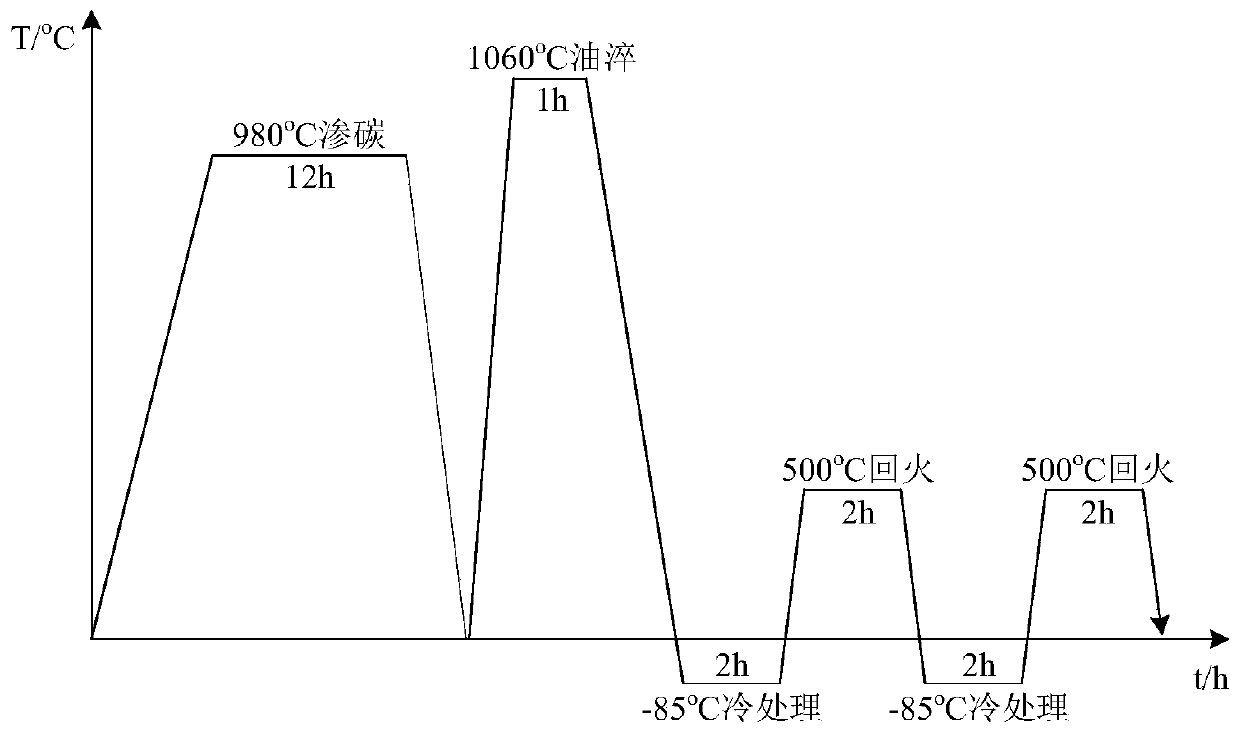

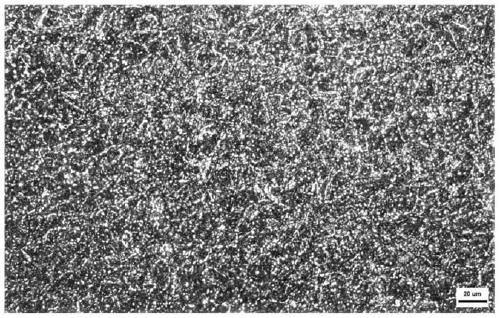

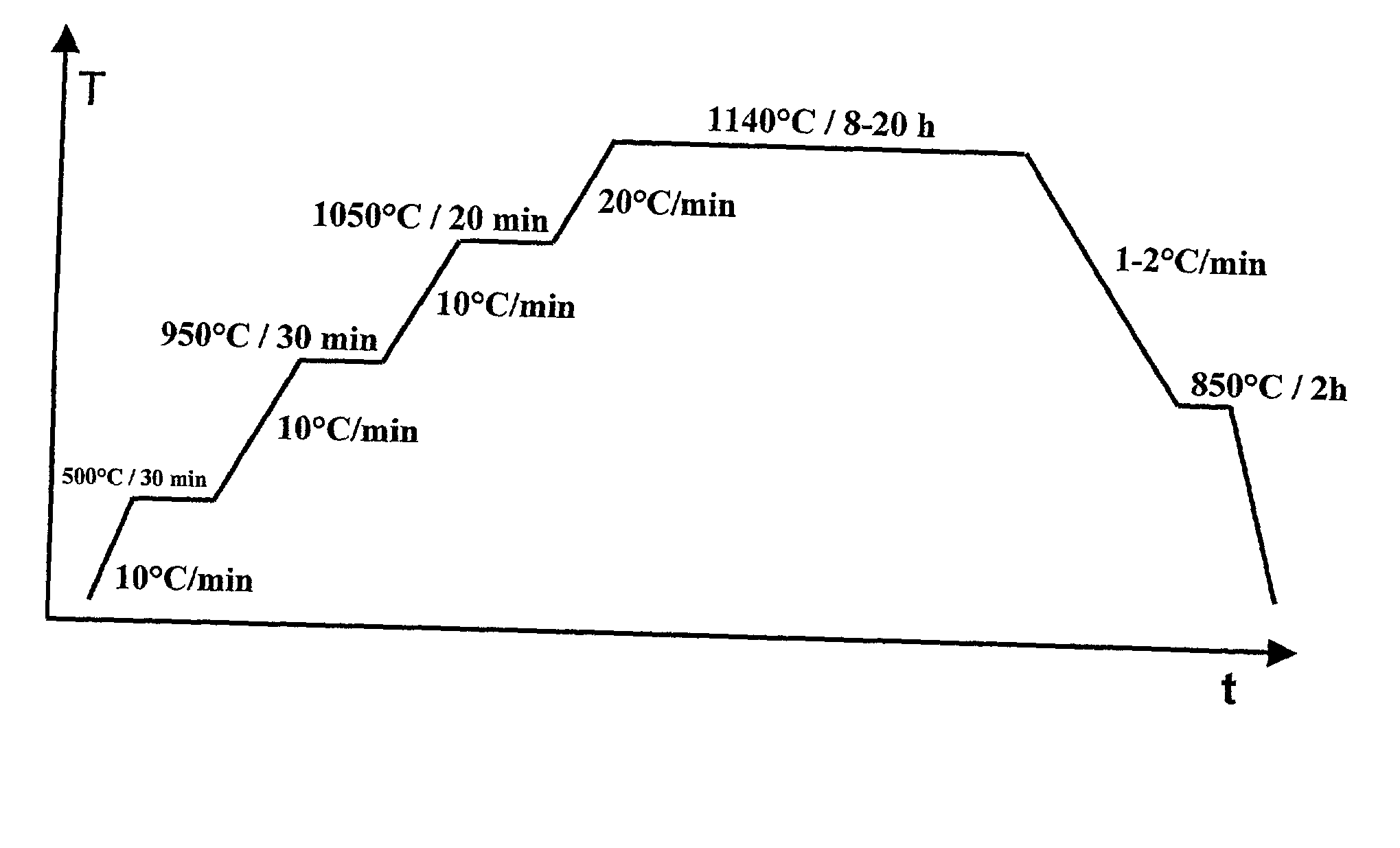

Low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel

ActiveCN109735794ASolve pollutionHigh fatigueSolid state diffusion coatingQuenchingPrepared Material

The invention relates to a low-pressure vacuum carbonizing heat treatment method of high-temperature carburized stainless steel. The method comprises the treatment steps of low-pressure vacuum carbonizing, quenching, deep cooling and high-temperature tempering; and the steps can be repeatedly performed. The low-pressure vacuum carbonizing process uses a saturated value adjusting method for multi-section pulse carbonizing; a carbonizing agent adopts acetylene gas; the carbonizing temperature is 850-1050 DEG C; the carbonizing pressure is 100-2000 Pa; and the powerful seepage and dispersion circulating period is 20-70 times. The treatment method is safe, energy-saved and environment-friendly, can eliminate intergranular oxidation, realizes precise control of the seepage layer depth, and canguarantee excellent service performances of prepared materials above 400 DEG C.

Owner:NORTHEASTERN UNIV

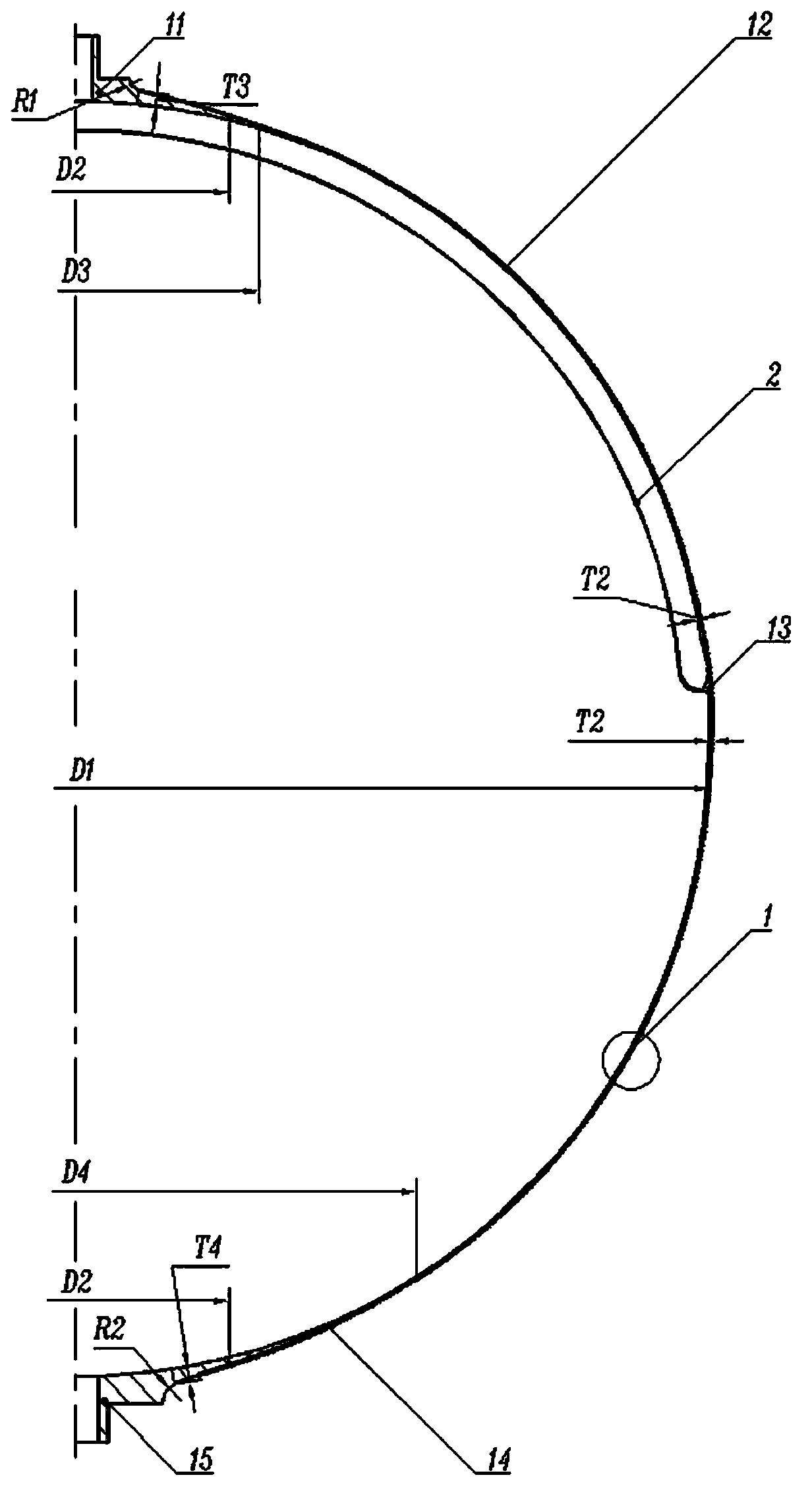

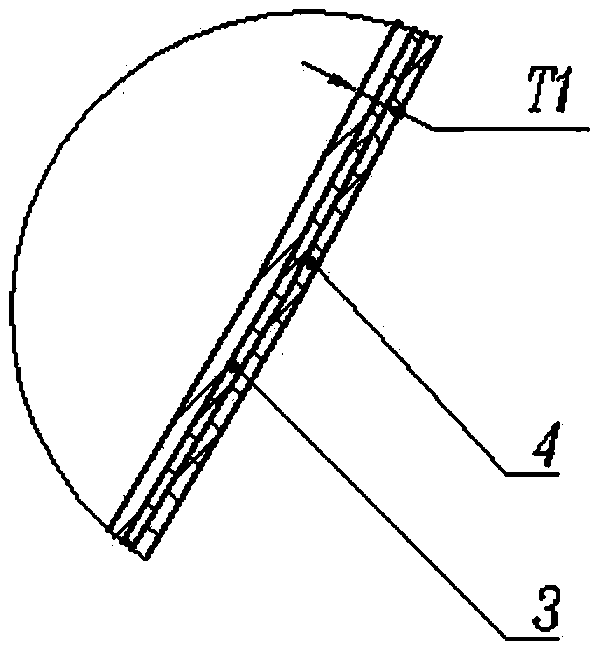

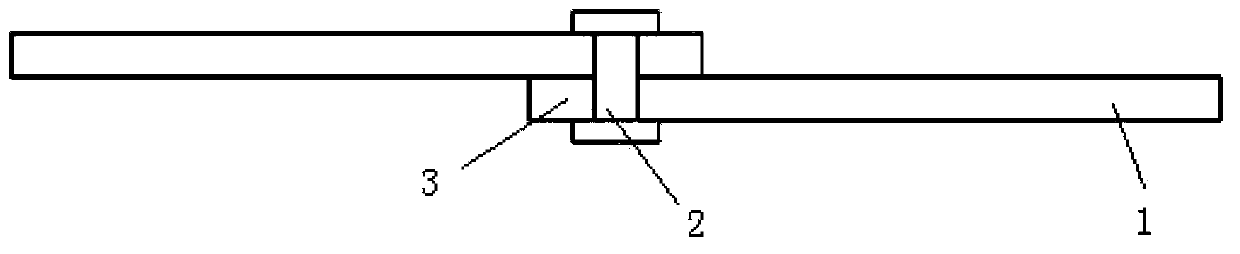

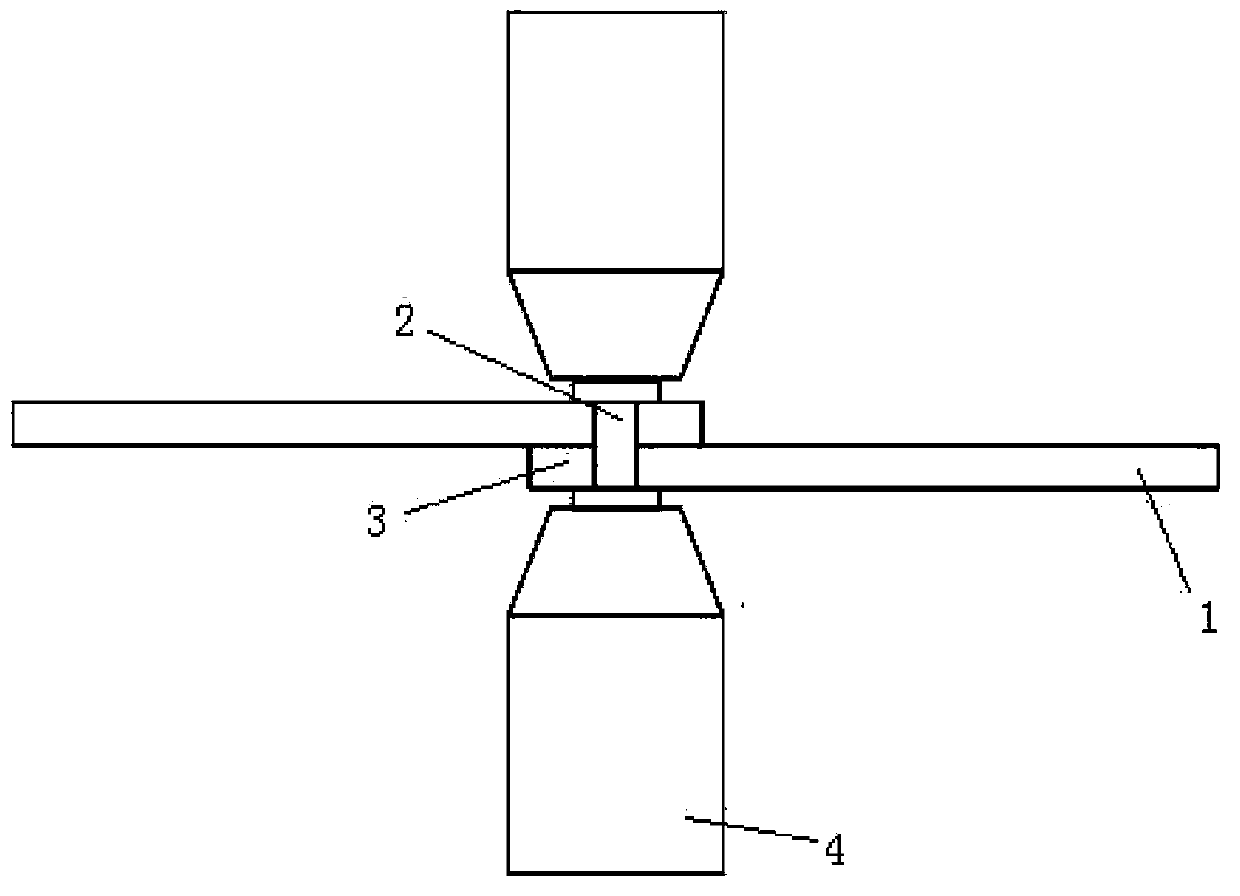

Metal diaphragm storage box made of carbon-fiber composite materials and manufacturing method thereof

ActiveCN103437913ASimple structureGood manufacturing processRocket engine plantsCarbon fiber compositeFlange

The invention provides a metal diaphragm storage box made of carbon-fiber composite materials and a manufacturing method thereof. The metal diaphragm storage box comprises a liner 1 and a metal diaphragm 2 and also comprises an insulating layer 3 and a carbon-fiber composite material layer 4, wherein the liner 1 comprises an upper flange 11, an upper hemisphere 12, a connecting ring 13, a lower hemisphere 14 and a lower flange 15; the upper hemisphere 12 and the lower hemisphere 14 are connected by the connecting ring 13; the upper flange 11 is connected with the upper hemisphere 12; the lower flange 15 is connected with the lower hemisphere 14; the metal diaphragm 2 is butted with the connecting ring 13; the outer surface of the liner 1 is coated with the insulating layer 3; the outer surface of the insulating layer 3 is wound with the carbon-fiber composite material layer 4, and is connected with the carbon-fiber composite material layer 4 in a bonding manner. The metal diaphragm storage box provided by the invention has the advantages that the problems of large weight and low structure efficiency of the metal diaphragm storage box are solved, the light-weight design of the metal diaphragm storage box is realized, the cost is reduced and the performance of a product is improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

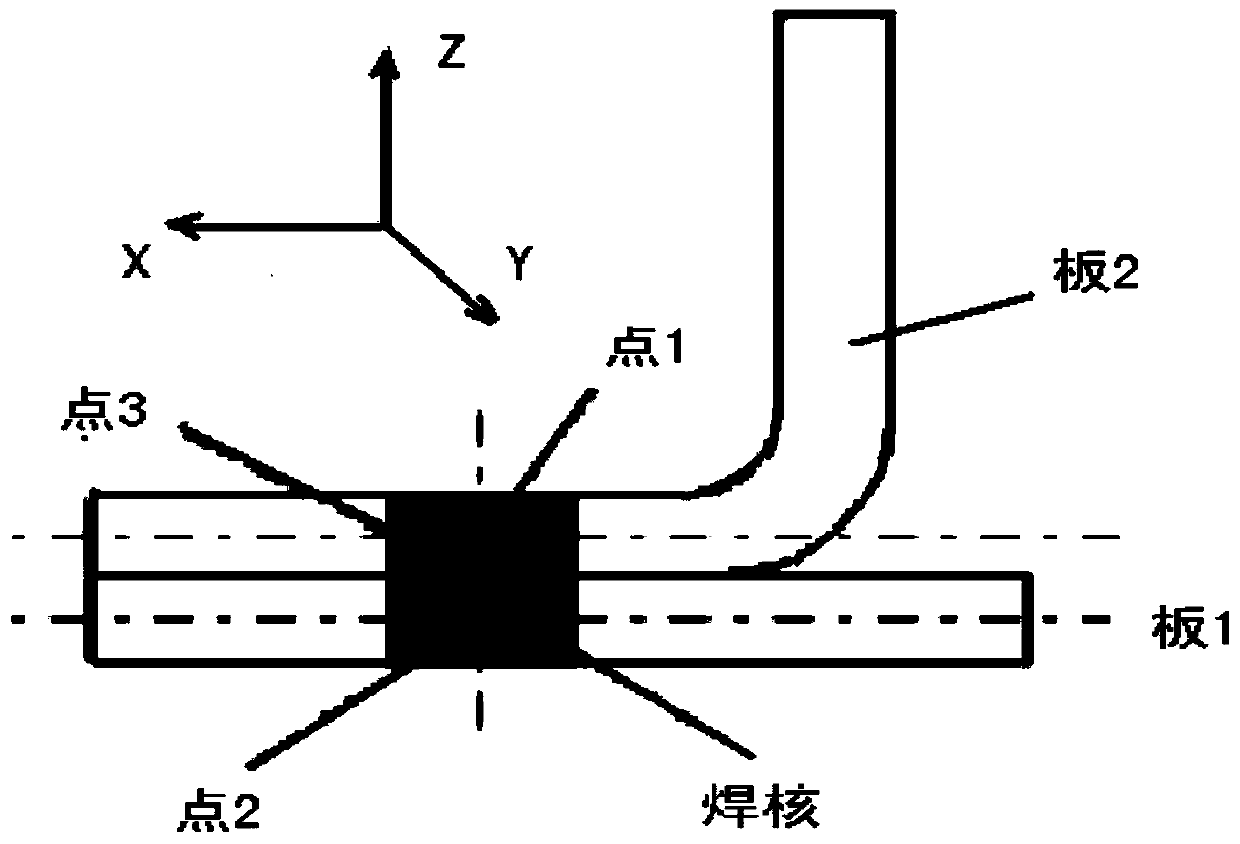

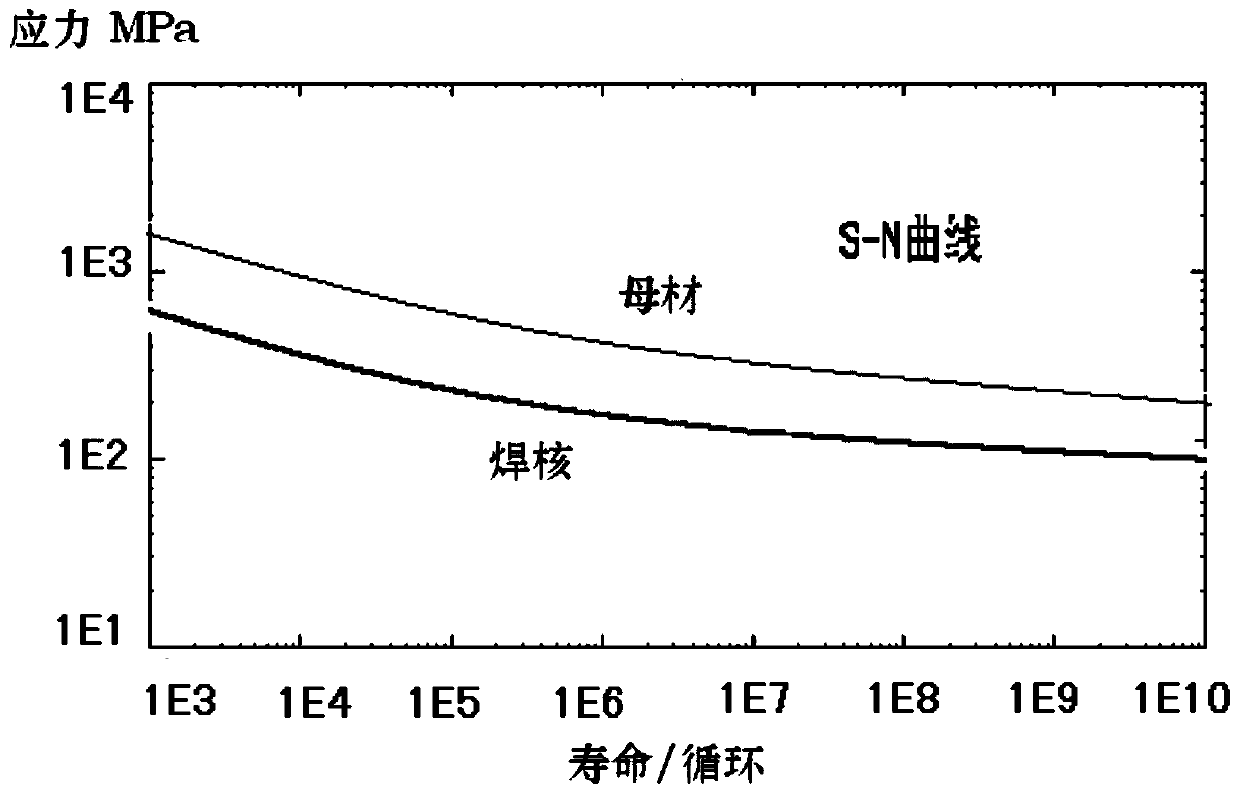

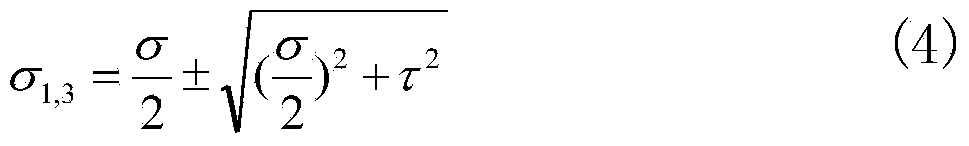

Method for calculating and analyzing fatigue life of airplane structure welding spots

InactiveCN103995919AHigh fatigueReduce manufacturing costSpecial data processing applicationsFatigue damagePrincipal stress

The invention belongs to the field of calculation and analysis of fatigue life of an airplane structure, and relates to a method for calculating and analyzing fatigue life of airplane structure welding spots. The method is characterized in including the following steps that structure stress of a weld nugget is calculated by means of an equivalent stiffening bar unit simulating the weld nugget, and principal stress with the largest absolute value serves as a damage parameter; by means of material fratigue performance tests, an S-N curve of the weld nugget and a parent material is obtained; the effective stress course of each calculation point is calculated through a quasi-steady-state solution, a stress spectrum is determined, fatigue damage is calculated in a damage accumulation method, and distribution situations of damage and service life of all weld spots are obtained. The method has the advantages that the fatigue life of the weld points can be predicted through calculation in the initial stage of design by putting forward to a weld spot fatigue life calculation model and an analysis method suitable for engineering application, the distribution situations of the weld spots of a whole structure are known, and the number and the distribution mode of the weld spots in the actual process can be guided to be reasonably adjusted.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Durable fine wire lead for therapeutic electrostimulation and sensing

InactiveUS20090299446A1Increase flexibilityFirmly connectedSpinal electrodesTransvascular endocardial electrodesElectrical conductorCardiac pacemaker electrode

A cardiac pacemaker, other CRT device or neurostimulator has one or more fine wire leads. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal buffer cladding, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The buffered fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar leads can include several conductors side by side within a glass / silica fiber, or can be concentric metal coatings in a structure including several fiber layers. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

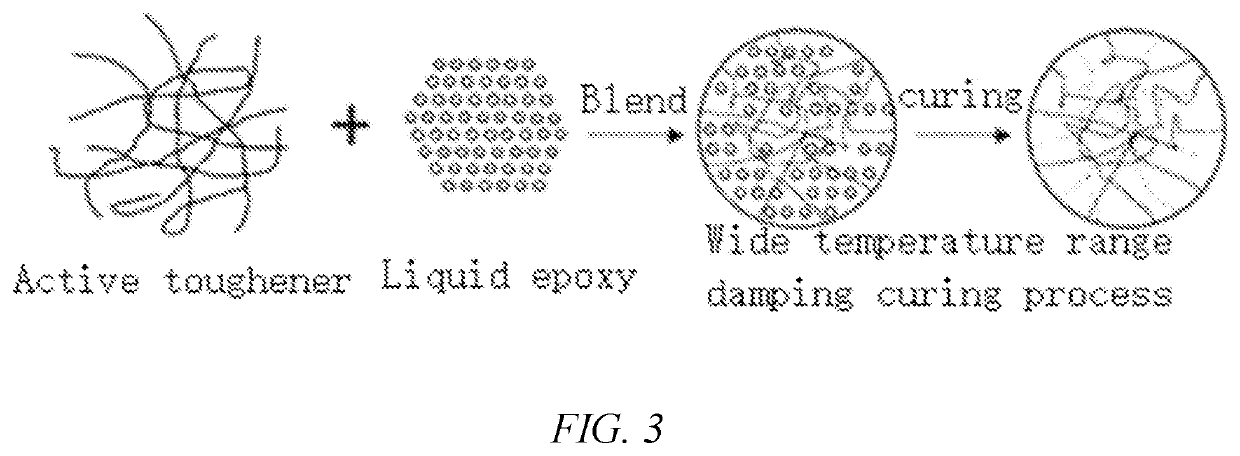

Anti-fatigue cold mixed epoxy resin material, preparation method and application thereof

ActiveUS20210253842A1Inhibitory activityReduced activityIn situ pavingsMacromolecular adhesive additivesEpoxyEndcapping

The invention relates to an anti-fatigue cold mixed epoxy resin material, preparation method and application thereof, comprising component A and component B with mass ratio of 1:1-10:1, component A comprising fluid epoxy resin, active toughener, active diluents, coupling agent and defoamer; component B is any one of or a mixture of two or more than two of alicyclic amine or amino terminated polyether, cyanoethylamine, phenolic modified amine or hydroxyalkyl modified amine. Introduced epoxy terminated organosilicon block polyurethane prepolymer breaks the limitation that elongation at fracture of epoxy resin system based on “sea-island structure” is difficult to break through 100%. The invention is suitable for bridge deck pavement of long-span cable bearing bridge, waterproof bonding material or used for airport pavement, municipal viaduct, ramp and other occasions with high requirements for fatigue resistance of pavement material.

Owner:SINOROAD TRANSPORTATION SCI & TECH CO LTD

Method for isothermal brazing of single crystal components

InactiveUS20030066177A1Solution value is not highHigh fatiguePolycrystalline material growthAfter-treatment detailsSingle crystalMechanical property

A process of brazing cracks and gaps in a single crystal article which takes places isothermally under the following conditions: the temperature of the isothermal solidification is between TLiqidus, B>Liqidus, Braze< / highlight>+5*(wt-%B<subscript>Bra0*(wt-%BBraze)), while (wt-% B*wt-%Cr) is between erial< / highlight>-70*(wt-%B<subscript>Braze< / highls, Braze) is above 140° C. This results in an homo0 and (T<subscript>solv.gamma', base material< / higmal solidified, brazed joint with mechanical prope above 140° C. This results in an homogeneous gamma / gamma'-microstructure of the isothermal solidified, brazed joint with mechanical properties similar to those of the base material.

Owner:ANSALDO ENERGIA IP UK LTD

Modification method for improving surface nano indentation property of material

ActiveCN103422098AHigh fatigueImprove fatigue lifeSolid state diffusion coatingHigh densityDislocation

The invention discloses a modification method for improving the surface nano indentation property of a material. The modification method combines three technologies of mechanical shot blasting, surface alloying and laser shock peening effectively, parts realize the surface nanocrystallization and alloying modification through shot blasting and pack aluminization, and the surfaces of the parts are subjected to laser shock peening complex treatment. The sequence of the technologies improves the surface nano uniformity of the material greatly, and shortens the diffusion time; meanwhile, the high-ductility deformation of the material is caused, and high-amplitude residual compressive stress is applied on the surface of the material, and the surface of the material is subjected to high-density dislocation. The parts prepared by the peening method have a good nano indentation property, high abrasive resistance, high corrosion stability and high temperature oxidation resistance, and the fatigue lives of the parts at the normal temperature and high temperature are prolonged greatly.

Owner:江苏大学扬州(江都)新能源汽车产业研究所

Hot-rolled ferrite bainite dual-phase steel strip for wheel with 590MPa class tension strength and preparation method thereof

ActiveCN109536845AStable performanceImprove fatigue performanceProcess efficiency improvementWeld seamDual-phase steel

Provided is a hot-rolled ferrite bainite dual-phase steel strip for a wheel with 590MPa class tension strength. The strip is prepared from, by weight, 0.05-0.10% of C, 0.40-0.70% of Si, 1.40-1.70% ofMn, P less than and equal to 0.020%, S less than and equal to 0.004%, 0.020-0.060% of Al, 0.015-0.035% of Nb, 0.20-0. 40% of Cr, N less than and equal to 0.0060, O less than and equal to 0.0020% and the balance of Fe and inevitable impurities. A preparation method is provided, and the method comprises the the following steps of hot metal pretreatment->converter smelting->LF+RH furnace refining->slab continuous casting->heating->rough rolling and finish rolling->control cooling->rolling->finished product inspection->factory leaving. The 590MPa class wheel steel has stable performance, effectively avoids an unsuited fatigue test which is often encountered in the use of a high-strength wheel steel, cracking of rim welding, thinning of a weld seam and cracking of a center hole of a spoke, andis a material ideal for light weight of the wheel.

Owner:BENGANG STEEL PLATES

High-strength steel for automotive wheels and manufacture method thereof

InactiveCN101831585AHigh strengthHigh fatigueManufacturing convertersMetal rolling arrangementsSheet steelHigh intensity

The invention relates to high-strength steel for automotive wheels and a manufacture method thereof, belonging to the technical field of high-strength stamping steel. The steel for automotive wheels comprises the following components in percentage by weight: 0.07-0.12 percent of C, 0.01-0.1 percent of Si, 1.0-1.2 percent of Mn, 0.008-0.015 percent of P, not more than 0.008 of S, 0.020-0.040 percent of Al and the balance of Fe and other impurity elements. The manufacture method has the processes of: molten iron preprocessing for desulfurization, processing by a top-and-bottom combined blown converter, refining treatment by an LF furnace, continuous casting of plate blanks, thermal rolling and finished product obtaining. Compared with traditional steel for wheels, the invention has the advantages that the tensile strength can reach 380-480 MPa, and the elongation rate is 26.0-43.0 percent under the condition that noble metals, such as Nb, and the like are not added. The steel plate with high strength, high fatigue resistance and high stamping performance can be obtained with low alloying cost to effectively lighten the self weight of an automobile and reduce the oil consumption; and therefore, the high-strength steel is an ideal steel plate for producing automobile wheel rims and spokes.

Owner:SHOUGANG CORPORATION +1

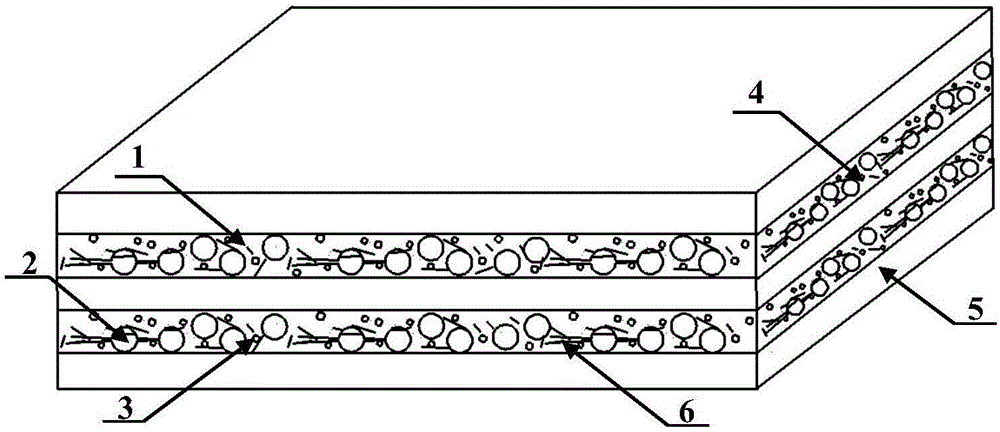

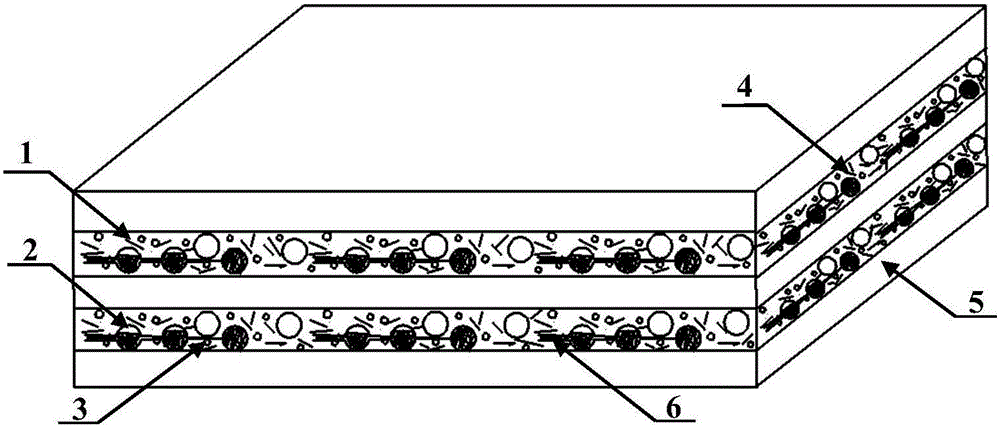

Fiber/metal layer structure composite and preparation method thereof

InactiveCN106553397AAchieve self-healingMeeting urgent needsSynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a fiber / metal layer structure composite and a preparation method thereof, and relates to the field of manufacturing of functional composites. The fiber / metal layer structure composite comprises alternate fiber resin layers and metal layers; rubber layers can be further added; repairing agent microcapsules and a catalyst are added in resin; and micron strength enhanced particles can be further added. The preparation method comprises the steps of wetting fibers through resin, so as to prepare the fiber resin layers; carrying out surface treatment on metal sheets, so as to prepare the metal layers; alternately laying the fiber resin layers and the metal layers in a mold cavity; and carrying out heating, pressurization and curing treatment on the layer structures in the mold cavity. According to the fiber / metal layer structure composite, advantages of the fiber resin composite, metals and rubber are combined, the composite has relatively high designability, and the designed material is a functional composite with the prominent characteristics of high specific strength, fatigue resistance, corrosion resistance, high damping, and the like, and meets the urgent requirements of fields like aerospace, national defense, rail transit and automobiles on new materials to a certain extent.

Owner:JILIN UNIV

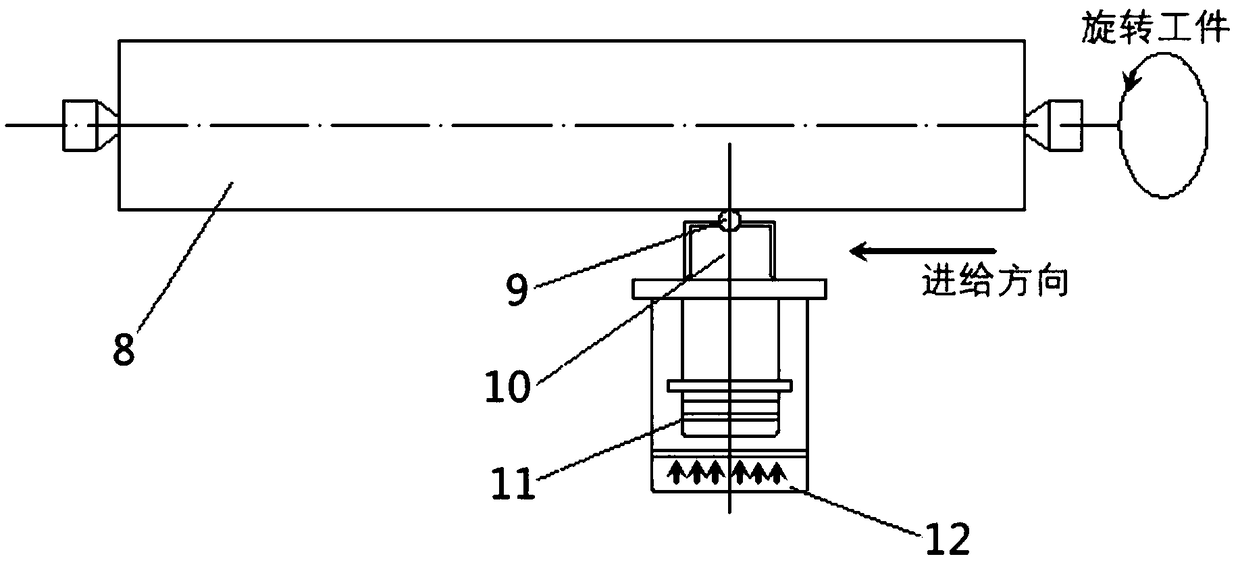

Repairing technology for ultrasound rolling strengthening of shaft type component surface laser cladding layer

InactiveCN109338358AAdd ultrasonic rolling processSmall grain sizeMetallic material coating processesSurface layerHardness

The invention discloses a repairing technology for ultrasound rolling strengthening treatment of a shaft outer circle surface laser cladding layer, and belongs to the technology of shaft type component repairing and strengthening. The repairing technology specifically comprises the steps that to remove surface impurities and make the cladding layer and a base body have good bonding strength, first-time turning machining is conducted on the surface of a shaft needing to be repaired, a certain amount of outer circle surface layer is removed, then, laser cladding is conducted, the diameter of theshaft obtained after laser cladding is slightly larger than the diameter of the surface of the finally-repaired shaft, then, second-time turning machining is conducted on the cladding surface, finally, ultrasound rolling strengthening is conducted, and accordingly the final repairing diameter is formed. According to the repairing technology, operation is simple, the repairing layer is high in hardness, good metallurgy bonding is formed between the repairing layer and the base body, and disengaging is avoided; and after ultrasound rolling, surface-layer grains are fine, large residual compressive stress is formed, accordingly, the fatigue performance of the shaft is improved, and the shaft can be a stirring shaft with a stirring function in mine machines.

Owner:NANCHANG UNIV

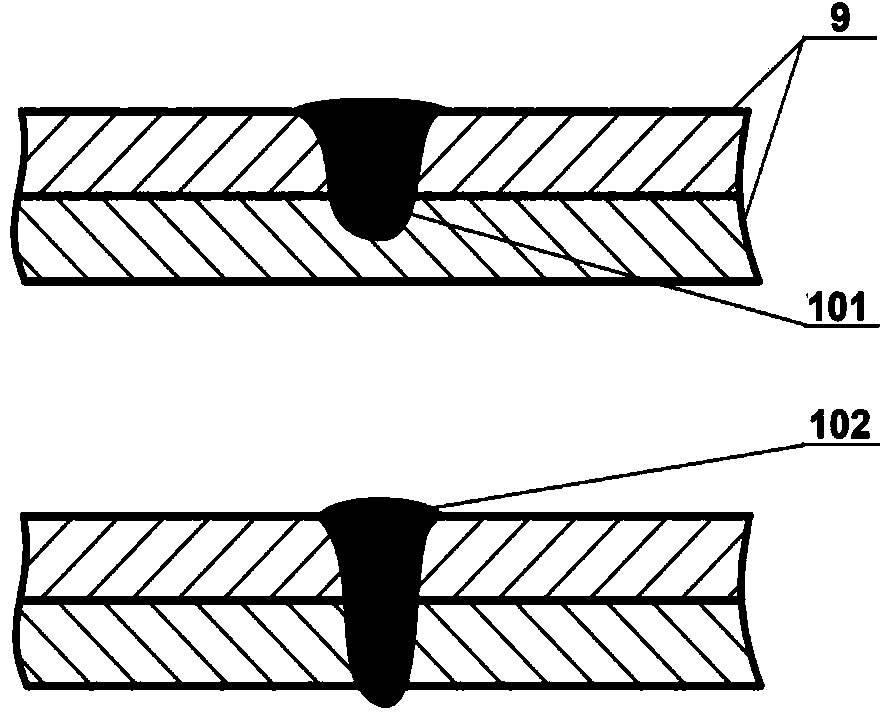

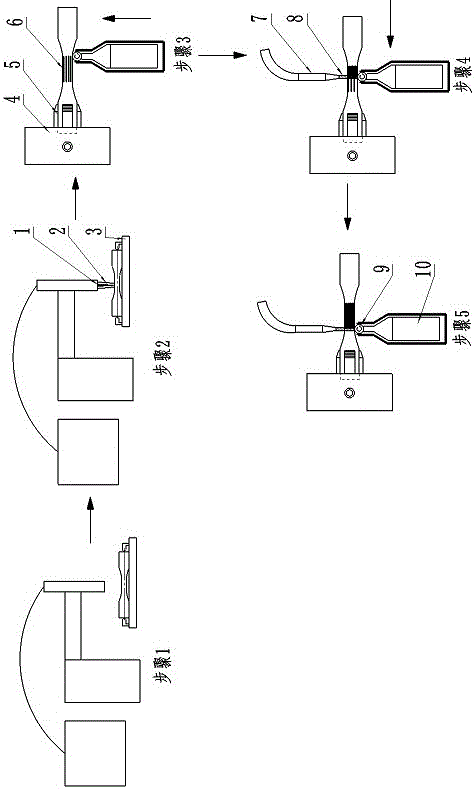

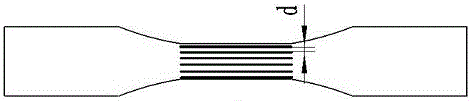

Spot welding method and application thereof in aluminum alloy and steel

InactiveCN103350276ALow heat inputImprove welding qualityResistance welding apparatusSpot weldingUltimate tensile strength

The invention discloses a spot welding method. Aiming at aluminum alloy plates, aluminum alloy and various steel dissimilar materials, the method adds a solid adding material which is generally a rivet in a welded plate and then carries out spot welding at the riveting place. The tensile strength of a spot-welding lap joint which is welded with the method is higher than that of a spot-welding test piece which is welded under same parameters, meanwhile the welding quality of the spot-welding lap joint is good, and the spot-welding lap joint does not have obvious cracks or gas holes.

Owner:TIANJIN UNIV

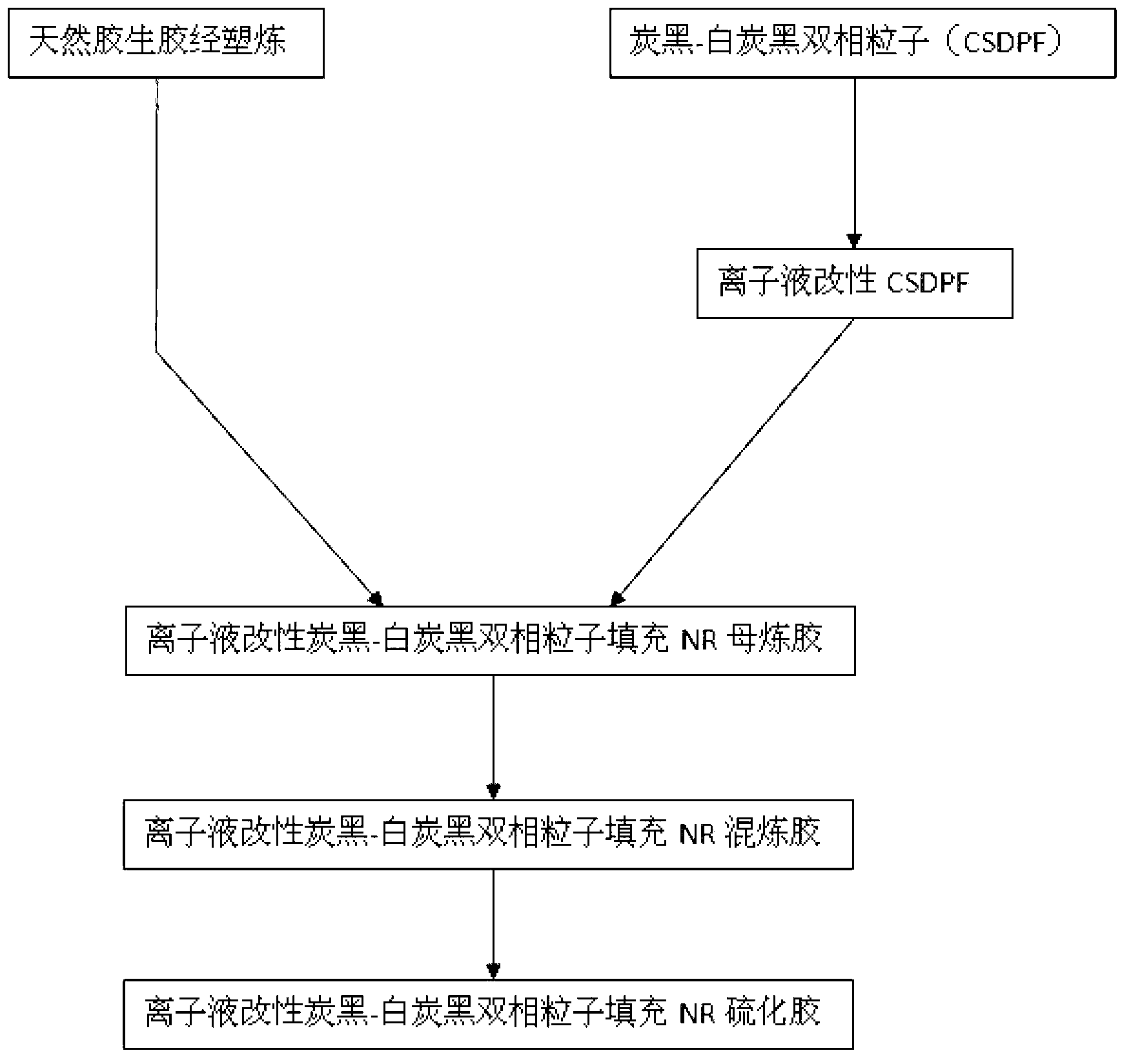

Ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and preparation method thereof

ActiveCN103275365AGood mechanical propertiesImprove mechanical propertiesVulcanizationPolymer science

The invention relates to ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and a preparation method thereof. The rubber comprises the following constituents: natural rubber, vulcanizing agent, ionic liquid, carbon black-white carbon black double-phase particles, zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent and resin. The rubber has excellent stretch resistance and tear resistance performances, good fatigue resistance performance, good abrasive resistance, and good thermo-oxidative aging resistance performance, is low in dissipated heat, can prolong the service life of products during the use, can be applied to various rubber products, and particularly applied to tire tread rubber with high mechanical property requirements and good dynamic mechanical properties.

Owner:NANJING UNIV OF SCI & TECH

Method of manufacturing rivets having high strength and formability

InactiveUS6843404B2Good molding effectRaise the ratioCooking-vessel materialsRivetsHigh intensityMechanical property

A rivet having improved formability is provided. The rivet has a shank having a head at one end. The shank and the head have a refined grain structure. The rivet is manufactured from the region of the workpiece having a refined grain structure by first forming a region having a refined grain structure in a workpiece and then forming the rivet. The refined grain structure results in improved mechanical properties, such as formability, strength, toughness, ductility, corrosion resistance, and fatigue resistance. The improved formability of the rivet reduces the formation and propagation of cracks during the manufacture and installation of the rivets.

Owner:THE BOEING CO

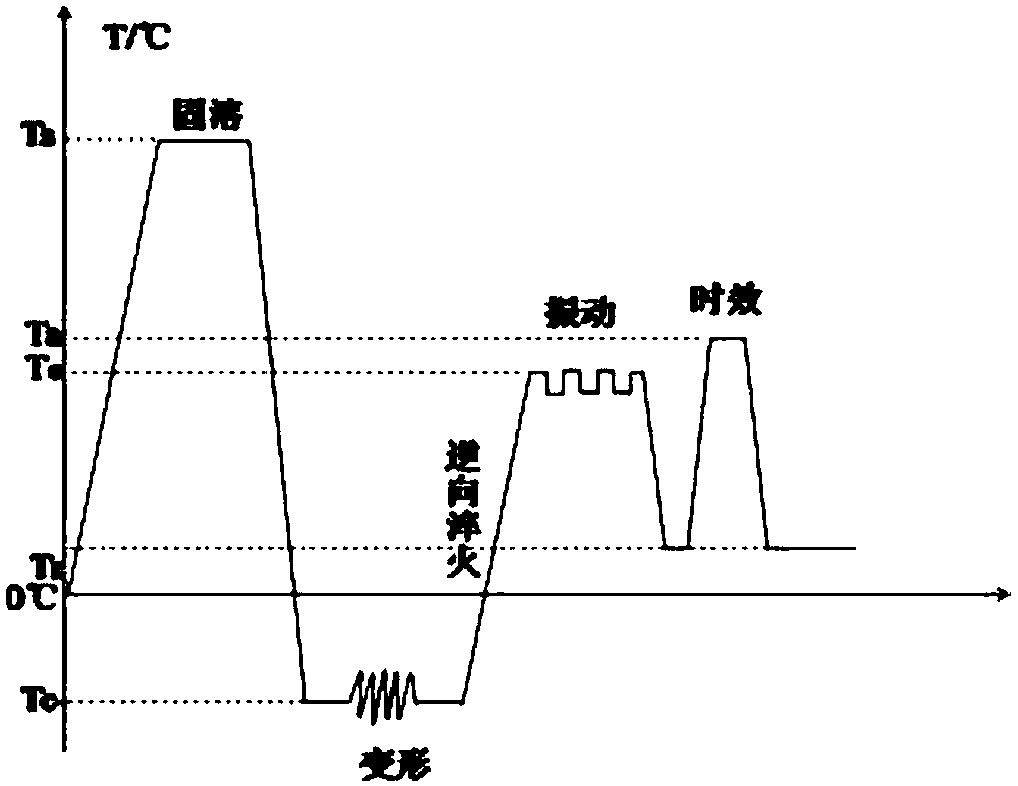

Heat treatment technology for preparing high-performance low-residual stress aluminum alloy

ActiveCN108531836AReduce residual stressHomogenization of dislocation distributionQuenchingSolution treatment

The invention relates to a heat treatment technology for preparing a high-performance low-residual stress aluminum alloy, and belongs to the technical field of aluminum alloy thermomechanical treatment. The method comprises the steps that 1, after an aluminum alloy sample is subjected to solution treatment and heat preservation, then is subjected to low-temperature quenching, and the transfer timedoes not exceed 10 seconds; 2, the sample obtained in the step 1 is subjected to cryogenic deformation to obtain a cryogenic deformation sample, the cryogenic deformation treatment temperature is lower than minus 120 DEG C, and the cryogenic deformation is equal or greater than 5%; 3, the cryogenic deformation sample obtained in the step 2 is put into a hot medium, the cryogenic deformation sample is vibrated by a vibration exciter, heat preservation and vibration maintaining are carried out, and the sample after the vibration reverse quenching treatment is obtained; and 4, the sample after the vibration reverse quenching treatment in the step 3 is subjected to aging treatment, and a finished product is obtained. The aluminum alloy prepared by the heat treatment technology has high comprehensive performance and low residual stress, and the stability of the material in service process is remarkably improved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH +1

Low stressed self anchoring method for group anchor steel tension cables

InactiveCN1424465AReliable anchoringAchieve self-anchoring effectCable-stayed bridgeBridge structural detailsEngineeringSelf anchoring

Owner:柳州市威尔姆预应力有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com