Ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and preparation method thereof

A technology for modifying carbon black and white carbon black, which is applied in the field of rubber-like polymer composite materials, and can solve problems such as rising, mechanical properties not mentioned, tensile and tearing properties meeting the required requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

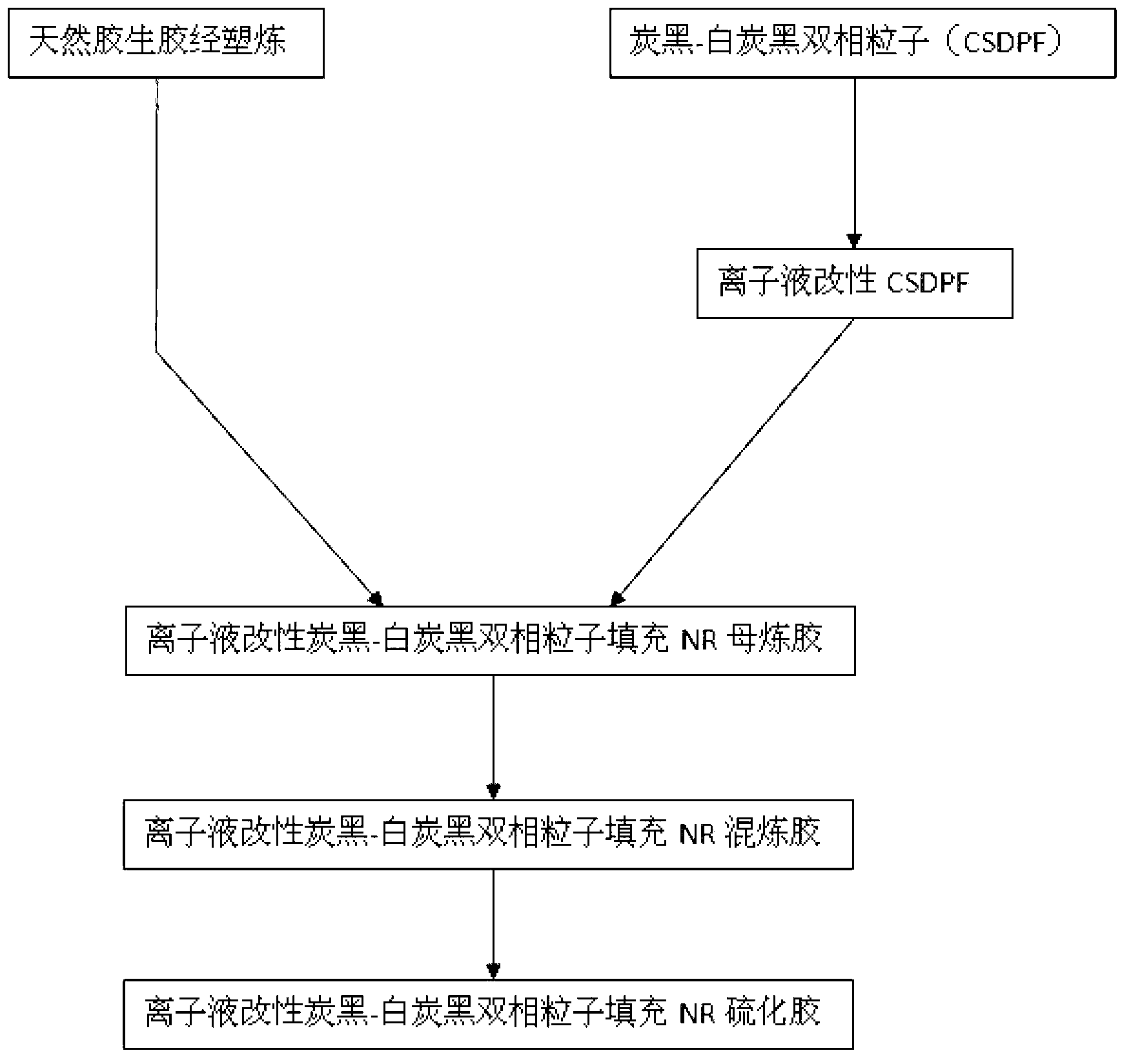

[0031] Attached figure 1 , Preparation of ionic liquid modified carbon black-white carbon black dual phase particles (CSDPF) filled natural rubber compound preparation includes the following steps:

[0032] Step 1: Modification of carbon black-silica dual-phase particles: Take 50 parts of carbon black-silica dual-phase particles CSDPF2125 in a beaker, add ethanol, and add ionic liquid (1-methylimidazole) mercapto amber After 0.5 part of acid salt, ultrasonically dispersed for 1h, after cooling, transfer it into a beaker, then use a microporous filter membrane to suction filter, and the filter cake is dried in a vacuum oven at 105°C;

[0033] Step 2: 100 parts of the raw rubber of Malaysia 1# smoked sheet rubber are masticated on two rollers for 15 minutes to obtain the masticated rubber;

[0034] Step 3: Add 1.4 parts of antioxidant RD, 1.4 parts of antioxidant 4010NA, modified carbon black-white carbon black dual phase granule CSDPF 2125 to the internal mixer in the plastified rubb...

Embodiment 2

[0039] The content of ionic liquid modified CSDPF 2125 in the formula of Example 2 is 40 parts, sulfur 2.5 parts, antioxidant RD 1.2 parts, antioxidant 4010NA 1.2 parts, and coumarone resin 4 parts. Other implementation processes are the same as in Example 1. The tensile strength of the obtained vulcanizate was 31.29MPa, the elongation at break was 593%, the tear strength was 122.2KN / m, and the AKRON abrasion volume was 0.210cm 3 , Thermal oxygen aging coefficient 94%, 340,000 times of tensile fatigue fracture; tanδ (70℃) is 0.118, tan δ (0℃) is 0.113.

Embodiment 3

[0041] The formula of Example 3 contains 3 parts of sulfur, 1 part of antioxidant RD, 1 part of antioxidant 4010NA, and 3 parts of coumarone resin. The other implementation process is the same as that of Example 2. The tensile strength of the obtained vulcanizate is 30.22MPa, and it is broken. The elongation is 613%, the tear strength is 115.2 KN / m, and the AKRON abrasion volume is 0.20cm 3 , The thermal oxygen aging coefficient is 92%, the number of tensile fatigue fracture is 380,000 times; tanδ (70℃) is 0.120, tan δ (0℃) is 0.117.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com