Patents

Literature

124results about How to "Low tear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

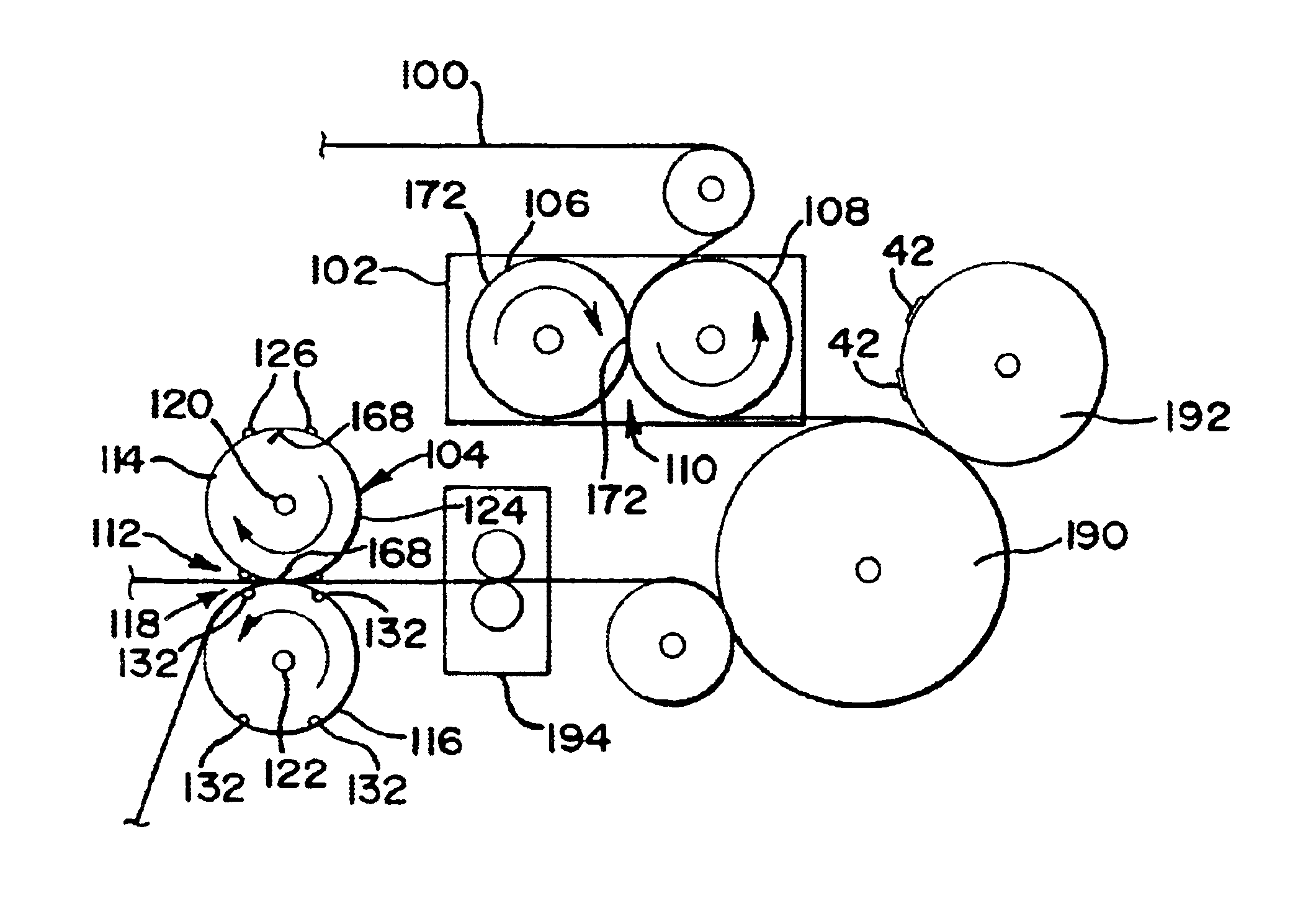

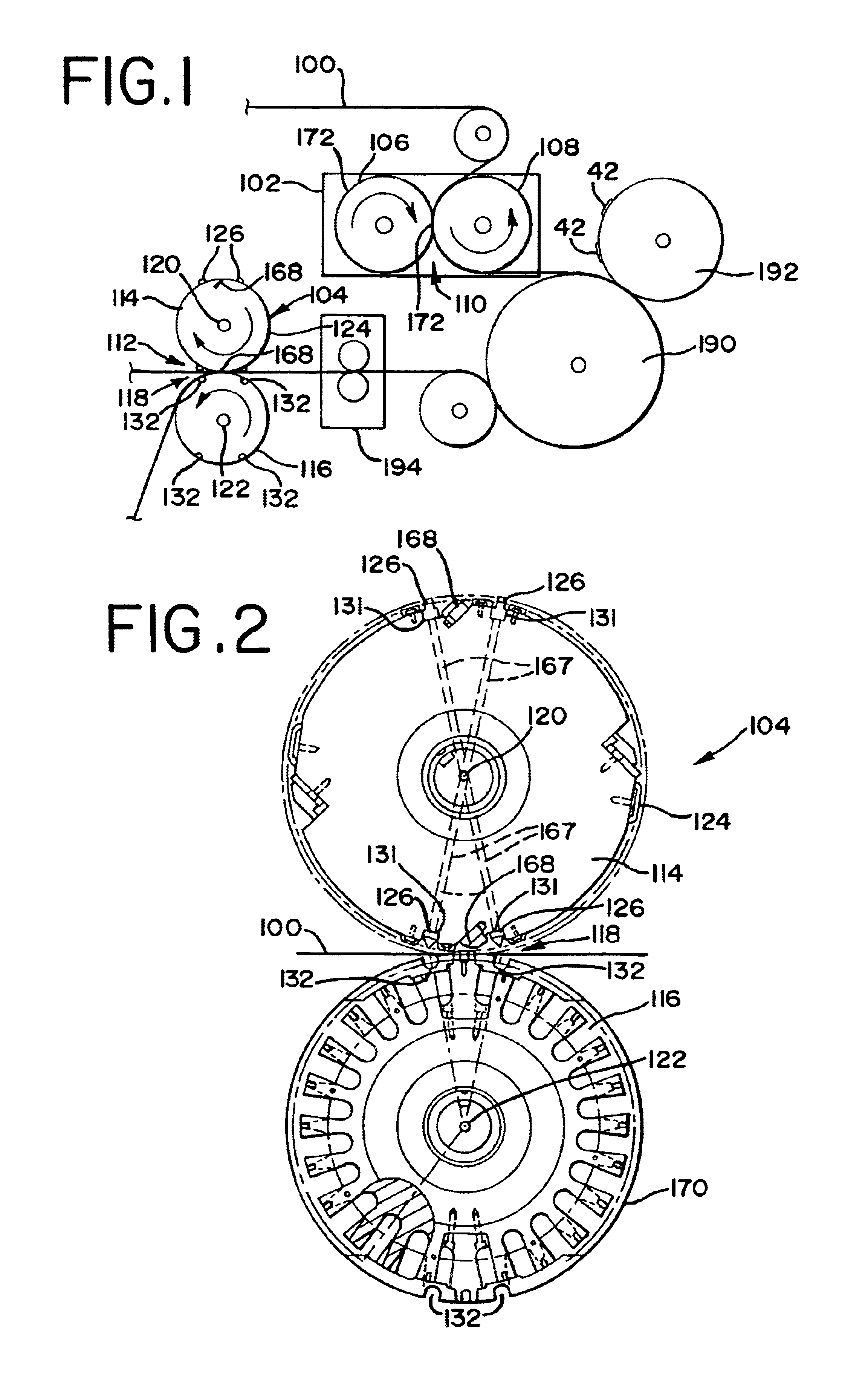

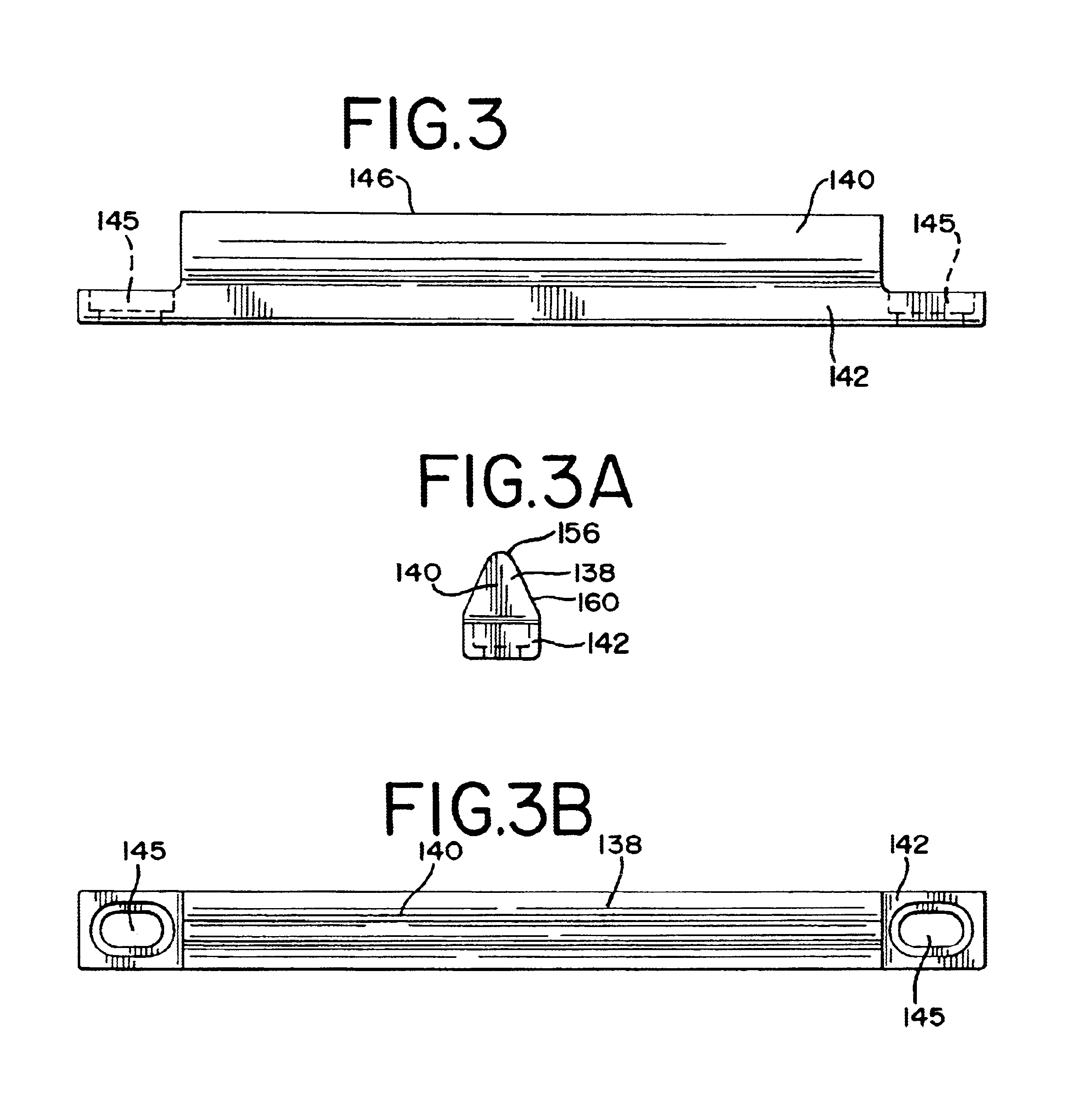

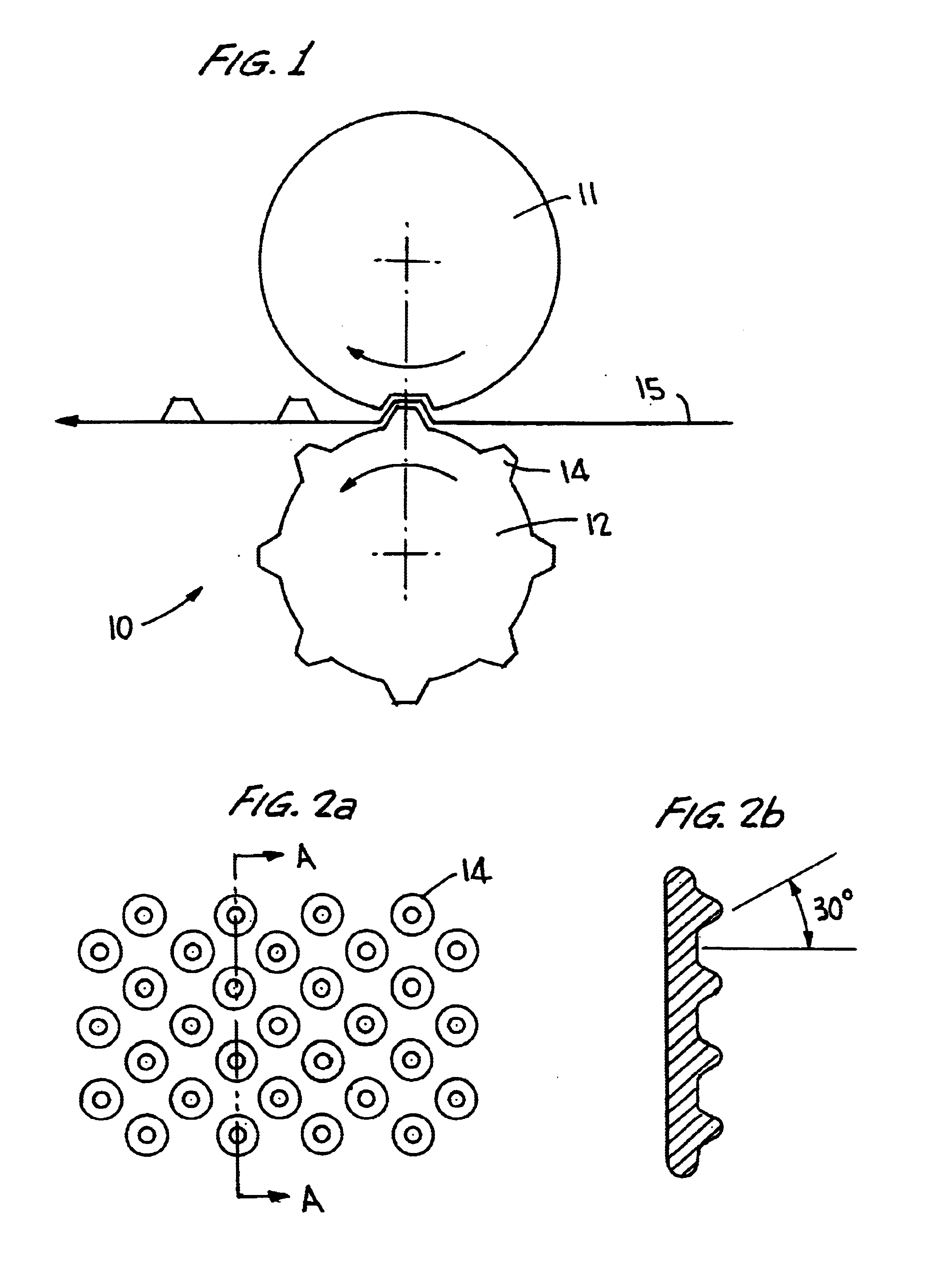

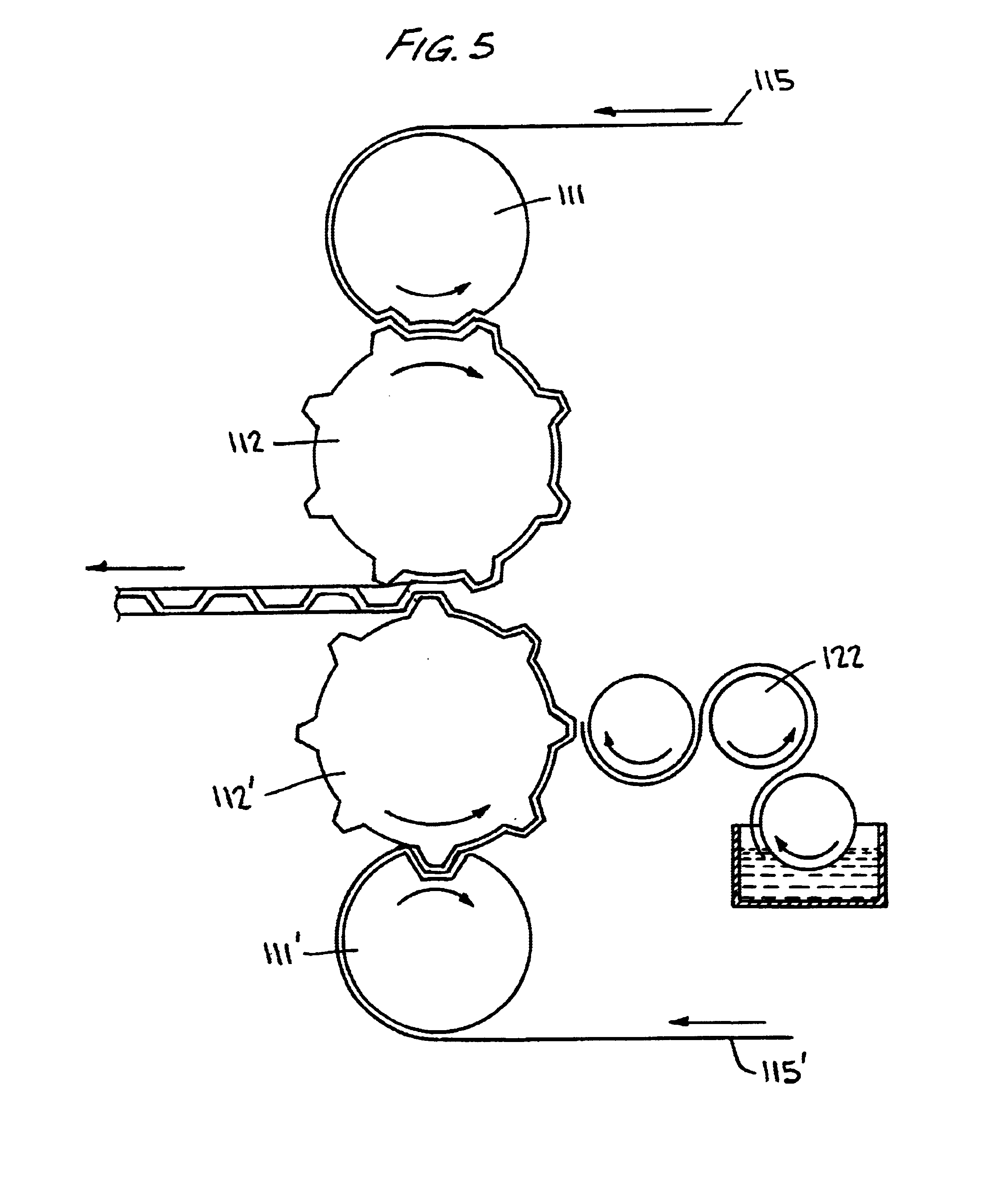

Method for weakening a portion of a web

InactiveUS6838040B2Easily brokenLow tear strengthButtonsMechanical working/deformationEngineeringUltimate tensile strength

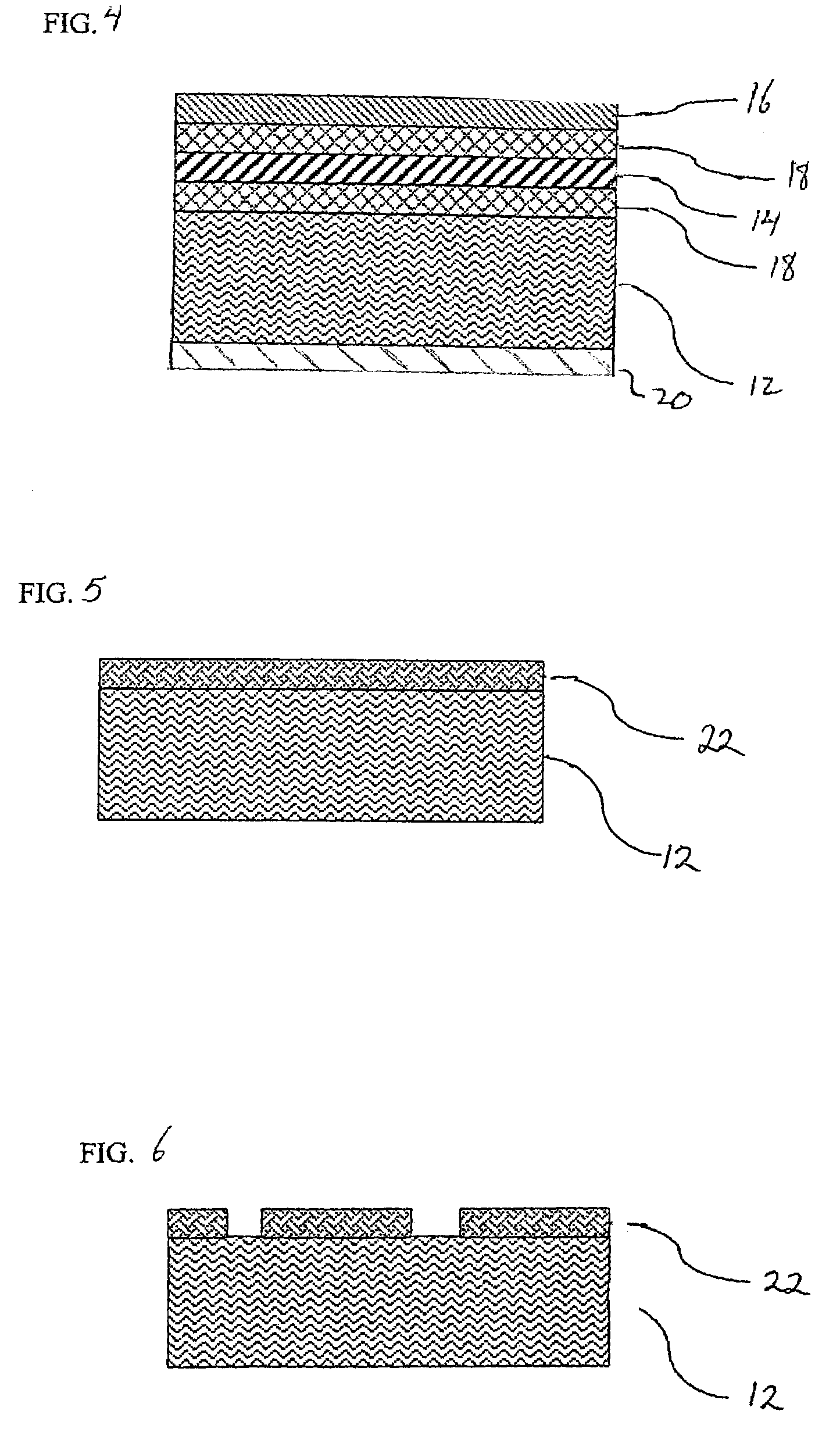

A method for weakening a portion of a web includes moving a web in a machine direction between at least a first location and a second location, wherein the second location is positioned downstream of the first location, forming a line of weakness in the web at the first location, wherein the web has a first tensile strength across the line of weakness, and weakening the line of weakness at a second location, wherein the web has a second tensile strength across the line of weakness after the line of weakness is weakened at the second location and wherein the first tensile strength is greater than the second tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

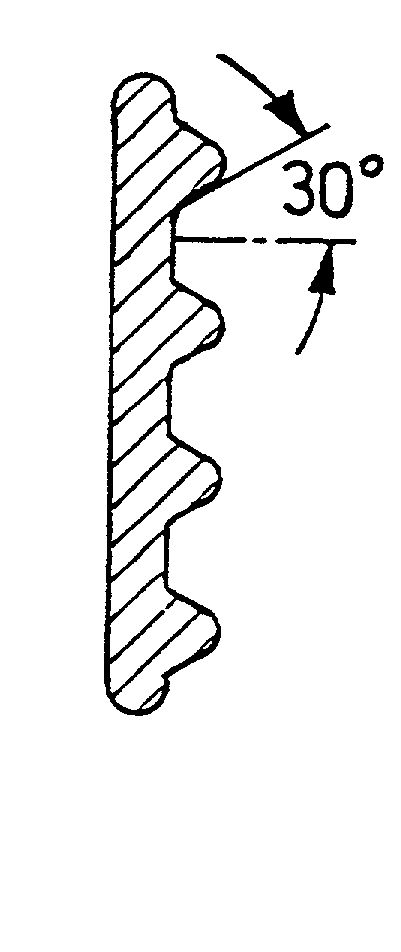

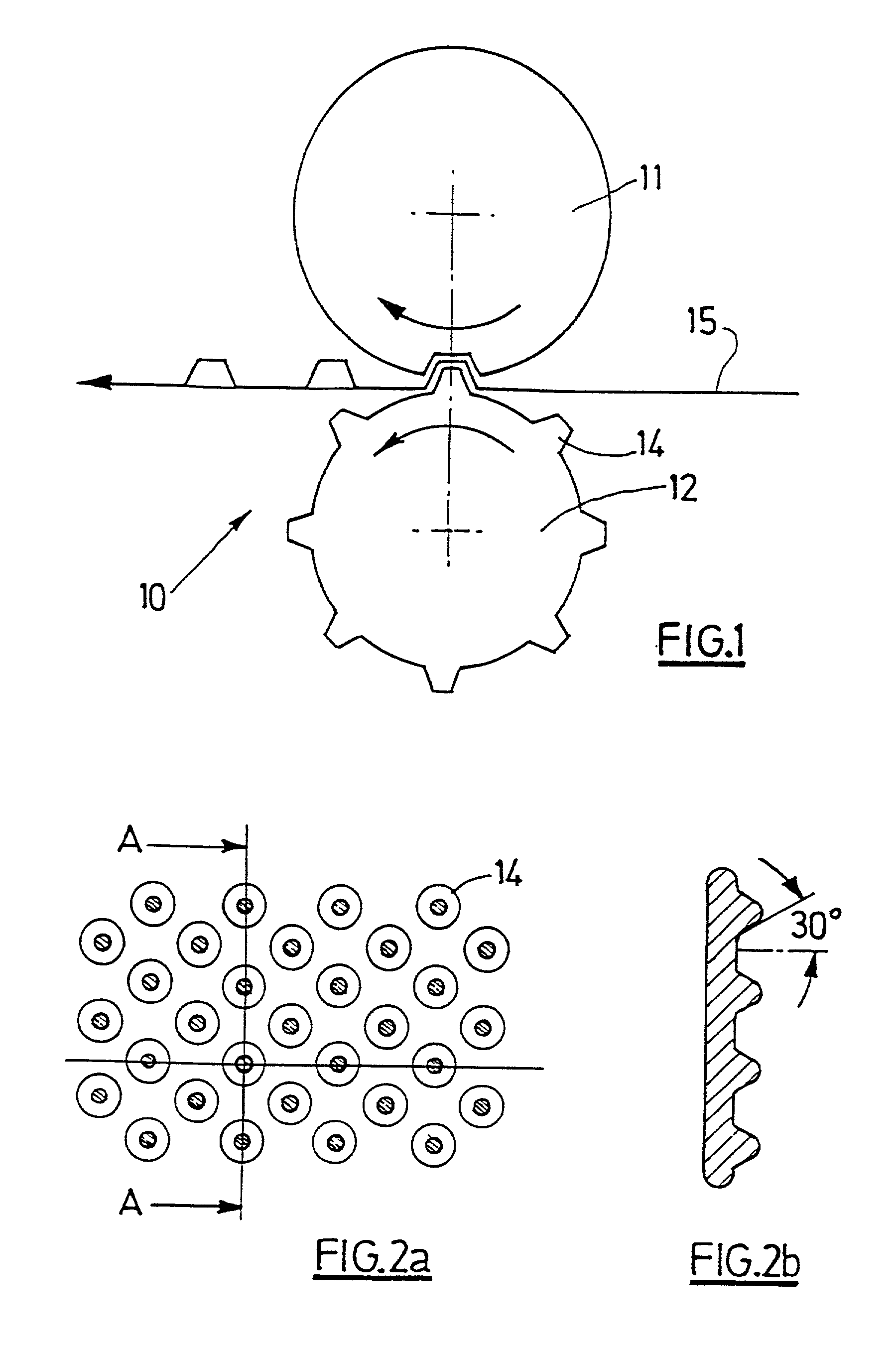

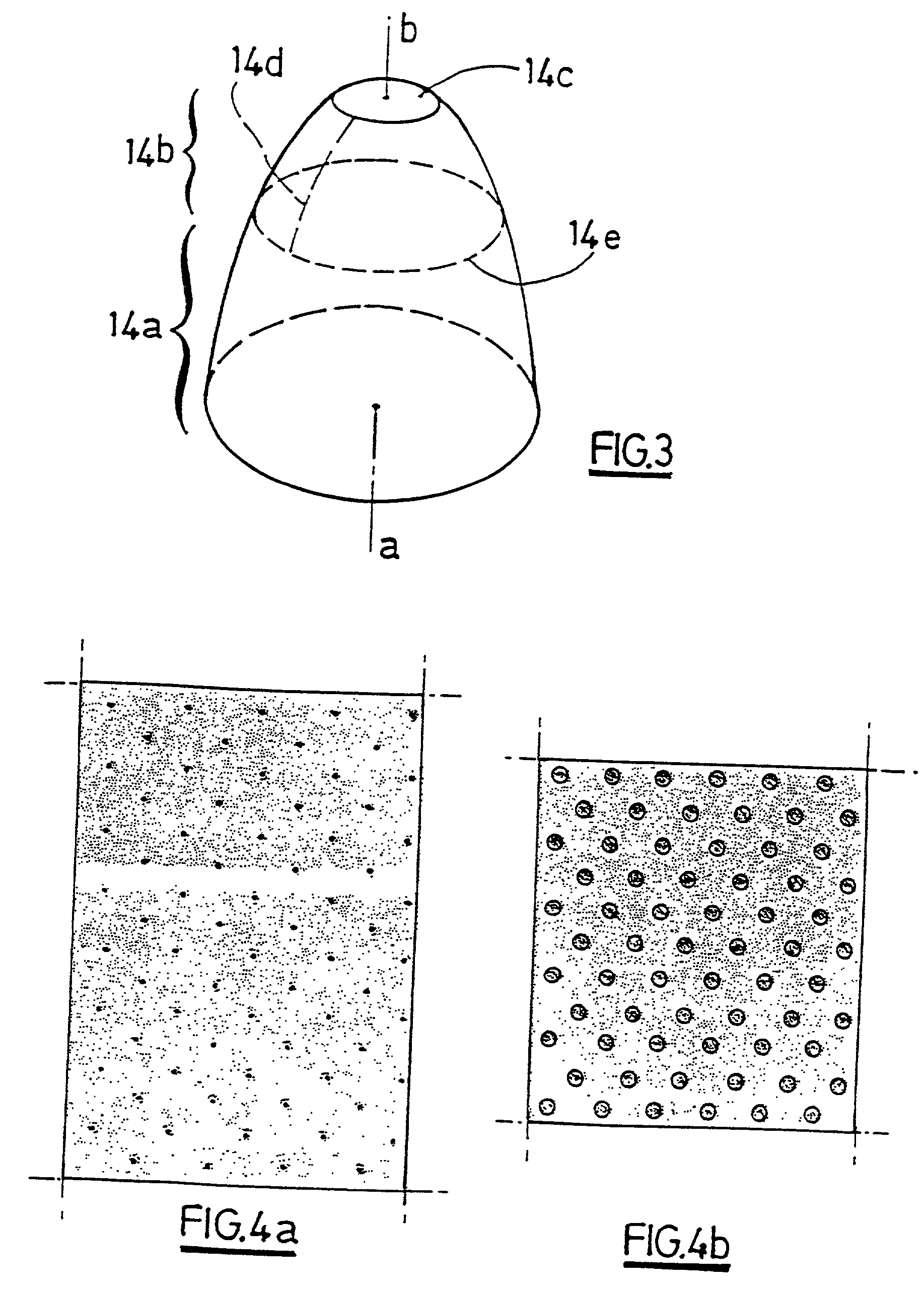

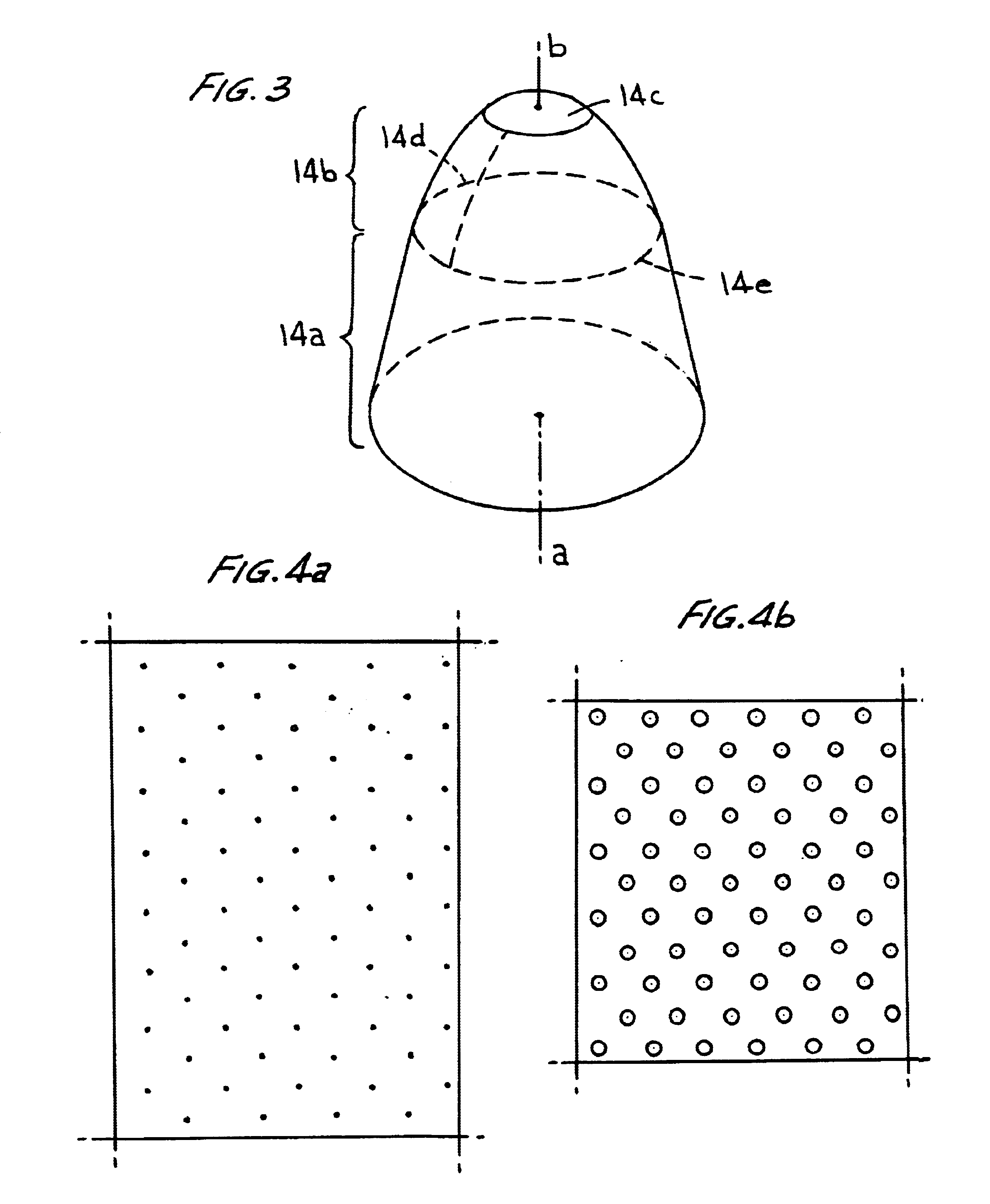

Method for fabricating an embossed sheet of cellulose tissue, a product so made and an embossing cylinder

InactiveUS20030008109A1Increasing the thicknessLow tear strengthNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseWood veneer

The invention relates to a method for manufacturing a sheet of paper tissue which is embossed by an embossing cylinder of which the surface is fitted at least in part with embossing elements. The elements include a frustoconical base portion and a tip portion. The method is characterized in that the tip segment includes a flat of which the area is less than 75% of the smaller cross-sectional area of the base. Preferably the area of the flat is less than 20% of the base cross-sectional area. The invention furthermore concerns a sheet thusly manufactured and to sheets made of several plies of which at least one is a ply of the invention.

Owner:ESSITY OPERATIONS FRANCE

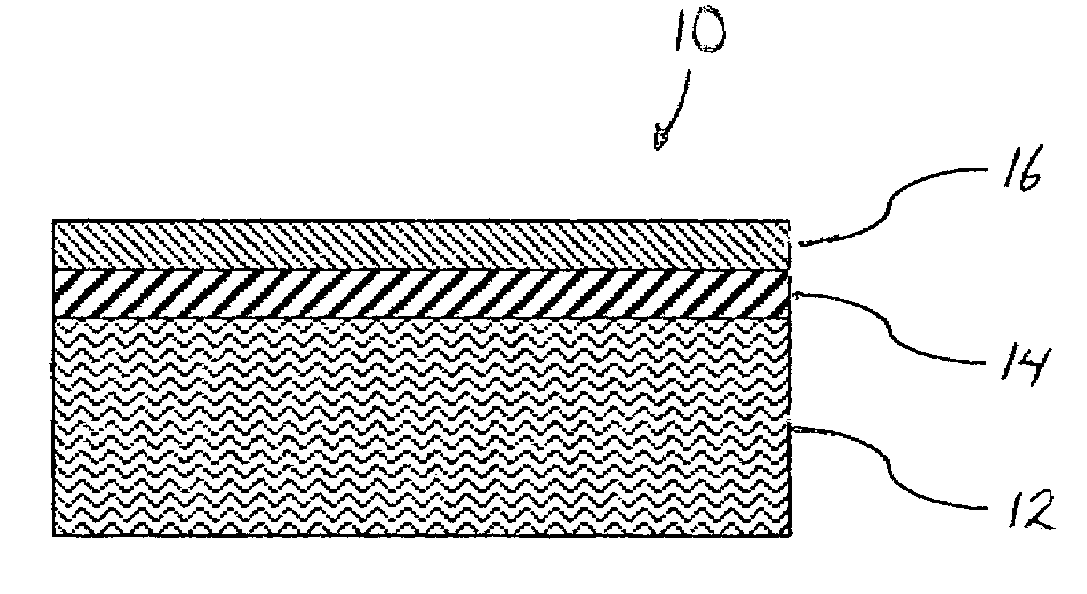

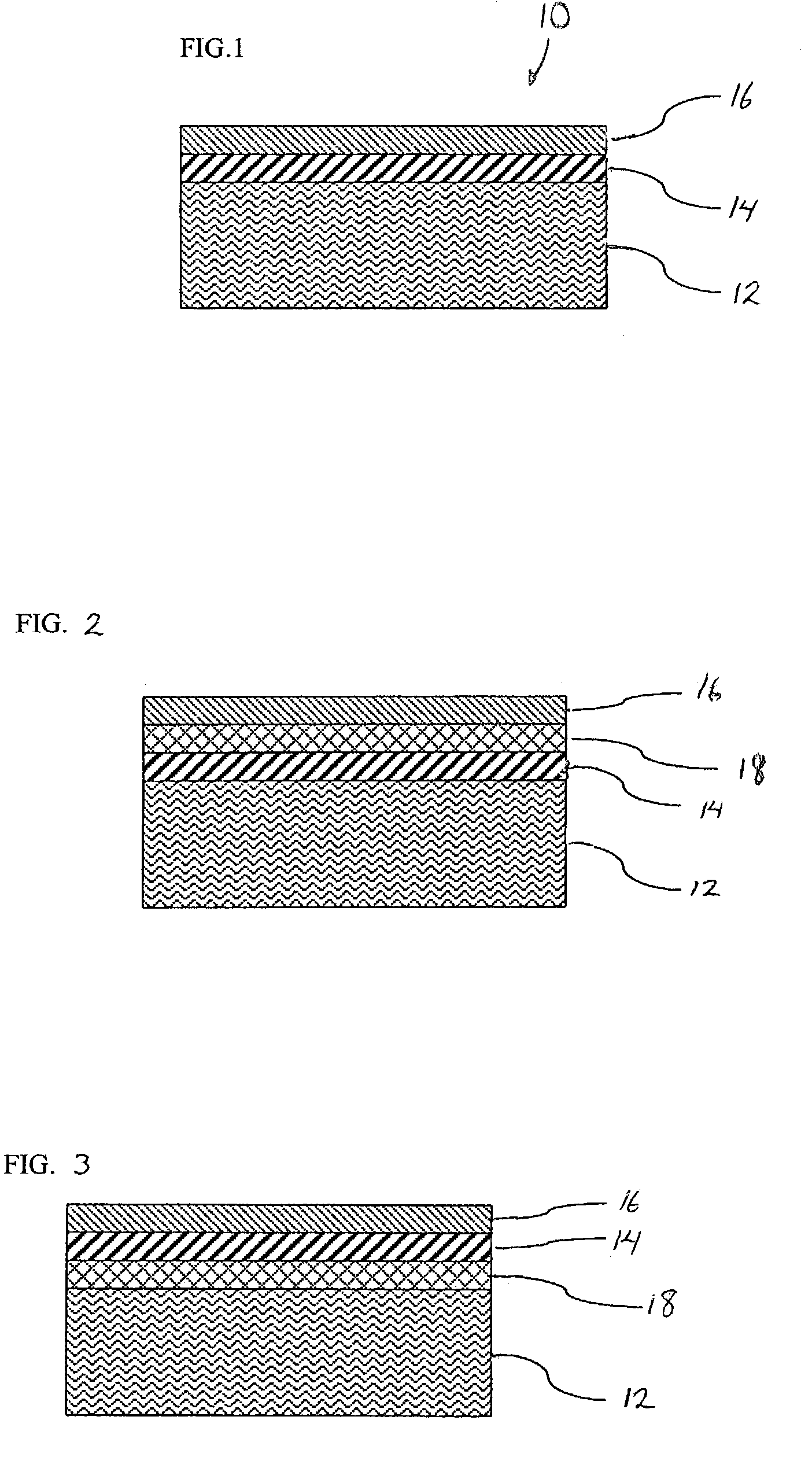

Paperboard substrate for blister packaging

A packaging laminate comprising a paperboard substrate for providing a base layer, a tear-resistant polymer layer applied to said substrate, and a heat seal polymer layer applied to said tear-resistant polymer. This laminate structure is particularly useful for blister pack packaging.

Owner:GRAPHIC PACKAGING INT

Sanitary Tissue Products

ActiveUS20170306566A1Less stressImprove strength performanceReinforcing agents additionPaper/cardboardFiberBiomedical engineering

Owner:THE PROCTER & GAMBLE COMPANY

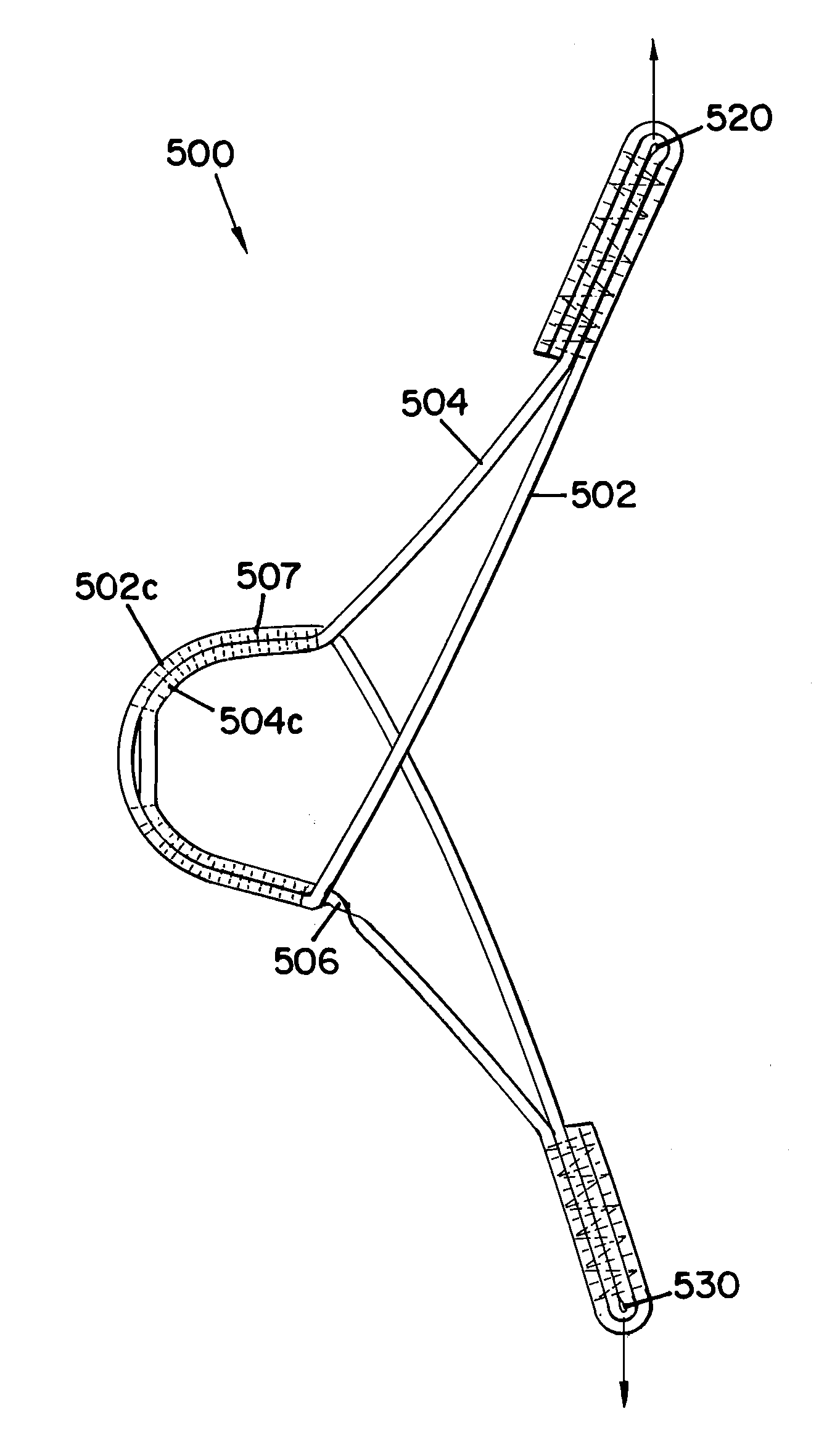

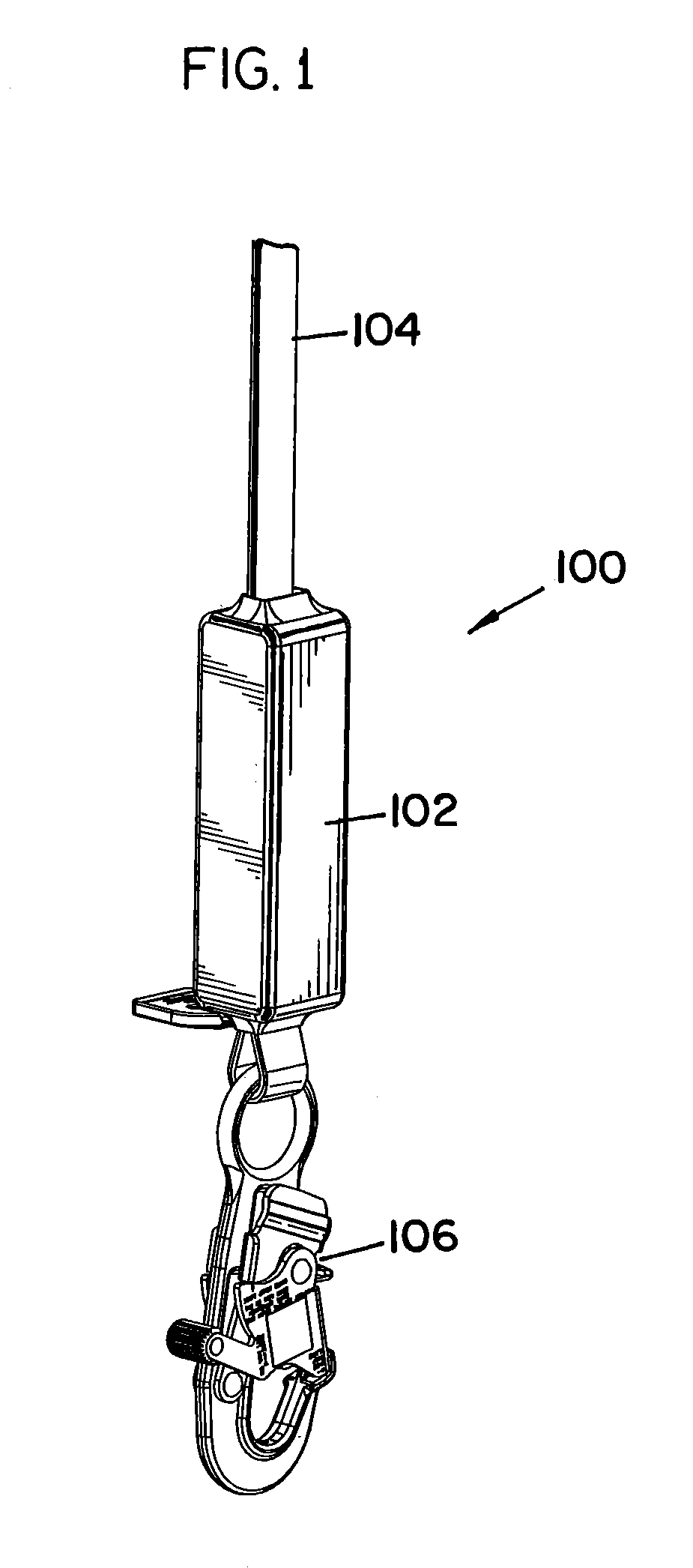

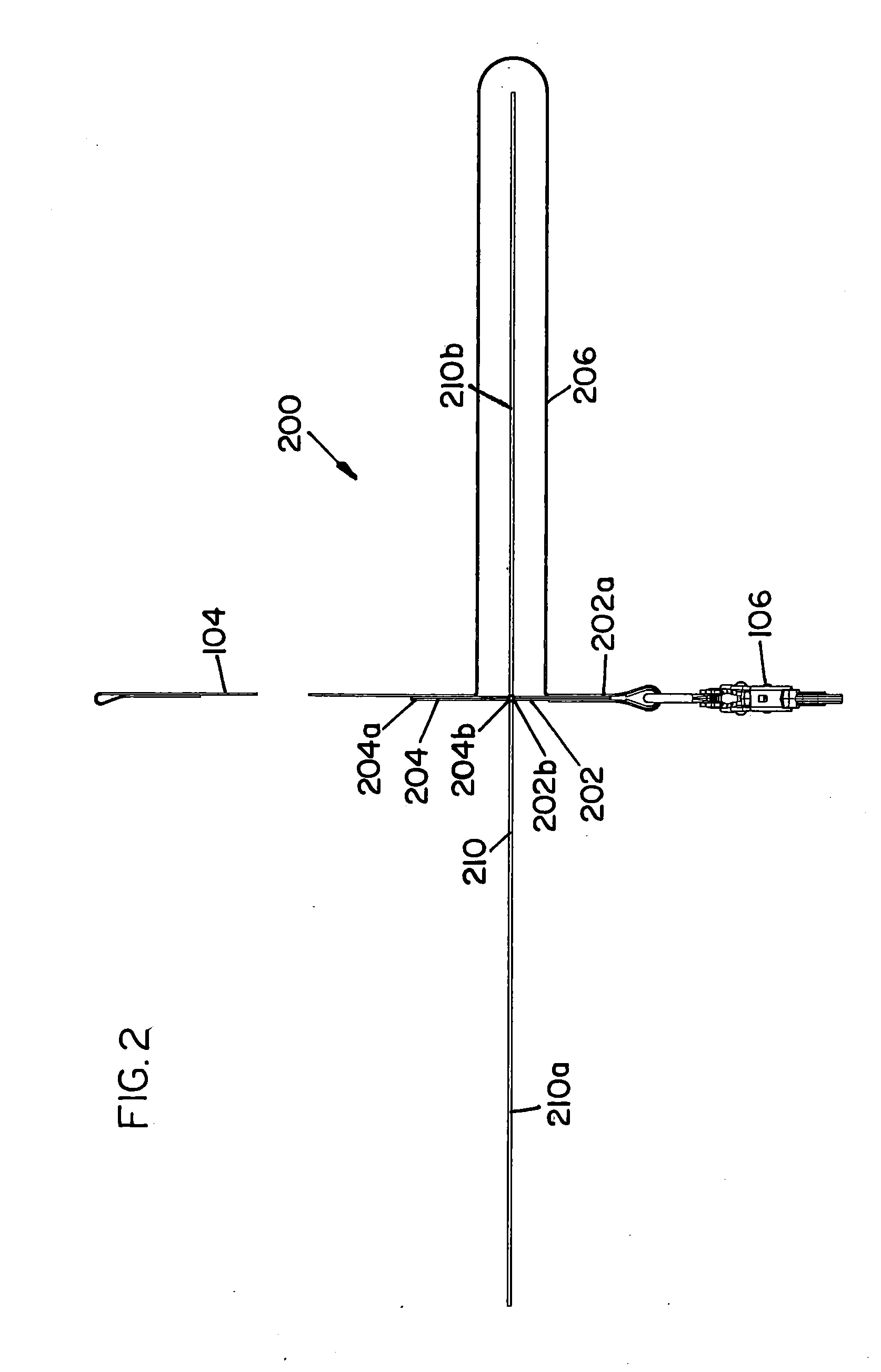

Energy absorber

InactiveUS20130105246A1Low tear strengthSafety beltsLayered productsEngineeringUltimate tensile strength

An energy absorber is provided that includes a first energy absorbing webbing, a second energy absorbing webbing and a plurality of connecting fibers. The plurality of connecting fibers couple at least a portion of the first energy absorbing webbing to at least a portion of the second energy absorbing webbing. The plurality of connecting fibers are configured and arranged to form at least two different tear strength areas in the at least one portion of the first energy absorbing webbing coupled to the at least one portion of the second webbing. The at least two different tear strength areas having select tear strengths.

Owner:D B IND

Butadiene rubber

The invention relates to a butadiene rubber including following components: 30-50 parts of a cis-polybutadiene mixture, 5-9 parts of cyclohexane, 1-3 parts of cobalt oxide, 2-5 parts of zinc oxide, 3-7 parts of sulfur, 1-3 parts of stearic acid, 1-5 parts of nickel naphthenate, 5-9 parts of triisobutyl aluminium, 2-4 parts of boron trifluoride diethyl etherate, 2-6 parts of heptane, 3-8 parts of hydrogenated gasoline, 15-19 parts of an accelerant NS, 10-13 parts of HAF, 11-15 parts of ASTM-typed 103 oil, 2-8 parts of an aluminum oxygen clinker and 2-5 parts of chloroxylenol. The cis-polybutadiene mixture consists of cis-1,4-polybutadiene and cis-1,3-polybutadiene, wherein a weight ratio of the cis-1,4-polybutadiene to the cis-1,3-polybutadiene is 2:5 in the mixture. The butadiene rubber contains the cis-polybutadiene mixture so that the butadiene rubber is effectively reduced in tear strength, is enhanced in anti-slippery performance and adhesive property, and is low in heat-generating property.

Owner:QINGDAO DTCN NEW MATERIAL TECH DEV

Novel platinum vulcanizing agent and preparation technology thereof

InactiveCN104927363ATo achieve the purpose of cross-linking vulcanizationFast vulcanizationEnvironmental resistancePolymer science

The invention relates to the technical fields of a vulcanizing agent and a preparation technology of the vulcanizing agent, particularly to a novel platinum vulcanizing agent and a preparation technology thereof. The novel platinum vulcanizing agent comprises a component A and a component B which are respectively added while in use, wherein the component A is the mixture of methyl vinylsiloxane rubber and a 1,3-divinyltetramethyldisiloxane platinum complex compound; the component B is the mixture of methyl hydrogen polysiloxane, gas phase silicon dioxide and an inhibitor. Compared with the prior art, the novel platinum vulcanizing agent disclosed by the invention uses the methyl vinylsiloxane rubber as a carrier, and under the existence of a platinum catalyst, vinyl double bonds and the methyl hydrogen polysiloxane are liable to generate a silicon hydrogen addition reaction, so that the purpose of cross-linking vulcanization is realized; the gas phase silicon dioxide is added for adjusting the hardness of vulcanization products, the vulcanization speed is high and is 1 / 3-1 / 2 higher than the vulcanization speed of the conventional platinum vulcanizing agent, and the production efficiency is improved; the vulcanization temperature is 10%-30% lower than that of the conventional platinum vulcanizing agent, and the purposes of energy conversation and environmental protection are achieved; the addition proportion is 30%-50% lower than that of the conventional platinum vulcanizing agent, and the production cost is reduced; the inhibitor is used, the storage time is greatly prolonged, and the storage time can reach 20-48h; in addition, the hygiene grade and the environmental protection grade are high, and the preparation technology is simple.

Owner:东莞市圣力堡有机硅科技有限公司

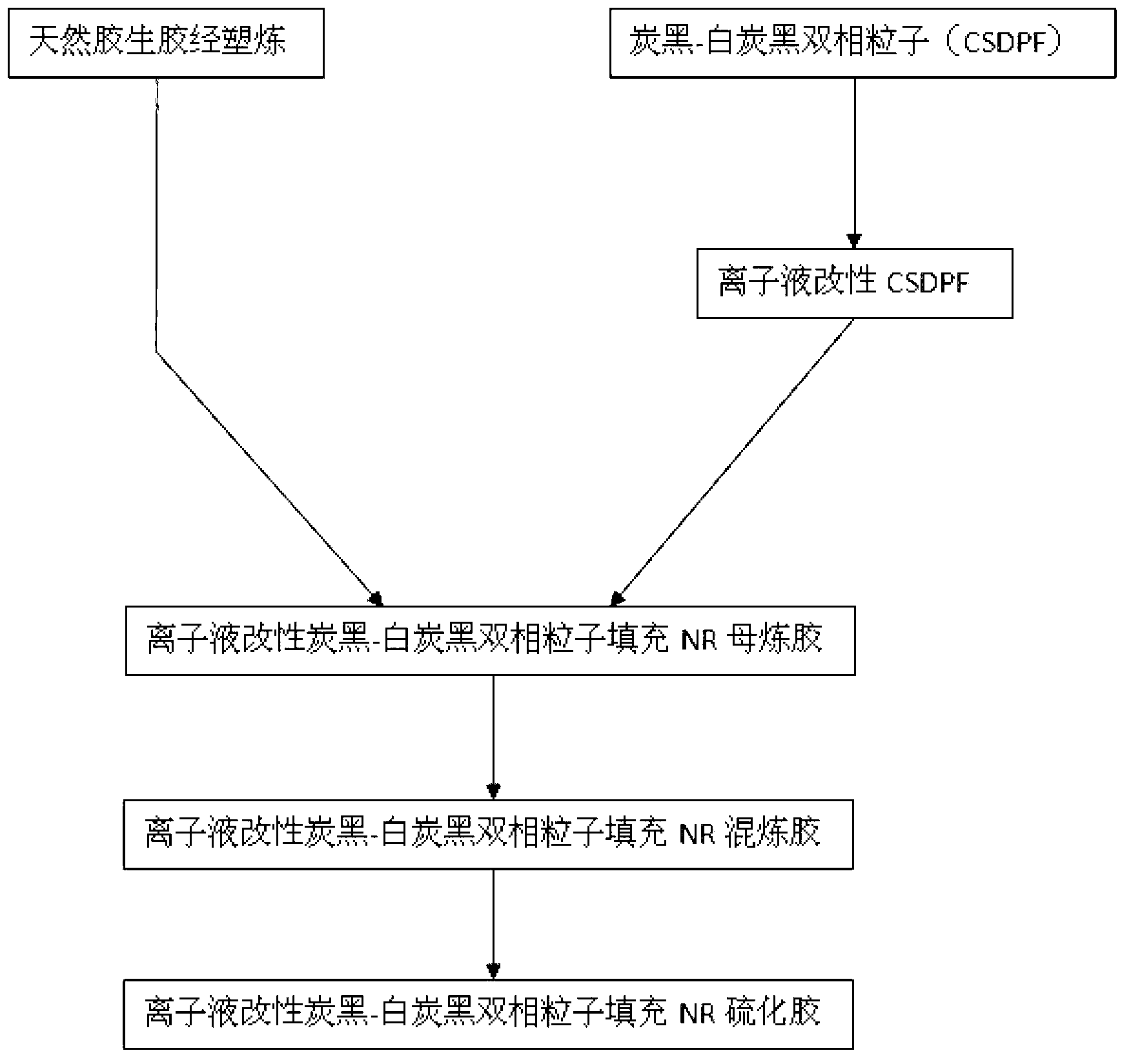

Ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and preparation method thereof

ActiveCN103275365AGood mechanical propertiesImprove mechanical propertiesVulcanizationPolymer science

The invention relates to ionic liquid modified carbon black-white carbon black double-phase particle filling natural rubber and a preparation method thereof. The rubber comprises the following constituents: natural rubber, vulcanizing agent, ionic liquid, carbon black-white carbon black double-phase particles, zinc oxide, stearic acid, vulcanization accelerator, anti-aging agent and resin. The rubber has excellent stretch resistance and tear resistance performances, good fatigue resistance performance, good abrasive resistance, and good thermo-oxidative aging resistance performance, is low in dissipated heat, can prolong the service life of products during the use, can be applied to various rubber products, and particularly applied to tire tread rubber with high mechanical property requirements and good dynamic mechanical properties.

Owner:NANJING UNIV OF SCI & TECH

Method for fabricating an embossed sheet of cellulose tissue, a product so made and an embossing cylinder

InactiveUS6942755B2Increasing the thicknessLow tear strengthNon-fibrous pulp additionNatural cellulose pulp/paperWood veneerCellulose

Owner:ESSITY OPERATIONS FRANCE

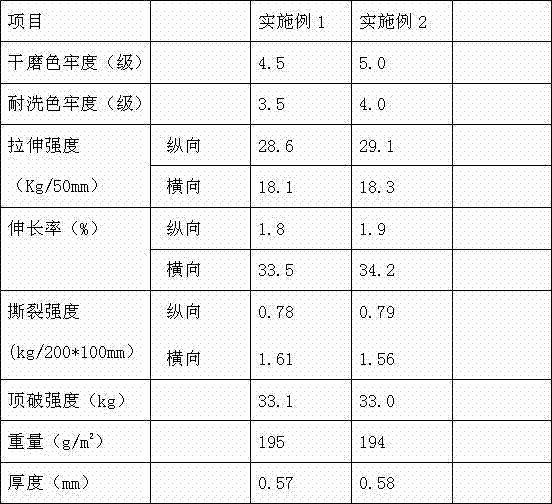

Skin-imitated microfiber fabric

ActiveCN103042776ASmall dyeable rangeCan be dyed in a wide rangeSynthetic resin layered productsDyeing processSolvent freeEngineering

A skin-imitated microfiber fabric belongs to the technical field of top grade clothing fabric and is formed in the way that acrylon superfine short fiber is processed by two carding machines and a lapping machine to form two-layer webs, knitted fabric taking polyester filament yarns or pure spun polyesters as raw materials is laid on one-layer web, then the other-layer web is laid on the knitted fabric so as to obtain Single-Layer Sandwich Base Cloth; the Single-Layer Sandwich Base Cloth is subjected to preneedling and high-pressure spunlace to obtain Double-Layer Sandwich Base Cloth; the Double-Layer Sandwich Base Cloth is subjected to special bonding, presetting, dyeing, setting, drying, singeing and ironing so as to obtain the skin-imitated microfiber fabric; and the total fineness of polyester filament yarns is 50 D to 100 D, the total fineness of pure spun polyesters is 30 S to 90 S, and the fineness of the acrylon superfine short fiber is 0.6 to 3.0 D. The skin-imitated microfiber fabric has shining color and luster, good handle, elasticity and draping, and tearing strength of more than 70 N, can be cleaned for use repeatedly, and omits the step of impregnating DMF (Dimethyl Formamide) polyurethane, so that Skin Feel is realized, and a novel solvent-free high-density superfine fabric is provided.

Owner:ZHEJIANG MEISHENG NEW MATERIALS CO LTD

High-wear resistance cable sheath material

ActiveCN103265738AGood physical propertiesDimensionally stableInsulated cablesInsulated conductorsWaxPolypropylene

The invention discloses a high-wear resistance cable sheath material. The high-wear resistance cable sheath material comprises the following raw materials by weight: 90 to 100 parts of chloroprene rubber DCR114, 10 to 20 parts of EPDM 4770R, 15 to 20 parts of nanometer bauxite, 20 to 30 parts of a modification filling material, 8 to 10 parts of dioctyl sebacate, 3 to 4 parts of polypropylene adipate, 4 to 6 parts of acetyl triethyl citrate, 2 to 4 parts of zinc oxide, 6 to 8 parts of chlorinated paraffin, 2 to 3 parts of antimony trioxide, 2 to 4 parts of triphenyl phosphite, 1 to 2 parts of the anti-aging agent MB, 1 to 2 parts of the promoter CZ and 0.8 to 1 part of sulphur. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

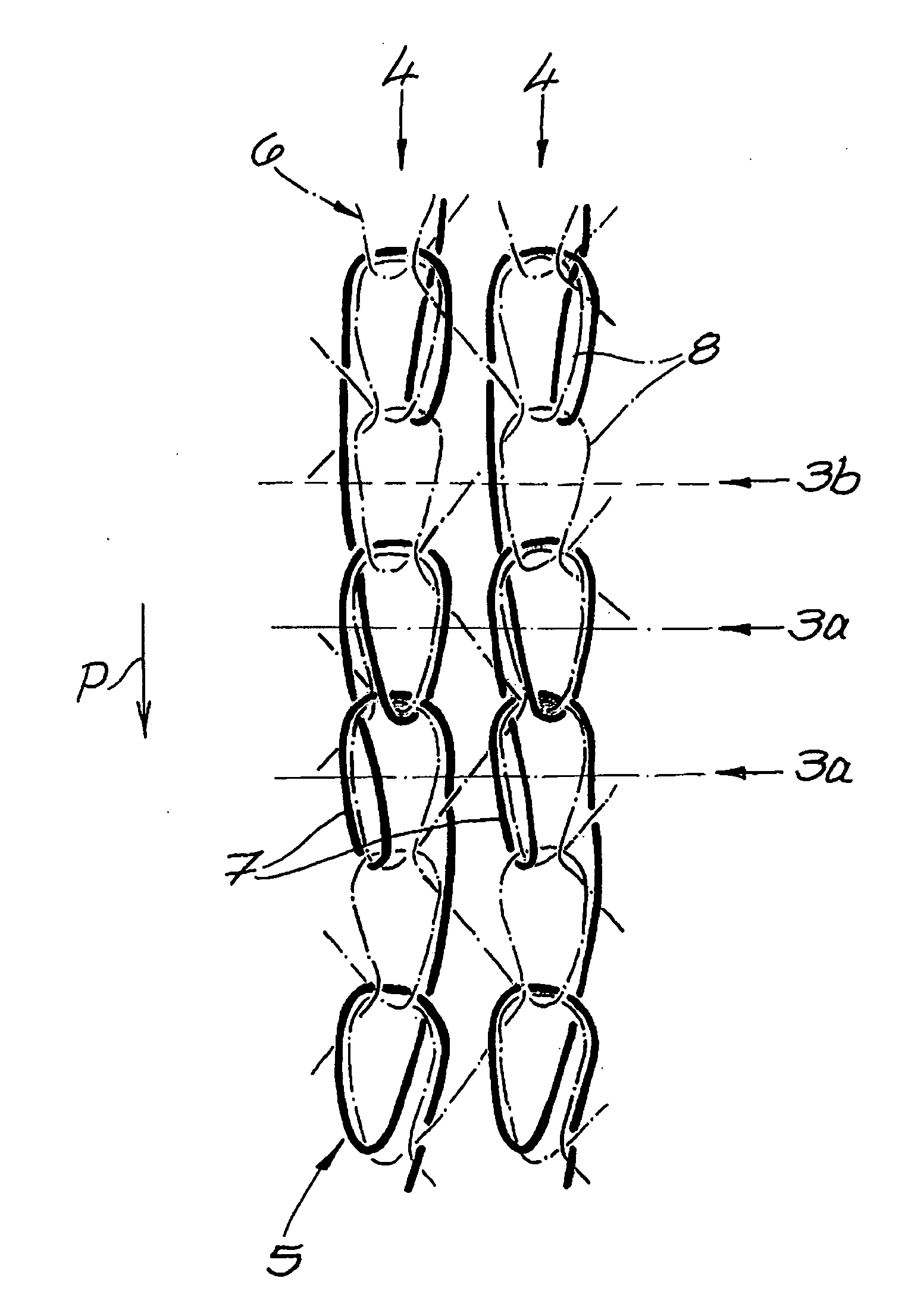

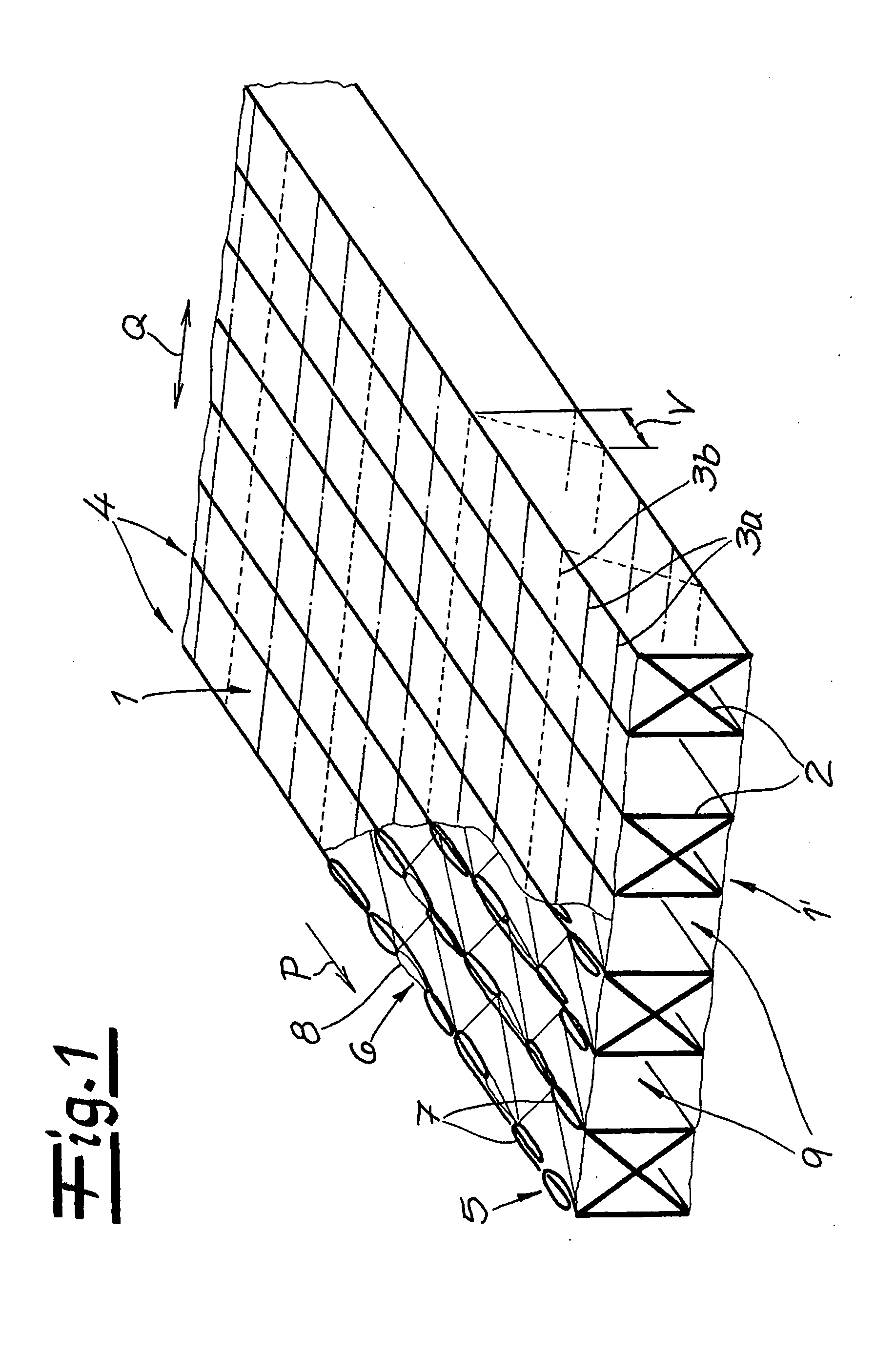

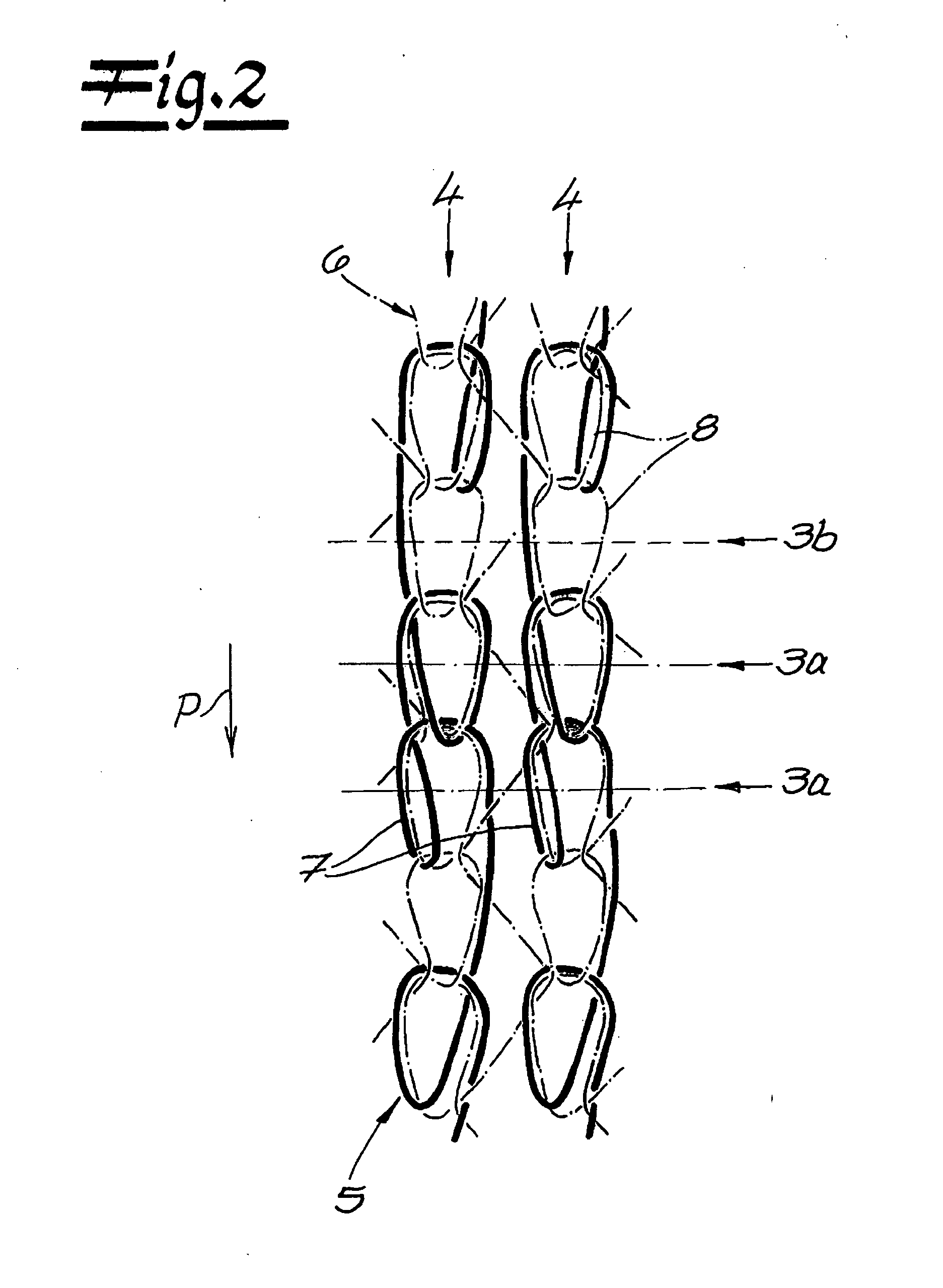

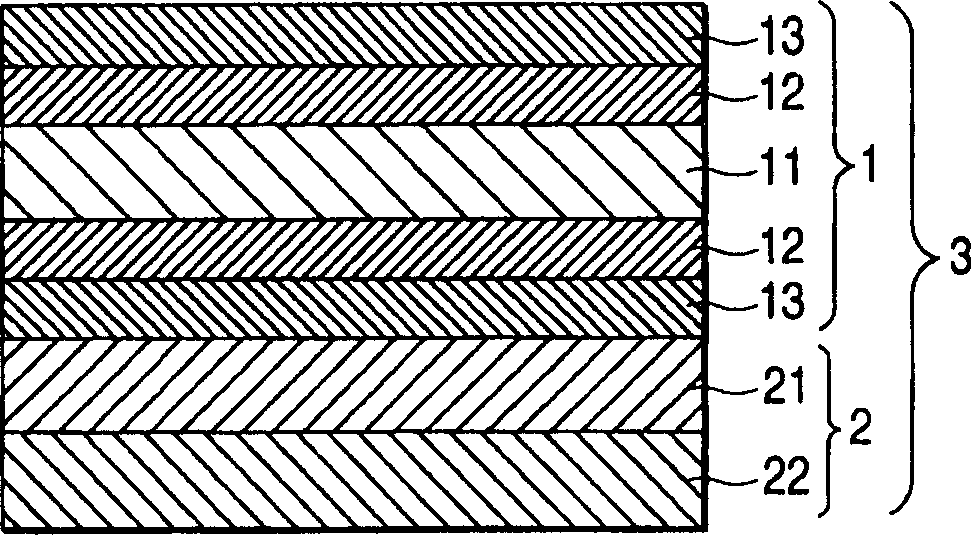

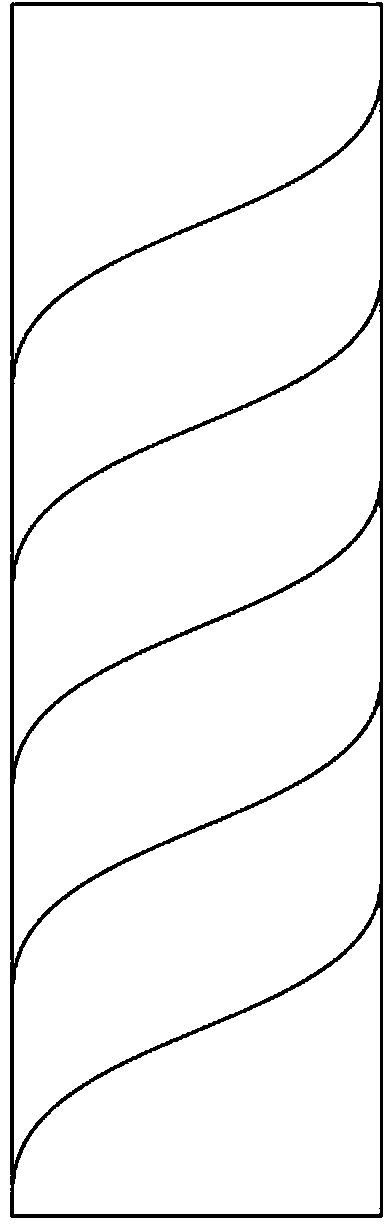

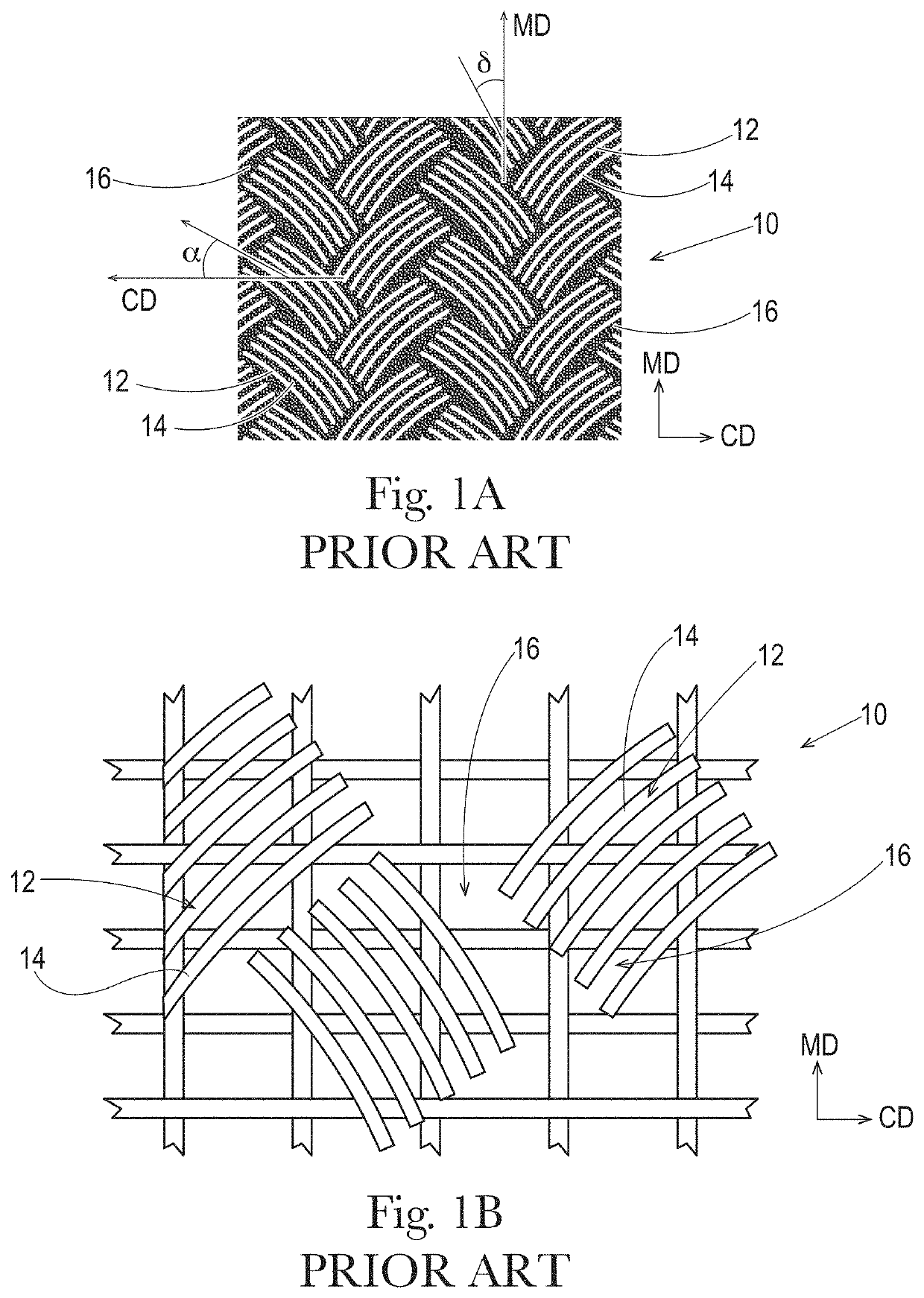

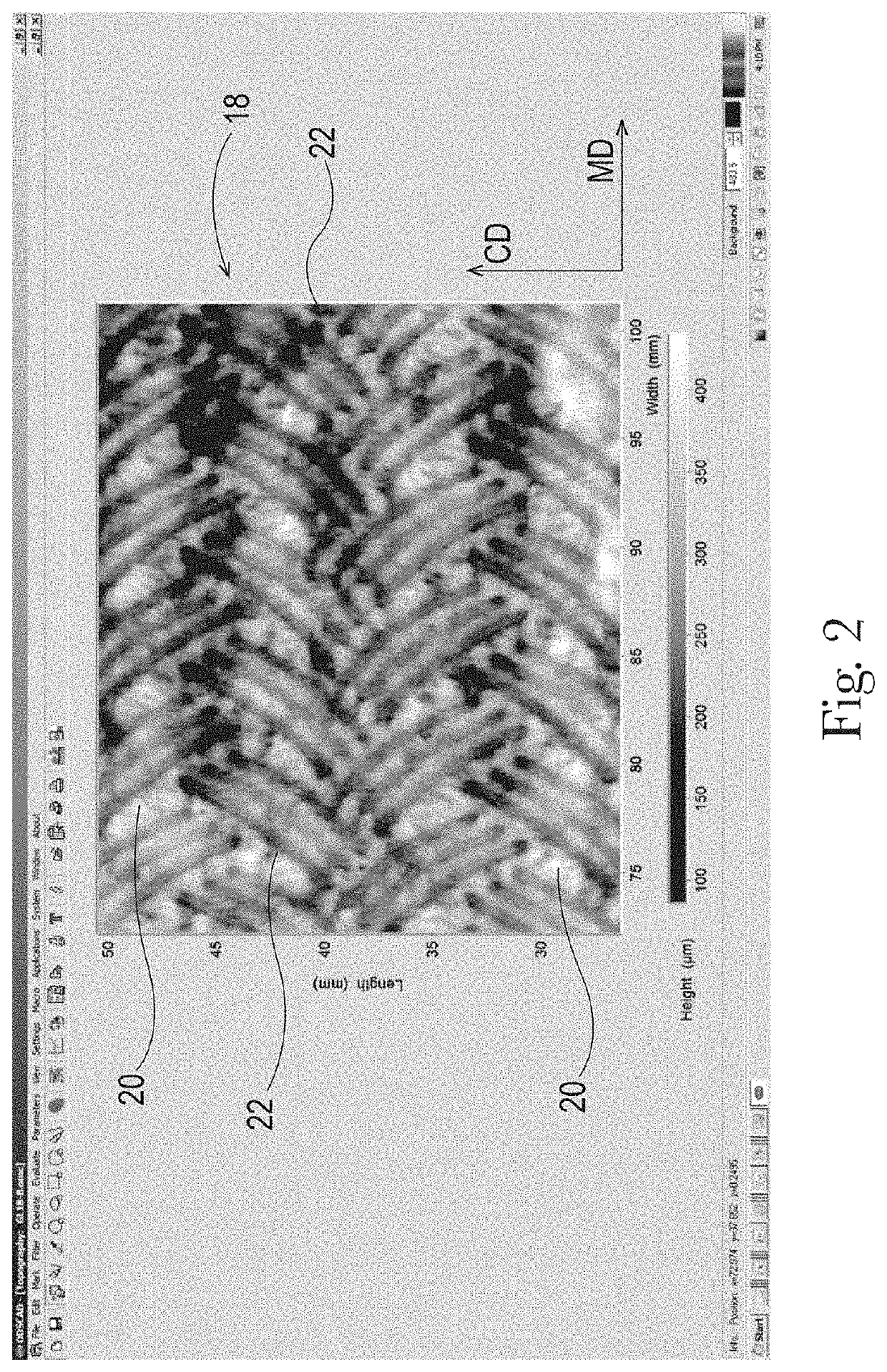

Spacer textile

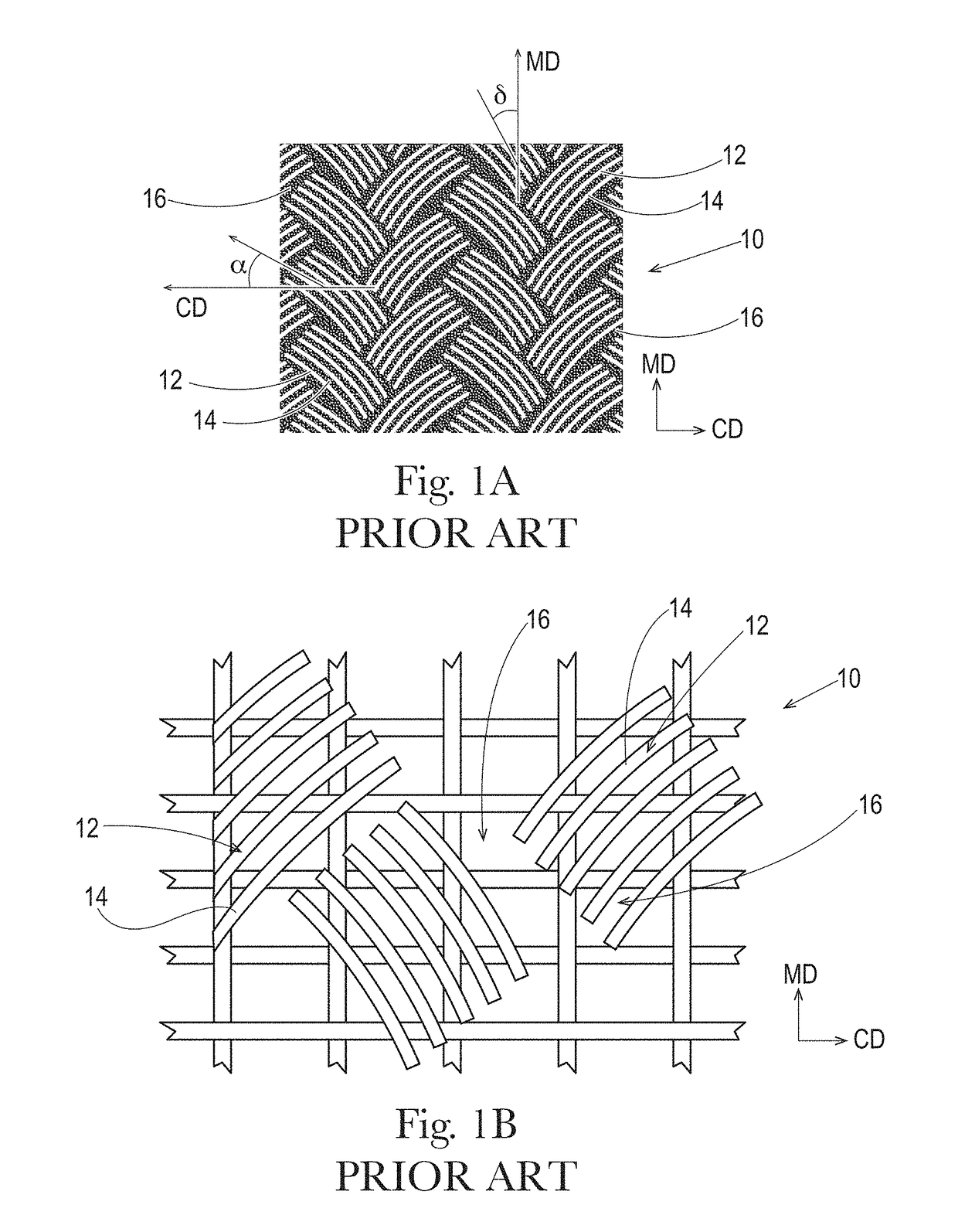

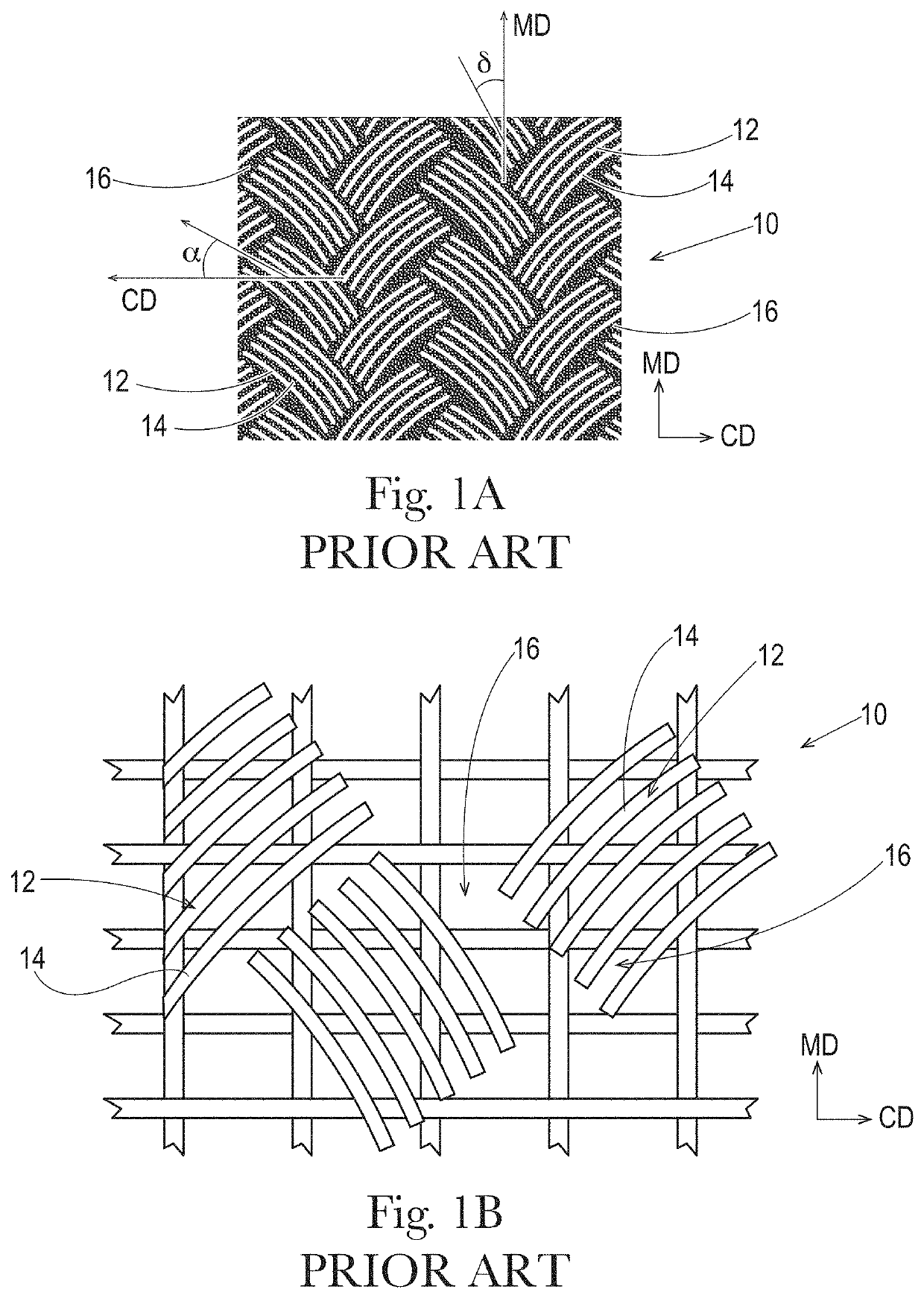

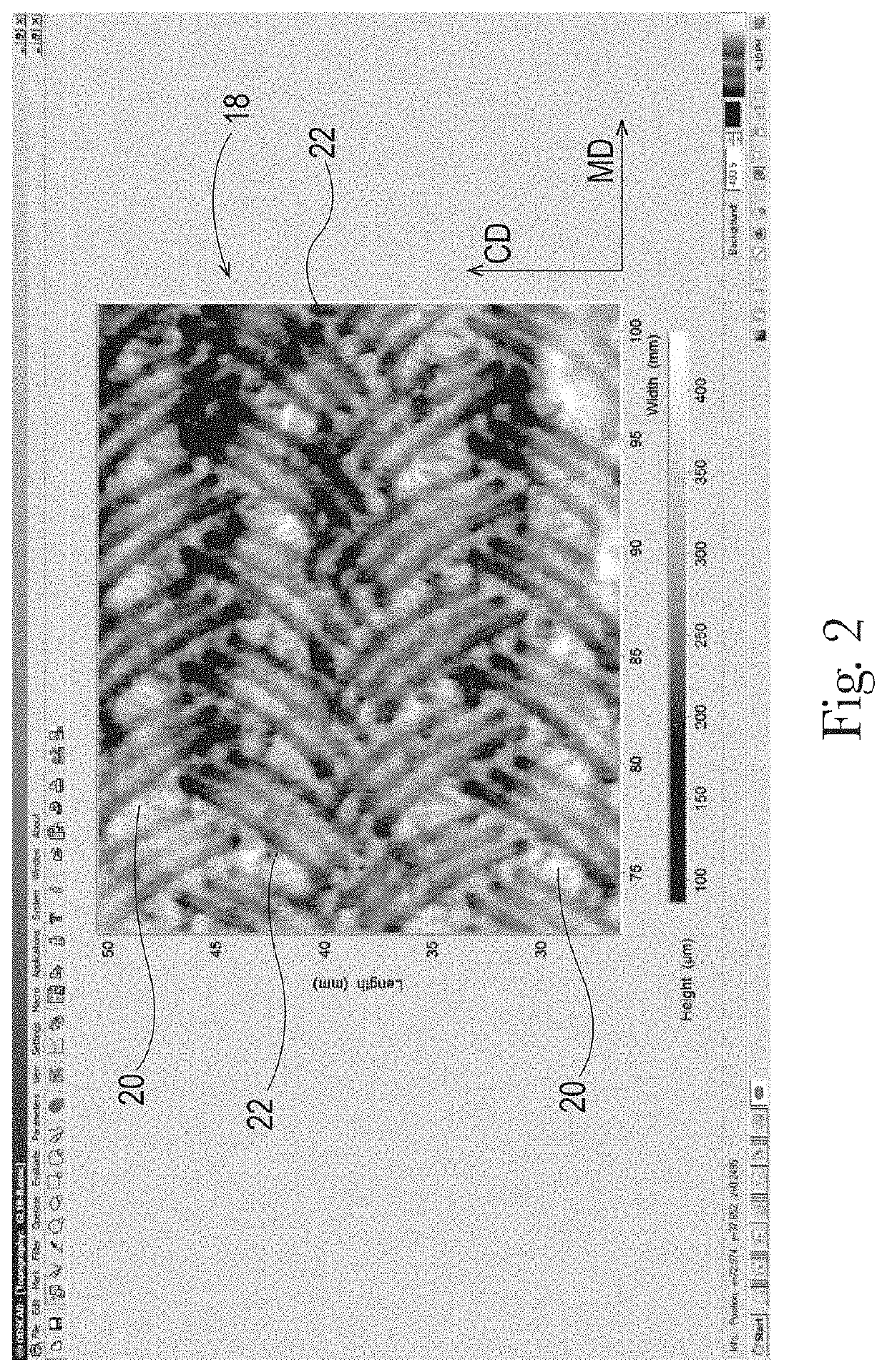

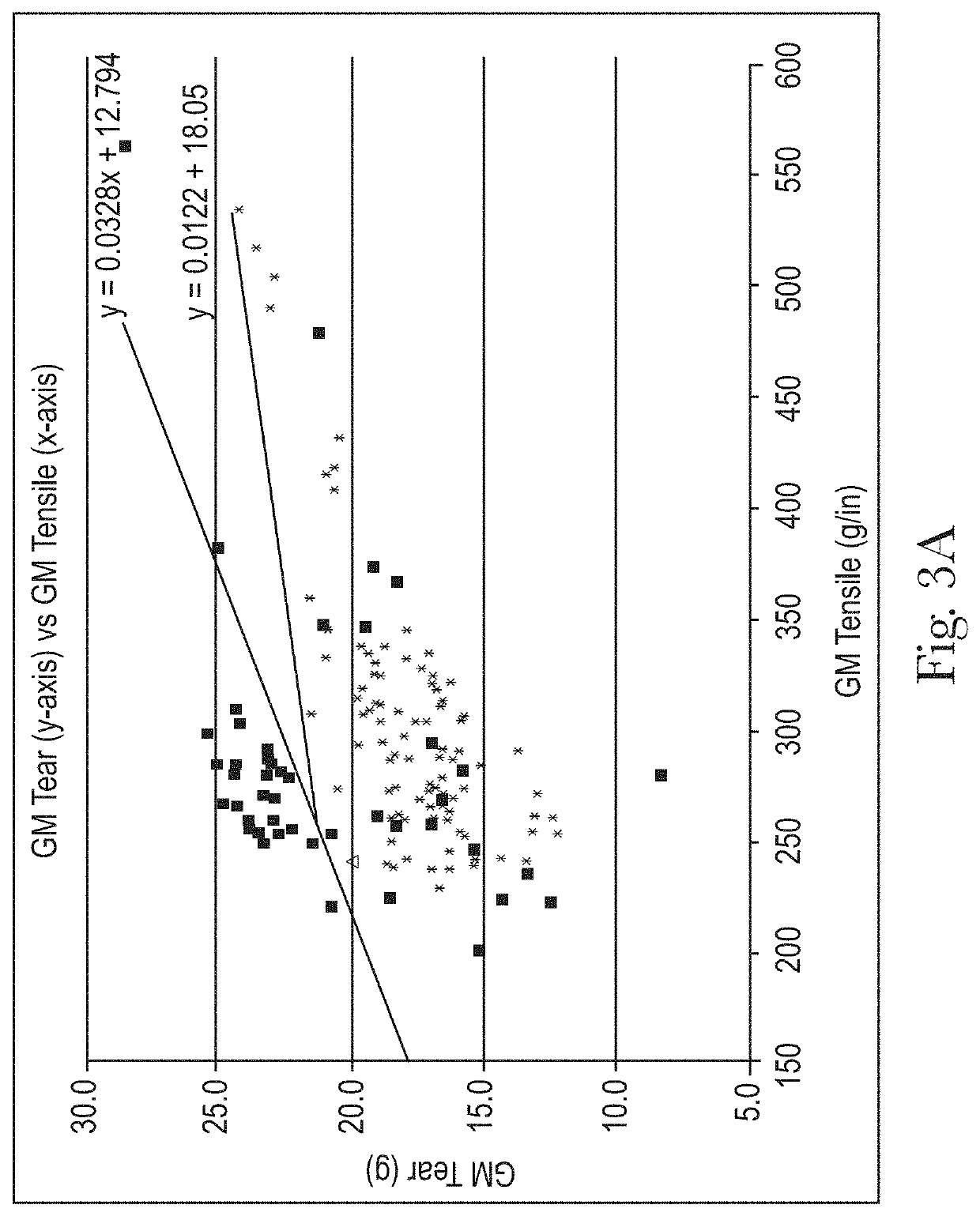

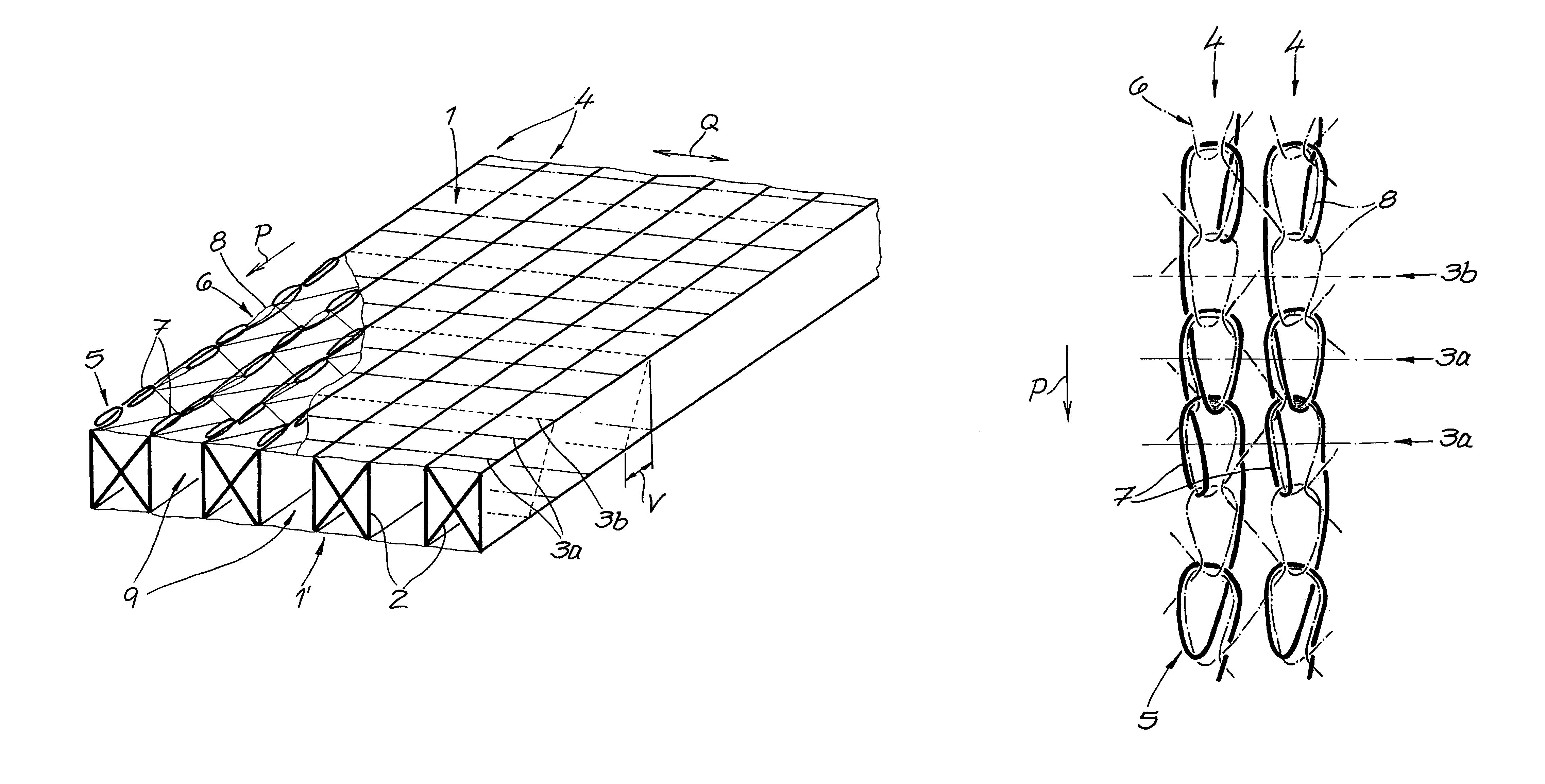

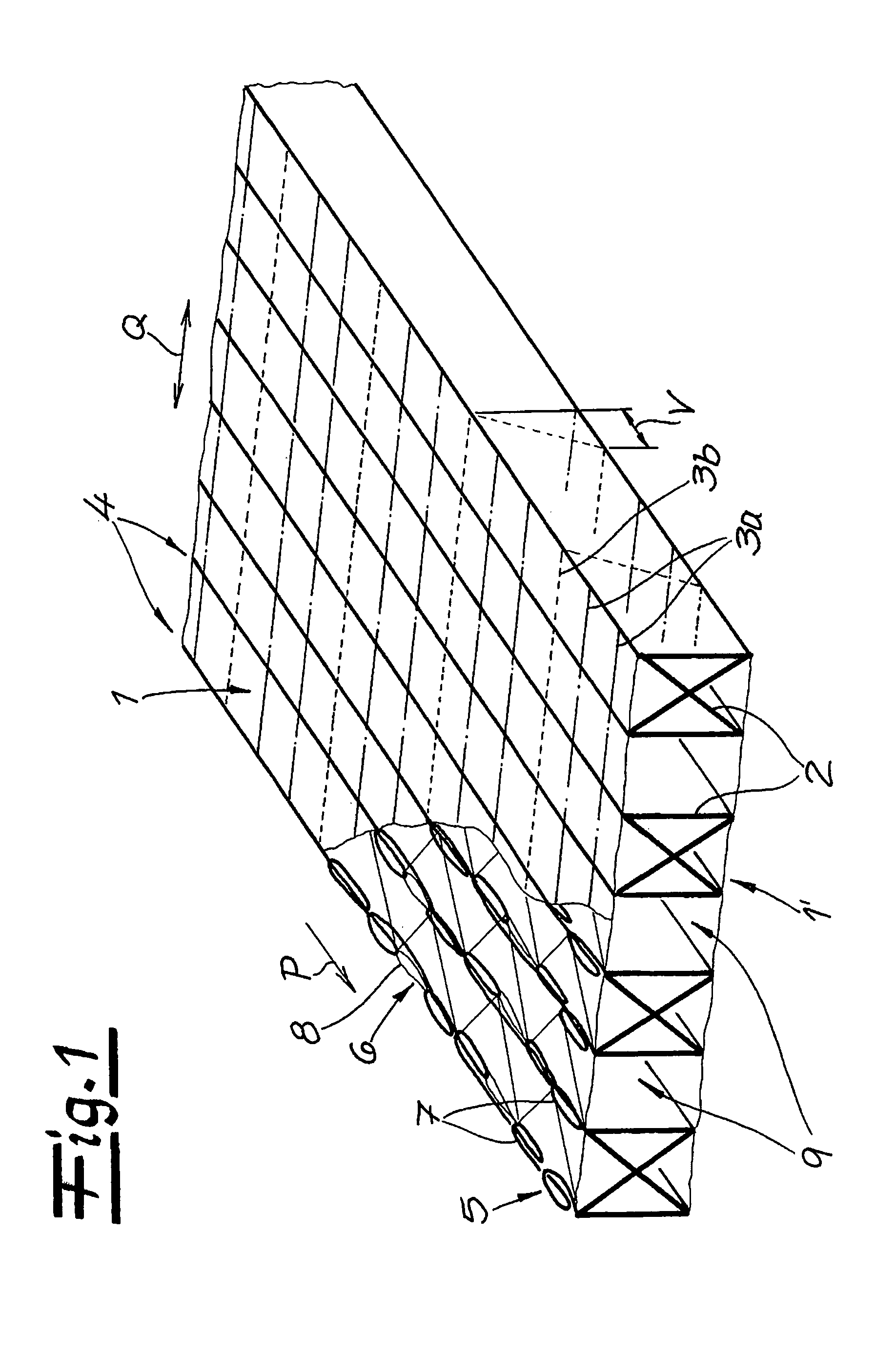

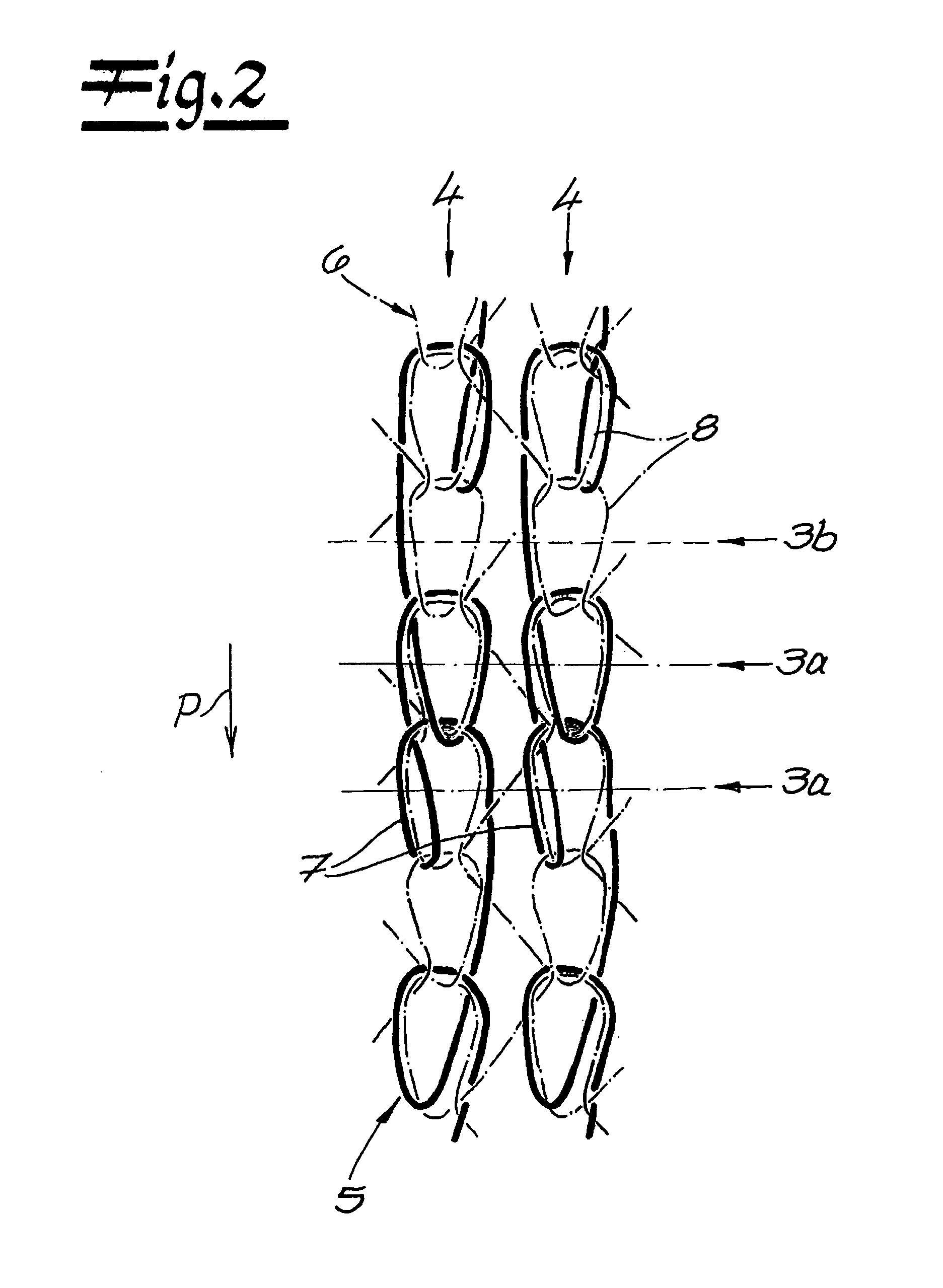

ActiveUS20120055202A1Uniform pressure-elastic propertyLow tear strengthOrnamental textile articlesWarp knittingEngineeringTextile

A spacer textile, particularly knitted spacer textile, has two cover plies spaced apart from one another, and spacer threads that connect the cover plies with one another. The cover plies are formed from a main thread system and a further thread system, forming courses that follow one another in the production direction. According to the invention, a first course is formed at least by the main thread system, and a second courses is formed by the further thread system. The thread or threads of the main thread system is / are guided without forming stitches, in the production direction, in the second course, and the cover plies have a lower tear strength there, when pulled in the production direction.

Owner:MULLER TEXTIL

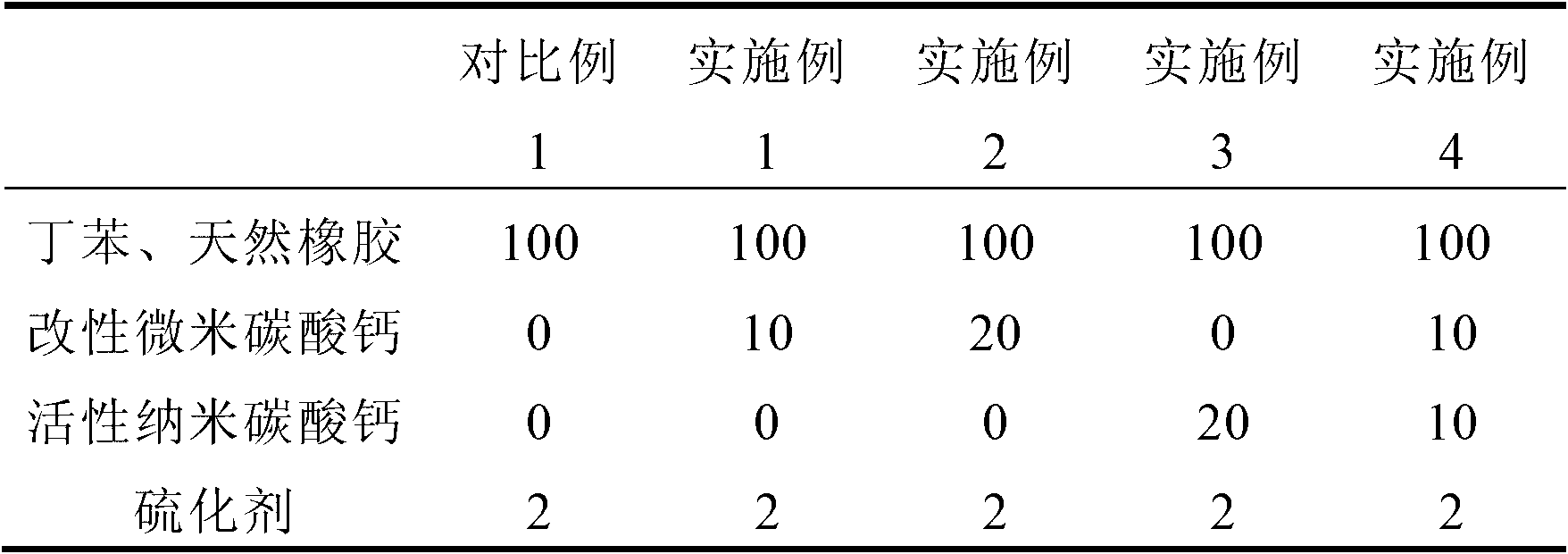

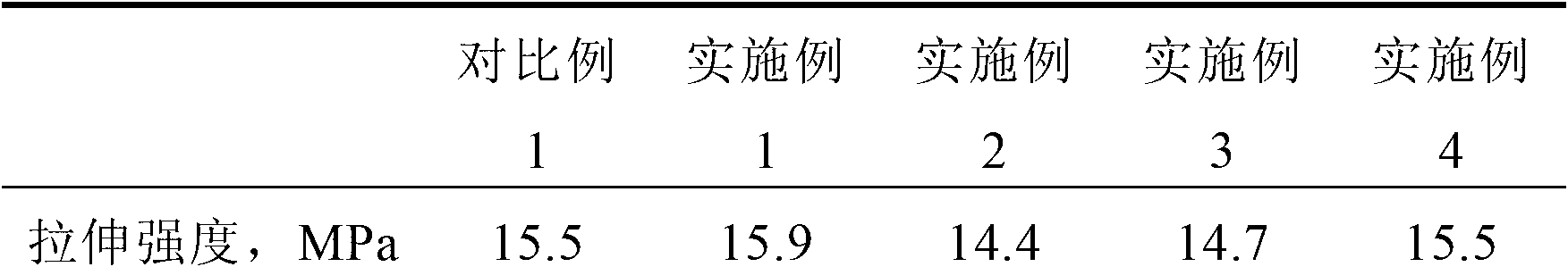

Preparation method of calcium carbonate modified butylbenzene/natural rubber composite material

InactiveCN102796294AAchieve incremental cost reductionRealize reinforcementUltimate tensile strengthToughness

The invention discloses a preparation method of a calcium carbonate modified butylbenzene / natural rubber composite material, which is characterized by comprising a micrometer calcium carbonate surface treatment through using a surface conditioning agent which contains unsaturated bond and a function group capable of reacting with a calcium carbonate surface group, and comprising a mixed modification technology for butylbenzene / natural rubber composite material through using modified calcium carbonate and active nanometer calcium carbonate. The increased amount and reduced cost of the butylbenzene / natural rubber by calcium carbonate can be ensured, and the good strength and toughness of butylbenzene / natural rubber can be kept. The method has the characteristic of simple production technology, and can be directly used in the industrial production.

Owner:ZHEJIANG UNIV OF TECH +2

Flame retardant cable sheath material

ActiveCN103265739AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesPolymer scienceCompression set

The invention discloses a flame retardant cable sheath material. The flame retardant cable sheath material comprises the following raw materials by weight: 97 to 100 parts of chloroprene rubber SN23, 10 to 15 parts of chlorinated polyethylene, 15 to 20 parts of hydrotalcite, 8 to 10 parts of magnesium carbonate, 18 to 25 parts of a modification filling material, 4 to 5 parts of trioctyl trimellitate, 3 to 4 parts of methylpentachlorostearate, 1 to 2 parts of an anti-aging agent ODA, 1 to 2 parts of a promoter TMTM, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 3 to 4 parts of ethylene bis stearamide, 2 to 4 parts of aluminum tripolyphosphate, 1 to 2 parts of ferrocene, 1 to 2 parts of an anti-oxidant 168 and 1 to 3 parts of benzotriazole. The cable sheath material produced in the invention has excellent physical properties, a stable dimension, low shrinking percentage, high tensile strength, great tearing strength, strong resilience and good resistance to oil, heat, burning, sunlight, ozone, acid and alkali and chemical reagents; and the modification filling material provided by the invention has good dispersibility and low surface tension, enables tensile strength and stress at definite elongation of the cable sheath material to be further improved, reduces heat generation and compression set, delays the ageing speed of the cable sheath material, is capable of resisting acid and alkali and allows production cost to be reduced.

Owner:ANHUI KANGLIYA CO LTD

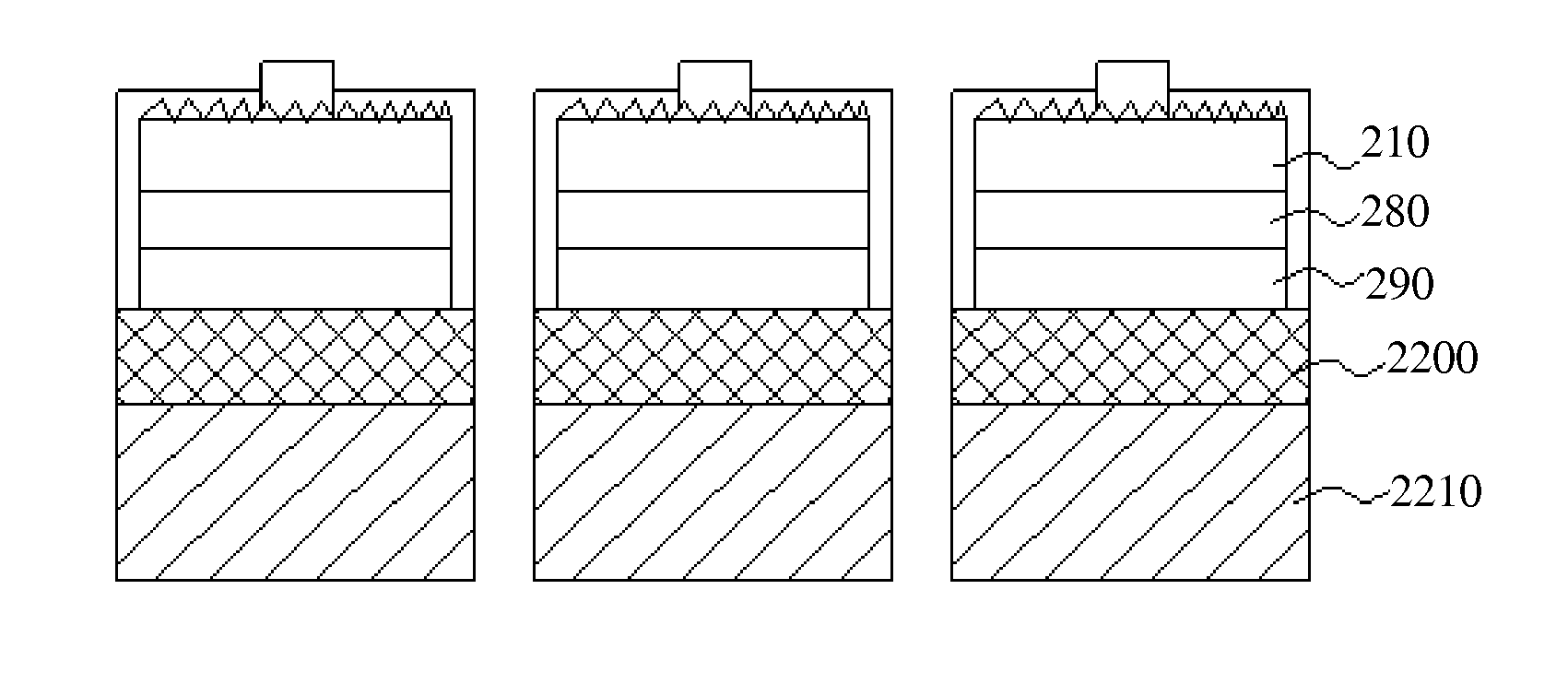

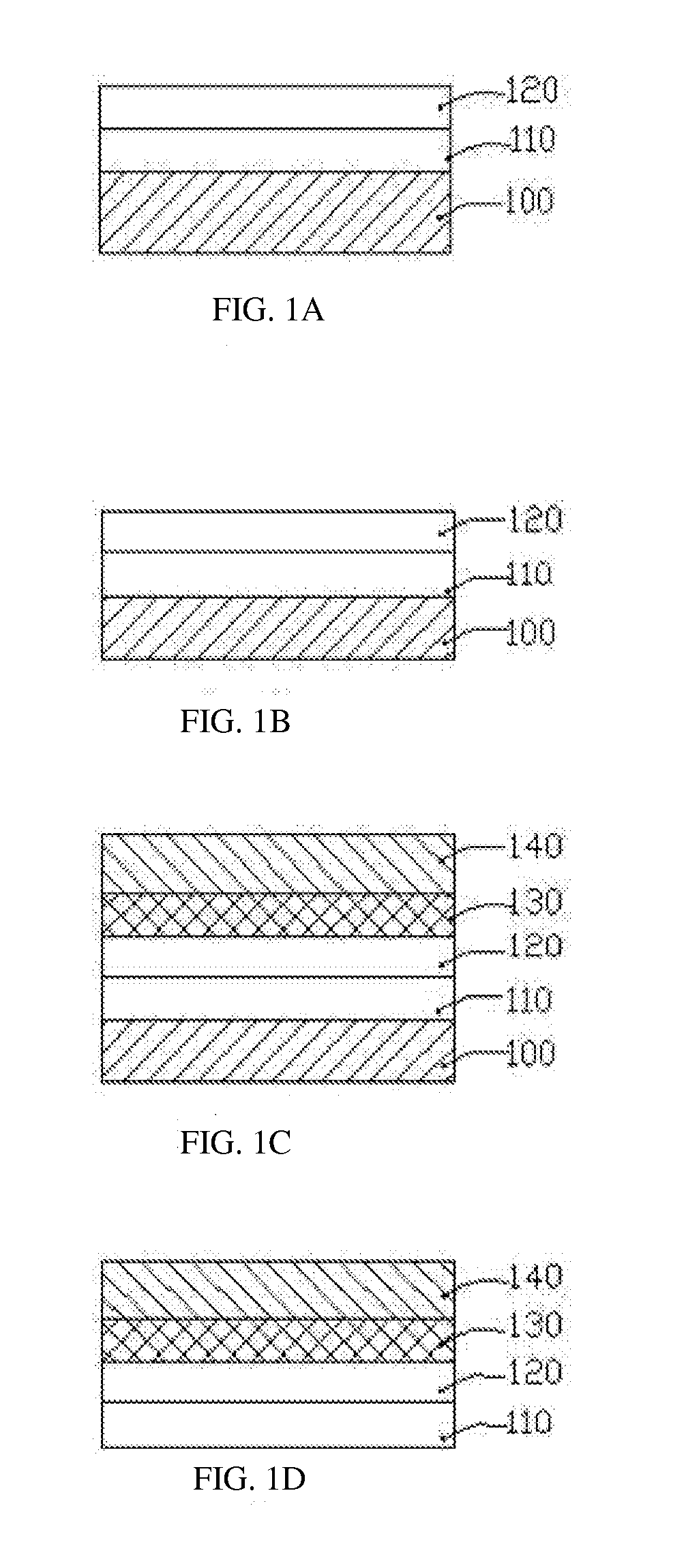

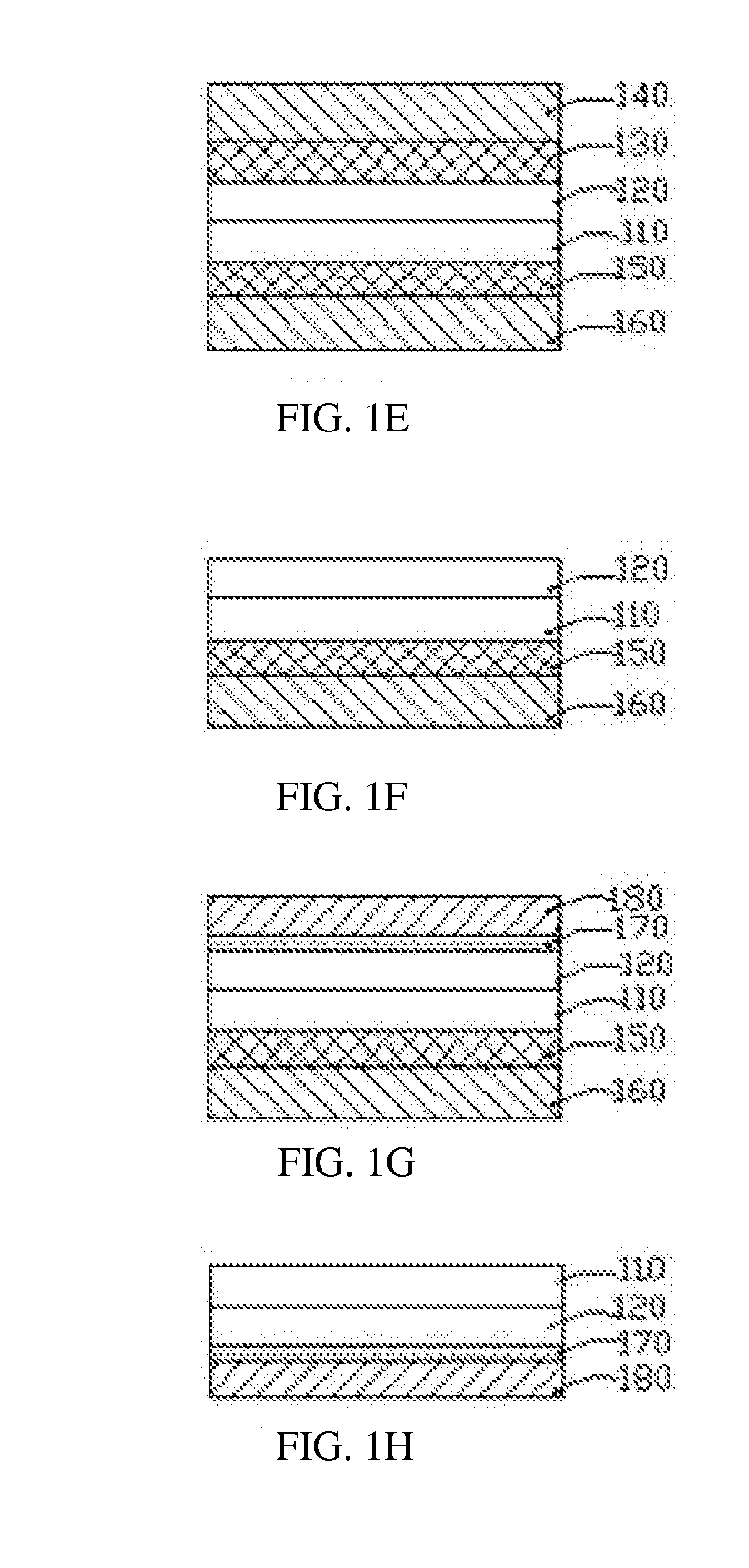

Method for manufacturing gallium nitride-based film chip

ActiveUS20140147987A1Low tear strengthReduce harmSolid-state devicesSemiconductor/solid-state device manufacturingGallium nitrideSemiconductor

A method for manufacturing gallium nitride-based film chip is provided. The method comprises: growing a gallium nitride-based semiconductor multilayer structure on a sapphire substrate; thinning and polishing the sapphire substrate; coating a reflecting compound metal layer on the gallium nitride-based semiconductor multilayer structure by evaporating; coating a first glue on the reflecting compound metal layer and solidifying the first glue with a first temporary substrate; peeling the sapphire substrate off by laser; coating a second glue on the peeling surface and solidifying the second glue with a second temporary substrate; removing the first temporary substrate and the first glue; bonding the reflecting compound metal layer with a permanent substrate by eutectic bonding; removing the second temporary substrate and the second glue.

Owner:SHINEON INNOVATION TECH CO LTD +1

Sanitary tissue products

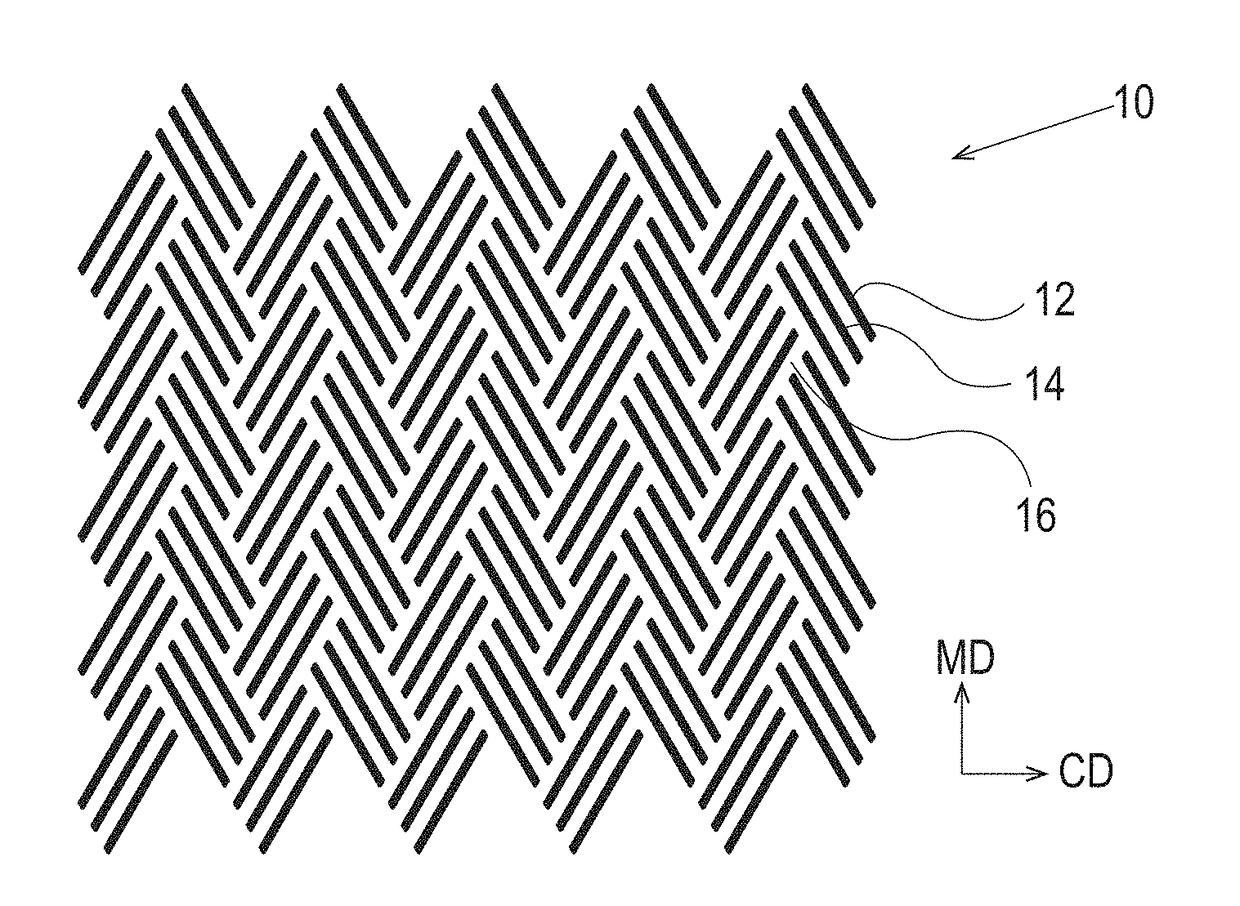

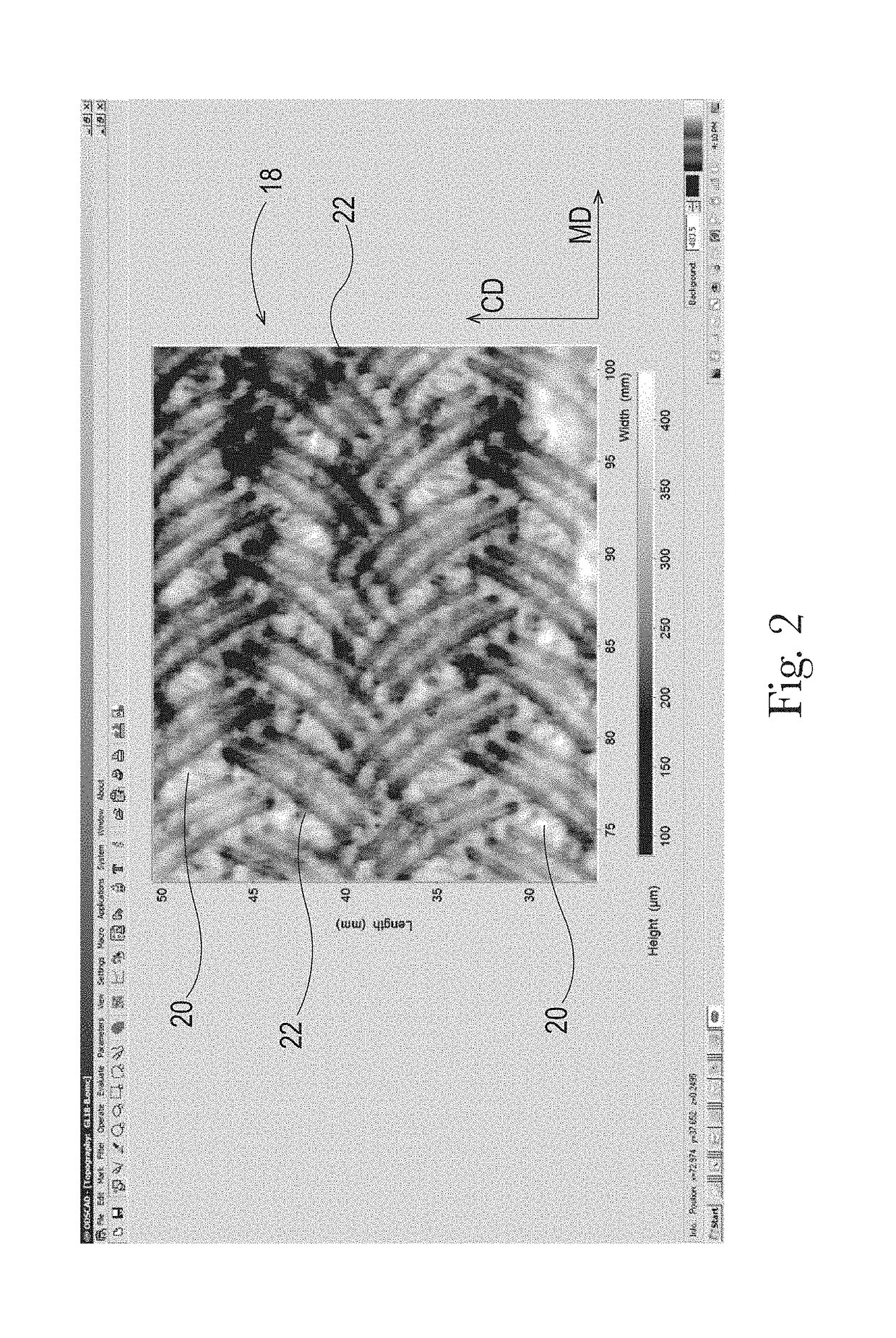

ActiveUS10711402B2Less stressImprove strength performanceReinforcing agents additionPaper/cardboardToilet paperBiology

Owner:THE PROCTER & GAMBLE COMPANY

Ageing resistant cable sheath material

ActiveCN103242574AGood physical propertiesDimensionally stableRubber insulatorsInsulated cablesCross-linkDispersity

The invention discloses an ageing resistant cable sheath material which comprises the following raw materials in parts by weight: 95-101 parts of neoprene A-30, 20-30 parts of nano calcium carbonate, 10-16 parts of modified filler, 6-9 parts of ethylene bis stearamide, 4-6 parts of epoxidized soybean oil, 15-20 parts of chlorinated polyethylene, 2-3 parts of diphenylamine, 10-15 parts of potassium feldspar powder, 2-4 parts of dibasic lead phosphate, 2-3 parts of antioxygen DSTP, 3-5 parts of barium stearate, 0.8-1 part of a cross-linking agent ATC, 0.8-1 part of an accelerant TMTD and 1-2 parts of dipentamethylenethiuram. The prepared ageing resistant cable sheath material has excellent performance, size stability, low shrinking percentage, has strong tensile strength, strong tearing strength, strong resilience force performance and also has good oil resistance, heat resistance, sunlight resistance, ozone resistance, acid / alkali resistance and chemical reagent resistance; and the modified filler has good dispersity and surface tension, can further improve the tensile strength and stress at definite elongation of the cable sheath material and reduce heating and compression set of the cable sheath material, is capable of slowing down the aging speed of the cable sheath material, resisting acid and alkali corrosion and reducing production cost.

Owner:ANHUI KANGLIYA CO LTD

Spacer textile

ActiveUS8286451B2Uniform pressure-elastic propertyLow tear strengthOrnamental textile articlesWarp knittingEngineeringUltimate tensile strength

A spacer textile, particularly knitted spacer textile, has two cover plies spaced apart from one another, and spacer threads that connect the cover plies with one another. The cover plies are formed from a main thread system and a further thread system, forming courses that follow one another in the production direction. According to the invention, a first course is formed at least by the main thread system, and a second courses is formed by the further thread system. The thread or threads of the main thread system is / are guided without forming stitches, in the production direction, in the second course, and the cover plies have a lower tear strength there, when pulled in the production direction.

Owner:MULLER TEXTIL

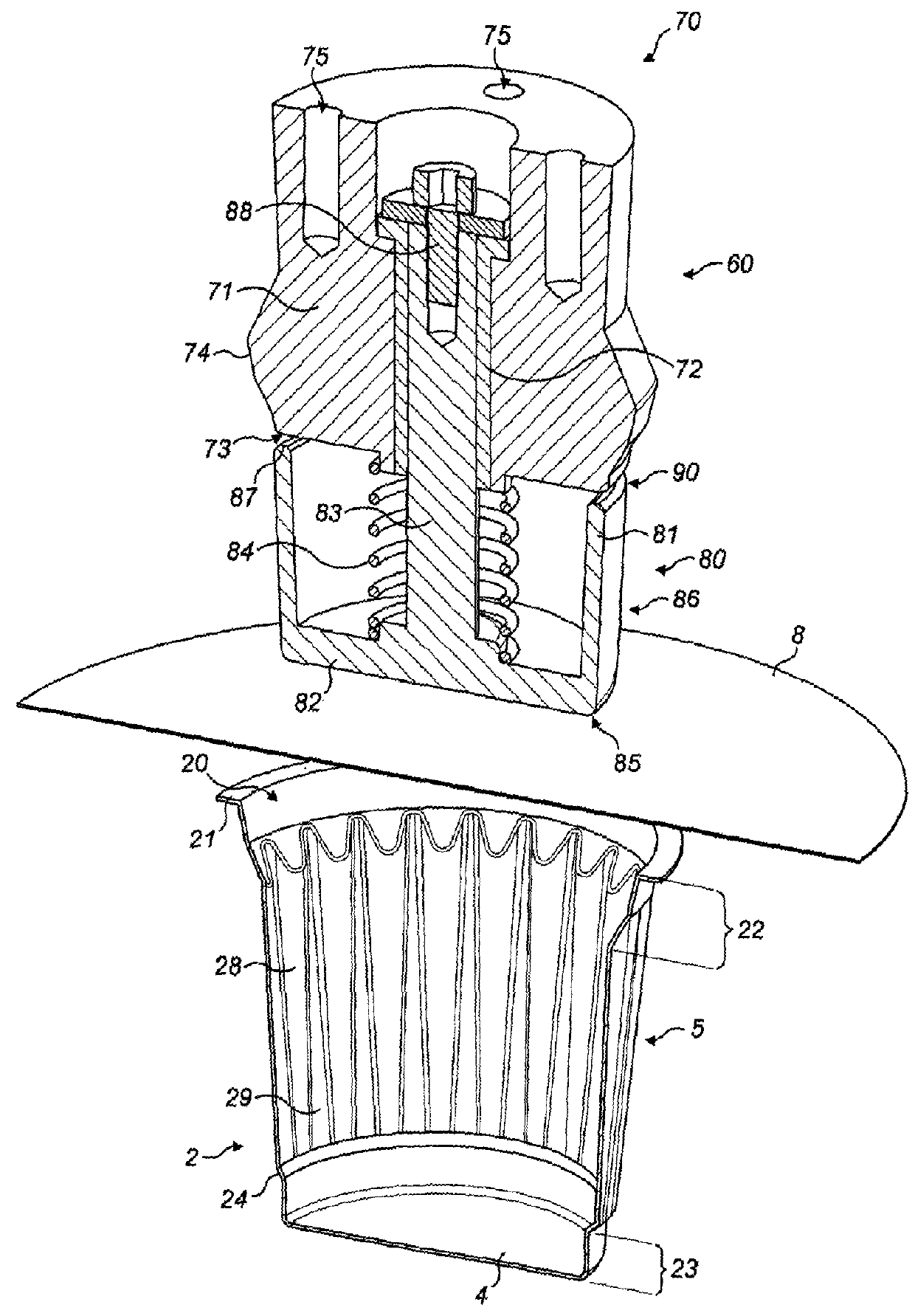

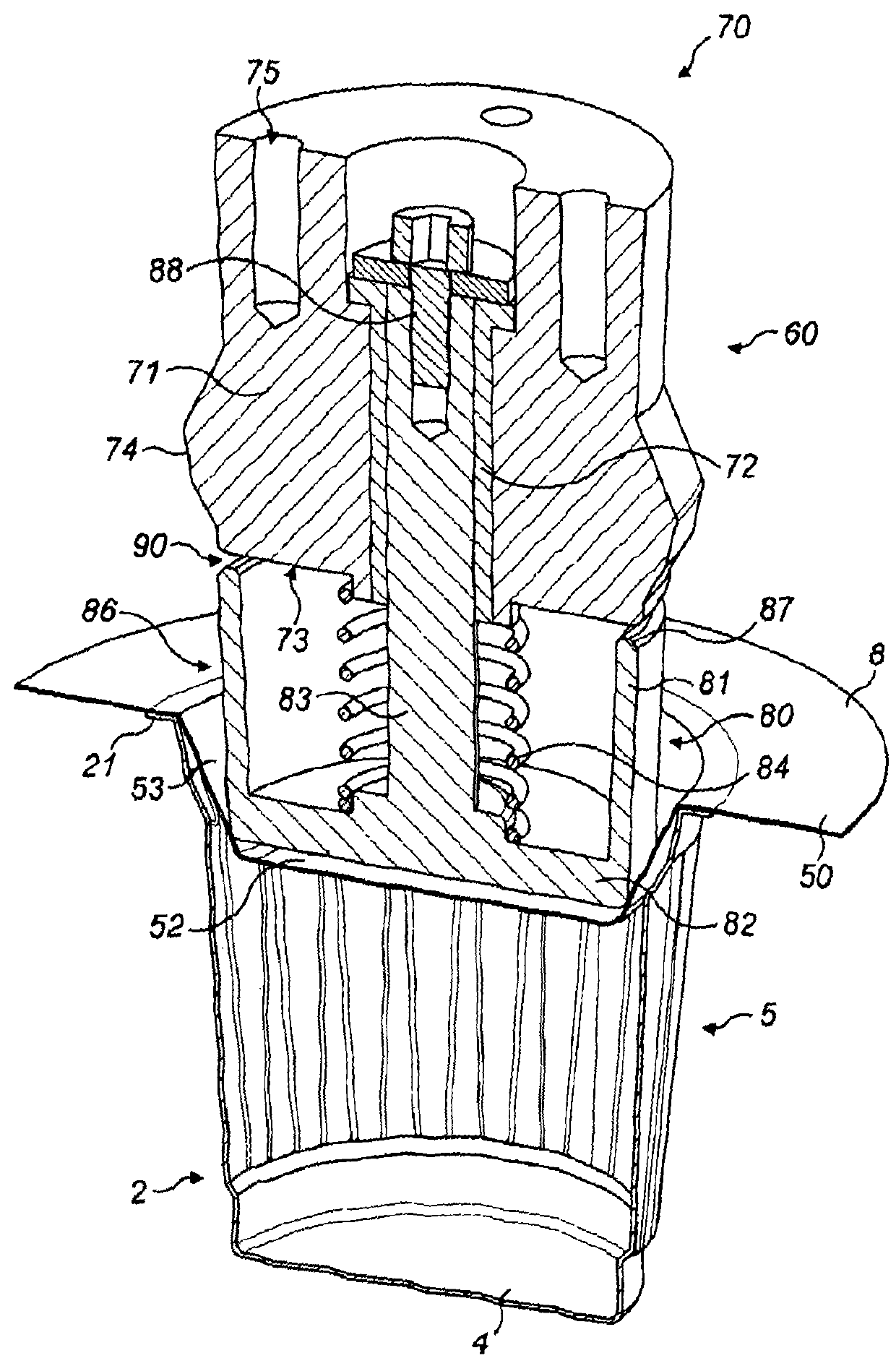

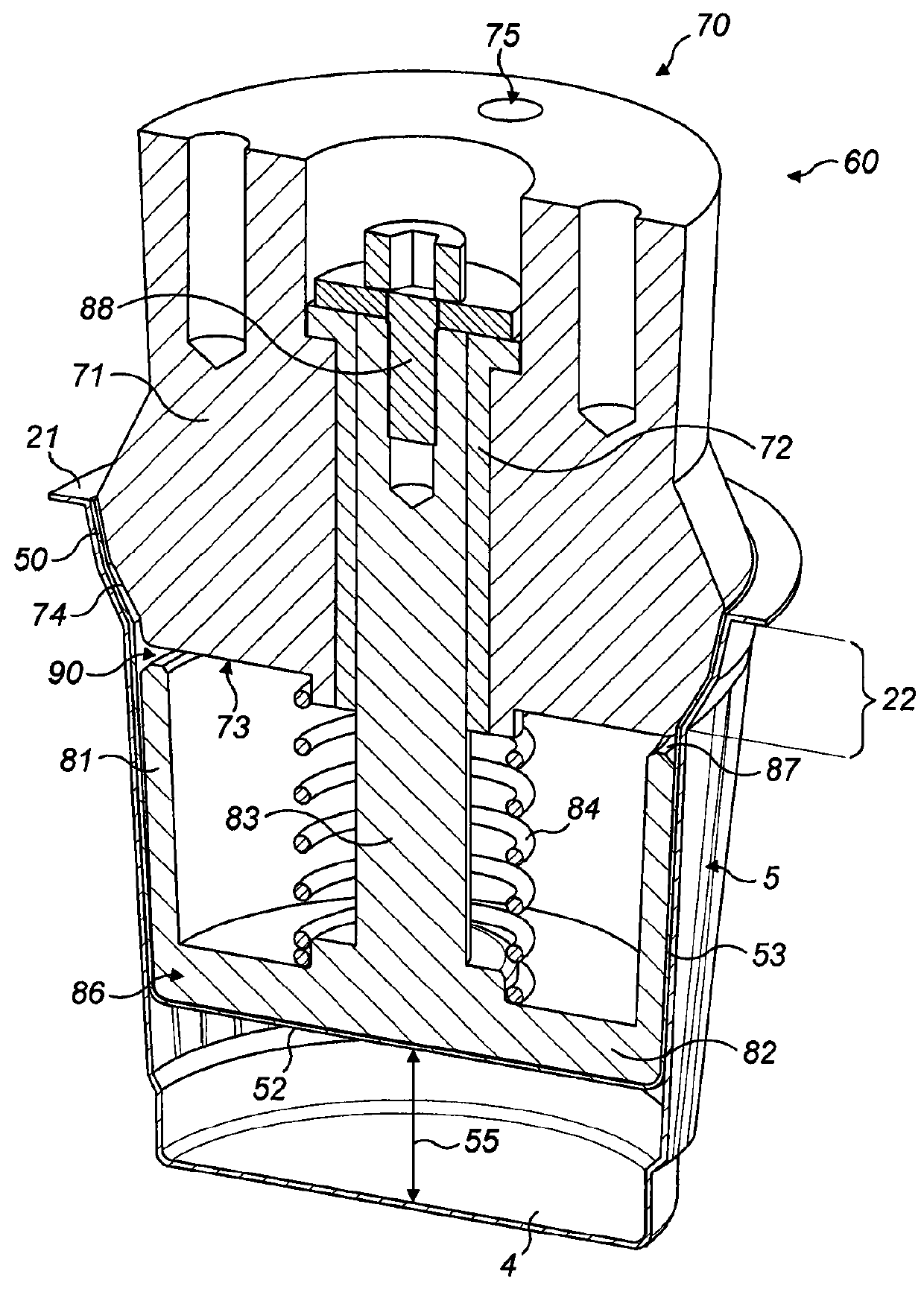

Capsules

ActiveUS9963256B2Less complicatedLikelihood is lessened and avoidedPackaging foodstuffsAdhesivesBiomedical engineeringFilter element

The present invention provides a method of assembling a filter element (8) with a cup-shaped capsule body (2) using a combined weld-head (70) and former (80), comprising the steps of positioning the filter element (8) at or near a mouth of the cup-shaped capsule body (2), moving the combined weld-head (70) and former (80) so as to contact and drive the filter element (8) into the cup-shaped capsule body (2), wherein, the filter element (8) is deformed by a sprung-loaded former (80) of the combined weld-head (70) and former (80) to form a cup-shaped filter element (56), and using a weld-head (70) of the combined weld-head (70) and former (80) to bond the cup-shaped filter element (56) to the cup-shaped capsule body (2). The present invention further provides a method of making a beverage capsule and a beverage capsule produced using this method.

Owner:MONDELEZ UK R&D

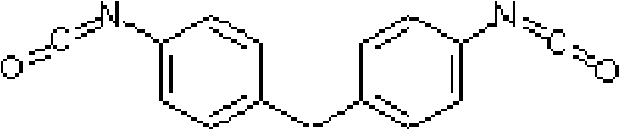

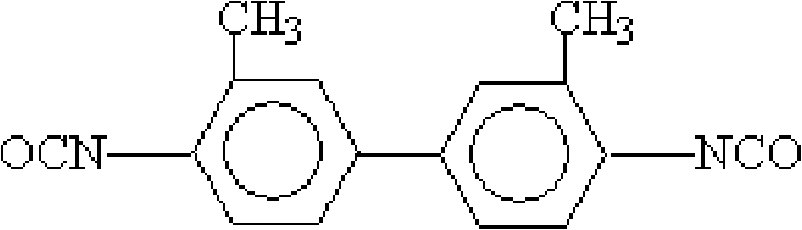

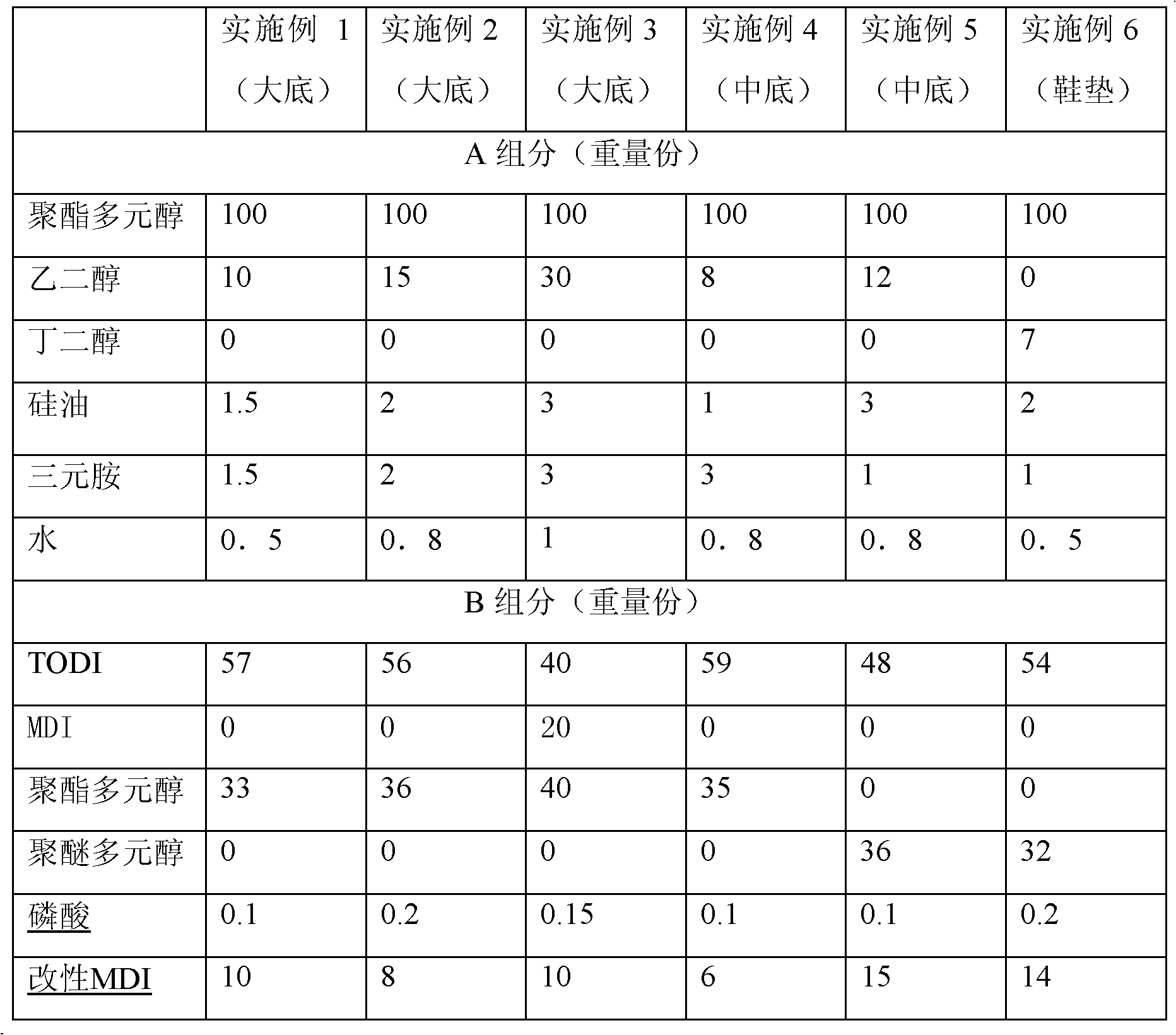

Polyurethane resin for shoes

The invention discloses polyurethane resin for shoes, comprising a component (A) and a component (B). The polyurethane resin for shoes is characterized in that the component (A) comprises 100 parts of polyester polyol and 8-30 parts of ethylene glycol and / or butanediol, the component (B) comprises 40-60 parts of 3,3'-dimethyl-4,4' diphenyl diisocyanate and 30-45 parts of polyester polyol and / or polyether glycol. A finished product prepared by substituting TODI (3,3-Tolidine-4,4-Diisocyanate) for MDI (4,4'-Diphenylmethane Diisocyanate) through a foaming reaction has the matter properties, suchas excellent compression ratio, better wear resistance, bending resistance, tensile strength, tearing strength, and the like under low density. Because of the steric hindrance effect and the electronic effect of 3,3'-dimethyl-4,4'diphenyl diisocyanate methyl-o-side, the activity of the polyurethane resin is weaker than the activity of the diphenylmethane diisocyanate, and the prepared prepolymer is stable and mild in the foaming reaction without generating a bubble falling phenomenon. Because the activity of the TODI reaction is weaker than that of the MDI reaction, the storage stability of the isocyanate combination liquid is greatly improved.

Owner:山东崇舜新材料科技有限公司

Decohesion lining and pressure-sensitive adhesive therewith

InactiveCN1424371ALow densityReduce wearLayered productsThin material handlingEngineeringUltimate tensile strength

A release liner which is effective in diminishing cutting blade abrasion and has satisfactory tear strength includes a base material layer and a release agent layer disposed over at least one side of the base material layer, wherein the maximum cut resistance force imposed on a cutting blade when the release liner is cut therewith is 230 N / 30 mm or lower and the release liner has a tear strength of 0.6 N or higher.

Owner:NITTO DENKO CORP

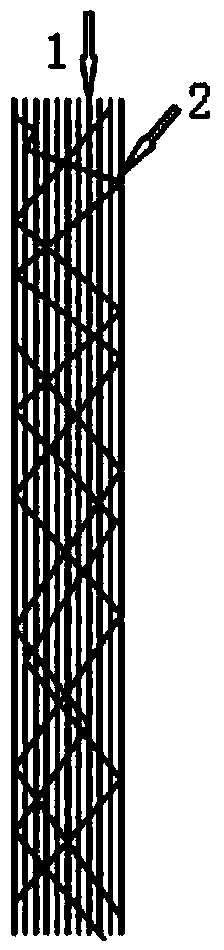

Platinum alloy knitted catalysis net for ammonia oxidation

InactiveCN1792435AReduce lossImprove anti-poisoning performanceNitric oxideMetal/metal-oxides/metal-hydroxide catalystsPlatinumAlloy

A knitted multi-layer 3D catalyst net made of Pt-alloy wire (0.06-0.09 mm in diameter) features that said Pt alloy contains Pd (0-6 Wt%), Ph (2-10), Ce (0-0.015) and Pt (rest). It can be used for oxidizing ammonia to prepare nitric acid. Its advantages are high catalytic activity, high-temp strength and resistance against Pt poisoning, and large contact area.

Owner:SINO PLATINUM METALS CO LTD

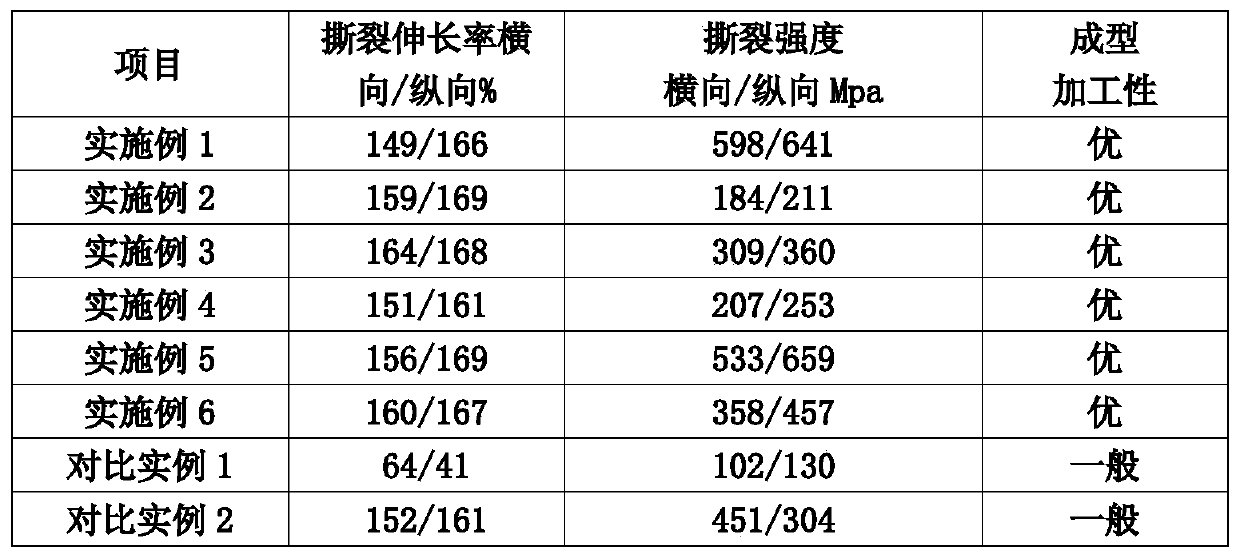

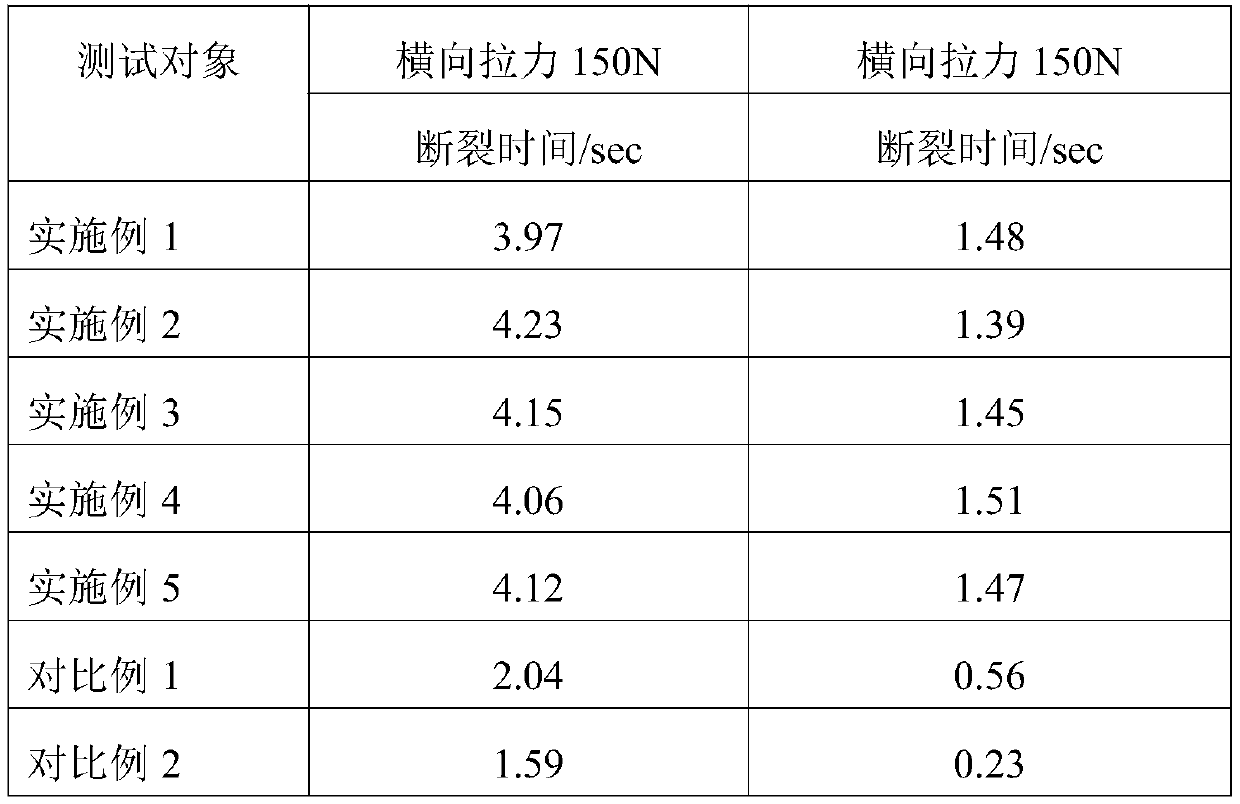

Kinesio tape combined by two different kinds of warp and weft fibers as well as preparation method of kinesio tape

ActiveCN103862779ALow tear strengthGood reflective rateSucessive textile treatmentsSynthetic resin layered productsFiberYarn

The invention discloses a kinesio tape combined by two different kinds of warp and weft fibers as well as a preparation method of the kinesio tape. The kinesio tape is formed by weaving warp yarns and weft yarns, wherein the warp yarns are core-spun elastic yarns of full cotton or artificial cotton; the weft yarns are chemical fibers, and are woven to form an elasticity-free interlaced yarn structure. According to the invention, because different fibers are adopted by the warp yarns and weft yarns; the twist-degree-free interlaced yarn structure is adopted by the weft yarns, so that a fabric is flexible and close to skin, and the comfort, the quick-dry property and flanging-prevention property are far superior to those of full-cotton or mucilage-glue similar products.

Owner:CHANGZHOU DL MEDICAL & HEALTH EQUIP

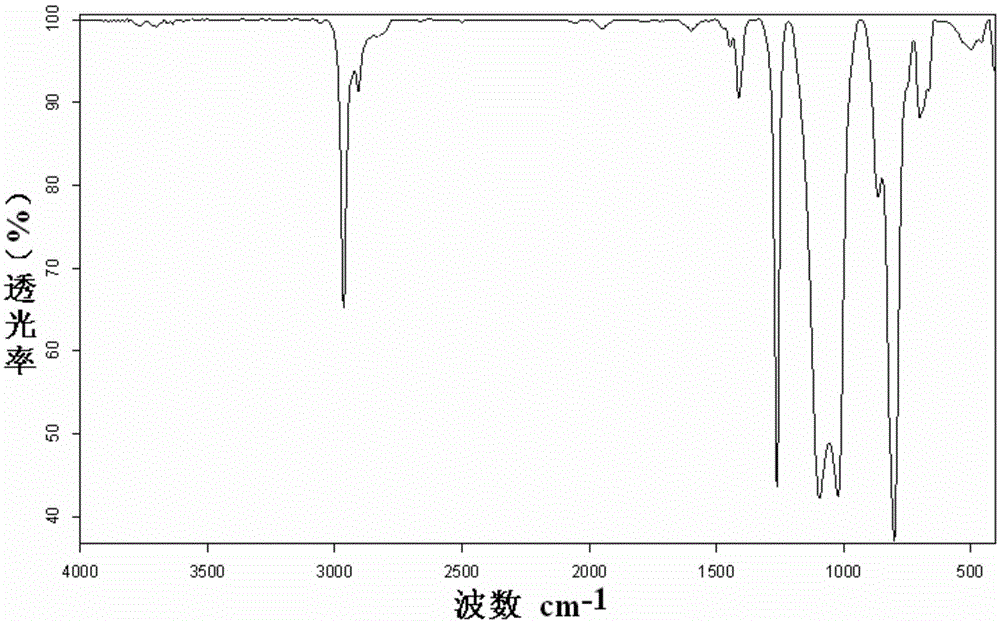

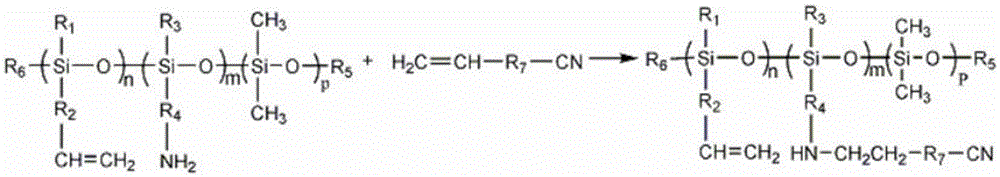

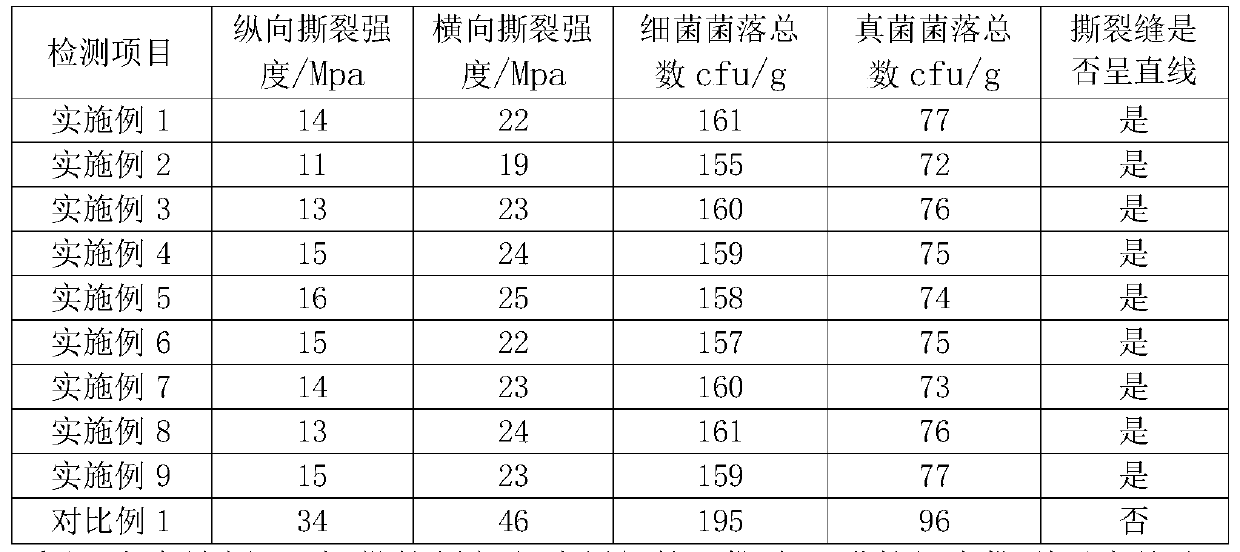

Synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and preparation method of addition type heat vulcanized nitrile silicone rubber

The invention relates to a synthesis method of high molecular weight polysiloxane containing nitrile group and vinyl at the same time and a preparation method of addition type heat vulcanized nitrile silicone rubber. The high molecular weight polysiloxane containing nitrile group and vinyl at the same time is prepared by performing amino group and double bond addition reaction on polysiloxane containing amino group and vinyl at the same time and compound containing unsaturated bonds and nitrile group. The addition type heat vulcanized nitrile silicone rubber is prepared through the synthesized high molecular weight polysiloxane containing nitrile group and vinyl at the same time. The synthesis method is simple and controllable, and high in synthesis efficiency; as the synthesized polysiloxane containing nitrile group and vinyl at the same time contains nitrile groups, the polarity and solubility parameters of polysiloxane are changed, and the prepared addition type heat vulcanized nitrile silicone rubber can have the performance of solvent oil resistance, and can be applied to various oil resistance and low temperature resistance places.

Owner:SHANDONG UNIV

Tearable packaging film and preparation method thereof

The invention relates to a tearable packaging film and a preparation method thereof, and belongs to the technical field of cast films. The raw materials for preparing the tearable packaging film include, by weight, LDPE, LLDPE, HDPE, PP, metallocene polyethylene, a lubricant, a dispersant, an antibacterial agent and a crystallization nucleating agent, wherein the antibacterial agent comprises teapolyphenols and chitin fibers; and the crystallization nucleating agent comprises dibenzylidene sorbitol, p-hydroxybenzoic acid and poly(phenyl 4-methoxyl-4'-acryloyloxybenzoate). The invention also discloses the preparation method of the tearable packaging film. The preparation method comprises the following steps: S1, mixing, and extrusion plasticizing; S2, extrusion casting; S3, calendering setting; and S4, corona, trimming and rolling. The packaging film is convenient to tear.

Owner:天津登峰卫生用品材料有限公司

Sanitary Tissue Products

PendingUS20220010495A1Less stressImprove strength performancePaper/cardboardTissue/absorbent paperBiotechnologyToilet paper

Owner:THE PROCTER & GAMBLE COMPANY

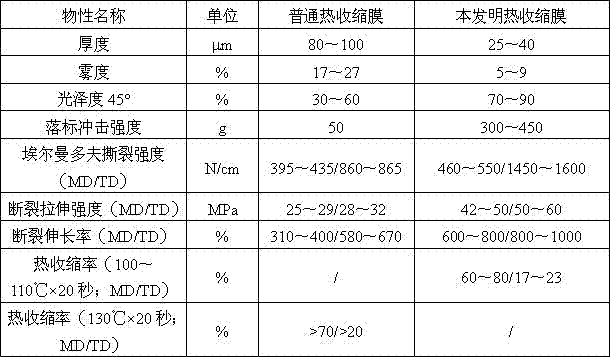

High-strength ultrathin heavy-packaged thermal contraction film and preparation method thereof

ActiveCN107244121ADissolution inhibitionReduce riskSynthetic resin layered productsFlat articlesLinear low-density polyethylenePolymer science

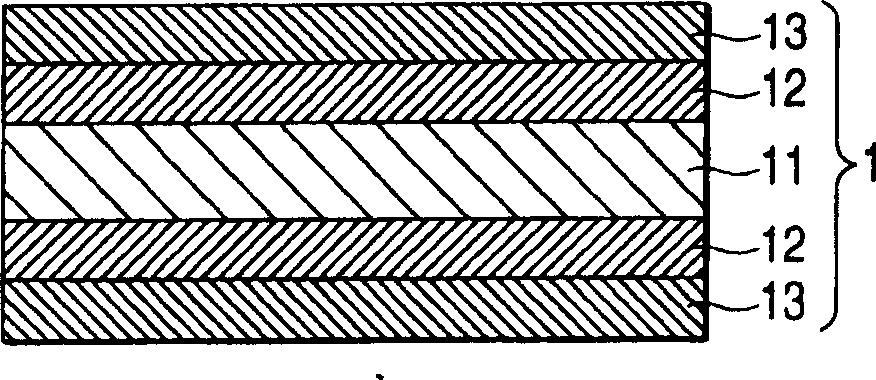

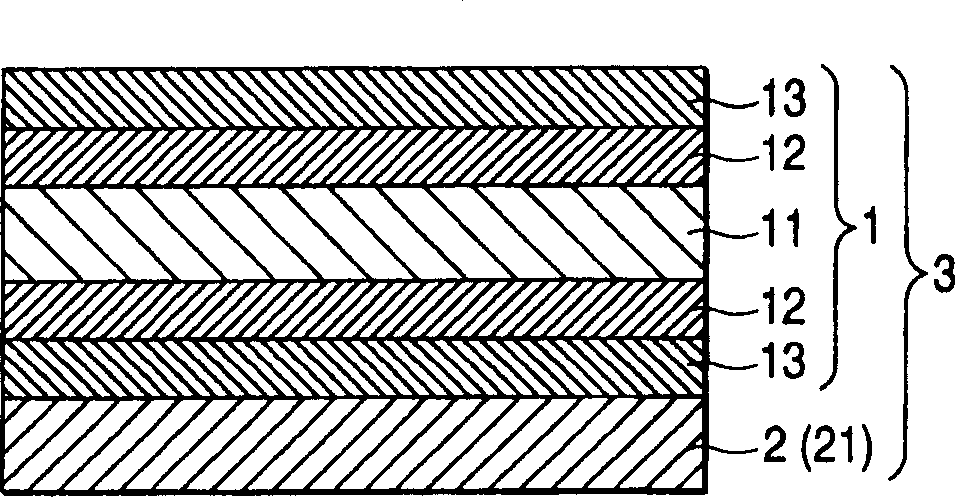

The invention discloses a high-strength ultrathin heavy-packaged thermal contraction film and a preparation method thereof and belongs to the technical field of package films. The thickness of the thermal contraction film disclosed by the invention is 25 to 40mu m; the thermal contraction film is formed by three layers of co-extruded adhered films of an outer layer, a middle layer and an inner layer; a thickness ratio of the outer layer to the middle layer to the inner layer is 1 to (3 to 5) to 1; the outer layer is prepared from high-density polyethylene, metallocene polyethylene (1), linear low-density polyethylene, hydroxyl modified vinisol and amorphous copolyester; the middle layer is prepared from linear low-density polyethylene, high-density polyethylene, metallocene polyethylene (2), hydroxyl modified vinisol and amorphous copolyester; the inner layer is prepared from high-density polyethylene, linear low-density polyethylene, metallocene polyethylene (1), and amorphous copolyester. The thickness of the thermal contraction film disclosed by the invention is ultrathin, materials are saved by 55.6% to 72.2%, and the thermal contraction film has excellent low temperature contraction performance, high strength, simple technology and suitability for large-scale industrial production.

Owner:无锡市方成彩印包装有限公司 +1

Method for producing polyphenylene sulfide film

InactiveCN109957125ASmall polydispersity coefficientExcellent polydispersity coefficientWax coatingsChemical industryPolymer science

The invention discloses a method for producring a polyphenylene sulfide film. Sodium sulfide and p-dichlorobenzene are used as raw materials, N-methyl-2-pyrrolidone is used as a solvent, 1,3,5-trichlorobenzene and 2,4,6-trichlorobenzene molecular weight regulators are added to control the molecular weight distribution coefficient of polycondensation synthesized polyphenylene sulfide resin, an antioxidant is added to the synthetic polyphenylene sulfide resin, all above materials are mixed according to a certain ratio to form a raw material for the polyphenylene sulfide film, the material is extruded by a twin-screw extruder, goes through a T-shaped mold, and is biaxially drawn into the polyphenylene sulfide film, and the polyphenylene sulfide film undergoes corona and anti-adhesion agent treatment, and then is wound into a polyphenylene sulfide film roll. The film obtained in the invention can be widely used in the fields of electronic appliances, military industry, aerospace, machinery, chemical industry and the like.

Owner:德阳科吉高新材料有限责任公司

Low-shrinkage composite PE laminating material and preparation method thereof

InactiveCN111205542AHigh tensile strengthHigh thermal stability and barrier propertiesPolyacrylamideAnoxomer

The invention provides a low-shrinkage composite PE laminating material and a preparation method thereof, and relates to the technical field, and the low-shrinkage composite PE laminating material isprepared from the following raw materials: low density polyethylene, modified polylactic acid, poly(1, 2-propylene glycol adipate), modified nano cellulose, polyacrylamide and an antioxidant. The low-shrinkage composite PE laminating material disclosed by the invention has relatively high tensile strength, elongation at break and tearing strength. Compared with the prior art, the non-toxic biomassdegradable material has high heat stability and barrier property, has a wide application prospect, repeatedly screens the dosage of each raw material, enables the raw materials to be suitable for melt strength and melt flowability required by casting film formation, and also improves the adhesiveness of a coating film and substrate paper. The raw materials have the advantages of the high boilingpoint, low volatility, good environmental sanitation, high viscosity, no toxicity and biodegradability.

Owner:厦门维豪环保科技股份有限公司

Rubber composition

ActiveUS20190153206A1Facilitate cross-linkingImprove the heating effectOther chemical processesVehicle sealing arrangementsPolymer scienceMooney viscosity

A rubber composition, comprising i) an ethylene-α-olefin-non-conjugated-diene copolymer having—a Mooney viscosity ML (1+8) at 150 ° C. ≥85 MU and—an ethylene content≤63 wt. %—the diene content is 4 to 8% by weight of the ethylene-a-olefin-non-conjugated-diene copolymer i), —the non-conjugated diene is a combination of 5-ethylidene-2-norbornene (ENB) and 5-vinylnorbornene (VNB), —the ethylene-α-olefin-non-conjugated-diene copolymer i) has an amount of VNB between 0.05 and 1 wt. %, and has a Mw of at least 400,000 g / mol and, ii) an extender oil of 10 to 40 phr based on the copolymer i) with the sum of the EPDM copolymer i) and the oil ii) amounting to at least 95 wt. % of the composition.

Owner:ARLANXEO NETHERLANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com