Skin-imitated microfiber fabric

A technology of imitation leather and microfiber, applied in the processing of textile materials, liquid/gas/steam textile material processing, layered products, etc., can solve the problems of hard hand feeling, single color, poor drape, etc., and achieve a wide range of dyeing , bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

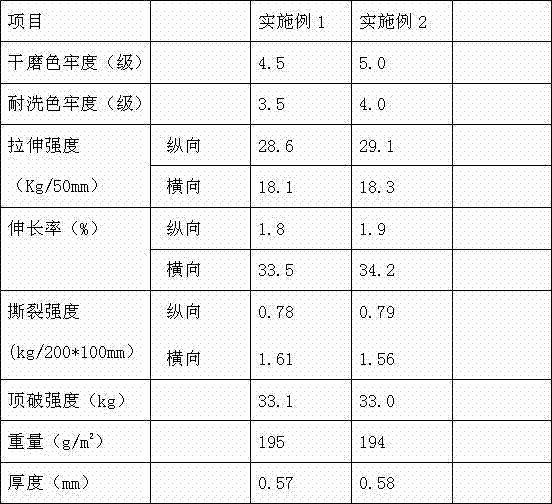

Examples

Embodiment 1

[0027] Raw material: 100% acrylic superfine staple fiber, purchased from Shanghai Litende International Trading Company.

[0028] Polyester filament or pure polyester yarn; the total fineness of polyester filament is 68D-75D, purchased from Zhejiang Xingfa Chemical Fiber Group Co., Ltd.;

[0029] In the present invention, the cationic dye, pretreatment agent, cationic leveling agent and softener in the bath can be conventional dye auxiliaries, and its selection has no influence on the performance of the product of the present invention.

[0030] Weaving using the following steps

[0031] (1) The production of non-woven fiber web, using acrylic ultra-fine staple fiber as raw material, the non-woven fiber web is obtained after carding and laying. Acrylic ultra-fine staple fiber accounts for 100%, and the fineness of acrylic ultra-fine staple fiber is 0.6 D- 3.0D, the length is 38-51mm, the non-woven fiber web has 0.2-0.5g / cm 2 Density and thickness of 0.6-1.9mm;

[0032] ...

Embodiment 2

[0049] The difference from Example 1 is that the knitting base fabric in step (1) is made of pure polyester yarn as raw material, and the base fabric is obtained by knitting, and the total fineness of pure polyester yarn is 30S-90S;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com