Patents

Literature

1102results about How to "Little elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

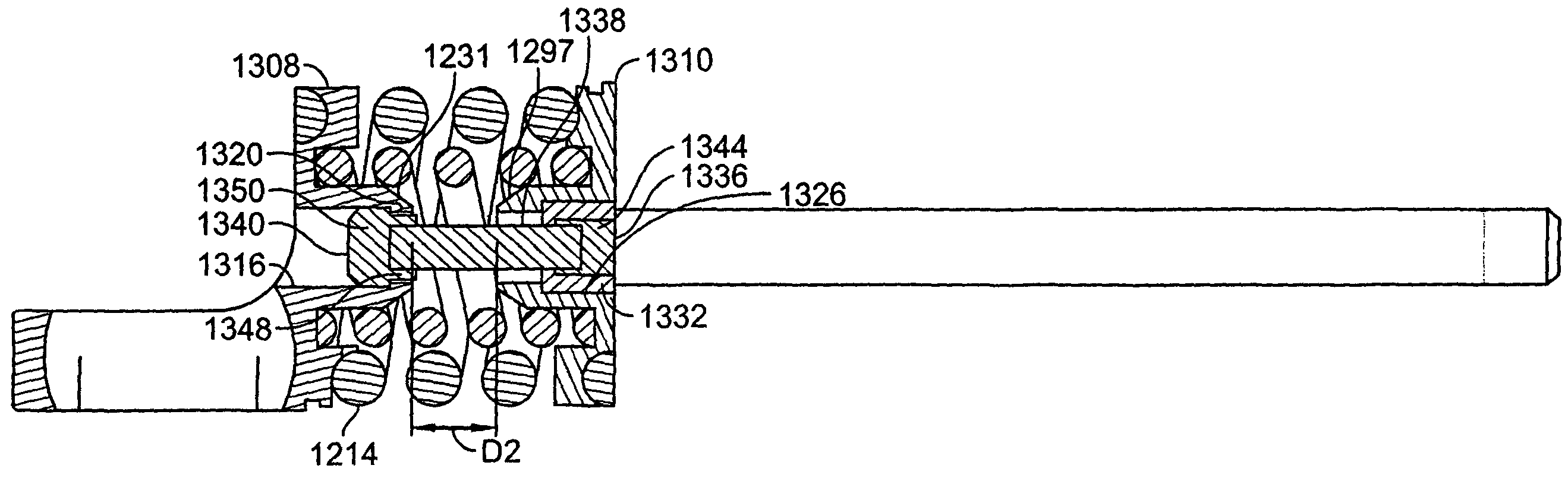

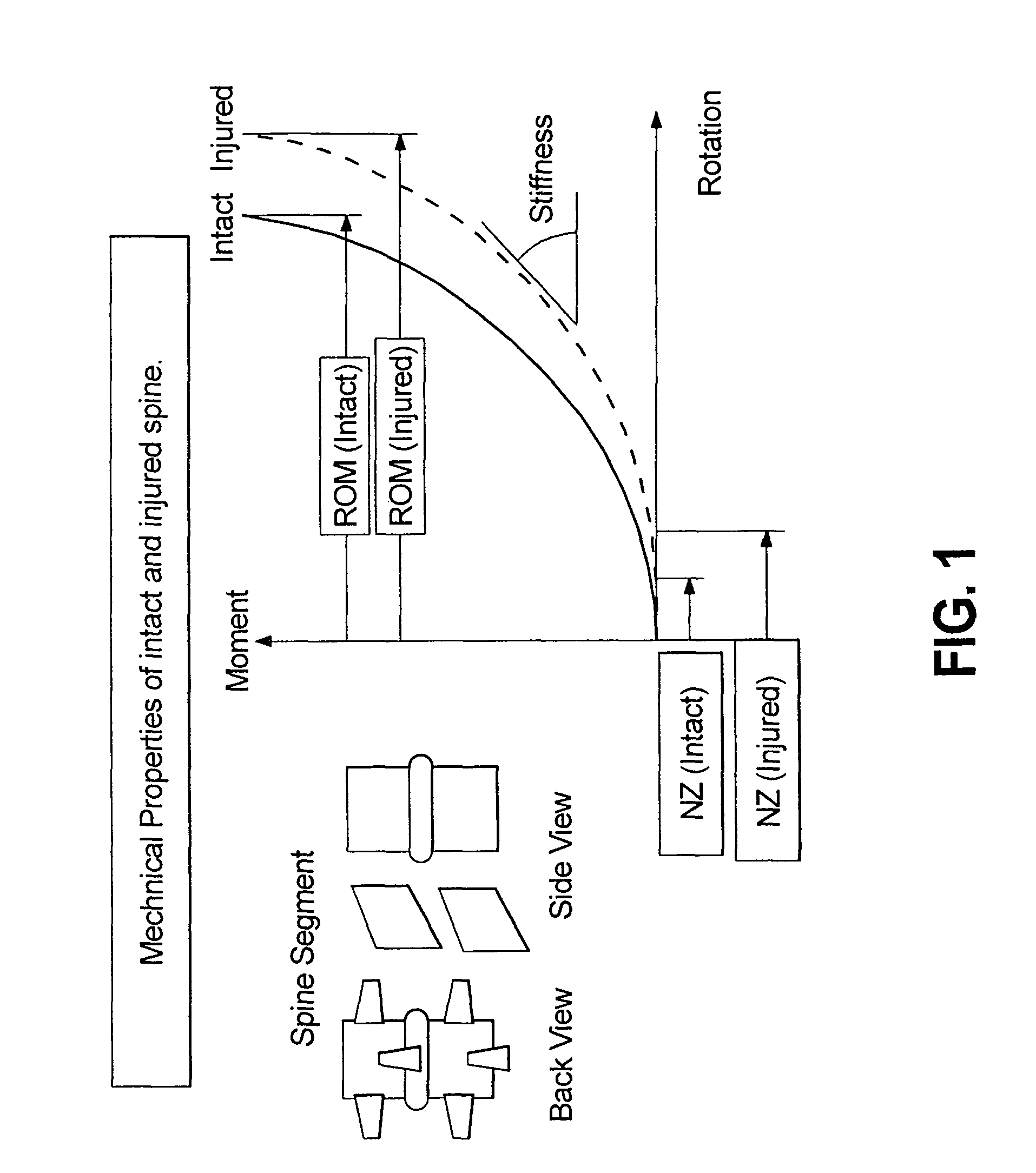

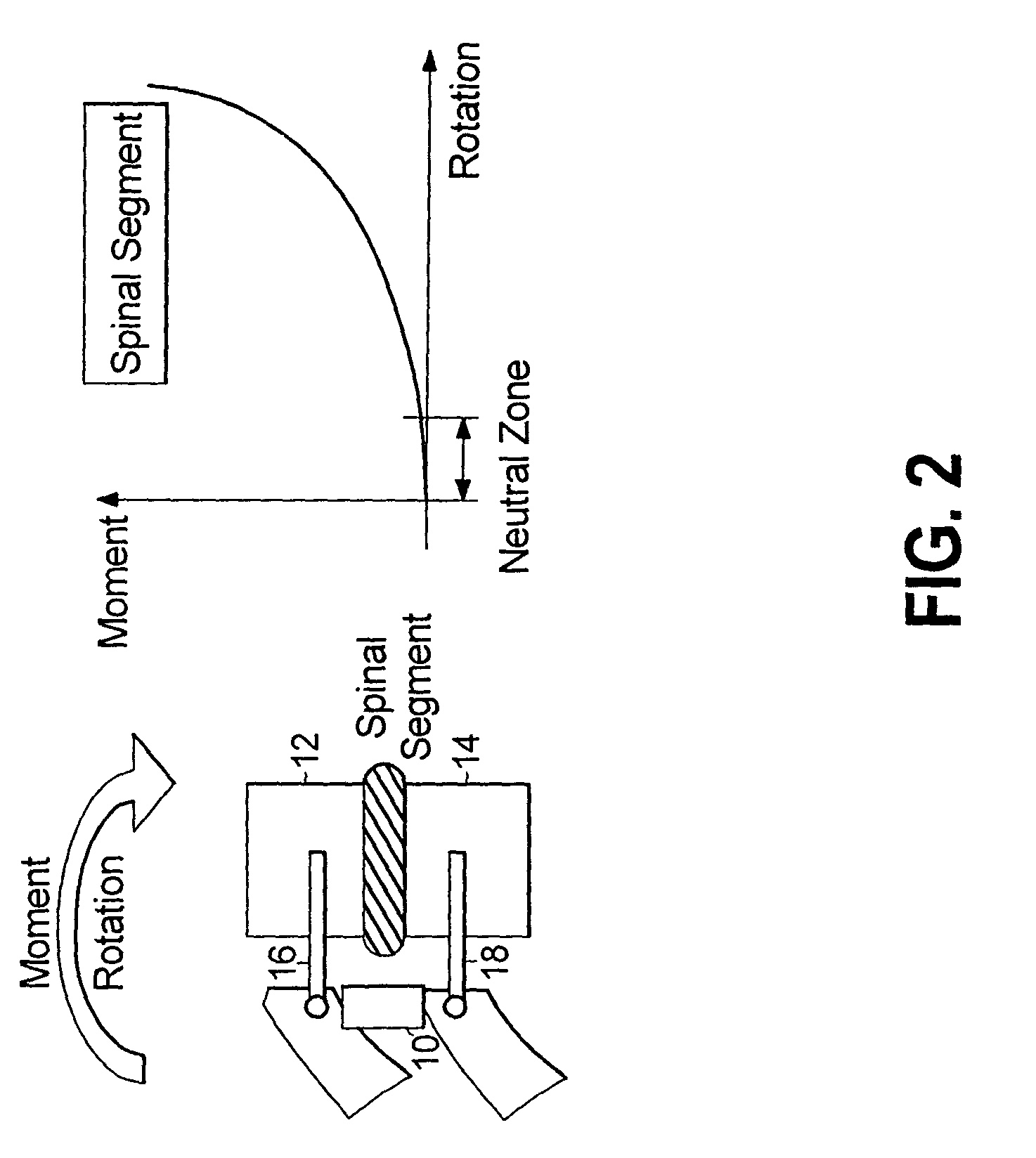

Dynamic spine stabilization device with travel-limiting functionality

InactiveUS20070043356A1Enhance alignment and durabilityLimit distanceInternal osteosythesisJoint implantsSpinal columnClassical mechanics

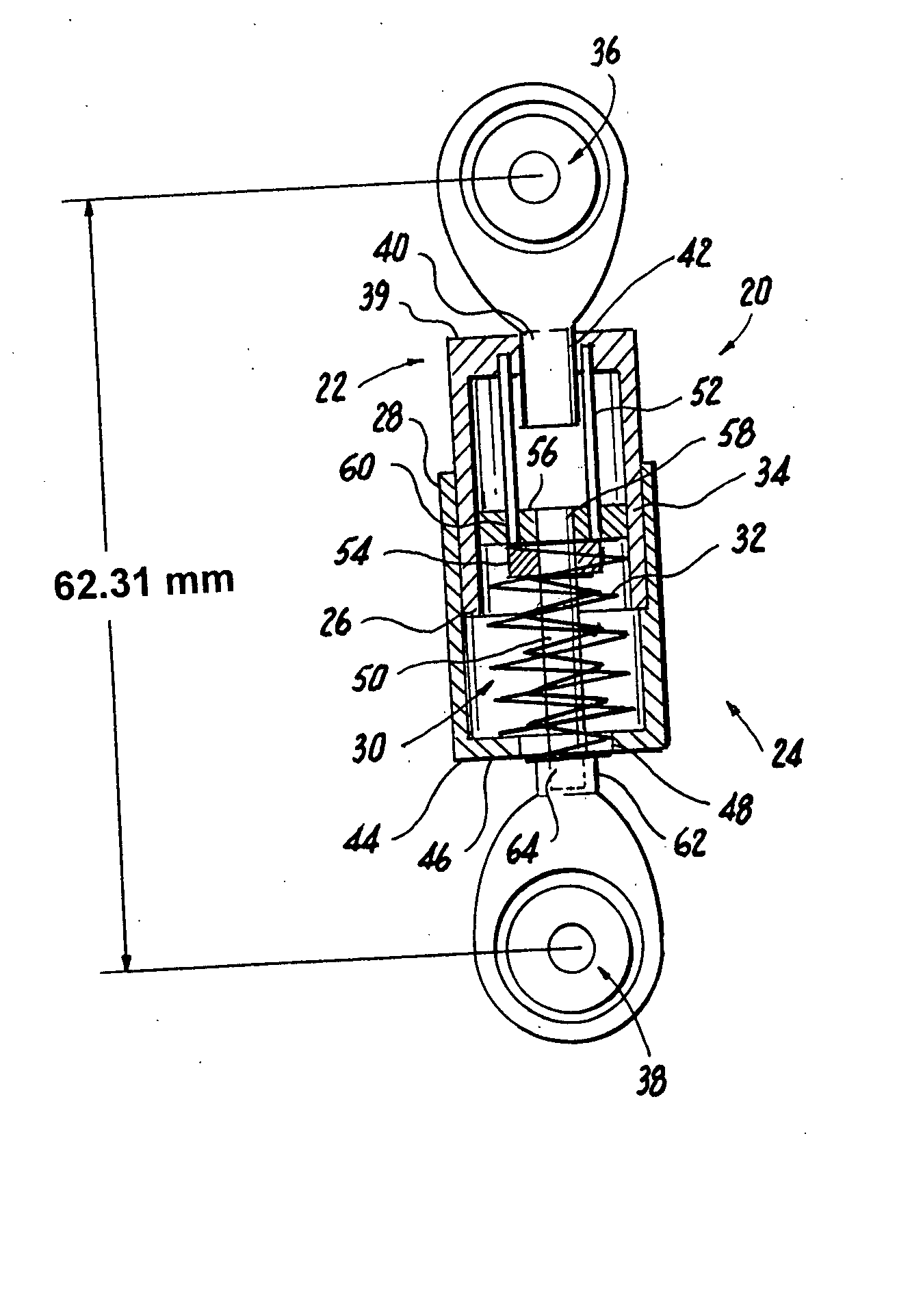

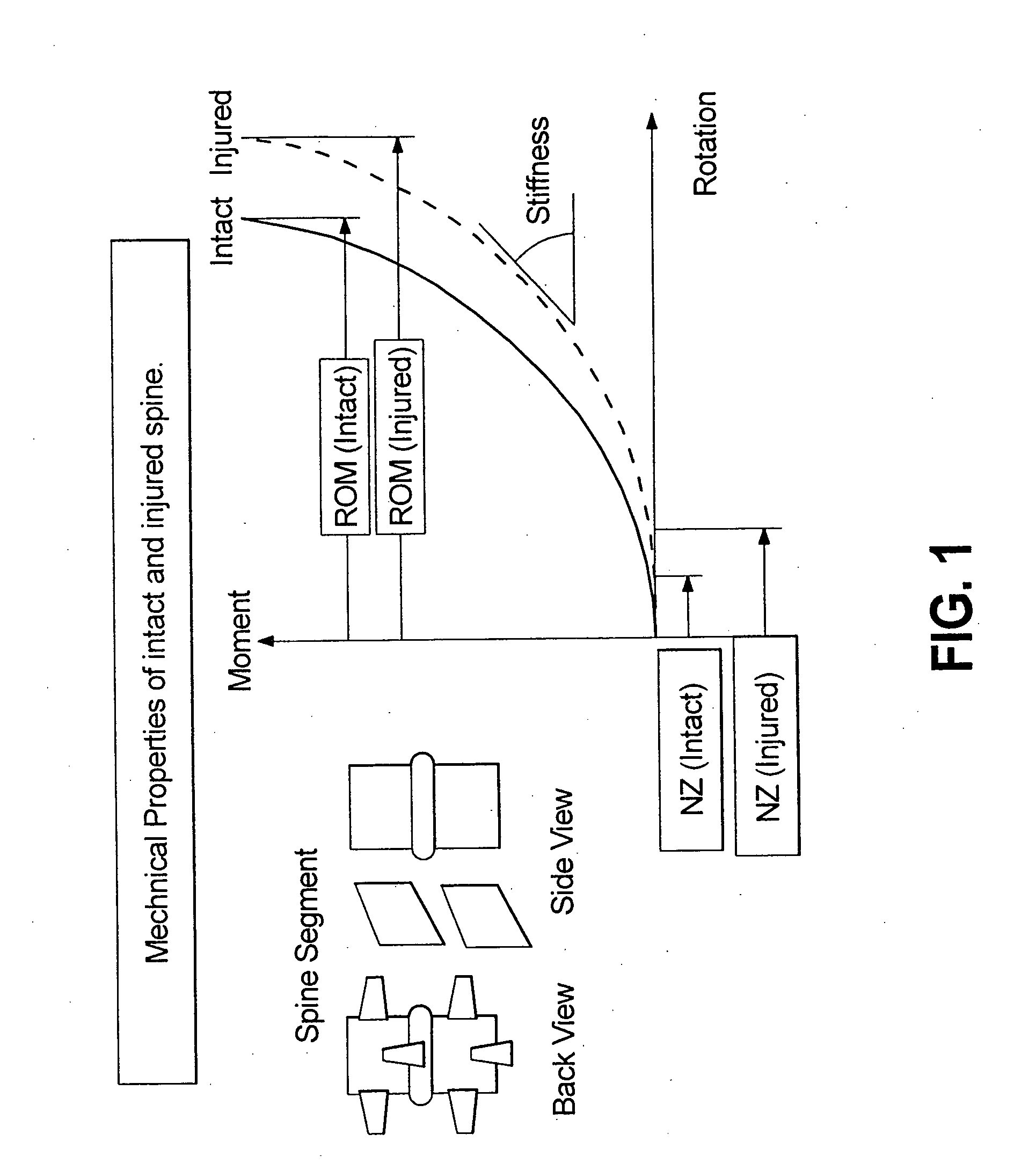

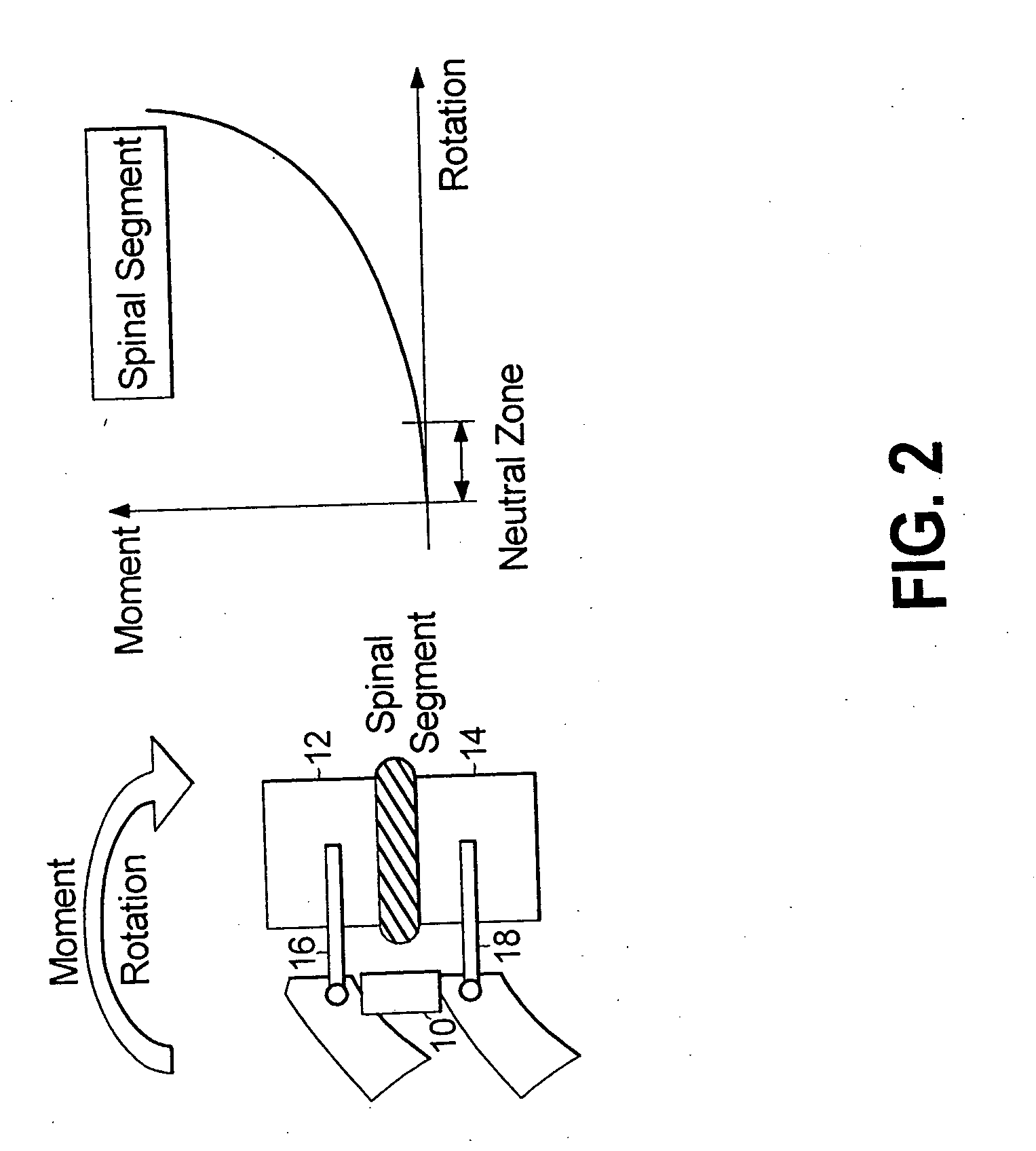

Spinal stabilization devices, systems and methods are provided that include a stabilization member including a first structural member that mounts to a pedicle screw, a second structural member adjacent the first structural member and that can move away therefrom, a resilient element mounted between the structural members and that elongates to accommodate relative movement therebetween, and a travel-limiting structure mounted between the structural members and that defines and imposes upon the stabilization member a maximum distance by which the first and second structural members may be separated. The travel-limiting structure can include an axially inextensible, laterally flexible elongate element, e.g., wire-rope cable, disposed between the structural members. The resilient element extends between respective first ends of the structural members, while the travel-limiting structure can include terminations at opposite ends of the elongate element and mounted to respective second ends of the structural members opposite the first ends thereof.

Owner:RACHIOTEK

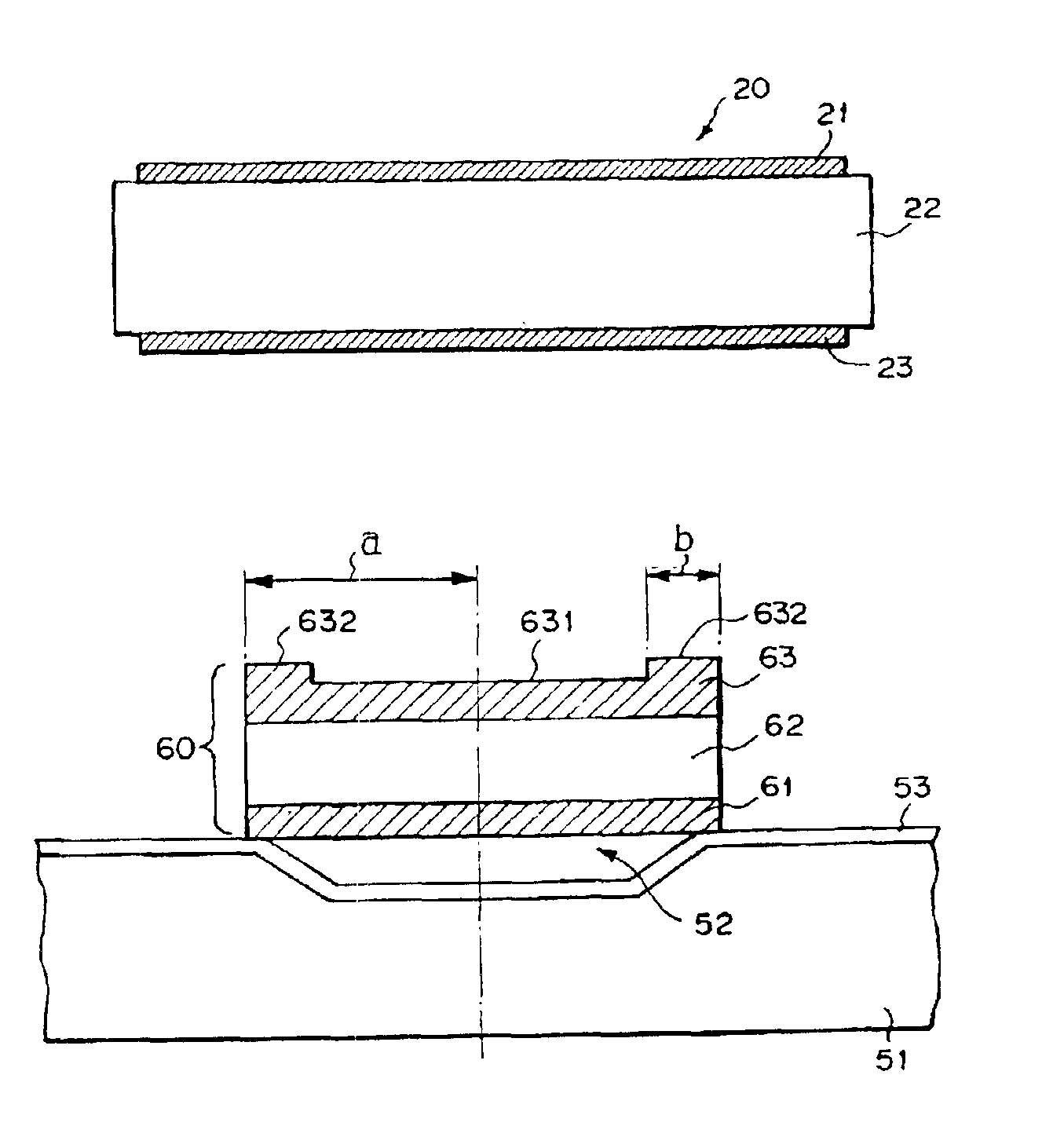

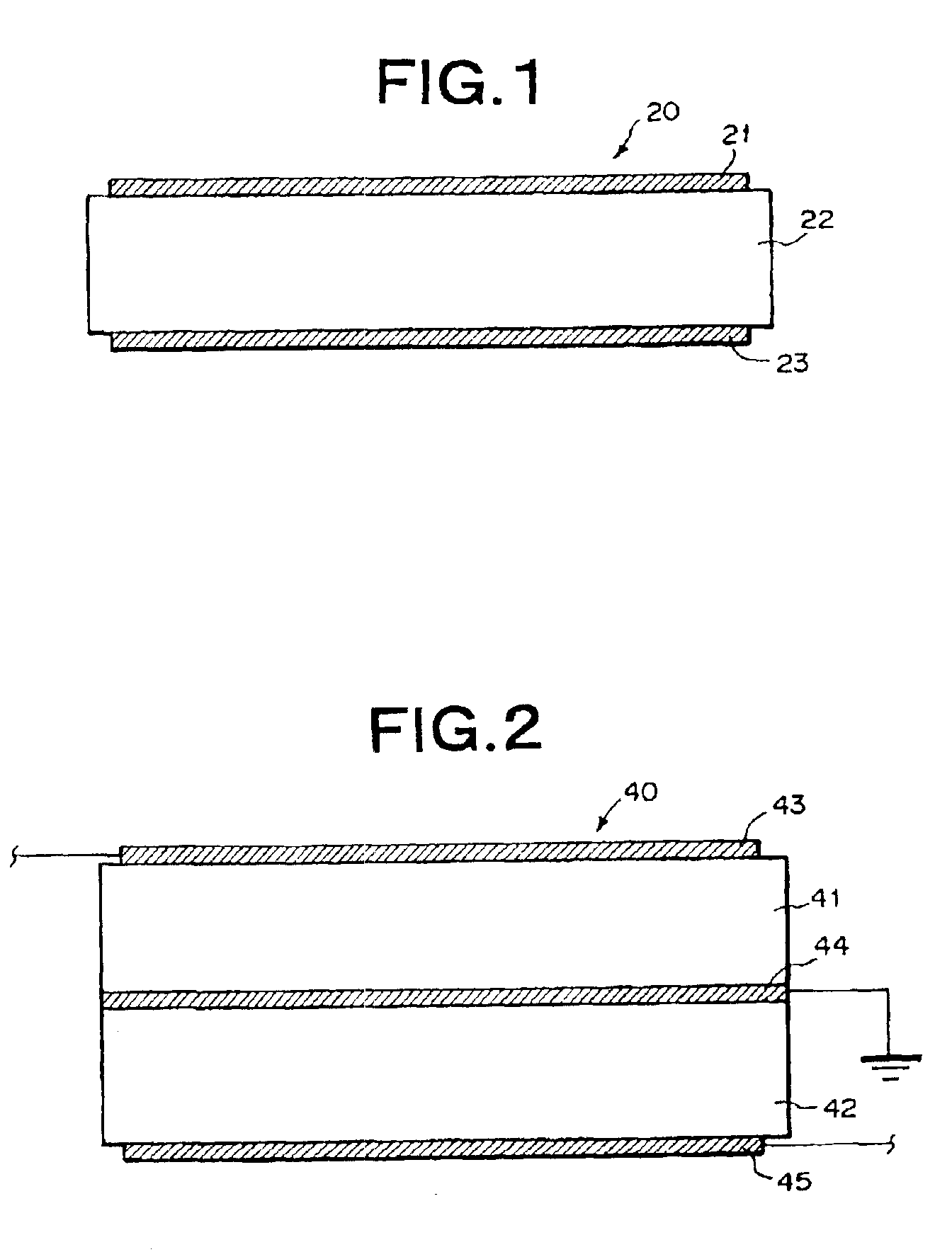

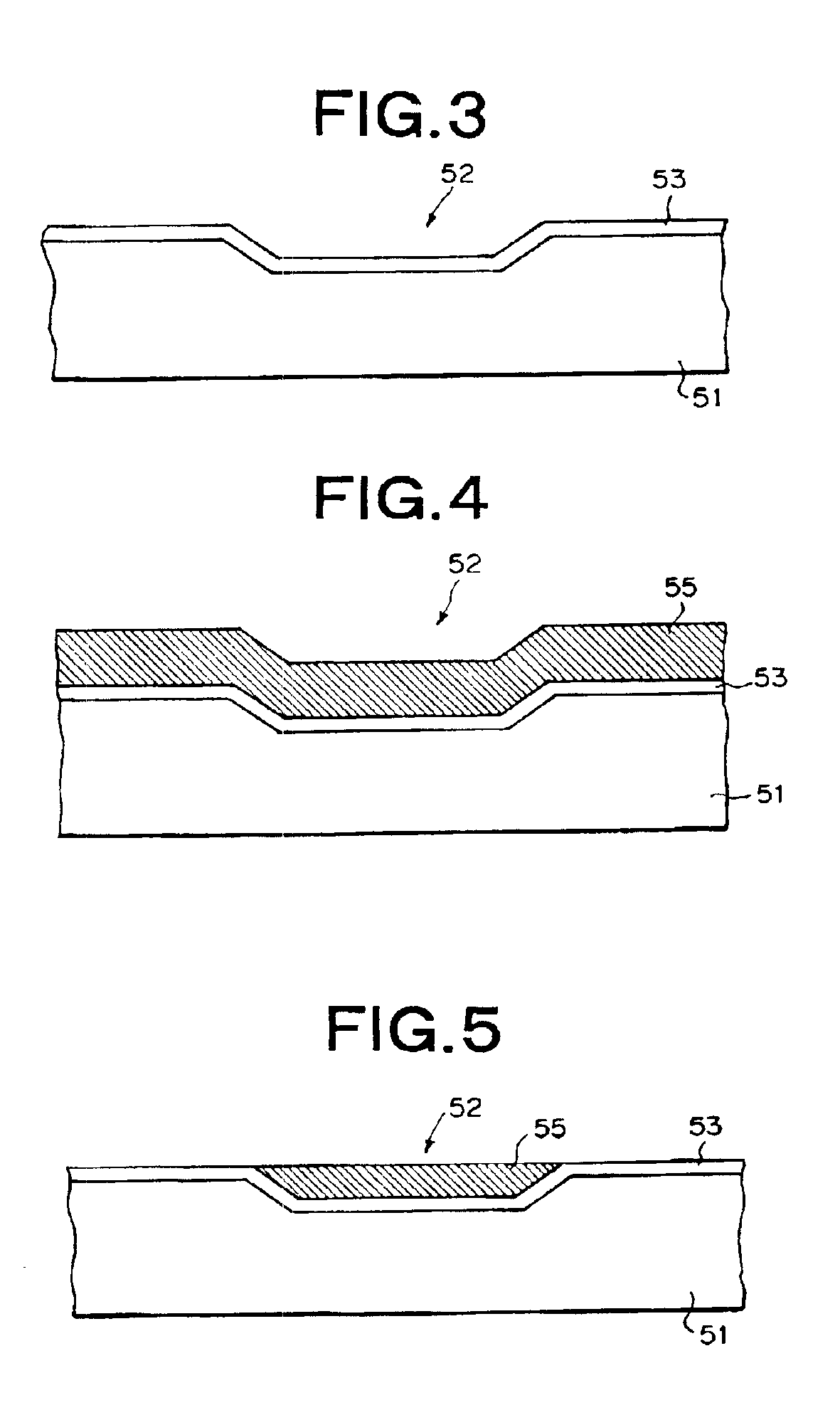

Thin film acoustic resonator and method of producing the same

InactiveUS6842088B2Improve temperature stabilityImprovement factorNanotechPiezoelectric/electrostrictive device manufacture/assemblyThin-film bulk acoustic resonatorElectromechanical coupling coefficient

Owner:MEMS SOLUTIONS INC

Dynamic spine stabilization device with travel-limiting functionality

InactiveUS7811309B2Enhance alignment and durabilityLimit distanceInternal osteosythesisJoint implantsSpinal columnClassical mechanics

Owner:RACHIOTEK

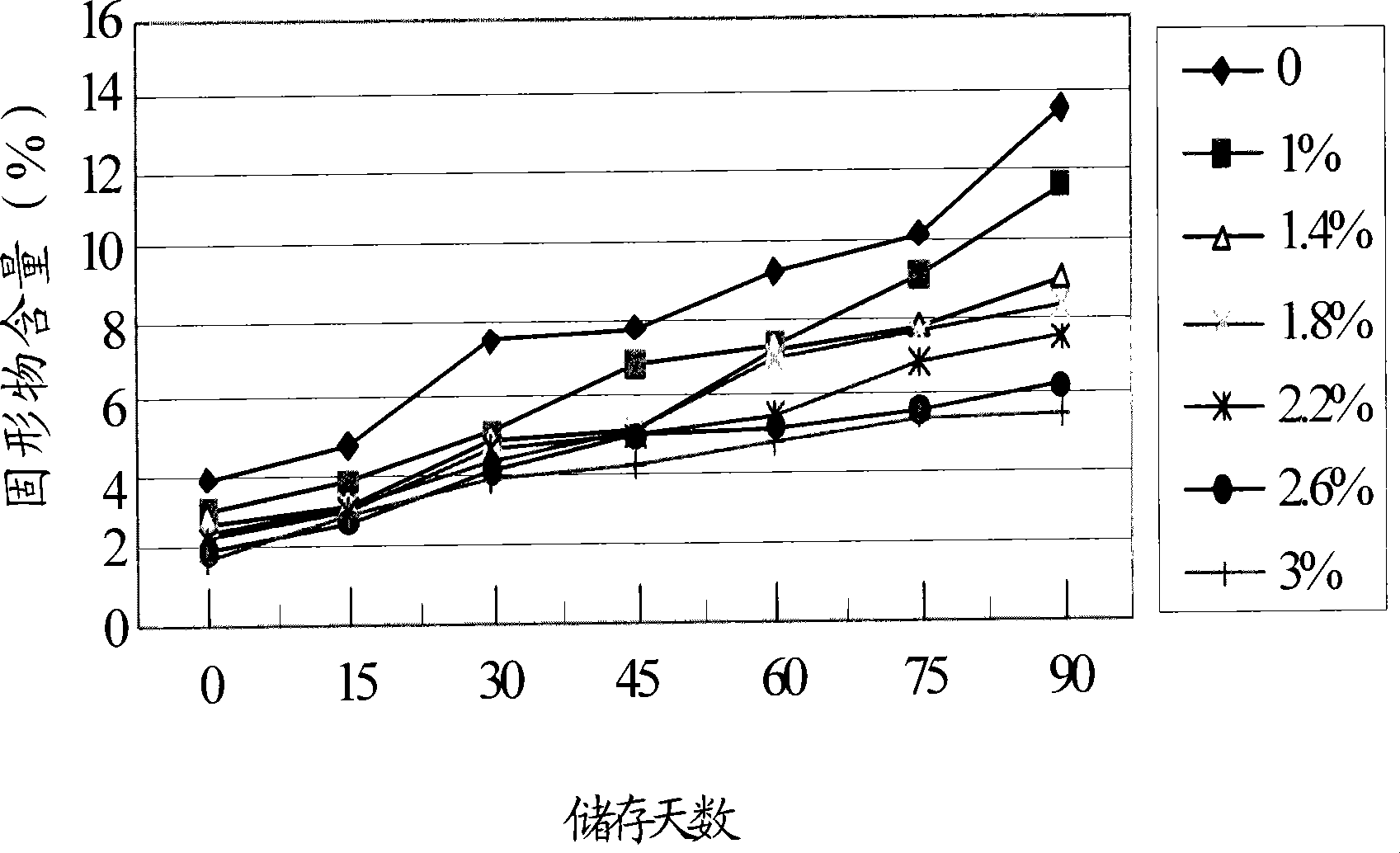

Quick-freezing cooked wheaten food improver and flour, quick-freezing dumpling, noodle and ravioli containing the same

The invention relates to a modifying agent for fast-freezing wheaten food, which contains: (A) 20 to 50 weight portions of sorbierite; (B) at least one kind of 3.5 to 20 weight portions of a thickening agent; (C) at least one kind of 10.2 to 55 weight portions of a flour gluten fortifier; and (D) at least one kind of 10.5 to 38 weight portions of phosphate. A finished product of the fast-freezing wheaten food containing the modifying agent has the skin which is difficult to crack and change color, has good water boiling performance, prolongs freshness period, and has the advantages of bright skin, smooth taste, good elasticity, and no soup turbidness at the same time. And the modifying agent has the advantages of low price and so on.

Owner:ANGELYEAST CO LTD

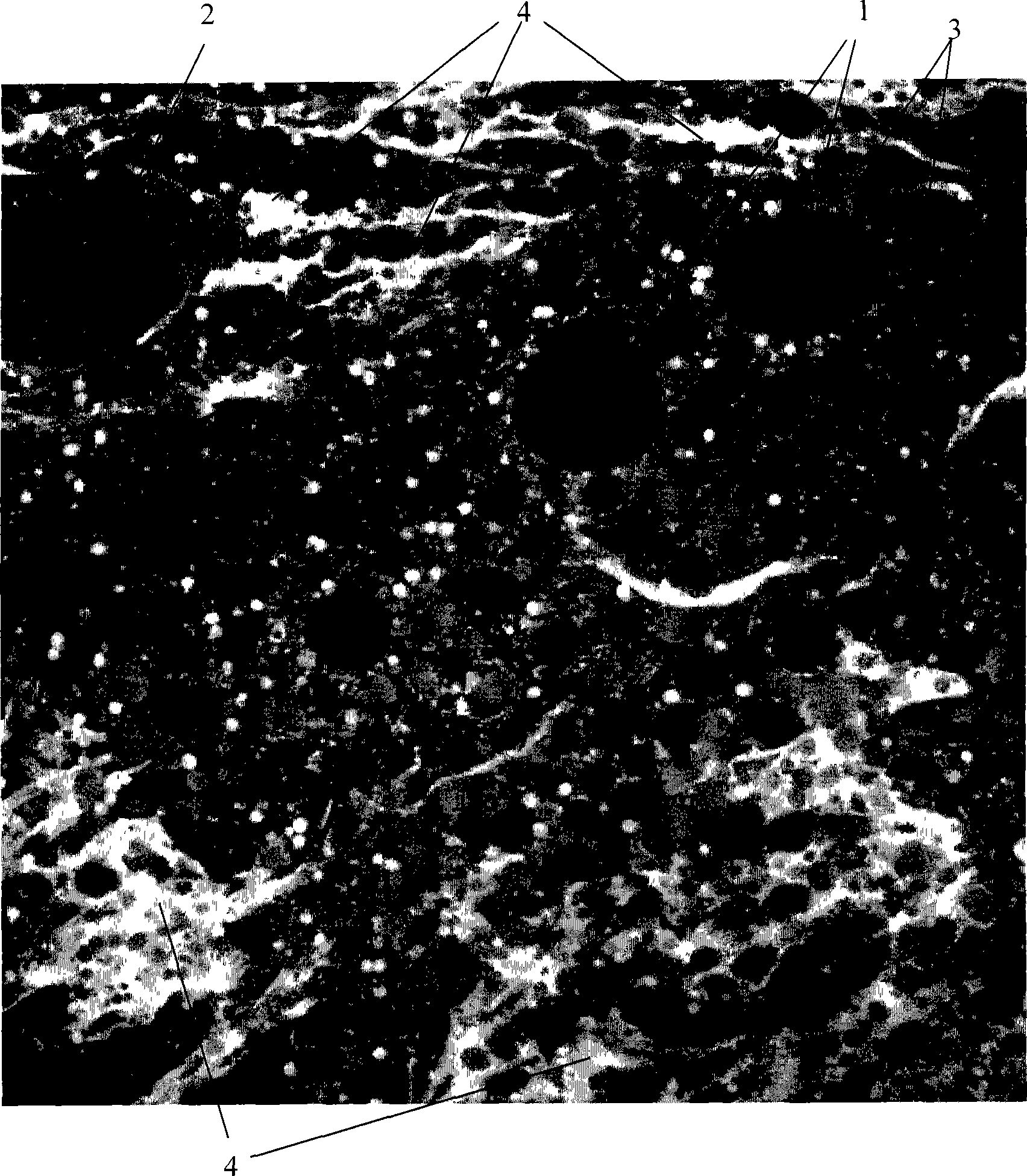

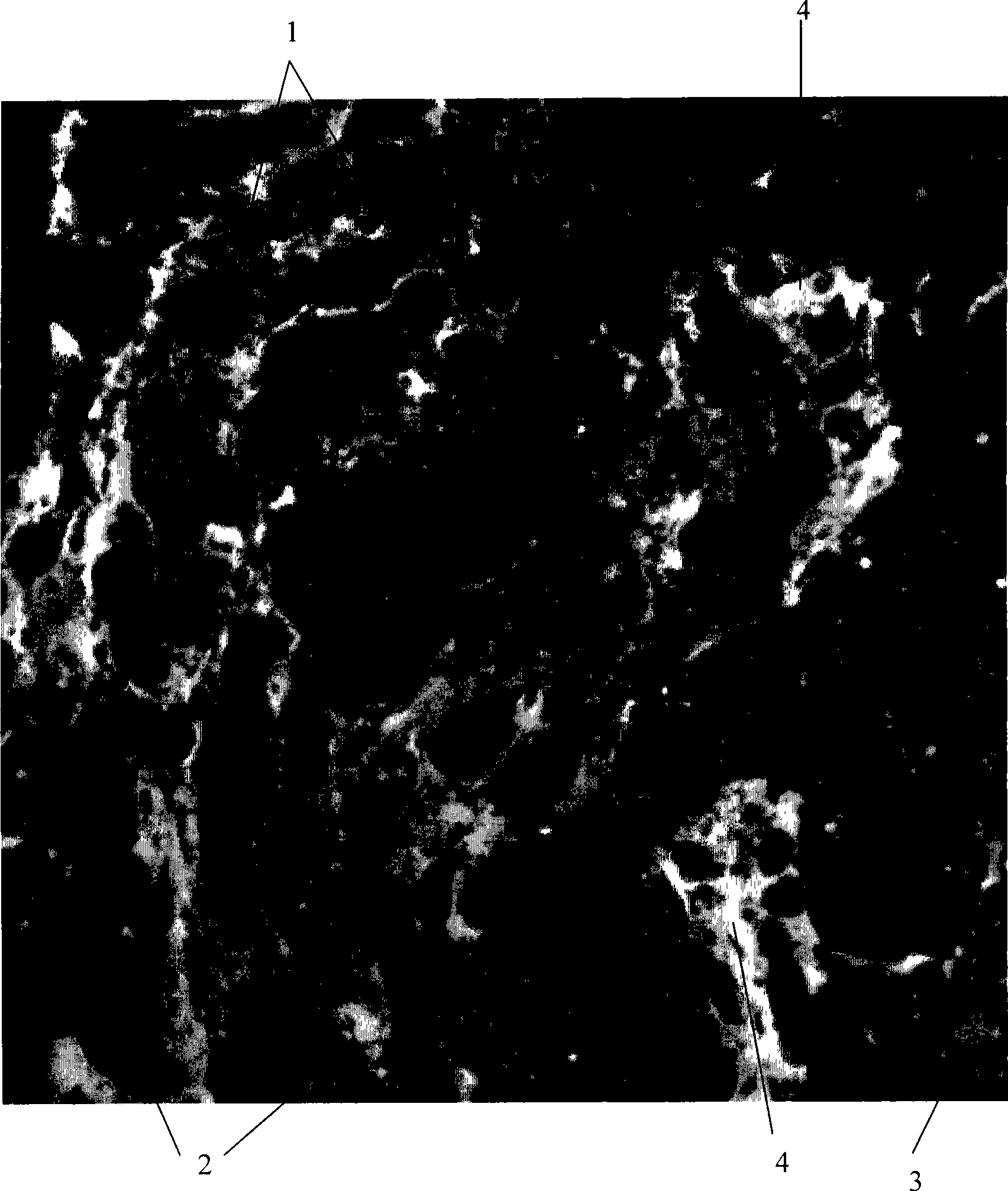

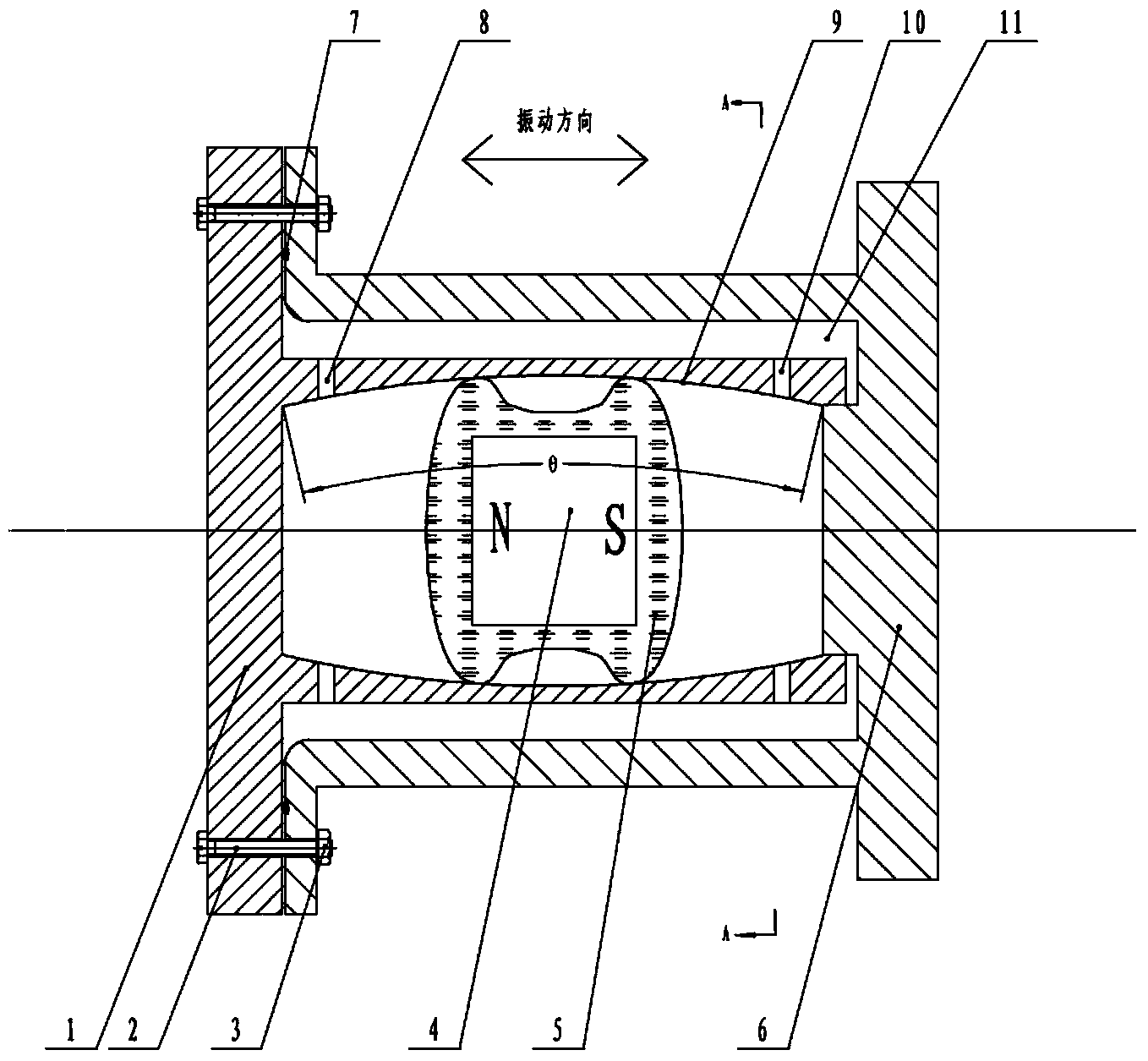

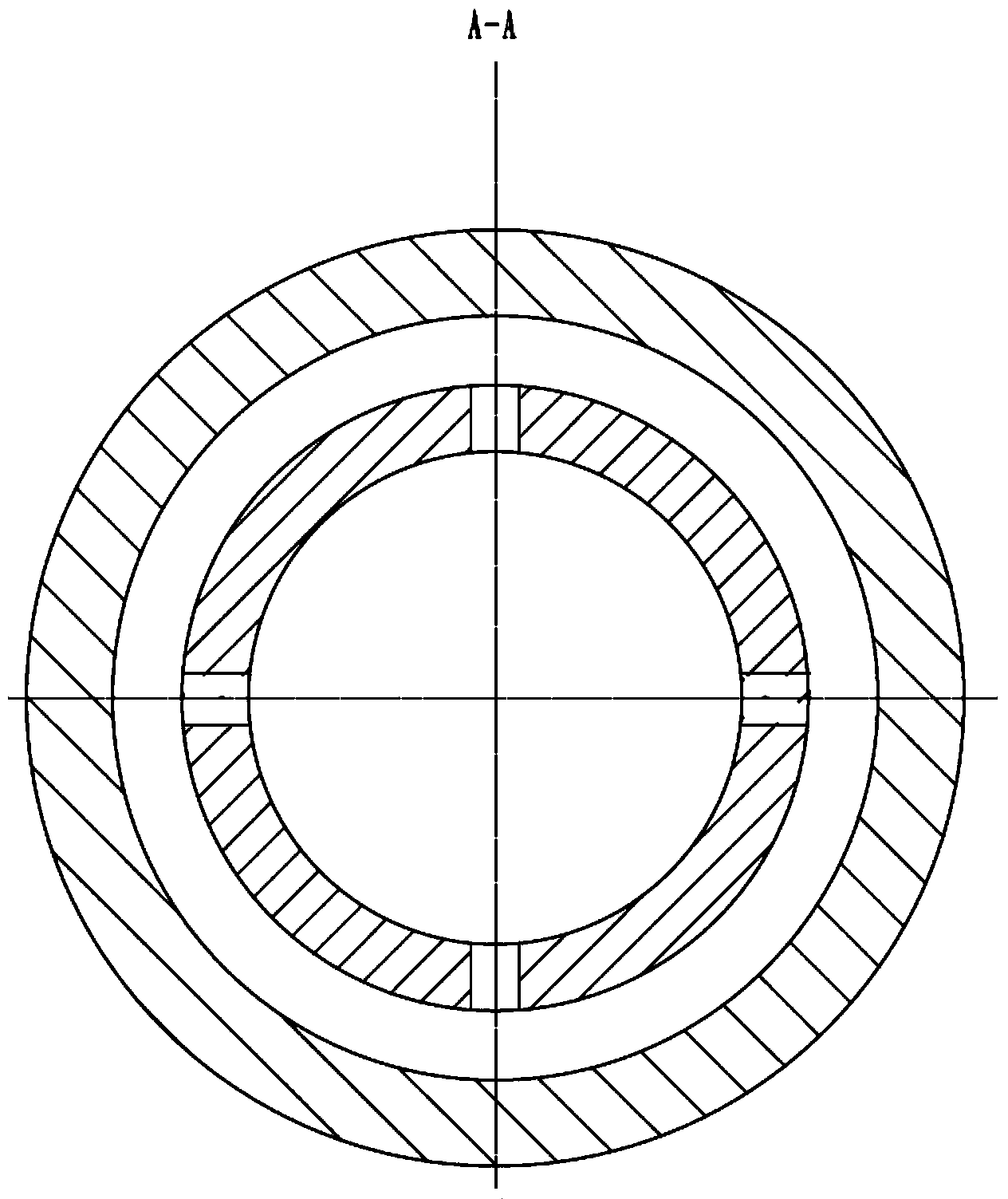

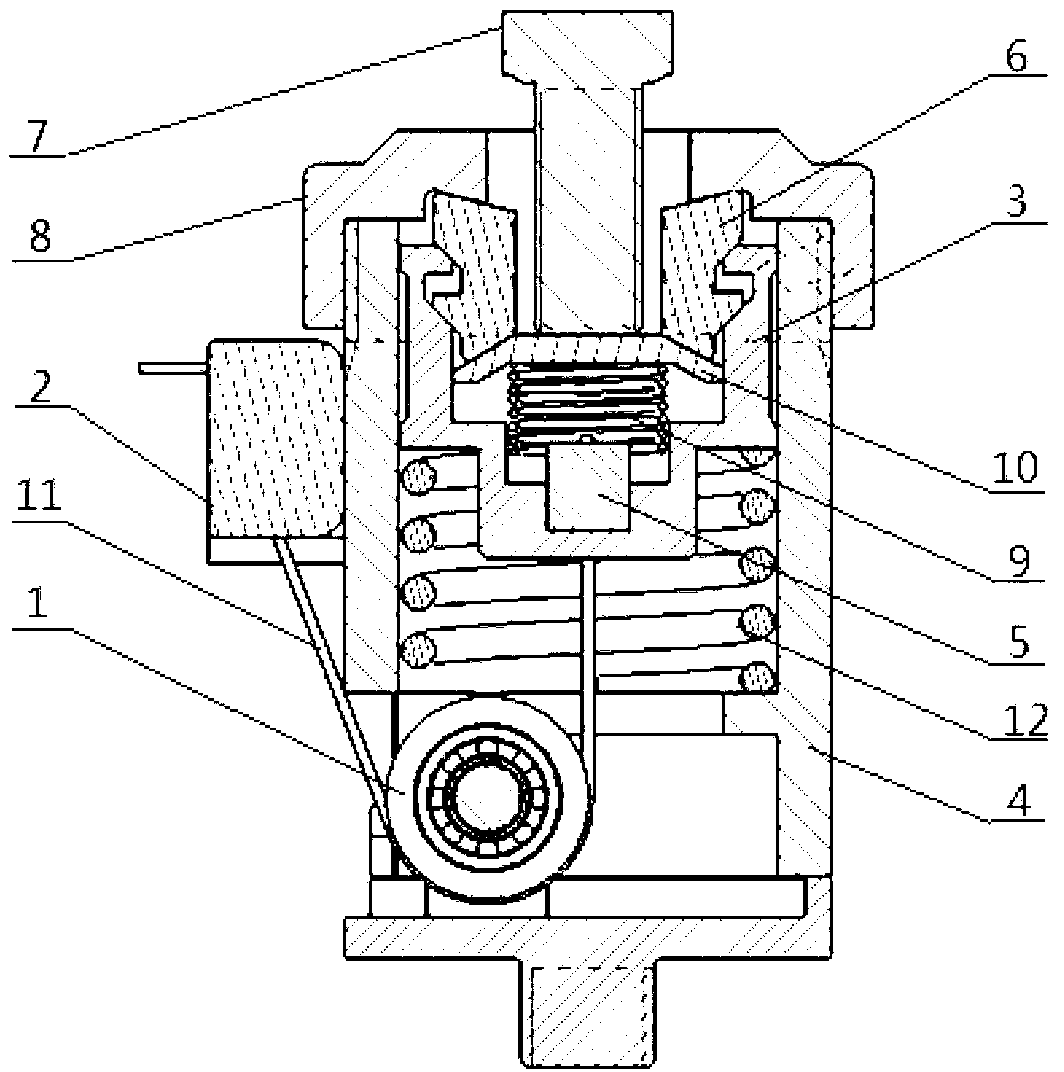

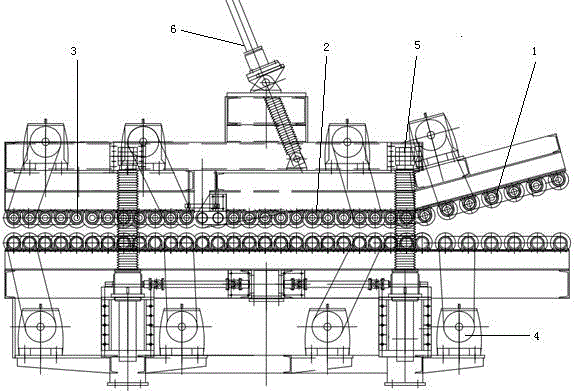

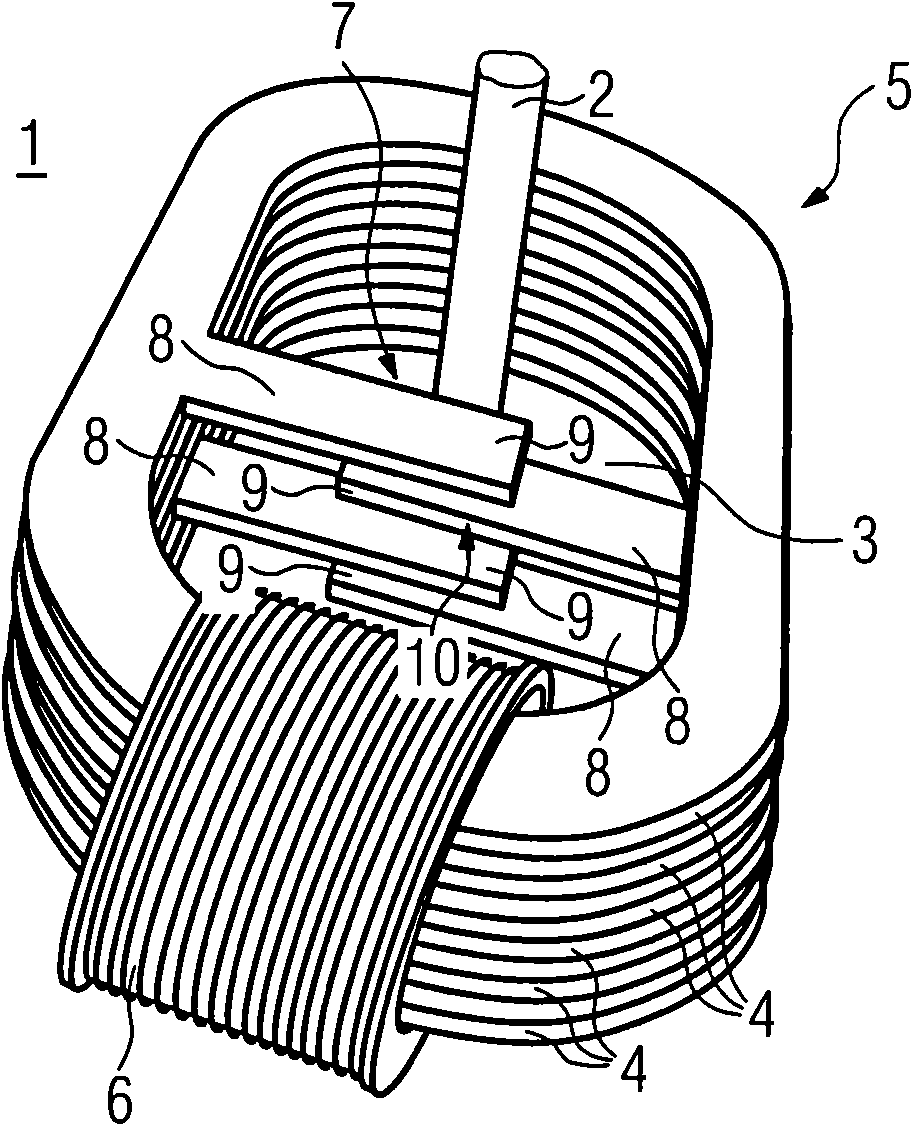

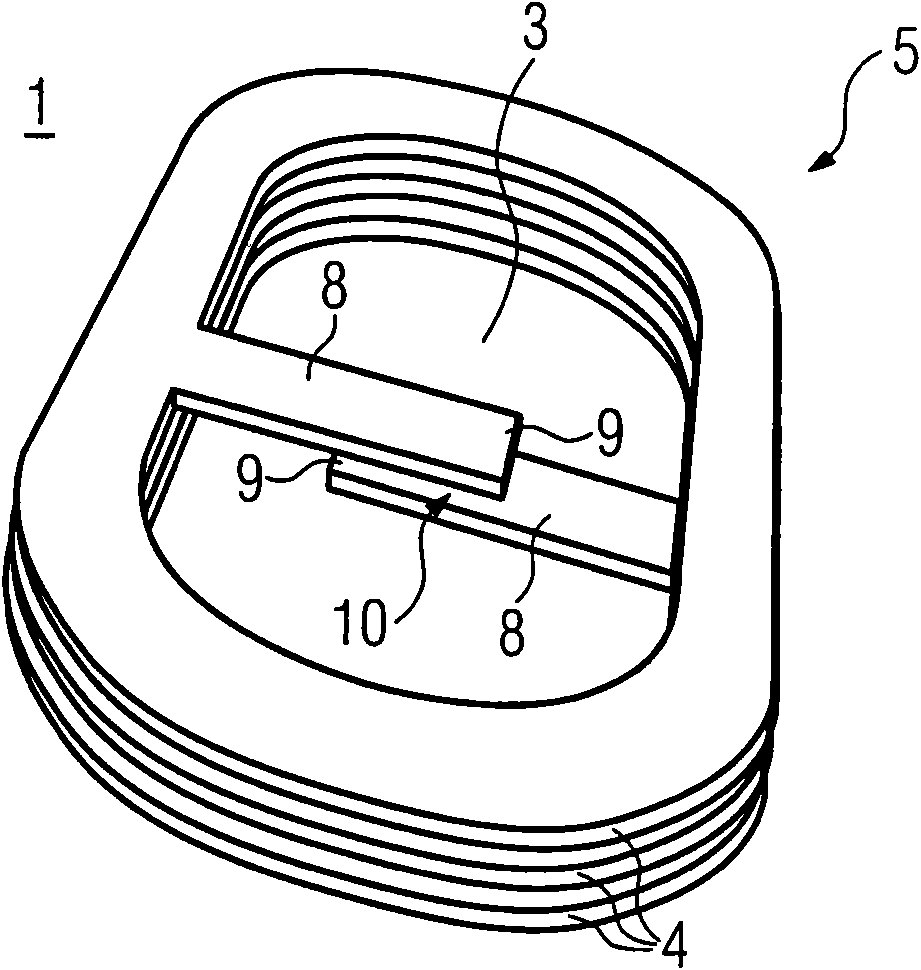

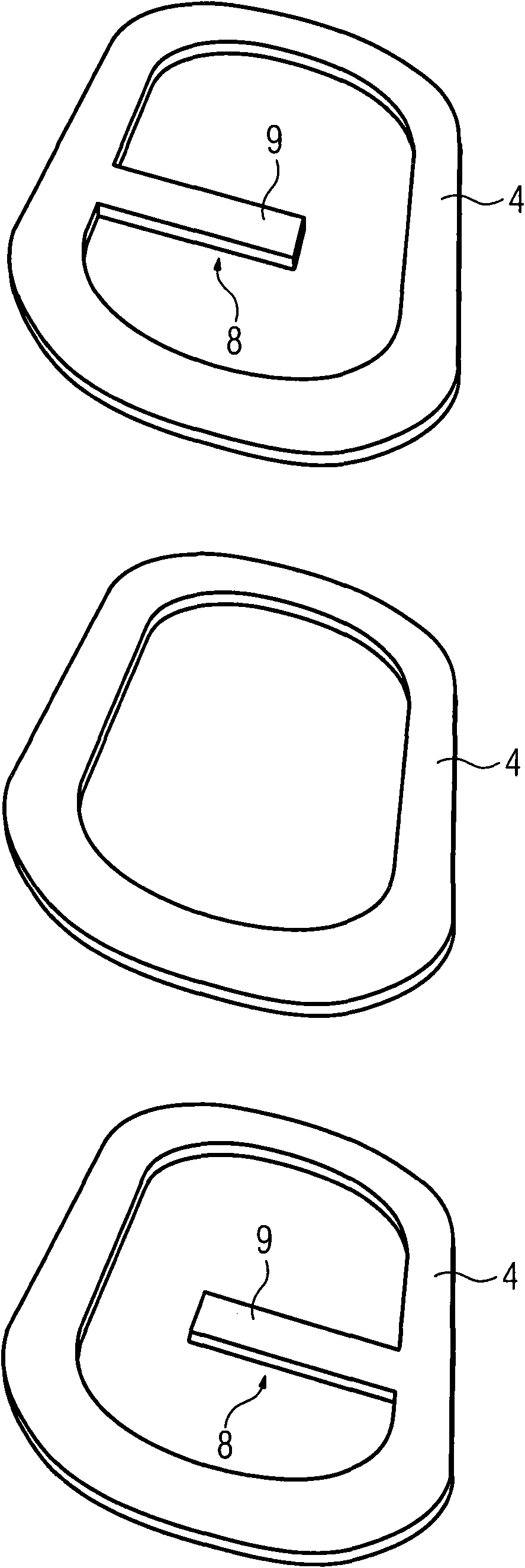

Magnetic liquid damping shock absorber with arc-shaped inner wall axial section

InactiveCN104074903ALittle elasticityIncreased viscous frictionMagnetic springsMagnetic liquidsEngineering

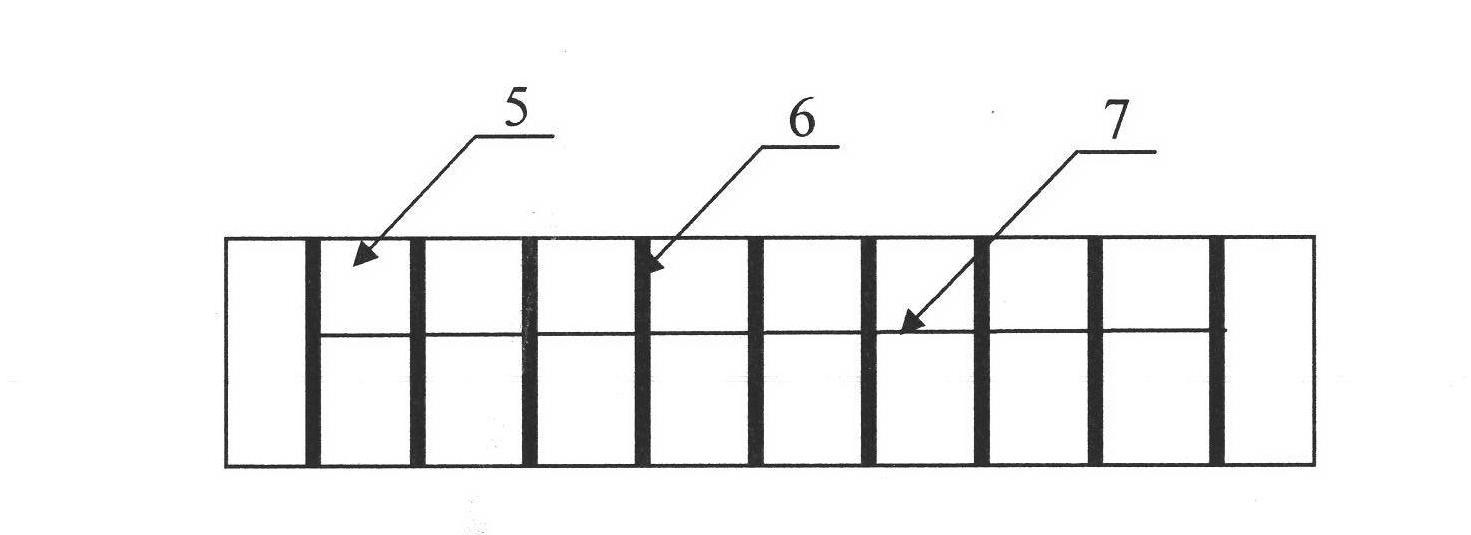

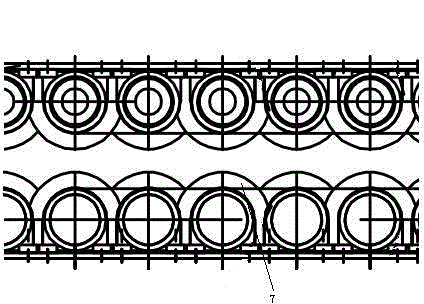

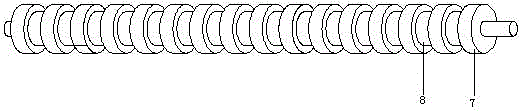

The invention discloses a magnetic liquid damping shock absorber with an arc-shaped inner wall axial section, which is suitable for shock absorption for a long object in a spacecraft. The device comprises a non-magnetic-conducting shell (1), a bolt (2), a nut (3), a permanent magnet (4), a magnetic liquid (5), a non-magnetic housing (6), an O-shaped ring (7), air hole (8), a shell inner wall surface (9) with an arc-shaped inner wall axial section, an air hole (10) and an interlayer air gap (11), wherein connection among the various portions above is as follows: the permanent magnet (4) is installed in the non-magnetic-conducting shell (1), the magnetic liquid is coated on the permanent magnet (4), and the non-magnetic housing (6) and the non-magnetic-conducting shell (1) are sealed by the O-shaped ring (7), and rigidly connected by the bolt (2) and the nut (3); the inner wall axial section of the non-magnetic-conducting shell (1) is arc-shaped, and the corresponding central angle theta is 1-15 degrees. The device is quite sensitive to an inertia force, and capable of carrying out effective shock absorption on shock with the characteristics of a low frequency, a small displacement and a low accelerated speed.

Owner:BEIJING JIAOTONG UNIV

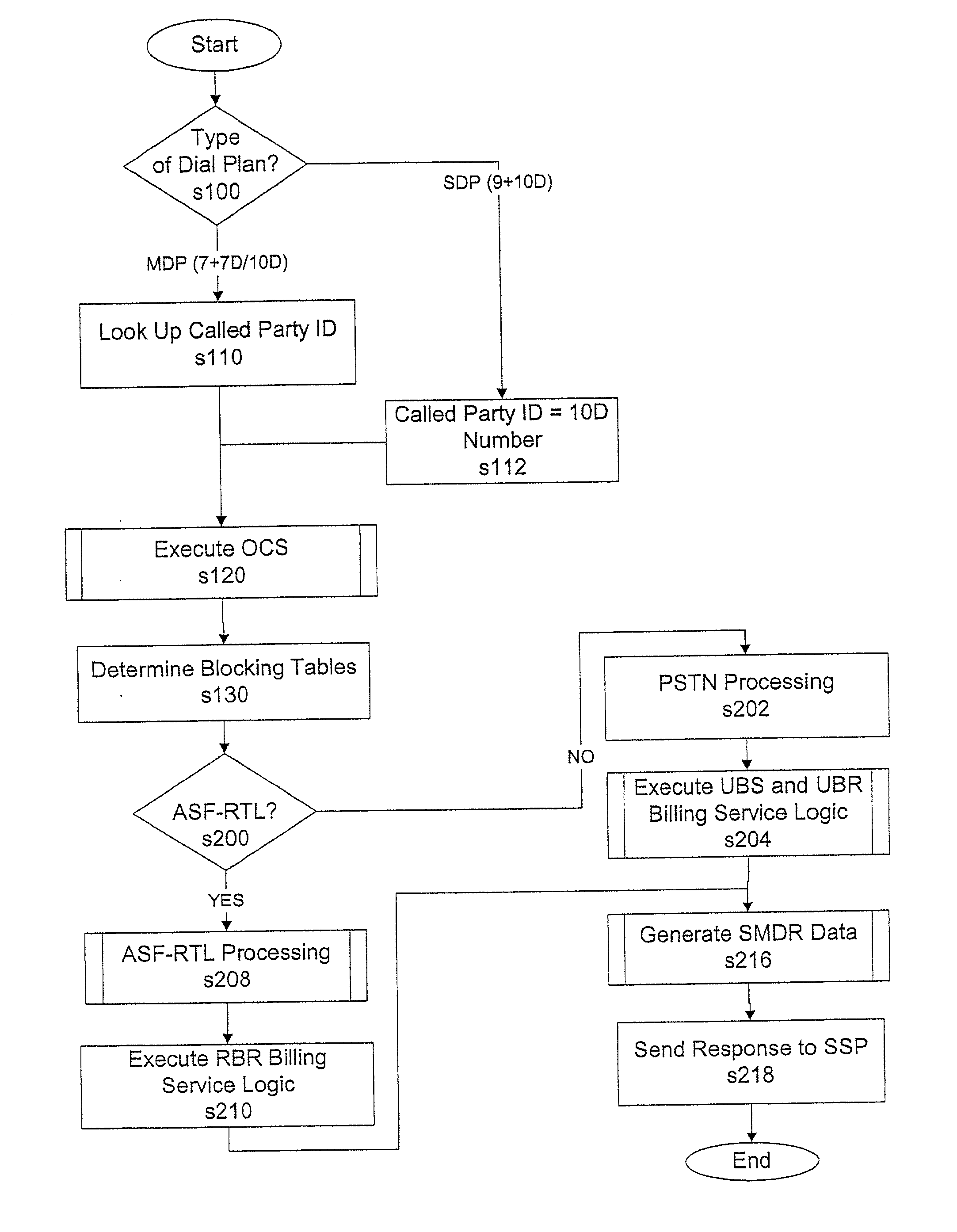

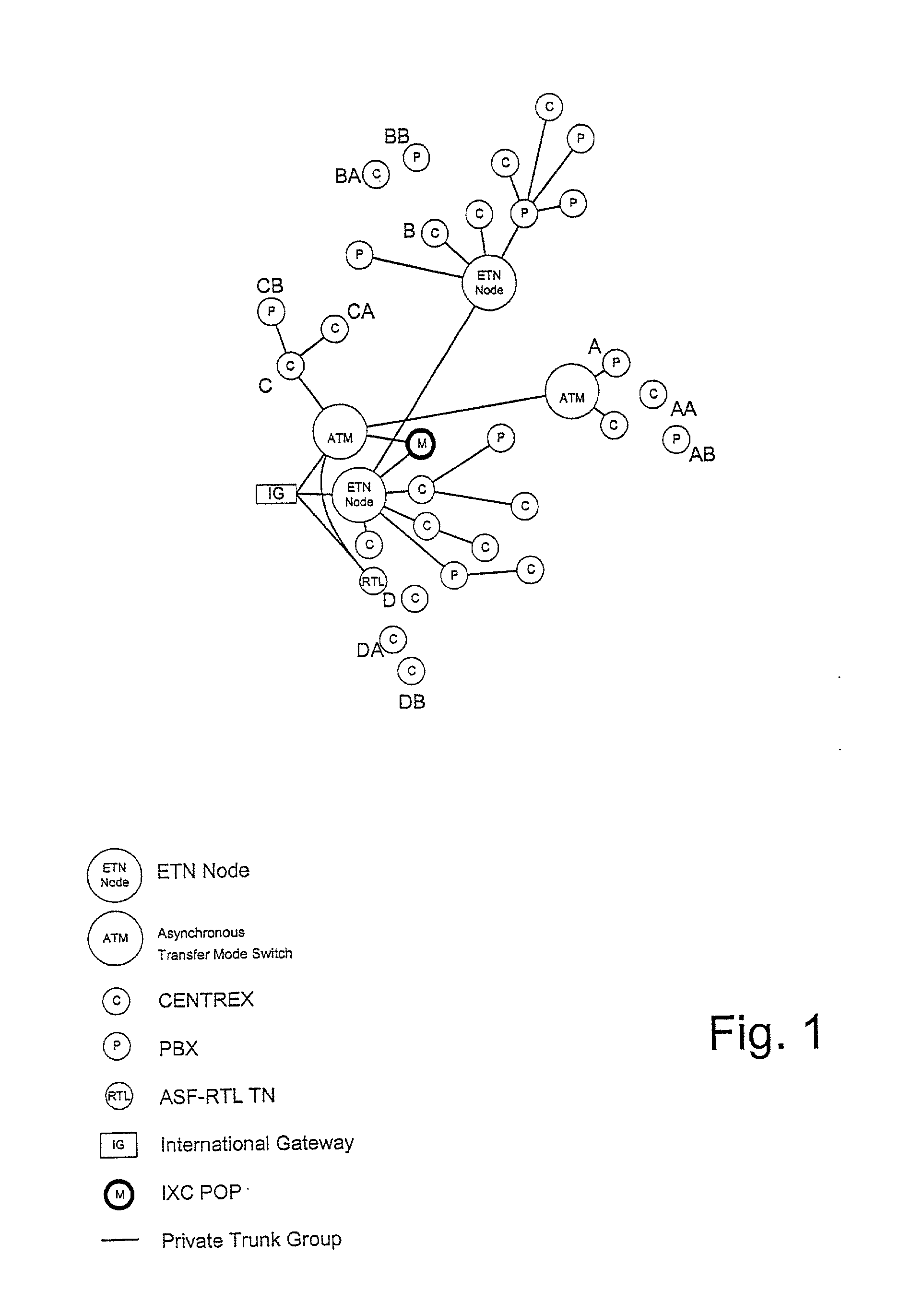

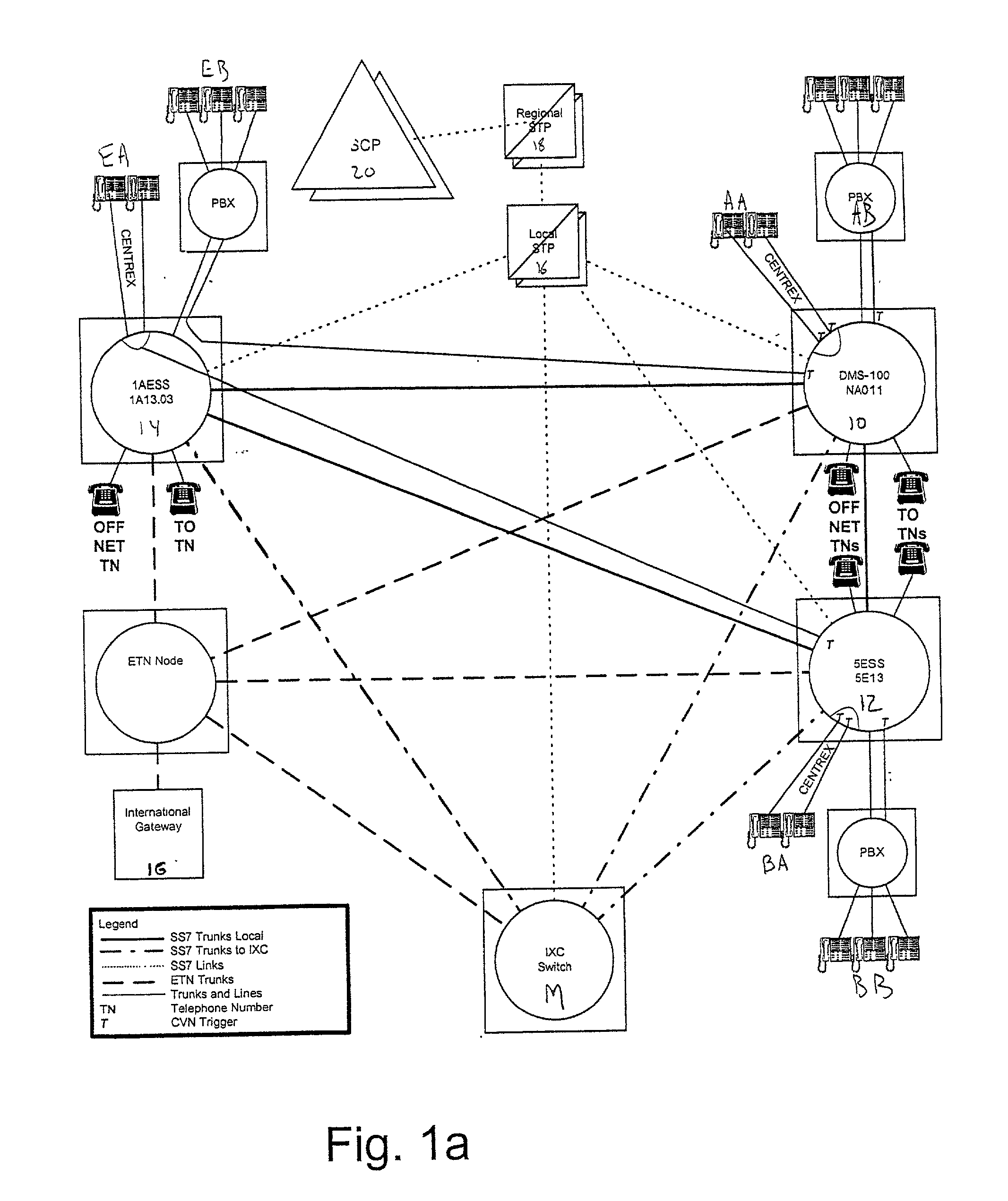

Dialing plan service including outgoing call screening, remote tie-line routing, call data reporting and billing

InactiveUS20020136374A1Reduce network expenseAddress rising pricesAutomatic exchangesScreening callService control

A method and system include screening and routing telephone calls, generating calling data reports and discounting billing for a customer's wide area centrex / PBX network, which includes an abbreviated dialing plan. A service control point (SCP) determines whether to block an outgoing call based on stored blocking tables and a privilege class of the calling station. The SCP determines whether to route the call through a private trunk group from a host switch to a private facility, and through an alternative trunk group when the private trunk group is unavailable. The SCP determines whether the call is eligible for discounted billing and generates a billing record, which is modified by a service switching point to indicate the discount. The SCP also samples calling data from service switching points and transmits the sampled data to a front end processor for formatting into station message detail recording (SMDR) data.

Owner:MIND FUSION LLC

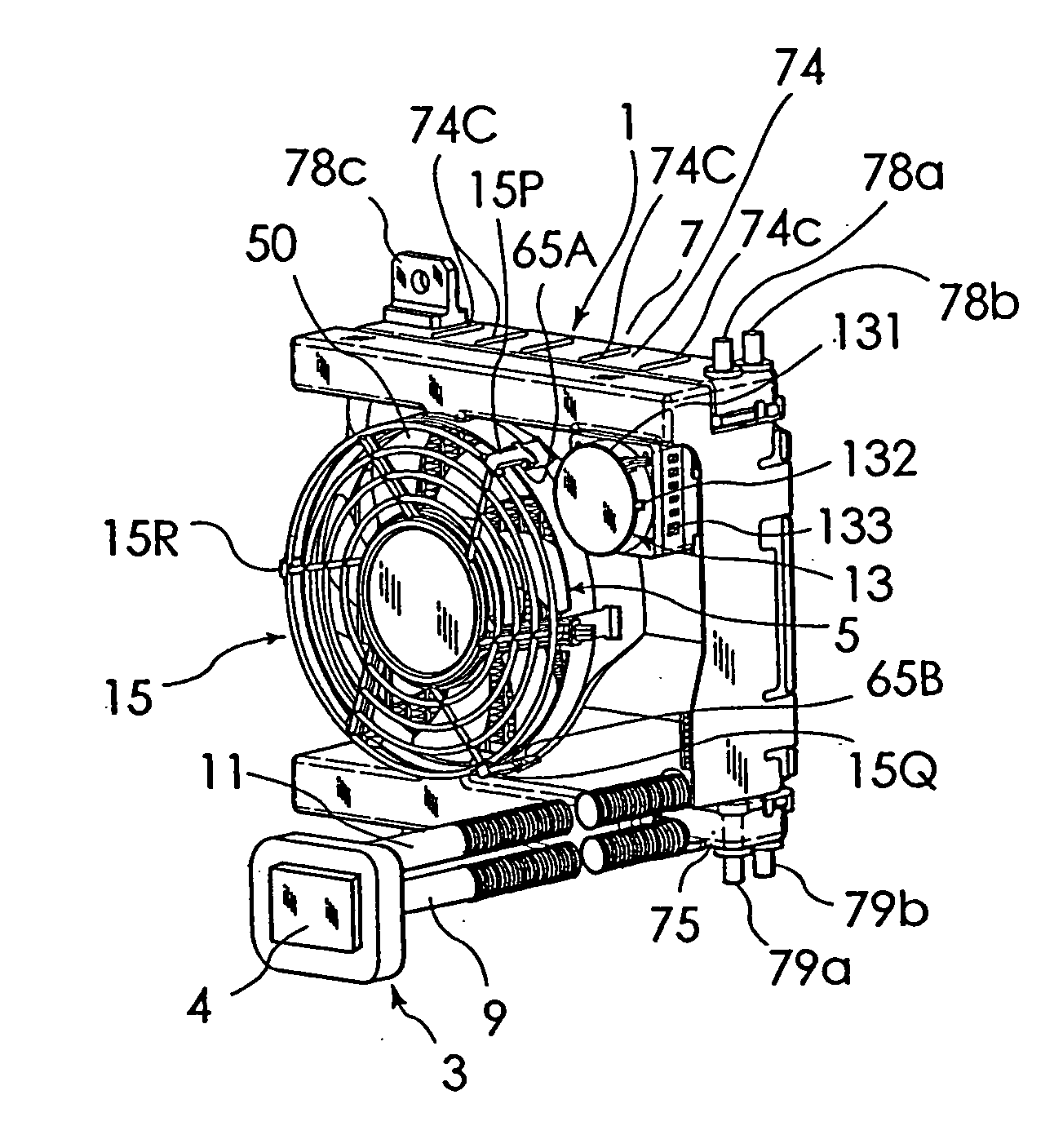

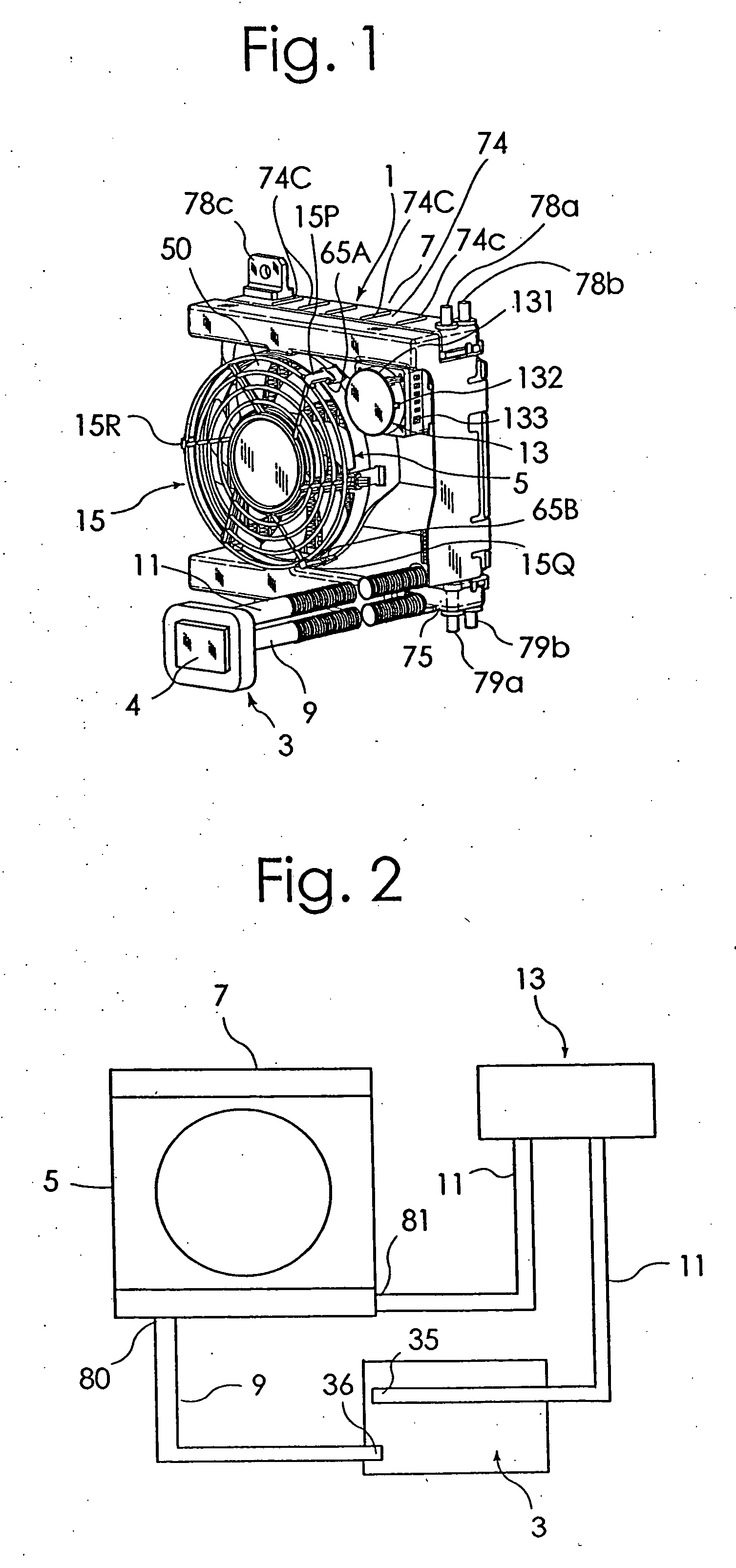

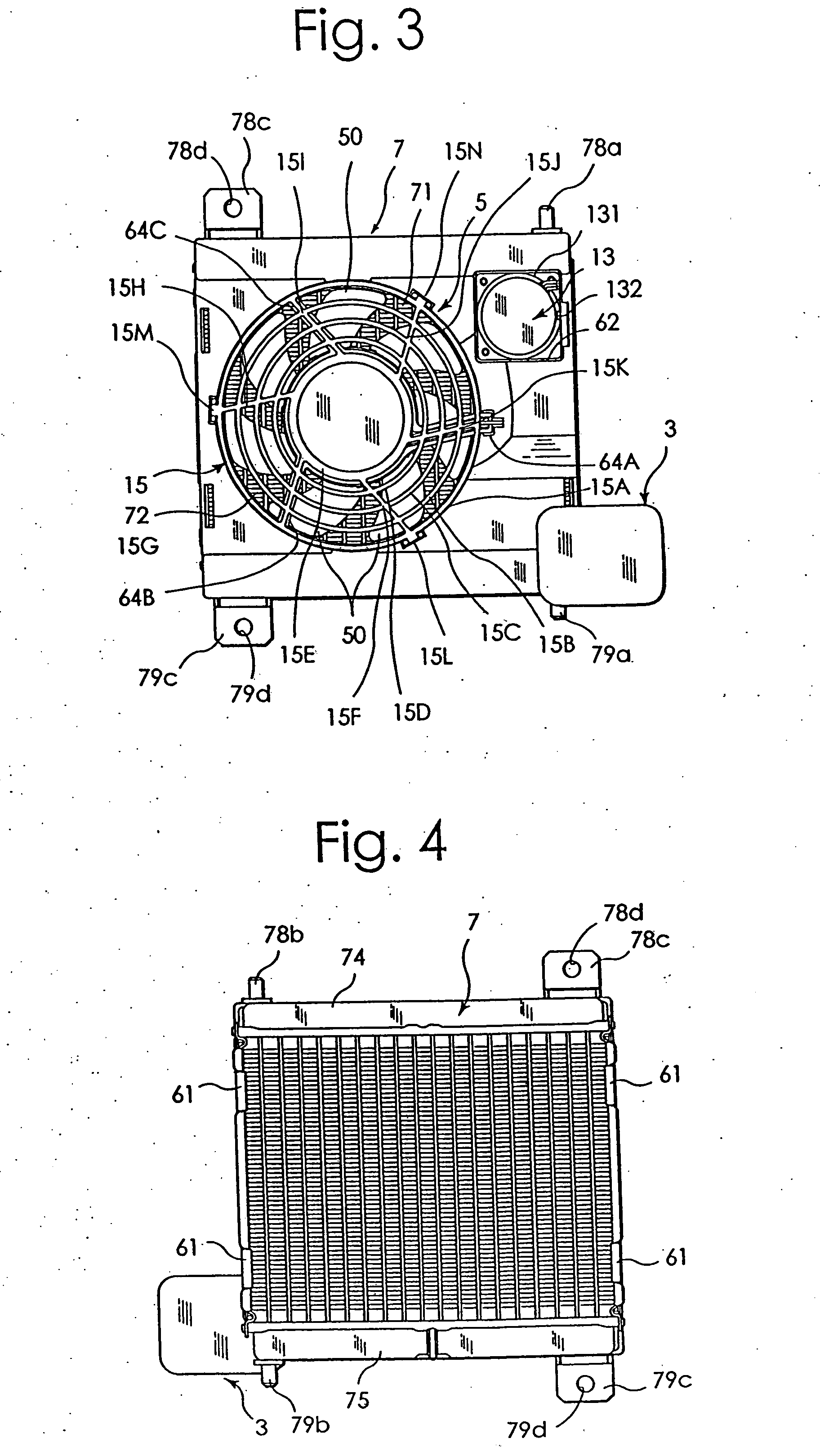

Electronic component cooling apparatus

ActiveUS20050168939A1Not to damageHigh mechanical strengthDomestic cooling apparatusDigital data processing detailsNuclear engineeringElectronic component

A small water-cooling type electronic component cooling apparatus is provided. The electronic component cooling apparatus comprises a so-called water-cooling heat sink 3 , a radiator 7 cooled by an electric fan 5 , first and second coolant paths 9, 11 for circulating a coolant between the heat sink 3 and the radiator 7 , and an electric pump 13 to supply a moving energy to the coolant. The electric pump 13 is arranged at a position facing the heat-radiating portion of the radiator 7.

Owner:SANYO DENKI CO LTD +1

Softrock-like material and preparation method

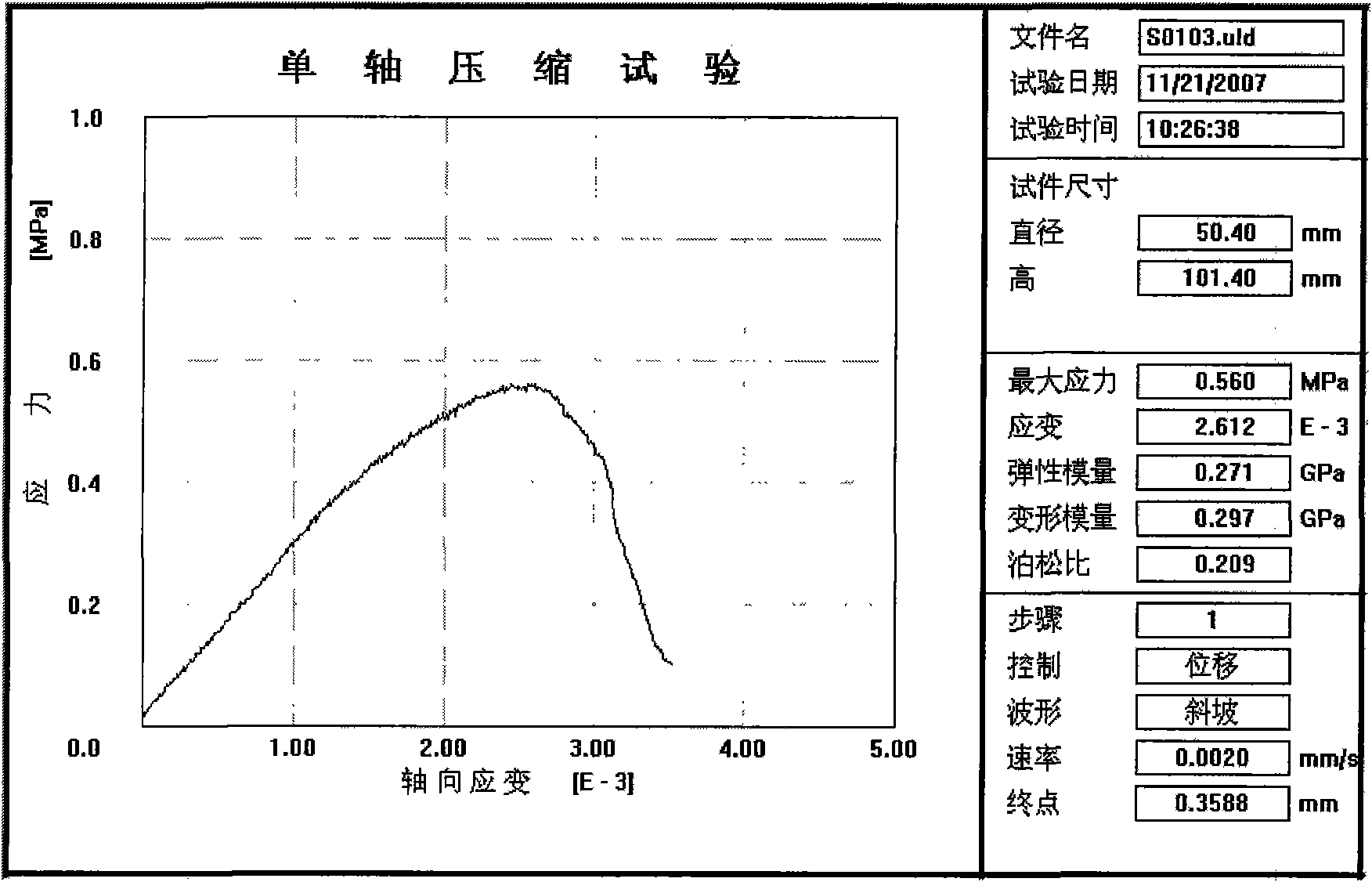

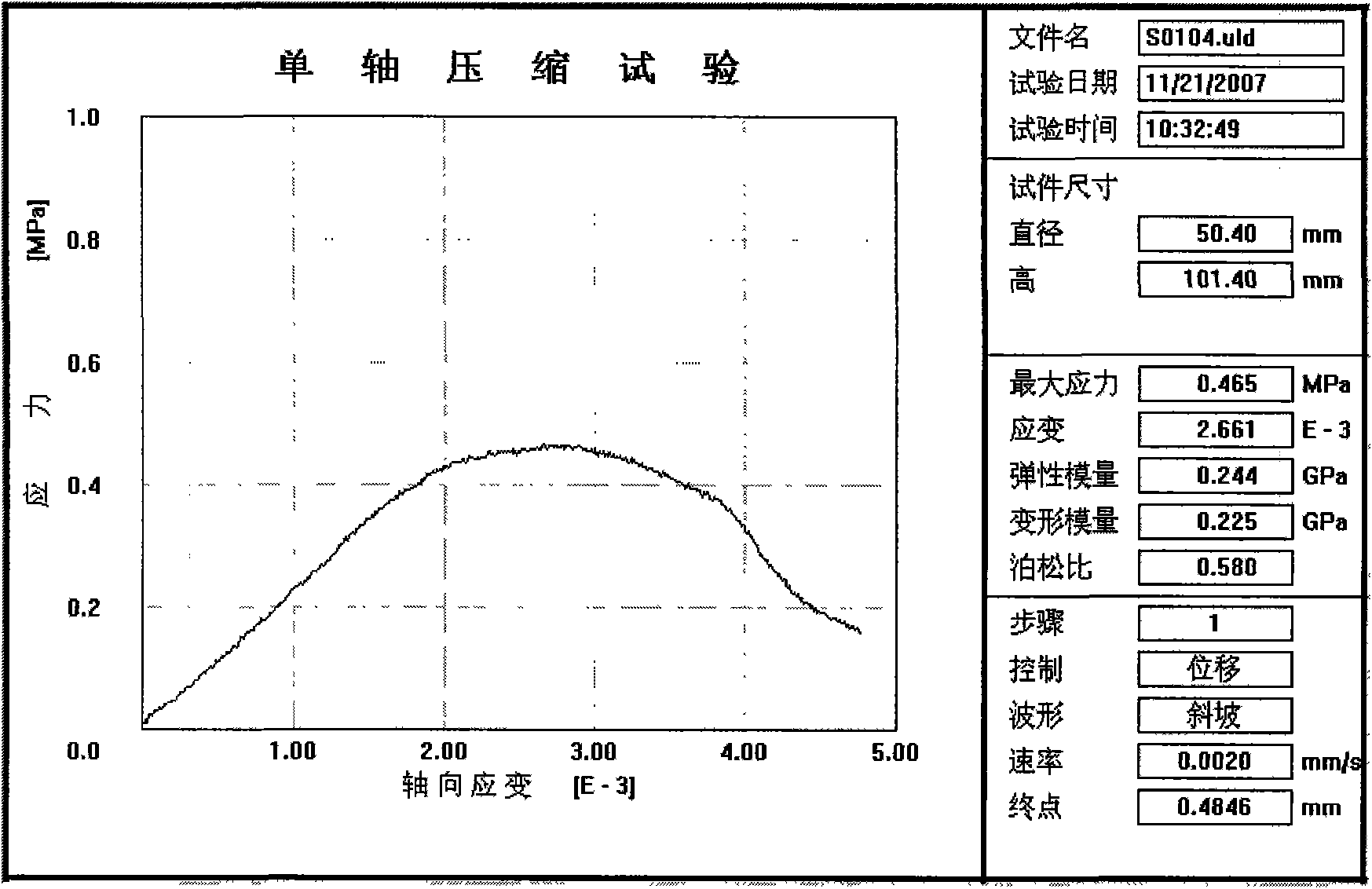

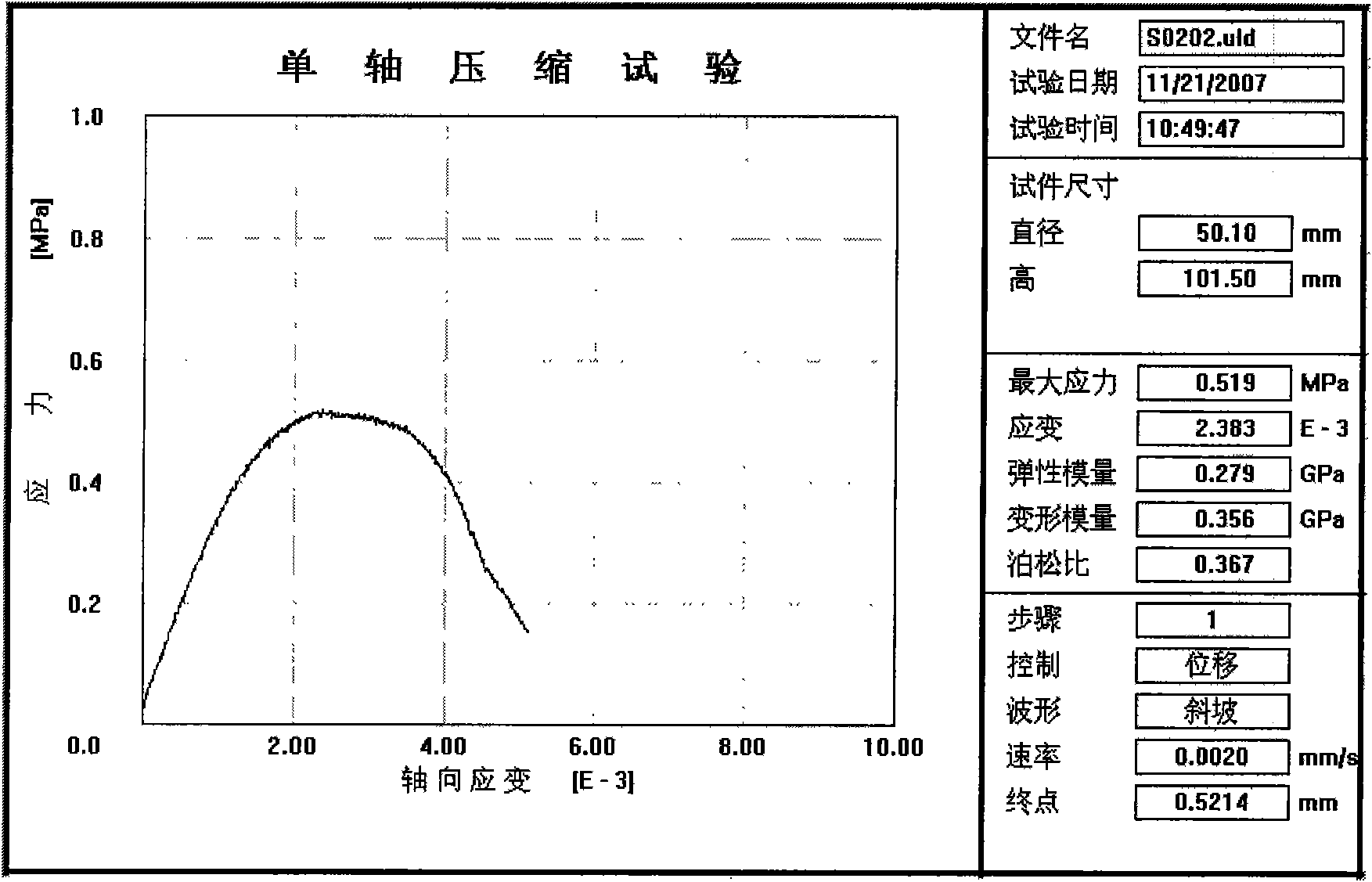

InactiveCN101614629ALight weightLittle elasticityPreparing sample for investigationEarth material testingFilling materialsSlurry

The invention discloses a softrock-like material and a preparation method thereof. The softrock-like material is composed of filler, aggregate, cementitious materials, additives and water in certain proportion. The preparation method comprises the steps of: 1. weighing the raw materials; 2. loading and stirring: adding water in a stirrer, causing the barrel wall of the stirrer to be smooth, then starting the stirrer, and adding the filler, aggregate, cementitious materials and additives sequentially followed by continuous stirring; 3. adding water and stirring: adding water during stirring, setting the speed of the stirrer at high and continuing stirring; 4. shaking and forming: discharging the materials, pouring the slurry into a pre-manufactured die, vibrating with a vibrating rod, causing the slurry to be even, removing foam and finally scraping the surface of the model to be level; and 5. maintaining in a baking house: sending the manufactured die into the baking house for maintenance. The material has the characteristics of low volume-weight, low compression strength and elastic modulus, stable property, easy processing, low cost and no toxicity, and is suitable for geomechanics research on softrock exploration and stability of softrock underground gas storage cavity.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

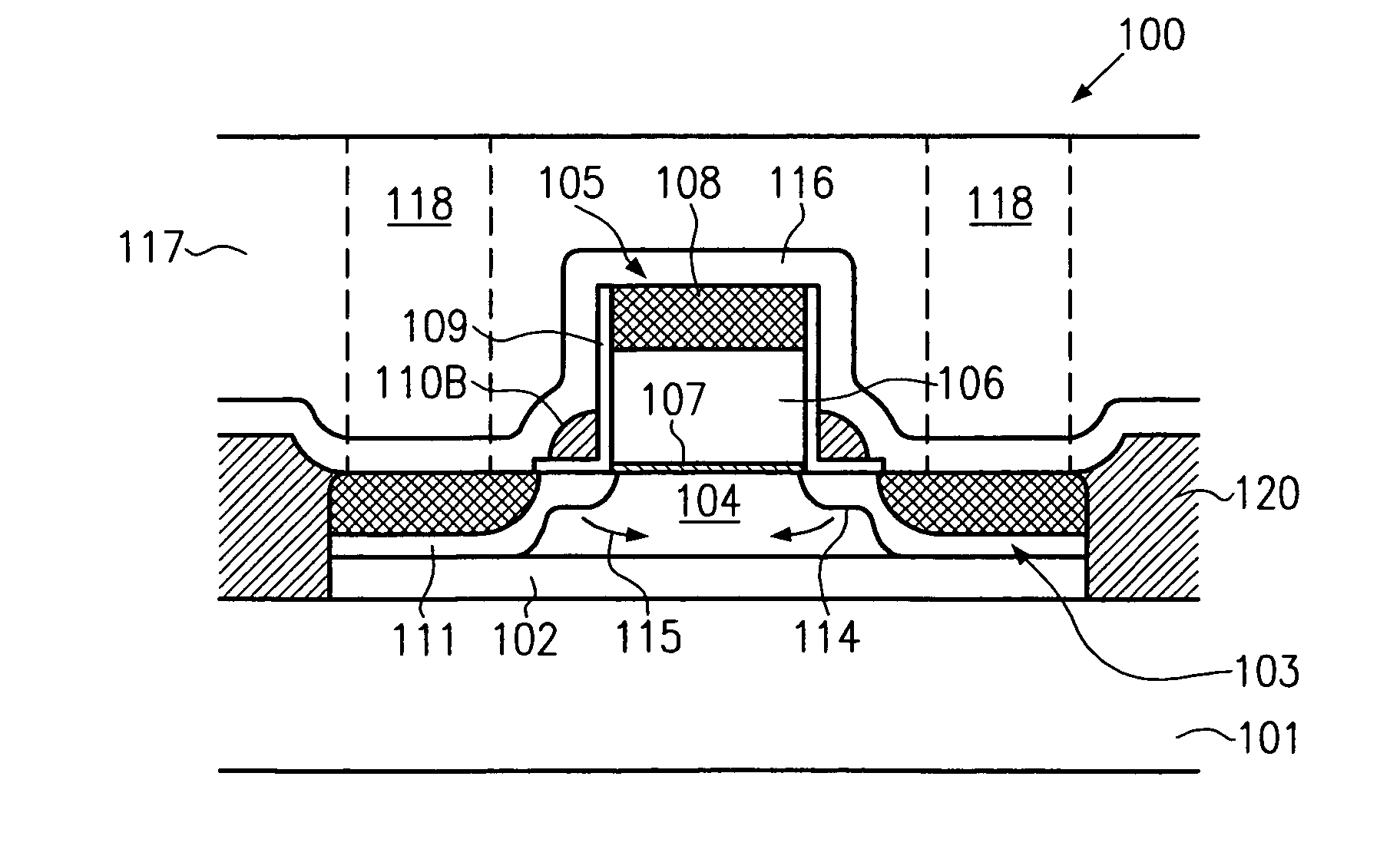

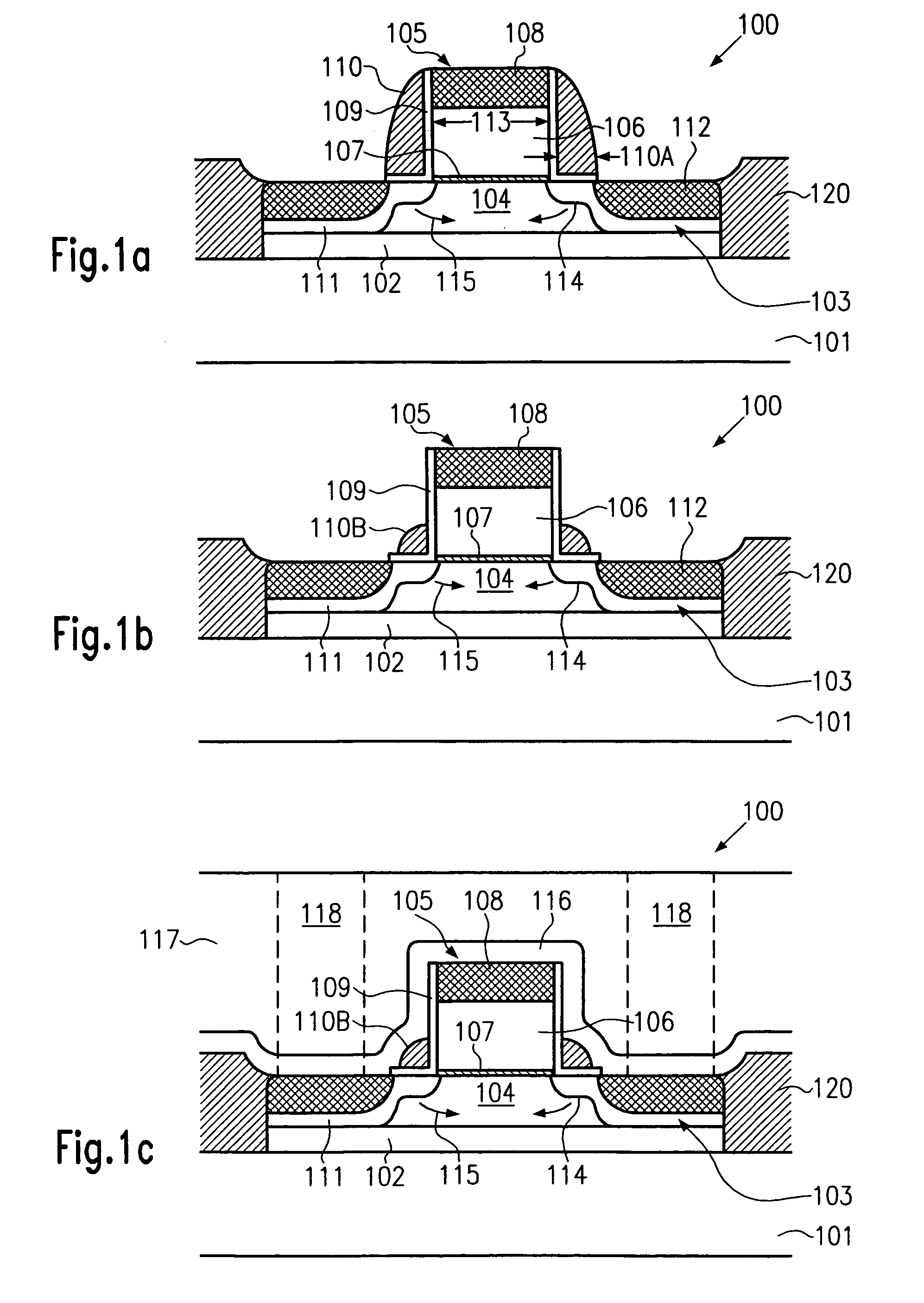

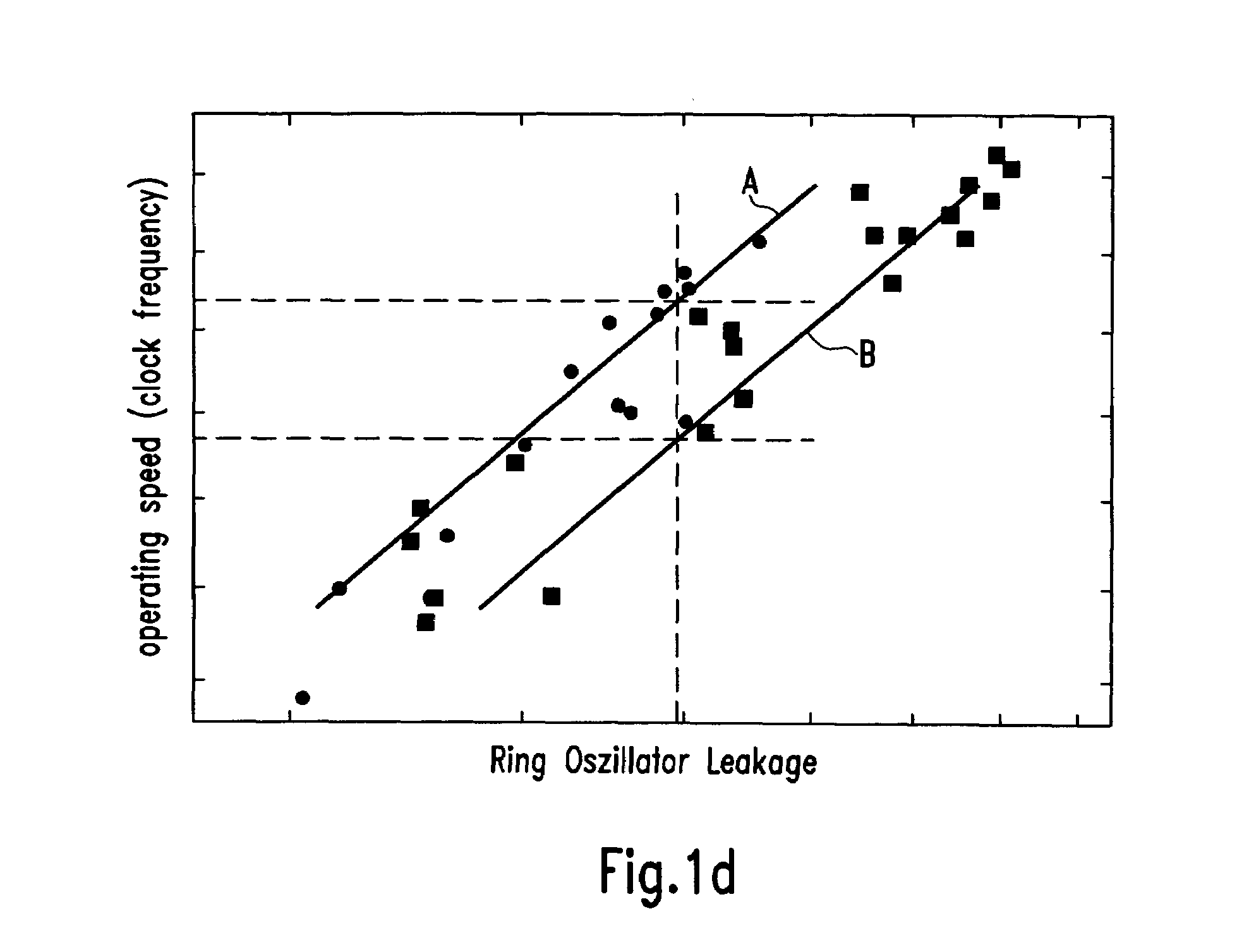

Technique for controlling mechanical stress in a channel region by spacer removal

ActiveUS7314793B2Significant stressLittle elasticitySemiconductor/solid-state device manufacturingSemiconductor devicesCouplingEngineering

During the formation of a transistor element, sidewalls spacers are removed or at least partially etched back after ion implantation and silicidation, thereby rendering the mechanical coupling of a contact etch stop layer to the underlying drain and source regions more effective. Hence, the mechanical stress may be substantially induced by the contact etch step layer rather than by a combination of the spacer elements and the etch stop layer, thereby significantly facilitating the stress engineering in the channel region. By additionally performing a plasma treatment, different amounts of stress may be created in different transistor devices without unduly contributing to process complexity.

Owner:GLOBALFOUNDRIES US INC

Preparation method of flexible silica aerogel

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

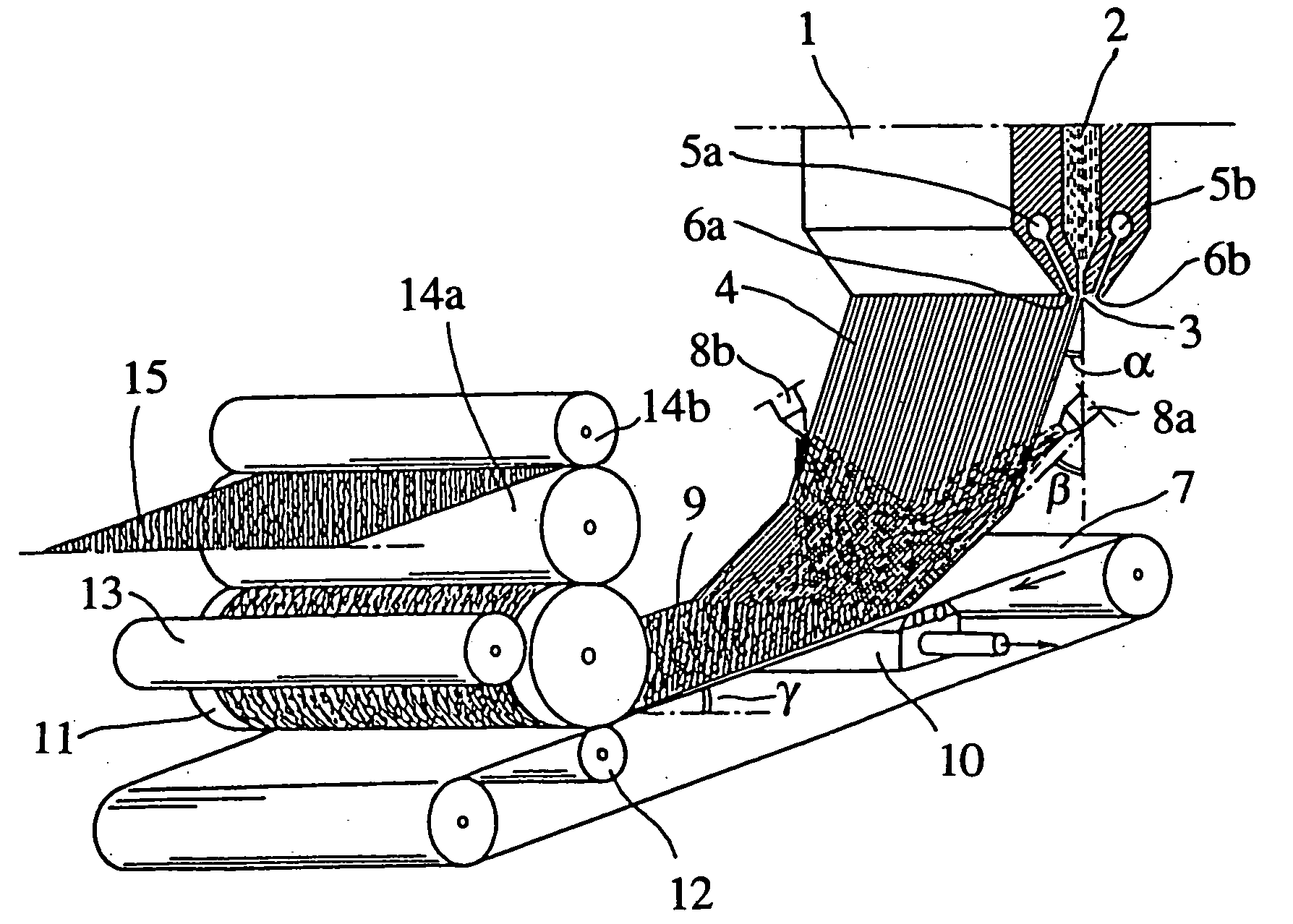

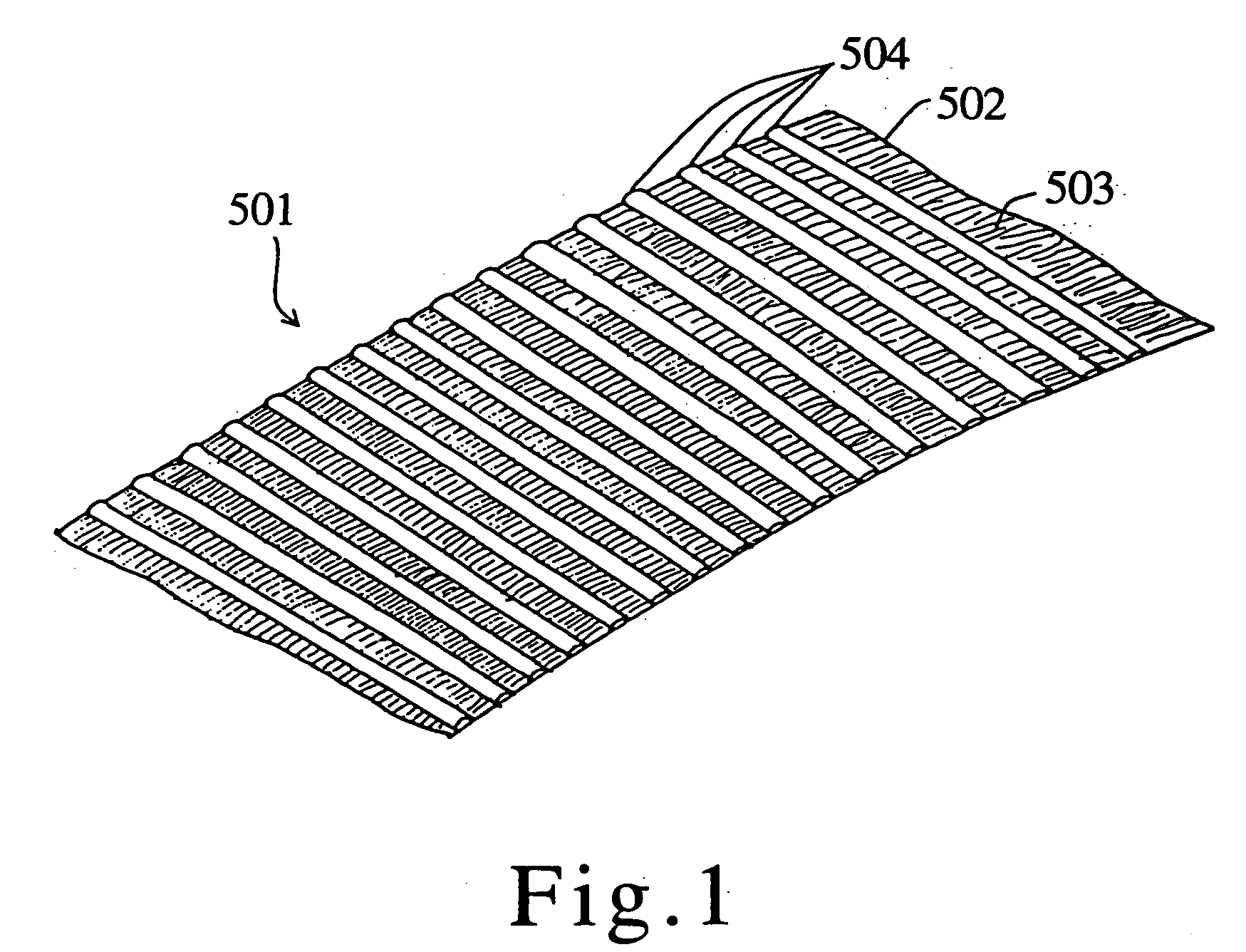

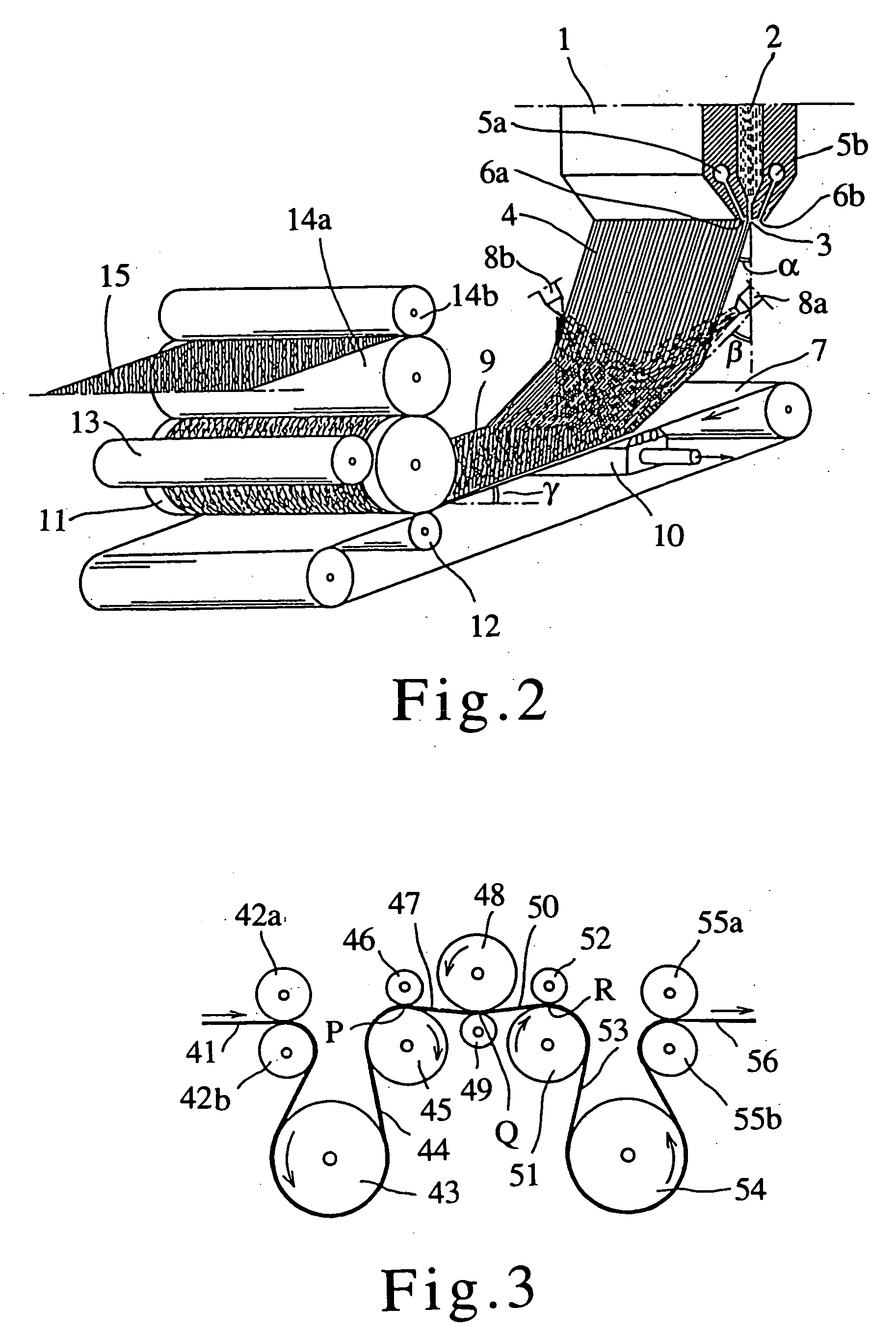

Composite sheet having elasticity, elastic web made from thermoplastic elastomer, and method and apparatus of manufacturing the same

InactiveUS20040166756A1ElasticityAir permeabilitySynthetic resin layered productsWoven fabricsThermoplastic elastomerEngineering

A composite sheet comprises a nonwoven fabric and a rubber elastic material bonded onto the nonwoven fabric. The nonwoven fabric has nonelastic fibers aligned in one direction and has elongation of 100% or higher in a direction perpendicular to the aligned direction of the nonelastic fibers. The rubber elastic material is bonded to the nonwoven fabric in a pattern having orientation perpendicular to the aligned direction of the nonelastic fibers.

Owner:NIPPON PETROCHEMICAL CO LTD +1

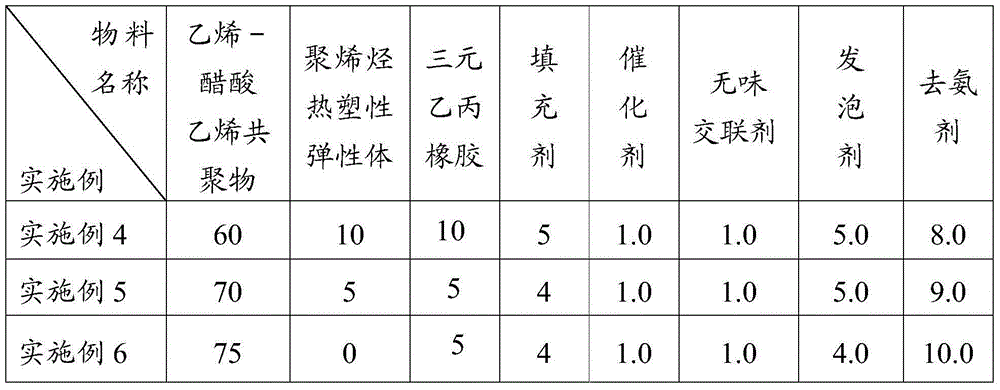

EVA composite foam material and preparation method thereof

The invention provides an EVA composite foam material and a preparation method thereof. The EVA composite foam material comprises the following components in parts by weight: 50-90 parts of an ethylene-vinyl acetate copolymer, 0-30 parts of a polyolefin thermoplastic elastomer, 0-30 parts of ethylene propylene diene monomer, 0-20 parts of a filler, 0.7-2.5 parts of a tasteless crosslinking agent, 1-8 parts of a foaming agent and 5-10 parts of a deammoniation agent. The EVA composite foam material is free of ammonia gas flavor and peculiar smell, good in elasticity and good in physical property. The preparation method of the EVA composite foam material comprises the following steps: (1) weighing the components of the EVA composite foam material; (2) pouring all the components excluding the tasteless crosslinking agent, the deammoniation agent and the foaming agent into an internal mixer for mixing; (3) adding the crosslinking agent, the deammoniation agent and the foaming agent into the mixed materials for mixing; (4) pouring the obtained mixture into a granulator for granulation and then foaming to obtain the EVA composite foam material free of ammonia flavor.

Owner:ANTA CHINA

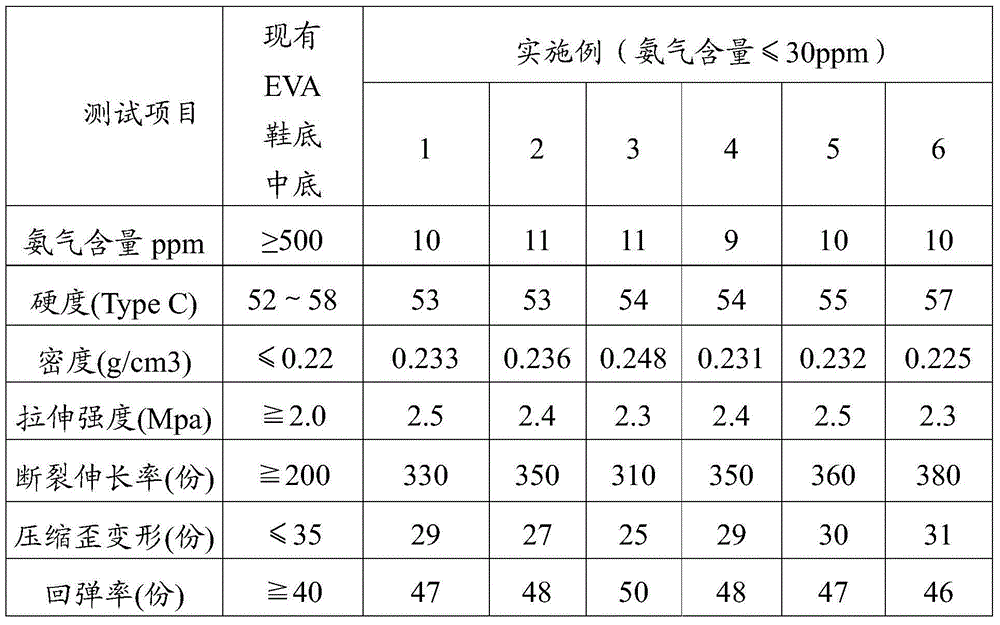

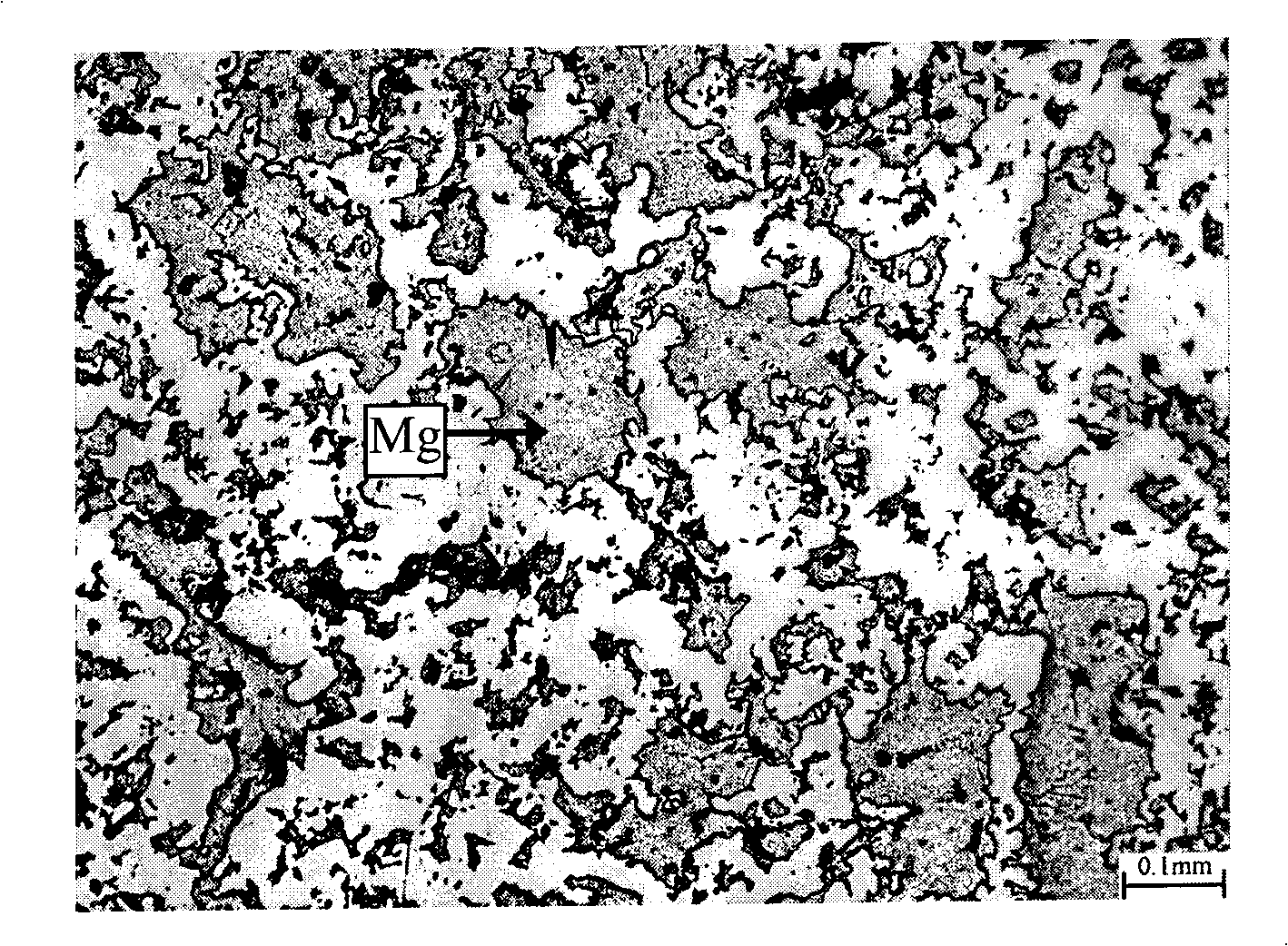

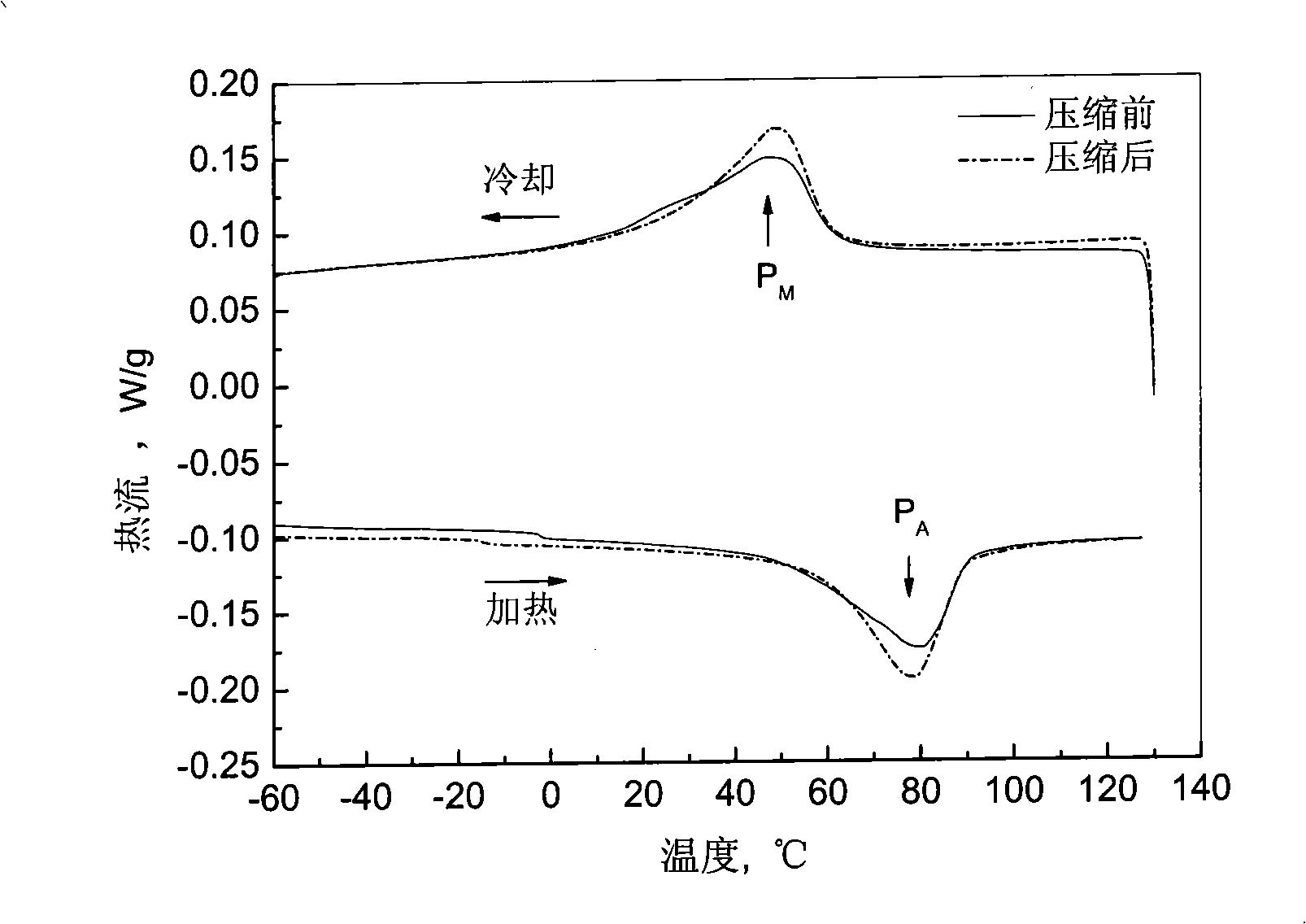

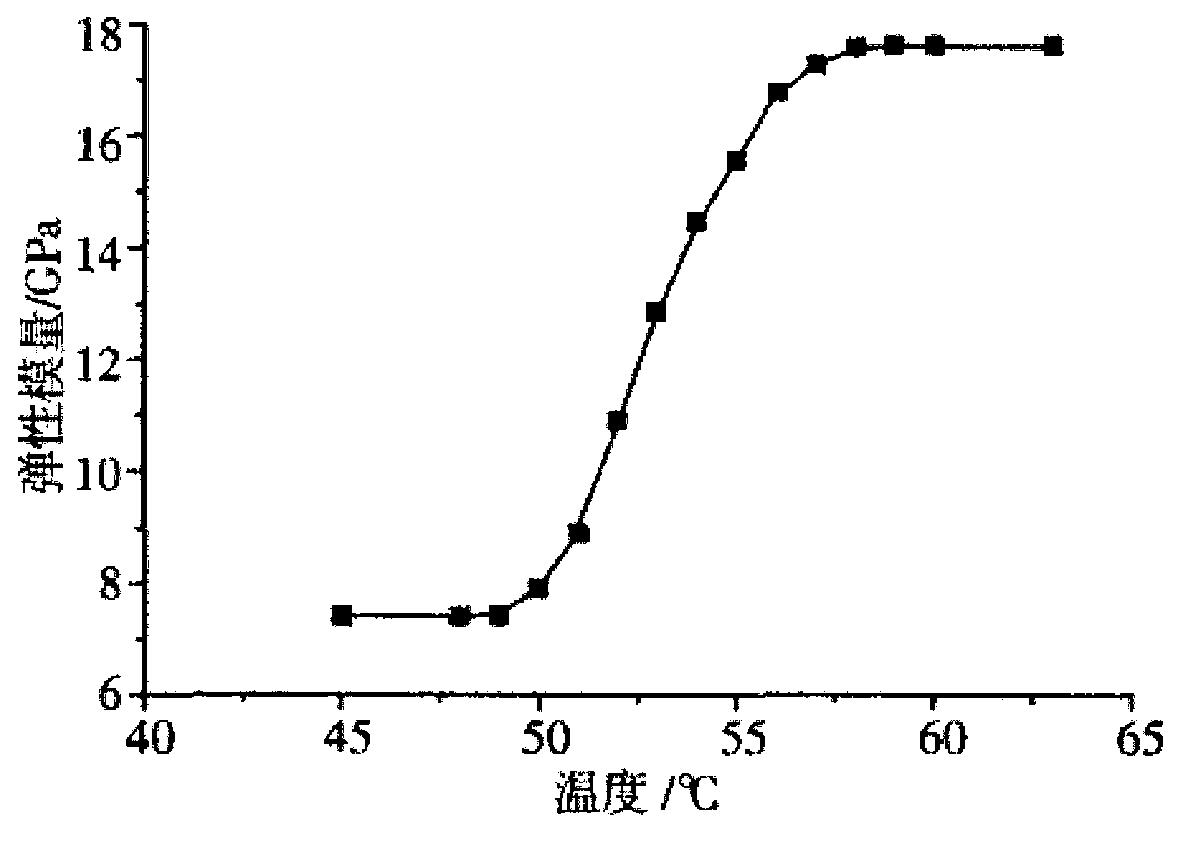

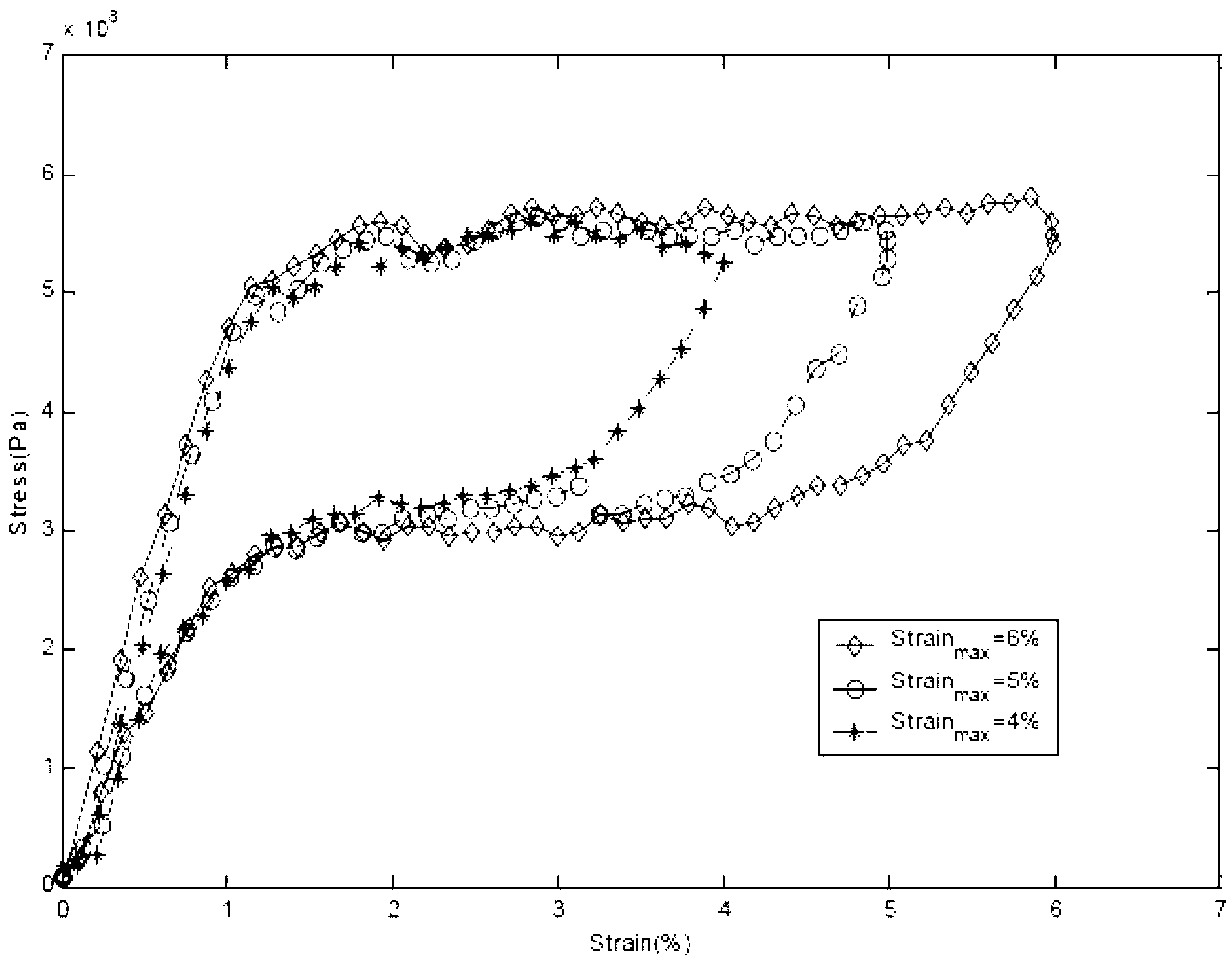

Preparation of composite type light high-strength nickel-titanium memory alloy-based high damping material

The invention discloses a preparation method of a compound type light-weight high-intensity nickel-titanium memorial alloy base high damping material. In the method, a powder sintering method is mainly used as a foundation and a pressureless infiltration technology is used as assistance; a pore-creating technology is firstly adopted; and a unit metal powder cascade sintering method is used for preparing a porous nickel-titanium alloy the holes of which are uniformly distributed; and then the pressureless infiltration technology is adopted for inducing the pure magnesium or magnesium alloy phase with high intrinsic damping, low density and micron scale into the porous nickel-titanium alloy, thereby preparing the high-damping magnesium(or magnesium alloy) / nickel-titanium memorial alloy base compound material the damping control phase of which is magnesium or the magnesium alloy. The compound nickel-titanium memorial alloy prepared by the invention still has the shape memory effect and the superelasticity action as well as has weight lighter than that of the compact nickel-titanium memorial alloy and intensity and damping capacity more excellent than that of the common porous nickel-titanium memorial alloy. The preparation method has good technical suitability, simple preparation process and low cost, and can be used for manufacturing the light-weight high-intensity compound damping materials, damping structures and apparatuses.

Owner:SOUTH CHINA UNIV OF TECH

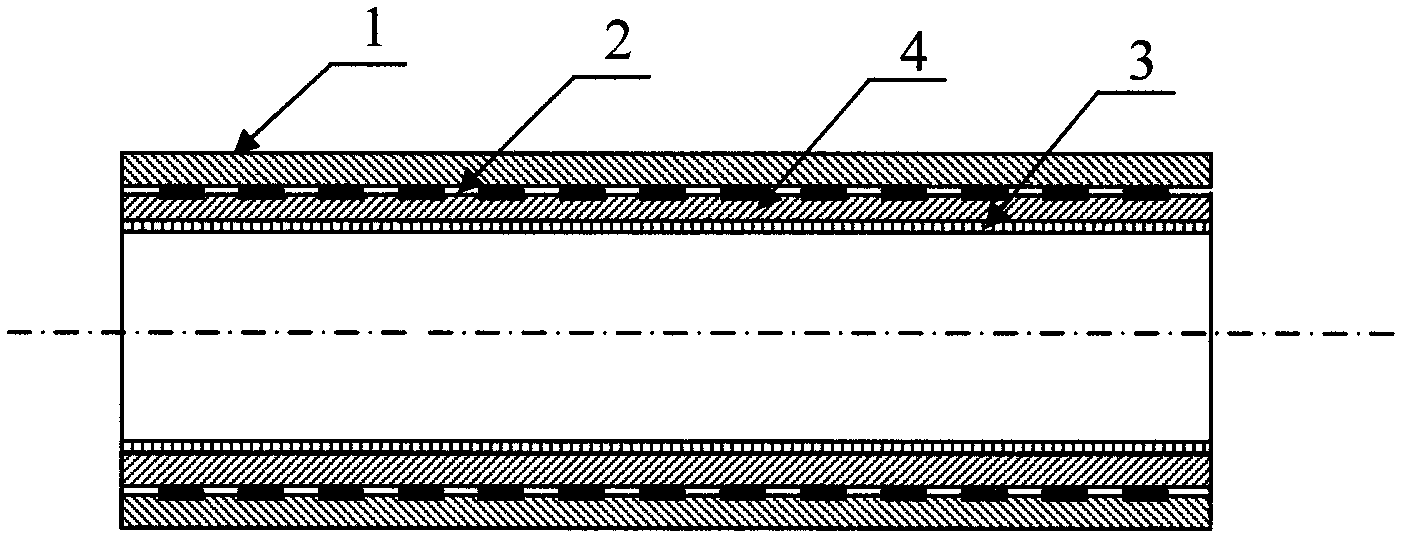

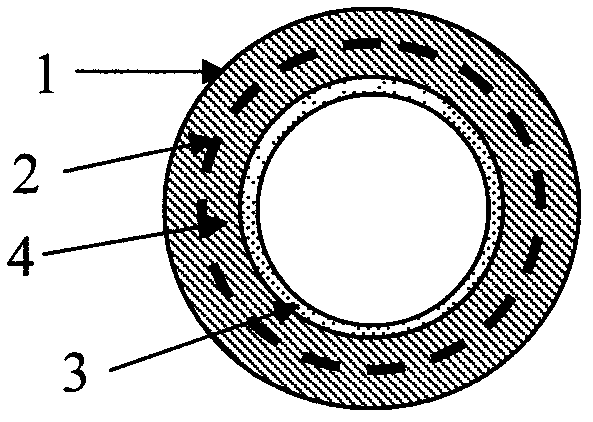

Medical scaffold with inner coating film, and preparation method for medical scaffold

InactiveCN102430157ALittle elasticityEliminate defects with high embolism rateStentsCoatingsFiberMedical equipment

The invention relates to medical equipment, particularly a medical scaffold with an inner coating film, and a preparation method for the medical scaffold, and belongs to the field of medical equipment. In the medical scaffold with the inner coating film, a non-woven inner coating film of which fibers are distributed on the axial direction of the medical scaffold is prepared on the inner surface of an inner film by an electrospinning method by taking a coating film scaffold as a basis, wherein the coating film scaffold consists of a netlike scaffold which is formed by weaving medical alloy wires, an electrospinning non-woven inner film and an electrospinning non-woven outer film; and the thickness of the inner coating film is 2 to 6 mu m. During preparation of the medical scaffold with the inner coating film, the inner coating film, the inner film and the outer film are prepared sequentially, and the inner coating film in the medical scaffold improves the biocompatibility with tract tissues of a human body, facilitates adhesion, migration and reproduction of endothelial cells at two ends of the medical scaffold, promotes quick endothelialization of the medical scaffold, and prevents the medical scaffold from becoming narrow again. The preparation method for the medical scaffold is simple, convenient to operate, and low in cost, and suitable for preparation of medical scaffolds with different diameters and lengths.

Owner:WUHAN TEXTILE UNIV

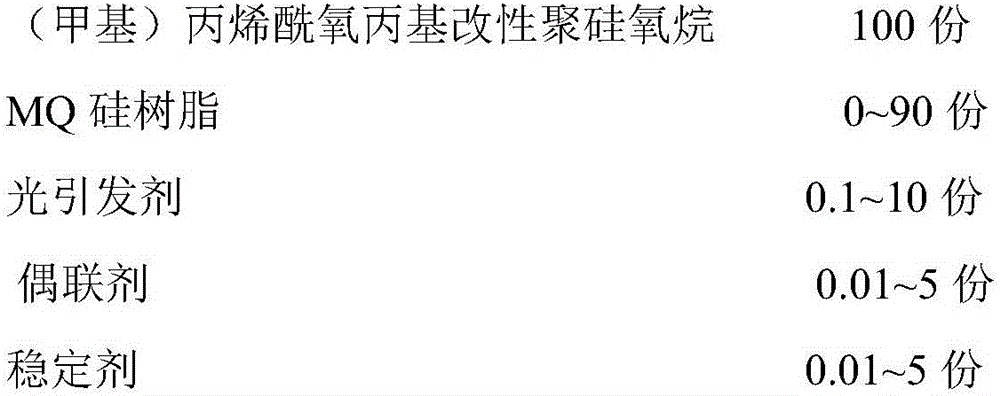

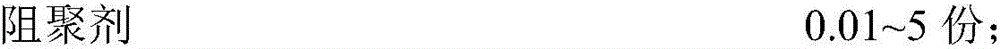

Ultraviolet-curing liquid optical silica gel used for reworkable gluing as well as preparation method and application thereof

InactiveCN106497505AReduce scrap rateAnti-yellowing and agingNon-macromolecular adhesive additivesAdhesiveOptical transmittance

The invention belongs to the technical field of preparation of adhesives and specifically discloses an ultraviolet-curing liquid optical silica gel used for reworkable gluing. The ultraviolet-curing liquid optical silica gel used for reworkable gluing comprises the following ingredients in parts by weight: 100 parts of methacryloyloxyethyl modified polysiloxane; 0-90 parts of MQ silicon resin, 0.1-10 parts of a photoinitiator, 0.01-5 parts of a coupling agent, 0.01-5 parts of a stabilizer and 0.01-5 parts of a polymerization inhibitor. The liquid optical silica gel provided by the invention has high light transmittance, small shrinking percentage, small yellowing index and good reworkable performance; the liquid optical silica gel can be repeatedly used for gluing an optical element and a screen; meanwhile, the rejection rate of materials can be effectively controlled, the production cost of enterprises is greatly reduced, and the application prospect is wide.

Owner:矽时代材料科技股份有限公司

Heat-conduction and electric-conduction hot melt glue and preparation method thereof

InactiveCN103540280AGood compatibilityReduce the amount addedNon-macromolecular adhesive additivesElectrically-conducting adhesivesThermoplasticPolymer science

The invention relates to a heat-conduction and electric-conduction hot melt glue and a preparation method thereof. The hot melt glue is high in heat-conduction and electric-conduction properties under a precondition that the elasticity and bonding strength of the original hot melt glue; the heat conduction coefficient reaches more than 2.0w / m.k. According to the hot melt glue, base materials comprise styrene thermoplastic elastomers (SEBS) and styrene-butadiene-styrene thermoplastic elastomers (ESBS) modified by epoxidation; a thickening agent comprises two of hydrogenated rosin, terpene resin and C9 petroleum resin; a filler is graphene solid powder with heat-conduction and electric-conduction functions; the addition amount of the base materials accounts for 30-40%; the addition amount of thickening resin accounts for 30-50%; the addition amount of the solid graphene powder accounts for 1.5-3.5%; the addition amount of the other accessory ingredient naphthenic oil accounts for 15-18%; the addition amount of an antioxidant accounts for 1-2%; the heat-conduction and electric-conduction hot melt glue is prepared from the components of the hot melt glue through a melt blending method.

Owner:SHENYANG JIANZHU UNIVERSITY

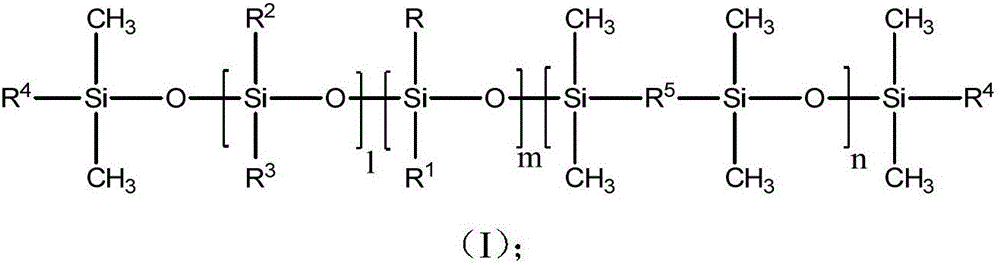

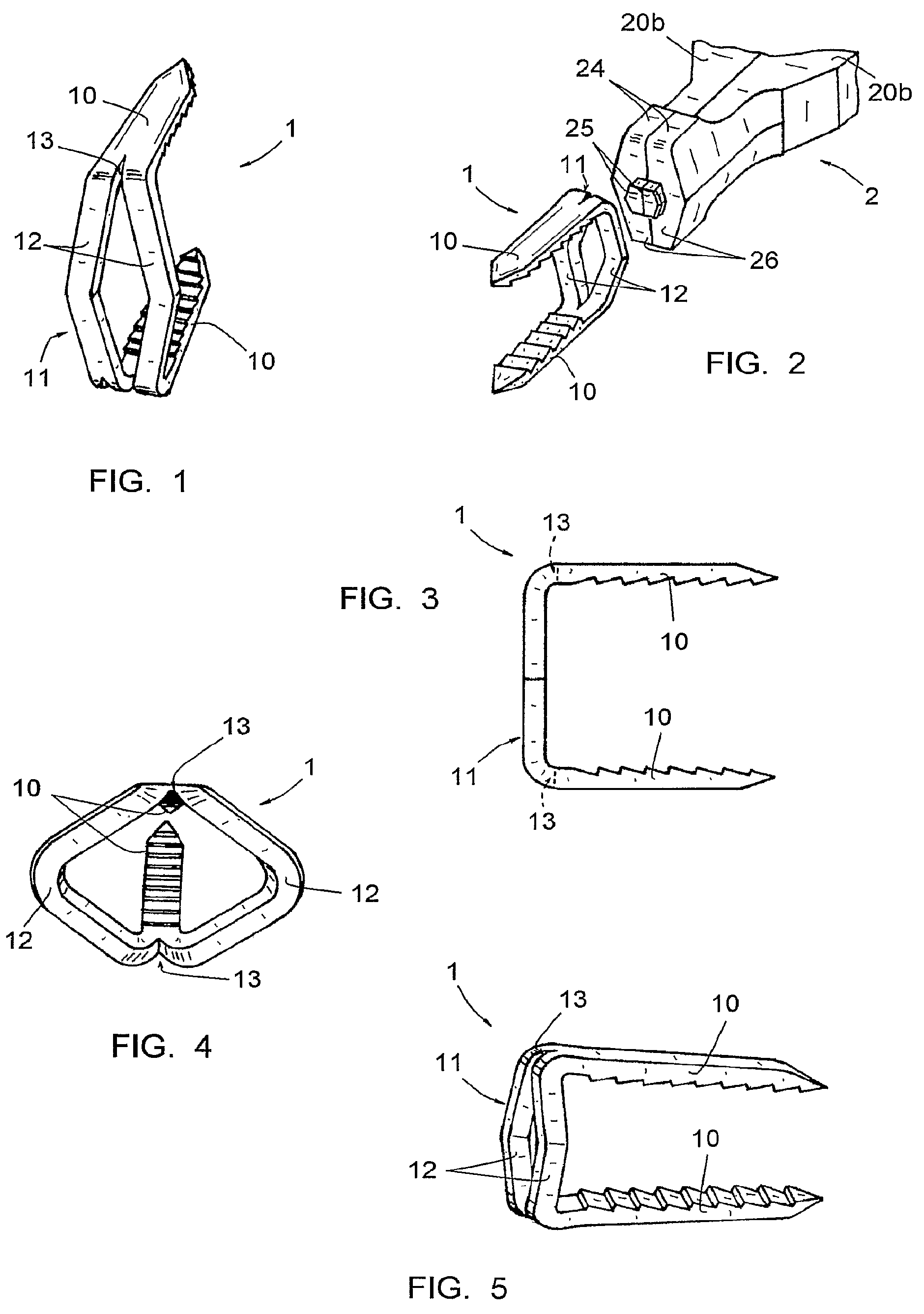

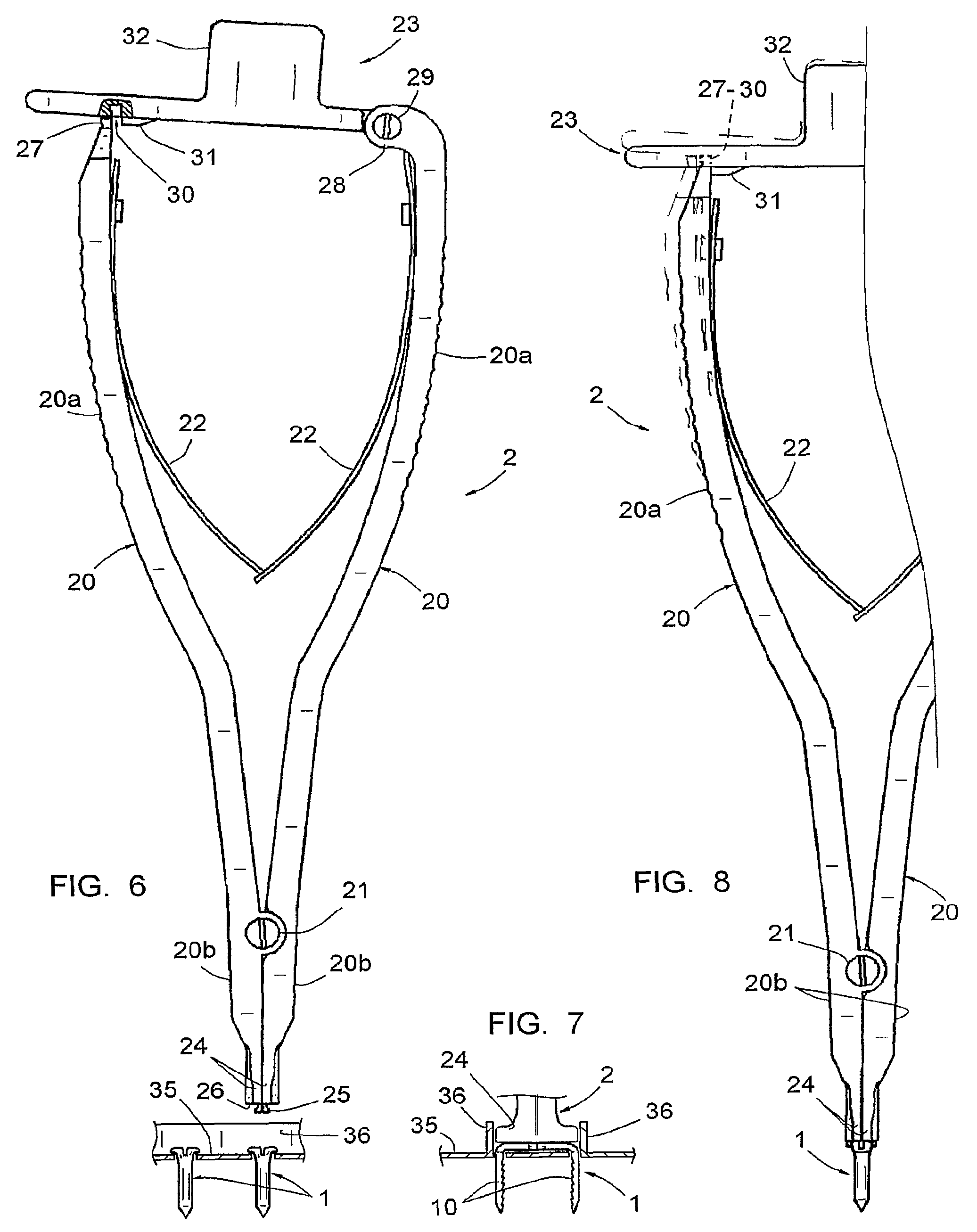

Vertebral osteosynthesis equipment

ActiveUS9034037B2Eliminates any insertionPositioning is simple and fastInternal osteosythesisSurgical furnitureEngineeringBone Cortex

This equipment includes at least one U-shaped clip (1) whose lateral branches (10) have sections and widths such that they may be inserted in the vertebral bodies (100) of two vertebrae by impaction on the intermediate branch (11) of the clip (1), so as to rest along the cortical bones of the vertebral bodies, and whose intermediate branch (11) is deformable in such a way as to allow a reduction of the distance between the lateral branches (10); the intermediate branch, before implantation, has a length such that one of the lateral branches (10) may be positioned slightly above the cortical bone forming the plate of the subjacent vertebra while the other lateral branch (10) may be positioned slightly below the cortical bone forming the plate of the subjacent vertebra, and has, after deformation, a length such that the two lateral branches (10) may be brought closer to each other.

Owner:MEDICREA INT SA

Decellularization cornea preparation method

The invention relates to a decellularization cornea preparation method, which adopts steps of corneal epithelium layer removing, ultraviolet cross-linking, viral inactivation, decellularization treatment, gradient dehydration, radiation protection and sterilization. According to the present invention, the prepared decellularization cornea has characteristics of complete antigen removing, no excitation of host acquired immunity reaction, good biocompatibility, low damage on nature corneal stroma, maintaining of structure characteristics of the nature corneal, and maintaining of effective components of the nature corneal so as to provide physical and chemical properties similar to the nature corneal; and after the prepared decellularization cornea is transplanted, animal experiment results show that characteristics of transparent transplanted cornea, no scar formation, no melting generation and no neovascularization are provided, the transplanted cornea and the recipient bed are completely integrated after transplanting a month, the transplanted cornea is subjected to complete epithelization after three months, corneal stroma cells migrate toward the decellularization cornea graft so as to prove that the tissue just takes place slow reconstruction, and the transplanted cornea after 6 months does not show significant difference in histology and appearance detection compared with the nature cornea.

Owner:SHAANXI BIO REGENERATIVE MEDICINE CO LTD

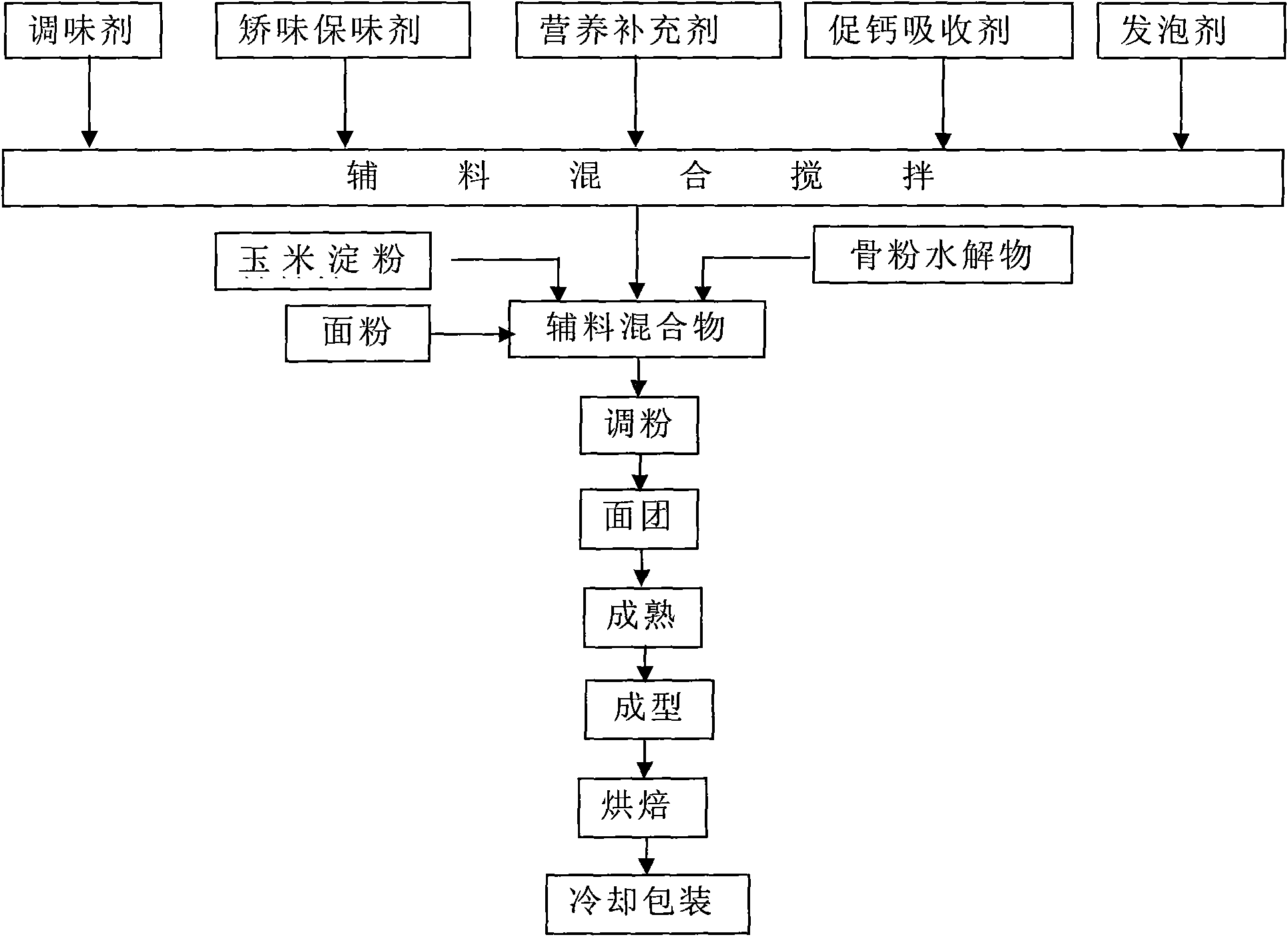

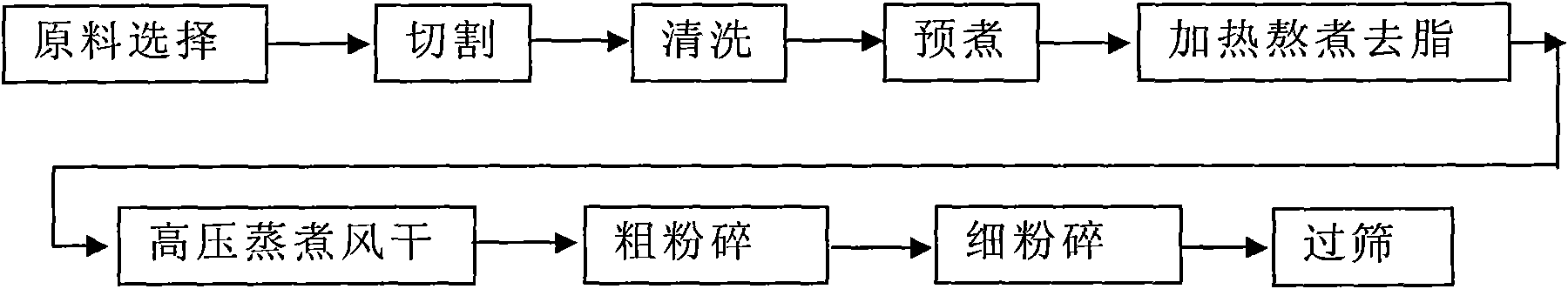

Nutritional biscuit with high bone calcium and making method thereof

InactiveCN101606545AIt has the effect of correcting and preserving flavorImprove and improve organizational structureDough treatmentBakery productsFlavorFoaming agent

The invention relates to a nutritional biscuit with high bone calcium and a making method thereof, belonging to a processing and making technique of foods required by the life of human beings. The nutritional biscuit is formed by preparing and processing the following raw materials according to a certain proportion formula and a certain production technology and comprises the following raw materials according to the formula and the mixture ratio: 950g of flour, 50g of corn starch, 350g to 450g of cattle bone powder hydrolyzing substance, 240g to 260g of flavoring agent, 140g to 160g of flavoring taste-retaining agent, 280g to 300g of nutritional extender, 80g to 100g of calcium absorption promoter, 6g to 8g of foaming agent and 1ml of butter essence. The product contains high effective calcium and abundant nutrition, the color of the surface of the biscuit is bright, and the biscuit has a deep red brown color, has the special flavor of bone, is soft, savory and crisp and has no peculiar odor. The processing procedure of the invention is shown as the attached drawing of the abstract.

Owner:GUIZHOU UNIV

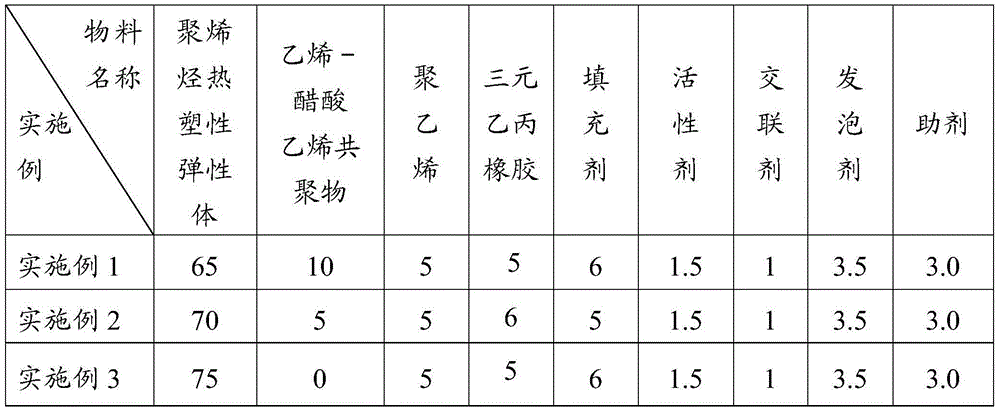

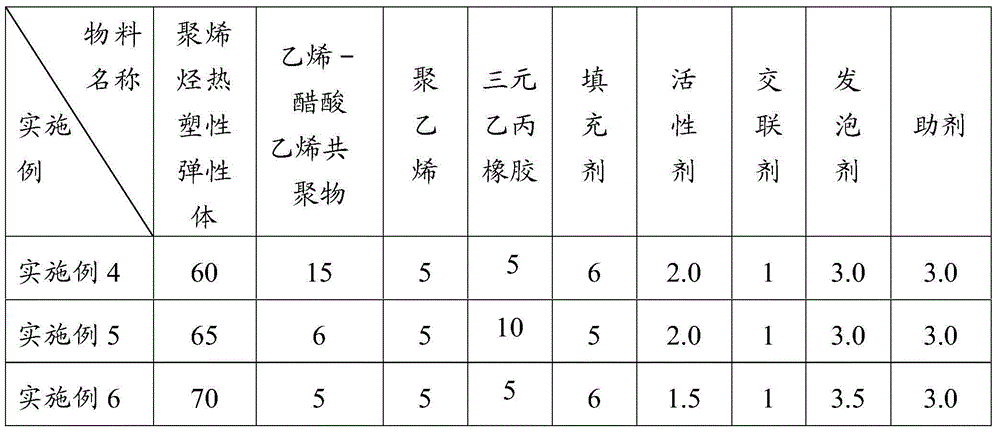

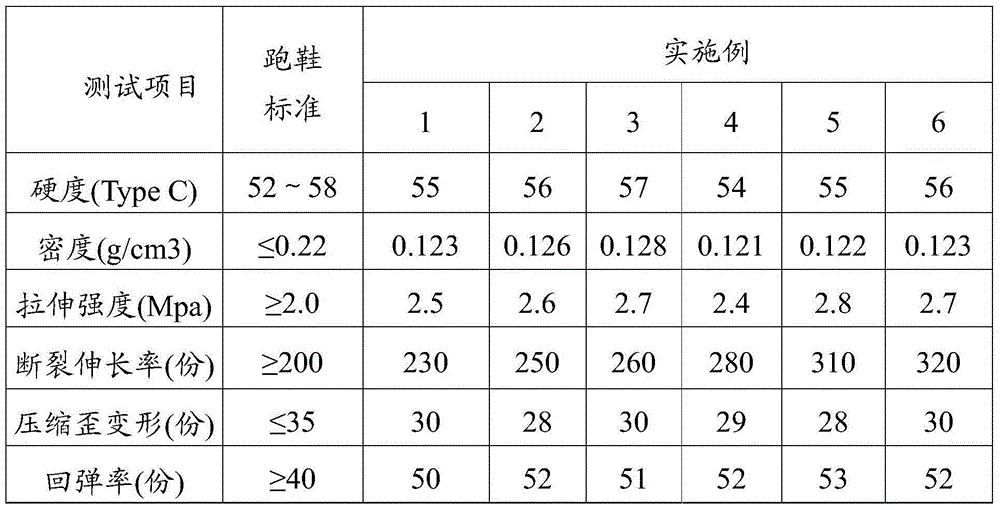

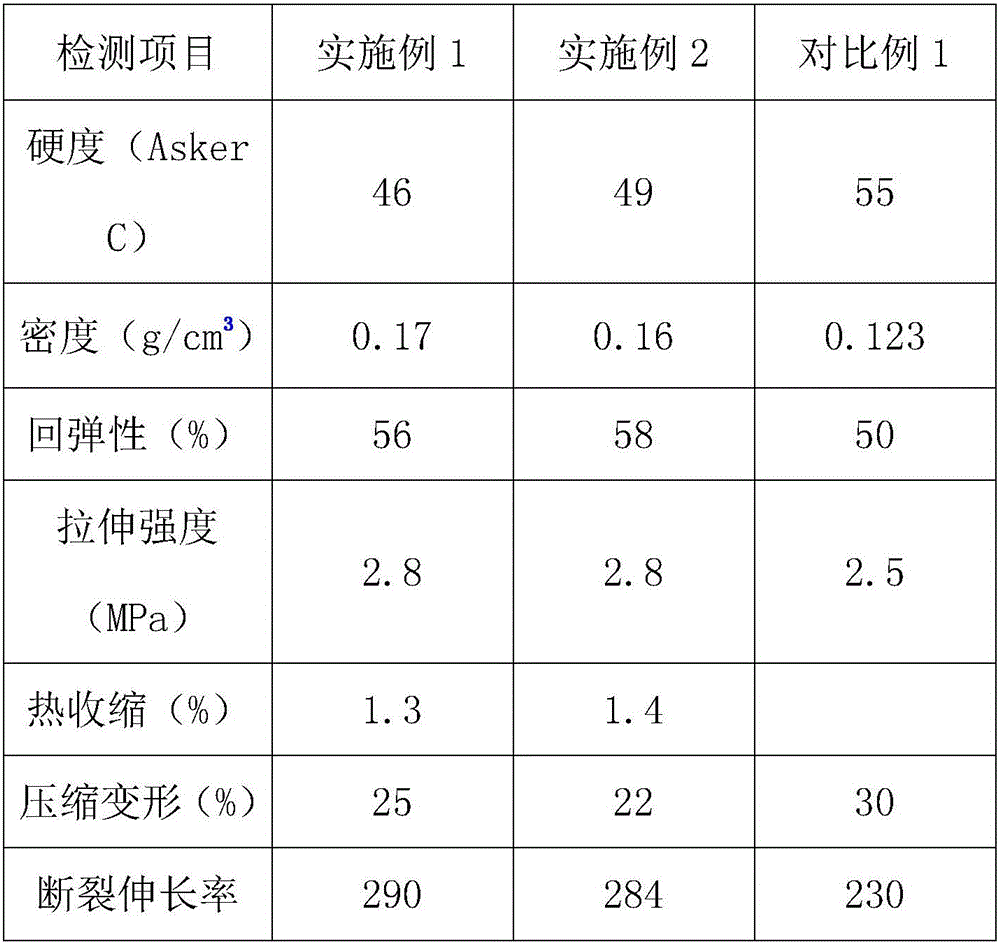

EVA (Ethylene Vinyl Acetate) composite foaming material and preparation method thereof

The invention provides an EVA (Ethylene Vinyl Acetate) composite foaming material and a preparation method thereof. The EVA composite foaming material comprises the following components in parts by weight: 55-90 parts of a polyolefin thermoplastic elastomer, 0-35 parts of EVA, 0-25 parts of polyethylene, 0-15 parts of ethylene-propylene-diene-monomer rubber, 0-15 parts of a filling agent, 0.5-2.5 parts of an active agent, 0.5-2.5 parts of a cross-linking agent, 1-6 parts of a foaming agent and 1-7 parts of an auxiliary agent. The EVA composite foaming material is low in density and excellent in elasticity. The preparation method for the EVA composite foaming material comprises the following steps: (1), weighing the various components included in the EVA composite foaming material; (2), pouring all the components except the cross-linking agent and the foaming agent into an internal mixer for mixing; (3), adding the cross-linking agent and the foaming agent into the mixed materials for mixing; pouring the obtained mixture into a pelletizer for pelletizing, and then foaming, so as to obtain the EVA composite foaming material.

Owner:ANTA CHINA

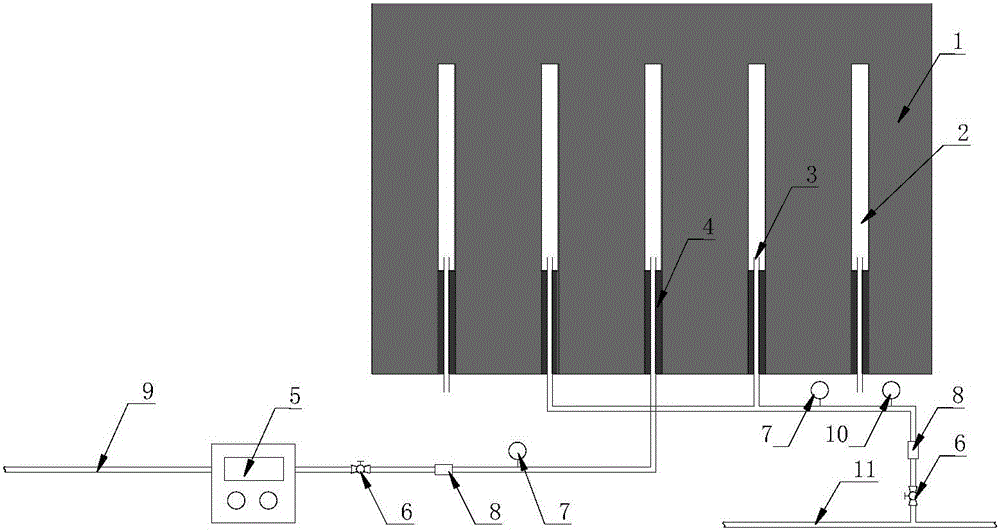

Coal seam gas fracturing and mash gas driving method

The invention relates to a coal seam gas fracturing and mash gas driving method, which comprises two stages including a hole sealing fracturing stage and a mash gas driving stage. According to the method, firstly, hole drilling construction is performed in a coal seam; then, a high-pressure rubber pipe is embedded in a drilling hole, and hole sealing is performed; any one drilling hole is selected as a fracturing drilling hole; high-pressure gas is injected into the fracturing drilling hole; the coal seam is fractured through gas pressure energy; the gas permeability of the coal seam is improved; and other drilling holes around the fracturing drilling hole are subjected to mash gas extraction when the high-pressure gas is injected into the fracturing drilling hole. Under the condition of non-ideal gas fracturing effects caused by high coal hardness or great ground stress and the like, high-pressure water can be firstly used for fracturing, and then, high-pressure gas is introduced into the hole; and meanwhile, the drilling holes around the fracturing drilling hole are subjected to mash gas extraction. The method has the advantages that the adsorption performance differences of coal bodies on the mash gas and the fracturing gas are considered; the gas fracturing effect is combined with the mash gas driving effect; the mash gas extraction efficiency can be effectively improved; the number of mash gas extraction holes is reduced; and the inhibiting effect of water on mash gas deabsorption is reduced. The method is simple; safety and reliability are realized; and the effect is good.

Owner:CHINA UNIV OF MINING & TECH

Shape memory alloy (SMA) group rolling rod type large load releasing mechanism

InactiveCN103231813AStrong impact resistanceLarge release loadCosmonautic component separationShape-memory alloyShock resistance

The invention provides a shape memory alloy (SMA) group rolling rod type large load releasing mechanism. A segmented nut of the mechanism is firmly hooped by a hooping cylinder through rolling rods, simultaneously the upper end face and the lower end face of the segmented nut are respectively matched with an end cover and a separating ejector block, so that the segmented nut is a total nut and cannot move vertically. Groove are arranged on the segmented nut, so that when separation is needed, and the hooping cylinder moves downwards to drive the rolling rods to roll downwards and properly enter the grooves of the segmented nut when moving to a certain position, so that the segmented nut can obtain radial displacement. When releasing is finished, the hooping cylinder moves upwards under the effect of an SMA reset spring and simultaneously push the rolling rods out from the grooves, and the segmented nut draws close toward the inside to form an integral thread, so that repeated using function of the mechanism can be achieved, the segmented nut is fit with the separating ejector block through a conical surface, and the separating ejector block is matched with the hooping cylinder through two end faces. The shape memory alloy (SMA) group rolling rod type large load releasing mechanism is strong in shock resistance, releases large load and has the redundancy design and high reliability.

Owner:BEIHANG UNIV +1

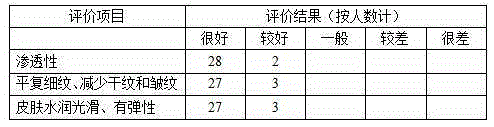

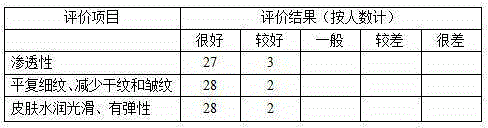

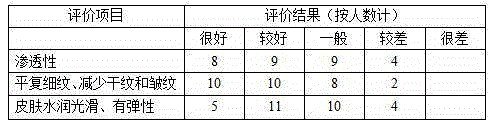

Anti-wrinkle face cream and preparation method thereof

ActiveCN105147591AAnti agingImprove youthCosmetic preparationsToilet preparationsEthylhexyl palmitateApple extract

The invention belongs to the technical field of cosmetics, and in particular relates to an anti-wrinkle face cream and a preparation method thereof. The anti-wrinkle face cream comprises butanediol, ethylhexyl palmitate, caprylic / capric triglyceride, glycerol, polyglycerol-10, ethylhexyl isononanoate, polymethyl methacrylate, polydimethylsiloxane, ceteareth-21, cetostearyl alcohol, ceteareth-2, acrylic acid (ester) type / acrylamide copolymer, betaine, avocado fruit butter, a lactic acid bacillus / balausta fermentation product extract, an arctic rock chlamydomonas essence, a starfish essence, a ginseng extract, a lucid ganoderma extract, an apple extract, tocopheryl acetate and the like. The anti-wrinkle face cream provided by the invention is good in penetrability and easy to absorb, can effectively replenish water and preserve moisture, and can repair skin wrinkles and inhibit generation of the winkles, thereby delaying skin aging.

Owner:广州科玛生物科技股份有限公司

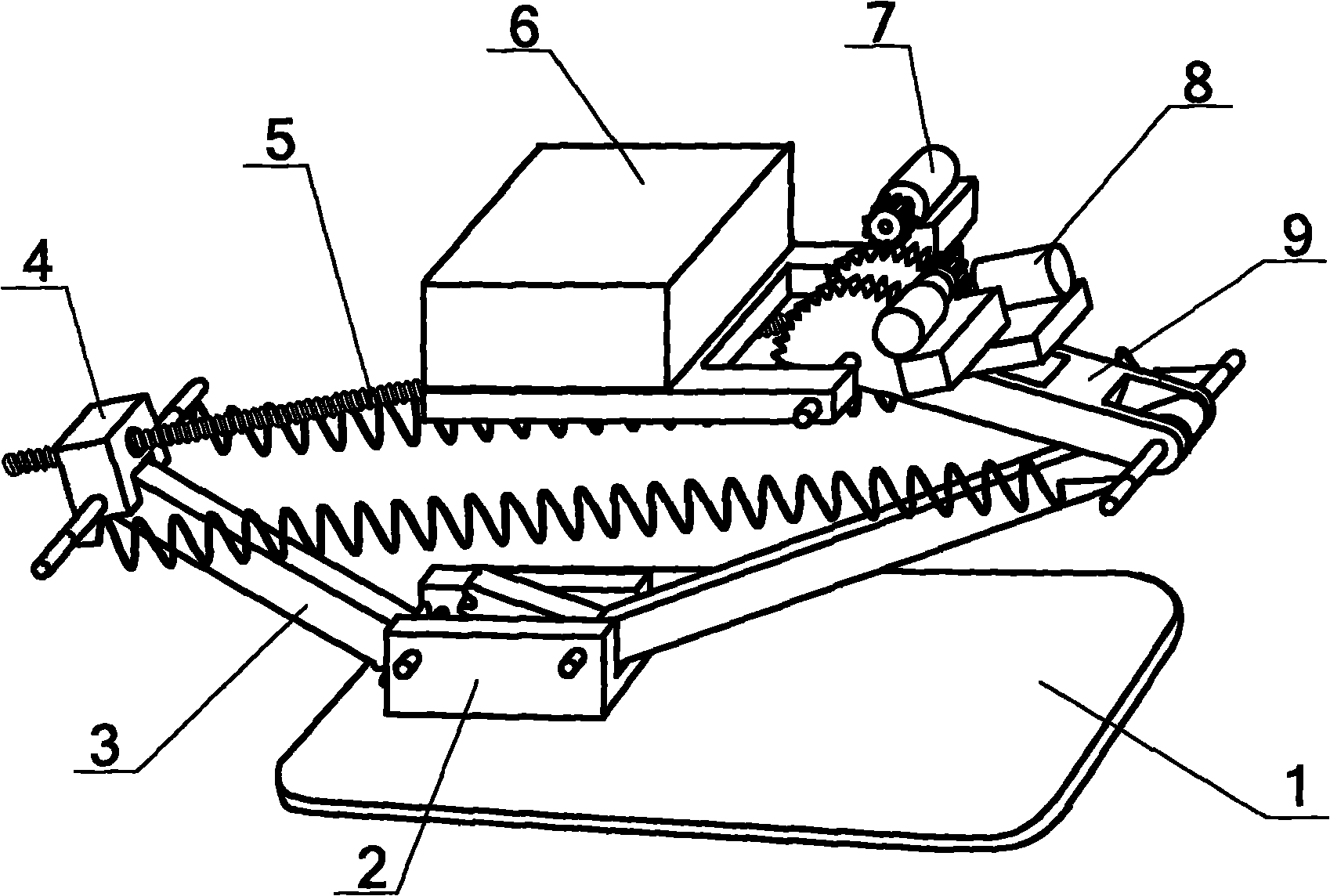

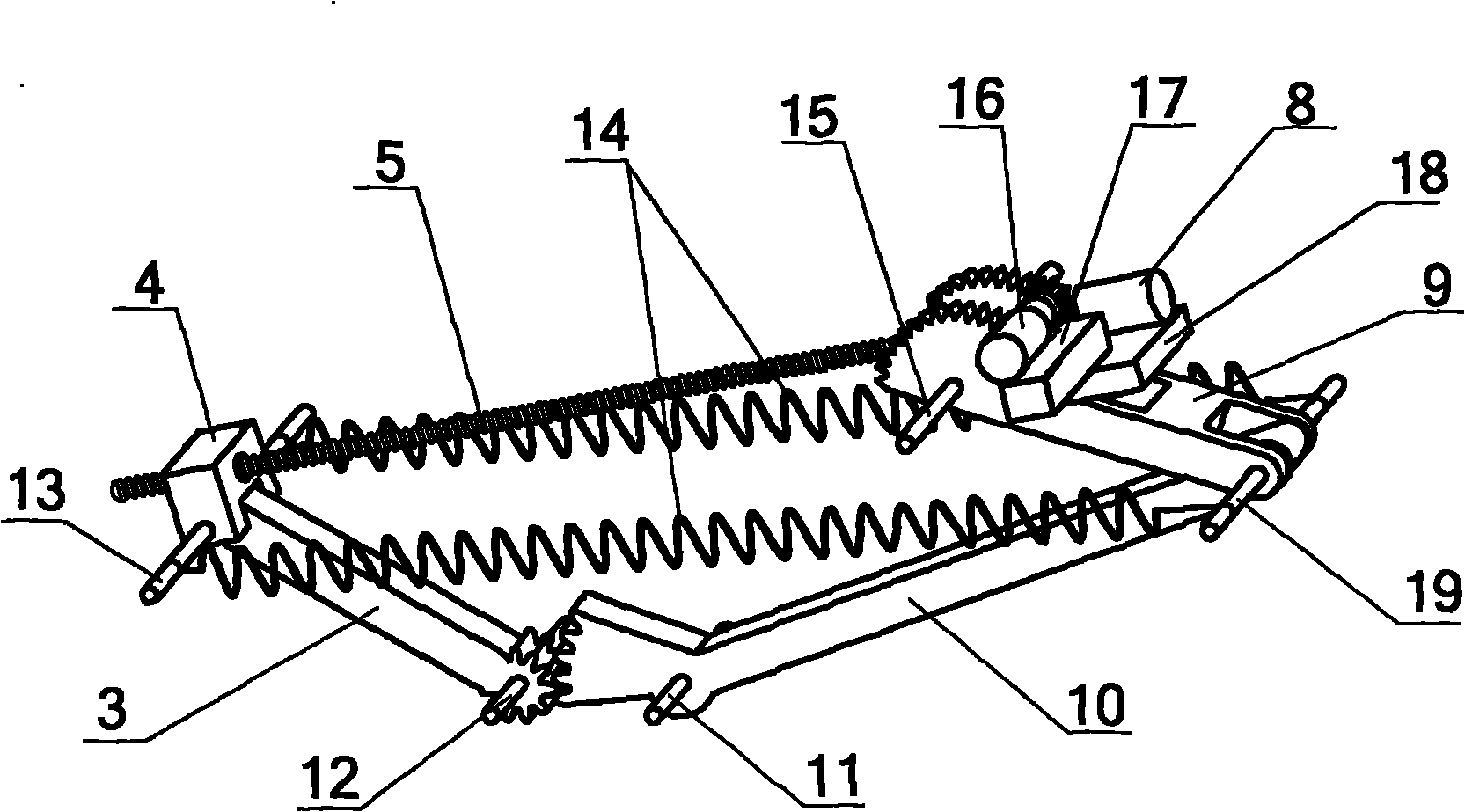

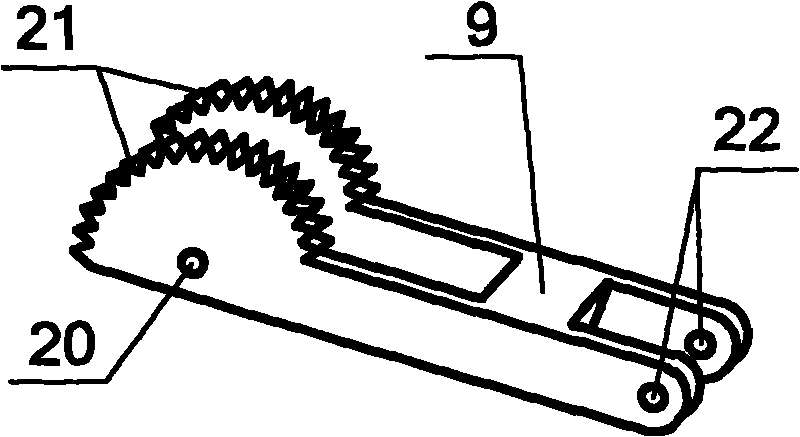

Bionic hopping robot with two degrees of freedom

InactiveCN102050156AMeet scientific detection requirementsAdjust the take-off angleVehiclesTwo degrees of freedomStructural deformation

The invention discloses a bionic hopping robot with two degrees of freedom, comprising a robot body device, a leg device and a sole device. With respect to the robot body device, the horizontal state of the robot body during whole hopping procedure is maintained by using a robot body gesture adjusting mechanism to adjust an included angle between the robot body device and a thigh rod. The leg device moves a nut with a shaft by using a screw nut mechanism during the gesture adjusting procedure according to a structural deformation construction principle so as to extend and shorten a spring, and uses a leg gesture adjusting motor as a drive to complete a hopping preparing gesture of the screw nut mechanism and the thigh rod; during the energy storing procedure, the stretching of the spring is completed by a screw driving motor with a relatively small power by using the relatively big transmission ratio of the screw nut mechanism, so as to realize the storing of energy; and different preparing gestures of the leg device before taking off are adjusted according to different positions of the nut on the screw when the energy storing procedure is completed, so that the adjustment of a taking off angle of the hopping robot is realized. The structure of the bionic hopping robot is simple and reliable, and the bionic hopping robot is suitable for multiple uses such as planetary exploration and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

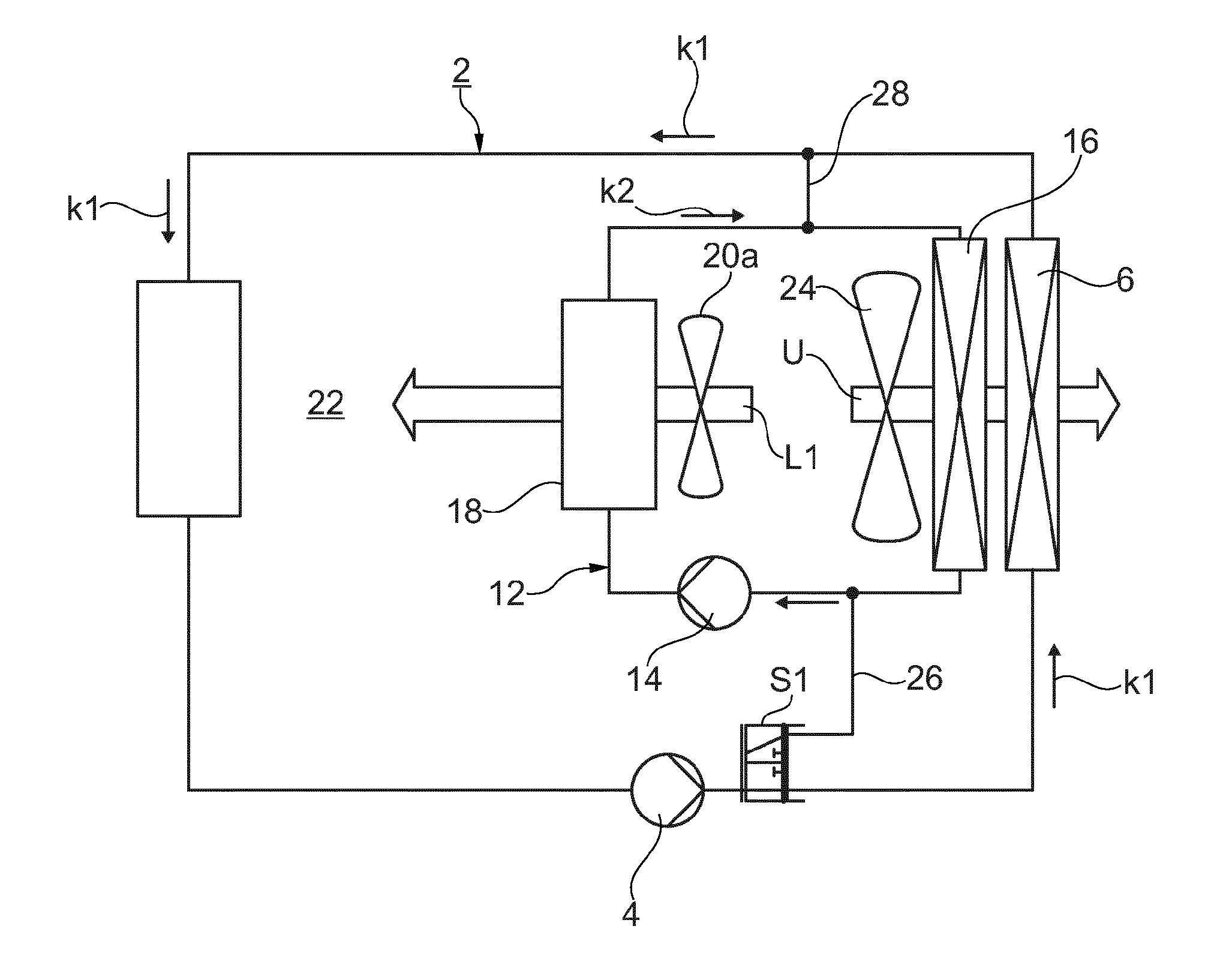

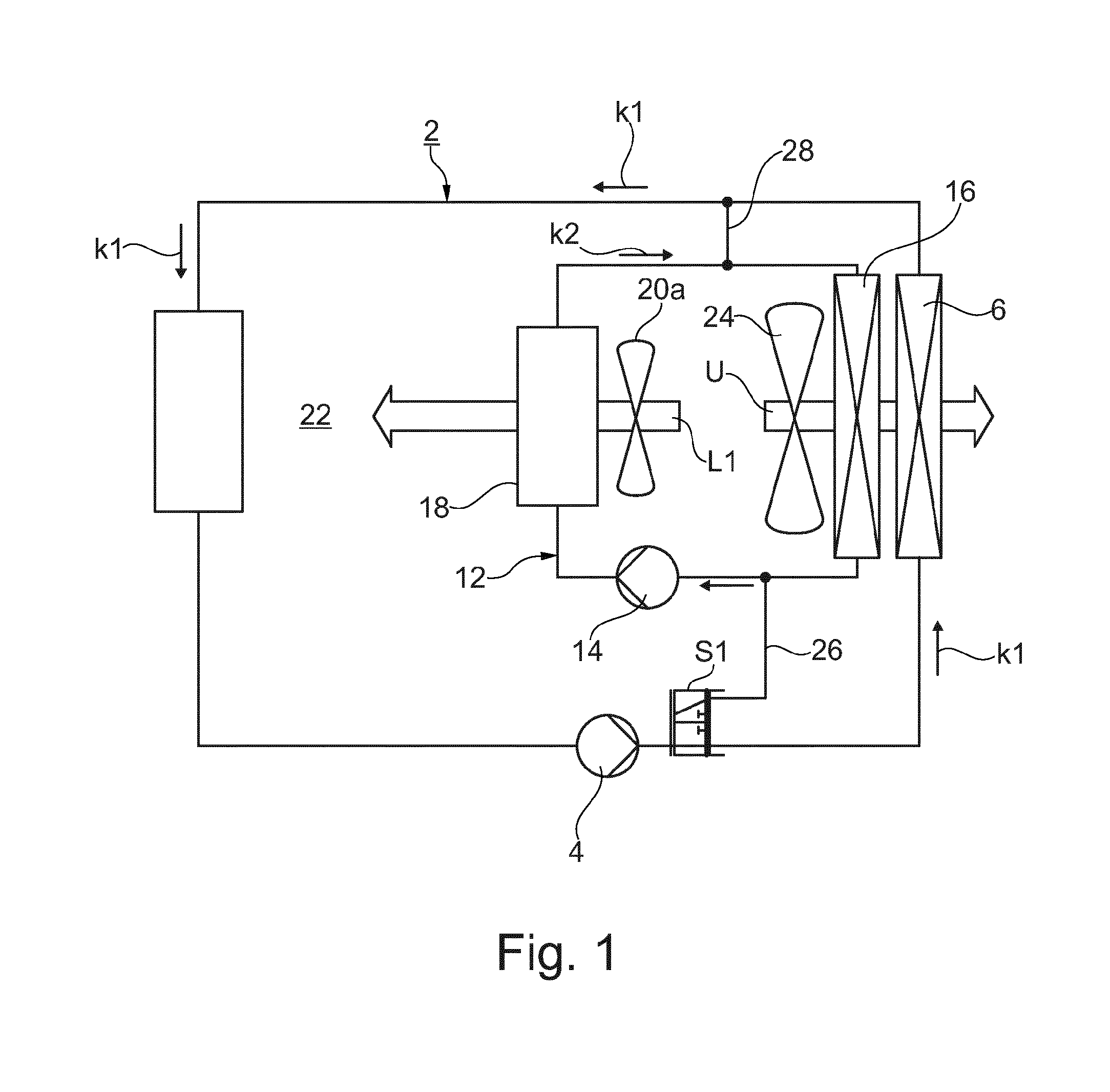

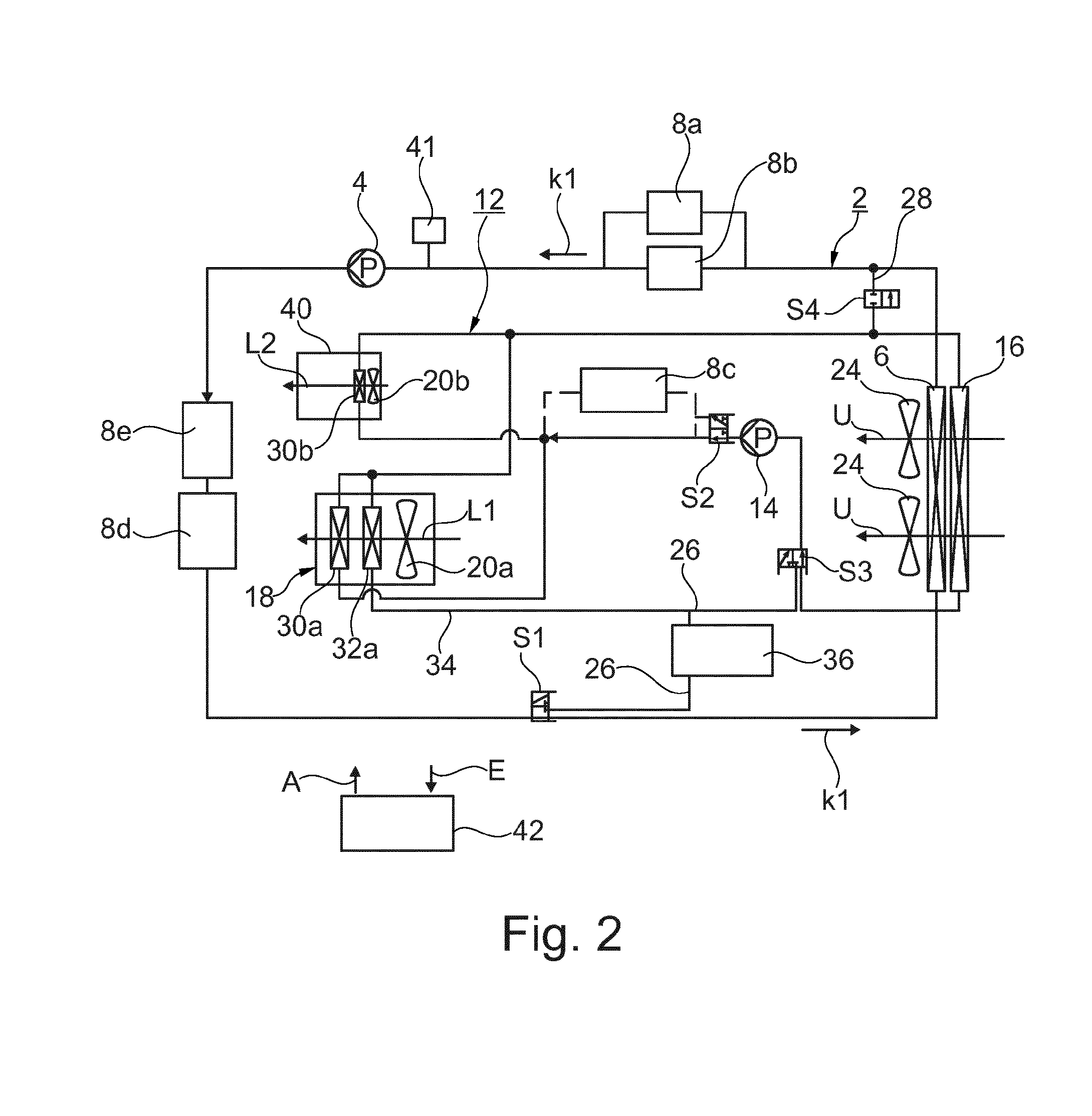

Thermal management for an electric or hybrid vehicle and a method for air-conditioning the interior of such a motor vehicle

ActiveUS20160297280A1Improve energy efficiencyEasy to adjustAir-treating devicesVehicle heating/cooling devicesMobile vehicleTemperature control

An energy-efficient thermal management system for an electric or hybrid vehicle is provided. The system has a first coolant circuit for controlling the temperature of electric components of an electric powertrain, an air-conditioning unit being provided for air-conditioning an interior. A second coolant circuit air-conditions the interior and is operable independently of the first coolant circuit. Each coolant circuit comprises a pump and a respective ambient heat exchanger. In order to control the temperature of the interior, a temperature control device which can be designed as a Peltier module is integrated into the second coolant circuit, said temperature control device operating in the manner of a heat pump for heating purposes. The two coolant circuits can be coupled to each other in order to exchange heat. An additional temperature control device can be integrated in order to air-condition an interior component in a decentralized manner, in particular a seat.

Owner:GENTHERM GMBH +2

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Ampholytic surfactant fracturing fluid and preparation method thereof

The invention relates to ampholytic surfactant fracturing fluid and a preparation method thereof. The ampholytic surfactant fracturing fluid comprises the following components in percentage by mass: 3 to 5 percent of ampholytic surfactant, 0.5 to 1 percent of anionic surfactant, 2 to 4 percent of inorganic salt, 0.3 to 0.5 percent of alcohol with low molecular weight, 0 to 5 percent of pH value regulator, 0.5 percent of clay stabilizer and the balance of water. The preparation method comprises the following steps of: adding the ampholytic surfactant, the anionic surfactant, the alcohol with low molecular weight, the pH value regulator, and the clay stabilizer into water, stirring for 5 to 10 minutes to obtain uniform and stable suspension, adding the inorganic salt, and stirring for 1 to 2 minutes to obtain fluid with high visco-elasticity. The ampholytic surfactant fracturing fluid is used for fracturing of an oil and gas field of which the formation temperature is 60 to 80 DEG C, residues are avoided after gel breaking, and a stratum is not damaged.

Owner:PETROCHINA CO LTD

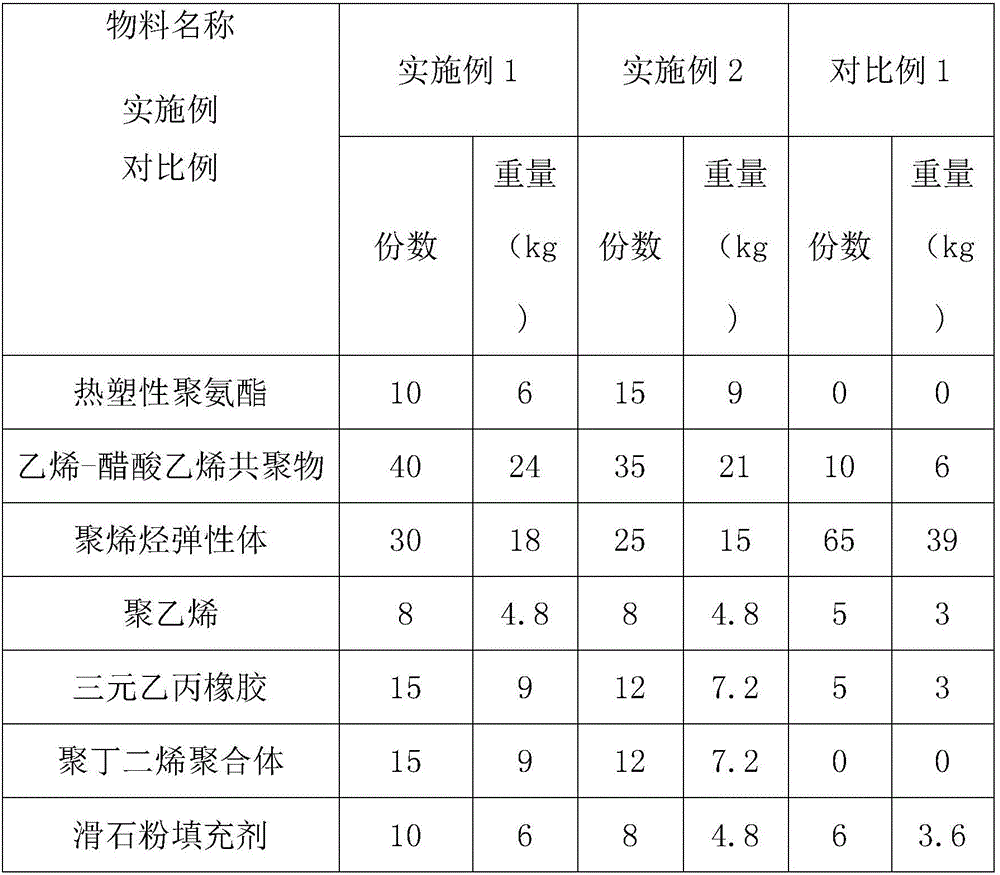

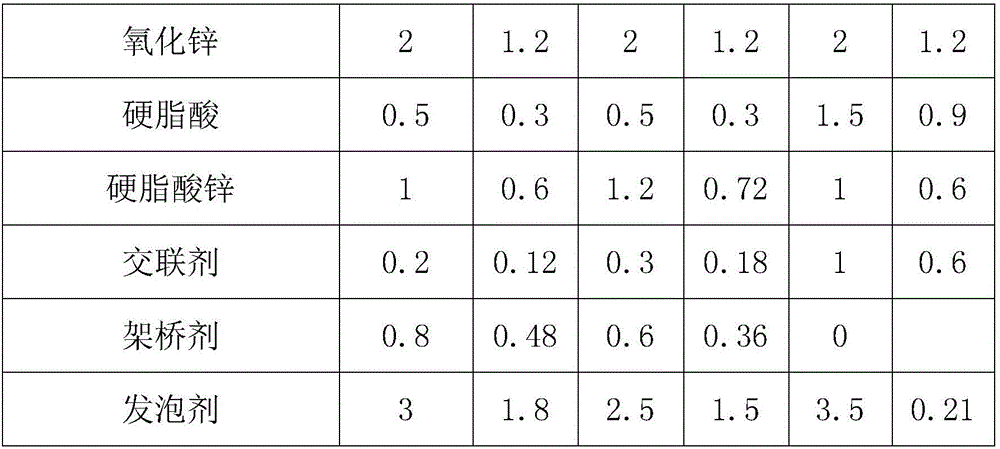

Thermoplastic polyurethane composite foamed material and preparation method thereof

The invention provides a thermoplastic polyurethane composite foamed material and a preparation method thereof. The thermoplastic polyurethane composite foamed material is prepared from 10-25 parts of polyurethane, 35-45 parts of ethylene-vinyl acetate copolymers, 15-30 parts of polyolefin elastomers, 6-10 parts of polyethylene, 6-18 parts of ethylene propylene diene monomers, 6-15 parts of polybutadiene polymers, 3-5 parts of filler, 1.5-2.2 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 0.8-1.4 parts of zinc stearate, 0.1-0.4 parts of a cross-linking agent, 0.7-1.0 part of a bridging agent and 2.5-3.5 parts of a foaming agent. The thermoplastic polyurethane composite foamed material is high in rebound resilience, resistant to compression and good in tear resistance. The preparation method of the thermoplastic polyurethane composite foamed material comprises steps as follows: 1) components except zinc oxide, the cross-linking agent, the bridging agent and the foaming agent are weighed; 2) all the components weighed in the step 1) are mixed; 3) the rest components are weighed; 4) the components weighed in the step 3) are added to a material obtained after mixing in the step 2) for mixing; 5) granulation is performed; 6) foaming is performed.

Owner:ANTA CHINA

Circuit breaker and current transformer for corresponding circuit breaker

ActiveCN101685725ALittle elasticityProtective switch detailsVariable inductancesElectricityMagnetic tension force

The present invention relates to a circuit breaker and a current transformer (1) for the corresponding circuit breaker, wherein the circuit breaker is used for disconnecting primary current that passes in a conductor; the primary current supplies electricity to the circuit needed protecting, wherein a disconnecting device for disconnecting is provided, and wherein the current transformer (1) supplies electricity to the disconnecting device, and the current transformer (1) is provided with a main magnetic circuit (5) passing around the conductor (2), and at least a secondary winding (6) with an iron core formed by a part of the main magnetic circuit (5). A magnetic branch (7) is mounted in parallel to the core of the secondary winding (6), wherein the branch has additional magnetic resistance. The additional magnetic resistance is reduced automatically for current higher than rated current of the breaker, in case of short circuit, by magnetic forces producing in the branch to obtain anefficient reduction of magnetic resistance in the parallel branch (7).

Owner:SUZHOU SIEMENS ELECTRIC APPLIANCE

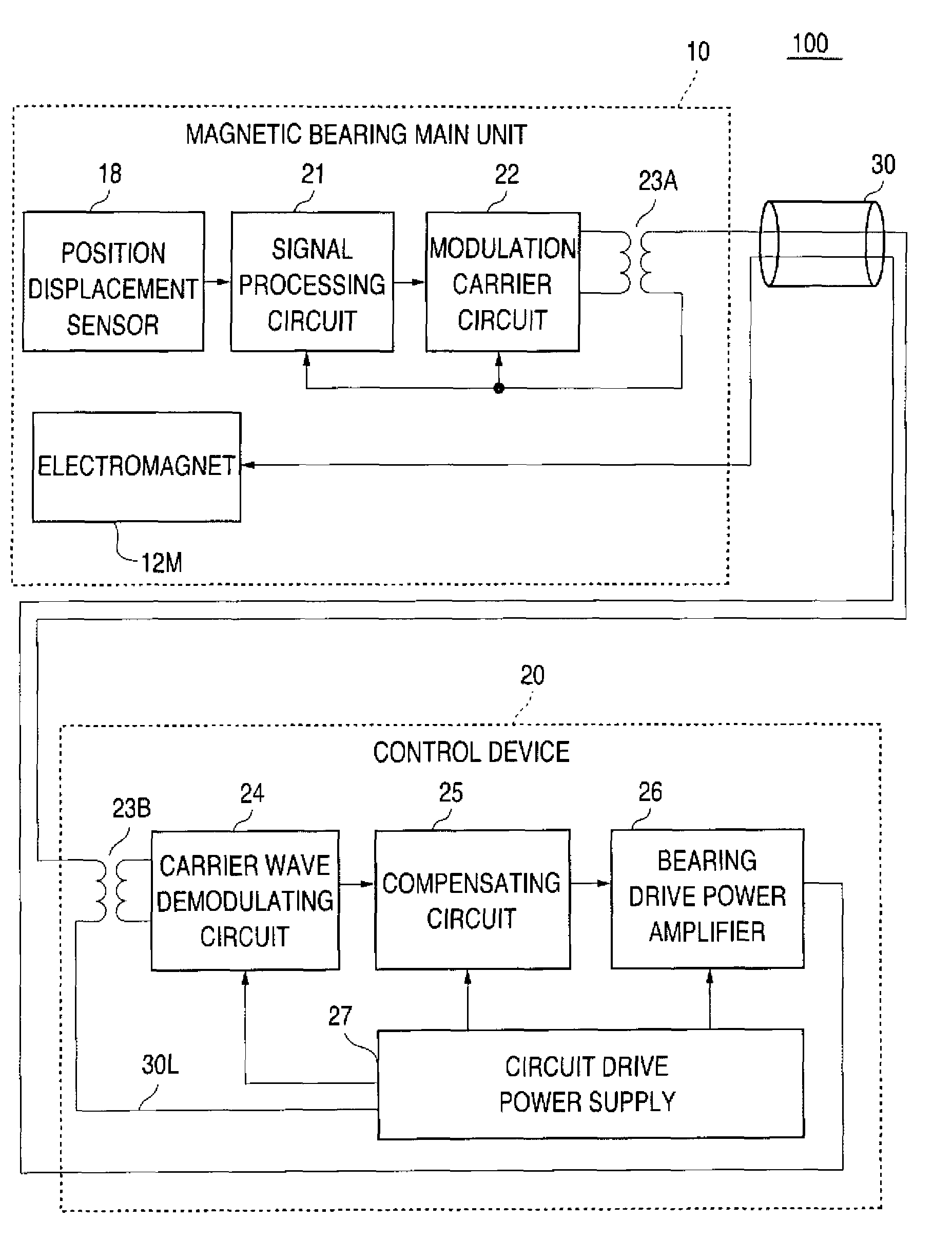

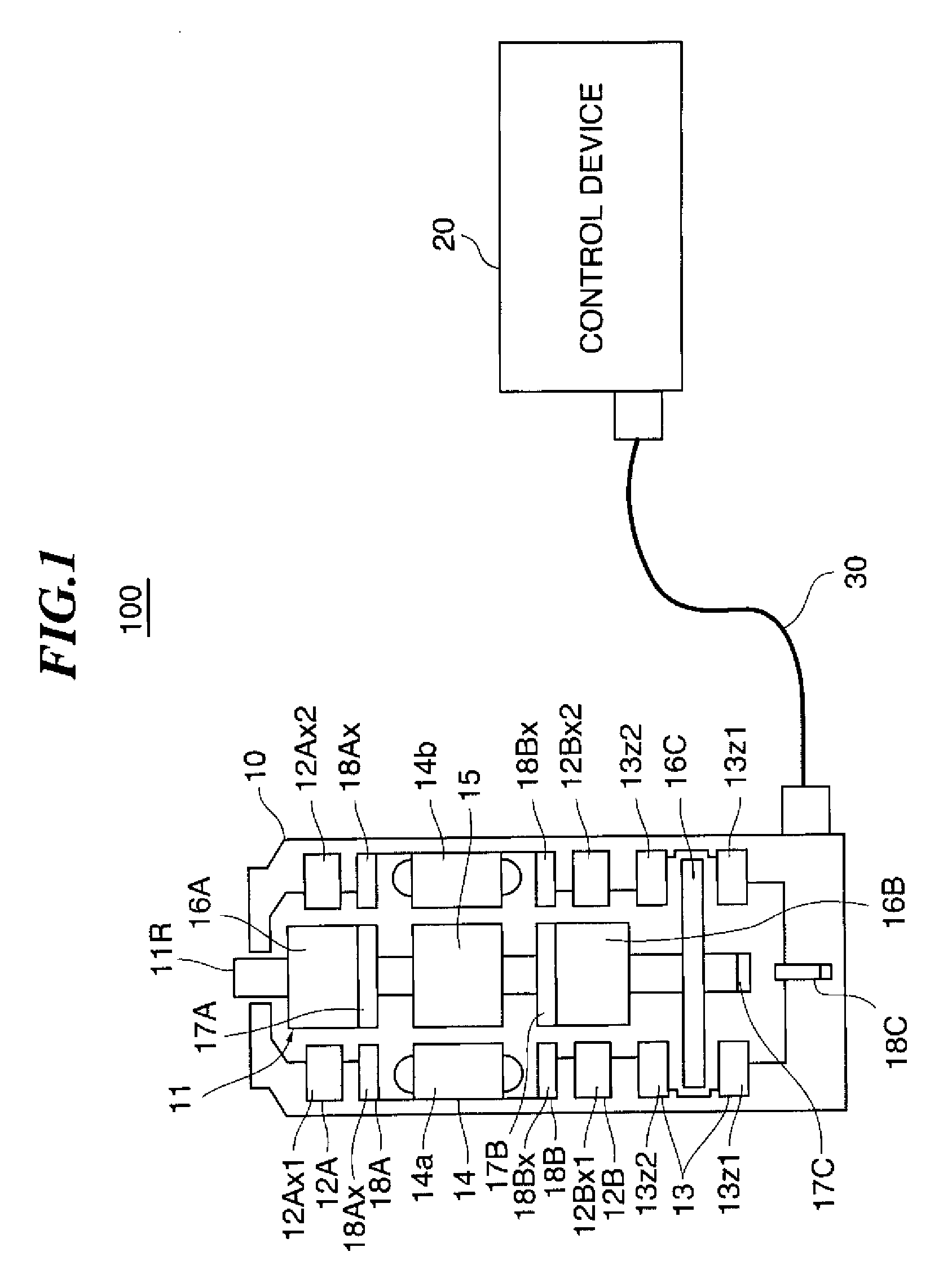

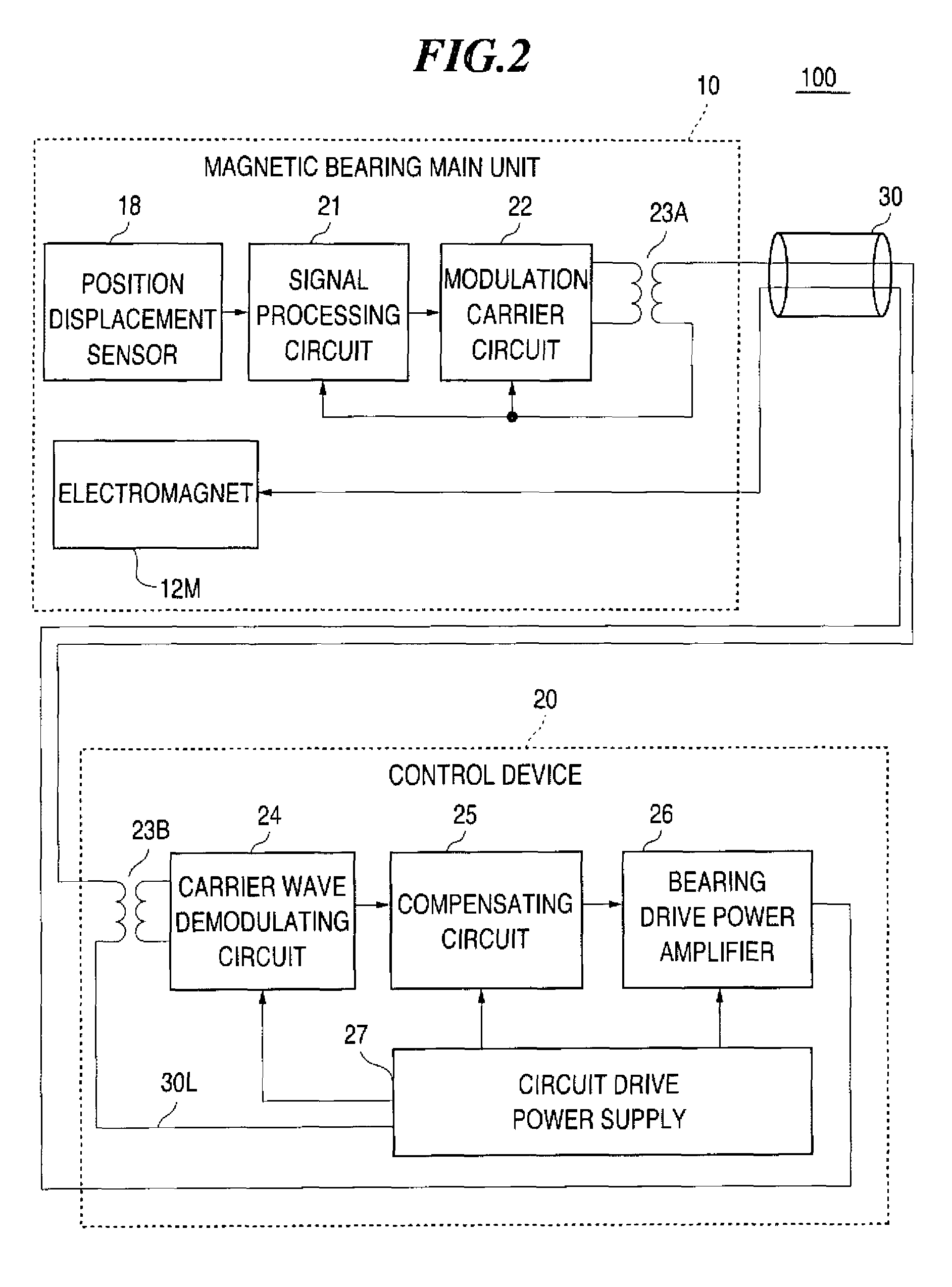

Magnetic bearing device, rotating mechanism, and model identification method of rotating machinery main unit

ActiveUS7737590B2Little elasticityWeight increaseMultiple dynamo-motor startersBearing assemblyElectricityMagnetic bearing

Problem of the present invention is to enable elimination or reduction of a signal wire in a dedicated cable for a magnetic bearing device for supplied an electric power from a control device to a magnetic bearing main unit via the dedicated cable. A magnetic bearing device 100 according to the present invention has a magnetic bearing main unit 10 having an electromagnet 12M for magnetically levitating and rotatably supporting a magnetic rotating body 11 and functioning as a magnetic bearing, a control device 20 having a compensating circuit 25 for generating a control signal for controlling a levitation position of the magnetic rotating body 11, and an electricity supply line 30L for supplying an electric power from the control device 20 to the magnetic bearing main unit 10. The magnetic bearing main unit 10 has a modulation carrier circuit 22 for generating a modulated wave and a first alternating-current coupling section 23A for transmitting the generated modulated wave to the control device 20 by the alternating-current coupling with the electricity supply line 30L. The control device 20 has a second alternating-current coupling section 23B for separating the modulated wave alternating-current coupled from the electricity supply line 30L and a carrier wave demodulating circuit 24 for detecting the separated carrier signal wave.

Owner:EBARA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com