Patents

Literature

38results about How to "Strong damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

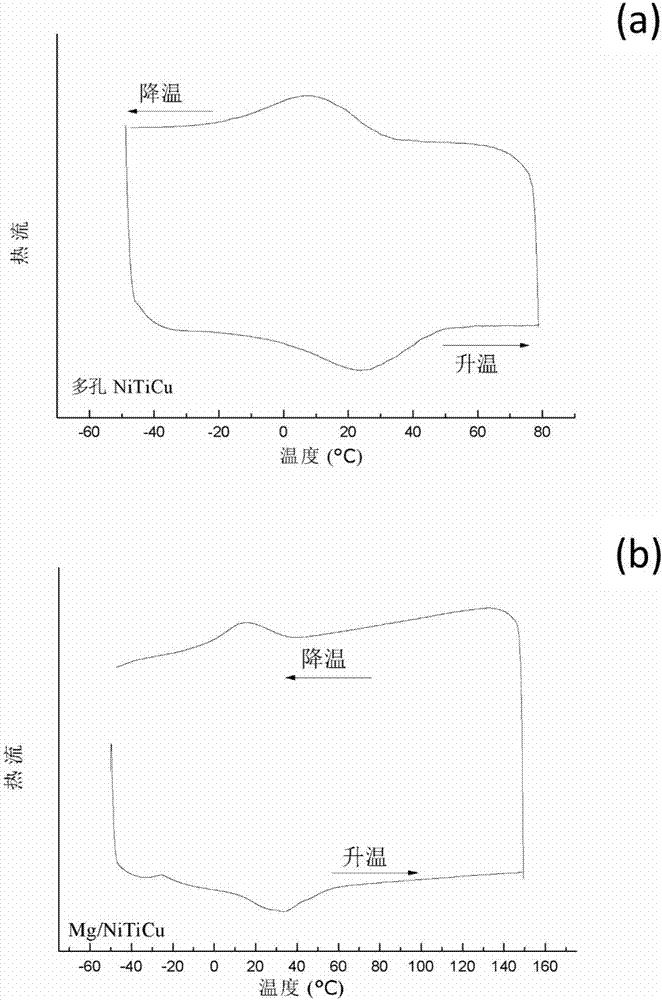

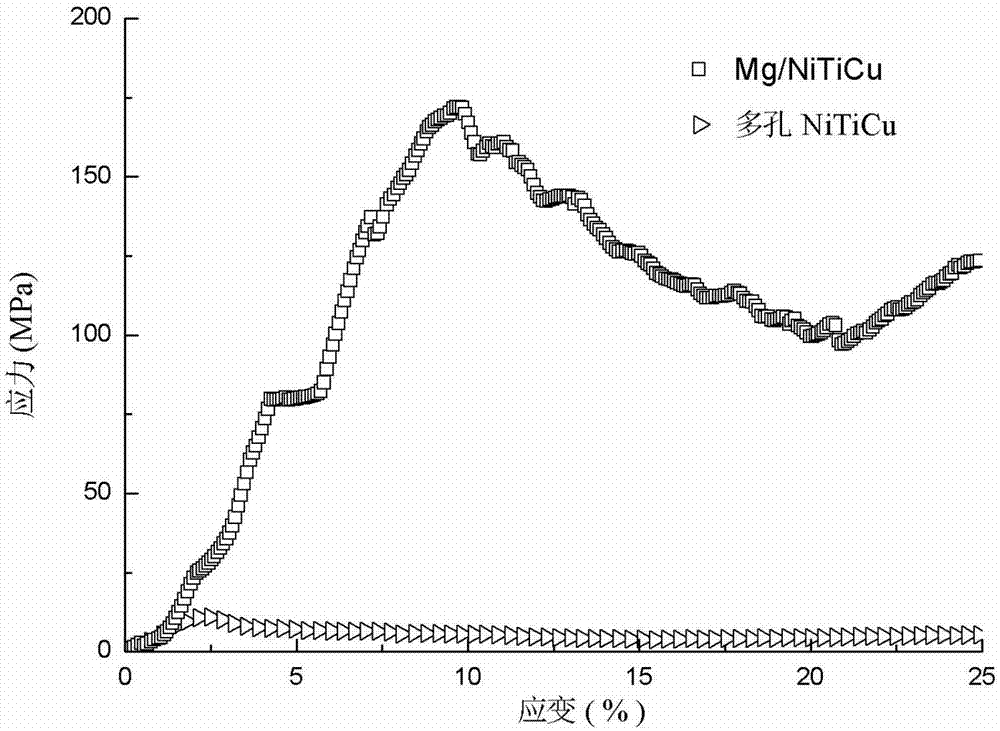

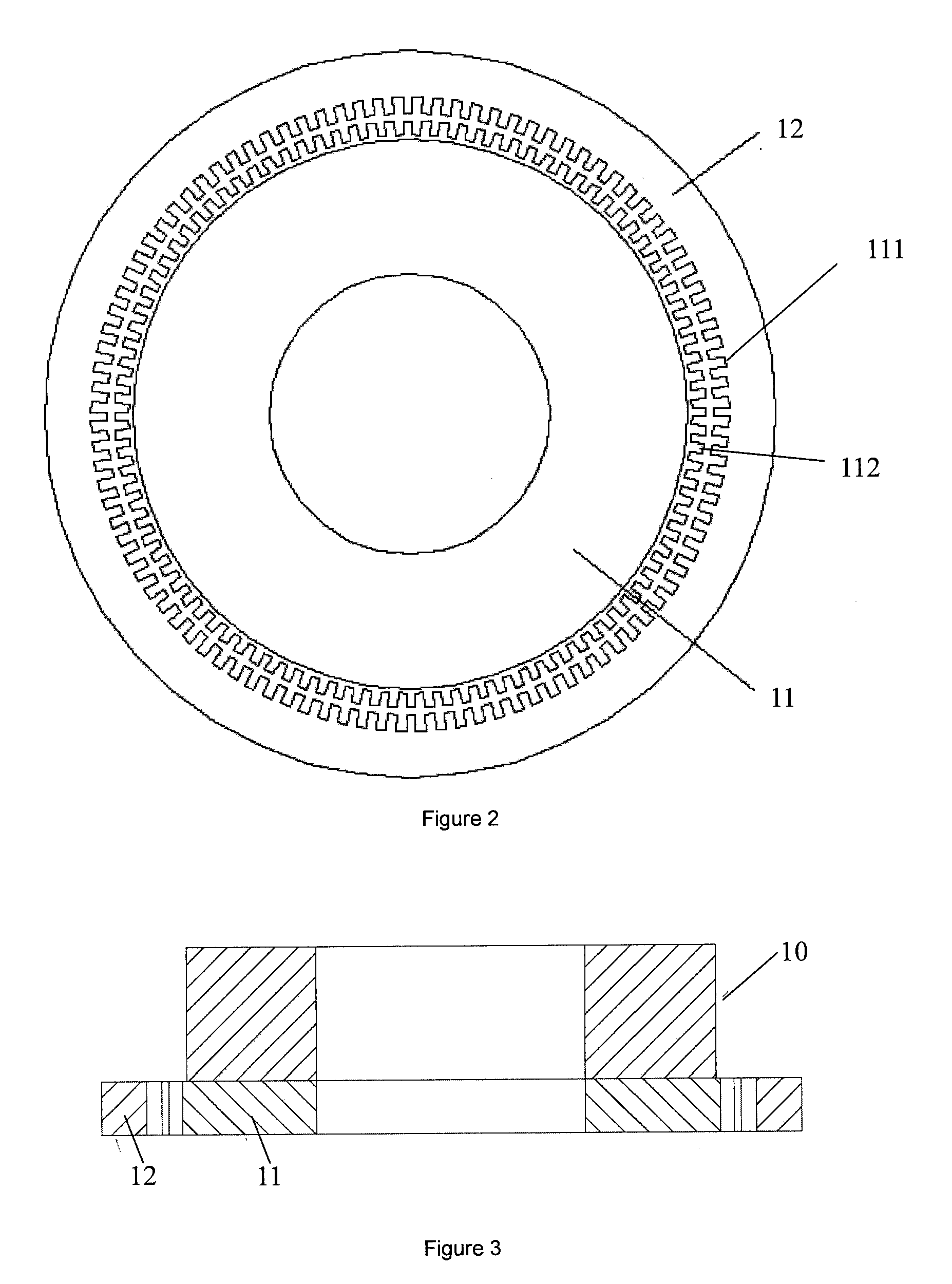

Preparation of composite type light high-strength nickel-titanium memory alloy-based high damping material

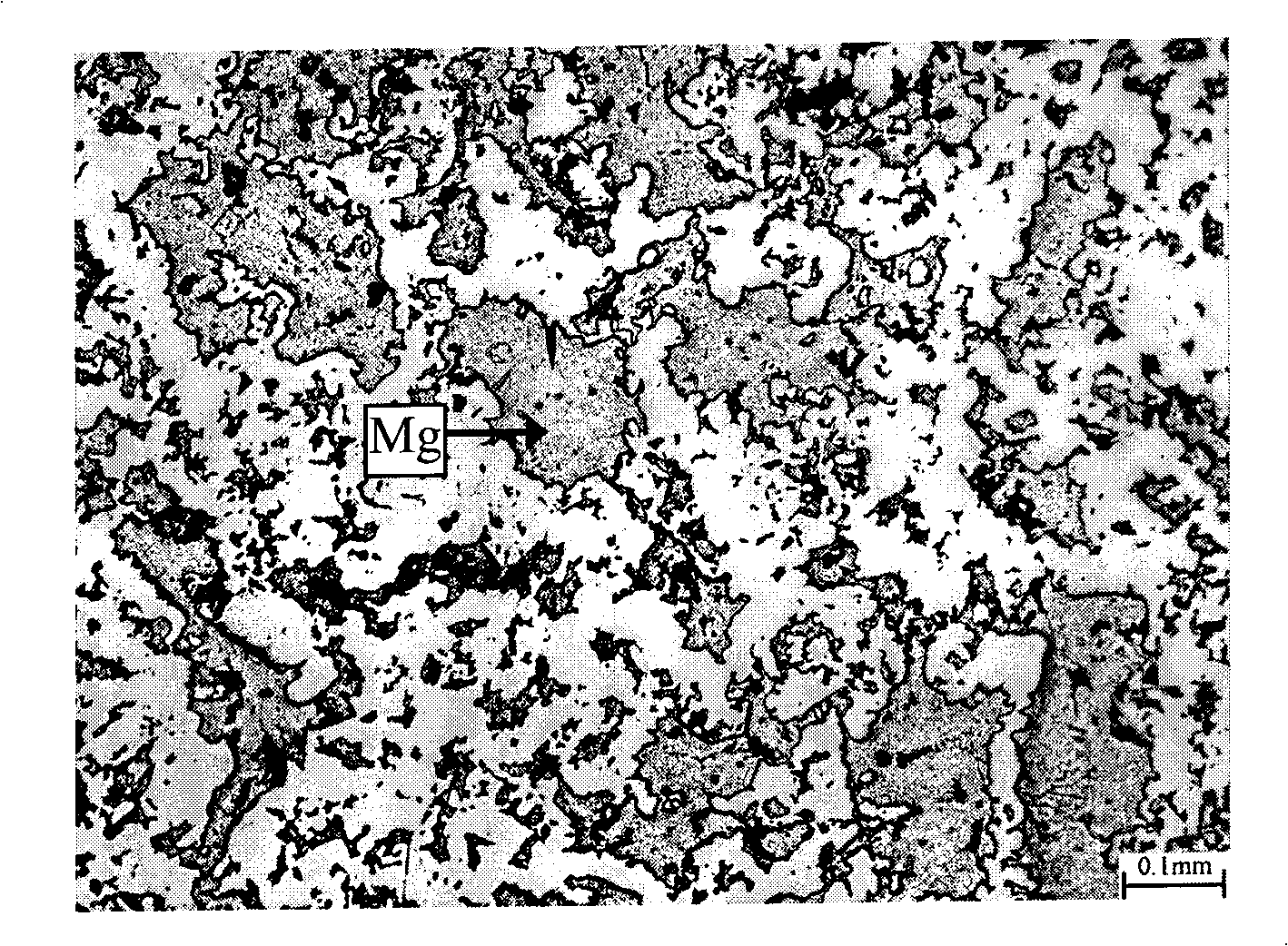

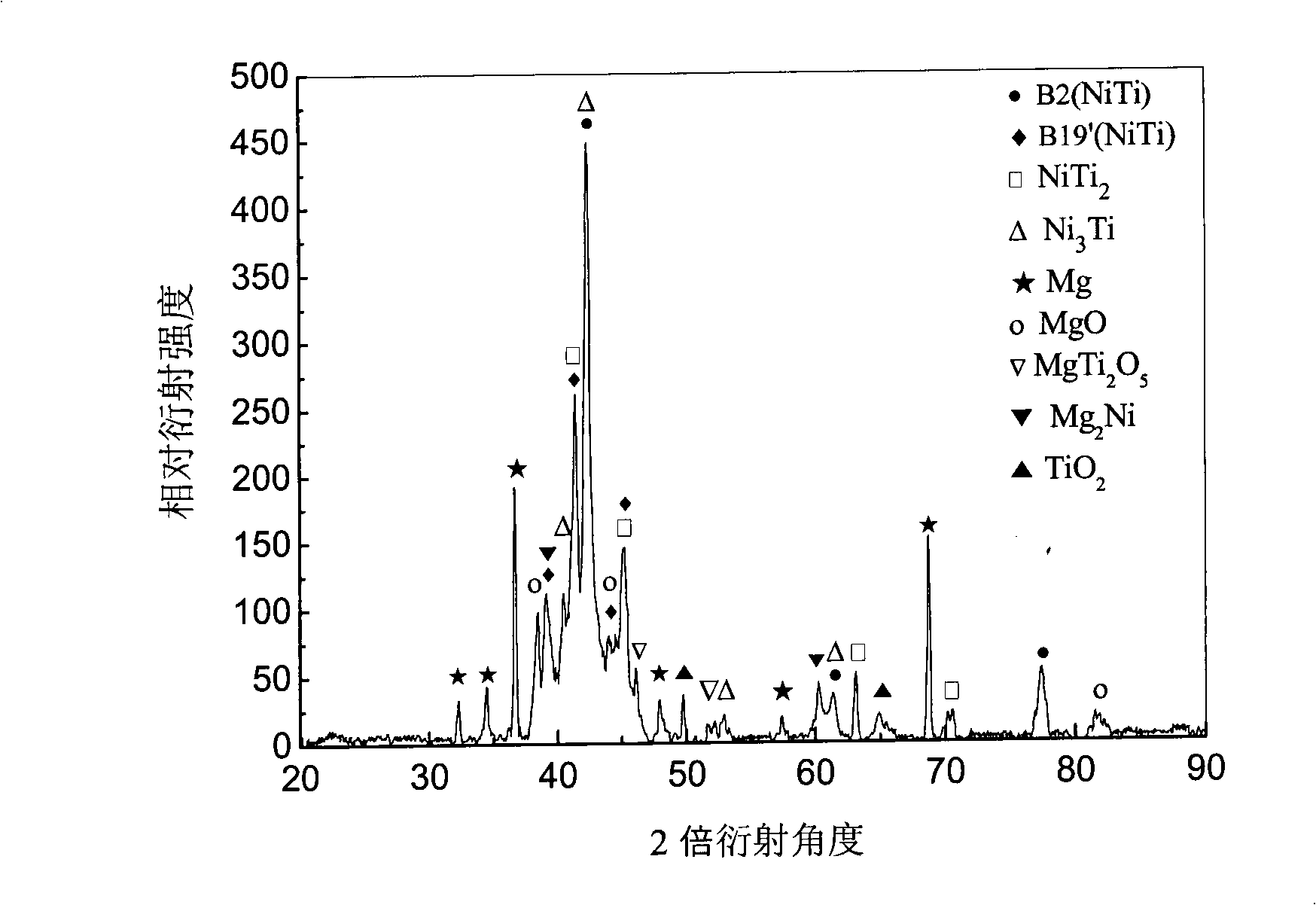

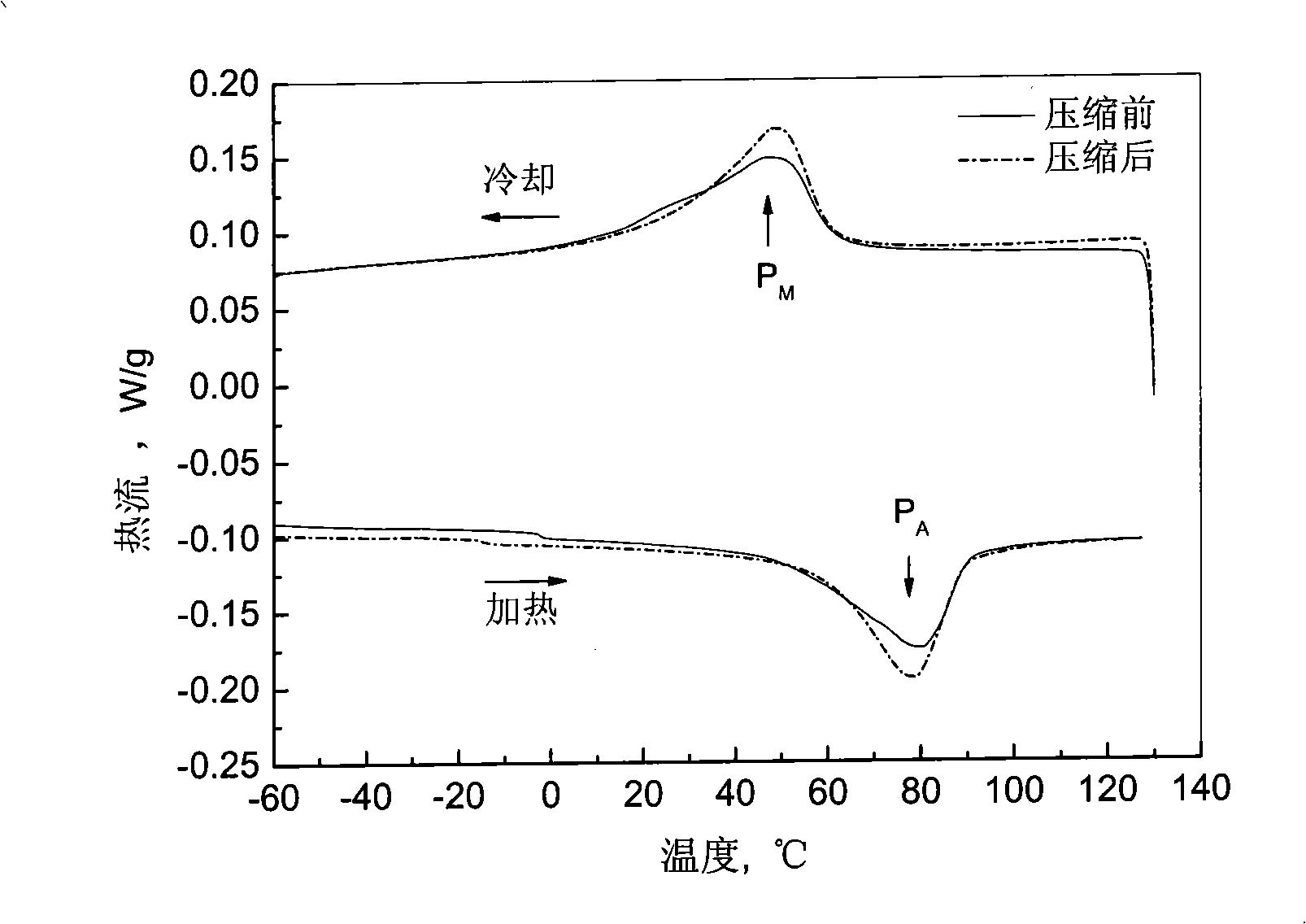

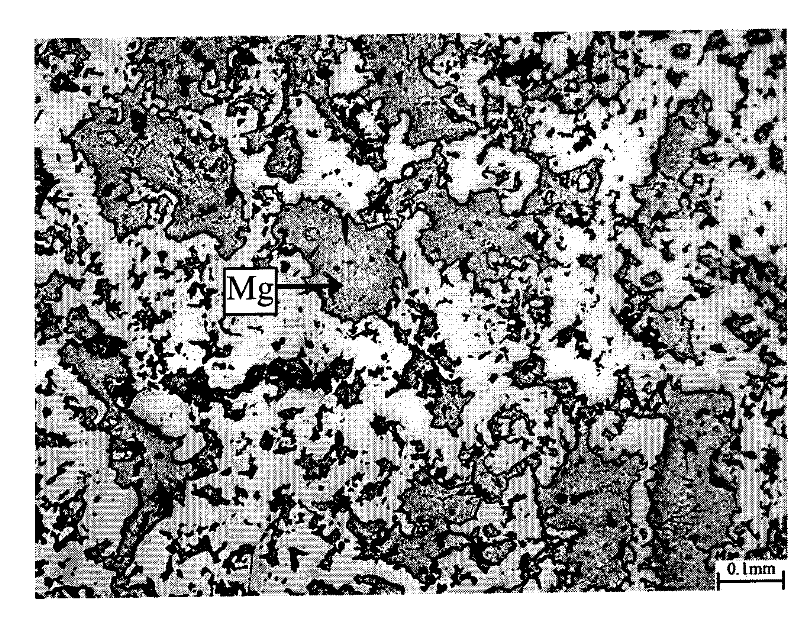

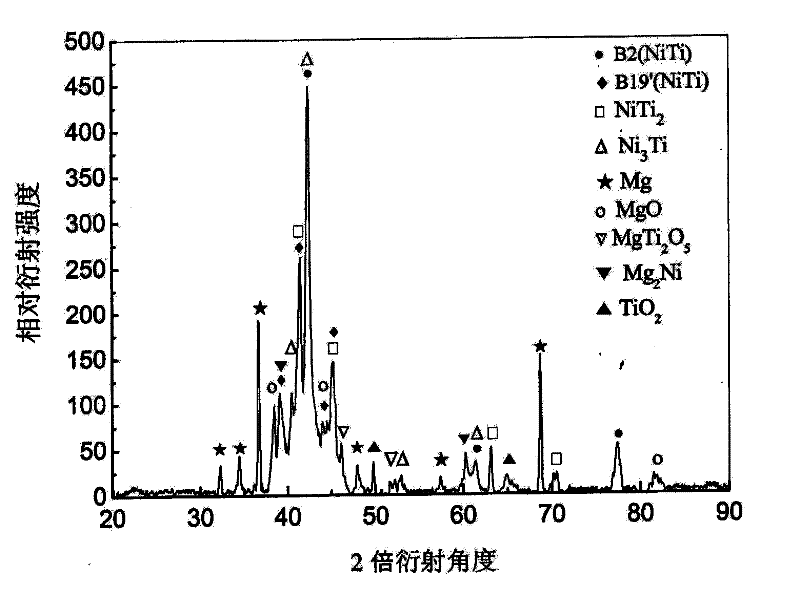

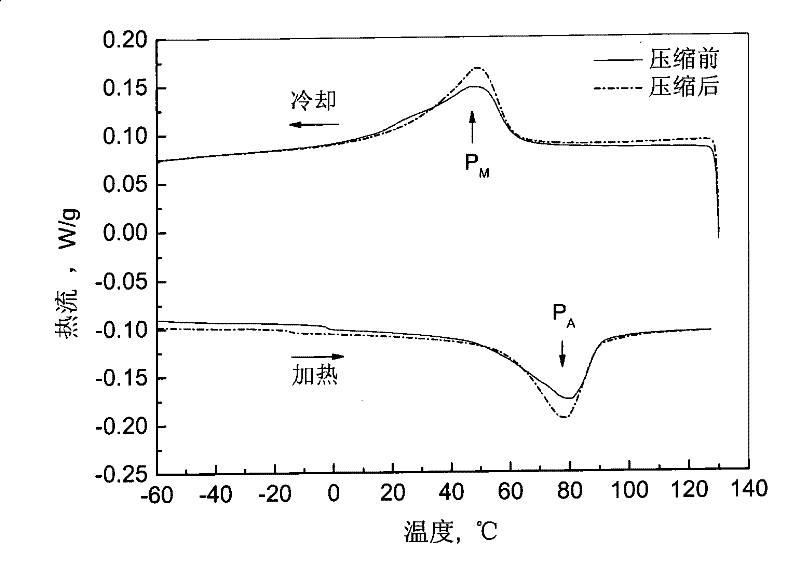

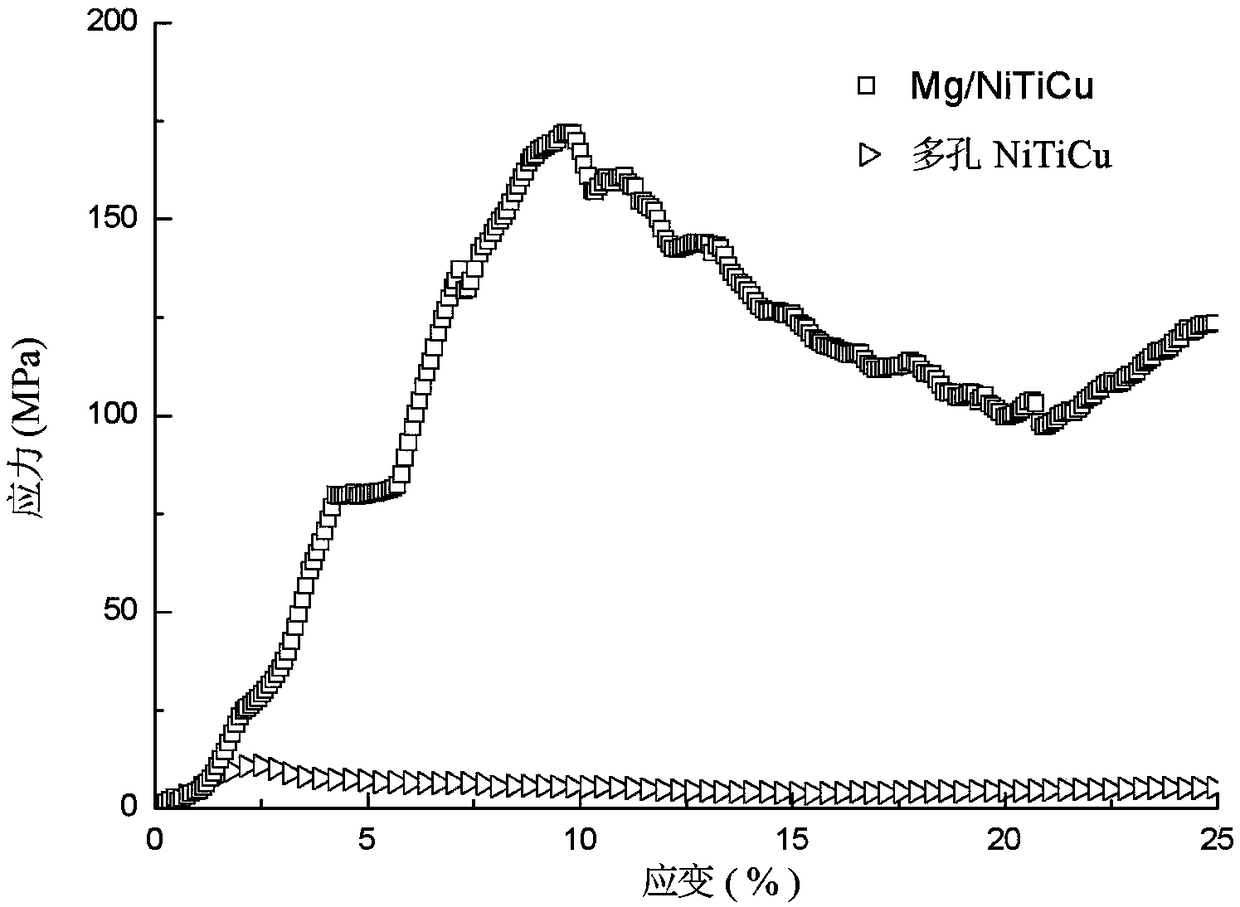

The invention discloses a preparation method of a compound type light-weight high-intensity nickel-titanium memorial alloy base high damping material. In the method, a powder sintering method is mainly used as a foundation and a pressureless infiltration technology is used as assistance; a pore-creating technology is firstly adopted; and a unit metal powder cascade sintering method is used for preparing a porous nickel-titanium alloy the holes of which are uniformly distributed; and then the pressureless infiltration technology is adopted for inducing the pure magnesium or magnesium alloy phase with high intrinsic damping, low density and micron scale into the porous nickel-titanium alloy, thereby preparing the high-damping magnesium(or magnesium alloy) / nickel-titanium memorial alloy base compound material the damping control phase of which is magnesium or the magnesium alloy. The compound nickel-titanium memorial alloy prepared by the invention still has the shape memory effect and the superelasticity action as well as has weight lighter than that of the compact nickel-titanium memorial alloy and intensity and damping capacity more excellent than that of the common porous nickel-titanium memorial alloy. The preparation method has good technical suitability, simple preparation process and low cost, and can be used for manufacturing the light-weight high-intensity compound damping materials, damping structures and apparatuses.

Owner:SOUTH CHINA UNIV OF TECH

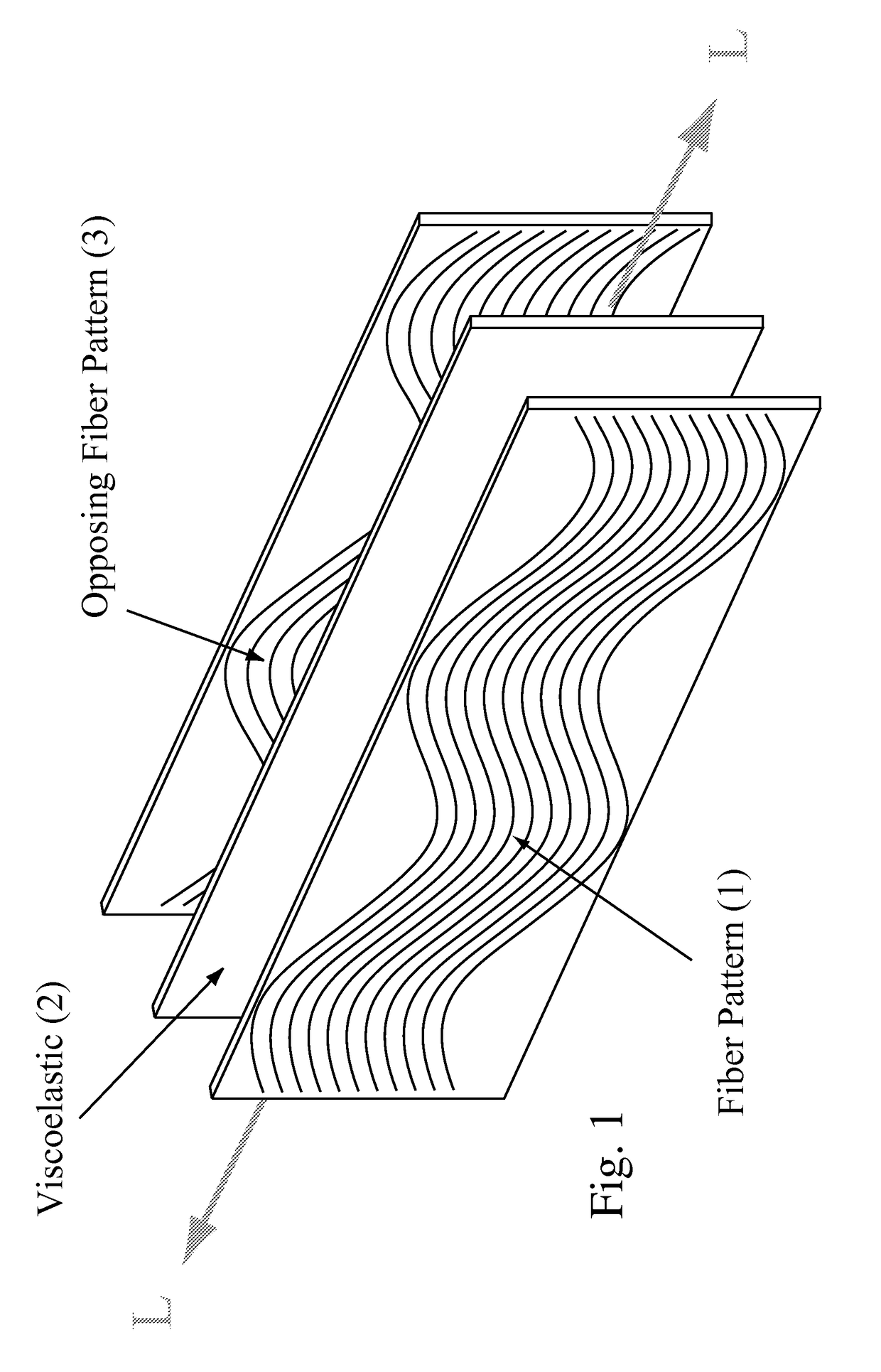

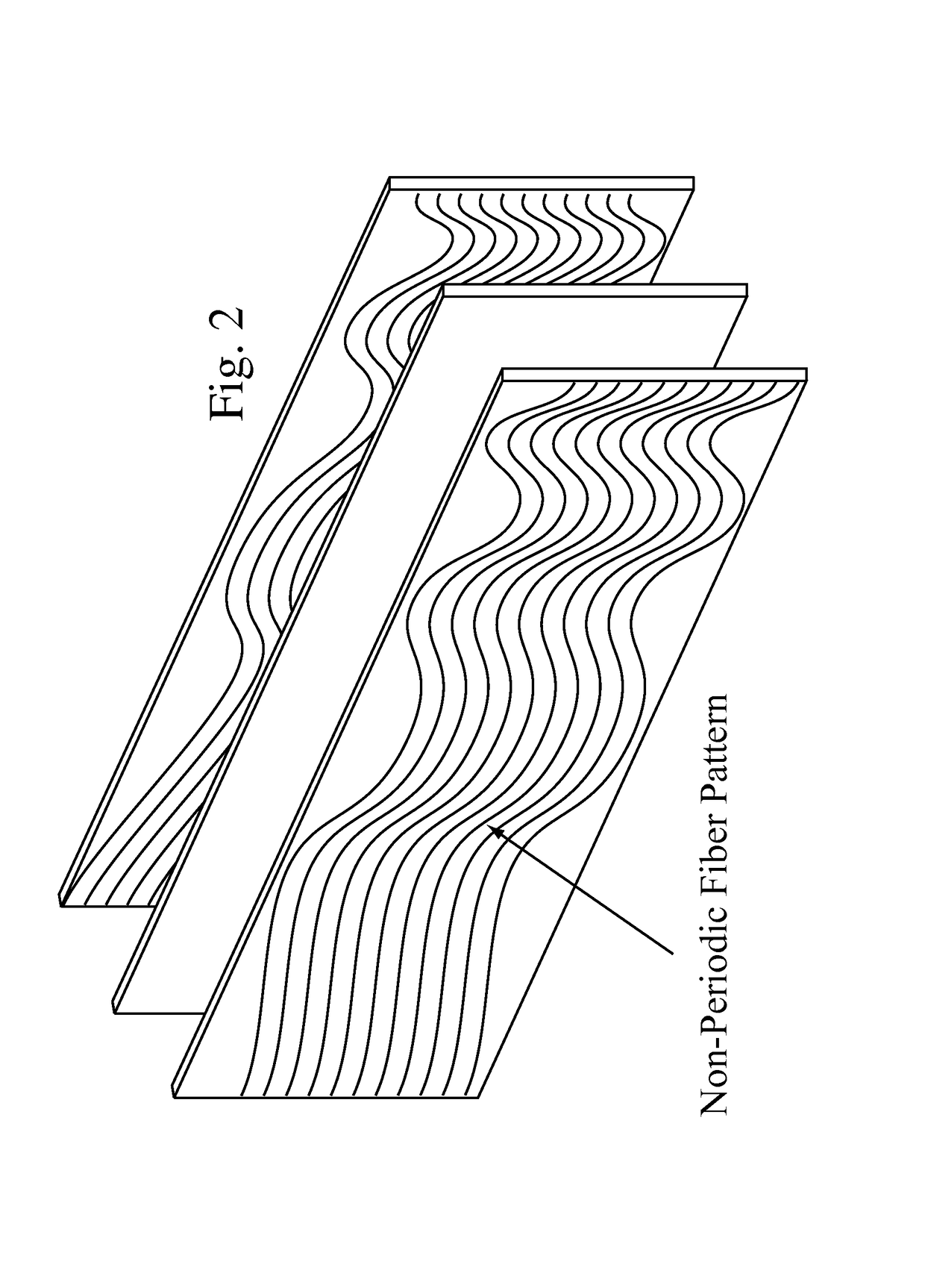

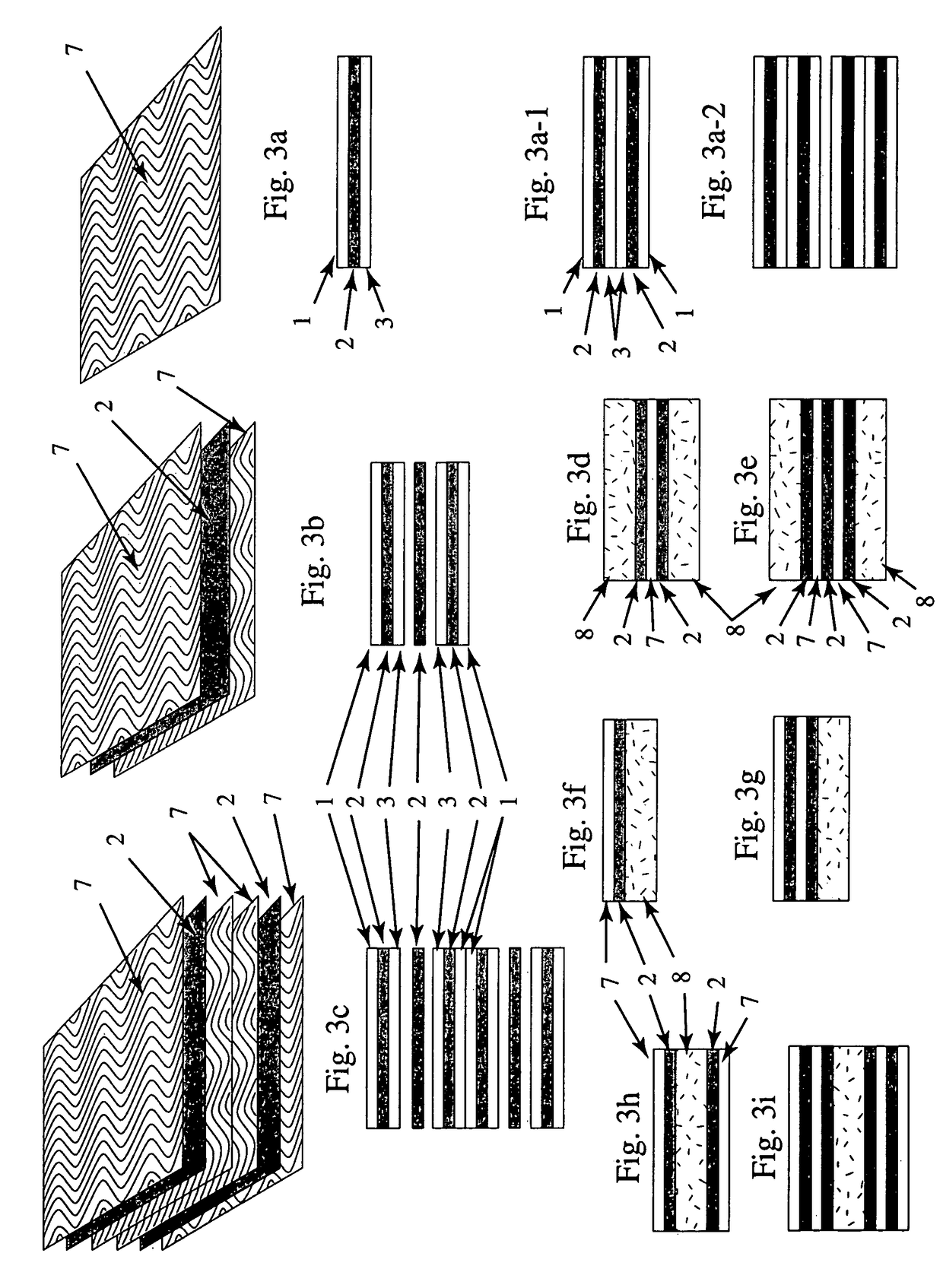

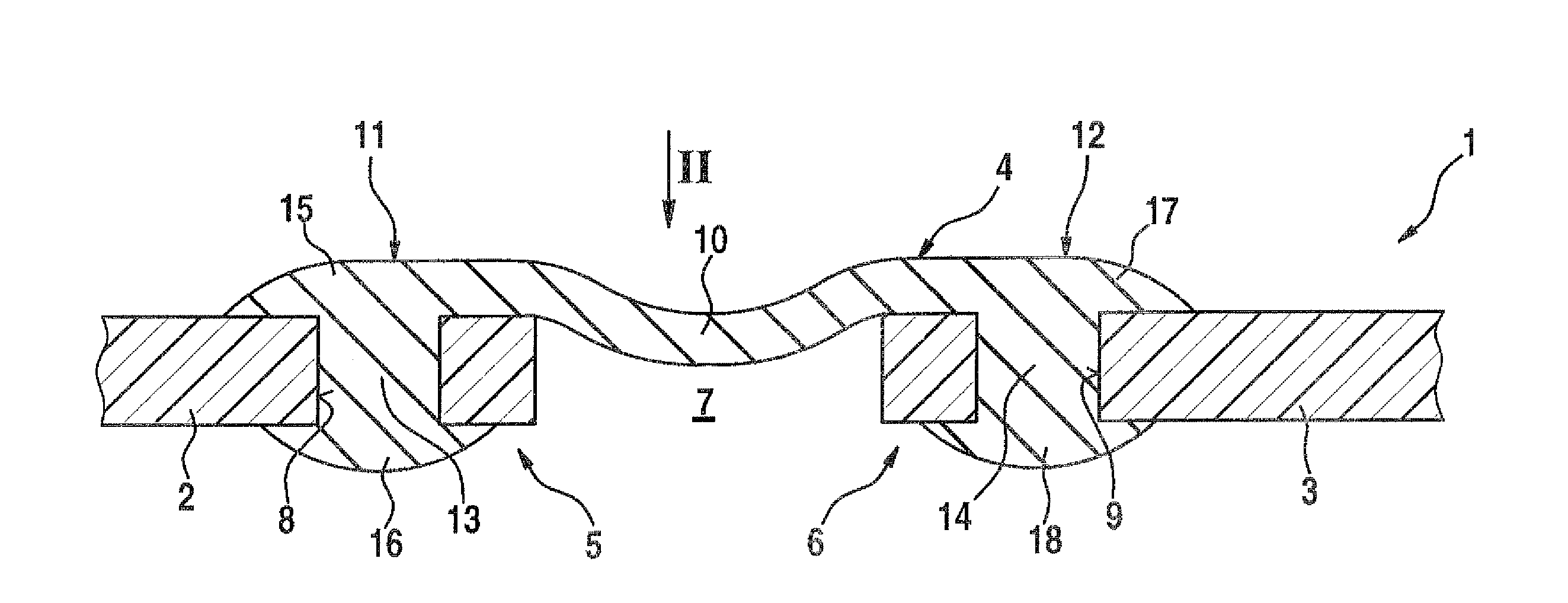

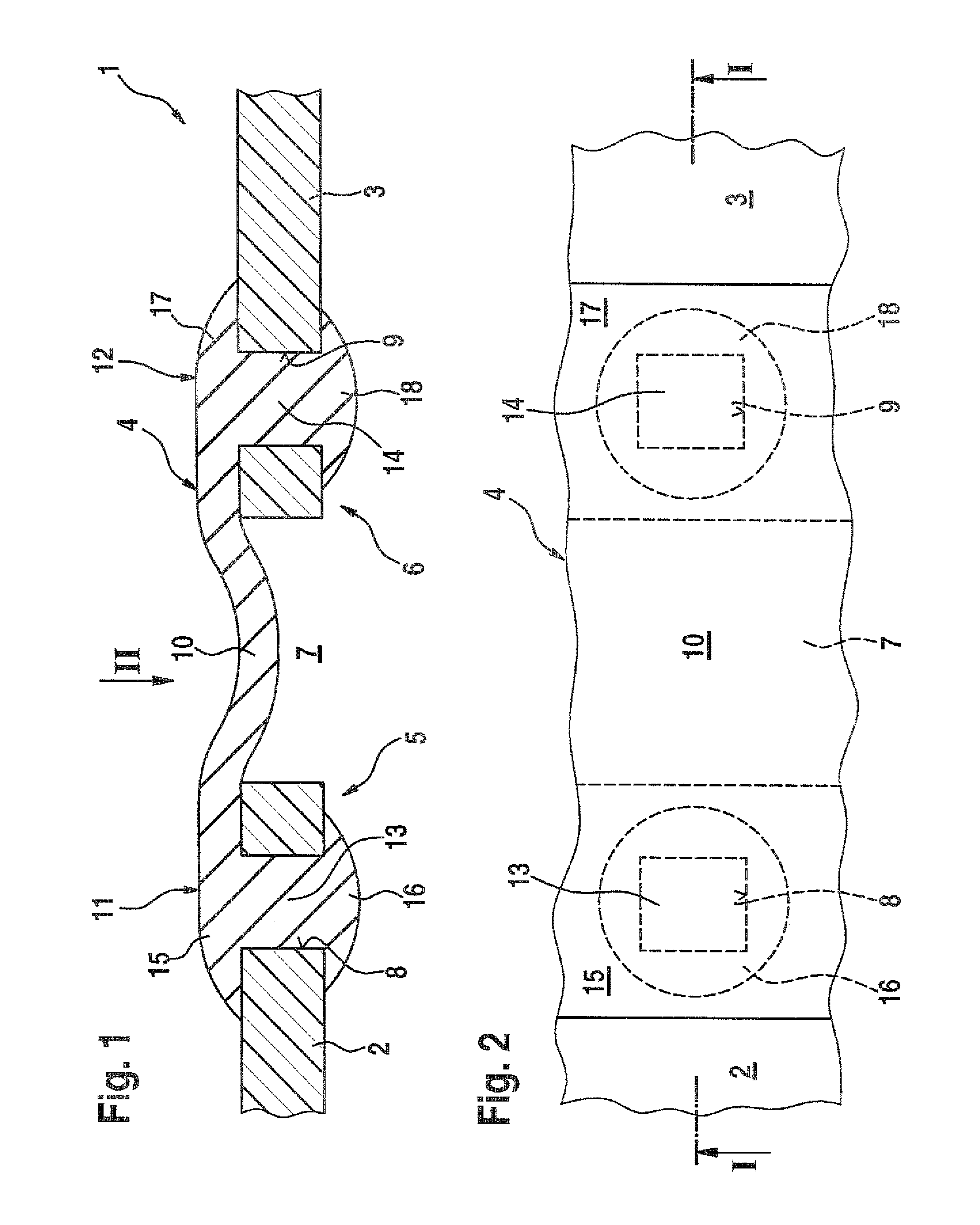

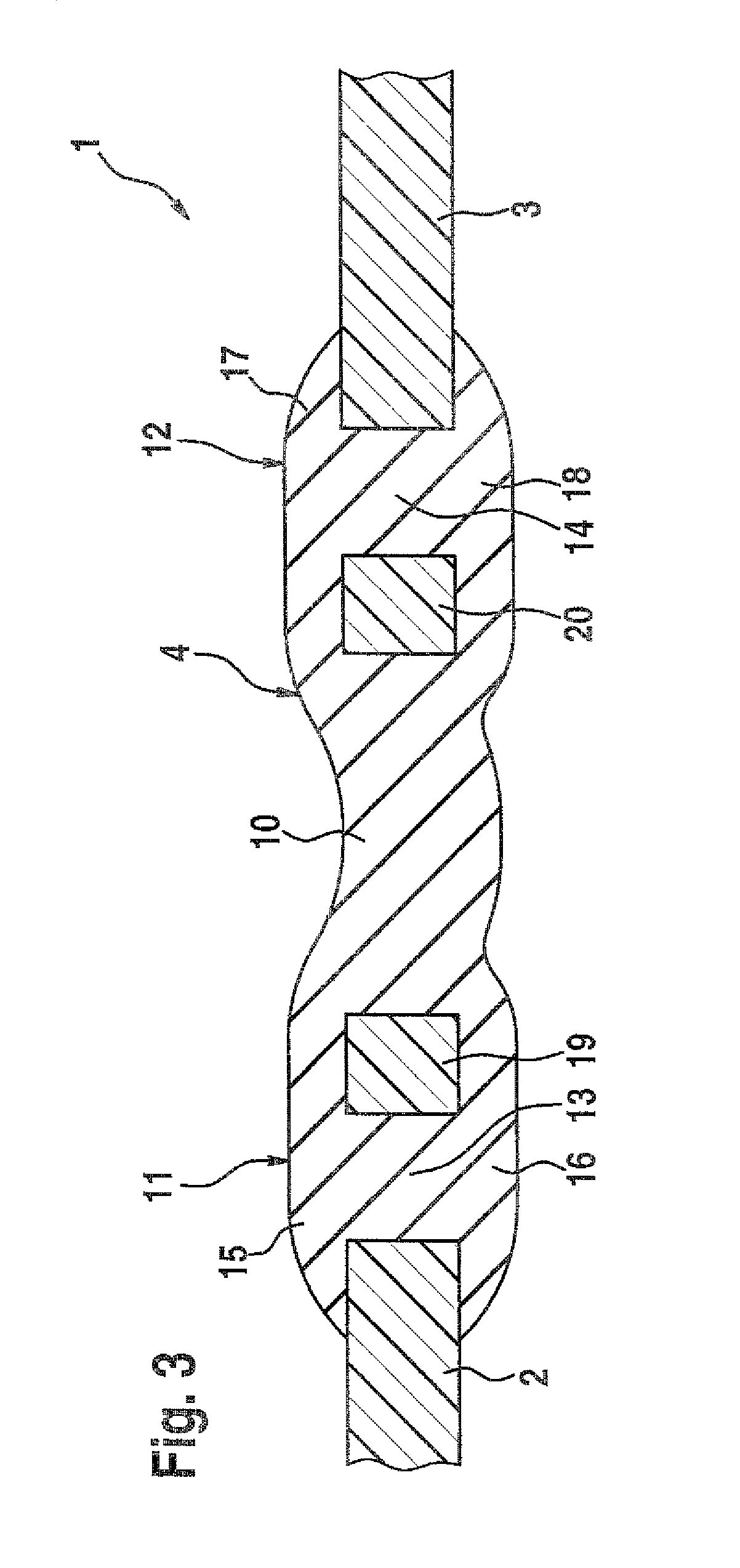

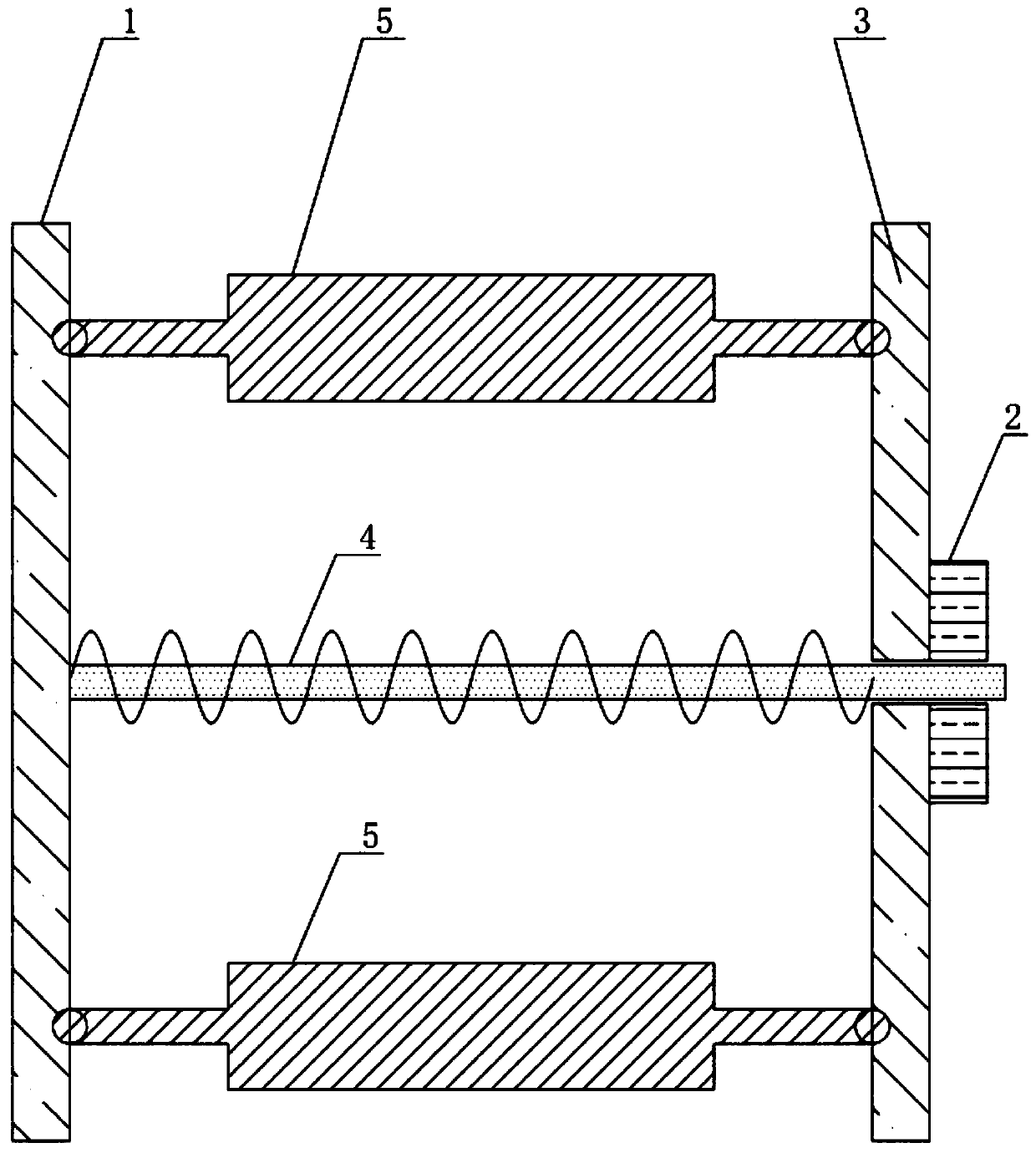

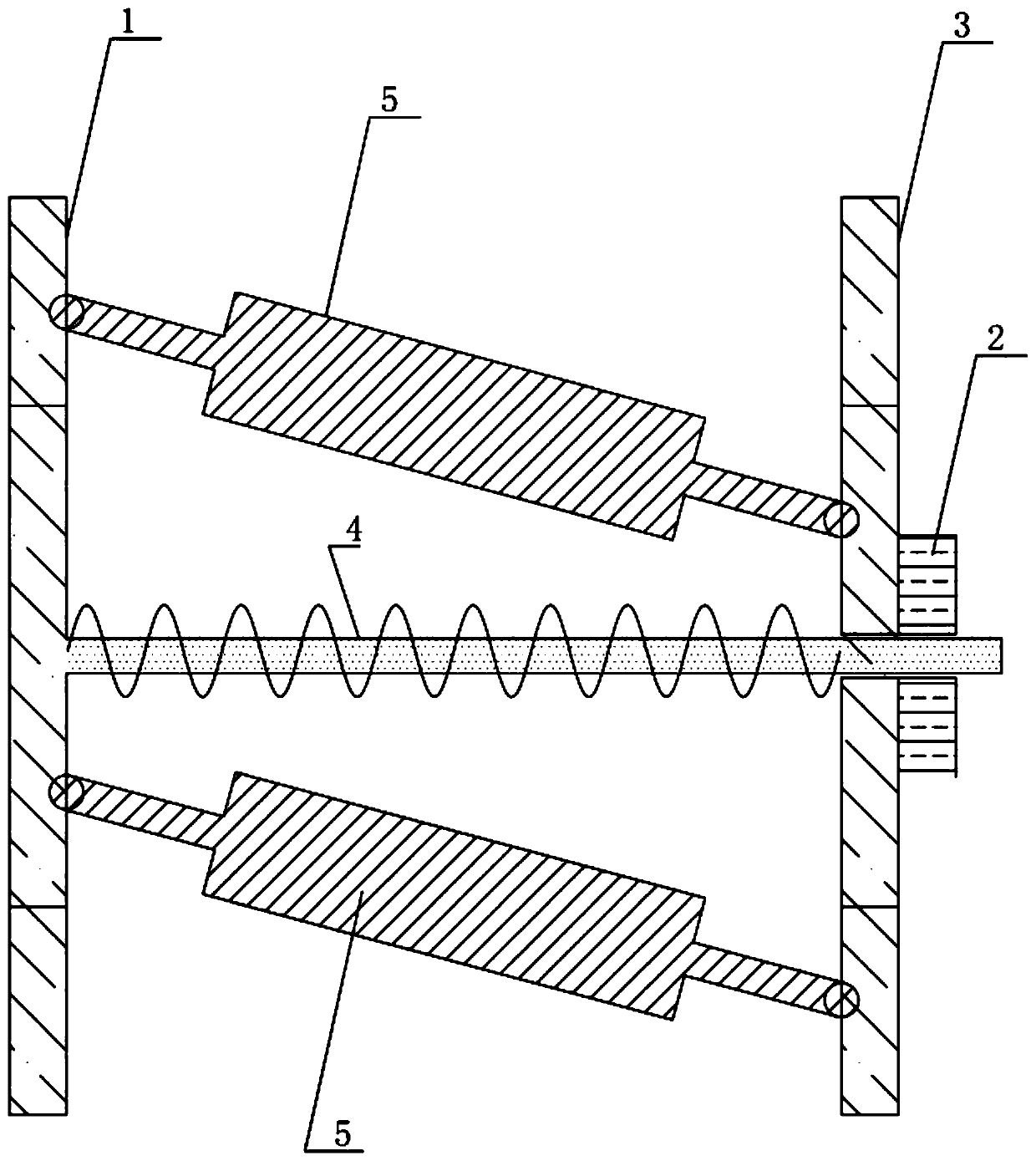

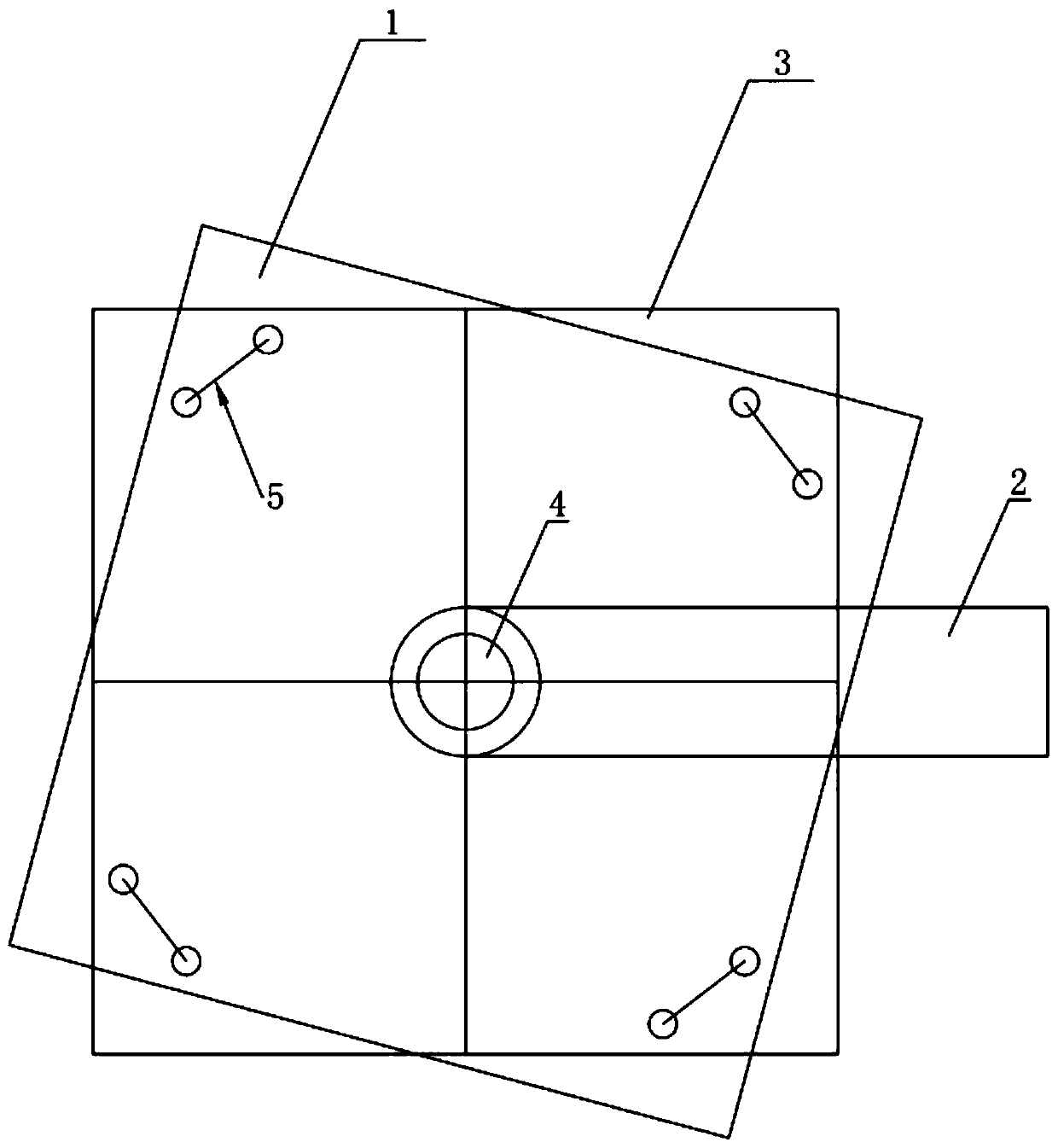

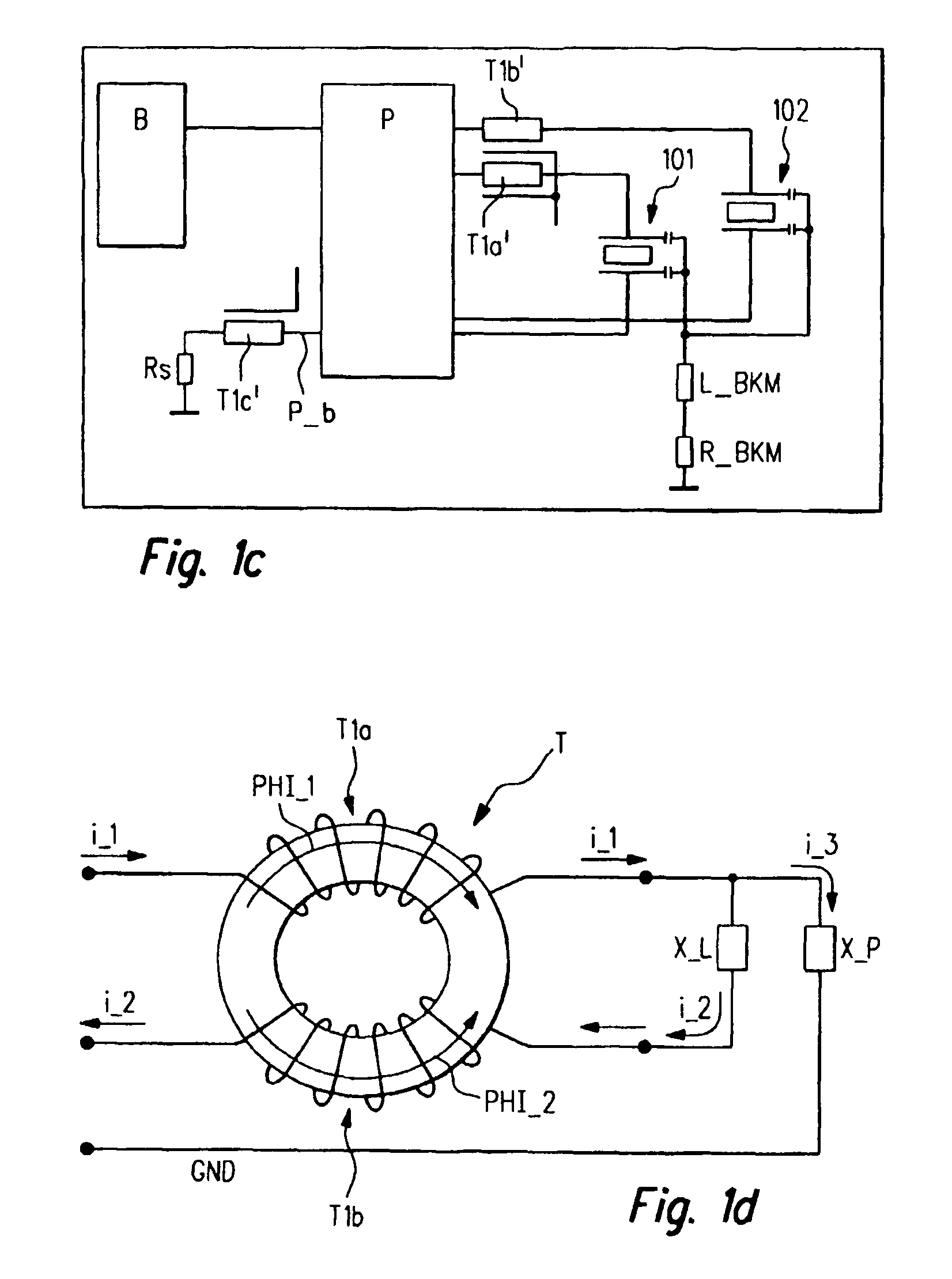

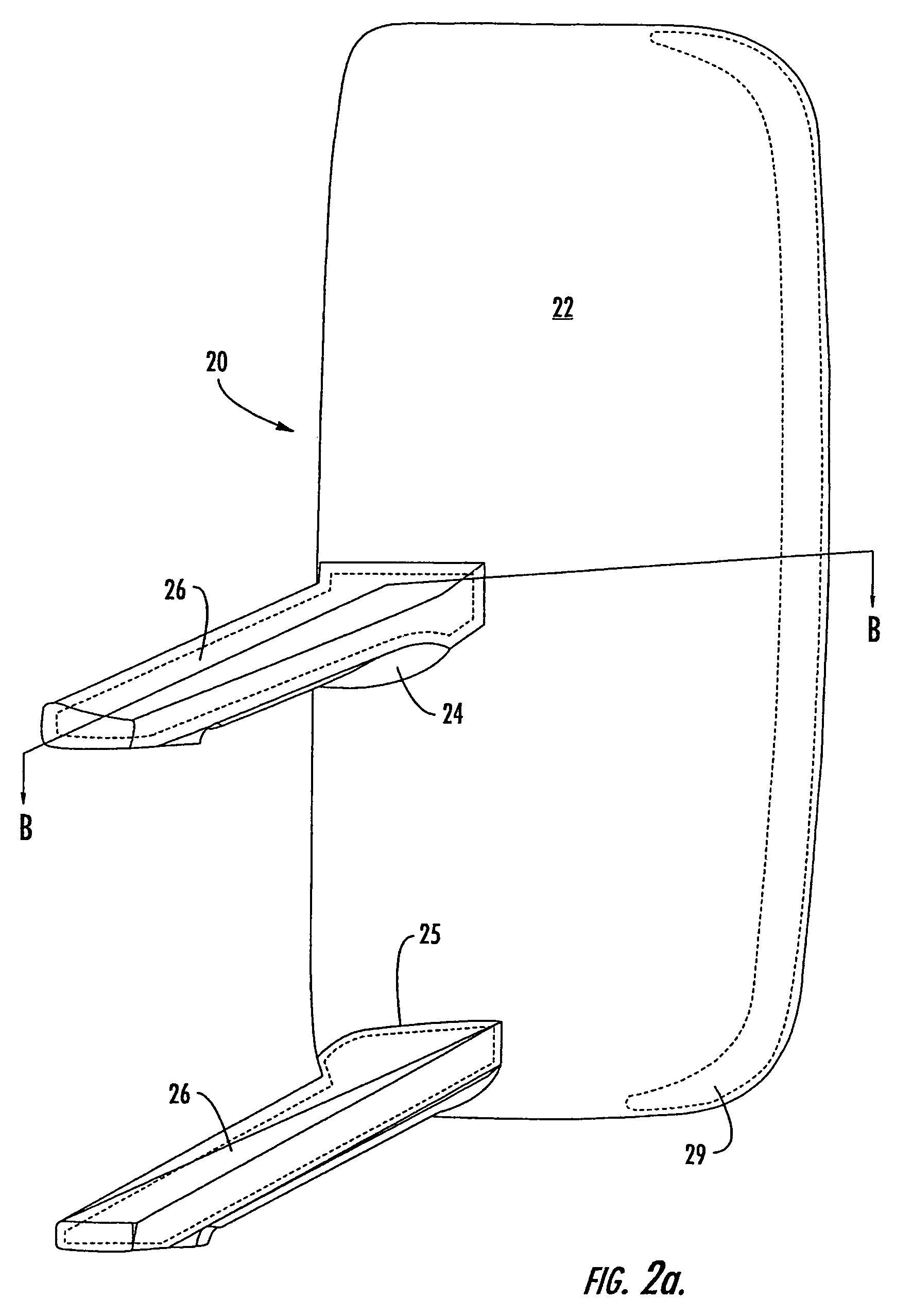

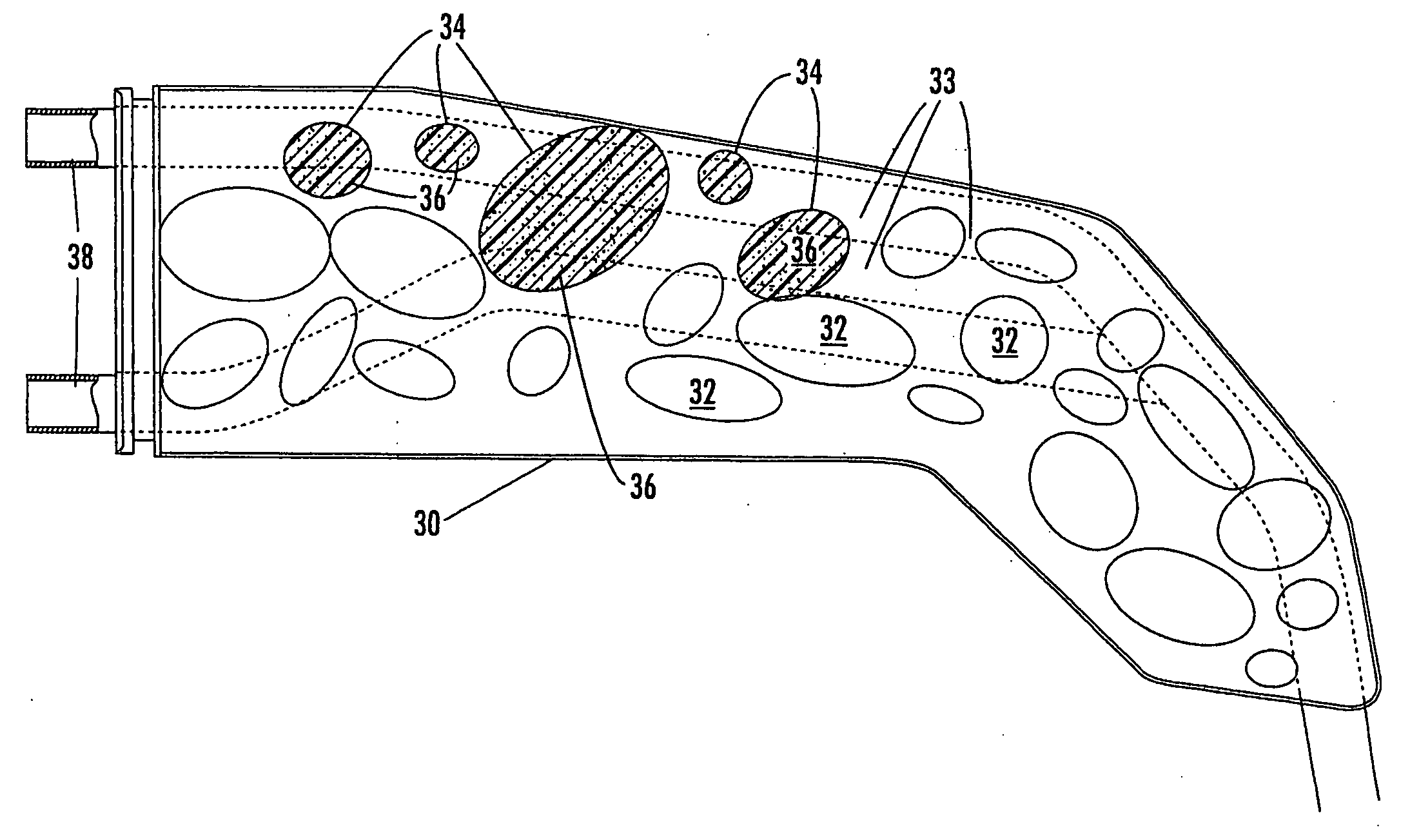

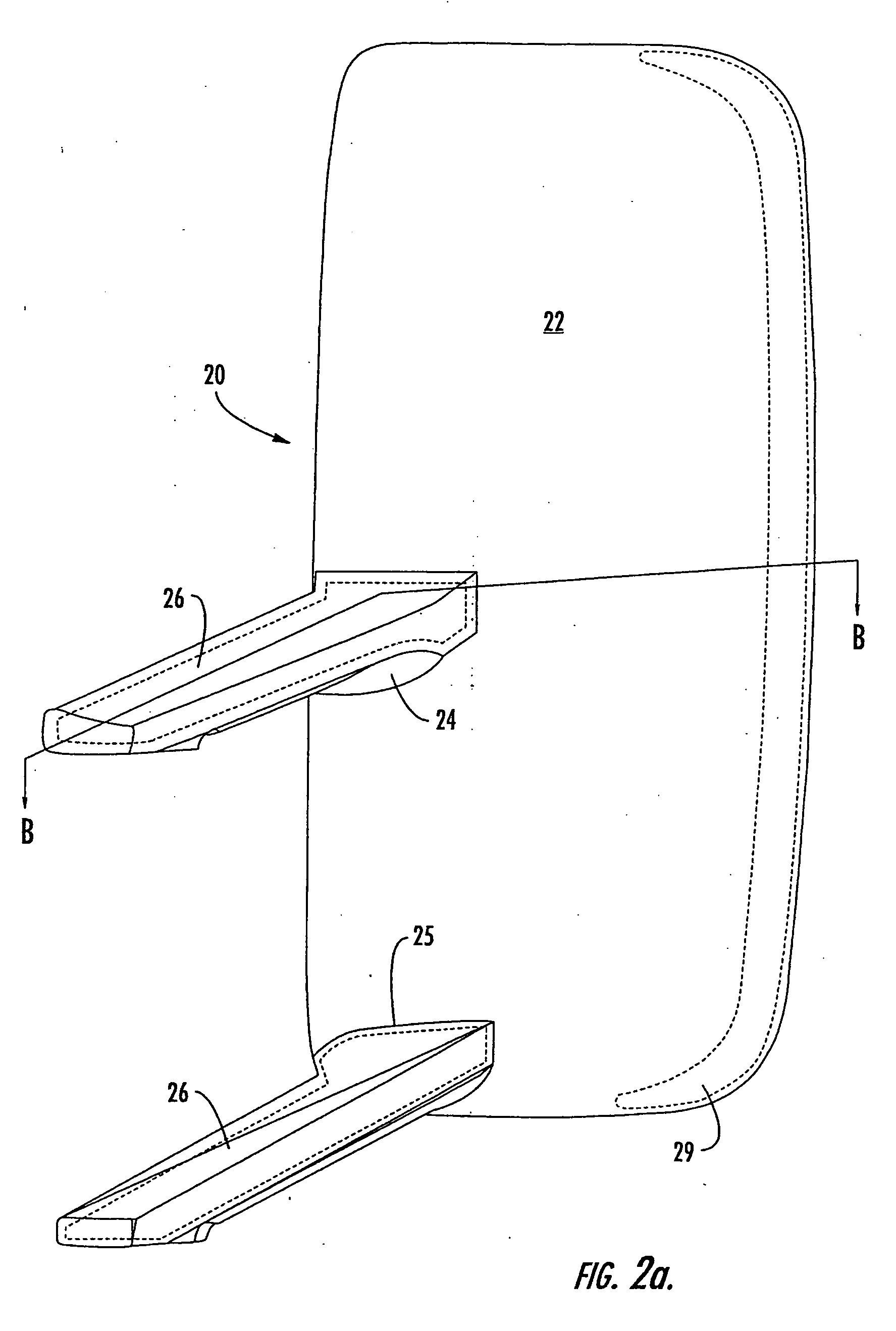

Wavy composite structures

InactiveUS7906191B2Improve suppression propertiesImprove axial stiffnessRotating vibration suppressionProtective buildings/sheltersFiberAngular orientation

Construction and advantages of improved wavy composite structures made from wavy composite, unidirectional composites, and damping materials is revealed. By combining wavy composite laminae in various waveforms, offsets, angular orientations and material combinations, it is possible to provide axial, torsion, or shear properties equivalent to unidirectional materials but without the limitations related to fiber discontinuity, labor costs for fabrication, and weakness at seams where laminates overlap. By combining wavy composite layers with unidirectional crossplies, or by using woven mats with various fill fiber levels where the warp fibers are sinuously arranged, improved strength and damping is possible. Several examples of both wavy crossply laminates and unidirectional crossply laminates are analyzed and compared.

Owner:PRATT WILLIAM F

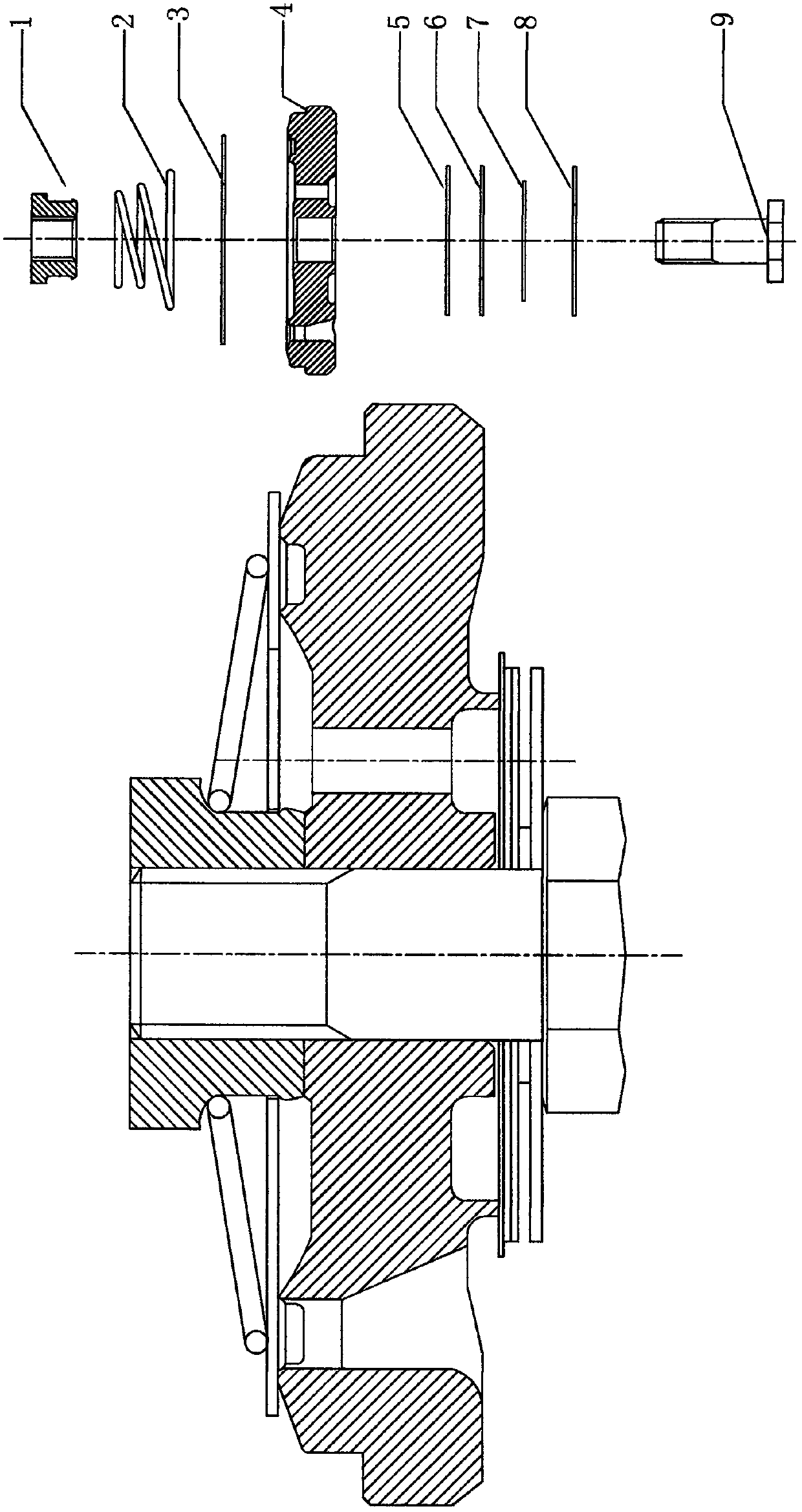

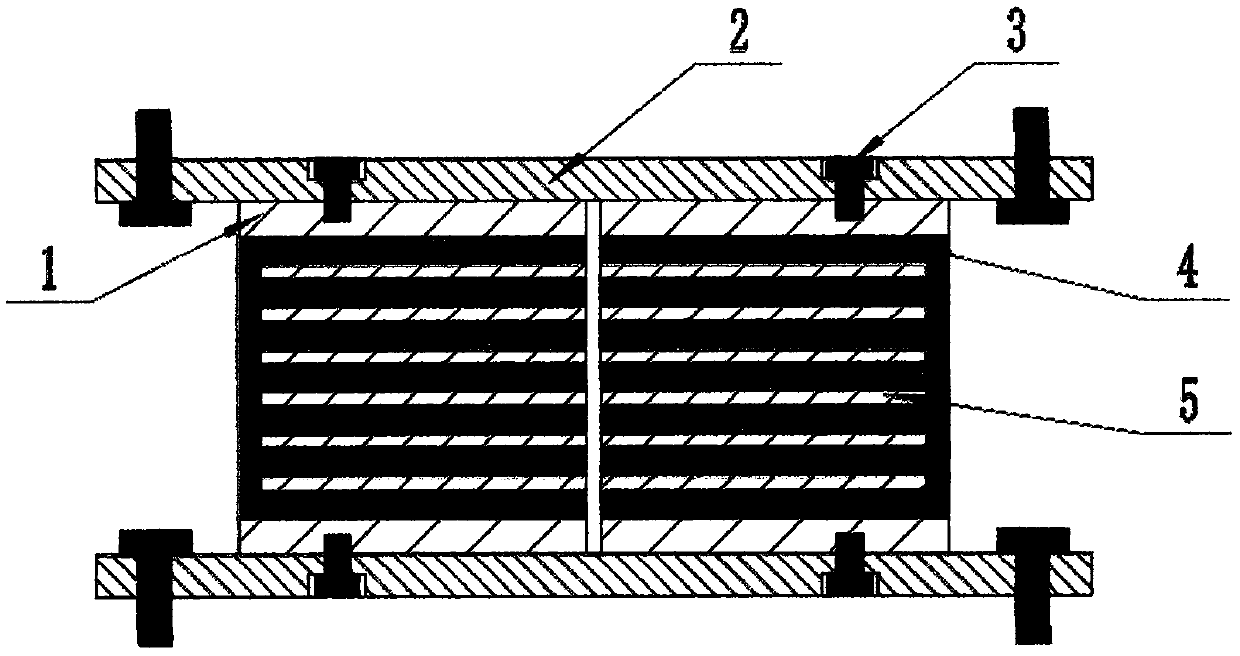

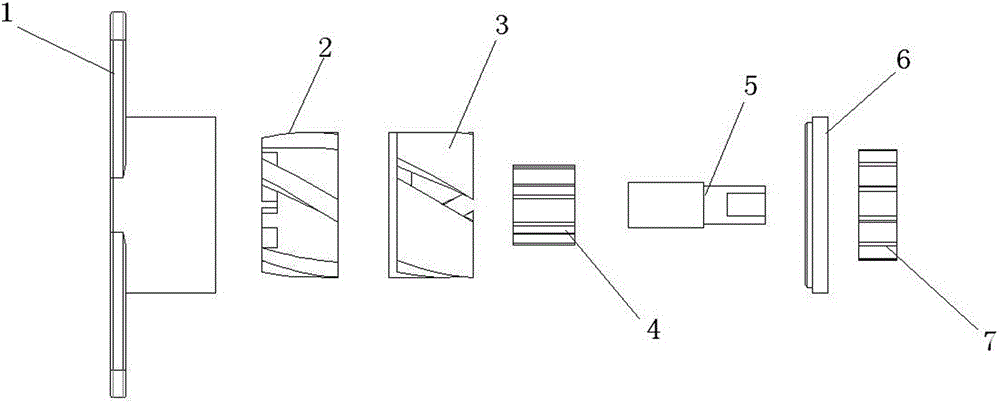

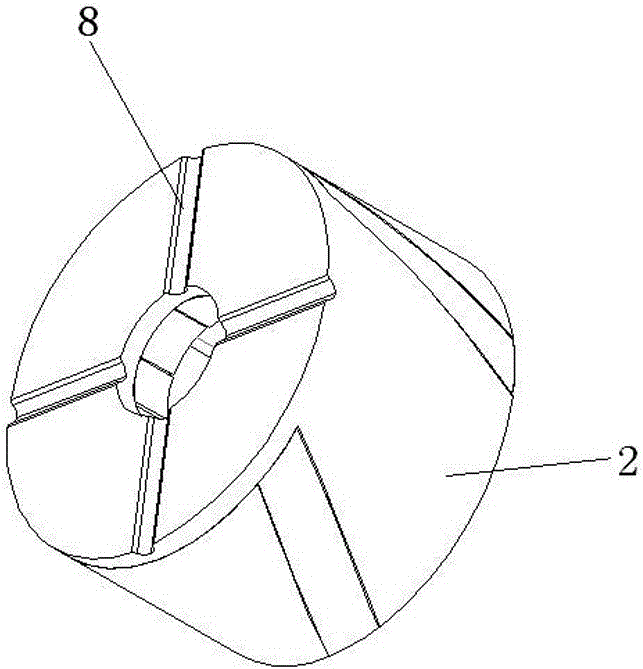

Automotive shock absorber with micro porous metal fiber felt as damping element

InactiveCN107687492AIncrease the apertureHigh porositySpringsShock absorbersPorous metalMetal fibers

Provided is an automotive shock absorber with micro porous metal fiber felt as a damping element. High viscosity hydraulic oil is adopted in the shock absorber; the micro porous metal fiber felt, rather than a common hydraulic valve is adopted as the damping element damping element, the hydraulic oil is forcefully divided by metal fibers to flow when flowing in micropores of the metal fiber felt;strong shearing and inner friction happen in an interface zone of the hydraulic oil and the metal fiber felt, and therefore an effective damping effect is achieved; and the vibrating energy can be fast and efficiently absorbed, the driving comfort is improved, and an abstract drawing is a typical schematic diagram of the automotive shock absorber with the micro porous metal fiber felt as the damping element.

Owner:北京久硕新材科技发展有限公司

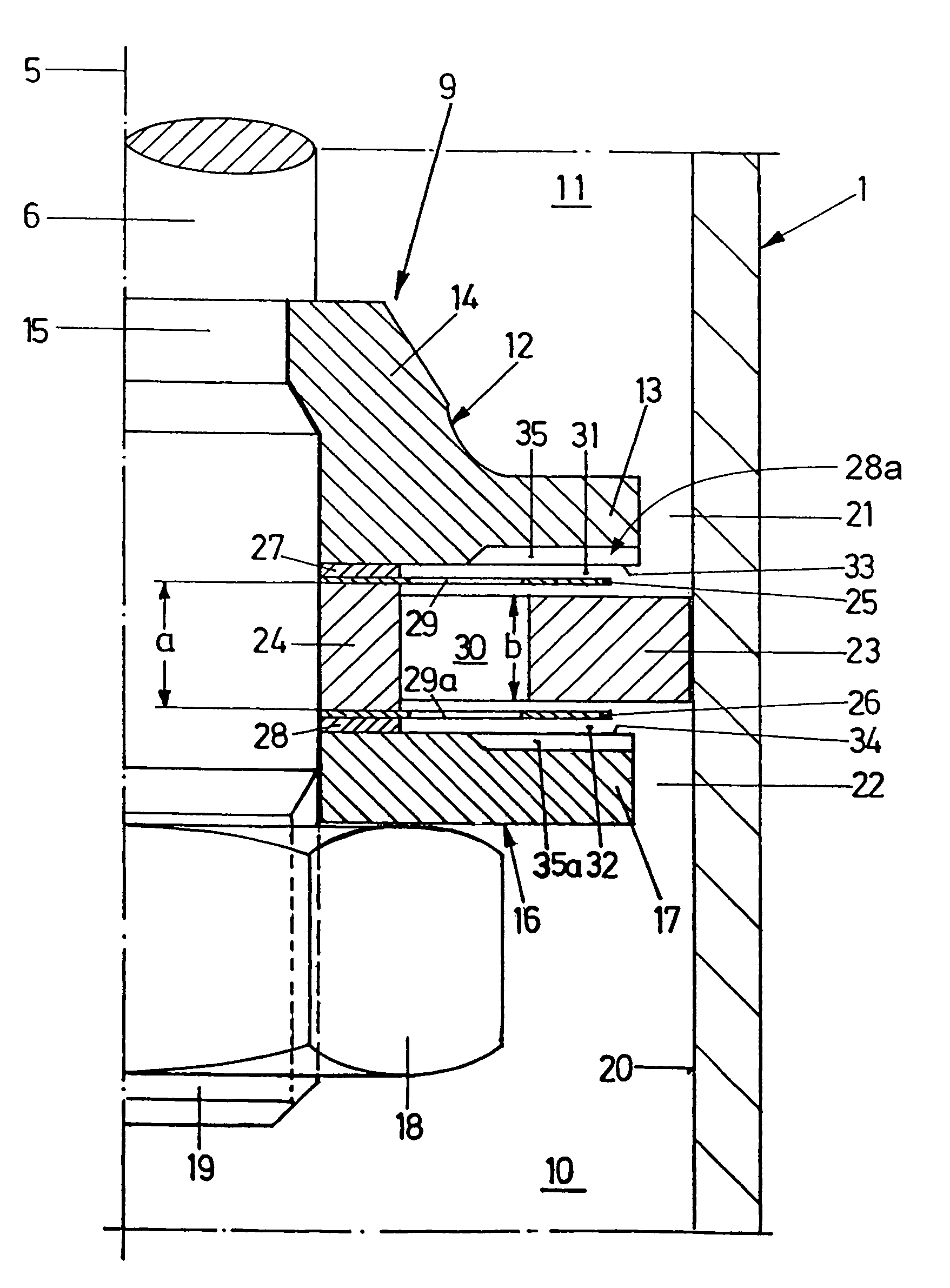

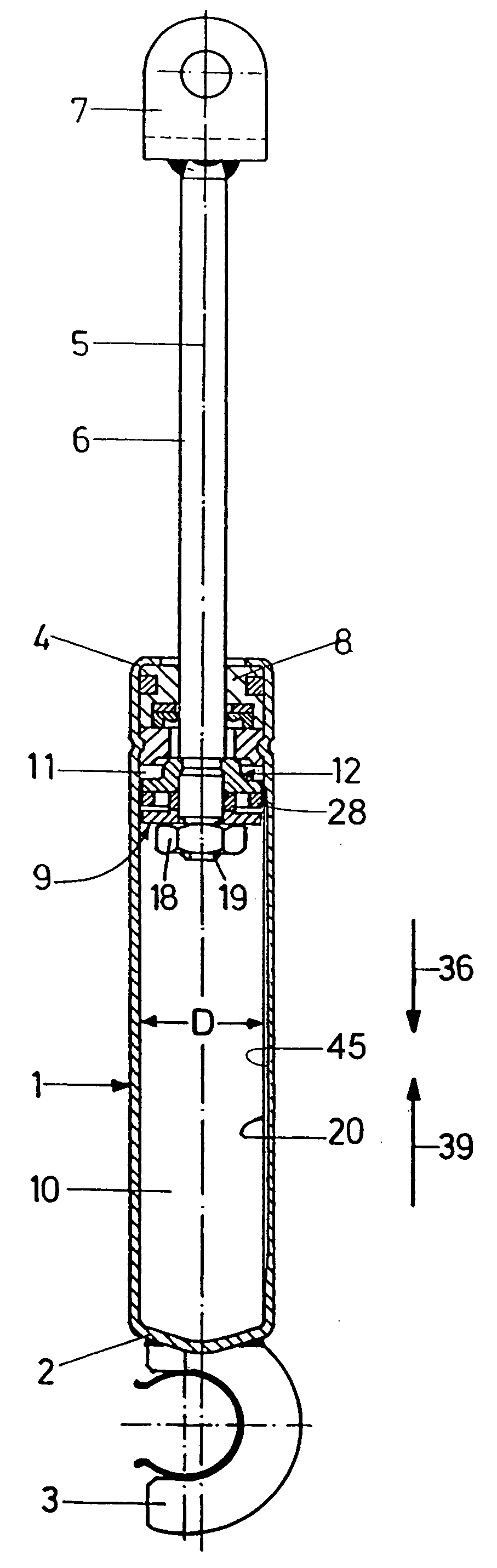

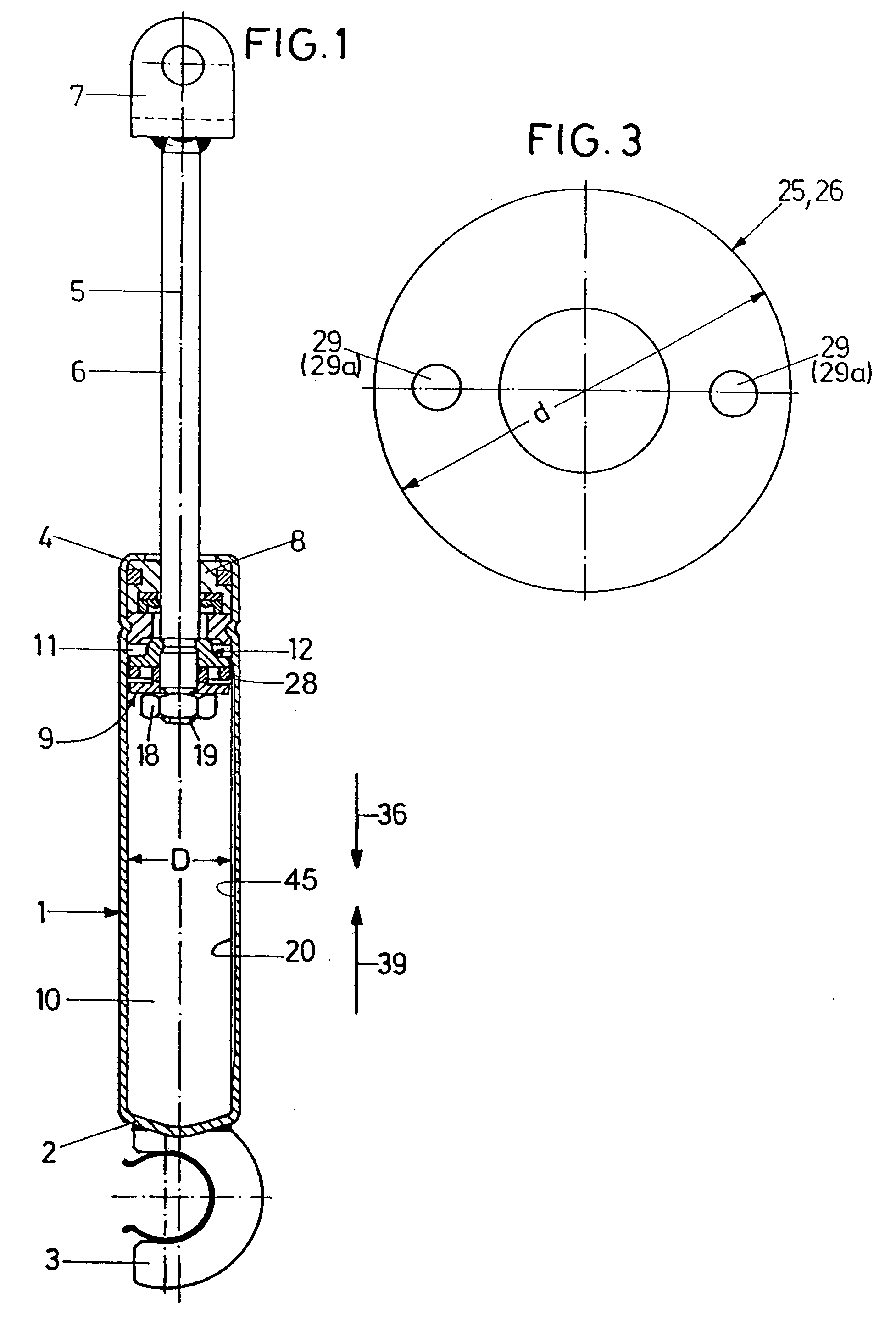

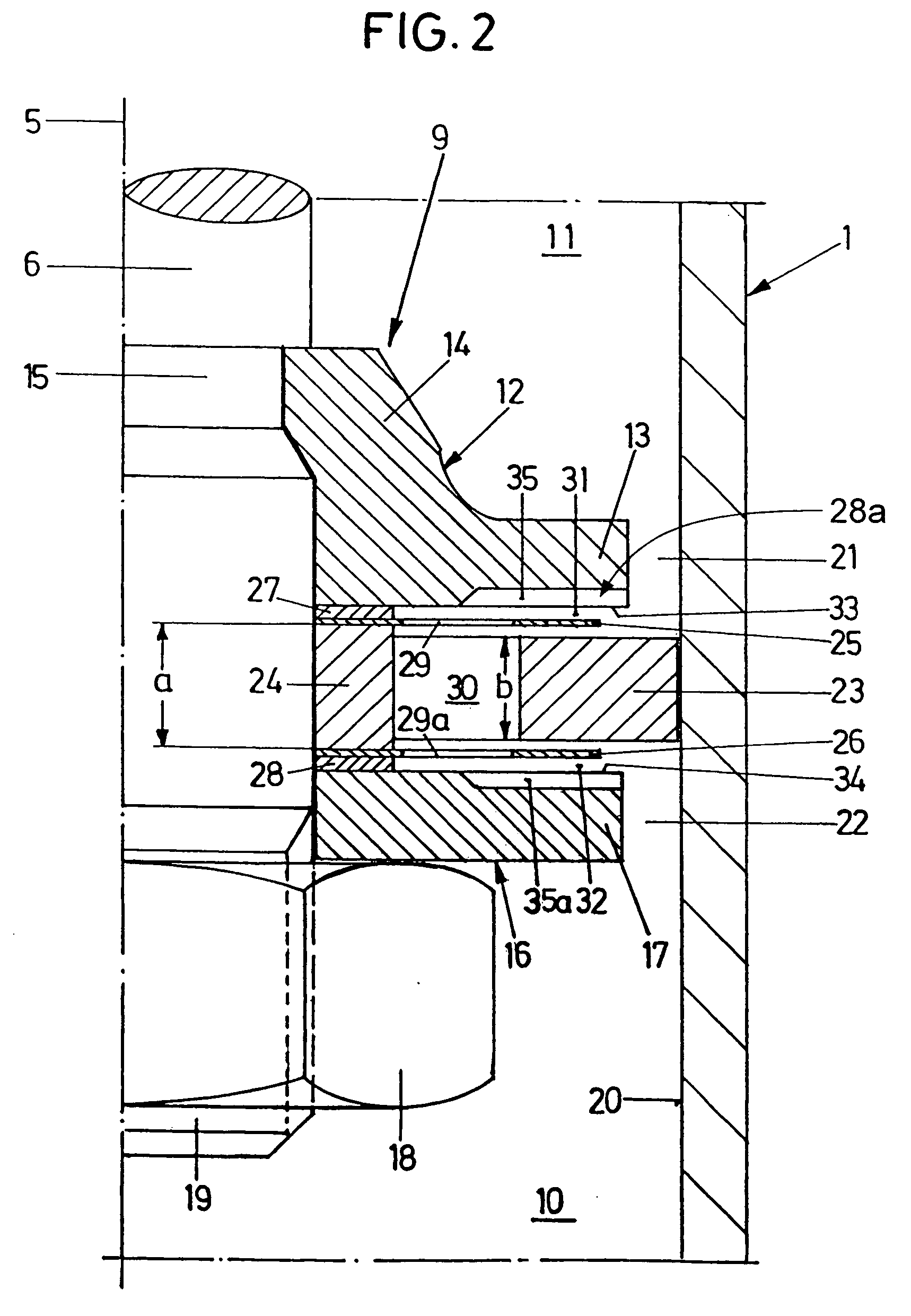

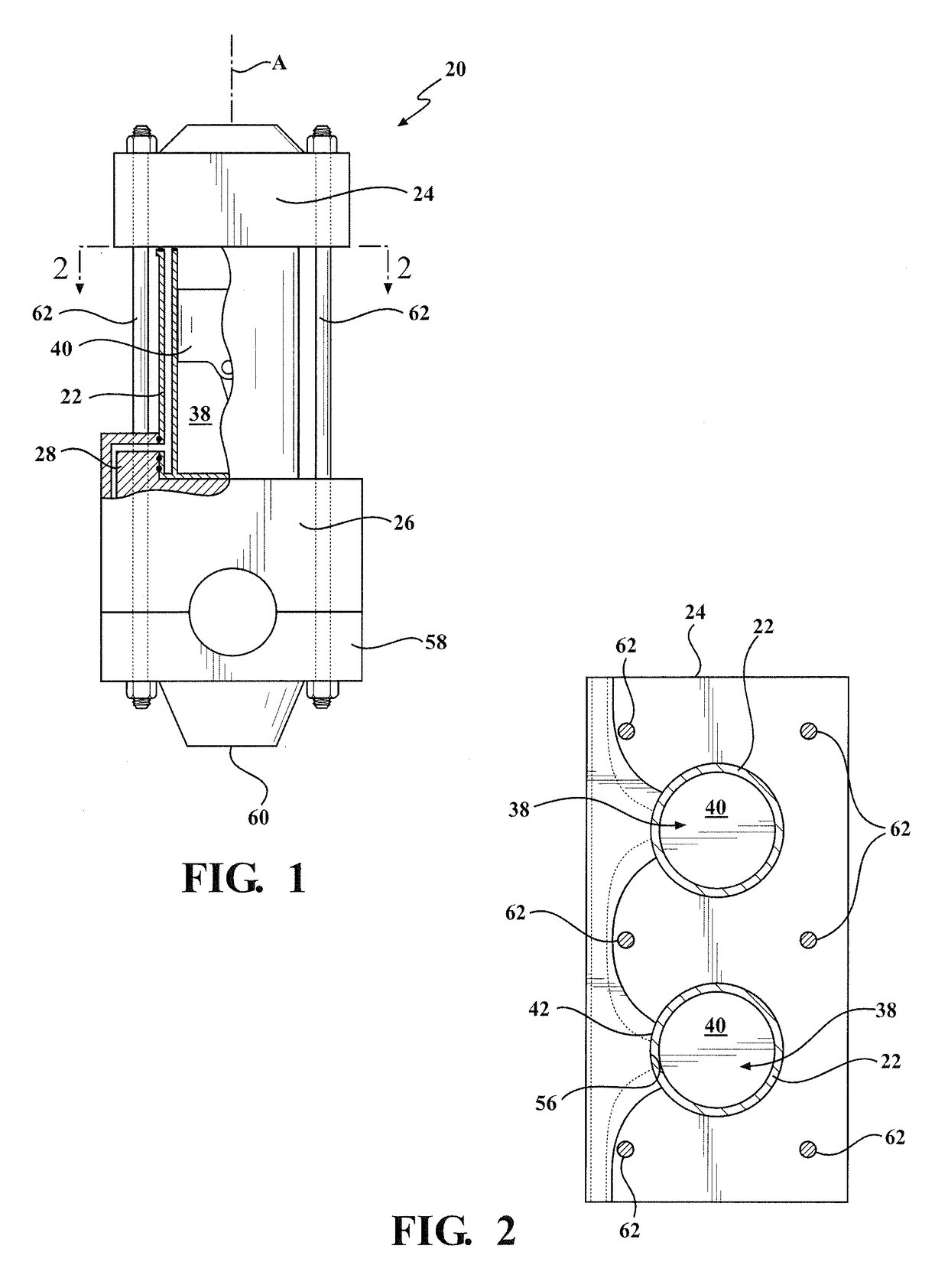

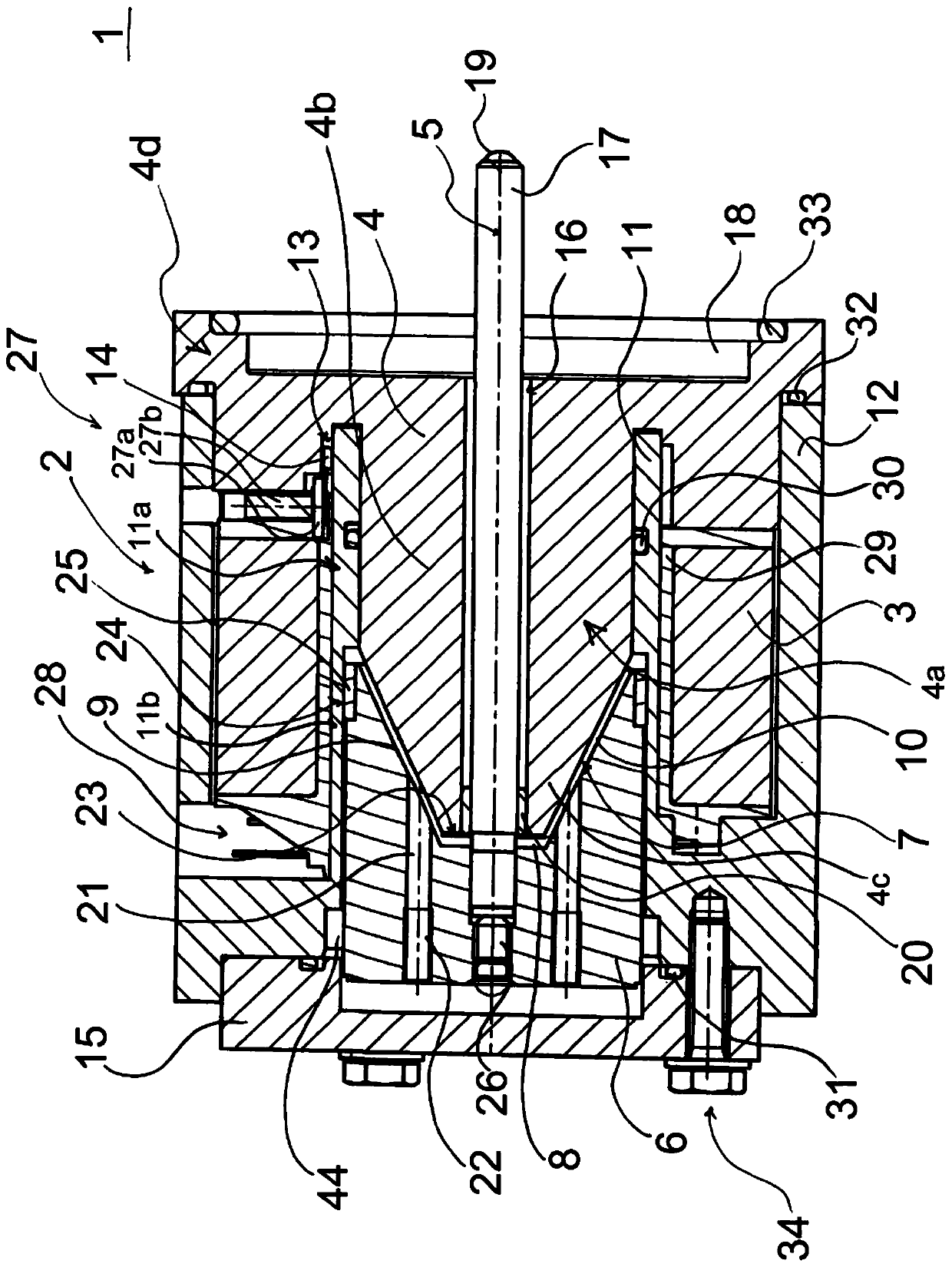

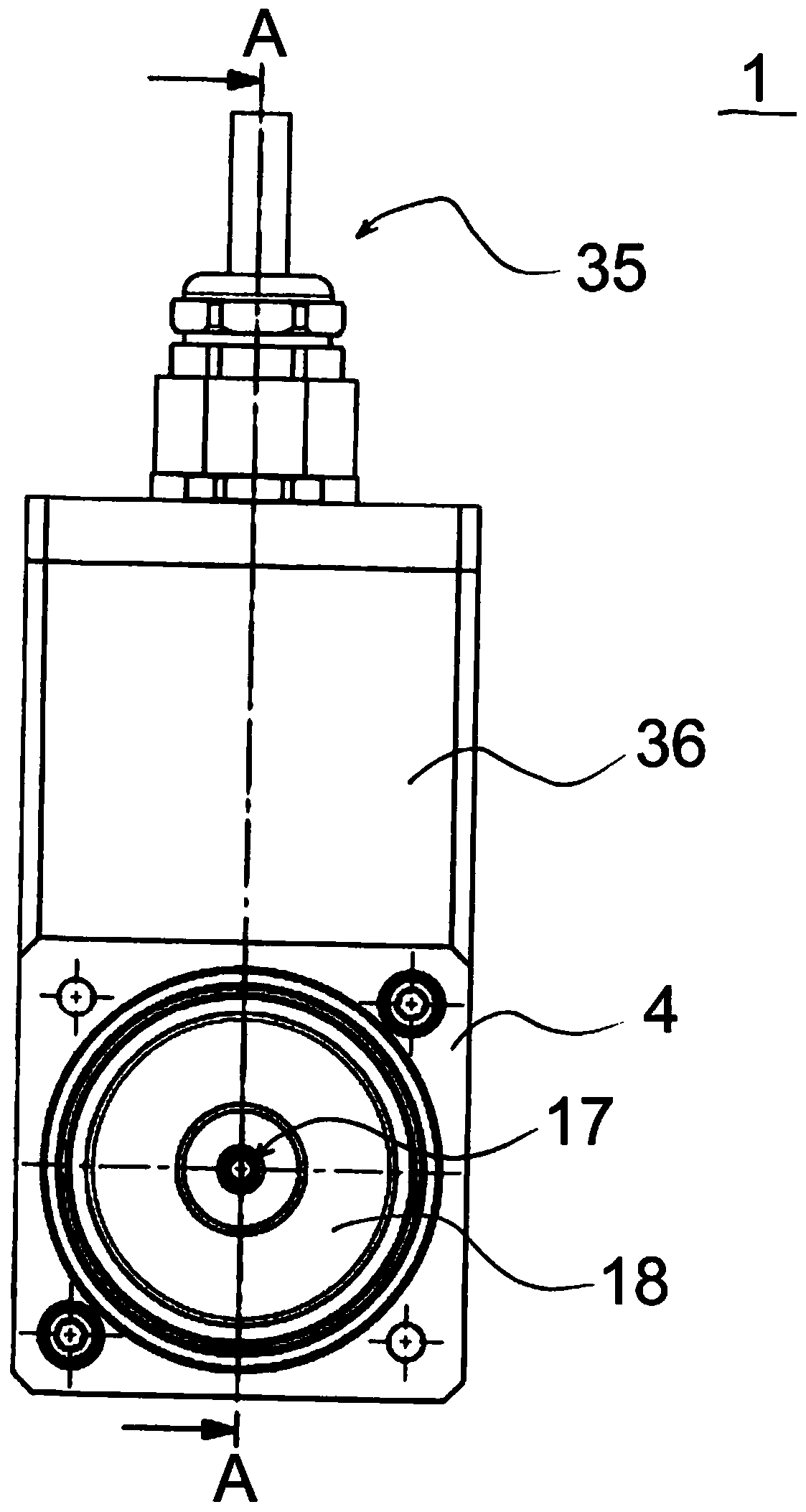

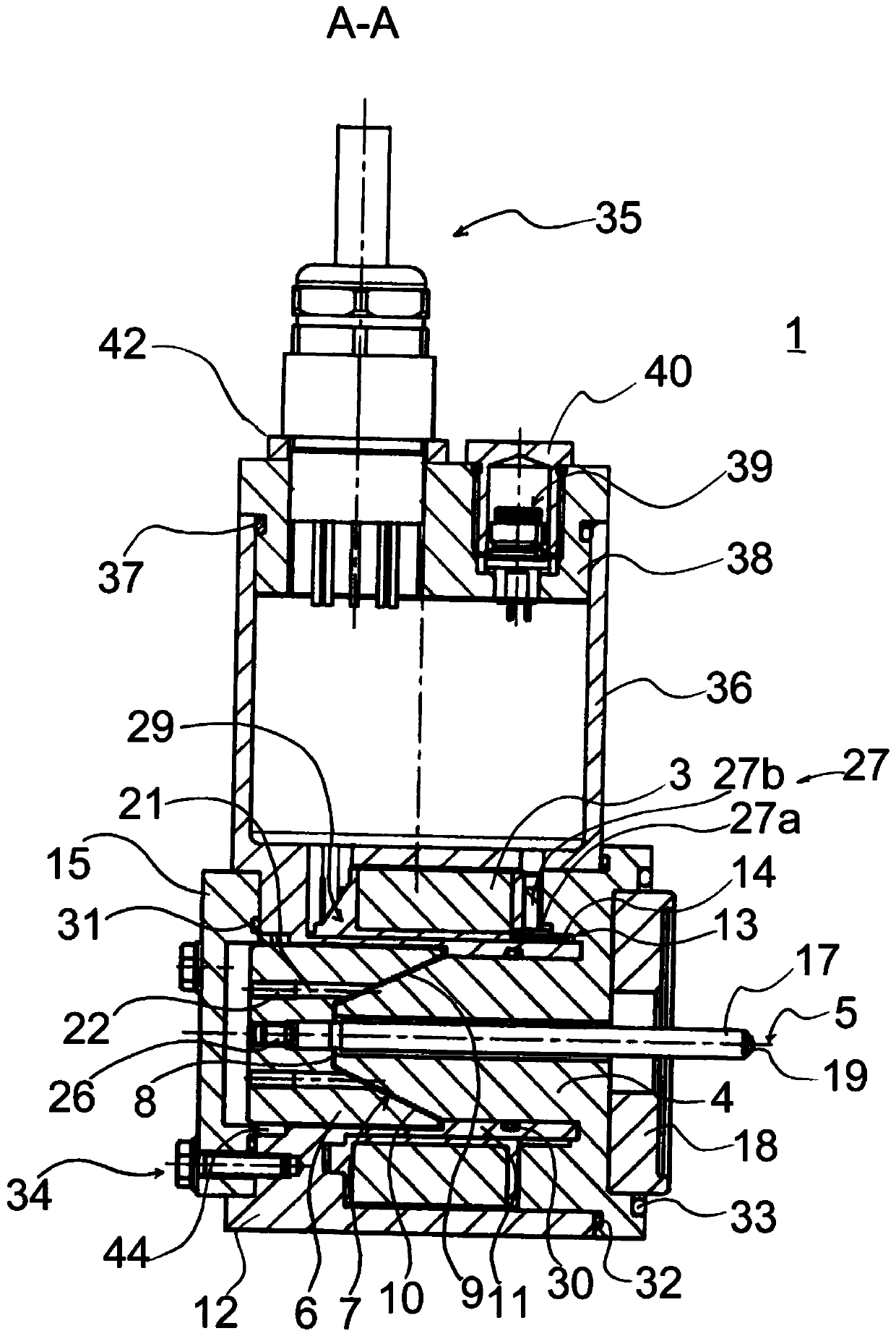

Gas spring

InactiveUS7073642B2Excellently controllable stroke behaviourNegatively affectedLiquid springsGas based dampersGas springEngineering

A gas spring comprises a cylindrical casing, in which a piston rod is guided for displacement concentric of a central longitudinal axis. A damping piston is mounted on the piston rod, dividing the interior of the casing into two sectional casing chambers. A filling of compressed gas is provided inside the casing. A damping device is provided for velocity-dependent damping of a motion of stroke of the damping piston and another damping device is provided for path-dependent damping of a motion of stroke of the damping piston. The result is a gas spring of excellently controllable stroke behaviour.

Owner:SUSPA

Gas spring

InactiveUS20050045438A1Excellently controllable stroke behaviourNegatively affectedLiquid springsGas based dampersGas springEngineering

A gas spring comprises a cylindrical casing, in which a piston rod is guided for displacement concentric of a central longitudinal axis. A damping piston is mounted on the piston rod, dividing the interior of the casing into two sectional casing chambers. A filling of compressed gas is provided inside the casing. A damping device is provided for velocity-dependent damping of a motion of stroke of the damping piston and another damping device is provided for path-dependent damping of a motion of stroke of the damping piston. The result is a gas spring of excellently controllable stroke behaviour.

Owner:SUSPA

Elastic connection between housing parts of motor-driven power tools

InactiveUS8833486B2Produced economicallyIncrease flexibilityPortable percussive toolsPortable power-driven toolsMotor driveEngineering

An elastic connection is established between housing parts of a power-driven machine tool by an elastic connecting element which is attached in form-locking fashion to at least one of the housing parts to be connected, in such a way that the connecting element has a land penetrating a breach of the housing part, and this land connects covering parts of the connecting element that are located in coincidence with the breach.

Owner:ROBERT BOSCH GMBH

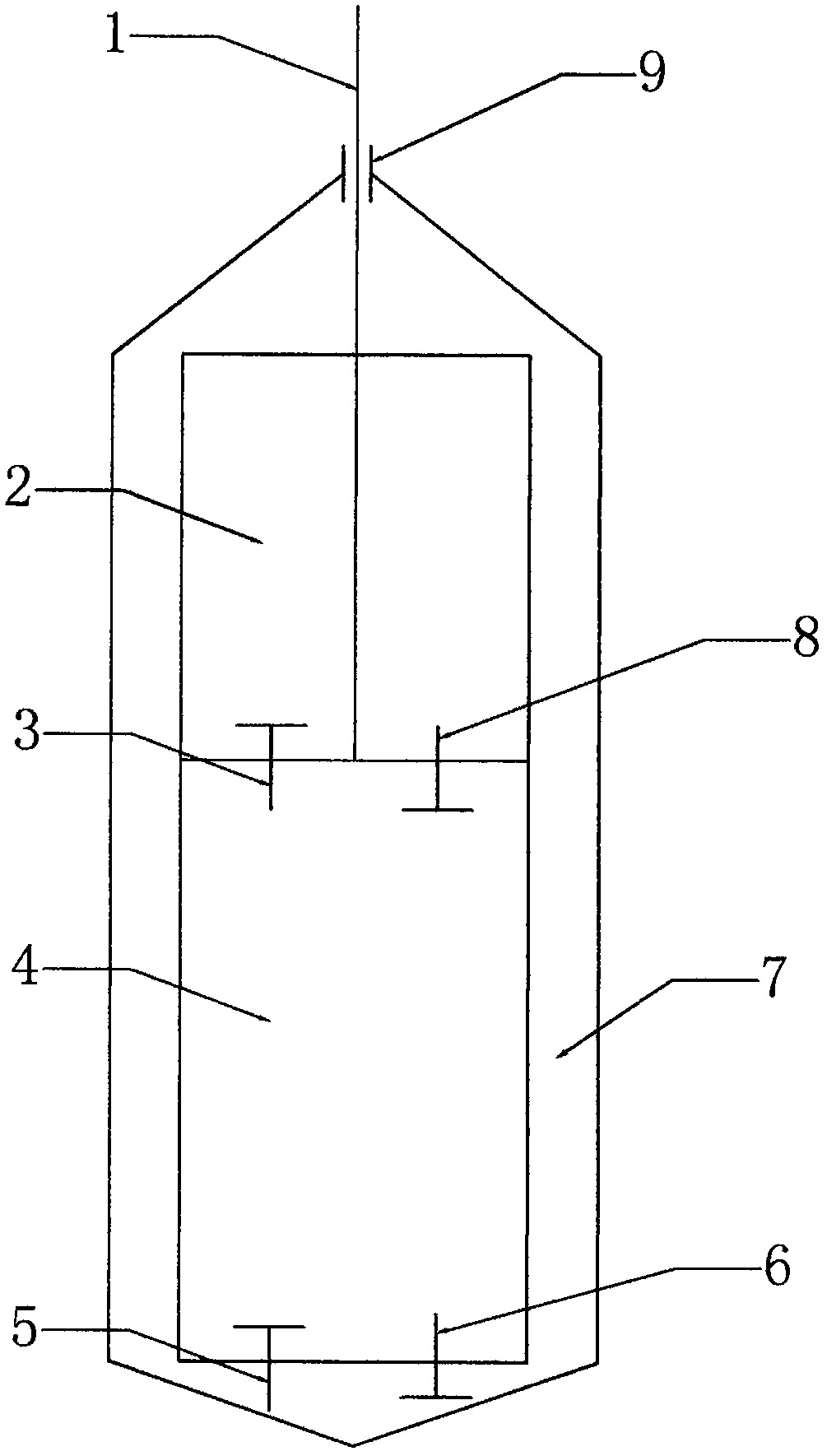

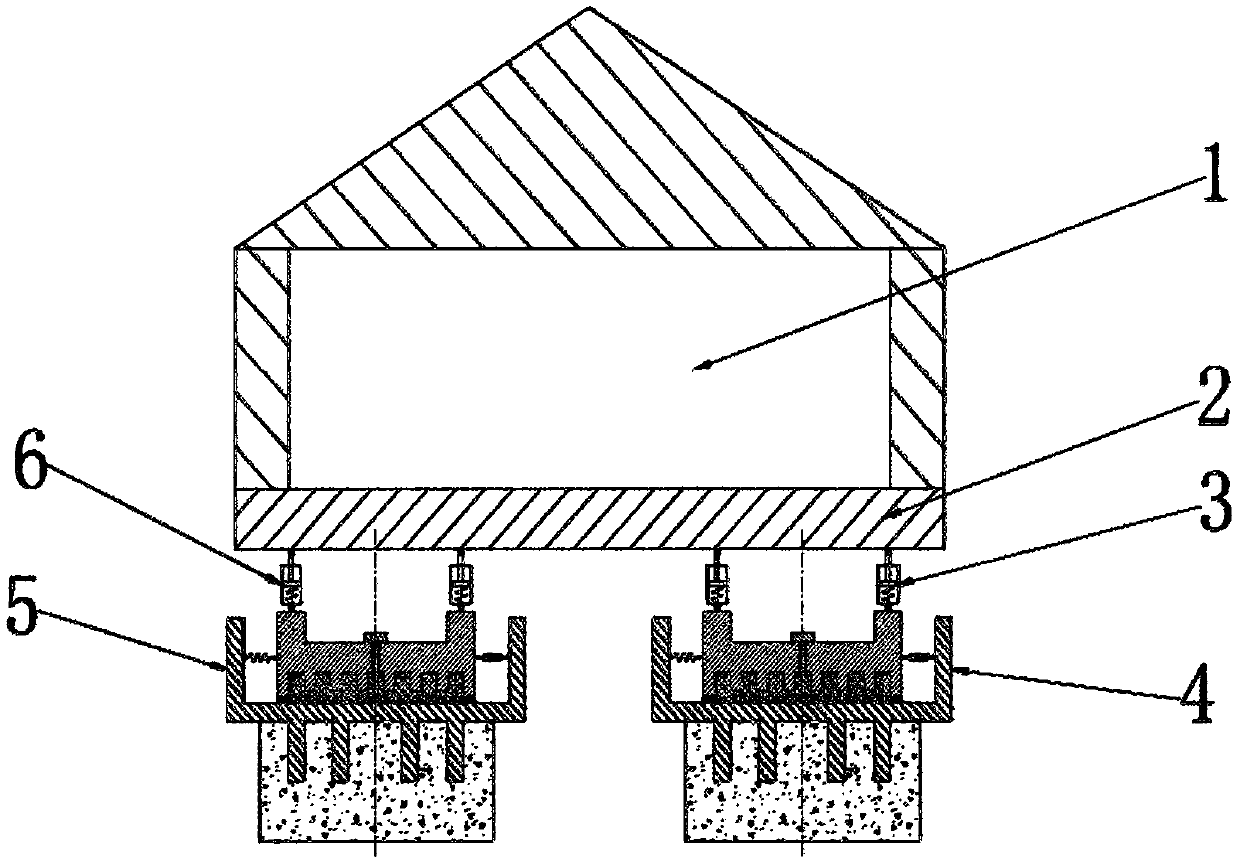

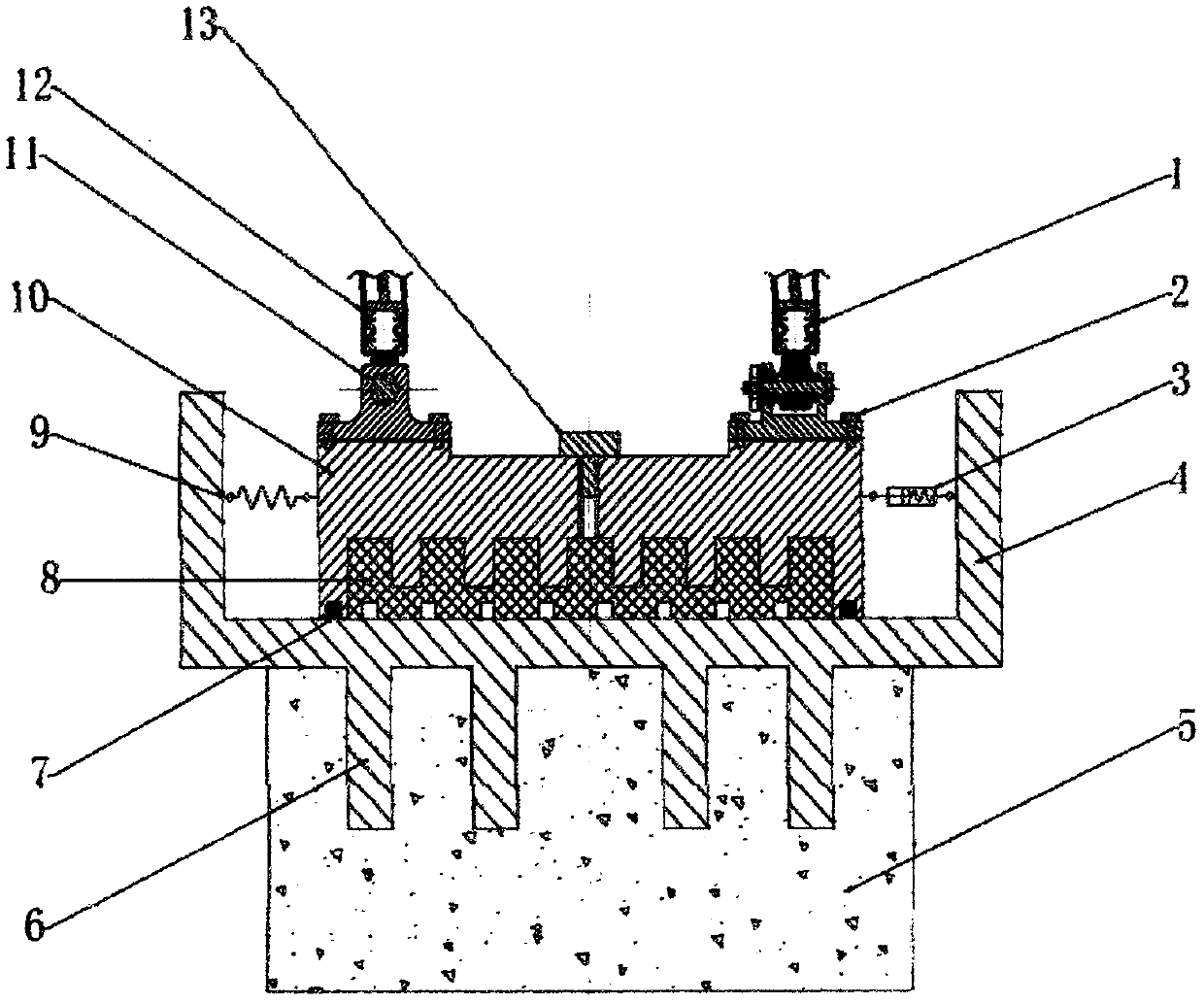

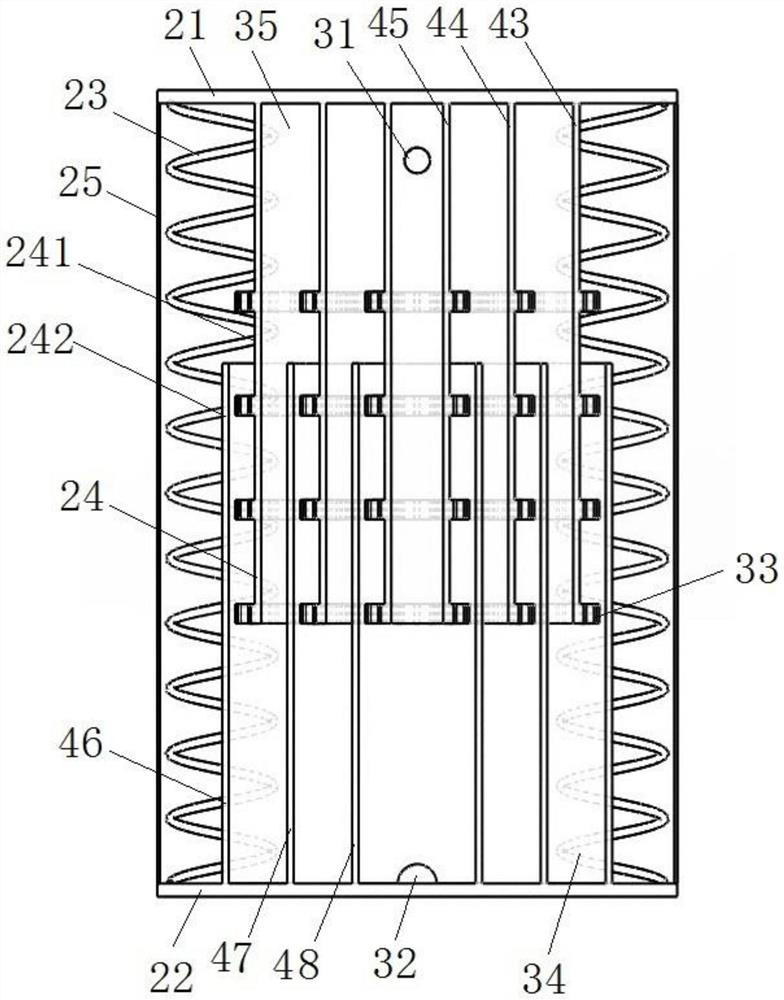

Building structural foundation with three-dimensional shock insulation and vibration attenuation

InactiveCN109853766AReduce the deformationGuarantee effective supportProtective buildings/sheltersShock proofingSmall amplitudeEnergy absorption

The invention provides a building structural foundation with three-dimensional shock insulation and vibration attenuation. The building structural foundation with three-dimensional shock insulation and vibration attenuation mainly comprises a steel structural small platform laid the roots in a foundation, a shock absorber mounting sliding table and an elastic damping shock absorber, wherein a polytetrafluoroethylene based coating is prepared on the steel structural small platform; a self-lubricating composite material containing oil is adopted in the shock absorber mounting sliding table to beused as a sliding friction pair; according to the elastic damping shock absorber, disc spring support is adopted on the lower surface of a main piston, a liquid damping medium below a floating pistonhas low internal pressure in a static state, and the shock absorber works stably for a long time and no oil leakage occurs; an upper mounting joint and a lower mounting joint of the shock absorber have a slight cardan joint adjusting function; when an earthquake happens, the steel structural small platform vibrates with small amplitude following the foundation under the influence of earthquake waves, the mounting sliding table, the shock absorber on the upper part of the mounting sliding table and a building slide relatively on the steel structural small platform, so that earthquake energy inthe horizontal direction is weakened and input to the building on the upper surface; and the shock absorber has damping and energy absorption functions in the vertical direction, and thus, three dimensions have shock insulation and vibration attenuation protection action.

Owner:李鑫

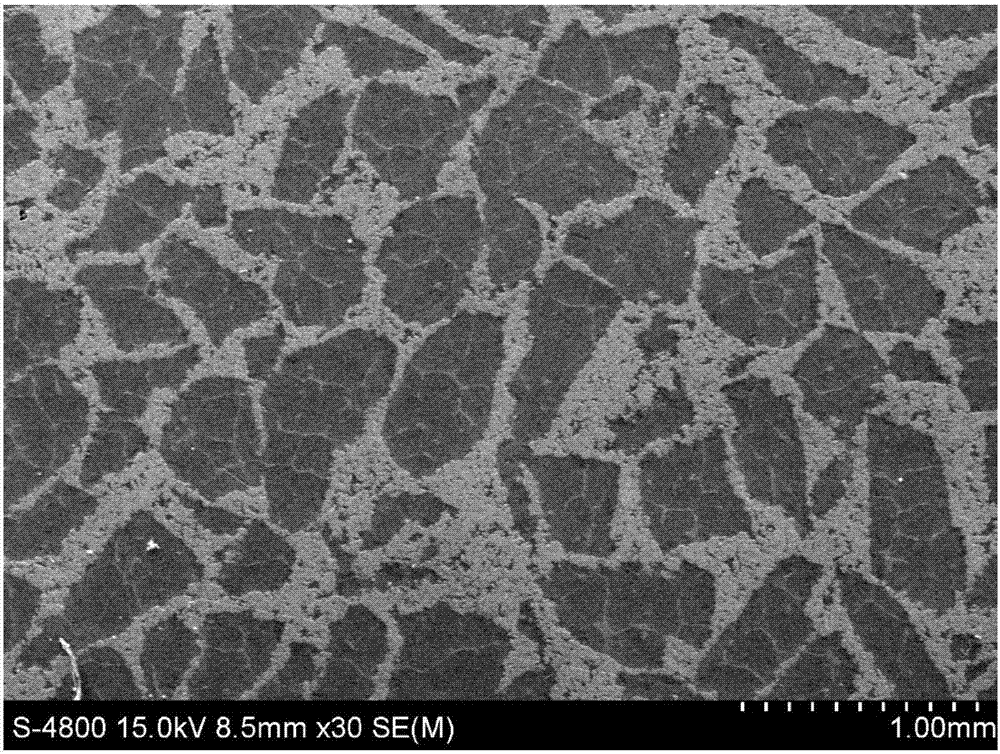

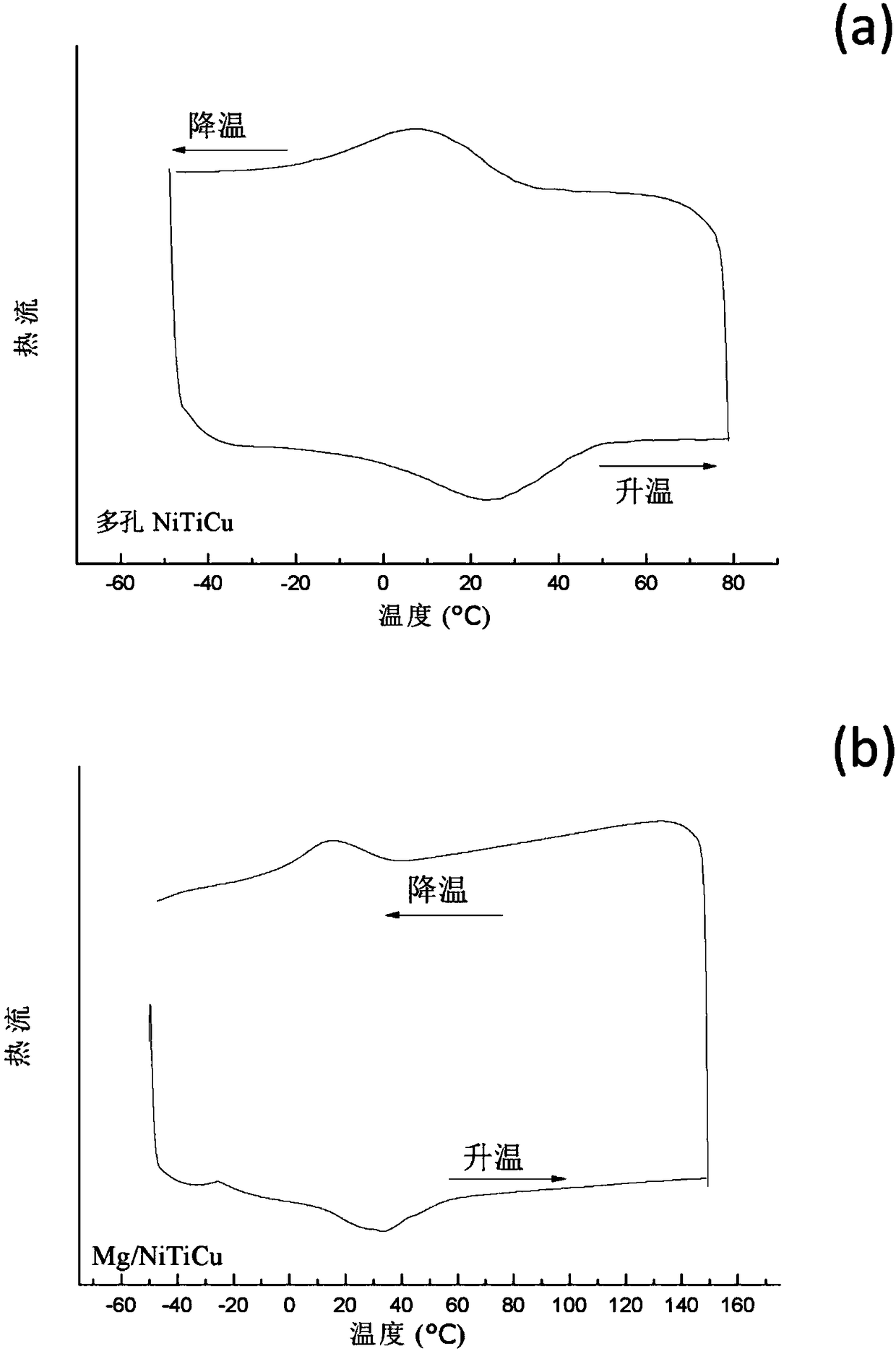

Method for preparing TiNiCu shape memory alloy damping composite

The invention relates to manufacturing of a damping material, in particular to a method for preparing a TiNiCu shape memory alloy damping composite. A porous TiNiCu shape memory alloy is prepared, holes of the TiNiCu shape memory alloy are filled with metal Mg, and the TiNiCu shape memory alloy damping composite, namely, Mg / TiNiCu is prepared. The defects that in an existing porous TiNiCu shape memory alloy preparation method, the porosity, the aperture and the hole type are all hard to control; and an existing technology of introducing Mg into the porous alloy cannot be used for filling porous TiNiCu alloy with Mg, and the damping performance and other mechanical performance of an alloy product need to be improved are overcome.

Owner:HEBEI UNIV OF TECH

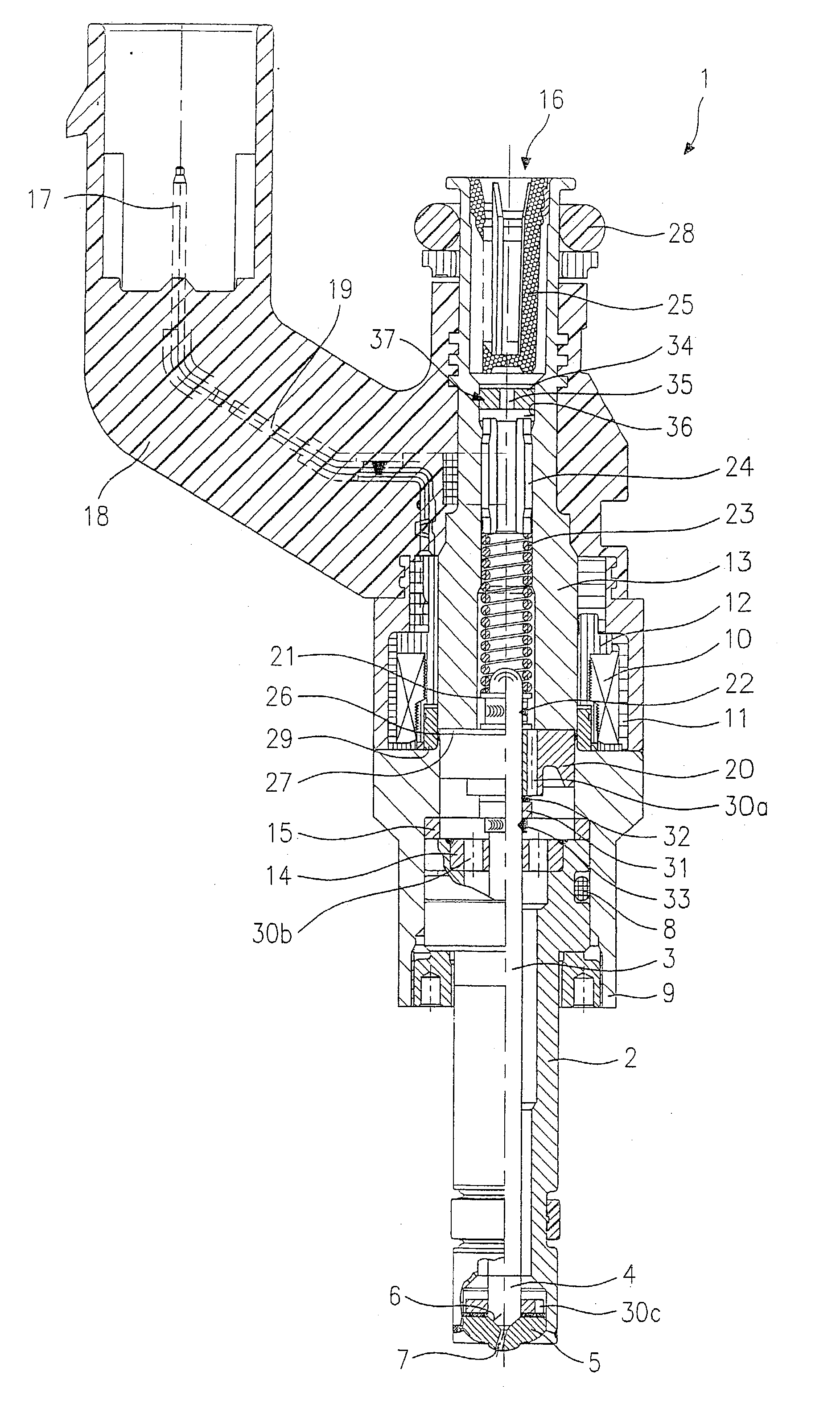

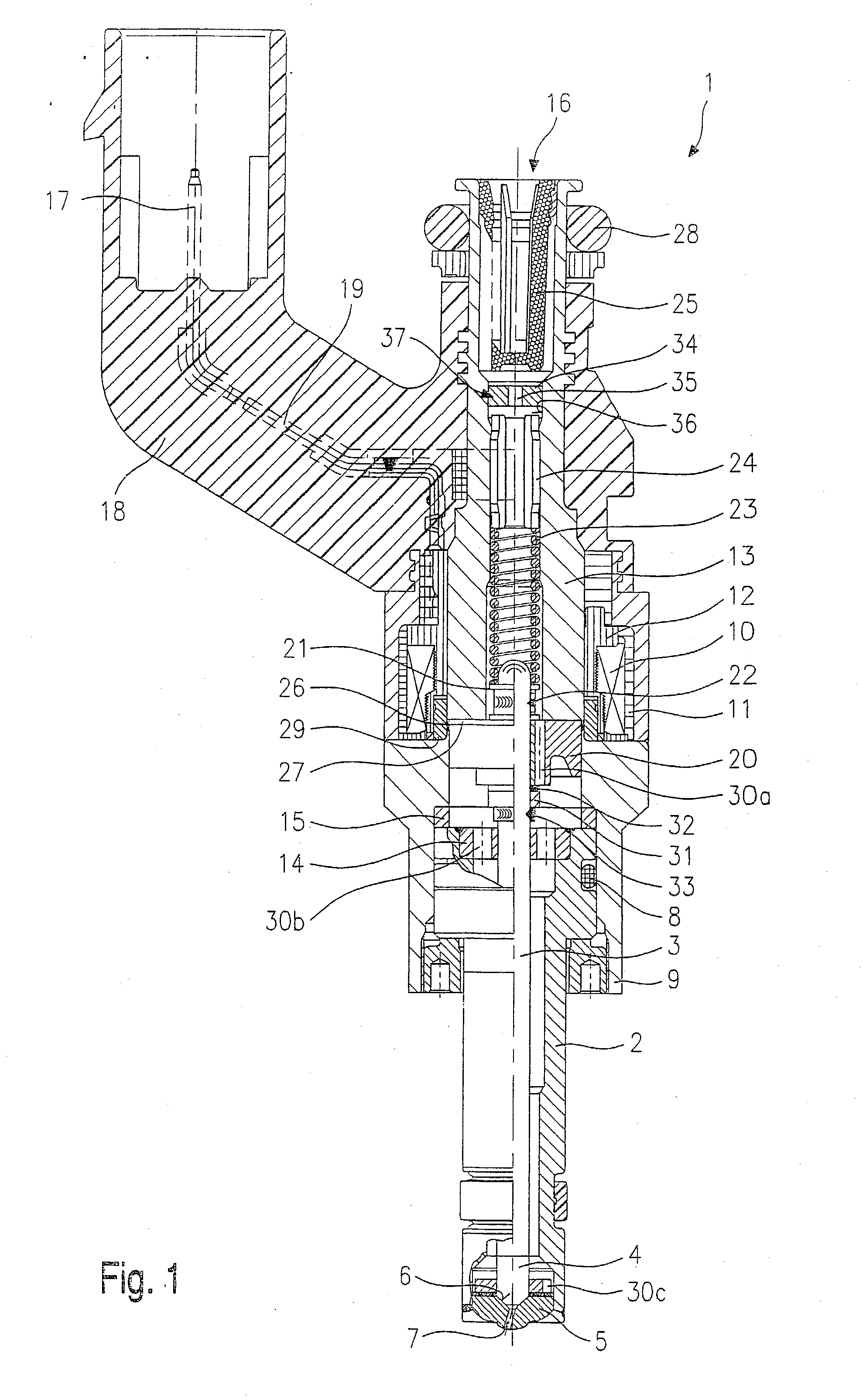

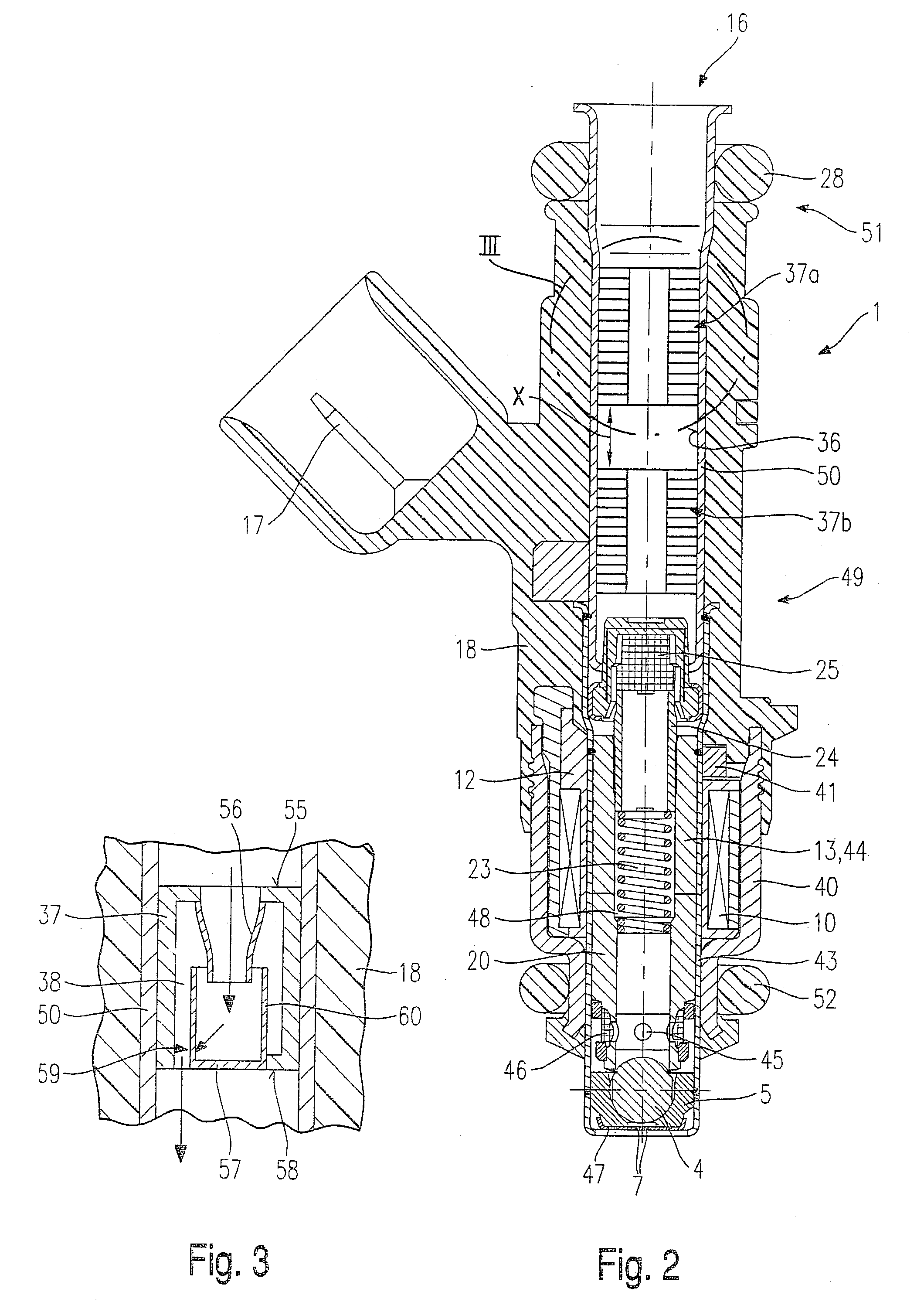

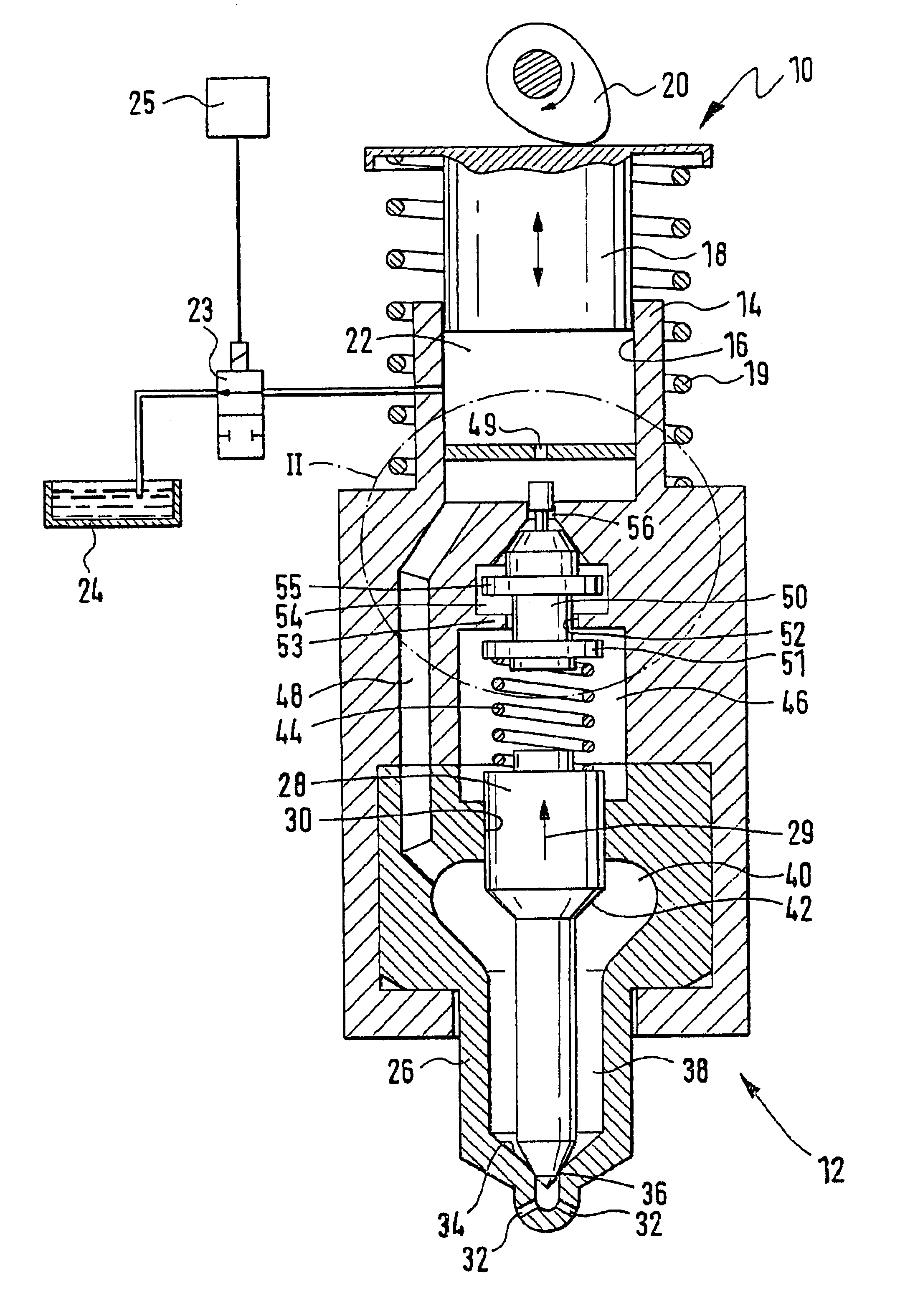

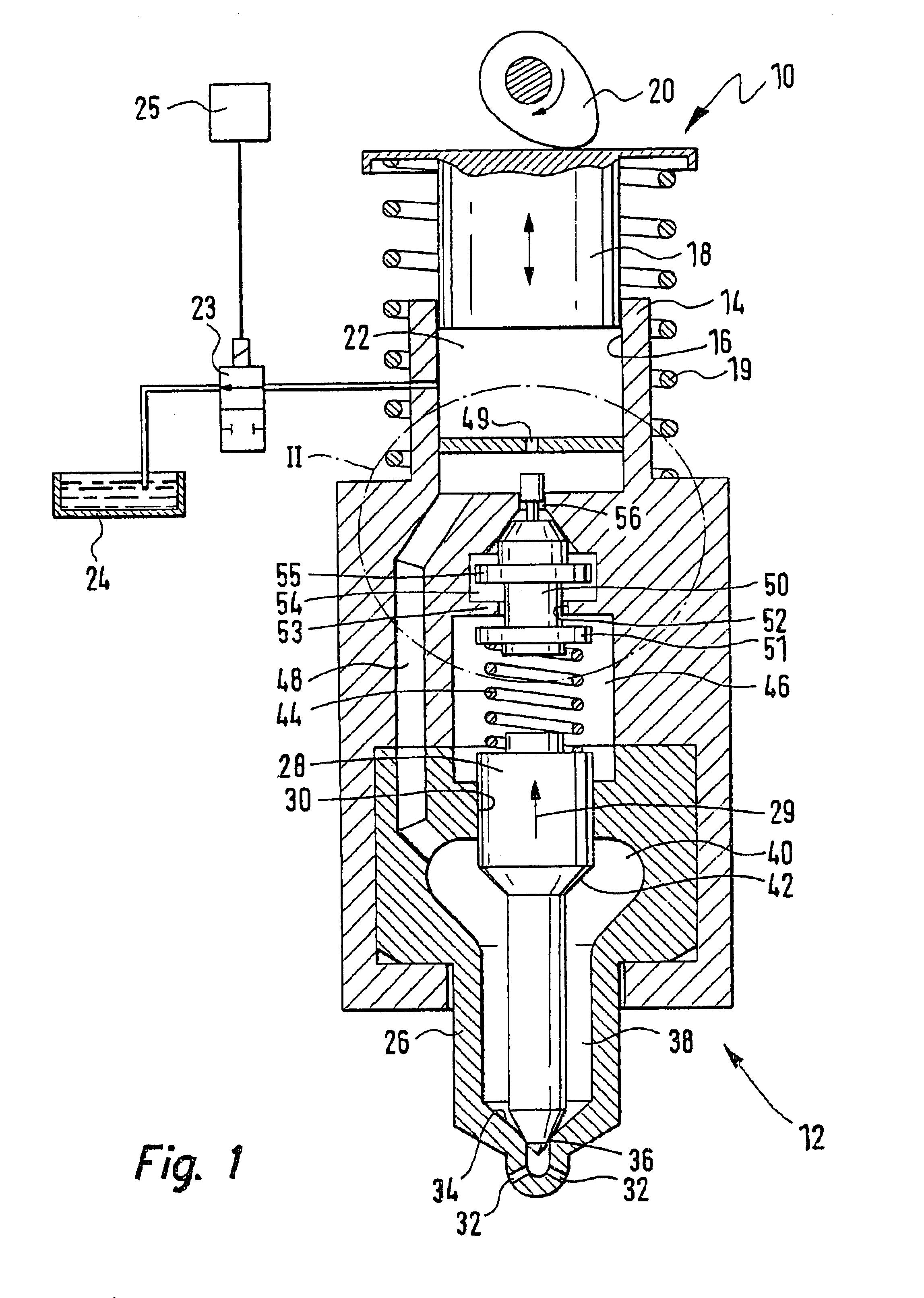

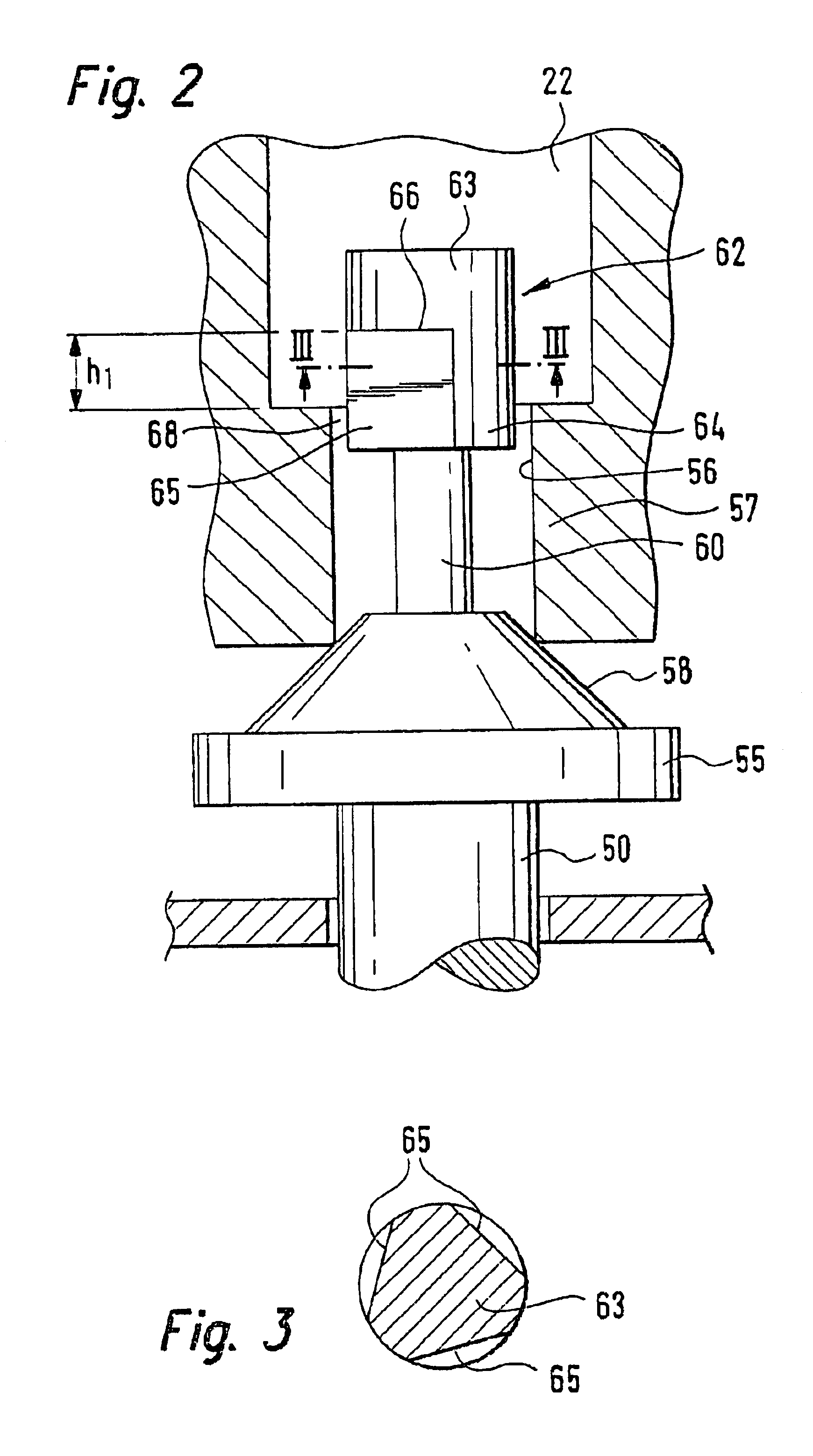

Fuel injection valve with a damping element

InactiveUS20030155448A1Prevent pulsationEffective dampingInternal combustion piston enginesSpray nozzlesEngineeringValve seat

A fuel injector (1) is provided with a magnetic coil (10) which cooperates with an armature (20) acted upon by a restoring spring (23), the armature forming an axially movable valve part with a valve needle (3). A valve-closure member (4) which forms a sealing seat with a valve-seat member (5) is provided at the valve needle (3). At least one damping element (37) is disposed in an opening (36) of the fuel injector (1) through which fuel flows.

Owner:ROBERT BOSCH GMBH

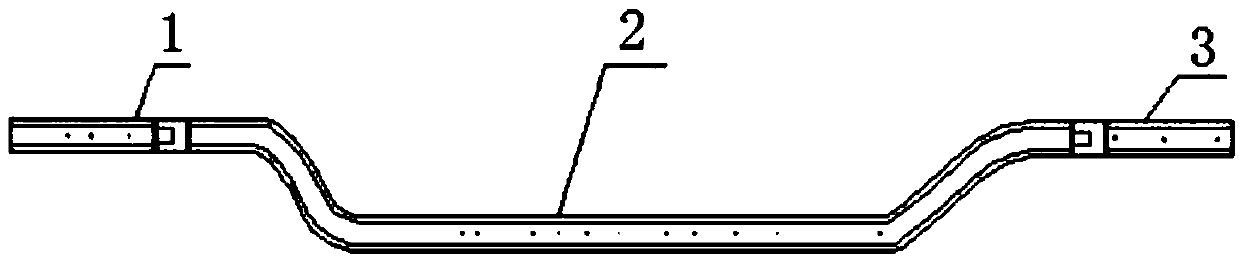

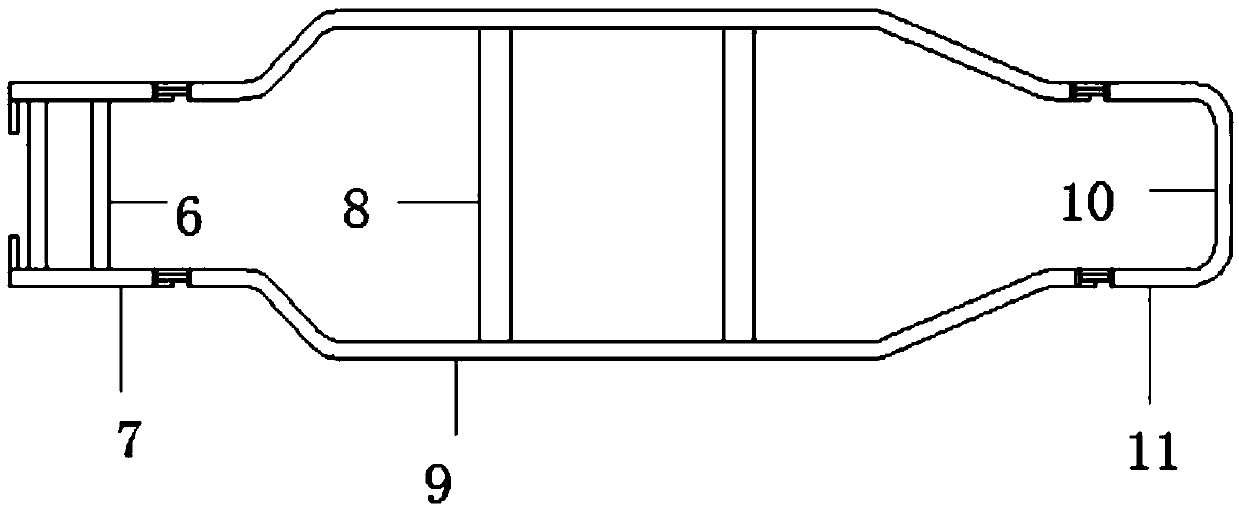

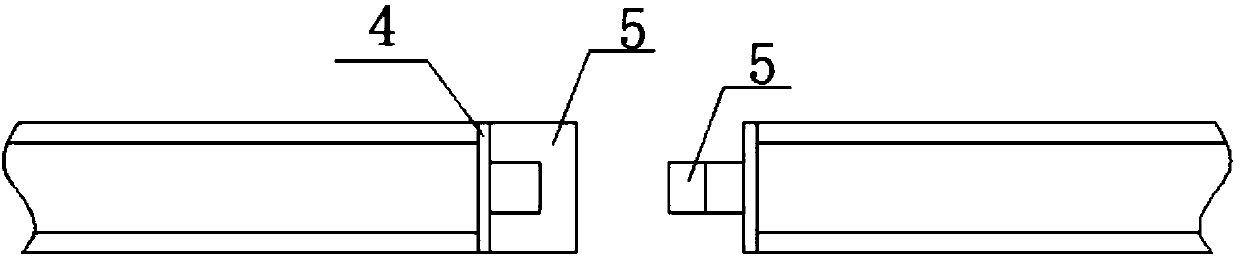

Combined car frame of car

PendingCN107585211ALight in massLower center of gravityUnderstructuresSuperstructuresVehicle frameAlloy

The invention discloses a combined car frame of a car. The combined car frame of the car comprises a car frame body front section, a car frame body middle section and a car frame body rear section, wherein the car frame body middle section is lower than the car frame body front section and the car frame body rear section. The car frame body front section comprises at least two car frame body frontsection longitudinal beams and at least two car frame body front section cross beams. The car frame body middle section comprises at least two car frame body middle section longitudinal beams and atleast two car frame body middle section cross beams. The car frame body rear section comprises at least two car frame body rear section longitudinal beams and at least one car frame body rear sectioncross beam. The car frame body front section, the car frame body middle section and the car frame body rear section are made of alloys. By transforming the structural design of the car frame and modifying material section of the car frame, the combined car frame has the advantages of simple structure, low mass, good car stability, good vibration reduction and absorption effects and high bearing capacity; and meanwhile the production cost is reduced, energy is saved, pollution is relieved, and broad development and application prospects are achieved.

Owner:JILIN UNIV

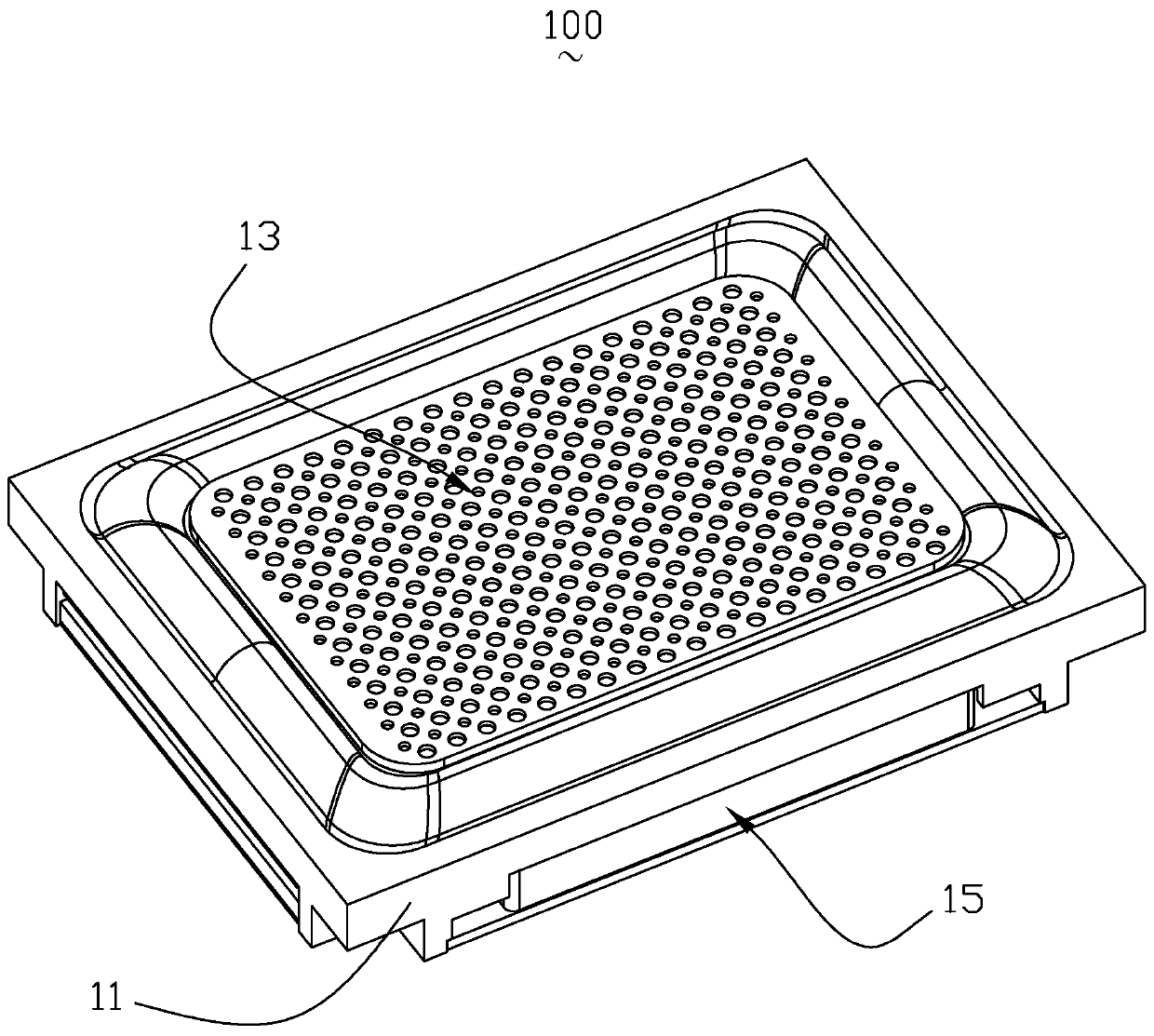

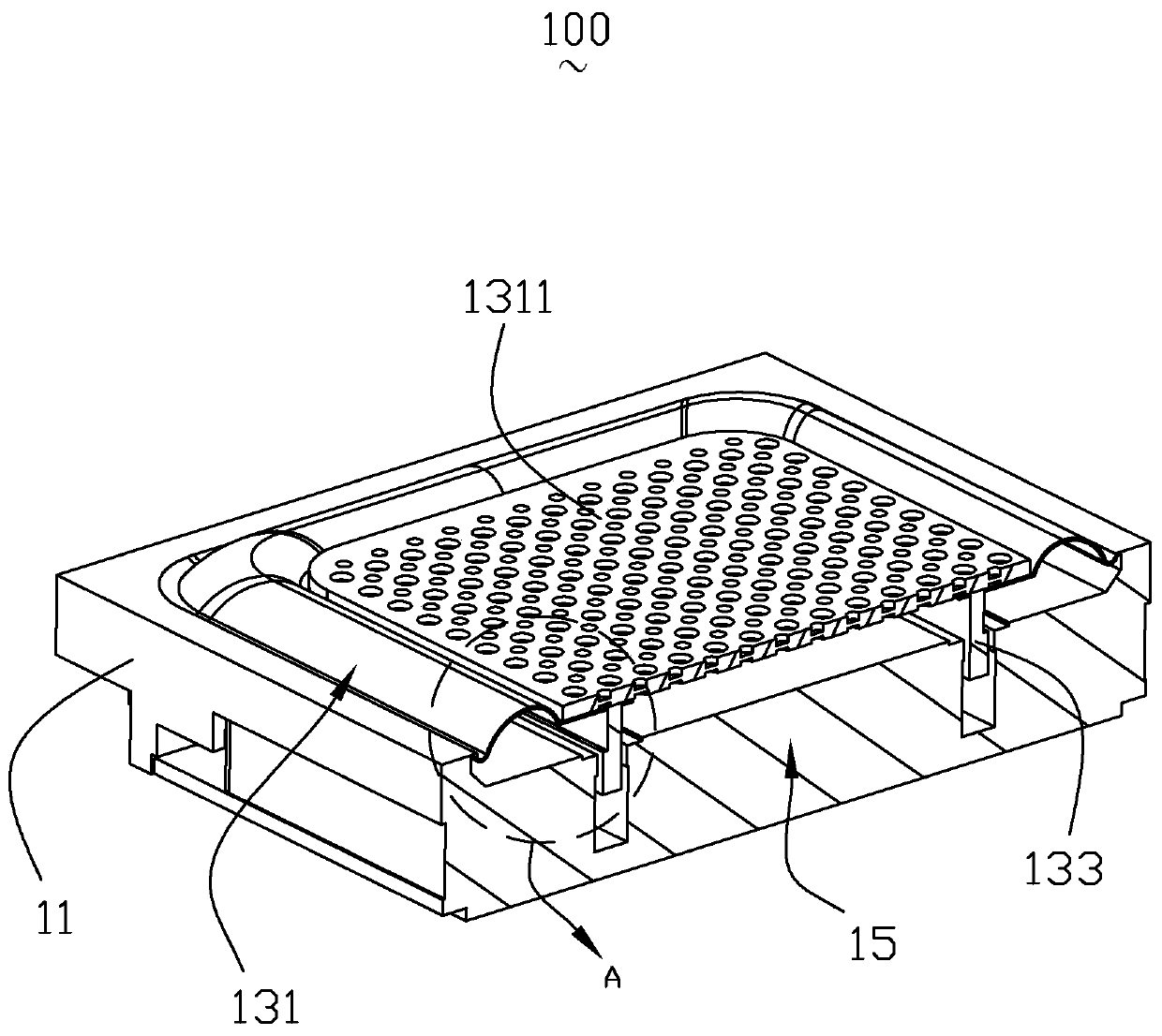

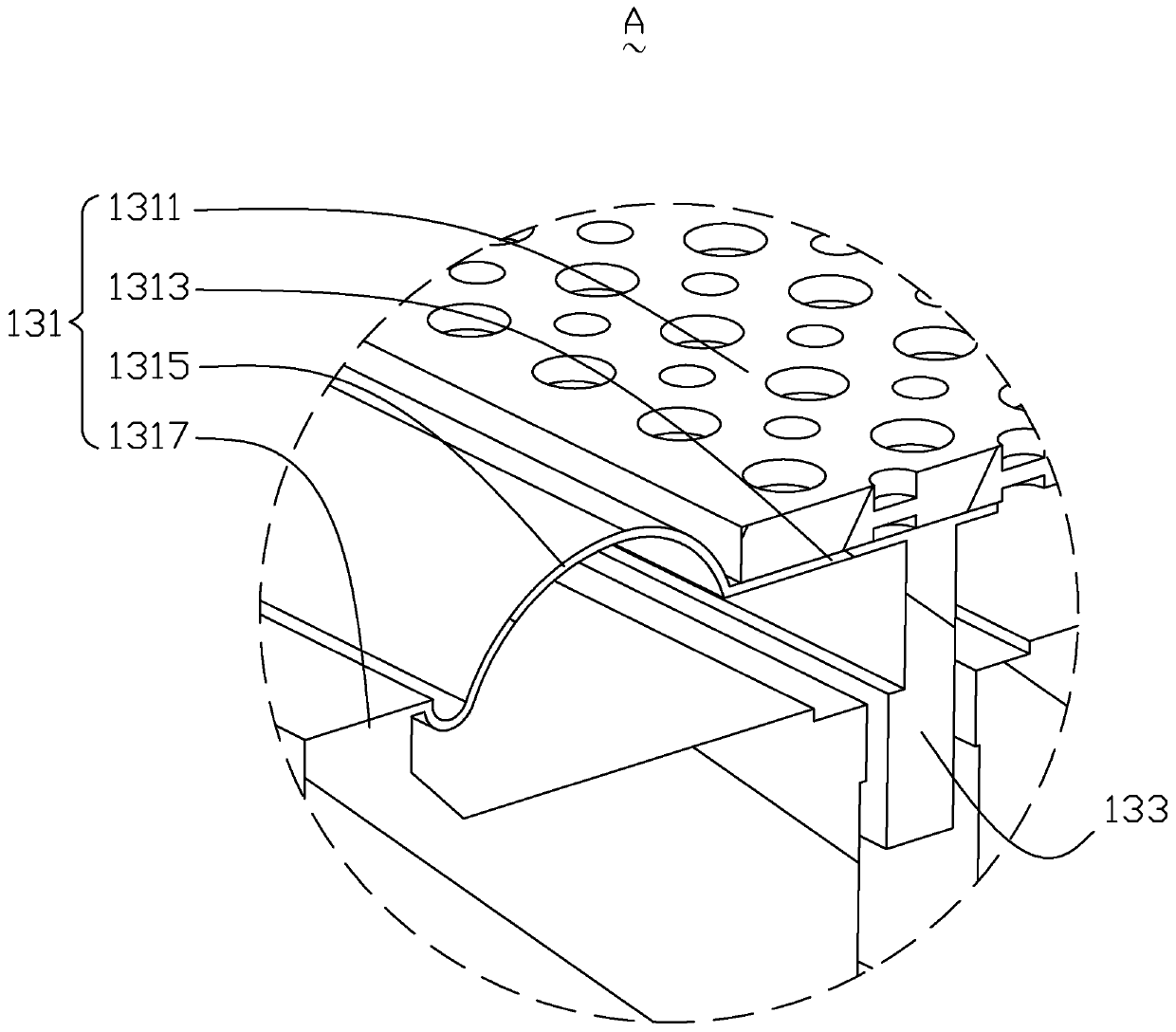

Loudspeaker

InactiveCN110536217ASave energyReduced amplificationNon-planar diaphragms/conesEngineeringLoudspeaker

The invention provides a loudspeaker which comprises a basin stand, a vibration system and a magnetic circuit system, the vibration system and the magnetic circuit system are respectively fixed on thebasin stand, the vibration system comprises a vibrating diaphragm fixed on the basin stand and a voice coil driving the vibrating diaphragm to vibrate and produce sound, the vibrating diaphragm comprises a globe roof, and two ends of the globe roof along the vibration direction are provided with microporous structures. Compared with the prior art, the loudspeaker provided by the invention has theadvantages that the two ends of the globe roof along the vibration direction are arranged into the microporous structures, so that when the loudspeaker is assembled into the loudspeaker box, the airflow noise in the front cavity of the loudspeaker box can be effectively reduced, and the purposes of improving the performance and the tone quality are achieved.

Owner:AAC TECH PTE LTD

Device for passively slowing relative rotation of ultra-large floating body

The invention relates to a device for passively slowing relative rotation of an ultra-large floating body, which comprises a main base and an auxiliary base, wherein the main base is arranged at intervals, and the auxiliary base is provided with holes; the outer side of the auxiliary base is butted with a sliding rod, one end of a guide rod is connected with the inner side of the main base, the other end of the guide rod sequentially runs through the holes and the sliding rod of the auxiliary base, and a slowing device for slowing the rotation is wound on the periphery of the guide rod; a plurality of torsion rods are symmetrically arranged between the main base and the auxiliary base by taking the guide rod as a center, one end of each torsion rod is hinged with the main base, and the other end of each torsion rod is hinged with the auxiliary base. The device for passively slowing relative rotation of the ultra-large floating body has simple structure and convenient use, has higher independence, and can achieve passive constrained motion and provide restoring force through the main base, the auxiliary base, the guide rod and the torsion bar; the torsion bar has stronger damping without manual intervention, and is convenient to install and disassemble on the sea.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

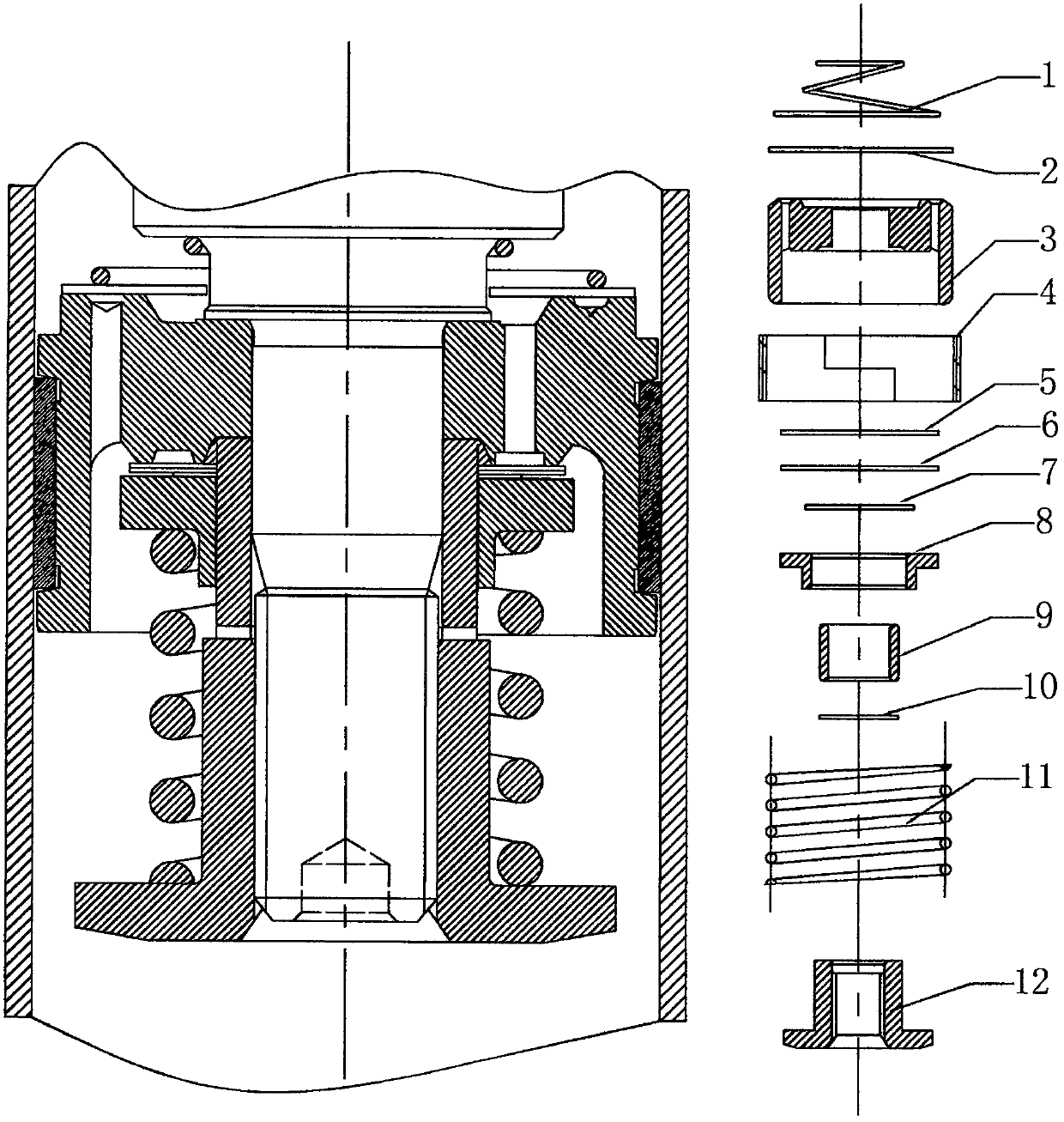

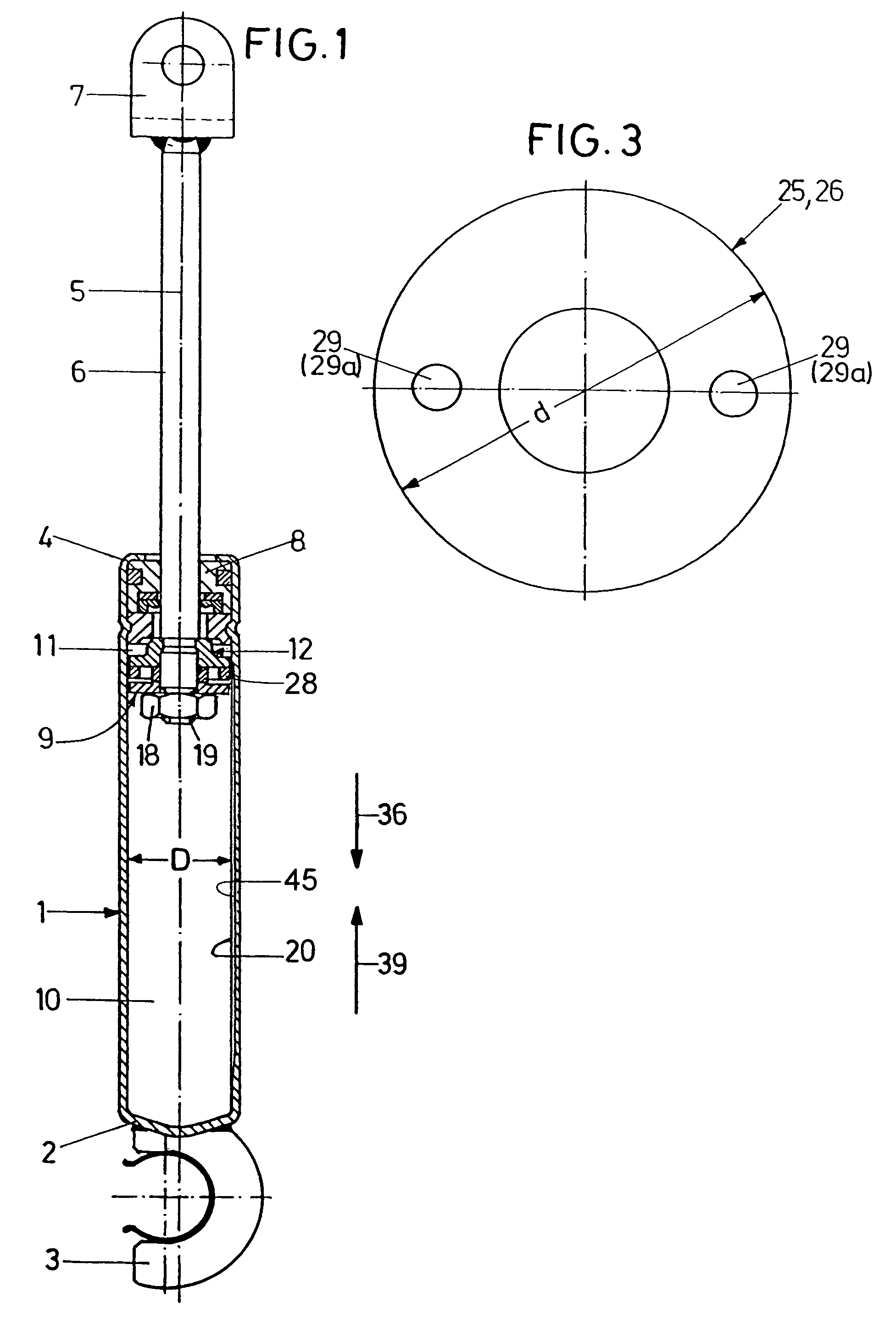

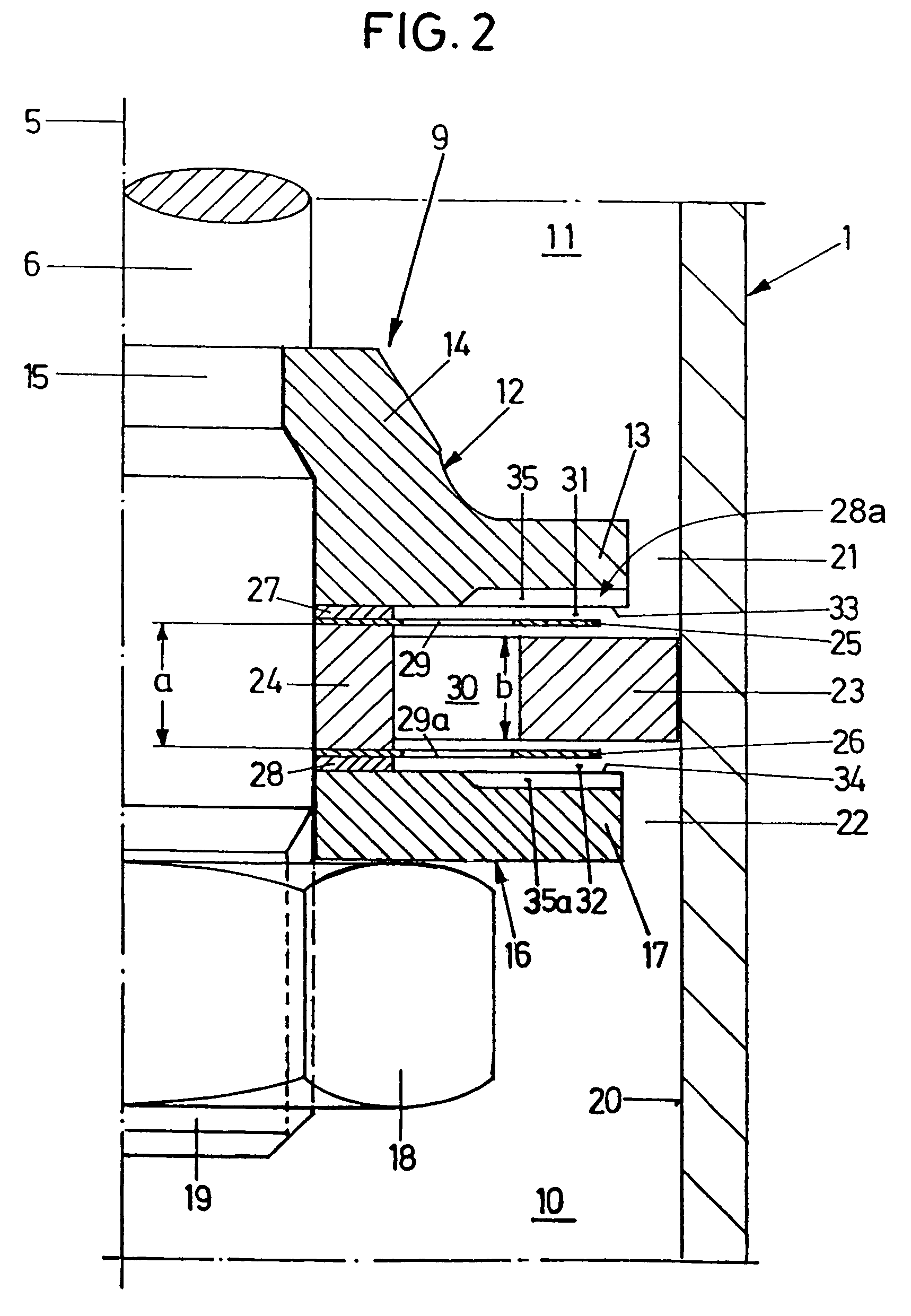

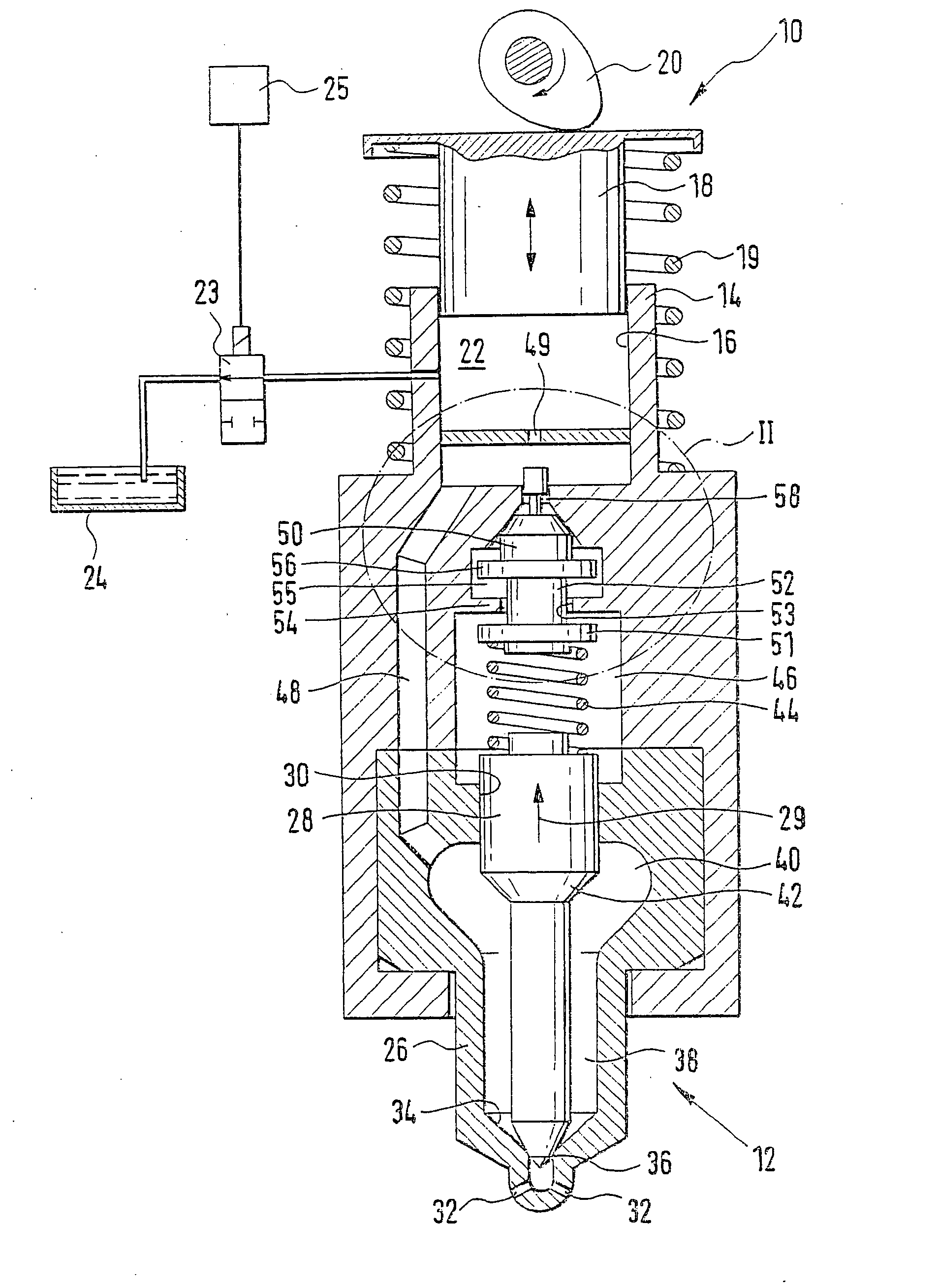

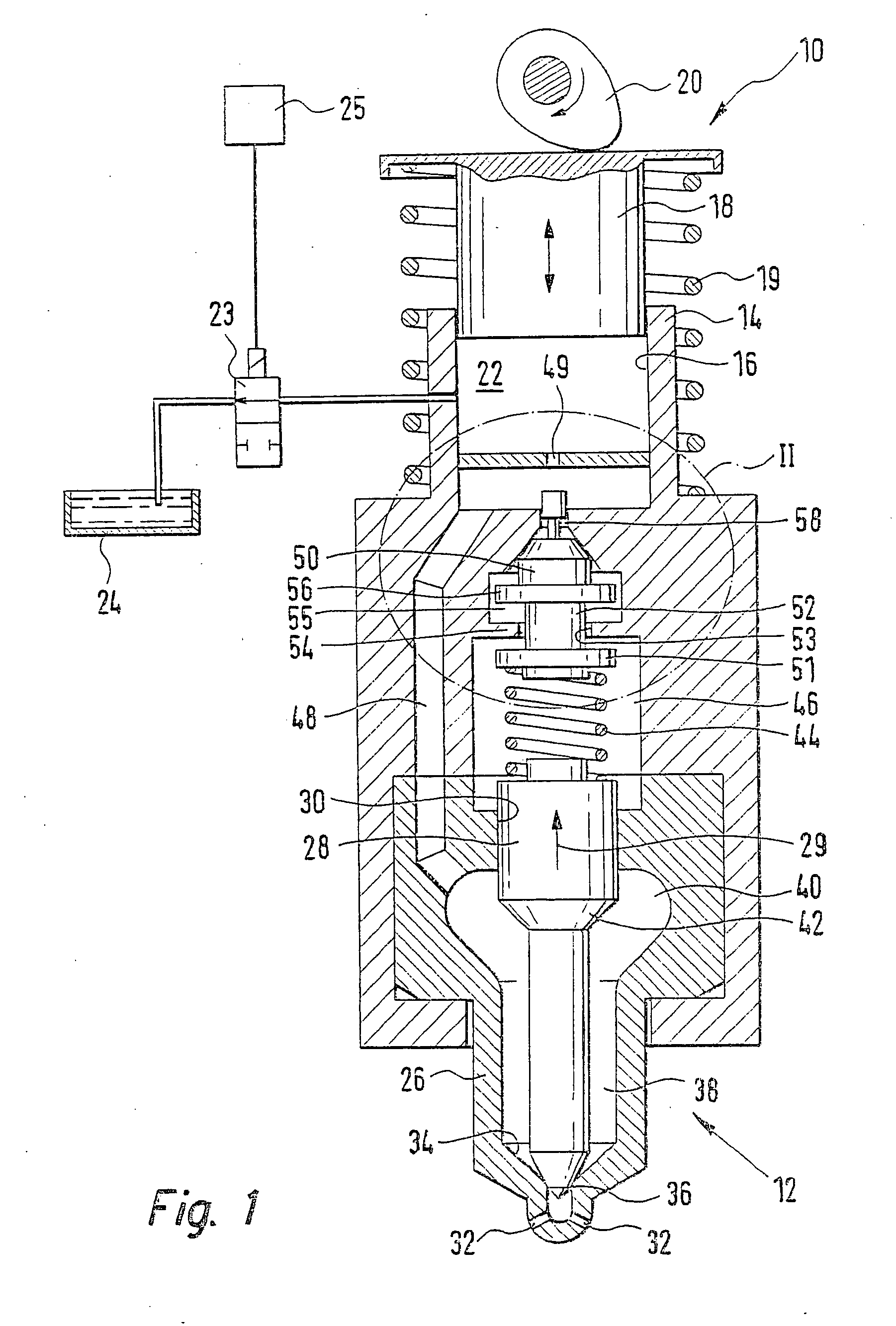

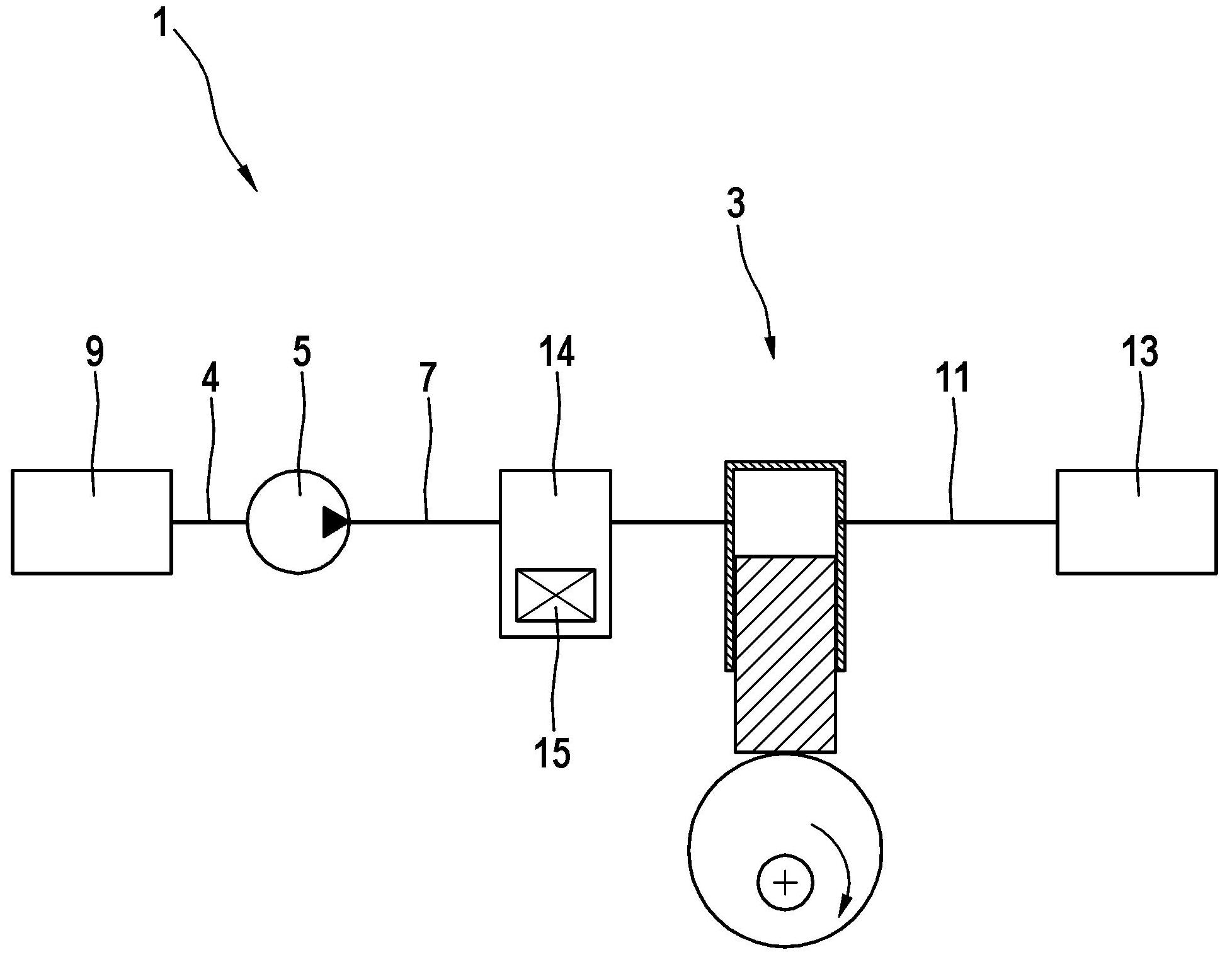

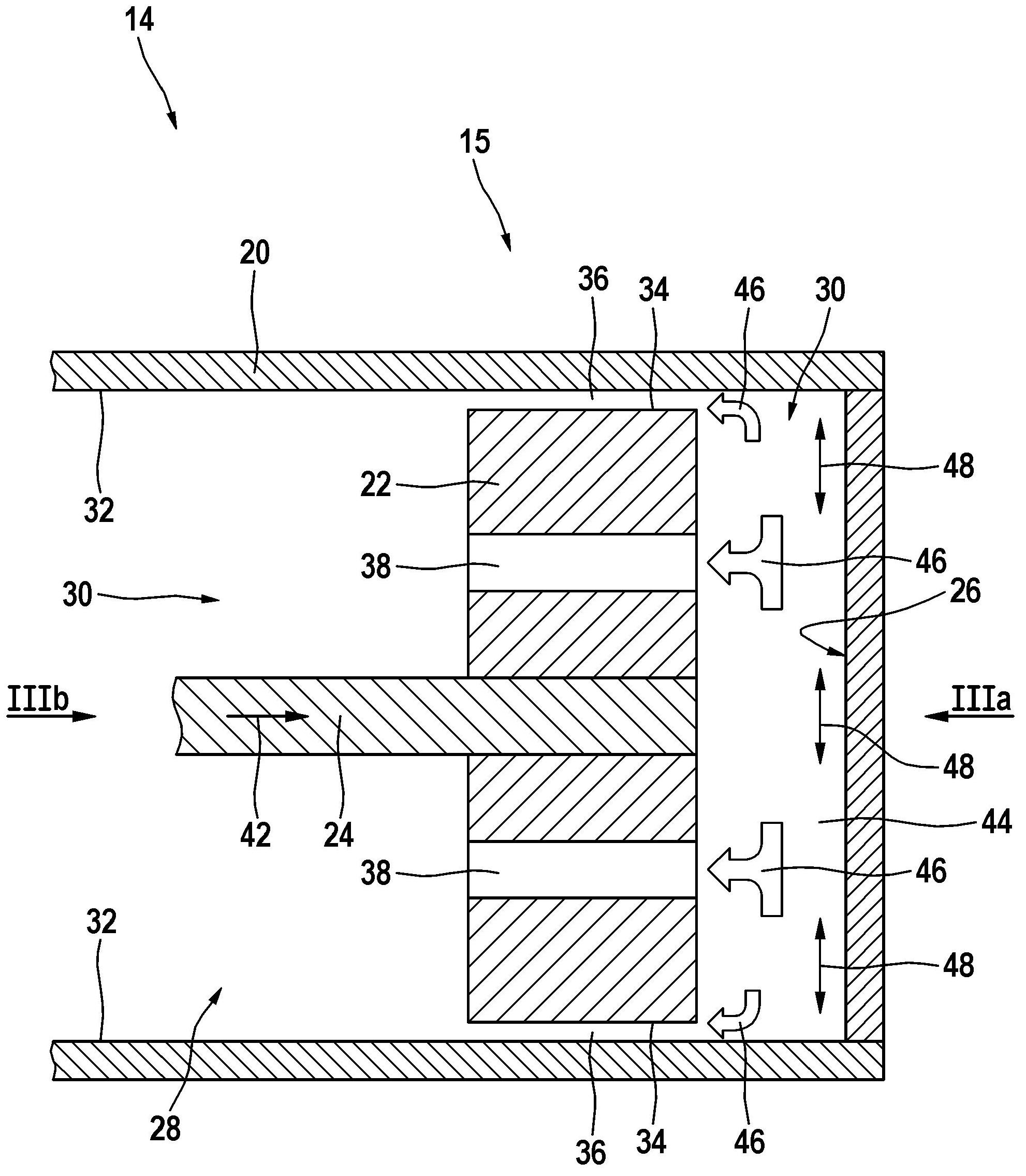

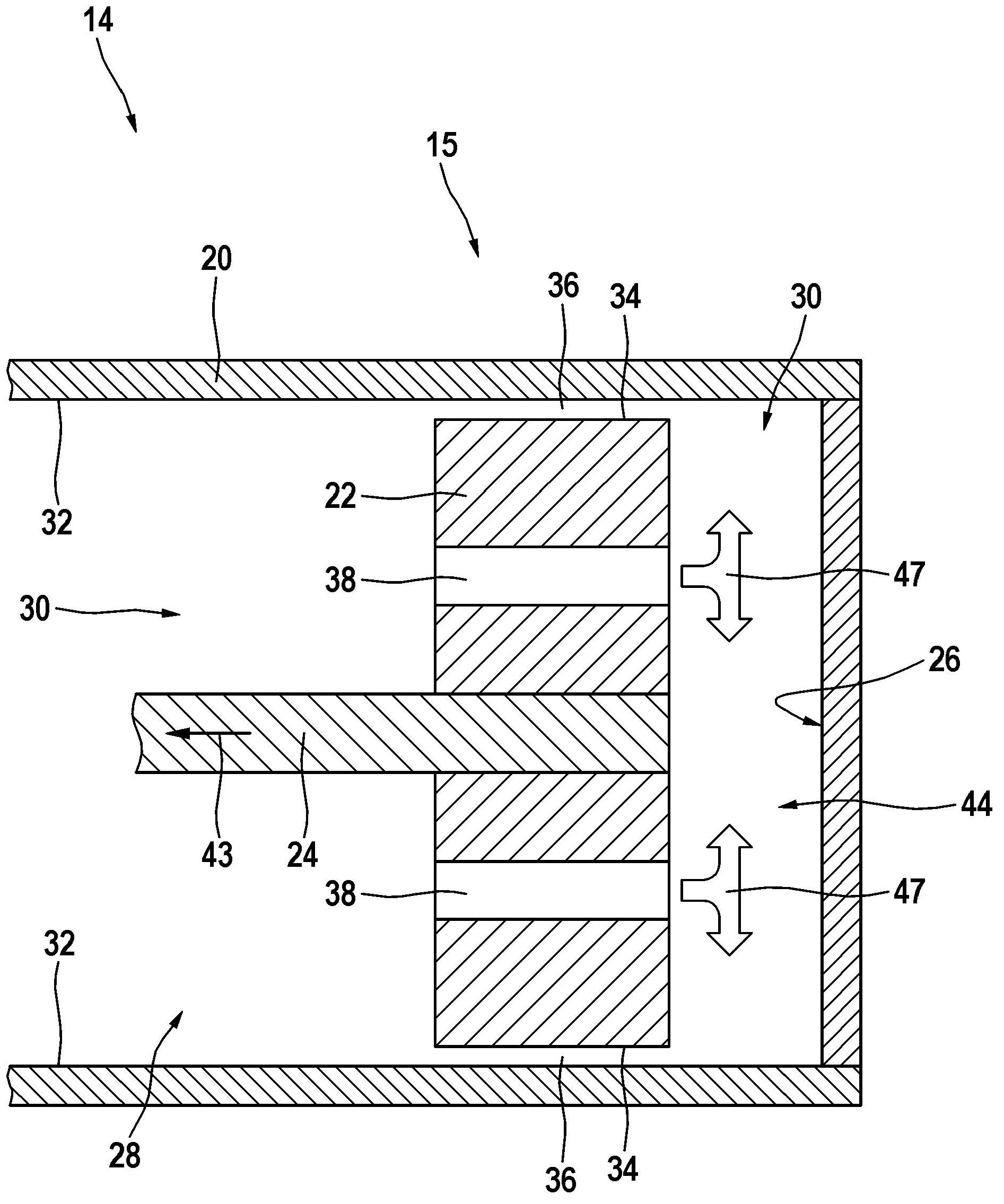

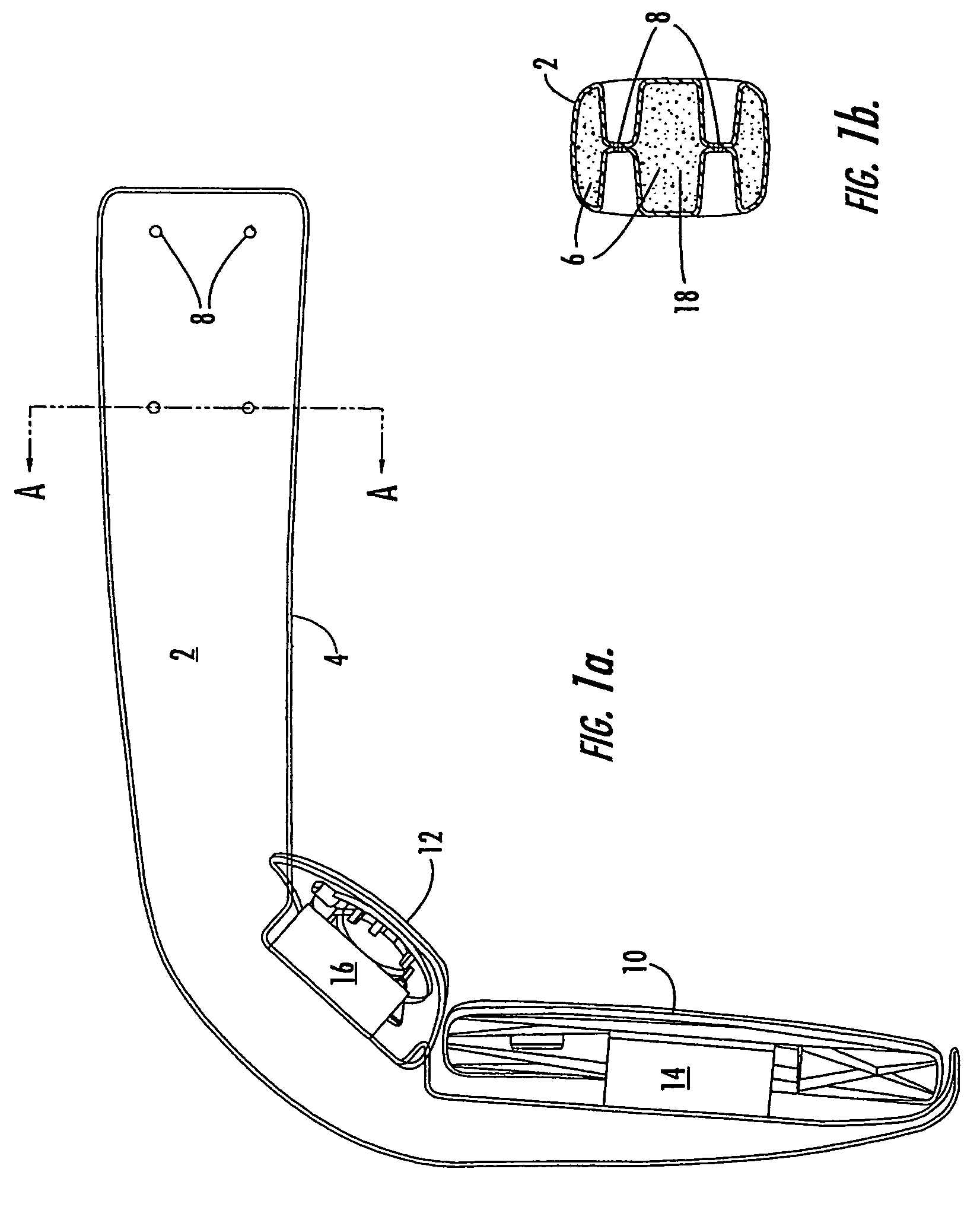

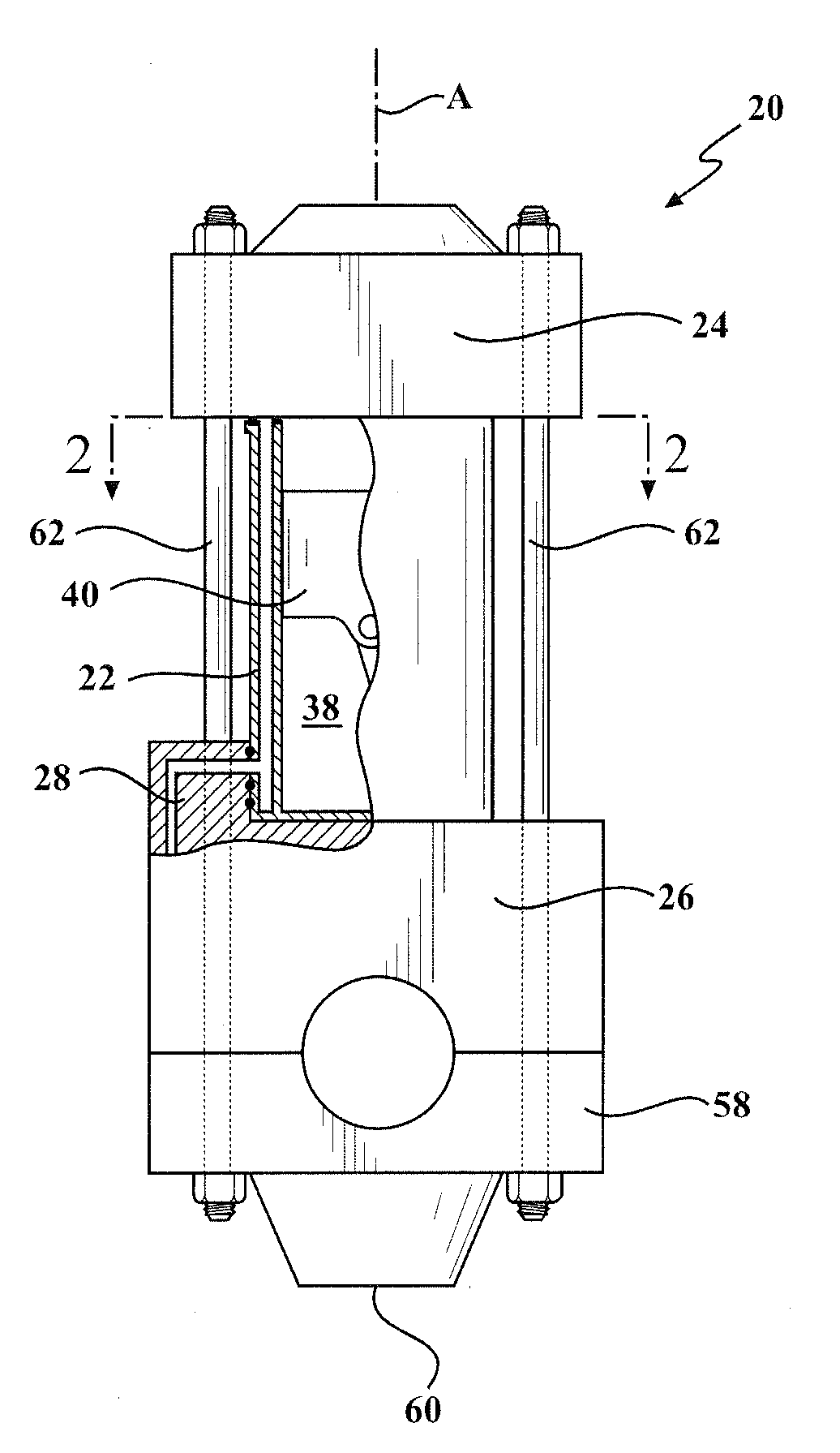

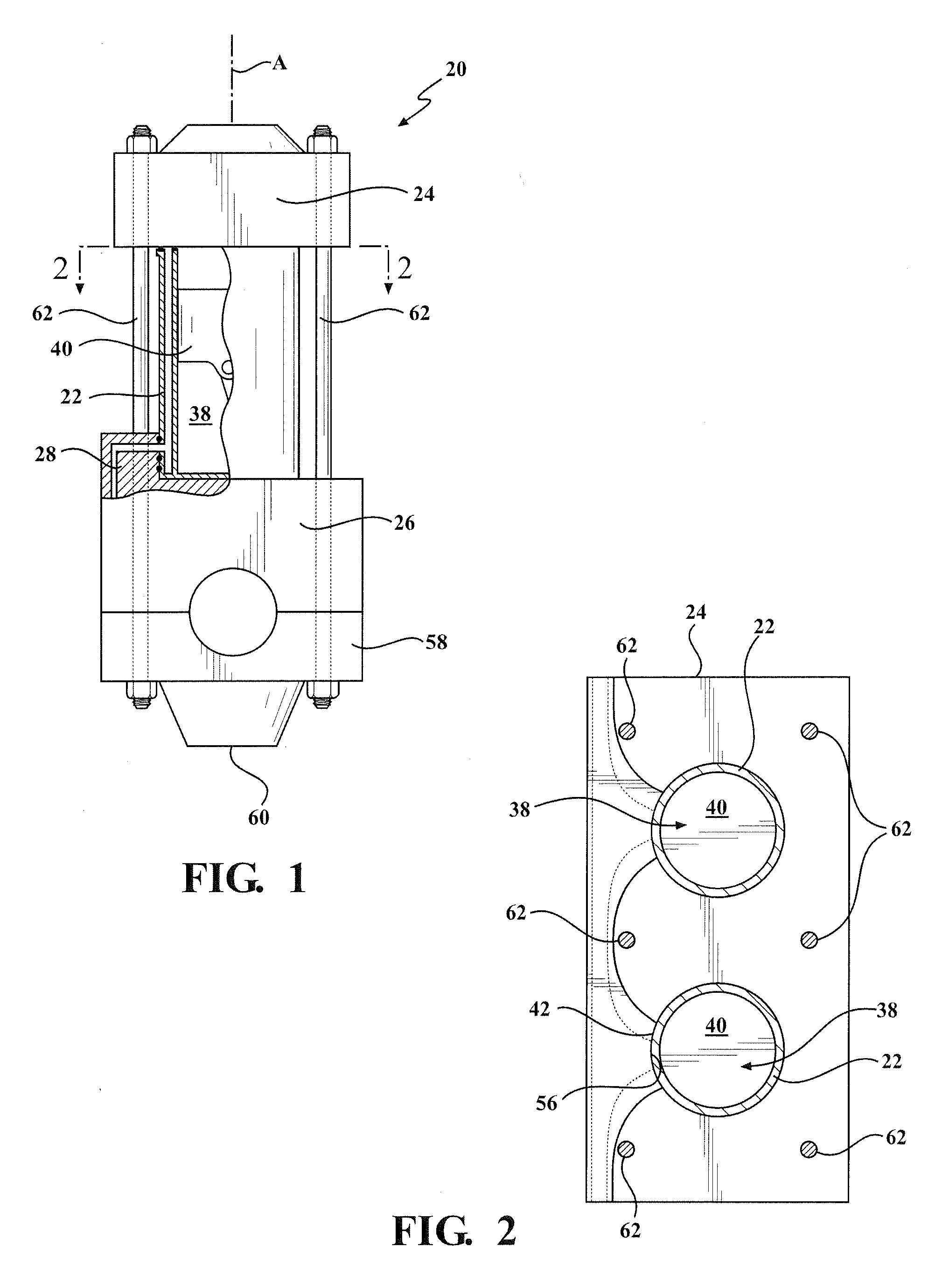

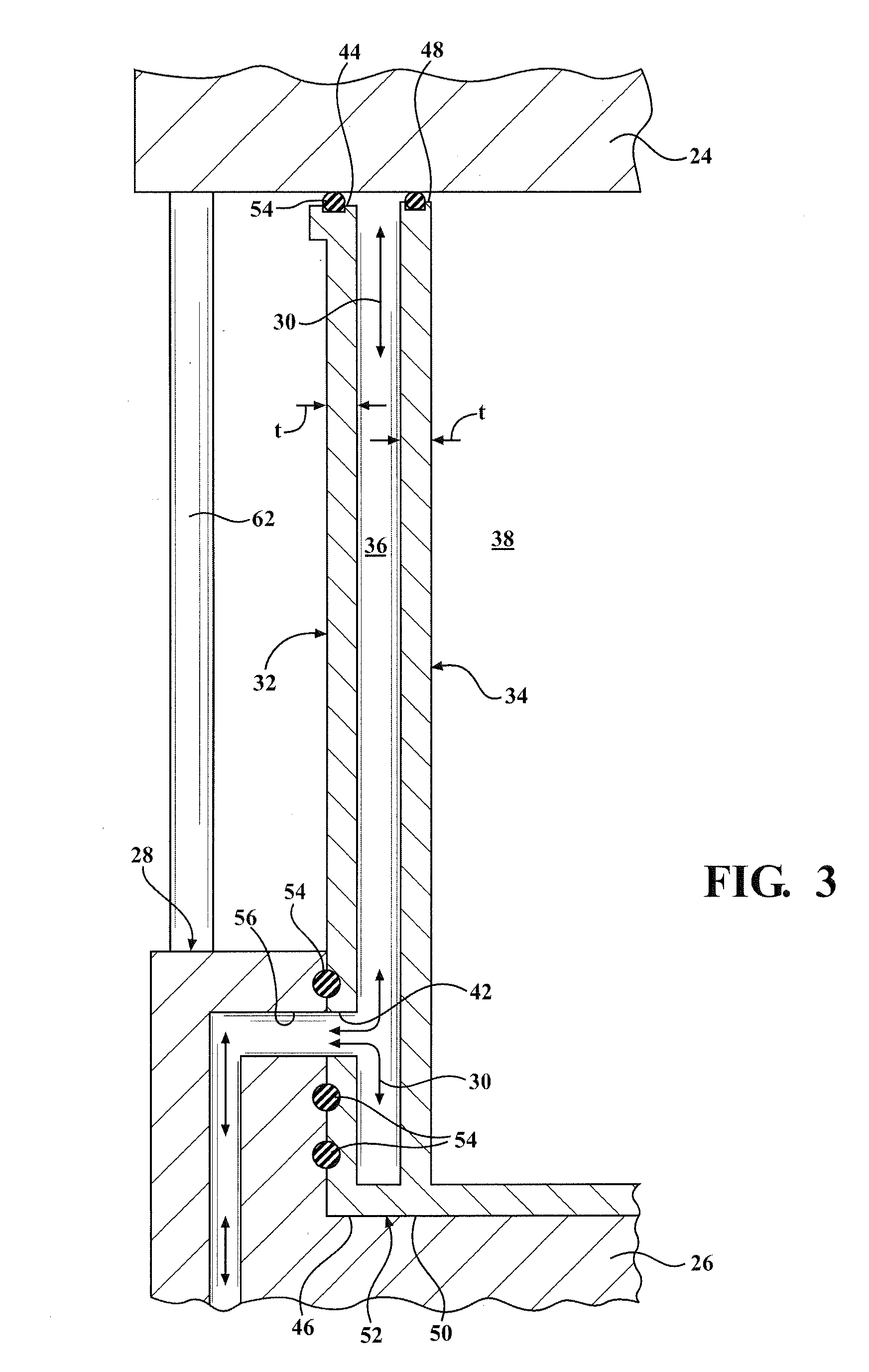

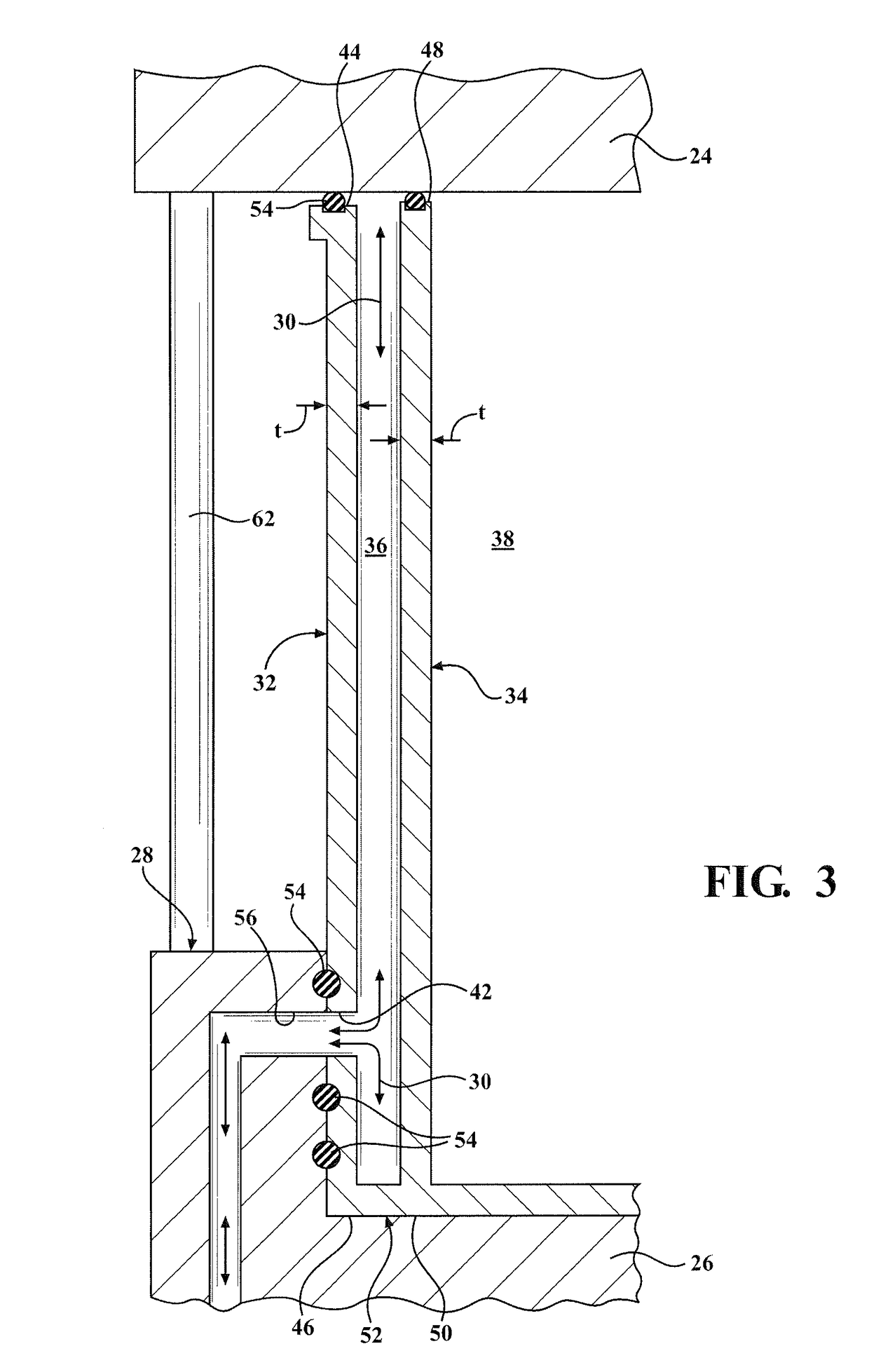

Fuel injection system for an internal combustion engine

InactiveUS6889661B2Less motionStrong dampingMachines/enginesFuel injecting pumpsEngineeringInternal combustion engine

A fuel injection system having a high-pressure pump and a fuel injection valve for each cylinder of the engine in which the pump has a work chamber, and the injection valve has a valve member movable in an opening direction counter to the force of a closing spring braced between the injection valve member and a displaceable storage piston that is acted upon, on its side remote from the closing spring, by the pressure in the pump work chamber. The storage piston is movable into a storage chamber counter to the force of the closing spring, and the deflection stroke motion of the storage piston is limited by a stop. The storage piston has one shaft portion of smaller cross section, disposed in an outset position in a connecting bore, and one portion of larger cross section disposed outside the connecting bore toward the pump work chamber, and upon the deflection stroke motion of the storage piston into the storage chamber, its shaft portion of larger cross section dips into the connecting bore.

Owner:ROBERT BOSCH GMBH

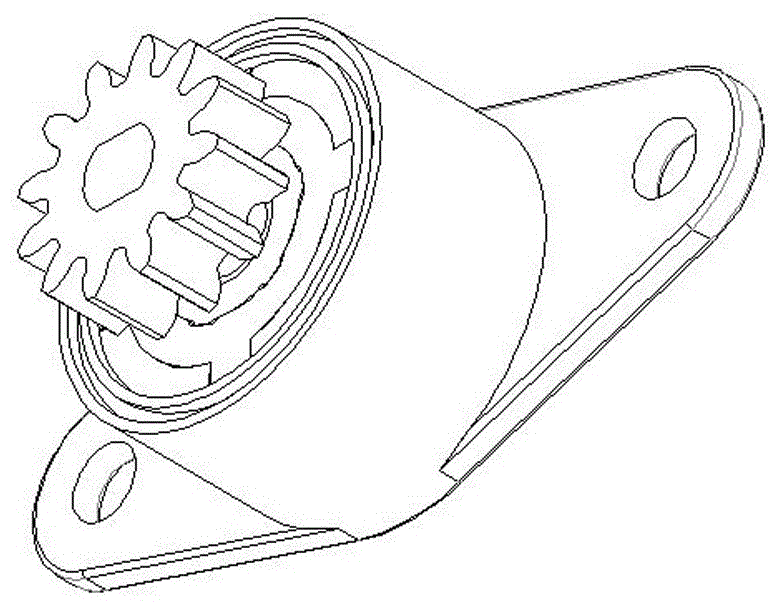

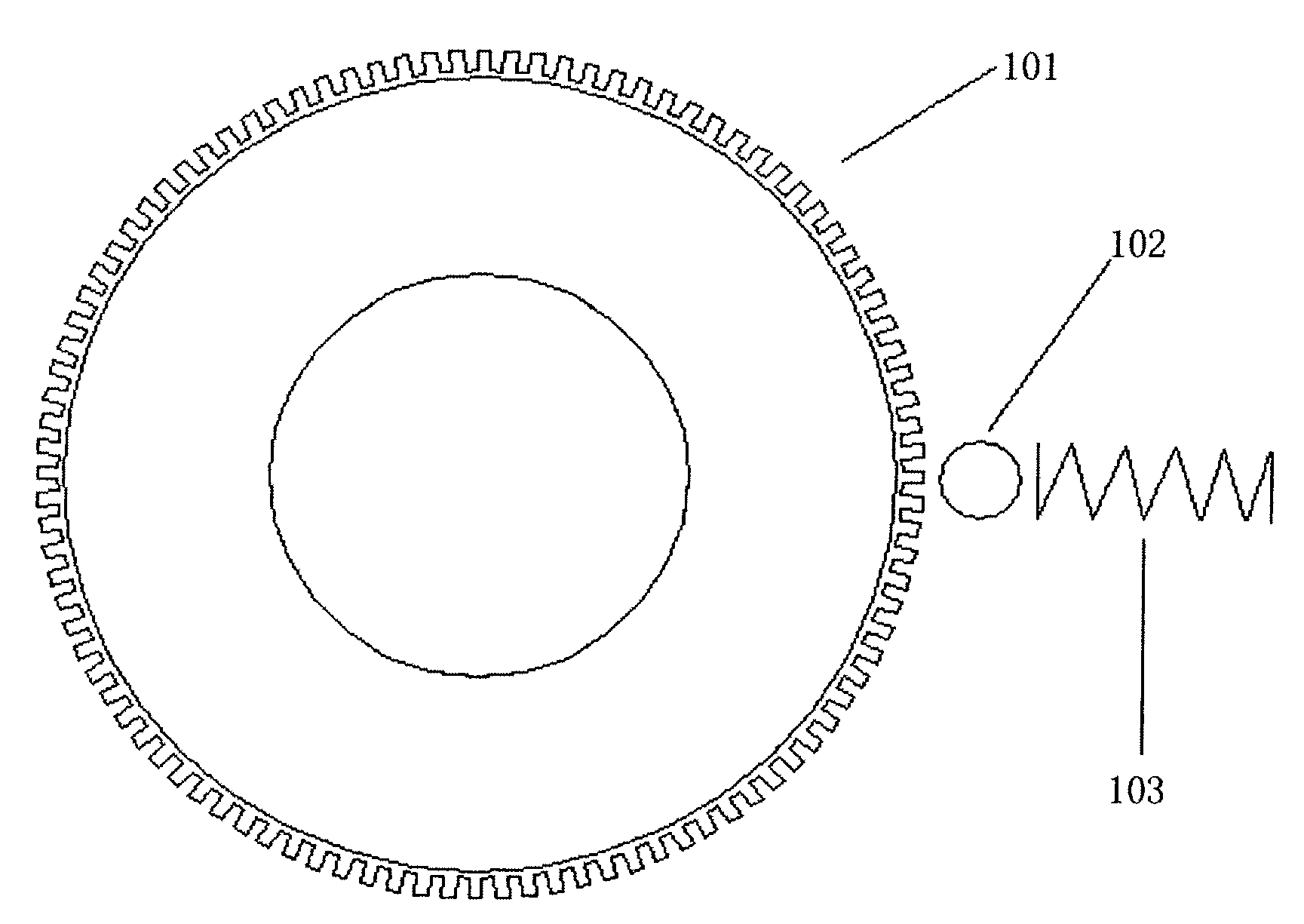

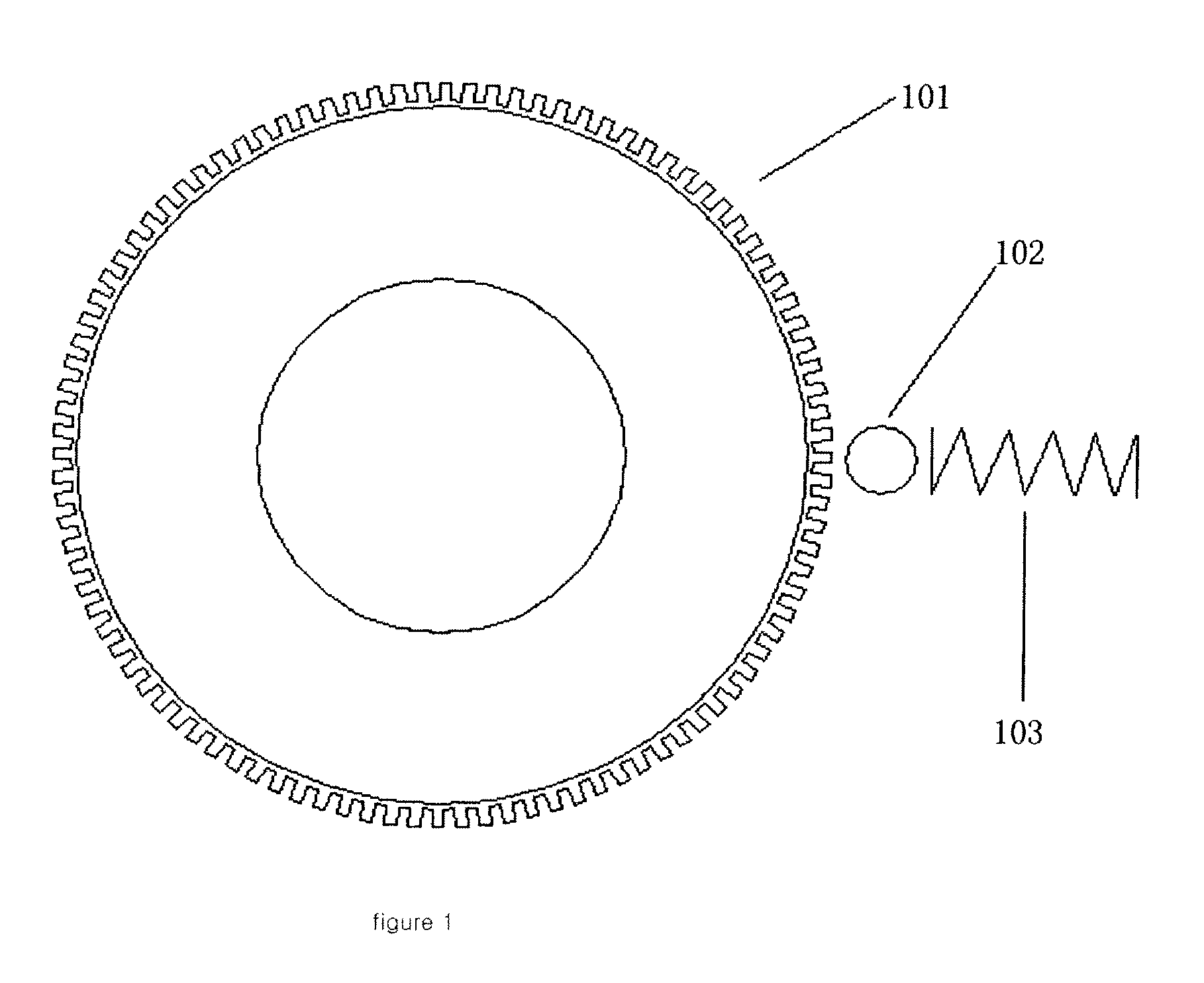

One-way rotary damper

ActiveCN105781304BCan withstand impactIncrease dampingBuilding braking devicesWing accessoriesEngineeringShock absorber

Owner:SUZHOU SHENGDE PRECISION ELECTRIC

Hand and press-button dual-way manual pulse generator with built-in indicator lamps

ActiveUS20100033168A1Feel goodEasy detectionProgramme controlPrecision positioning equipmentComputer hardwareControl signal

The present invention discloses a hand and press-button dual-way manual pulse generator with built-in indicator lamps, which comprises a rotation pulse input unit and a CPU. The CPU is connected with a forward rotation indicator lamp and an inverse rotation indicator lamp. The rotation signal input unit and / or the press-button signal input unit transmit the output signal to the CPU. The rotation pulse input unit transmits the output signal to the CPU where the output signal is processed and the control signal is then output through the difference chip. Meanwhile, the CPU collects control signals through the feedback circuit to realize self-check when the machine is turned on. The pulse generator has a non-contact structure extending significantly its service life than the prior art, which makes it durable. In addition, by installing a controller, built-in indicator lamps, and press-button control on the manual pulse generator, it offsets the technical defects of the current manual pulse generator, reduces the fault incidence, and greatly enhances work efficiency. Besides, the manual pulse generator has a simple structure that it is easy to manufacture and to widely spread in the field of the machine tool control.

Owner:KEDE NUMERICAL CONTROL CO LTD

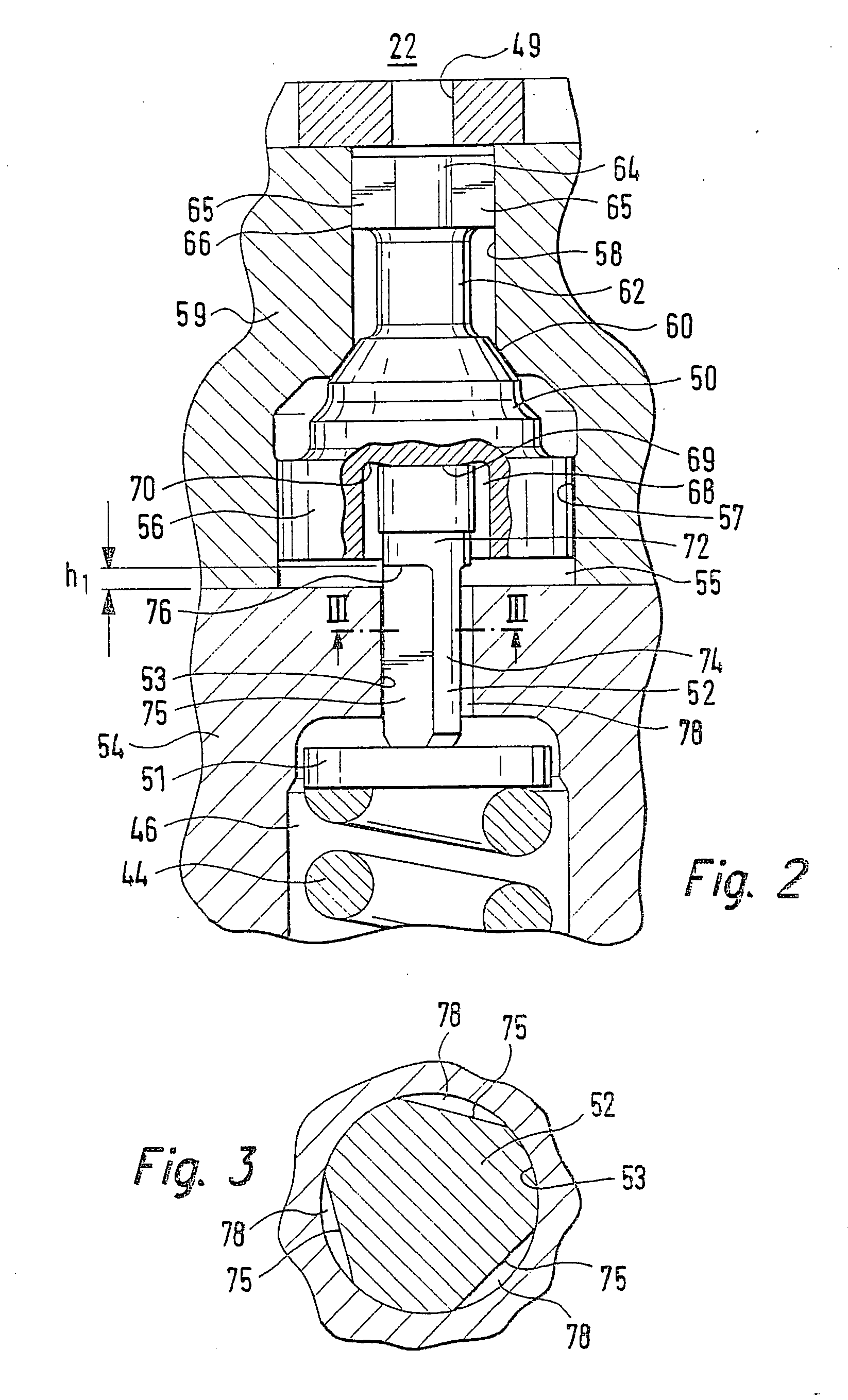

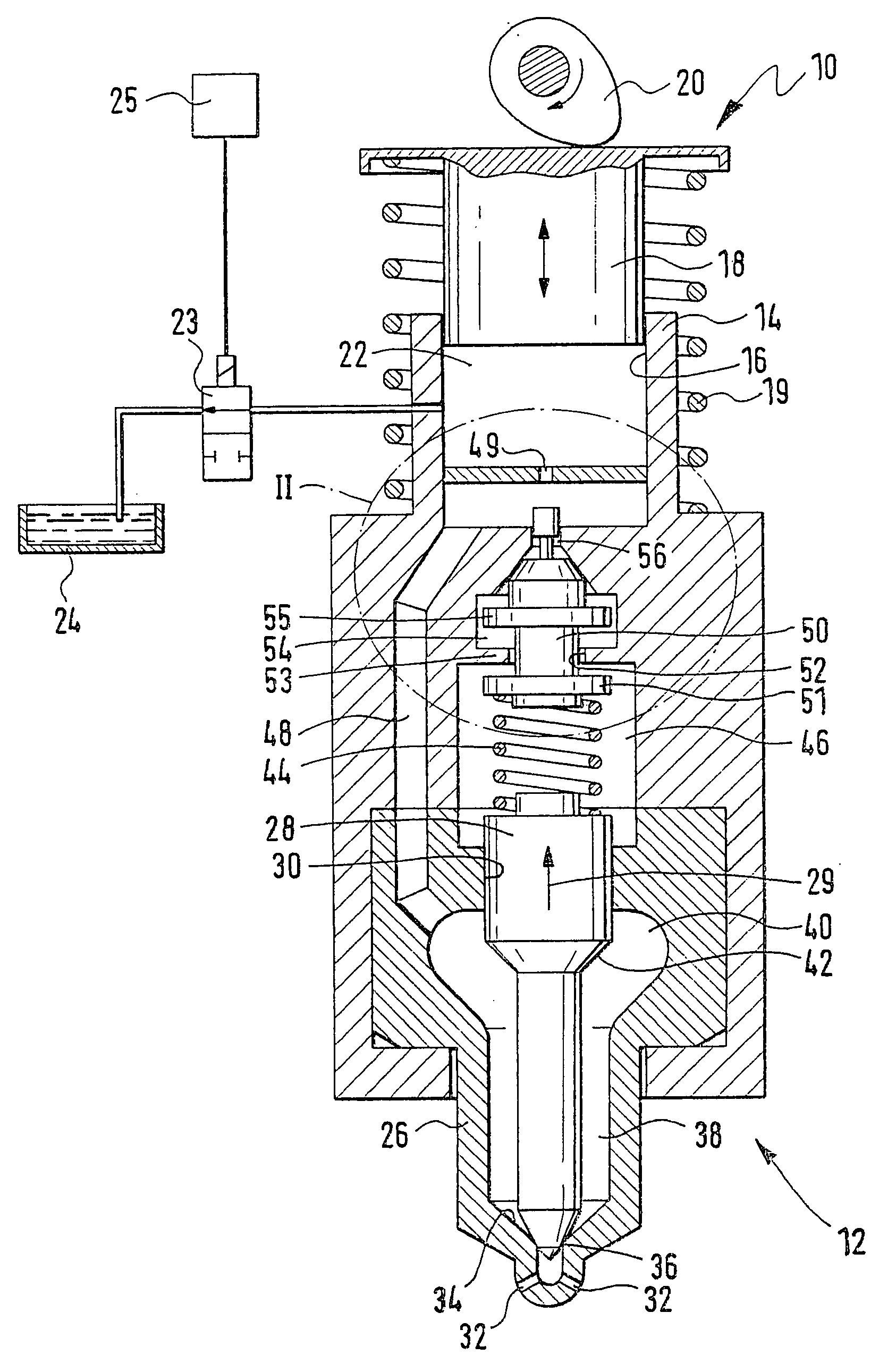

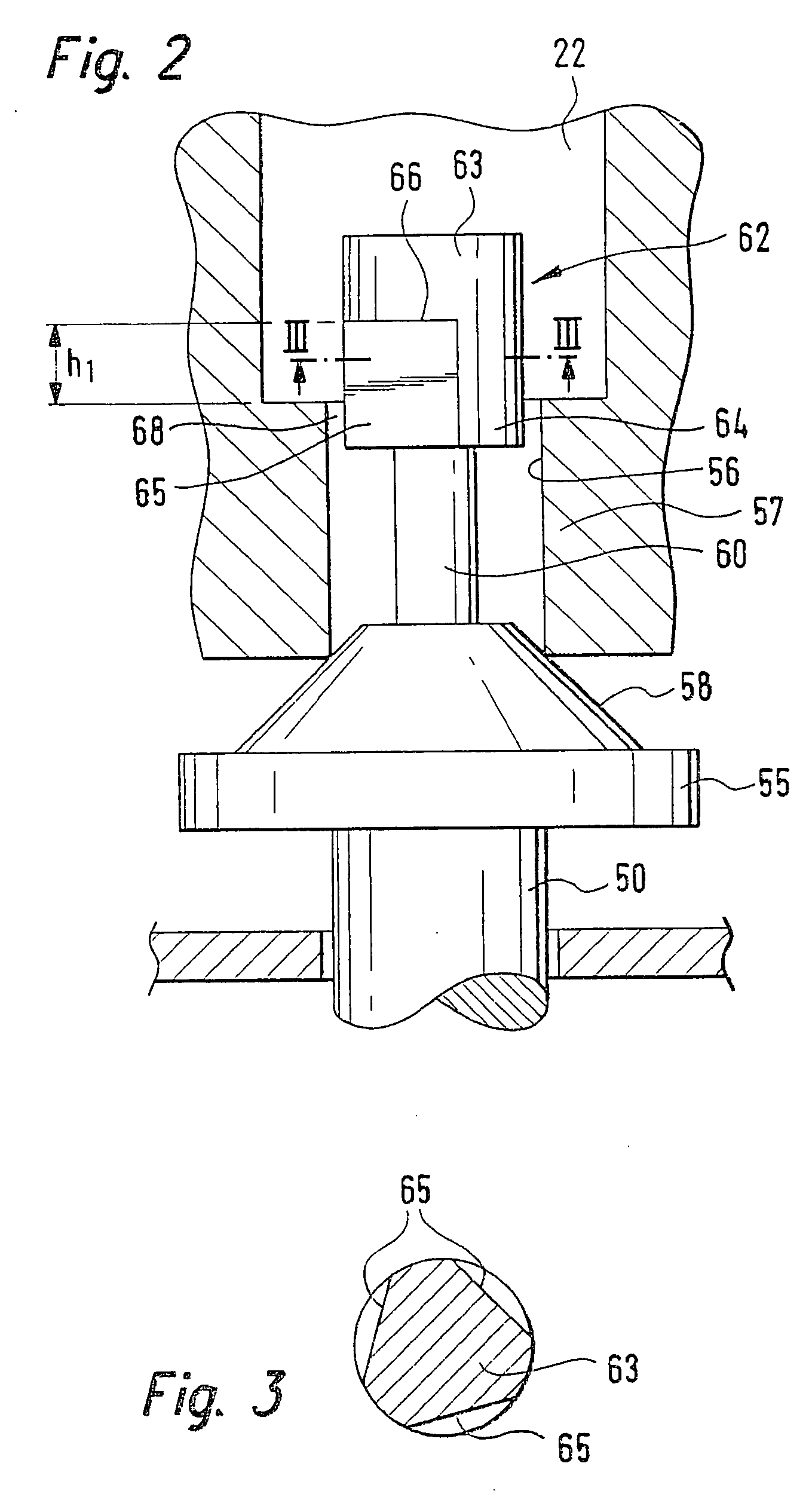

Fuel injection system for an internal combustion engine

InactiveUS20040045529A1Strong dampingLess motionMachines/enginesFuel injecting pumpsEngineeringInternal combustion engine

The fuel injection system has a high-pressure fuel pump (10) and a fuel injection valve (12) for a cylinder of the engine. The high-pressure fuel pump (10) has a pump work chamber (22), and the fuel injection valve (12) has an injection valve member (28) by which at least one injection opening (32) is controlled and which is movable in an opening direction (29) counter to the force of a closing spring (44); the closing spring (44) is braced on one end on the injection valve member (28) and on the other end on a displaceable storage piston (50) that is acted upon, on its side remote from the closing spring (44), by the pressure prevailing in the pump work chamber (22). The storage piston (50) is movable into a storage chamber (55) counter to the force of the closing spring (44), and the deflection stroke motion of the storage piston (50) into the storage chamber (55) is limited by a stop (54). A shaft part (52), which has one shaft portion (74) of smaller cross section disposed in an outset position in a connecting bore (53) and one shaft portion (72) of larger cross section disposed outside the connecting bore (53) in the storage chamber (55), is movable with the storage piston (50), and upon the deflection stroke motion of the storage piston (50) into the storage chamber (55), the shaft portion (72) of larger cross section dips into the connecting bore (53).

Owner:ROBERT BOSCH GMBH

Electromagnetically actuated volume control valve, in particular for controlling the delivery volume of a high-pressure fuel pump

ActiveCN102686868ASlow downReduce adhesionMachines/enginesFuel injecting pumpsEngineeringControl valves

The invention relates to an electromagnetically actuatable volume control valve, in particular for controlling the delivery volume of a high-pressure fuel pump. The volume control valve comprises a movement chamber (28), which can be filled with a fluid (30), a moving part (22) of an electromagnetic actuating device arranged in said chamber, and a stop (26). When the moving part (22) rests against the stop (26), a contact area is present between the moving part (22) and the stop (26). The contact area is defined by a surface of the moving part (22) and a surface of the stop (26). The contact area is smaller than the total area of the moving part (22) or the stop (26).

Owner:ROBERT BOSCH GMBH

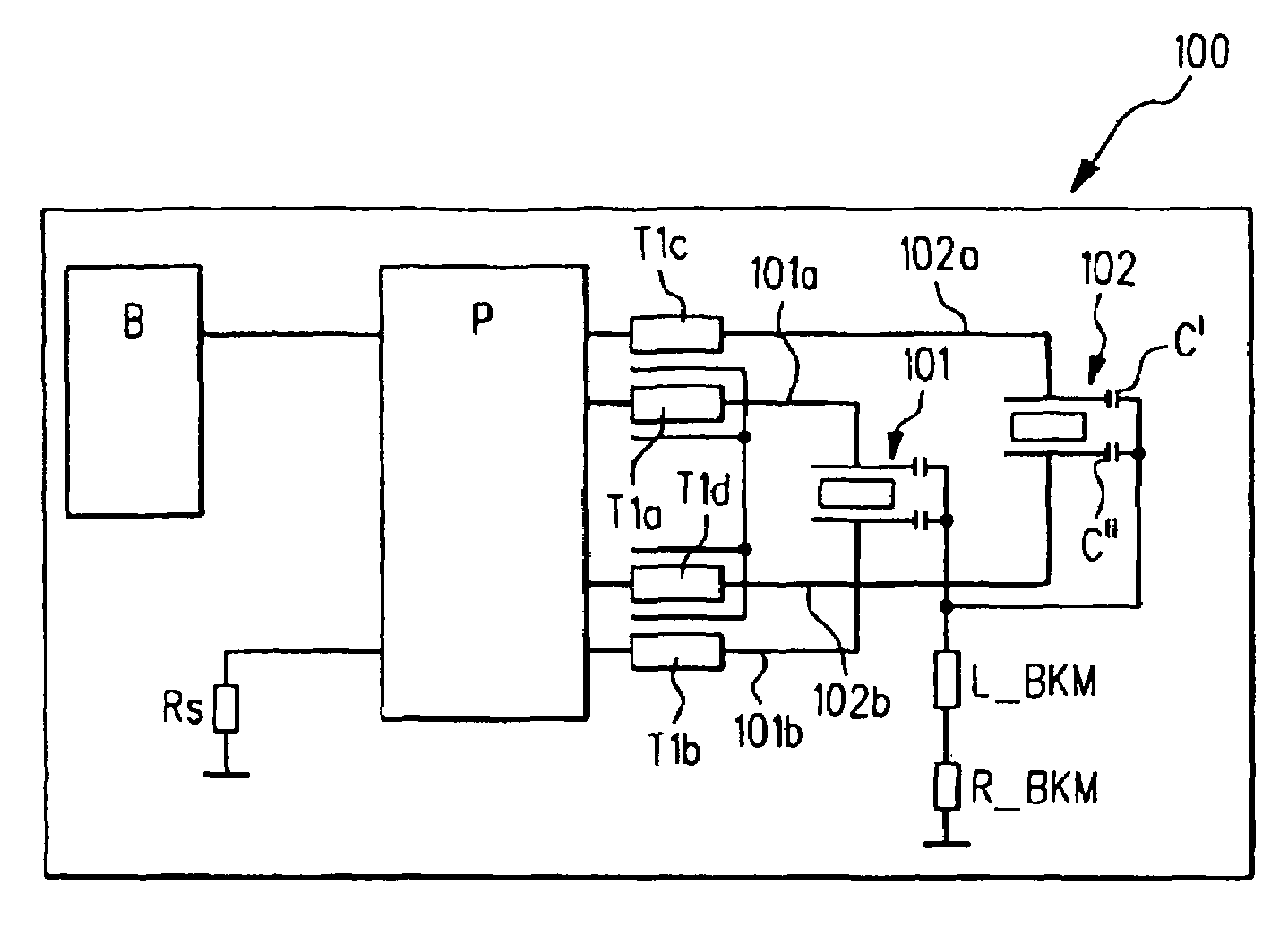

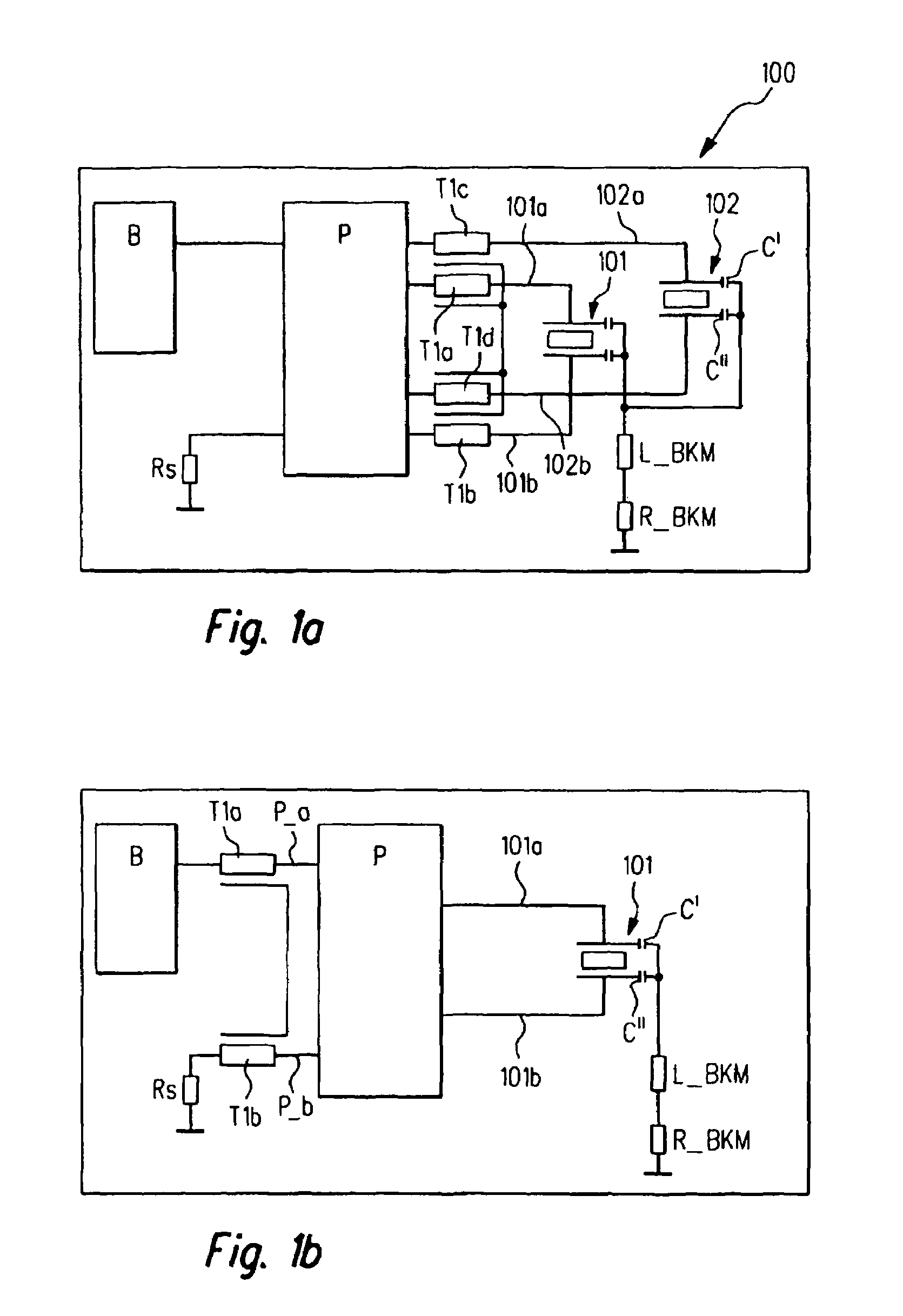

Control circuit for an actuator

InactiveUS7415971B2Strong dampingHigh impedanceElectrical controlPiezoelectric/electrostriction/magnetostriction machinesInductorEngineering

In a control circuit for at least one actuator, in particular for a capacitive actuator of an injection system of an internal combustion engine, a control current can be applied to the actuator.The control circuit has an inductor, e.g., having a core and having multiple windings, the windings being designed and connected to the control circuit such that a control current flowing into the actuator and a control current flowing out of the actuator each flow through different windings of the inductor, and a magnetic flux induced in the inductor or its core by the control current flowing into the actuator and a magnetic flux induced in the inductor or its core by the control current flowing out of the actuator mutually compensate one another.

Owner:ROBERT BOSCH GMBH

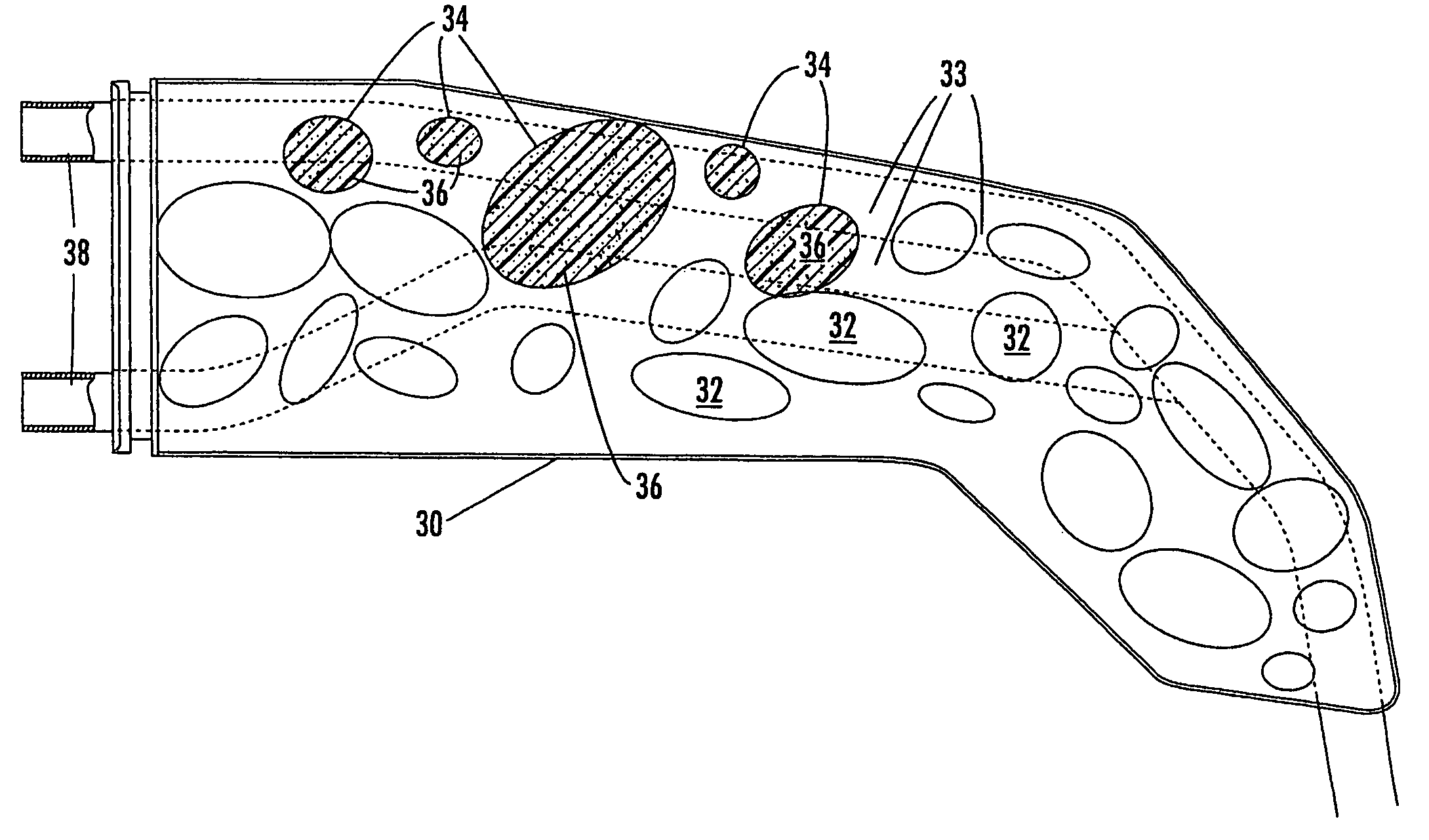

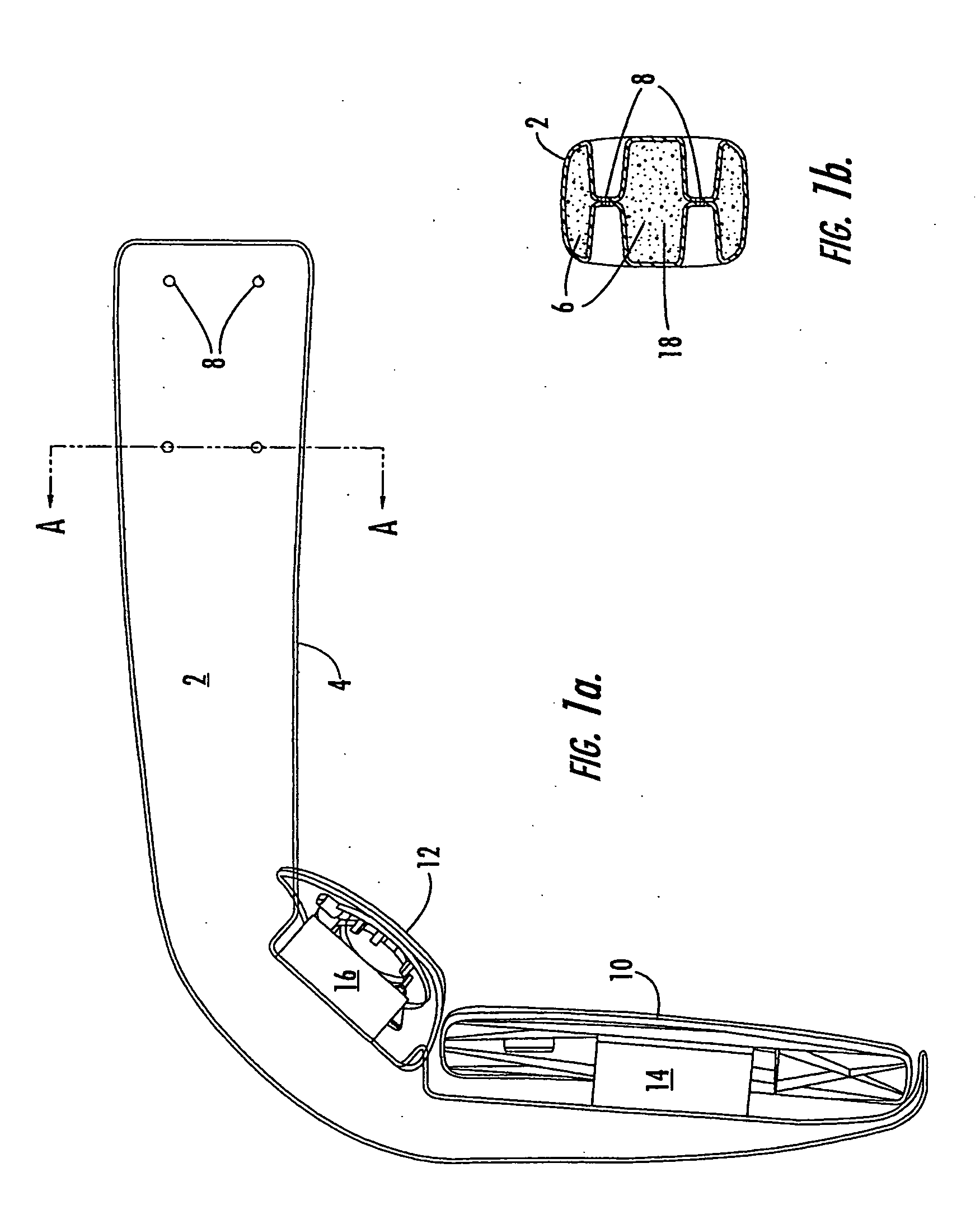

Fillable and stiffened rearview mirror assembly

InactiveUS7445734B2Improve stabilityVibratory behavior of the carrier can be so positively affectedMirrorsLaminationEngineeringRear-view mirror

A fillable rearview mirror assembly and method of molding a carrier for the assembly are provided. The mirror assembly has a hollow carrier that can be at least partially filled with a material having a density different than that of the carrier. A mirror can be attached to the carrier and the carrier attached to the vehicle.

Owner:LANG MEKRA NORTH AMERICA LLC

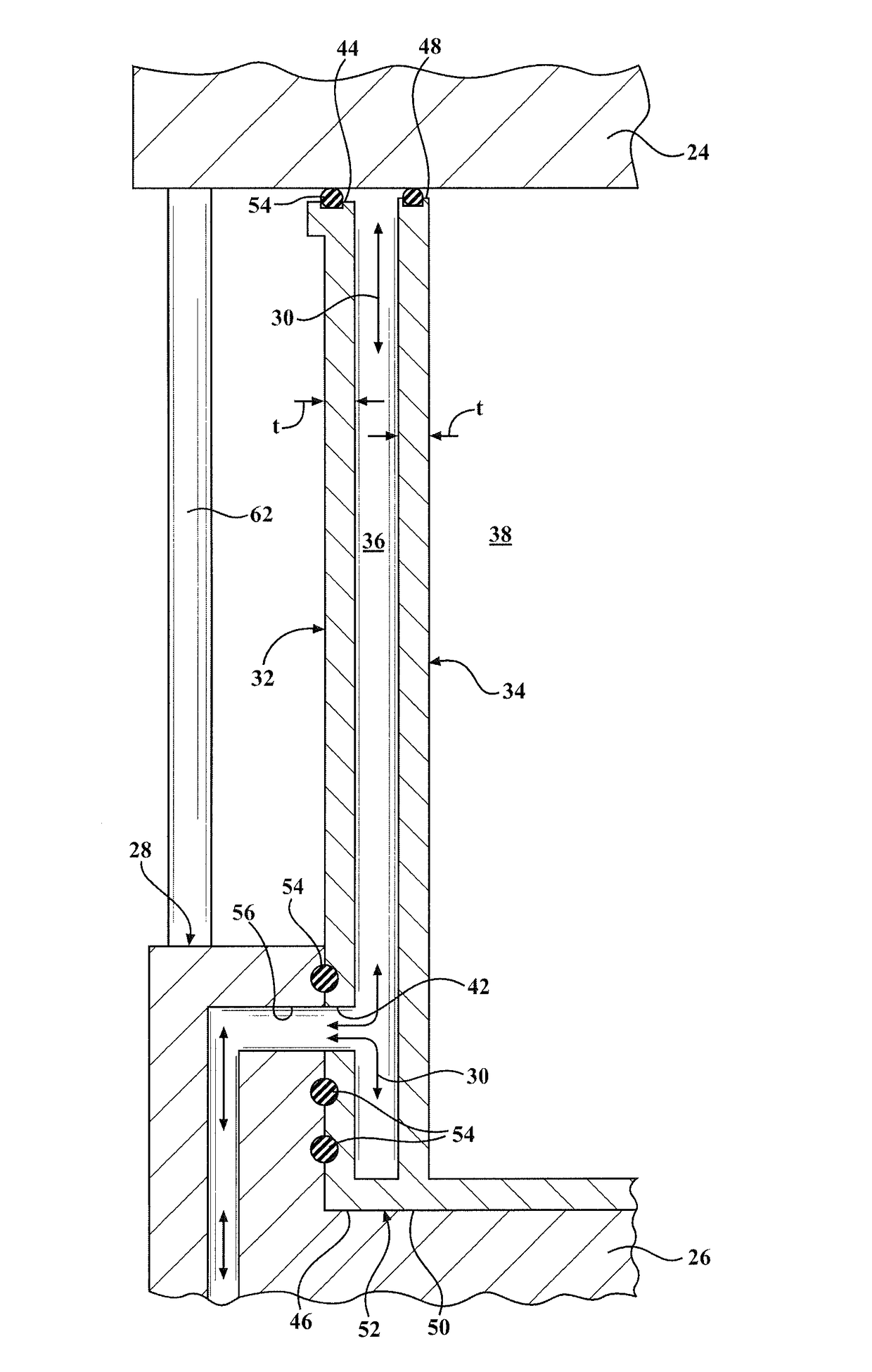

Double wall self-contained liner

A robust engine assembly having reduced weight and efficient cooling, without an increase in fuel consumption or carbon dioxide emissions, is provided. The engine assembly includes a double-wall cylinder liner clamped between a cylinder head and a crankcase. A manifold is disposed along a portion of the cylinder liner and includes fluid ports aligned with fluid ports of the cylinder liner to convey cooling fluid to a cooling chamber located between the walls of the cylinder liner. For example, the manifold can be a low-loss hydraulic manifold cast integral with the crankcase. Tie rods connect the cylinder head to the crankcase to clamp the cylinder liner in position. Alternatively, the tie rods can be connected to a main bearing cradle located beneath the crankcase. No attachment features extend into the walls of the cylinder liner, which is especially advantageous when the cylinder liner is formed of aluminum.

Owner:FEDERAL MOGUL MOTORPARTS LLC

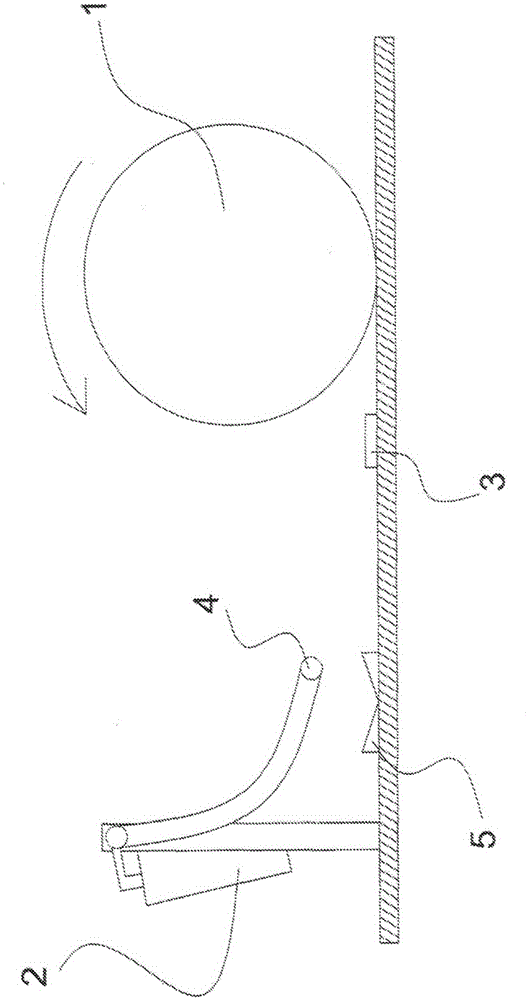

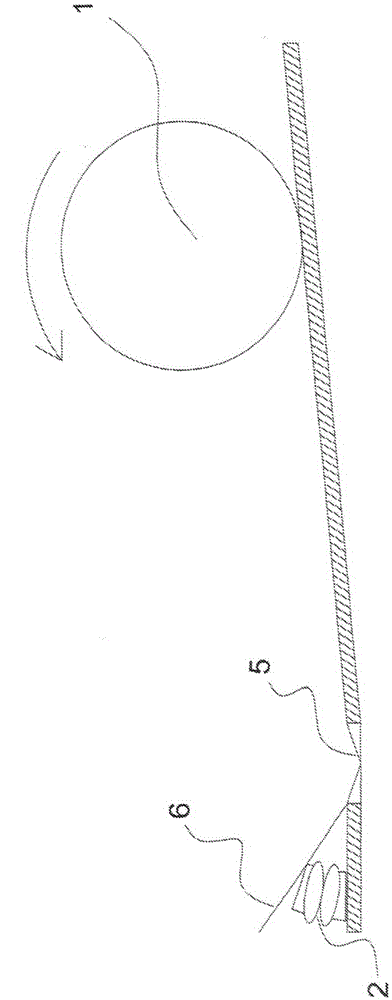

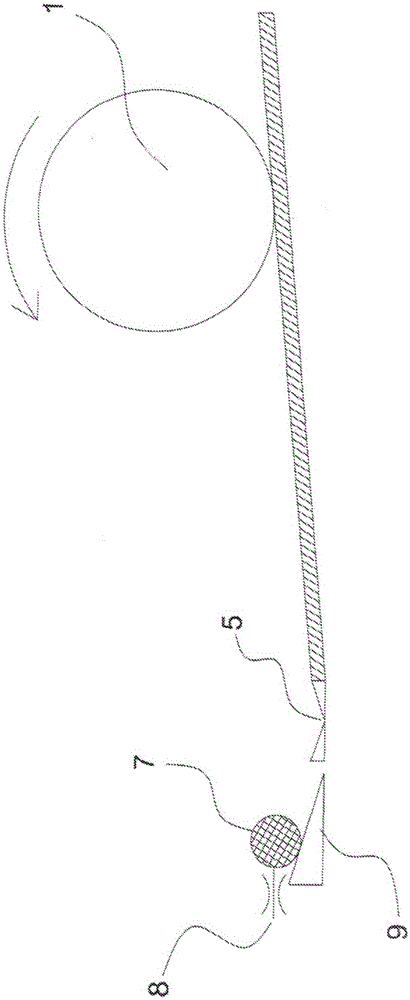

Method and apparatus for receiving of a cylindrical body and the use of the method and the apparatus

ActiveCN105324321AGood reception efficiencyImprove energy efficiencySpringsManual conveyance devicesBiomedical engineeringCompressed air

The invention relates to a method and an apparatus for receiving cylindrical bodies (1; 1, 16). In the method according to the invention, the receiving utilises tight, self-restoring pressure elements (7), in which by adjusting the inflow and / or outflow of compressed air, the motion speed of the cylindrical body (1; 1, 16) is decelerated. The apparatus according to the invention includes a pressure element (7) within the elastic and tight material of which is installed self-restoring porous material (10). Furthermore, the invention relates to the use of the method and the apparatus for receiving a cylindrical body.

Owner:SOVELLUSMESTARIT

Double wall self-contained liner

InactiveUS9803583B2Reduce consumptionEmission reductionCylinder headsCylindersCylinder headCooling chamber

Owner:FEDERAL MOGUL MOTORPARTS LLC

Fillable and stiffened rearview mirror assembly

InactiveUS20050057832A1Limit on characteristicImprove stabilityMirrorsLaminationVolumetric Mass DensityRear-view mirror

A fillable rearview mirror assembly and method of molding a carrier for the assembly are provided. The mirror assembly has a hollow carrier that can be at least partially filled with a material having a density different than that of the carrier. A mirror can be attached to the carrier and the carrier attached to the vehicle.

Owner:LANG MEKRA NORTH AMERICA LLC

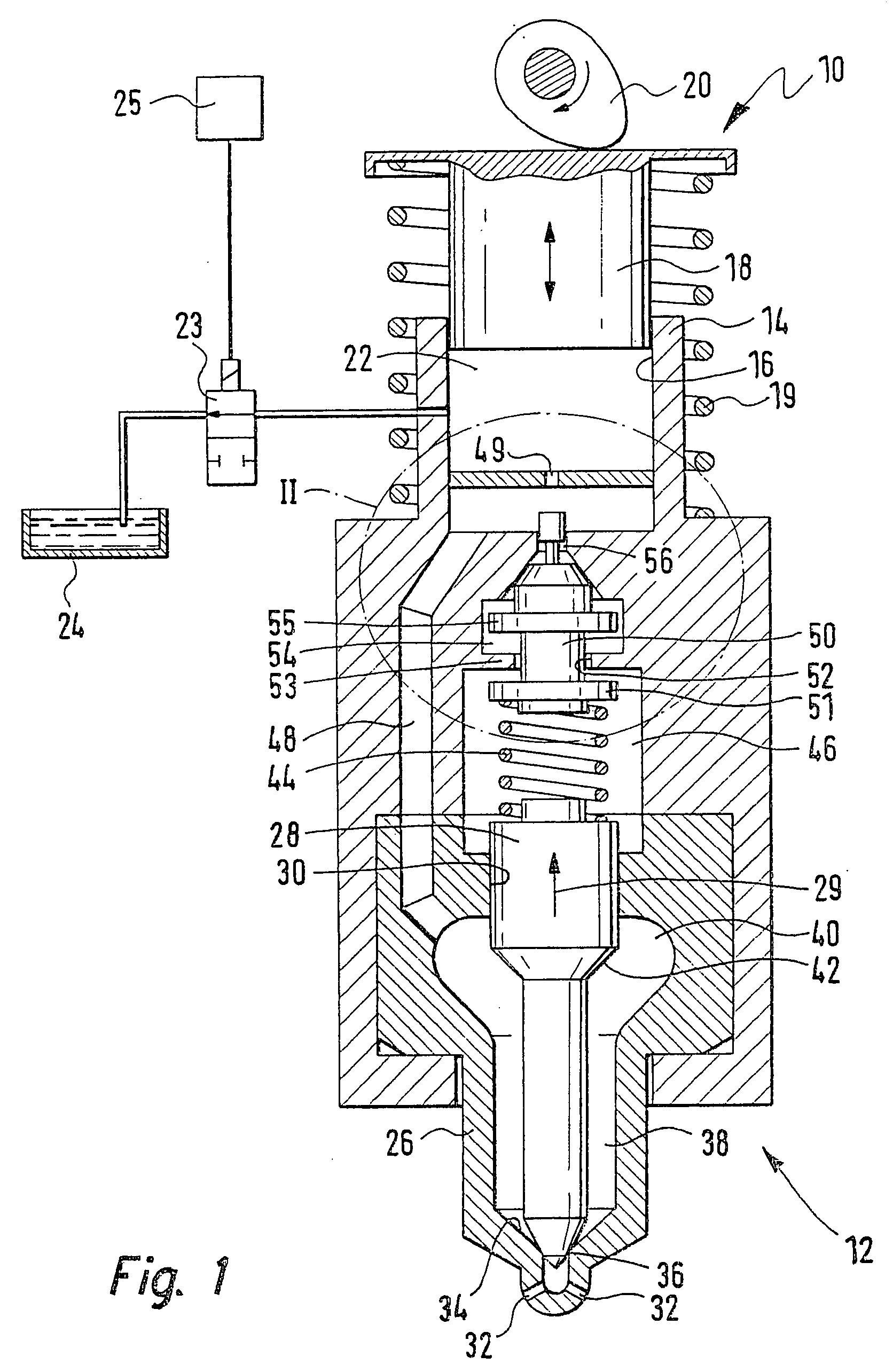

Fuel injection system for an internal combustion engine

InactiveUS20040025840A1Strong dampingShorten speedMachines/enginesFuel injecting pumpsEngineeringInternal combustion engine

The fuel injection system has a high-pressure fuel pump (10) and a fuel injection valve (12) for a cylinder of the engine. The high-pressure fuel pump (10) has a pump work chamber (22), and the fuel injection valve (12) has an injection valve member (28) by which at least one injection opening (32) is controlled and which is movable in an opening direction (29) counter to the force of a closing spring (44); the closing spring (44) is braced on one end on the injection valve member (28) and on the other end on a displaceable storage piston (50) that is acted upon, on its side remote from the closing spring (44), by the pressure prevailing in the pump work chamber (22). The storage piston (50) is movable into a storage chamber (54) counter to the force of the closing spring (44), and the deflection stroke motion of the storage piston (50) into the storage chamber (54) is limited by a stop (53). The storage piston (50) has one shaft portion (74) of smaller cross section, disposed in an outset position in a connecting bore (56), and one shaft portion (63) of larger cross section, disposed outside the connecting bore (56) toward the pump work chamber (22), and upon the deflection stroke motion of the storage piston (50) into the storage chamber (54), its shaft portion (63) of larger cross section dips into the connecting bore (56).

Owner:ROBERT BOSCH GMBH

Preparation of composite type light high-strength nickel-titanium memory alloy-based high damping material

InactiveCN101407867BImprove mechanical propertiesImprove damping performanceMicron scaleTitanium alloy

The invention discloses a preparation method of a compound type light-weight high-intensity nickel-titanium memorial alloy base high damping material. In the method, a powder sintering method is mainly used as a foundation and a pressureless infiltration technology is used as assistance; a pore-creating technology is firstly adopted; and a unit metal powder cascade sintering method is used for preparing a porous nickel-titanium alloy the holes of which are uniformly distributed; and then the pressureless infiltration technology is adopted for inducing the pure magnesium or magnesium alloy phase with high intrinsic damping, low density and micron scale into the porous nickel-titanium alloy, thereby preparing the high-damping magnesium(or magnesium alloy) / nickel-titanium memorial alloy basecompound material the damping control phase of which is magnesium or the magnesium alloy. The compound nickel-titanium memorial alloy prepared by the invention still has the shape memory effect and the superelasticity action as well as has weight lighter than that of the compact nickel-titanium memorial alloy and intensity and damping capacity more excellent than that of the common porous nickel-titanium memorial alloy. The preparation method has good technical suitability, simple preparation process and low cost, and can be used for manufacturing the light-weight high-intensity compound damping materials, damping structures and apparatuses.

Owner:SOUTH CHINA UNIV OF TECH

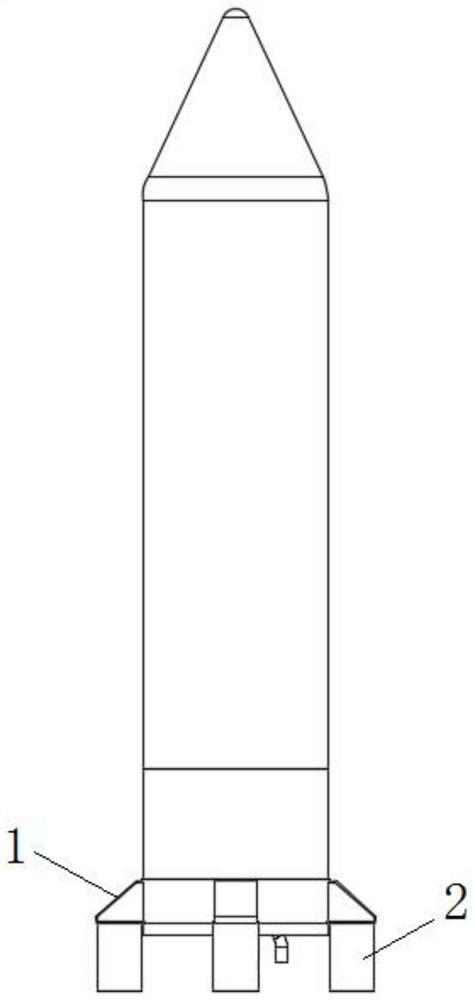

Landing leg mechanism for recovering rocket

PendingCN114132532ACompact structureImprove buffering effectSystems for re-entry to earthCosmonautic landing devicesClassical mechanicsRocket

The invention provides a landing leg mechanism for recovering a rocket, the landing leg mechanism comprises an on-rocket mounting support and a plurality of landing leg devices, the on-rocket mounting support is fixed at the bottom of the rocket, and the plurality of landing leg devices are uniformly fixed on the on-rocket mounting support at intervals; the landing leg device comprises a top plate, a bottom plate, a buffer spring and a damping buffer mechanism; the top plate is fixed on the mounting support on the rocket; the top ends of the buffer springs are fixedly connected with the top plate, and the bottom ends are fixedly connected with the bottom plate; and the top end of the damping buffer mechanism is fixedly connected with the top plate and the bottom end is fixedly connected with the bottom plate. When the rocket is landed, the four landing legs make contact with the ground, the landing leg structures are compact, good buffering and damping capacity is achieved, and meanwhile the high-temperature-resistant environment is achieved.

Owner:北京中科宇航技术有限公司

Preparation method of tinicu shape memory alloy matrix damping composite material

The invention relates to manufacturing of a damping material, in particular to a method for preparing a TiNiCu shape memory alloy damping composite. A porous TiNiCu shape memory alloy is prepared, holes of the TiNiCu shape memory alloy are filled with metal Mg, and the TiNiCu shape memory alloy damping composite, namely, Mg / TiNiCu is prepared. The defects that in an existing porous TiNiCu shape memory alloy preparation method, the porosity, the aperture and the hole type are all hard to control; and an existing technology of introducing Mg into the porous alloy cannot be used for filling porous TiNiCu alloy with Mg, and the damping performance and other mechanical performance of an alloy product need to be improved are overcome.

Owner:HEBEI UNIV OF TECH

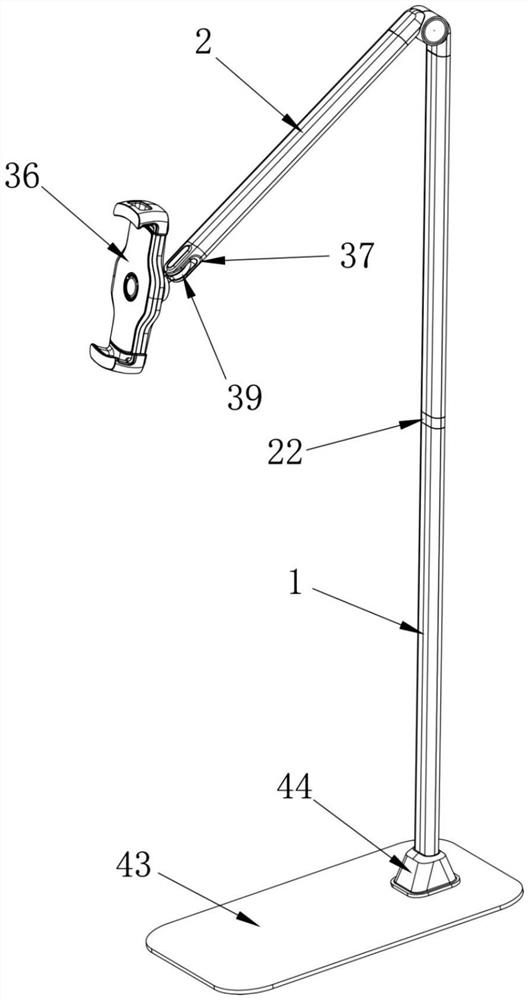

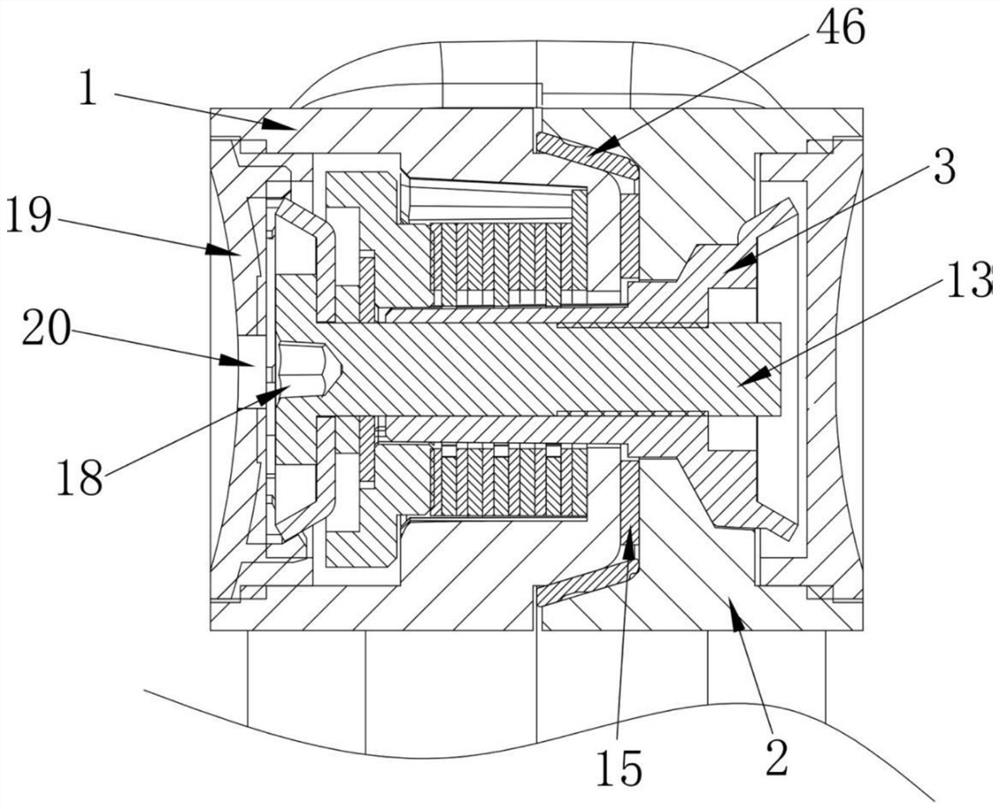

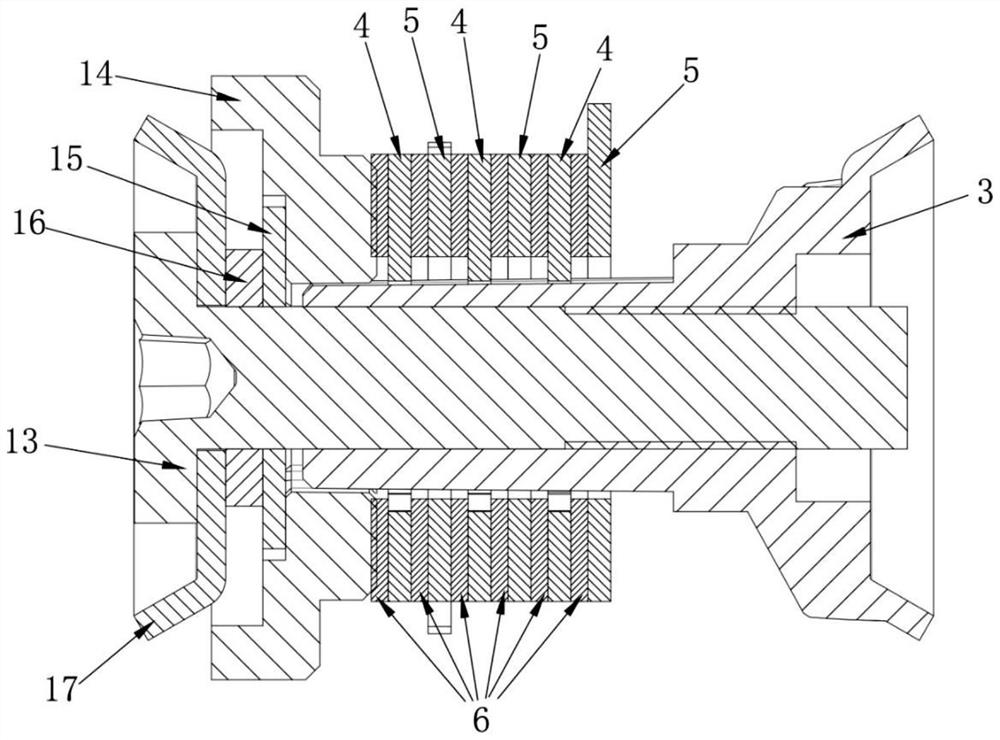

Mobile phone and tablet support with damping structure

PendingCN113915486AWith damping effectStrong dampingRod connectionsStands/trestlesTablet computerClassical mechanics

The invention provides a mobile phone and tablet computer support with a damping structure. The mobile phone and tablet support comprises a first connecting rod and a second connecting rod which are hinged with each other, and a first damping structure is mounted at the hinged part of the first connecting rod and the second connecting rod. The first damping structure comprises a limiting shaft, one end of the limiting shaft is connected with the second connecting rod, and the other end of the limiting shaft extends into the first connecting rod. The extending end of the limiting shaft is sleeved with a plurality of first damping fins in the axial direction, and a plurality of second damping fins corresponding to the first damping fins are installed on the inner wall of the first connecting rod in the axial direction. During use, the limiting shaft drives the first damping fins to rotate, and the first damping fins and the second damping fins are matched to generate a damping effect. According to the mobile phone and tablet support with the damping structure, the defects that an existing damping structure is poor in use effect and the damping size cannot be adjusted are overcome.

Owner:YUYAO LEDE COMP SCI & TECH CO LTD

Electromagnetically actuated drives for linear motion

ActiveCN108027087BStrong dampingOperating means/releasing devices for valvesElectromagnets with armaturesLinear motionAxis of symmetry

The invention relates to an electromagnetic driving device (1), which is used to realize linear motion, and the electromagnetic driving device (1) comprises a coil (3), a core (4) and an armature (6) The electromagnet (2), the armature (6) can move linearly along the axis of symmetry (5) of the core (4), wherein between the core (4) and the armature (6) An air gap (7) is formed between them. In order to provide a simple, compact, cost-effective and flexible application of electromagnetic drives in high pressure systems, and to precisely position the piston at any given position at an optimized extension speed, the air gap (7) has a base (8) and two branches (9, 10), said branches (9, 10) extending symmetrically with respect to said axis of symmetry (5), and said air gap (7) being substantially frusto-conical in longitudinal section and said branches (9, 10) are arranged to form an included angle α with respect to said axis of symmetry (5) of said core (4).

Owner:VOITH PATENT GMBH

A kind of silent anti-vibration composite floor and its preparation method

InactiveCN106751479BIncrease elasticityEasy to produce resonance effectCovering/liningsWood working apparatusCyclohexanoneEpoxy

The invention discloses a muting and shockproof composite floor. The muting and shockproof composite floor comprises: a composite material, wherein the composite material is prepared from, by weight, 40-65 parts of epoxy resin, 10-20 parts of aerosol, 30-60 parts of wood shavings, 20-60 parts of rubber particles, 10-20 parts of hydroxypropyl methyl cellulose, 3-10 parts of aliphatic glycidol ether, 0.2-1 part of fatty acid amide, 0.2-1 part of acrylate, 0.2-1 part of hydrogenated ester castor oil, 0.2-1 part of polyamide and 20-40 parts of cyclohexanone; and an outer frame (1) made of solid strips, wherein the composite material is wrapped in the outer frame (1). The composite floor produced from woodwork processing residues and waste tire pellets has good waterproofing, anti-moth, anti-static electricity, sound insulation, damping and heat insulation functions, and comprehensively has the high-efficiency utilization values of wood and the no-pollution recycling values of waste tires.

Owner:CHONGQING ACADEMY OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com