Patents

Literature

73results about How to "Reduce the deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

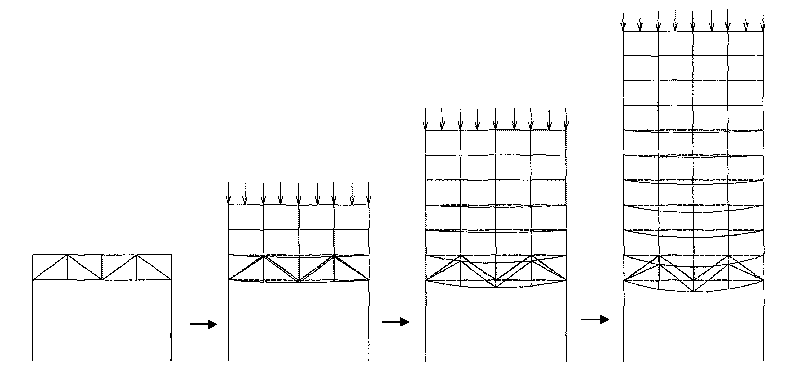

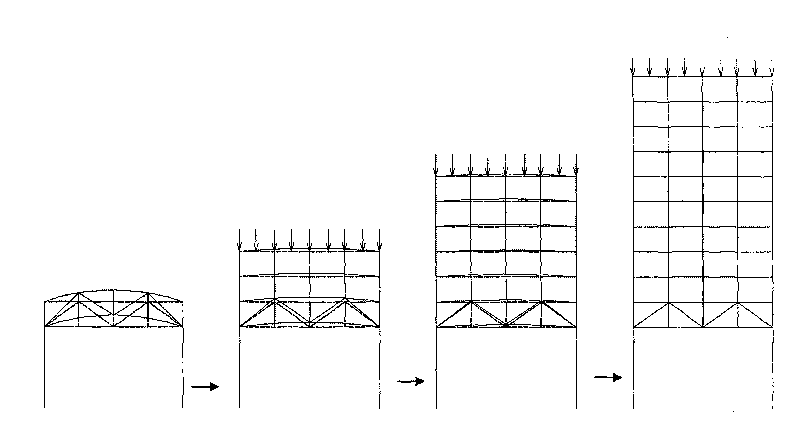

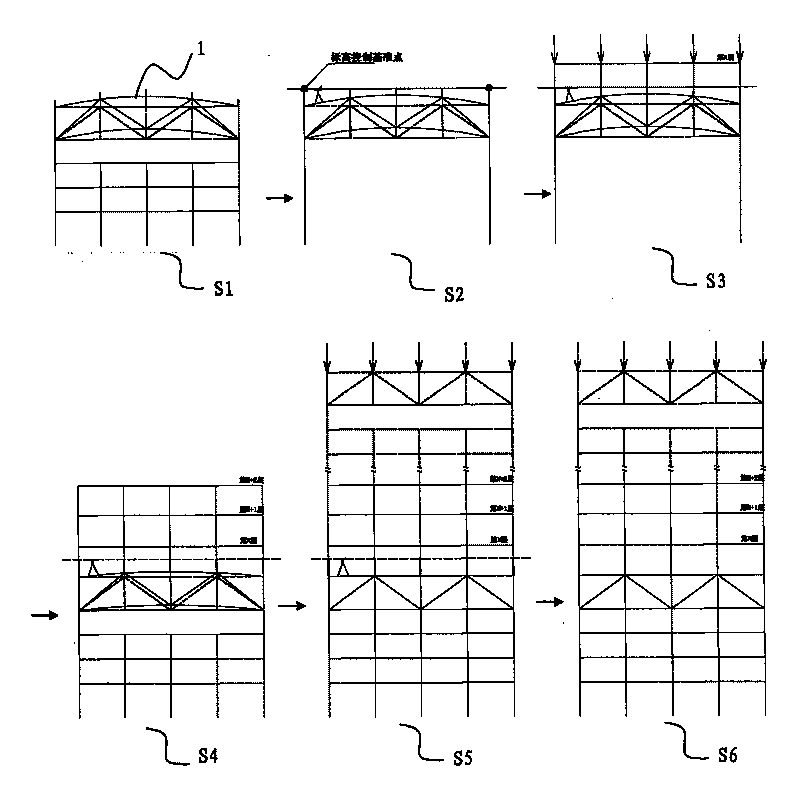

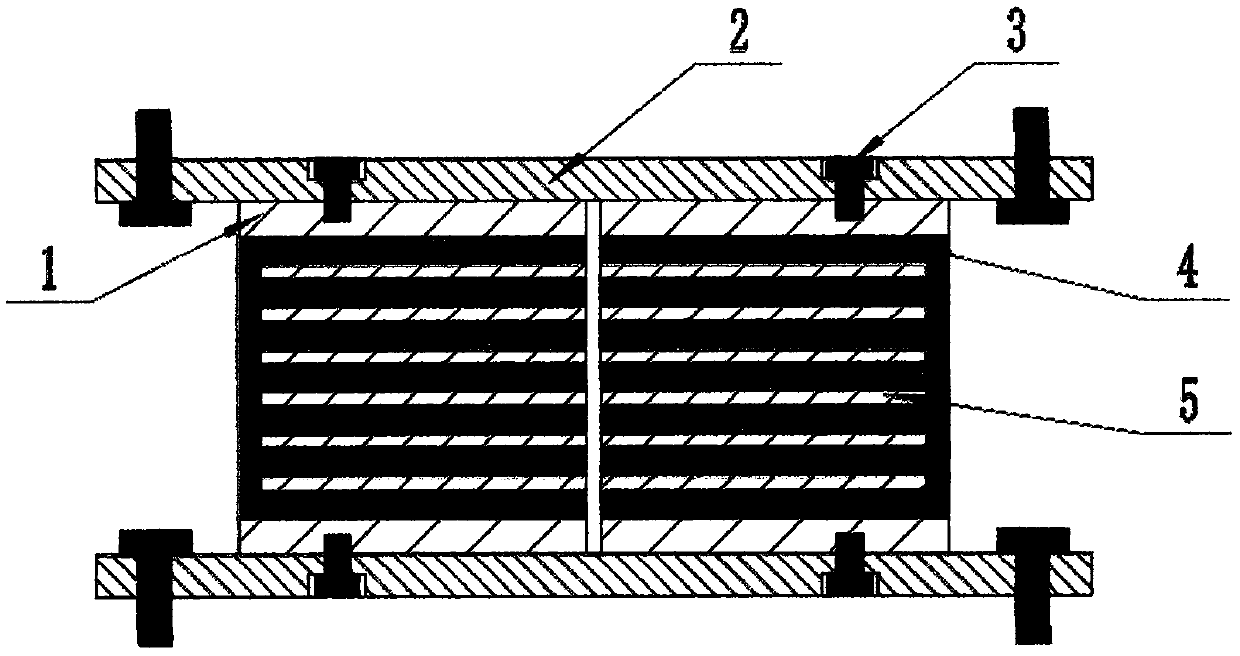

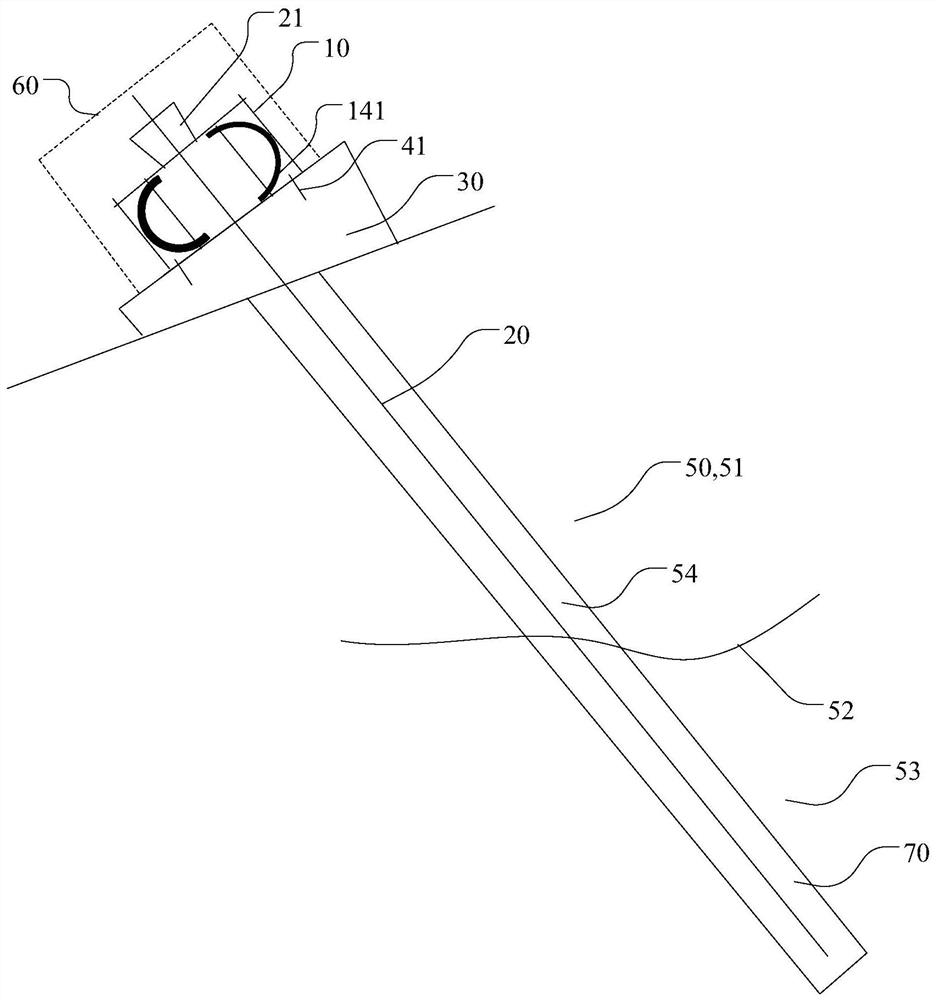

Device and method for elevation synchronous compensation for super-high structure construction

ActiveCN101691813AGood for internal force controlEasy to operateBuilding material handlingFloor slabReference level

The invention discloses a method and a device for elevation synchronous compensation for a super-high structure construction. The device comprises a plurality of groups of columns used on an upper layer of a lifting conversion truss, and a jacking device which makes the columns correspondingly level with a reference level line, wherein the jacking device is arranged above the conversion truss and corresponds to the columns. The method comprises the following steps that: the columns, beams and plates of each layer are constructed layer by layer from bottom to top, and after the construction of each layer is finished, the device for the synchronous compensation is adjusted so that each column is correspondingly leveled with the reference level line and the structure each layer is achieved to be level; when the structure is constructed to an upper track conversion truss or the top of the structure is sealed, an upper layer of concrete of the conversion truss is cast to underpin the device for the synchronous compensation so as to achieve the permanent connection of the structure; and finally, the device for the synchronous compensation is dismounted. The method and the device can effectively control the deformation of a horizontal structure in a construction process so as to effectively reduce the deformation extent of the structure, and avoid oversized structural deflections which cause larger additional stresses at local panel points and endanger the quality of floor-slab layers.

Owner:SHANGHAI CONSTRUCTION GROUP +1

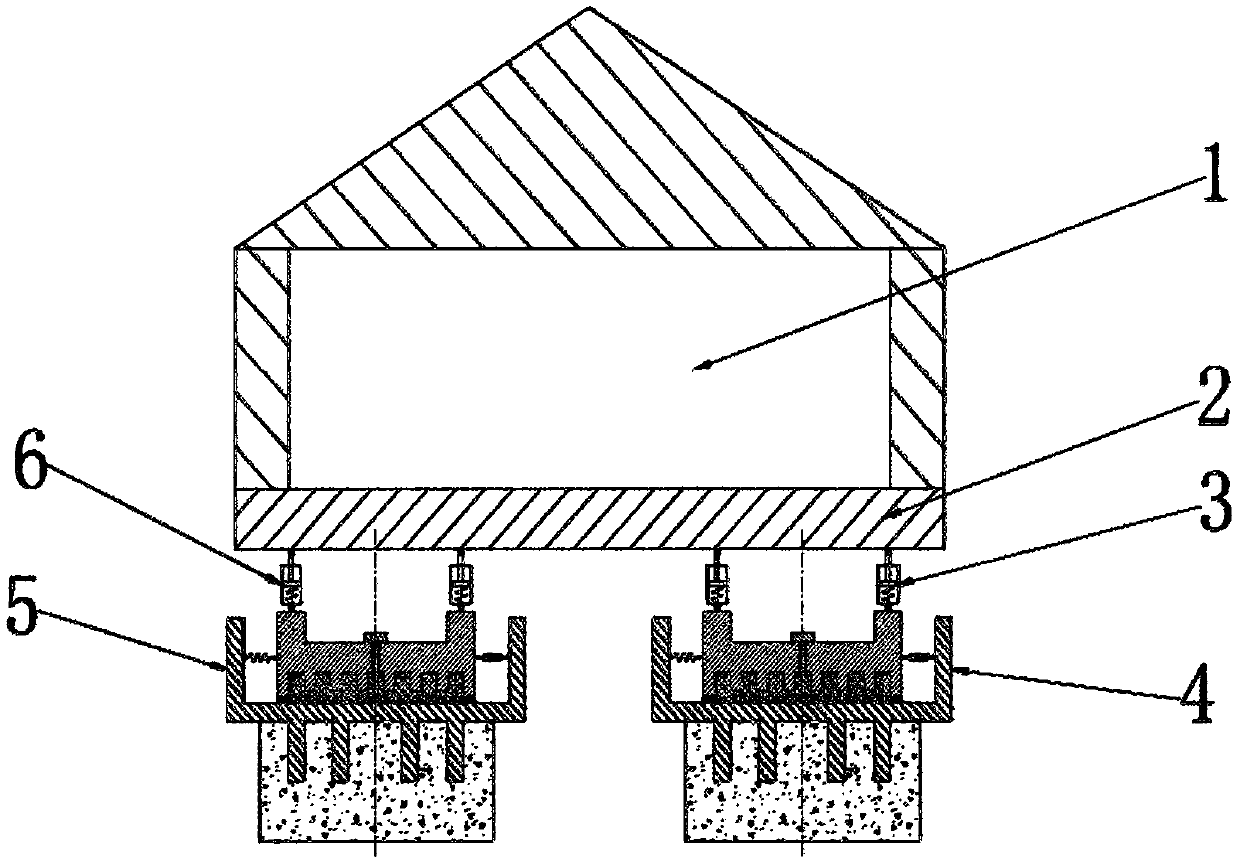

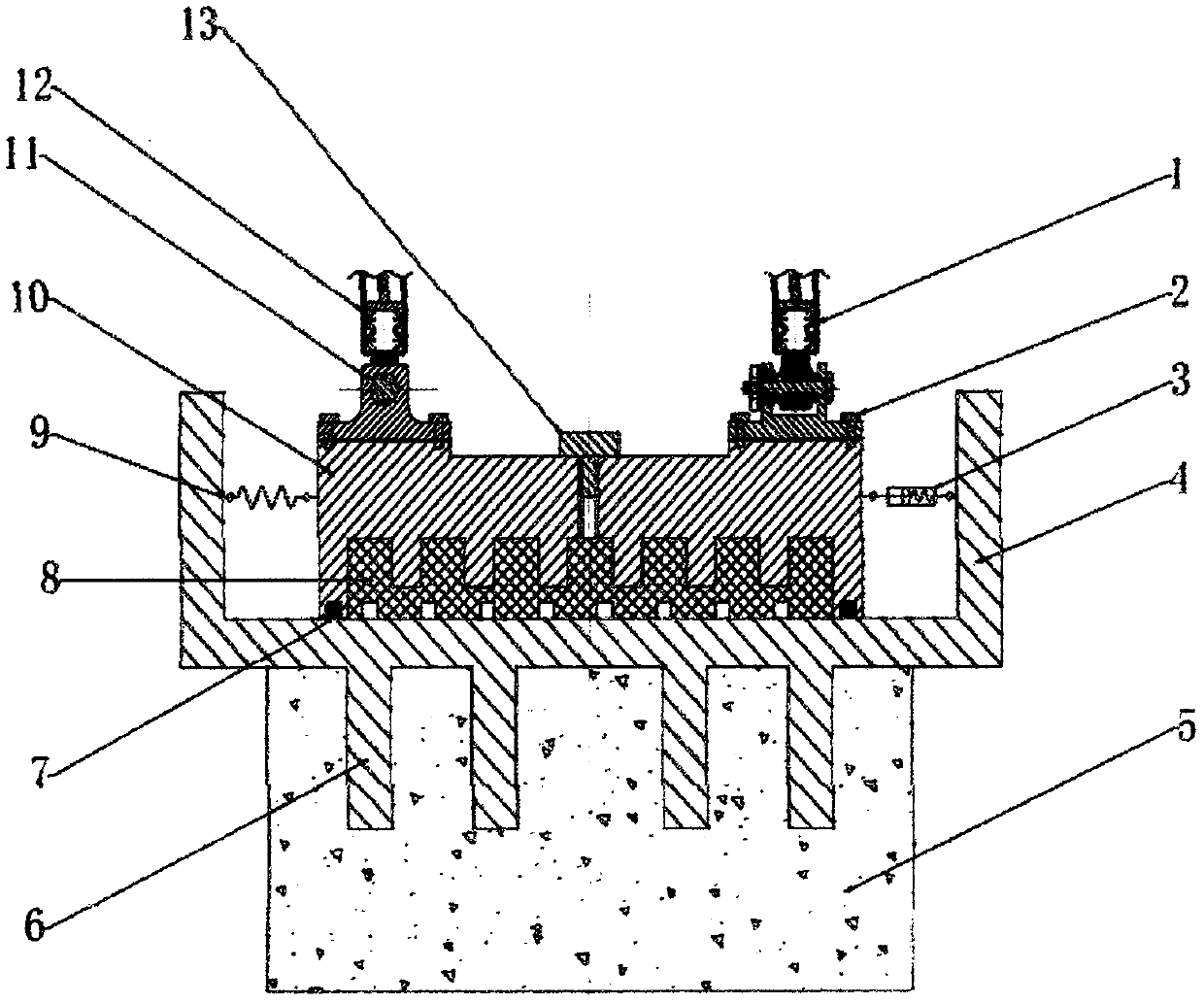

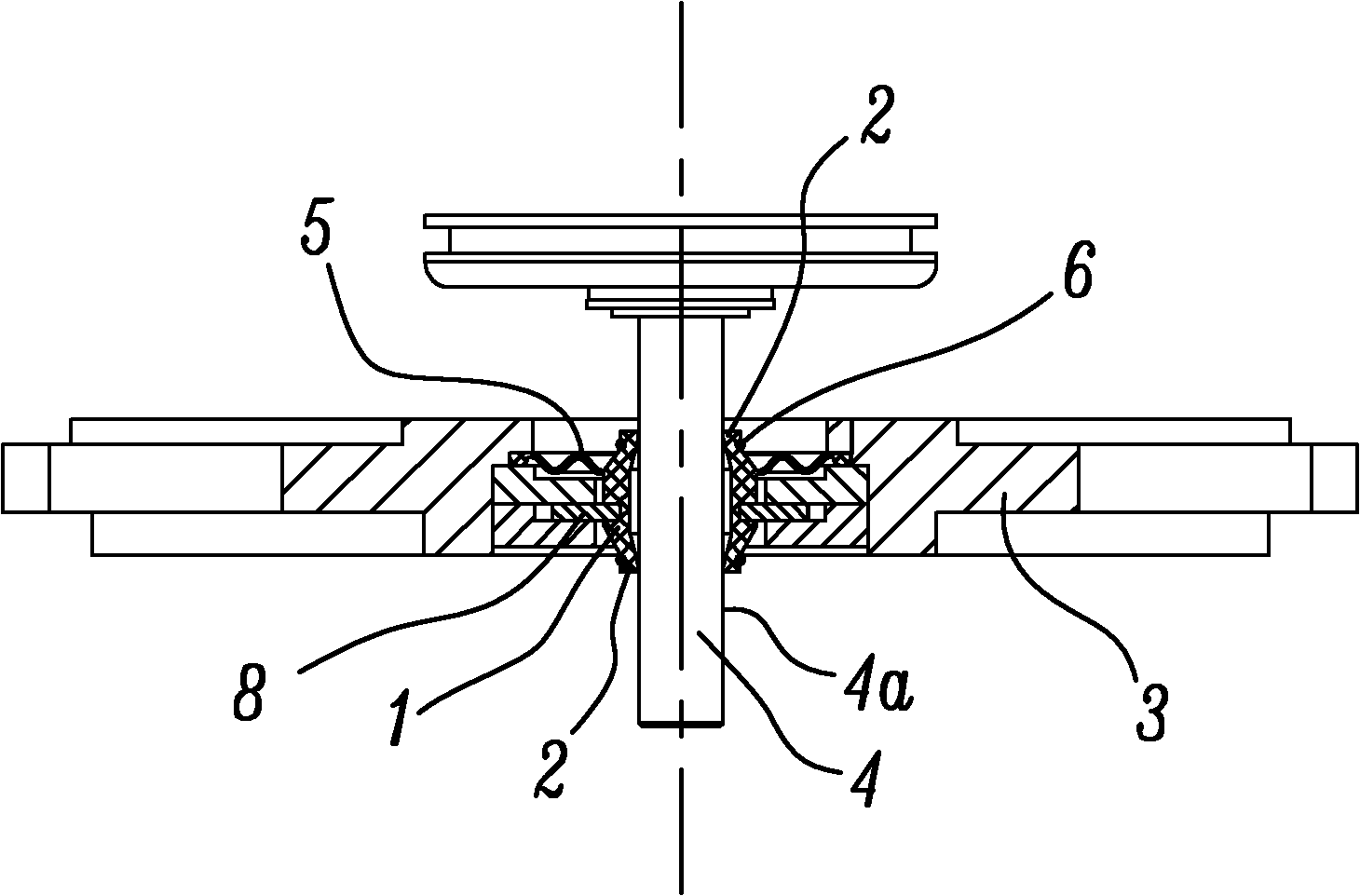

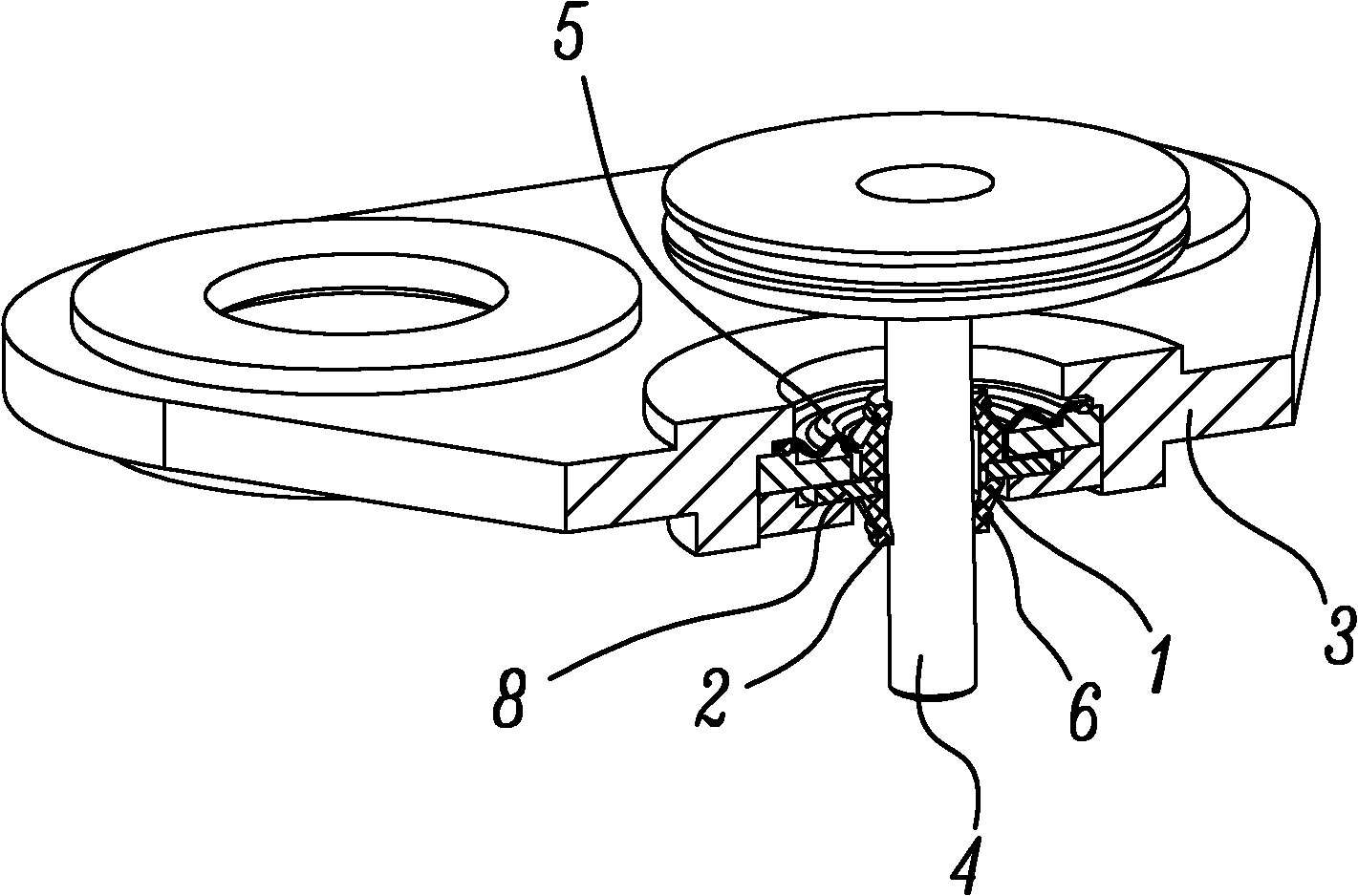

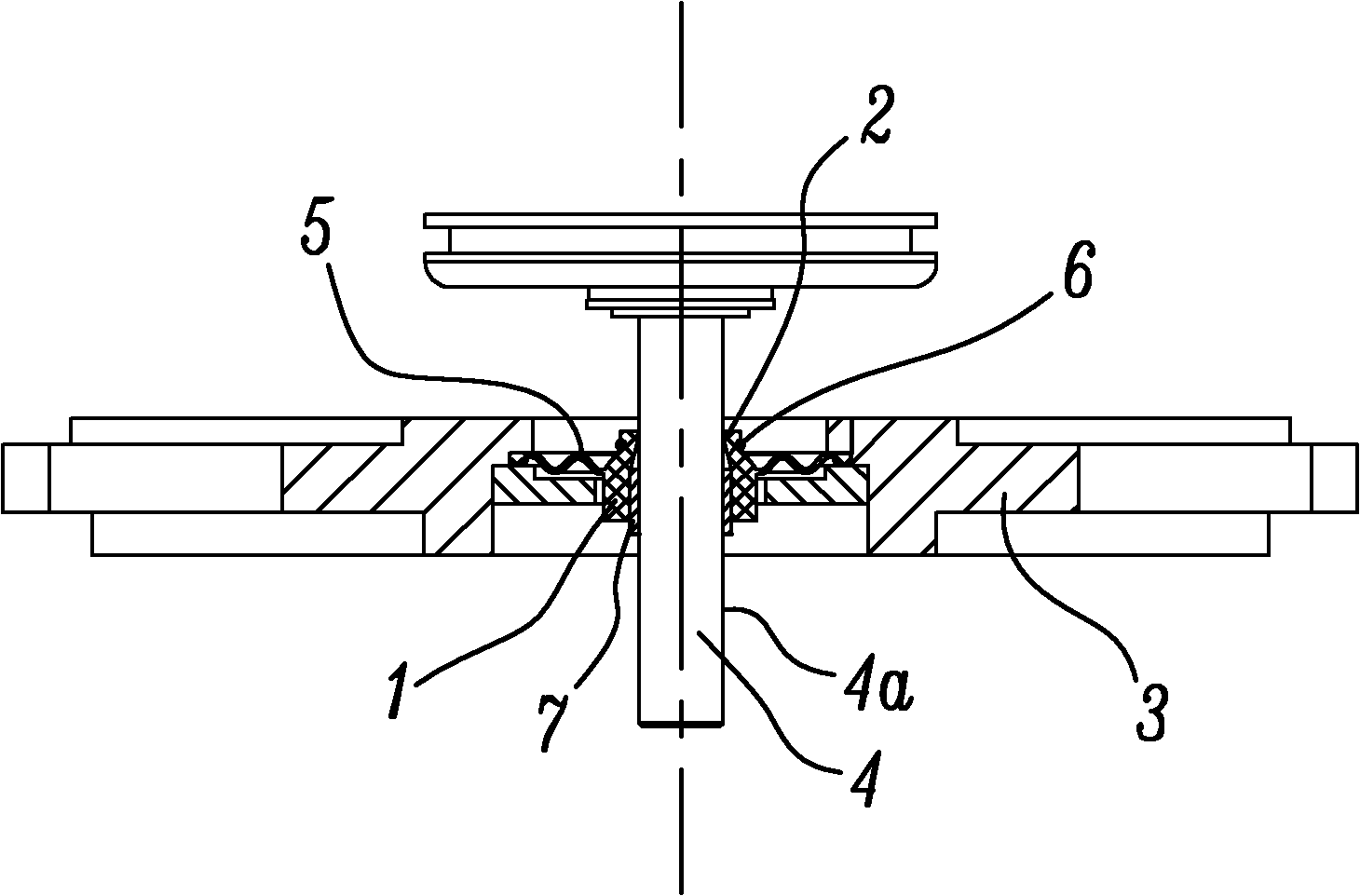

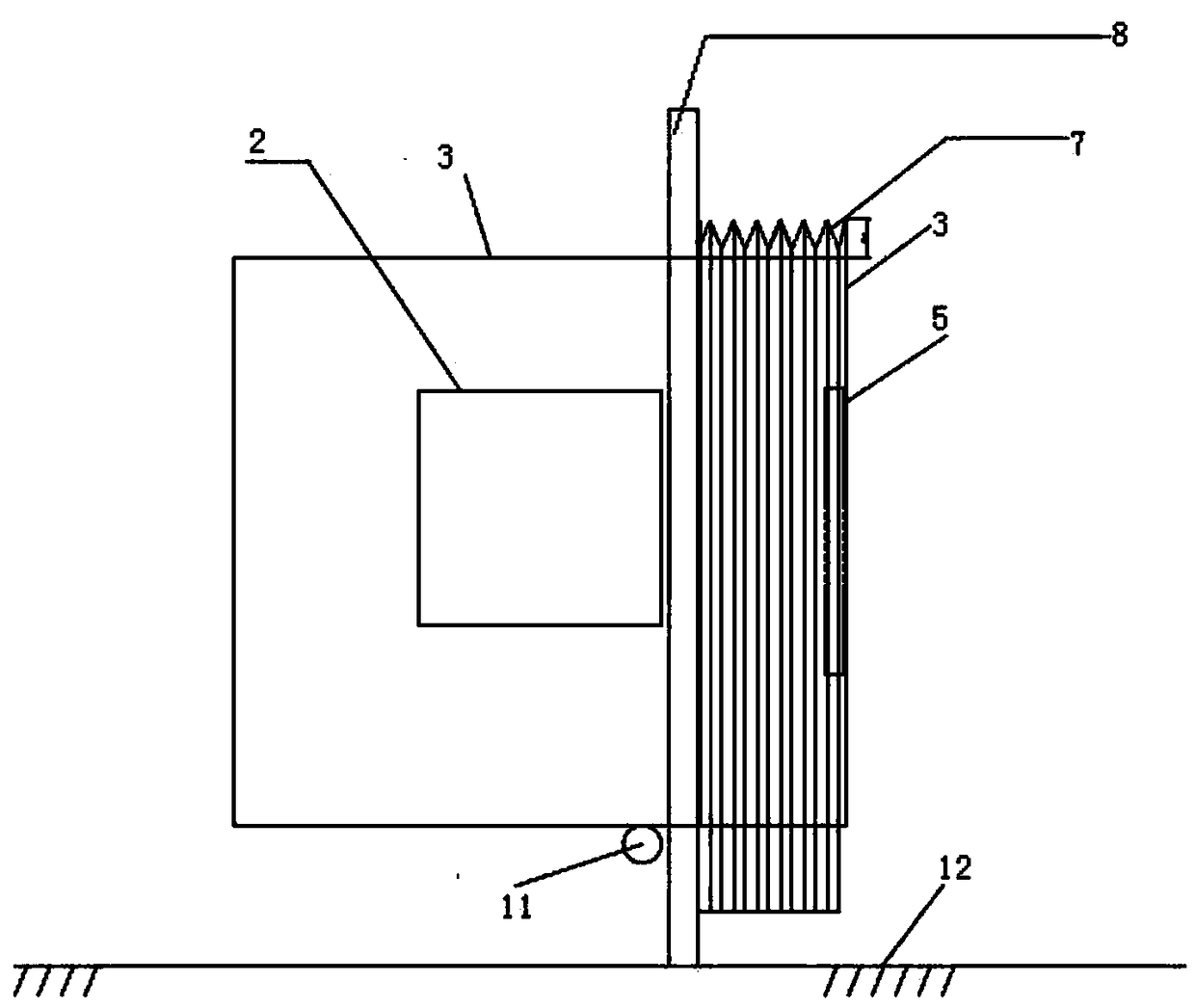

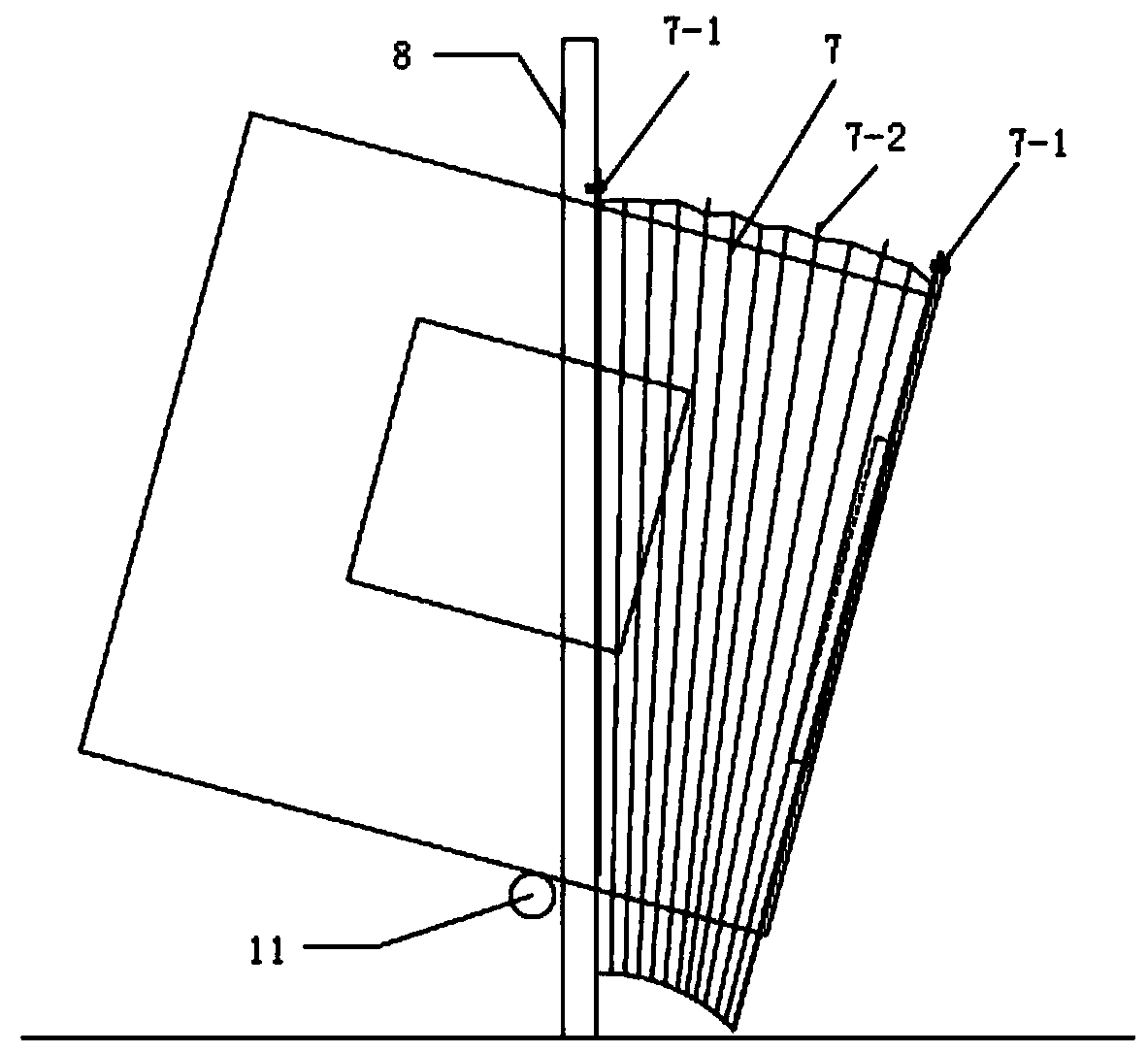

Building structural foundation with three-dimensional shock insulation and vibration attenuation

InactiveCN109853766AReduce the deformationGuarantee effective supportProtective buildings/sheltersShock proofingSmall amplitudeEnergy absorption

The invention provides a building structural foundation with three-dimensional shock insulation and vibration attenuation. The building structural foundation with three-dimensional shock insulation and vibration attenuation mainly comprises a steel structural small platform laid the roots in a foundation, a shock absorber mounting sliding table and an elastic damping shock absorber, wherein a polytetrafluoroethylene based coating is prepared on the steel structural small platform; a self-lubricating composite material containing oil is adopted in the shock absorber mounting sliding table to beused as a sliding friction pair; according to the elastic damping shock absorber, disc spring support is adopted on the lower surface of a main piston, a liquid damping medium below a floating pistonhas low internal pressure in a static state, and the shock absorber works stably for a long time and no oil leakage occurs; an upper mounting joint and a lower mounting joint of the shock absorber have a slight cardan joint adjusting function; when an earthquake happens, the steel structural small platform vibrates with small amplitude following the foundation under the influence of earthquake waves, the mounting sliding table, the shock absorber on the upper part of the mounting sliding table and a building slide relatively on the steel structural small platform, so that earthquake energy inthe horizontal direction is weakened and input to the building on the upper surface; and the shock absorber has damping and energy absorption functions in the vertical direction, and thus, three dimensions have shock insulation and vibration attenuation protection action.

Owner:李鑫

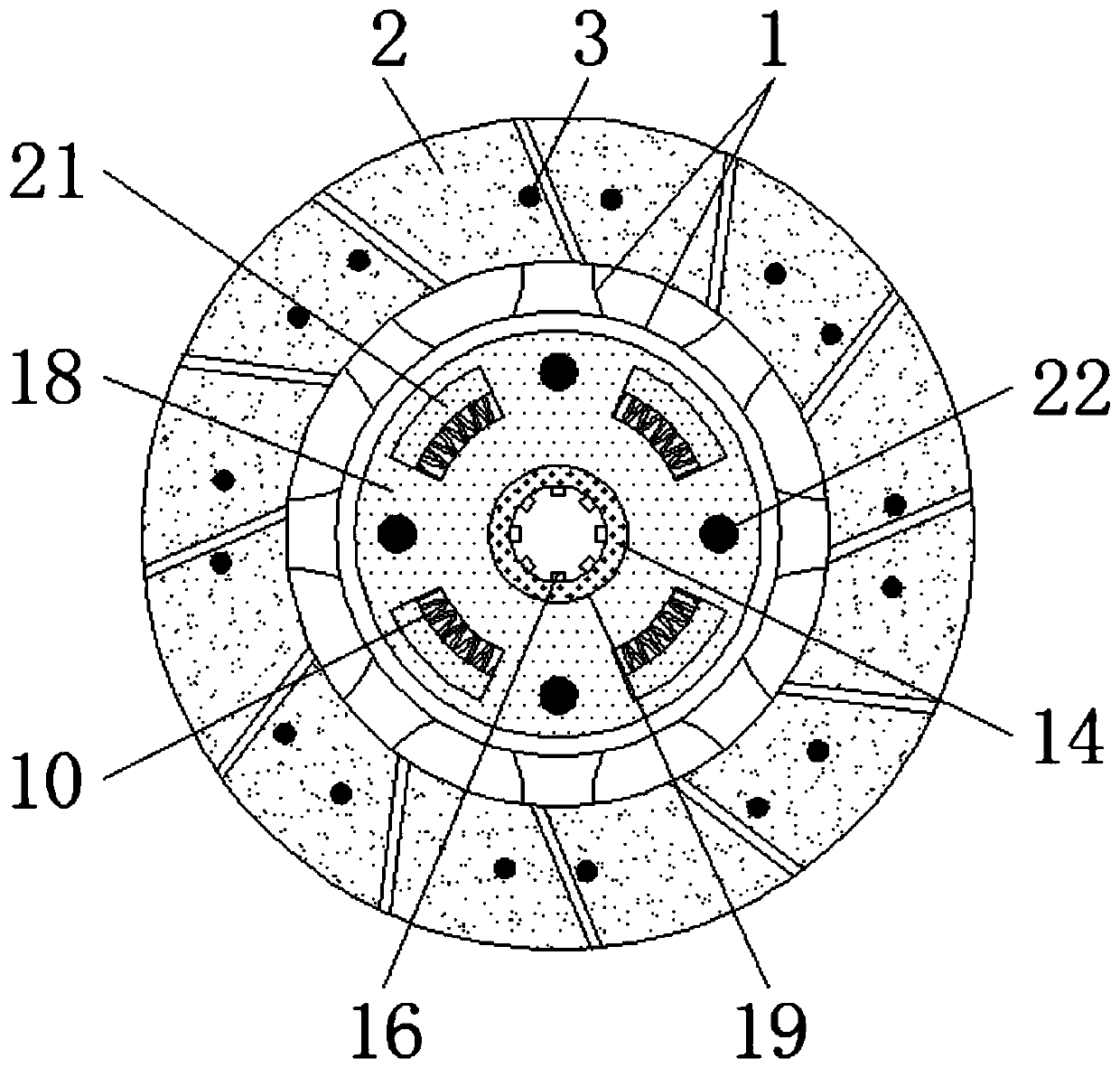

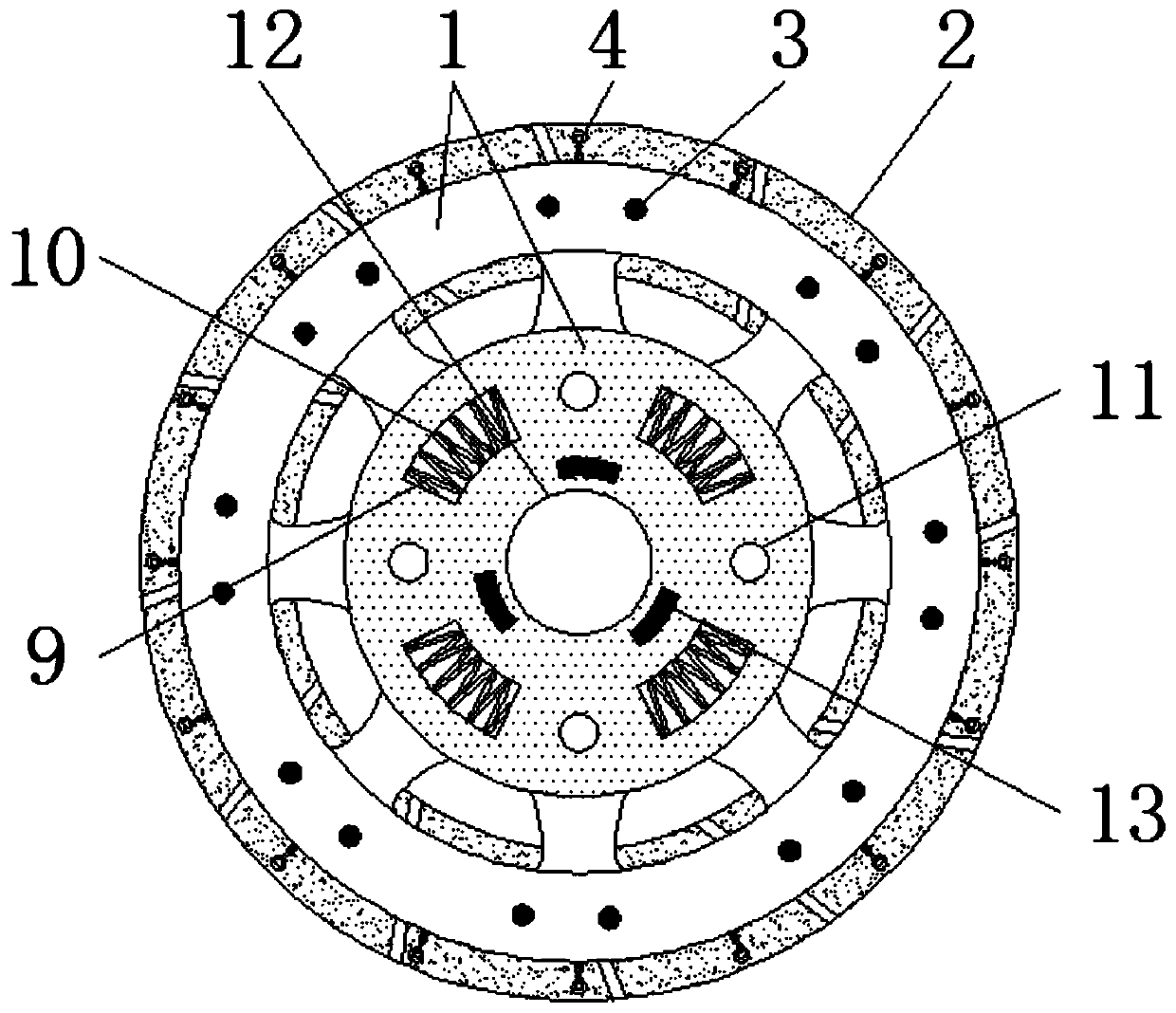

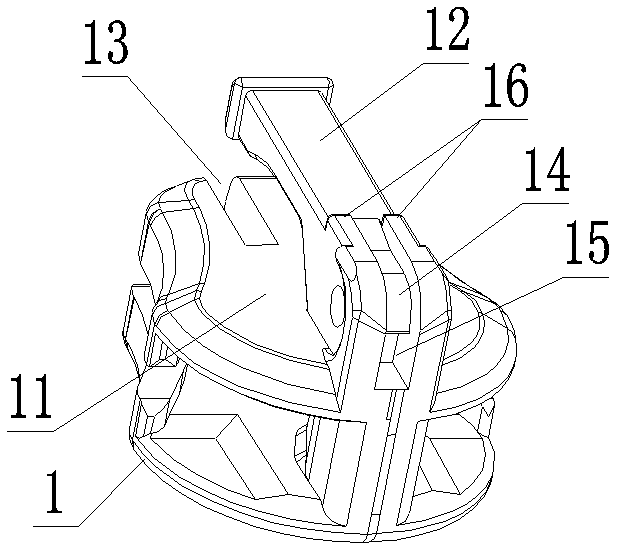

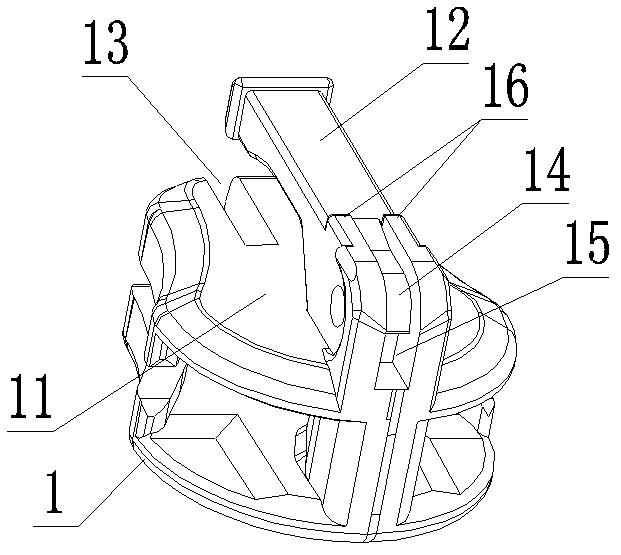

Novel nonlinearity wrench transmission clutch driven plate assembly

ActiveCN110043572AReduce the deformationReduce lossFriction clutchesVibration suppression adjustmentsEngineeringWrench

The invention discloses a novel nonlinearity wrench transmission clutch driven plate assembly. The novel nonlinearity wrench transmission clutch driven plate assembly comprises a clutch driven piece,friction pieces, a driven plate hub, a driven piece cover plate and connection rivets. The edge of the clutch driven piece is provided with the friction pieces. The clutch driven piece is provided with first rivet holes. The back face of the driven plate hub is fixedly provided with a second fixing protruding plate. A center hole is formed in the center position of the driven piece cover plate, and the driven piece cover plate is provided with second rivet holes and half-covered windows. The connection rivets are connected with the first rivet holes and the second rivet holes. According to thenovel nonlinearity wrench transmission clutch driven plate assembly, by means of the novel structural design, supporting damping can be carried out on the edge parts of the friction pieces through the device, it is guaranteed that in the stress process of the friction pieces, deformation amplitude is reduced, after the friction pieces are not stressed, recovering is rapid, meanwhile, through thedesigned structure of auxiliary damping springs for working, the loss of the damping springs is effectively reduced, and the service life of the whole device is prolonged.

Owner:浙江华信汽车零部件有限公司

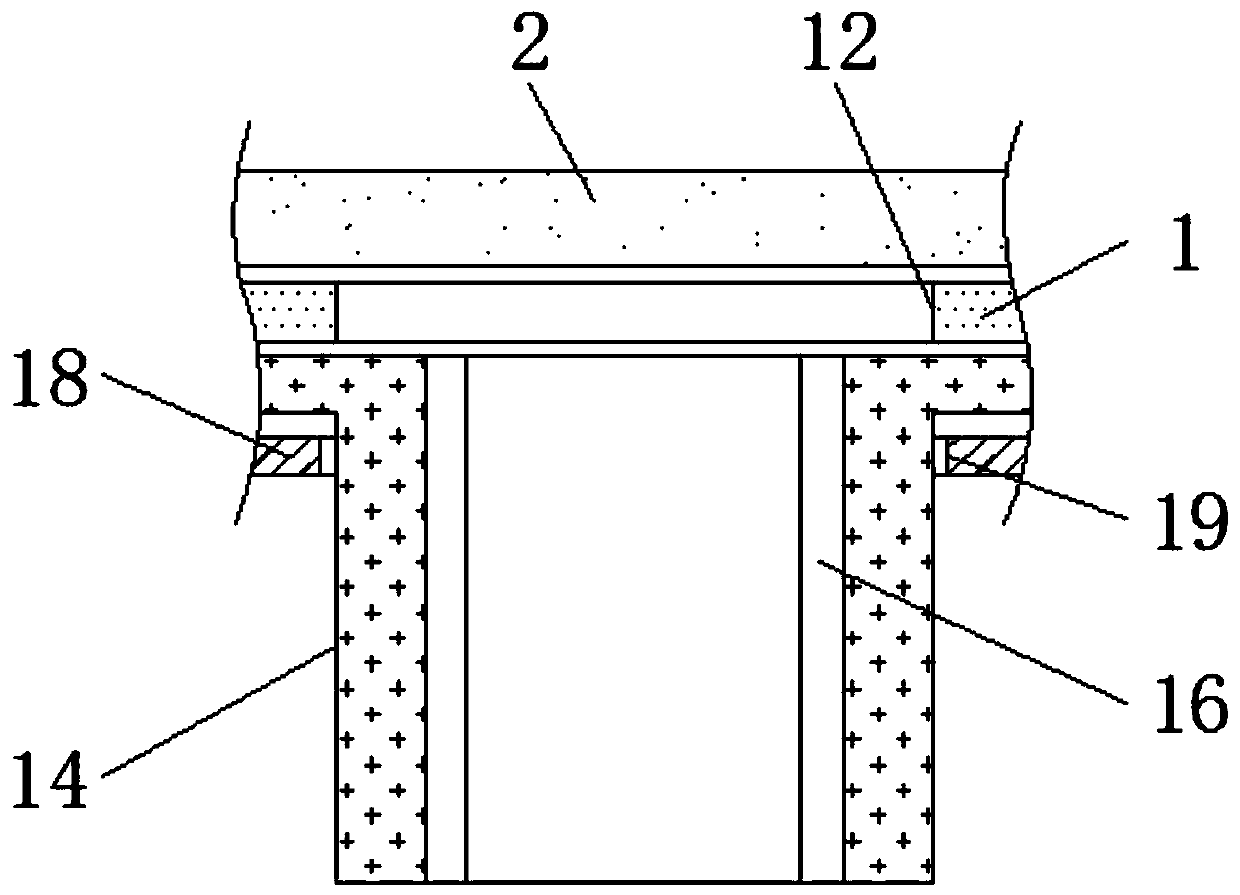

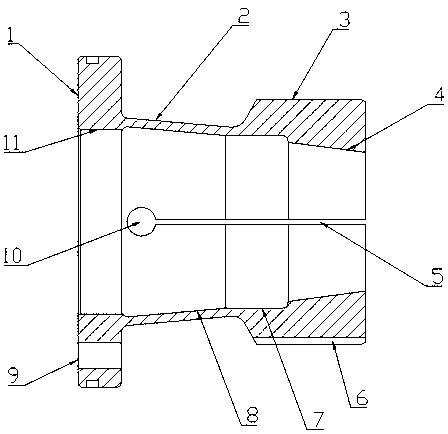

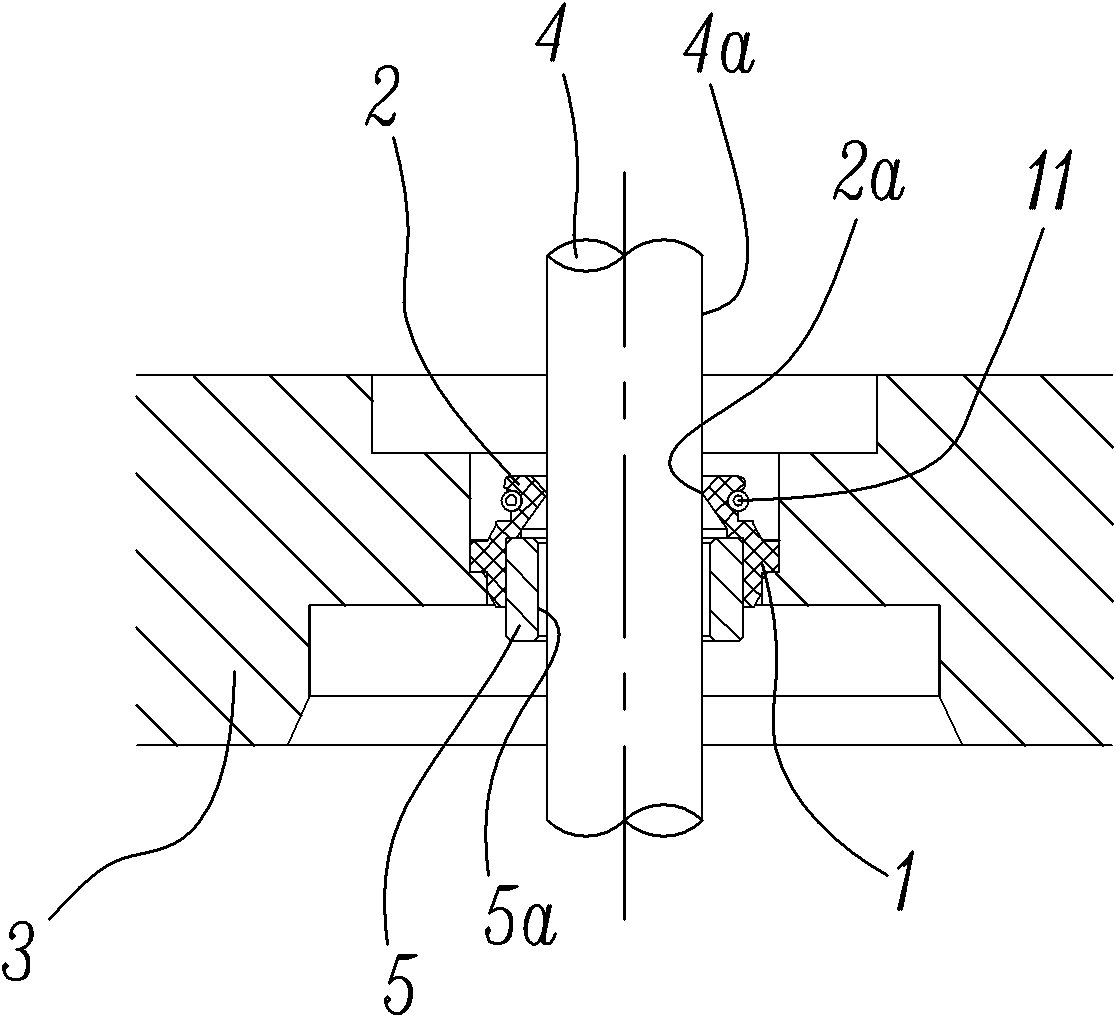

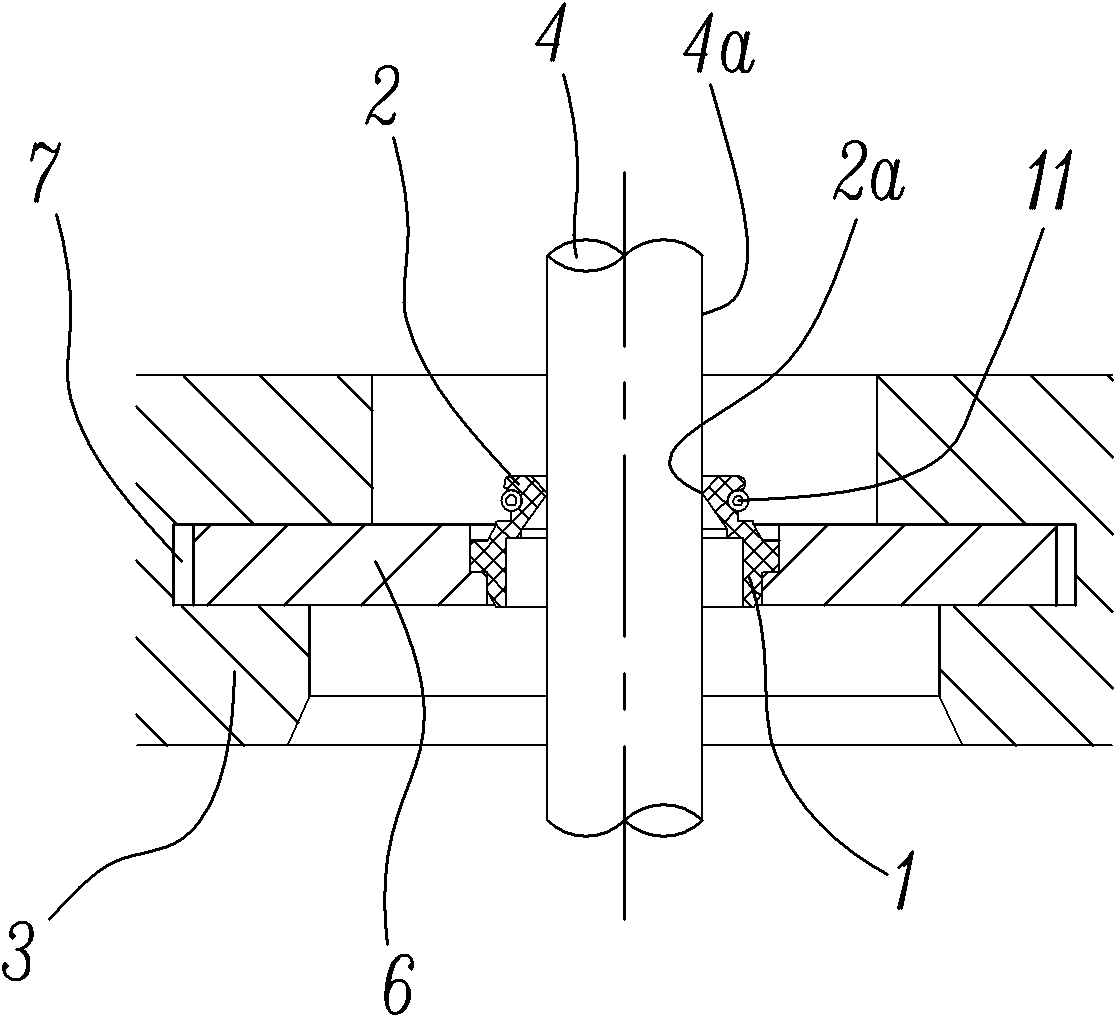

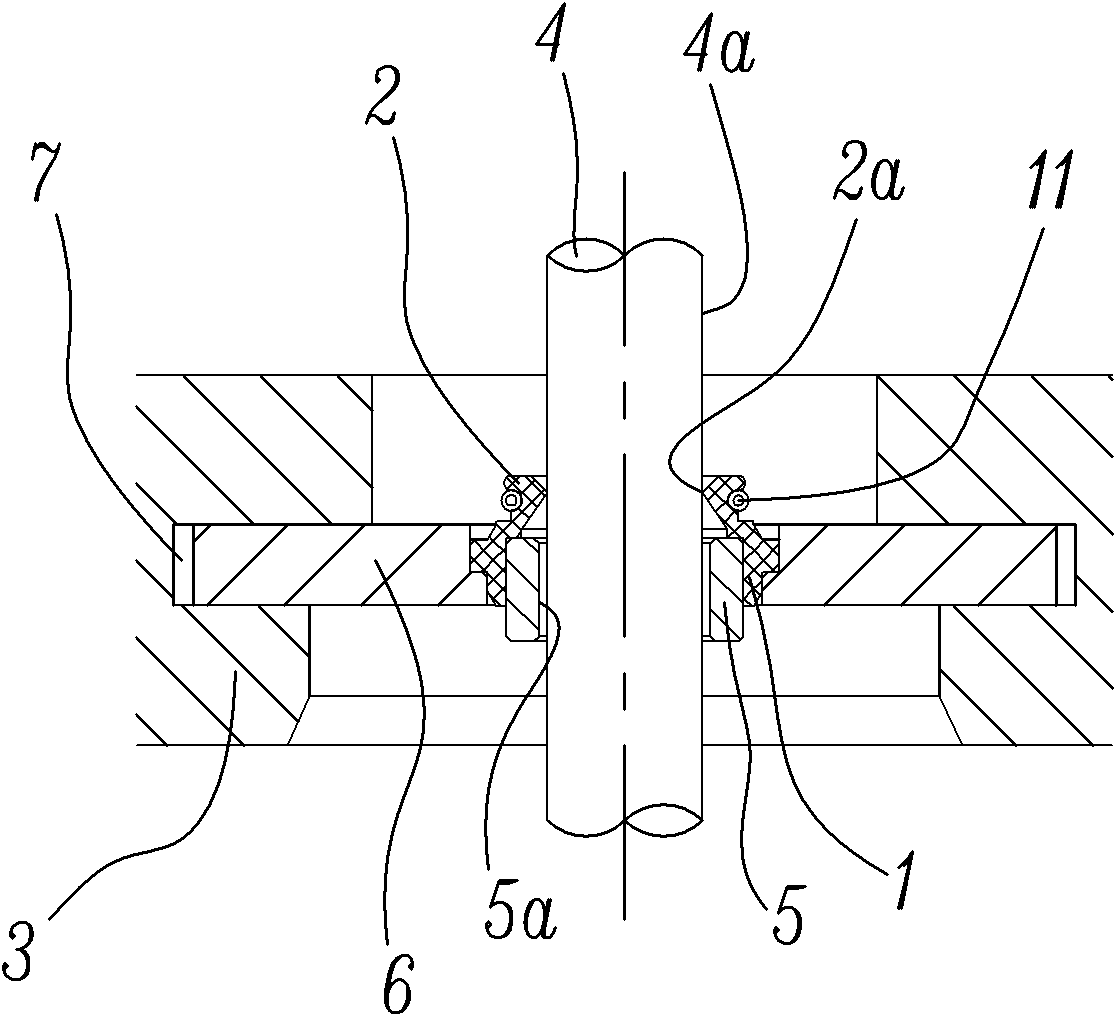

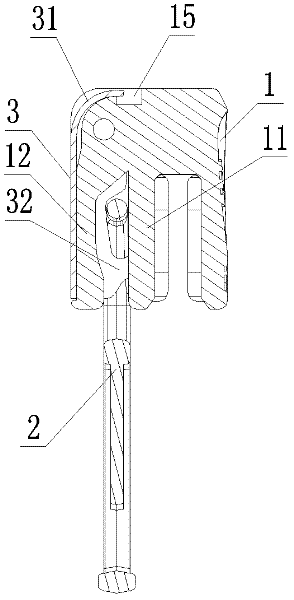

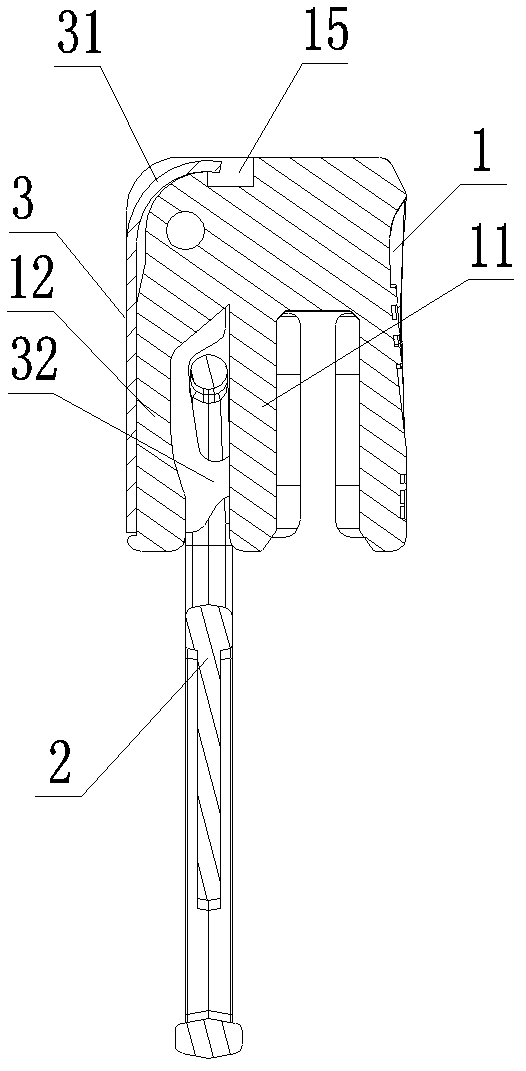

Supporting tool for machining and method for machining tensioning sleeve by using supporting tool

ActiveCN109848293AAccurate control of dimensional accuracyAccurate control of geometric tolerancesRevolution surface grinding machinesGrinding work supportsNatural stateMachining process

The invention provides a supporting tool for machining and a method for machining a tensioning sleeve by using the supporting tool. The supporting tool comprises a base and a supporting body, an installing groove is formed in the end face of the base, the supporting body is inserted behind the installing groove, the supporting body and the installing groove are connected through screws, a threadedthrough hole is formed in the center shaft and at the position of a center axis where the base and the supporting body connect, and a groove is formed in the supporting body and corresponds to the threaded through hole. In the machining process, the supporting tool internally supports the interior of the tensioning sleeve intermediate, the tensioning sleeve intermediate is changed into a workingstate from a natural state to be further machined, the deformation direction and the deformation amount can be effectively controlled, the deformation range is reduced, so that the dimensional precision and the form and location tolerance of the tensioning sleeve can be accurately controlled; and the concentricity, the coaxiality and the circular runout precision of the tensioning sleeve under theworking state can be ensured, the production cost is effectively reduced, and the using effect of the tensioning sleeve is improved.

Owner:无锡高晟成型科技有限公司

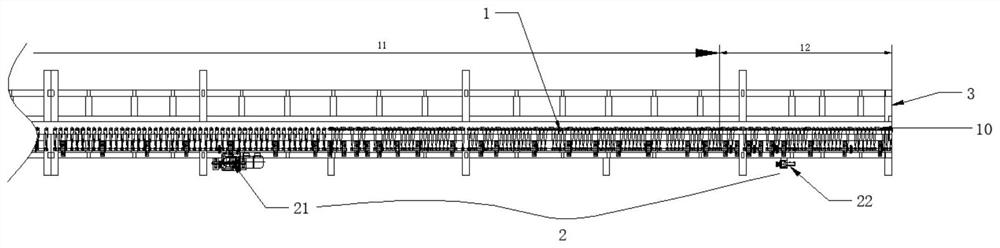

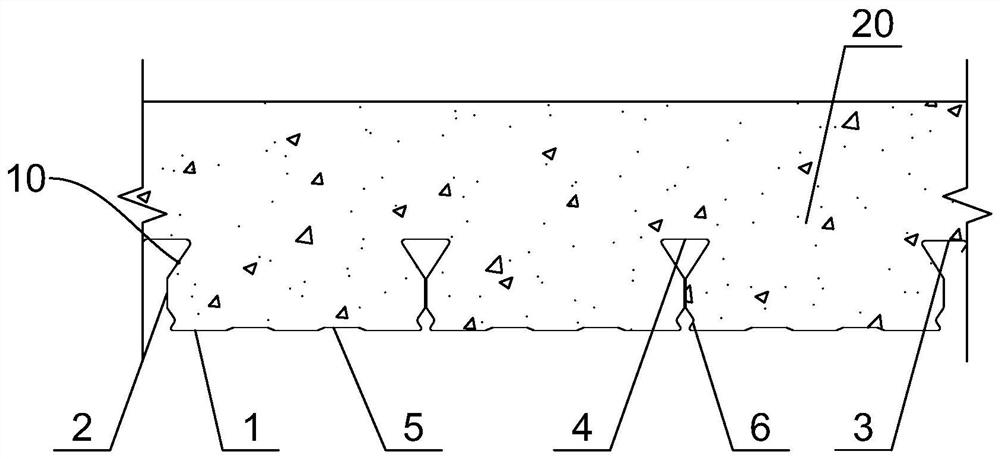

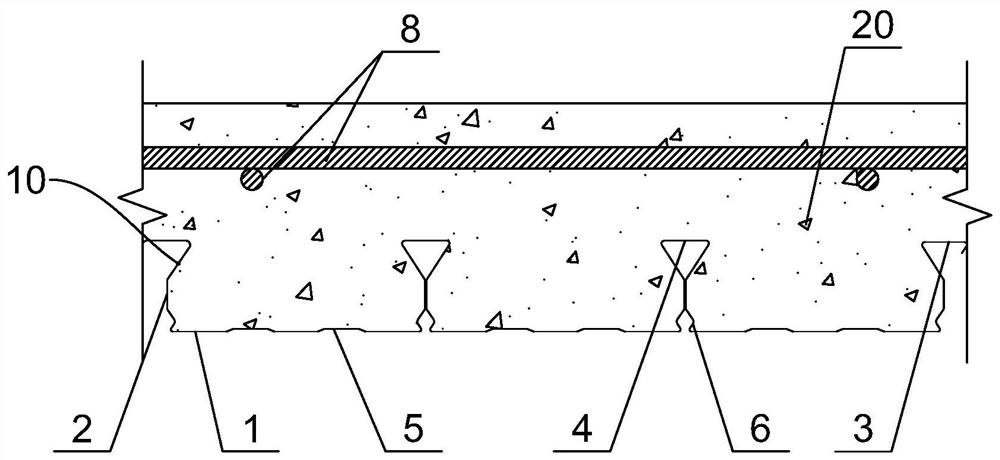

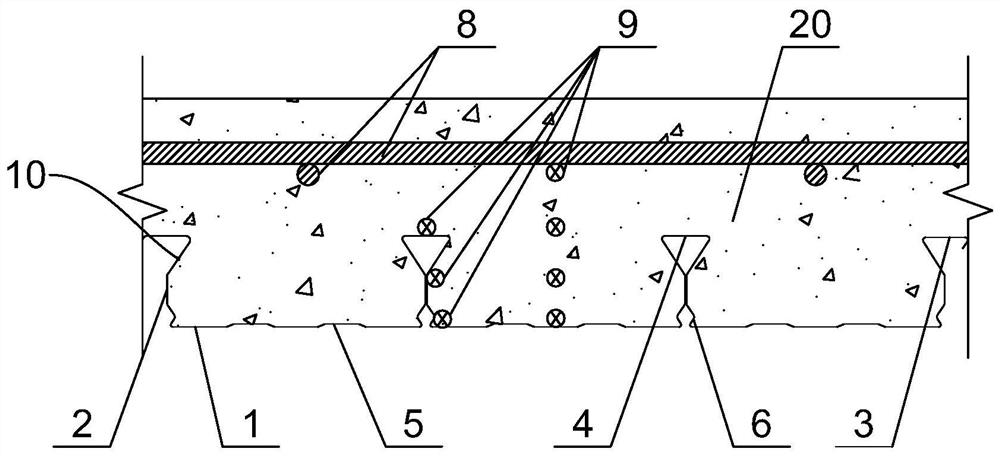

Production process of external wall panel of prefabricated concrete shear wall

ActiveCN110614718ASmooth and efficient production lineImprove efficiencyConstruction materialCeramic shaping apparatusProduction lineUltimate tensile strength

The invention discloses a production process of an external wall panel of a prefabricated concrete shear wall, and relates to the technical field of building construction processes. The production process comprises the following steps of mold clearing, mold mounting, bottom layer bar mounting, bottom layer burying, bottom layer distribution, extrusion plate pavement, external page mesh pavement, concrete pouring and compacting, aftertreatment, component maintenance, mold dismounting, component hoisting and finished product storage. According to the process, existing production process processes are overturned, production line production becomes smooth and efficient from originally jamming, component quality is greatly improved, potential safety hazards of components are reduced, labor intensity is greatly reduced, and cost is reduced; and special tools are adopted for mold dismounting and mounting, operation is simple and rapid, and a solid foundation is laid for automation of the nextstep.

Owner:山东联强建筑工业科技有限公司

Shaft seal structure

ActiveCN101936396AReduce the deformationImprove distribution uniformityEngine sealsEngineeringMechanical engineering

The invention belongs to the field of mechanical engineering and relates to a shaft seal structure. The shaft seal structure comprises a shaft seal body, a seal lip, an end plate and a dynamic rod, wherein a floating guide sleeve or / and a floating guide vane is arranged on the shaft seal; the dynamic rod passes through the floating guide sleeve and is in clearance fit with the floating guide sleeve; the floating guide vane is in clearance fit with the end plate; and both the floating guide sleeve and the floating guide vane are connected with the shaft seal body hermetically. The shaft seal structure is a floating guide sleeve or floating guide vane structure; the floating guide sleeve and the floating guide vane can drive the shaft seal body and have certain displacement relative to the end plate; the floating guide sleeve is subjected to the shaking movement of the dynamic rod and the force generated by the shaking movement, the deformation range of the seal lip relative to that of a dynamic rod body is reduced, the circular degree of the opening of the seal lip and the distribution uniformity of tightening force of the opening attaching to the dynamic rod are increased, and thefollowing performance of the shaft seal body relative to the dynamic rod is increased due to the existence of the floating guide vane, so that the shaft seal can still keep excellent tightness even if the shaft seal is in vibration and swinging states.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

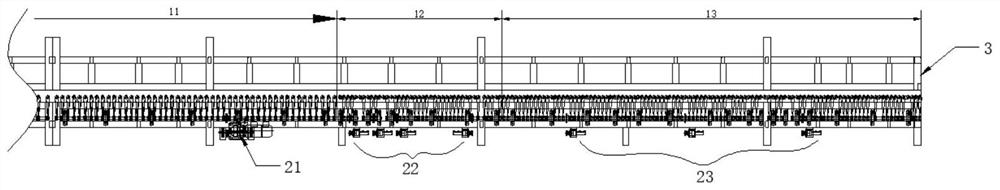

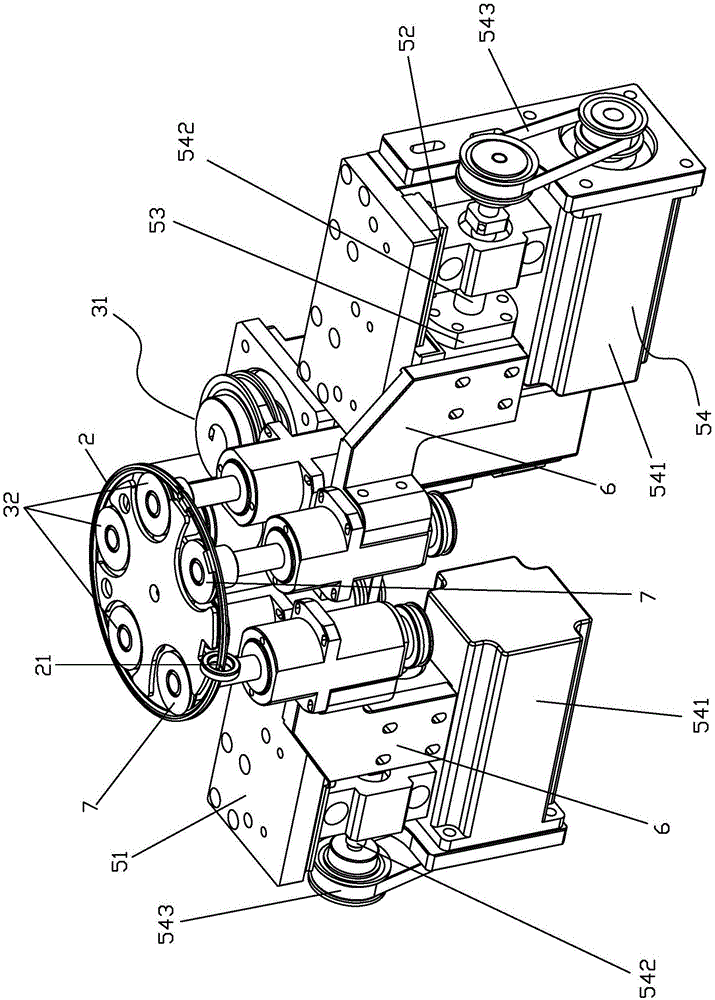

Conveying method of heating furnace in continuous glass toughening furnace

PendingCN111908781AReduce the deformationImprove the defects that are prone to "wavy lines"Glass transportation apparatusGlass tempering apparatusTemperingHeating furnace

The invention provides a conveying method of a heating furnace of a continuous glass toughening furnace, and belongs to the field of glass toughening. According to the method, a heating furnace conveying line is divided into a normal-speed section, an acceleration section and a rapid section, wherein in the normal-speed section, the glass is driven to be conveyed at a constant speed at the speed of V flat; in the rapid section the glass is driven to be conveyed at a constant speed at the speed of V<rapid>, V<rapid> being larger than V<normal>; and in acceleration section, variable-speed conveying of the glass is controlled, and the glass is limited at the temperature required by heating to tempering in the rapid section. According to the invention, the accelerating section on the conveyingline of the existing heating furnace is advanced, and meanwhile, the quick section is added behind the accelerating section, so that the glass is limited at the temperature required by the quick section to be heated to be tempered, i.e., the glass is completely heated in the quick moving process and moves in a quick passing manner before being heated to a softening point; as a result, the deformation amplitude of the glass is effectively reduced, so that the defect that raised grains are likely to appear on the surface of the glass is overcome, the effect is more obvious especially for ultrathin glass with the glass thickness smaller than or equal to 2.5 mm, and the flatness of the glass can reach 0.2 mm or below.

Owner:宣城吉鼎玻机械有限公司

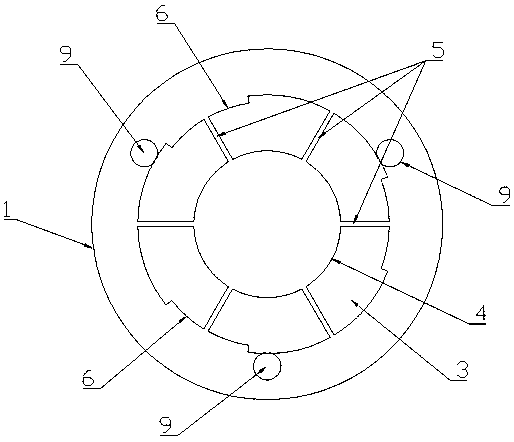

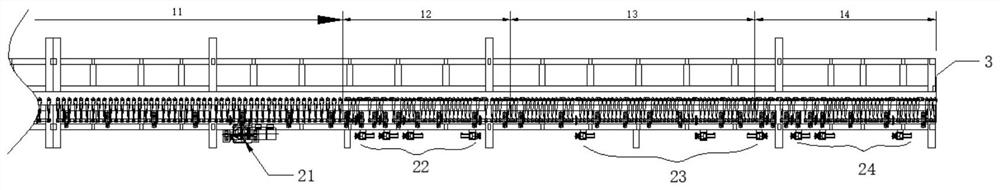

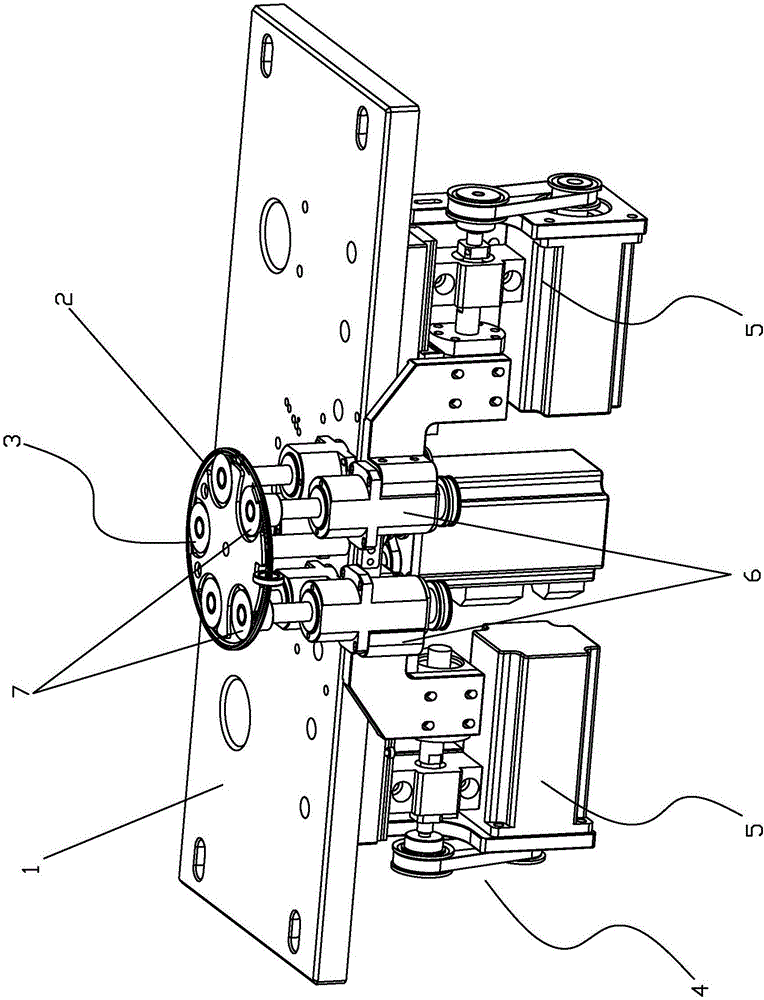

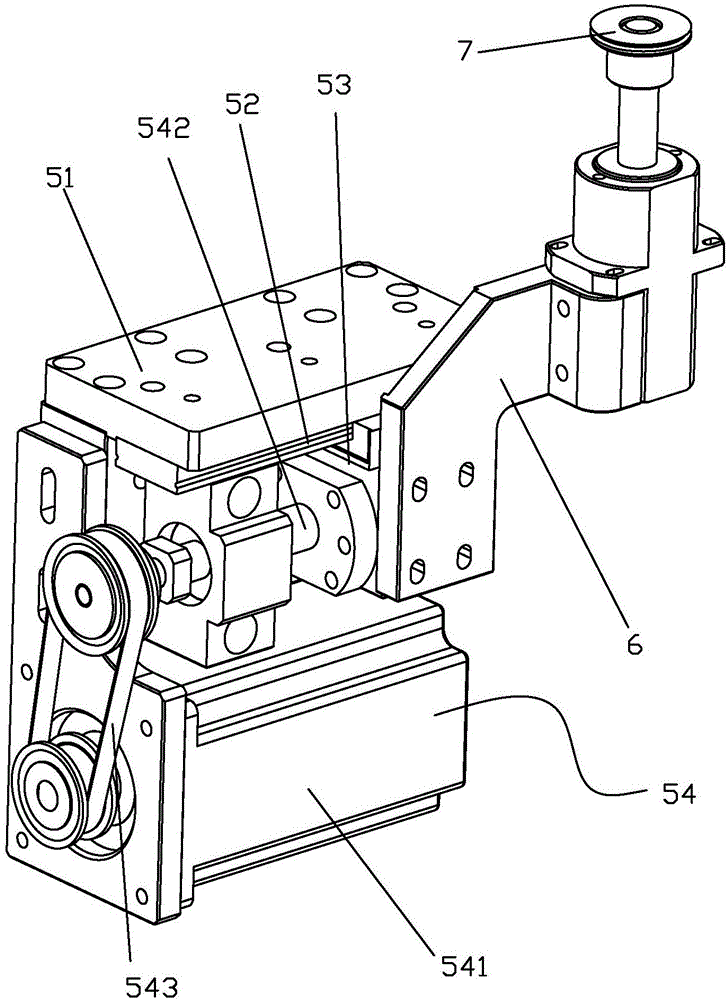

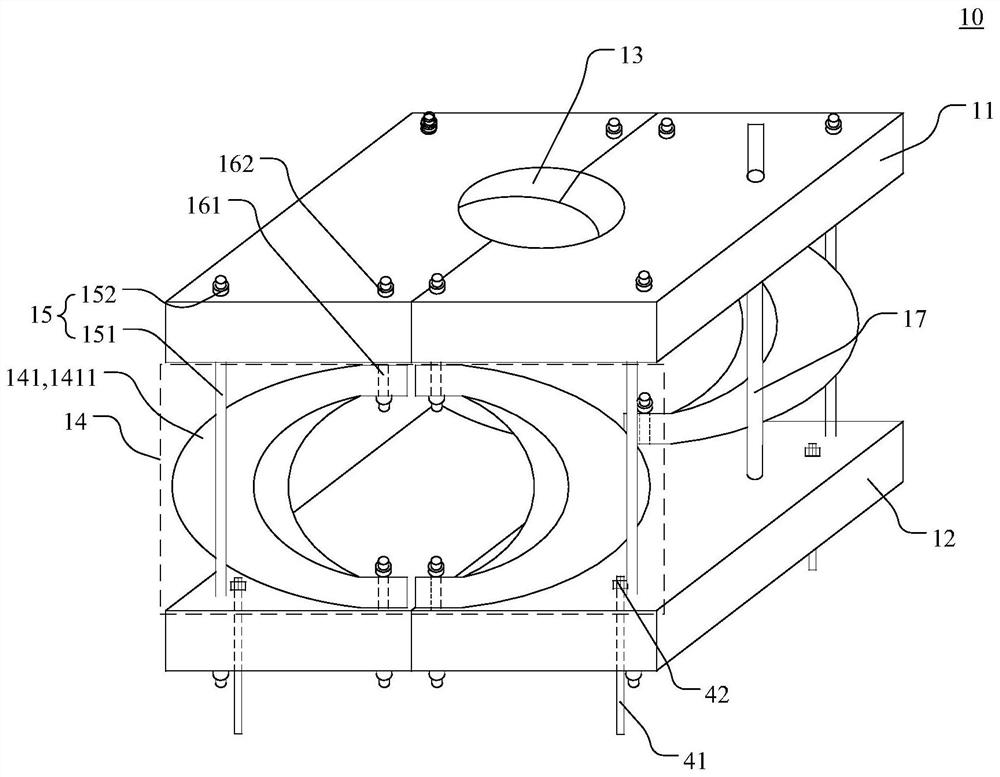

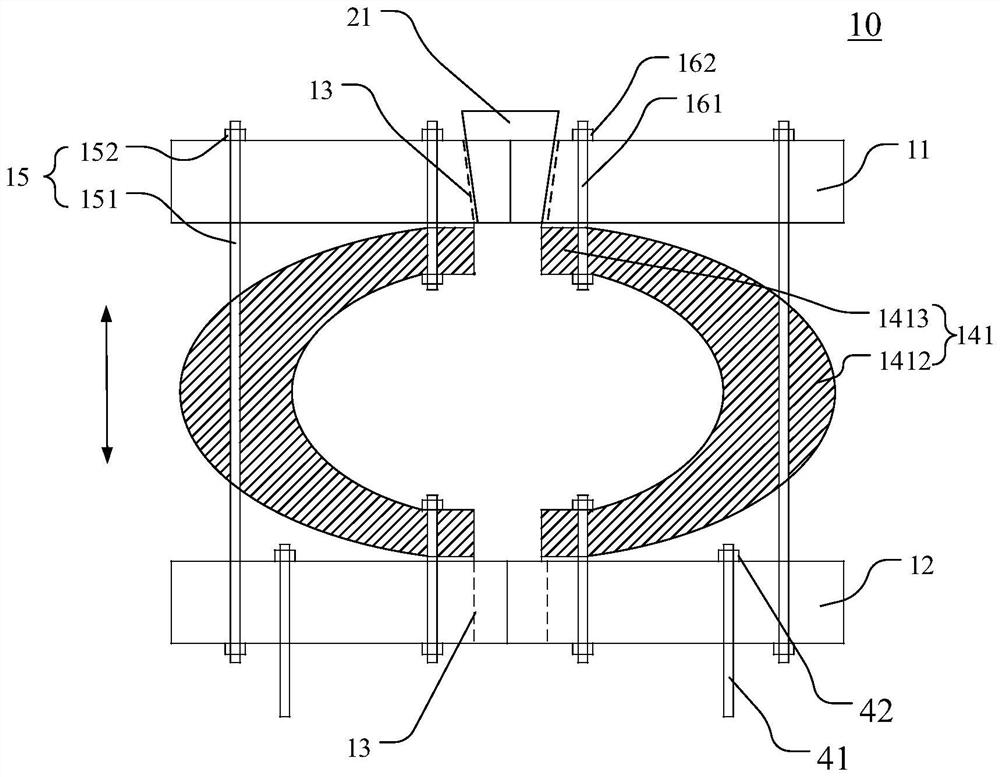

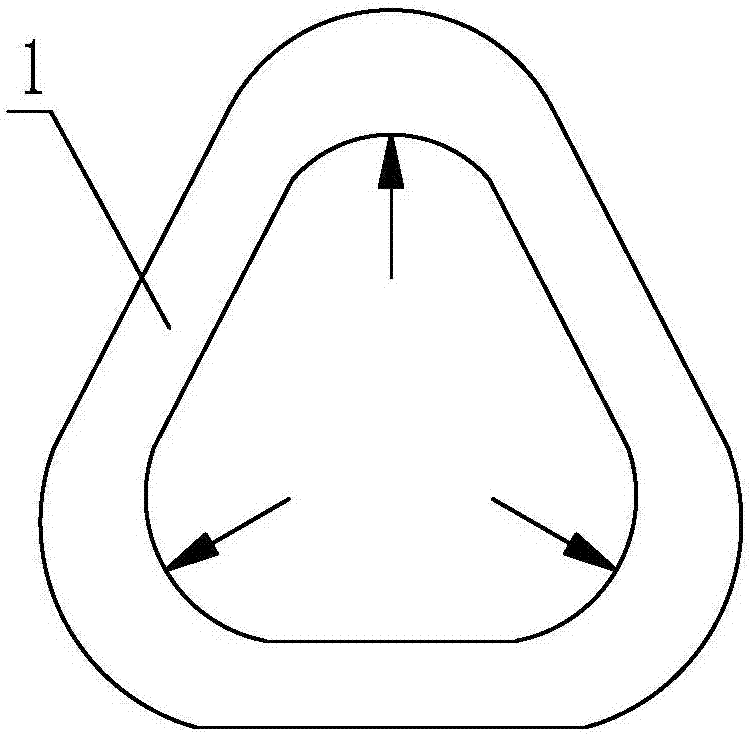

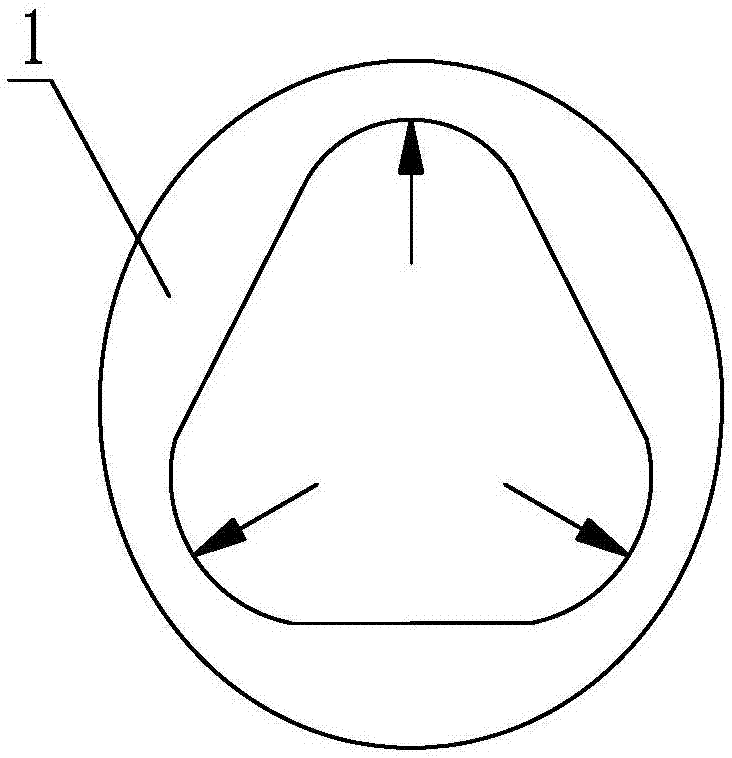

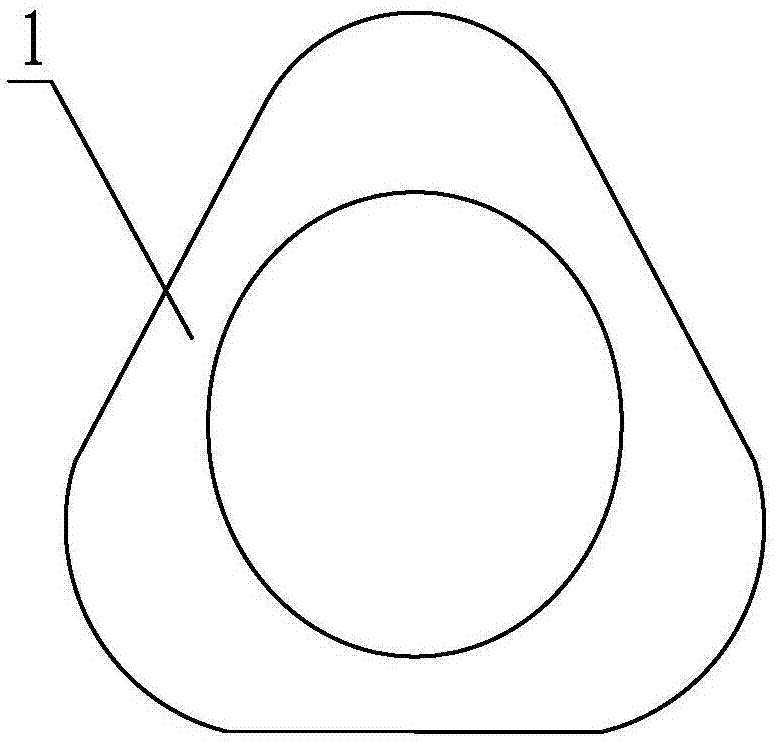

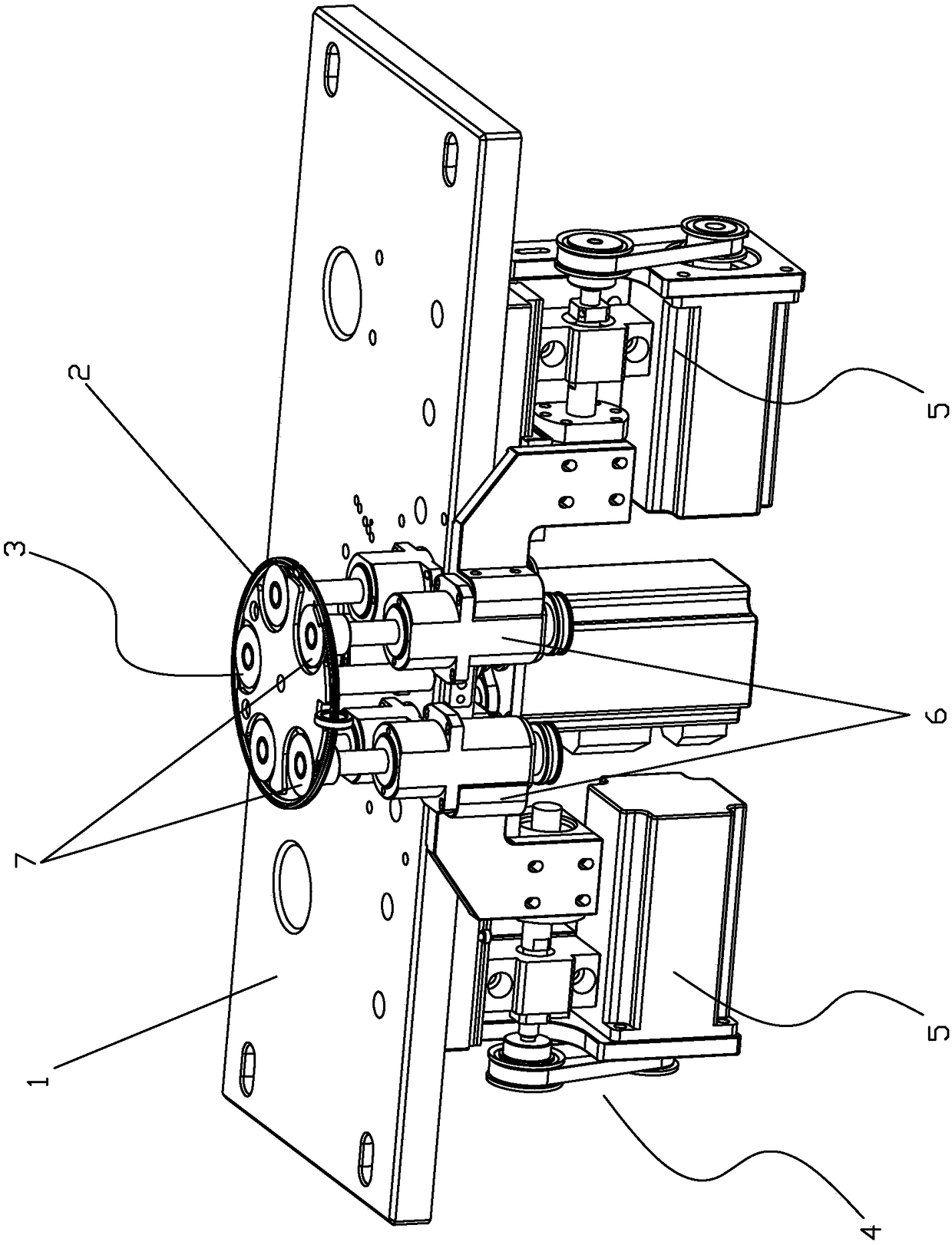

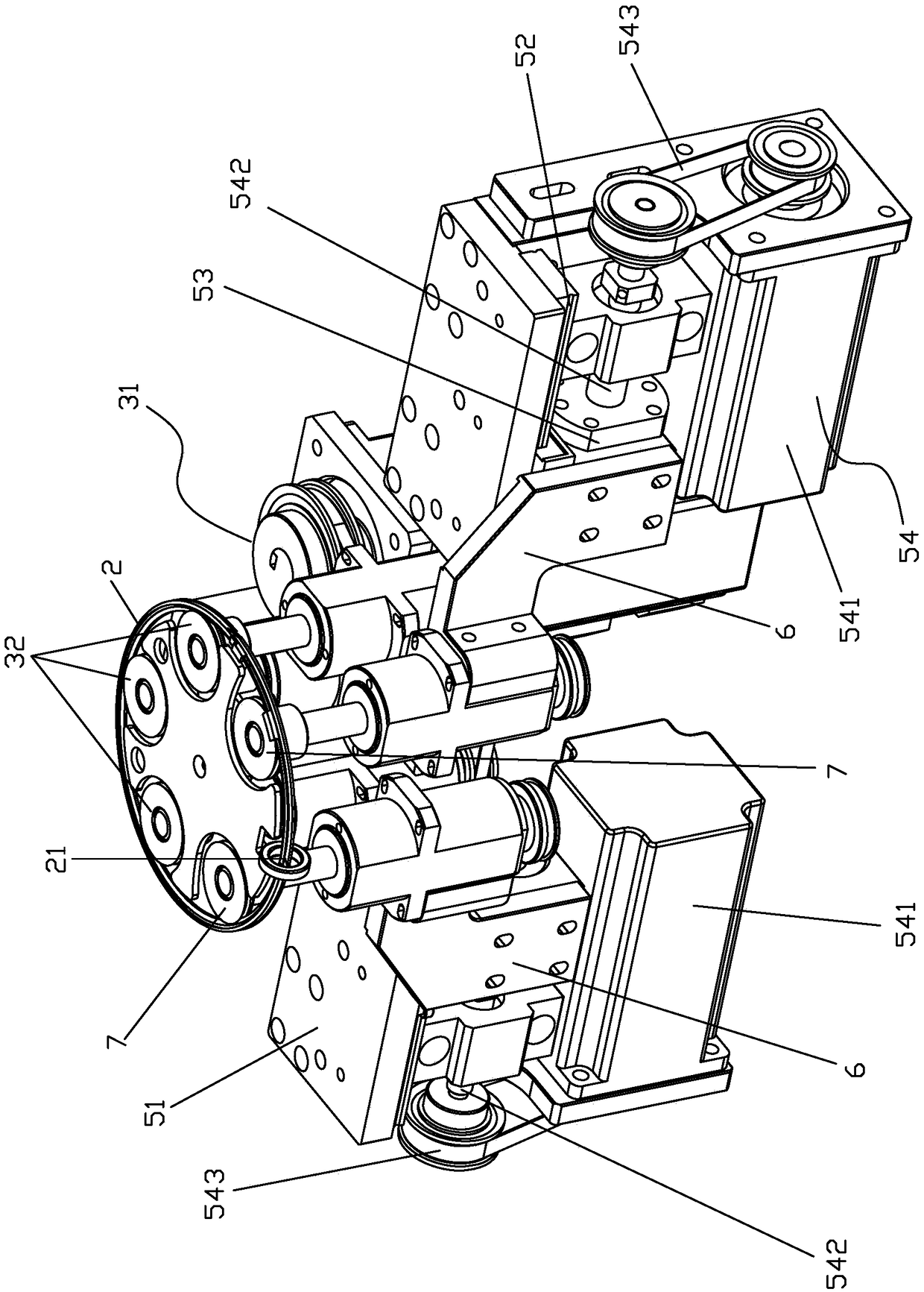

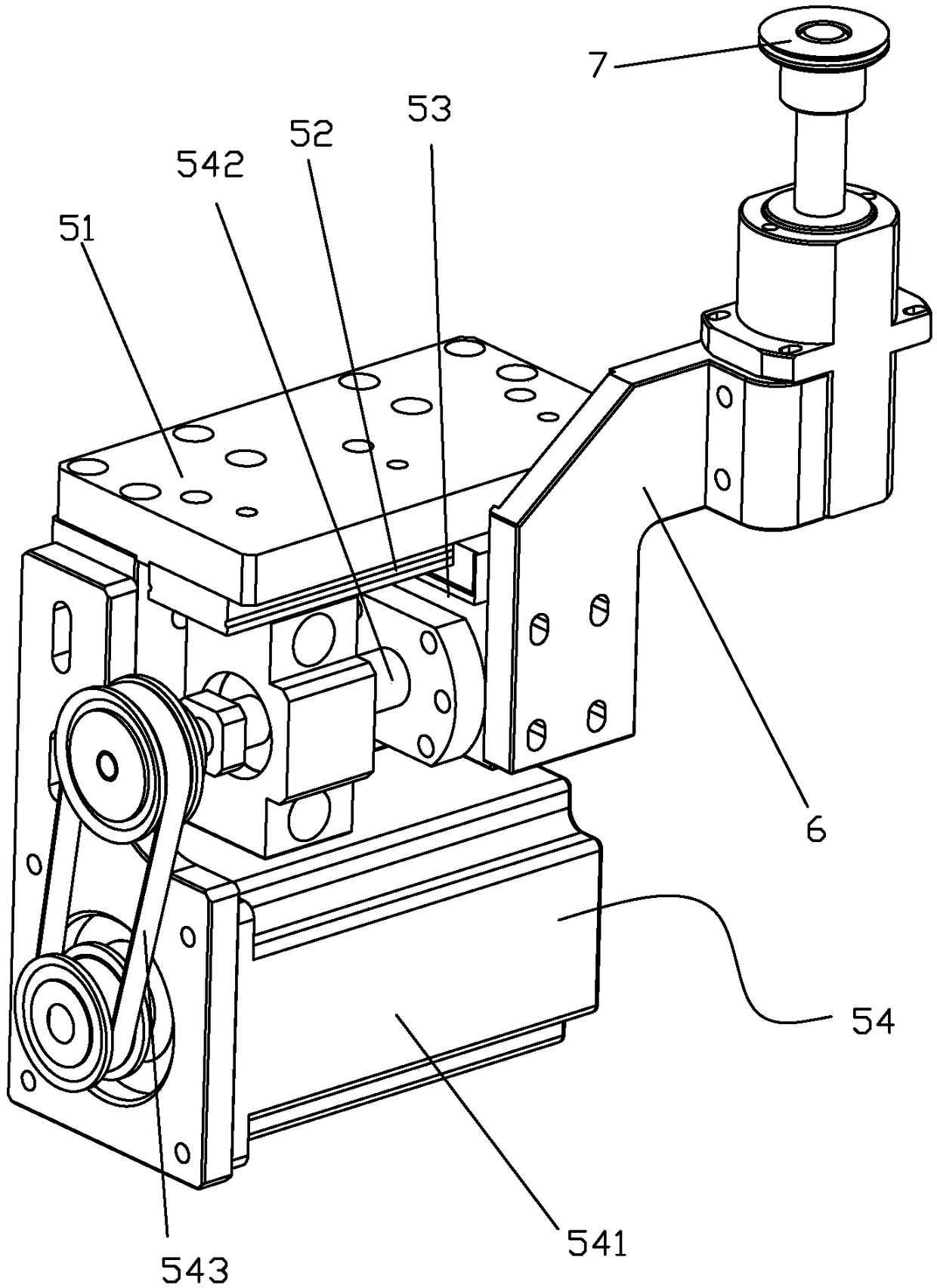

Automatic wire storage ring opening and closing device for winding machine

ActiveCN106504889AReduce the deformationDeformation is easy to recoverInductances/transformers/magnets manufactureWinding machineAutomatic control

The invention discloses an automatic wire storage ring opening and closing device for a winding machine. The automatic wire storage ring opening and closing device comprises a work bench and a wire storage ring arranged on the work bench, wherein a ring opening is arranged in the wire storage ring; the automatic wire storage ring opening and closing device is characterized in that a rotary driving mechanism for driving the wire storage ring to rotate and a ring opening and closing mechanism capable of opening the wire storage ring in a same plane along the ring opening are arranged on the work bench. According to the ring opening and closing mechanism disclosed by the invention, the force is applied to the outer side of the ring in parallel from the inner circumference of the wire storage ring to open the ring, so as to put a magnetic ring; the material of the wire storage ring has certain elasticity, the force is applied to the outer side of the ring in parallel to open the wire storage ring and the wire storage ring is opened in the same plane; and compared with a dislocated ring opening mode, the automatic wire storage ring opening and closing device has the advantages that the deformation amplitude of the wire storage ring is small, the deformation is easy to restore, the service life of the wire storage ring is prolonged and automatic control on the opening and closing states of the wire storage ring is achieved.

Owner:ZHONGSHAN COMPETENT AUTOMATION EQUIP CO LTD

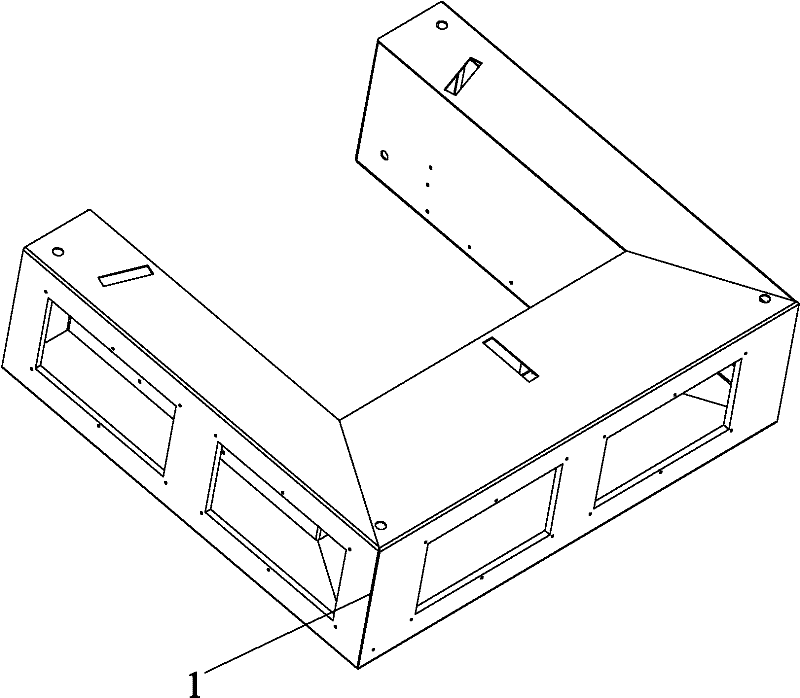

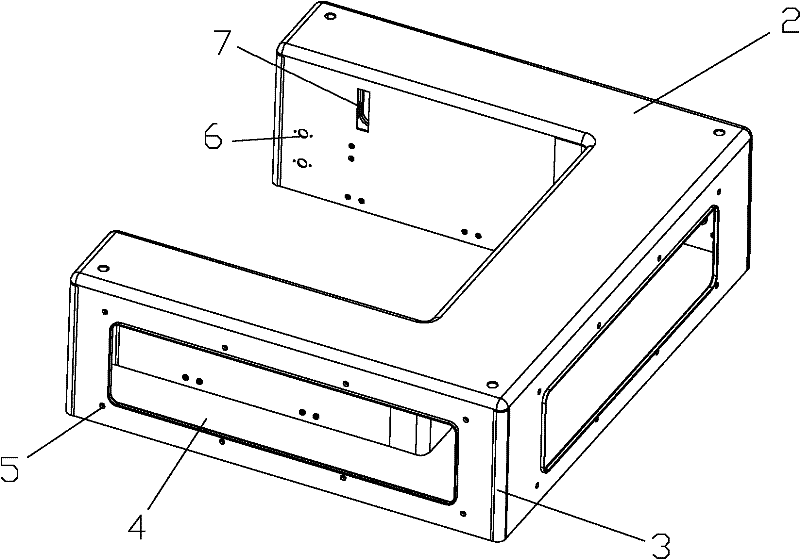

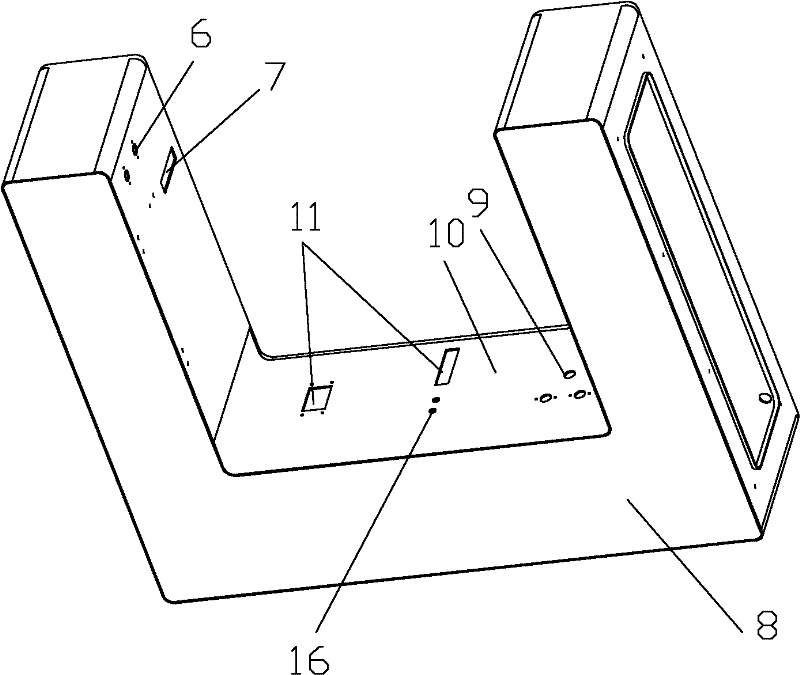

Case for combined scale and method for manufacturing same

ActiveCN102155977BReduce the difficulty of welding processReduce difficultyWeighing apparatus detailsScrew threadIndustrial engineering

The invention provides a method for manufacturing a case for a combined scale, comprising the following steps: (1) cutting a main case plate profile, a bottom plate, inner wall plate profiles and all corner splicing plate profiles; (2) arranging installation windows, installation holes and thread holes on the main case plate profile and the inner wall plate profiles, and flanging the installationwindows; (3) pressing the main case plate profile integrally, maintaining the pressure, and then taking out; pressing the inner wall plate profiles to obtain inner wall plates, and pressing the corner splicing plate profiles to obtain corner splicing plates; and (4) connecting the formed main case, the inner wall plates, the corner splicing plates and the bottom plate together to obtain the case for the combined scale. The invention further provides the case for the combined scale, which is manufactured by adopting the method. The case for the combined scale comprises the main case, the innerwall plates, the bottom plate and the corner splicing plates and further comprises a top panel, inner panels and outer panels, which are integrally formed. The invention has the advantages of being simple in process and convenient for large-scale production.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

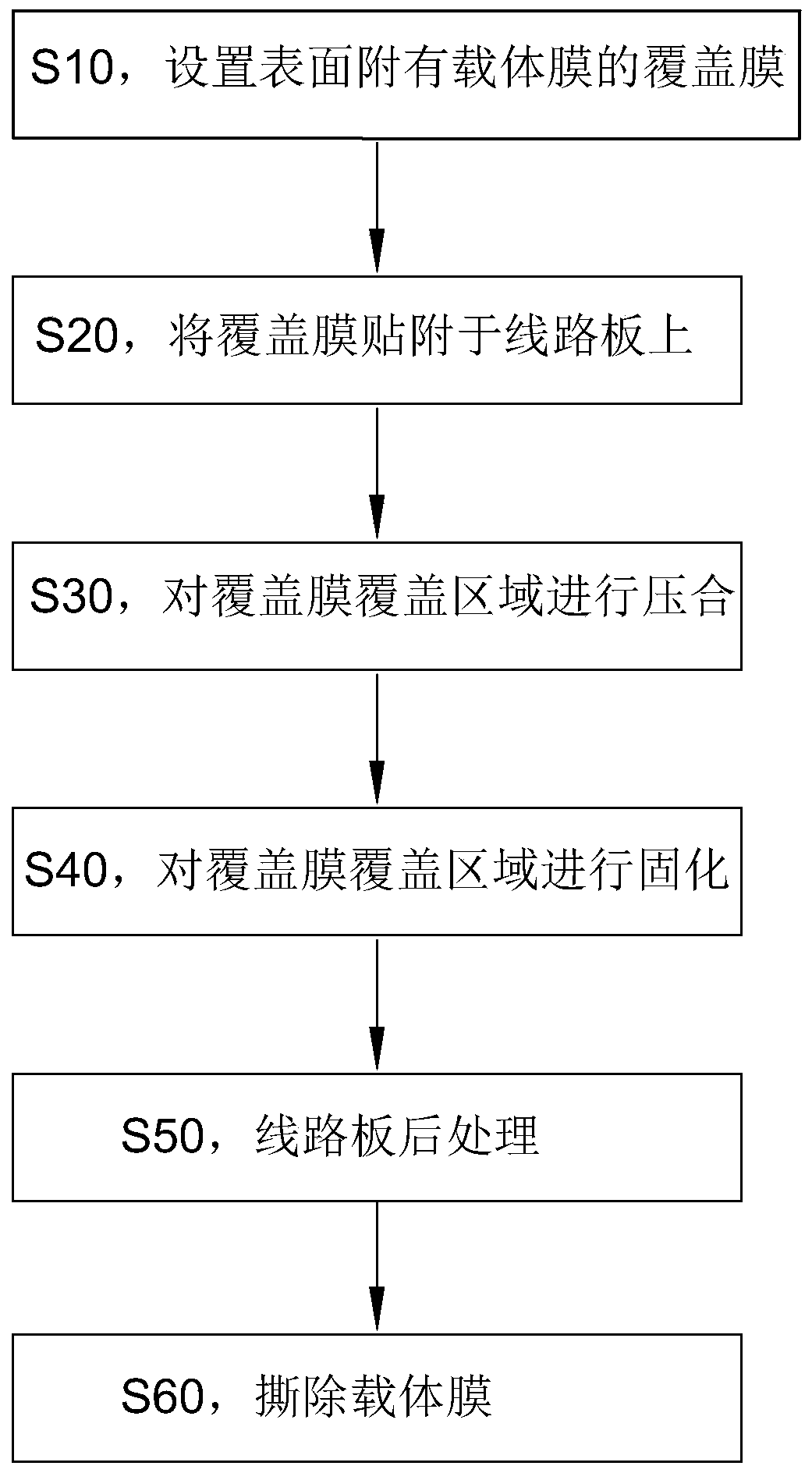

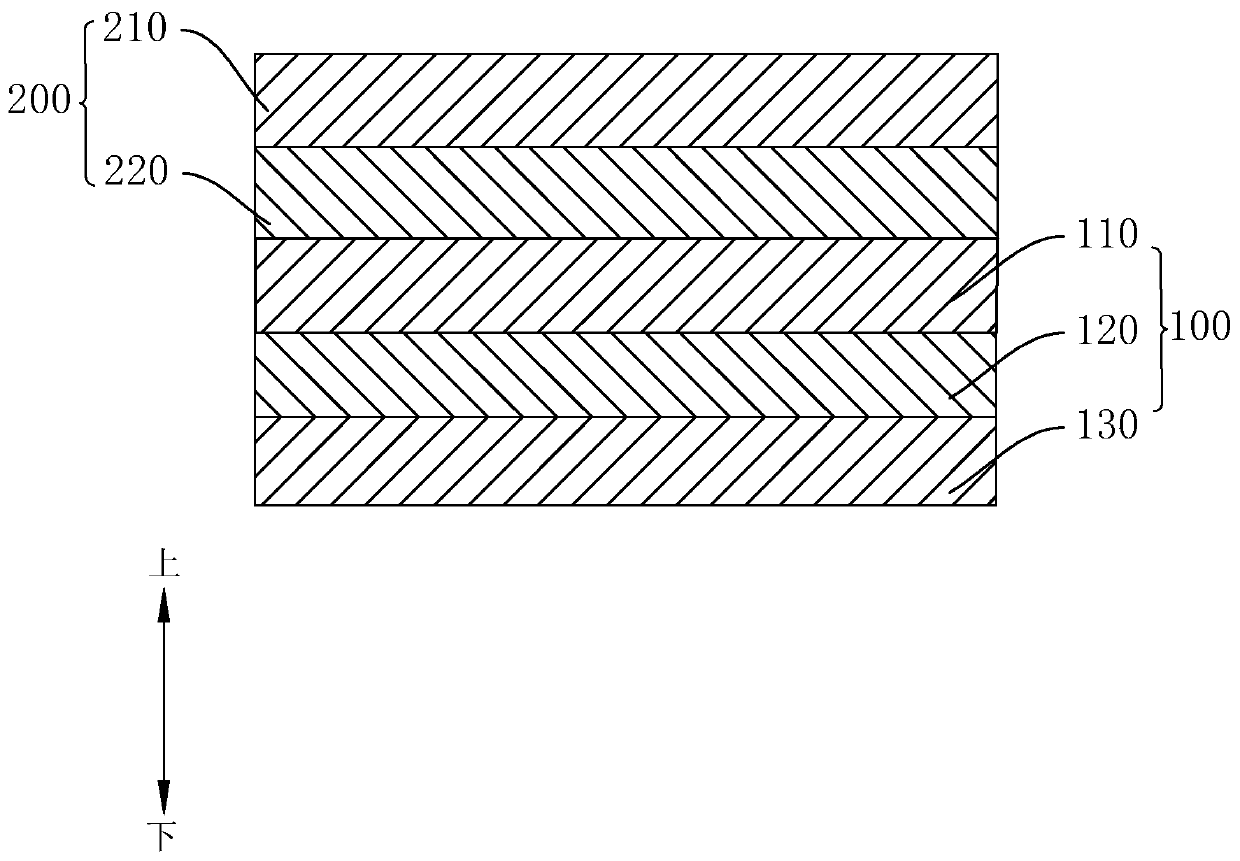

Circuit board and cover film laminating process

ActiveCN111065214AHigh surface flatnessIncreasing the thicknessNon-metallic protective coating applicationEngineeringMechanical engineering

The invention discloses a circuit board and cover film laminating process. The circuit board and cover film laminating process comprises the steps of arranging a cover film with a carrier film attached to the surface, attaching the cover film to a circuit board, pressing a covering area of the cover film, curing the covering area of the cover film, post-processing the circuit board and tearing offthe carrier film. According to the circuit board and cover film laminating process, by attaching the carrier film to the cover film, the thickness of the cover film is increased, the tearing strengthof the cover film is optimized, and the deformation amplitude of the cover film is reduced when the cover film and the circuit board are laminated, so that the laminating quality of the cover film onthe circuit board is improved, and the surface flatness of the circuit board is optimized.

Owner:SHENZHEN XINYU TENGYUE ELECTRONICS

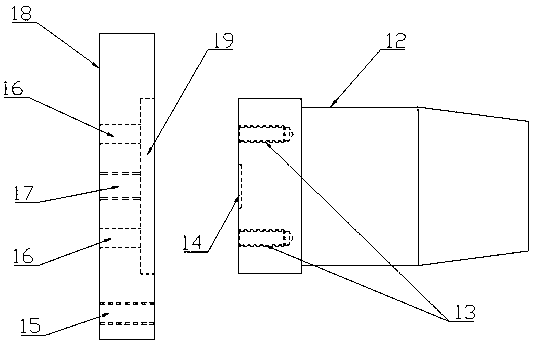

Anchoring device, prestress anchoring structure and construction method of prestress anchoring structure

ActiveCN112663605AReduce deformationExtended service lifeBuilding reinforcementsBulkheads/pilesGeotechnical engineeringStructural engineering

The invention discloses an anchoring device, a prestress anchoring structure and a construction method of the prestress anchoring structure. The anchoring device comprises a first anchor plate and a second anchor plate, the first anchor plate and the second anchor plate are both provided with via holes allowing prestressed tendons to penetrate therethrough, elastic pieces are arranged between the first anchor plate and the second anchor plate and provided with bent structures bent in the first direction, the two ends of the elastic pieces are fixedly connected with the first anchor plate and the second anchor plate respectively, the anchoring device further comprises a fastening assembly, the fastening assembly comprises first bolts and first fastening nuts, the first bolts penetrate through the first anchor plate and the second anchor plate, and the first fastening nuts are in threaded connection with the parts, penetrating out of the first anchor plate and the second anchor plate, of the first bolts. According to the anchoring device, the elastic pieces are arranged between the two anchor plates, so that the anchoring device can generate elastic deformation under stress, and when the anchoring device is applied to the prestress anchoring structure, the anchoring device generates elastic deformation under earthquake power reciprocating impact to play a role in resisting earthquakes, and the possibility of disasters such as collapse and landslide is reduced.

Owner:SHANDONG JIANZHU UNIV

Reciprocating oil seal structure of compressor

InactiveCN101922440AImprove sealingReduce the deformationPositive displacement pump componentsPositive-displacement liquid enginesPetroleum engineeringReciprocating compressor

The invention belongs to the technological field of compressors, relating to a reciprocating oil seal structure of a straight reciprocating compressor, which comprises an oil seal main part, a seal lip, an end plate and a connecting rod, wherein the connecting rod passes through the oil seal main part and the seal lip; the seal lip is hermetically matched with the external surface of the rod body of the connecting rod; an abducent seal fin is adopted; the seal fin is fixedly and hermetically connected with the oil seal main part or is integrated with the oil seal main part; the external ring margin of the seal fin is fixedly and hermetically connected with the end plate; the elasticity of the seal fin is utilized as a compensation to ensure that the oil seal main part can trace the shake of the connecting rod in time; the transformation range of the seal lip is reduced relative to the rod body of the connecting rod, and the degree the lip of the seal lip fits the connecting rod is further increased. The invention can ensure that the oil seal keeps good sealability when the oil seal structure is in shacking condition.

Owner:ZHEJIANG HONGYOU AIR COMPRESSOR MFG

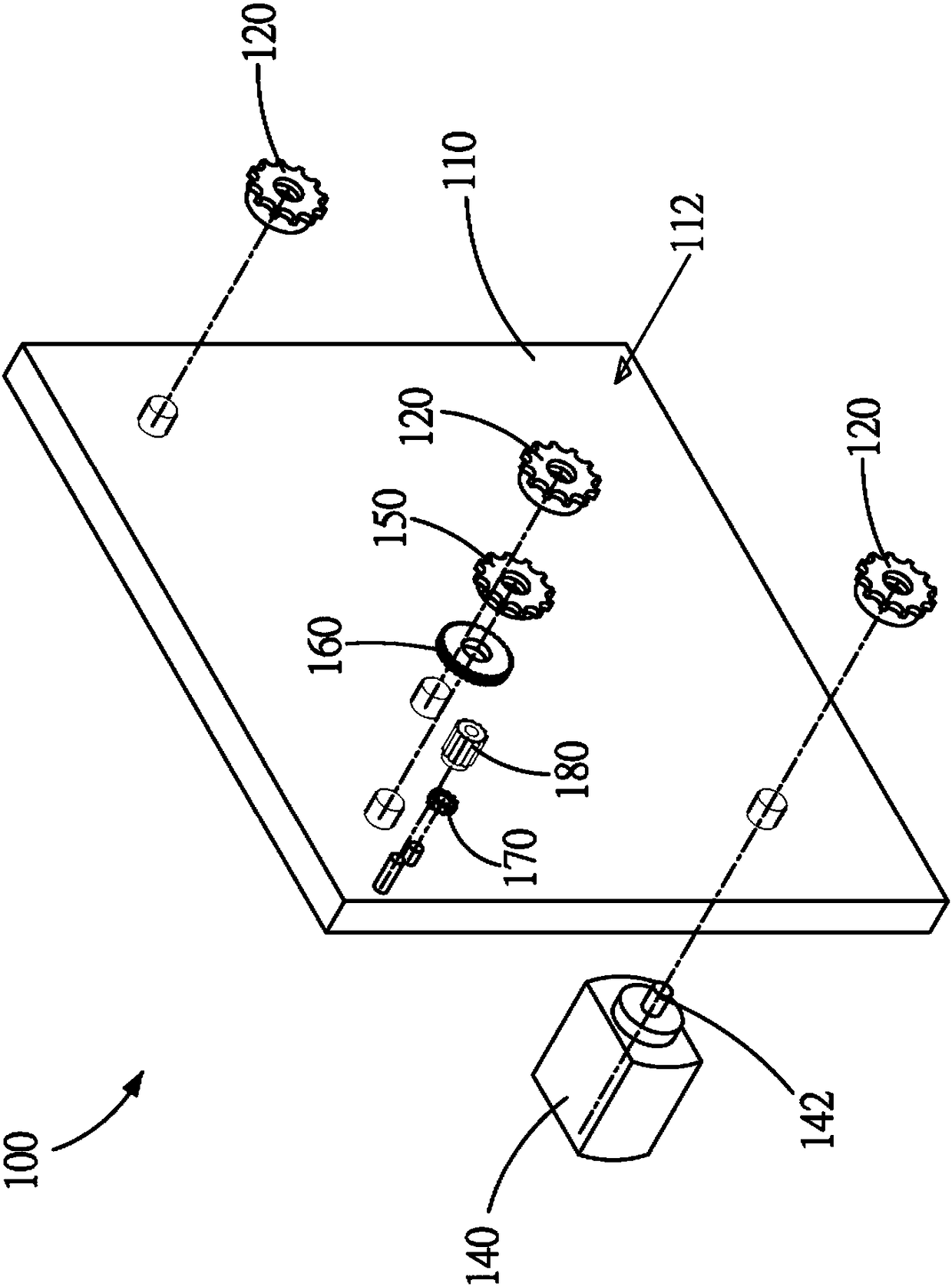

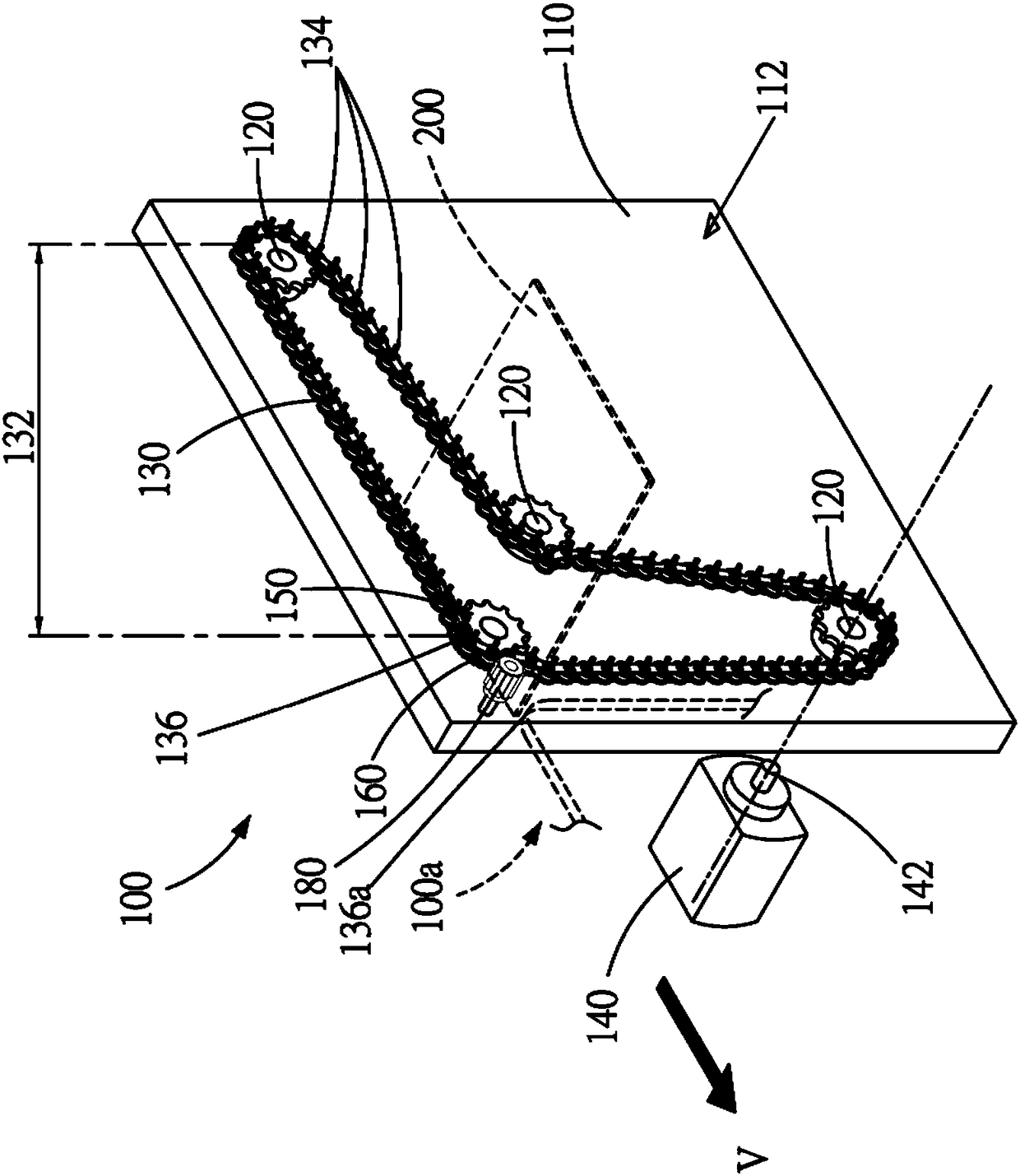

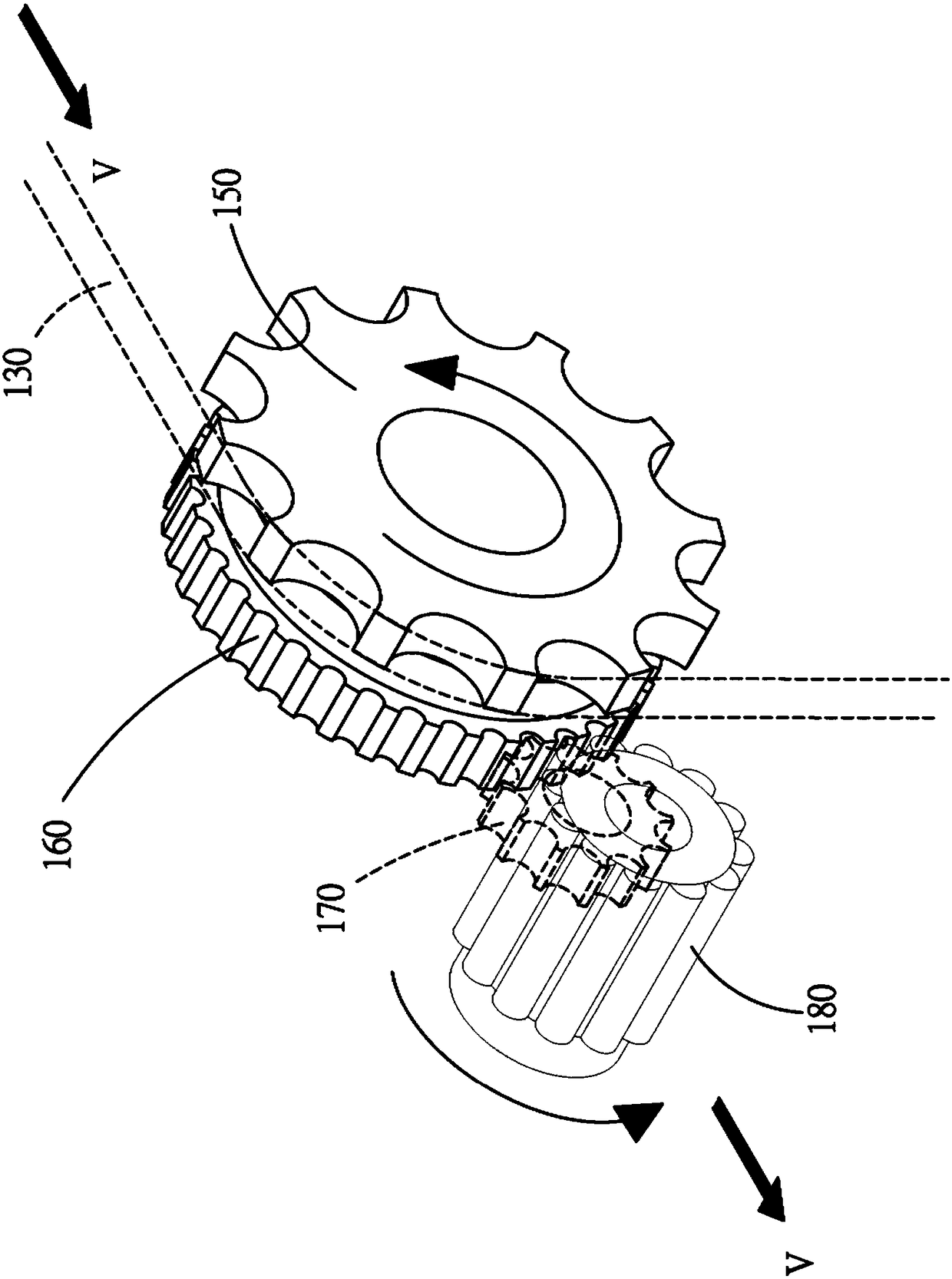

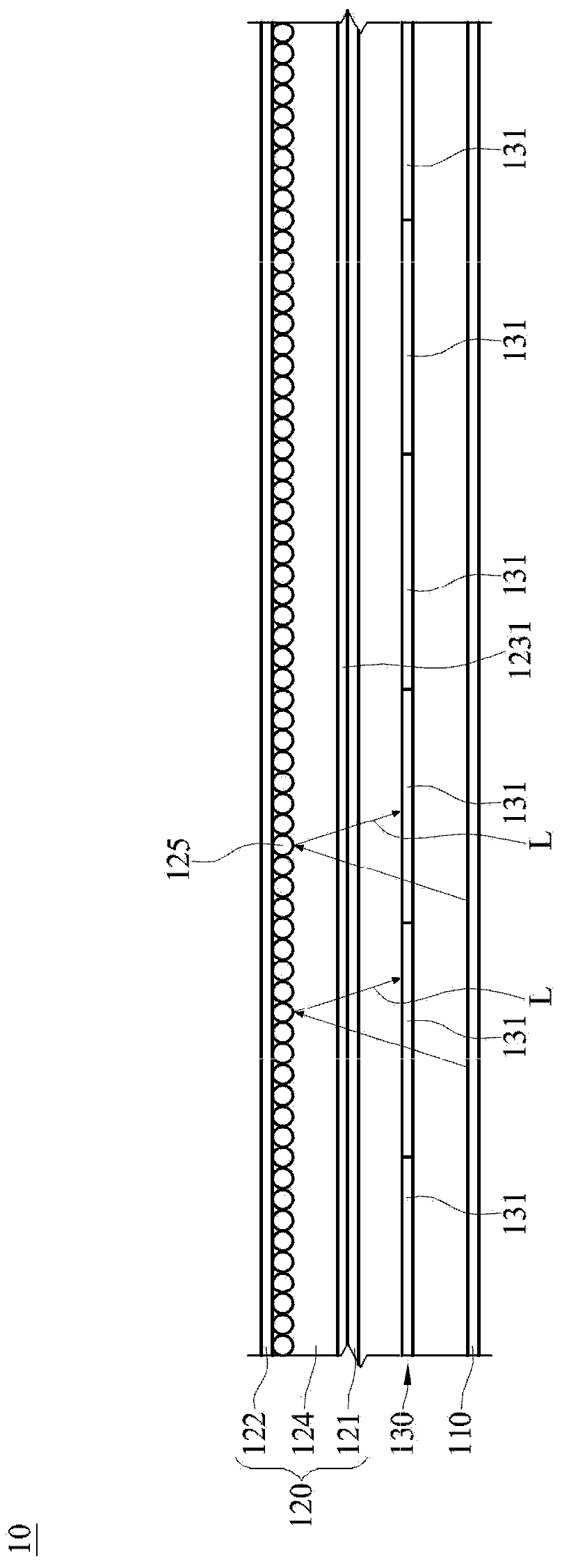

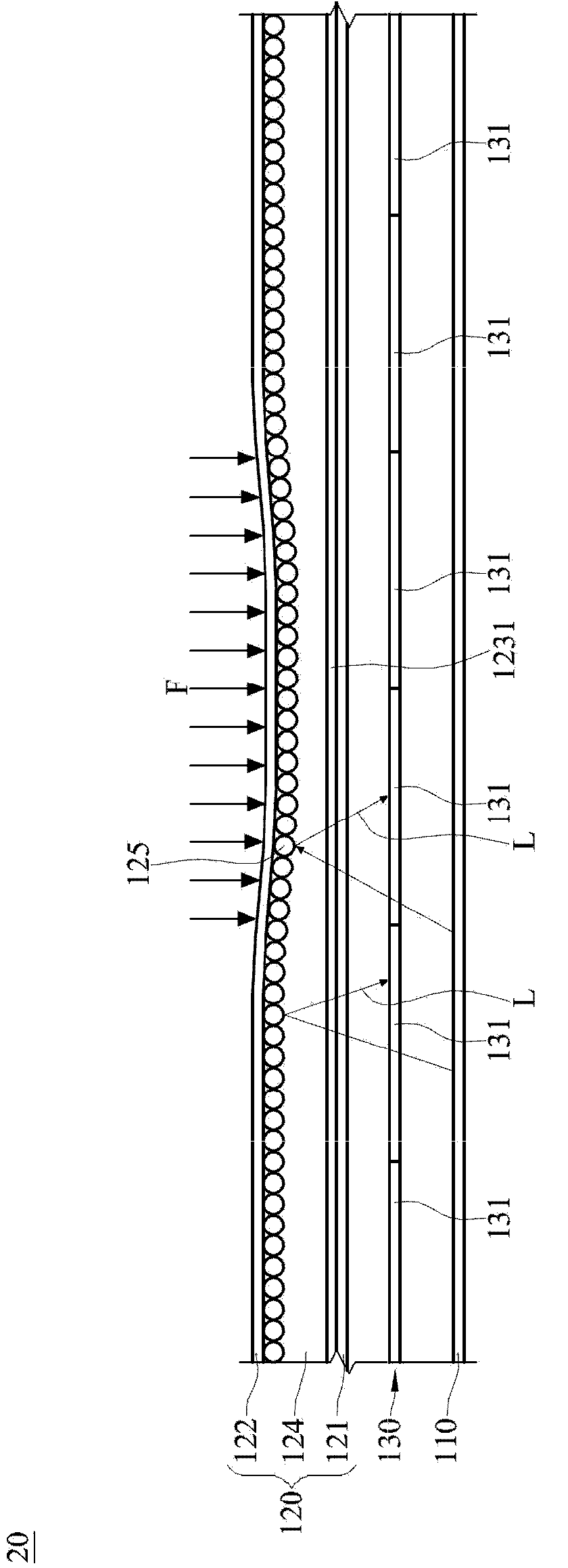

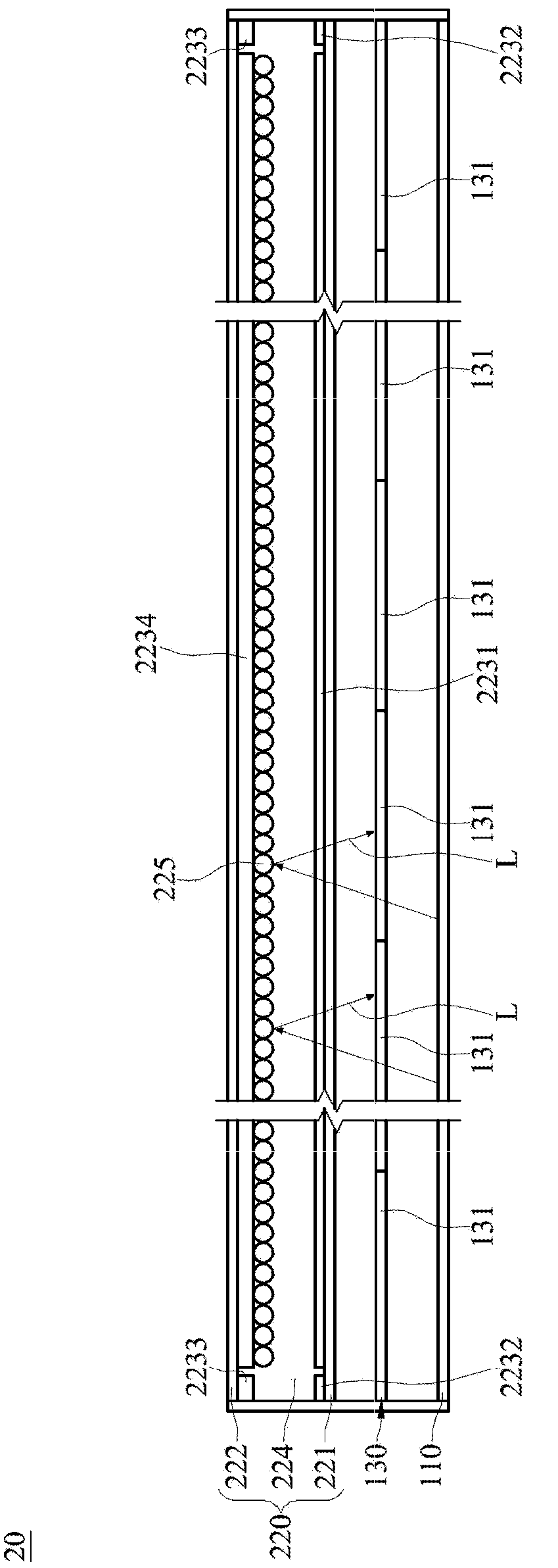

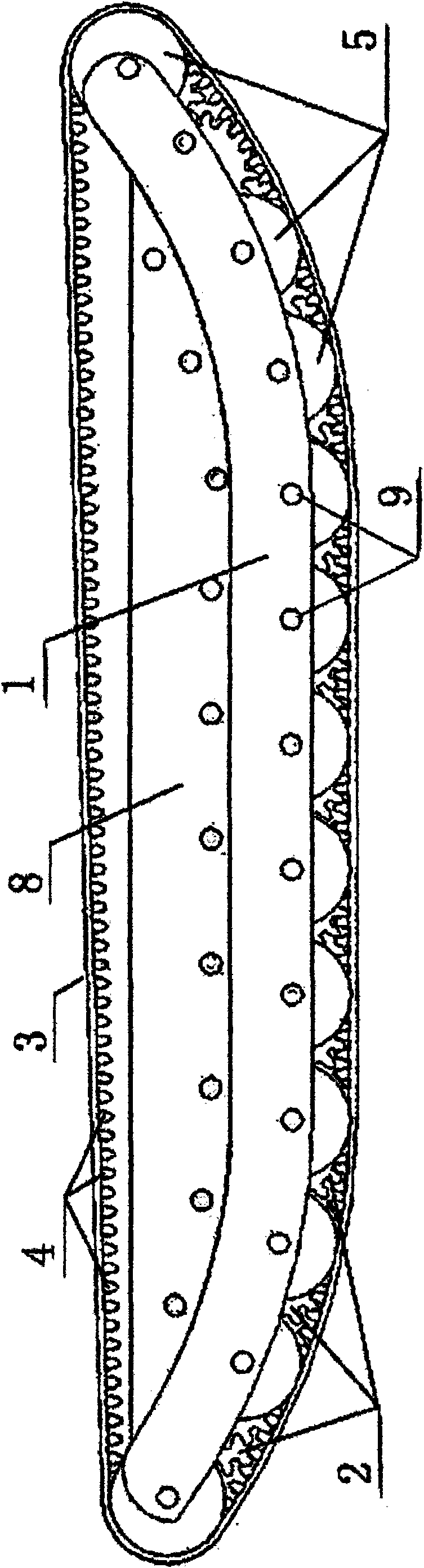

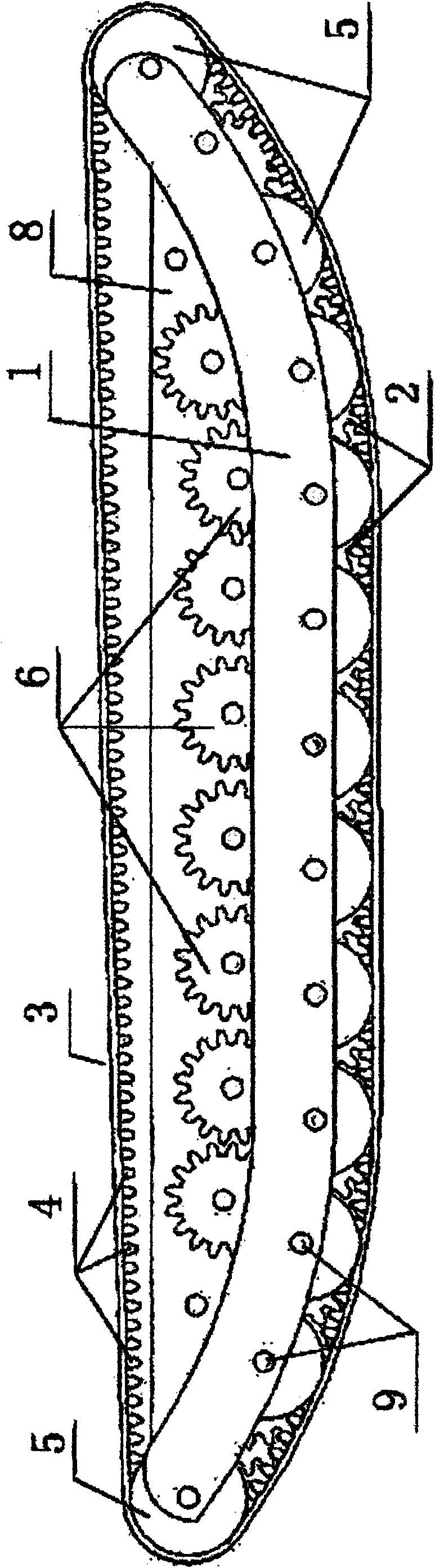

Plate conveying platform and plate conveying system

InactiveCN108792435AReduce the deformationAvoid falling conditionsConveyorsCharge manipulationEngineeringDriving mode

The invention discloses a plate conveying platform. The plate conveying platform comprises a base, a plurality of transmission coupling wheels, a flexible closed loop transmission piece, a driven coupling wheel, a driven gear, a relay gear and a driving gear; the base is provided with a setting surface, the plurality of transmission coupling wheels are arranged on the setting surface in a pivotingmode, the flexible closed loop transmission piece forms a closed loop and is surrounded and coupled to the transmission coupling wheel, a linear conveying section is arranged on the closed loop, andone end of the linear conveying section is a connecting end; and the driven coupling wheel, the driven gear, the relay gear and the driving gear are arranged on the setting surface, the driving gear and the linear conveying section are enabled to be synchronous through the mutual coupling relation, and then a plate which leaves the linear conveying section is received outside the connecting end inan active driving mode.

Owner:GIGA BYTE TECH CO LTD

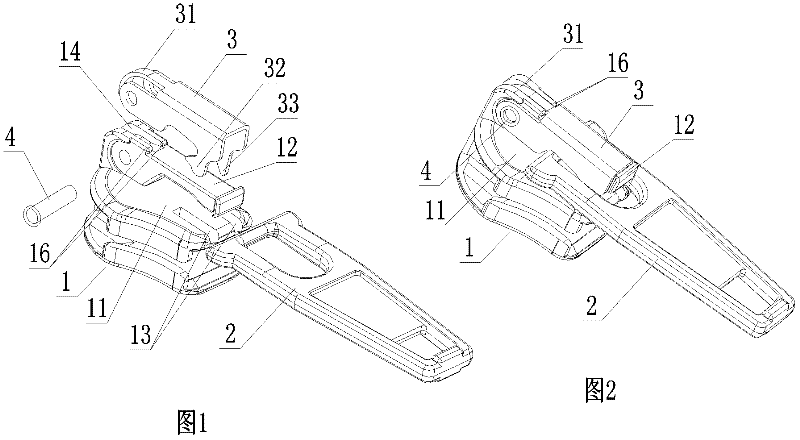

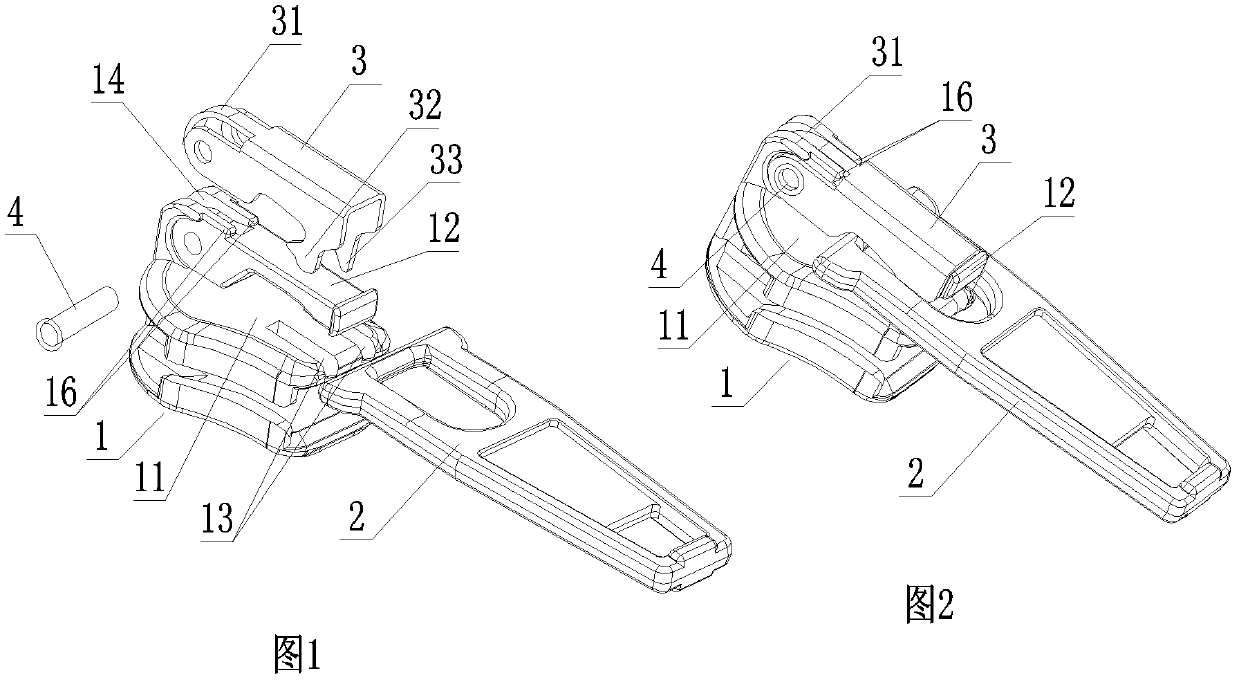

Zipper slider with demountable pull tab

ActiveCN102641022AReduce the deformationAvoiding the Problem of Metal FatigueSlide fastenersEngineeringSlide plate

The invention discloses a zipper slider with a demountable pull tab, which comprises a zipper slider body, a pull tab and a hook. An upper slide plate of the zipper slider body is provided with a pull nose covered with the hook, and two lateral groove walls at the hinge end of the hook are hinged to the root of the pull nose. The hinge end of the hook is provided with a spring plate extending in a curved manner towards the root of the pull nose. The inner side of the hook spring plate and the groove bottom of a containing groove are both designed into involute surfaces gradually opening along the extension direction of the spring plate. The spring plate is forced to swing and deform by mutual interference between the inner side of the spring plate and the groove bottom of the containing groove, and the containing groove is provided with a recess allowing for rotation of the spring plate, so that the lengthwise extrusion deformation of the spring plate is avoided. The hook spring plate of the zipper slider compared with the existing zipper slider with a demountable pull tab has reduced deformation amplitude, the problem that metal fatigue of the spring plate is easy to occur is solved, and the service life of the zipper slider is prolonged.

Owner:开易(浙江)服装配件有限公司

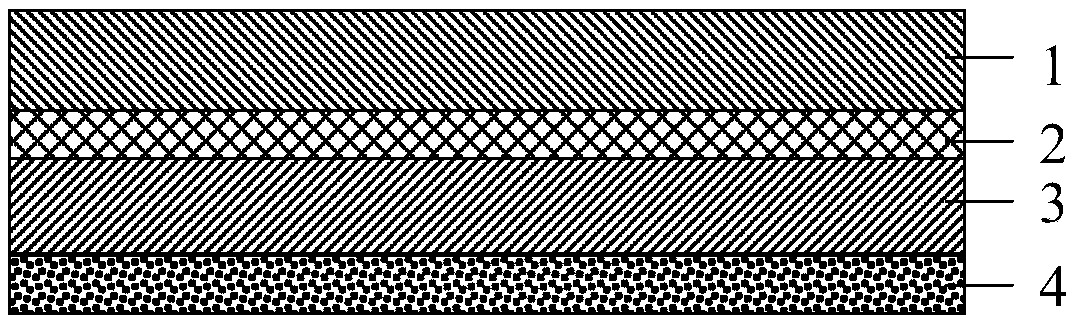

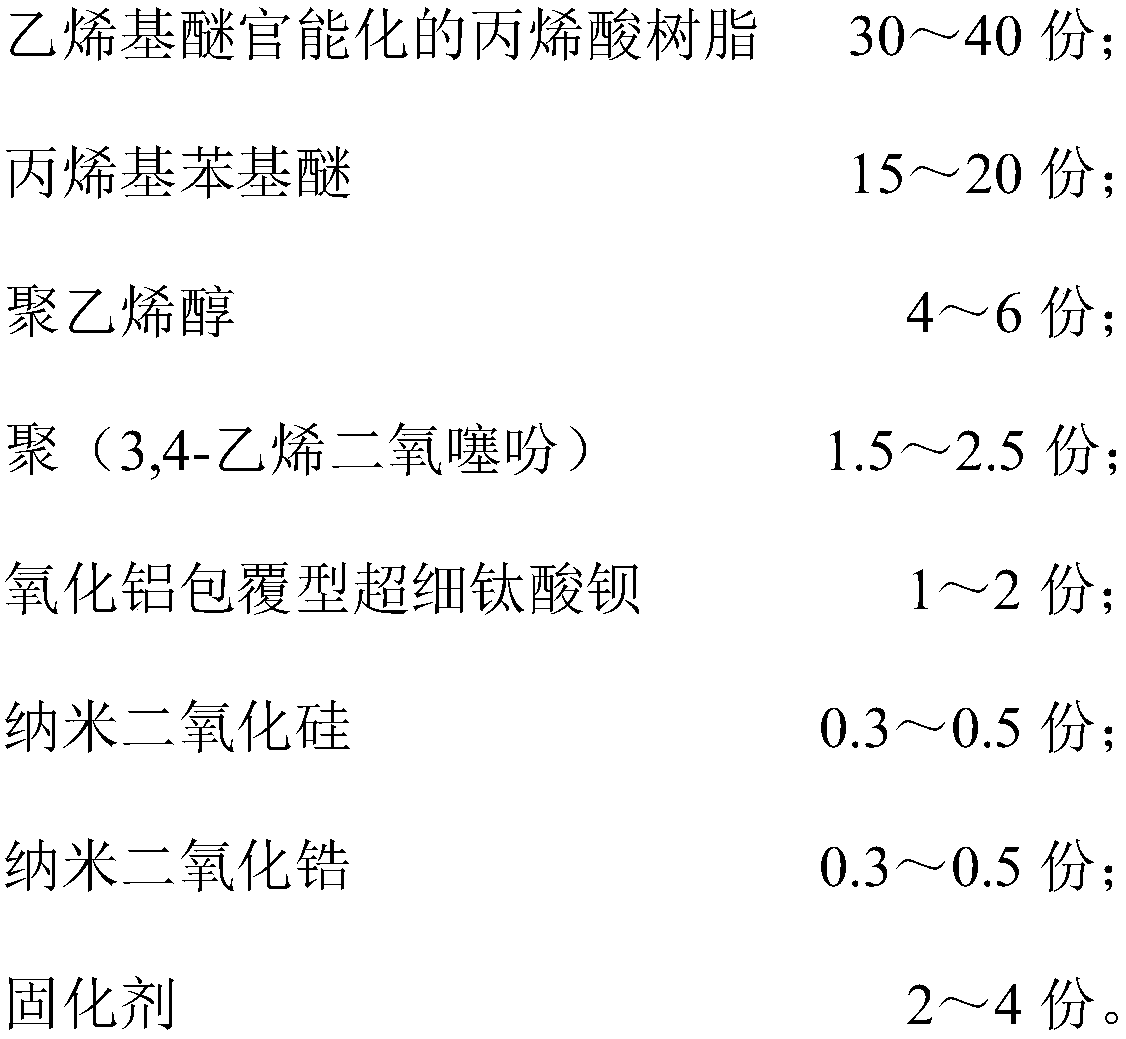

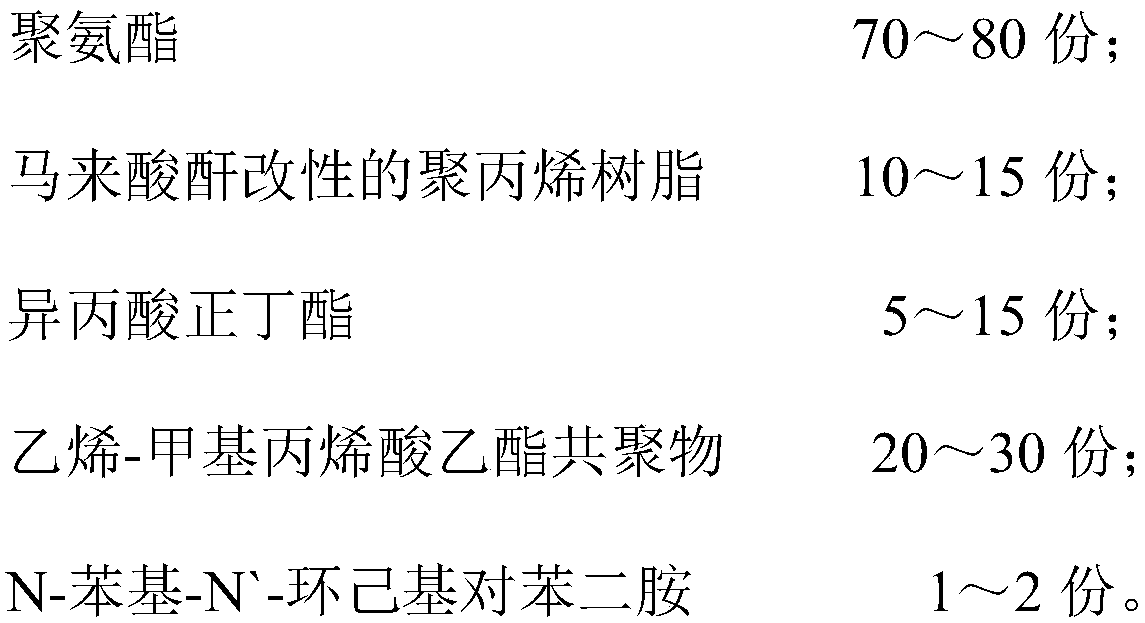

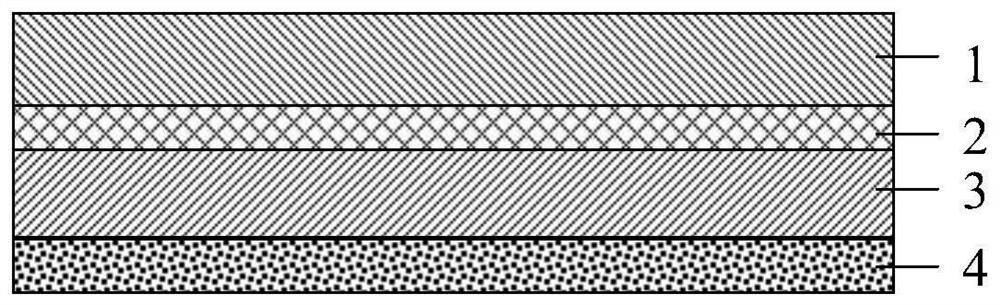

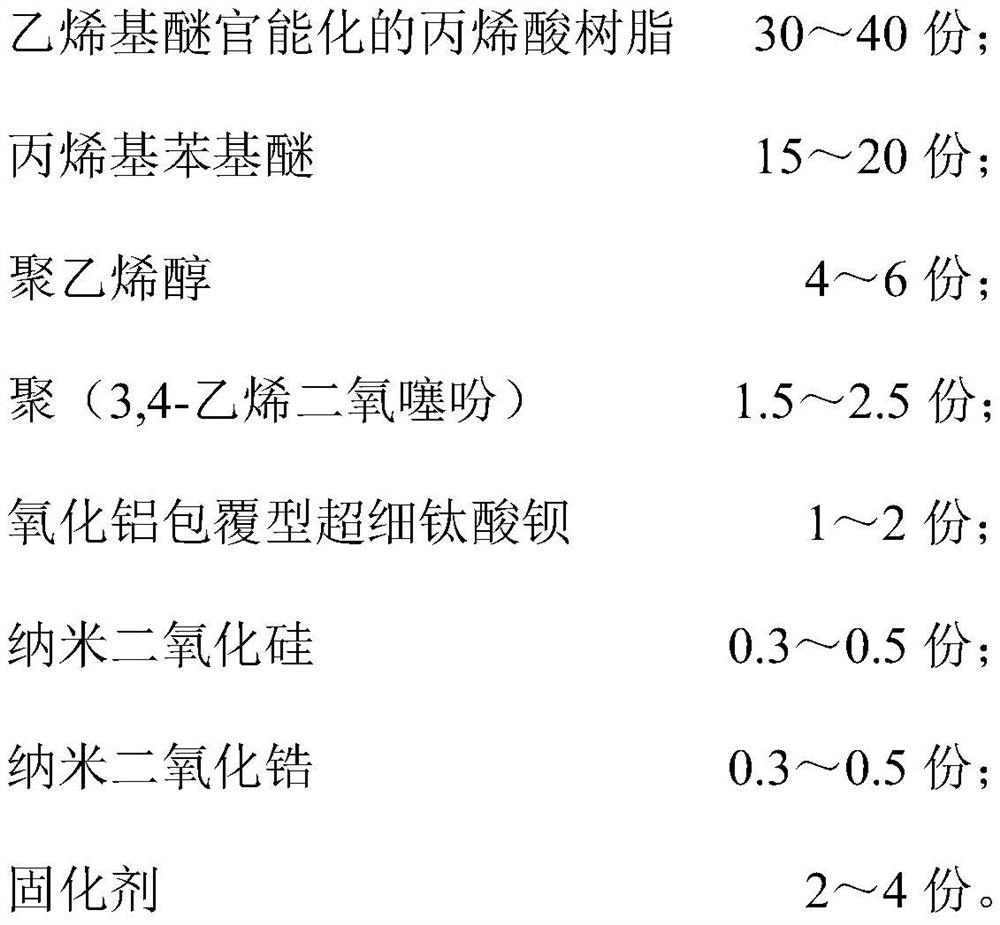

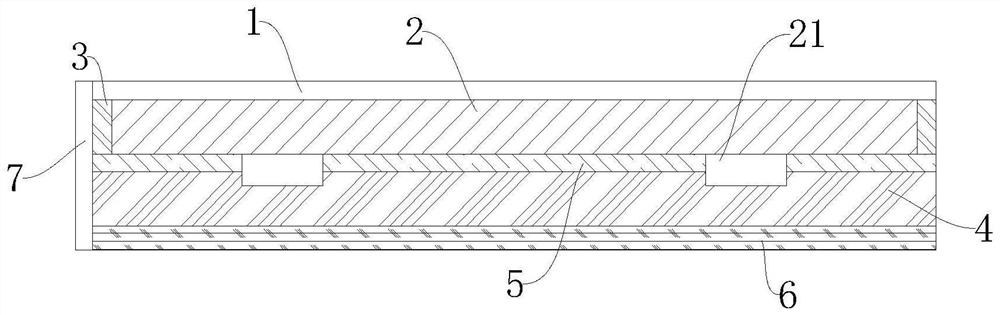

Release film for circuit board

ActiveCN109435390AStable hot meltImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPolyvinyl alcohol

The invention belongs to the technical field of electronic materials, and particularly relates to a release film for a circuit board. The release film comprises a supporting layer, an adhesive layer,an aluminum foil layer and a release heat sealing layer. The release heat sealing layer comprises vinyl functionalized acrylic resin, allyl phenyl ether, polyvinyl alcohol, poly(3, 4-ethylene dioxythiophene), alumina coated superfine barium titanium, nano silicon dioxide, nano zirconium dioxide and curing agent. The release film has stable hot melting performance within a wide temperature range, thereby having high sealability with the circuit board; adhesion strength of the release heat sealing layer to the aluminum foil layer is higher than that of the same to the circuit board, so that stripping of the release heat sealing layer from the circuit board is facilitated, the release heat sealing layer cannot be transferred onto a circuit board material when being torn off, and appearance uniformity of the circuit board is ensured.

Owner:浙江海顺新材料有限公司 +1

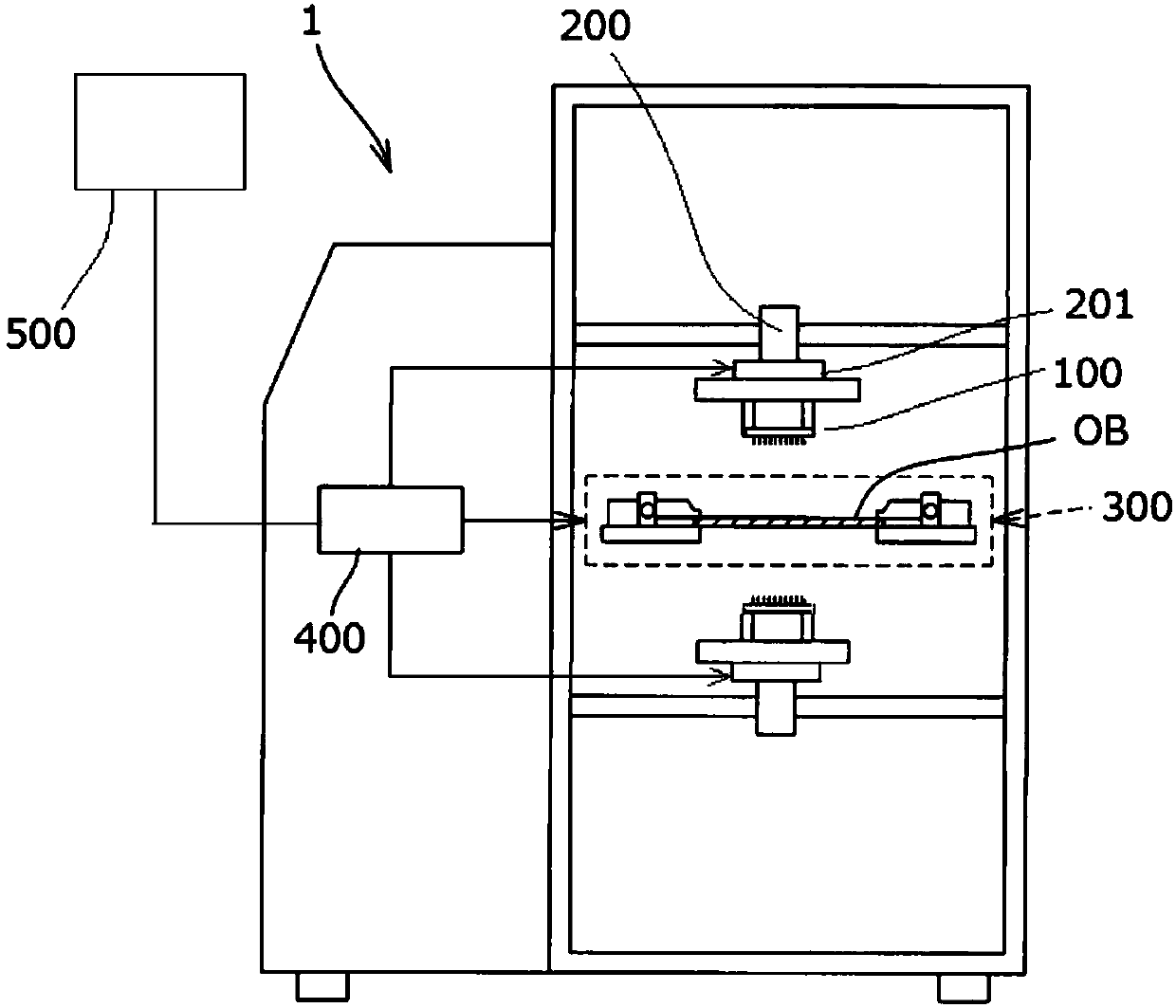

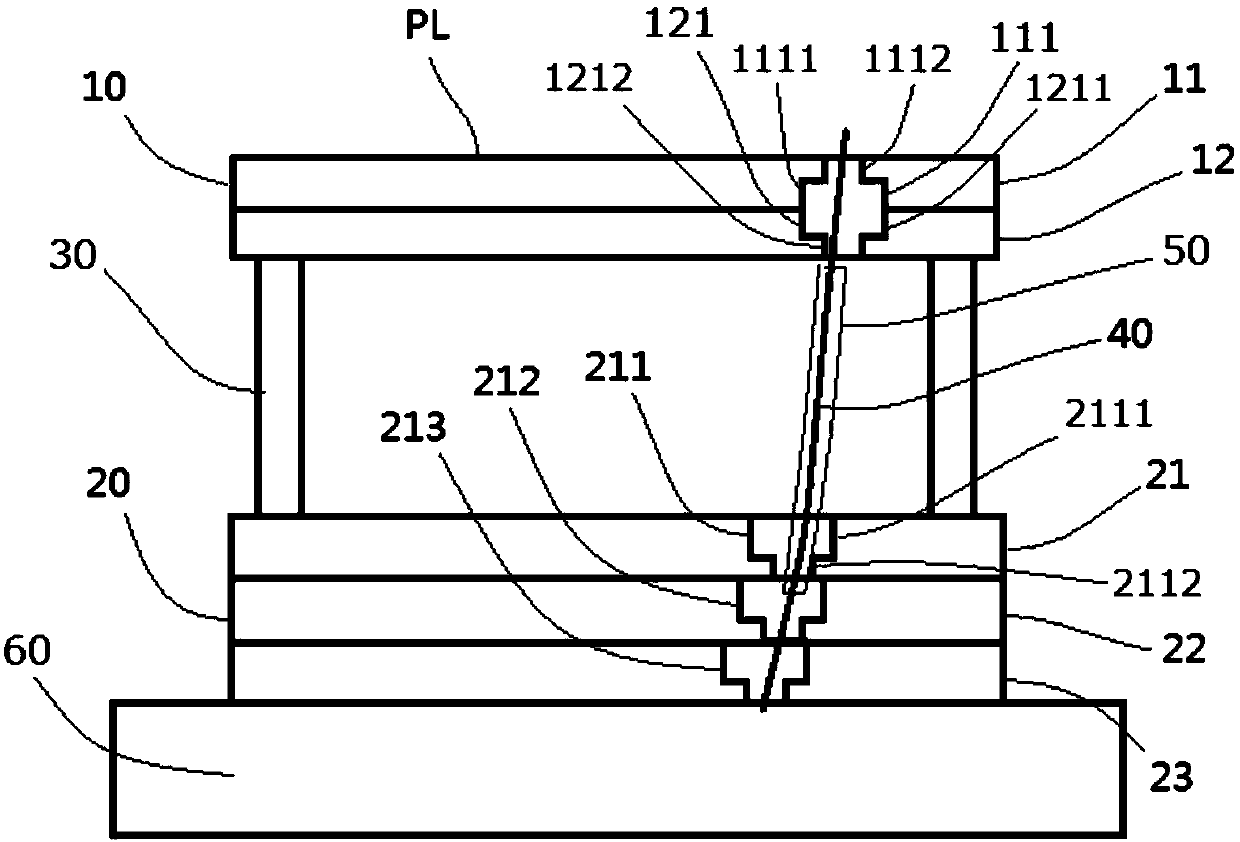

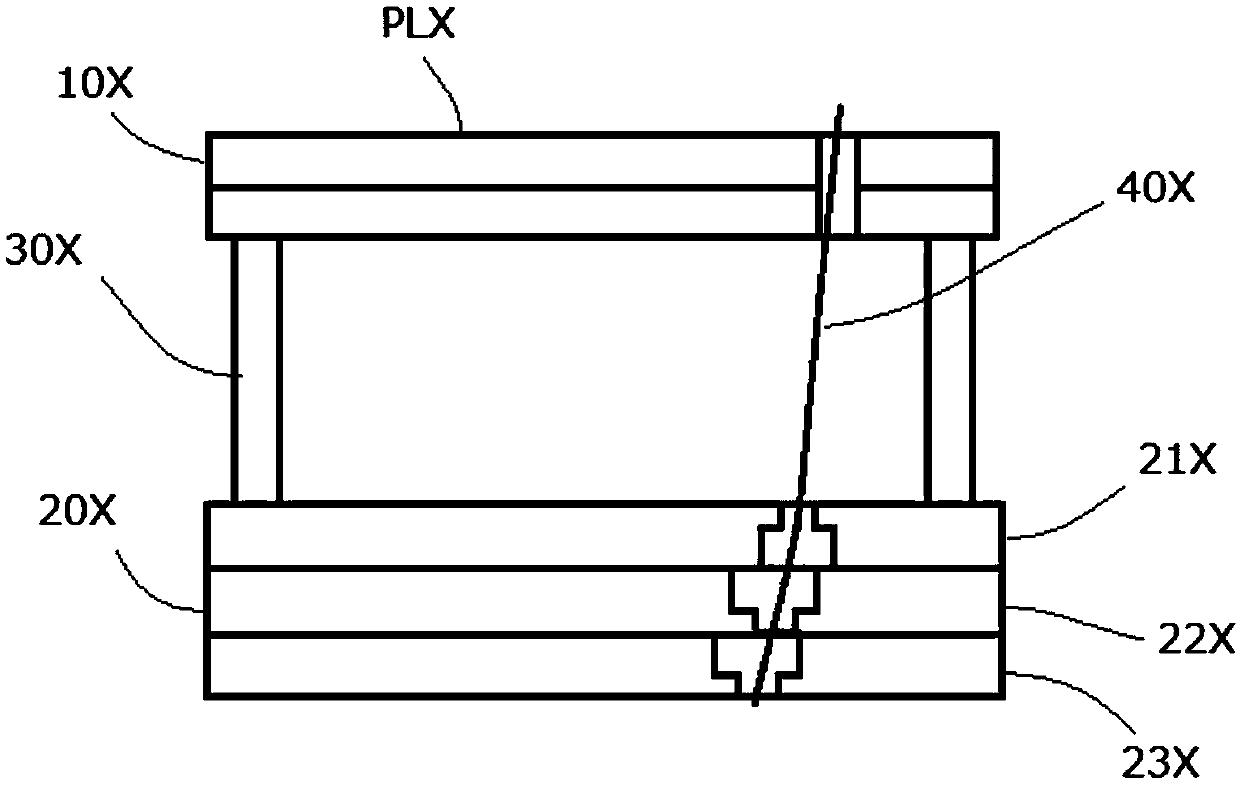

Inspection fixture

ActiveCN109613307AAvoid wear and tearReduce wearElectronic circuit testingMeasurement instrument housingBiomedical engineeringElectrode

The inspection fixture of this invention helps ensure the contact accuracy of the front end of a probe with the inspection point of an inspection object, and extends the life of the probe. The inspection fixture of the present invention comprises: an inspection side support having an abutting surface abutting against the inspection object; an electrode side support spaced apart from the inspectionside support; and a plurality of flexible probes. The flexible probes, the base ends of which are connected to the electrode, and the front ends of which protrude from the abutting surface to be in contact with the inspection object, penetrate through the electrode side support and the inspection side support. The electrode side support has a plurality of electrode side support plates arranged inthe arranged direction of the inspection side support and the electrode side support, and each of the electrode side support plates has a first through hole for the probes to penetrate. The first through hole of the electrode side support plate nearest to the inspection side support has a large diameter portion and a small diameter portion. The small diameter portion is apart from the inspectionside support than the large diameter portion, and the diameter of the small diameter portion is smaller than the diameter of the large diameter portion.

Owner:尼得科精密检测设备(浙江)有限公司

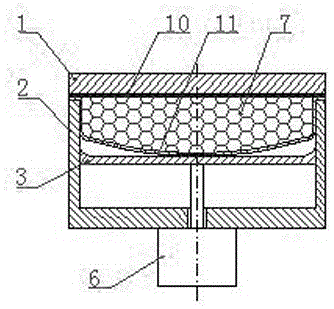

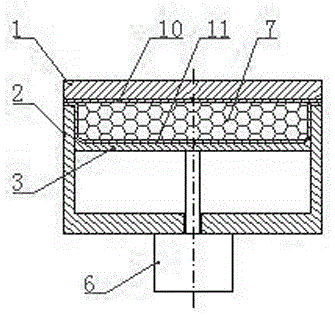

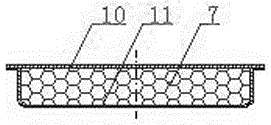

Fire-resistant composite floor slab and fire-resistant performance test method thereof

ActiveCN111608315APrevent burstHigh strengthMaterial heat developmentFloorsFloor slabStructural engineering

The invention discloses a fire-resistant composite floor slab and a fire-resistant performance test method thereof. The fire-resistant composite floor slab comprises a fire-resistant steel or fire-resistant weather-proof steel compression floor support plate, and concrete, wherein the fire-resistant steel or fire-resistant weather-proof steel compression floor support plate comprises shaped ribs with closed hollow parts; the concrete is poured on the floor support plate; the floor support plate is made of a base material without coating and films; after the concrete is poured, the upper surface is scraped and maintained; the concrete and the floor support plate are combined as a whole; the whole is used as the fire-resistant composite floor slab; in the initial stage of fire, the deformation of the fire-resistant composite floor slab is delayed, and the deformation amplitude is reduced; in the intermediate stage and high temperature stage, the fire-resistant composite floor slab does not collapse, and the deformation force and overall combination effect of the fire-resistant composite floor slab are maintained; after fire, the bonding performance between the concrete and the floorsupport slab is maintained, the fire-resistant composite floor slab does not fall apart, the deformation recovery degree and remaining bearing capacity of the fire-resistant composite floor slab are higher than 5%, and the fire-resistant composite floor slab still has a combination effect and integrity. The testing method comprises the following steps of: testing mechanical properties of materials, testing the shear-bonding performance and fire resistance of the fire-resistant composite floor slab, testing the residual load-bearing performance and shear-bonding performance after fire, synthesizing new shear adhesion-bonding coefficients, and summing up fire prevention safety factors.

Owner:BAIANLI STEEL STRUCTURE APPL SCI TECH

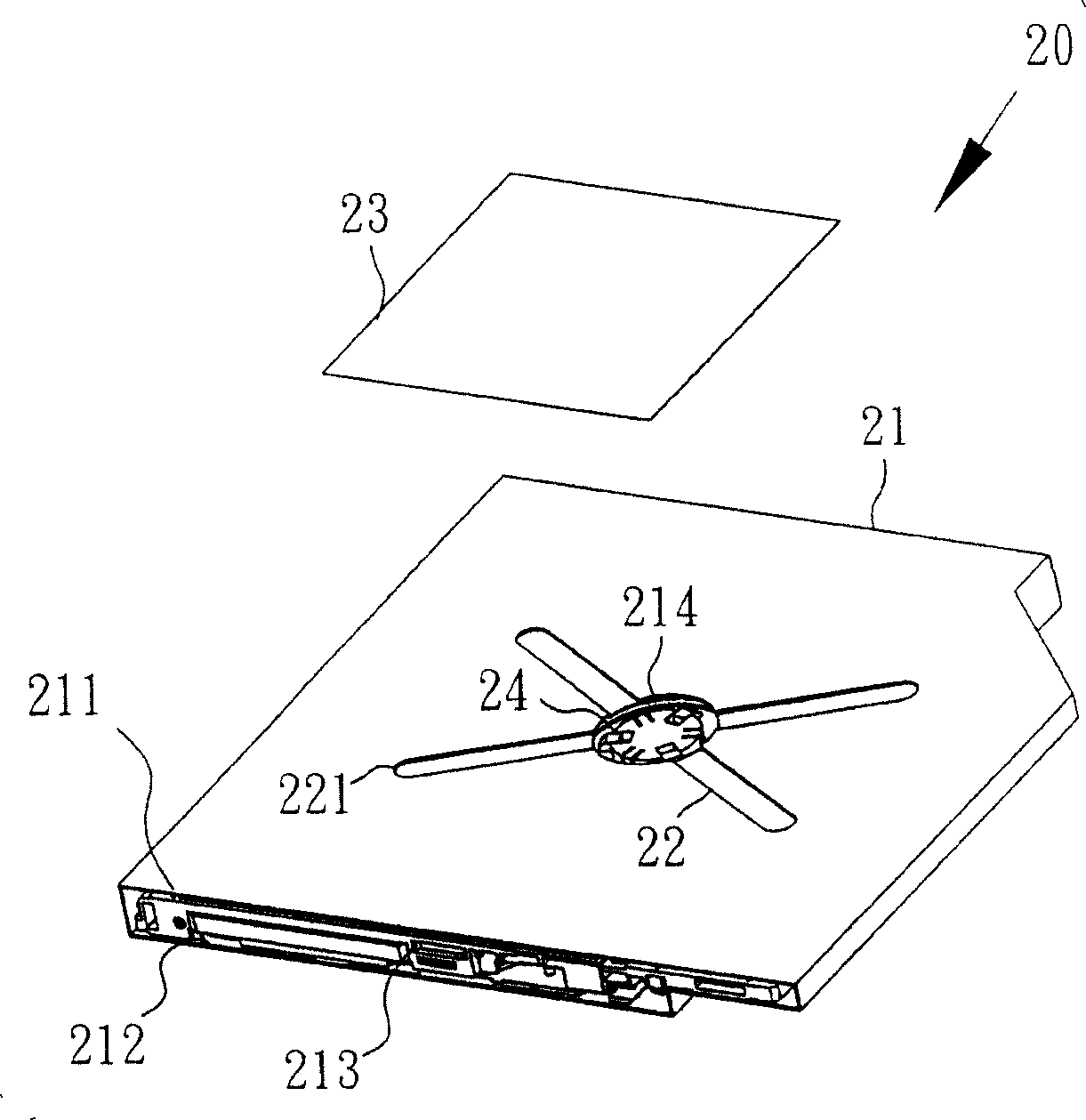

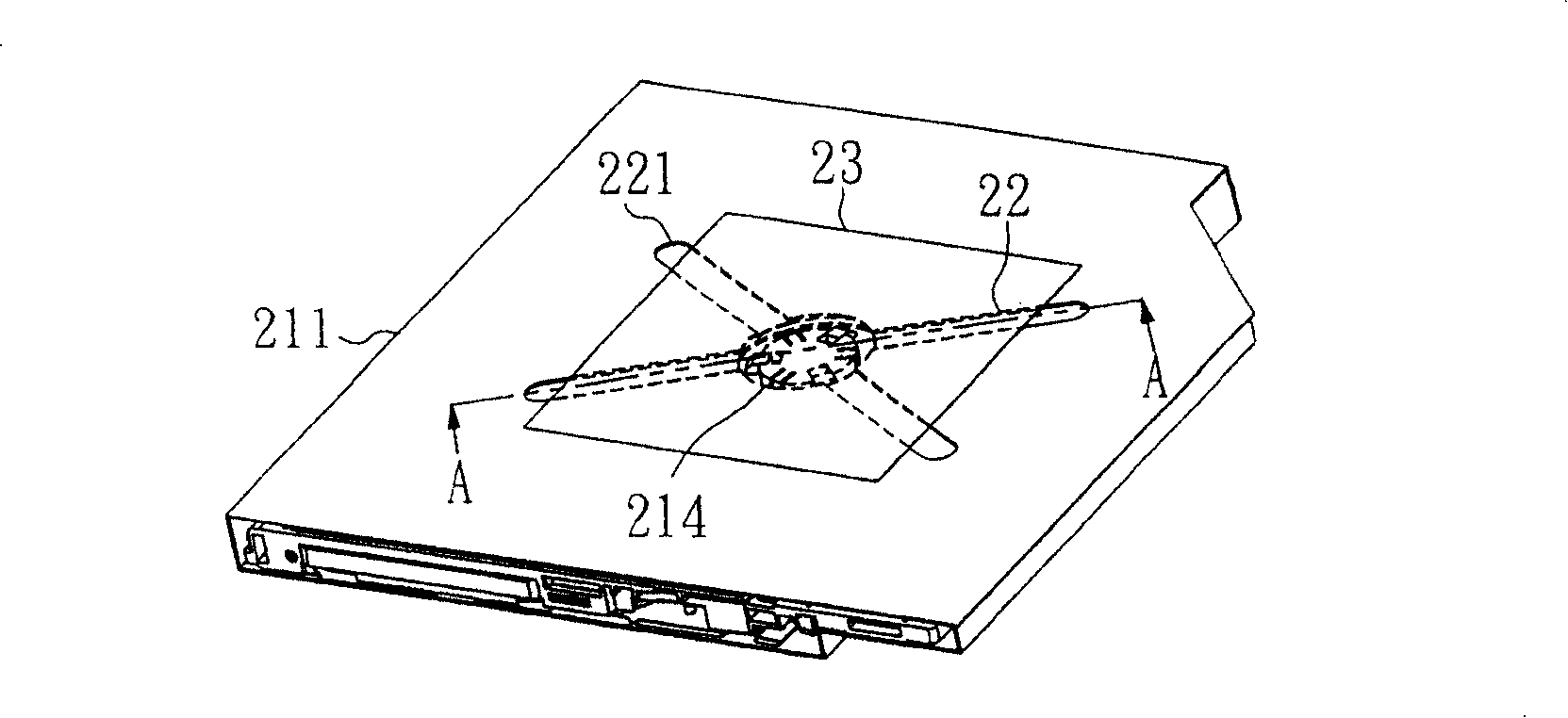

Input device

InactiveCN103412685AReduce the deformationExtended service lifeInput/output processes for data processingLight sensingComputer module

An input device comprises a backlight module, a panel, and an optical sensing module, wherein the panel is arranged on the backlight module and comprises an electrode substrate, a flexible substrate, a first electrode, a fluid layer, and multiple phoresis particles; the flexible substrate is arranged on the electrode substrate and spaced from the electrode substrate for a certain distance; the first electrode and the fluid layer are arranged between the electrode substrate and the flexible substrate; the phoresis particles have an electric property and can be movably arranged in the fluid layer; the phoresis particles have a reflection characteristic so as to reflect light rays and external light and are used for laying on the flexible substrate under the drive of a first electric field provided by the first electrode; the optical sensing module is arranged between the backlight module and the panel; and when the first electrode provides the first electric field, the light rays are reflected by the phoresis particles onto a light sensing unit of the optical sensing module.

Owner:AU OPTRONICS CORP

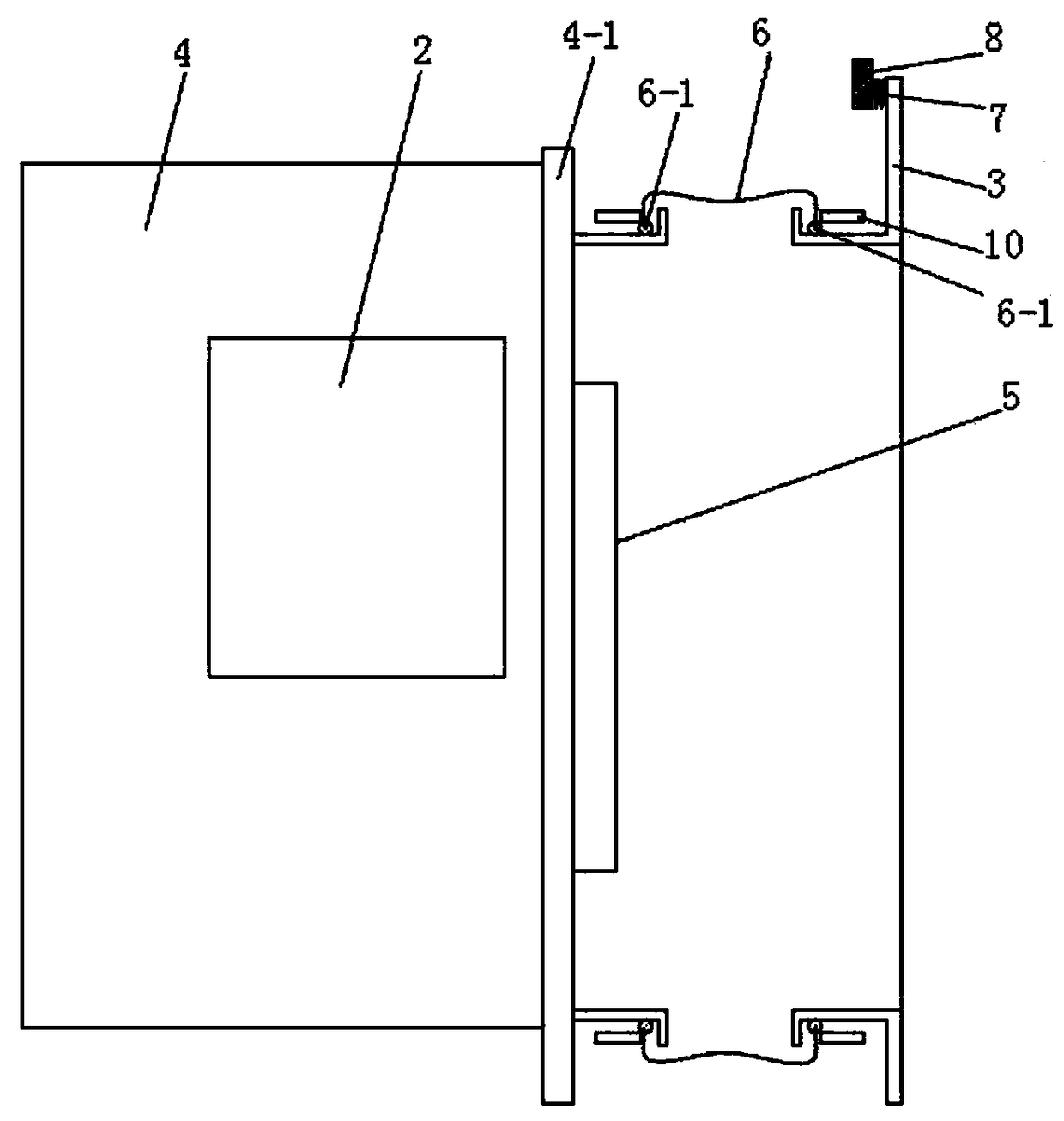

Accordion cover type sealing structure of double-door washing machine

InactiveCN109137397AReduce labor intensityLabor savingOther washing machinesTextiles and paperEngineeringMechanical engineering

An accordion-cover-type sealing double-door washing machine comprises an isolation sealing component 1 and an isolation sealing component 2. The rear side of the isolation sealing component 1 is installed on the periphery of the front end cover of the outer cylinder of a washing machine body. The front side of the isolation sealing component 1 is installed on the periphery of the front side rear end of the outer shell of the washing machine body. The upper frame and the rear ends of the two vertical frames of the isolation sealing component 2 are installed on the front end of a fixed isolationwall. The upper frame and the front ends of the two vertical frames of the isolation sealing component 2 are installed on the upper portion of the front side rear end of the outer shell and two sides. The rear end of the lower frame of the isolation sealing component 2 is installed on the front lower end of the fixed isolation wall. The front end of the lower frame of the isolation sealing component 2 is installed on the lower portion of the front side rear end of the outer shell. A discharge door is located in the middle portion of the front side end of the outer shell. The forefront end ofthe discharge door is located on the front side outer end of the wall. In the invention, through the isolation sealing components 1 and 2, air between a loading door and the front end of a clothes taking door is effectively realized not to flow, and the pollution of a feeding door to the discharge door is effectively prevented. Based on the above structure, the structure has a good application prospect.

Owner:SHANDONG DACHENG WASHING MACHINERY CO LTD

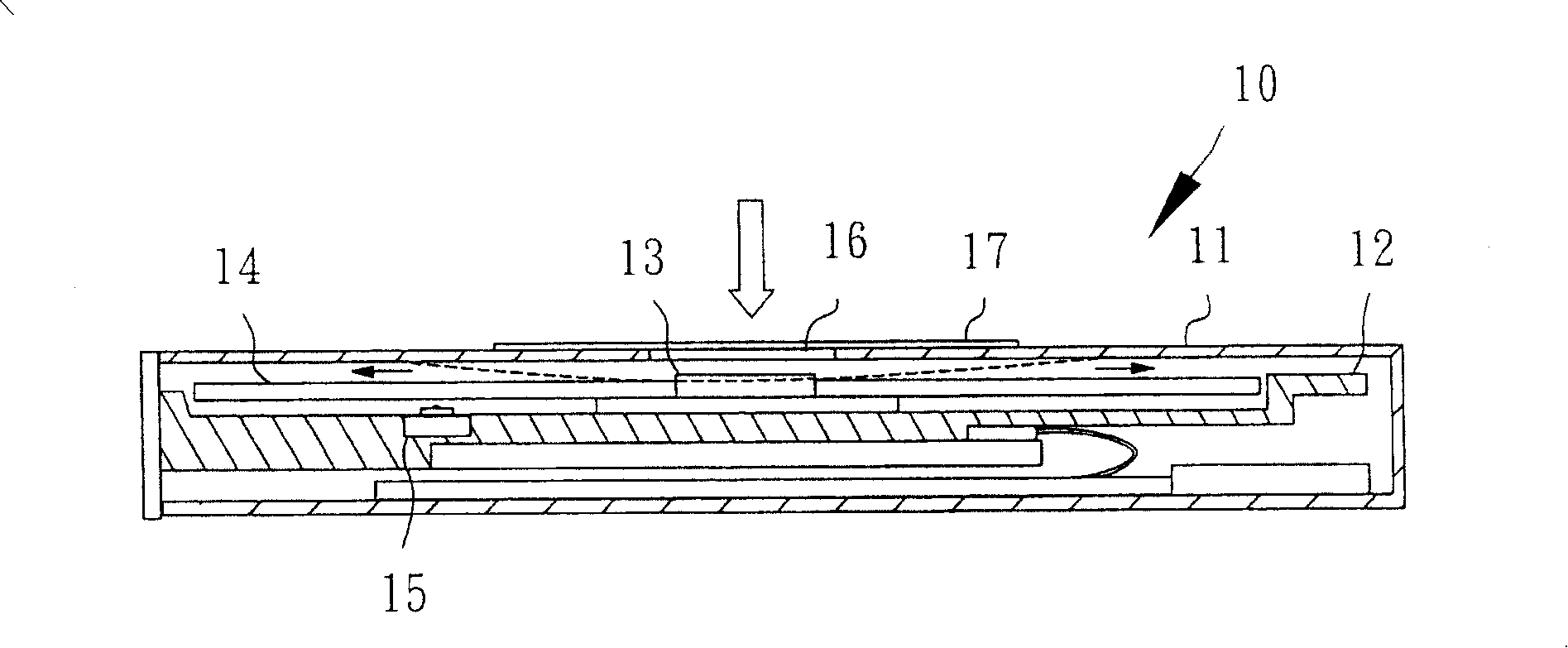

Casing structure of CD ROM

InactiveCN101202097AImprove structural strengthReduce the deformationUndesired vibrations/sounds insulation/absorptionRecord information storageRecordable CDCD-ROM

The invention discloses a CD-ROM driver casing structure, consisting of an upper casing and a lower casing. A main shaft motor is arranged in the casing. The upper casing is positioned above the main shaft motor and is provided with a through hole. A plurality of air channels are separately arranged around the through hole on the upper casing. A downward depression of the casing forms a lower groove, and one end of the groove is communicated with a neighboring part of the main shaft motor through the through hole and the other end is a communication port. A label is adhered to the casing to cover the air channels and the through hole, One end of the communication port of the air channel is extended towards the edge of the casing and the communication port is preserved beyond the covering area of the label so as to balance the pressure difference between the internal and external parts of the CD-ROM driver.

Owner:QUANTA STORAGE INC

Method for machining thin-wall bearing rings by adopting digital controlled lathe

InactiveCN107309440AIncrease contact areaReduce the deformationBearing componentsTurning machinesThin walledEngineering

The invention relates to a numerically controlled lathe processing method for a thin-walled bearing ring, which relates to the field of mechanical processing of the bearing ring. The present invention solves the problem that the existing thin-walled bearing rings are easily deformed under the action of clamping force, cutting force and cutting heat generated in the cutting process due to the thin wall of the bearing rings during the processing process. It is difficult to guarantee the dimensional accuracy, shape accuracy, position accuracy and surface roughness of the ferrule. The method of the present invention comprises the following steps: step 1, when using a numerically controlled lathe to process the thin-walled bearing ring, use the first jaw to clamp the thin-walled bearing ring; step 2, rough turning the thin-walled bearing ring Outer diameter and inner diameter; Step 3, finish turning the outer diameter and inner diameter of the thin-walled bearing ring; Step 4, fine-turning the inner diameter of the outer diameter of the thin-walled bearing ring, so far, the entire turning process of the thin-walled bearing ring is completed . The invention is used for turning processing of thin-walled bearing rings.

Owner:AVIC HARBIN BEARING

Zipper slider with demountable pull tab

ActiveCN102641022BReduce the deformationAvoiding the Problem of Metal FatigueSlide fastenersEngineeringSlide plate

The invention discloses a zipper slider with a demountable pull tab, which comprises a zipper slider body, a pull tab and a hook. An upper slide plate of the zipper slider body is provided with a pull nose covered with the hook, and two lateral groove walls at the hinge end of the hook are hinged to the root of the pull nose. The hinge end of the hook is provided with a spring plate extending in a curved manner towards the root of the pull nose. The inner side of the hook spring plate and the groove bottom of a containing groove are both designed into involute surfaces gradually opening along the extension direction of the spring plate. The spring plate is forced to swing and deform by mutual interference between the inner side of the spring plate and the groove bottom of the containing groove, and the containing groove is provided with a recess allowing for rotation of the spring plate, so that the lengthwise extrusion deformation of the spring plate is avoided. The hook spring plate of the zipper slider compared with the existing zipper slider with a demountable pull tab has reduced deformation amplitude, the problem that metal fatigue of the spring plate is easy to occur is solved, and the service life of the zipper slider is prolonged.

Owner:开易(浙江)服装配件有限公司

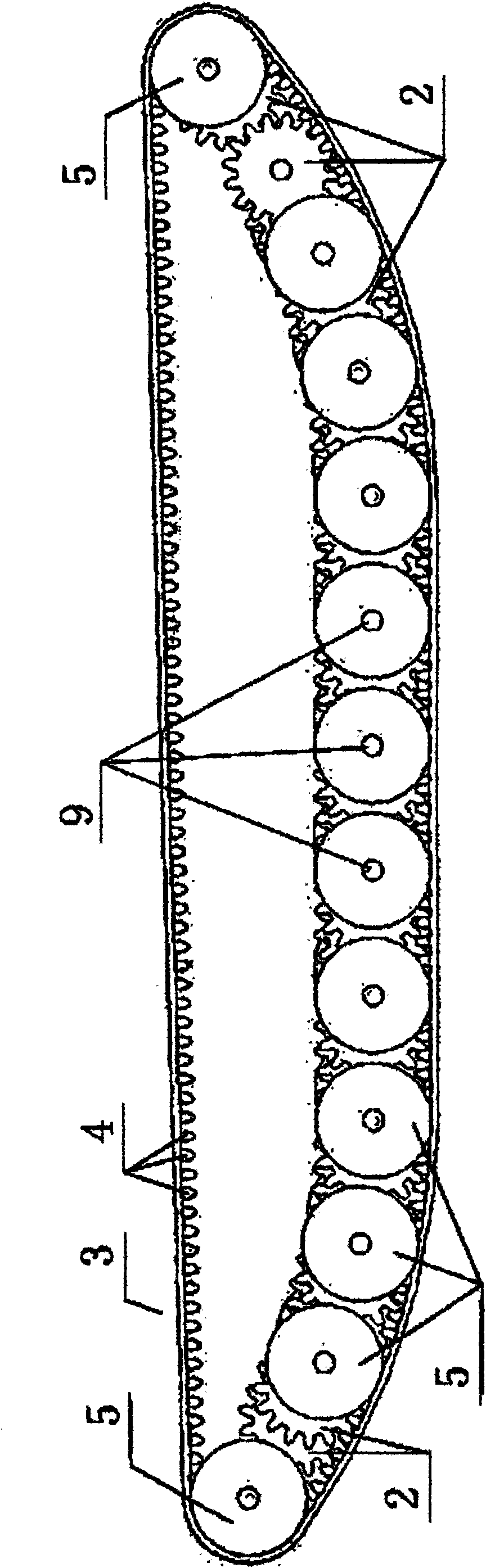

Staggered supporting wheel type crawler device

InactiveCN102050161AReduce secondary impactLarge secondary impactEndless track vehiclesEngineeringPulley

Owner:孙继华

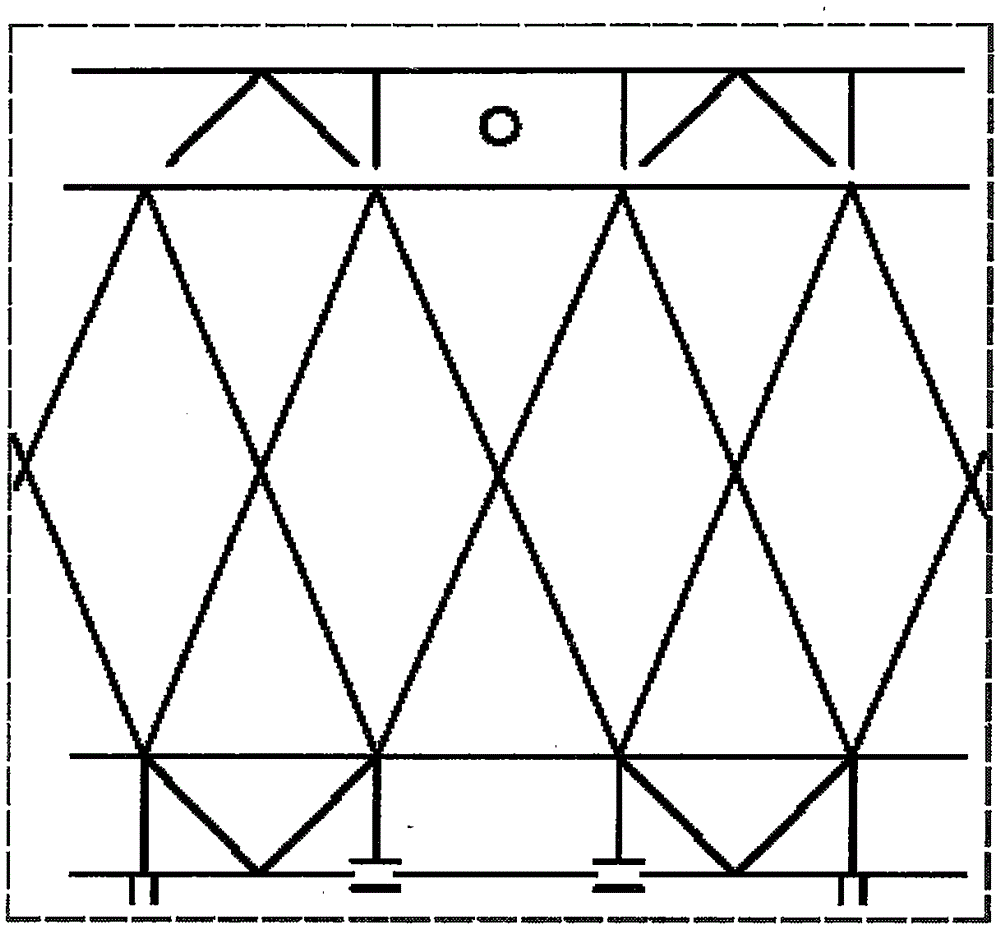

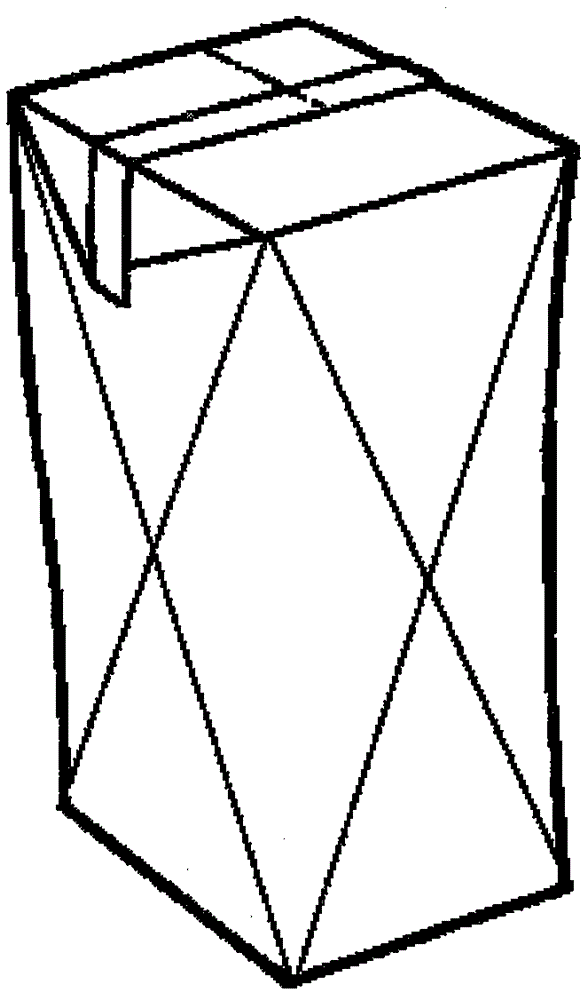

Blank of diamond type packing box for containing liquid and packing box

The invention relates to a blank of a diamond type packing box for containing liquid and the packing box. The blank is a flaky packing material. The packing material is provided with a first horizontal fold used for forming an upper top face sealing seam, a second horizontal fold used for forming an upper top face, a third horizontal fold used for forming a lower bottom face and a fourth horizontal fold used for forming a lower bottom face sealing seam. Vertical folds used for forming side face sealing seams are arranged on the left side and the right side of the packing material. Four vertical folds used for forming the rectangular upper top face are arranged between the first horizontal fold and the second horizontal fold. Four vertical folds used for forming the rectangular lower bottom face are arranged between the third horizontal fold and the fourth horizontal fold. In the rectangle formed by two sides at the same position of the upper top face and two sides at the same position of the lower bottom face, a first diagonal and a second diagonal are both folds. The deformation degree of the packing box is lowered, the holding comfort degree of the packing box is increased, and the outer shape of the packing box is enriched.

Owner:SHANDONG BIHAI PACKAGING

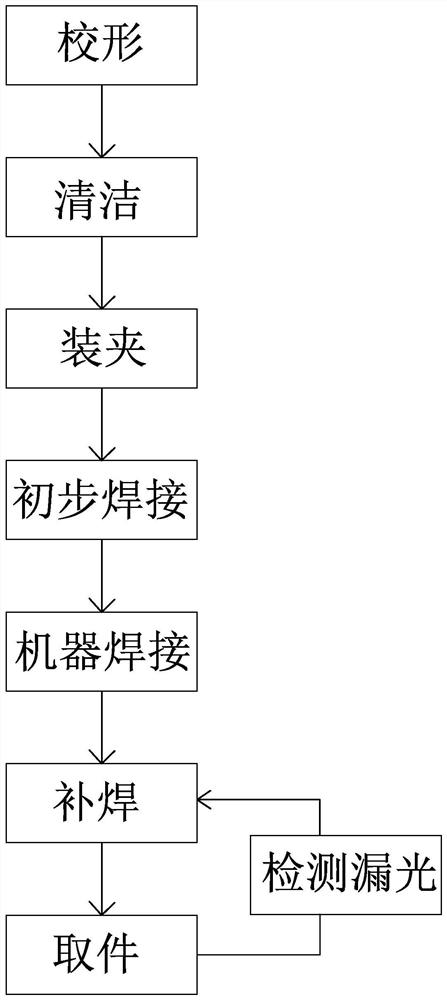

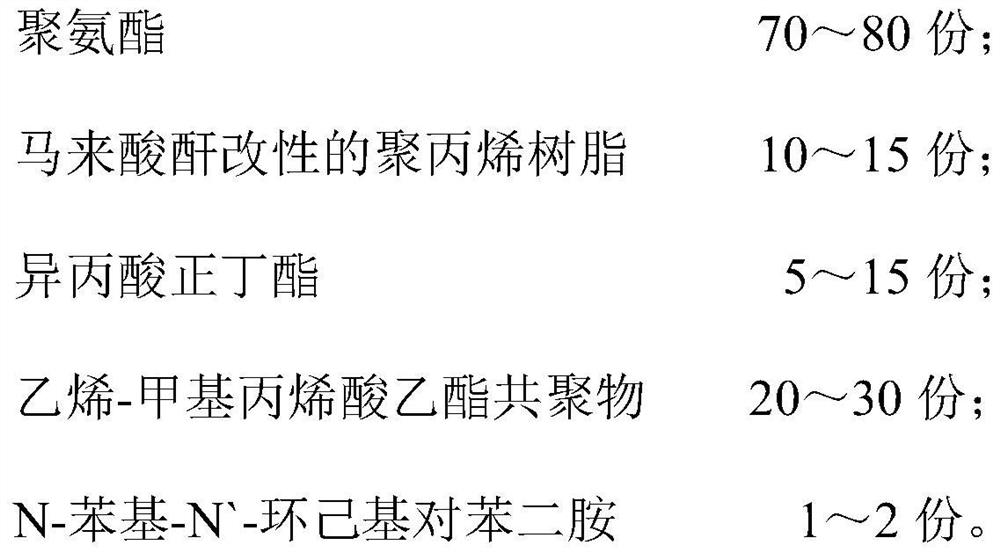

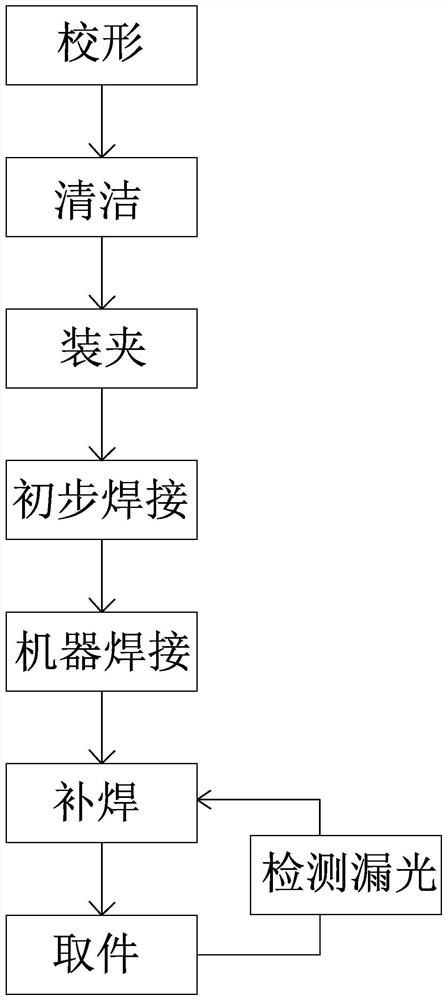

Machining process of low-deformation aluminum alloy welding aviation part

ActiveCN112045282APrevent oxidationAvoid blackeningWelding accessoriesMachining processClose contact

The invention provides a machining process of a low-deformation aluminum alloy welding aviation part, and belongs to the technical field of welding. The machining process of the low-deformation aluminum alloy welding aviation part comprises the following steps that S1, shape correction is carried out, specifically, burrs on the four sides of a cover and a box body are removed thoroughly through ascraper or a file, the four sides of the cover are knocked inwards through a small hammer to be slightly bent inwards to be in an arc shape, the four fillets of the cover and the four fillets of the box body are shaped to be consistent in transition, and the cover and the box body are matched free of dislocation; S2, cleaning is carried out, specifically, the portions, needing to be welded, of thecover and the box body are wiped clean with acetone; S3, clamping is carried out, specifically, the box body and the cover are placed into a tool, after the box body and the cover are placed in place, the box body is opened from inside to outside and in contact with the cover, and the welding edge of the box body is in close contact with the welding edge of the cover; S4, primary welding is carried out; S5, machine welding is carried out; S6, repair welding is carried out; and S7, part taking is carried out. The machining process has the advantages of being small in deformation during weldingand good in welding sealing performance.

Owner:海宁红狮宝盛科技有限公司

Vacuum gas-filling packaging machine used for fully-automatic hot forming

ActiveCN106697363AReduce the deformationUniform packaging thicknessPackaging under vacuum/special atmosphereWrapper twisting/gatheringElectric heatingEngineering

The invention discloses a vacuum gas-filling packaging machine used for fully-automatic hot forming. A heat-sealing working room of the vacuum gas-filling packaging machine comprises a heat-sealing circuit board, a heat-sealing working lower room, a reshaping mould and a reshaping air cylinder, wherein the reshaping mould is mounted in a U-shaped chamber of the heat-sealing working lower room in a sliding mode; the reshaping air cylinder is mounted on the bottom of the heat-sealing working lower room; a piston rod of the top end of the reshaping air cylinder is connected with the reshaping mould; a heat-sealing circuit board capable of moving up and down is arranged at the upper end of the heat-sealing working lower room; and corresponding forming grooves are formed in adjacent surfaces of the heat-sealing electric-heating circuit board and the heat-sealing working lower room. The vacuum gas-filling packaging machine has the advantages that: an upper film and a lower film for product package are co-deformed to form a soft box for accommodating a packaged material, so that deformation amplitude is small, packaging thickness is uniform, and damage of package is greatly reduced; and moreover, special requirements, on product shape symmetry, of some products are also met.

Owner:逄锦芳

Release film for circuit board

ActiveCN109435390BStable hot meltImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinPolyvinyl alcohol

The invention belongs to the technical field of electronic materials, and particularly relates to a release film for a circuit board. The release film comprises a supporting layer, an adhesive layer,an aluminum foil layer and a release heat sealing layer. The release heat sealing layer comprises vinyl functionalized acrylic resin, allyl phenyl ether, polyvinyl alcohol, poly(3, 4-ethylene dioxythiophene), alumina coated superfine barium titanium, nano silicon dioxide, nano zirconium dioxide and curing agent. The release film has stable hot melting performance within a wide temperature range, thereby having high sealability with the circuit board; adhesion strength of the release heat sealing layer to the aluminum foil layer is higher than that of the same to the circuit board, so that stripping of the release heat sealing layer from the circuit board is facilitated, the release heat sealing layer cannot be transferred onto a circuit board material when being torn off, and appearance uniformity of the circuit board is ensured.

Owner:浙江海顺新材料有限公司 +1

A Processing Technology for Welding Aviation Components with Low Deformation Aluminum Alloy

ActiveCN112045282BPrevent oxidationAvoid blackeningWelding accessoriesMachining processClose contact

The invention provides a processing technology for welding aviation components with low deformation aluminum alloy, which belongs to the field of welding technology. A processing technology for low-deformation aluminum alloy welding aviation parts, including the following steps: S1, shape correction: use a scraper or file to remove the burrs on the four sides of the cover and the box body, and use a small hammer to knock the four sides of the cover inward to make it slightly Bend to the inside to form an arc, and the four rounded corners of the cover and the box body are shaped until the transition is consistent, and there is no misalignment; S2. Cleaning: Use acetone to wipe the lid and the box body to be welded clean; S3. Clamping: Put the box body And the cover is put into the tooling. After the box body and the cover are placed in place, the box body is stretched from the inside to the outside and is in contact with the cover, so that the welding edge of the box body and the cover is in close contact; S4, preliminary welding; S5, machine welding; S6 , repair welding; S7, picking up parts. The invention has the advantages of small deformation during welding and good welding sealing performance.

Owner:海宁红狮宝盛科技有限公司

Ceiling corner machining structure and construction technology

PendingCN114182872AHigh strengthFirmly connectedCeilingsBuilding material handlingArchitectural engineeringStructural engineering

The invention discloses a suspended ceiling corner machining structure and a construction technology, and relates to the technical field of suspended ceiling construction. A suspended ceiling corner machining structure comprises a wall corner mounting frame, a nine-centimeter plate and a gypsum board, the wall corner mounting frame is fixedly arranged at a building roof wall corner, the nine-centimeter plate is embedded in the wall corner mounting frame, a bonding layer is arranged between the nine-centimeter plate and the gypsum board and used for connecting the nine-centimeter plate and the gypsum board, and a putty layer is arranged on the lower side wall of the gypsum board. The construction technology of the suspended ceiling corner machining structure comprises the following steps that surveying and setting out are conducted, and line snapping is conducted on the peripheral walls according to the designed elevation of a suspended ceiling; the wall corner mounting frame is mounted according to the surveying and setting-out position, during mounting, the wall corner mounting frame is cut into an L shape and fixed through self-tapping screws, and the inner side length of the L angle is larger than or equal to 300 mm; the nine-centimeter plate is embedded in a mounting groove in the wall corner mounting frame; by adopting the construction process, the flatness of the suspended ceiling structure can be improved, the problems of cracking and damage of the suspended ceiling are reduced, and the service life of the suspended ceiling structure is prolonged.

Owner:广西中庭装饰工程集团有限责任公司

Automatic opening and closing device for wire storage ring for winding machine

ActiveCN106504889BReduce the deformationDeformation is easy to recoverInductances/transformers/magnets manufactureWinding machineAutomatic control

The invention discloses an automatic wire storage ring opening and closing device for a winding machine. The automatic wire storage ring opening and closing device comprises a work bench and a wire storage ring arranged on the work bench, wherein a ring opening is arranged in the wire storage ring; the automatic wire storage ring opening and closing device is characterized in that a rotary driving mechanism for driving the wire storage ring to rotate and a ring opening and closing mechanism capable of opening the wire storage ring in a same plane along the ring opening are arranged on the work bench. According to the ring opening and closing mechanism disclosed by the invention, the force is applied to the outer side of the ring in parallel from the inner circumference of the wire storage ring to open the ring, so as to put a magnetic ring; the material of the wire storage ring has certain elasticity, the force is applied to the outer side of the ring in parallel to open the wire storage ring and the wire storage ring is opened in the same plane; and compared with a dislocated ring opening mode, the automatic wire storage ring opening and closing device has the advantages that the deformation amplitude of the wire storage ring is small, the deformation is easy to restore, the service life of the wire storage ring is prolonged and automatic control on the opening and closing states of the wire storage ring is achieved.

Owner:ZHONGSHAN COMPETENT AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com