Ceiling corner machining structure and construction technology

A corner and ceiling technology, applied in the direction of ceilings, building components, building structures, etc., can solve the problems of serious, cracking, low service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

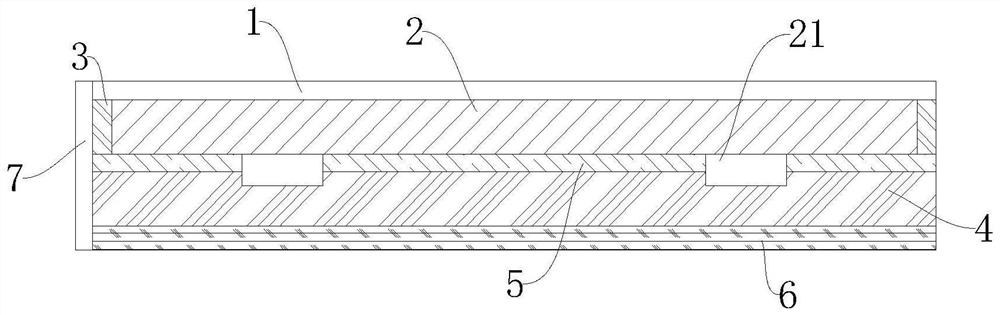

[0041] Please refer to Figure 1-Figure 2 , the present embodiment provides a suspended ceiling corner processing structure, which includes a corner mounting frame 1, a nine-centiboard 2 and a gypsum board 4, the above-mentioned corner mounting frame 1 is fixed at a corner of a building roof, and the above-mentioned nine-centiboard 2 is embedded in the above-mentioned corner Mounting frame 1, an adhesive layer 5 is provided between the above-mentioned nine-centiboard 2 and the above-mentioned gypsum board 4, and the above-mentioned adhesive layer 5 is used to connect the above-mentioned nine-centiboard 2 and the above-mentioned gypsum board 4, and the lower side wall of the above-mentioned gypsum board 4 Putty layer 6 is provided.

[0042]In this embodiment, the corner mounting frame 1 can be installed at the corner of the building roof to provide support for the nine-percent board 2 and enhance the strength of the ceiling structure; the nine-percent board 2 is embedded in the...

Embodiment 2

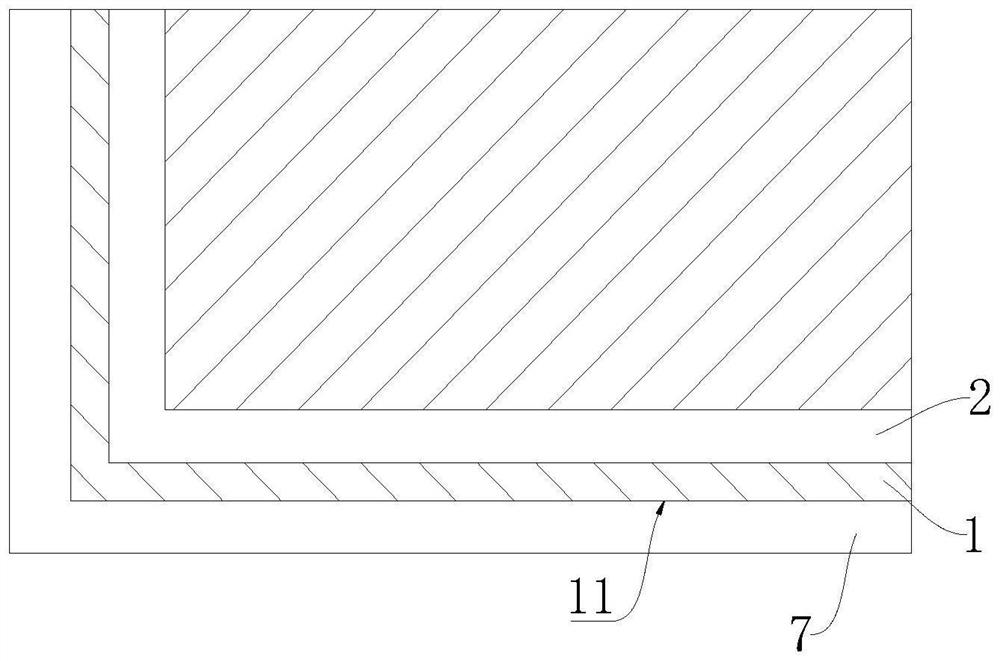

[0046] Please refer to Figure 1-Figure 2 , In this embodiment, on the basis of Embodiment 1, the above-mentioned corner mounting frame 1 is L-shaped.

[0047] In this embodiment, the corner mounting frame 1 is L-shaped, so that the corner mounting frame 1 fits more compactly with the corner of the building, reduces the gap between the suspended ceiling structure and the roof of the building, and improves the stability of the suspended ceiling structure.

[0048] In some implementations of this embodiment, the above-mentioned corner mounting frame 1 includes a horizontal dragon frame and a vertical dragon frame, and the horizontal dragon frame and the vertical dragon frame are combined to form an L-shaped corner mounting frame 1, which is convenient for installation and fixing.

[0049] Specifically, the inner side length of the above-mentioned corner mounting frame 1 shall not be less than 300 mm, so as to ensure the installation strength of the corner mounting frame 1 .

[...

Embodiment 3

[0053] Please refer to Figure 1-Figure 2 In this embodiment, on the basis of some of the above-mentioned embodiments, a protective layer 3 is provided on the peripheral side wall of the above-mentioned nine-centimeter board 2 .

[0054] In this embodiment, the peripheral side wall of the nine-centiboard 2 is provided with a protective layer 3, and the peripheral side wall of the nine-centiboard 2 can be protected by the protective layer 3, so as to prevent the nine-centiboard 2 from being installed with the corner mounting frame 1 Collision damage occurs; or collision damage occurs between the adjacent nine-centiboards 2, causing the gap between the nine-centiboards 2 to increase, prone to deformation, and reducing the flatness and aesthetics of the suspended ceiling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com