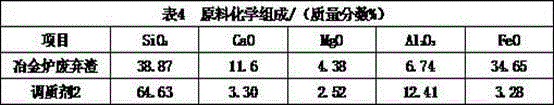

Patents

Literature

934 results about "Mineral wool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral wool is any fibrous material formed by spinning or drawing molten mineral or rock materials such as slag and ceramics. Applications of mineral wool include thermal insulation (as both structural insulation and pipe insulation, though it is not as fire-resistant as high-temperature insulation wool), filtration, soundproofing, and hydroponic growth medium.

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

SiO2 aerogel/inorganic cotton compound thermal insulation felt and preparation method thereof

The invention relates to a SiO2 aerogel / inorganic cotton compound thermal insulation felt and a preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The method comprises the following steps of: compounding silica sol and inorganic cotton; ageing the silica sol and the inorganic cotton; carrying out modification and solvent replacement processing; and drying at normal pressure to obtain the SiO2 aerogel / inorganic cotton compound thermal insulation felt. The preparation method of the SiO2 aerogel / inorganic cotton compound thermal insulation felt, which is disclosed by the invention, is characterized in that cheap and easily-obtained industrial raw materials, such as industrial sodium silicate, industrial silica sol, glass wool, rock wool and mineral wool are adopted, the production cost can be lowered, and the ordinary pressure drying technology is convenient and easy to realize, is simple to operate and is suitable for large-scale industrial production. Meanwhile, the product is nontoxic and harmless and does not pollute the environment.

Owner:DALIAN POLYTECHNIC UNIVERSITY

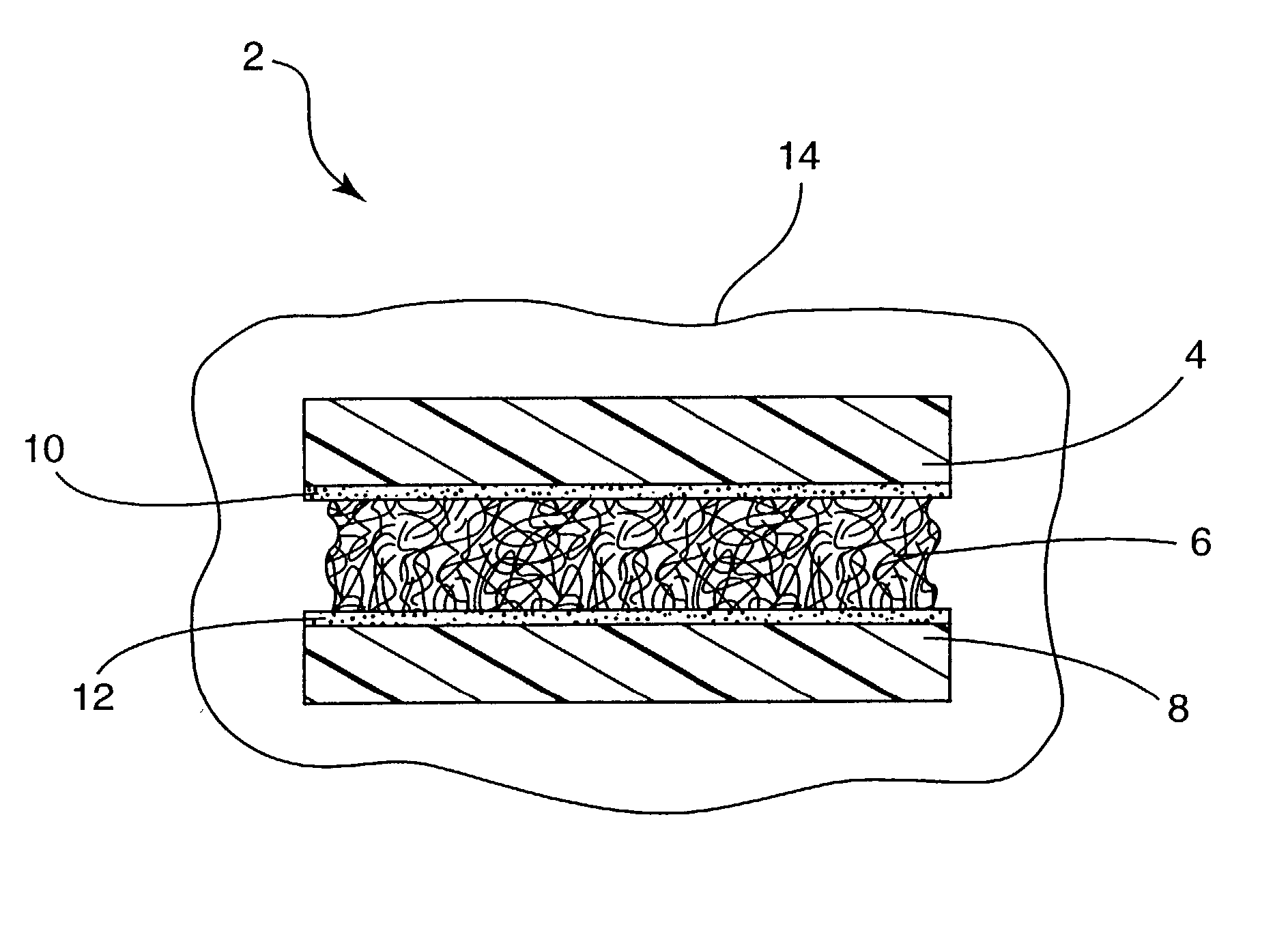

Fire stop article

InactiveUS7018699B2Minimize exposureEasy to installBuilding roofsElectrical apparatusGraphiteAlkali metal

A composite fire stopping article capable of fire stopping through-penetrations without the need for a secondary reinforcement structure includes an interior insulating material, such as mineral wool, sandwiched between layers of an intumescent material. The insulating material and intumescent material may be enclosed in a bag formed of a polymeric material. The intumescent material is substantially free of graphite and consists essentially of filler material, binder material, and a hydrated alkali metal silicate intumescent component.

Owner:3M INNOVATIVE PROPERTIES CO

Acoustic ceiling tiles made with paper processing waste

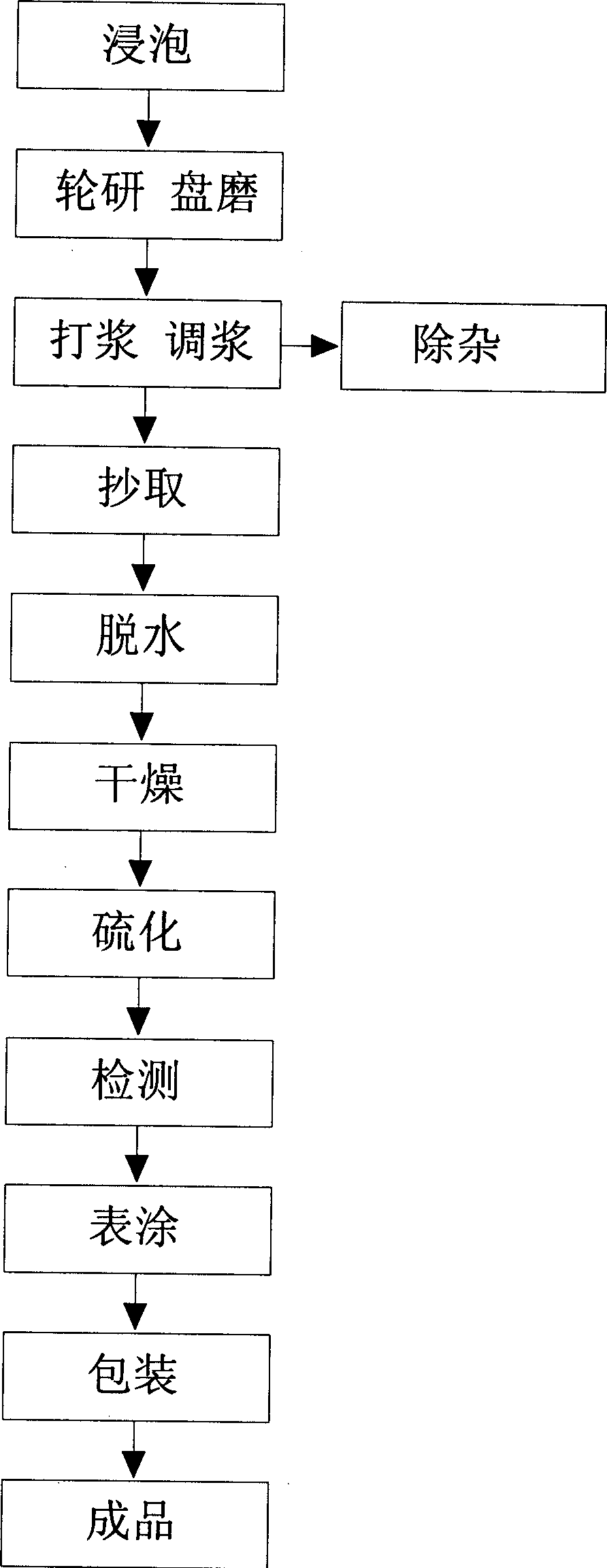

ActiveUS20090173464A1Promote absorptionReduce the amount of solutionFibreboardNatural cellulose pulp/paperCellulose fiberSlurry

A composition and process suitable for making acoustic tiles are disclosed. Certain embodiments of the composition comprise: perlite; inorganic material selected from the group consisting of calcium sulfate, calcium carbonate, clay and mixtures thereof; a binder selected from the group consisting of starch, a combination of starch and cellulosic fibers, latex, kraft paper gel and mixtures thereof; optionally mineral wool; optionally gypsum; and cellulosic fiber, wherein at least a portion of the cellulosic fiber and at least a portion of the inorganic material are pulp and paper processing waste comprising cellulosic fiber, clay and calcium carbonate. Certain embodiments of the process comprise: forming an aqueous slurry; continuously flowing slurry onto a moving foraminous wire to form a cake; dewatering the cake to form a base mat; and drying the base mat.

Owner:USG INTERIORS INC

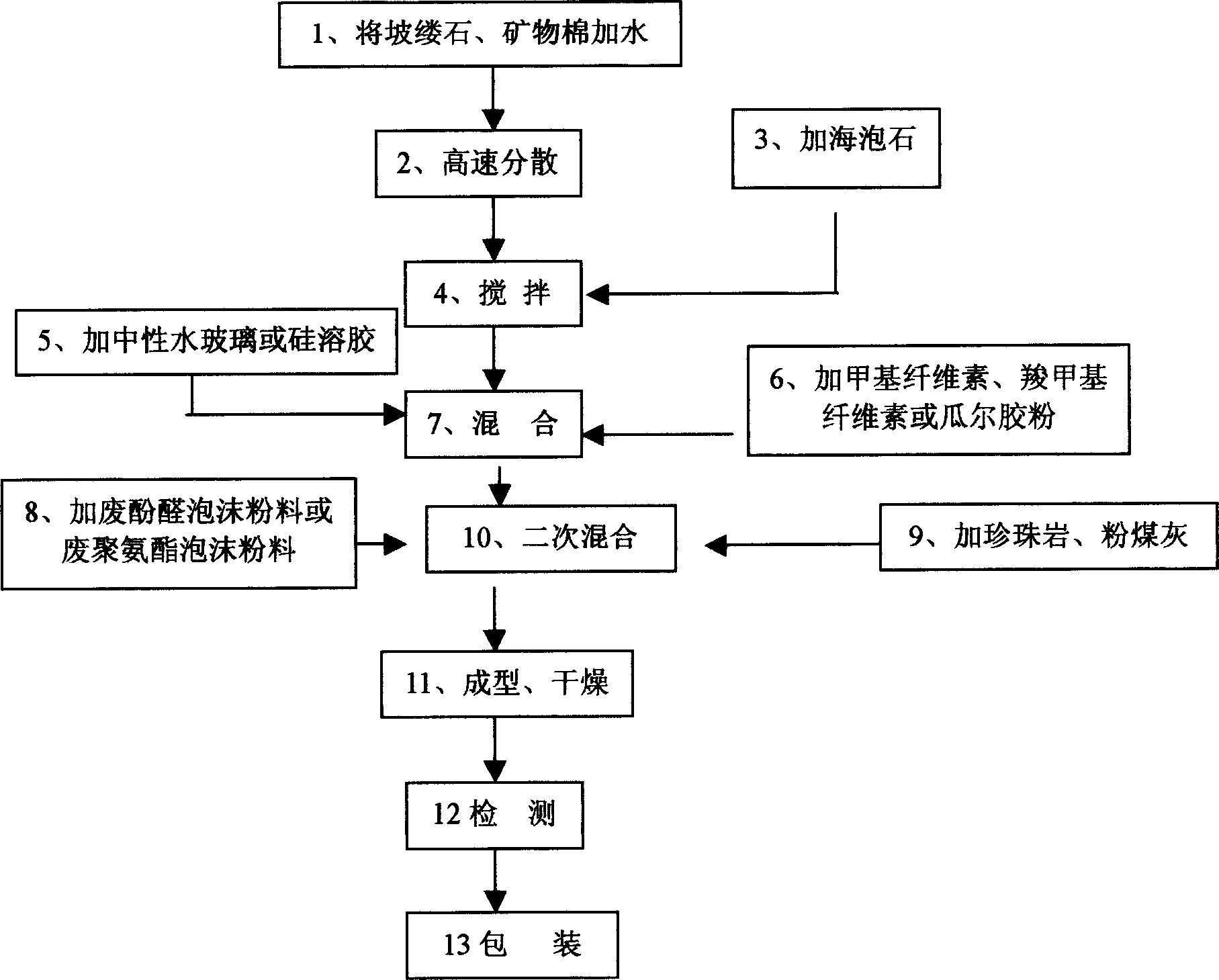

Composite material thermal insulation plate

InactiveCN1511808ANo pollution in the processStrong self-breathing functionThermal insulationSolid waste managementAdhesiveHeat conducting

The thermal insulating plate of composite material is produced with waste foamed phenolic plastic powder as basic heat insulating material, flyash as stuffing, expanded perlite as aggregate, mineral wool, glass wool, sepiolite and palygorskite as reinforcing material, neutral water glass or silica sol as inorganic adhesive and guar gum, methylcellulose or CMC as organic adhesive, and through high speed dispersion, stirring, mixing, molding, forming and drying. The thermal insulating plate has low heat conducting coefficient, is non-inflammable, smell-less, non-toxic, long in service life and wide in application range. The production process adopts industrial waste as main components and produces no waste, and used plate may be reused, so that the present invention is significant in environment protection.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

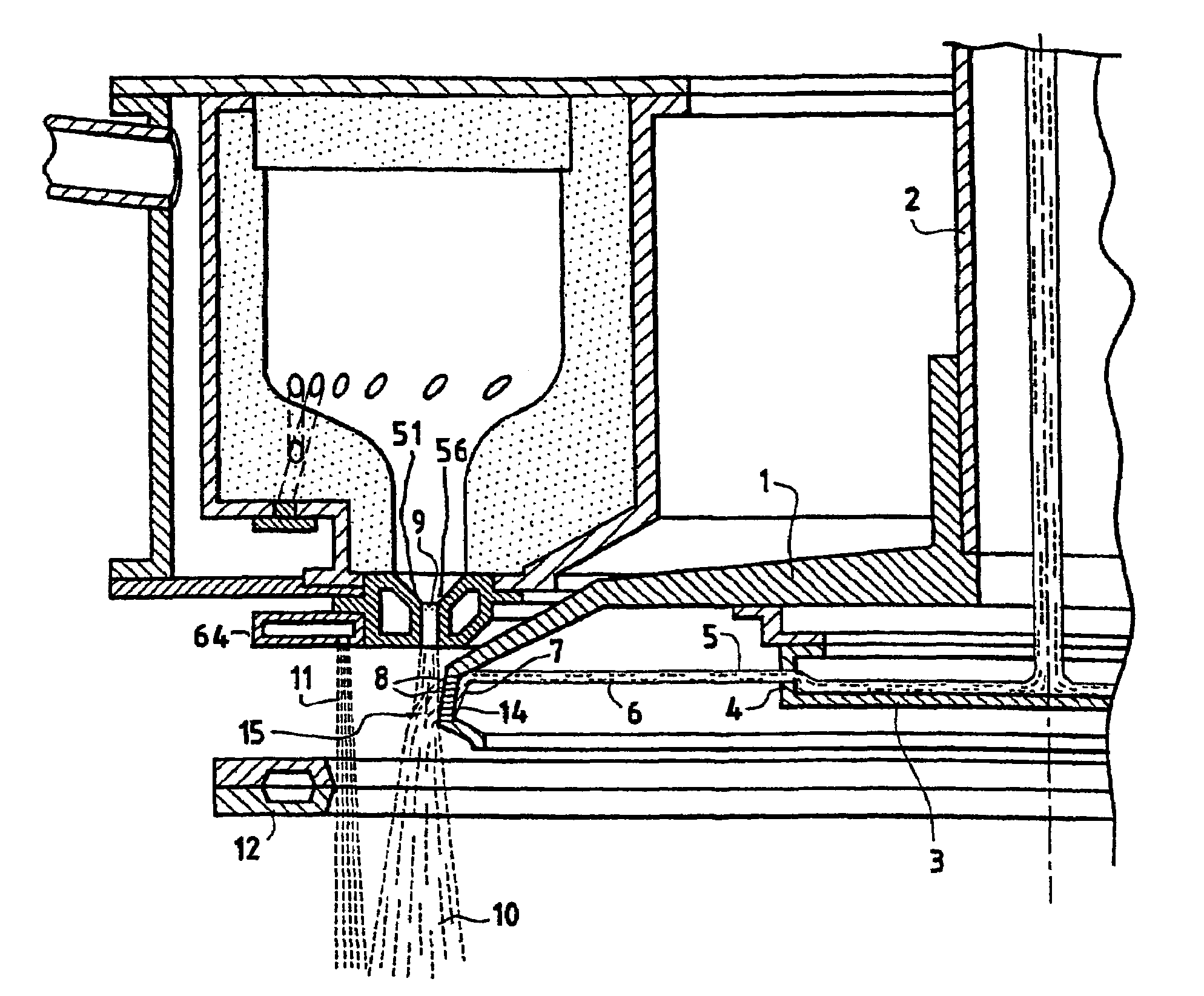

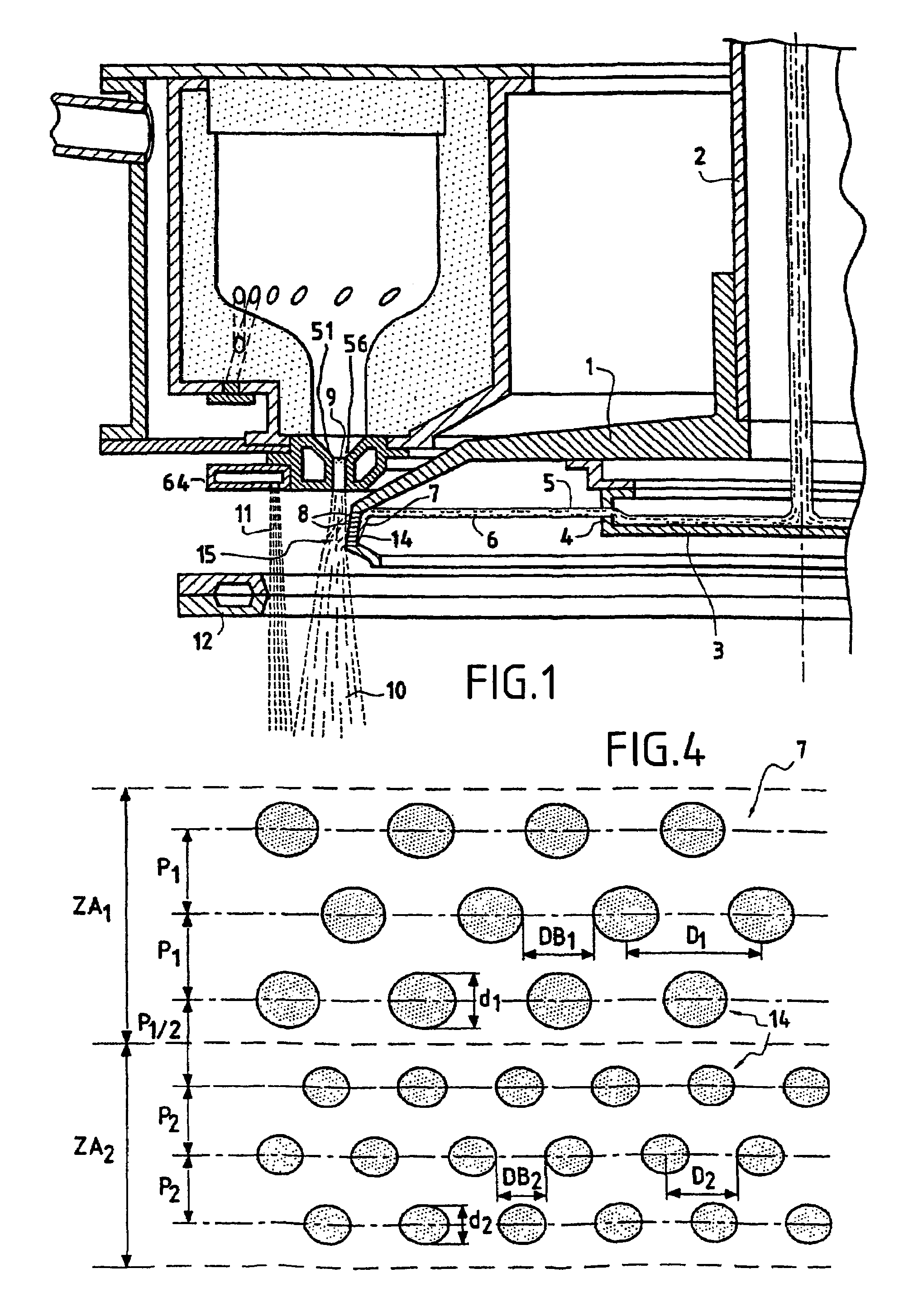

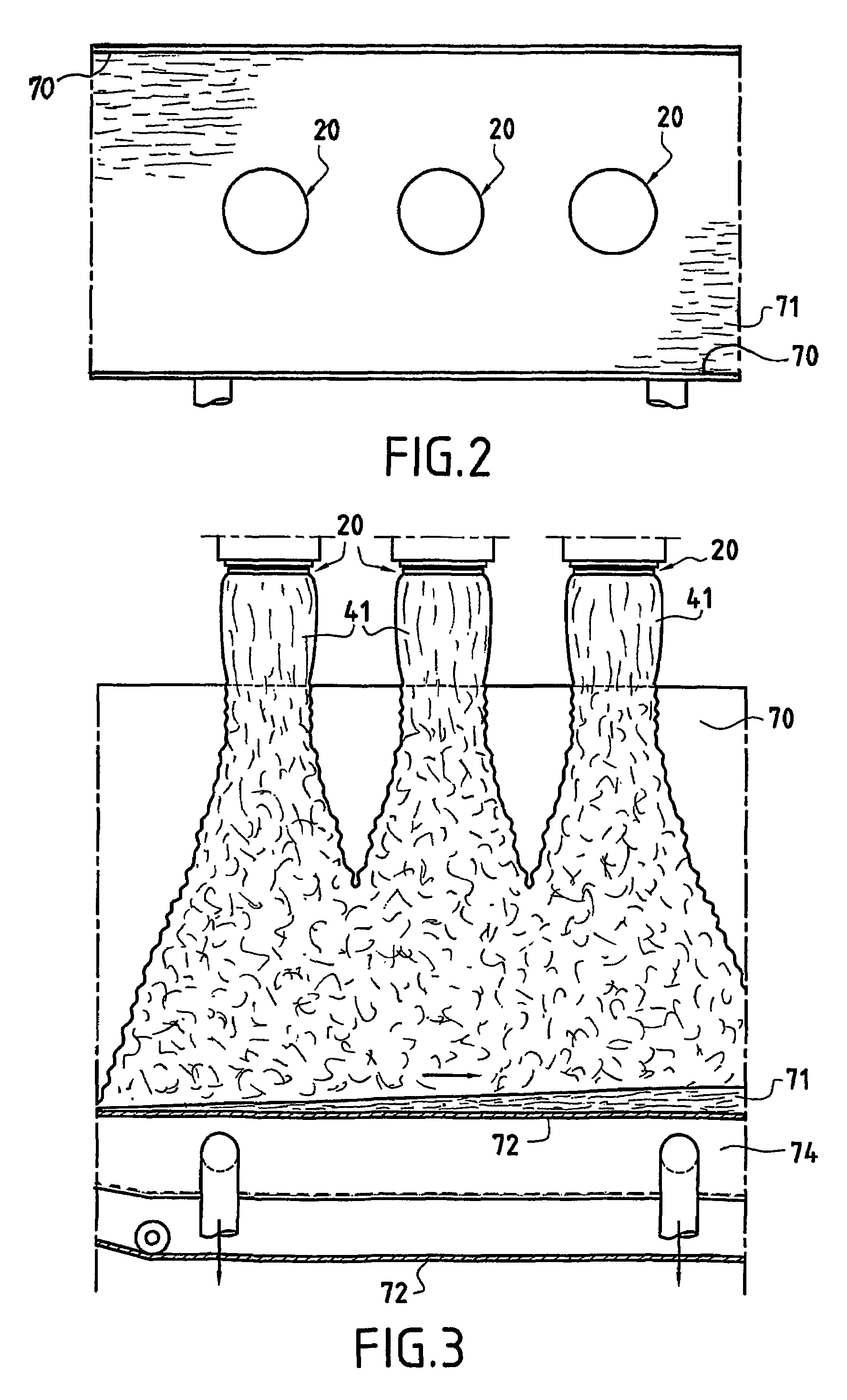

Process and device for formation of mineral wool and mineral wool products

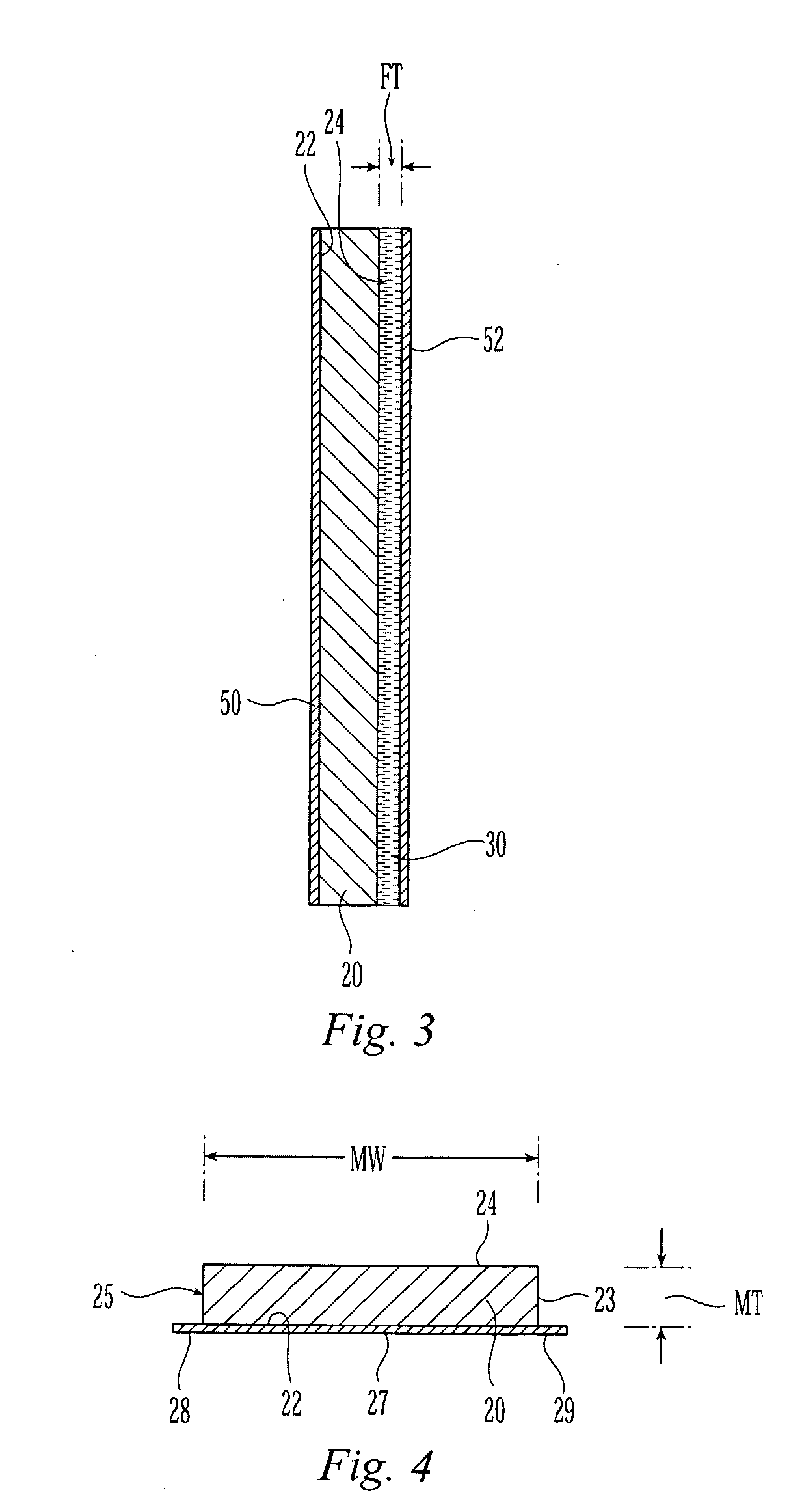

InactiveUS7458235B2High thickness recovery measurementEasy to compressGlass making apparatusSynthetic resin layered productsGlass fiberFiber

A method is provided to produce fine diameter glass fibers with fewer defects through a combination of lower attenuating gas velocities and the use of spinners having more and smaller holes. The method uses a device for internal centrifugation of mineral fibers including a centrifuge equipped with a peripheral band perforated with orifices distributed in a plurality of annular zones arranged on top of each other, assuming that the centrifuge is in centrifugation position. The device includes at least two annular zones whose number of orifices per unit of surface area differs by a value greater than or equal to 5%, 10%, or 20%.

Owner:SAINT-GOBAIN GLASS FRANCE

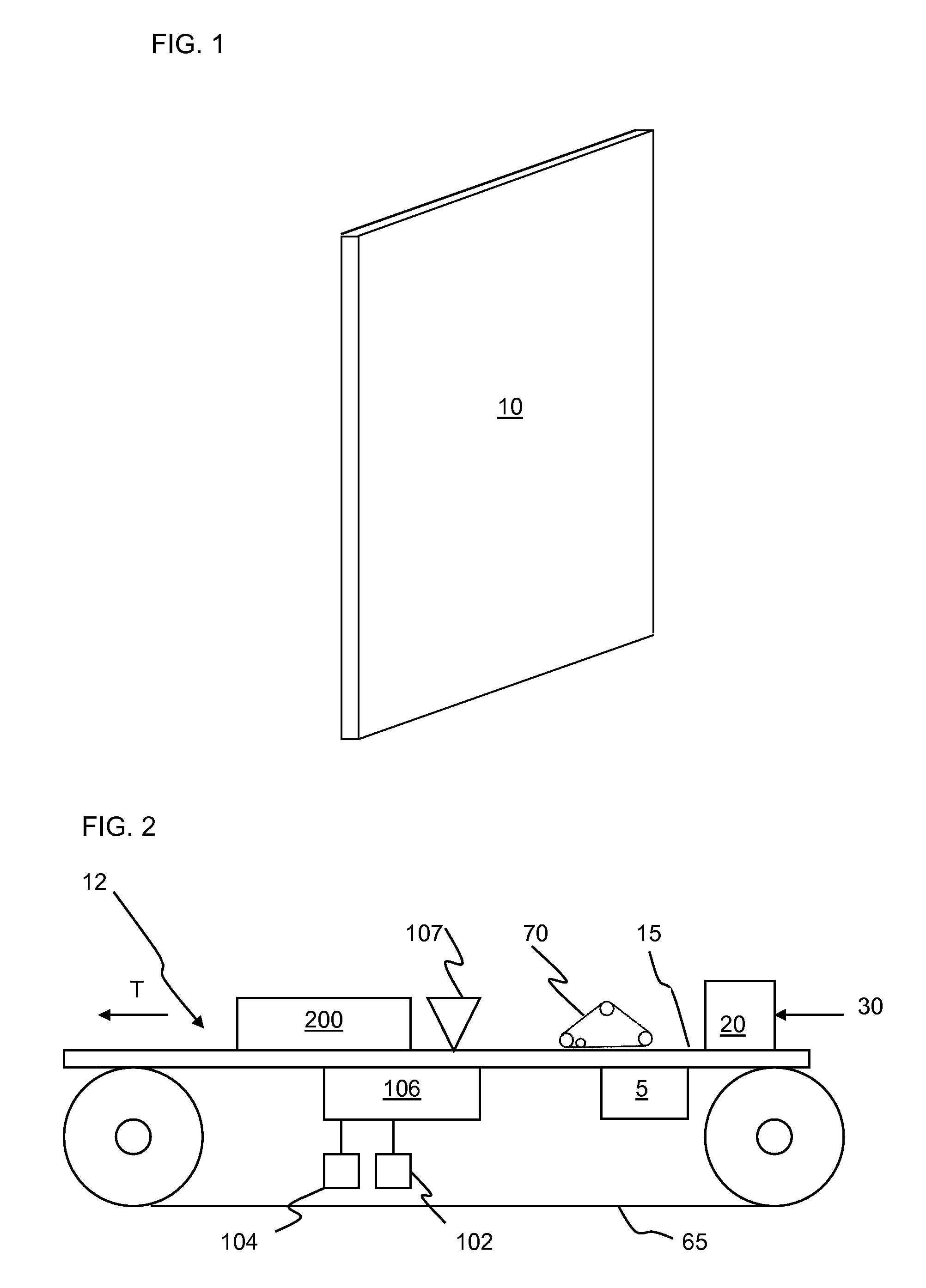

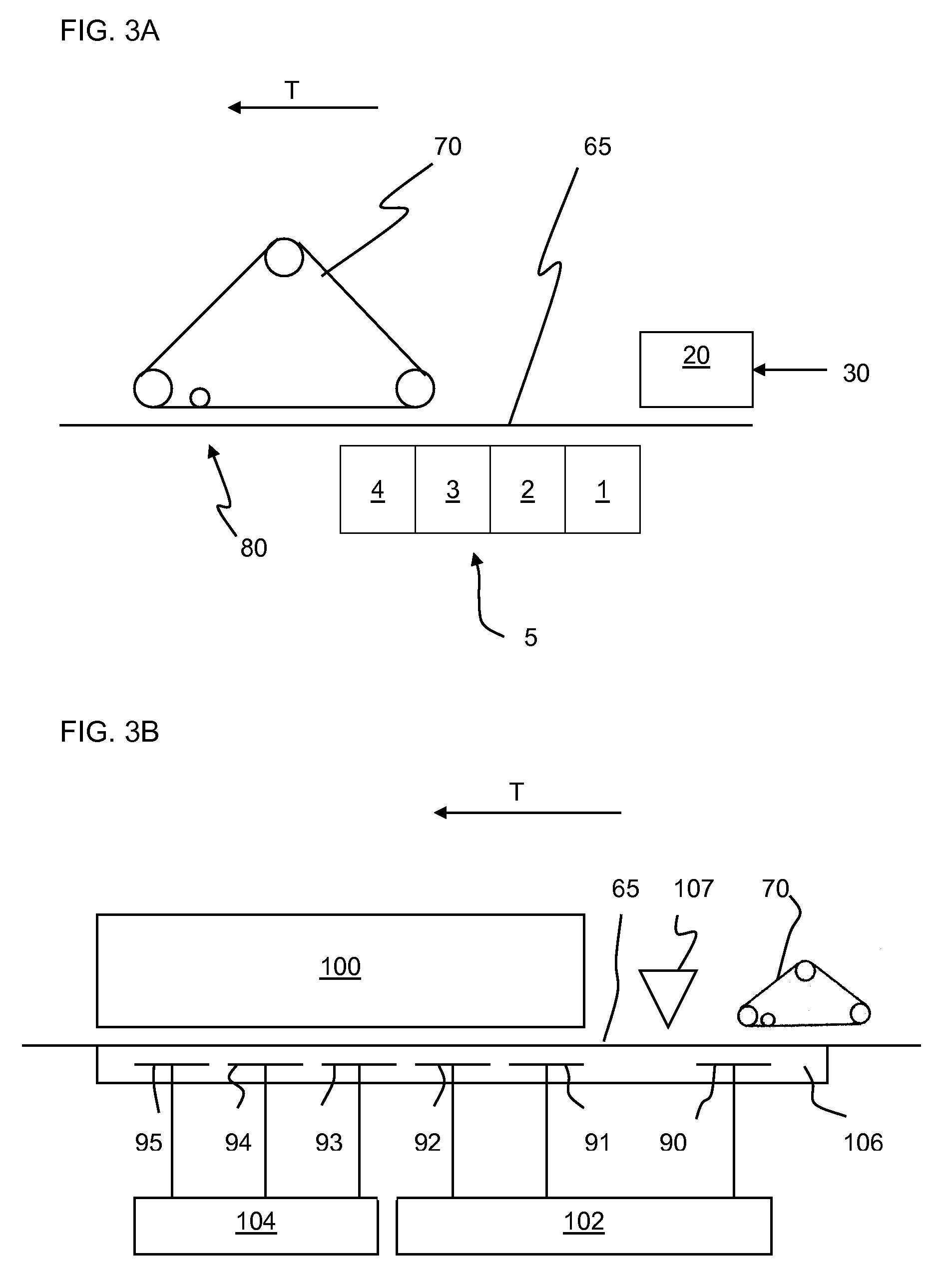

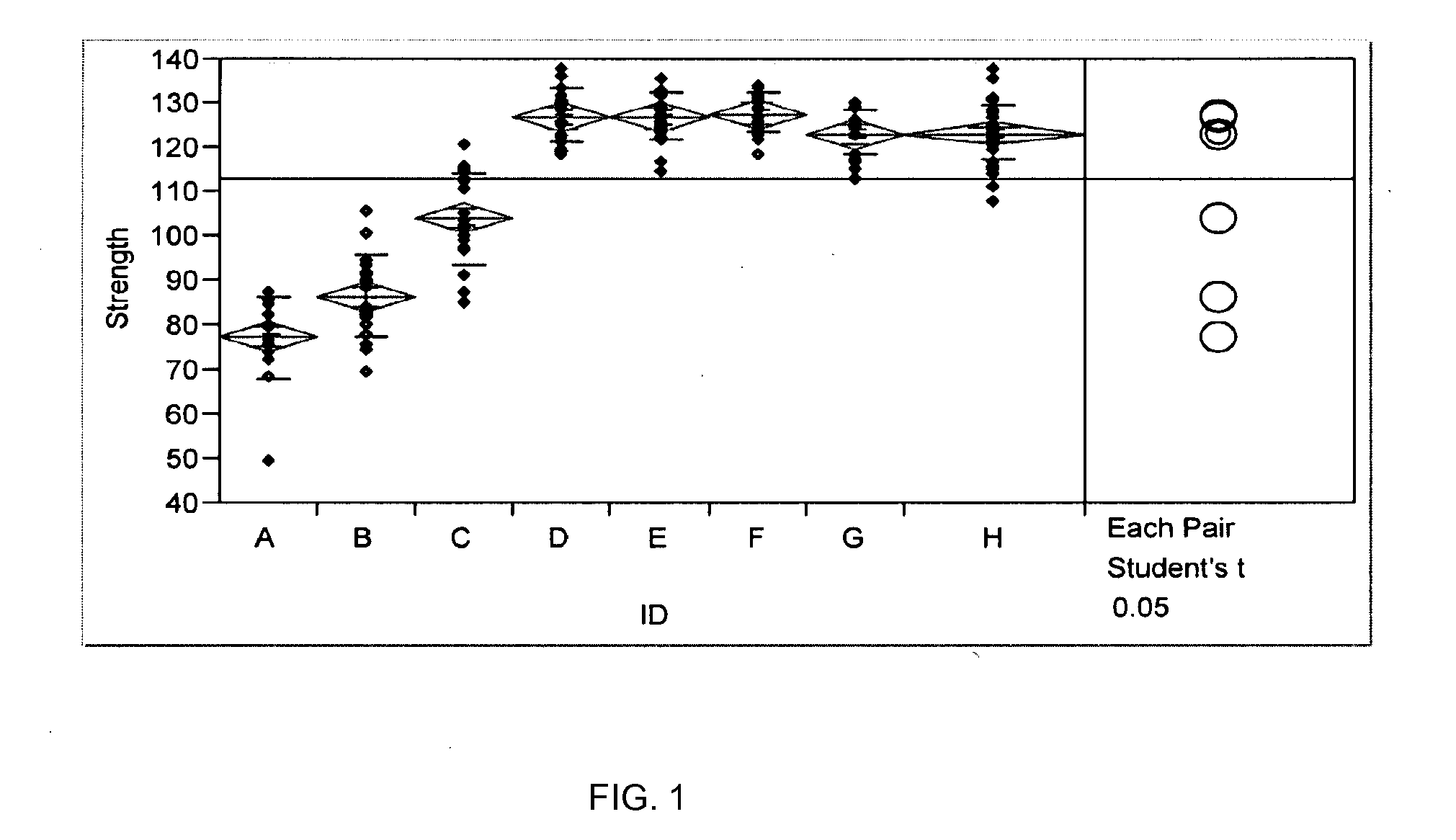

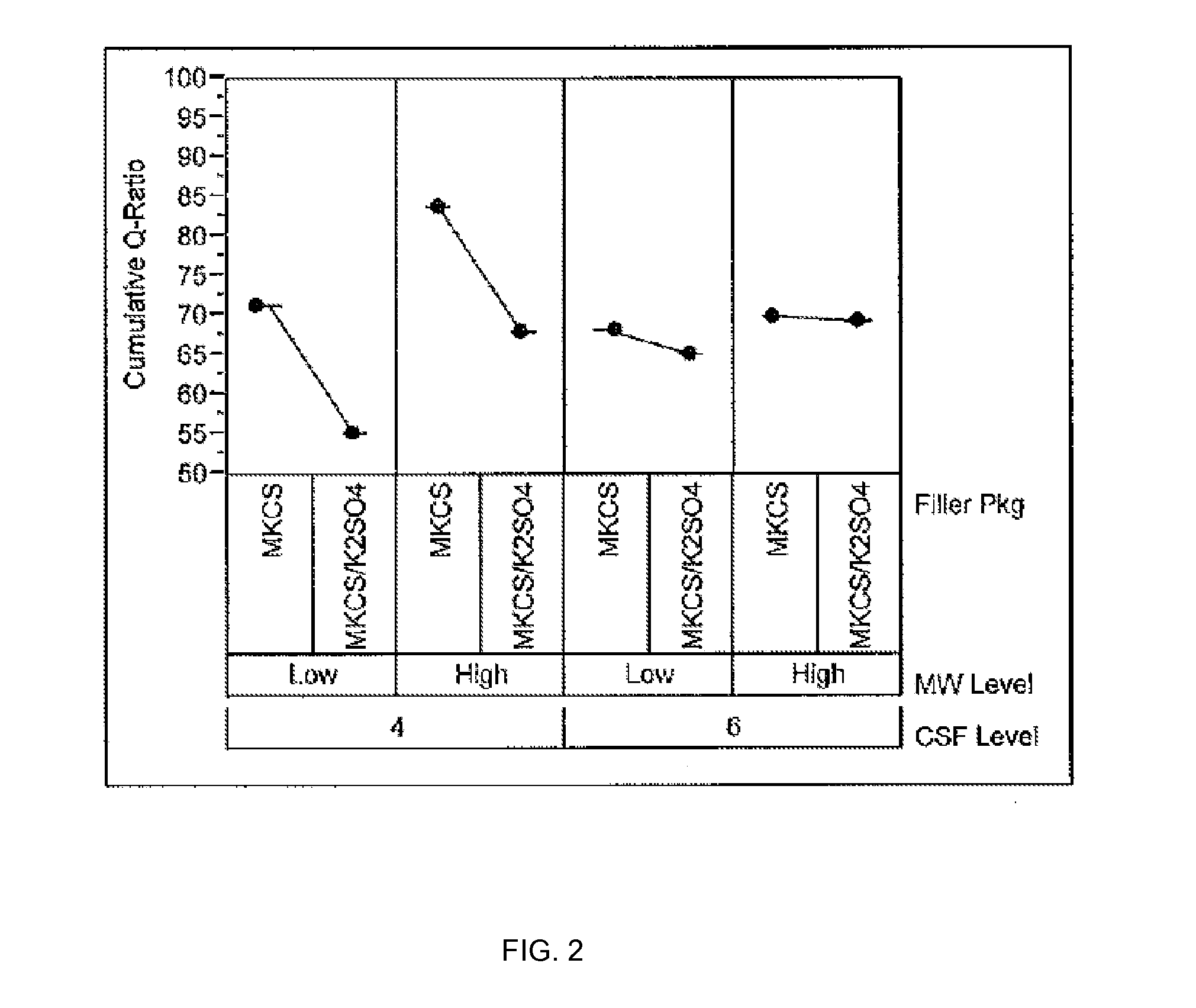

Process for producing a low density acoustical panel with improved sound absorption

A process useful for producing low density high mineral wool based acoustical panels with improved acoustical absorption properties using a water felting process is disclosed. The process includes forming a dilute slurry mixture including water, mineral wool, a thermoplastic binder and / or starch; and distributing the dilute slurry on a porous carrier to have the slurry dewatered to a base mat by gravity drainage to remove water by gravity. A vacuum is adjusted to gradually apply vacuum to the gravity dewatered base mat to further dewater the base mat without subjecting the mat to static pressure that would compress the base mat. The base mat is dried to form an acoustical ceiling product that has a low density and excellent acoustical absorption properties.

Owner:USG INTERIORS INC

High strength low density board for furniture industry

InactiveUS6268042B1Decreasing mineral wool contentIncreasing cellulosic fiber contentConstruction materialSolid waste managementCellulose fiberHigh intensity

A high strength, low density fiber board panel for use in the furniture industry is provided, including mineral wool, a lightweight aggregate material, cellulosic fiber, a binding agent and gypsum. The mineral wool makes up approximately 0% to 33%, the lightweight aggregate material approximately 25% to 41%, the cellulosic fiber approximately 20% to 35%, the binding agent approximately 5% to 9%, and the gypsum approximately 0% to 23%, of the dry solids weight of the panel.

Owner:UNITED STATES GYPSUM CO

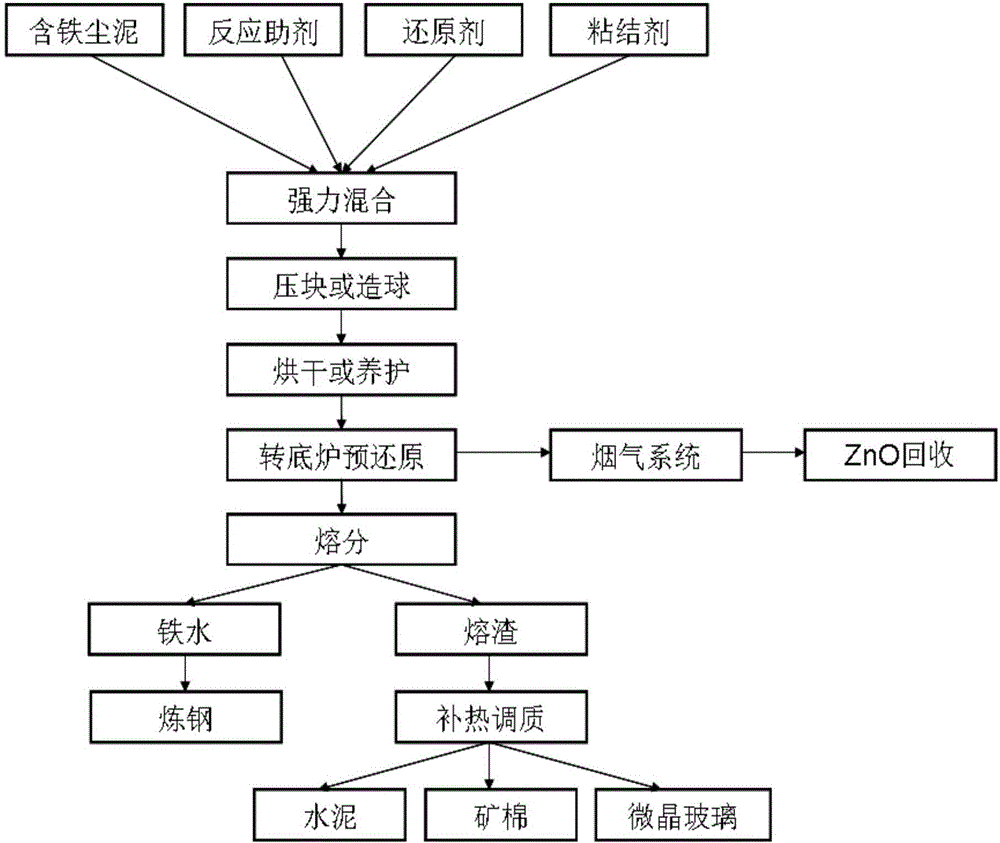

Technique for comprehensively utilizing iron-containing dust mud

InactiveCN104694758AImprove utilization efficiencyObvious advantages in energy saving and environmental protectionGlass making apparatusCement productionSteelmakingRed mud

The invention discloses a technique for comprehensively utilizing iron-containing dust mud, which is characterized by comprising the following steps: preparing iron-containing dust mud into blocks or balls by block pressing, ball pressing or balling, drying the ball or blocky red mud, adding the red mud into a rotary hearth furnace, carrying out ZnO removal, alkali metal removal and FeOx pre-reduction on the dust mud in the rotary hearth furnace technique, recovering ZnO from rotary hearth furnace flue gas, and pre-reducing to obtain the metalized pellet DRI; and adding the DRI generated from the rotary hearth furnace into a melting furnace to perform slag-iron separation, sending the separated molten iron into a steelmaking technique, and carrying out concurrent heating hardening and tempering on the dust mud molten slag separated from the metal, wherein the product can be used for producing cement, mineral wool, microcrystalline glass or other high-added-value silicate products. Thus, the technique enhances the comprehensive utilization efficiency of the whole iron-containing dust mud, and enhances the comprehensive utilization economic benefit of the iron-containing dust mud.

Owner:BAOSTEEL DEV CO LTD

Mineral wool plant substrate

The invention relates to a mineral wool plant substrate comprising a coherent matrix of mineral wool and up to 20 volume % of an ion-exchange agent comprising a variable and / or fixed ion-exchange capacity of about 15, preferably 30 and most preferably 40 meq / 100 g dry weight or more.

Owner:ROCKWOOL INT AS

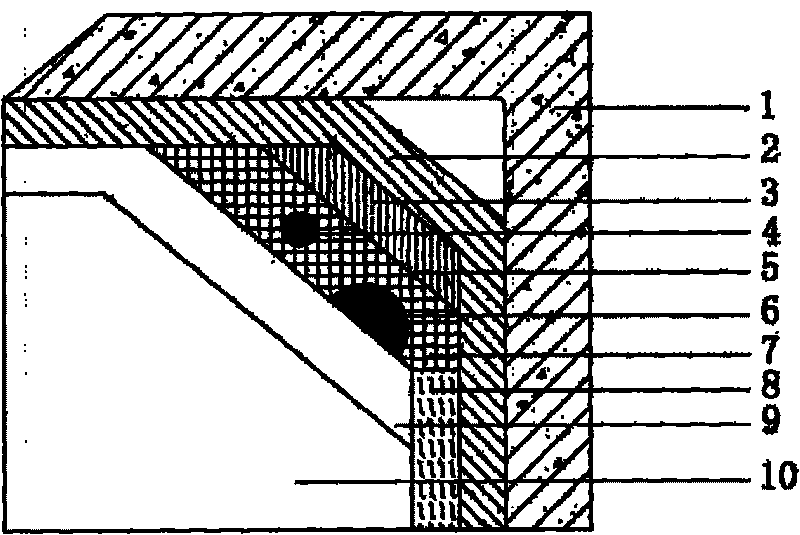

Fire-proof type exterior wall composite thermal insulation decorative board and manufacture method thereof

The invention belongs to the technical field of building materials and particularly relates to a fireproof composite thermal-insulation decorative board for an exterior wall and a preparation method thereof. The fireproof composite thermal-insulation decorative board for the exterior wall is characterized in that the fireproof composite thermal-insulation decorative board for the exterior wall comprises a fireproof thermal insulation layer, a strengthening layer and a decoration layer. The thickness of the fireproof thermal insulation layer is between 30 and 80mm, and the fireproof thermal insulation layer consists of rock wool and a calcium silicate board, or mineral cotton and the calcium silicate board, or a rock wool board and the calcium silicate board, or a mineral cotton board and the calcium silicate board, or one of the mineral cotton board and the rock wool board, wherein the rock wool, the mineral cotton, the rock wool board, and the mineral cotton board are all subjected to hydrophobic treatment by organic silicon. The thickness of the strengthening layer is between 3 and 8mm, and the strengthening layer is polymer mortar or the calcium silicate board. The decoration layer is fluorobcarbon coating, metallic paint, stone like coating or crylic acid emulsion paint. The thermal insulation board is arranged on the wall surface through a mode with the combination of adhesion and anchorage. The invention can prevent the thermal-insulation decorative board for the exterior wall from being burnt and destroyed too early during fire hazards, protect the safety of personal life of personnel and properties in buildings during the fire hazards, and has the advantages of controllable quality of prefabricated forming, assembled construction, and integrated decoration and thermal insulation functions.

Owner:武汉科华高新材料发展有限公司

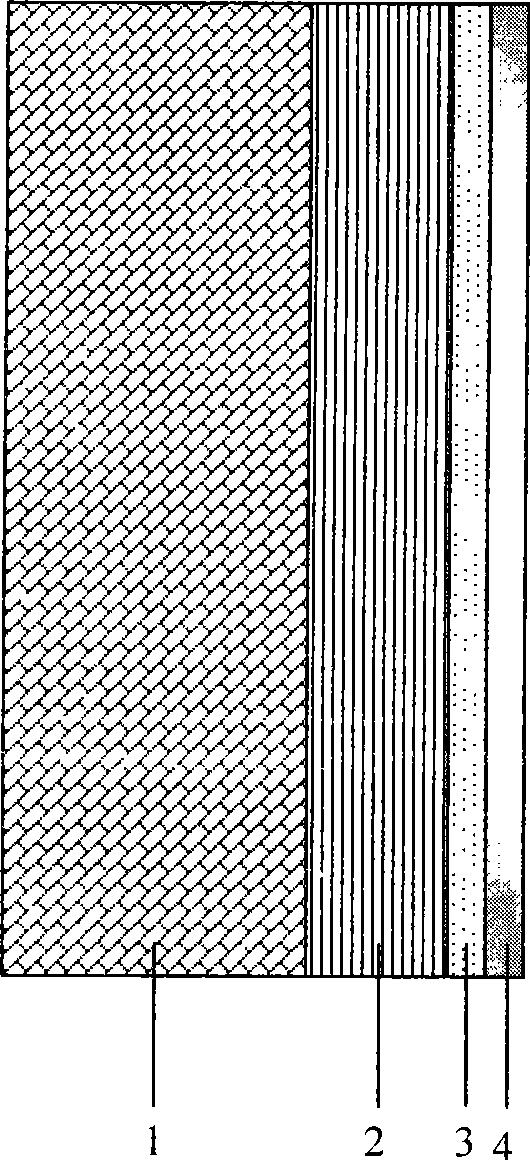

Spray foam and mineral wool hybrid insulation system

A reduced thickness and / or reduced width insulation product is provided for use in combination with spray-on foam insulation. The insulation product is configured to be inserted into standard-size spaces between adjacent wall studs to which a spray-on foam insulation has been applied. The reduced size of the insulation product is specifically designed so that the combined width and thickness of the insulation product and the spray-on foam insulation fill the entirety of the building space, but do not overfill the space.

Owner:CERTAINTEED CORP

Screened sealing material without asbestos fiber and its prepn process

InactiveCN1847355ASo as not to damageHigh tensile strengthOther chemical processesHigh resistanceSodium Bentonite

The present invention is screened sealing material without asbestos fiber and its preparation process. The sealing material is prepared with fiber 10-70 wt%, stuffing 30-80 wt%, adhesive 1-10 wt%, latex 5-20 wt% and compounding agent 4-10 wt%, where the latex is synthetic latex or natural latex, the adhesive is polymer adhesive or polymer adhesive composition, the stuffing is graphite powder, bentonite, etc. of granularity over 120 meshes, and the fiber is 1000 deg.c over high temperature treated mineral wool fiber, short glass fiber, ceramic fiber, etc. The sealing material has high tensile strength, high oil tolerance, high heat resistance, long service life and no harmful asbestos.

Owner:舟山海山机械密封材料股份有限公司

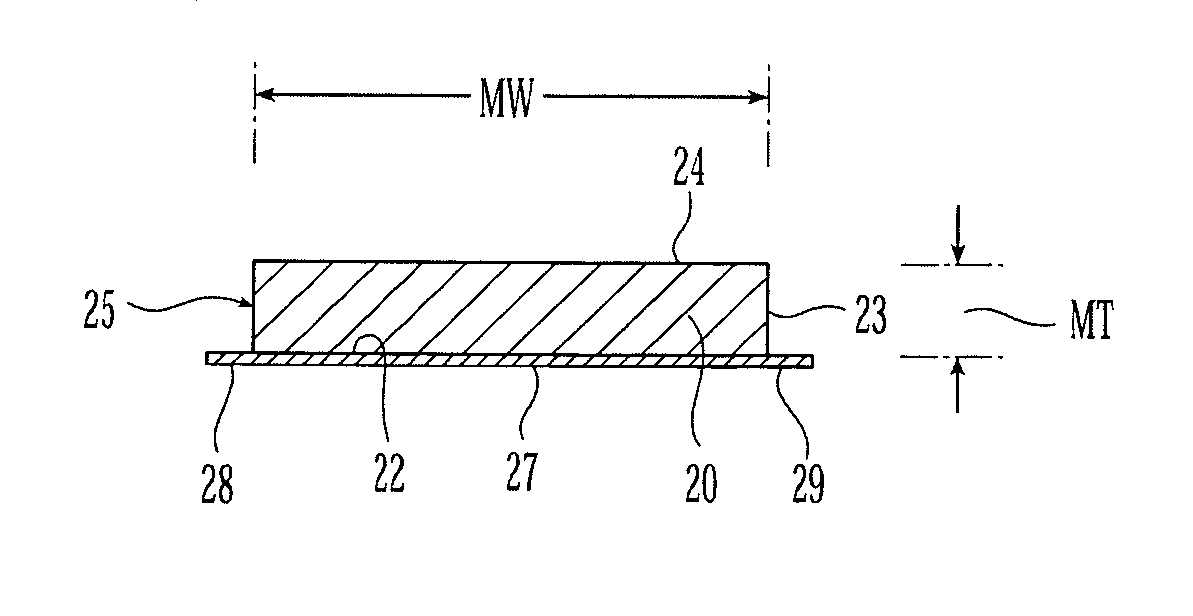

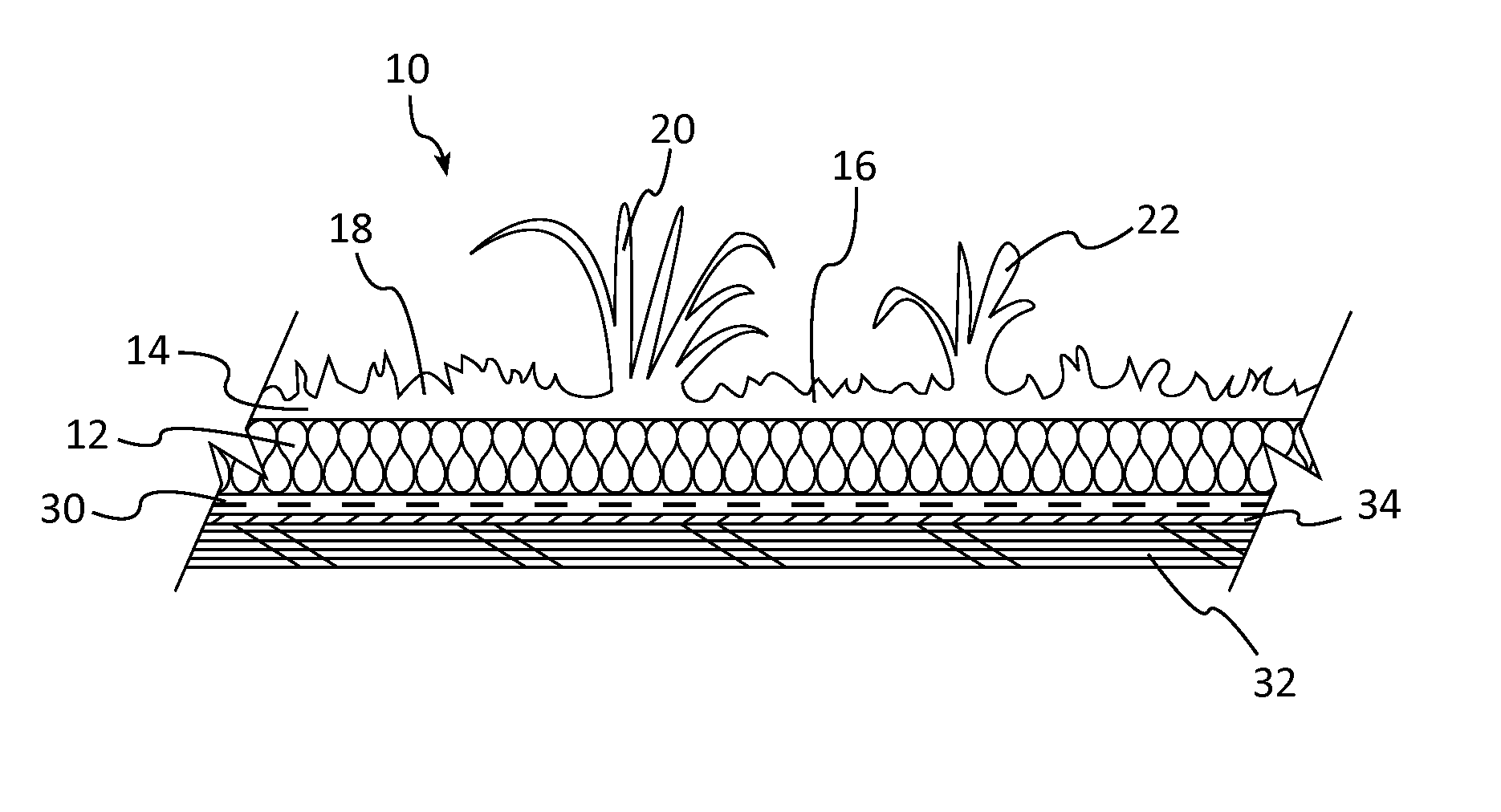

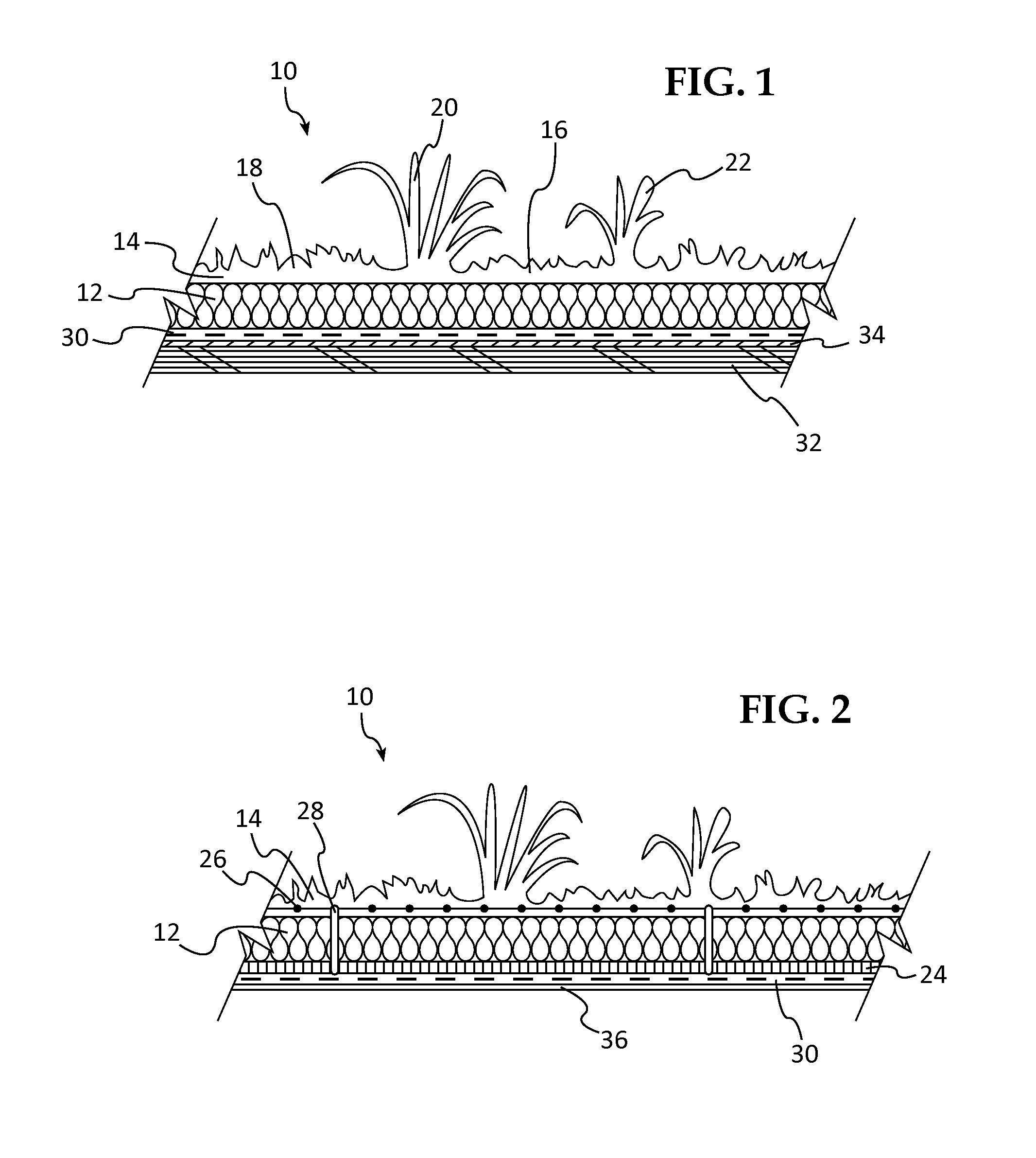

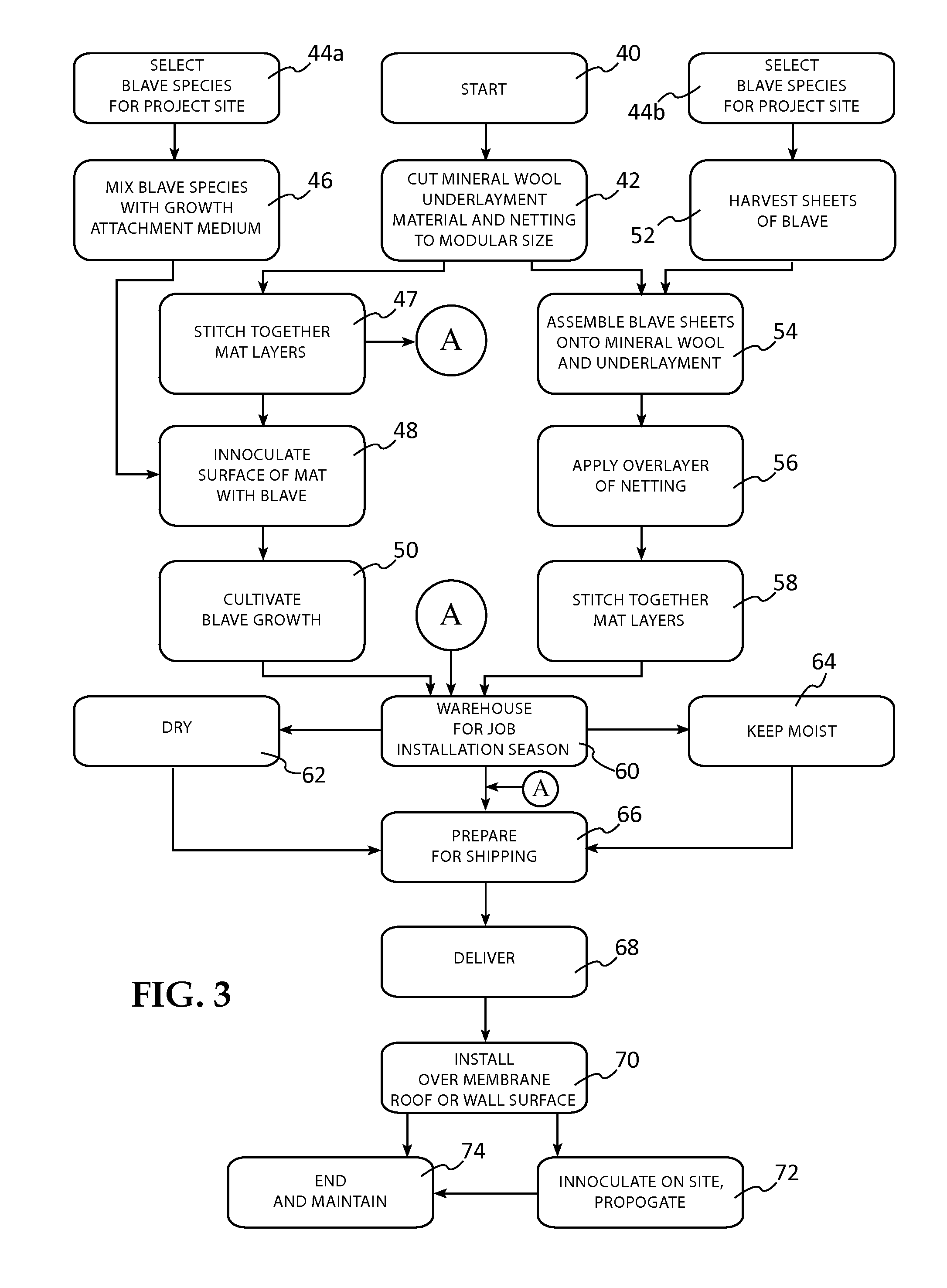

Living Roof and Wall Systems Using Cultivated Mineral Wool Mats to Support BLAVEs, Methods of Cultivation and InnoculantsTherefor

ActiveUS20110197504A1Improve integrityImproves Structural IntegrityRoof improvementHops/wine cultivationAdhesiveCell culture media

Soil-free living roof and wall systems comprising a living layer of Bryophytes, Lichen, And Vascular Epiphytes (BLAVE) on the surface of a thin, light-weight, flexible, fire-resistant mat of mineral wool having a density in the range of about 6-12 lbs / cu ft and thickness in the range of about ⅜″ to about ¾″. Mats are provided in modular units on the order of 2′×4′; no irrigation or growth medium is used. The mats are adhered to a roof or wall with adhesive or mastic, or may be secured with fasteners. In the preferred embodiment, modular units include flexible mineral wool mats over a base sheet of non-woven plastic fibers, on the order of from 2-4 mm thick, and a wide-mesh plastic netting over the BLAVE layer, sewn through to the base layer. Methods of mat module manufacture, innoculant mix production, installation and cultivation / propagation of BLAVE are disclosed.

Owner:ARCHIPHYTE

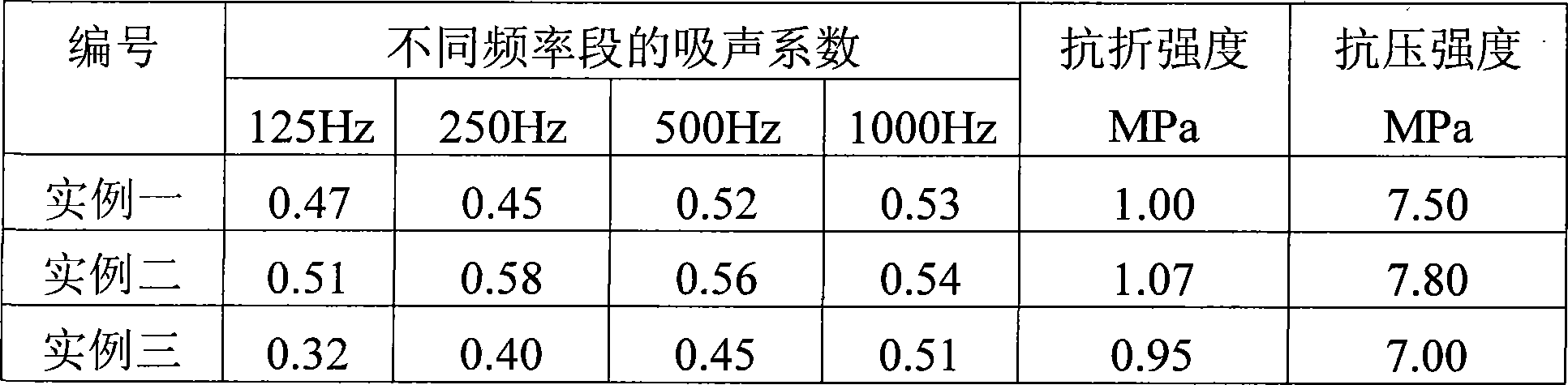

Decoration acoustic absorption sheet material of tripolite and method for producing the same

InactiveCN101428999AWith sound absorption and sound insulationMoisture-adjusting and anti-cleaning lotionFiberAcoustic absorption

The invention discloses a diatomite decorative acoustic board, which belongs to the field of building material. The invention solves the problems that the prior porous acoustic material has low acoustical absorptivity to middle and low frequencies, a mineral wool acoustic board pollutes the environment and so on. The board consists of 70 to 80 weight percent of diatomite, 18 to 25 weight percent of gypsum, 1 to 3 weight percent of pigment, 0.9 to 1.5 weight percent of adhesive, and 0.1 to 0.5 weight percent of fiber; the content of SiO2 in the diatomite is more than 85 percent, and the white content is more than 82; and the white content of the gypsum is more than 90 degrees. The method for preparing the board comprises the following steps: solid materials, namely the diatomite, the gypsum, the adhesive, the pigment and the fiber are added into a mortar mixer to be stirred for 20 to 30min, water which accounts for 1 to 1.5 times of the amount of the solid materials is added into the mixture after the mixture is stirred evenly to be prepared into uniform slurry, the slurry is cast into board molds with different specifications, and the mold stripping and drying are performed after 24h of maintenance. The board has functions of sound absorption and sound insulation, humidity conditioning and dewing prevention, fire resistance and flame retardation, thermal insulation, environmental protection, beautiful decoration, high strength, light mass, easy installation, convenient maintenance and so on, and is suitable for mass production.

Owner:北京大地远通(集团)有限公司 +1

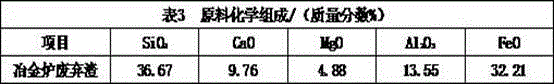

Method for producing mineral wool fiber by using high-temperature liquid waste slags of metallurgical furnace as raw material

InactiveCN104529147AImprove acid resistanceImprove waterproof performanceGlass making apparatusLiquid wasteFiber

The invention provides a method for producing a mineral wool fiber by using high-temperature liquid waste slags of a metallurgical furnace as a raw material. The method is characterized by comprising the following steps: discharging the high-temperature liquid waste slags of the metallurgical furnace, allowing the waste slags to flow into a heat insulting electric furnace and keeping the temperature; melting the slags to generate fibers; melting a hardening and tempering agent; drawing and blowing the fibers by using a high-voltage fan; and blowing the generated mineral wool into a wool collecting chamber. The method is simple and convenient to operate; the fiber filaments are smaller than 7 micrometers in diameter, long and good in toughness; sensible heat in the raw material is fully utilized; comprehensive utilization of different industrial waste materials such as copper, lead, zinc, nickel, tin and high-temperature liquid waste slags are realized; the prepared mineral wool fiber is better than rock wool and mineral wool produced by other methods in acid resistance and waterproofness, excellent in technical performance, wide in application and applicable to preparing excellent environment-friendly energy-saving heat-insulating materials; the method disclosed by the invention is relatively low in investment cost, reliable in technology, low in resource consumption, environment-friendly and clean in production and obvious in economic benefits.

Owner:江西自立环保科技有限公司

Double-face sound-absorbing contacting oral cavity sound shield without cotton

InactiveCN1644802AWith renewableSolution to short lifeNoise reduction constructionNoise controlFiber

Owner:SHANGHAI JIAO TONG UNIV

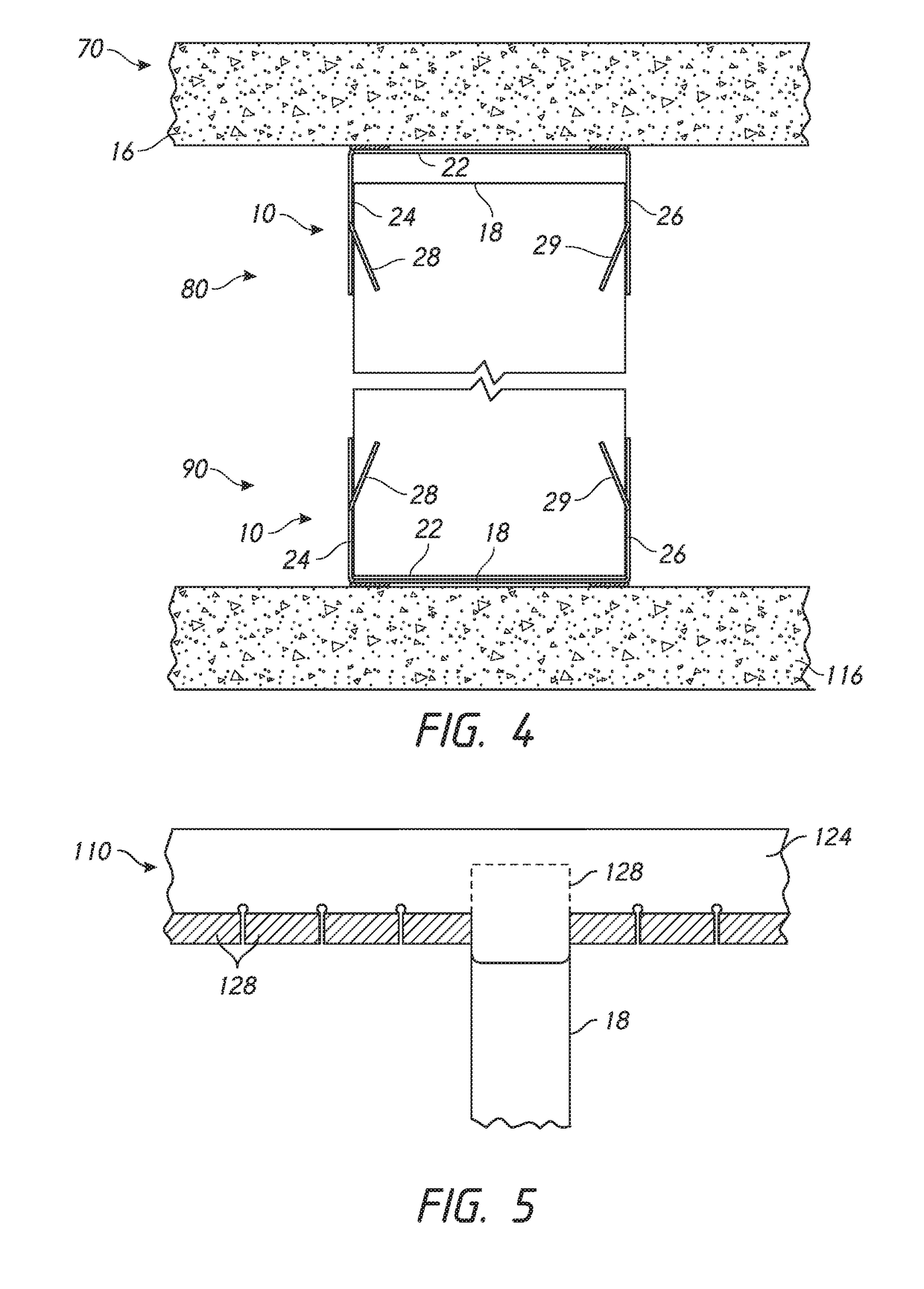

Fire and sound resistant insert for a wall

InactiveUS8074412B1Shorten the timeSave effortRoof coveringConstruction materialEngineeringWall plate

An element is inserted between the upper edge of a wallboard and a fluted ceiling. The element has a lower edge adapted to snugly accommodate the upper edge of the wallboard and an upper edge shaped and adapted to accommodate the fluted shape of the ceiling. The element is snugly fixed to the wallboard and includes mineral wool and calk fire putty sandwiched between two layers of sheet metal.

Owner:GOGAN THOMAS +1

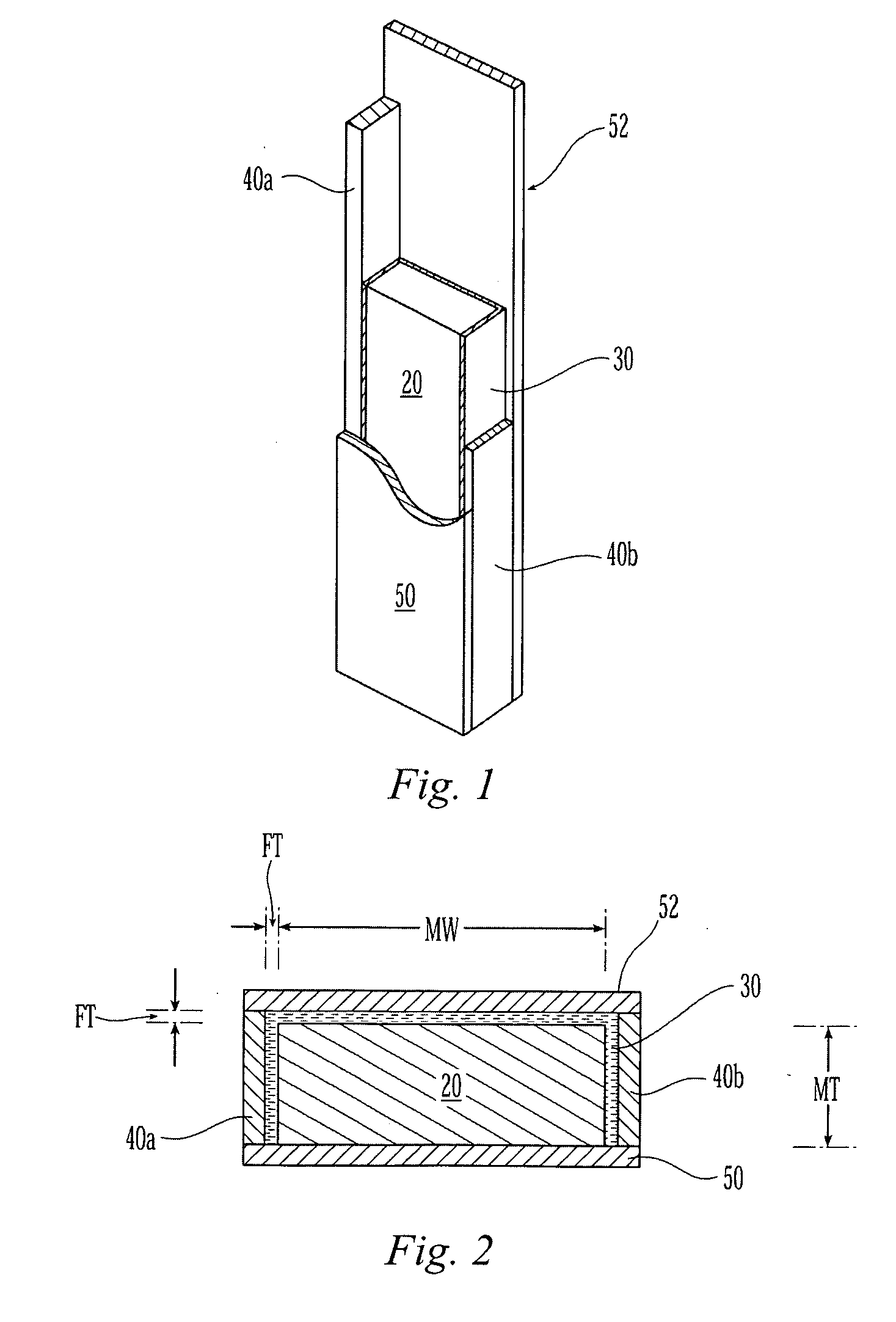

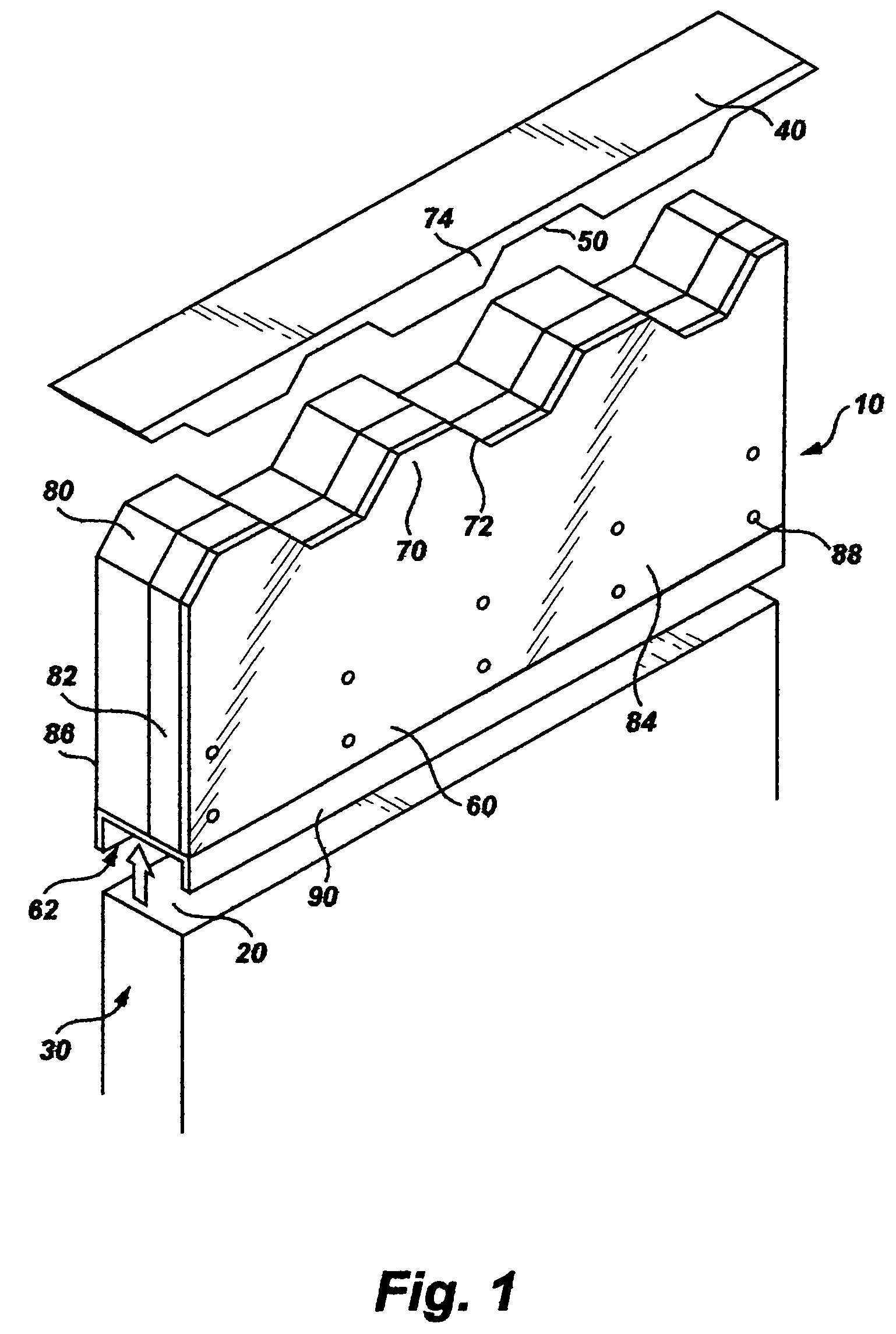

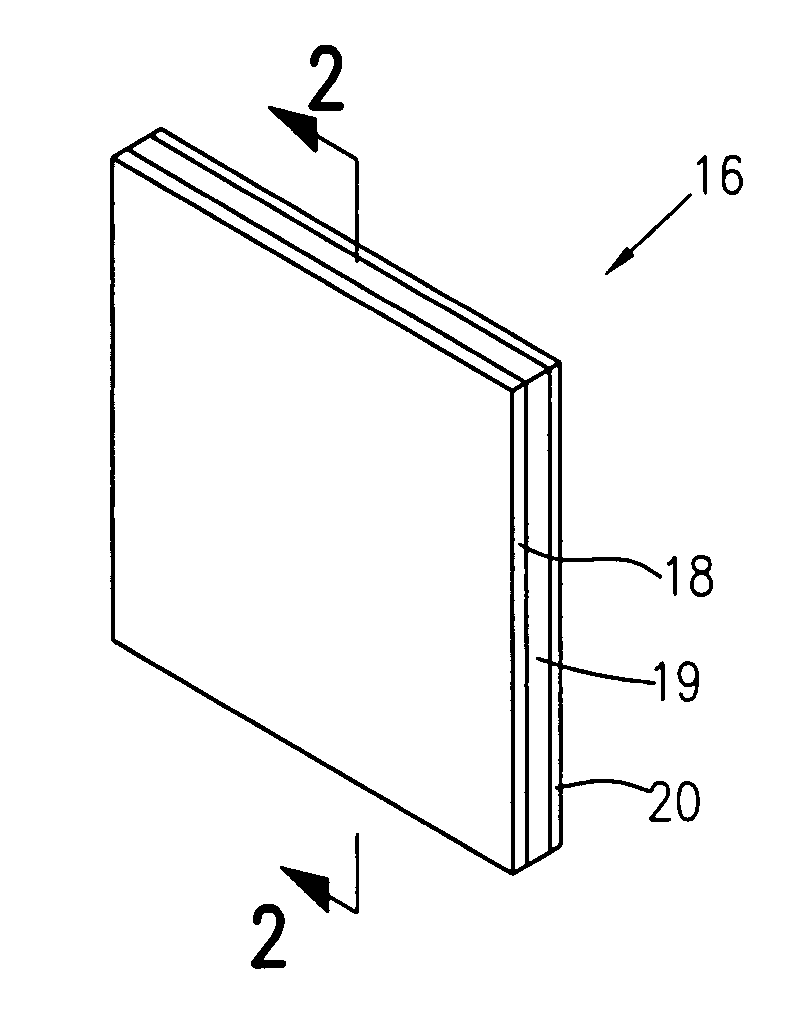

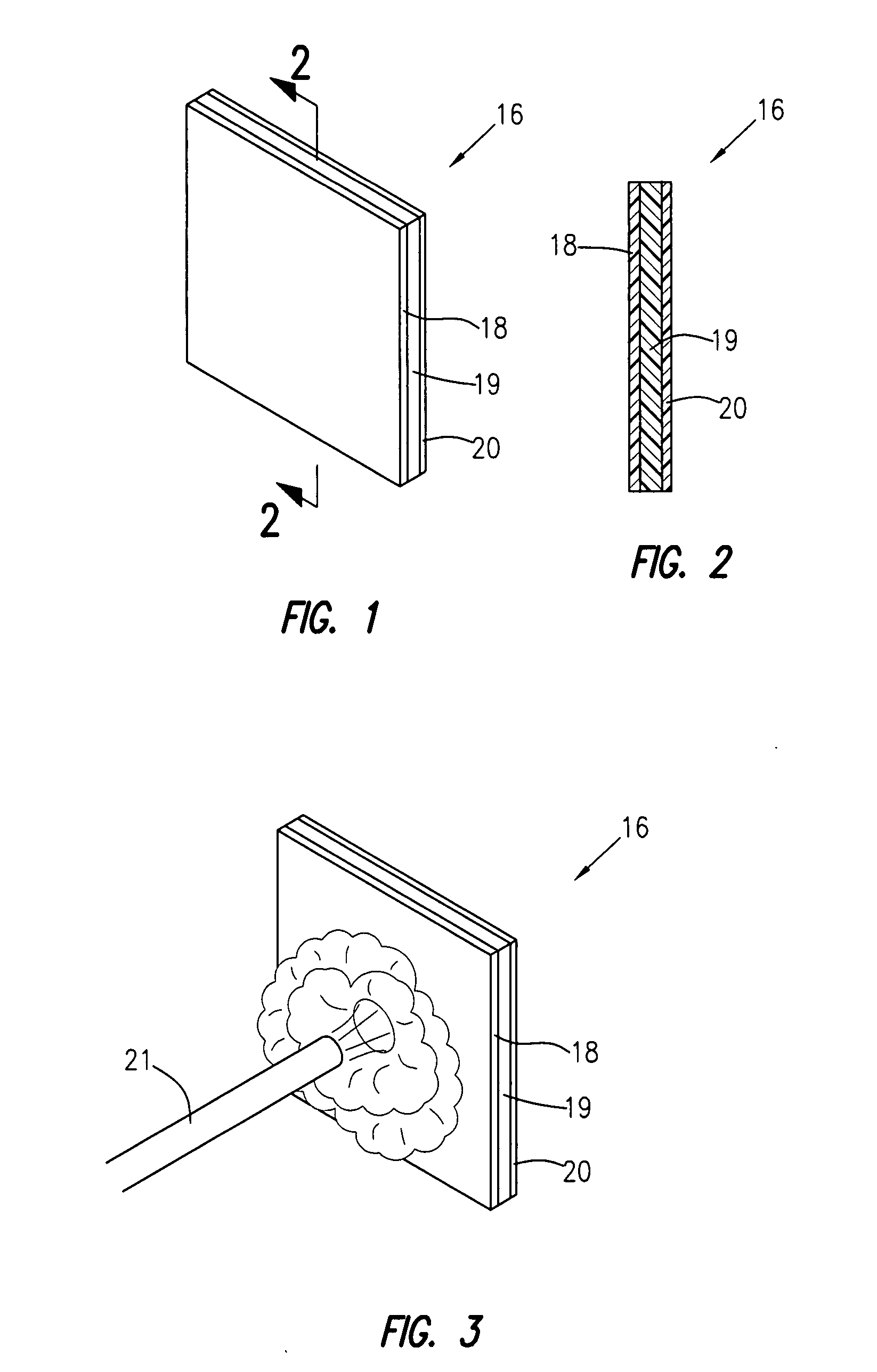

Layered fire retardant barrier panel

InactiveUS20080070024A1Withstands high-temperaturesSlow heat transferSynthetic resin layered productsCeramic layered productsFiberGlass fiber

A fire retardant barrier panel (16) comprising a first protective layer (18) of a first material and a fire resistant phenolic-based resin layer (19) bonded to the protective layer. The first material may be selected from the group consisting of gypsum, ceramic fiber, phenolic foam, basalt, fiberglass, carbon fiber, mineral wool and intumescent materials. The resin may be a phenol or phenolic resin. The fire retardant barrier panel may further comprise a second protective layer (20) bonded to the resin layer (19) such that the resin layer is between the first and second protective layers. The second protective layer (20) may be selected from the group consisting of gypsum, ceramic fiber, phenolic foam, basalt, fiberglass, carbon fiber, mineral wool and intumescent materials.

Owner:CURRAN WILLIAM F +1

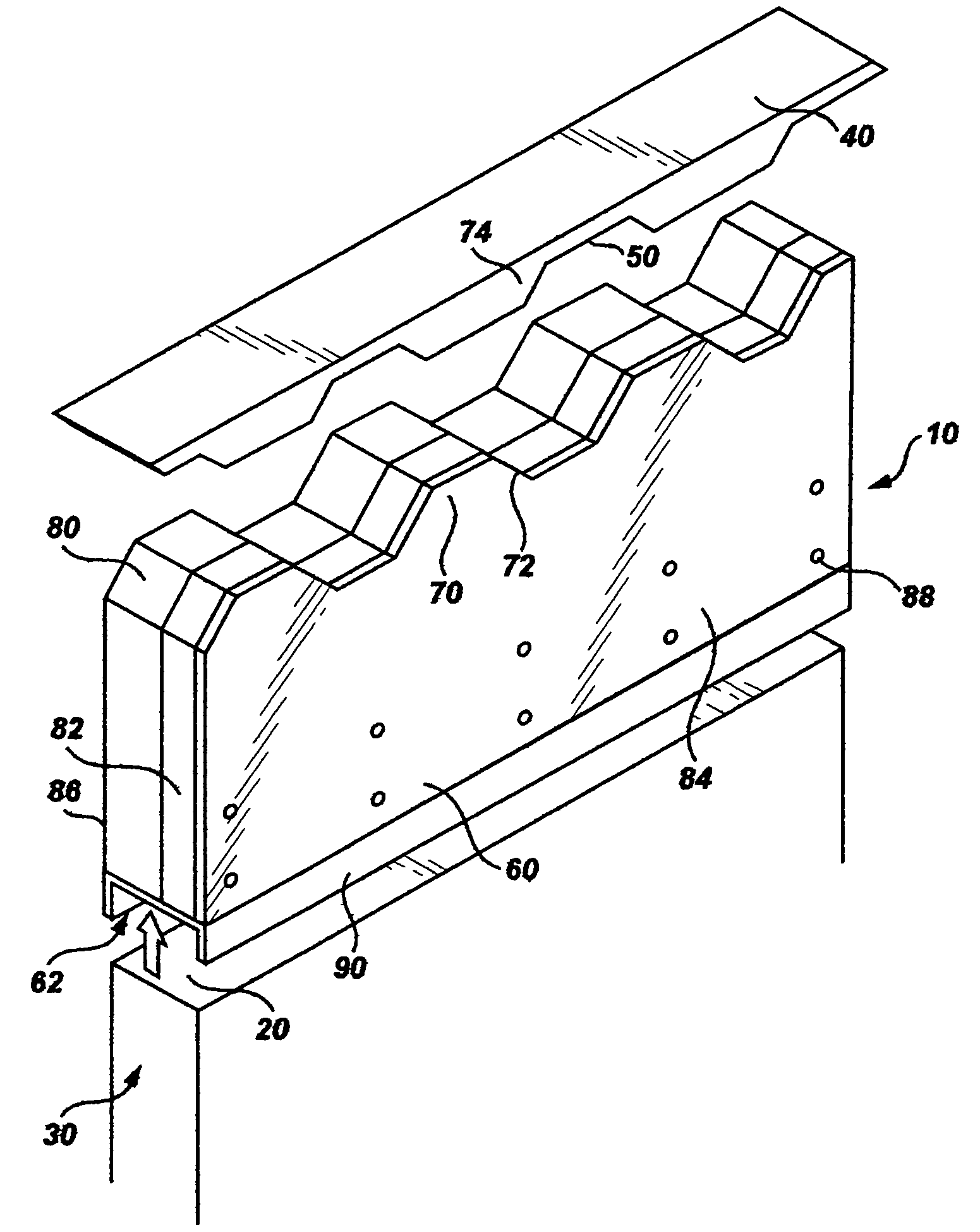

Tab track fire-rated wall assembly with dynamic movement

InactiveUS20180195282A1Prevent side to side movementExtra costConstruction materialWallsWall studEngineering

A fire-rated head-of-wall assembly includes a header track having bendable tabs, a pair of which is configured to hold a wall stud in place relative to the header track. An upper wallboard piece abuts against the ceiling and a lower wallboard piece is spaced from the upper wallboard piece to form a gap. A fire-resistant material, such as mineral wool, is positioned within the gap. An outer wallboard piece spans across the gap.

Owner:CALIFORNIA EXPANDED METAL PRODS

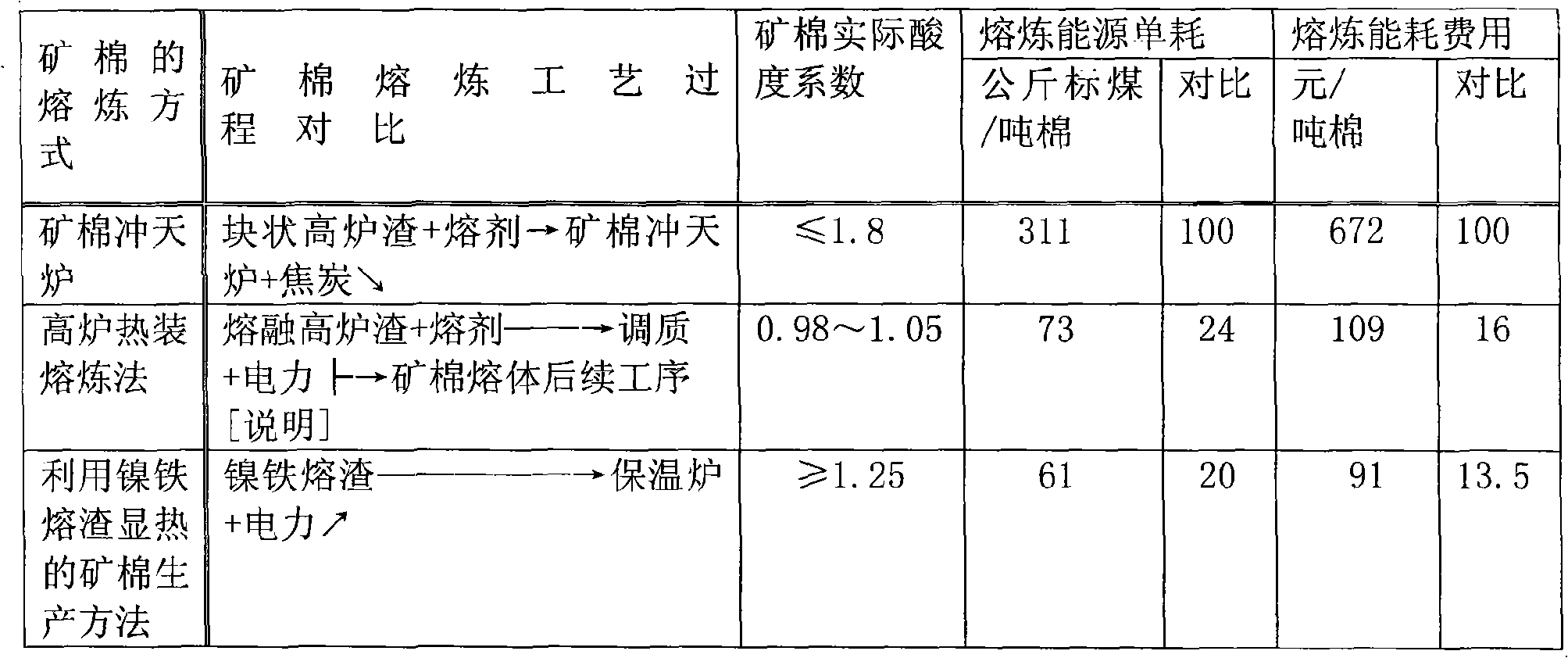

Method for preparing mineral wool by using ferronickel dross sensible heat

InactiveCN101293731AReduced service lifeMeet quality requirementsGlass making apparatusThermal insulationCotton fibre

The invention relates to the technical filed of mineral cotton production, which is a method for producing mineral cotton by using the sensible heat of ferronickel slag. The method includes the following steps: laterite-nickel ore is adopted as basic material, and the ferronickel slag with the temperature of 1450 to 1500 DEG C and acidity coefficient being equal to or more than 1.25 is poured into a power thermal insulation furnace with the capacity being 15 tons without adding any fusing agent; the temperature of melts is adjusted and kept within the range of 1350 to 1400 DEG C; then the melts with adjusted temperature are correctly led to a four-roller centrifugal machine by a water-cooling controllable head piece and a diversion trench so as to lead the ferronickel slag to be directly transformed into the mineral cotton fiber with high quality. Electrode materials in the power thermal insulation furnace are metal or carbon.

Owner:杨铧 +1

Ceramic fiber back lining board

A backing ceramic-fibre board as refractory is prepared from aluminium silicate fibre, organic fibre, mineral wool, expanded pearlite, clay, starch, polyacrylamide, and polymerized aluminium chloride through proportional mixing, preparing paste, shaping, drying and post-processing.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Method for manufacturing composite mineral wool board for building insulation

ActiveCN102501300AEasy constructionHigh tensile strengthCeramic shaping apparatusHeat proofingAdhesiveVolumetric Mass Density

The invention discloses a method for manufacturing a composite mineral wool board for building insulation. The method uses special interface agents as adhesives, a fiberglass mesh fabric completely wraps the surface of the high-density mineral wool board for the building to improve defects of an inorganic mineral wool board, and the mineral wool board can meet the requirements of national or industrial relevant standards and becomes a level-A non-combustible, flexible, high-strength, waterproof, air-permeable, high-weatherability and heat-insulation mineral wool material for the building. Experiments prove that the composite mineral wool board for building insulation, manufactured by the method, meets the relevant requirements of the national or industrial standards of Rock wool products for exterior insulation and finish systems (GB / T25975-2011), External thermal insulation composite system based on expanded polystyrene (JG149-2003), fire prevention regulations for buildings (GB50016) and the like.

Owner:CHANGAN UNIV

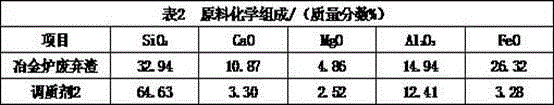

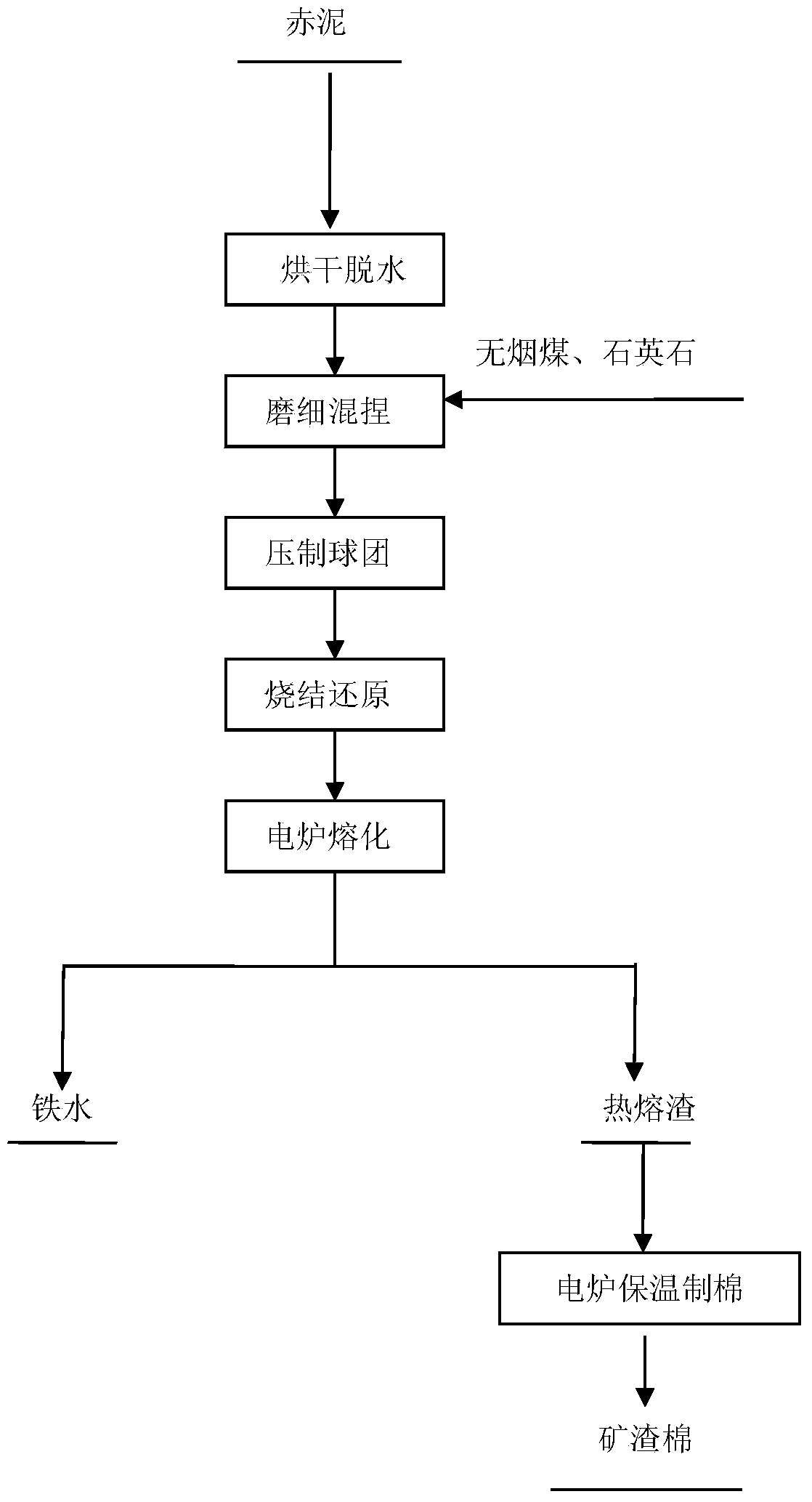

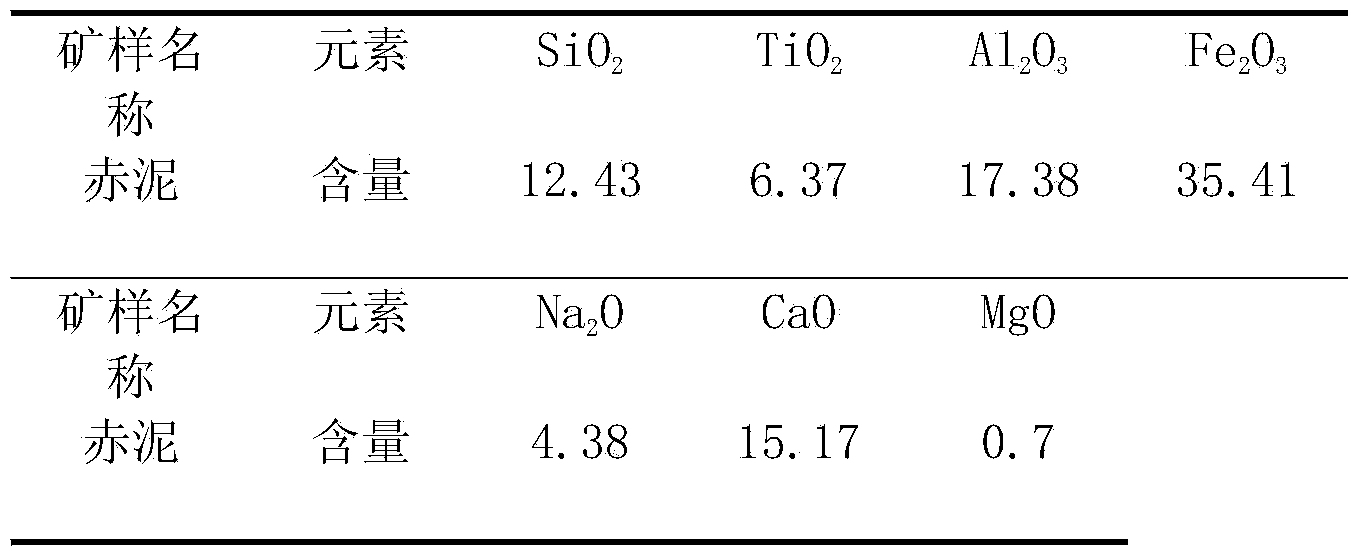

Method for producing high-strength and high-flexibility heatproof mineral wool and iron by using red mud

ActiveCN104046771ARealize comprehensive utilizationReduce pollutionGlass making apparatusProcess efficiency improvementRed mudSlag

The invention discloses a method for producing high-strength and high-flexibility heatproof mineral wool and iron by using red mud, and belongs to the field of comprehensive resource recycling in the non-ferrous metal metallurgy industry. The method comprises the following steps: 1, dehydrating and drying red mud, adding a reducing agent and a conditioning agent, and uniformly mixing; 2, adding pellets into a rotary kiln, and carrying out sintering pre-reduction; 3, adding hot pellets into an electric furnace, fusing, separating iron and slag, discharging molten iron through an iron outlet, and discharging the slag through a slag outlet; 4, collecting the slag discharged from the slag outlet, carrying out heat insulation by using the electric furnace, discharging, and processing to prepare the mineral wool; and 5, collecting the discharged molten iron. The method realizes the comprehensive utilization of a secondary non-ferrous metallurgy resource by using the red mud as a raw material to produce the mineral wool and iron, reduces environment pollution, maintains the ecologic balance and realizes the sustainable development. The high-strength and high-flexibility heatproof mineral wool can be produced, the recovery rates of the mineral wool and iron are high, and the economic benefit is substantial. The method also has the advantages of simple technology and easy popularization.

Owner:JILIN JIEN NICKEL IND +2

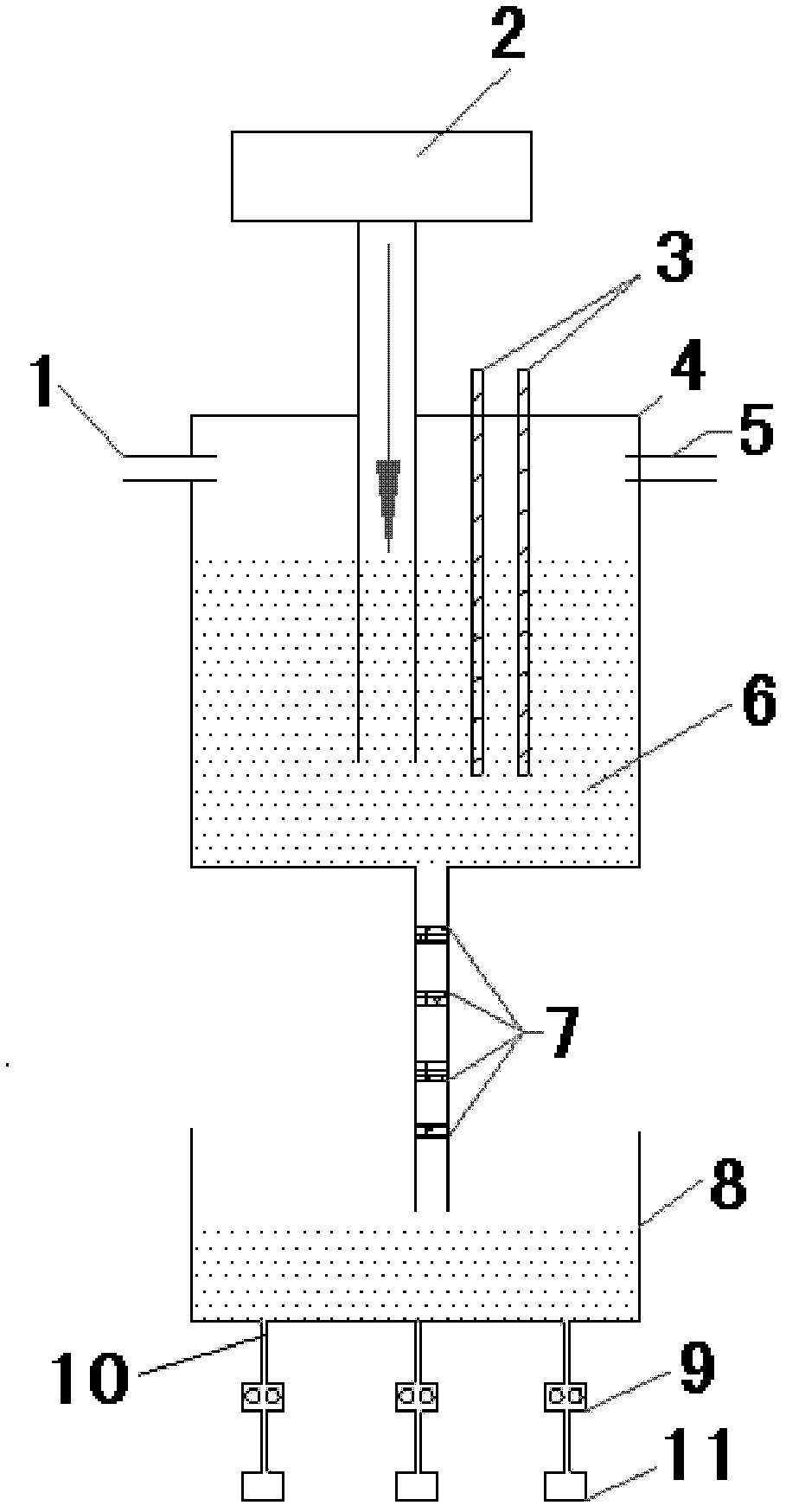

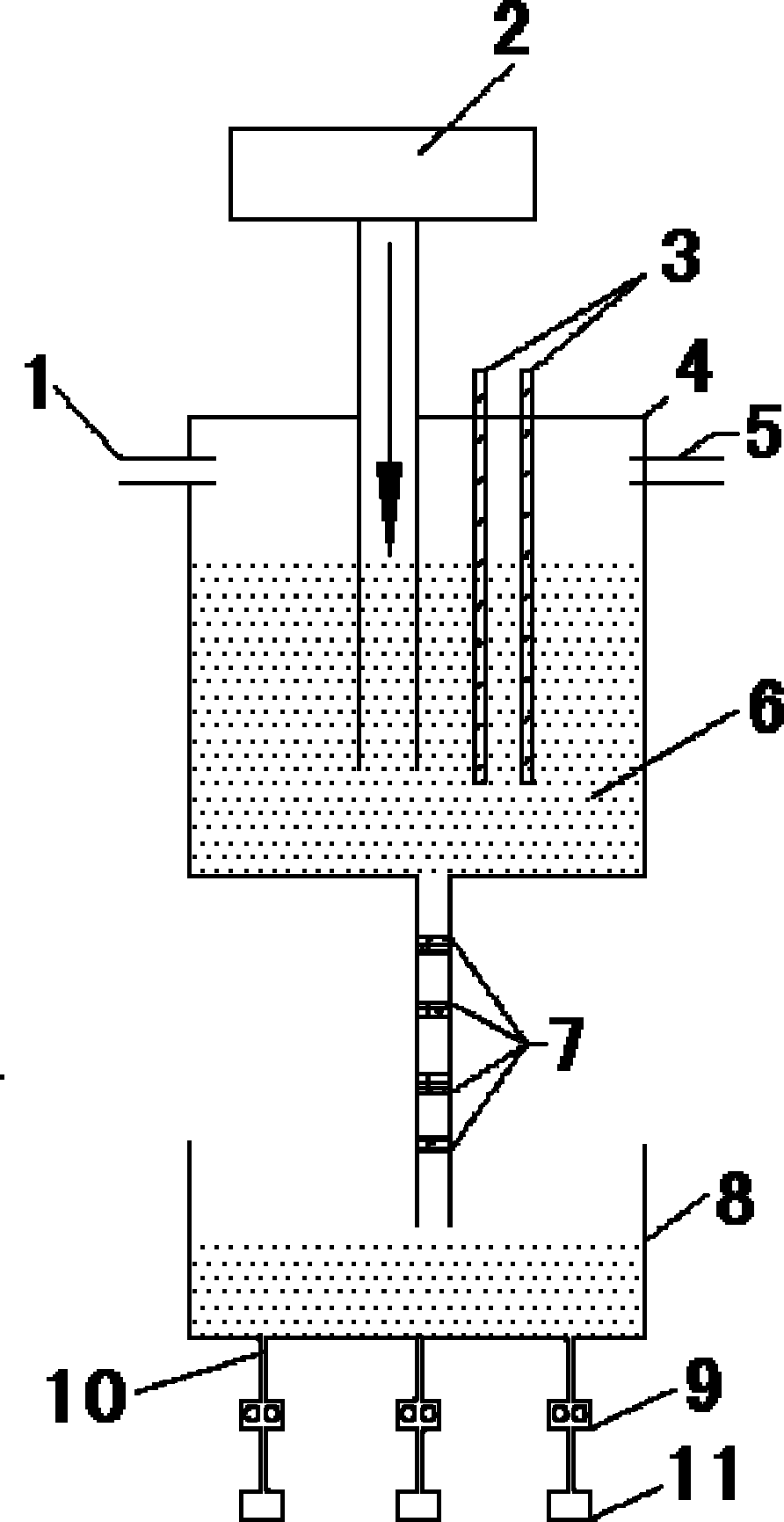

One-stage mineral wool technology high-effectly utilizing industrial furnace smelting slag heat

InactiveCN1418834AObvious fluctuationsSolve the problem of continuous temperature measurementGlass making apparatusQuality levelManganese

The one-step method for producing mineral wool by using industrial furnace molten slag sensible heat includes the following steps: according to the requirement for chemical composition of mineral wool adding proper auxiliary raw material, at the same time, in homogenizing furnace making concurrent heating and regulating its chemical composition temp. and viscosity to make them reach to the requirements of mineral wool molten body, making molten body acidity coefficient be up to 1.1-1.8 (acidity coefficient=SiO2+Al2O3 / CaO+MgO), and the molten body temp. is 1300-1340 deg.C, homogenizing its chemical components, feeding the thermally-refined molten body into high-speed centrifuge and feeding it into fibre-forming procedure of mineral wool so as to obtain the invented product.

Owner:杨铧

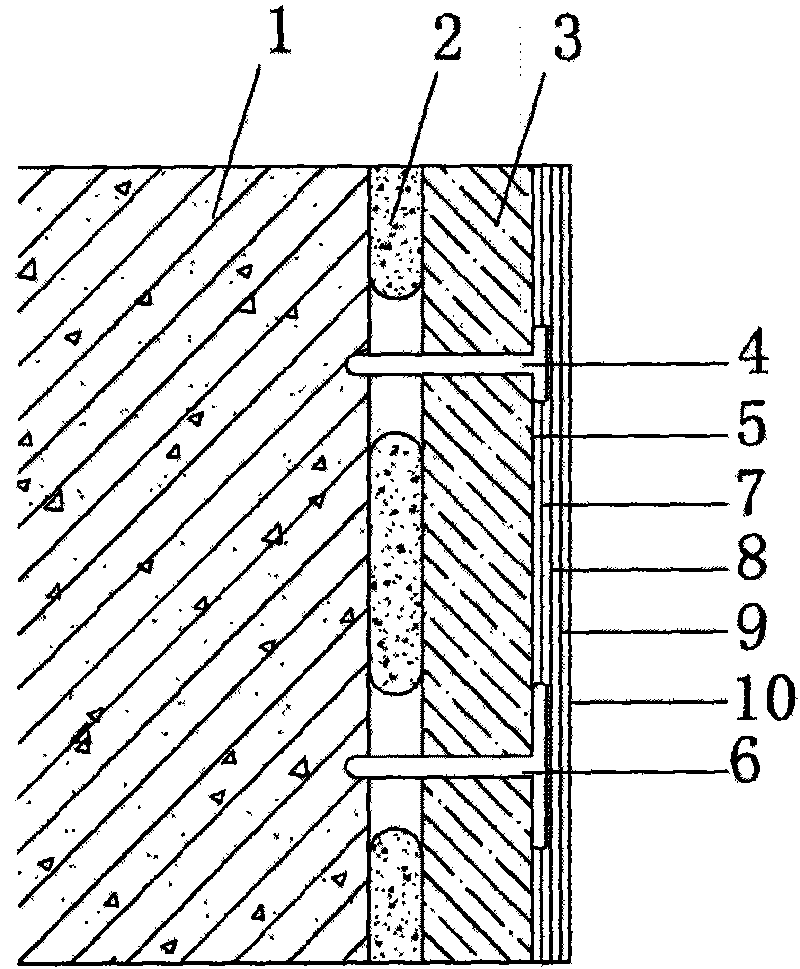

Anorganolith/slag wool thin-plastered outer wall thermal insulation system and construction technology

InactiveCN101701476ASimple construction processImprove insulation effectCovering/liningsClimate change adaptationSlagEngineering

The invention provides an anorganolith / slag wool thin-plastered outer wall thermal insulation system, comprising a basement layer, a bonding layer, a thermal insulation layer, an anti-crack protective layer and a veneer layer, wherein the thermal insulation layer is a rock / slag wool thermal insulation layer, adopts a combination mode of fixing anchor bolts and sticky nails by bonding mortar and a rock / slag wool thermal insulation plate to fix the rock / slag wool thermal insulation plate with the basement layer; the density range of the rock / slag thermal insulation is 80-220kg / m3, and 10% of deformation compression resistance strength is larger than 30kPa; the outer side of the thermal insulation layer is the anti-crack protective layer which adopts reinforced fiberglass mesh or hot-galvanizing wiremesh and anti-crack mortar to manufacture an integral structure, adopts a metallic gasket type integral anchor bolt with wind load resistance to fix the rock / slag wool thermal insulation plate on a wall body of the basement layer firmly, and performs integral connection of the alkali-resisting fiberglass mesh or galvanized steel wire netting with the wall body of the basement layer of the rock / slag wool thermal insulation plate; and the outside of the anti-crack protective layer is the veneer layer. The invention has the advantages of good thermal insulation effect, simple construction, high bonding strength, good fire-resisting performance and the like.

Owner:鳄鱼制漆(上海)有限公司

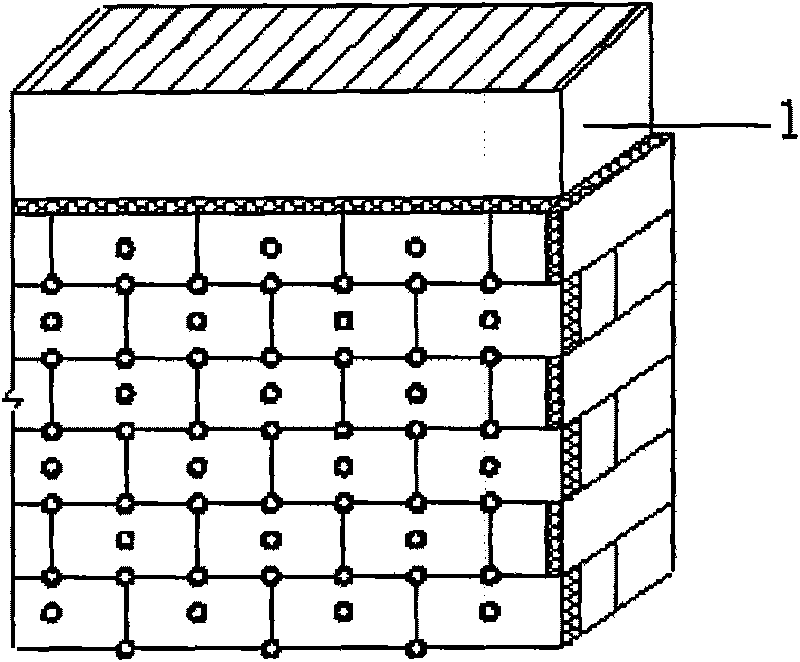

Installation process for autoclaved lightweight concrete board partition wall

The invention relates to installation process for autoclaved lightweight concrete board partition wall, which is characterized in the process includes steps of: cleaning the field, paying out, Z type piece welding, installing corner units or U-type card, in-situ installing the board, regulating, installing hook bolts and other accessories, welding and twisting for fixture, performing anti-corrosive treatment at the welding point, filling mineral wool in the slot, slot repairing / injecting glue, cleaning and inspecting. The beneficial effect is that features of the ALC board is capable of ensuring strength, security and reliability of the connection at the connecting point, and rotation capability in the plane. When relatively large horizontal displacement occurs in the structure, the wall board rotates and moves along, thus the horizontal force transmitted by the structure is dispelled. Therefore, the partition wall has excellent earthquake resistance, and is especially suitable for buildings in earthquake areas, typhoon areas, high-rise steel structure buildings, and part of buildings which has relatively vibration, relatively large displace and deformation. The popularization of the installation process for the ALC board partition wall is capable of bringing benefits to the building construction.

Owner:CHINA CONSTR DONGFANG DECORATION CO LTD

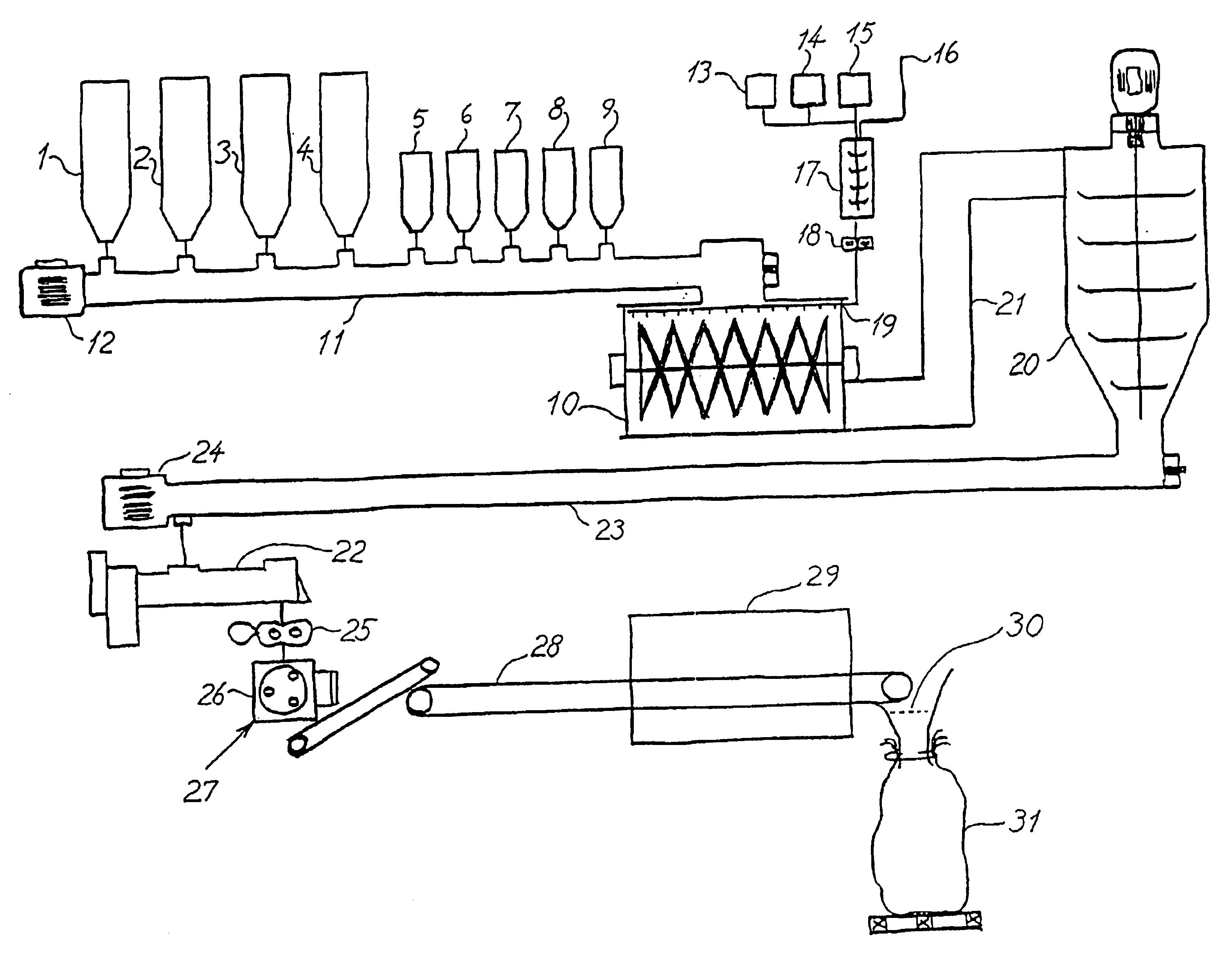

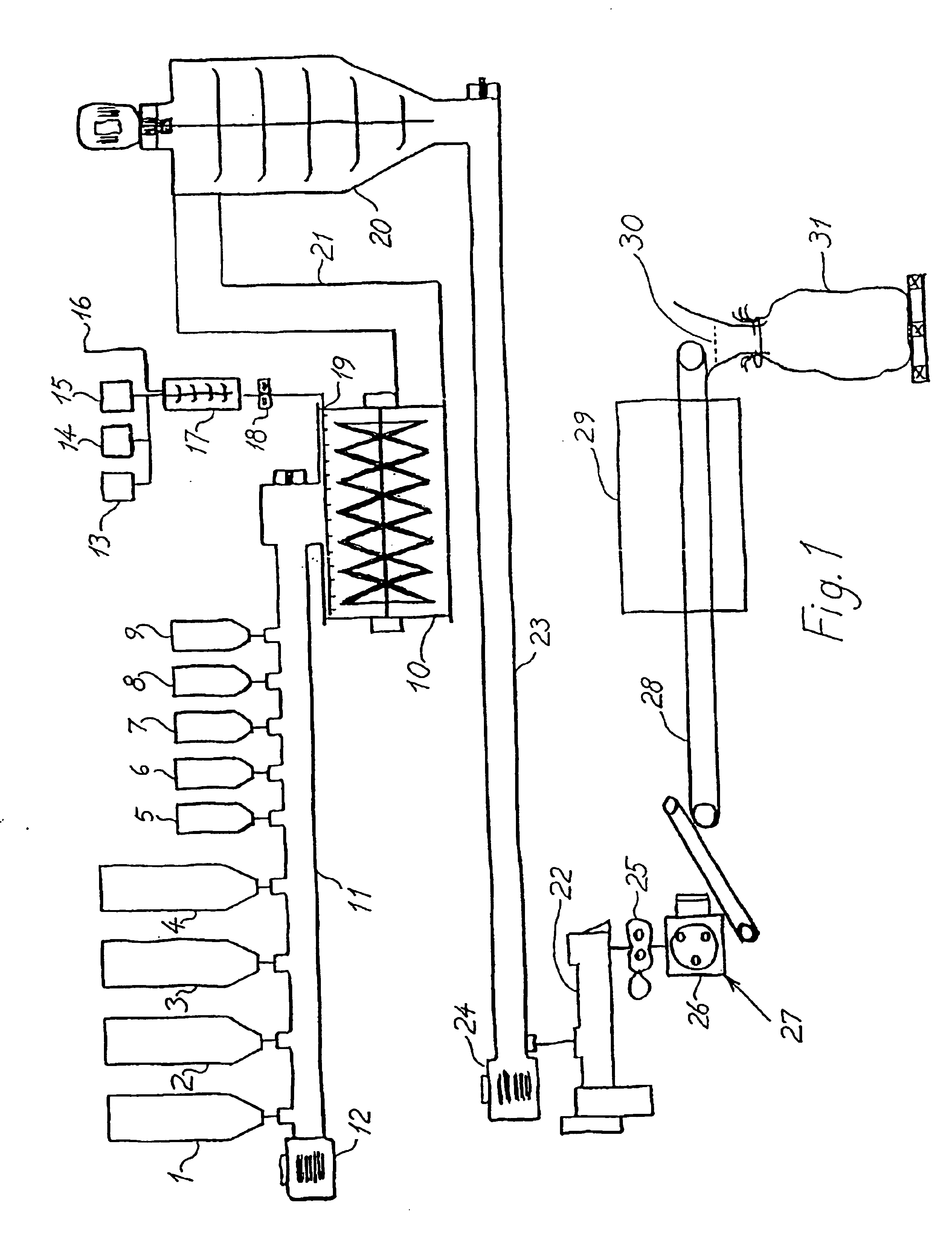

Method for processing mineral wool

ActiveCN102659309AReduce processing energy consumptionReduce processing costsGlass making apparatusGlass productionSlagProcessing cost

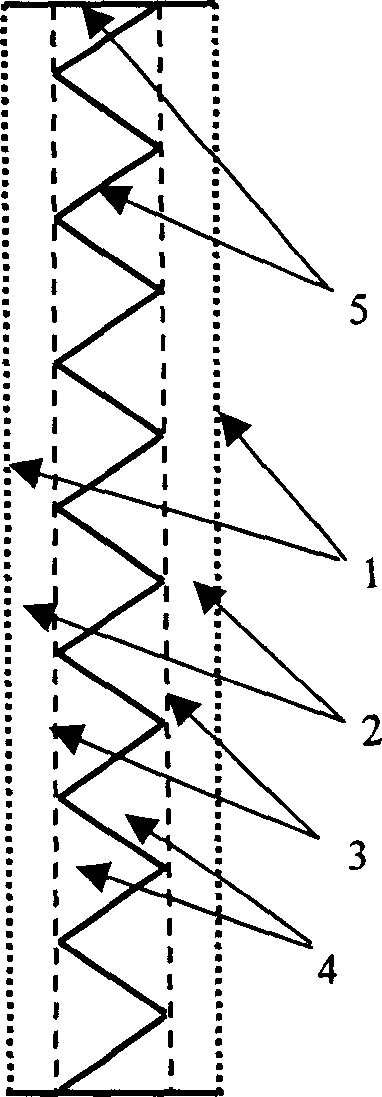

The invention provides amineral wool processing method applied to the mineral wool production field. The said processing steps of mineral wool comprises 1)adding liquid blast furnace slag ,which is used as a raw material, into a melting quenching and tempering furnace (4),andblowing sandstone ,which is used as a modified material, and sodium carbonate ,which is used as an viscosity improving agent, into the melting quenching and tempering furnace (4); 2) after melting and mixing the liquid blast furnace slag, sandstone and sodium carbonate at a high temperature , conveying the high-temperature melt to an intermediate reservoir (8) through a flow mixing arrangement (7); 3) after the liquid high-temperature melt (6) in the intermediate reservoir (8) flows out from a slag outlet of the intermediate reservoir (8), performing silk throwing with a centrifugal silk throwing machine (9) to form mineral wool. The processing method for mineral wool disclosed by this invention can remarkably reduce the energy consumption during the mineral wool processing and effectively utilize the potential heat energy of the high temperature slag to reduce the energy waste, therefore minimizing the processing cost of mineral wool.

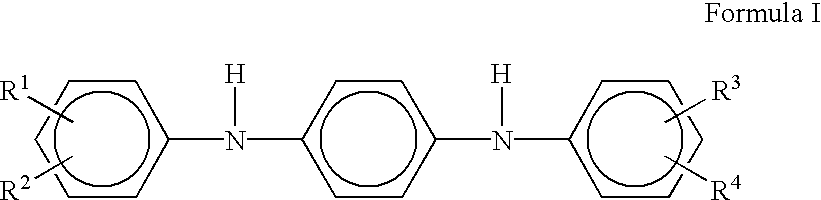

Microfiber Reinforcement for Abrasive Tools

InactiveUS20120100784A1Improved wheel lifeProlong lifePigmenting treatmentOther chemical processesMaterials scienceMicrofiber

An abrasive article includes an organic bond material, an abrasive material dispersed in the organic bond material, mineral wool microfibers uniformly dispersed in the organic bond material, the mineral wool microfibers being individual filaments, one or more reinforcement and / or chopped strand fibers dispersed in the organic bond material and one or more active fillers including, for example, a manganese compound. The abrasive article can be used in the abrasive processing of a workpiece.

Owner:SAINT GOBAIN ABRASIVES INC +1

Binder systems derived from amorphous silica and bases

InactiveUS6866709B1Excellent binder systemProcess stabilityGas treatmentSolid waste managementFiberPorosity

The present invention relates to compositions comprising the reaction product of amorphous silica or ultra-fine silica and one or more bases. The present invention also relates to materials and method involving the use of such products. In particular, the present invention i.a. relates to new mineral wool products, e.g. products comprising man-made vitreous fibres (such as glass fibres, slag fibres, stone fibres and rock fibres) or perlite, having included therein a binder component which comprises amorphous silica and aklali metal organosiliconates, e.g. potassium methyl siliconate. An important feature of such products is the preparation of the binder systems under vigorous mixing. Such products provide good fire, heat and sound insulating properties. The present invention also provides to a method for removing odorous substances from a gas where materials prepared from ultra-fine silica, water, and one or more components enabling porosity-conferring binding of the material, e.g. a base or bases. Furthermore, the invention provides methods for thixotroping bitumen.

Owner:HOLBEK KJELD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com