Technique for comprehensively utilizing iron-containing dust mud

A technology of iron dust sludge and process, applied in the field of comprehensive utilization of iron dust sludge, can solve the problems of low DRI quality, insufficient removal of impurities by direct reduction process, limitation of comprehensive utilization of iron dust sludge, etc., so as to improve economic benefits and improve The effect of comprehensive utilization efficiency and reduction of process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

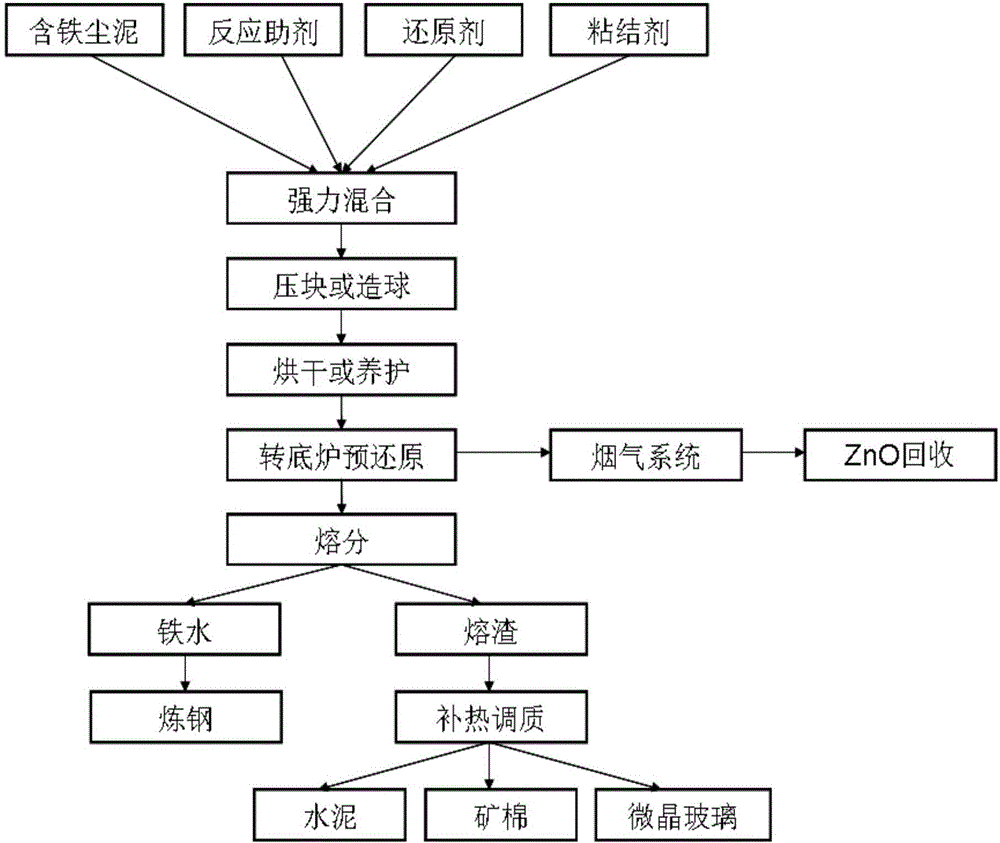

[0028] Such as figure 1 Shown: Iron-containing dust produced in the iron and steel production process, FeOx% in iron-containing dust is about 55%, C% is about 3%, ZnO% is about 0.7%, CaO% is about 12%, and reaction aids, reducing agents, Binder, through strong mixing and mixing, after briquetting (briquetting) or pelletizing process, the iron-containing dust is made into lumps or balls, and after drying or curing, the dried lumps or balls Added to the rotary hearth furnace, in the pre-reduction process of the rotary hearth furnace, the ZnO in the dust sludge enters the flue gas system. ZnO removal, alkali metal removal and pre-reduction were performed in a rotary hearth furnace, ZnO was recovered in the flue gas of the rotary hearth furnace, and metallized pellets DRI were obtained after pre-reduction. The DRI produced by the rotary hearth furnace is added to the melting furnace to separate the molten slag and iron. The separated molten iron enters the steelmaking process, an...

Embodiment 2

[0030] Such as figure 1 Shown: Aluminum Al 2 o 3 Iron-containing dust sludge 1 produced in the production process, FeOx% in iron-containing dust sludge is about 40%, ZnO% is about 0.05%, CaO% is about 12%, SiO 2 % about 8%, with reaction aids, reducing agents, binders, through strong mixing and mixing, and then through briquetting (briquetting) or pelletizing process, the iron-containing dust is made into lumps or balls, after drying After drying or curing, the dry block or spherical red mud is added to the rotary hearth furnace in the rotary hearth furnace pre-reduction process. Alkali metal removal and pre-reduction in a rotary hearth furnace to obtain metallized pellets DRI after pre-reduction. The DRI produced by the rotary hearth furnace is added to the melting furnace to separate the molten slag and iron. The separated molten iron enters the steelmaking process, and the separated dust and sludge slag can be used to produce cement, mineral wool or High value-added sil...

Embodiment 3

[0033] Such as figure 1 Shown: Iron-containing dust, mixed with reaction aids, reducing agents, and binders by force, after briquetting (briquetting) or pelletizing process, the iron-containing dust is made into lumps or balls , after drying or curing, the dried massive or spherical dust sludge is added to the rotary hearth furnace. In the pre-reduction process of the rotary hearth furnace, the ZnO in the dust sludge enters the flue gas system. ZnO removal, alkali metal removal and pre-reduction were performed in a rotary hearth furnace, ZnO was recovered in the flue gas of the rotary hearth furnace, and metallized pellets DRI were obtained after pre-reduction. The DRI produced by the rotary hearth furnace is added to the melting furnace to separate the molten slag and iron. The separated molten iron enters the steelmaking process, and the separated dust and sludge slag is used to produce mineral wool after conditioning and heating.

[0034] The difference between Example 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com