Patents

Literature

4020 results about "Tempering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures.

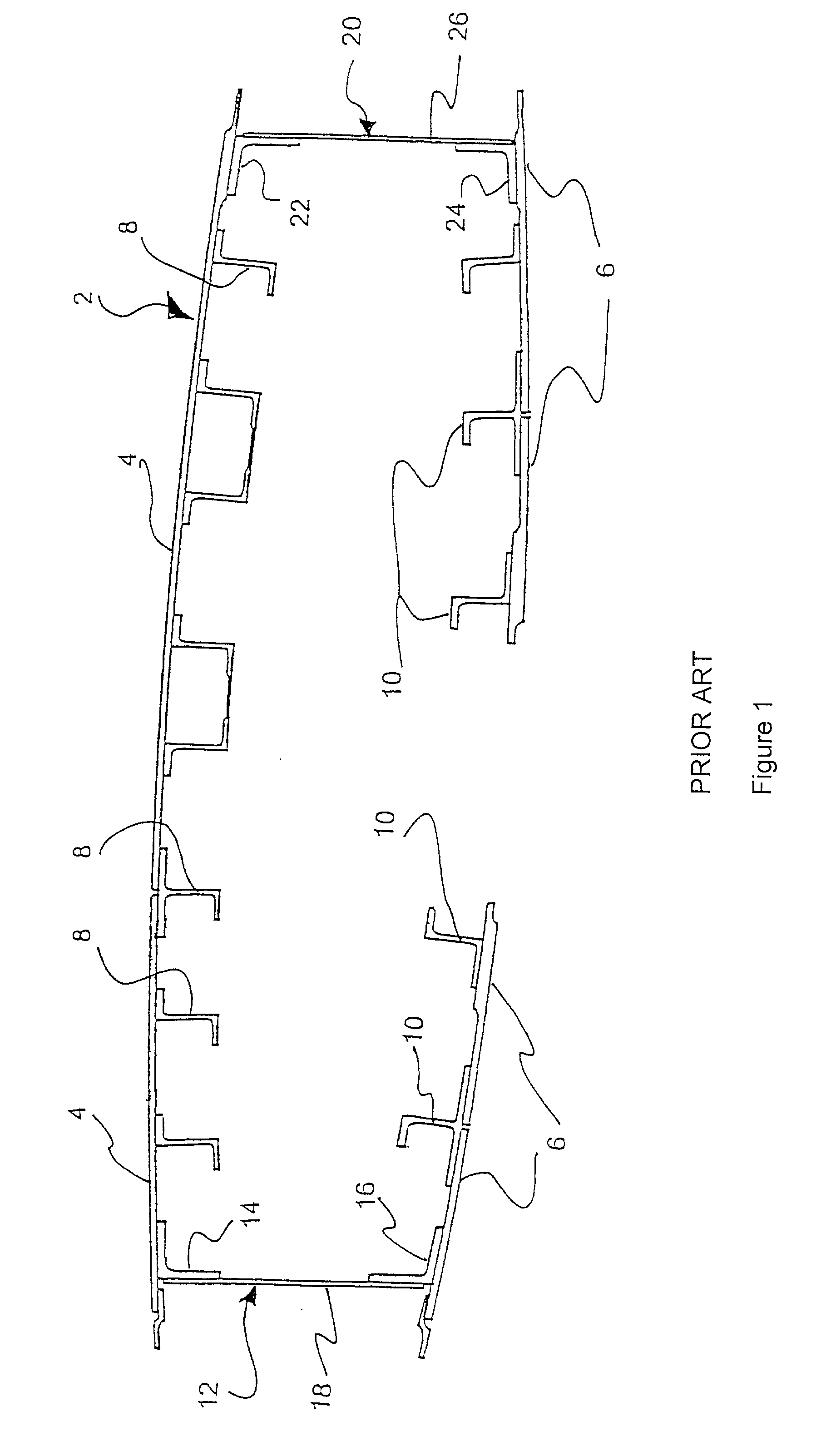

Aluminum alloy having superior strength-toughness combinations in thick gauges

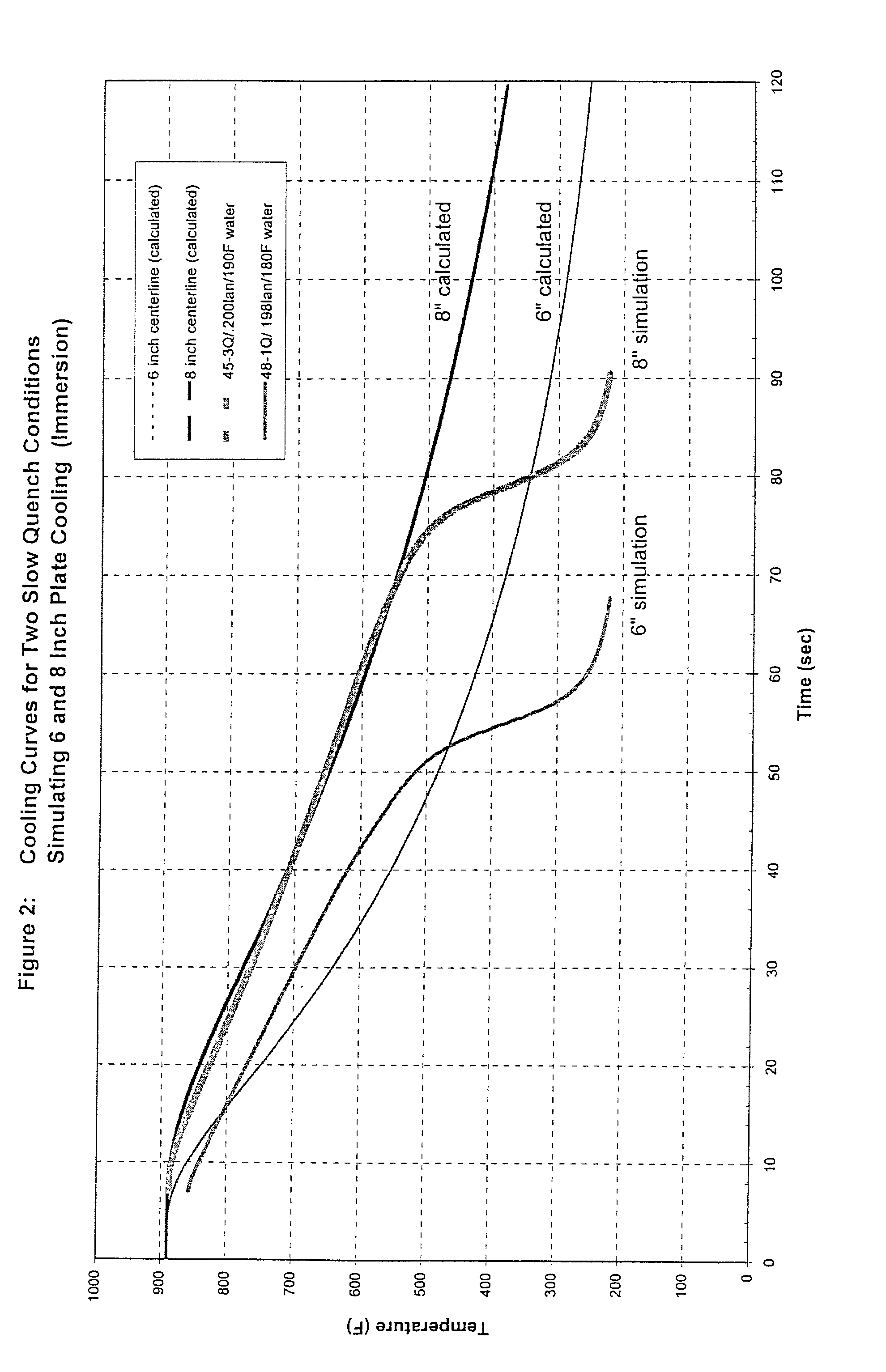

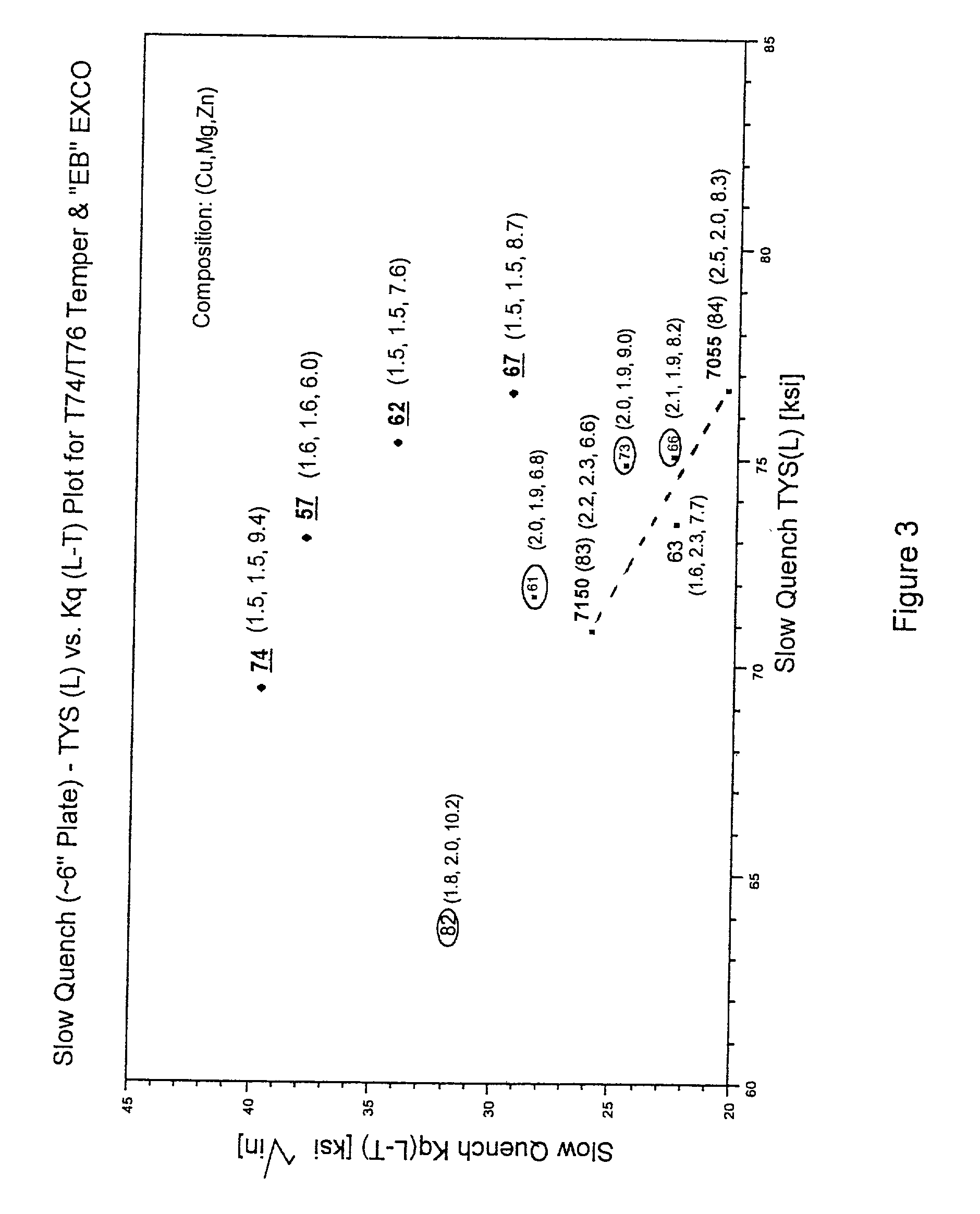

A 7XXX series aluminum alloy having reduced quench sensitivity suitable for use in aerospace structural components, such as integral wing spars, ribs, extrusions and forgings comprises, in weight %: 6 to 10 Zn, 1.3 to 1.9 Mg, 1.4 to 2.2 Cu, wherein Mg<=Cu+0.3, one or more of 0 to 0.4 Zr, up to 0.4 Sc, up to 0.2 Hf, up to 0.4 Cr, up to 1.0 Mn and the balance Al plus incidental additions including Si, Fe, Ti and the like plus impurities. By controlling the Mg content to 1.3 to 1.7 wt. %, limiting Mg<=Cu+0.3 and 6.5<=Zn<=8.5, the alloy provides significantly improved combined strength and fracture toughness in heavy gauges. For example, in a six-inch thick plate there is provided a combination of about 75 ksi quarter-plane tensile yield strength (L) with a fracture toughness (L-T) of about 33 ksi{square root}in which progresses by artificial aging / tempering to a combined strength and fracture toughness of about 67 ksi tensile yield strength (L) and a fracture toughness (L-T) of about 40 ksi{square root}in. The alloy product possesses equally attractive combinations of strength and fracture toughness when intentionally quenched slowly following solution heat treatment so as to lessen dimensional distortion, particularly in shapes of varying cross section.

Owner:ARCONIC INC

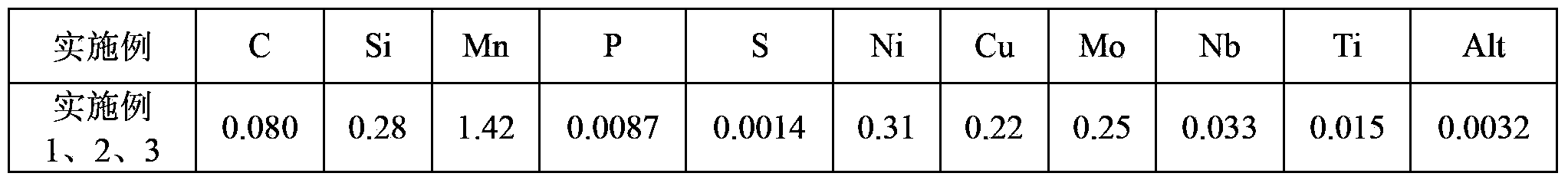

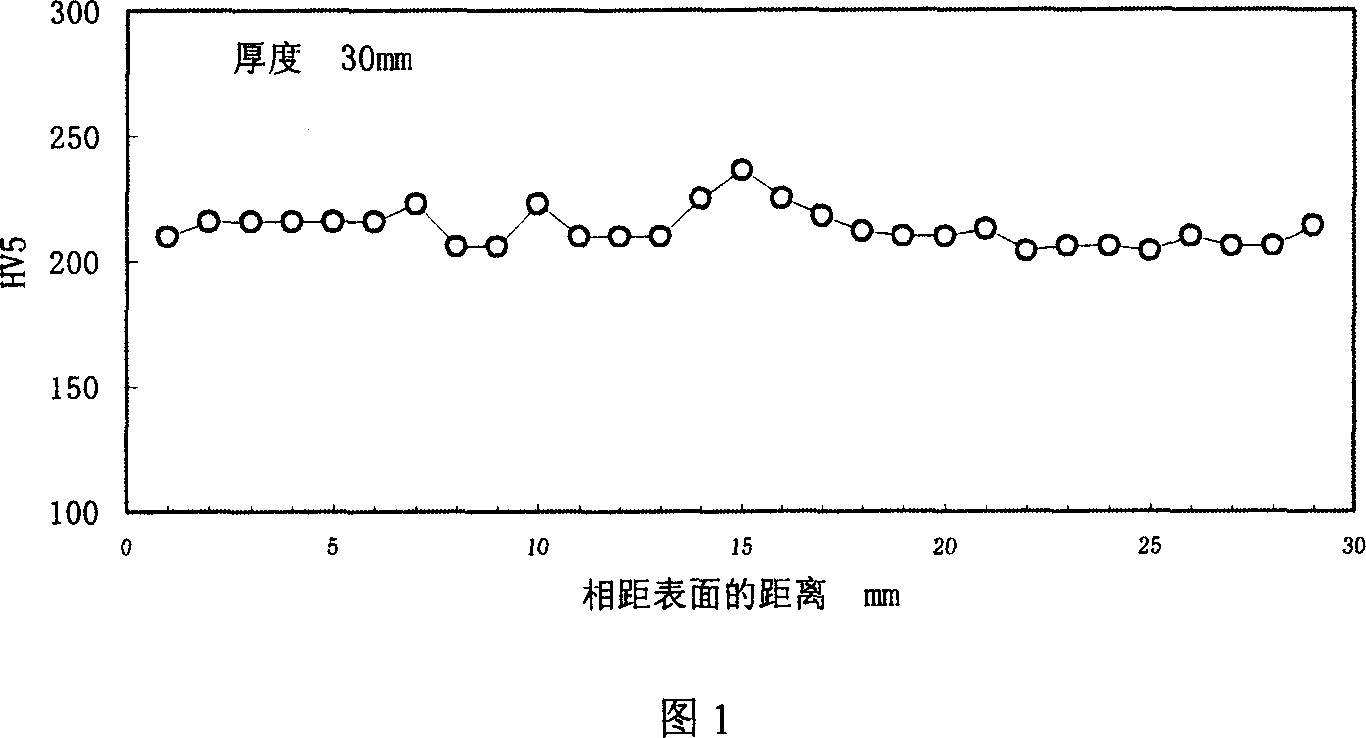

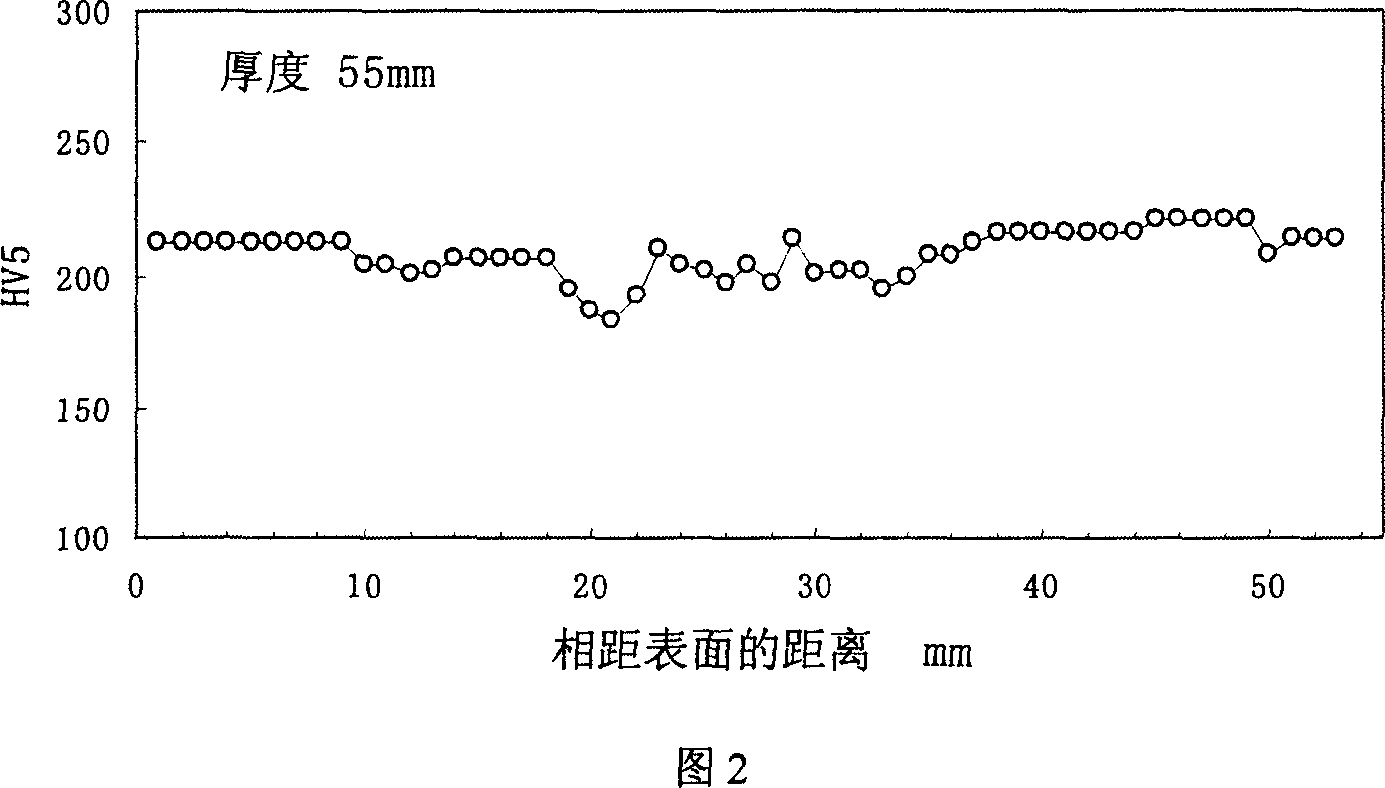

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

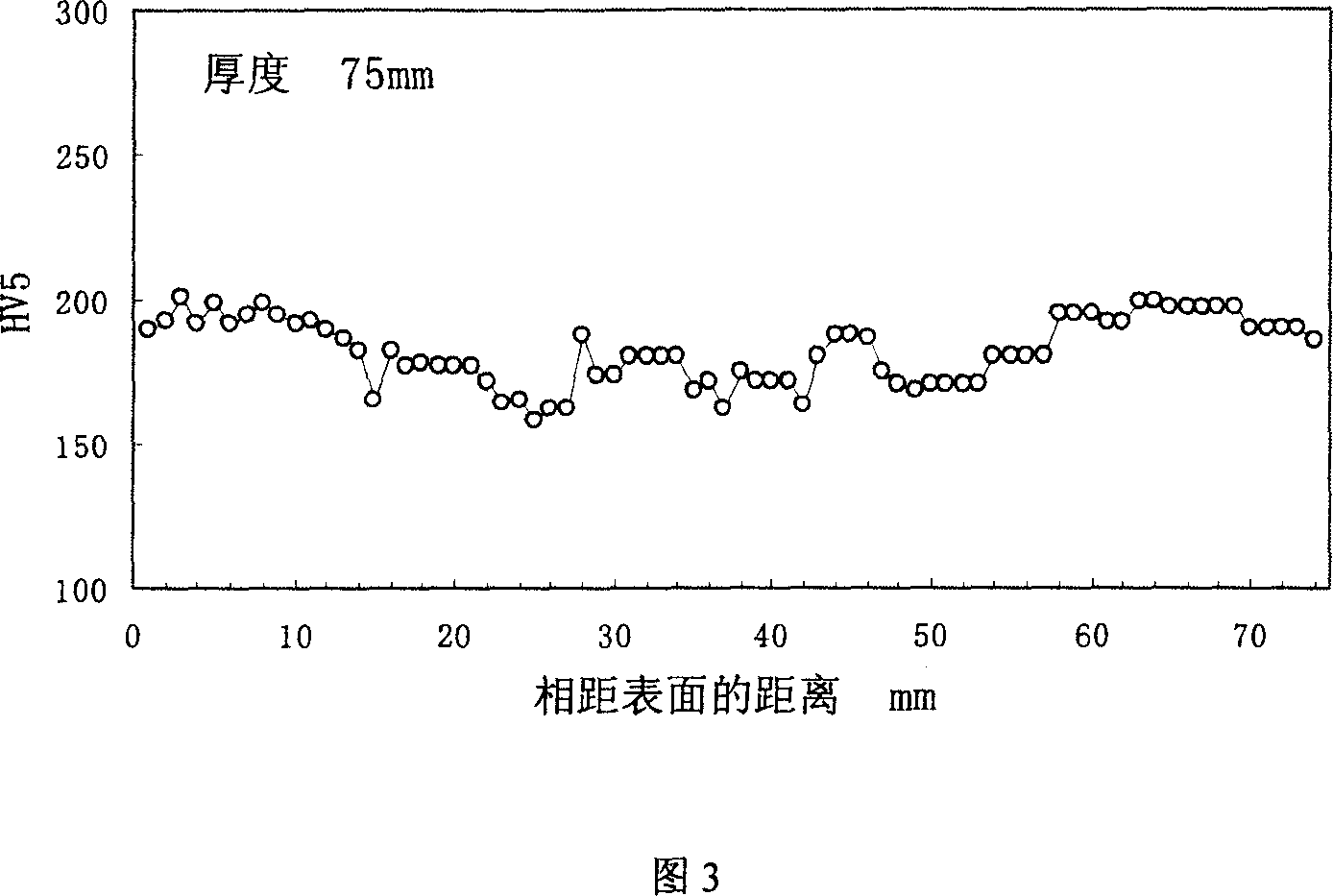

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

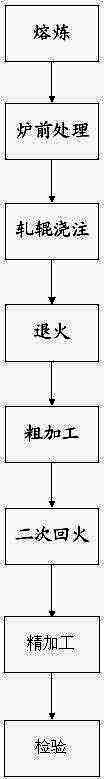

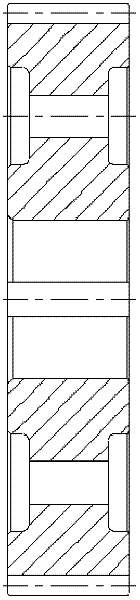

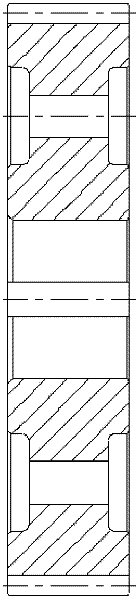

High-speed steel roll ring and its production

A high-speed steel roller ring for rolling wire or rod material contains C, W, Mo, V, Cr, Al, Ni, Co, Nb, Ti, Ce, Na, Mg, Si, Mn, S, P and Fe proportionally. It is prepared through smelting in electric furnace, centrifugal casting, and annealing, high-temp quenching and tempering twice. Its advantages are high hardness, tension strength and toughness for breaking, smooth surface and high size stability.

Owner:XI AN JIAOTONG UNIV

Thick steel plate with great line energy and low welding crack sensitivity and its production process

The present invention discloses one kind of thick steel plate with great line energy and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.10 wt%, Si 0.15-0.40 wt%, Mn 1.20-1.60 wt%, P not more than 0.015 wt%, S not more than 0.007 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo 0.15-0.30 wt%, V 0.02-0.06 wt%, Al 0.015-0.045 wt%, Ti 0.010-0.034 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 %. The production process includes pre-treatment of molten iron, smelting in converter, LF furnace plus VD furnace vacuum treatment, two stage controlled rolling, on-line laminar flow cooling, tempering at 600-680 deg.c and other steps. The produced steel plate has no need of quenching and tempering treatment.

Owner:ANGANG STEEL CO LTD

Low-temperature high-strength, high-toughness steel and preparing method therefor

InactiveCN101024870AHigh strengthGuaranteed toughnessHeat treatment process controlLift systemThermal treatment

The invention relates to a low-temperature, high-intensity, high-toughness steel and the making method thereof, applicable to the environment down to -60 deg.C, adopting low-carbon Cr-Ni-Si-Mn-Mo-V alloy, and its chemical composition includes in mass percent (mass%): C: 0.16-0.24,Si:1.0-1.4, Mn:1.10-1.50,Cr:0.80-1.20,Ni:1.00- 1.40,Mo:0.20-0.40,V:0.05-0.20,S=<0.035,P=<0.035,Cu =<0.050, and the rest Fe. And its making method comprises: (1) smelting; (2) forging: heating at 1280-1320deg.C, where initial forging temperature: 1100-1250deg.C, final forging temperature >=850deg.C; annealing after forging, where heating temperature: 700+-30deg.C, and tapping temperature =<300deg.C; (3) thermal treatment: normalizing: air cooling at 930-950deg.C; tempering: air cooling at 790-720deg.C; quenching: oil cooling at 900-930deg.C; and tempering: air cooling at 200-260deg.C; (4) supersonic crack detection and magnetic particle crack detection. And it is especially applied to the materials for flying rings, hocks, pin shafts, etc, in the lifting systems of mechanical facilities.

Owner:RG PETRO MACHINERY GROUP

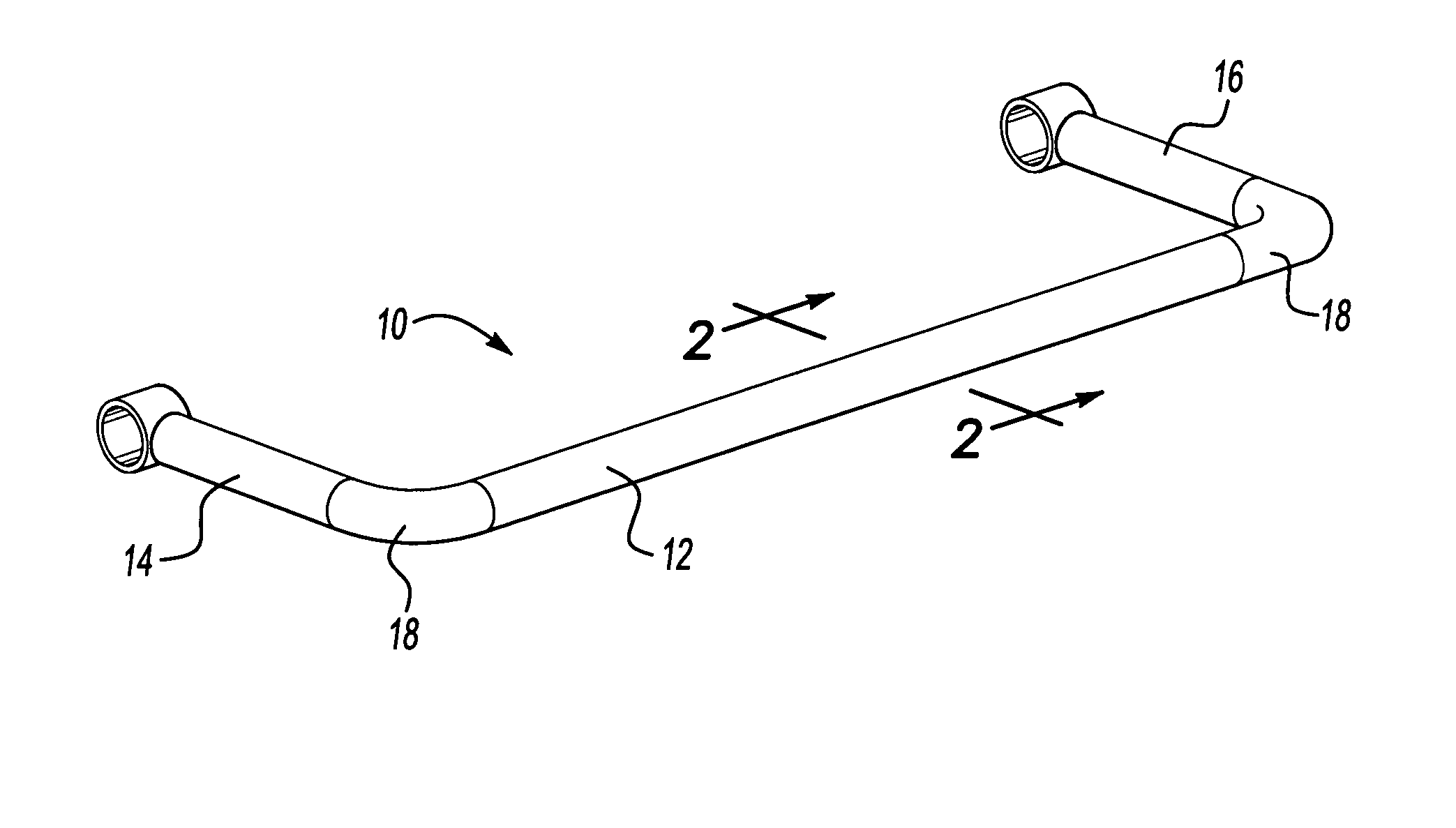

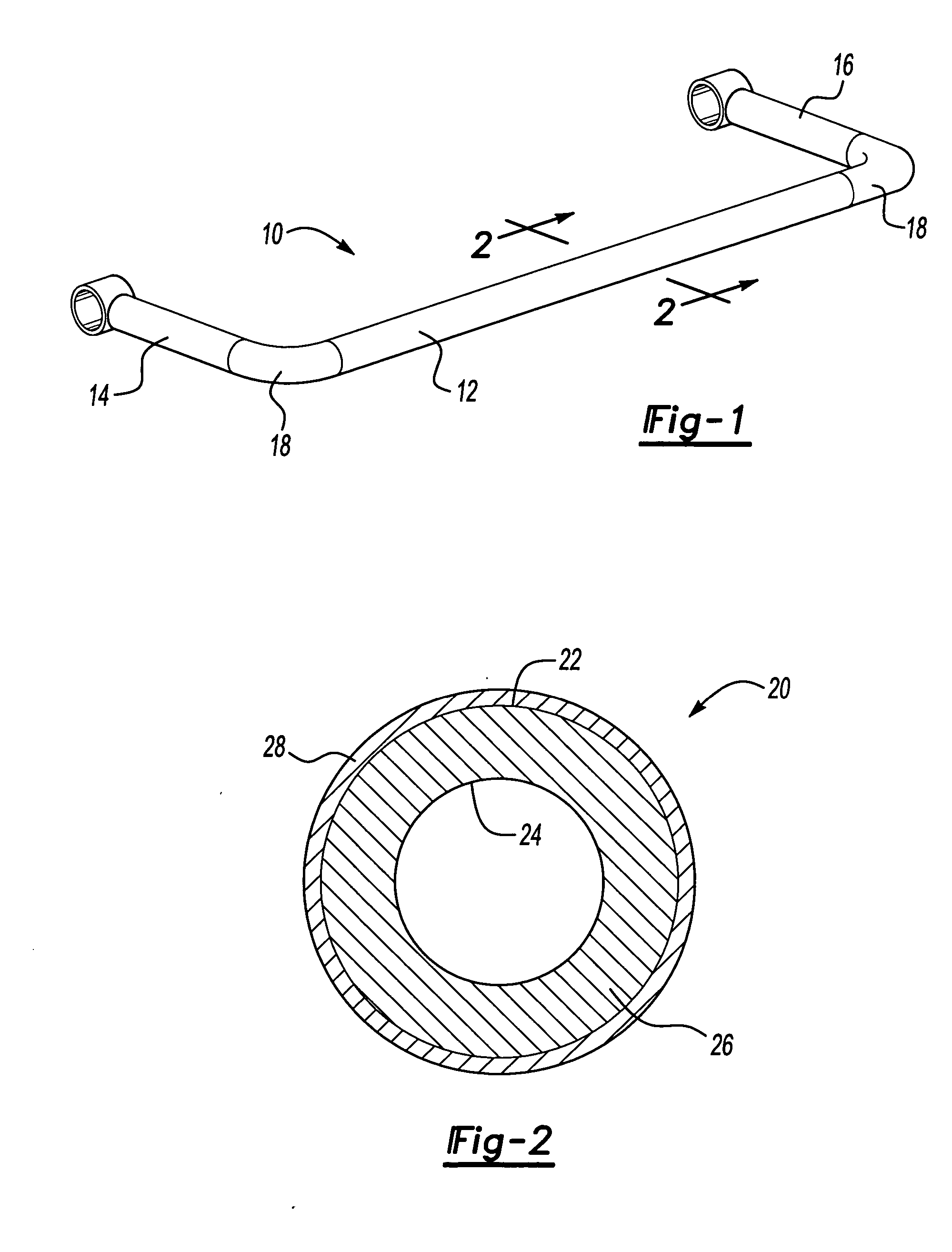

Stabilizer bar

InactiveUS20060243355A1Reduce manufacturing costHigh hardnessFurnace typesInterconnection systemsTemperingClassical mechanics

A tubular stabilizer bar for a vehicle suspension is formed from an as-quenched steel material that is not subjected to a tempering process, and which has a hardness of at least 40 Rockwell C. The stabilizer bar includes an ultimate tensile strength that is greater than 200 ksi with a ratio of yield strength to ultimate tensile strength that is no more than 0.9. The stabilizer bar is significantly harder and has significantly improved fatigue life without compromising ductility, when compared with prior designs.

Owner:MERITOR SUSPENSION SYST U S

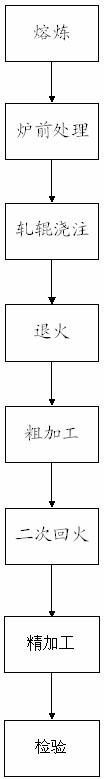

Boron-contained centrifugal composite high-speed steel roller and manufacturing method thereof

InactiveCN102615106AImprove composite effectNot easy to peel offRollsMetal rolling arrangementsUltimate tensile strengthWear resistance

The invention discloses a boron-contained centrifugal composite high-speed steel roller, which comprises an outer layer of the high-speed steel roller, a middle layer of the high-speed steel roller and a core of the high-speed steel roller. The manufacturing method includes steps of smelting, interrupted front treatment, roller pouring, annealing, rough machining, double tempering, finish machining and testing. By the method, three-layer composite roller technology is adopted in the boron-contained centrifugal composite high-speed steel roller, composite ability of the outer layer of the high-speed steel roller and the core of the high-speed steel roller is increased, the roller is less prone to spalling, high in rigidity and accident resistant ability, fine in abrasion resistance, safe in use, low in energy consumption and short in cycle in heat treatment, oxidation and decarburization of the roller and roller breakage in use are avoided. The manufacturing method is simple and hot quenching process is omitted.

Owner:常熟市轧辊厂有限公司

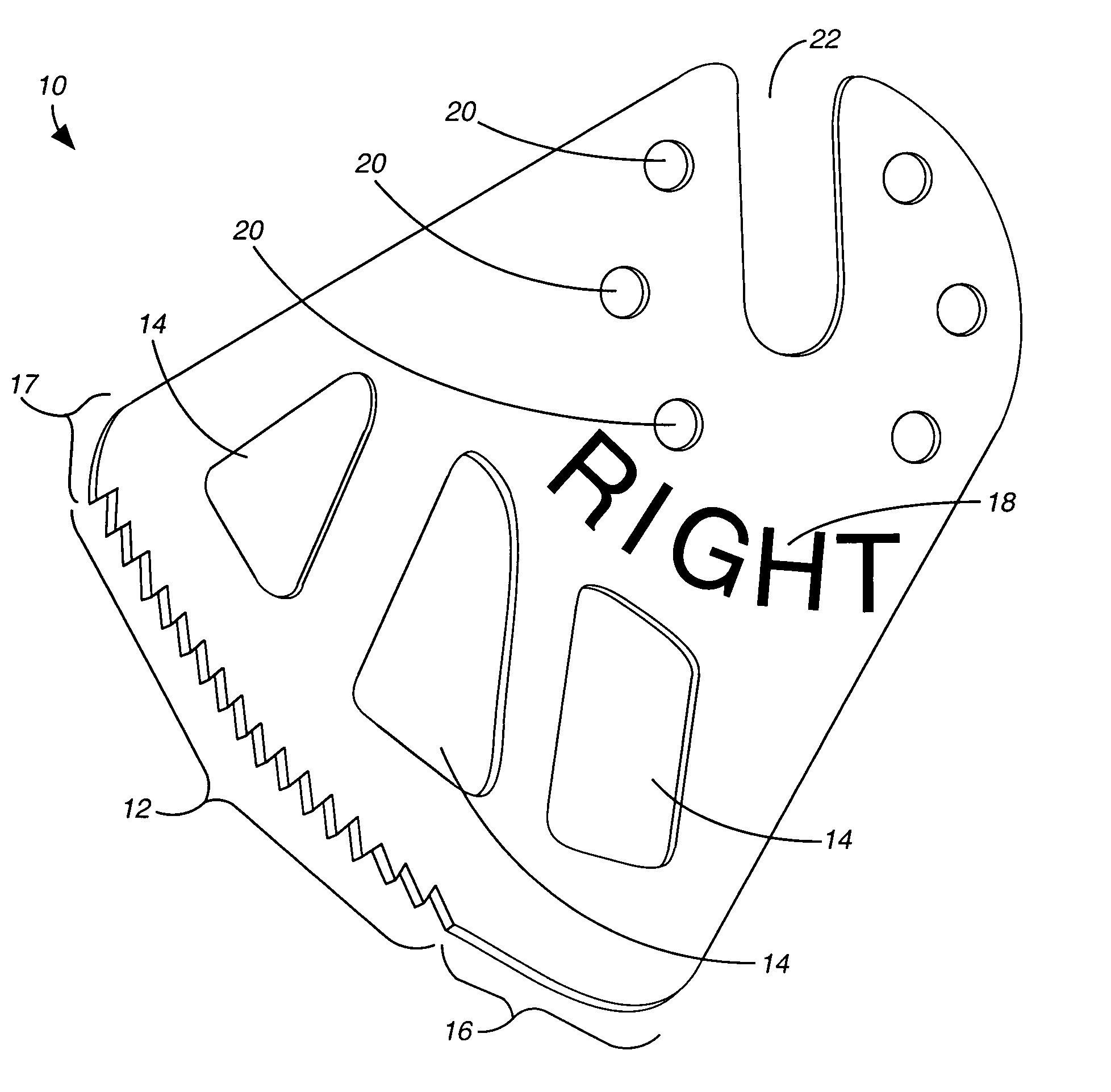

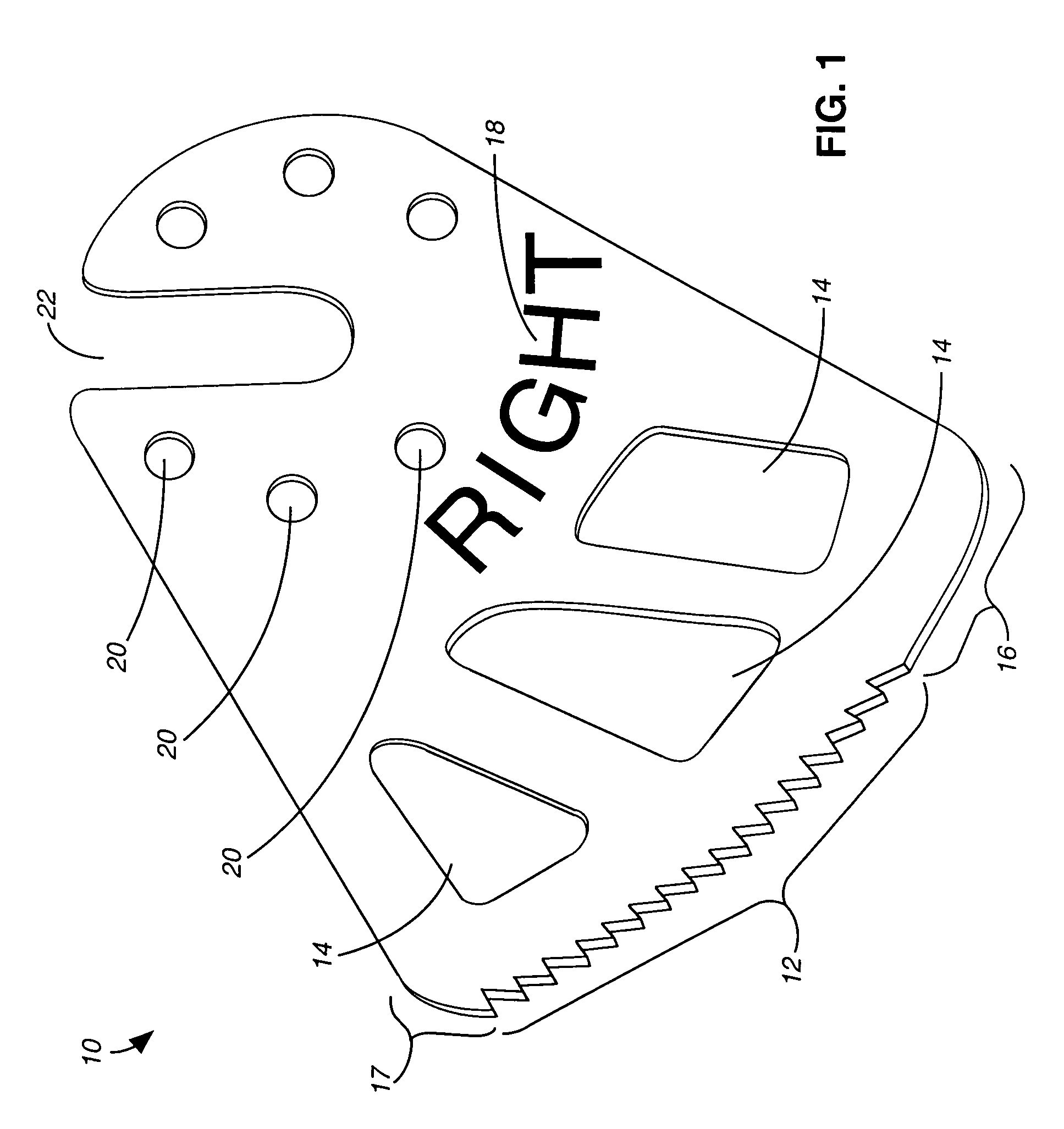

Cutter blade for cast saw

InactiveUS20060123959A1Improve patient safetyImprove securityDiagnosticsMetal sawing toolsCompound (substance)Engineering

A cast saw blade includes a hardened metal blank having a hub section and a cutting edge with an integral cutting depth guide. The cutting depth guide includes one or more apertures near the cutting edge. The blade includes a rounded sector blade cutting edge to minimize the amount of materials required. The cutting edge is only partially toothed, and partially smooth and dull. The blade is attached to a saw via a hub section that includes seven mounting holes around a central arbor, so that the blade is compatible with all prior cast saw hubs. The arrangement of the teeth makes a directional blade. The blade is easily reversed to cut in the opposite direction. Both sides of the blade are marked to indicate the cutting direction. The blade is formed through a chemical etching process to eliminate annealing and tempering after machining.

Owner:ELITE MEDICAL EQUIP

Thermal treatment method for wear-resistant low alloy steel

InactiveCN102758067AImprove wear resistanceImprove mechanical propertiesHeat treatment process controlTemperingMetallic materials

The invention discloses a thermal treatment method for wear-resistant low alloy steel, and relates to the field of the machining of metal materials. The thermal treatment method provided by the invention comprises the following steps of: heating a low alloy steel workpiece in thermal equipment, discharging out of a furnace after heat preservation at constant temperature, immediately putting the part which needs wear resistance in the workpiece discharged out of the furnace into a quenching pond which is filled with water and quenching oil at the same time to be quenched, naturally cooling after quenching, transforming the workpiece into a tempering furnace, preserving the heat in a heating way, and carrying out furnace cooling or air cooling in a discharging way after the heat is preserved. The thermal treatment method disclosed by the invention has the characteristics that the local water quenching, the local oil quenching and the local air cooling of the workpiece can be combined with one another, the hardness, the strength and the abrasive resistance of the part which is easy to wear in the workpiece can be improved as required, the workpiece is guaranteed to be hard to wear, the impact toughness of the part which needs high tenancy can be guaranteed, the whole comprehensive mechanical property of the workpiece can be improved, and the use requirement of wear-resistant pieces such as the wear-resistant plate hammer, the lining plate, the hammer head, the impact plate, the bucket teeth and the like can be met. The thermal treatment method disclosed by the invention has the advantages of being simple and easy, and low in production cost.

Owner:JINAN UNIVERSITY

Forging process of wind power main shaft

ActiveCN102615478AImprove mechanical propertiesMetal-working apparatusFurnace typesTemperingMetallurgy

The invention relates to a processing method of a wind power main shaft, in particular to a forging process of a wind power main shaft. The forging process of the wind power main shaft comprises the following steps of: selecting material, heating, upsetting, drawing out for ejection, blanking, forming by second fire, upsetting a workpiece in a mold to form a flange, clamping the flange with a fixture, forming a shaft body to a required size, carrying out furnace cold-hot treatment on the workpiece, normalizing tempering primary recrystallization or normalizing tempering secondary recrystallization, warming and cooling three times, sawing, carrying out blank flaw detection, turning roughly, carrying out flaw detection for the second time, tempering detection, mechanical property detection and the like, carrying out flaw detection for the third time, and turning finely.

Owner:HANGZHOU RONGLI CASTING & FORGING

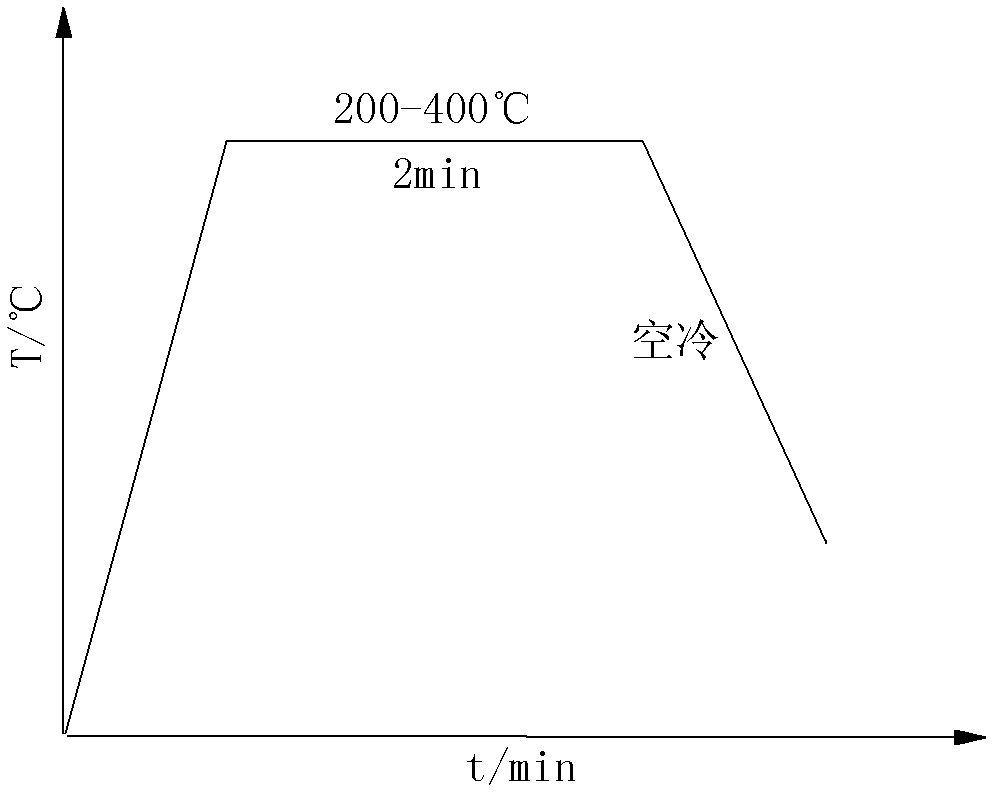

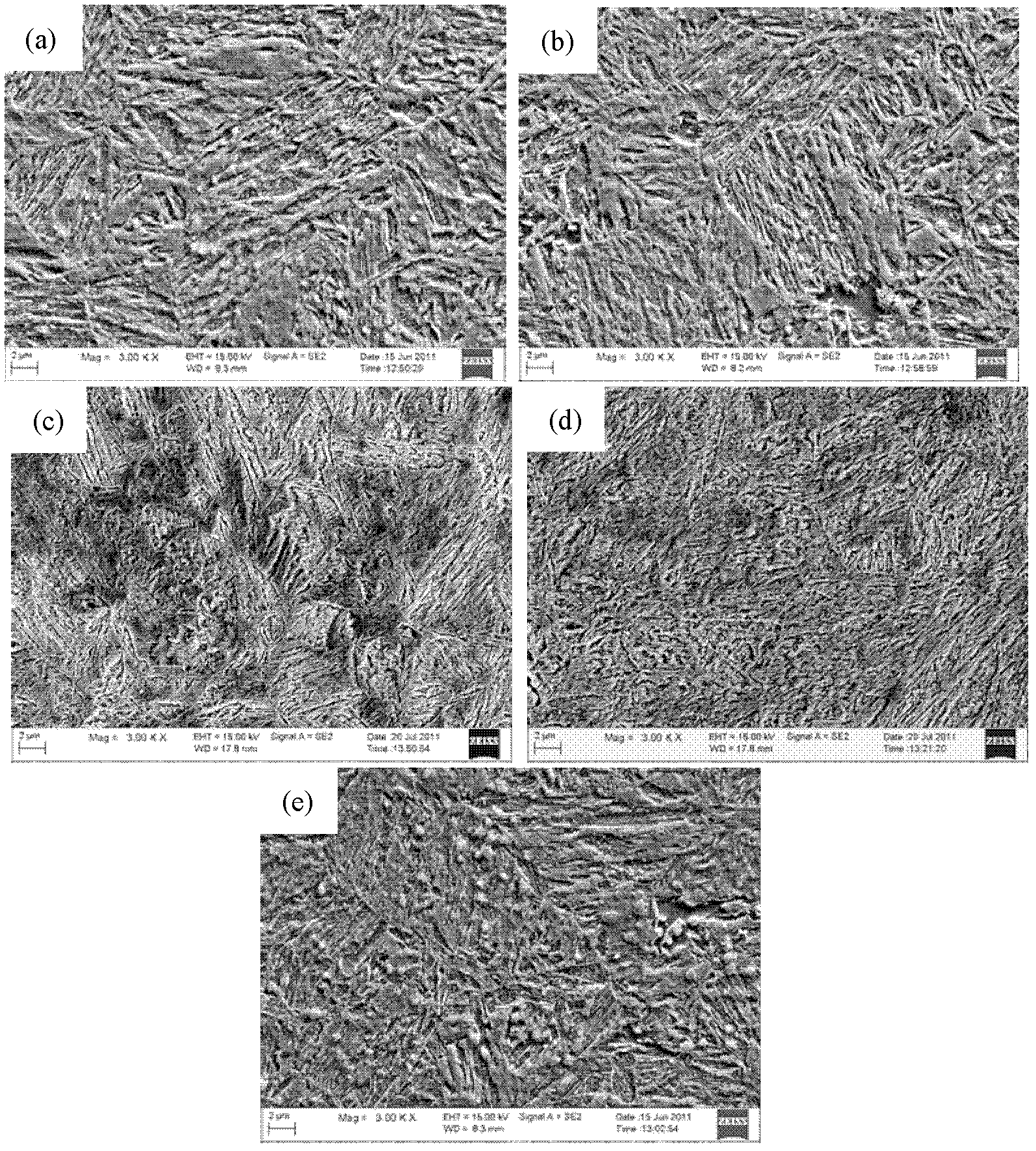

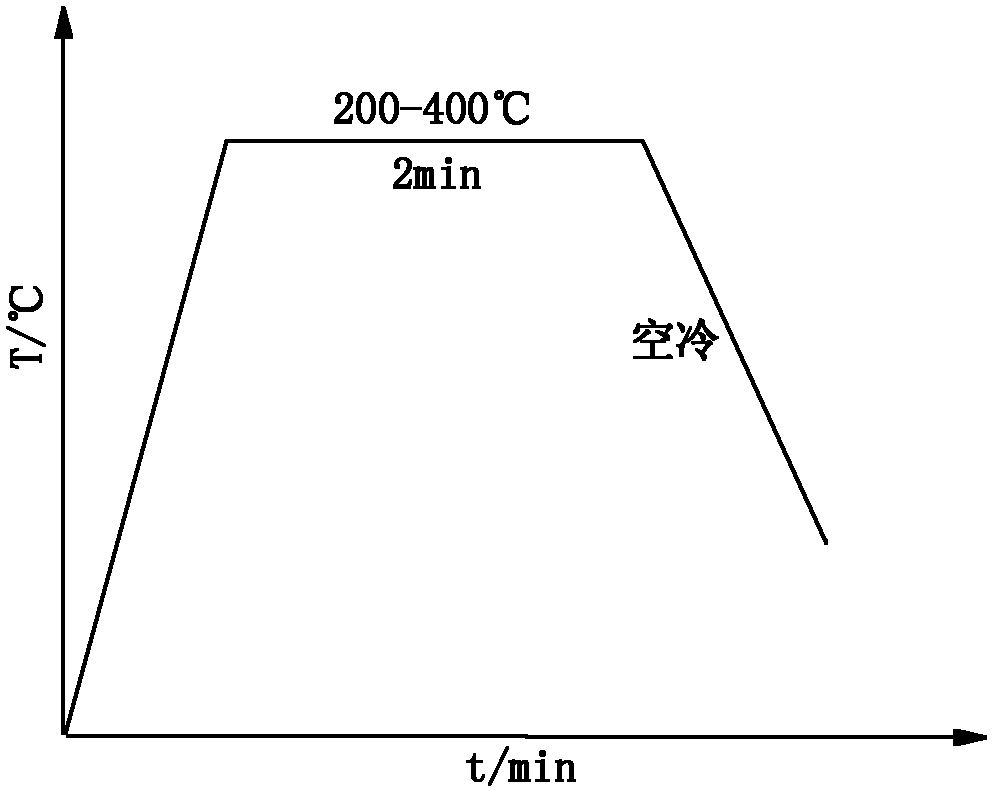

A heat treatment method for high-strength and toughness hot-formed steel sheets for automobiles

The invention provides a heat treatment method for high-strength and toughness hot-formed steel plates for automobiles, which belongs to the technical field of high-strength steels for automobiles, and aims to solve the problems of high strength but poor plasticity of steel plates for hot-formation at present. Technical measures to solve the problem: the mass percentage of the components is: C: 0.2~0.4%, Si: 0.1-0.5%, Mn: 1.0~2.0%, Cr: 0.1~0.5%, B: 0.001-0.005%, Ti : 0.01~0.05%, Al: 0.01-0.1%, P: <0.02%, S: <0.01%, N: <0.01%, and the balance is iron and unavoidable impurities. In the range of ~500℃, tempering treatment is carried out for 1-5min. The invention has the advantages that after the tempering treatment, the plasticity of the hot-formed steel is significantly improved while the strength is slightly reduced, and the toughness of the steel plate after hot stamping is improved.

Owner:UNIV OF SCI & TECH BEIJING

High intensity variable section spring piece under high stress and method for producing the same

ActiveCN101397629AAddress fatigue performance on surfacesAddresses significantly increased susceptibility to internal defectsFurnace typesProcess efficiency improvementTemperature controlHigh intensity

The invention relates to a high-strength variable cross-section reed which can bear high-stress, comprising the components with mass mixture ratios as follows: 0.46 to0.62 percent of C, 0.20 to 2.00 percent of Si, 0.30 to 0.90 percent of Mn, 0.8 to 1.20 percent of Cr, 0.10 to 0.20 percent of V, 0.005 to 0.1 percent of Al, and the rest of Fe and impurity. The manufacturing method of the reed is that: temperature control and variable cross-section rolling is carried out to a spring flat steel which has the components and mass mixture ratios under 700 DEG C to 950 DEG C to form the variable cross-section reed which is then heated to 86 DEG C to 950 DEG C for quenching, tempering is carried out at temperature of 380 DEG C to 450 DEG C, and then stress shot blasting is carried out to the pulled stress surface by adopting the steel shot with diameter from 0.8 mm to1.0 mm at the speed of 50 to 90mm / s under the bending stress of 800MPa to 1600MPa. The high-strength variable cross-section reed effectively solves the problem that fatigue property on the surface and the inside defect sensibility is significantly increased under the high stress condition after the strength is improved, the tensile strength is more than1800MPa, and the performance thereof is much better than the performance level of domestic spring and achieves the international leading level.

Owner:NANJING NAVECO AUTOMOBILE CO LTD

Cast steel for bearing parts in mechanical lifting system and its making process

The present invention relates to one kind of cast steel for bearing parts in mechanical lifting system and its making process. The cast steel of Cr-Ni-Mo line consists of C 0.15-0.30 wt%, Mn 0.60-1.10 wt%, Si 0.3-0.8 wt%, Ni 0.4-1.1 wt%, Cr 0.4-1.1 wt%, Mo 0.15-0.40 wt%, S less than 0.025 wt%, P less than 0.025 wt%, and residual elements including Cu, W and V less than 0.60 wt%. The making process of the cast steel includes the following technological steps: making steel in MF furnace or electric arc furnace; casting in sand mold with equivalent circular kiel test rod; normalizing, quenching and tempering of both cast part and test rod in the same furnace; and non-destructive detection of the cast part.

Owner:河南石油勘探局南阳石油机械厂

High-grade large-strain pipeline steel and manufacturing method of steel pipe

The invention relates to a high-grade large-strain pipeline steel and a manufacturing method of a steel pipe. The high-grade large-strain pipeline steel comprises the following components in percentage by mass: 0.04-0.08 percent of C, 1.50-1.90 percent of Mn, 0.15-0.30 percent of Si, not more than 0.010 percent of P, not more than 0.003 percent of S, 0.005-0.03 percent of Al, 0.002-0.005 percent of Ca, not more than 0.005 percent of N, and the balance of Fe, wherein the carbon equivalent is not more than 0.55 percent and cold cracking sensitivity coefficient is not more than 0.25. The manufacturing method comprises the following steps of: carrying out smelting, Ca treatment, refining and degassing on the pipeline steel; carrying out continuous casting on the pipeline steel to form a thick plate blank; carrying out finish rolling on the thick plate blank; tempering at low temperature to prepare a hot rolling steel plate; moulding and welding the steel plate; and expanding to manufacture the steel pipe with the yield strength of 485-630MPa, the tensile strength of 570-750MPa, uniform plastic deformation elongation of 8-15 percent, strain ageing sensitivity coefficient of not more than 0.40 and Charpy impact toughness of 220-350J at -20 DEG C.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

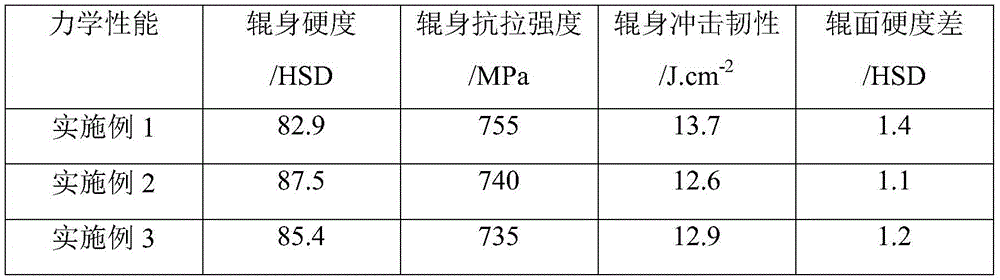

Abrasion-resistance high-speed steel composite roller and preparation method thereof

The invention discloses an abrasion-resistance high-speed steel composite roller and a preparation method thereof, and belongs to the technical field of rollers. The composite roller forms a whole through roller body high-speed steel and roller core nodular cast iron by means of centrifuge composite casting. The roller body molten steel is controlled to comprise, by mass, 1.5%-2.4% of C, 3.5%-6.0% of Cr, 3.5%-6.0% of Mo, 3.5%-6.0% of V, 1.5%-3.5% of W, 0.6%-1.2% of Nb, 0.5%-1.2% of Ni, 0.3%-0.8% of Si, 0.3%-0.8% of Mn, 0-0.04% of S, 0-0.04% of P and the balance Fe. The roller body molten steel is deoxidized, external-furnace modification treatment is conducted on the molten steel through multi-element micro-alloy wires, and then pouring is conducted on a centrifugal machine to form the roller; the roller core is made of nodular cast iron, tempering is conducted on the roller after quenching, and therefore the characteristics of being high in hardness, high in toughness, good in abrasive resistance and the like are realized, and an excellent using effect is achieved.

Owner:安徽环渤湾高速钢轧辊有限公司

Overlaying manufacture repair technology for roll forging die

The invention discloses an overlaying manufacture repair technology for a roll forging die, belonging to the technical field of die overlaying technologies. According to the overlaying manufacture repair technology, the problems of poorer wear resistance at normal temperature and high temperature, cold-heat fatigue resistance, heat stability and high-temperature oxidation resistance due to direct use of low-heat-resistant steel 5CrMnMo and 5CrNiMo in the prior art are mainly solved. The overlaying manufacture repair technology is mainly characterized by comprising the following treatment steps of selecting the low-heat-resistant steel 5CrMnMo and 5CrNiMo die steel as substrates and enabling the heat treatment hardness HRC (Rockwell Hardness) to be 34-42, or integrally processing the surface of a die cavity to be repaired downwards or outwards for 10-15mm and preheating before welding the die; overlaying a priming coat with the thickness of 3-6mm by using an overlaying metal welding material with HRC of 34 to 42; overlaying a transition layer with the thickness of 3-6mm by using a die overlaying welding material with HRC of 42 to 48; overlaying a work layer with the thickness of 5-8mm by using an alloy overlaying material with HRC greater than 55; and carrying out tempering treatment after welding, furnace cooling to 90-190DEG C and discharging the material out of the furnace. The overlaying manufacture repair technology disclosed by the invention has the characteristics that the manufacturing period of the die is shortened, processing expenses are saved and the downtime is shortened and is mainly used for an overlaying manufacture and repair method of a hot forging rotary die.

Owner:HUBEI TRI RING AXLE

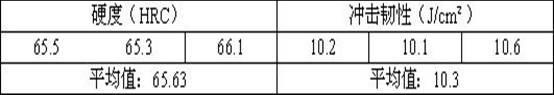

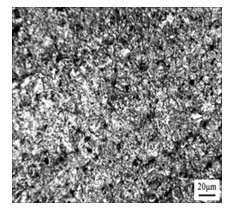

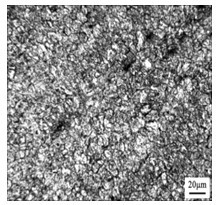

Hypoeutectic high-chromium white cast iron and preparation method thereof

The invention discloses a hypoeutectic high-chromium white cast iron, which comprises the following components calculated according to mass fraction: 1.9-2.4 of C, 16-22 of Cr, less than or equal to 0.8 of Si, less than or equal to 0.7 of Mn, 0.5-1.0 of Ni, 1.0-1.7 of Mo, less than 0.04 of S, less than 0.06 of P, 0.05-0.4 of RE, 0.5-1.0 of Cu, 0.05-0.15 of Zn, 0.1-0.3 of V and the balance of Fe. The preparation method comprises the following steps of: defining the mixture ratio according to the requirement of mass fraction and mixing; mixing scrap steel and pig iron in an intermediate-frequency induction furnace and heating the mixture to be melt; after molten iron is smelt, sequentially adding high carbon ferro-chrome, manganese iron, nickel and molybdenum and smelting again; feeding a zinc ingot with small granularity and rare earth or vanadium at the bottom of a casting ladle, covering a steel sheet or scrap iron and compacting; pouring the molten iron into the casting ladle and carrying out metamorphism and deslagging treatment; casting the molten iron and forming to obtain a hypoeutectic high-chromium white cast iron piece; then placing the hypoeutectic high-chromium white cast iron piece into a heat treatment furnace for thermally treating; and quenching and tempering to obtain a hypoeutectic high-chromium white cast iron material with the hardness of 60-66HRC (Hardness Rockwell) and the impact ductility of 10-14J / cm<2>. The hypoeutectic high-chromium white cast iron has the advantages of low cost, high wear resistance and reliable use safety. In addition, the preparation method of the hypoeutectic high-chromium white cast iron is simpler, and is easy in operation and strong in practicability.

Owner:云南化铸科技有限责任公司

Track link production method and track link produced by the same

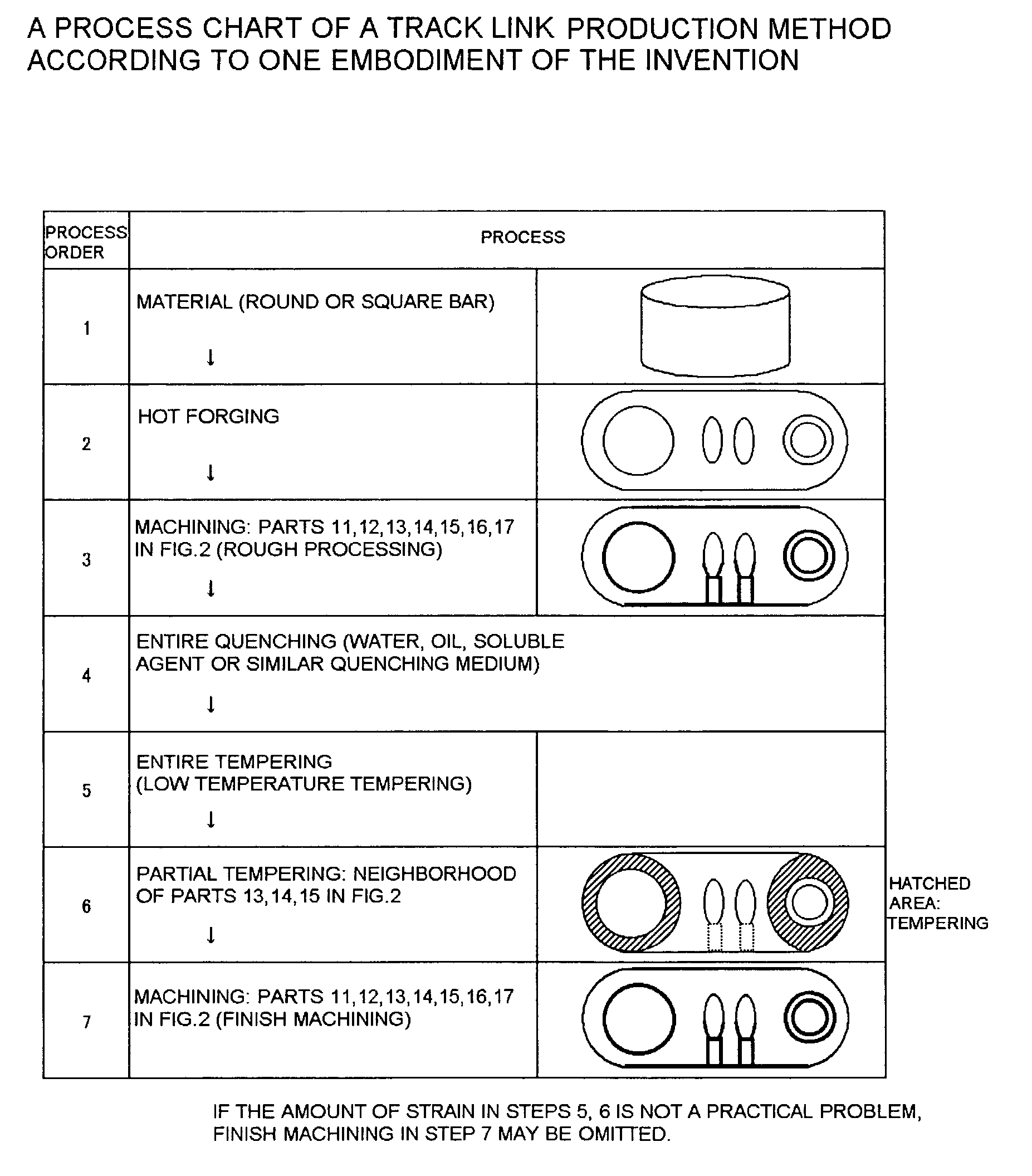

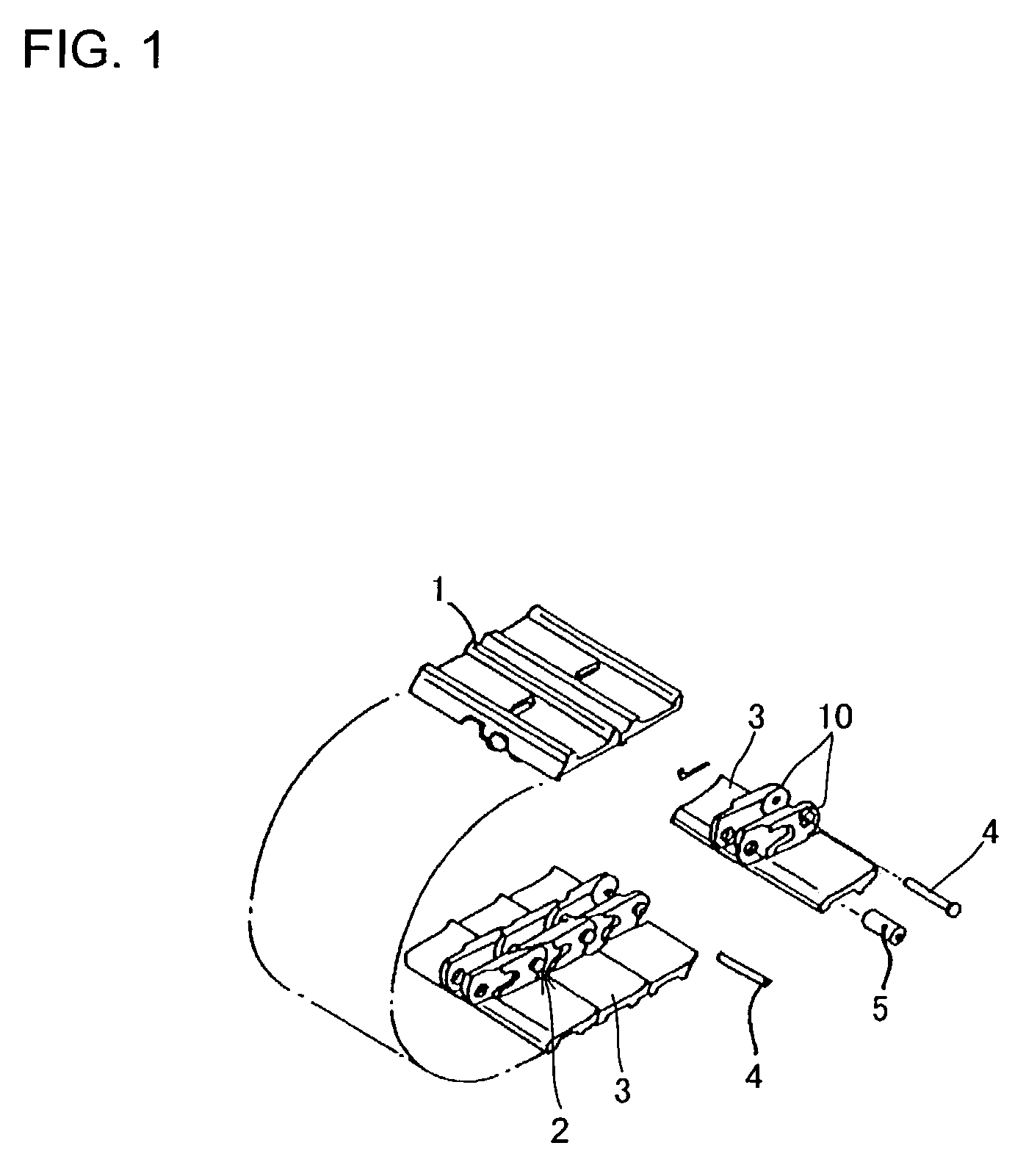

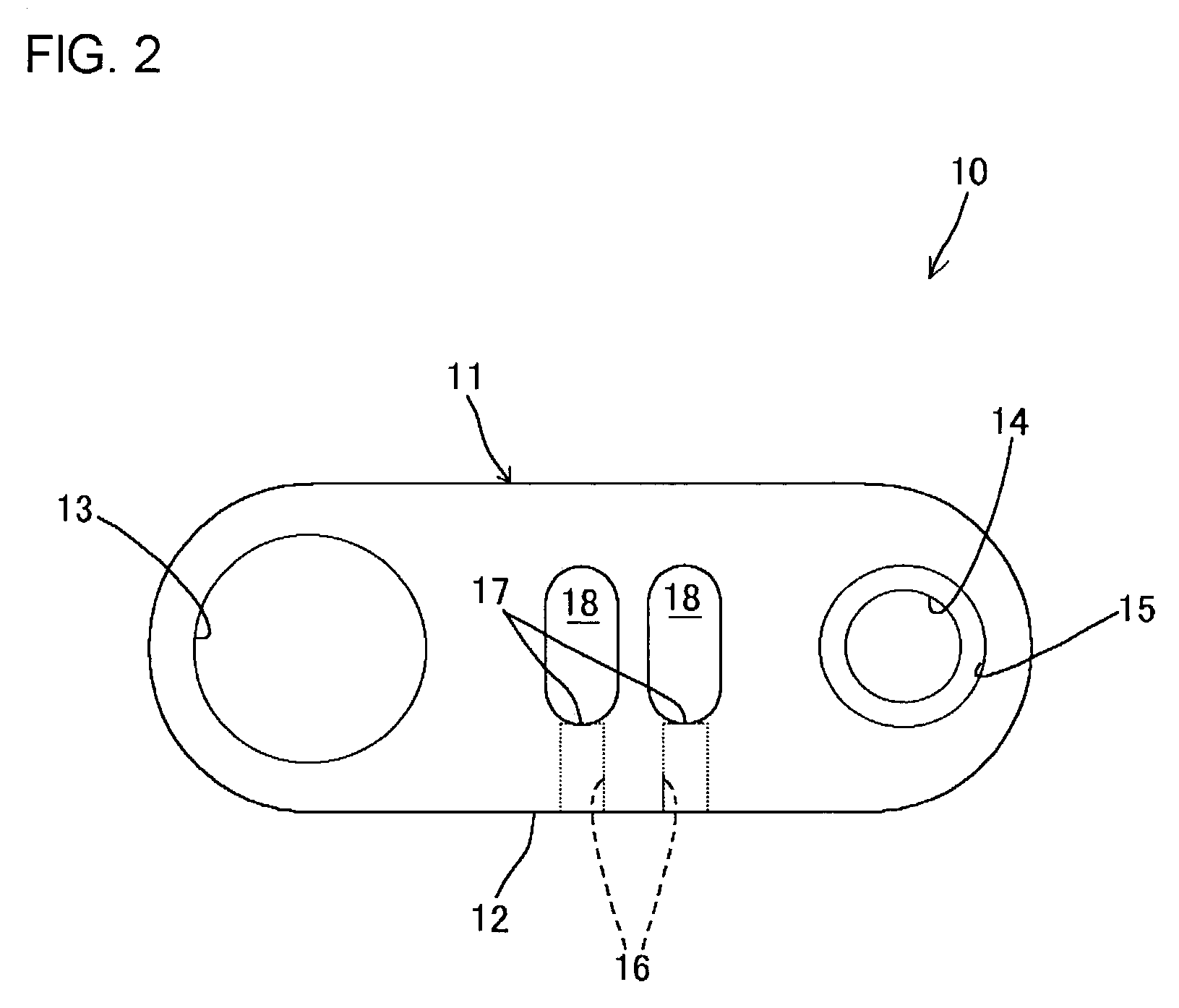

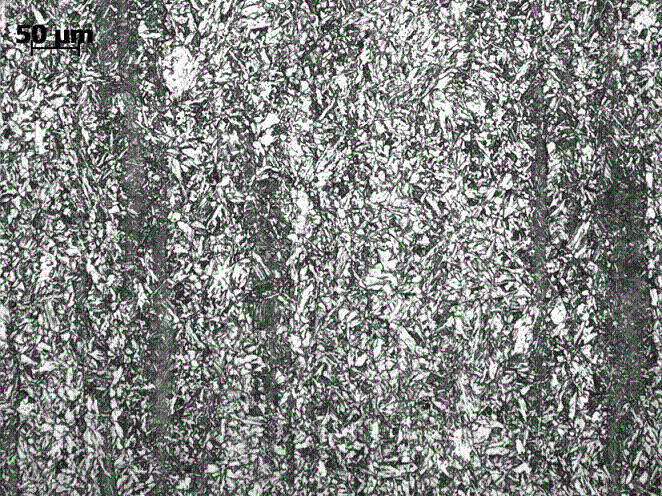

InactiveUS7040080B2Delayed failureIncrease pressureConnecting rodsMetal-working apparatusHigh dimensionalMachining process

There are proposed a track link production method capable of providing markedly improved wear life with good cost performance and a track link produced by this method. To this end, the track link production method includes a heat treatment process (Steps 4, 5) of applying quenching and low temperature tempering treatment to a whole link material after hot forging (Step 2), and is designed such that desired machining is applied to the link material (Step 3) before the heat treatment process (Steps 4, 5) and such that after the heat treatment process (Steps 4, 5), tempering (Step 6) and finish machining (Step 7) are sequentially applied to some of the parts which have undergone the machining process, the some parts including at least parts where high dimensional accuracy is required.

Owner:KOMATSU LTD

Spring steel and preparation method thereof

InactiveCN101671792AImprove fatigueOvercome the disadvantage of low fatigue strengthSpring steelQuenching

The invention discloses spring steel. Based on the total weigh of the spring steel, the spring steel comprises 0.56 to 0.64 weight percent of C, 1.6 to 2 weight percent of Si, 0.6 to 0.9 weight percent of Mn, 0 to 0.015 weight percent of Ti, 0.0055 to 0.03 weight percent of S, 0.01 to 0.02 weight percent of Als and the balance of Fe and inevitable impurities, wherein the weight ratio of the S to the Als is 0.55 to 3; and the Als is acid soluble aluminum. The invention also provides a preparation method of the spring steel, which comprises: subjecting the raw material of the spring steel to primarily smelting, refining, cold forming, rolling, quenching and tempering, wherein the composition of the raw material of the spring steel ensures the composition of the spring steel obtained is the same as the composition of the spring steel of the invention. The spring steel is high in fatigue resistance. The production method is simple and reduces cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Low-compression ratio hot-rolled 9Ni steel thick plate and manufacturing method thereof

The invention discloses a low-compression ratio hot-rolled 9Ni steel thick plate and a manufacturing method thereof. The low-compression ratio hot-rolled 9Ni steel thick plate comprises, by mass, 0.035-0.075% of C, 0.15-0.25% of Si, 0.50-0.80% of Mn, less than or equal to 0.006% of S, less than or equal to 0.008% of P, 8.9-9.5% of Ni, 0.020-0.045% of Al and the balance Fe and impurities. The manufacturing method comprises the following steps of converter smelting, LF and RH refining, continuous casting of a thick plate blank having the thickness of 150mm, two-stage rolling, rolled workpiece laminar cooling, and heat treatment adopting an out-line quenching and tempering technology. The low-compression ratio hot-rolled 9Ni steel thick plate has simple alloy components and a low cost. Based on a low-compression ratio, the steel thick plate having the thickness above 35mm is rolled and has a good plate shape. After heat treatment, transverse impact energy at a temperature of -196 DEG C is greater than or equal to 160J. The low-compression ratio hot-rolled 9Ni steel thick plate has a good strength-toughness matching degree.

Owner:NANJING IRON & STEEL CO LTD +1

Large-thickness and high-strength steel plate applicable to low temperature and manufacturing method thereof

InactiveCN104357755AImprove plasticityGood lamellar tear resistanceTemperingUltimate tensile strength

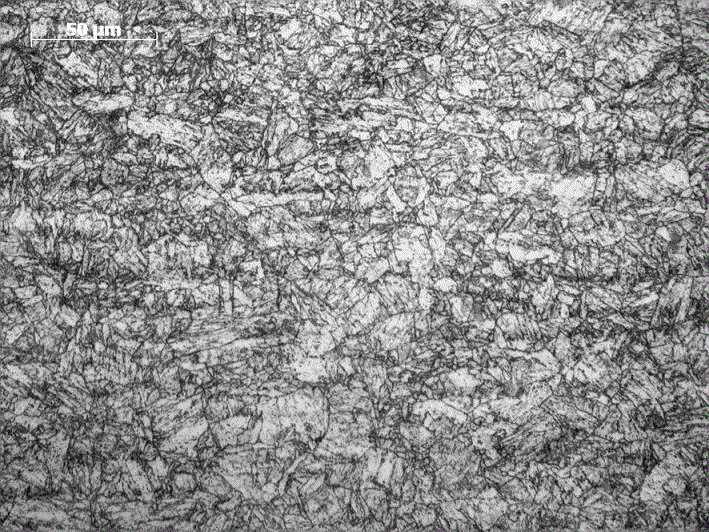

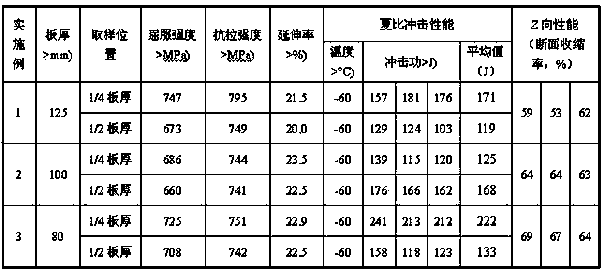

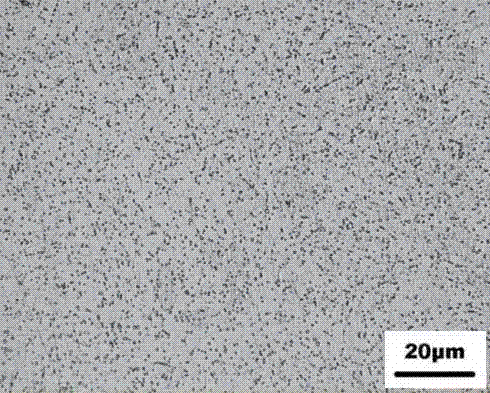

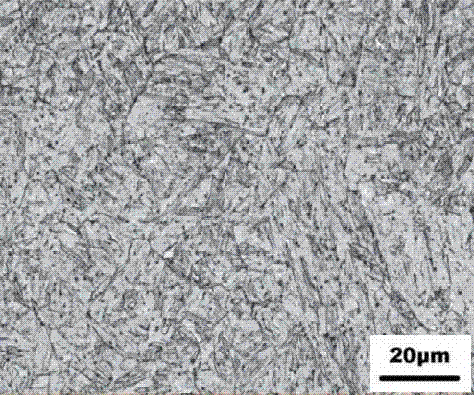

The invention discloses a large-thickness and high-strength steel plate applicable to low temperature. The steel plate comprises the following chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.35% of Si, 0.95-1.25% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.005% of S, 0.35-0.55% of Cr, 0.35-0.55% of Mo, 0.88-1.5% of Ni, 0.20-0.40% of Cu, 0.02-0.08% of Al, 0.03-0.05% of V, 0.02-0.04% of Nb, smaller than or equal to 0.02% of Ti, smaller than or equal to 0.006% of N, 0.0008-0.002% of B and the balance of Fe and inevitable impurity elements. The manufacturing method of the steel plate adopts the following process flows: smelting and continuously casting, slowly cooling by covering, clearing at a certain temperature, heating, rolling, performing air cooling and straightening, slowly cooling, and quenching and tempering. The manufactured steel plate has the thickness of 80-125mm, has high strength, good ductility and high low-temperature toughness, can be adapted to a minus 60 DEG C low-temperature environment, can meet a requirement on high Z-direction performance, and has excellent overall performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

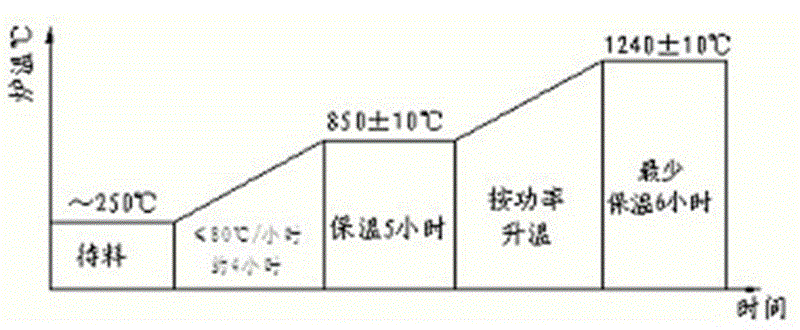

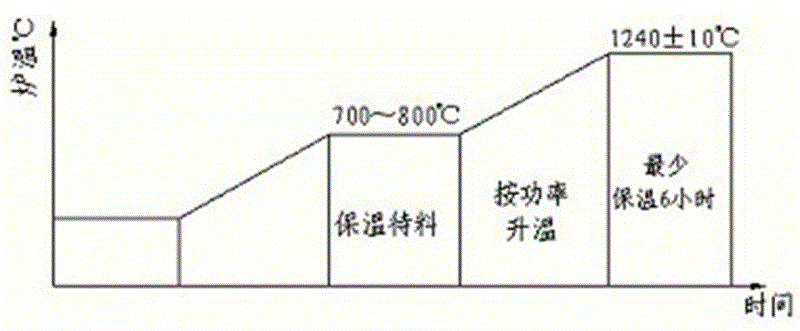

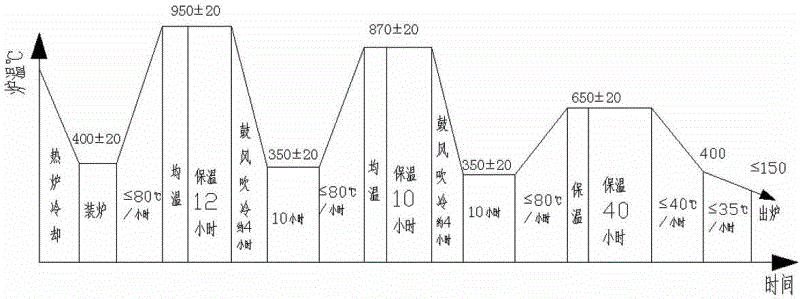

Chromium-molybdenum-vanadium hotwork tool-die steel and heat treatment process thereof

The invention relates to low-cost chromium-molybdenum-vanadium hotwork tool-die steel and a heat treatment process thereof and belongs to the technical field of alloy steel manufacturing processes. The steel comprises the following components by weight percent: 0.3-0.4% of C, 0.6-1.2% of Si, 0.6-1.2% of Mn, 3.5-4.5% of Cr, 0.8-1.2% of Mo, 0.4-0.8% of V, less than 0.02% of P, less than 0.02% of S and the balance of Fe. The preparation process of the hotwork tool-die steel is as follows: mixing, smelting, casting and then remelting electroslag; carrying out homogenization treatment at 1200-1280 DEG C for 8-10 hours, then forging, and carrying out ultrafining heat treatment and isothermal annealing treatment; and finally quenching and tempering, namely heating steel ingots to 1000-1100 DEG C to be austenitized and carrying out tempering two to three times at 560-620 DEG C after carrying out oil quenching or high pressure gas quenching. The hotwork tool-die steel has the advantages of high heat stability and roughness and good heat fatigue property.

Owner:SHANGHAI UNIV

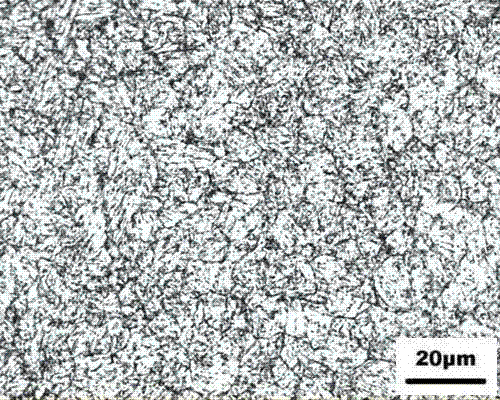

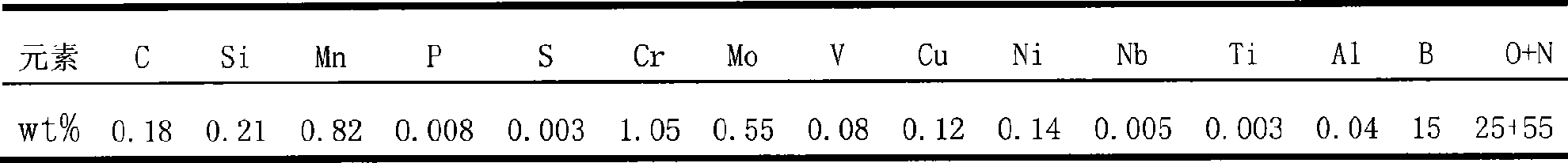

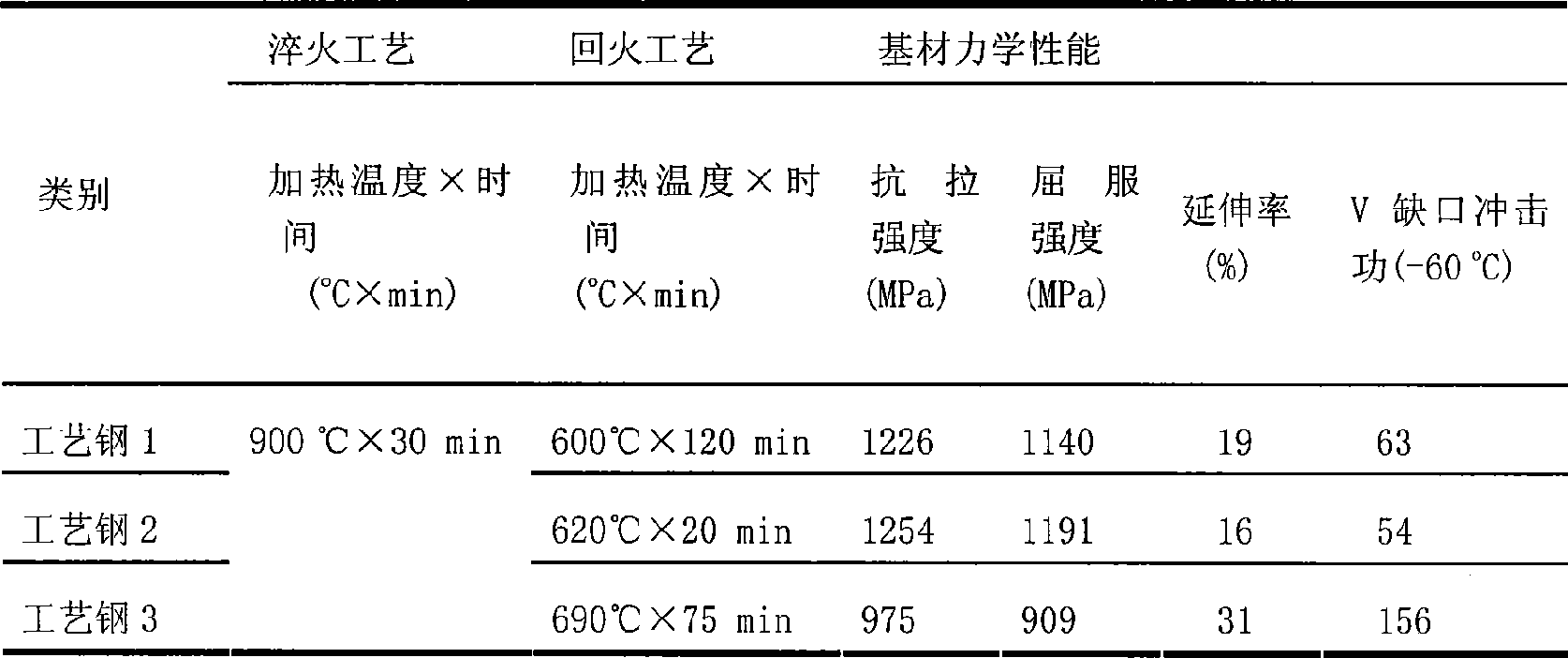

High plasticity, high tenacity and ultra-high tensile steel, and manufacturing method thereof

InactiveCN101481779ATemperature control deviceProcess efficiency improvementQuenchingHeat processing

The invention discloses a steel with high plasticity, high toughness and high strength and a manufacturing method thereof. The chemical compositions of the steel are as follows in terms of weigh percentage: 0.15 to 0.30 of C, 0.20 to 1.40 of Mn, 0.10 to 0.50 of Si, less than or equal to 0.015 of P, less than or equal to 0.012 of S, less than or equal to 0.20 of Ni, 0.40 to 1.50 of Cr, 0.25 to 1.35 of Mo, 0 to 0.10 of V, less than or equal to 0.2 of Cu, 0.01 to 0.05 of Al, 0.0005 to 0.0020 of B, less than or equal to 0.010 of (O+N) and the balance of Fe and impurities. The manufacturing method comprises the following steps: smelting according to the formula, continuous casting into a blank, hot rolling into plates or tubes, quenching at the temperature of 875 to 930 DEG C and holding the temperature for 25 to 40 minutes, tempering at the temperature of 625 to 675 DEG C for 30 to 90 minutes, then air cooling, and quenching and tempering heat treatment. The steel has yield strength of more than or equal to 1000MPa, tensile strength of more than or equal to 1100MPa, zero-degree-centigrade charpy impact work of more than or equal to 100J, specific elongation of 20 to 30 percent and is applicable to manufacture important structures of engineering machinery, high buildings and oil well pipes, and the like.

Owner:YANSHAN UNIV

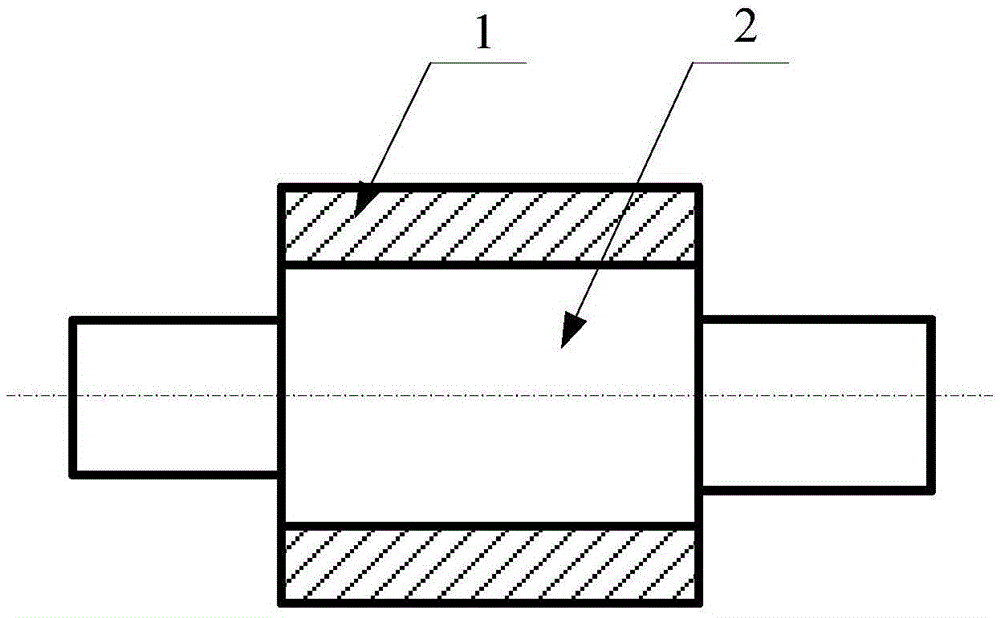

Cold roll for rolling lithium battery guard plate and manufacturing method thereof

ActiveCN103397267AHigh strengthImprove wear resistanceRollsMetal rolling arrangementsInduction hardeningService condition

The invention discloses a cold roll for rolling a lithium battery guard plate and a manufacturing method thereof. The cold roll contains the following chemical components in percentage by mass: 0.7-1.0% of C, 0.2-1.0% of Si, 0.2-0.6% of Mn, no more than 0.02% of P, no more than 0.02% of S, 2.0-4.0% of Cr, 0.2-0.6% of Ni, 0.2-0.8% of Mo, 0.1-0.5% of V and the balance of Fe and inevitable impurities. The manufacturing method of the cold roll comprises the processing steps of electroslag steel ingot fusion casting, roll blank forging, quenching and tempering treatment, induction hardening treatment, cold treatment, final heat treatment, machining and the like. The cold roll disclosed by the invention has high hardness and wear resistance; and under the service condition of the same strength, the service life of the cold roll is prolonged by 45-55% in comparison with the service life of the original common chrome steel cold roll, and the roll body case hardness of the cold roll can be up to 97-105 HSD.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Quenching and tempering method in tooth punching process of gear with medium-hard tooth surface

InactiveCN102501035AHigh hardnessReduce pittingSolid state diffusion coatingFurnace typesHobbingTempering

Owner:NANJING JINXIN TRANSMISSION EQUIP

Hot-work die steel for extrusion wheel and manufacturing method thereof

InactiveCN102534391AImprove hardenabilityReduced temper softening resistanceMetal-working apparatusTemperingThermal fatigue

The invention relates to hot-work die steel for an extrusion wheel and a manufacturing method of the die steel. The invention adopts the technical scheme that the manufacturing method comprises the following steps: hot-forging after scrap steel or molten iron and scrap steel are smelted in an electric furnace and are subjected to electroslag remelting or vacuum induction melting and then carry out spheroidizing annealing at a temperature of 700-880 DEG C; quenching at a temperature of 1,020-1,120 DEG C and tempering at a temperature of 530-650 DEG C, wherein the hot-work die steel has a hardness of up to 40-52HRC and a tensile strength of up to 1,850-1,955MPa. The hot-work die steel comprises the following chemical components in percentage by weight: 0.30-0.50wt% of C, 0.80-1.20wt% of Si, 0.2-0.5wt% of Mn, 3.00-5.00wt% of Cr, 1.00-1.50wt% of Mo, 0.70-1.20wt% of V, 0.005-0.03wt% of N and less than 0.030wt% of P, less than 0.030wt% of S and the balances of Fe and inevitable impurities. The steel has the characteristics of low cost, good thermal fatigue property, high heat stability and excellent comprehensive property and can be used for manufacturing the extrusion wheel of a continuously-extrusion-molded coating machine and other hot-work dies.

Owner:WUHAN UNIV OF SCI & TECH

Ultra-high strength steel with yield strength level of 1100MPa-1200MPa and production method of steel

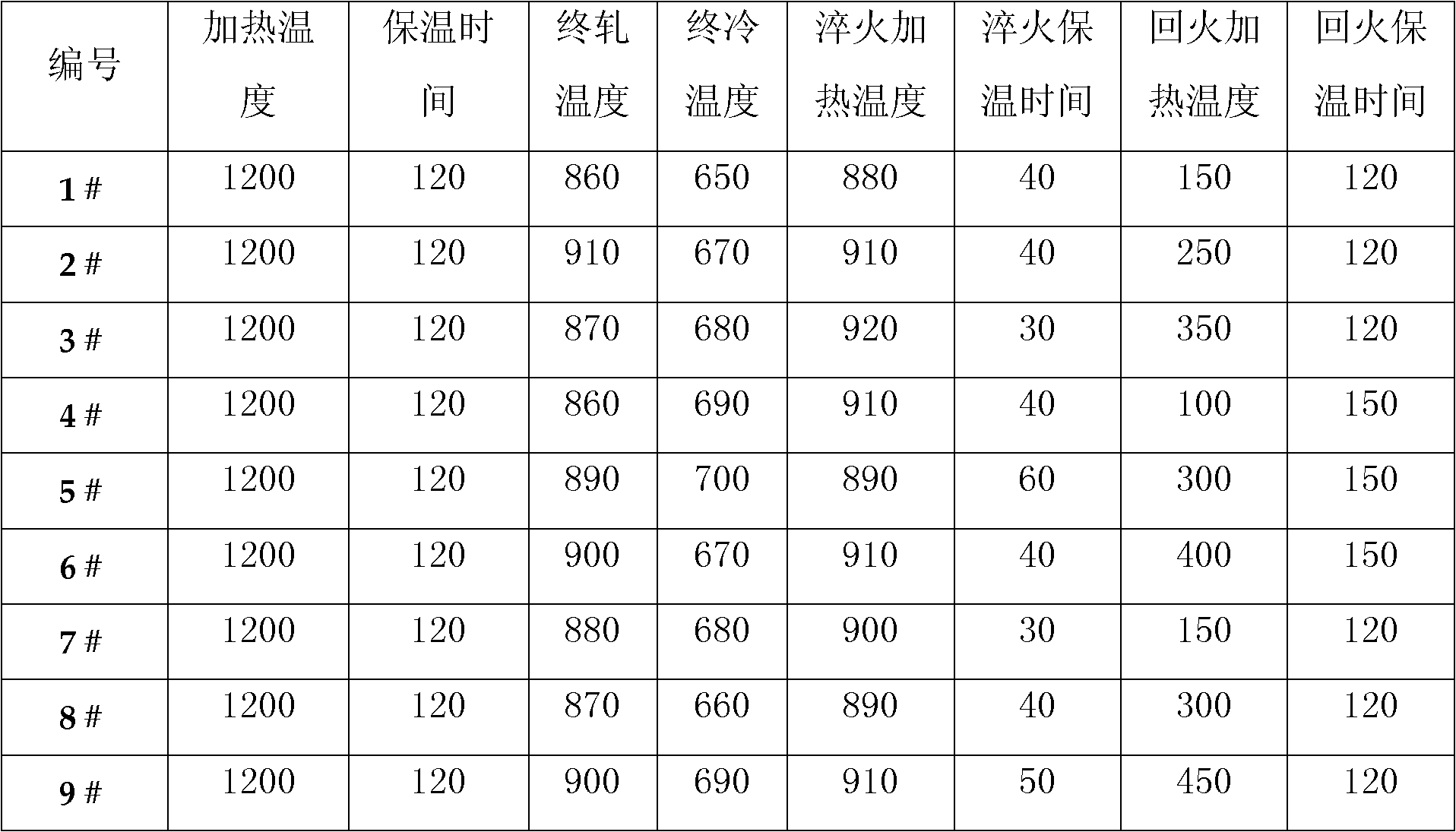

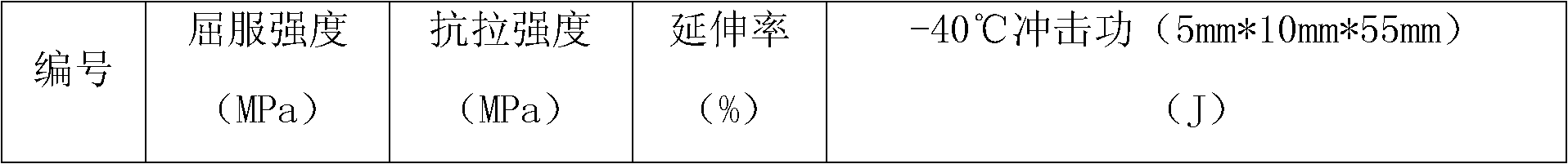

The invention provides ultra-high strength steel with yield strength level of 1100MPa-1200MPa and a production method of the steel. The chemical constituents (weight percentage) include: 0.15-0.18% of C, 0.20-0.25% of Si, 0.85-1.25% of Mn, 0.20-0.60% of Cr; and 0.45-0.65% of Mo, 0.035-0.060% of V, 0.015-0.020% of Nb, 0-0. 55% of Ni, 0-0.035% of Cu, 0.01-0.06% of Al, no more than 0.015% of P, no more than 0.01% of S, no more than 0.008% of N, the balance of Fe and unavoidable impurities. The production method includes: smelting and casting into casting blank; and heating the casting blank to 1150-1250 DEG C, wherein the final rolling temperature is 860-920 DEG C, the coiling temperature is 650-750 DEG C, the quenching heating temperature is 880-930 DEG C, the thermal insulation time is 20-90min, the tempering heating temperature is 100-450 DEG C, the thermal insulation time is over 90min. Slow cooling or air cooling is conducted to room temperature. For the steel plate produced with the constituents and the technology, the yield strength is 1150-1230MPa, the tensile strength is 1250-1340MPa, the elongation is 11-13.5%, and the impact power value at minus 40 DEG C is 21-34J.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com