Patents

Literature

84results about How to "Good lamellar tear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength steel plate for big thickness tall building structure and production method thereof

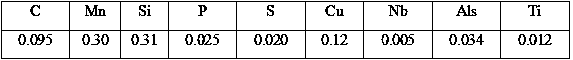

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

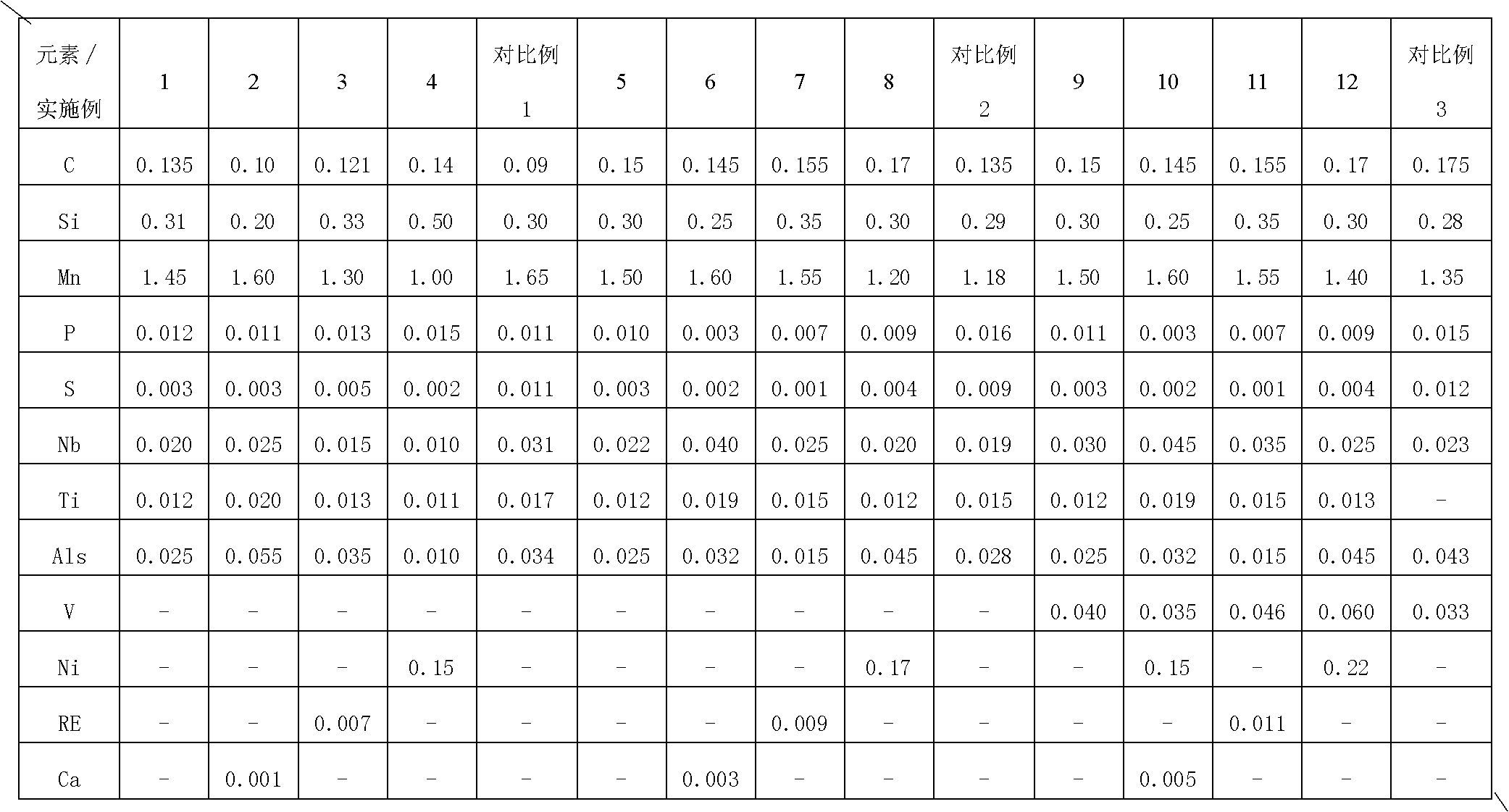

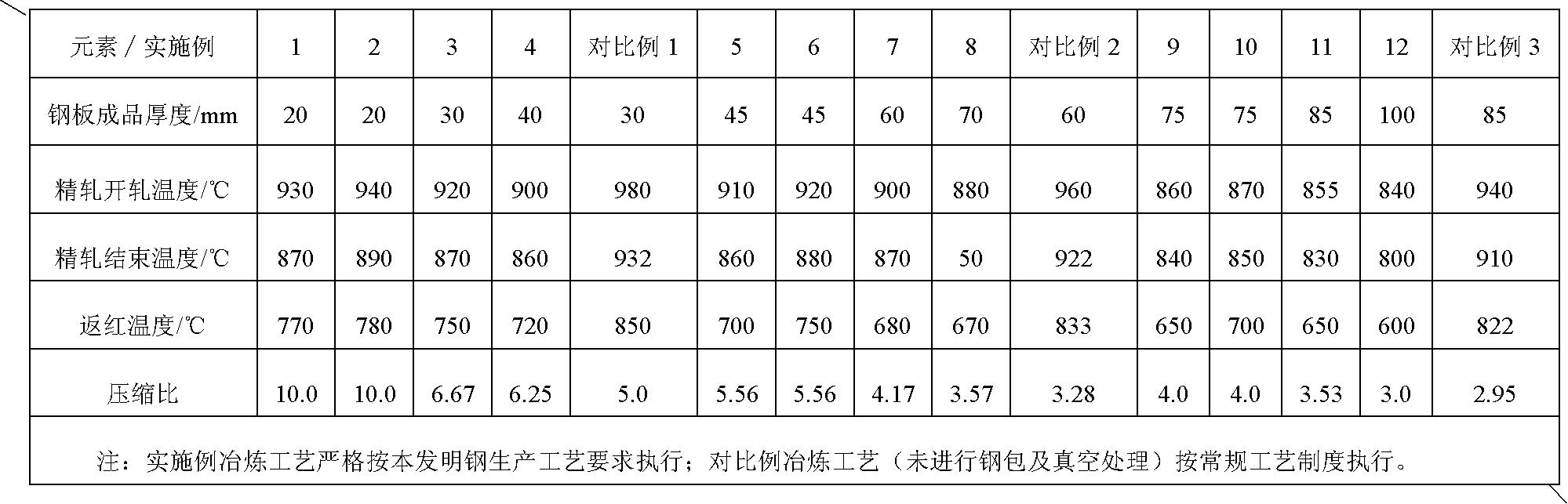

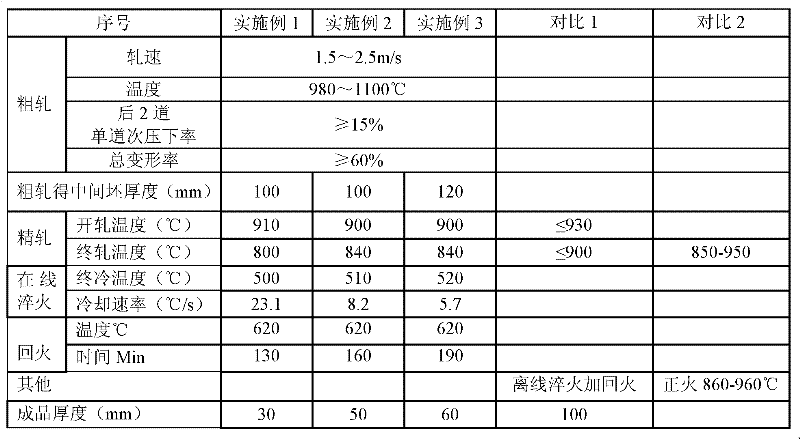

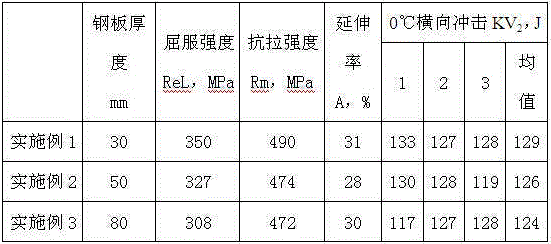

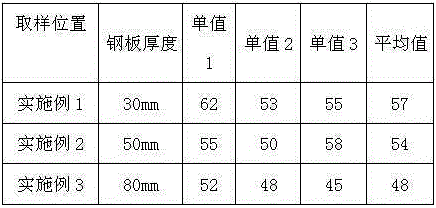

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

Large thickness quenched high strength steel and production method thereof

InactiveCN101363101AEquivalent lowGood welding performanceRoll mill control devicesMetal rolling arrangementsPower stationSheet steel

The invention belongs to the field of metal materials and discloses a large-thickness and high-strength quenched and tempered steel plate and a production method thereof. The steel plate mainly consists of the following chemical components by weight percentages: not more than 0.18% of C, 0.1-0.4% of Si, not more than 1.2% of Mn, 0.7-1.7% of Ni, 1.0-1.5% of Cr, 0.4-0.6% of Mo, 0.03-0.08% of V, 0.02-0.04% of Al, 0.0005-0.0020% of B, Fe and unavoidable impurities. The molten steel designed according to the components of the invention can be rolled into the large-thickness steel plate by smelting process, casting process, heating process, rolling process, water cooling process and quenching and tempering process. The steel plate has the advantages of reasonable component design, good comprehensive properties and low production cost, can be applied to off-shore oil production platform engineering, power stations, engineering scaffolds and other industries and has good application prospect.

Owner:WUYANG IRON & STEEL

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

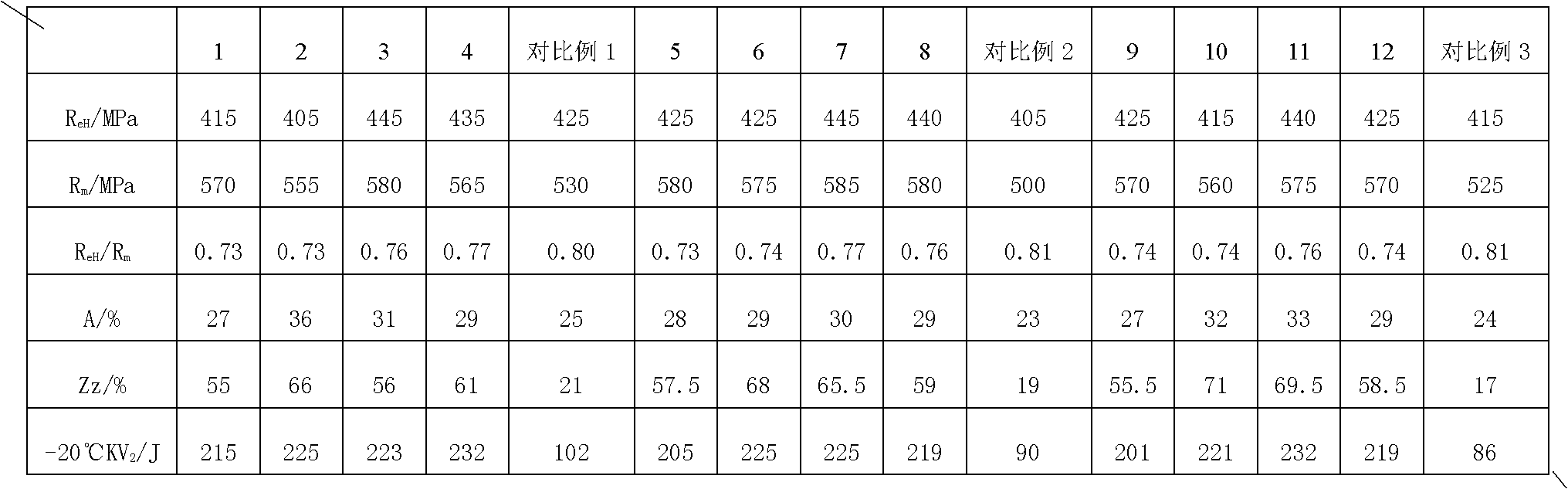

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

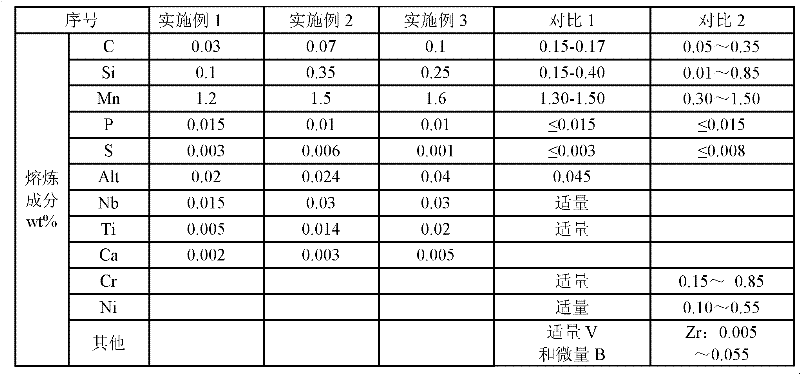

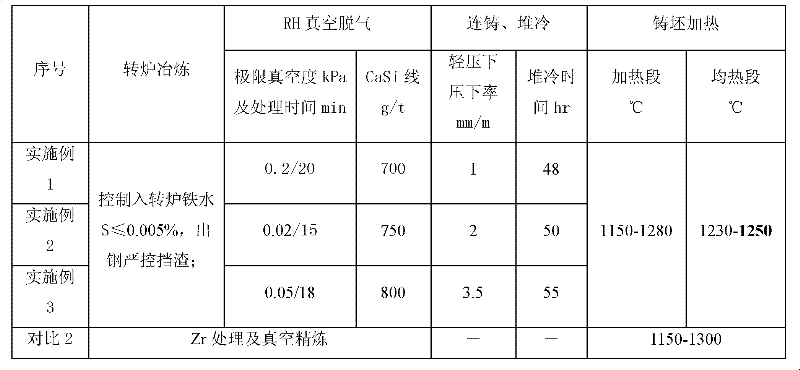

Quake-proof construction steel with lamellar tearing resistance and excellent performance and production method thereof

InactiveCN101994058AGood welding performanceSimplify welding production processProof constructionSheet steel

The invention relates to quake-proof construction steel with lamellar tearing resistance and excellent performance and a production method thereof. The steel is suitable for steel plates of which the thicknesses are between 20 and 100 millimeters and comprises the following chemical components: less than or equal to 0.015 percent of C, less than or equal to 0.015 percent of Si, less than or equal to 0.015 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.02 to 0.04 percent of Nb, 0.005 to 0.020 percent of Ti, 0.010 to 0.060 percent of Als and the balance of Fe. The method comprises the following steps of: performing the pretreatment of molten iron; performing desulfuration treatment; controlling target components of a smelting terminal point, wherein the target components comprise 0.05 to 0.07 percent of [C] and less than or equal to 0.015 percent of [P]; refining through a ladle furnace, and feeding aluminum wires and blasting argon; performing relative humidity (RH) vacuum treatment, and introducing the argon before the treatment; adding SiCa wires; casting continuously and performing the pouring of full-process protection; heating casting blanks; performing rough rolling; performing precision rolling; and cooling. The steel of the invention has the excellent quake-proof performance (ReH / Rm is less than or equal to 0.77); and the contractibility rate of a cross section in the full-thickness direction is between 40 and 70 percent, so the steel meets the requirements of key stressed points of major constructions such as steel structure work and the like fully.

Owner:武钢集团有限公司

Large-thickness and high-strength steel plate applicable to low temperature and manufacturing method thereof

InactiveCN104357755AImprove plasticityGood lamellar tear resistanceTemperingUltimate tensile strength

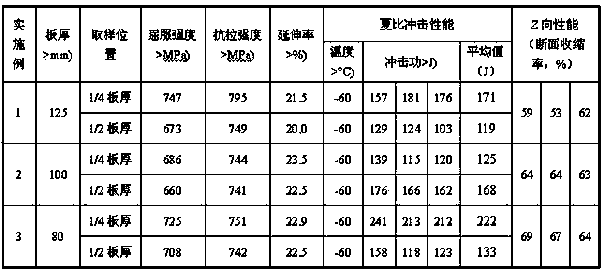

The invention discloses a large-thickness and high-strength steel plate applicable to low temperature. The steel plate comprises the following chemical components in percentage by mass: 0.08-0.15% of C, 0.15-0.35% of Si, 0.95-1.25% of Mn, smaller than or equal to 0.01% of P, smaller than or equal to 0.005% of S, 0.35-0.55% of Cr, 0.35-0.55% of Mo, 0.88-1.5% of Ni, 0.20-0.40% of Cu, 0.02-0.08% of Al, 0.03-0.05% of V, 0.02-0.04% of Nb, smaller than or equal to 0.02% of Ti, smaller than or equal to 0.006% of N, 0.0008-0.002% of B and the balance of Fe and inevitable impurity elements. The manufacturing method of the steel plate adopts the following process flows: smelting and continuously casting, slowly cooling by covering, clearing at a certain temperature, heating, rolling, performing air cooling and straightening, slowly cooling, and quenching and tempering. The manufactured steel plate has the thickness of 80-125mm, has high strength, good ductility and high low-temperature toughness, can be adapted to a minus 60 DEG C low-temperature environment, can meet a requirement on high Z-direction performance, and has excellent overall performance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Large-thickness steel plate for oceaneering and production method thereof

The invention belongs to the technical field of steel and iron, and in particular discloses a large-thickness steel plate for oceaneering and a production method thereof. The large-thickness steel plate for oceaneering comprises the following components in percentage by weight: 0.07-0.09 percent of C, 0.15-0.40 percent of Si, 1.40-1.50 percent of Mn, not more than 0.012 percent of C, not more than 0.005 percent of S, 0.60-0.70 percent of Ni, 0.030-0.040 percent of Nb, 0.020-0.045 percent of Al, 0.13-0.17 percent of Mo, 0.04-0.05 percent of V, 0.012-0.020 percent of Ti and the balance of Fe and inevitable impurities. The large-thickness steel plate for oceaneering has the advantages of pure steel quality, good low-temperature impact toughness, high thickness (Z direction) tensile cross section contractibility rate, large thickness, high strength, good low-temperature aging impact toughness and low product cost. The large-thickness steel plate for oceaneering, provided by the invention,is suitable for use of large-thickness structures for oceaneering.

Owner:WUYANG IRON & STEEL +1

High-tensile quenched and tempered steel plate for large-thickness structures and production method thereof

InactiveCN102080185AGood lamellar tear resistanceImprove low temperature toughnessRoll force/gap control deviceTemperature control deviceChemical compositionSheet steel

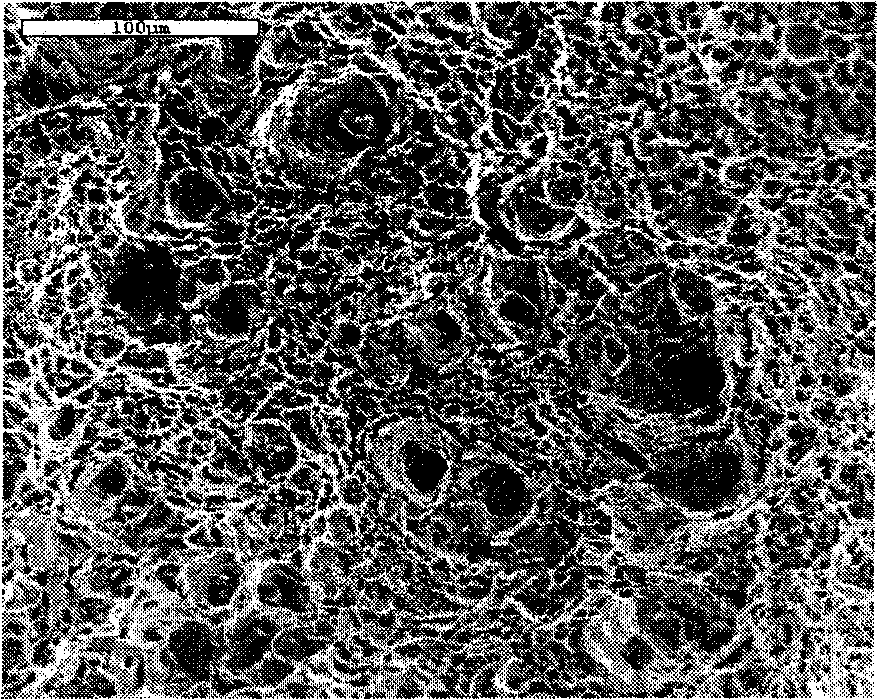

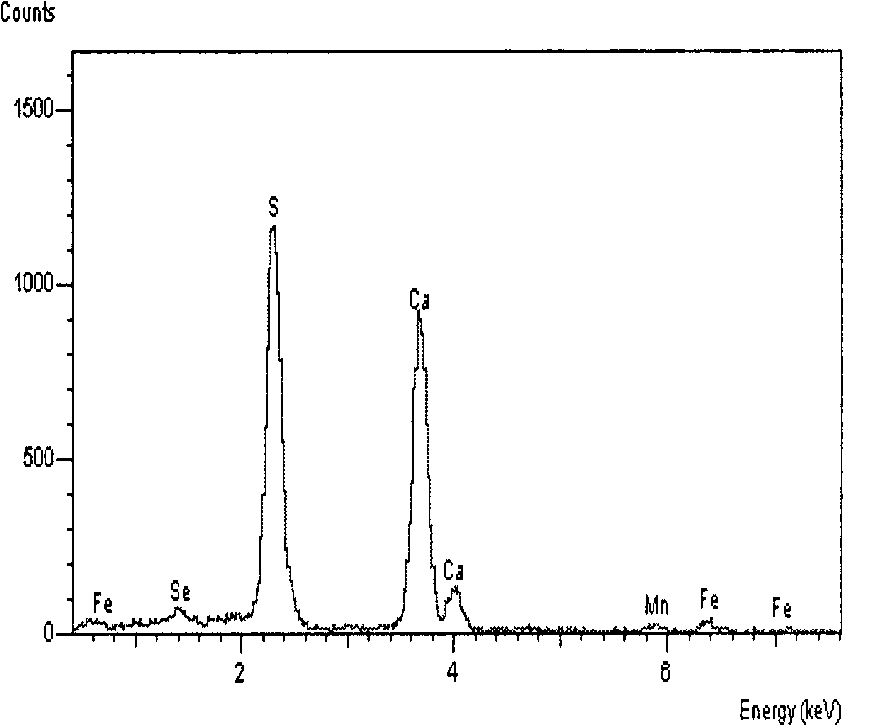

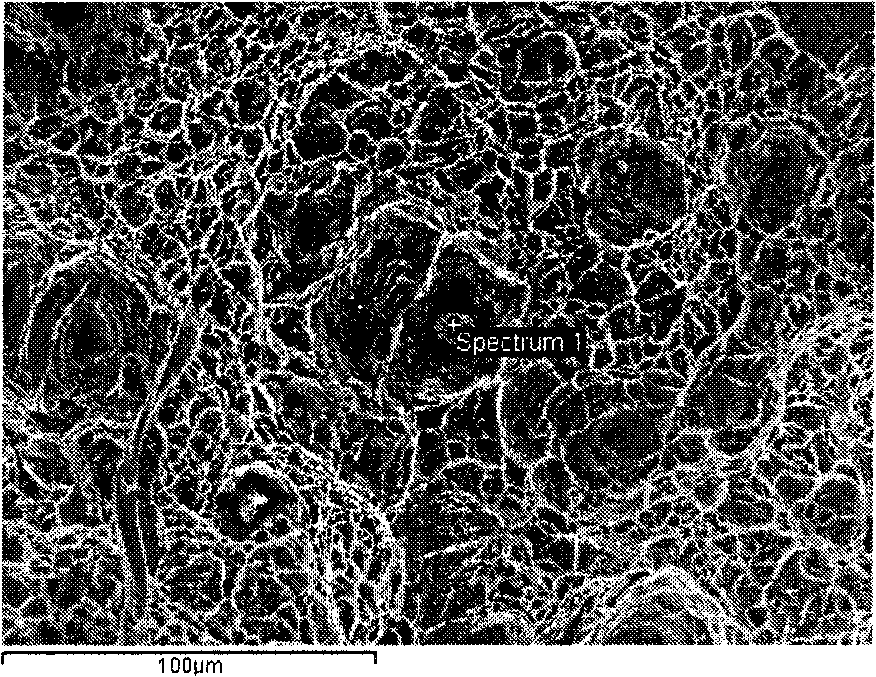

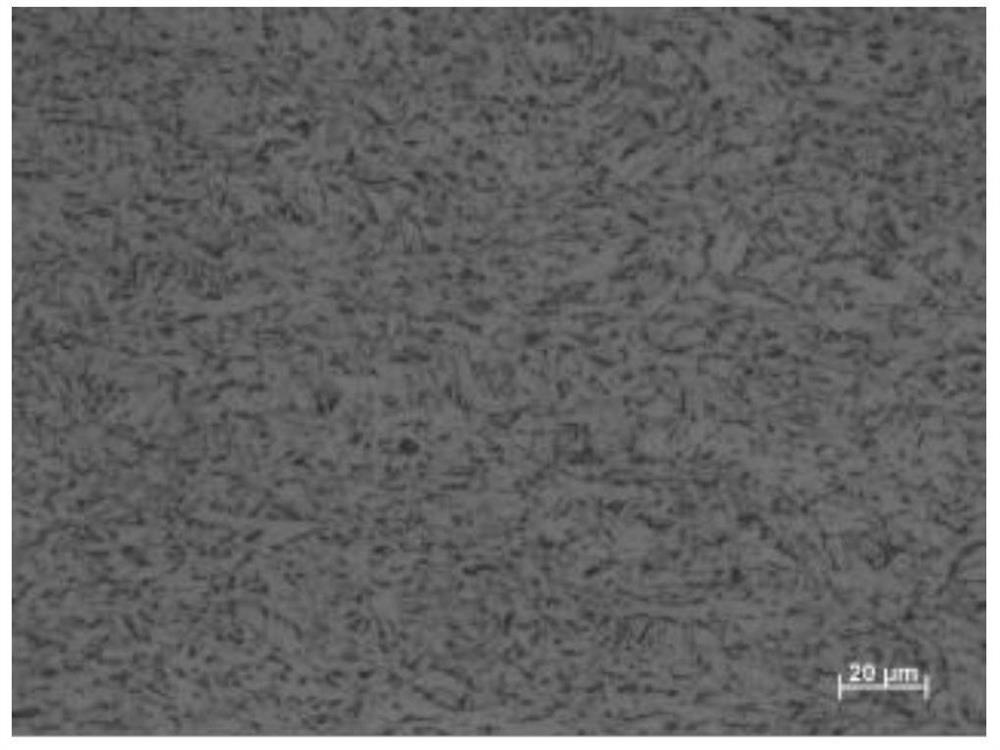

The invention discloses a high-tensile quenched and tempered steel plate for large-thickness structures and a production method thereof, wherein the high-tensile quenched and tempered steel plate comprises the following chemical compositions in percentage by weight: less than or equal to 0.19% of C, less than or equal to 0.50% of Si, 1.00-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, less than or equal to 0.20% of microalloying elements (Nb+V+Ti+Ni), less than or equal to 0.050% of Als, and the balance of Fe and residual elements. By reasonably taking a chemical composition design on composite multicomponent microalloying elements and adopting an LF+VD (ladle refining + vacuum degassing)process, the purity of the steel plate is ensured, and the sum of levels of various inclusions is not more than 3.0; and by utilizing a thermo mechanical control process and adopting normalizing treatment, the grain fineness number of the steel plate reaches level 9.0-10.0; by means of the effective implementation of the measures, the extra-thick steel plates (thickness: greater than or equal to 100mm) for high-rise buildings with guaranteed flaw detection and mechanical properties are produced successfully.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

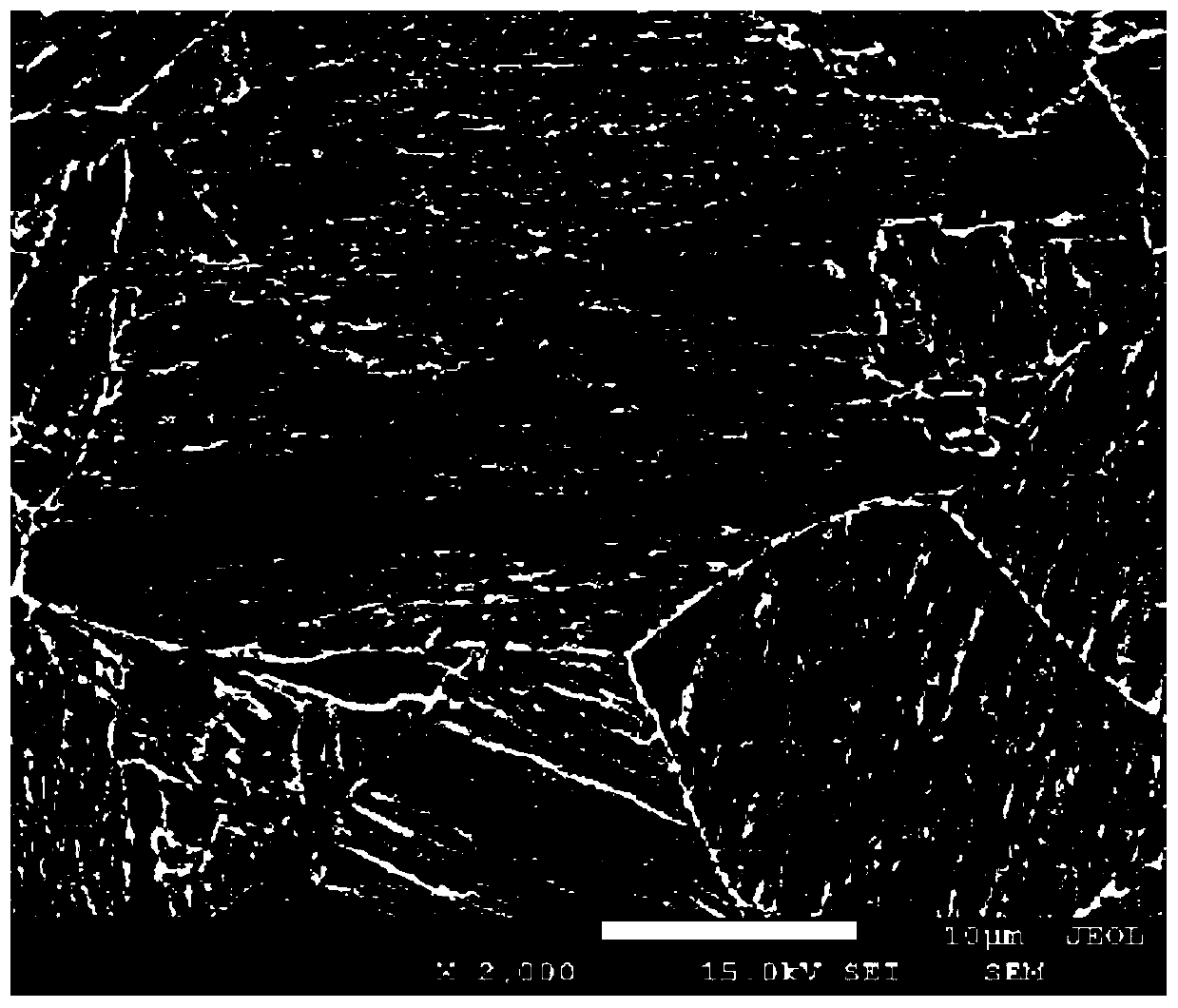

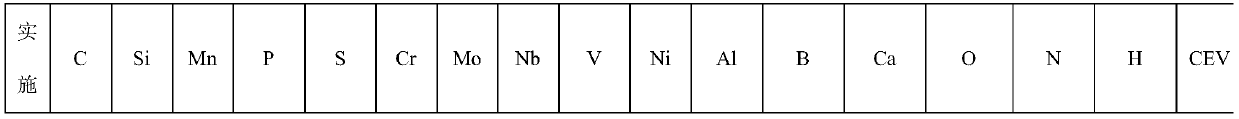

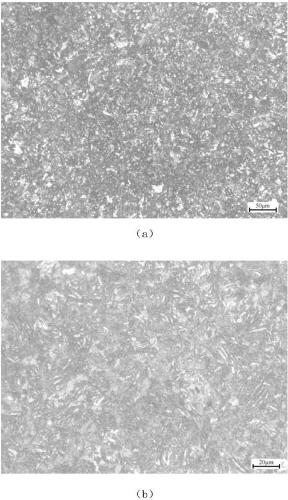

Large-thickness lamellar tearing-resistant high-strength steel plate with 960 MPa-level yield strength and production method thereof

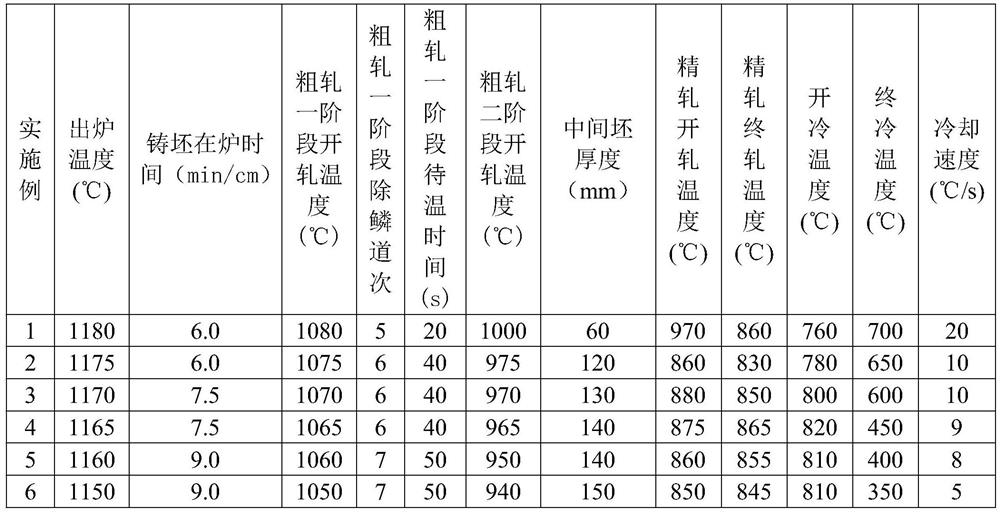

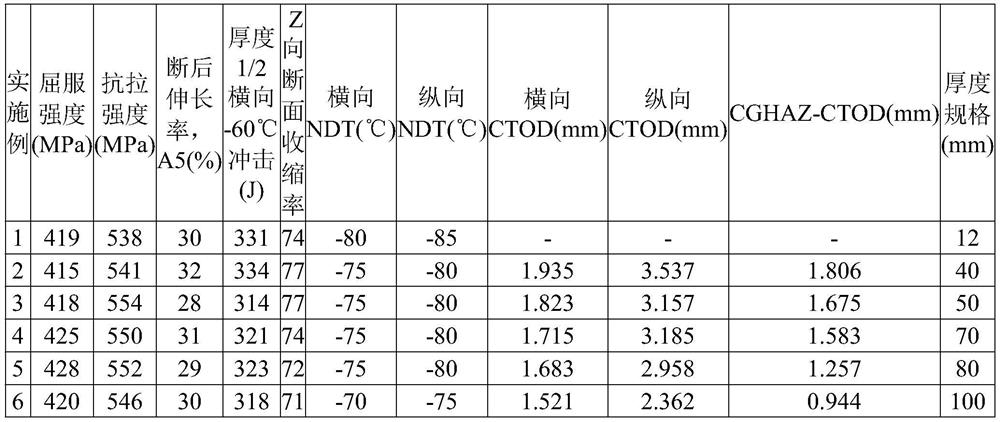

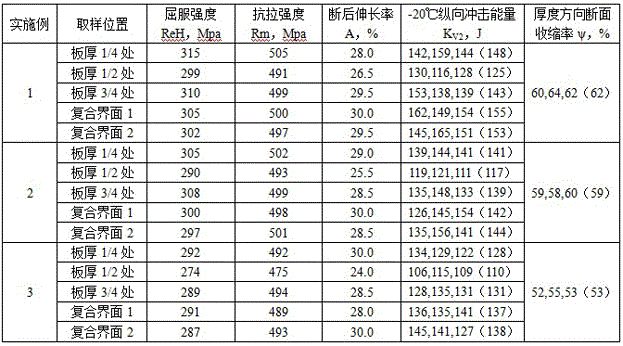

ActiveCN110318008APromoting degenerationImproved through-thickness performanceFurnace typesIncreasing energy efficiencyMechanical propertyMaterials science

The invention relates to a large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength and a production method thereof. The chemical components ofthe large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength comprises, by weight, 0.15-0.20% of carbon, 0.10-0.40% of silicon, 0.90-1.30% of manganese, 0.010-0.040% of niobium, 0.010-0.045% of vanadium, smaller than or equal to 0.010% of titanium, 0.03-0.06% of aluminum, 0.50-1.00% of nickel, smaller than or equal to 0.1% of copper, 0.30-0.80% of chromium, 0.20-0.70% of molybdenum, 0.001-0.005% of boron, 0.001-0.005% of calcium, smaller than or equal to 0.010% of phosphorus, smaller than or equal to 0.002% of sulphur, smaller than or equal to 0.002% of oxygen, smaller than or equal to 0.004% of nitrogen, smaller than or equal to 0.00015% of hydrogen and the balance iron and inevitable impurity elements. The technological steps of thesteel plate comprises smelting, secondary refining, vacuum degassing, calcium treatment, continuous casting, heating, rolling, steel plate slow cooling, quenching and tempering. The large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength has high comprehensive mechanical property; the yield strength is greater than or equal to 960 MPa; thetensile strength is greater than or equal to 1000 MPa; the Charpy impact power at a low temperature of minus 40 DEG C is greater than or equal to 30J; the Z-direction tensile fracture surface shrinking rate is greater than or equal to 35%; and the lamellar tearing-resistant property is good.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Large-thickness rolled steel plate instead of case one for large-sized ball mill and production method thereof

InactiveCN101956130AGood toughness indexIncrease thickness specificationTemperature control deviceMetal rolling arrangementsMolten steelHydrogen treatment

The invention discloses a large-thickness rolled steel plate instead of a cast one for a large-sized ball mill and a production method thereof. The steel plate is formed by smelting the following components by weight percent: 0.160-0.190% of C, less than or equal to 0.45% of Si, 1.300-1.500% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.020-0.050% of Als, 0.015-0.025% of Nb and the balance Fe and inevitable impurities. The method comprises the following steps: smelting molten steel in an electric furnace; refining in an LF refining furnace; performing vacuum treatment in a vacuum degassing furnace; and casting, electroslag remelting, heating, rolling to finished product, cooling, performing hydrogen expanding treatment and normalizing and the like to prepare into the finished product thick steel plate. The invention has the following advantages: 1) the strength and toughness are matched favorably, the yield strength Re is more than or equal to 265 MPa, Rm is 430-600 MPa, the longitudinal impact power is more than or equal to 34J at the temperature of 0 DEG C, and A is more than or equal to 17%; 2) the lamellar tearing resistance is good, and Z is more than or equal to 35%; 3) the steel of the invention is purer, P is less than or equal to 0.015%, and S is less than or equal to 0.005%: 4) the internal quality is more compact, and can satisfy the requirement of the A578C class detection standard; and 5) the maximum thickness of the steel plate can achieve 288mm.

Owner:WUYANG IRON & STEEL +1

Modified EH550 super-thick steel plate for marine engineering and manufacturing method thereof

The invention discloses a modified EH550 super-thick steel plate for marine engineering and a manufacturing method thereof. The steel contains 0.08% to 0.15% of C, 0.20% to 0.55% of Si, 0.80% to 1.35%of Mn, less than or equal to 0.01% of P, less than or equal to 0.03% of S, 0.04% to 0.08% of V, 0.015% to 0.45% of Als, 0.003-0.015% of N, 0.50-0.90% of Ni, 0.20-0.40% of Cr, 0.002-0.03% of Mo, 0.02%to 0.05% of Nb, 0.20-0.40% of Cu, less than or equal to 0.04% of Ti, and the balance of Fe and unavoidable impurities. The method employs two-stage controlled rolling, the first-stage rolling temperature is 1100-1150 DEG C, the one-stage finishing rolling temperature is 990-1130 DEG C, the second-stage rolling temperature is 700-780 DEG C, and the final rolling temperature is 680-750 DEG C. The heat treatment method of quenching before sub-quenching is used, and after quenching, the steel plate is tempered, and the steel plate having a thickness of 80-100 mm is obtained. The impact toughnessof a core is more than 200J, and the comprehensive performance is uniform at different positions.

Owner:ANGANG STEEL CO LTD

Low alloy extremely-thick steel plate produced through two-blank composition and having excellent interior quality, low-temperature impact toughness and lamination crackresistant property

The invention relates to a low alloy extremely-thick steel plate having the excellent interior quality, low-temperature impact toughness and lamination crackresistant property. A fracture surface continuous casting plate blank of 370 or 450 mm is adopted to serve as a base blank to be subjected to two-blank composition through electronic beam welding in a vacuum chamber, and the thickness of composite blanks are 710-720 mm and 870-880 mm correspondingly; and the composite blanks are taken as blank materials to produce the low alloy extremely-thick steel plate with the steel plate thickness being larger than 150-400 mm through work procedures of heating, rolling and normalizing. The steel plate has the good interior quality and excellent mechanical performance, flaw detection can meet the standard levels such as I levels of EN10160 S2E3, A578C, GB / T2970, the thickness-direction performance can meet Z35, and low-temperature impacting of minus 40 DEG C can meet the unit value being larger than or equal to 100 J.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-thickness steel plate for ocean platform and production method for steel plate

The invention discloses a high-thickness steel plate for an ocean platform. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.18 percent of C, 0.30 to 0.40 percent of Si, 1.2 to 1.4 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.020 to 0.045 percent of Al, 0.02 to 0.05 percent of Nb, 0.05 to 0.1 percent of V, and the balance of Fe and inevitable impurities. The high-thickness steel plate for the ocean platform is reasonable in chemical component design and low in production cost. The steel plate is prepared by adopting an electroslag remelting process and a normalizing heat treatment process, and the thickness of the prepared steel plate reaches 300 millimeters. The finished steel plate has the advantages of high yielding strength, excellent Z-directional performance, high negative temperature impact power, high elongation and high low-temperature impact toughness resistance and lamellar tearing resistance.

Owner:WUYANG IRON & STEEL +1

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

The invention which belongs to the technical field of steel concretely discloses an extra thick quenched and tempered steel plate for an ocean platform tooth bar and a production method thereof. The extra thick quenched and tempered steel plate for the ocean platform tooth bar comprises the following components, by weight, 0.14-0.18% of C, 0.15-0.35% of Si, 0.95-1.30% of Mn, equal to or less than0.015% of P, equal to or less than 0.005% of S, 2.35-2.55% of Ni, 0.35-0.55% of Cr, 0.40-0.60% of Mo, 0.020-0.050% of Nb, 0.010-0.030% of Ti, 0.020-0.045% of total Al, and the balance Fe and inevitable impurities, and the thickness of the steel plate reaches 177.8mm. The extra thick quenched and tempered steel plate for the ocean platform tooth bar, which is prepared through carrying out steps ofsmelting by an electric furnace, steel ingot casting by a die, TMCP rolling, fully enclosed quenching and tempering by a well type heating furnace, and the like, has the advantages of high yield strength, good elongation, excellent Z-directional performance, good low temperature impact toughness, good layered tearing resistance, and low production cost.

Owner:WUYANG IRON & STEEL +1

Steel plate for pressure vessel with yield strength being 345 MPa stage and production method

InactiveCN106591703AGood lamellar tear resistanceImprove low temperature toughnessChemical compositionImpurity

The invention discloses a steel plate for a pressure vessel with the yield strength being the 345 MPa stage and a production method. The steel plate comprises chemical components including, by weight, 0.15%-0.18% of C, 0.15%-0.35% of Si, 1.40%-1.50% of Mn, not larger than 0.008% of P, not larger than 0.002% of S, 0.020%-0.040% of Al, 0.020%-0.035% of Nb, not larger than 0.003% of O and the balance Fe and inevitable impurities. The production method includes the heating process, the rolling process and the heat treatment process. According to the steel plate for the pressure vessel with the yield strength being the 345 MPa stage, the clean steel technology idea is adopted; the steel plate has the beneficial effects that the purity degree is high, and -10 DEG C low temperature impact toughness and plasticity mainly show that the extending rate is excellent, and the lamellar tearing resistance is excellent; and the steel for the pressure vessel can meet the requirement for developing to high plasticity and high toughness, and the steel plate can be widely used for the pressure vessel industry.

Owner:WUYANG IRON & STEEL

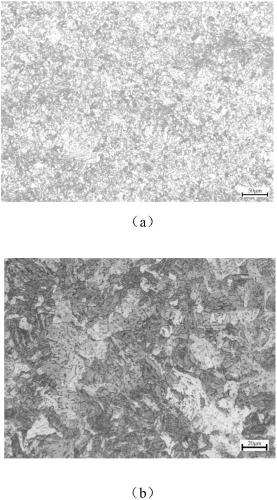

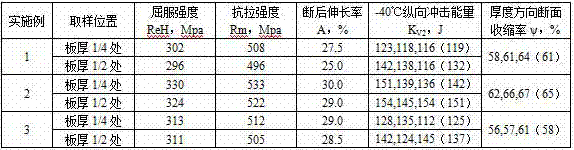

Engineering steel with excellent low-temperature impact toughness and lamellar tear resistance in core and production method thereof

ActiveCN102268615AGood heart toughnessGood lamellar tear resistanceProcess efficiency improvementAntimonyImpact toughness

The invention relates to a production method of an engineering steel material with excellent core low-temperature impact toughness and lamellar tearing resisting performance. The engineering steel material comprises the following main components in percentage by weight: 0.030-0.010 percent of carbon, 1.20-1.60 percent of manganese, 0.10-0.35 percent of silicon, 0.015-0.03 percent of niobium, 0.005-0.020 percent of titanium, 0.020-0.040 percent of total aluminum, and not less than 0.10 percent of calcium / total aluminum; the engineering steel material also comprises the following residual components in percentage by weight: not more than 0.006 percent of nitrogen, not more than 0.004 percent of oxygen, not more than 0.015 of phosphorus, not more than 0.006 percent of sulfur, not more than 0.04 percent of arsenic, not more than 0.03 percent of stannum and not more than 0.02 percent of antimony; and except the main components and the residual components, the balance is ferrum. According to the engineering steel material and the production method provided by the invention, without adding nickel, vanadium and other expensive alloying elements and without adopting offline quenching and tempering treatment and other expensive equipment, the steel material with the yield strength of not less than 420 Megapascal and the excellent core toughness and lamellar tearing resisting performance can be obtained by only adopting a niobium and titanium micro-alloyed low carbon-manganese-niobium-titanium component system and fitting with an online quenching and tempering process.

Owner:SHAOGUAN IRON & STEEL GROUP CORP GUANGDONG PROV +1

Marine work steel plate with excellent low-temperature toughness and low yield ratio and manufacturing method thereof

ActiveCN112877601AHigh strengthImprove low temperature toughnessRoll force/gap control deviceTemperature control deviceTemperingSlow cooling

The invention discloses a maritime work steel plate with excellent low-temperature toughness and low yield ratio and a manufacturing method thereof. The steel contains the following components: 0.06%-0.12% of C, 0.20%-0.40% of Si, 1.45%-1.65% of Mn, less than or equal to 0.01% of P; less than or equal to 0.002% of S, 0.15%-0.25% of Ni, 0.15%-0.30% of Cu, 0.015%-0.04% of Nb, 0.007%-0.025% of Ti, 0.015%-0.045% of Alt, and the balance of iron and inevitable impurities. The casting blank heating temperature is 1150-1180 DEG C, the first-stage rolling temperature is 1100-1150 DEG C, the second-stage rolling temperature is 890-940 DEG C, the single-pass reduction rate is larger than or equal to 9%, the third-stage rolling temperature is 800-840 DEG C, the accumulated reduction rate is 35%-50%, and the finish rolling temperature is 770-810 DEG C; the initial cooling temperature is 710-750 DEG C, the average cooling speed is greater than or equal to 5 DEG C / s, and the self-tempering temperature is 280-350 DEG C; the slow cooling pit is insulated and cooled, and the stacking time is longer than or equal to 24 hours; and the steel plate has excellent toughness at -40 DEG C.

Owner:ANGANG STEEL CO LTD

Super-thick steel plate for construction with excellent Z-directional performance and production method thereof

InactiveCN101845588AGood lamellar tear resistanceEasy to operateMolten metal pouring equipmentsChemical compositionSheet steel

The invention relates to a super-thick steel plate for construction with an excellent Z-directional performance, which is characterized in that the chemical composition (by weight percentage) of steel is as follows: C accounts for 0.10-0.22 percent, Si accounts for 0.10-0.50 percent, Mn accounts for 1.0-2.0 percent, P accounts for less than or equal to 0.025 percent, S accounts for less than or equal to 0.006 percent, Nb accounts for 0.01-0.06 percent, V accounts for 0.02-0.11 percent, Ti accounts for 0.005-0.025 percent, Ca accounts for 0.0004-0.0040 percent, Alt accounts for 0.01-0.05 percent, H accounts for less than or equal to 0.0002 percent, and the rest is Fe and inevitable impurities. The thickness of the steel is more than or equal to 60mm. The production of the super-thick steel plate comprises the following steps: deep desulphurization of molten iron, combined blowing on the top and bottom of a converter, refining outside the converter, die casting, blooming, reheating of a cogged ingot, free rolling, air cooling and normalizing; wherein the cogged ingot is reheated to be 1100-1250 DEG C; and the steel plate is heated to be 860-920 DEG C for normalizing. The super-thick steel plate has an excellent Z-directional performance, and can be widely applied in the constructional engineering field such as high-rise buildings, large-span stadiums and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Large-thickness high-performance SA302GrC steel plate and production method thereof

The invention relates to a large-thickness high-performance SA302GrC steel plate and a production method thereof, belonging to the technical field of steel smelting processes. According to the technical scheme, the production method comprises procedures of smelting, casting, heating, rolling, cooling after rolling, normalizing, accelerated cooling and tempering; and the steel plate is prepared from the following chemical ingredients in percentage by mass: 0.10-0.18% of C, 0.15-0.40% of Si, 1.20-1.45% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.40-0.55% of Ni, 0.45-0.60% of Mo, and the balance of Fe and inevitable impurities. The steel plate has the following advantages that the obdurability matching is good, the yield strength Re is greater than or equal to 345Mpa, the transverse Charpy impact in the position which is 1 / 4 of the plate thickness at minus 10 DEG C is less than 41J, the steel quality is purer, the lamellar tearing resisting property is good, the through thickness direction Z is greater than or equal to 35%, the welding property is good, and the thickness of the steel plate is 135mm. The steel plate which is produced by using the production method provided by the invention has the characteristics of high purity, uniformity in component and internal compactness, and has good obdurability matching.

Owner:WUYANG IRON & STEEL +1

High-toughness quantitative-reduction ship plate marine steel and preparation method thereof

The invention discloses high-toughness quantitative-reduction ship plate marine steel. A steel plate comprises the following chemical components by weight percent: 0.04%-0.14% of C, 0.15%-0.45% of Si,0.90%-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.010%-0.040% of Nb, 0-0.20% of Cr, 0-0.030% of V, 0.005%-0.020% of Ti, 0.015%-0.050% of Als, less than or equal to 30 ppm of N, less than or equal to 30 ppm of O, less than or equal to 2 ppm of H, and the balance Fe and inevitable impurities, wherein Als is acid-soluble aluminum; a welding crack sensitivityindex (Pcm) of the steel plate is less than or equal to 0.22%; and a carbon equivalent value (CEV) is less than or equal to 0.39%. The steel plate is not liable to be broken and damaged, and has goodstrength and toughness, welding performance and crack arrest performance.

Owner:SD STEEL RIZHAO CO LTD

Low-alloy extra-thick structure steel plate with the thickness being 400-610 mm and manufacturing method thereof

The invention relates to a low-alloy extra-thick structure steel plate with the thickness being 400-610 mm. Chemical components of the steel plate is redesigned; the contents of elements of S,P,H,O and N are controlled to improve the purity degree of liquid steel; the low-temperature impact toughness of the extra-thick steel plate is improved; the oxygen content is decreased, and by combining the hot rolling process, the content of oxides in steel is effectively decreased; and the favorable condition is created for achieving metallic bonding of a composite interface. Three continuous casting slab with the 370 mm sections are used as base slabs and composited; the thickness of a composite slab is 1050-1090 mm; the composite slab serves as a slab material, and production is conducted through processes of heating, rolling and normalizing; the steel plate has the good internal quality and excellent mechanical property; flaw detection can meet the standard levels of EN10160 S1E1, A578B, A435 and the like; thickness directional performance can meet Z35; and low-temperature impact at -20 DEG C can meet the requirement that the single value is larger than or equal to 100J.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-uniformity steel plate with super-thick structure and manufacturing method thereof

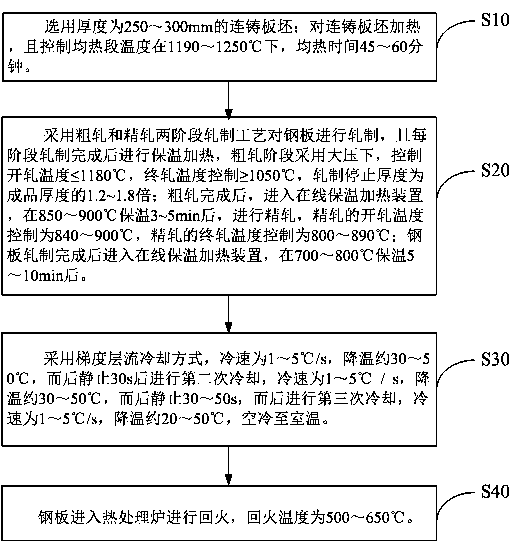

ActiveCN110306117AEven heat dissipationUniform grain refinementHigh intensityUltimate tensile strength

The invention discloses a high-uniformity steel plate with a super-thick structure and a manufacturing method thereof. The steel plate is prepared from C, Si, Mn, P, S, Nb, Ti, Cu, Als and the balanceFe and impurities. The manufacturing method comprises the steps that a mode of optimizing a rolling cooling process and sequentially conducting rough rolling, fine rolling and heat preservation or heating is adopted, so that the temperature uniformity of the surface and the core part of a steel blank in the rolling process is guaranteed, and uniform refining of internal tissue grains of steel isachieved; in the cooling process, a segmented stepped cooling mode is adopted, the temperature tissue uniformity of the steel plate in the thickness direction is further guaranteed by means of the redreturning process of stepped cooling, and the internal tissue grains are further refined, so that the high-uniformity super-thick steel plate is obtained. According to the high-uniformity steel platewith the super-thick structure and the manufacturing method thereof, the intensity difference of the surface-close layer, the position about 1 / 4 thickness and the position about 1 / 2 thickness of thesteel plate is smaller than or equal to 15 MPa, and the steel plate is uniform in strength property, high in strength and toughness and excellent in lamellar tearing resistant property and welding property.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

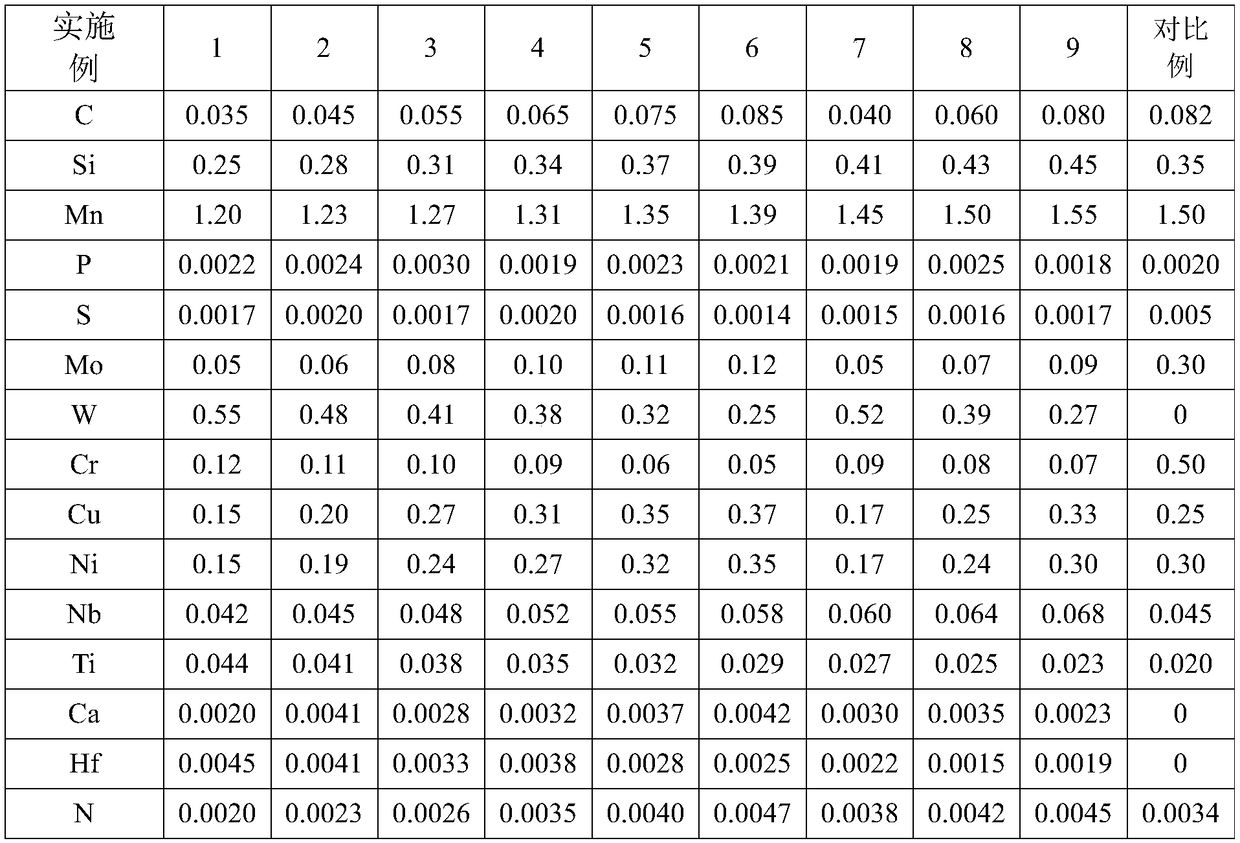

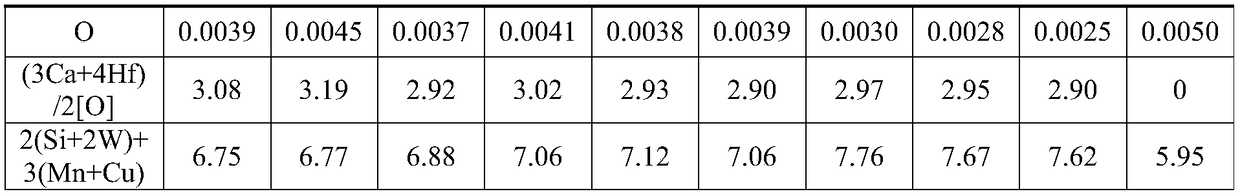

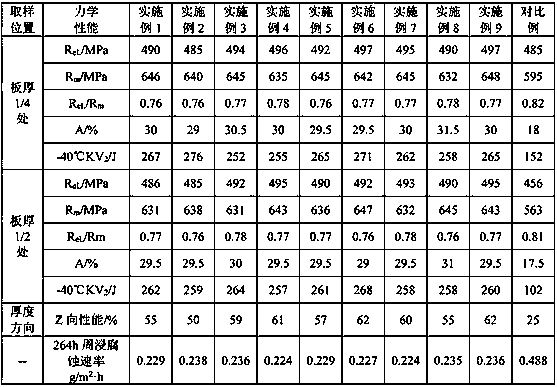

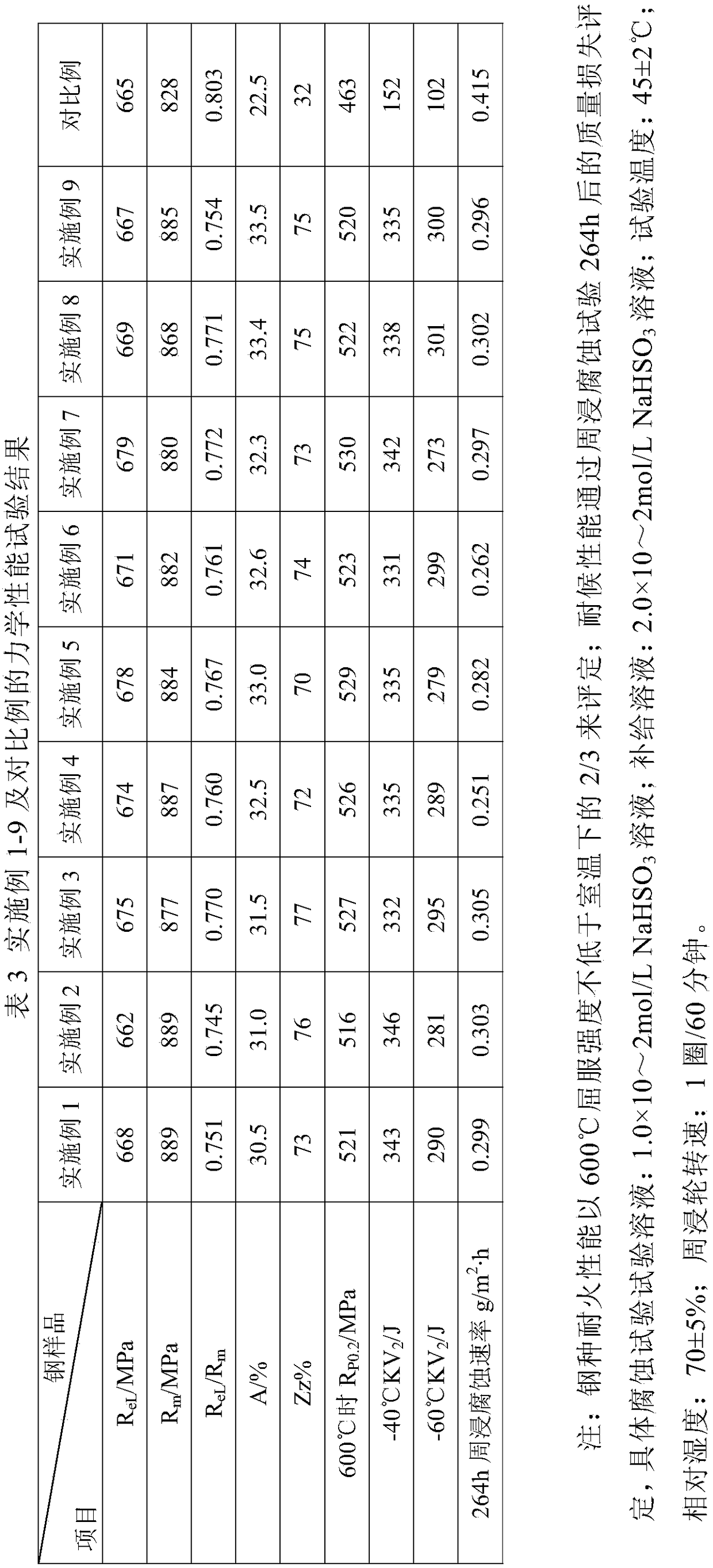

Welding structure fire-resistant and weather-resistant steel with yield strength being 550 MPa or above and production method

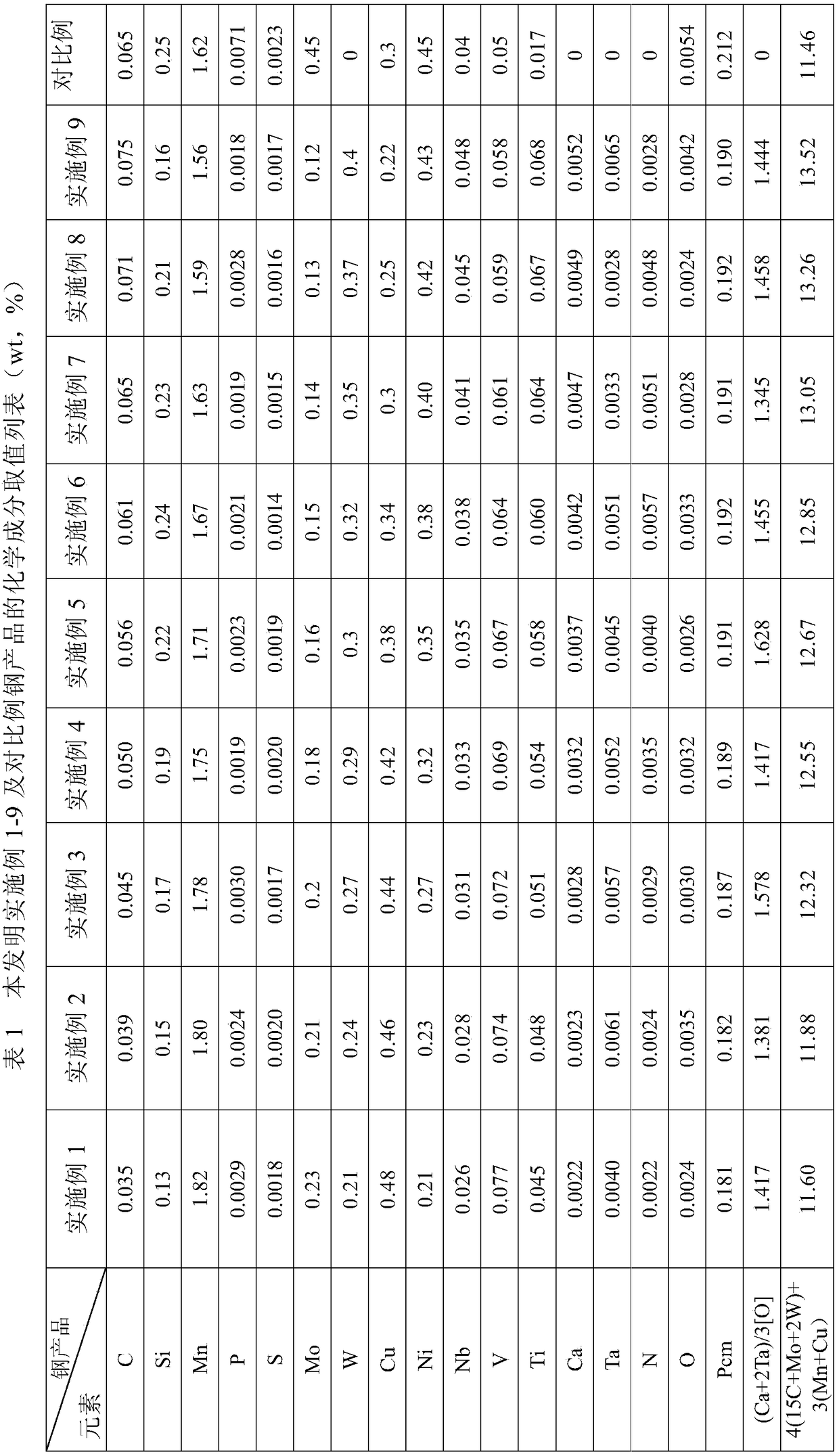

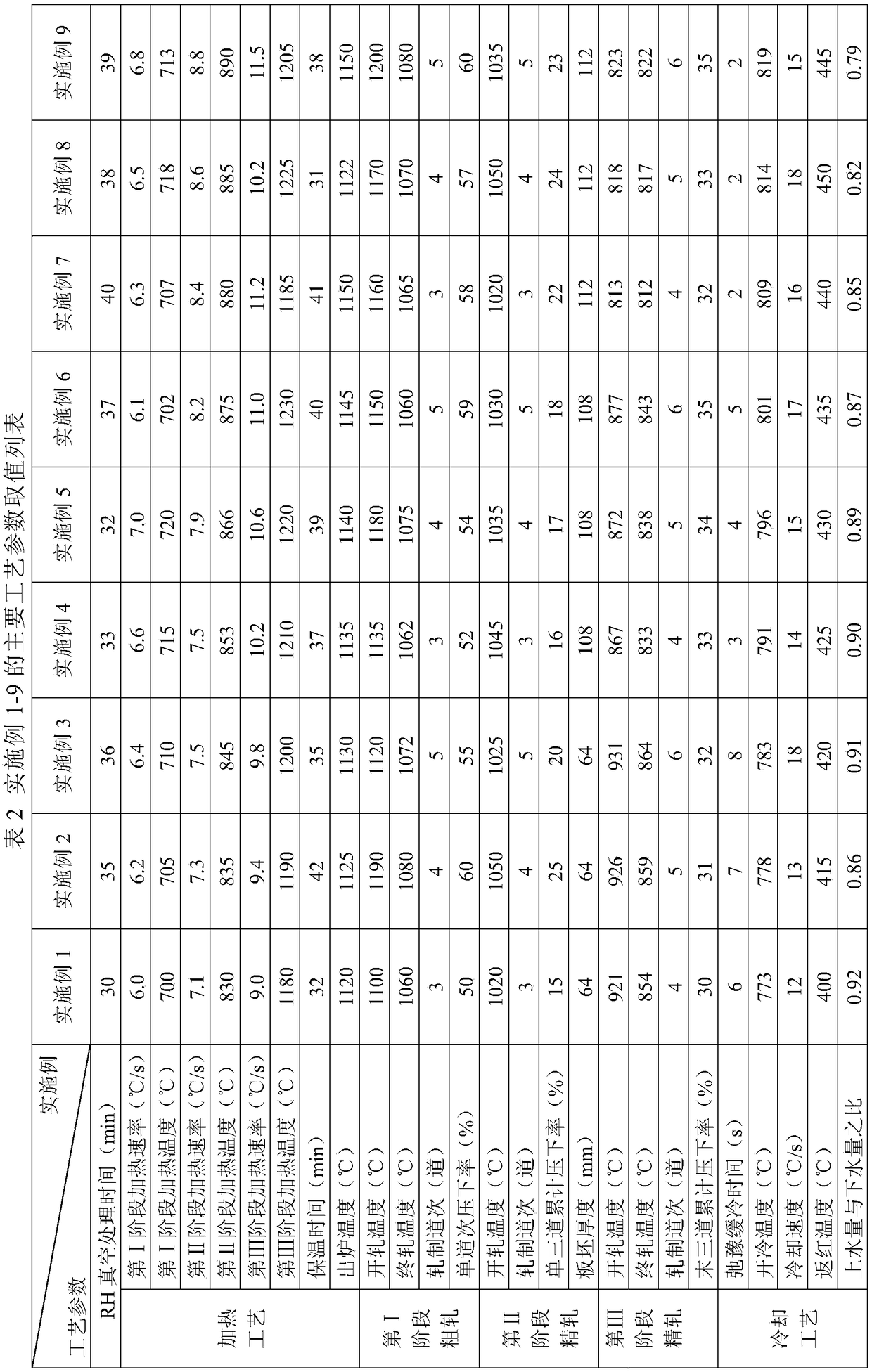

Welding structure fire-resistant and weather-resistant steel with the yield strength being 550 MPa or above comprises components, by weight percent, 0.035 wt%-0.085 wt% of C, 0.25 wt%-0.45 wt% of Si,1.20 wt%-1.55 wt% of Mn, 0.003 wt% or below of P, 0.002 wt% or below of S, 0.05 wt%-0.12 wt% of Mo, 0.25 wt%-0.55 wt% of W, 0.05 wt%-0.12 wt% of Cr, 0.15 wt%-0.37 wt% of Cu, 0.15 wt%-0.35 wt% of Ni, 0.042 wt%-0.068 wt% of Nb, 0.023 wt%-0.044 wt% of Ti, 0.0020 wt%-0.0042 wt% of Ca, 0.0015 wt%-0.0045 wt% of Hf, 0.0020 wt%-0.0047 wt% of N and 0.0025 wt%-0.0045 wt% of O. A production method comprisesthe steps that a casting blank is heated section by section, rough rolling, finish rolling and cooling are sequentially carried out, and air cooling is carried out until the room temperature is reached. According to the welding structure fire-resistant and weather-resistant steel with the yield strength being 550 MPa or above, ReL is 550 MPa or above, Rm is 750 MPa or above, ReL / Rm is 0.78 or below, the ductility A is 30 % or above, the Z-directional performance is 65 % or above, -60 DEG C KV2 is 300 J or above, excellent fire resistance, weather resistance, lamellar tearing resistance, the welding performance, the cold and hot processing performance and the large-deformation resistance are achieved, preheating is not needed before welding, and heat treatment is not needed after welding.

Owner:武汉钢铁有限公司

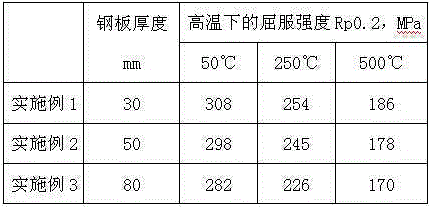

Steel plate of thermal-pressure-resistant container used for furnace shell and manufacturing method of steel plate

The invention relates to the technical field of manufacturing of steel plates of thermal-pressure-resistant containers, in particular to a steel plate of a thermal-pressure-resistant container used for a furnace shell and a manufacturing method of the steel plate. The steel plate is prepared from, by mass, 0.12-0.20% of C, 0.10-0.35% of Si, 0.50-0.90% of Mn, 0-0.020% of P, 0-0.005% of S, 0.25-0.35% of Mo, 0.020-0.050% of Alt and the balance Fe and inevitable residual elements. The carbon equivalent of the steel plate is smaller than or equal to 0.43%. The steel plate can be applicable to the environment with the working temperature as high as 500 DEG C and cope with challenges of bad conditions such as high temperature, mechanical shock and thermal stress. In addition, the function of improving the high-temperature performance of steel through the Mo element is brought into play ingeniously, and therefore the steel is still excellent in strength and hardness at a high temperature and can further meet the using requirements in various application fields. The steel plate is stable in performance, high in safety coefficient, low in cost and can also be applied to the field of nuclear power pressure container construction.

Owner:SHANDONG IRON & STEEL CO LTD

High-low-temperature-toughness extra-thick corrosion-resistant steel plate with yield strength of higher than 460 MPa and production method of steel plate

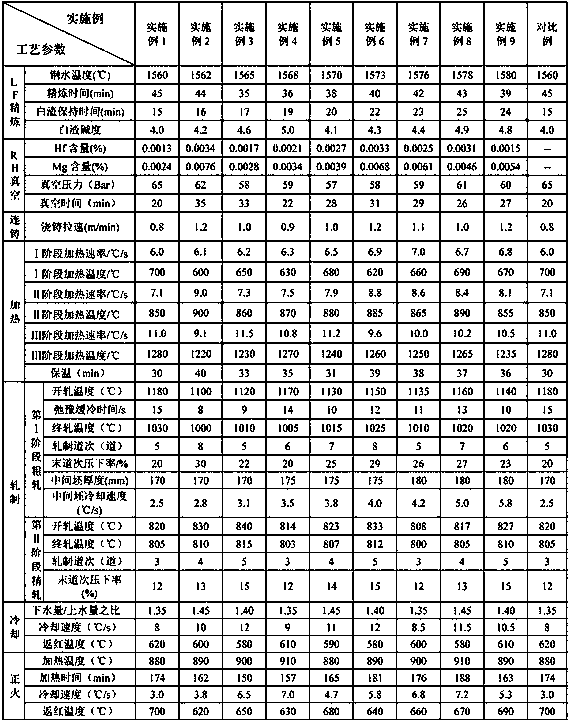

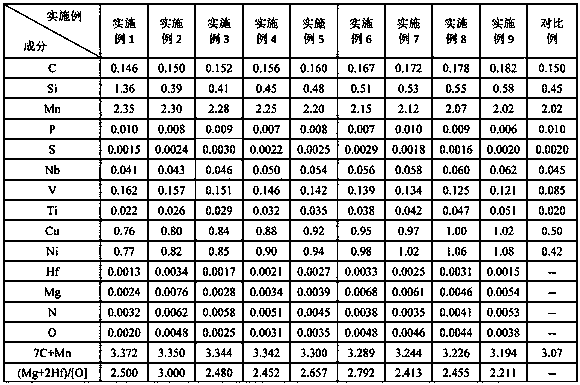

The invention discloses a high-low-temperature-toughness extra-thick corrosion-resistant steel plate with the yield strength of higher than 460 MPa and a production method of the steel plate. The steel plate contains the following chemical components in percentage by mass: 0.146-0.182% of C, 0.36-0.58% of Si, 2.02-2.35% of Mn, 0.041-0.062% of Nb, 0.121-0.162% of V, 0.022-0.051% of Ti, 0.76-1.02% of Cu, 0.77-1.08% of Ni, 0.0013-0.0034% of Hf, 0.0024-0.0076% of Mg, no more than 0.010% of P, no more than 0.003% of S, (32-62)x10<-4>% of [N], (20-48)x10<-4>% of [O], and the balance of Fe and inevitable impurities, wherein the mass percentages of part of the above chemical components have to meet the following relations: 1, the sum of 7C and Mn is equal to 3.25-3.42%; and 2, the quotient of thesum of Mg and 2Hf divided by [O] is equal to 2.16-3.12. The extra-thick corrosion-resistant steel plate has the beneficial effects that a lot of precious metals such as Mo and Cr need not be added andthe production process is simple; the produced extra-thick corrosion-resistant steel plate of 120-130 mm is high in strength, high in plasticity, low in yield ratio, high in low-temperature toughness, as well as excellent in corrosion-resistant property, anti-lamellar-tearing property, welding property and cold-hot processing property; and the property uniformity of all parts of the steel plate is high.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

Steel for marine drilling platform

Owner:无锡市森信精密机械厂

Welded structure refractory and weathering steel with yield strength being no less than 620 MPa and production method thereof

The invention relates to a welded structure refractory and weathering steel with yield strength being no less than 620 MPa and production method thereof, and the welded structure refractory and weathering steel with the yield strength being no less than 620 MPa comprises, by mass, 0.035-0.075% of C, 0.13-0.24% of Si, 1.56-1.82% of Mn, no more than 0.003% of P, no more than 0.002% of S, 0.12-0.23%of Mo, 0.21-0.40% of W, 0.22-0.48% of Cu, 0.21-0.43% of Ni, 0.026-0.048% of Nb, 0.058-0.077% of V, 0.045-0.068% of Ti, 0.0022-0.0052% of Ca, 0.0028-0.0065% of Ta. The welded structure refractory and weathering steel with the yield strength being no less than 620 MPa has good mechanical properties, excellent fire resistance, weather resistance and resistance to laminar tearing, as well as the excellent welding property.

Owner:武汉钢铁有限公司

Preparation method of steel for ocean drilling platform

InactiveCN103789675ACorrosion resistance in marine environmentSuitable for useChemical compositionThermal treatment

The invention discloses a preparation method of steel for an ocean drilling platform. The steel comprises the following chemical ingredients by weight percent: 0.12-0.15% of C, 0.40-0.60% of Si, 0.60-0.80% of Mn, 2.00-2.20% of Cr, 0.10-0.30% of Al, 0.50-0.70% of Mo, no more than 0.015% of P, no more than 0.010% of S, 0.20-0.40% of Cu, 1.20-1.40% of Ni, 0.025-0.045% of Ti, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: 1) smelting, refining and continuously casting into a billet; 2) soaking the steel billet; 3) carrying out hot rolling, wherein the open rolling temperature is 1130-1160 DEG C, and the final rolling temperature is controlled at 920-950 DEG C; 4) carrying out thermal treatment, namely carrying out normalizing treatment under the condition that the temperature is 880-920 DEG C, and naturally cooling.

Owner:无锡市森信精密机械厂

Extra thick quenched and tempered steel plate for ocean platform tooth bar and production method thereof

Owner:WUYANG IRON & STEEL +1

Large-thickness steel plate for oceaneering

The invention belongs to the technical field of steel and iron, and in particular discloses a large-thickness steel plate for oceaneering and a production method thereof. The large-thickness steel plate for oceaneering comprises the following components in percentage by weight: 0.07-0.09 percent of C, 0.15-0.40 percent of Si, 1.40-1.50 percent of Mn, not more than 0.012 percent of C, not more than 0.005 percent of S, 0.60-0.70 percent of Ni, 0.030-0.040 percent of Nb, 0.020-0.045 percent of Al, 0.13-0.17 percent of Mo, 0.04-0.05 percent of V, 0.012-0.020 percent of Ti and the balance of Fe and inevitable impurities. The large-thickness steel plate for oceaneering has the advantages of pure steel quality, good low-temperature impact toughness, high thickness (Z direction) tensile cross section contractibility rate, large thickness, high strength, good low-temperature aging impact toughness and low product cost. The large-thickness steel plate for oceaneering, provided by the invention, is suitable for use of large-thickness structures for oceaneering.

Owner:WUYANG IRON & STEEL +1

Weather-resistance bridge high-strength steel plate and production method thereof

InactiveCN101876032BIncrease thickness specificationExcellent performance indexWeather resistanceUltimate tensile strength

Owner:WUYANG IRON & STEEL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com