Patents

Literature

119results about How to "Uniform grain refinement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

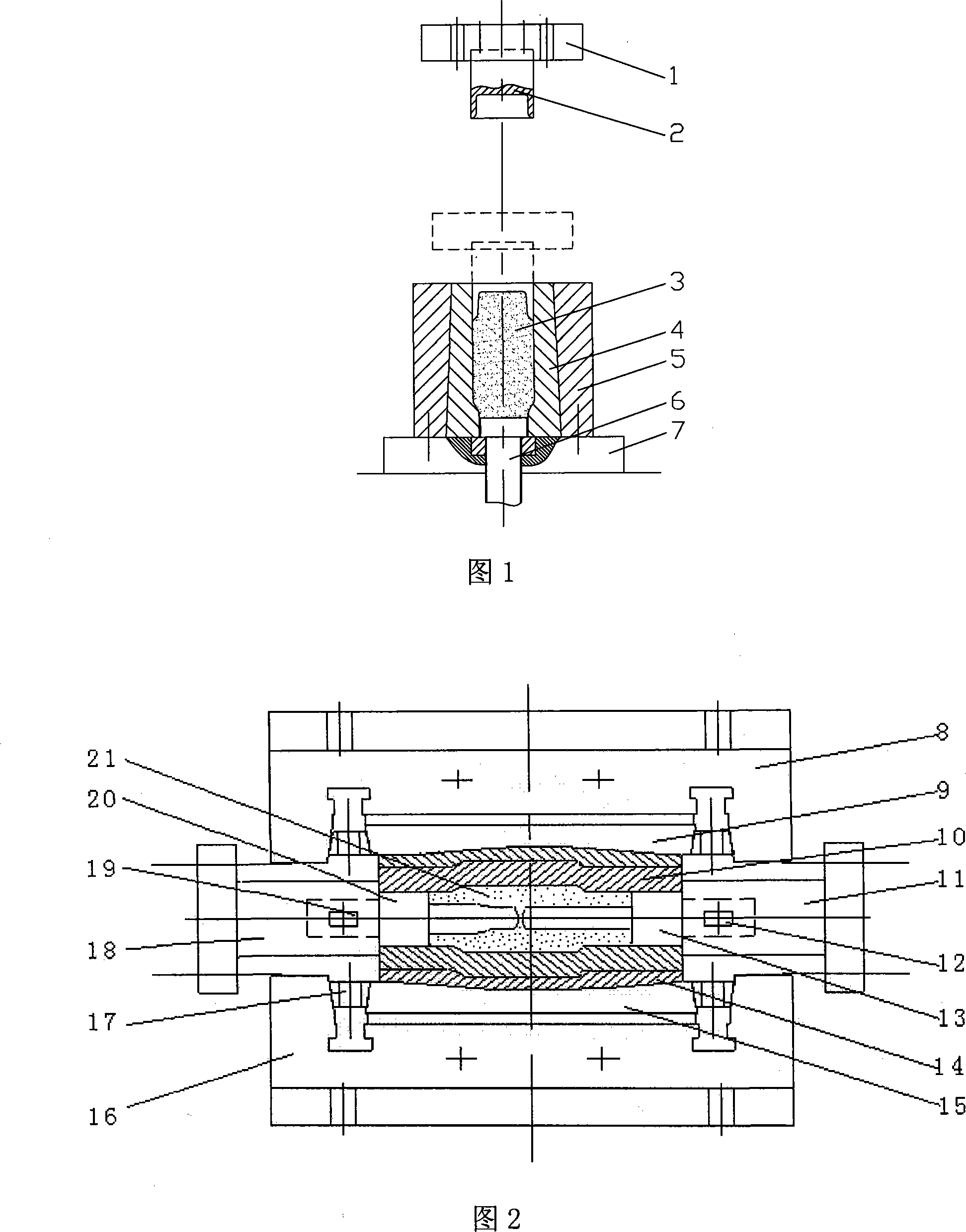

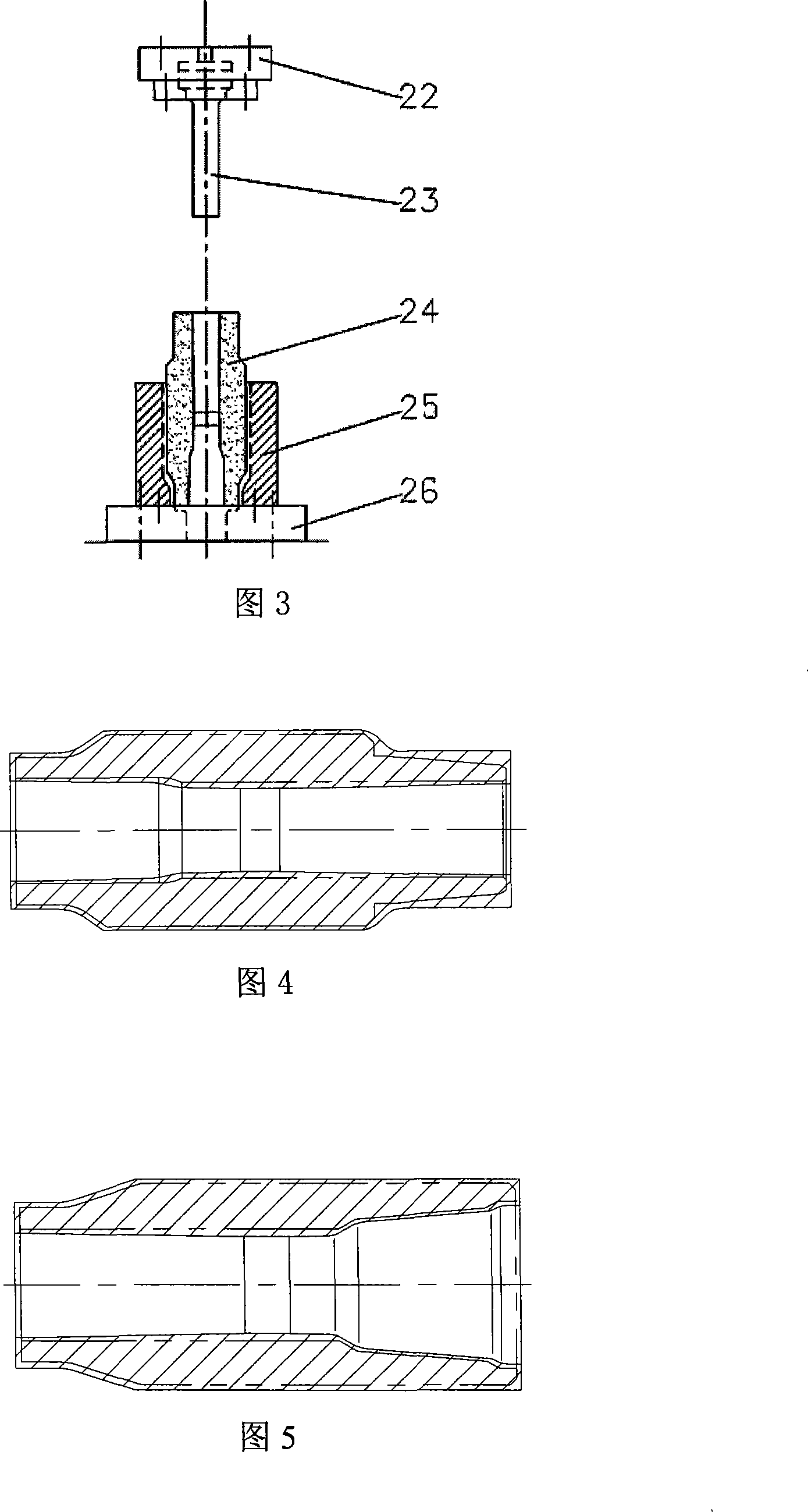

Drill pipe joint precision die forging process

InactiveCN101181730AEasy to moldSmall machining allowanceForging/hammering/pressing machinesMedium frequencyMaterial consumption

The invention discloses a precise die forging technique of a petroleum drill rod connector and is characterized in that: 1) flan material is prepared with a band saw; 2) the flan material is heated quickly at a temperature that is suitable for forging by a medium frequency electric induction furnace; 3) then the flan material is extruded in a close type into a prefabricated flan and a flan makes concave die on a quick flan-making oil hydraulic machine; 4) a molding concave by die level method extrudes and presses the prefabricate flan into a connector die forging piece on the quick flan-making oil hydraulic machine which can implement combination of the upper molding concave die and the lower molding concave die and relative extrusion and pressing from right and left and inner holes of the connector die forging piece is provided with wad; 5) finally a hole punching die punches away the recess inside the inner hole of the forging piece on a special hole punching oil hydraulic machine to obtain the connector forging piece with accurate specifications, excellent structure performance and central through holes. The invention has the advantages of good streamline distribution, material conservation, environmental protection and high production efficiency.

Owner:JIANGYIN LONGCHENG DRILLING & PRODN MACHINERY MFG

Aluminum alloy for high-pressure casting

The invention relates to aluminum alloy for high-pressure casting. The aluminum alloy for high-pressure casting comprises, by weight percentage, 4.5-7.5 % of silicon, 0.5-1.0 % of copper, 0.5-1.0 % of magnesium, 0.3-1.0 % of iron, 0.3-0.5 % of zinc, 0.3-0.5 % of manganese, 0.3-0.5 % of nickel, 0.13-0.15 % of strontium, 0.01-0.003 % of titanium, less than 0.003 % of boron, and lead as the rest. The aluminum alloy for high-pressure casting effectively improves the strength and tenacity of aluminum alloy, grains in the aluminum alloy microstructure are refined evenly, and the high-pressure casting performance of the aluminum alloy is effectively improved.

Owner:虞海香

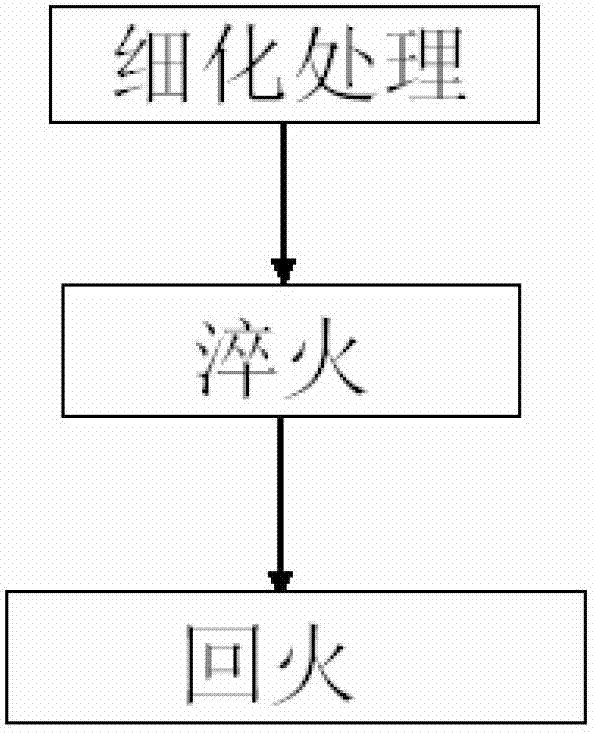

Heat treatment process for ultra-large type tube plate forge piece of pressure container

ActiveCN103305672AHigh hardnessUniform grain refinementFurnace typesHeat treatment furnacesPerformance indexForge

The invention relates to a heat treatment process for an ultra-large type tube plate forged piece of a pressure container and belongs to the technical field of large forged piece heat treatment processes. The heat treatment process comprises a forged heat treatment process and a performance heat treatment process, wherein normalizing, normalizing and high-temperature tempering are performed in the forged heat treatment process; quenching and high-temperature tempering are performed in the performance heat treatment process. Compared with a conventional one-time normalizing and tempering process, the heat treatment process has the advantages that through the forged heat treatment process in which the normalizing, normalizing and high-temperature tempering are performed, grains can be further refined and uniformized, the degree of grain size is improved, and good organization conditions are prepared for the subsequent heat treatment; through the performance heat treatment process in which quenching and high-temperature tempering are performed, good comprehensive performance indexes can be obtained.

Owner:洛阳中创重型机械有限公司

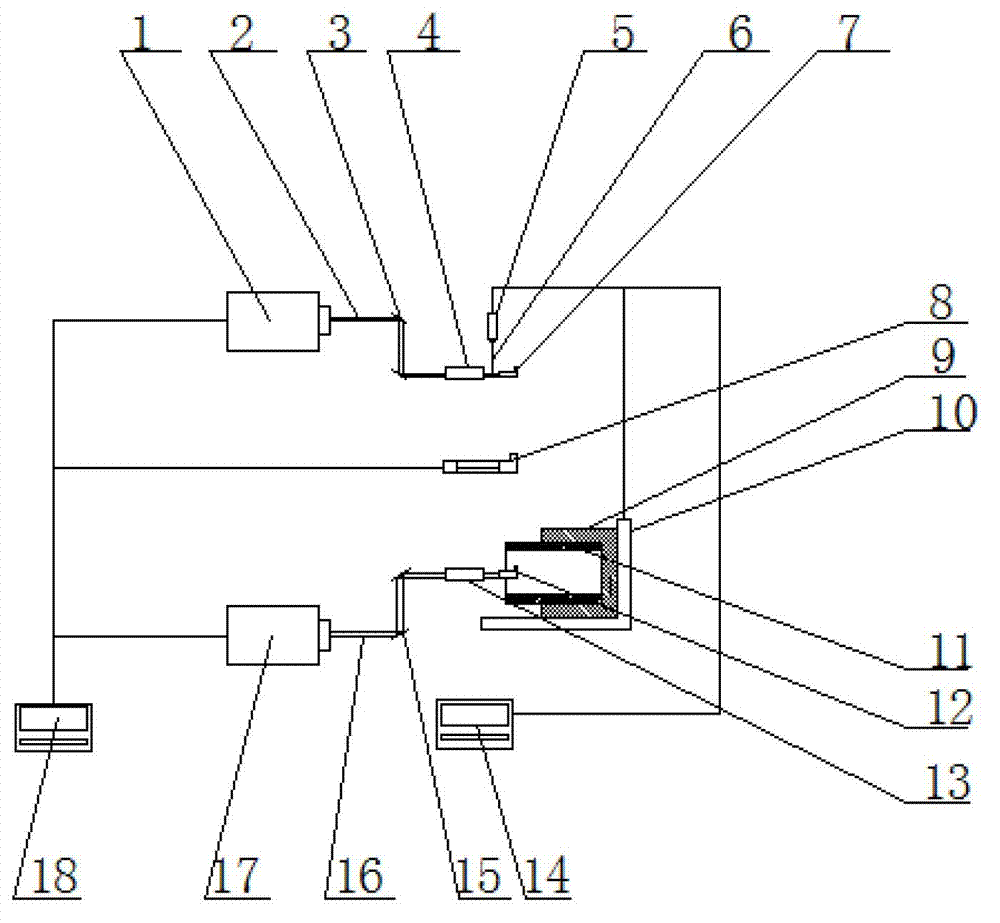

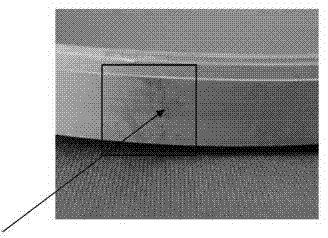

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

Method for refining 1Cr10Co6MoVNbN stainless steel forging grains

The invention relates to a method for refining 1Cr10Co6MoVNbN stainless steel forging grains. The method comprises: carrying out refinement, quenching and tempering on a forging, and reasonably controlling temperatures and thermal insulation times in various step to obtain the grain-refined stainless steel part. According to the present invention, one time heat treatment process for grain refining is added before the final part heat treatments of quenching and tempering are performed, such that the grains can be uniformly refined; when the temperature reaches the phase change temperature, the phase change occurs, such that the phase change stress is generated inside the system due to the phase change volume effect, the formed single-phase austenite generates slightly deformation, and the austenite is subjected to recrystallization so as to achieve the grain refinement effect, improve the qualification rate, and reduce a large amount of scrap loss.

Owner:AECC AVIATION POWER CO LTD

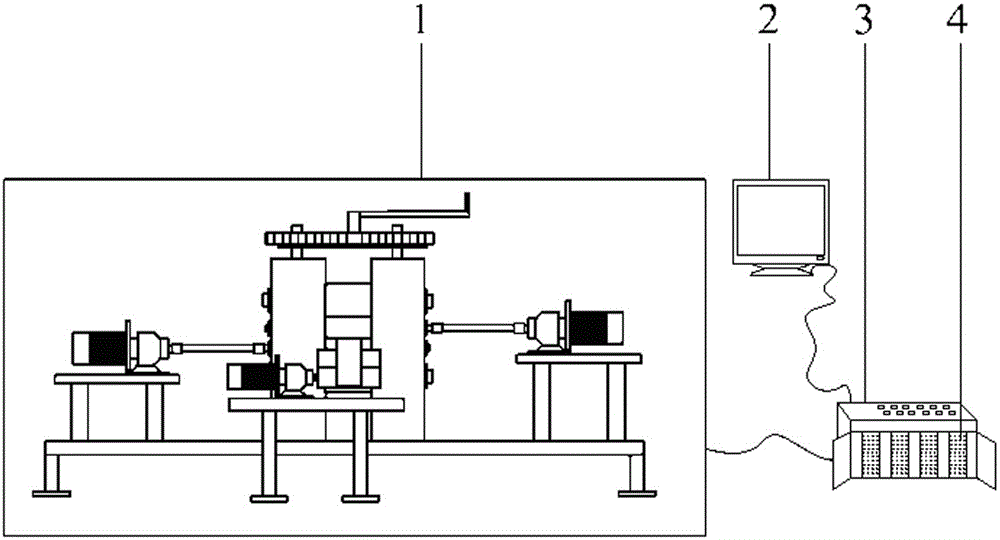

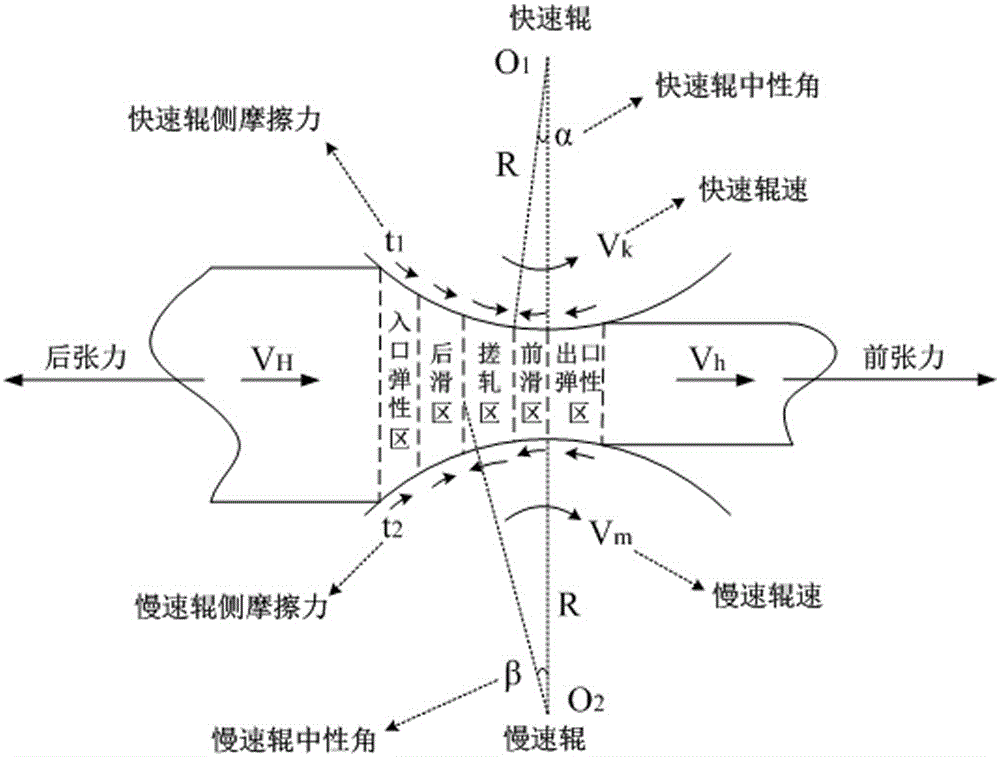

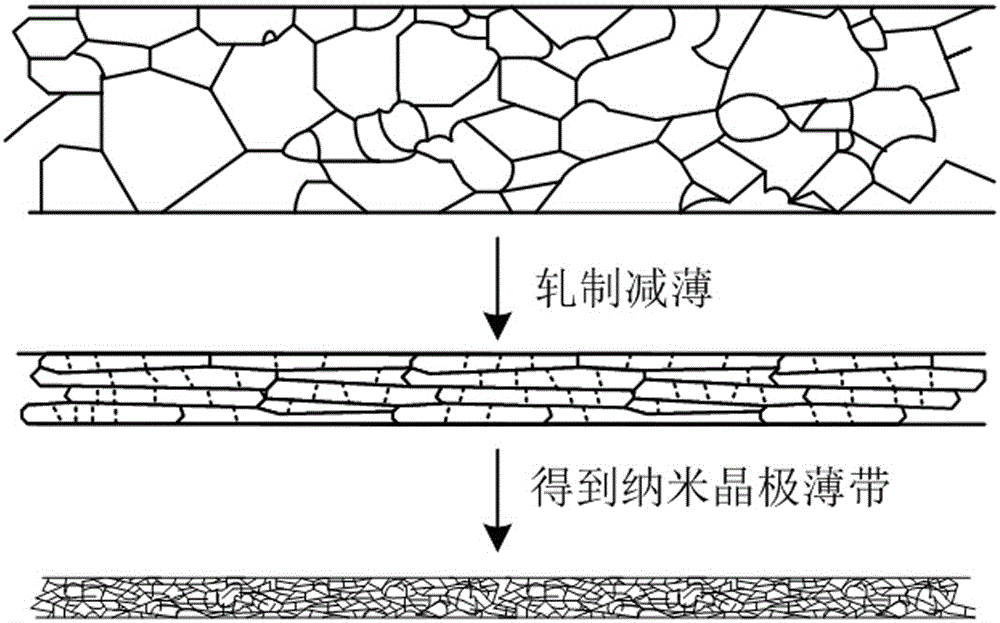

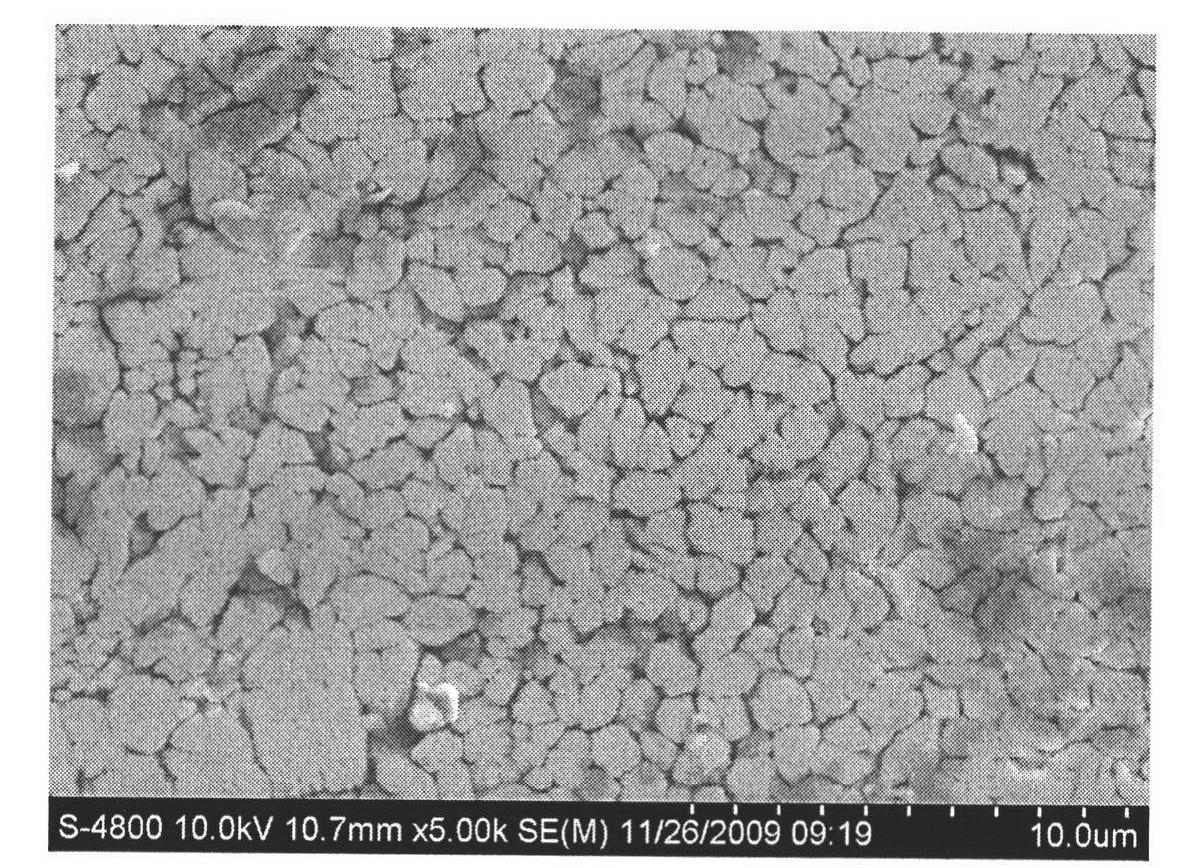

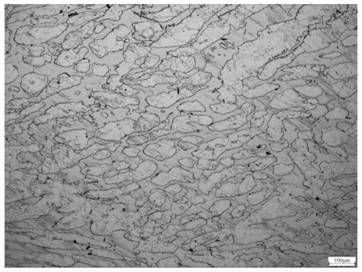

Method for manufacturing ultra-thin nanocrystalline metal strip

ActiveCN105080966AUniform grain refinementPromote fragmentationMetal rolling arrangementsRoll speed control deviceMetal stripsMicrometer

The invention provides a method for manufacturing an ultra-thin nanocrystalline metal strip and belongs to the technical field of rolling. The method includes the following steps that 1, raw materials, such as steel or copper or aluminum or nickel or titanium or molybdenum strips are adopted, or an alloy strip of the metal serves as a rolled piece, and the depth of the strips ranges from 200 micrometers to 500 micrometers; 2, the rolling speed, the different speed ratio, the different speed ratio adjusting step length, the pre-tightening pressure and front-rear tensile stress of an asynchronous ultra-thin strip rolling machine are set; 3, the rolling machine is started to conduct one-pass rolling, and the different speed ratio is adjusted online while rolling; 4, the depth of the rolled piece is measured, and the rolling speed, the different speed ratio, the different speed ratio adjusting step length, the front-rear tension and the pre-pressing force are reset; 5, the rolling machine is started to conduct next-pass rolling, and the different speed ratio is adjusted while rolling; and 6, the step 2 to the step 5 are carried out repeatedly till the depth of the rolled piece ranges from 1 micrometer to 5 micrometers. By means of the method, continuous production of the ultra-thin nanocrystalline metal strip can be achieved without intermediate annealing.

Owner:NORTHEASTERN UNIV

Method for preparing inoculant for refining as-cast structure of spring steel and application method thereof

ActiveCN102168220AEasy dispersive distributionUniform grain refinementSpring steelMechanical property

The invention discloses a method for preparing an inoculant for refining an as-cast structure of spring steel and an application method thereof, and relates to alloy steel. The preparation method comprises the following steps of: preparing materials in a molar ratio of Fe:V:Nb:Al of (3.2-5.6):(0.5-1.5):(1.9-4.3):(1.5-3.5), melting, and centrifuging and rapidly quenching and melt-spinning to obtain a flaky rapidly-solidified FeVNbAl intermediate alloy inoculant with the average thickness of between 0.1 and 0.3mm, the average width of between 1 and 2.5mm and the average length of between 3 and 8mm, namely the inoculant for refining the as-cast structure of the spring steel. The application method comprises a step of using the inoculant for refining the as-cast structure of the spring steel by a metal melt casting method. The inoculant has a remarkable effect of refining matrix grains and structures of the spring steel, so that the comprehensive mechanical properties and the service performance of a spring steel material are further improved.

Owner:HEBEI UNIV OF TECH

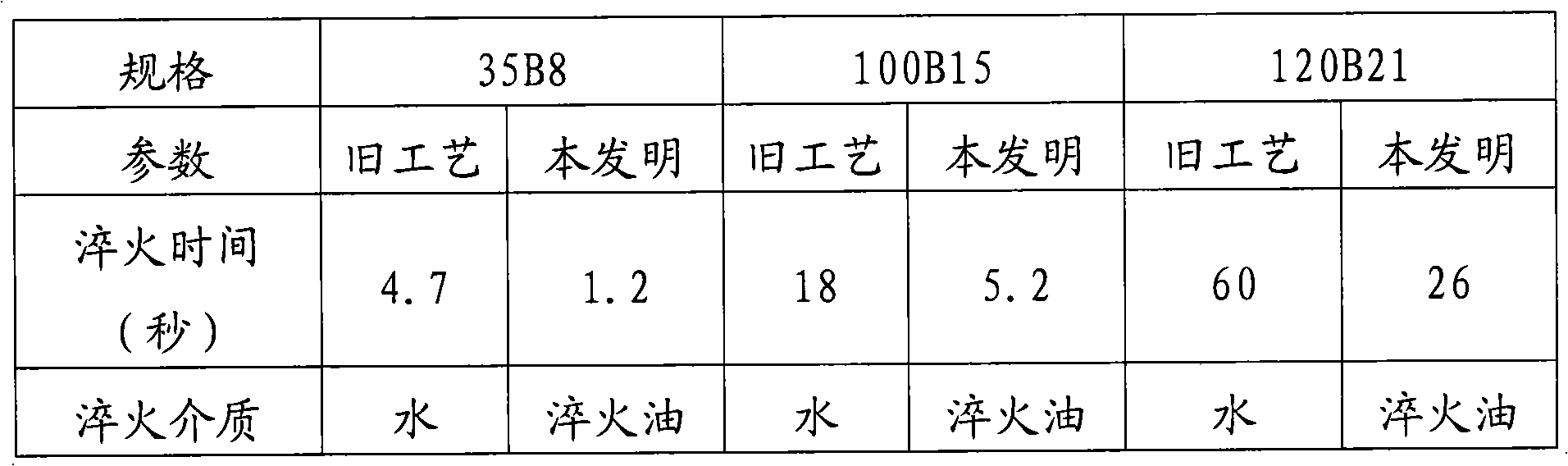

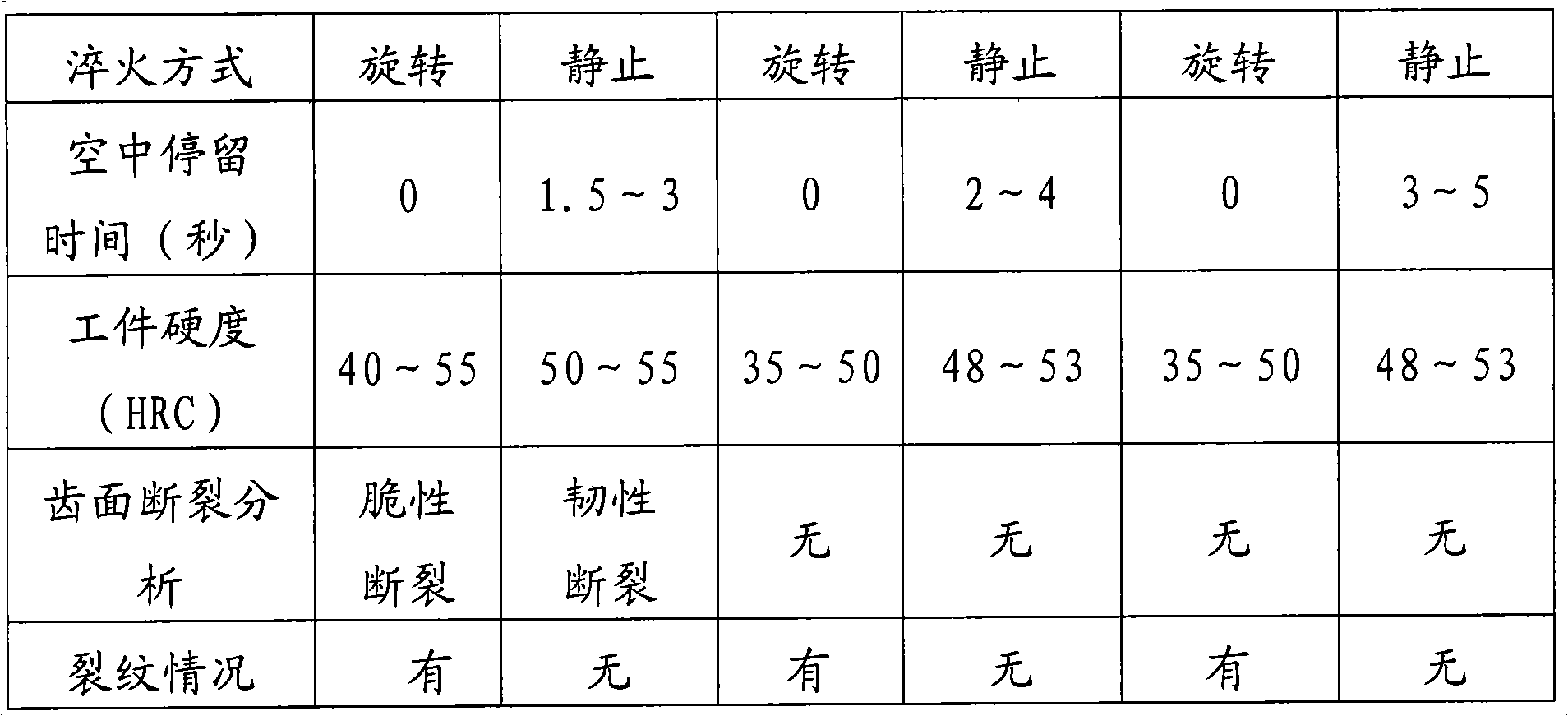

Sprocket tooth part induction heat treatment process

InactiveCN101838729AImproving the level of induction heat treatment processImprove craftsmanshipFurnace typesIncreasing energy efficiencyElectricitySprocket

The invention relates to a sprocket tooth part induction heat treatment process, which comprises the following steps: after installing an induction coil, installing a sprocket work piece at a work piece position in the induction coil, adjusting the heights of the induction coil and the sprocket work piece to ensure the centers of the induction coil and the sprocket tooth part to correspond with each other and to ensure the clearance to be uniform; supplying water and electricity to the induction coil and rotating the sprocket to ensure the tooth part to be heated; when the sprocket tooth part is heated to a quenching temperature, after the workpiece stays for 1.5-5 seconds in the air, leading the sprocket tooth part to enter into quenching oil vertically without rotation; taking the sprocket out of the quenching oil after quenching is finished, and washing after draining dry; and after draining dry again, putting the sprocket into a tempering furnace to be heated to a tempering temperature, and taking the sprocket out of the furnace when a holding time is reached. By adopting the sprocket tooth part induction heat treatment process, cracks or fracture of the sprocket tooth part can be avoided after the induction heat treatment, and after the induction heat treatment, the hardness of the sprocket tooth part is uniform, which differs within HRC 5 degrees, high-quality surface harness of the sprocket tooth part can be obtained, and the service life of the sprocket is prolonged.

Owner:王锦堂

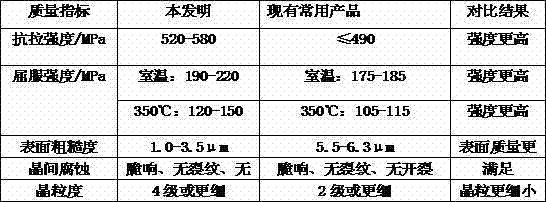

Flange for wind power drum and manufacturing technique thereof

ActiveCN103045960APrevent precipitationGuaranteed corrosion resistanceFlanged jointsTemperingChemical composition

The invention provides a flange for a wind power drum, and a manufacturing technique thereof. The flange comprises the chemical compositions in percentage by weight: 0.15-0.22 percent of C, 0.55-0.65 percent of Si, 0.65-0.75 percent of Mn, 5-8 percent of Ni, 4-6 percent of Cr, 0.65-0.85 percent of Nb, 0.25-0.45 percent of Cu, 0.05-0.07 percent of N, 0.05-0.07 percent of Mo, 0.7-0.9 percent of Al, 0.02-0.03 percent of S, 0.08-0.09 percent of Ti, 0.01-0.04 percent of V, 0.002-0.003 percent of B, 1-2 percent of rare earth lanthanide series and the balance of Fe. According to the invention, with the heating processing procedures of two-time normalization and two-time tempering, the excellent corrosion resistance of the flange is ensured, and meanwhile, high tensile strength and high yield strength are achieved; and the flange is ensured to have smaller surface roughness, more uniform and stable tissue, and less air holes and sand holes.

Owner:WUXI HUAERTAI MACHINERY MFG

Corrosion-resistant steel plate for ocean platform and production method of steel plate

The invention belongs to the technical field of ferrous metallurgy, and discloses a corrosion-resistant steel plate for an ocean platform and a production method of the steel plate. The corrosion-resistant steel plate is prepared firstly from the combination of proper components in percentage by weight and then by carrying out KR molten iron pretreatment, converter smelting, argon-blowing station fed with aluminum wire, LF furnace refining, VD vacuum refining, continuous casting, heating, controlled rolling and controlled cooling, heap cooling, quenching, tempering and the like. According to the corrosion-resistant steel plate for the ocean platform and the production method of the steel plate, compared with the prior art, the produced steel plate has the advantages of excellent corrosion resistance, good low-temperature impact toughness and excellent comprehensive performance, and is especially suitable for being used under cold weather and seawater corrosion conditions.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

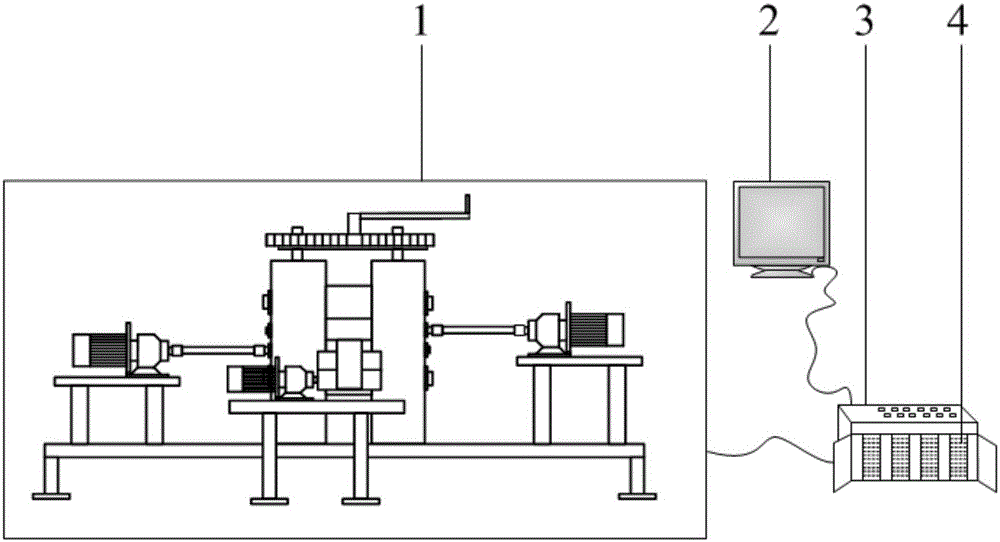

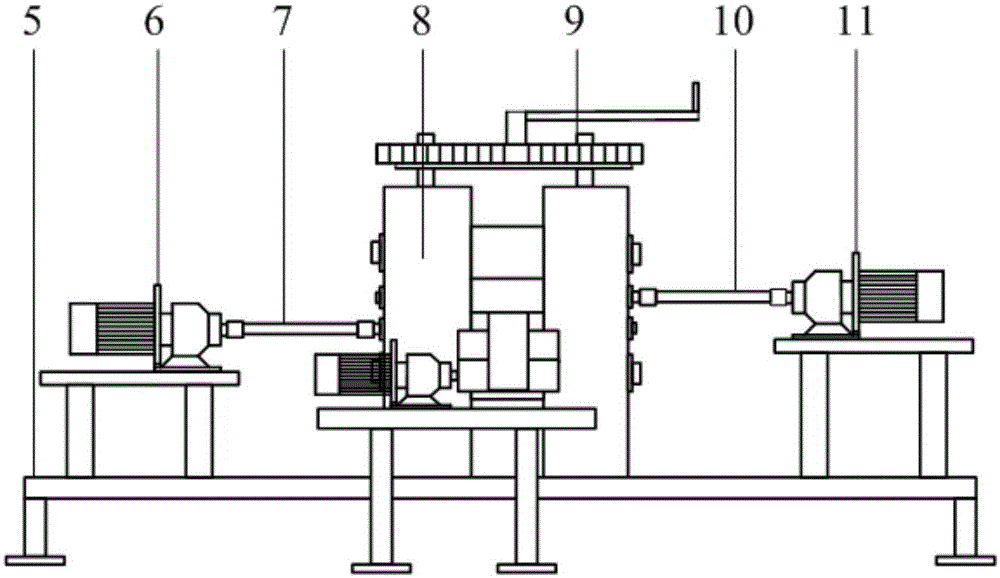

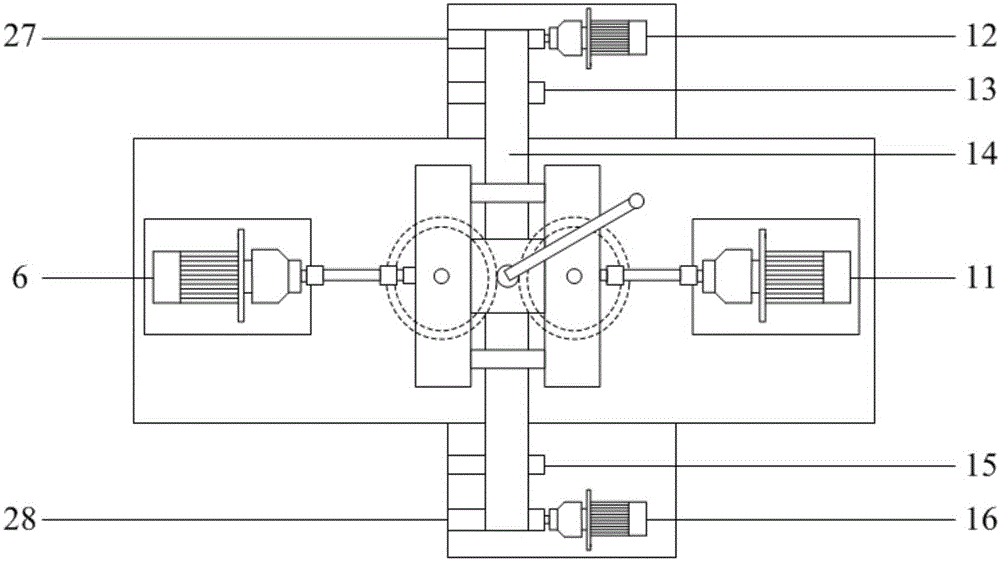

Metal ultra-thin strip negative roll gap rolling method allowing different-speed ratio to be adjusted online

ActiveCN105057349AConducive to increasing the amount of thinningImprove rolling efficiencyRoll force/gap control deviceMetal rolling arrangementsHuman–machine interfaceEngineering

Provided is a metal ultra-thin strip negative roll gap rolling method allowing the different-speed ratio to be adjusted online. The same initial value is set for the speed of an upper working roll and the speed of a lower working roll on a human-computer interface, and the adjustment step length of the different-speed ratio is set; initial tension and initial pre-pressing force are applied to a rolled piece; the upper working roll and the lower working roll are started synchronously; after the rolling speed is stable, the initial tension of the rolled piece is increased online, so that the initial tension is increased to set tension; a roll gap is pressed downwards online until rolling force reaches a set stable rolling range, and negative roll gap synchronous rolling under target rolling force is started; before rolling is finished, the speed of the upper working roll is selected to be increased or decreased online according to the rolling pass, so that the different-speed ratio is equal to one; the roll gap is lifted online, the rolling force is reduced to a pre-shutdown set range, and the set tension is reduced to the initial tension online; the upper working roll and the lower working roll are synchronously stopped at a thick area of the rolled piece, and synchronous shutdown at the thick area of the rolled piece under the rolling force in the pre-shutdown set range and the initial tension is achieved; and the steps are repeated until the rolled piece is thinned to reach a target thickness.

Owner:NORTHEASTERN UNIV

Forging and heat treatment process of marine anticorrosion pull rod duplex stainless steel forge piece

ActiveCN112893510AOptimizing Forging PerformanceSmall tissueFurnace typesProcess efficiency improvementSolution treatmentSS - Stainless steel

The invention discloses a forging and heat treatment process of a marine anticorrosion pull rod duplex stainless steel forge piece, and belongs to the technical field of stainless steel forging treatment. The forging and heat treatment process is characterized by comprising the following steps that S1, smelting raw materials to obtain a steel ingot; S2, forging and heating the steel ingot; S3, forging the steel ingot to obtain a forge piece, specifically, the forging comprises three heating numbers, 1, in the first heating number, the forging temperature of the steel ingot is 1140-1160 DEG C; in the second heating number, the forging temperature of the steel ingot is 1120-1140 DEG C; in the third heating number, the forging temperature of the steel ingot is 1070-1100 DEG C; S4, the forge piece heat treatment, specifically, the forge piece heat treatment comprises the following steps of 1, water cooling treatment of the forge piece after forging; 2, forging rough machining; 3, the forge piece solution treatment; and S5, the forge piece finish machining. The method has the advantages that the uniform refining degree of crystal grains is improved, and the service life of the forge piece is greatly prolonged.

Owner:无锡继平新材料科技有限公司

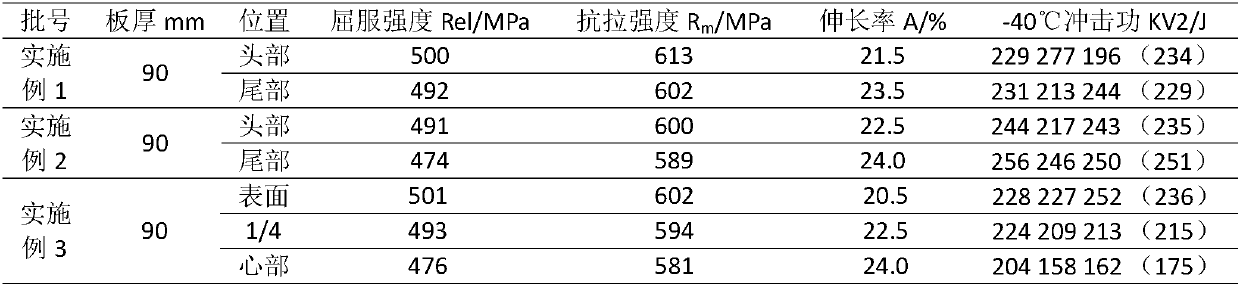

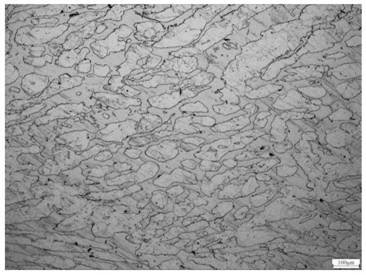

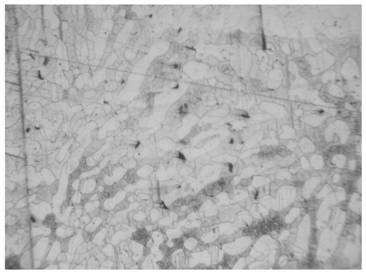

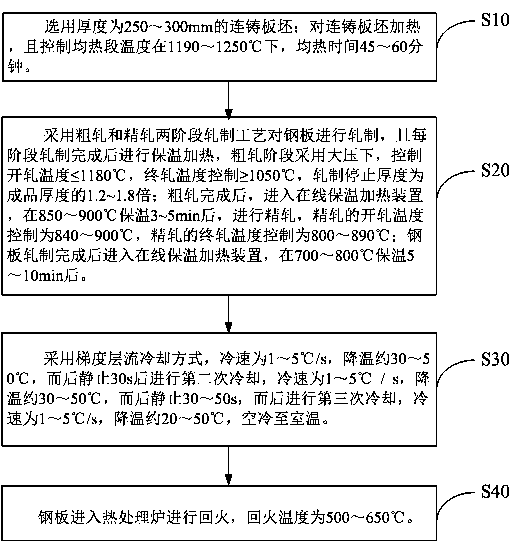

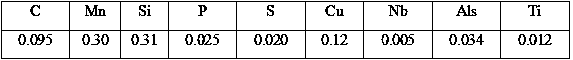

High-uniformity steel plate with super-thick structure and manufacturing method thereof

ActiveCN110306117AEven heat dissipationUniform grain refinementHigh intensityUltimate tensile strength

The invention discloses a high-uniformity steel plate with a super-thick structure and a manufacturing method thereof. The steel plate is prepared from C, Si, Mn, P, S, Nb, Ti, Cu, Als and the balanceFe and impurities. The manufacturing method comprises the steps that a mode of optimizing a rolling cooling process and sequentially conducting rough rolling, fine rolling and heat preservation or heating is adopted, so that the temperature uniformity of the surface and the core part of a steel blank in the rolling process is guaranteed, and uniform refining of internal tissue grains of steel isachieved; in the cooling process, a segmented stepped cooling mode is adopted, the temperature tissue uniformity of the steel plate in the thickness direction is further guaranteed by means of the redreturning process of stepped cooling, and the internal tissue grains are further refined, so that the high-uniformity super-thick steel plate is obtained. According to the high-uniformity steel platewith the super-thick structure and the manufacturing method thereof, the intensity difference of the surface-close layer, the position about 1 / 4 thickness and the position about 1 / 2 thickness of thesteel plate is smaller than or equal to 15 MPa, and the steel plate is uniform in strength property, high in strength and toughness and excellent in lamellar tearing resistant property and welding property.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

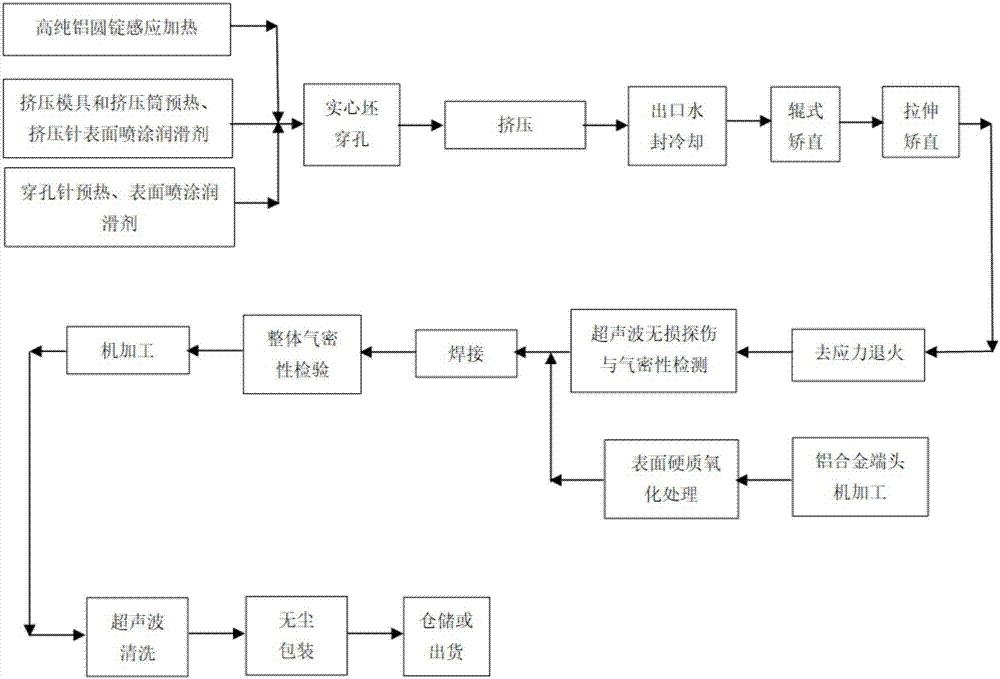

Manufacturing method for high-purity aluminum rotating target

The invention relates to a manufacturing method for a high-purity aluminum rotating target. The manufacturing method comprises the following steps of: selecting a high-purity aluminum circular ingot,and performing thermal perforating and extruding treatment on the high-purity aluminum circular ingot, thereby obtaining high-purity aluminum tube blank; straightening and performing annealing treatment; selecting an aluminum alloy as a target end head material, and performing surface hard oxidization treatment on the target end head material, thereby obtaining an aluminum alloy end head; and welding the aluminum alloy end head of the high-purity aluminum tube blank, thereby obtaining the high-purity aluminum rotating target. According to the high-purity aluminum rotating target manufactured by the manufacturing method, defects such as cracks, air holes, looseness, impurities and layering inside a microscopic structure are greatly reduced, the microscopic structure is fine and uniform, andthe grain size is not greater than 100 microns; a leakage rate value measured by a helium mass spectrum leakage detector is smaller than or equal to 5*10<-10> Pa.m<-3> / s; and dimensional tolerance and integral flatness form and location tolerance in the length direction, the width direction and the thickness direction are as low as 0.05 mm, surface roughness is smaller than Ra 0.4 micron, and processing precision meets user requirements.

Owner:广东欧莱高新材料股份有限公司 +1

Ribbed rebar wire rod made of ultra-fine grained steel and production process of ribbed rebar wire rod

InactiveCN106282778AReduce weldingReduce transportationTemperature control deviceMetal rolling arrangementsWire rodChemical composition

The invention relates to a ribbed rebar wire rod made of ultra-fine grained steel and a production process of the ribbed rebar wire rod. The ribbed rebar wire rod comprises the following chemical components in percentage by weight: 0.21-0.24% of C, 0.60-1.30% of Mn, 0.15-0.50% of Si, no less than 0.035% of P, no less than 0.035% of S, and the balance of iron and inevitable impurities. According to the production process, a whole-process low-temperature controlled rolling method is adopted; the spinning temperature is controlled to be 650-720 DEG C; the intake pressure of a pinch roll is adjusted to be 7.0-8.0 bar; the clamping force of the pinch roll is adjusted to be 5.0-7.0 bar; and the ribbed rebar wire rod made of ultra-fine grained steel is produced by adopting a TMCP (thermos-mechanical control process) method. The ribbed rebar wire rod produced according to the TMCP method is uniform in grain refinement, low in oxidation burning loss, lower in energy consumption and raw material consumption, and low in production cost.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

Zn-Mg alloy ingot and preparation method thereof

The invention relates to a Zn-Mg alloy ingot and a preparation method thereof. The Zn-Mg alloy ingot comprises the following raw materials by mass: 5.0%-6.5% of Zn, 0.45%-0.55% of Zr, 0.08%-0.15% of Ca, 0.3%-0.5% of Ce, 1.0%-1.5% of Yb, no more than 0.03% of inevitable impurities, and the balance Mg. The preparation method of the Zn-Mg alloy ingot comprises a smelting process and a heat treatmentprocess, wherein the melting process comprises the steps of material weighing and drying, smelting, refining, standing and casting, and the heat treatment process comprises the steps of solid solutiontreatment and aging treatment. According to the Zn-Mg alloy ingot prepared with the method provided by the invention, through rear earth adding treatment and heat treatment, the corrosion resistanceand mechanical property of the alloy ingot can be improved effectively, and crystal grains in the alloy ingot structure are further refined uniformly, so that the comprehensive performance of alloy isimproved effectively.

Owner:安徽恒利增材制造科技有限公司

Method for manufacturing refractory metal pipe

The invention provides a method for manufacturing a refractory metal pipe and relates to a method for manufacturing near-net molding of molybdenum pipes, tungsten pipes and molybdenum and tungsten alloy pipes. The method comprises the following steps of: (1) molding refractory metal powder by compression, sintering and machining to obtain a pipe billet; (2) compactly filling the pipe cavity of the manufactured pipe billet by using aluminum oxide powder; (3) swagging the pipe billet filled with the aluminum oxide powder; (4) thermally treating; and (5) machining to obtain the refractory metal pipe. By the method, the manufactured pipe has high density, refined and uniform crystalline grains and fewer defects in comparison with a sintered pipe; moreover, the pipe performance is improved, the cuttings discharge is low, and the manufacturing efficiency is high; the diameter of the tungsten pipe and the molybdenum pipe can be adjusted flexibly; and the refractory metal pipe has outstanding cost advantage. The method is simple in production, low in investment, short in process flow, low in metal consumption, high in comprehensive yield rate and fast in response, and can be used for conveniently and quickly manufacturing the molybdenum pipes, the tungsten pipes and the molybdenum and tungsten alloy pipes of different specifications in mass production.

Owner:JINDUICHENG MOLYBDENUM CO LTD

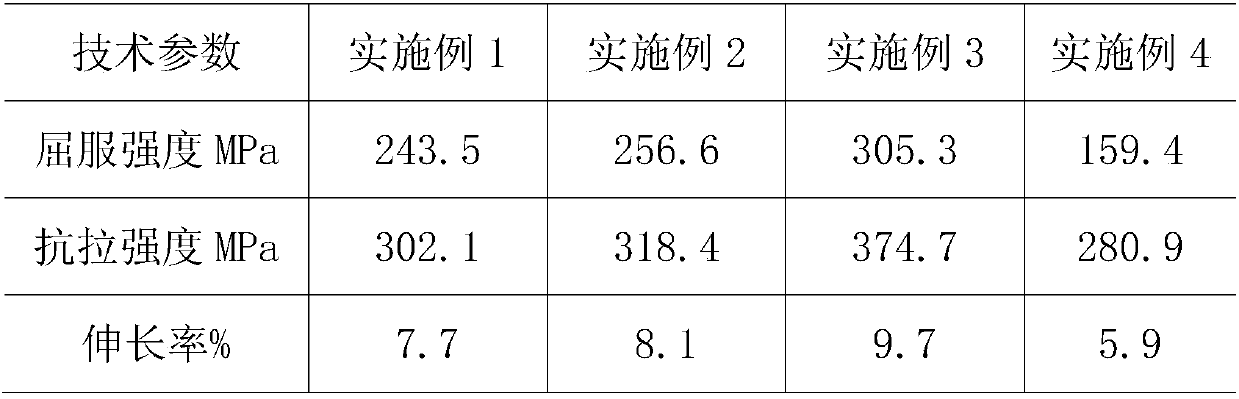

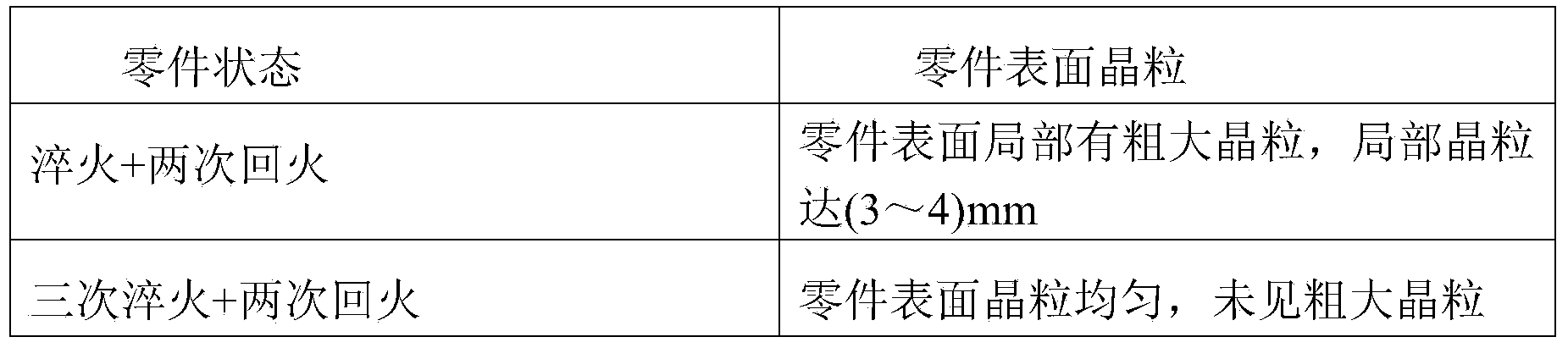

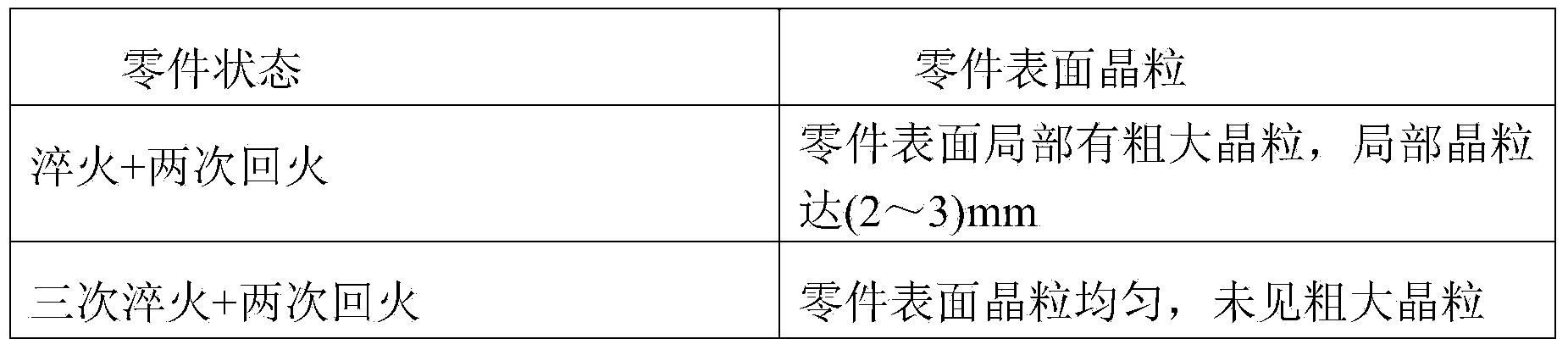

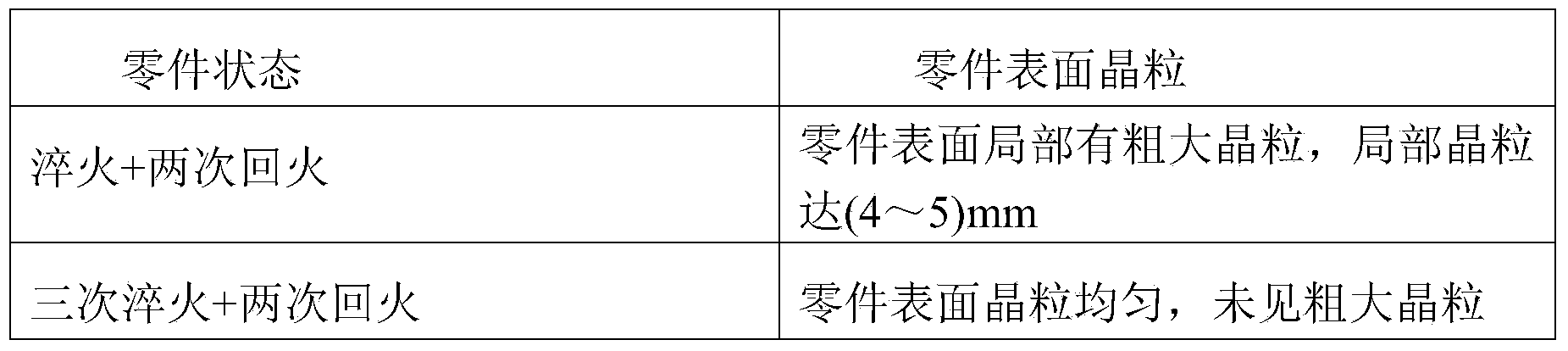

Method for refining surface grains of 2Cr10NiMoVNb stainless steel forgings through quenching three times

ActiveCN103555895AIncrease the heat treatment and quenching processGrain refinementMartensite transformationAlloy

The invention proposes a method for refining surface grains of 2Cr10NiMoVNb stainless steel forgings through quenching three times. A thermal treatment quenching procedure of refining grains twice is added before final thermal treatment quenching and tempering of spare parts; the twice quenching procedure is about 100 DEG C lower than the traditional quenching procedure in temperature, so that the grains are evenly refined. According to the method, aiming at uneven fineness of the grains in 2Cr10NiMoVNb alloy forging structures, the quenching collocation of combining middle temperature (about 150-250 DEG C over the austenite transformation temperature), low temperature (about 100-200 DEG C over the austenite transformation temperature), and high temperature (about 300 DEG C over the austenite transformation temperature) is adopted, so that the forgings are repeatedly subjected to austenite-martensite transformation, the large grains are gradually refined in the transformation process, and finally, the alloy structure is homogenized and the grains are refined. The adopted thermal treatment technology for refining the grains is simple, and can be achieved by heating and heat preservation, and air cooling; a complicated technique is avoided.

Owner:AECC AVIATION POWER CO LTD

Processing method of refining grains of biphasic titanium alloy bar

The invention discloses a processing method of refining grains of a biphasic titanium alloy bar. A preform body of the biphasic titanium alloy bar is rolled, the temperature X of the phase transformation point of the rolled preform body of the biphasic titanium alloy bar is measured, the rolled preform body of the biphasic titanium alloy bar is drawn by three passes, and the biphasic titanium alloy bar with the refined grains is obtained; the drawing temperatures of the three passes are all (X-100) to (X-200) DEG C, and the drawing speeds are all 3-5m / min; and the drawing deformation quantities of the three passes are 4%-8%. Under the total deformation amount of the titanium alloy bar is constant, the drawing process is increased, and the deformation process is increased. On a certain basis, the deformation degree of bar processing can be increased to achieve grain refinement through reasonable processing and distribution. The processing method of the titanium alloy bar with ultra-finegrain suitable for mass production is provided under the premise of small cost increasing.

Owner:西安赛特思迈钛业有限公司

Method and device for controlling austenite grain size of continuous casting slab, and product

The invention discloses a method and device for controlling the austenite grain size of a continuous casting slab, and a product, and belongs to the technical field of metallurgical continuous casting. A crystallizer is included, a foot roller cooling area is connected and arranged at the lower part of the narrow surface of the crystallizer, and a spraying mechanism is matched with the foot rollercooling area. On one hand, the narrow surface cooling can be increased to further prevent the growth of original austenite grains, the grains are uniformly refined, and the microstructure strength ofthe surface layer of a casting blank is improved; on the other hand, the transverse temperature gradient of the narrow surface area of the casting blank can be reduced, and the shrinkage stress in the subsequent cooling process can be reduced, so that the narrow surface crack defect is prevented.

Owner:MAANSHAN IRON & STEEL CO LTD

Heating treatment technology for aluminum alloy castings

InactiveCN107620017ASufficient hardenabilityHigh mechanical strengthMechanical propertyMaterials science

The invention discloses a heating treatment technology for aluminum alloy castings, and relates to the technical field of metal casting. The heating treatment technology comprises the following stepsthat (1) vacuum homogenization preheating is carried out; (2) first-time normalizing is carried out; (3) second-time normalizing is carried out; (4) high-temperature tempering is carried out; (5) vacuum hardening is carried out; and (6) annealing is carried out. According to the heating treatment technology for the aluminum alloy castings, the heating temperature is appropriately improved for prolonging the soaking time, and therefore structural transformation of the aluminum alloy castings can be sufficient, the mechanical property and the impact toughness are effectively improved, and the heating treatment technology is suitable for application and popularization.

Owner:和县华顺铸造有限公司

Heat treatment technology for engine shield

ActiveCN107190130AHigh hardnessUniform grain refinementFurnace typesHeat treatment furnacesRoom temperatureWater cooling

The invention discloses a heat treatment technology for an engine shield. The heat treatment technology comprises the steps of 1) carrying out normalizing, specifically, carrying out secondary normalizing treatment on the cast-formed engine shield; 2) carrying out high-temperature tempering, specifically, carrying out heat preservation on the normalized shield in a furnace at 340-380 DEG C for 6-8 hours, carrying out high-temperature tempering to increase the temperature to 670-730 DEG C, carrying out heat preservation for 8-10 hours, gradually cooling the shield until the temperature is lower than 120 DEG C, and discharging the shield from the furnace; 3) carrying out quenching, specifically, raising the temperature of the shield to 680-720 DEG C, carrying out heat preservation for 2-3 hours, increasing the temperature to the quenching temperature of 820-880 DEG C, carrying out heat preservation for 4-5 hours, and then carrying out water cooling to the room temperature; and 4) carrying out annealing, specifically, the shield is finally heated to 380-420 DEG c, carrying out heat preservation for 8-10 hours, increasing the temperature to the annealing temperature of 660-720 DEG C, carrying out heat preservation for 10-12 hours, and carrying out air cooling to the room temperature. According to the heat treatment technology, the heating temperature is properly increased and the heat preservation time is prolonged, and therefore the structure of alloy steel of the engine shield can be fully converted, the mechanical property and the impact toughness of the engine shield can be effectively improved, and the good comprehensive mechanical property requirements of the automobile engine shield can be met.

Owner:SHANDONG ZHONGTUO NEW ENERGY CO LTD

Heat treatment process after forging of ultra-heavy tube plate forgings splicing-welded in pressure container

ActiveCN103343212AUniform grain refinementRefined grain sizeFurnace typesHeat treatment furnacesGranularityIngot

The invention belongs to technology for heat treatment process of heavy forgings and relates to heat treatment process after the forging of ultra-heavy tube plate forgings splicing-welded in a pressure container. An ultra-heavy tube plate is divided into three pieces for forging and shaping respectively, so that the sizes of steel ingots are reduced, the forging ratio is increased, the forging permeability is improved, and common internal defects of mingled cracks and so on are avoided; and the heat treatment process after the forging of the ultra-heavy tube plate forgings adopts the technological process of twice normalizing plus high-temperature tempering, so that compared with the traditional process of once normalizing plus high-temperature tempering, the heat treatment process has the advantages that grains are further refined and well-distributed, the grain fineness number is improved furthest, and favorable organizational conditions are prepared for subsequent thermal refining.

Owner:洛阳中创重型机械有限公司

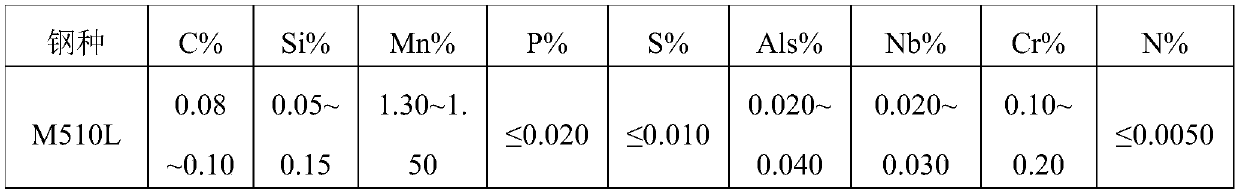

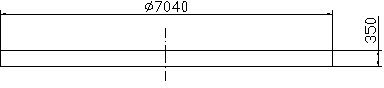

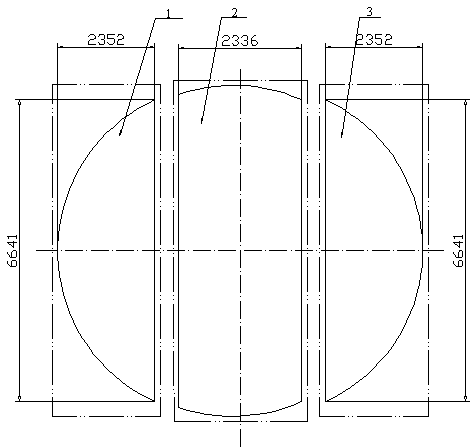

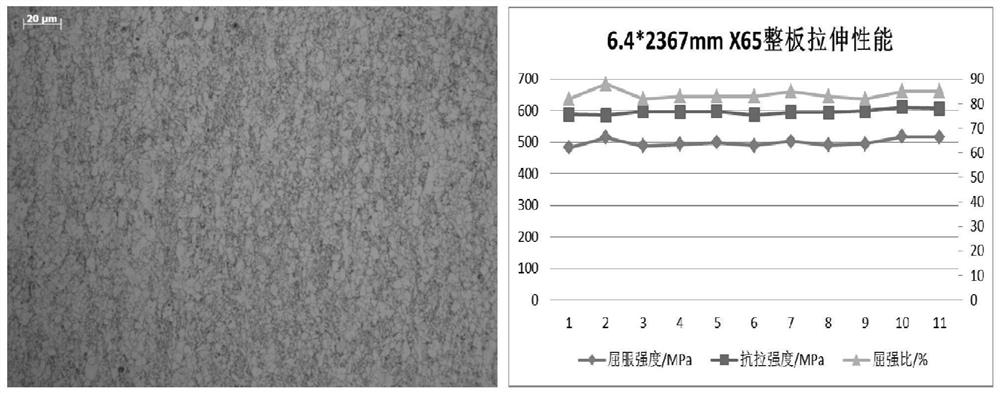

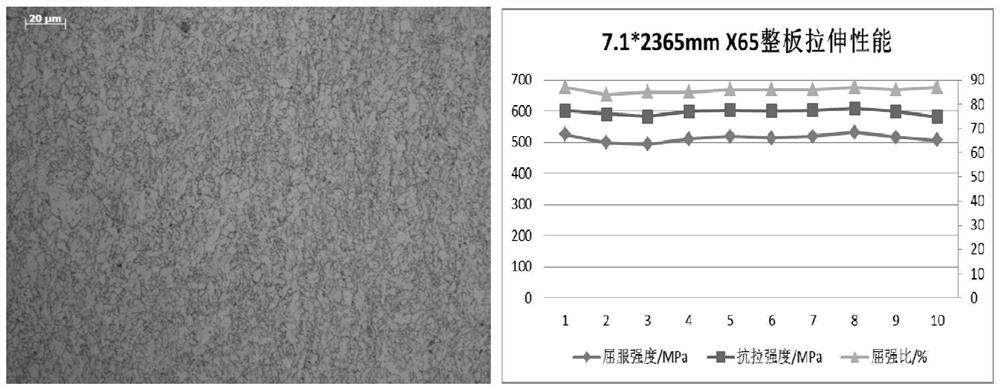

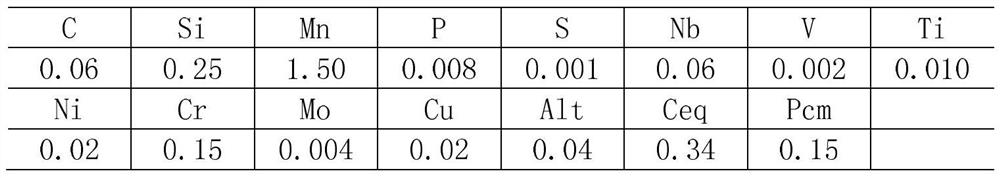

Thin-specification X65 steel-grade pipeline steel of single-stand steckel mill and rolling method

InactiveCN111790754AImprove temperature uniformityImprove the uniformity of mechanical propertiesTemperature control deviceTension/compression control deviceLine tubingRolling mill

The invention discloses thin-specification X65 steel-grade pipeline steel of a single-rack steckel mill and a rolling method. The steel is composed of the following components in percentage by weight:0.03 to 0.07 percent of C; 0.10 to 0.30 percent of Si, 1.30 to 1.70 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.0050 percent of S, 0.040 to 0.060 percent of Nb, less than or equal to 0.10 percent of V, 0.006 to 0.020 percent of Ti, 0.10 to 0.25 percent of Cr, less than or equal to 0.30 percent of Ni, less than or equal to 0.10 percent of Mo, less than or equalto 0.10 percent of Cu, 0.015 to 0.050 percent of Al and the balance of Fe and impurities. According to the rolling method, a blank with the thickness of 150 mm is used for producing the thin-specification pipeline steel plate with the finished product specification of (6-8) mm X65 grade. By controlling the tapping temperature, the coiling furnace temperature, the second-stage initial rolling temperature, the rough rolling final pass reduction rate, the final rolling speed, ACC cooling and the like, the thin-specification X65 steel-grade pipeline steel plate with the performance and the plateshape meeting the requirements is obtained, the productivity and the yield of a rolling mill are improved, and the performance percent of pass is high.

Owner:NANJING IRON & STEEL CO LTD

Preparing method of brake pad friction block

The invention discloses a preparing method of a brake pad friction block. The preparing method comprises the steps that raw materials are subject to temperature rising in argon atmosphere to be in a molten state, and vacuum heat preservation is carried out, so that a first material is obtained; the first material is out of a furnace to be casted, the first material is cooled to 375 DEG C to 395 DEG C, and surface machining is carried out to obtain a second material; the second material is subject to temperature rising to reach Ta DEG C, austenitizing is carried out, heat preservation is carried out, the second material is taken out to be placed in a nitrate bath at he temperature of 200 DEG C to 220 DEG C, the material is subject to temperature rising to reach Tb DEG C, heat preservation is carried out, the material is subject to oil cooling to 100 DEG C to 120 DEG C, the material is subject to temperature rising to Tc DEG C to be tempered, heat preservation is carried out, and the second material is subject to air cooling to the room temperature to obtain the brake pad friction block; and Ta=1050+Ka*(nCo+nMo) / nNb, the value of Ka ranges from 60 to 70, Tb=355+Kb*(nCo+nMo) / nNb, the value of Kb ranges from 18 tp 20, Tc=200+Kc*100*(nNb+nCo+nMo), and the value of Kc ranges from 170 to 200.

Owner:WUHU DONGZHENG AUTOMOTIVE IND

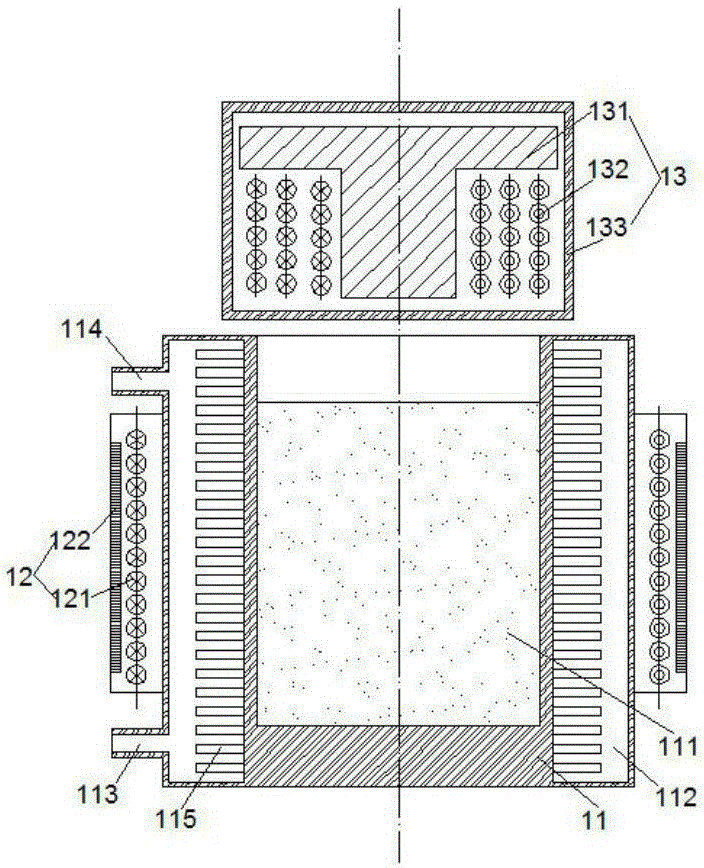

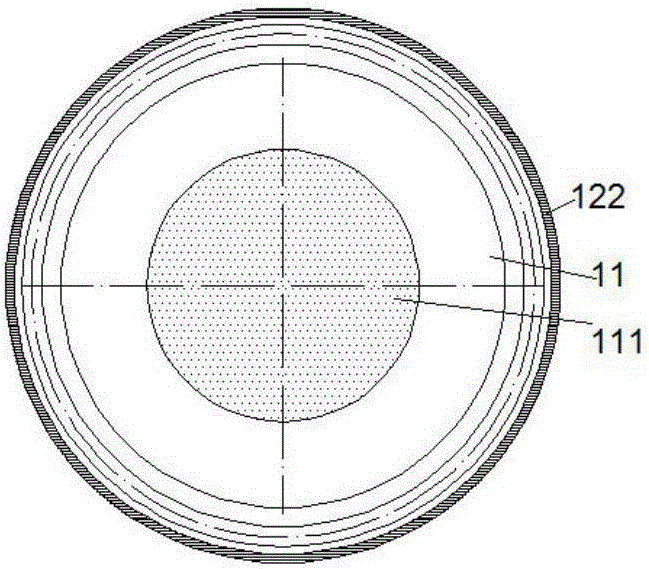

Composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin

ActiveCN106424567AReduce warm-up costsWarm up evenlyFoundry mouldsFoundry coresElectromagnetic pulseWater cooling

The invention discloses a composite electromagnetic pulse solidification structure treatment device and method for casting of ultralumin. The treatment device comprises a metal mold, a side electromagnetic pulse device and a top electromagnetic pulse device, wherein an inner chamber of the metal mold is used for storing a melt; the sidewall of the metal mold comprises an outer layer and an inner layer; a water cooling cavity is formed between the outer layer and the inner layer; a cooling water inlet is formed in the bottom part of the water cooling cavity, and a cooling water outlet is formed in the top part of the water cooling cavity; the side electromagnetic pulse device is arranged at the outer wall of the metal mold; the top electromagnetic pulse device is positioned right above the inner chamber of the metal mold. According to the composite electromagnetic pulse solidification structure treatment device for casting of the ultralumin, electromagnetic energy can enter the melt to the maximum, so that the metal mold can be uniformly preheated, and the core structure of an ultra-thick casting can be uniformly thinned through the electromagnetic energy while the solidification supercooling degree of a casting blank is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

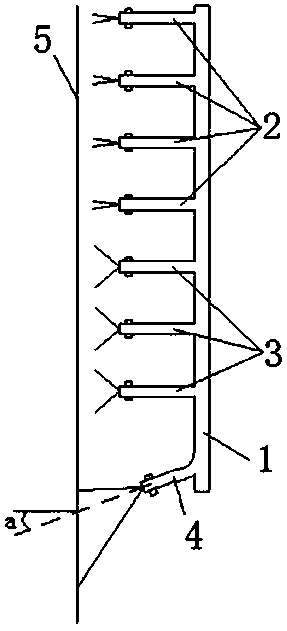

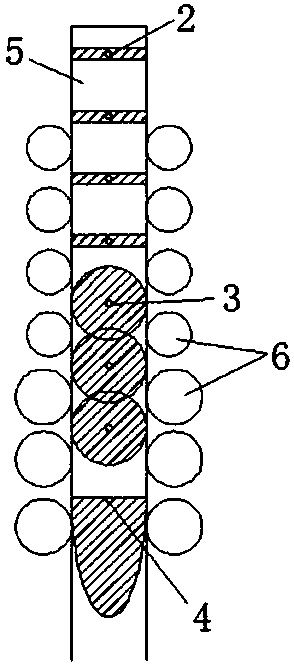

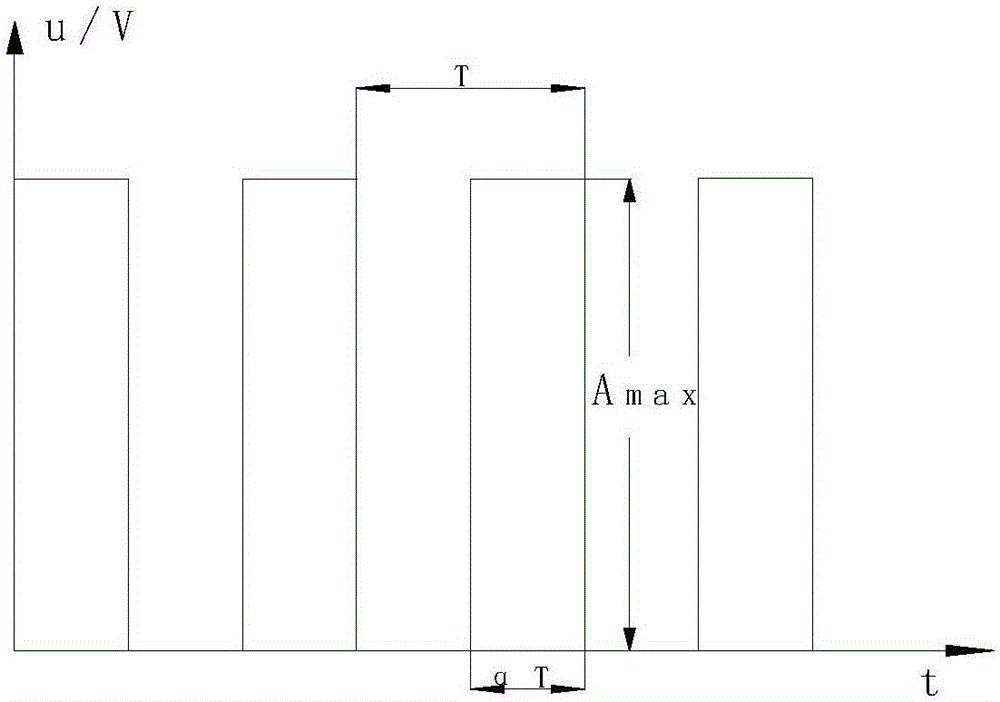

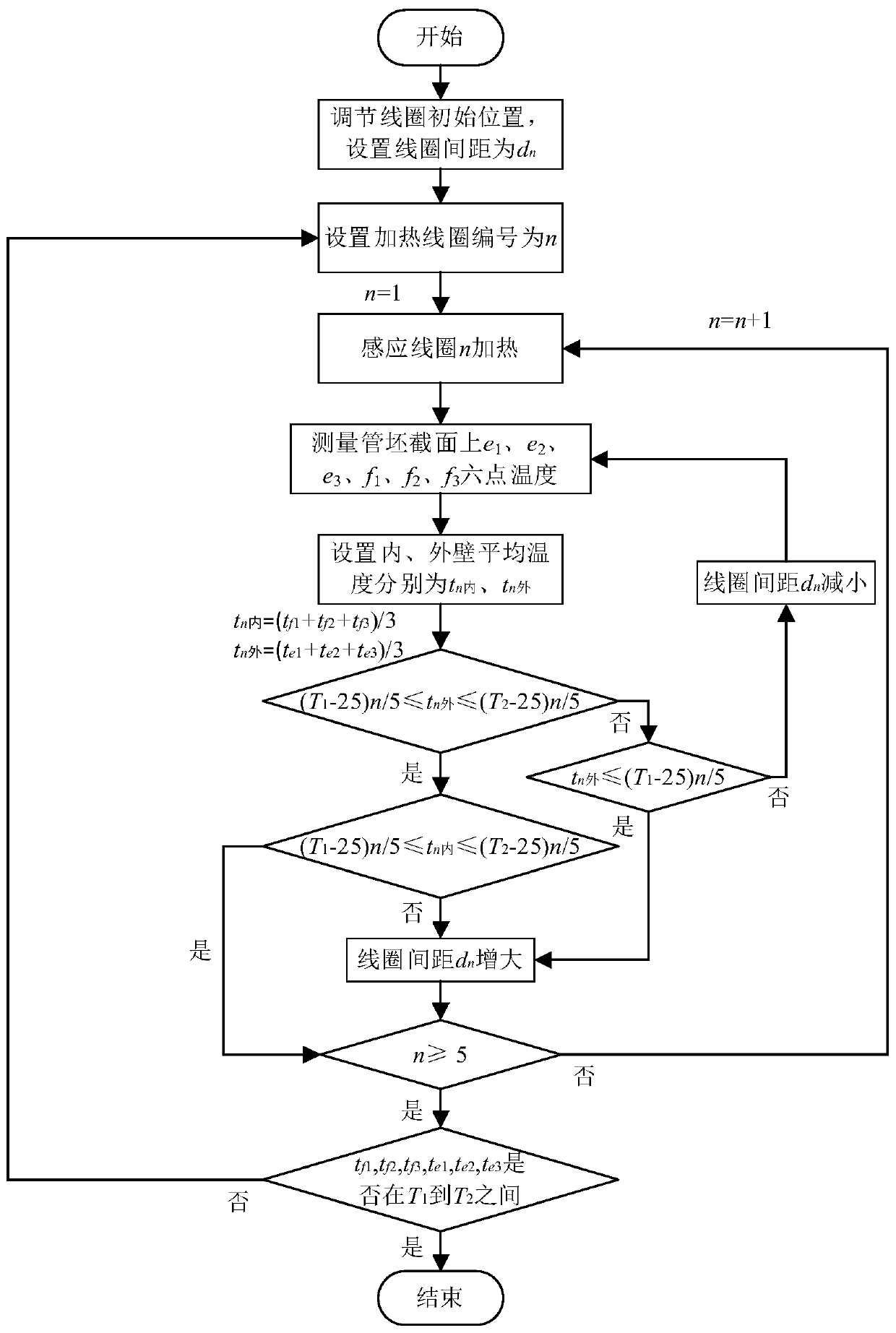

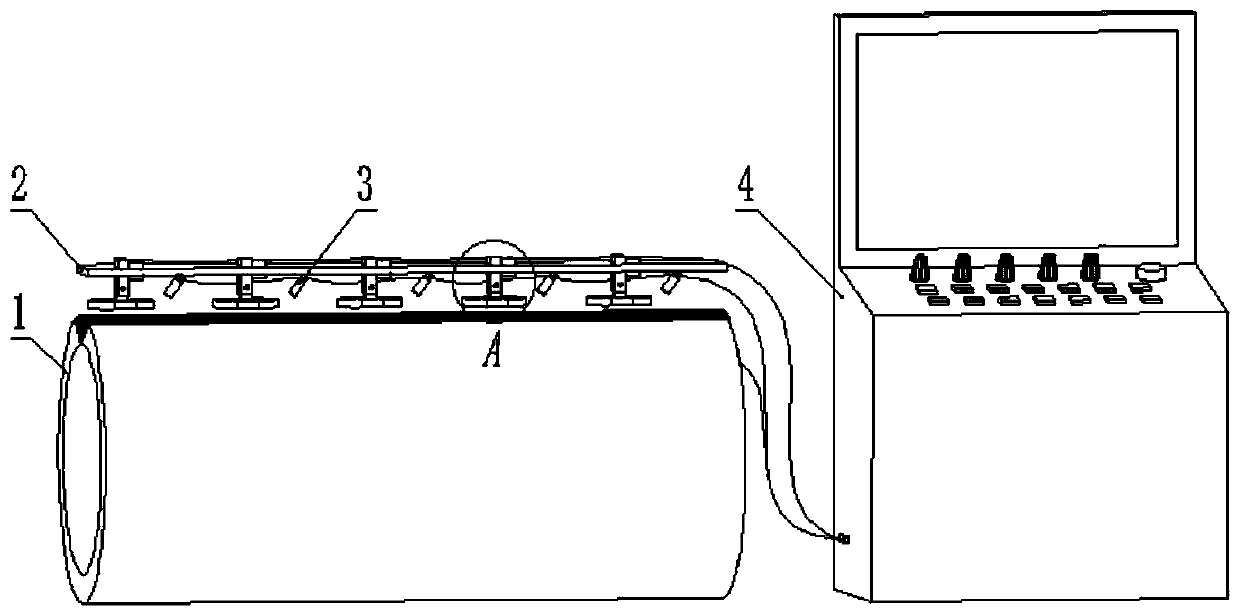

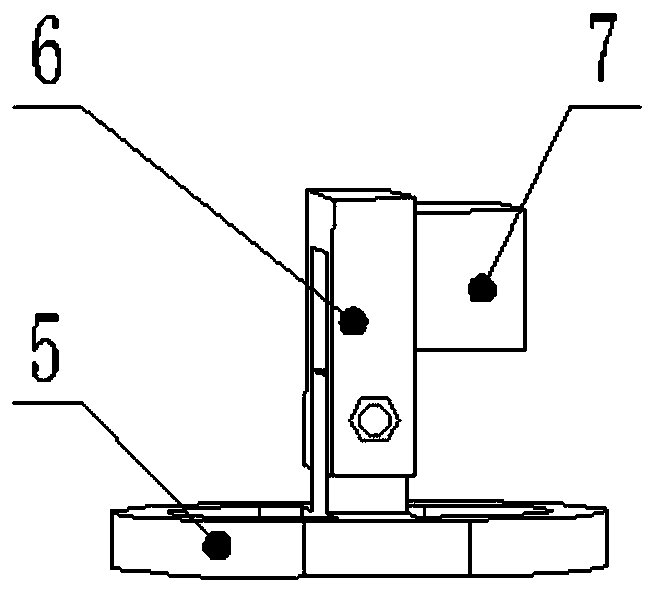

Discrete device and discrete method for heating straight welded pipe by coils

ActiveCN109971940AImprove heat treatment effectUniform temperature riseFurnace typesIncreasing energy efficiencyTreatment effectWeld seam

The invention discloses a discrete device and a discrete method for heating a straight welded pipe by coils. The device comprises a discrete induction heating device, a temperature measuring feedbackdevice and a control console. The discrete induction heating device comprises a coil bracket, a coil fixing sleeve, a control slide block and five horizontally arranged induction coils adjustable in separation distance. Each induction coil is controlled to be adjusted by the control console. The temperature measuring feedback device comprises an outer wall temperature measuring device and an innerwall temperature measuring device. The outer wall temperature measuring device comprises five infrared thermodetectors L1-L5. The inner wall temperature measuring device comprises five infrared thermodetectors L6-L10. Dynamic temperature measurement on heating points in various stages in welded pipe welding seam is carried out constantly, the control console receives a temperature feedback signalof the temperature measuring feedback device to control and adjust the positions of the induction coils constantly, and finally, the inner and outer temperatures at the weld seam of the welded pipe meet a heat treatment temperature demand synchronously, so that the heat treatment effect is optimized and the heat treatment quality is improved.

Owner:河北华洋钢管有限公司

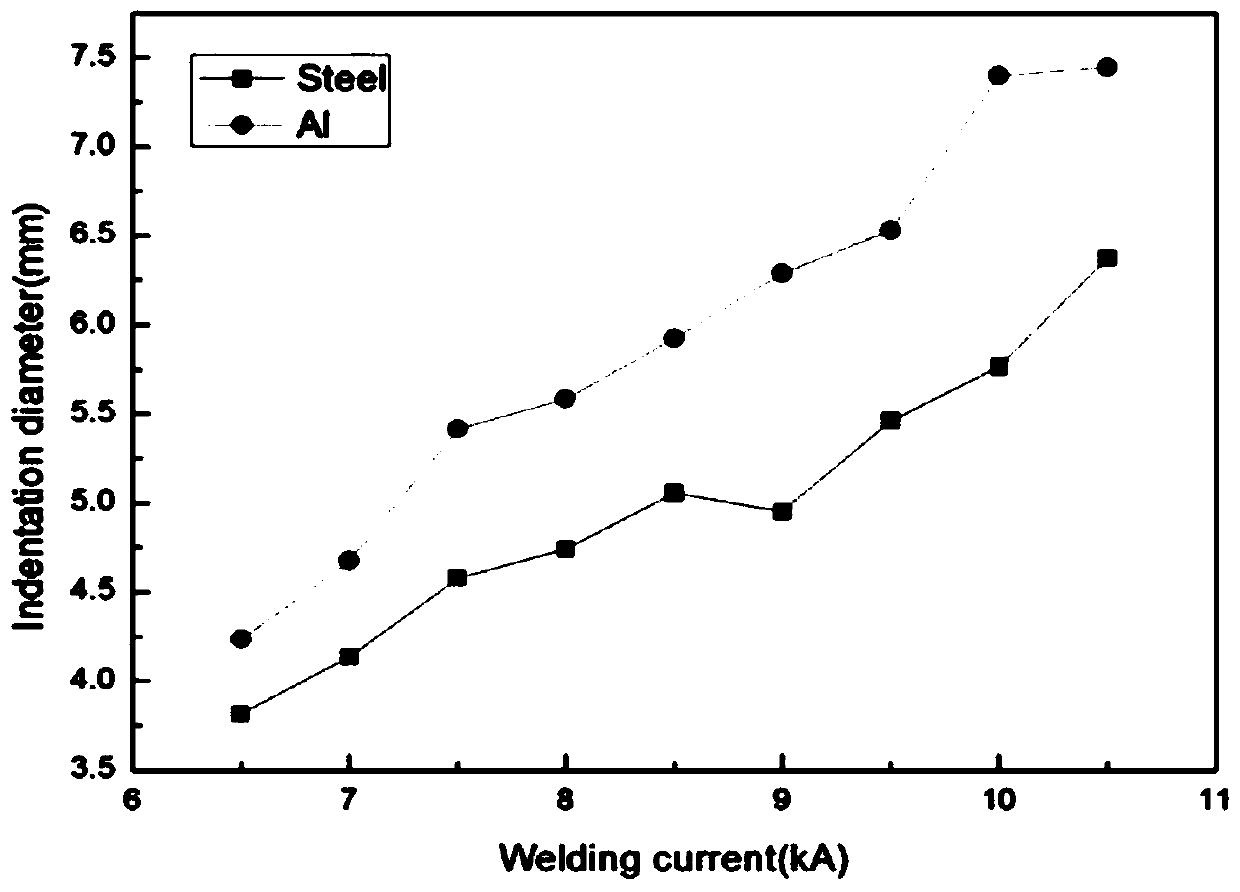

6061-T6 aluminum alloy and TRIP980 high-strength steel dissimilar alloy resistance point welding method

ActiveCN110280880AAdded warm-up stepImprove plasticityWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceCrazing

The invention discloses a 6061-T6 aluminum alloy and TRIP980 high-strength steel dissimilar alloy resistance point welding method. The welding conditions of resistance point welding are as follows: the welding current is 6.5 kA to 10.5 kA, the welding time is 15 cyc to 60 cyc and the electrode pressure is 1 kN to 3.5 kN. Due to addition of Cu, the plasticity and toughness of a joint can be effectively improved under the condition of increasing the drawing force of the joint, the breakage mode is button breakage and is ductile-brittle breakage, the welding head preheating step is increased, the cooling speed after welding is reduced and the welding stress is reduced; and due to increment of preheating current, the metal plasticity can be improved, a workpiece is easy to fit closely, splashing is avoided, crack is avoided and the mechanical property of the point welding joint is improved.

Owner:INNER MONGOLIA UNIV OF TECH

Treatment method for improving acid corrosion resistance of chemical pump shaft

InactiveCN107312918AImproved resistance to intergranular corrosionImprove surface qualityFurnace typesMetallic material coating processesSolution treatmentAfter treatment

The invention discloses a treatment method for improving the acid corrosion resistance of chemical pump shafts, which includes: (1) solid solution treatment and irradiation treatment; (2) phosphating treatment; (3) cleaning and drying; after being treated by the method of the invention The high-quality pump shaft can fully dissolve the carbide and ferrite in the pump shaft material structure in the austenite matrix, thereby obtaining a single austenite structure, and greatly improving the corrosion resistance of the stainless steel pump shaft.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

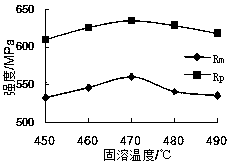

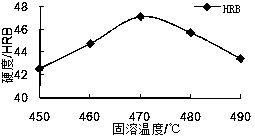

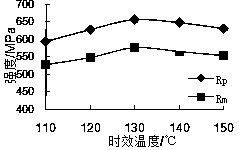

Heat treatment technology for 7-series high-strength aluminum alloy

The invention relates to a heat treatment technology for a 7-series high-strength aluminum alloy, and belongs to the technical field of aluminum alloy heat treatment. The heat treatment technology includes the steps that solution treatment is firstly carried out, wherein the solution treatment temperature is 470+ / -5 DEG C, and the solution treatment time is 60+ / -20 min; then initial aging treatment, shape change treatment and final aging treatment are then carried out, wherein the initial aging treatment is carried out at the temperature being 130+ / -5 DEG C, and the initial aging treatment time ranges from 9 h to 39 h; stretchable shape change treatment is carried out at the room temperature, wherein the shape change amount ranges from 35% to 45%; and final aging treatment is carried out at the temperature being 120+ / -5 DEG C, wherein the final aging treatment time ranges from 4 h to 20 h. The alloy obtained after heat treatment is even and fine in grain, the recrystallization degree is higher, and an obvious precipitated phase can be seen. The strength of the alloy reaches 683 MPa, the hardness reaches 87.2 HRB, and the elongation rate reaches 16.8%; and compared with a traditional single heat treatment technology, the strength of the alloy is improved, and the ductility and the toughness of the alloy are improved to a large extent.

Owner:HUANGHE S & T COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com