Patents

Literature

1430results about How to "Improve craftsmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

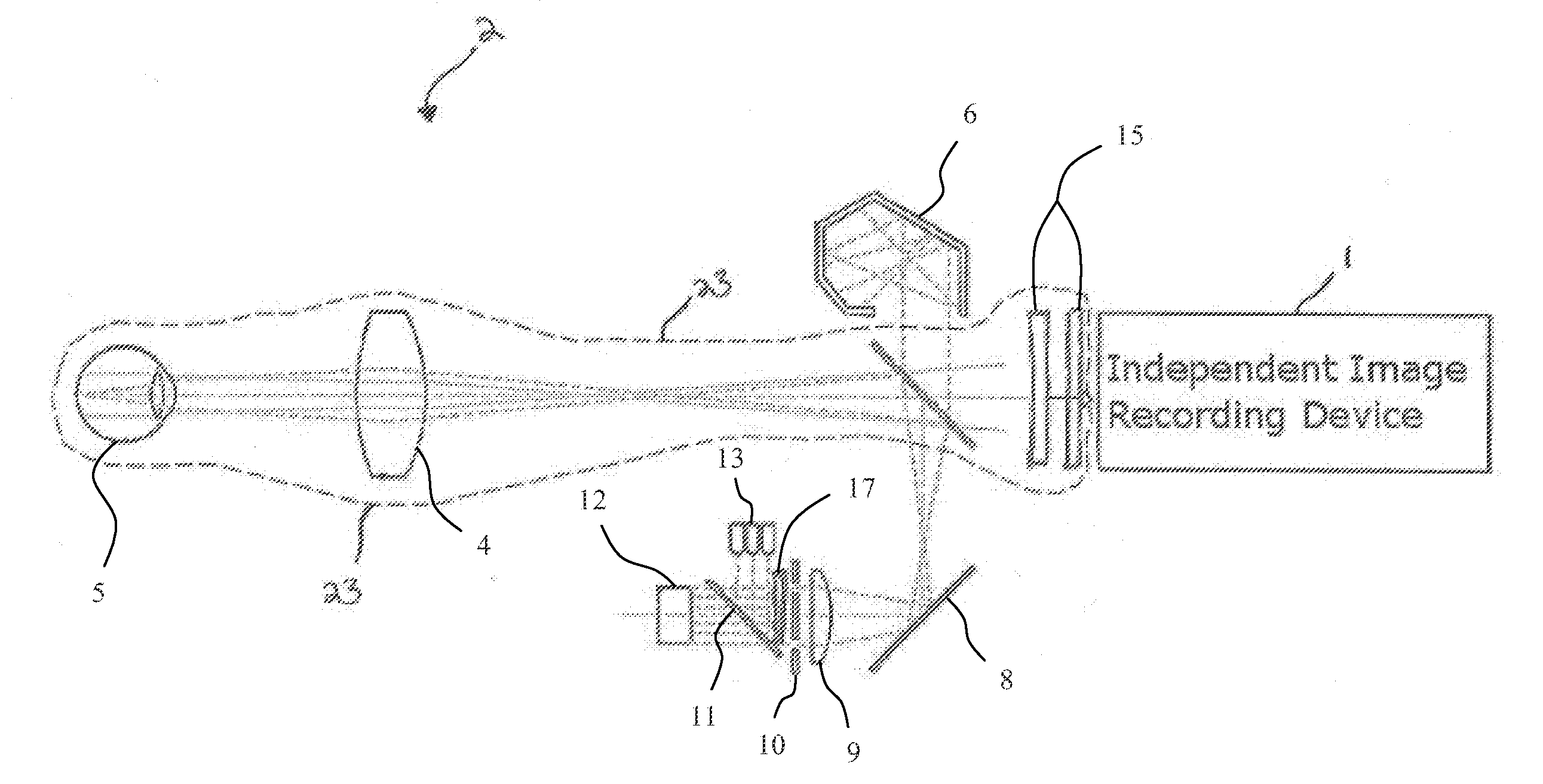

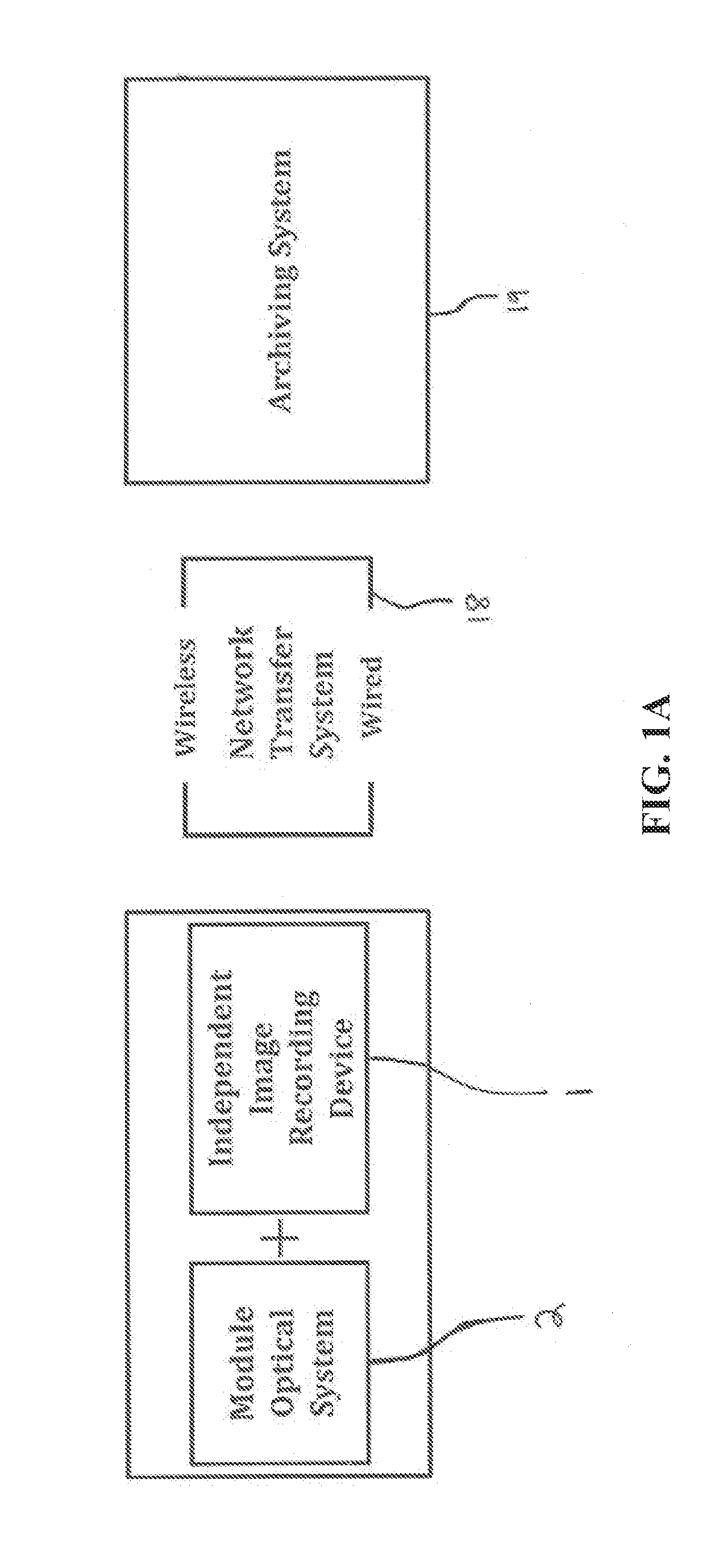

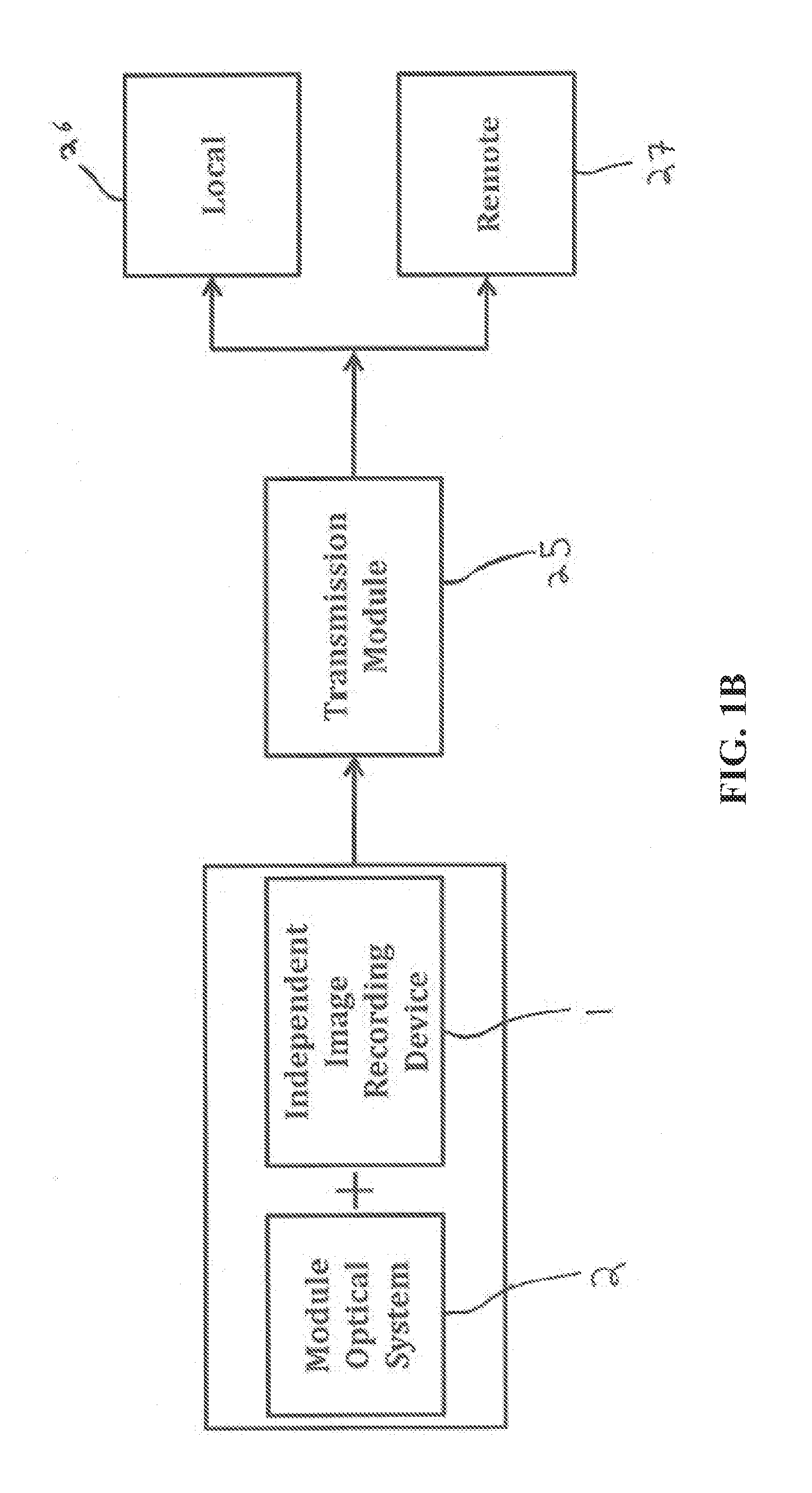

Hand-held portable fundus camera for screening photography

ActiveUS20120229617A1Low costEasy to useTelevision system detailsAcquiring/recognising eyesFundus cameraHand held

System and Method pertaining to the modification and integration of an existing consumer digital camera, for example, with an optical imaging module to enable point and shoot fundus photography of the eye. The auto-focus macro capability of existing consumer cameras is adapted to photograph the retina over an extended diopter range, eliminating the need for manual diopter focus adjustment. The thru-the-lens (TTL) auto-exposure flash capability of existing consumer cameras is adapted to photograph the retina with automatic flash exposure eliminating the need for manual flash adjustment. The consumer camera imaging sensor and flash are modified to allow the camera sensor to perform both non-mydriatic focusing of the retina using infrared illumination and standard color flash photography of the retina without the need for additional imaging sensors or mechanical filters. These modifications and integration of existing consumer cameras for fundus photography of the eye significantly improve ease of manufacture and usability over existing fundus cameras.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

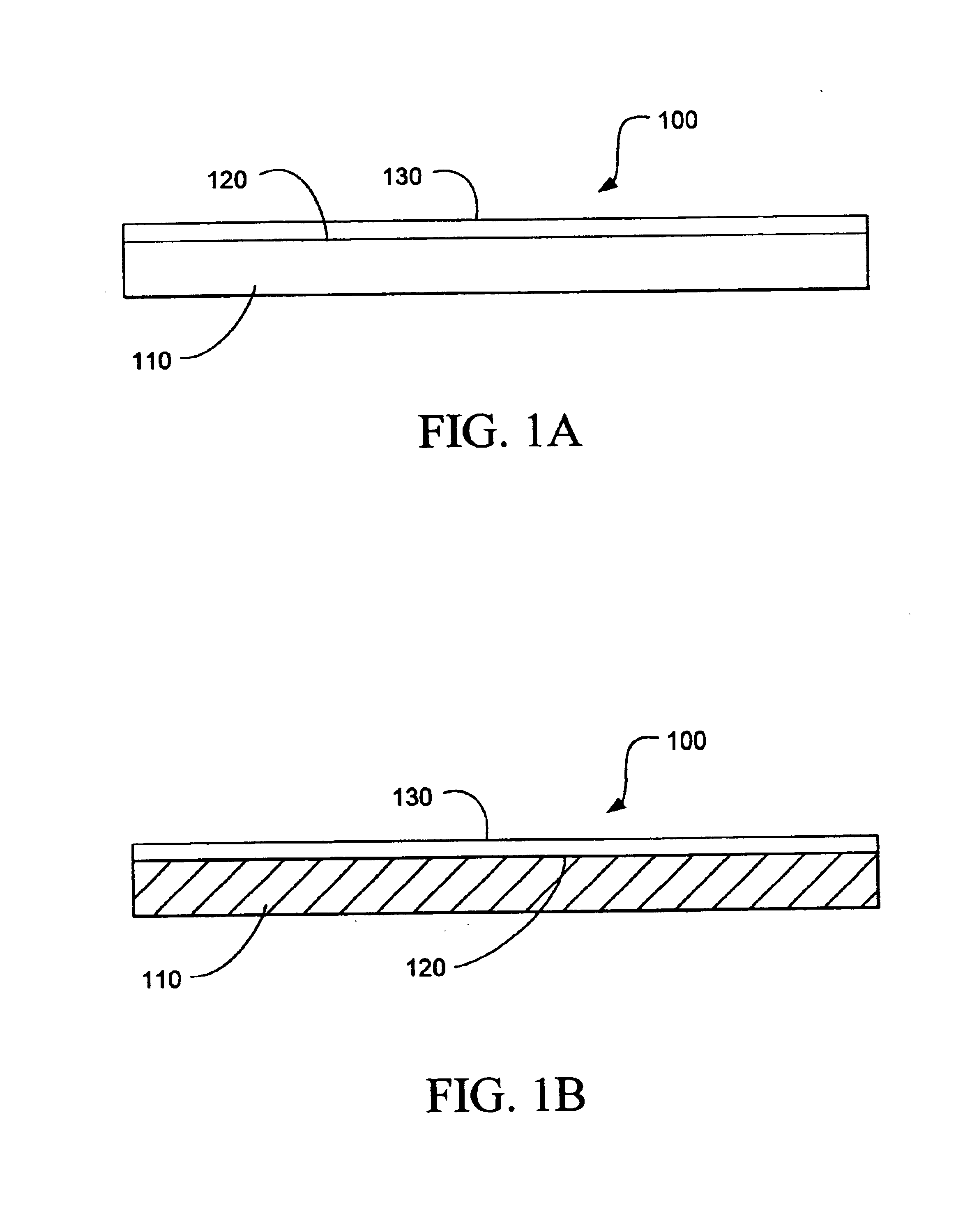

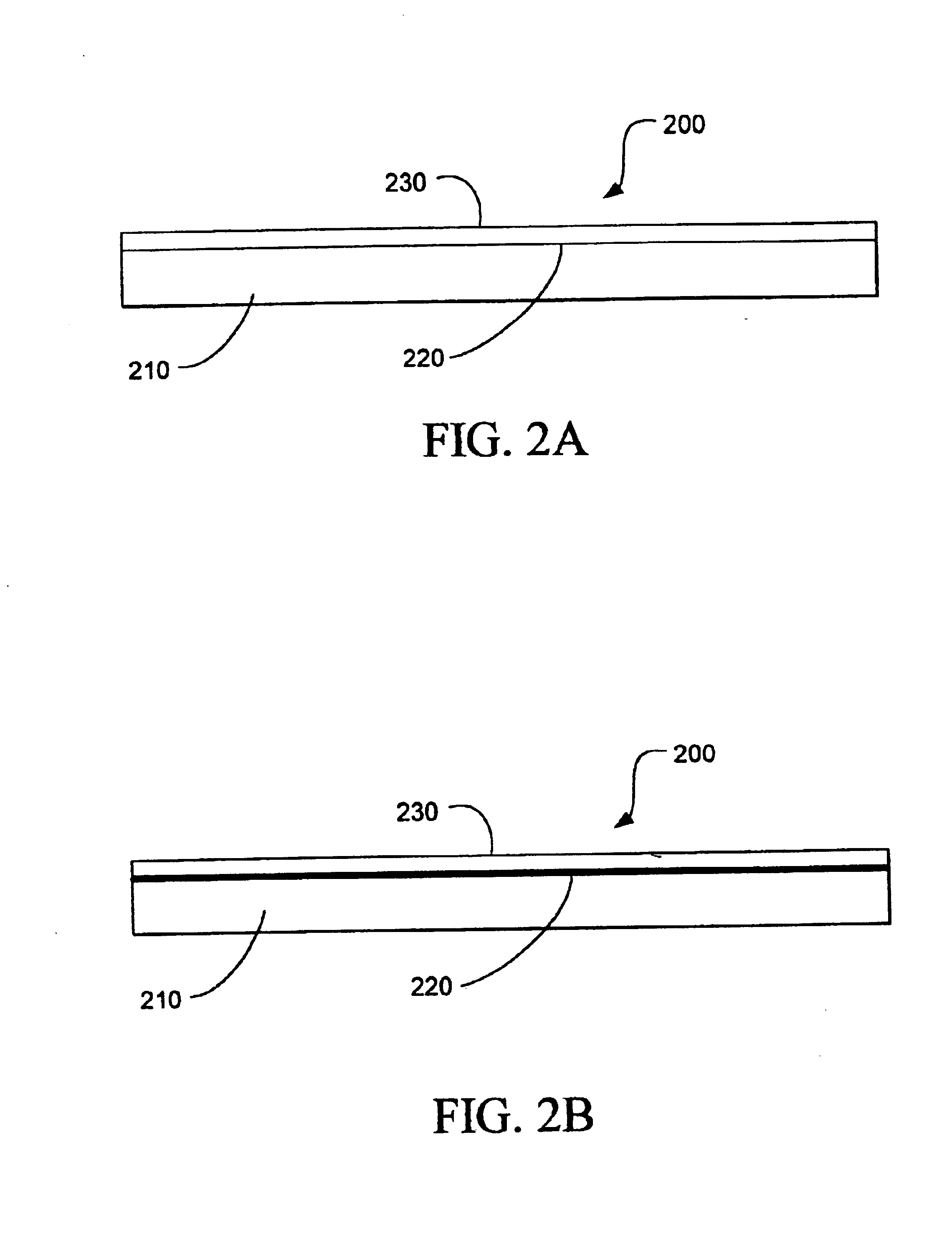

Directory read inhibitor for optical storage media

InactiveUS6838144B2Low costChange is minimalLayered productsPhotomechanical apparatusOptical reflectionTime function

Systems and methods are described for inhibiting the readability of an optical media due to changes in a pseudo-reflective material that composes the optical media after the optical media has been exposed to air for a predetermined time. An optical media includes a data encoded component. At least a fraction of the data encoded component transforms from a substantially optically reflective state to a substantially optically non-reflective state as at-least-in-part a function of time from an initializing event. The systems and methods provide advantages because of low cost, limited content lifetime, avoidance of rental returns and minimum changes to existing manufacturing processes.

Owner:FLEXPLAY TECH INC

High-elongation aluminum alloy material and preparation method thereof

ActiveCN101525709AHigh strengthImprove creep resistanceTemperature control deviceMetal rolling arrangementsRare-earth elementElectrical conductor

The invention relates to a high-elongation aluminum alloy material and a preparation method thereof. The high-elongation aluminum alloy material contains 0.30-1.20% of iron, 0.03-0.10% of silicon, 0.01-0.30% of rare earth elements, and aluminum and inevitable impurities in weight percentage. The aluminum alloy is made from materials according to a fusion casting process and half-annealing treatment. An aluminum alloy conductor made by the method has high elongation and good safety and stability in use.

Owner:ANHUI JOY SENSE CABLE

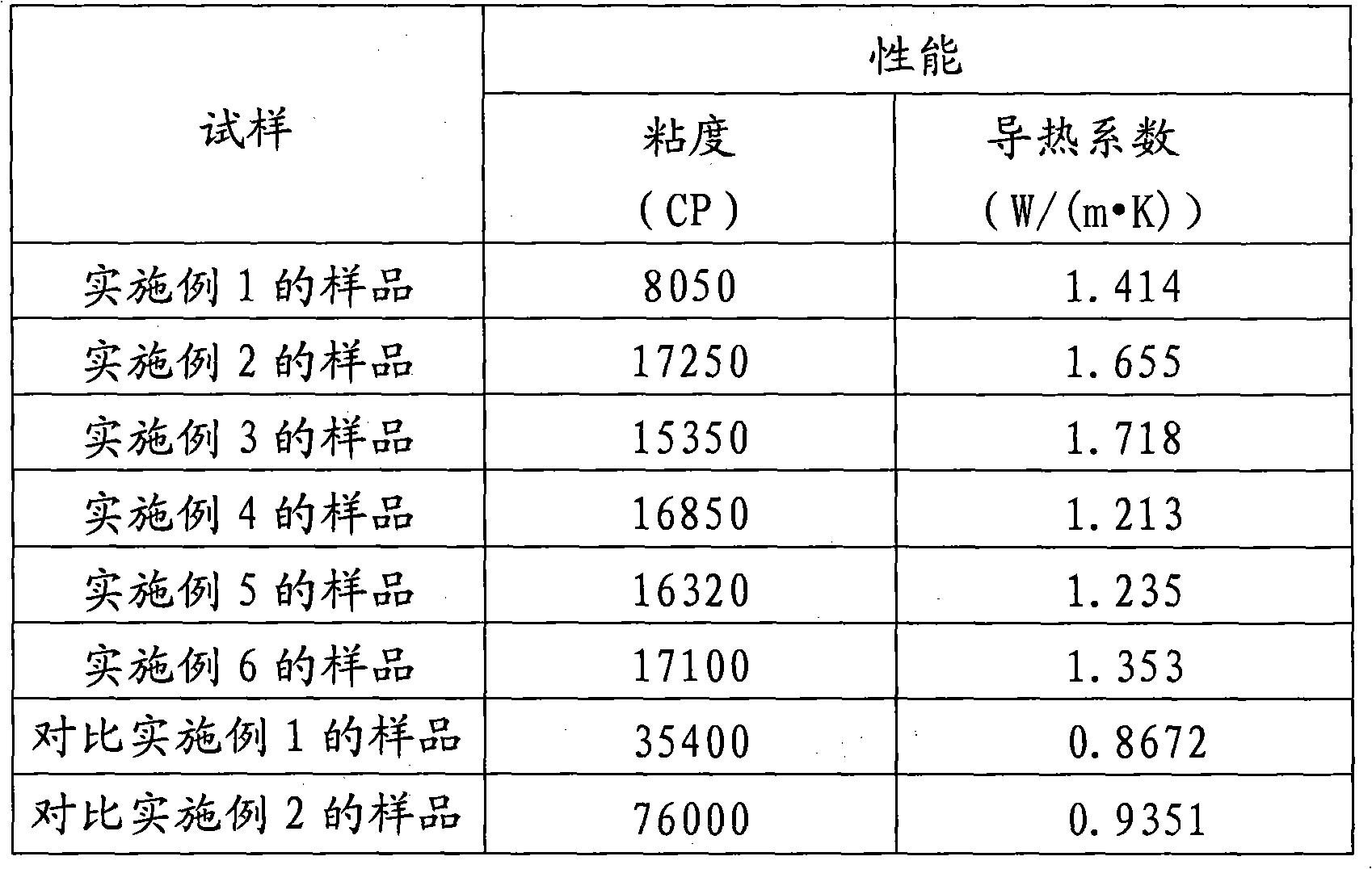

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

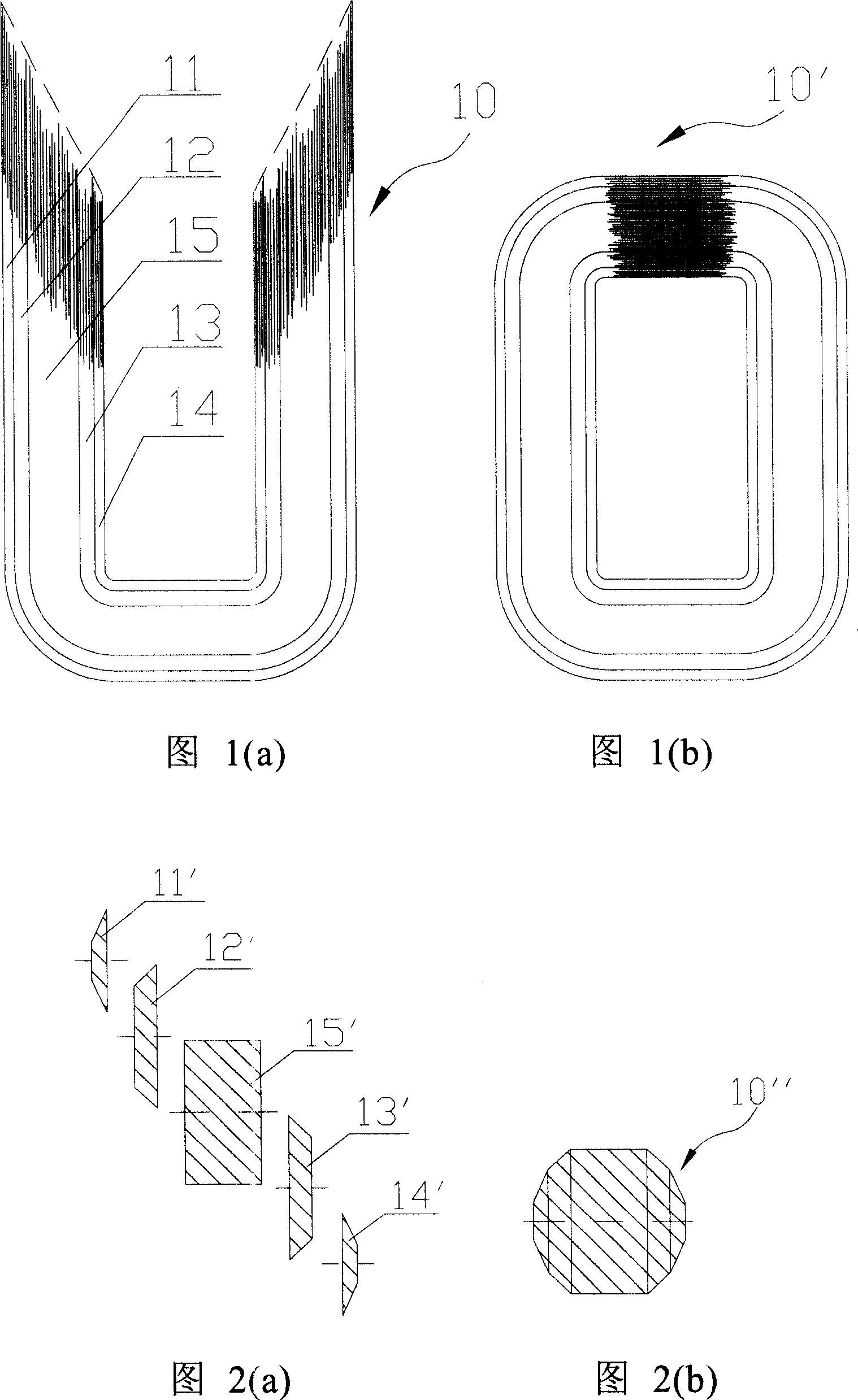

Amorphous alloy roll-core and its production method

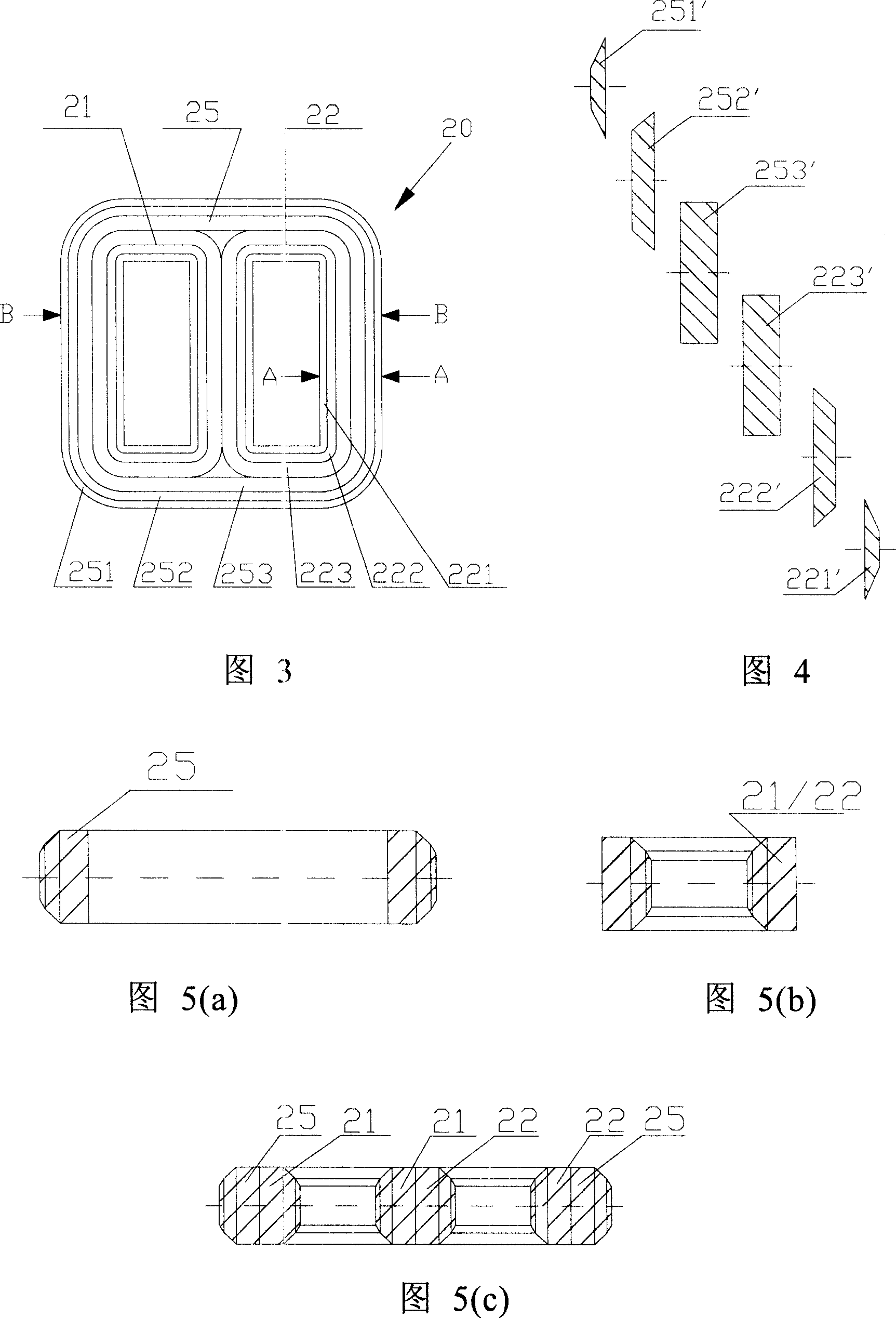

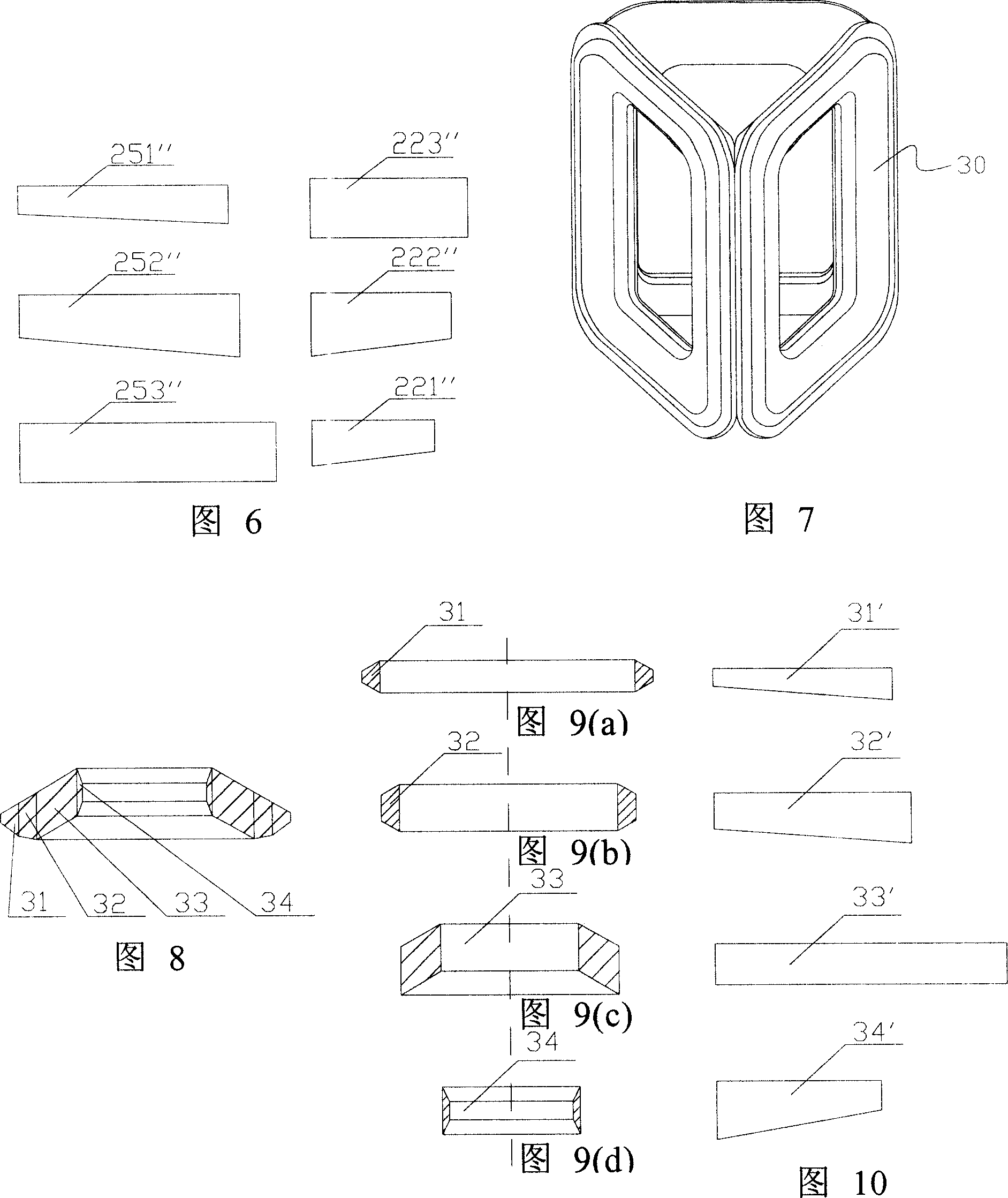

ActiveCN101150006AReduce turn lengthSave copperTransformers/inductances magnetic coresInductances/transformers/magnets manufactureButt jointTransformer

This invention relates to a non-crystal alloy rolled iron-core and its manufacturing method, in which, the iron-core is formed by several single frames winded in different sections and the section shape of the butt-joint iron-core is in a pre-designed Quasi-circular, quasi-polygon or a complex shape made of non-crystal alloy material or non-crystal alloy and silicon steel ribbon, in which, the one with the largest section is taken as the master frame rolled continuously with the straight non-crystal alloy ribbon and other single frames are formed by rolling different shapes of silicon steel ribbons, besides, the butt-joint core can be either close one or an open one, can be either single phase iron-core, three phase three posts planar core or a three phase five posts planar core or a three phase solid core.

Owner:NEWONDER SPECIAL ELECTRIC

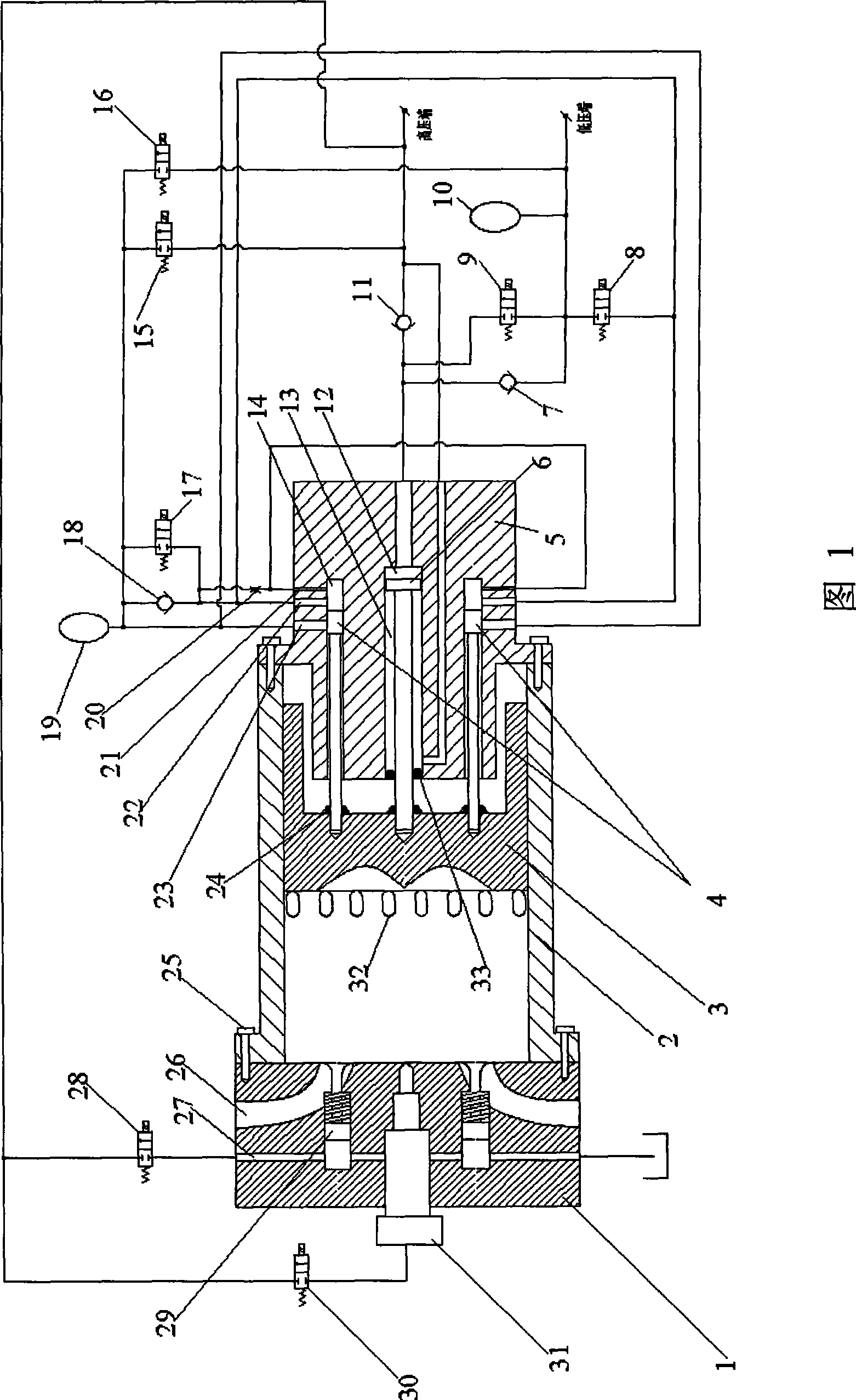

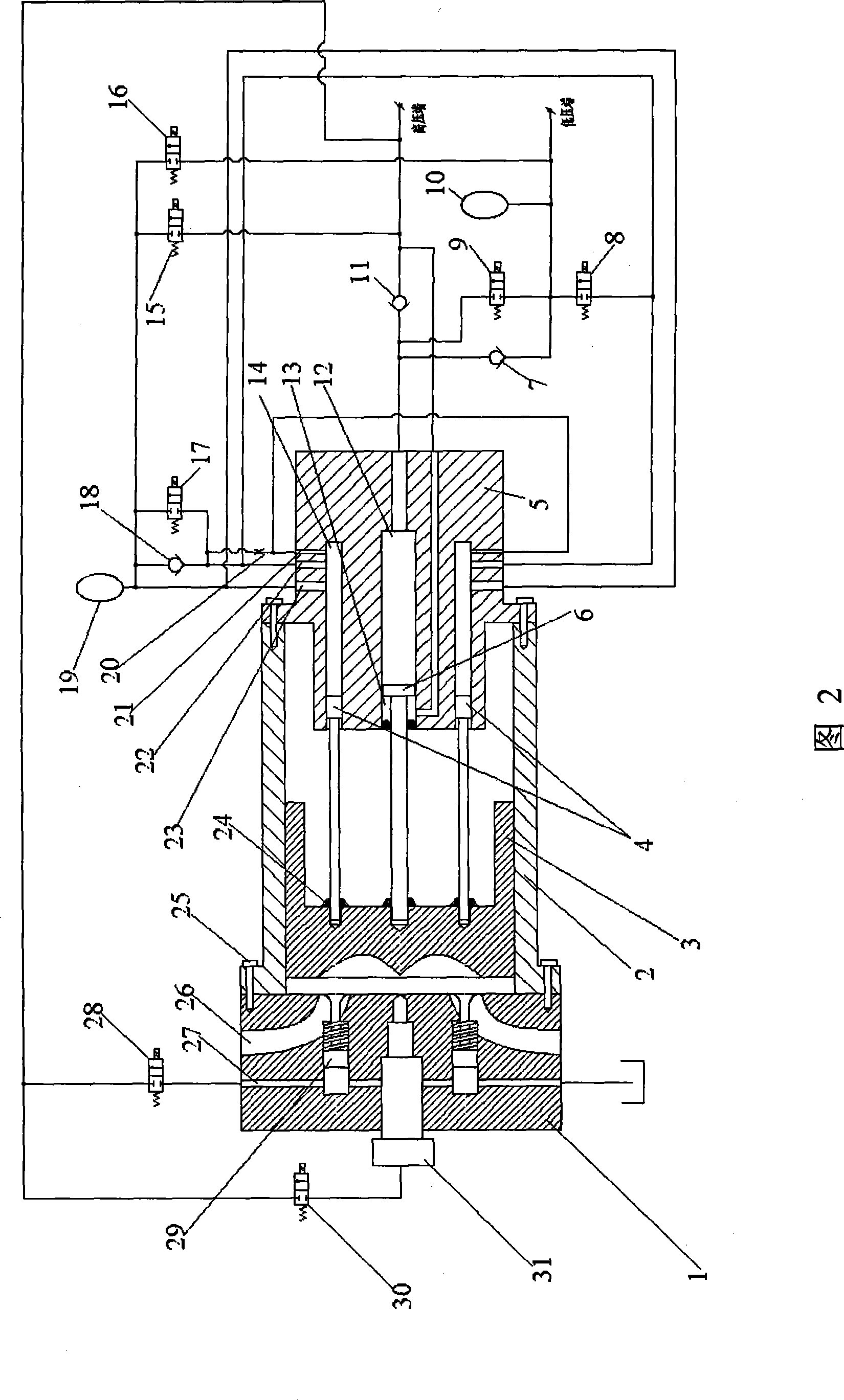

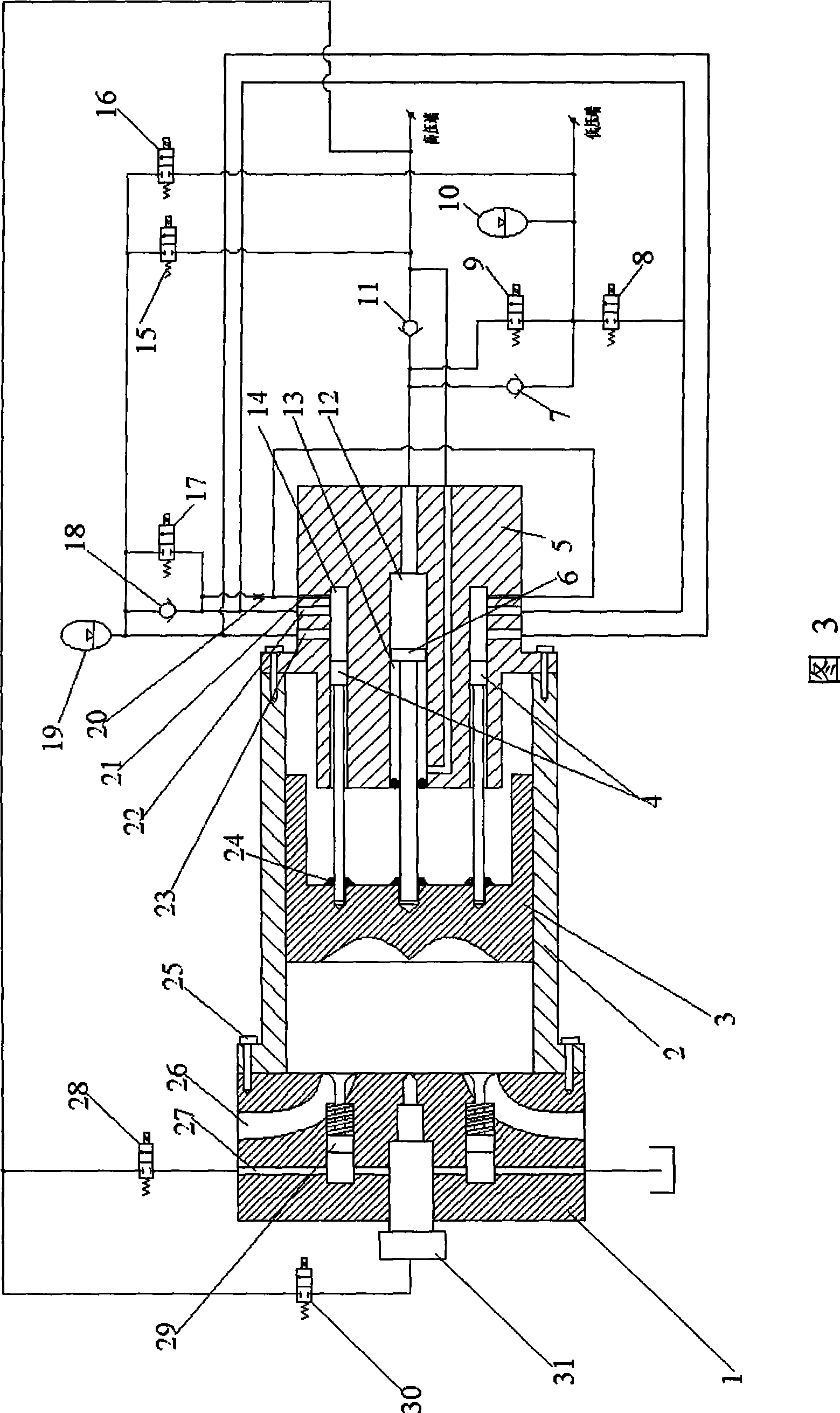

Single-piston type hydraulic free piston engine

InactiveCN101363397AReduce axial sizeSolve unfavorable situations such as economic deterioration and emission deteriorationReciprocating piston enginesFree-piston engineEnergy transfer

The invention discloses a single-piston type hydraulic free piston engine; in the invention, a traditional reciprocating piston internal combustion engine and a plunger-typed hydraulic pump are integrated into a whole, a pump piston and two compression pistons are simultaneously and directly connected with a power piston in a rigid manner to form a piston component, therefore, a crank link mechanism which can transform the reciprocating movement of the pistons into rotary motion in the internal combustion engine, and a swash plate mechanism which can transform the rotary motion of the pistons into reciprocating movement in a plunger pump can be omitted, and the piston of the internal combustion engine is directly connected with the plunger of the hydraulic pump in a rigid manner. By adopting the technical proposal of the invention, a driving chain can be shortened, the repeated transformation between different movement forms can be omitted, the energy transfer form between an engine and a drive system can be optimized, and the soft readjustment of a power drive unit can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Al-Fe-Cu alloy material and preparation method thereof

The invention particularly relates to an Al-Fe-Cu alloy material and a preparation method thereof. The Al-Fe-Cu alloy material comprises the following components in percentage by weight: 0.20-1.30 wt% of Fe, 0.01-0.08 wt% of Cu, 0.06-0.15 wt% of Si, 0.02-0.10 wt% of rare-earth element and the balance of Al and unavoidable impurities. The aluminum alloy is prepared by casting and semi-annealing raw materials. When the aluminum alloy is prepared, the alloy material is semi-annealed, and thus, the adverse effects of stress on a conductor structure in the process of drawing and twisting are reduced, the electric conductivity reaches and even exceeds 61% of IACS (International Annealed Copper Standard) (the electric conductivity standard of an aluminum conductor for a general electrician is 61% of IACS), and the performances of elongation and the flexibility of the aluminum alloy are improved greatly by annealing. The performances of the elongation of a cable made of the aluminum alloy wire can reach 30%, the flexibility is 25% higher than that of a copper cable, and the resistivity maintains in a lower level.

Owner:安徽省惠尔电气有限公司

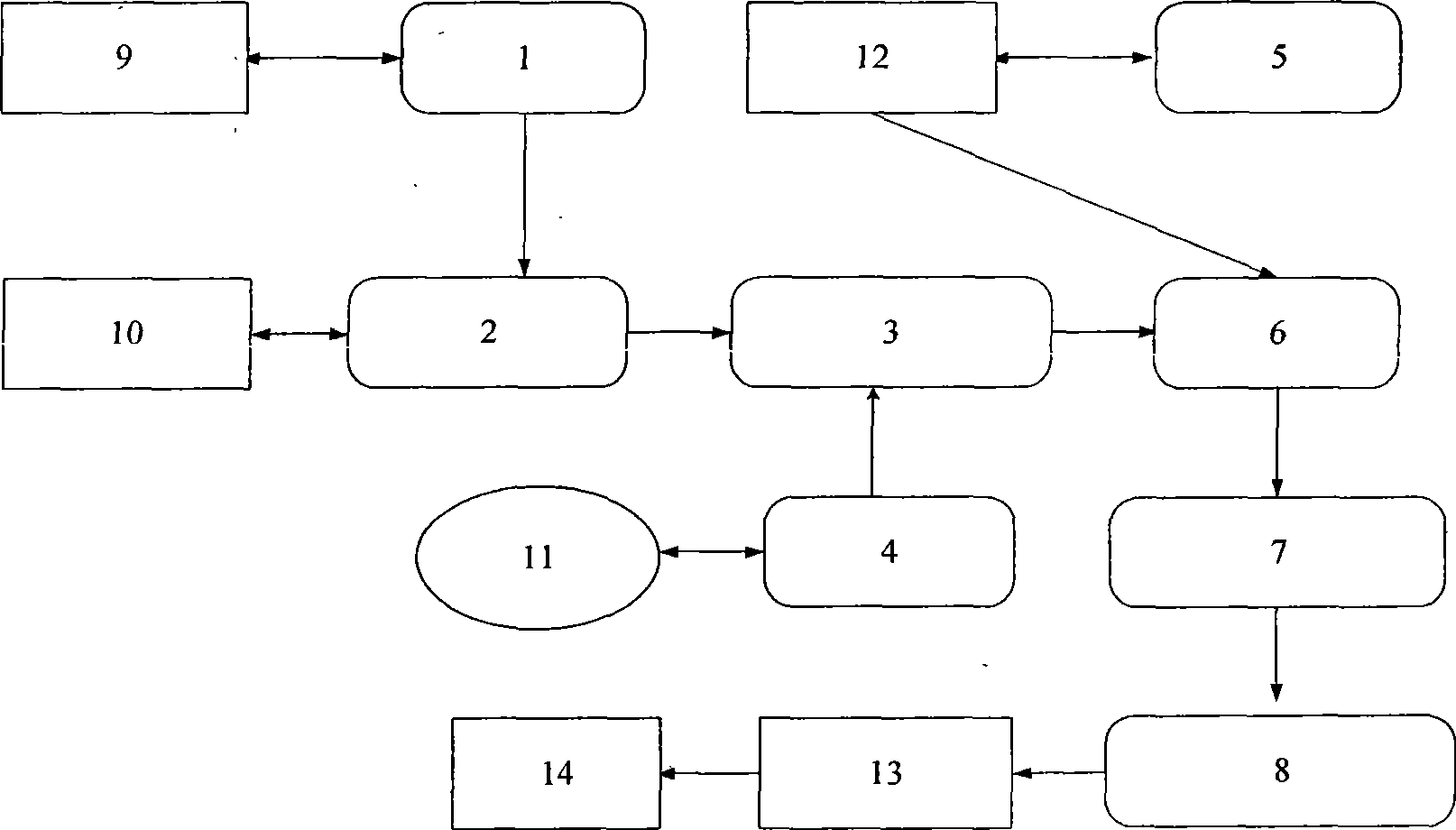

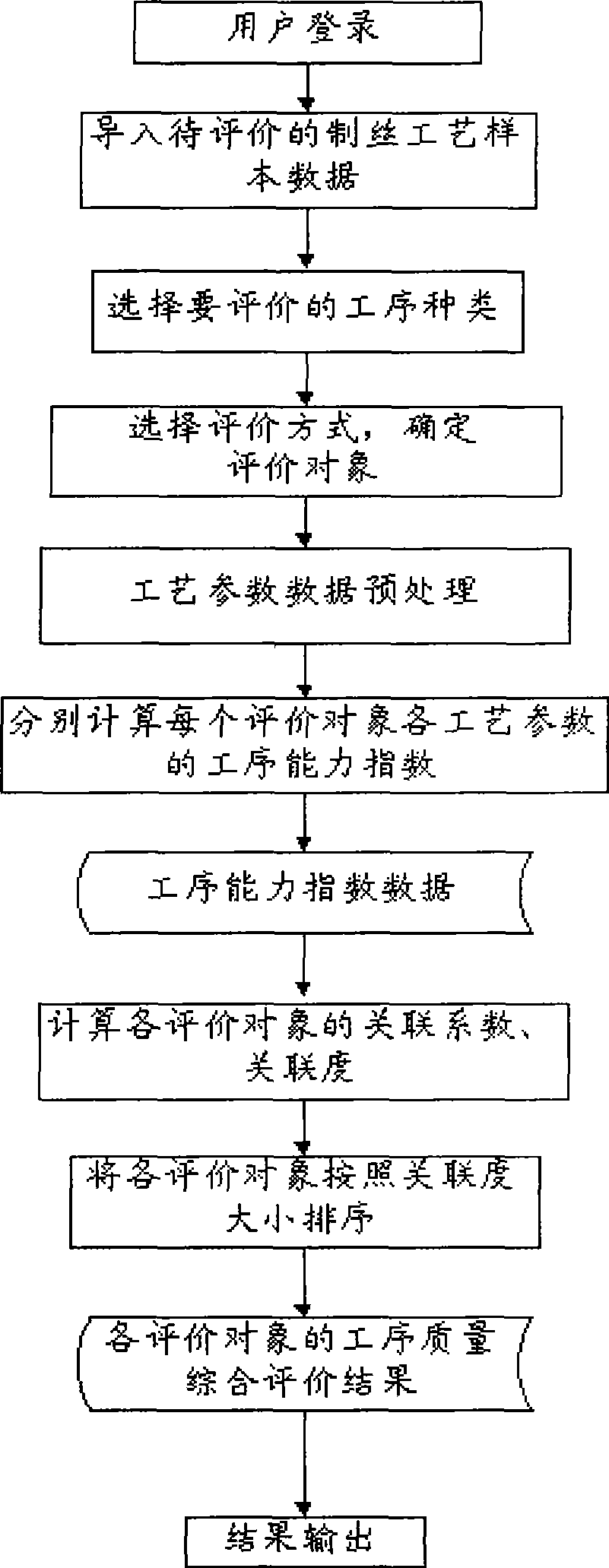

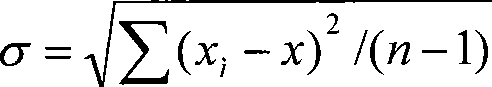

Cigarette working procedure quality overall evaluation system and method based on gray correlation analysis

ActiveCN101414183ASolve the ambiguous situation of process capability evaluationFunctional job improvementTotal factory controlProgramme total factory controlGrey correlation analysisProcess quality

The invention discloses a comprehensive cigarette process quality evaluation system based on grey correlation analysis and a method thereof, aims at overcoming the disadvantage that the existing single process evaluation method can not comprehensively evaluate the overall process quality of the cigarette process, and changing the situation of fuzzy process capability evaluation of a whole line at present. The evaluation system and the method thereof help comprehensively evaluates the quality of a plurality of processes, and can effectively grasp comprehensive situation of the process quality so as to provide basis for the continuous improvement in the process quality, and provide assurance for quality improvement of cigarette products. The system and the method combine the single-process quality evaluation method and the grey correlation analysis method. The method comprises the following steps: firstly, computing process capability indexes of various process parameters; then, comprehensively evaluating a Cpk value by the grey correlation method; finally, obtaining a comprehensive evaluation result which is taken as a process quality rank of various evaluated objects. Production practice can be effectively directed by analyzing the Cpk and the process quality ranking result.

Owner:CHINA TOBACCO SHANDONG IND +1

Rare earth thick film circuit electrical heating element based on aluminum nitride minicrystal ceramic substrates and its preparation technique

ActiveCN101321415AHigh thermal conductivityImprove electrical performanceHeating element materialsRare earthHigh power density

The invention provides a controllable electrical heating element of rare-earth thick-film circuit based on aluminum nitride microcrystal ceramic base plate and manufacturing method thereof, comprising base pieces and serial electronic sizing agents which are manufactured on the base pieces. The serial electronic sizing agents comprise package sizing agent and electronic sizing agent, and are all composed of three parts including a functional phase, an inorganic bonding phase and an organic carrier. The serial electronic sizing agents further comprise rare-earth resistance sizing agent. The base piece is ALN aluminum nitride microcrystal ceramic base piece. The serial electronic sizing agents are manufactured on the base piece by means of thick film circuit. The invention synchronously further provides formulations of ALN aluminum nitride microcrystal ceramic base piece, rare-earth envelopment sizing agent, rare-earth resistance sizing agent and rare-earth electrode sizing agent. The invention is environment-friendly, safe and reliable by providing with equal and controllable heating temperature field, large power, high power density, high efficiency of heat conduction, high speed of response, high efficiency for saving energy, strong capability of thermal-shock resistance, small volume and wide application range.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

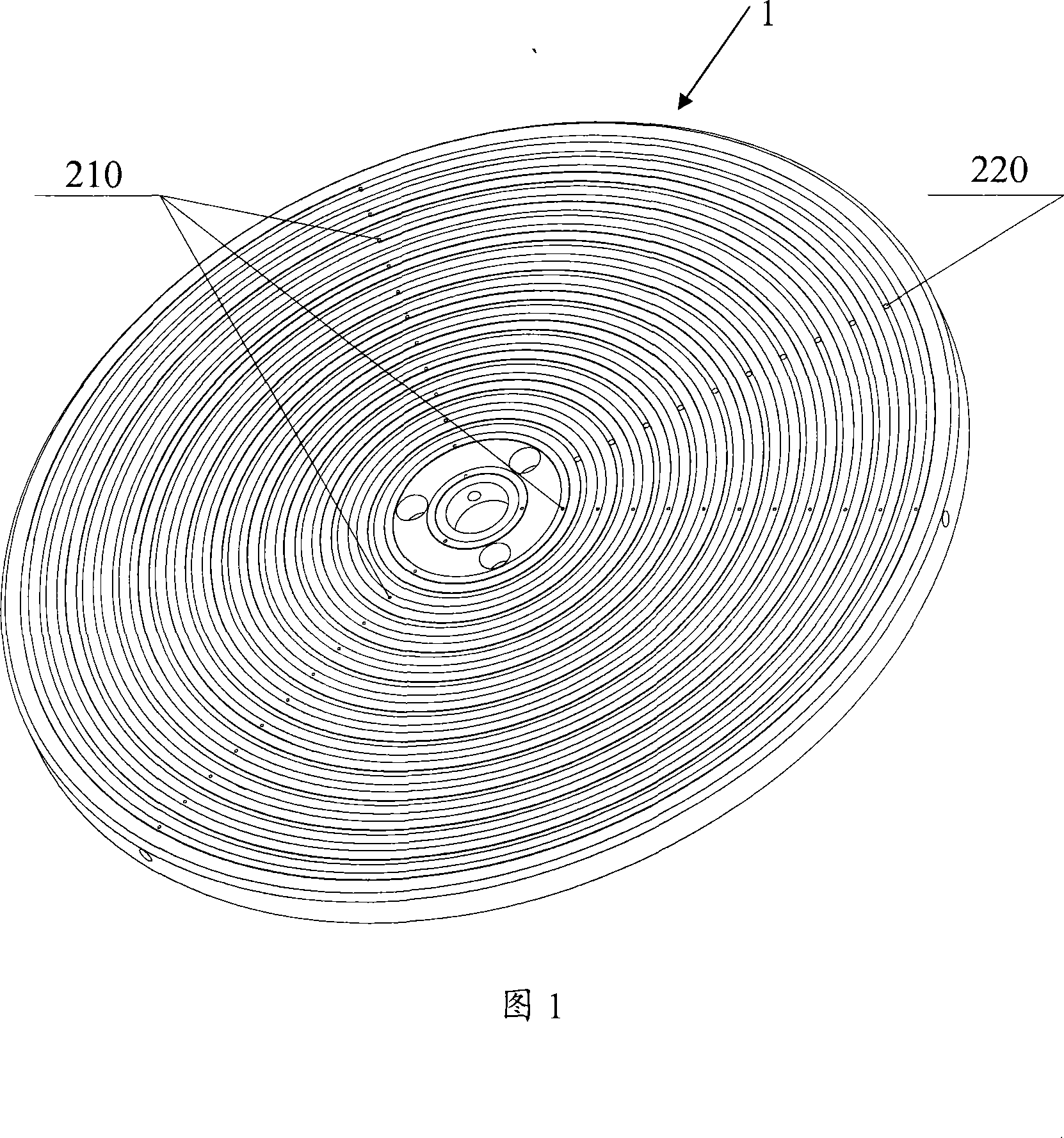

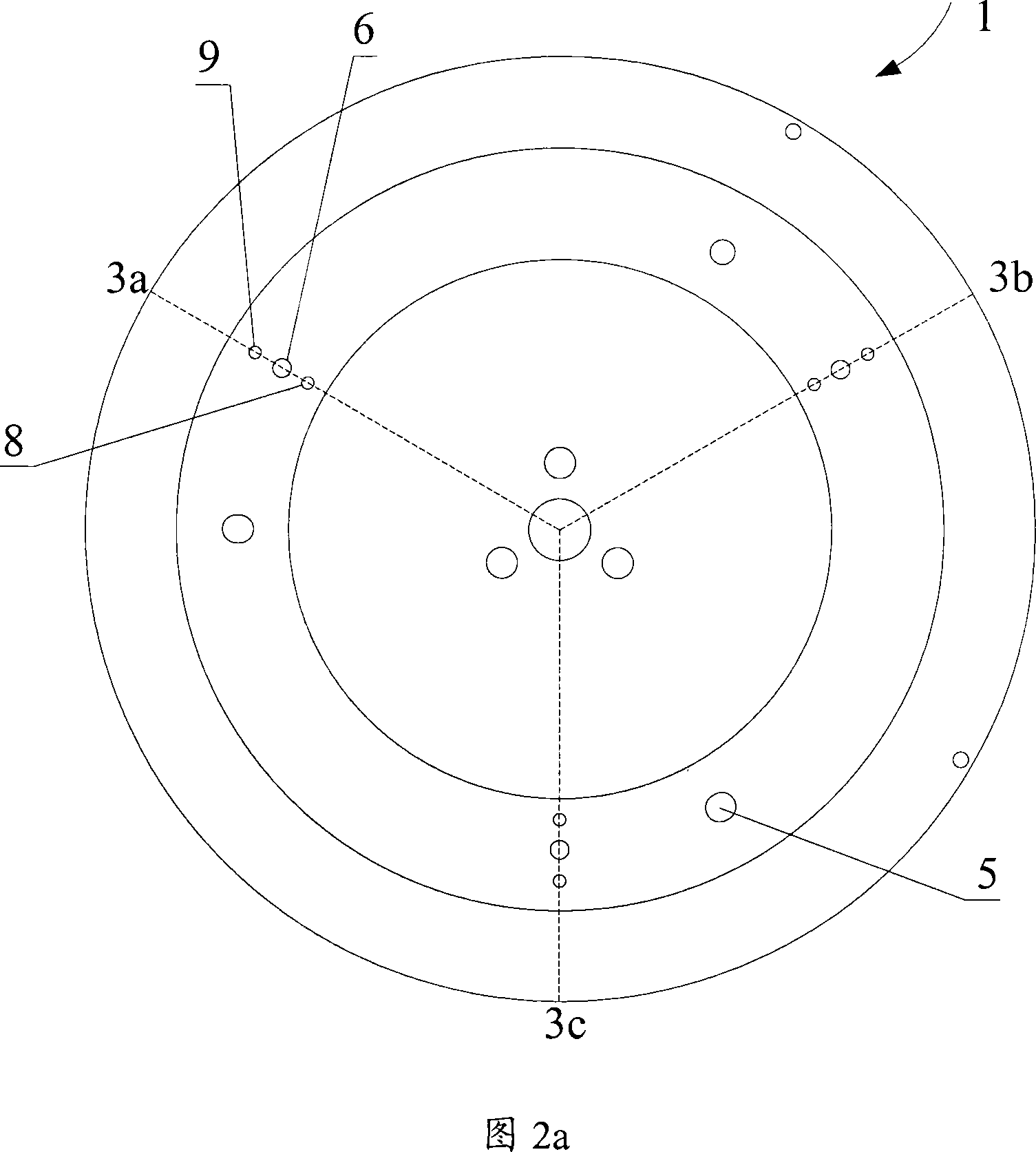

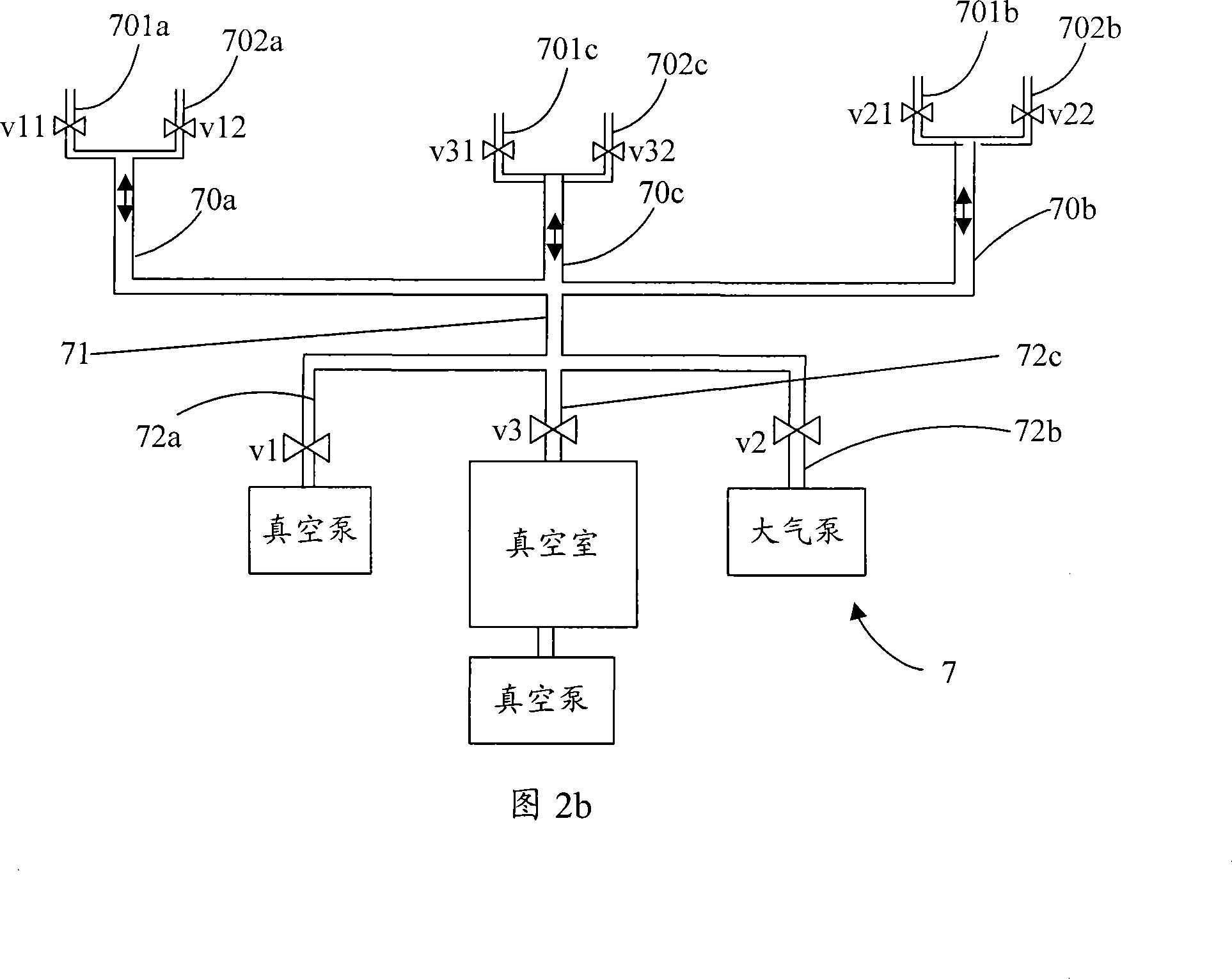

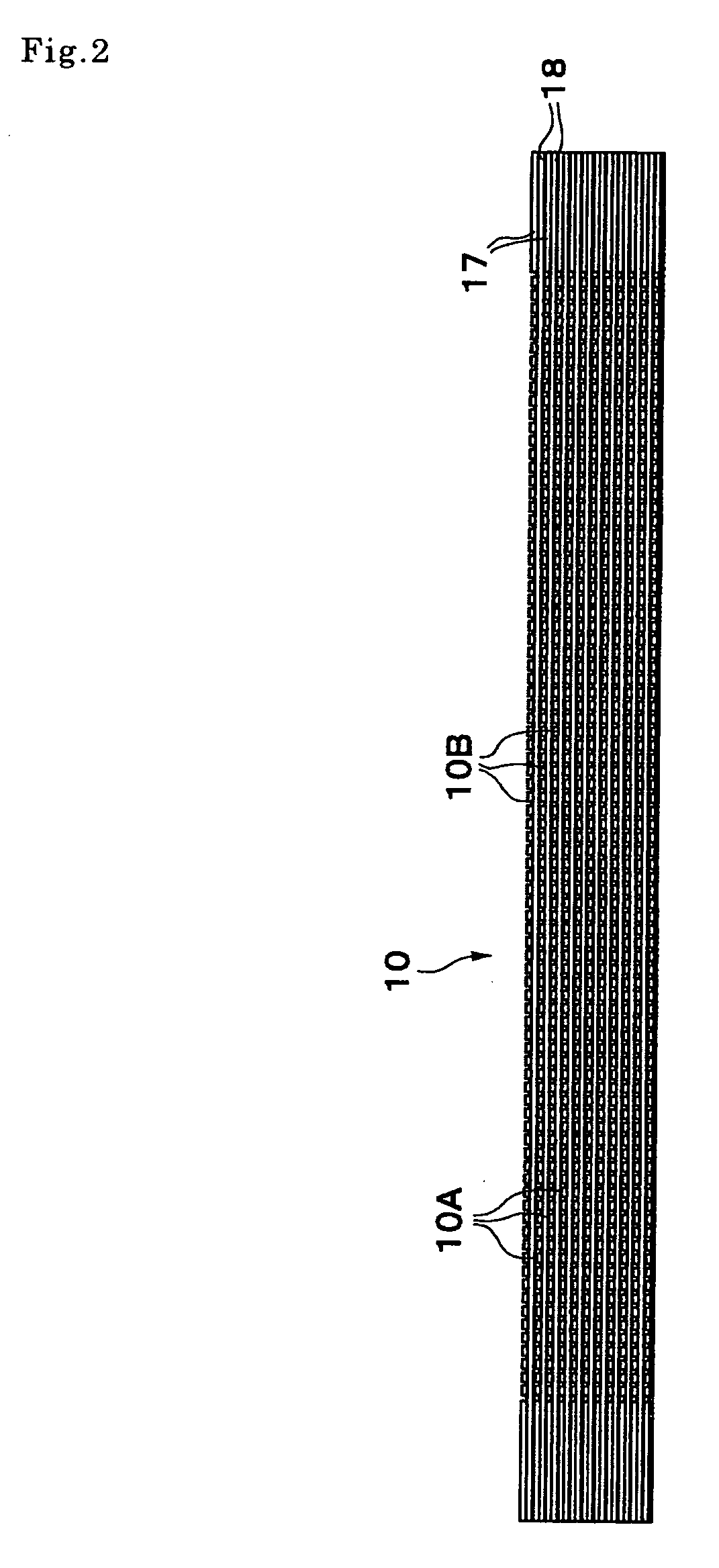

Silicon slice fixing part

ActiveCN101196693AAchieve fixationReduce deformationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusAtmospheric airEngineering

The invention discloses a silicon wafer fixing component, which comprises a plurality of vacuum absorption holes for absorbing silicon wafers, vacuum through holes for communicating the vacuum absorption holes and a plurality of concentric annular grooves for supporting the silicon wafer. The annular groove comprises a vacuum groove and an atmosphere groove arranged at interval in turn, the vacuum absorption hole is positioned in the vacuum groove. The silicon wafer fixing component is also provided with a technics hole isolating the vacuum through hole, the vacuum through hole is isolated after the technics hole is filled, when the technics hole internal side is communicated with the gas controlling device, the technics hole can be used for absorbing No. eight silicon wafer; when both the internal and external sides of the technical hole are communicated, the technics hole can be used for absorbing No. 12 silicon wafer. The atmosphere groove is also internally provided with an atmosphere through hole, the atmosphere through hole can discharge atmosphere between the silicon wafer and the absorption surface, so as to reduce the deformation of the silicon wafer. In addition, by considering the processing manufacturability, the annular groove can be designed into a trapezoid to reduce the processing deformation. The silicon fixing component adopts silicon carbide precision ceramic as the material, the technics performance of the silicon fixing component is improved and the service life is prolonged.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD +1

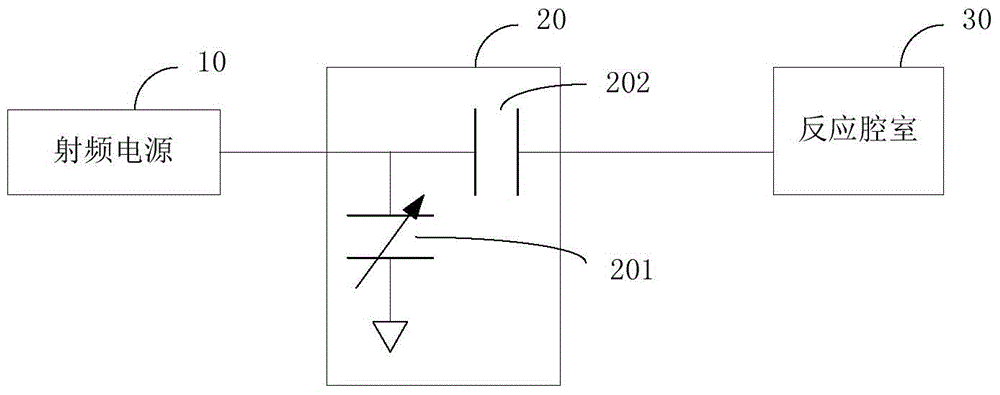

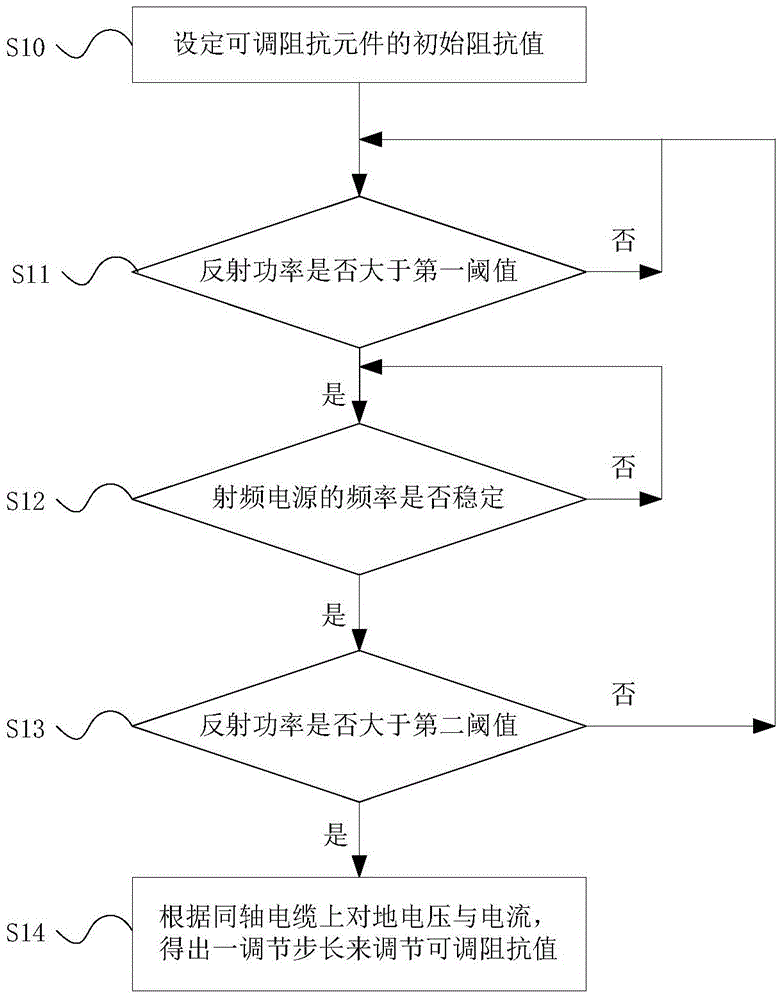

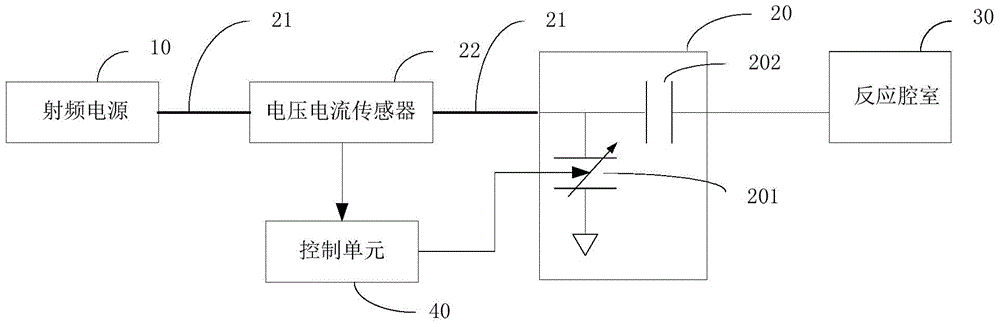

Automatic impedance matching method for plasma reaction chamber

ActiveCN104377106AAutomates the impedance matching processImprove craftsmanshipElectric discharge tubesPower flowCoaxial cable

The invention relates to an automatic impedance matching method for a plasma reaction chamber. The method comprises the following steps that (a) an initial impedance value of an adjustable-impedance element is set; (b) whether reflection power measured on a coaxial cable is larger than a first threshold value or not is judged; if yes, the step (c) is performed, and if not, the step (b) is performed circularly; (c) whether the frequency of an RF power source is stable or not is judged; if yes, the step (d) is performed, and if not, the step (c) is performed circularly; (d) whether the reflection power measured on the coaxial cable is larger than a second threshold valve or not is judged; if yes, the step (e) is performed, and if not, the step (b) continues to be performed; (e) the impedance value of the adjustable-impedance element is adjusted through an adjusting step length, wherein the phase difference alpha between the adjusting step length and to-earth voltage and current and / or the value of V / Icosinealpha-50 are both positive or negative, and the second threshold value is larger than the first threshold value. The accurate impedance adjusting step length is provided for the adjustable-impedance element in the impedance matching circuit, and matching efficiency is improved.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

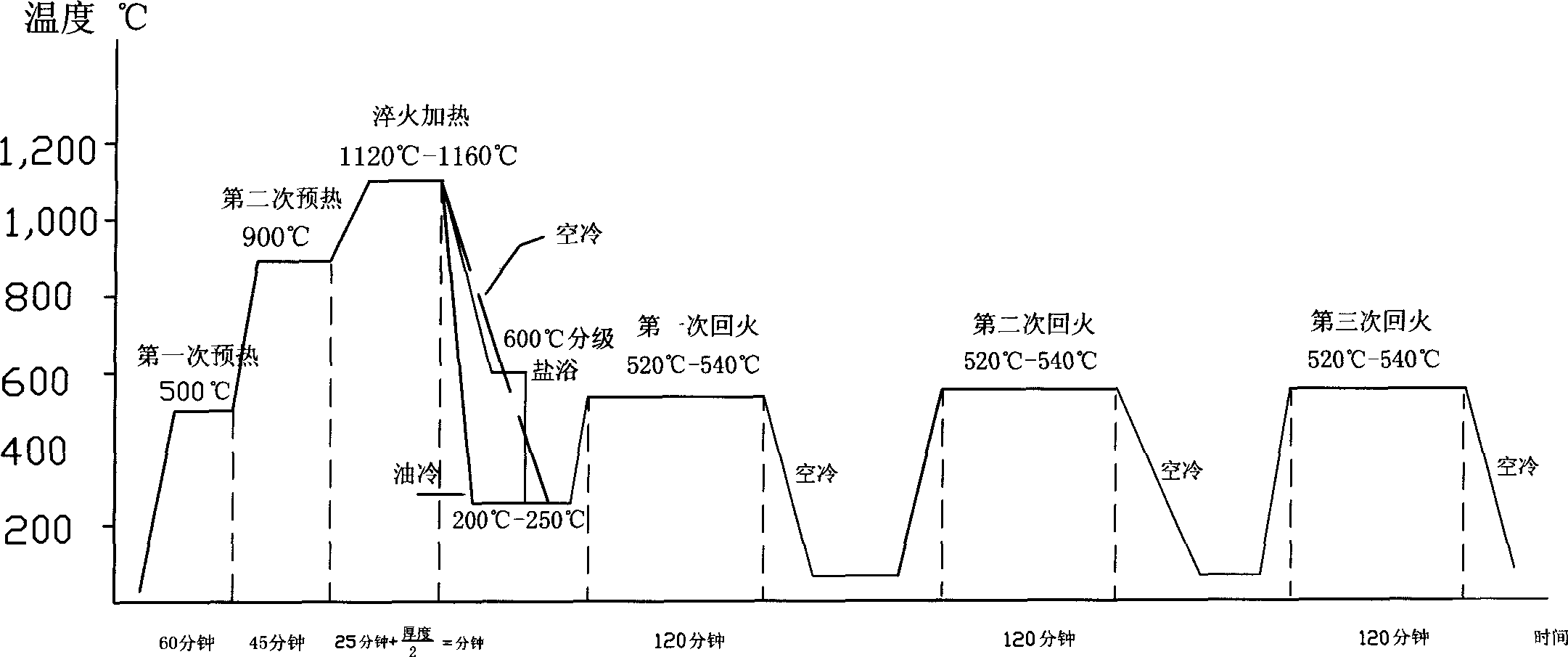

Novel chrome steel high speed steel and heat treatment process thereof

InactiveCN1827825AImprove toughnessImprove wear resistanceHeat treatment process controlQuenching agentsThermal treatmentHigh-speed steel

The invention relates to a novel high-speed alloys steel, in particular a novel chromium series high speed steel and its heat treatment process. The steel comprises the components (by weight percent) of C 0.85%-1.05%, Si 0.2-0.4%, Mn 0.2-0.4%, Cr 9.0-11.0%, W 4.5-6.5%, Mo 0.6-2.0%, V 0.6-2.0%, Ni 0.1-0.3%, Co 0.3-5.0%, Nb 0.8%-1.8%, S <=0.015%, P<=0.02%, and balancing Fe. The high speed steel has enough tenacity and abrasion-resistance, its thermal treatment process is also disclosed.

Owner:周向儒

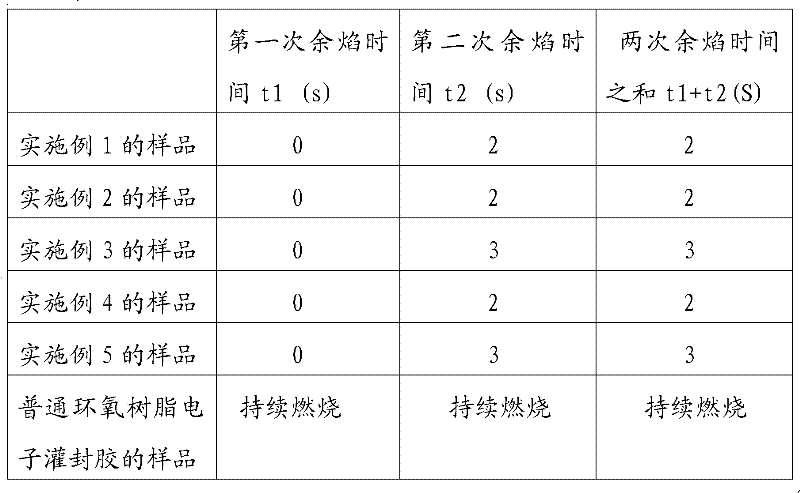

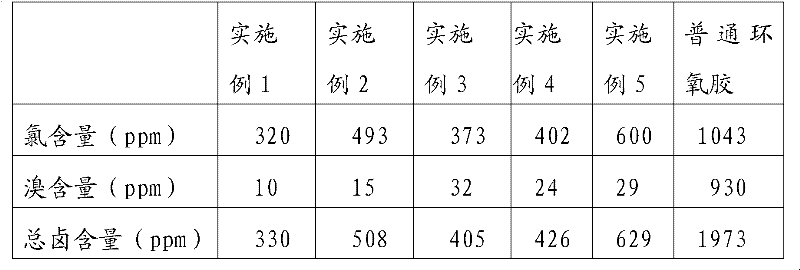

Halogen-free flame-retardant epoxy resin electronic pouring sealant

InactiveCN102516914ASatisfy Halogen Free RequirementsImprove flame retardant performanceNon-macromolecular adhesive additivesOther chemical processesEpoxyHalogen

The invention relates to a halogen-free flame-retardant epoxy resin electronic pouring sealant which is formed by mixing an A component and an amine curing agent according to the weight ratio of 100:4-13, wherein the A component comprises the following raw materials in parts by weight: 30-40 parts of halogen-free epoxy resin, 40-65 parts of flame-retardant fillers, 2-7 parts of halogen-free active diluting agents, 2-7 parts of halogen-free liquid flame retardants, 1-5 parts of toughening agents, 0.1-0.5 part of coupling agent and 0.1-0.5 part of pigment. The invention has the beneficial effects that the pouring sealant is free from halogen and satisfies the halogen-free requirements; the flame retardance is independent of a halogen-added flame retardant, so that the environment friendliness is achieved; the fame retardant ability is strong and can achieve the grade UL94-V0; and with the adoption of a double-component system, not only can the room-temperature curing be achieved, but also the thermal curing can be achieved, so that the operation is covneneint.

Owner:YANTAI DARBOND TECH

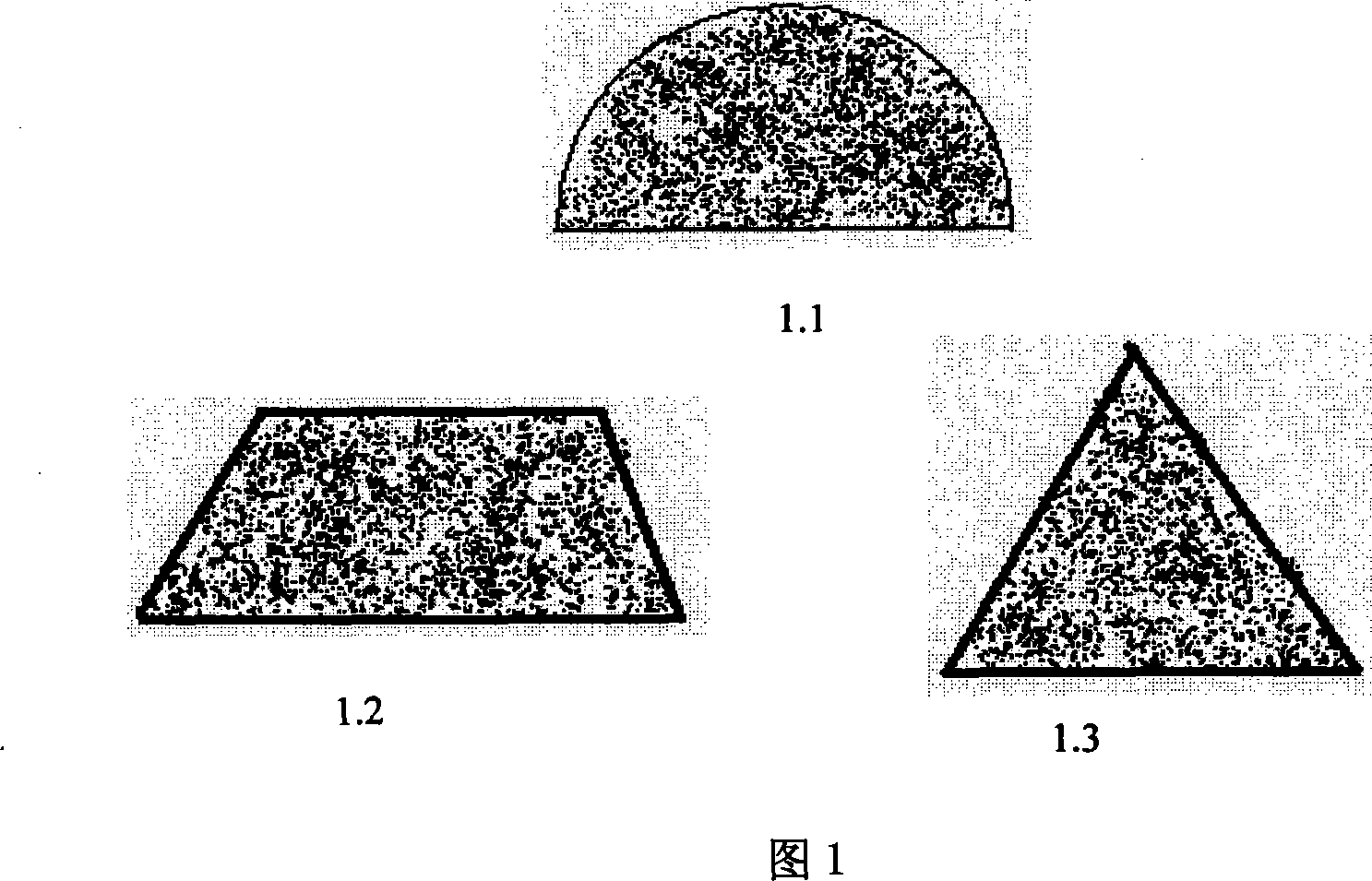

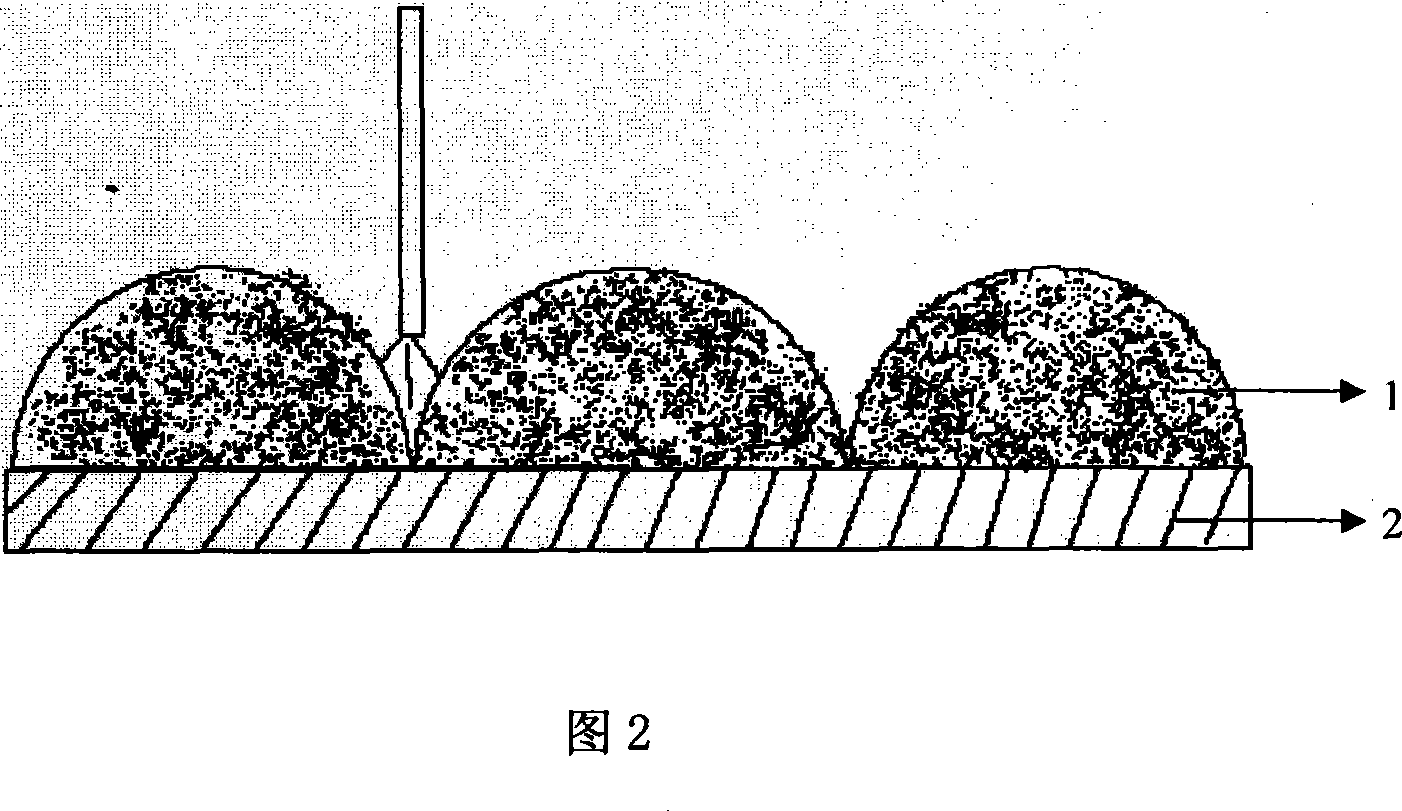

Alloy powder block used for built-up welding

InactiveCN101053931ASpeed up meltingSolve the problem that it is difficult to melt and easy to be blown away by the plasma flow force of the arcArc welding apparatusHigh frequency current welding apparatusPlasma jetAdhesive

The present invention discloses the alloy pulverescent used for builtup weld. The present invention is characterized in that the alloy pulverescent is produced by metal, iron alloy powder, adhesive and plasticizer, wherein the weight ratio of component is that metal and iron alloy powder : adhesive : plasticizer = 100 : 5~15 : 0~8; the alloy pulverescent is discretionary geometrical body, wherein the size, length and surface shape of the alloy pulverescent can be discretionarily determined according to the requirement of the surface which is to be builtup welded, and the splicing margina thickness of the alloy pulverescent is 0~0.1mm when the alloy pulverescent is arranged on the surface which is to be builtup welded. In the present invention, by designing the cross section geometry of the alloy pulverescent, the electric arc can more easily pass through the alloy pulverescent which is difficult to be melted so as to melt the base metal, and the melting of the base metal accelerates the melting of the alloy pulverescent, thereby the problem of that the alloy pulverescent is difficult to be melted and is easy to be blown about by the plasma jet of the electric arc can be solved, and the production efficiency is greatly improved.

Owner:SHANDONG UNIV

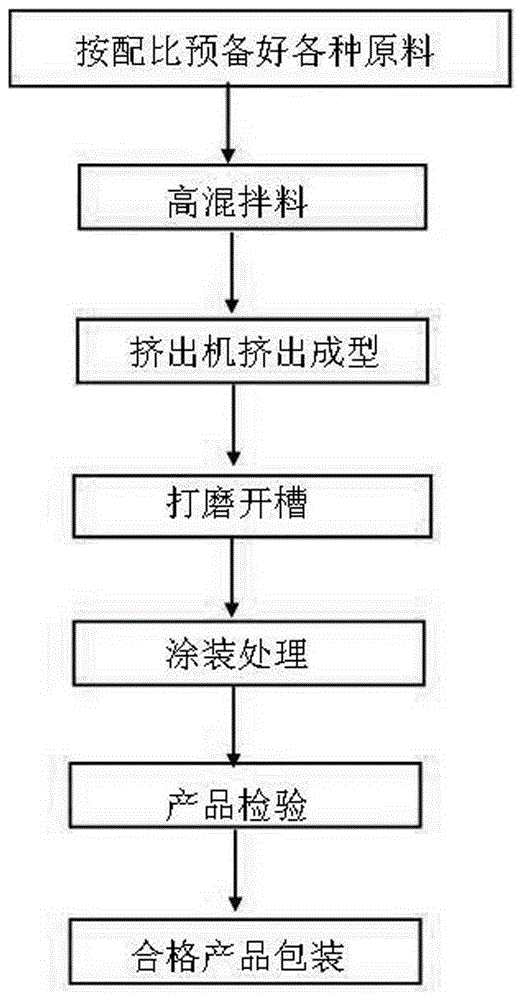

Stone-wood floor and production technology and laying method thereof

The invention belongs to the technical field of indoor and outdoor building decorative materials and production technologies thereof, and provides a stone-wood floor and a production technology and laying method thereof. The stone-wood floor is prepared from, by weight, 90-100 parts of ground limestone, 30-35 parts of PVC, 0.3-0.6 part of stearic acid, 2-2.5 parts of chlorinated polyethylene, 0.5-1.0 part of a foaming agent, 6-7 parts of a foaming control agent and 2-3 parts of a stabilizer. The raw materials are highly mixed and stirred, extruded, molded, ground, slotted and coated to obtain a finished product. The processing procedures are simplified, the cost is lowered, the product quality is improved, the hardness, abrasion resistance and flexibility of the produced product are improved, PVC is foamed to generate pores through the foaming technology, and the pores are filled with microstructures such as the ground limestone, so that the product density reaches 1.2 g / cm<3> which is close to that of a pure wood floor, and the cheap and fine stone-wood floor can be truly obtained.

Owner:南召县磊鑫钙业新型材料科技有限公司

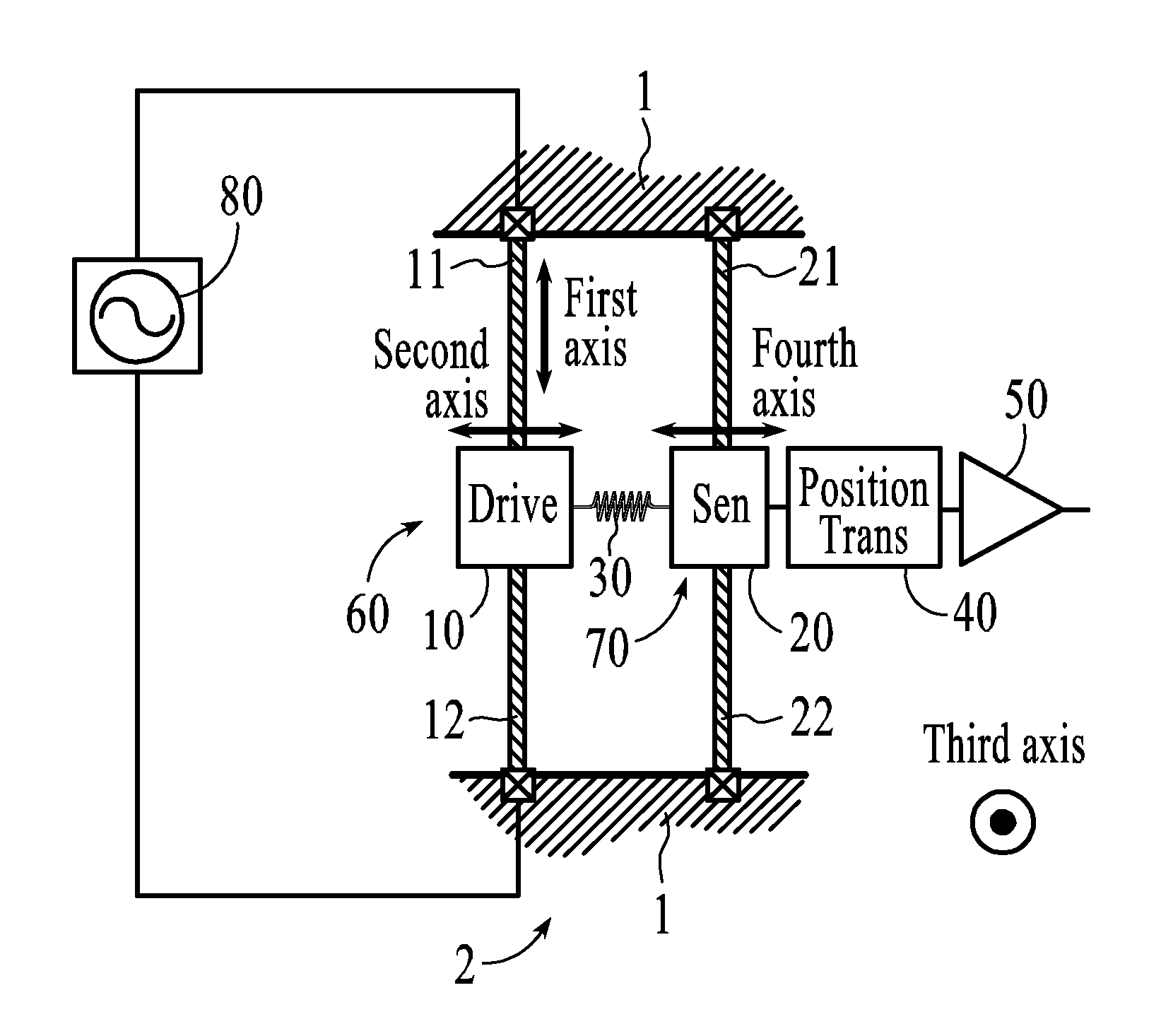

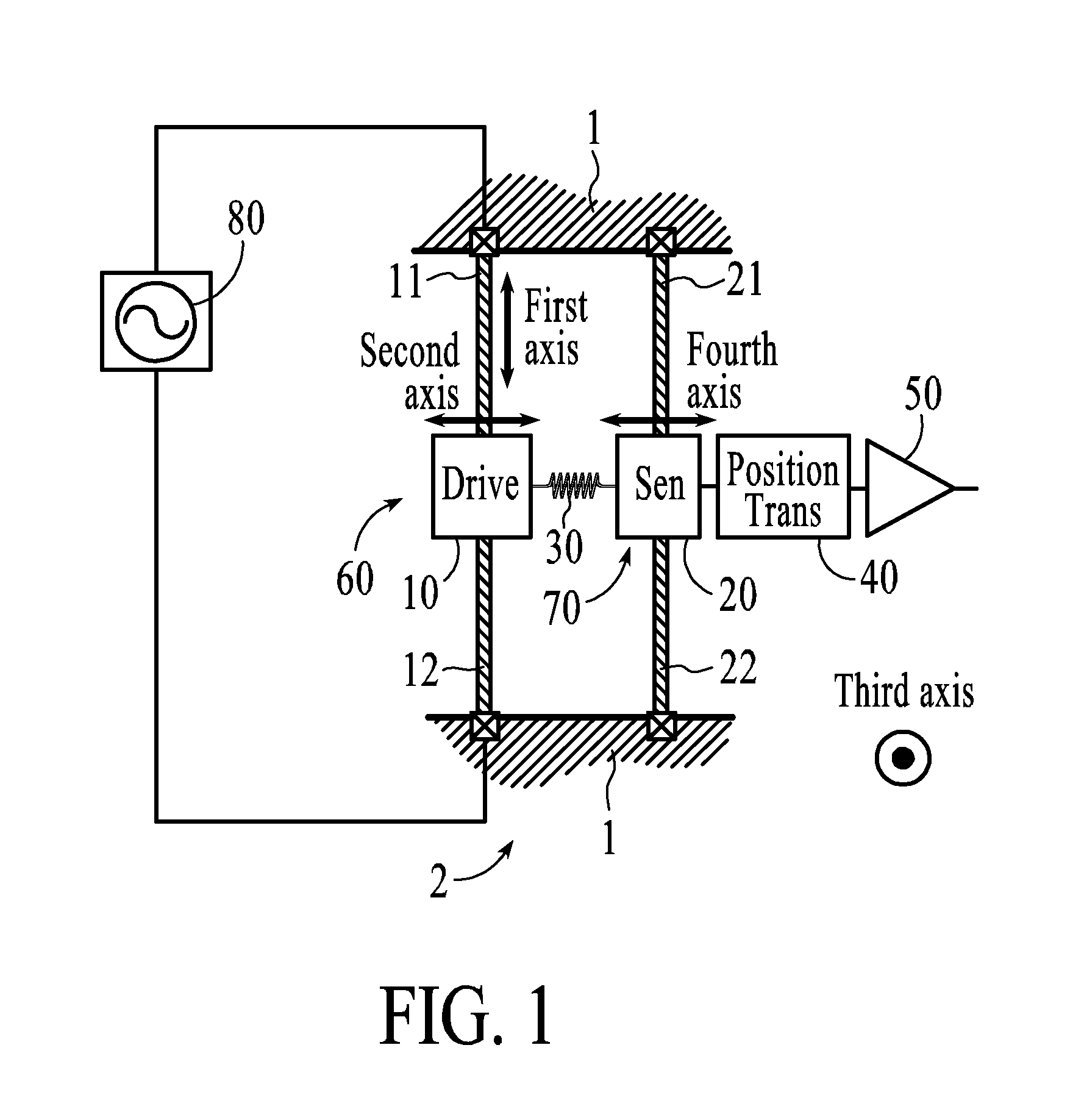

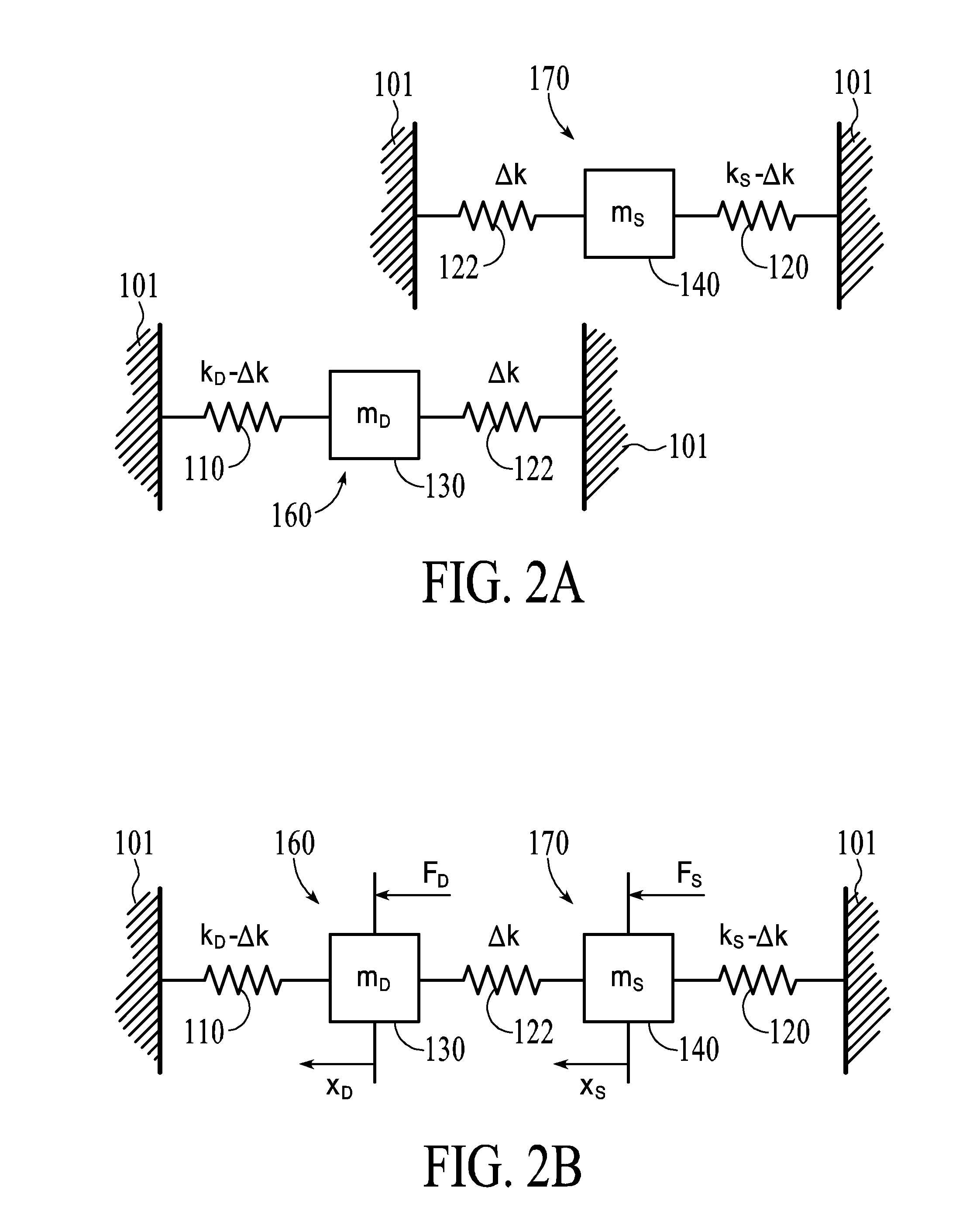

Micromachined resonant magnetic field sensors

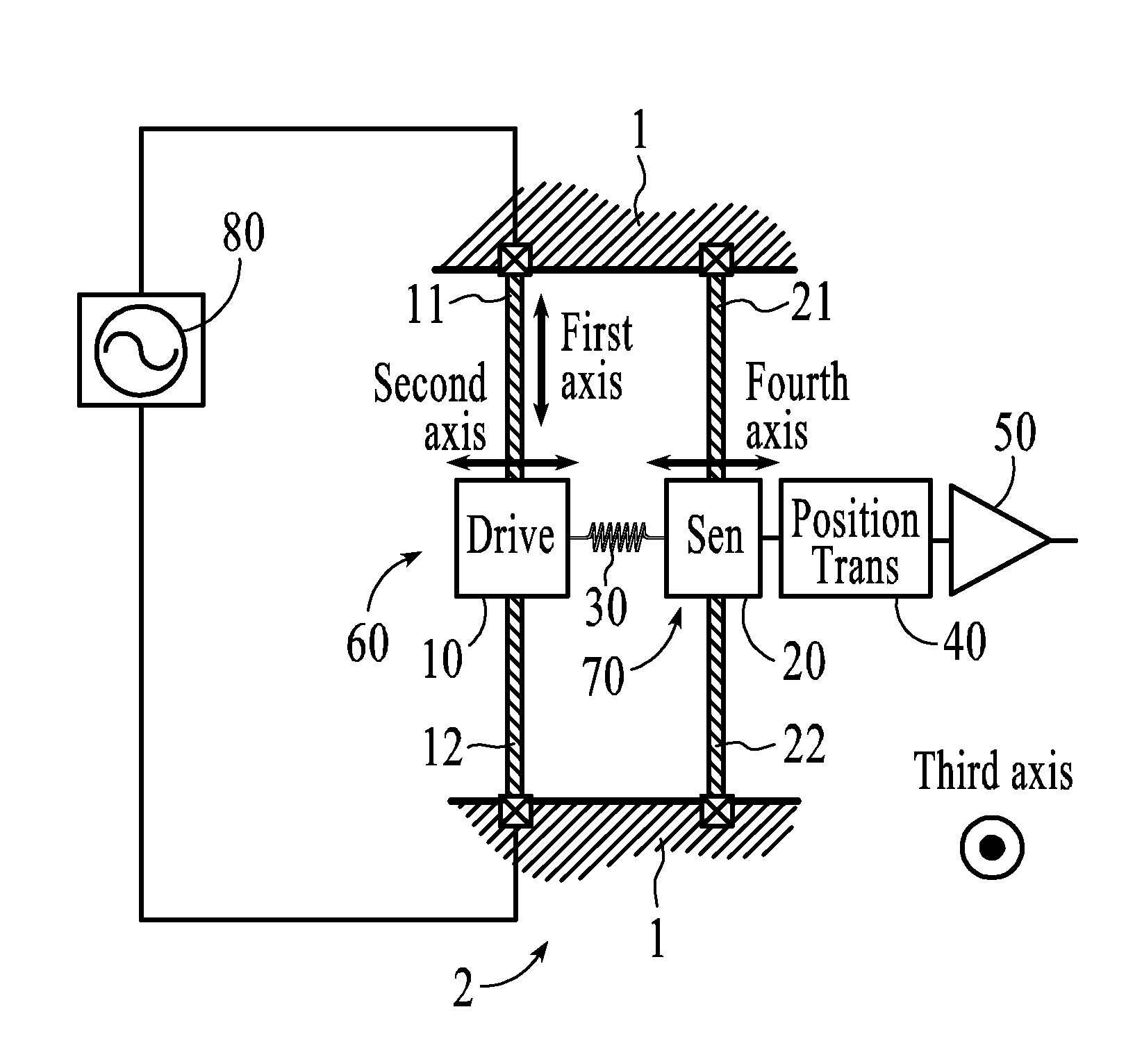

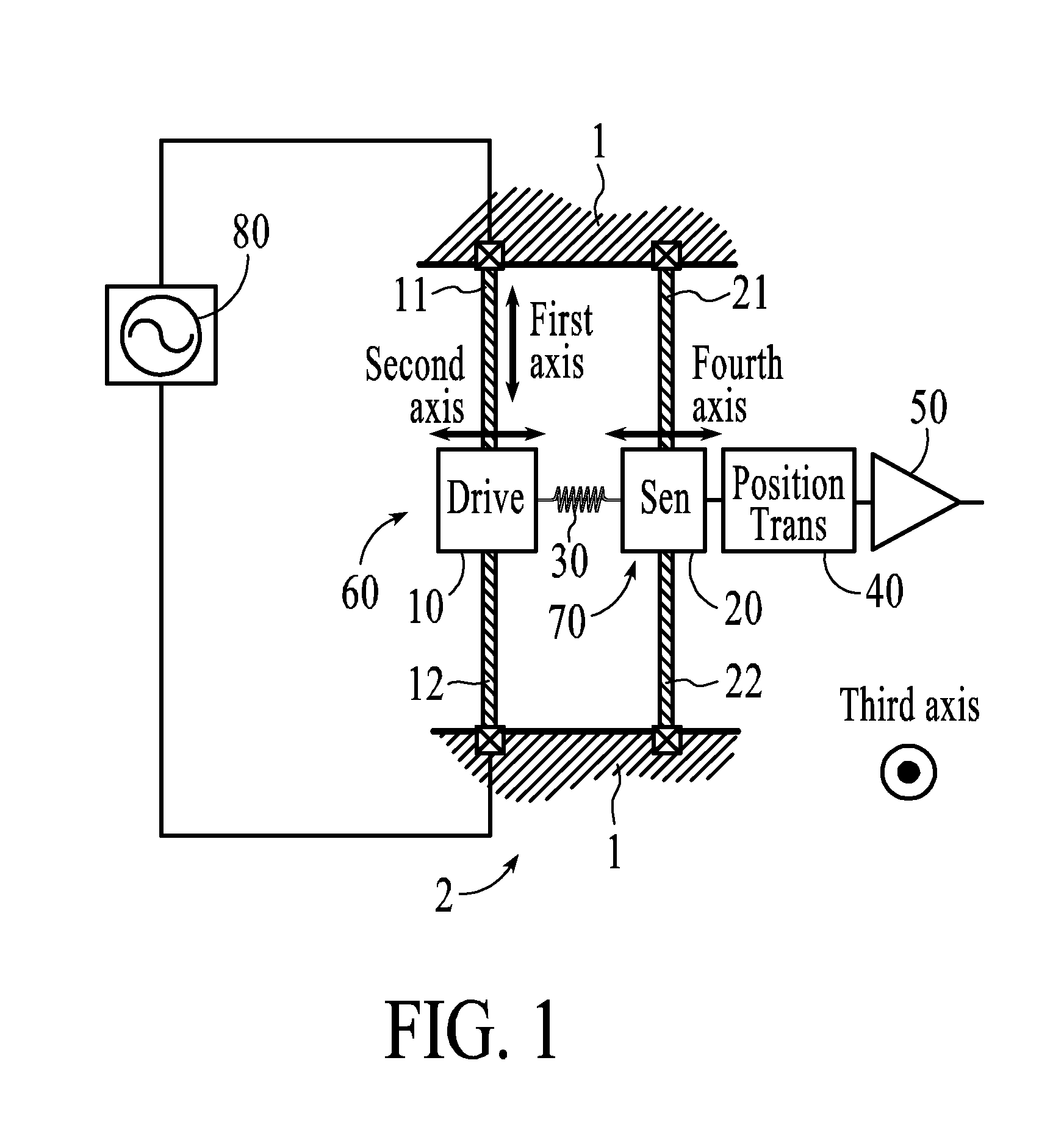

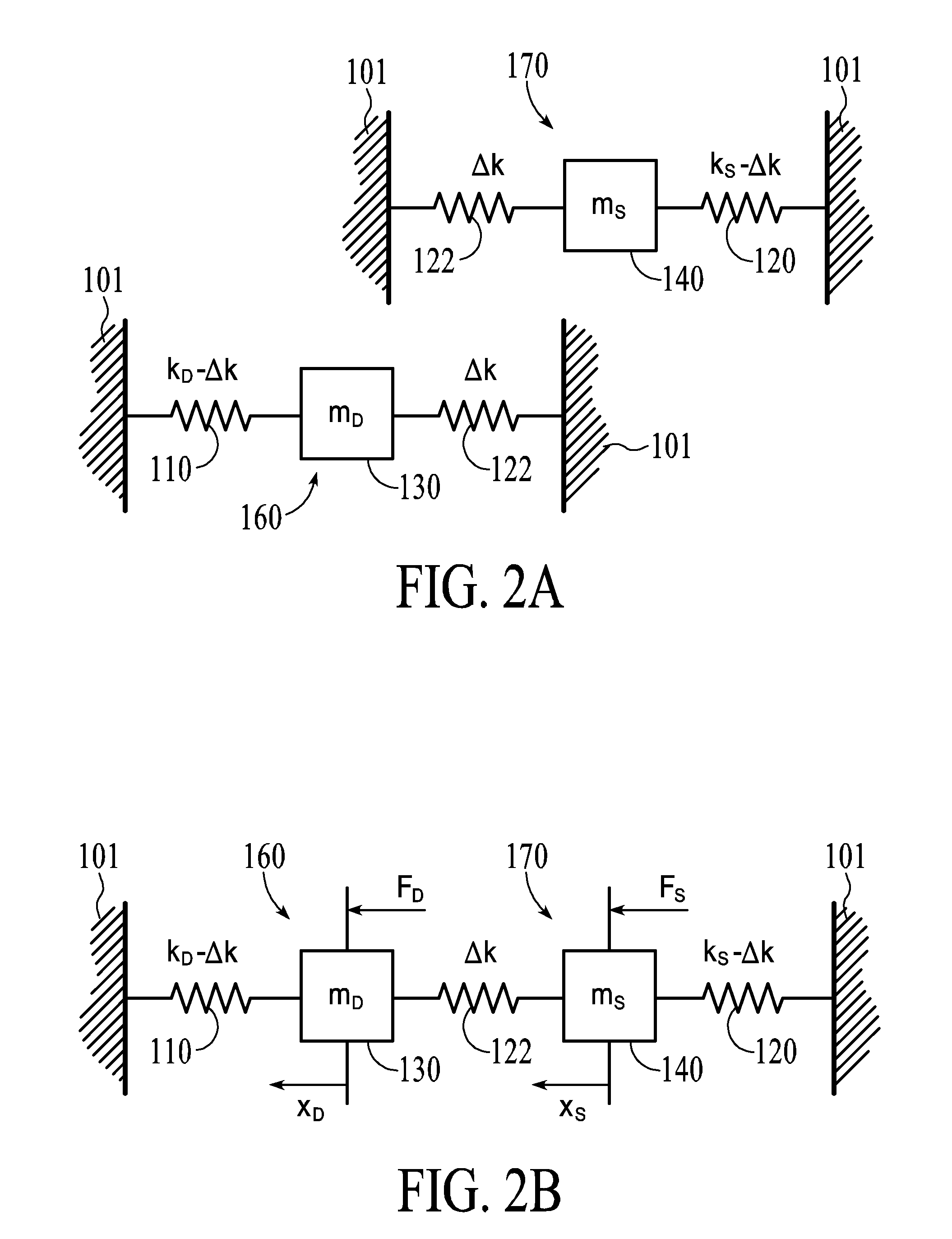

ActiveUS20120176128A1High sensitivityLow costMagnetic field measurement using permanent magnetsElectrodynamic magnetometersPower flowCoupling

A micromachined magnetic field sensor comprising is disclosed. The micromachined magnetic field comprises a substrate; a drive subsystem, the drive subsystem comprises a plurality of beams, and at least one anchor connected to the substrate; a mechanism for providing an electrical current through the drive subsystem along a first axis; and Lorentz force acting on the drive subsystem along a second axis in response to a magnetic field along a third axis. The micromachined magnetic field sensor also includes a sense subsystem, the sense subsystem comprises a plurality of beams, and at least one anchor connected to the substrate; wherein a portion of the sense subsystem moves along a fourth axis; a coupling spring between the drive subsystem and the sense subsystem which causes motion of the sense subsystem in response to the magnetic field; and a position transducer to detect the motion of the sense subsystem.

Owner:INVENSENSE

Laser synthesis preparation method of intermetallic compound and granule reinforced composite material

InactiveCN1546694AThe ingredients are designed to be simpleReduce manufacturing costHigh power lasersChemical compound

The invention relates to a laser synthesis preparation method of intermetallic compound and granule reinforced composite material which includes, using the powder stock containing the same elements with the intermetallic compound to be prepared, adding additionally elements during the process of sedimentation and mixing, forming local molten pool on the base material surface through high power laser irradiation, feeding the mixed powder into molten pool, stacking up to obtain large area coating, block material or formed parts, adjusting powder components or laser technique to obtain intermetallic compound or particle reinforcement intermetallic composite material with dissimilar compositions, structure and property.

Owner:TSINGHUA UNIV

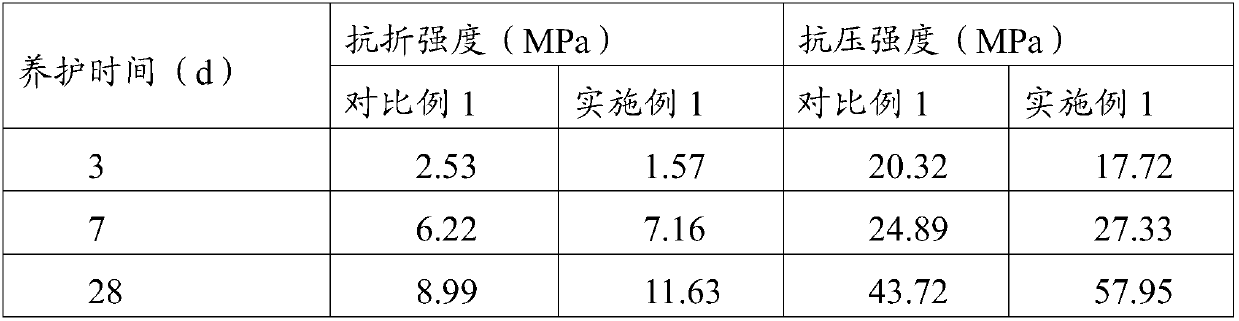

Method for comprehensively utilizing fine coal gasification slag

ActiveCN107857496AHigh activityImprove adsorption capacityOther chemical processesSolid waste managementCycloneSlag

The invention discloses a method for preparing an adsorption material from fine coal gasification slag. The method comprises the following steps: 1, taking a proper amount of the fine coal gasification slag, and adding water to prepare a fine coal gasification slag slurry with the solid content being 10-30 wt%; 2, fully stirring the slurry prepared in step 1, performing gravity cyclone separation,collecting the obtained heavy separation product to obtain a silicon-rich composite slurry, and collecting the obtained light separation product to obtain a carbon-rich composite slurry; and 3, carrying out solid-liquid separation and drying on the carbon-rich composite slurry to obtain the carbon-rich adsorption material, and further preparing other products from the remaining silicon-rich composite slurry. The method realizes the high-added value recycling of the fine coal gasification slag.

Owner:鄂尔多斯市慧恒科技有限责任公司

Instant balls and preparation method thereof

The invention relates to instant balls and a preparation method thereof. According to the formula, the install balls comprise the following raw materials by weight: 30 to 45 percent of minced fillet, 5.25 to 9 percent of chicken, 11 to 22.25 percent of fat pork, 6.25 to 10 percent of pork ham, 6 to 11.25 percent of potato starch, 8.25 to 17 percent of water, 1.35 to 1.90 percent of salt, 1.45 to 2.15 percent of sugar, 0.11 to 0.19 percent of polyphosphate, 0.31 to 0.44 percent of monosodium glutamate, 0.23 to 0.60 percent of seasoning fish meal, 1.5 to 2.5 percent of scallion, 0.75 to 2 percent of soy sauce, 0.08 to 0.18 percent of sesame oil, 0.08 to 0.20 percent of pork cream, 0.08 to 0.2 percent of meat fine powder, 0.25 to 0.75 percent of yellow wine and 1.25 to 5 percent of pigskin jelly. The skin of the instant balls has elasticity, white luster and crisp mouthfeel; and the stuffing has much soup, is oily but not greasy, and has pure taste.

Owner:PENGLAI JINGLU FISHERY

High-silicon aluminum alloy cylinder sleeve material and fabrication method thereof

ActiveCN103045920ASolve the disadvantages of unfavorable wear resistanceEasy to useLubricationMechanical property

The invention relates to a high-silicon aluminum alloy cylinder sleeve material, which is characterized by comprising the following components by weight percent: 18.0-26.0 percent of Si, 2.0-5.0 percent of Fe, 3.0-7.0 percent of Ni, 1.8-3.0 percent of Cu, 0.5-0.8 percent of Mg, 0.5-0.8 percent of Mn, 0.1-0.3 percent of V and the balance of Al, wherein the amount of Fe and Ni is larger than or equal to 7 percent and less than or equal to 10 percent, and the amount of Fe, Ni and Si is larger than or equal to 27 percent and less than or equal to 33 percent. The high-silicon aluminum alloy cylinder sleeve material and products, which are prepared by the invention, are high in technological property, mechanical property and tribological property; such functions of a hard-spot phase of the cylinder sleeve working face, as bearing, abrasion resistance, oil storage in peripheral concave pits, cooling and lubrication, are prominent to the utmost; and size of particles in the cylinder sleeve and working face tribological shape size are effectively controlled, so that the use effect is better.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Prepn of solid catalyst for olefin polymerization

The present invention discloses preparation of solid catalyst for olefin polymerization. The preparation process has lowered contact temperature between the component A of dialkoxy magnesium compound and the component B titanium compound, and high bulk density of the component A or raised dropped amount of the component B to raise the bulk density of the polymer. The catalyst prepared through the improved process has high activity, high isotactic degree and high hydrogenation regulating performance as well as capacity of raising the bulk density of the polymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

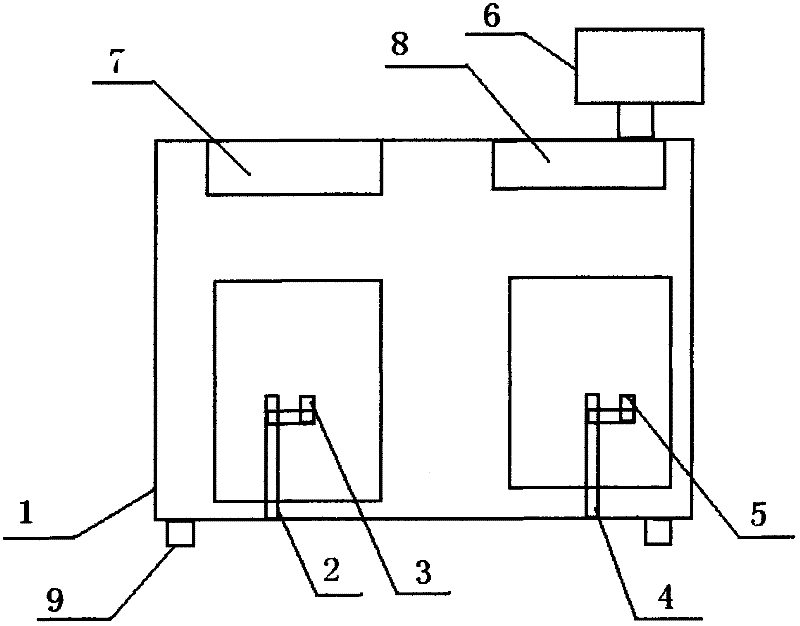

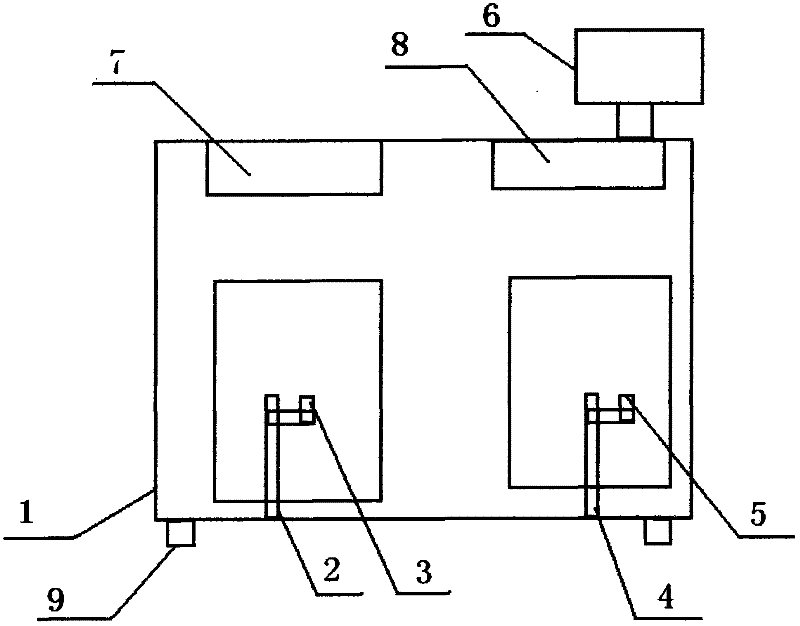

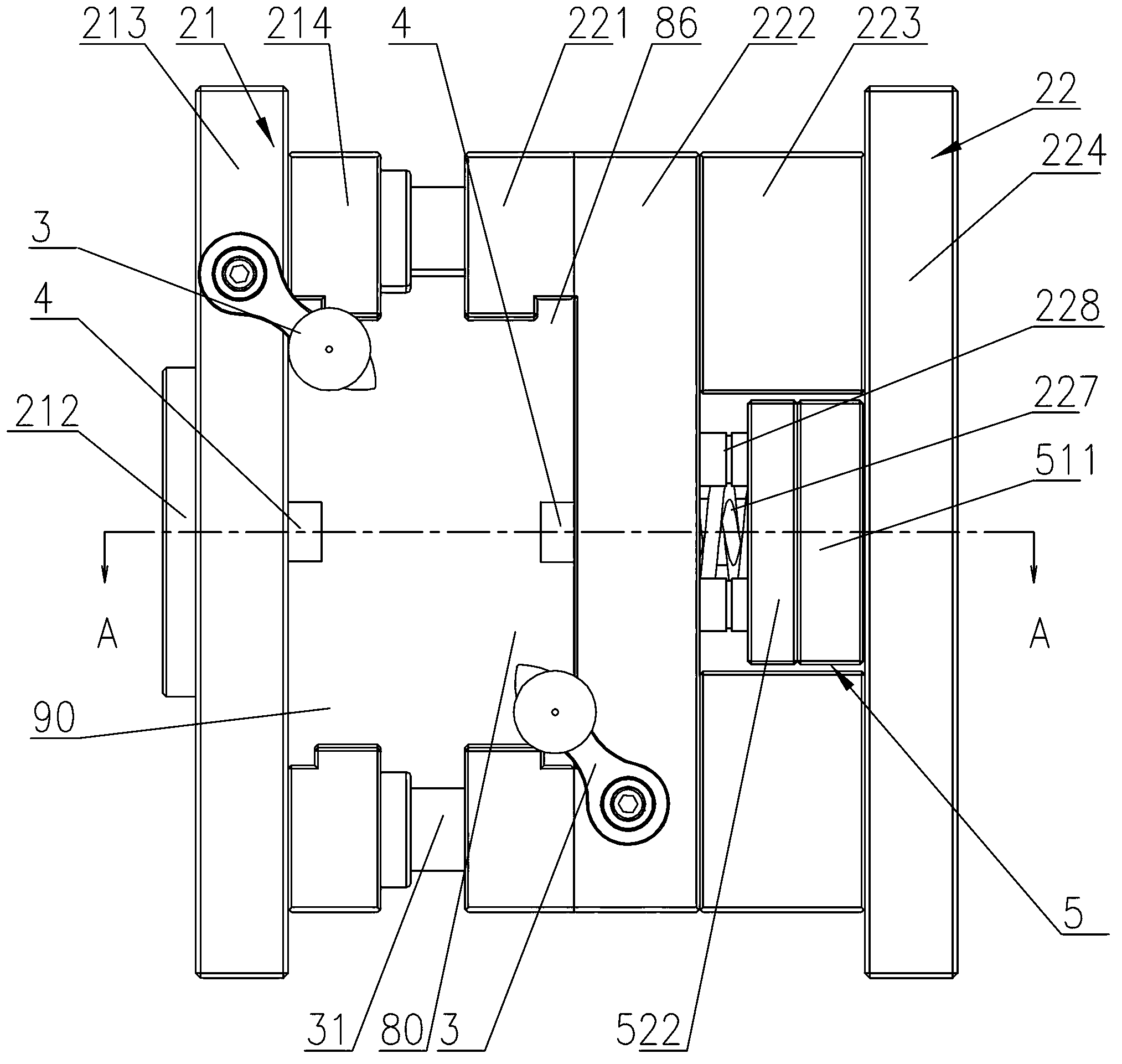

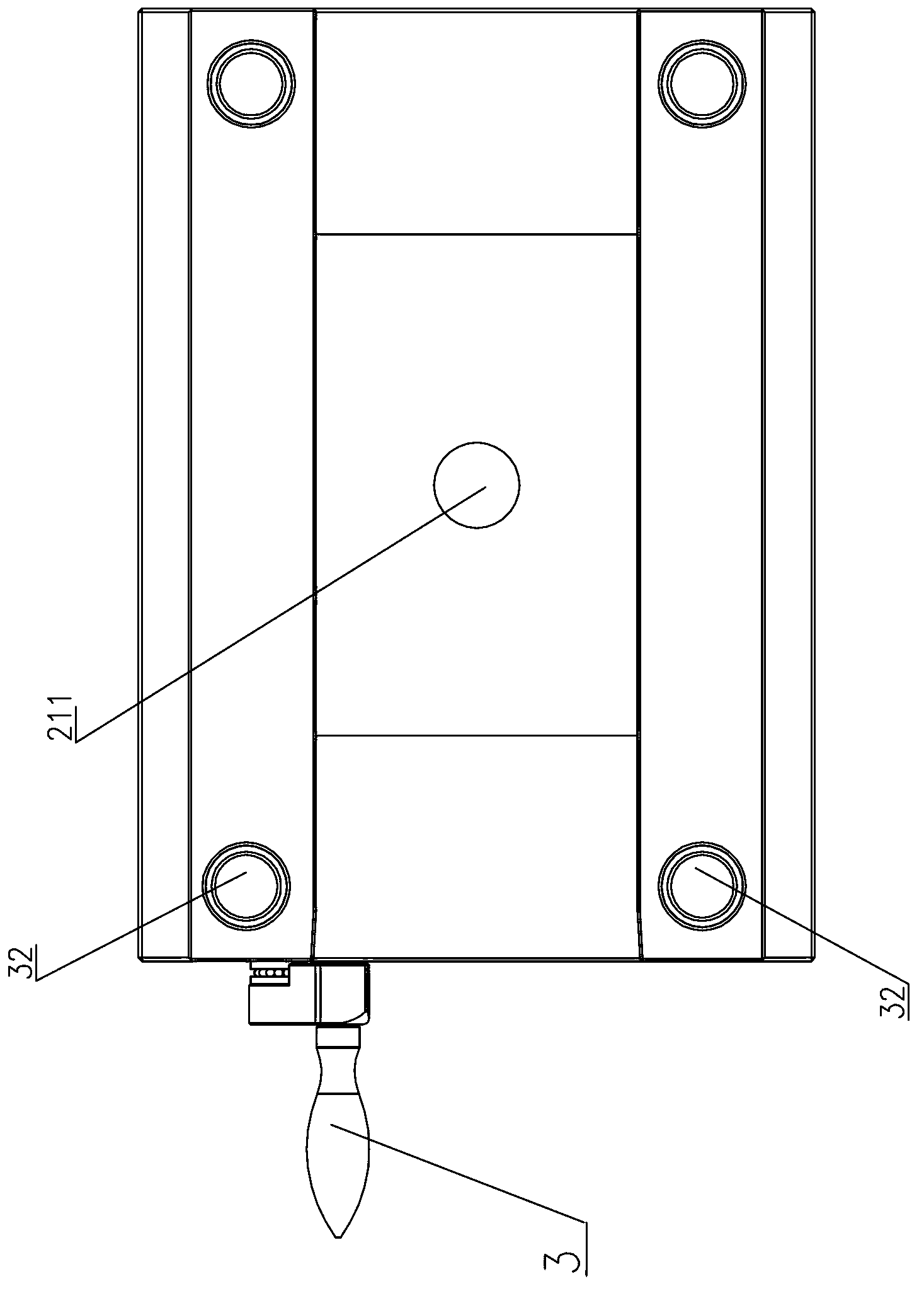

A LED display module detection device and detection method thereof

InactiveCN102288543AComprehensive monitoringImprove craftsmanshipMaterial analysis by optical meansTesting optical propertiesLED displayComputer engineering

The invention discloses an LED display module detection device and a detection method thereof. An LED display module detection device comprises a detection device body, a first lifting platform and a second lifting platform arranged on a base inside the detection device body , the first camera device is set on the first lifting platform, the second camera device is set on the second lifting platform, and an output detection display unit is placed on the operating table of the detection device body directly above the first camera device. A platform for placing a display unit to be tested is set on the operating table of the detection device body directly above the second camera device, and a display platform and a display unit detection system are also set on the detection device body.

Owner:深圳中科光华科技有限公司

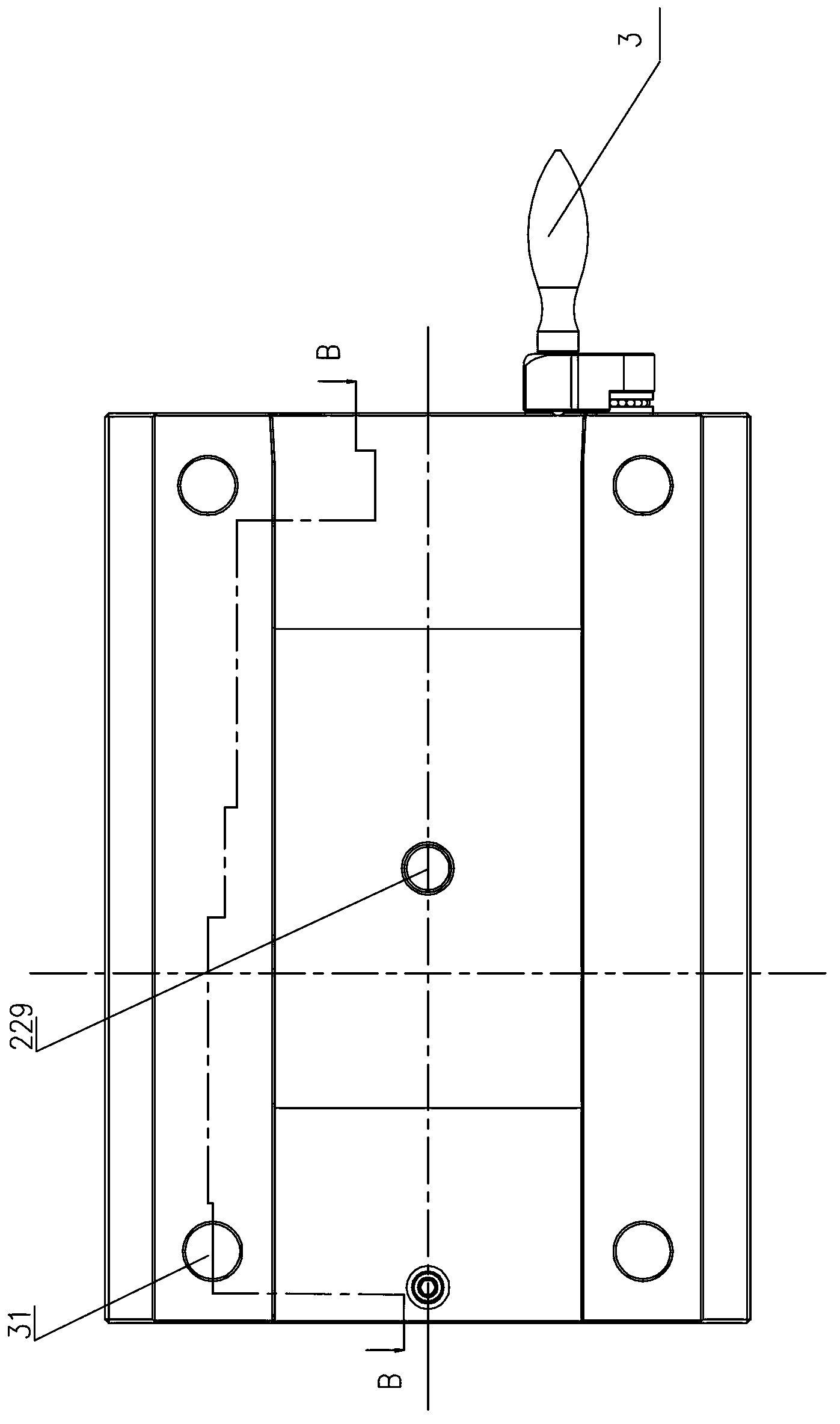

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

Micromachined resonant magnetic field sensors

ActiveUS20120176129A1High sensitivityLow costMagnetic field measurement using permanent magnetsPower flowOffset cancellation

A micromachined magnetic field sensor is disclosed. The micromachined magnetic field sensor comprises a substrate; and a drive subsystem partially supported by the substrate with a plurality of beams, and at least one anchor; a mechanism for providing an electrical current through the drive subsystem along a first axis; and Lorentz force acting on the drive subsystem along a second axis in response to a magnetic field vector along a third axis. The micromachined magnetic field sensor also includes a position transducer to detect the motion of the drive subsystem and an electrostatic offset cancellation mechanism coupled to the drive subsystem.

Owner:INVENSENSE

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

High strength aluminum copper alloy vehicle wheel material and liquid forging forming method

ActiveCN103924139AImprove process performanceOvercome poor mobilityMetal-working apparatusRare-earth elementAluminium

The invention relates to a high strength aluminum copper alloy vehicle wheel material and a liquid forging forming method. The material comprises following components by weight percent: 4.5-5.5% of Cu, 0.3-0.5% of Mn, 0.15-0.35% of Ti, 0.05-0.3% of V, 0.05-0.2% of Zr, 0.005-0.06% of B, 0.01-0.3% of Cd, 0.01-0.2% of Nd, 0.01-0.1% of Er, and the balance of Al. The aluminum copper alloy vehicle wheel prepared by the liquid forging forming method has good comprehensive chemical property and high product percent of pass, has the tensile strength greater than 400MPa, the yield strength greater than 300MPa, and the elongation greater than 10%, thus meeting the technical requirement of heavy load automobiles; particularly, due to the addition of a small quantity of rare earth element Er in the alloy formula, the aluminum copper alloy material structure is further refined, and the comprehensive property of the product is obviously improved; in addition, due to the addition of rare earth element Nd and grain refined elements like Ti, Zr and B, hot crack of the aluminum copper alloy is effectively avoided in solidifying, and the percent of pass of the vehicle wheel prepared by the liquid forging forming method is sharply improved.

Owner:天津立中轻合金锻造有限公司

Space robot gripper mechanism

The invention discloses a space robot gripper mechanism, namely an end effector of a mechanical arm, which solves the problems of small gripping range, non-unique locking position, high probability of losing a target during griping and the like existing in the conventional gripper mechanism, greatly simplifies the entire mechanism and also improves the manufacturability. In the mechanism, a palm surface 1, an upper bearing seat 3, a lower bearing seat 4 and a box bottom 7 form a basic frame of the entire mechanism; two finger shafts 9 are arranged in bearing holes between the palm surface 1 and the upper bearing seat 3; two fingers 2 and 5 are fixedly connected with the finger shafts 9; the shaft ends of the two finger shafts are provided with gears 19; a motor 11 and a brake shaft 22 are arranged in through holes between the upper bearing seat 3 and the lower bearing seat 4; the shaft ends of the brake shaft 22 and the motor 11 are provided with gears 21; the gripper box bottom 7 is connected with the bearing seats and an external mechanism through flanges; and a box wall 6 is interconnected with the palm surface 1 and the box bottom 7 to package the entire gripper mechanism. The mechanism has the advantages of compact design, small volume, easiness of machining, convenience in assembly and disassembly and the like.

Owner:BEIJING UNIV OF POSTS & TELECOMM

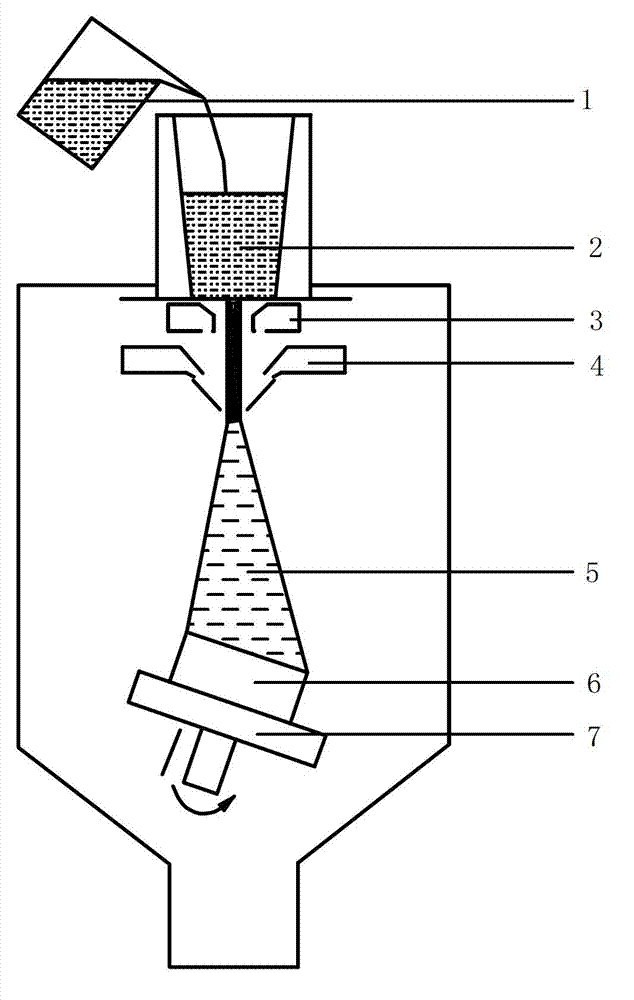

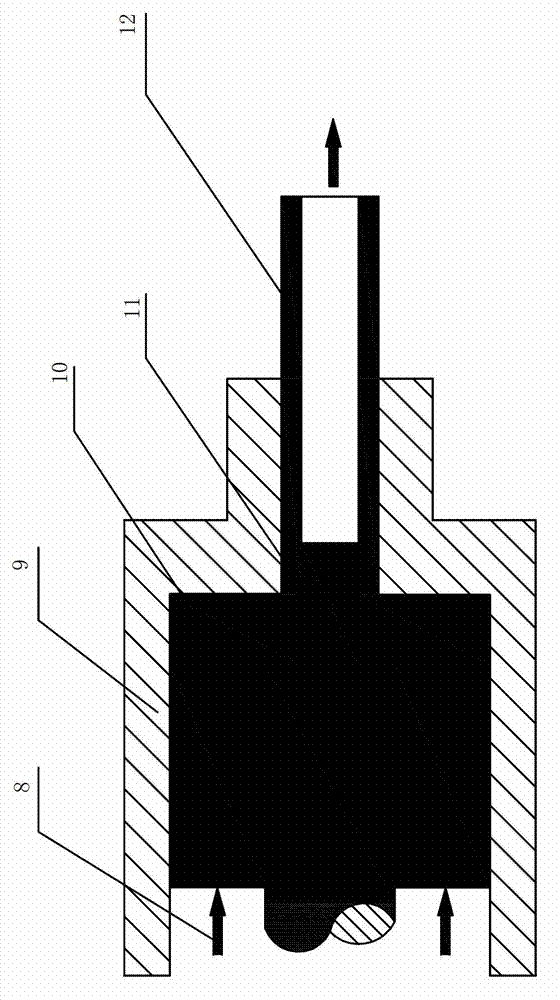

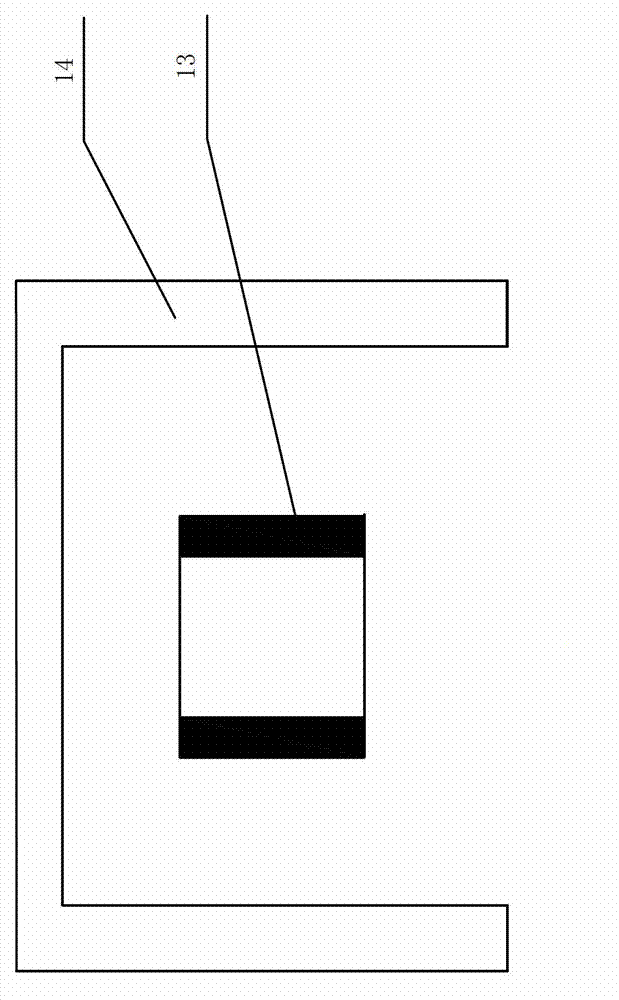

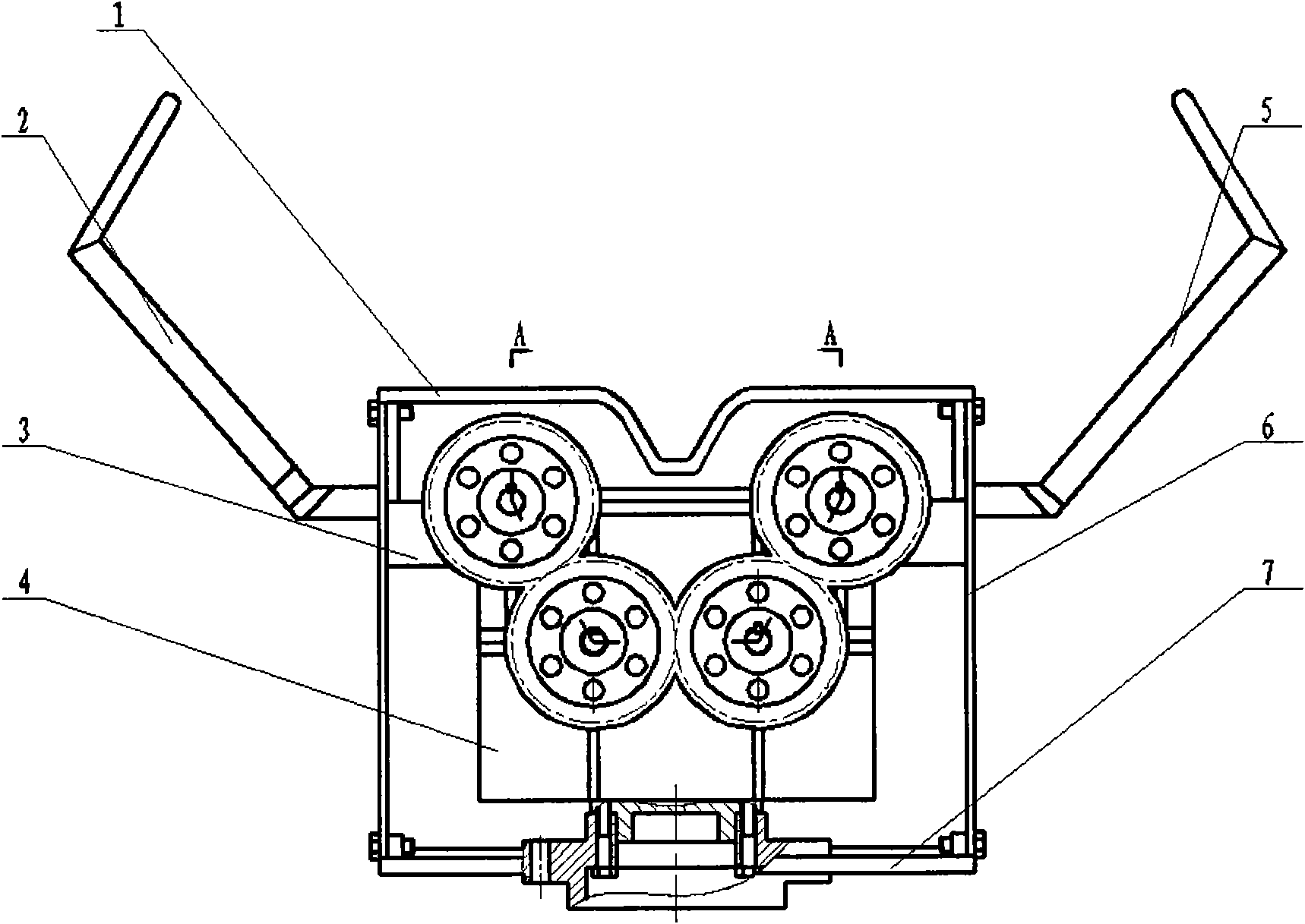

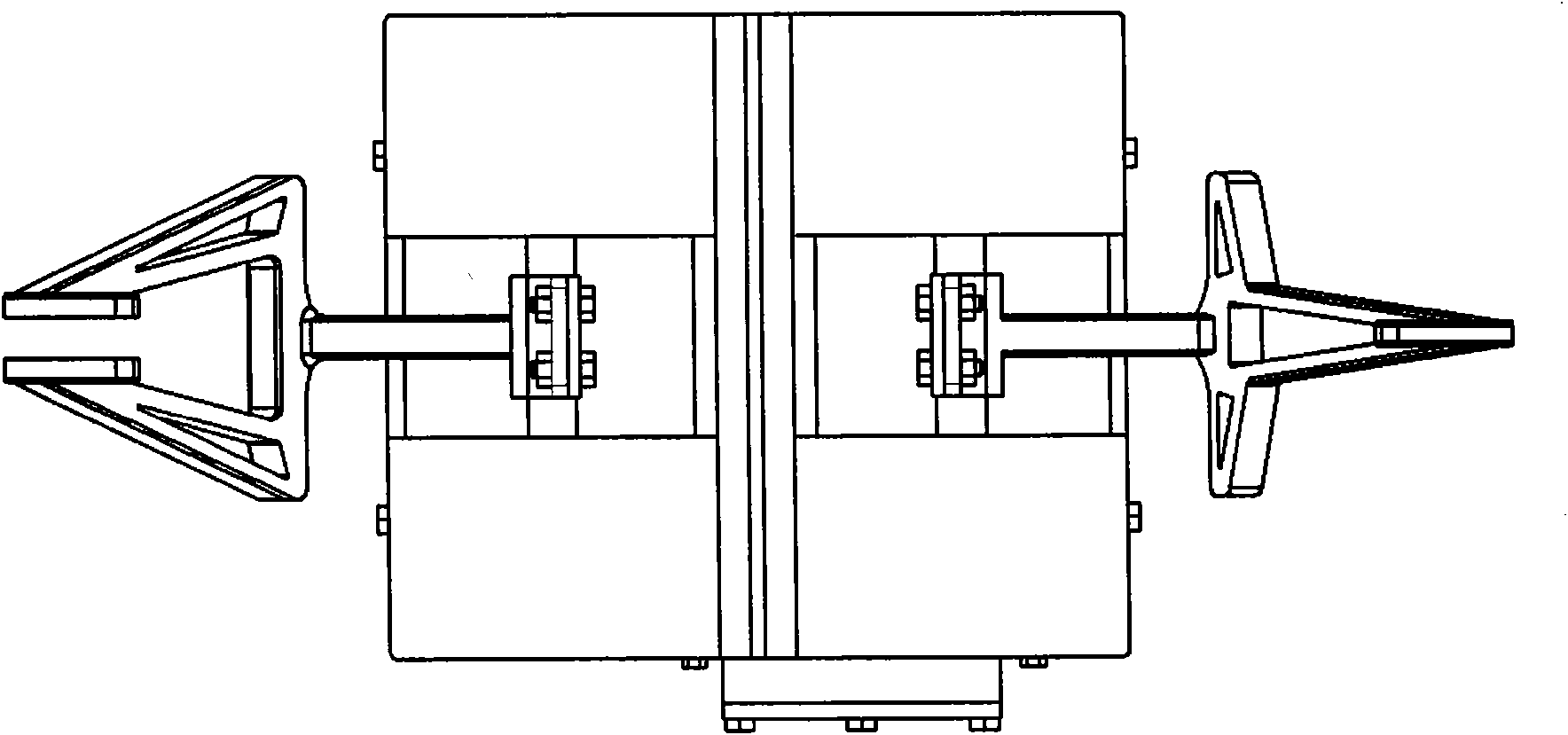

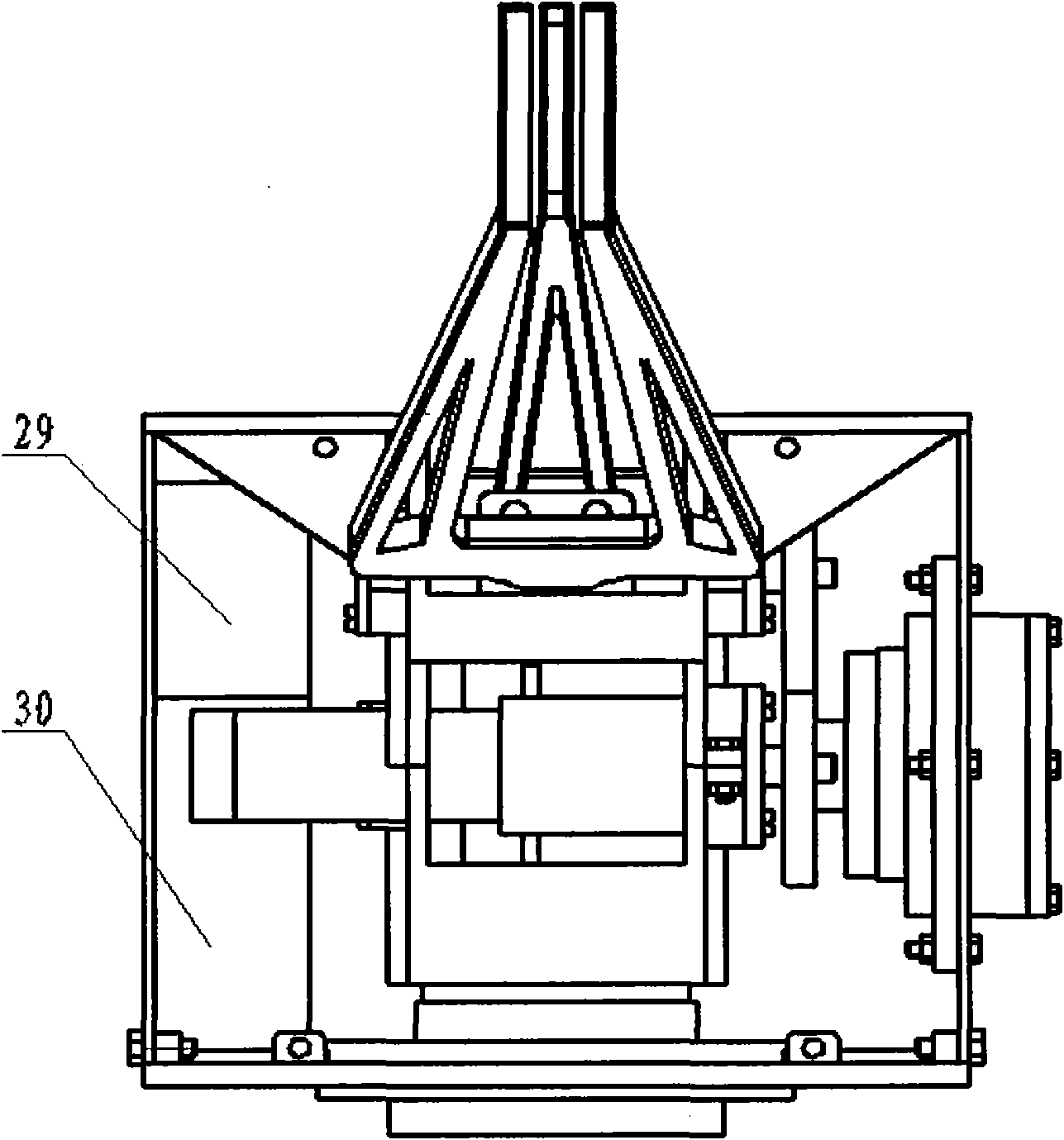

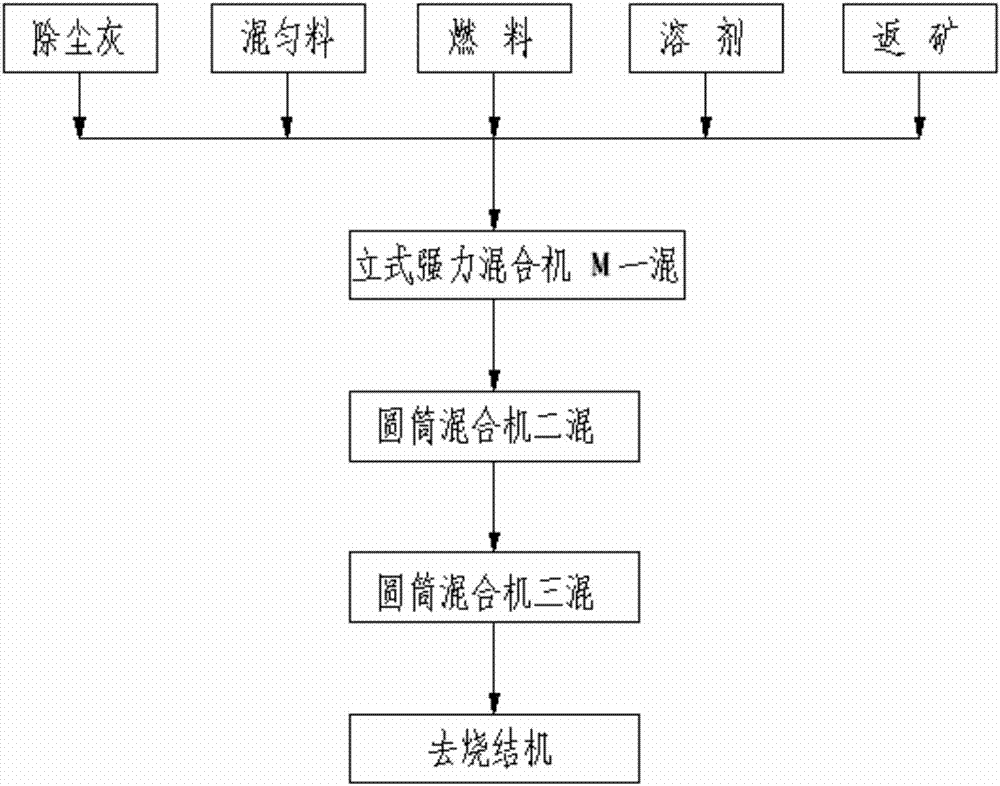

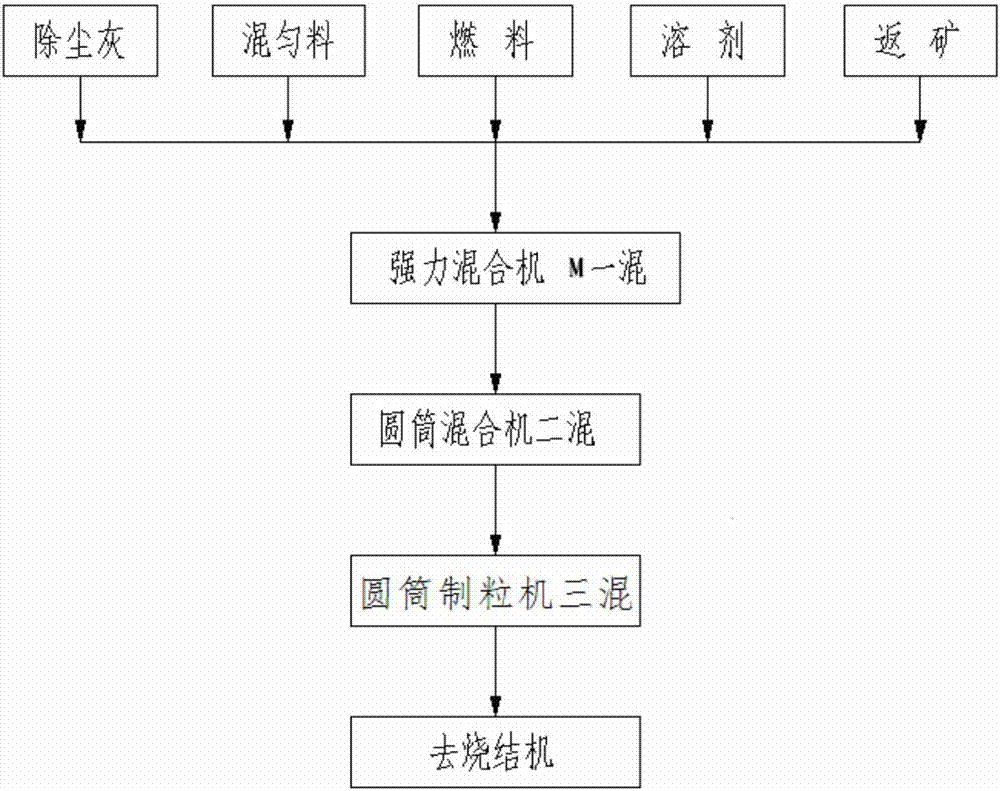

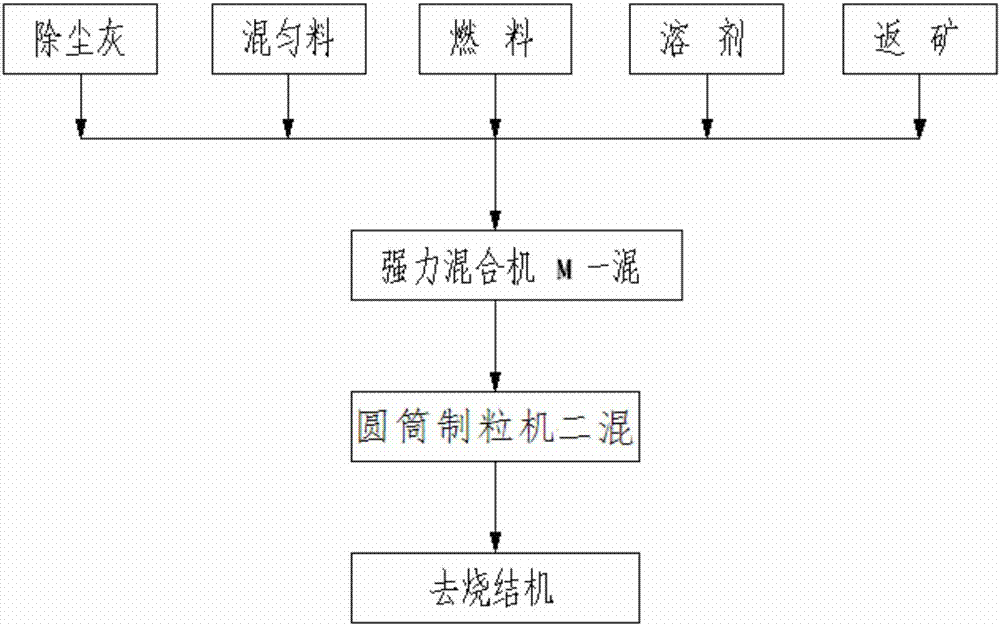

Strong mixing technology for sintering production and device thereof

ActiveCN107304461AIncrease profitSmall footprintTransportation and packagingMixersMixed materialsSolvent

The invention provides a mixing method for sintering production. The mixing method comprises the following steps that 1, iron ore powder, solvent and fuel are conveyed into a strong mixing machine, water is added, and mixing of the first stage is carried out; 2, the material obtained after mixing of the first stage is conveyed into a first cylinder mixing machine, water is added, and mixing of the second stage is carried out; 3, the material obtained after mixing of the second stage is conveyed into a second cylinder mixing machine or a cylinder pelletizer, water is added, mixing of the third stage is carried out, and a mixed material is obtained. By the adoption of the vertical strong mixing machine, the occupied area can be reduced, moreover, the sintering strength of sintered ore can be improved, the yield of the sintered ore is increased, energy is saved, emission is reduced, and multiple advantages are brought to increase of profits of sintering factories.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

High-strength and high-elasticity-modulus casting Mg-RE alloy and preparation method thereof

The invention discloses a high-strength and high-elasticity-modulus casting Mg-RE alloy and a preparation method thereof. The casting Mg-RE alloy comprises 8-14wt% of Gd, 2-6wt% of Y, 1-5wt% of Zn, 0.5-2.5wt% of Si, 0.4-1wt% of Zr, the impurity elements of Fe, Cu and Ni and the balance of Mg, wherein the total content of the impurity elements of Fe, Cu and Ni is smaller than 0.02wt%. The preparation method includes the steps of smelting and heat treatment. According to the preparation method, Si is added and reacts with Mg and RE in an MG alloy to generate a high-elasticity-modulus Si-containing phase, meanwhile, Zn is added and reacts with Mg and RE in the Mg alloy to generate a stable eutectic phase, in this way, the crystallization range of an alloy melt is reduced, melt fluidity is improved, and accordingly through the following corresponding heat treatment process, the alloy has high room-temperature strength and elasticity modulus.

Owner:SHANGHAI JIAO TONG UNIV

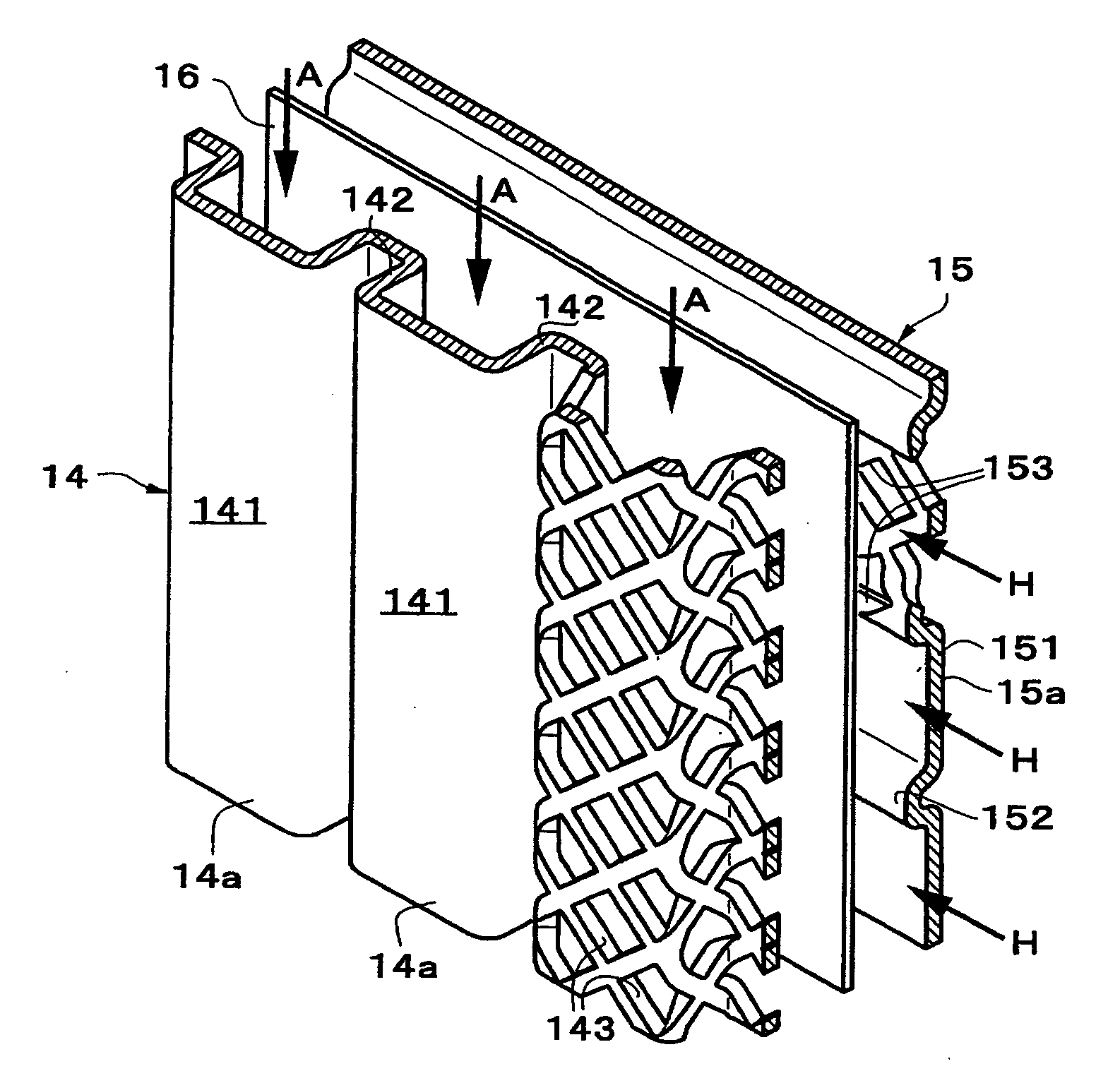

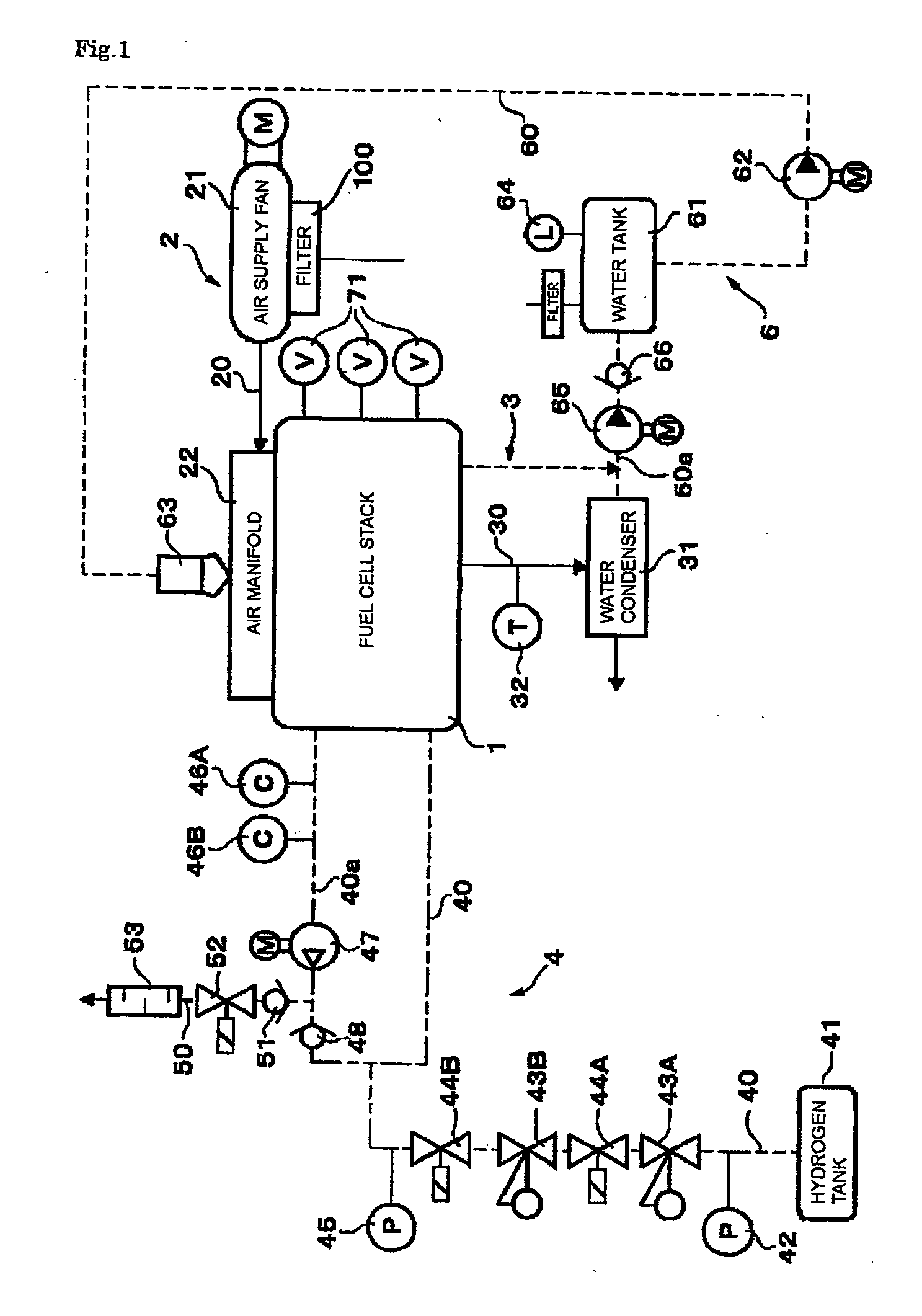

Separator and fuel cell using that separator

ActiveUS20050221146A1Reduce areaDistribute pressureFuel cells groupingWater management in fuel cellsGaseous diffusionFuel cells

A separator of a fuel cell, which is inserted between single cells, each single cell having an electrolyte sandwiched between electrodes, in order to stack the single cells together, includes gas diffusion portions which are arranged so as to cover a surface of the electrodes and in which are formed multiple air holes for gas diffusion, and spacer portions which form parallel divided gas passages on the back side of portions of the gas diffusion portions which cover the surface of the electrodes. The gas diffusion portions and the spacer portions are integrally formed by bending a wire mesh member to have a rectangular corrugated plate shaped cross-section. As a result, the air holes are formed evenly between the electrodes and the separator and high contact pressure is ensured by the contact of the fine wire mesh, thereby making it possible to both have the gas diffuse evenly and reduce the power collection resistance.

Owner:EQUOS RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com