Injection mould with rapidly-replaced mould cores

A technology for injection molds and mold cores, applied in the field of molds, can solve problems such as the influence of replacement efficiency, low tensile strength, and high labor intensity of operators, and meet the requirements of reducing operating proficiency, reducing physical requirements, and improving mold changing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

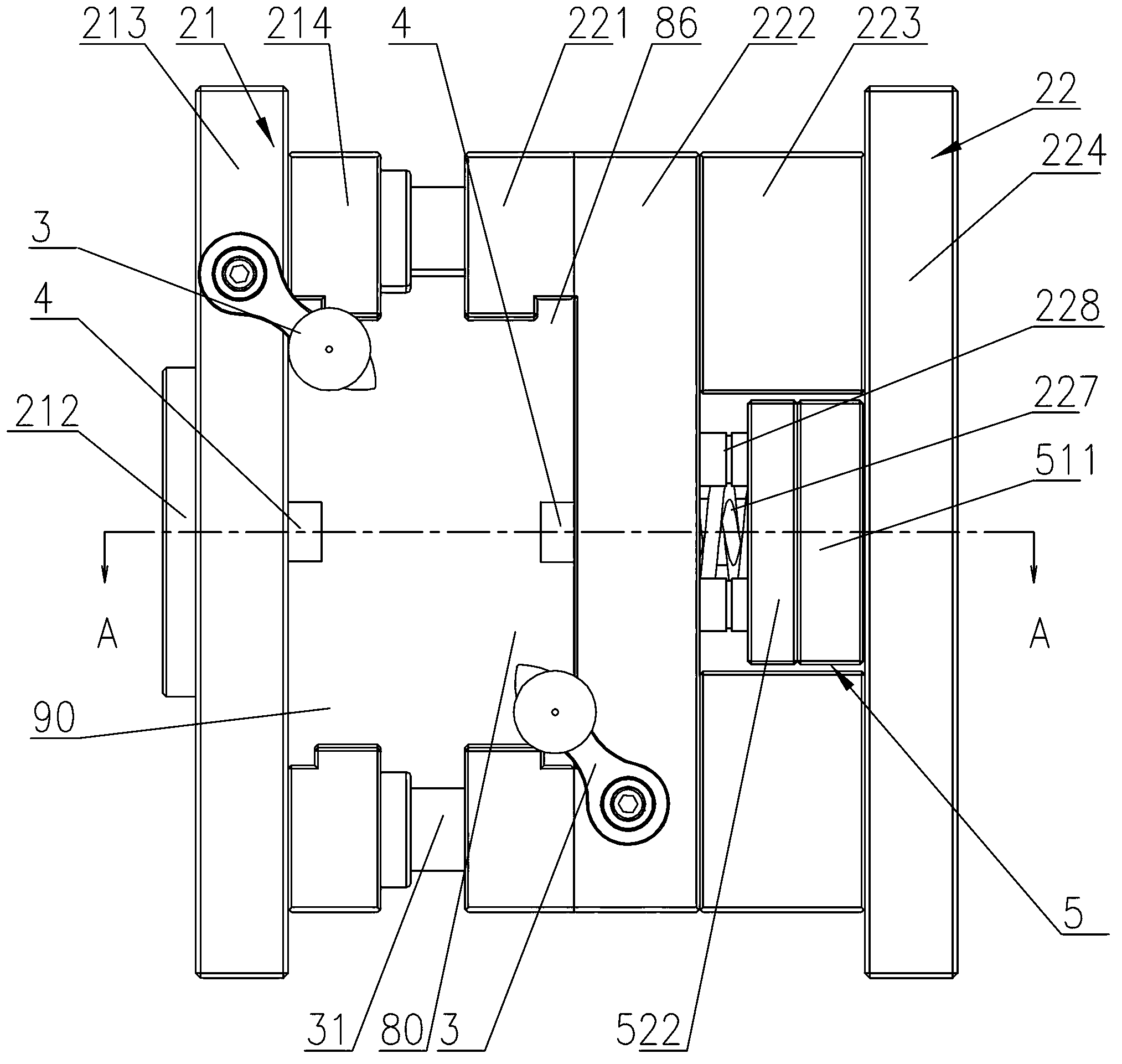

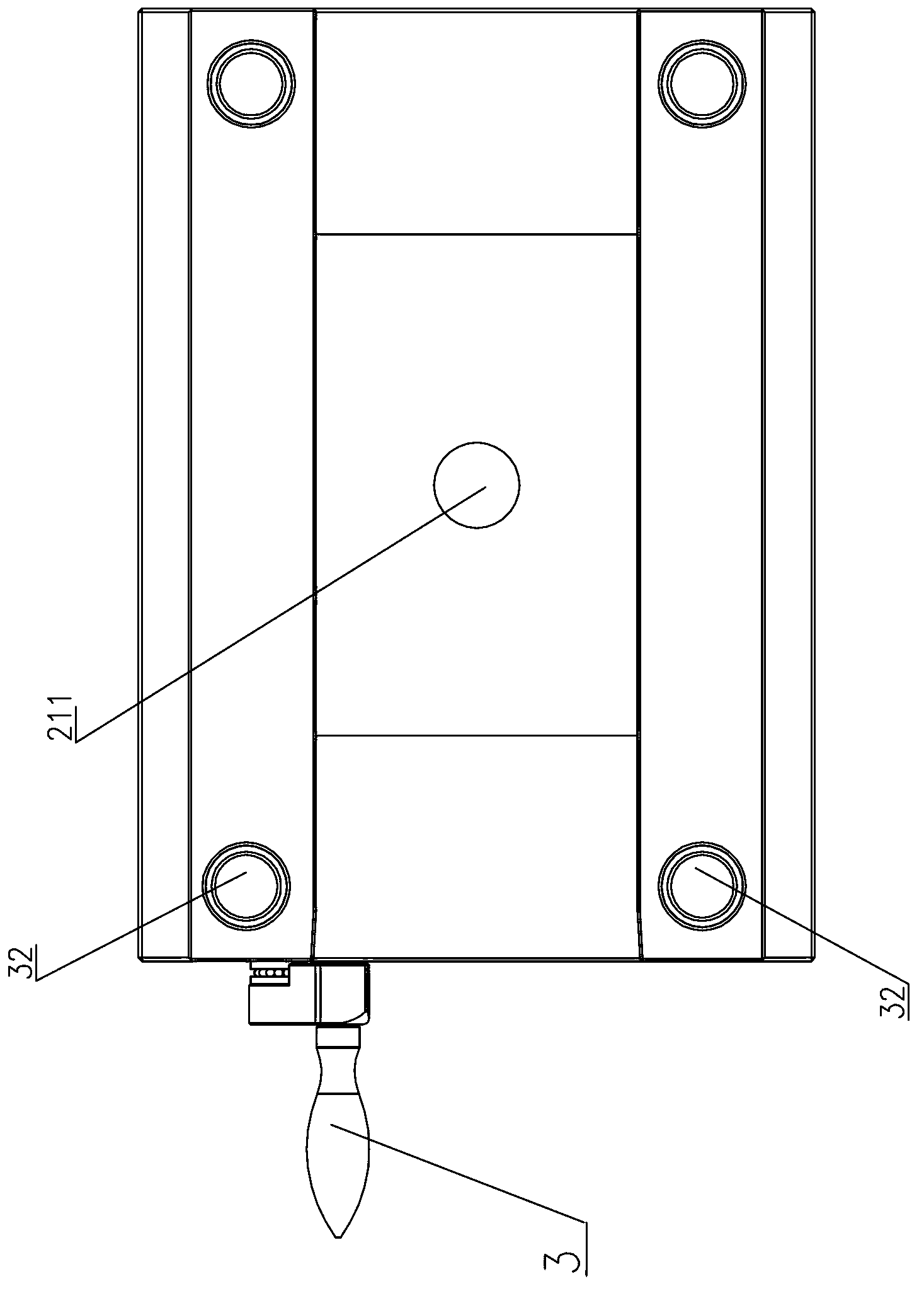

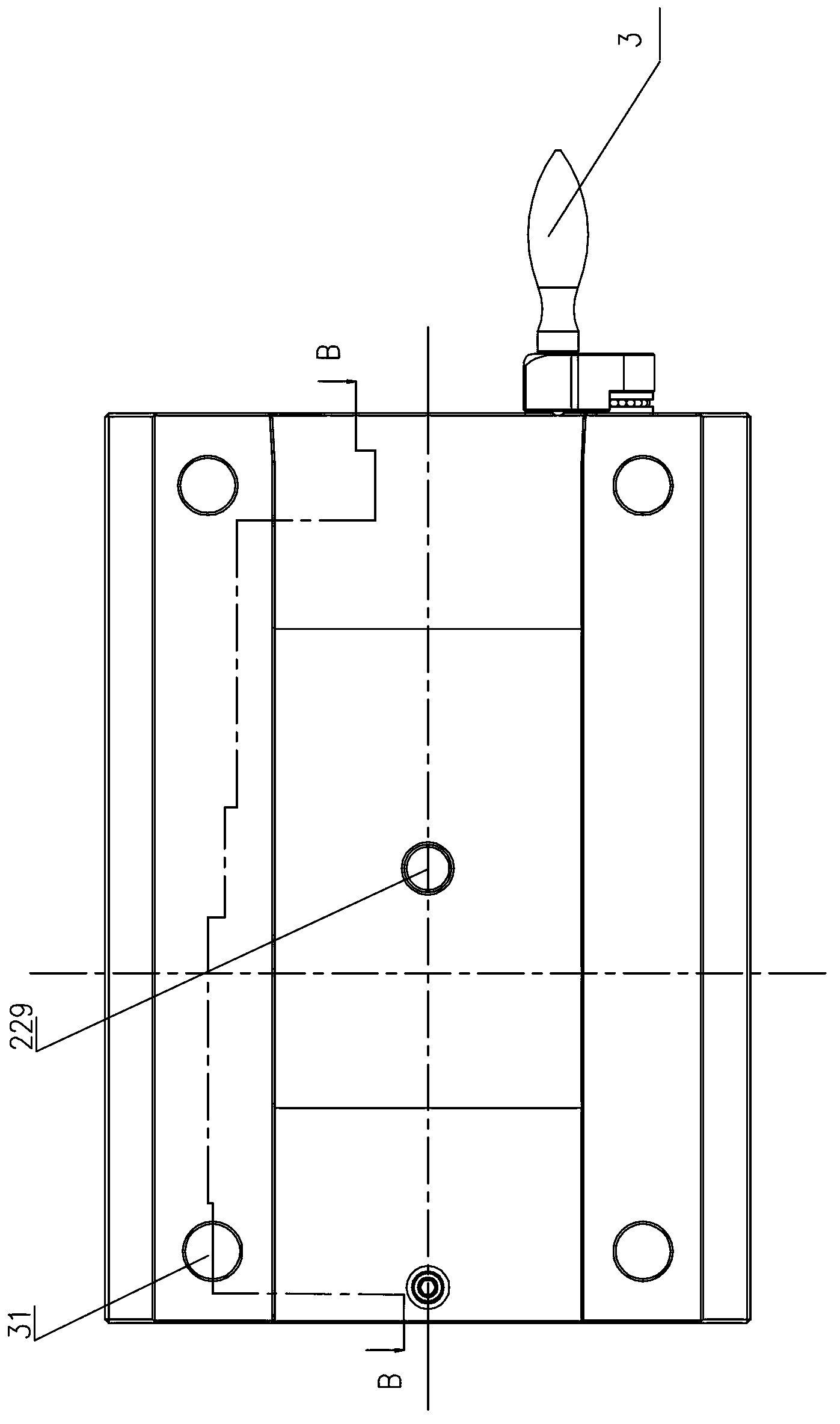

[0055] Such as Figure 1-12 , 19 shows an injection mold that can quickly replace the mold core of the present invention. In this embodiment, the test standard sample is made, see Picture 9 , The injection mold is composed of a movable mold and a fixed mold. Among them, the movable mold and the fixed mold include forming parts, an ejection mechanism, a mold guide part and a pouring system. The main body of the movable mold is composed of a movable mold base 22 and a movable mold base 22. The main body of the fixed mold is composed of a fixed mold base 21 and a fixed mold core 11 movably mounted on the fixed mold base 21. The movable mold base 22 and the fixed mold base 21 are collectively called the mold base, and the movable mold core 12 The mold core 11 and the fixed mold core 11 are collectively called the mold core. The mold core is a movable molding part separated from the mold base. The mold core is a cube-shaped block. The injection mold cavity is set in the mold core. Th...

Embodiment 2

[0076] Such as Figure 13-18 As shown, the difference between this embodiment and embodiment 1 is that the injection mold cavity on the mold core is different, see Figure 15 The injection molded parts applicable to the mold core of this embodiment are the cantilever beam 91, the bending standard test strip 92, and the impact standard test strip 93. Two movable inserts 70, 71 are provided on the clamping surface of the fixed mold core 11. The movable inserts are distributed back and forth around the pouring hole (that is, the inner channel 54 of the sprue sleeve). There are two mold cavities 73 on the clamping surface of the movable mold core 12, and the two mold cavities on the movable mold core and The movable inserts 70 and 71 correspond to each other. The movable inserts are located in the cavity of the movable mold core when the mold is closed to form four injection cavities for single injection molding. That is, the movable inserts 70 and 71 are respectively located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com