Patents

Literature

109results about How to "Quick die change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

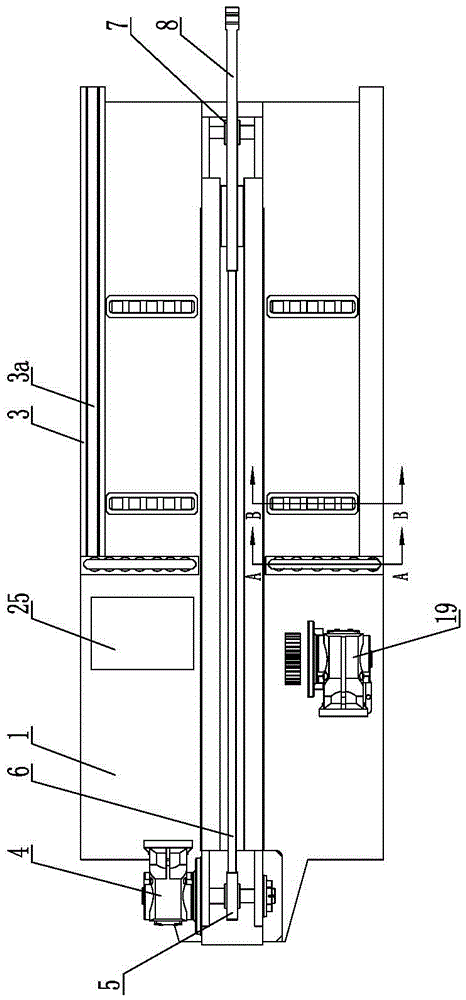

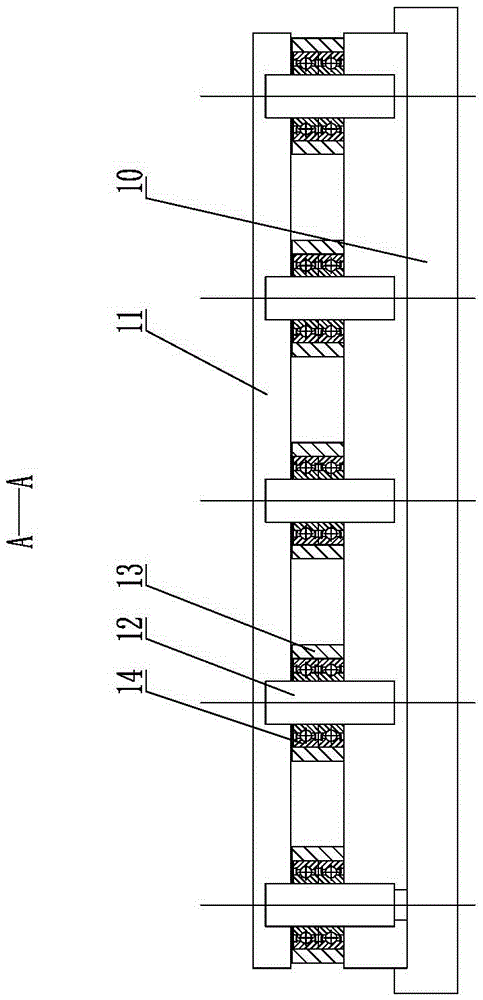

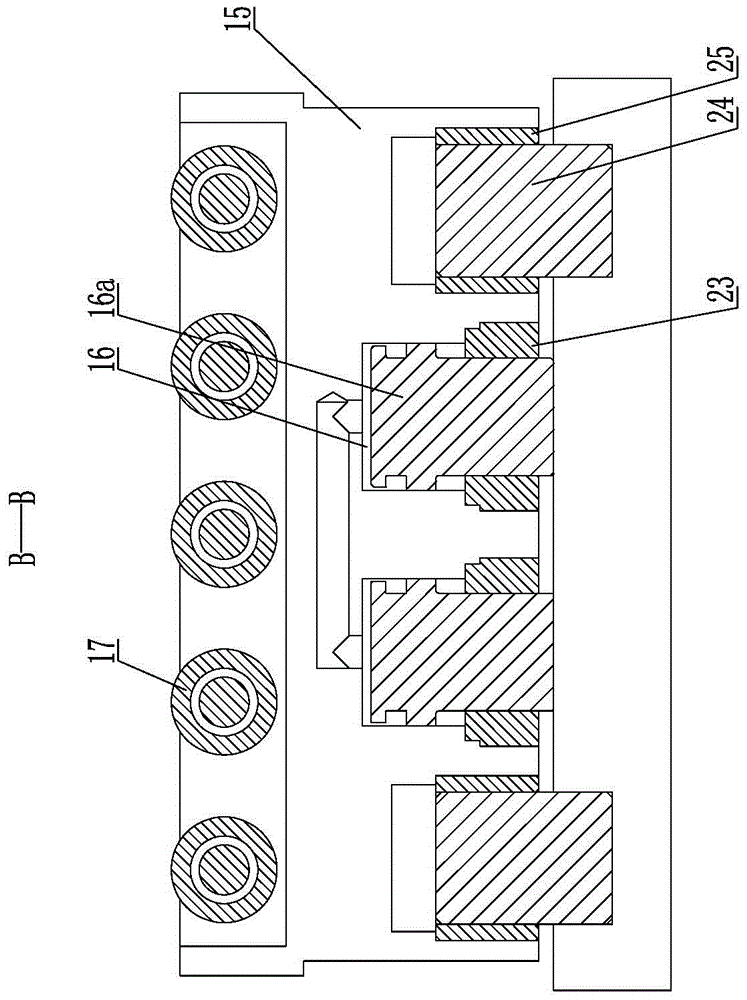

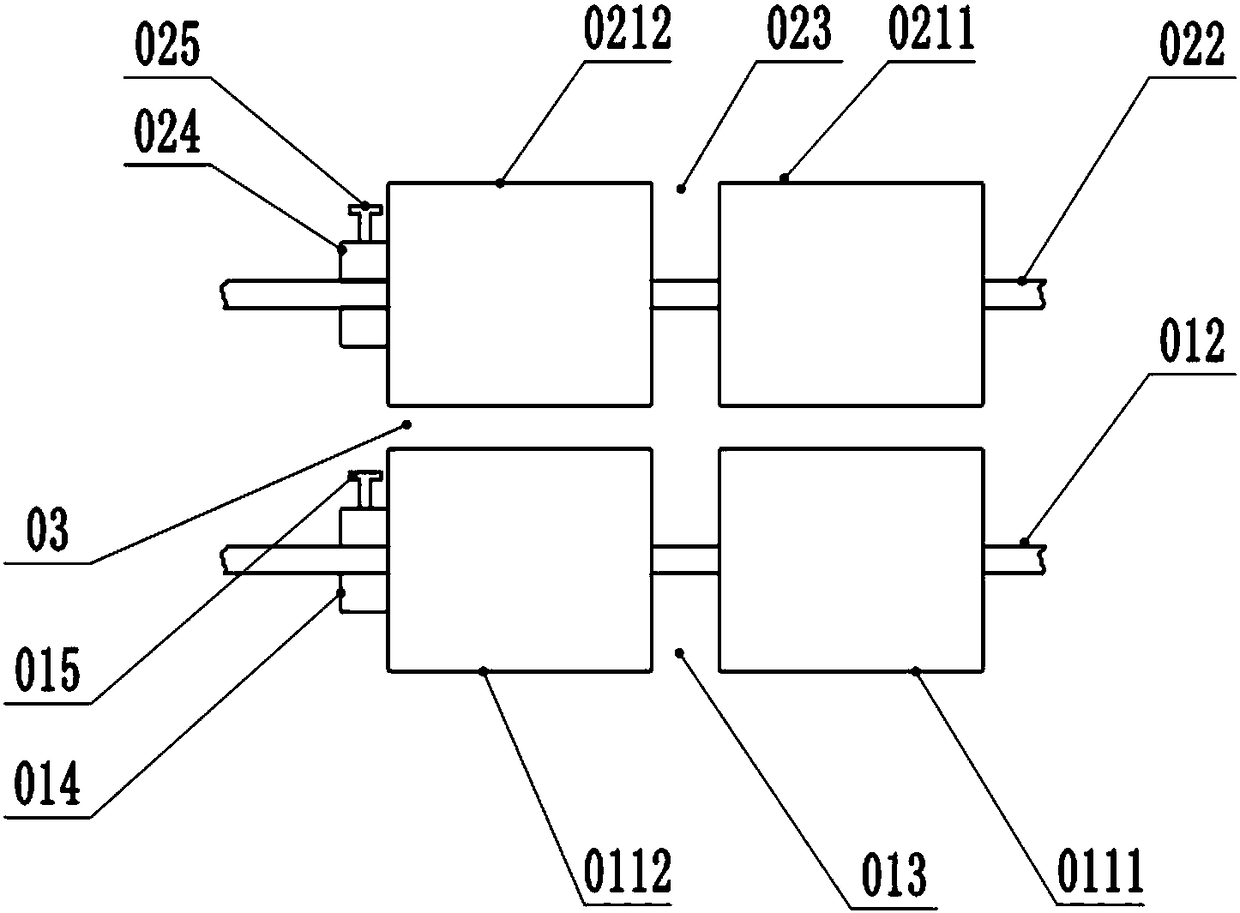

Automatic die-changing processing equipment

ActiveCN102601245AQuick die changeImprove processing efficiencyShaping toolsIndustrial engineeringSelf weight

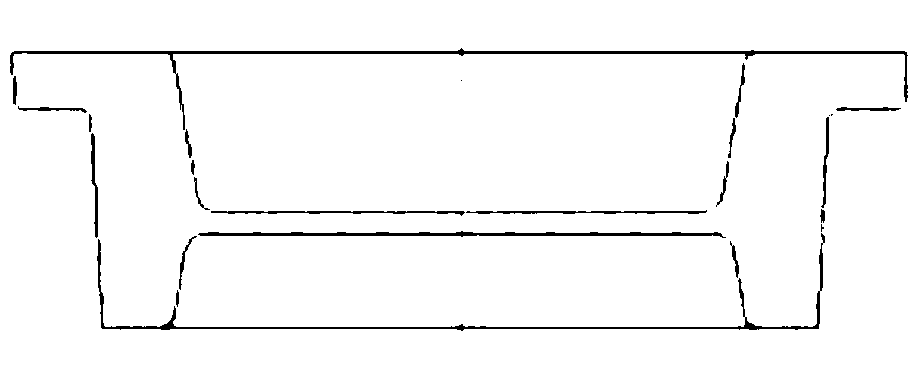

The invention relates to automatic die-changing processing equipment which comprises a frame, a punch, a working table and at least two dies arranged horizontally on the working table. The frame is provided with a bearing table for fixing the working table. A lifting track extending horizontally is arranged on the bearing table in a liftable way. The working table is arranged above the lifting track. The lifting track has two working positions. When the lifting track is located in the first working position, the upper part of the lifting track protrudes out of the upper surface of the bearing table, the lifting track is supported below the working table, and the lower surface of the working table is separated from the upper surface of the bearing table. When the lifting track is in the second working position, the lifting track is held in the bearing table, the upper part of the lifting track is not higher than the upper surface of the bearing table, and the bearing table is supported below the working table. The automatic die-changing processing equipment lifts the working table through the lifting track and is fixed by the self-weight of the die, so that a plurality of dies can be changed rapidly.

Owner:JIANGSU BAIXUE ELECTRIC APPLIANCES

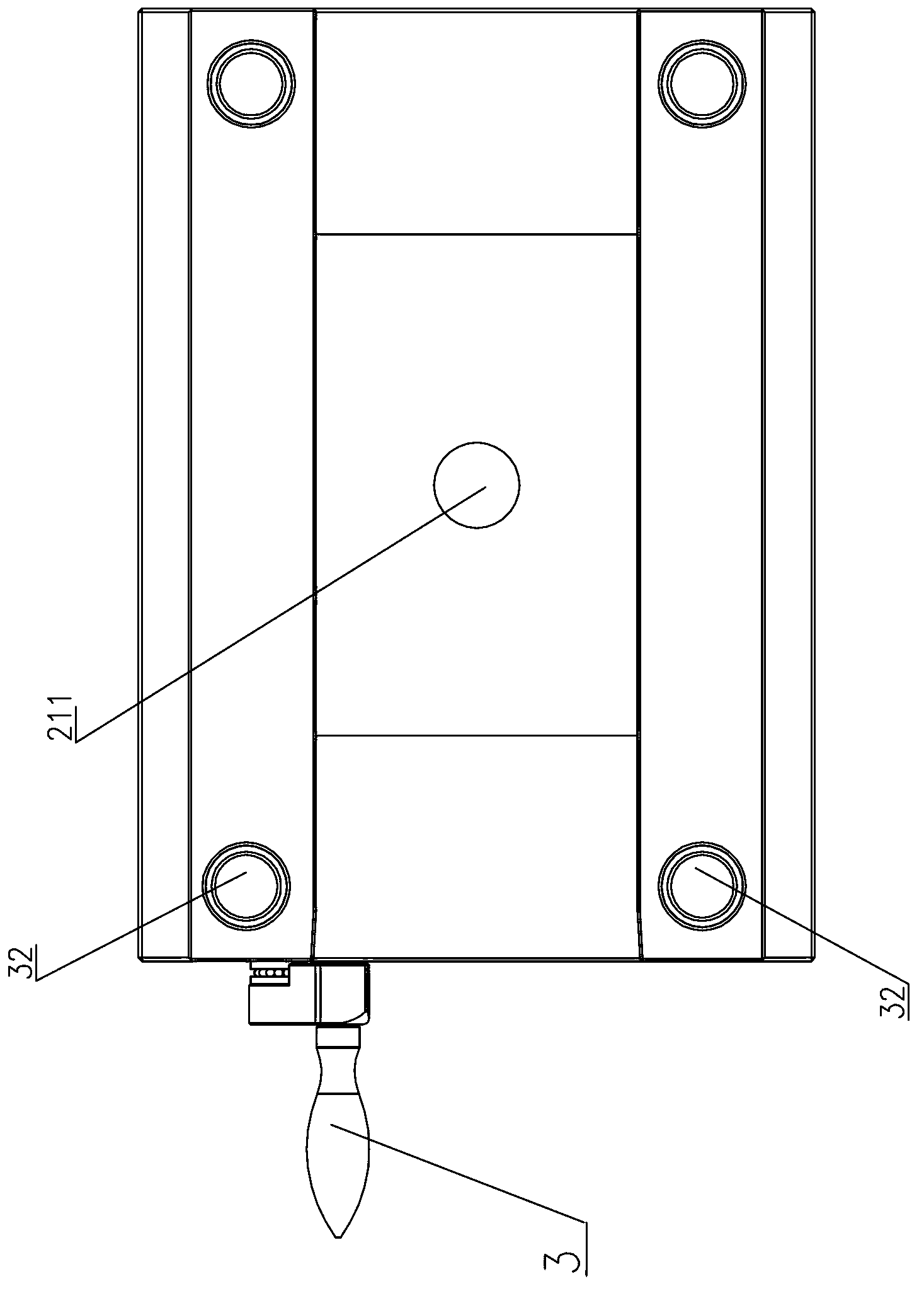

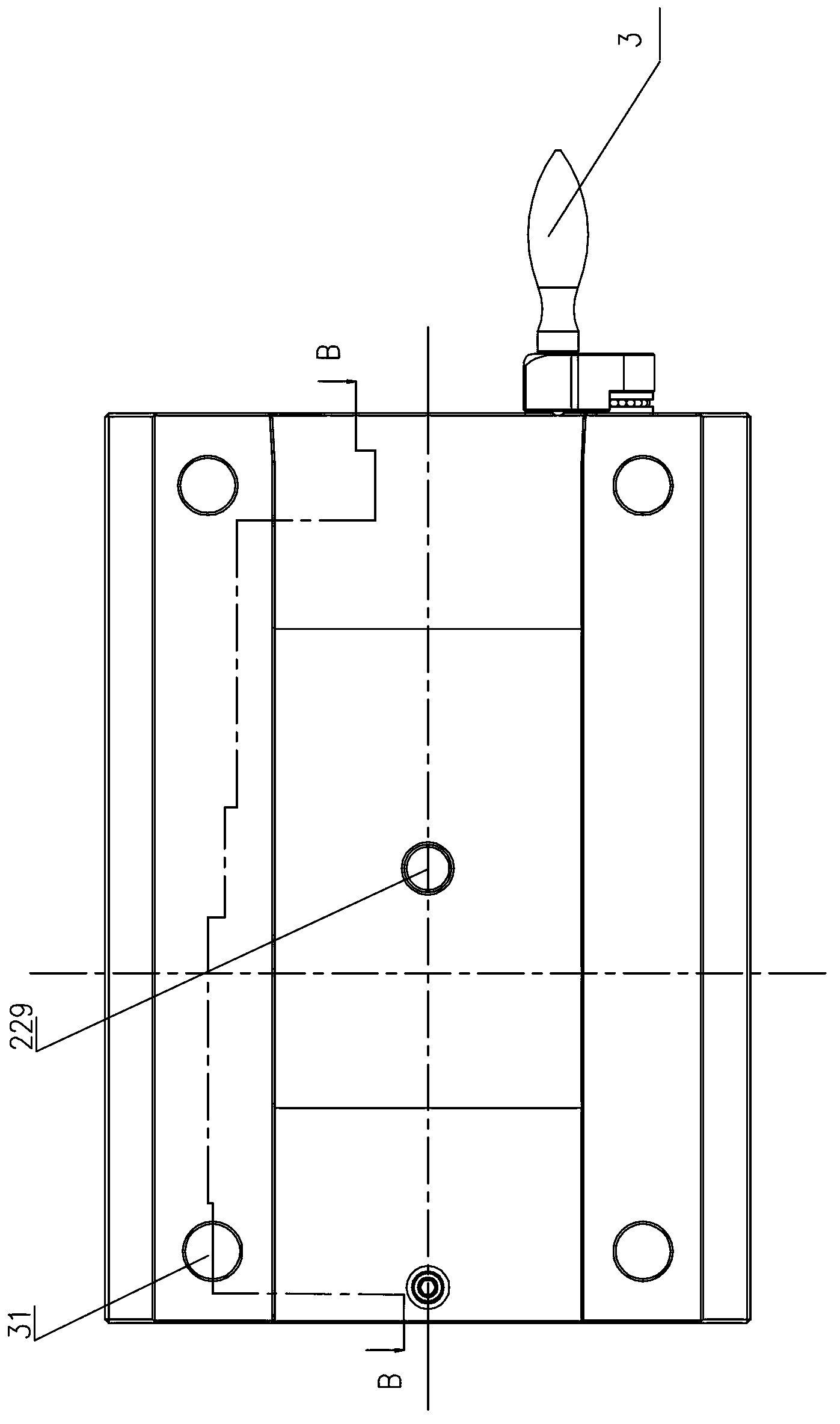

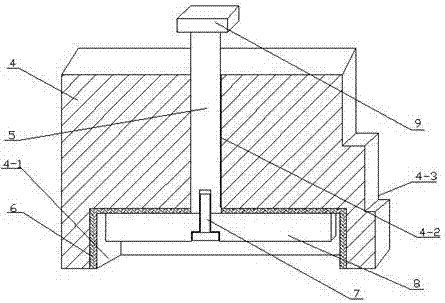

Injection mould with rapidly-replaced mould cores

The invention discloses an injection mould with rapidly-replaced mould cores. The injection mould is composed of a movable mould and a stationary mould, wherein a main body of the movable mould is composed of a movable mould base and a movable mould core movably arranged on the movable mould base; a main body of the stationary mould is composed of a stationary mould base and a stationary mould core movably arranged on the stationary mould base; the butt joint faces of the movable mould base and the stationary mould base are respectively provided with a mould core mounting sliding chute which horizontally extends from front to back; at least the front ends of the mould core mounting sliding chutes are provided with plug-in mounting holes for mounting or dismounting the mould cores; the mould cores are provided with tracks matched with the mould core mounting sliding chutes so as to move along the mould core mounting sliding chutes; and the mould cores are inserted to or dismounted from the mould core mounting sliding chutes on the mould bases through the plug-in mounting holes, thus the mould cores are replaced. According to the invention, only one set of mould base needs to be manufactured to be matched with the mould cores of different cavities which are manufactured according to spline standards tested based on different performance indexes; the mould replacing operation is easier and more convenient than that of the prior art, so that the mould replacing time is greatly shortened; and the manufacturing cost of various test spline moulds can also be greatly reduced.

Owner:广州现代塑料有限公司

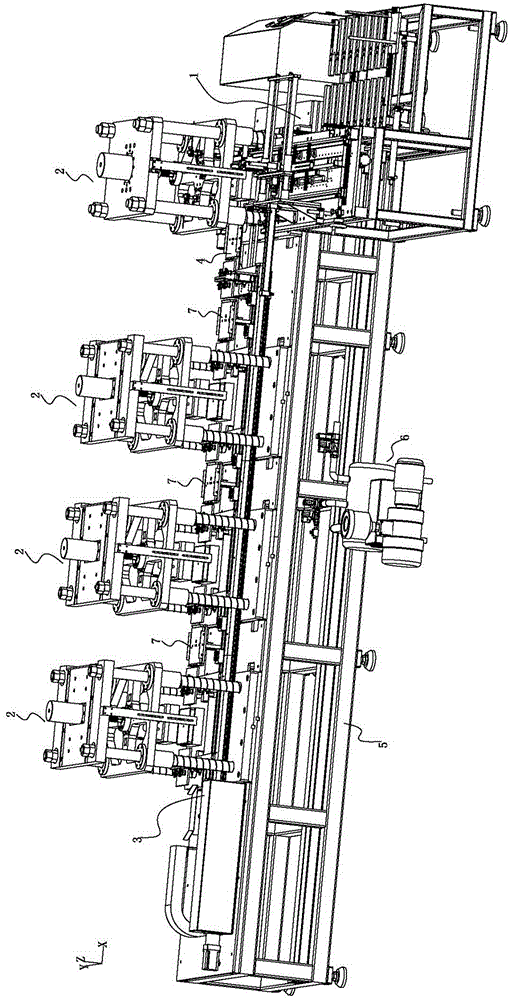

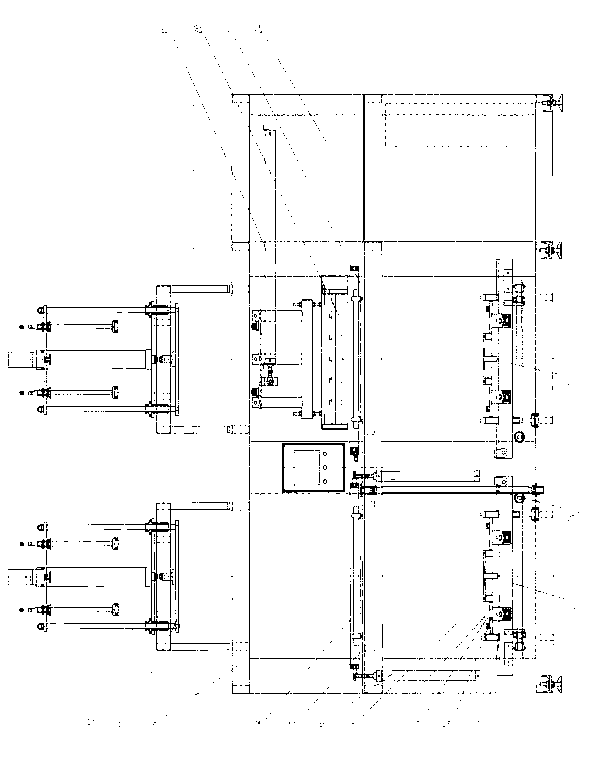

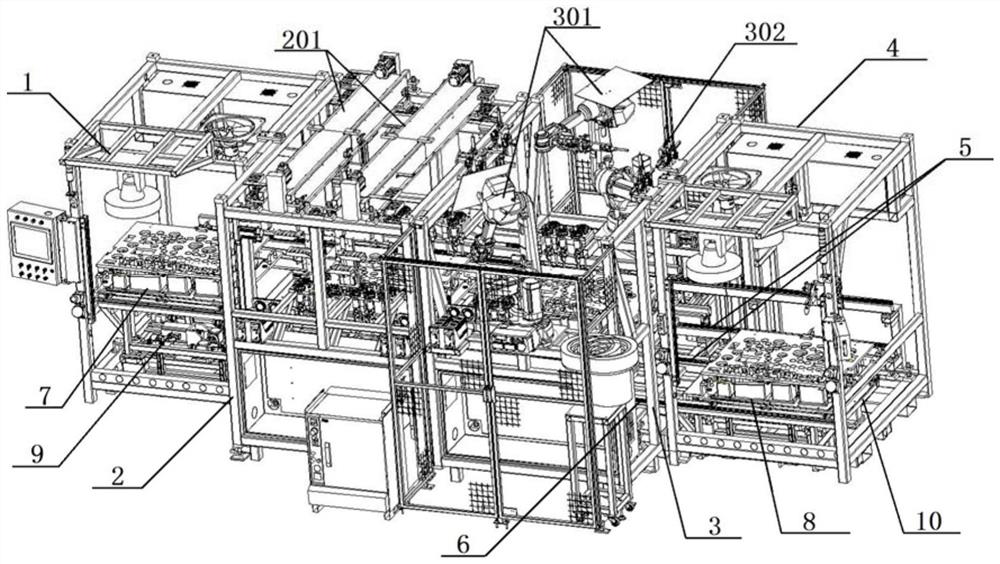

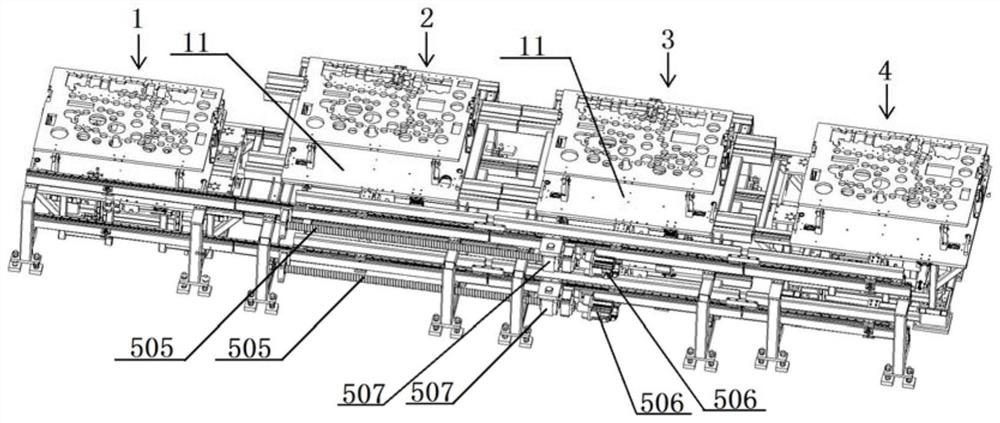

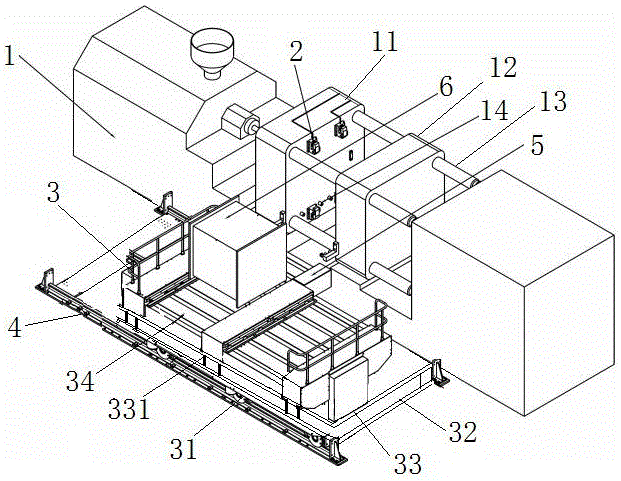

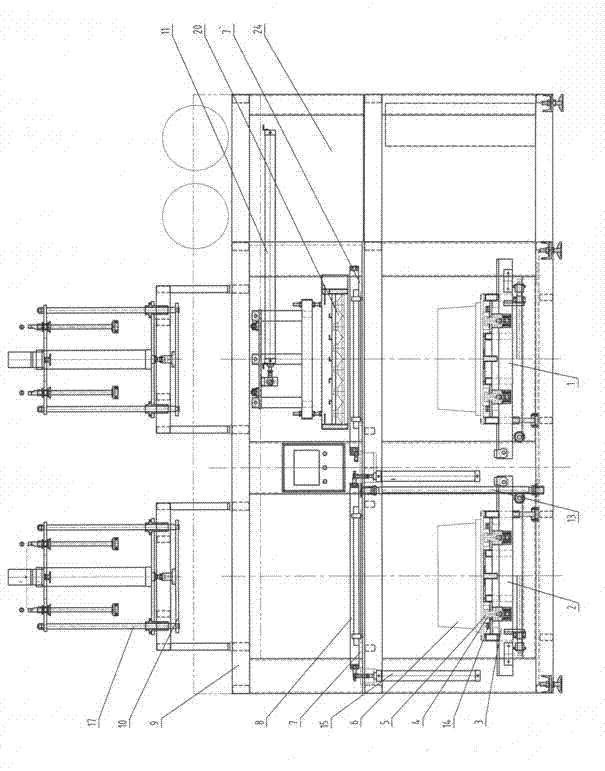

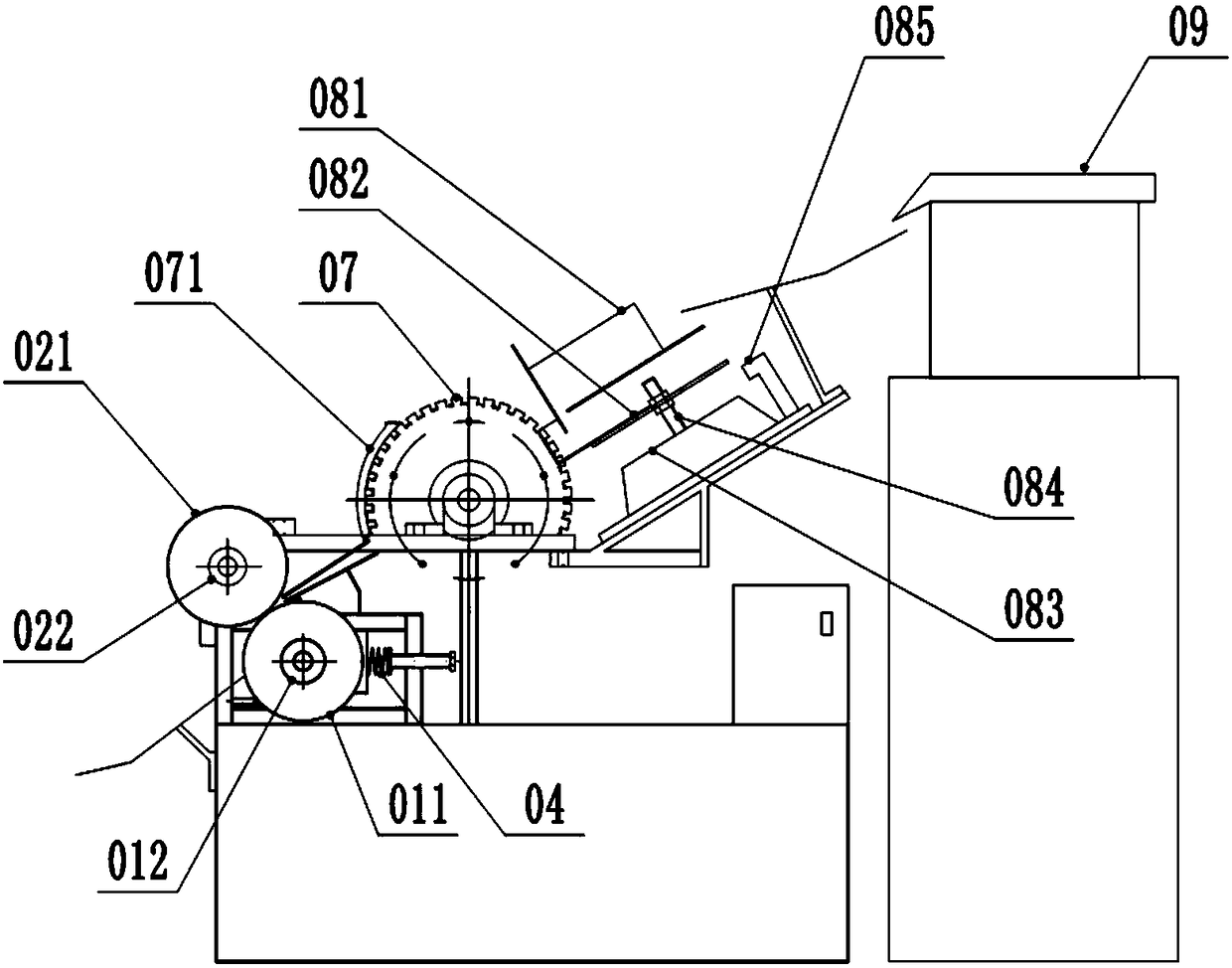

Integrated type full-automatic can making machine

InactiveCN105033090AReduce noiseHigh precisionShaping toolsMetal-working feeding devicesPunchingControl system

The invention discloses an integrated type full-automatic can making machine which comprises a control system, a machine frame, multiple die frame mechanisms, a feeding mechanism and a hydraulic pneumatic system. The die frame mechanisms comprise the punching die frame mechanism, the trimming die frame mechanism, the edge turning die frame mechanism and the setting die frame mechanism. A material transfer mechanism is arranged on the machine frame and parallel to the die frame mechanisms. The material transfer mechanism comprises multiple material transfer manipulators which are arranged on gaps between the die frame mechanisms. Material storage tables are further arranged on the gaps between the die frame mechanisms. The feeding mechanism transfers sheet type cans to the die frame mechanisms. The material transfer mechanism drives the material transfer manipulators to move synchronously, so that the cans move between the die frame mechanisms and the material storage tables, and the die frame mechanisms punch and form the transferred cans to complete can making. The integrated type full-automatic can making machine is low in noise, high in precision, adjustable in punching speed, good in tensile property, long in service life, high in integration degree, intelligent in can making and high in production efficiency.

Owner:东莞市特仕机电科技有限公司

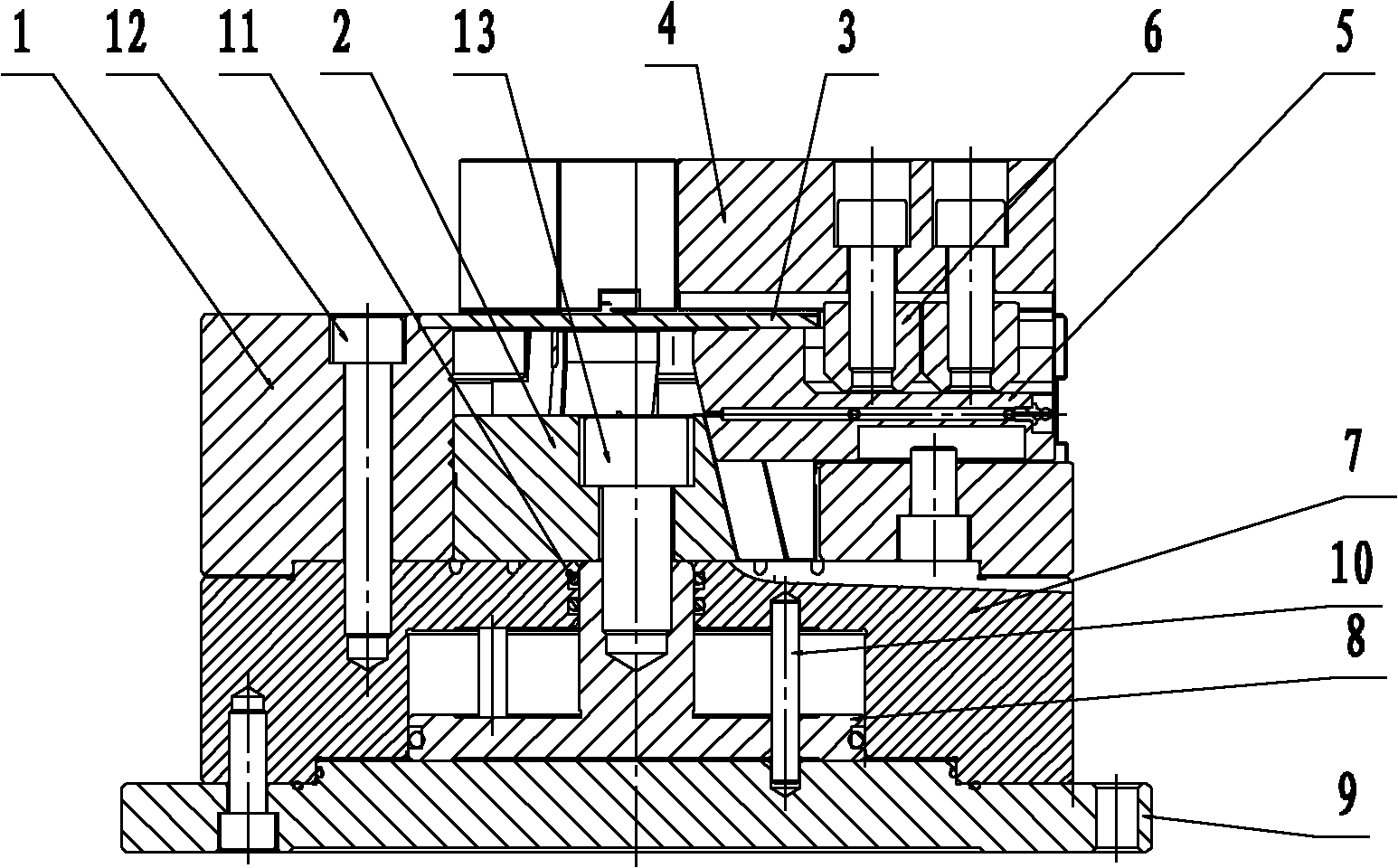

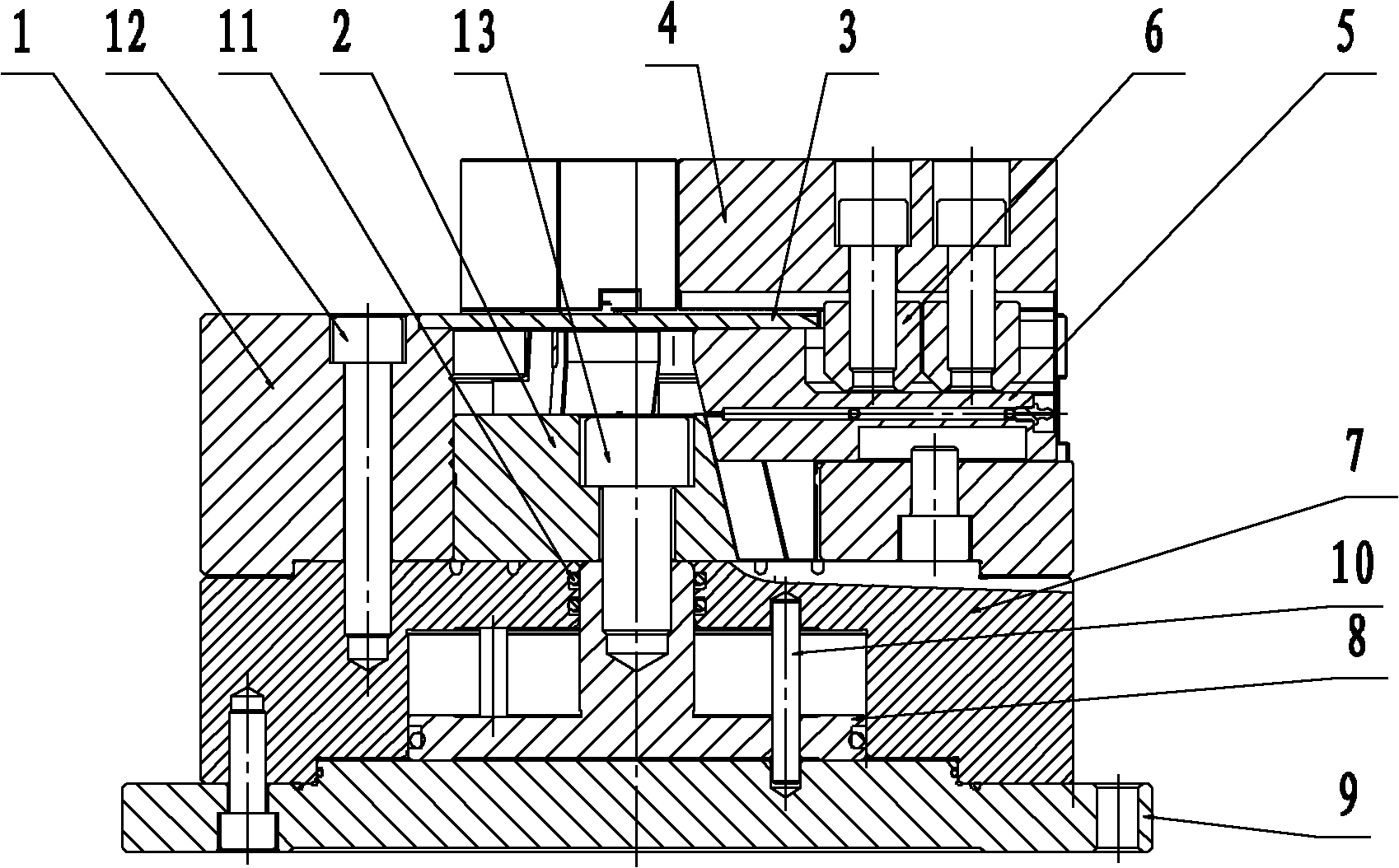

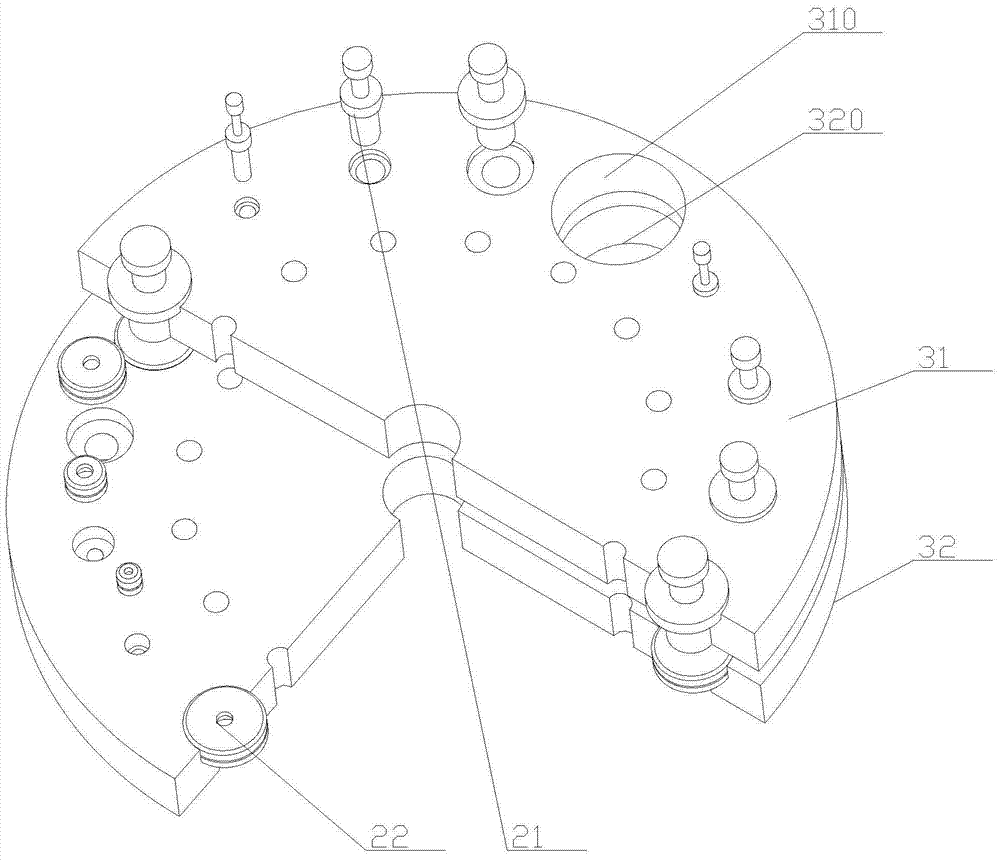

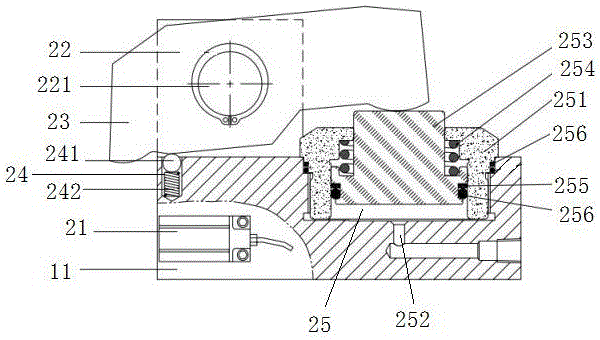

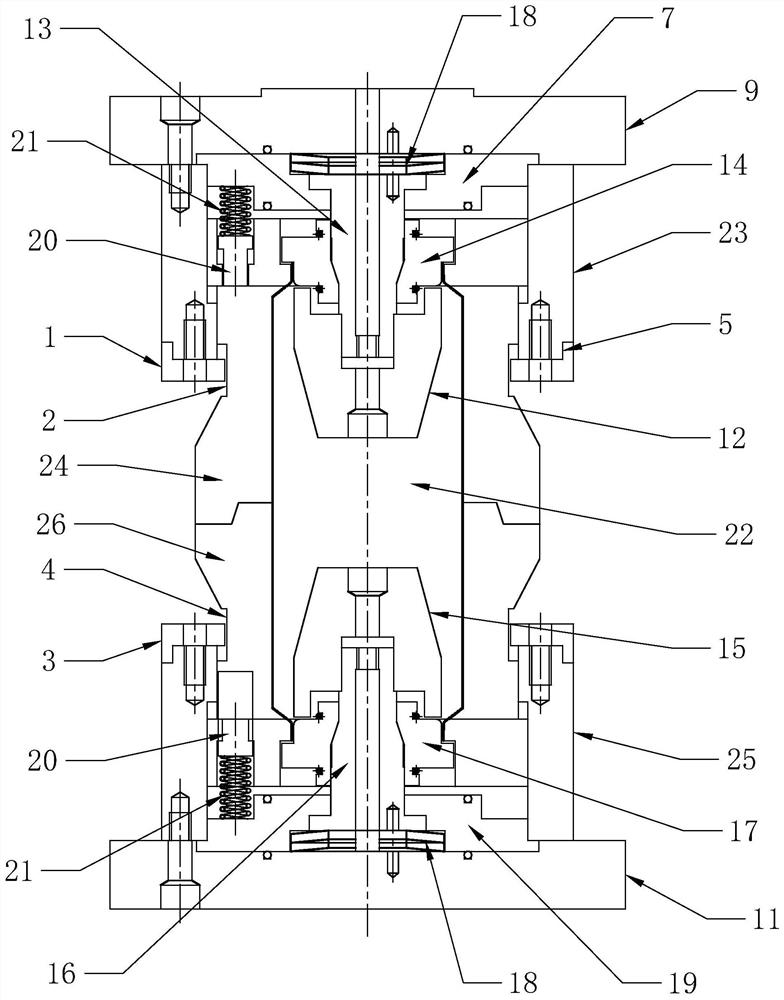

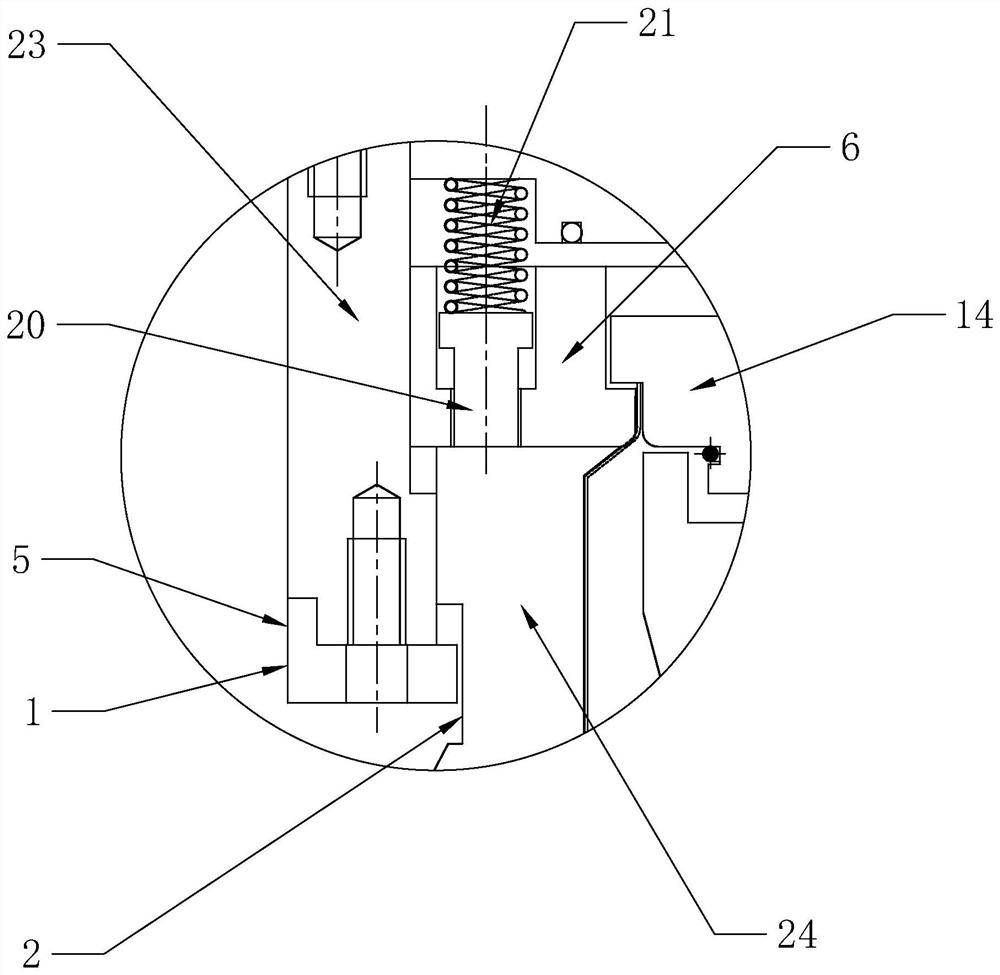

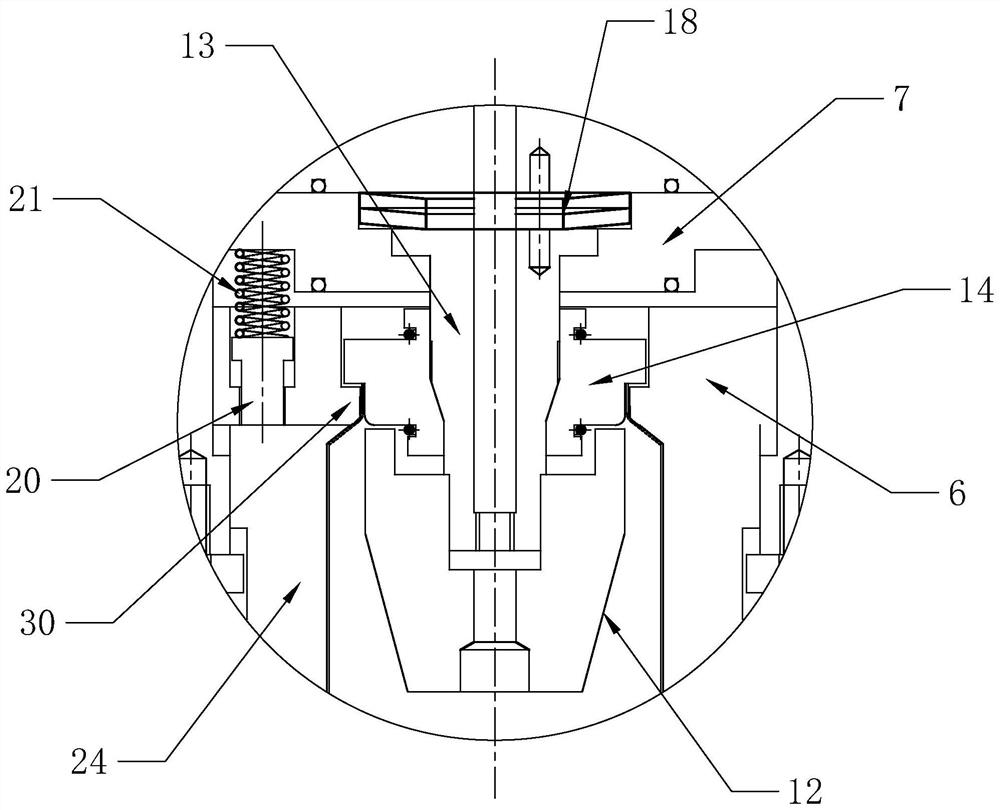

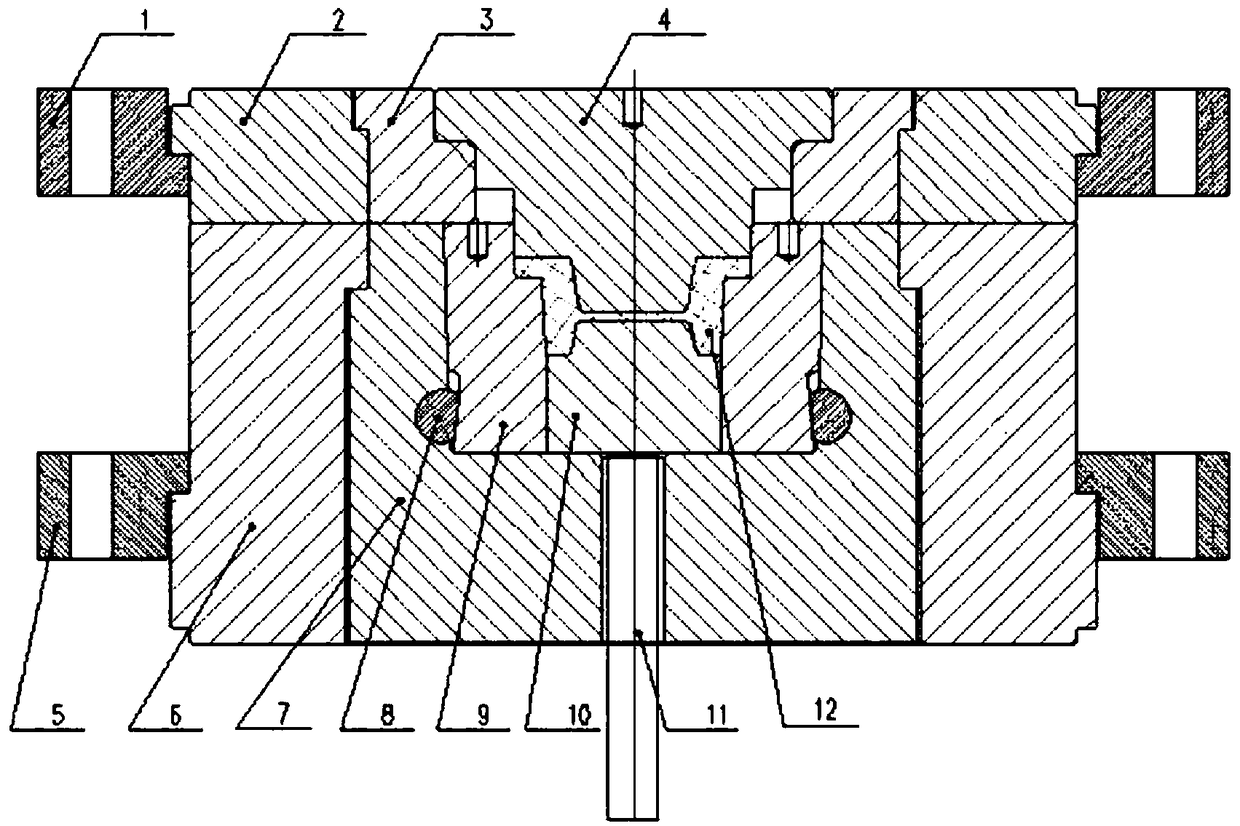

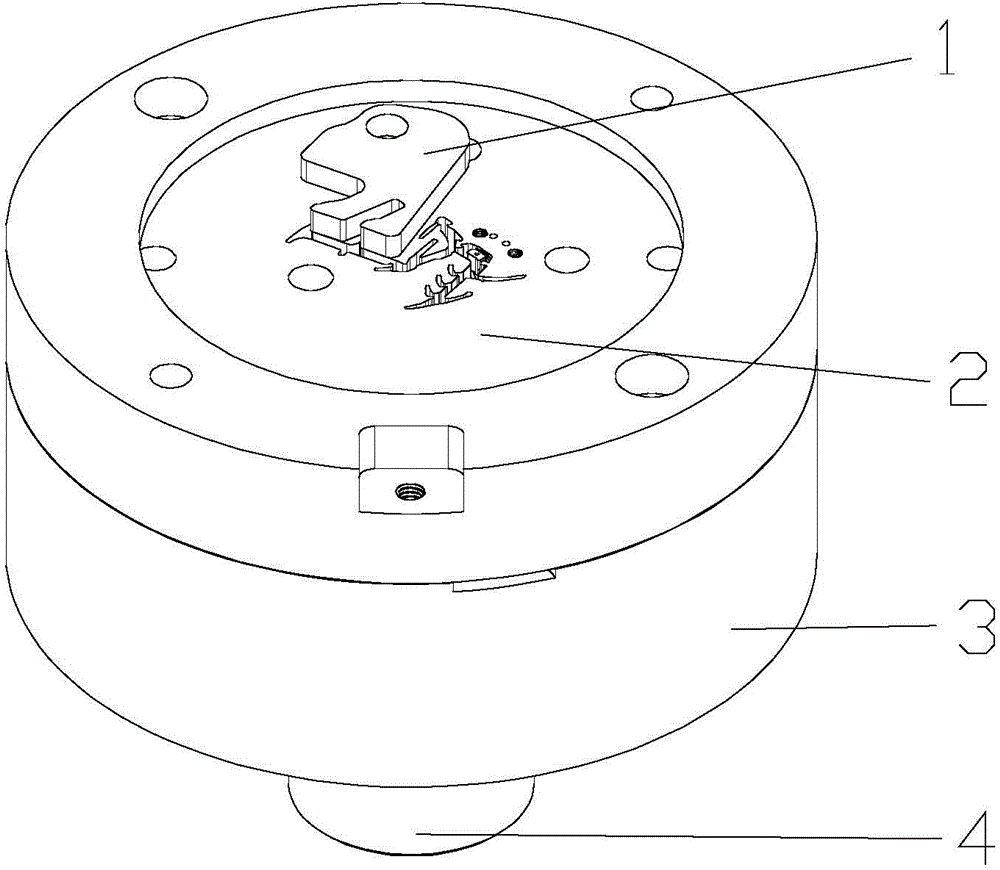

Vertical type fixed hydraulic power chuck

The invention relates to a vertical type fixed hydraulic power chuck which comprises a chuck body, a wedge catch system, a blocking cover, three claws, three slide carriages and six T-shaped blocks, and is characterized in that an oil cylinder body and a base form an oil cylinder main body; a piston is installed in the oil cylinder body and slides in the oil cylinder body along the direction of a guiding shaft; an upper oil chamber and a lower oil chamber are formed above and below the piston; the control hydraulic oil of the upper oil chamber and the lower oil chamber is controlled by a left oil inlet and outlet hole or a right oil inlet and outlet hole; the piston is connected with the wedge catch system by a driving connecting screw; under the driving of the piston, the wedge catch system slides up and down in the chuck body; and the chuck body is connected seamlessly and fixedly with the oil cylinder body by a connecting bolt. The structure of the invention is simple, compact and reasonable, the vertical type fixed hydraulic power chuck connects the cylinder body and the chuck integrally and is loaded on a work bench, a workpiece can be loaded and clamped conveniently, and quick die changing can be realized, thereby greatly lightening the labor intensity, shortening the clamping time, improving the productivity, having adjustable clamping force, and being suitable for matching with a numerical control machining center.

Owner:江苏无锡建华机床附件集团有限公司

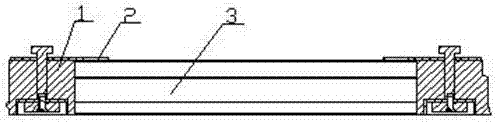

Automatic wax injection press

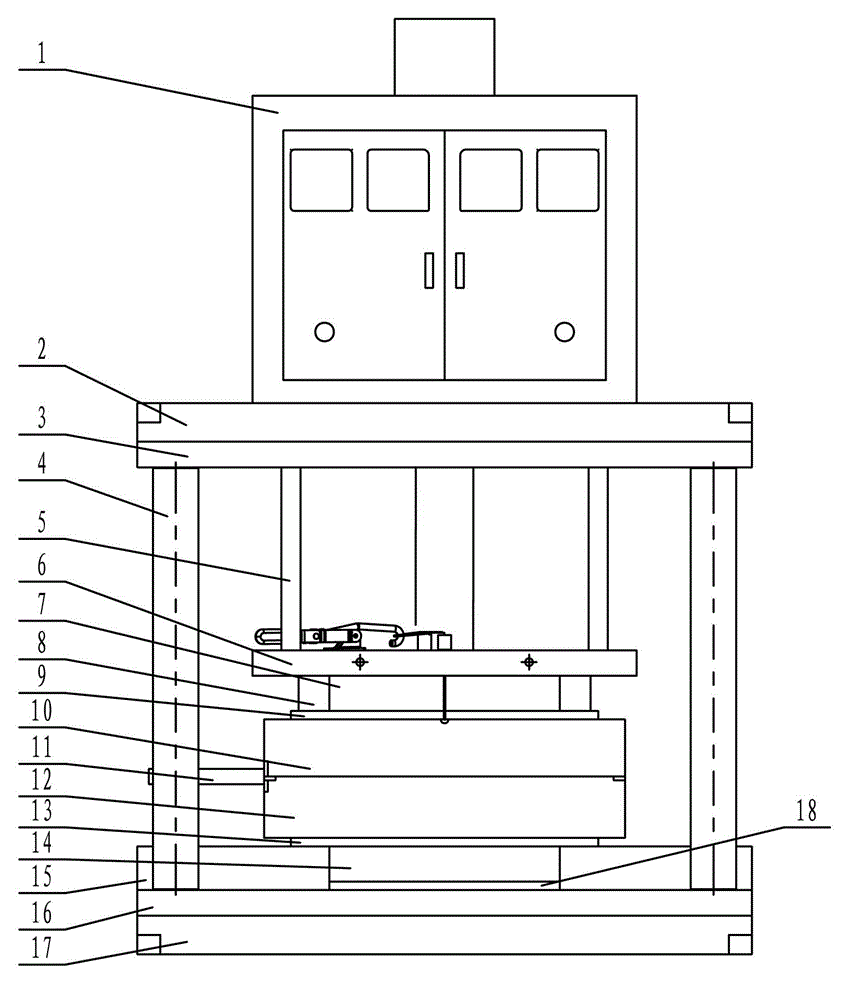

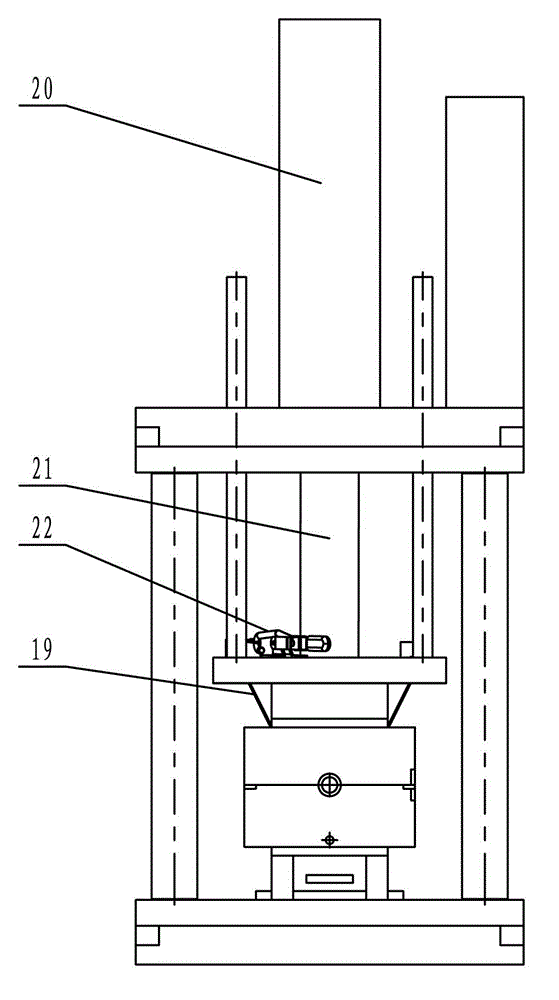

ActiveCN102717027AQuality improvementQuick die changeFoundry moulding apparatusWaxInvestment casting

The invention relates to an automatic wax injection press which is particularly used for automatic production of wax patterns, and belongs to the technical field of precision investment casting pattern making. The automatic wax injection press mainly comprises an electric cabinet, a reinforcing plate, a wax injection press cover plate, support pillars, an upper working table, a first magnetic sucking disc, an upper transitional plate, an upper die, a lower die, a lower transitional plate, a second magnetic sucking disc, a wax injection press seat, a magnetic sucking disc mounting board, an oil cylinder and a piston rod, wherein the lower transitional plate is magnetically adsorbed on the second magnetic sucking disc; the lower die is fixedly connected onto the lower transitional plate; the upper die is positioned on the lower die; a gate stick is connected to one side of the upper die and that of the lower die; the upper die is fixedly connected onto the upper transitional plate; and the upper transitional plate is magnetically adsorbed on the first magnetic sucking disc. The automatic wax injection press has the advantages as follows: the structure is simple, compact and reasonable; the automatic production of the wax patterns reduces the labor intensity of workers and improves work efficiency; the quality of the produced wax patterns is stable; and the die changing is fast, and the service lives of the dies are long.

Owner:鹰普(中国)有限公司

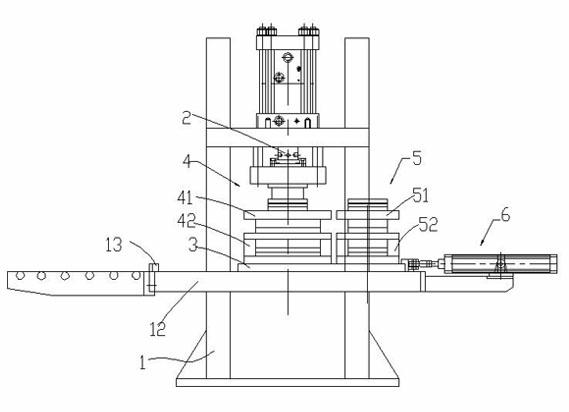

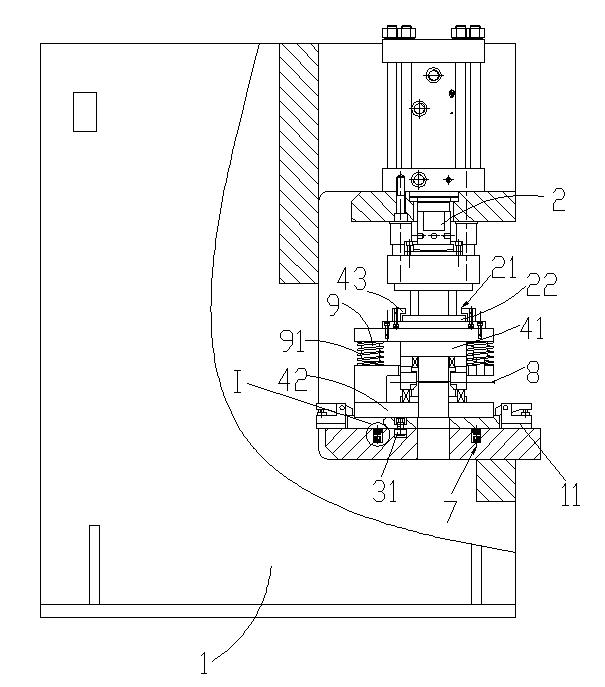

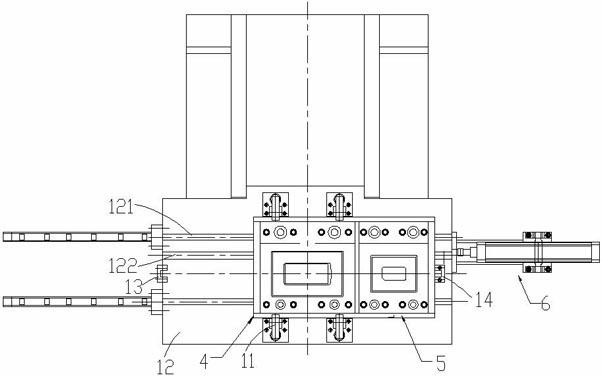

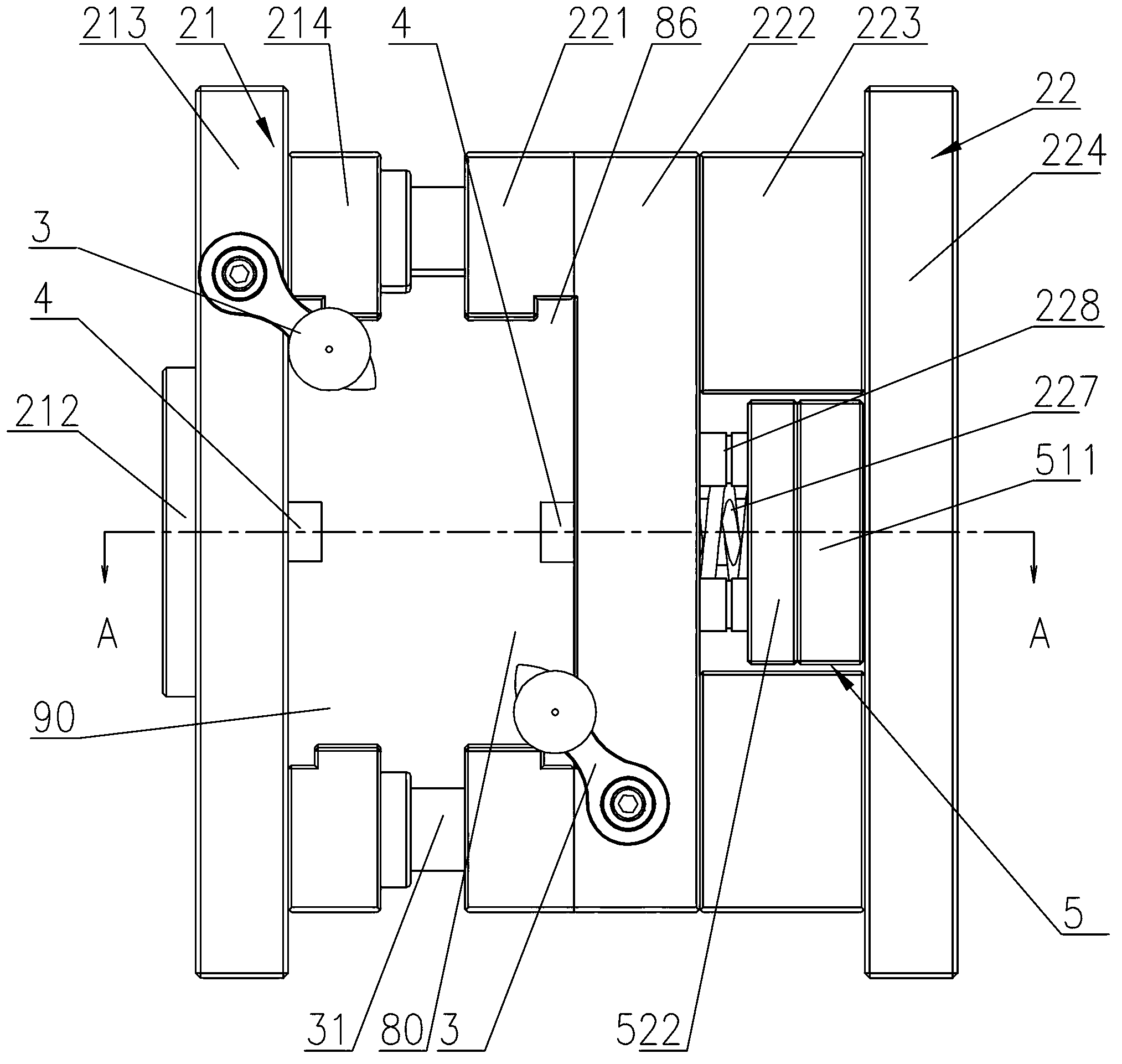

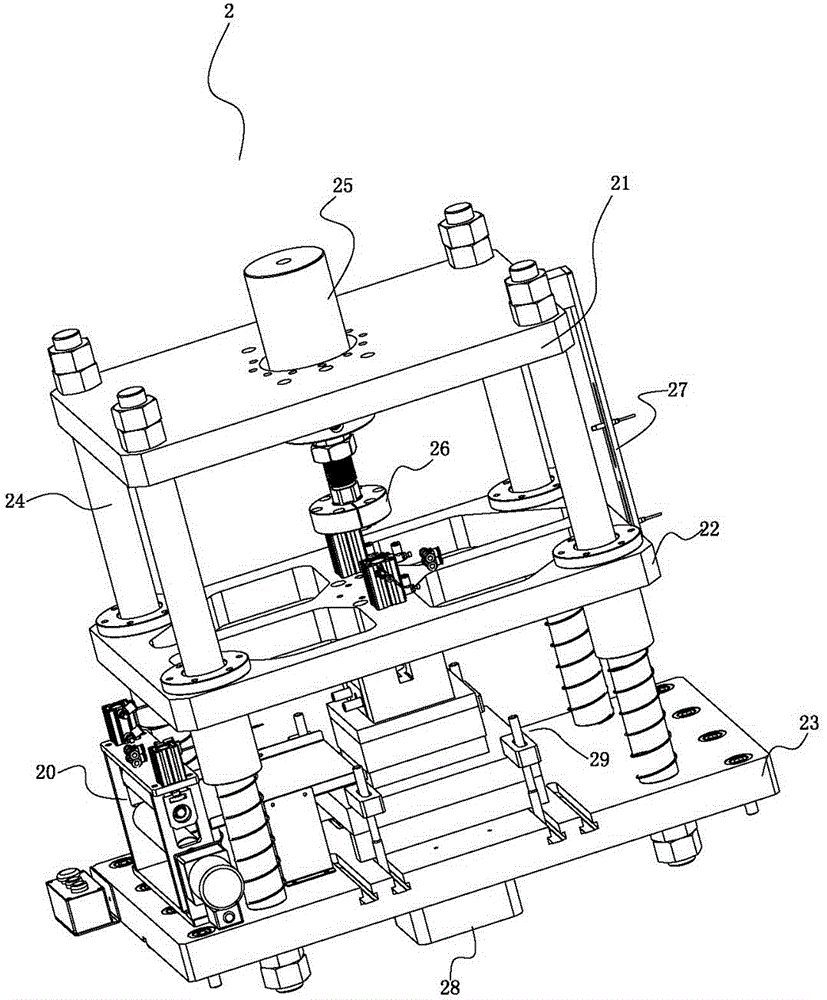

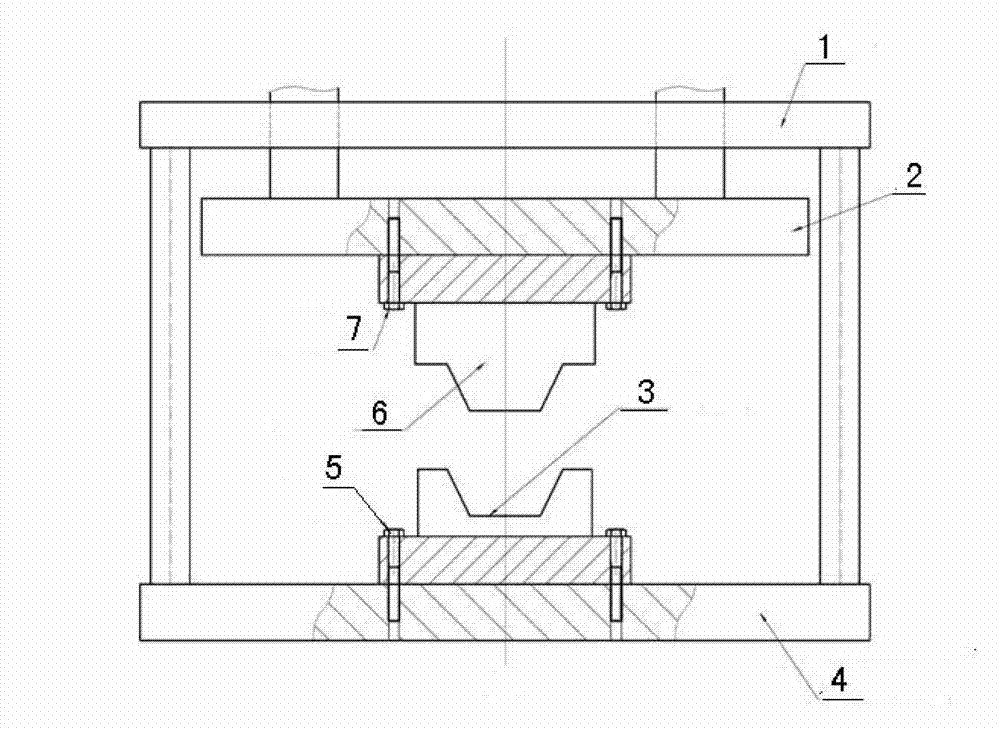

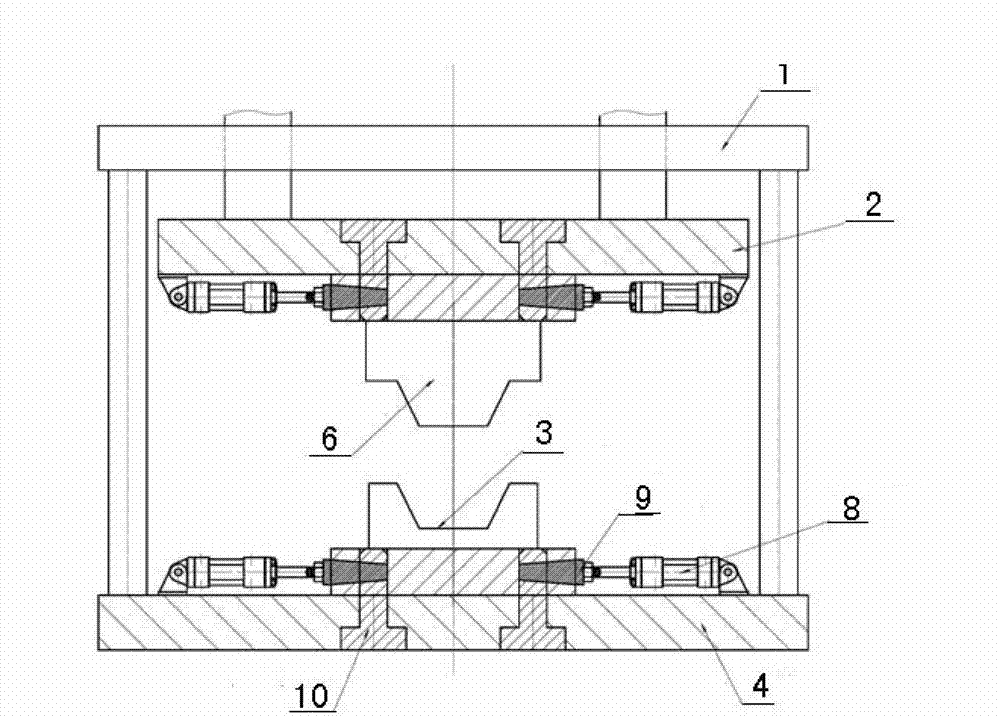

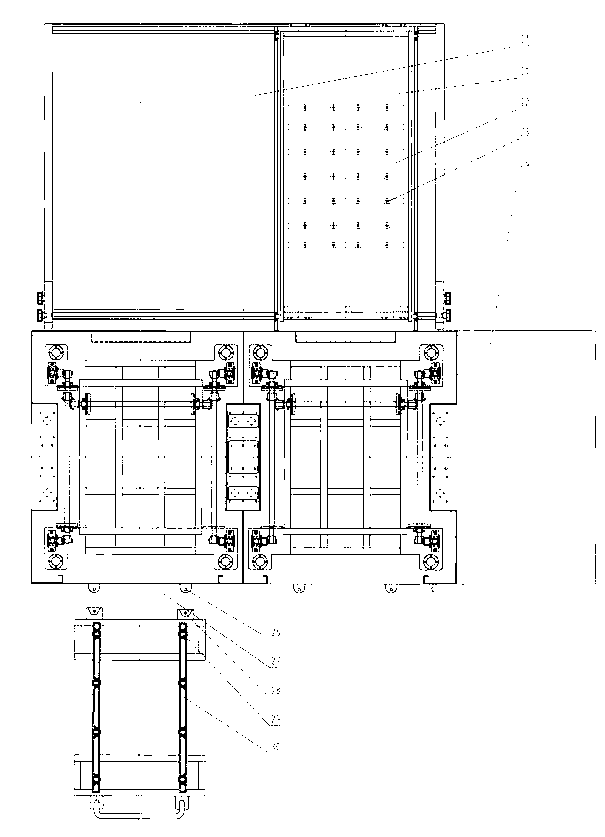

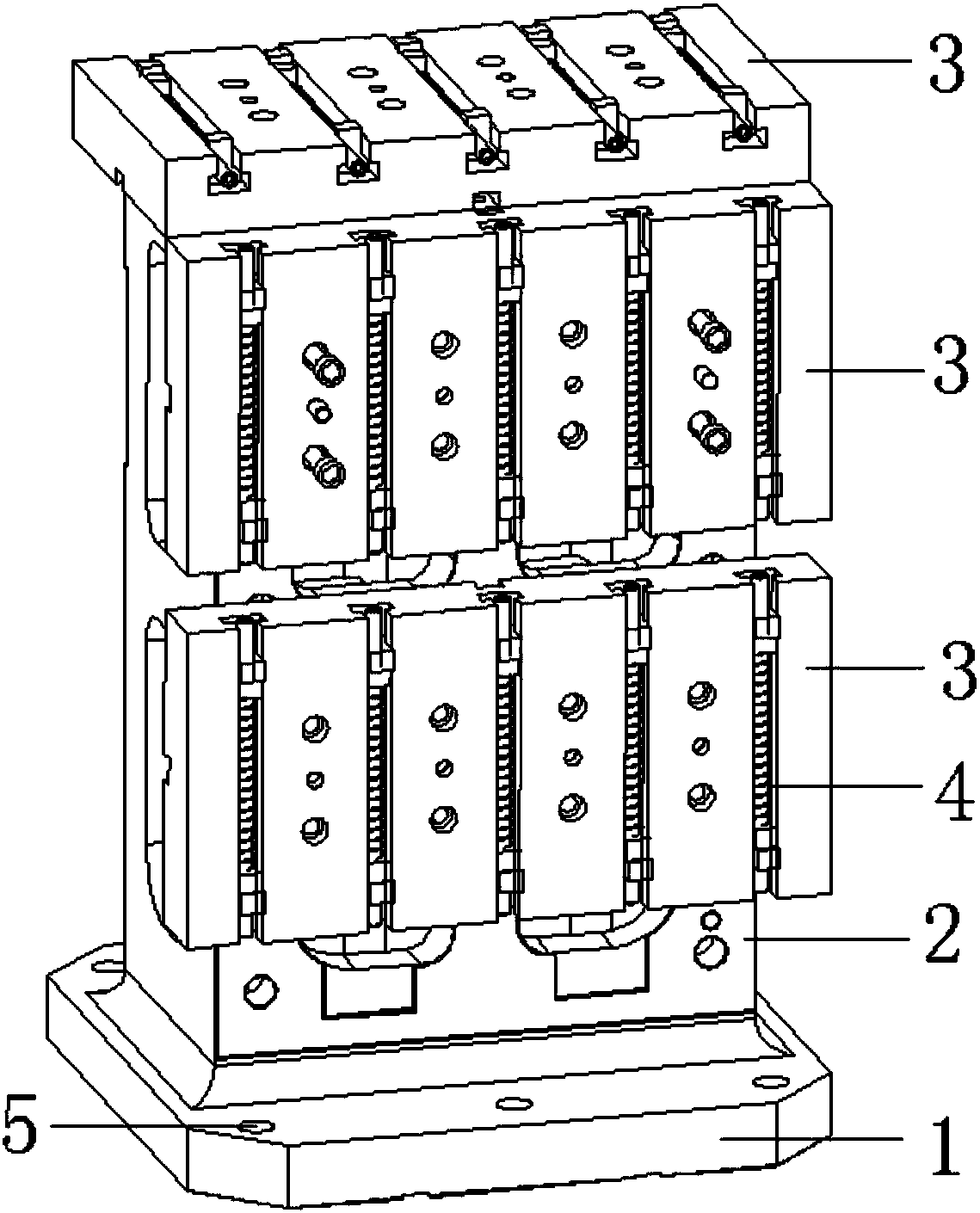

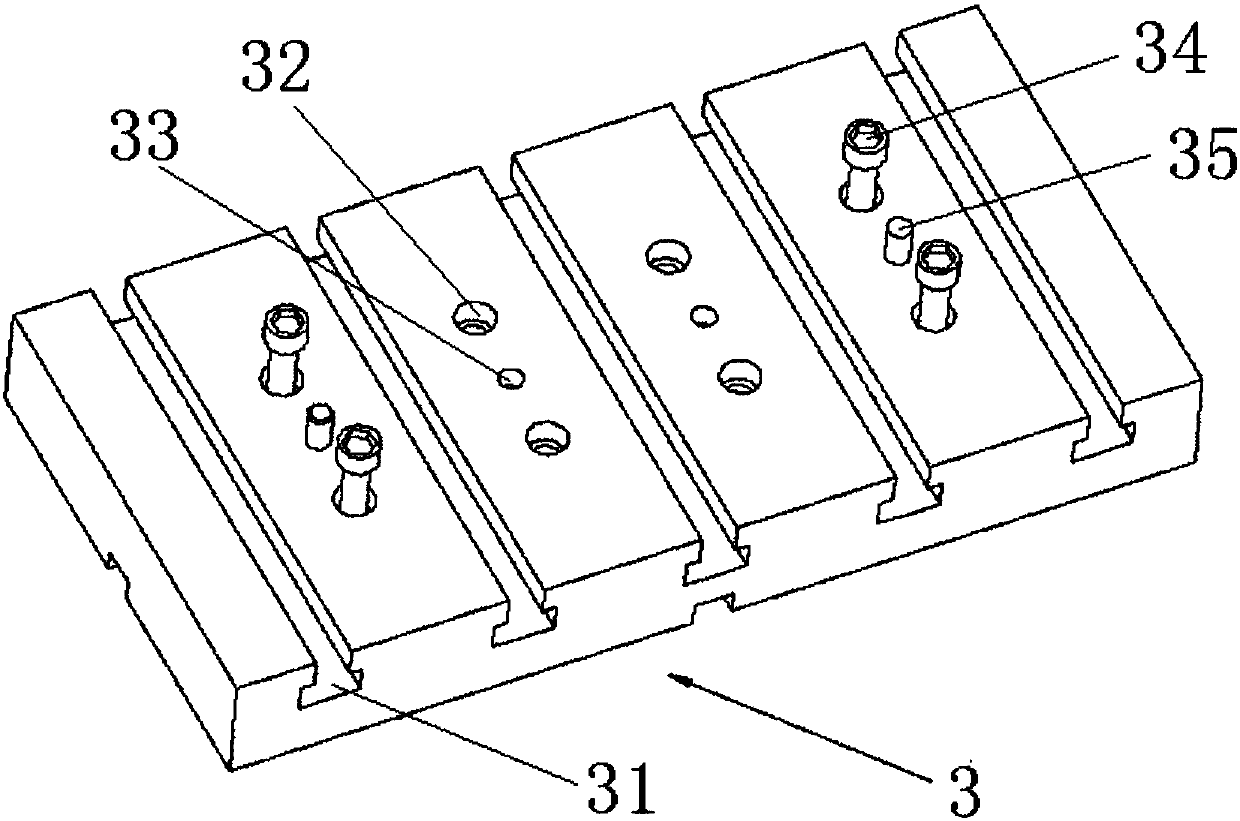

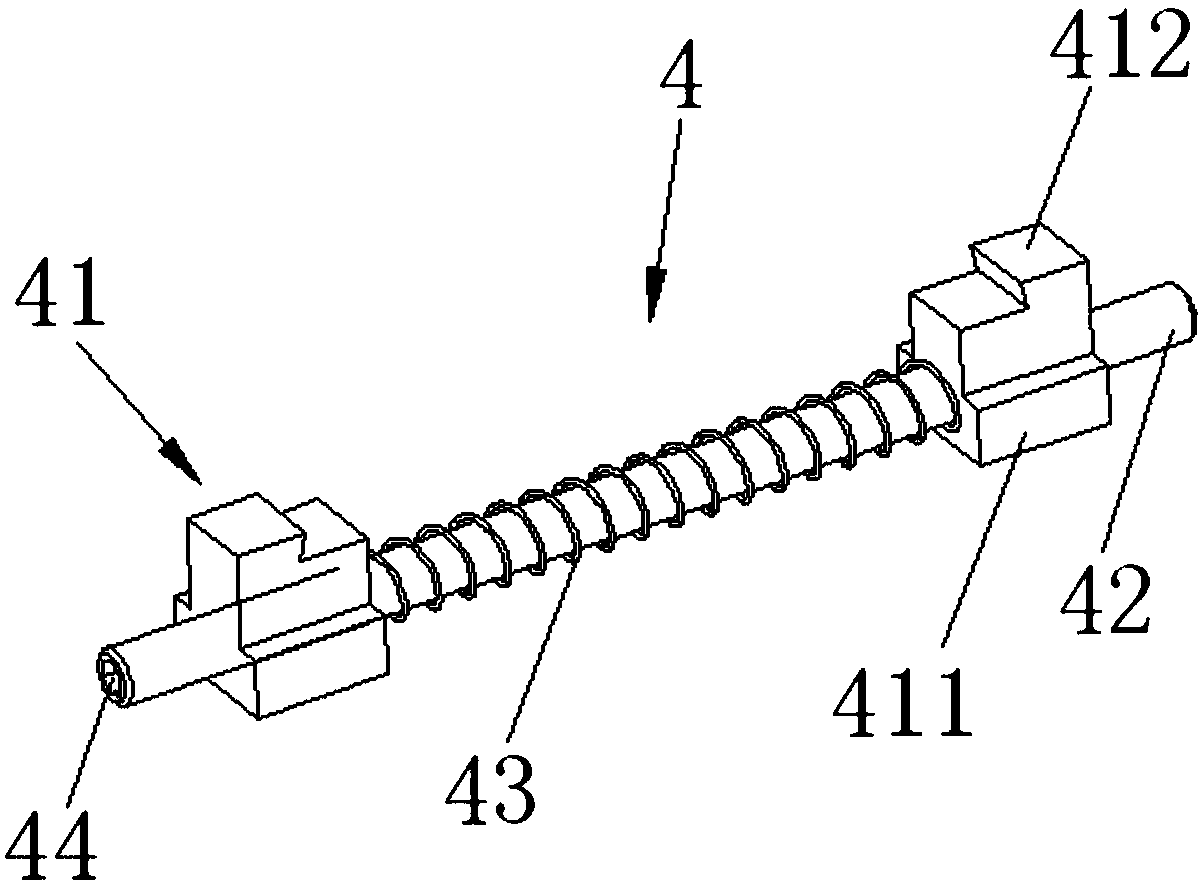

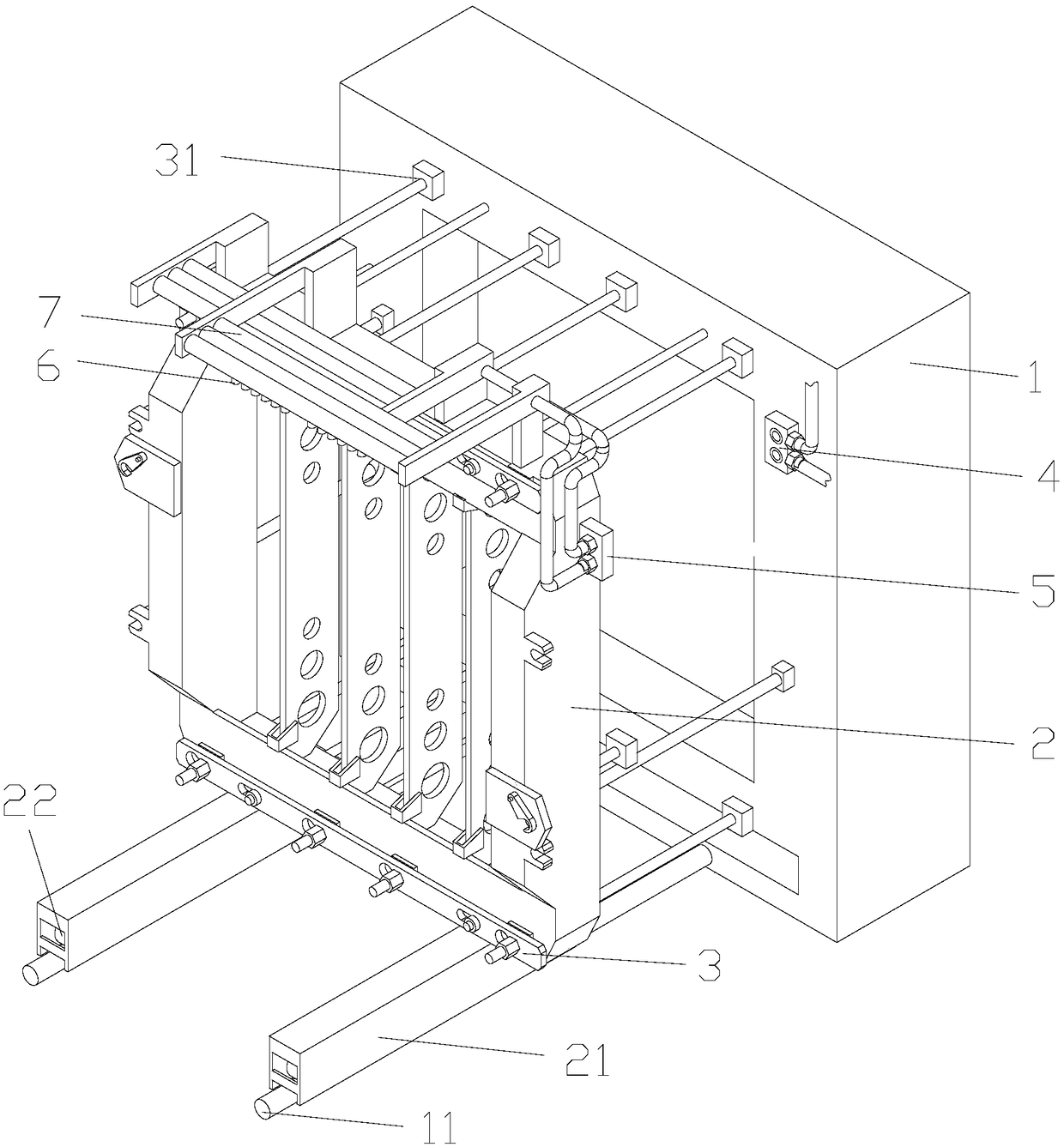

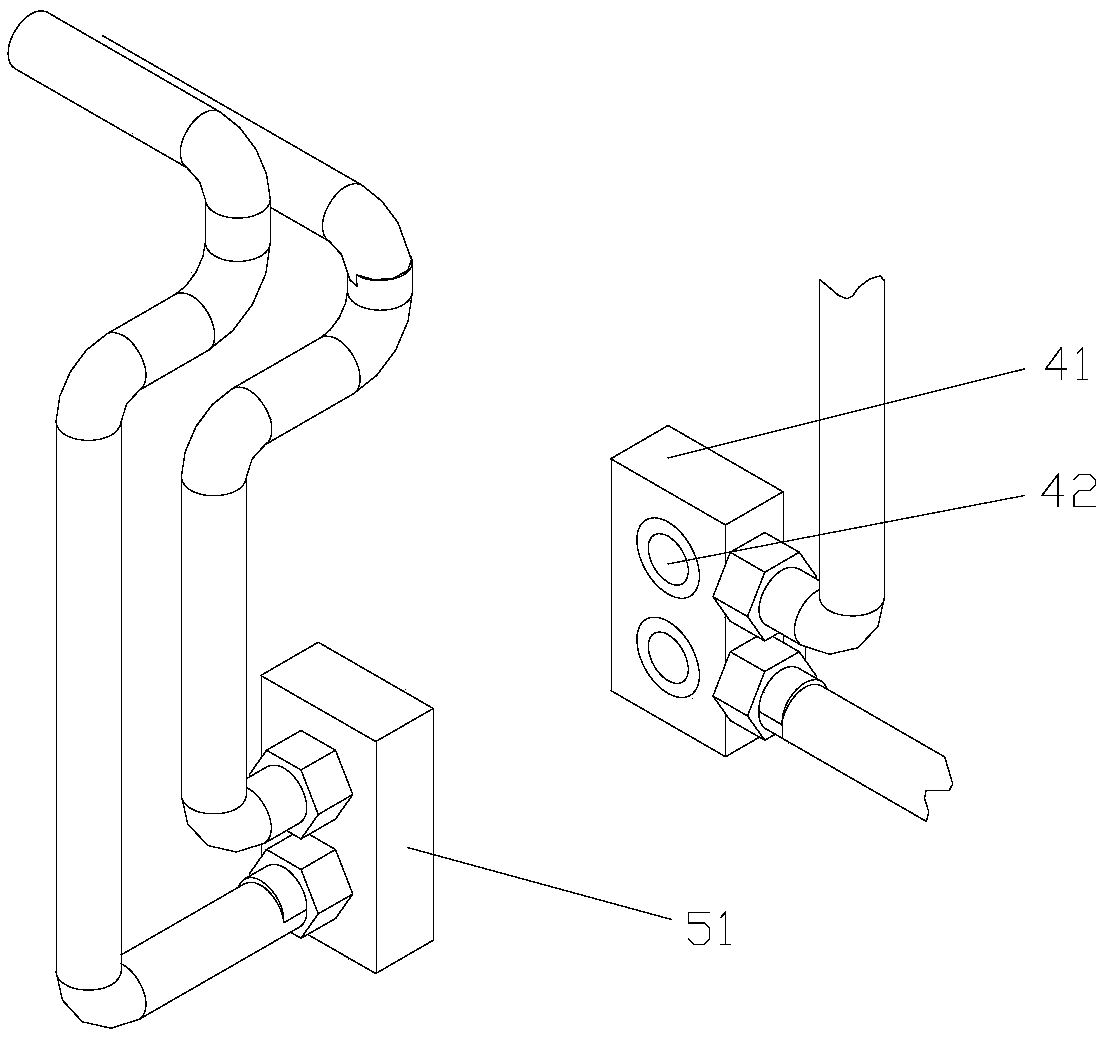

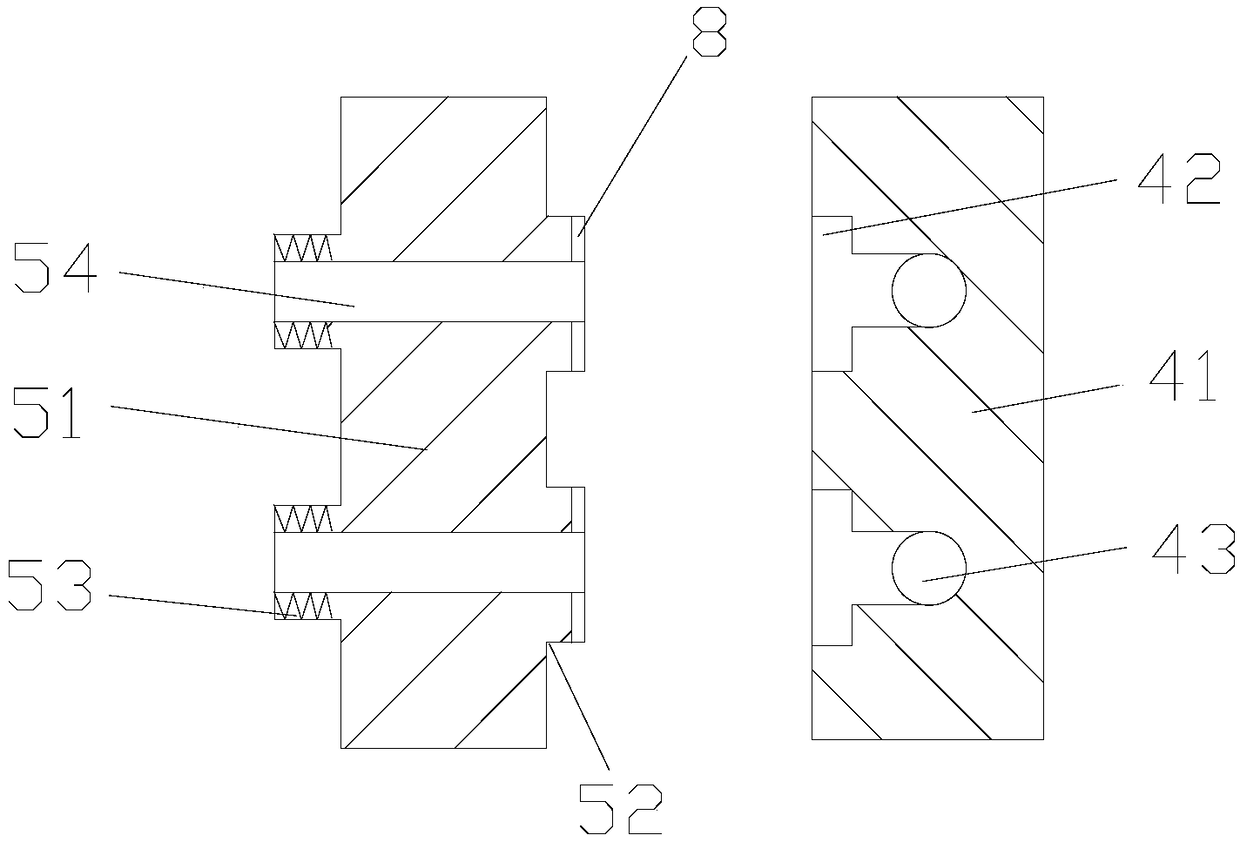

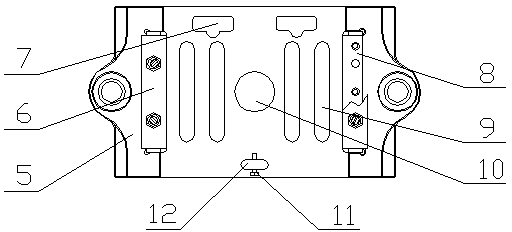

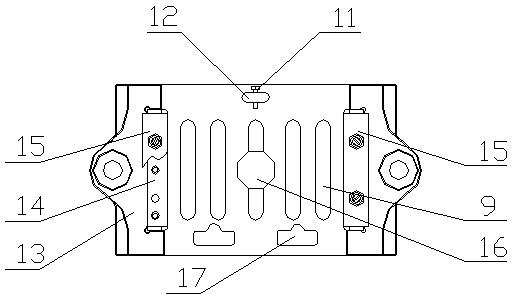

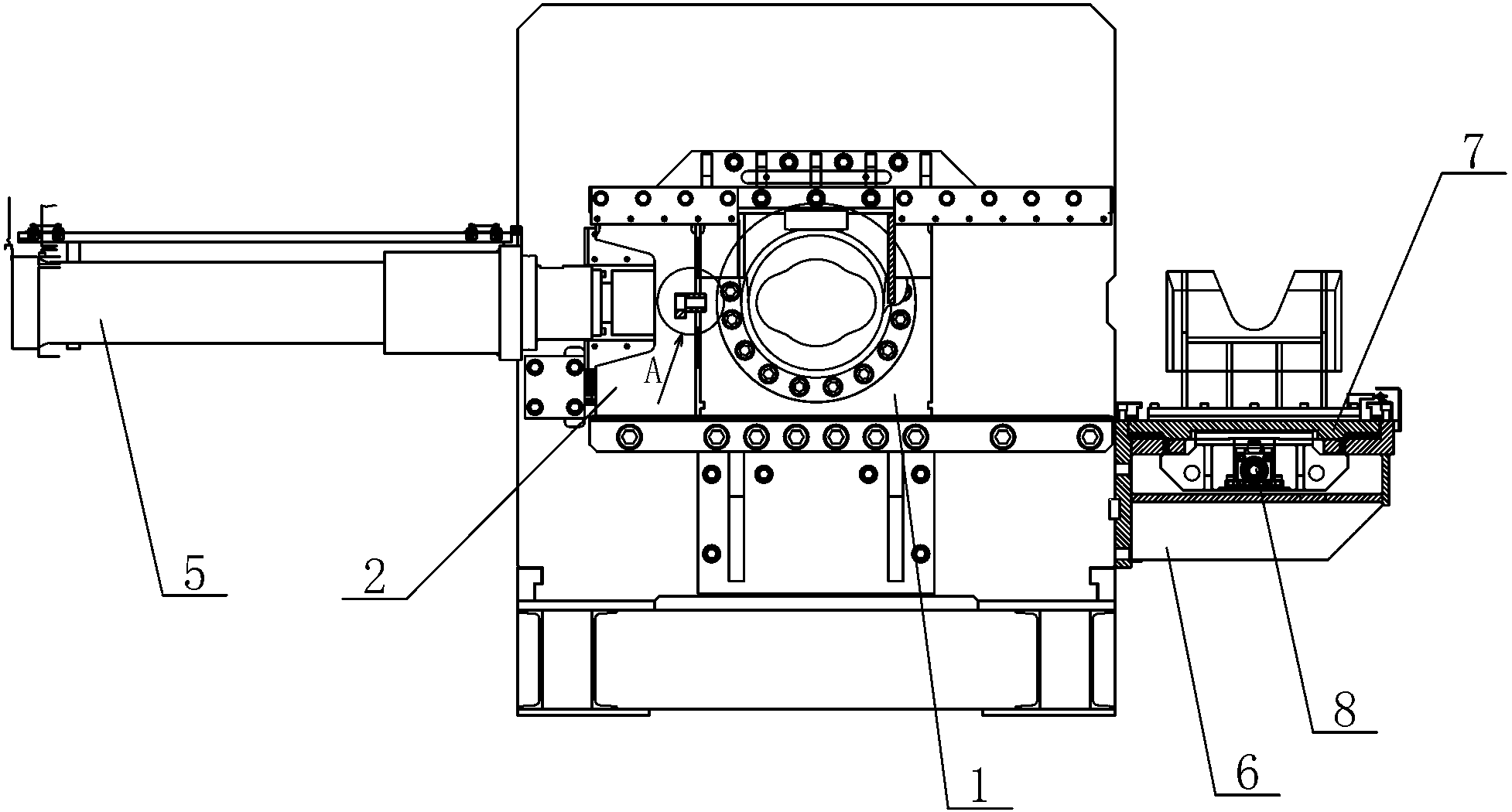

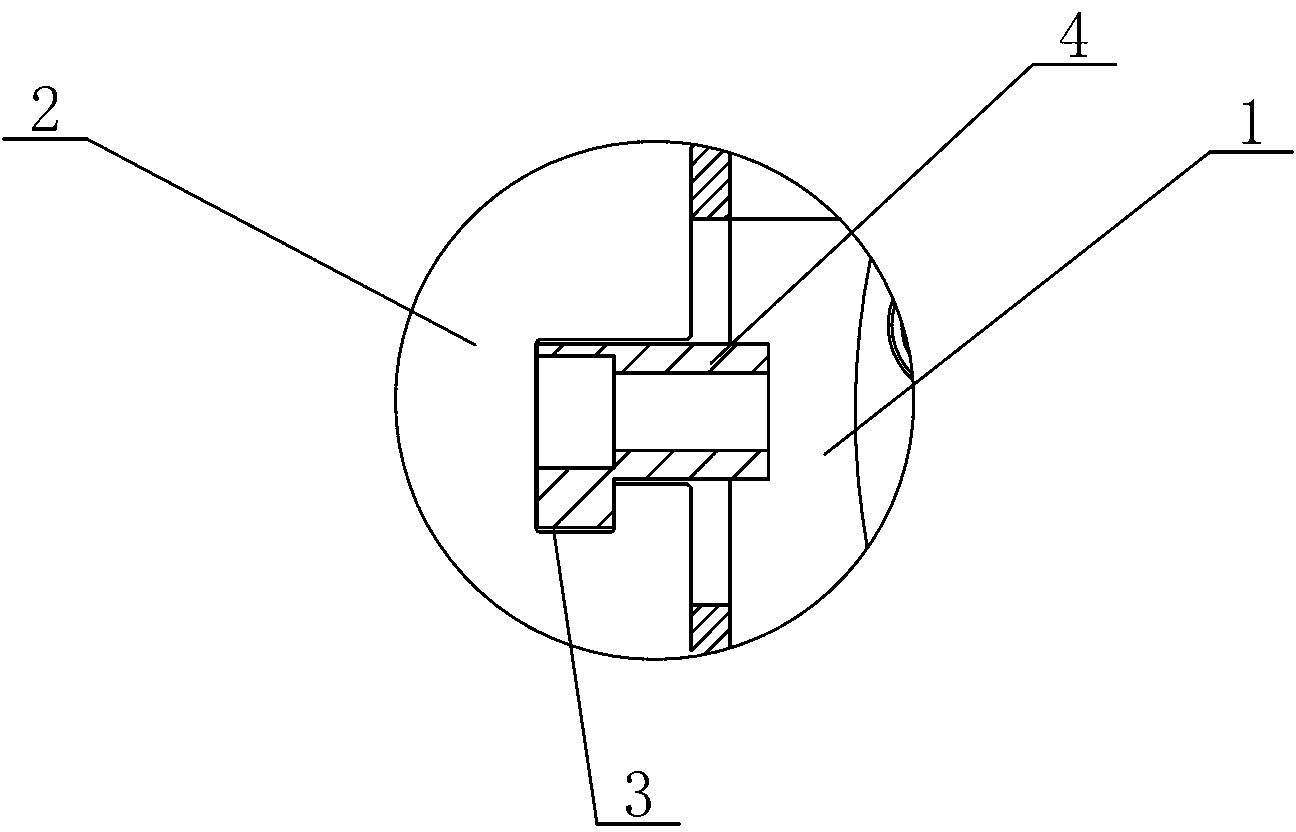

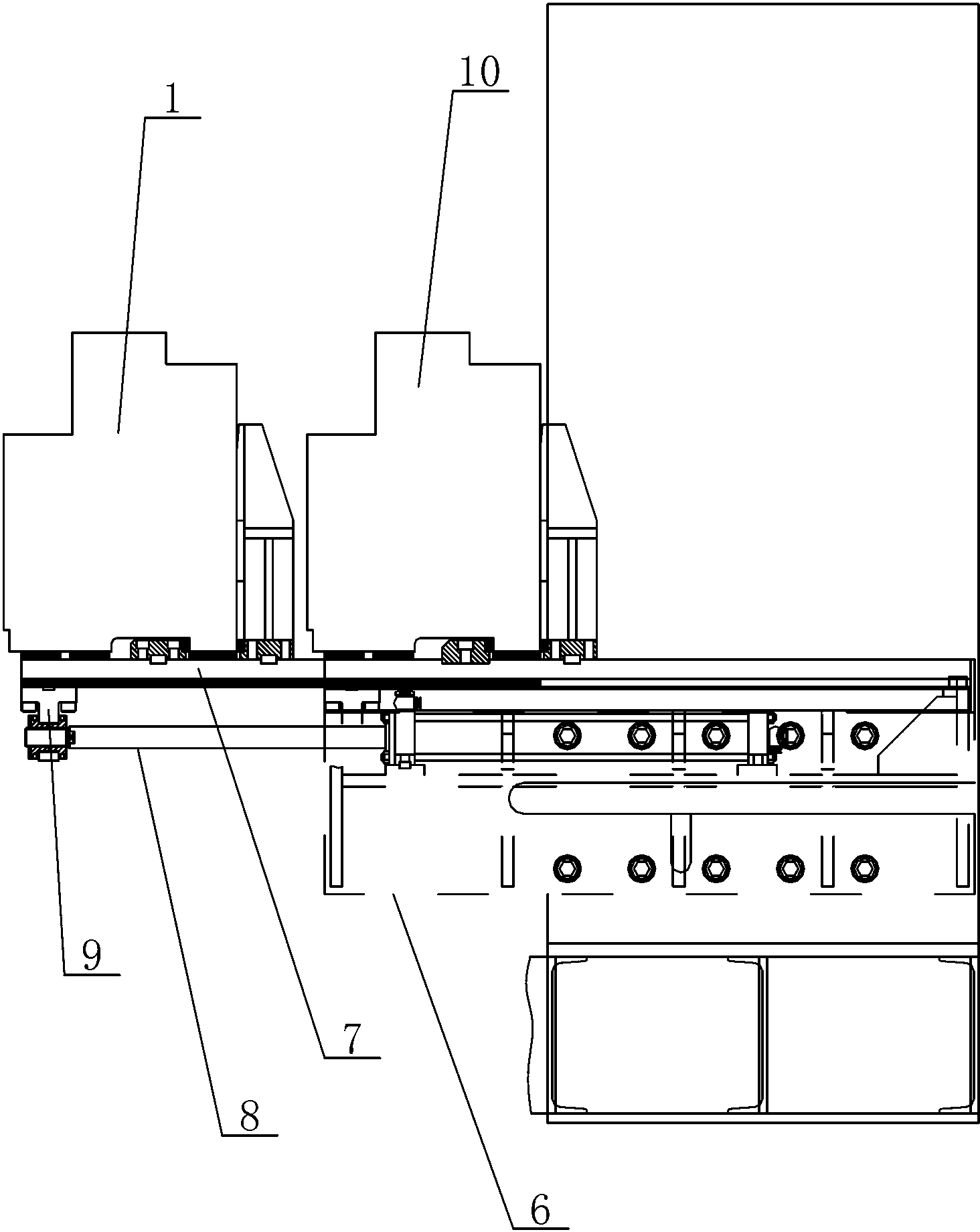

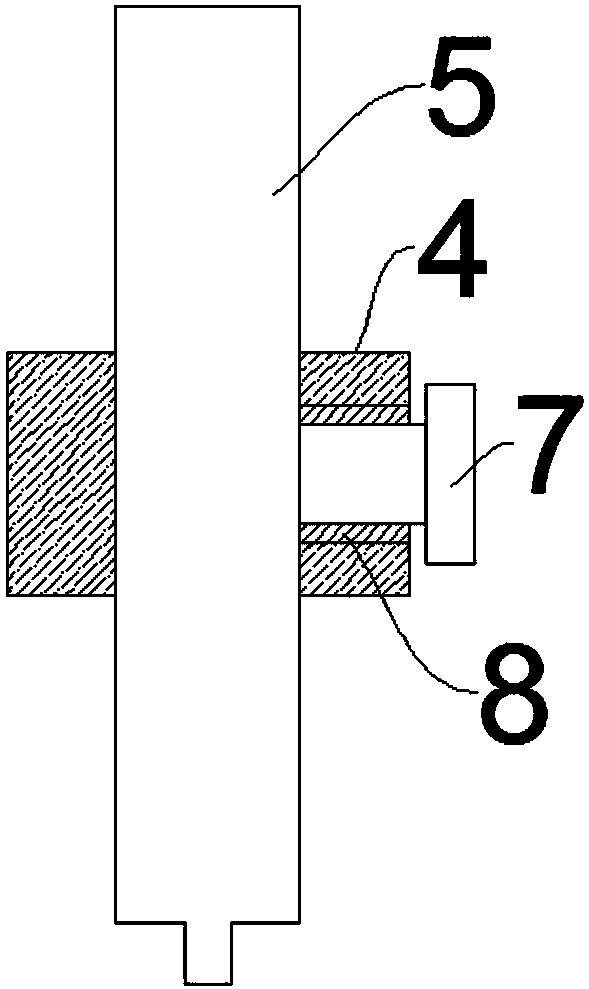

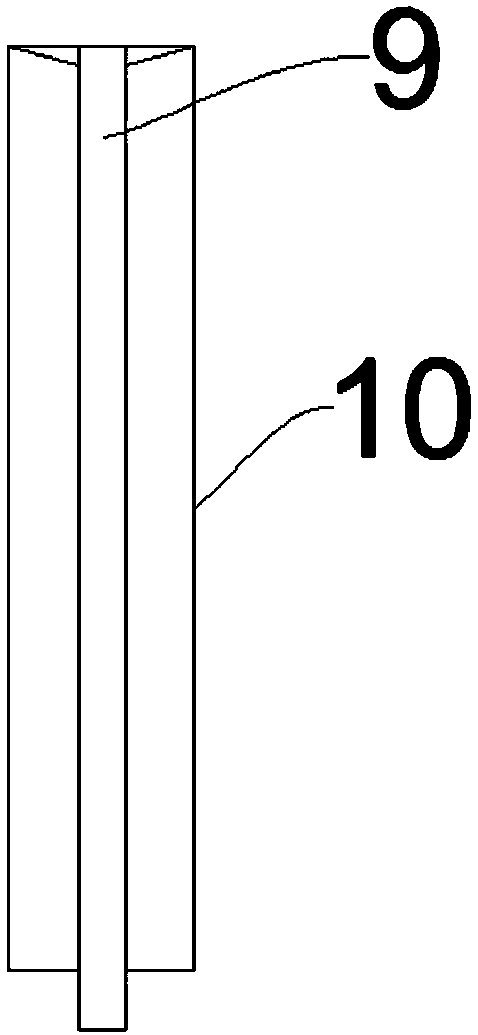

Quick die replacement mechanism for low pressure casting machine

The invention relates to a quick die replacement mechanism for a low pressure casting machine. The mechanism comprises a frame (1), an upper die fixing plate (2), a lower die (3), a lower die fixing plate (4), an upper die (6), hydraulic oil cylinders (8), bolts (9) and latches (10), wherein two groups of hydraulic locking mechanisms are symmetrically arranged on each of the upper die fixing plate (2) and the lower die fixing plate (4). The mechanism is characterized in that the bolts (9) are pulled to be separated from the latches (10) by the hydraulic oil cylinders (8), so that the dies are separated from the fixing plates, and on the contrary, the bolts (9) are pushed to be inserted into the latches (10) by the hydraulic oil cylinders (8), so that the dies are locked on the fixing plates. The locking mechanisms are appropriately added on the basis of the conventional low pressure casting machine, so that die replacement time is shortened from at least half an hour to at most ten minutes, time and labor are greatly saved, the utilization rate of equipment is improved to the greatest extent, and the dies are quickly replaced.

Owner:江苏天宏智能装备有限公司

Full-automatic plate plastics sucking moulding machine

The invention discloses a full-automatic plate plastics sucking moulding machine. The plastics sucking moulding machine comprises a rack, molding devices, a heating device, a transport device and a material table. The plastics sucking moulding machine is characterized in that there are two molding devices. A first guide rail and a second guide rail are arranged on the rack. The heating device is connected with a power source. The heating device moves along the first guide rail to the molding position of the molding device. The transport device comprises a transport table. The lower end face of the transport table is equipped with suckers, The suckers are connected with an air source. The second guide rail comprises a longitudinal guide rail, a transverse guide rail and an axial guide rail. The power source drives the transport table to move along the second guide rail from the material sucking position of the material table to the molding position of the molding device. The plastics sucking moulding machine takes double positions, and loads and takes materials automatically. The plastics sucking moulding machine raises the production efficiency greatly, reduces the power consumption, transports and takes materials through the transport device to replace manual operations, and reduces the production cost.

Owner:温州瑞佳吸塑机械有限公司

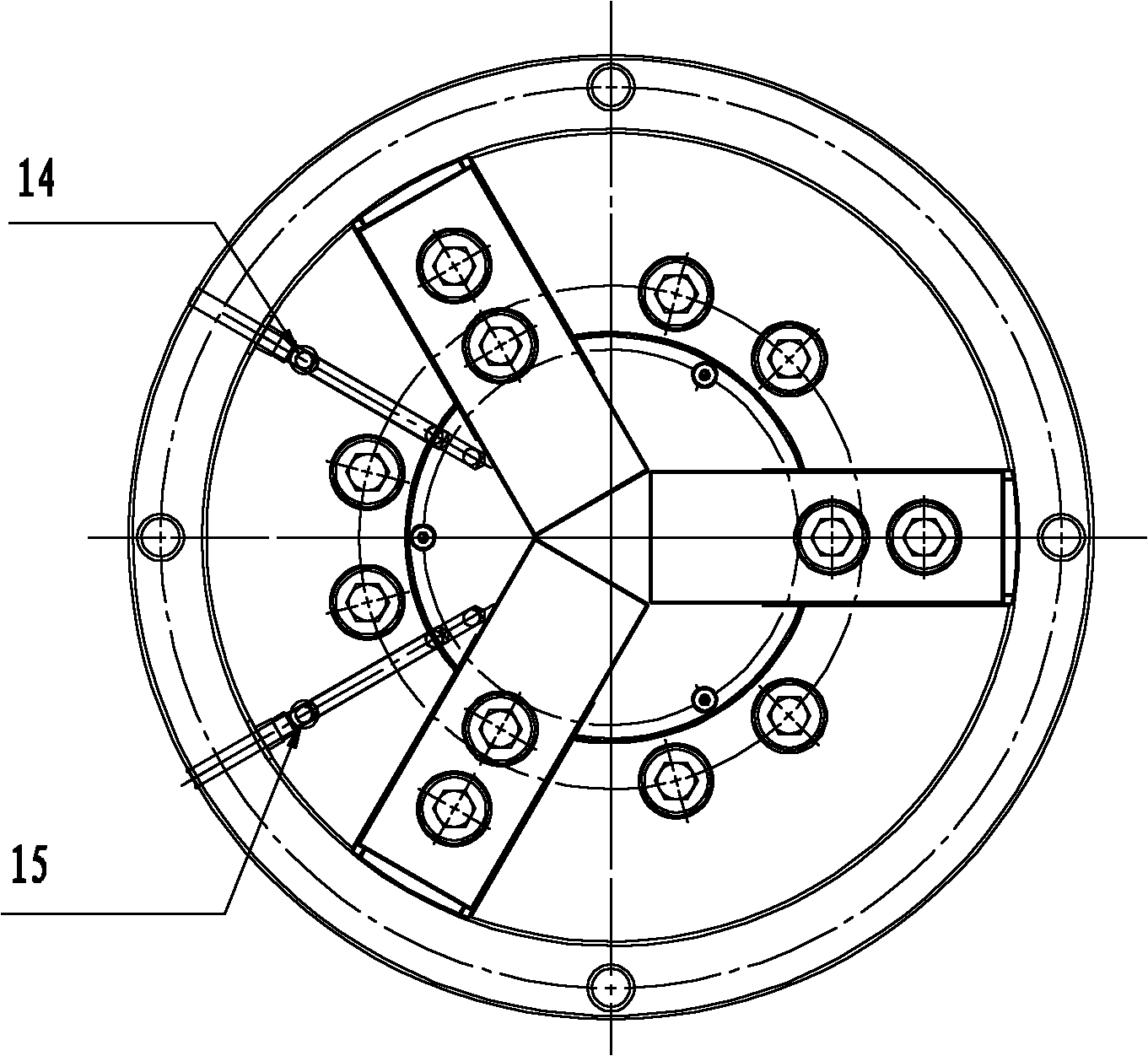

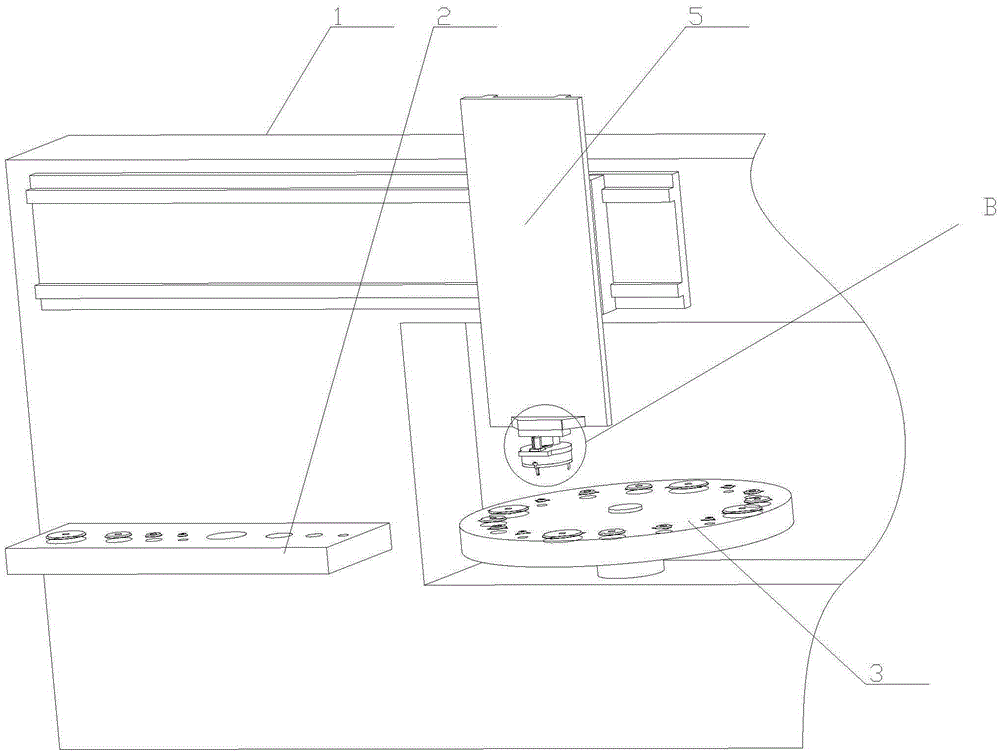

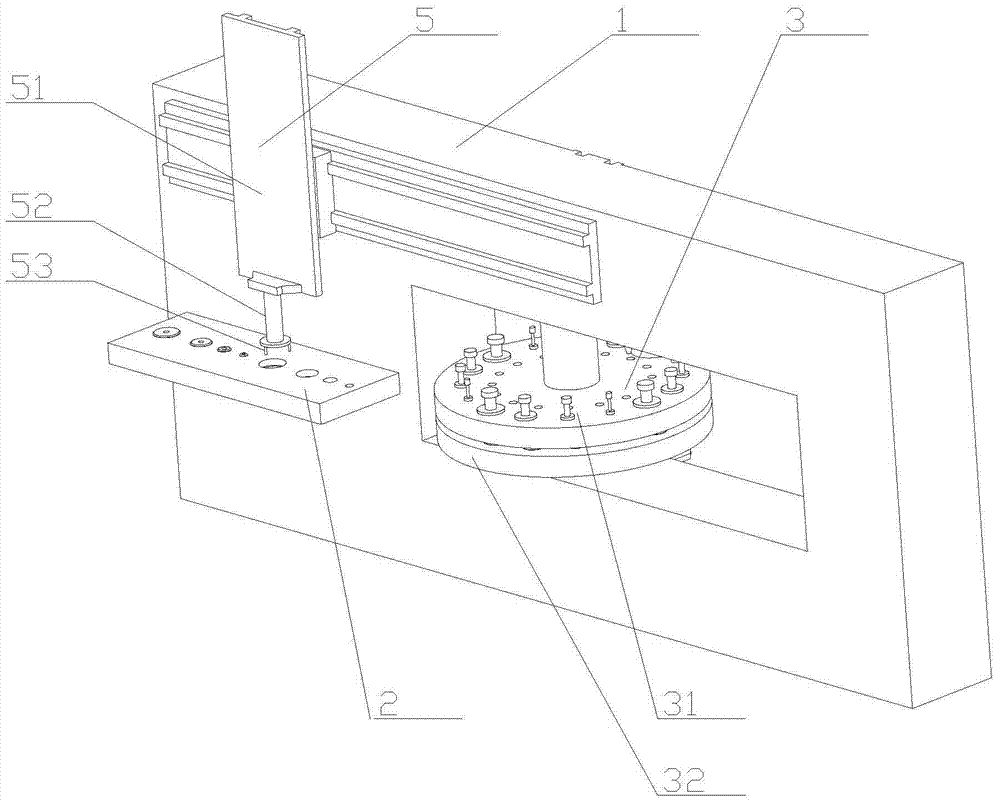

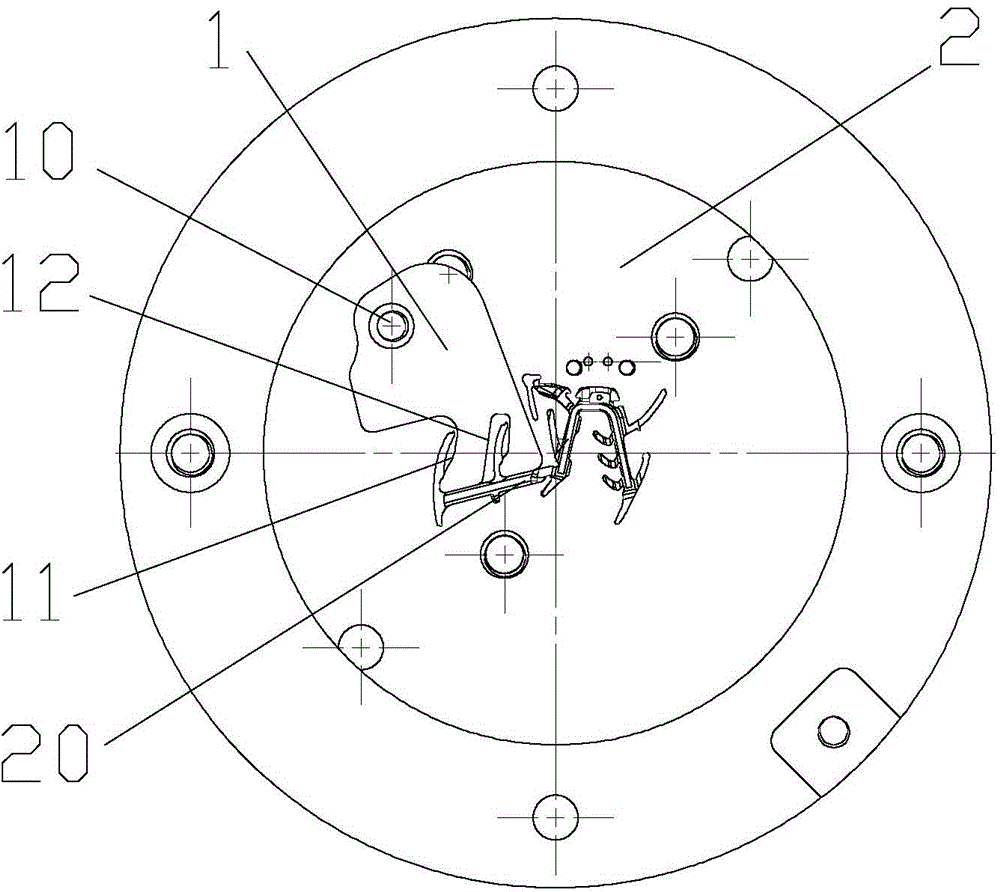

Die replacing device for numerical control turret punch press

The invention relates to the field of auxiliary equipment for a numerical control turret punch press, in particular to a die replacing device for the numerical control turret punch press. The die replacing device for the numerical control turret punch press is exquisite in structure, high in working efficiency and good in stability. When used, the die replacing device for the numerical control turret punch press can effectively clamp dies in various sizes and also can accurately and efficiently put the dies into die positions, and therefore rapid die replacement is achieved. When a cam disc rotates, arc-shaped cam grooves are used for driving clamping jaws to linearly move along radial sliding holes in a reciprocating mode, and therefore the dies below a guide plate can be conveniently and efficiently grabbed or released. The die replacing device for the numerical control turret punch press is high in working efficiency and good in stability. The die replacing device for the numerical control turret punch press can effectively clamp the dies of various sizes and also can accurately and efficiently put the dies into the die positions, and therefore the purpose of rapid die replacement is finally achieved.

Owner:江苏扬力数控机床有限公司

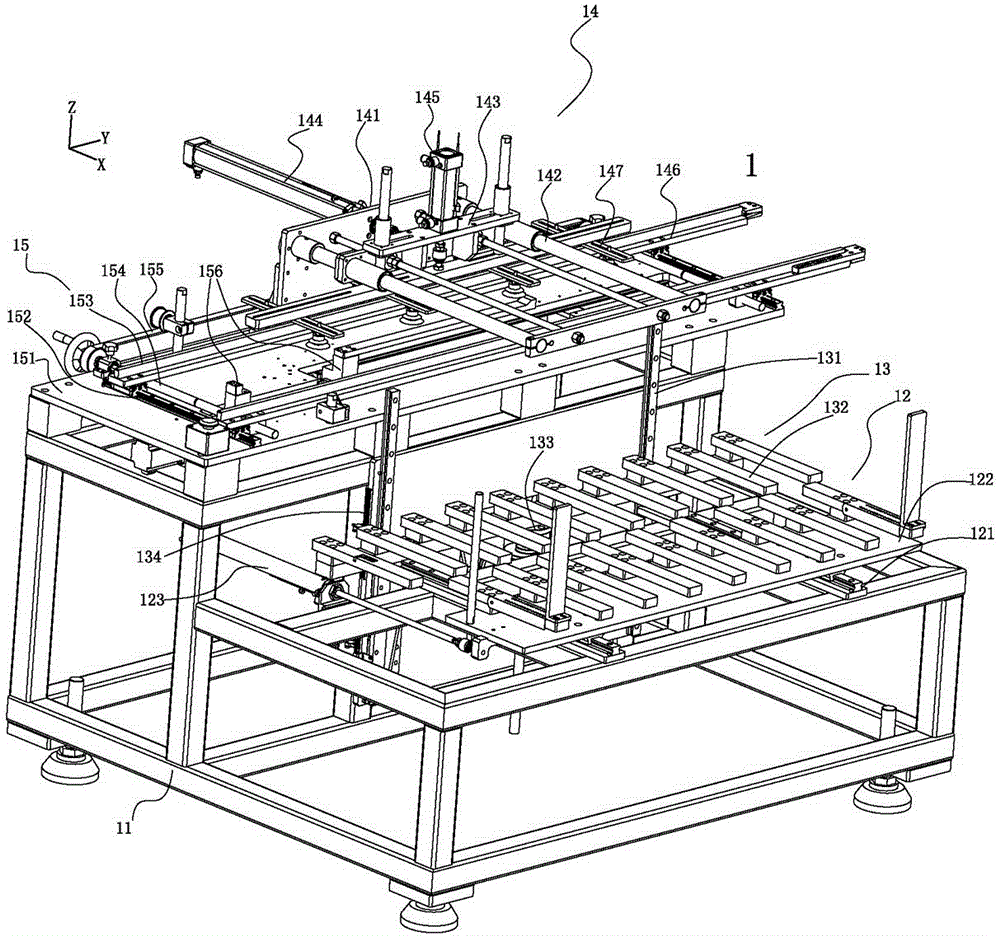

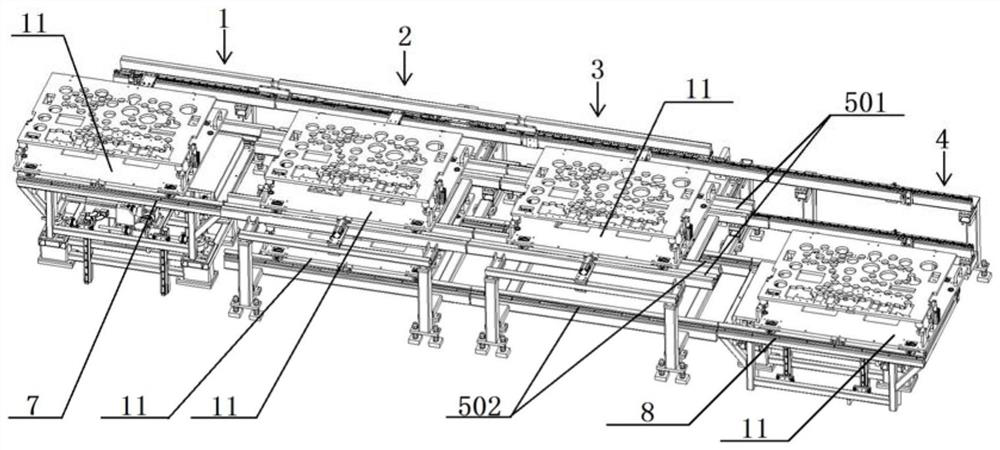

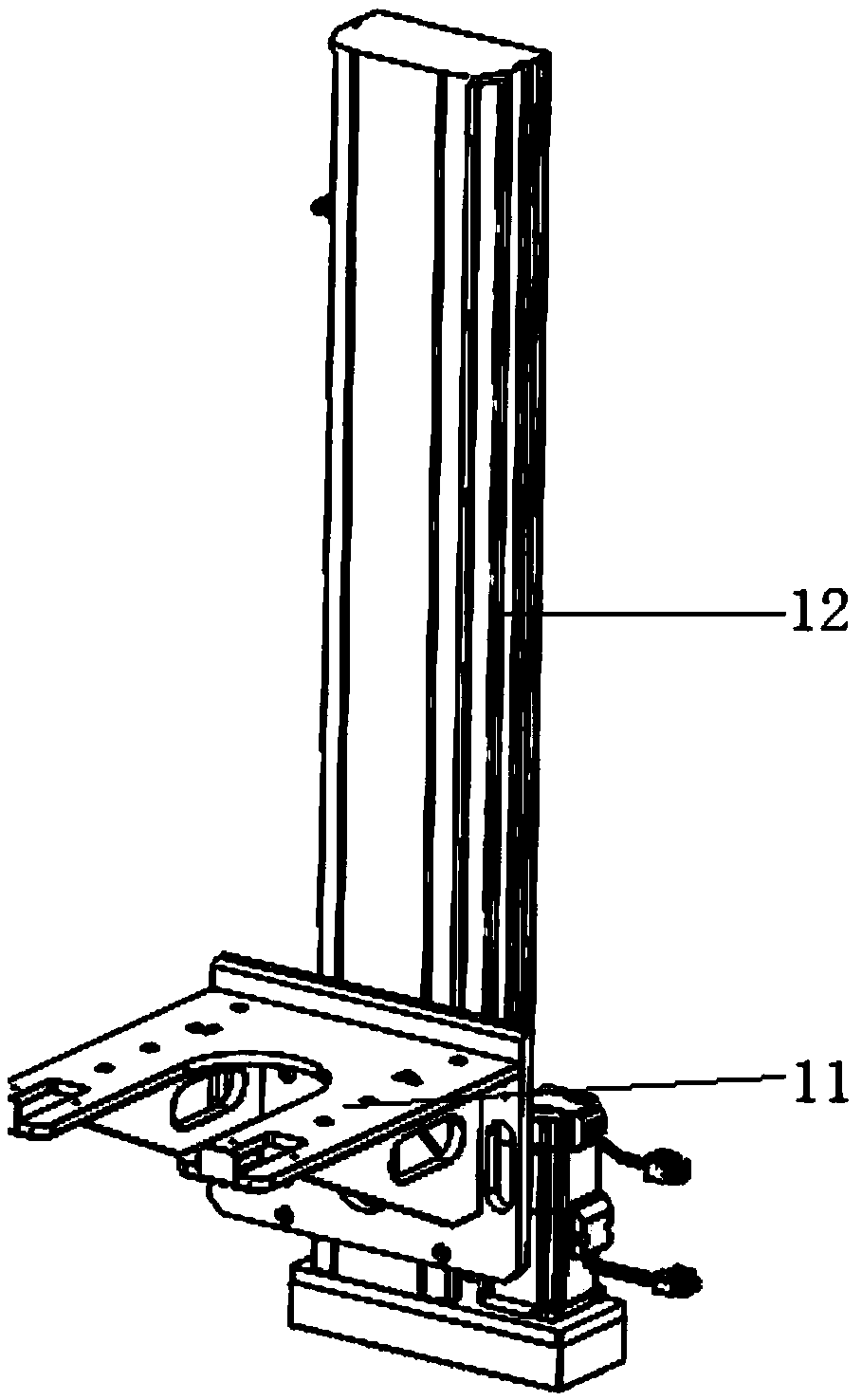

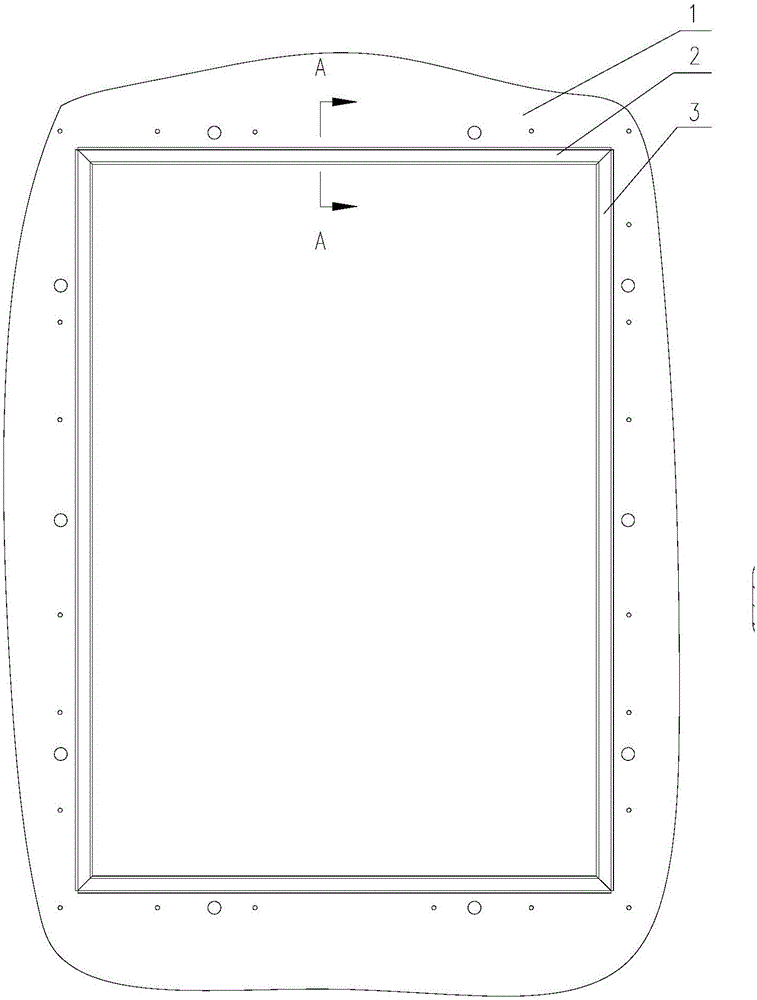

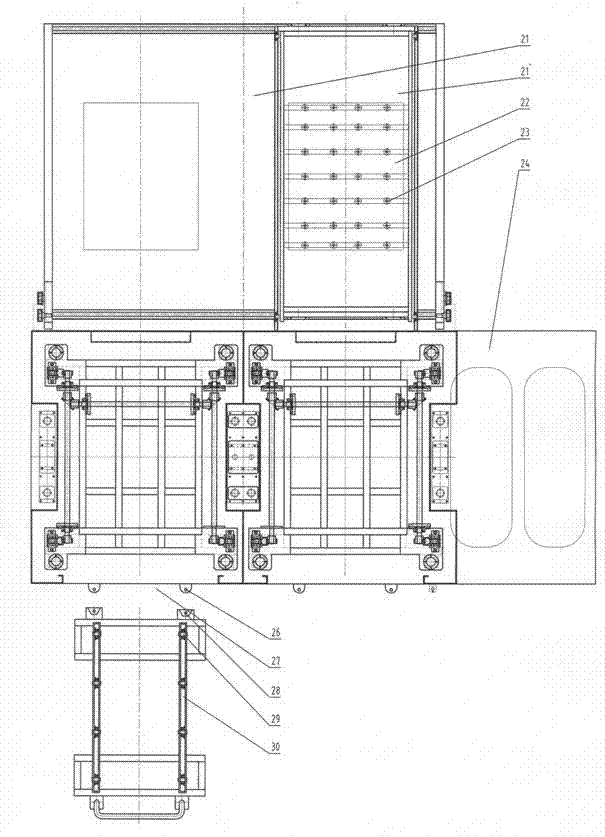

Flexible welding production line for automobile door trim panel

PendingCN112339277ARealize flexible collinear productionFlexible welding realizedDomestic articlesManufacturing lineIndustrial engineering

The invention relates to a flexible welding production line for an automobile door trim panel. The flexible welding production line comprises a workpiece placing station frame, two sets of flexible welding station frames, a workpiece taking station frame, an upper-layer tool conveying rail, a lower-layer tool return rail and two sets of transfer guide rails, wherein the workpiece placing station frame serves as a workpiece placing station, a first forming die lifting mechanism is arranged on the workpiece placing station frame, one set of transfer guide rails are installed on the first formingdie lifting mechanism in the horizontal direction, and the first forming die lifting mechanism is used for transferring a forming die located on the lower-layer tool return rail to the upper-layer tool conveying rail; and a second forming die lifting mechanism is arranged on the workpiece taking station frame, the other set of transfer guide rails are installed on the second forming die lifting mechanism in the horizontal direction, and the second forming die lifting mechanism is used for transferring the forming die located on the upper-layer tool conveying rail to the lower-layer tool return rail. The flexible welding production line has the advantages of being suitable for various small-batch automobile door trim panel projects and capable of realizing flexible collinear production ofvarious products.

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

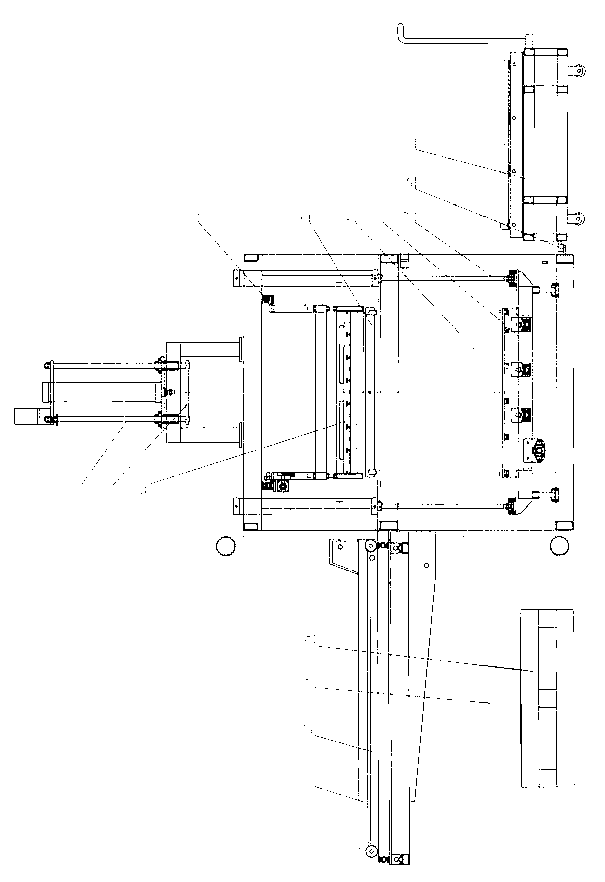

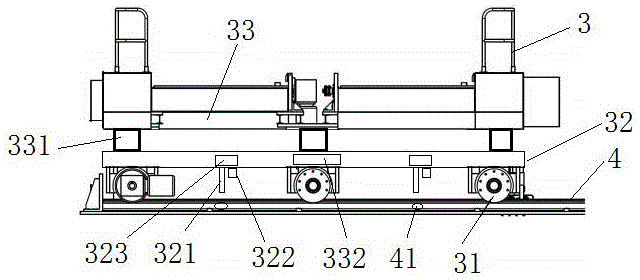

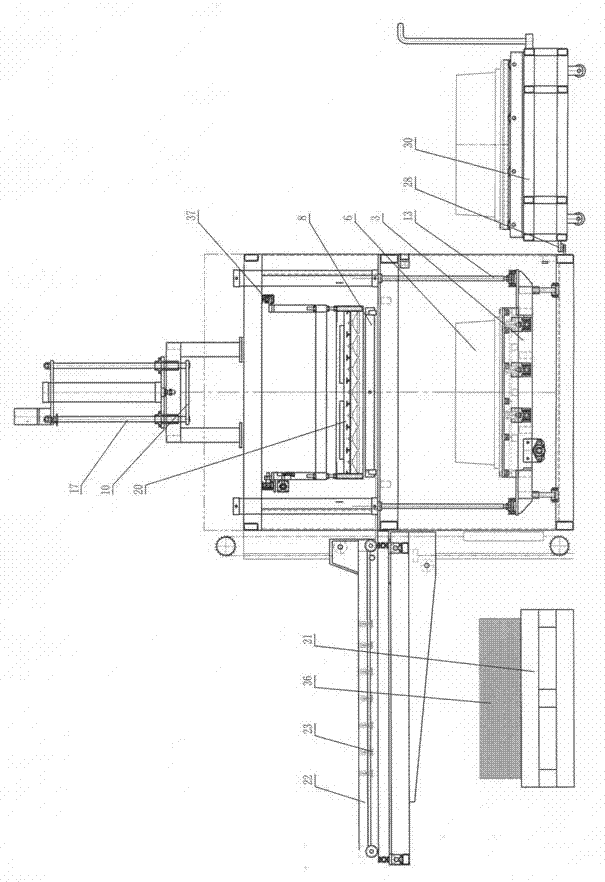

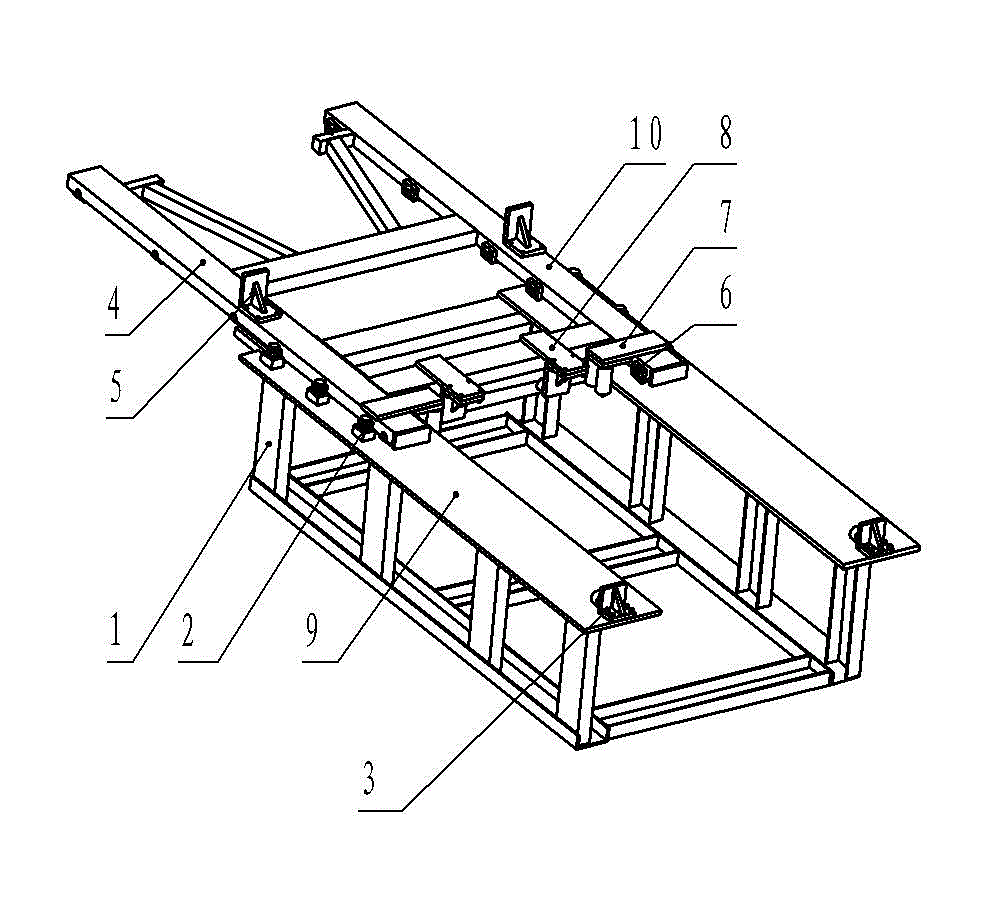

Die changing trolley of press machine and die changing method

The invention discloses a die changing trolley of a press machine in the field of press machines. The die changing trolley comprises a trolley body; the bottom of the trolley body is provided with wheels, the trolley body is provided with a driving mechanism, a pair of die carrier guide rails and a die carrier pushing-pulling mechanism, the die carrier pushing-pulling mechanism comprises a pushing-pulling motor, the output end of the pushing-pulling motor is provided with a belt pulley I, and the belt pulley I is connected with a belt pulley II in a driving way through a belt to which a sliding pothook is connected; the lower part of a die carrier is provided with double rows of die carrier rollers, the trolley body is provided with a die carrier limiting mechanism comprising a base plate, the base plate is provided with a slide wheel axle which is rotatably connected with a side wheel, and the upper end of the side wheel axle is provided with a pressing plate; and the trolley body is provided with a die carrier lifting mechanism in parallel, the die carrier lifting mechanism comprises a roller carrier controlled by a hydraulic cylinder to lift, horizontal rollers are horizontally arranged on the roller carrier, and roller shafts of the horizontal rollers are parallel to the die carrier guide rails. By using the die changing trolley, the die carrier of the press machine can be rapidly changed, the die changing time can be shortened, and the die changing efficiency can be increased.

Owner:YANGLI GRP CORP LTD

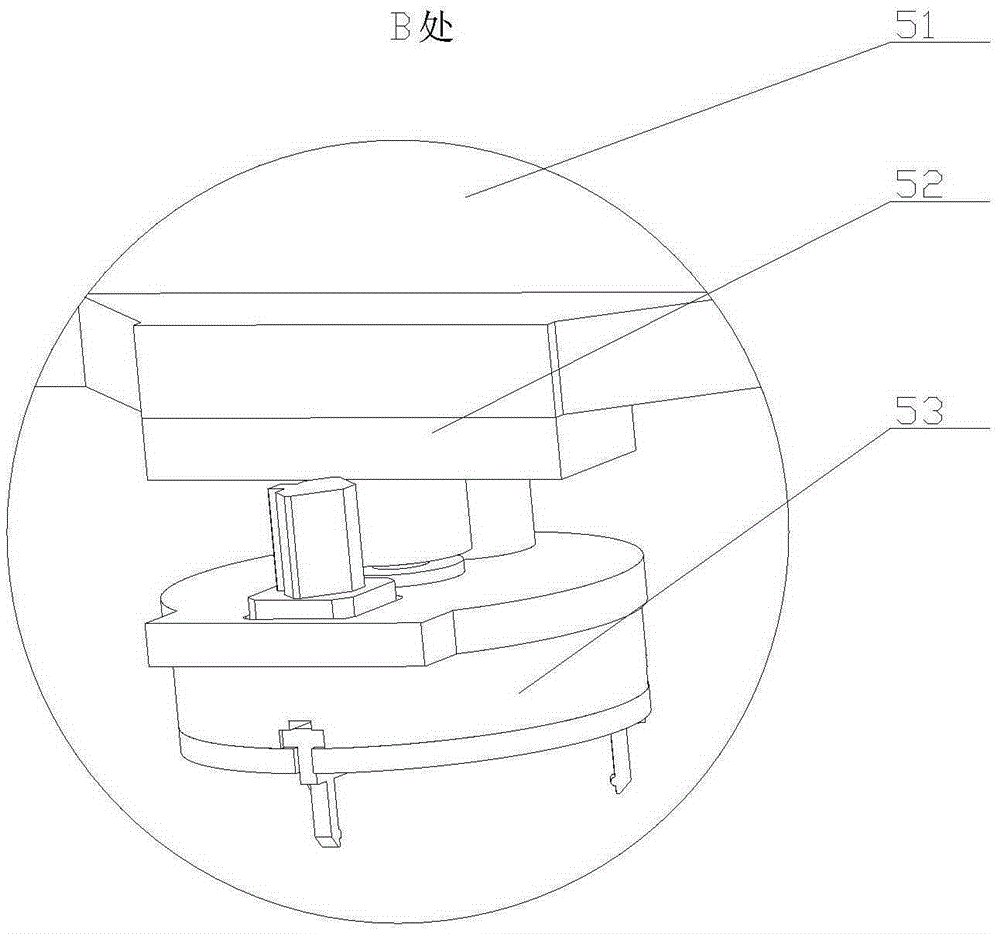

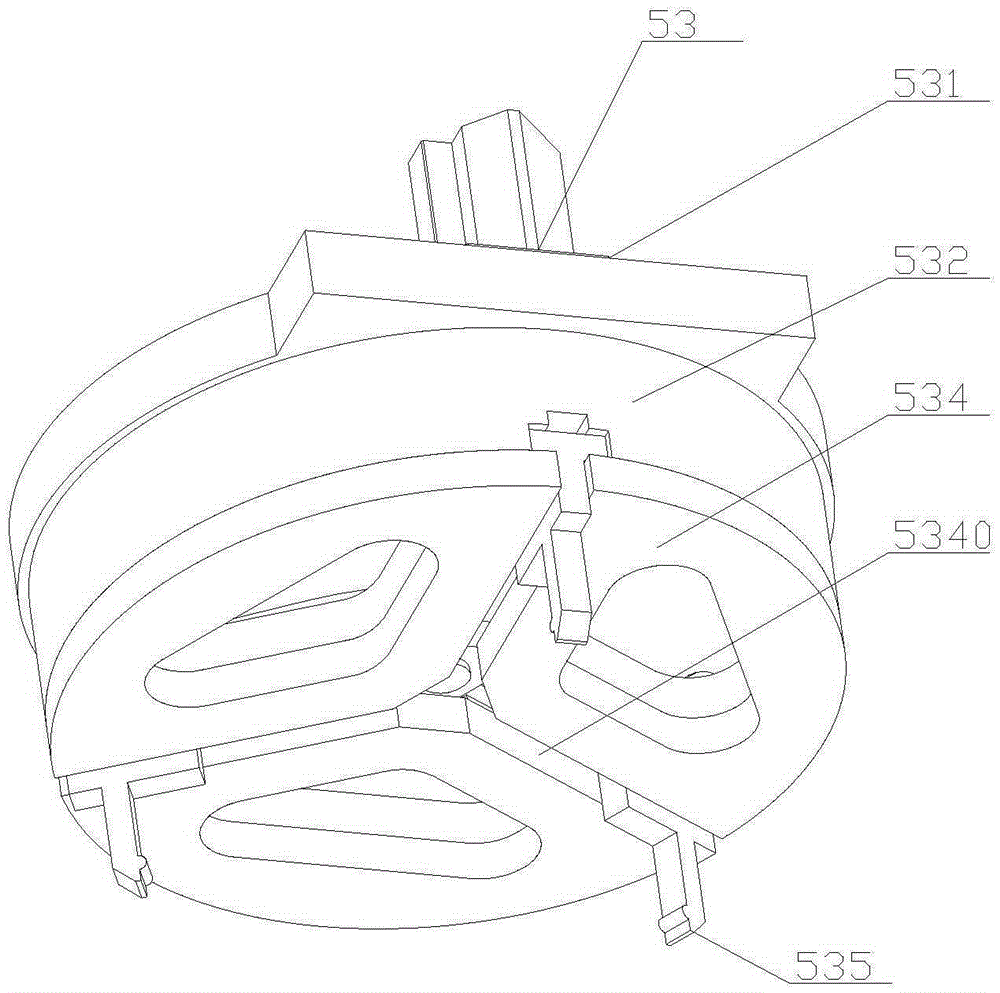

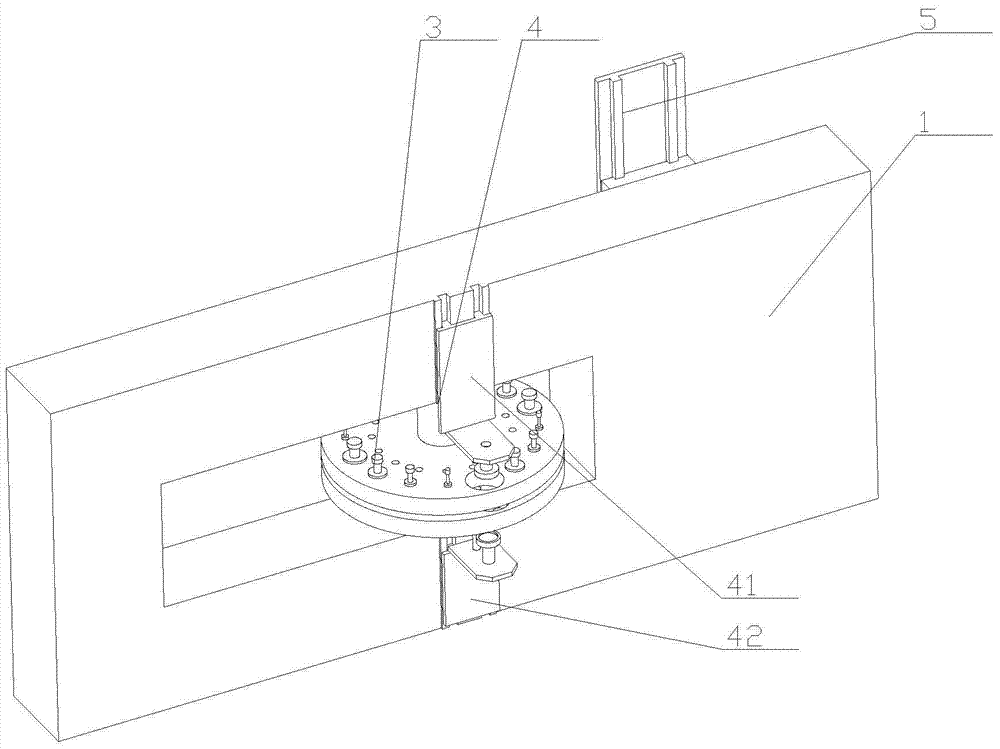

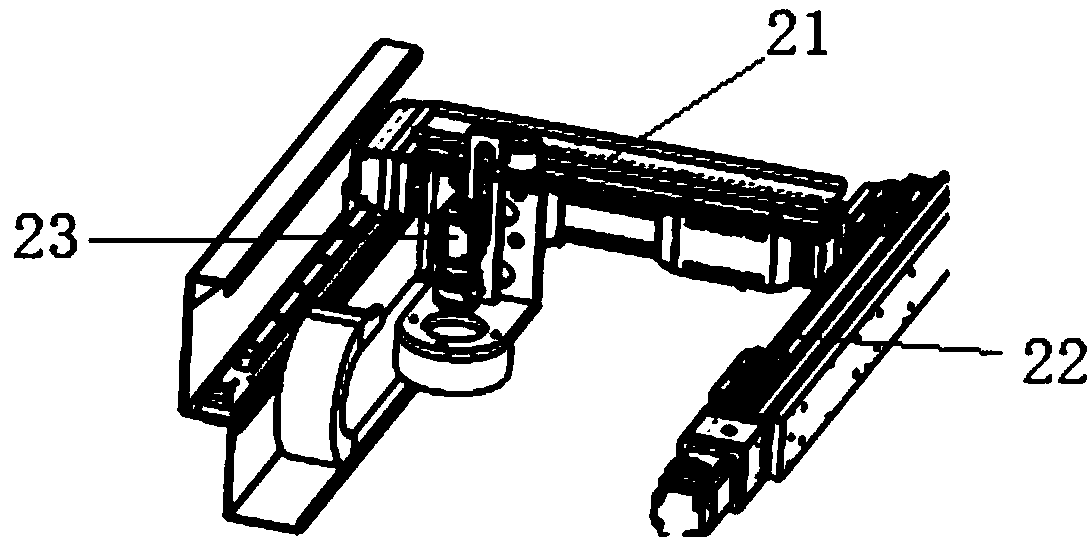

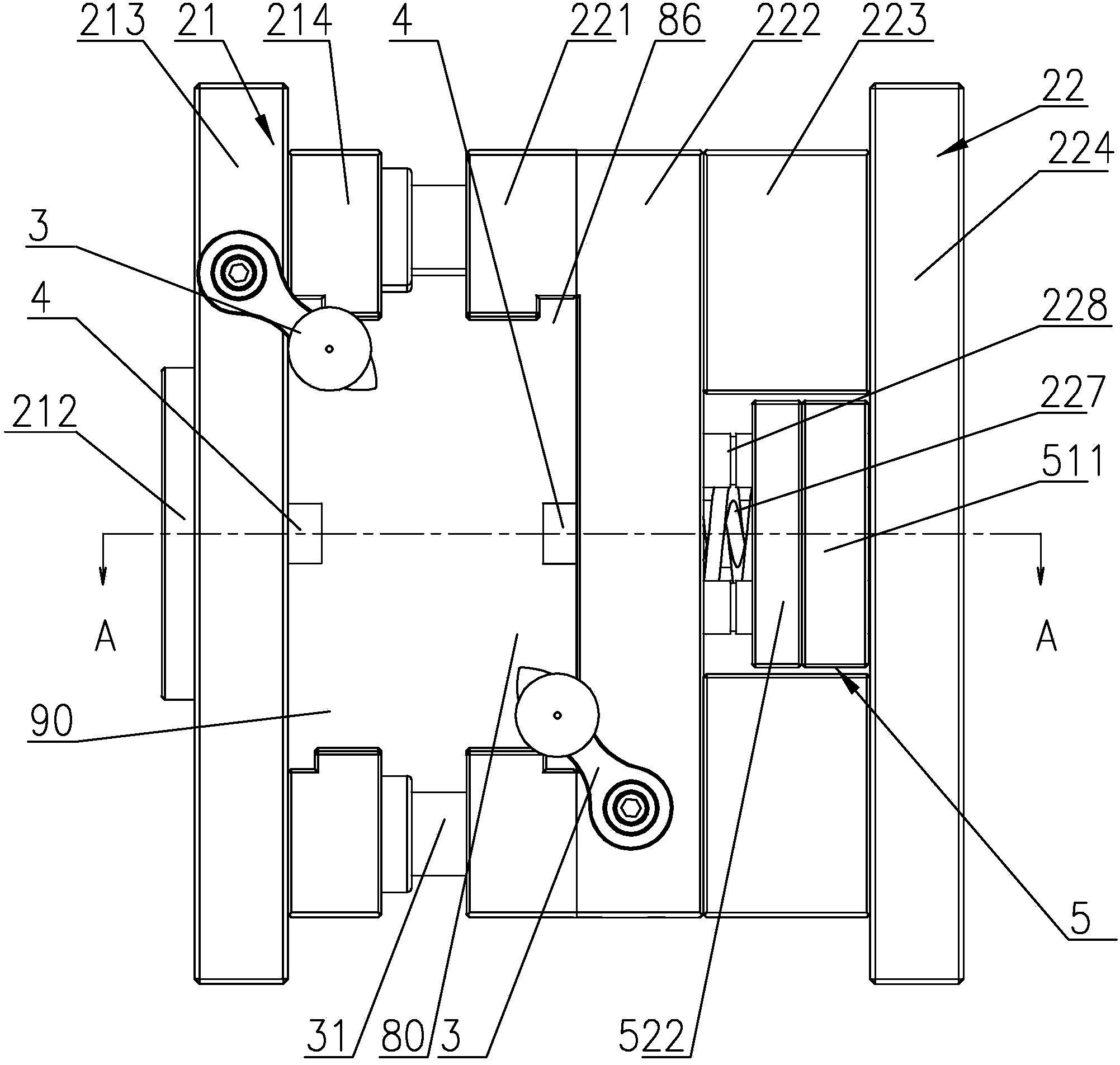

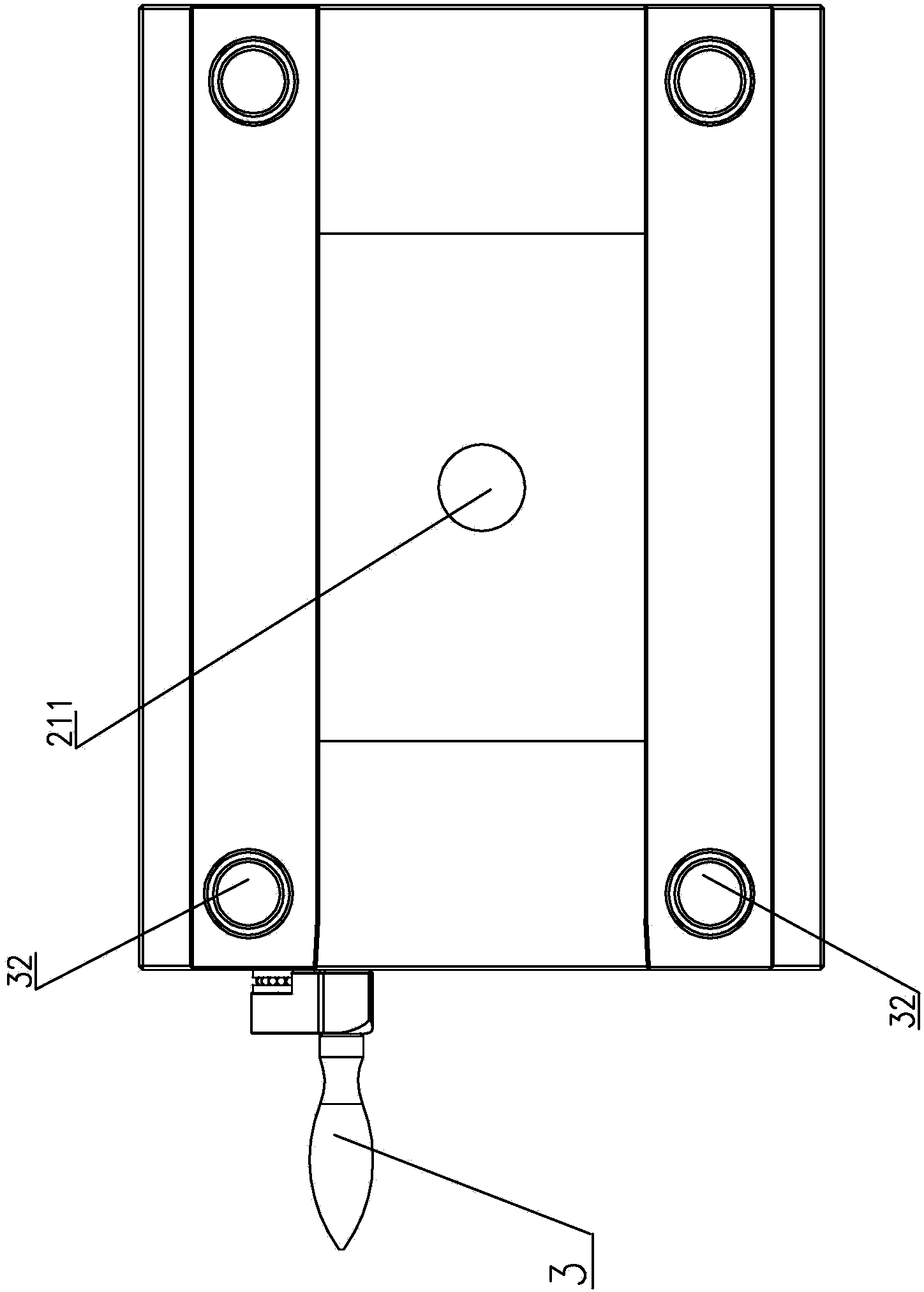

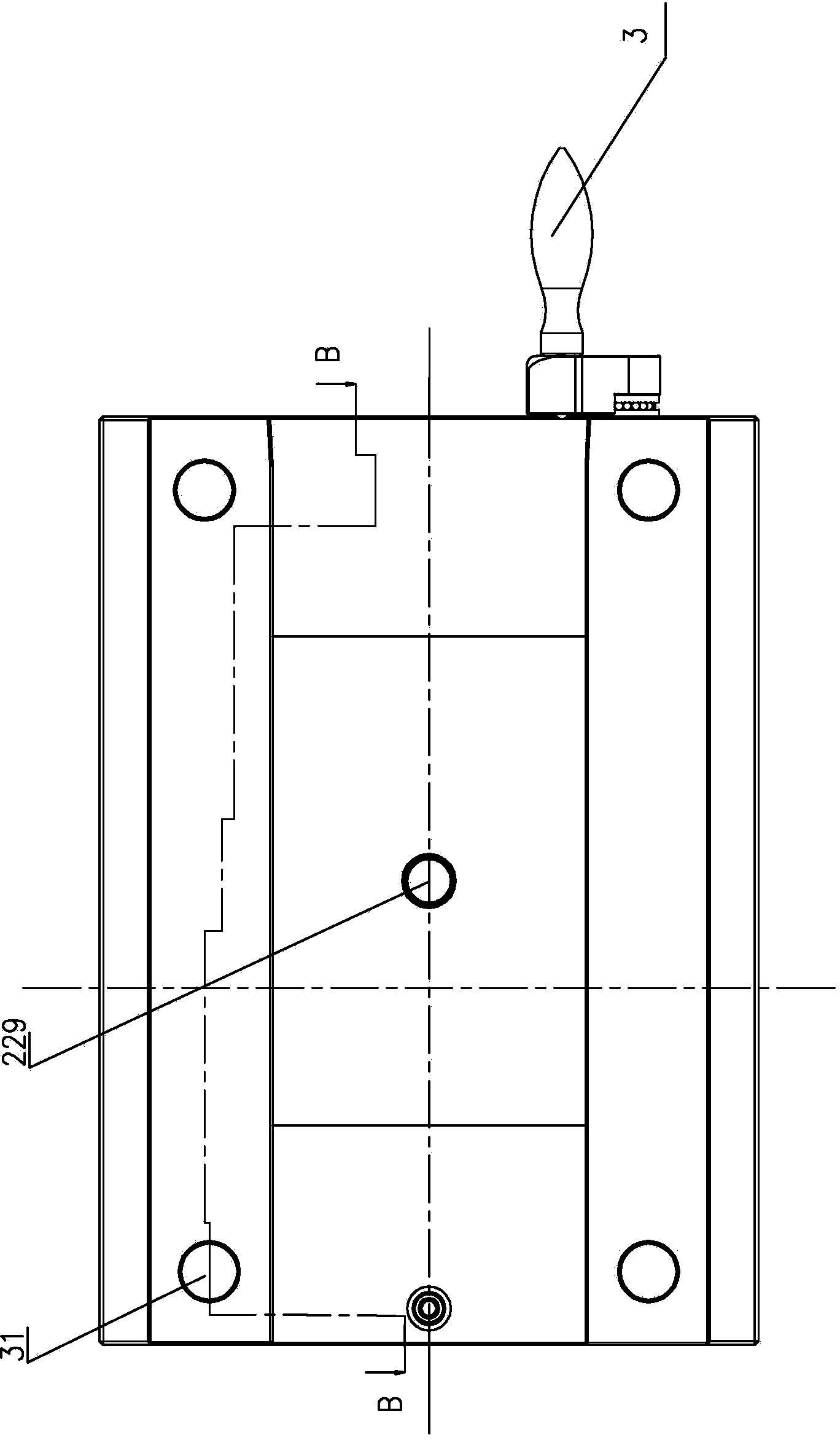

A CNC turret punch press

ActiveCN105436245BAchieving wear and tearWear condition judgmentShaping toolsMetal working apparatusReciprocating motionVisual inspection

A numerical control turret punch press relates to the technical field of numerical control turret punch press automation. The numerical control turret punch press is compact in structure, high in reliability and convenient to use, conveniently detects the wear condition of a die based on a visual inspection technology under the condition of reserving the main body structure of the original turret punch press, can rapidly change the die after detection, and has high automation degree. When a cam disc rotates, a die changing device drives a clamping jaw to make linear reciprocating movement along a radial sliding hole through an arc-shaped cam groove, so that the die below a guide plate can be conveniently and efficiently grabbed or released. The work efficiency is high, and the stability is great. A die wear detection device and the die changing device are effectively arranged, the technical problem in the prior art that the wear condition of the die cannot be detected or judged is effectively solved, and after detection, the die out of the wear standard can be conveniently, efficiently and rapidly taken out and changed. As a whole, the numerical control turret punch press has high automation degree, great use effect and high work efficiency.

Owner:江苏扬力数控机床有限公司

Universal mold change trolley system

The invention discloses a universal mold change trolley system which comprises a transverse slide rail, a plurality of injection molding machines and a mold change trolley. The injection molding machines are arranged on two sides of the transverse slide rail. The mold change trolley comprises a jacking bottom plate and a mold change platform; the jacking bottom plate is fixed to the top of chassis by the aid of a plurality of lifting columns; at least one hydraulic locking fixture is arranged in each injection molding machine; each hydraulic locking fixture comprises a support shaft, a compression plate, a first groove, a steel ball, a first spring, a second groove, an oil cylinder barrel, a piston and a second spring; oil inlets and outlets are formed in the bottoms of the second grooves; one end of the bottom of each compression plate can be in contact with the corresponding steel ball in rotation procedures, and the other end of each compression plate can be in contact with an extending end of a T-shaped handle of the corresponding piston. The universal mold change trolley system with the structure has the advantages that molds can be automatically and quickly changed, the problems of unsafe characters and long change time when existing molds are changed can be solved, and workload on workers can be relieved; the universal mold change trolley system is high in universality, and the molds can be pertinently changed for different models of injection molding machines; the molds can be accurately clamped, and the universal mold change trolley system is high in positioning precision.

Owner:JIANGSU ZHISHI TECH CO LTD

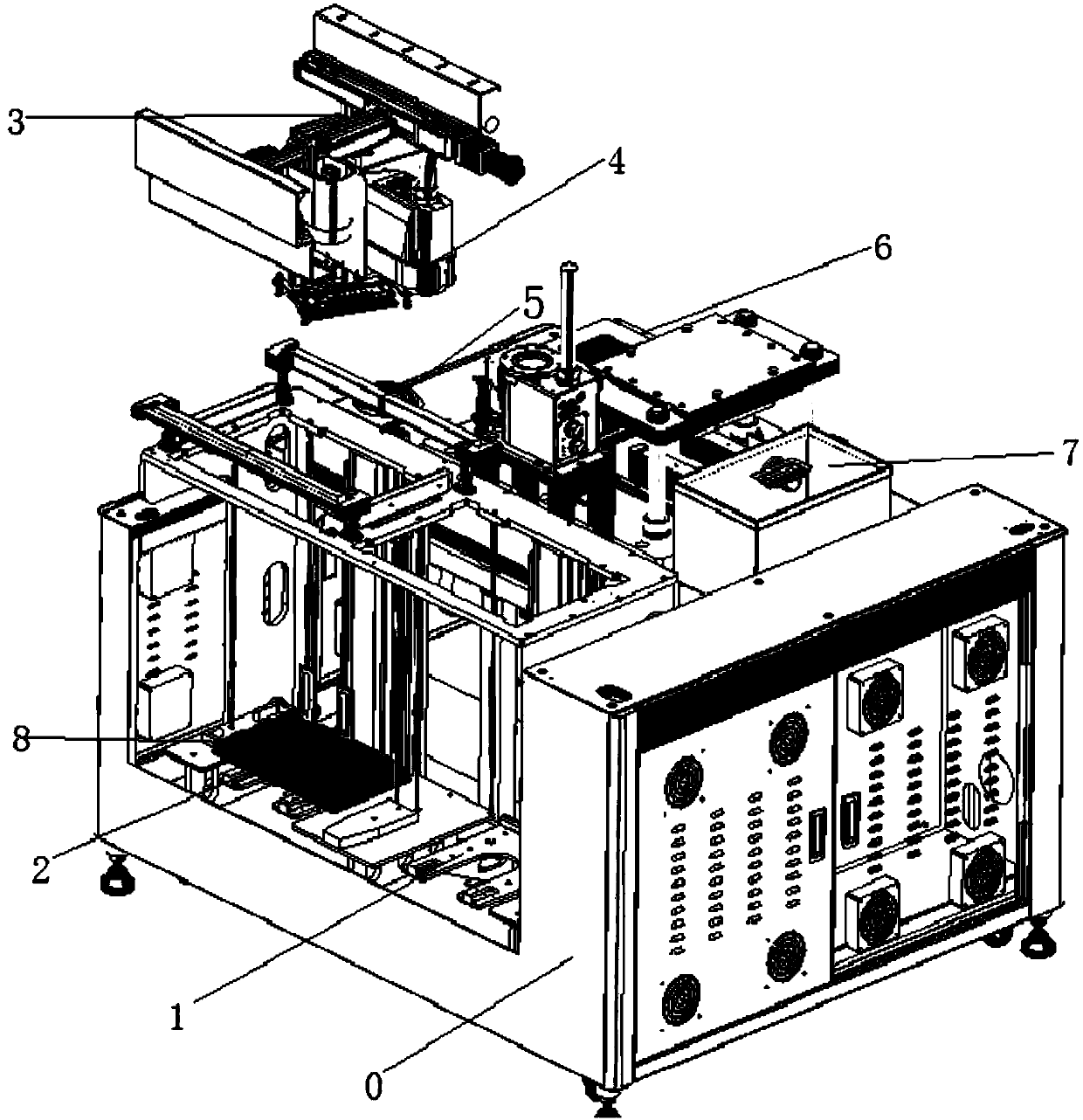

Battery PCM jointed board automatic blanking machine

ActiveCN109676687AIncrease productivityHigh degree of automationMetal working apparatusPunch pressPulp and paper industry

The invention provides a battery PCM jointed board automatic blanking machine. The battery PCM jointed board automatic blanking machine comprises a machine cabinet. The machine cabinet comprises an empty blister box stacking mechanism, a product blister box feeding mechanism, a jointed board visual photographing positioning mechanism, a four-axis mechanical arm feeding mechanism, a mark visual positioning system, a drawer type servo punch press and a waste scrap collection mechanism, wherein the empty blister box stacking mechanism and the product blister box feeding mechanism are arranged onthe inner side of the machine cabinet, the jointed board visual photographing positioning mechanism, the four-axis mechanical arm feeding mechanism, the mark visual positioning system, the drawer typeservo punch press and the waste scrap collection mechanism are arranged on a workbench on the upper surface of the machine cabinet. According to the battery PCM jointed board automatic blanking machine, automatic feeding is carried out through the product blister box feeding mechanism, full-automatic production of the machine is achieved by using CCD visual photographing positioning, and the production efficiency of products is greatly improved; switching between various products can be completed by replacing a suction nozzle module of a suction structure, and quick module replacement is achieved; and board division is completed by using the drawer type servo punch press to punch a PCM jointed board, the stability of the machine is improved, full-automatic unmanned operation on PCM jointed board division is achieved, the machine is high in automation degree, high in stability, high in production efficiency and good in compatibility, and then the labor cost is greatly reduced.

Owner:惠州市华阳智能技术有限公司

Injection mould capable of being easily de-molded

The invention discloses an injection mould capable of being easily de-molded. The injection mould is formed by a movable mould and a fixed mould, which are used as the injection mould, wherein each one of the movable mould and the fixed mould comprises a molding part, a pushing-out mechanism, a mould guide part and a pouring system; a mould cavity is arranged in the mould; the mould cavity is arranged on the mould closing face of the single injection mould, namely, the mould cavity is arranged on the mould closing face of the movable mould or the mould closing face of the fixed mould; the mould closing face of the other injection mould has no mould cavity and is a plane; the movable mould and the fixed mould are closed to form the complete injection mould cavity. According to the injection mould disclosed by the invention, the structure of only arranging the mould cavity on the single injection mould is applicable to injection of a standard test sample strip or an injection piece with the similar shape. The injection mould has the beneficial effects of being beneficial to simplification of the structure of the mould, improving the manufacturability of the mould and reducing the cost of the mould.

Owner:广州现代塑料有限公司

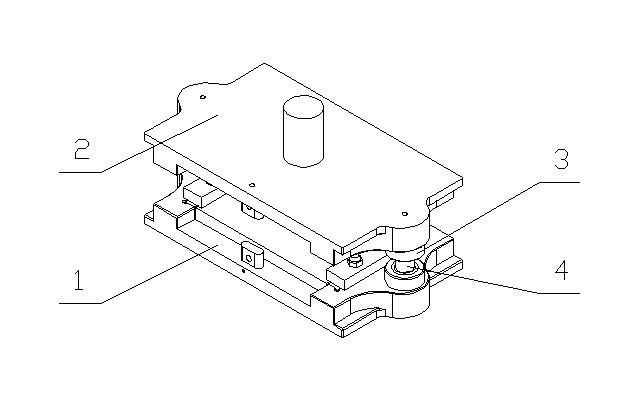

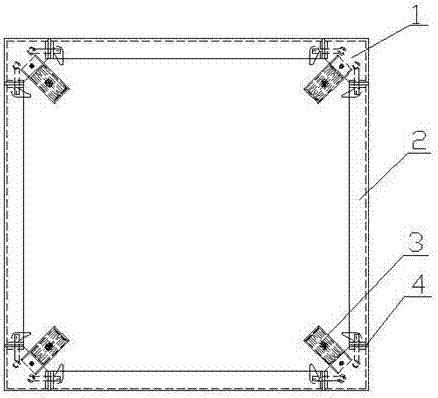

Fast clamping system

ActiveCN107803680AFit tightlyImprove machining accuracyPositioning apparatusPhotovoltaic energy generationClassical mechanicsEngineering

The invention discloses a fast clamping system. The fast clamping system comprises a pedestal with a hanger, clamp fixing bases and clamps, wherein the clamp fixing bases and the clamps are movably fixed to the hanger. The clamp fixing bases are provided with mounting grooves matched with the corresponding clamps. Each clamp comprises a fastening screw rod with the two ends being provided with threads and dovetail clamping blocks located at the two ends of the fastening screw rod. The dovetail clamping blocks comprise positioning parts which are matched with the mounting grooves in the clamp fixing bases for positioning and clamping parts with dovetail structures. The positioning parts of the dovetail clamping blocks are screwed at the two ends of the corresponding fastening screw rods separately. By adoption of the fast clamping system, the multi-operation, multi-position and multi-part machining requirements can be met, and clamping rigidity is good; moreover, clamping force is evenly distributed, predeformation of parts is reduced and machining precision is improved; and the adaptability is high, the parts and the surfaces of the fixing bases can be tightly attached easily through the clamping blocks, and there is no need for workers to inspect the fitness of the bottom faces of the parts.

Owner:ZHEJIANG XIZI AVIATION IND

Punching die for transmission cover

InactiveCN107470446AGuarantee the quality of finished productsImprove pass ratePerforating toolsManufacturing cost reductionPunching

The invention relates to a punching die for a transmission cover. A guide device is arranged between a lower die base and an upper die base, a concave die is arranged on the lower die base, and a cylindrical pin and an inner die pass between the concave die and the lower die base. The hexagonal screw is fixed and installed, the upper die base is provided with a die handle, the bottom surface of the upper die base is provided with a punch, a punch fixing plate is sleeved on the punch, and a punch fixing plate is provided between the upper die base and the upper die base. A backing plate, the upper end of the punch is sleeved with a discharge plate, the upper die base and the discharge plate are connected by a discharge screw, and the discharge screw between the fixed plate of the punch and the discharge plate is sleeved with a discharge plate. The first spring, the second spring is set between the punch fixing plate and the unloading plate, to ensure the quality of the finished product and high pass rate, the fast mold changing device reduces the preparation workload and preparation time for stamping production, and has a long service life. manufacturing cost.

Owner:周秋野

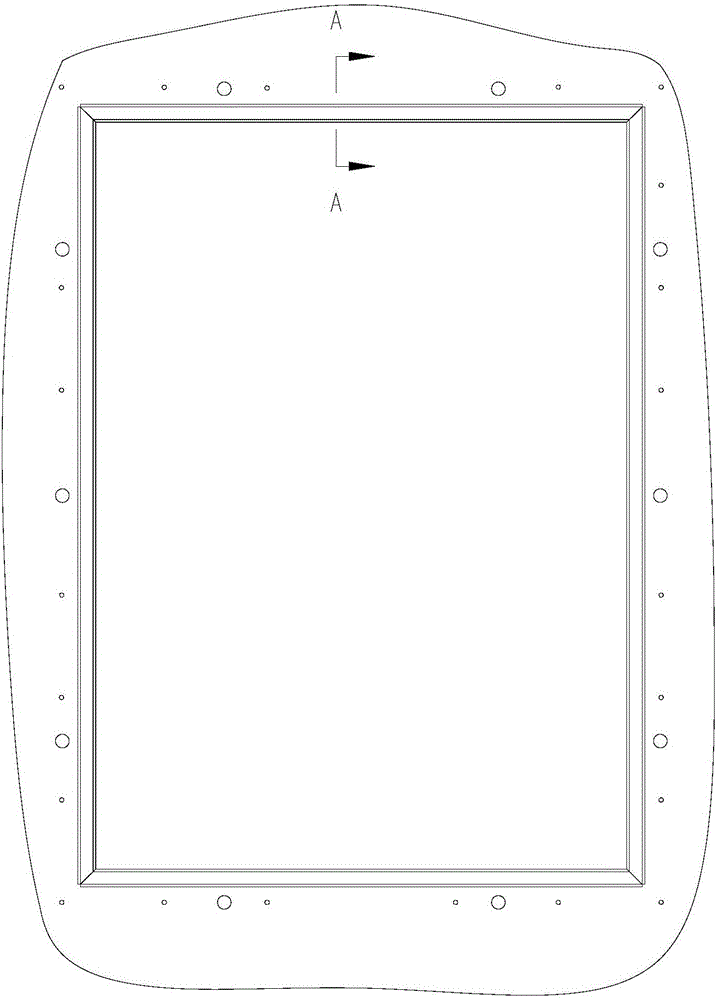

Rapid mold changing structure of foaming molding apparatus

The invention provides a rapid mold changing structure of a foaming molding apparatus. The rapid mold changing structure comprises a foaming molding device, a mold base for mounting a foaming mold anda locking mechanism used for mounting the mold base on the foaming molding device; the foaming molding device is provided with a guide rail, the mold base is slidably mounted on the guide rail, the foaming molding device is provided with a first quick interface for outputting gas, the mold base is provided with a second quick interface in butt joint with a first quick interface, the mold base isfurther provided with output ports for feeding the gas into the foaming mold, and the multiple output ports are connected to the second quick interface through connecting tubes. The rapid mold changing structure can realize rapid mold changing of the foaming mold and greatly saves the time for replacing the mold; and the assembly and disassembly operation of the mold and complex air supply pipe connection can be carried out in advance, so that the replacing time is greatly shortened, and the molding efficiency of the foaming molding apparatus is greatly improved.

Owner:FACKEL MACHINERY FUJIAN

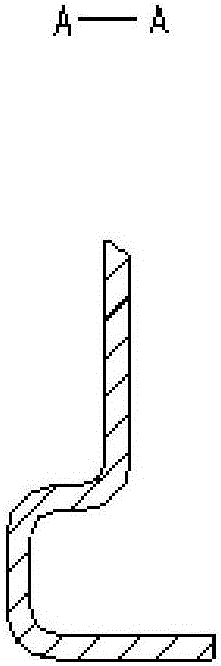

Concentric-square-shaped groove frame machining method and series connection insert joint bending die

ActiveCN106734443ASolve the production narrow mouth problemReduce the length of split weldingShaping toolsUltimate tensile strengthWelding defect

The invention provides a concentric-square-shaped groove frame machining method and a series connection insert joint bending die, and belongs to the technical field of mechanical stamping. Welding defects are reduced, leveling labor hours caused by heat deformation are shortened, and the labor intensity is reduced; and the problem about production narrow openings of Z-shaped bending is solved. The die is composed of three parts including a male die assembly, a female die assembly and a positioning device; insert series connection combining and jointing male and female die inserts are adopted in the male die assembly and the female die assembly correspondingly; the male die assembly comprises seven male die inserts of the same structure and with different lengths; and the concentric-square-shaped groove frame machining method comprises three times of bending. An insert joint tool bending process technology is used for reducing the split welding length, and a common angle supplementing process method is used for manufacturing. Bending of multiple products is completed through the insert joint bending die, the die manufacturing cost is reduced, die replacement can be rapidly carried out, and the product batch consistency is improved.

Owner:BEIJING NORTH VEHICLE GROUP CORP

Self-demolding sealing and swelling water swelling mold of cup body

PendingCN113579048AShorten the lengthReduce drawingEjection devicesManufacturing engineeringWire drawing

The invention provides a self-demolding sealing and swelling water swelling mold of a cup body, and belongs to the technical field of forming equipment. The mold solves the problems that long core rods are adopted in existing water swelling molds, and wire drawing and even bumping are prone to being generated during long core rod pipe insertion. The mold comprises an upper mold assembly, a lower mold assembly, an upper core rod assembly and a lower core rod assembly, the upper mold assembly and the lower mold assembly are symmetrically arranged up and down, the upper core rod assembly and the lower core rod assembly are symmetrically arranged up and down, water swelling forming space is formed between the upper mold assembly and the lower mold assembly and between the upper core rod assembly and the lower core rod assembly, the upper mold assembly comprises an upper mold sleeve and an upper mold cavity, and the lower mold assembly comprises a lower mold sleeve and a lower mold cavity. After up-down mold compounding of the water swelling mold, the upper mold cavity can move upwards relative to the upper mold sleeve and is buckled with the upper core rod assembly to be used for blocking an upper opening of the water swelling forming space, and the lower mold cavity can move downwards relative to the lower mold sleeve and is buckled with the lower core rod assembly to be used for blocking a lower opening of the water swelling forming space. The mold has the advantages that the lengths of an upper core rod and a lower core rod are greatly reduced, and the situations of wire drawing, bumping and the like caused by pipe insertion during production are reduced.

Owner:浙江雄泰家居用品股份有限公司

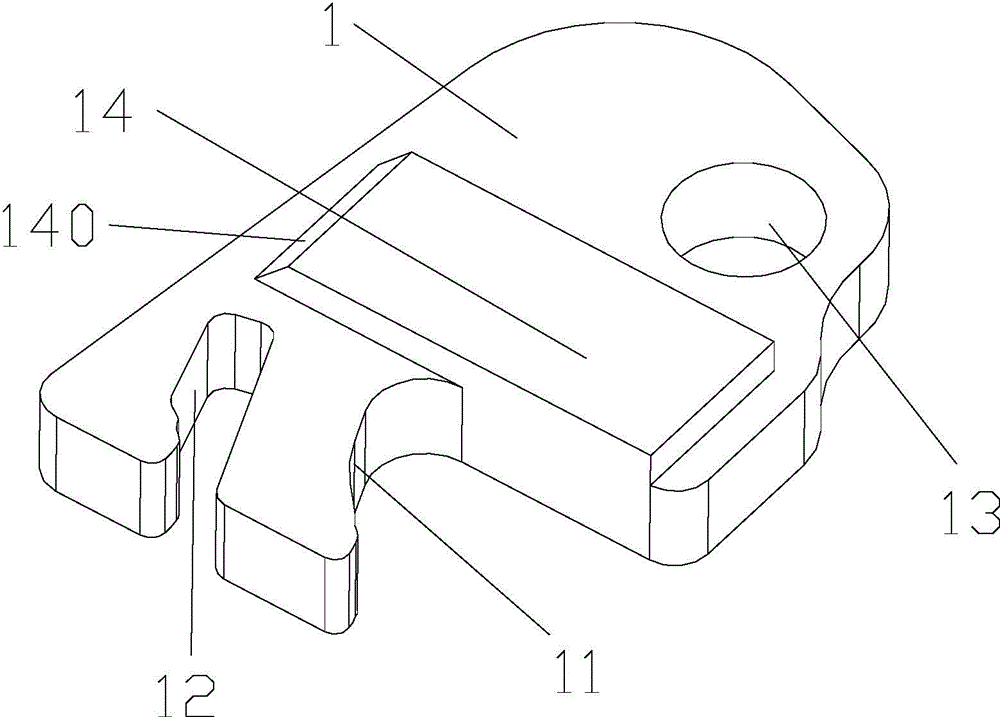

Quick die replacing device for prefabricated member hole and using method of quick die replacing device

PendingCN107214825AShort timeThe time is short, which can realize fast mold change.Mould separation apparatusMould fastening meansEngineeringWelding process

The invention relates to a quick die replacing device for a prefabricated member hole. The quick die replacing device comprises rubber magnetic box corner connecting pieces, a pressing plate and edge dies. The rubber magnetic box corner connecting pieces and the edge dies are alternatively connected end to end to form a closed hole flat die structure, the pressing plate is installed above the rubber magnetic box corner connecting pieces, and the two ends of the pressing plate are tightly pressed above two adjacent edge dies correspondingly. The invention further comprises a using method of the quick die replacing device for the prefabricated member hole. The quick die replacing device has the beneficial effects that the structure is simple, the die replacing speed is high, fewer welding processes exist, cleaning carried out between die manufacturing process and in the later period is better saved, the manufactured hole has the beneficial effects of being high in quality yield and the like, and use is convenient.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

Full-automatic plate plastics sucking moulding machine

The invention discloses a full-automatic plate plastics sucking moulding machine. The plastics sucking moulding machine comprises a rack, molding devices, a heating device, a transport device and a material table. The plastics sucking moulding machine is characterized in that there are two molding devices. A first guide rail and a second guide rail are arranged on the rack. The heating device is connected with a power source. The heating device moves along the first guide rail to the molding position of the molding device. The transport device comprises a transport table. The lower end face of the transport table is equipped with suckers, The suckers are connected with an air source. The second guide rail comprises a longitudinal guide rail, a transverse guide rail and an axial guide rail. The power source drives the transport table to move along the second guide rail from the material sucking position of the material table to the molding position of the molding device. The plastics sucking moulding machine takes double positions, and loads and takes materials automatically. The plastics sucking moulding machine raises the production efficiency greatly, reduces the power consumption, transports and takes materials through the transport device to replace manual operations, and reduces the production cost.

Owner:温州瑞佳吸塑机械有限公司

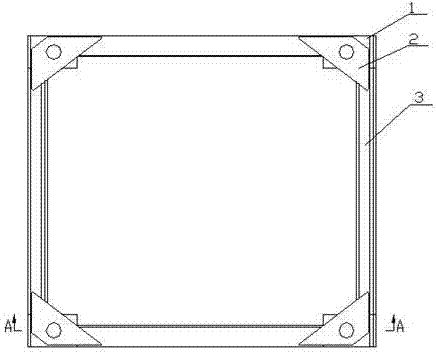

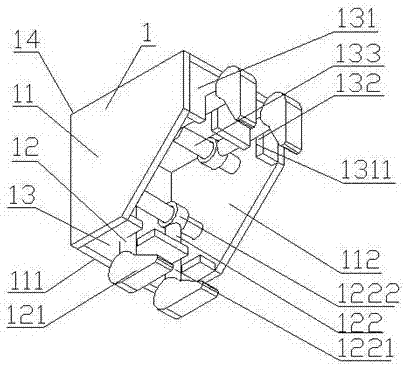

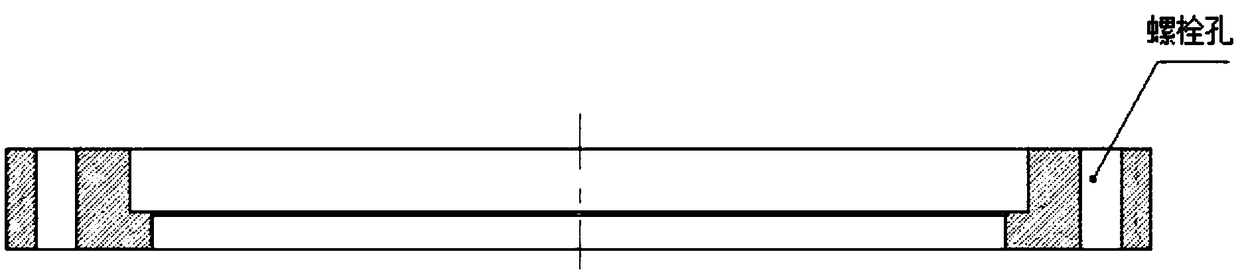

Multipurpose quick-assembly die frame

The invention relates to a multipurpose quick-assembly die frame which comprises an upper die frame, a lower die frame and a guide device. The upper die frame comprises a die shank, an upper die plate, upper locking blocks, upper compressing blocks and upper positioning blocks, the die shank is mounted in the center of the upper die plate, the upper locking blocks are mounted on the left side and the right side of the upper die plate, the upper compressing blocks are connected with the upper locking blocks by bolts, and the upper positioning blocks are mounted at a side edge of the upper die plate; the lower die frame comprises a lower die plate, lower locking blocks, lower compressing blocks and lower positioning blocks, the lower locking blocks are mounted on the left side and the right side of the lower die plate, the lower compressing blocks are connected with the lower locking blocks by bolts, and the lower positioning blocks are mounted at a side edge of the lower die plate. The multipurpose quick-assembly die frame has the advantages that a function that various working procedures share the same die frame is realized, the die manufacturing cost is saved, and the die manufacturing cycle is shortened.

Owner:HUNAN TONGXIN ENTERPRISE

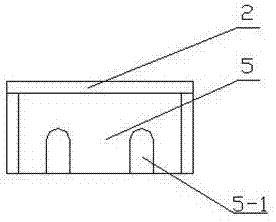

Rapid mould replacing device of extruding machine

The invention discloses a rapid mould replacing device of an extruding machine. The rapid mould replacing device comprises a mould frame arranged in the extruding machine, wherein the mould frame is of a splitting structure and comprises a mould base and a mould base connection base; the mould base and the mould base connection base are connected through a connection part; the mould base connection base is connected with a first driving device; a front plate of the extruding machine is fixedly provided with a base; the base is provided with a slide plate; the slide plate is connected with a second driving device; the second driving device drives the slide plate to move along the base. According to the rapid mould replacing device of the extruding machine disclosed by the invention, not only can the production cost be reduced to the certain extent, but also non-working time in a mould replacing process is shortened and the working efficiency is improved.

Owner:WUXI WEITE MACHINERY

Quick die replacing device for prefabricated member hole and using method of quick die replacing device

ActiveCN107214823AIncrease productivityReduce scrap rateMould separation apparatusMould fastening meansElectrical and Electronics engineering

The invention relates to a quick die replacing device for a prefabricated member hole and a using method of the quick die replacing device. Edge dies are included, corners formed by every two adjacent edge dies are fixedly connected through a quick buckling mechanism, the quick buckling mechanisms are fixed to a trolley face through magnetic boxes, the edge dies and the quick buckling mechanisms are alternatively arranged to form a closed hole die plate structure, the ends of the edge dies are provided with connecting parts used in cooperation with the quick buckling mechanisms, and the quick buckling mechanisms and the connecting parts are detachably connected; and a using method of the above quick die replacing device for the prefabricated member hole is further included. The quick die replacing device is simple in structure and easy to machine and manufacture; once the quick buckling mechanisms are machined, repeated use can be achieved, and the using rate is higher; and the pouring quality of connecting hole die plate positions between the quick buckling mechanisms and the edge dies is good, the yield of a prefabricated member with the hole is facilitated, the production efficiency can be greatly improved, and the economic performance is further facilitated.

Owner:NINGXIANG YUANDA RESIDENTIAL IND CO LTD

Straightener

PendingCN108598010AStraightening effect is stableImprove efficiencySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:连云港瑞而盛电子科技有限公司

Universal combined type die forging tool

InactiveCN109351904AImprove general performanceGood repair costForging/hammering/pressing machinesEngineeringForge

The invention discloses a universal combined type die forging tool. The universal combined type die forging tool is composed of an upper press ring, an upper die sleeve, an upper transition sleeve, anupper die core, a lower press ring, a lower die sleeve, a lower transition sleeve, a lower die, a lower die core, an ejector rod and the like. The upper die sleeve is matched with the upper transition sleeve, the lower die sleeve is matched with the lower transition sleeve, the upper die sleeve and the lower die sleeve are used for positioning and fixing the upper transition sleeve and the lowertransition sleeve separately, the upper transition sleeve and the lower transition sleeve are used for positioning and fixing the upper die core and the lower die, a fastening pin is used for fastening and positioning the lower die, and the ejector rod ejects a formed forge piece out of a lower die cavity. The universal combined type die forging tool can be used for producing all parts below the production extreme dimension of a certain type of forging device and can well control the die manufacturing cost, and meanwhile has the characteristics of being convenient to mount and dismount, low inmaintenance cost, long in service life, good in interchangeability and the like.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

Quick mold change travelling table

The invention discloses a quick mold change travelling table, and relates to the technical field of machining. The quick mold change travelling table comprises a cuboid frame style base, wherein two long sliding plates are arranged on the base along the length direction; limiting blocks are arranged at the front ends of the long sliding plates, and a plurality of guide pulleys are arranged on the back portions of the long sliding plates in the length direction; a cuboid sliding support is arranged above the long sliding plates; a plurality of pulleys are arranged between the sliding support and the long sliding plates; guide wheels are arranged on the left side and the right side of the front end of the sliding support, and a positioning block is arranged at the front end of the sliding support; a mold positioning baffle plate is arranged in the middle of the sliding support. By adopting the quick mold change travelling table, the problems of difficulty in changing large-sized molds, waste of time and labor and influence on the service life of a crane in the prior art can be solved.

Owner:柳州市超凌顺机械制造有限公司

Gluing device for lithium battery winding machine

InactiveCN108461825AReduce maintenance frequencyReduce downtimeFinal product manufactureSecondary cellsWinding machineEngineering

The invention provides a gluing device for a lithium battery winding machine. The gluing device for the lithium battery winding machine comprises a gluing device body, a rotating shaft, a bracket anda driving mechanism; the gluing device body comprises a fixing piece, a suction mechanism and at least one suction nozzle; the suction nozzle is arranged on the fixing piece; a suction port is formedat one end, far away from the fixing piece, of the suction nozzle; the suction nozzle is connected and communicated with a gas outlet of the suction mechanism through a hose; the other end of the fixing piece is connected with the middle part of the rotating shaft; the rotating shaft is transversely rotatably arranged on the bracket and is in transmission connection with the driving mechanism; andthe driving mechanism drives the rotating shaft and drives the gluing device body to rotate. The gluing device for the lithium battery winding machine, which is provided by the invention, solves theproblems that winding gluing is uneven and adhesive tape debugging consumes long time, reduces rejection rate and increases battery manufacturing qualification rate.

Owner:SHENZHEN RUILONG NEW ENERGY TECH

Mouth-type mold capable of forming automobile sealing strip with two kinds of sections

Owner:SAIC METZELER SEALING SYST

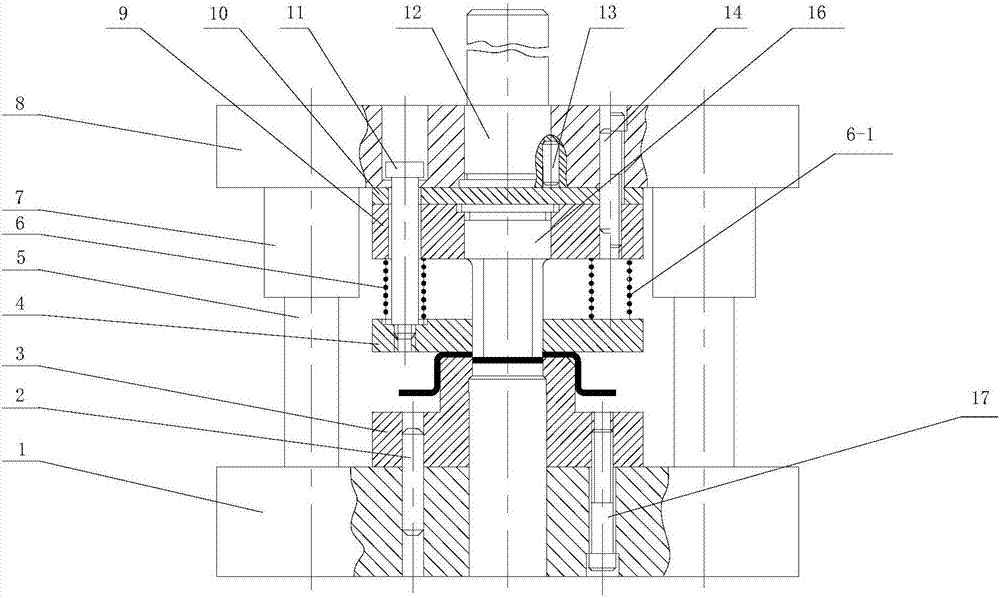

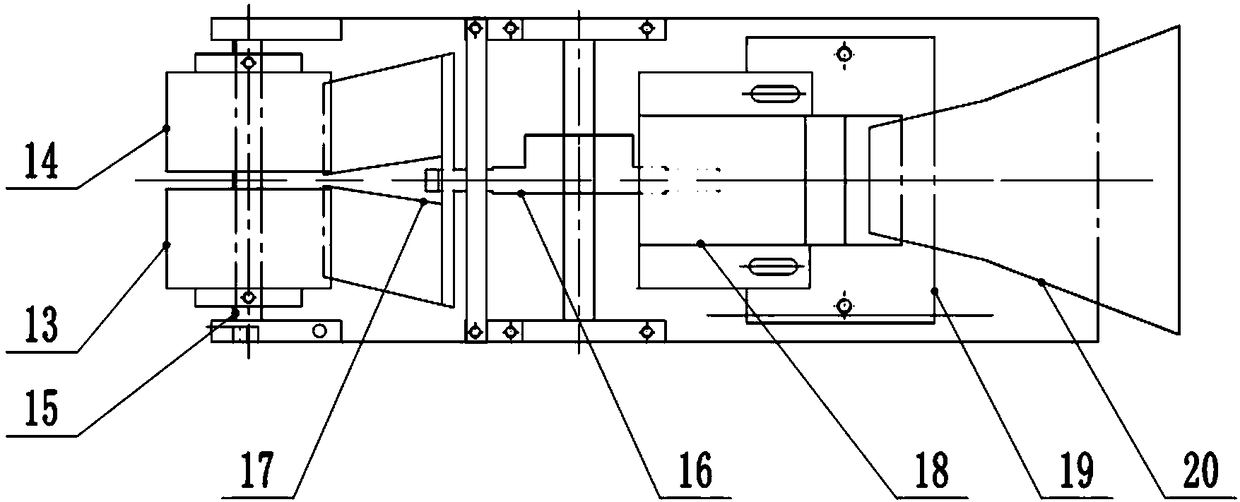

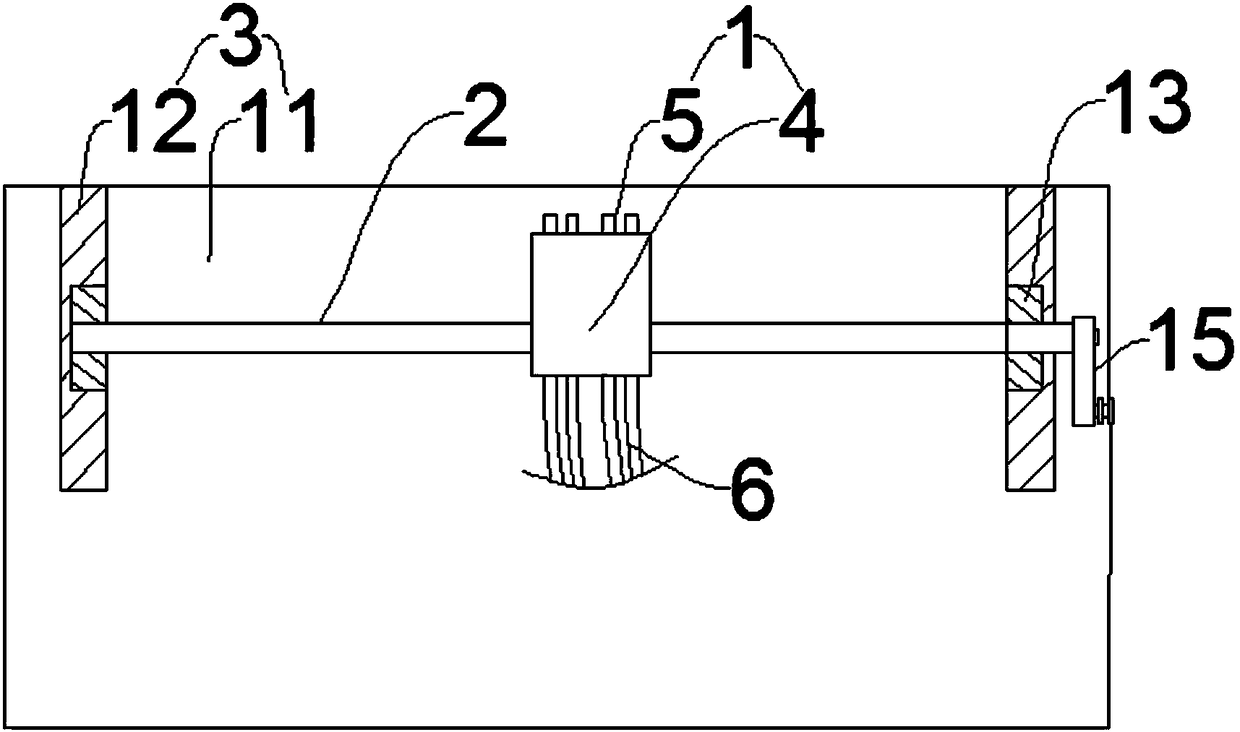

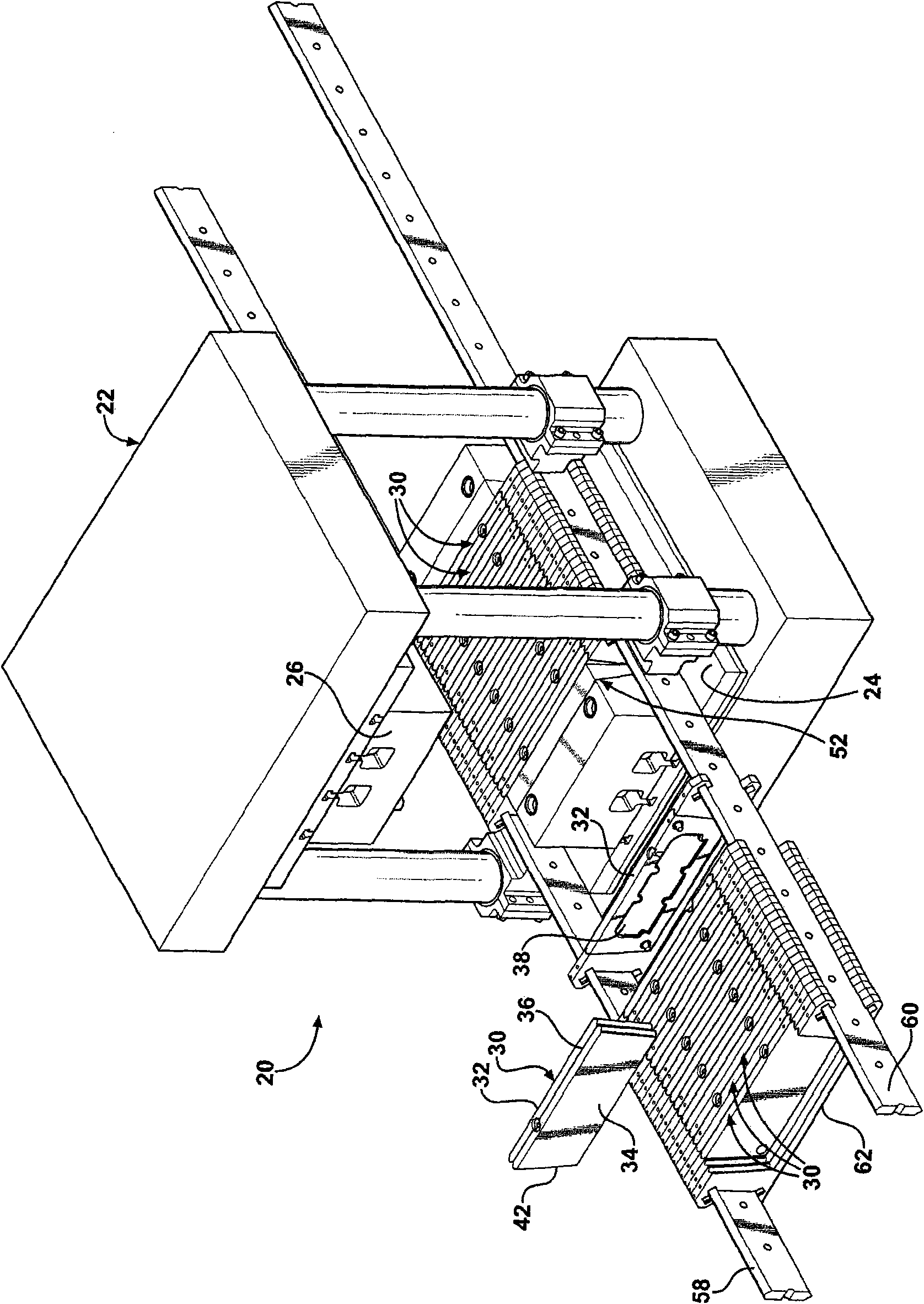

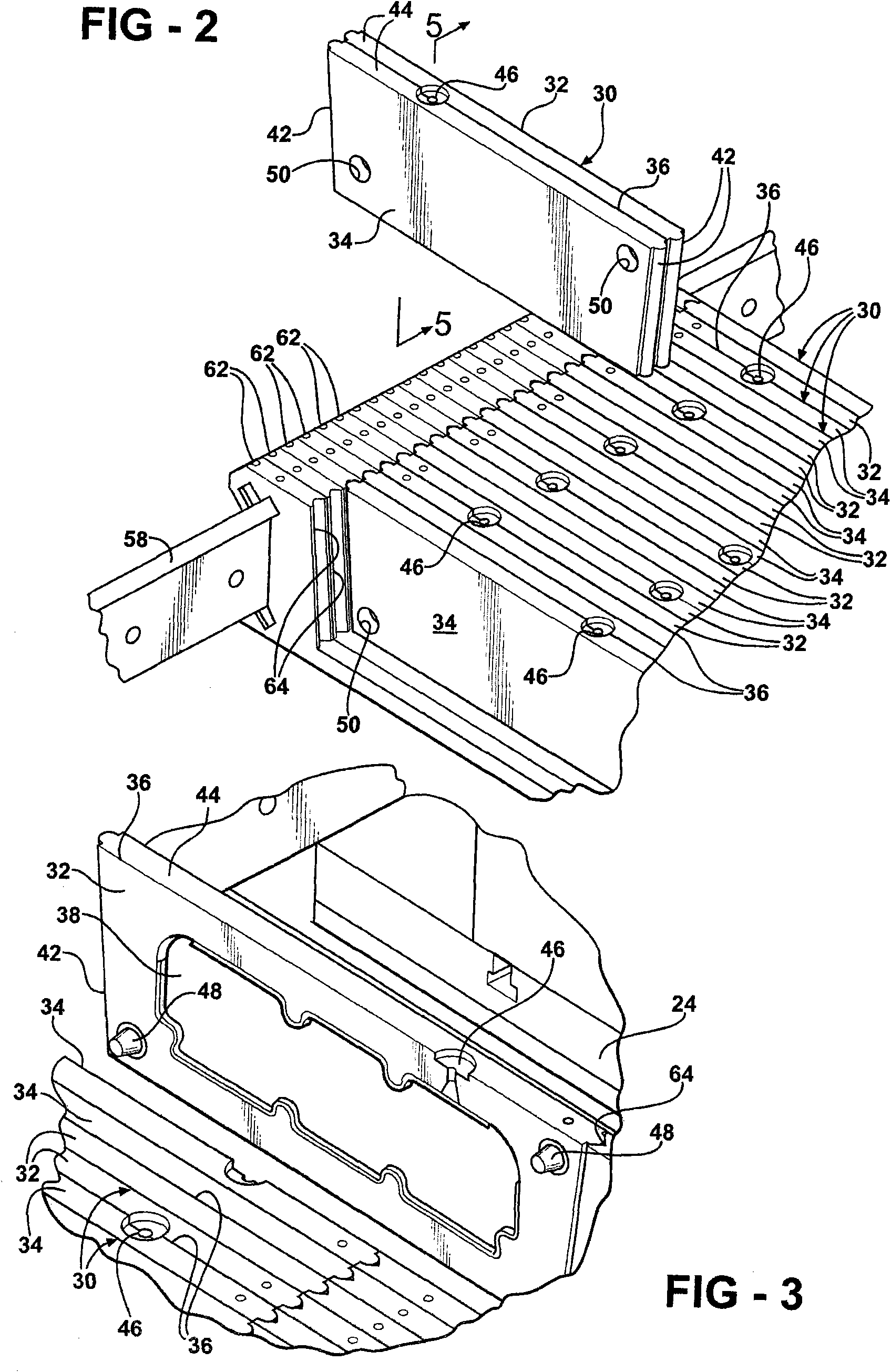

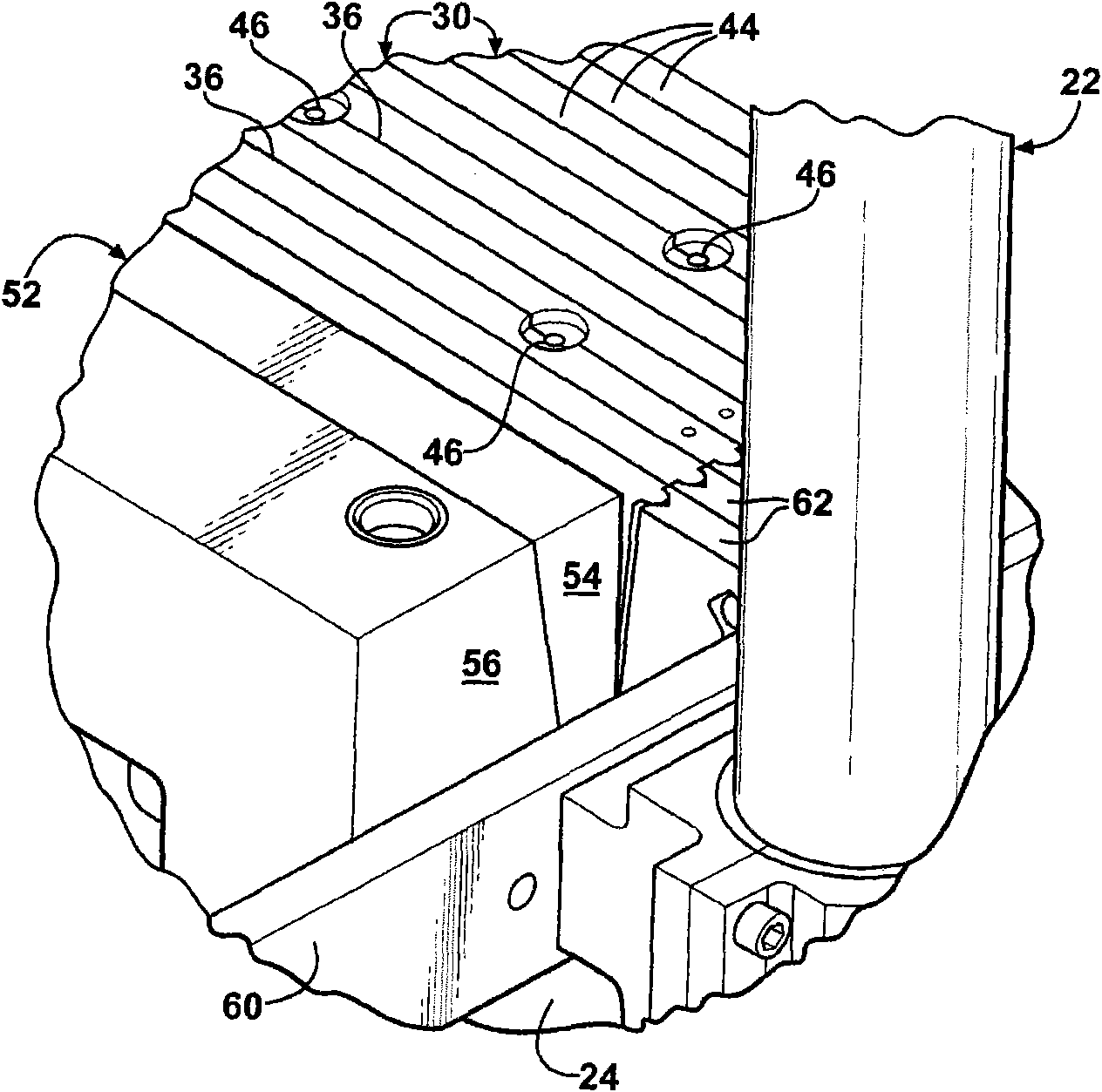

High cavitation, low tonnage rubber mold machine and method

InactiveCN101541490AQuick die changeHigh product throughputShaping press ramReciprocating motionIndustrial engineering

A rubber injection molding apparatus and method for simultaneously molding a plurality of work parts (40) in separate molds (30) using a single, vertically oriented press machine (22). A clamping mechanism (52) is responsive to the vertical, reciprocating motion of the press ram (26) for converting the generally vertical motion of the press ram (26) into a horizontal clamping force to squeeze and hold the molds while rubber is injected into their cavities (38). The molds (30) each have two mold halves (32, 34) joining one another along a parting line interface (36) with the mold cavity (38) in between. The mold halves (32, 34) are received in universal carriers (62), which in turn are suspended between and slideable along spaced - apart first (58) and second (60) rails. A large number of mold cavities (38) can be filled simultaneously using a vertically oriented press machine (22). The plurality of molds (30) may contain different part configurations which are filled simultaneously in a single molting operation. Because the molds (30) are not fastened to platens as in prior art vertical press machines, changeover times are substantially decreased.

Owner:FEDERAL MOGUL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com