Multipurpose quick-assembly die frame

A formwork and formwork technology, applied in the field of multi-purpose general formwork, can solve the problems of suppressing the extensiveness of applications, changing the structure of the formwork greatly, and being difficult to popularize, etc., achieving rapid die change and shortening the die production cycle. , the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

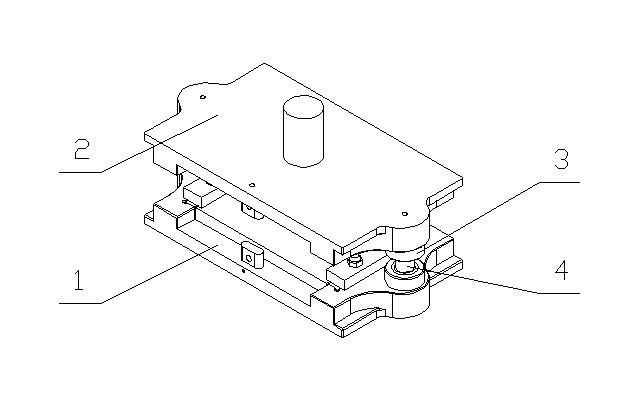

[0020] A multi-purpose fast-loading mold base, comprising an upper mold base 2, a lower mold base 1, and a guide device, the guide device includes a guide sleeve 3, a guide post 4, and the guide sleeve 3 is installed on the upper mold base 2. The guide post 4 is installed on the lower formwork 1, and the guide sleeve 3 forms a sliding fit with the guide post 4. During the stamping process, the lower mold frame 1 is fixedly installed on the punching machine, and the upper mold frame 2 is fixed on the punch of the punch press. The frame 1 forms relative movement and precise alignment, and the guide sleeve 3 continuously slides up and down on the guide post 4 to form a stamping guide and ensure the precision of stamping.

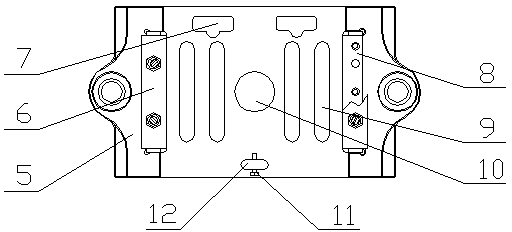

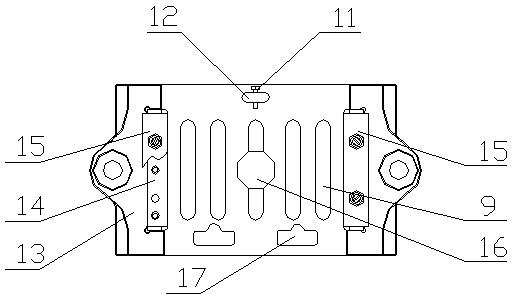

[0021] The upper mold base 2 includes a mold handle 10, an upper template 5, an upper locking block 8, an upper pressing block 6, and an upper positioning block 7. The mold handle 10 is installed in the circular hole in the center of the upper template 5 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com