Patents

Literature

3921 results about "Punch press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A punch press is a type of machine press used to cut holes in material. It can be small and manually operated and hold one simple die set, or be very large, CNC operated, with a multi-station turret and hold a much larger and complex die set.

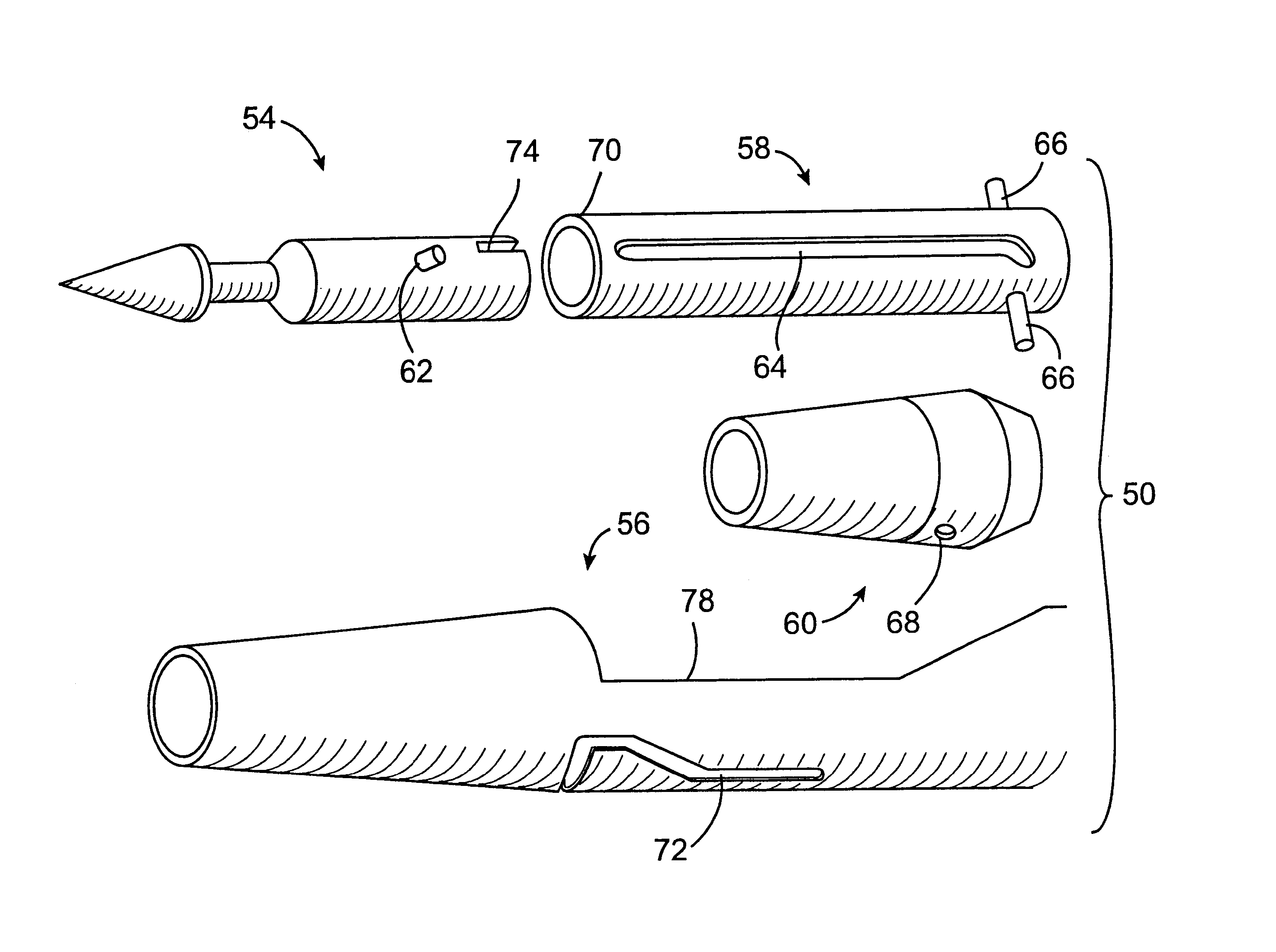

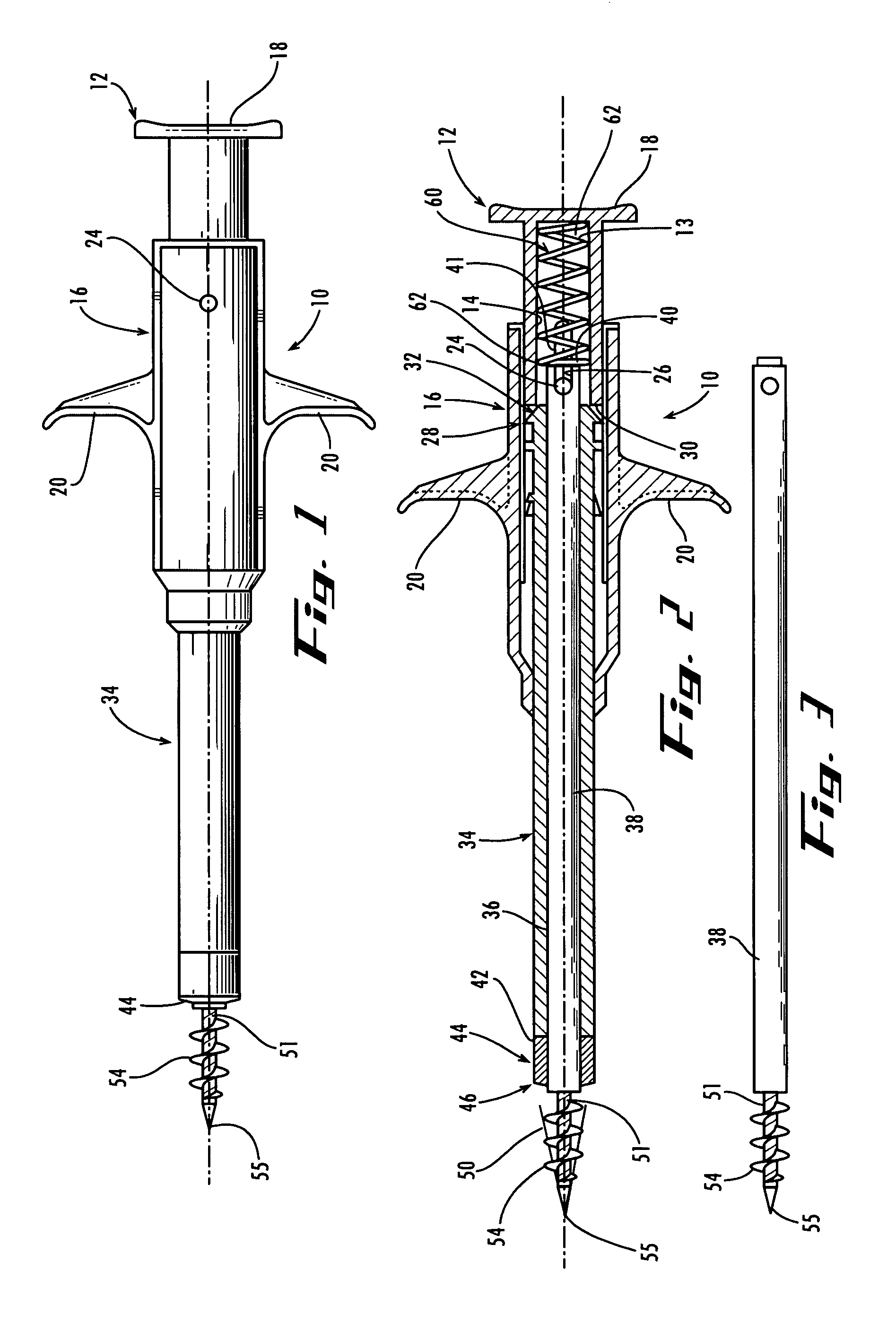

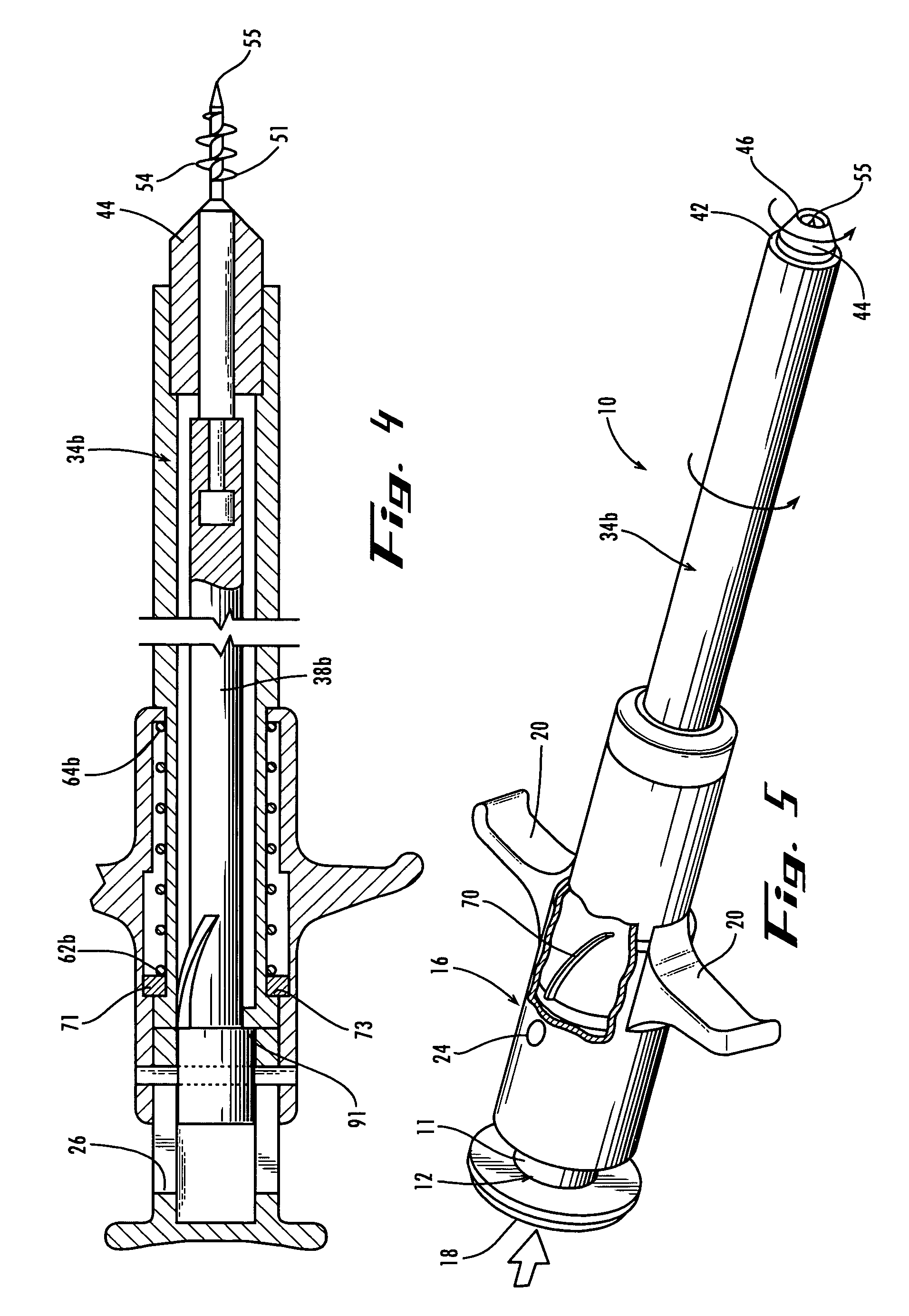

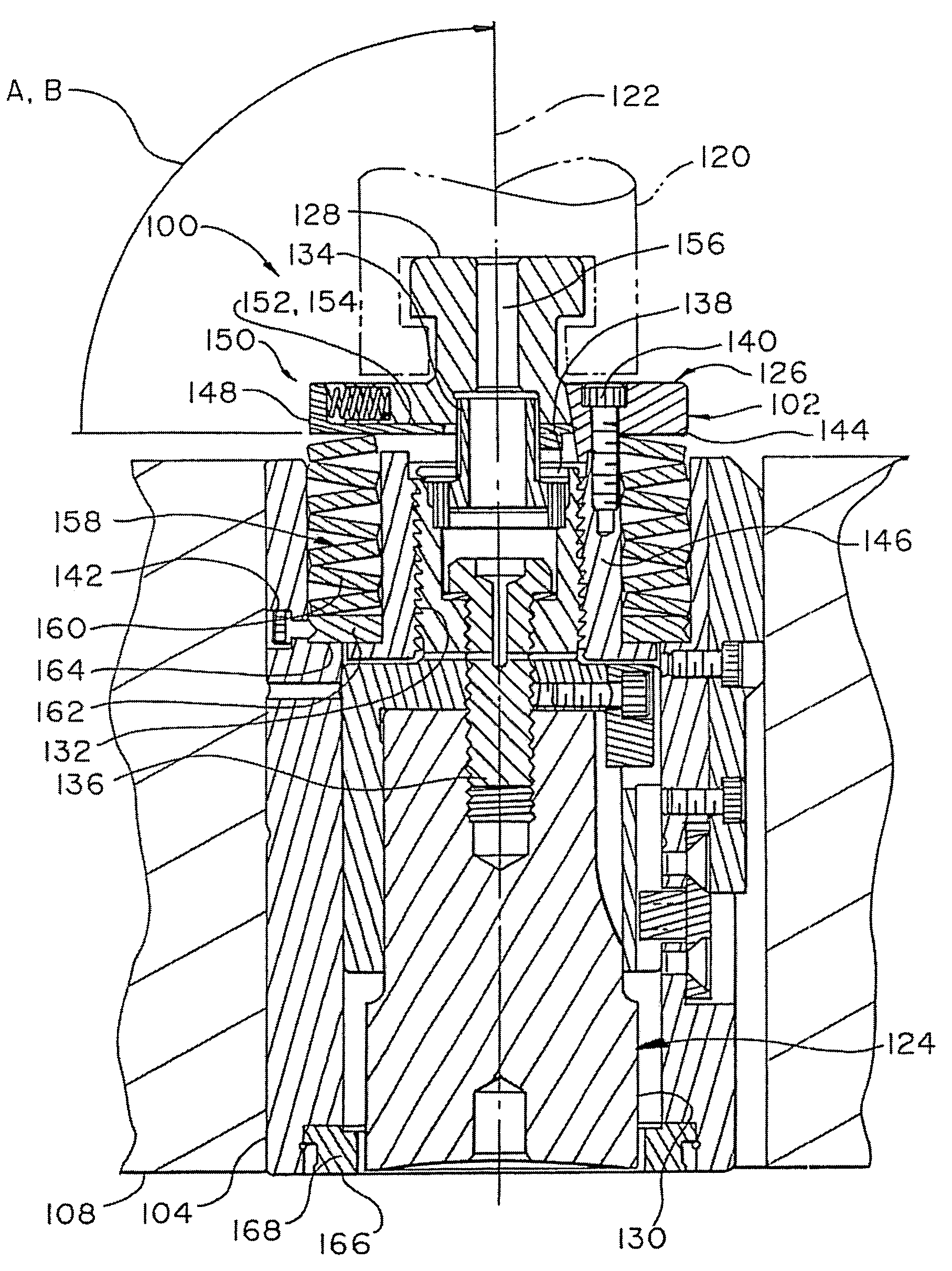

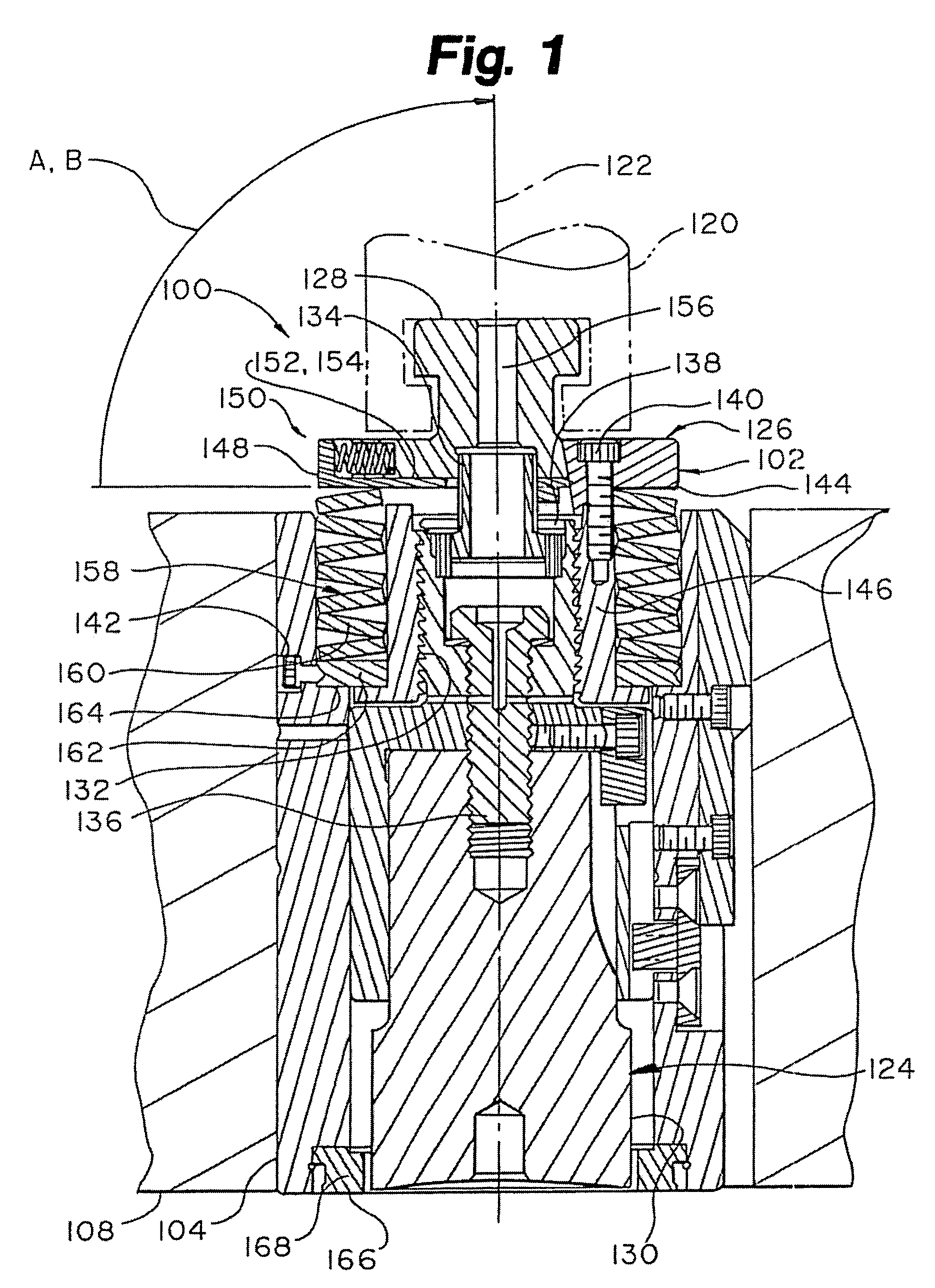

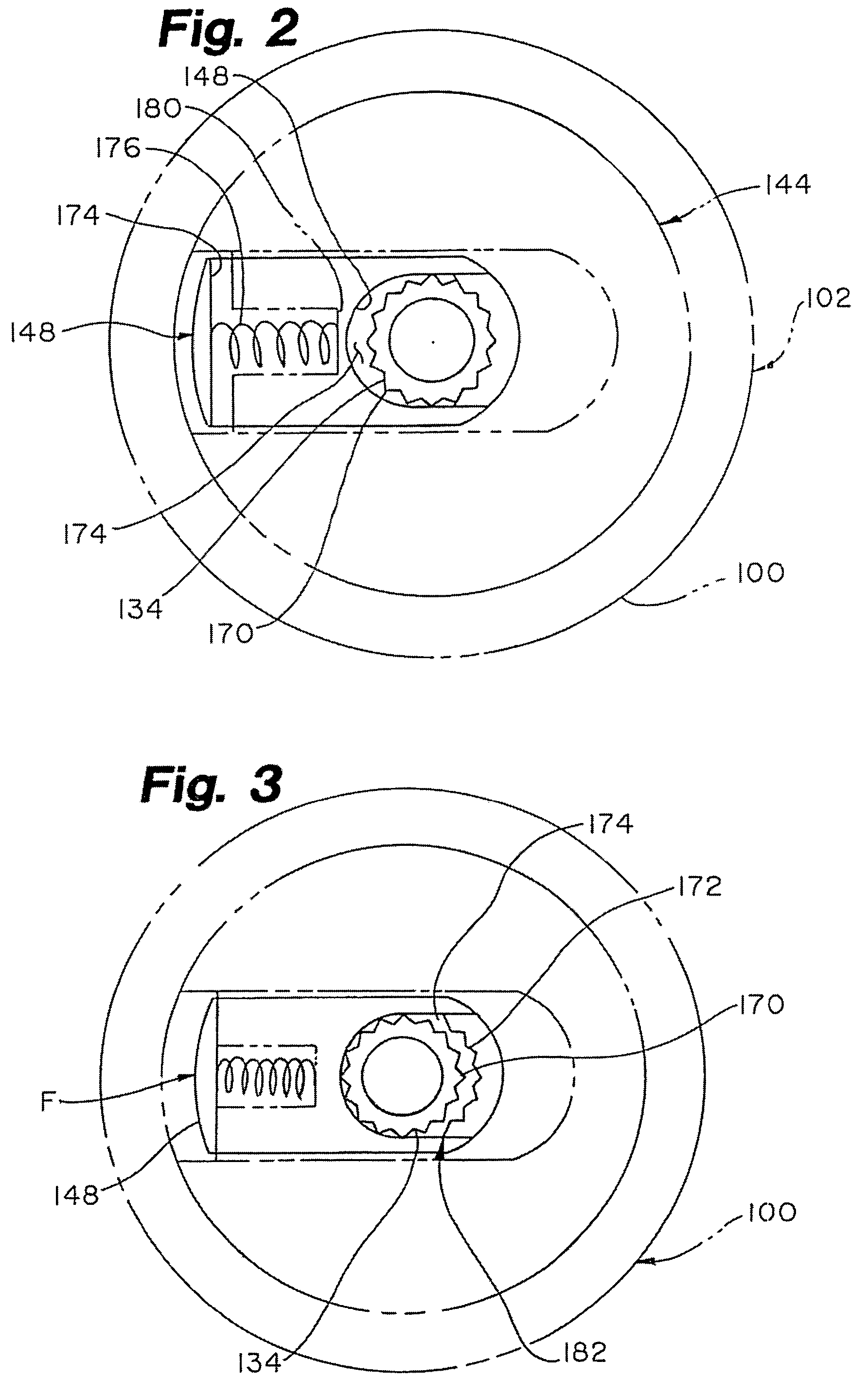

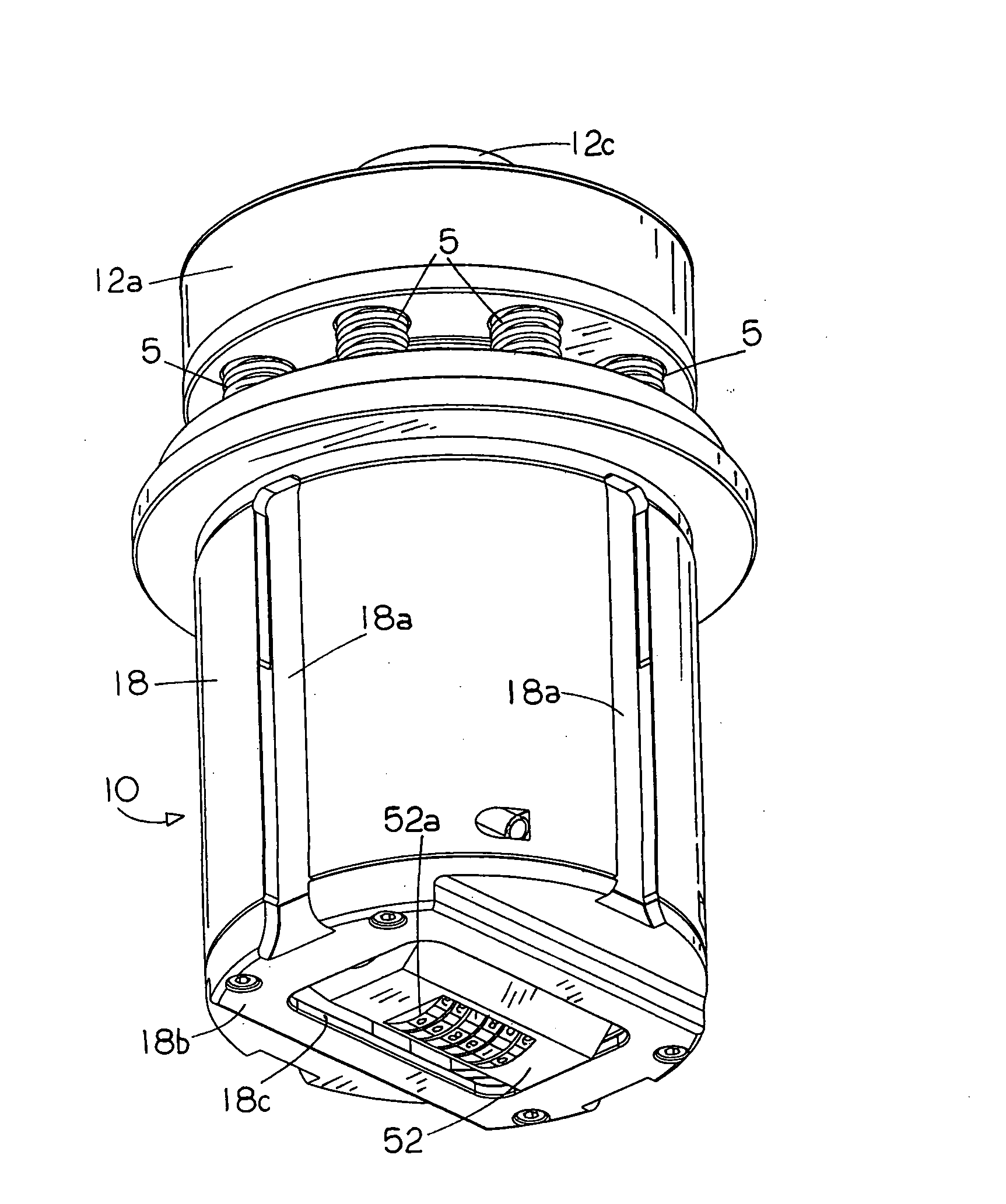

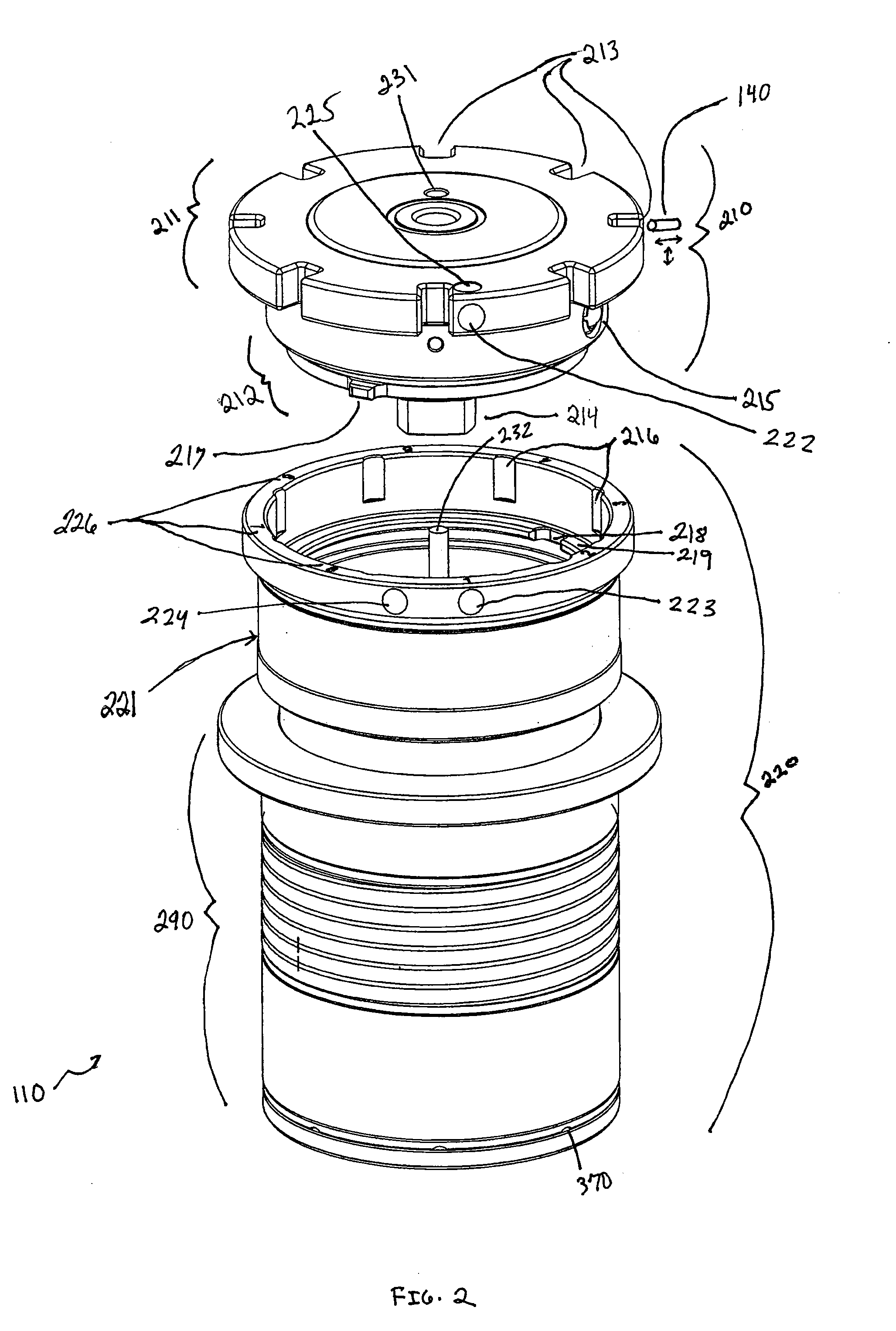

Tissue punch

A tissue punch for creating a hole in the wall of a target blood vessel for receiving an anastomosis device includes a piercing element for penetrating the tissue and a cutting element for cutting a plug of tissue around the pierced hole. The tissue punch includes a trocar for inserting the piercing element. After punching is complete, the piercing element is removed from the trocar through a side wall of the trocar so that a medical device can be deployed through the trocar lumen. The tissue punch may also include a tissue trap for trapping the plug of tissue.

Owner:AESCULAP AG

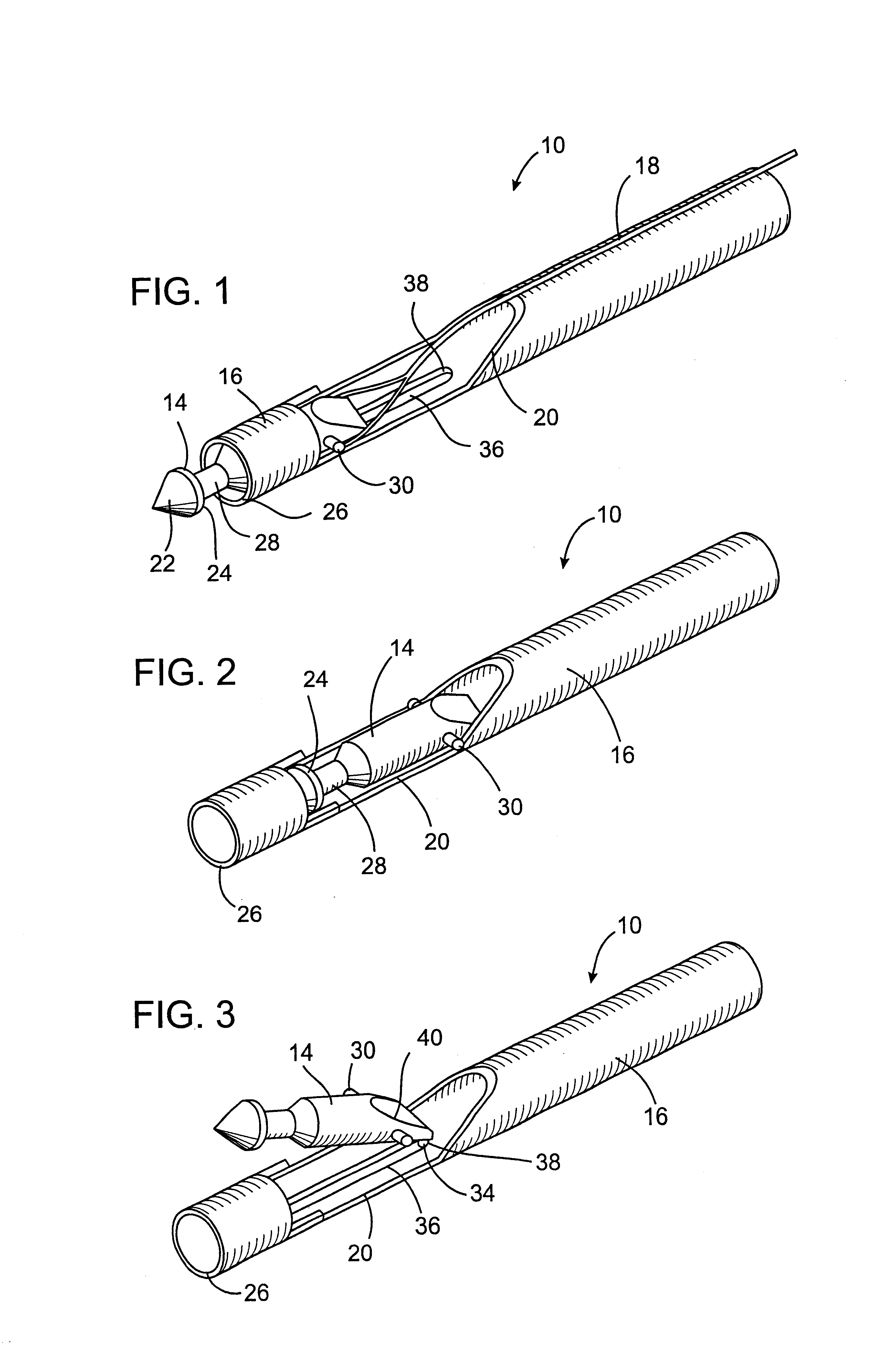

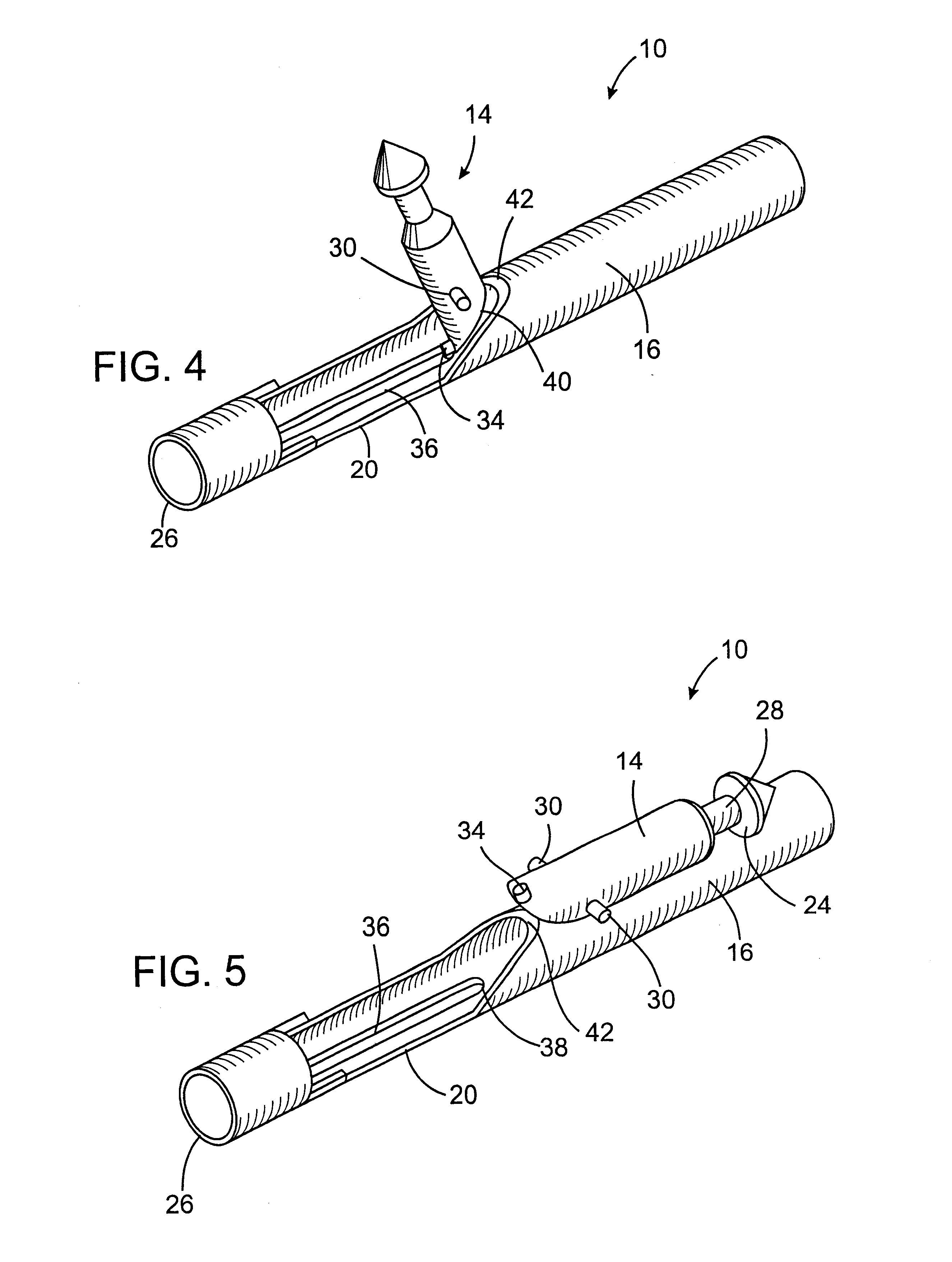

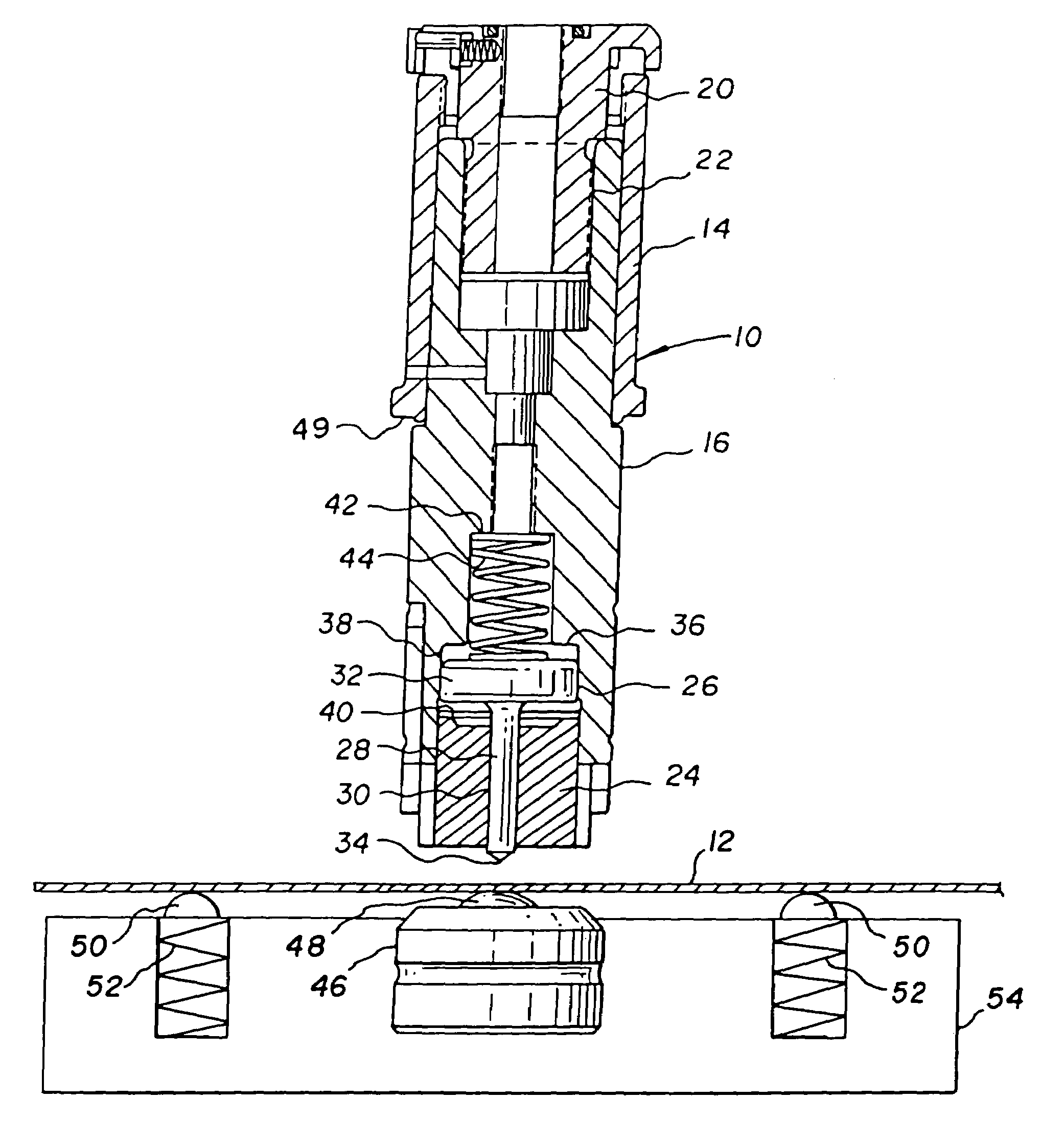

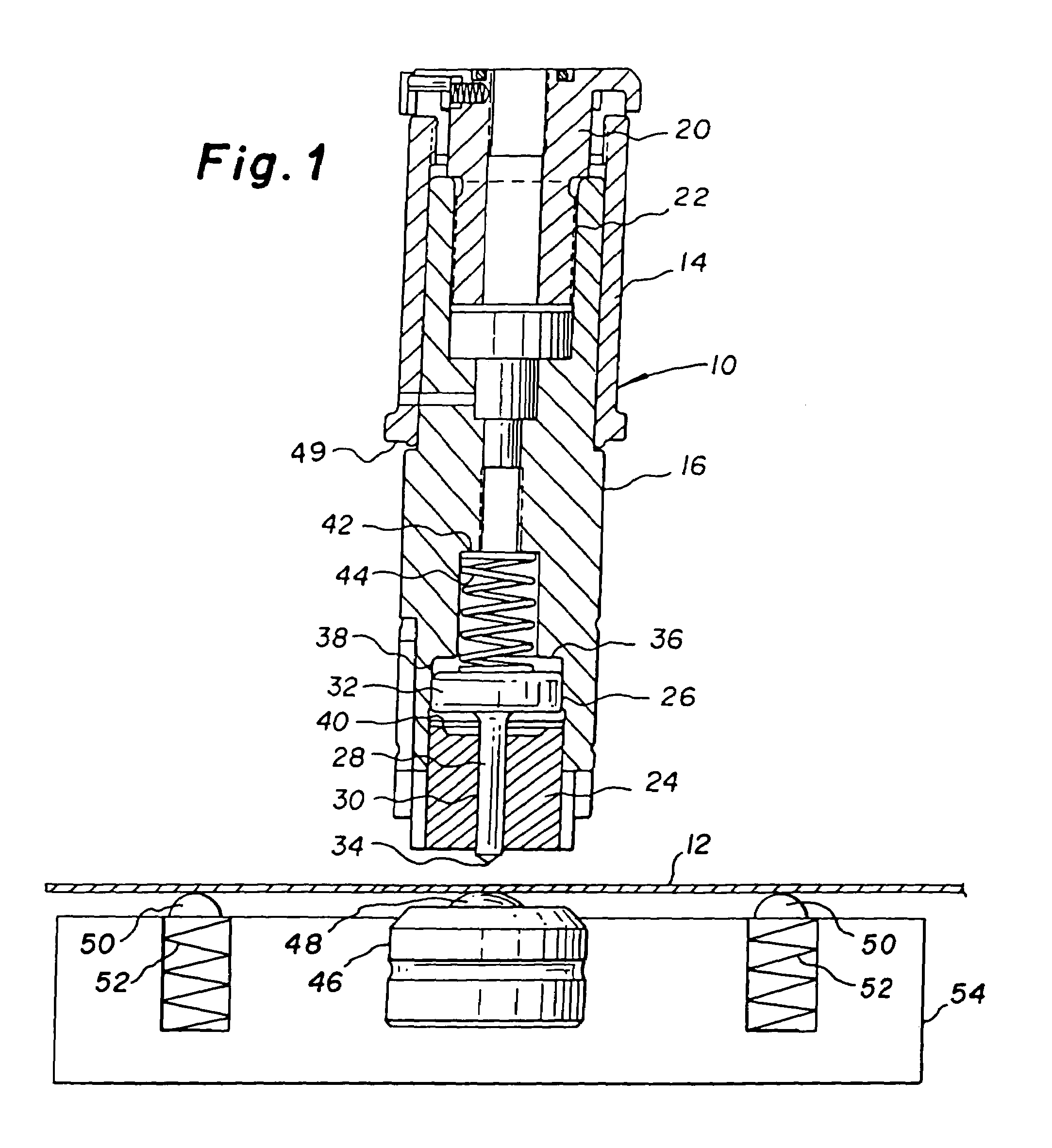

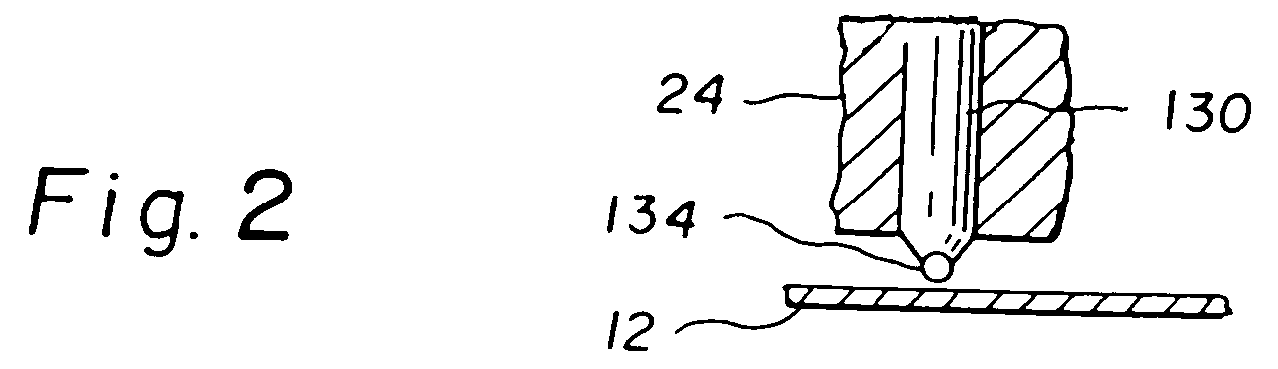

Medical punch and surgical procedure

InactiveUS7258694B1Clean and accurate cutFacilitates screwing the punchIncision instrumentsDiagnosticsPunch pressEngineering

A medical punch includes a longitudinally dividable anvil with a reduced cross-sectional dimension facilitating insertion of the anvil into the vessel wall to achieve a clean aperture in the vessel wall by cooperative shearing action of a cutting edge and an anvil edge. In another embodiment, the instrument incorporates a measuring device for determining the thickness of a vessel wall between an anvil and a distal end of a cylindrical structure which together form a caliper, and the measuring device can also constitute a medical punch by cooperative shearing action of a cutting edge and an anvil to achieve a clean aperture in the vessel wall.

Owner:MAQUET CARDIOVASCULAR LLC

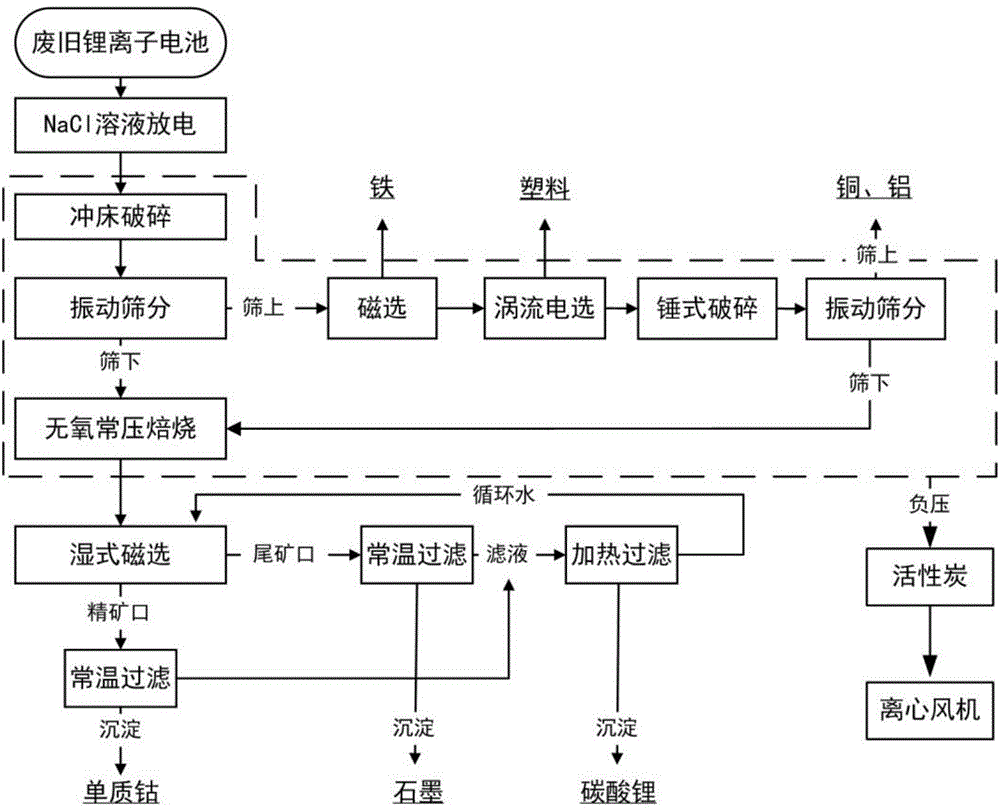

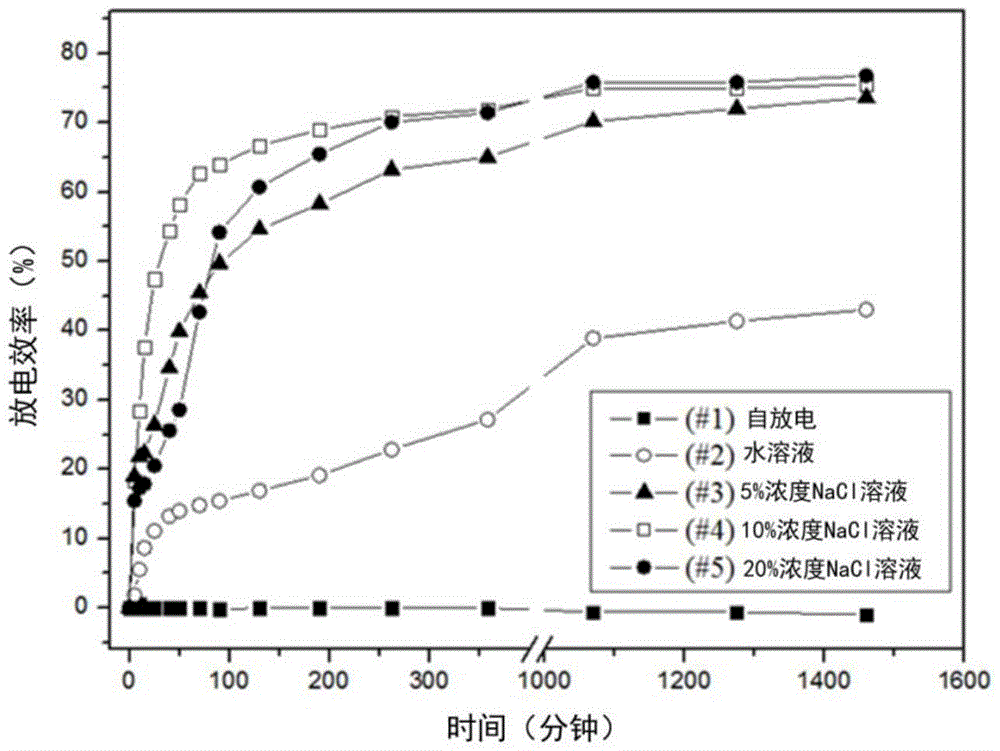

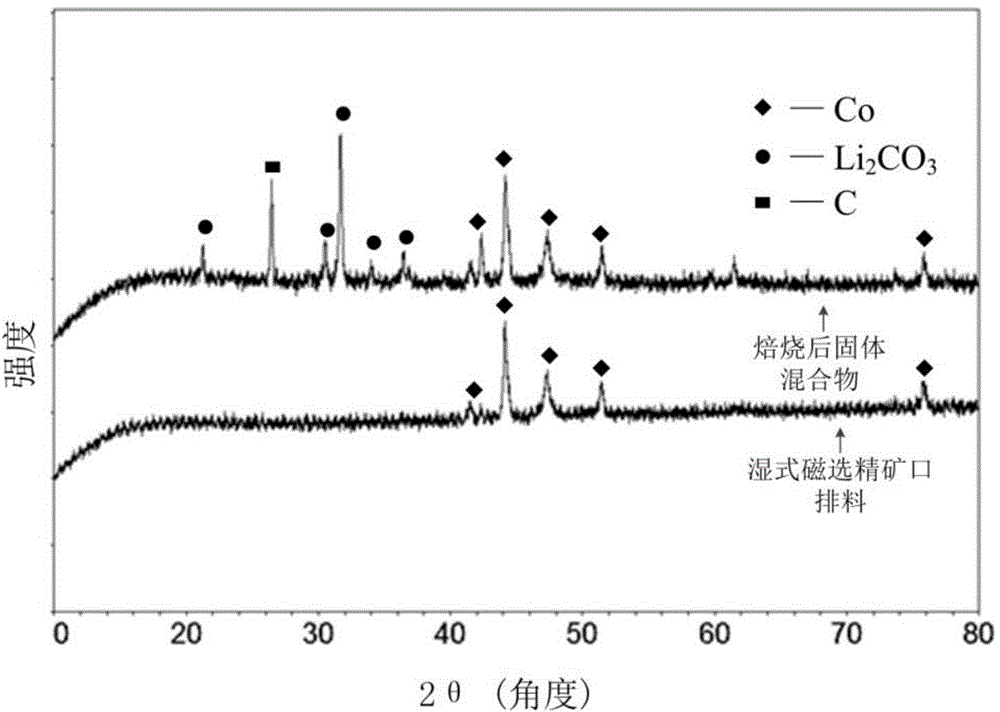

Method for recycling waste lithium cobalt oxide lithium ion battery

ActiveCN104577249AFully resourcedReduce lossesWaste accumulators reclaimingBattery recyclingPunch pressCobalt

The invention relates to a method for recycling waste lithium cobalt oxide lithium ion battery. The method is characterized in that valuable components in the waste lithium ion battery are completely recycled by integrating the processes of crushing by a punch press, magnetic separation, eddy current selection, anaerobic atmospheric roasting, temperature-variable filtering and the like, and products with the relatively high additional values, such as elemental crude cobalt, lithium carbonate, graphite, copper, aluminum, iron, and plastics are obtained. Manners of crushing by a punch press, magnetic separation, eddy current selection and the like are adopted for performing material separation, so that the original physical properties of materials are kept. Meanwhile, positive powder and negative powder of an electrode material are cooperatively treated, the negative graphite material is effectively utilized, the in-situ preparation of a resource can be realized, and the waste lithium ion battery can be relatively completely recycled. The anaerobic atmospheric roasting is adopted, so that the reaction condition is relatively loose, the loss of a graphite material is reduced, the cost is saved, the technological flow is simplified, and the industrial application practice can be facilitated.

Owner:SHANGHAI JIAO TONG UNIV

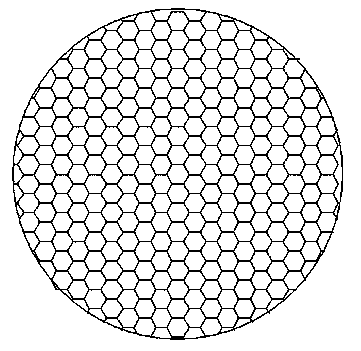

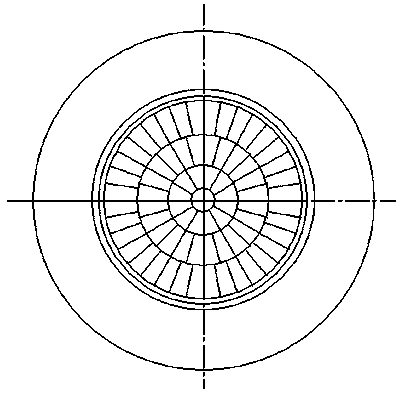

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

Adjustable length punch assembly

Owner:WILSON TOOL INT

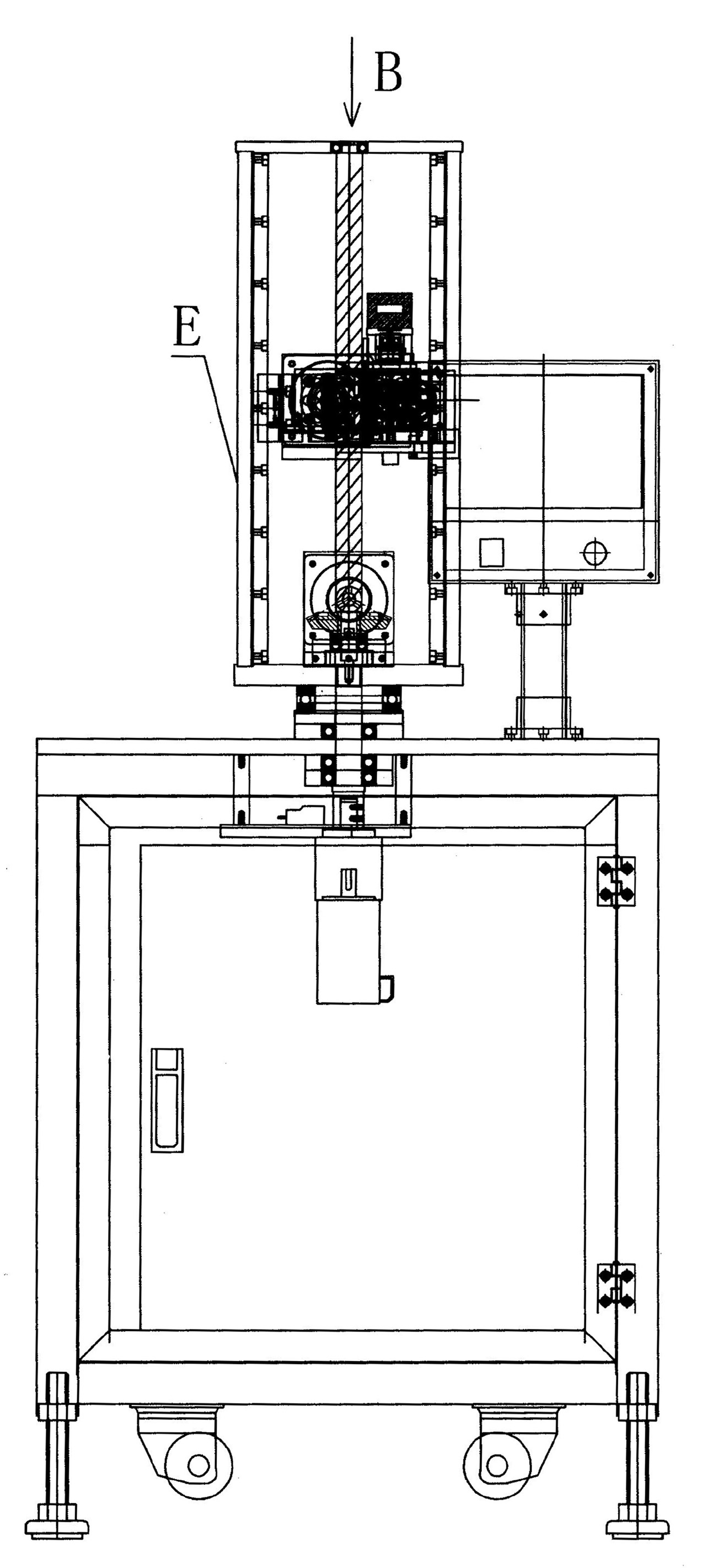

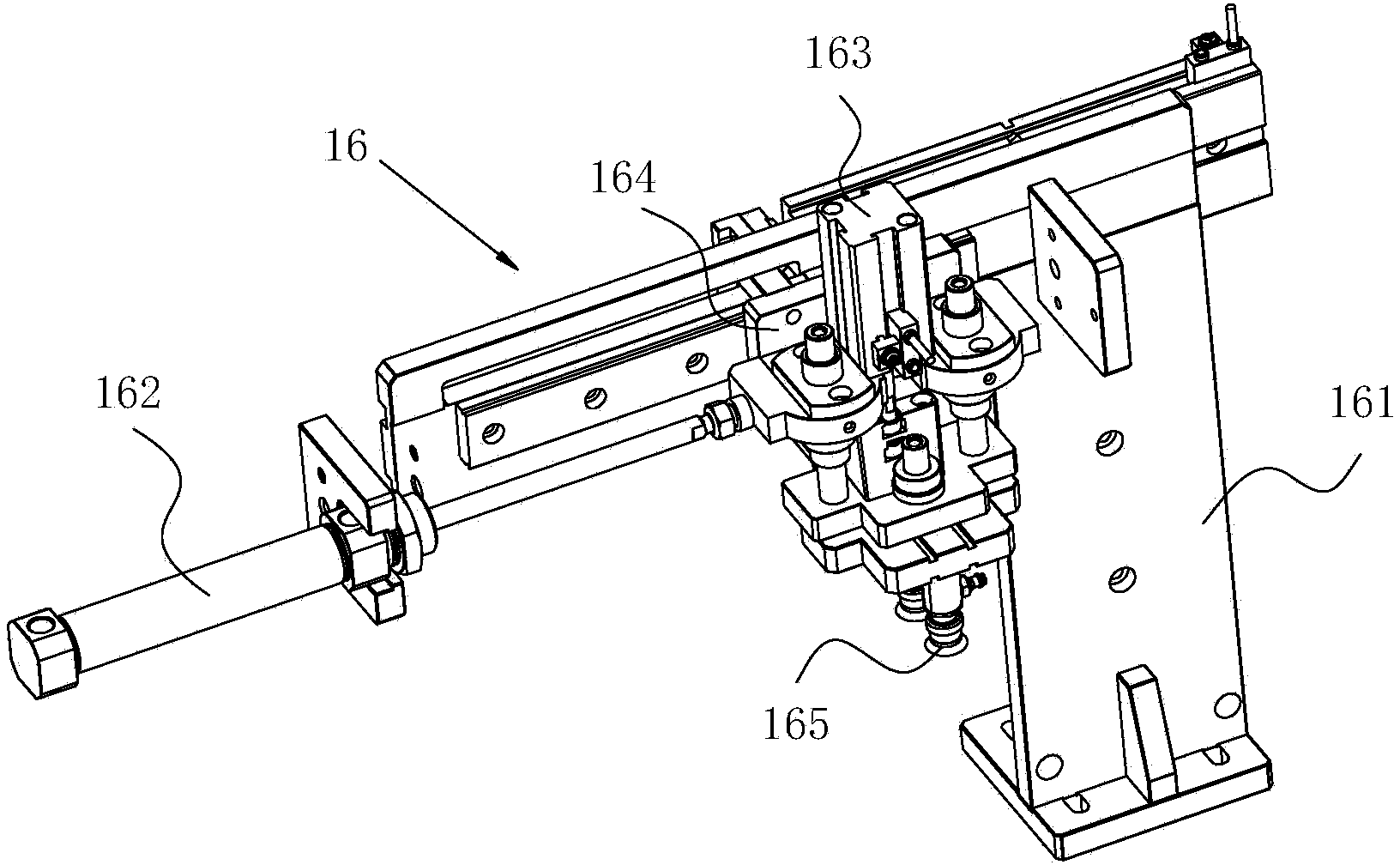

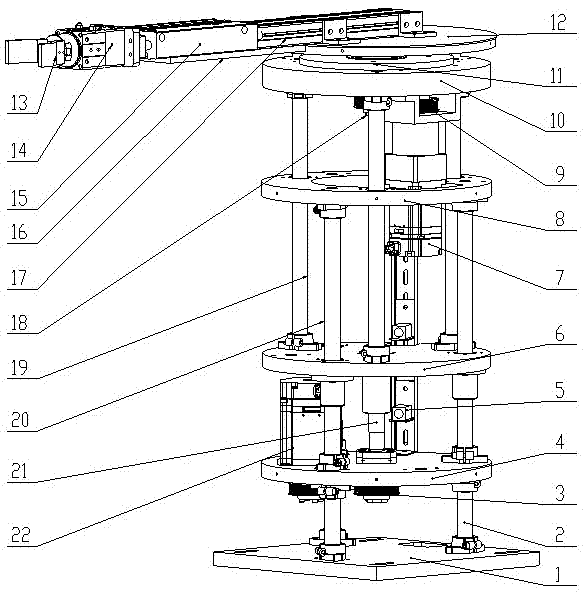

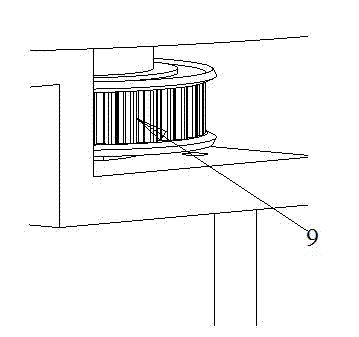

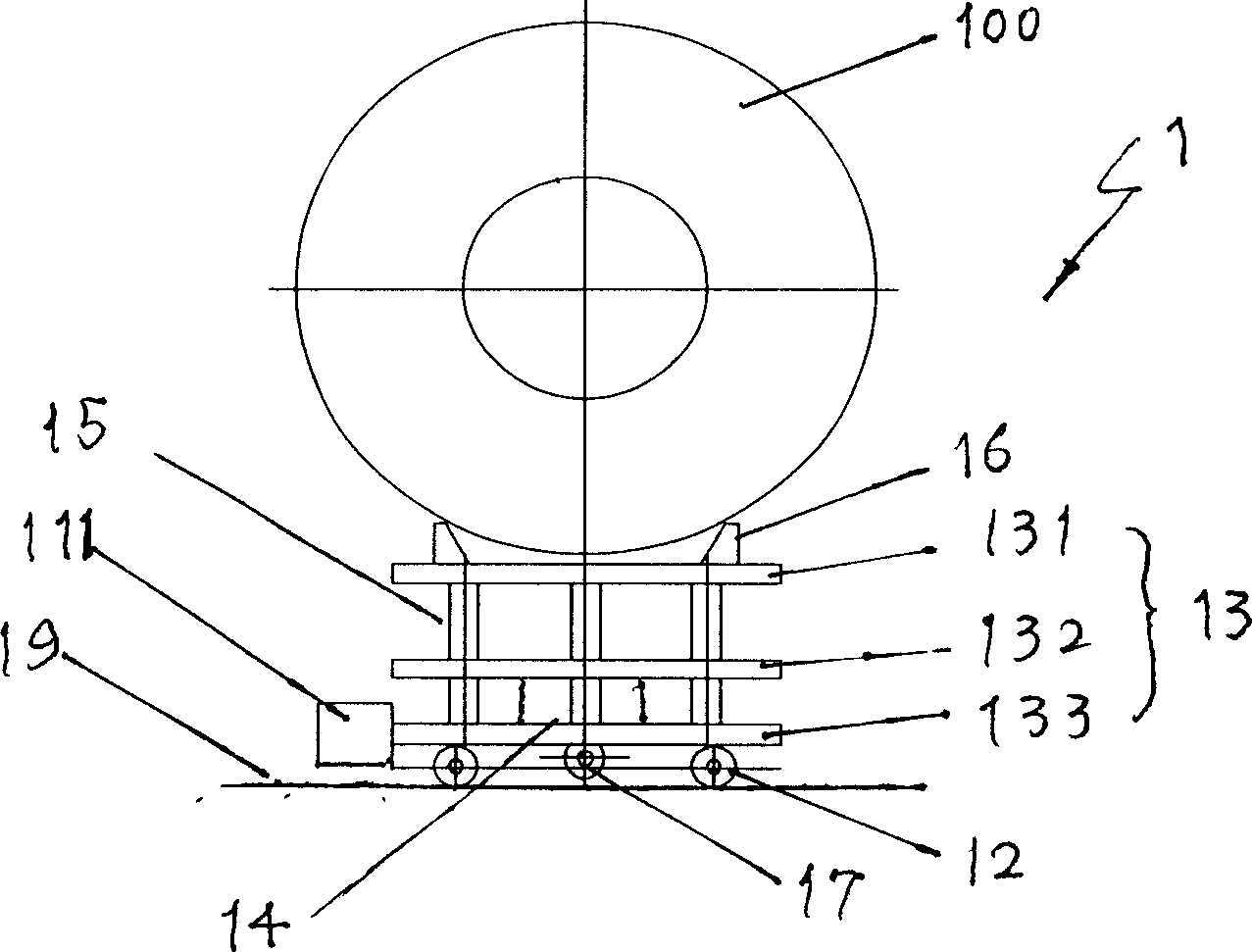

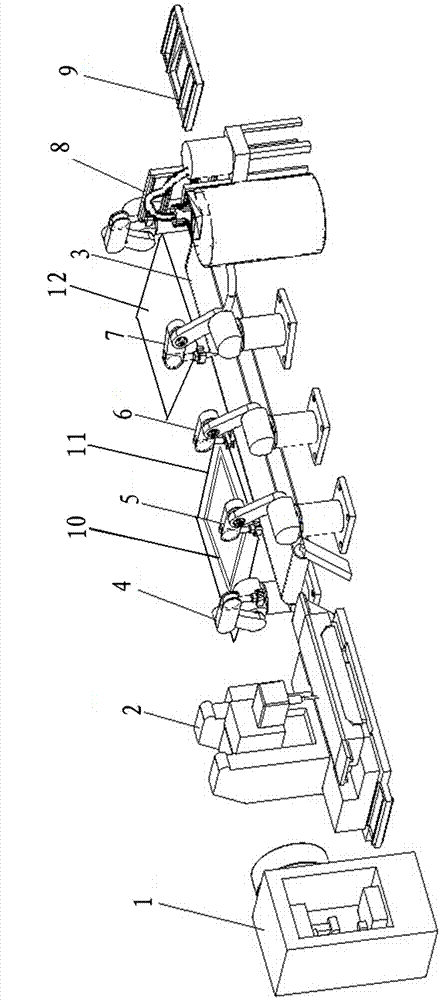

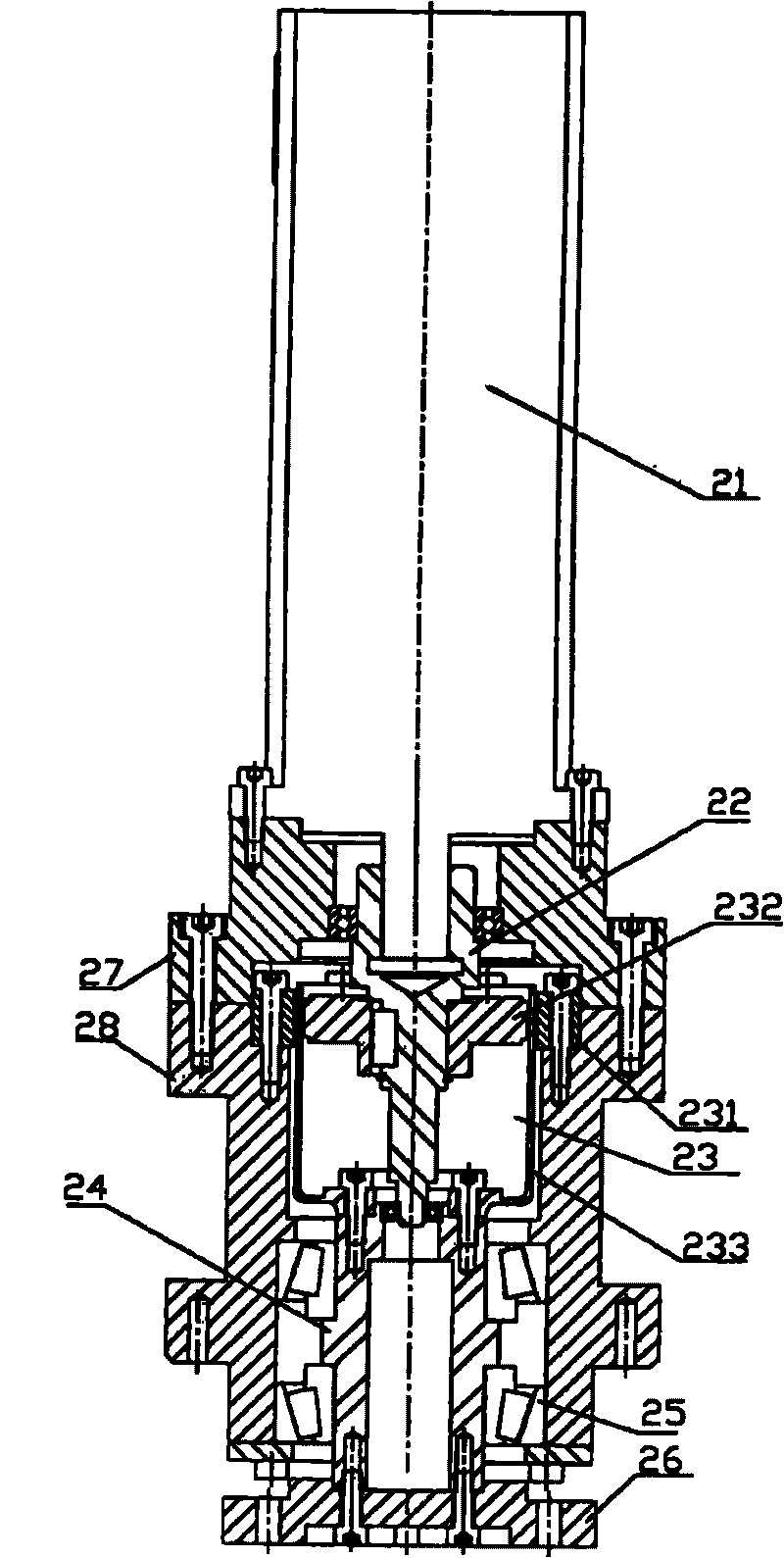

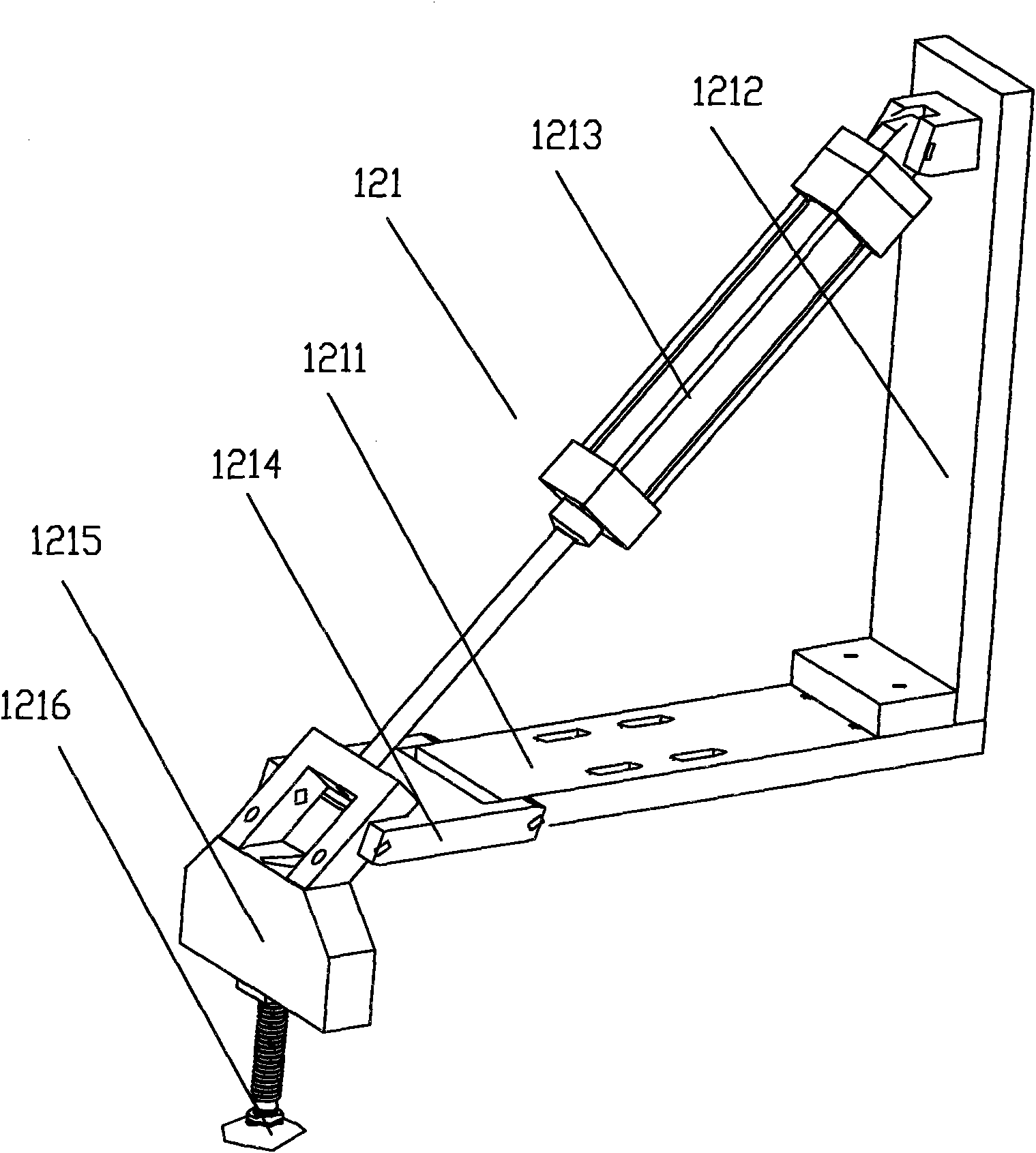

Intelligent mechanical arm of punch press

InactiveCN101947607AWork fasterOperating speed and power savingProgramme-controlled manipulatorMetal-working feeding devicesPunch pressGear wheel

The invention relates to an intelligent mechanical arm of a punch press. In the invention, a horizontal movement mechanism of the mechanical arm is transmitted by adopting a stepper motor and a linear ball screw; a mechanical arm rolling-over mechanism is transmitted by adopting a stepper motor and a gear, connected by a rolling-over spindle and rolled over by a driving arm, and the driving arm is provided with the mechanical horizontal movement mechanism which rolls over together; the mechanical horizontal movement mechanism is transmitted by adopting a servo motor and a planetary reducer; an executing end rotating movement mechanism is transmitted by a stepper motor and a synchronizing wheel, an executing part is a vacuum sucking disc, and the executing end rotating movement mechanism is arranged on the arm of the horizontal movement mechanism; a vertical movement mechanism is transmitted by adopting a stepper motor, a pair of bevel gears, a ball screw and a screw nut sleeve; and the horizontal movement mechanism, the rolling movement mechanism and the executing end rotating movement mechanism are all arranged on the screw nut sleeve of the vertical movement mechanism. The invention adopts a servo system in the aspect of electrical control to ensure that the running speed of the machine is improved, electricity is saved, and the effects of energy saving and environmental protection are achieved.

Owner:FOSHAN DINGFENG ROBOT

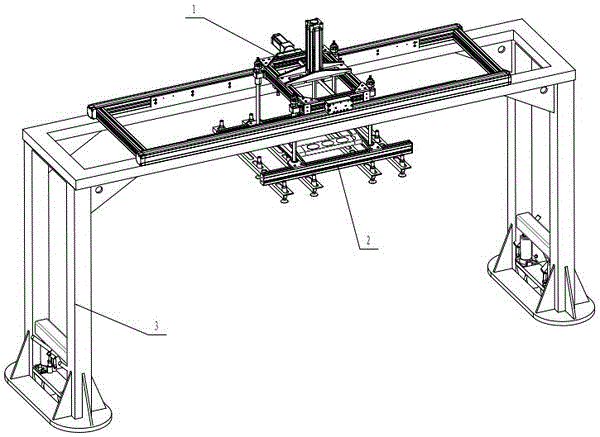

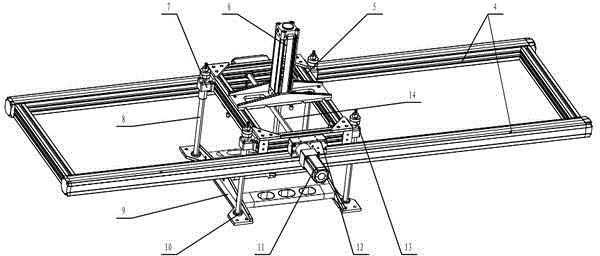

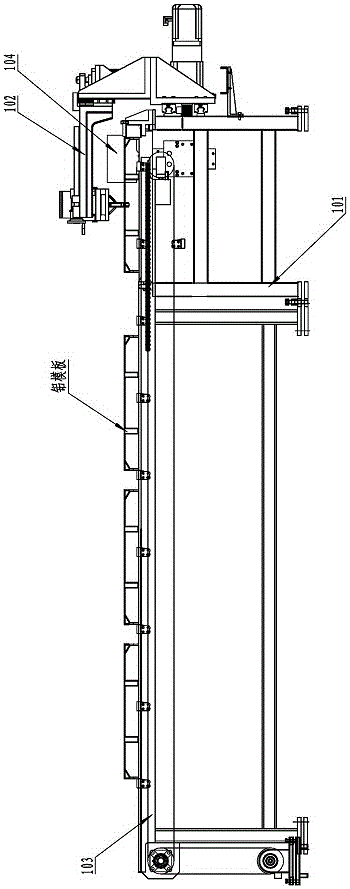

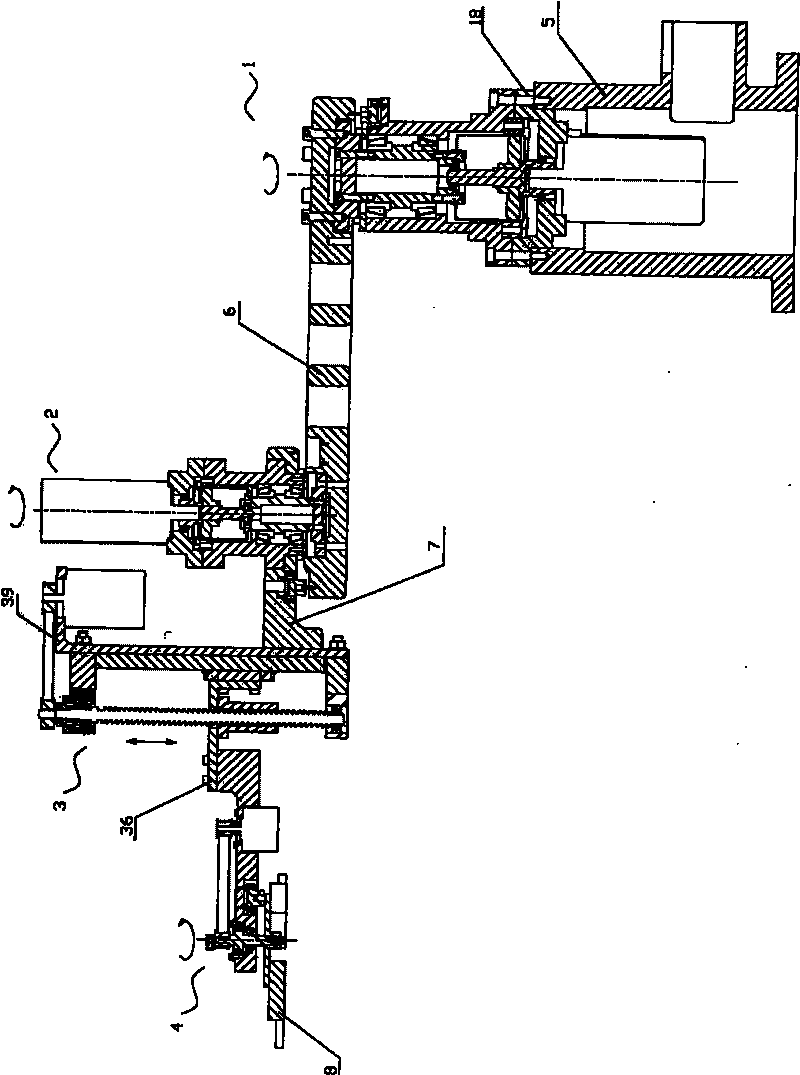

Automatic conveyer of work piece

ActiveCN104816945AIncrease stiffnessIncrease load capacityManipulatorConveyor partsPunch pressSilicon

The invention refers to the production field of automatic punching of a silicon steel sheet, and particularly relates to an automatic conveyer of a work piece. The automatic conveyer comprises a conveying robot, an absorbing system, and a mobile supporting mechanism; the absorbing system is arranged at the bottom part of the conveying robot, and the conveying robot is arranged on the mobile supporting mechanism. The conveying robot is a bi-axial robot, and the bi-axial robot comprises a horizontal movement mechanism and a vertical movement mechanism; the vertical movement mechanism is fixedly linked to the horizontal movement mechanism through a screw. The automatic conveyer of the work piece adopts a synchronous drive mode of a module with double synchronous belts in horizontal direction; during the horizontal conveying process, the automatic conveyer is high in speed, rigidity and bearing capacity and long in conveying distance; the automatic conveyer can be adapted to the high-speed production frequency of the existing punch press, and the production efficiency is improved.

Owner:中国东方电气集团有限公司

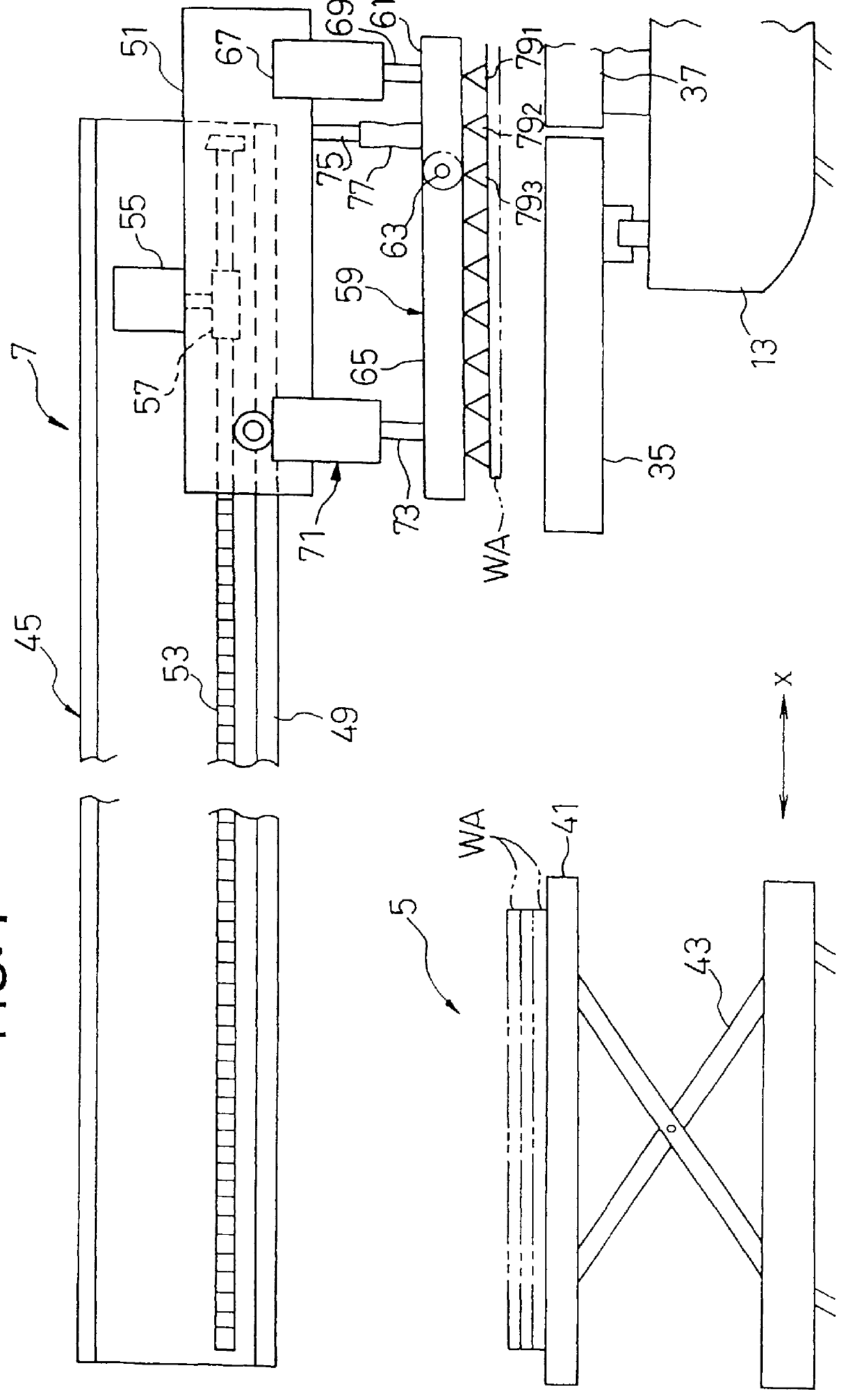

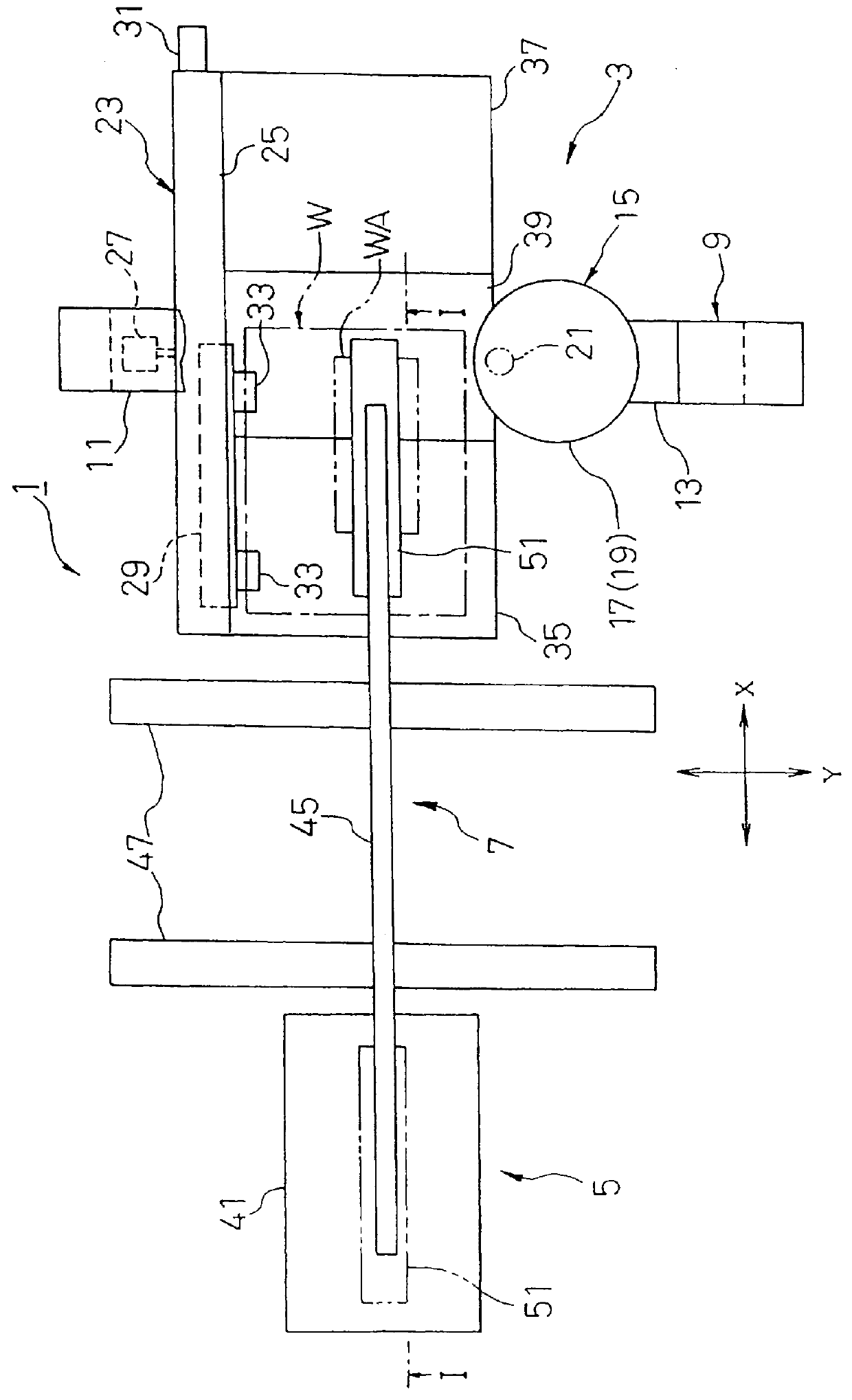

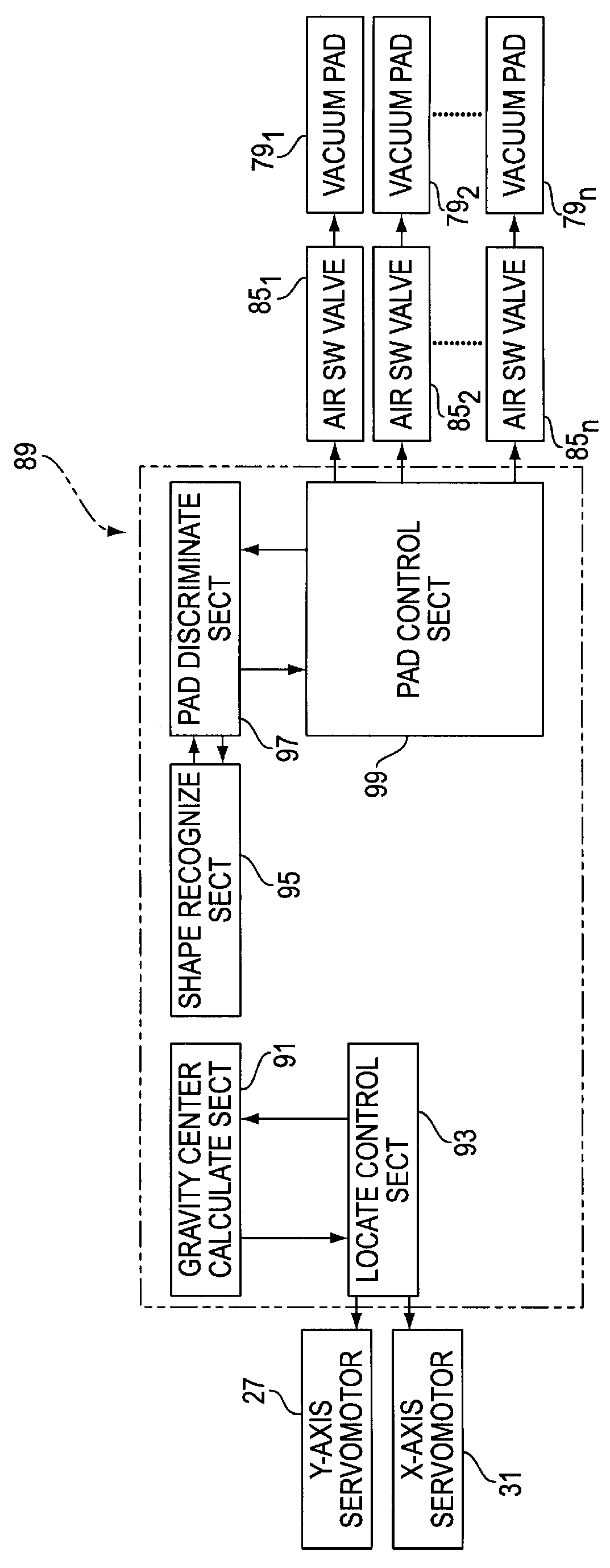

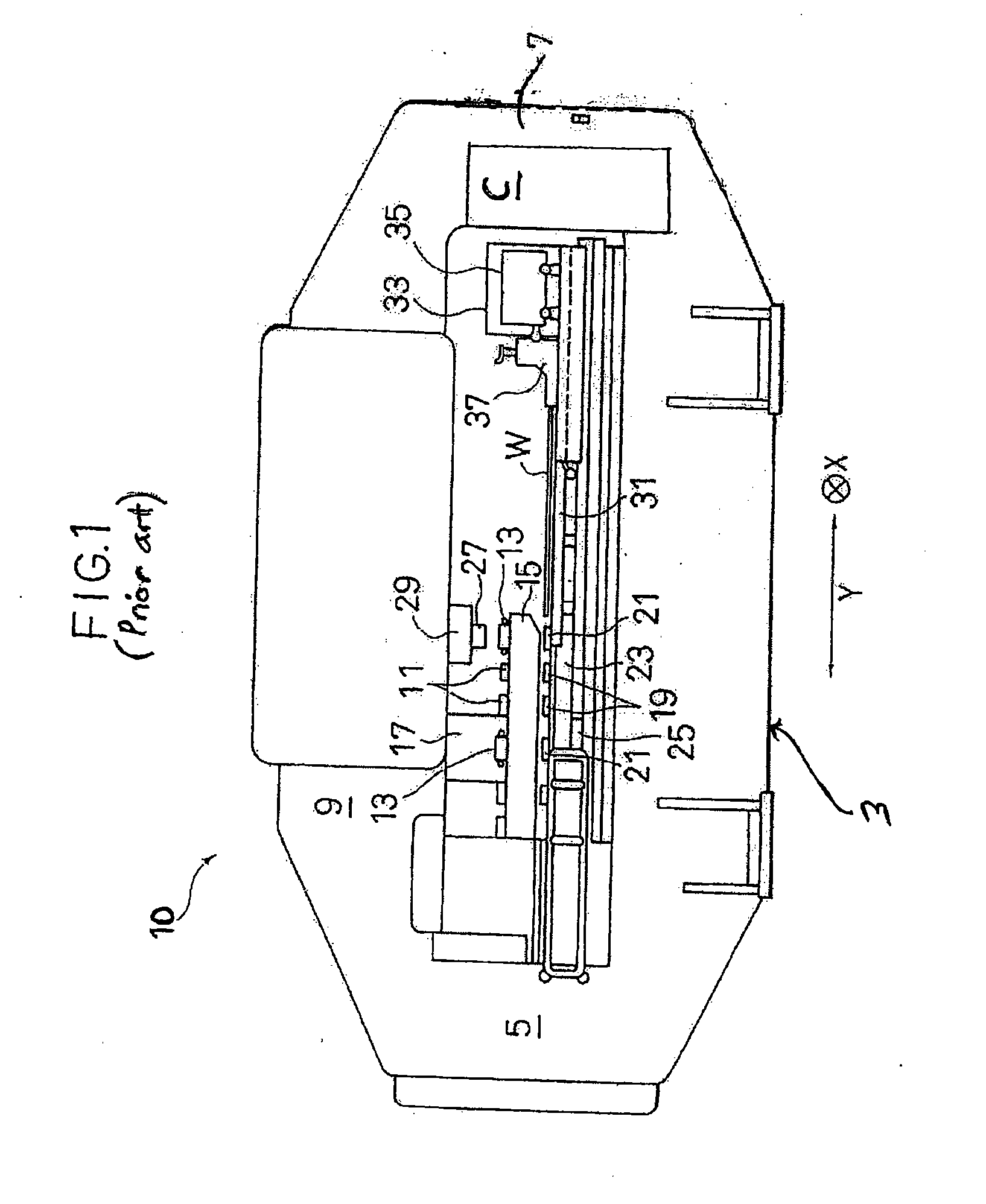

Punched plate material carrying-out system

InactiveUS6055895AReduce in quantitySmall sizeAutomatic control devicesMetal-working feeding devicesPunch pressManufacturing data

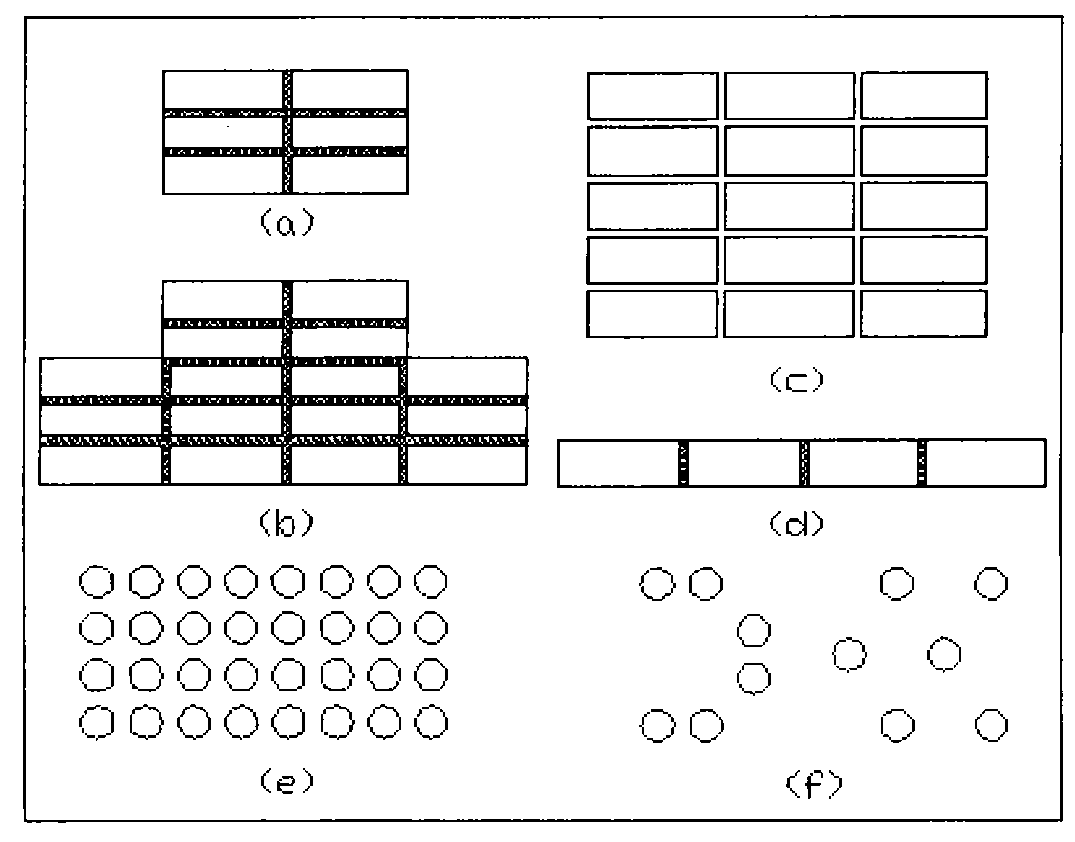

A slider of the punch carry out unit is moved in the X-axis direction adjacent a punching section of the punch press machine before or after a plate material is punched into a punched product by a punch press machine. At the same time, a gravity center and a shape of the punched product are calculated and recognized on the basis of the manufacturing data. On the basis of the obtained gravity center and the shape of the punched product, the gravity center of the punched product is moved under the lift arm by the X- and Y-axis locating mechanism. Vacuum pads located just over the punched product are selected or discriminated. Then, the lift arm is lowered and the punched product is held by actuating only the discriminated vacuum pads. During this lift motion, it is preferable to bend one end of the punched product slightly upward to easily separate the punched product from the remaining flat plate material. After the punched product has been lifted, the punched product is moved horizontally away from the punch press, and is then lowered on the punched product supporting unit by releasing only the actuated vacuum pads. Since only the vicinity of the gravity center of the punched product is held by a minimum possible number of the vacuum pads, irrespective of the size and shape of the punched products, the number of the vacuum pads can be reduced.

Owner:U S AMADA

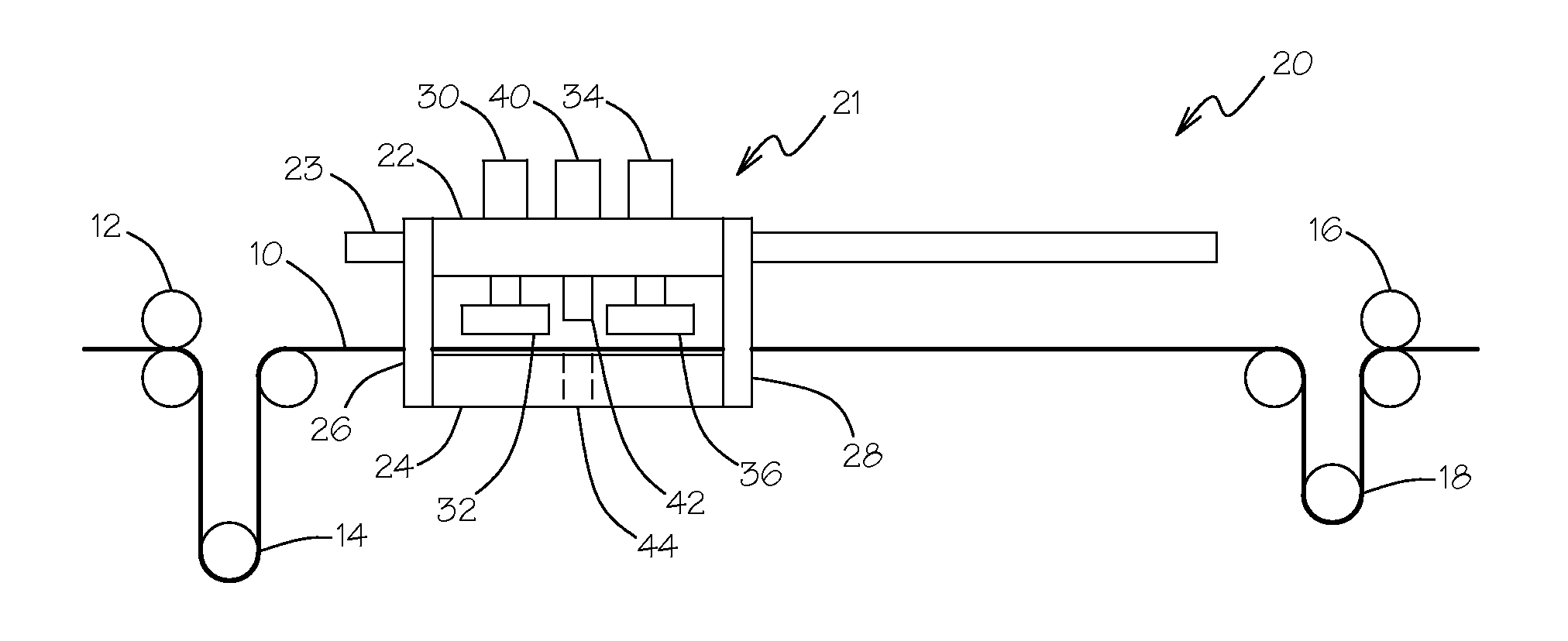

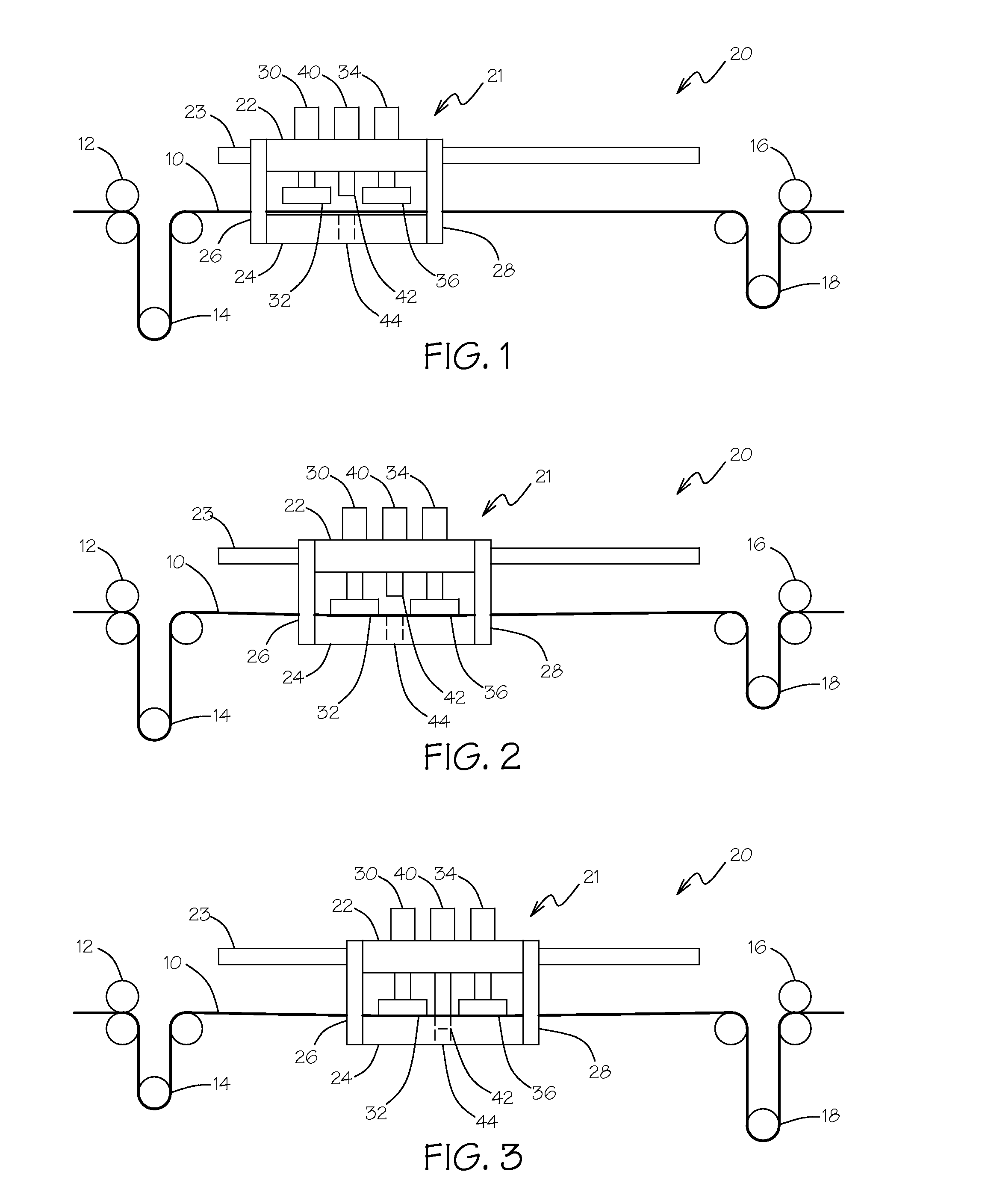

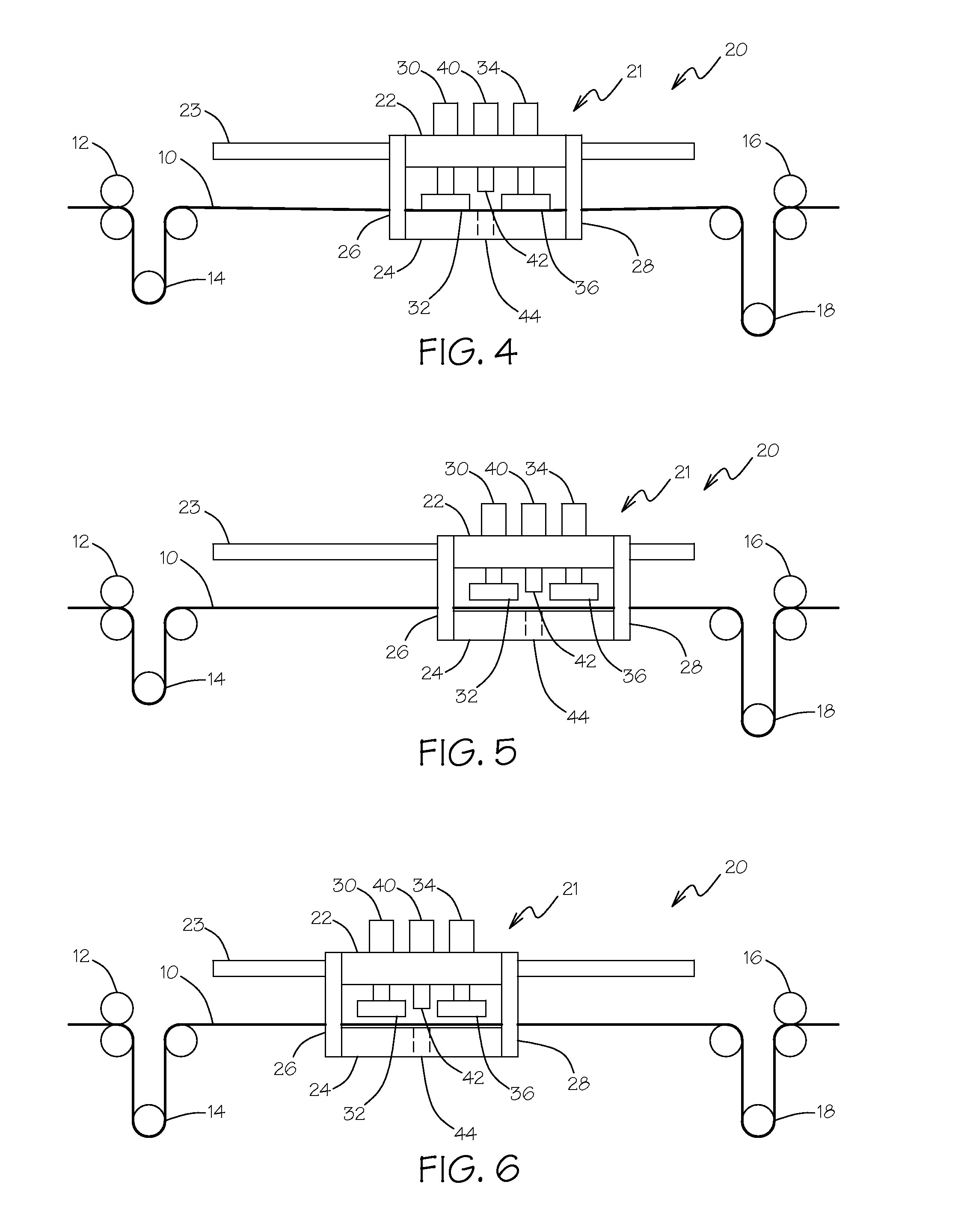

Flying punch for webs

A punching station for a web includes a web transport system that operates to advance the web in a first direction at a first rate. A clamp intermittently grips a portion of the web to advance the portion in the first direction at a second rate. A punch is coupled to the clamp such that the punch moves in the first direction together with the clamp. A punch block cooperates with the punch. The punch block is coupled to the clamp such that the punch block moves in the first direction in unison with the clamp. A punch actuator causes the punch to penetrate the web and then to be withdrawn from the web while the web is gripped by the clamp.

Owner:SMART BOTTLE

Punch press tool for stamping successive multicharacter impressions into a workpiece

ActiveUS20080314220A1Addressing machinesMechanical working/deformationPunch pressReciprocating motion

A punch press tool for stamping successive multicharacter impressions into a workpiece such as a piece of steel, sheet metal, or other workpiece, includes a guide body in which a stamp driver is slidably mounted for being driven downwardly toward the workpiece by a punch press ram which is a standard part of a high speed commercial punch press. A multicharacter marking stamp is supported at the lower end of the stamp driver for reciprocal movement therewith. The marking stamp includes multicharacter wheels that are rotated automatically during operation for advancing characters in sequence responsive to the movement of a character advancing arm. At least one character stamp operating lever is operatively associated with the punch press tool for articulation responsive to motion imparted to the tool by the ram. The lever has an operating element that is operatively associated with the character advancing arm of the multicharacter stamp for indexing the arm to enable successive characters thereof to be placed in an operating position responsive to a stroke of the punch press ram.

Owner:MATE PRECISION TOOLING

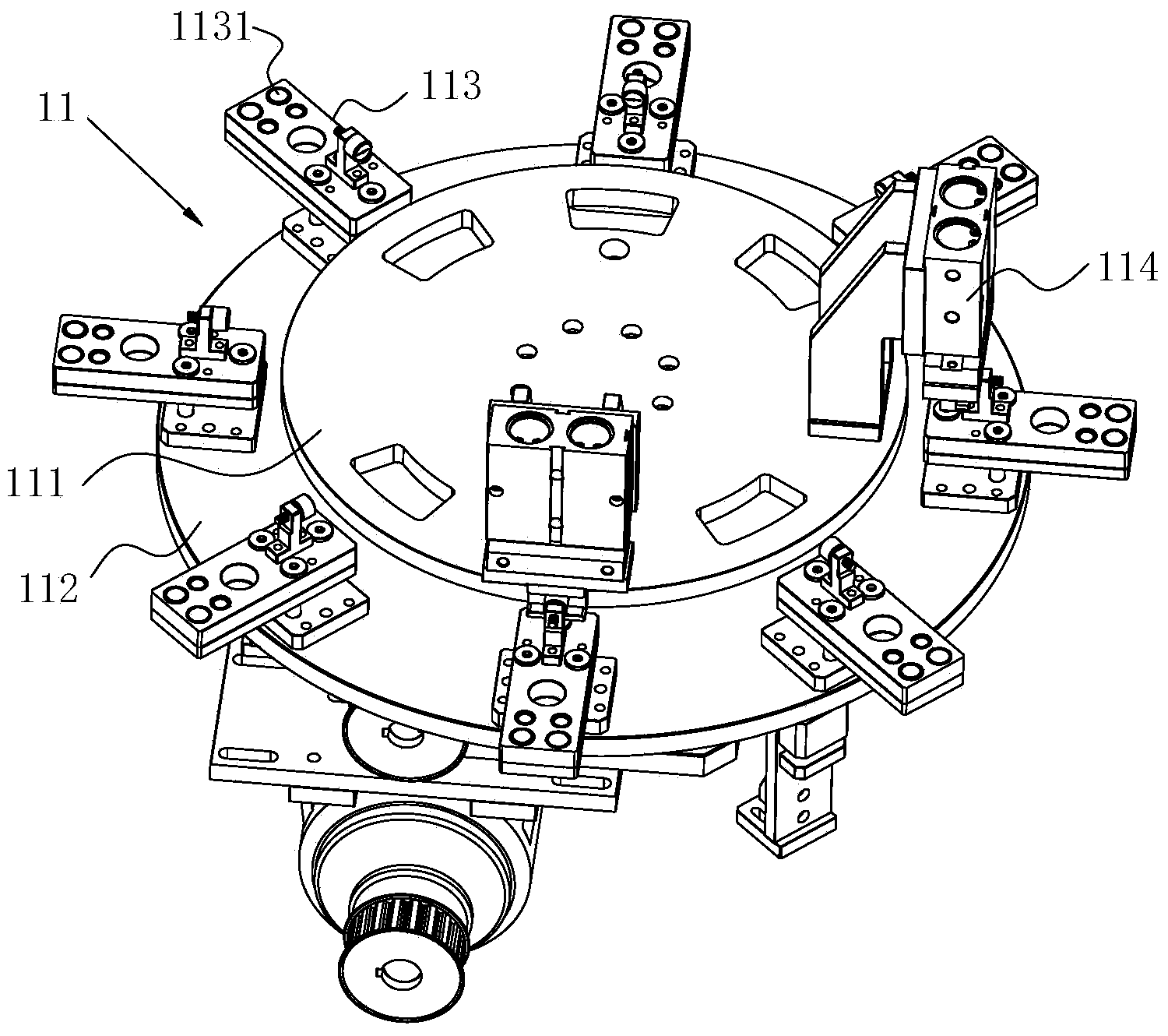

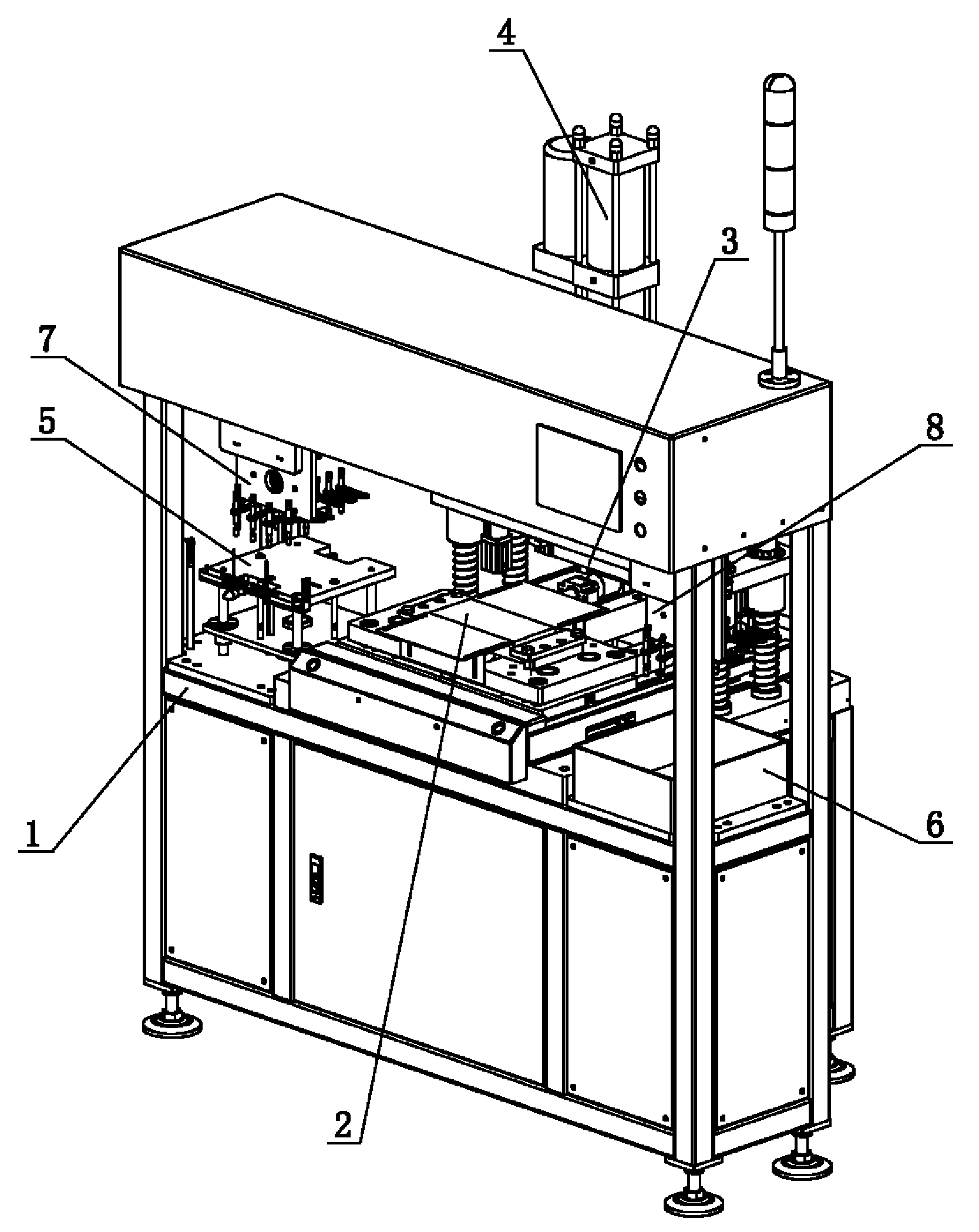

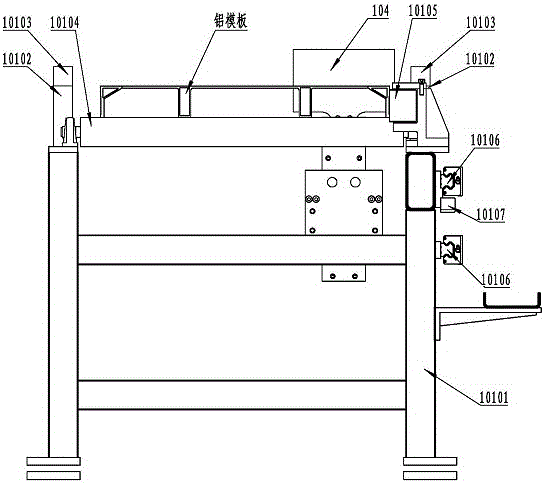

Automatic battery end cover assembling machine

ActiveCN104241694ARealize automatic feedingRealize the assemblyAssembling battery machinesFinal product manufacturePunch pressEngineering

The invention discloses an automatic battery end cover assembling machine which comprises a rack and a central rotary table, wherein a plurality of positioning molds are uniformly arranged at the periphery of the central rotary table; a pre-assembling device, an iron ring feeding component, a punch press component and a finished product blanking component, corresponding to the positioning molds, are sequentially arranged on the rack; the pre-assembling device comprises a cover plate feeding component, a pole feeding component and an assembly component which is arranged between the cover plate feeding component and the pole feeding component and is used for assembling cover plates and poles; feeding mechanical arms which are used for transferring materials to the positioning molds are respectively arranged on one side of the assembly component, as well as between the iron ring feeding component and the central rotary table. According to the automatic battery end cover assembling machine, due to arrangement of the central rotary table with the plurality of positioning molds, as well as the feeding component, the assembly component, the punch press component and the finished product blanking component for various parts, which cooperate with the central rotary table, battery end covers can be automatically fed, assembled and discharged, and the production efficiency and reliability are effectively improved.

Owner:荆门亿纬创能锂电池有限公司

Method and apparatus for marking workpieces

InactiveUS7168364B2Reduce noiseNumberMechanical working/deformationTypewritersContact pressurePunch press

A method and an apparatus are provided for marking a sheet-shaped workpiece using a marking tool. The marking tool is mounted in a punch holder of a punch press and a counter-support is fixed in place on a side opposite of a marking surface of the workpiece to be marked. The surface of the workpiece is marked by displacing the workpiece in its plane while engaging the marking tool with the workpiece. In one form, a support roller provides counter-support. In another form, an elastic element is cooperatively associated with the punch stroke of the punch press to translate an exactly defined contact pressure force between the tool tip and the workpiece to be marked.

Owner:MATE PRECISION TOOLING

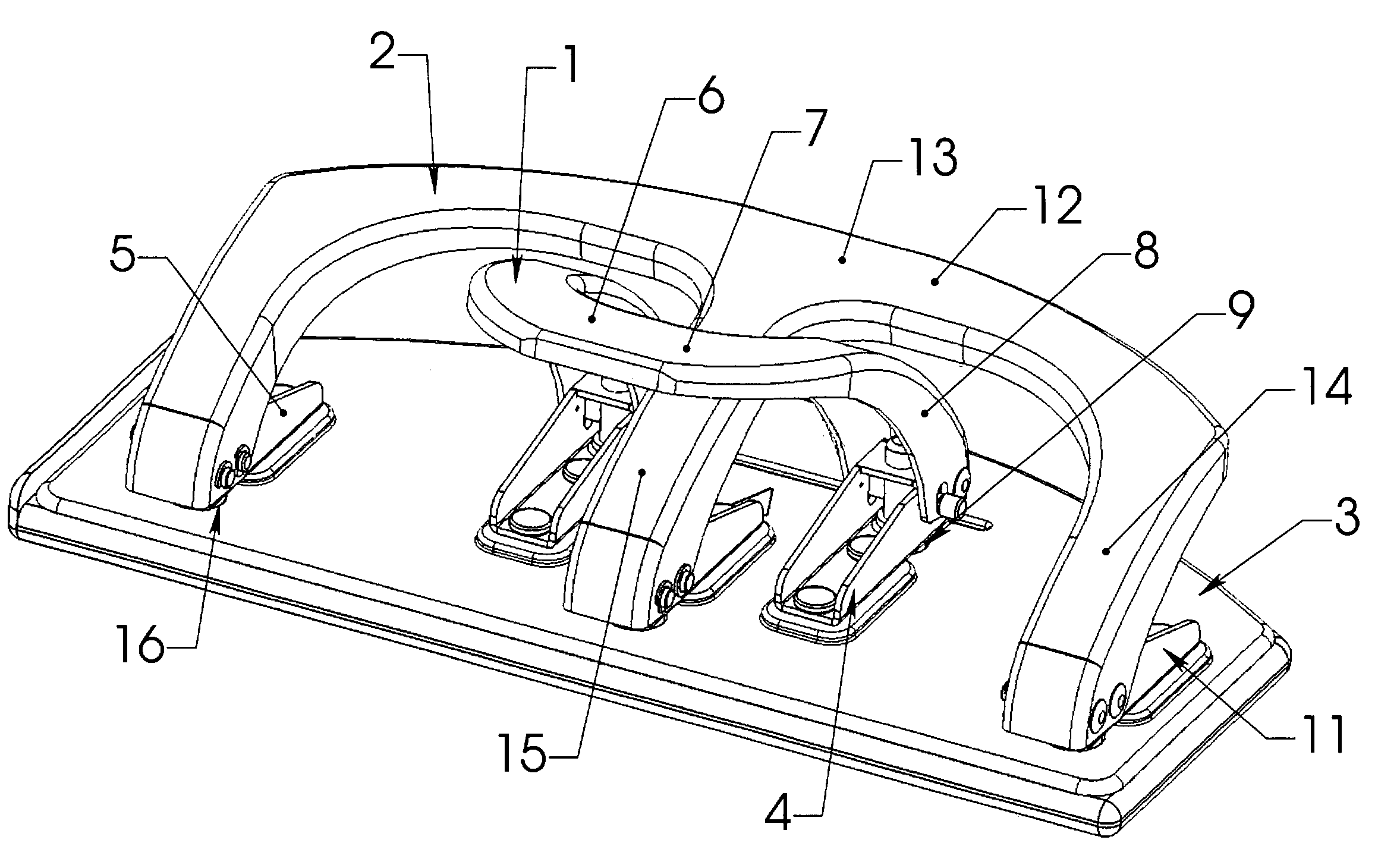

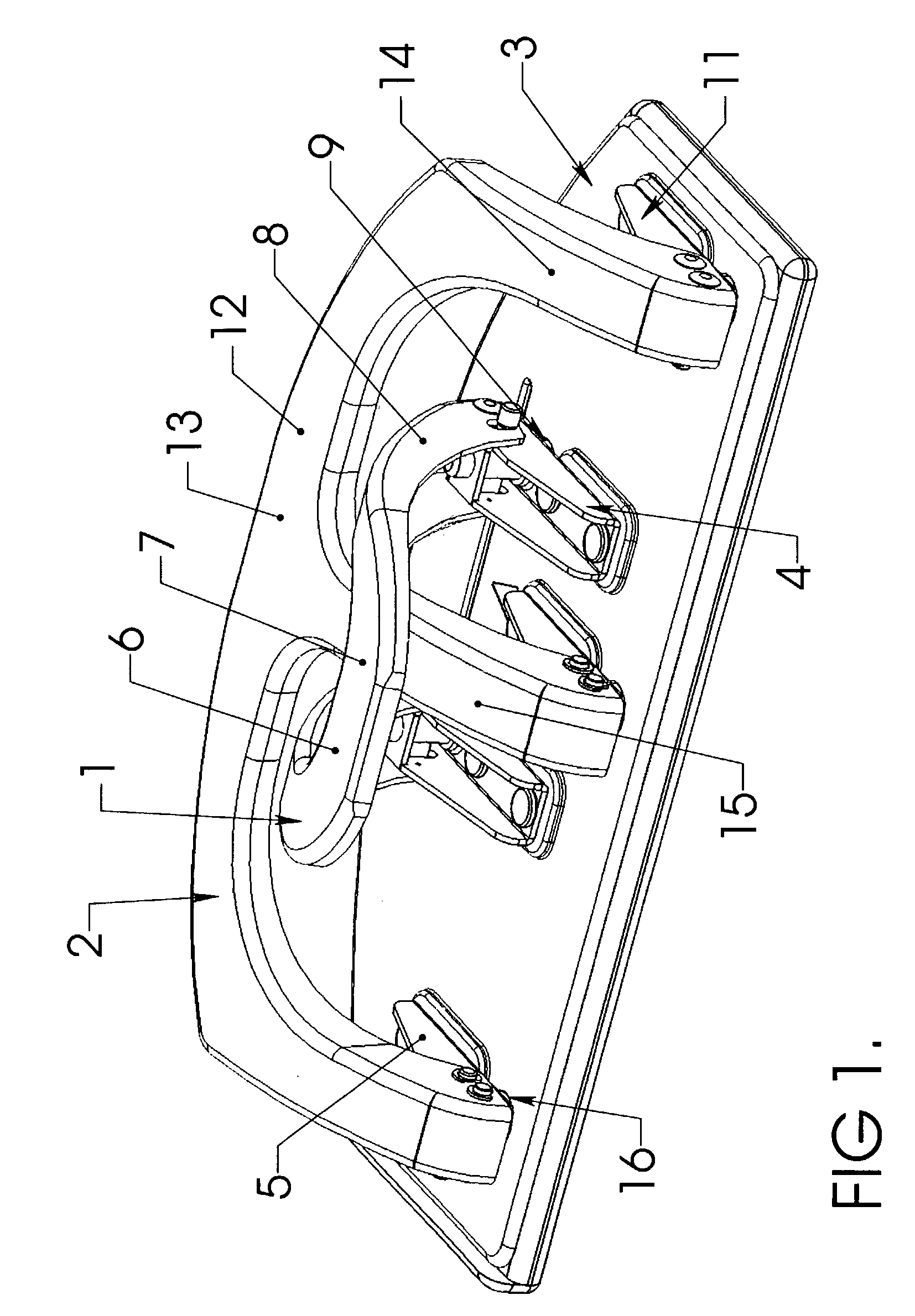

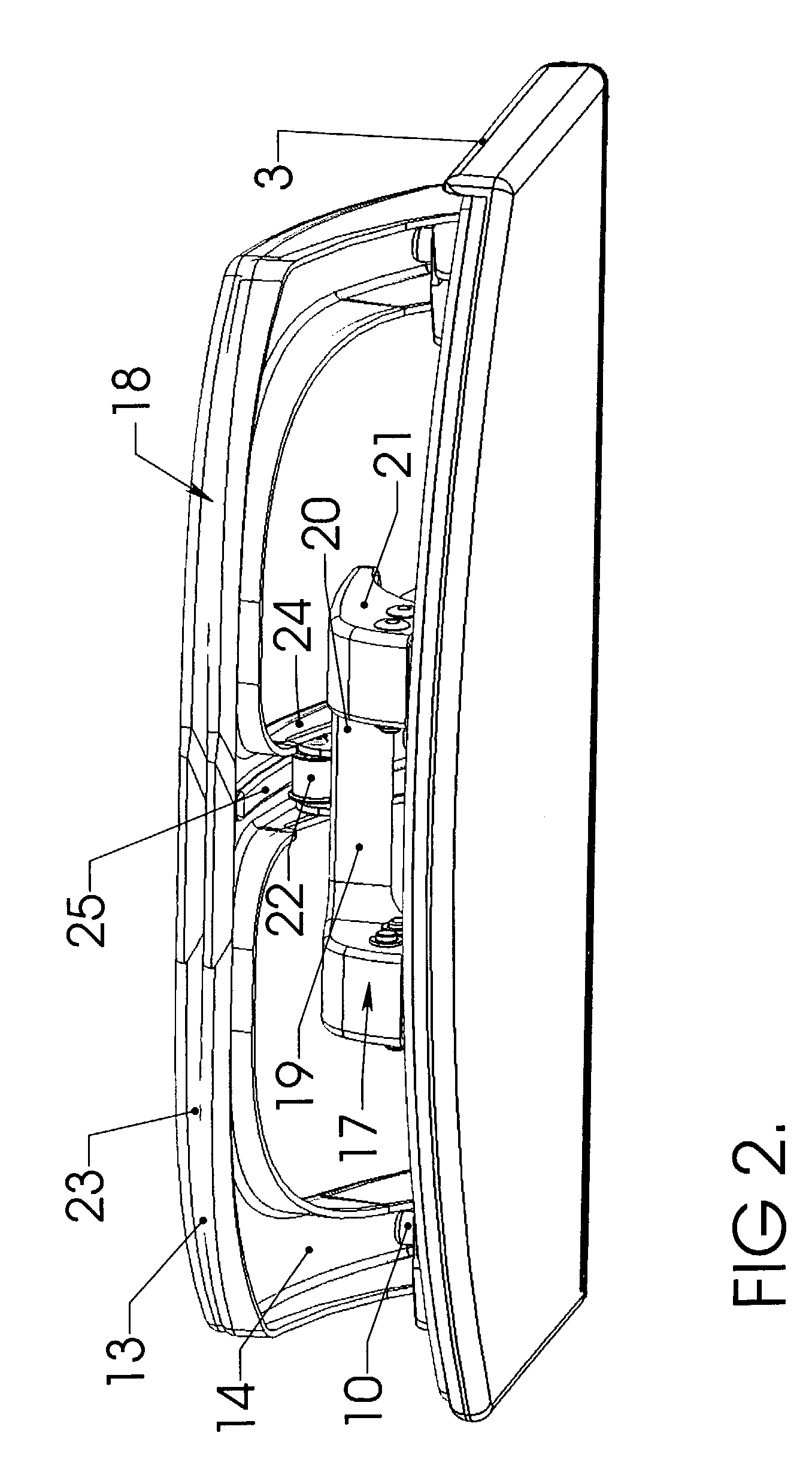

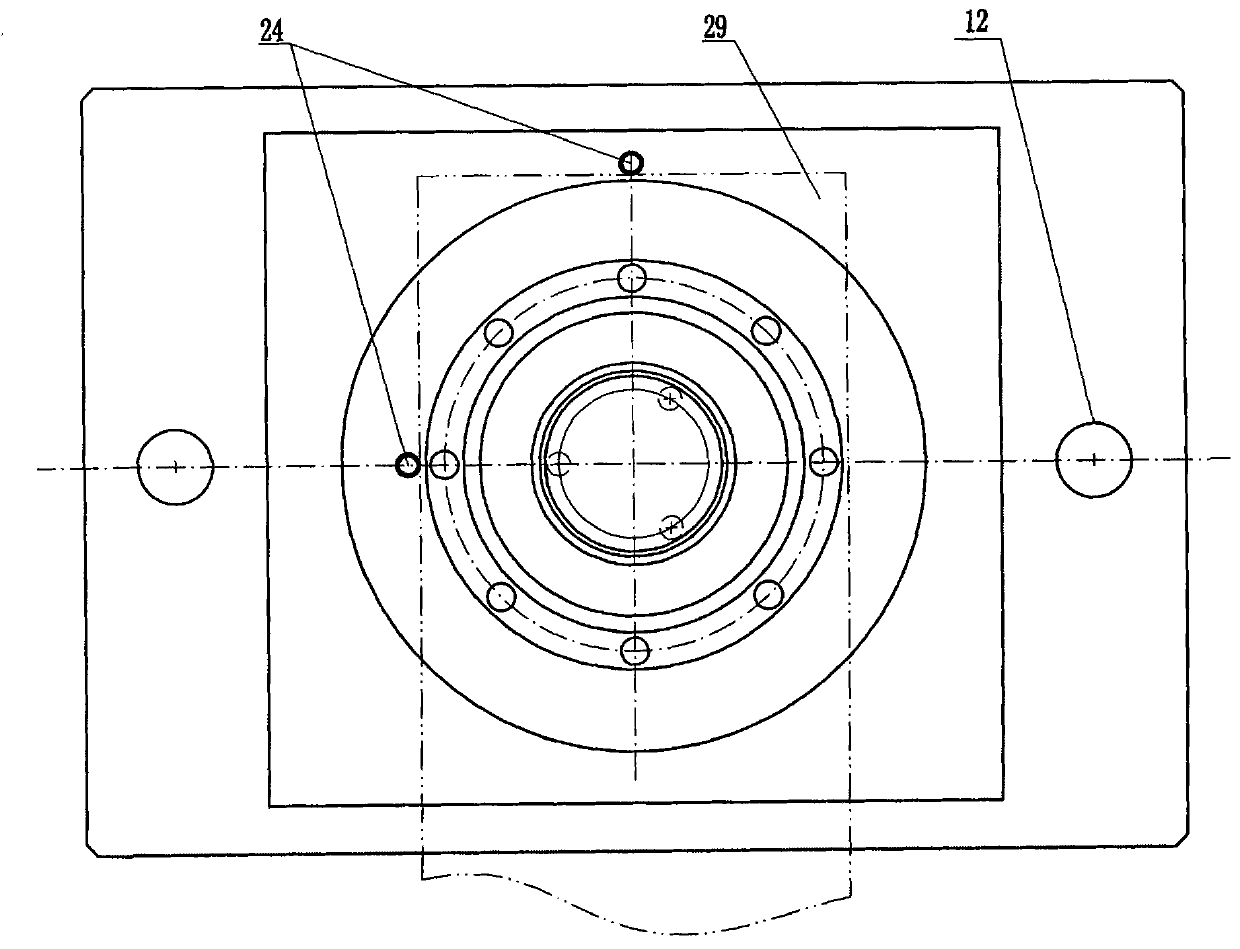

Dual purpose puncher

A dual-purpose puncher combining two-hole and three-hole punch assemblies, is shown and described. The dual purpose puncher provides a duality of uses to the consumer without the necessity for readjustment.In the preferred embodiment, the two-hole punch assembly is positioned opposingly to the three-hole stationary punch assembly in such a way that a central arm of the press lever frame of the three-hole punch assembly passes between two arms of the press lever frame of the two-hole punch assembly.In another embodiment, the modified press lever frame of the three-hole punch assembly slidably engages the modified press lever frame of the two-hole punch assembly thereby driving both, the punch set of the two-hole punch assembly and the punch set of the three-hole punch assembly.Either embodiment combines both punch assemblies and a platform into a single unit while reducing the platform's footprint.

Owner:MARTIN YALE INDS +1

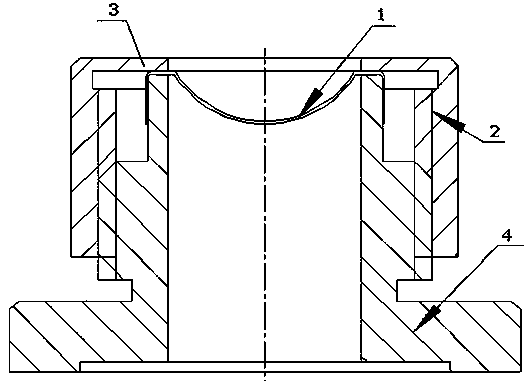

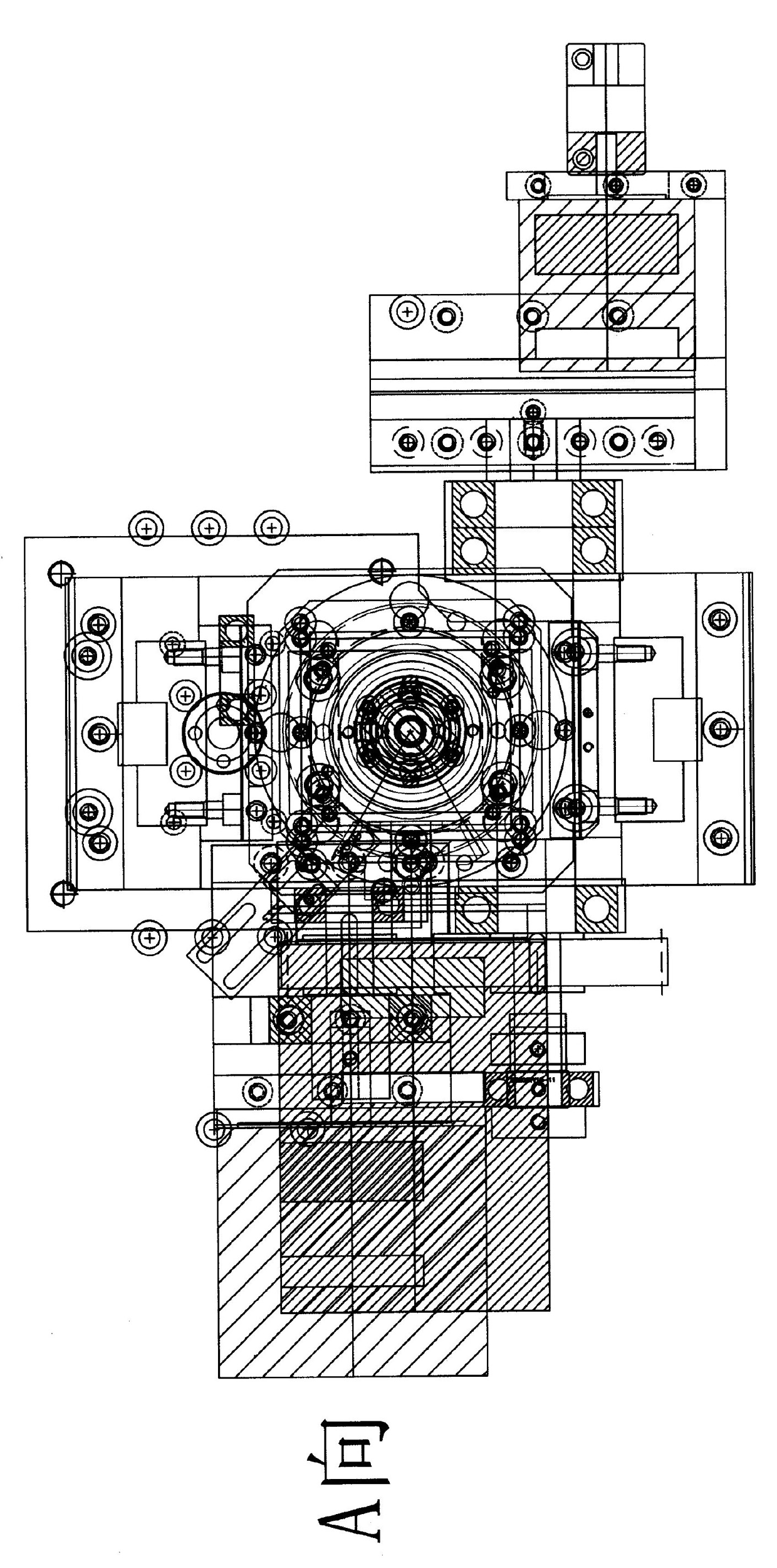

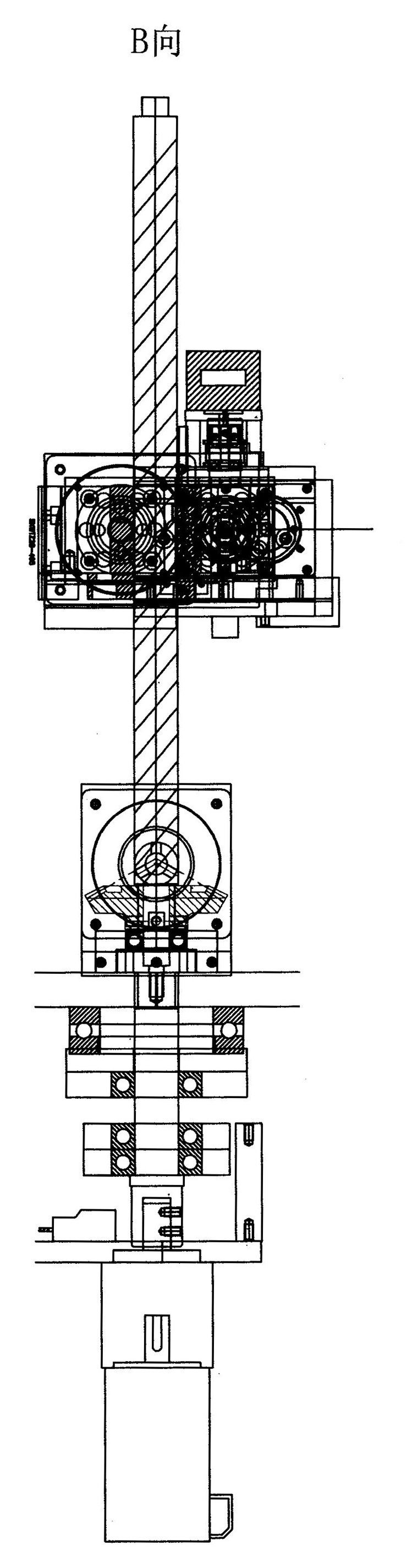

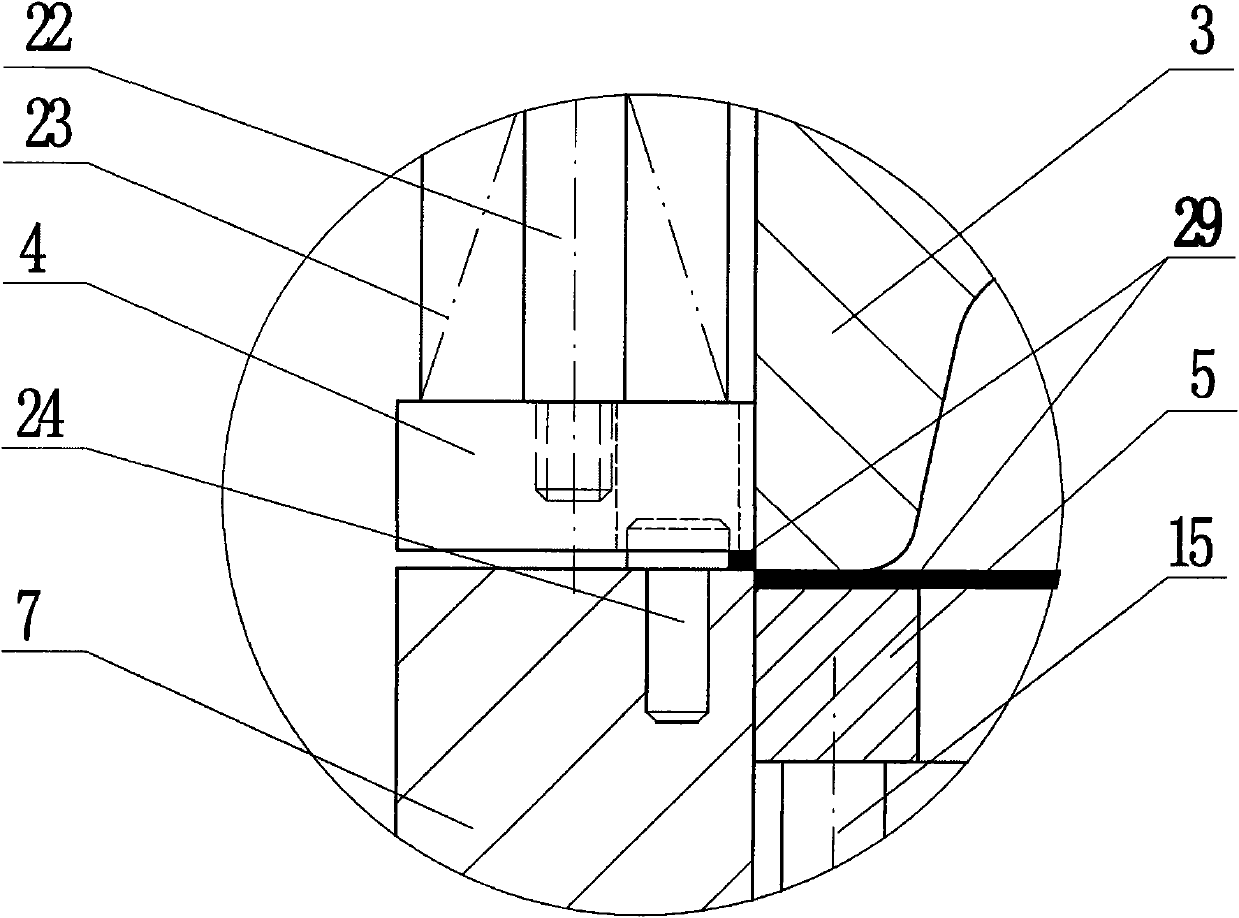

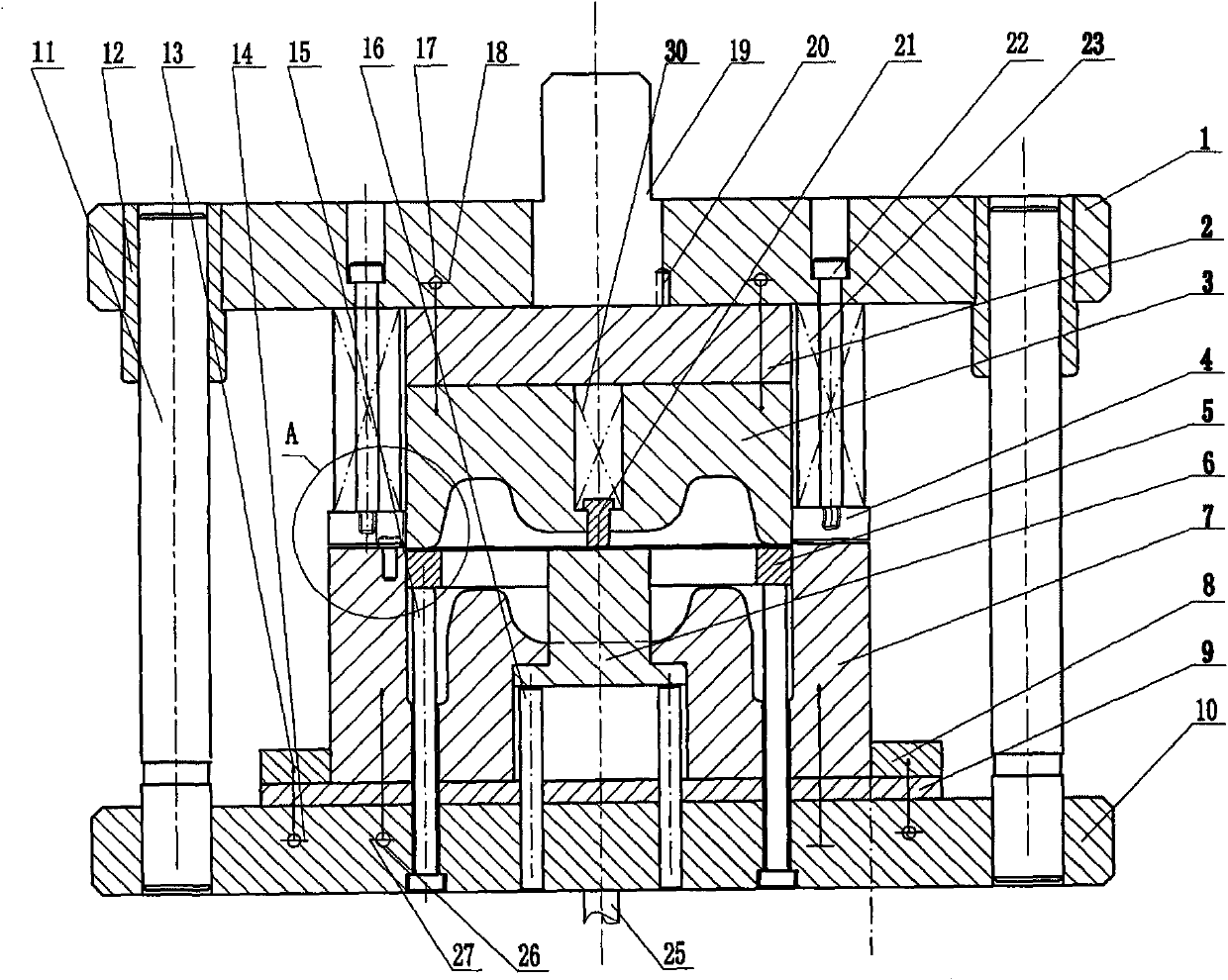

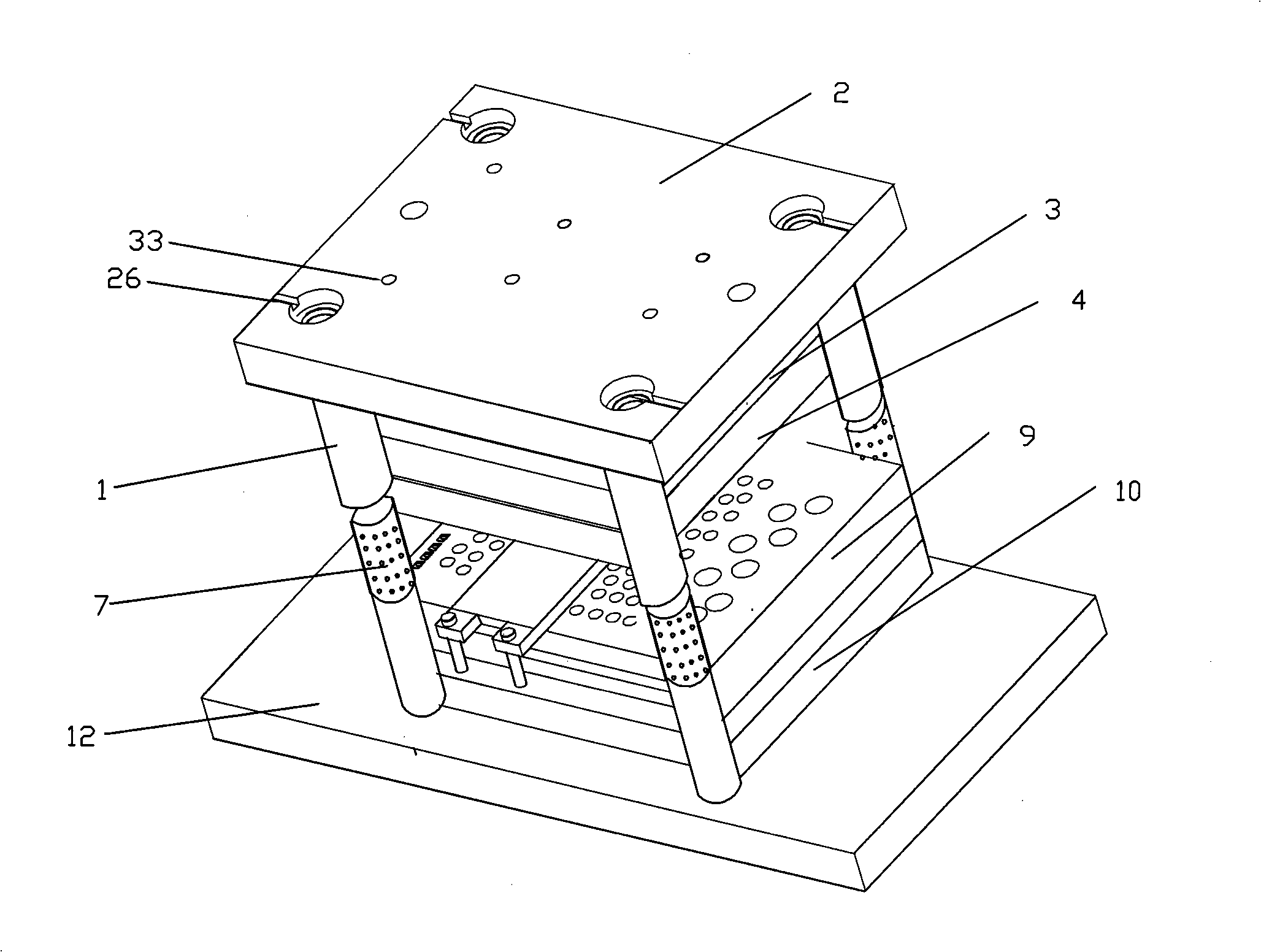

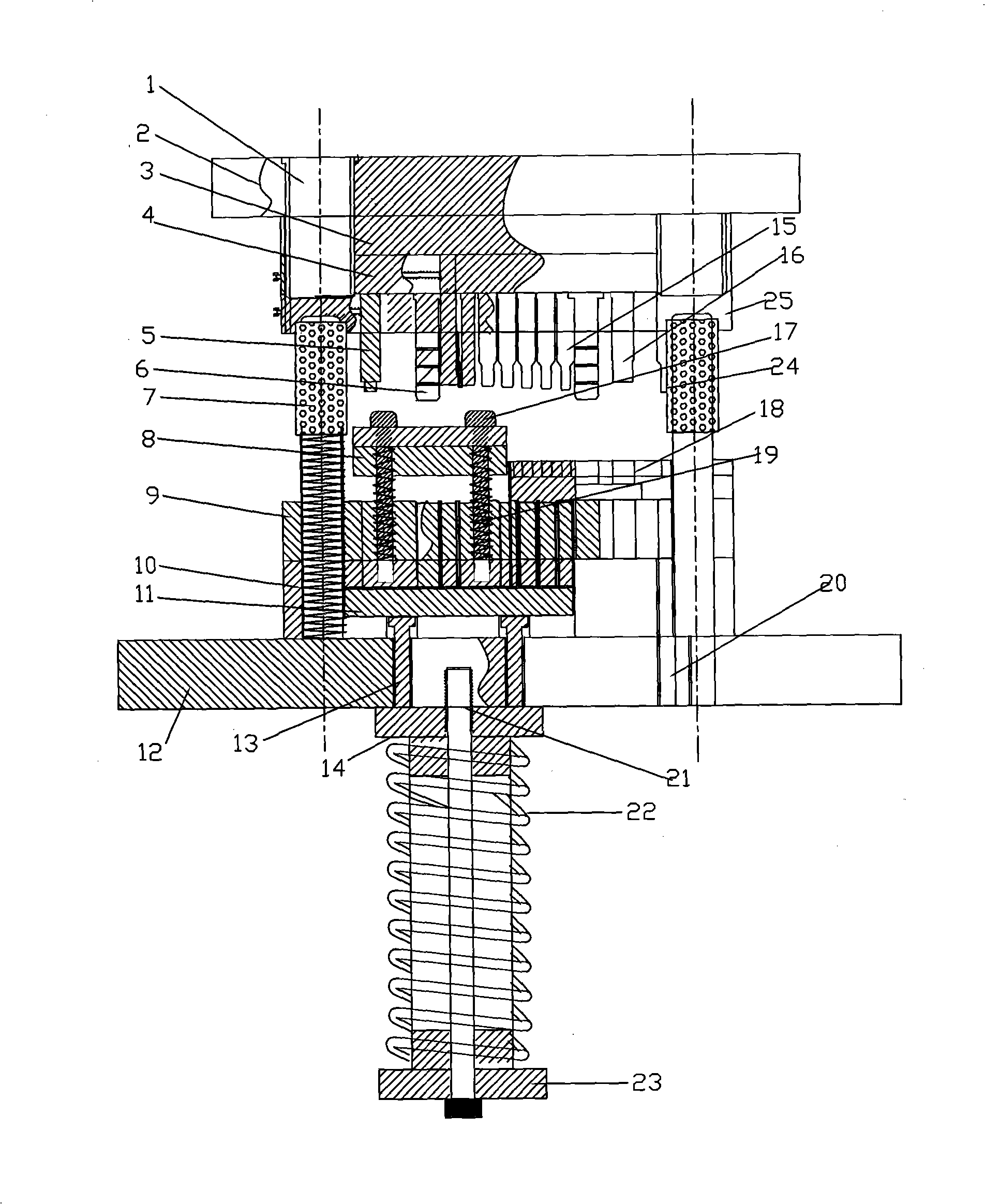

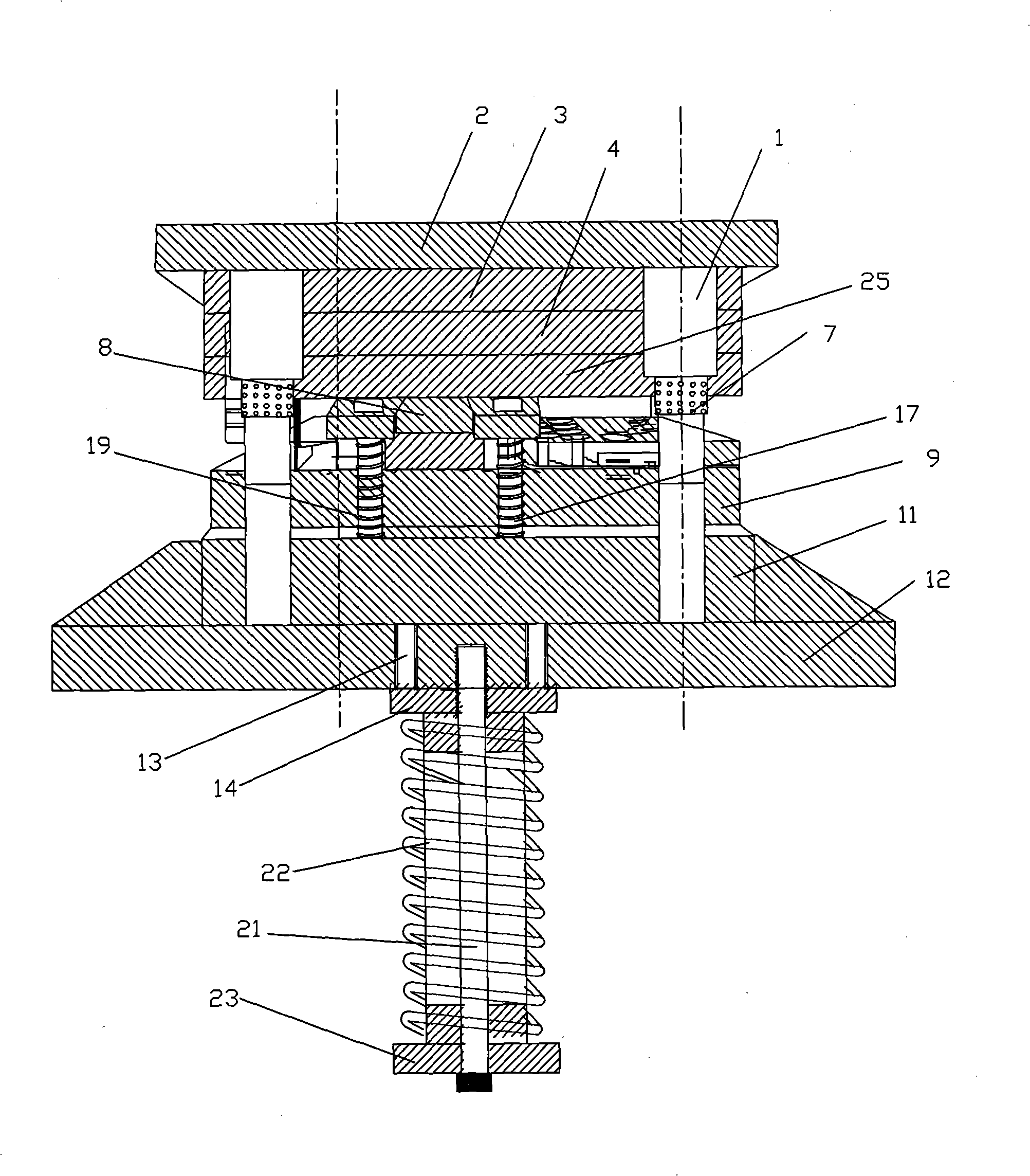

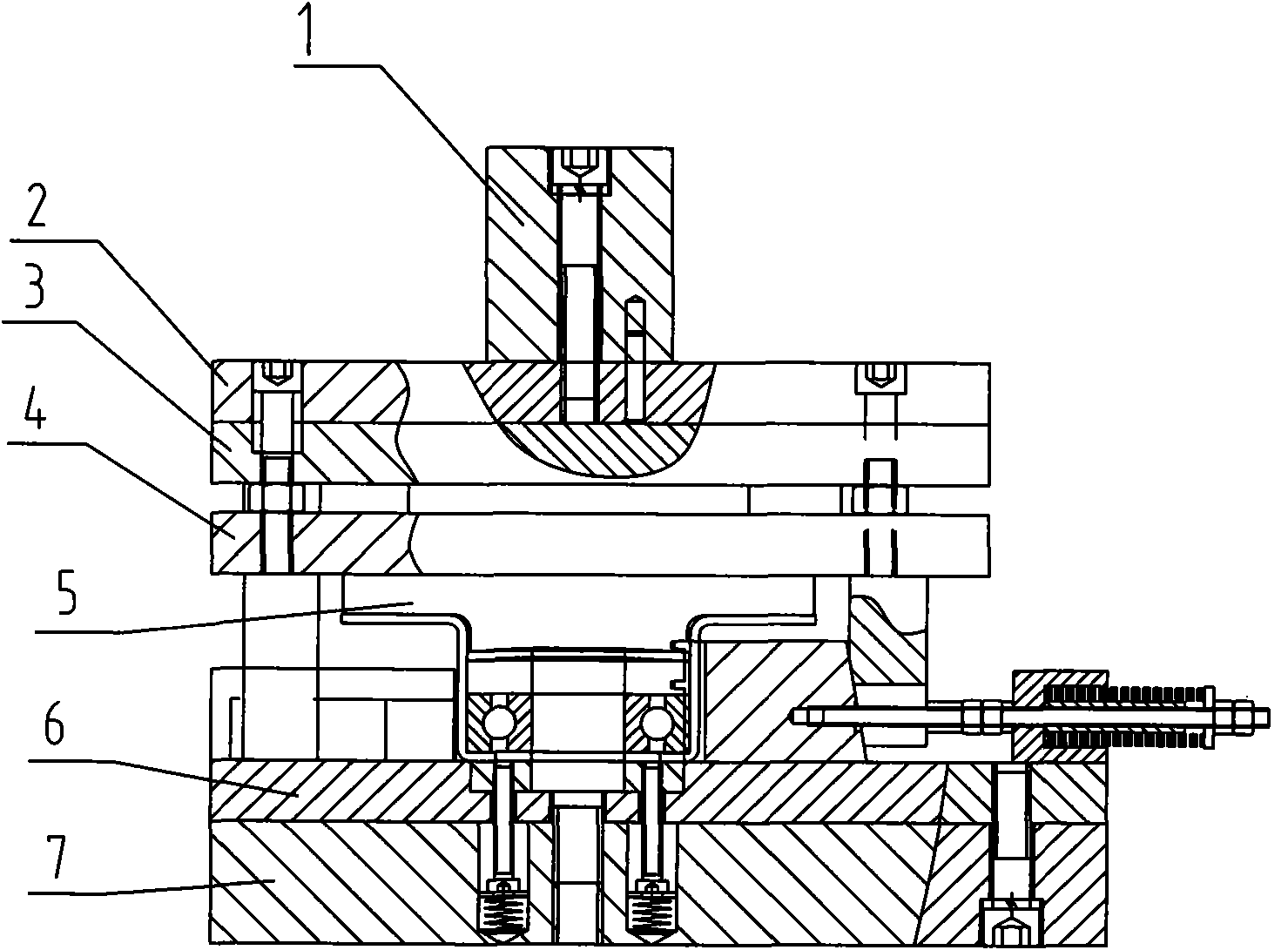

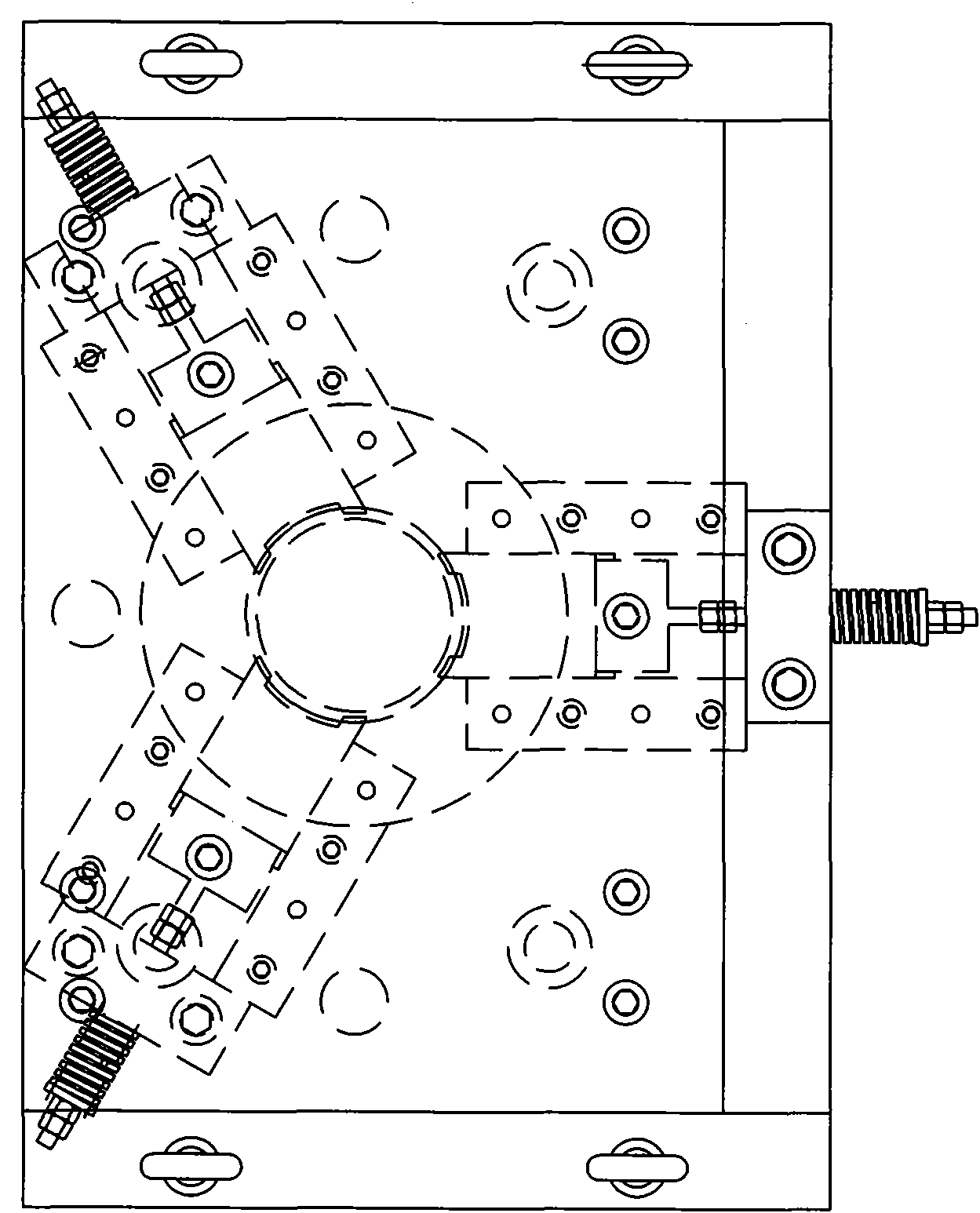

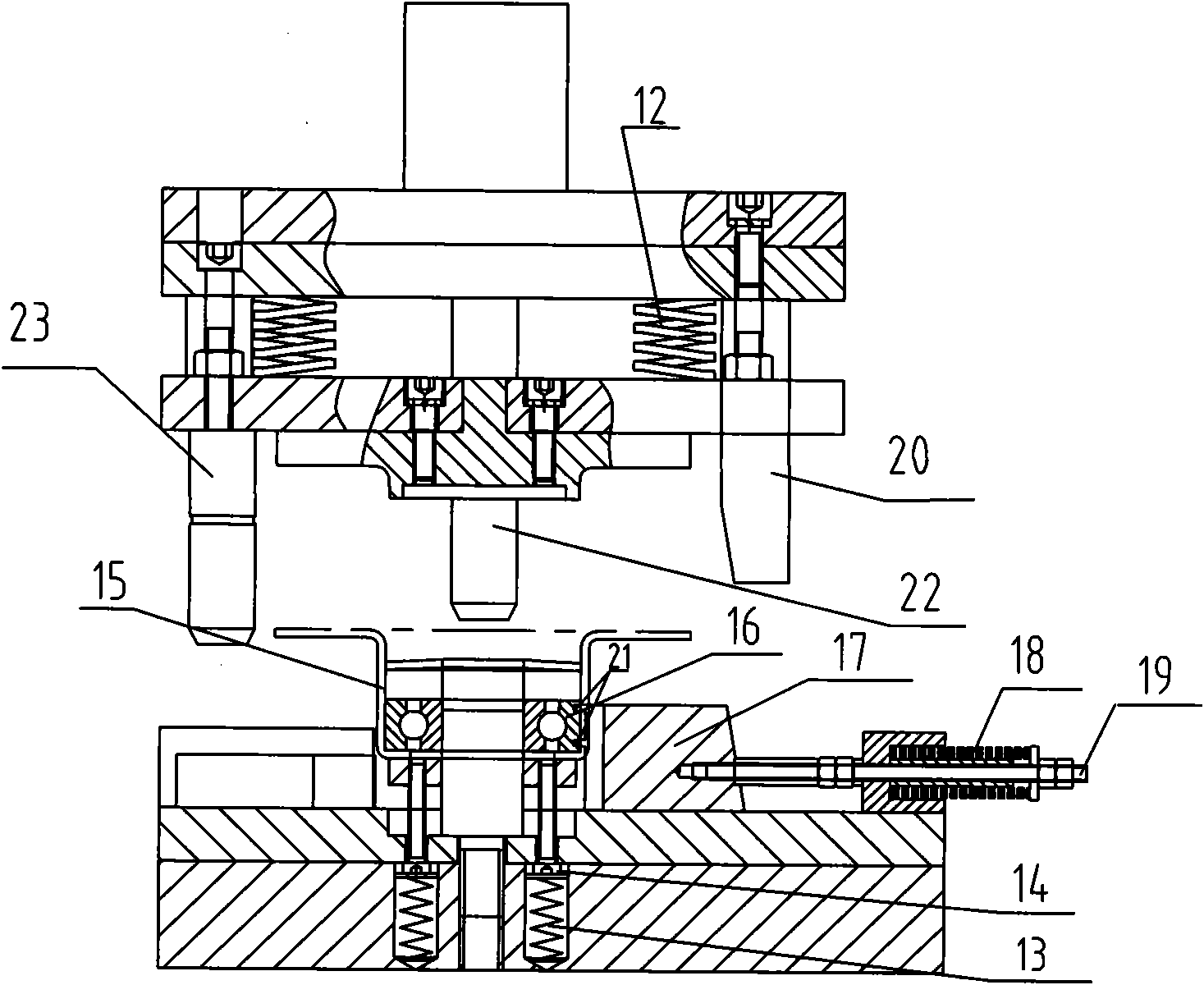

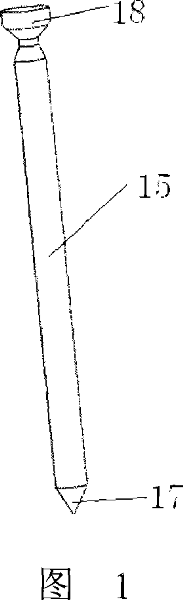

Punching device for buffer support of rear shock absorber of automobile

The invention discloses a punching device for a buffer support of a rear shock absorber of an automobile, which comprises an upper die plate, a lower die plate, a die plate motion guide device, a male die, an upper stripper plate, a female die and a lower stripper plate, and is characterized in that the male die is fixed on the lower surface of the upper die plate, the upper stripper plate is fixed on the lower surface of the upper die plate through a stripper bolt penetrating a stripper spring, the female die is fixed on the upper surface of the lower die plate, the lower surface of the upper striper plate is in contact with the female die, the lower stripper plate is fixed with a tray of a punch through a pull rod penetrating the lower die plate, a stripper push rod is further arranged between the lower stripper plate and the tray of the punch, the male die and the upper stripper plate can slide relatively, and the female die and the lower stripper plate can slide relatively. The punching device can well realize blanking and forming once in the device, save a large number of process steps, greatly save the production cost, improve the production efficiency and ensure the product quality; furthermore, the punching device has low manufacturing cost, economy and durability.

Owner:CHONGQING HUAQING AUTOMOBILE PARTS

Automatic manipulator of caster support press line

InactiveCN102848379ARealize lifting movementRealize pickup and deliveryProgramme-controlled manipulatorMetal-working feeding devicesRotary stagePunch press

The invention relates to an automatic manipulator of a caster support press line. The automatic manipulator comprises a shell, a structural support, an electric manipulator, a driving device and a control device. The structural frame comprises a fixing plate, guide columns, an upper base, a lower base, an upper lifting table, a lower lifting table and a rotating table, and the upper base, the lower base, the upper lifting table and the lower lifting table are supported by the guide columns in a crossing manner; the electric manipulator is mounted on the rotating table; the driving device comprises two stepper motors, one stepper motor is mounted on the upper lifting table, is connected with a rotary shaft of the rotating table by a synchronous belt pulley and drives the manipulator to rotate, and the other stepper motor is mounted on the lower base, is connected with the lifting tables by a synchronous belt pulley and a lead screw and enables the manipulator to ascend and descend; and the control device comprises sensors and a programmable controller. The automatic manipulator is low in cost and easy to operate, is simple, convenient and stable, can move in various manners, has dust and chip prevention functions, can accurately extend onto a cavity of a punch press according to different characteristics of dies at different stations of the press line, picks up and delivers workpieces and replaces workers to carry out tasks such as carrying, feeding and discharging.

Owner:SOUTH CHINA UNIV OF TECH

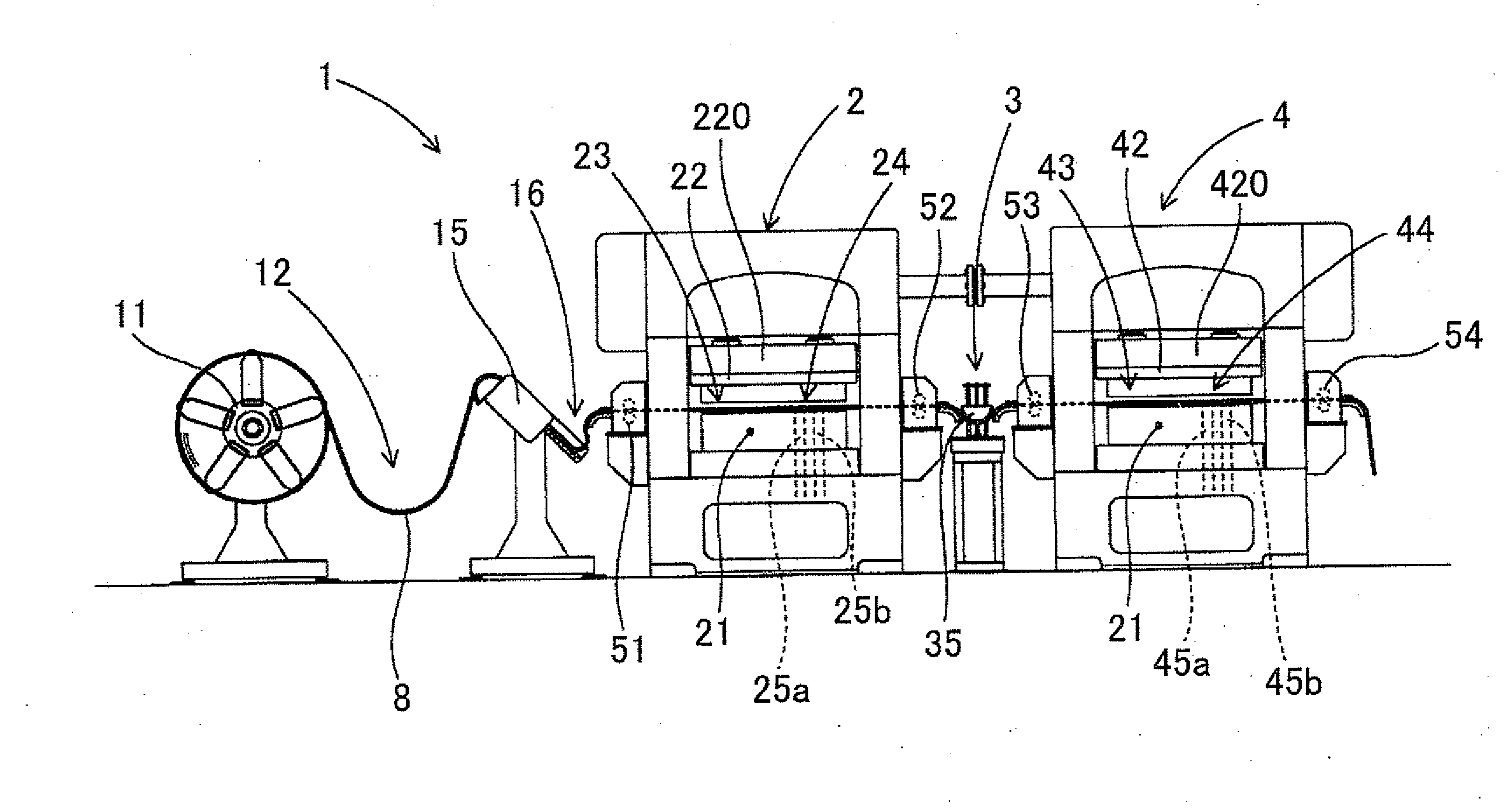

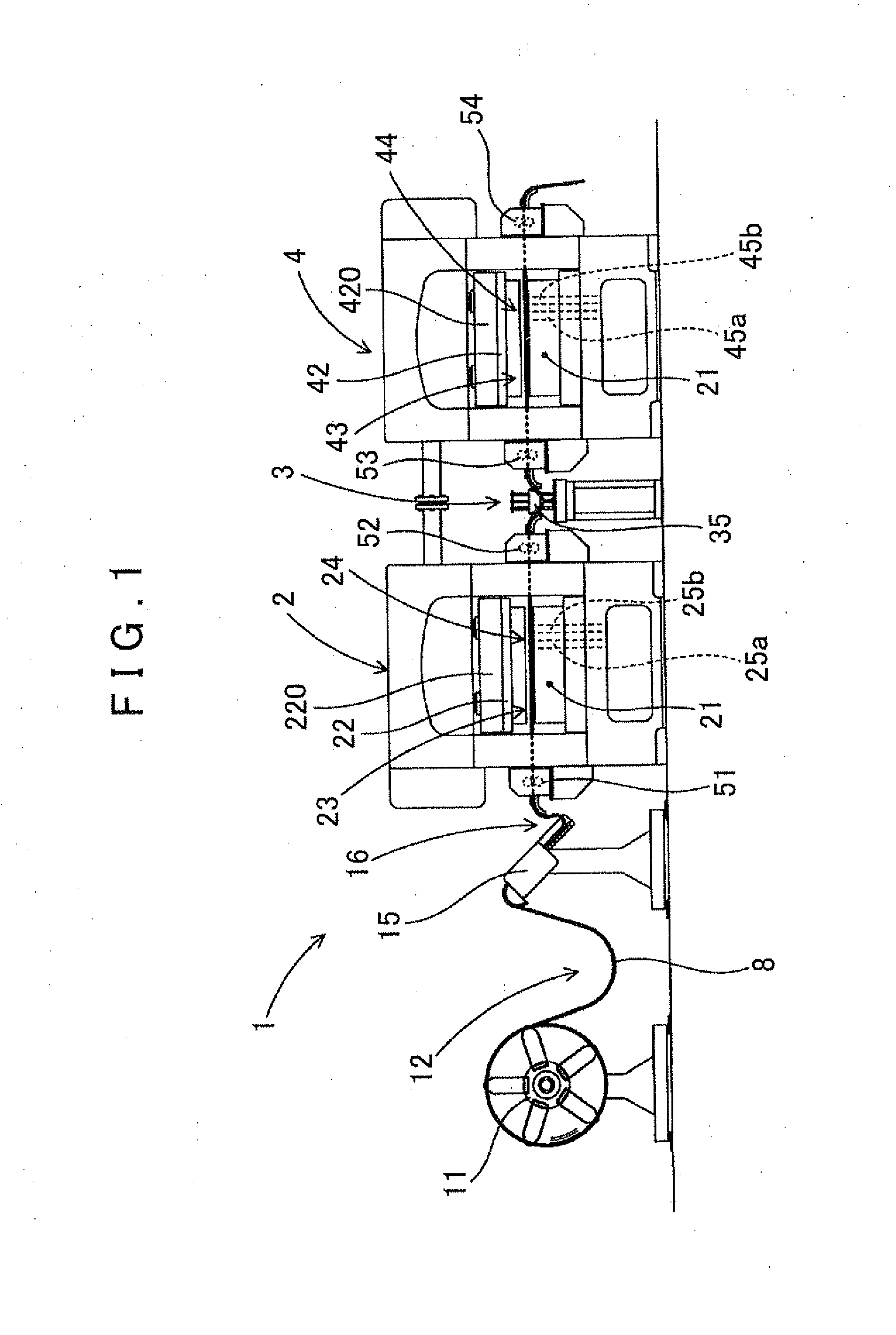

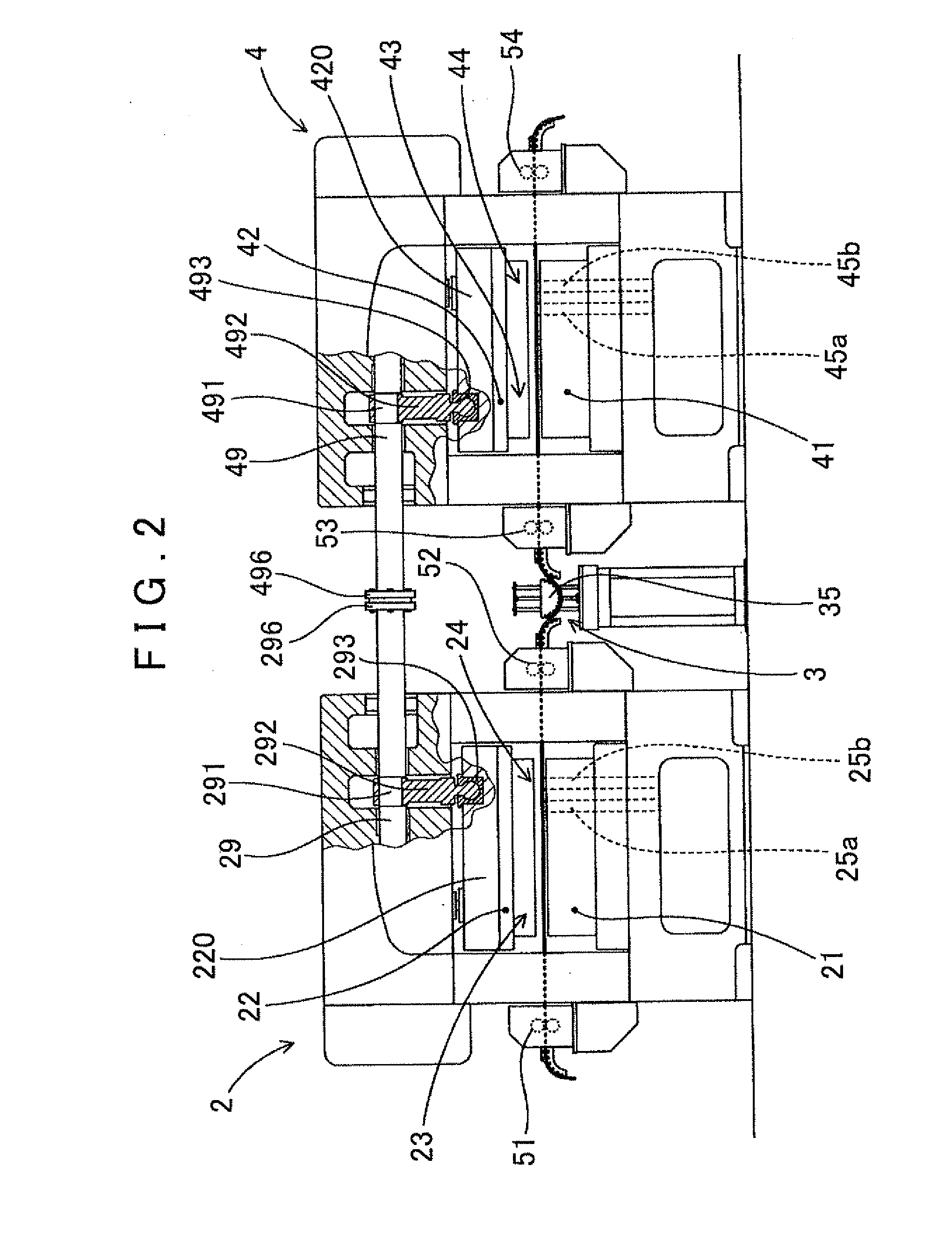

Laminated core punching apparatus

ActiveUS20110232076A1The relative position is appropriateRemarkable effectAssembly machinesOther manufacturing equipments/toolsSheet steelPunch press

A laminated core punching apparatus, configured such that a stator-punching press machine that has a molding die performing a partial punching gradually approaches the shape of the stator core piece. There is a punching die to punching out the stator core piece from a strip-form steel plate, and two stator lamination stations. A rotor-punching press machine and a stator-punching press machine are constructed to operate synchronously. An intermediate loop portion capable of causing a strip-form steel plate to hang down in a loop is provided in order to adjust a length of the strip-form steel plate between the two press machines, and a loop guide portion that guides a loop locus of the strip-form steel plate from above so that the strip-form steel plate does not invert is disposed above the intermediate loop portion to be capable of ascending and descending.

Owner:NORITSU KIKAI SEISAKUSHO

Punching machine mold of metal button and method for processing metal button using the mold

InactiveCN101406918AQuality assuranceReduce product differentiationShaping toolsButtonsPunch pressEngineering

The invention discloses a punching mould for machining a metal button and a method for machining the metal button by utilizing the mould. In the mould, a guide sleeve and a liquid bead sleeve which are arranged on a top slab and a soleplate are matched with each other in order that the positions of an upper mould and a lower mould keep relative fixing; simultaneously, a small guide column of the upper mould and a small guide column of the lower mould are matched with each other in order that the a side blade, a stretching pin, a printing mould and the like keep relative fixing with the position of a mould hole of the lower mould respectively; a stamping machine is utilized to carry out blocking stamping, further stamping, pattern printing, feed dropping and other machining sequentially on the button, thereby realizing the automation of button machining, greatly improving production efficiency and eliminating potential safety hazards.

Owner:深圳市联星服装辅料有限公司

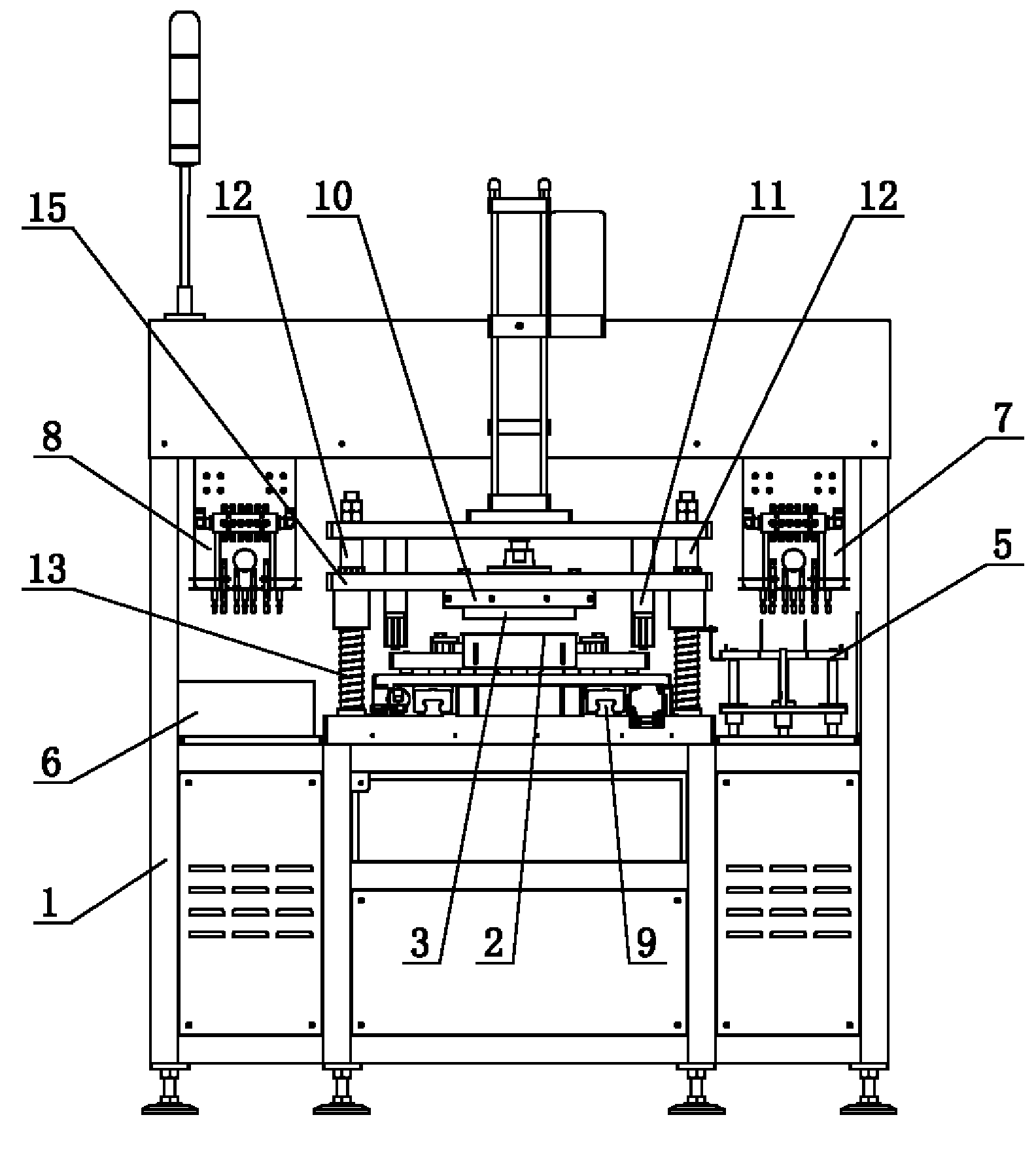

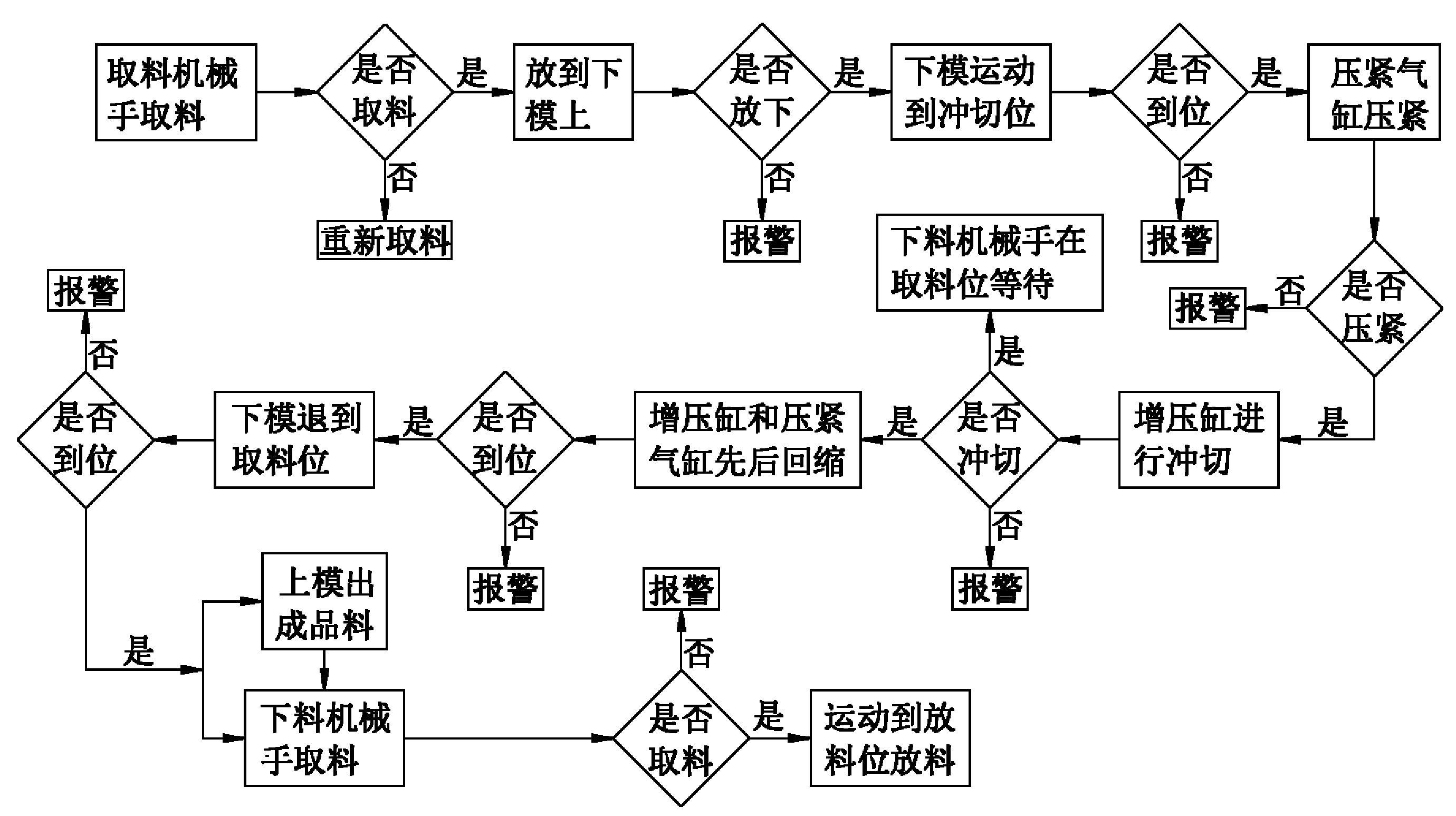

Automatic punch equipment and processing method thereof

ActiveCN104227781AImprove processing qualityRealize automatic processingMetal working apparatusConveyor partsAutomatic test equipmentPunch press

The invention relates to the technical field of FPC (flexible printed circuit) processing equipment, in particular to automatic punch equipment. The automatic punch equipment comprises a lower die, an upper die and a pressure cylinder, wherein the lower die is arranged on a rack, the upper die is located right above the lower die, and the pressure cylinder is used for driving the upper die to vertically move; the pressure cylinder is fixedly arranged on the rack; the rack is also provided with a feeding tray and a discharging tray; a feeding manipulator is arranged above the feeding tray; a discharging manipulator is arranged above the discharging tray; the processing method for the automatic punch equipment comprises the following steps: clamping an FPC material from the feeding tray by the feeding manipulator and transferring the FPC material to the lower die, and backwards moving the lower die to a punching position from a material fetching position; downwards moving the upper die to perform punching processing and then, returning to an original position; forwards moving the lower die to return to the material fetching position; transferring an FPC finished product into the discharging tray from the material fetching position by the discharging manipulator. Automatic processing of FPC punching is realized; manual feeding and discharging actions are not needed; a feeding position and a discharging position are more accurate; the processing quality of the punch equipment is greatly improved.

Owner:GUANGDONG HUAHENG INTELLIGENT TECH CO LTD

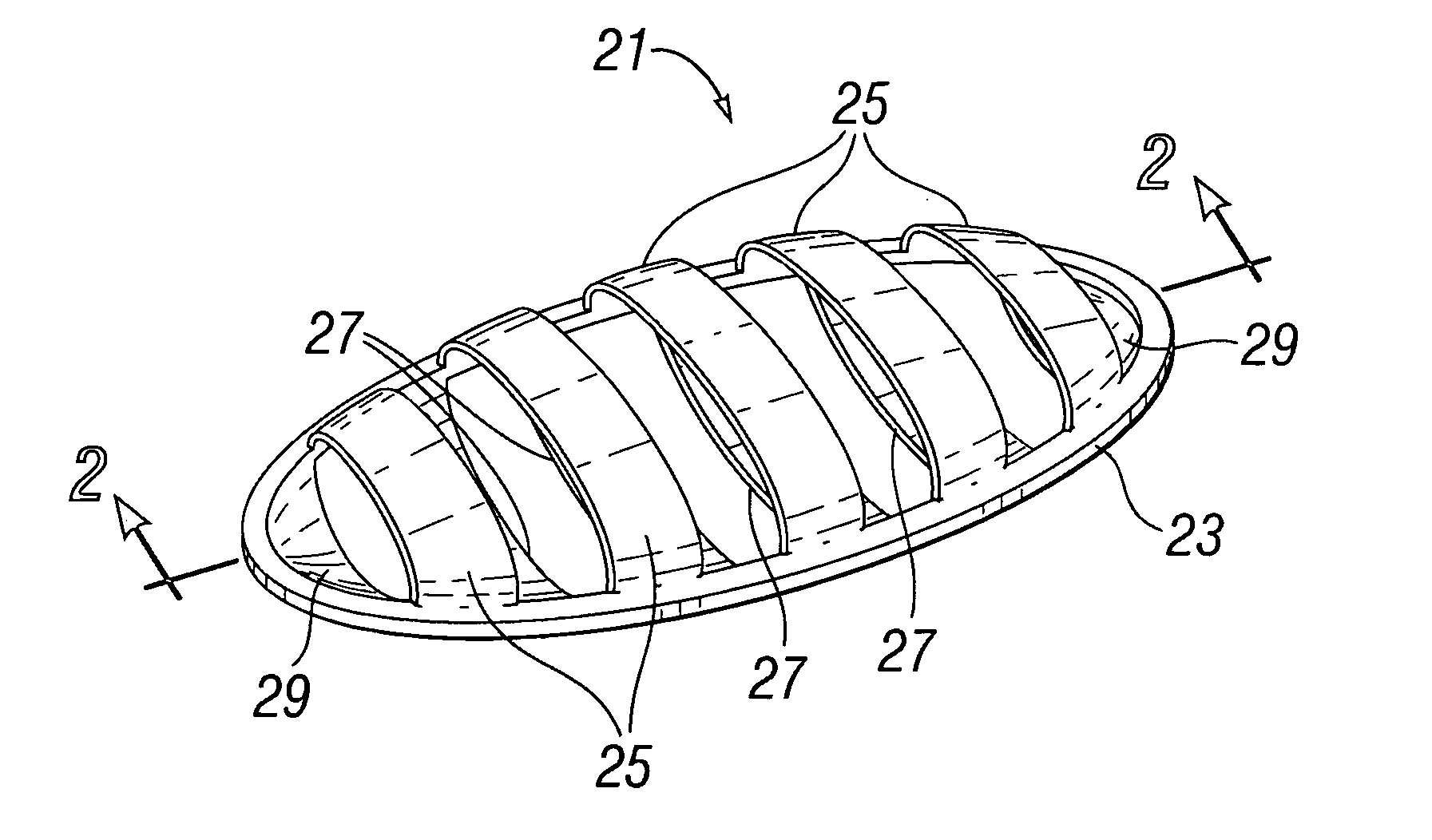

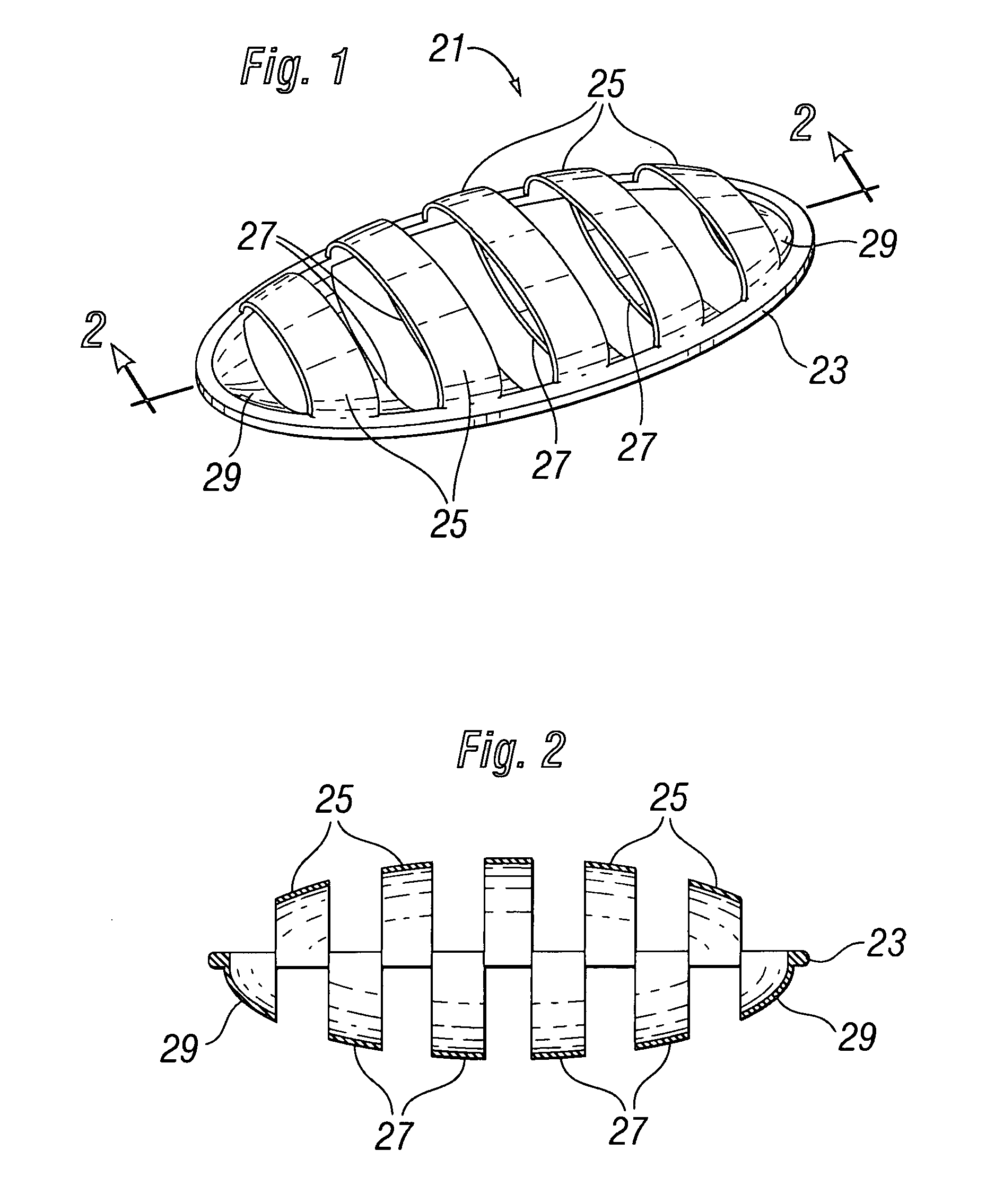

Manual odor removal structure

InactiveUS20100042113A1Increase surface areaHigh appearance requirementsSurgeryDetergent mixture composition preparationPunch pressOrganic matter

A volumetric stainless steel structure is provided by punch pressing a single blank and results in a volumetric presentation of alternating bands of stainless steel material. The spacing of the bands is sufficient to provide (1) an interruption in the surface to surface contact which might entrap organic species and (2) a space which allows the epidermis to be scrubbed, manipulated and massaged by the rounded edge of the bands as the hands manipulate it in a way similar the manipulation of soap. Further, the alternating bands provide internal surface area, in the form of the inside of the bands which are protruding, for additional adsorptive area.

Owner:DAKA RESEARCH INC

Device for positing bearing in twelve-point pressing bearing seat

InactiveCN101850386AReduce the difficulty of assemblyExtended service lifeShaping toolsSocial benefitsPunch press

The invention discloses a device for positing a bearing in a twelve-point pressing bearing seat, belonging to the technical field of a tool mould. The device comprises an upper mould and a lower mould. The upper mould comprises a connecting sleeve, a top board, an upper board, a middle board and a pressing block; the lower mould comprises a bottom board and a lower board which is arranged on the upper end face of the bottom board, and a punching block is connected with a spring driving and reversing mechanism which is fixed on the bottom board through a screw rod; and the bottom board and the lower board are further provided with a spring material reversing mechanism. When the device is used on a punching machine and the upper mould downward moves, an inclined surface of a punching head is contacted with an inclined surface of the punching block, so that the punching block moves to the center, and twelve punching convex points are evenly distributed on the upper layer and the lower layer on the pressing bearing seat, thereby fixing the bearing and the sealing, and preventing the bearing and the sealing from moving in series when installing and using the bearing seat. The device has the benefit effects of prolonging the service life of the bearing seat, reducing the labor intensity of workers, and creating a certain economic benefit and social benefit for enterprises.

Owner:徐州绿源重工科技发展有限公司

Closed type rivet automatic producing device

Owner:宁波至上特种紧固件有限公司

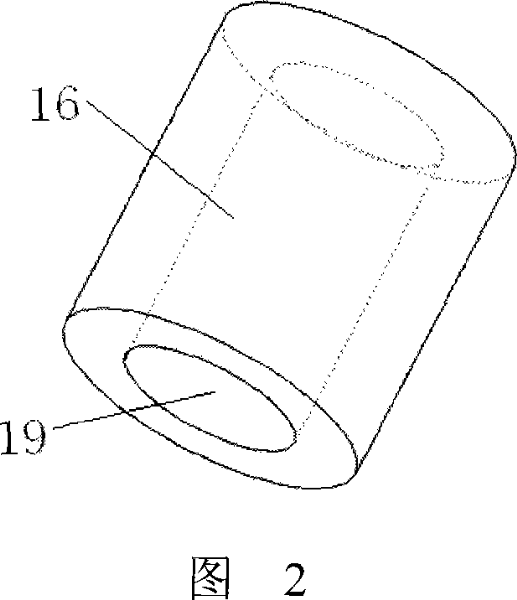

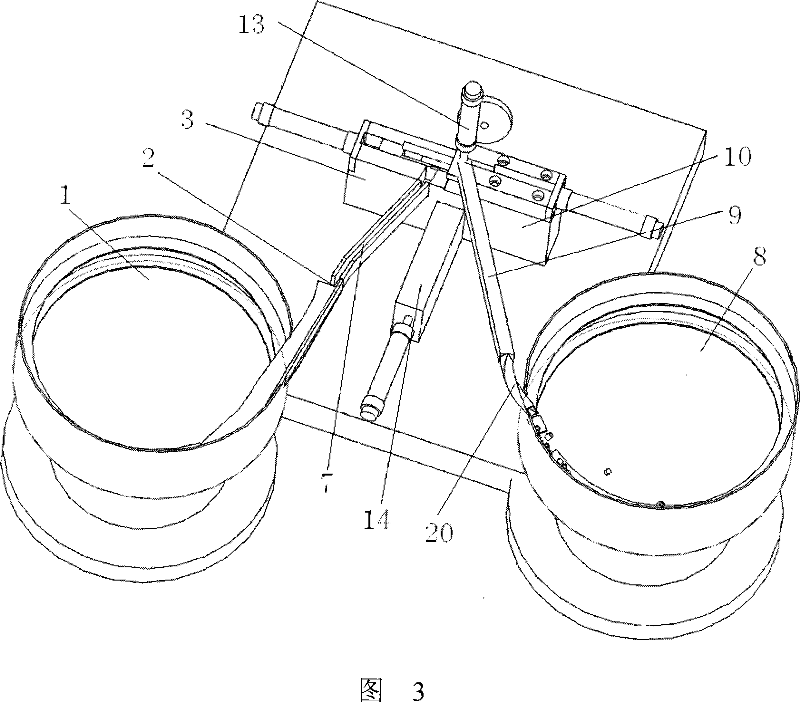

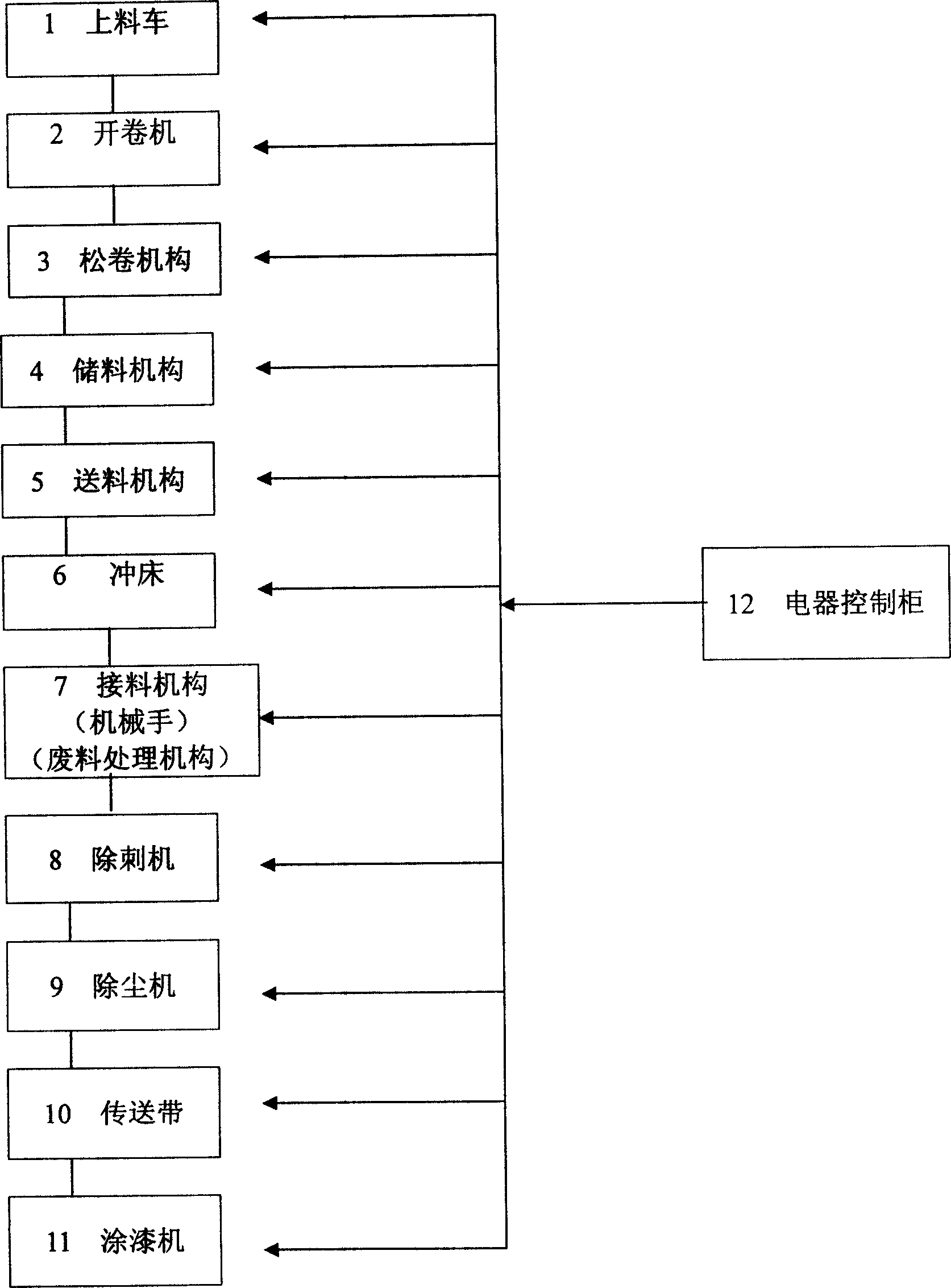

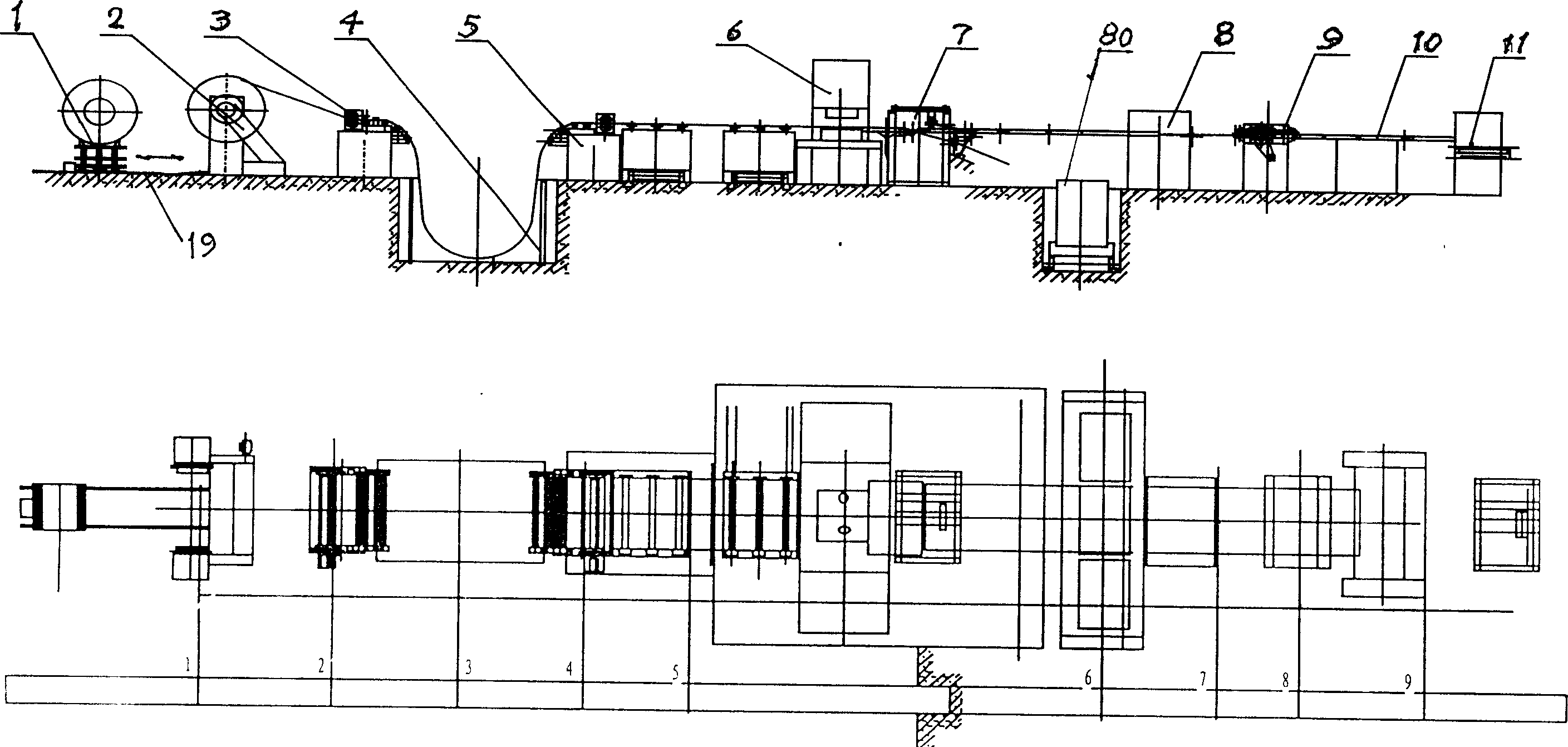

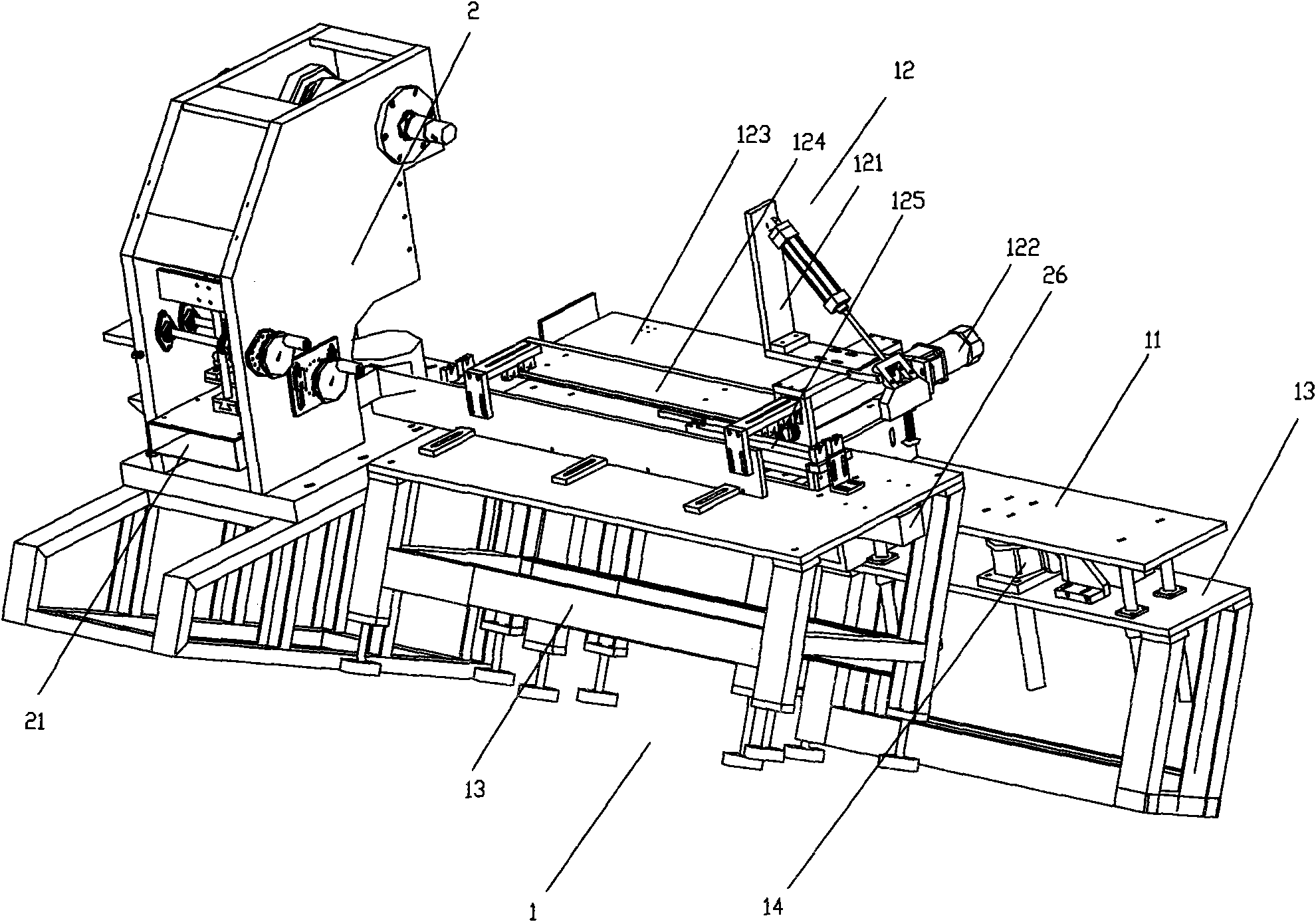

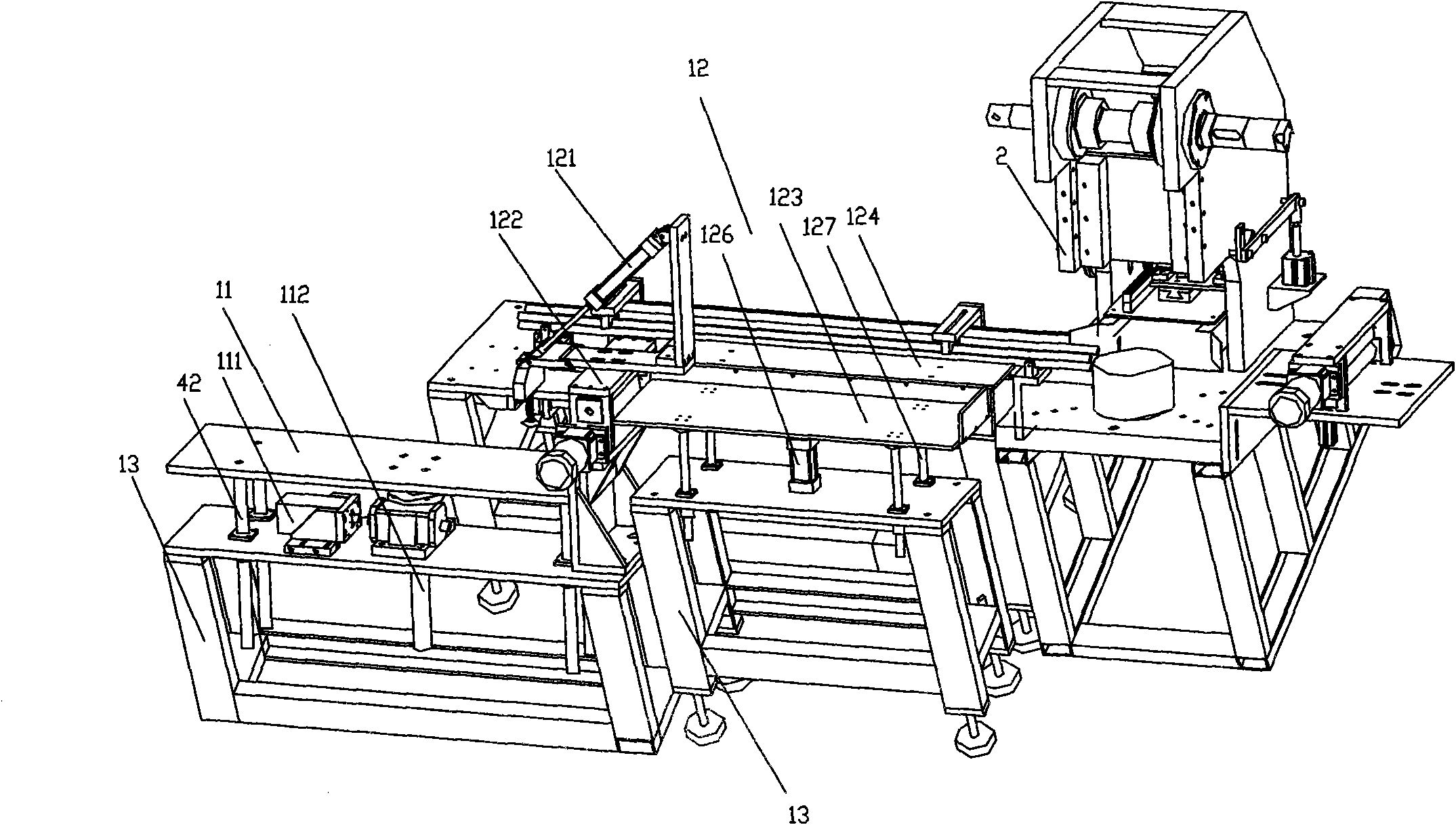

Automatic production line for punch

The present invention relates to an automatic production line of punching machine. It includes successively-connected burring machine, belt conveyer and paint-coating machine after the punching machine. It is characterized by that before punching machine the dewiling mechanism, coil-opening mechanism, material-storing mechanism and material-feeding mechanism are successively connected, between punching machine and burring machine a material-receiving mechanism is connected, and between the burring machine and belt conveyer a dust remover is connected. The described material-receiving mechanism mainly includes mechanical arm, rolling mechanism, cutting mechanism and waste material processing mechanism. All the mechanisms are controlled by electric control cabinet and correspondent program.

Owner:天津职业大学

Method for manufacturing aluminum alloy hub

The invention discloses a method for manufacturing an aluminum alloy hub. The method comprises the following steps: first, manufacturing an aluminum alloy hot rolled plate into a round-sheet-shaped blank; second, stretching the round-sheet-shaped blank into a disc-shaped blank through a spinning machine or punch press; third, extruding the spoke central part of the disc-shaped blank; fourth, punching and trimming the extruded blank; fifth, arranging the punched and trimmed blank into the spinning machine and spinning the blank into a hollow rotating body hub blank with high strength; sixth, conducting stabilizing treatment or solid solution aging hot treatment on the hollow rotating body hub blank formed in a spinning mode; seventh, conducting machining and surface treatment. According to the method for manufacturing the aluminum alloy hub, a material and manufacturing process used by the aluminum alloy hub are improved, Al-Mg-Si aluminum alloy bars in a cast state are adopted as a raw material so that the aim of simplifying the process can be achieved, and the process of upsetting, forging and prefabricating the disc-shaped blank and the like are not needed before spinning forming.

Owner:ZHEJIANG GKO IND CO LTD

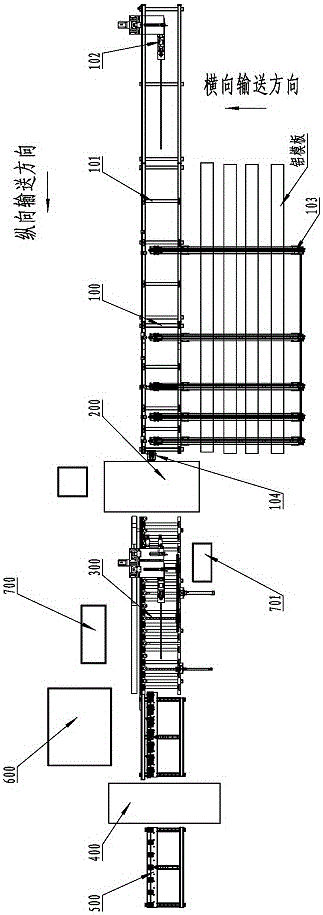

Numerically-controlled sawing and punching integrated production line for aluminum frameworks

ActiveCN106392650AIncrease productivityImprove machining accuracyOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention discloses a numerically-controlled sawing and punching integrated production line for aluminum frameworks. The numerically-controlled sawing and punching integrated production line comprises a sawing machine feeding device, a sawing machine, a sawing machine discharging and punching machine feeding device, a punching machine, a punching machine discharging channel, a hydraulic system and an electrical control system. The sawing machine feeding device comprises a transverse feeding device, a sawing machine feeding channel and a sawing machine feeding trolley; the transverse feeding device is located on one side of the sawing machine feeding channel and is inserted into the sawing machine feeding channel in a penetrating mode; and the sawing machine trolley moves forwards along guide rails arranged on a sawing machine feeding frame. The sawing machine discharging and punching machine feeding device comprises a sawing machine discharging channel, a punching machine feeding channel and a punching machine feeding trolley. A sawing machine discharging frame and a punching machine feeding frame are connected together through guide rails and a rack. The punching machine feeding trolley is driven by a servo motor B and is provided with front clamps and rear clamps, and relay feeding is achieved; and the rear clamp assembly clamps the workpieces when being used for feeding the workpieces away from the sawing machine and near the punching machine, and the front clamp assembly is used for feeding the workpieces when the punching machine conducts punching. The numerically-controlled sawing and punching integrated production line has the advantages of being high in production efficiency and machining precision.

Owner:济南天辰智能装备股份有限公司

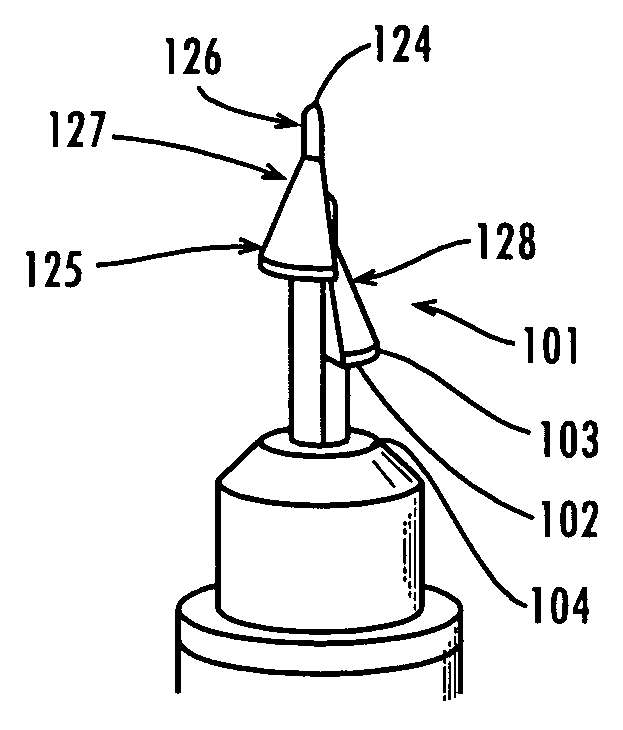

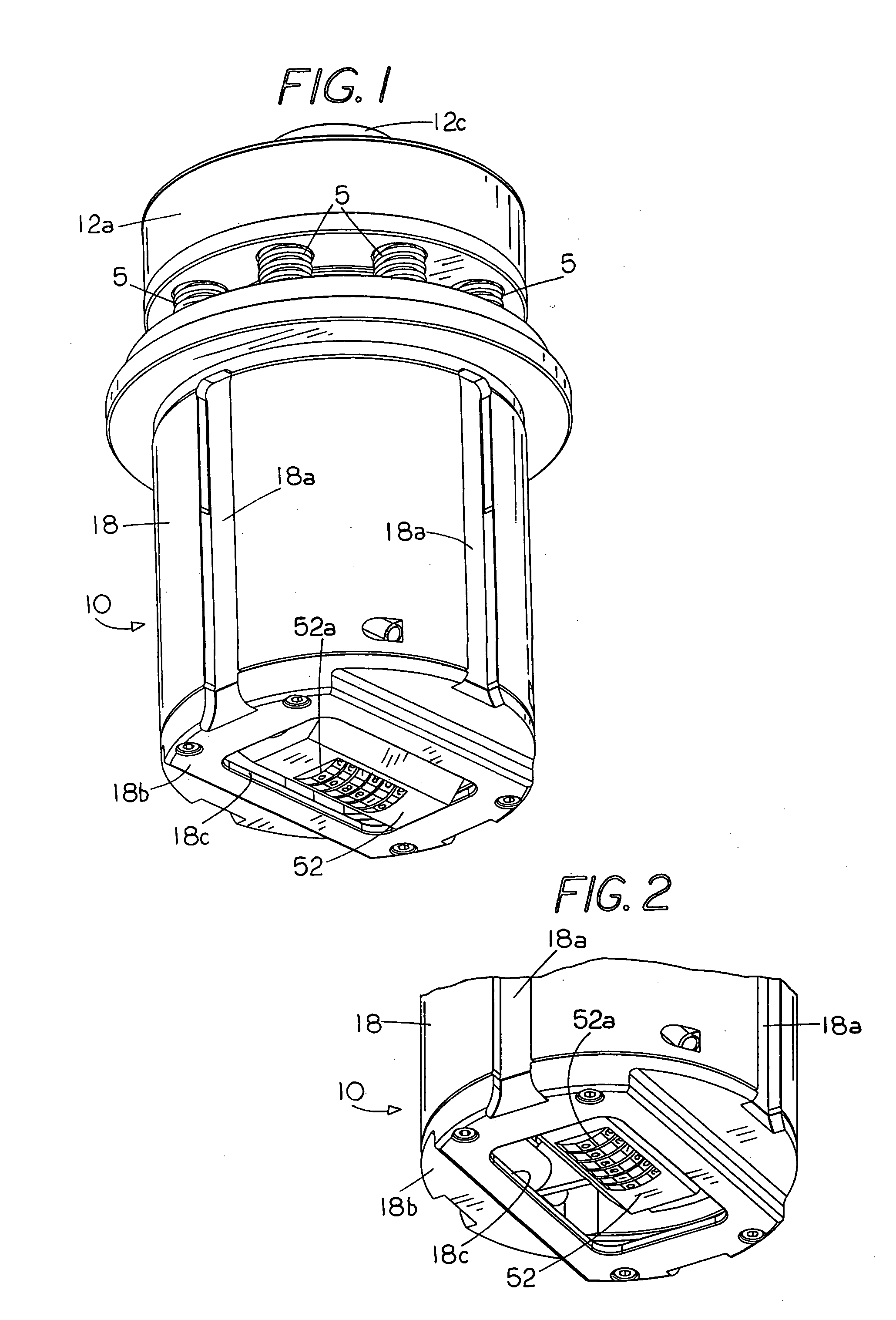

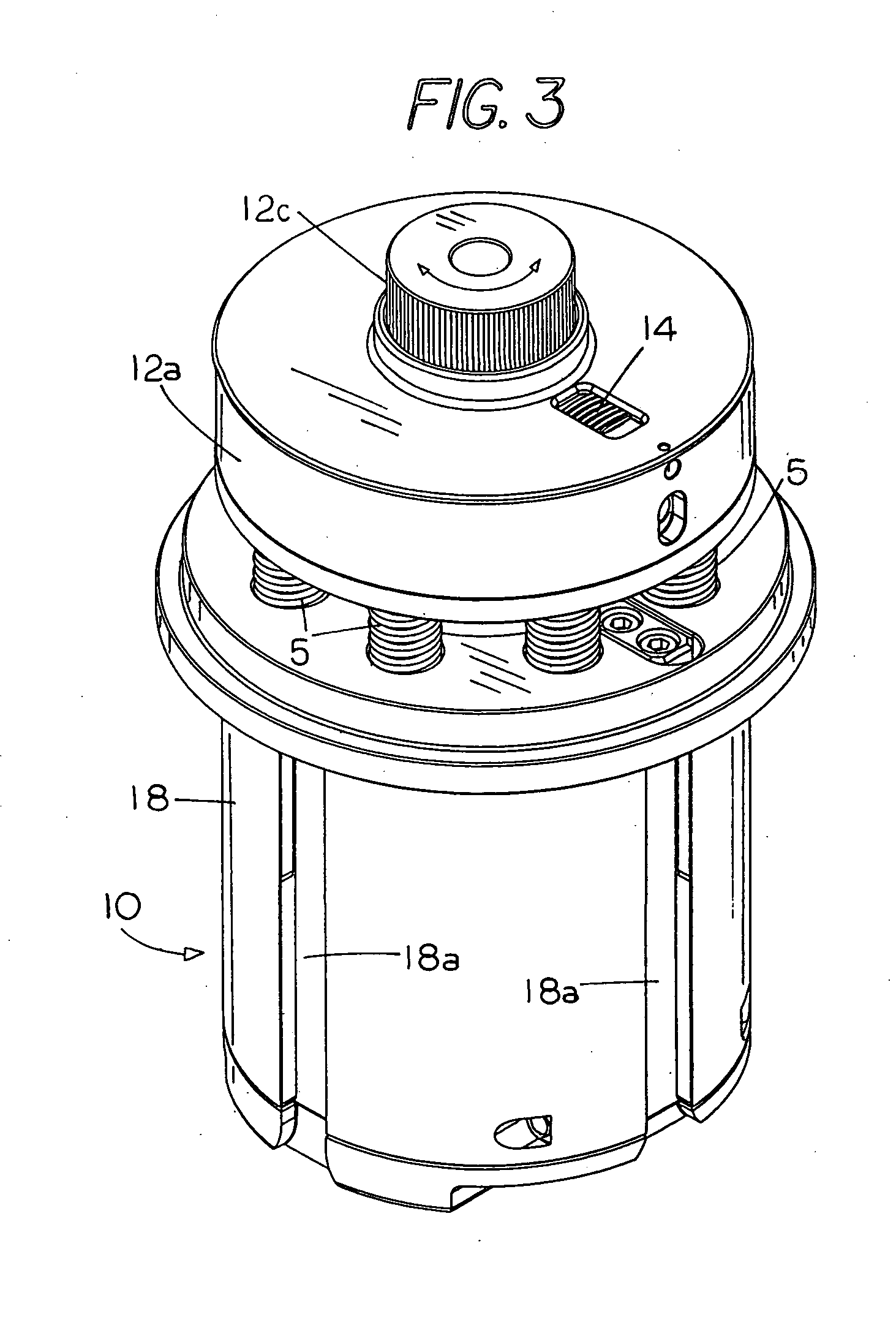

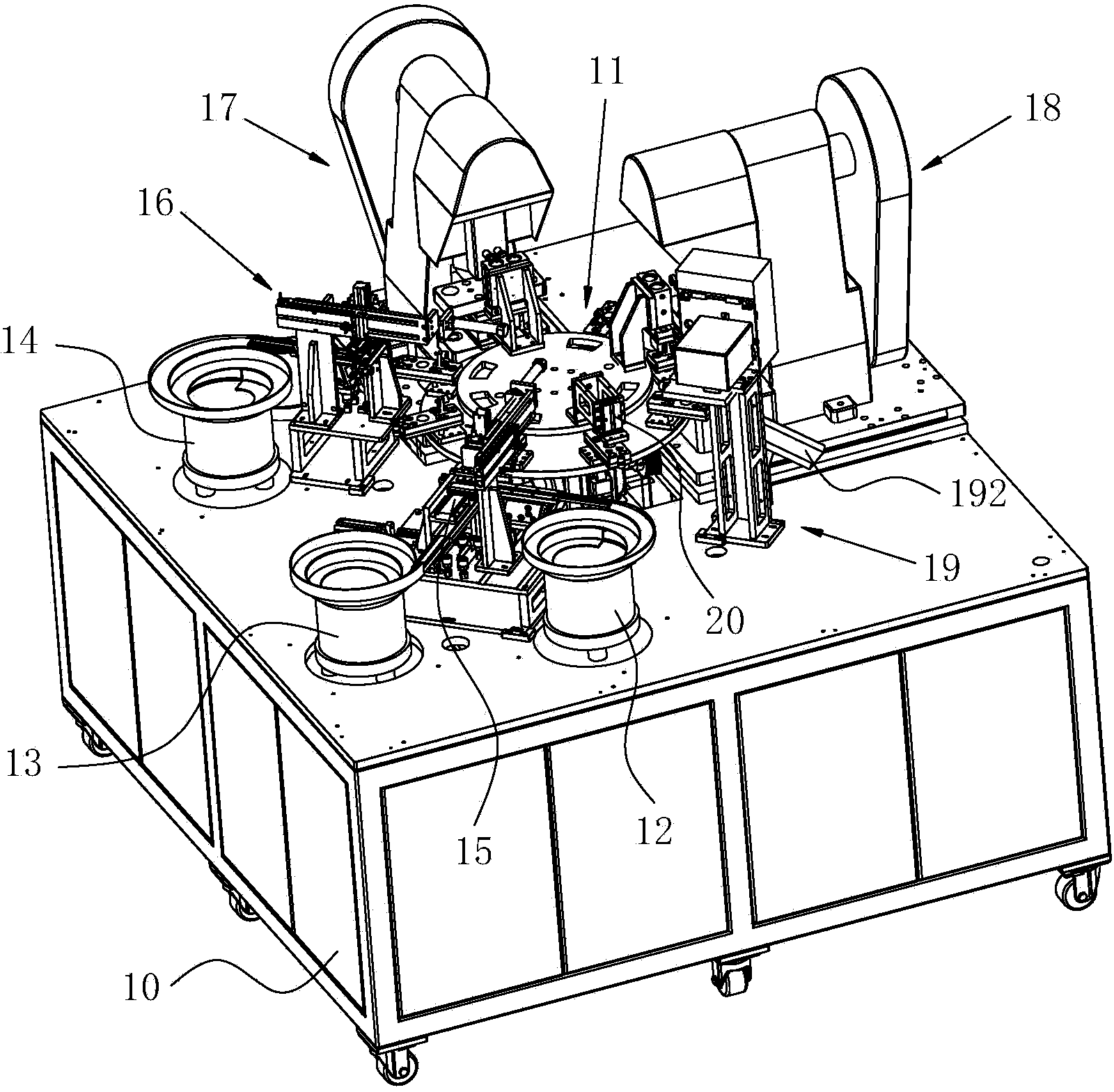

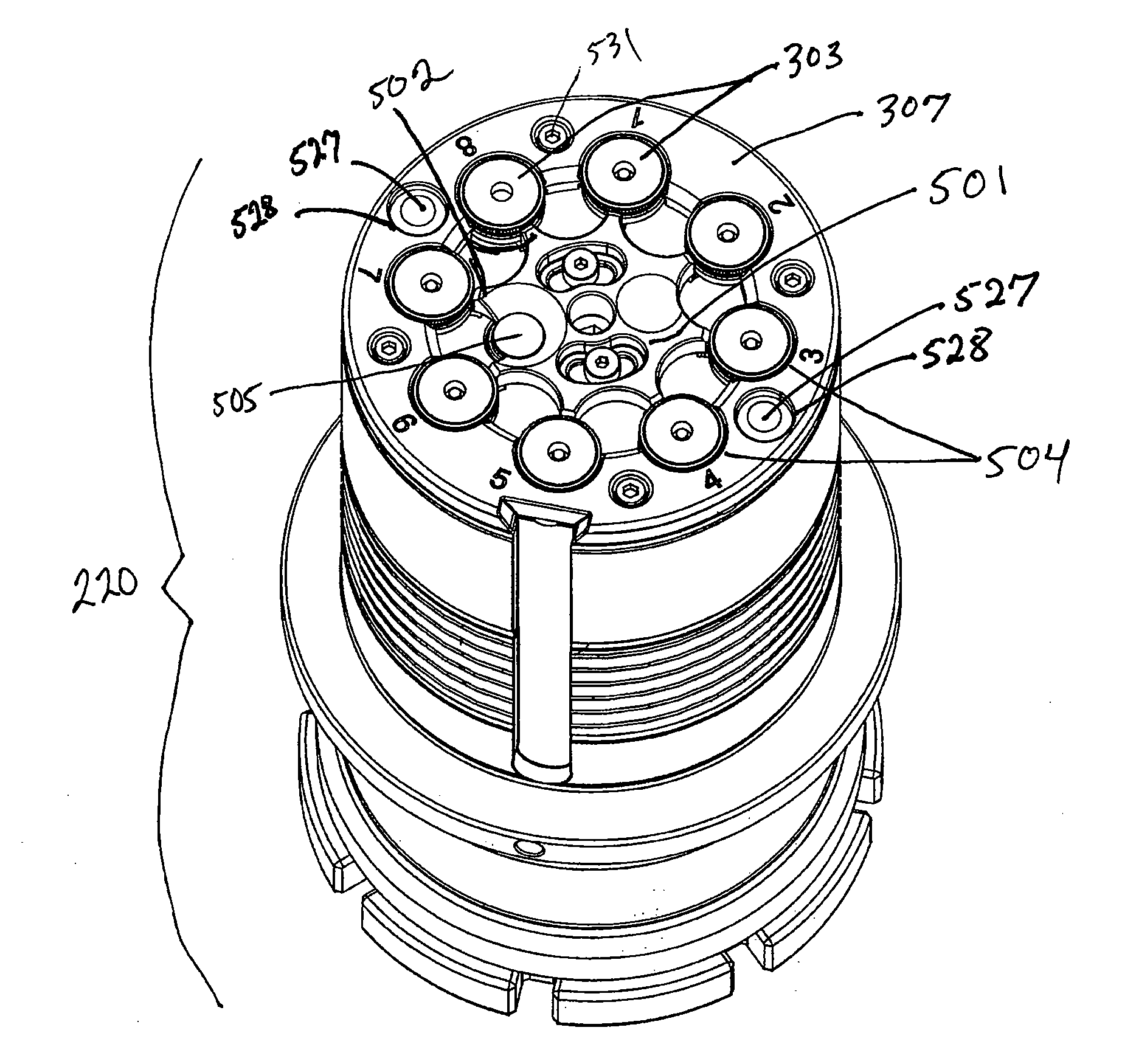

Multiple Punch and Die Assembly

ActiveUS20110107888A1Prevent movementAutomatic/semiautomatic turning machinesShaping toolsIndependent motionPunch press

A multiple punch and die assembly adapted to be placed in a punch press having a punch ram for imparting movement to a selected punch assembly for carrying out a punching or forming operation comprises a punch assembly for holding a plurality of selectively operable punches mounted for independent movement in the punch assembly so as to selectively engage a workpiece. The punch assembly has a punch carrier for reciprocal motion within a punch guide and a striker body engaging the punch carrier, said striker body being selectively, toollessly connectable to the punch carrier by a pair of tabs located on a lower circumference of the striker body, said pair of tabs located on a lower circumference of the striker body with a radial separation other than 180 degrees. A circumferential lip in the punch carrier receives the pair of tabs and has corresponding radially separated reliefs for allowing the pair of tabs to pass the circumferential lip, the engagement of the pair of tabs by the circumferential lip thereby locking the striker body to the punch carrier while permitting relative rotation of the striker body and punch carrier to select a punch for engagement by the striker. A detent means releasably positions the striker body in one of a plurality of operating positions, at which a punch is positioned for being struck selectively by the ram via the striker body such that one punch is driven to an operating position when at least one other punch is in inactive. In another embodiment the assembly has a stripper retainer that has precision pockets for holding strippers corresponding to the selectively operable punches.

Owner:MATE PRECISION TECH INC

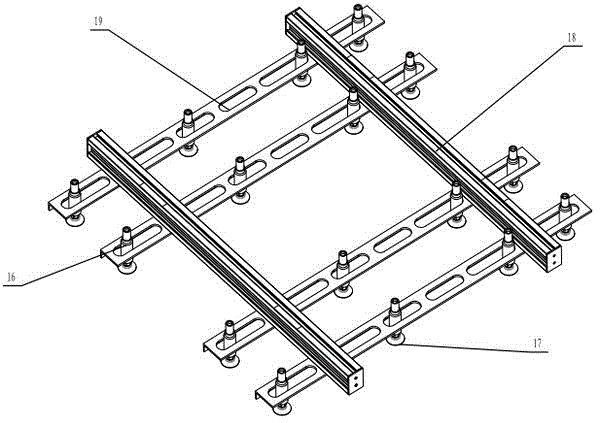

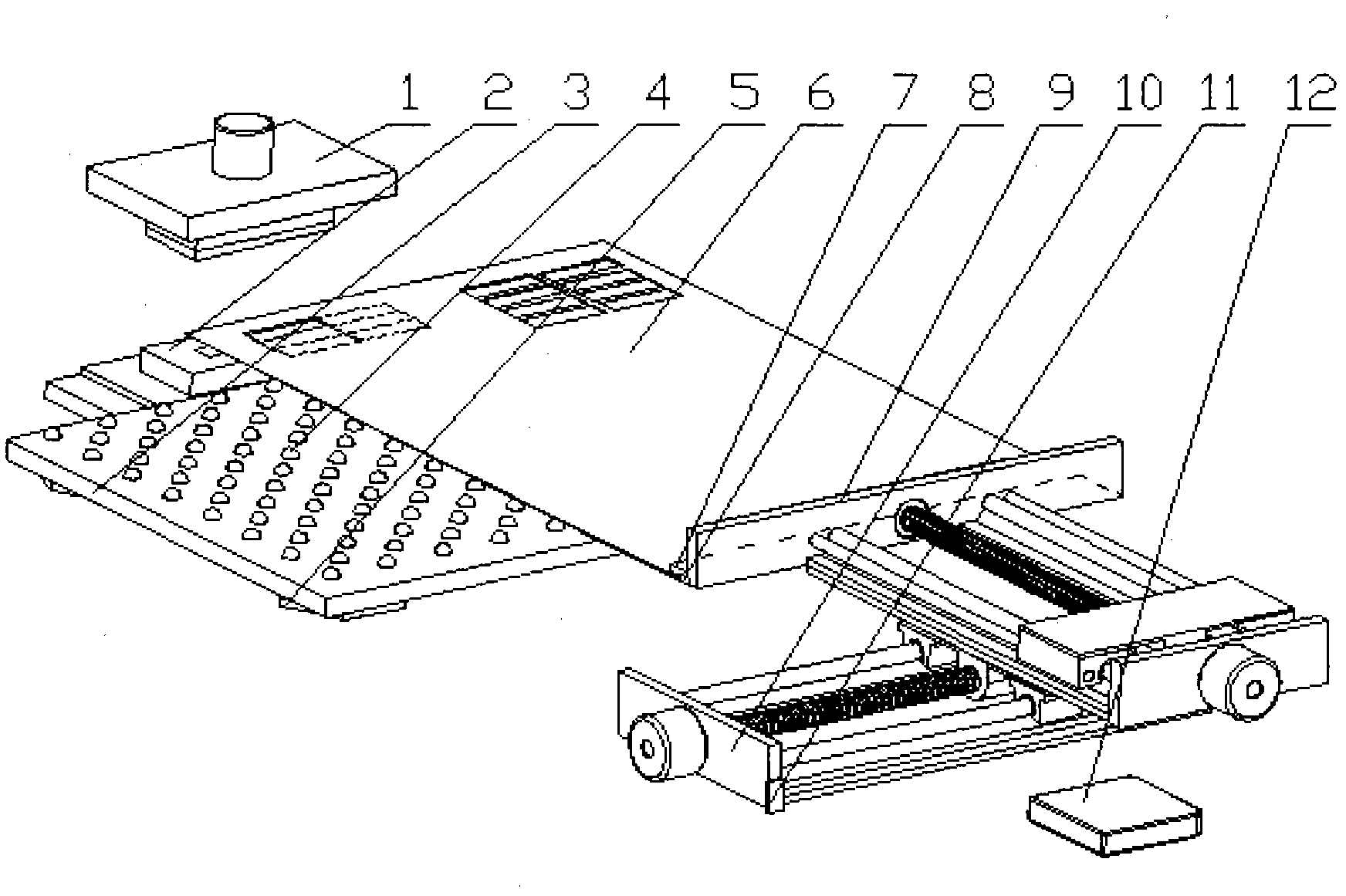

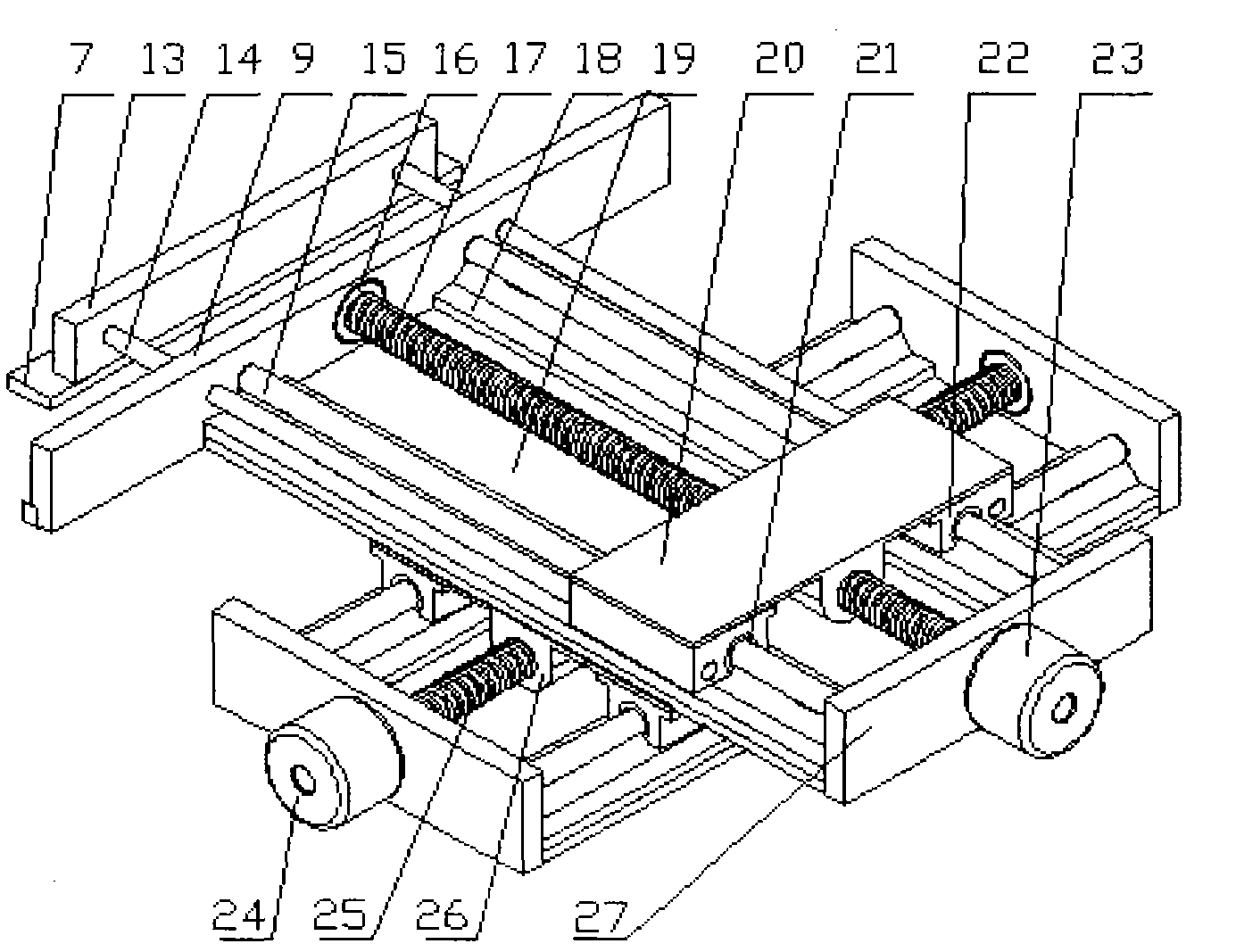

Universal automatic feeding device for punch press

InactiveCN102350463AMeet production needsMetal-working feeding devicesPositioning devicesPunch pressBall bearing

The invention discloses a universal automatic feeding device for a punch press. The universal automatic feeding device comprises a ball backing plate, balls, a regulating nut, a magnetic suction plate, a positioning nail, a metal positioning backer, a computer slot, a push plate, a push rod, a light-rail guide rod, a bearing, ball screw rods, a guide rod support, a light-rail base plate, moving guide plates, a ball bearing bush, a light-rail guide pillar, servo motors, bearing fixing plates and a computer, wherein two special light rails which are connected in a cross manner are arranged on the device in design, the two special light rails are respectively provided with one servo motor which is used for respectively driving the corresponding ball screw rod to rotate, the magnetic suction plate is connected onto the upper-layer light rail and is used for tightly sucking a metal plate to be punched, the servo motors are controlled by the computer so as to realize automatic metal plate feeding in the directions of back and forth as well as left and right. The universal automatic feeding device for the punch press is suitable for various punch presses to complete precise punching on workpieces of various shapes and automatic discharging of various punched pieces.

Owner:王崇庆

Assembling line for glass-fiber reinforced plastic windows

InactiveCN102756281AReduce workloadImprove work efficiencyAssembly machinesOther manufacturing equipments/toolsProduction lineGlass fiber

Owner:SHANGHAI DIANJI UNIV

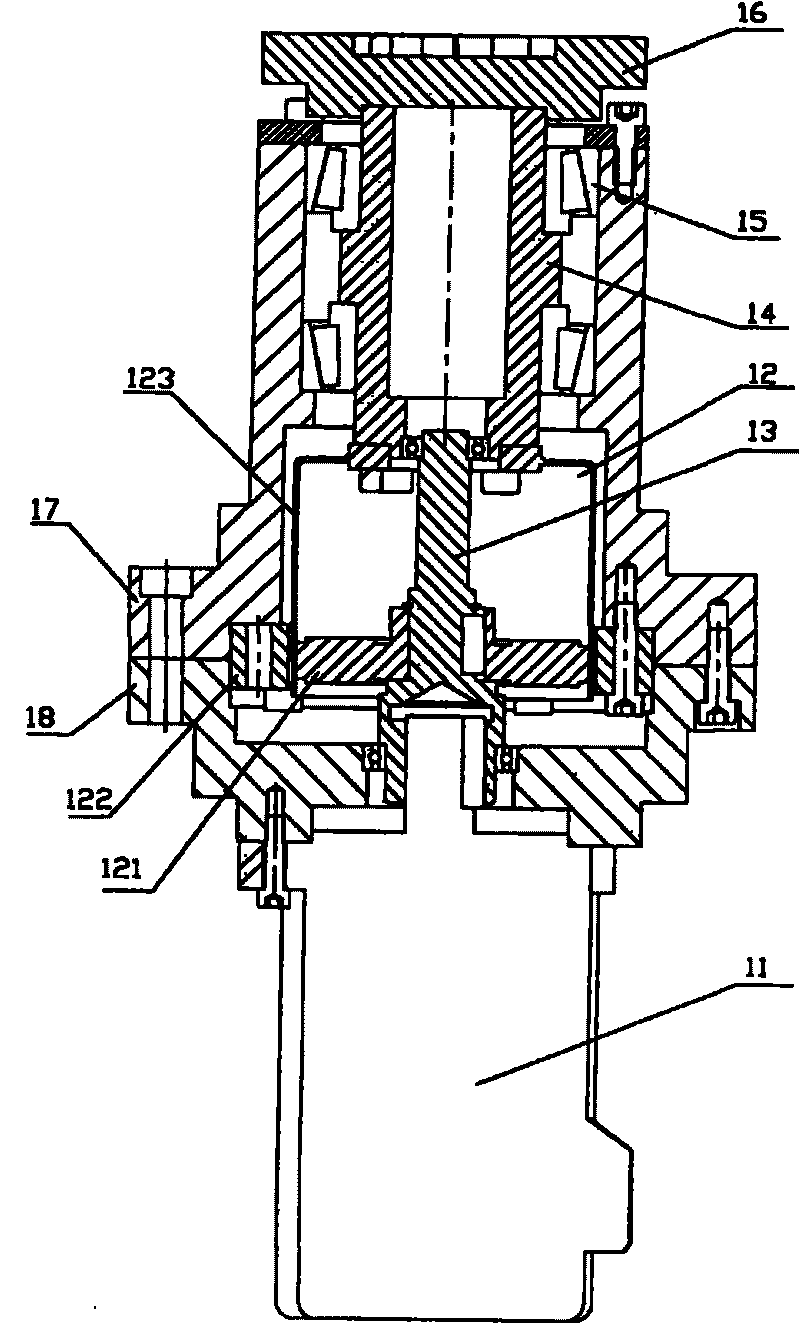

Charging and blanking robot of punch press

InactiveCN101758497AEasy to adjustImprove work efficiencyProgramme-controlled manipulatorMetal-working feeding devicesPunch pressReduction drive

The invention discloses a charging and blanking robot of a punch press, comprising four joints, a base, two arms and an end effector, wherein the first joint, the second joint and the fourth joint have the degree of freedom of rotation, and the third joint has the degree of freedom of up and down translation; one end of the first joint is connected with the base by an input end shell; the other end of the first joint is connected with one end of the first arm by a first joint output flange; the other end of the first arm is connected with a second joint output flange of the second joint; a third joint connecting plate is connected with the joint rack of the fourth joint; and a fourth joint output rotary table is provided with the end effector. A harmonic transmission mode is adopted by a first joint transmission device and a second joint transmission device of the robot. Aiming at the characteristic that a harmonic speed reducer only can bear torque but can not bear bending moment, a pair of tapered roller bearings is arranged on an output shaft and is used for bearing overturning bending moment. The transmission mode has compact structure, high transmission efficiency, small return difference and high transmission accuracy.

Owner:ZHEJIANG UNIV

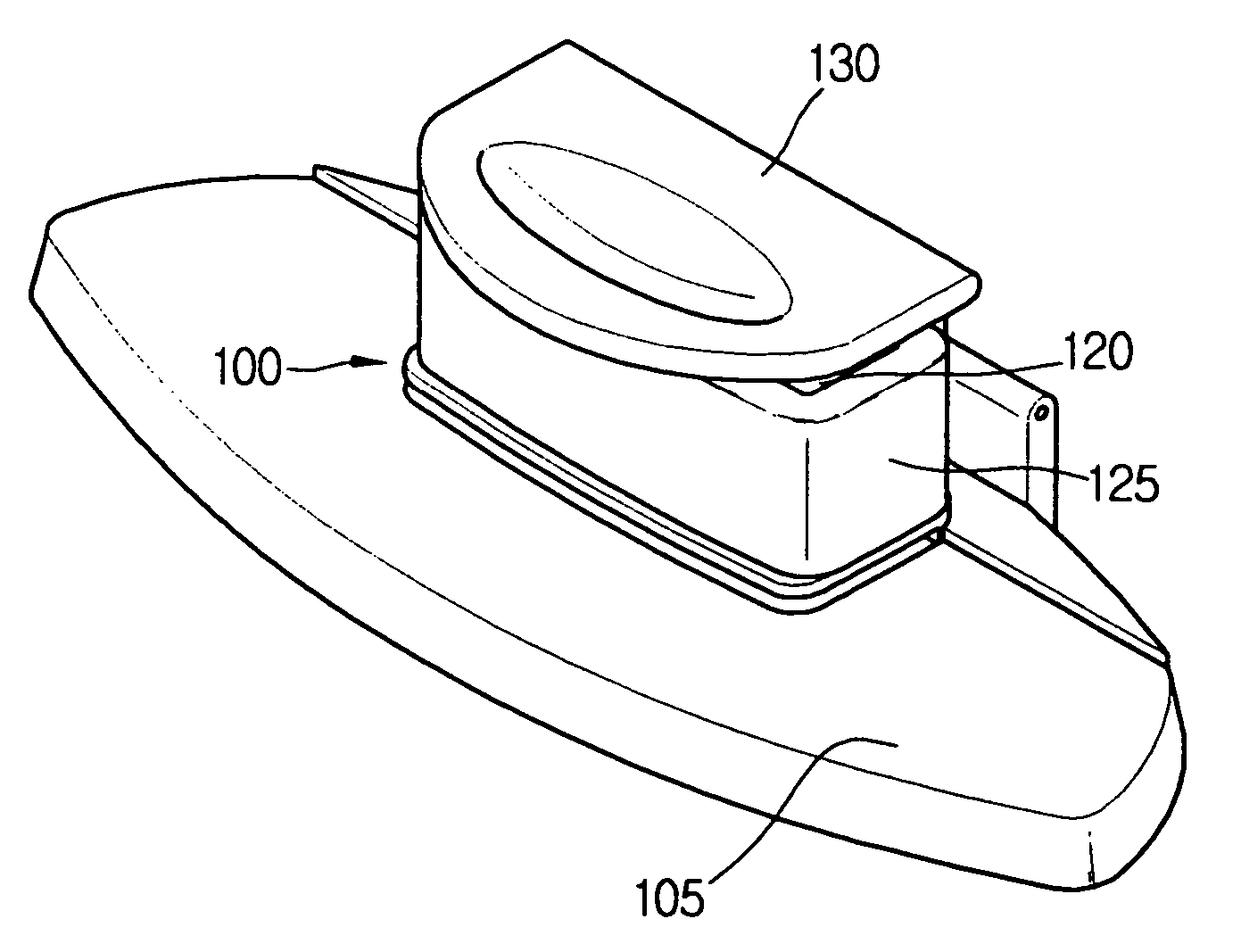

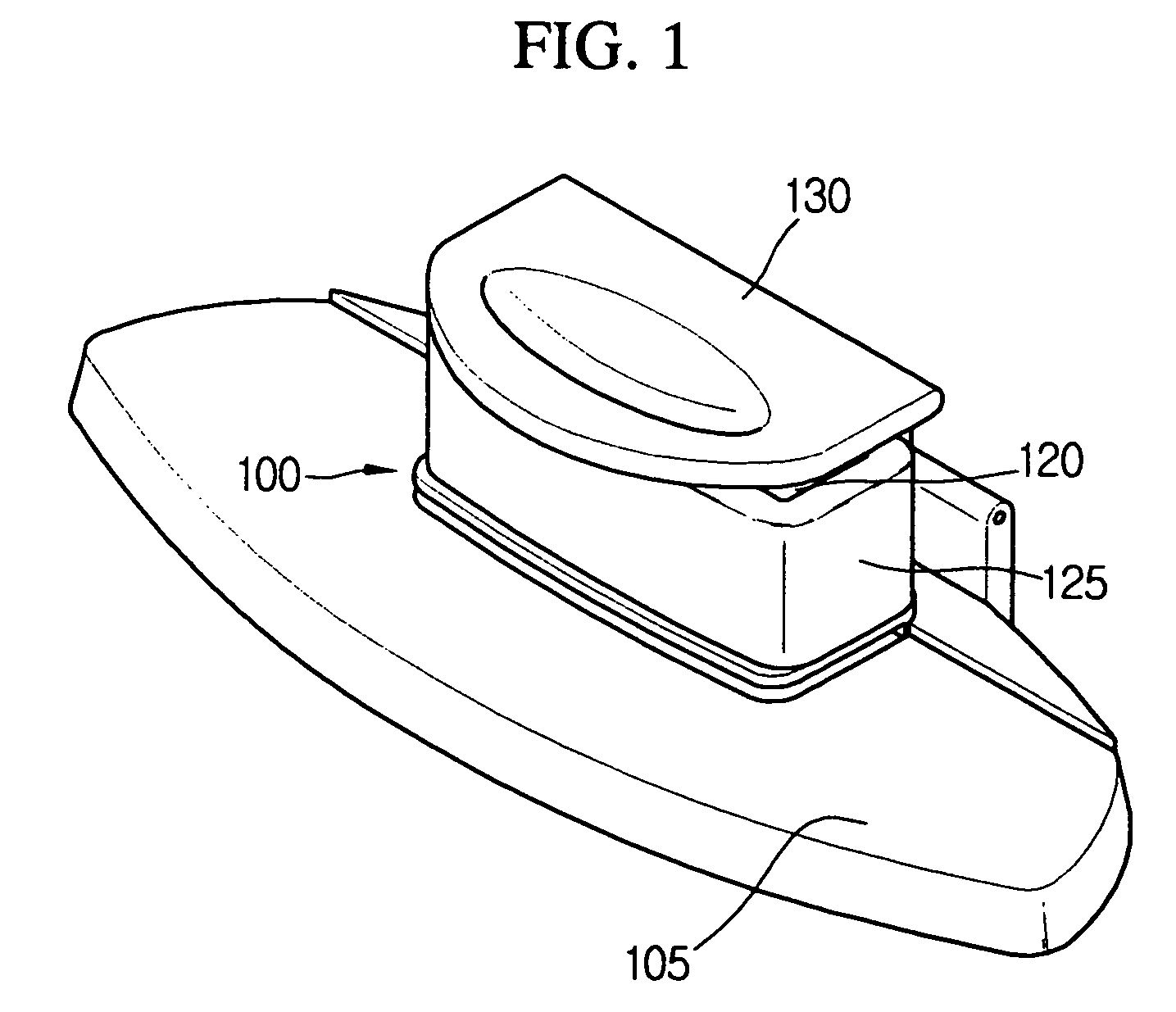

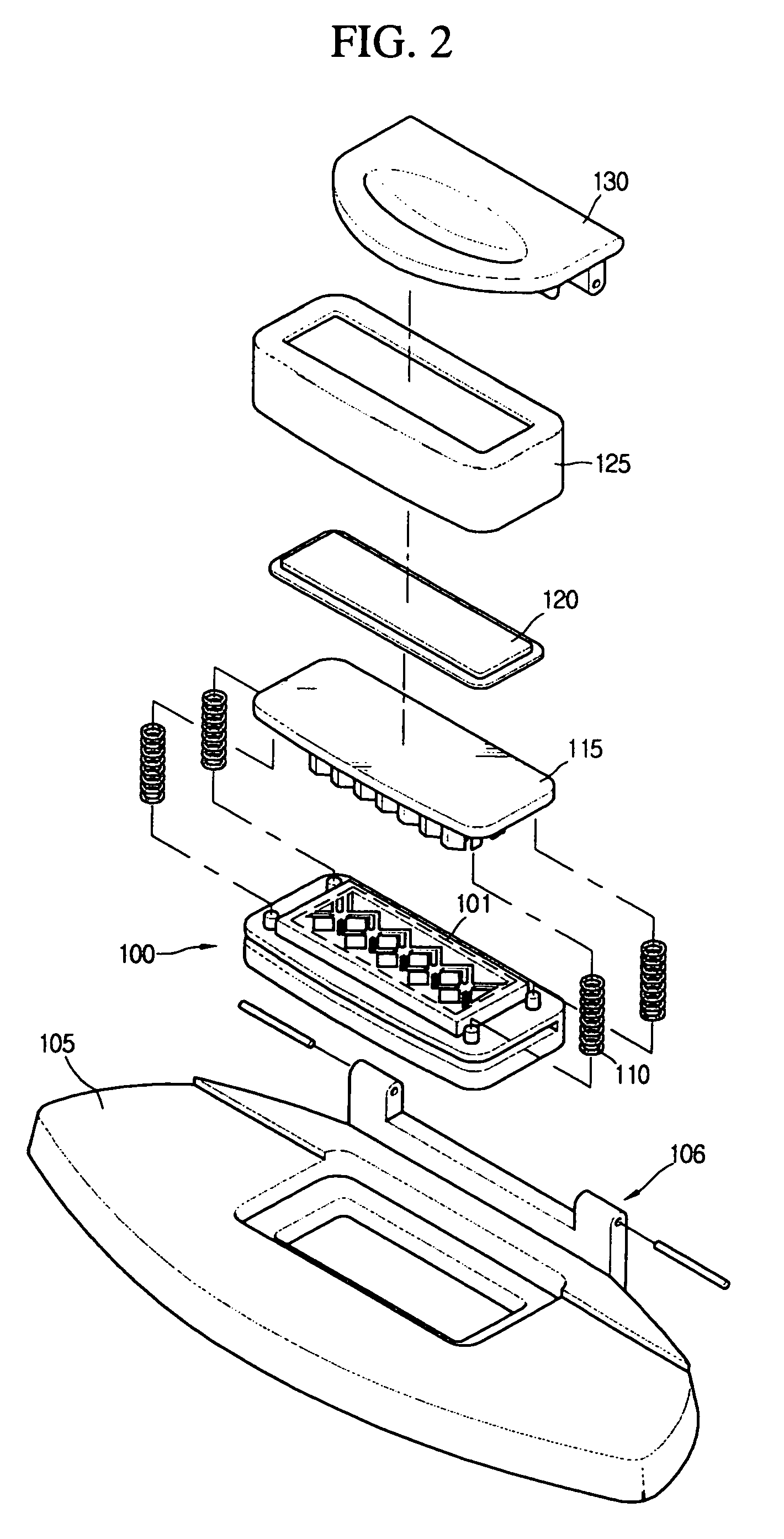

Punch capable of punching and embossing simultaneously

A punch capable of simultaneously punching and embossing a sheet member such as a card, a letter paper, a picture, a board, or a paper in a predetermined pattern is disclosed. The punch includes a jig having a cutting hole of a predetermined pattern and a punching area on which a convex embossment is spaced apart from the cutting hole; a base for fixing the jig and giving a support surface to supply a sheet member to the punching area; a punching member including a first punch pin having a cutting blade corresponding to the cutting hole and a second punch pin having a concave embossment corresponding to the convex embossment, the punching member punching and embossing the supplied sheet member with moving vertically against the jig; and an elastic body interposed between the punching member and the jig to bias the punching member upward.

Owner:DN CRAFT

Automatic stamping equipment production line for metal tanks

InactiveCN102310152AAutomate deliveryFully automatedMetal-working feeding devicesPositioning devicesProduction linePunch press

The invention relates to an automatic stamping equipment production line for metal tanks. The automatic stamping equipment production line comprises feeding machinery, a stamping machine and a conveying device, wherein the feeding machinery comprises a material placing frame, a feeding device and a feeding machine frame; the material placing frame is provided with a lift device; the operation of the lift device and the like is controlled by a programmable logical controller (PLC) or a computer controller; the stamping machine is provided with an inclined stamping machine and a common stamping machine at least; and the inclined stamping machine and the common stamping machine are respectively provided with an overturning device and a cover absorbing and feeding device. By the automatic stamping equipment production line for the metal tanks, laminated sheet-like metal materials are placed on the material placing frame, are conveyed to an inclined material placing sliding table through a material absorbing device and a feeding roller device, are automatically fed by a material pushing hand, and are fed into the inclined stamping machine for stamping and cutting; and after finishing stamping, stamped semi-finished materials can directly slide into the accommodating groove of a clamshell rotating drum through an adjusting device for sliding discharge materials so as to realize 180-degree overturning; the stamped semi-finished materials can be fed into the lower mould of the stamping equipment by conveying the cover absorbing and feeding device at the lower end of the common stamping machine, so that automatic conveying is realized; and the common stamping machine finishes secondary stamping and forming to realize full-automatic operation.

Owner:王冠华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com