Punching device for buffer support of rear shock absorber of automobile

A technology of stamping device and shock absorber, applied in the field of stamping device, can solve the problems of low production efficiency, low dimensional accuracy of parts, complicated production process, etc., and achieve the advantages of low manufacturing cost, improving production efficiency, saving process and production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

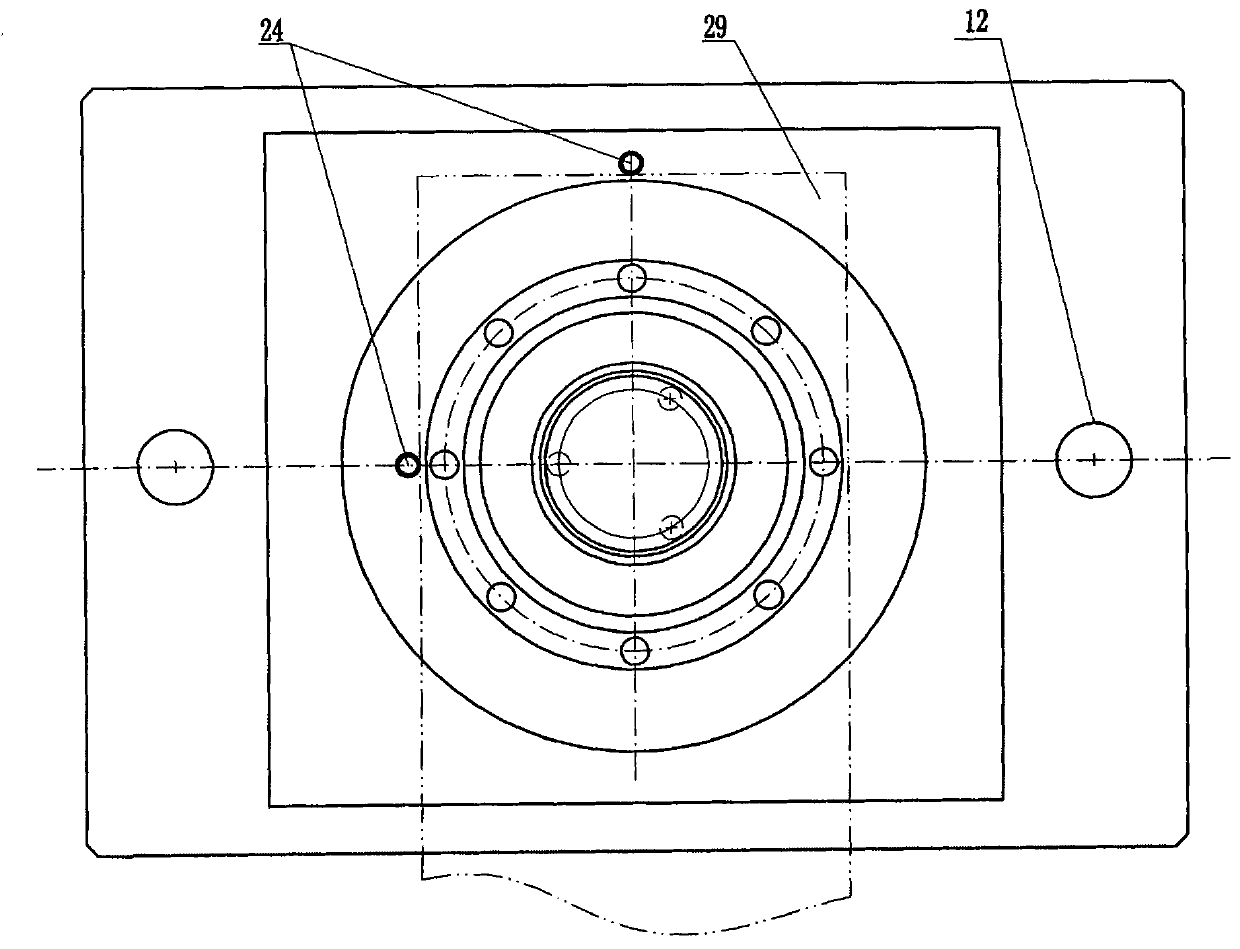

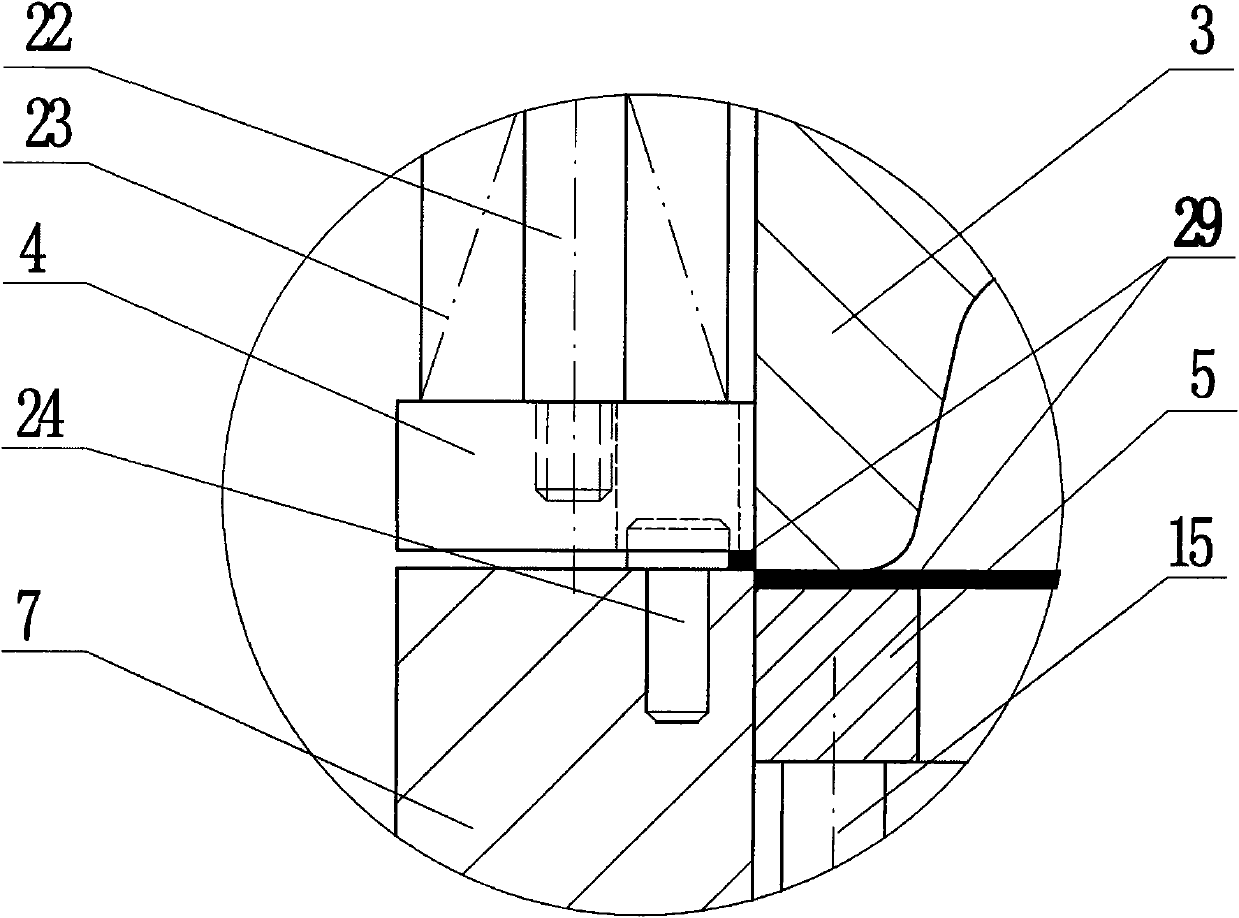

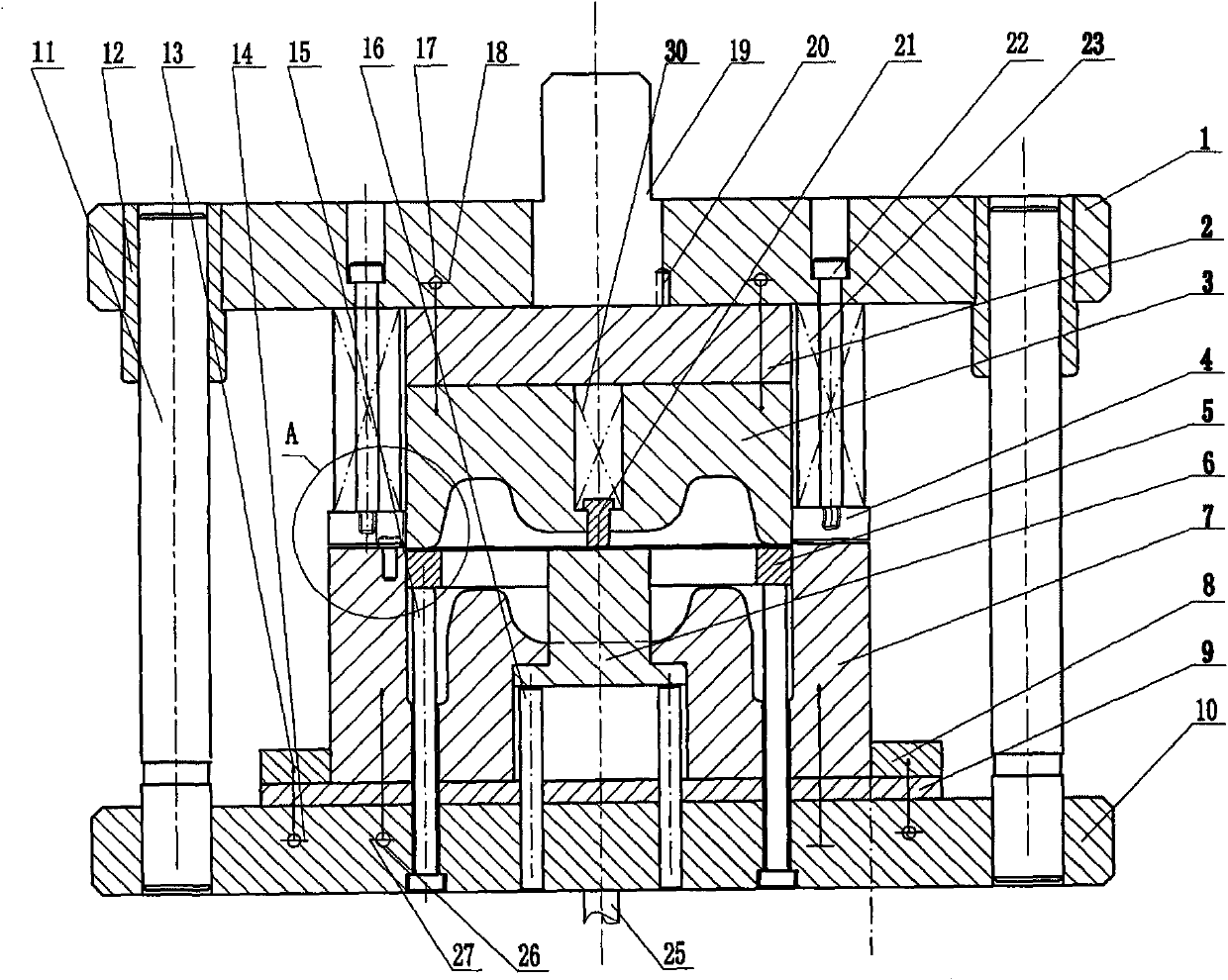

[0034] like figure 1 As shown in the figure, the punching device of the automobile rear shock absorber buffer bracket of the present invention includes the unloading screw 22 passing through the upper template 1, the unloading spring 23 and the upper unloading plate 4 in order to be threadedly connected, and the punch 3. The upper backing plate 2 is fixed on the upper template 1 by the screws 18 and the cylindrical pins 17. There is also a ejector 21 in the center of the punch 3. Under the action of the discharge spring 30, the ejector 21 is always in a protruding position. For the punch 3, when the upper platen 1 is moving downward and the upper discharge plate 4 is in contact with the plane of the plate 29, the plane where the lower end surface of the ejector 21 is located and the plane of the plate 29 are also in contact with each other.

[0035] The die 7 is fixed on the lower die plate 10 by four screws 27 and two locating pins 26. The die 7 is provided with a lower strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com