Automatic chip removal type vertical machine tool

An automatic discharge and machine tool technology, applied in metal processing machinery parts, maintenance and safety accessories, grinding/polishing safety devices, etc., can solve the problems of unfavorable waste recycling, low chip removal efficiency, and difficult chip removal for vertical machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

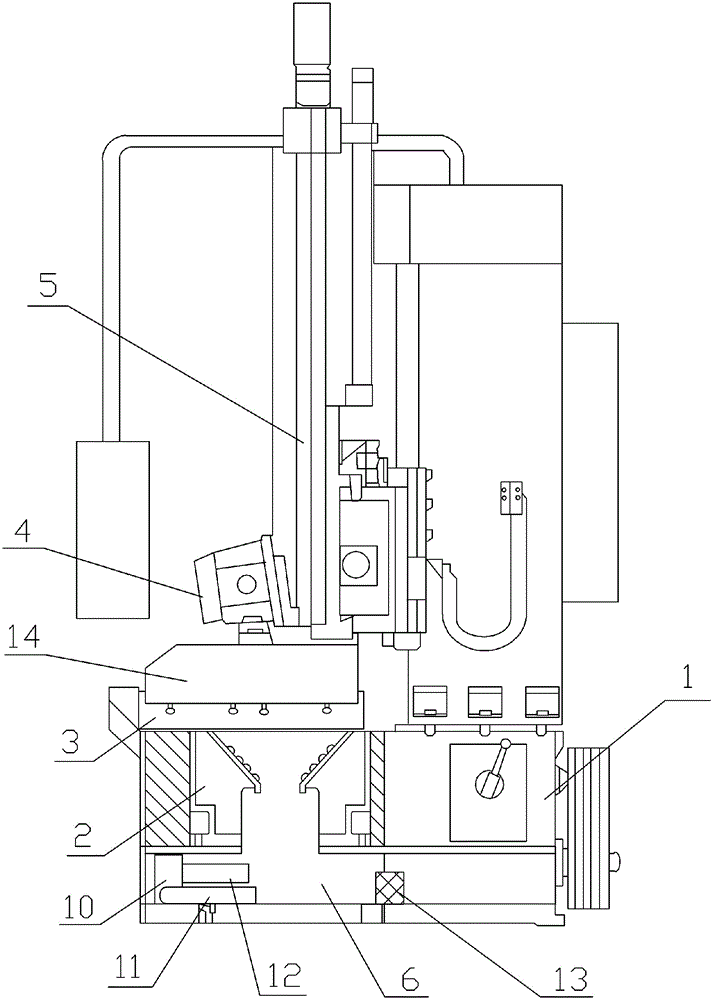

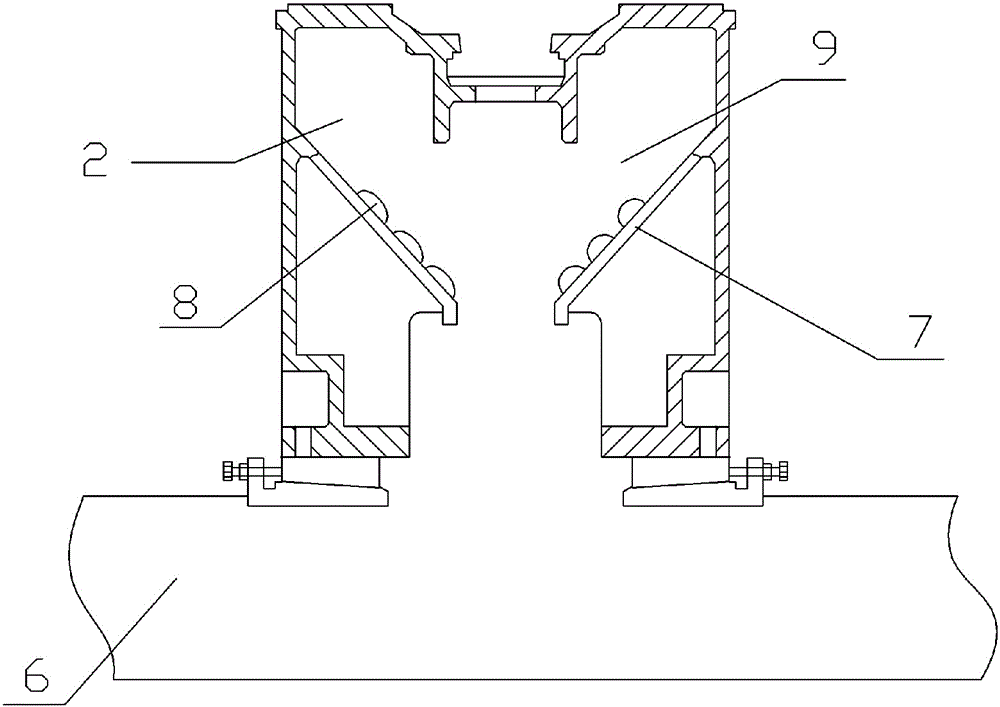

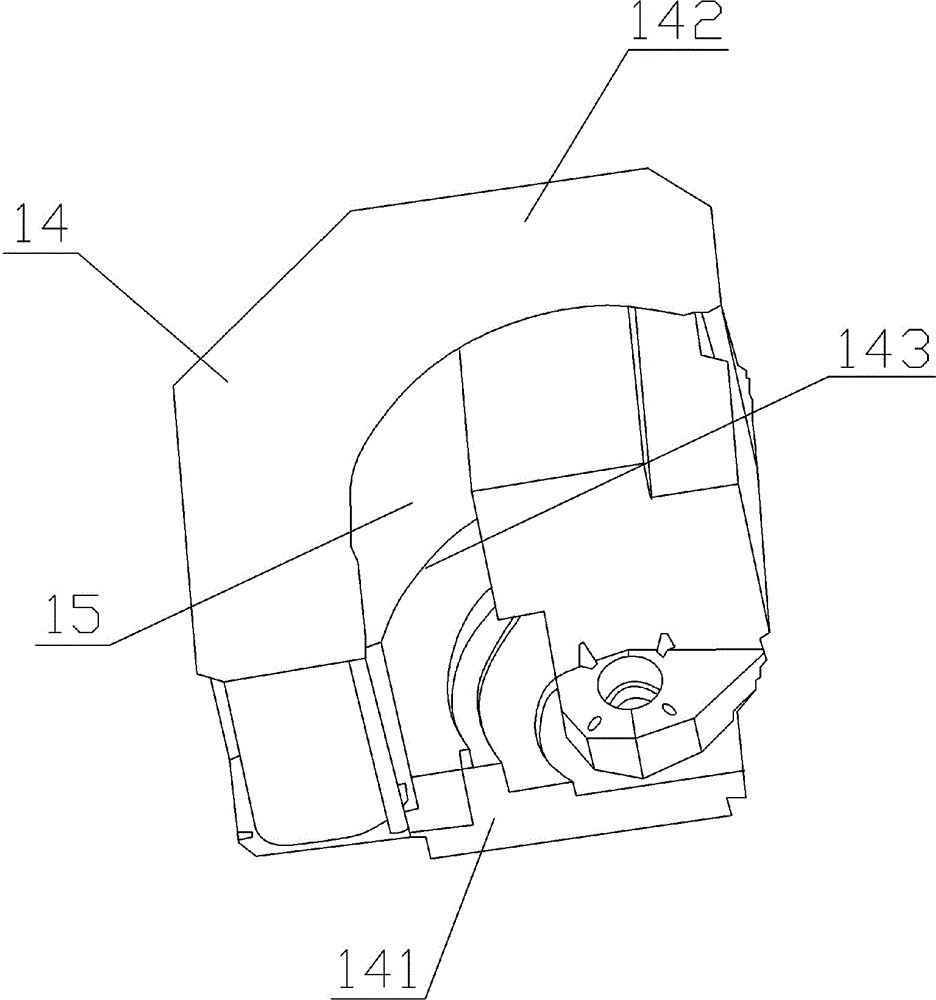

[0014] The reference signs in the accompanying drawings of the specification include: bed 1, chip removal mechanism 2, turntable base 3, turntable 4, machine tool spindle 5, material receiving and feeding box 6, front and rear inclined plates 7, vibrator 8, waste guide collection Space 9, motor 10, propeller 11, propulsion plate 12, limit block 13, protective frame 14, protective plate 15, bottom plate 141, top plate 142, guide 143.

[0015] Such as figure 1 As shown, an automatic chip removal vertical machine tool includes a bed 1 and a chip removal mechanism 2, the bed 1 is provided with a turntable base 3, the turntable base 3 is provided with a turntable 4, and the bed 1 is also provided with There is a machine tool spindle 5 connected to the turntable 4;

[0016] combine figure 2 As shown, the chip removal mechanism 2 includes a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com