Patents

Literature

92results about How to "Improve chip removal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

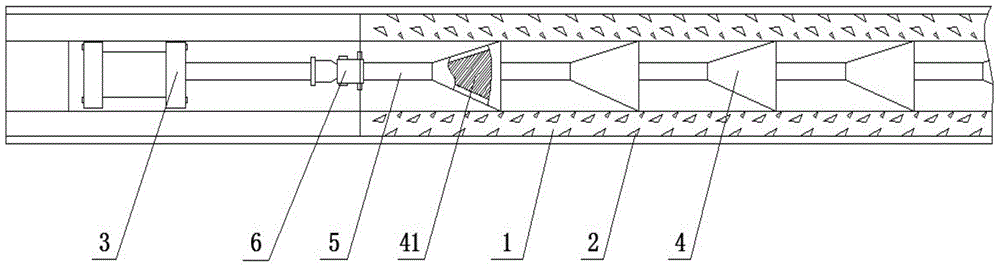

In-hole jet-suction cuttings removing and reaming method for horizontal directional drilling

ActiveCN103527092ASimple construction operationImprove chip removal efficiencyFlushingDrilling machines and methodsReamerDrill hole

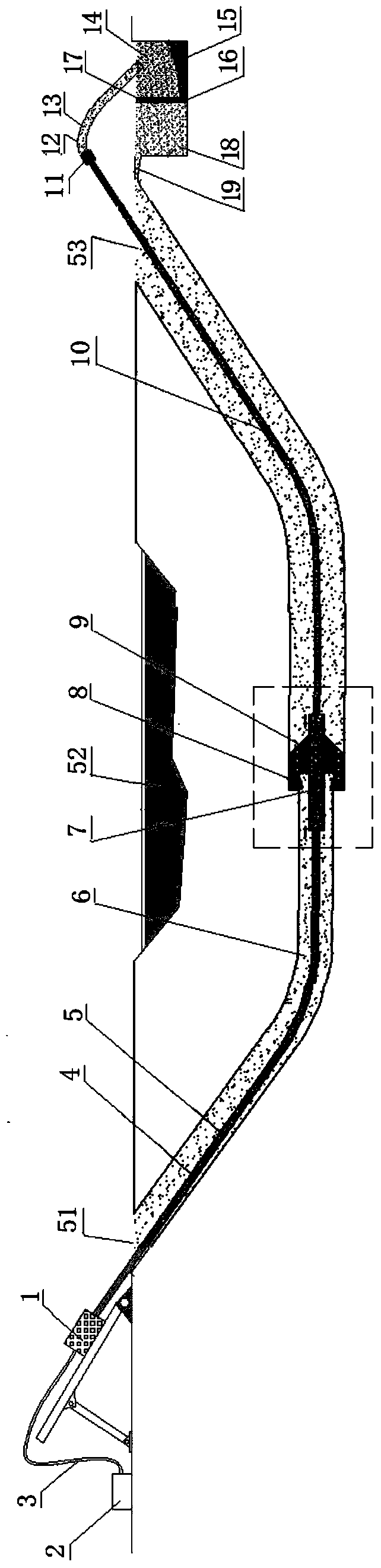

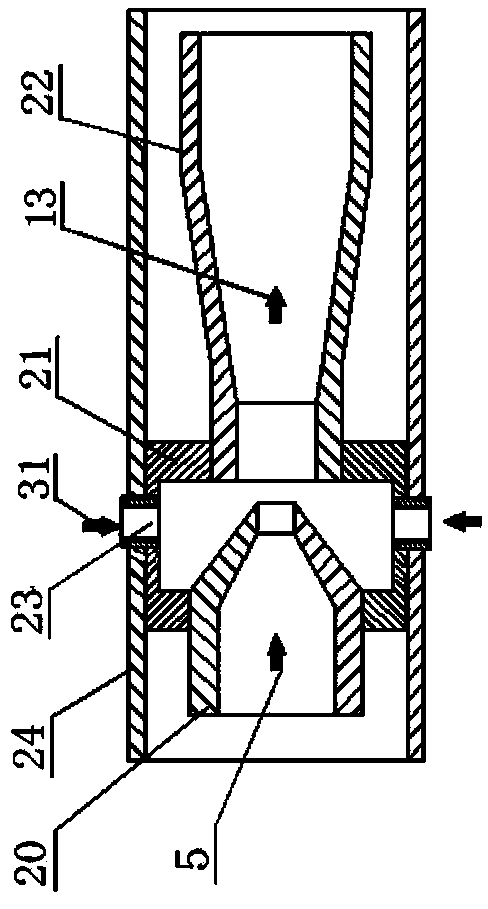

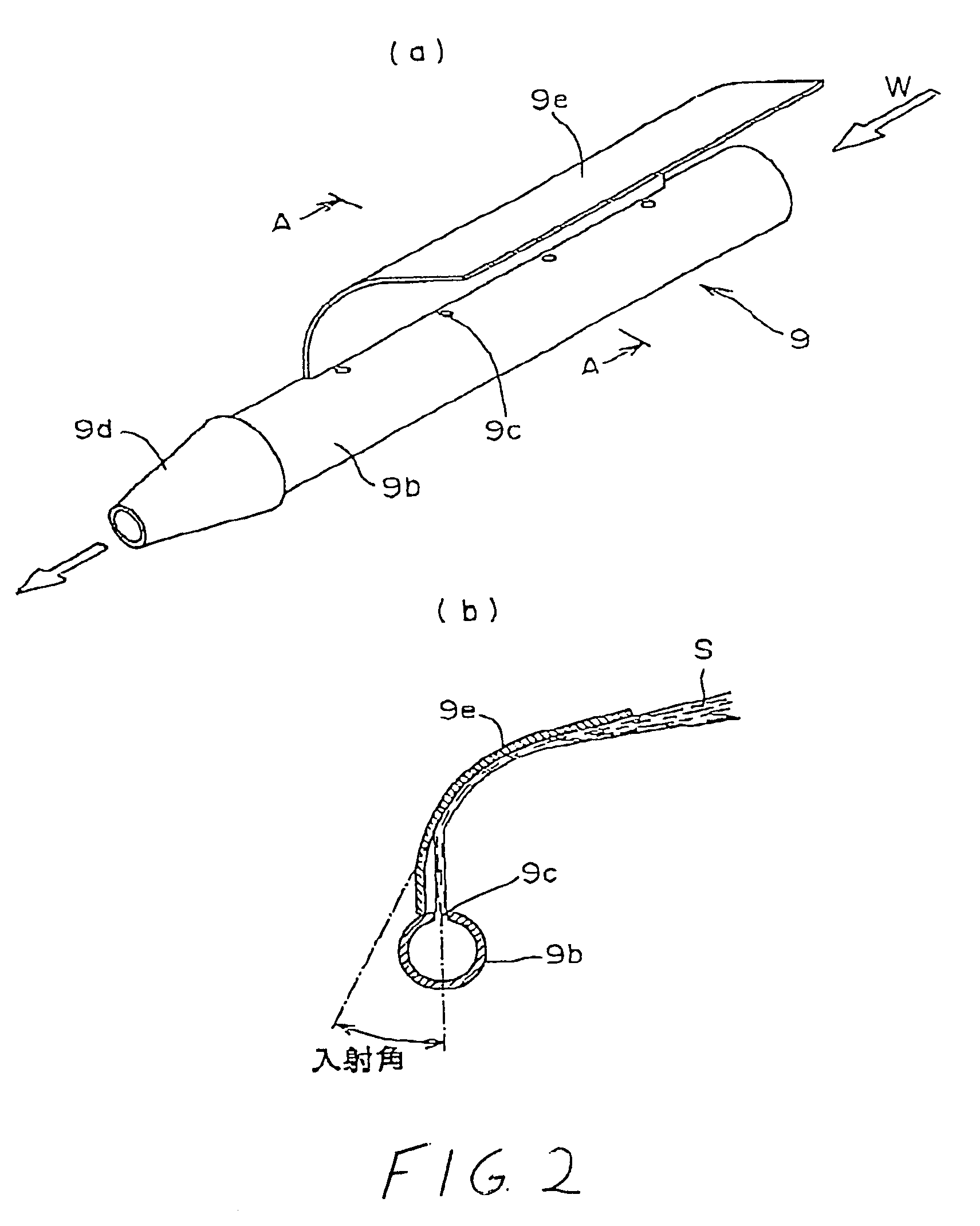

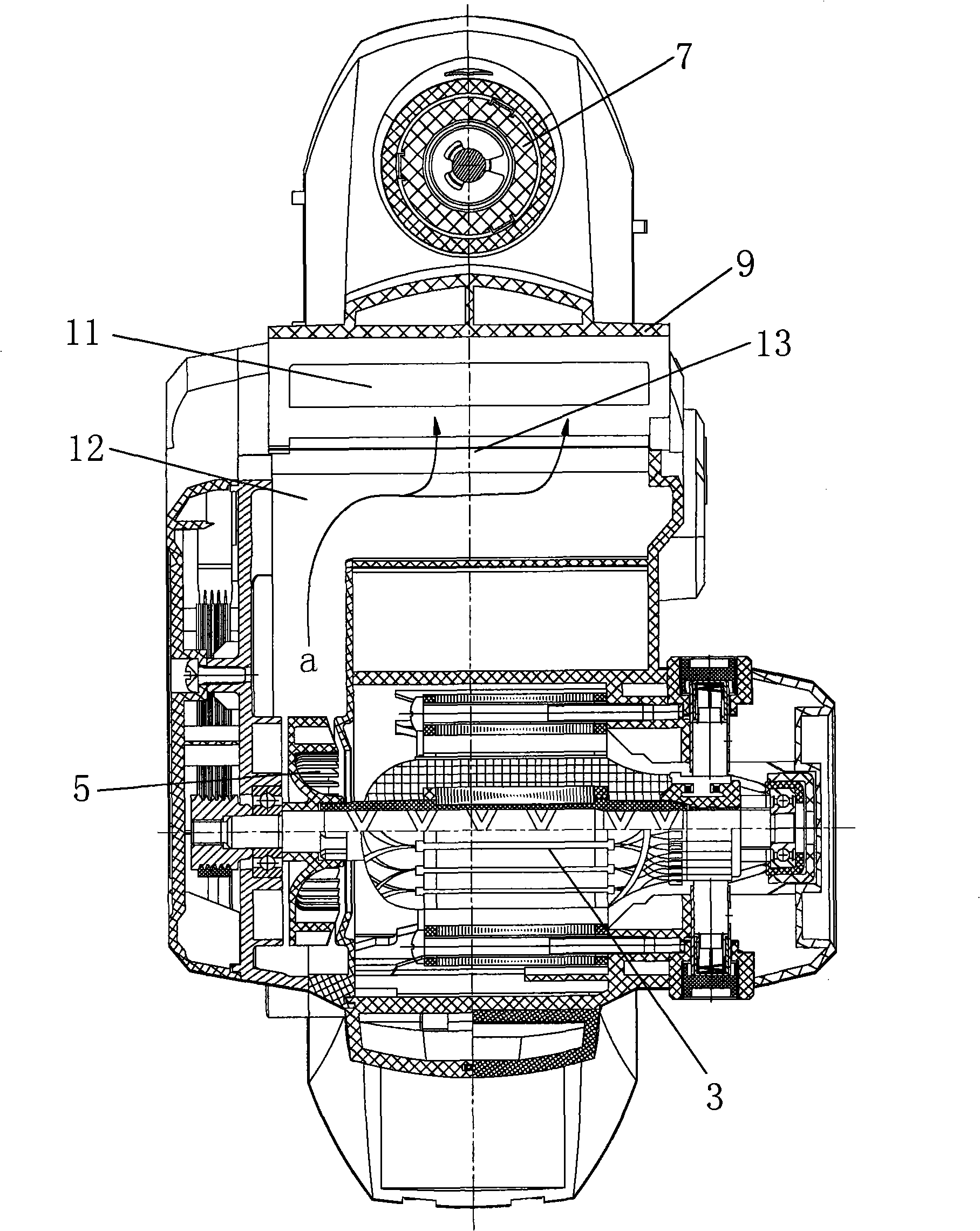

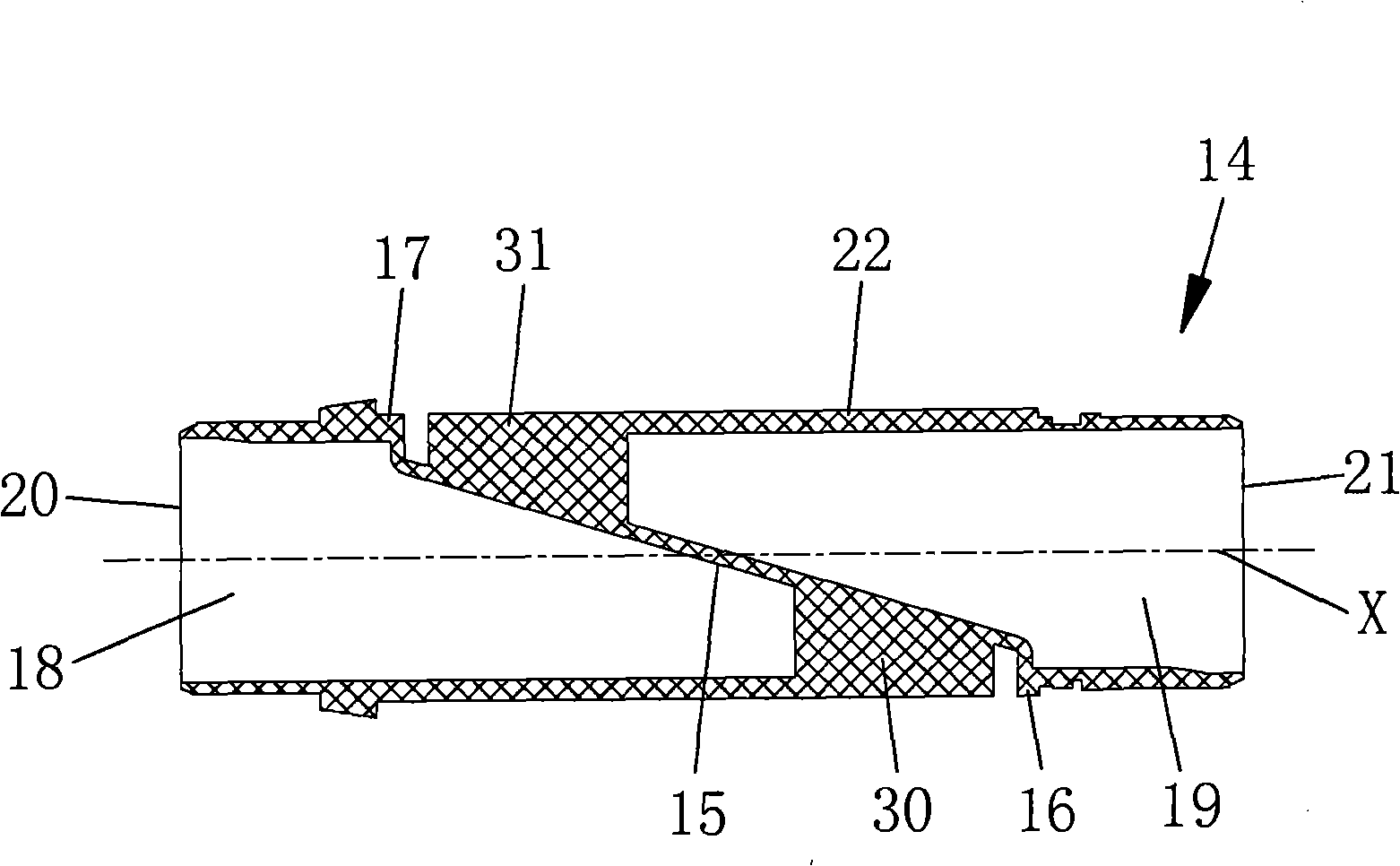

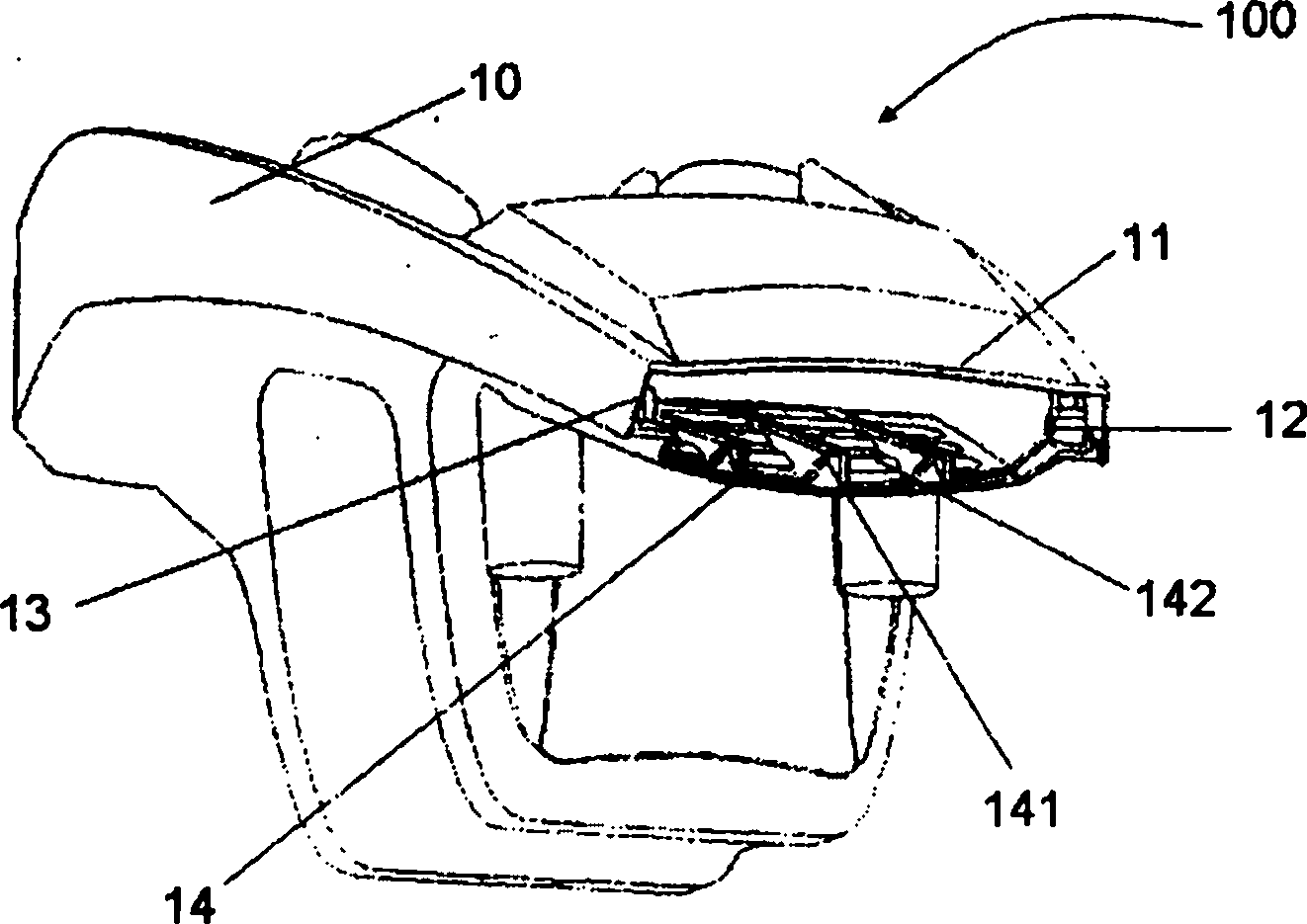

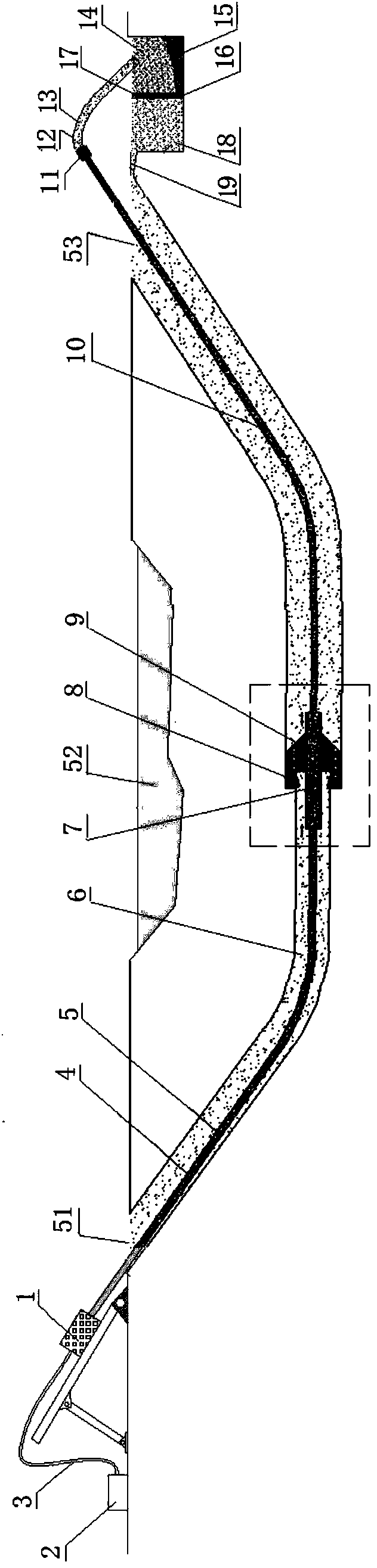

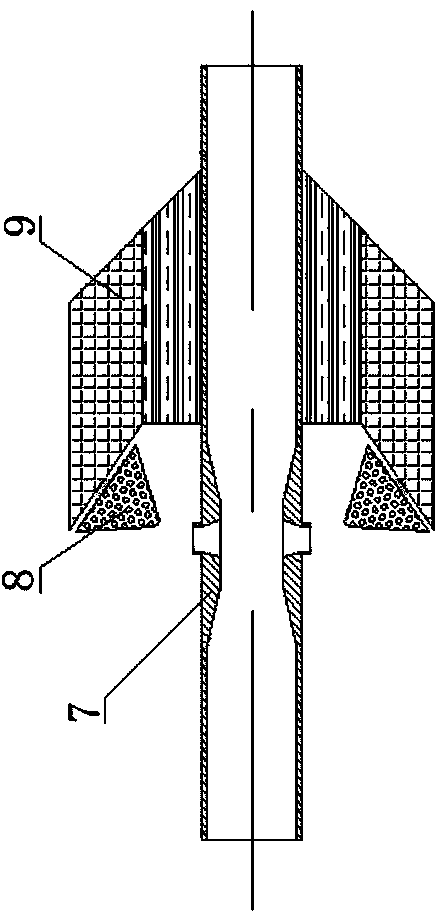

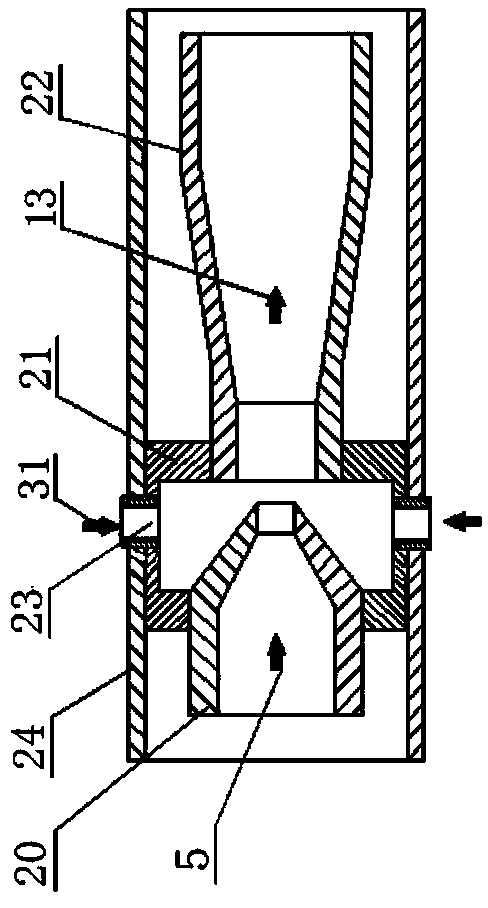

The invention relates to an in-hole jet-suction cuttings removing and reaming method for horizontal directional drilling. The in-hole jet-suction cuttings removing and reaming method includes that after completing drilling of a guide hole, a jet-suction type reamer is connected onto a drill pipe on an unearthed side, a drill pipe or pipeline is connected onto the rear of the reamer, a slurry pump or an air compressor is started up during reaming, and high-pressure fluid is delivered from the a high-pressure rubber hose, a drilling machine and the drill to the inner side of the reamer; the high-pressure fluid is jetted out from a jet flow nozzle at a high speed, negative pressure is generated in a suction chamber, and slurry fluid containing drilling cuttings on the periphery of the reamer is sucked into the suction chamber through suction inlets and blended with the high-pressure fluid jetted out from the nozzle in a throat and expansion section prior to being discharged into an earth surface sedimentation tank through the drilling pipe or the pipeline at the rear of the reamer and flowing back to a drilling hole after purification and blending; the reamer comes out from an earth-digging side to complete primary reaming, and if the drilled hole needs to be further enlarged, then a larger reamer is selected to perform repeated reaming till the hole diameter acquirement is met. By the method, drilling cuttings conveyance speed is dozens of times even a hundred times that of a conventional mode, so that cuttings can be removed thoroughly, and cuttings removal efficiency is high.

Owner:陕西中科非开挖技术股份有限公司

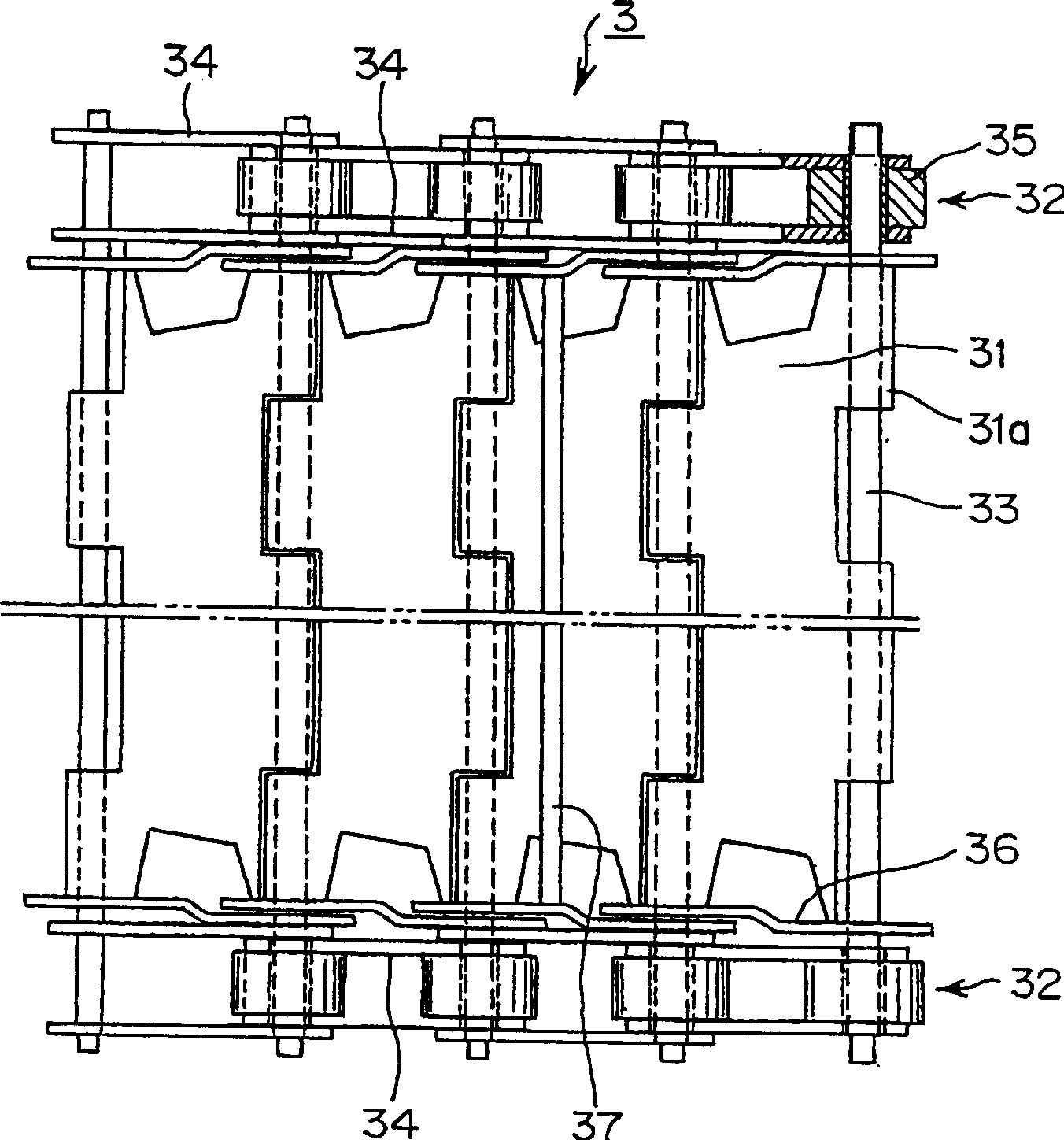

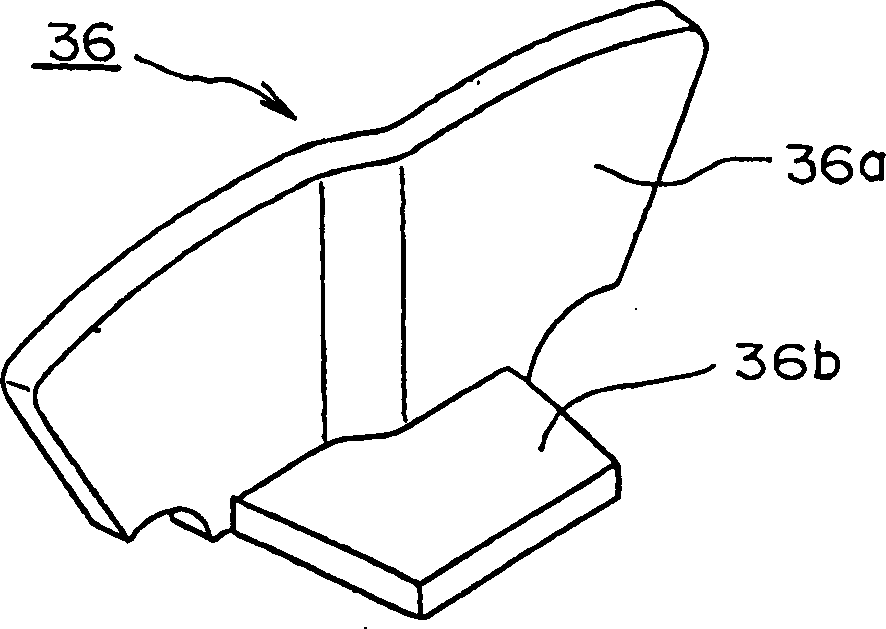

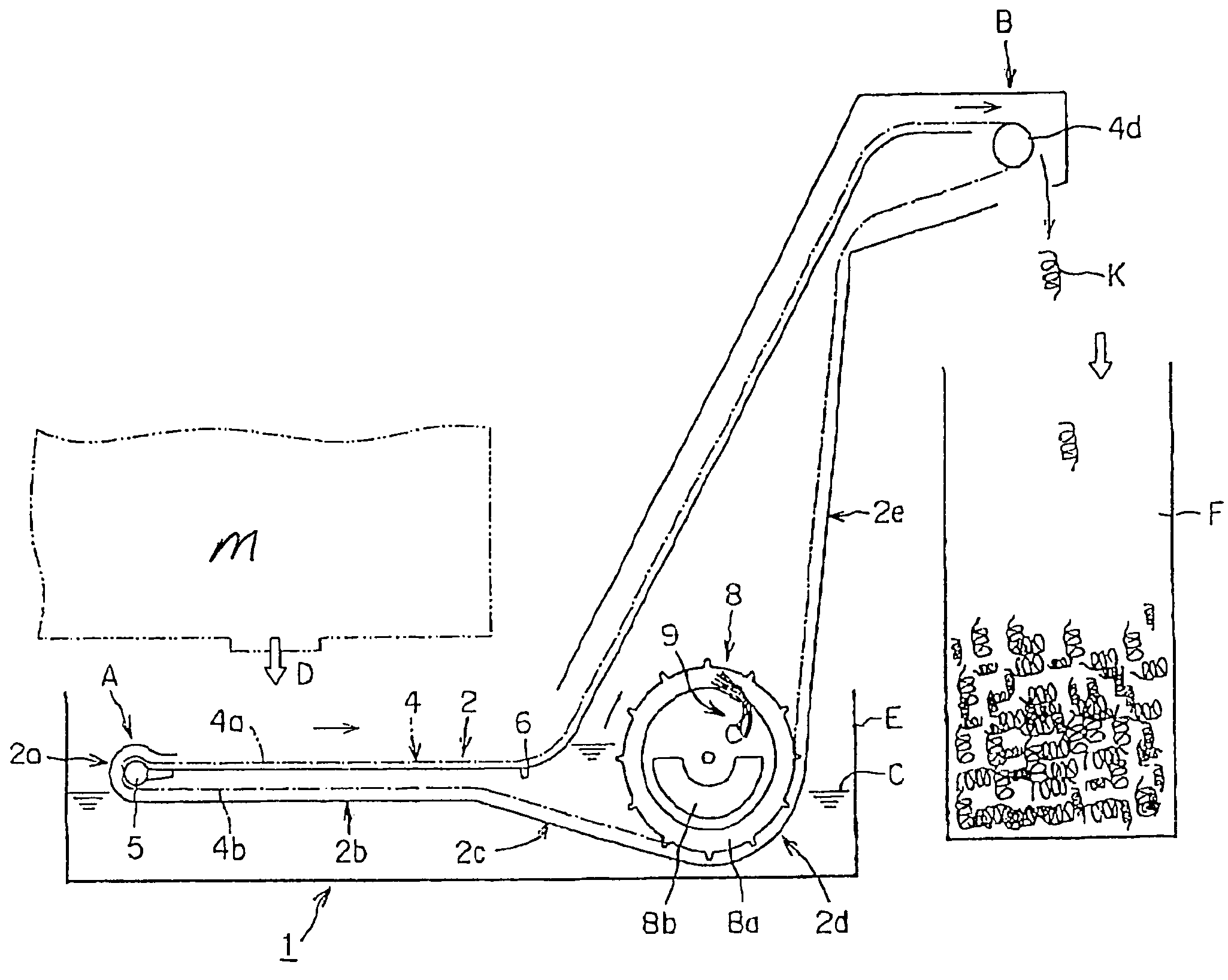

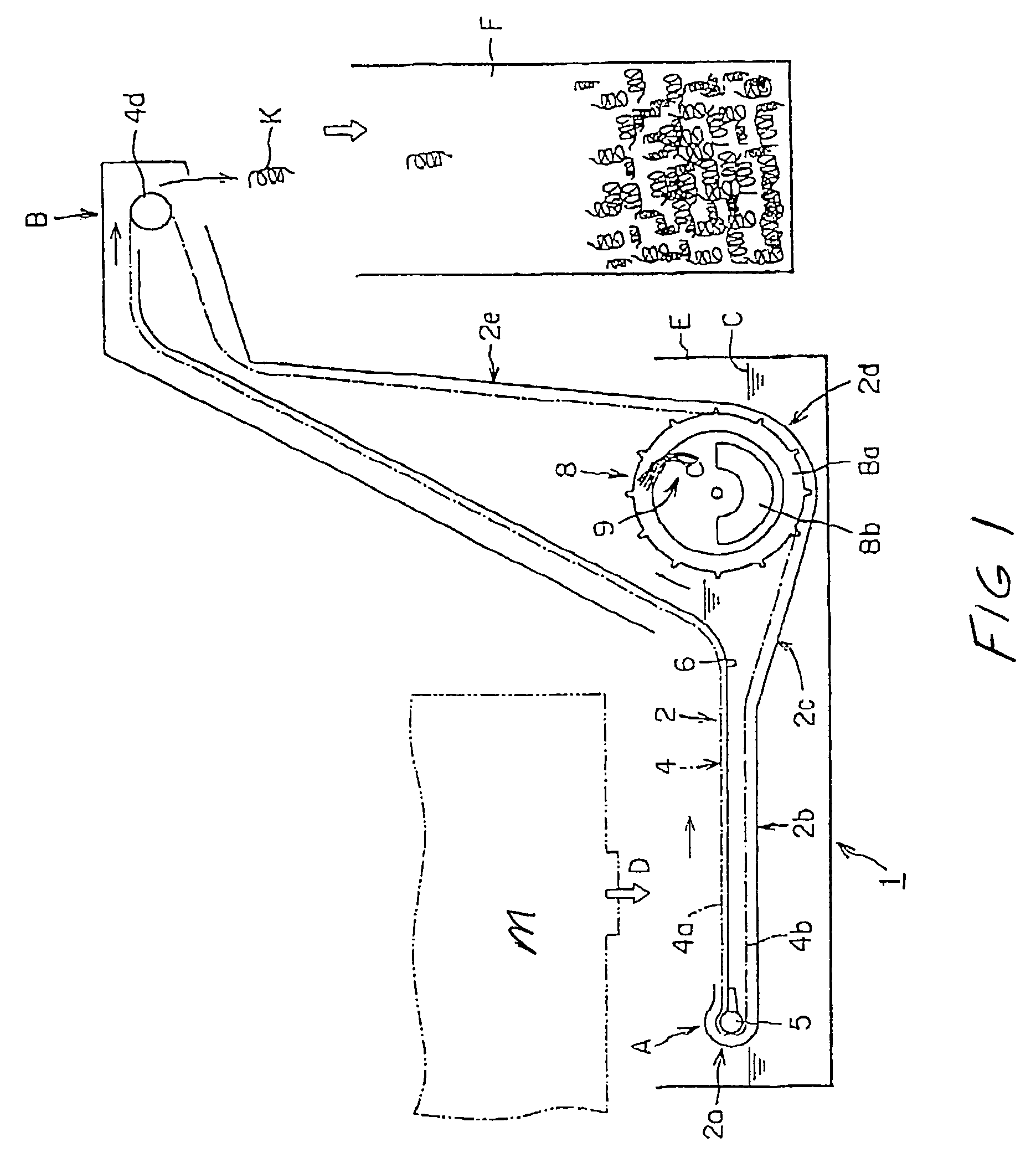

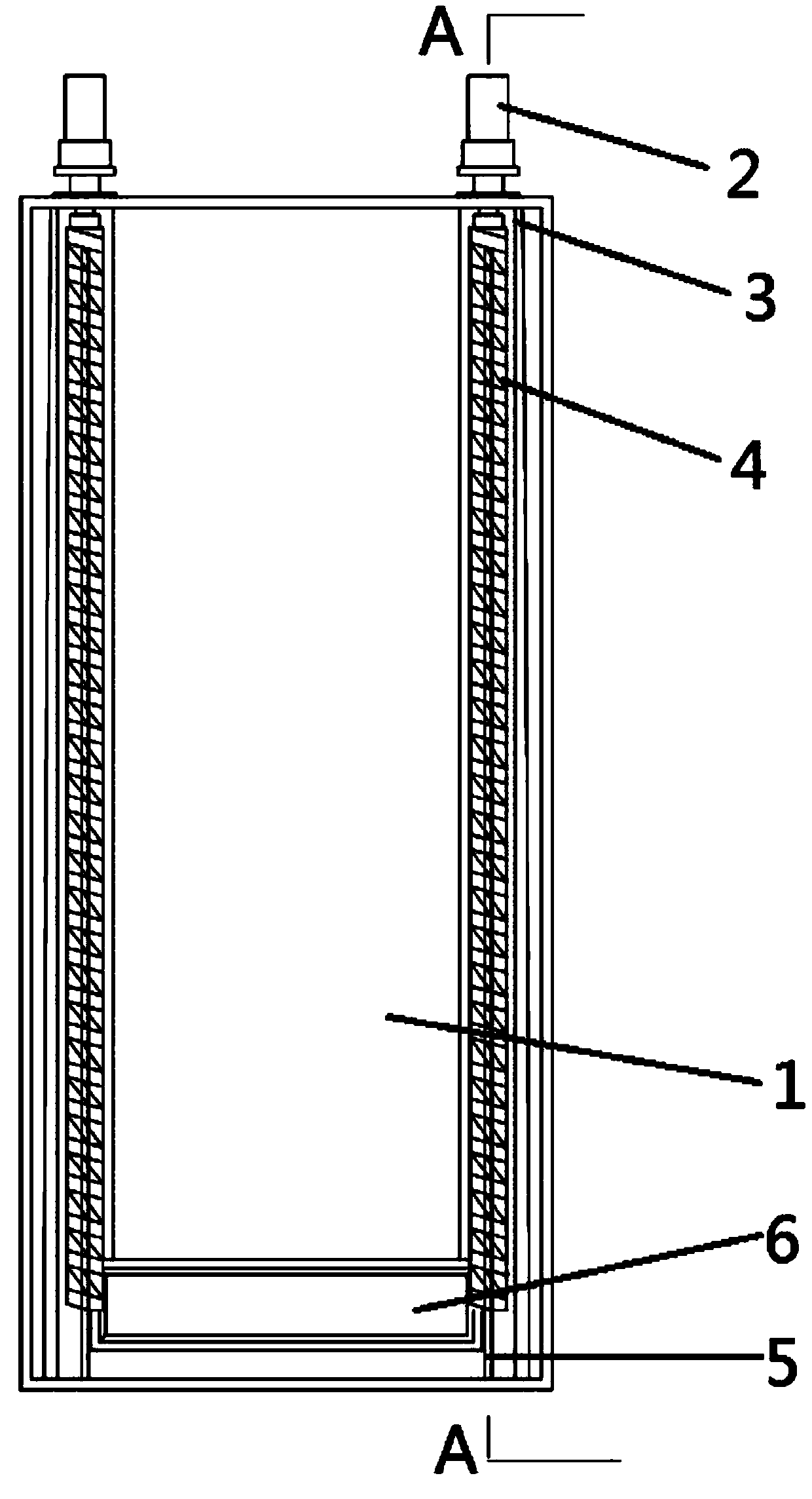

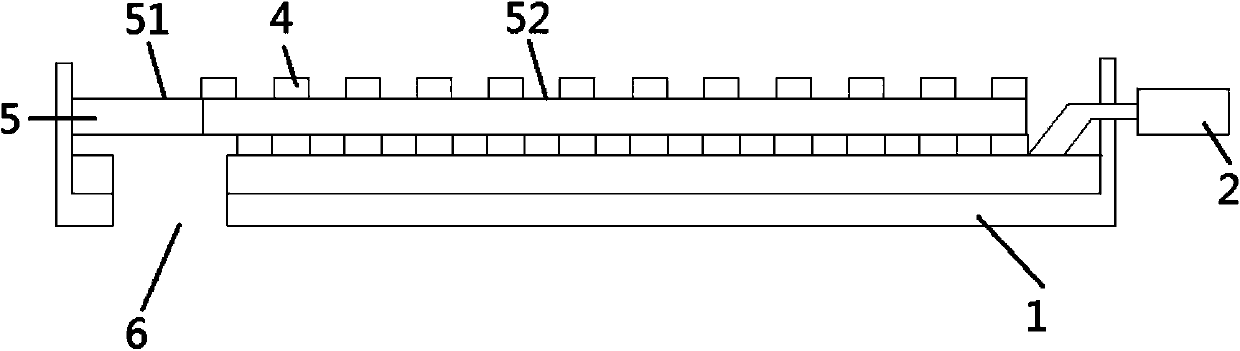

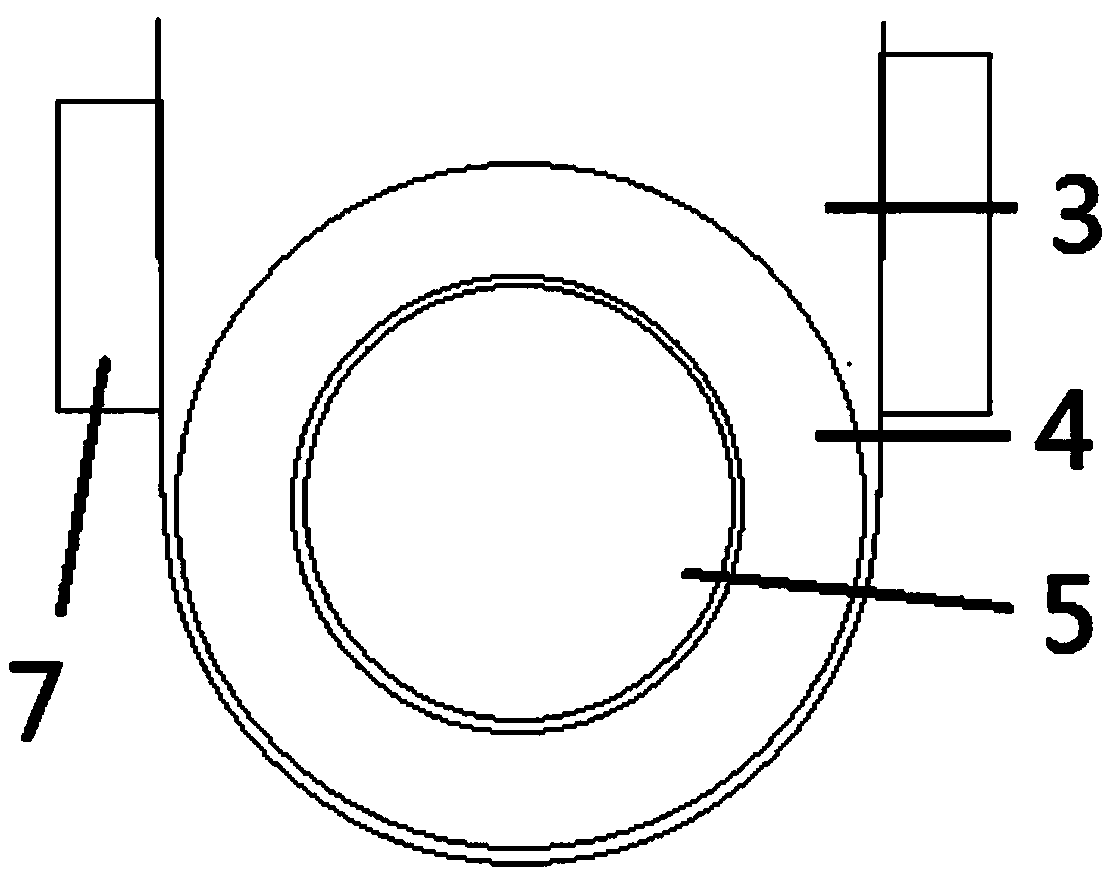

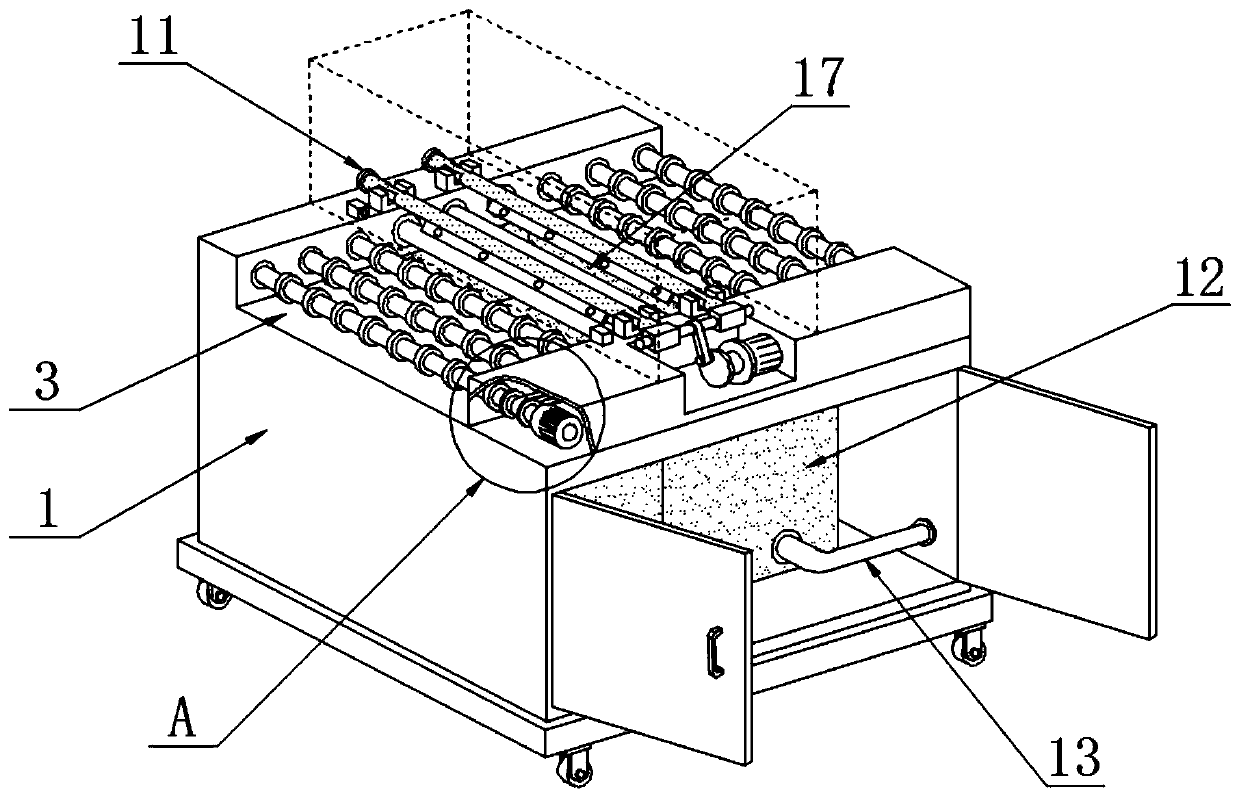

Scraps exhausting belt conveyer system

InactiveCN1383907AImprove chip removal efficiencyConveyorsMetal working apparatusEngineeringConveyor belt

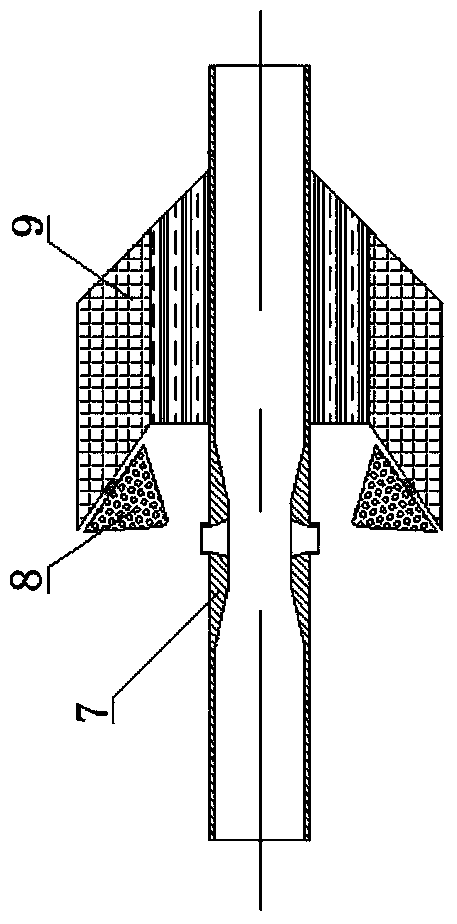

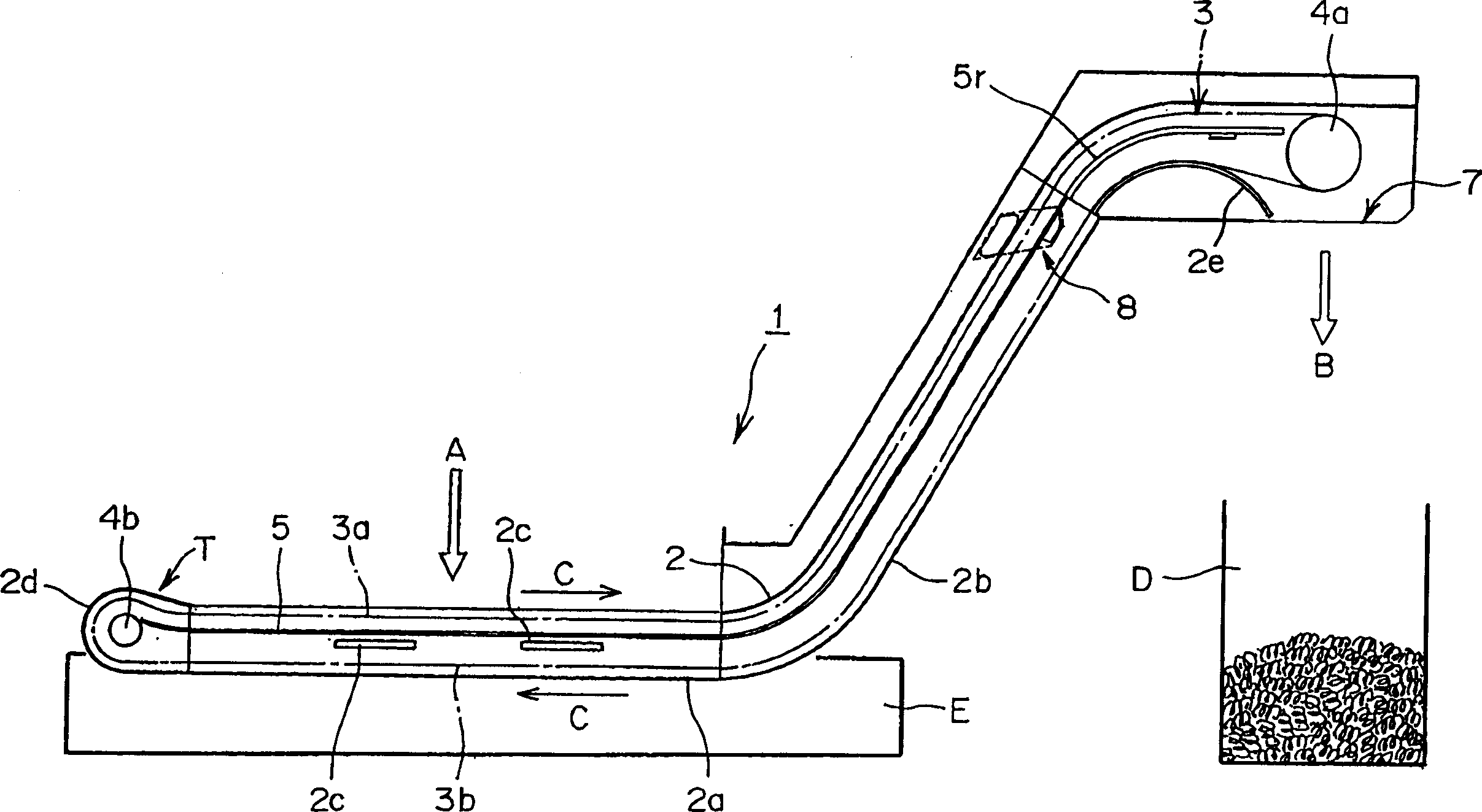

A chip discharge conveyor system includes a partition plate (5) disposed below a discharge run (3a) of a circulating endless hinged belt in confronted relation to the discharge belt run along the length thereof. Outer cleats (37) are attached to an outer circumferential surface of the hinged belt, and inner cleats (38) are attached to an inner circumferential surface of the hinged belt. At a conveyor tail end (T) where the hinged belt makes an upward turn, small chips (K2), which have been caught on a return run (3b) of the hinged belt, are transferred to the partition plate (5) while they are held by and between a cylindrical member (6) and the hinged belt. The small chips are subsequently conveyed along the partition plate (5) and finally discharged outside a used coolant treatment tank. <IMAGE>

Owner:美芙兰国际公司

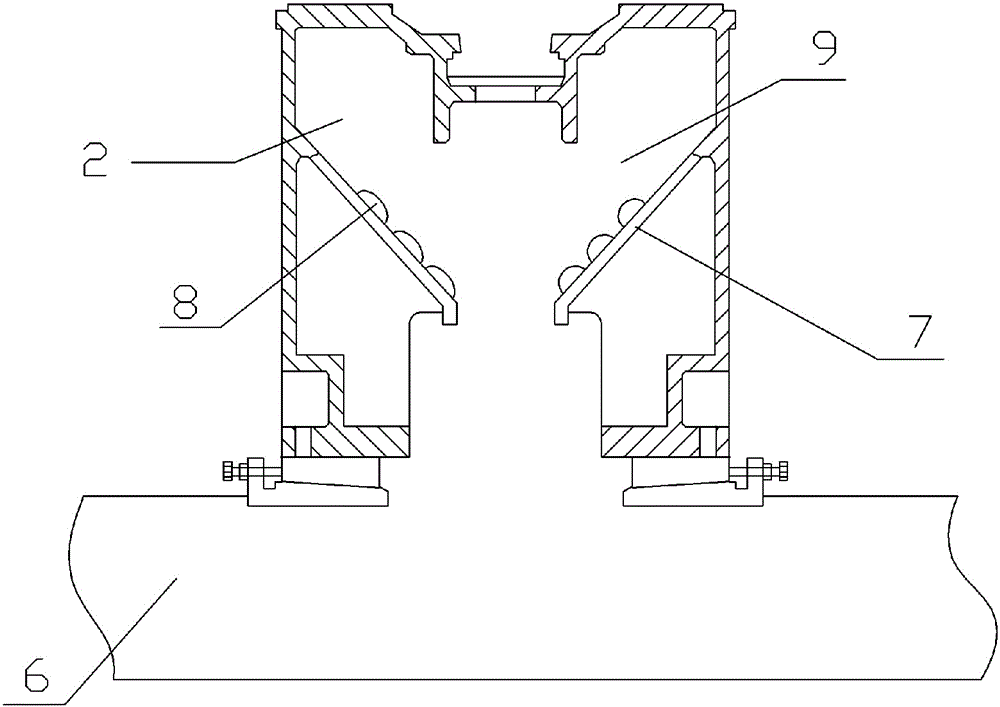

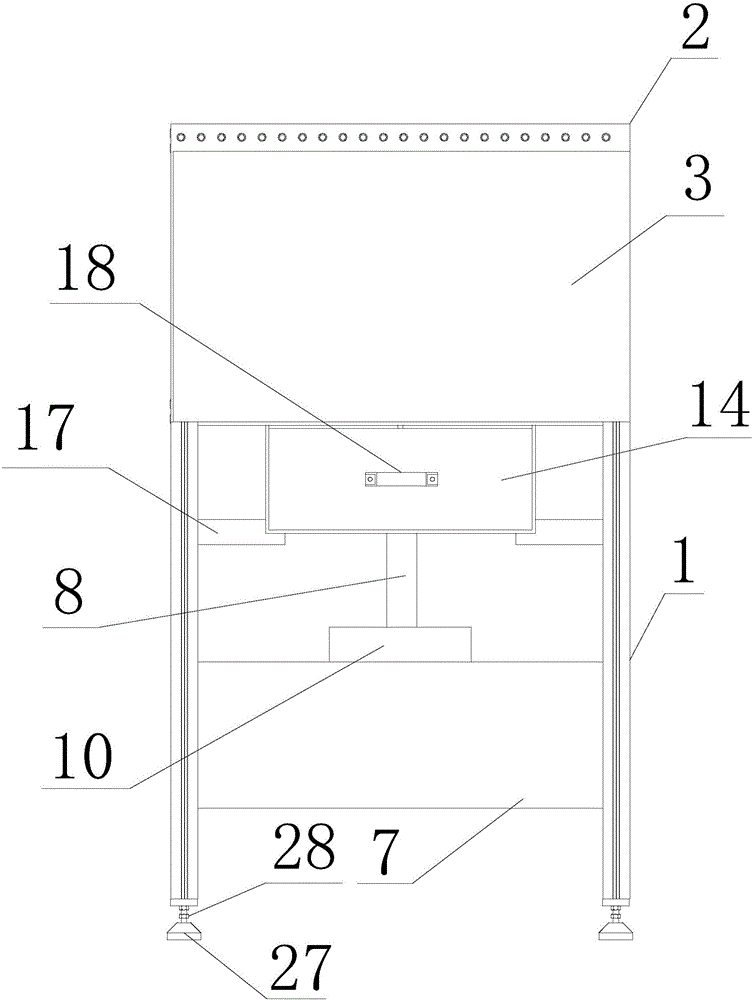

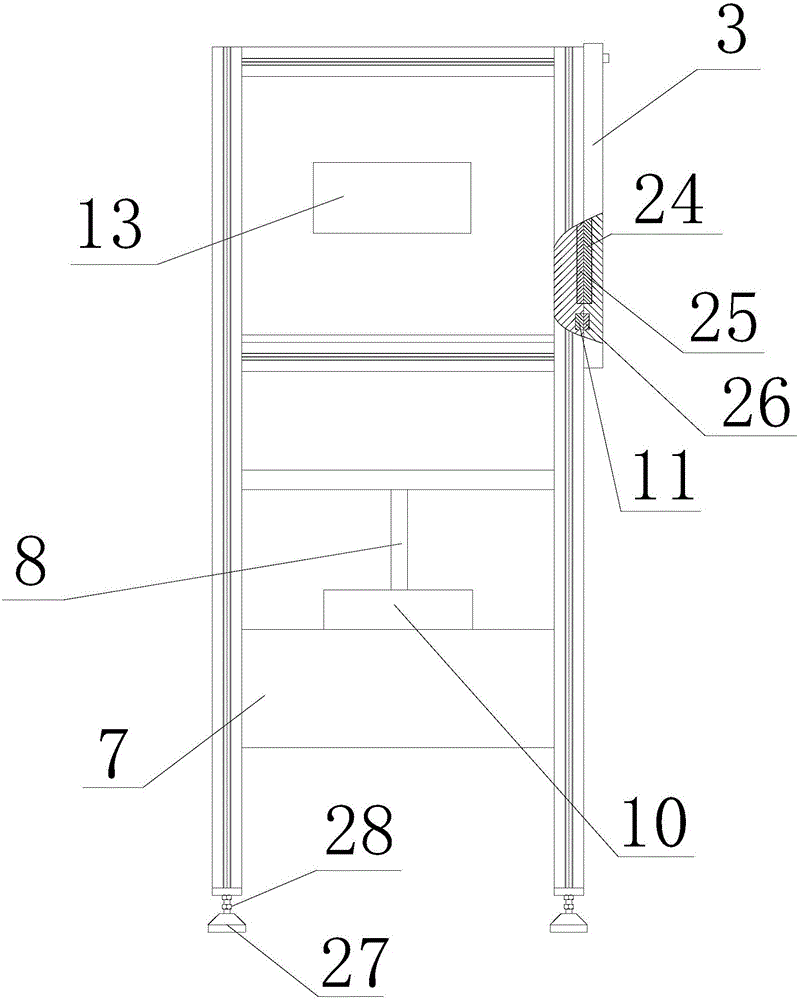

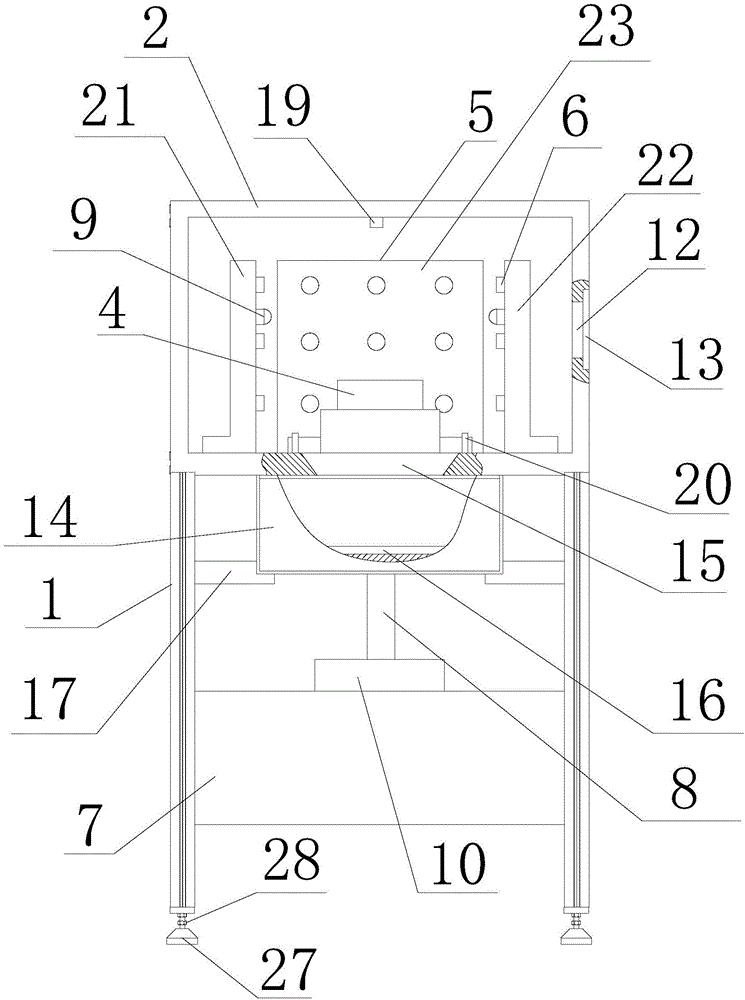

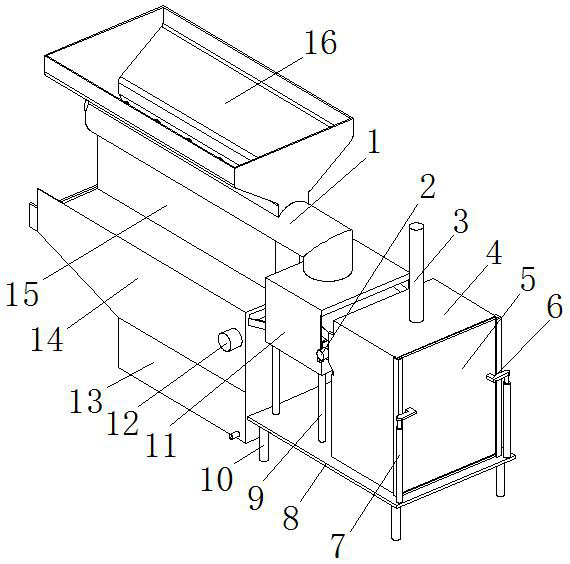

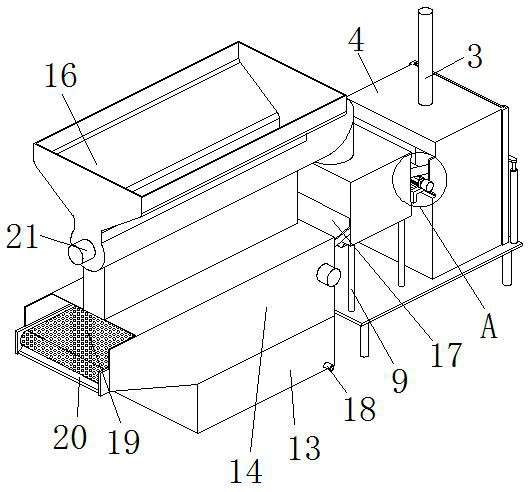

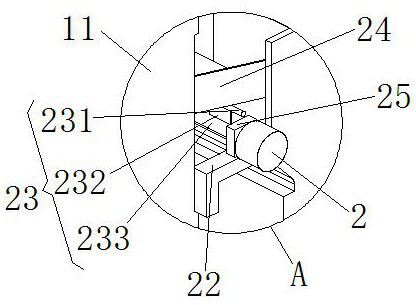

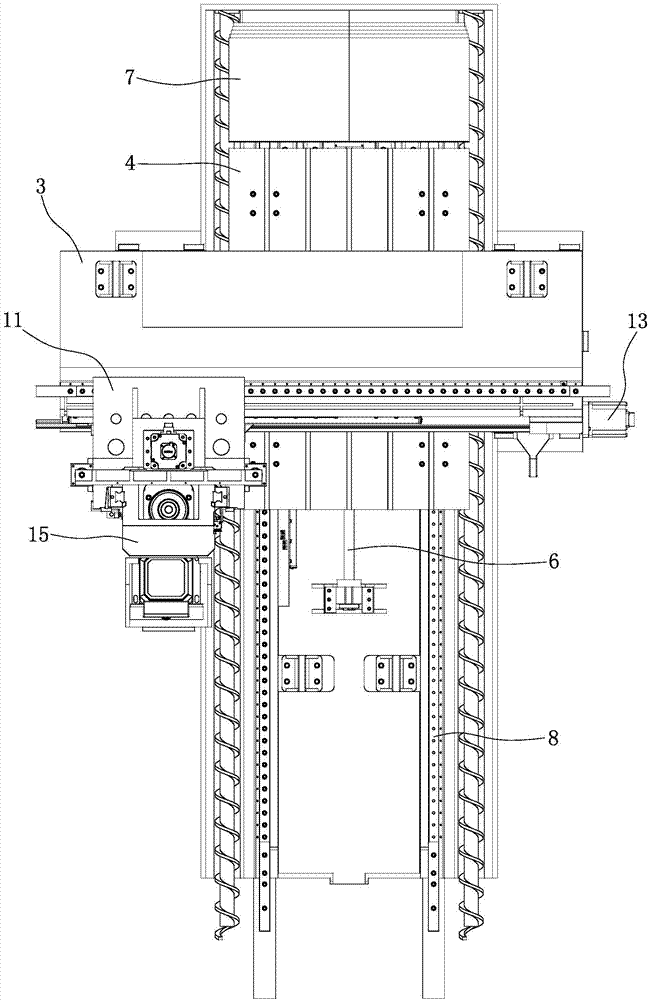

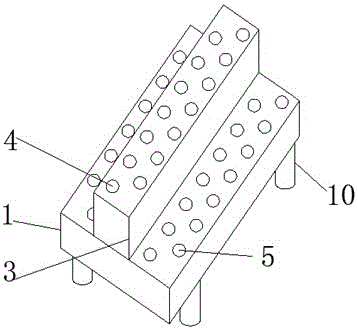

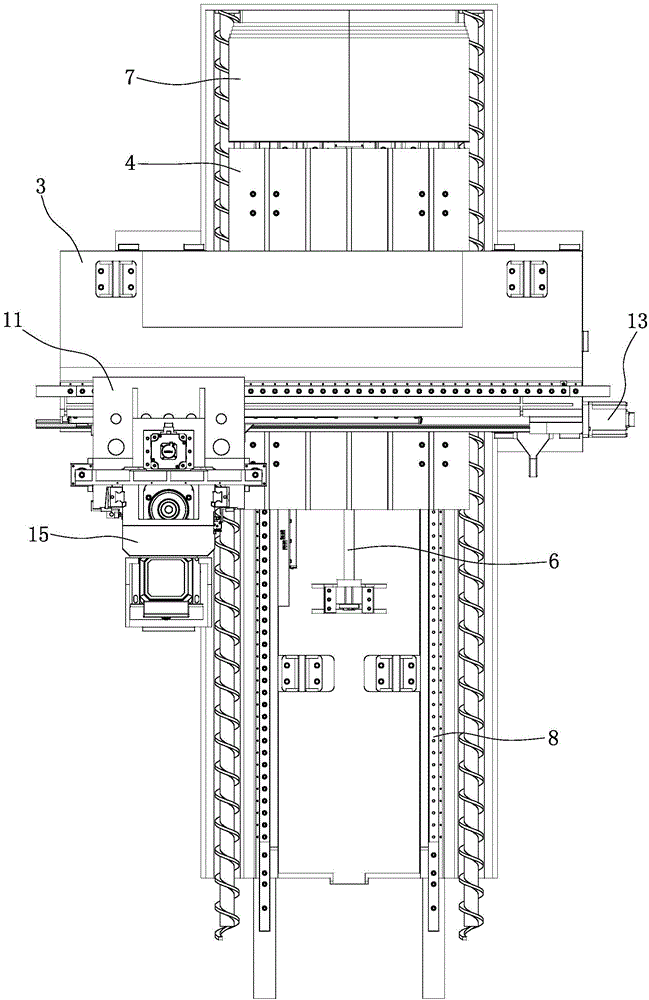

Gantry fragment discharging mechanism

ActiveCN103991003AImprove stability and reliabilityImprove chip removal efficiencyMaintainance and safety accessoriesEngineeringUltimate tensile strength

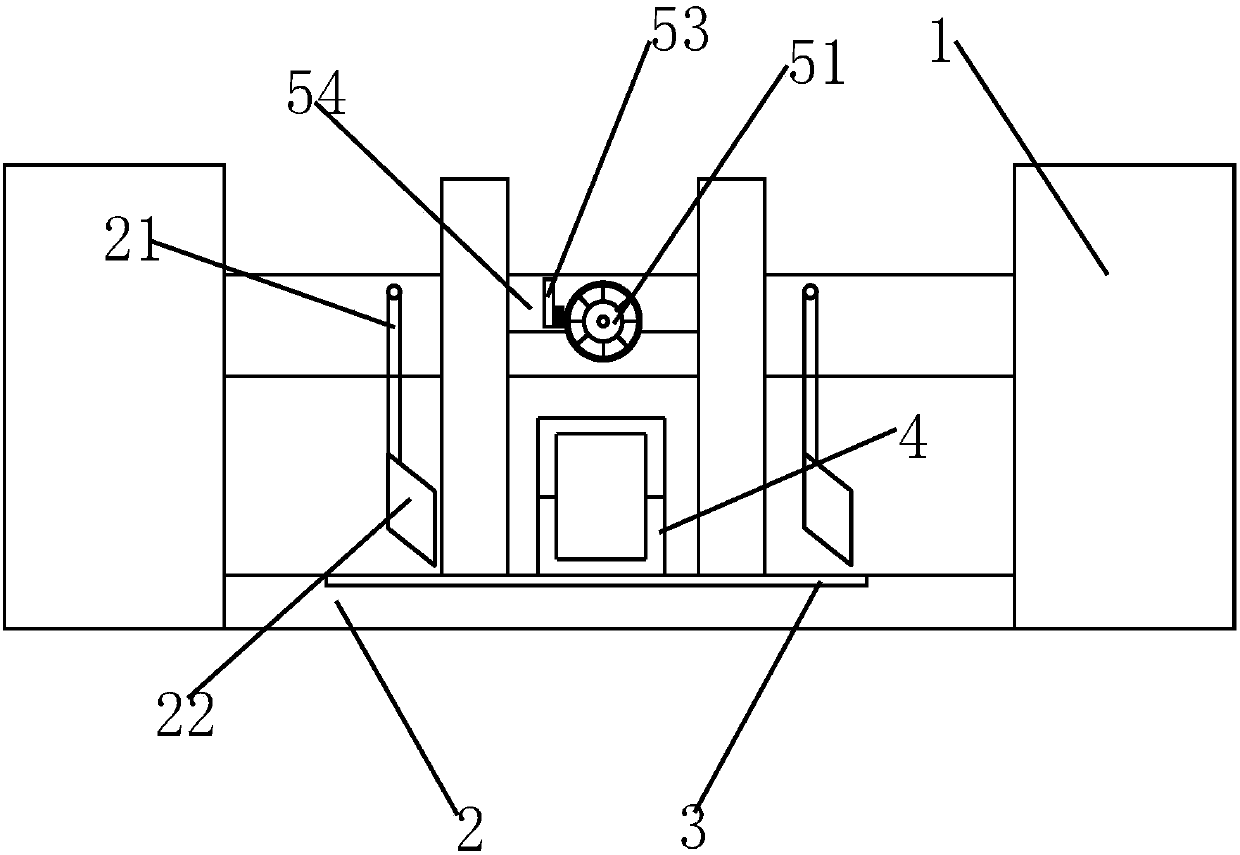

The invention discloses a gantry fragment discharging mechanism. The purpose is to provide the gantry fragment discharging mechanism which can automatically discharge fragments and is obvious in fragment discharging effect. The gantry fragment discharging mechanism is installed on a gantry milling machine body and comprises fragment discharging grooves and a fragment discharging device, wherein the number of the fragment discharging grooves is two. The two fragment discharging grooves are formed in the two sides of the gantry milling machine body respectively. The fragment discharging device comprises motors and fragment discharging rods, wherein the motors are installed on the gantry milling machine body, and the fragment discharging rods are installed in the fragment discharging grooves. The fragment discharging rods are spiral. One end of each fragment discharging rod is connected with the corresponding motor. The gantry fragment discharging mechanism has the advantages that through the design of the spiral fragment discharging rods, the fragments are automatically discharged; through the design of a positioning rod, the efficiency of automatically discharging the fragments is improved, and stability and reliability of the fragment discharging mechanism are improved; through the design of vibration exciters, the efficiency of discharging the fragments is greatly improved in the fragment discharging grooves, the structure is simple, operation is convenient, labor intensity of operators is effectively relieved, and working efficiency of a gantry milling machine is effectively improved.

Owner:宁波川田精密机械有限公司

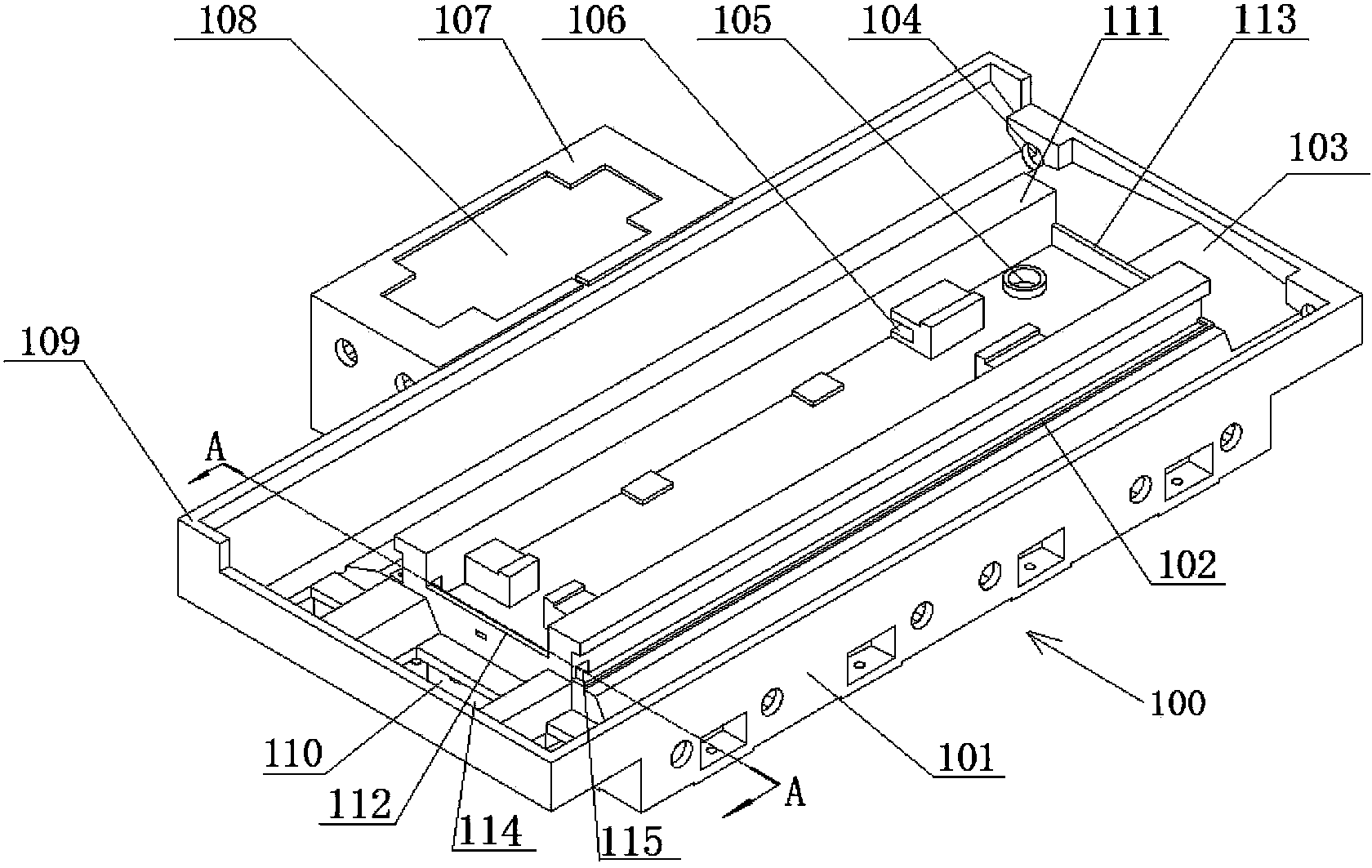

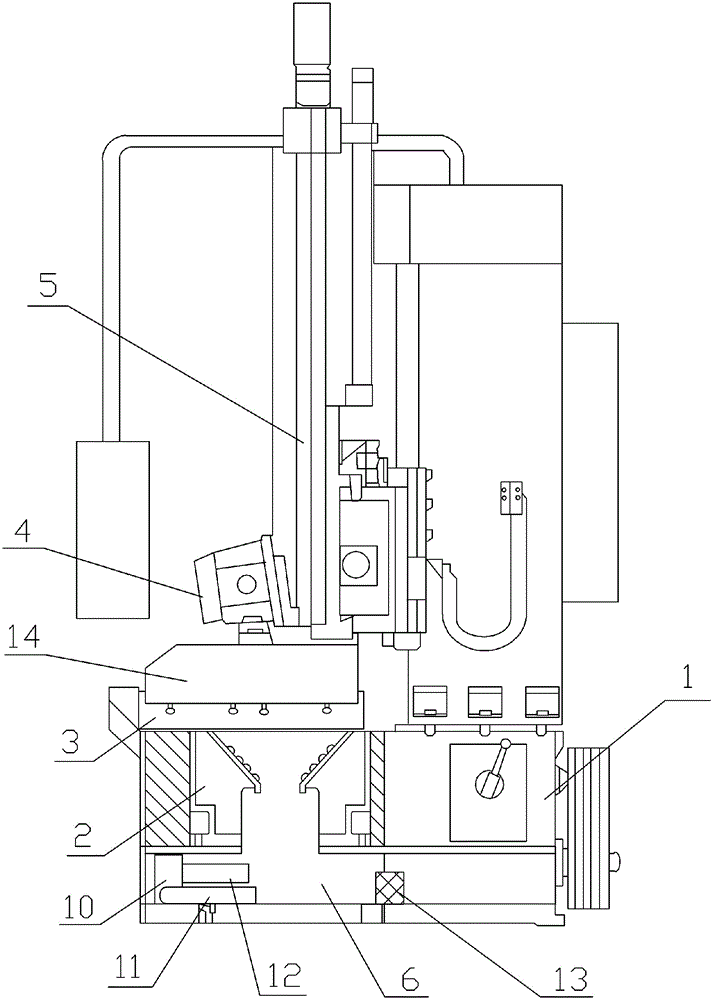

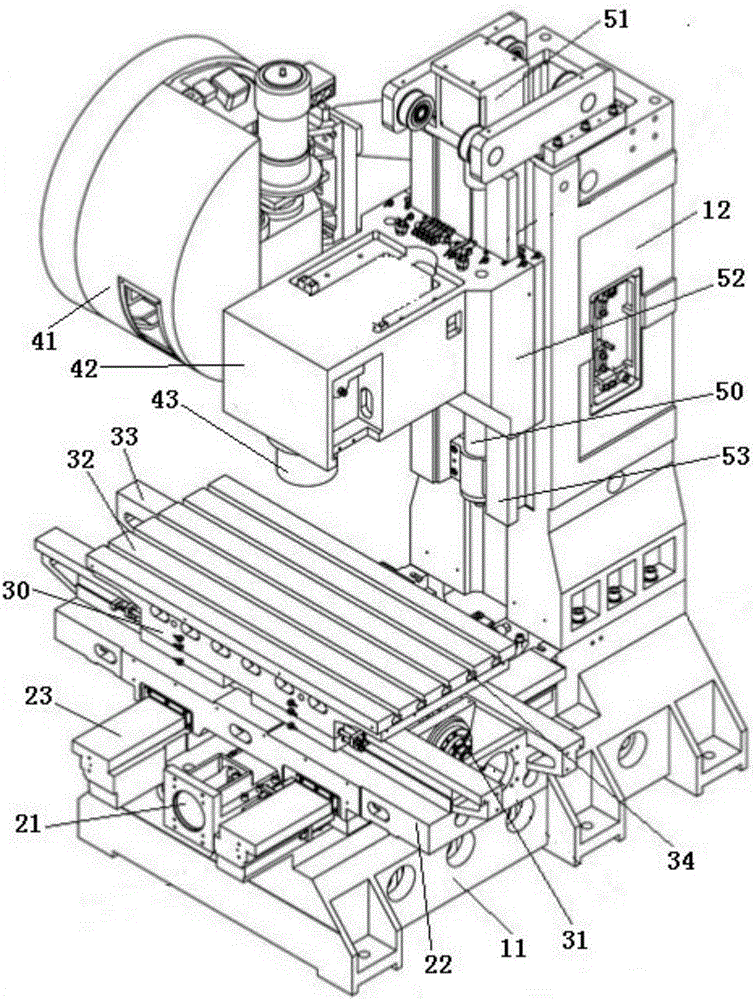

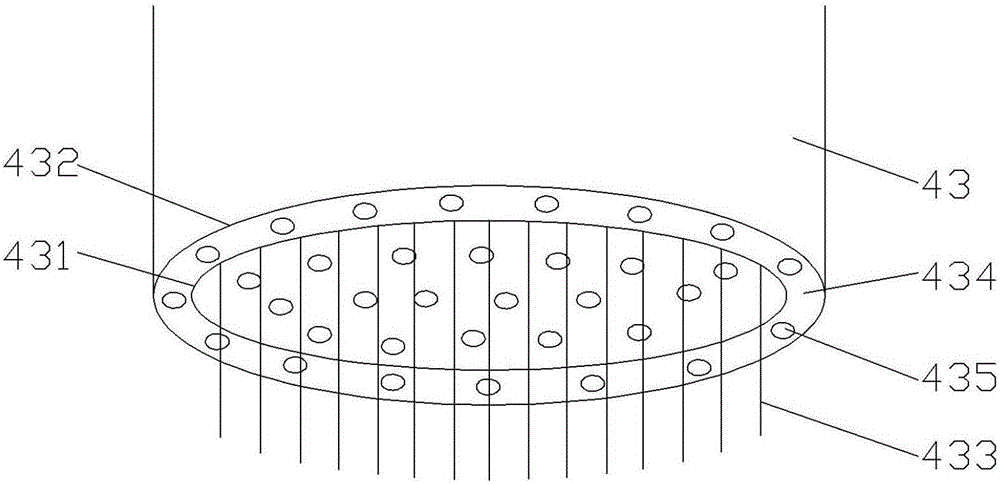

Optical-mechanical structure for vertical machining center

InactiveCN103447888ARunning without jitterGuaranteed uptimeOther manufacturing equipments/toolsLarge fixed membersEngineeringMachining

The invention discloses an optical-mechanical structure for a vertical machining center. The optical-mechanical structure comprises a lathe bed, a standing column, a carriage, a workbench, a spindle box, a pulley, an X-axis transmission mechanism, a Y-axis transmission mechanism, a Z-axis transmission mechanism and a counterweight balance device. The standing column and the carriage are fixed on the lathe bed. The Z-axis transmission mechanism is mounted on the standing column. The spindle box is slidably disposed on the standing column and in drive connection with the Z-axis transmission mechanism. The pulley is fixed at the top of the standing column. The counterweight balance device is disposed on the standing column and connected with the spindle box through steel wire rope winding on the pulley. The X-axis transmission mechanism is mounted on the lathe bed. The carriage is slidably disposed on a slide rail of the lathe bed and in drive connection with the X-axis transmission mechanism. The Y-axis transmission mechanism is mounted on the carriage. The workbench is slidably disposed on a slide rail of the carriage and in drive connection with the Y-axis transmission mechanism. The Y-axis transmission mechanism is above the X-axis transmission mechanism. The optical-mechanical structure is shake-free and stable in operation, and accordingly machining precision is increased.

Owner:SHANGHAI BINSHENG ELECTRONICS MACHINERY

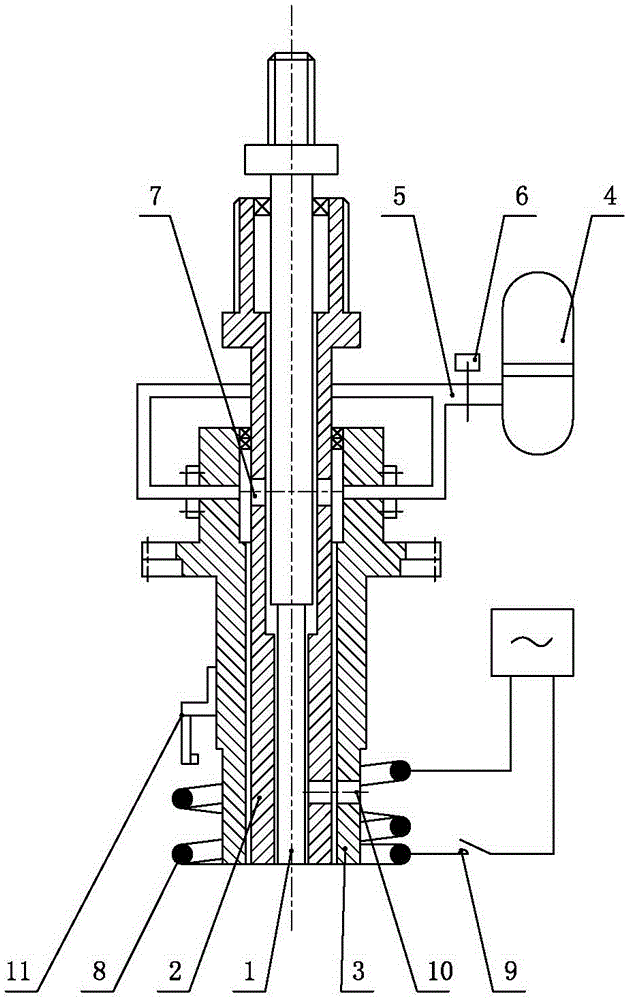

Accumulated chipping removing device of stir friction spot welding apparatus

InactiveCN105108316AConducive to dischargeImprove chip removal efficiencyNon-electric welding apparatusMagnet coilSpot welding

The invention discloses an accumulated chipping removing device of a stir friction spot welding apparatus. The accumulated chipping removing device comprises an upper computer, an electromagnetic coil and a high pressure gas source, wherein the high pressure gas source is communicated with an inner cavity of a jacket of a stirring head by a high pressure pipe; a gas inlet is formed in a sleeve of the stirring head; the gas inlet penetrates through the side wall of the sleeve and is corresponding to a gas outlet of the high pressure pipe; the high pressure pipe is connected with an electropneumatic valve; the electropneumatic valve is in signal connection with the upper computer; the electromagnetic heating coil encircles the jacket; a power supply circuit of the electromagnetic heating coil is provided with an electromagnetic switch; and the electromagnetic switch is also in signal connection with the upper computer. According to the accumulated chipping removing device of a stir friction spot welding apparatus, accumulated chippings are discharged from beneath the stirring head by virtue of high pressure draft; meanwhile, the electromagnetic heating coil is used for heating the stirring head, the accumulated chippings which are accumulated inside the stirring head are heated to form a fusion state, so that the accumulated chippings are favorably discharged, and the chipping removing work efficiency is improved; and compared with a mode that the accumulated chippings are discharged by a chemical soak solution, the accumulated chipping removing device has the advantages that the efficiency is high and no pollution is caused.

Owner:昆山斯格威电子科技有限公司

Automatic chip removal type vertical machine tool

InactiveCN104924145AConvenient for centralized and thorough recyclingEasy chip removalMaintainance and safety accessoriesGrinding/polishing safety devicesMachining processMachine tool

The invention discloses an automatic chip removal type vertical machine tool which comprises a machine tool body and a chip removal mechanism. The machine tool body is provided with a rotating table base. The rotating table base is provided with a rotating table. The machine tool body is further provided with a machine tool main shaft connected with the rotating table. The chip removal mechanism comprises a material receiving and feeding box arranged at the bottom of the machine tool body, a front inclined panel and a rear inclined panel, wherein the front inclined panel and the rear inclined panel are arranged in the machine tool body. The upper portion of the front inclined panel and the upper portion of the rear inclined panel are connected with the front face and the rear face of the machine tool body respectively. The lower portion of the front inclined panel and the lower portion of the rear inclined panel incline inwards. A waste chip guide and collection space is formed by the front inclined panel and the rear inclined panel in the machine tool body. The space is communicated with the material receiving and feeding box. One end in the material receiving and feeding box is provided with a thruster with a motor and a propulsion plate. The other end in the material receiving and feeding box is provided with a limiting block. The machine tool body is further provided with a protection frame and a vertical protection plate. The protection frame is fixedly connected to the rotating table base of the machine tool body. The automatic chip removal type vertical machine tool aims to solve the problems that in the machining process of an existing vertical machine tool, it is difficult to remove chips, the chip removal efficiency is low, and waste chips cannot be discharged thoroughly.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

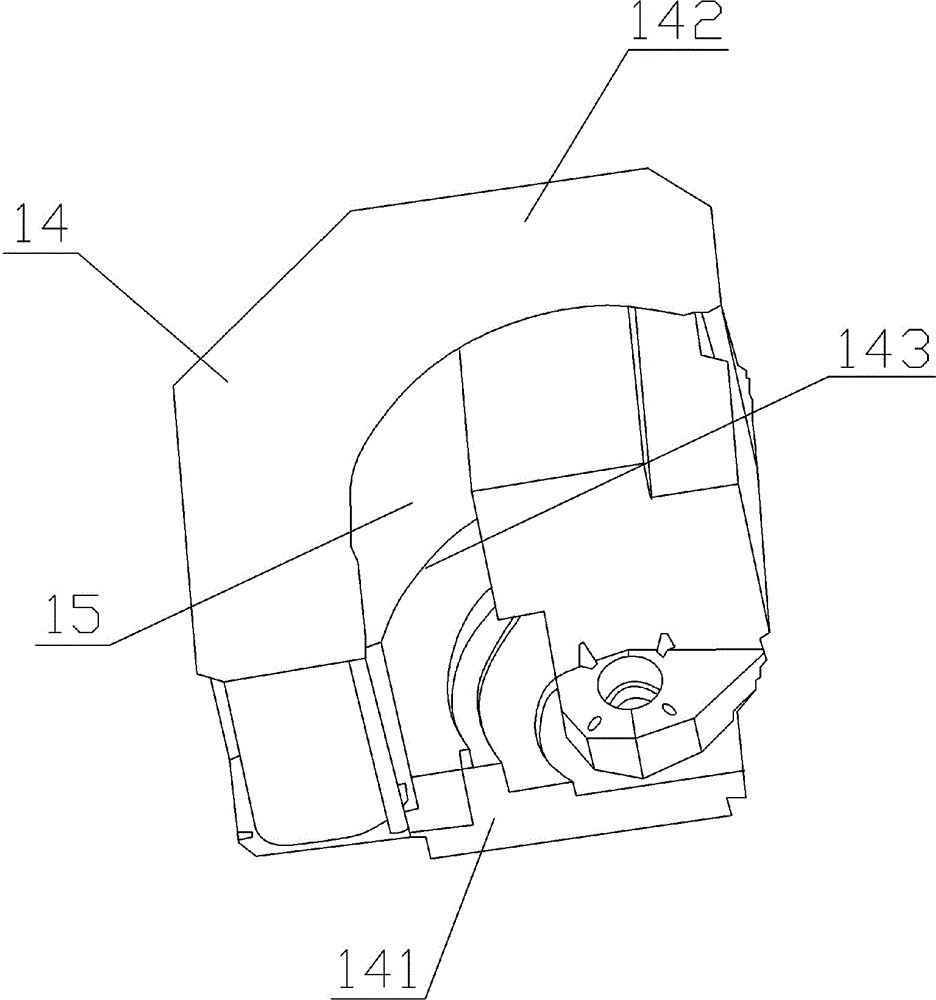

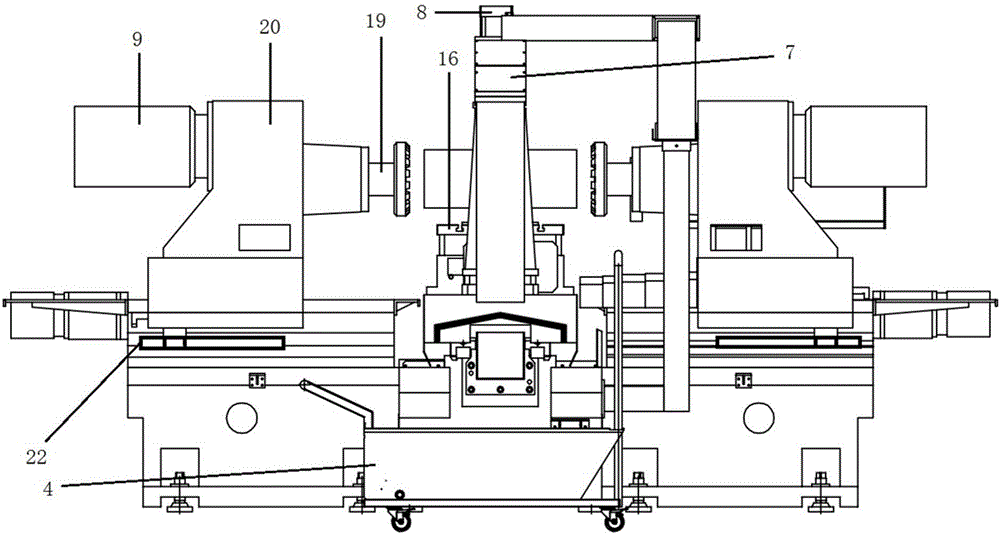

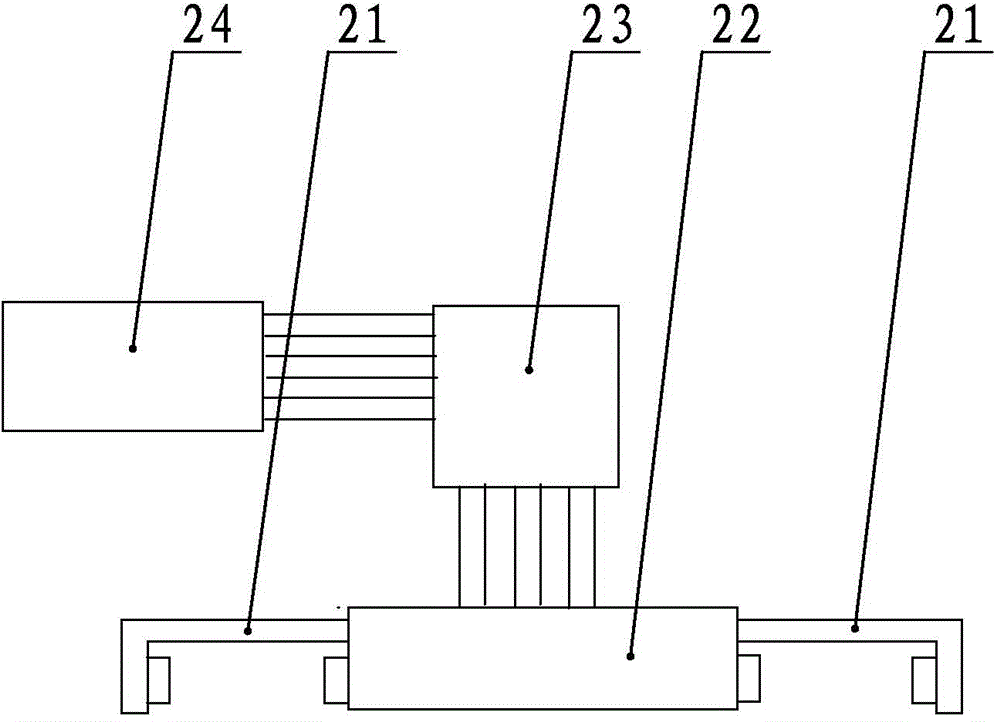

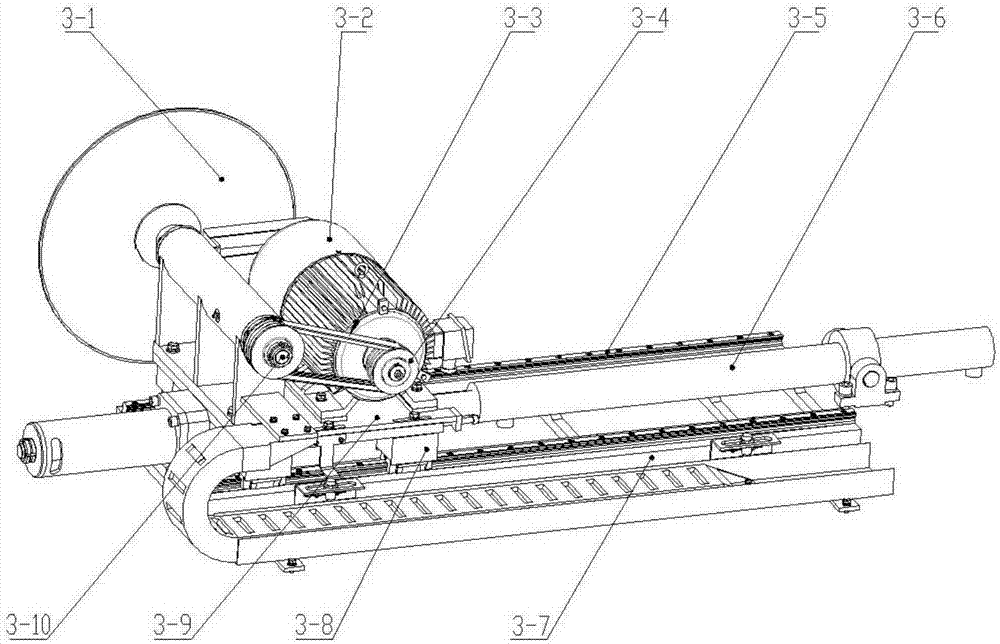

Duplex head milling machine

PendingCN106256468AImprove processing efficiencyRealize full processingMeasurement/indication equipmentsMilling machinesAgricultural engineeringEngineering

The invention discloses a duplex head milling machine. The duplex head milling machine comprises a base, a pedestal, a workbench, a crossbeam, stand columns, two milling heads and two transmission mechanisms. The pedestal is arranged in the center of the base and is slidingly connected to the base. The workbench is installed on the pedestal. The crossbeam is arranged above the pedestal and is installed on the pedestal through the stand columns. The transmission mechanisms are arranged on the base and are slidingly connected to the base. The two transmission mechanisms are respectively and symmetrically arranged at left and right sides of the pedestal. The milling heads are installed on the transmission mechanisms. The duplex head milling machine can automatically rotate a workpiece and realize double surface processing through the two milling heads, has a simple structure, is convenient for operation, effectively reduces operation personnel labor intensity, improves planer-type milling machine work efficiency, is conducive to later maintenance, has a long service life, has high safety, has a high workpiece processing precision and can realize automatic chip removal and waste chip recovery.

Owner:宁波川田精密机械有限公司

Chip blowing device for three-pin shaft fork

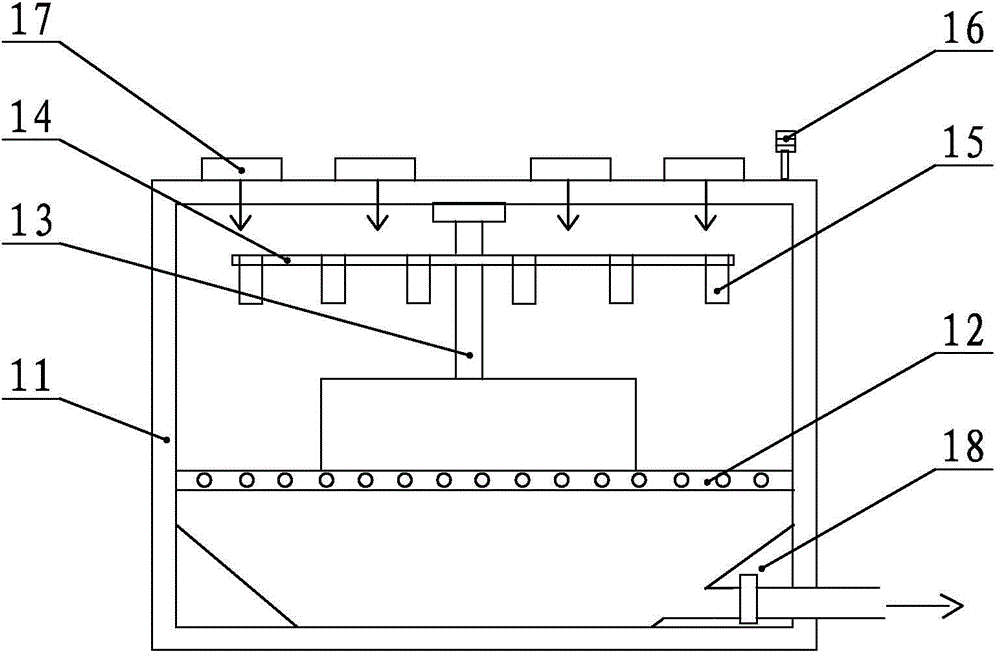

InactiveCN106076972AImprove chip removal efficiencyImprove securityDirt cleaningCleaning using gasesEngineeringGas supply

The invention relates to a chip blowing device for a three-pin shaft fork, and solves the defects of low chip removing efficiency and easiness in generation of accidents when removing chips on the three-pin shaft fork in the prior art. The chip blowing device for the three-pin shaft fork is provided with a box body on a frame; a fixed base is arranged in the box body; a support plate is arranged in the box body; a gas nozzle is arranged on the support plate; a gas supply device supplies compressed gas into the gas nozzle; and the compressed gas is blown to the three-pin shaft fork by the gas nozzle to realize the function of blowing away the chips on the three-pin shaft fork. Compared with the prior art, the chip blowing device for the three-pin shaft fork improves the chip removing efficiency of the three-pin shaft fork, needs no manual operation of technicians when removing the chips on the three-pin shaft fork, and improves the safety.

Owner:ZHEJIANG TELFORD PRECISION DRIVE MFG CO LTD

Oscillation dusting machine

InactiveCN105013768AMeet cleanlinessImprove chip removal efficiencyCleaning processes and apparatusInterior spaceEngineering

The invention discloses an oscillation dusting machine. The oscillation dusting machine comprises a rack. A dust falling plate is horizontally arranged in the rack to divide the interior space into an upper part and a lower part. A rotary table is horizontally arranged in the space on the upper side of the dust falling plate through a rotating shaft, and the rotary table is at least provided with a circle of vibration devices in the radial direction and indicator lamps communicated with the vibration devices. A blowing draught fan corresponding to the rotary table is arranged on the upper side of the rotary table, and a suction draught fan is arranged on the lower side of the dust falling plate. Cut tidy cloth piles are clamped in cloth pile clamps and are subjected to alternative reciprocating vibration in longitudinal and transverse directions, and cloth clippings on the cloth piles are shaken off. Air with the clippings is pumped out of the oscillation dusting machine through the blowing draught fan on the top of the machine and the suction draught fan at the bottom of the machine. After an alarm is given after oscillation is finished, dust-free cloth piles are all in the place and can be directly packaged after being taken down, and the clipping removing efficiency can be greatly improved and the labor cost can be greatly reduced on the premise that the cleanliness of dust-free cloth is met and the cloth piles are kept tidy.

Owner:LONGTEK SCI SUZHOU CO LTD

Chip blowing device for stamping die

ActiveCN105214999AImprove chip removal efficiencyPut an end to harmCleaning using gasesEngineeringControl switch

The invention discloses a chip blowing device for a stamping die. The stamping die comprises a lower die body, a mandrel arranged on the lower die body, an upper die body which can rise and fall, and the chip blowing device. The chip blowing device comprises a mandrel base, a horizontal installation frame, a vertical installation frame, an upper air pipe installation base and a lower air pipe installation base. The mandrel base is arranged on the side, away from the workpiece inlet end, of the mandrel and connected with the end, away from the workpiece inlet end, of the mandrel through a connecting arm. One end of the horizontal installation frame is fixed to the mandrel base. The vertical installation frame is installed on the horizontal installation frame. An upper high-pressure air blowing pipe is arranged on the upper air pipe installation base, and lower high-pressure air blowing pipes facing the stamping surface of the lower die body are arranged on the lower air pipe installation base. The upper high-pressure air blowing pipe and the lower high-pressure air blowing pipes are connected with a high-pressure air source through one-way control switches respectively. The one-way control switches are connected with a first travel switch arranged on the upper die body and a second travel switch arranged on one side of the workpiece inlet end of the mandrel. By the adoption of the chip blowing device, full-automatic chip removal of the stamping surface of the upper die body and the stamping surface of the lower die body is achieved.

Owner:上海金众汽车配件有限公司

Automatic chip removal device for machine tool

ActiveCN112453994AAchieve up and down swingEasy to deal withMaintainance and safety accessoriesComputer hardwareElectric machinery

The invention discloses an automatic chip removal device for a machine tool. The device comprises a chip removal pipe, a chip compression box, a bottom plate, a slag-liquid separation box, a liquid storage box, a reciprocating swing mechanism and a conveying frame. A spiral discharging paddle is arranged in the chip removal pipe, a third motor is arranged at the left end of the chip removal pipe,and an output shaft of the third motor penetrates into the chip removal pipe and is connected with the spiral discharging paddle. A chip collecting groove is formed in the chip removal pipe, and the discharging end of the chip removal pipe is connected with the slag-liquid separation box. The conveying frame is arranged below the chip removal pipe, a roller is arranged on the conveying frame, a filtering conveying belt is arranged on the roller, cooling liquid and small-particle chips are separated through the filtering conveying belt, and the small-particle chips are conveyed out. A scrapingplate is arranged at the left end of the conveying frame. The automatic chip removal device for the machine tool is novel in structural design and good in chip removal effect, chip particles can be classified, separated treatment is facilitated, large chips are compressed, space is saved, frequent chip treatment is avoided, and time is saved.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

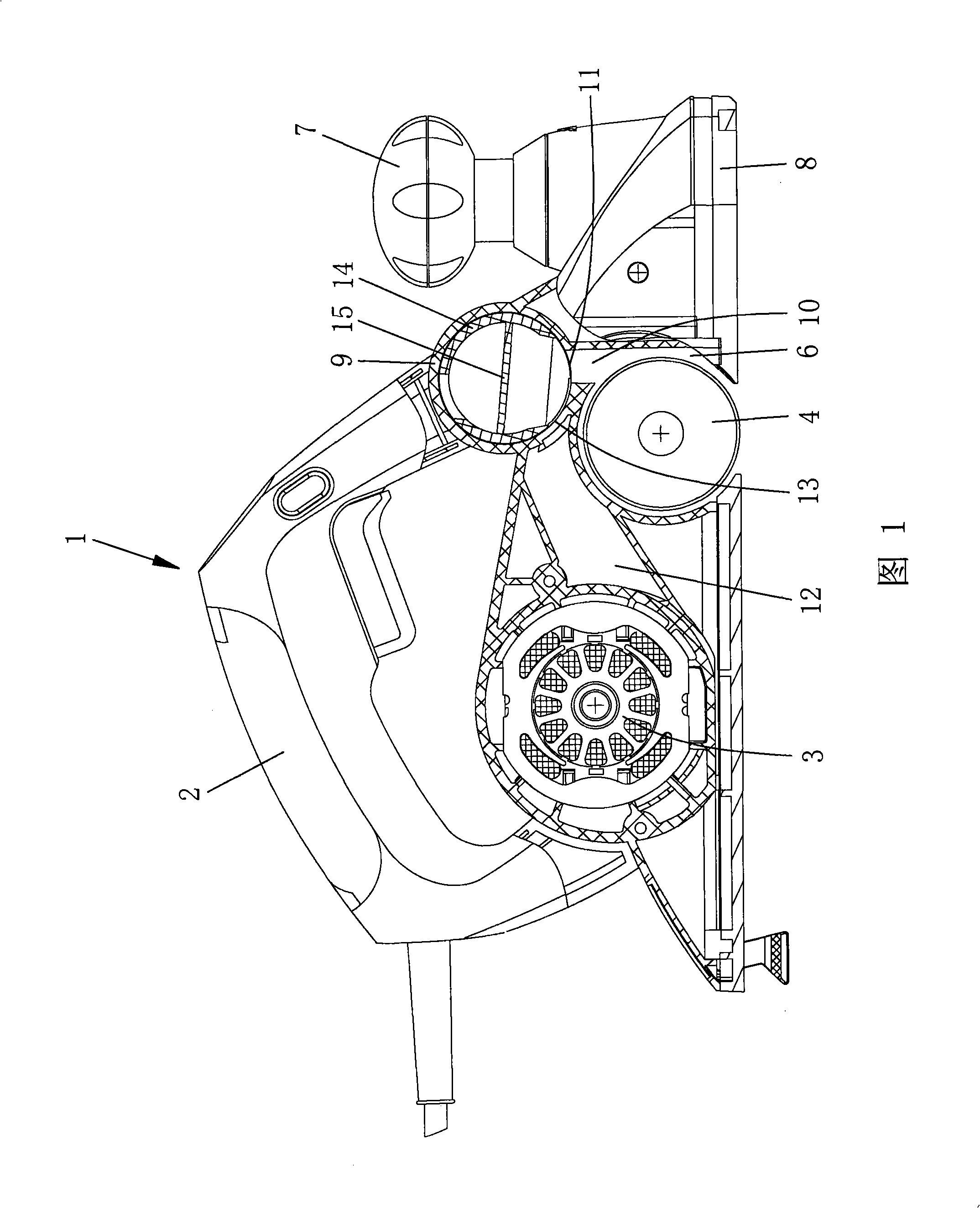

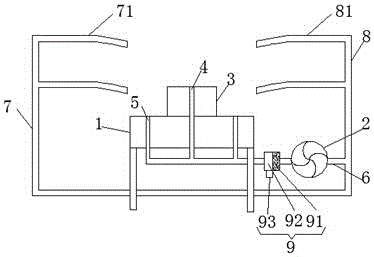

Power tool

InactiveCN101332599ANot easy to block chipsWon't accumulateHand planesPortable planing/slotting machinesPower toolMotive power

The invention discloses a power tool which comprises a shell, a power source arranged in the shell, a fan connected with the power source and a tubular chip removal valve arranged on the shell; a reversing plate is arranged in the chip removal valve, air inlets are arranged on the tube walls of the chip removal valve at the two sides of the reversing plate, the airflow generated by rotation of the fan enters the chip removal valve from the air inlets, a splitter plate is arranged on the reversing plate near the air inlets, the splitter plate divides the airflow entering the chip removal valve into at least two parts, one part of the airflow is used for reversing the chip entering the chip removal valve, and another part of the airflow is used for blowing chip, therefore, the chip does not accumulate in the chip removal valve, chip removal is thorough and chip removal efficiency is high, and the power tool is not easy to be blocked by the chip in the process of operation.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

Automatic cleaning machine

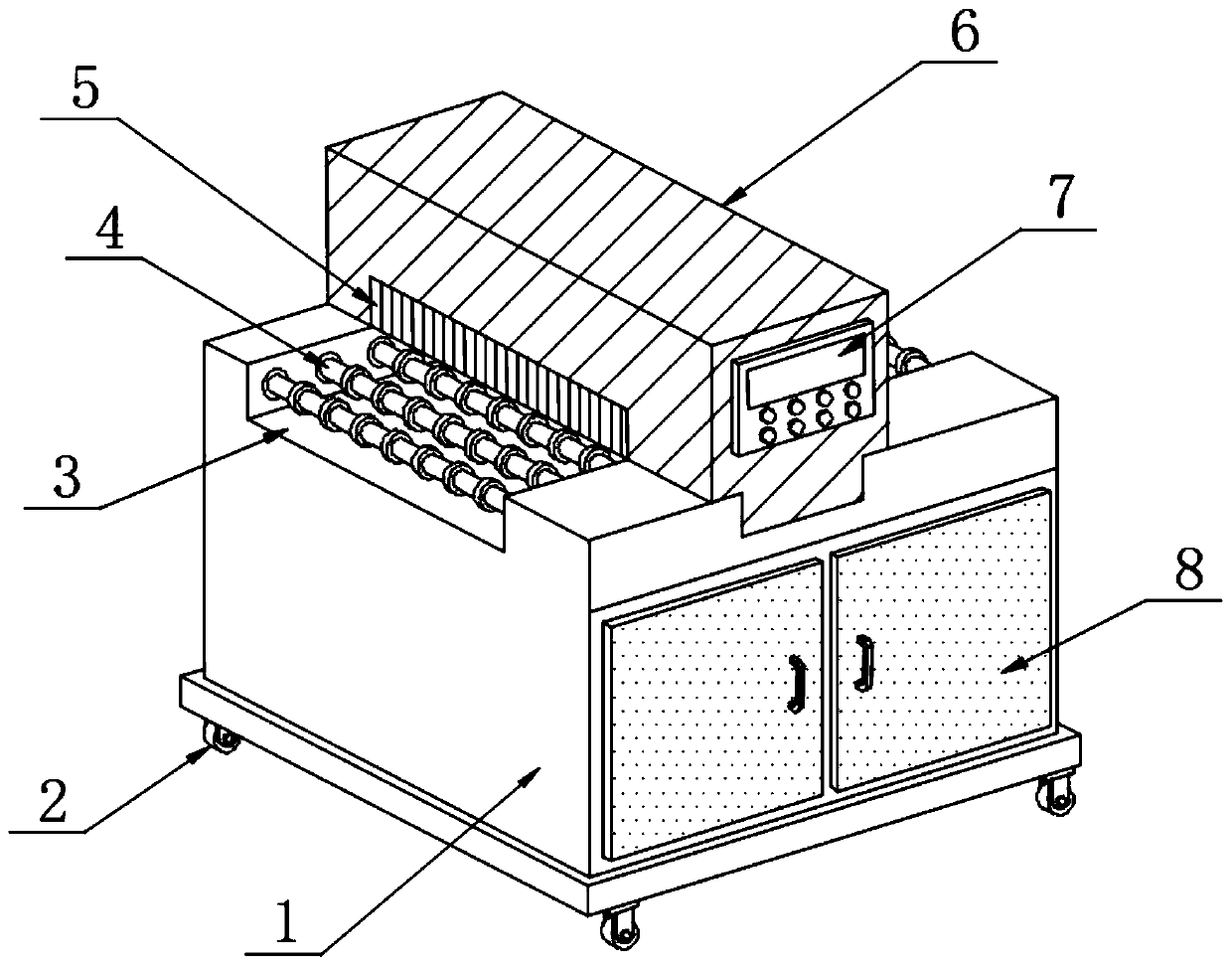

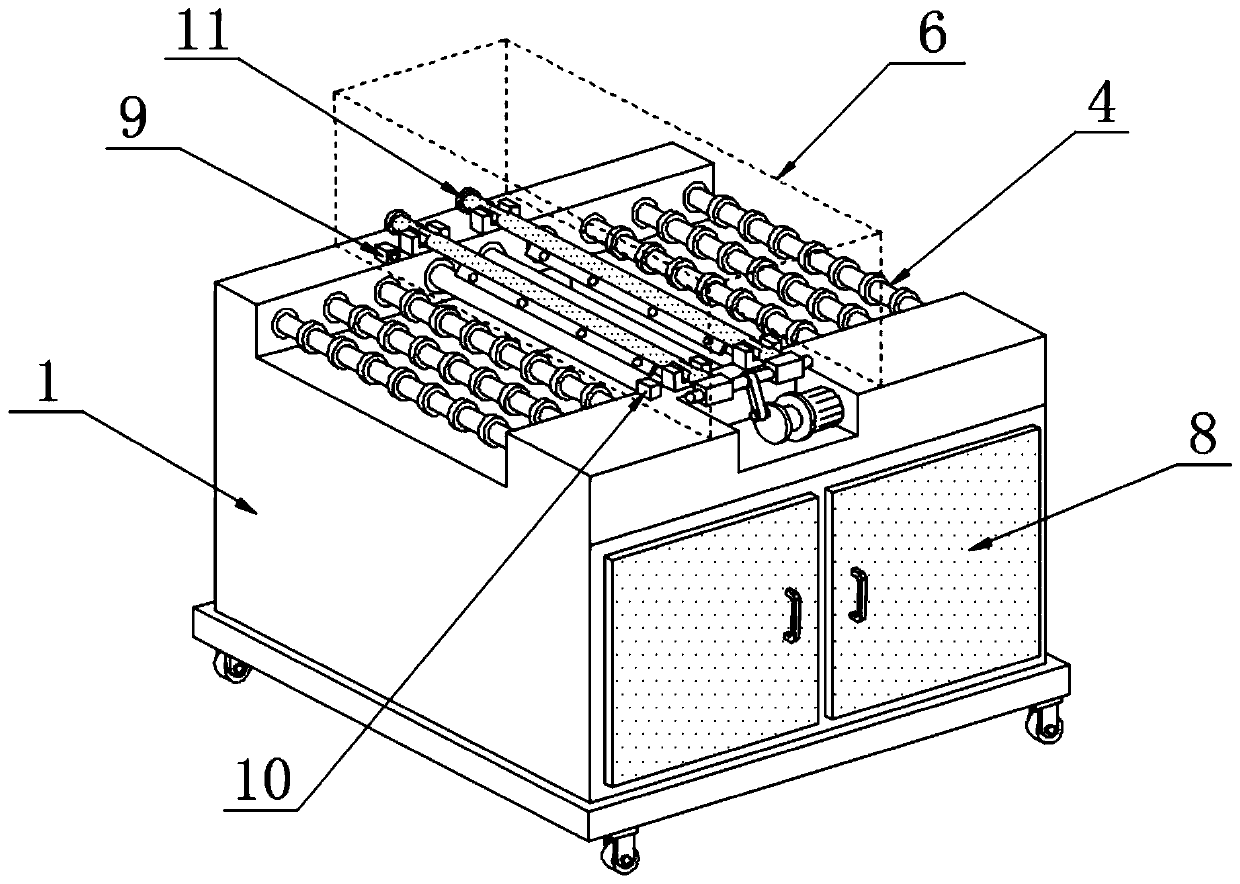

InactiveCN109821818ASave manpower and material resourcesLarge coverage areaDirt cleaningCleaning using gasesDouble rowEngineering

The invention discloses an automatic cleaning machine and relates to the technical field of cleaning machines. The automatic cleaning machine comprises a chassis and moving pulleys arranged at four corners at the lower end of the chassis, wherein an inverted n-shaped conveying groove is formed in the upper end of the chassis; and a conveying roller for conveying material is mounted at the upper end, positioned on the inner side of the conveying groove, of the chassis. The automatic cleaning machine adopts the photoelectricity sensing manner to automatically sense the material and automaticallystart an air blowing structure; in addition, double rows of air-blowing ports can thoroughly blow off sweeps on the material; swing type automatic compressed air injection sweep removal is cooperatedwith the air-blowing ports designed by 60 degrees obliquely, so that the purposes of being large in coverage area, small in compressed air emission and extremely high in sweep removing capacity are realized, and the problem the air blowing dead angle problem is solved; and moreover, a transparent air-blowing mask and a windproof curtain are adopted to prevent the phenomenon that sweeps fly everywhere during the sweep blowing process, and the material sweep removal efficiency is further improved.

Owner:江苏贺鸿电子有限公司

Stepping chip removing device

InactiveCN104627615AThere will be no problem of jammingImprove chip removal efficiencyConveyorsHydraulic cylinderEngineering

The invention provides a stepping chip removing device. The stepping chip removing device comprises a chip removing case, a plurality of barbs, a plurality of chip removing boxes and a hydraulic cylinder, wherein the barbs are arranged on the two sidewalls of the chip removing case, the chip removing boxes are movably arranged in the middle of the chip removing case and connected through connecting shafts, and the hydraulic cylinder is connected with the connecting shaft at the foremost end. A connecting piece is arranged between the hydraulic cylinder and the connecting shaft at the foremost end. An electromagnet is arranged in each chip removing box. The stepping chip removing device has the advantages that when the hydraulic cylinder conducts pushing, the electromagnets are powered on, and scraps can be attracted to the chip removing boxes to the maximum extent and conveyed; when the hydraulic oil retracts, the electromagnets are powered off, the chip removing boxes can hardly take the pushed scraps back when retracting, and the scraps will not get stuck; the stepping chip removing device has the advantages of high chip removing efficiency and high speed.

Owner:TIANJIN MAIKE TECH DEV

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

Chip removal device for fashion model

InactiveCN106583291AReduce frictionAvoid bruisesDirt cleaningCleaning using toolsWaste collectionEngineering

The invention discloses a chip removal device for a fashion model. The chip removal device comprises a frame, a chip removal mechanism and an adjusting mechanism. The frame comprises a base and a vertical stand. The adjusting mechanism comprises an X-axis moving mechanism and a Y-axis moving mechanism. The Y-axis moving mechanism comprises a Y-axis lead screw drive mechanism, a Y-axis sliding block and Y-axis sliding rails. The X-axis moving mechanism comprises an X-axis lead screw drive mechanism, an X-axis sliding block and X-axis sliding rails. A plurality of grooves are formed in the upper surface of the X-axis sliding block. The chip removal mechanism comprises a waste collection tank, a chip removal control box and a chip removal head. The chip removal head comprises an inner cylinder, an outer cylinder and a brush. The front end part of the inner cylinder is connected with that of the outer cylinder through an annular ring. A plurality of air suction holes are formed in each of the inner cylinder and the outer cylinder. An exhaust fan motor is arranged in the chip removal control box. The chip removal device is compact in structure, is convenient to operate, can remove chips of the fashion model automatically and quickly, is high in chip removal quality, and is high in chip removal efficiency.

Owner:浙江福华展示道具有限公司

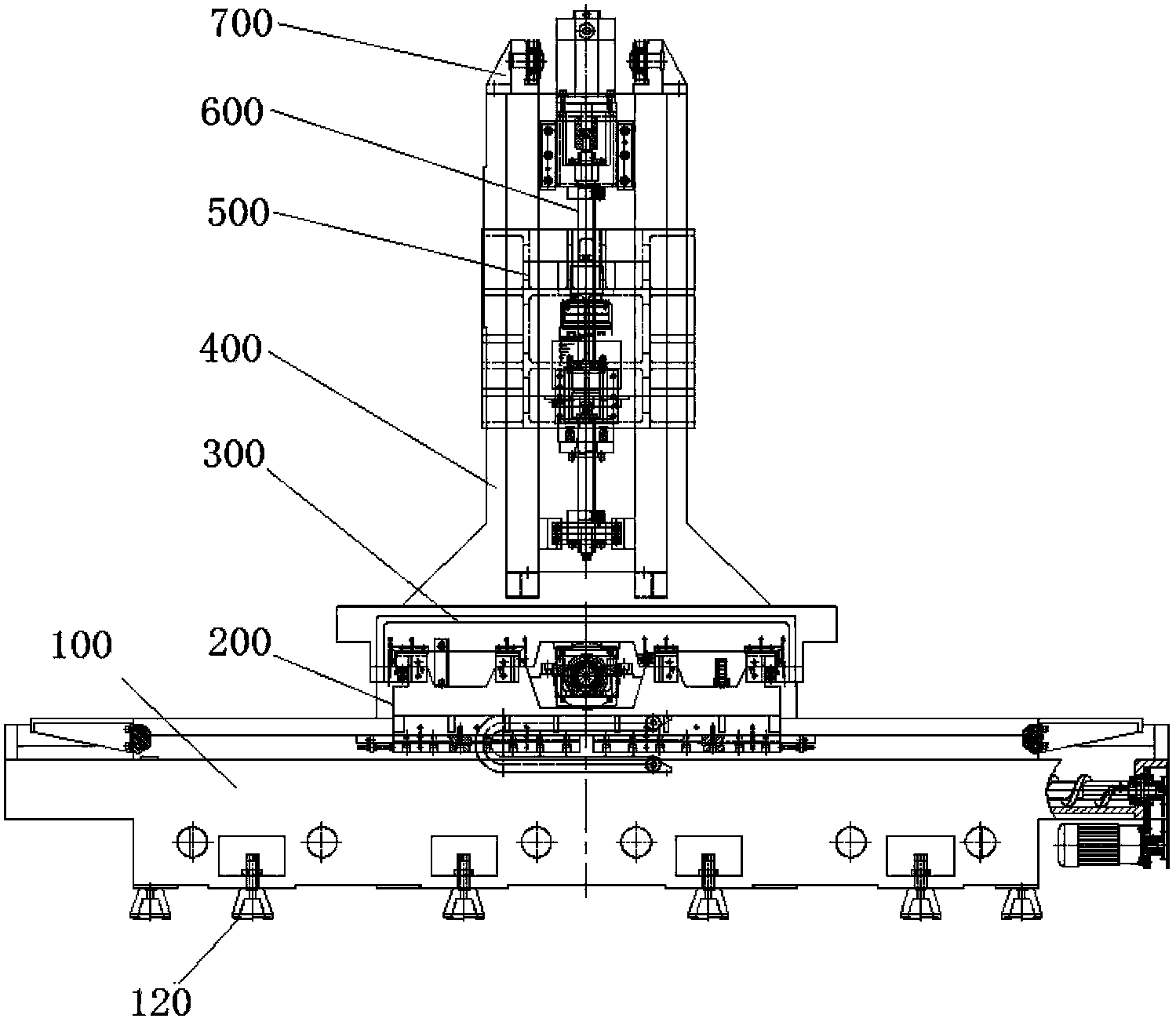

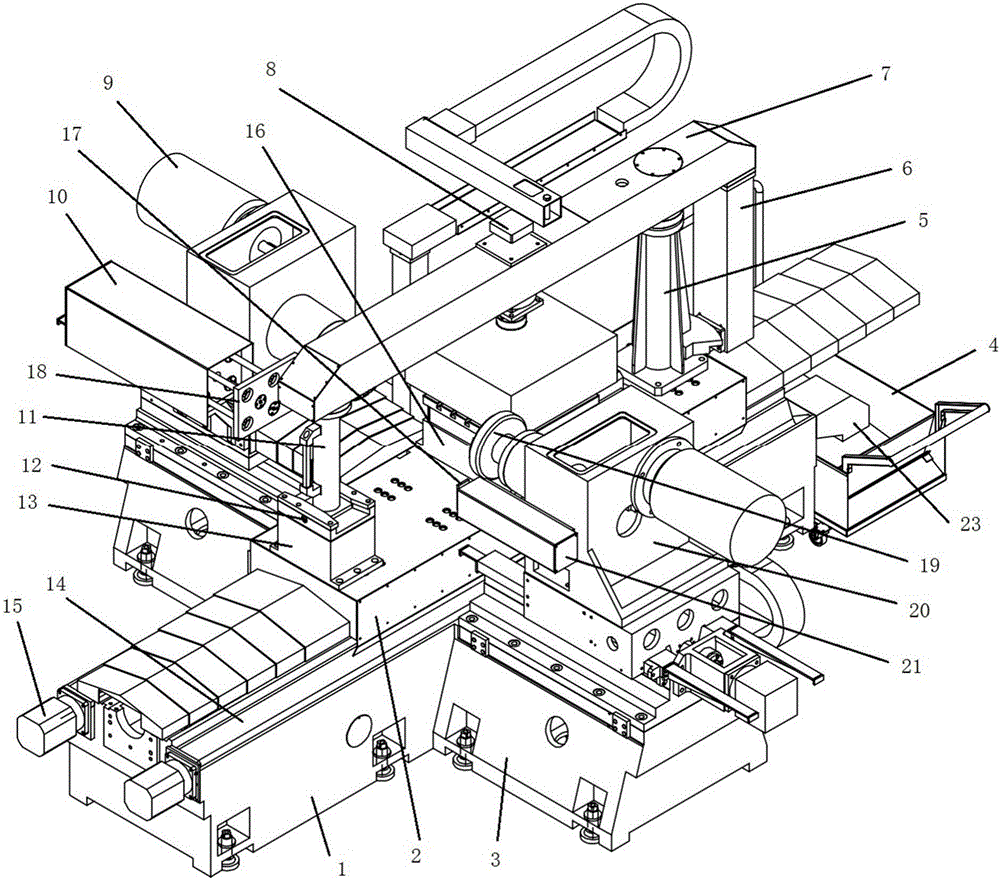

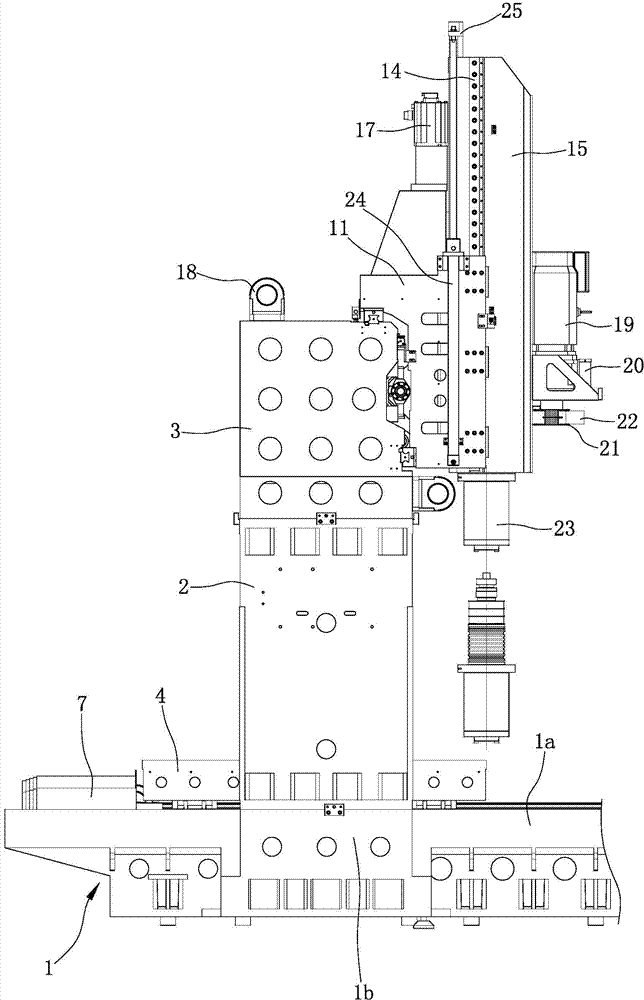

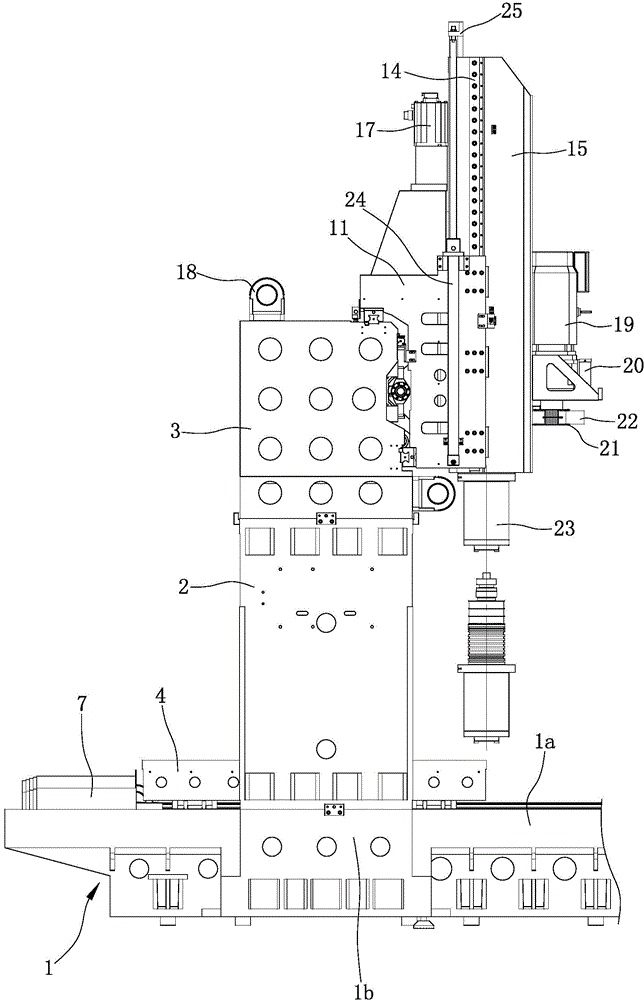

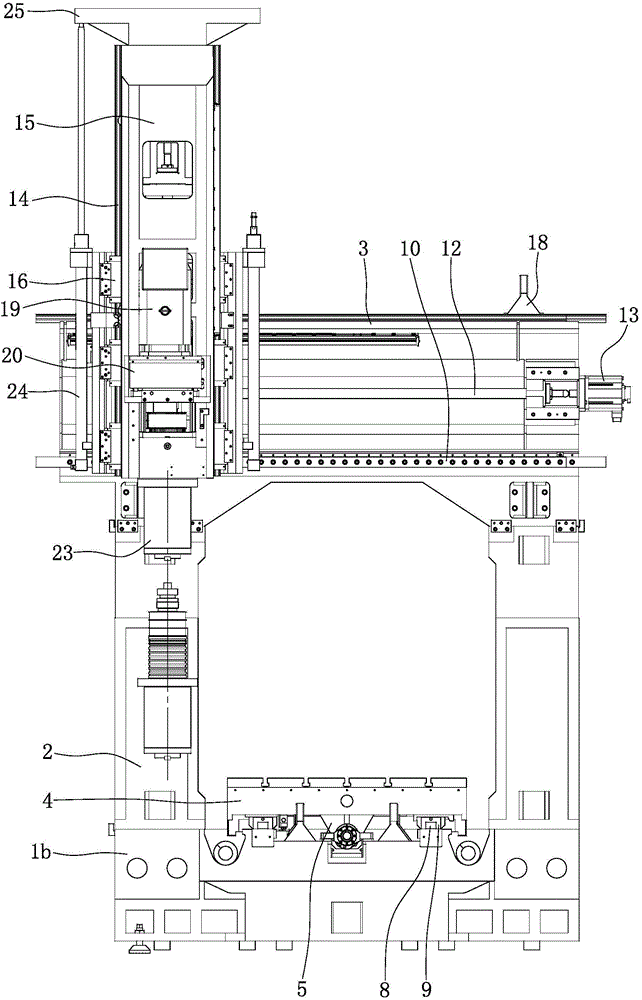

Portal machining center combination for large part machining

InactiveCN104842204AEasy to shapeAuto excludeFeeding apparatusMaintainance and safety accessoriesDrive wheelLow speed

The invention discloses a portal machining center combination for large part machining. A support (1b) is a square frame body. An X-axis nut base (5) at the bottom of a working table (4) is in screw-thread fit with an X-axis lead screw (6). Nitrogen balancing cylinders (24) are symmetrically arranged on the left side and the right side of a Y-axis slide base (11). Cylinder bodies of the nitrogen balancing cylinders (24) are fixed to the Y-axis slide base (11). An output shaft of a main shaft motor (19) is connected with the input end of a gearbox (20). An output shaft of the gearbox (20) is sleeved with a driving wheel (21). The driving wheel (21) is connected with a driven wheel of a main shaft (23) through a belt (22). The movement in each axial direction is achieved through the large-torque motor and a screw-nut pair, complex profiles can be machined, high-speed cutting can be achieved, the low-speed large-torque cutting can be achieved as well, the nitrogen balancing cylinders are used for balancing the gravity of the main shaft box, and the stability of the Z-axis movement is ensured.

Owner:CHONGQING MASITER PRECISION MACHINERY

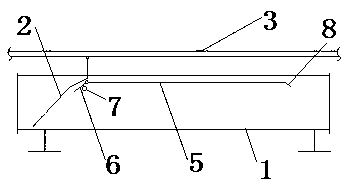

Chip removing guide rail for production equipment

InactiveCN105945588AImprove chip removal efficiencyExtended service lifeLarge fixed membersMaintainance and safety accessoriesSafety coefficientExhaust pipe

The invention discloses a chip removing guide rail for production equipment. The chip removing guide rail comprises a base and an induced draft fan; first chip removing holes are formed in a guide rail body, and second chip removing holes are formed in the two sides of the base; the lower ends of the first chip removing holes and the lower ends of the second chip removing holes communicate with an intake port of the induced draft fan through pipes; a main exhaust pipe of the induced draft fan communicates with a left exhaust pipe and a right exhaust pipe; the left exhaust pipe communicates with left exhaust branch pipes, and the right exhaust pipe communicates with right exhaust branch pipes; upper and lower two sets of left exhaust branch pipes are provided; exhaust ports of the upper and lower two sets of left exhaust branch pipes correspond to the upper ends of the first chip removing holes and the upper ends of the second chip removing holes separately; and the right exhaust branch pipes and the left exhaust branch pipes are symmetrical about a perpendicular bisection plane of the base. The chip removing guide rail for the production equipment has such advantages as high chip removing efficiency, no dead angle, long service life, low production cost and high safety coefficient, and is suitable for large-scale popularization.

Owner:张维秀

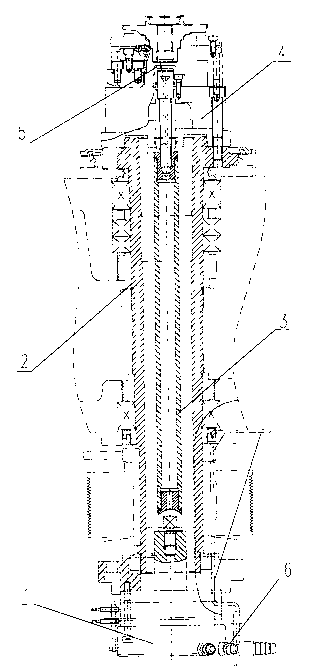

Lathe spindle center spraying cooling device

InactiveCN103317386AEasy dischargeGuaranteed machining accuracyMaintainance and safety accessoriesDischarge efficiencySpray nozzle

The invention provides a lathe spindle center spraying cooling device which aims at solving the problem that when a digital controlled lathe is used for machining an inner hole of a part, cooling liquid carries out washing to the inside from the machining end of the part, and the washing direction is different from the swarf discharging direction of the part. The lathe spindle center spraying cooling device is characterized in that an oil cylinder is assembled at the back end of a lathe spindle, the two ends of a hollow pulling rod are connected with a hollow piston rod of the oil cylinder and a connecting rod in the center of a chuck respectively, the chuck is installed at the front end of the spindle through a bolt, a spraying nozzle is connected with the chuck through a bolt, all threaded rotary connecting parts are sealed by sealing rings, and a pipe connector is installed on the oil cylinder. Cooling water sequentially passes through the pipe connector, the oil cylinder, the pulling rod in the center of the spindle, the chuck and the spraying nozzle to be sprayed on the inner hole of the part. The lathe spindle center spraying cooling device has the advantages that the spraying direction of the cooling water is the same as the swarf discharging direction, and the swarf discharging efficiency is improved.

Owner:SHENYANG NO MACHINE TOOL FACTORY

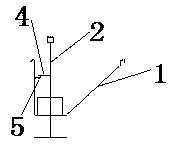

Driving structure of scrap removal rod

ActiveCN105500106AReduce resistanceReduce carrybackMaintainance and safety accessoriesEngineeringMetal

The invention discloses a driving structure of a scrap removal rod. The driving structure comprises a straight strip shaped scrap removal groove, the scrap removal rod, a driving rod, a supporting rod, a horizontal retaining bar, a guide bar, a limiting part and an oblique extension bar. The bottom end of the scrap removal rod is capable of extending into the bottom of the scrap removal groove; the driving rod which is positioned above the scrap removal groove is hinged to the top end of the scrap removal rod and used for driving the scrap removal rod to reciprocate along the length direction of the scrap removal groove; the supporting rod is fixed to the scrap removal rod; the horizontal retaining bar is used for supporting the supporting rod to move horizontally; the guide bar which is positioned at a first end of the retaining bar is hinged to the retaining bar and used for guiding the supporting rod to move towards the retaining bar; the limiting part is positioned below the guide bar and used for supporting the guide bar; the oblique extension bar which extends downwardly from a second end of the retaining bar is used for guiding the supporting rod to slide down gradually from the second end of the retaining bar. The driving structure of the scrap removal rod is reasonable in structure; the scrap removal rod in reverse movement can be lifted up, and consequently resistance of cutting liquid is reduced, the probability of returning of metal scraps is reduced, and scrap removal efficiency is improved; liquid in the scrap removal groove can be prevented from splashing in falling of the scrap removal rod.

Owner:SUZHOU DIHILL GREEN TECH

Production method of special mineral prospecting drill rod

The invention relates to the technical field of drill rod production methods and specifically relates to a production method of a special mineral prospecting drill rod. The method includes the following steps of raw material checking, rough machining, thermal processing and hardness checking, wherein the step of rough machining includes that oxide scales, black scales and the like of excircles of raw materials are firstly removed, then the raw materials are subjected to hole drilling, and the diameter of a drill hole is 116-130mm. By means of the production method of the special mineral prospecting drill rod, connection among drill rods is tight and firm, recoverable reserve is improved, the exploration drilling period is shortened, the service life of a drill tool is prolonged, and economic and technical norms of mine exploration drilling reach a new record.

Owner:JIANGSU HEXIN PETROLEUM MACHINERY

Wood chipper

InactiveCN102600945AImprove work efficiencyIncrease the opening areaGrain treatmentsDischarge efficiencyEngineering

The invention provides a wood chipper which comprises a chipper body and a chip outlet which is arranged at the lower end of the chipper body and defined by an upper wall, a lower wall and two side walls, wherein at least one of the upper wall, lower wall and two side walls of the chip outlet is provided with a curved surface; and the curved surface comprises at least one high point, and the distance between the high point and the surface of the wall opposite to the curved surface is less than the maximum distance specified by the corresponding safety standard, and the curved surface also comprises at least one low point and the distance from the low point to the surface of the wall opposite to the curved surface is longer than the corresponding safety distance. According to the wood chipper, the design of the curved surface is adopted by the surface of the wall of the chip outlet, so that the size of the opening of the chip outlet meets the safety standard, and the area of the opening can be enlarged to a certain degree, thus the discharge efficiency of chip can be improved, and the working efficiency of the wood chipper is further increased.

Owner:SKYBEST ELECTRIC APPLIANCE SUZHOU CO LTD

Hole Reaming Method of Injection Suction Chip Removal in Horizontal Directional Drilling

ActiveCN103527092BSolution to short lifeSimple construction operationFlushingDrilling machines and methodsComing outHigh pressure

Owner:陕西中科非开挖技术股份有限公司

Band sawing machine with flying chip prevention function

InactiveCN108031921AWith chip collection functionGuaranteed stable workMetal sawing devicesMetal sawing accessoriesEngineeringFault rate

The invention provides a band sawing machine with a flying chip prevention function. The band sawing machine has a chip collection function and is high in chip discharging effect, parts of chips can be conveniently stacked into a chip collecting groove, long sawing wires easily blocking a chip discharging hole can be discharged and do not need to be manually swept after band sawing machine stops,sawing chip amount in the chip collecting groove is less, and sawing chips of saw edge portions of a saw band can be effectively cleaned, so that the saw band can successfully work. A chip retaining plate is arranged on a guide arm, so that flying chips are resisted and collected into a discharging end, production environments are improved, production safety is ensured, fault rate is reduced, theservice life of the band sawing machine is prolonged, the chip retaining plate is movably connected with the guide arm through a rotating shaft, different angles of the chip retaining plate can be adjusted by the rotating shaft according to use conditions, and the best chip retaining effects are achieved.

Owner:王玲玲

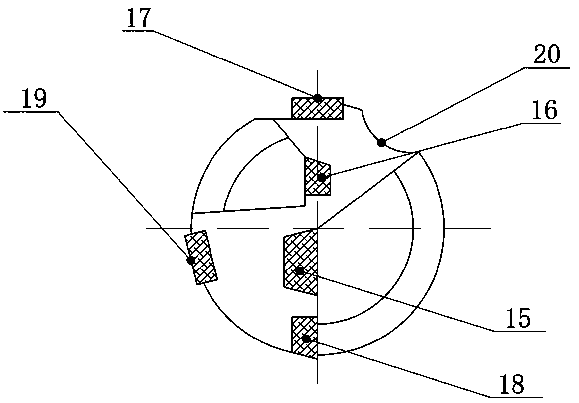

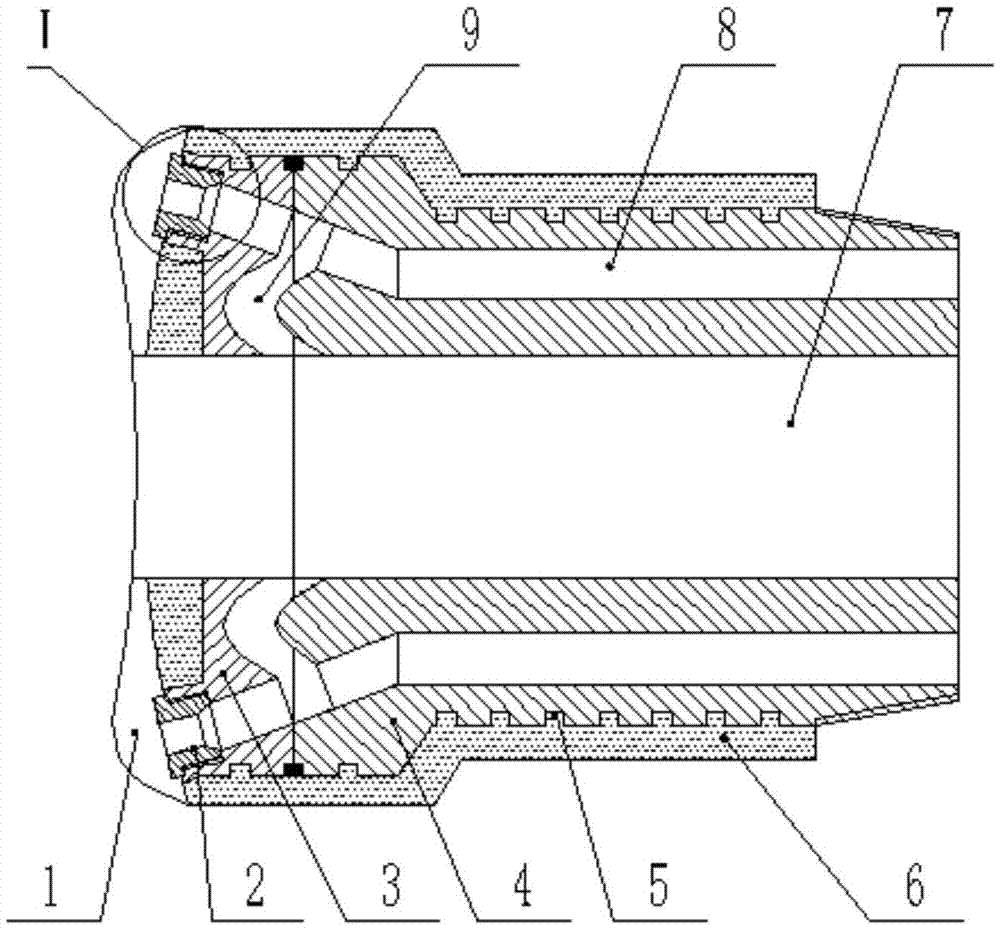

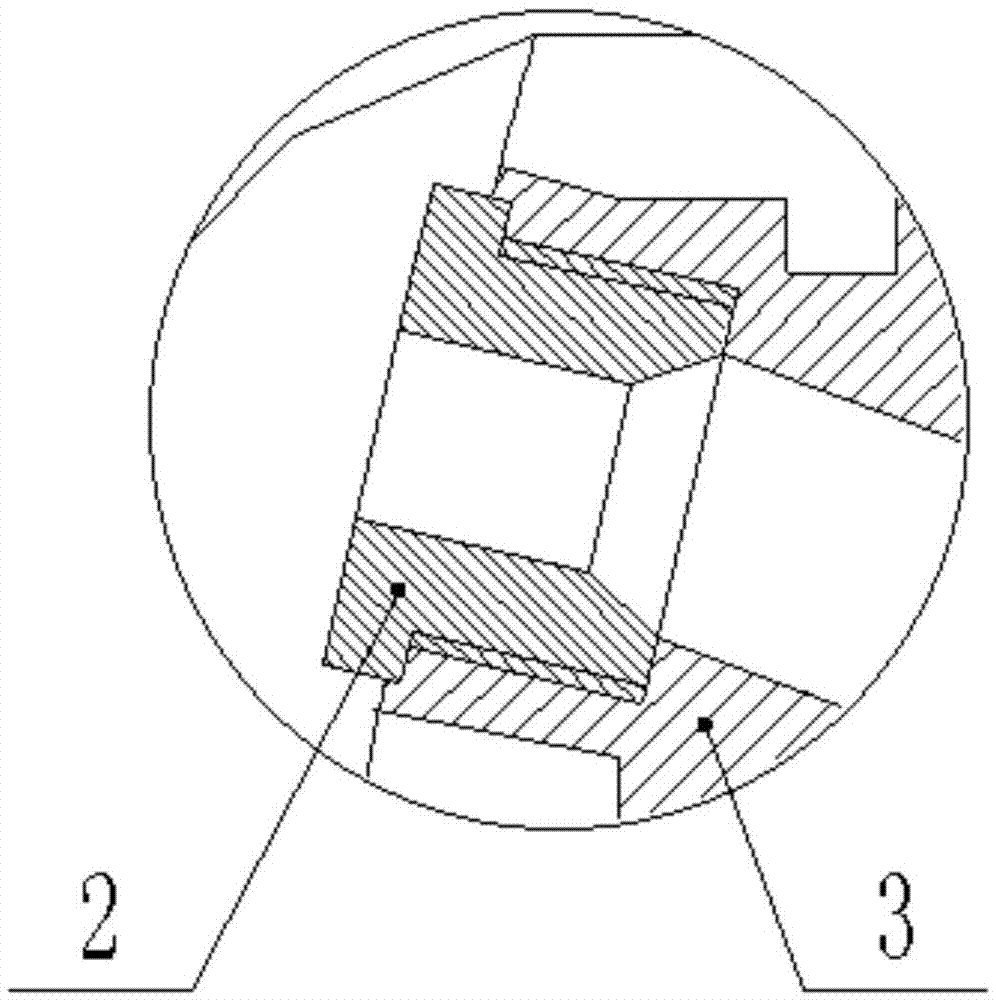

Floating-type multifunctional BTA deep-hole cutter system based on self-guiding

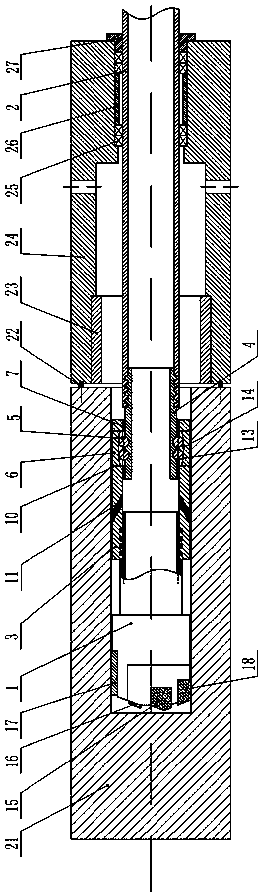

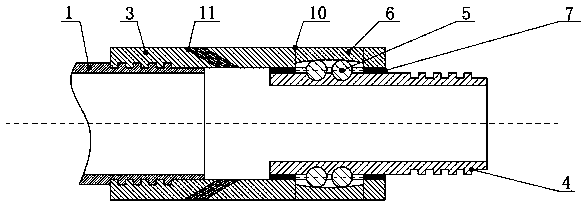

ActiveCN110814393AEliminate the effects ofImprove processing qualityTransportation and packagingMaintainance and safety accessoriesTool bitRubber ring

The invention provides a floating-type multifunctional BTA deep-hole cutter system based on self-guiding, and belongs to the technical field of deep-hole machining cutters. The system comprises a BTAcutter head and a drill rod, wherein the BTA cutter head and the drill rod are connected through a floating connection device. The floating connection device comprises a cutter head connecting piece,a cutter bar connecting piece, balls, an upper end cover, a rubber ring, vibration attenuation blocks and auxiliary guiding strips, wherein the front end of the cutter head connecting piece is connected with the BTA cutter head, the cutter head connecting piece is provided with upper end cover mounting holes, jet flow holes and cutting liquid grooves I, the cutter bar connecting piece is sleeved with the cutter head connecting piece and is provided with arc grooves, the rear end of the cutter bar connecting piece is connected with the drill rod, the balls are put in the arc grooves, the upperend cover is assembled in the upper end cover mounting holes, the rubber ring is arranged between the cutter head connecting piece and the cutter bar connecting piece, and the vibration attenuation blocks and the auxiliary guiding strips are assembled on the outer cylinder surface of the cutter head connecting piece. The BTA deep-hole cutter system can automatically eliminate the influence of bending and vibration of the drill rod on a self-guiding system in the BTA cutter deep-hole machining process, and more reasonable position vibration attenuation, better chipping removal and a more coordinated self-guiding function are achieved.

Owner:ZHONGBEI UNIV

Drill bit used for double-wall drill pipe reverse circulation drilling

The invention belongs to the field of drilling equipment, and especially relates to a drill bit used for double-wall drill pipe reverse circulation drilling. The drill bit comprises a drill bit body, and the drill bit body comprises a steel core and a tungsten carbide sinter layer. The outer side of the steel core is provided with an annular groove. The tungsten carbide sinter layer is sintered on the periphery of the steel core and a drilling surface, and is filled in the annular groove. The end of the tungsten carbide sinter layer is provided with a blade wing. The strength of the drill bit is ensured, and manufacturing cost of the drill bit is reduced. Specifically, a structure of attaching the tungsten carbide sinter layer out of the steel core is used, strength of the drill bit is ensured on structure, an integrated structure is abandoned, and a processing method of sintering silicon carbide after welding split steel cores, so that processing cost is effectively reduced.

Owner:大庆天瑞机械制造有限公司

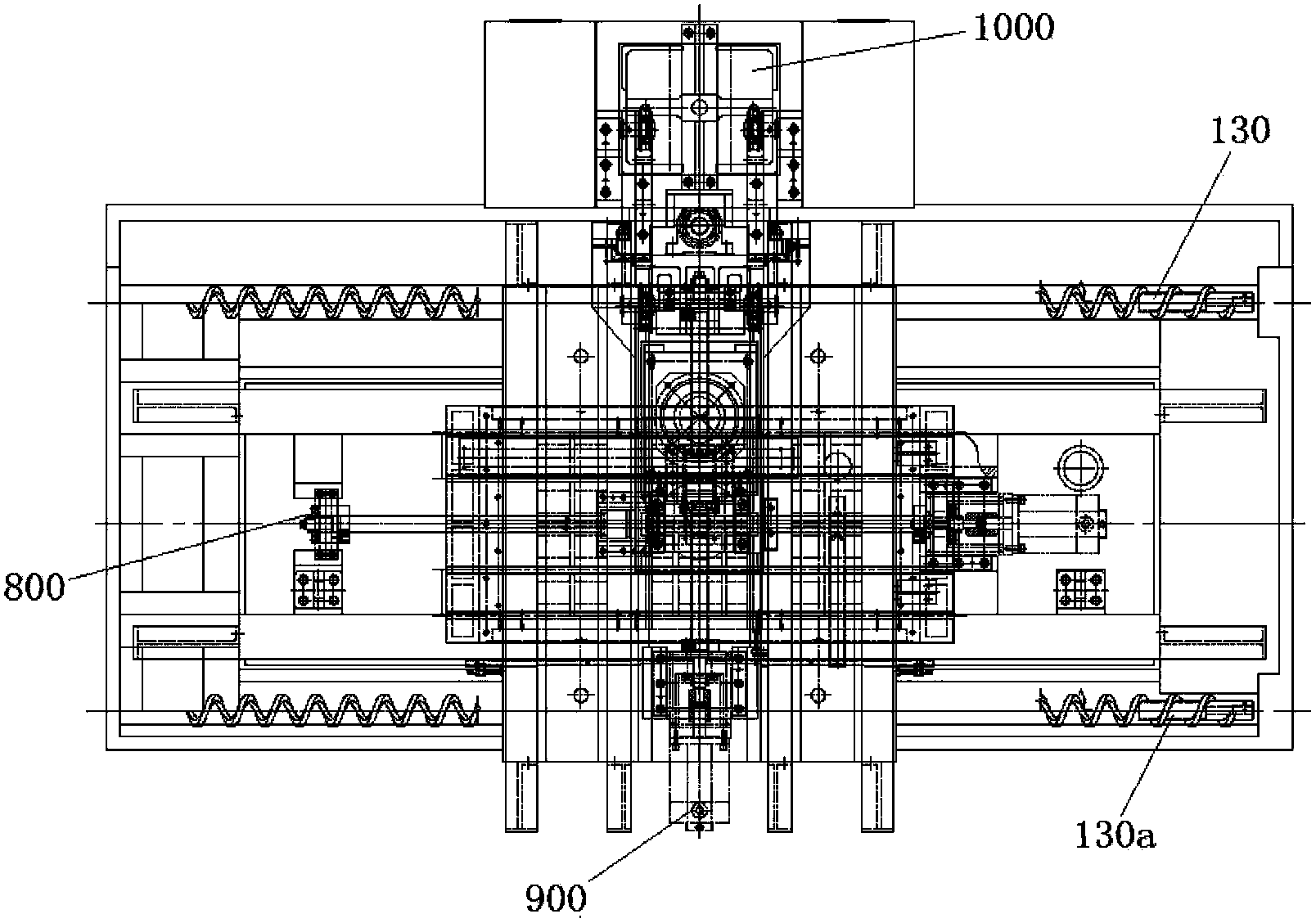

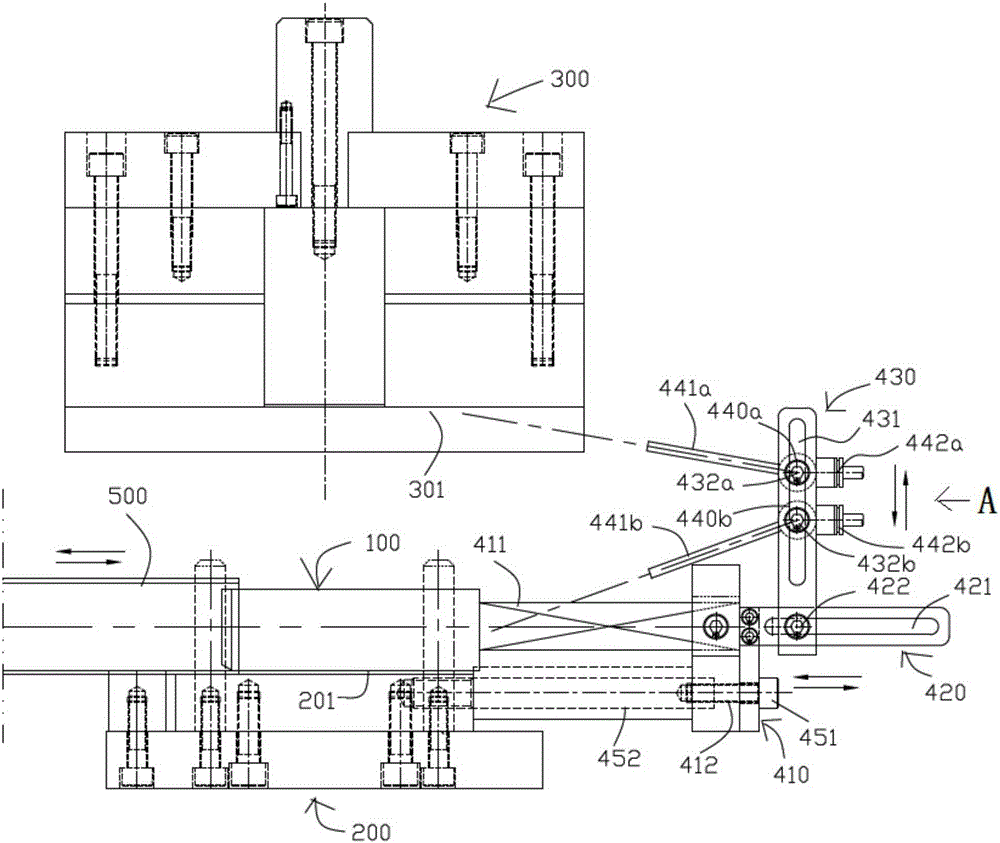

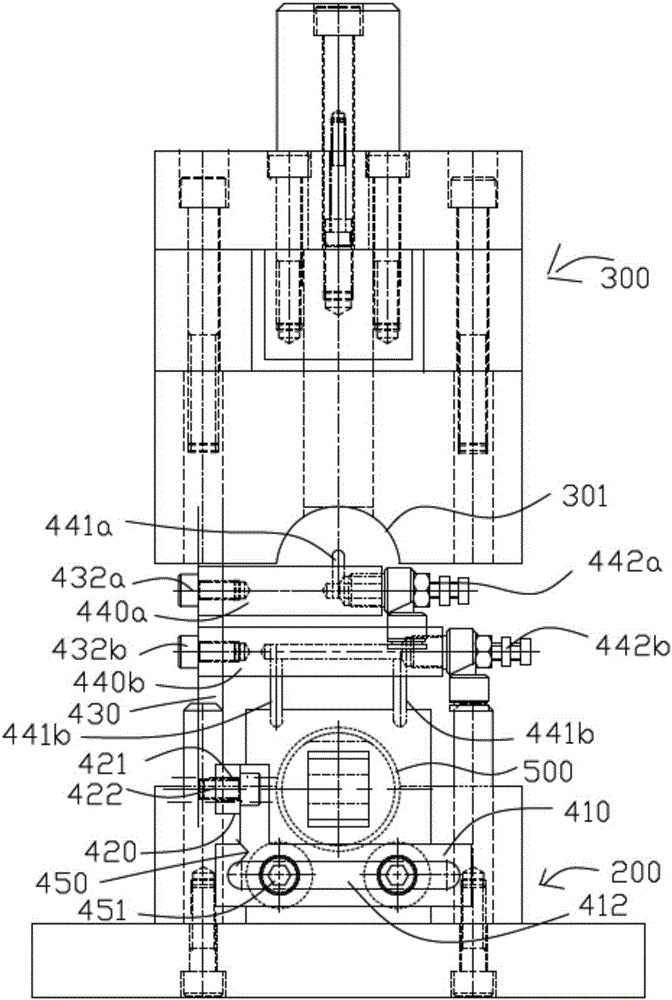

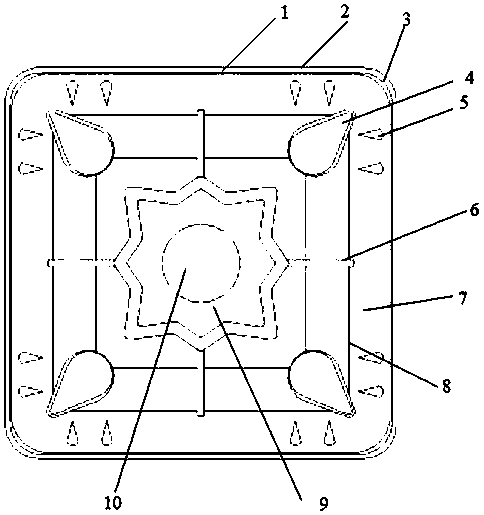

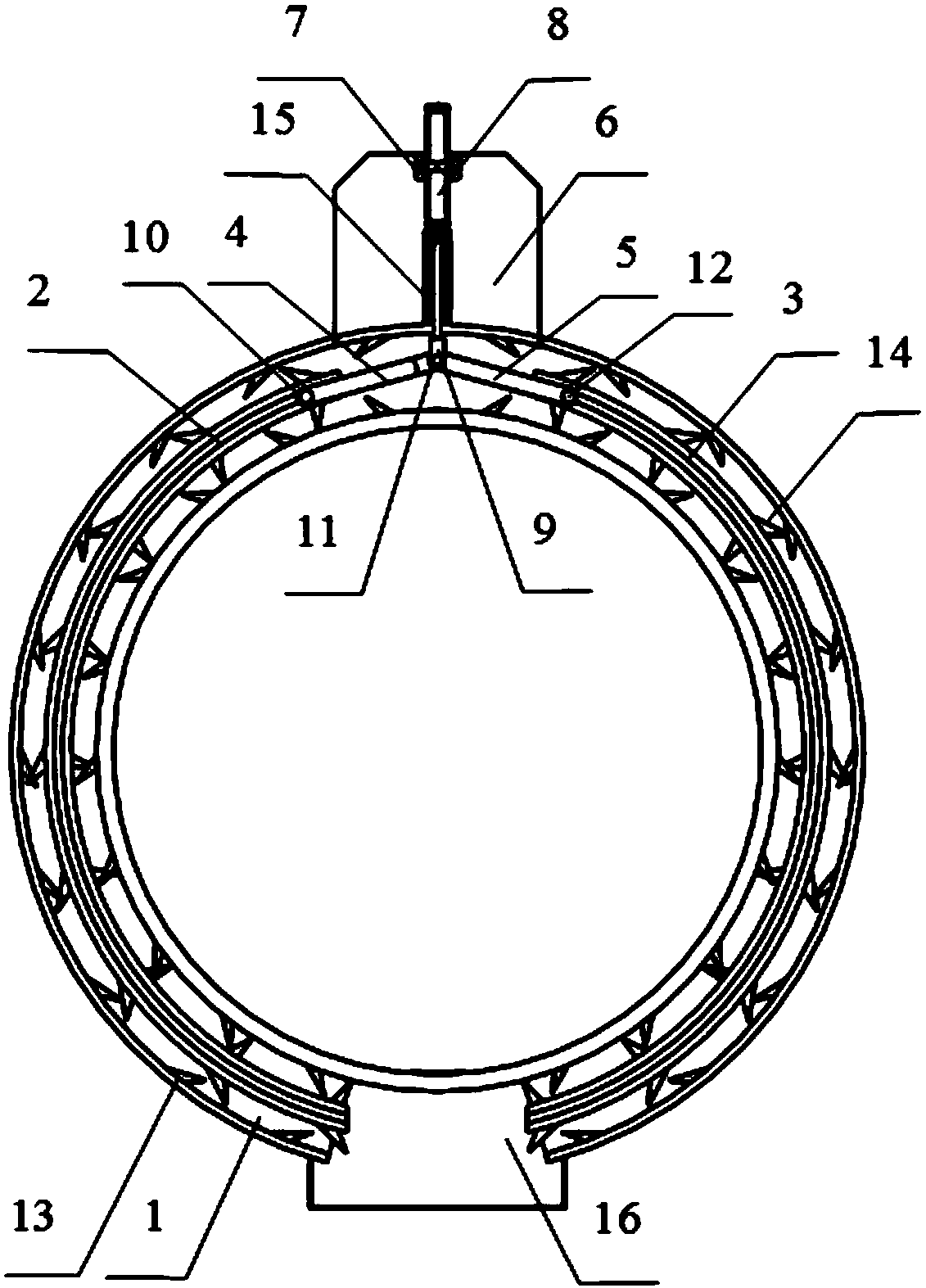

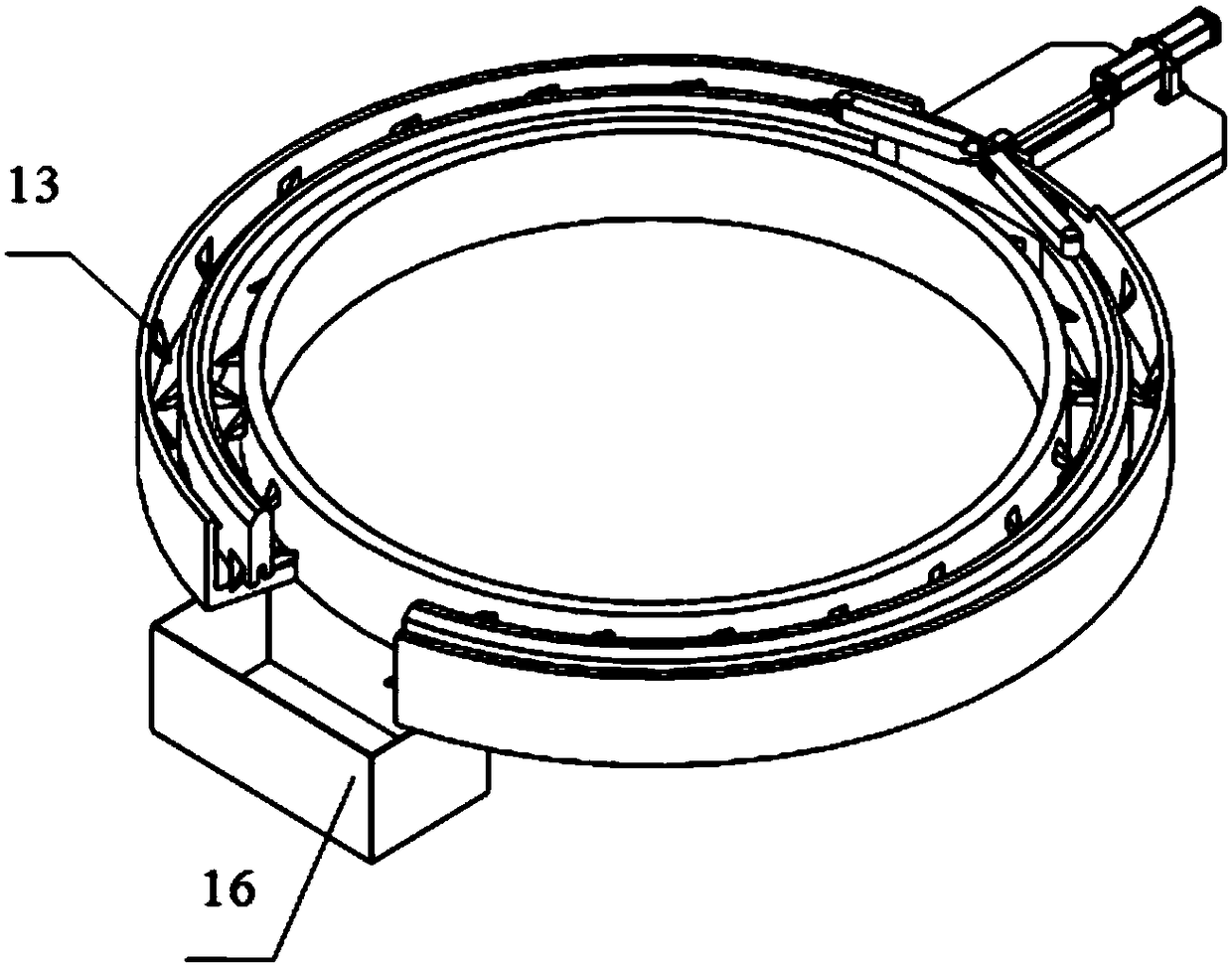

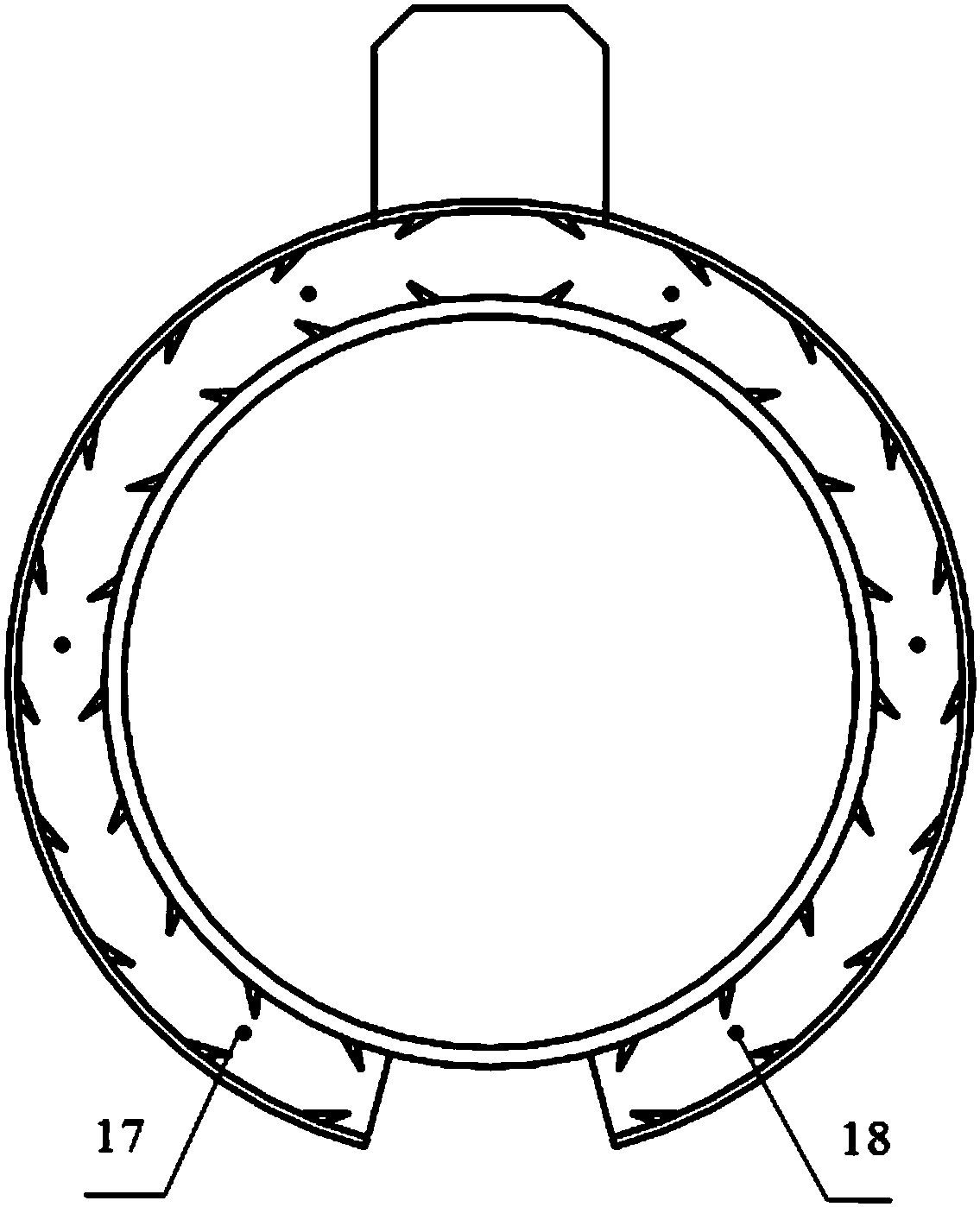

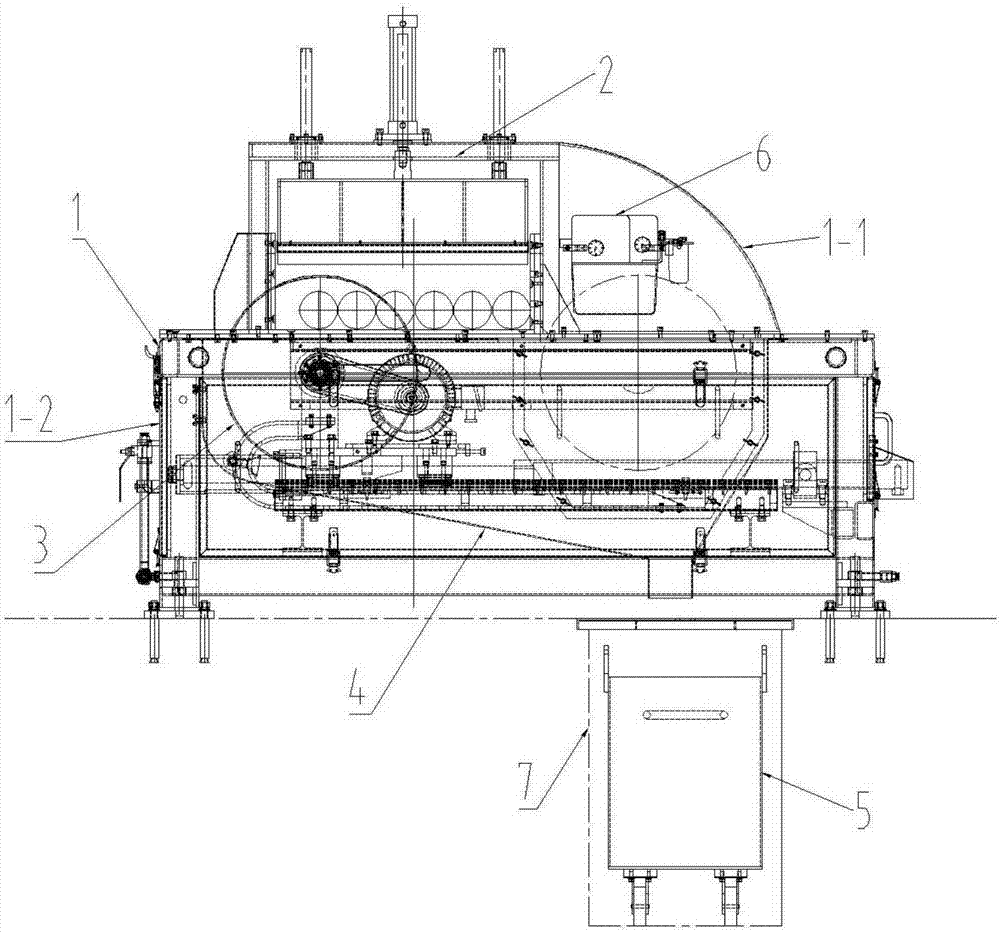

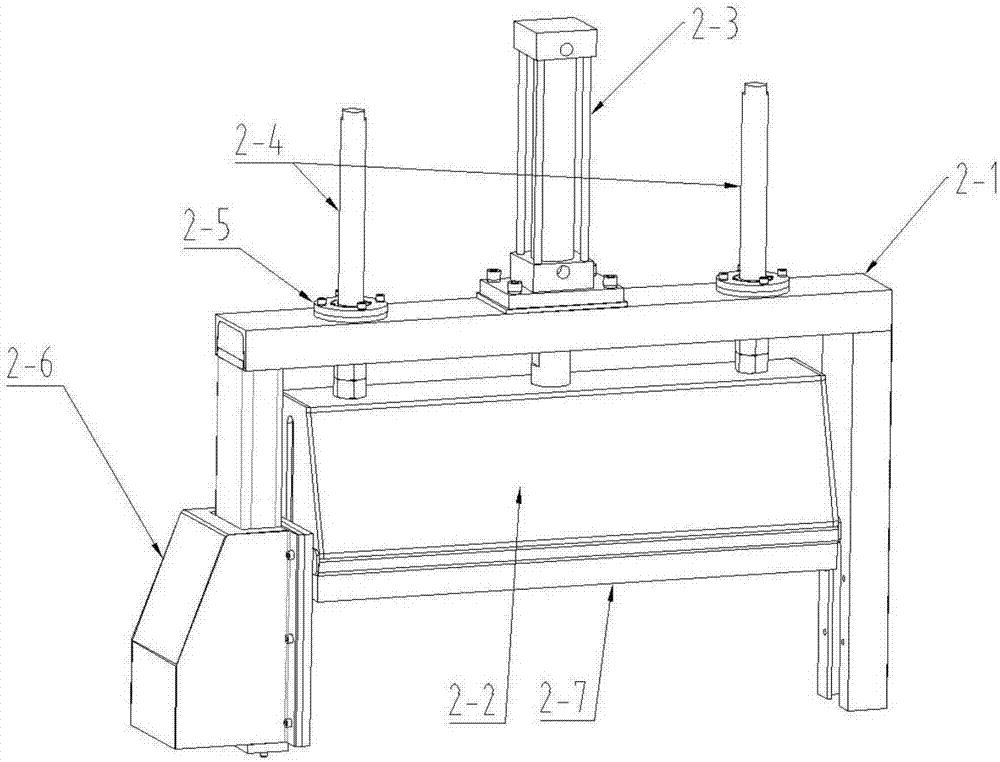

Annular bidirectional stepping push rod chip removal device

ActiveCN108555672AReduce labor intensityEfficient collectionMaintainance and safety accessoriesSmall footprintEngineering

The invention provides an annular bidirectional stepping push rod chip removal device, and particularly relates to a device for removing lump chips, long chips and roll chips generated by working procedures such as turning, milling, drilling and boring when a gantry type machine tool is used for machining large parts. The annular bidirectional stepping push rod chip removal device mainly solves the problem of low cleaning efficiency of iron chips generated in machining of the large parts by a rotating table on the gantry type machine tool, and the iron chips can be immediately generated, collected and discharged. The annular bidirectional stepping push rod chip removal device has the advantages of wide applicable range, high chip removal efficiency, low energy consumption, stability, reliability, low cost and small occupied area, the use environment of a site can be effectively improved, and the labor intensity of staff is reduced.

Owner:共享机床辅机(大连)有限公司

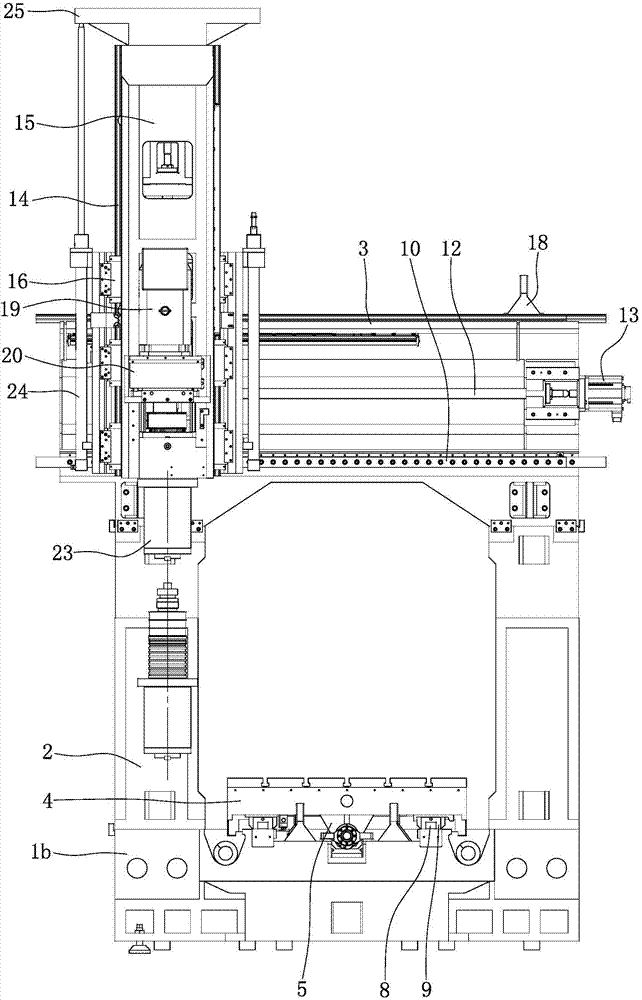

Power assembly of multifunctional high-precision CNC (computer numerical control) machining center

InactiveCN104875065AImprove chip removal efficiencyLow costFeeding apparatusMaintainance and safety accessoriesHigh torqueCylinder block

The invention discloses a power assembly of a multifunctional high-precision CNC (computer numerical control) machining center. Screw chip-dischargers are mounted in chip grooves arranged in the top of a support table; the front end of the top of the support table is provided with a retaining wall; an X-axial nut seat at the bottom of a workbench is in threaded fit with an X-axial screw; upper and lower Y-axial slide rails are mounted on the front end face of a cross beam; a Y-axial slide base is in sliding fit with the Y-axial slide rails through Y-axial sliders; nitrogen balance cylinders are arranged on left and right sides of the Y-axial slide base; cylinder blocks of the nitrogen balance cylinders are fixed to the Y-axial slide base; an output shaft of a spindle motor is connected to the input end of a gearbox; an output shaft of the gearbox is sleeved with a driving wheel; the driving wheel is connected with a driven wheel arranged on a spindle, through a belt. The power assembly has the advantages that chip discharging is smooth and thorough, water and oil leakage of an oil-water separator caused by mal-assembly is basically solved; the weight of a spindle box is balanced through the nitrogen balance cylinders, load of a Z-axial motor is effectively reduced, high-speed cutting is available, and low-speed high-torque cutting is also available.

Owner:CHONGQING MASITER PRECISION MACHINERY

Sawing cutting equipment

PendingCN107414181AAvoid Axial RunoutPrevent lockMetal sawing devicesMetal sawing accessoriesStructural engineeringMechanical engineering

The invention relates to sawing cutting equipment. The sawing cutting equipment comprises a machine frame assembly, a material pressing device, a saw head assembly, a saw cover assembly and a saw dust collecting assembly; the machine frame assembly comprises a machine frame base and a machine frame upper cover; the saw head assembly is arranged on the machine frame base; the material pressing device is arranged above the machine frame base; the saw cover assembly is arranged below the machine frame base and is connected with the machine frame upper cover; a saw dust outlet is formed in the bottom of the saw cover assembly; and the saw dust collecting assembly is arranged below the saw dust outlet. When the sawing cutting precision is ensured, the dust removal efficiency is improved; a design structure is simplified; and the equipment is more convenient to mount and maintain.

Owner:LIAONING ZHONGWANG MACHINERY EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com