Hole Reaming Method of Injection Suction Chip Removal in Horizontal Directional Drilling

A horizontally oriented, in-drilling technology, applied in drilling equipment and methods, drilling equipment, earth-moving drilling, etc., to achieve the effects of wide pressure range, high chip removal efficiency, and simple construction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: The present invention provides a horizontal directional drilling method for injecting and sucking chip removal and reaming in multi-stage reaming construction in hard formations, which is operated according to the following steps:

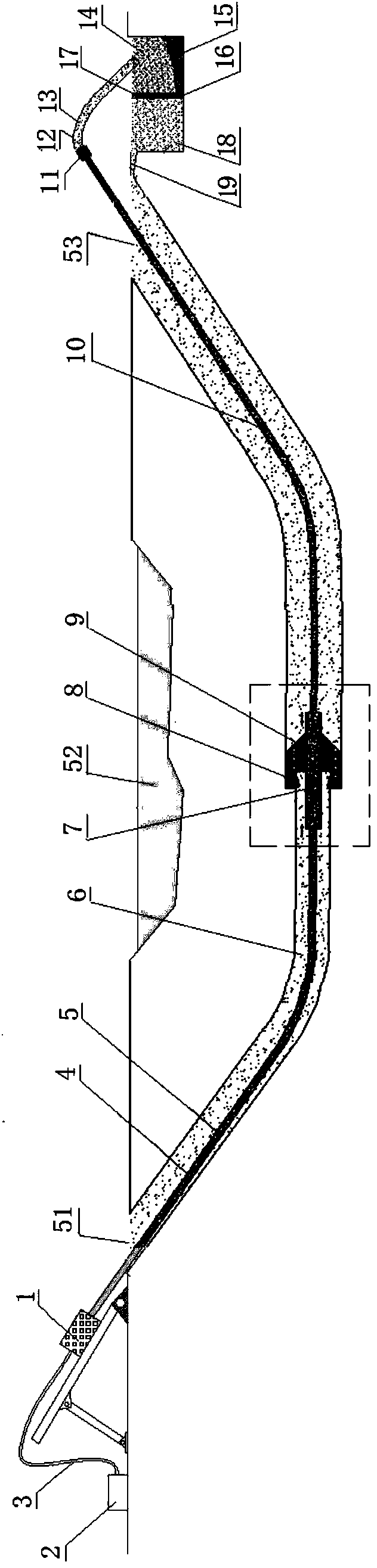

[0036] ⑴, see figure 1 According to the conventional method, the pilot hole drilling is carried out from the soil entry side 51, wherein the water area 52 is crossed until the drill pipe is drilled out from the excavation side 53, and a pilot hole drilling is completed.

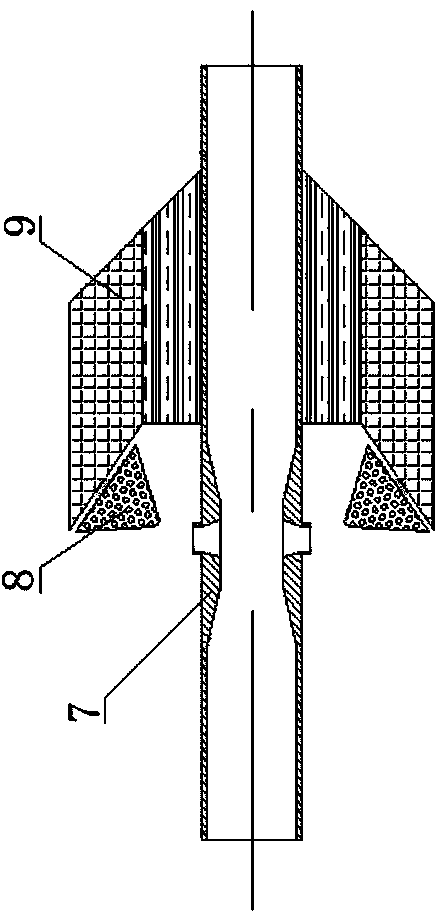

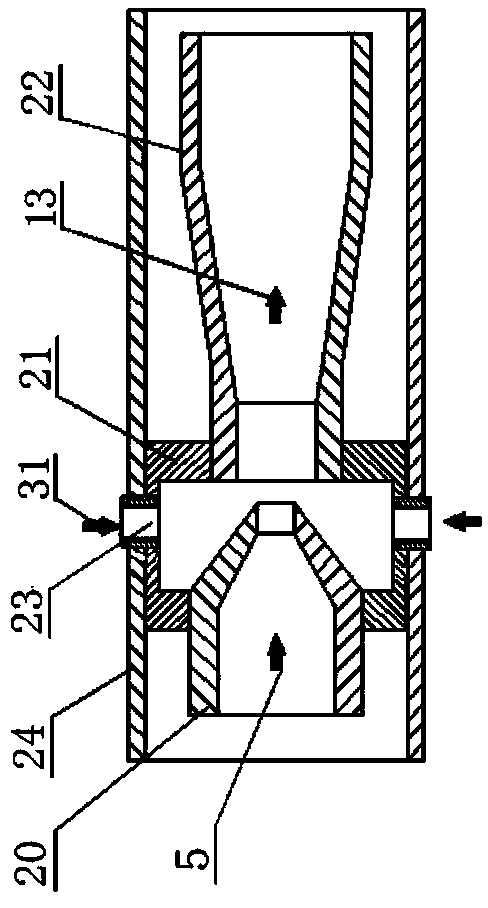

[0037] (2) Connect the jet-suction reamer to the drill pipe 4 on the unearthed side. see figure 2 , the jet-suction reamer is composed of a reamer body 9, a cutting part 8 and a jet-suction device 7; the reamer body 9 is the carrier of each component of the jet-suction reamer, and The cutting portion 8 is used to break up the formation; see image 3, the said jet suction device 7 includes a joint, an outer shell 24, a suction port 23, a jet nozzle 20, a su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com