Patents

Literature

8856results about How to "Reduce heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

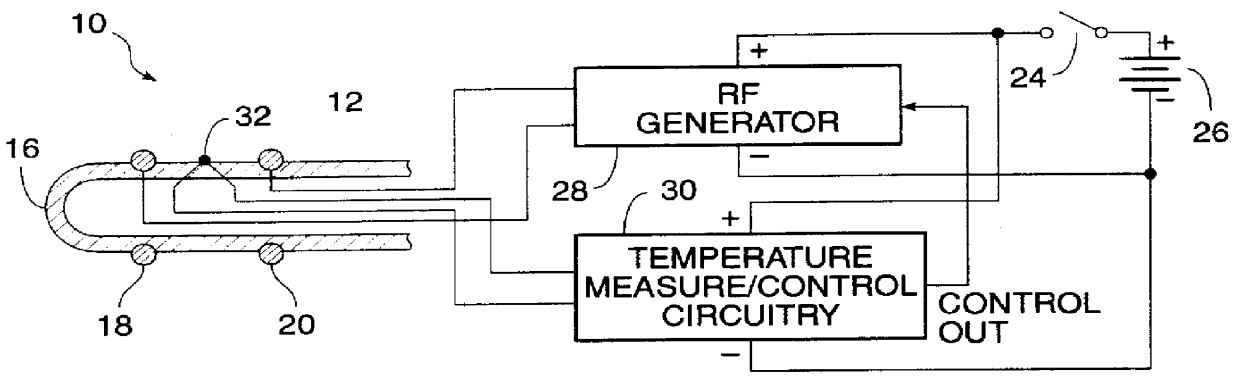

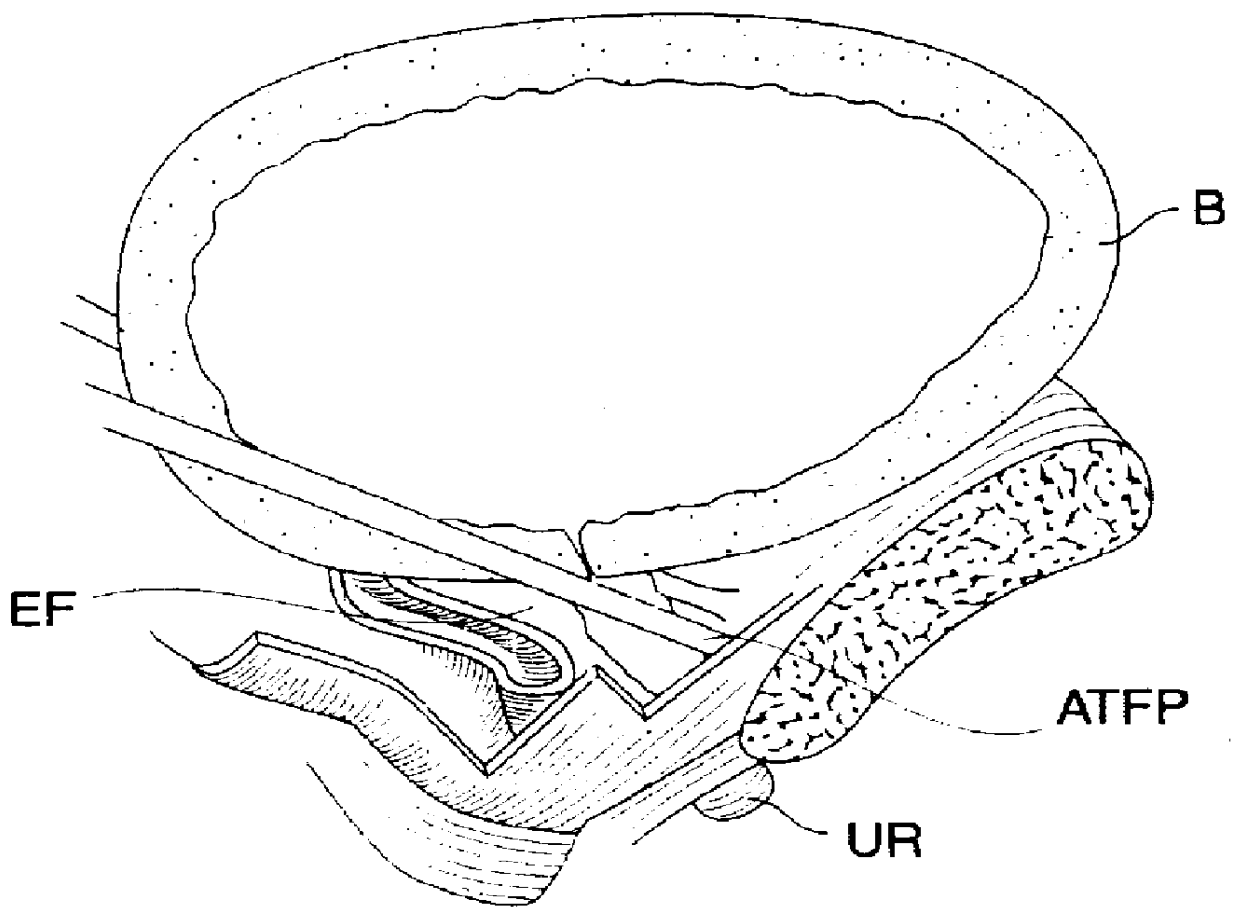

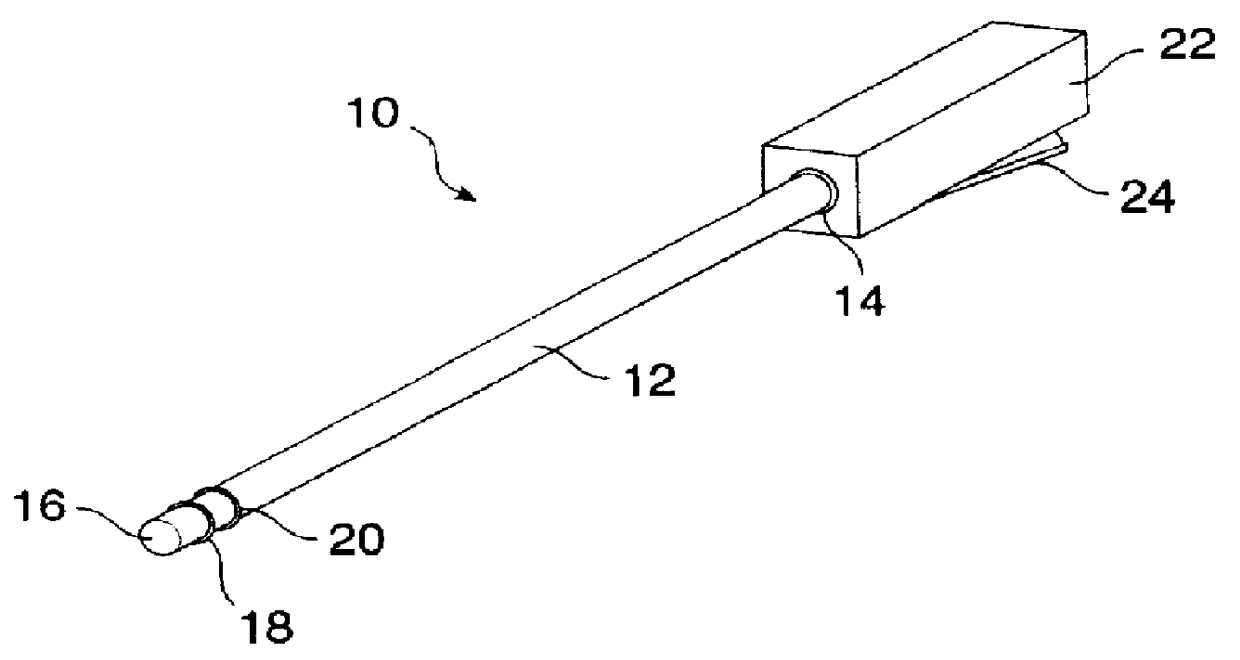

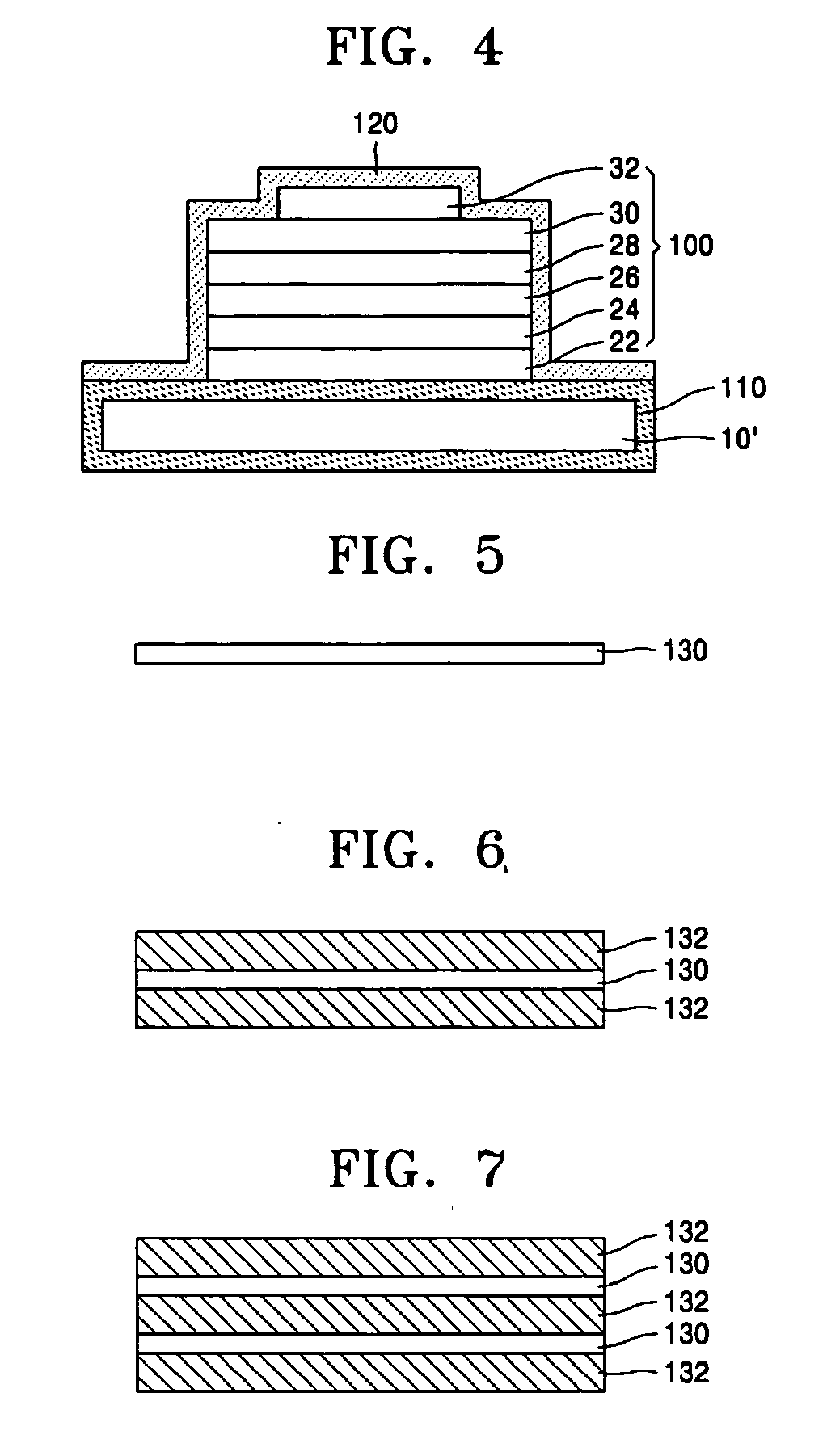

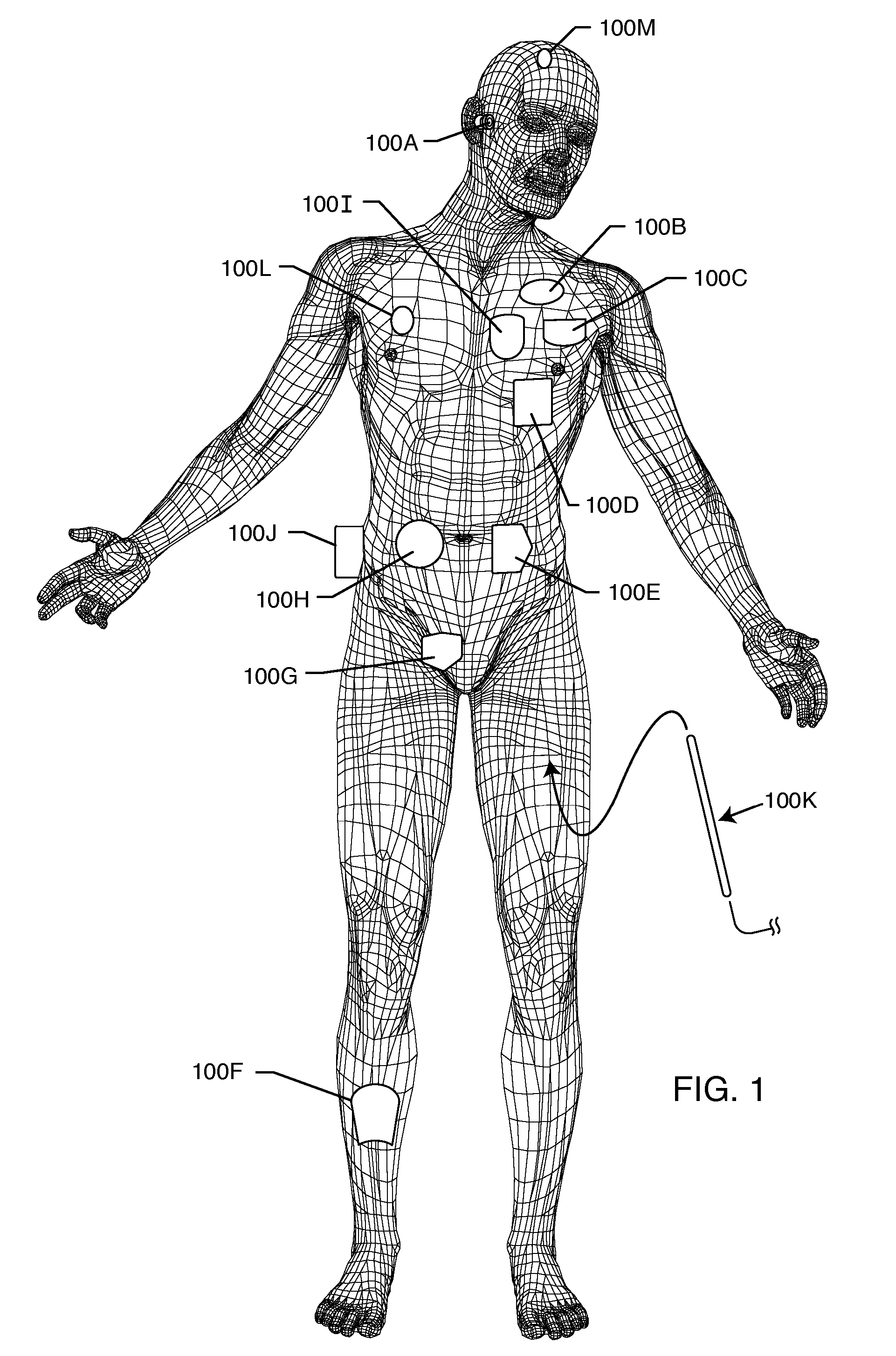

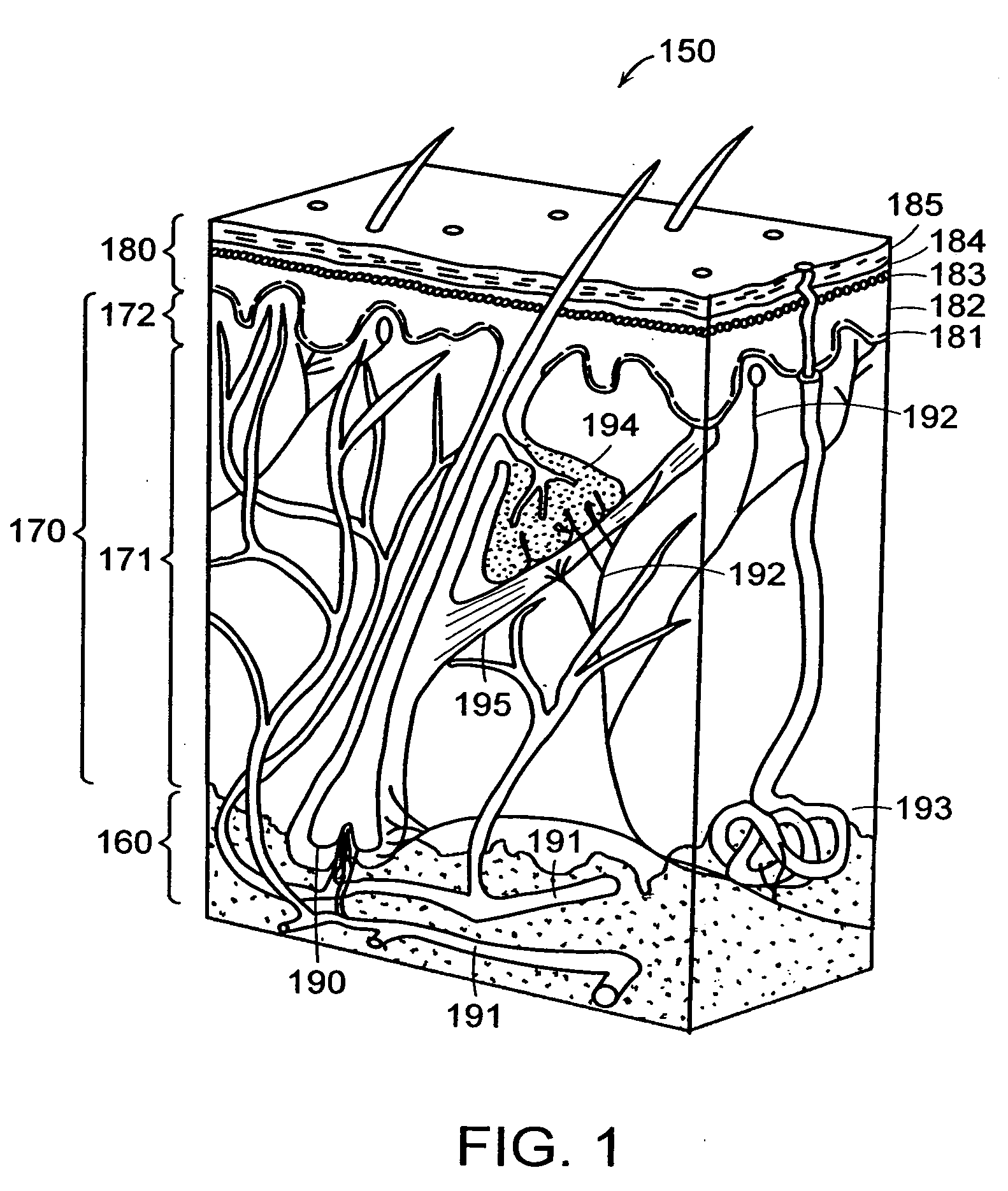

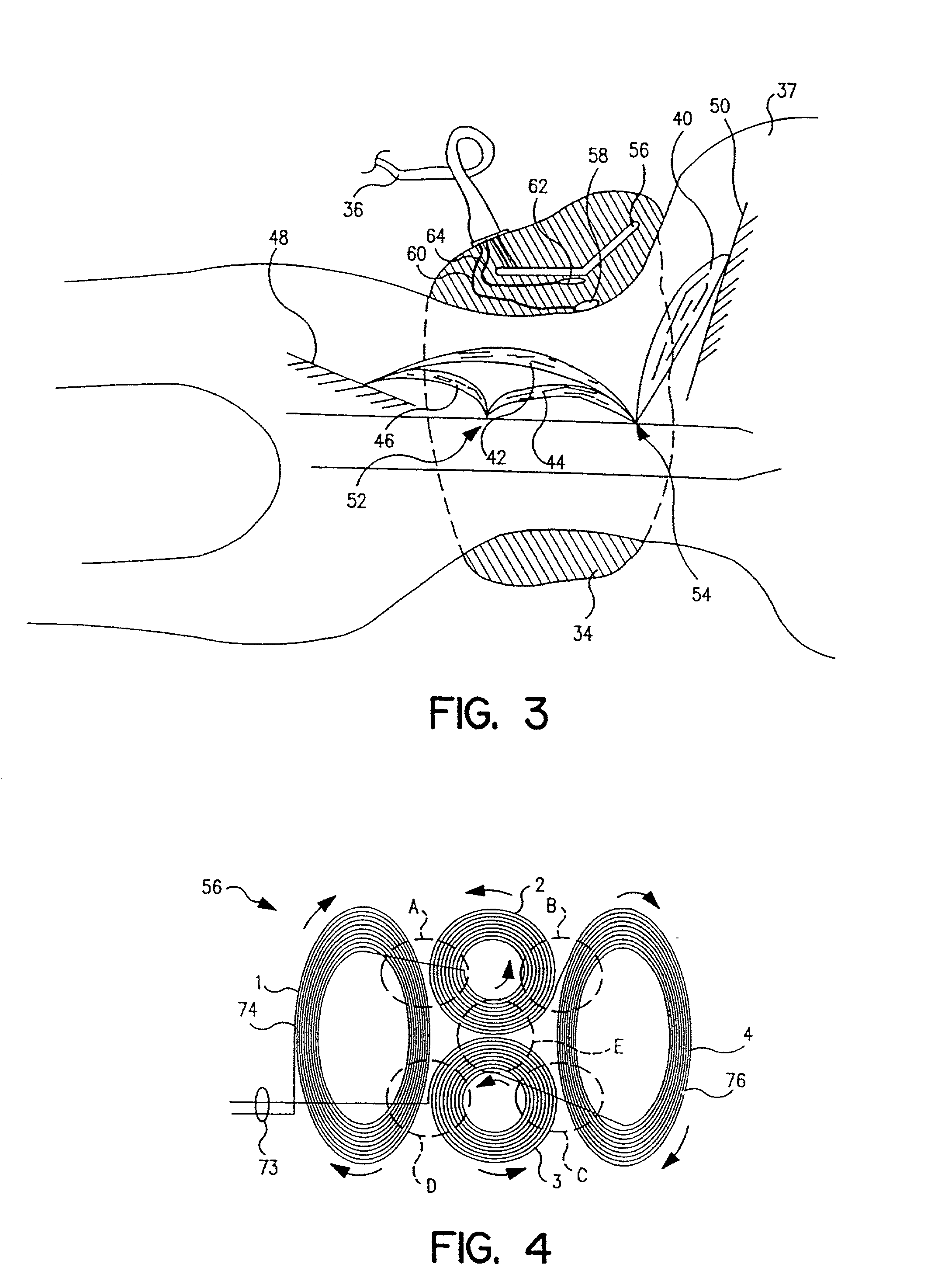

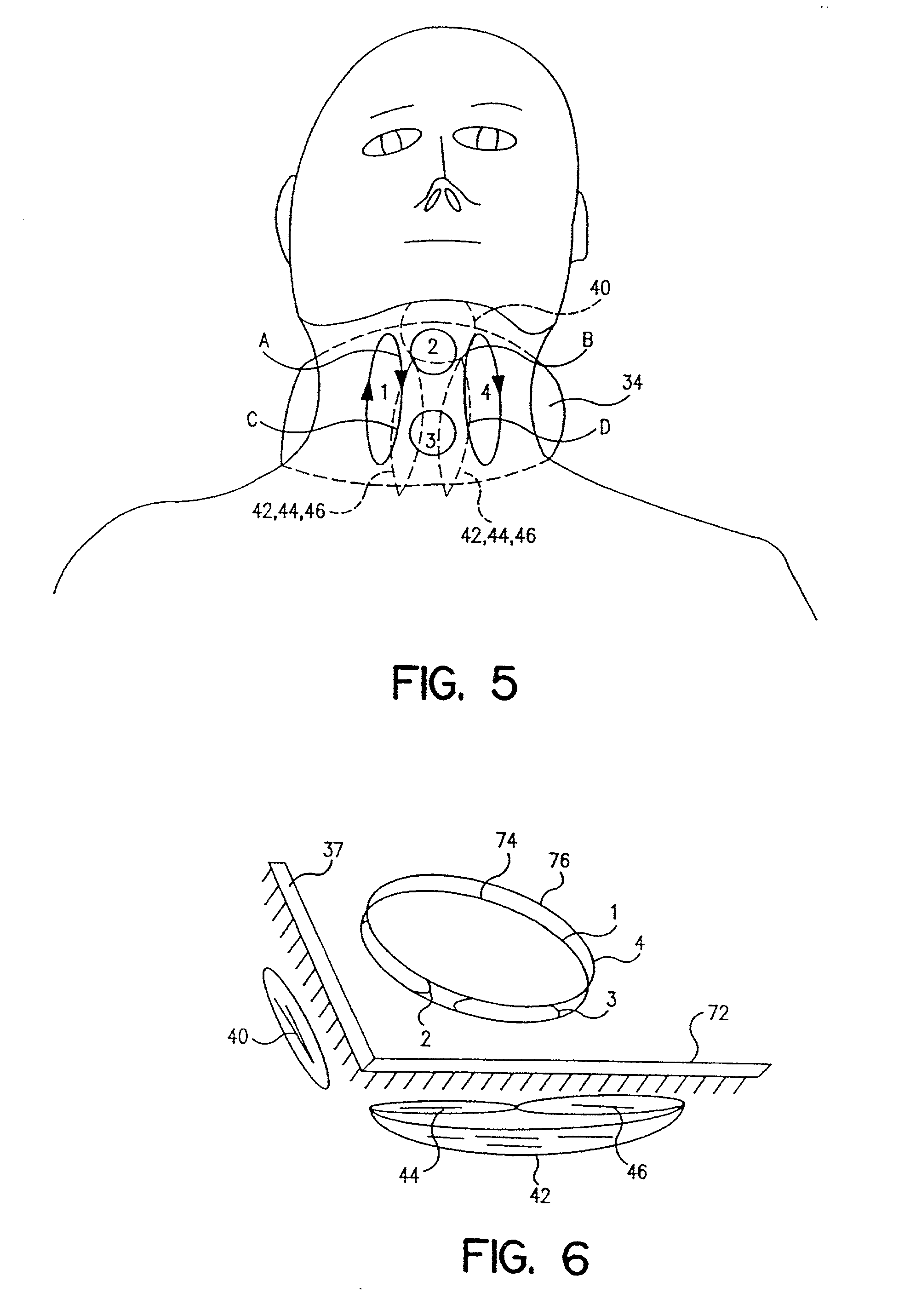

Devices, methods, and systems for shrinking tissues

InactiveUS6091995AReduce power levelControl depthSurgical needlesInternal electrodesSphincterPelvic supports

Devices, systems, and method for treating urinary incontinence generally rely on energy delivered to a patient's own pelvic support tissue to selectively contract or shrink at least a portion of that pelvic support tissue so as to reposition the bladder. The energy will preferably be applied to the endopelvic fascia and / or an arcus tendineus fascia pelvis. The invention provides a variety of devices and methods for applying gentle resistive heating of these and other tissues to cause them to contract without imposing significant injury on the surrounding tissue structures. Alternatively, heat-applying probes are configured to heat tissue structures which comprise or support a patient's urethra. By applying sufficient energy over a predetermined time, the tissue can be raised to a temperature which results in contraction without significant necrosis or other tissue damage. By selectively contracting the support tissues, the bladder neck, sphincter, and other components of the urinary tract responsible for the control of urinary flow can be reconfigured or supported in a manner which reduces urinary leakage.

Owner:VERATHON

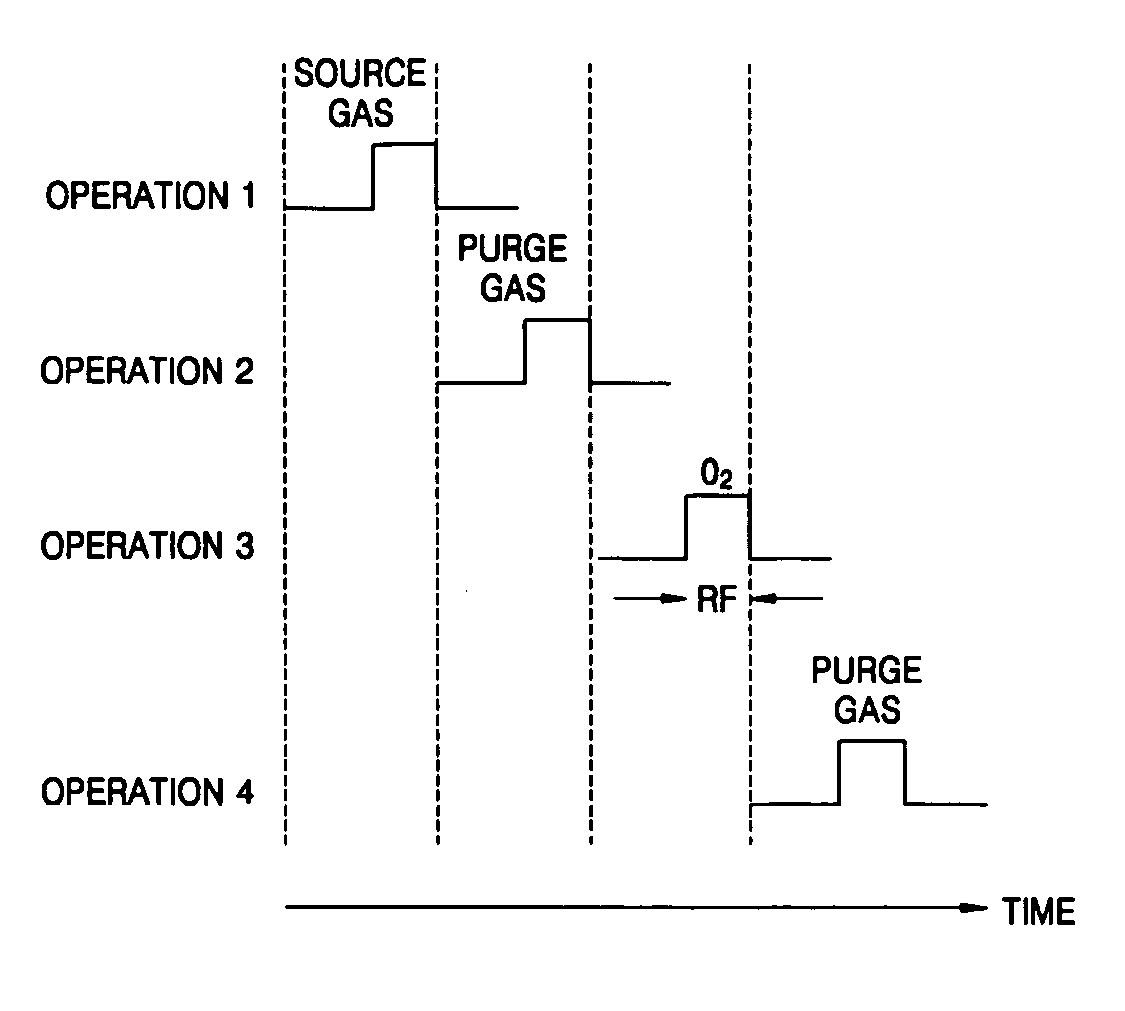

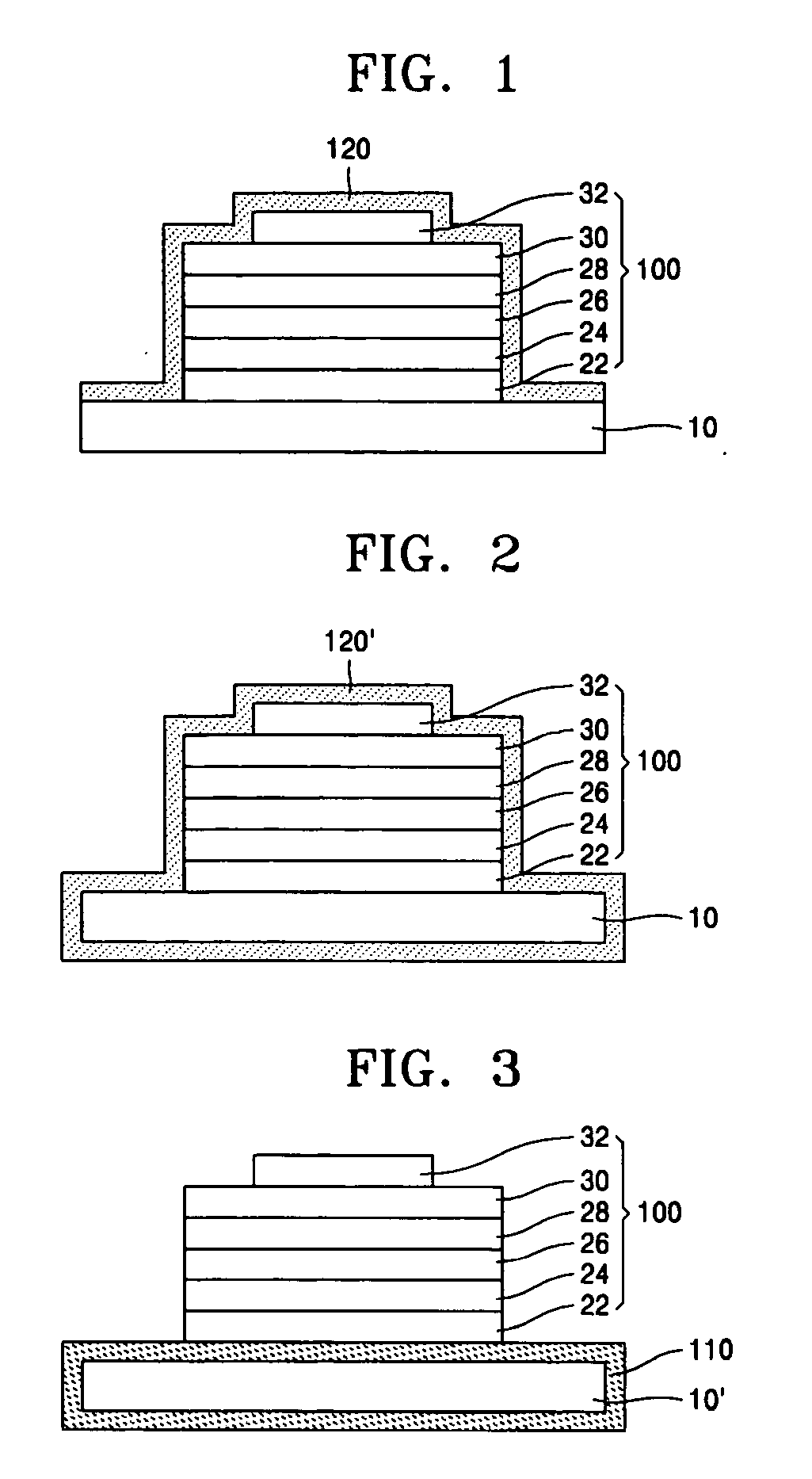

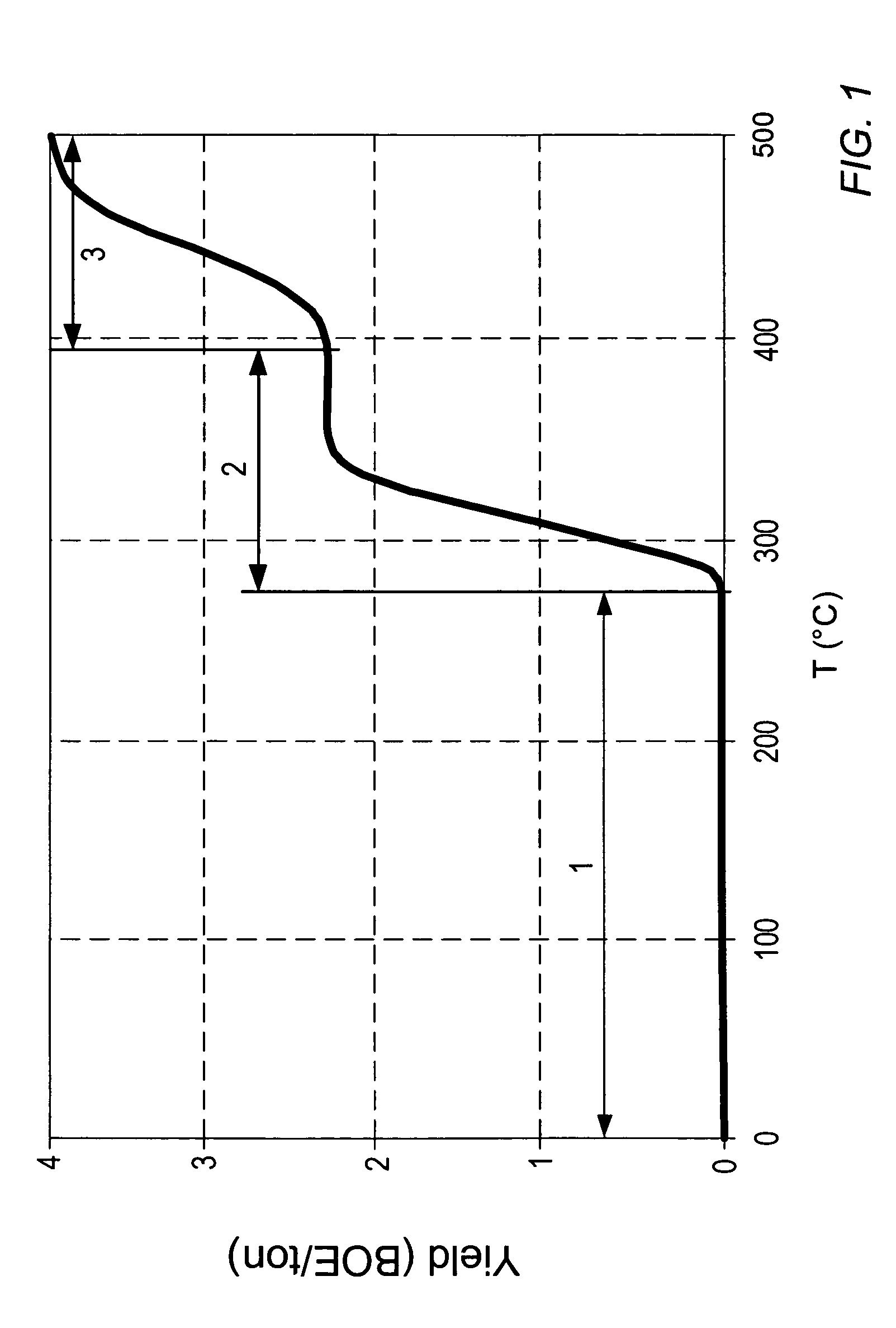

Method of fabricating passivation layer for organic devices

InactiveUS20050181535A1Reduce heatEasily deterioratedSolid-state devicesSemiconductor/solid-state device manufacturingOrganic devicesOptoelectronics

Provided is a method of fabricating a passivation layer for an organic device, including: forming the organic device on a substrate; and forming a passivation layer on the organic device. Here, forming the passivation layer on the organic device includes forming an inorganic thin film by thin film deposition using pulsed plasma.

Owner:ELECTRONICS & TELECOMM RES INST

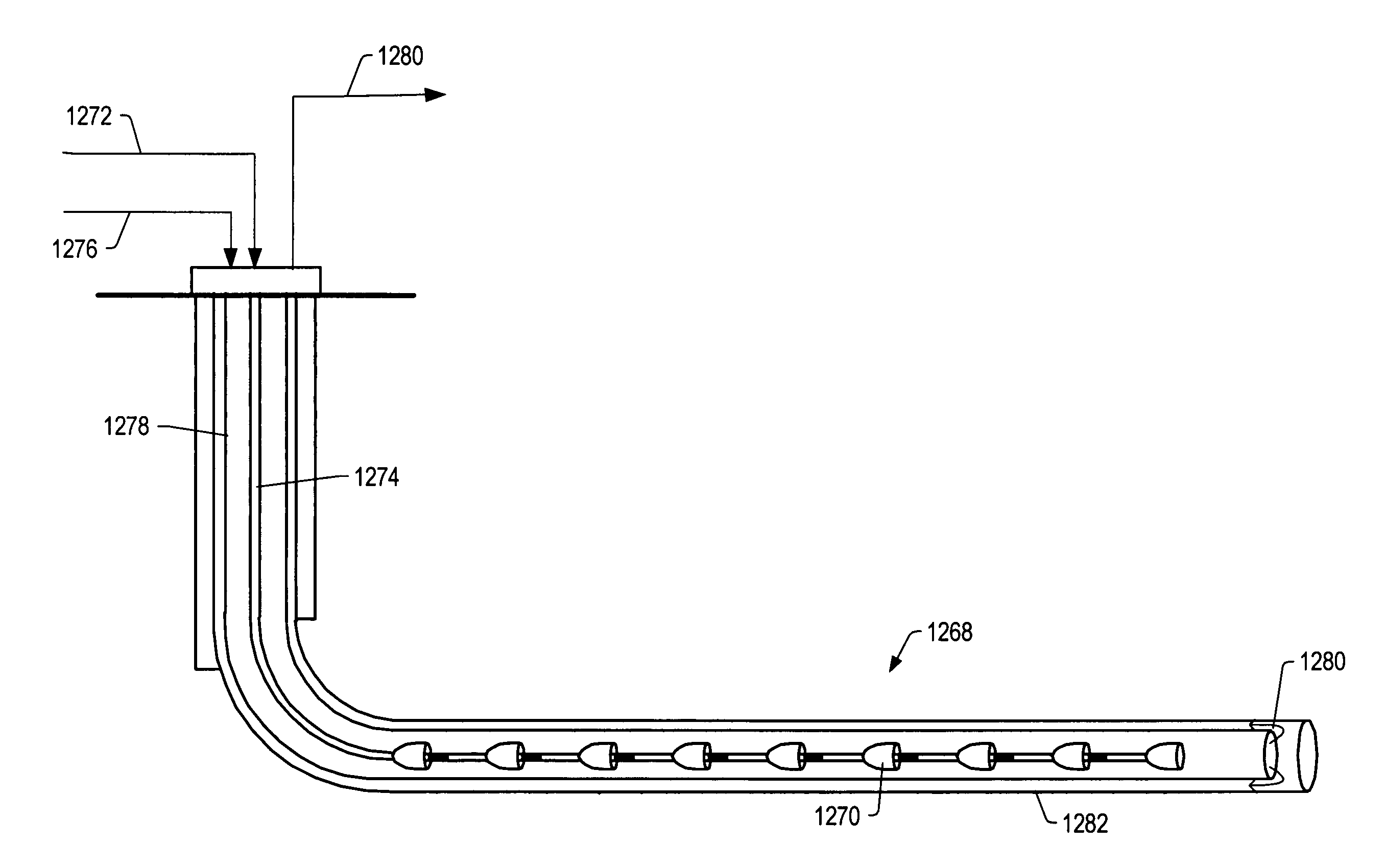

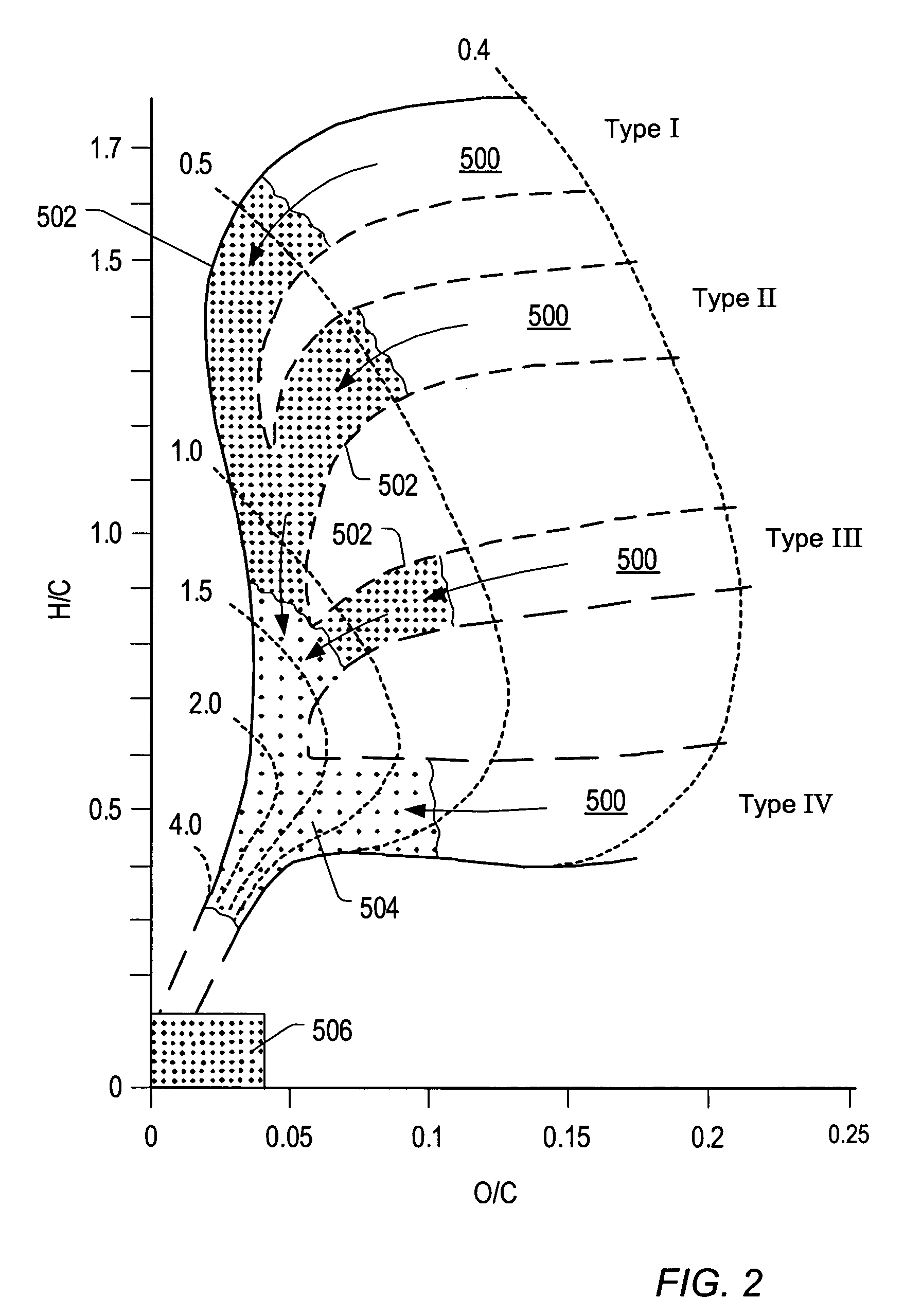

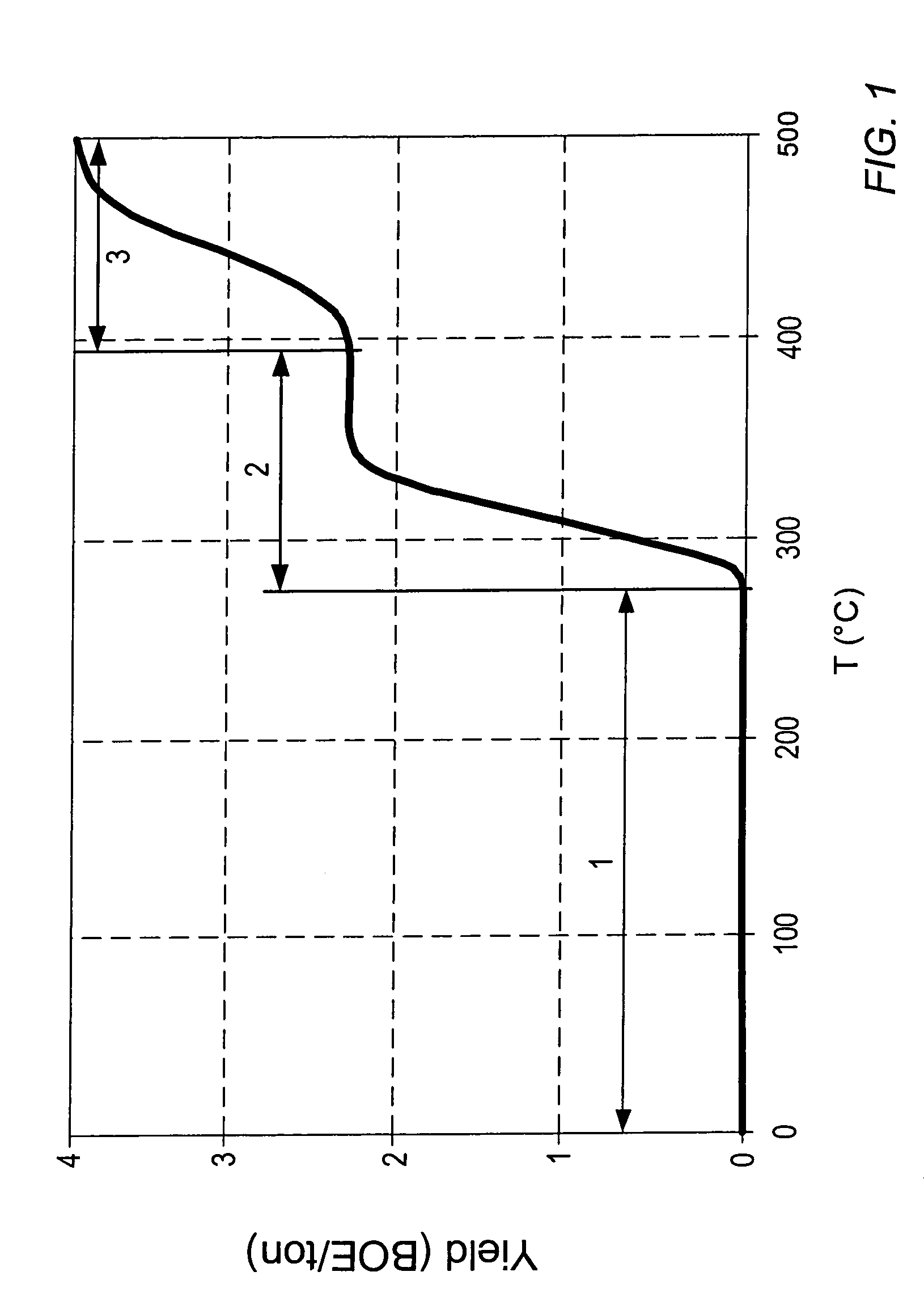

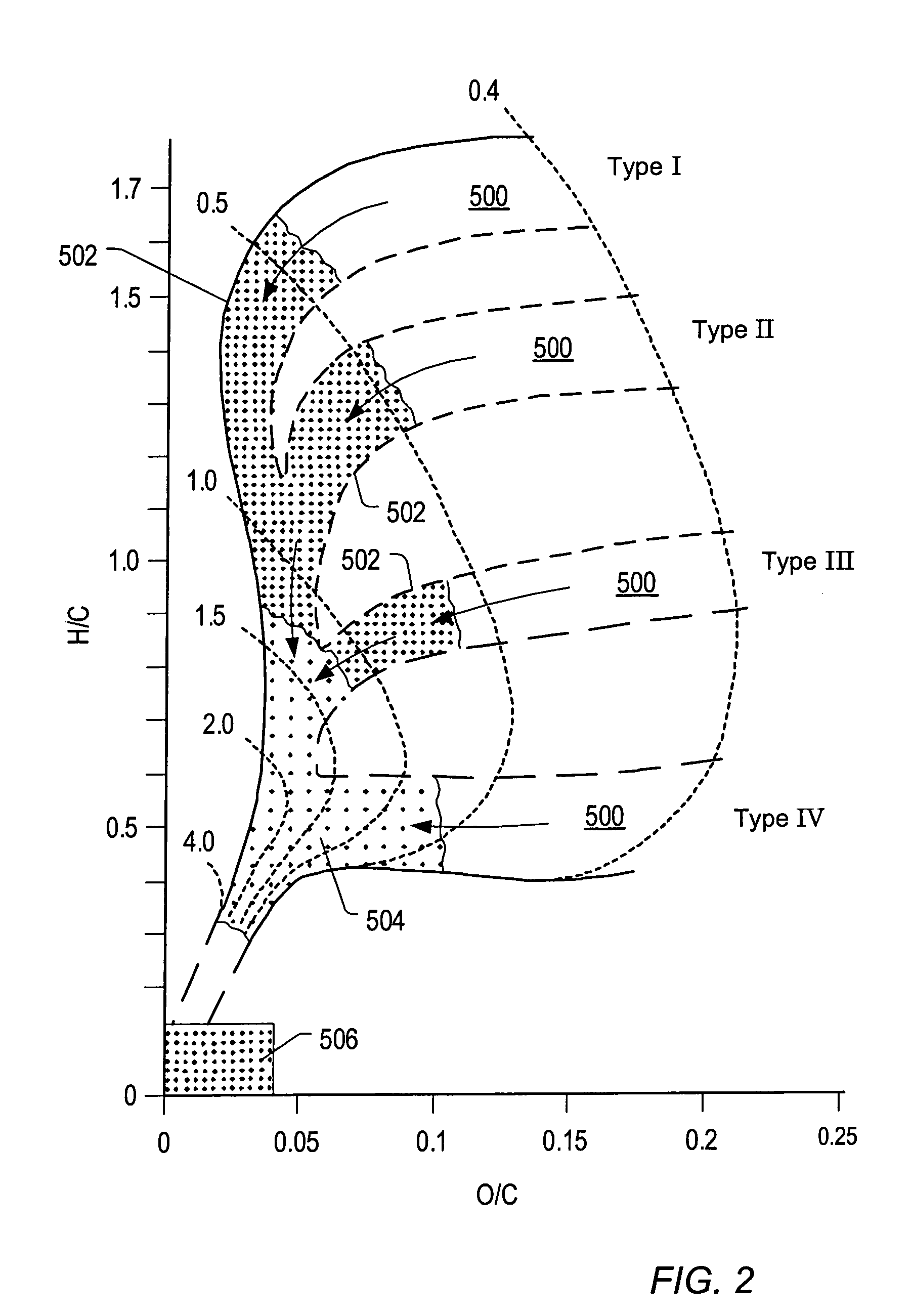

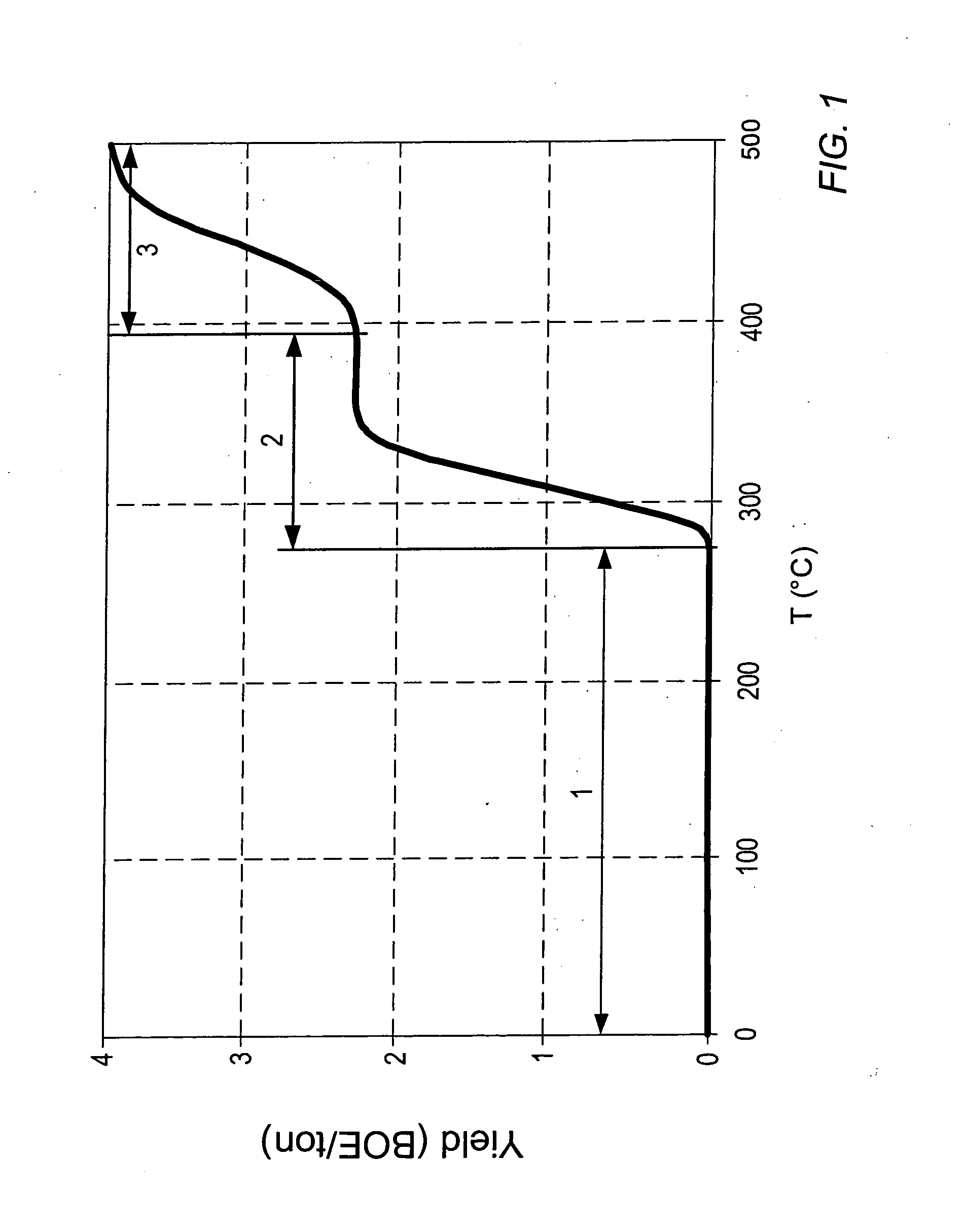

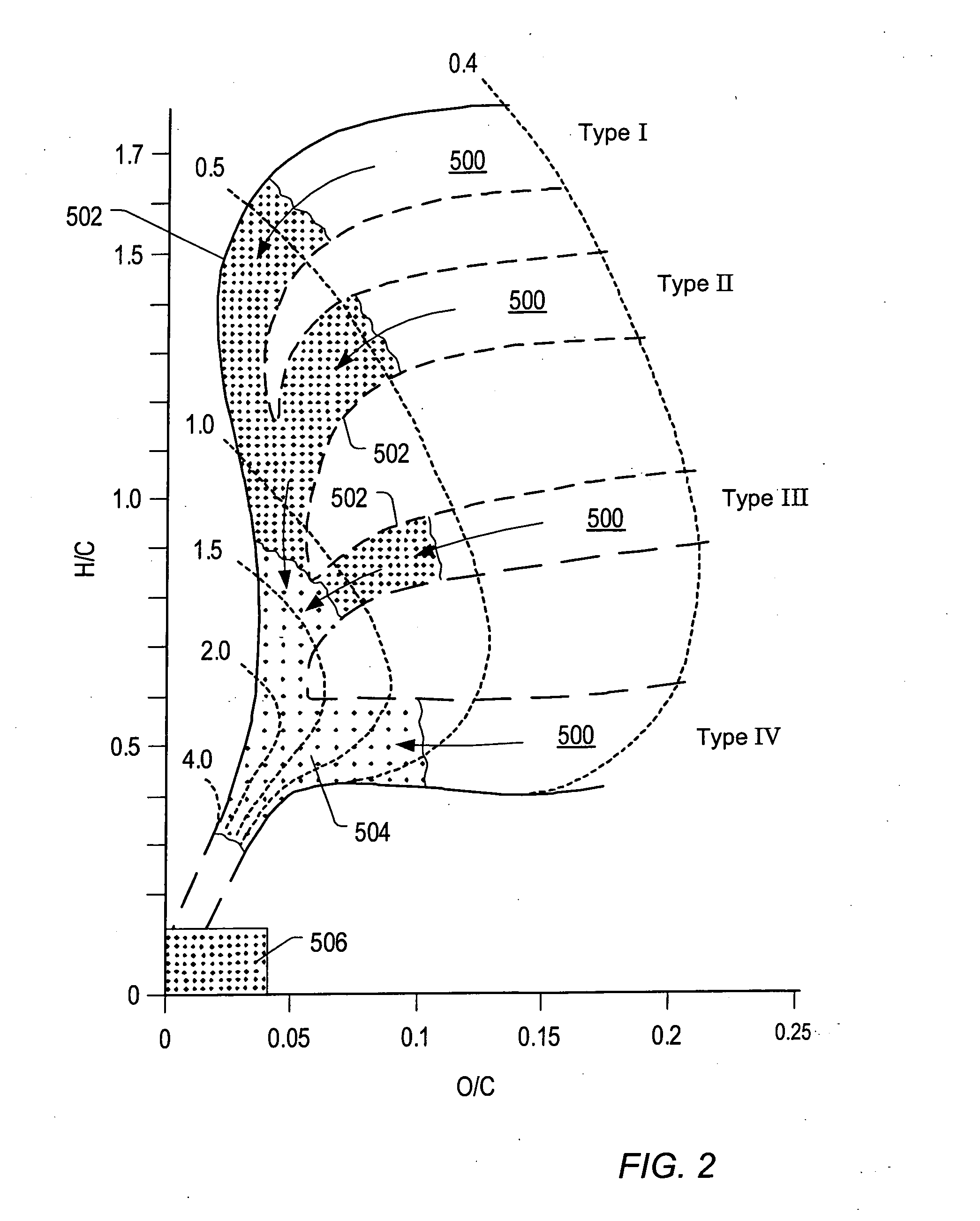

Thermal processes for subsurface formations

A process may include providing heat from one or more heaters to at least a portion of a subsurface formation. Heat may transfer from one or more heaters to a part of a formation. In some embodiments, heat from the one or more heat sources may pyrolyze at least some hydrocarbons in a part of a subsurface formation. Hydrocarbons and / or other products may be produced from a subsurface formation. Certain embodiments describe apparatus, methods, and / or processes used in treating a subsurface or hydrocarbon containing formation.

Owner:SHELL OIL CO

Electro-optical device and electronic device

InactiveUS6689492B1Reduce heatReduce releaseDischarge tube luminescnet screensSemiconductor/solid-state device detailsDisplay deviceEngineering

An object of the present invention is to provide an EL display device, which has a high operating performance and reliability. A third passivation film 45 is disposed under an EL element 203 which comprises a pixel electrode (anode) 46, and EL layer 47 and a cathode 48, to make a structure in which heat generated by the EL element 203 is radiated. Further, the third passivation film 45 prevents alkali metals within the EL element 203 from diffusing into the TFTs side, and prevents moisture and oxygen of the TFTs side from penetrating into the EL element 203. More preferably, heat radiating effect is given to a fourth passivation film 50 to make the EL element 203 to be enclosed by heat radiating layers.

Owner:SEMICON ENERGY LAB CO LTD

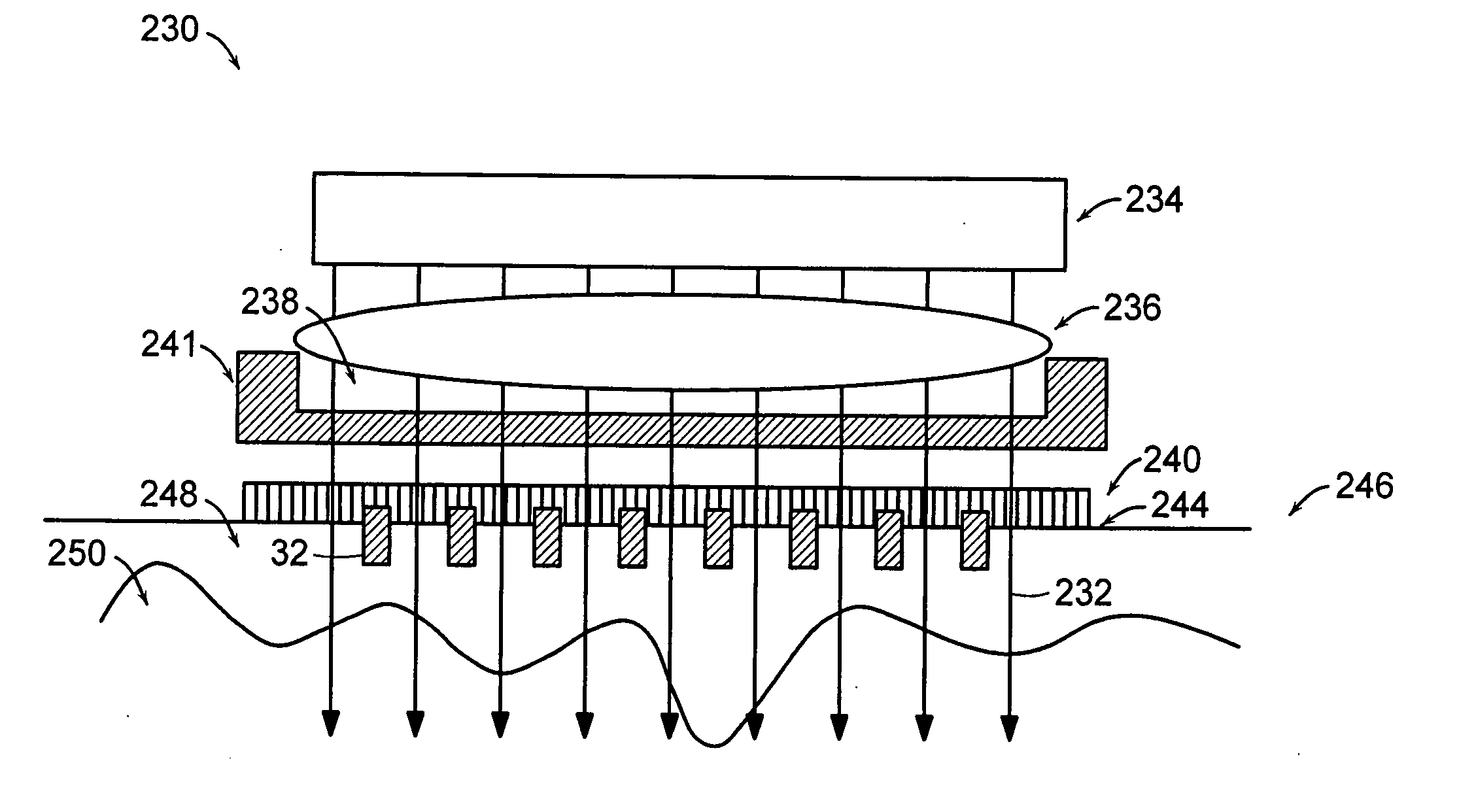

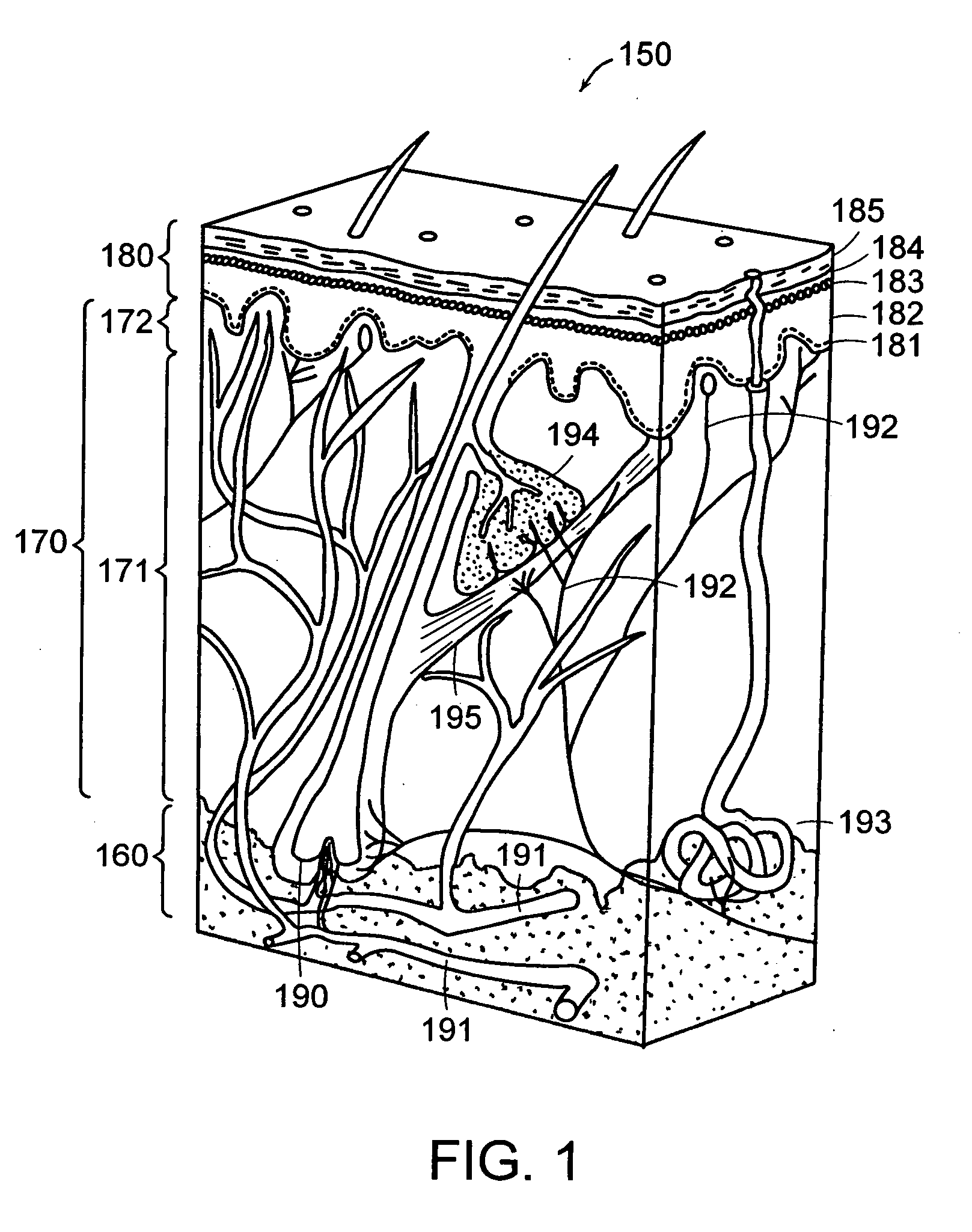

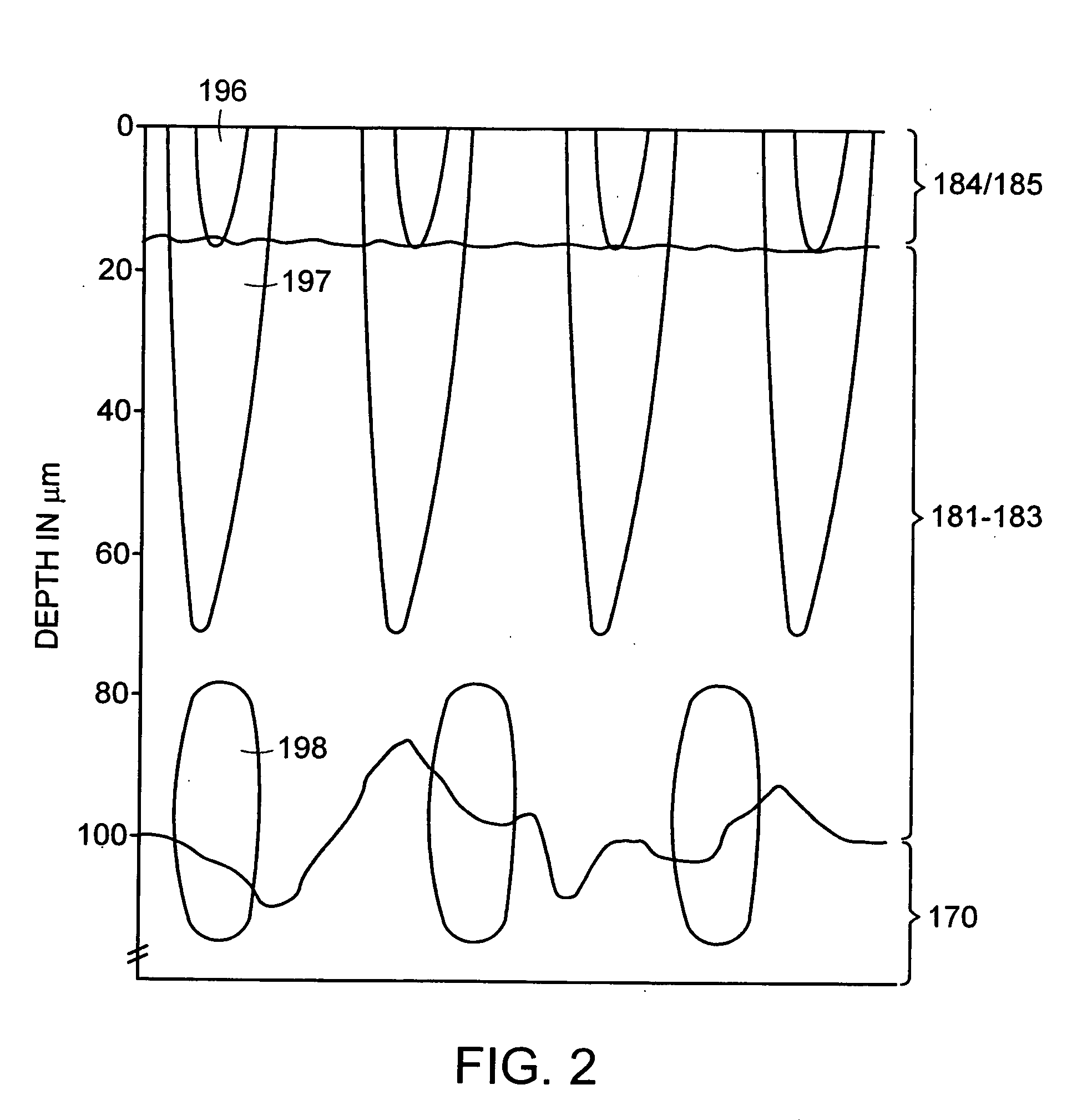

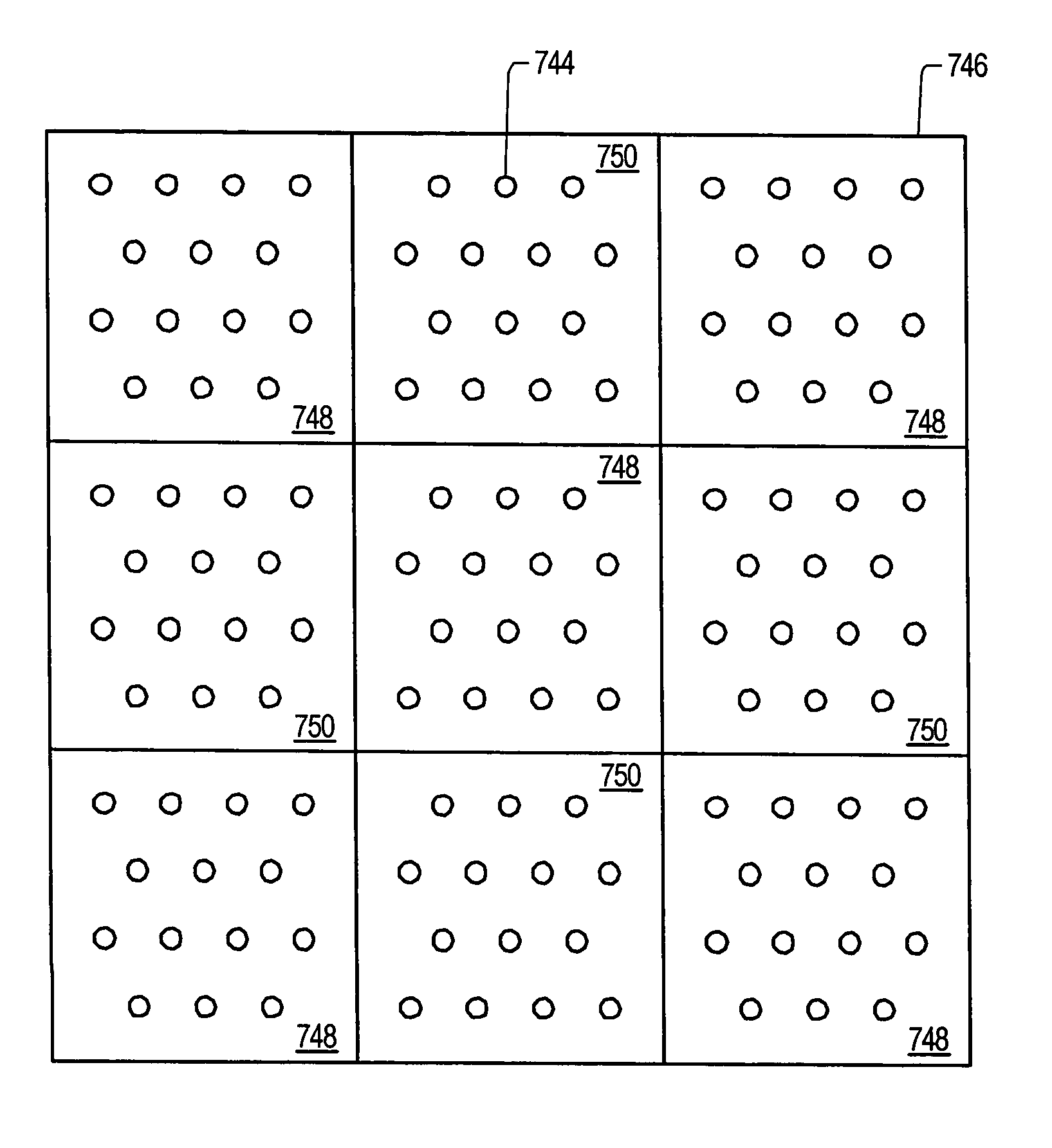

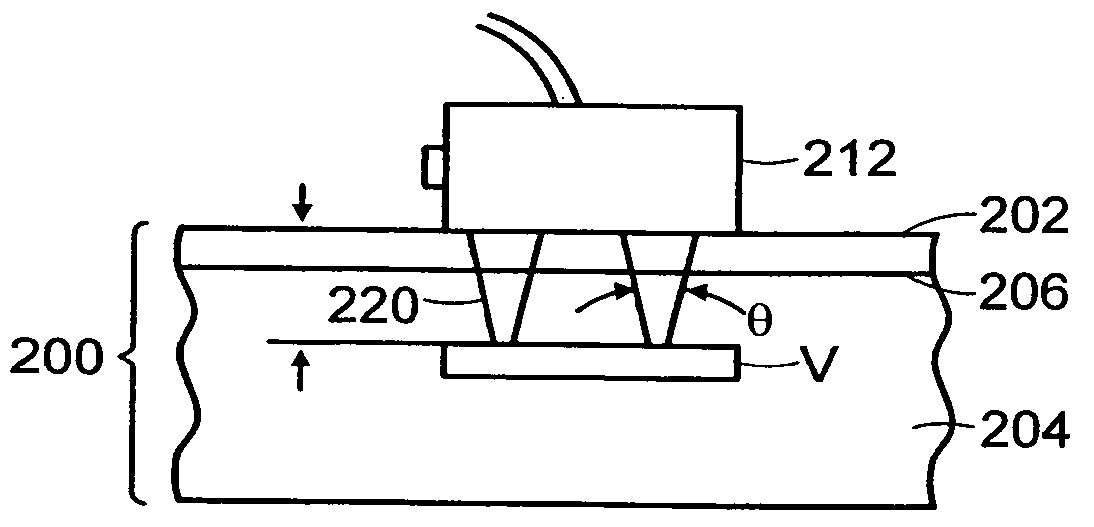

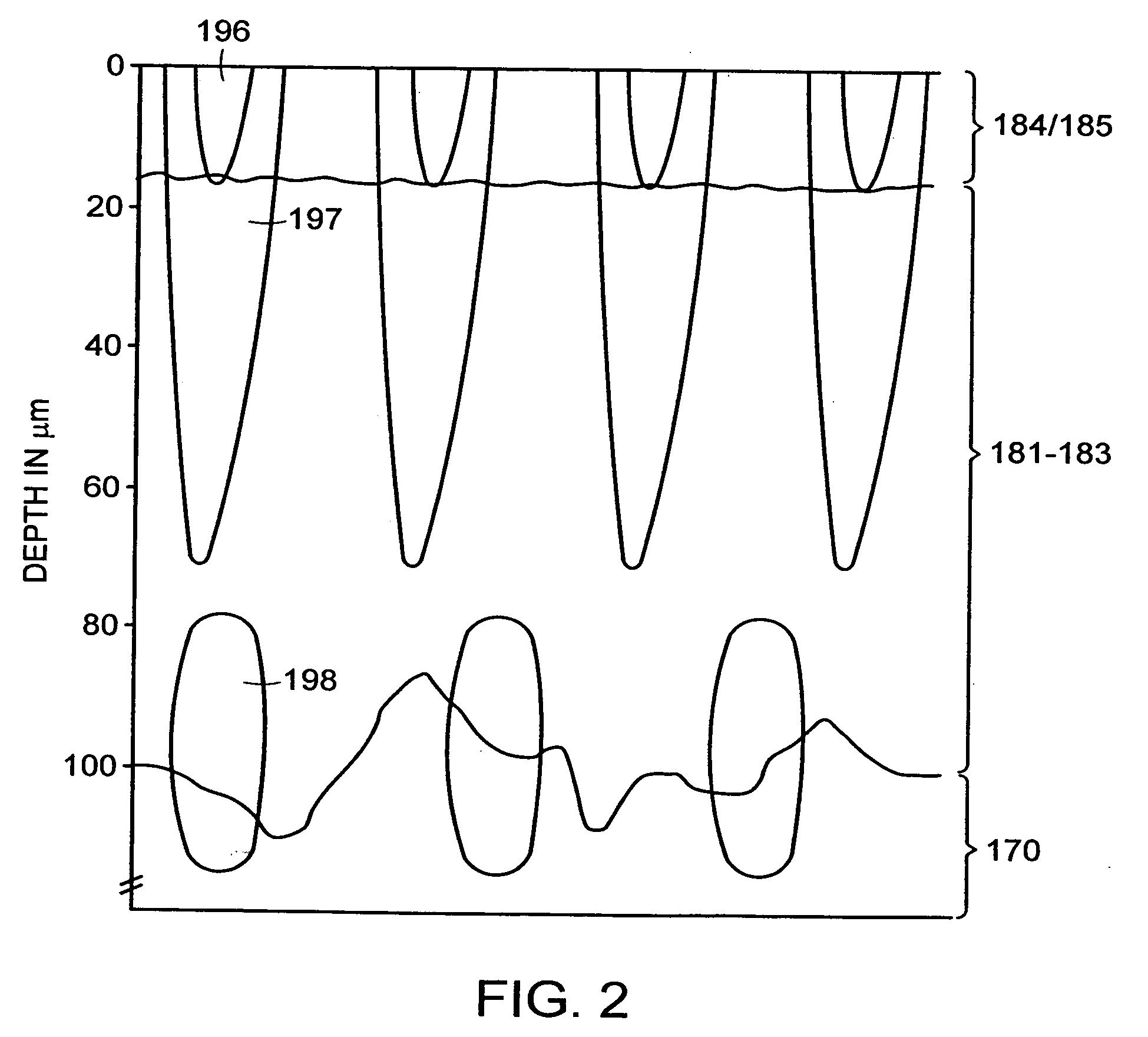

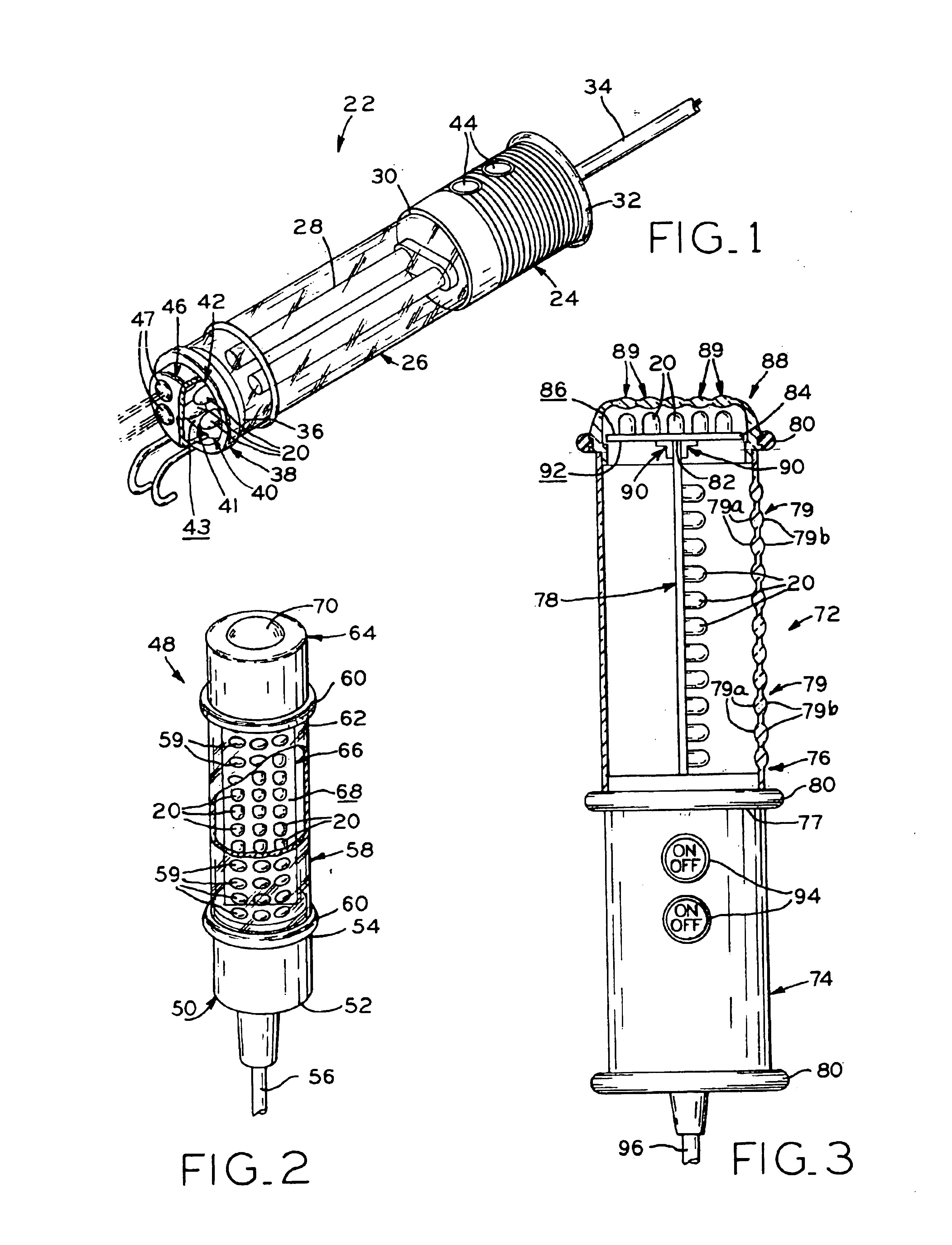

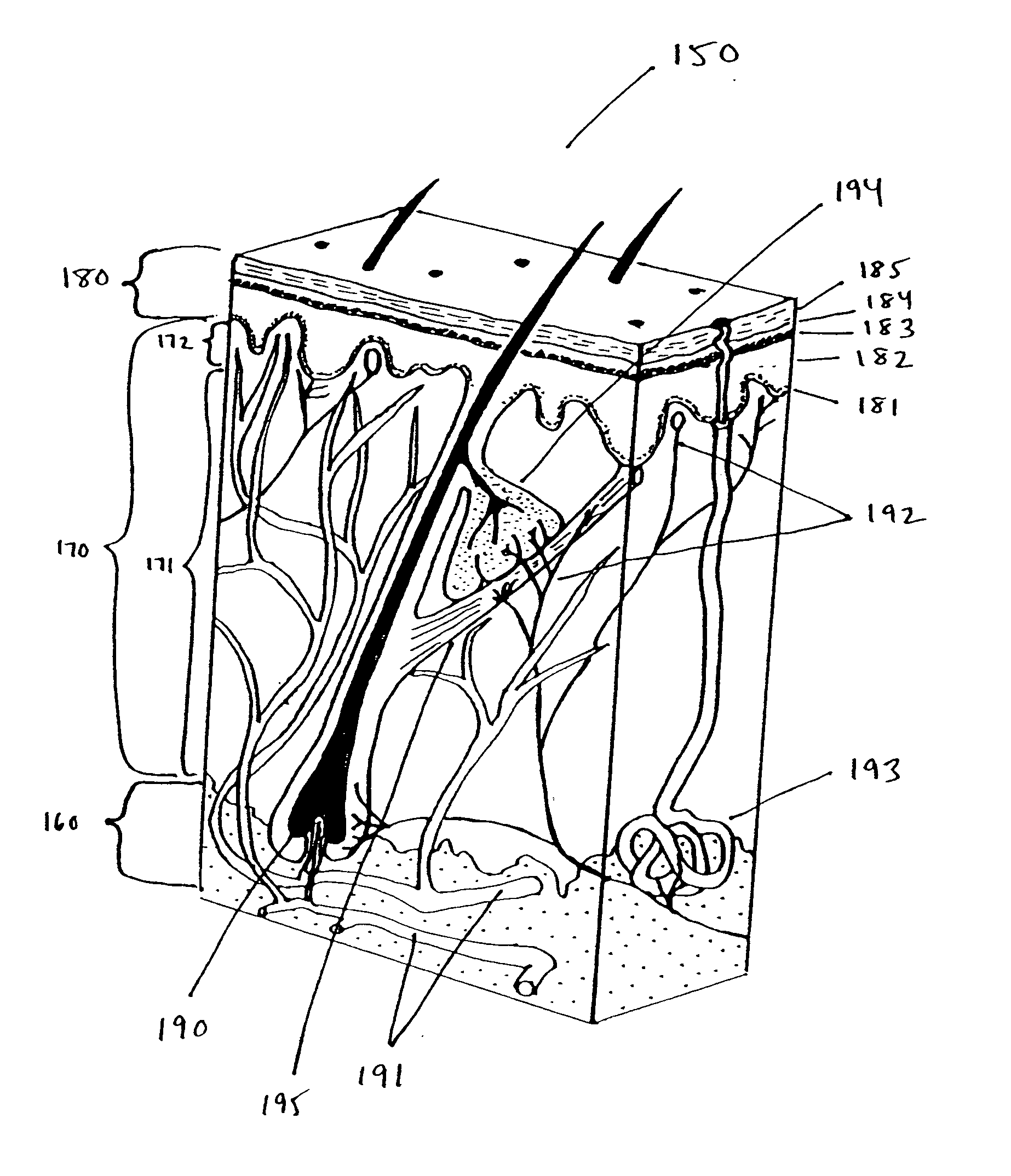

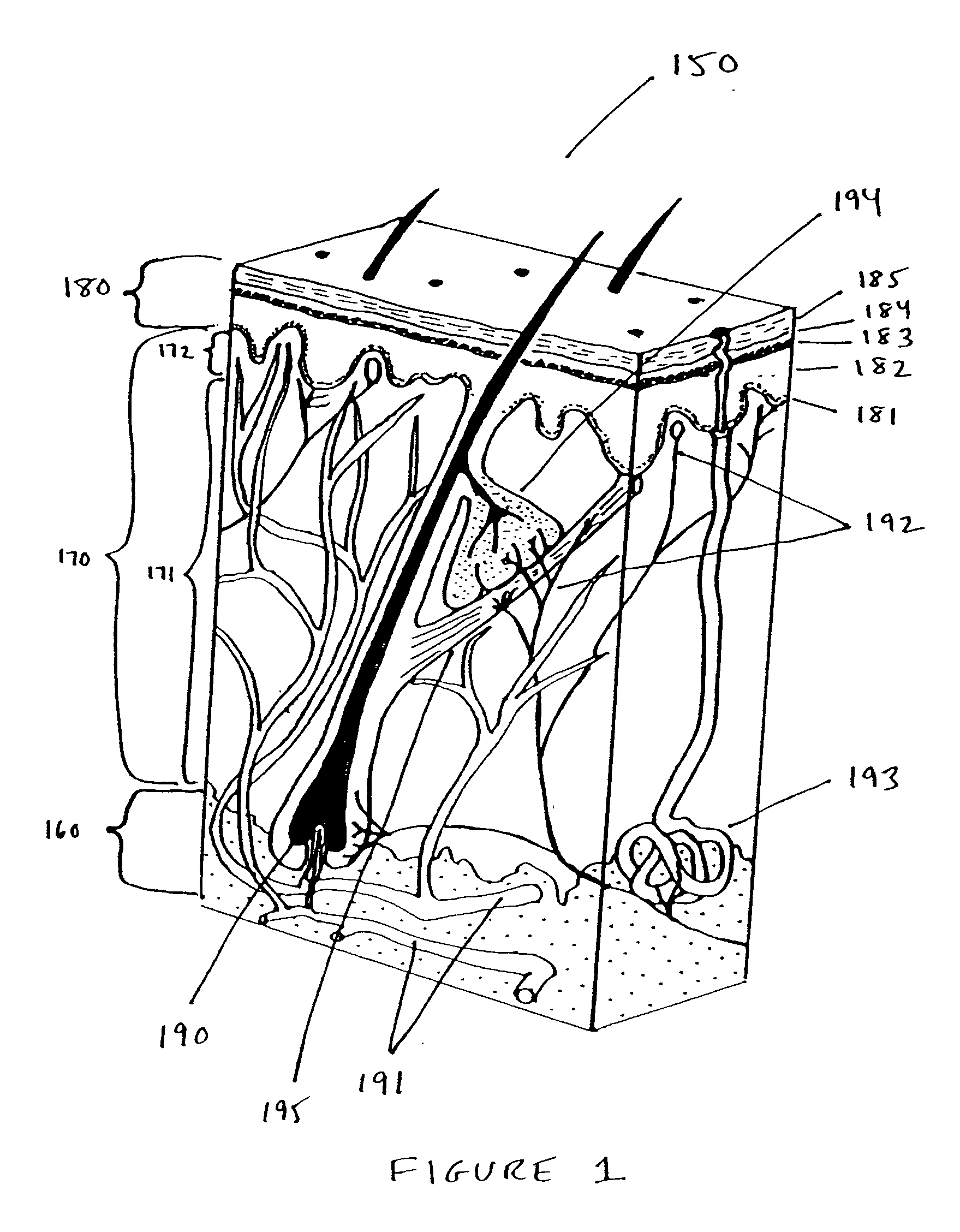

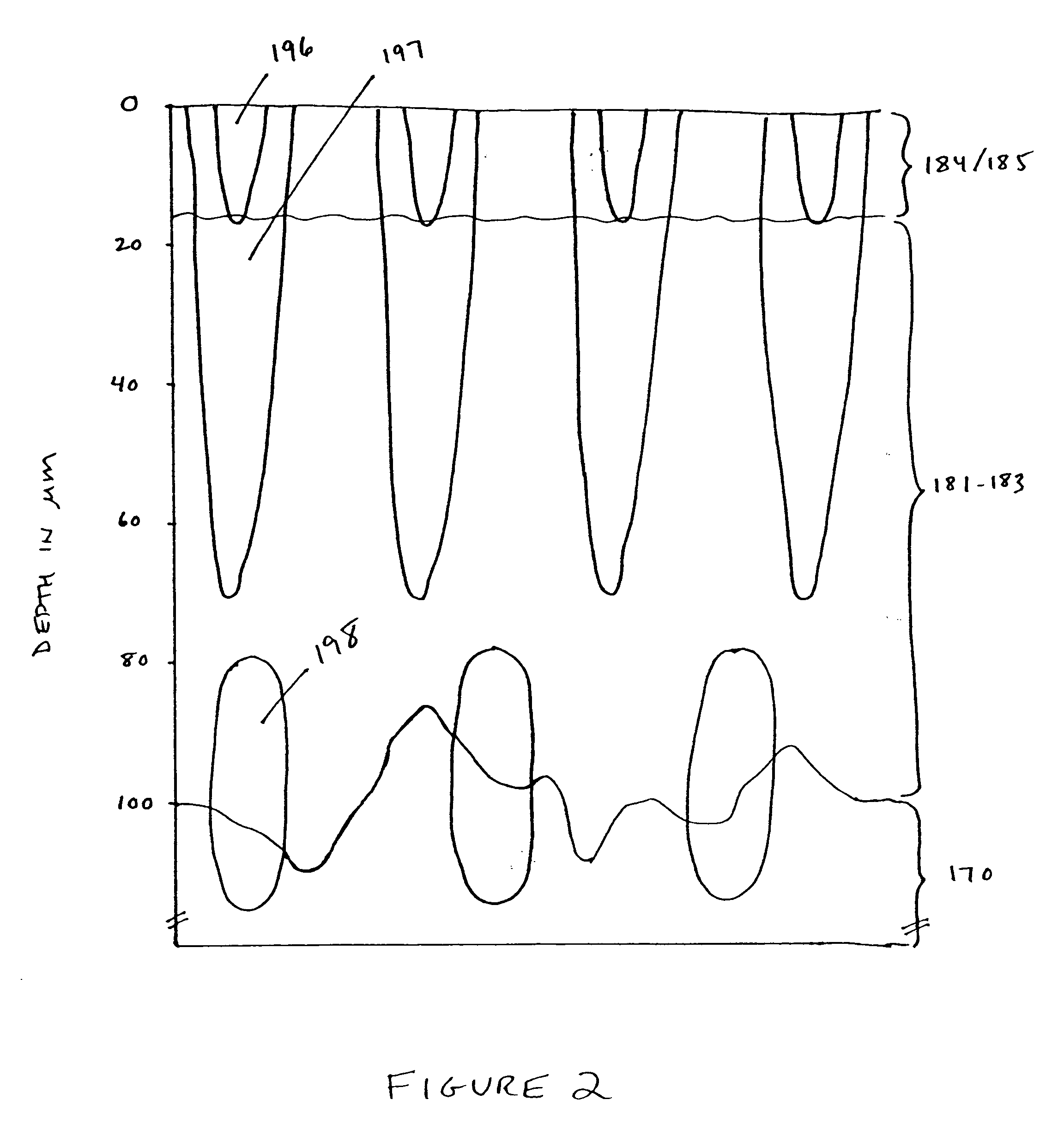

Methods and products for producing lattices of EMR-treated islets in tissues, and uses therefor

InactiveUS20060004306A1Big advantageSufficient amountElectrotherapyChiropractic devicesElectromagnetic radiationBiomedical engineering

Methods of treatment of tissue with electromagnetic radiation (EMR) to produce lattices of EMR-treated islets in the tissue are disclosed. Also disclosed are devices and systems for producing lattices of EMR-treated islets in tissue, and cosmetic and medical applications of such devices and systems.

Owner:PALOMAR MEDICAL TECH

Staged and/or patterned heating during in situ thermal processing of a hydrocarbon containing formation

A method for treating a hydrocarbon containing formation is described. The method for treating a hydrocarbon containing formation may include heating a first volume of the formation using a first set of heaters. A second volume of the formation may be heated using a second set of heaters. The first volume may be spaced apart from the second volume by a third volume of the formation. The first volume, second volume, and / or third volume may be sized, shaped, and / or located to inhibit deformation of subsurface equipment caused by geomechanical motion of the formation during heating.

Owner:SHELL OIL CO

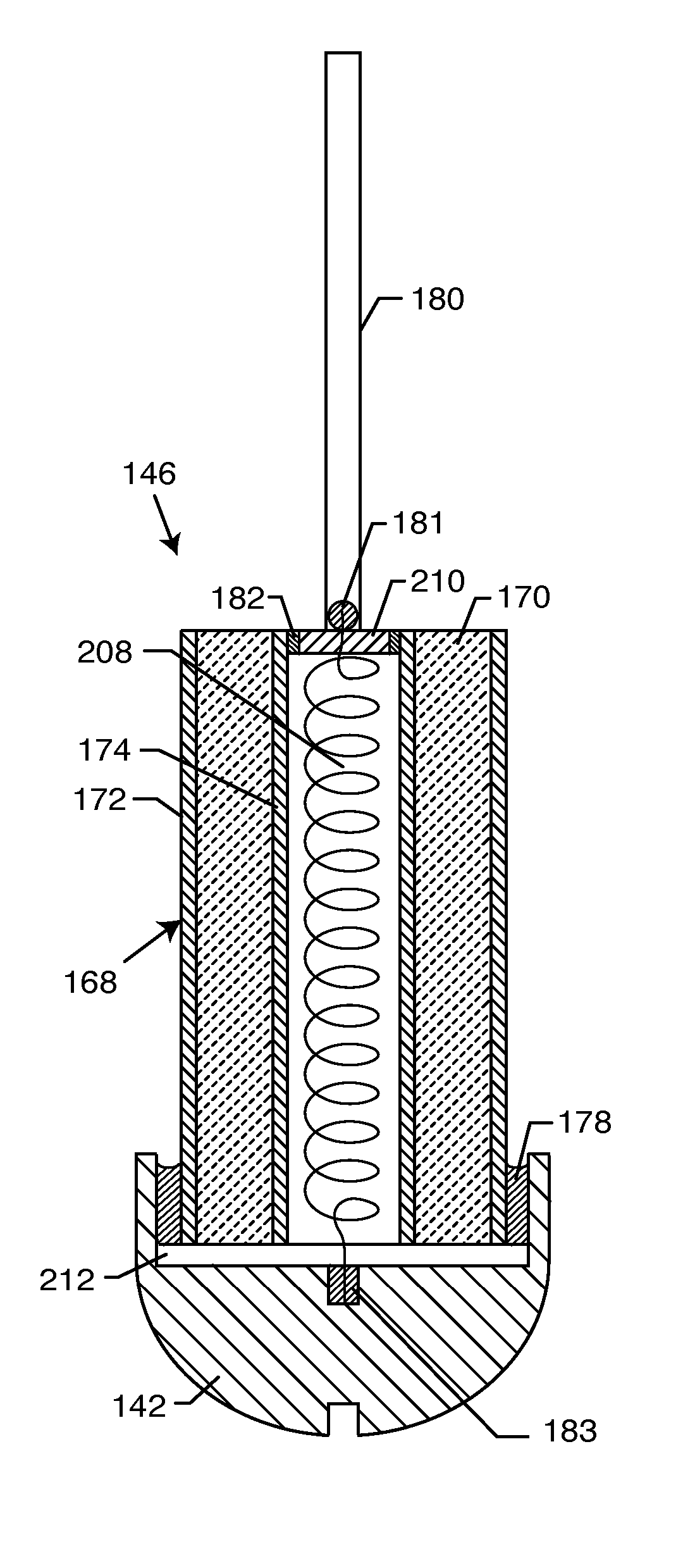

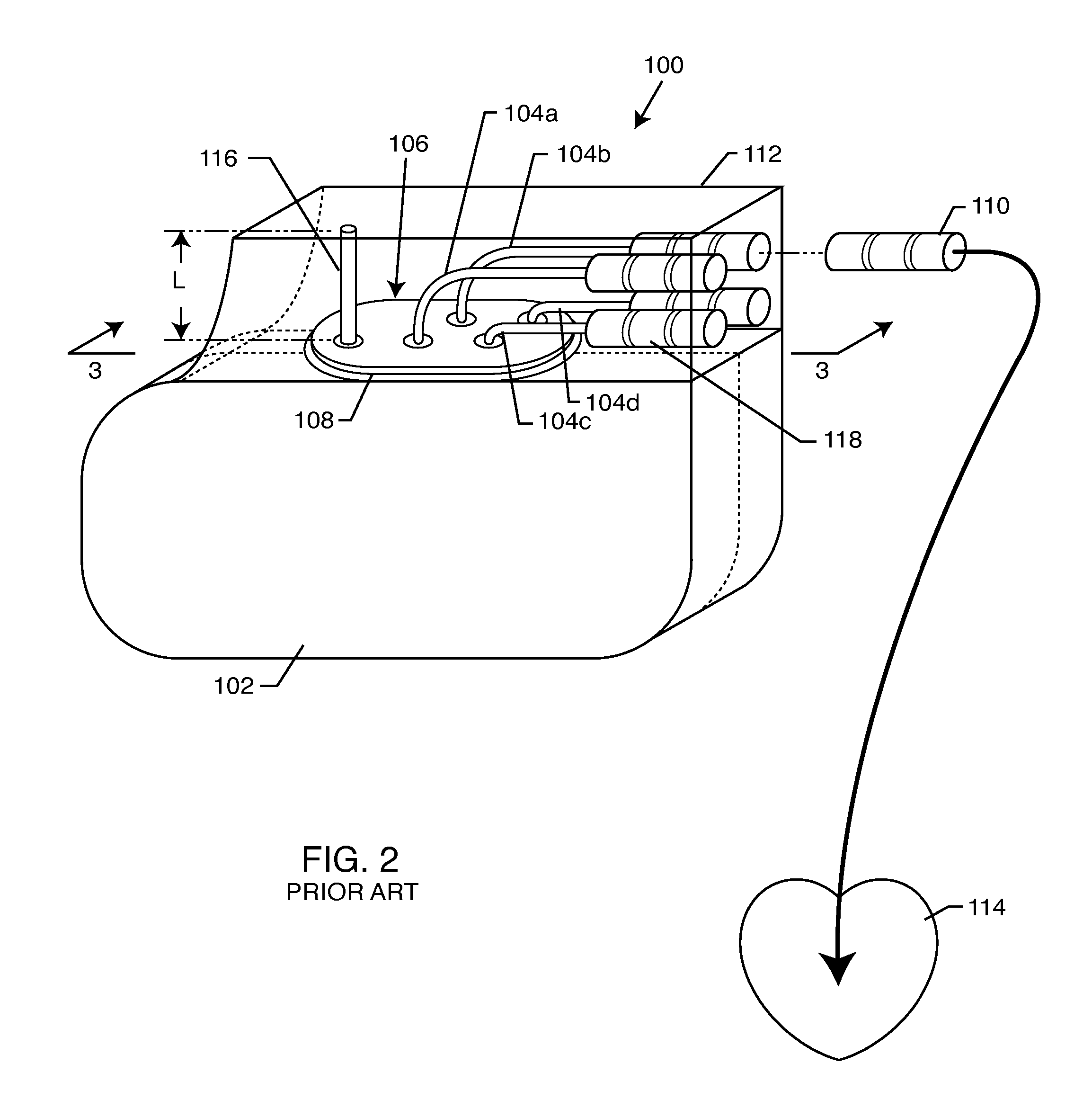

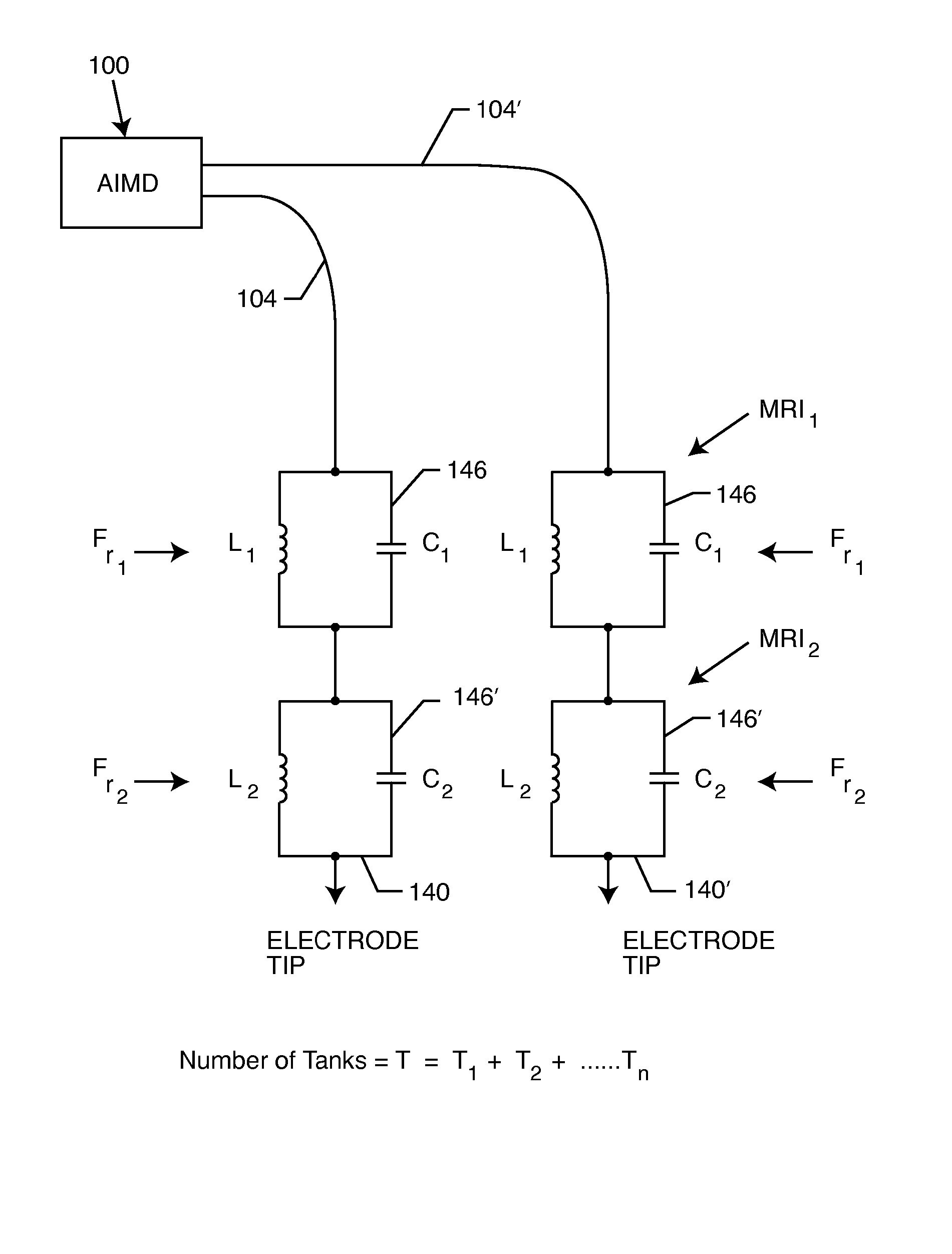

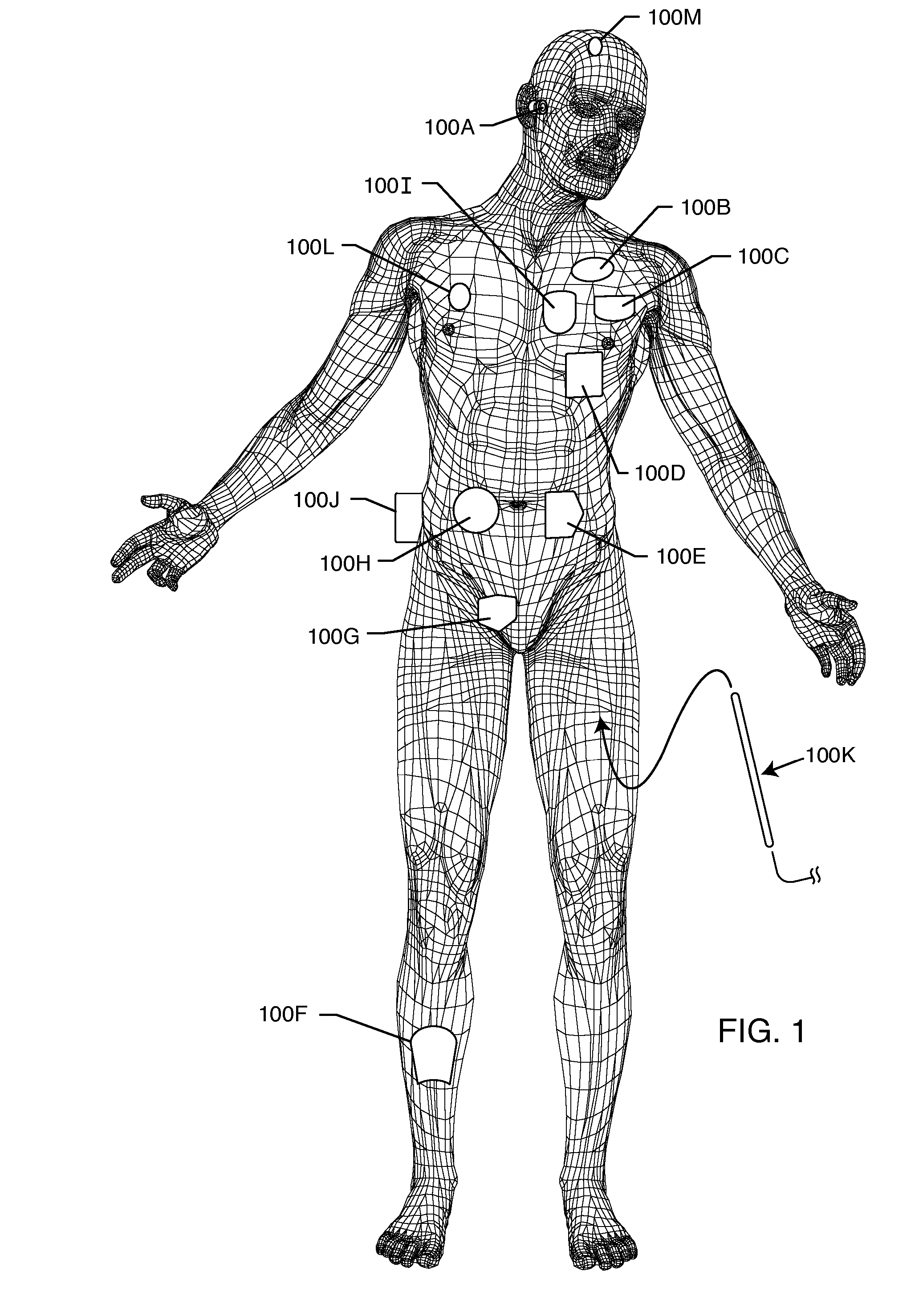

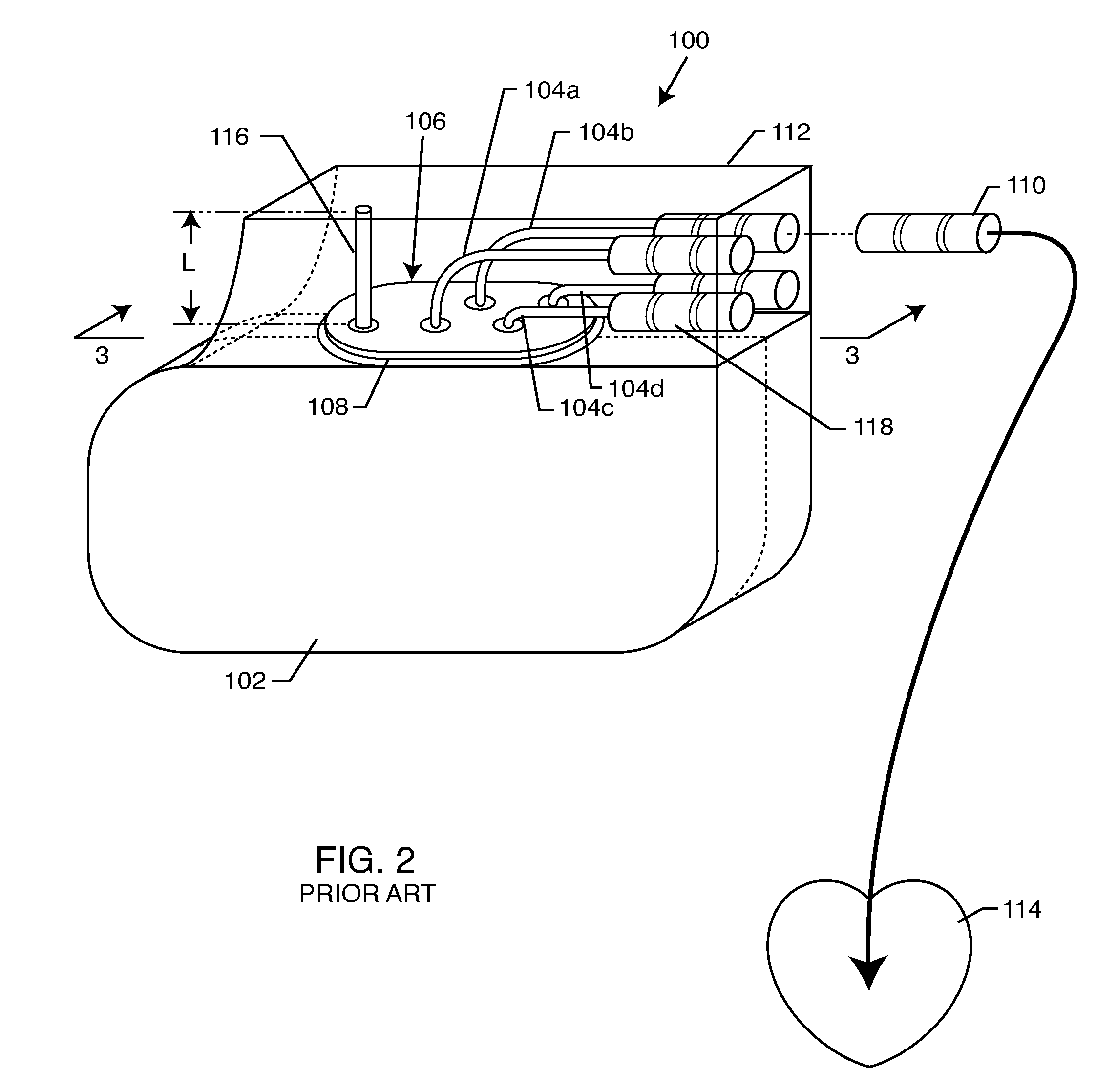

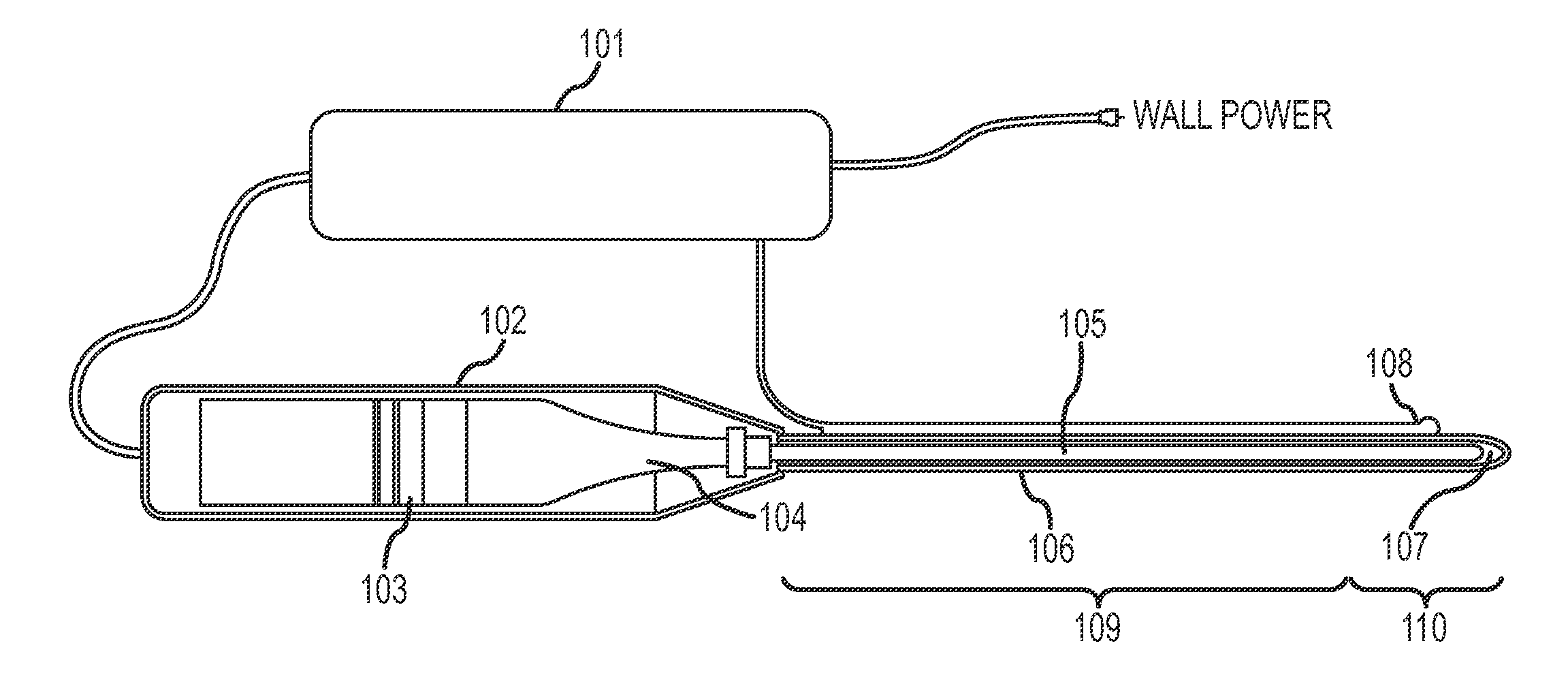

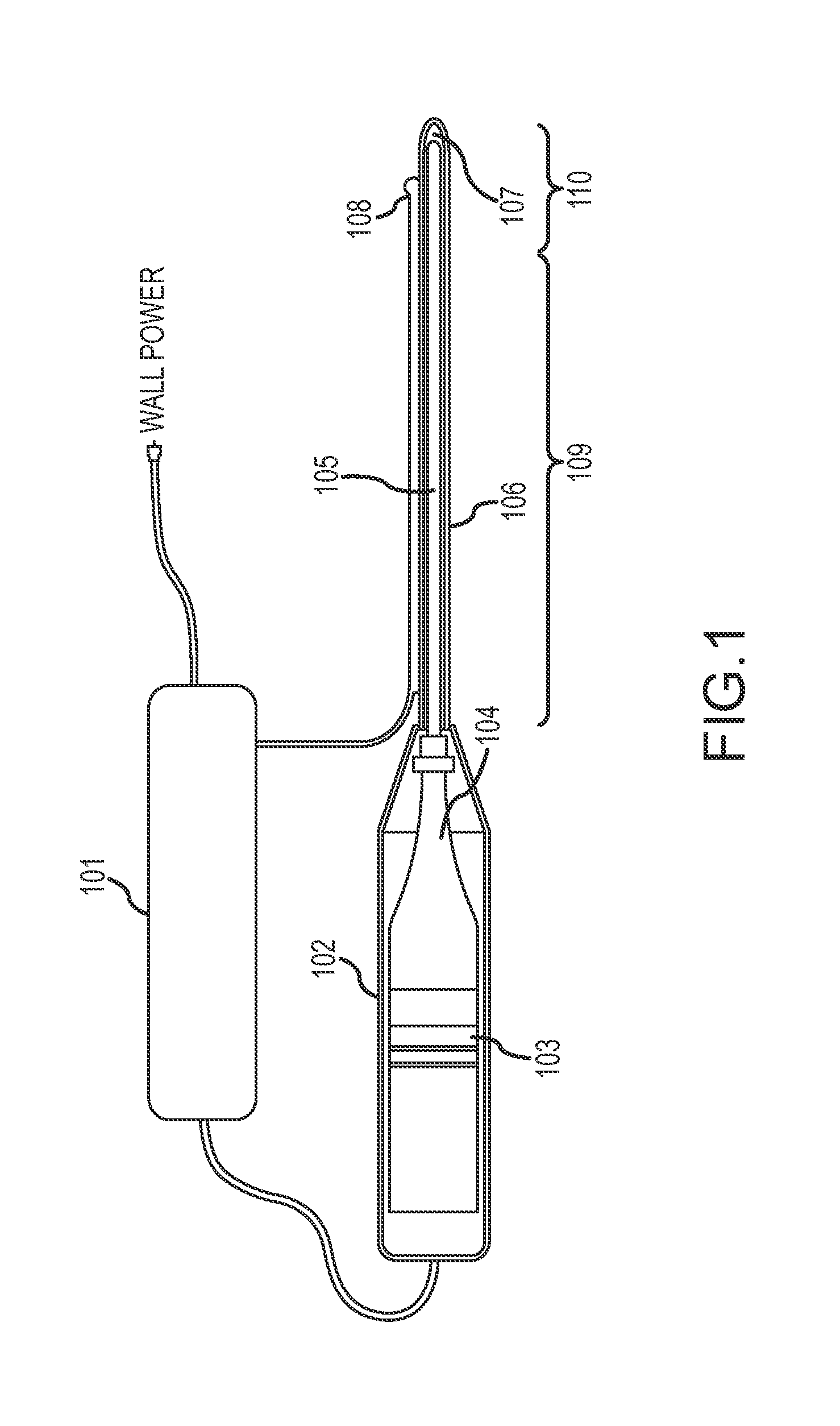

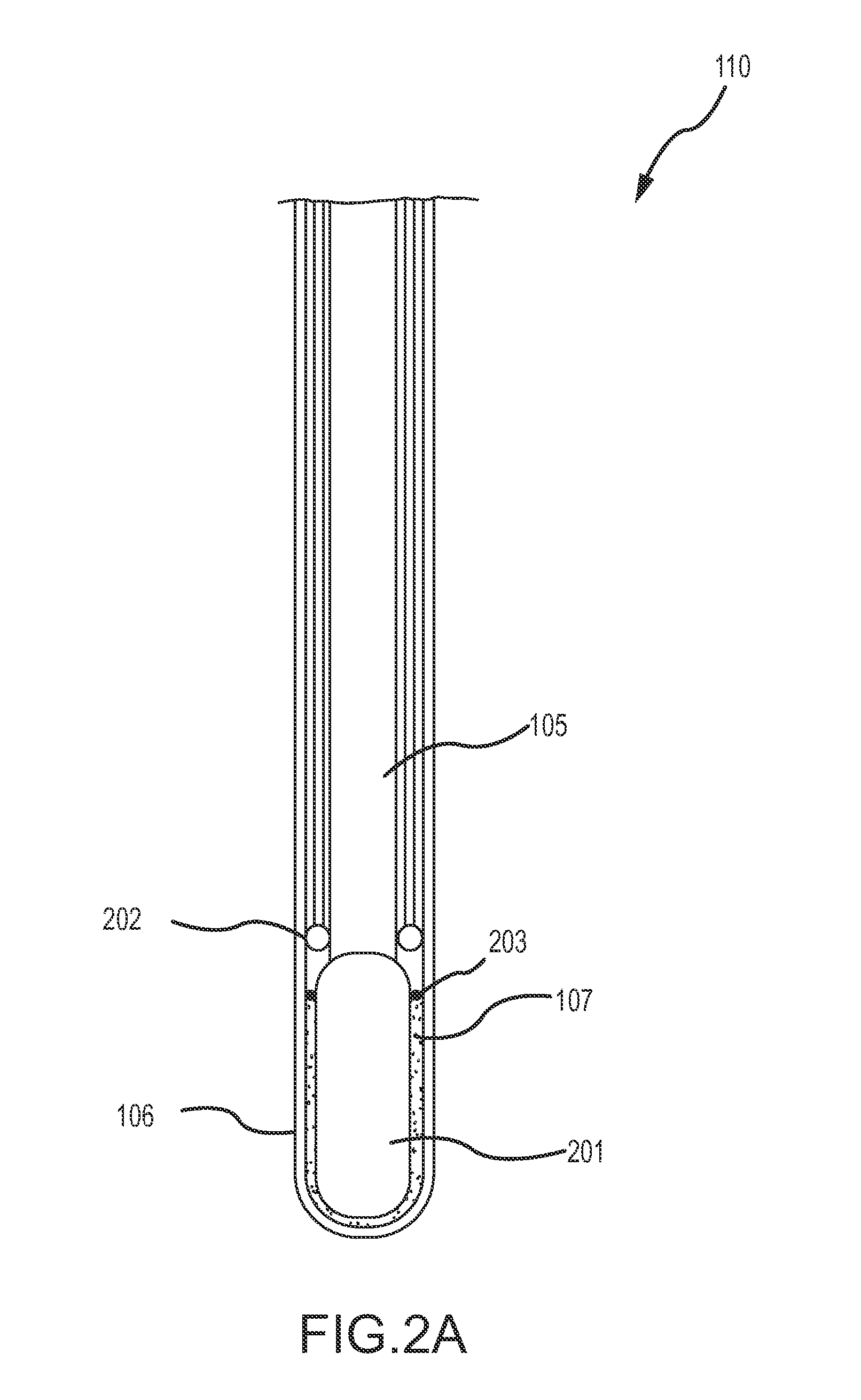

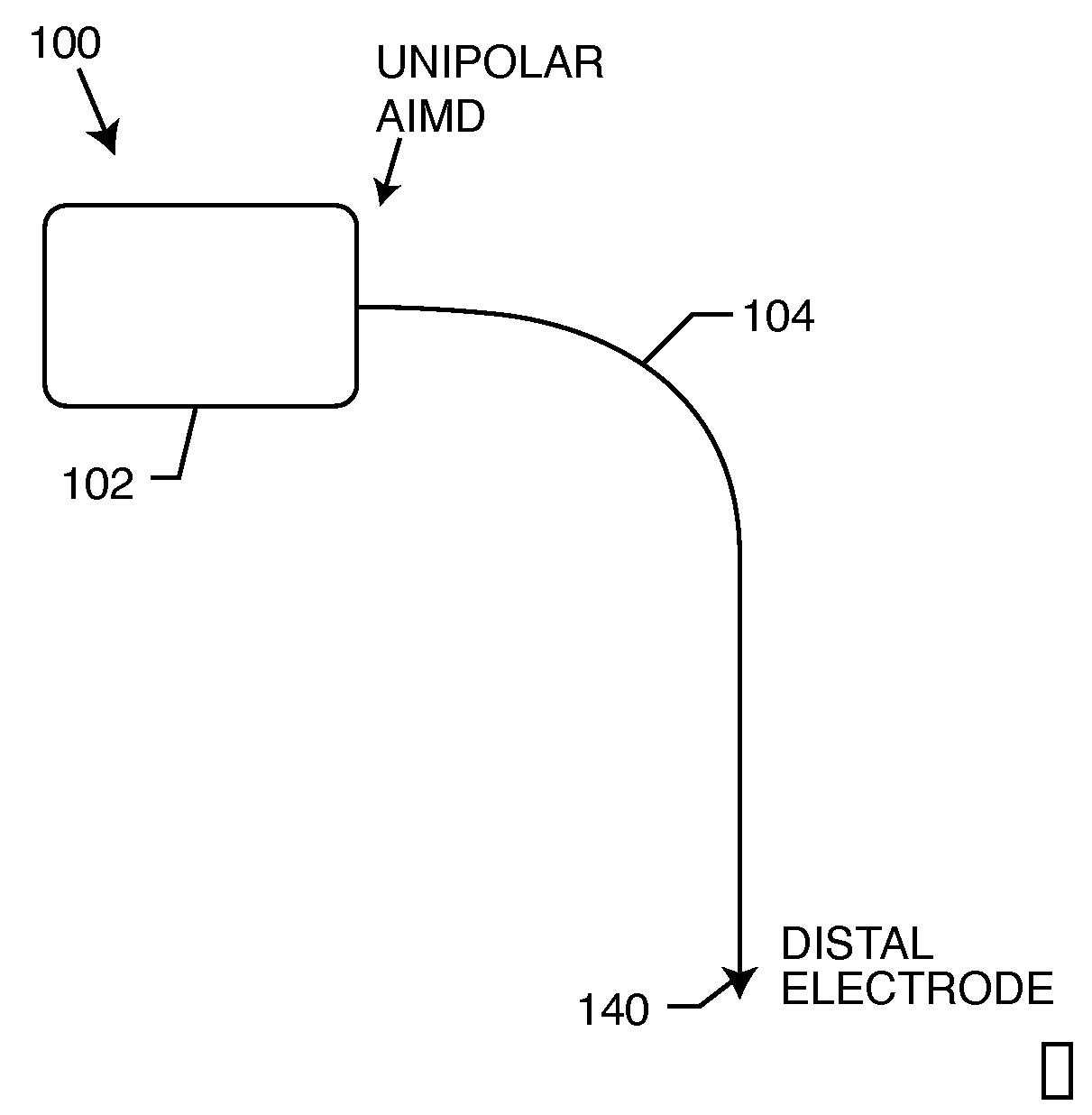

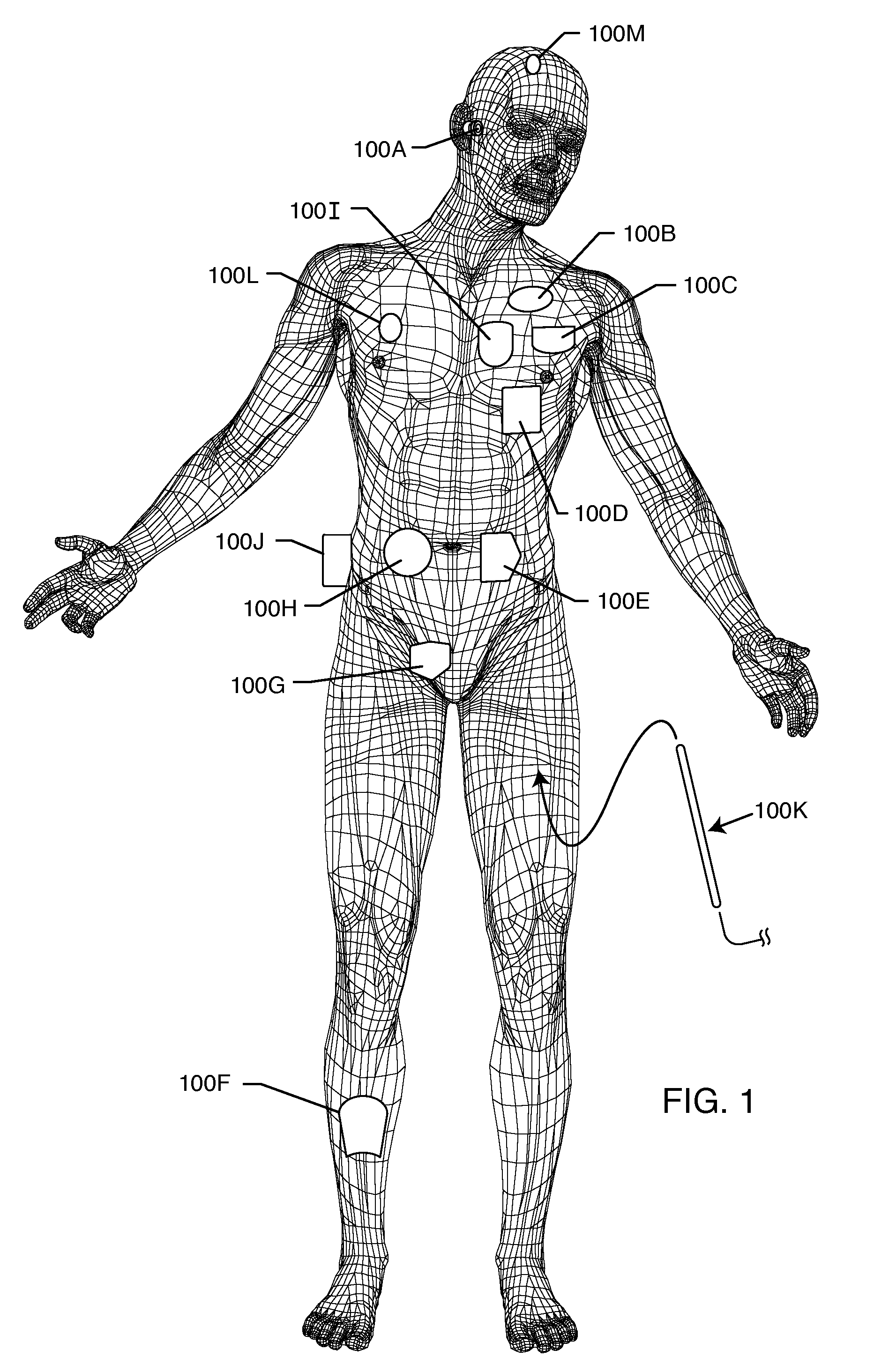

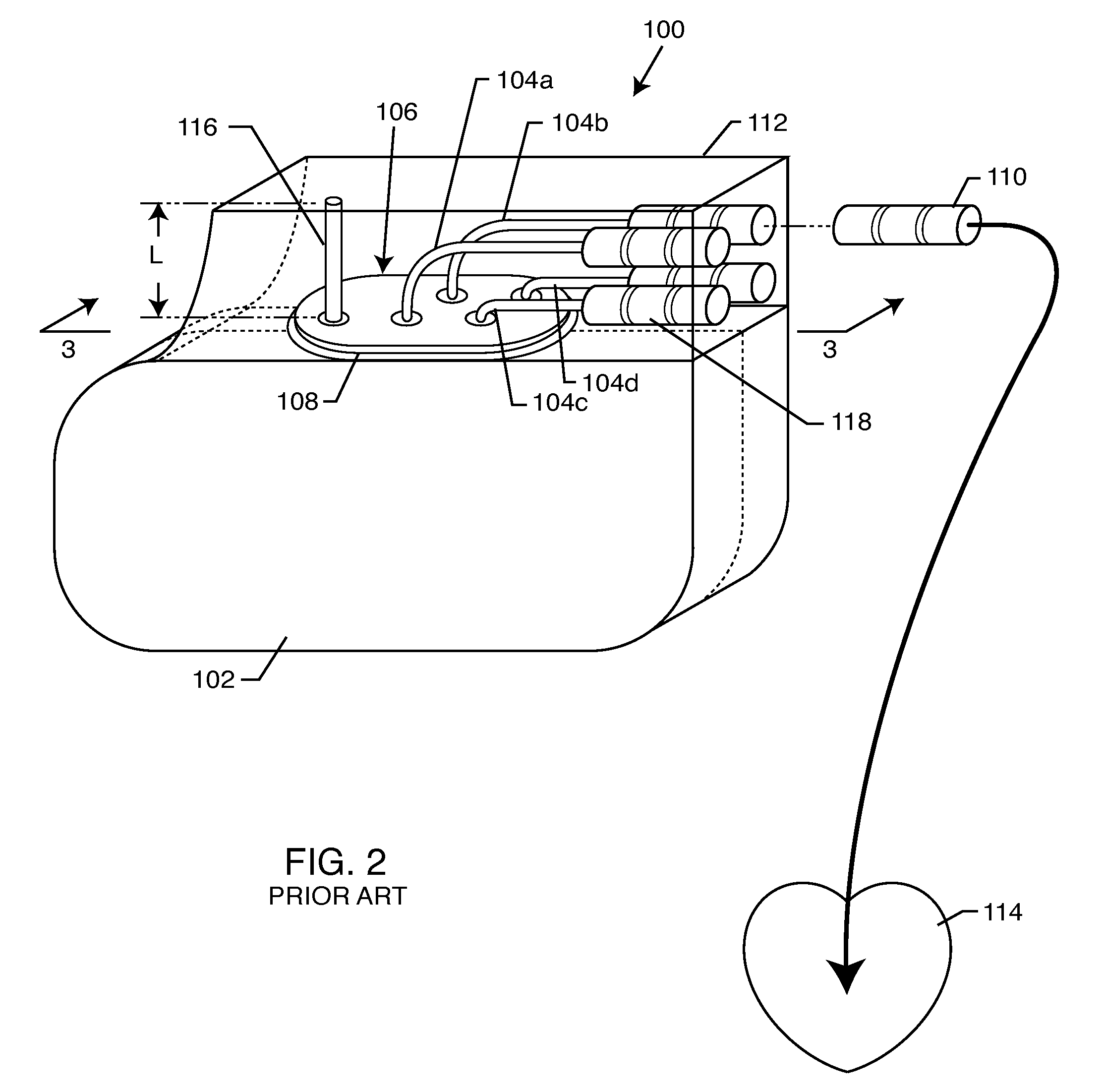

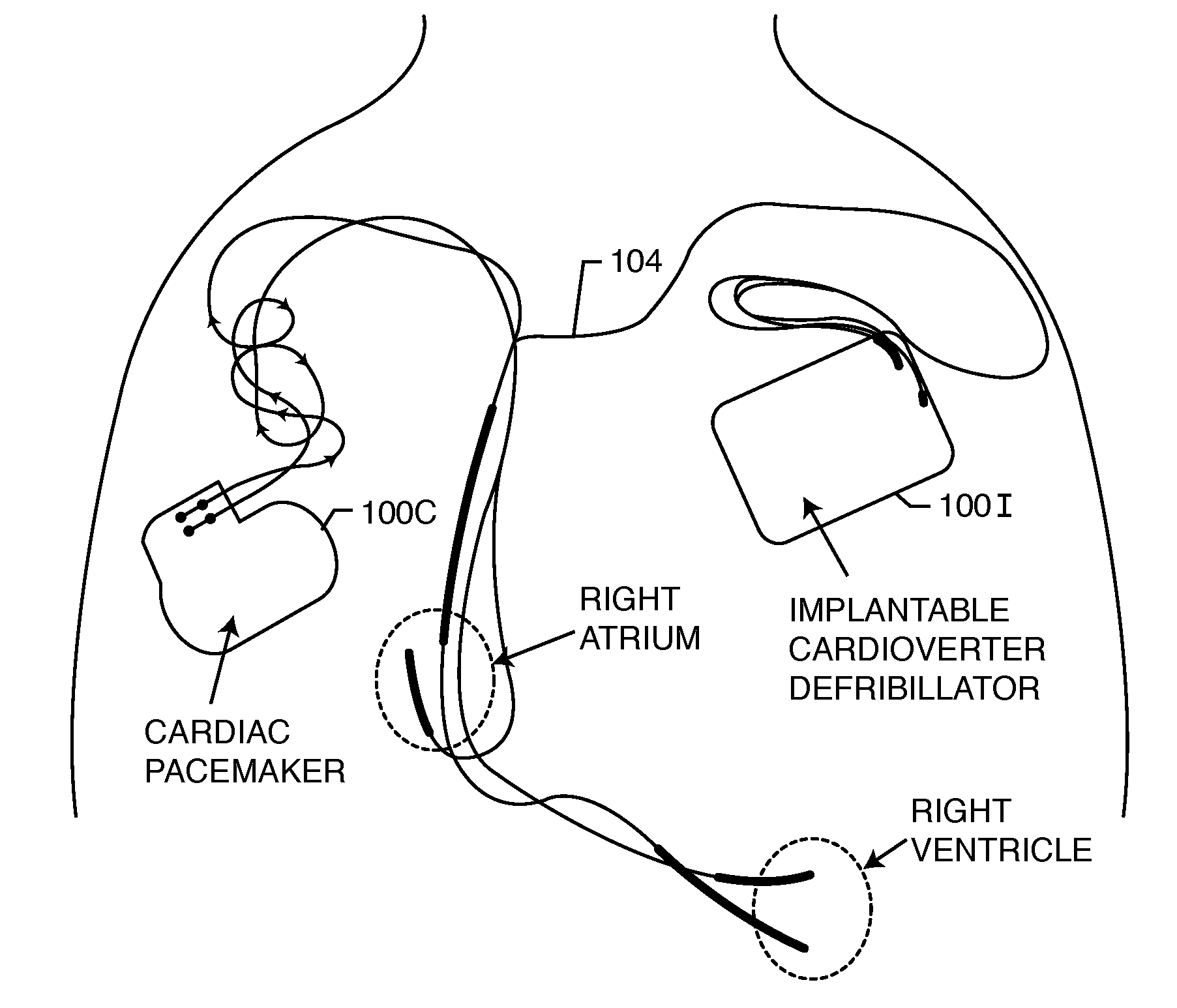

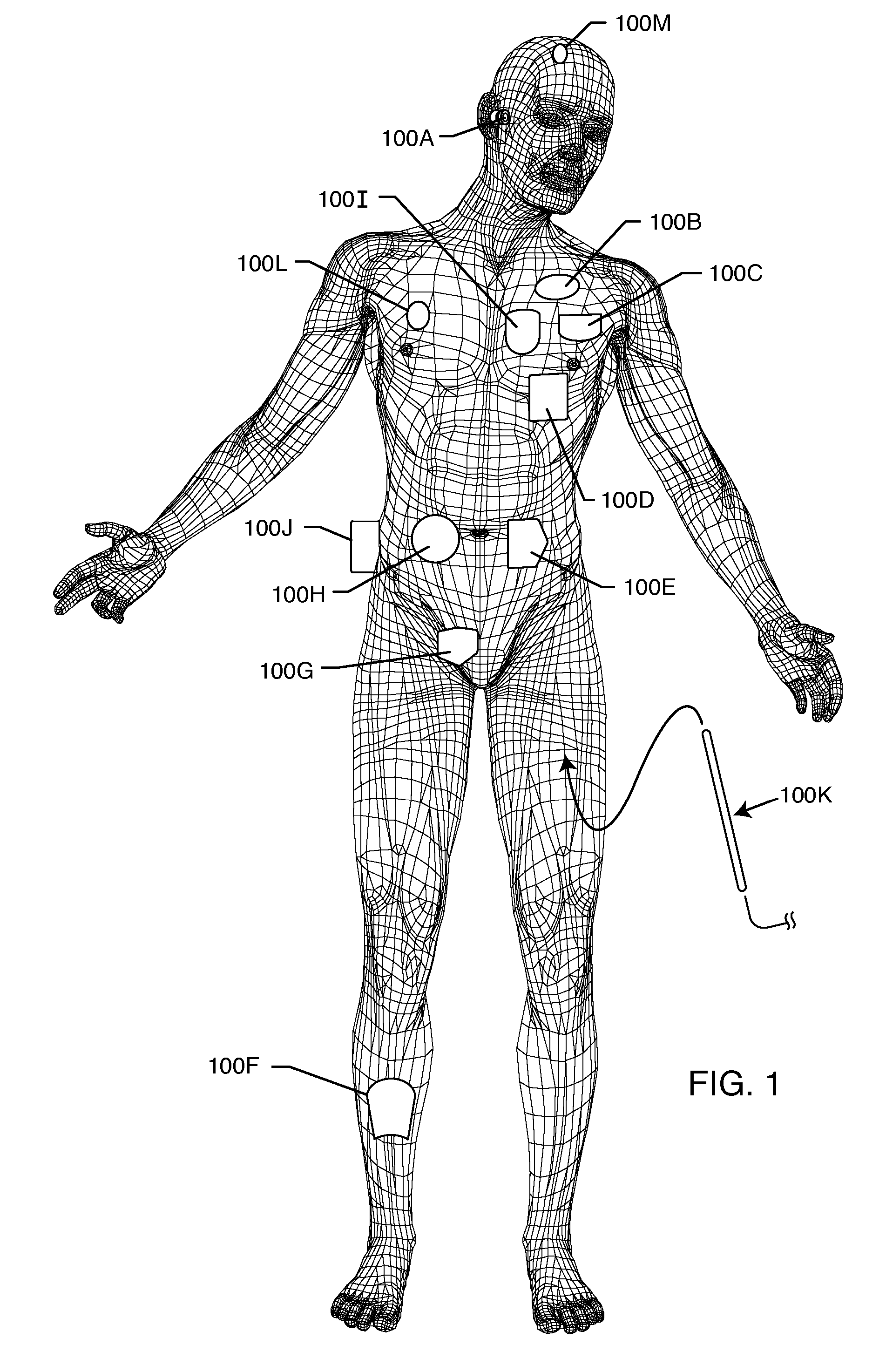

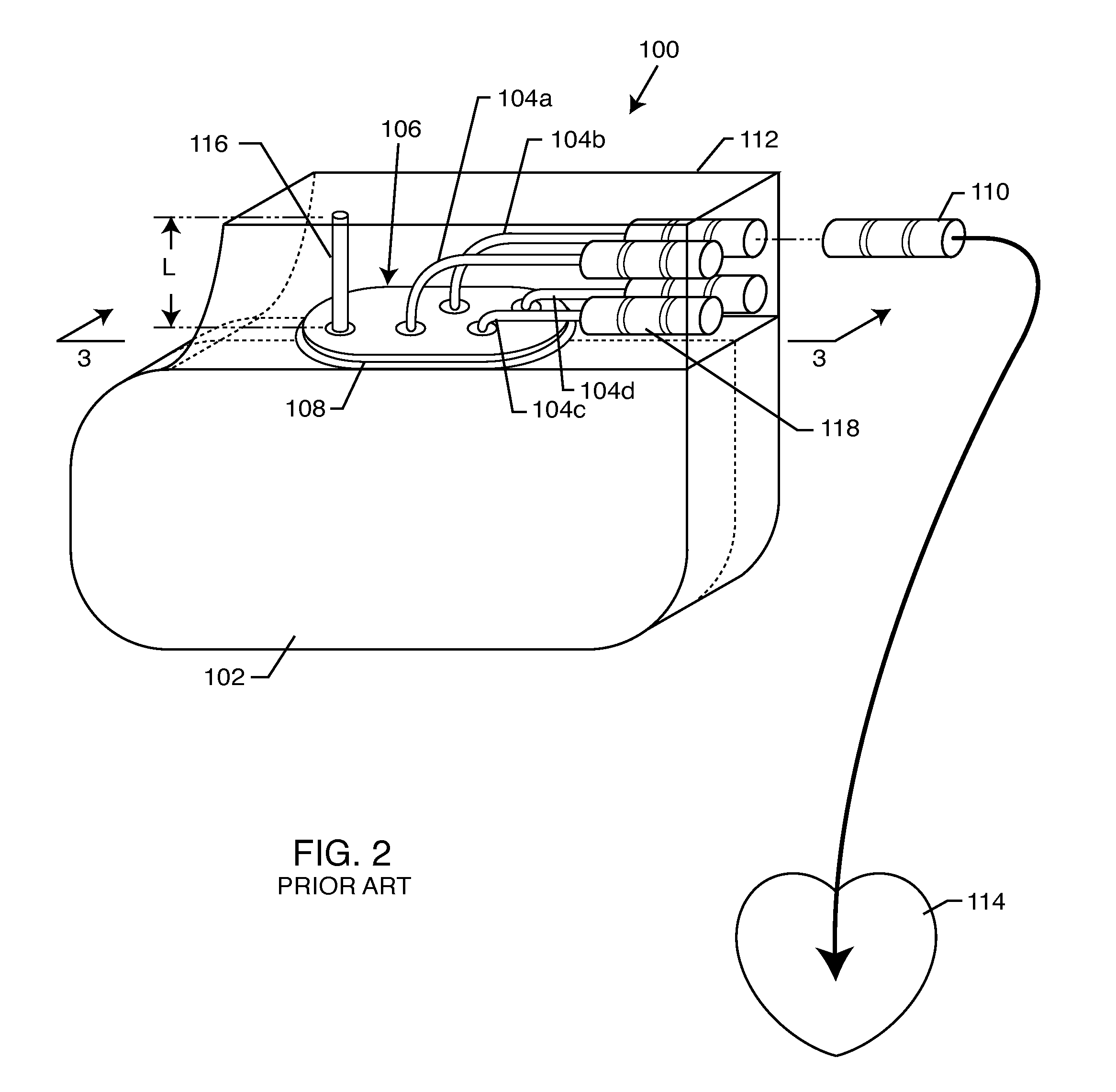

Tank filters placed in series with the lead wires or circuits of active medical devices to enhance MRI compatibility

ActiveUS20070112398A1Rapid imageryReduce sensitivityMultiple-port networksAnti-noise capacitorsMri compatibilityInductor

A TANK filter is provided for a lead wire of an active medical device (AMD). The TANK filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the TANK filter is resonant at a selected frequency. The Q of the inductor may be relatively maximized and the Q of the capacitor may be relatively minimized to reduce the overall Q of the TANK filter to attenuate current flow through the lead wire along a range of selected frequencies. In a preferred form, the TANK filter is integrated into a TIP and / or RING electrode for an active implantable medical device.

Owner:WILSON GREATBATCH LTD

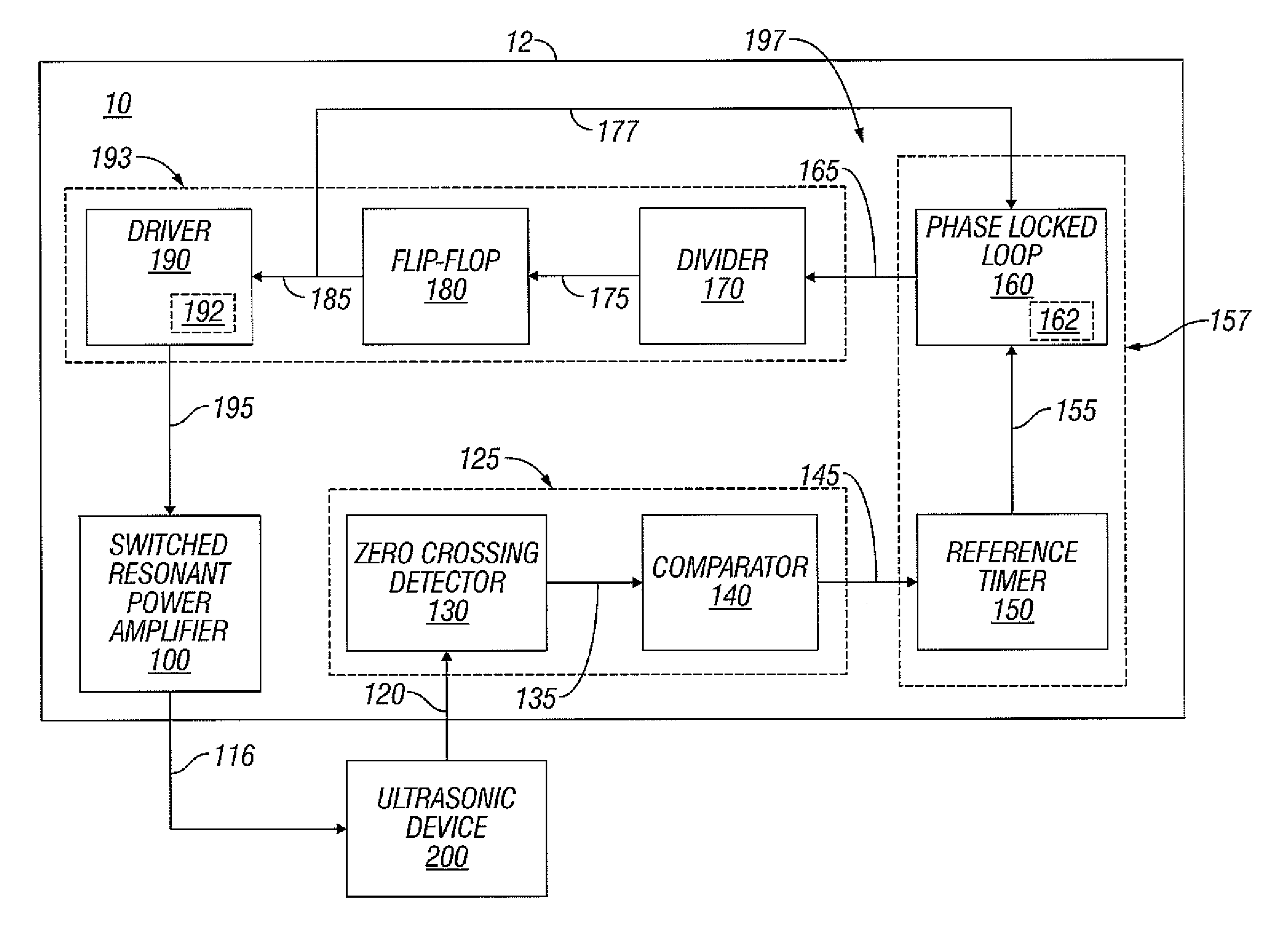

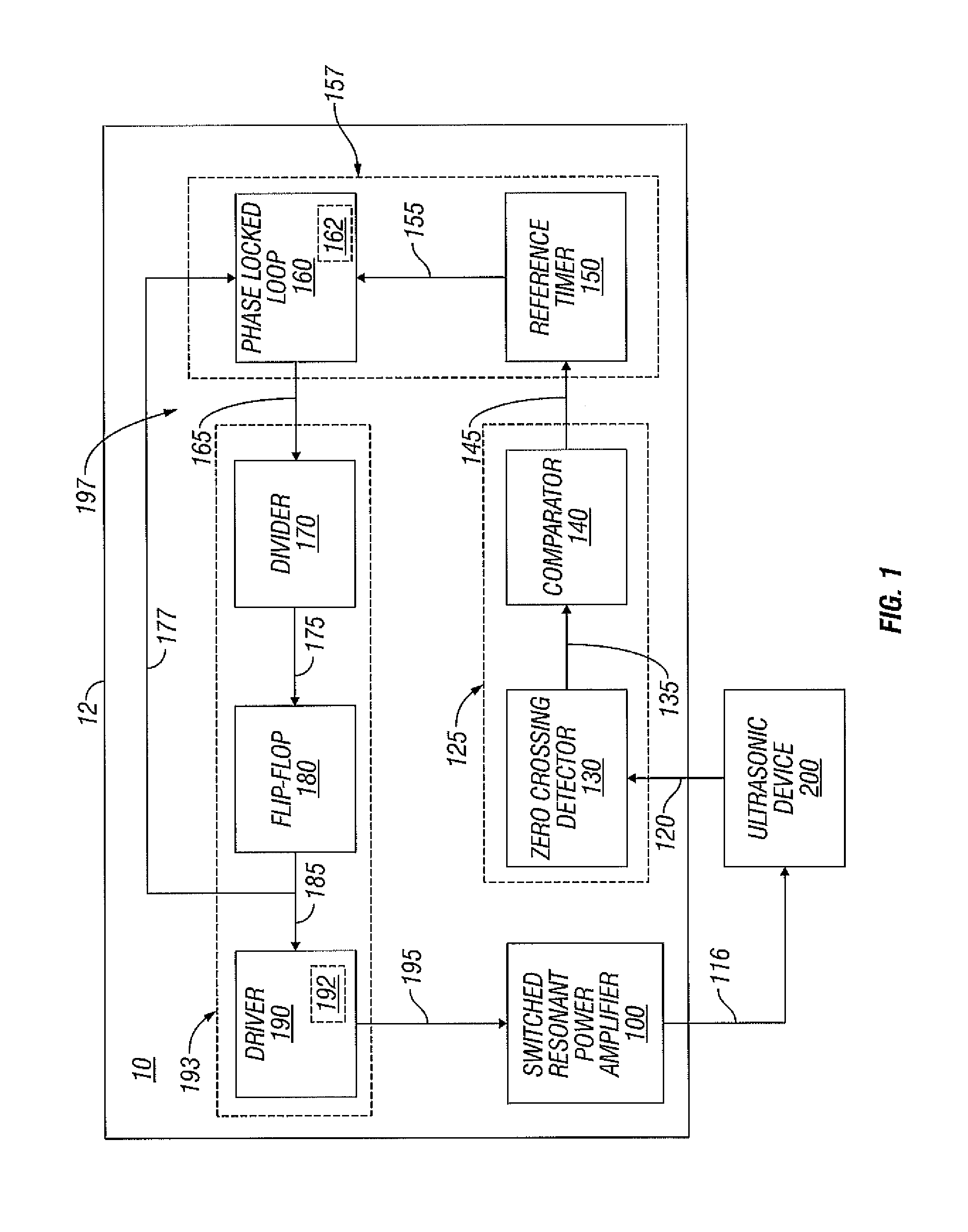

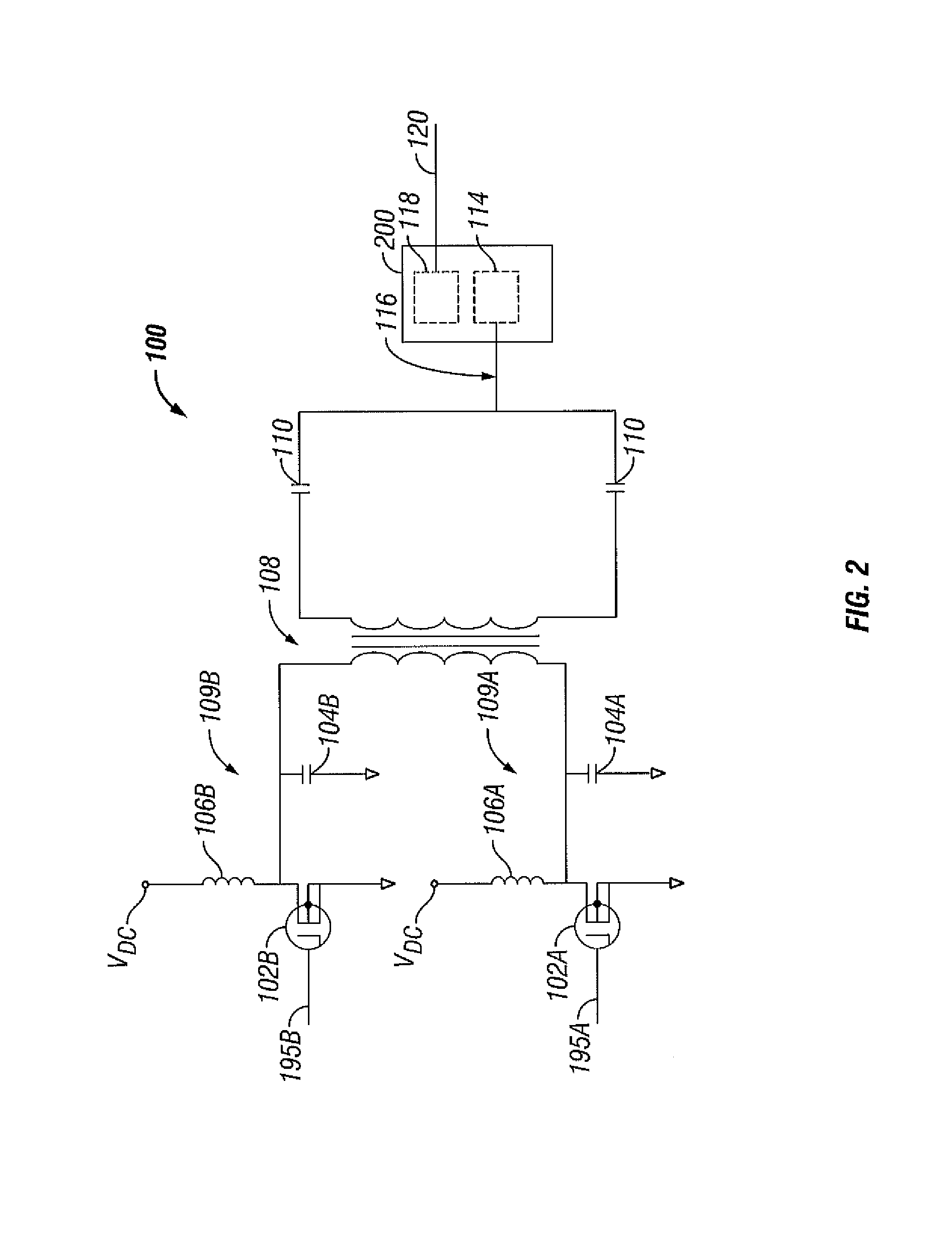

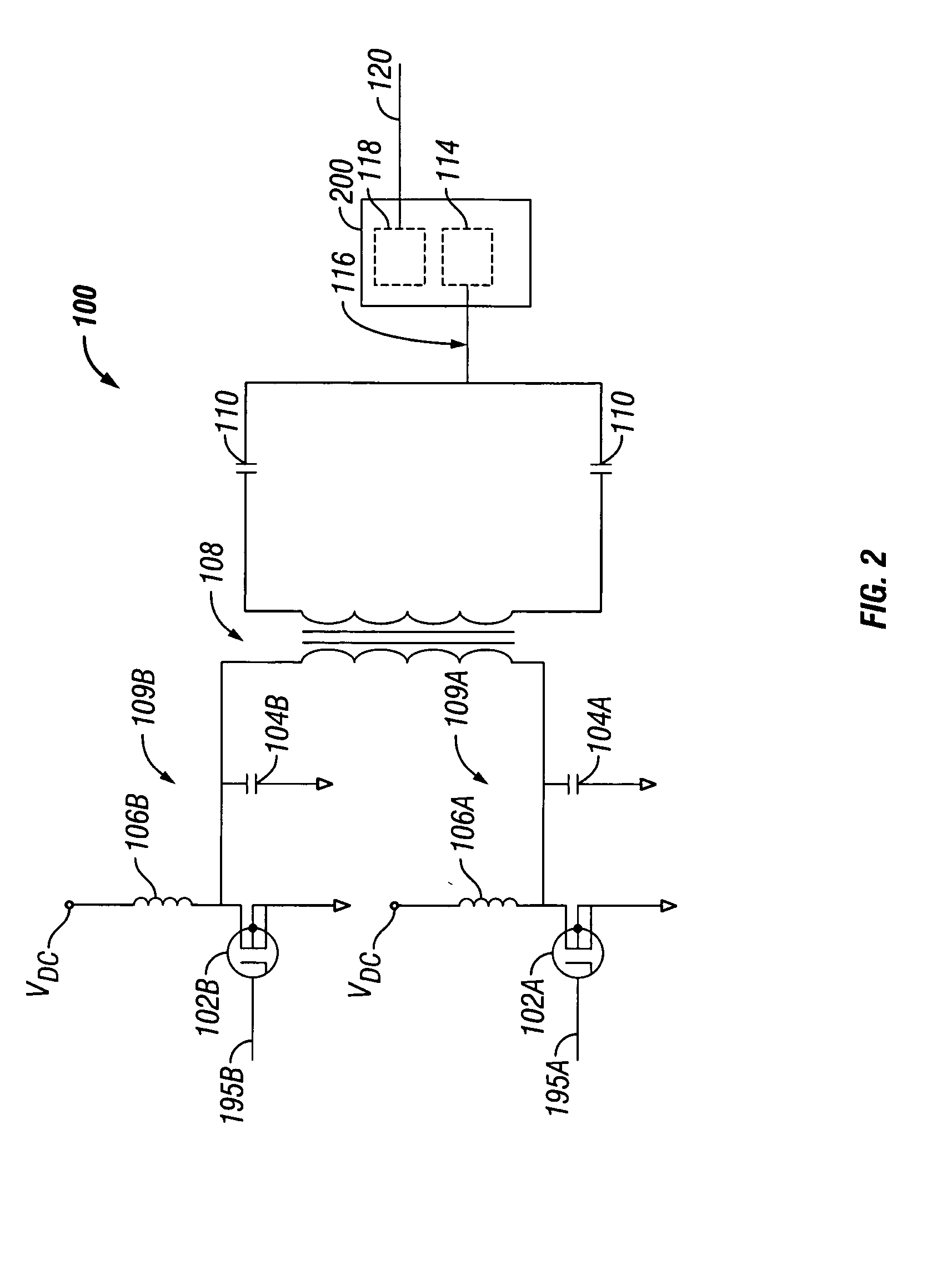

Switched resonant ultrasonic power amplifier system

ActiveUS7396336B2Operation efficiency can be improvedSmall footprintUltrasound therapyAmplifier modifications to raise efficiencyHemt circuitsControl ultrasound

Owner:COVIDIEN AG

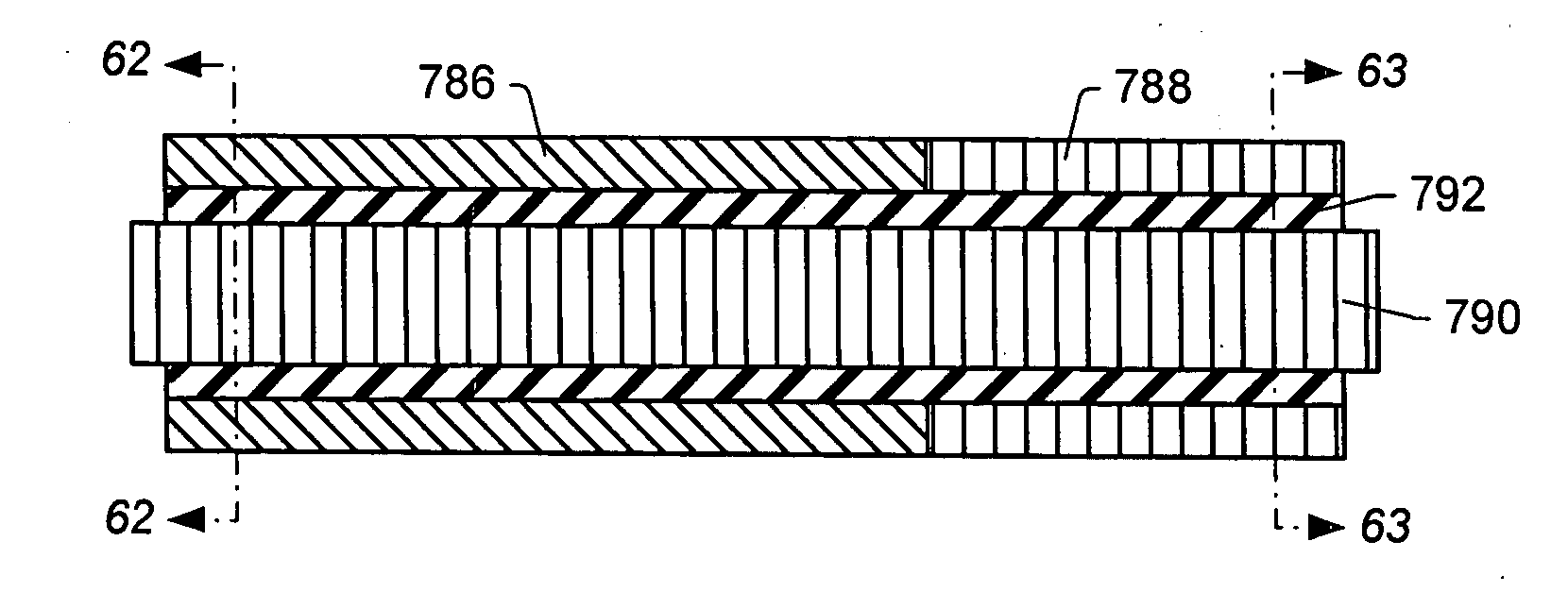

Non-ferromagnetic tank filters in lead wires of active implantable medical devices to enhance MRI compatibility

InactiveUS20080049376A1High impedanceMuch smaller and volumetrically efficientMultiple-port networksAnti-noise capacitorsCapacitanceEngineering

A TANK filter is provided for a lead wire of an active medical device (AMD). The TANK filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the TANK filter is resonant at a selected frequency. In a preferred form, the TANK filter reduces or even eliminates the use of ferro-magnetic materials, and instead uses non-ferromagnetic materials so as to reduce or eliminate MRI image artifacts or the force or torque otherwise associated during an MRI image scan.

Owner:WILSON GREATBATCH LTD

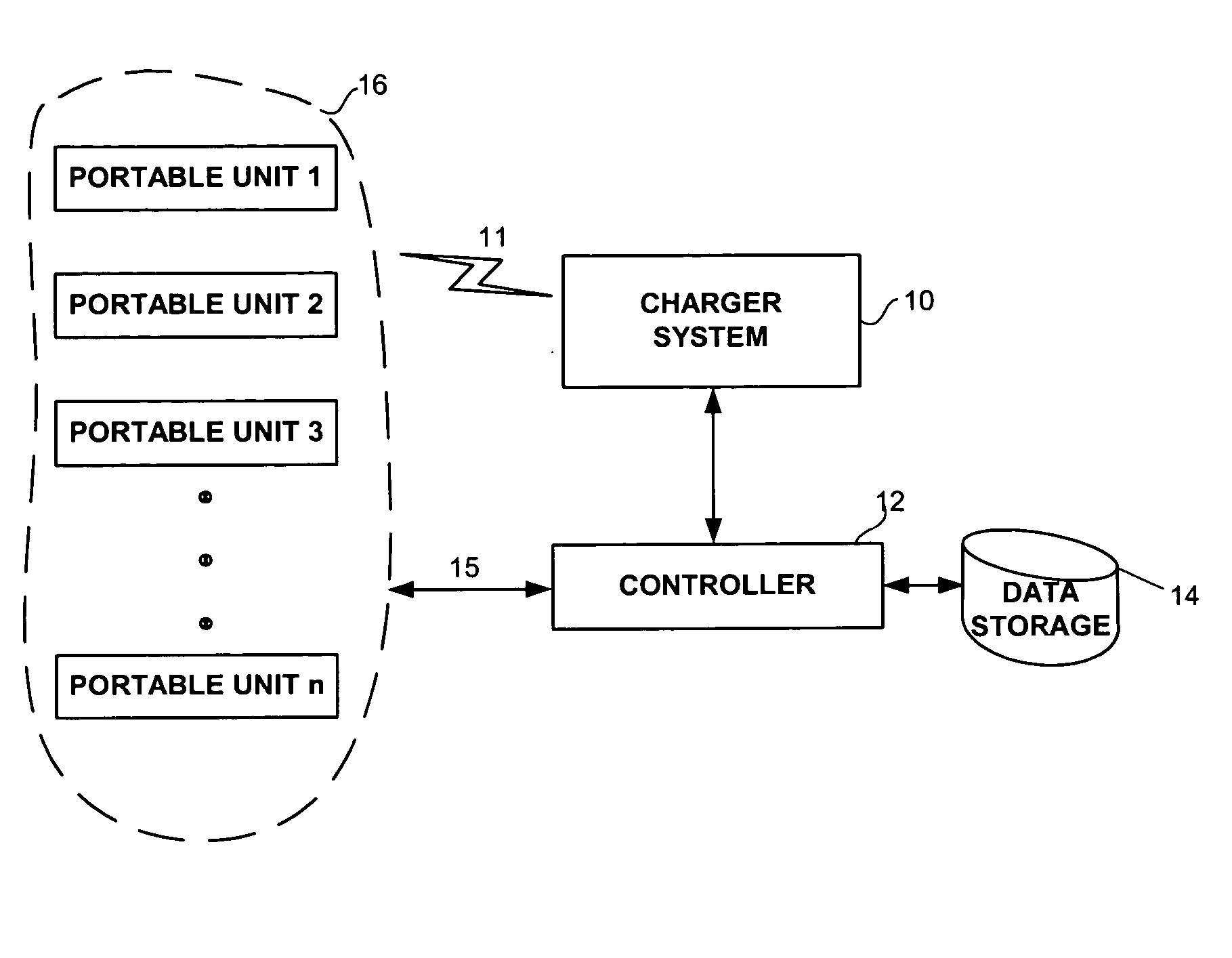

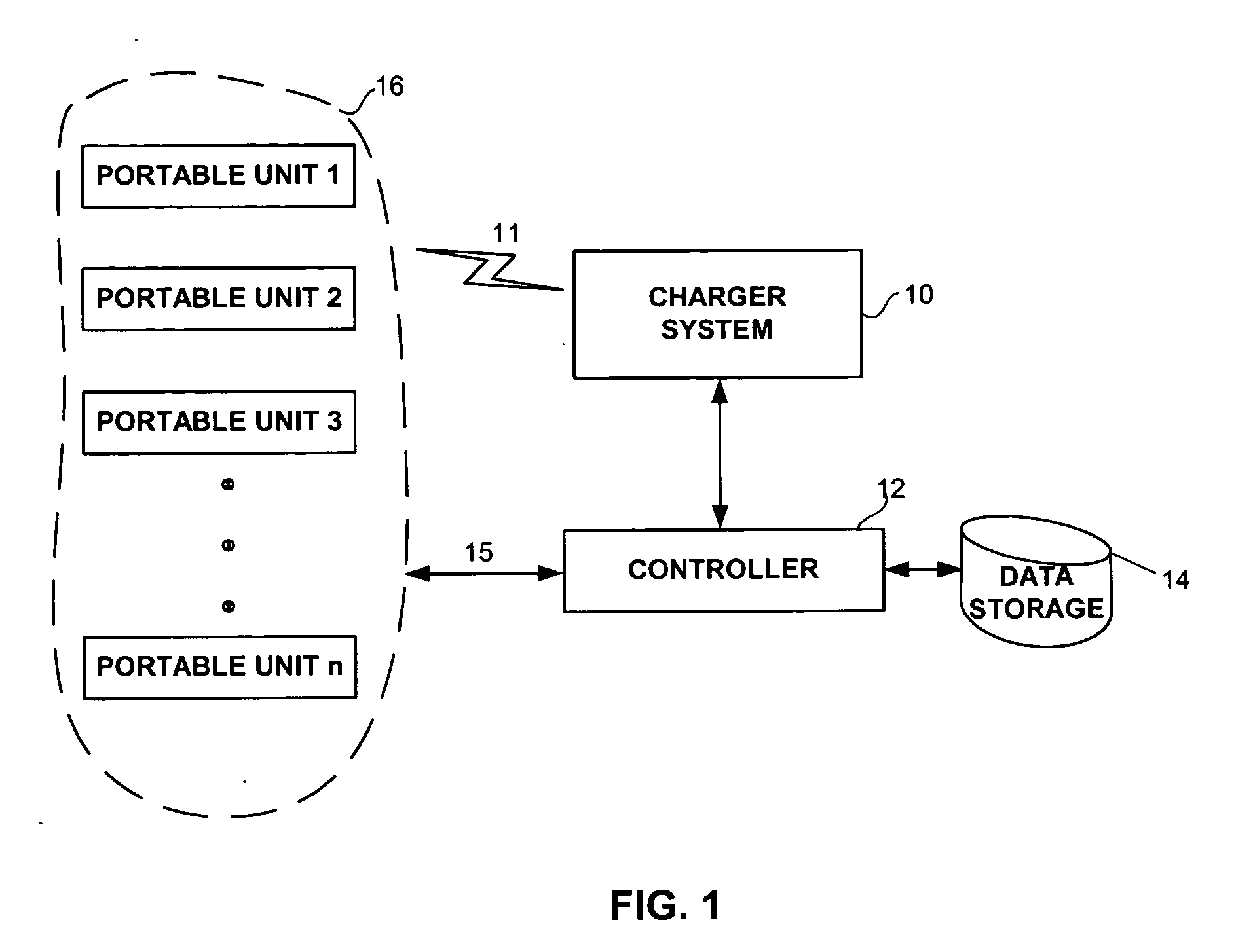

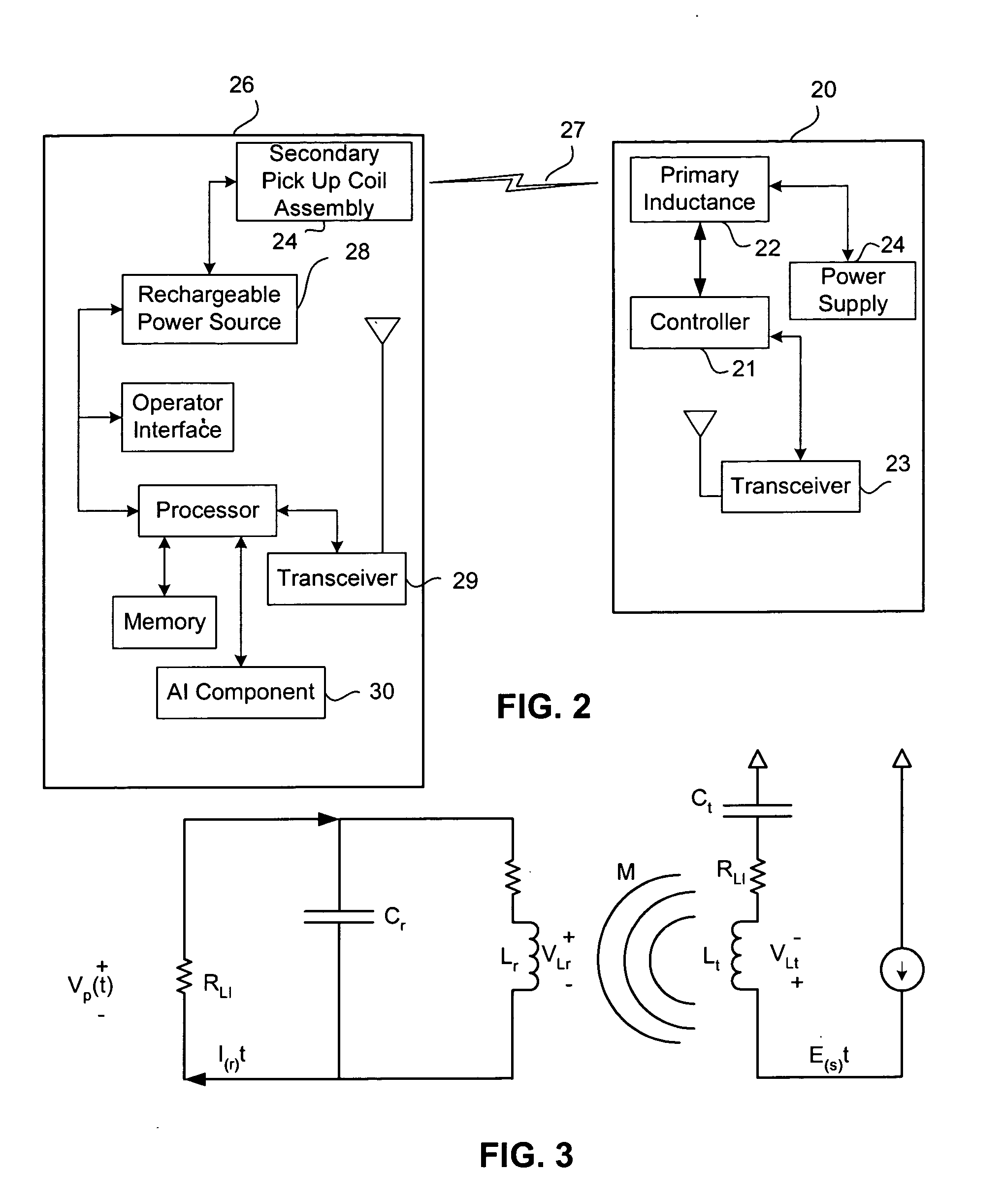

Opportunistic power supply charge system for portable unit

ActiveUS20050127866A1Heat lossGreat surface areaCircuit monitoring/indicationElectromagnetic wave systemState of chargeMagnetic flux

Systems and methods for opportunistically charging a rechargeable power source of a portable electronic unit are provided. The system includes a primary inductance assembly energized by a main power source for inducing an electro-magnetic flux in a secondary coil assembly associated with a power source of the portable unit. Such electro-magnetic flux creates an electric current that is subsequently employed for charging the power source of the portable unit. A controller of the charging system can monitor state of charge, and notify a user when a recharge is required. Scavenging modes may also be employed for recharging the main power source and the rechargeable source of the portable unit.

Owner:SYMBOL TECH LLC

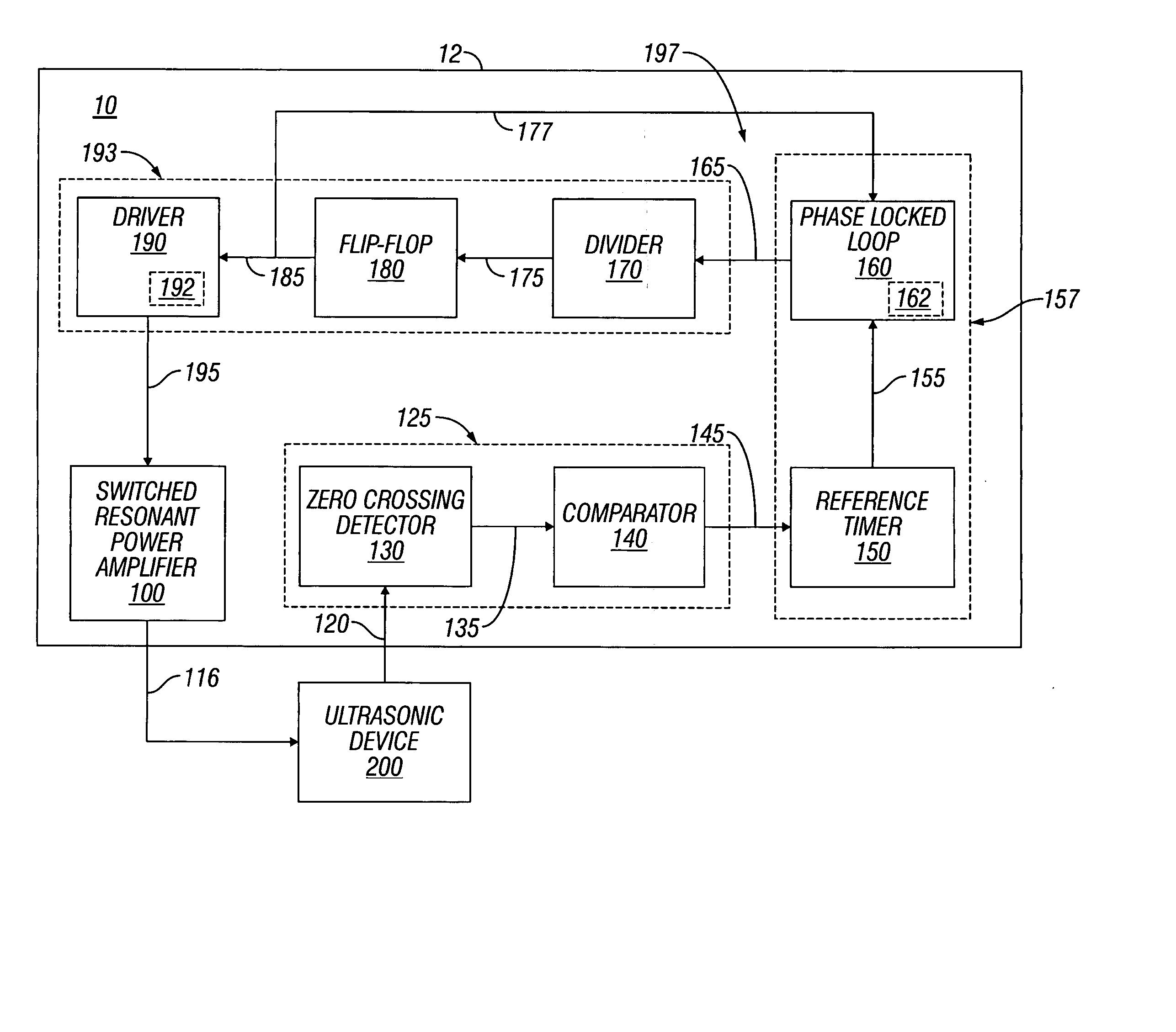

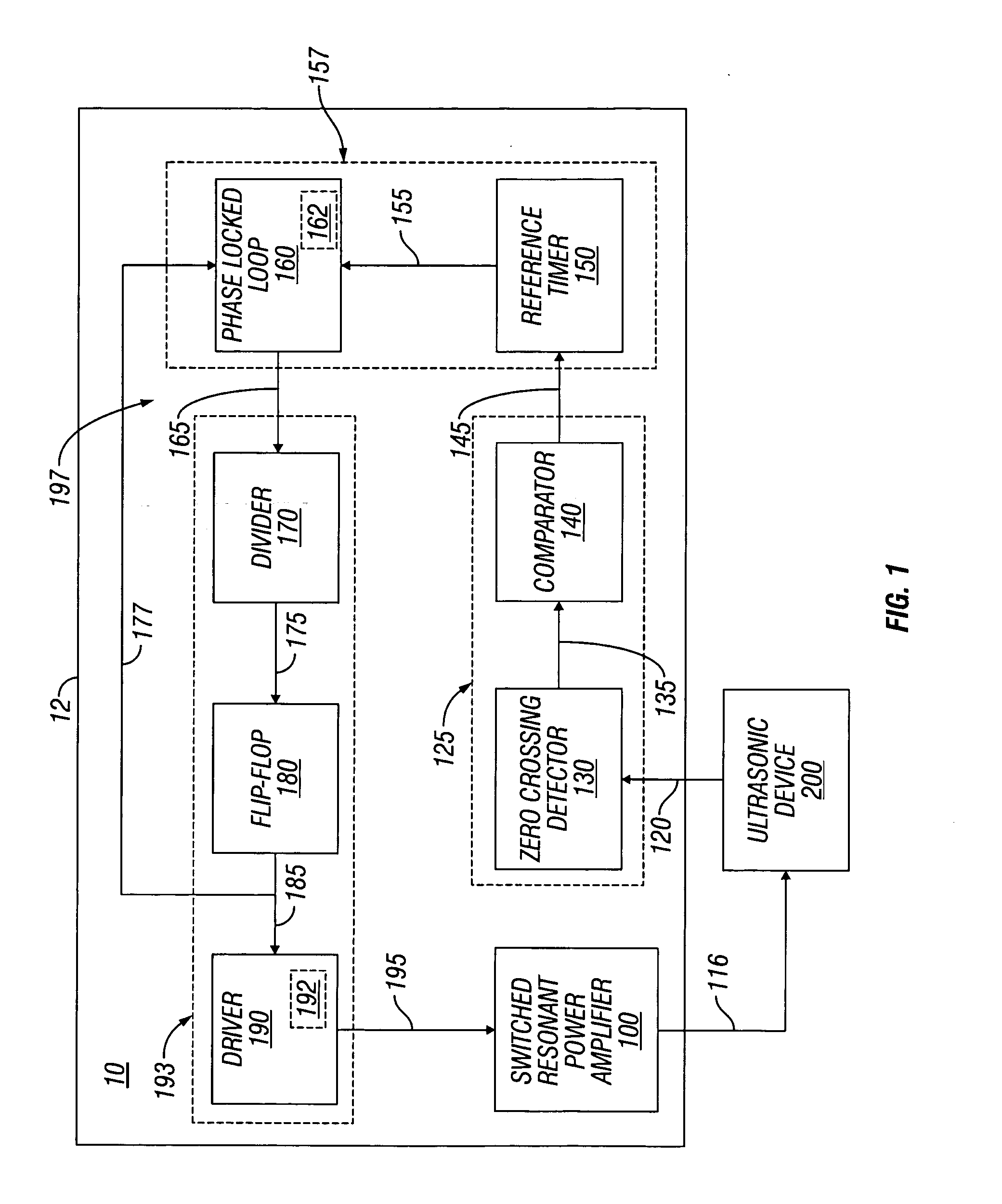

Switched resonant ultrasonic power amplifier system

ActiveUS20050149151A1Reduce frequencyControl outputUltrasound therapyAmplifier modifications to raise efficiencySonificationAudio power amplifier

A switched resonant power amplifier system for ultrasonic transducers is disclosed. The system includes an amplifier that receives and processes a driver output signal for generating a drive signal that is provided to an ultrasonic device for controlling output of the ultrasonic device. An output control circuit receives and processes a signal related to a feedback signal generated by the ultrasonic device and a divider reference signal, and generates a compensated clock signal that is adjusted for at least one of phase and frequency differences between the received feedback signal and the divider reference signal. A compensated drive circuit receives and processes the compensated clock signal for generating the divider reference signal, and for generating the driver output signal.

Owner:COVIDIEN AG

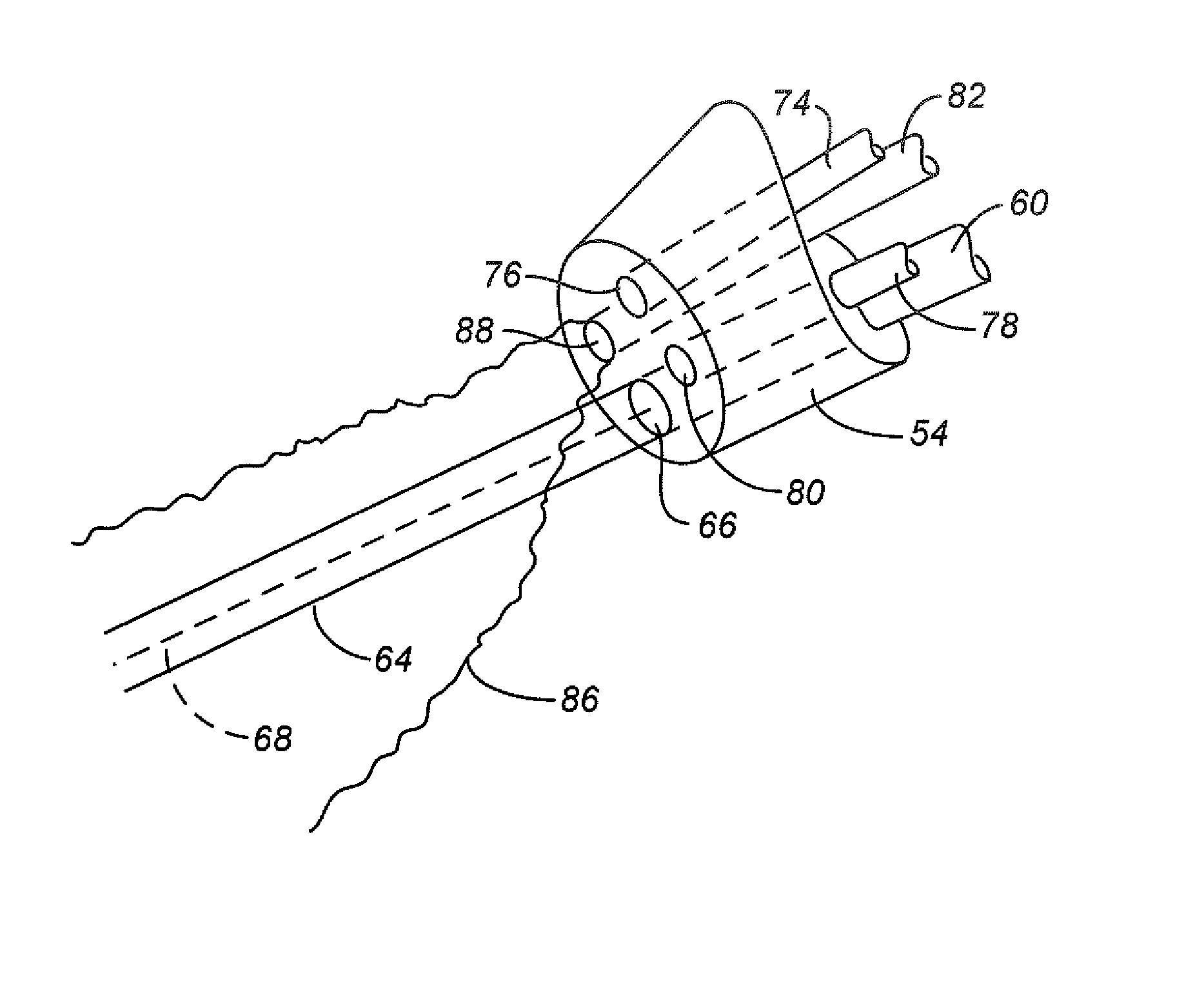

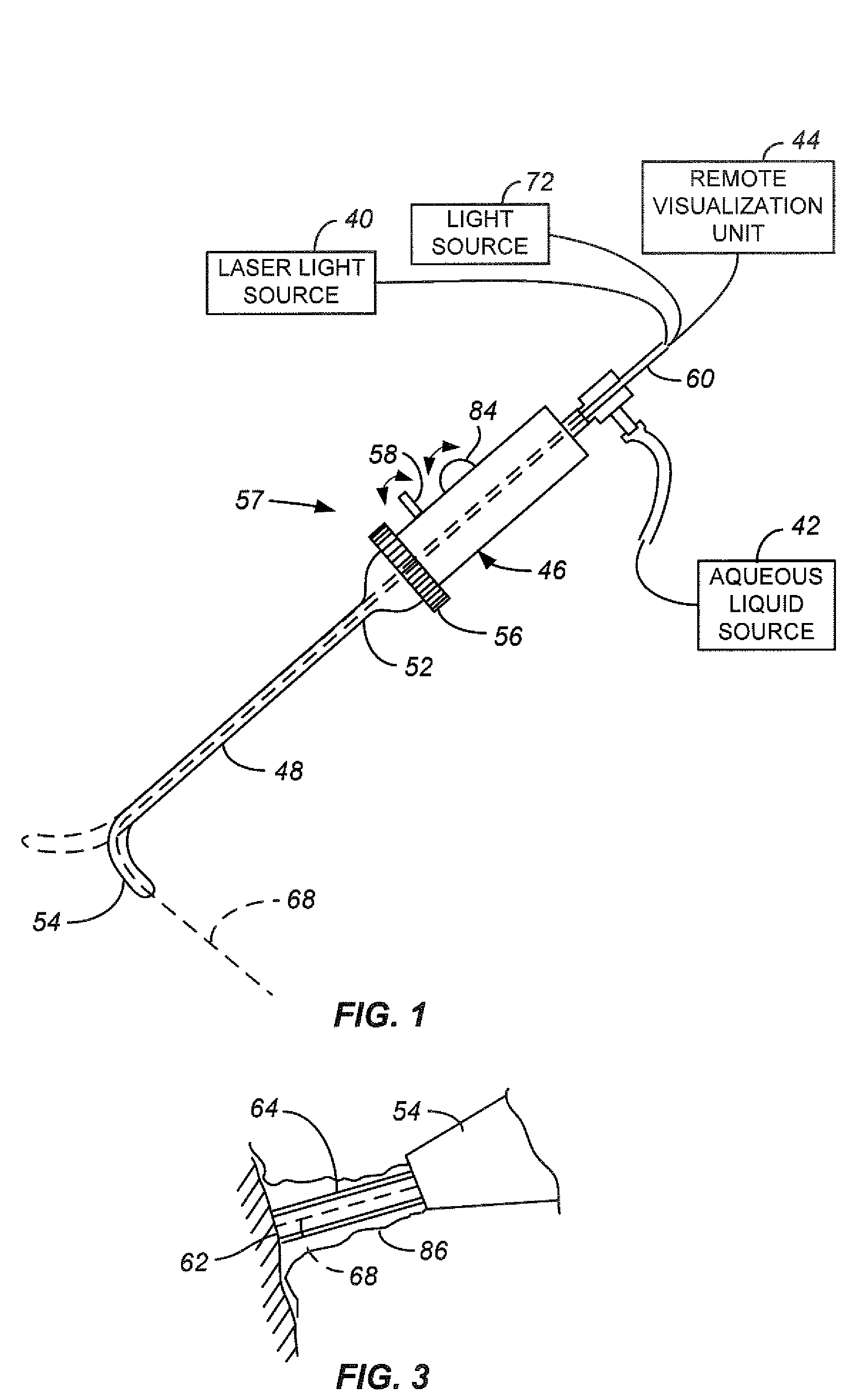

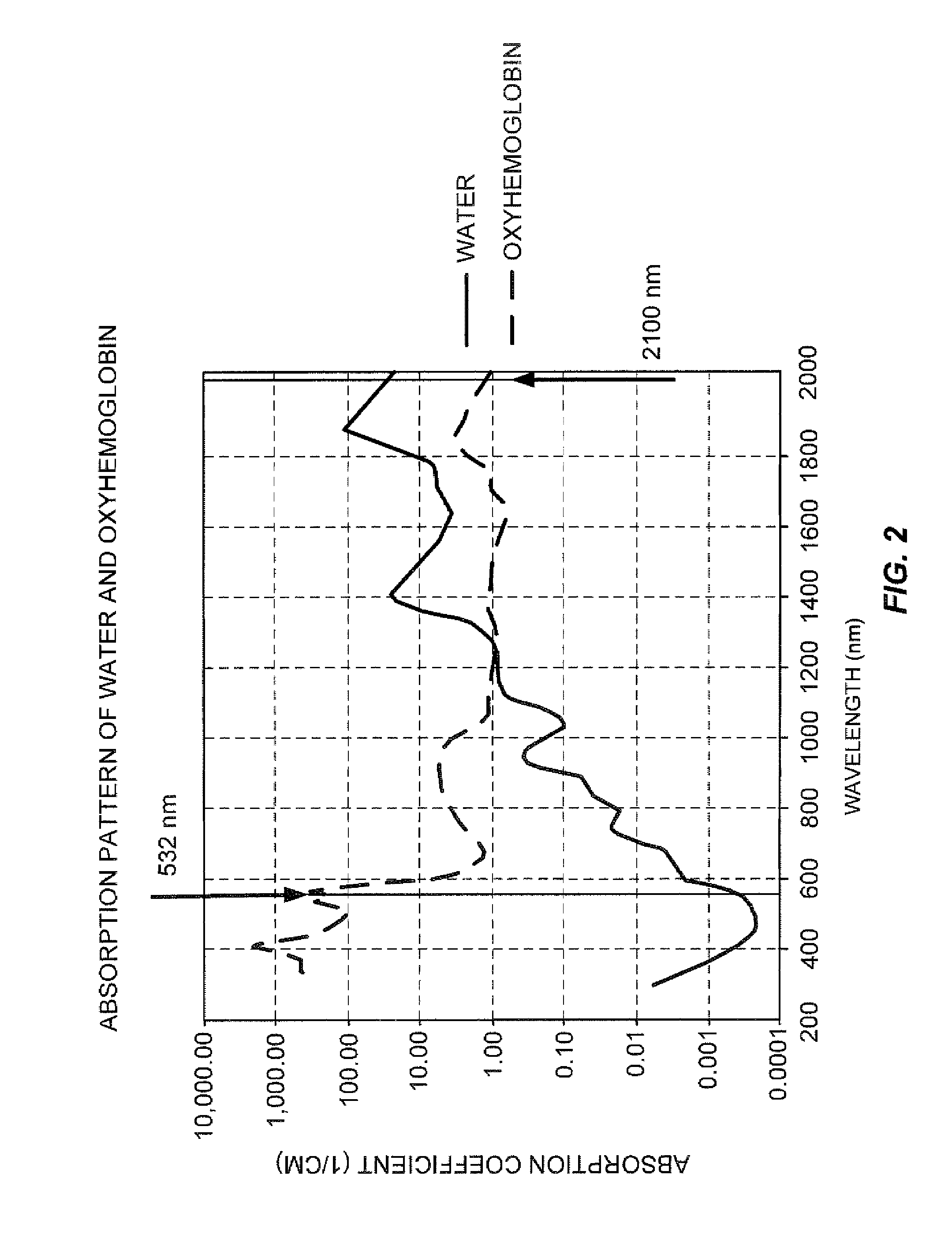

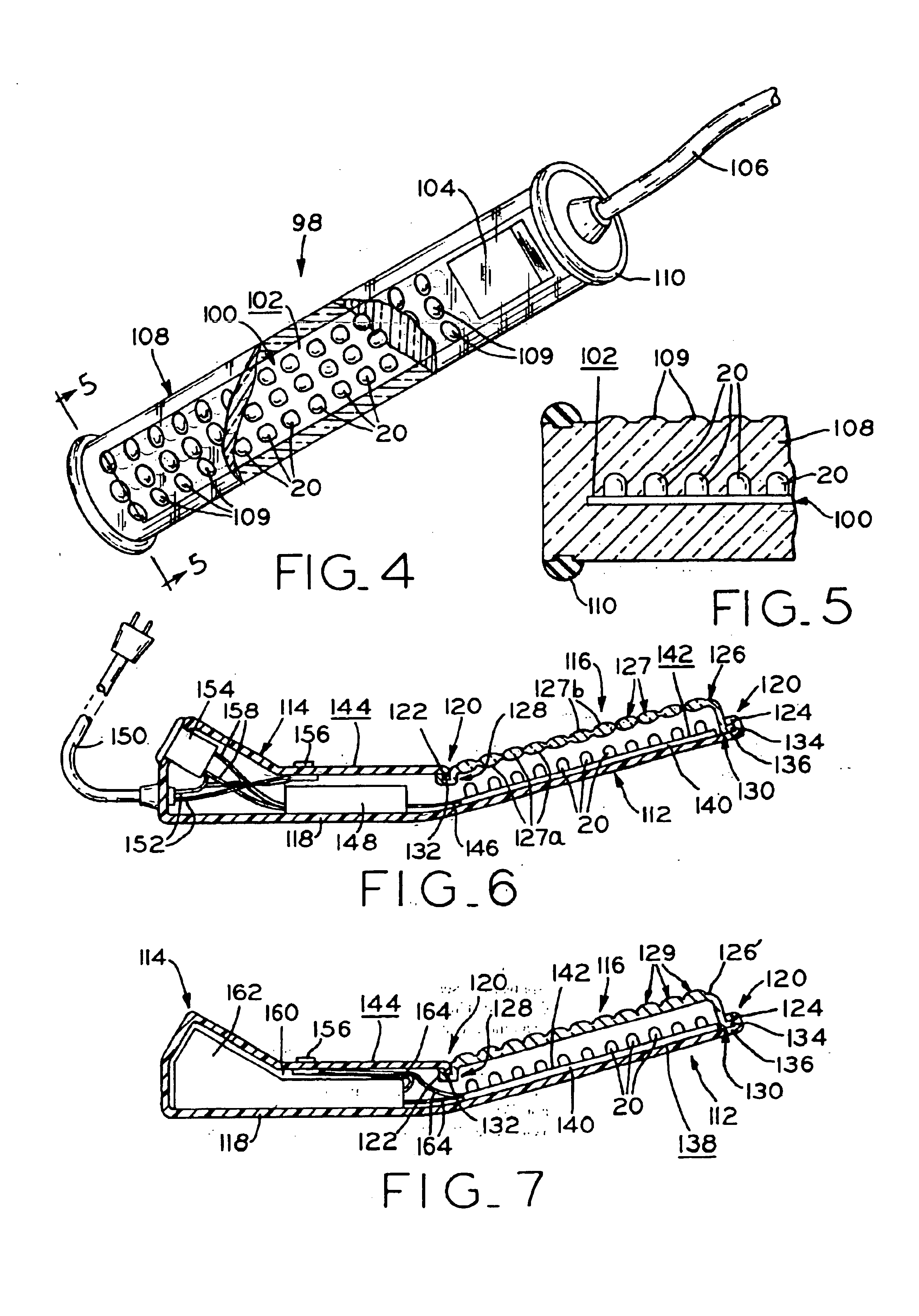

Laparoscopic Laser Device and Method

InactiveUS20070185474A1Reduce heatProtect from preventable damageLaser detailsEndoscopesMedicineVaporization

Laser radiation delivered to a treatment area causes vaporization of a substantially greater volume of tissue than the volume of residual coagulated tissue. The laser radiation may have a wavelength of about 300 nm to about 700 nm, may be used with a smoke suppressing irrigant, may have an average irradiance greater than about 5 kilowatts / cm2, and may have a spot size of at least 0.05 mm2. A laparoscopic laser device, for use with an insufflated bodily cavity, may include an elongate body adapted for insertion into an insufflated bodily cavity. A laser energy delivery element, at the distal end of the elongate body, may be coupleable to a source of tissue-vaporization-capable laser energy and capable of delivering laser energy along a laser energy path extending away from the laser energy delivery element. A smoke-suppressing liquid pathway, extending along the elongate body to an exit opening at the distal end, may be coupleable to a source of a smoke-suppressing liquid. The smoke-suppressing liquid is directed generally along the laser energy path. A remote visualization device may be used to view along the laser energy path.

Owner:AMS RES CORP

Variable frequency temperature limited heaters

InactiveUS20050006097A1Avoid deformationReduce heatThermal drillingInsulationElectrical resistance and conductancePower flow

A heater system may include an alternating current supply and an electrical conductor. Alternating current may be applied to one or more electrical conductors at a frequency between about 100 Hz and about 1000 Hz. The electrical conductors may be located in a formation. The electrical conductors may resistively heat upon application of the alternating electrical current. At least one of the electrical conductors may include an electrically resistive ferromagnetic material. The electrical conductor may provide a reduced amount of heat above or near a selected temperature. Heat may transfer from the electrical conductor to a part of formation.

Owner:SHELL OIL CO

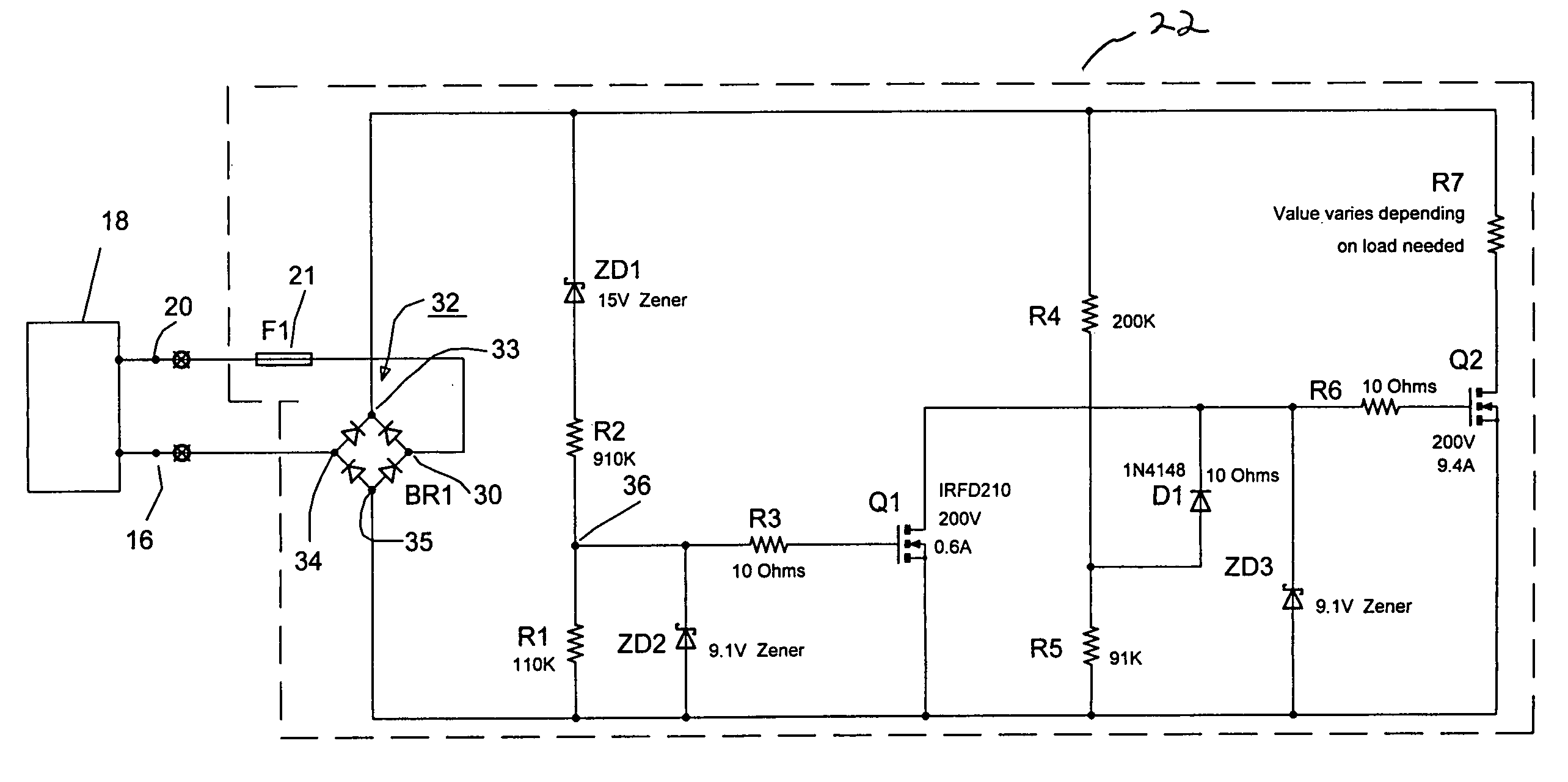

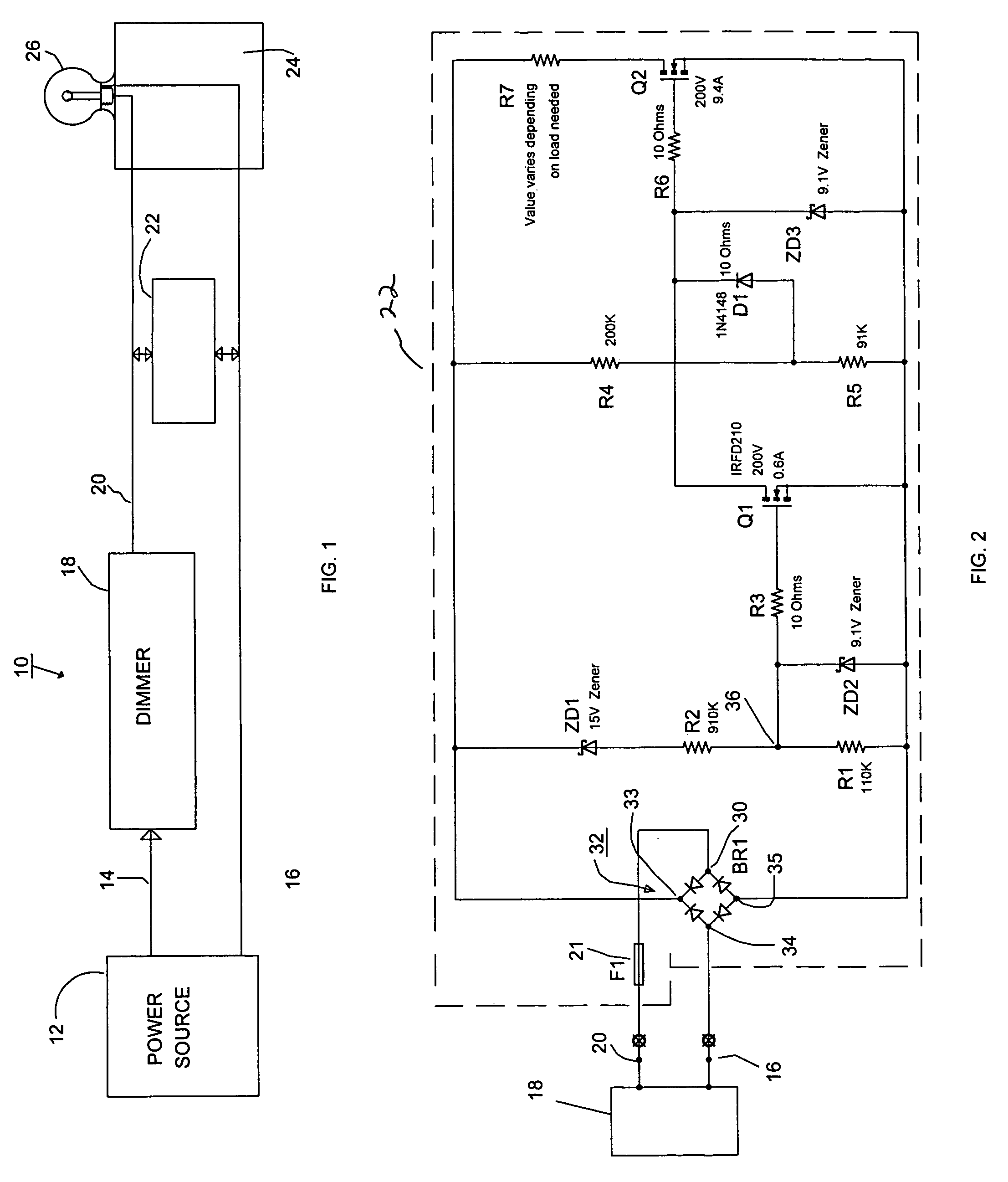

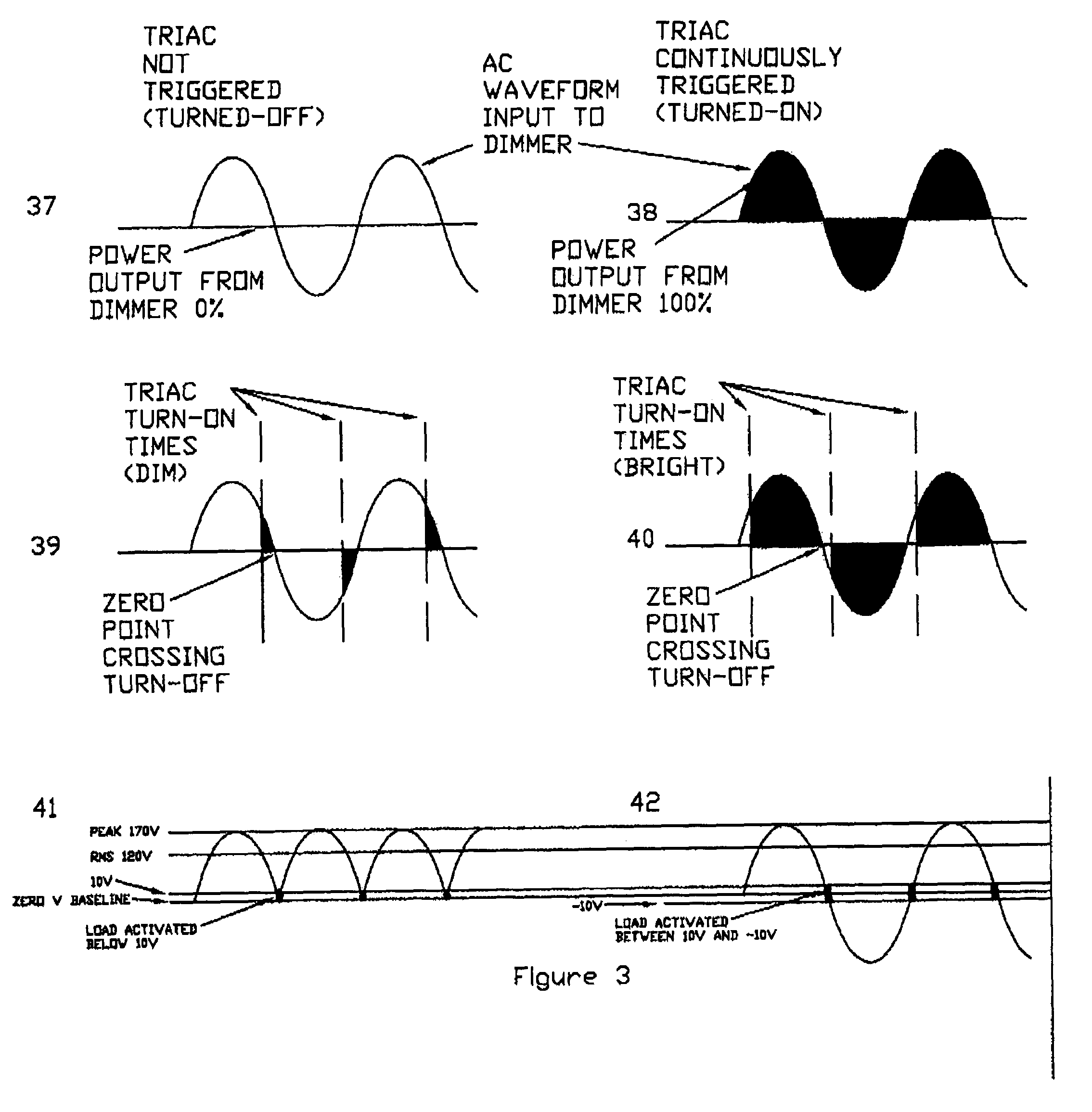

Dimmer circuit for LED

InactiveUS7102902B1Low heat generationReduce heatAc-dc conversion without reversalConversion with intermediate conversion to dcMOSFETZener diode

The AC output from a source is rectified and applied to a resistor / Zener diode circuit connection which determines the magnitude of the rectified voltage applied via a circuit to a first MOSFET device. The inverted output of the first MOSFET device is applied to the gate electrode of a second MOSFET device in a manner such that the second MOSFET device is ON even when the AC output passes through zero. The output of the second MOSFET device is connected to a resistor which determines the magnitude of the load applied to the dimmer.

Owner:LEDTRONICS

Methods and products for producing lattices of EMR-treated islets in tissues, and uses therefor

InactiveUS20060020309A1Sufficient amountReduce riskElectrotherapySurgical instrument detailsElectromagnetic radiationBiomedical engineering

Methods of treatment of tissue with electromagnetic radiation (EMR) to produce lattices of EMR-treated islets in the tissue are disclosed. Also disclosed are devices and systems for producing lattices of EMR-treated islets in tissue, and cosmetic and medical applications of such devices and systems.

Owner:PALOMAR MEDICAL TECH

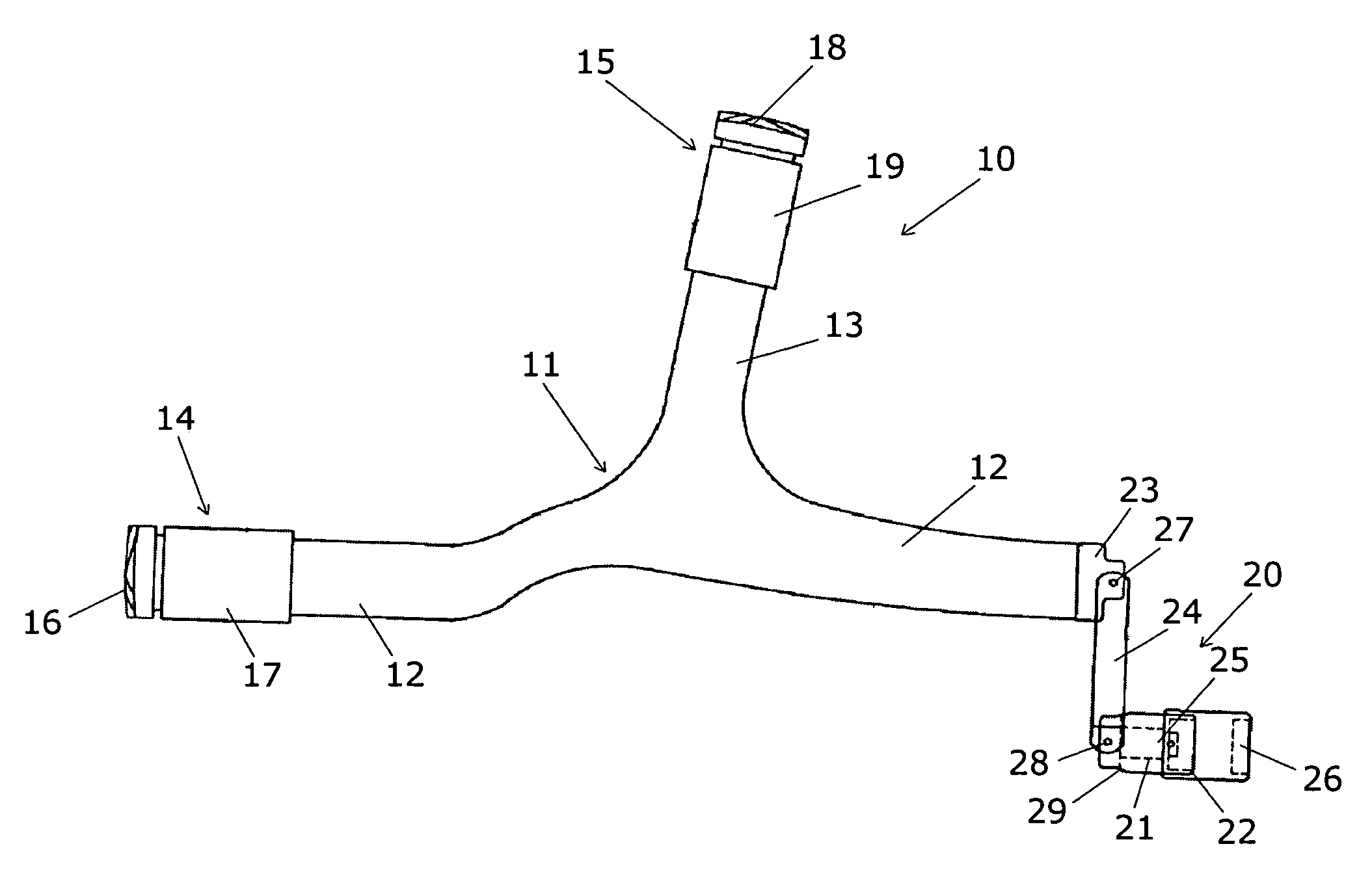

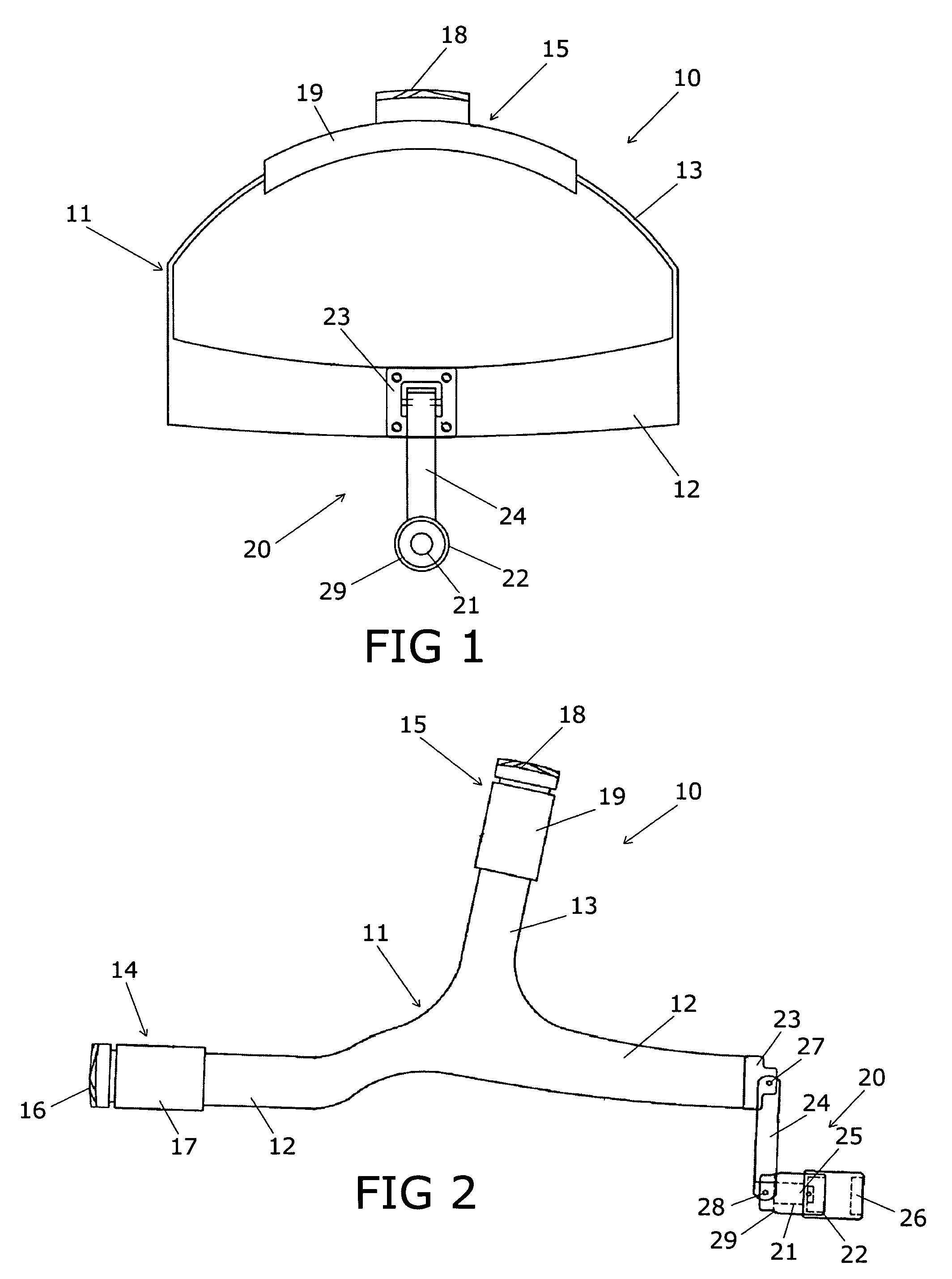

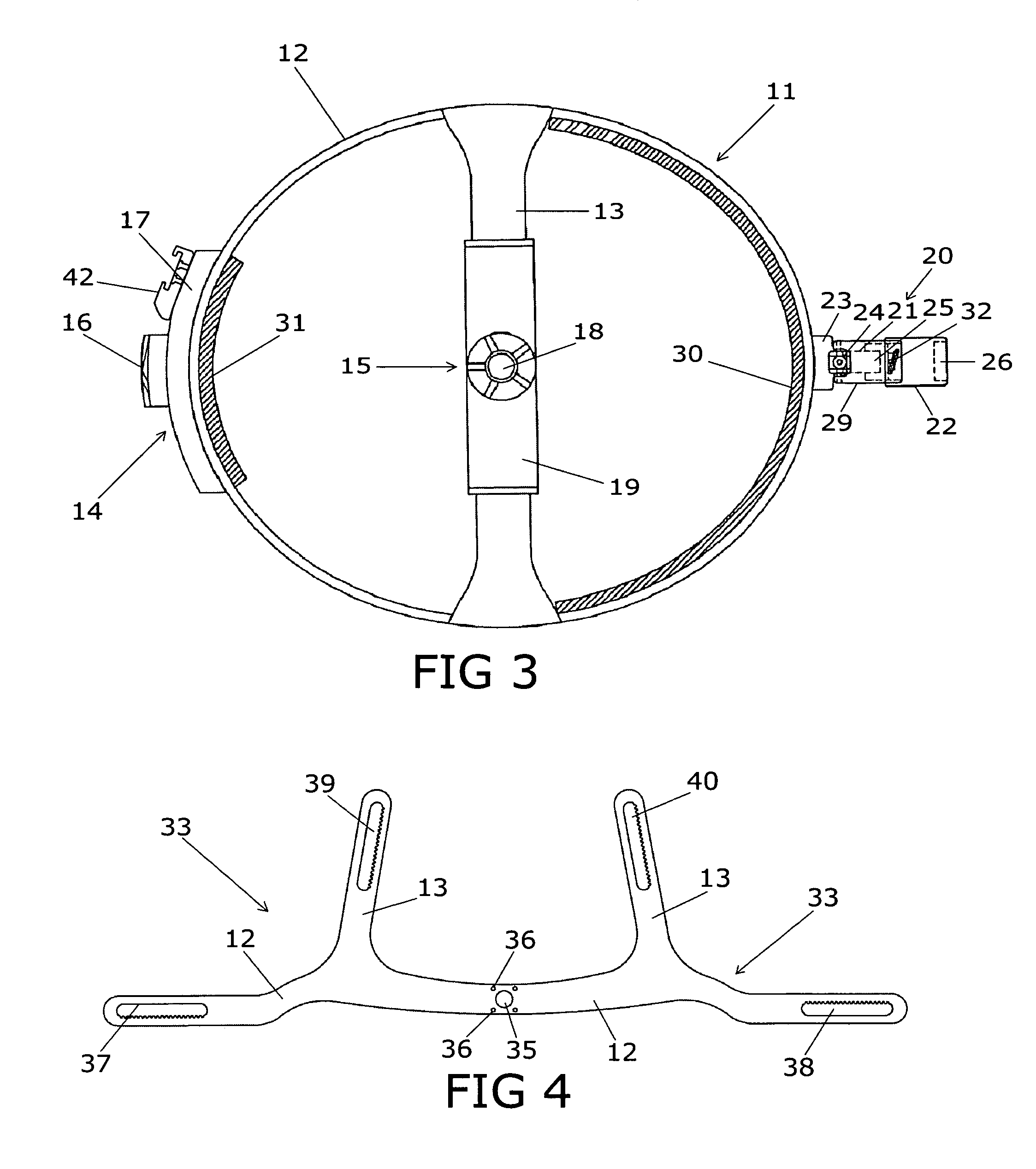

Muscle stimulating device and method for diagnosing and treating a breathing disorder

Owner:RIC INVESTMENTS LLC

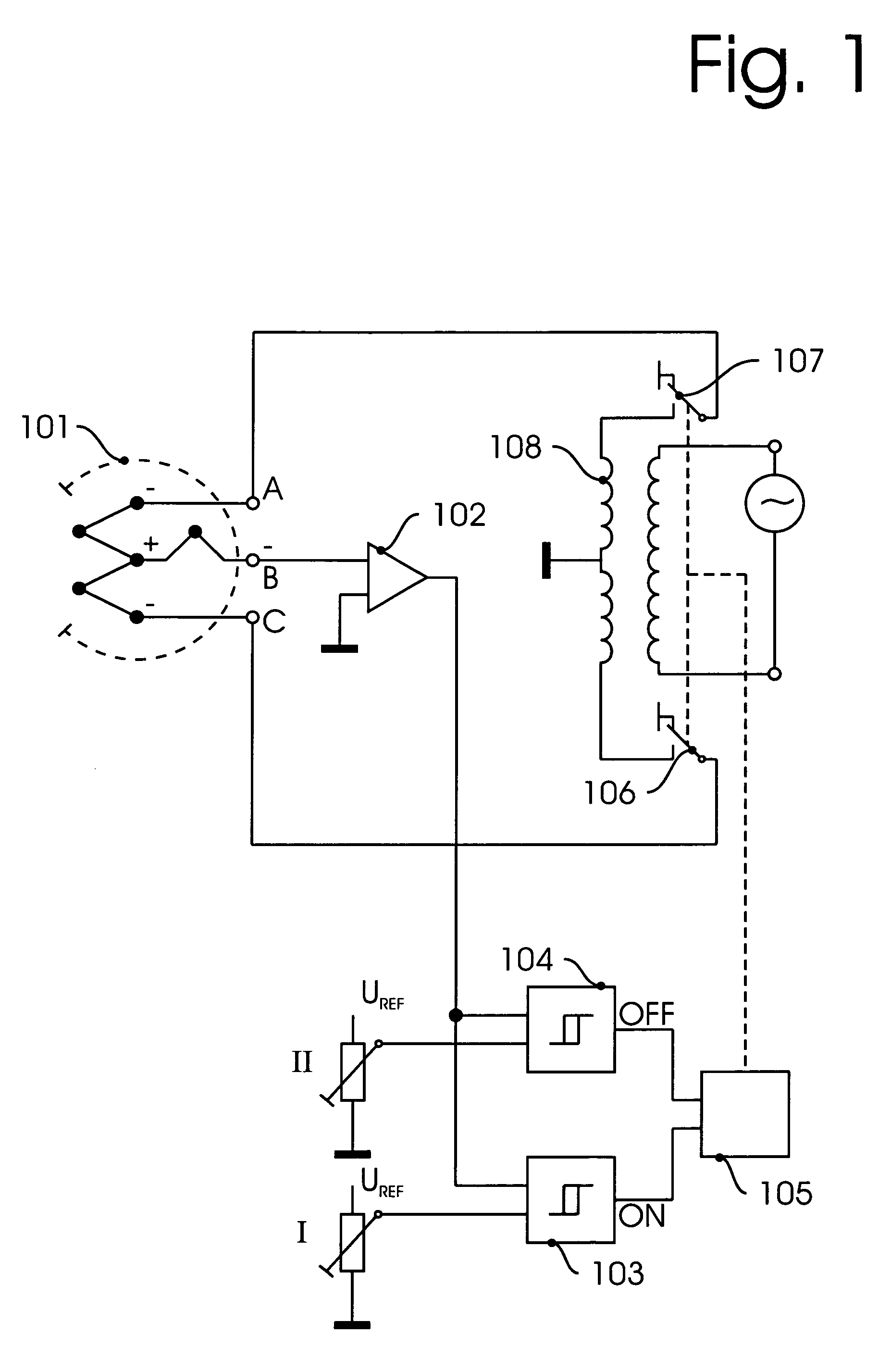

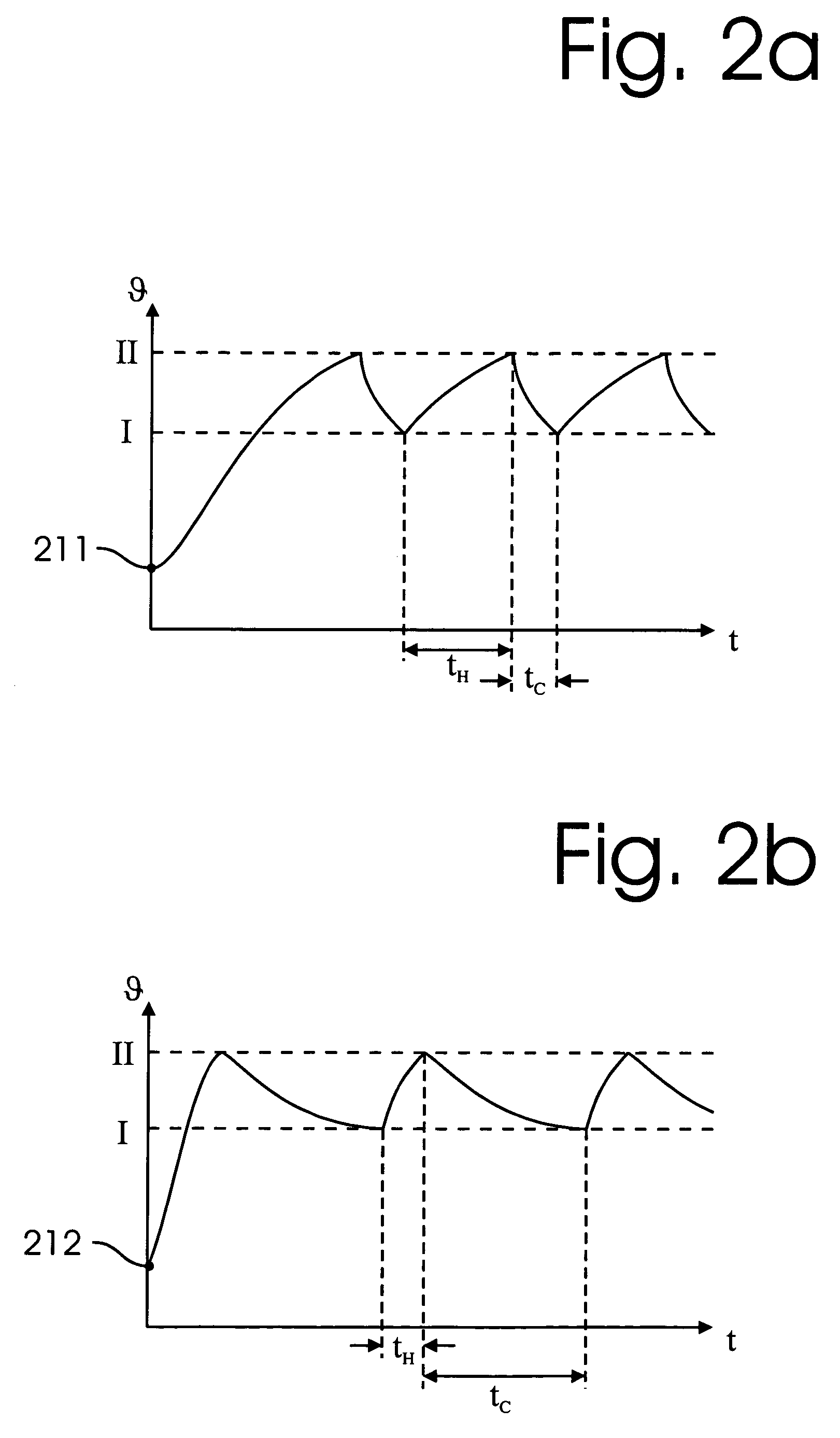

Thermocouple vacuum gauge

InactiveUS8047711B2Reduce heatLow thermal conductivityThermometer detailsVacuum gauge using heat conductivity variationHeating timeEngineering

A thermocouple vacuum sensor is provided, the thermocouple being surrounded by a gas or mixture of gases the pressure of which is to be measured. Cyclically the thermocouple is heated until its temperature reaches an upper temperature threshold. The thermocouple is subsequently cooled until its temperature reaches a lower temperature threshold. The heating time required to heat the thermocouple from the lower to the upper temperature threshold is measured. The cooling time required to cool the thermocouple from the upper temperature threshold to the lower temperature threshold may also be measured. The pressure surrounding the thermocouple may then be determined as a function of either the heating time, or the cooling time, or both.

Owner:HEINZ PLOECHINGER

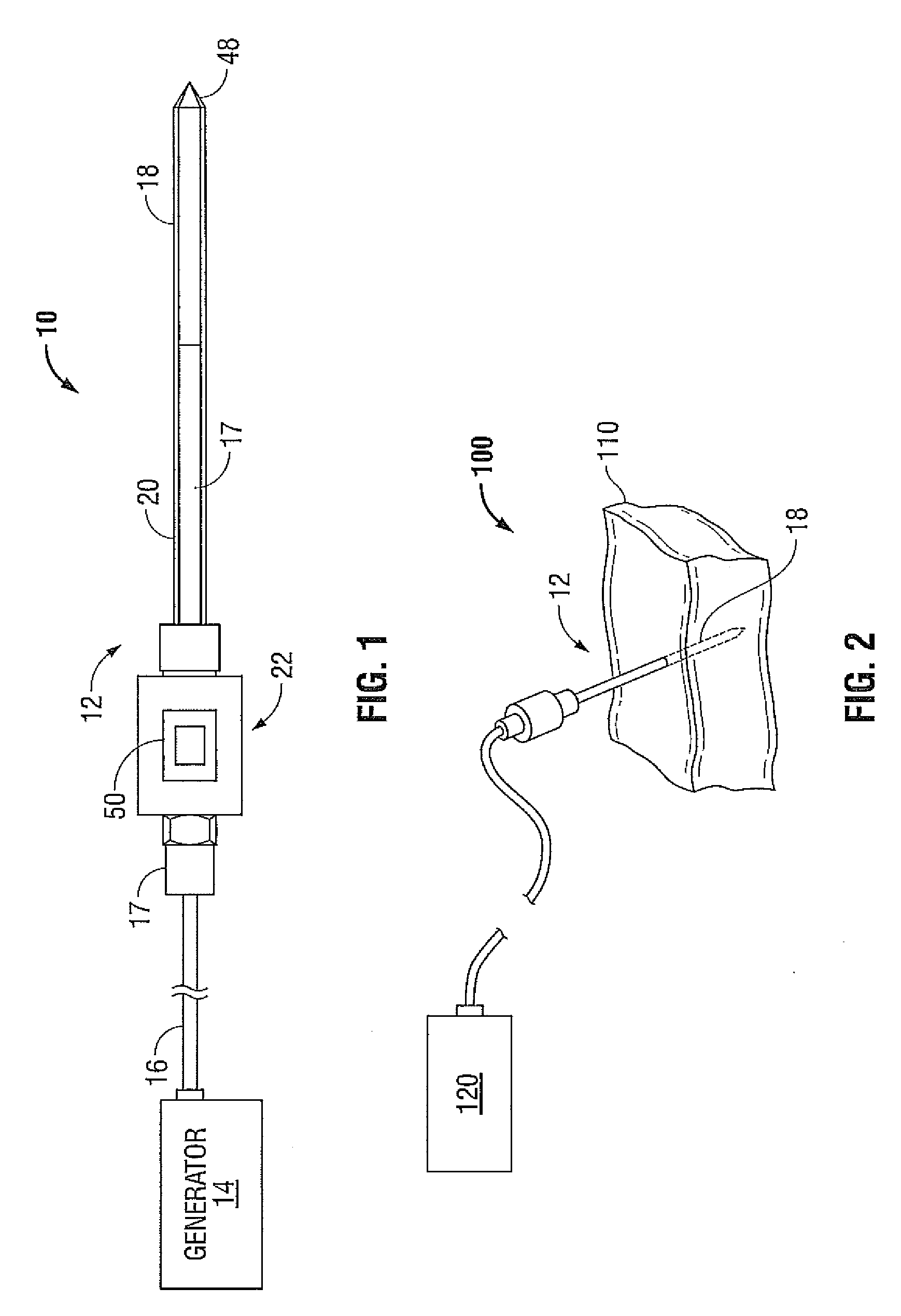

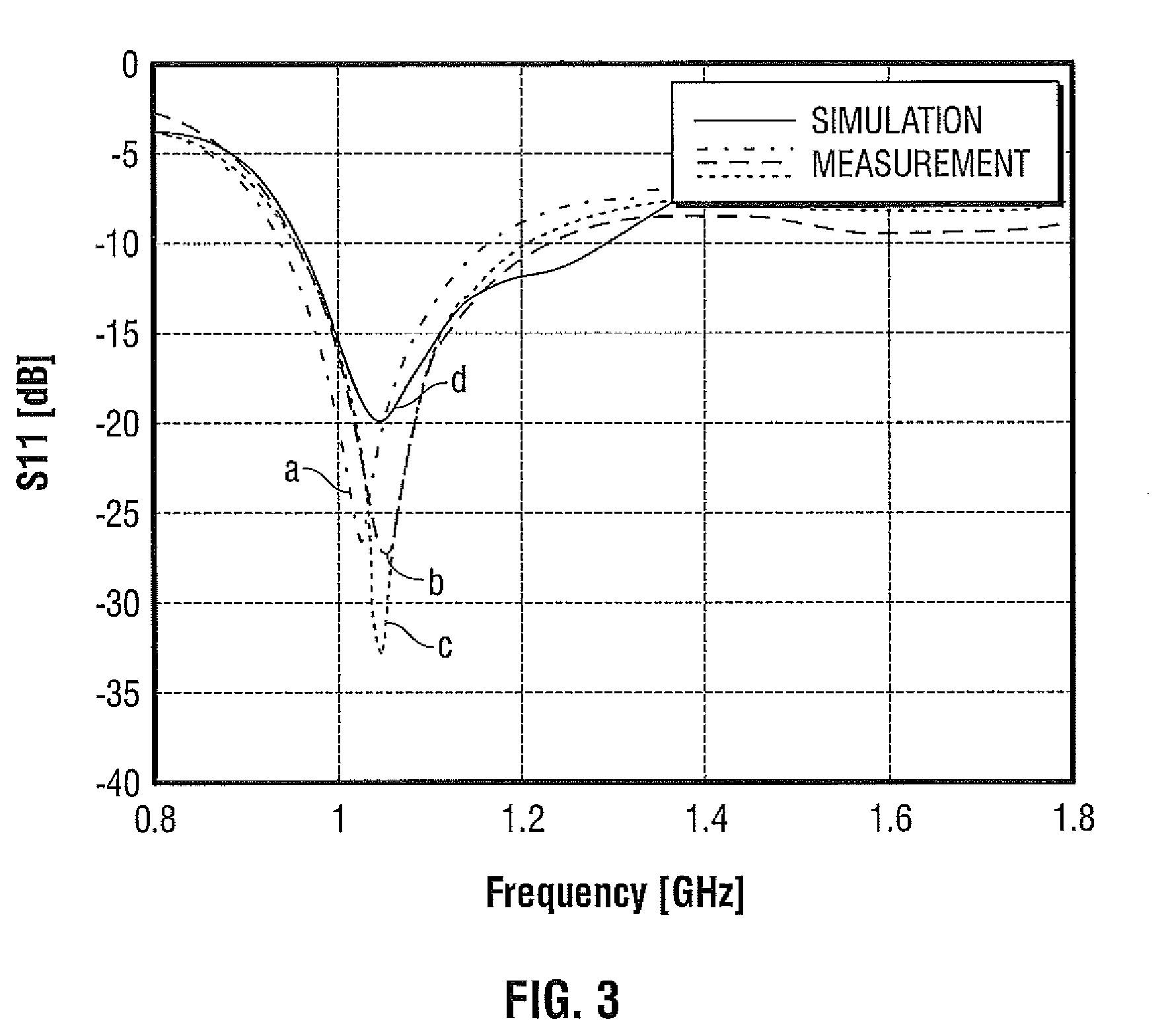

Frequency Identification for Microwave Ablation Probes

ActiveUS20100262134A1Weaken energyWider range of manufacturingDiagnosticsSurgical needlesMicrowaveIdentification device

A microwave ablation system is disclosed. The system includes a microwave antenna assembly that includes an identification device configured to store an optimal frequency of the microwave antenna assembly. The system also includes a generator configured to couple to the microwave antenna assembly and to output microwave energy at an operational frequency. The generator is further configured to read the optimal frequency from the identification device and to configure the operational frequency to substantially match the optimal frequency.

Owner:TYCO HEALTHCARE GRP LP

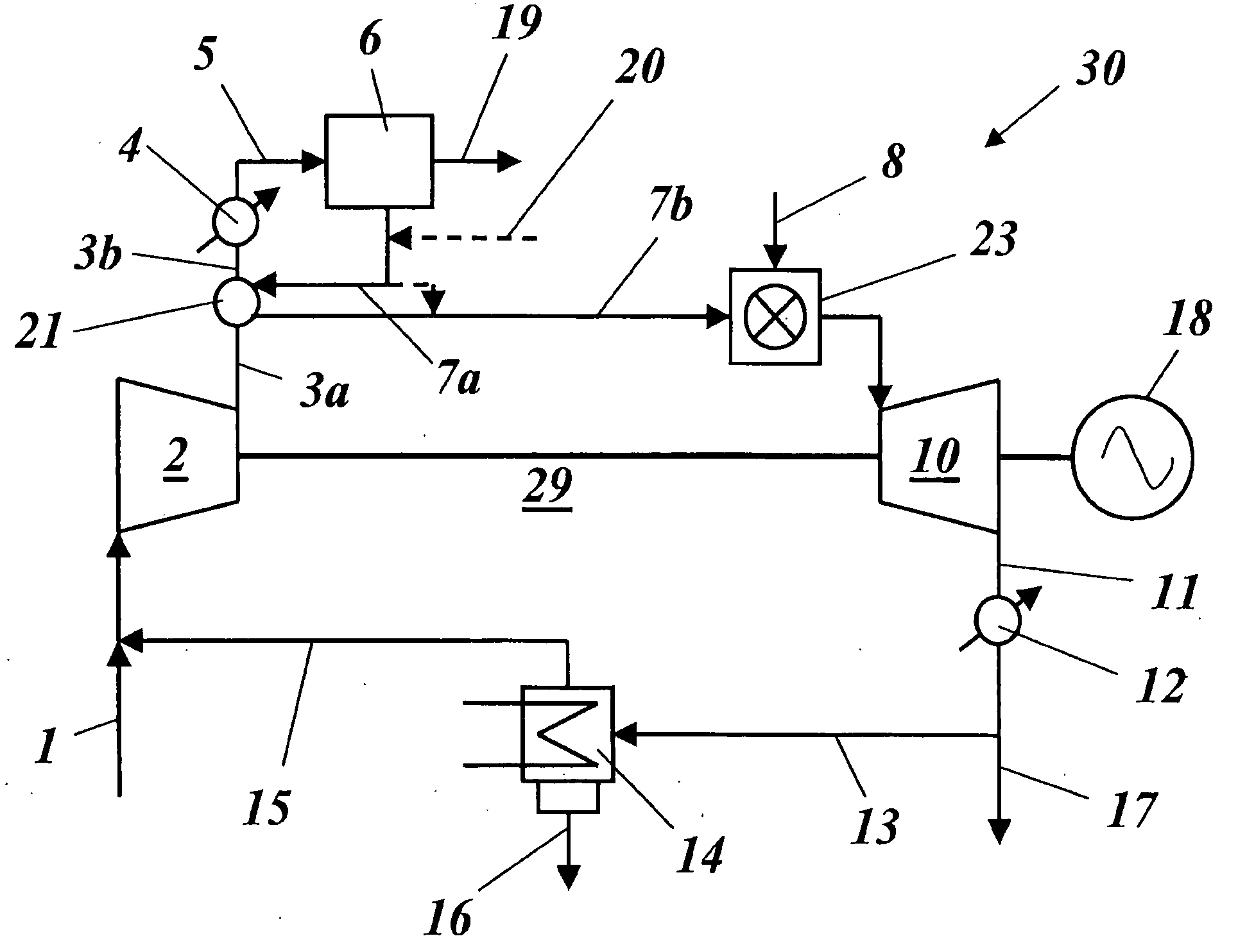

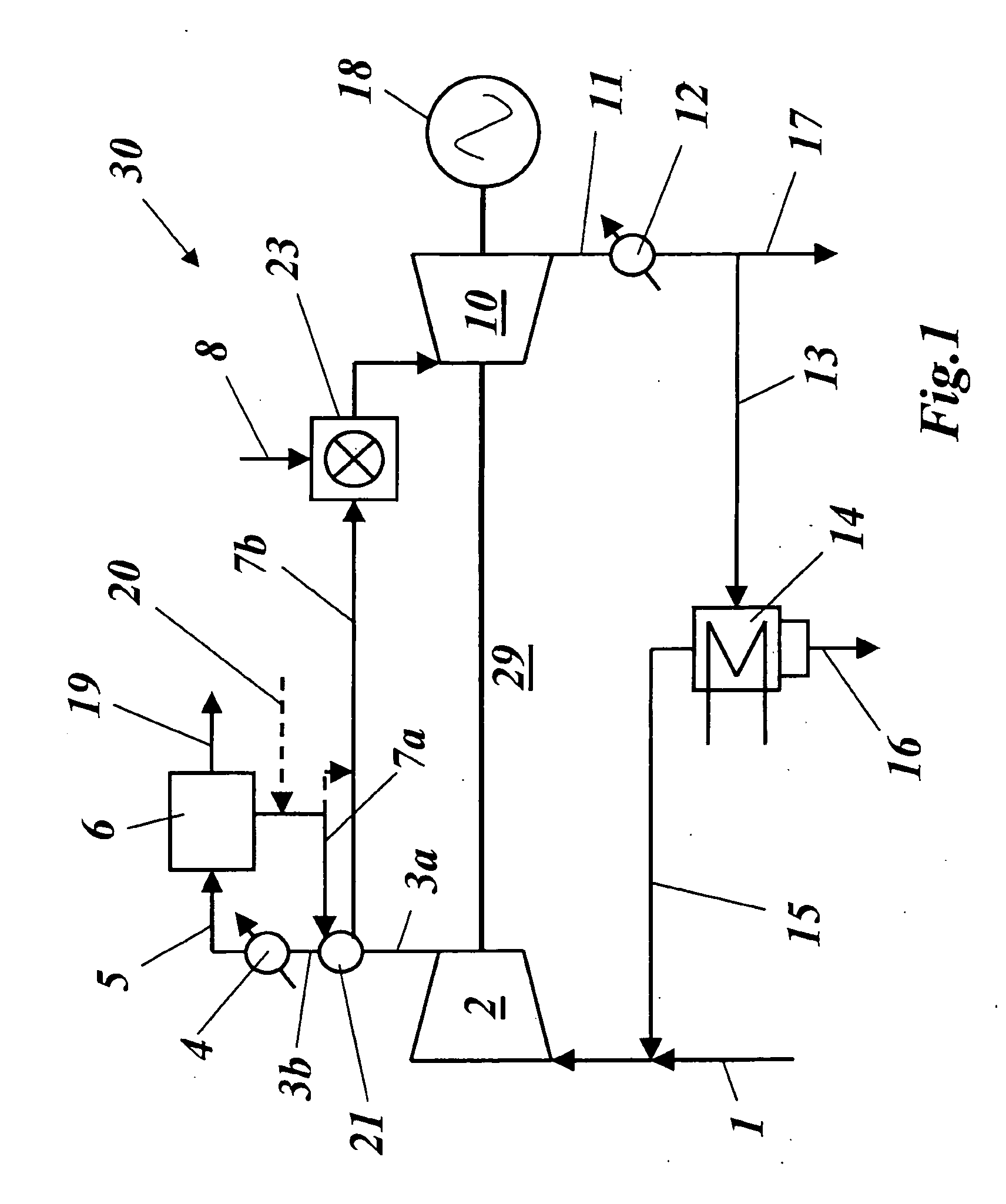

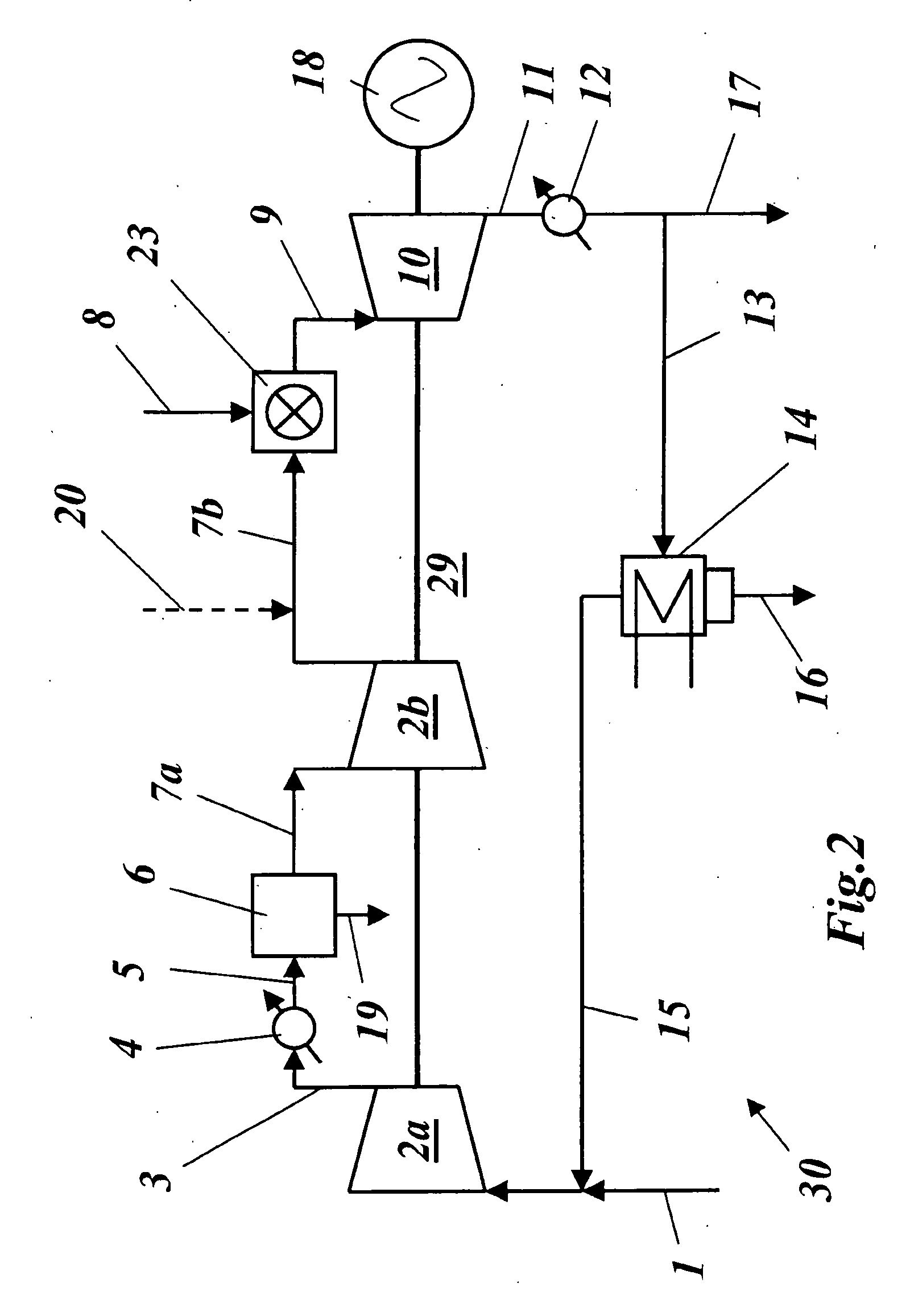

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

LED work light

InactiveUS6857756B2Reduce the amount of powerReduce heatElectric lighting for hand-held usePlanar light sourcesEngineeringLight-emitting diode

A work light for work or task areas which uses light-emitting diodes (LEDs) as the source of light. LED clusters are mounted on a circuit board which is located in a housing. The LED work lights may be powered by conventional 120 or 240-volt electrical outlets, a DC generator, a battery, a battery pack, or a car adapter.

Owner:GENERAL MFG

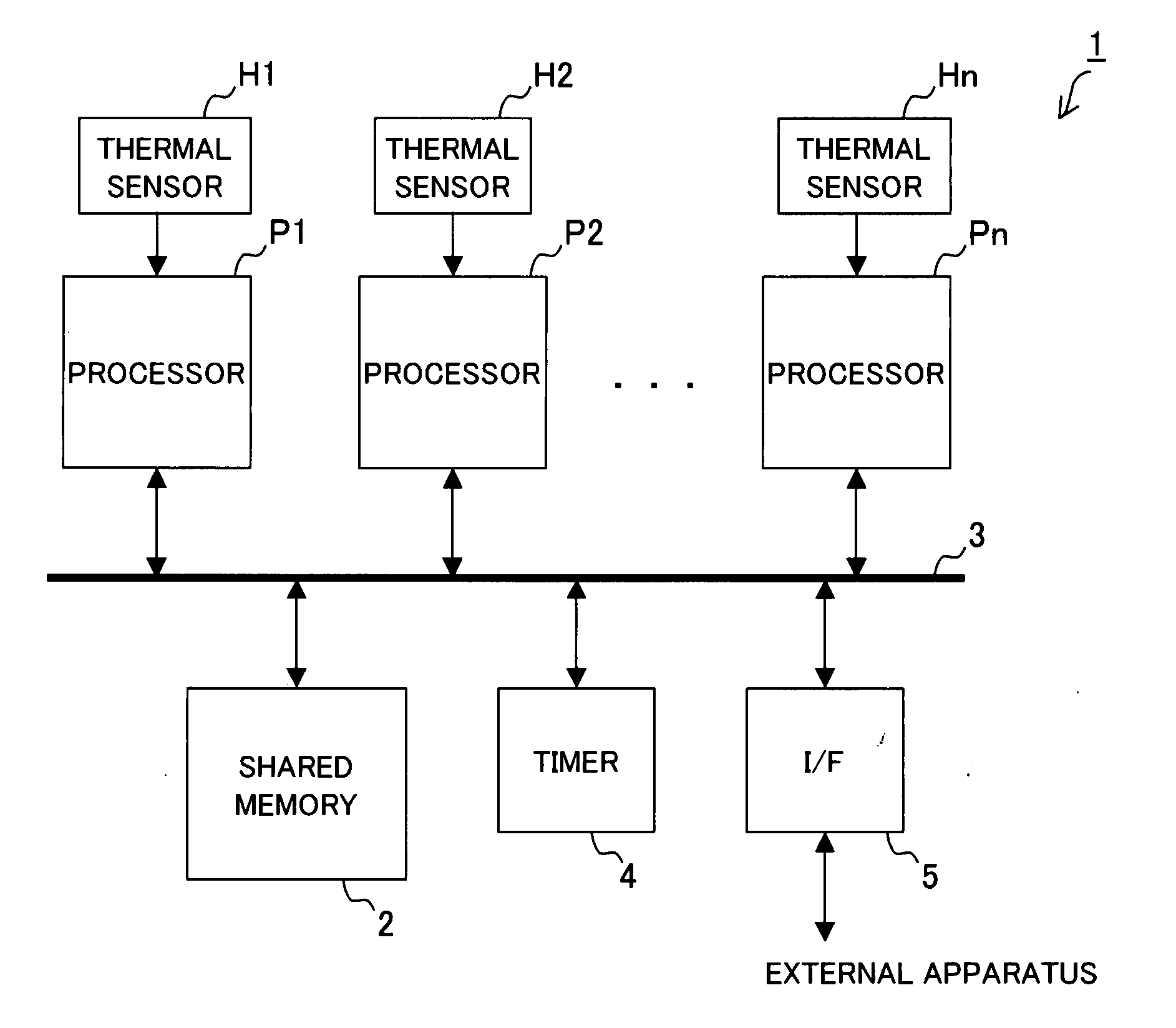

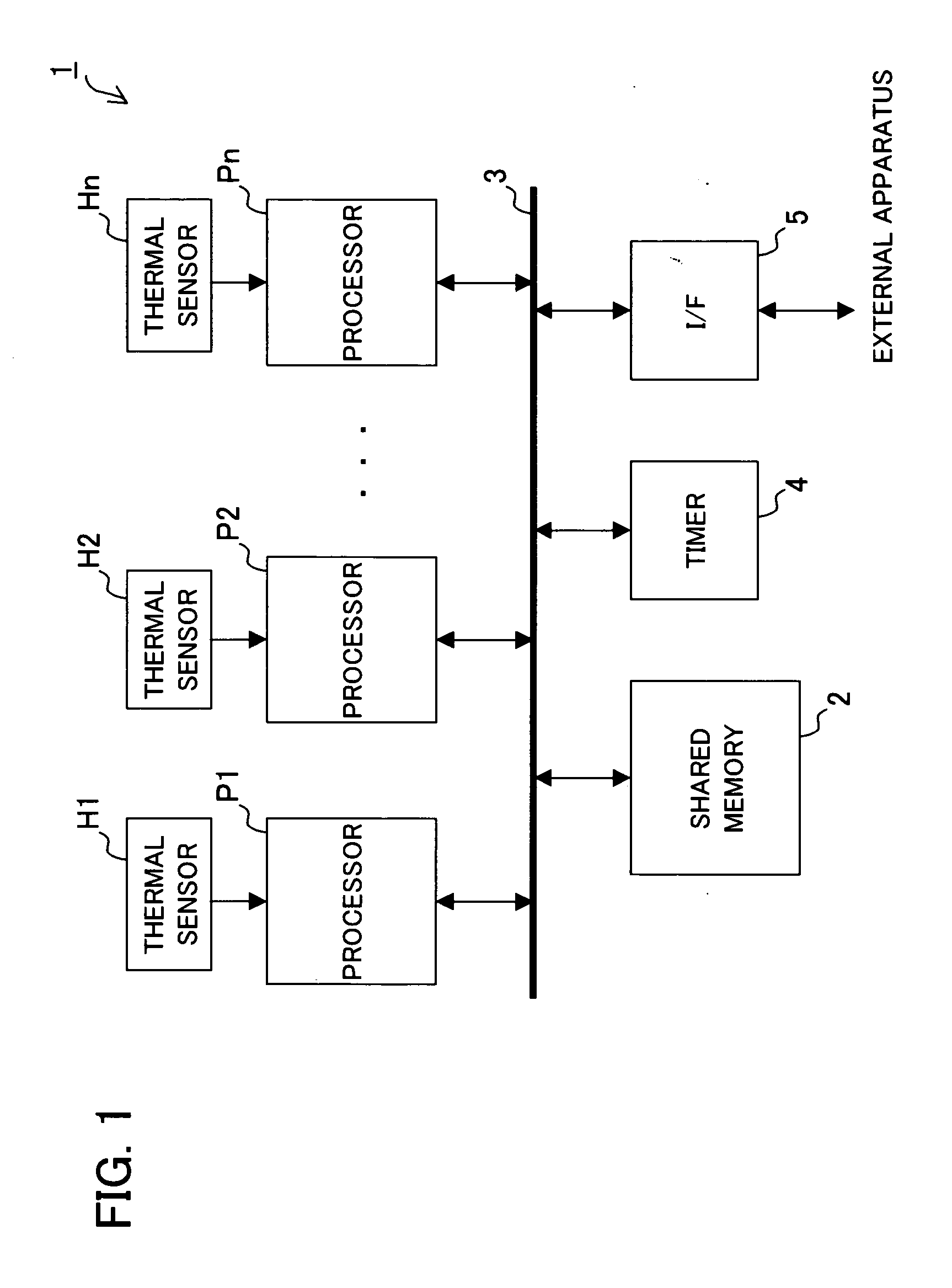

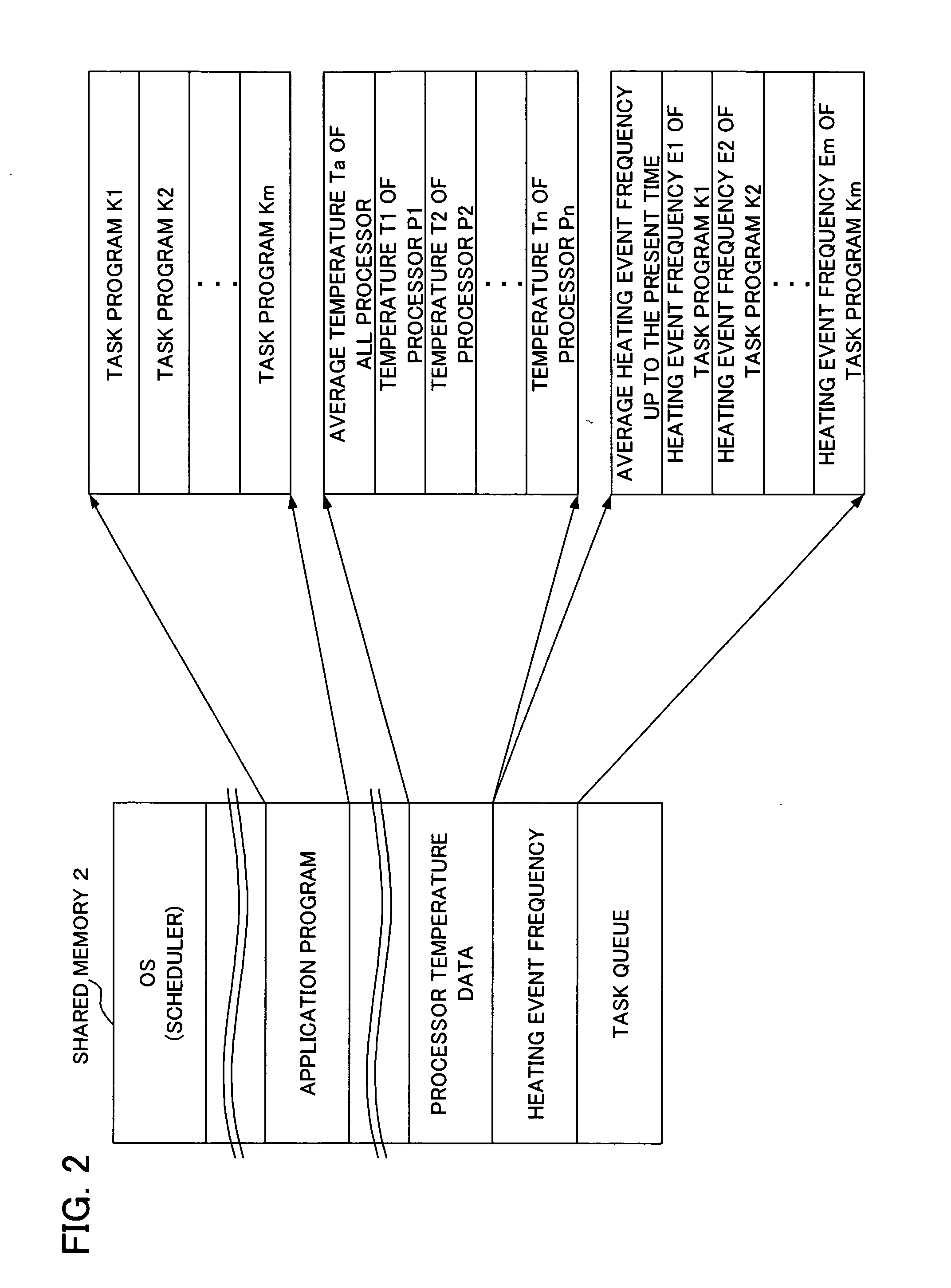

Task scheduling apparatus in distributed processing system

InactiveUS20050278520A1Raise the processing temperatureReduce heatEnergy efficient ICTProgram initiation/switchingProcessing elementHandling system

A task scheduling apparatus of a distributed processing system having a plurality of processing units for processing a plurality of distributed tasks is provided. As a first task scheduling method, the task scheduling apparatus allocates a task to a processing unit having the lowest temperature. As a second task scheduling method, the task scheduling apparatus selects a task based on both temperature of each processing unit and characteristic values of tasks related to degree of temperature rise or consumption power increase caused by execution, and allocates the selected task to the object processing unit. For example, as the second task scheduling method, a task producing a large degree of temperature rise (for example, a task having a number of instructions to be processed per unit time) is allocated to a processing unit having a low temperature. With such a scheduling method, uniform temperature of each processing unit can be obtained.

Owner:FUJITSU LTD

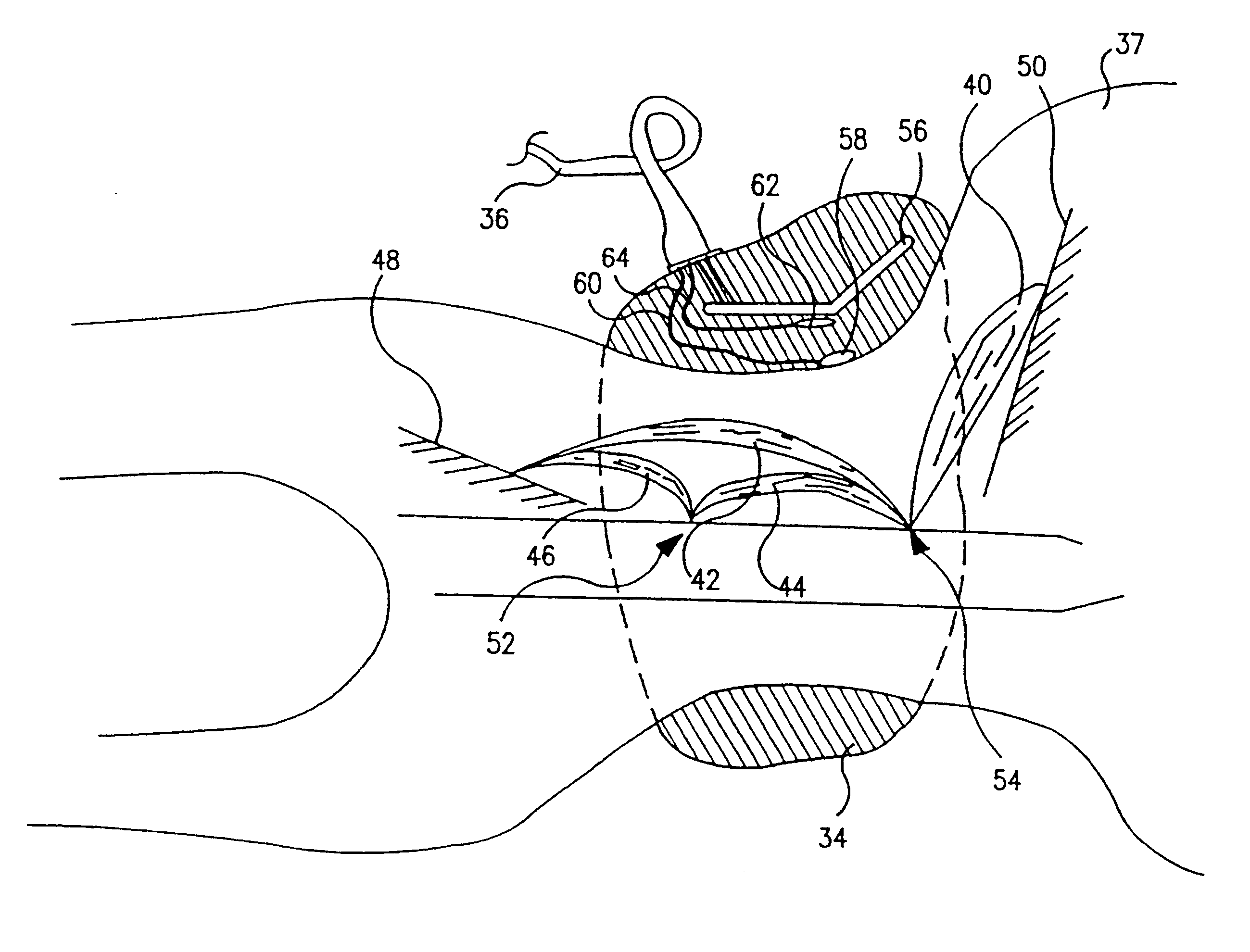

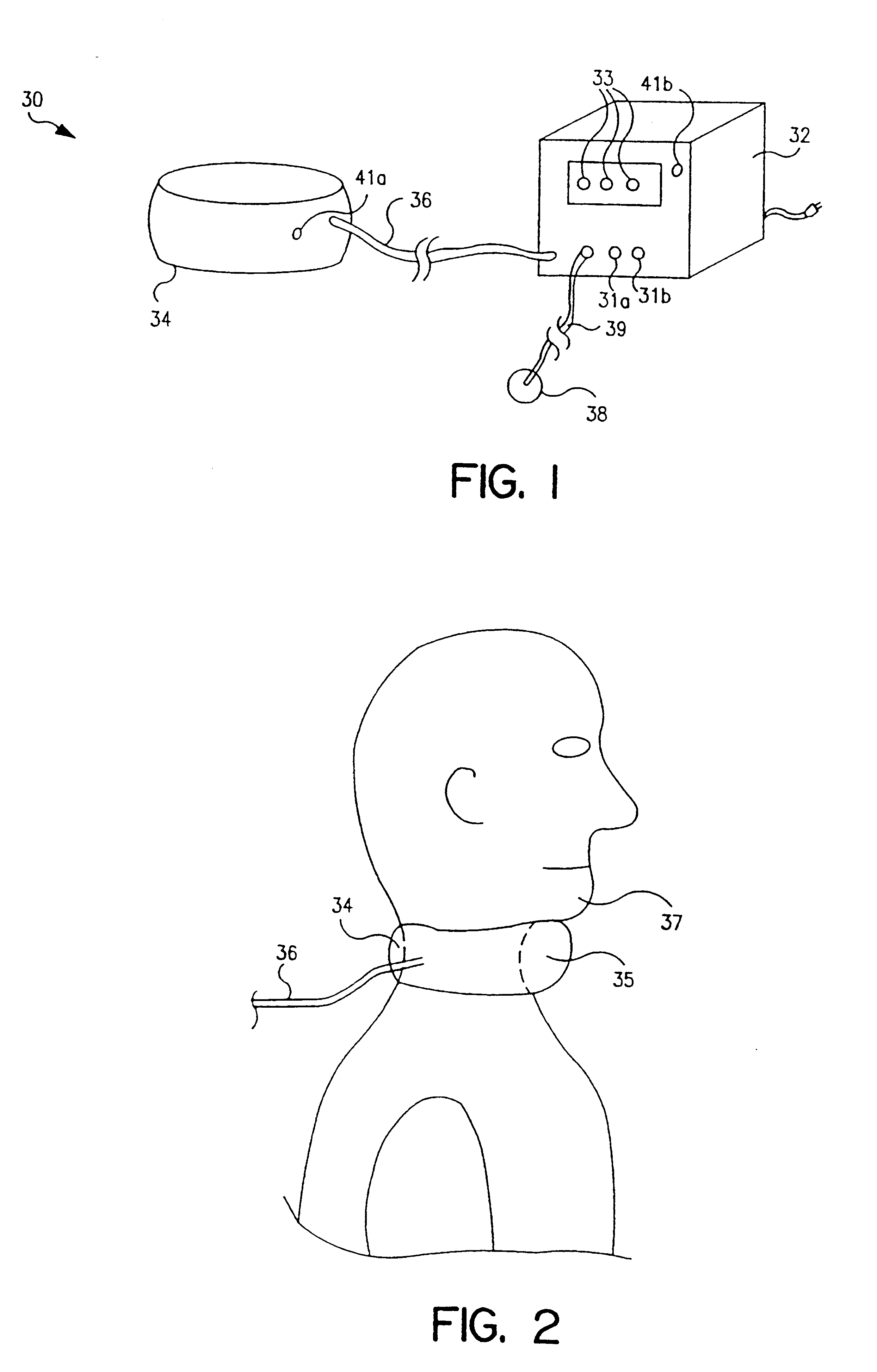

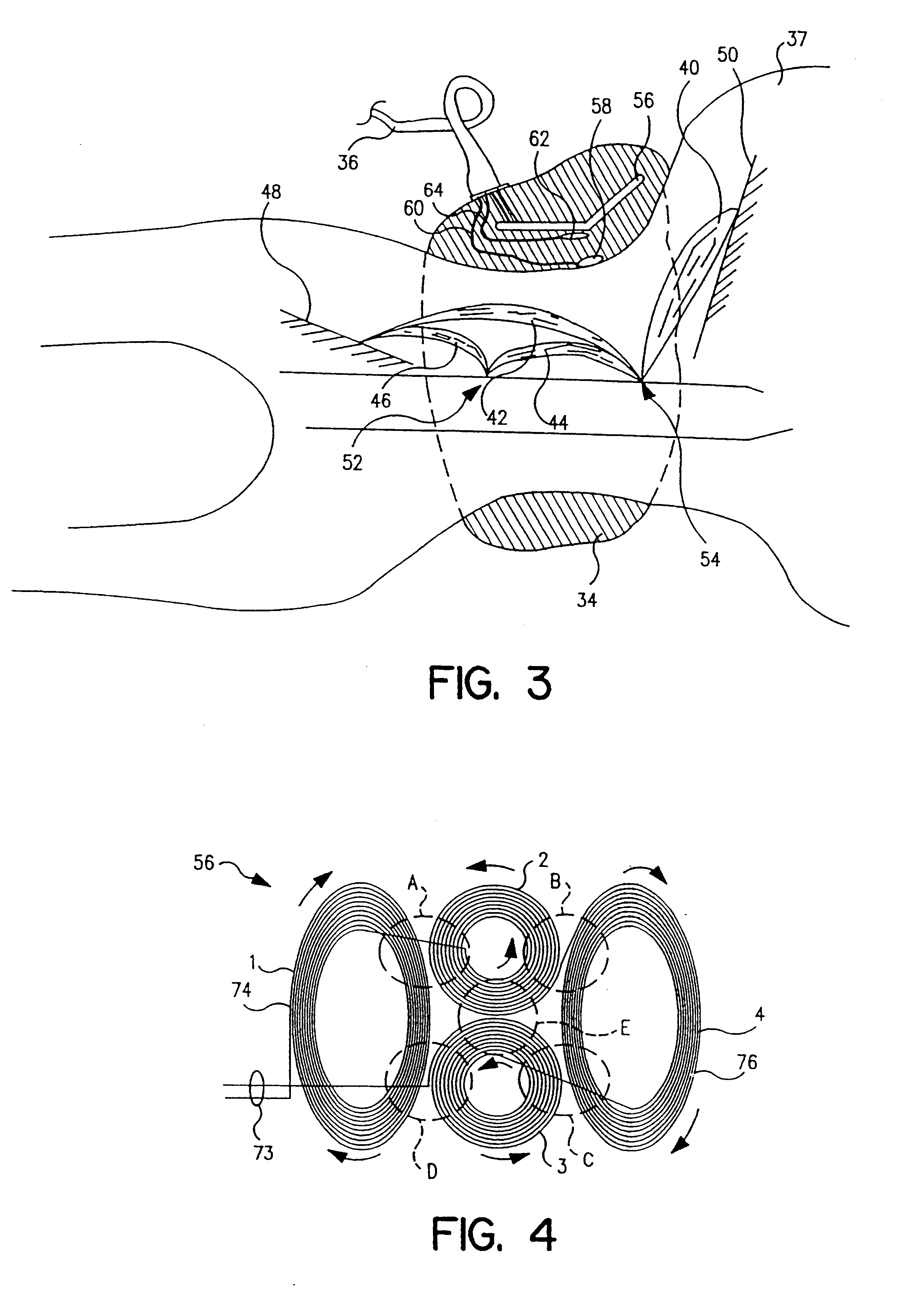

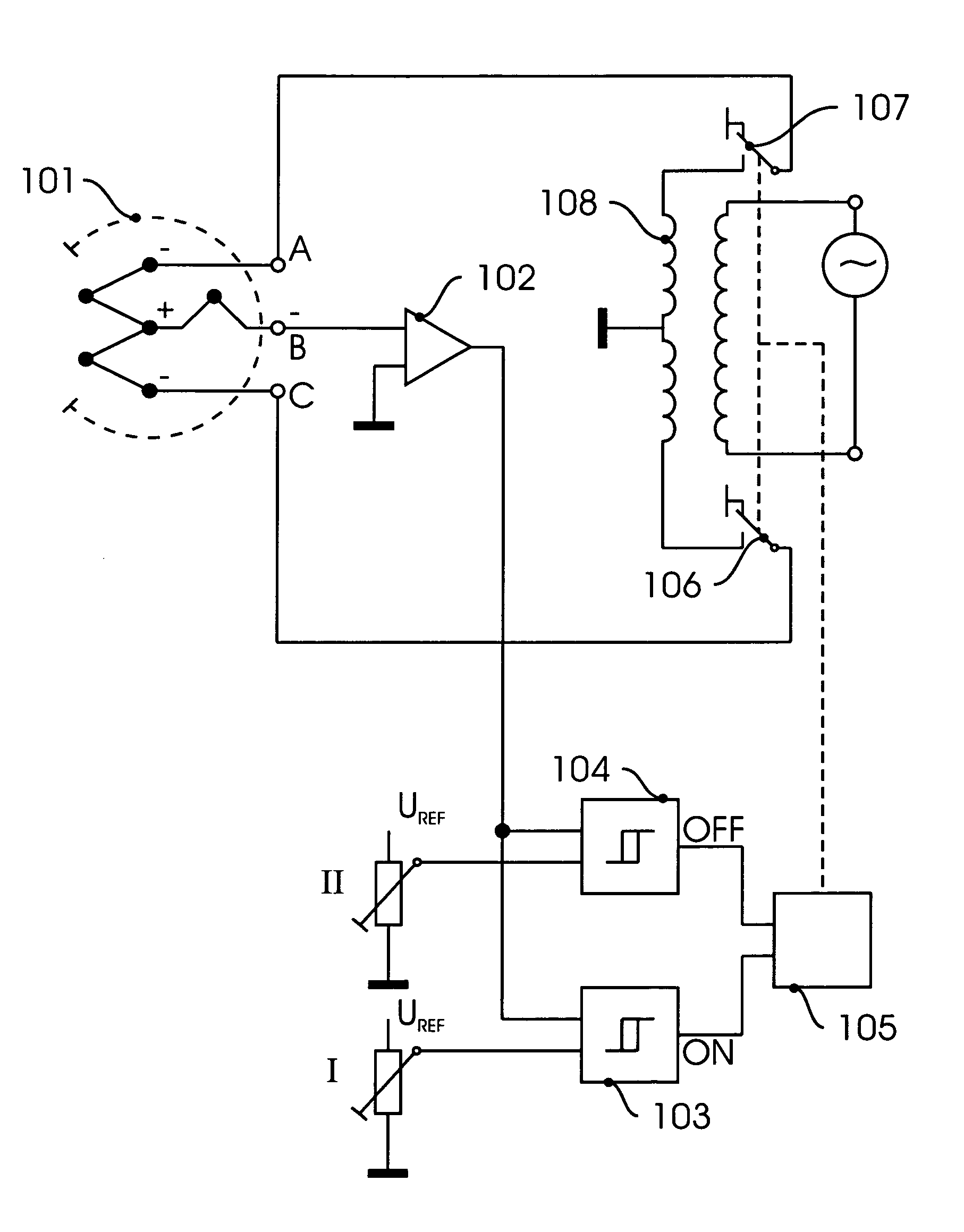

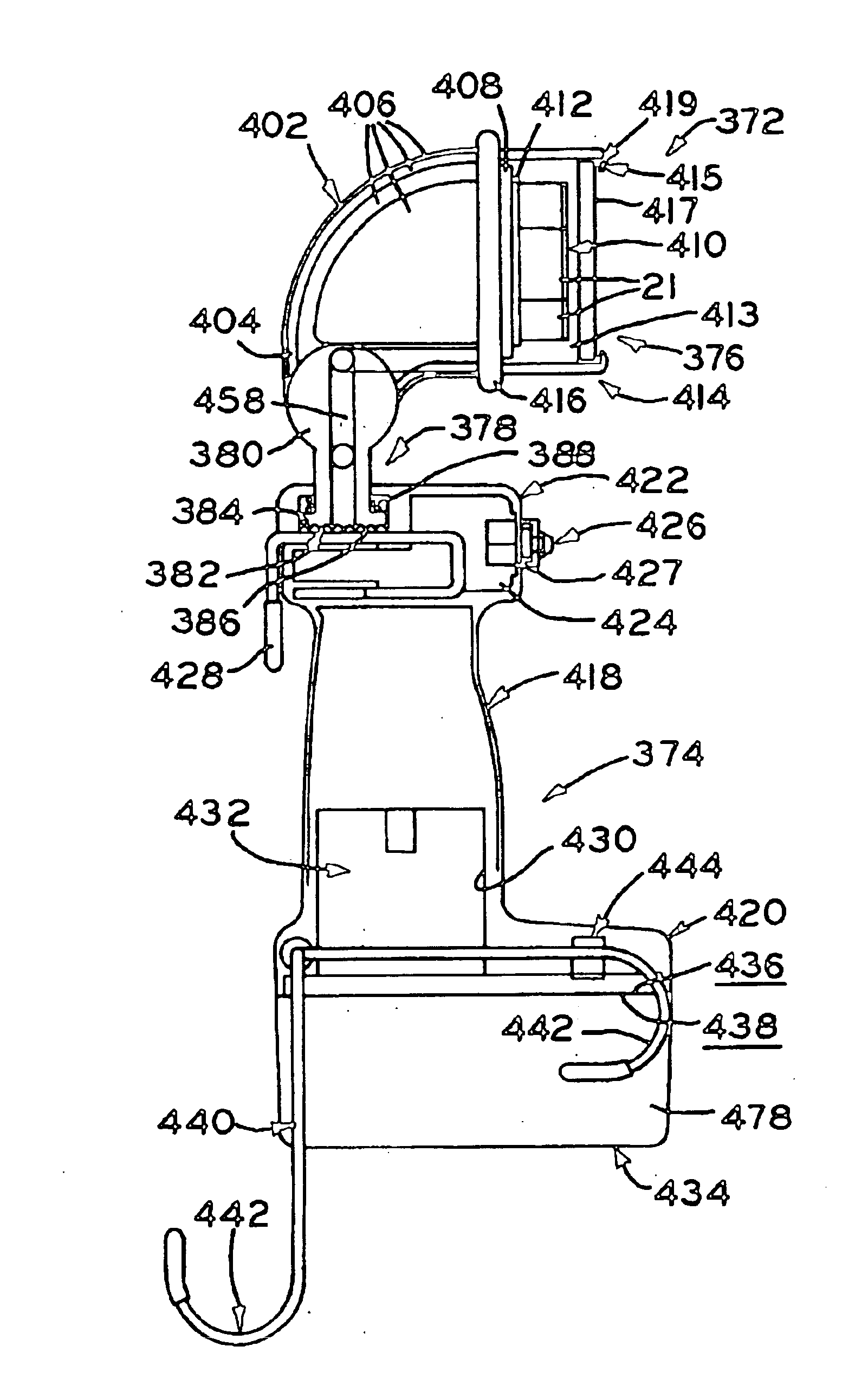

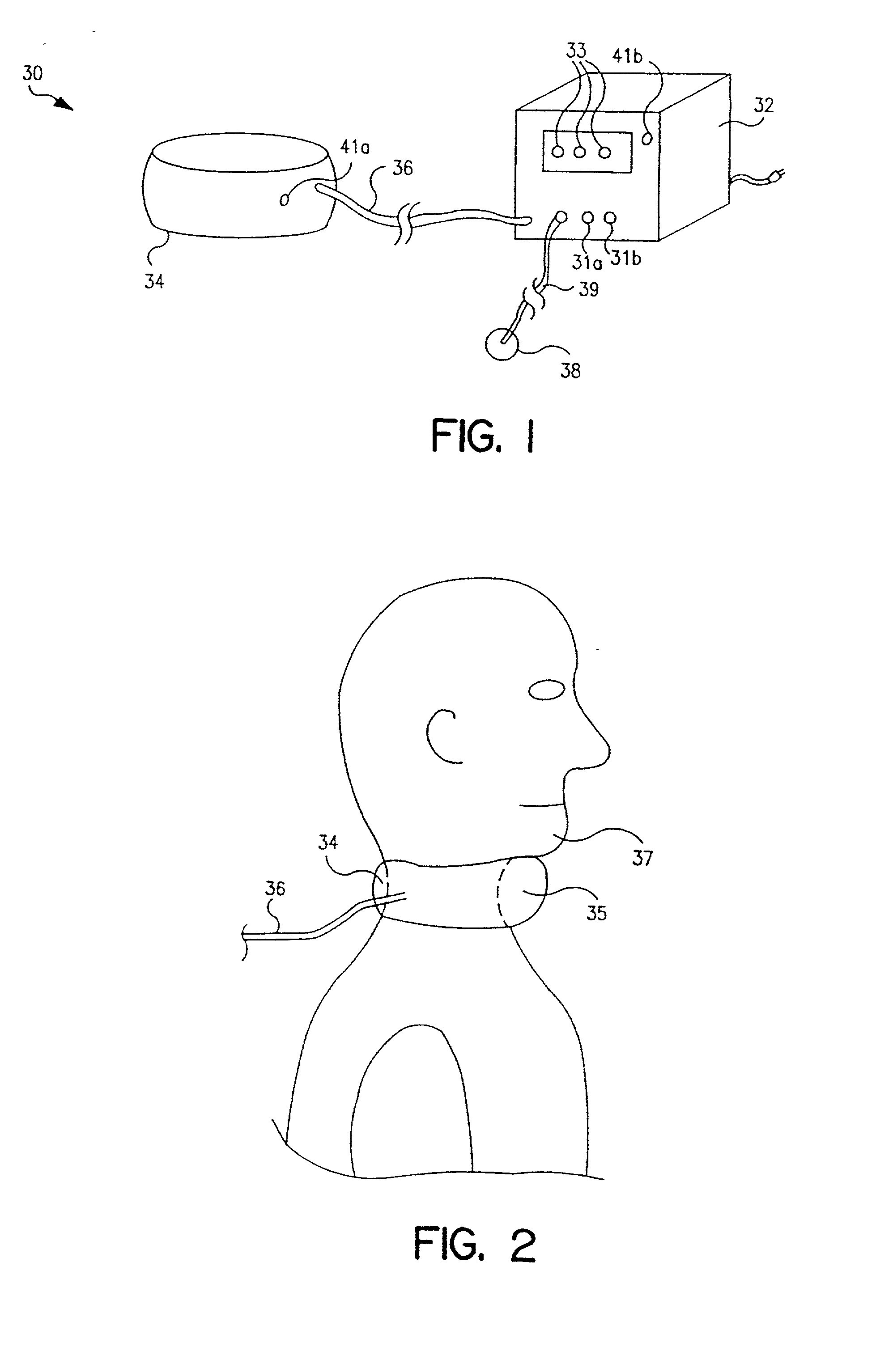

Muscle stimulating device and method for diagnosing and treating a breathing disorder

InactiveUS20010018547A1Reduce heatExcessive heatElectrotherapySurgeryMuscle toneIntensive care medicine

A device and method for magnetic stimulation of muscles for the diagnosis and relief of a breathing disorder, such as obstructive sleep apnea. Magnetic stimulation is used to stimulate muscles which serve to stabilize the upper airway of an individual whose nocturnal apneic events are related to diminished muscle tone. A sensor monitors a physiologic characteristic of the patient, a coil is energized to stimulate the appropriate muscles associated with the upper airway, a power supply provides power for energizing the coil, and a control system controls the application of power to the coil based on the output of the sensor. Diagnosis of obstructive sleep apnea is accomplished by measuring the subject's compliance in the presence and absence of the magnetic stimulation of the upper airway muscles. The smaller the difference between these two compliance levels, the more likely that patient suffers from obstructive sleep apnea.

Owner:RIC INVESTMENTS LLC

Methods and products for producing lattices of EMR-treated islets in tissues, and uses therefor

InactiveUS20060004347A1Big advantageSufficient amountElectrotherapySurgical instrument detailsBiomedical engineeringElectromagnetic radiation

Methods of treatment of tissue with electromagnetic radiation (EMR) to produce lattices of EMR-treated islets in the tissue are disclosed. Also disclosed are devices and systems for producing lattices of EMR-treated islets in tissue, and cosmetic and medical applications of such devices and systems.

Owner:PALOMAR MEDICAL TECH

Surgical headlight assembly

InactiveUS7210810B1Easily switchable power sourceEasily adjustLighting support devicesPoint-like light sourceEngineeringHeadphones

A surgical headlight assembly having a headset structure constructed of lightweight components. The headset structure has adjustable head strap members comprising a generally circular lateral band and a top band. A removable liner is attached to the inside surface of the adjustable headset structure. A lighting assembly which is adjustable with respect to the headset and which uses an adjustable LED is also provided connected to the lateral band. A battery pack is utilized to power the LED.

Owner:PMT

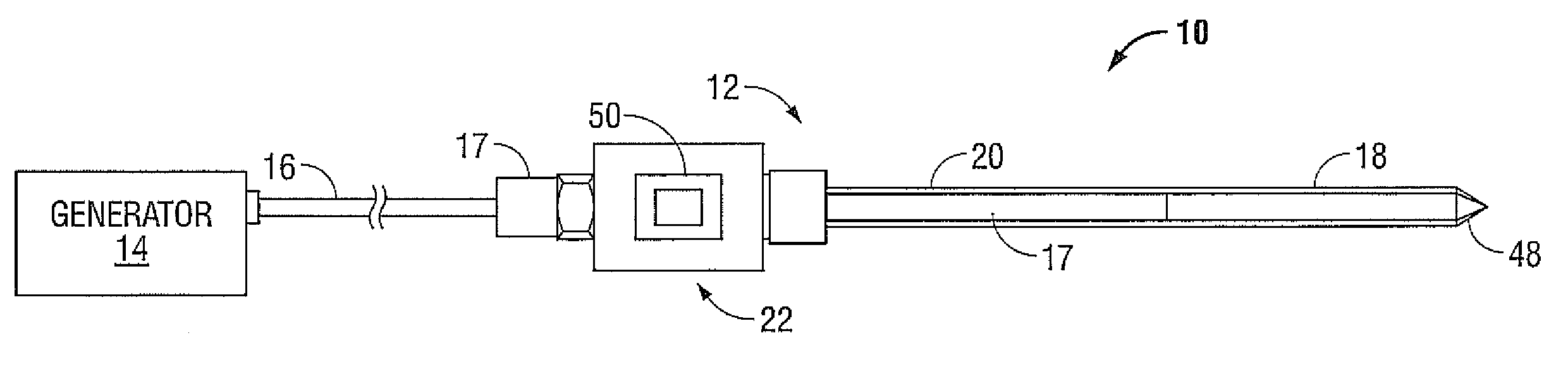

Ultrasonically heated probe

InactiveUS20140121569A1Maximize safe removalReduce heatUltrasound therapyChiropractic devicesHeat energyVibrational energy

A surgical device includes a probe having a proximate end configured to connect to an ultrasonic driver assembly that generates ultrasonic vibrational energy, and a shaft for conducting the ultrasonic vibrational energy from the proximate end to a distal end. The device also includes a canula located at least partially over the distal end of the probe. A material is interposed between the probe and the canula for converting the ultrasonic vibrational energy into heat energy.

Owner:SOLTA MEDICAL

Tank filters adaptable for placement with a guide wire, in series with the lead wires or circuits of active medical devices to enhance MRI compatibility

InactiveUS20080161886A1Reduce sensitivityReduce heatMultiple-port networksAnti-noise capacitorsEngineeringInductor

A tank filter is provided for a lead wire of an active medical device (AMD). The tank filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the tank filter is resonant at a selected frequency. A passageway through the tank filter permits selective slidable passage of a guide wire therethrough for locating the lead wire in an implantable position. The Q of the inductor may be relatively maximized and the Q of the capacitor may be relatively minimized to reduce the overall Q of the tank filter to attenuate current flow through the lead wire along a range of selected frequencies. In a preferred form, the tank filter is integrated into a TIP and / or RING electrode for an active implantable medical device.

Owner:WILSON GREATBATCH LTD

Tank filters utilizing very low k materials, in series with lead wires or circuits of active medical devices to enhance MRI compatibility

ActiveUS20080071313A1Low dielectric constantHigh strengthMultiple-port networksAnti-noise capacitorsCapacitanceEngineering

A TANK filter is provided for a lead wire of an active medical device (AMD). In a preferred form, the TANK filter is integrated into a TIP and / or RING electrode for an active implantable medical device. The TANK filter includes a capacitor in parallel with an inductor. The parallel capacitor and inductor are placed in series with the lead wire of the AMD, wherein values of capacitance and inductance are selected such that the TANK filter is resonant at a selected frequency to attenuate current flow through the lead wire along a range of selected frequencies. In a particularly preferred form, the TANK filter is manufactured using very low k materials of sufficient strength to handle forces applied thereto during installation and use.

Owner:WILSON GREATBATCH LTD

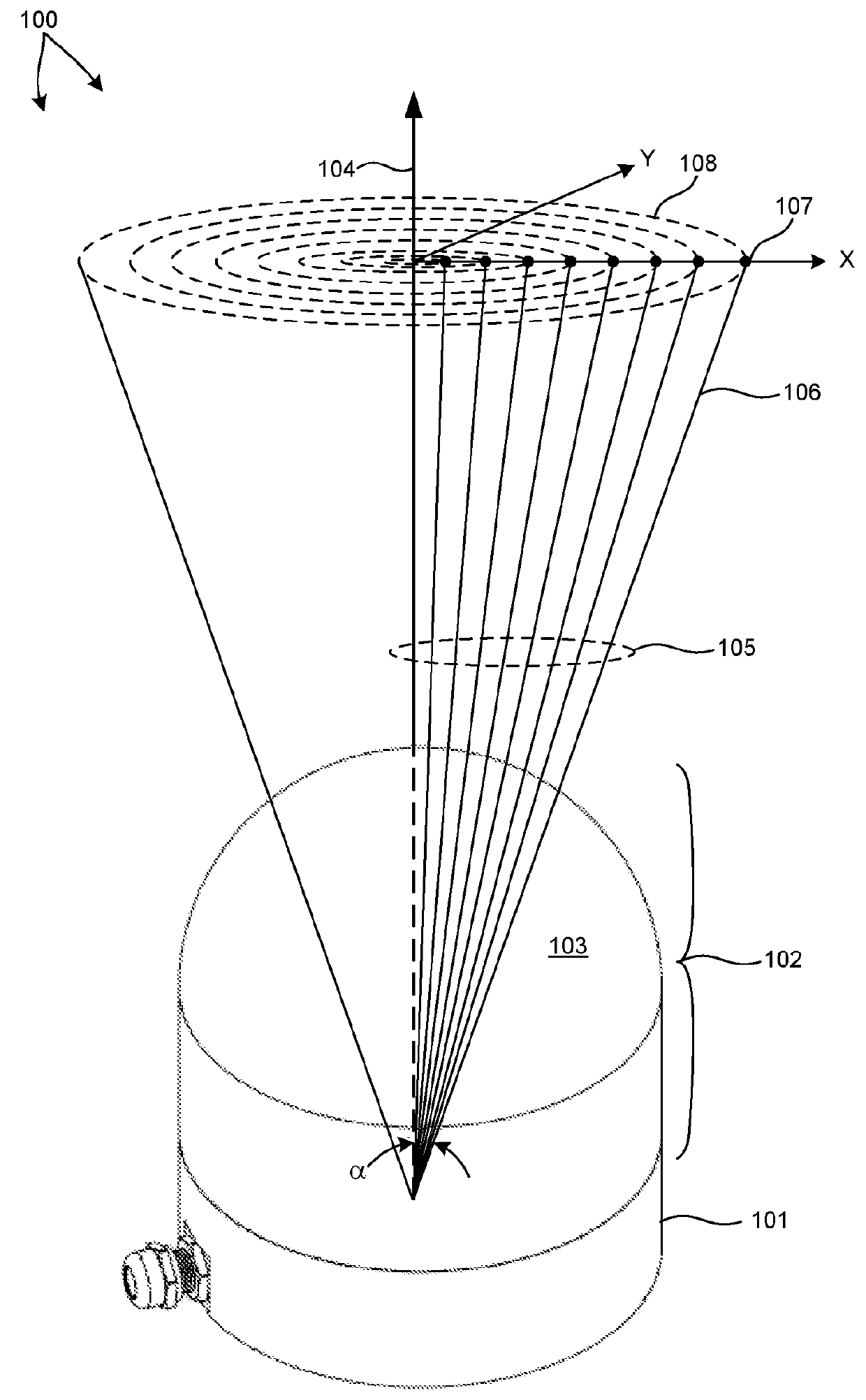

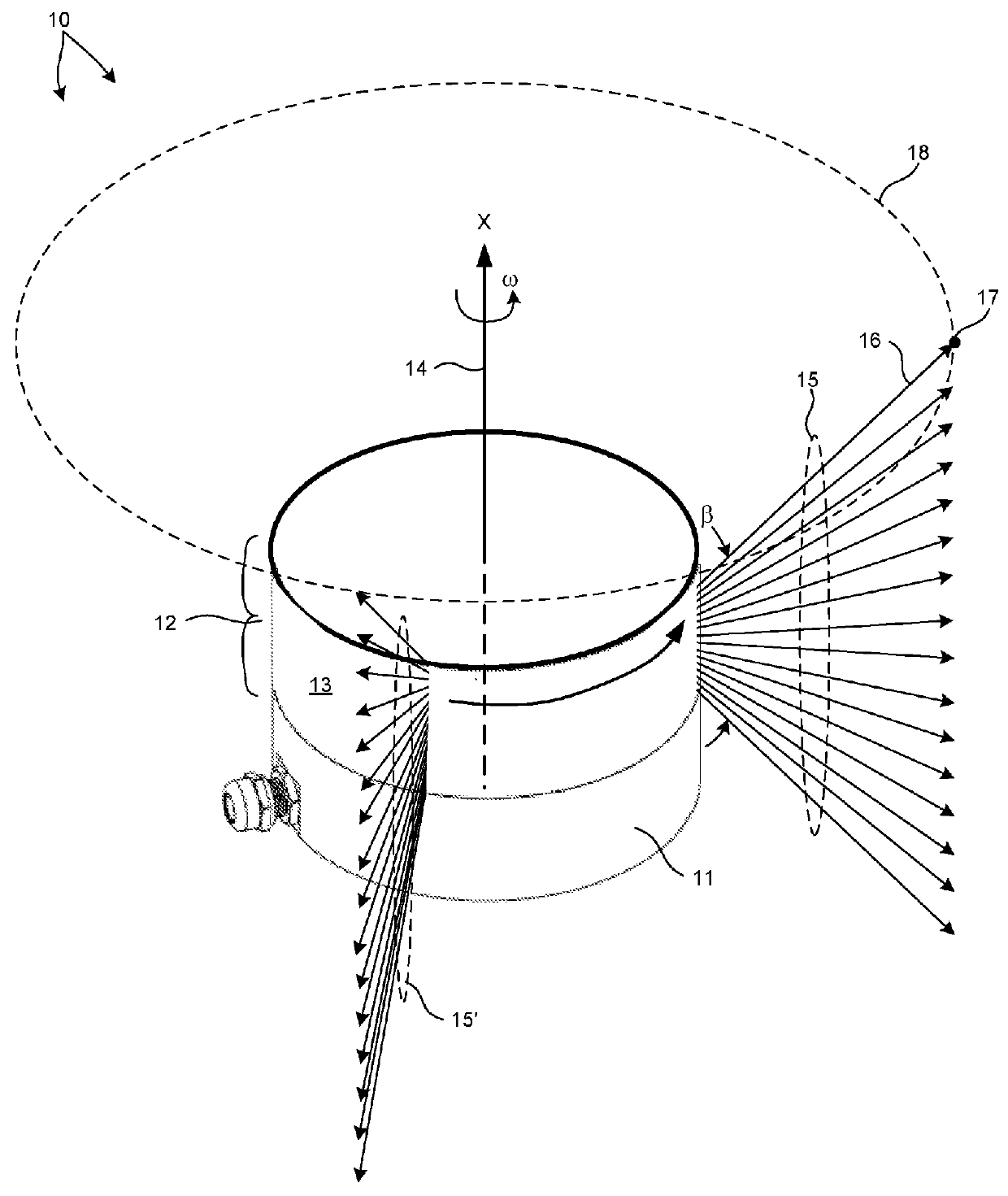

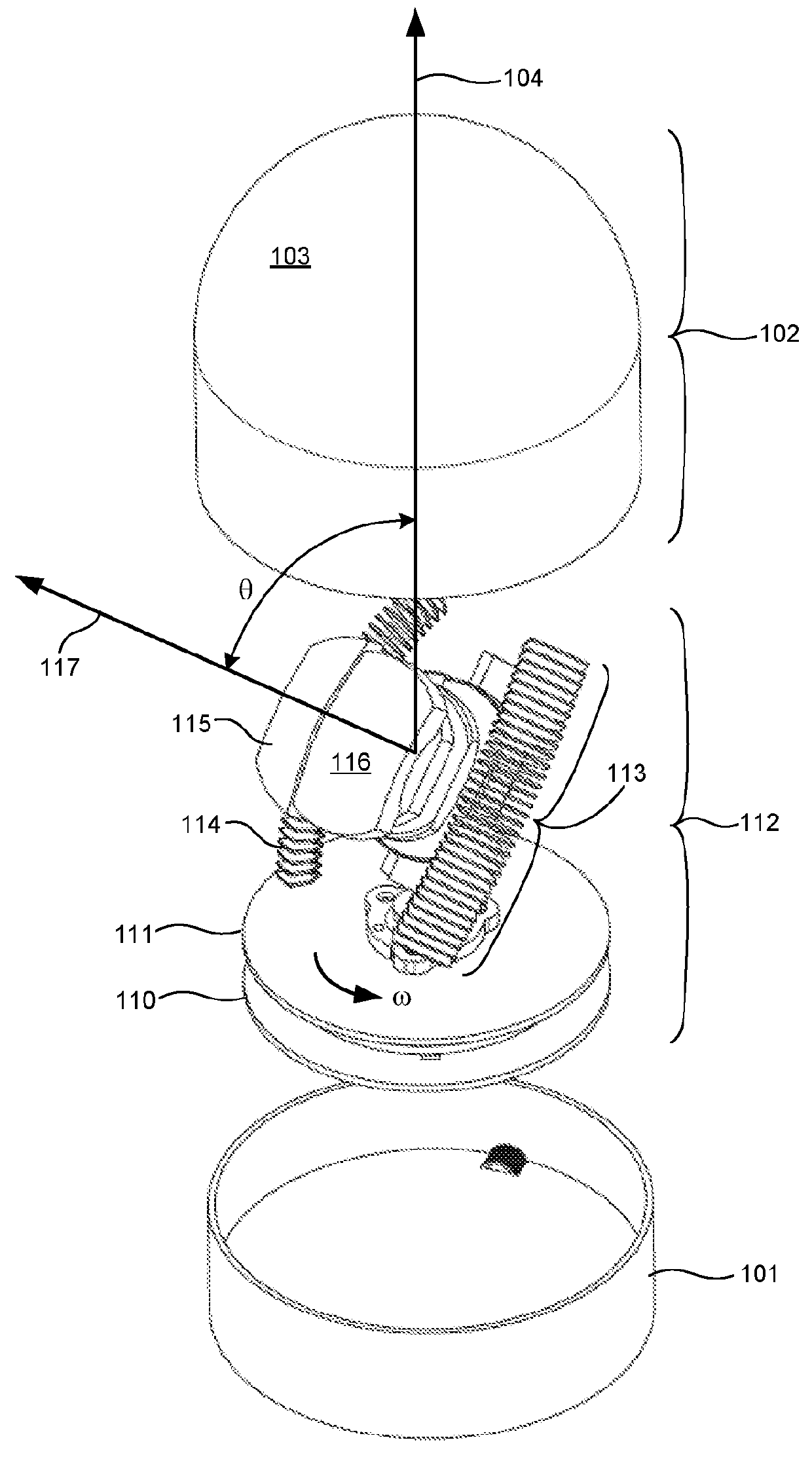

LIDAR Based 3-D Imaging With Varying Pulse Repetition

ActiveUS20170269209A1Reduce total energy consumption and heatReduce consumptionElectromagnetic wave reradiationSteroscopic systemsPulse beamRadar

Methods and systems for performing three dimensional LIDAR measurements with different pulse repetition patterns are described herein. Each repetitive pattern is a sequence of measurement pulses that repeat over time. In one aspect, the repetition pattern of a pulsed beam of illumination light emitted from a LIDAR system is varied to reduce total energy consumption and heat generated by the LIDAR system. In some examples, the repetitive pattern is varied by skipping a number of pulses. In some examples, the repetitive pattern of pulses of illumination light emitted from the LIDAR system is varied by changing a repetition rate of the sequence of emitted pulses. In some examples, the pulse repetition pattern is varied based on the orientation of the LIDAR device. In some examples, the repetition pattern is varied based on an object detected by the LIDAR device or another imaging system.

Owner:VELODYNE LIDAR USA INC

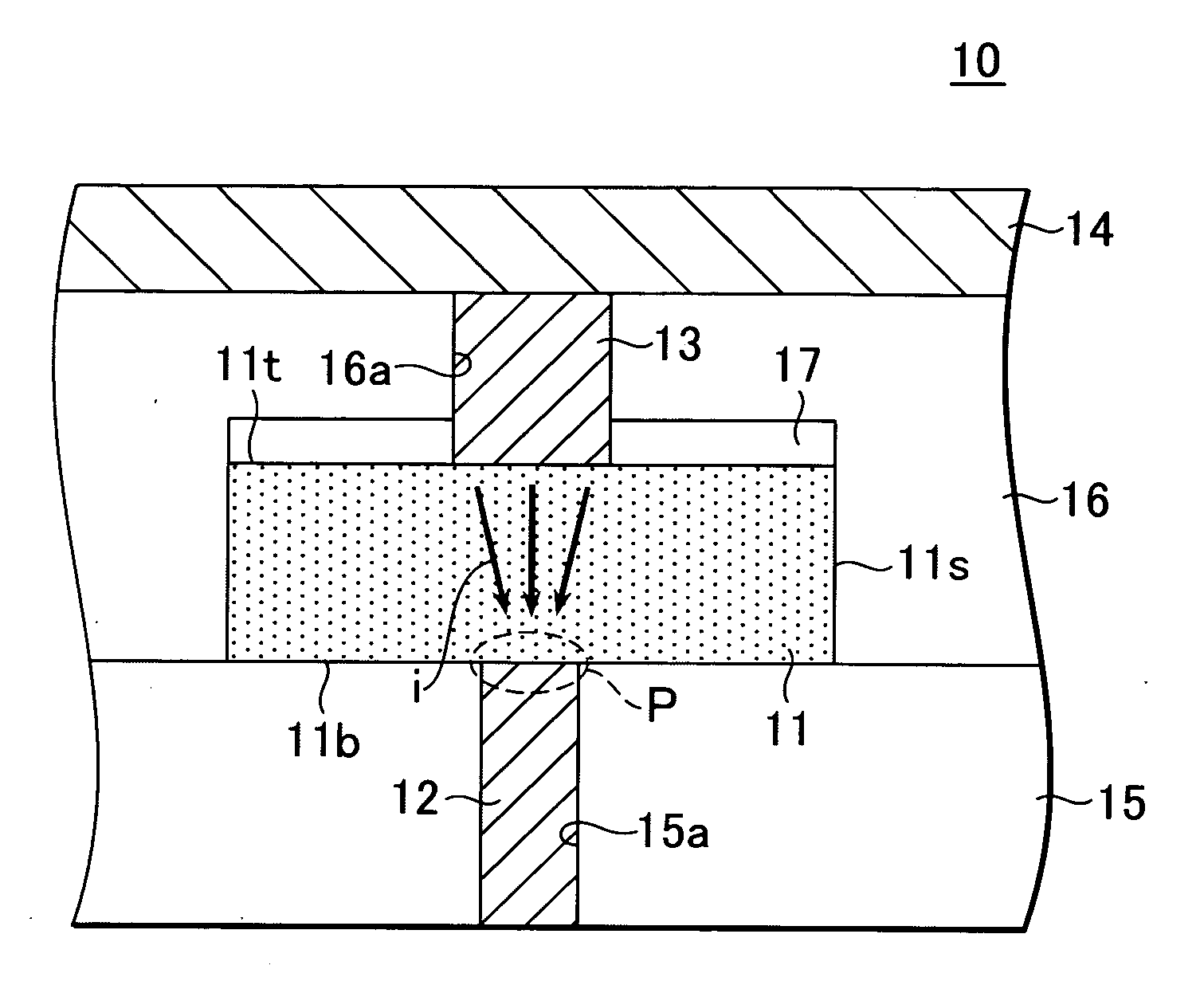

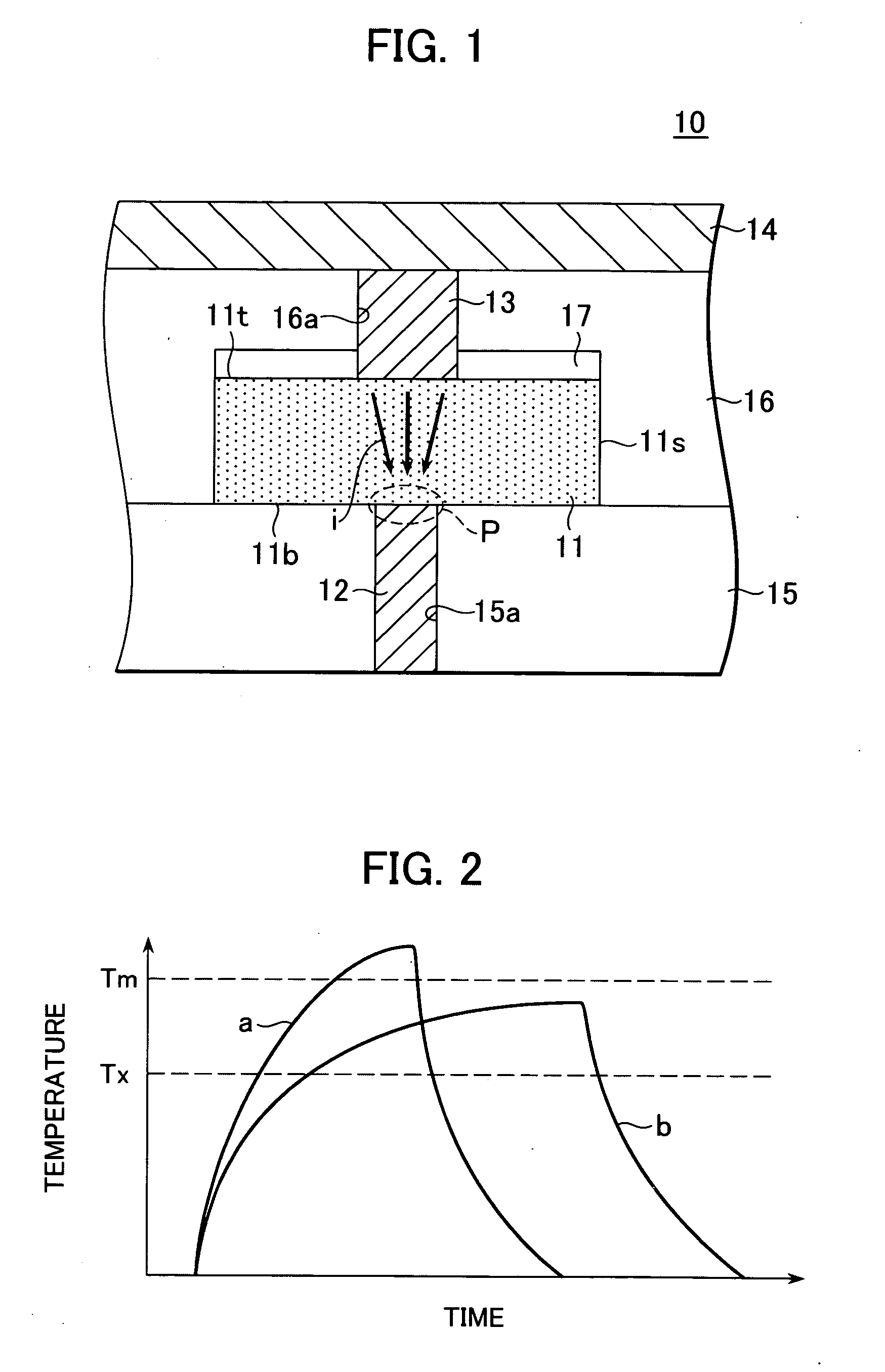

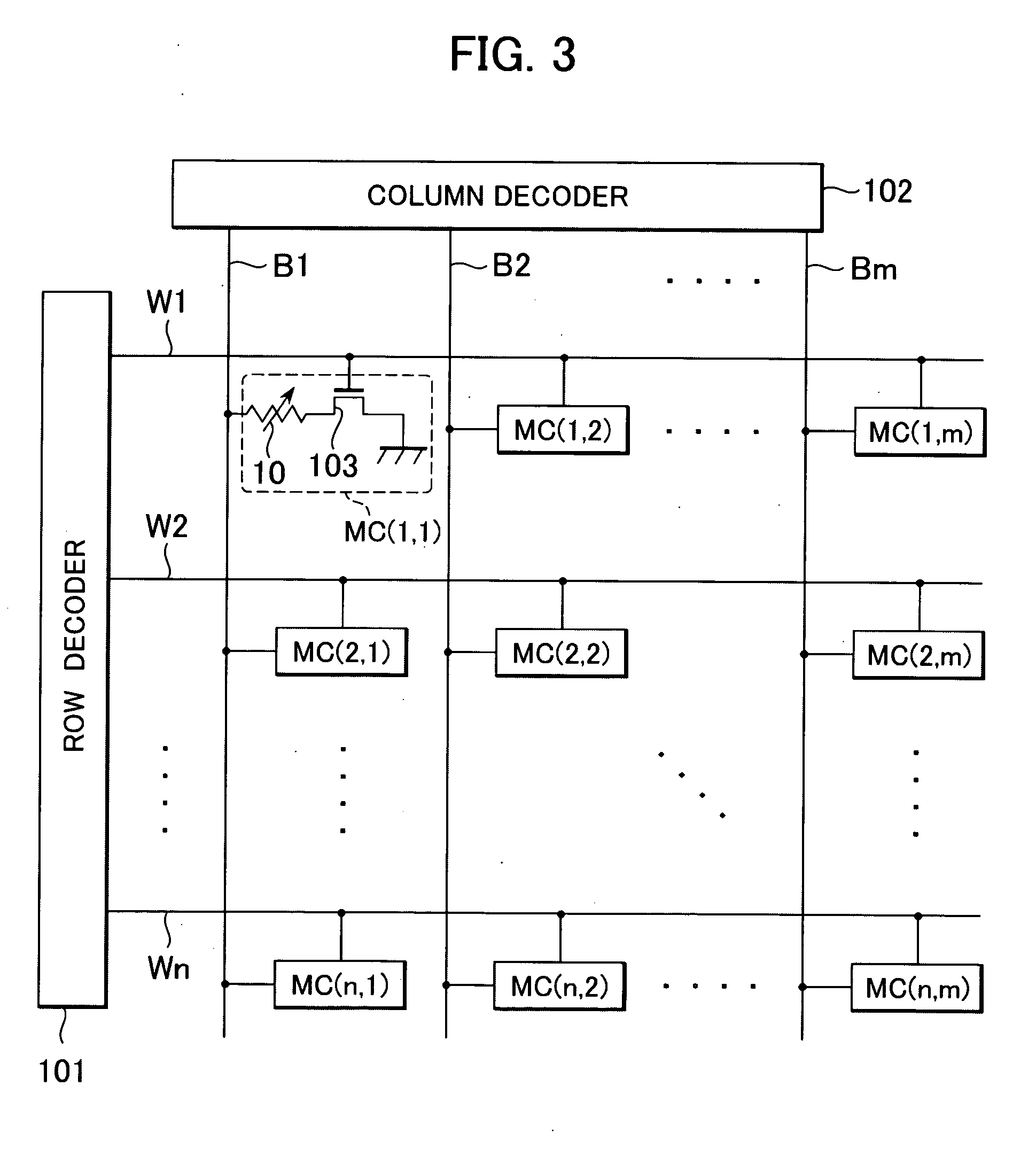

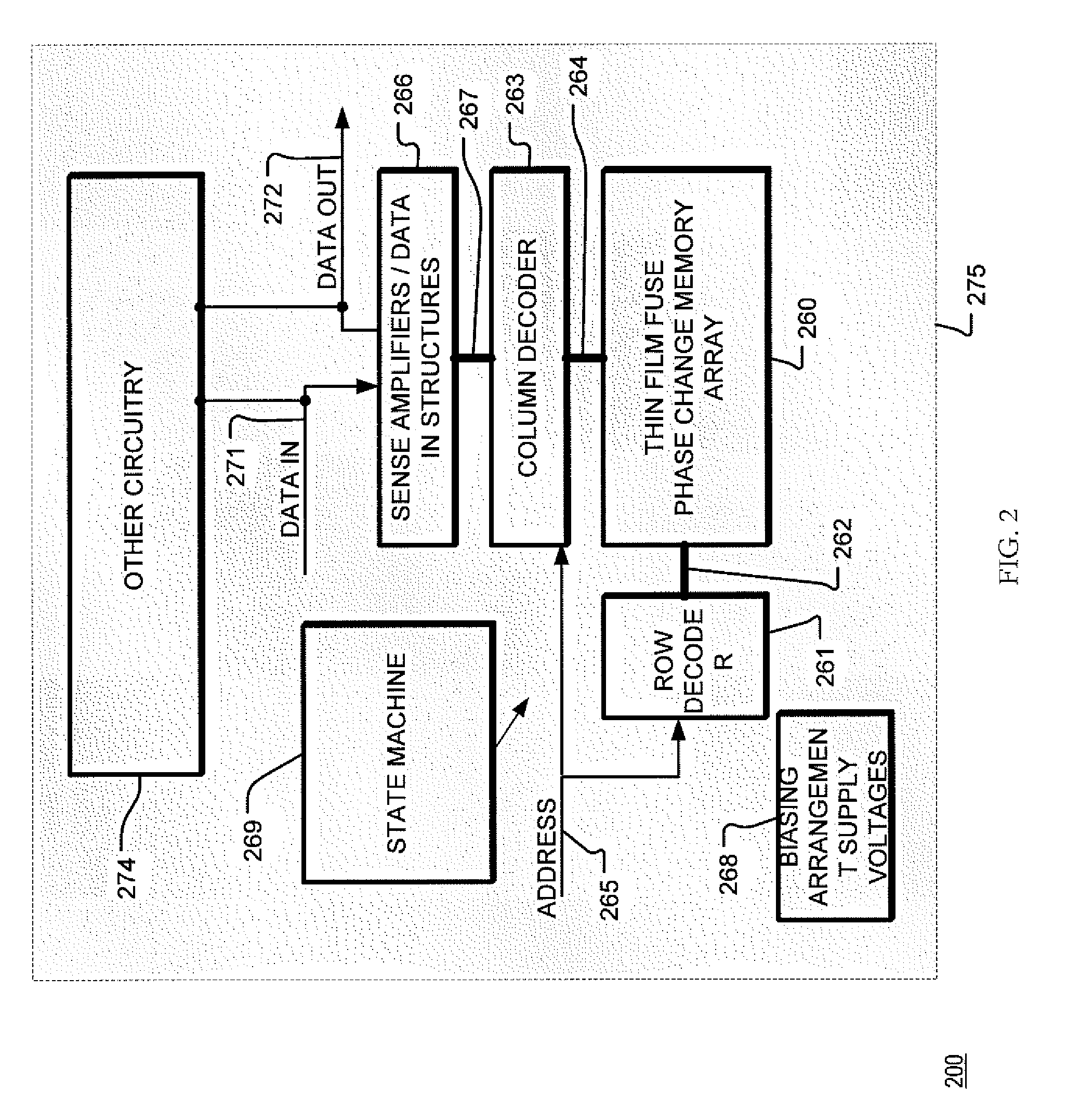

Electrically rewritable non-volatile memory element and method of manufacturing the same

InactiveUS20070063180A1Minimizing damageImprove thermal efficiencySolid-state devicesBulk negative resistance effect devicesEngineeringRecording layer

A non-volatile memory element includes a recording layer that includes a phase change material, a lower electrode provided in contact with the recording layer, an upper electrode provided in contact with a portion of the upper surface of the recording layer, a protective insulation film provided in contact with the other portion of the upper surface of the recording layer, and an interlayer insulation film provided on the protective insulation film. High thermal efficiency can thereby be obtained because the size of the area of contact between the recording layer and the upper electrode is reduced. Providing the protective insulation film between the interlayer insulation film and the upper surface of the recording layer makes it possible to reduce damage sustained by the recording layer during patterning of the recording layer or during formation of the through-hole for exposing a portion of the recording layer.

Owner:ELPIDA MEMORY INC

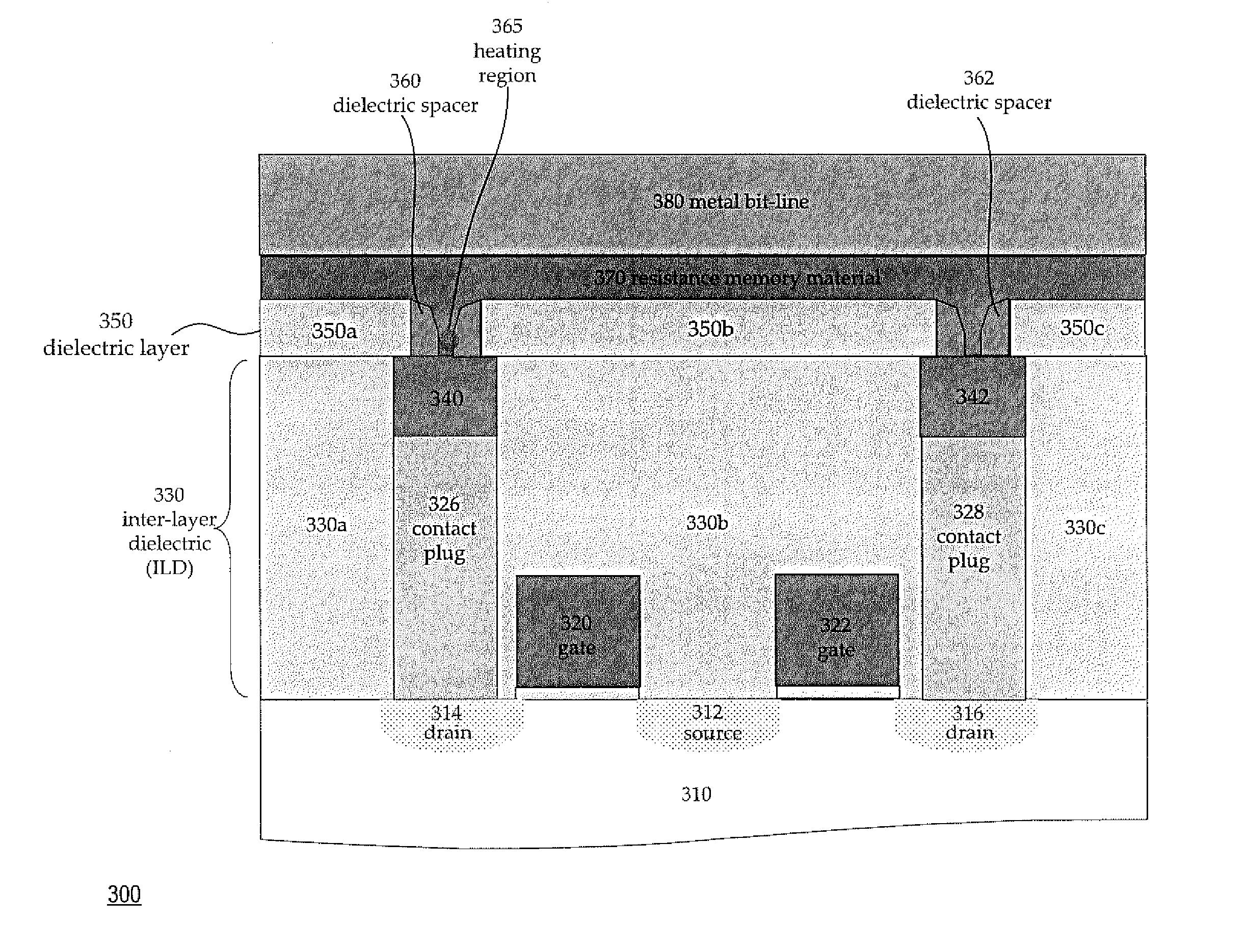

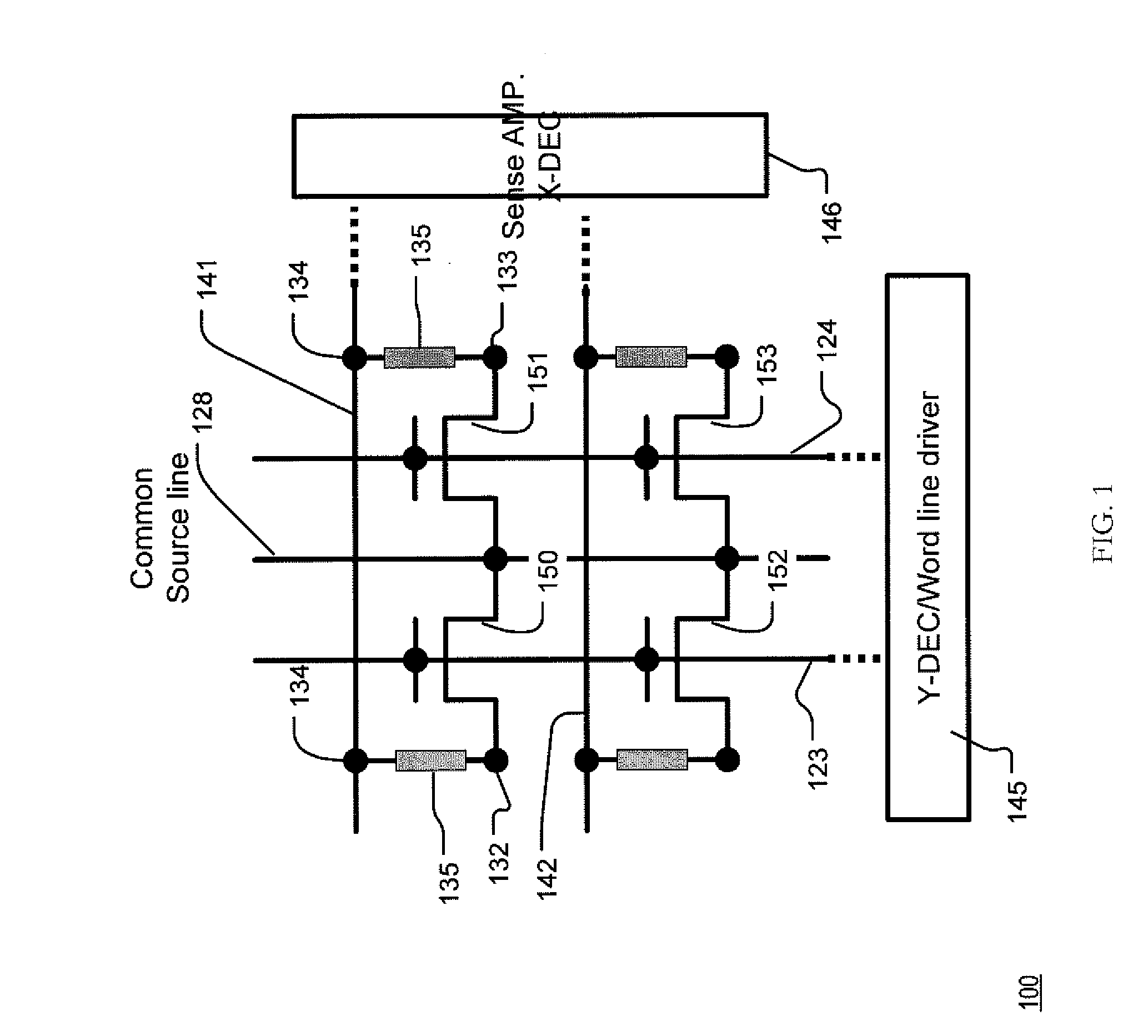

Structures and Methods of a Bistable Resistive Random Access Memory

ActiveUS20070257300A1Reduce heat dissipationReduce heatTransistorSolid-state devicesElectrical resistance and conductanceElectrical conductor

Structures and methods to form a bistable resistive random access memory for reducing the amount of heat dissipation from electrodes by confining a heating region in the memory cell device are described. The heating region is confined in a kernel comprising a programmable resistive memory material that is in contact with an upper programmable resistive memory member and a lower programmable resistive memory member. The lower programmable resistive member has sides that align with sides of a bottom electrode comprising a tungsten plug. The lower programmable resistive member and the bottom electrode function a first conductor so that the amount of heat dissipation from the first conductor is reduced. The upper programmable resistive memory material and a top electrode function as a second conductor so that the amount of heat dissipation from the second conductor is reduced.

Owner:MACRONIX INT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com