Patents

Literature

635 results about "Control ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

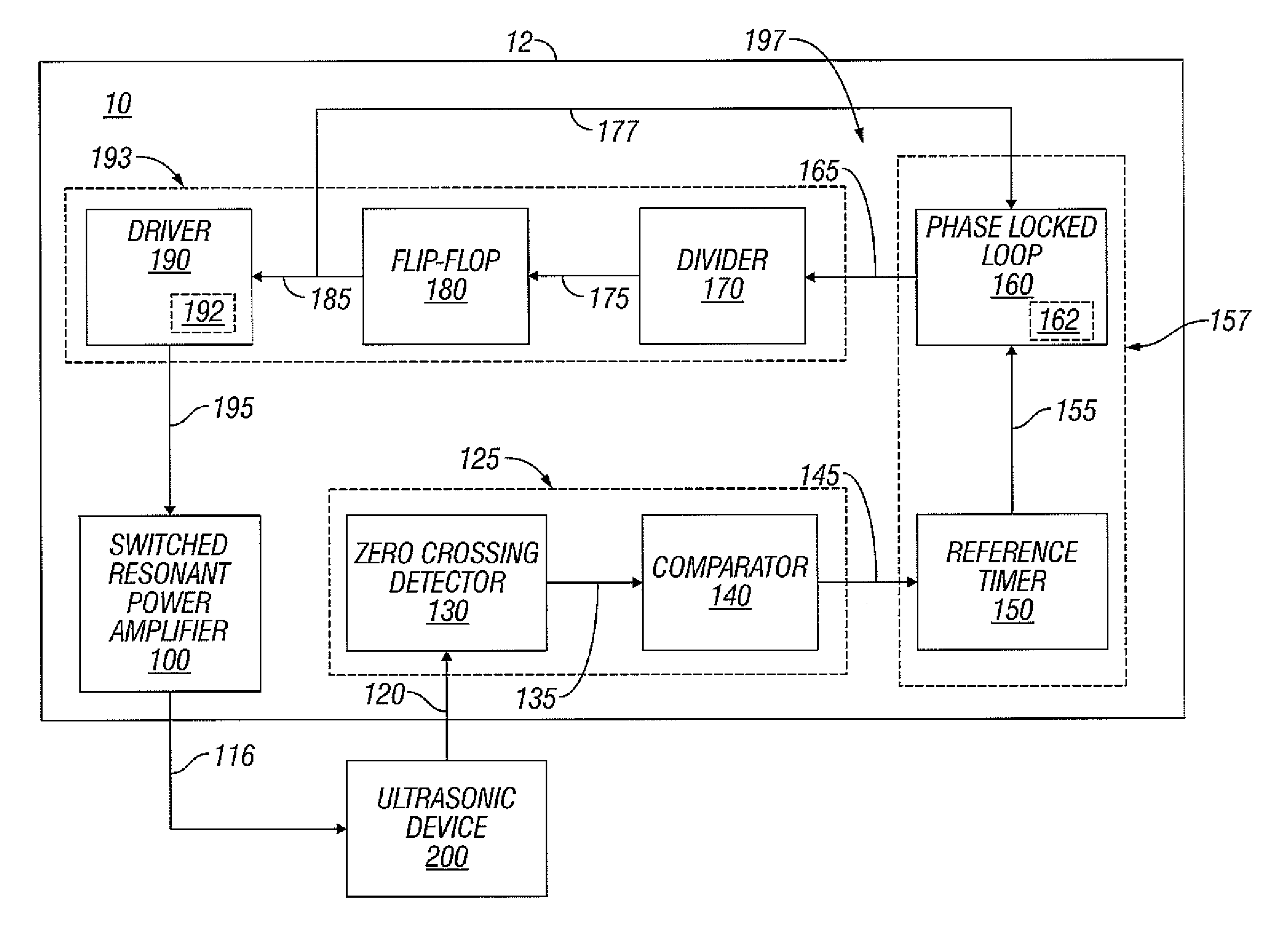

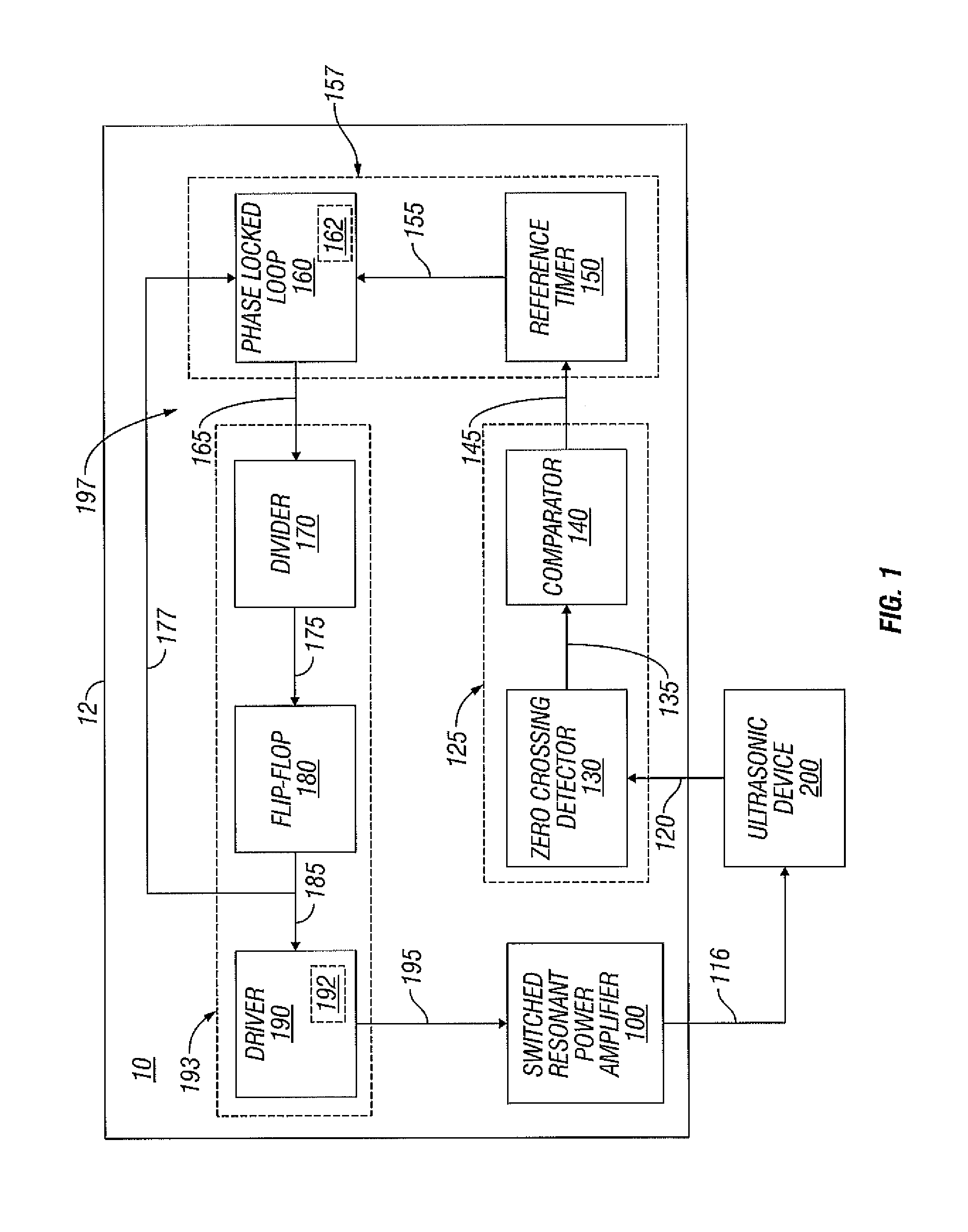

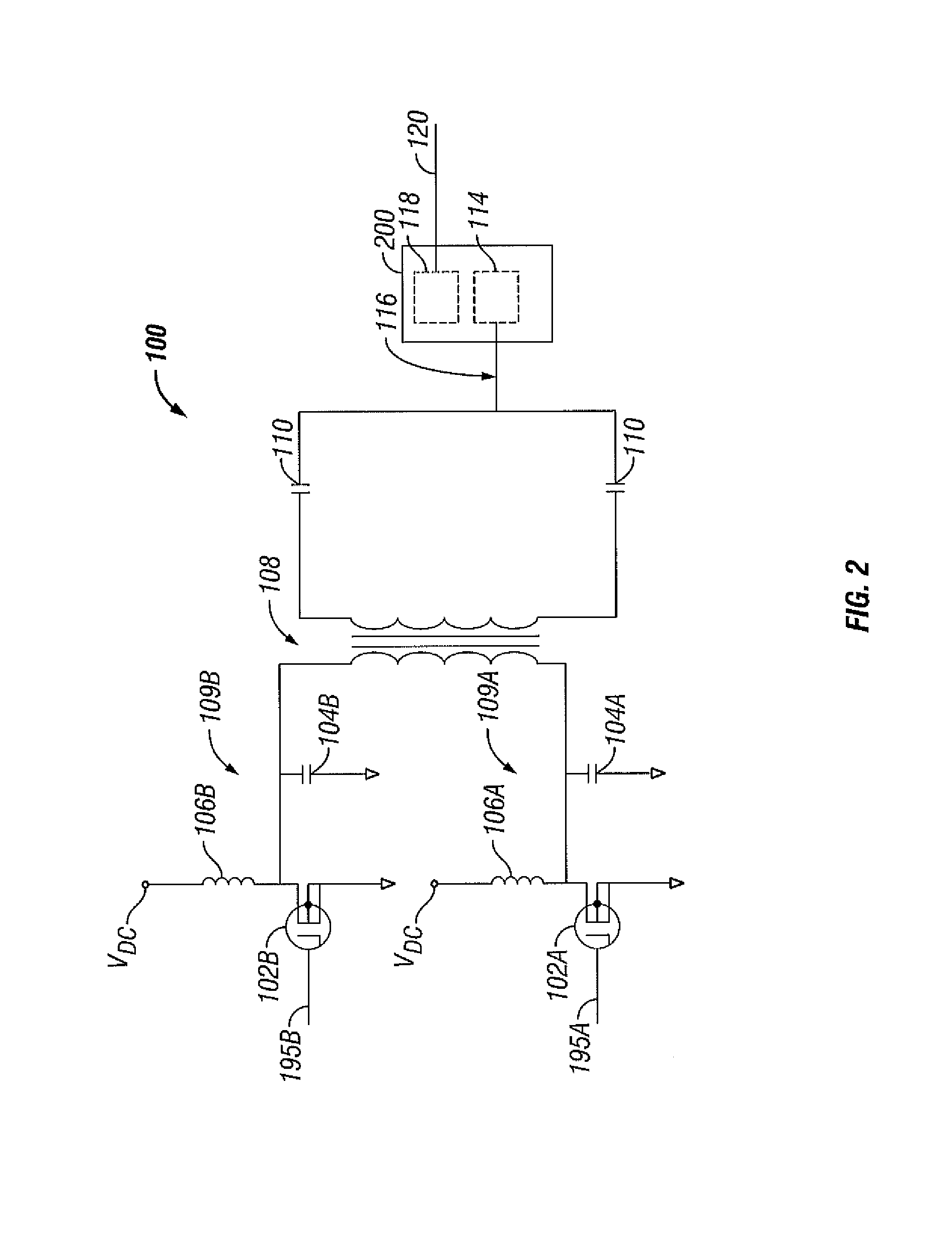

Switched resonant ultrasonic power amplifier system

ActiveUS7396336B2Operation efficiency can be improvedSmall footprintUltrasound therapyAmplifier modifications to raise efficiencyHemt circuitsControl ultrasound

Owner:COVIDIEN AG

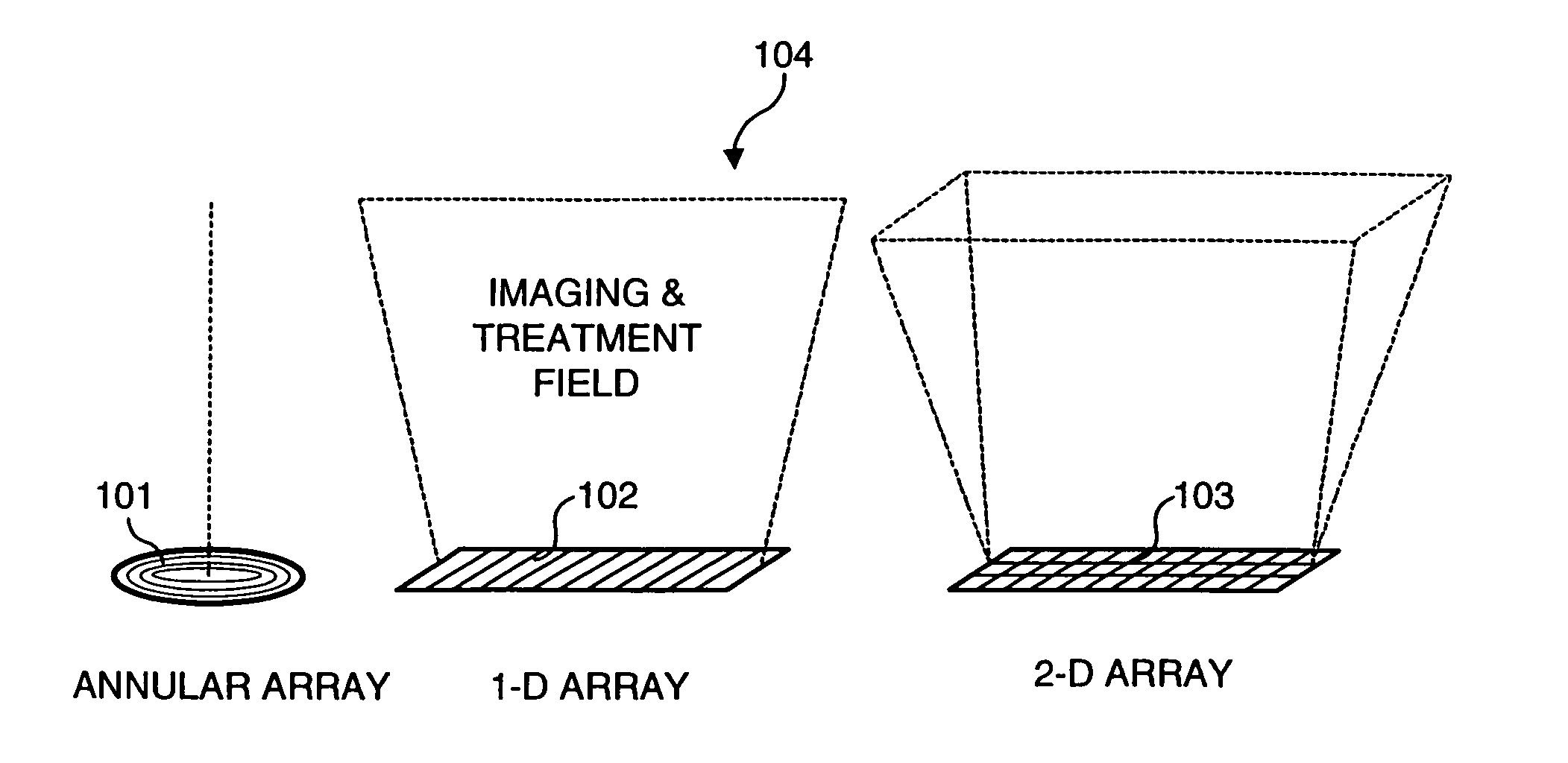

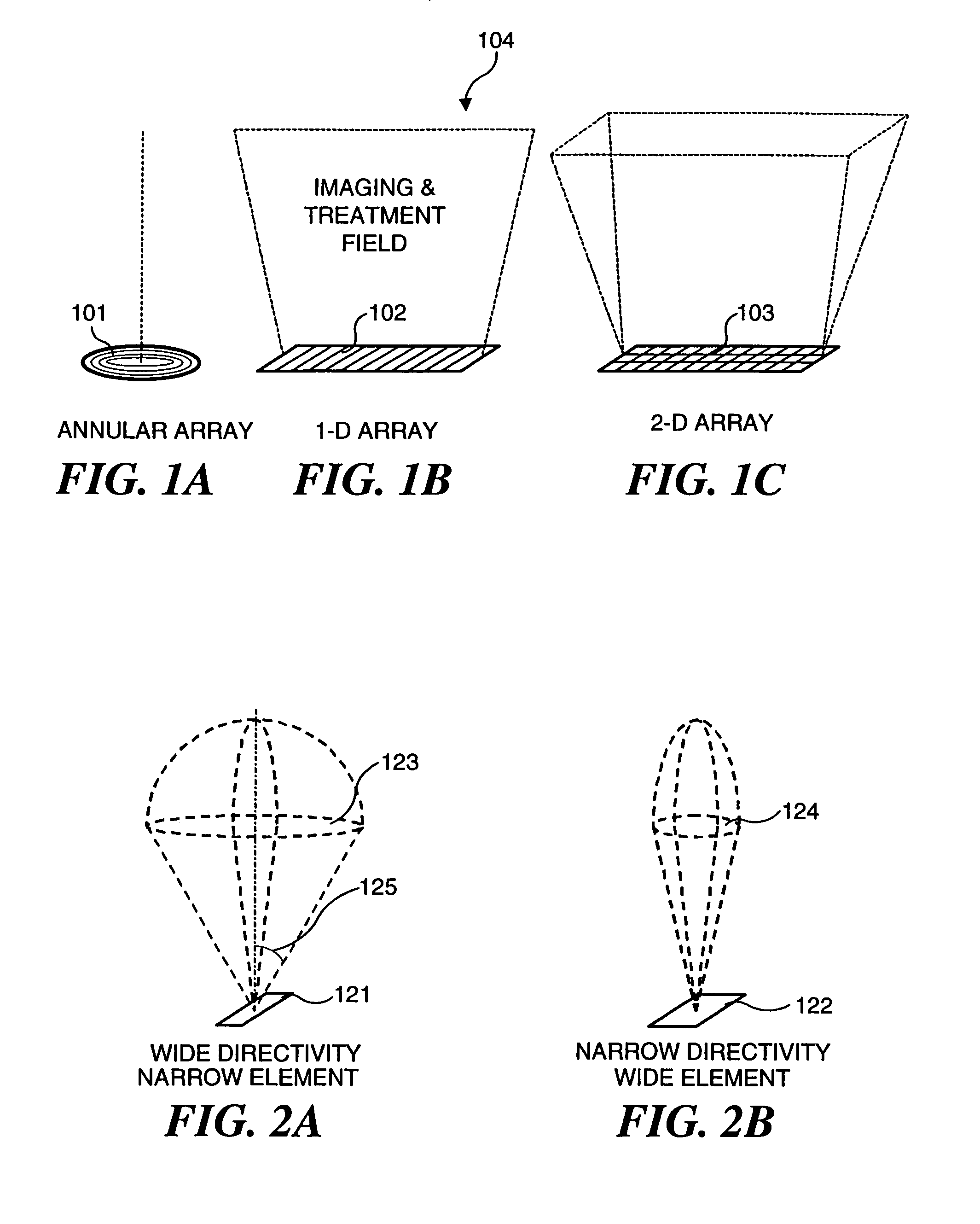

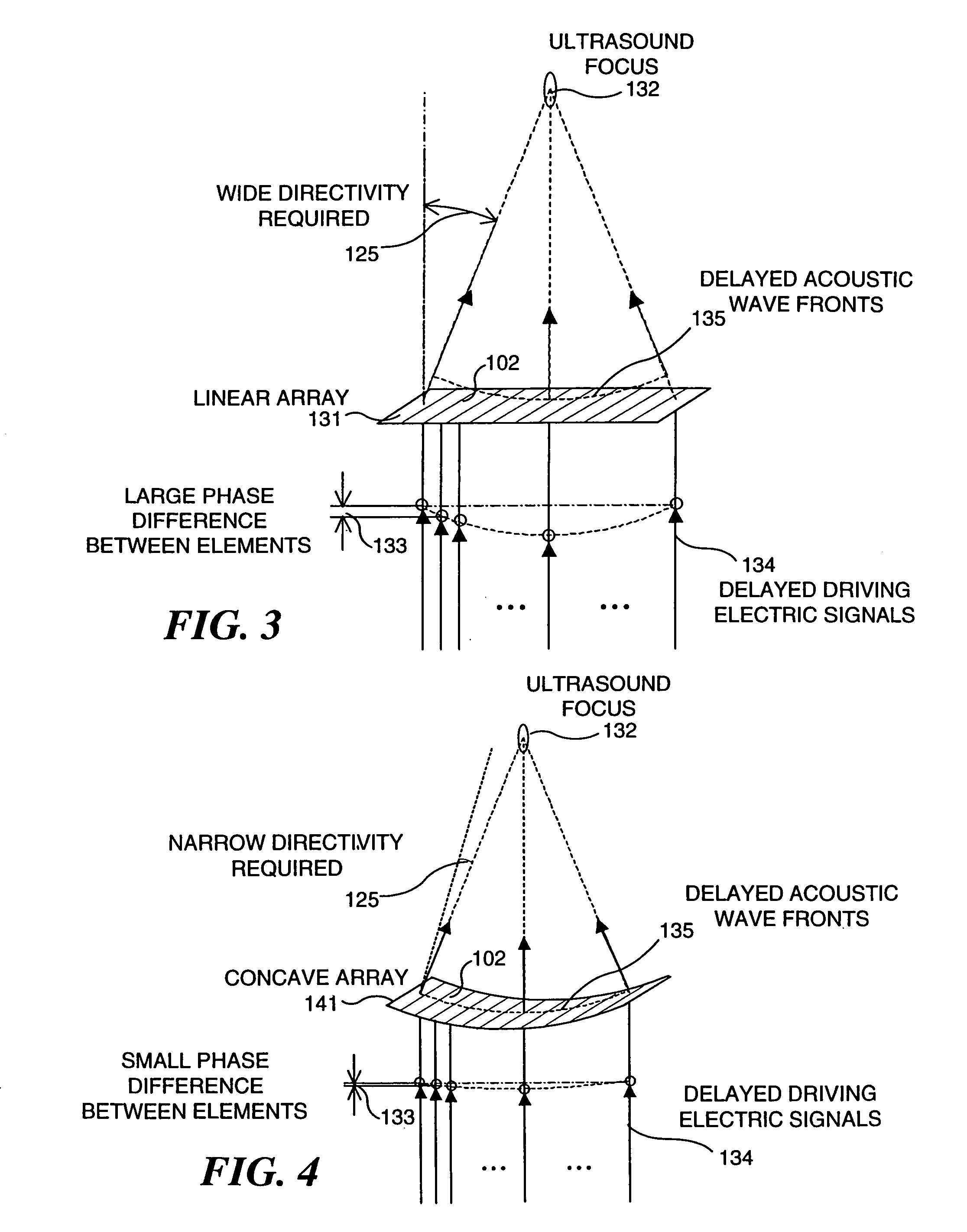

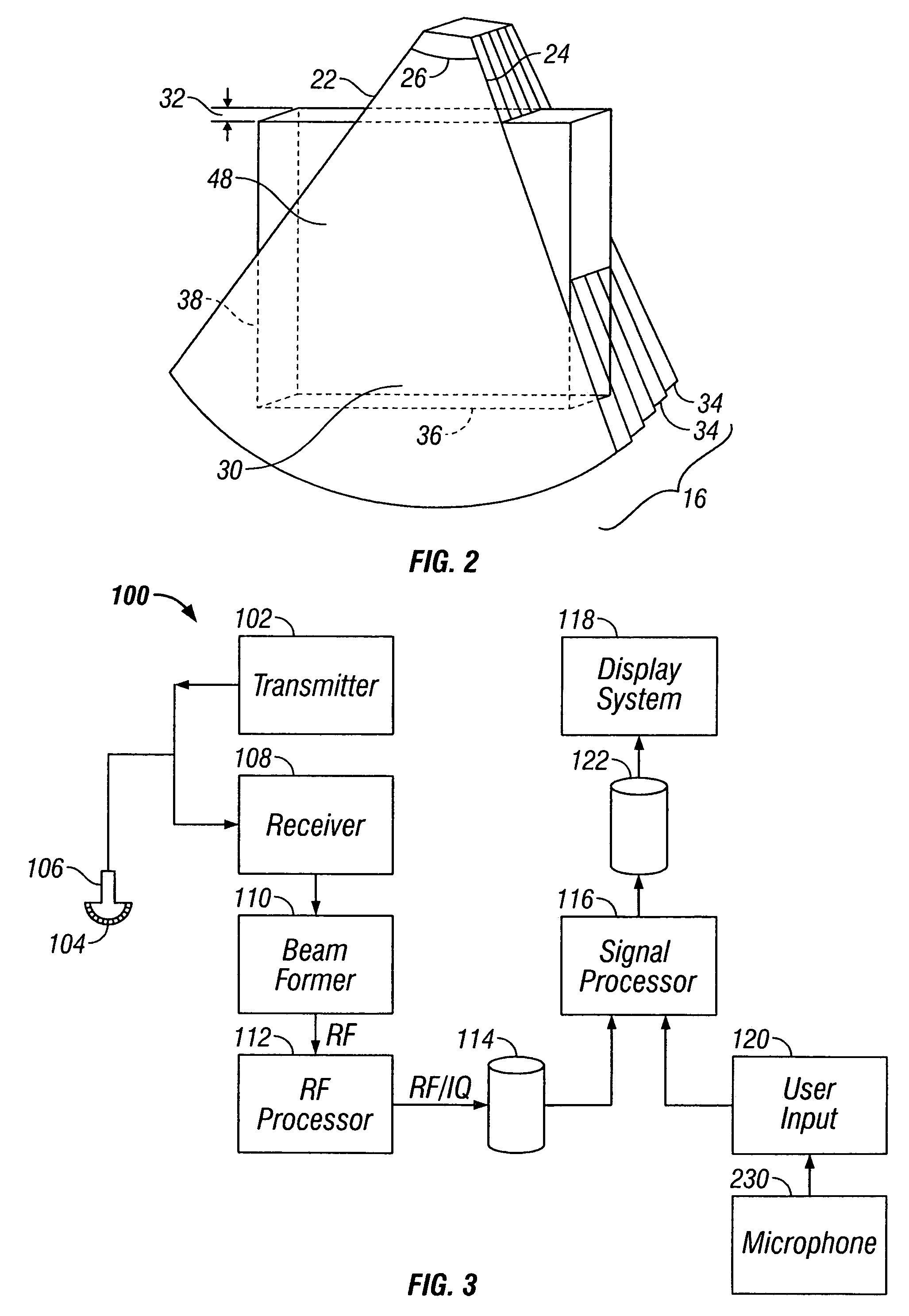

Ultrasound transducers for imaging and therapy

InactiveUS7063666B2Reduce in quantityReducing cross-talk and heatingUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectrical resistance and conductanceSonification

Owner:OTSUKA MEDICAL DEVICES

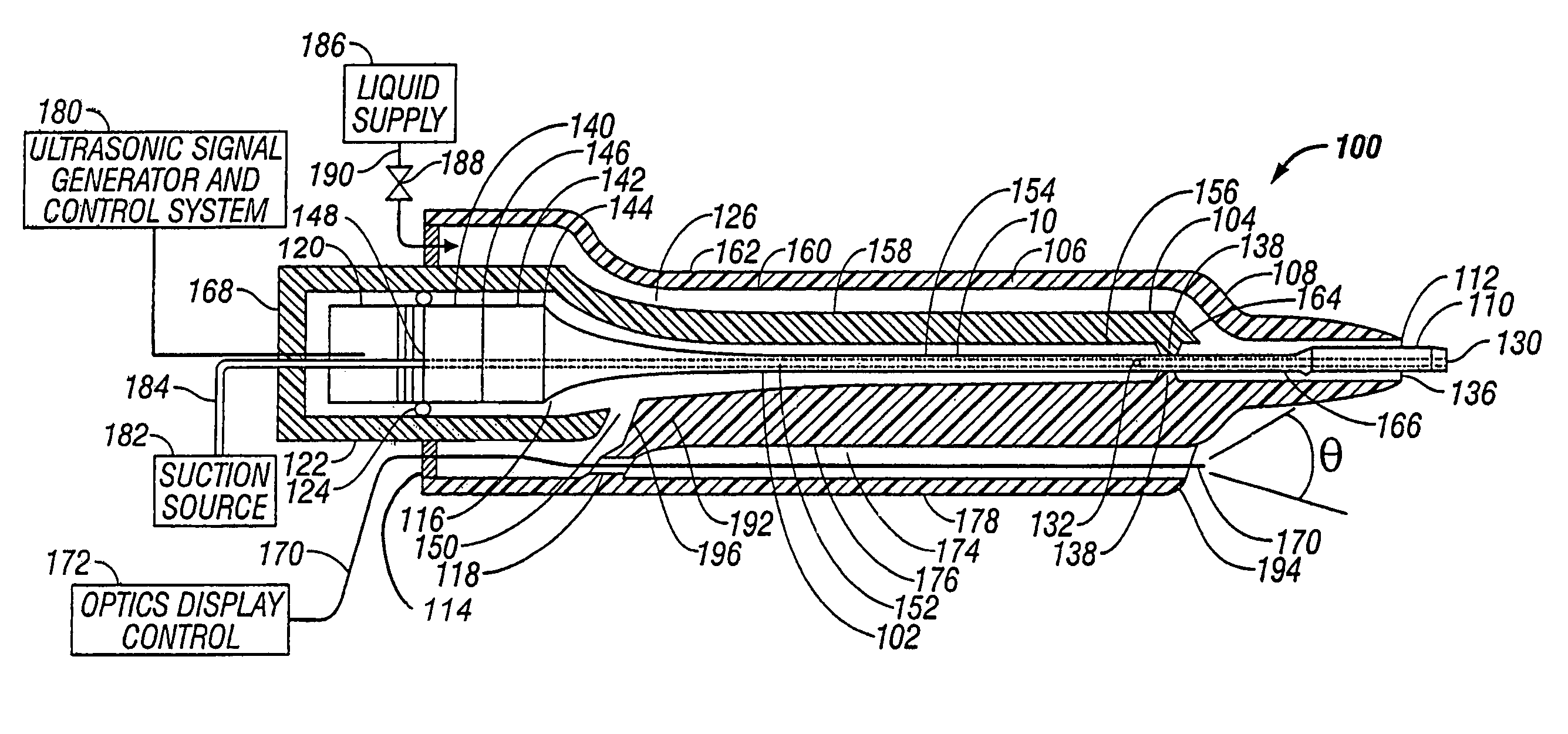

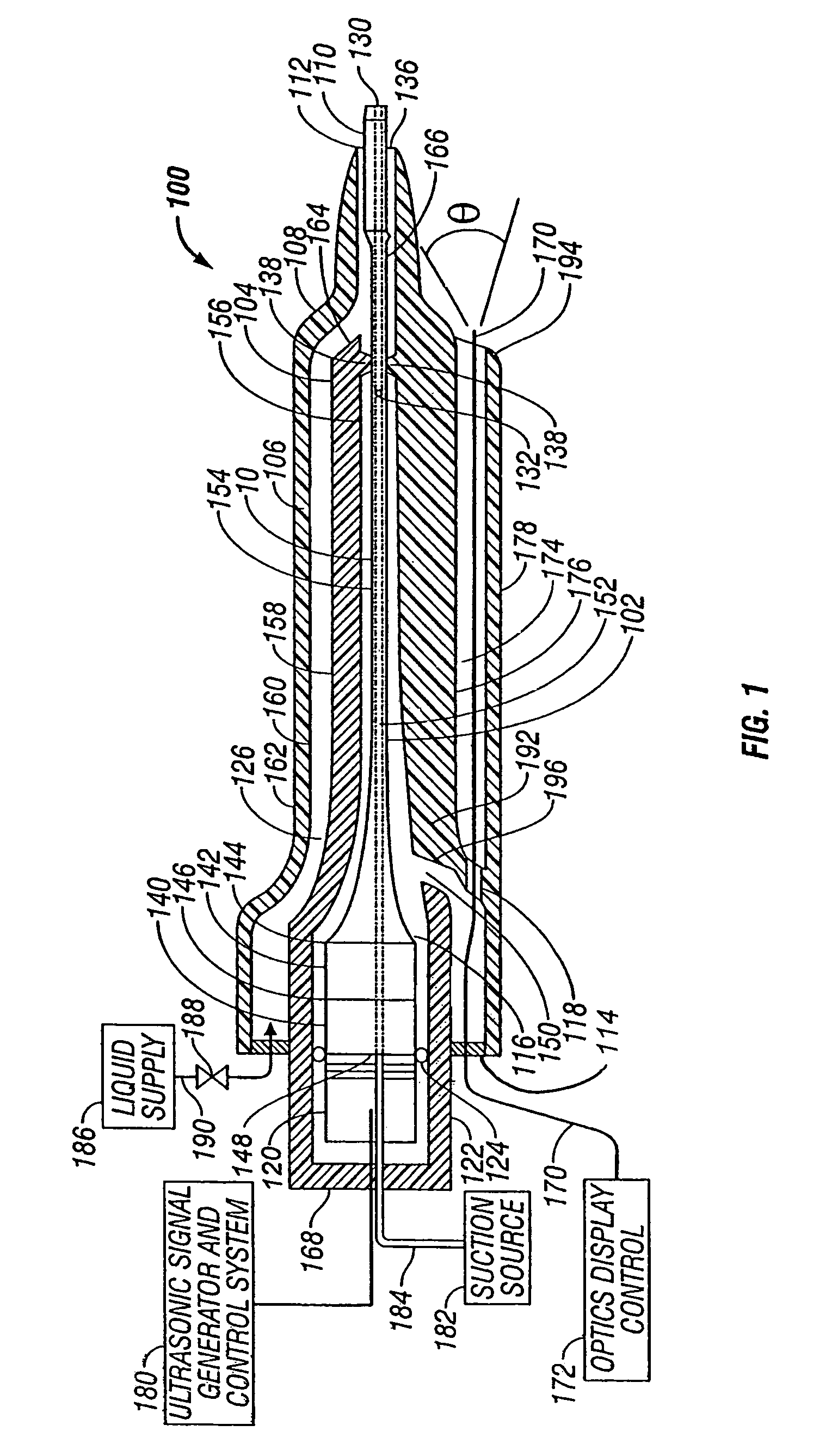

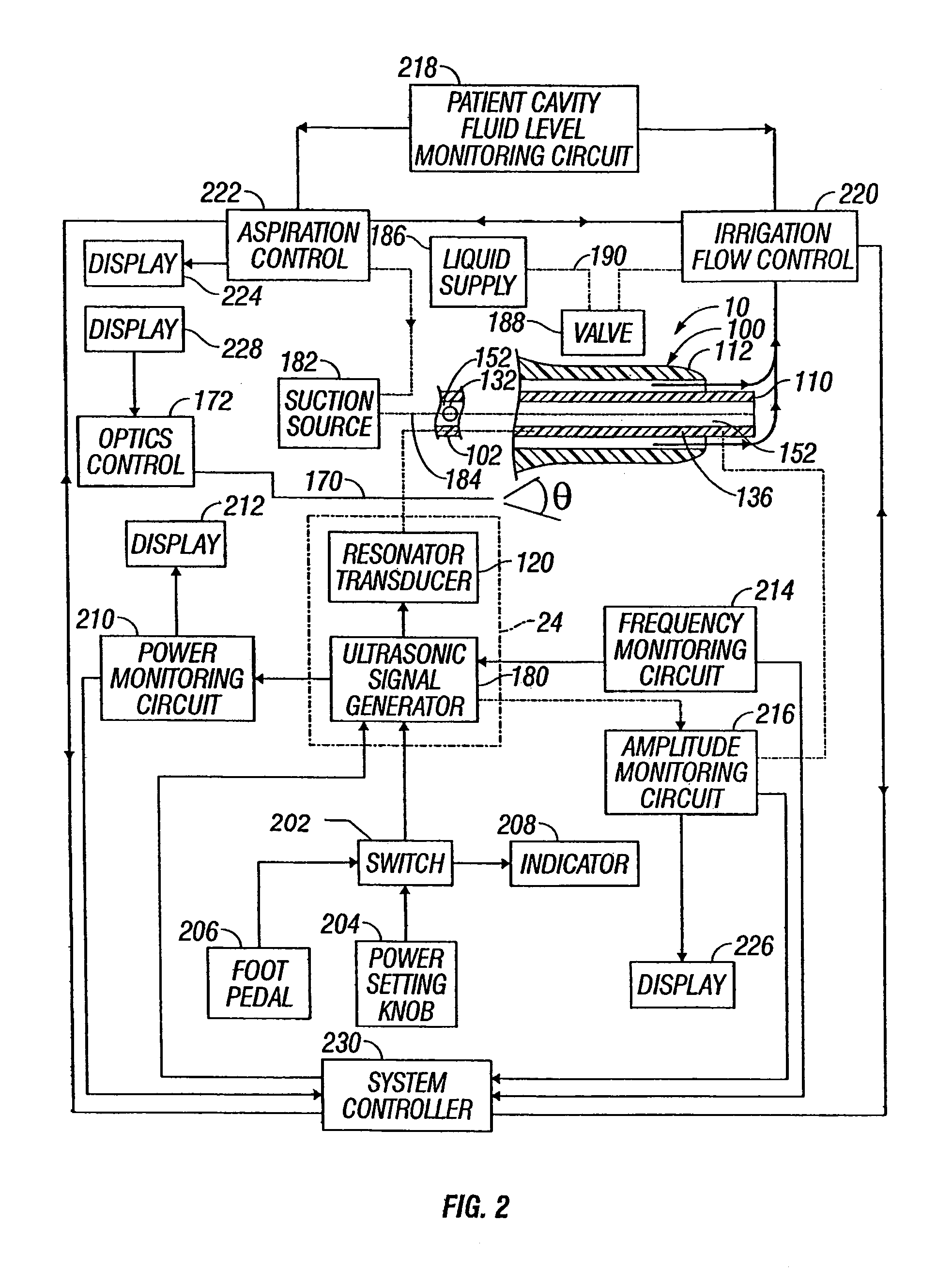

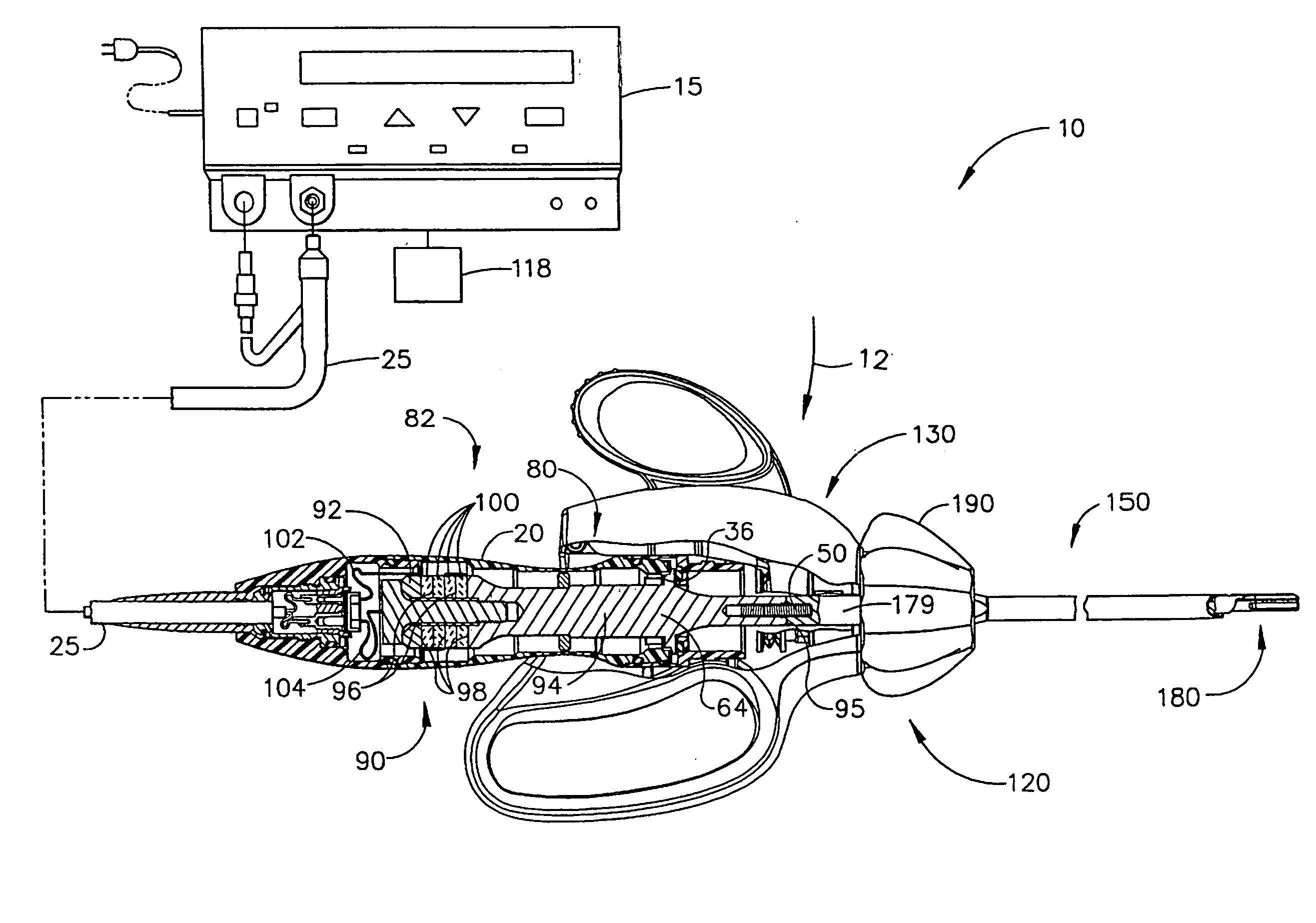

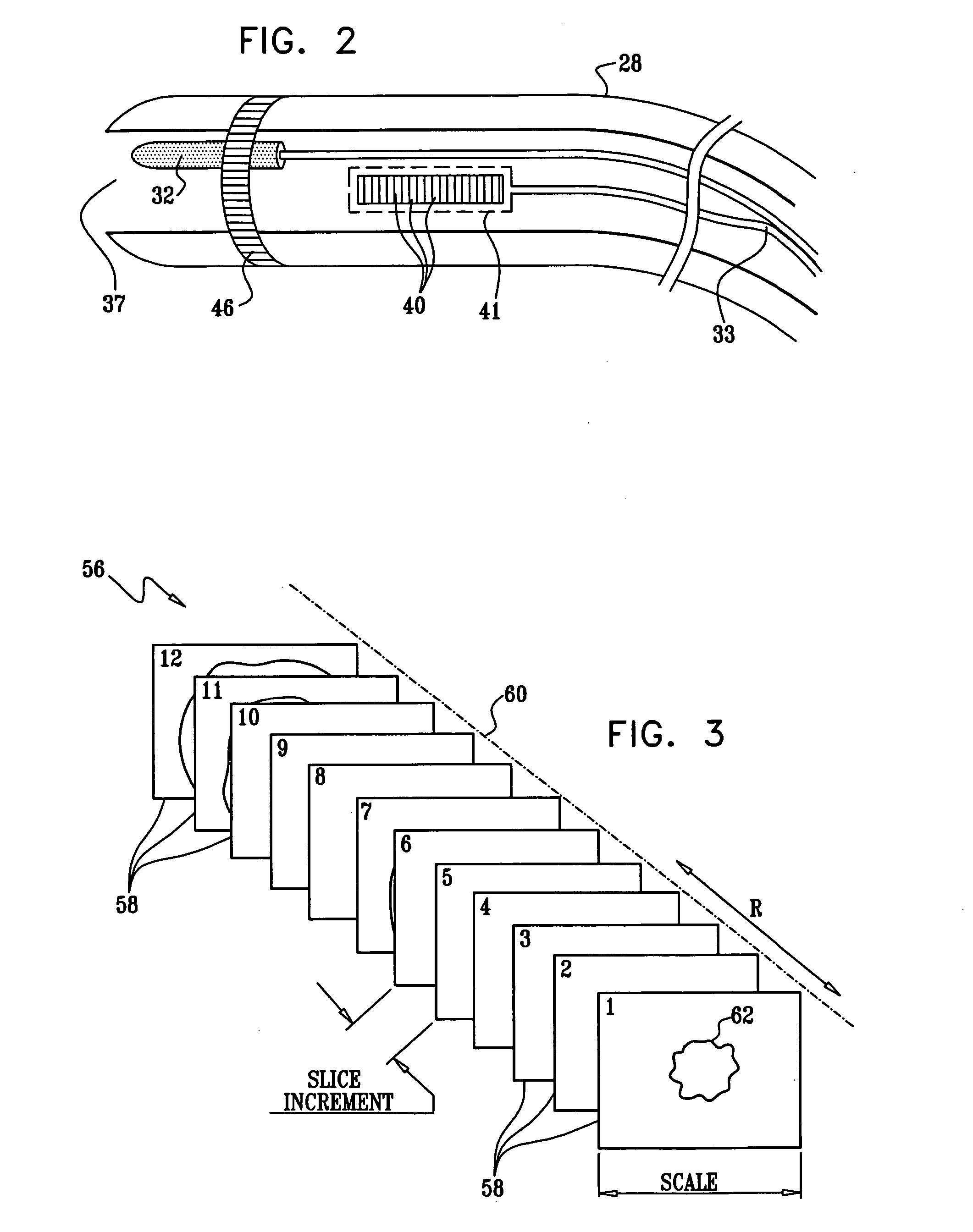

Endoscopic ultrasonic surgical aspirator for use in fluid filled cavities

ActiveUS7871392B2Minimize damping vibrationVibration minimizationDiagnosticsSurgeryControl powerMedicine

An ultrasonic horn assembly is configured so that irrigating fluid can be supplied only to a vibrating tip portion of the ultrasonic horn and so that suction aspiration can occur through a portion of the ultrasonic horn not in contact with the irrigating fluid. Controllers supplying irrigation fluid during a surgical procedure and controlling suction aspiration via monitoring of fluid level in the patient cavity are operatively coupled one to another to coordinate control of the fluid level in the patient cavity. Circuitry controlling power, frequency and amplitude of the tip of the ultrasonic horn occurring as a result of operation of a source of ultrasonic signal generating power controls either or both the supply of irrigation fluid and the suction aspiration so as to minimize damping of vibration of the tip of the ultrasonic horn. An optical viewing element is provided to view the tip of the ultrasonic horn.

Owner:INTEGRA LIFESCI IRELAND

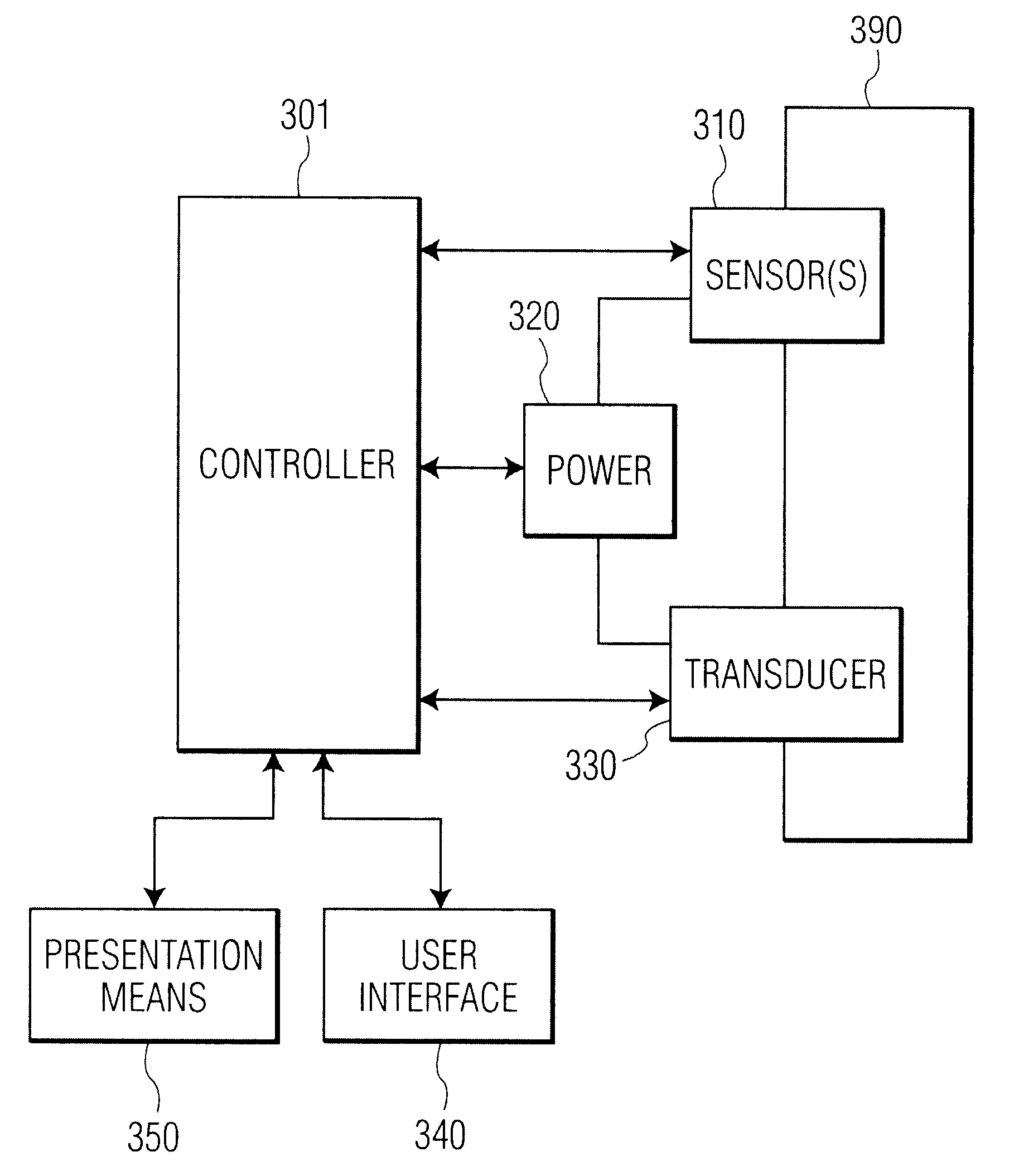

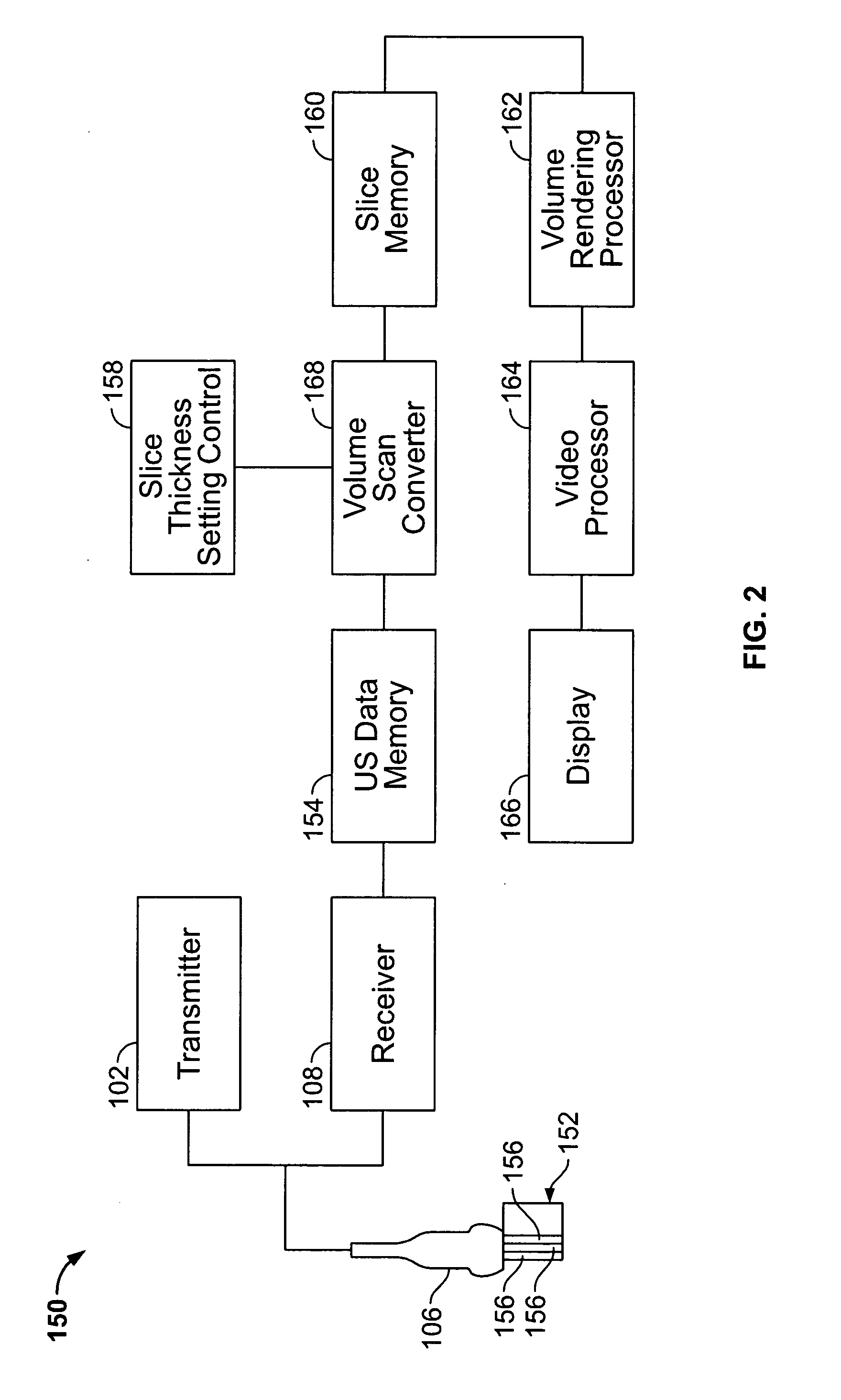

Imaging ultrasound transducer temperature control system and method

InactiveUS6669638B1Ultrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsTemperature controlUltrasonic sensor

A system and method for controlling the heat of an ultrasonic transducer is disclosed. The presently preferred embodiments of the present invention control the temperature of the transducer face by changing the imaging modes of the system. In a preferred embodiment, feedback from temperature sensing elements placed in the transducer is used to determine when to switch from a higher power imaging mode to a lower power imaging mode. In another preferred embodiment, the system switches from a higher power imaging mode to a lower power imaging mode after a predetermined period of time has elapsed. In yet another preferred embodiment, the system switches to a "mixed" imaging mode, where the system cycles rapidly between a higher power imaging mode and a lower power imaging mode, and the resulting data is combined to form a single image.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Imaging ultrasound transducer temperature control system and method using feedback

InactiveUS6905466B2Reduce the temperatureReduce temperatureUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesSonificationOperational system

A system and method for controlling the heat of an ultrasonic transducer is disclosed. In the presently preferred embodiments, the system and method controls the temperature of the transducer by changing operating system parameters based on feedback from temperature sensing elements placed in the transducer. The chosen mutable system parameters may be preset by the construction of the ultrasonic system, under the control of the ultrasonic system user, or a combination of the two. In several exemplary embodiments, the one or more mutable system parameters are altered by an amount proportionate to the difference between the current temperature and a preferred operating temperature. In another exemplary embodiment, the system switches to a lower power imaging mode when the temperature feedback indicates a threshold temperature has been reached.

Owner:KONINK PHILIPS ELECTRONICS NV

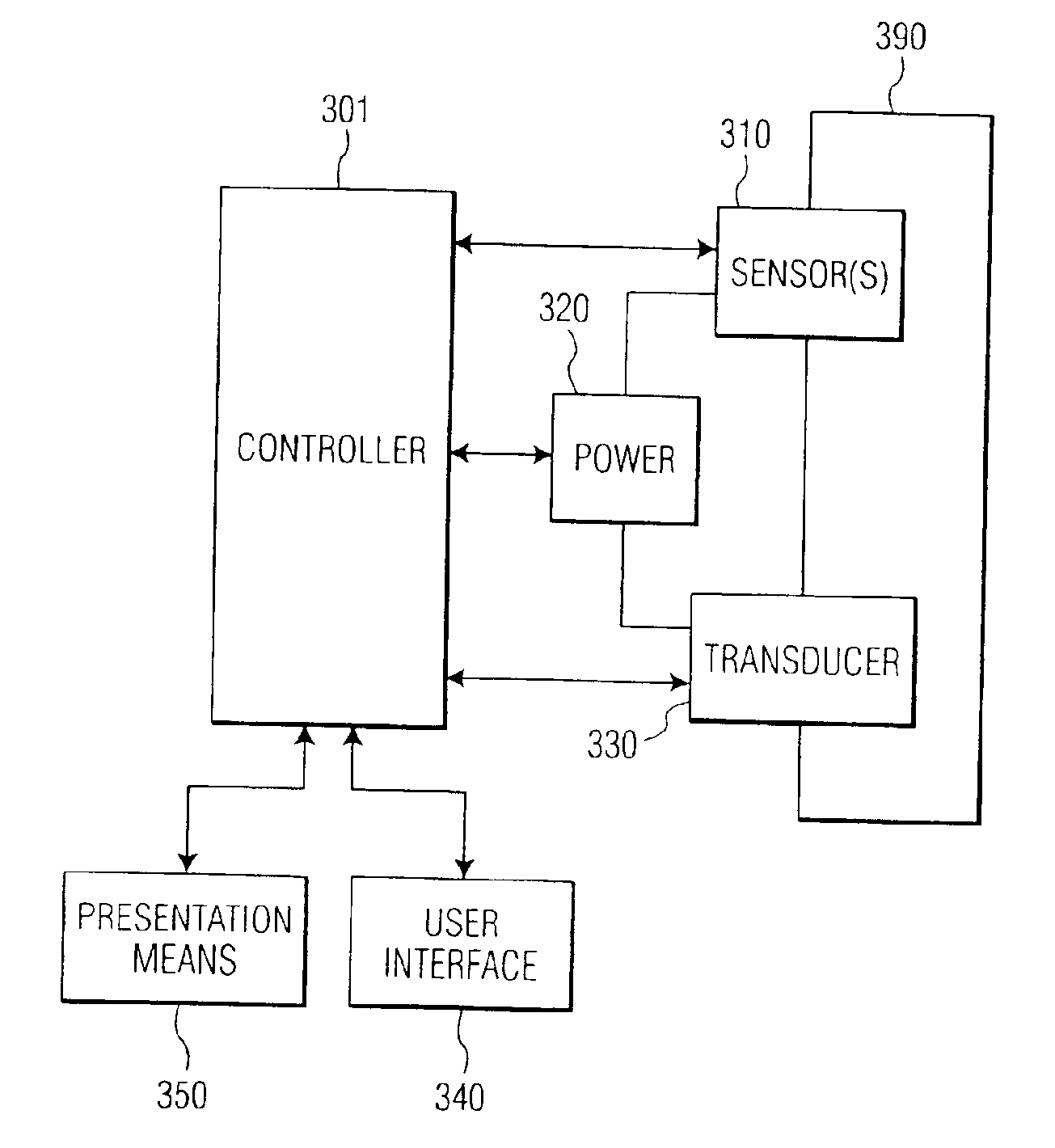

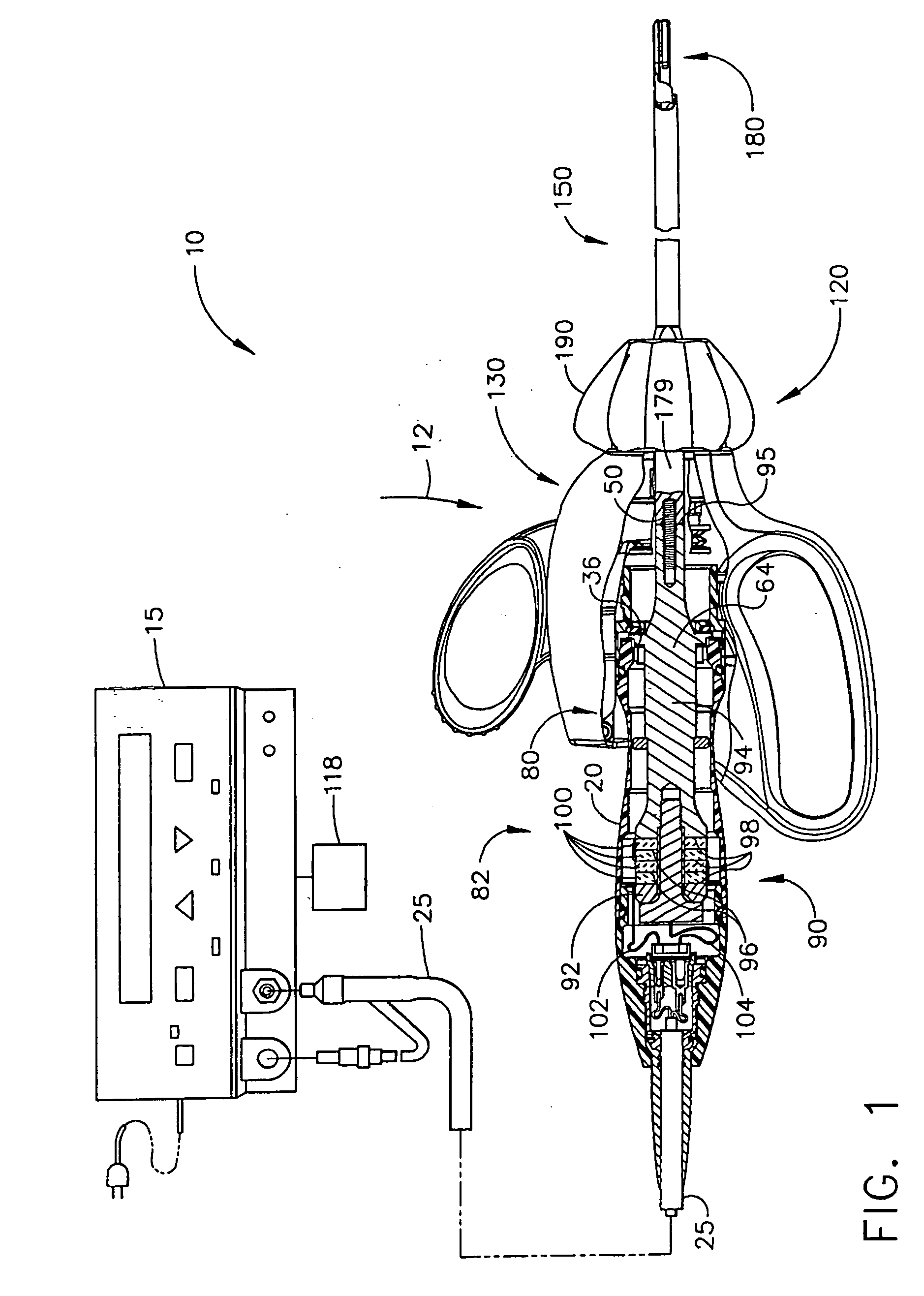

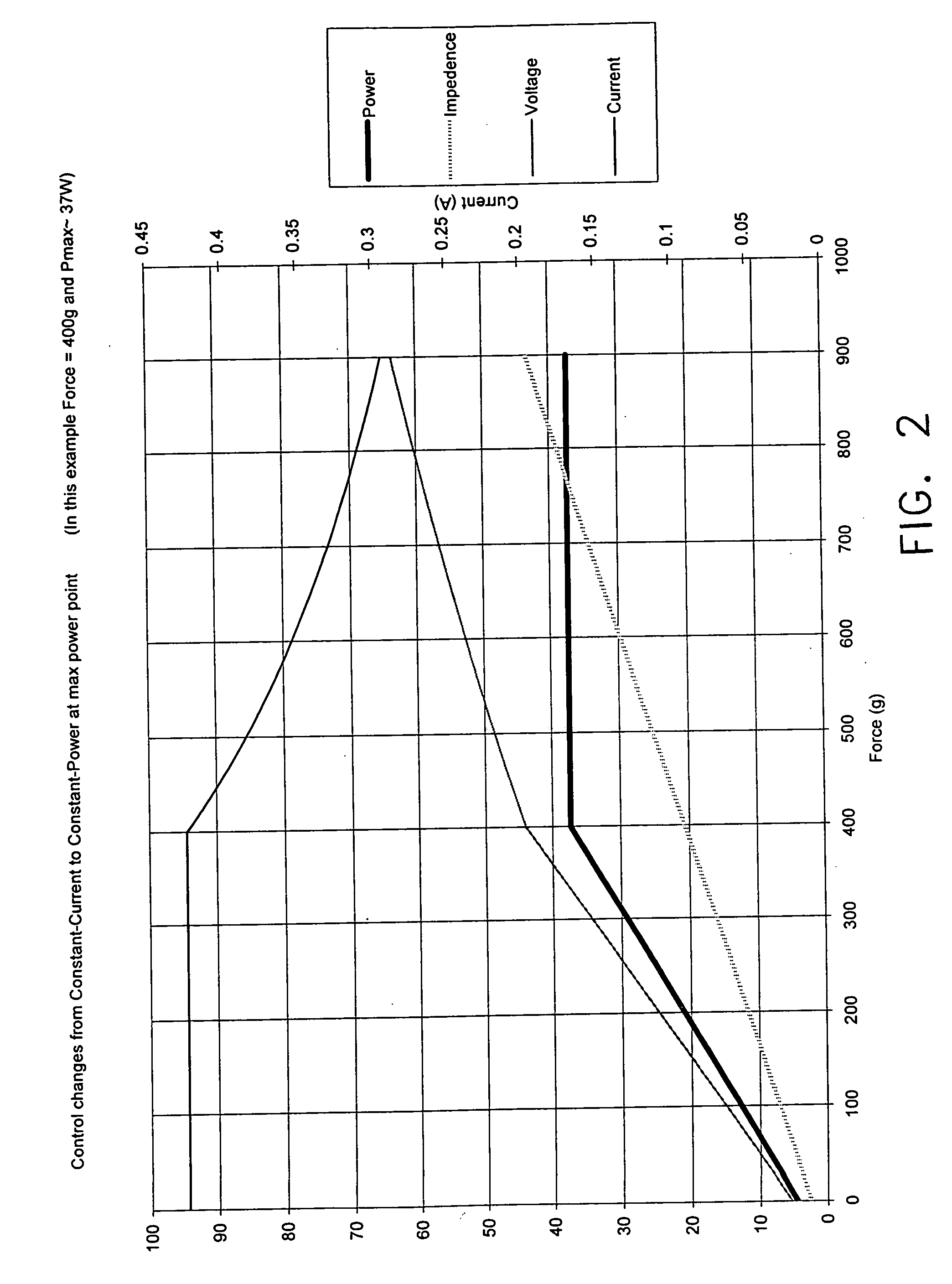

System for controlling ultrasonic clamping and cutting instruments

ActiveUS20060229514A1Constant powerMaintain powerUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyControl systemEngineering

A control system for use with an ultrasonic surgical instrument includes a generator supplying electrical energy to an ultrasonic surgical instrument, the electrical energy supplied by the generator being controlled such that power applied by the instrument is maintained constant once a predetermined pressure threshold is met. The control system operates by assigning a nominal power at which the ultrasonic instrument is to operate and adjusting the current and voltage applied to the ultrasonic surgical instrument so as to maintain the power applied by the ultrasonic surgical instrument at approximately the nominal power.

Owner:CILAG GMBH INTERNATIONAL

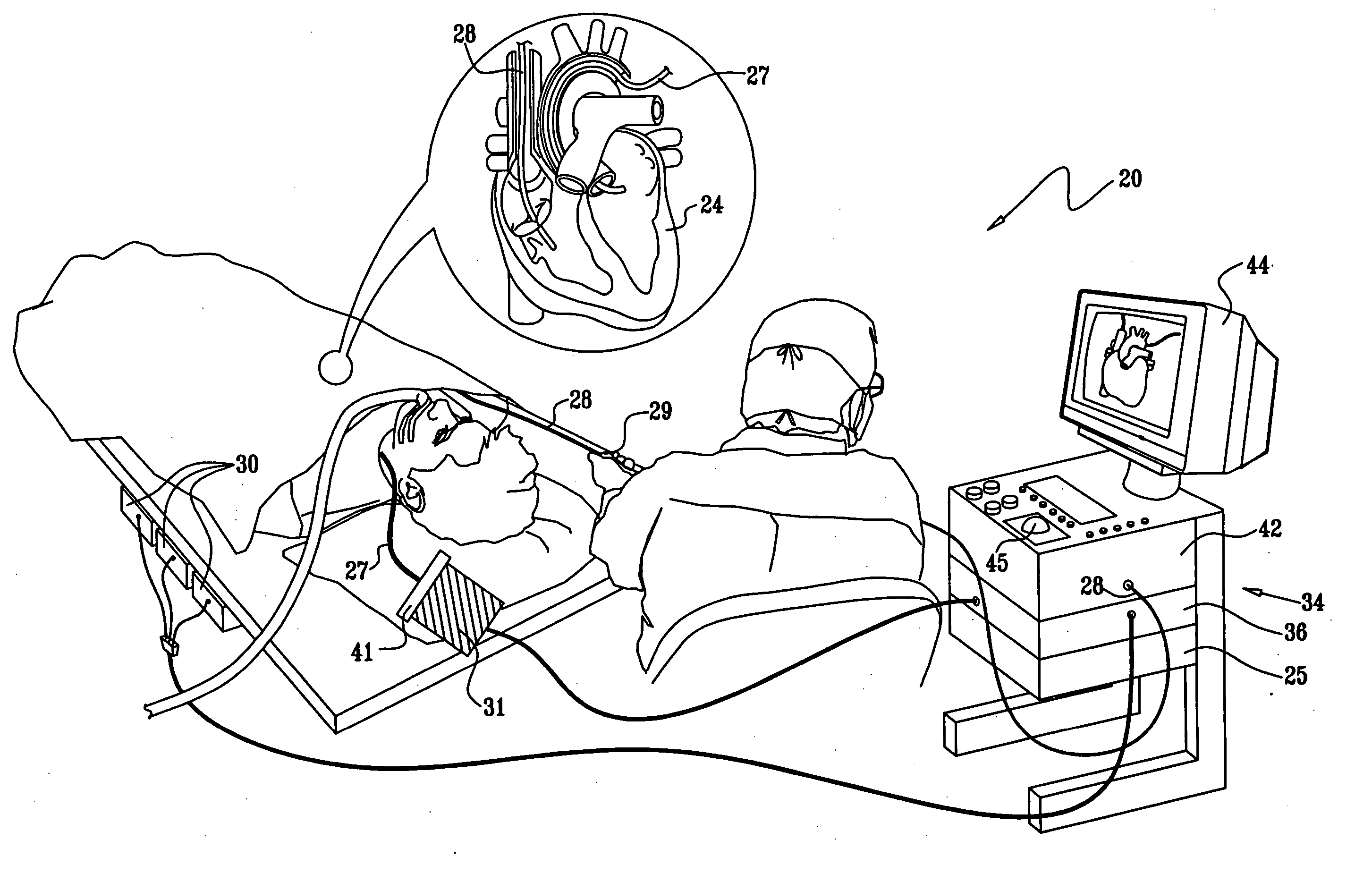

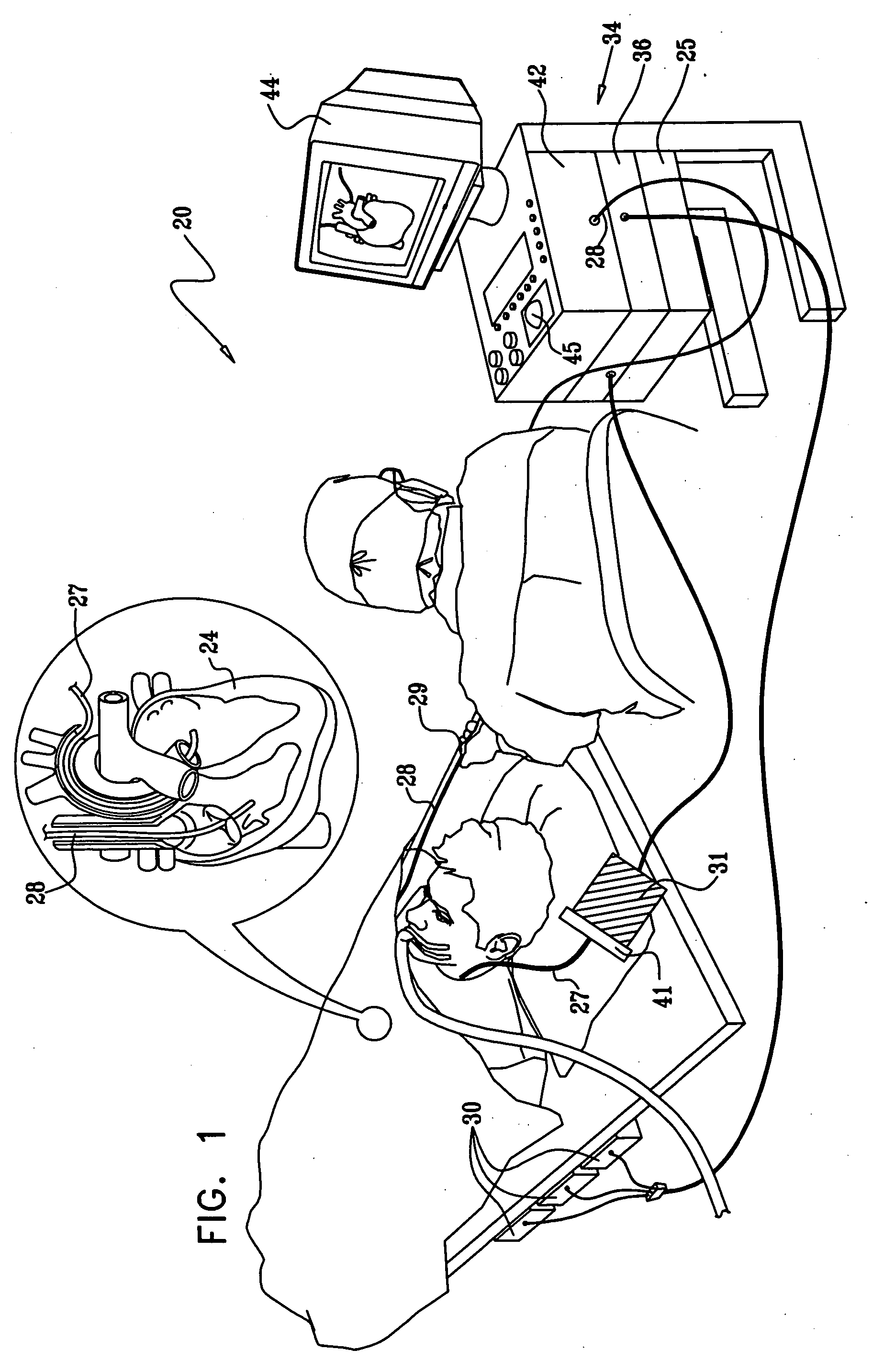

Controlling direction of ultrasound imaging catheter

InactiveUS20070106147A1Structure be loseImprove executionUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsUltrasound imagingControl ultrasound

The position of an imaging catheter in a body structure such as the heart is automatically controlled by a robotic manipulator such that its field of view at all times includes the distal end of a second catheter that is employed to effect a medical procedure. A processor receives signals from position sensors in the catheters. The processor utilizes the information received from the sensors and continually determines any deviation of the second catheter from the required field of view of the imaging catheter. The processor transmits compensation instructions to the robotic manipulator, which when executed assure that the imaging catheter tracks the second catheter.

Owner:BIOSENSE WEBSTER INC

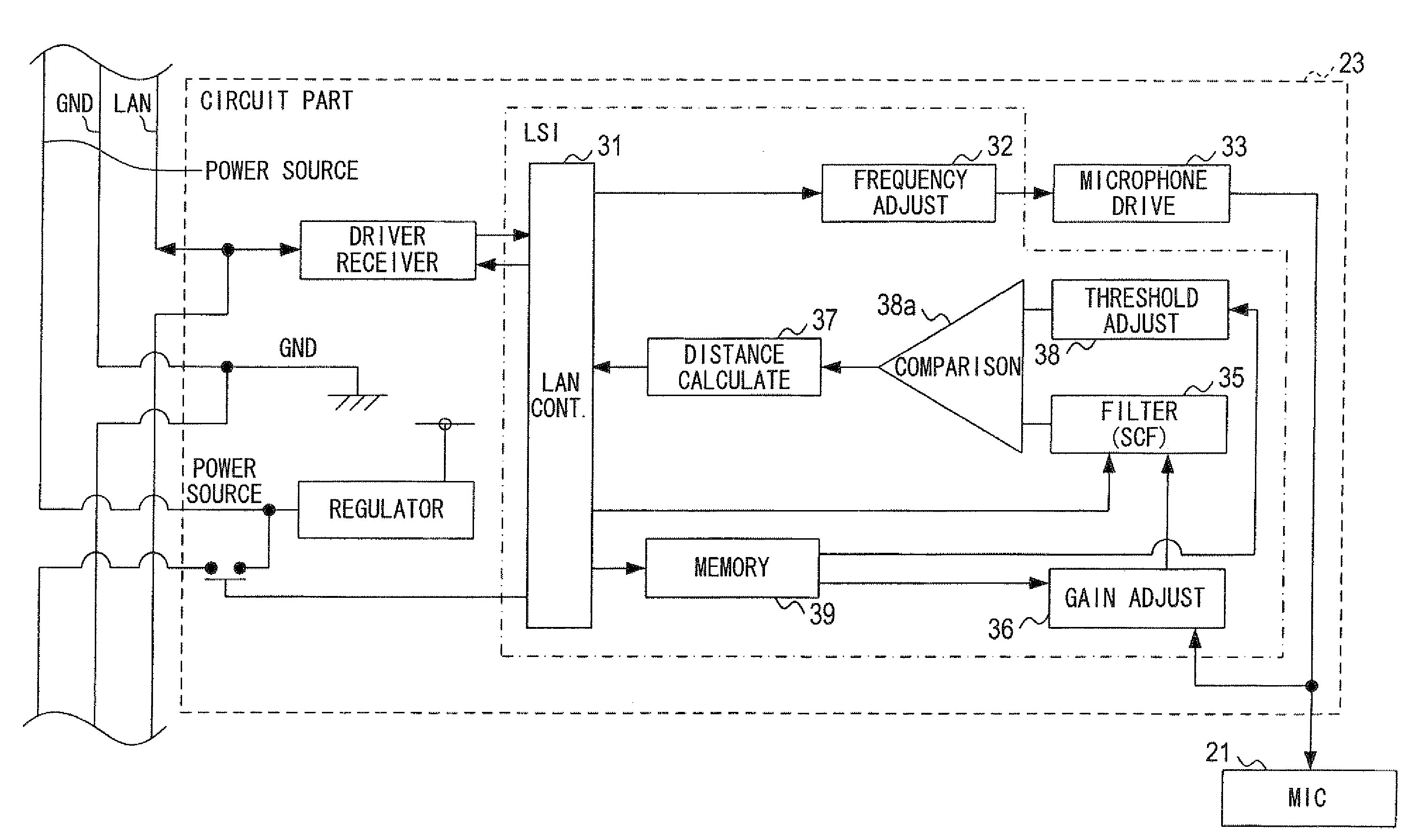

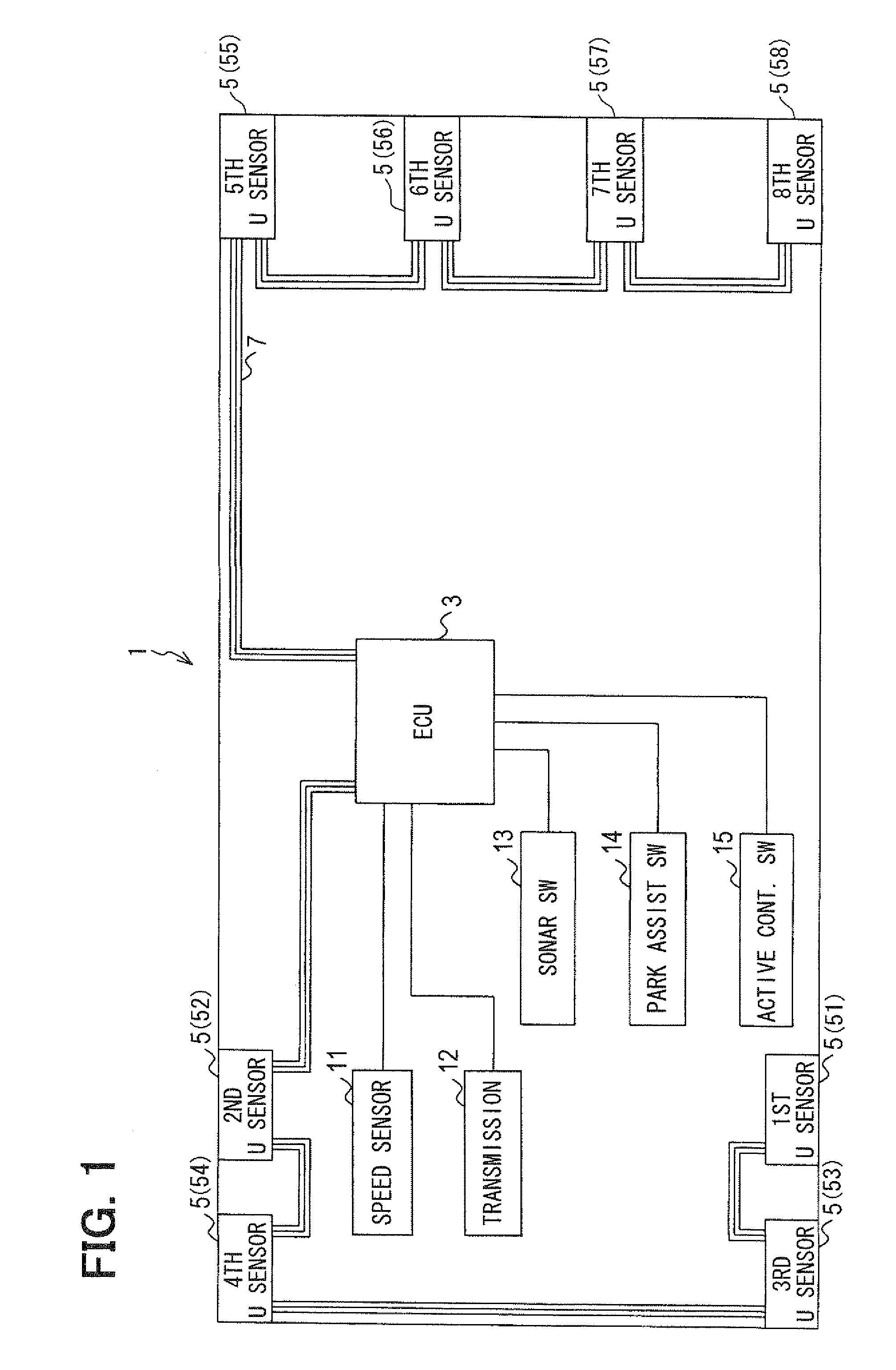

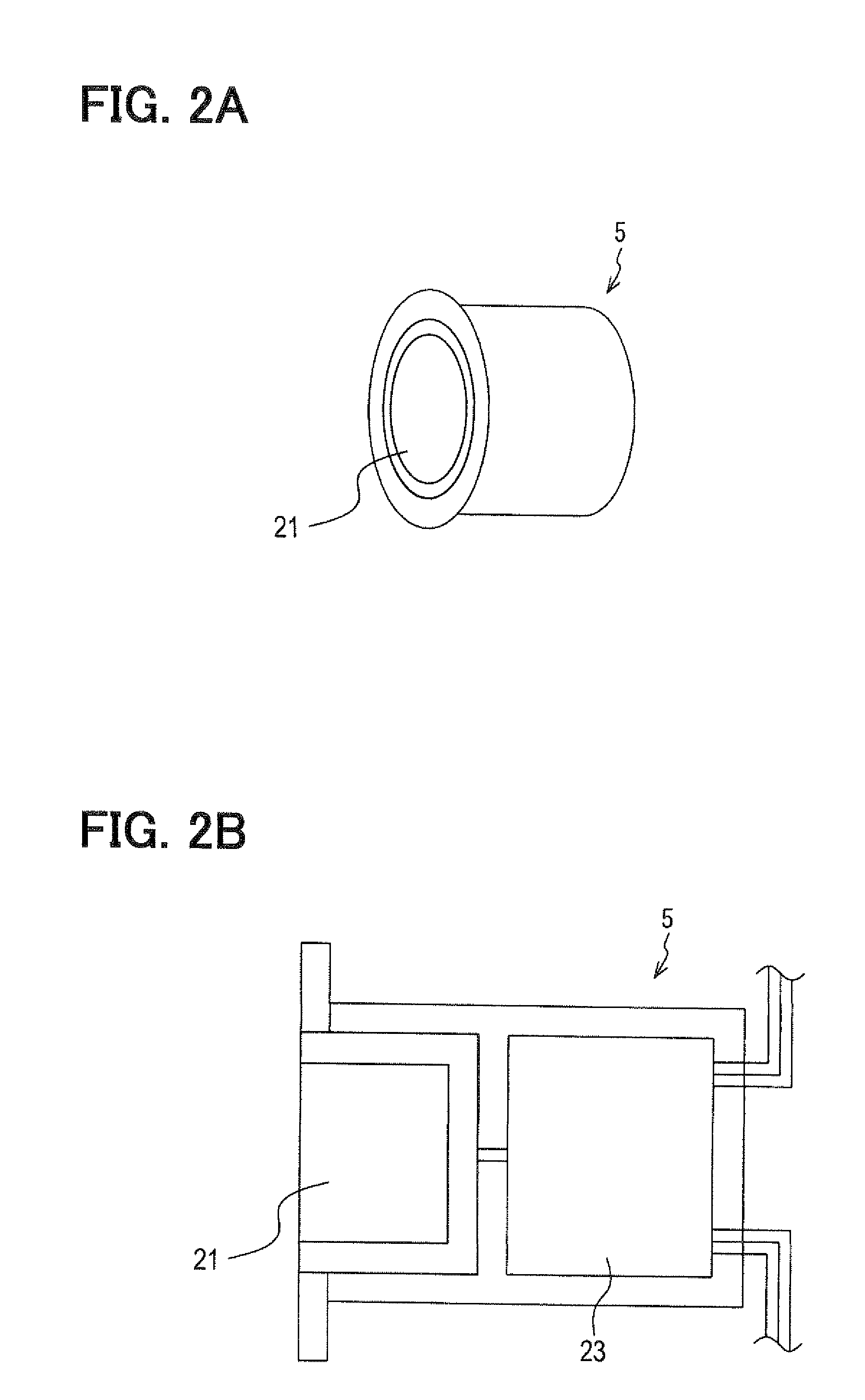

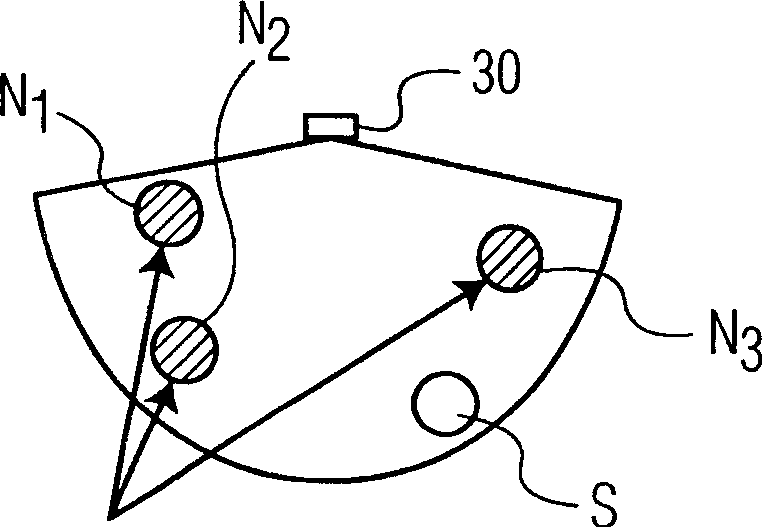

Obstacle detection apparatus

InactiveUS20090009306A1Detection errorReduce areaOptical signallingAcoustic wave reradiationUltrasonic sensorControl ultrasound

An obstacle detection apparatus for a vehicle is provided. The apparatus includes an ultrasonic sensor and a controller. The ultrasonic sensor detects a presence of an obstacle around the vehicle and a distance to the obstacle by transmitting an ultrasonic wave and receiving the ultrasonic wave reflected by the obstacle. The controller controls the ultrasonic sensor. The ultrasonic sensor includes an ultrasonic wave element. The ultrasonic wave element has multiple resonance modes. The ultrasonic sensor changes a directivity of the ultrasonic sensor by selecting one of the multiple resonance modes of the ultrasonic wave element in accordance with a command signal output from the controller.

Owner:DENSO CORP

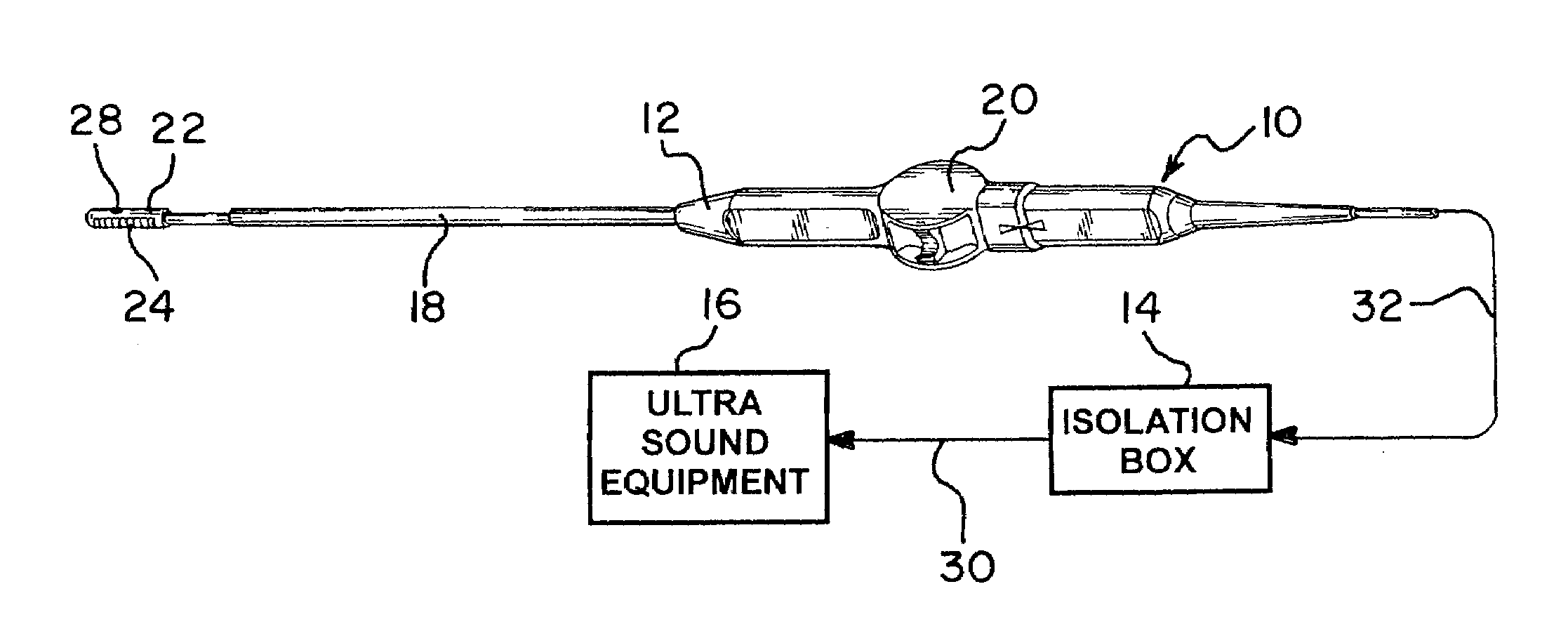

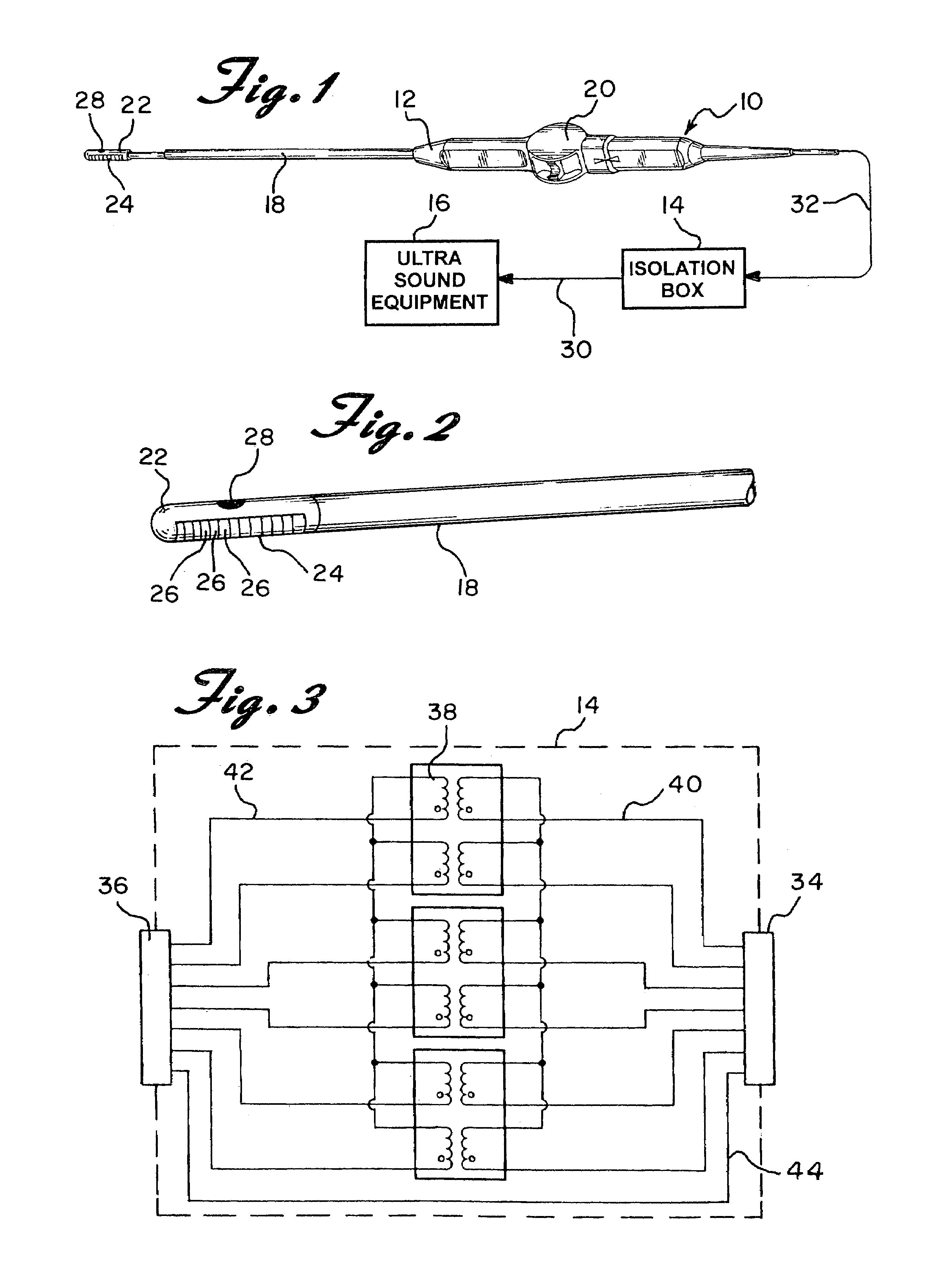

Ultrasound imaging catheter isolation system with temperature sensor

InactiveUS6908434B1Easy to placeUltrasonic/sonic/infrasonic diagnosticsSurgeryUltrasonic sensorControl ultrasound

An ultrasonic imaging catheter is disclosed that includes a thermistor mounted on the catheter in the vicinity of the ultrasound transducer for monitoring the temperature in the vicinity thereof. The electrical signal from the thermistor can be used to control the output of the ultrasound transducer to thereby control the temperature of the same. In a further aspect of the invention, an isolation box is provided that is external to the ultrasound machine itself and is connected to the same by a cable. Ideally, the isolation box which houses a sufficient number of isolation transformers, is small, so it can be placed easily on or near the patient's bed.

Owner:EP MEDSYST

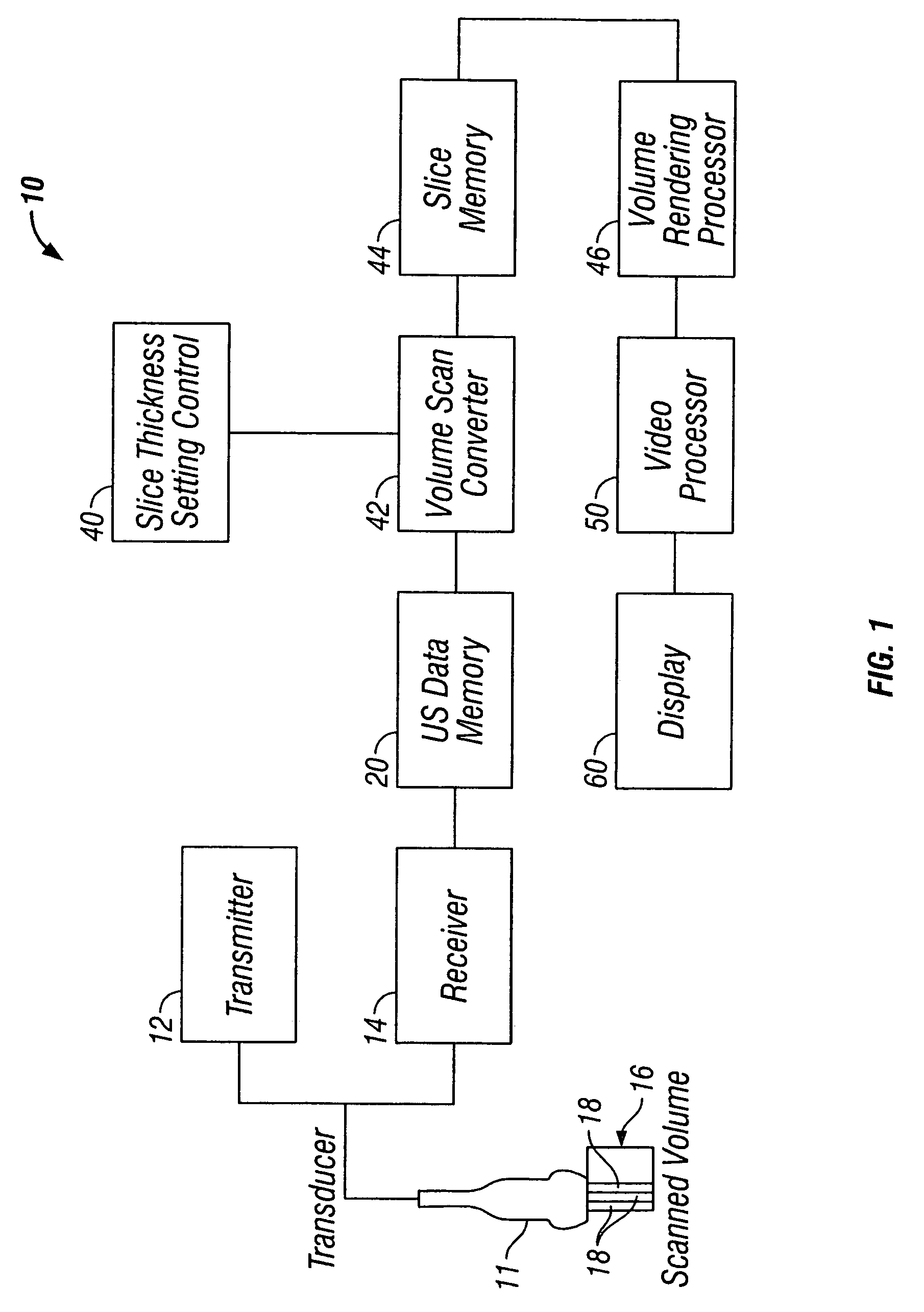

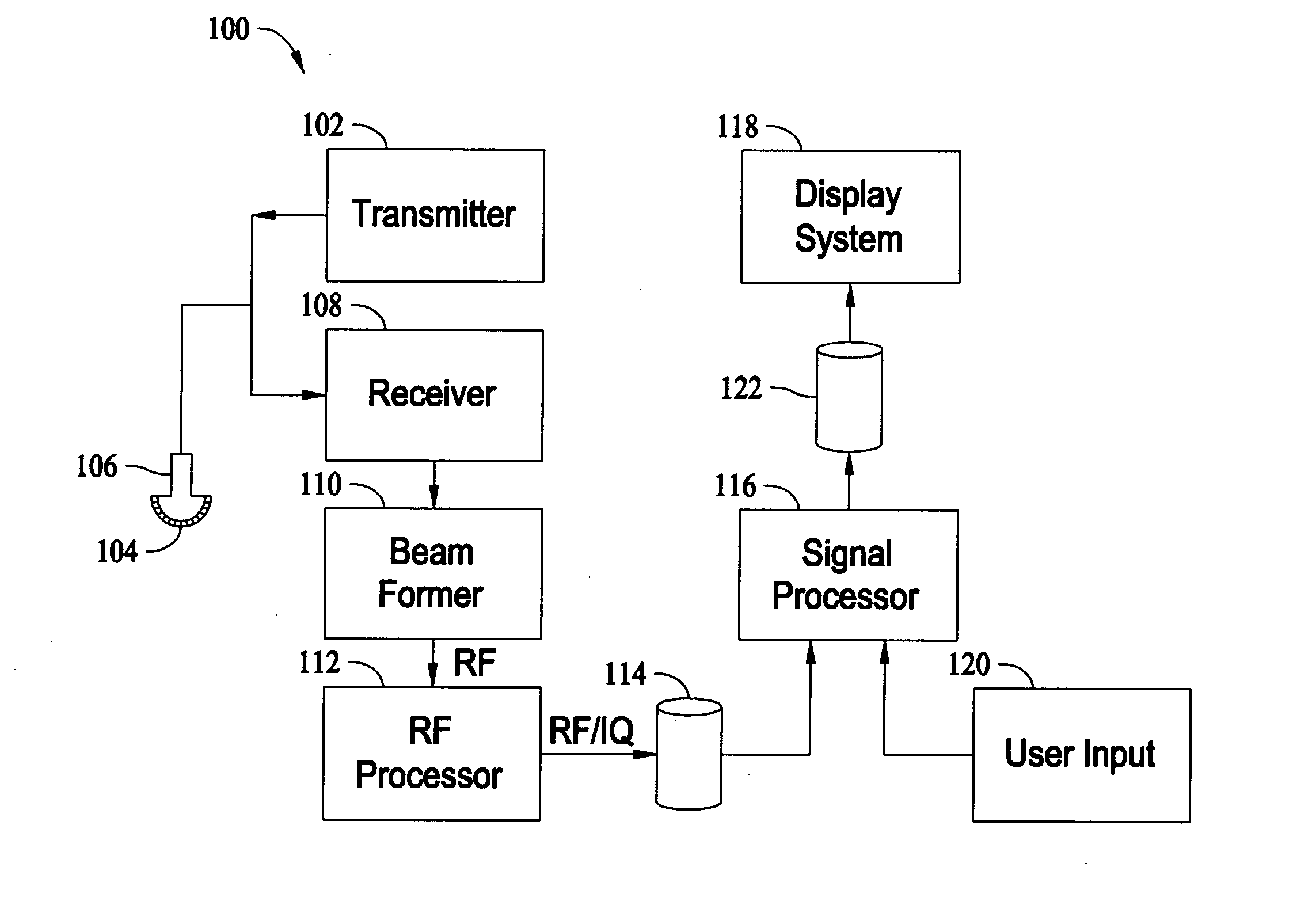

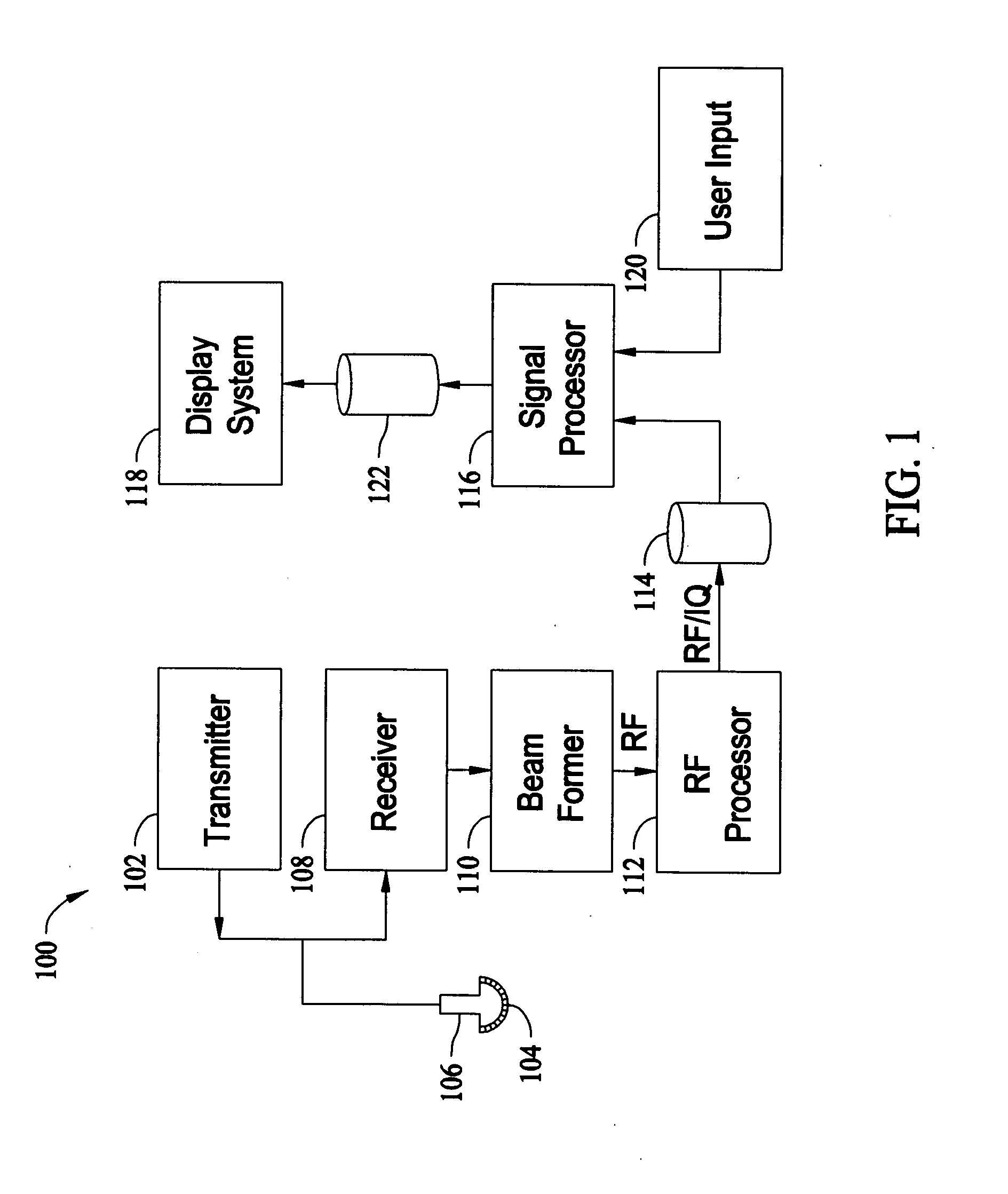

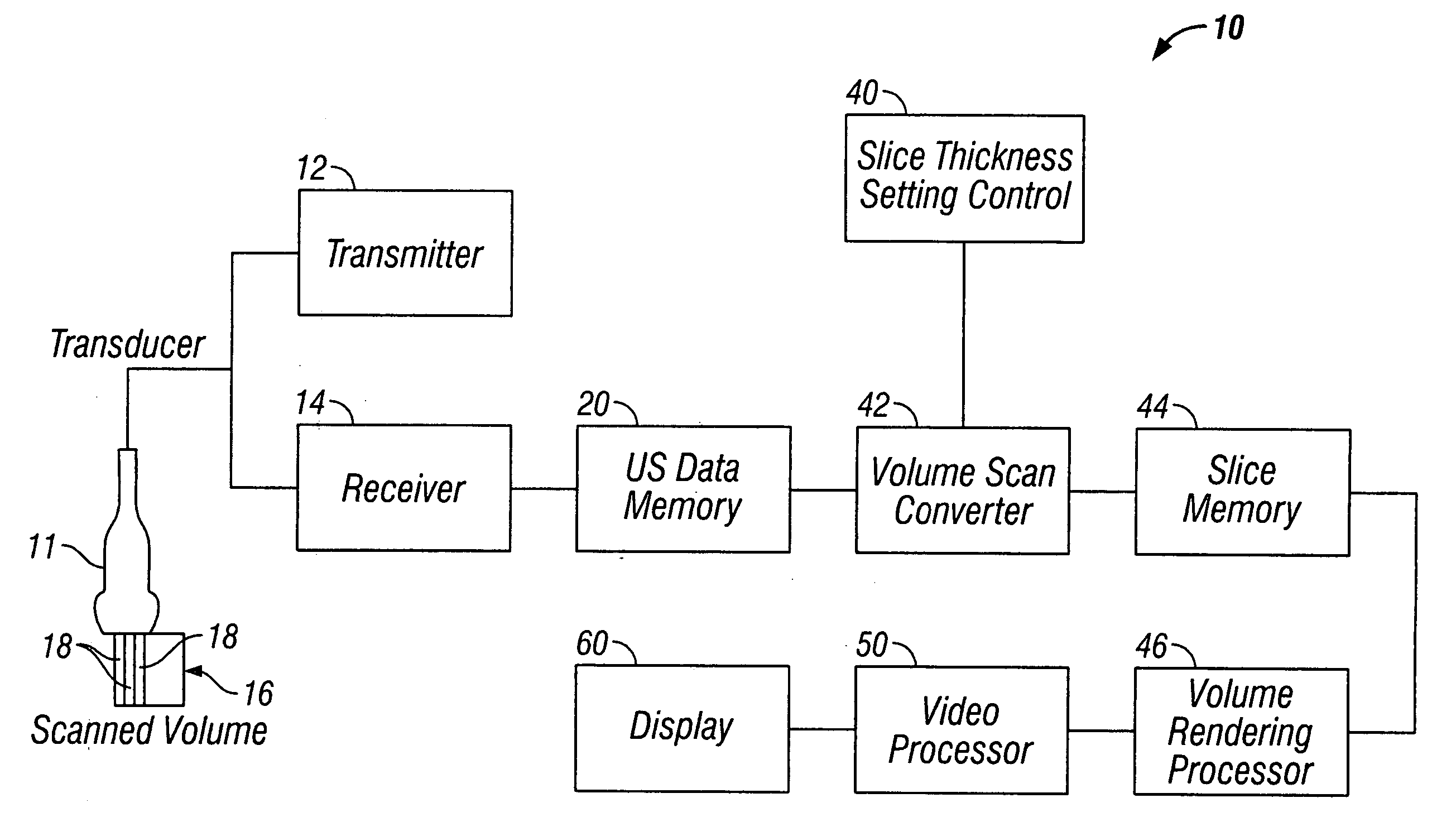

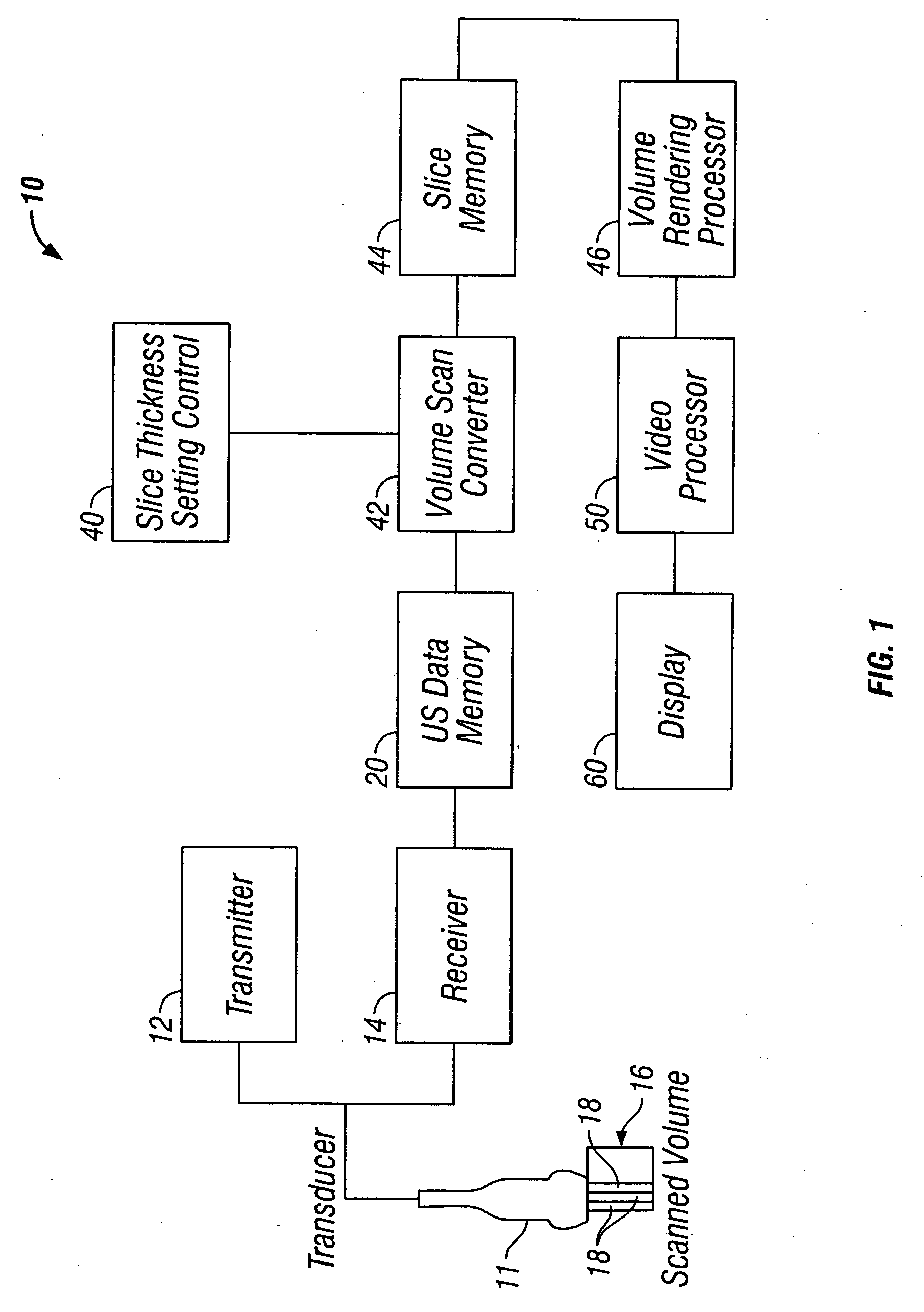

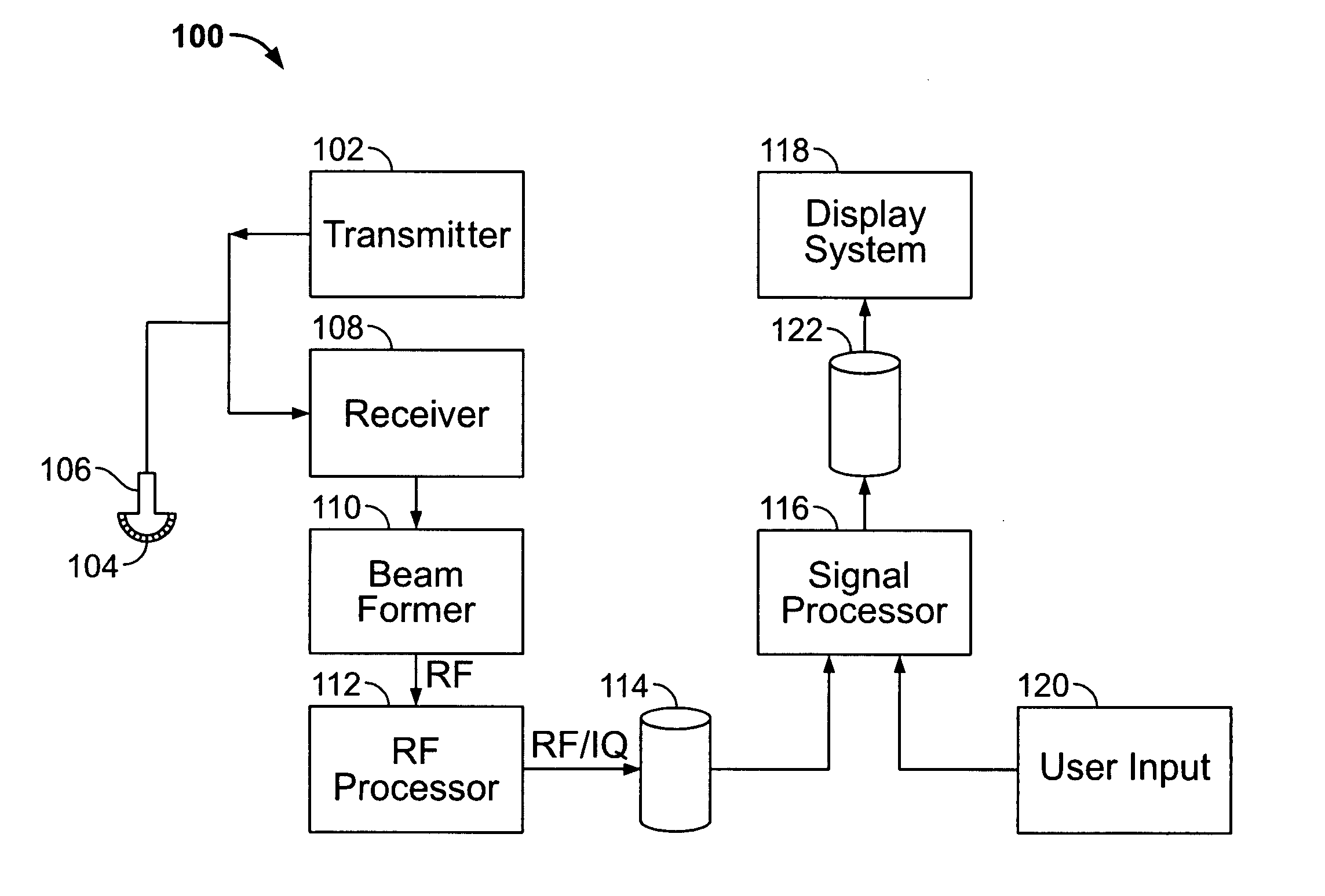

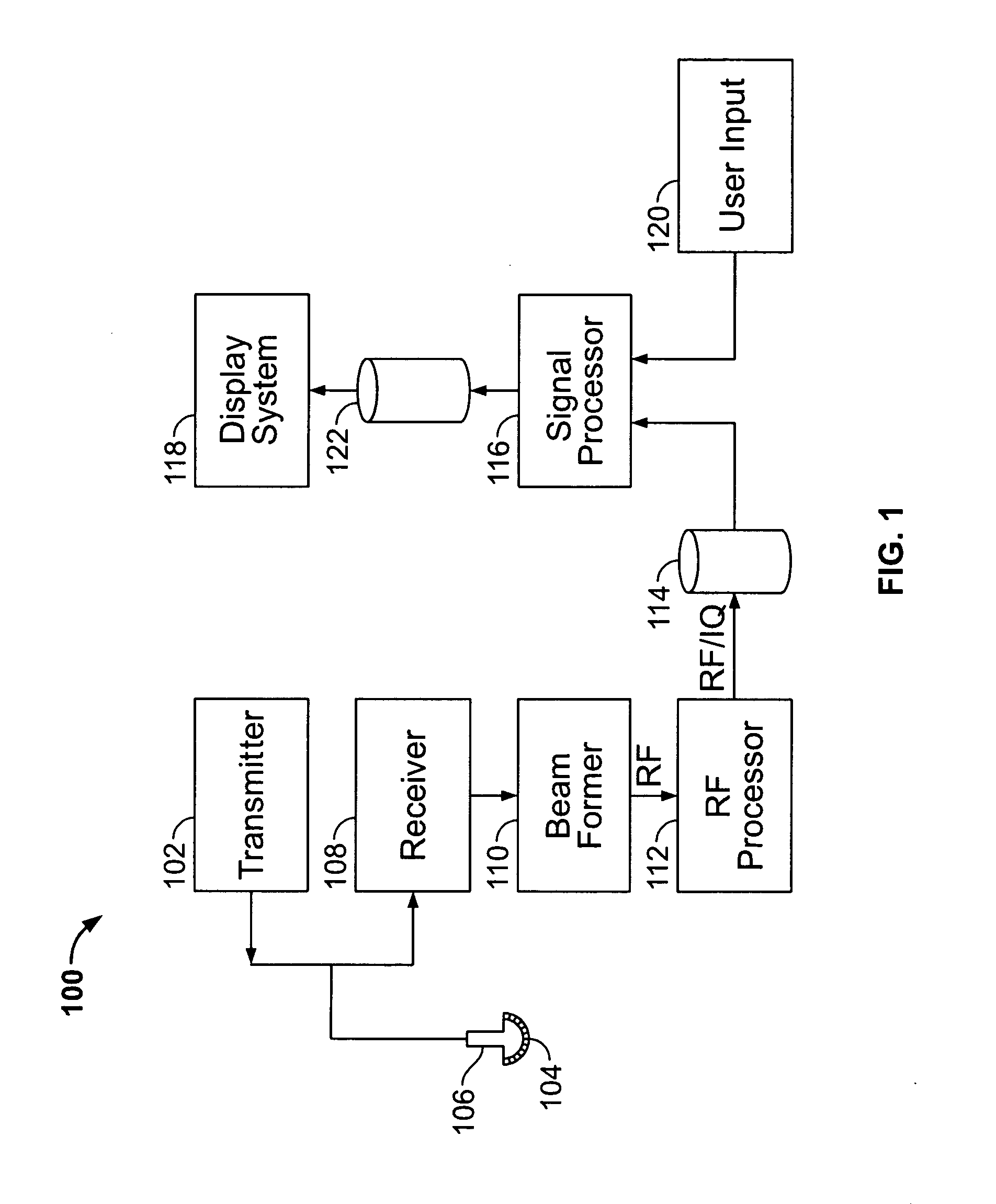

Method and apparatus for controlling ultrasound systems

ActiveUS7052459B2Ultrasonic/sonic/infrasonic diagnosticsWave based measurement systemsSonificationControl ultrasound

A method and system providing control of an ultrasound system with a user interface is provided. The user interface for controlling the ultrasound system includes a plurality of selectable elements for controlling operation of the ultrasound system and a plurality of identifiers. Each identifier corresponds to one of the plurality of selectable elements and associates control commands with the selectable elements.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

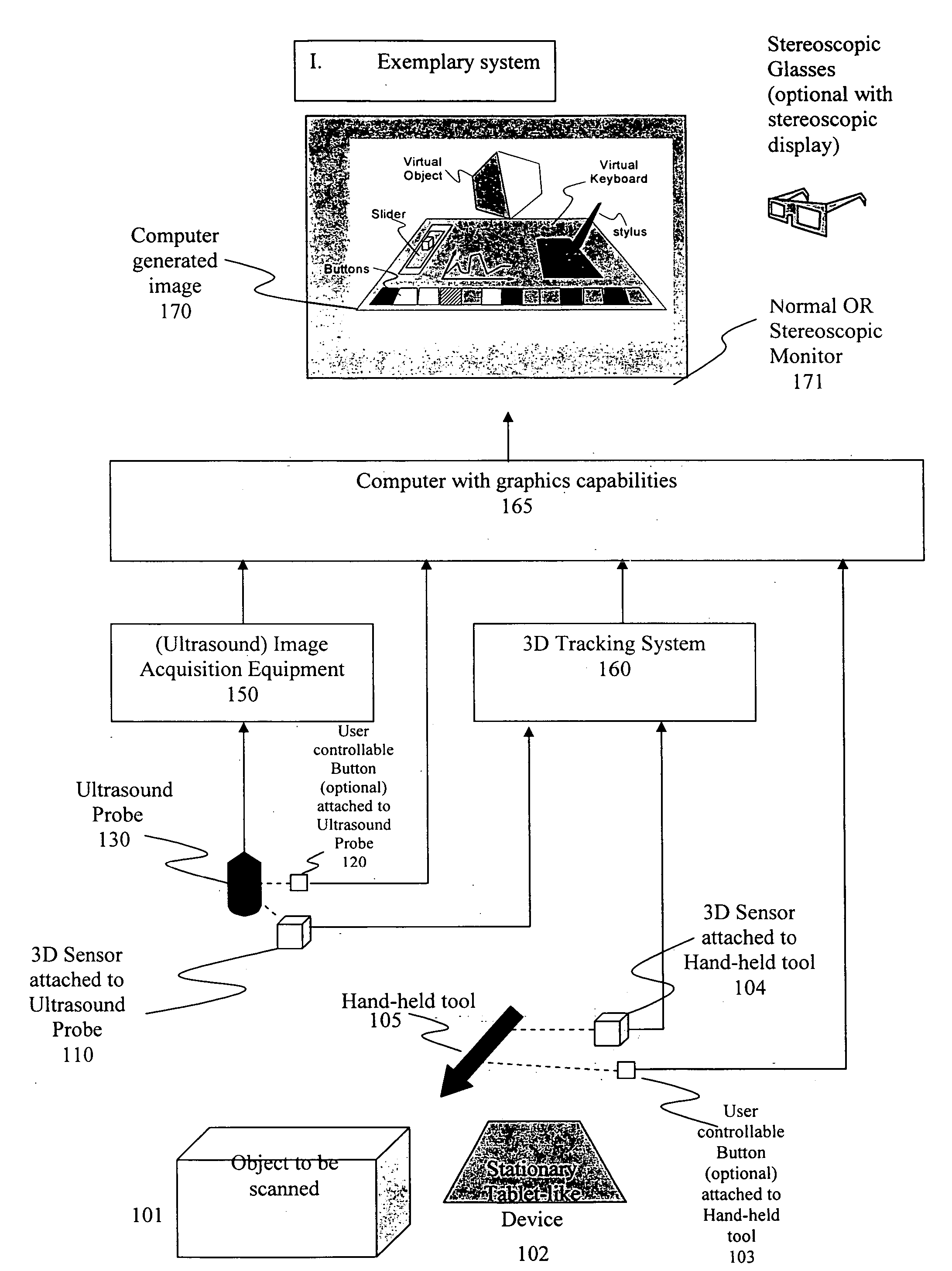

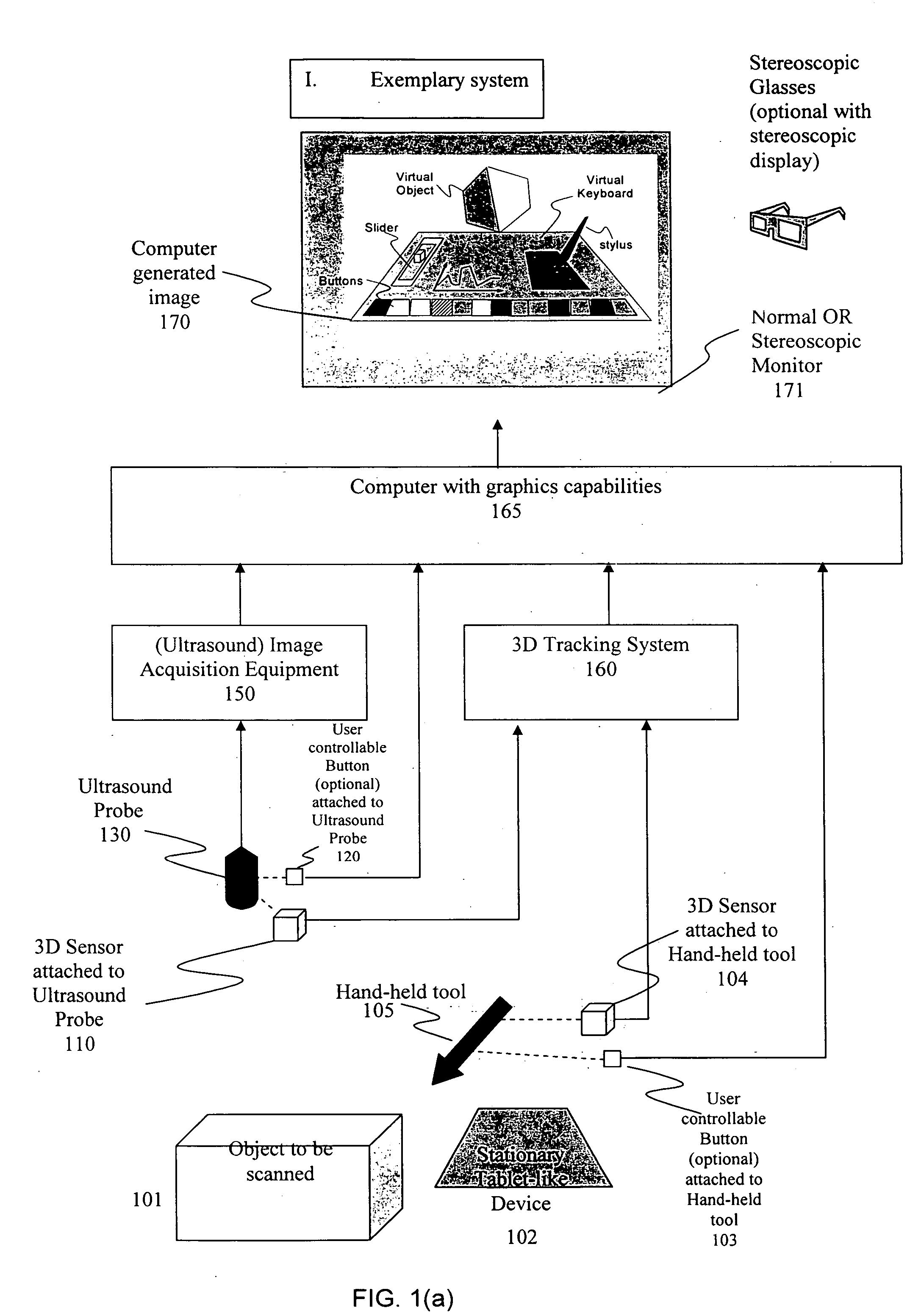

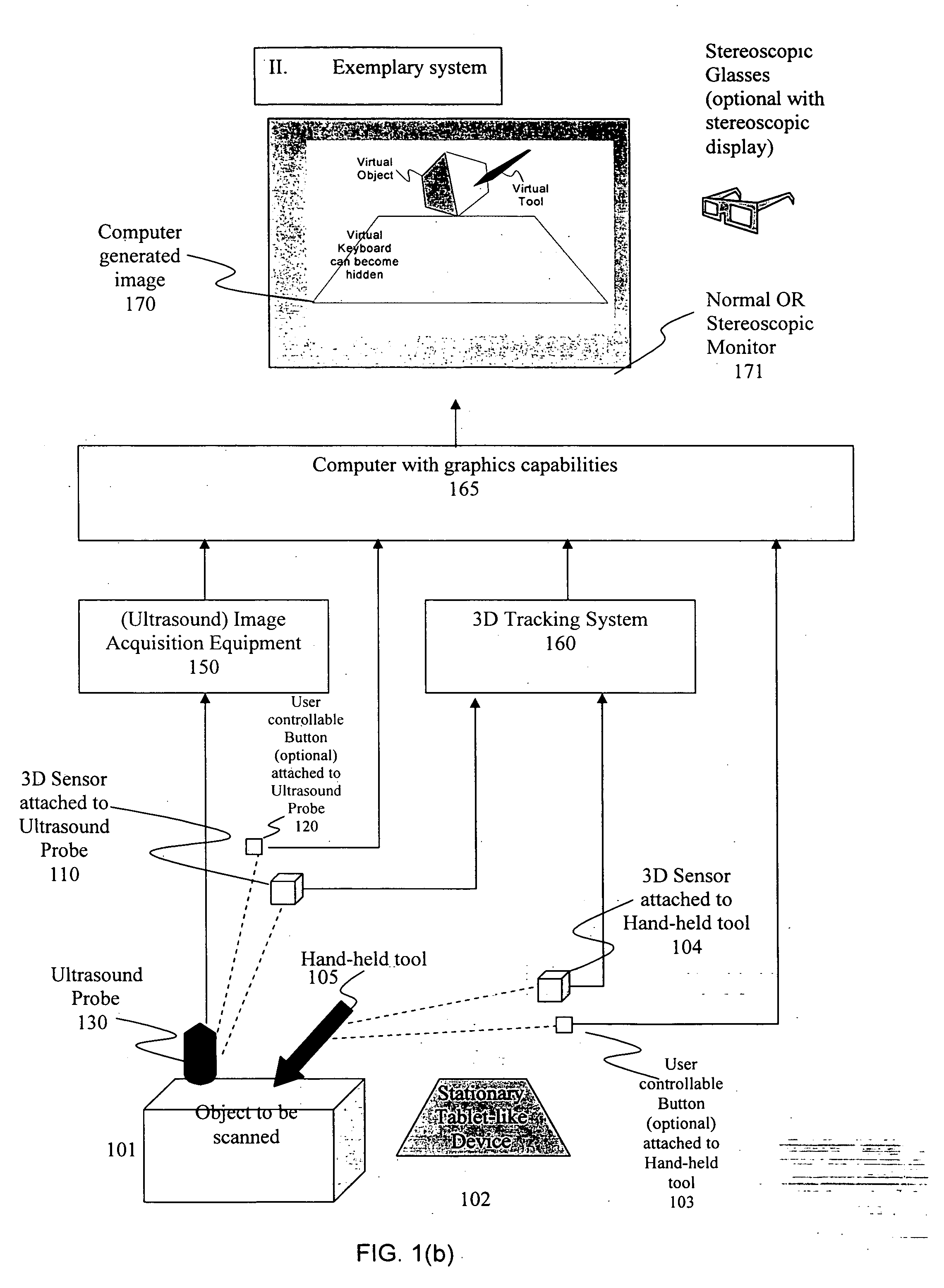

System and method for a virtual interface for ultrasound scanners

A virtual control system for substantially real-time imaging machines, such as, for example, ultrasound, is presented. In exemplary embodiments of the present invention, a virtual control system comprises a physical interface communicably connected to a scanner / imager, such as, for example, an ultrasound machine. The scanner / imager has, or is communicably connected to, a processor that controls the display of, and user interaction with, a virtual control interface. In operation, a user can interact with the virtual control interface by physically interacting with the physical interface. In exemplary embodiments according to the present invention the physical interface can comprise a handheld tool and a stationary tablet-like device. In exemplary embodiments according to the present invention the control system can further include a 3D tracking device that can track both an ultrasound probe as well as a handheld physical interface tool. In such exemplary embodiments a user can control scan and display functions of the ultrasound machine by moving a handheld tool relative to the stationary tablet, and can perform 3D interactive display and image processing operations on a displayed 3D image by manipulating the handheld tool within a defined 3D space. Alternatively, all control functions, those associated with scan and display control as well as those associated with 3D interactive display and image processing can be mapped to manipulations of the handheld tool in a defined 3D space.

Owner:BRACCO IMAGINIG SPA

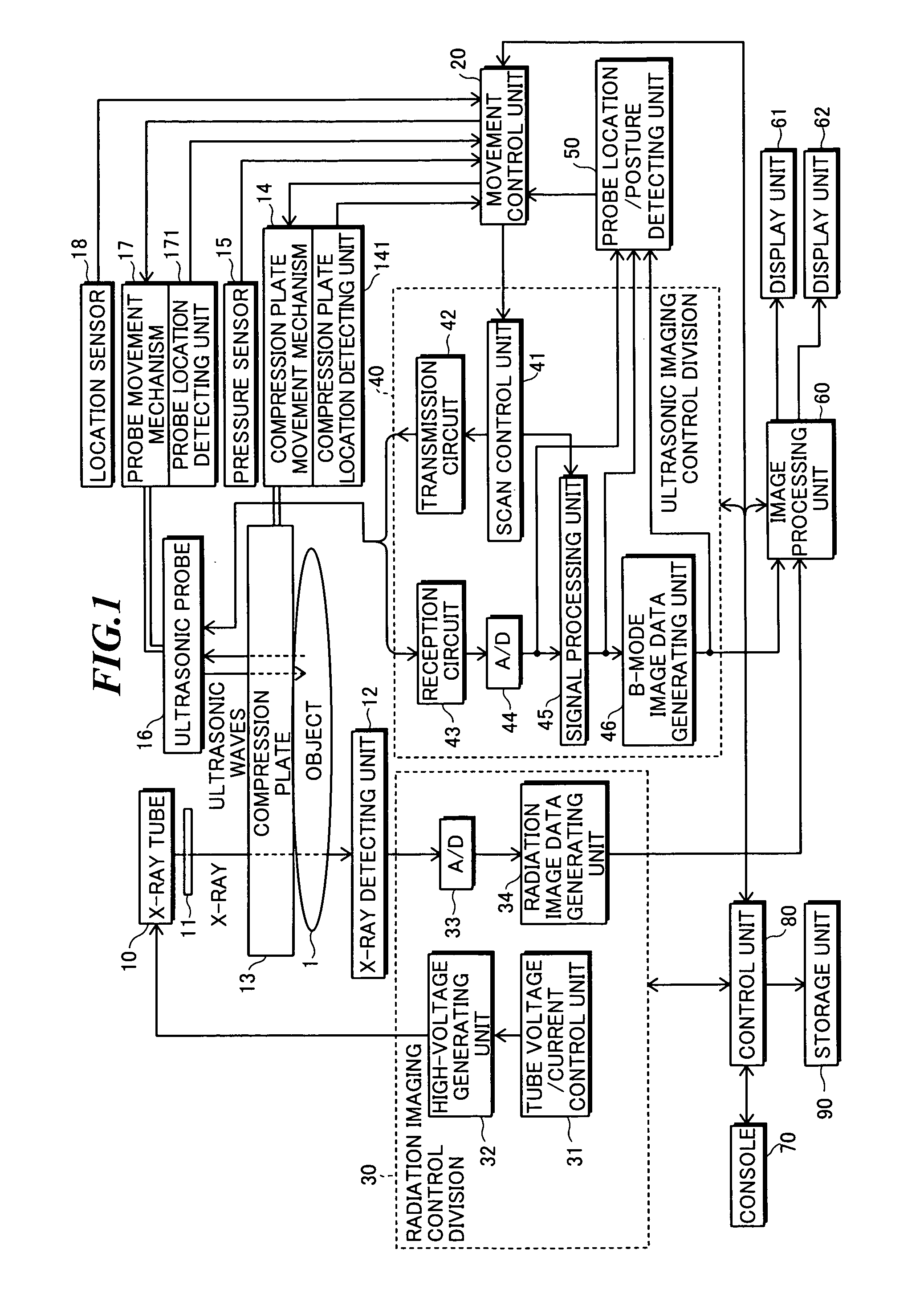

Ultrasonic diagnostic imaging system and control method thereof

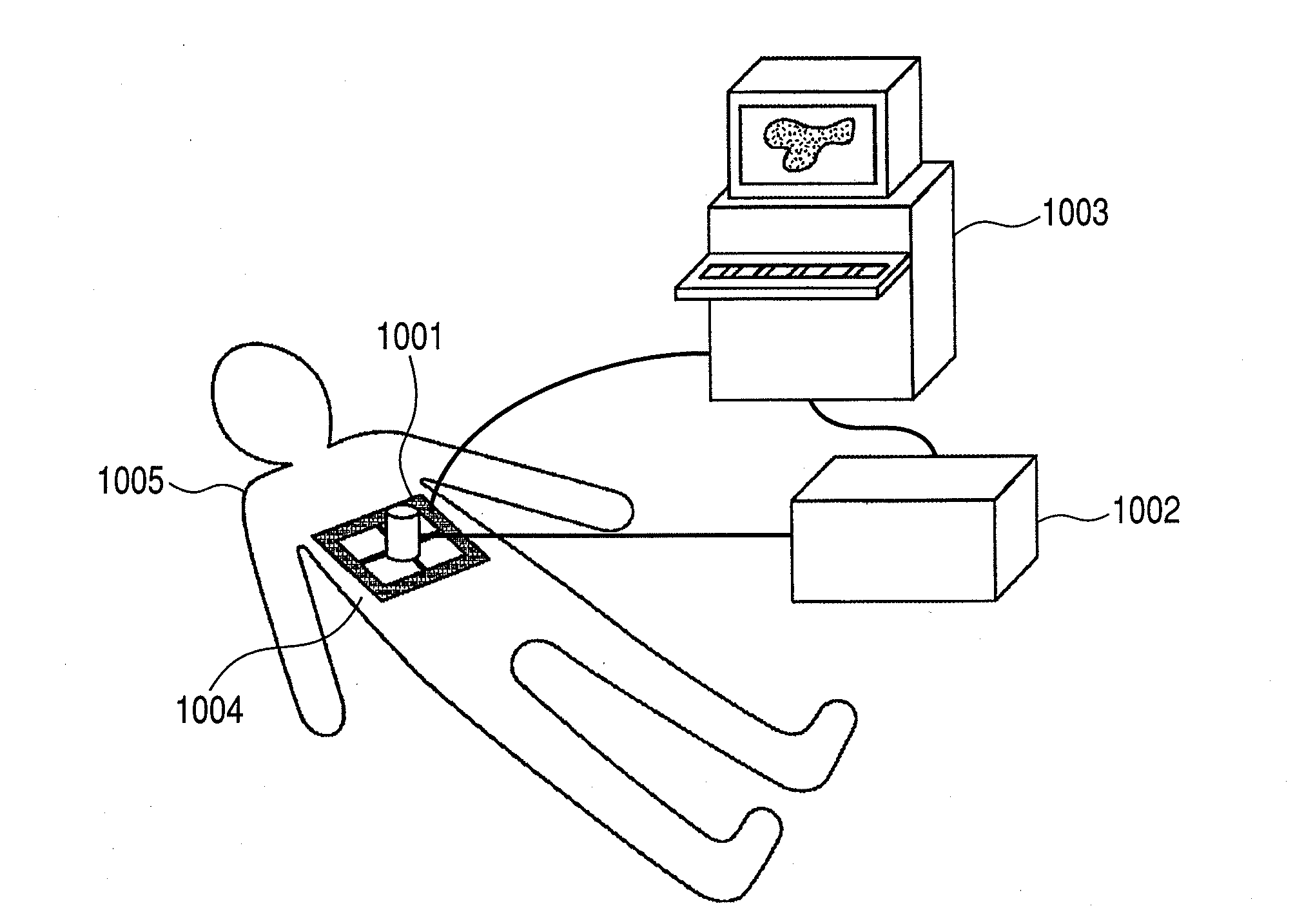

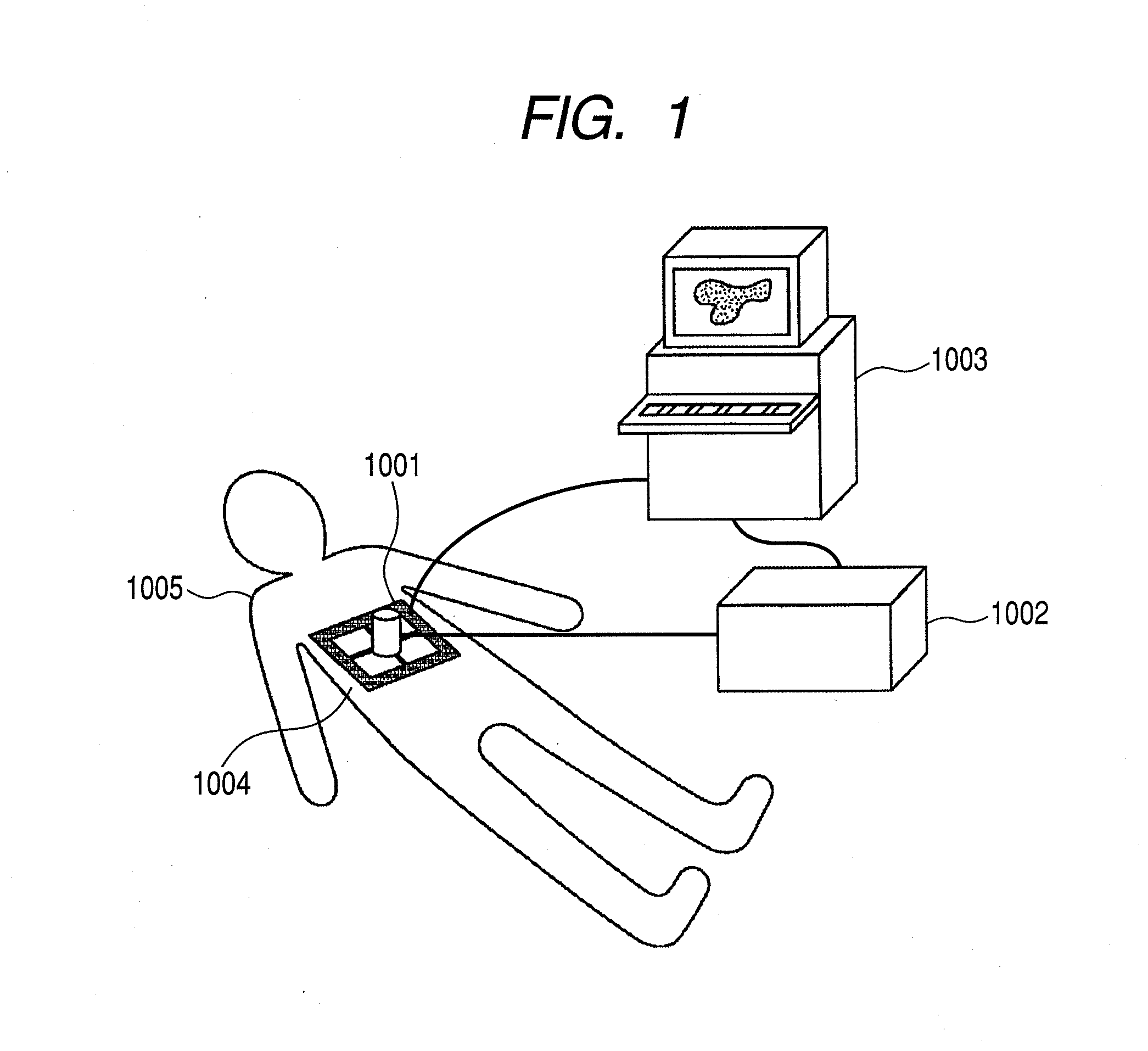

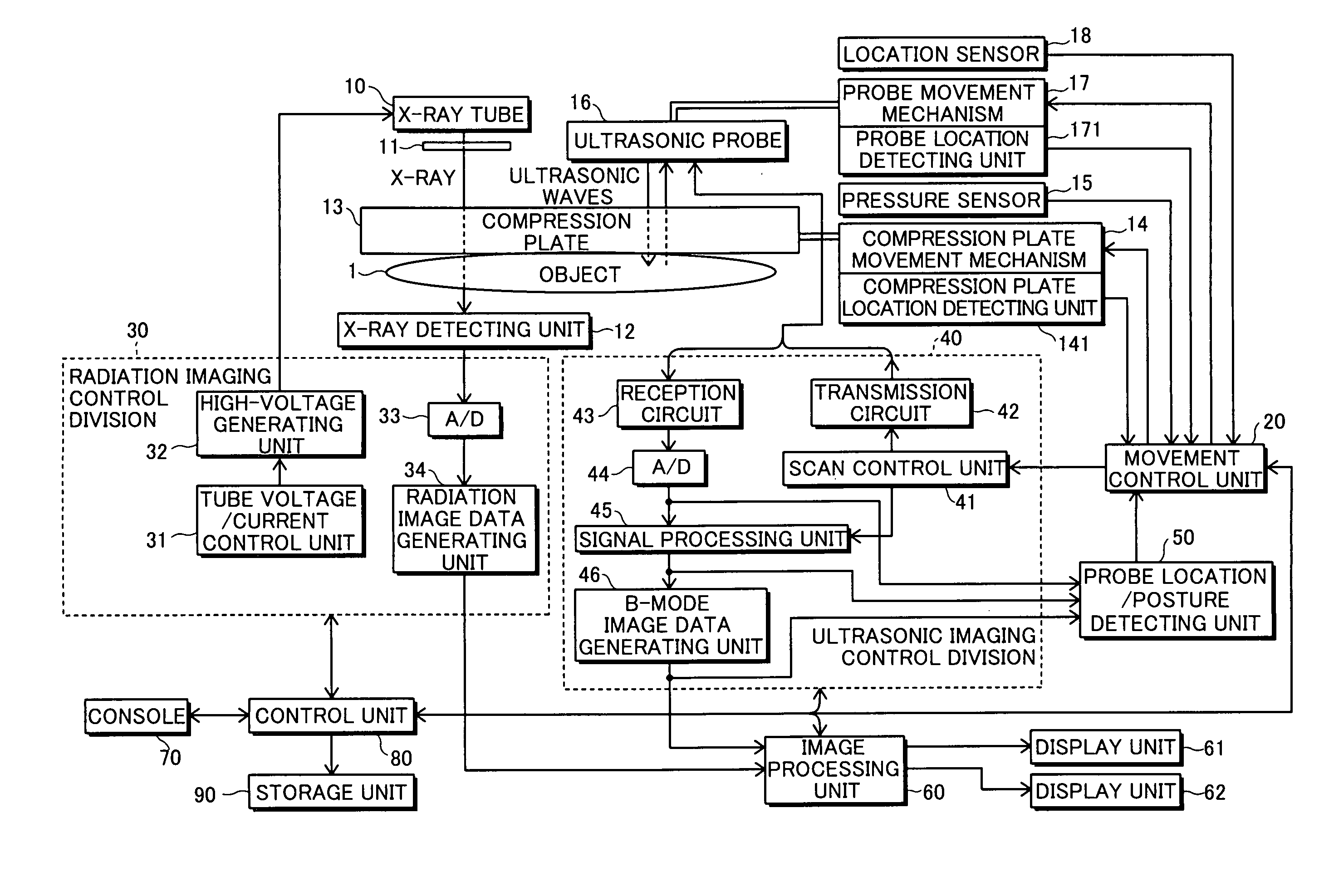

An ultrasonic diagnostic imaging system not depending on an operator who operates the apparatus is provided. The system includes a measuring unit (coordinate calculation section 2034) that measures a relative position and a relative posture of the ultrasonic probe with respect to an examinee using image information on the examinee acquired by the ultrasonic probe, a control amount calculation unit (2035) that calculates an amount of control of the position and posture of the ultrasonic probe based on the measurement result of the measuring unit and at least one of a probe control mechanism that controls the position and posture of the ultrasonic probe using the amount of control calculated by the control amount calculation unit and a guiding information presentation unit that presents information for guiding movement of the position and posture of the ultrasonic probe using the amount of control calculated by the control amount calculation unit.

Owner:CANON KK

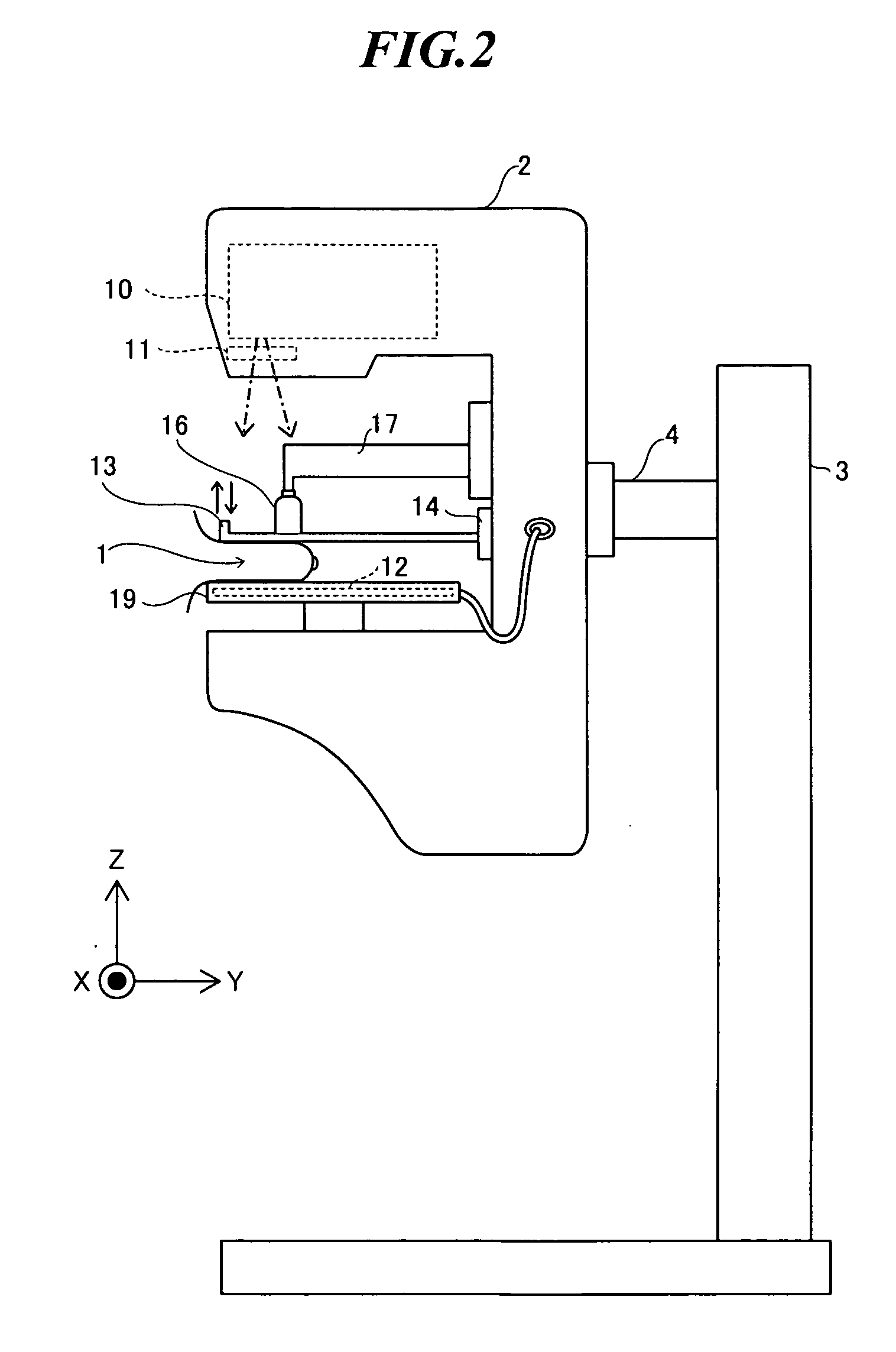

Medical imaging apparatus

InactiveUS20100030078A1Smooth motionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasonic imagingControl ultrasound

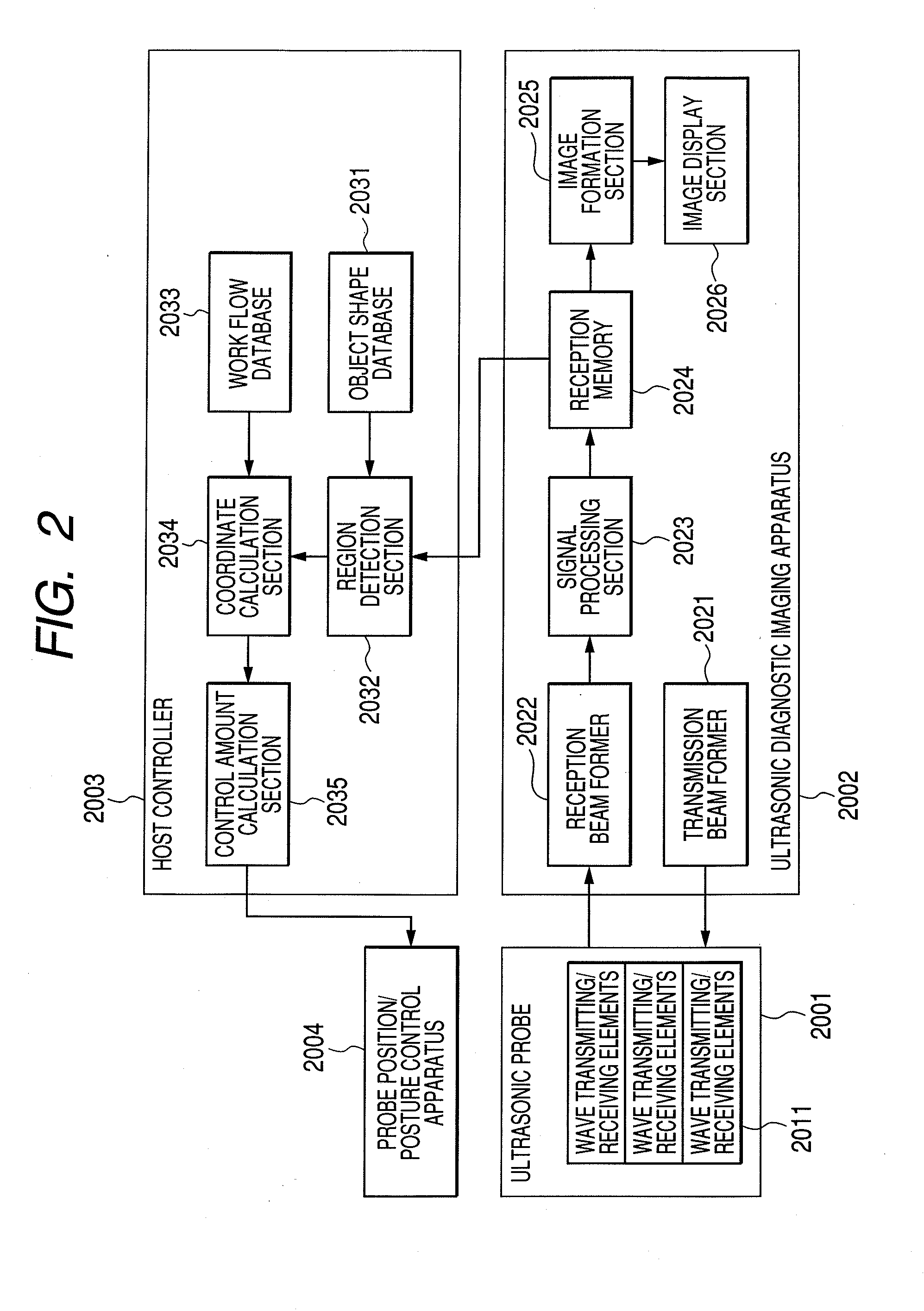

In a medical imaging apparatus for imaging mammary gland and breast while compressing the breast with a compression plate, the posture of an ultrasonic probe relative to the compression plate is kept constant and the moving motion of the ultrasonic probe is stabilized. The apparatus includes: an imaging stage; a compression plate; an ultrasonic probe provided to maintain acoustic connection to the compression plate, for transmitting ultrasonic waves according to drive signals and receiving ultrasonic echoes to output reception signals; an ultrasonic imaging unit for supplying the drive signals to the ultrasonic probe and generating image data based on the reception signals; a detecting unit for detecting a location and / or a posture of the ultrasonic probe relative to the compression plate; and a control unit for controlling the location and / or the posture of the ultrasonic probe based on a detection result of the detecting unit.

Owner:FUJIFILM CORP

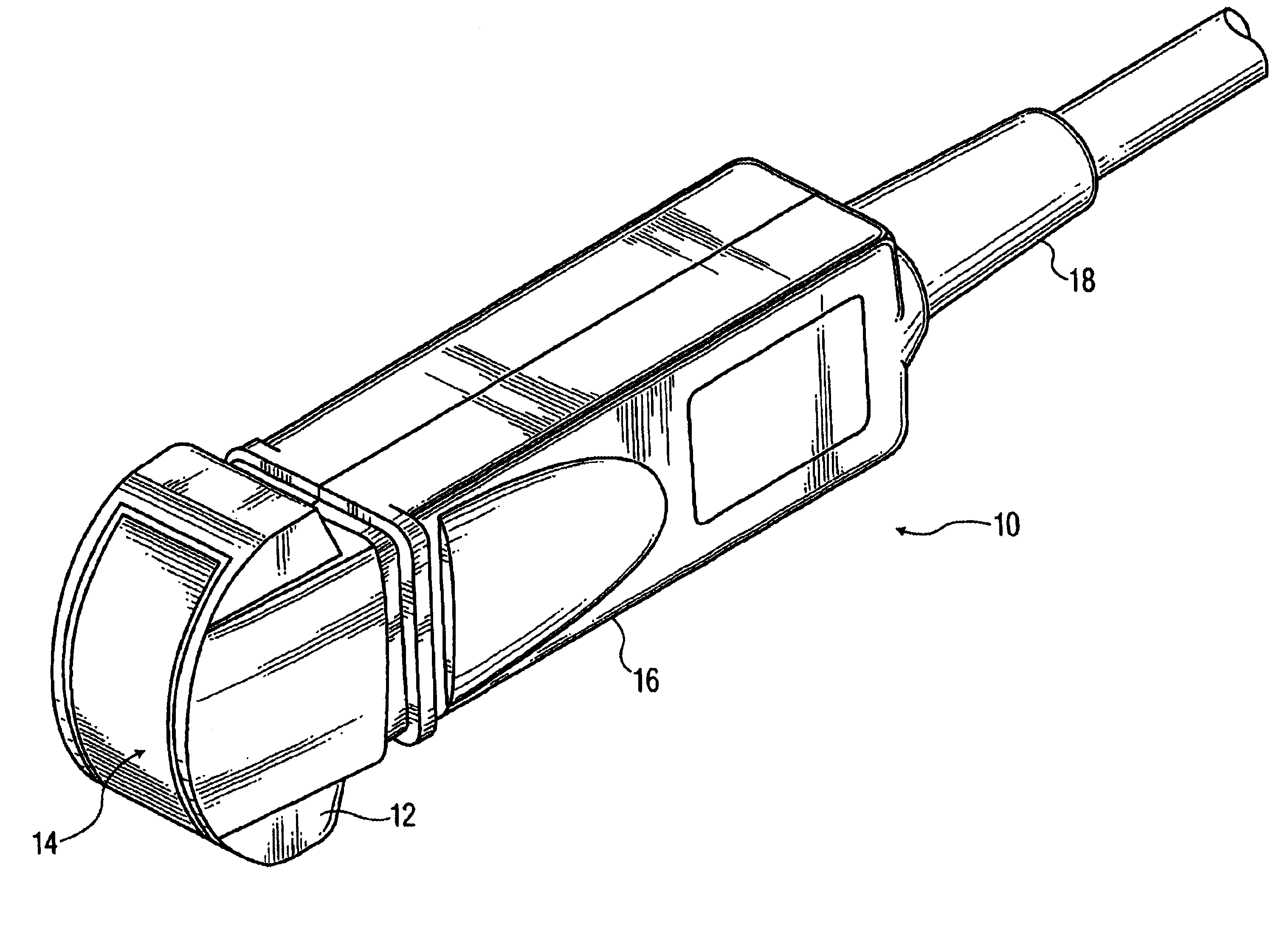

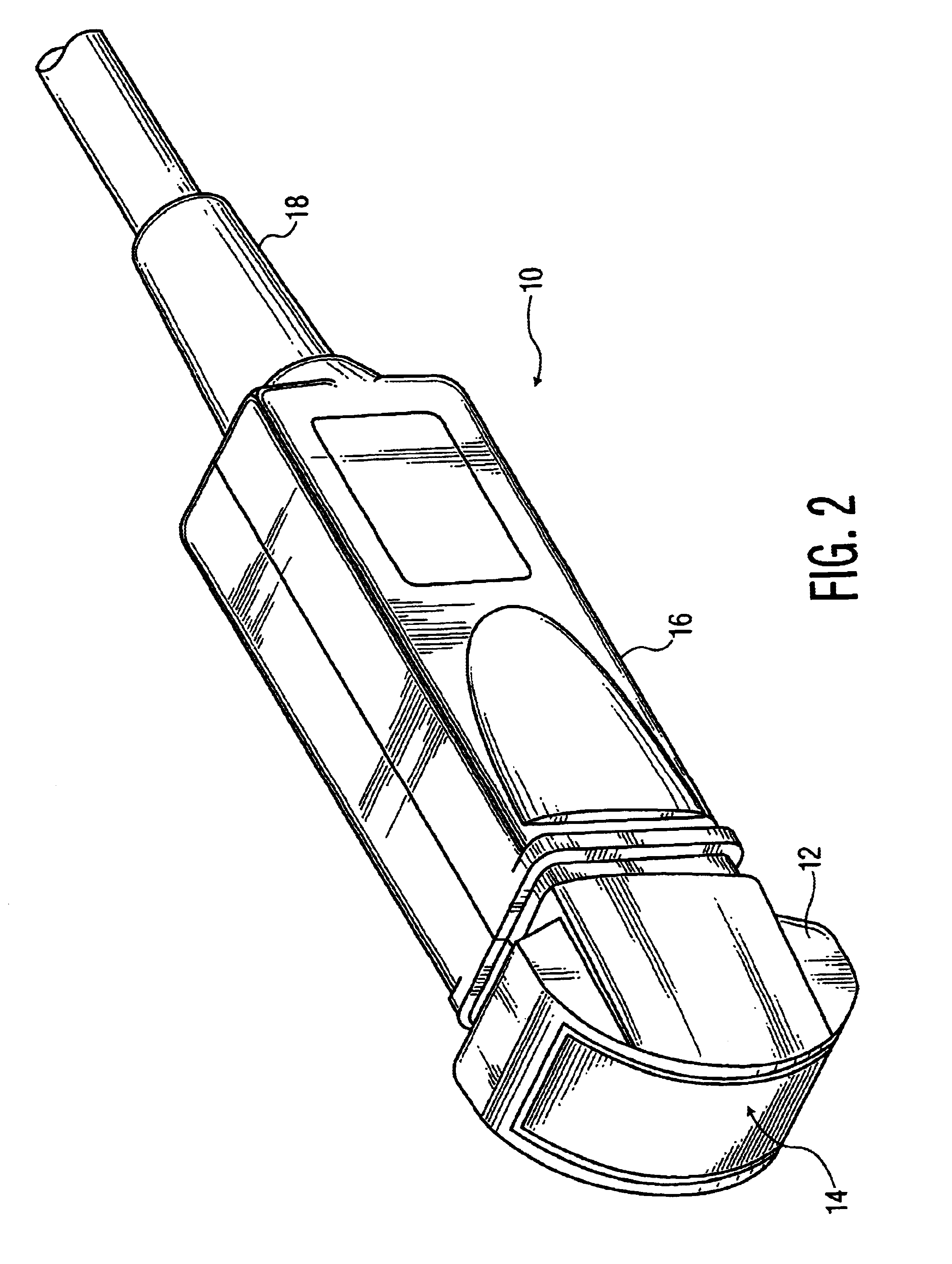

System and method for controlling ultrasound probe having multiple transducer arrays

A system and method for controlling an ultrasound probe are provided. The ultrasound probe includes a first transducer array and a second transducer array. The ultrasound probe further includes a transducer array selector component within a housing. The transducer array selector component is configured to generate a control signal based on a user input to selectively activate one of the first transducer array and the second transducer array.

Owner:GENERAL ELECTRIC CO

Camellia extraction liquid, and preparation method and application thereof

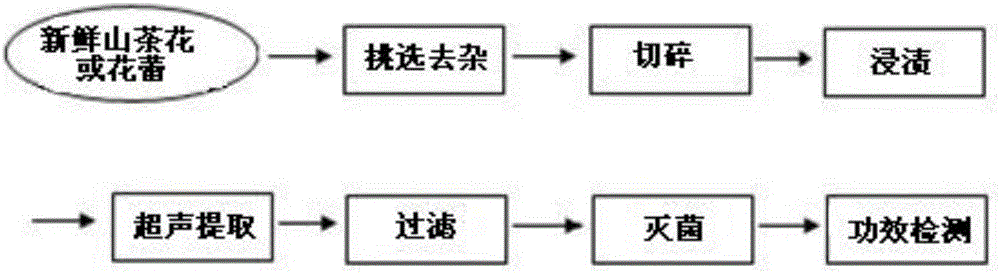

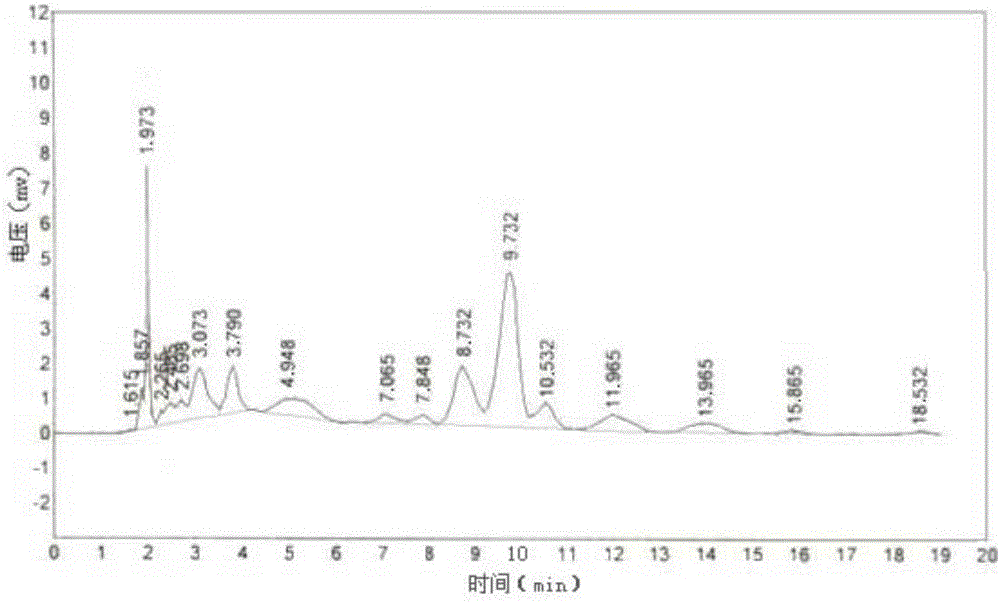

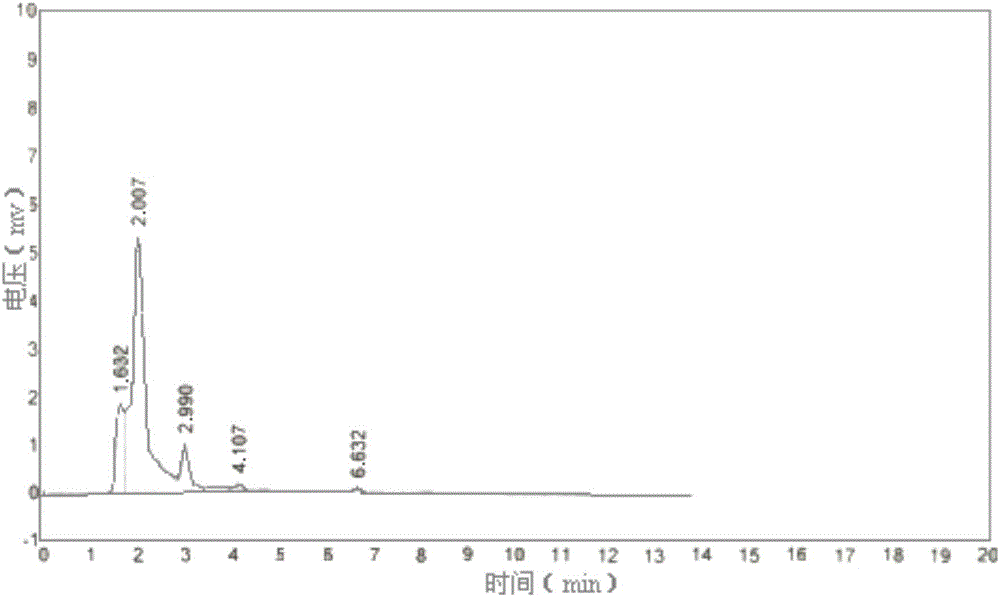

ActiveCN105997754AIncrease contentStrong antioxidantCosmetic preparationsToilet preparationsSolventBud

The invention provides a preparation method of camellia extraction liquid. The method comprises the following steps of 1) removing impurities of fresh camellia and / or fresh camellia buds; cutting up the fresh camellia and / or fresh camellia buds into small sections for use as raw materials; 2) taking a certain number of raw materials; putting the raw materials into an ultrasonic kettle; adding a solvent with the mass ratio being 1:(3-30); uniformly stirring the mixture; adding a certain amount of inorganic acid and / or organic acid; regulating the pH value to 1.3 to 3.0; soaking the materials for 10 to 30 min; 3) then performing ultrasonic treatment for 30 to 60min; controlling the ultrasonic frequency to be 20 to 25KHz, the ultrasonic power to be 1.0 to 2.0KW and the ultrasonic temperature to be 15 to 50 DEG C; then performing filtration, sterilization and detection to obtain camellia extraction liquid. The camellia extraction liquid maintains the color, luster, flavor and effective active ingredients of the camellia to the maximum degree; the anti-oxidation functional ingredients are overall; the contents are high; the safety and the stability are high; cosmetics prepared by using camellia extraction liquid as active ingredients have the excellent whitening, spot-reducing and anti-aging efficacies.

Owner:SHANGHAI DELTA IND

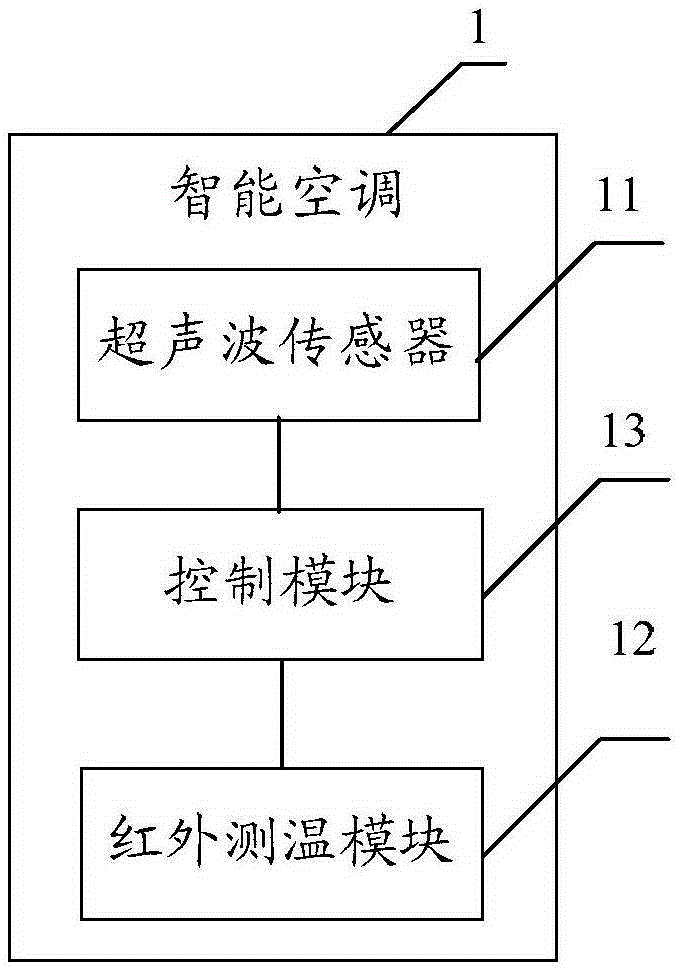

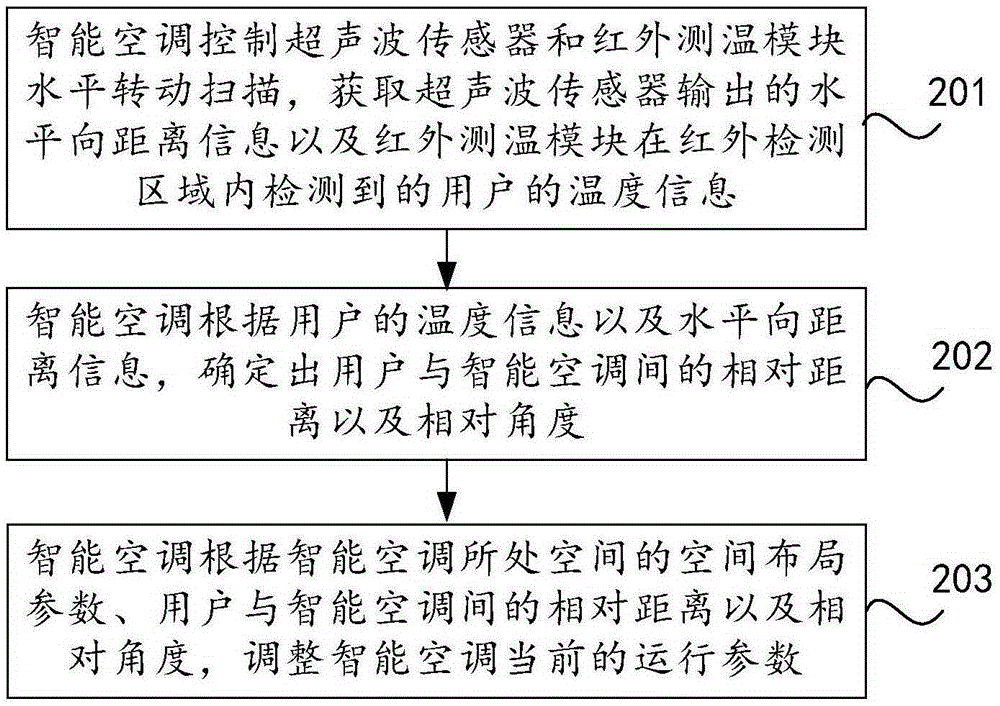

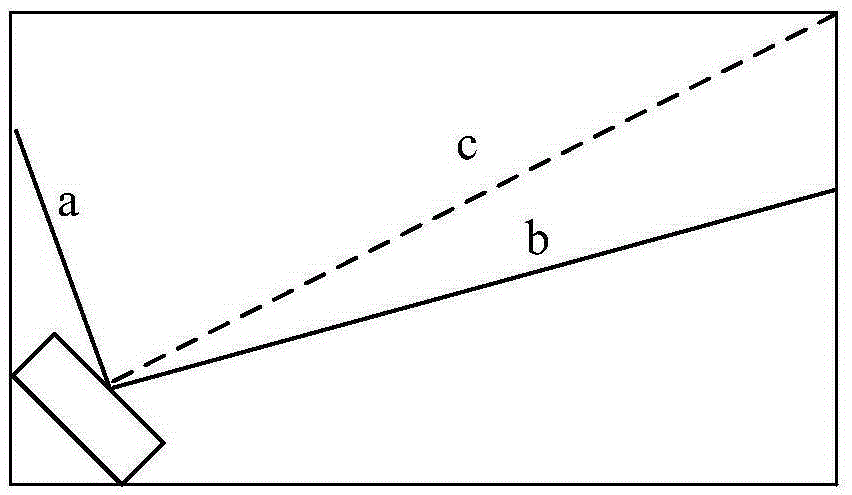

Control method for intelligent air conditioner and intelligent air conditioner

ActiveCN105588300AEasy to controlMechanical apparatusSpace heating and ventilation safety systemsUltrasonic sensorEngineering

The embodiment of the invention provides a control method for an intelligent air conditioner and the intelligent air conditioner and relates to the field of air conditioners. By the adoption of the control method for the intelligent air conditioner and the intelligent air conditioner, the problem that according to an air conditioner in the prior art, the relative positions of a user and the air conditioner cannot be accurately positioned, and consequentially accurate control over the air conditioner cannot be achieved is solved. The control method comprises the steps that an ultrasonic sensor and an infrared temperature measurement module are controlled to rotate horizontally for scanning, and the horizontal distance information output by the ultrasonic sensor and the user temperature information detected by the infrared temperature measurement module in an infrared detection area are obtained; the relative distance and relative angle between the user and the intelligent air conditioner are determined according to the user temperature information and the horizontal distance information, and spatial arrangement parameters include the position information of the intelligent air conditioner in a space; and the current operating parameter of the intelligent air conditioner is adjusted according to the spatial arrangement parameters of the space where the intelligent air conditioner is located, and the relative distance and relative angle between the user and the intelligent air conditioner. The control method is applied to the intelligent air conditioner.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

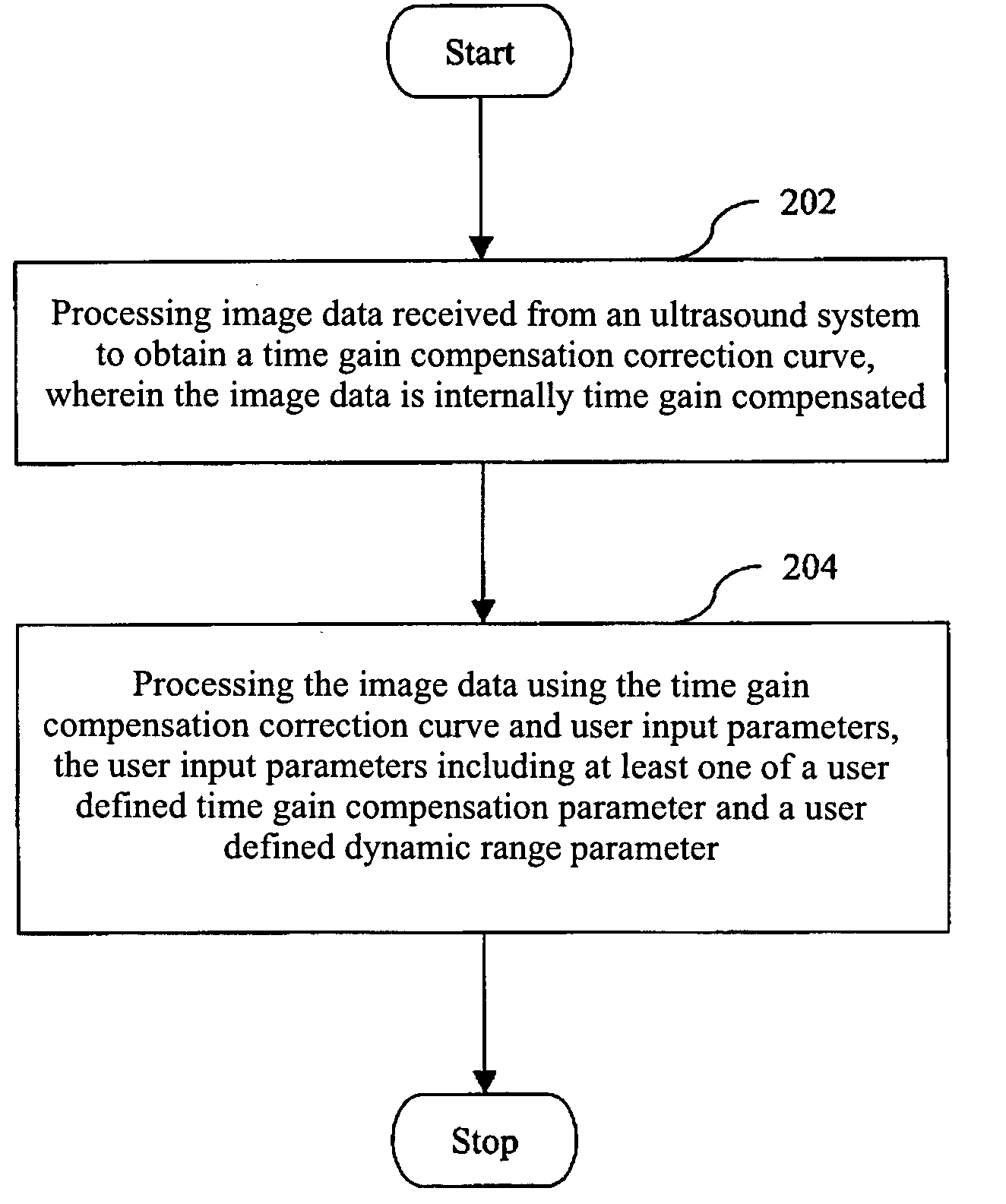

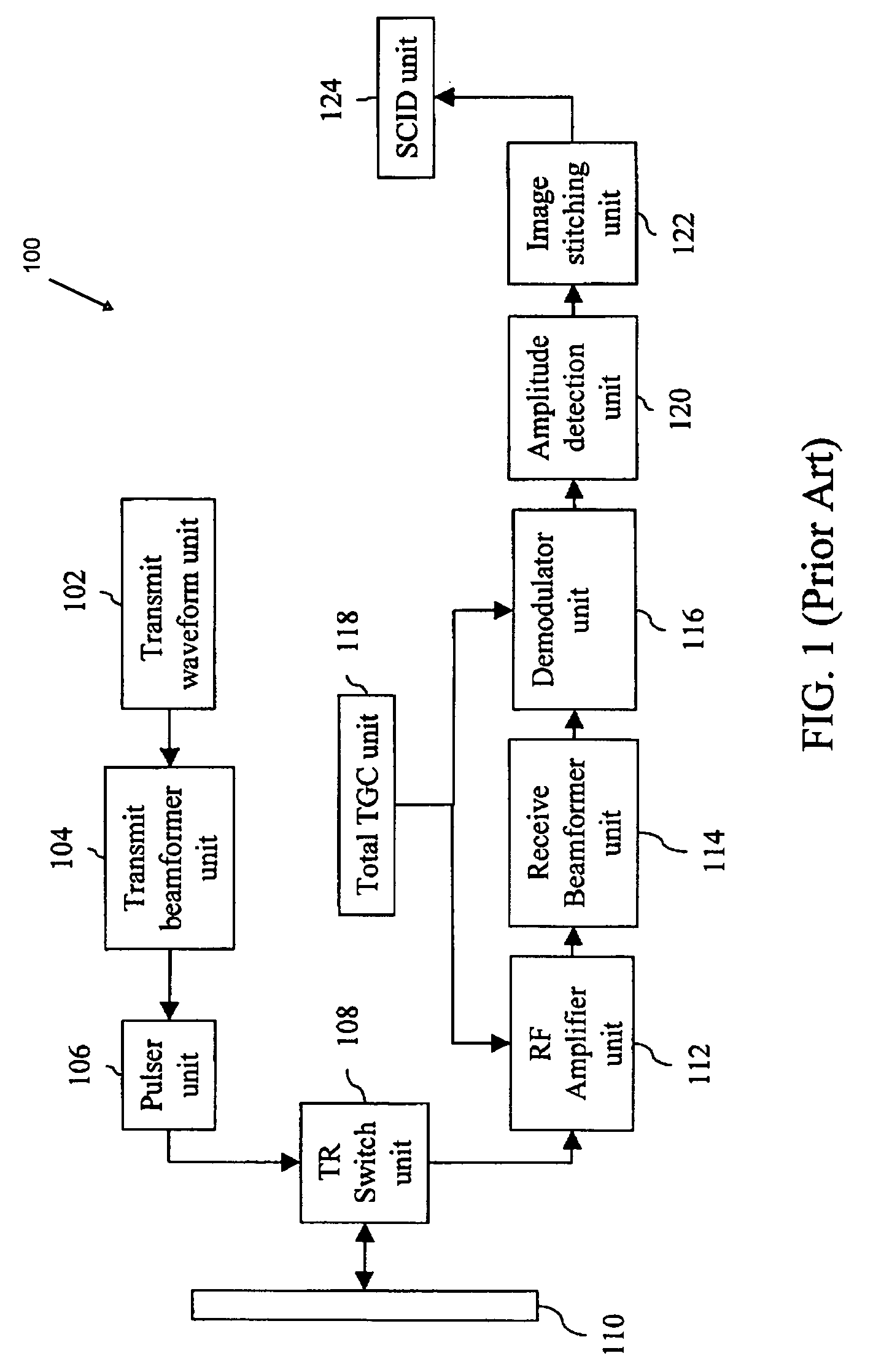

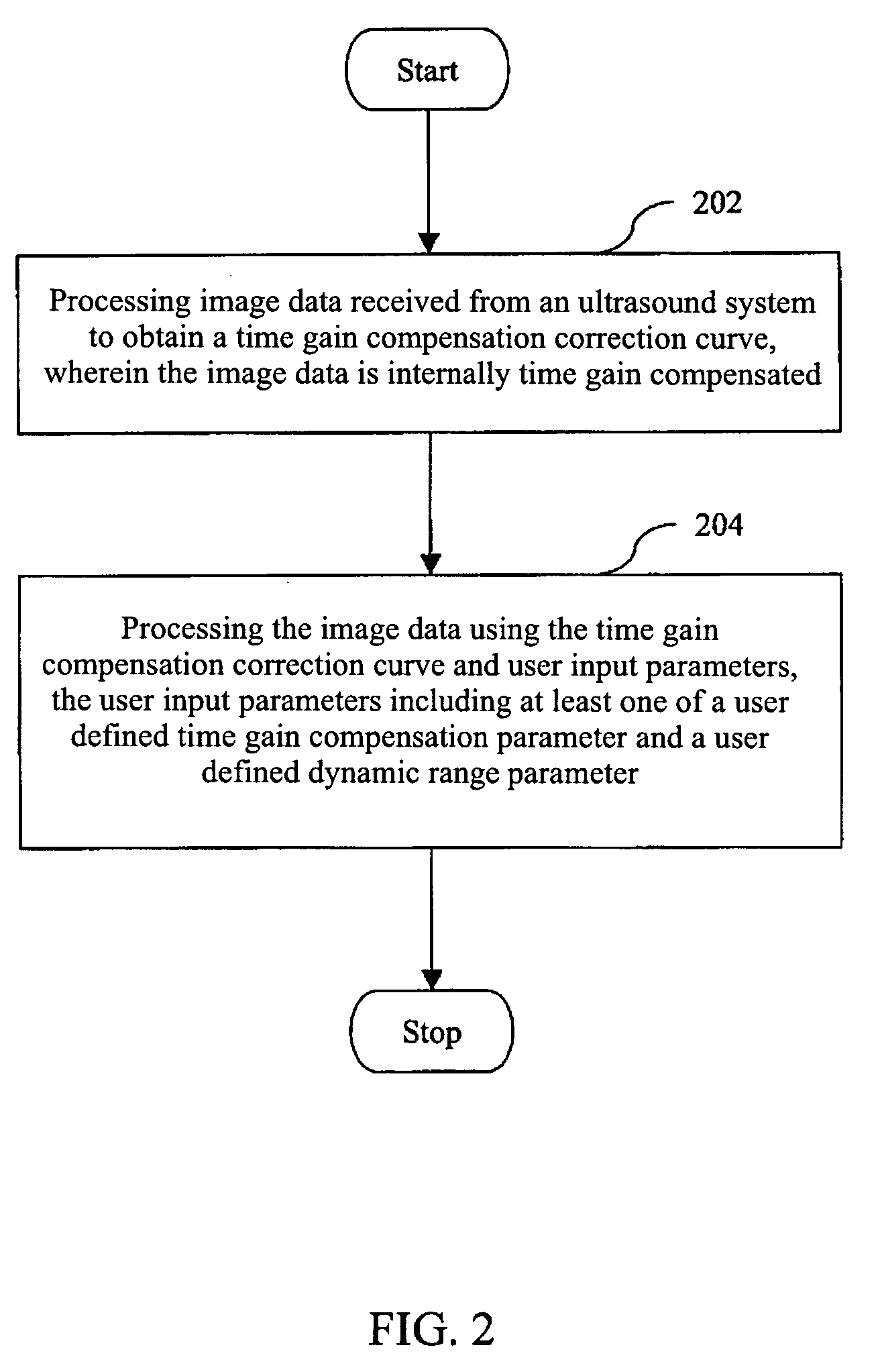

Method and system of controlling ultrasound systems

InactiveUS20060030775A1Ultrasonic/sonic/infrasonic diagnosticsImage enhancementControl ultrasoundTime gain compensation

A method and system for controlling an ultrasound system are provided. The method includes processing image data received from an ultrasound system to obtain a time gain compensation correction curve, wherein the image data is internally time gain compensated. The method further includes processing the image data using the time gain compensation correction curve and user inputs parameters. The user input parameters include at least one of a user defined time gain compensation parameter and a user defined dynamic range parameter.

Owner:GENERAL ELECTRIC CO

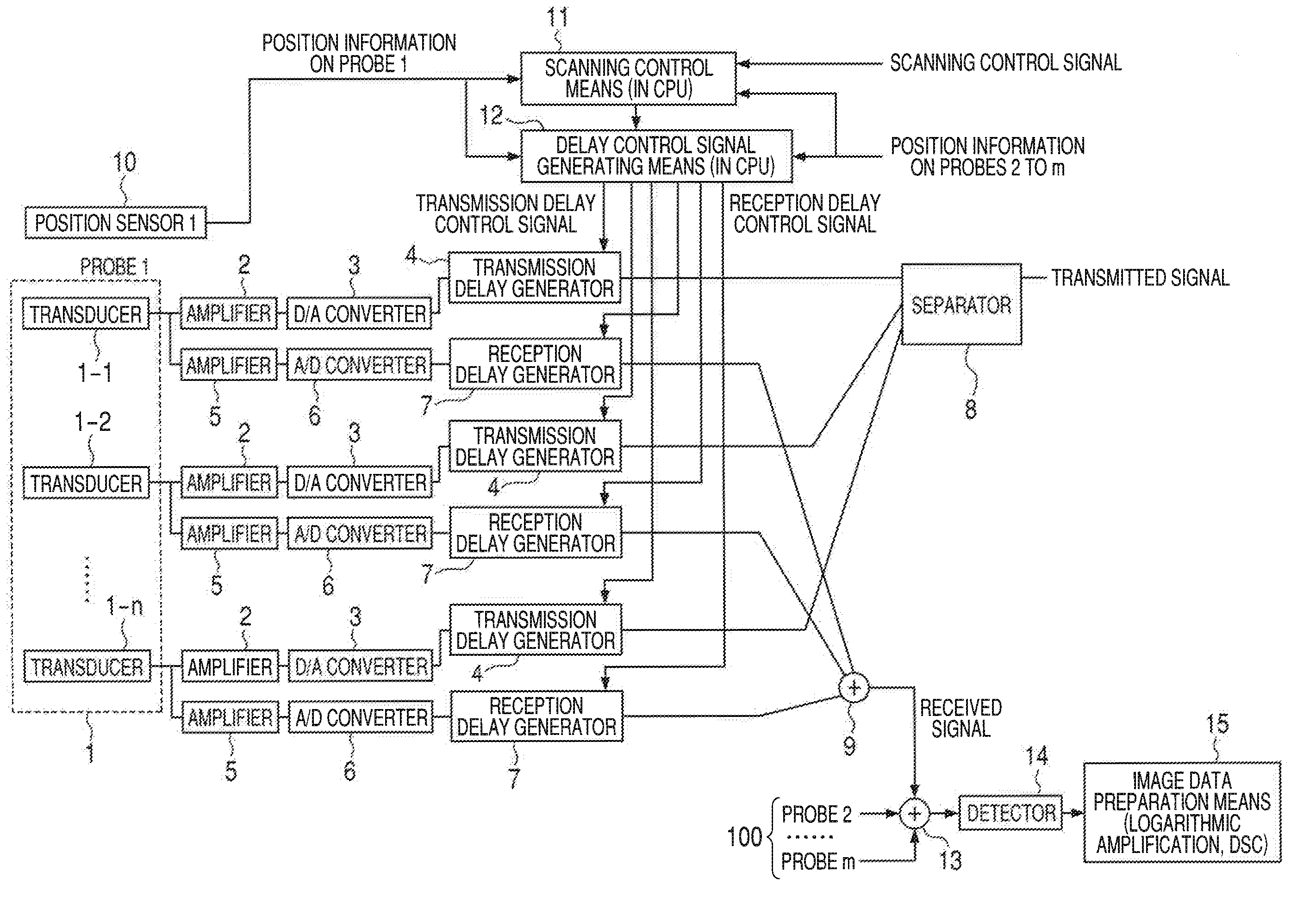

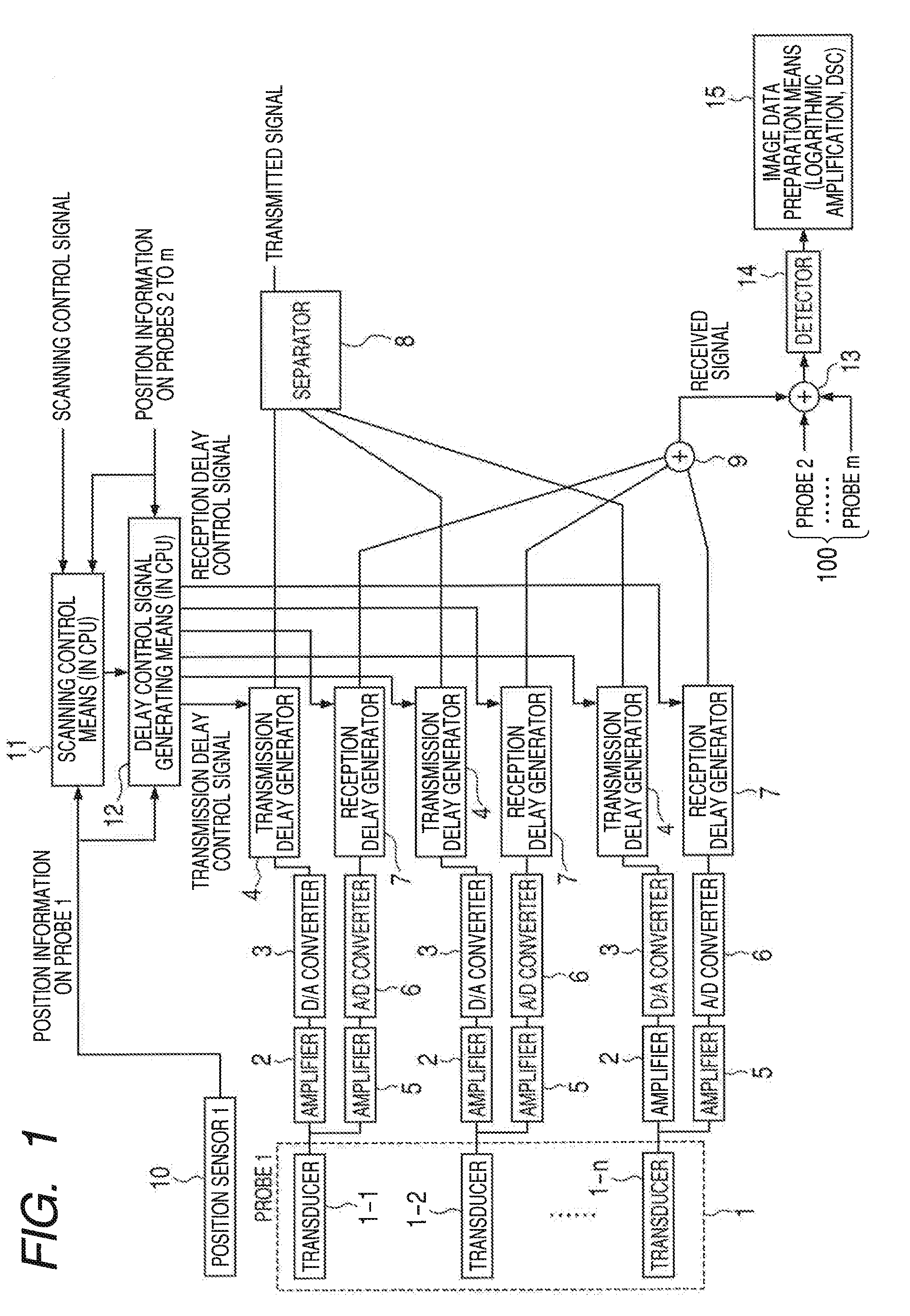

Diagnostic ultrasound apparatus

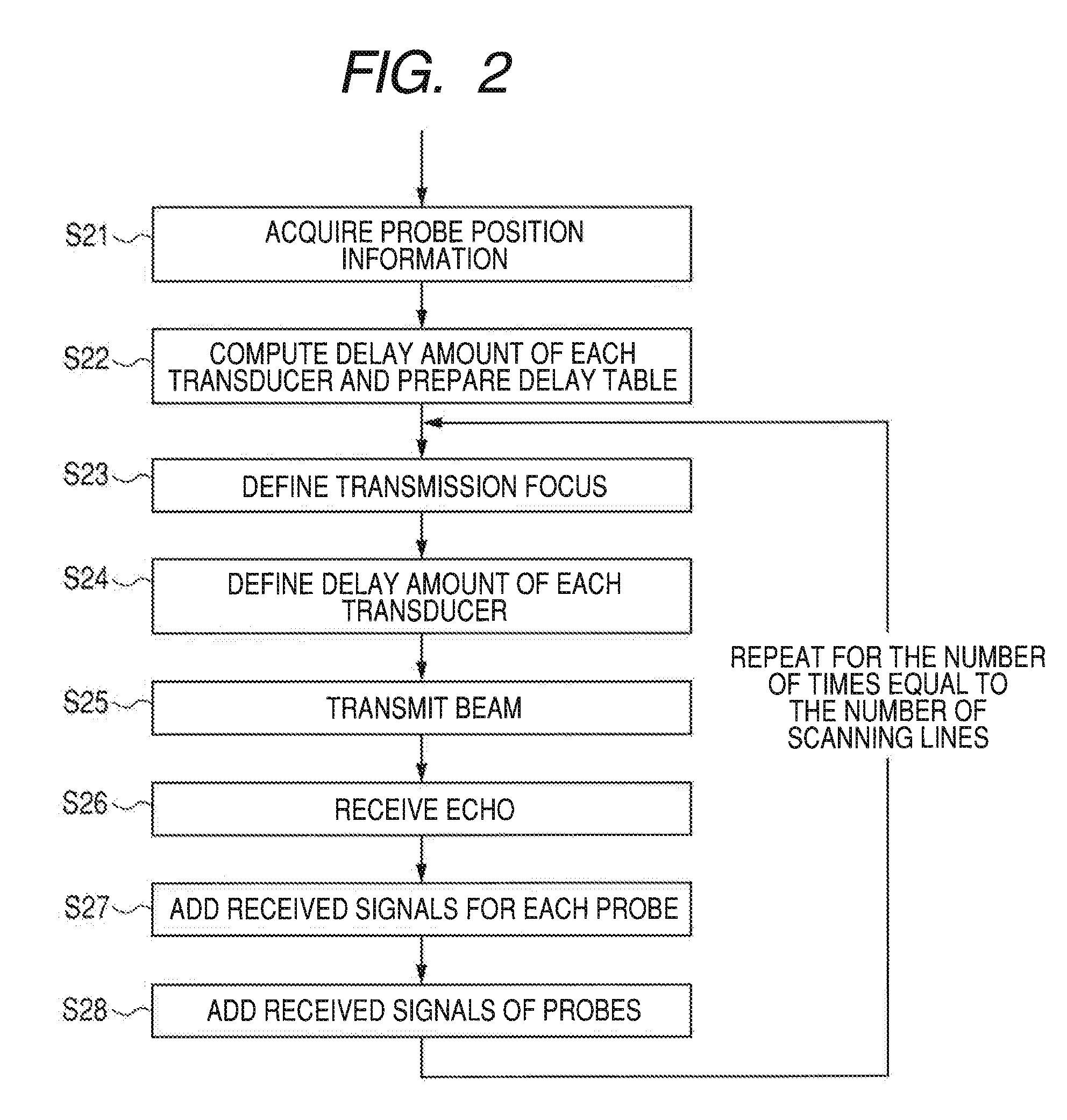

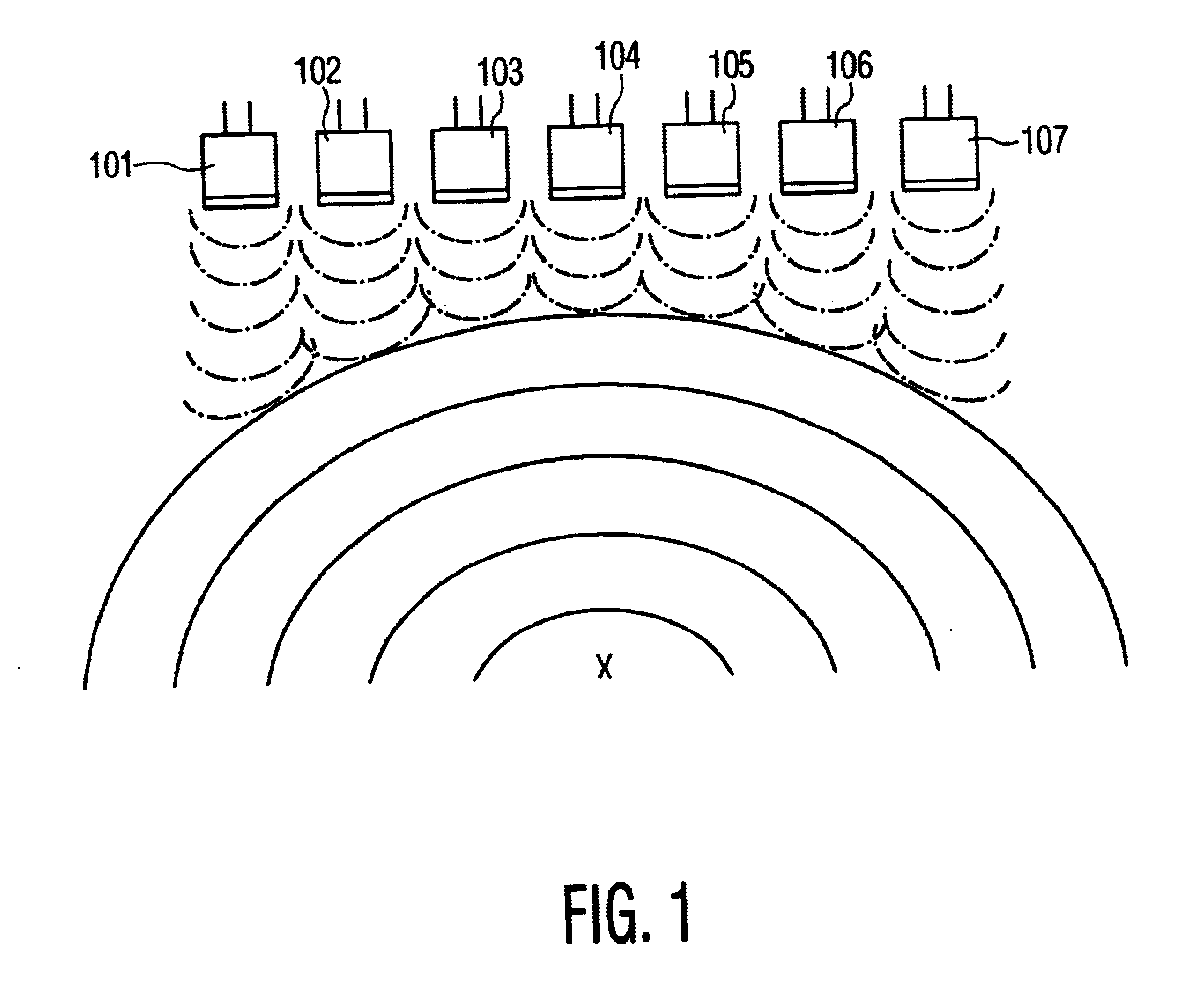

A novel diagnostic ultrasound apparatus has a plurality of ultrasound probes 1, delay means pairs 4 and 7 arranged respectively in the plurality of ultrasound probes to electronically delay the timings of transmissions or receptions of ultrasonic waves by the ultrasonic transducers, position / orientation detecting means 10 and delay control signal generating means for generating a delay control signal to control signal delays of the plurality of ultrasonic transducers of the plurality of ultrasound probes, using information acquired from the means 10. The delay control signal is input to the delay means to control the timings of transmission of ultrasonic waves to a target object of examination.

Owner:CANON KK

Operator supervised temperature control system and method for an ultrasound transducer

InactiveUS6663578B1Ultrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringUltrasound

A system and method for controlling the heat of an ultrasonic transducer is disclosed. In the presently preferred embodiments, the operator selects one or more mutable system parameters of the ultrasound system which will be changed if either the temperature becomes too great, or at the operator's command, or both.

Owner:PHILIPS ELECTRONICS NORTH AMERICA

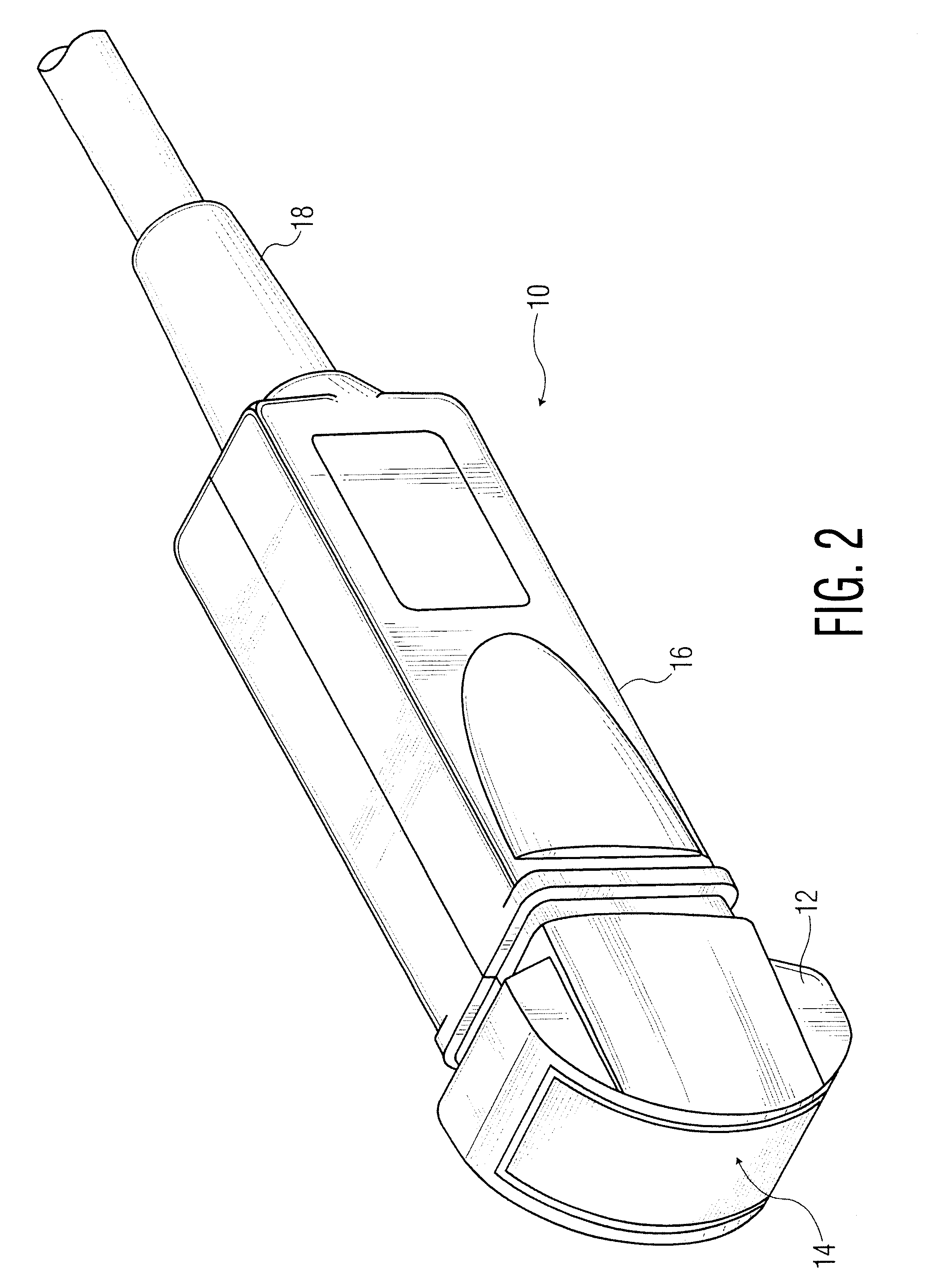

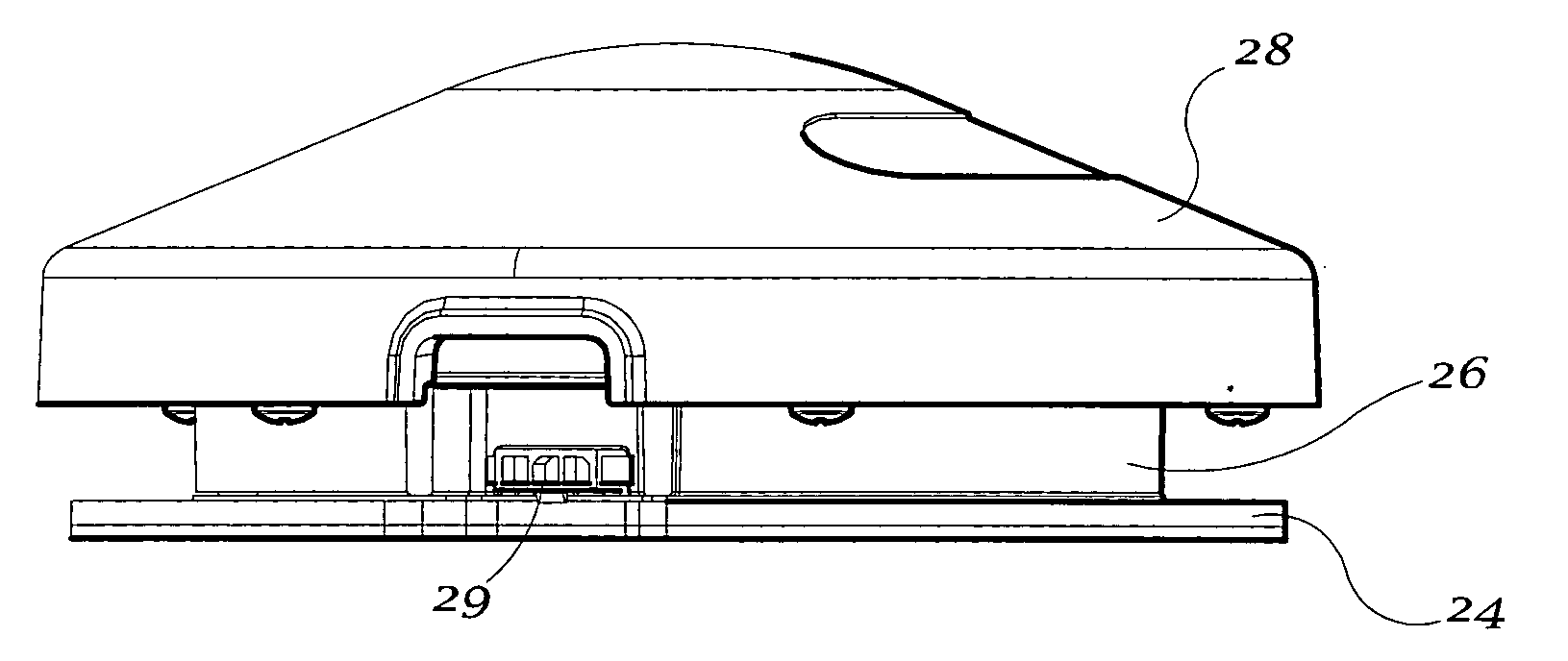

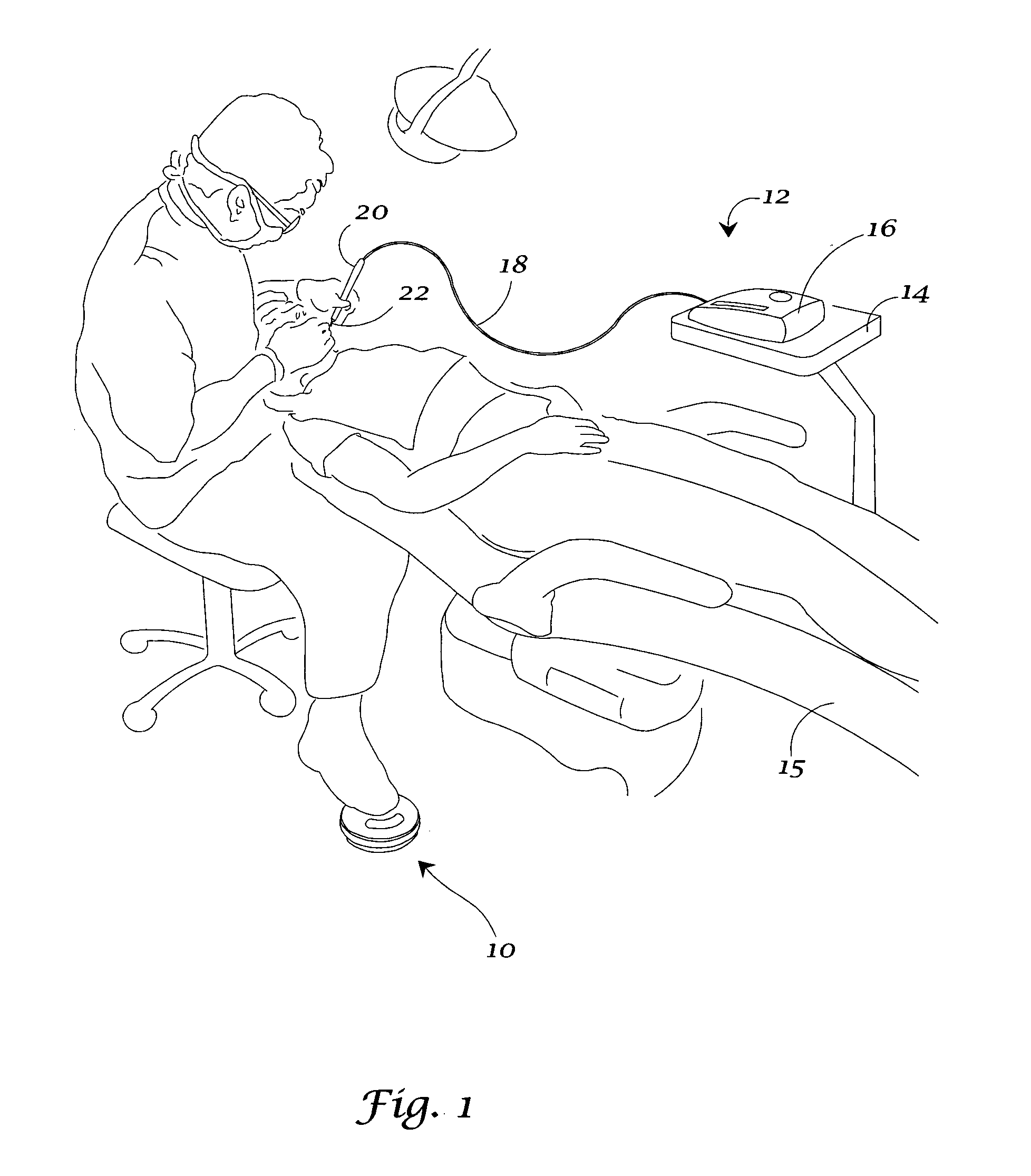

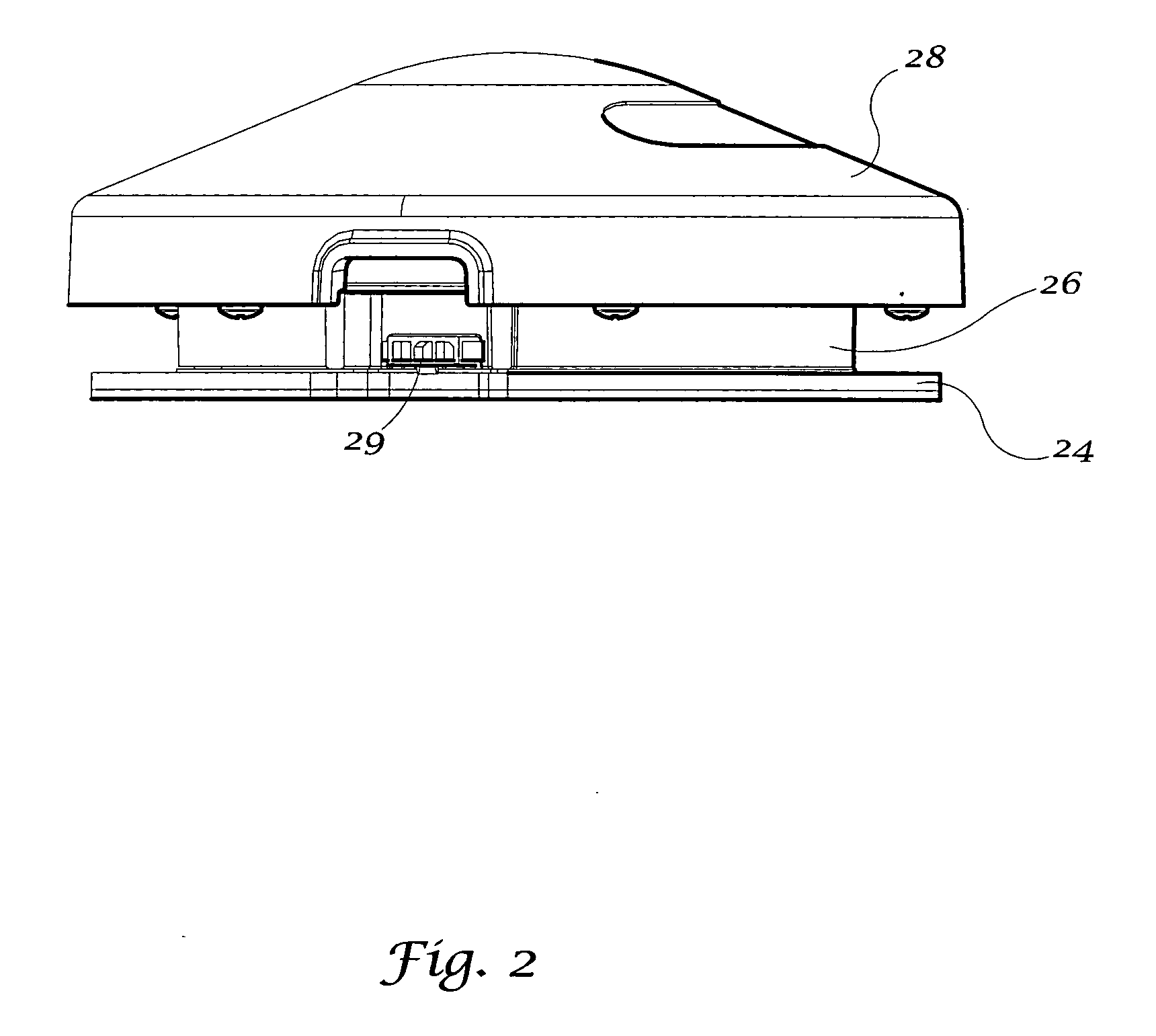

Foot switch for activating a dental or medical treatment apparatus

A foot switch device for activating a dental or medical treatment apparatus is provided. The foot switch device is particularly suitable for controlling an ultrasonic dental scaler. The foot switch device includes a base plate; a central housing attached to the base plate; an upper, moveable cover mounted on the housing; and a connecting collar attached to the upper cover for retaining the cover on the housing while allowing the cover to move upwardly and downwardly relative to the housing. The central housing contains a first electrical switch for transmitting a first signal to the apparatus, and a second electrical switch for transmitting a second signal to the apparatus. An operator depresses the upper cover with his or her foot to activate the switching mechanism and control the operation of the dental or medical apparatus.

Owner:DENTSPLY SIRONA INC

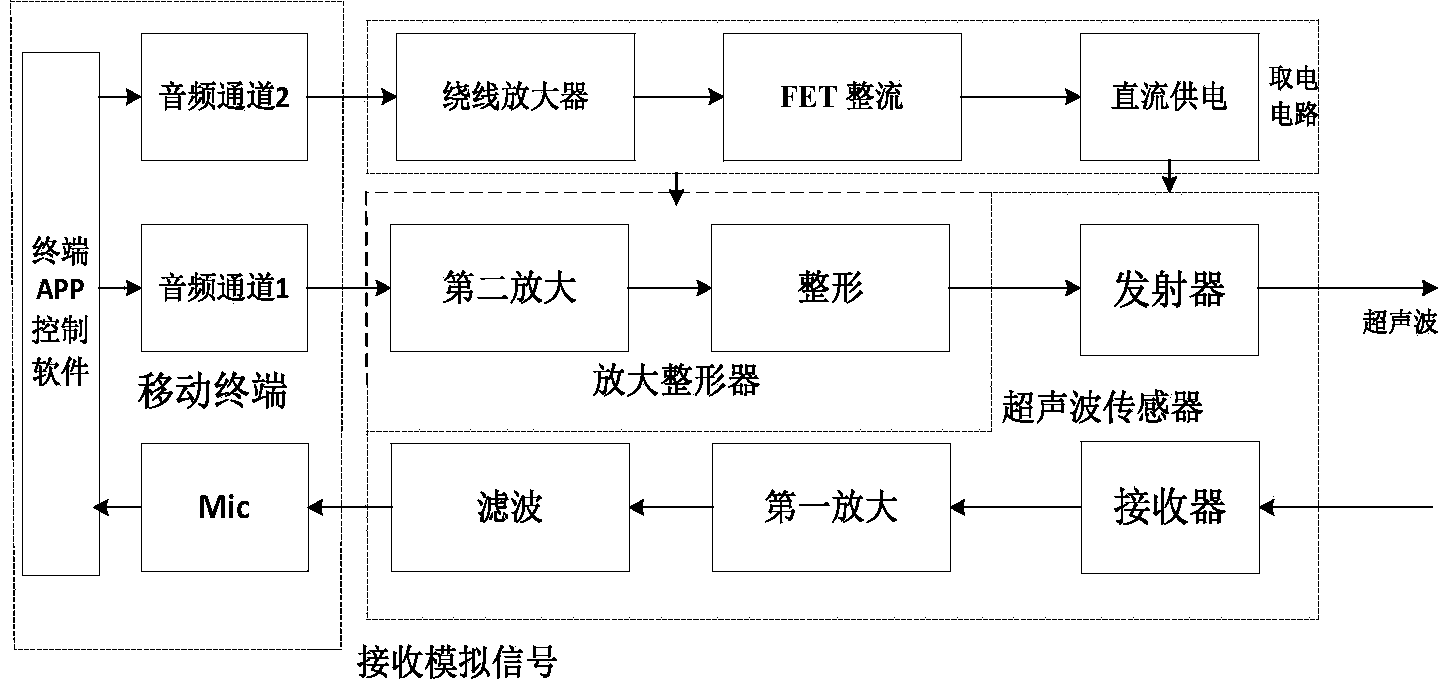

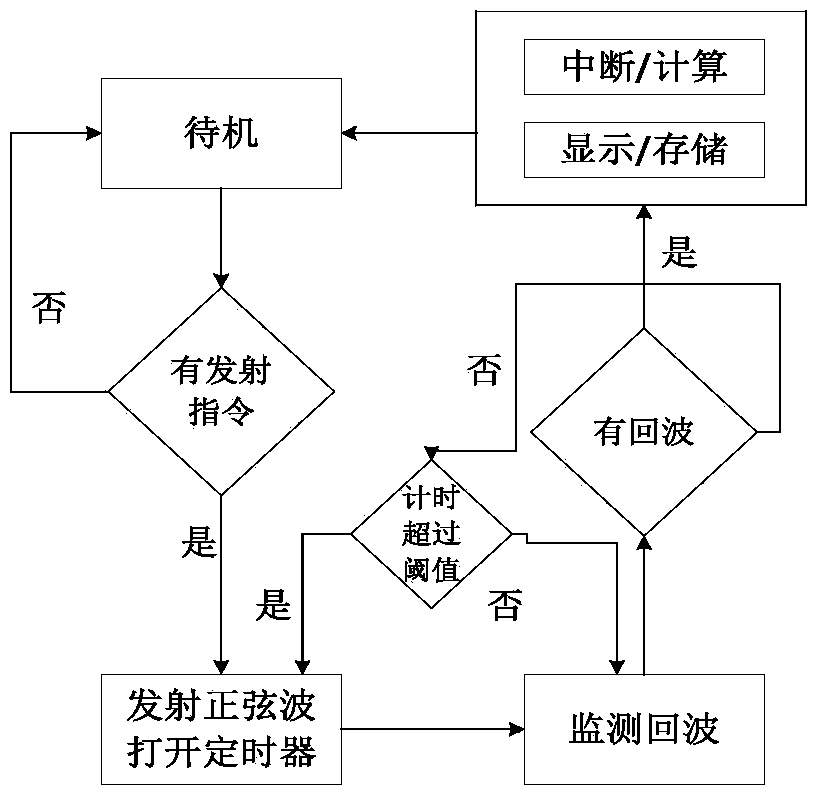

Ultrasonic distance measurement system and method for controlling ultrasonic distance measurement system to measure distance

ActiveCN103869321AFlexible operationReduce volumeProgramme controlComputer controlElectricityAnalog signal

The invention discloses an ultrasonic distance measurement system and a method for controlling the ultrasonic distance measurement system to measure the distance. The ultrasonic distance measurement system comprises an ultrasonic sensor and a mobile terminal, wherein the ultrasonic sensor is used for transmitting an ultrasonic signal to a measurement target and receiving an analog signal reflected by the target; the mobile terminal is used for receiving the analog signal received by the ultrasonic sensor through an audio port of the mobile terminal and carrying out timing operations, the distance is calculated on the basis of the obtained analog signal and a timing result, the obtained distance is stored and displayed, and the ultrasonic sensor is controlled to be started. The mobile terminal is adopted to serve as a processor, a cycle sine wave signal is output to a power obtaining circuit through a second channel of the audio port to serve as a power supply of the ultrasonic sensor, an intermittent power supply strategy is adopted, and electricity is saved; a cycle sine wave signal is transmitted to a transmitter of the ultrasonic sensor through a first channel of the audio port to provide a square signal with proper power for the ultrasonic sensor, and an echo signal of the ultrasonic sensor is received through a fourth channel of the audio port.

Owner:NAT SPACE SCI CENT CAS

Method and apparatus for controlling ultrasound systems

ActiveUS20050054920A1Ultrasonic/sonic/infrasonic diagnosticsWave based measurement systemsSonificationControl ultrasound

A method and system providing control of an ultrasound system with a user interface is provided. The user interface for controlling the ultrasound system includes a plurality of selectable elements for controlling operation of the ultrasound system and a plurality of identifiers. Each identifier corresponds to one of the plurality of selectable elements and associates control commands with the selectable elements.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

Ultrasonic probe intelligent continuous scanner and scanning method thereof

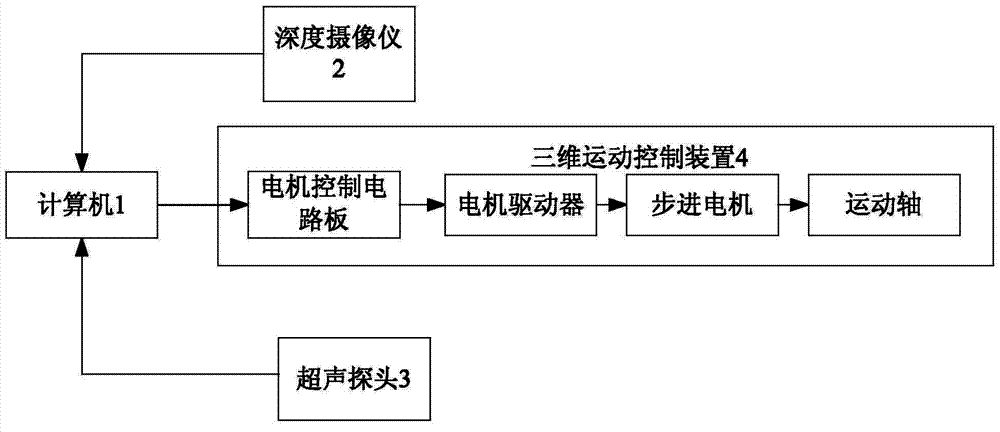

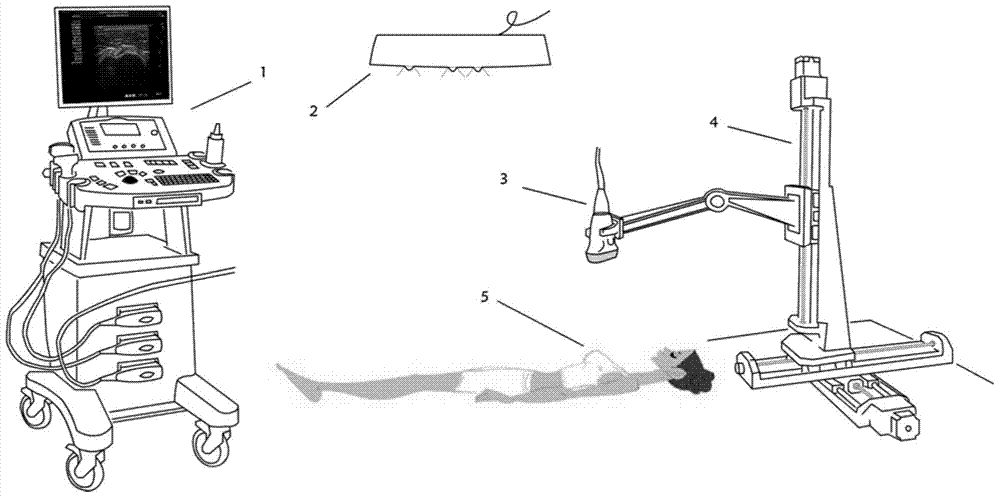

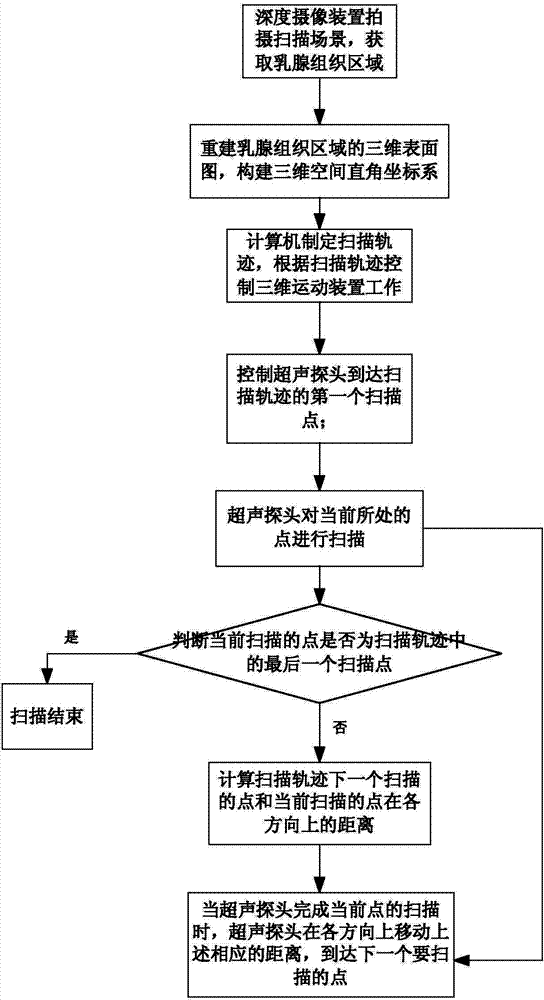

InactiveCN103690191AOvercomes the difficulty of scanning tissue with uniform pressureEnsure safetyUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsContinuous scanningControl ultrasound

The invention discloses an ultrasonic probe intelligent continuous scanner and a scanning method thereof. The ultrasonic probe intelligent continuous scanner comprises a computer and an ultrasonic probe connected with the computer, and also comprises a depth camera device and a three-dimensional motion control device which are connected with the computer; the ultrasonic probe is arranged on the three-dimensional motion control device used for controlling the ultrasonic probe to perform three-dimensional motion. A three-dimensional surface image is established according to the images shot by the depth camera device, and then the scanning tract of the ultrasonic probe is made, so the ultrasonic probe is always attached onto a scanned tissue with a uniform pressure in the scanning process, the defect that the tissue can not be scanned with the uniform pressure by a mechanical driving scanning mode in the prior art is overcome, and the safety of an inspected object is ensured. The ultrasonic probe intelligent continuous scanner and the scanning method thereof can be used in multiple fields of three-dimensional ultrasonic reestablishing, three-dimensional elastic imaging and the like, and have very large application value and prospect.

Owner:SOUTH CHINA UNIV OF TECH

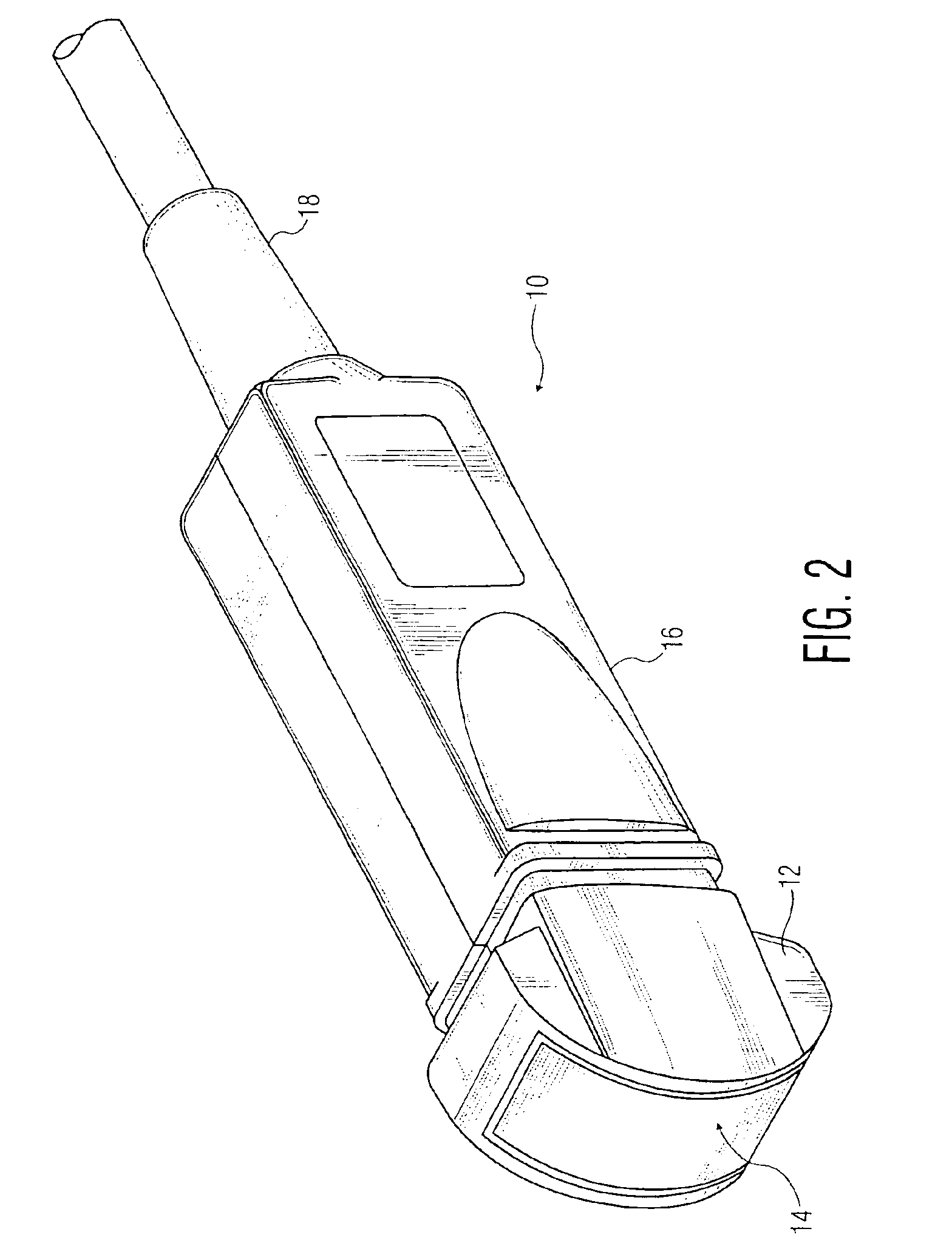

Connection apparatus and method for controlling an ultrasound probe

ActiveUS20050154312A1Ultrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringControl ultrasound

A connection apparatus and method for controlling an ultrasound probe are provided. The ultrasound probe includes a first chamber, a second chamber, a sealing member between the first and second chambers and a flexible connection member within each of the first and second chambers. The ultrasound probe further comprises a rigid connection interface forming at least part of the sealing member and connecting the flexible connection member in the first chamber with the flexible connection member in the second chamber.

Owner:GENERAL ELECTRIC CO

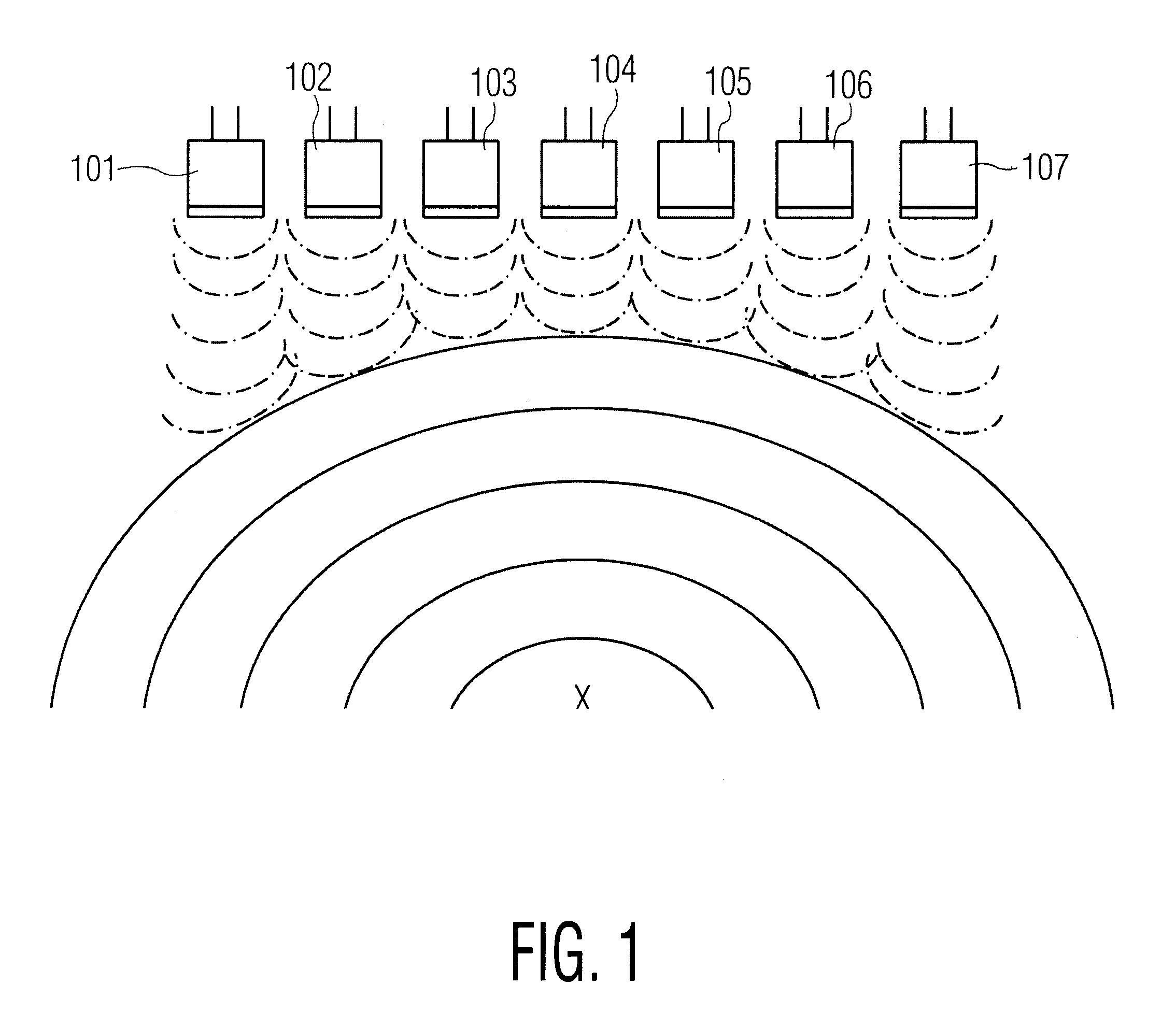

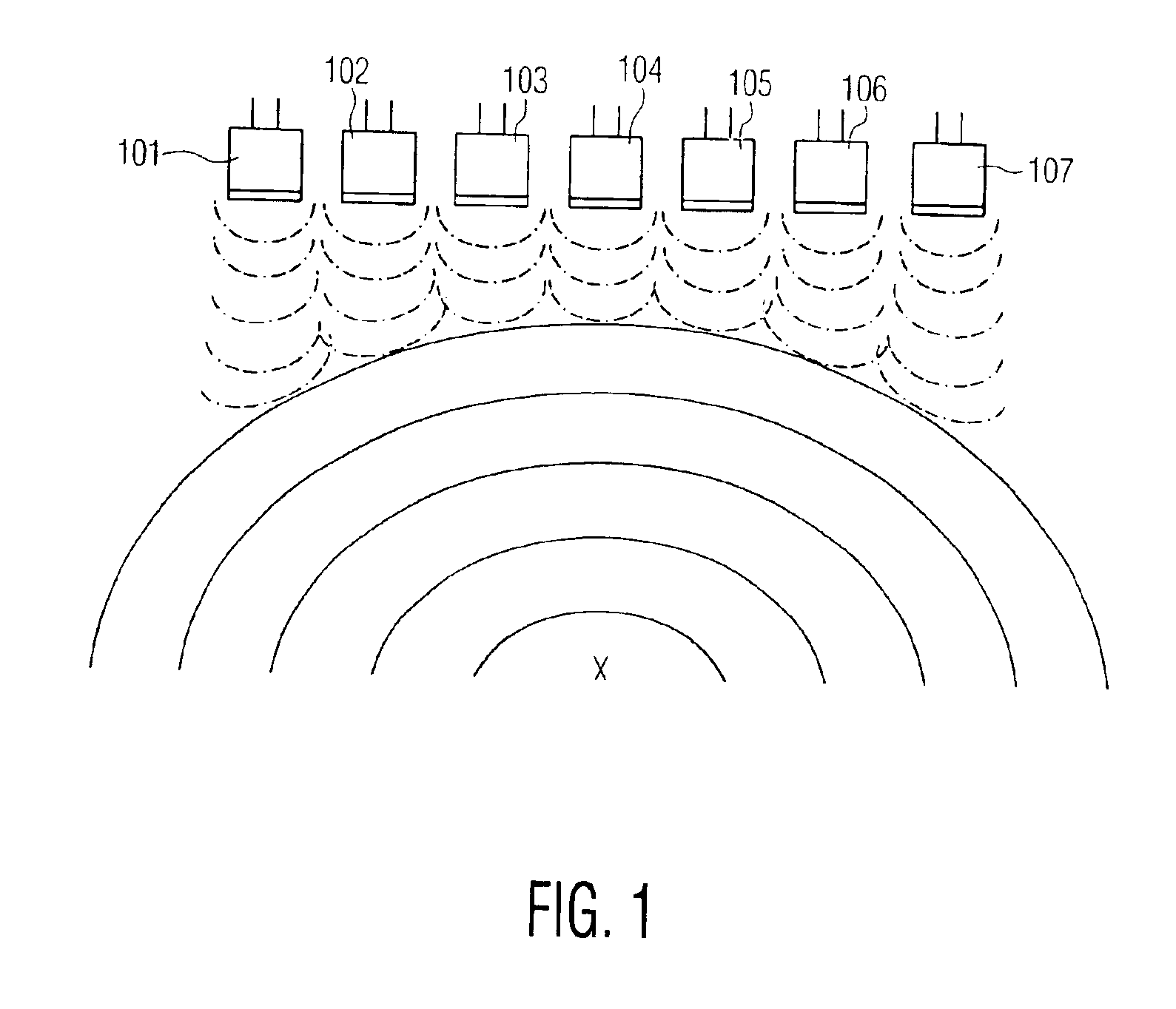

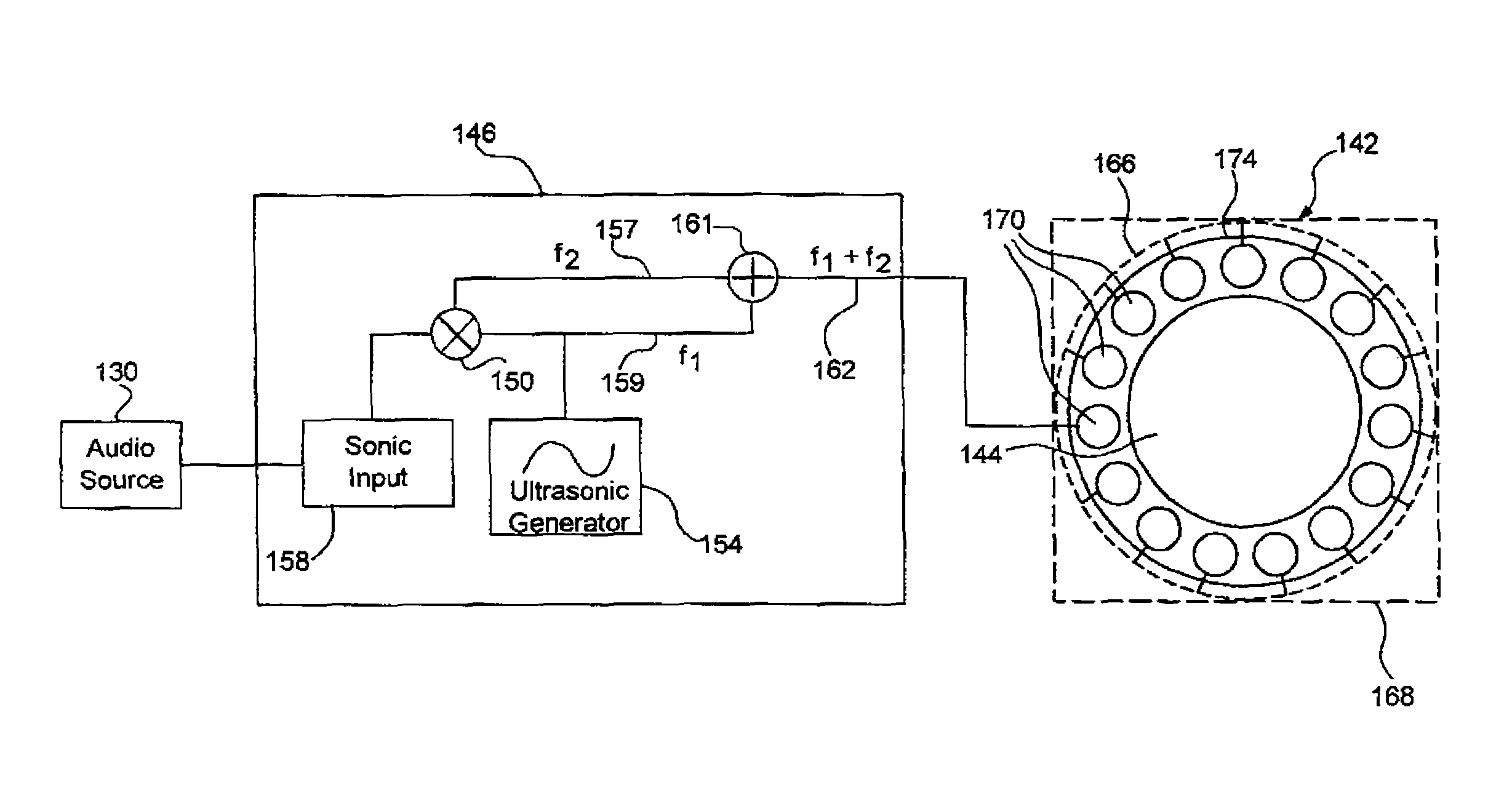

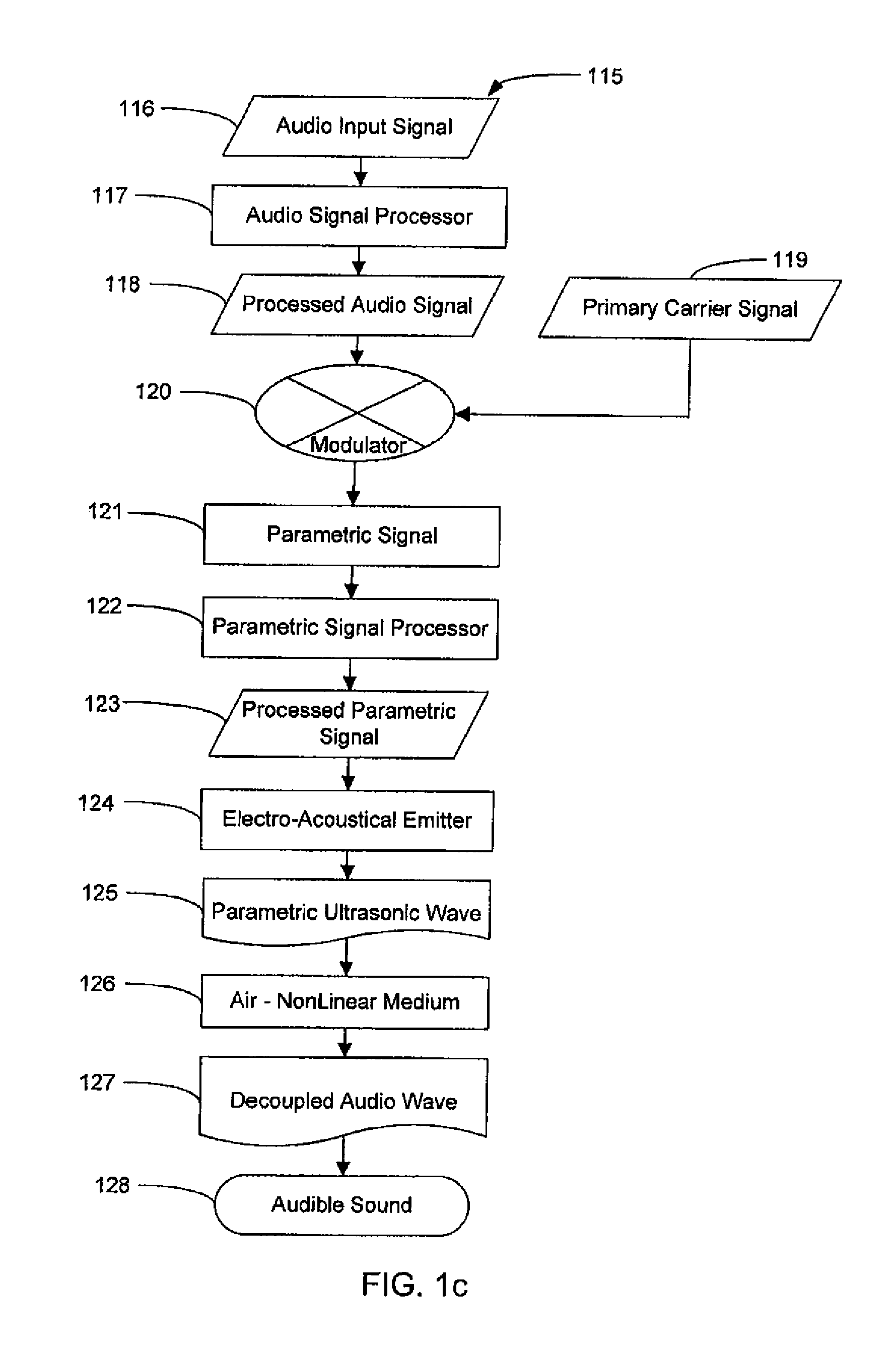

Parametric loudspeaker with improved phase characteristics

InactiveUS8199931B1Increase productionOutput maximizationPiezoelectric/electrostrictive transducersMagnetostrictive transducersSonificationCarrier signal

A method is disclosed for increasing a parametric output of a parametric loudspeaker system. The method can include the operation of providing multiple ultrasonic frequency emission zones that output signals in a frequency band. The phase relationships of the ultrasonic frequency emission zones can be correlated and controlled to increase phase coherence between each ultrasonic frequency emission zone to maximize parametric output. Correlating and controlling the phase relationships can include offsetting a frequency of a carrier signal applied to each emission zone from a resonant frequency of each emission zone in view of a rate of change of phase of each emission zone in a vicinity of each resonant frequency. Ultrasonic energy from the ultrasonic frequency emission zones can be generated, using the correlated phase relationship to increase the parametric output.

Owner:TURTLE BEACH

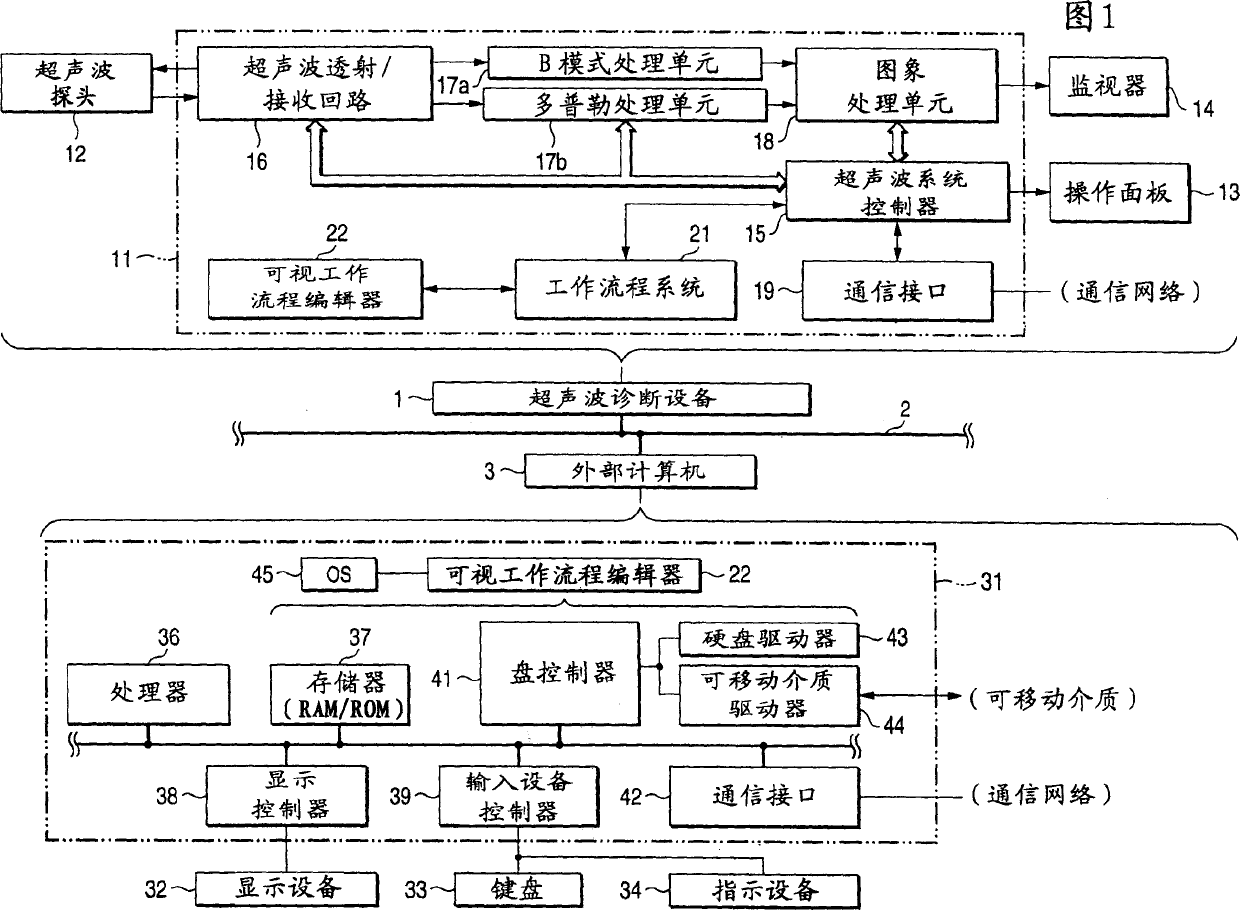

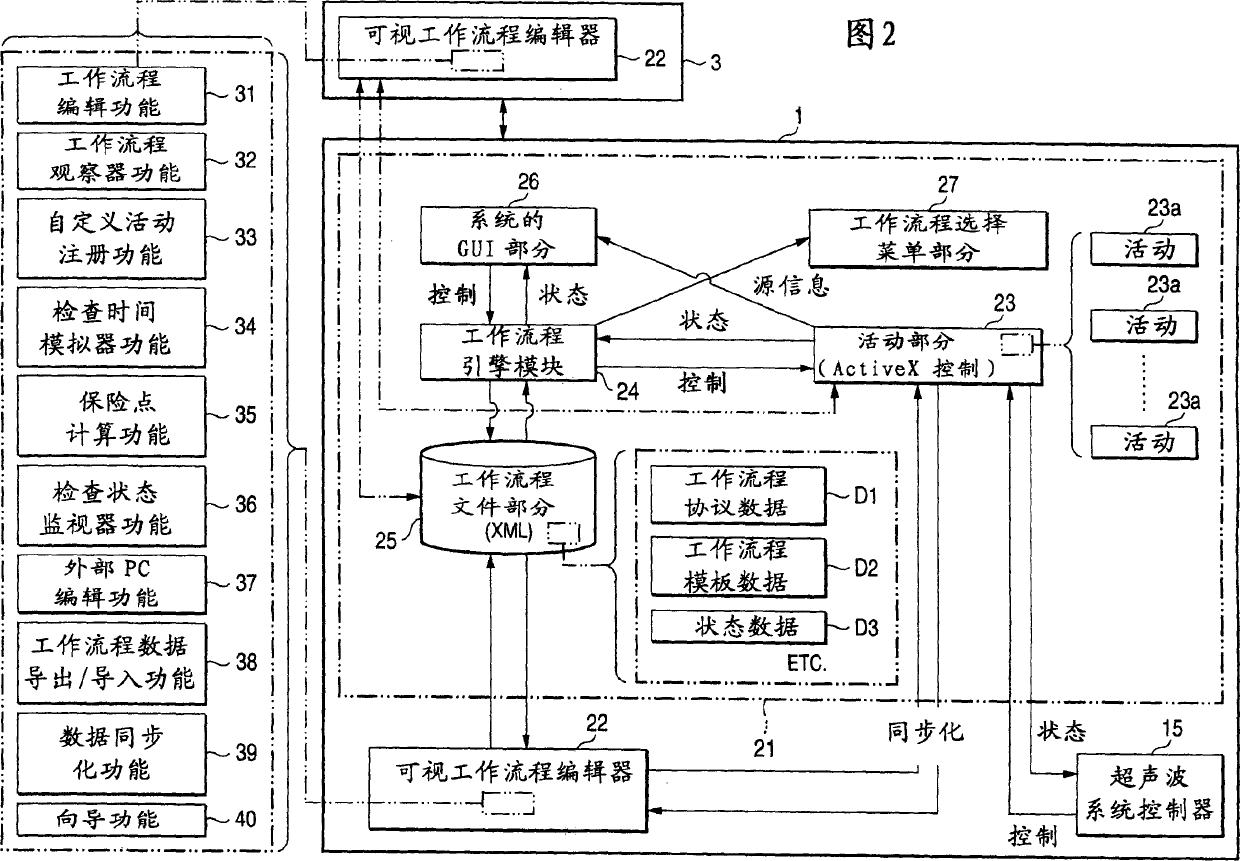

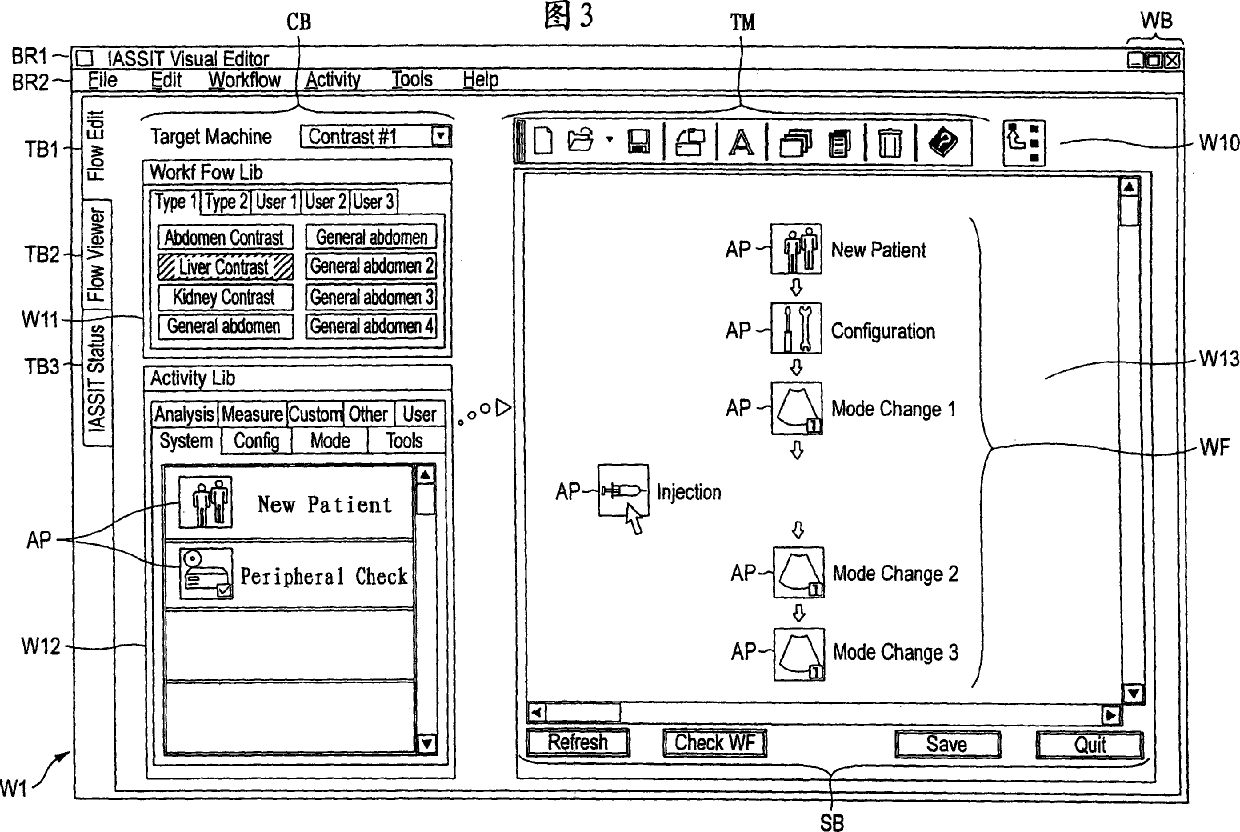

Ultrasonograph, work flow edition system, and ultrasonograph control method

InactiveCN1558738AWave based measurement systemsBlood flow measurement devicesControl ultrasoundExamination procedure

Owner:KK TOSHIBA

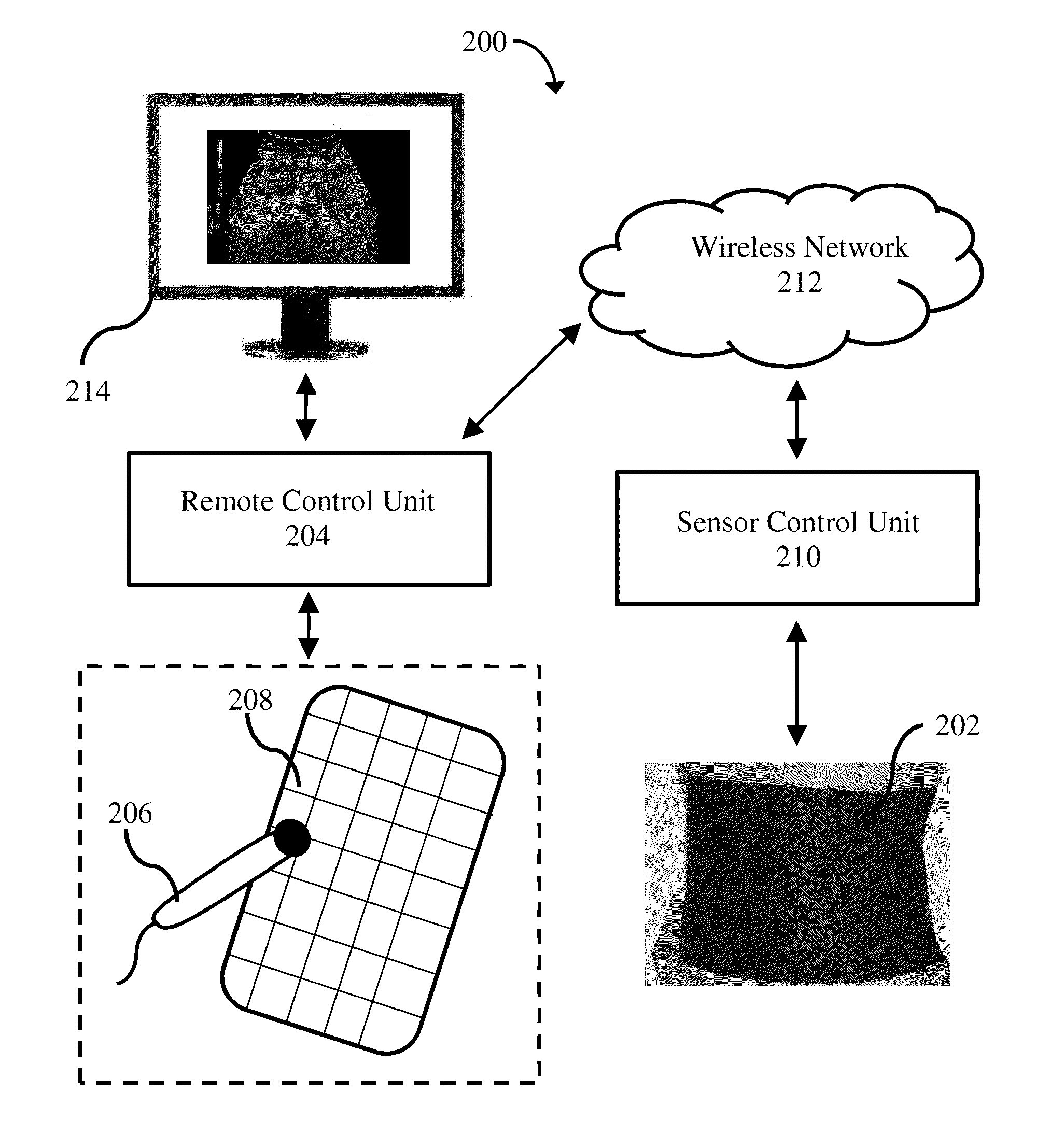

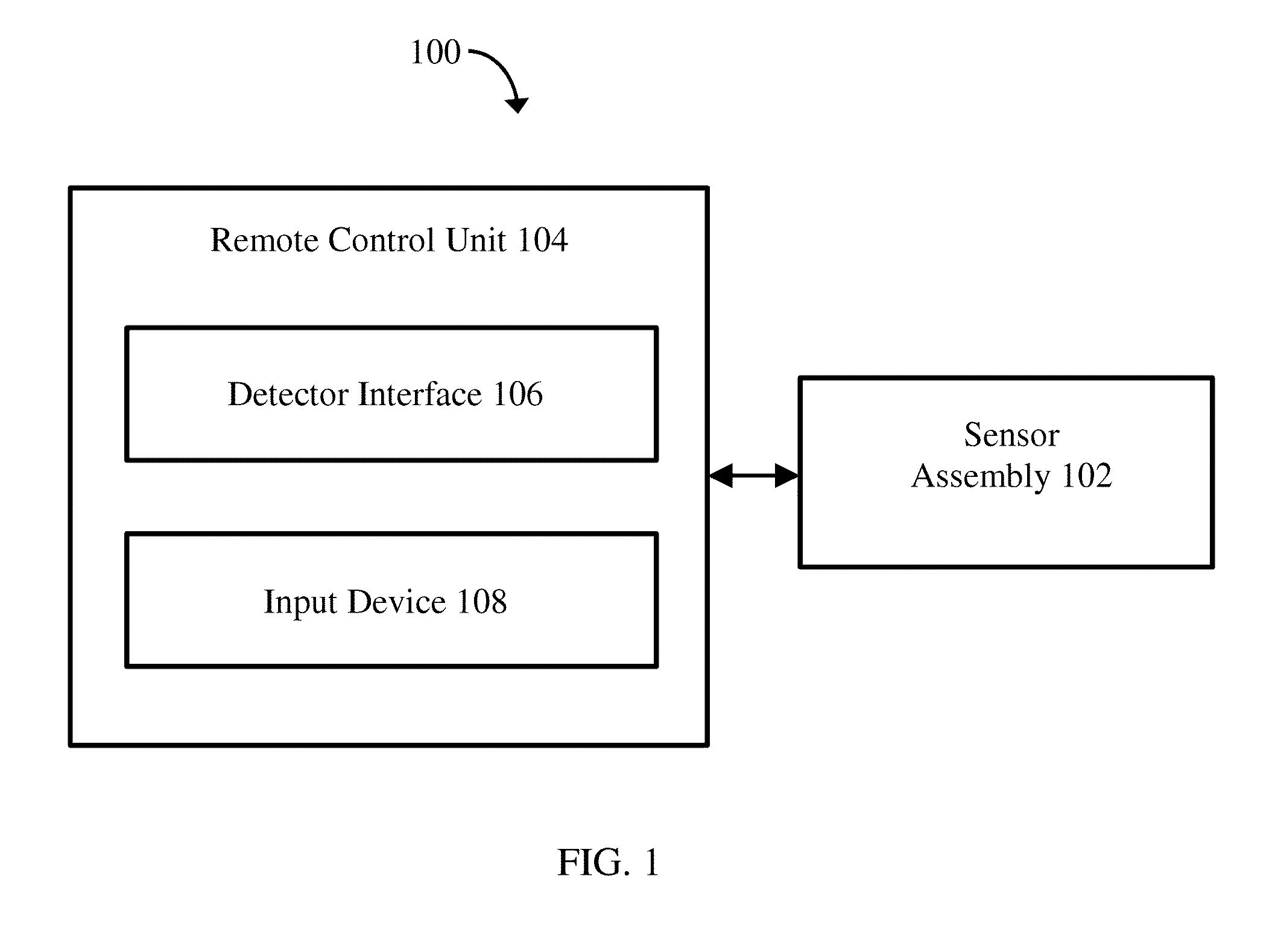

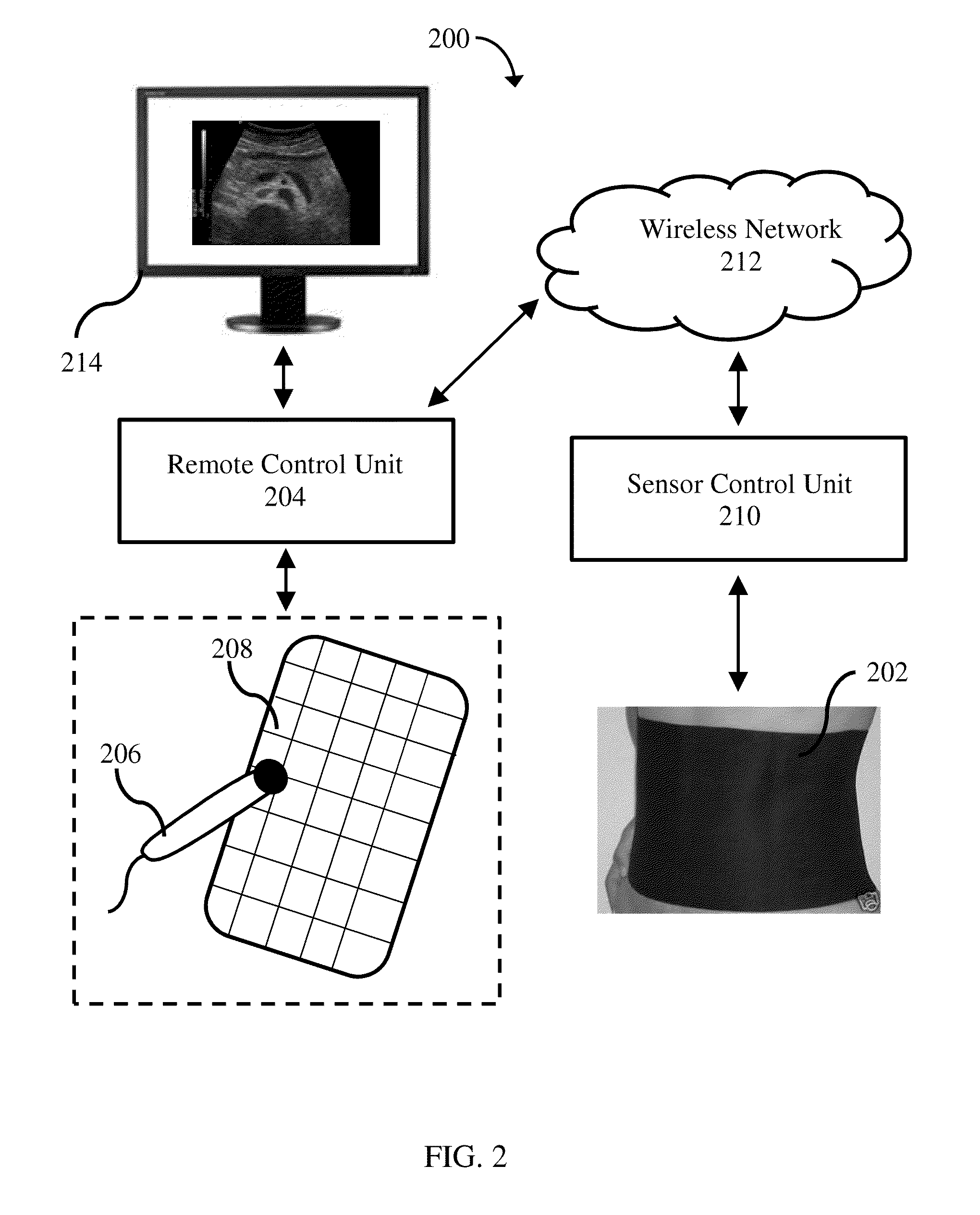

Remotely controlled ultrasound apparatus and ultrasound treatment system

An ultrasound apparatus comprising a sensor assembly configured to be positioned on a patient body portion, the sensor assembly comprises an array of sensors configured to be activated to acquire a plurality of images of the patient body portion, and a remote control unit comprising a detector interface configured to communicate wirelessly with the sensor assembly, and an input device operable by a user to interact with the detector interface, the input device is configured to transmit a plurality of input signals to the sensor assembly, wherein at least one input signal of the plurality of input signals activates at least one sensor of the array of sensors to acquire at least one image of the plurality of images.

Owner:GENERAL ELECTRIC CO

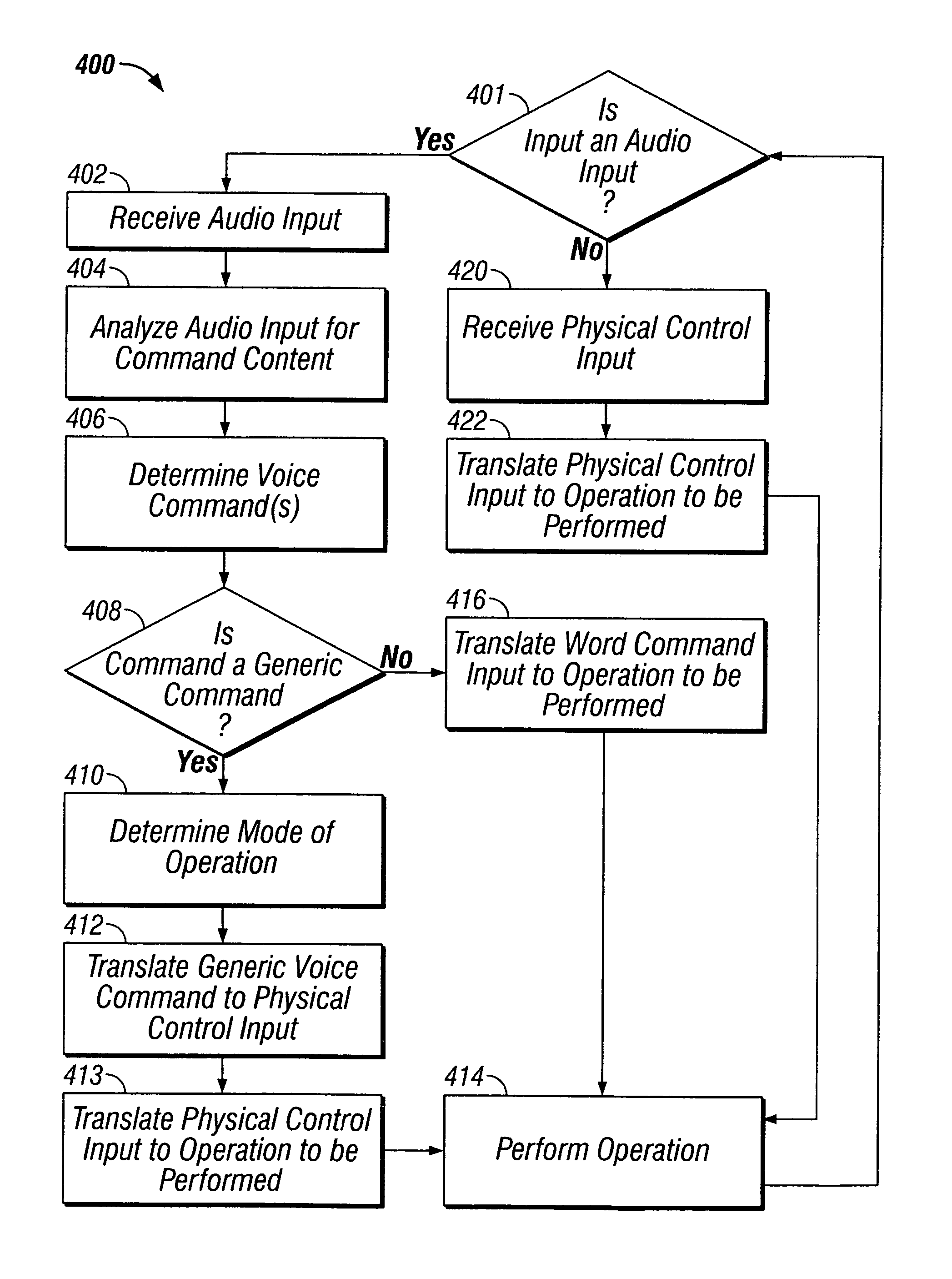

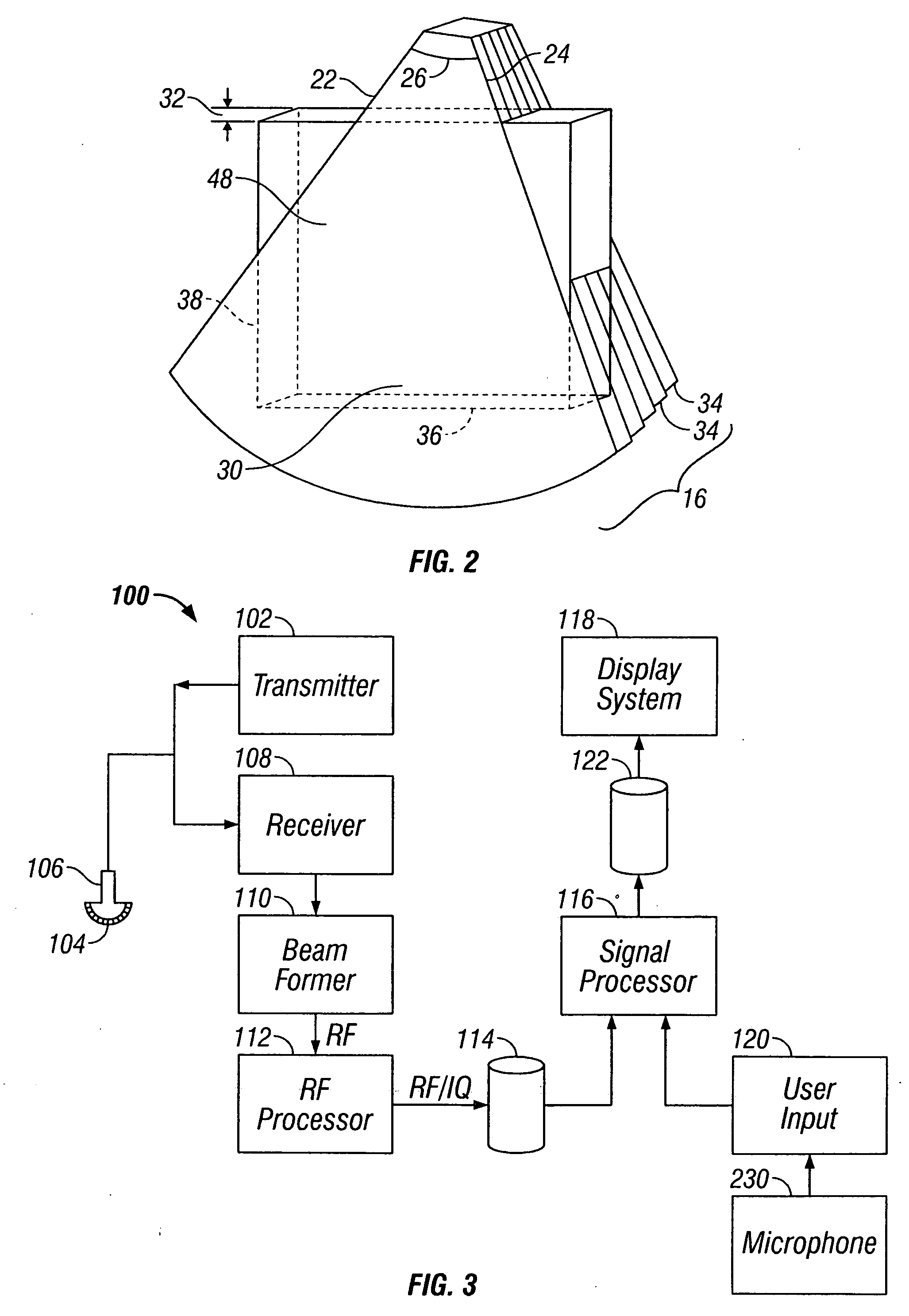

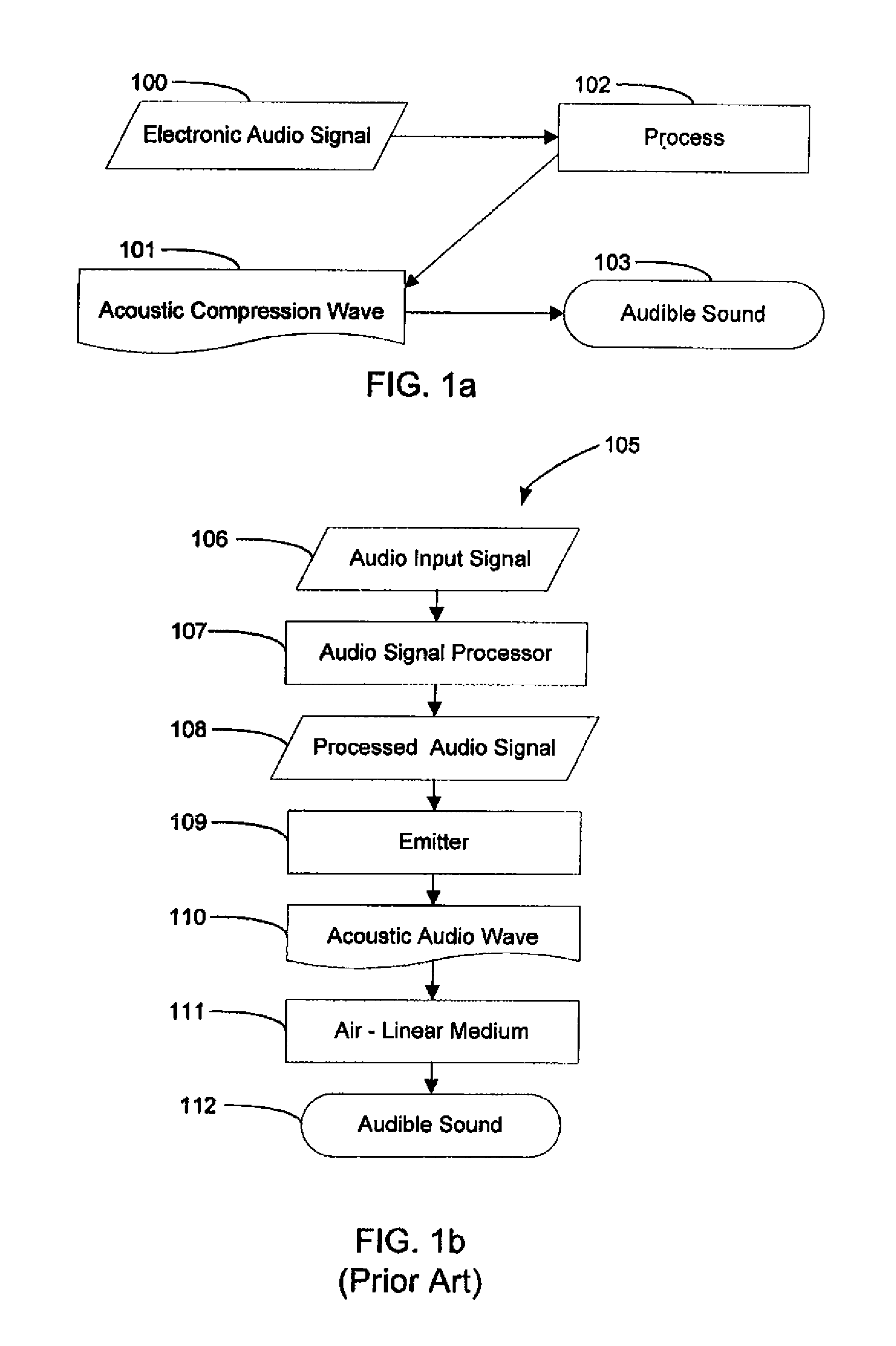

Ultrasound imaging system with voice activated controls using remotely positioned microphone

InactiveCN101427154AUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsUltrasound imagingSonification

An ultrasound imaging system includes a direction- tracking microphone that is able to determine the direction of a voice command and to cause the microphone to selectively receive acoustic inputs from the determined direction. A voice recognition then interprets the voice command and controls the operation of the ultrasound imaging system accordingly. The direction tracking microphone may, for example, select one of several unidirectional microphones that receives the loudest signal or a phased array of omnidirectional microphones.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

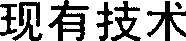

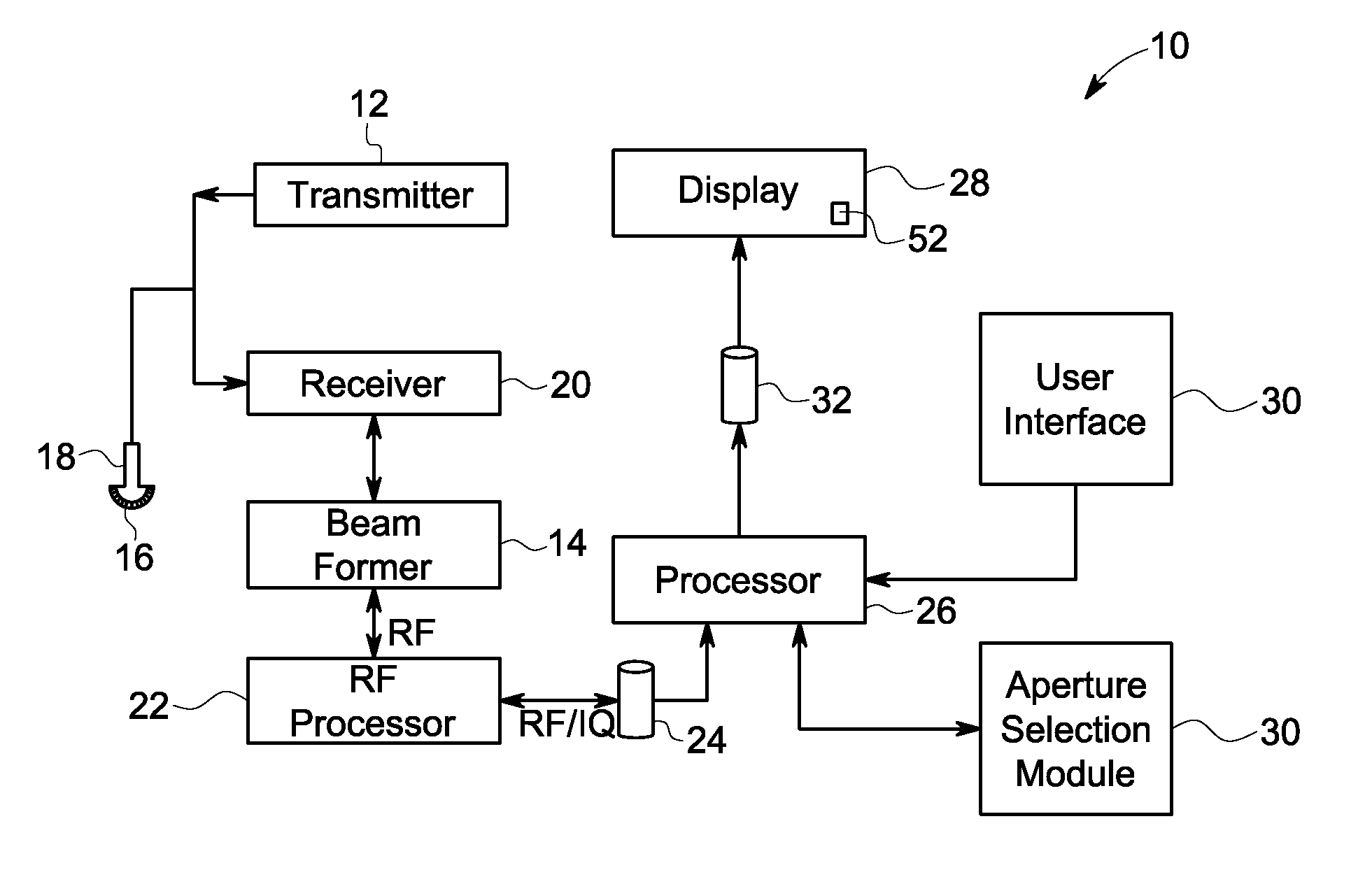

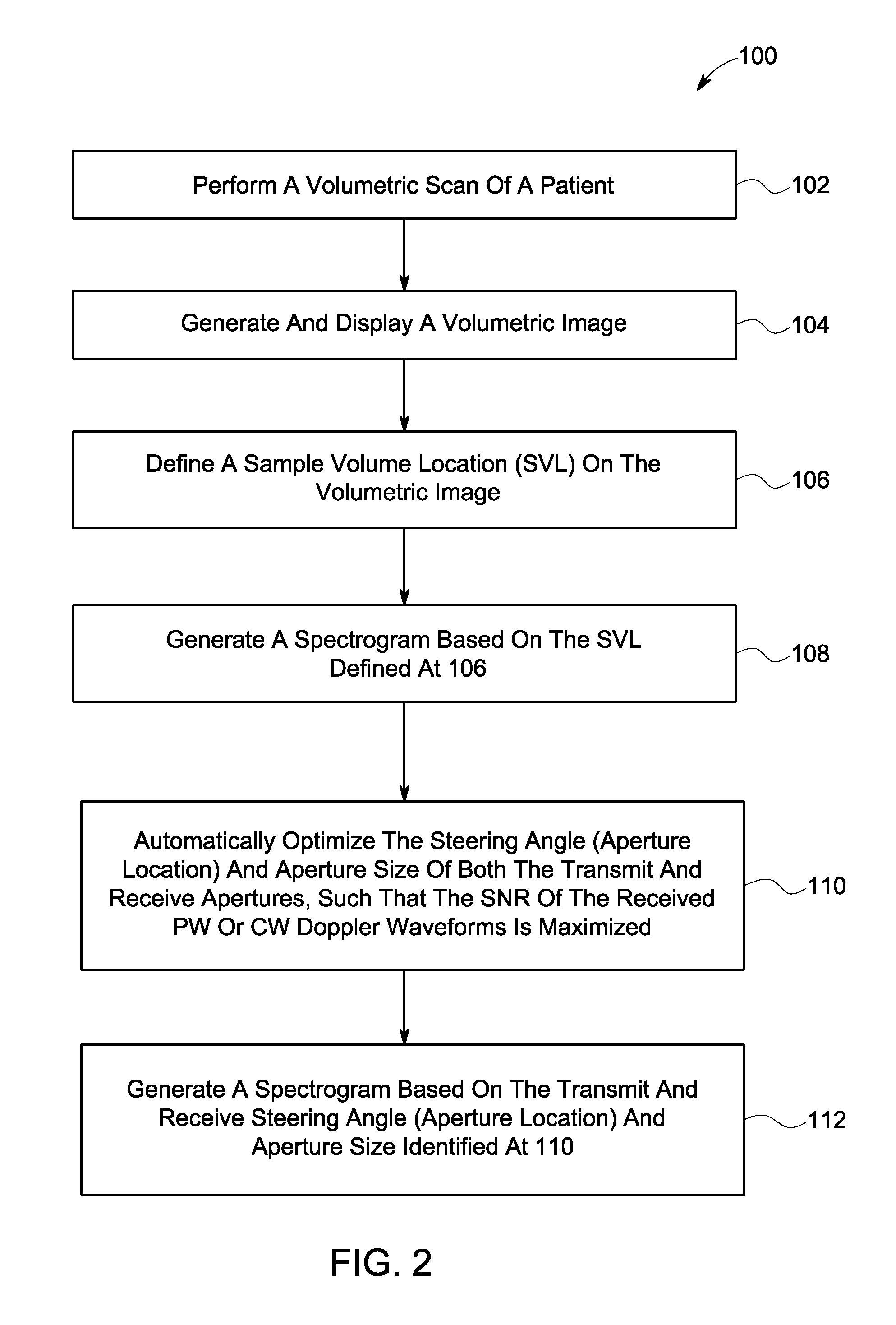

Method and apparatus for aperture selection in ultrasound imaging

A method for controlling an ultrasound imaging system includes defining a sample volume gate on a two-dimensional (2D) ultrasound image, the sample volume gate defining a location at which flow is to be estimated, automatically calculating a SNR for an initial transmit and receive steering position (aperture location) and aperture size, automatically calculating a SNR for a different second transmit and receive steering position (aperture location) and aperture size, automatically comparing the SNR for the first set of apertures to the SNR for the second set of apertures, and automatically adjusting the steering angle and an aperture size of an ultrasound probe's transmit and receive events based on the comparison.

Owner:GENERAL ELECTRIC CO

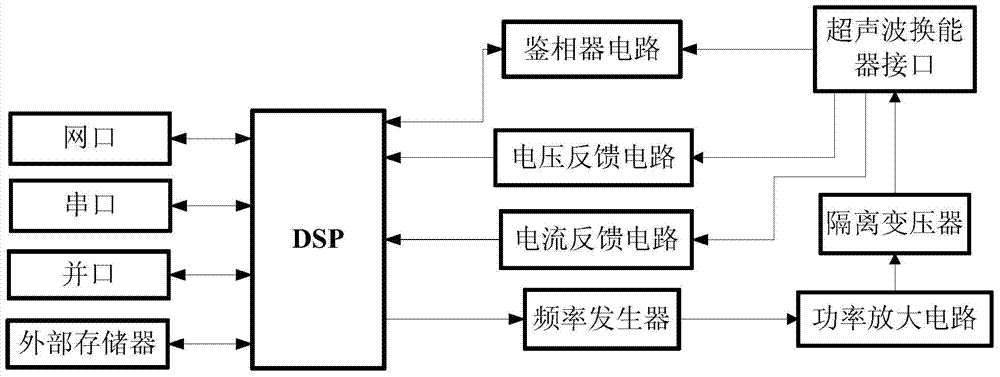

Ultrasonic transducer driving power supply

InactiveCN104516290AImprove energy conversion efficiencyImprove bonding qualityProgramme controlComputer controlDigital signal processingUltrasonic sensor

The invention provides an ultrasonic transducer driving power supply comprising a frequency generator, a phase discriminating circuit and a digital signal processor. The frequency generator is controlled by a control signal and used for outputting a driving signal to an ultrasonic transducer; the phase discriminating circuit is used for generating the control signal and performing phase locking according to a phase discrimination result; according to the control signal generated after phase locking, the digital signal processor is capable of controlling the frequency generator to output the driving signal enabling the ultrasonic transducer to generate resonance. The digital signal processor controls the frequency generator to sweep frequency for the ultrasonic transducer, the phase discriminating circuit discriminates the phase of the output signal of the ultrasonic transducer in the process, then the digital signal process determines resonance frequency of the ultrasonic transducer according to the phase discrimination result and outputs the control signal via phase locking, the frequency generator can control the ultrasonic transducer to maintain operation under the resonance condition, and accordingly energy conversion efficiency of the ultrasonic transducer is improved.

Owner:CETC BEIJING ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com