Patents

Literature

208results about How to "Constant power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

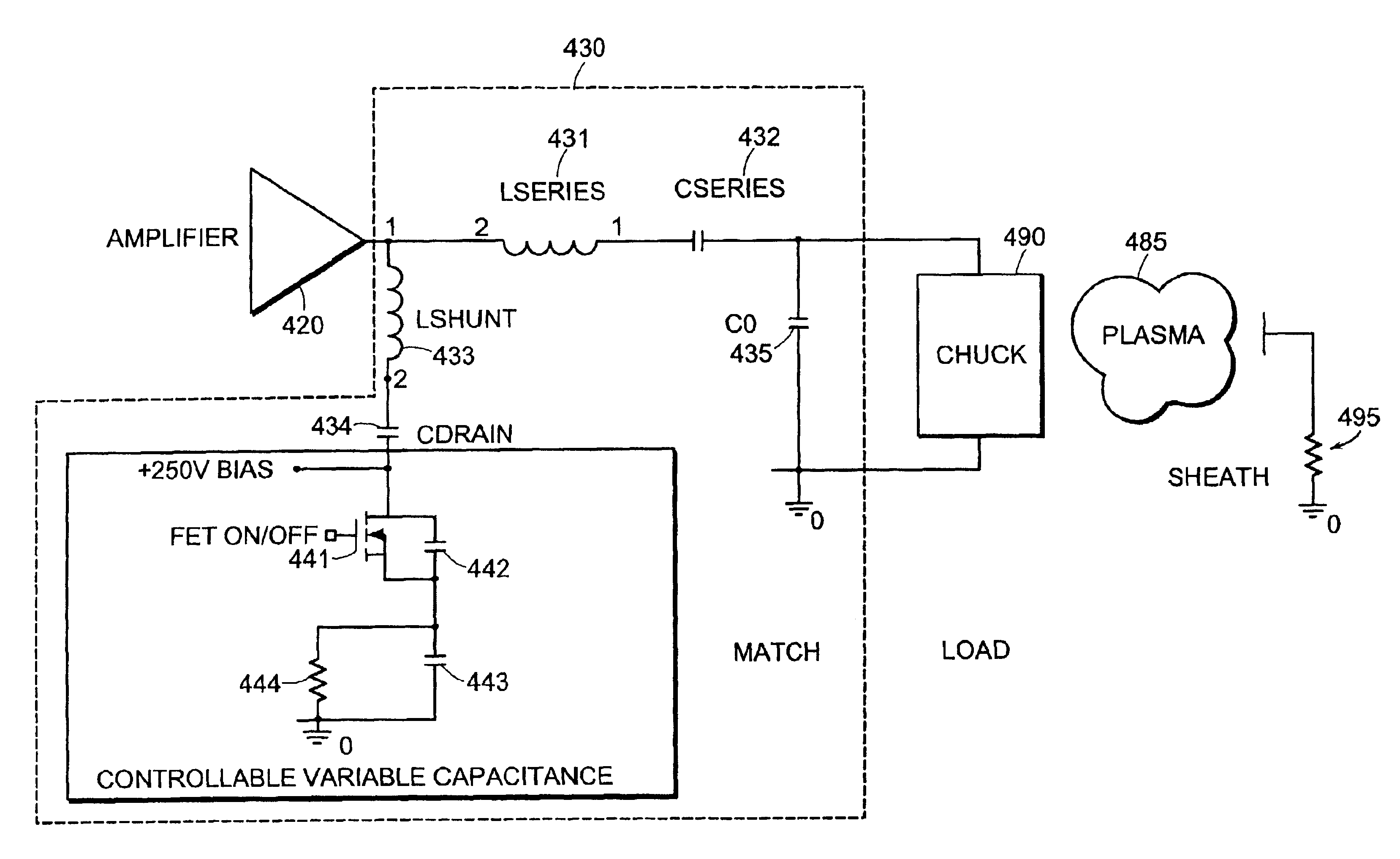

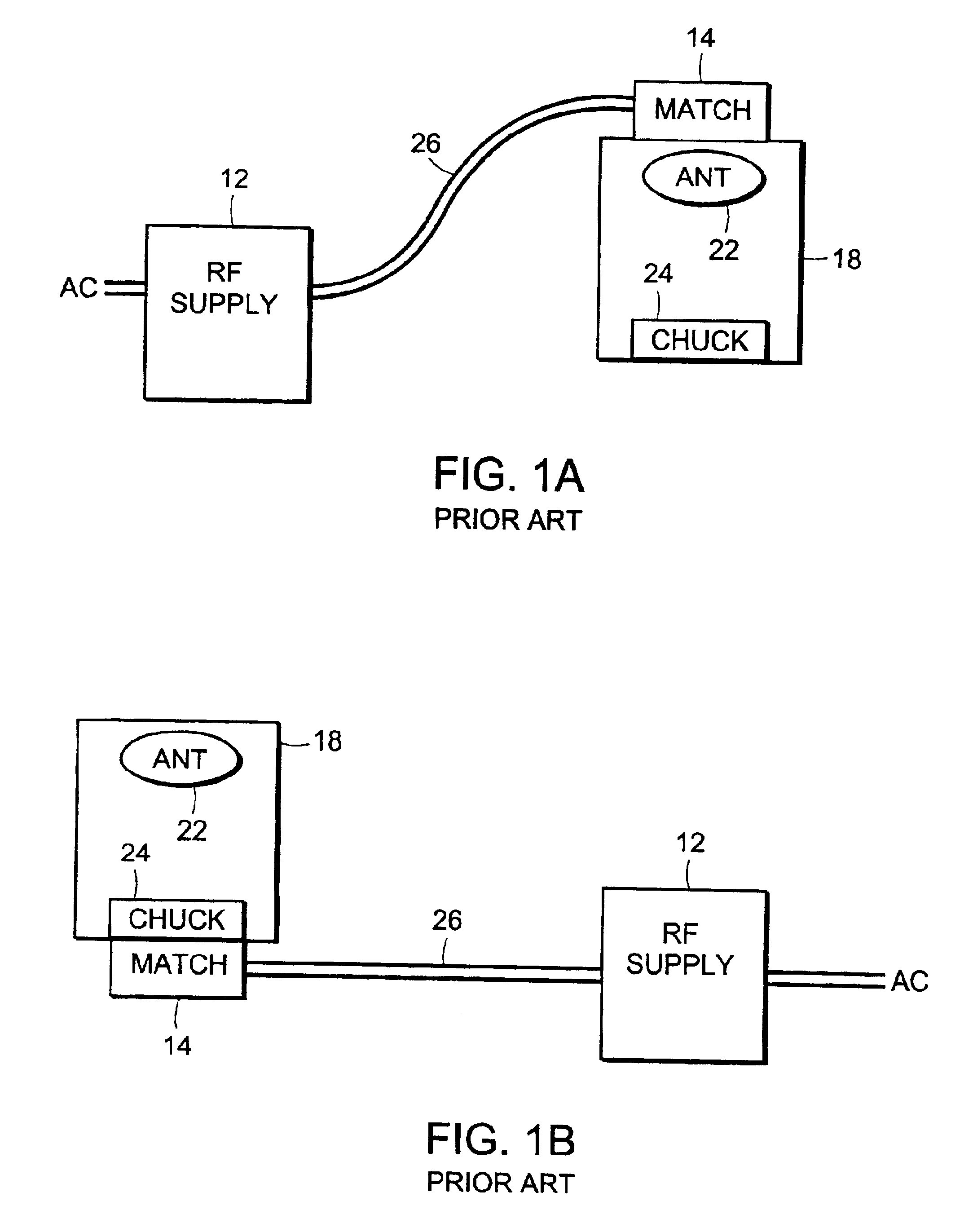

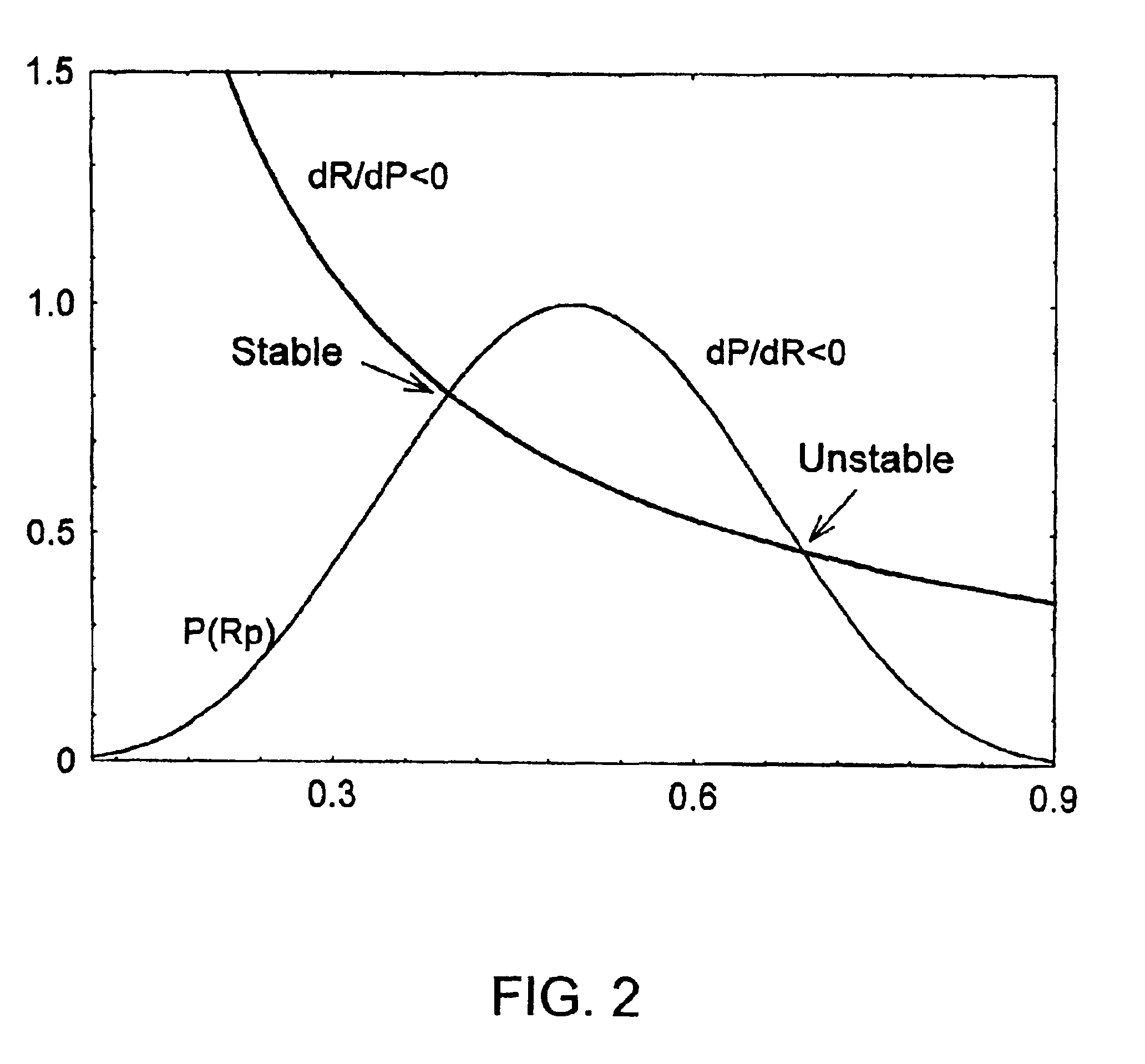

RF power supply with integrated matching network

InactiveUS6887339B1Eliminate useConstant powerMultiple-port networksElectric discharge tubesElectromagnetic couplingPlasma generator

The invention features an RF plasma generator. The RF plasma generator includes a variable frequency RF generator, comprising an H-bridge and an RF output. The RF generator generates electromagnetic radiation having a power. The RF plasma generator further includes a matching network that includes at least one variable impedance component. The matching network also includes a first port that is electromagnetically coupled to the output of the RF generator and a second port. The RF plasma generator also includes a load that is electromagnetically coupled to the second port of the matching network, and a plasma chamber for containing a plasma having a power. The plasma chamber is electromagnetically coupled to the load and receives electromagnetic radiation having a power from the load. Adjusting at least one of the frequency of the RF generator and the variable impedance component in the matching network changes the power in the plasma.

Owner:MKS INSTR INC

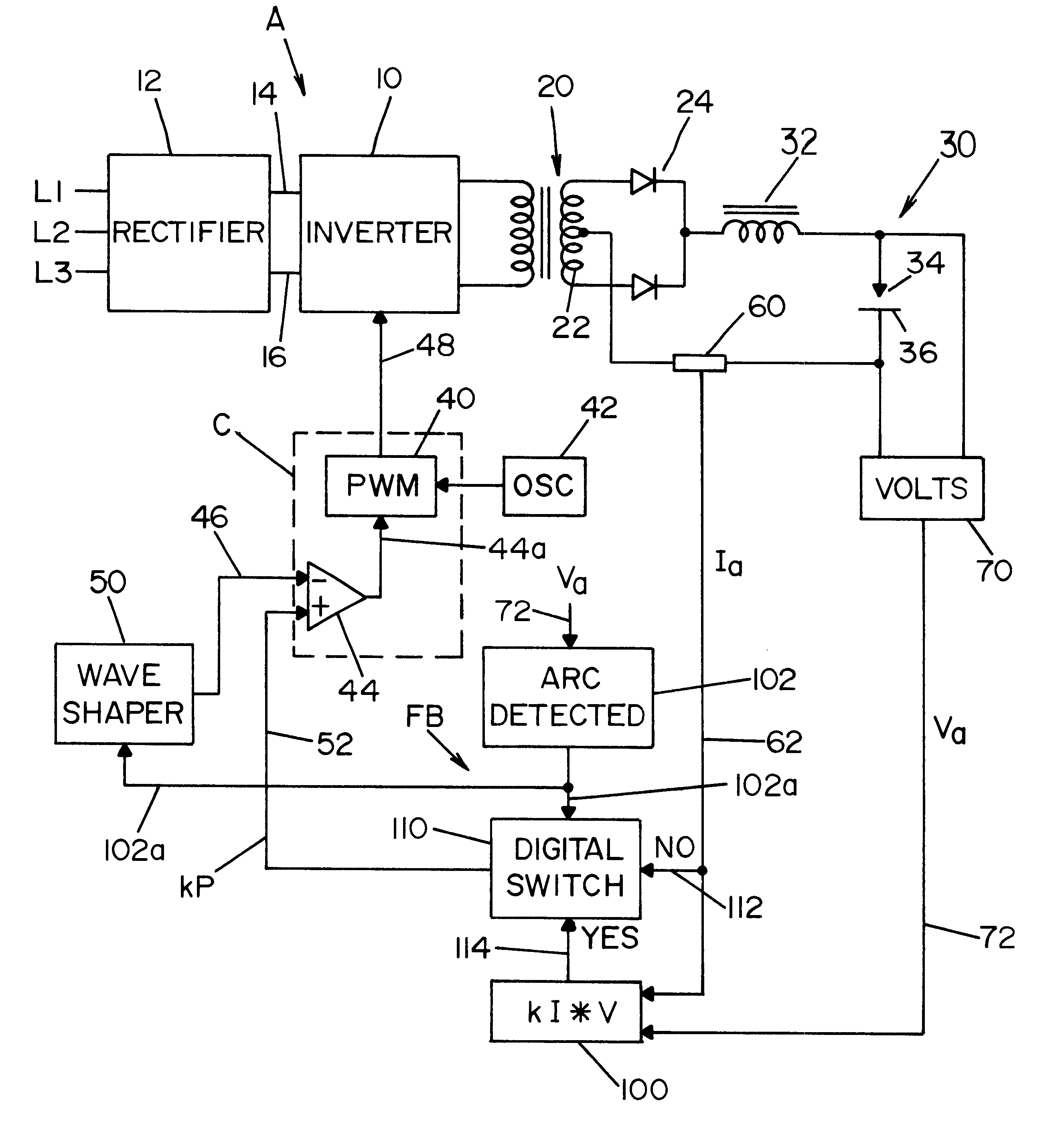

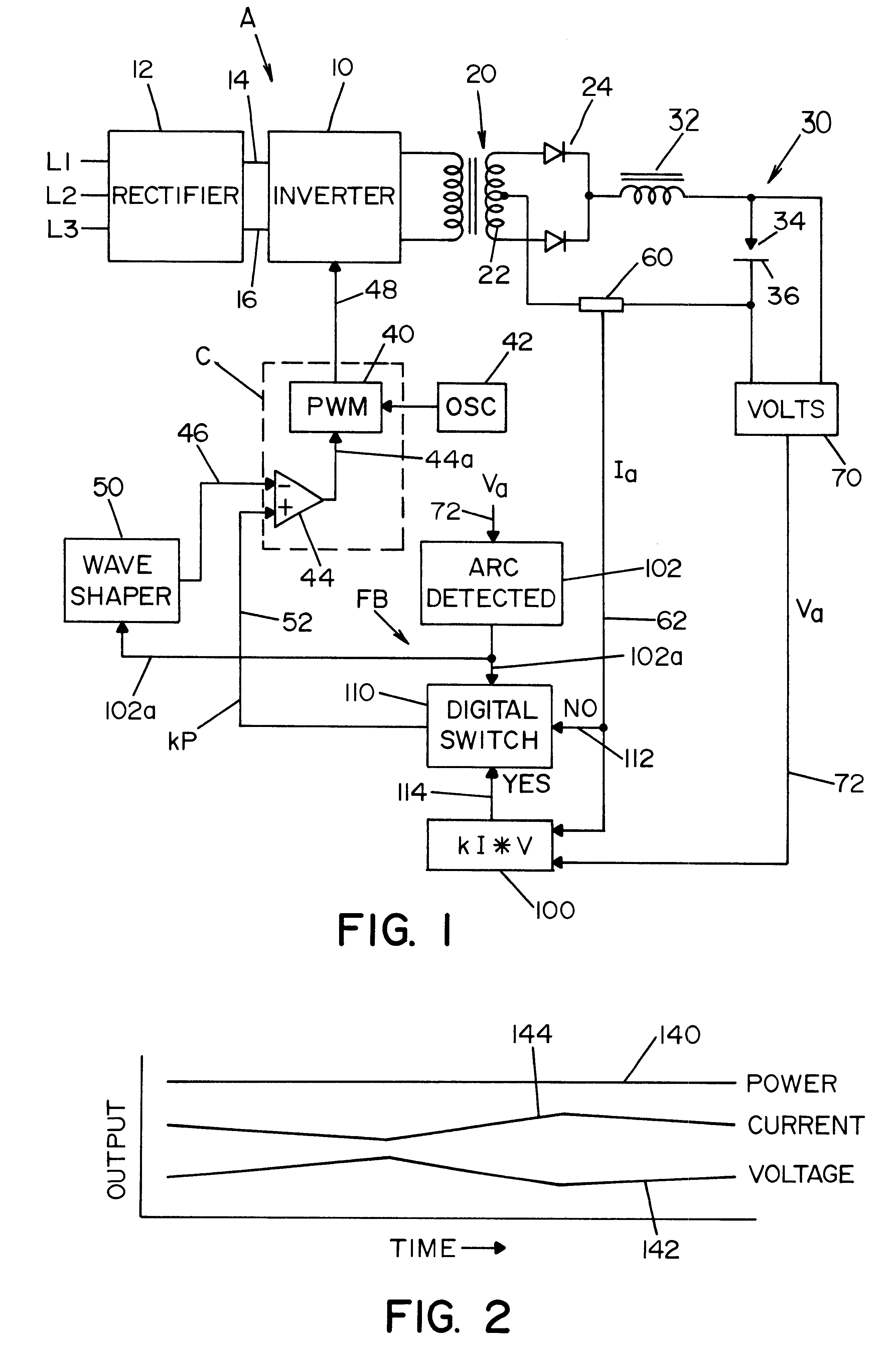

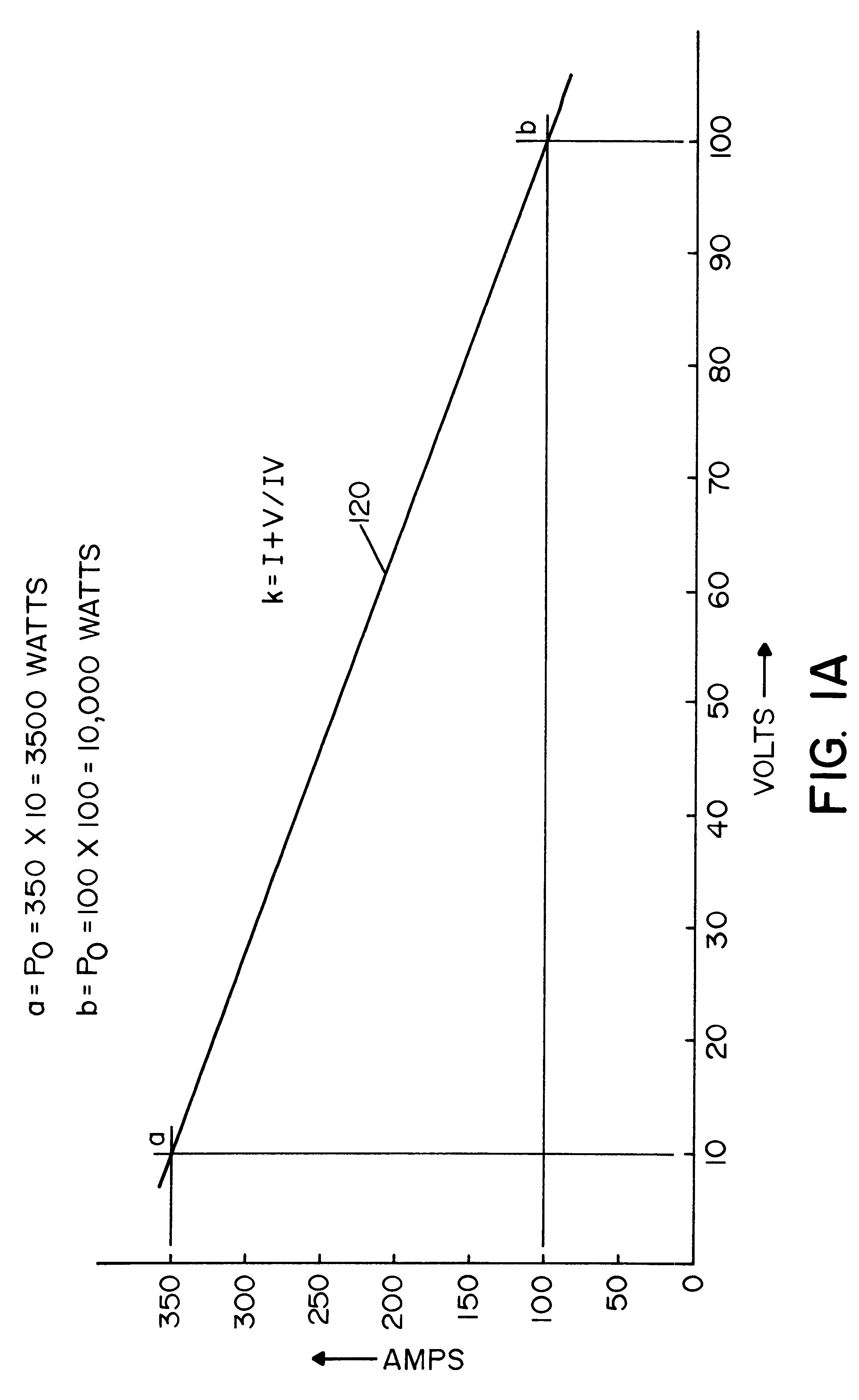

System and method for controlling an electric arc welder

InactiveUS6498321B1Inhibit currentRealize automatic adjustmentArc welding apparatusControl signalControl system

A control system for an electric arc welder performing a welding process between an electrode and a workpiece, which system comprises: a high speed switching type power supply with a controller operated at a switching frequency of at least about 10 kHz with an input current control signal to adjust the output current of the power supply; a first sensor sensing the actual arc voltage; a second sensor sensing the actual arc current; a first circuit for creating a power signal representing the desired real time power level at progressive times during the welding process; a second circuit for creating a function of the sensed actual voltage and the sensed actual current; and a third circuit for adjusting the current control signal in accordance with the difference between the power signal and the function of the actual voltage and current, preferably arc power.

Owner:LINCOLN GLOBAL INC

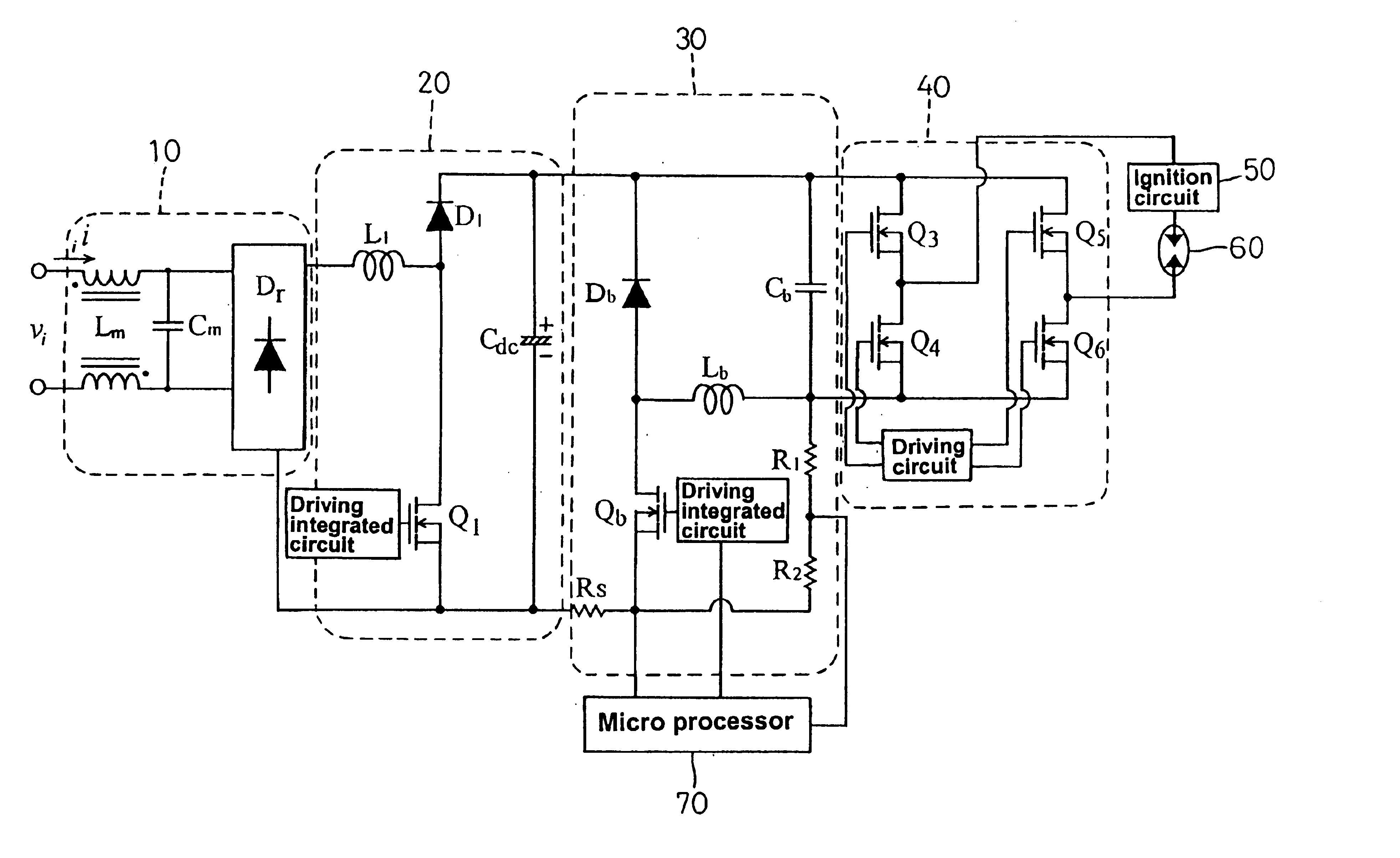

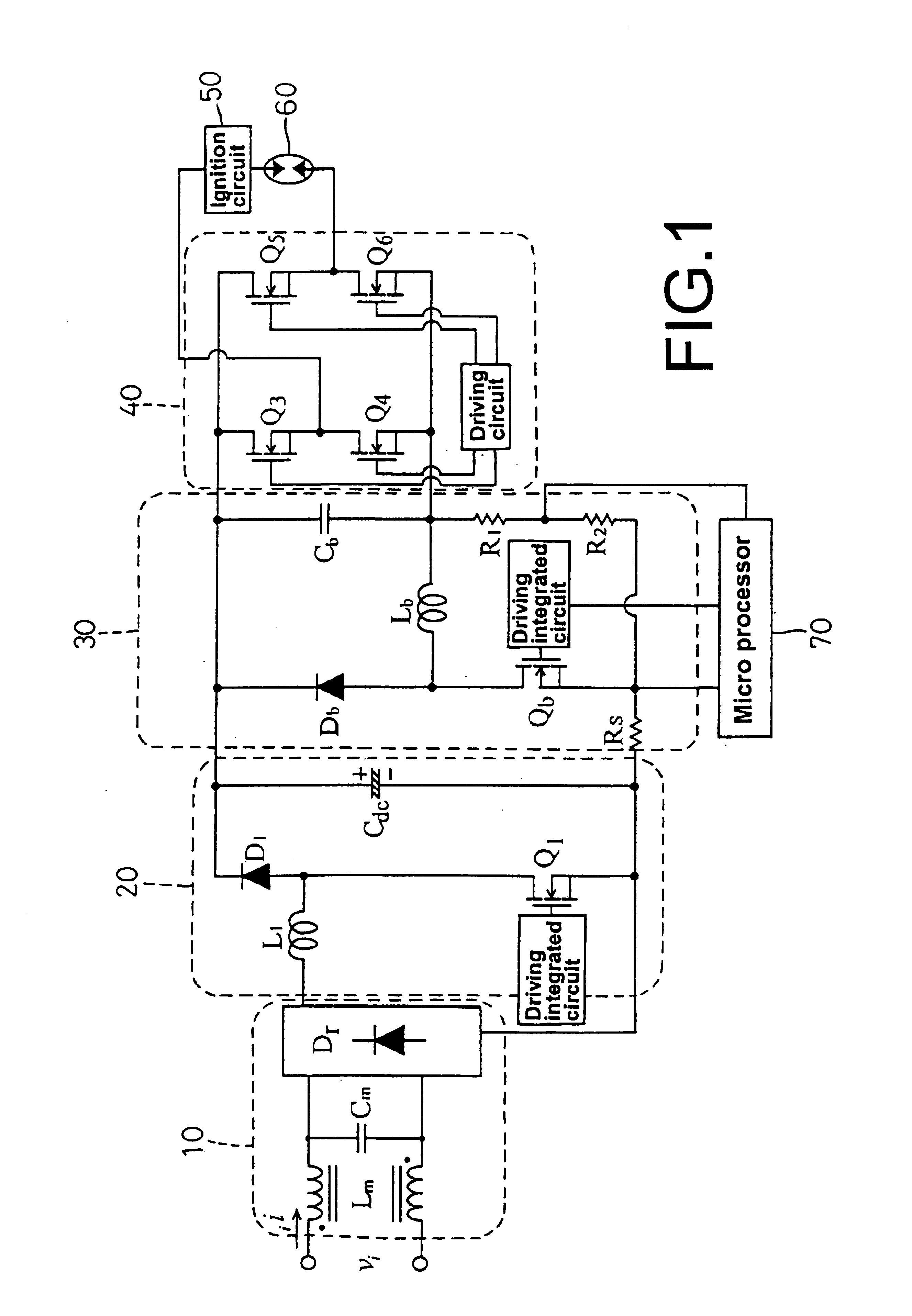

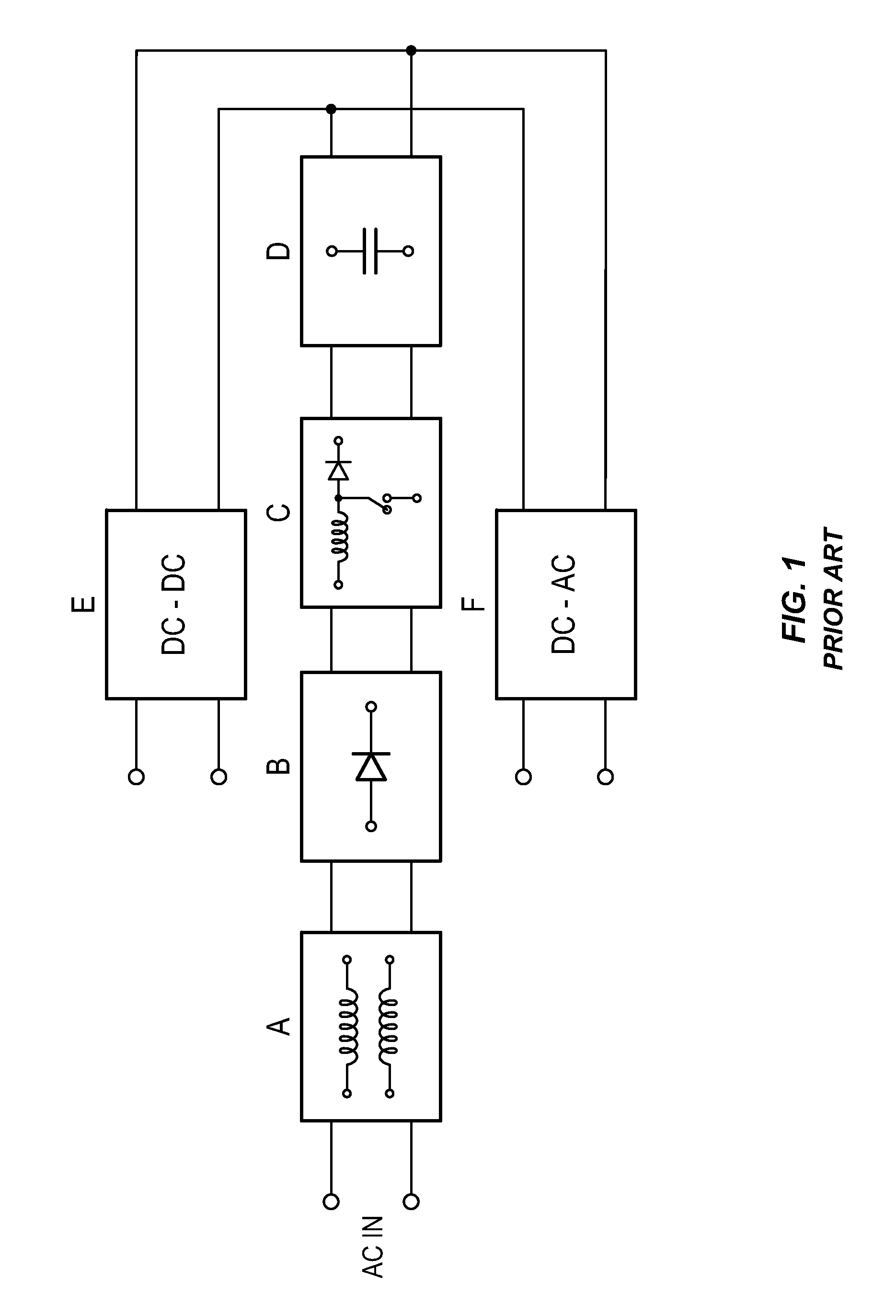

Three-stage electronic ballast for metal halide lamps

InactiveUS6856102B1Reduce power lossImprove efficiencyElectrical apparatusElectric light circuit arrangementFull bridgeThree stage

A three-stage electronic ballast for metal halide lamps mainly comprises a step-up converter, a step-down converter and a full-bridge DC-AC converter, wherein the step-down converter operates an inductor in a continuous boundary current mode to achieve reducing power loss and enhancing efficiency. Equipped with a micro processor, the electronic ballast further possesses the function of power regulation. The electronic ballast can be added with various protective functions without complex control circuits and sensing elements, thereby becoming a high-quality and low-cost electronic ballast for metal halide lamps.

Owner:LIGTEK ELECTRONICS

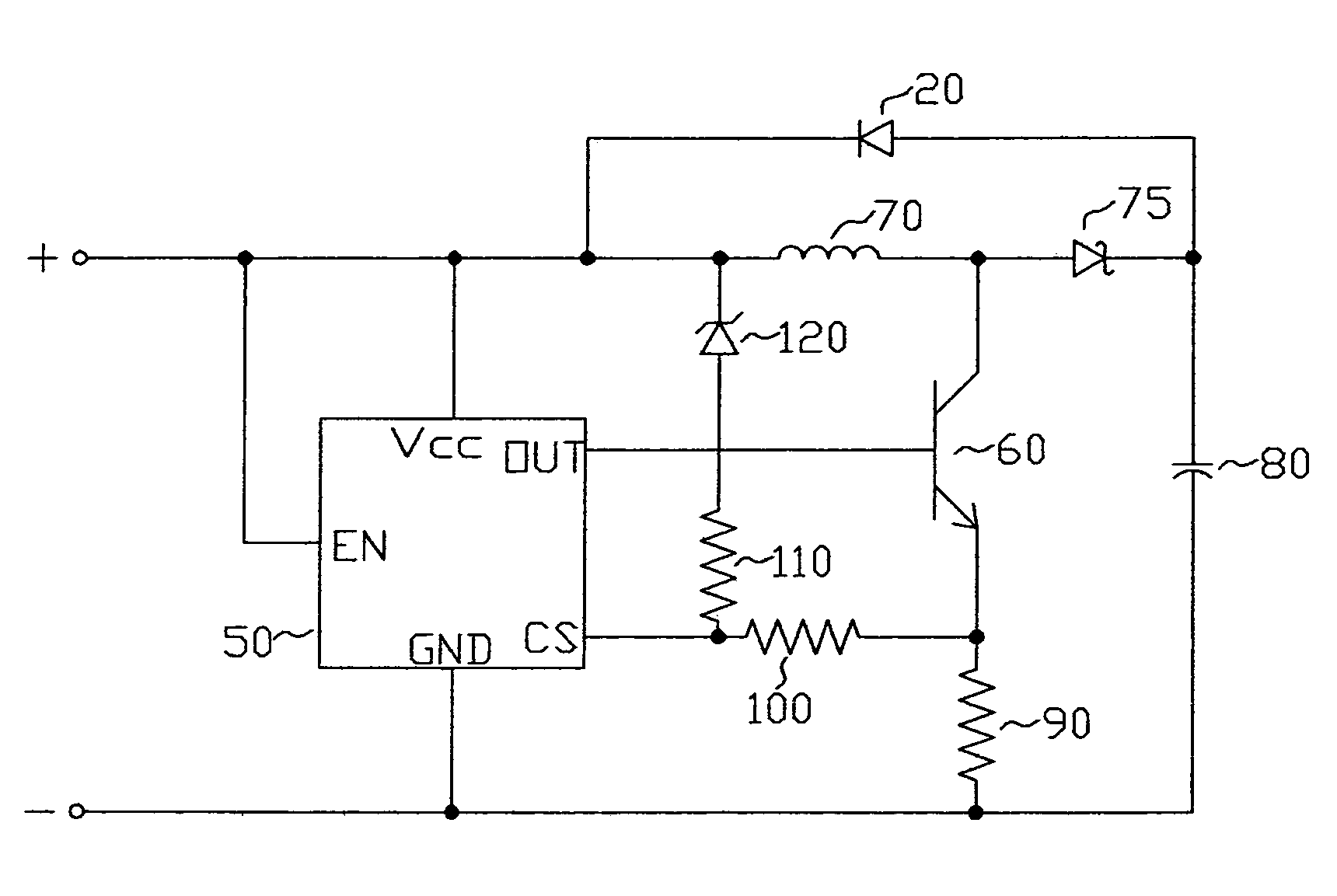

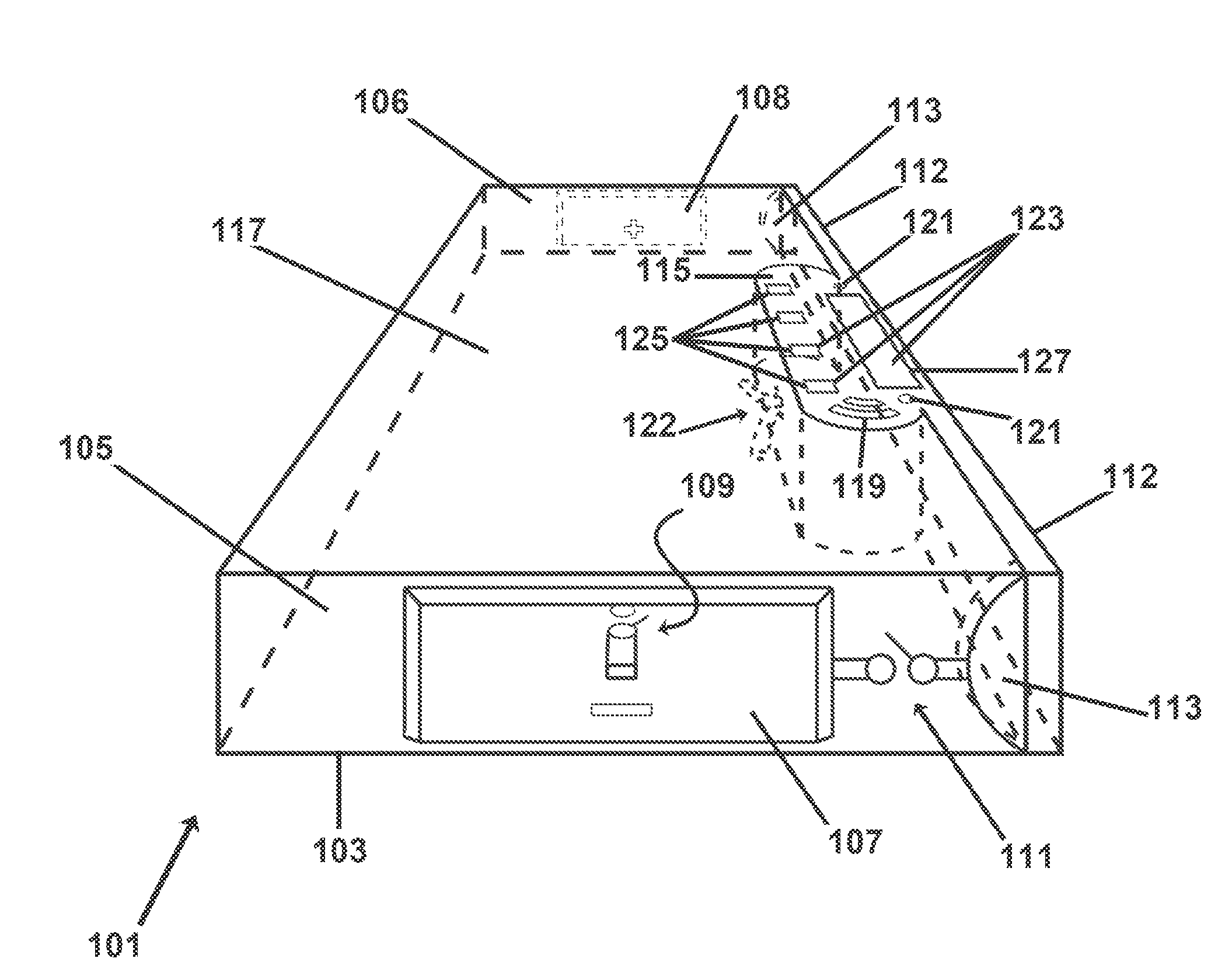

Circuit devices, circuit devices which include light emitting diodes, assemblies which include such circuit devices, flashlights which include such assemblies, and methods for directly replacing flashlight bulbs

ActiveUS7015650B2Increases percentage of useful powerExtend your lifePoint-like light sourceElectroluminescent light sourcesElectricityElectrical connection

A circuit device for providing energy to at least one electrical component, such as a light emitting diode (LED). The circuit device comprises a positive contact, an inductor, a diode and a negative contact in series. A first component contact for electrical connection to a cathode end of an electrical component, a second component contact for electrical connection to an anode end of an electrical component, a switch and a control device are also included. The first component contact is electrically connected to a junction between the positive contact and one end of the inductor; and the second component contact is electrically connected to a cathode end of the diode. There are also provided a circuit device further including an LED, an assembly including a circuit device and a bulb base, a flashlight including an assembly, and a method of directly replacing a flashlight bulb.

Owner:LEDDYNAMICS

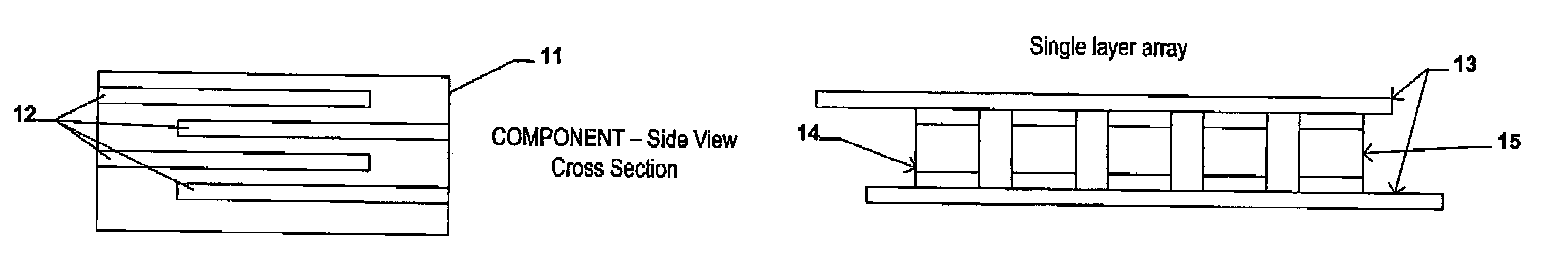

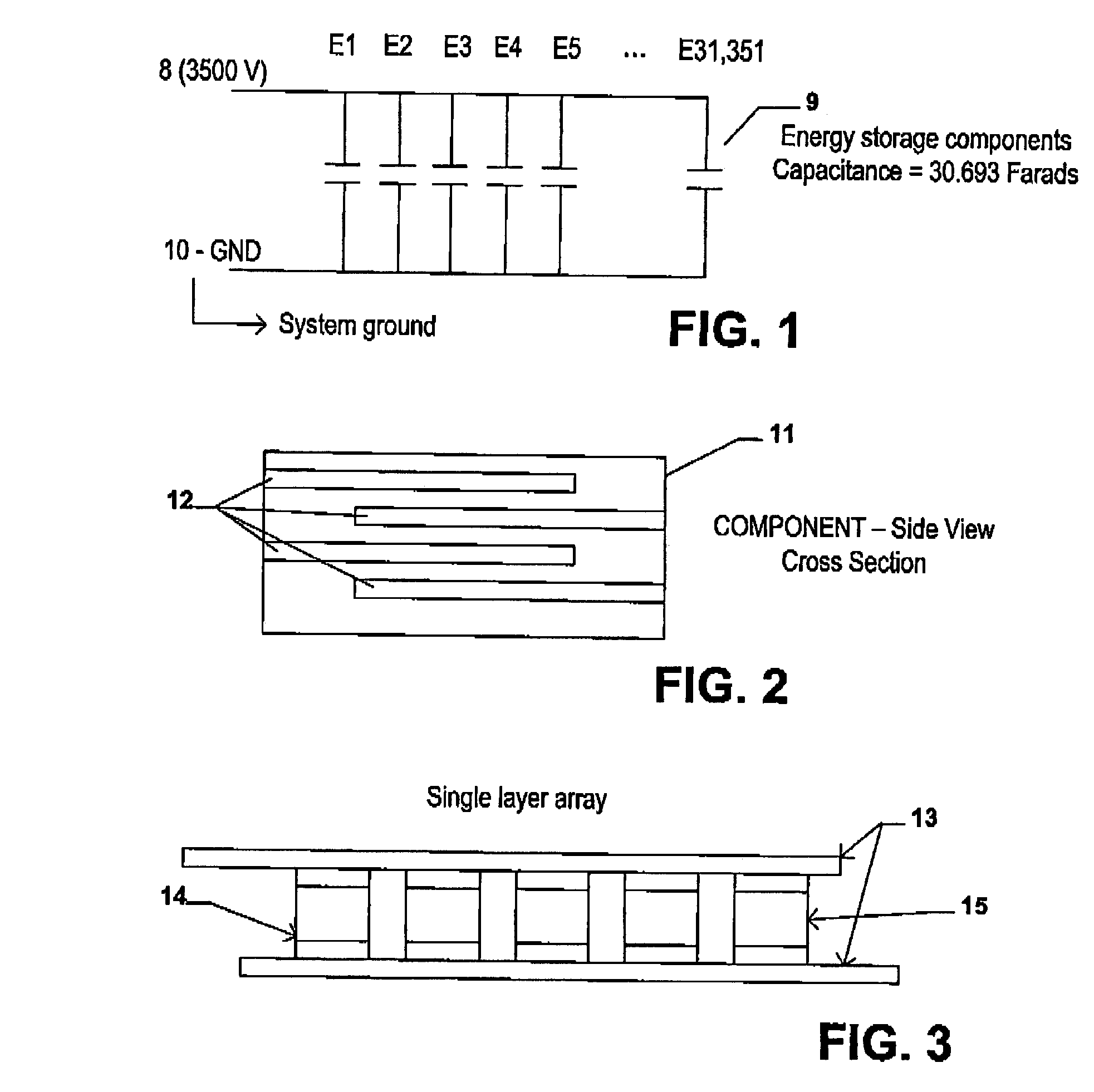

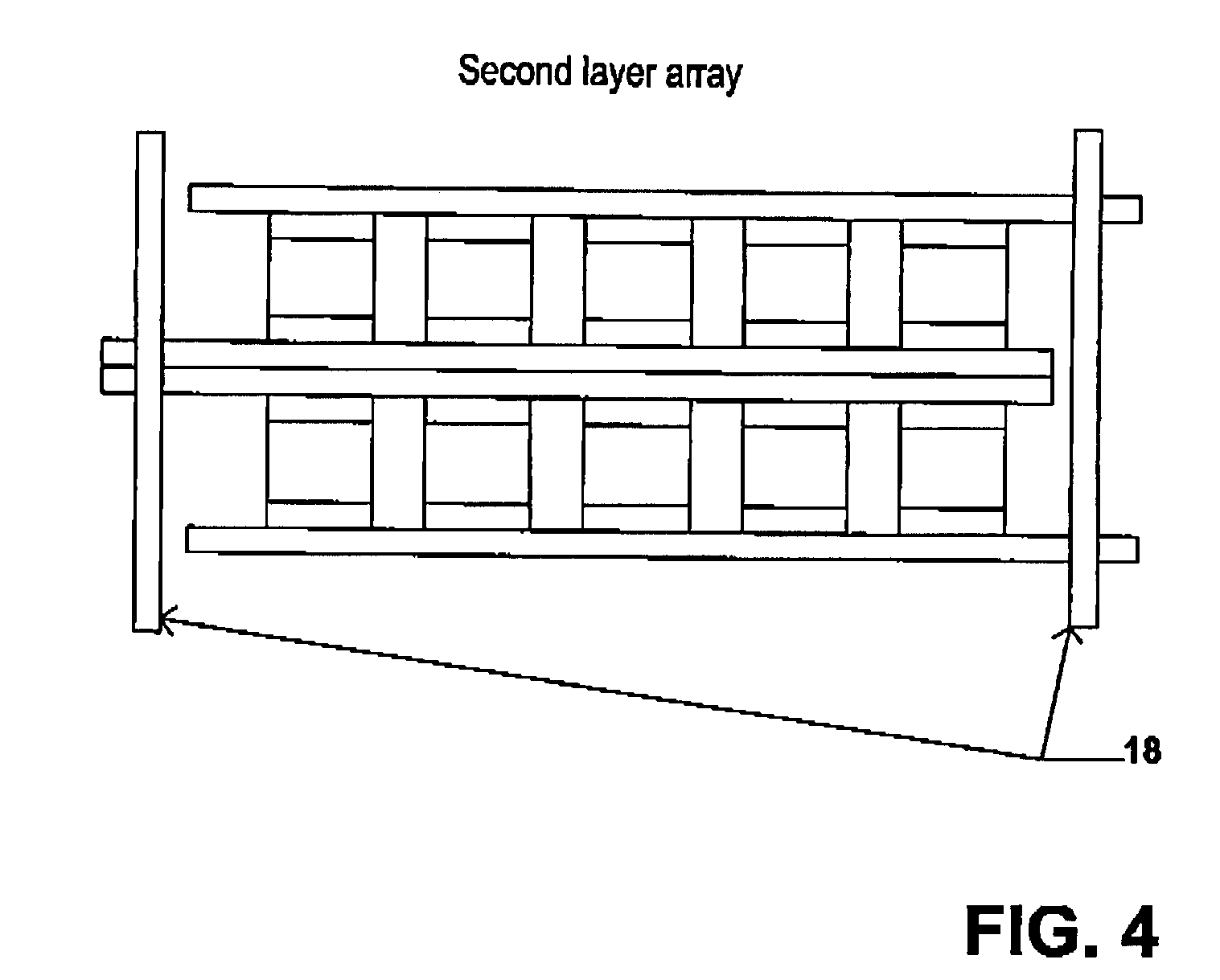

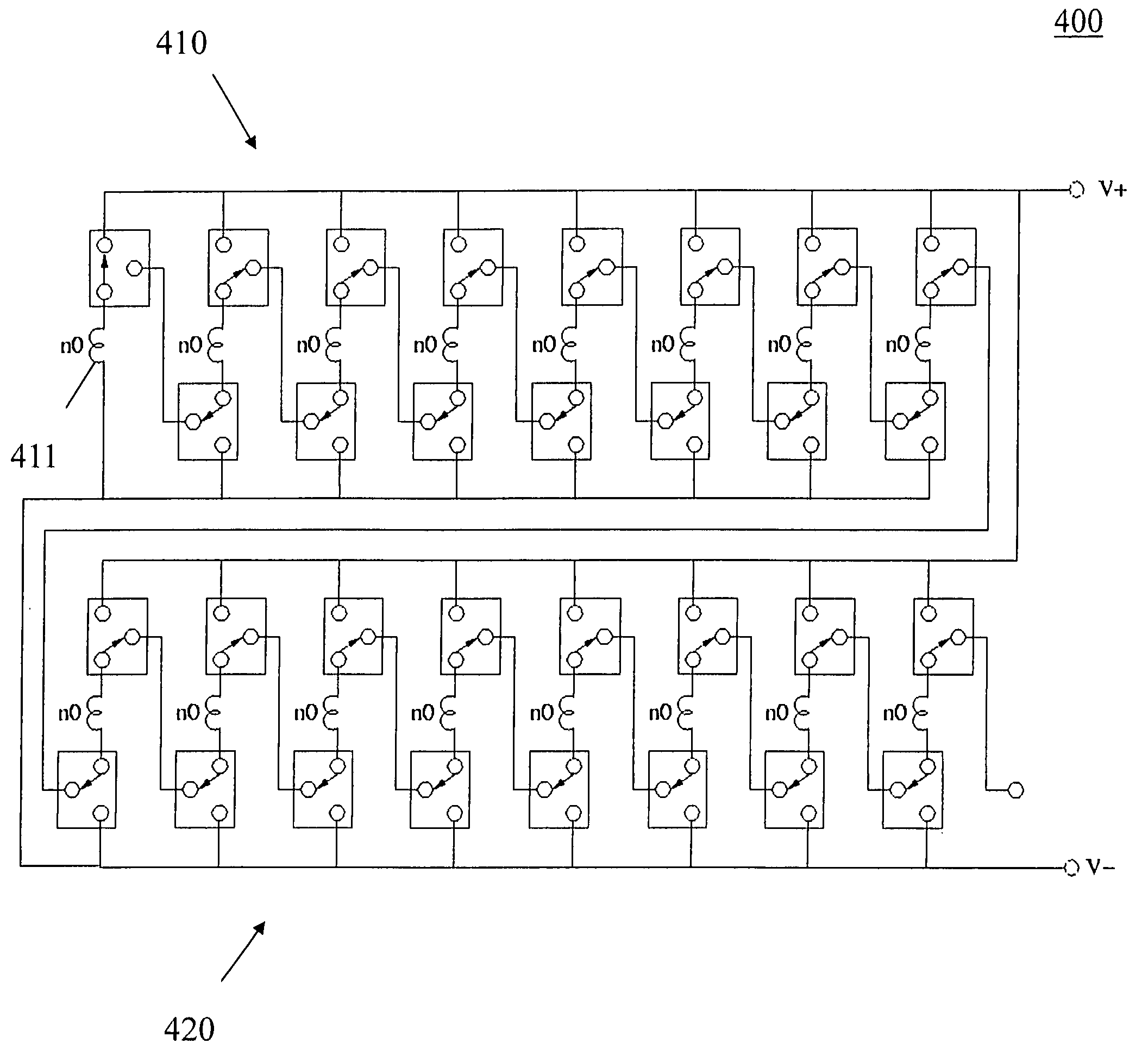

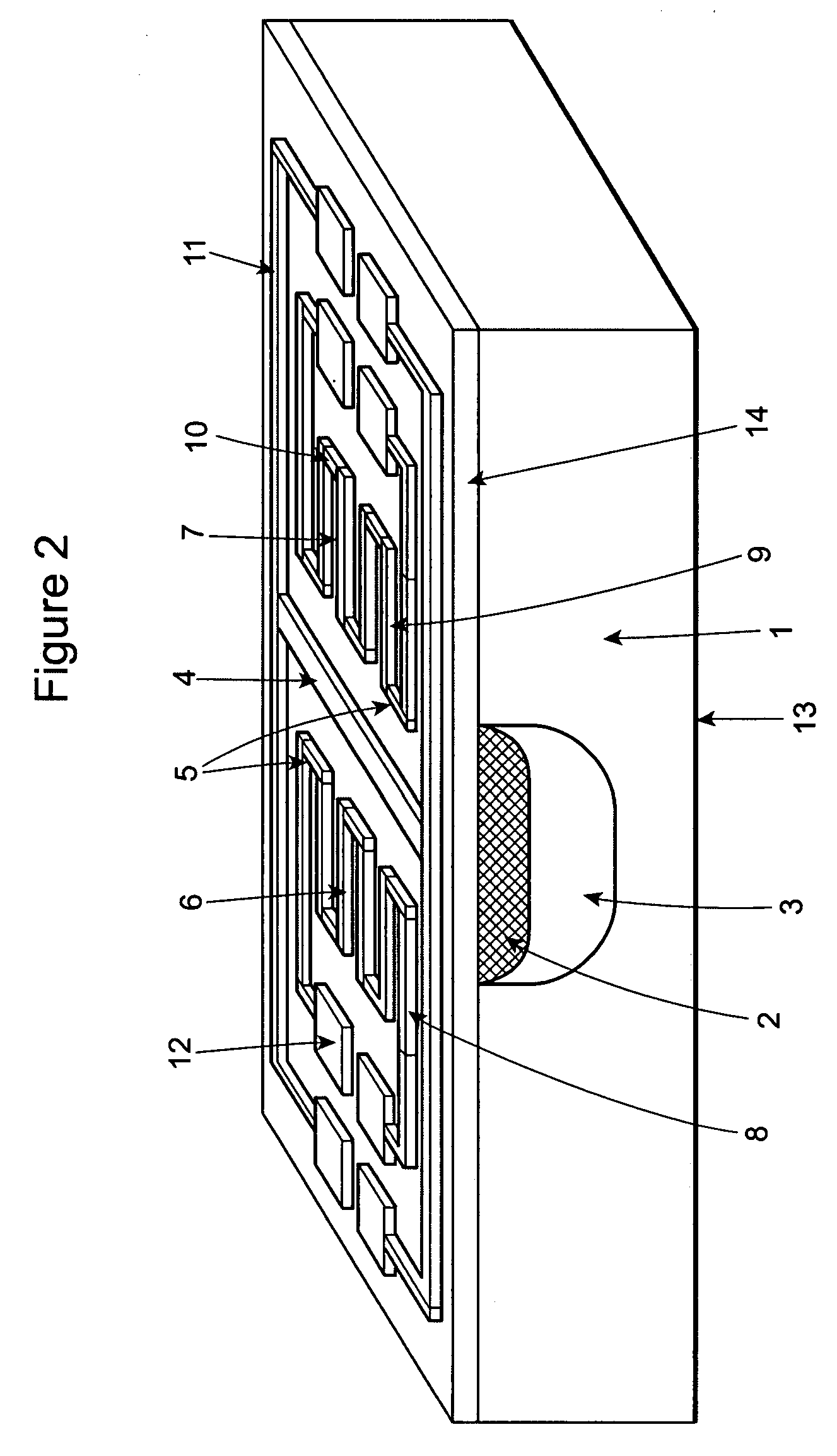

Utilization of poly(ethylene terephthalate) plastic and composition-modified barium titanate powders in a matrix that allows polarization and the use of integrated-circuit technologies for the production of lightweight ultrahigh electrical energy storage units (EESU)

InactiveUS7466536B1Low costLower sintering temperatureCell electrodesFixed capacitor dielectricManufacturing technologyBarium titanate

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is single coated with aluminum oxide and then immersed in a matrix of poly(ethylene terephthalate) (PET) plastic for use in screen-printing systems. The ink that is used to process the powders via screen-printing is based on a nitrocellulose resin that provide a binder burnout, sintering, and hot isostatic pressing temperatures that are allowed by the PET plastic. These lower temperatures that are in the range of 40° C. to 150° C. also allows aluminum powder to be used for the electrode material. The components of the EESU are manufactured with the use of conventional ceramic and plastic fabrication techniques which include screen printing alternating multilayers of aluminum electrodes and high-permittivity composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The 31,351 components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store at least 52.22 kW·h of electrical energy. The total weight of an EESU with this amount of electrical energy storage is 281.56 pounds including the box, connectors, and associated hardware.

Owner:EESTOR

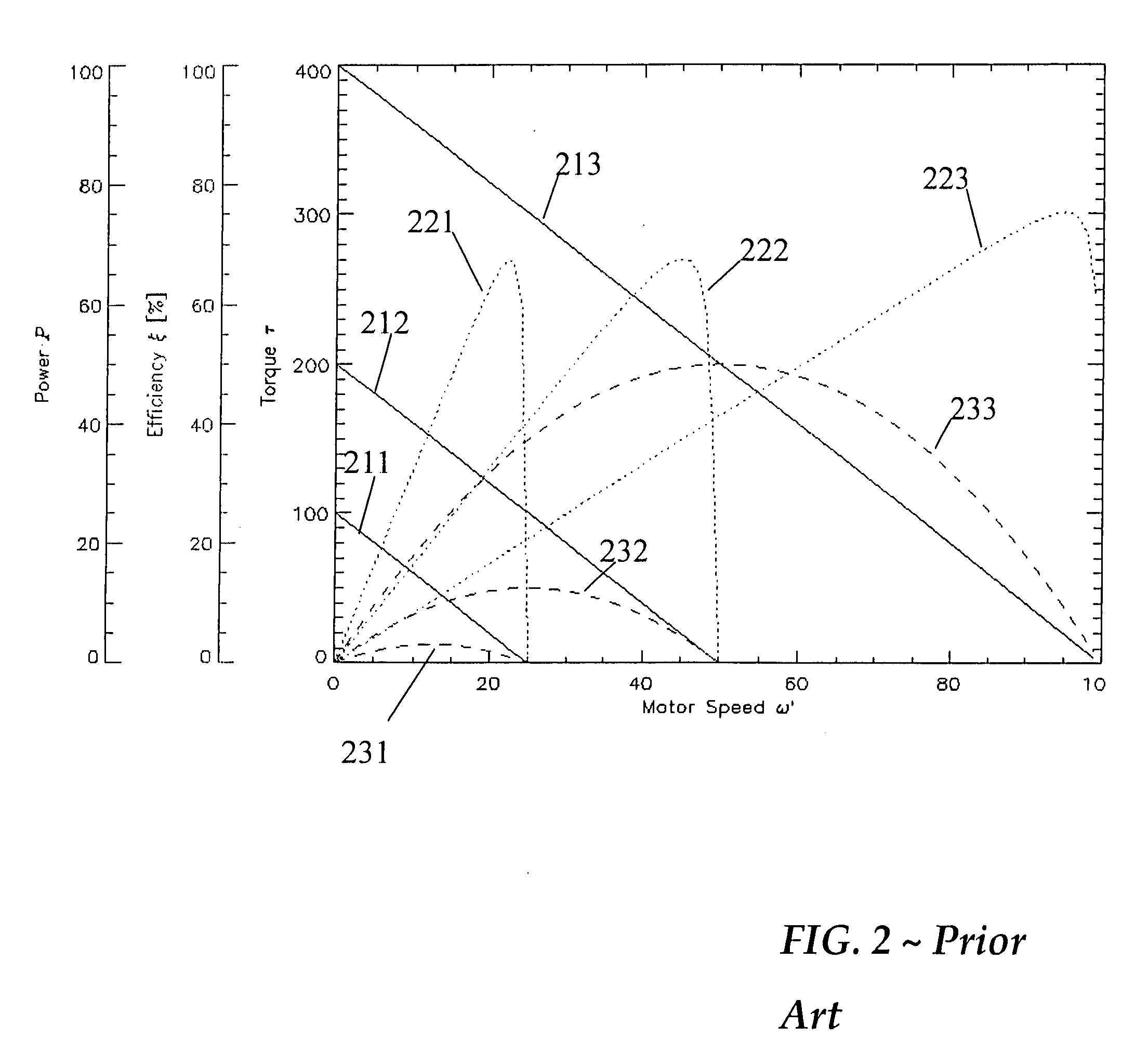

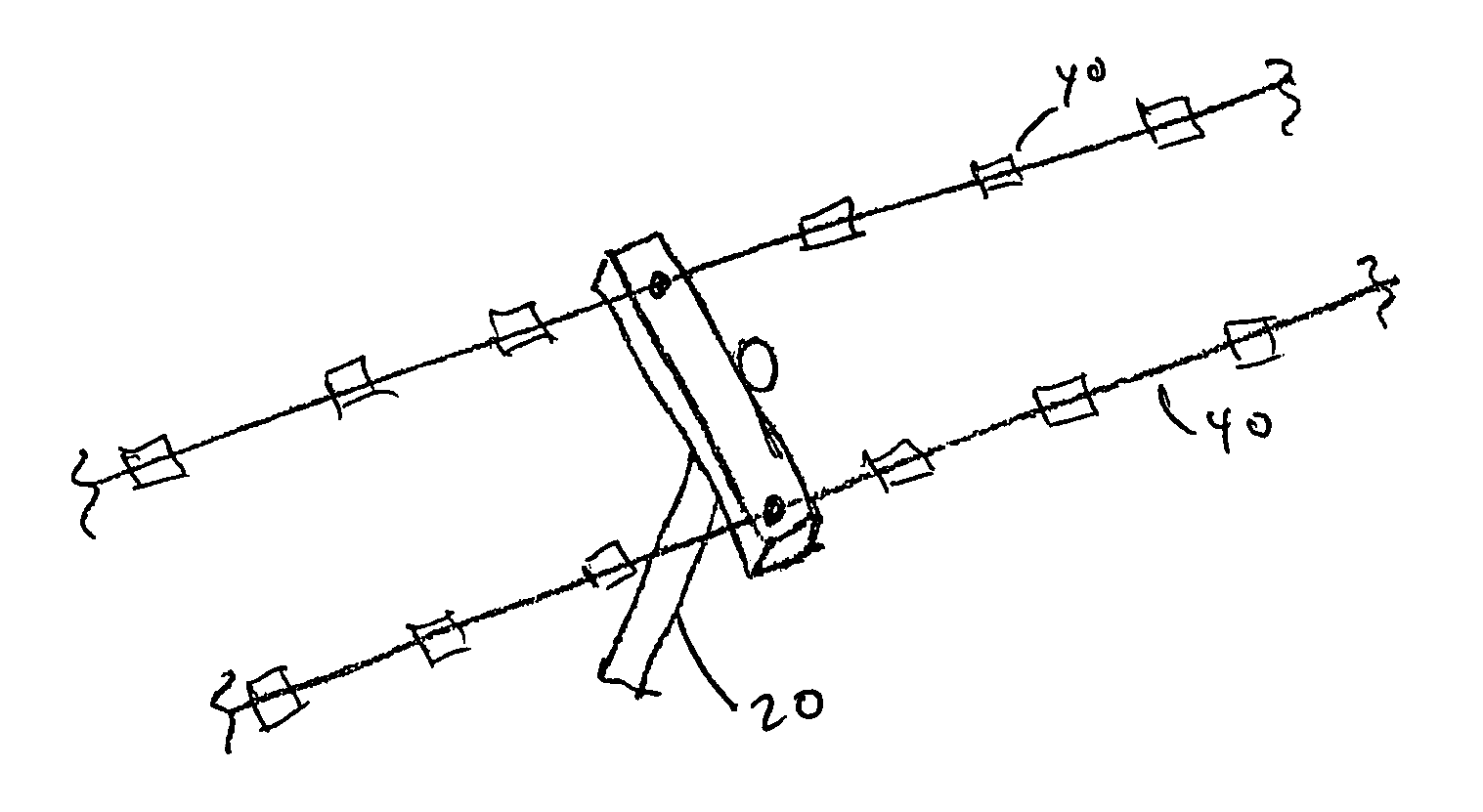

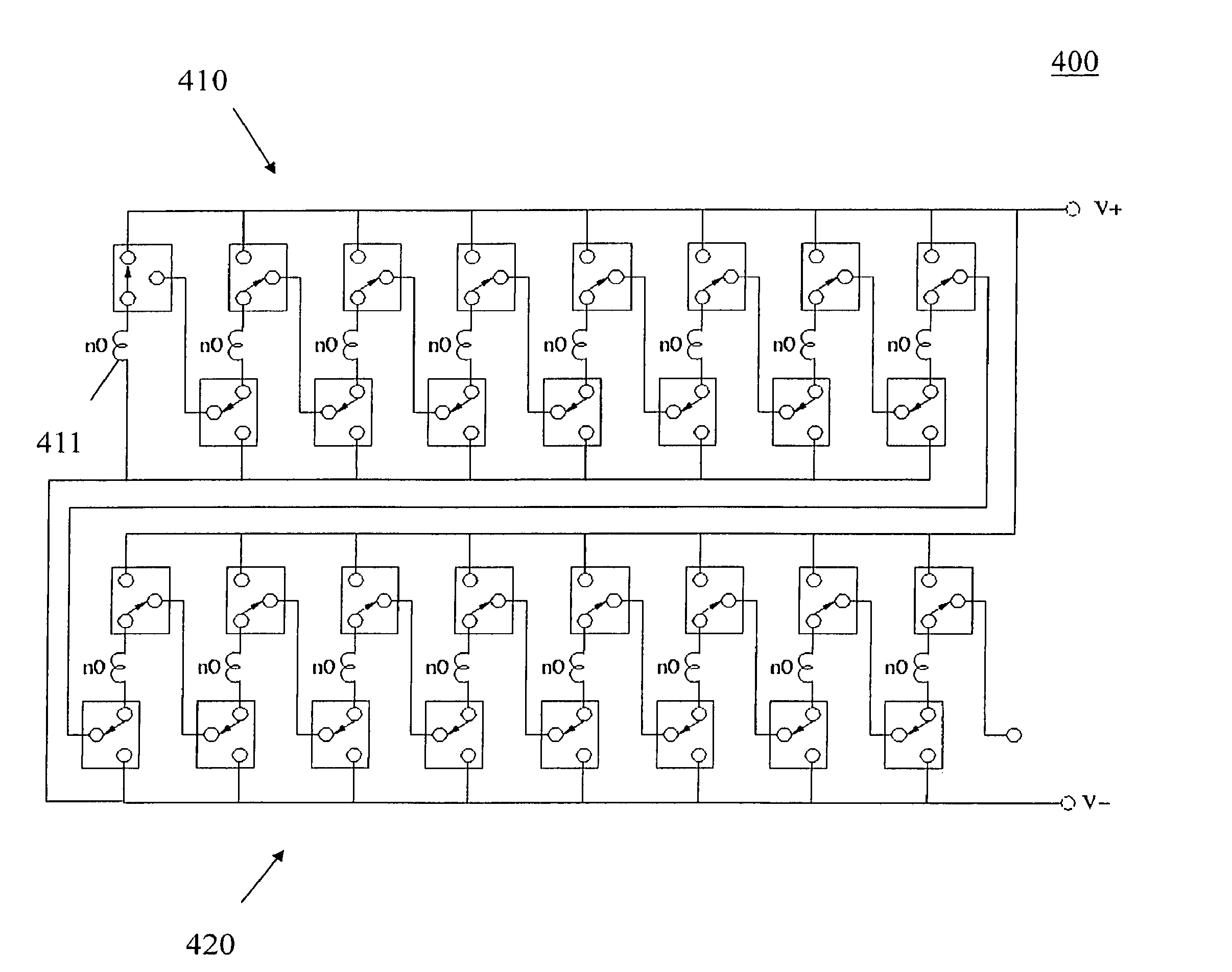

Adaptive winding system and control method for electric machines

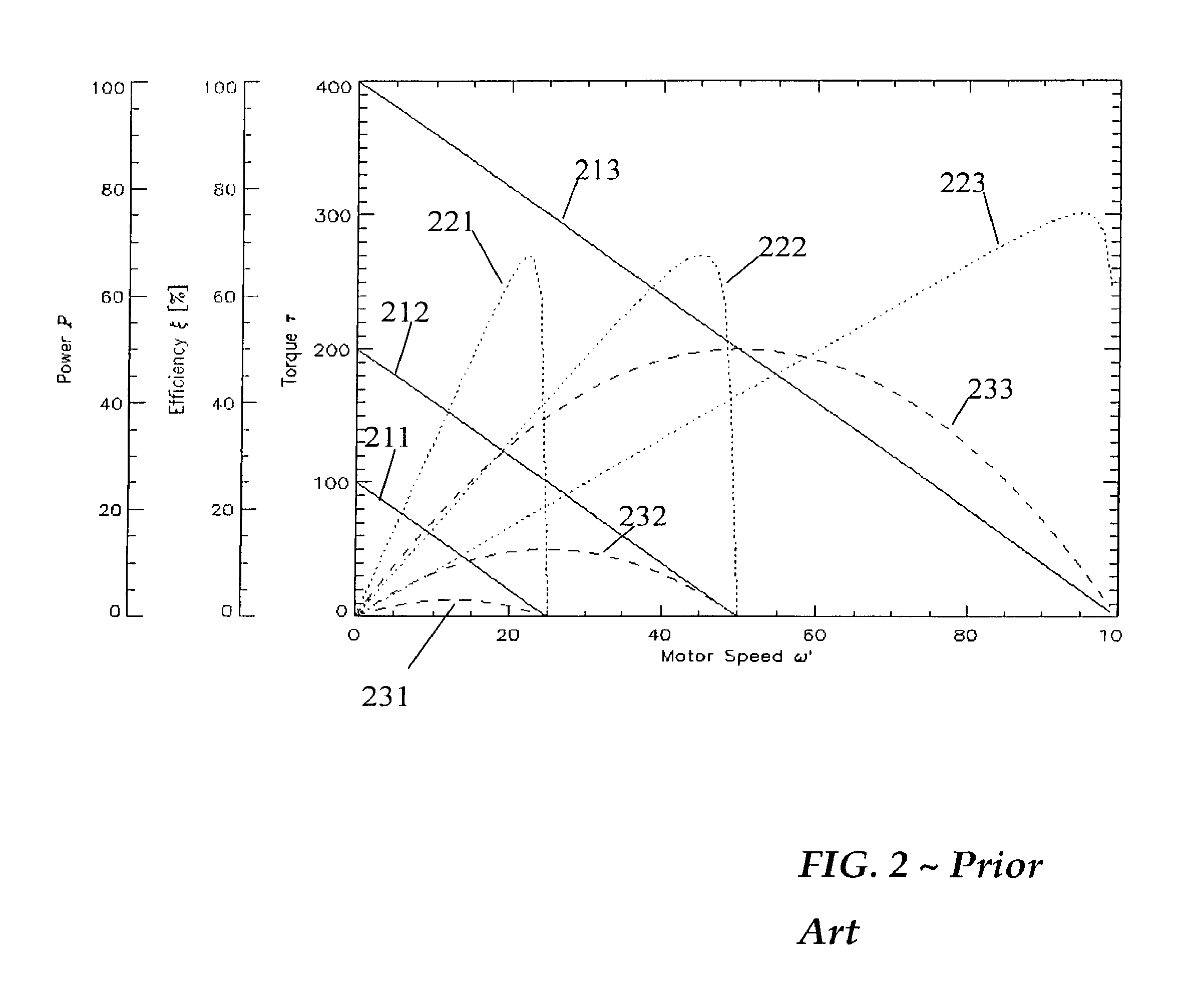

ActiveUS20080116759A1Improve efficiencyWide speed rangeSynchronous generatorsAC motor controlElectric machineEngineering

An adaptive winding configurations and control method is disclosed for the electromagnetic poles of electric machines, including motors and generators. Motors utilizing the inventive adaptive winding configuration and control method are able to dynamically adjust their operating characteristics to maintain a constant rated power over a large operating speed range with high efficiency. Generators employing the inventive adaptive winding configuration and control method are able to dynamically adjust their operating characteristics in response to a variable driving force to achieve maximum power conversion efficiency. These generators are also able to dynamically change their output voltage and current (thus charging speed) when charging batteries depending on the charged state of the battery, and on the expected duration of the input power.

Owner:LIN PANCHIEN

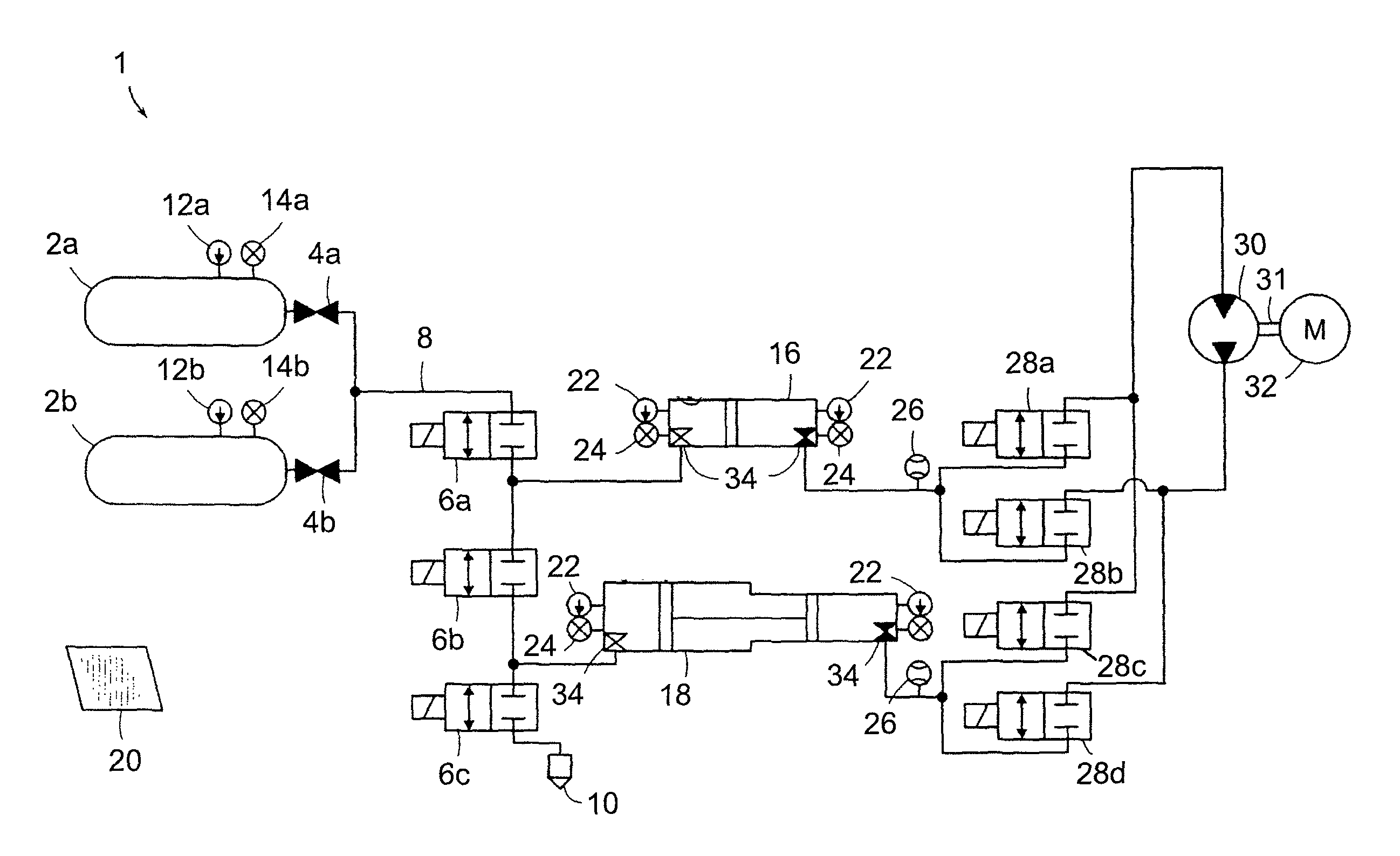

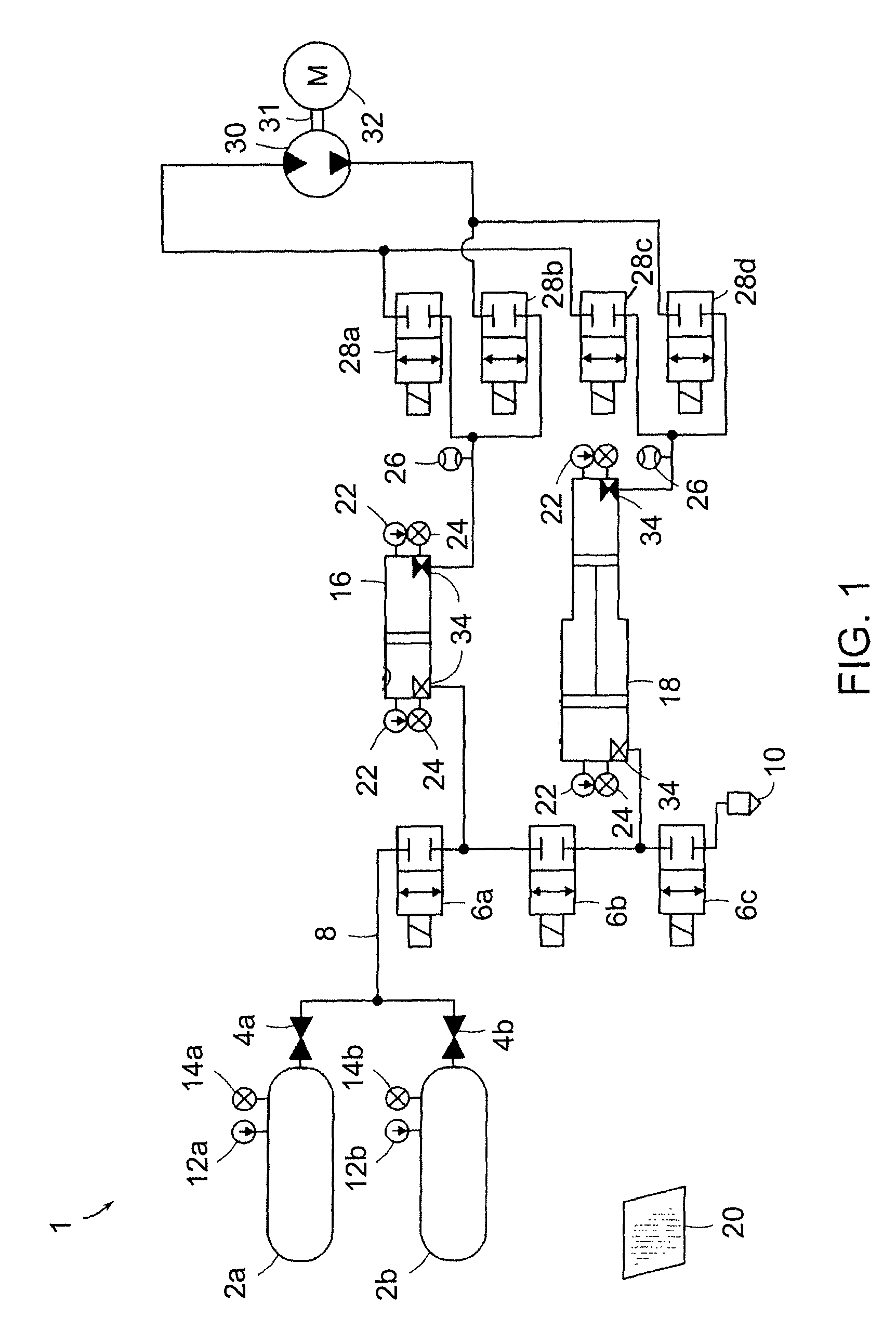

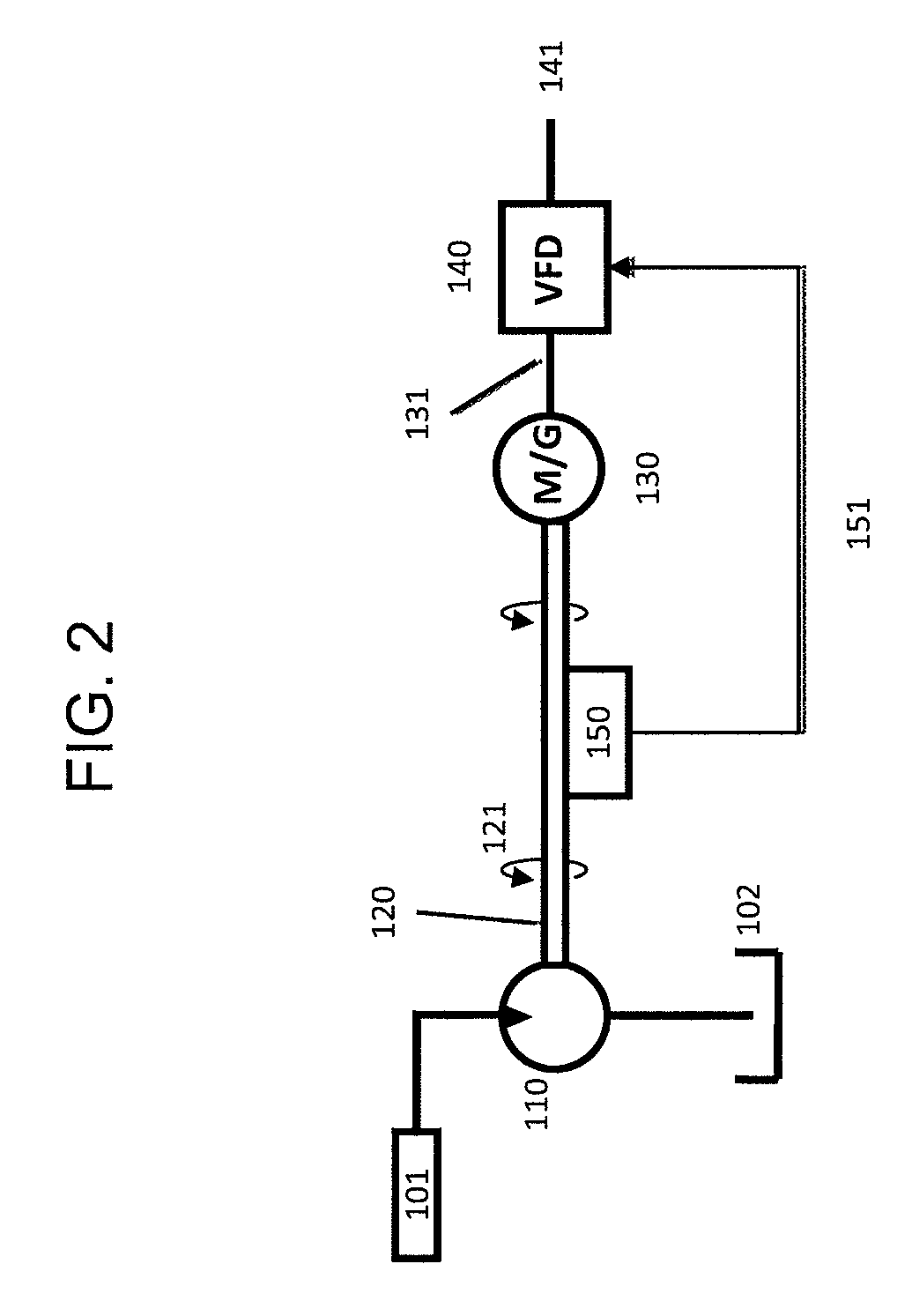

Systems and methods for improving drivetrain efficiency for compressed gas energy storage

InactiveUS7963110B2RPM increaseReduce loadElectrical storage systemFluid couplingsHydraulic motorPower flow

Owner:SUSTAINX

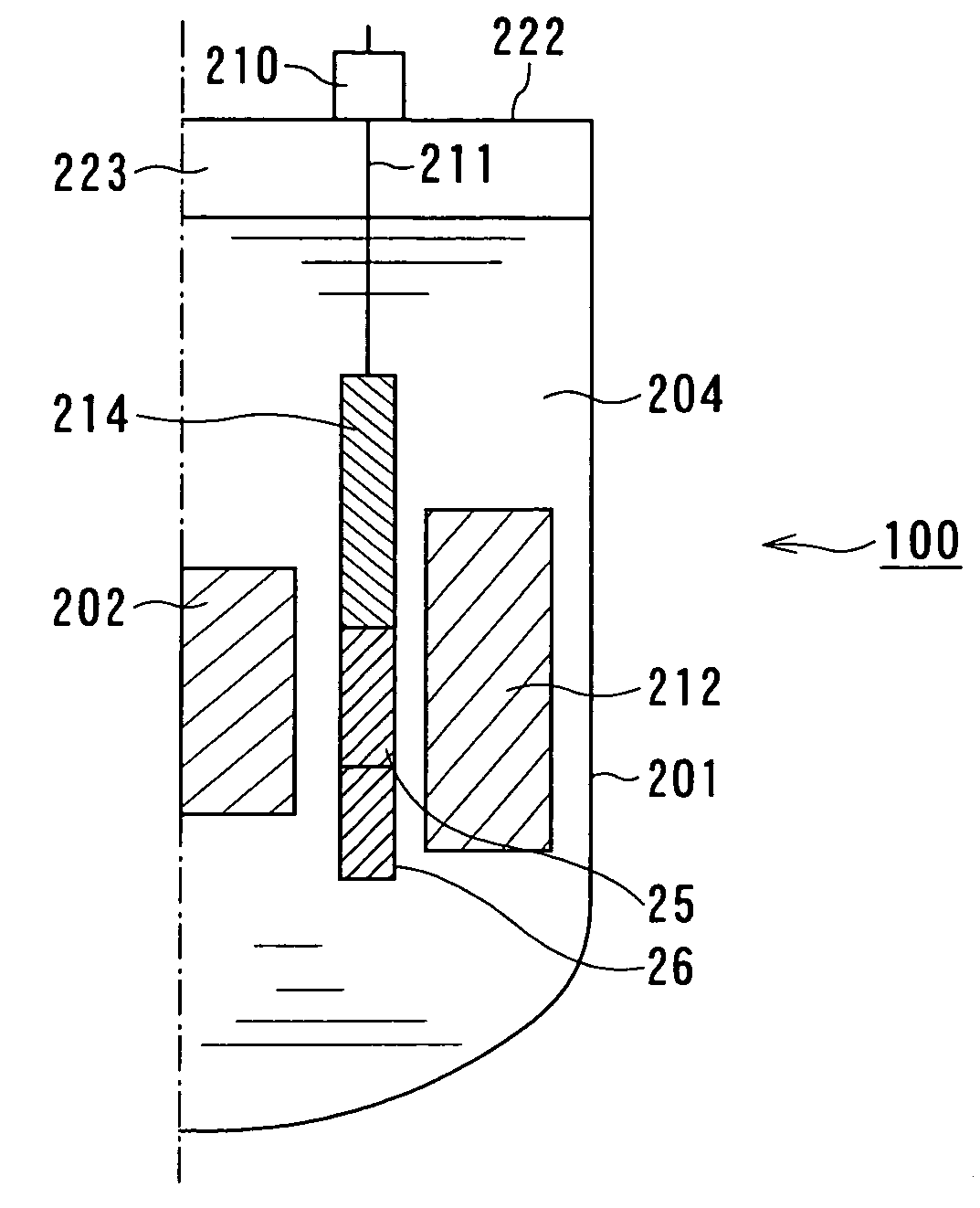

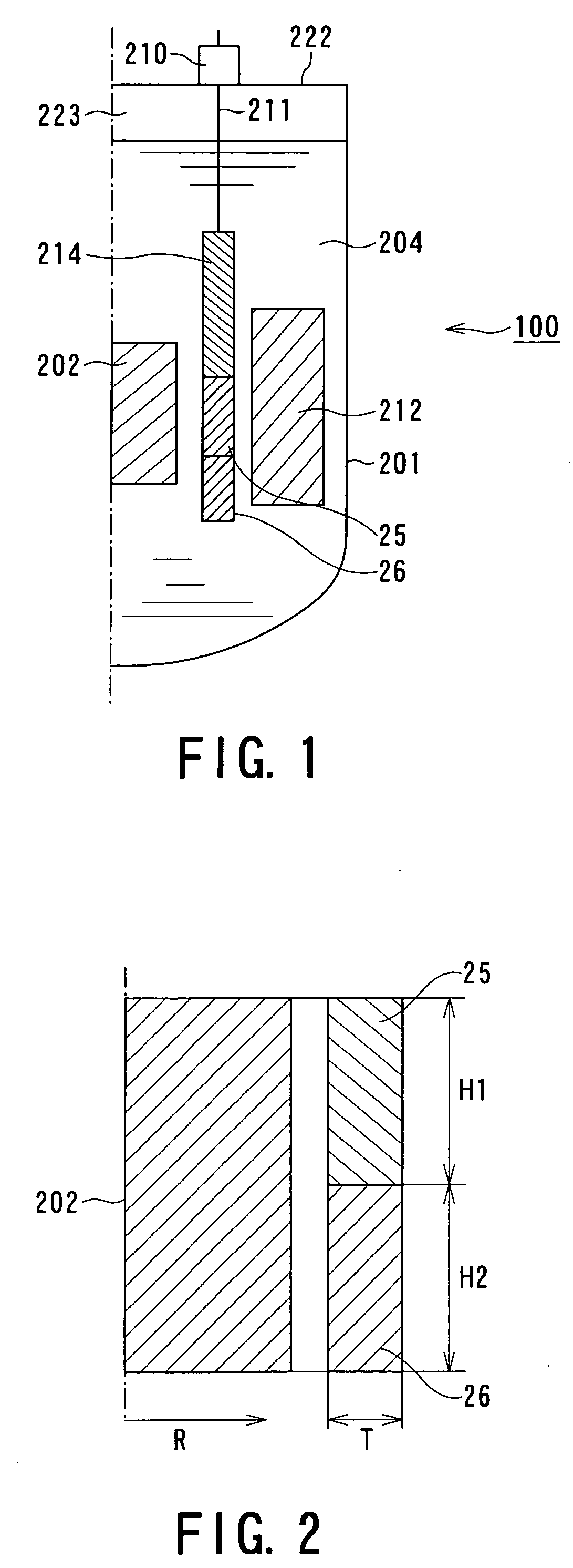

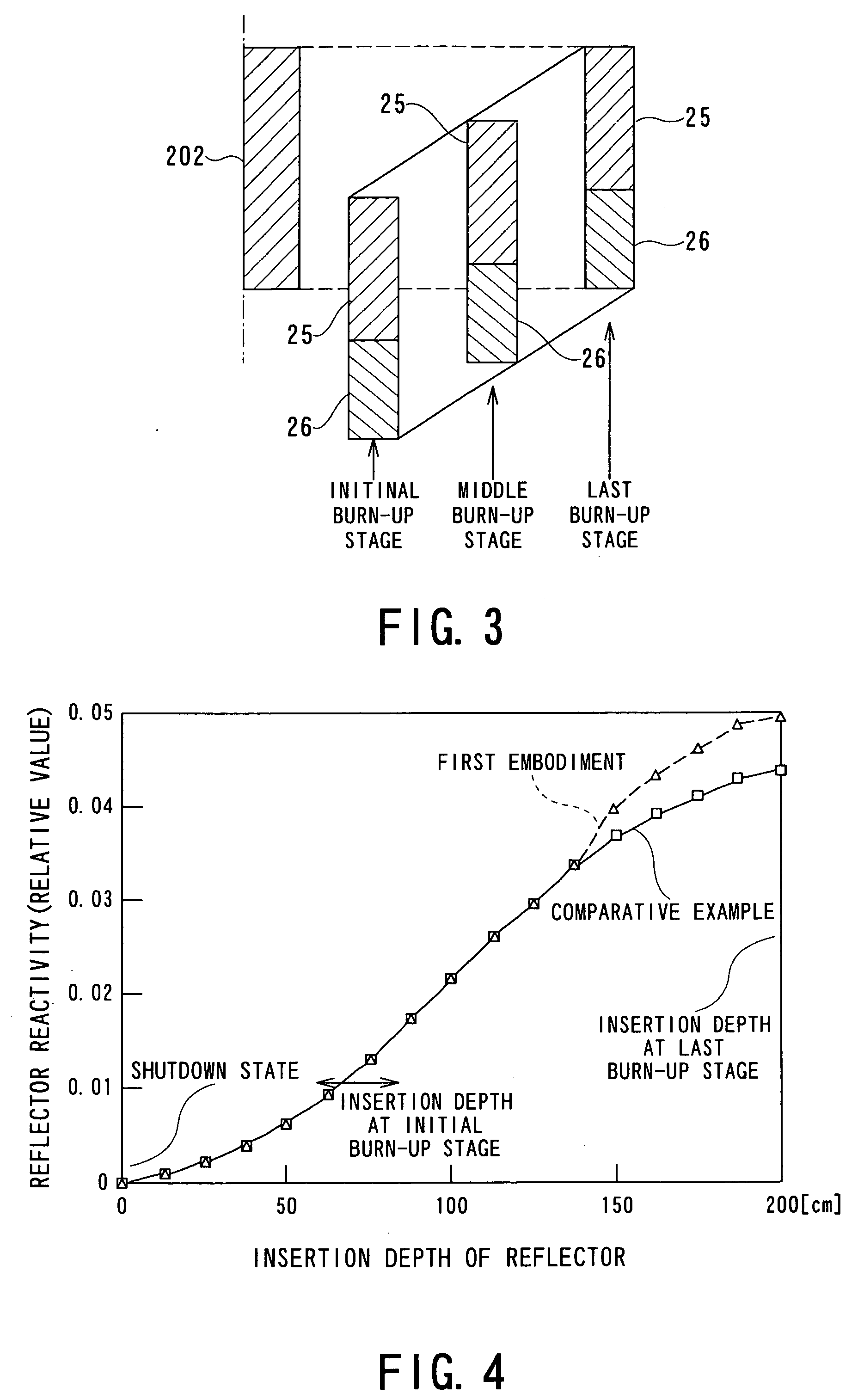

Fast reactor having reflector control system and neutron reflector thereof

InactiveUS20050220251A1Operation efficiency is highSlow changeNuclear energy generationNuclear engineering problemsNuclear engineeringControl system

A fast reactor having a reflector control system is provided which decreases the change in reactivity of the reactor core with time without performing control of a reflector lifting speed and that of a water flow rate. The above fast reactor has a liquid metal coolant, a reactor core immersed therein, and a neutron reflector which is provided outside the reactor core and which is moved in a vertical direction for adjusting leakage of neutrons therefrom for controlling the reactivity of the reactor core. The neutron reflector described above is gradually moved in an upward direction with the change in reactivity caused by fuel burn-up, and at least a part of a lower region of the neutron reflector is a high reflection region having a high neutron reflection ability as compared to that of the other region. The high reflection region is located from the bottom to a place between one fourth and one half of the height of the neutron reflector from the bottom end thereof.

Owner:KK TOSHIBA

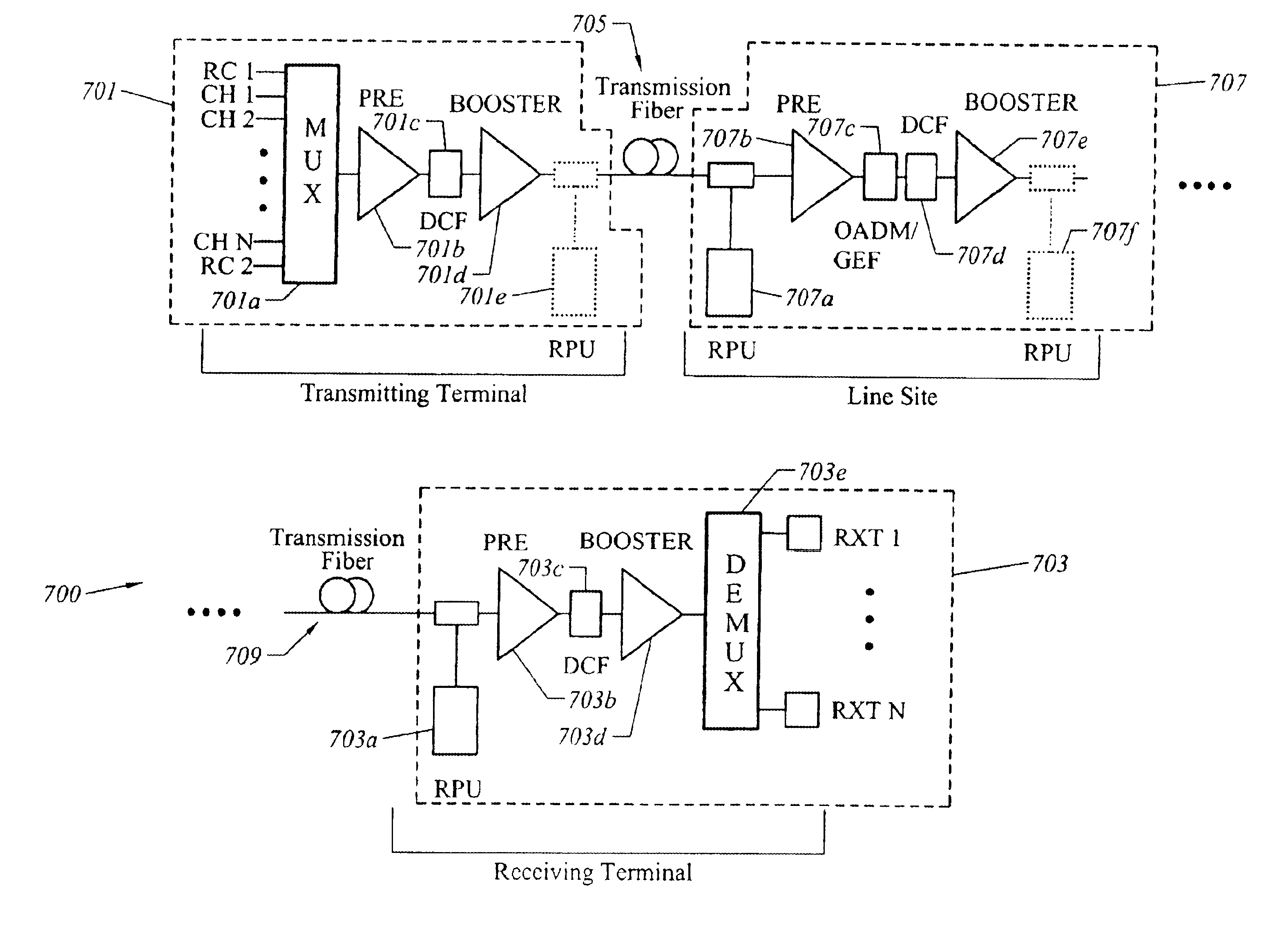

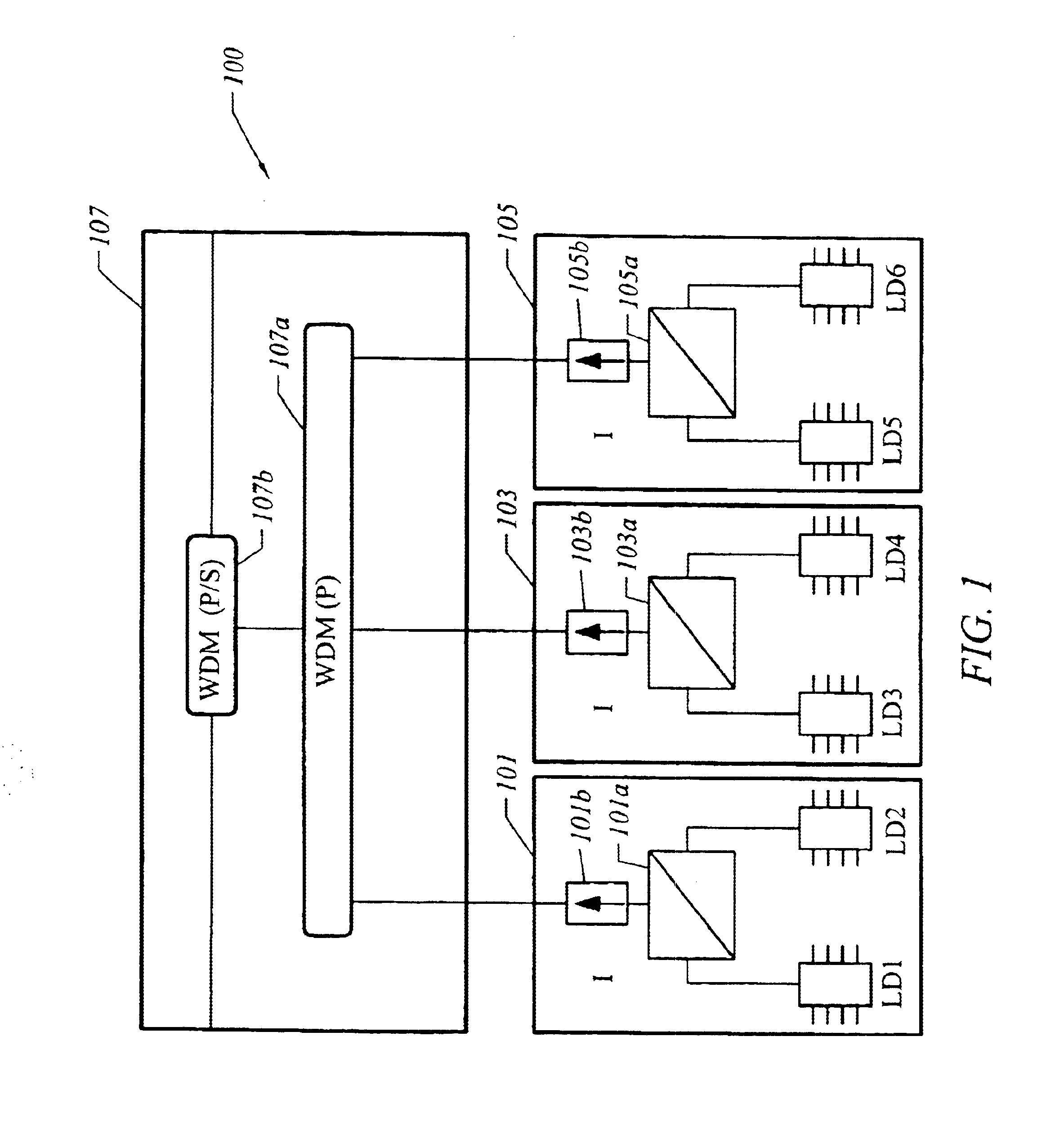

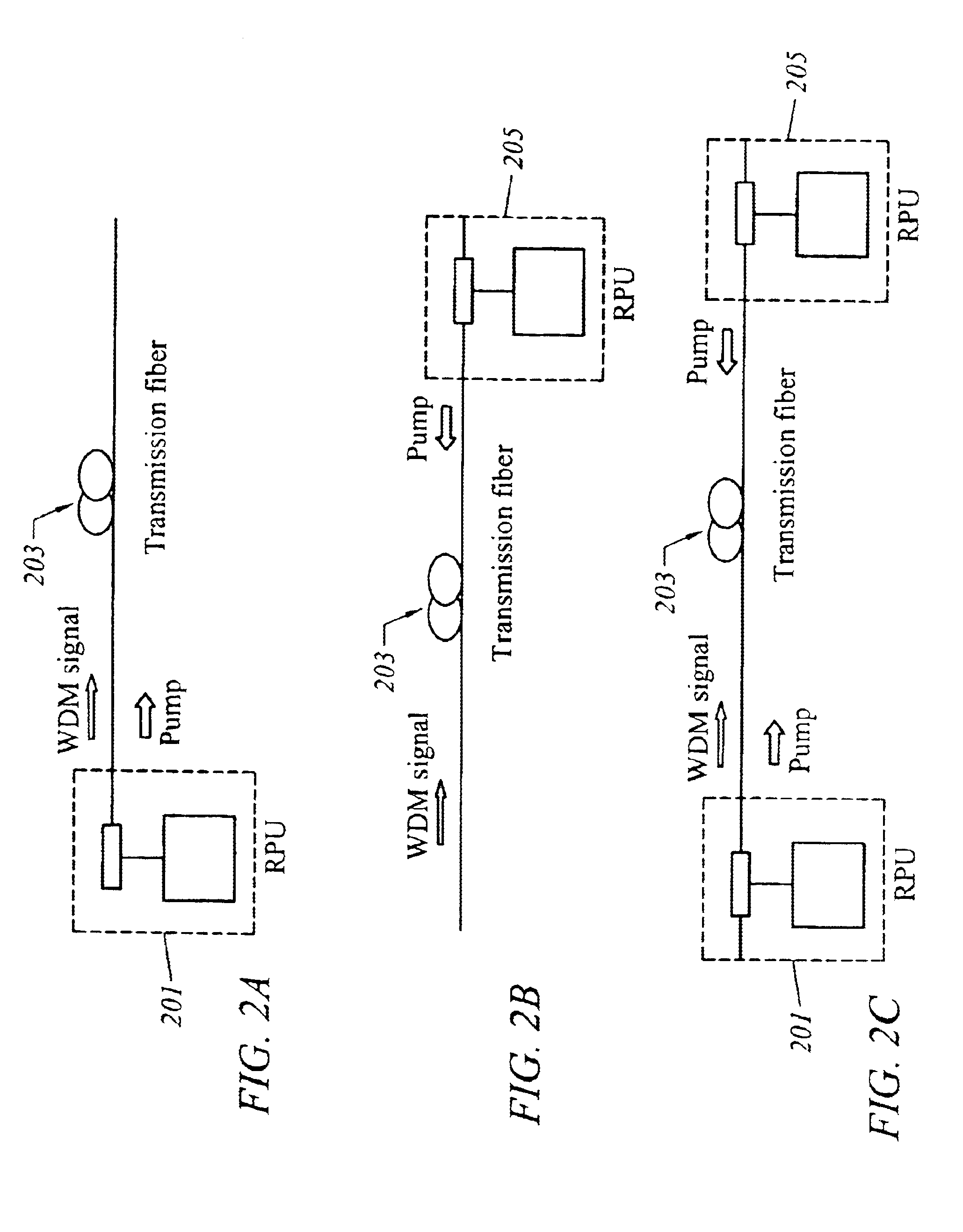

Automatic raman gain and tilt control for ultra-long-distance dense WDM optical communication system

InactiveUS6961522B1Minimizes non-linear effectConstant powerWavelength-division multiplex systemsElectromagnetic transmissionConstant powerErbium doped fiber amplifier

An approach for automatic Raman gain and tilt control for a WDM (Wavelength Division Multiplexing) optical communication systems is disclosed. An optical fiber carries a plurality of optical signals, in which at least one of the optical signals are reference signals. An optical gain unit (e.g., Raman pump unit) couples to the optical fiber and adjusts the reference signals to compensate, in part, for losses associated with the optical fiber and gain tilt accumulation. Upon detecting and analyzing the reference signals, a controller controls the optical gain unit and outputs a control signal to the optical gain unit based upon the analyzed reference signals. An optical amplifier is connected to the optical fiber and amplifies the optical signals. The optical gain unit provides a nearly constant power per channel at an input of the optical amplifier. Under this approach, a Raman gain control mechanism, combined with the use of gain controlled EDFA (Erbium Doped Fiber Amplifier), allows high transmission capacity over ultra-long distances without optical regeneration and with high flexibility.

Owner:CISCO TECH INC

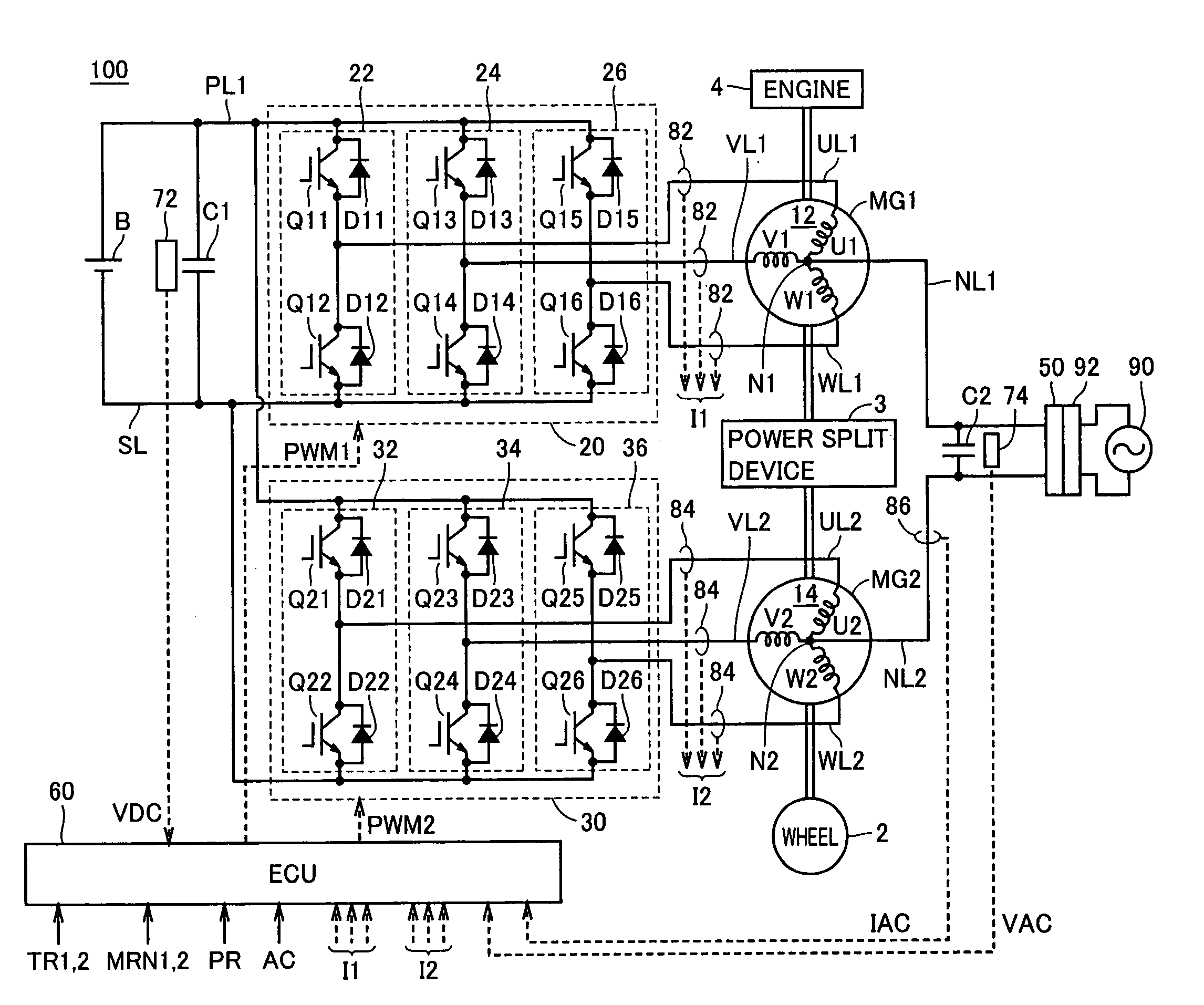

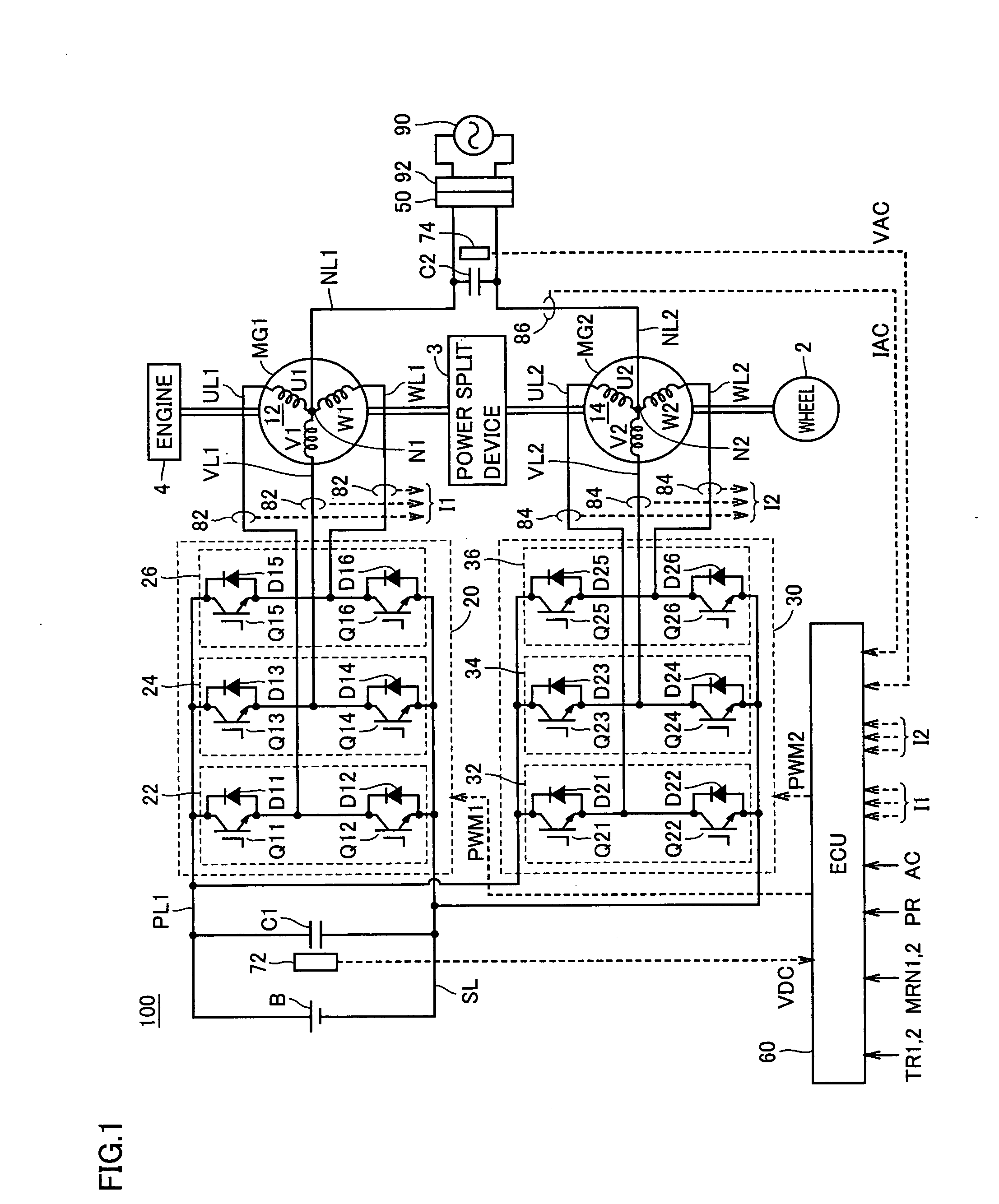

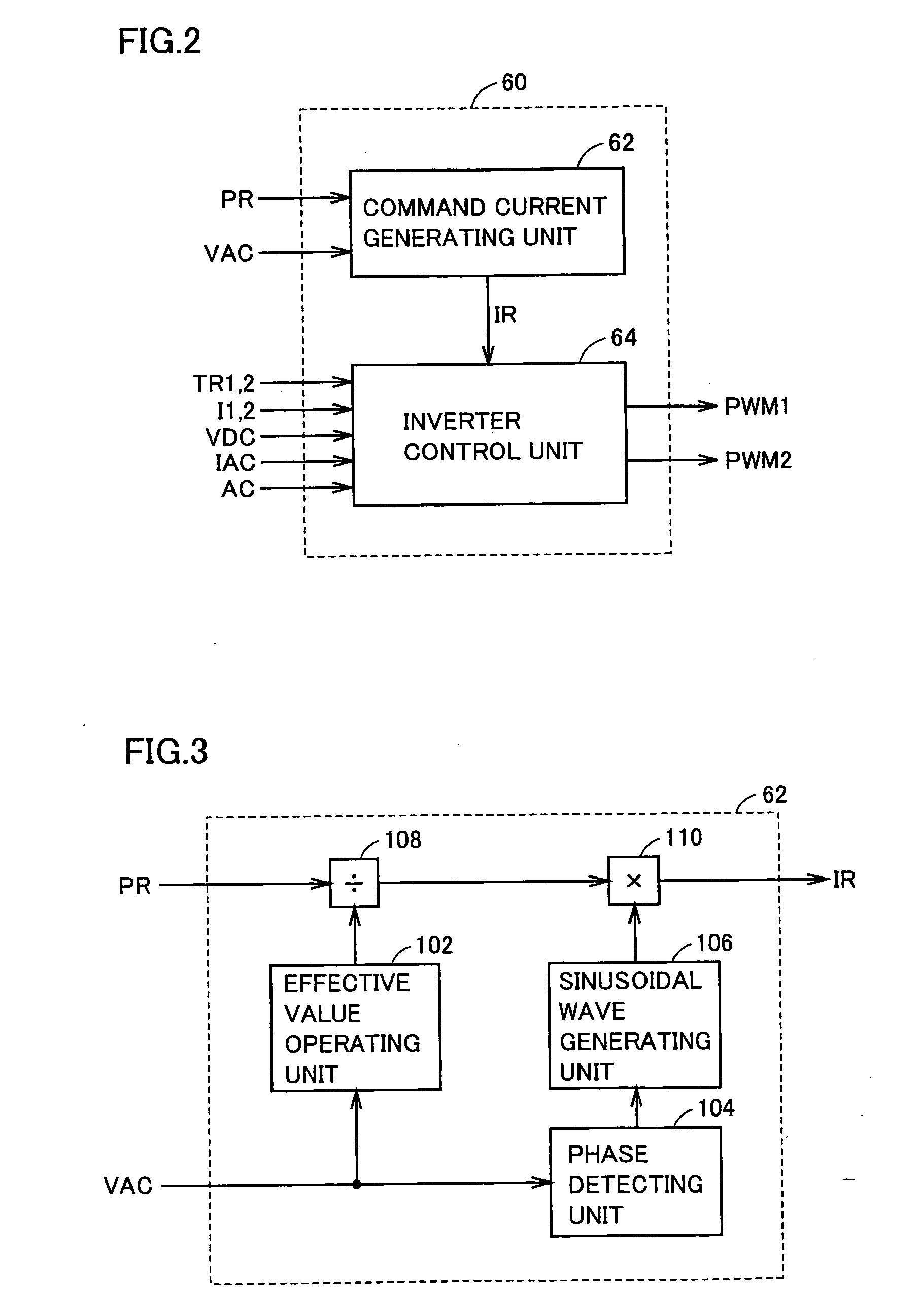

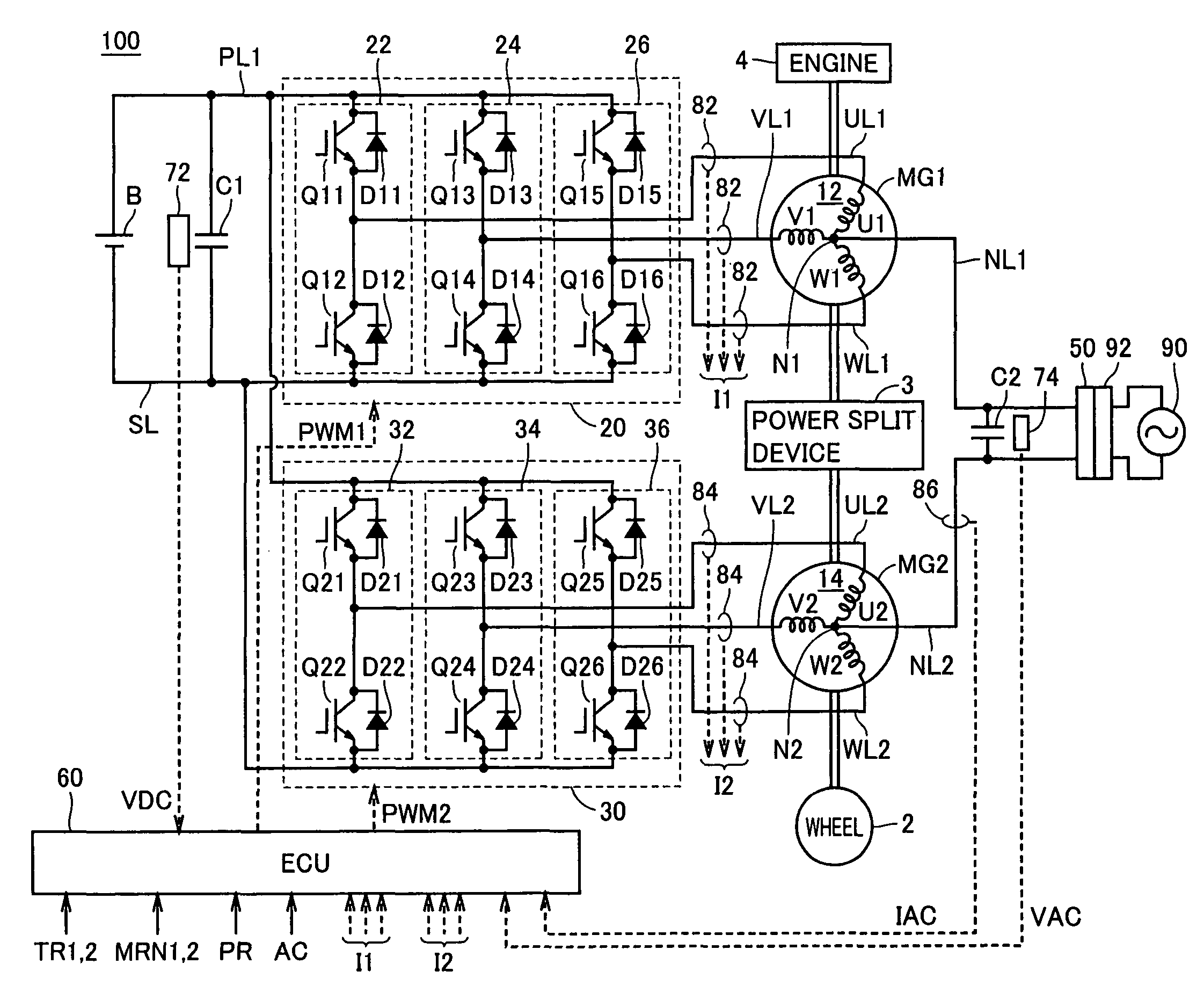

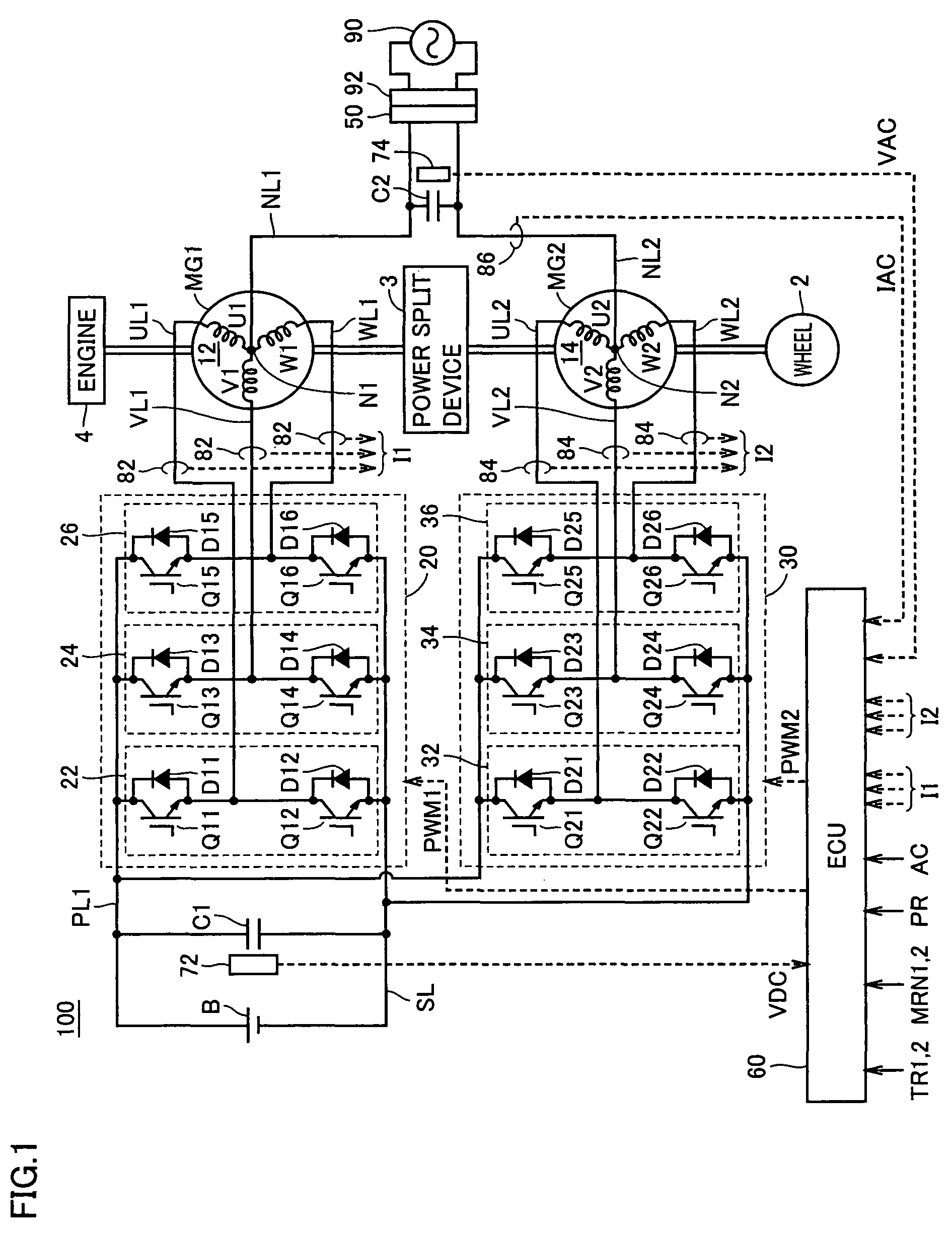

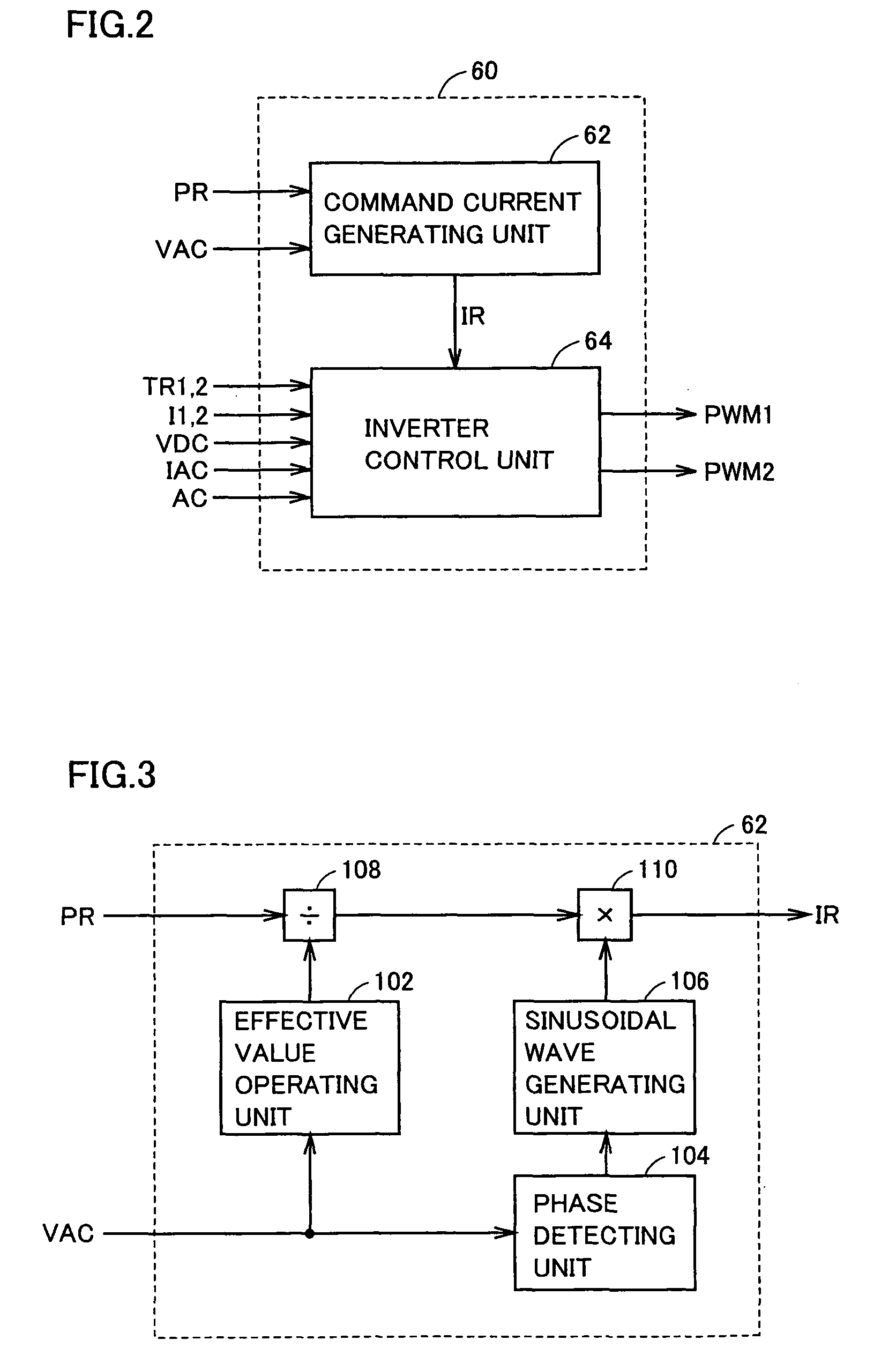

Power Controller and Vehicle Equipped with Power Controller

InactiveUS20090067205A1Reduce in quantityAvoid componentsAc-dc conversion without reversalConversion with intermediate conversion to dcPower controllerPower flow

An ECU detects an effective value and phase of a voltage from a commercial power supply, based on a voltage from a voltage sensor. Further, ECU generates a command current, which is a command value of current caused to flow through power lines and in-phase with the voltage of the commercial power supply, based on the detected effective value and the phase and on a charge / discharge power command value for a power storage device. Then, ECU controls zero-phase voltage of inverters based on the generated command current.

Owner:TOYOTA JIDOSHA KK

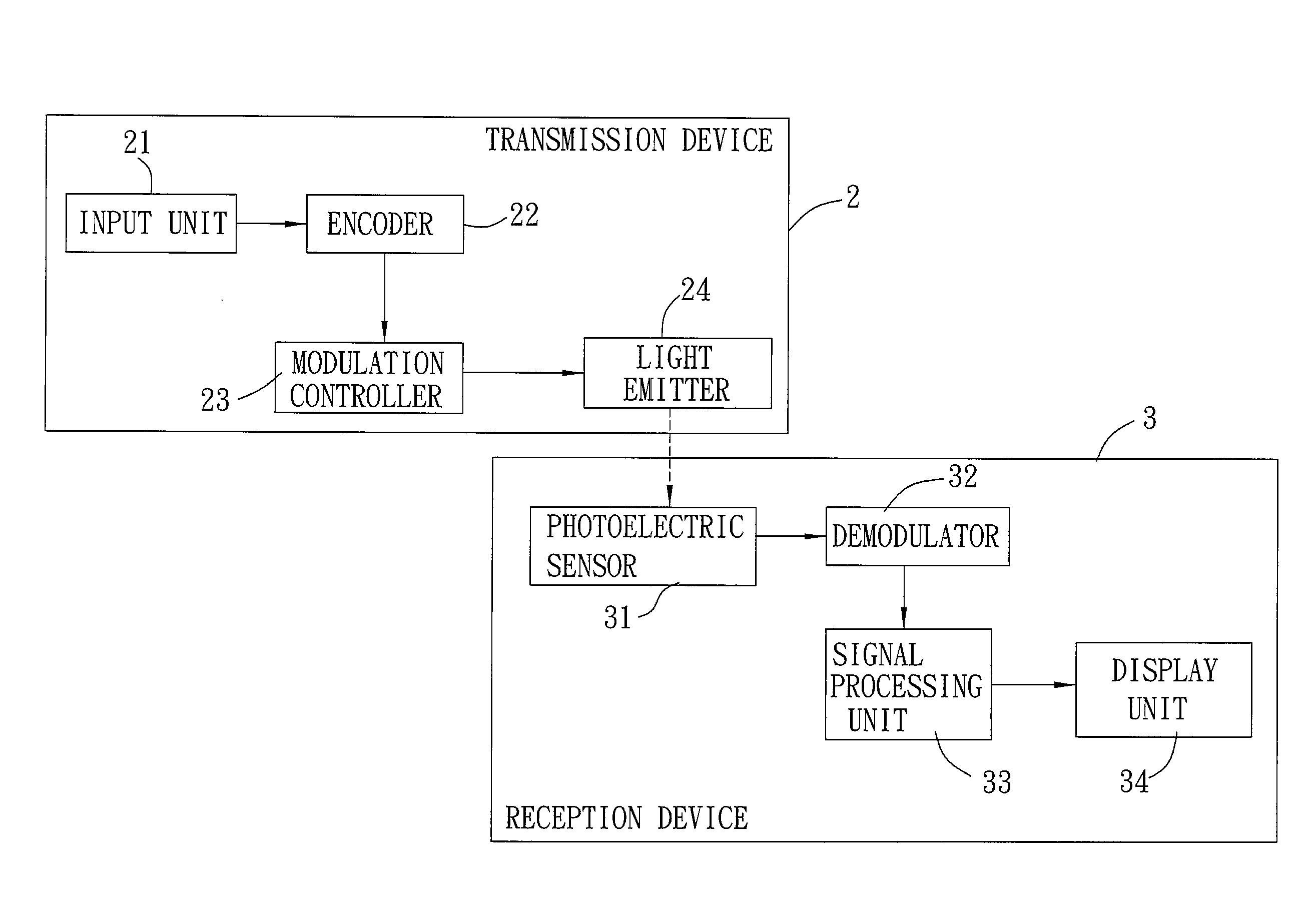

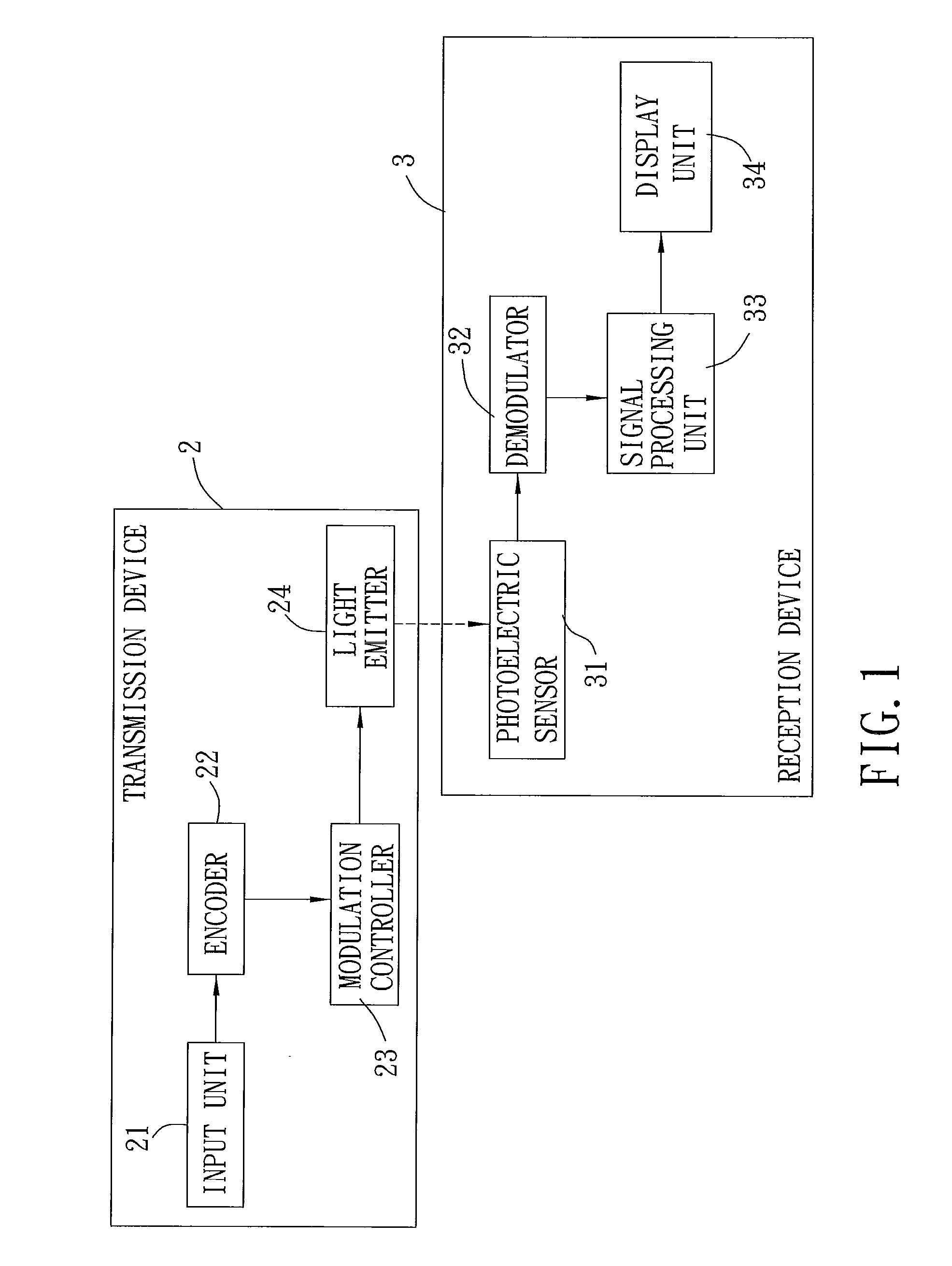

Real-time information transmission and reception system

ActiveUS20120169605A1Constant powerOvercomes drawbackInput/output for user-computer interactionCathode-ray tube indicatorsVIT signalsEngineering

In a real-time information transmission and reception system, a transmission device includes a light emitter driven by a modulated control signal generated by a modulation controller based on a code sequence, which is encoded from an input signal generated by an input unit and corresponding to information to be transmitted, to emit light. The modulated control signal has a constant average power, and various frequencies greater than 60 Hz. A reception device includes a photoelectric sensor for sensing the light emitted by the light emitter to generate a current signal that is demodulated and processed to generate a data output corresponding to the information and received by a display unit for displaying the information thereon.

Owner:KUN SHAN UNIVERSITY

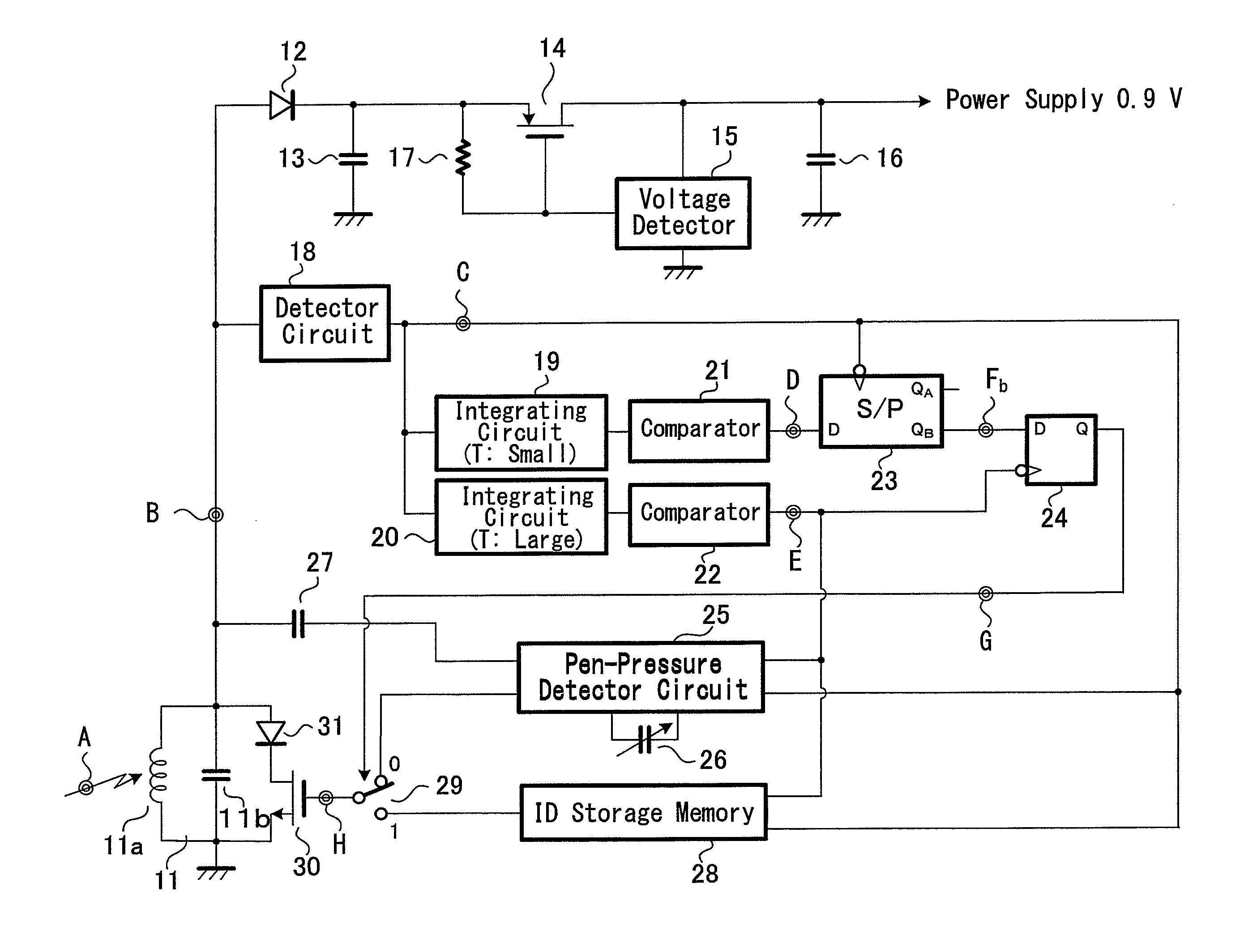

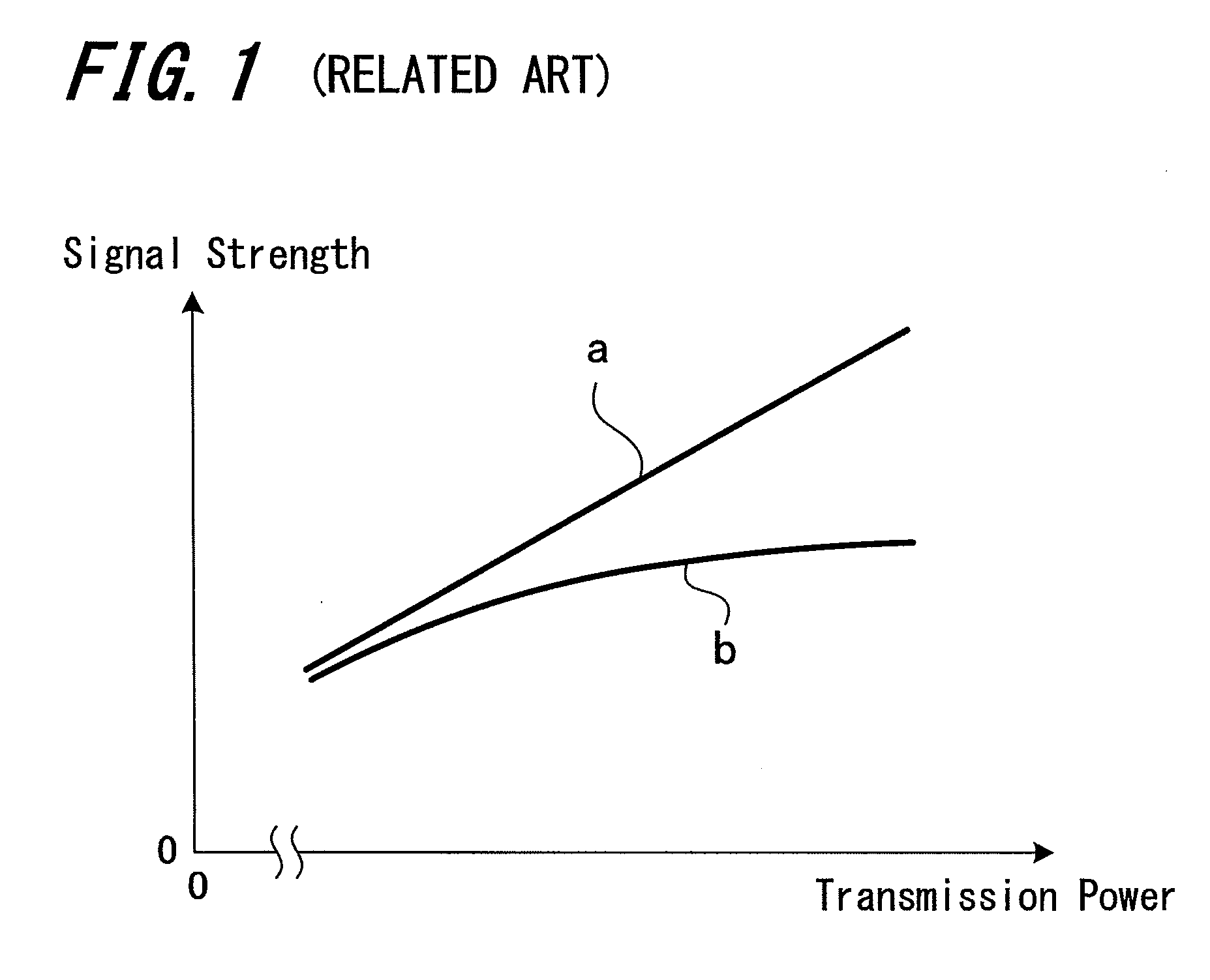

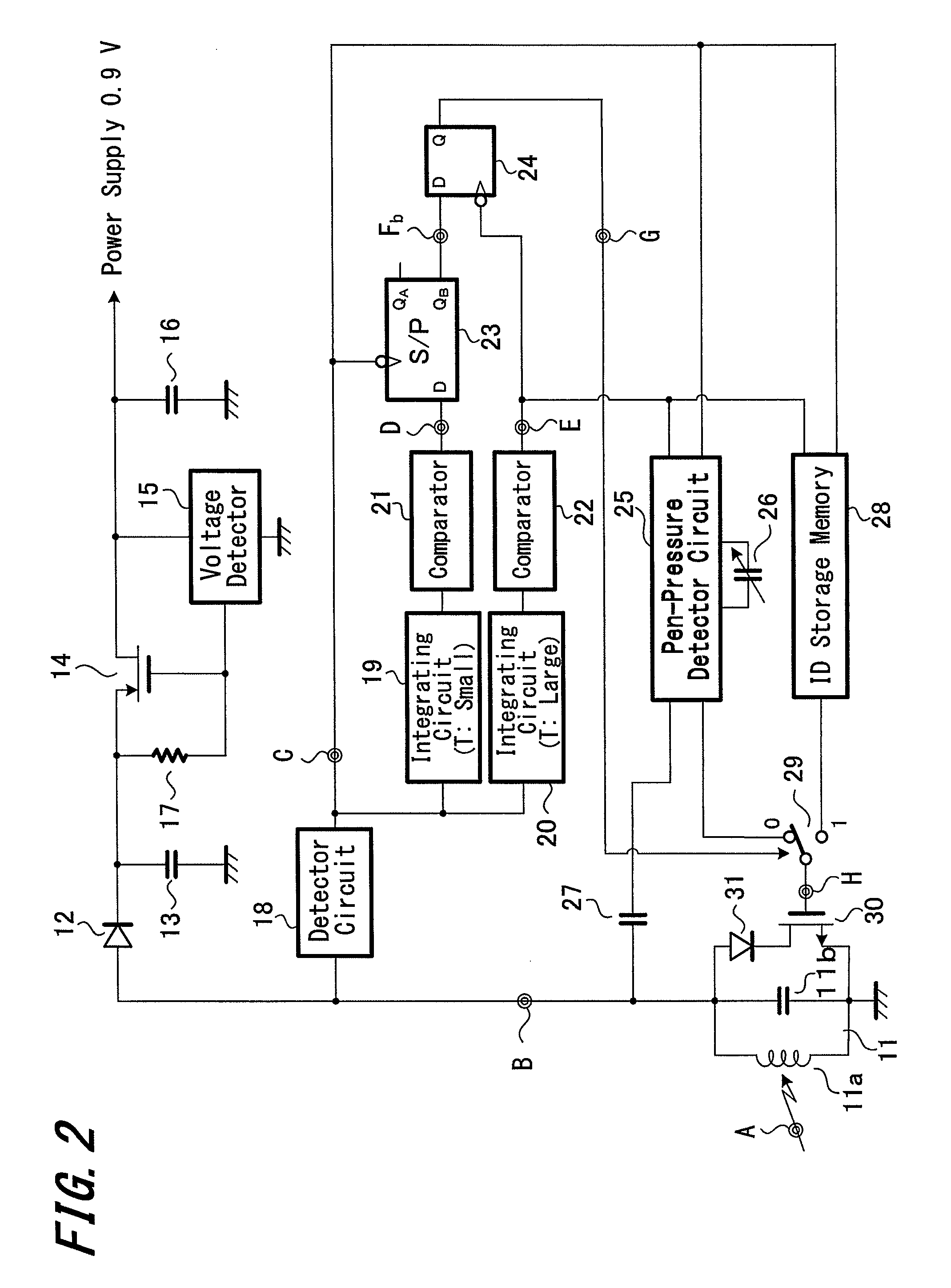

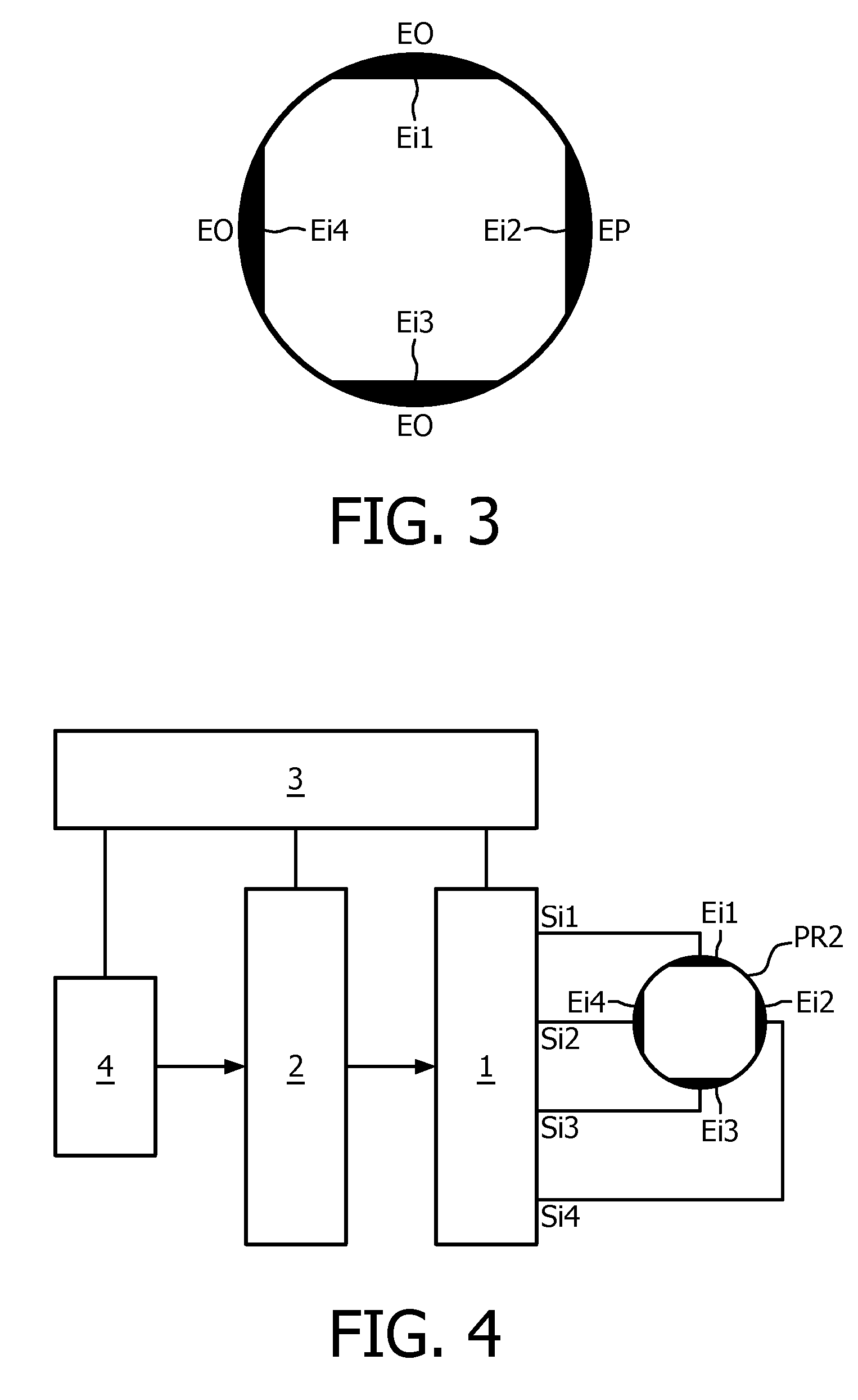

Position-detecting apparatus and position-indicating device

InactiveUS20080099254A1Reduce transmit powerConstant powerTransmission systemsGraph readingLocation detectionResonance

A position-detecting apparatus includes a tablet for transmitting an electromagnetic wave and a position-indicating device for generating a transmission signal based on the electromagnetic wave received from the tablet. The position-detecting apparatus detects a position on the tablet indicated by the position-indicating device. The position-detecting device includes: a resonance circuit having a coil and a capacitor, a power supply extraction unit, an information reply unit, and a voltage conversion unit configured to generate a second power supply having a predetermined voltage level which is lower than a first power supply extracted by the power supply extraction unit.

Owner:WACOM CO LTD

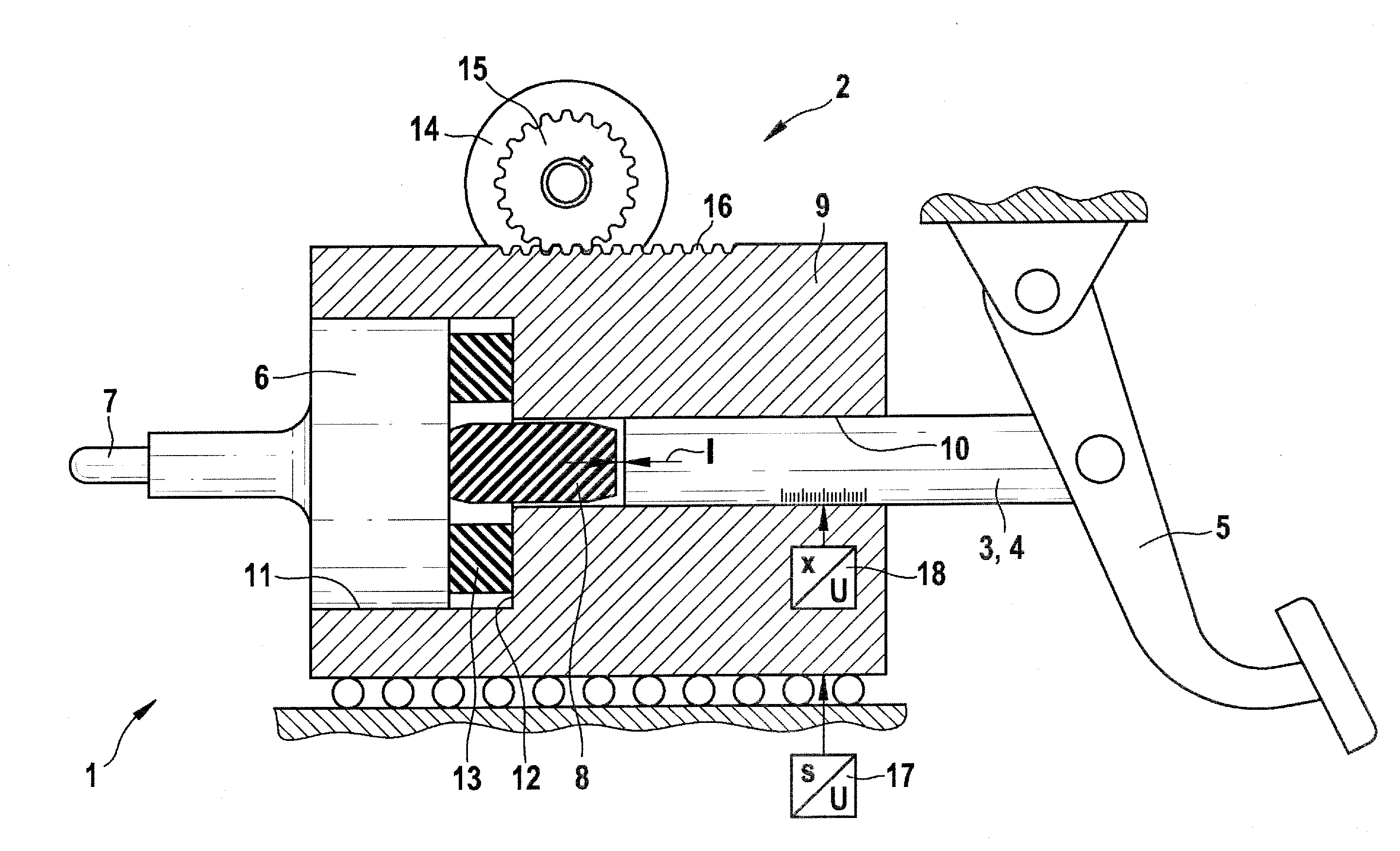

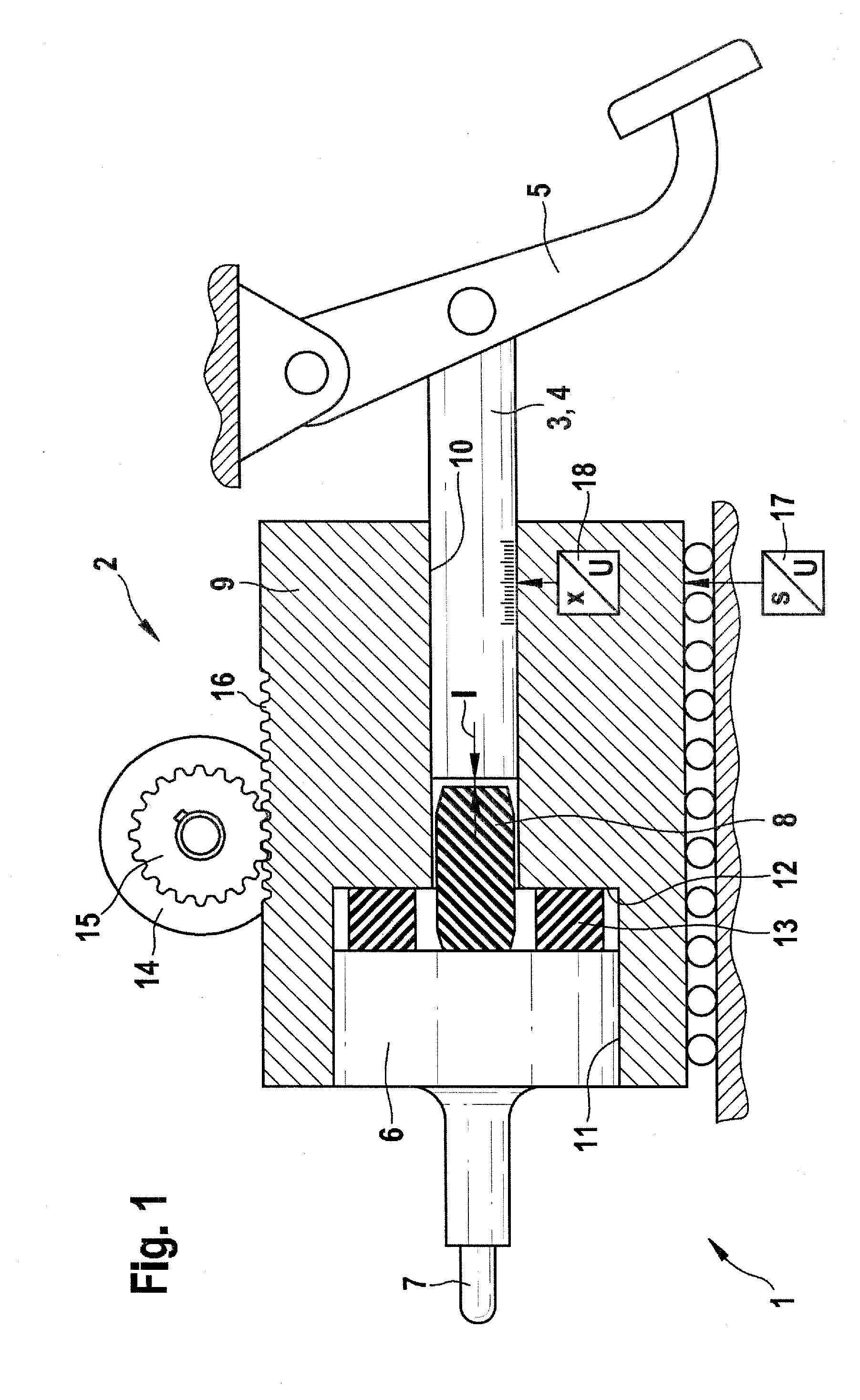

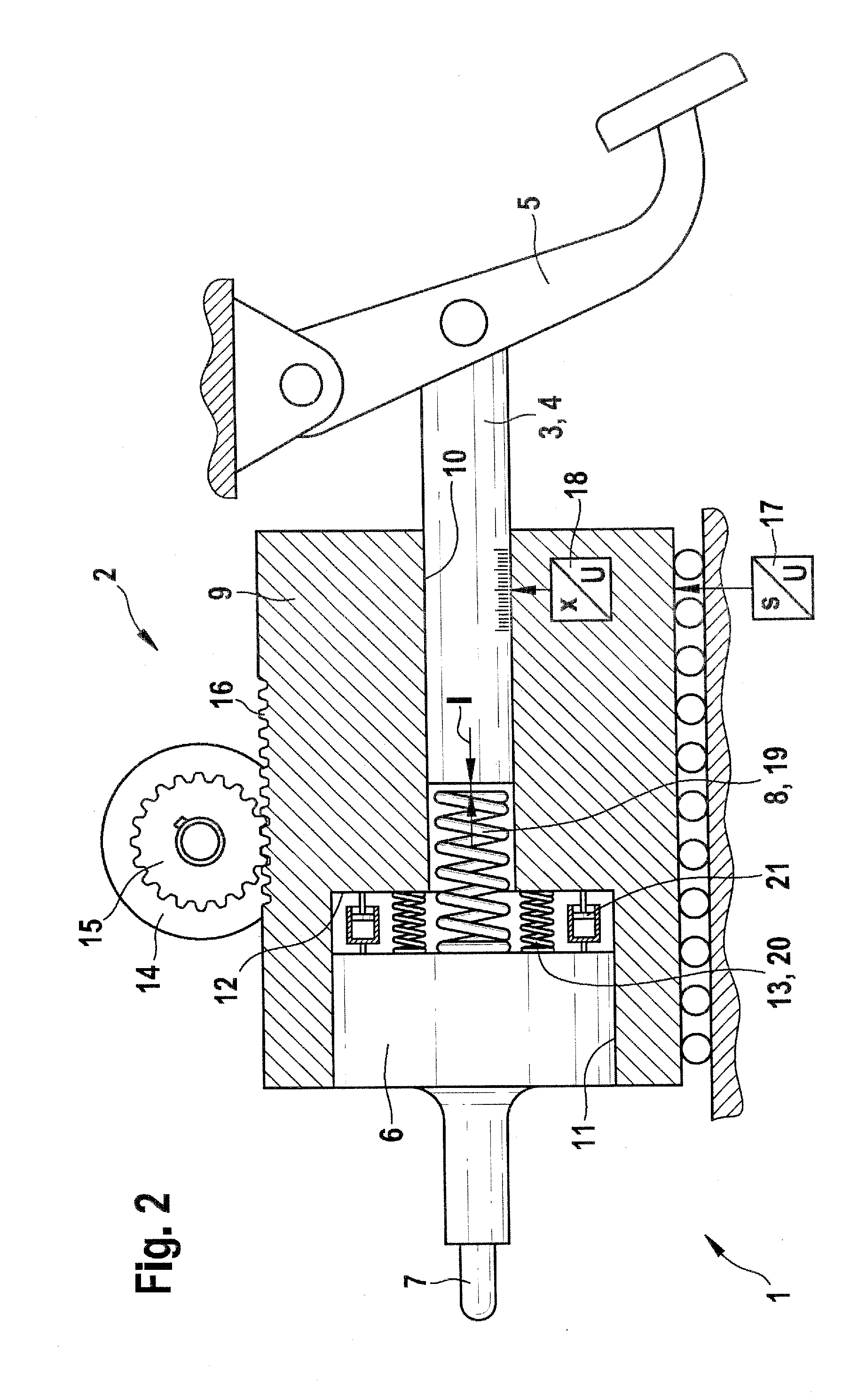

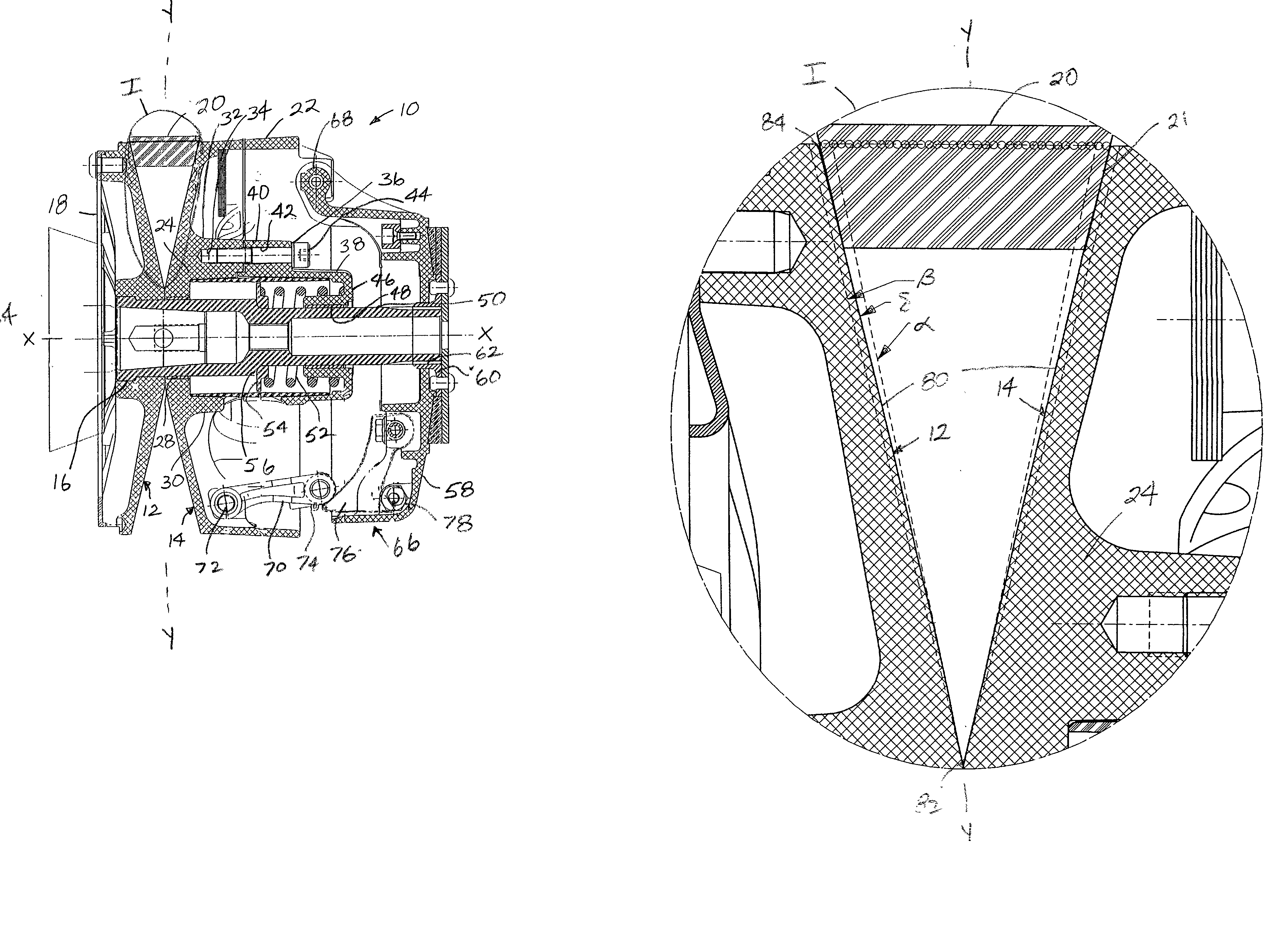

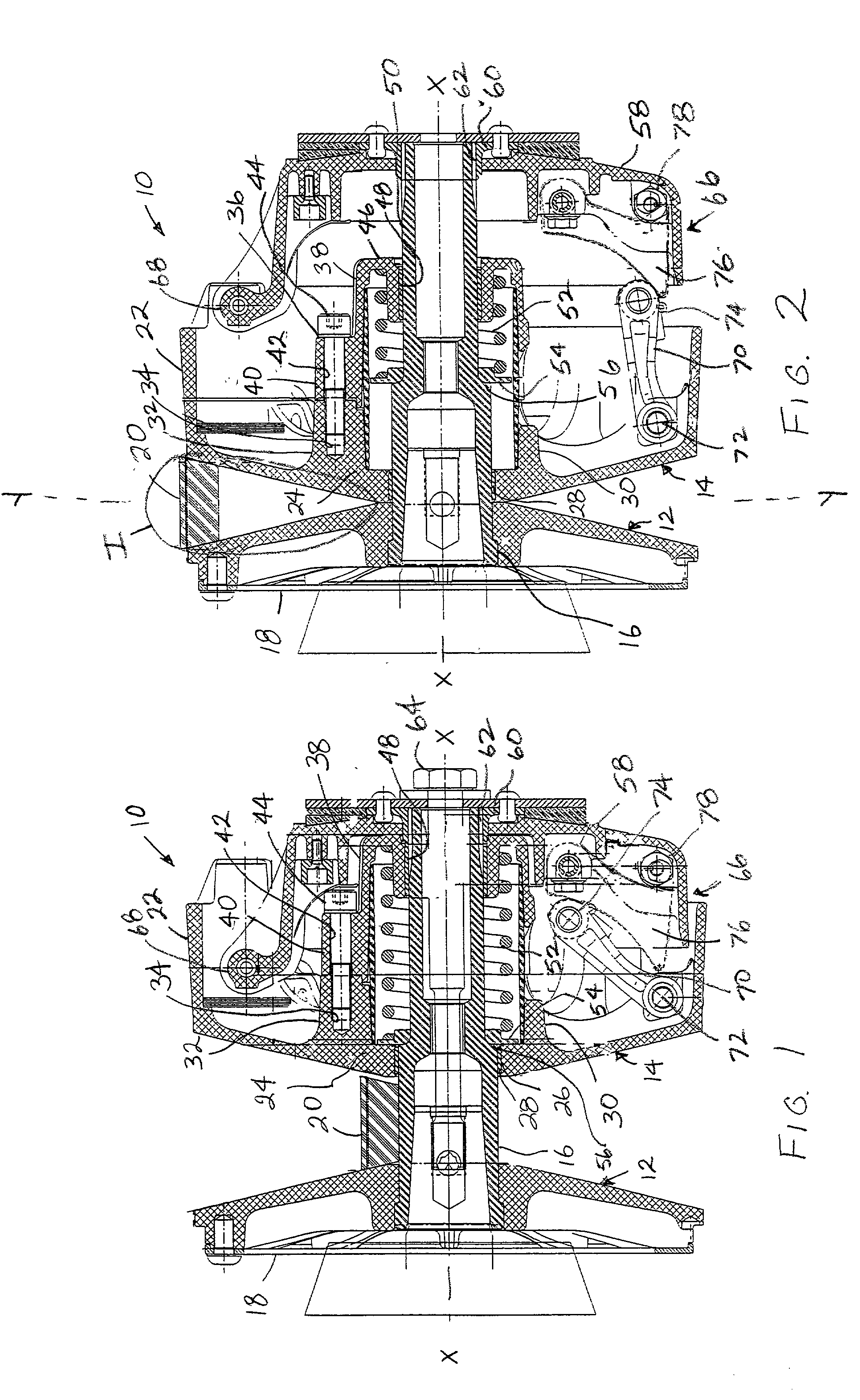

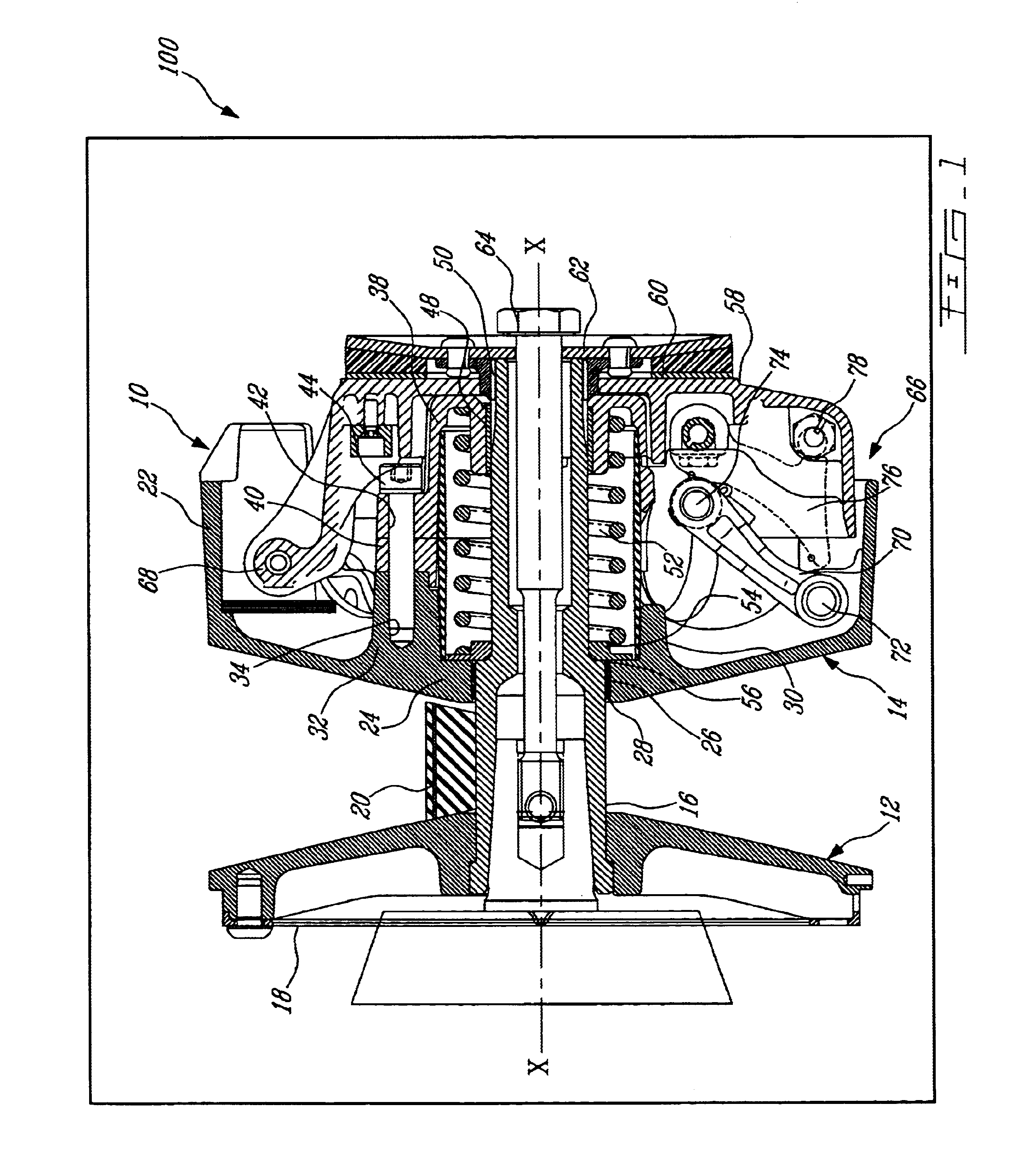

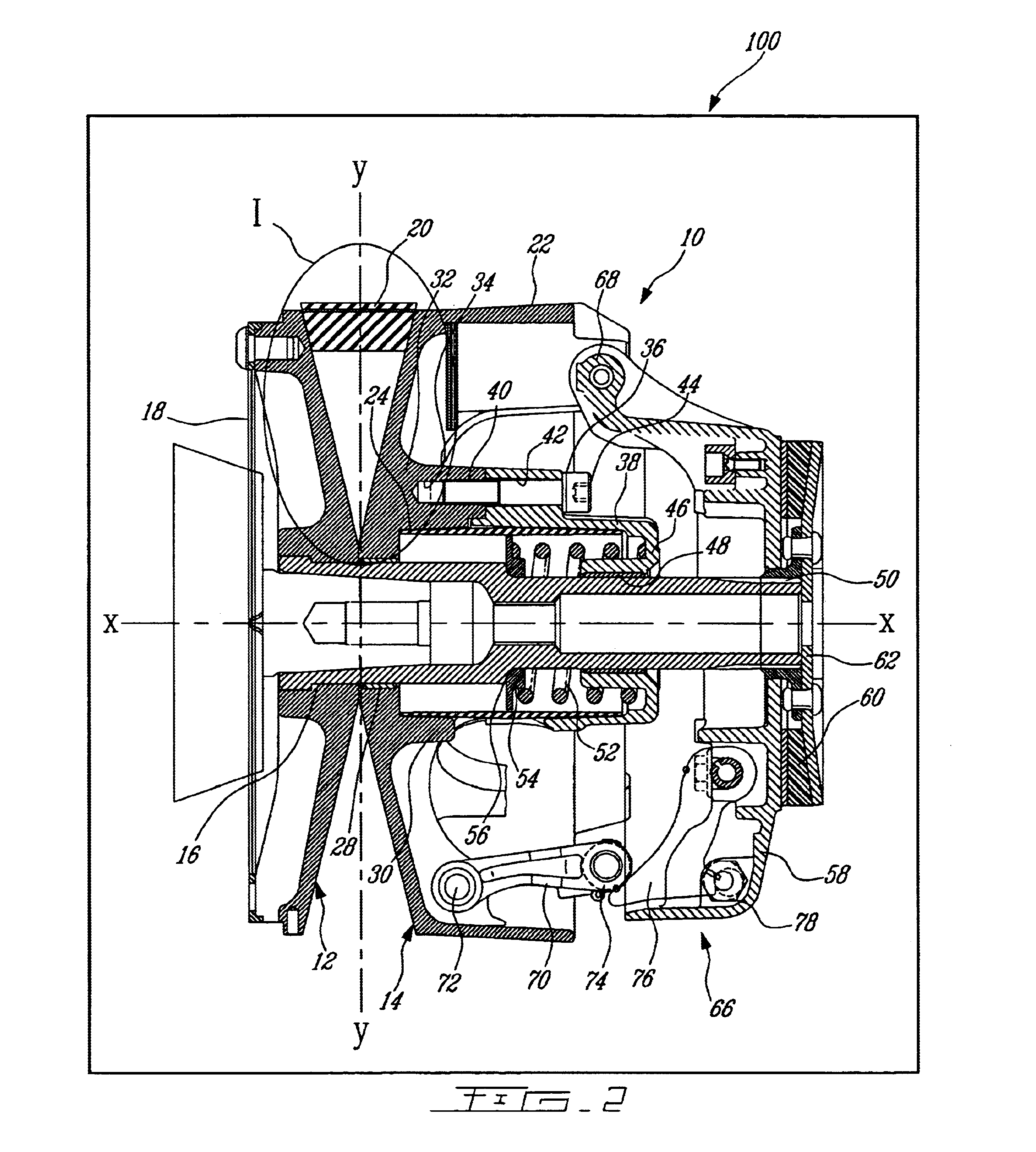

Brake booster

InactiveUS20110297493A1Increase brake forceConstant powerBraking action transmissionBrake actuating mechanismsElectromechanical actuatorMuscular power

The invention relates to an electromechanical brake booster having a piston rod to be actuated using muscular power, and an electromechanical actuator. Muscular power acting upon the pedal rod is transmitted via an elastic transmission element, for example a spring element, and the actuator power is transmitted separately thereof via its proper elastic transmission element which has for example a number of spring elements and dampers arranged in parallel thereto. The controllable brake booster is operated depending on a variable representing the relative deviation of the booster body and the input element. The brake booster according to the invention allows the adjustment of a booster characteristic which is variable in a wide range and which inter alia can depend on an actuation path, an actuation speed and / or an actuation acceleration. The switch-over to different modes, for example a sports mode, is also possible.

Owner:ROBERT BOSCH GMBH

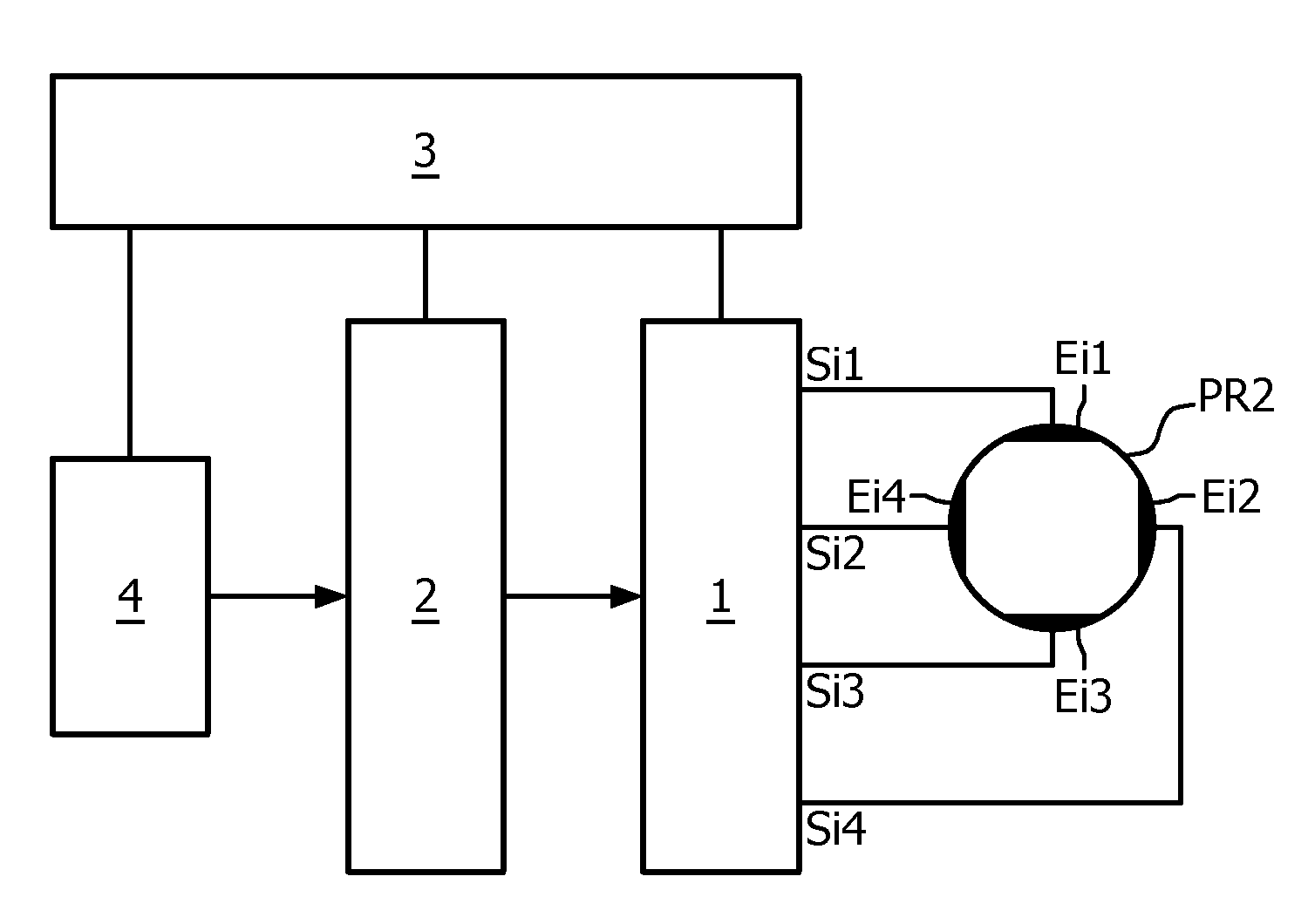

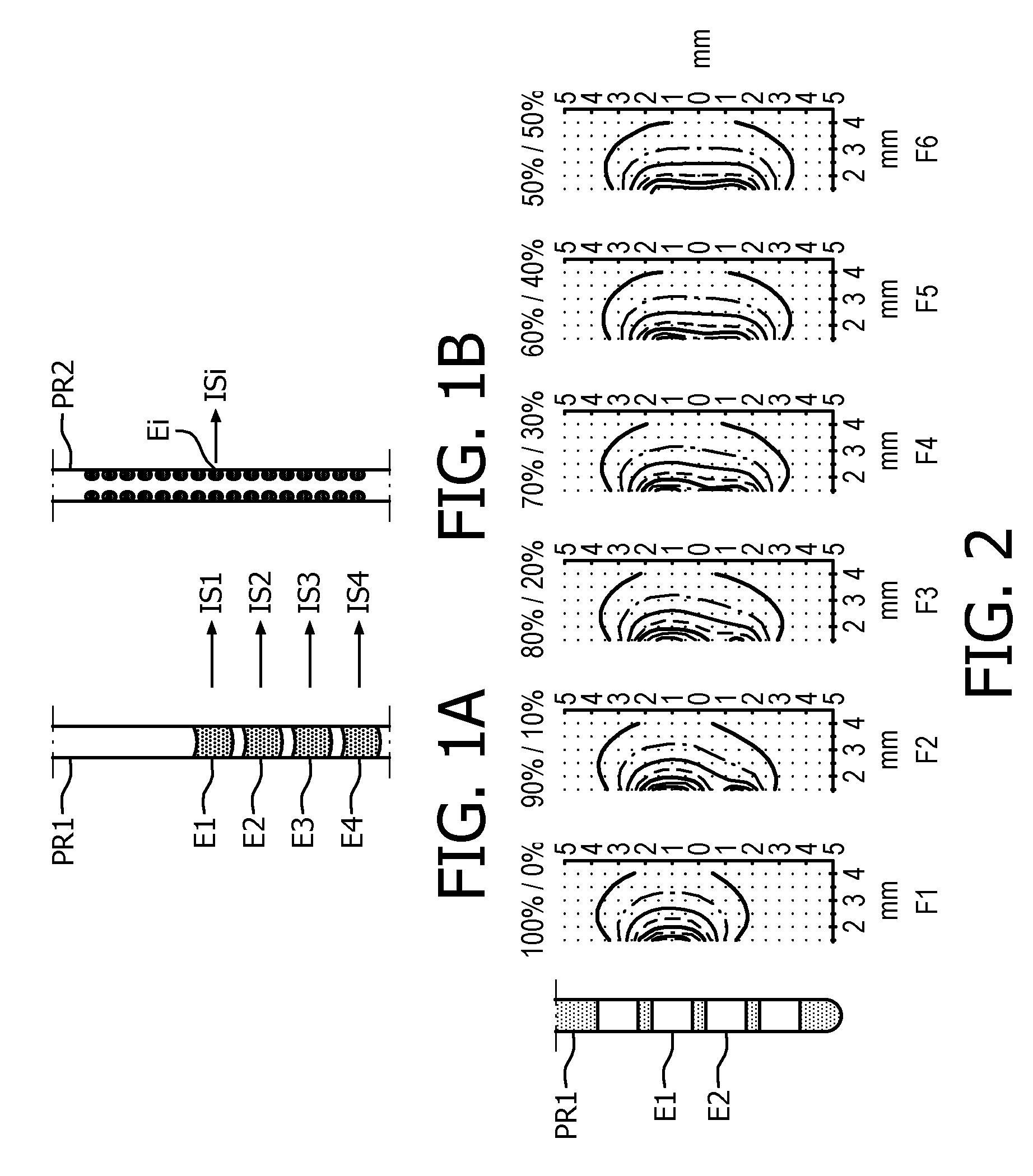

High Resolution Electrical Stimulation Leads

ActiveUS20120277821A1Efficient use ofIncrease volumeHead electrodesArtificial respirationElectricityEngineering

System for providing a stimulus comprising a probe with multiple electrodes each capable of providing a particular current to surrounding tissue a generator for providing to each of the electrodes the particular current a controller for controlling the generator to provide current to the electrodes to achieve a desired electrical field around the probe.

Owner:MEDTRONIC BAKKEN RES CENT

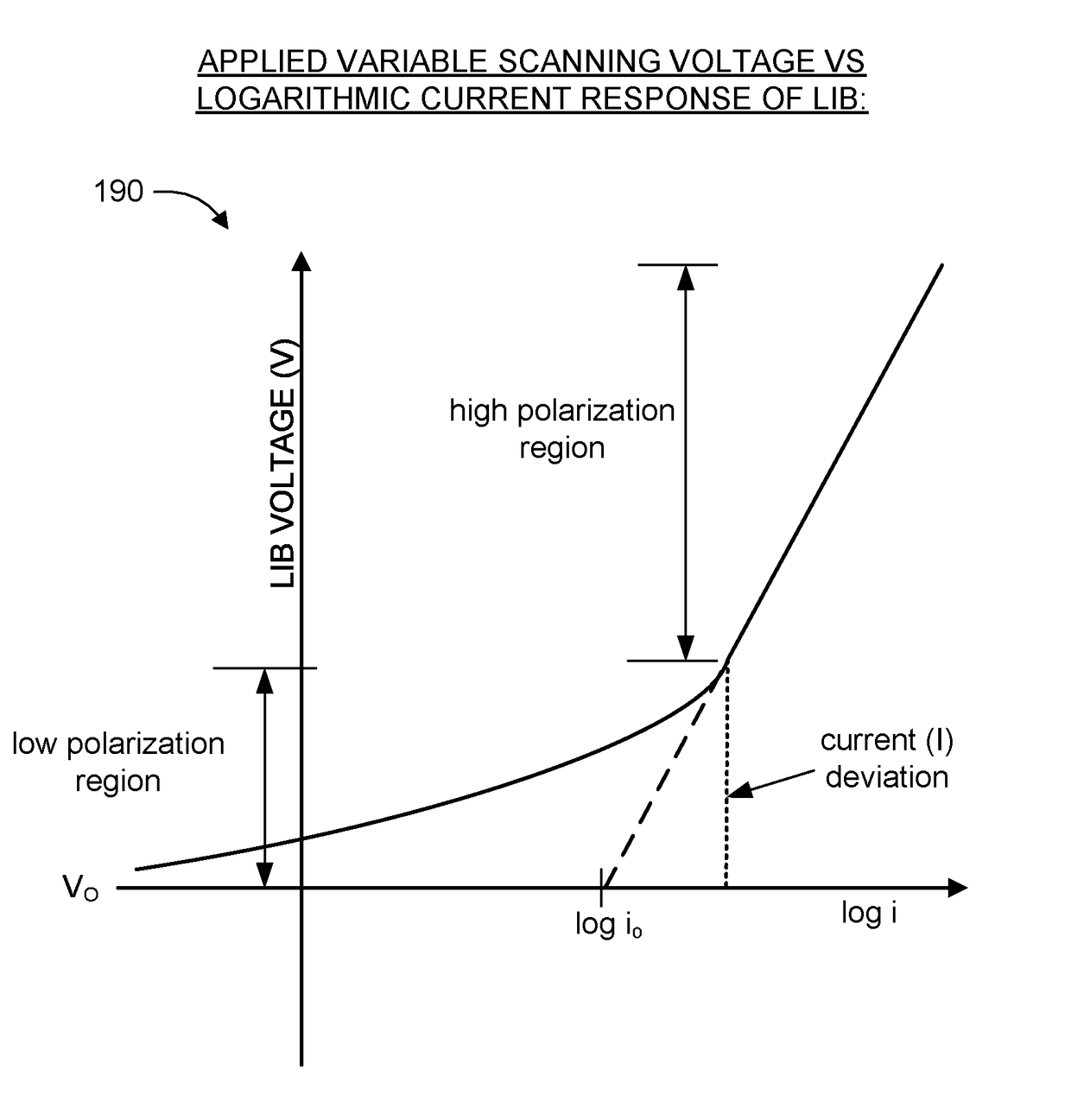

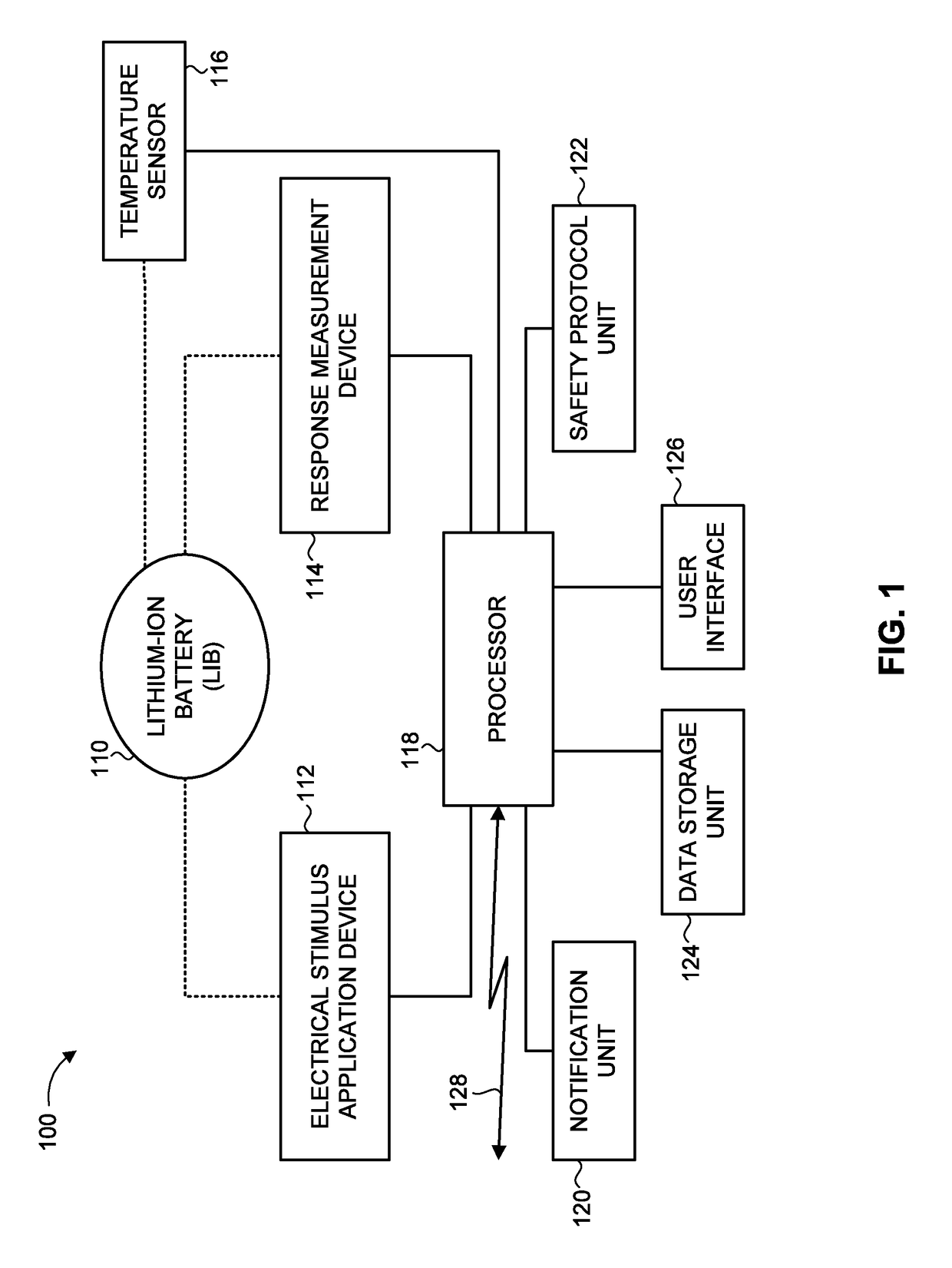

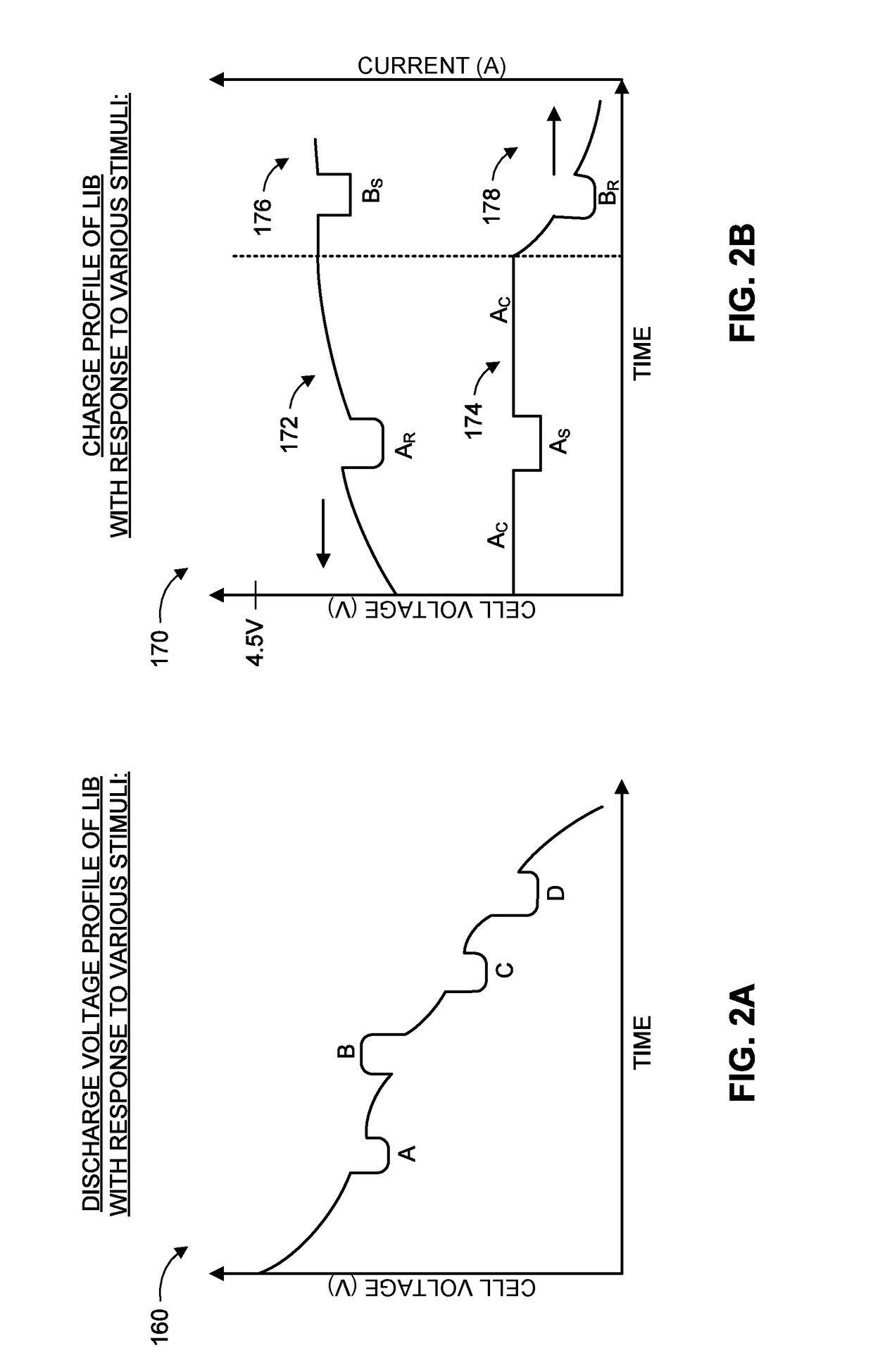

Lithium-ion battery safety monitoring

Method and system for monitoring the safety of a rechargeable Li-ion battery (LIB). An initial electrical state of the LIB is determined and altered by application or removal of DC electrical stimulus to trigger a time-varying response. The time-varying response of the LIB is measured, and at least one primary response parameter associated with the functional form of the measured response is extracted. At least one secondary response parameter is derived from the primary response parameter. A composite response parameter may be further derived from the primary response parameter and secondary response parameter. A likelihood of a short circuit precursor condition is determined in accordance with the primary response parameter, secondary response parameter and / or composite response parameter. Based on the determined likelihood, an alert of a potential short circuit derived hazard may be provided and / or a corrective measure to mitigate or prevent a short circuit derived hazard may be implemented.

Owner:ALGOLION LTD

Power controller and vehicle equipped with power controller

InactiveUS7891451B2Avoid componentsAvoid generatingAc-dc conversion without reversalConversion with intermediate conversion to dcPower controllerZero phase

An ECU detects an effective value and phase of a voltage from a commercial power supply, based on a voltage from a voltage sensor. Further, ECU generates a command current, which is a command value of current caused to flow through power lines and in-phase with the voltage of the commercial power supply, based on the detected effective value and the phase and on a charge / discharge power command value for a power storage device. Then, ECU controls zero-phase voltage of inverters based on the generated command current.

Owner:TOYOTA JIDOSHA KK

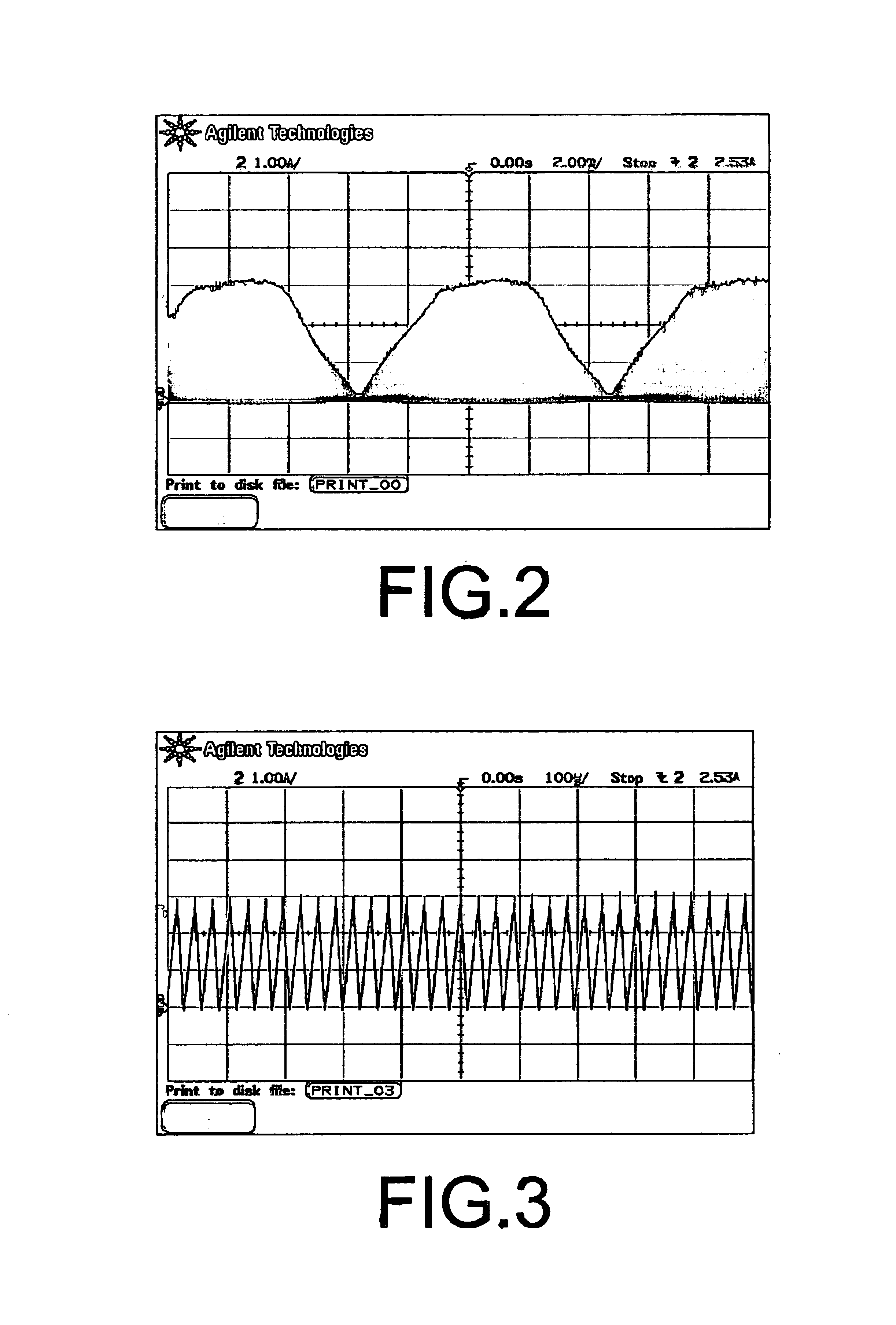

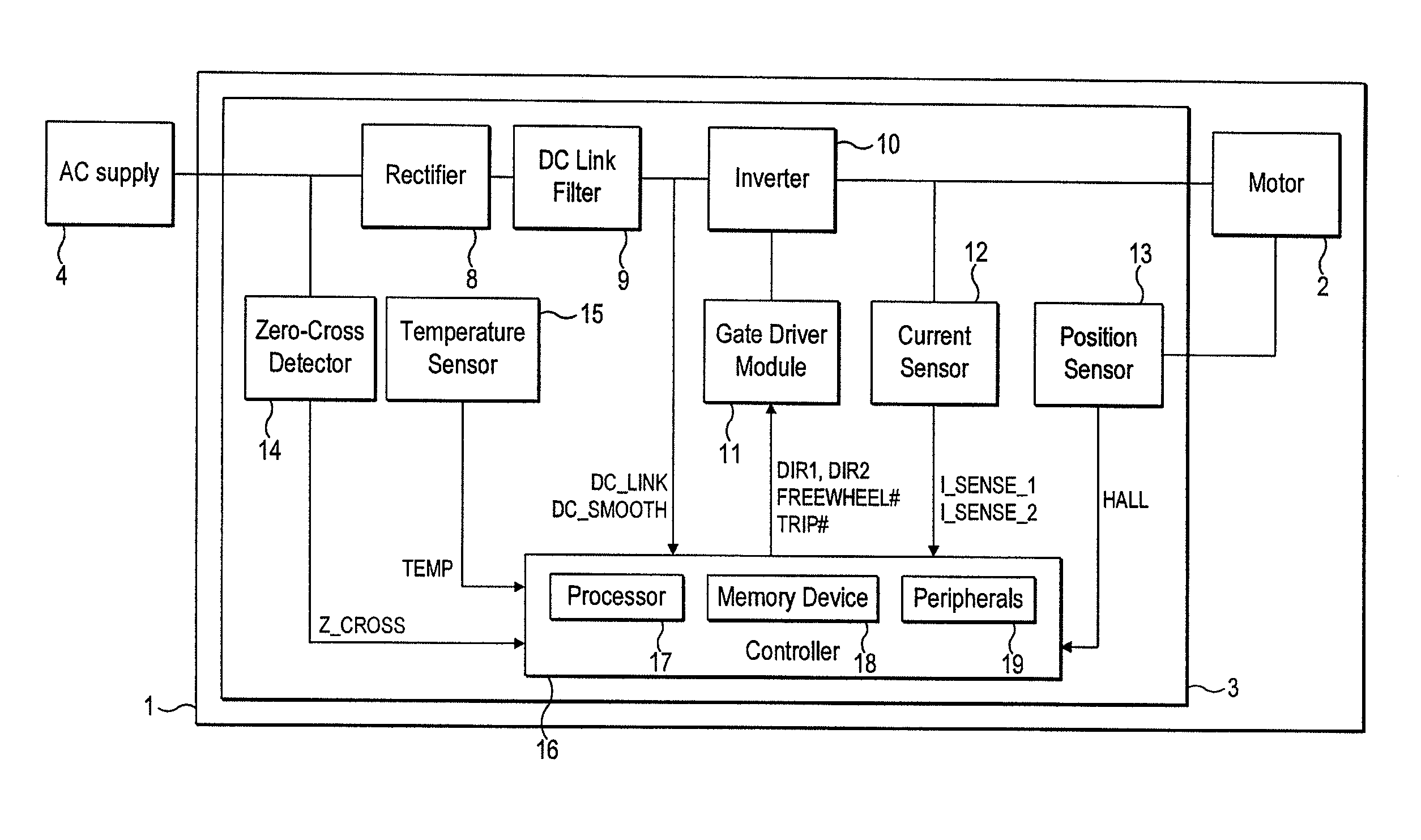

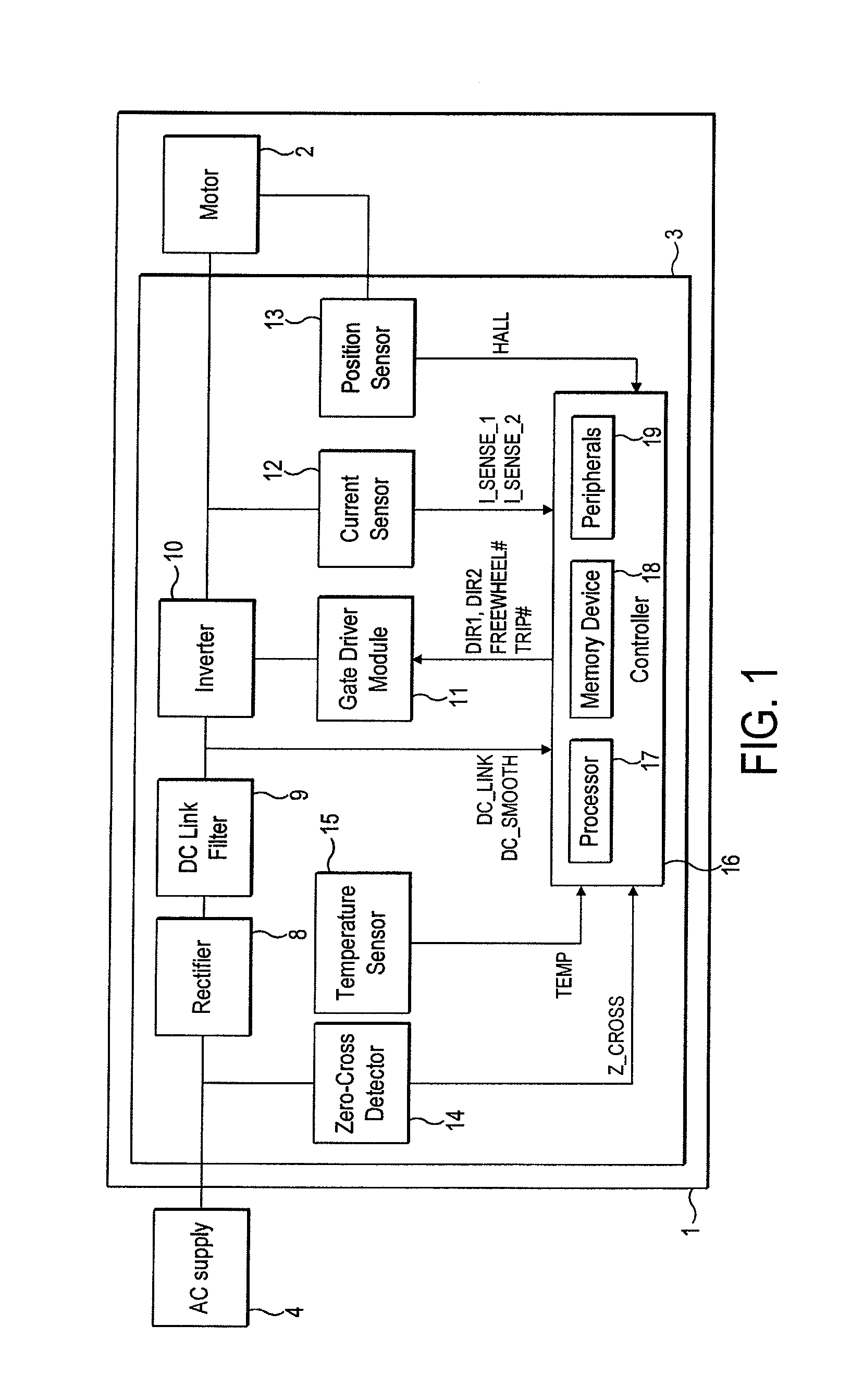

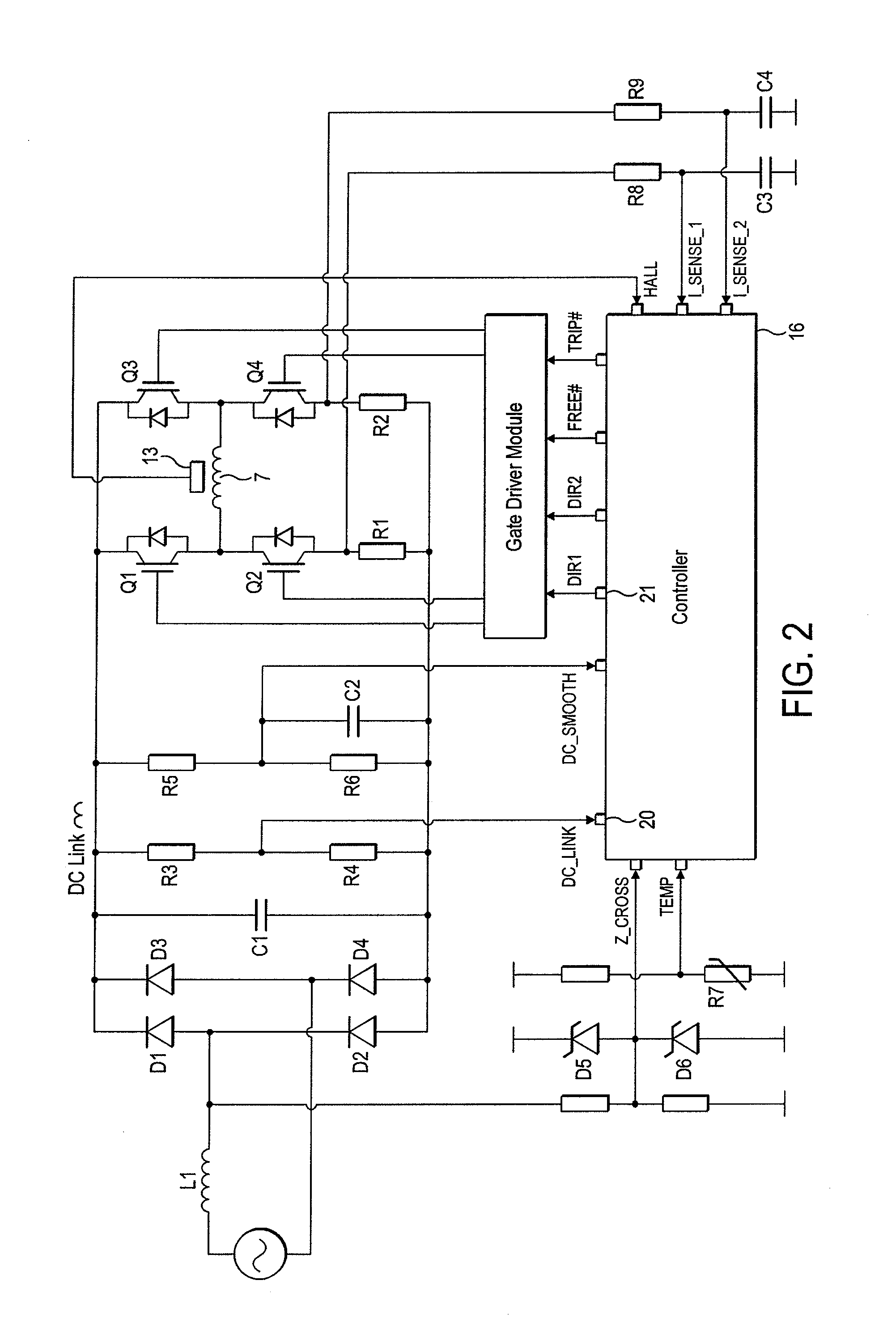

Control of a brushless permanent-magnet motor

ActiveUS20110254488A1Constant powerImprove power factorMotor/generator/converter stoppersSynchronous motors startersElectricityControl system

A method of controlling a brushless permanent-magnet motor that includes rectifying an alternating voltage to provide a rectified voltage having a ripple of at least 50%, and exciting a winding of the motor with the rectified voltage. The winding is excited in advance of zero-crossings of back EMF by an advance period and is excited for a conduction period over each electrical half-cycle of the motor. The advance period and / or the conduction period are then adjusted in response to changes in the speed of the motor and / or the RMS value of the alternating voltage so as to maintain constant average power. Additionally, a control system that implements the method, and a motor system that incorporates the control system.

Owner:DYSON TECH LTD

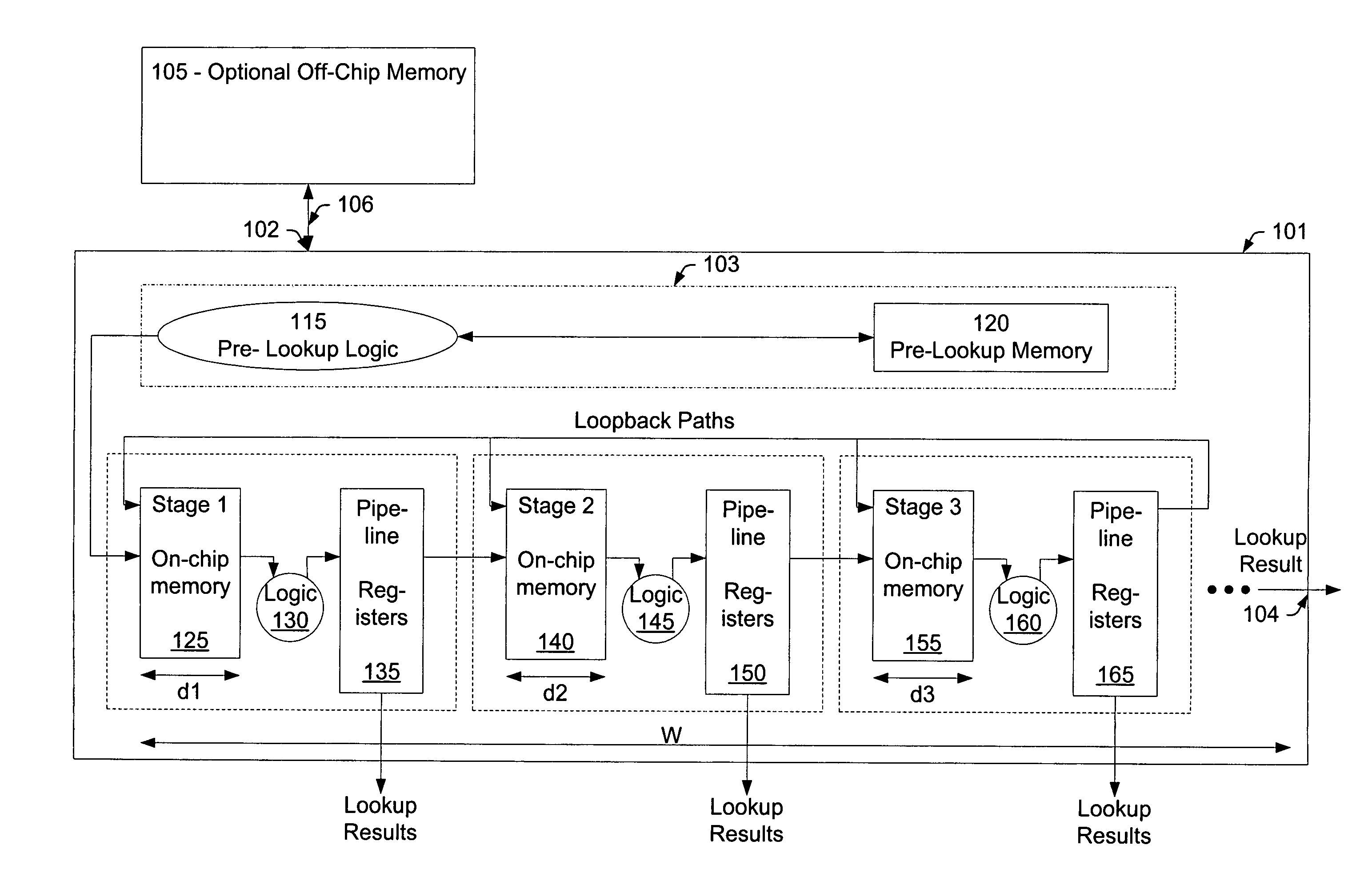

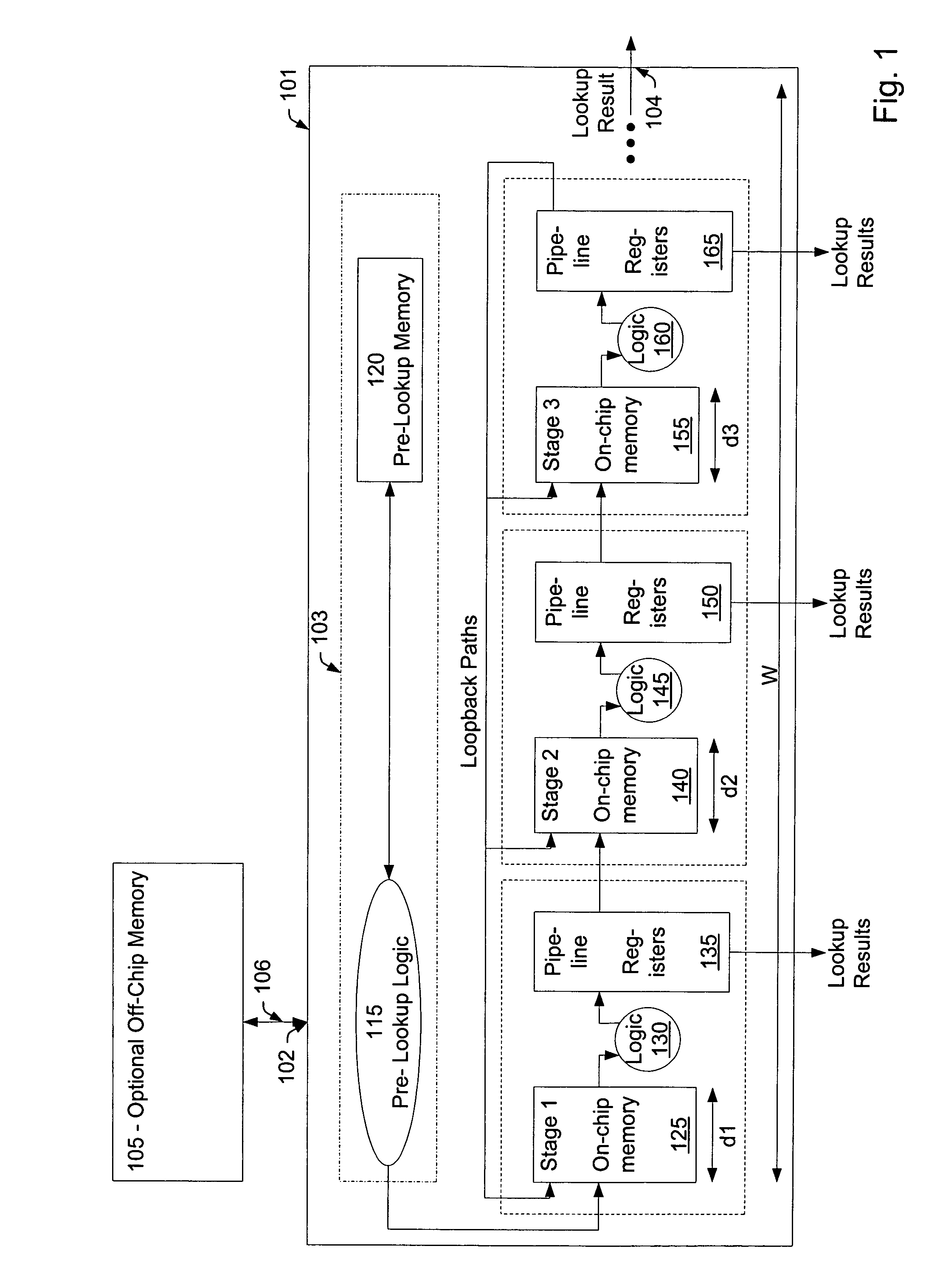

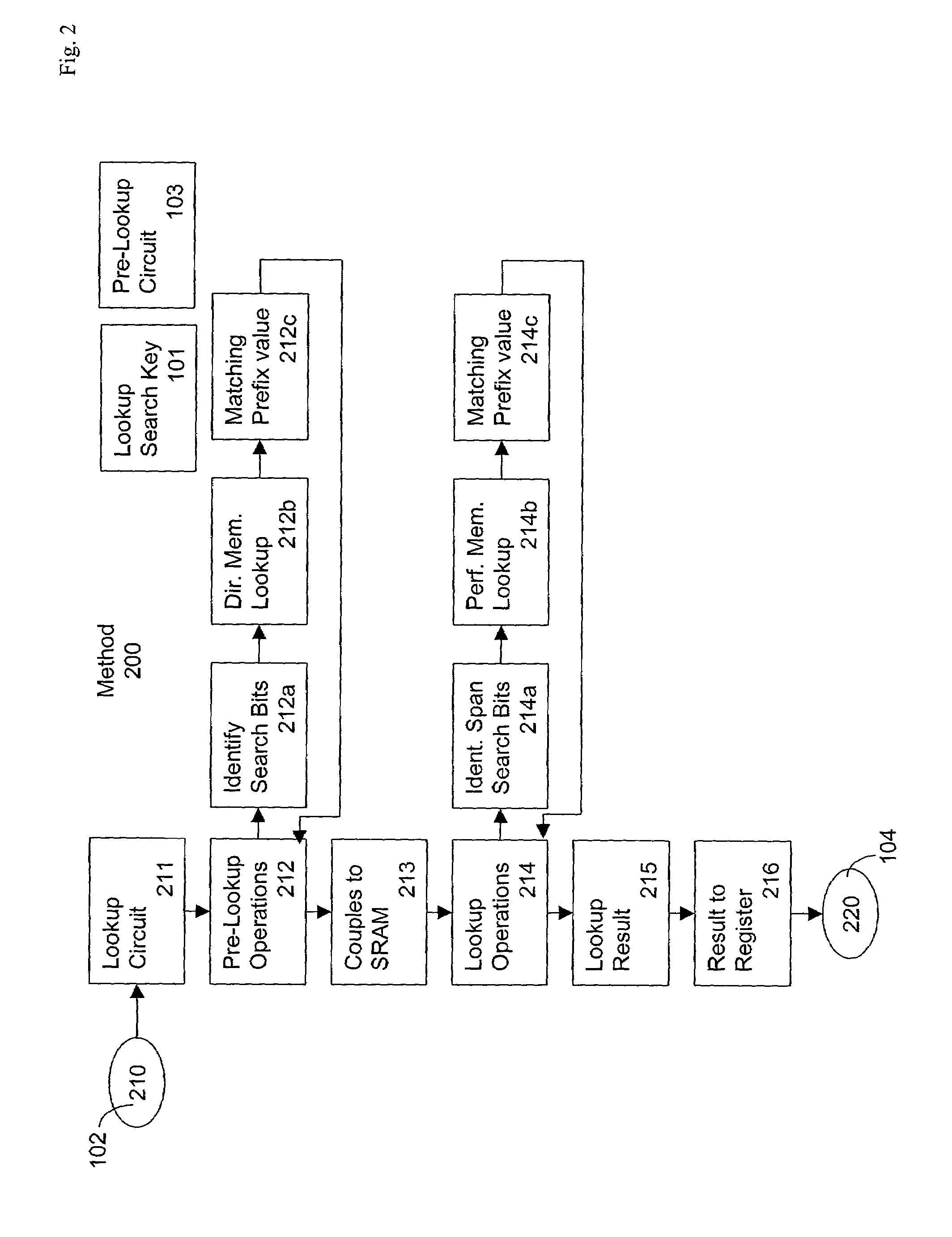

High-speed message forwarding lookups for arbitrary length strings using pipelined memories

InactiveUS7017021B2Low scaling factorConstant power requirementData switching networksMemory systemsRandom access memoryNetwork topology

The invention provides a method and system for lookup of message header information that has the advantages of low-power, speed, and flexibility. The invention uses a sequence of pipelined on-chip memories, each having only a portion of the header information intended for lookup. Each one of the on-chip memories simultaneously performs a lookup on a portion of the header information, allowing embodiments of the invention to operate on multiple messages worth of header information substantially simultaneously. The invention uses a novel data structure for recording destination addresses in the sequence of on-chip memories, having the property that moving information about destination addresses, or otherwise responding to changes in network topology is flexible, while at the same time maintaining relatively dense usage of the on-chip memories. The novel data structure allows embodiments of the invention to find the longest match destination address with no substantial additional processing over random-access memory lookup.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

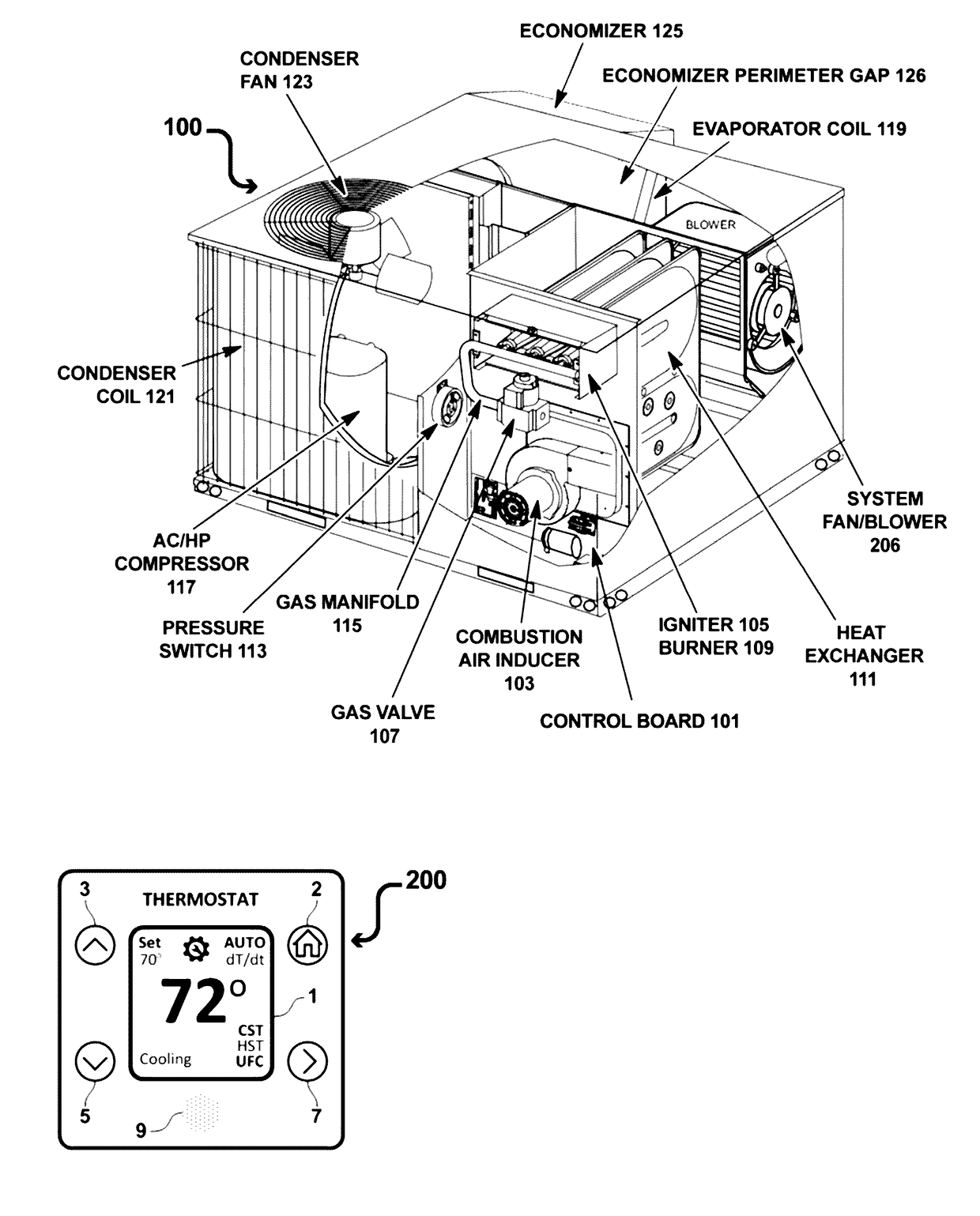

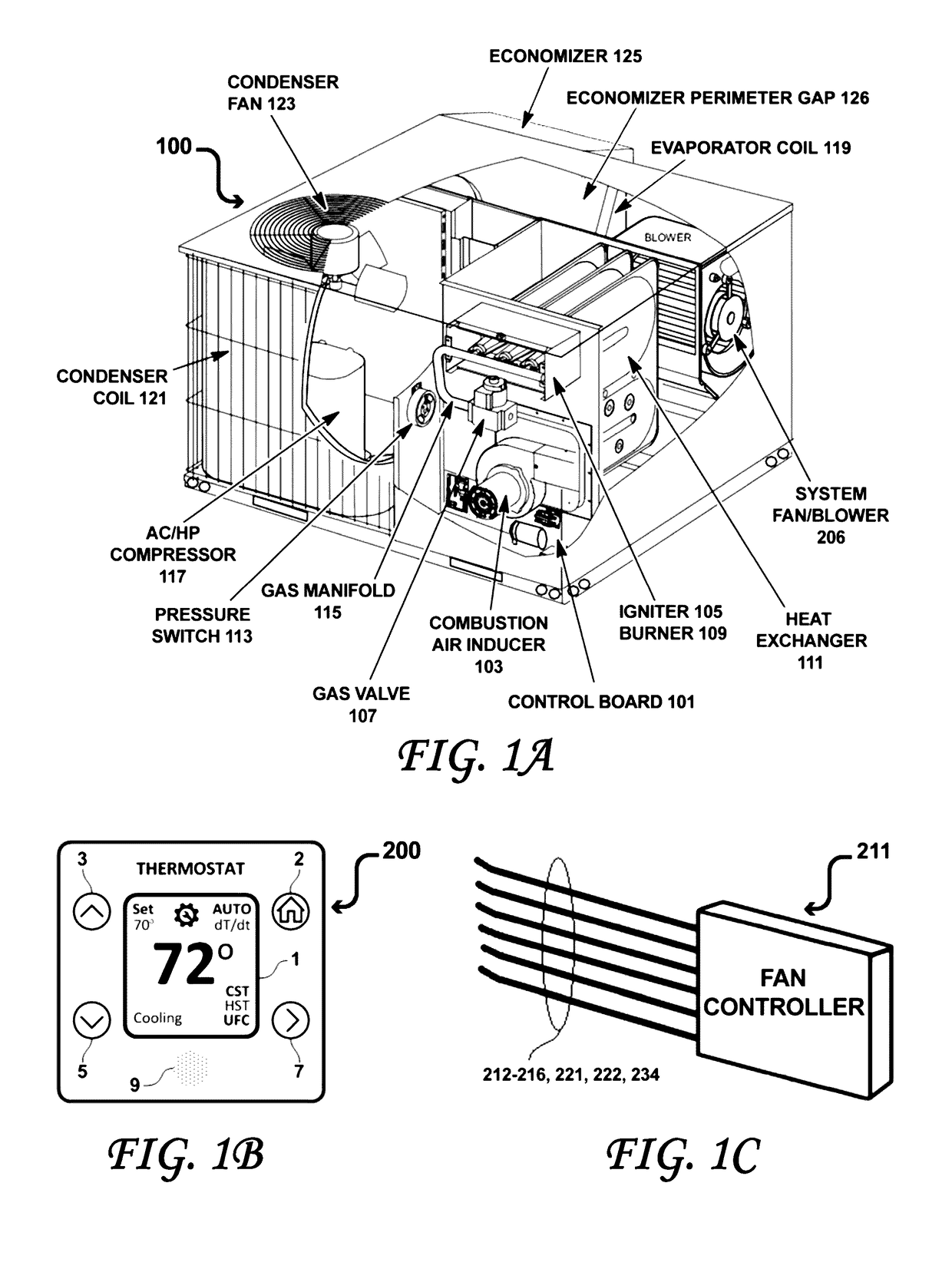

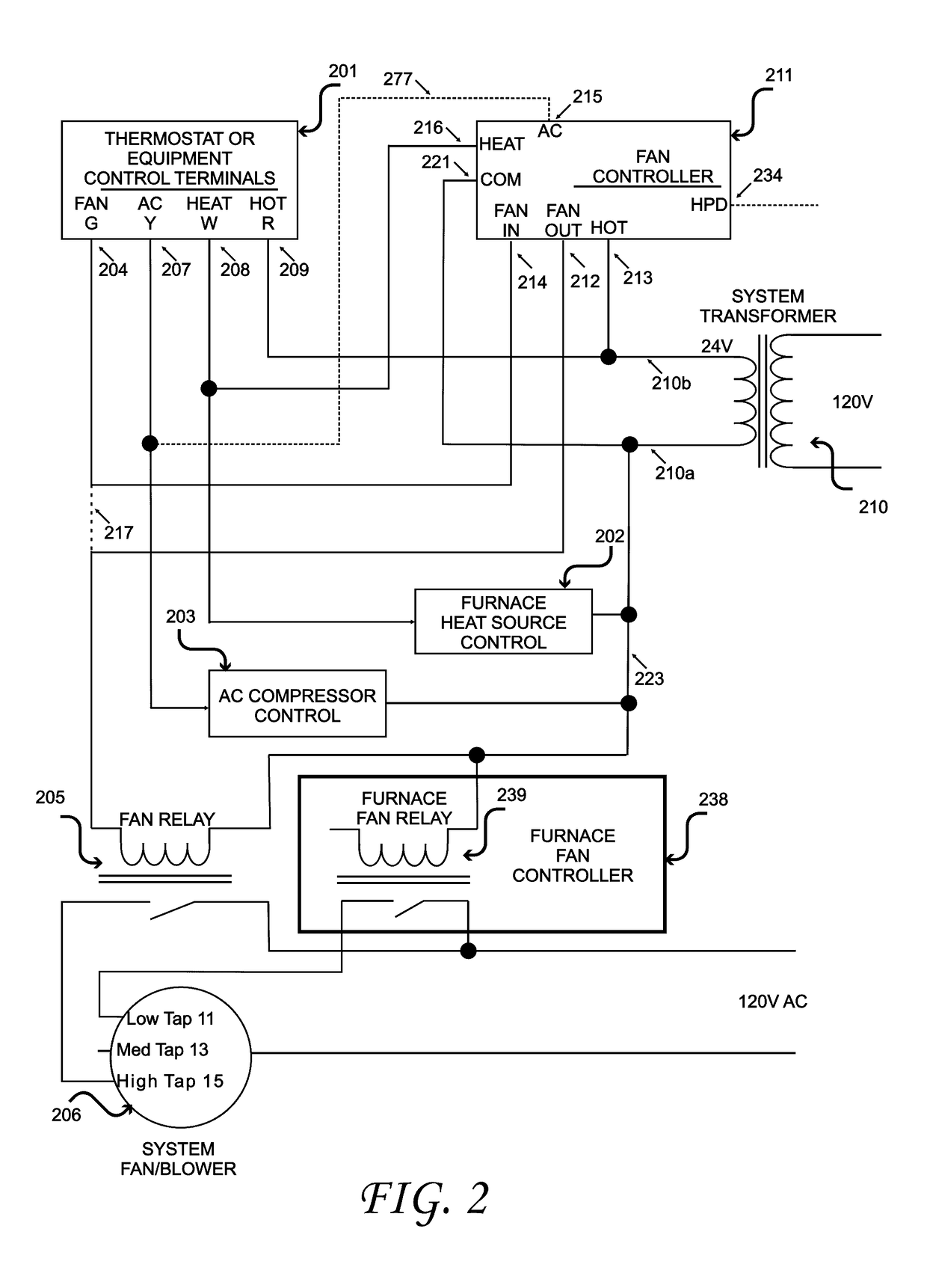

Fan Controller

ActiveUS20170115025A1Constant powerShort of heat sourceFluid heatersMechanical apparatusTime delaysEngineering

Owner:LAU JAMES

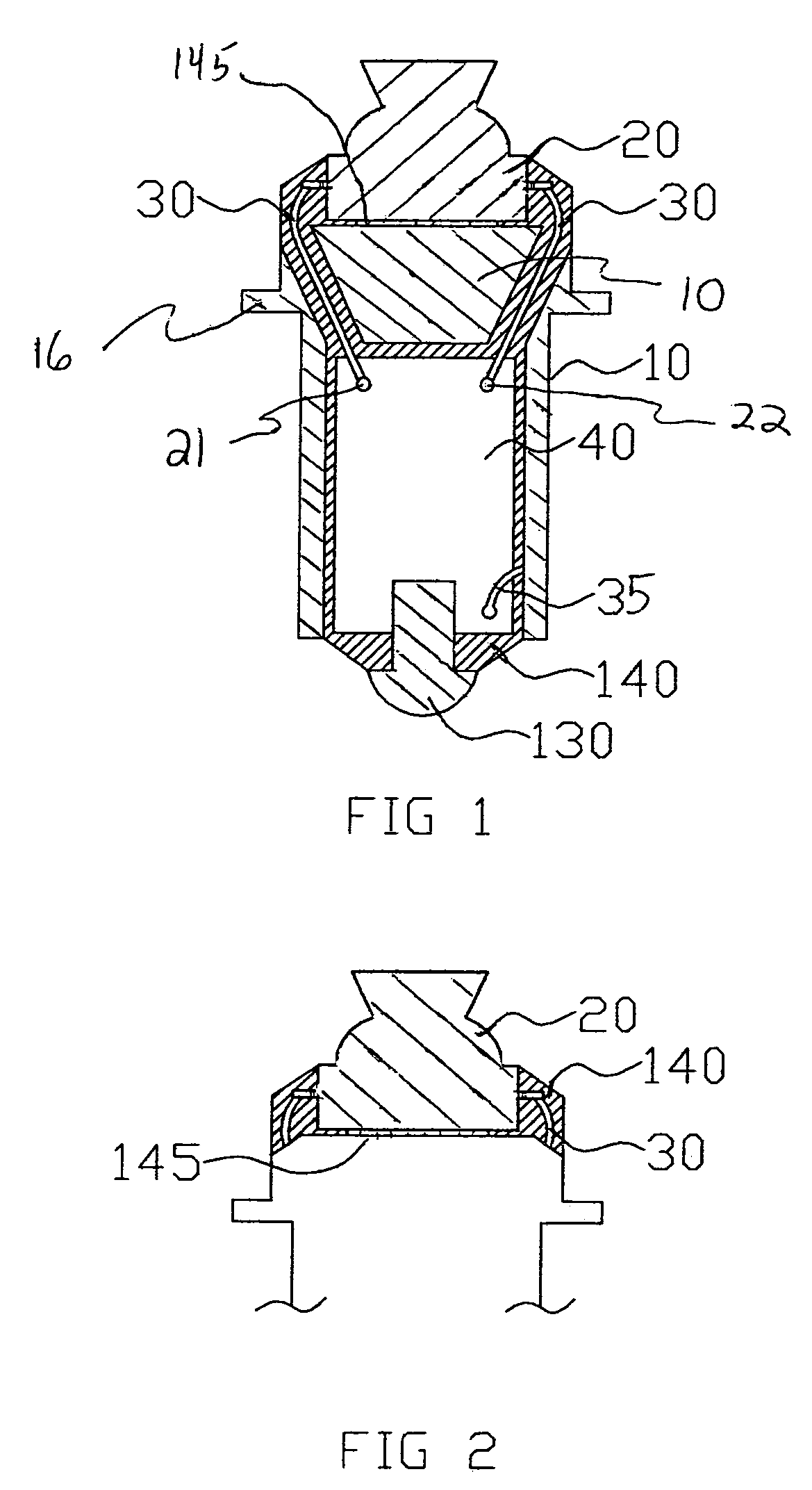

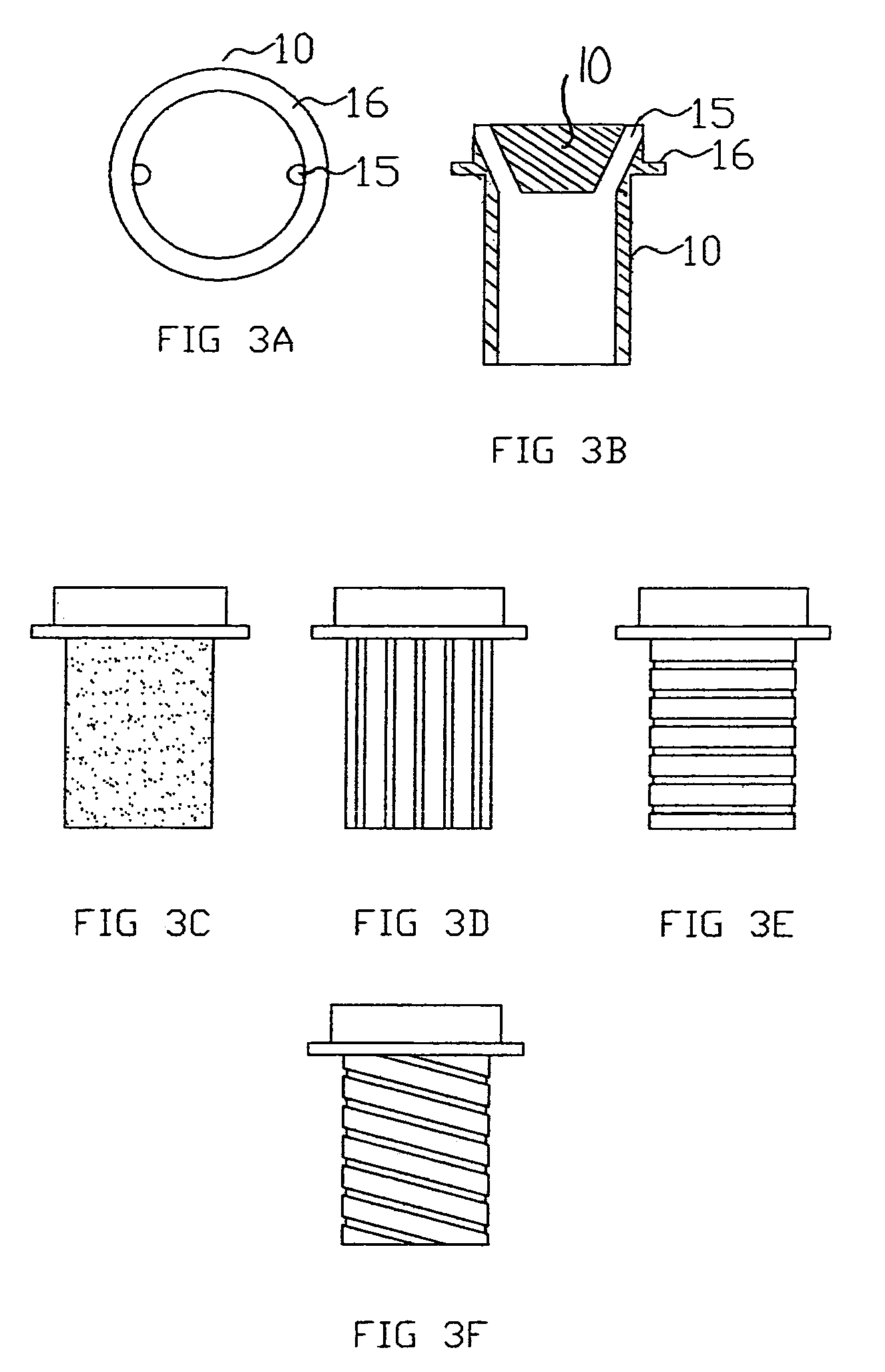

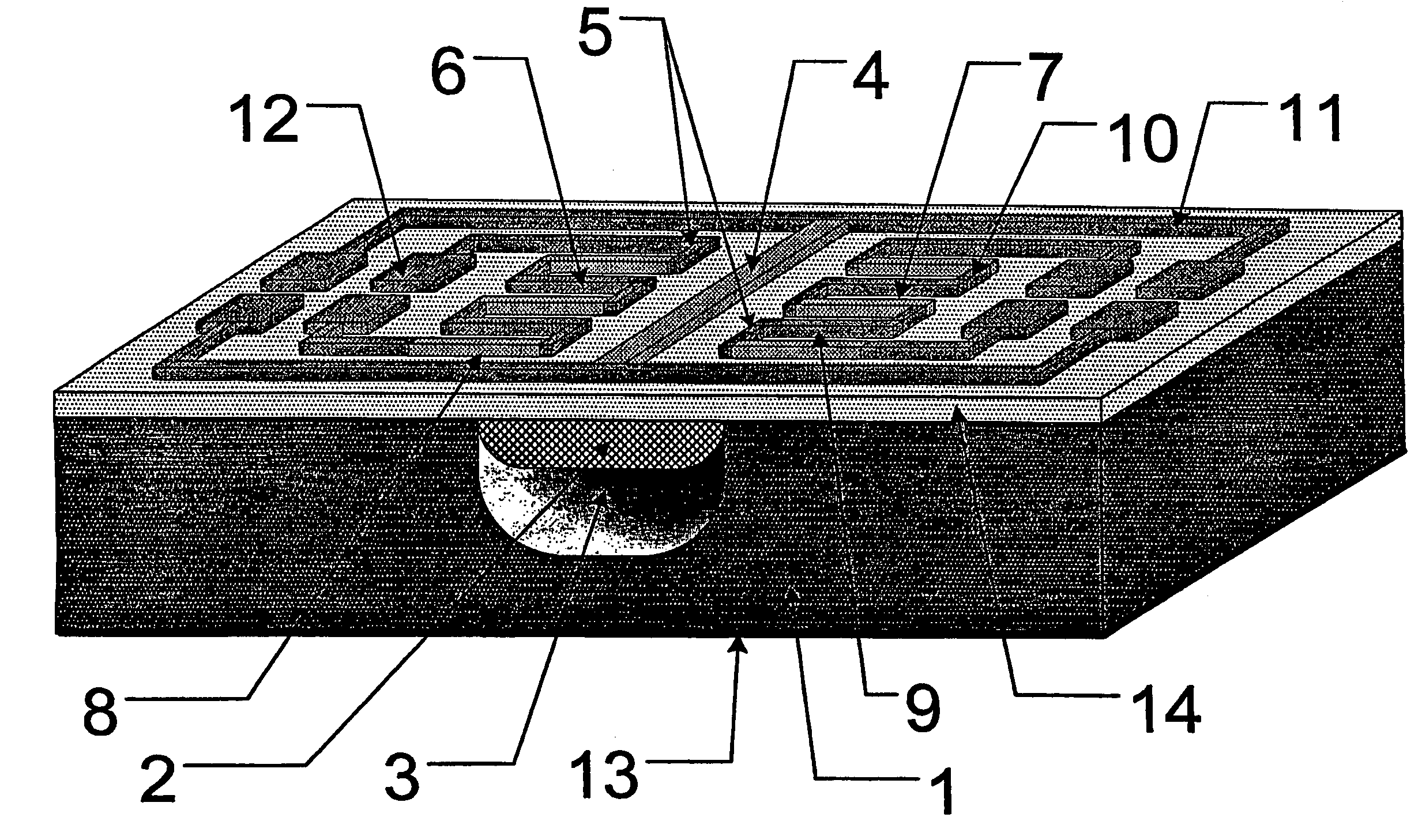

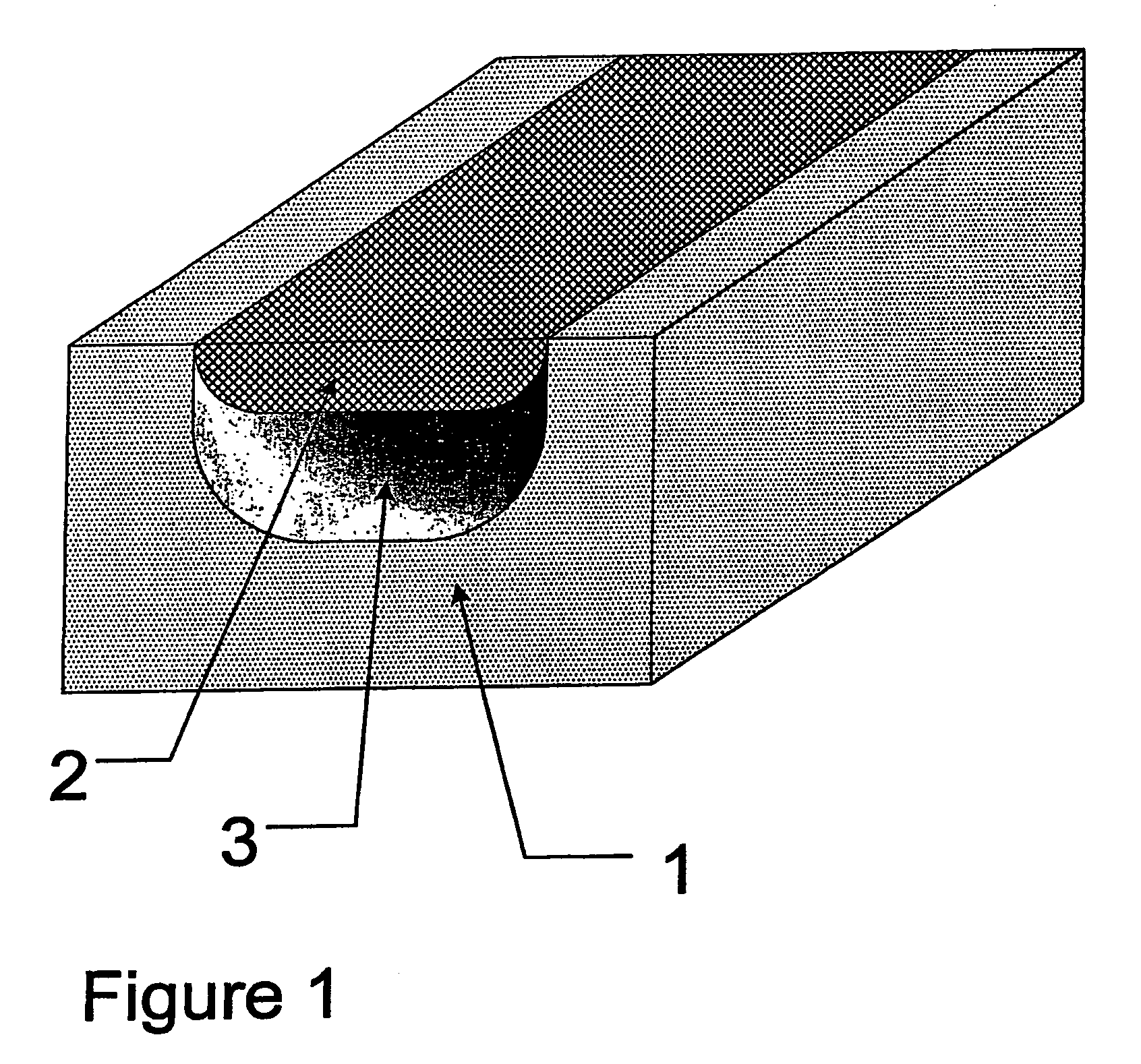

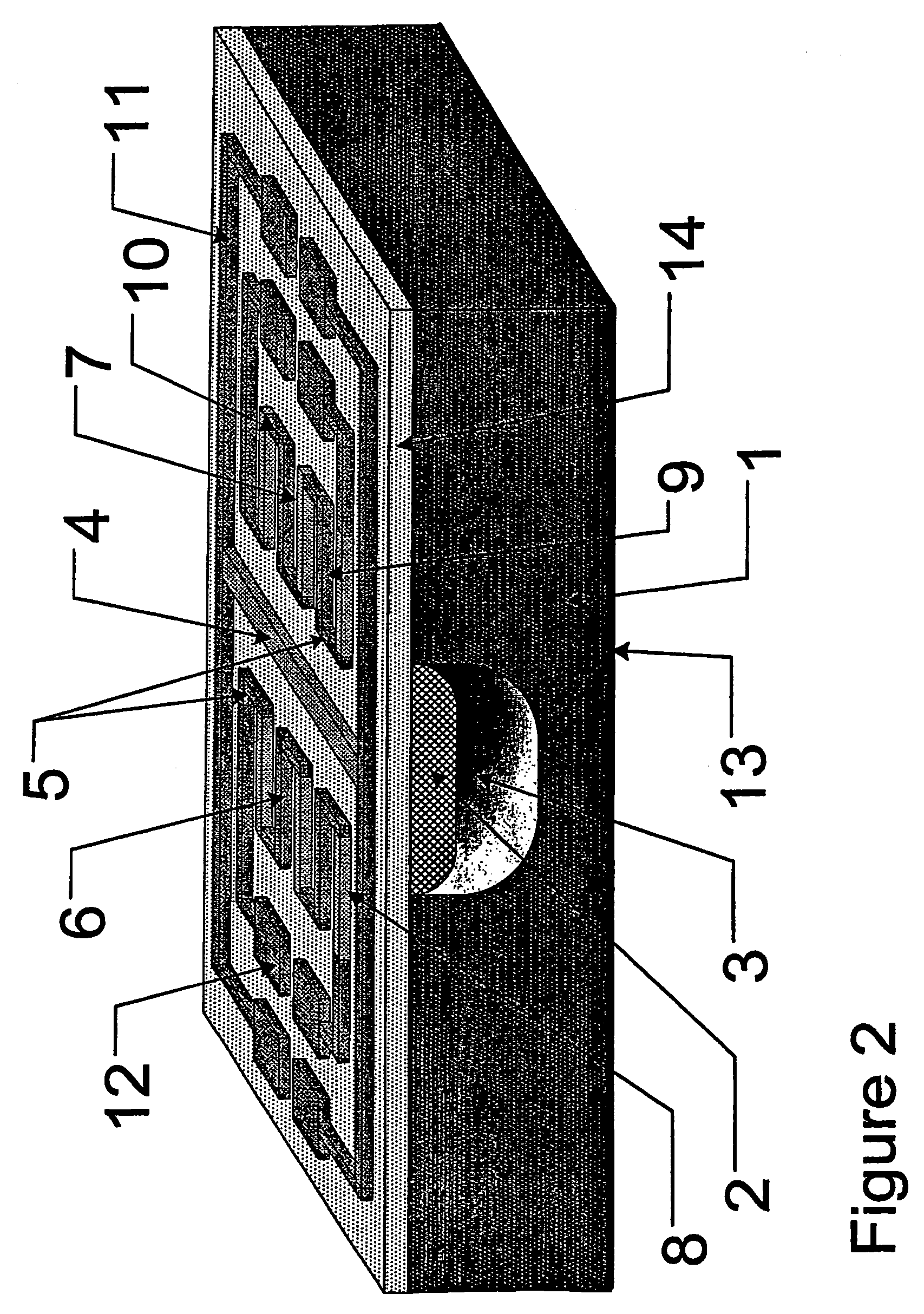

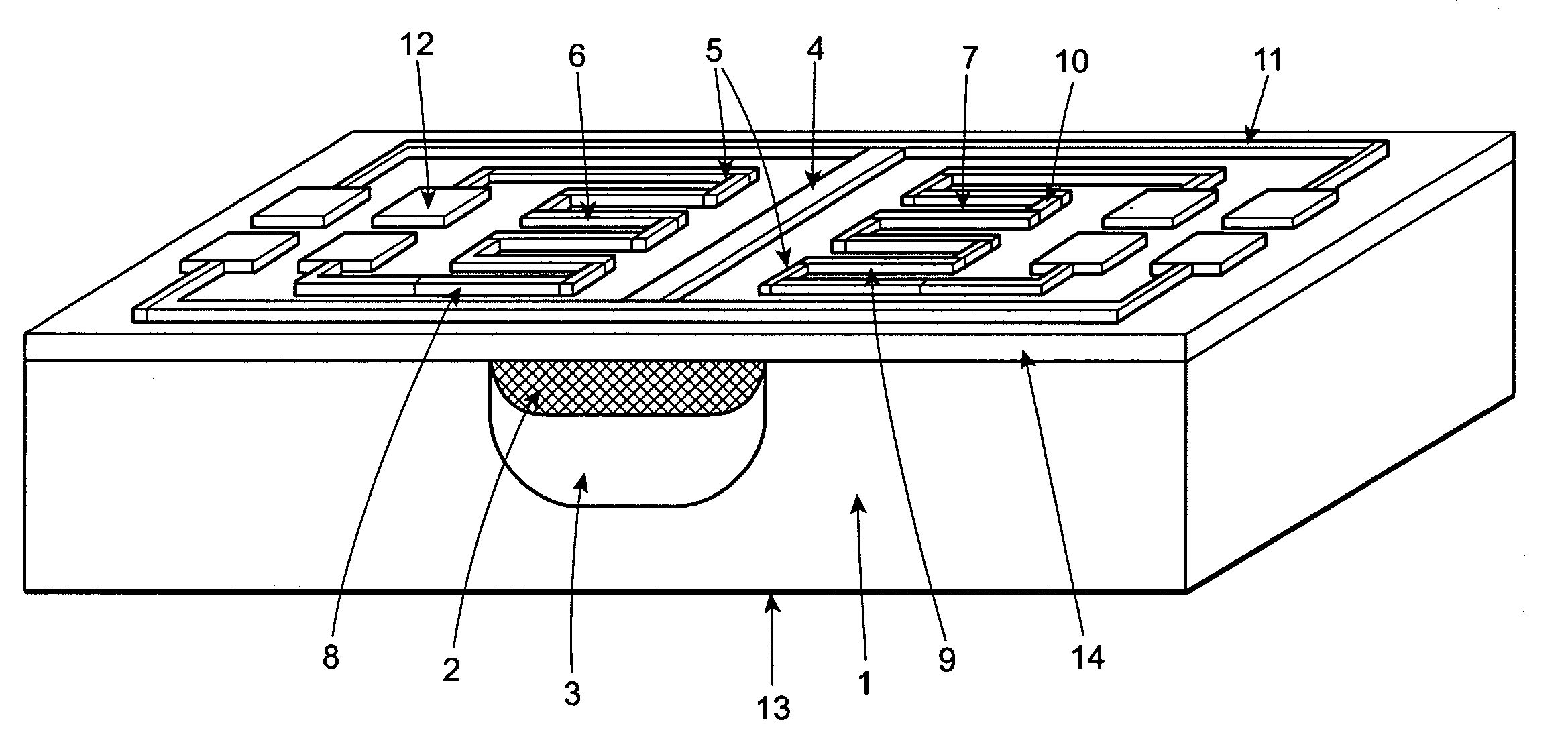

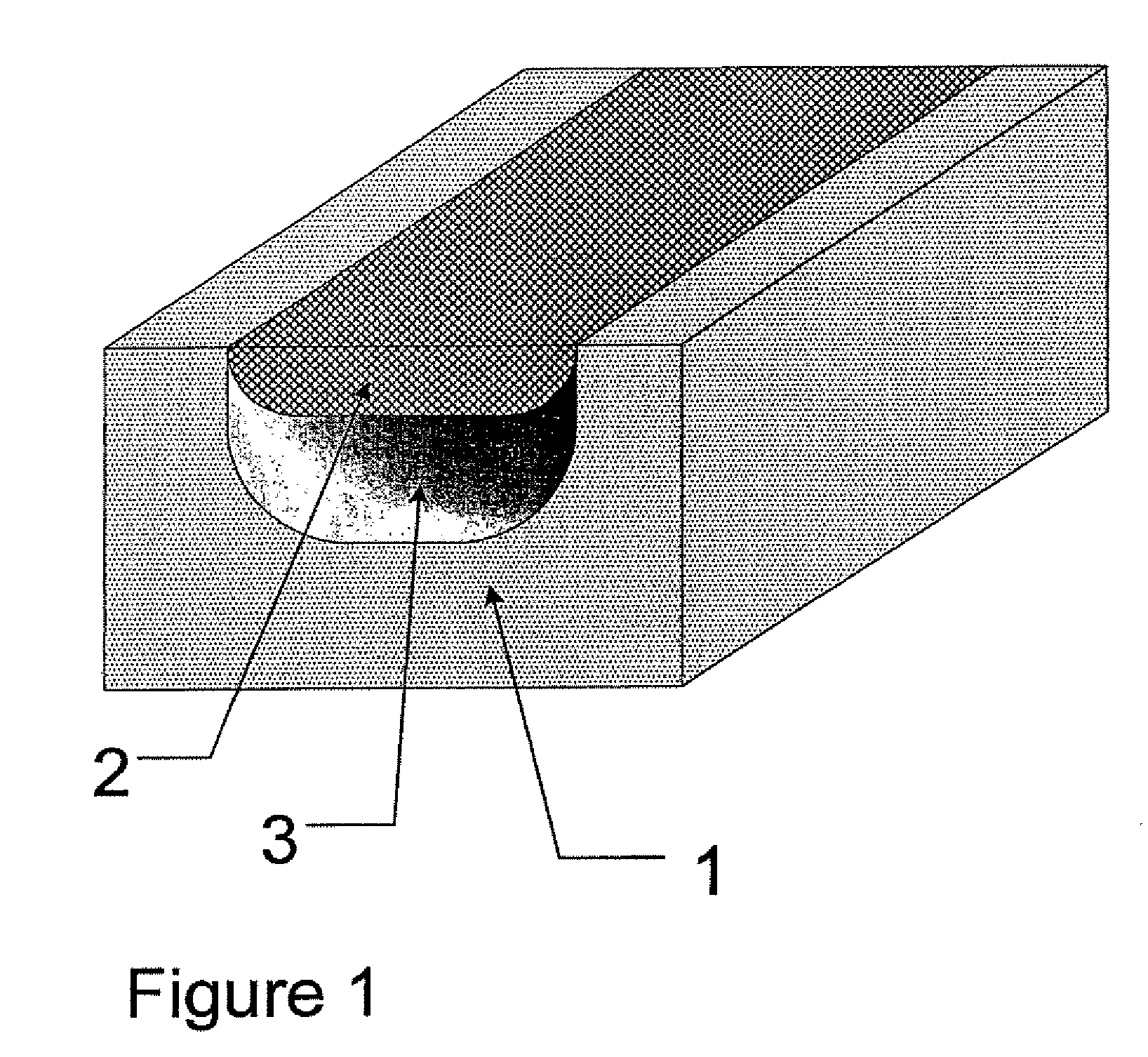

Low power silicon thermal sensors and microfluidic devices based on the use of porous sealed air cavity technology or microchannel technology

InactiveUS7233000B2Constant powerHigh sensitivityOptical radiation measurementVolume/mass flow measurementThermal isolationElectrolysis

This invention provides a miniaturized silicon thermal flow sensor with improved characteristics, based on the use of two series of integrated thermocouples (6, 7) on each side of a heater (4), all integrated on a porous silicon membrane (2) on top of a cavity (3). Porous silicon (2) with the cavity (3) underneath provides very good thermal isolation for the sensor elements, so as the power needed to maintain the heater (4) at a given temperature is very low. The formation process of the porous silicon membrane (2) with the cavity (3) underneath is a two-step single electrochemical process. It is based on the fact that when the anodic current is relatively low, we are in a regime of porous silicon formation, while if this current exceeds a certain value we turn into a regime of electropolishing. The process starts at low current to form porous silicon (2) and it is then turned into electropolishing conditions to form the cavity (3) underneath. Various types of thermal sensor devices, such as flow sensors, gas sensors, IR detectors, humidity sensors and thermoelectric power generators are described using the proposed methodology. Furthermore the present invention provides a method for the formation of microfluidic channels (16) using the same technique of porous silicon (17) and cavity (16) formation.

Owner:NASSIOPOULOU ANDROULA G +2

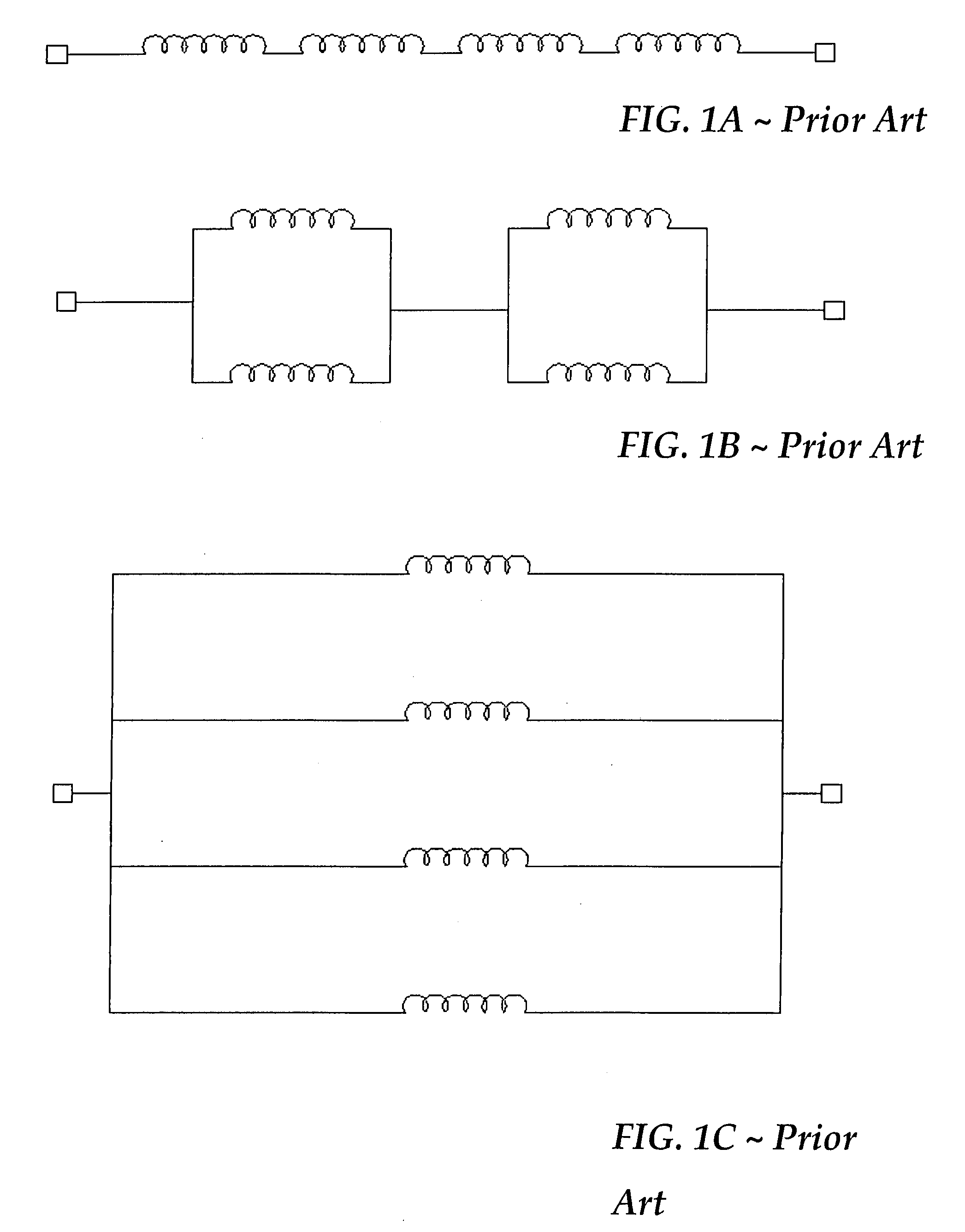

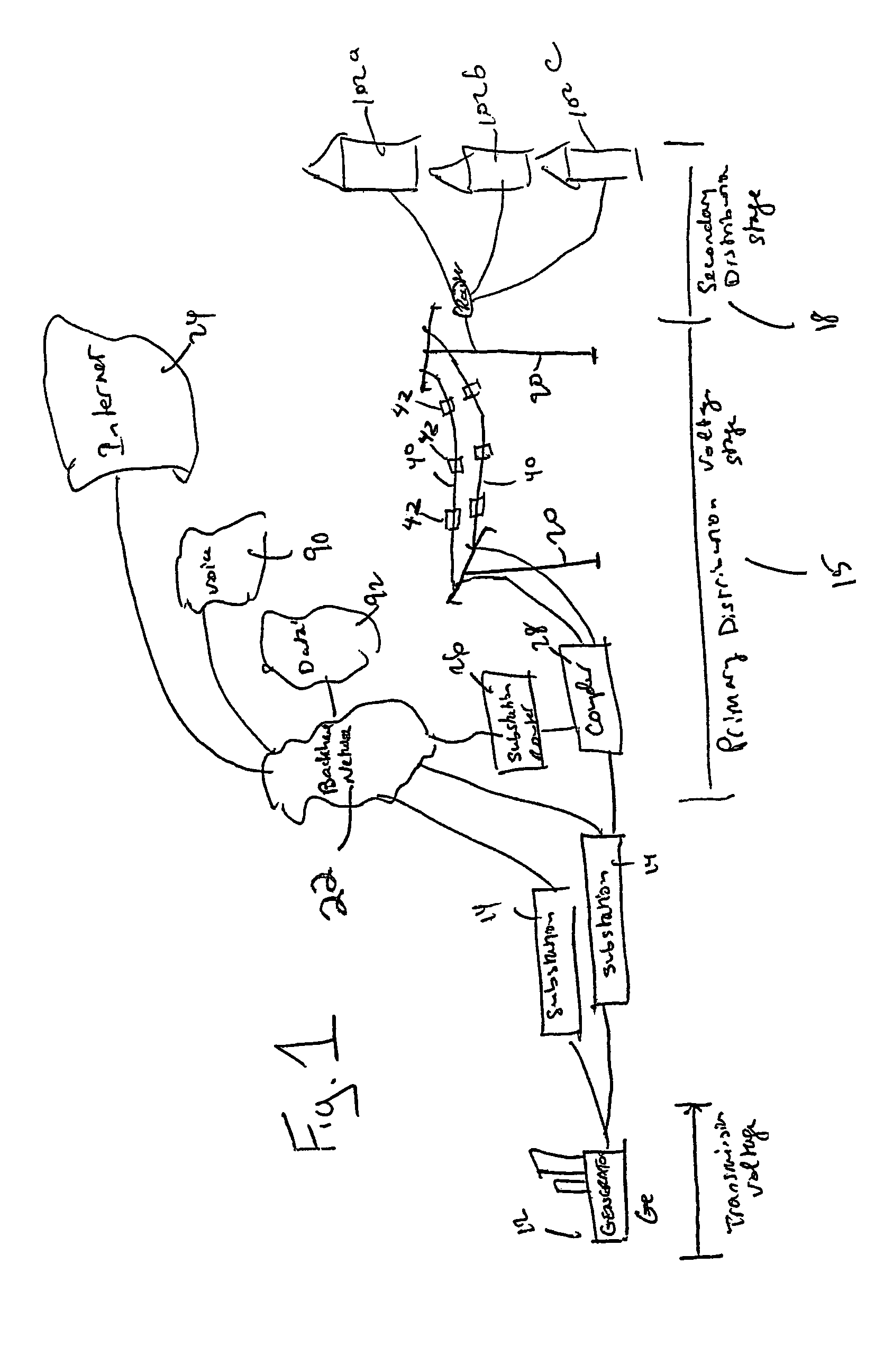

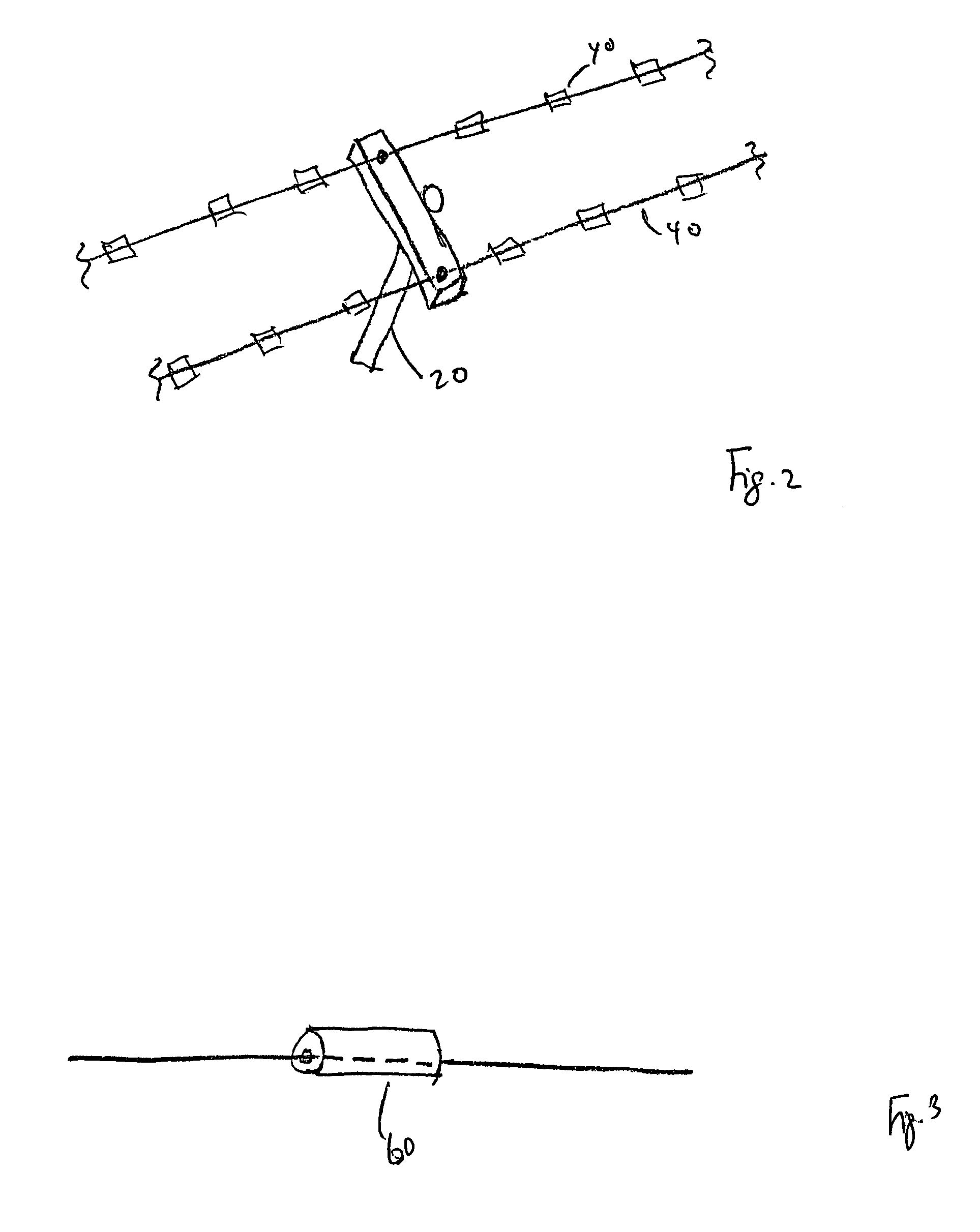

System and method for distributing broadband communication signals over power lines

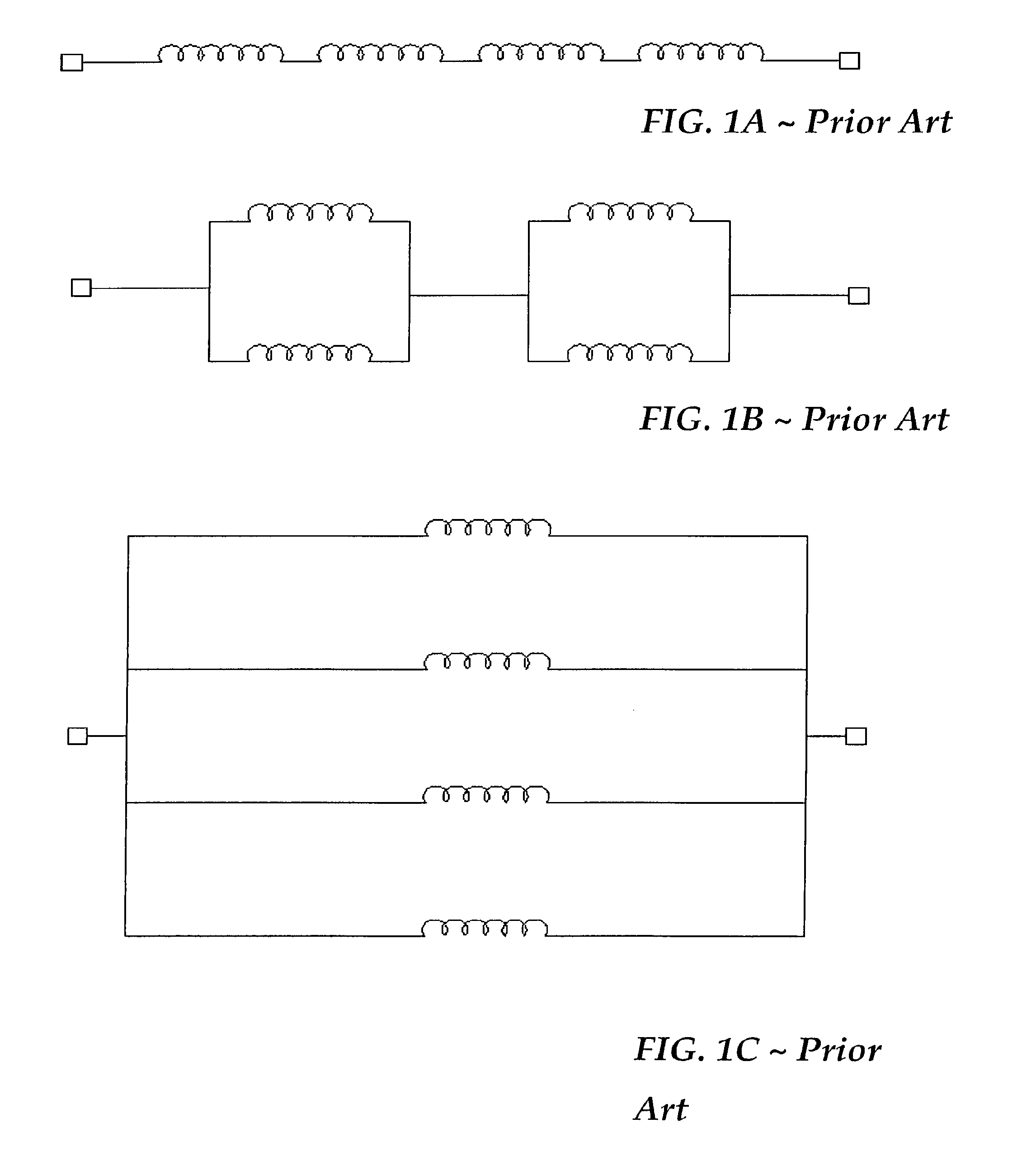

ActiveUS7079012B2Constant powerHigh frequency current signal,Electric signal transmission systemsFrequency-division multiplex detailsInductorEngineering

The present invention is directed to a method for decreasing high frequency (HF) radiation emission in a power line. The method involves transmitting a utility power signal over the power line and transmitting a high frequency communication signal over the power line so as to provide a combined utility and high frequency signal over the power line. A plurality of inductors are provided, disposed along the power line.

Owner:FOX ENTERTAINMENT GROUP

Low power silicon thermal sensors and microfluidic devices based on the use of porous sealed air cavity technology or microchannel technology

InactiveUS20080044939A1Improve insulation performanceImprove isolationThermometers using electric/magnetic elementsVolume/mass flow measurementThermal isolationMicrofluidic channel

This invention provides a miniaturized silicon thermal flow sensor with improved characteristics, based on the use of two series of integrated thermocouples (6, 7) on each side of a heater (4), all integrated on a porous silicon membrane (2) on top of a cavity (3). Porous silicon (2) with the cavity (3) underneath provides very good thermal isolation for the sensor elements, so as the power needed to maintain the heater (4) at a given temperature is very low. The formation process of the porous silicon membrane (2) with the cavity (3) underneath is a two-step single electrochemical process. It is based on the fact that when the anodic current is relatively low, we are in a regime of porous silicon formation, while if this current exceeds a certain value we turn into a regime of electropolishing. The process starts at low current to form porous silicon (2) and it is then turned into electropolishing conditions to form the cavity (3) underneath. Various types of thermal sensor devices, such as flow sensors, gas sensors, IR detectors, humidity sensors and thermoelectric power generators are described using the proposed methodology. Furthermore the present invention provides a method for the formation of microfluidic channels (16) using the same technique of porous silicon (17) and cavity (16) formation.

Owner:NASSIOPOULOU ANDROULA G +2

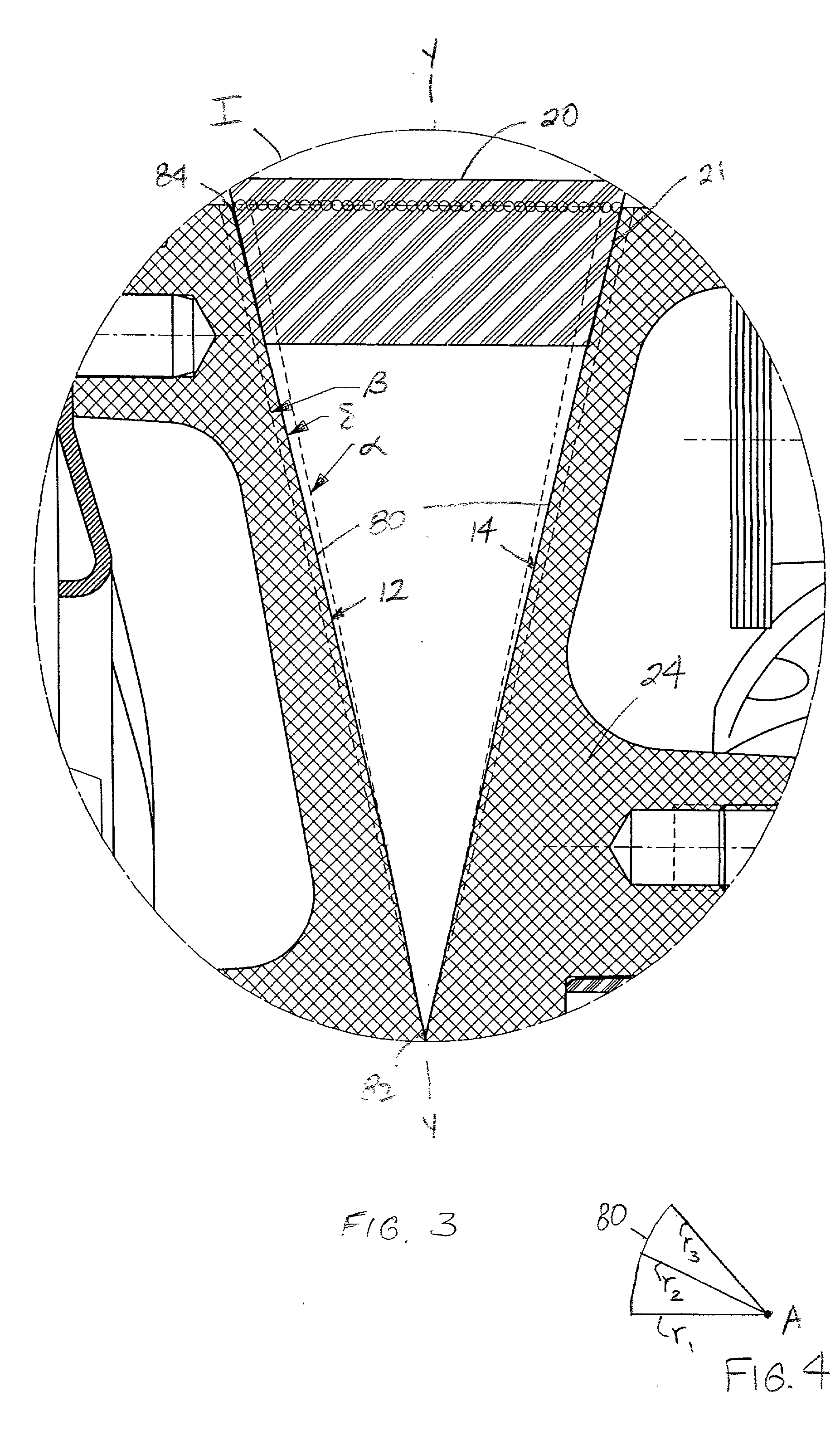

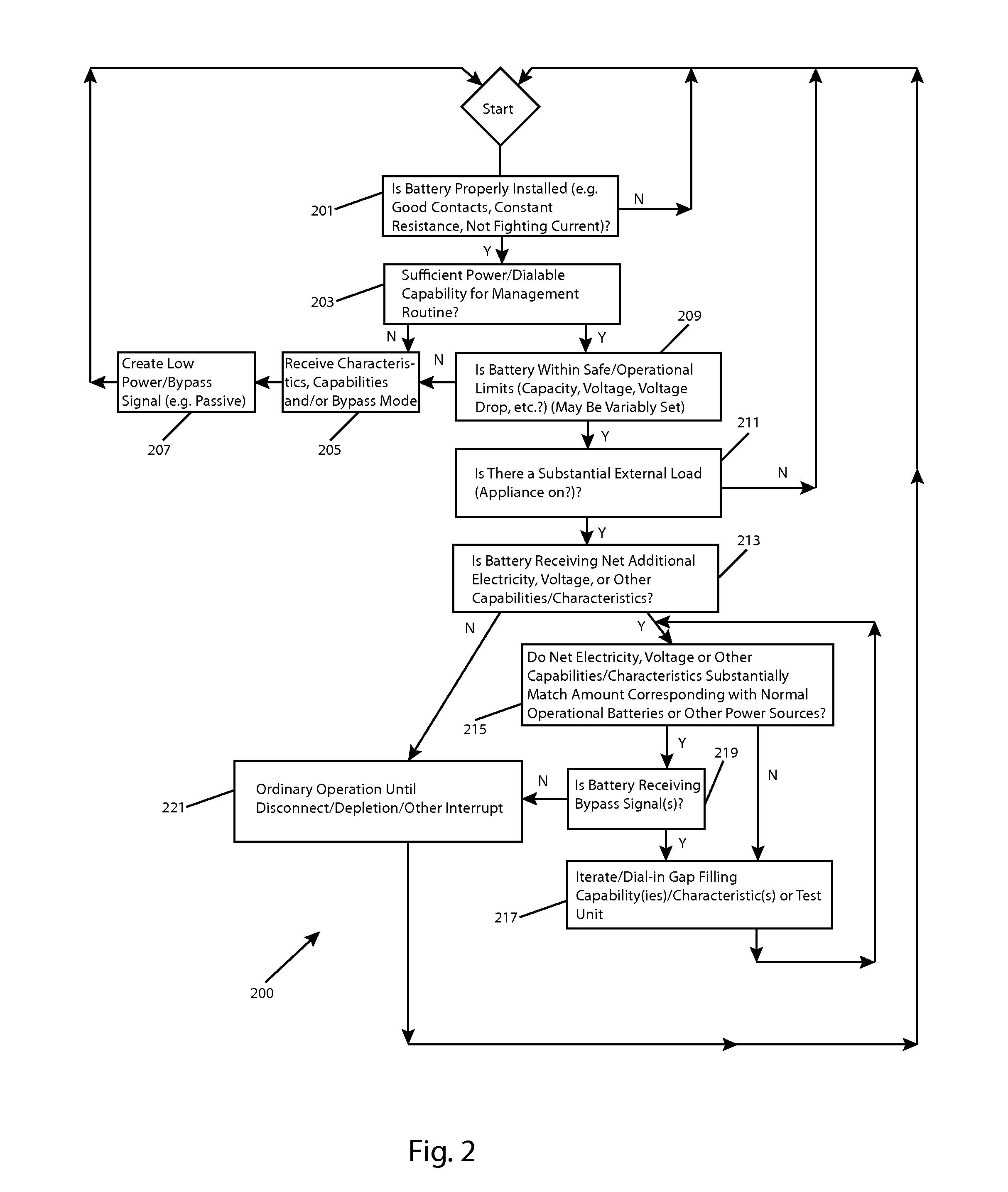

Pulley having progressively variable sheave angle

InactiveUS20020042313A1Constant powerReduce power lossV-beltsRopes and cables for vehicles/pulleyVariable angleFlange

A pulley system for use in a constant variable transmission includes a pair of pulley sheaves or flanges mechanically linked by a belt so that the outer surfaces of the belt interact with the inner surfaces of the flanges. At least one of the pulley flanges has an inclined inner surface disposed at an angle that changes progressively based on a curve have a variable radius. For example, the sheave angle can change progressively from 9 degrees to 12 degrees or from 12 degrees to 14 degrees, with no sharp or stepped edges. The belt can have a complementary angled surface also. The progressively variable angle allows the flange surface to more closely match the side surface of the belt, which can increase the belt life be reducing stress experienced by the belt. The pulley system is useable in a transmission for a vehicle, for example a snowmobile or an all terrain vehicle.

Owner:BOMBARDIER RECREATIONAL PROD INC

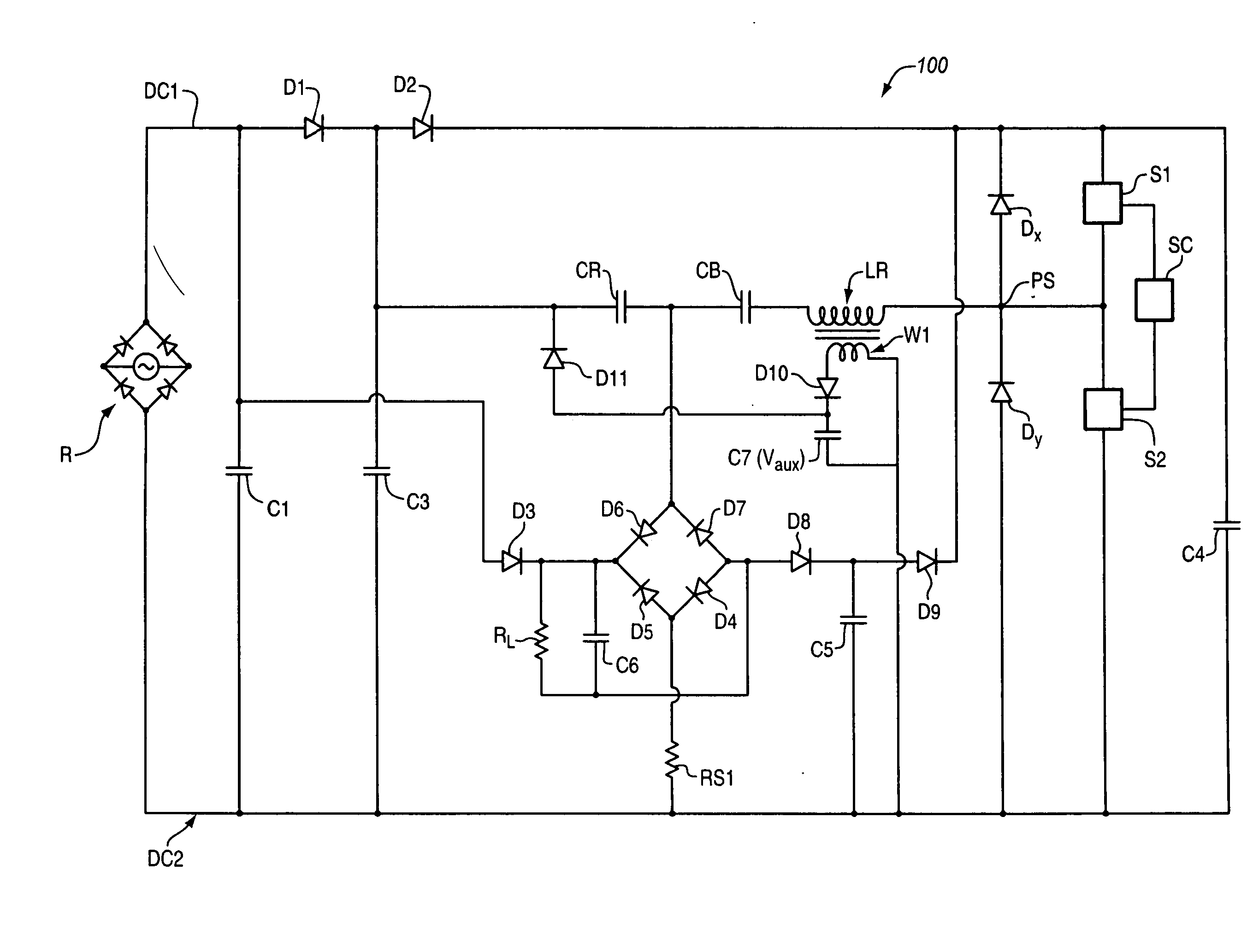

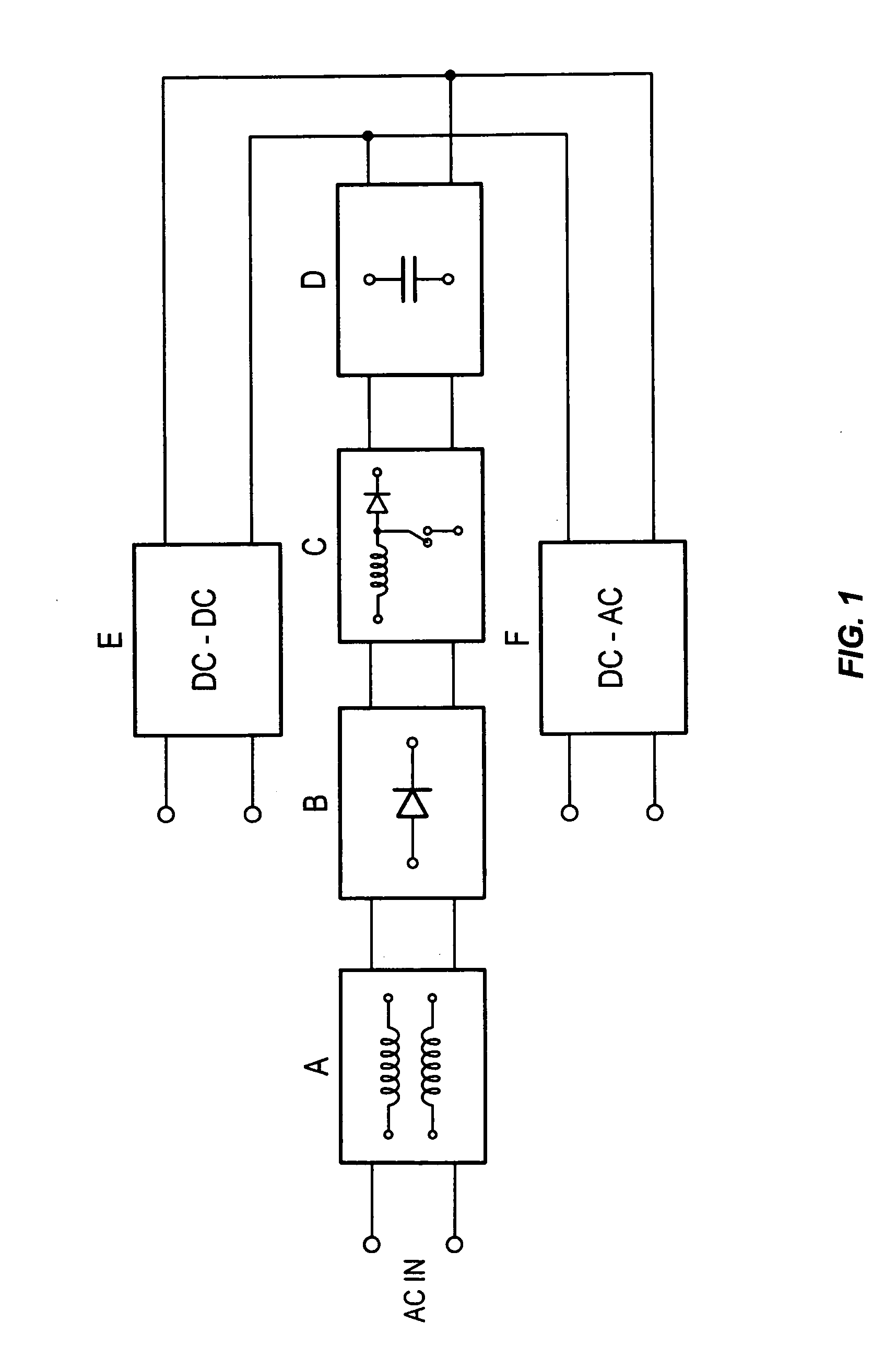

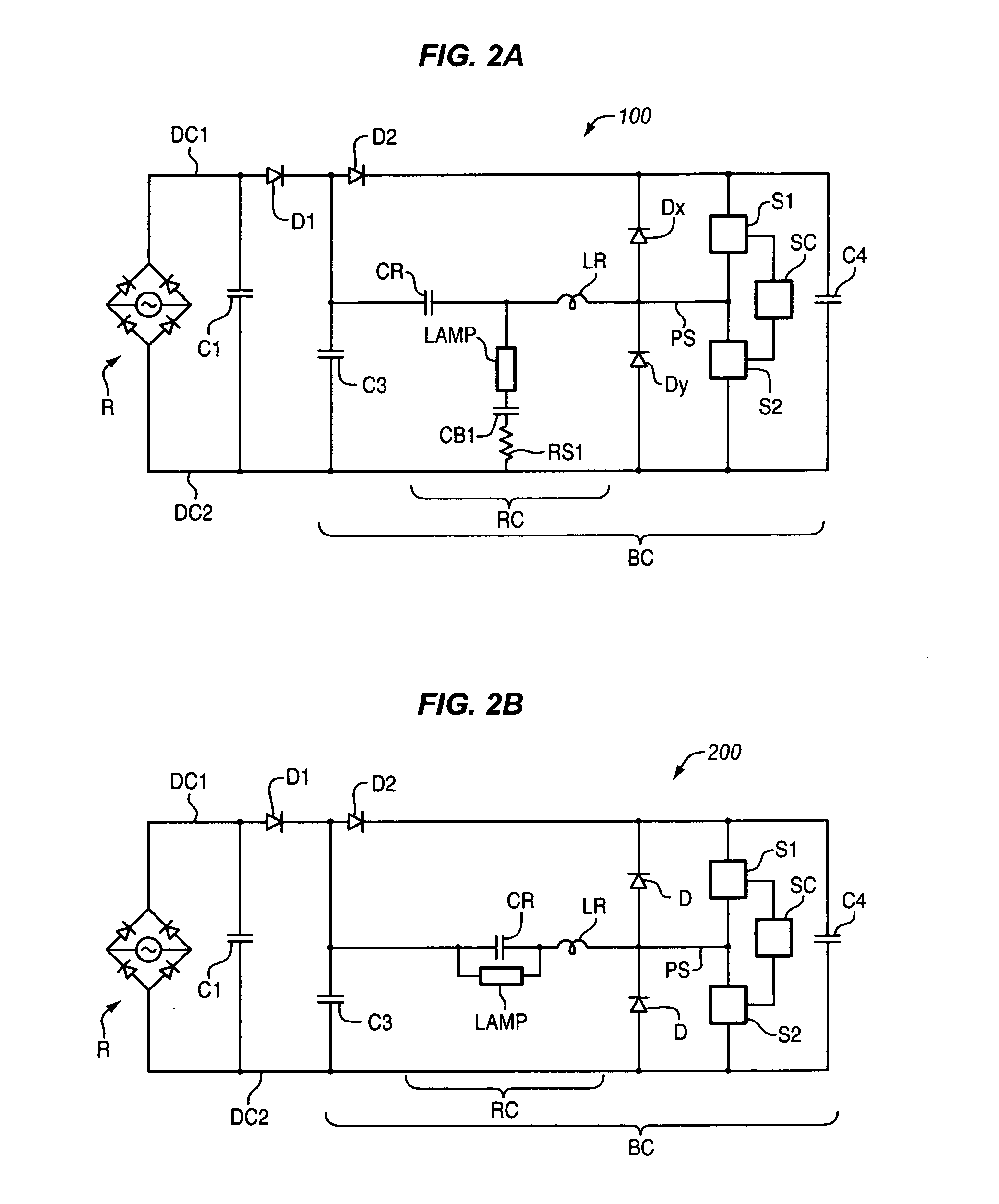

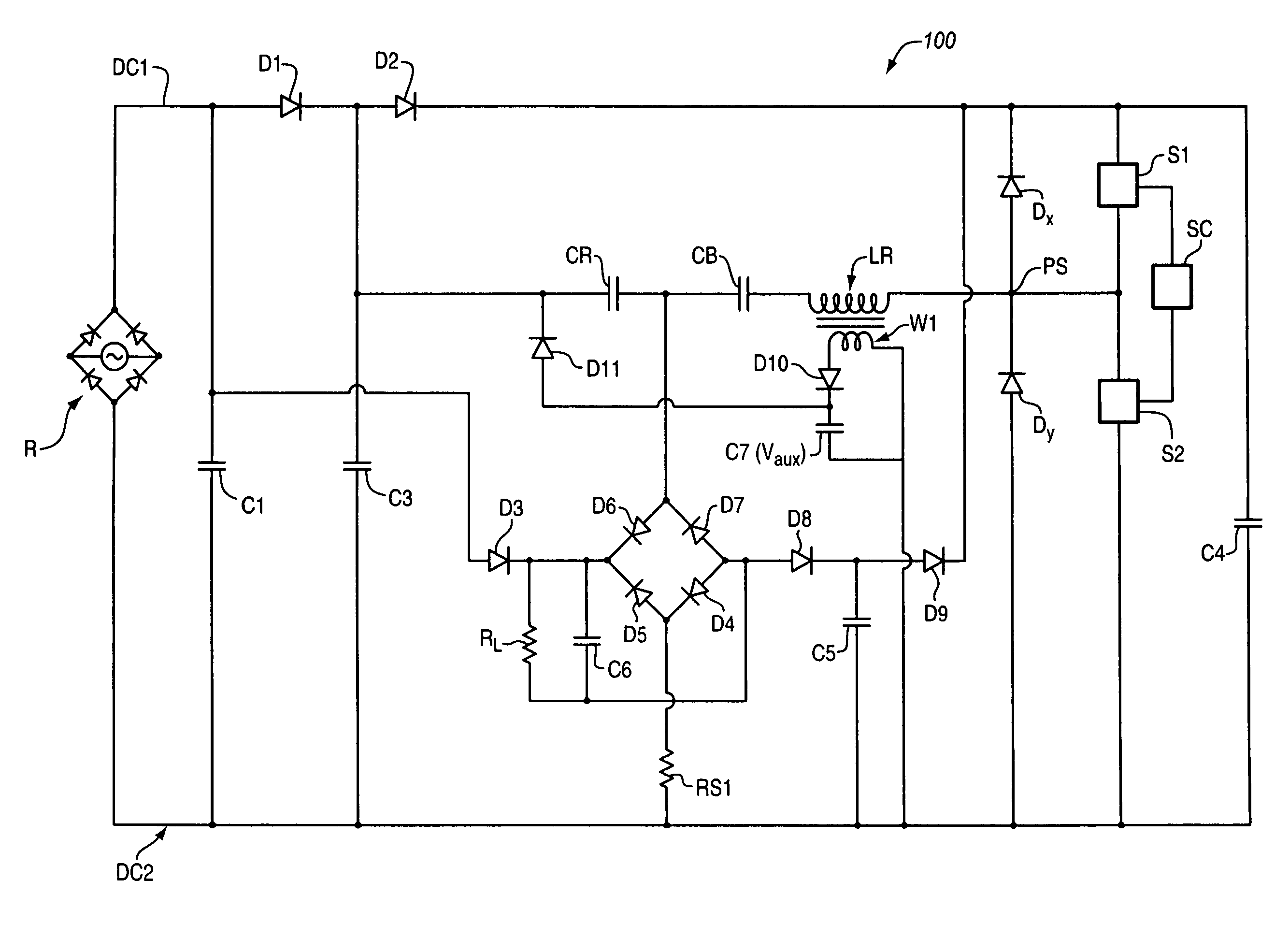

Single stage power factor corrected power converter with reduced AC inrush

InactiveUS20070217235A1Reduced AC inrushImprove output rippleDc network circuit arrangementsAc-dc conversion without reversalConstant powerTotal harmonic distortion

The improved single stage power converter circuit topology substantially reduces EMI that is conducted to the AC line, reduces input AC current inrush, improves output ripples by the use of an auxiliary supply near zero crossings of the line AC voltage, provides Power Factors greater than 0.95, provides Total Harmonic Distortions less than 15%, and maintains constant power, including constant power in a non-linear output load. Further, this circuit topology provides output open and short circuit protections by reducing current stress in power components. This topology can also make the power source to appear as a fast-acting variable impedance source, an ideal source for powering an output load that has negative resistance characteristics such as gas discharge lamps.

Owner:ENERGY CONSERVATION TECH

Adaptive winding system and control method for electric machines

InactiveUS7977842B2Improve efficiencyBroad speedSynchronous generatorsAC motor controlElectric machineEngineering

An adaptive winding configurations and control method is disclosed for the electromagnetic poles of electric machines, including motors and generators. Motors utilizing the inventive adaptive winding configuration and control method are able to dynamically adjust their operating characteristics to maintain a constant rated power over a large operating speed range with high efficiency. Generators employing the inventive adaptive winding configuration and control method are able to dynamically adjust their operating characteristics in response to a variable driving force to achieve maximum power conversion efficiency. These generators are also able to dynamically change their output voltage and current (thus charging speed) when charging batteries depending on the charged state of the battery, and on the expected duration of the input power.

Owner:LIN PANCHIEN

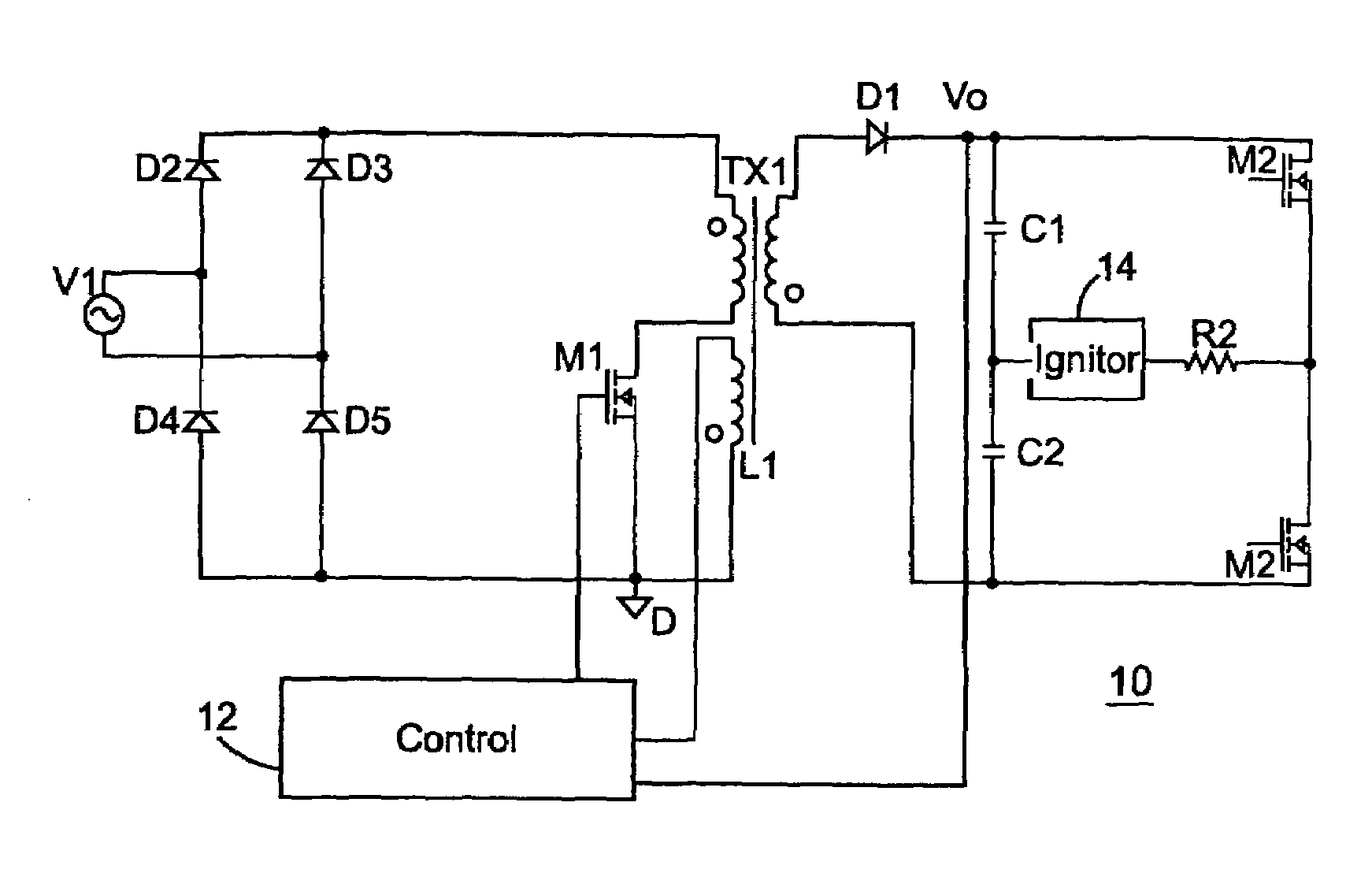

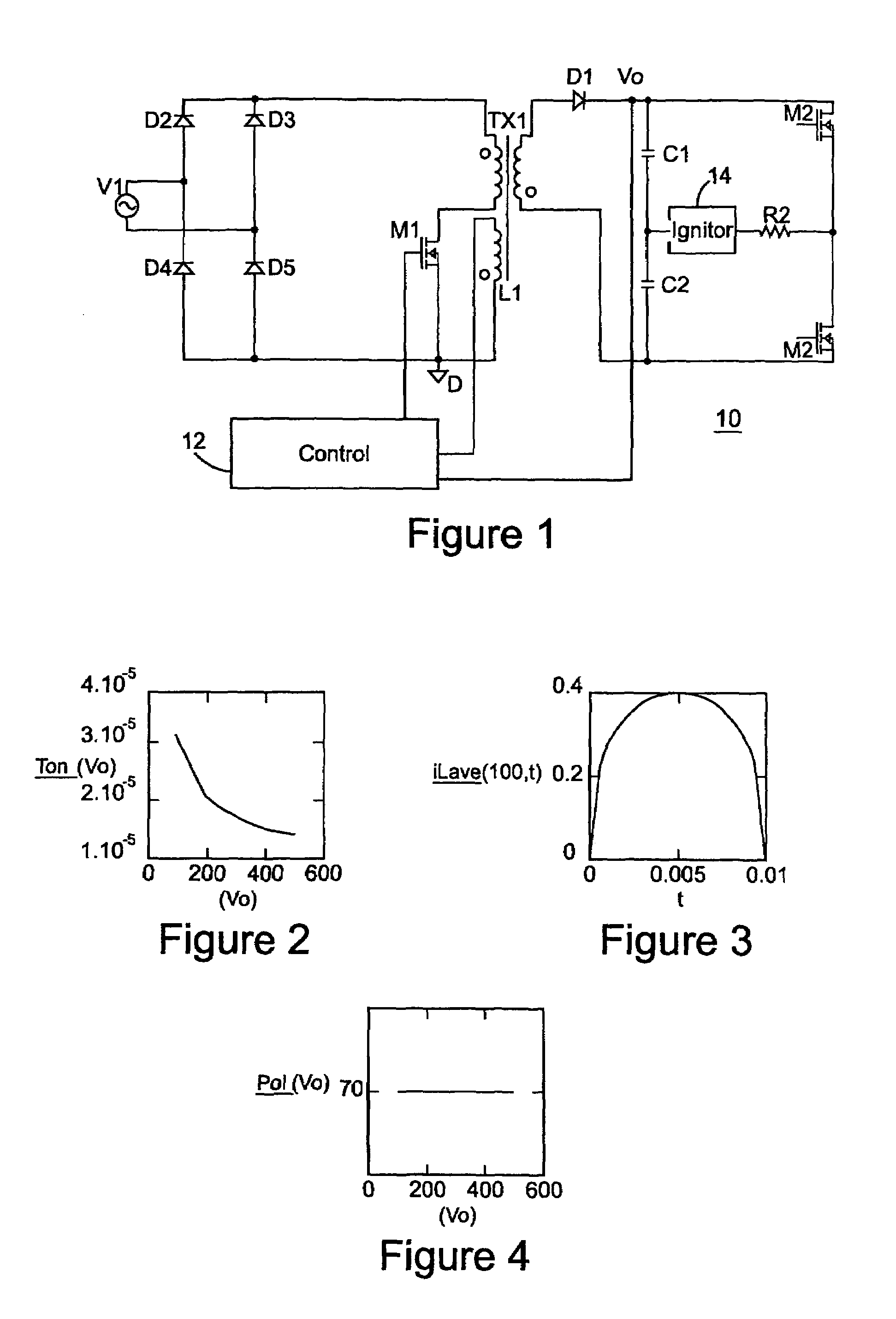

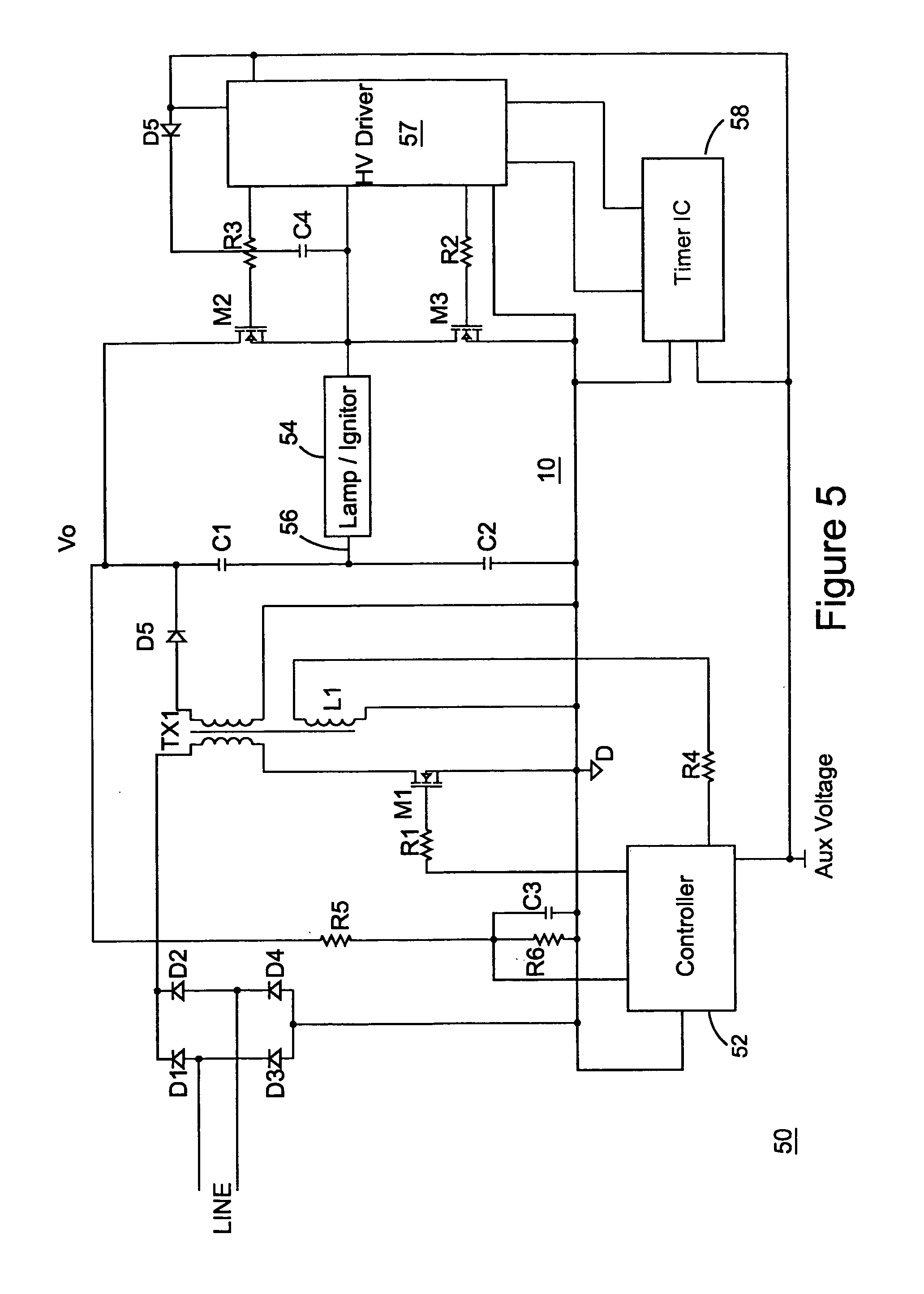

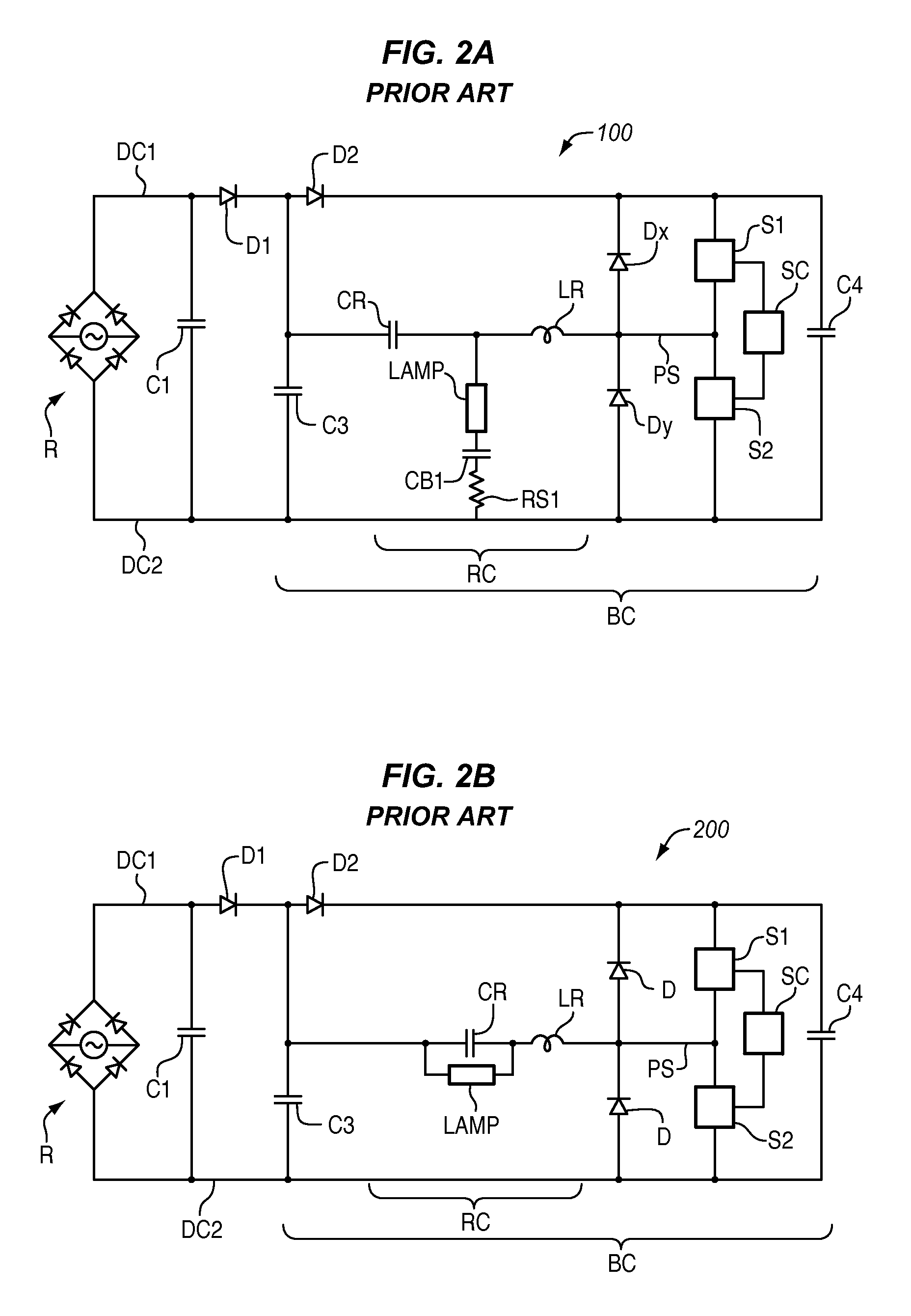

Simplified topology for HID lamps

InactiveUS7078870B2Constant powerStable deliveryElectric light circuit arrangementApparatus with intermediate ac conversionConstant powerPower factor

An HID ballast includes a flyback power converter with a simplified topology that permits power factor correction while supplying constant output power to drive an inverter supplying low frequency modulated power to the HID lamp. A switch is coupled in series with a transformer in the power converter to control current through the transformer to provide constant output power. The off time of the switch contributes to controlling the power factor of the ballast circuit. The transformer is operated in critical conduction mode, with an indication of zero current in the transformer used to determine the control for the switch. An output of the flyback power converter provides a feedback signal to obtain constant power output based on switching intervals applied to the switch coupled to the transformer. This simplified topology reduces part counts while providing a robust control that can be flexibly applied to a number of HID lamps.

Owner:INTERNATIONAL RECTIFIER COEP

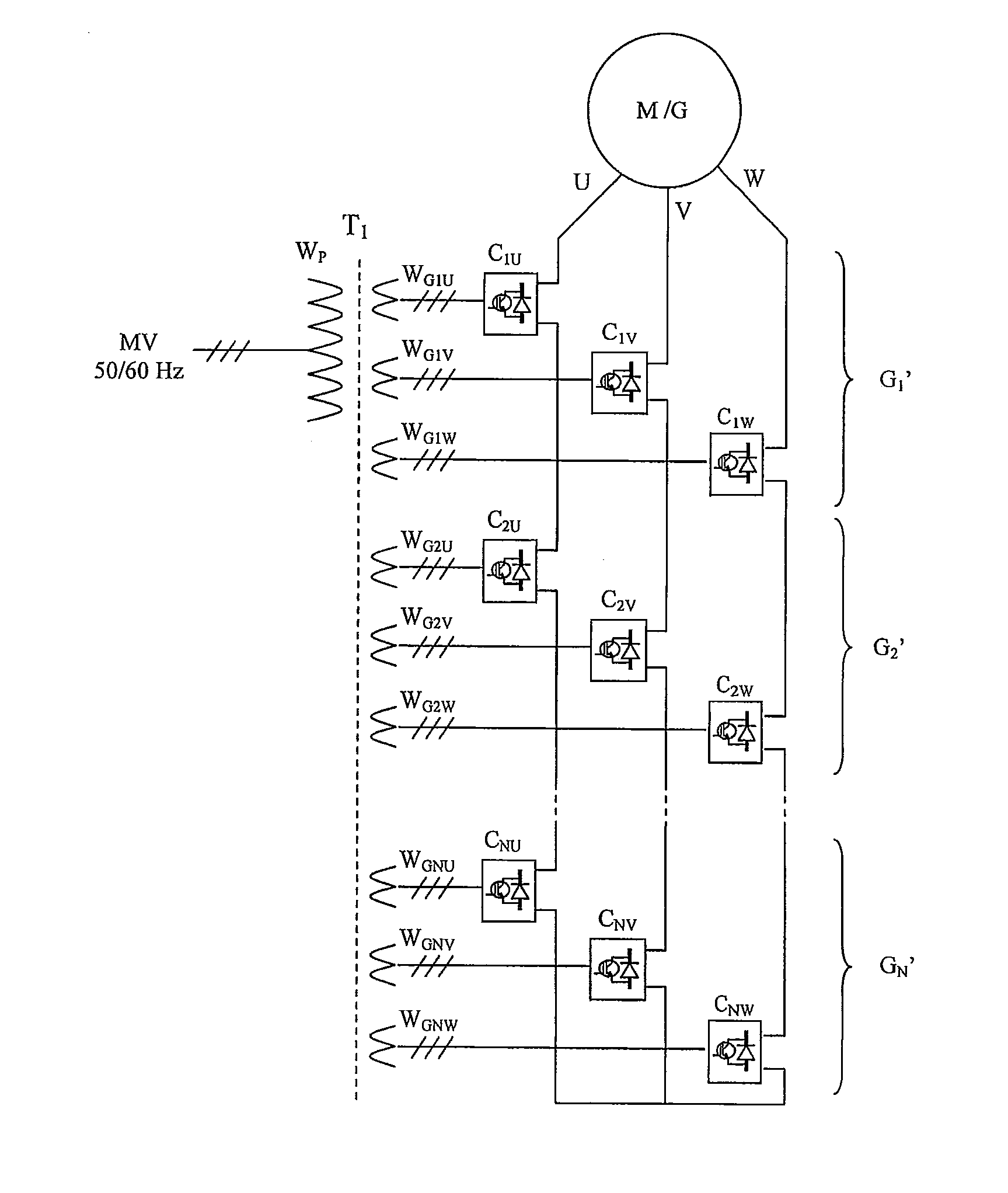

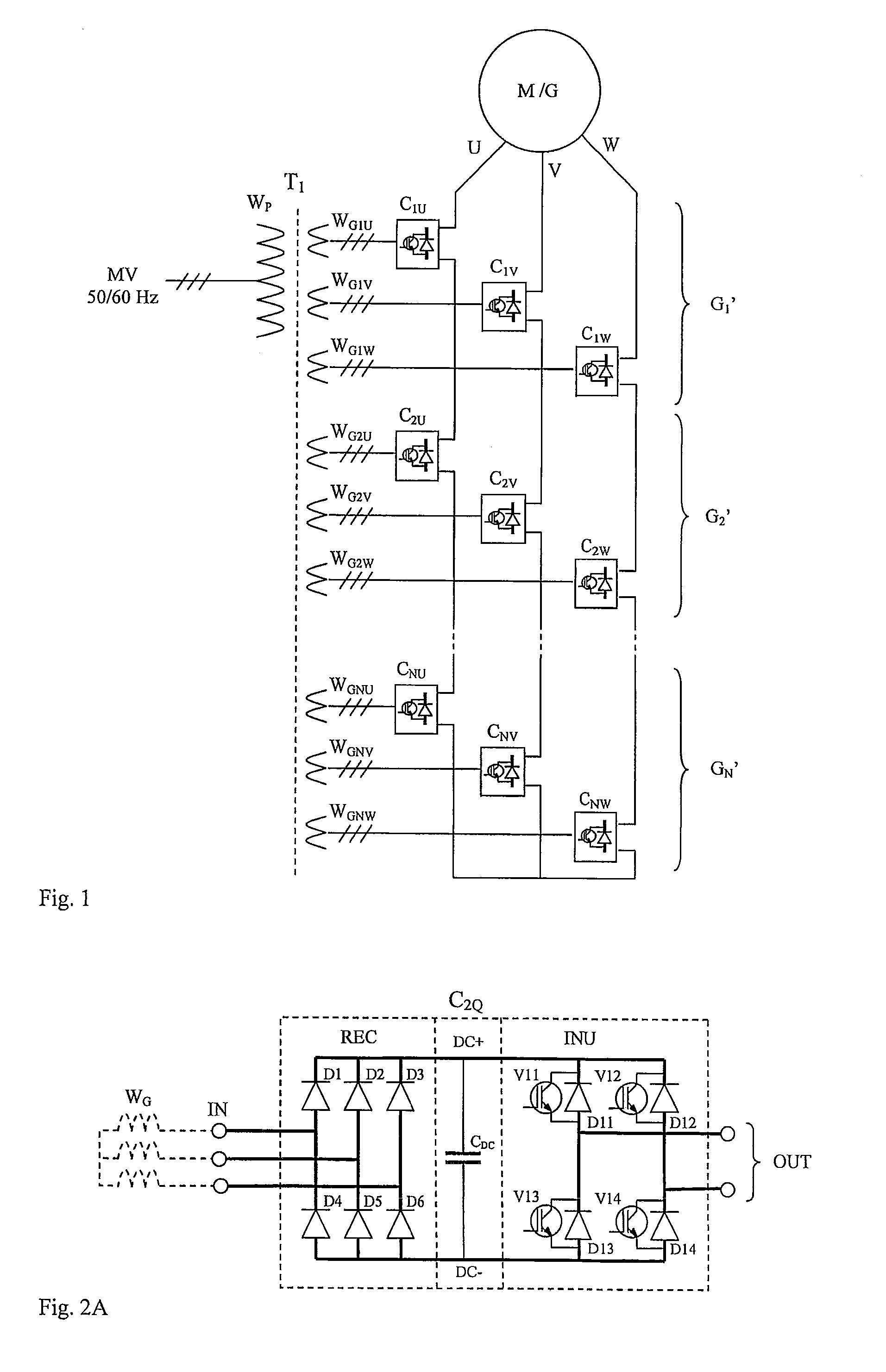

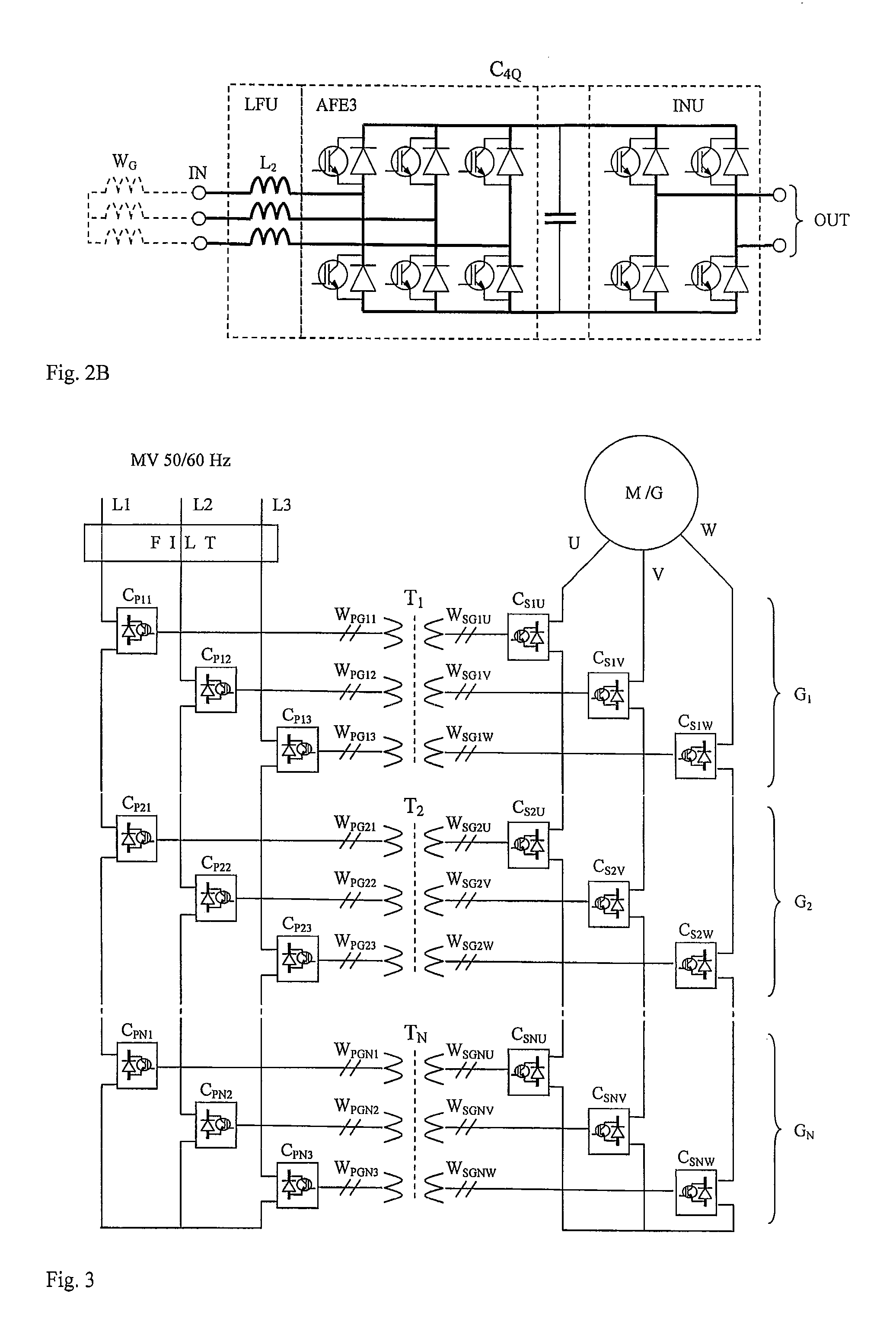

Power transmission method and power transmission apparatus

ActiveUS20100327793A1Avoid disadvantagesHigh voltageAC motor controlAc-dc conversion without reversalTransformerTransmitted power

Method and apparatus for controlling an apparatus transmitting power between two electricity networks or between an electricity network and a polyphase electric machine (M / G), which electricity networks can be polyphase alternating-current networks or one of them can be a single-phase direct-current network, and which apparatus comprises low-voltage power cells (C), which comprise a single-phase output connection (OUT). The power cells also comprise a single-phase input connector (IN), the power cells are arranged into groups (G1-GN, GP1-GPN1, GS1-GSN2, G1′″-GN′″) such that at least one power cell per each phase of the electricity network or of the electric machine belongs to each group, and the input terminals (IN) of all the power cells belonging to the same group are connected to a common transformer, which transformer comprises its own separate winding that is galvanically isolated from the others for the power cell connected to it. The controllable power semiconductor switches connected to the input connectors (IN) of all the power cells supplying power to the same transformer are controlled essentially cophasally with a 50% pulse ratio.

Owner:VACON OY

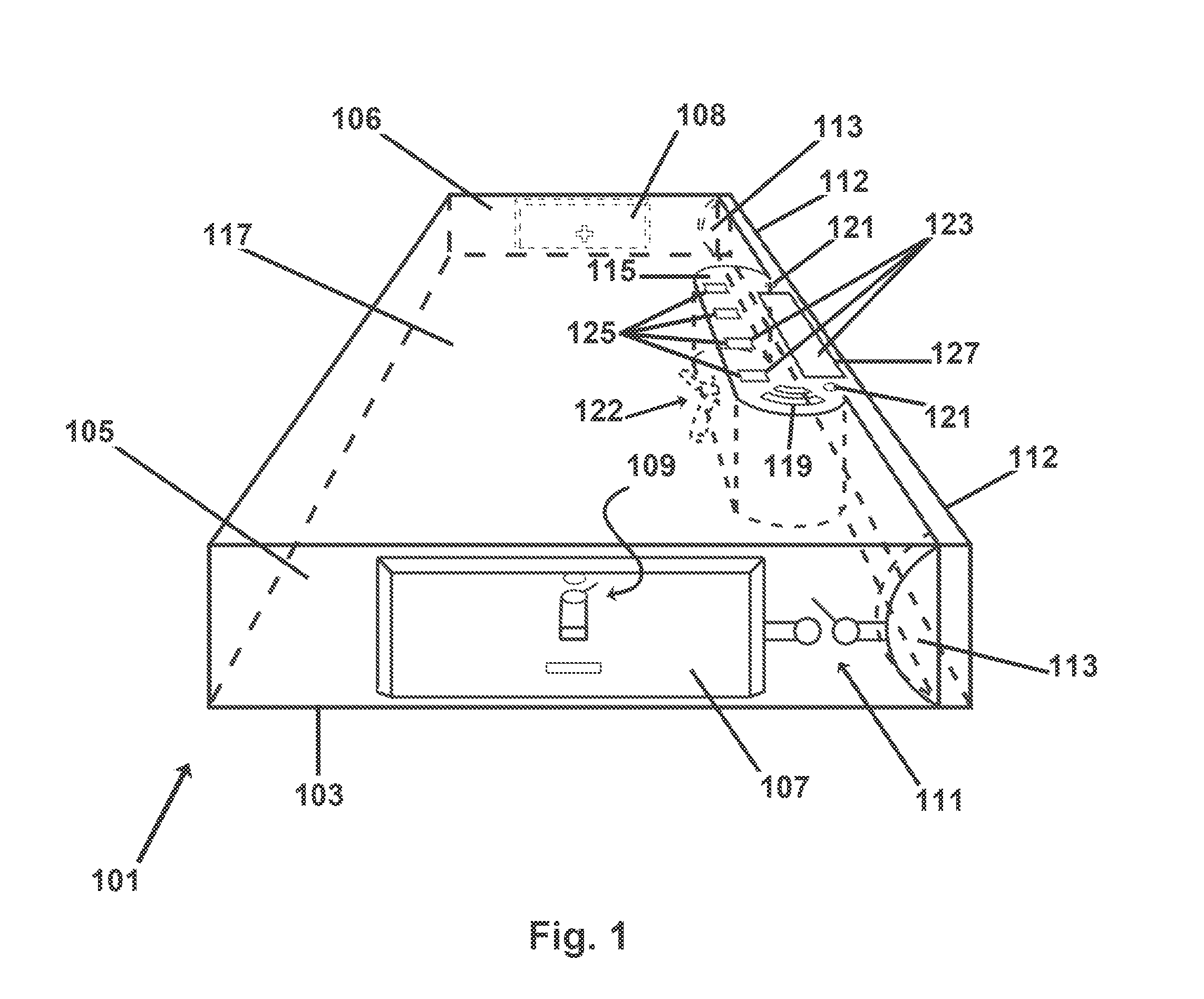

Techniques for Optimizing Power Supply Output

ActiveUS20140368168A1Reduced wiring requirementsReduce manufacturing costCharge equalisation circuitPhotometryPower flowControl system

New power output control systems are provided that maintain optimal voltage, current, and other electrical characteristics. In some aspects of the invention, a lagging or deteriorated power supply aspect is at least partially replaced to avoid limitations while the output of a specialized, stronger aspect is altered and addressed to supply the resulting power, voltage, current charge or other gap.

Owner:BECKMAN CHRIS

Pulley having progressively variable sheave angle

InactiveUS6656068B2Constant powerReduce power lossV-beltsRopes and cables for vehicles/pulleyEngineeringVariable angle

A pulley system for use in a constant variable transmission includes a pair of pulley sheaves or flanges mechanically linked by a belt so that the outer surfaces of the belt interact with the inner surfaces of the flanges. At least one of the pulley flanges has an inclined inner surface disposed at an angle that changes progressively based on a curve have a variable radius. For example, the sheave angle can change progressively from 9 degrees to 12 degrees or from 12 degrees to 14 degrees, with no sharp or stepped edges. The belt can have a complementary angled surface also. The progressively variable angle allows the flange surface to more closely match the side surface of the belt, which can increase the belt life be reducing stress experienced by the belt. The pulley system is useable in a transmission for a vehicle, for example a snowmobile or an all terrain vehicle.

Owner:BOMBARDIER RECREATIONAL PROD INC

Single stage resonant power converter with auxiliary power source

InactiveUS7706161B2Reduce current stressReduced AC inrushDc network circuit arrangementsAc-dc conversion without reversalConstant powerTotal harmonic distortion

The improved single stage power converter circuit topology substantially reduces EMI that is conducted to the AC line, reduces input AC current inrush, improves output ripples by the use of an auxiliary supply near zero crossings of the line AC voltage, provides Power Factors greater than 0.95, provides Total Harmonic Distortions less than 15%, and maintains constant power, including constant power in a non-linear output load. Further, this circuit topology provides output open and short circuit protections by reducing current stress in power components. This topology can also make the power source to appear as a fast-acting variable impedance source, an ideal source for powering an output load that has negative resistance characteristics such as gas discharge lamps.

Owner:ENERGY CONSERVATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com