Ultrasonic distance measurement system and method for controlling ultrasonic distance measurement system to measure distance

A distance measurement system, ultrasonic technology, applied in the field of distance measurement, can solve the problems of inconvenient portability, high cost, high power consumption, etc., and achieve the effects of low power consumption, flexible operation and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

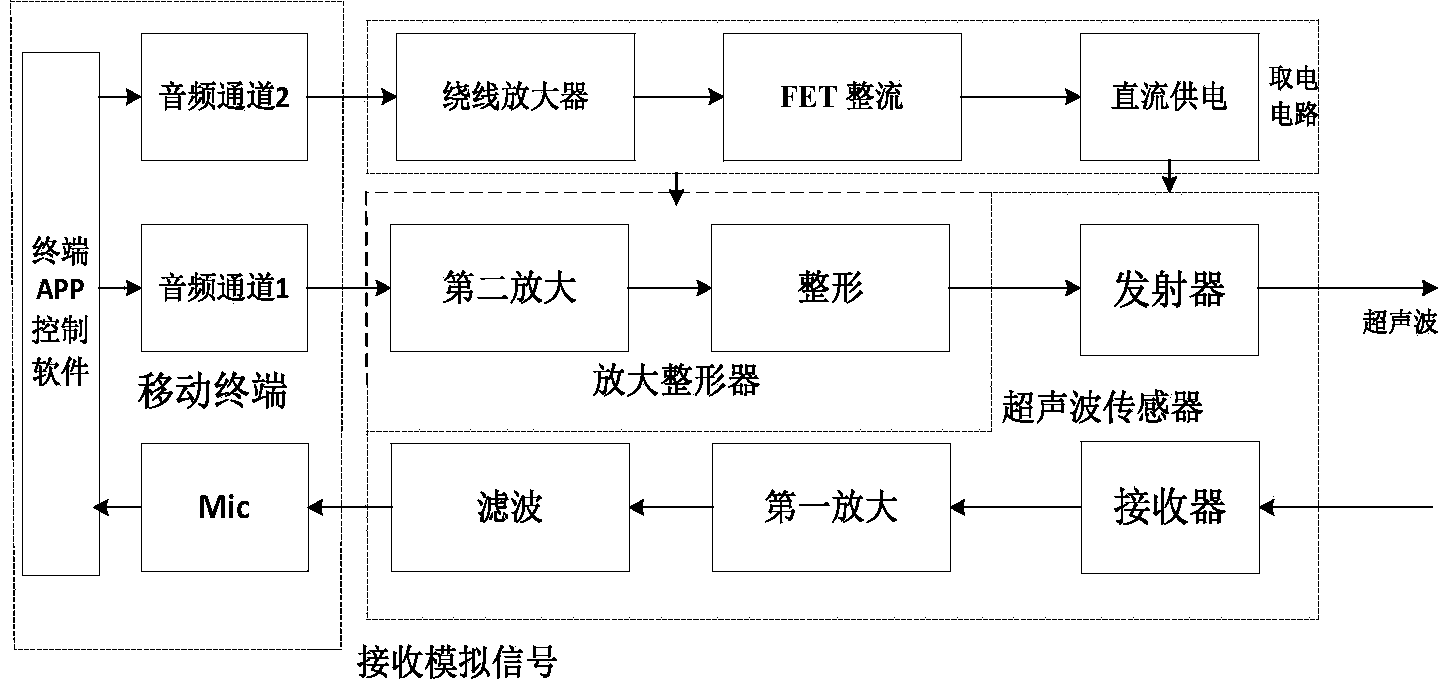

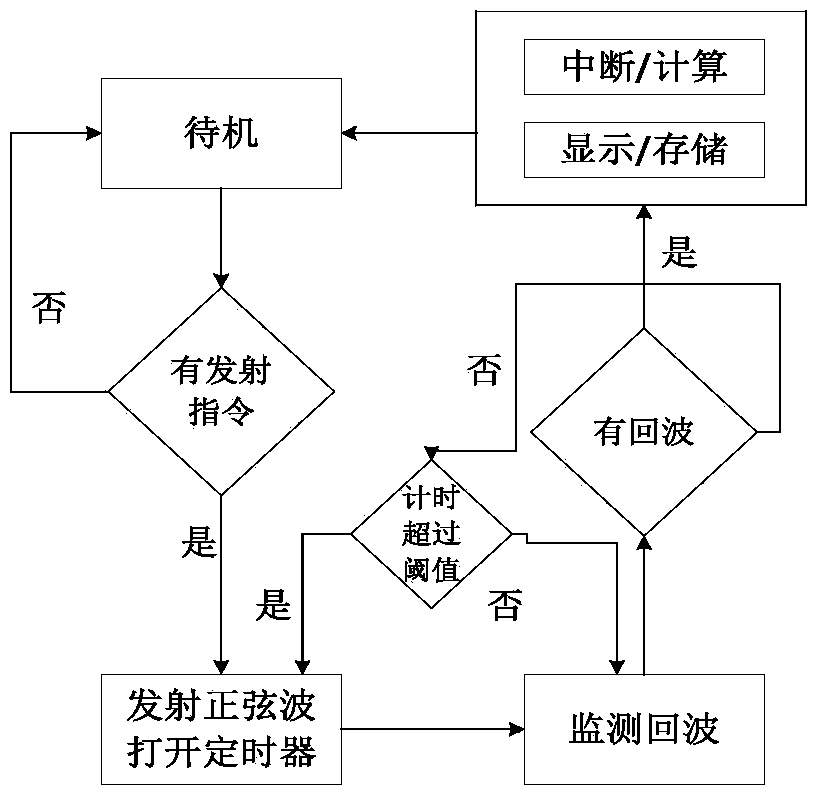

[0048] The ultrasonic range finder of the present invention does not use the single-chip microcomputer, independent display screen, battery, button of the prior art, but adopts the mobile terminal as the control center of signal transmission and reception, such as figure 1 As shown, it includes an ultrasonic sensor, an amplifier, a shaper, a power acquisition circuit and a mobile terminal, wherein the mobile terminal is the user's existing portable device, and the power acquisition circuit refers to converting the sine wave signal obtained from the audio port of the mobile terminal into a stable DC voltage circuit. Ultrasonic sensors include amplification, filtering, transmitters and receivers. The amplification and shaping circuit refers to a circuit that amplifies and shapes the sine wave signal output by the mobile terminal into a square wave signal with a moderate amplitude.

[0049] Integrate the audio port of the mobile terminal on the same connector, which consists of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com