Patents

Literature

4915results about How to "Smooth motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

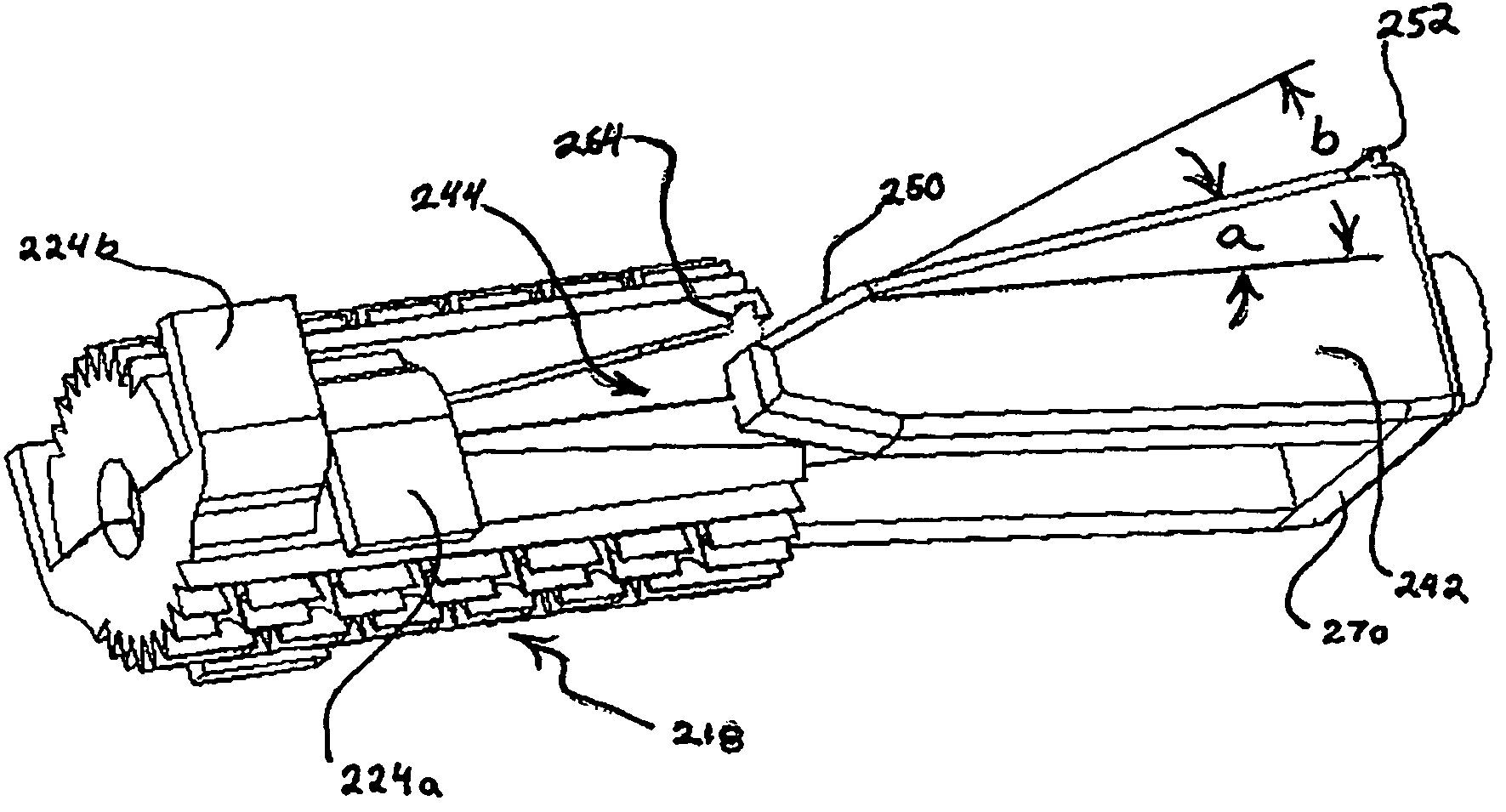

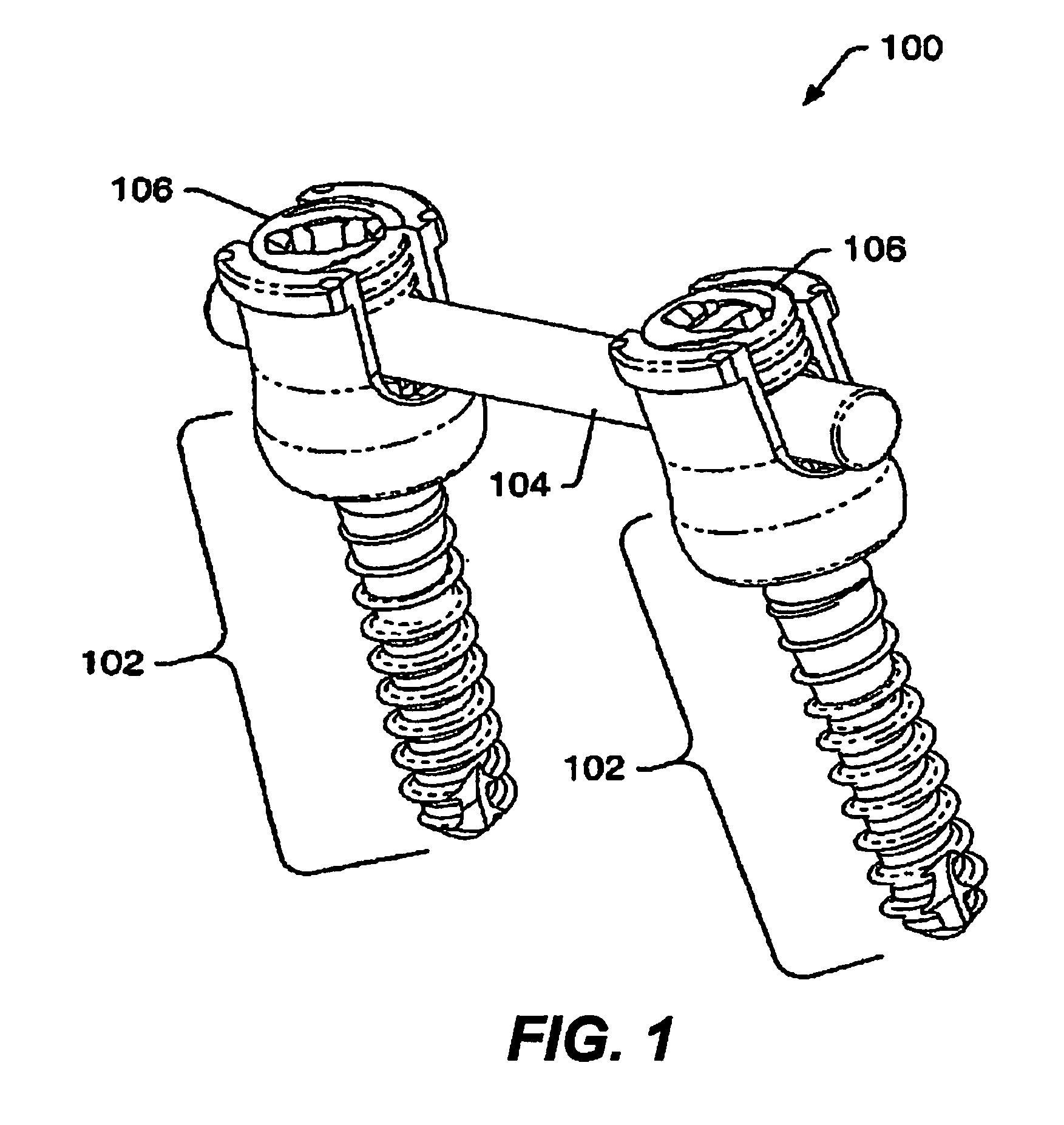

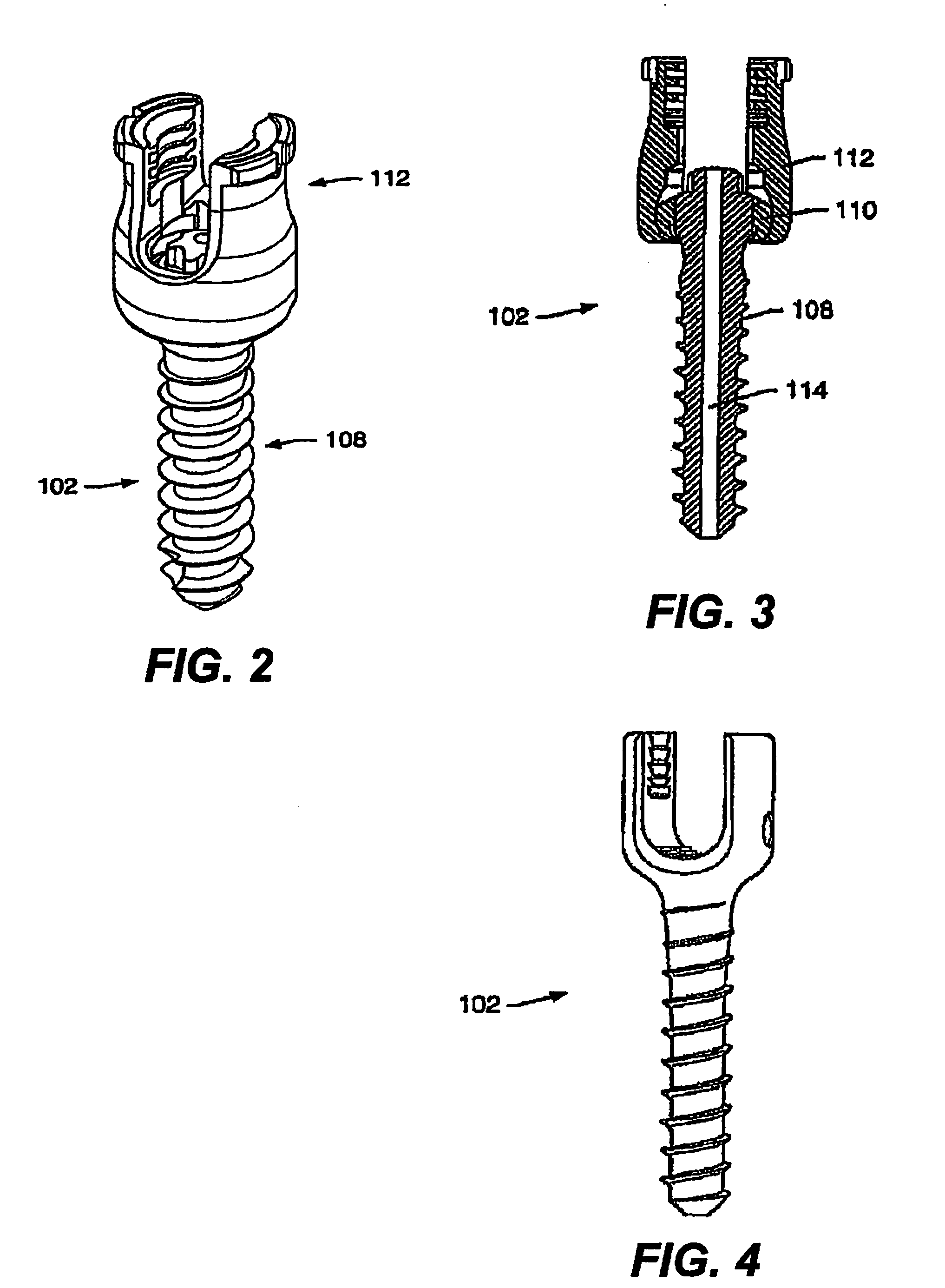

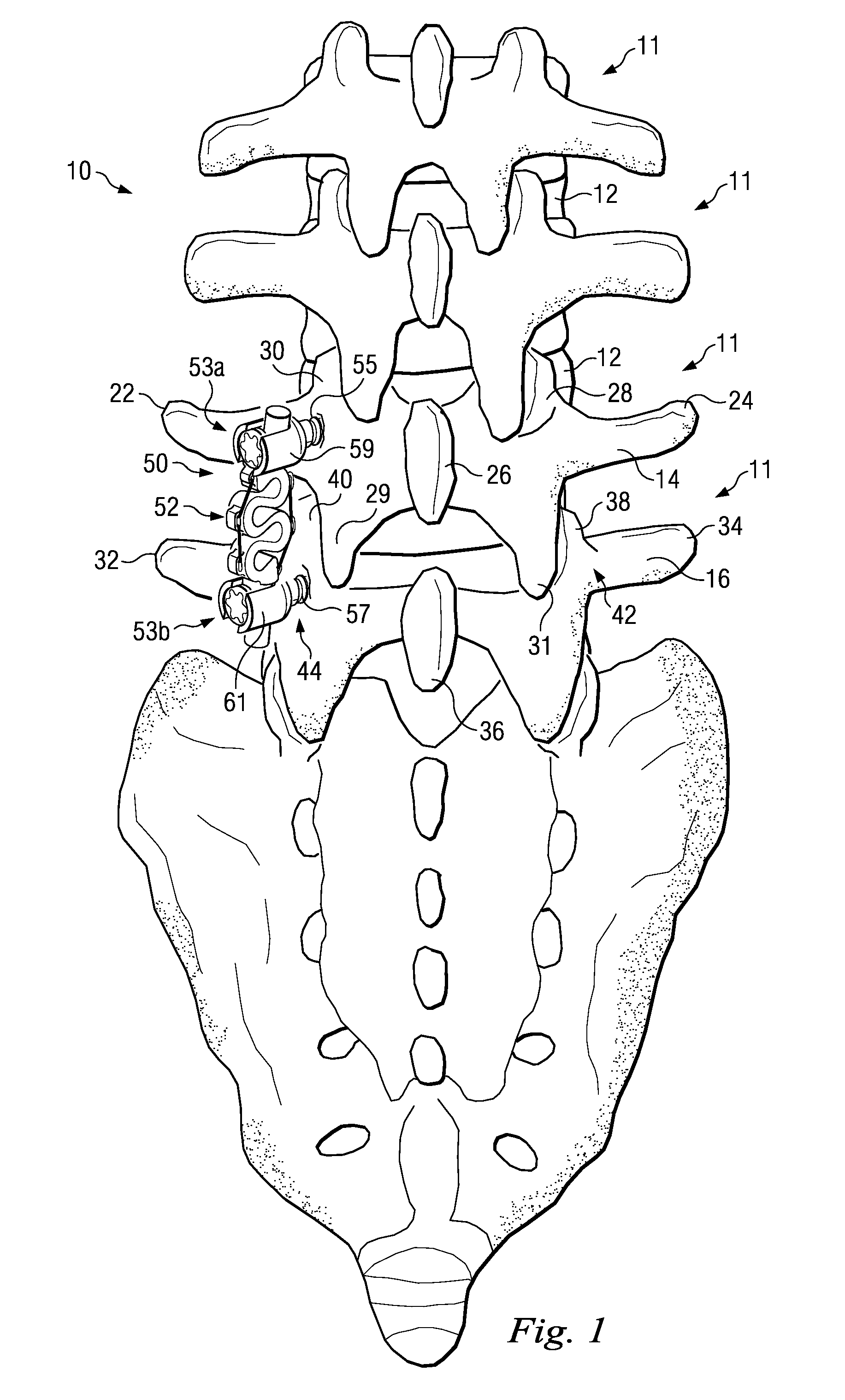

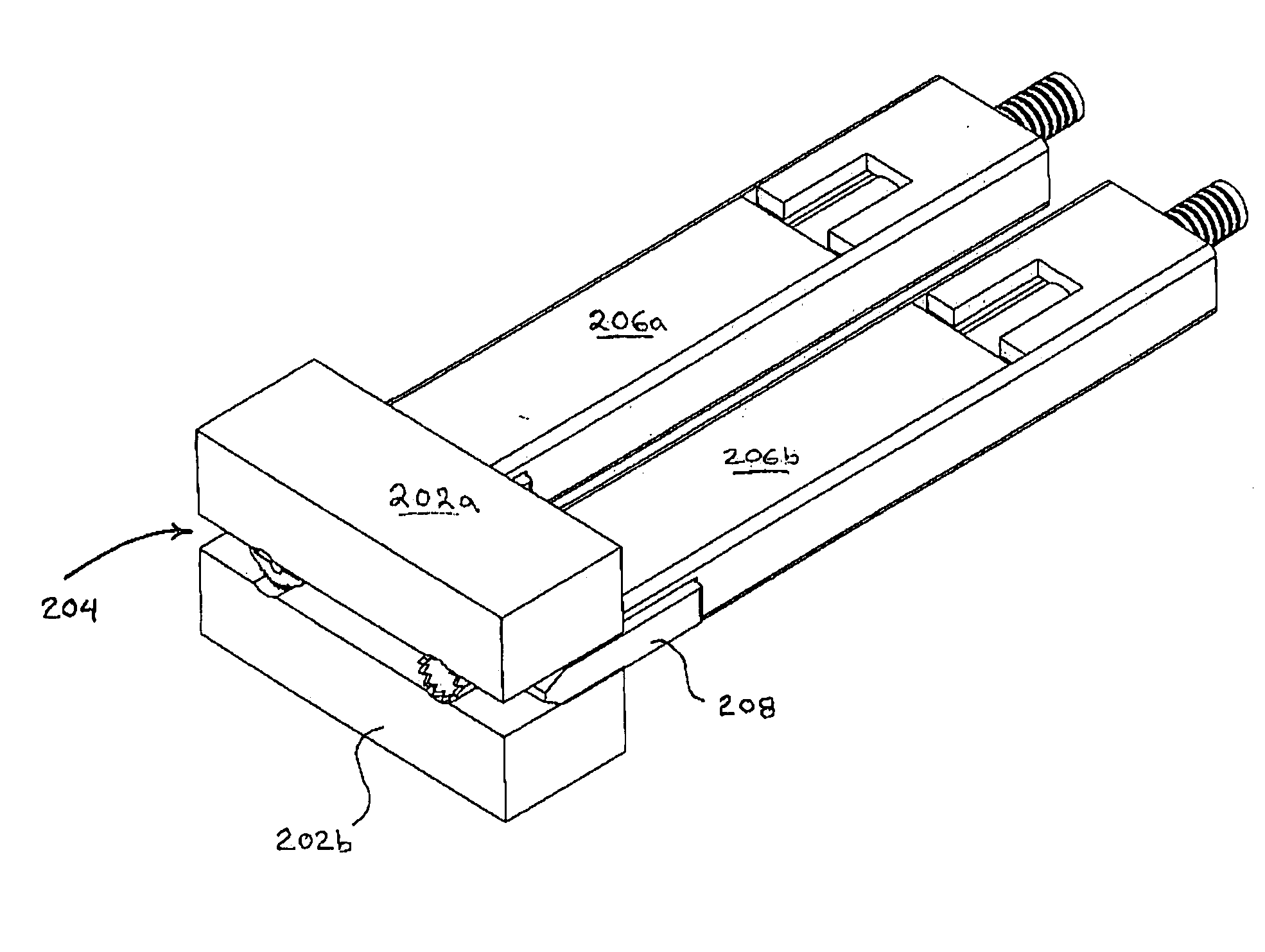

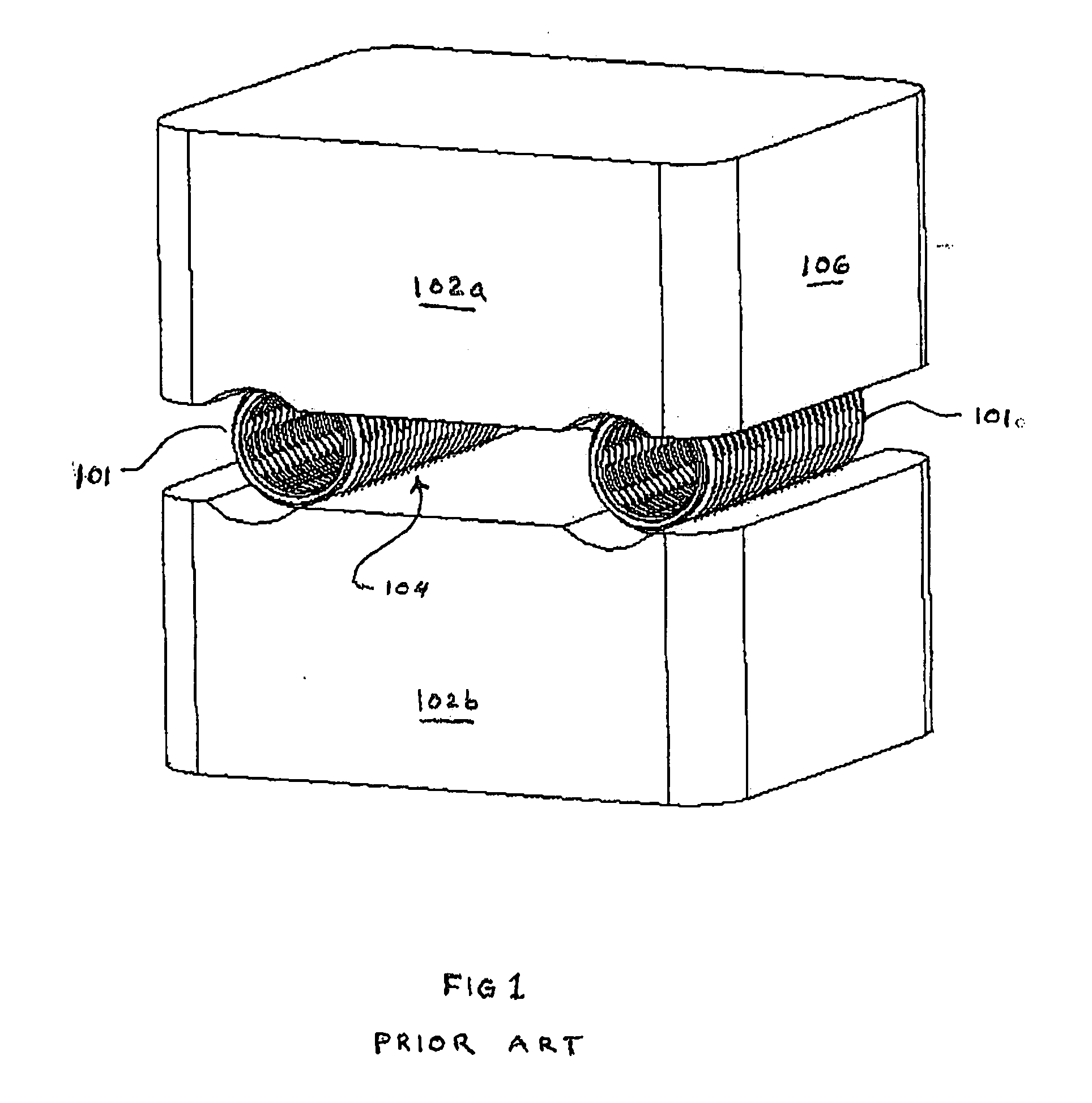

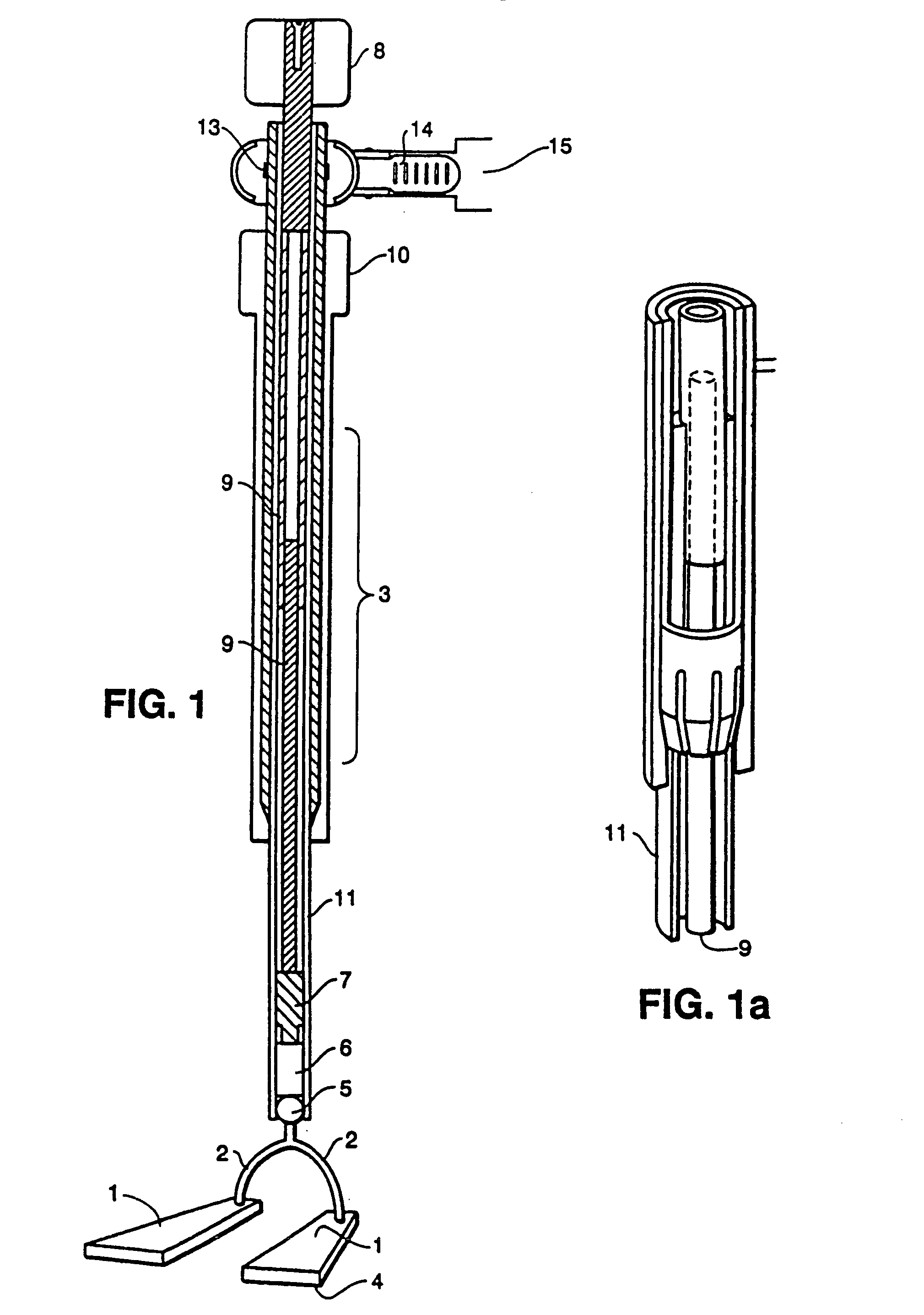

Linearly expanding spine cage for enhanced spinal fusion

ActiveUS7819921B2Diameter minimizationEffectively distractBone implantSpinal implantsSpinal columnVertical axis

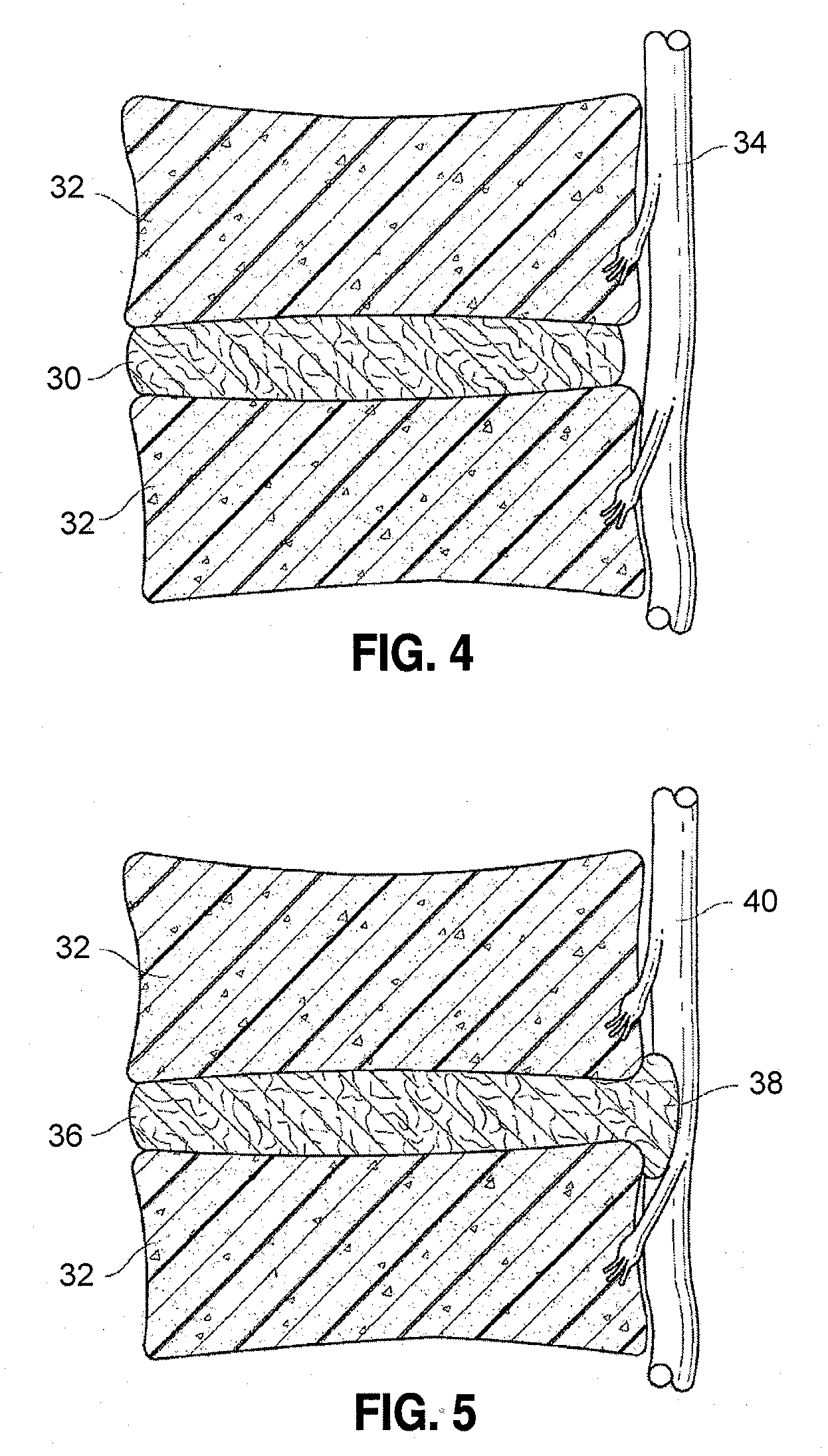

A linearly expanding spine cage has a minimized diameter in its unexpanded state that is equal to the diameter of an insertion groove cut into adjacent vertebral bodies. The cage conformably engages between the endplates of adjacent vertebrae to effectively distract the disc space, widen neuroforamina, stabilize the motion segments and eliminate pathologic spine motion. Angular deformities can be corrected, and natural curvatures maintained. The cage enhances spinal arthrodesis by creating a rigid spine segment. Expanding linearly (vertically, along the vertical axis of the adjacent spine) rather than uniformly, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. The cage width remains stable, so as to decrease impingement upon a second cage, or upon soft tissue structures in the immediate vicinity, including neural or vascular elements.

Owner:HOWMEDICA OSTEONICS CORP

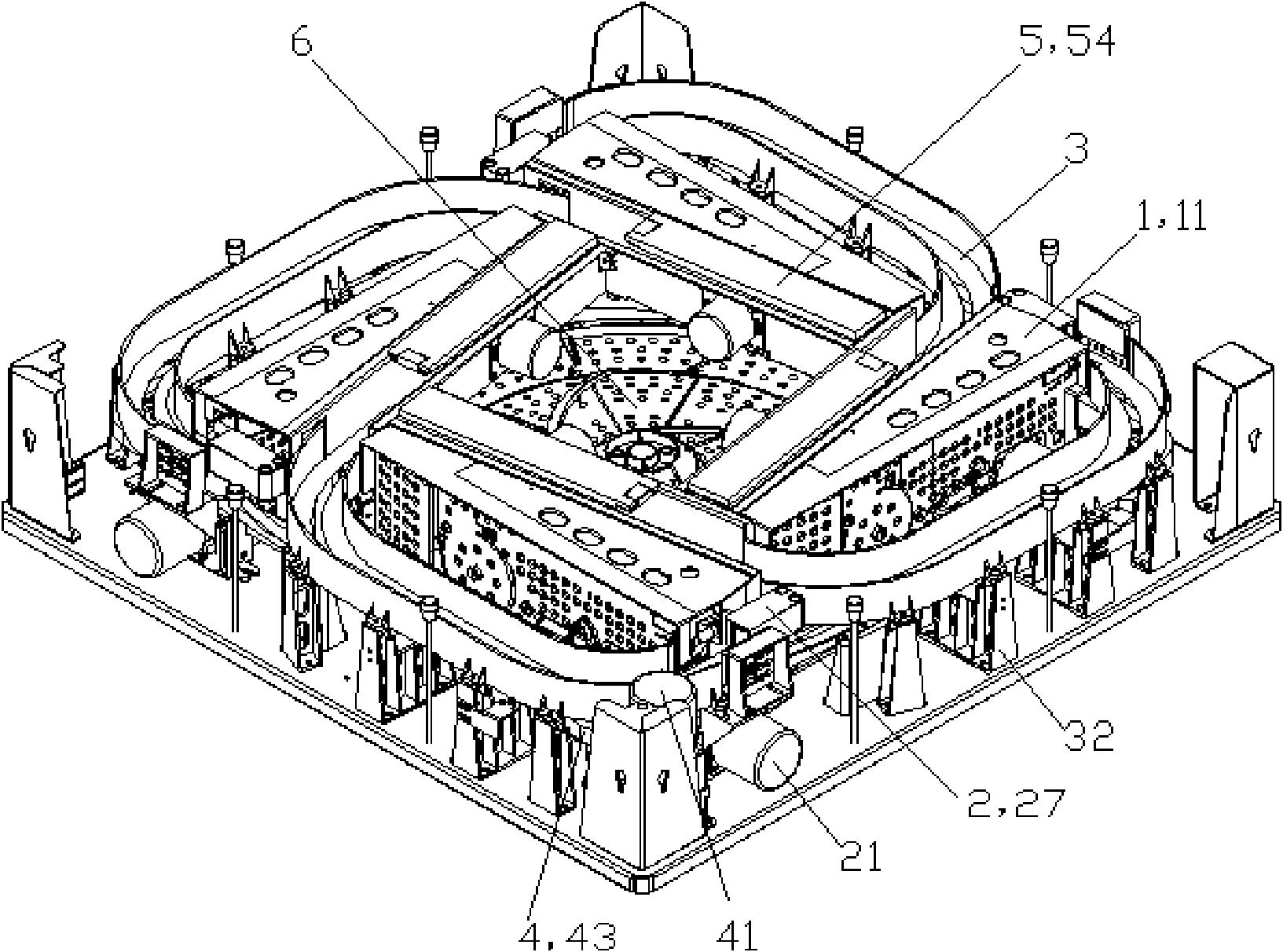

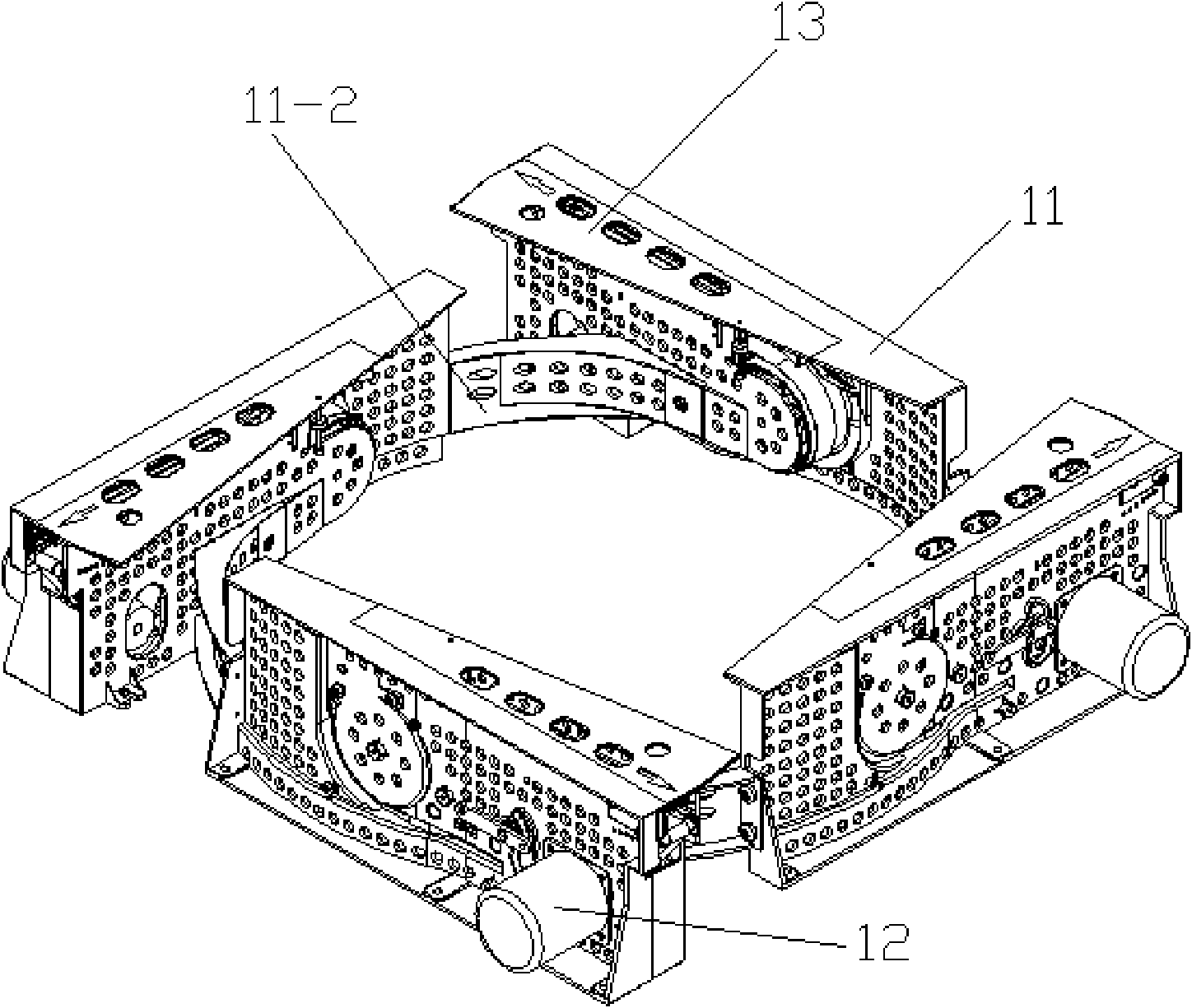

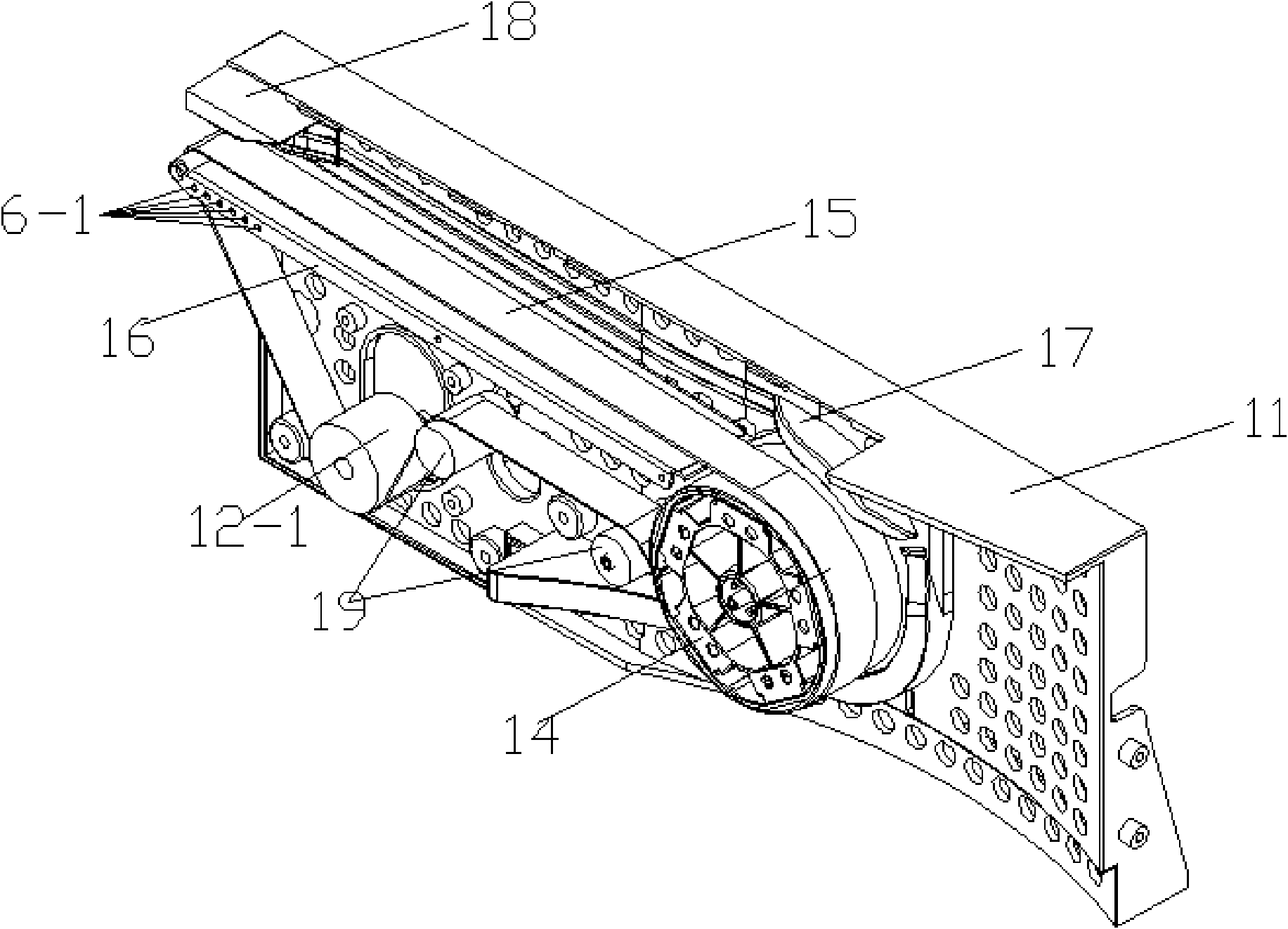

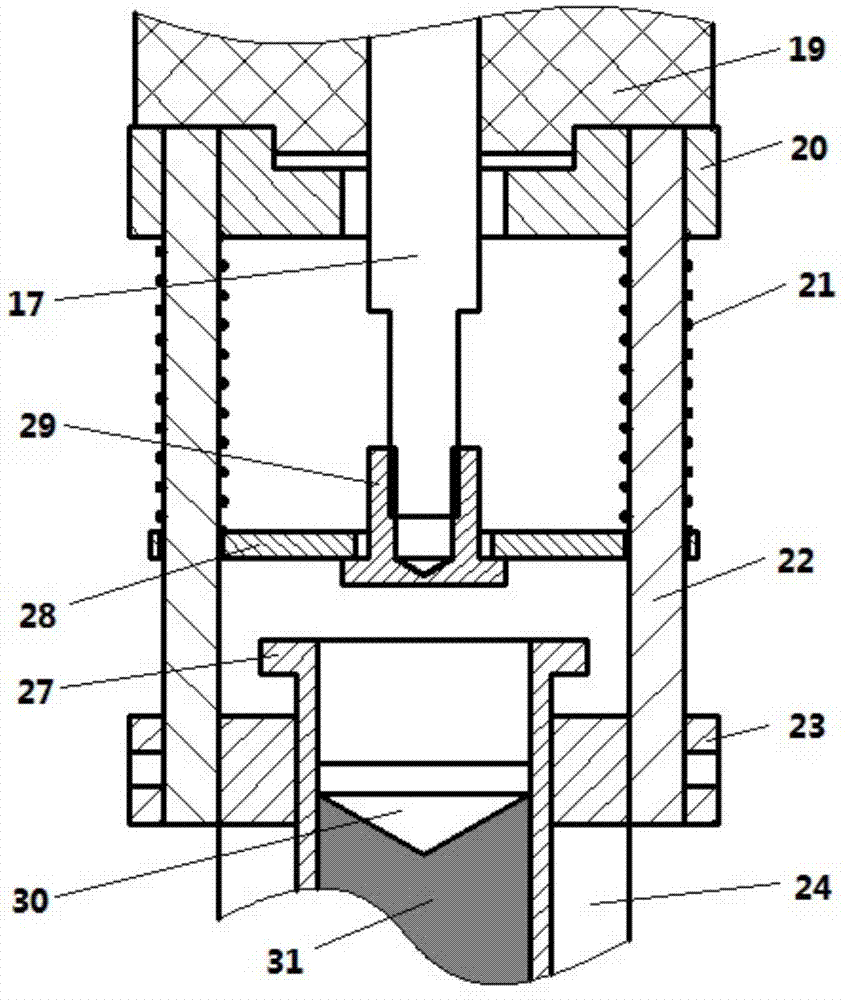

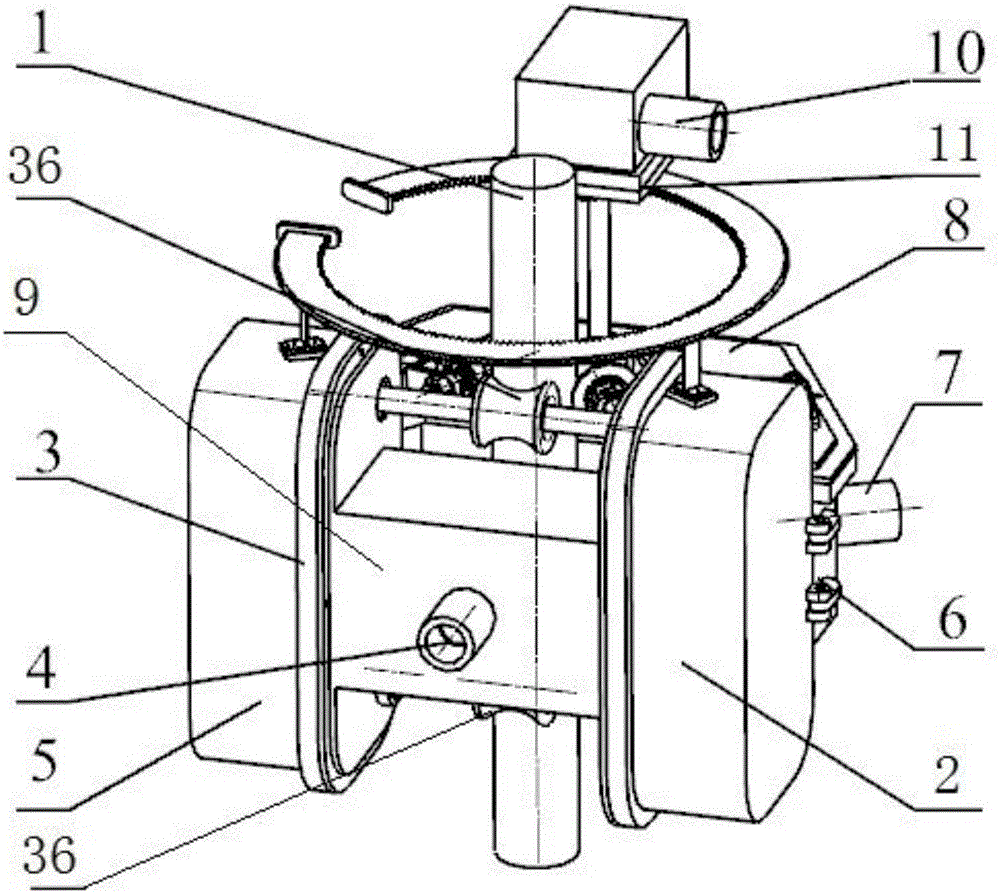

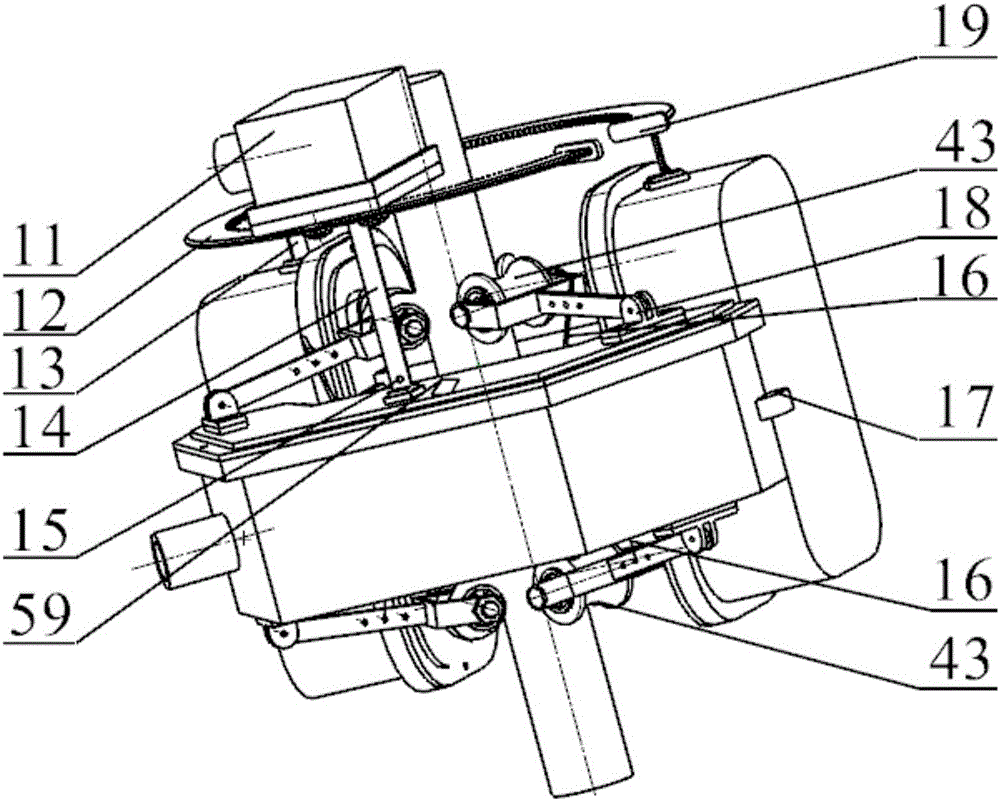

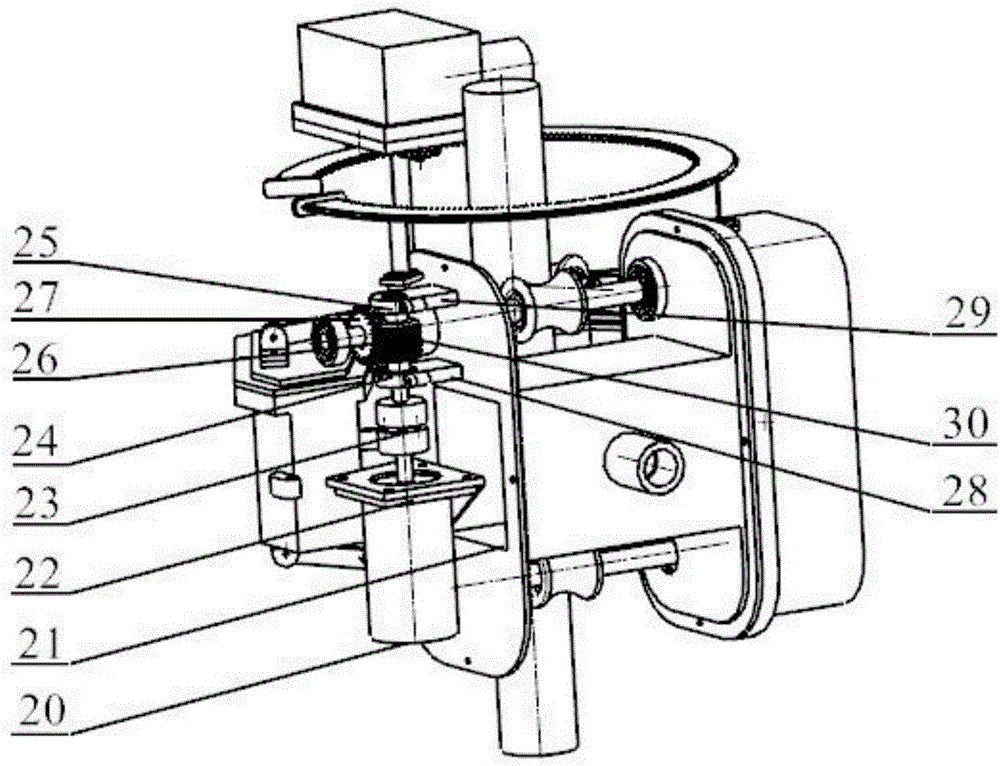

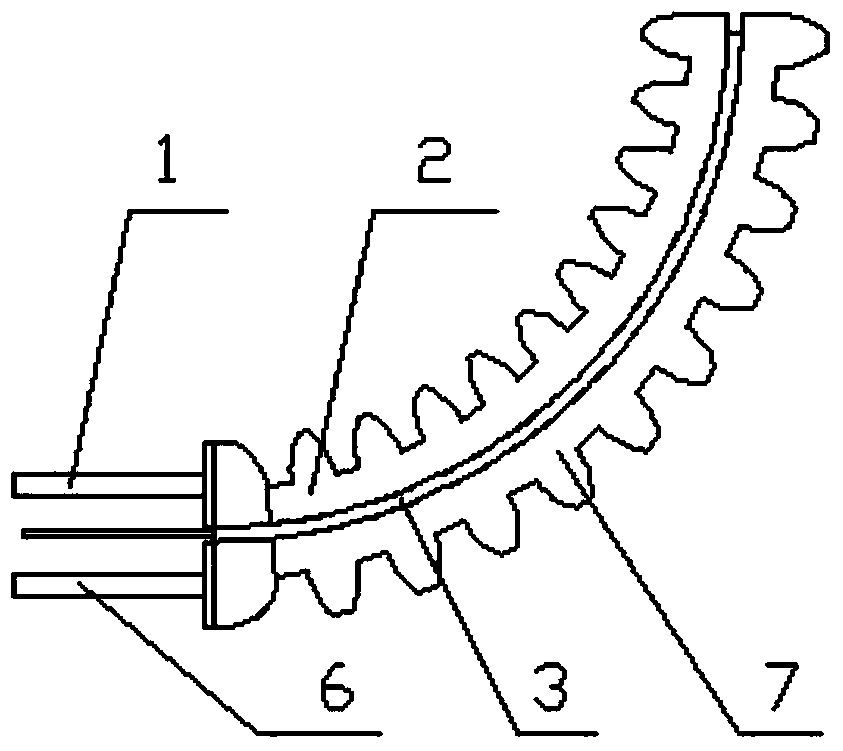

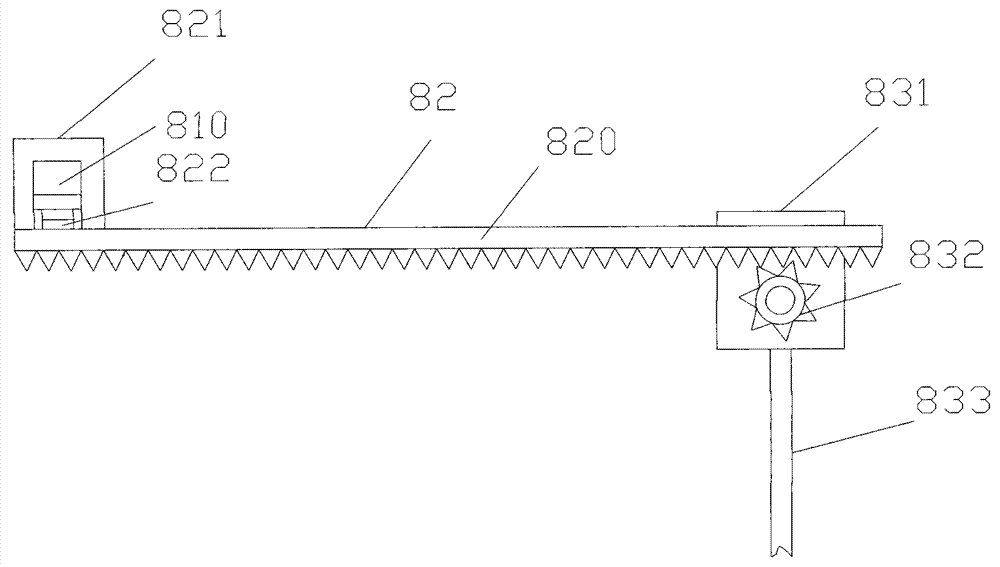

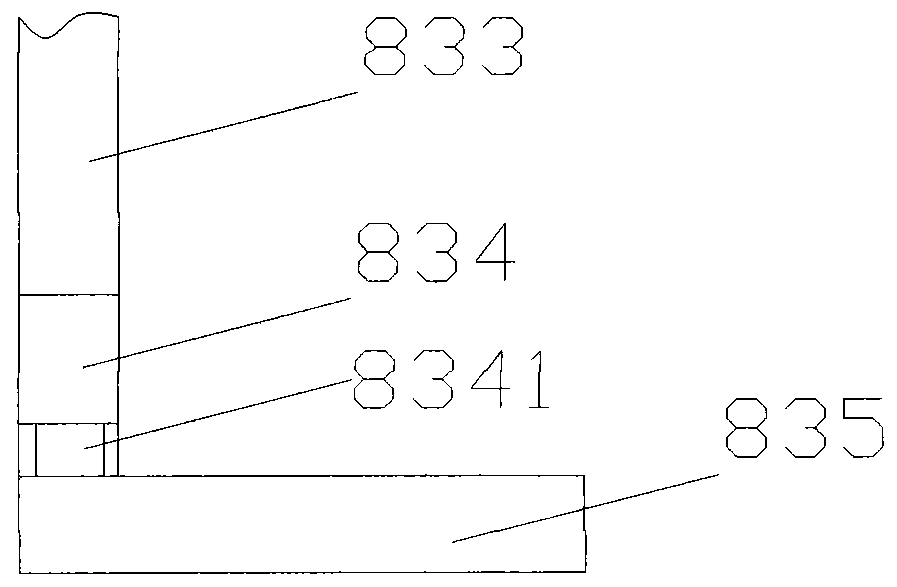

Fully-automatic mahjong machine

InactiveCN102133480AReduce manufacturing costGuaranteed uptimeIndoor gamesInlet channelTransmission belt

The invention relates to a fully-automatic mahjong machine comprising a board sending system, a board loading system, a board lifting system and a large shuffling disc. The board sending system comprises four board sending mechanisms, each board sending mechanism comprises a transmission rack, and a board sending motor, a board absorbing wheel, a transmission belt, a transmission platform, a board inlet guiding piece and a board outlet guiding piece fixed on the transmission rack; a board sending channel is arranged at the upper end of the transmission platform, the board absorbing wheel is tightly attached at the lower end of a board inlet opening of the board sending channel, the board inlet guiding piece is positioned above the board absorbing wheel, the board outlet guiding piece is positioned at a board outlet opening of the board inlet channel, the board sending motor is used for driving a motor guiding wheel, the motor guiding wheel is positioned below the transmission platform, and the transmission belt loops the motor guiding wheel, the board absorbing wheel and the transmission platform. In the invention, for the mahjong boards with different widths, the board sending mechanism of the mahjong machine can run normally by only replacing the corresponding board inlet guiding piece and the board outlet guiding piece, and a transmission rack cover does not need to be changed, so that the operation is simple and convenient, and the board inlet guiding piece and the board outlet guiding piece has extremely low production cost relative to the transmission rack cover.

Owner:程亮星

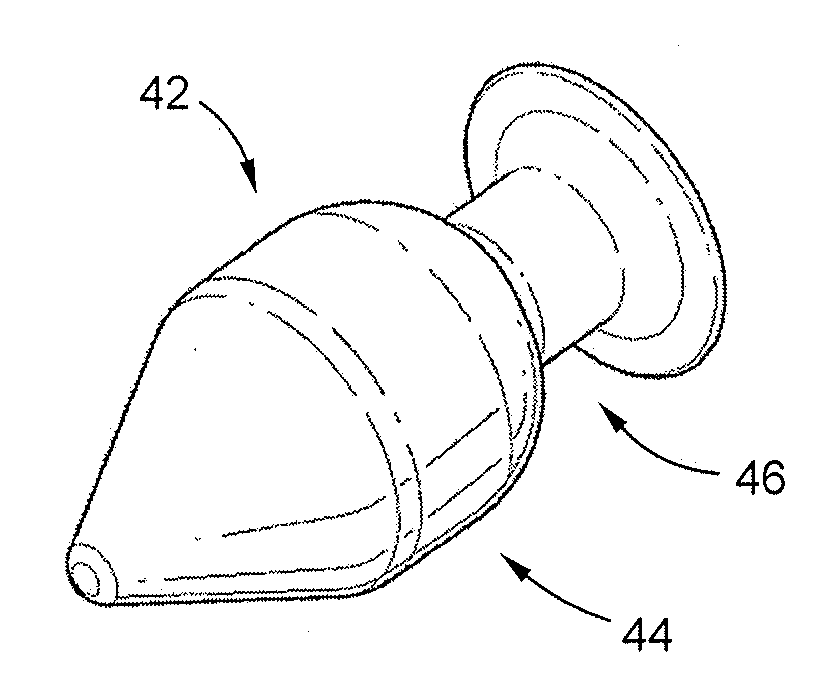

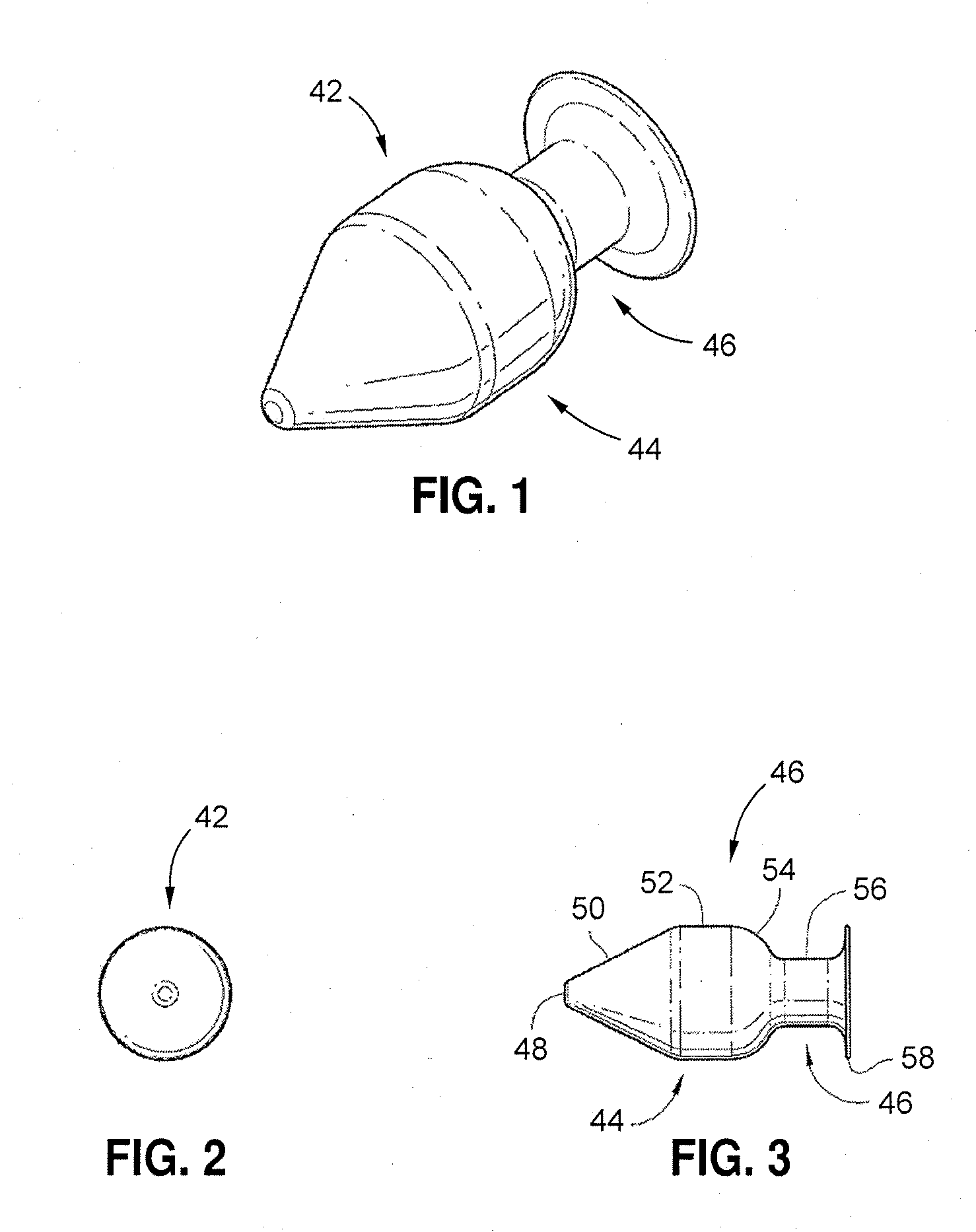

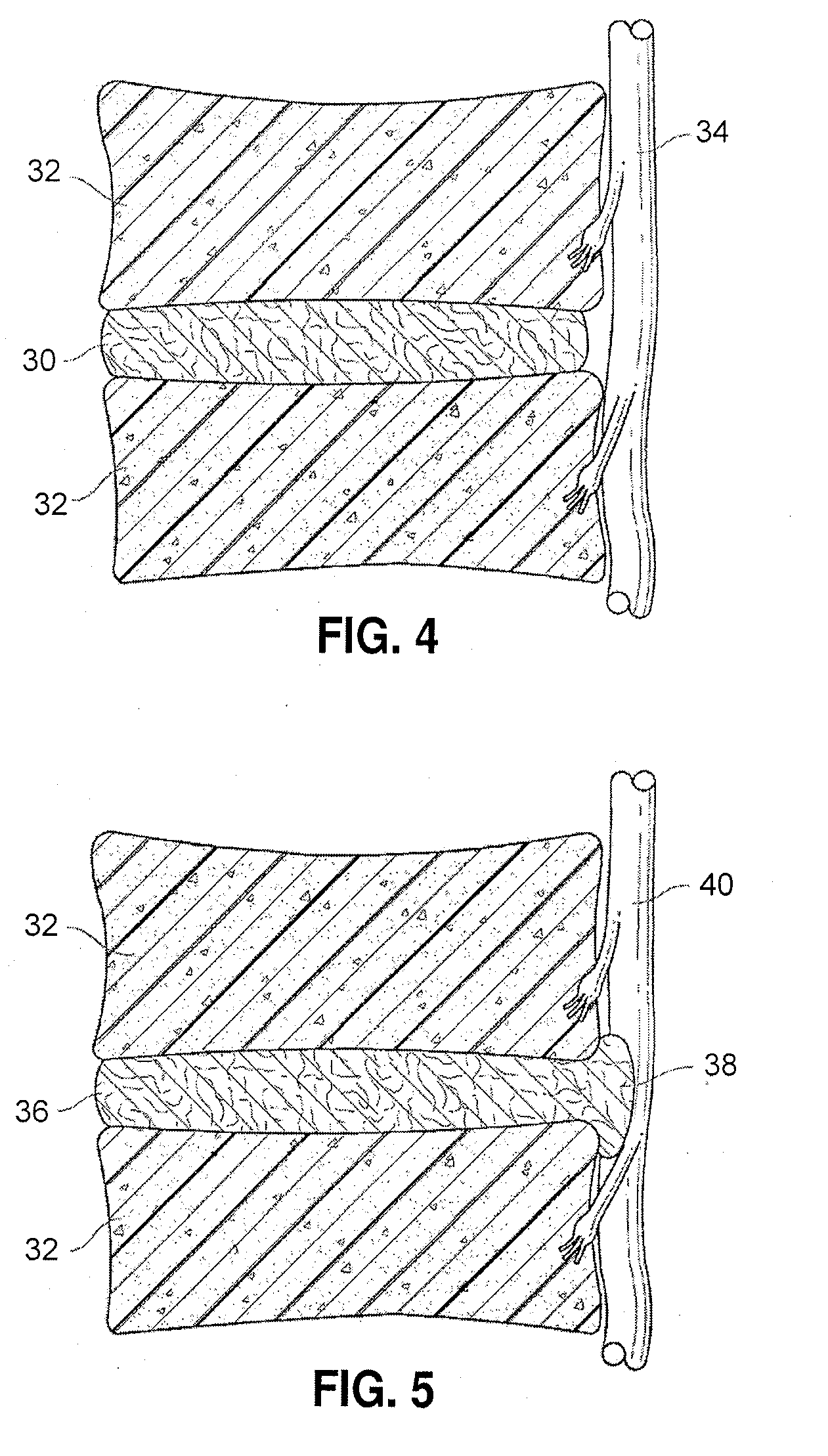

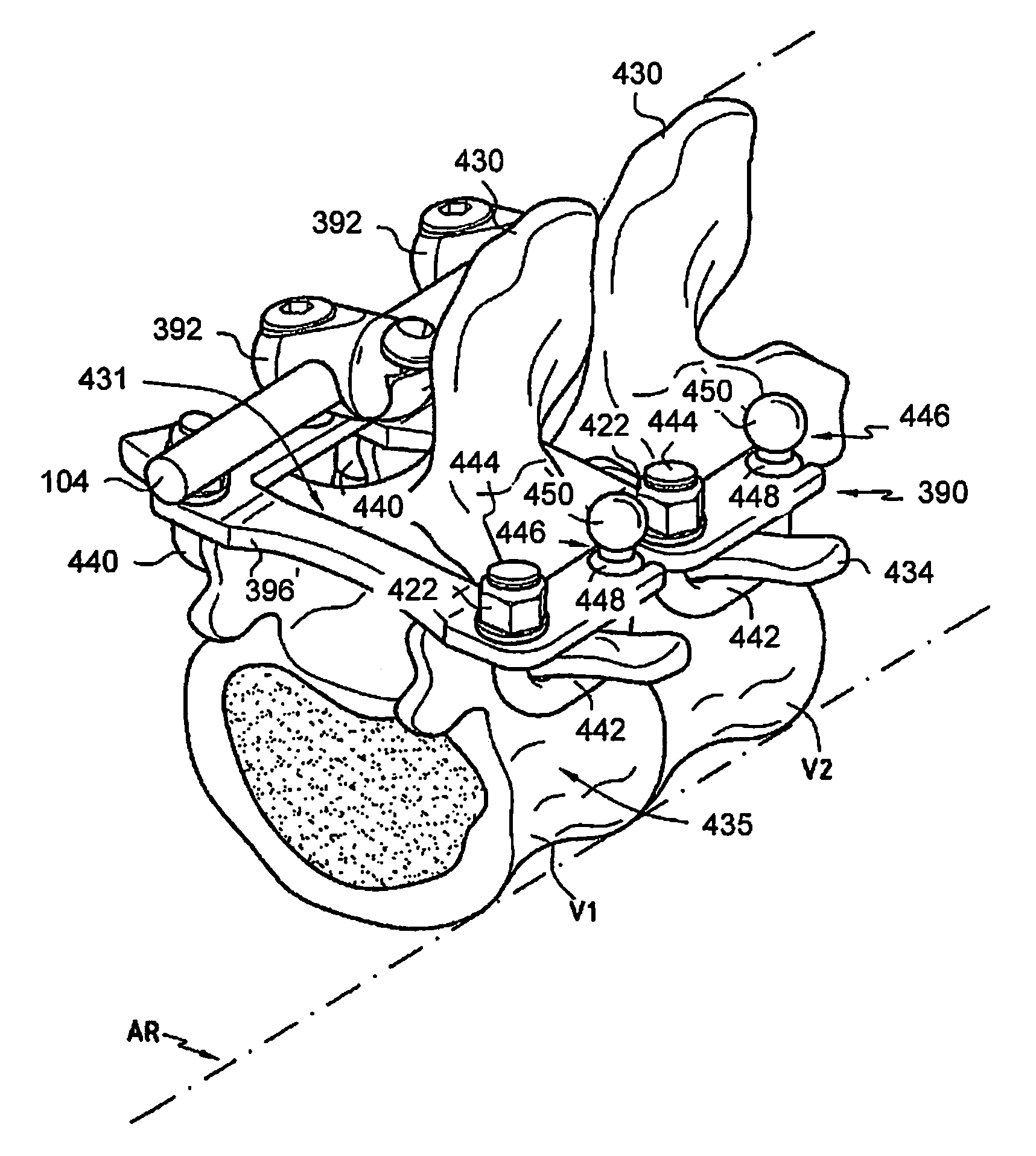

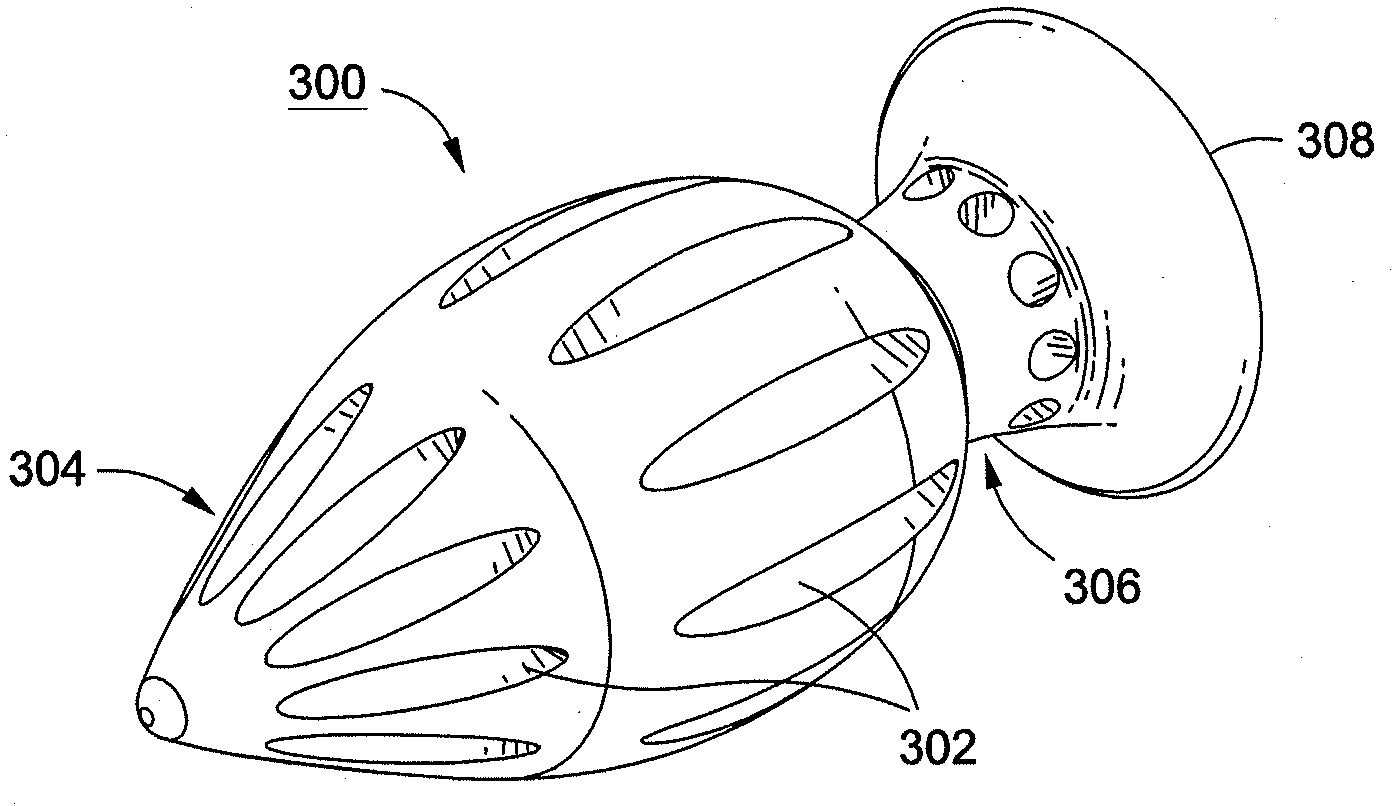

Spinal implants and methods

InactiveUS20090149959A1Reduce relative motionSmooth motionDiagnosticsBone implantPosterior regionIntervertebral disk

Owner:MAGELLAN SPINE TECH

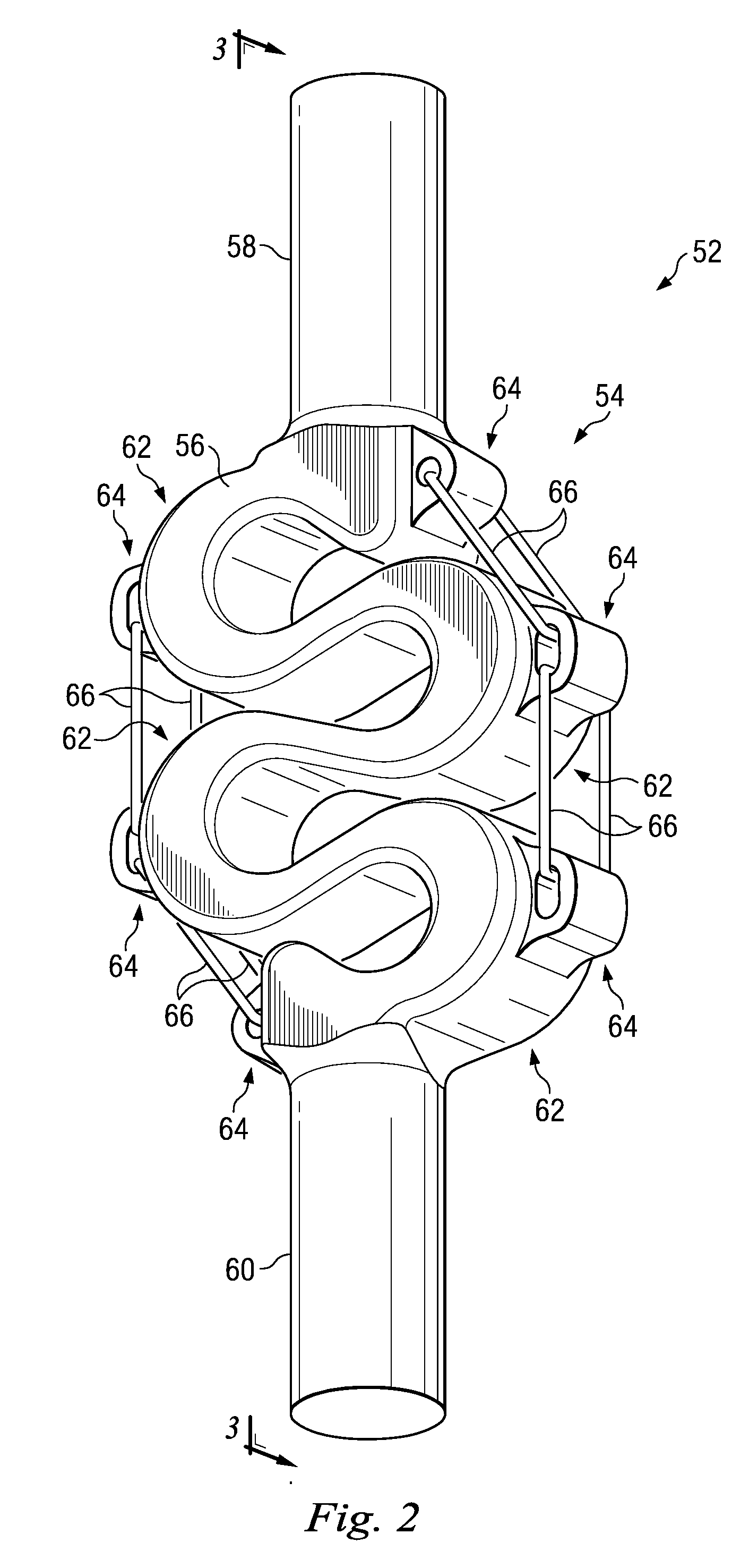

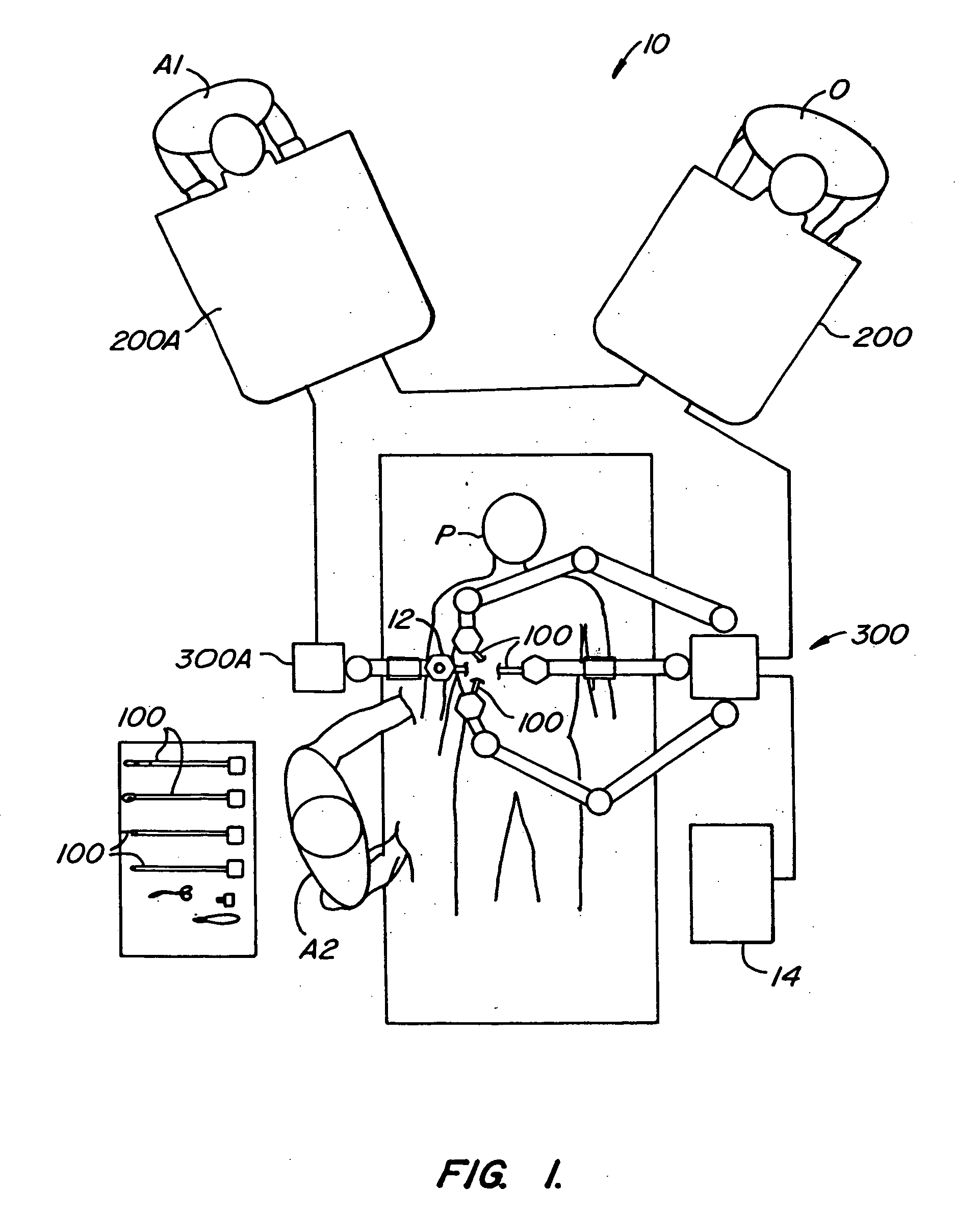

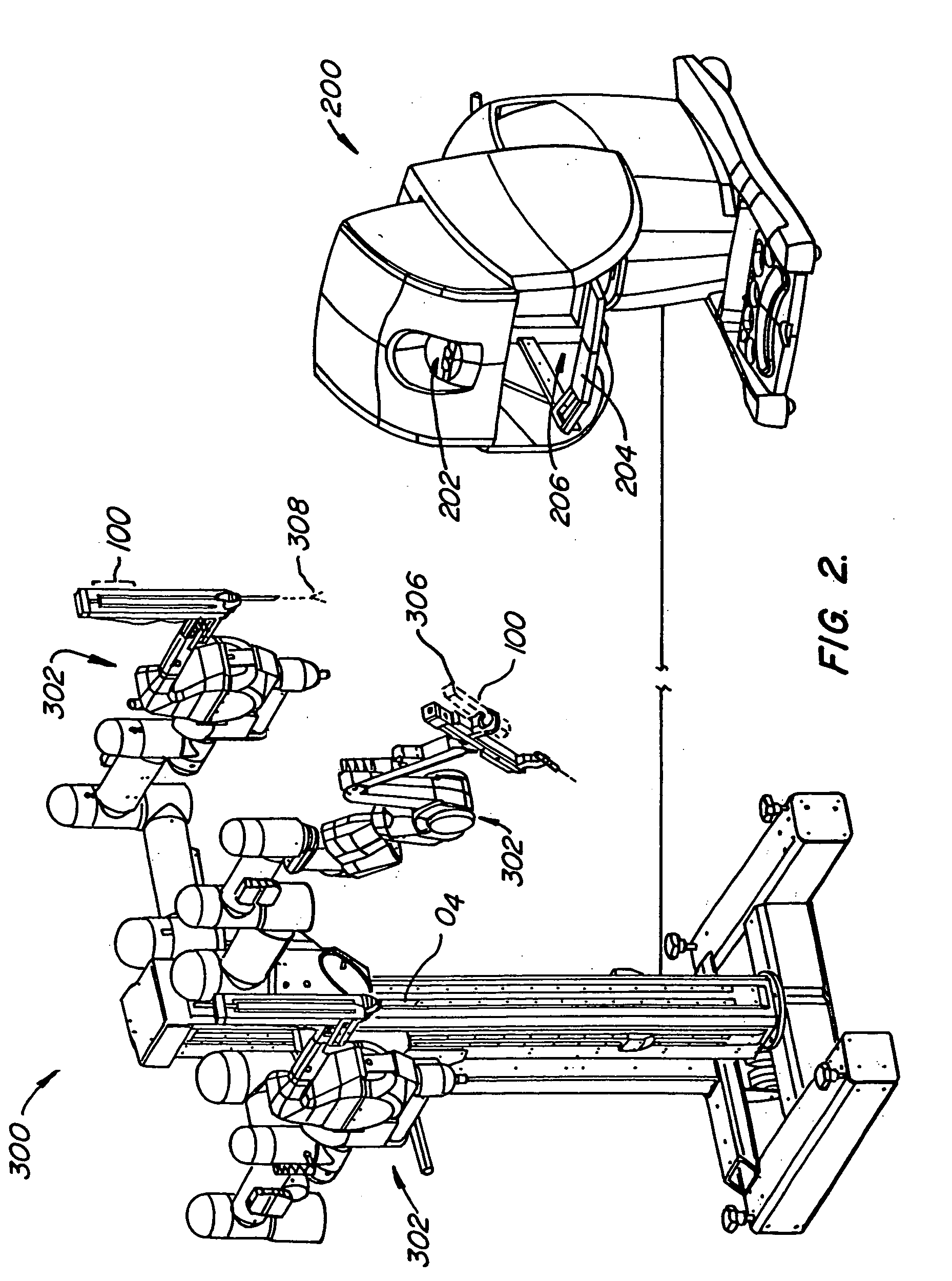

Endoscopic beating-heart stabilizer and vessel occlusion fastener

InactiveUS7250028B2Physiological motion of stabilizedAvoid relative motionSuture equipmentsDiagnosticsSurgical operationSurgical department

Owner:INTUITIVE SURGICAL OPERATIONS INC

Dynamic spine stabilization system

InactiveUS20090093843A1Stabilizing portions of the spineSmooth motionSuture equipmentsInternal osteosythesisBiomedical engineeringSpinous process

Owner:ZIMMER SPINE INC

Vertebral Stabilizer

ActiveUS20080234736A1Improve the immunitySmooth motionInternal osteosythesisJoint implantsEngineeringStress shielding

A bio-compatible stabilization system includes one or more inserters and a connector for traversing a space between one or more bony structures. The stabilization system is designed to reduce or eliminate stress shielding effects while functioning as a tension band. The connector includes an extendable member and an over-extension limiter that limits extension of the extendable member.

Owner:WARSAW ORTHODEPIC

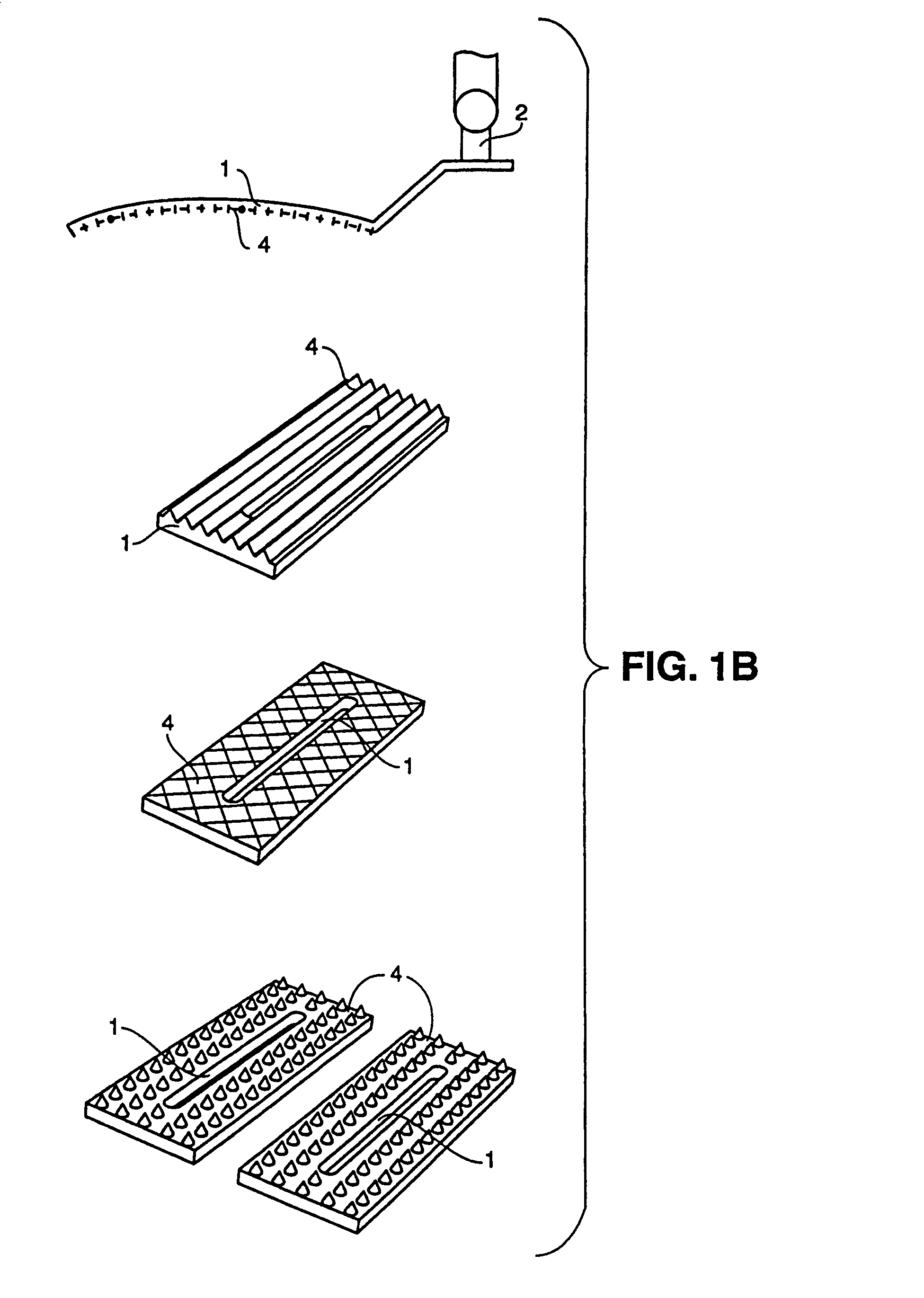

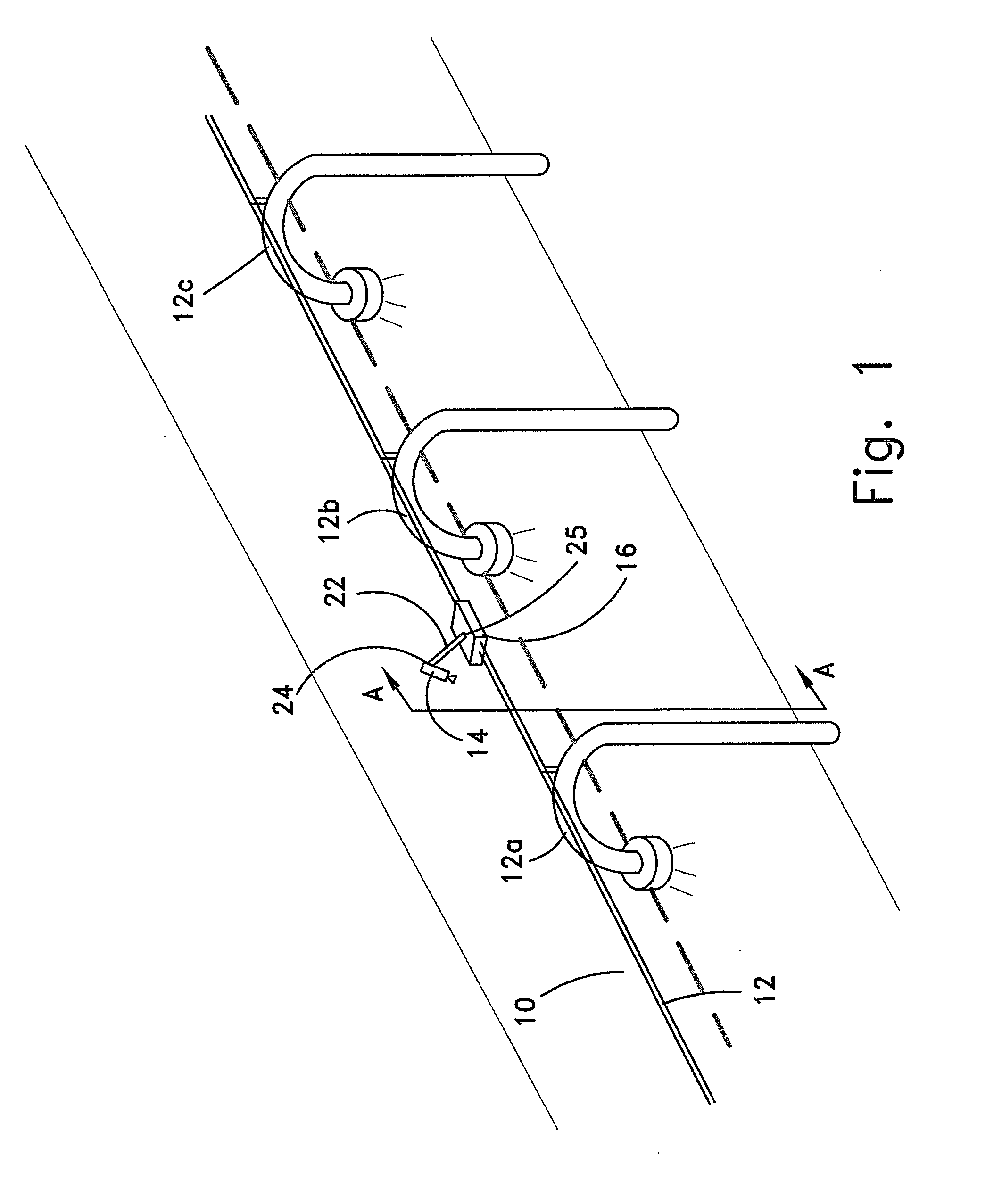

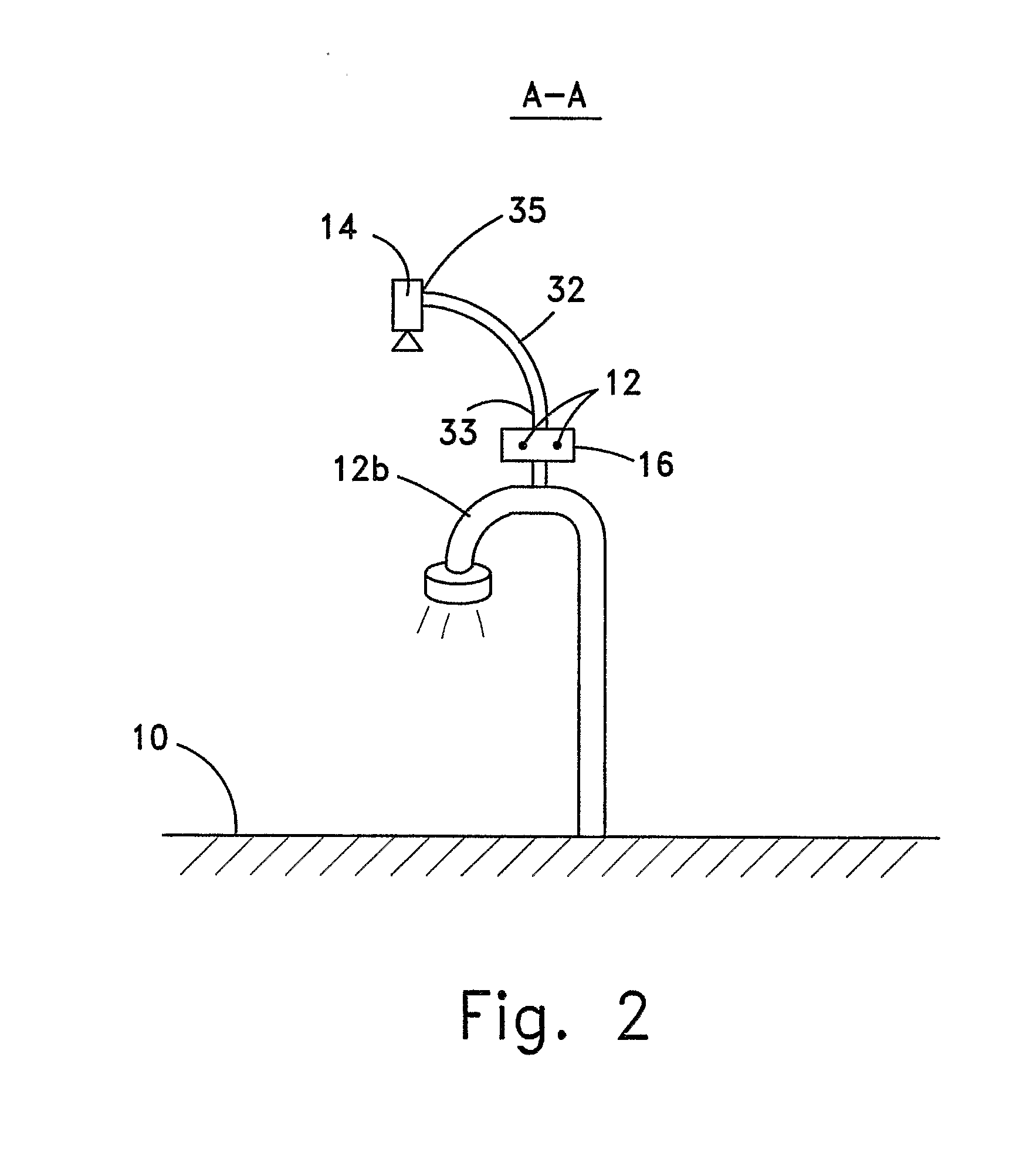

Spinal implants and methods

InactiveUS20090138015A1Reduce relative motionSmooth motionBone implantDiagnosticsPosterior regionIntervertebral disk

Spinal implants are disclosed that can be used for annular repair, facet unloading, disc height preservation, disc decompression, or for sealing a portal through which an intervertebral implant was placed. In some embodiments, an implant is placed within the intervertebral disc space, primarily within the region of the annulus fibrosus. In some embodiments, the implant is expandable. In some embodiments, the implant has a sealing tail structure comprising a tail flange and a linkage. In some embodiments, the sealing tail structure limits the extrusion or expulsion of disc material, either annulus fibrosus or nucleus, into the posterior region of the spine where it could impinge on nerves. In some embodiments, the tail structure is retained in place within the annulus fibrosus by means of an anchor. In some embodiments, the anchor is constructed from multiple components.

Owner:CONNER E SCOTT DR

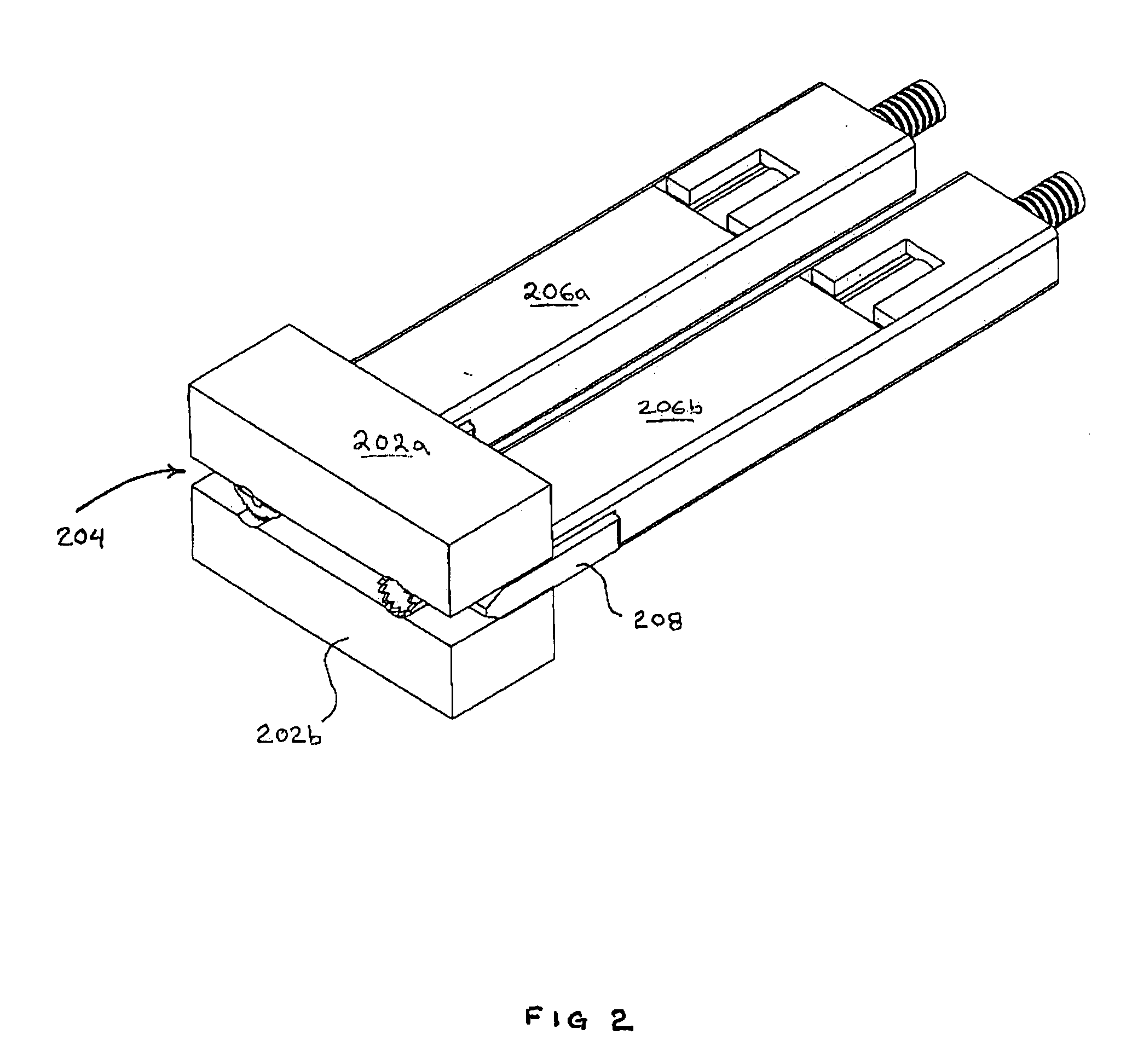

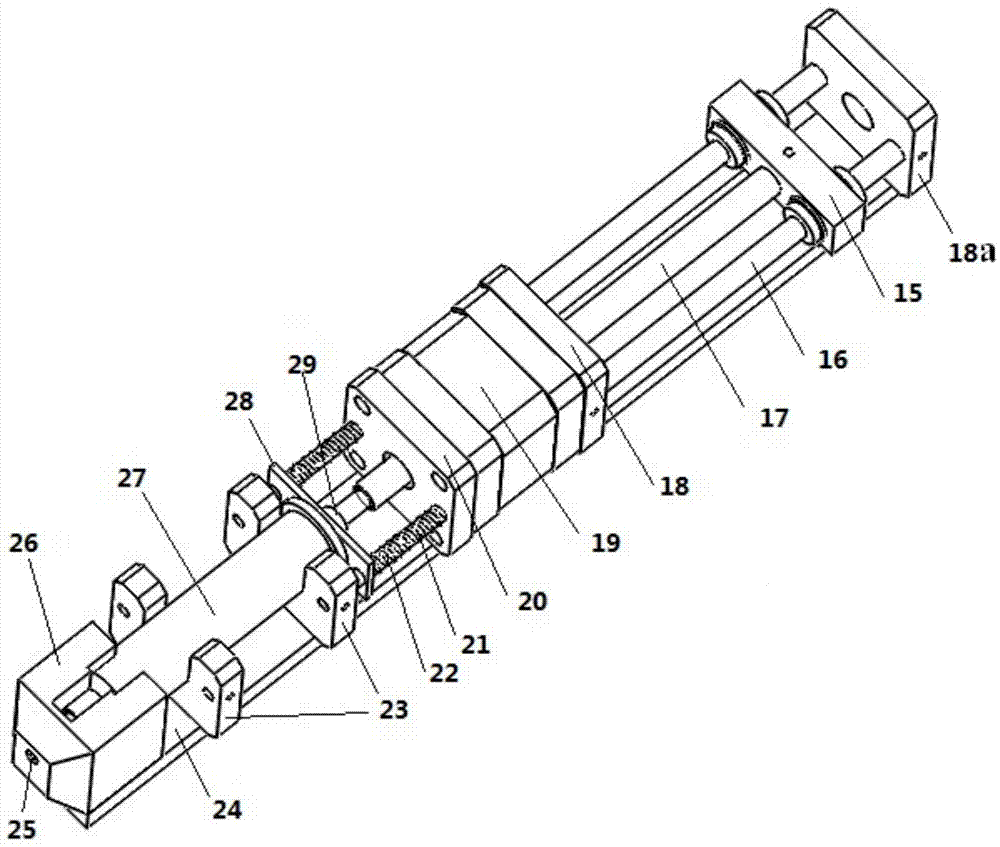

Thin-wall sliding sleeve disassembling fixture

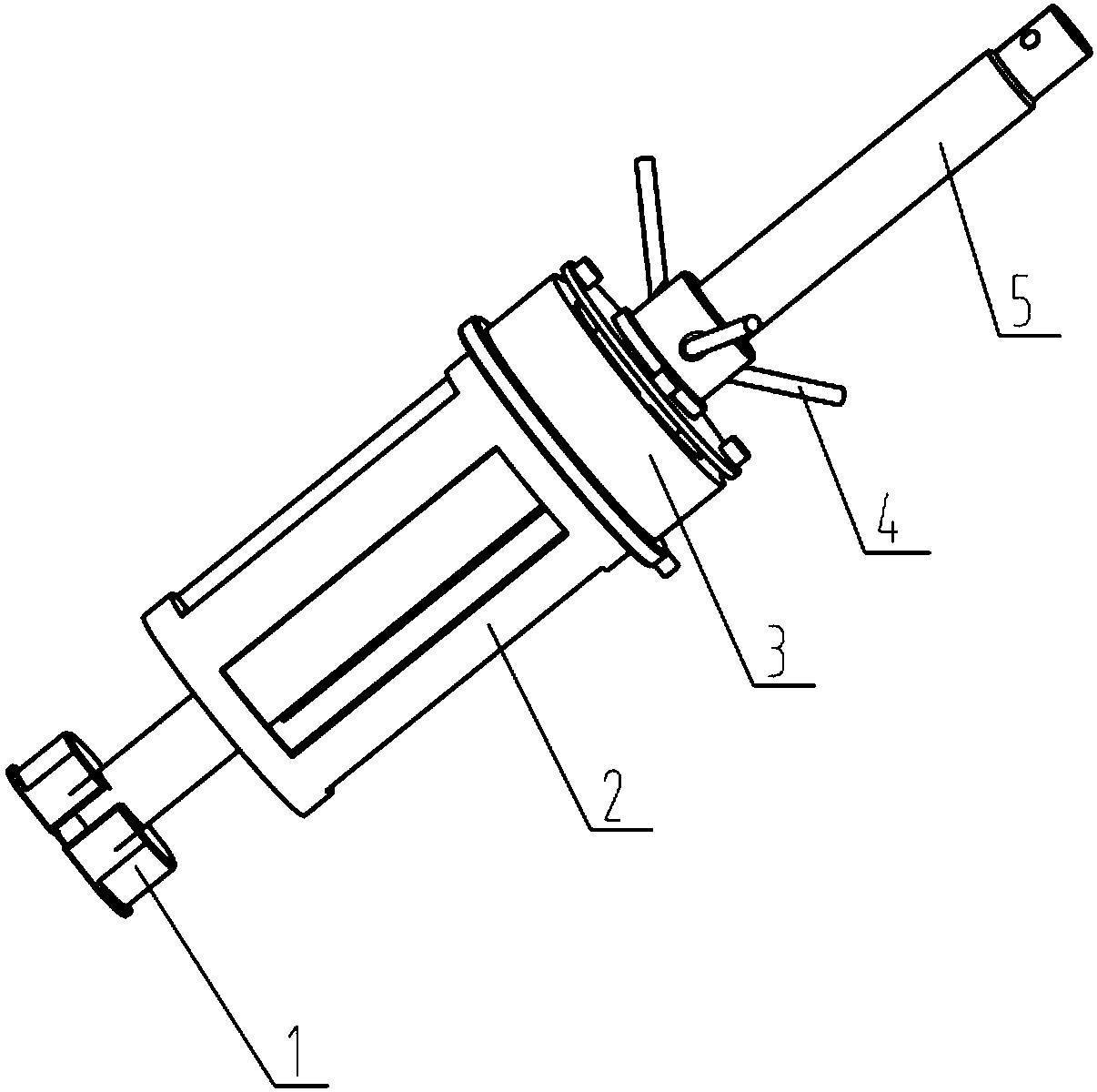

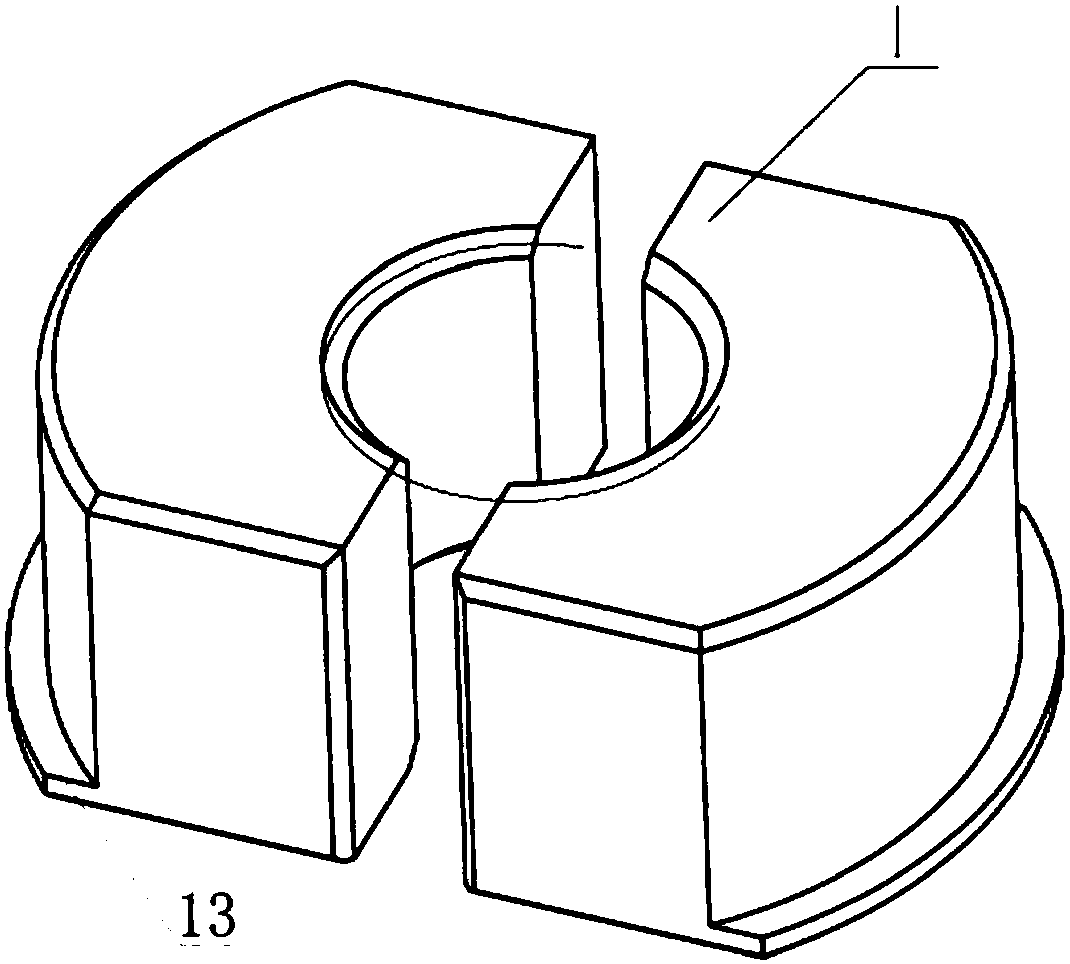

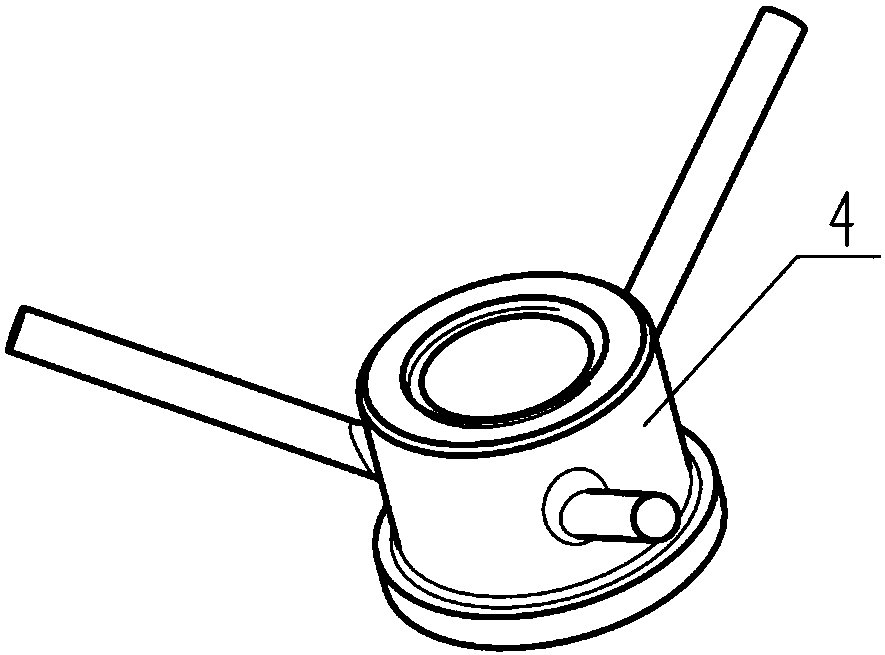

PendingCN108555826AEasy loadingGuaranteed fitMetal-working hand toolsEngineeringMechanical engineering

The invention provides a thin-wall sliding sleeve disassembling fixture. The thin-wall sliding sleeve disassembling fixture comprises a puller nut and a puller screw. The puller screw is in threaded connection with the puller nut. One end of the puller screw is provided with a clamping jaw. The puller screw is in threaded connection with the clamping jaw. A bracket and a hydraulic system are installed between the puller nut and the clamping jaw. The bracket and the hydraulic system are sheathed on the puller screw. The bracket is adjacent to the clamping jaw. The hydraulic system is adjacent to the puller nut. Through controlling the hydraulic system to boost pressure and reduce pressure, the disassembly of a thin-wall sliding sleeve can be realized. The thin-wall sliding sleeve disassembling fixture is small in volume, light in weight, smooth and steady in movement, and safe and convenient in operation, and capable of preventing the deformation of the thin-wall sliding sleeve and thescratching of a hole wall in an disassembling process.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

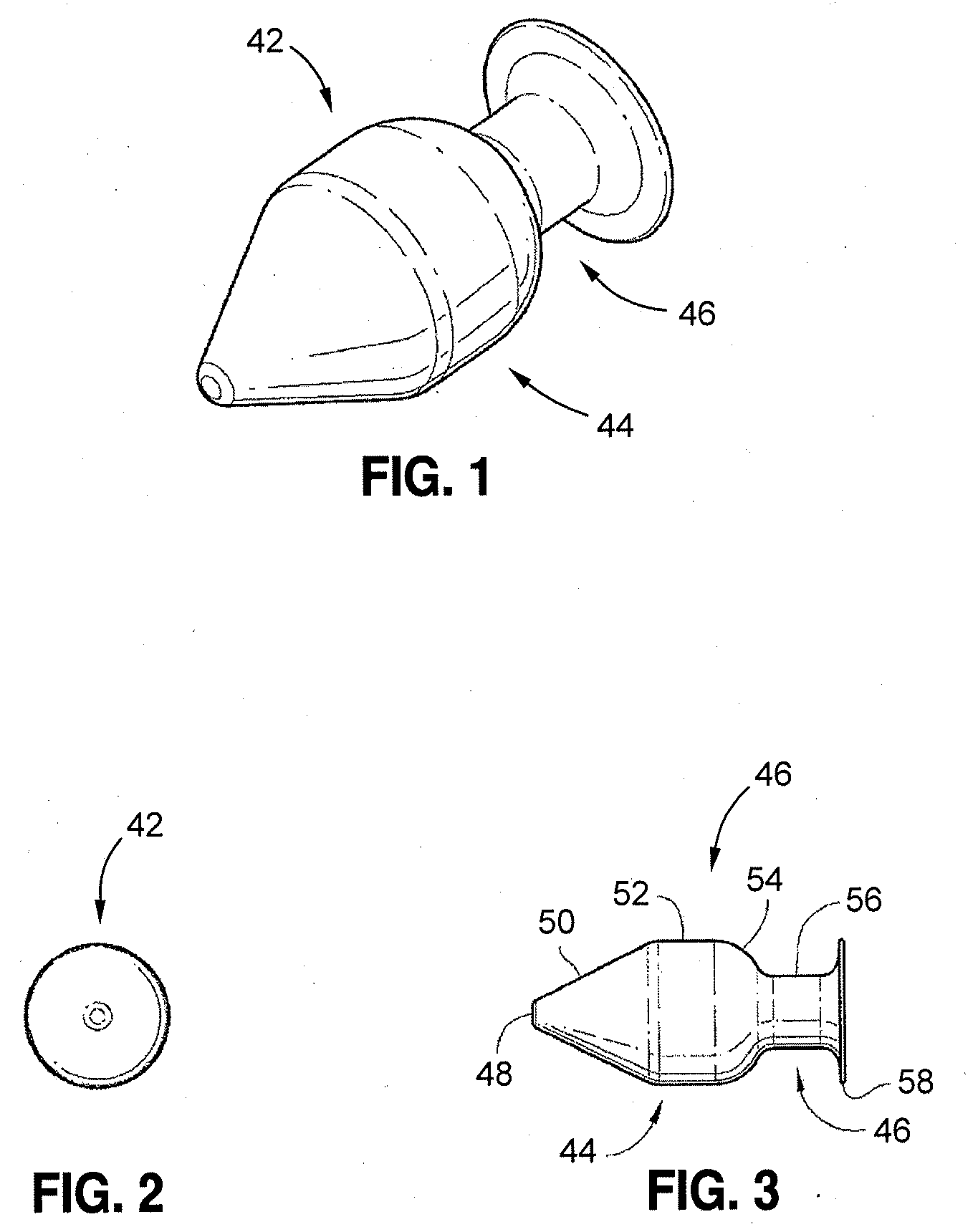

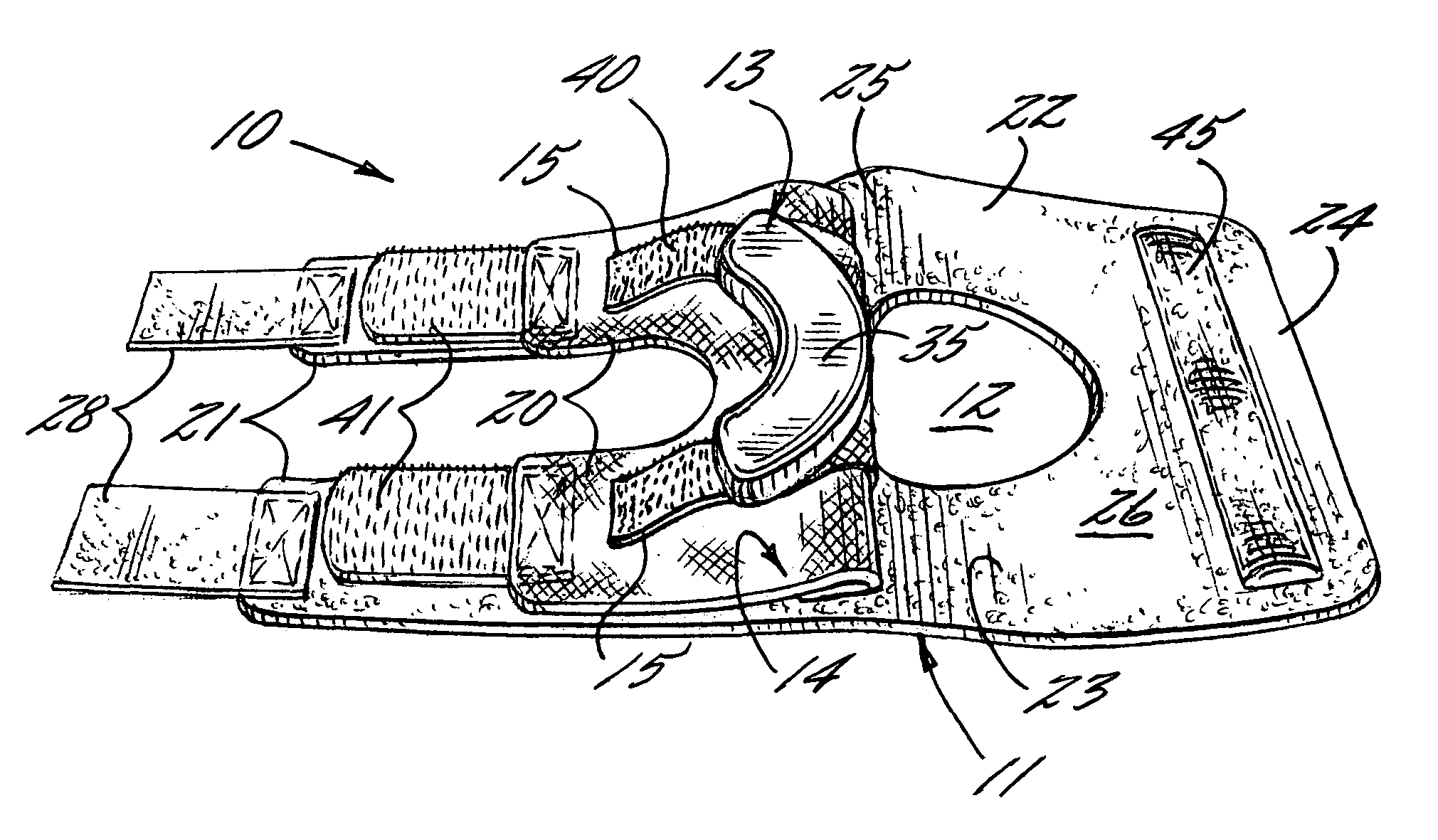

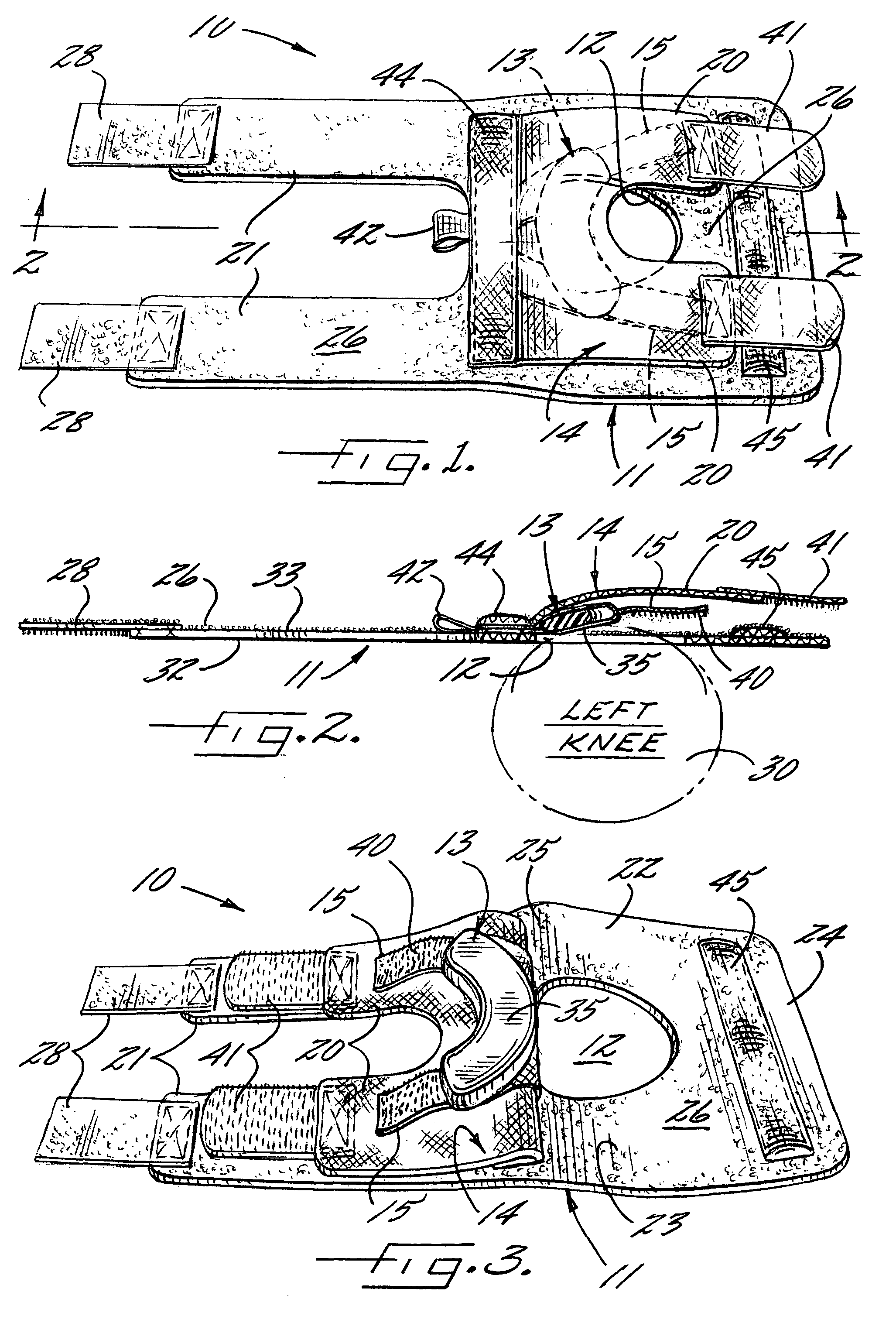

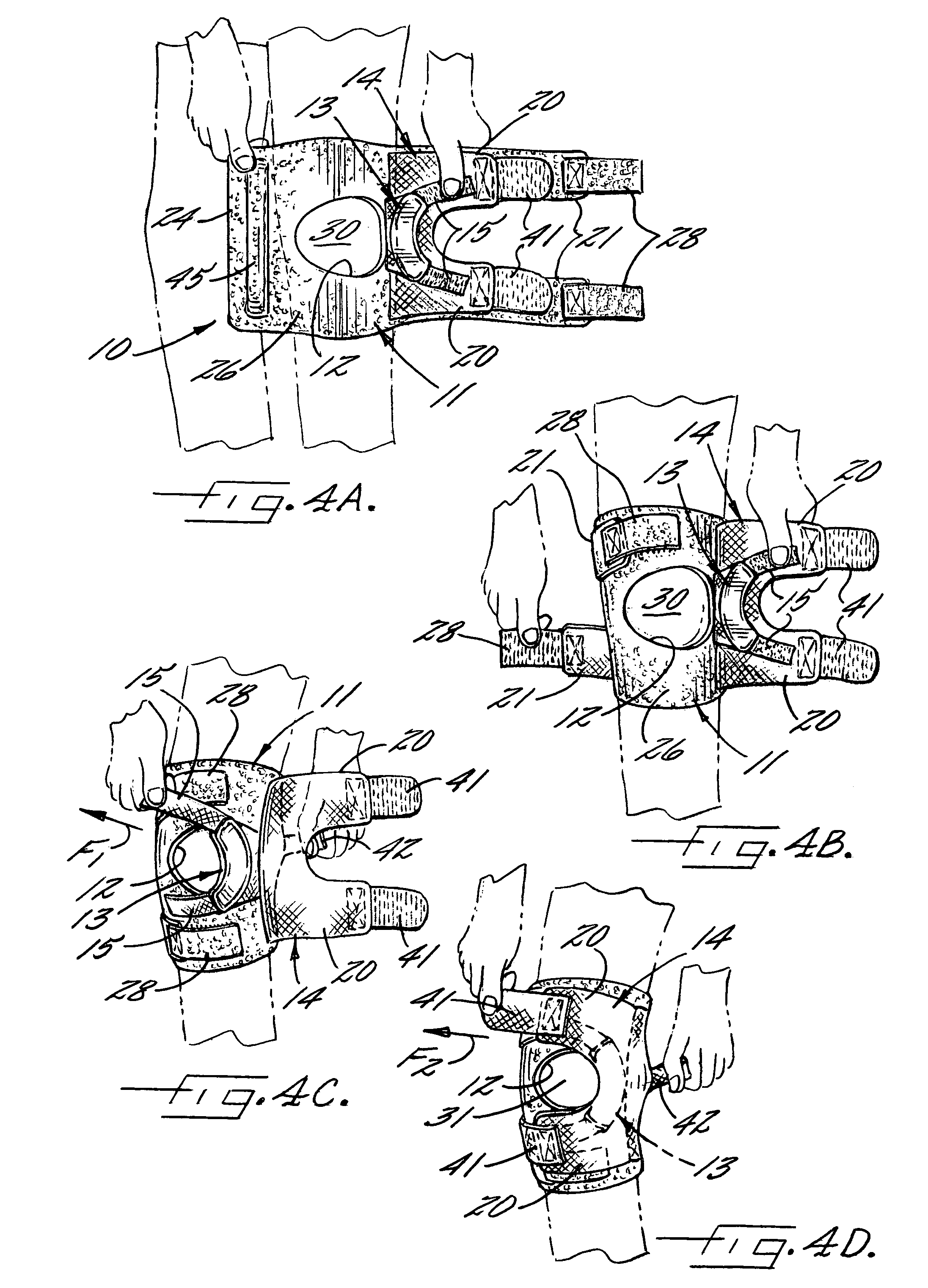

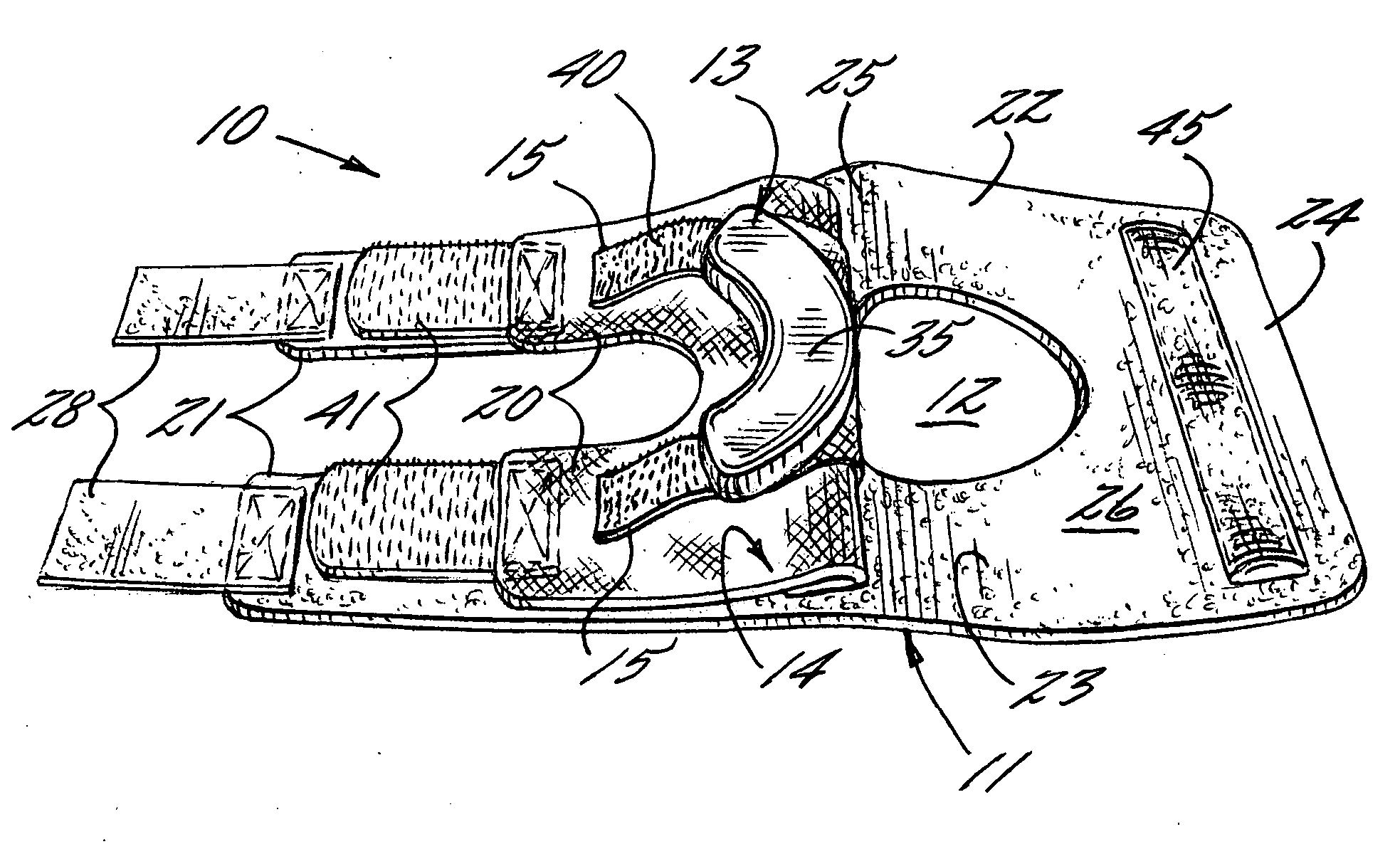

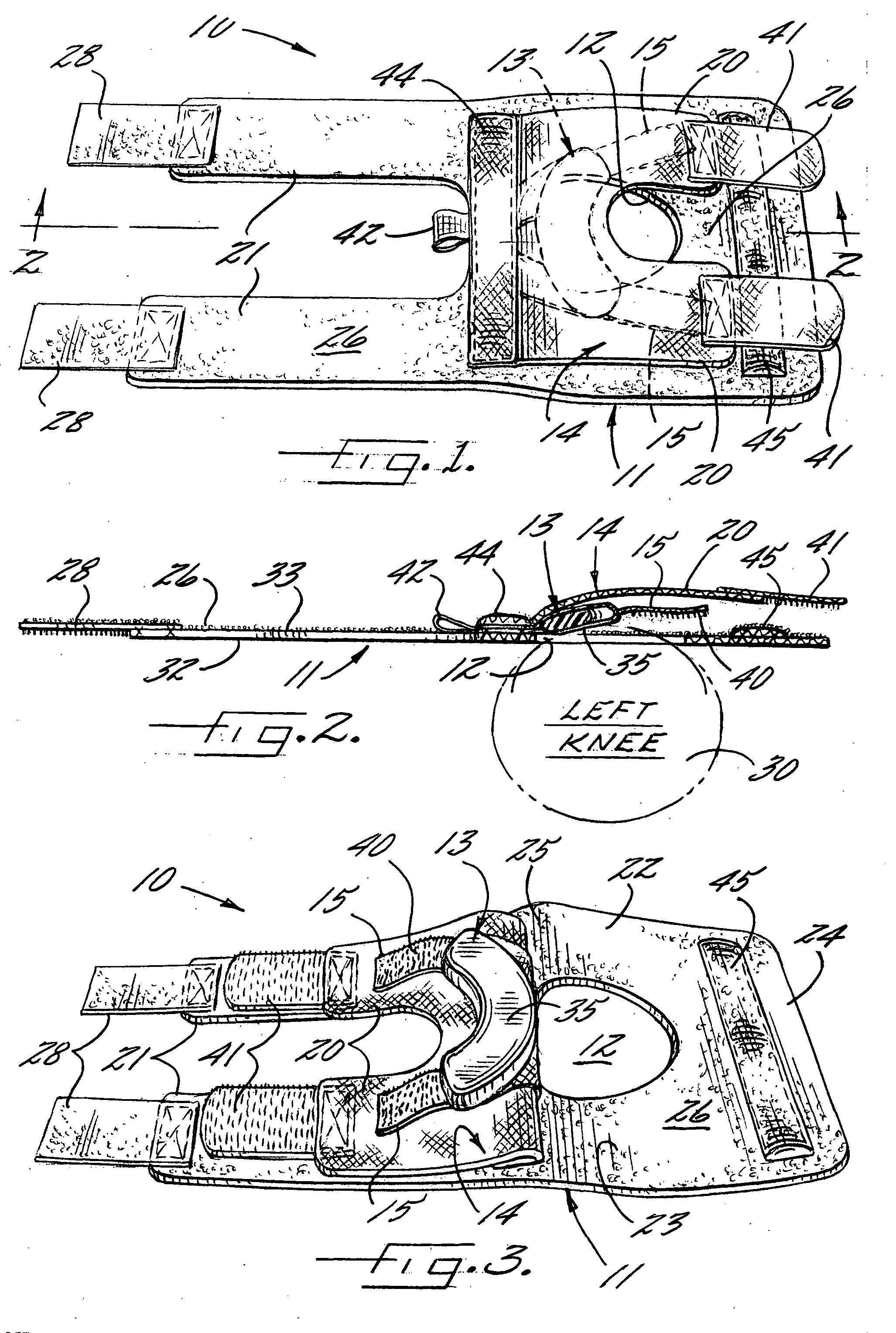

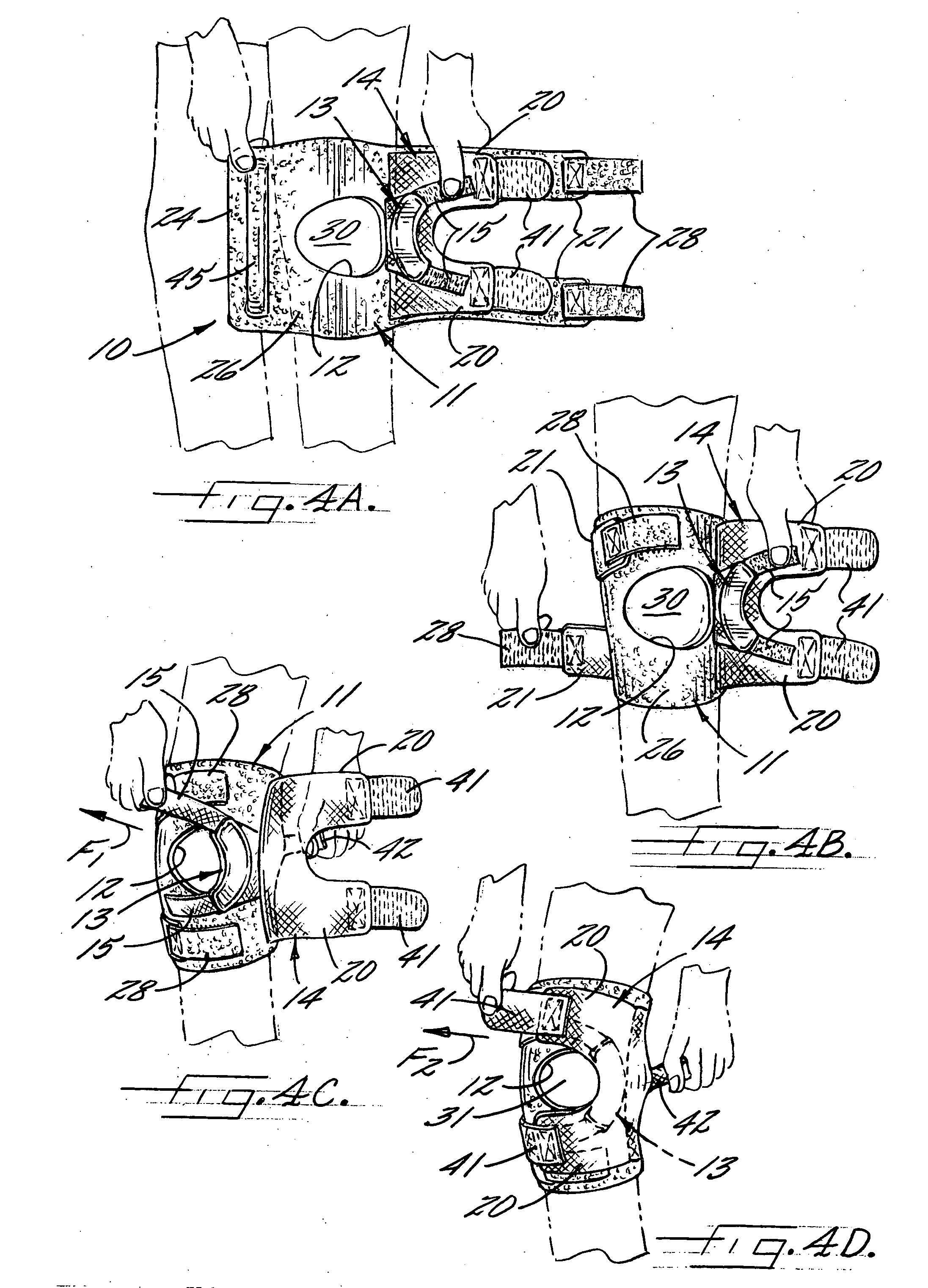

Patella stabilizing knee brace

An apparatus for stabilizing movement of the patella in the patellofemoral joint comprises in one embodiment a base having an opening, a buttress secured to the base sheet member, a tensioning member secured to the base sheet member, a pair of tensioning arms secured to the buttress, a pair of tensioning arms secured to the tensioning member, a pair of compression members formed from the base, and a stabilizing member secured to an edge of the base. A method of stabilizing movement of the patella in the patellofemoral joint during physical activities comprises in one embodiment the steps of positioning a support brace having an opening against the knee, extending a portion of the brace against the knee to apply a first force against portions of the knee in the opening, and extending another portion of the brace against the knee to apply a second force against the knee.

Owner:MEDICAL SPECIALTIES

Patella stabilizing knee brace

ActiveUS20050020951A1Restrict movementSmooth motionRestraining devicesFeet bandagesButtressKnee Joint

An apparatus for stabilizing movement of the patella in the patellofemoral joint comprises in one embodiment a base having an opening, a buttress secured to the base sheet member, a tensioning member secured to the base sheet member, a pair of tensioning arms secured to the buttress, a pair of tensioning arms secured to the tensioning member, a pair of compression members formed from the base, and a stabilizing member secured to an edge of the base. A method of stabilizing movement of the patella in the patellofemoral joint during physical activities comprises in one embodiment the steps of positioning a support brace having an opening against the knee, extending a portion of the brace against the knee to apply a first force against portions of the knee in the opening, and extending another portion of the brace against the knee to apply a second force against the knee.

Owner:MEDICAL SPECIALTIES

Linearly expanding spine cage for enhanced spinal fusion

ActiveUS20080188941A1Reduce painImprove functioningBone implantSpinal implantsVertebraSpinal arthrodesis

A linearly expanding spine cage has a minimized diameter in its unexpanded state that is equal to the diameter of an insertion groove cut into adjacent vertebral bodies. The cage conformably engages between the endplates of adjacent vertebrae to effectively distract the disc space, widen neuroforamina, stabilize the motion segments and eliminate pathologic spine motion. Angular deformities can be corrected, and natural curvatures maintained. The cage enhances spinal arthrodesis by creating a rigid spine segment. Expanding linearly (vertically, along the vertical axis of the adjacent spine) rather than uniformly, the cage height increases and holds the vertebrae with fixation forces greater than adjacent bone and soft tissue failure forces. Stability is thus achieved immediately, enabling patient function by eliminating painful motion. The cage width remains stable, so as to decrease impingement upon a second cage, or upon soft tissue structures in the immediate vicinity, including neural or vascular elements.

Owner:HOWMEDICA OSTEONICS CORP

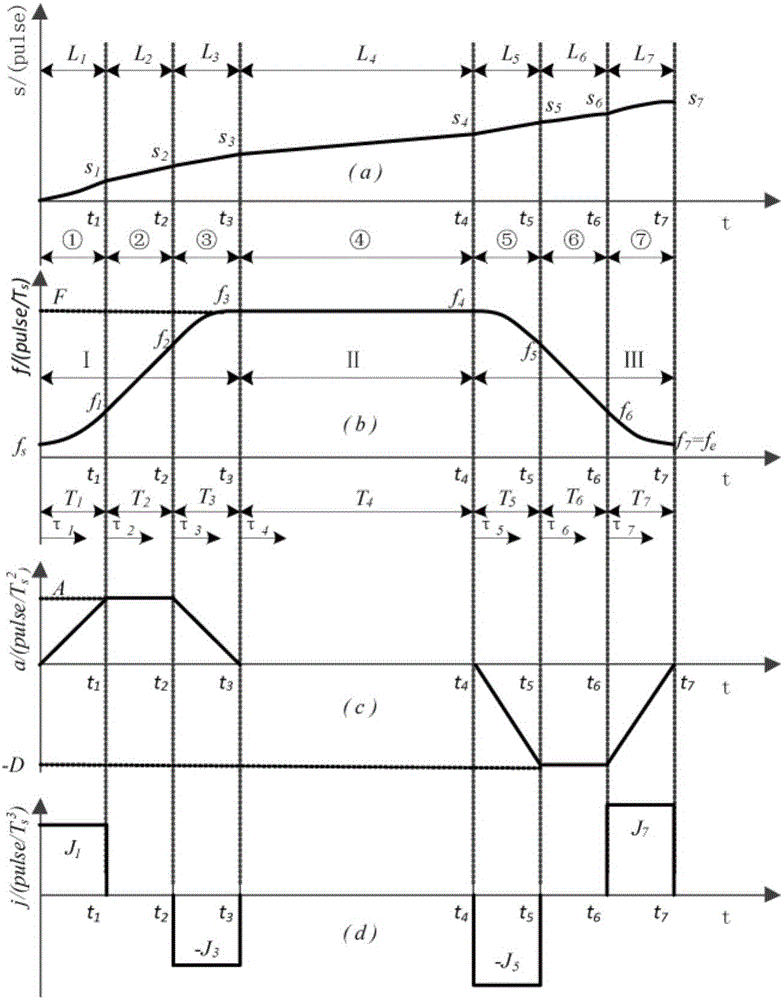

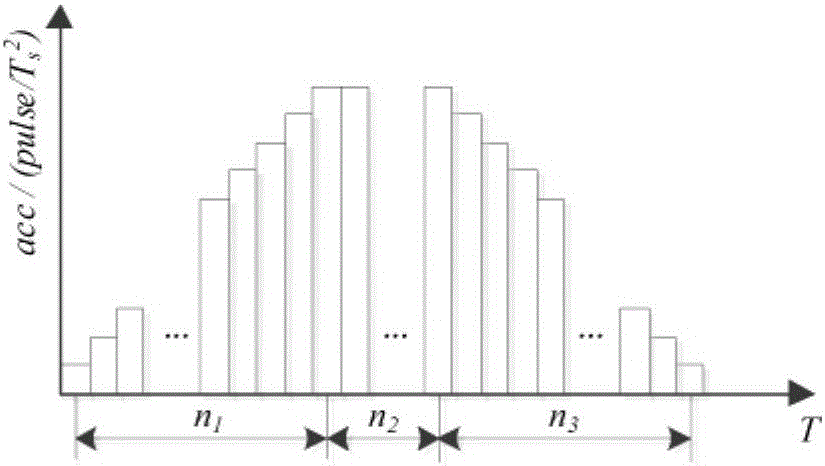

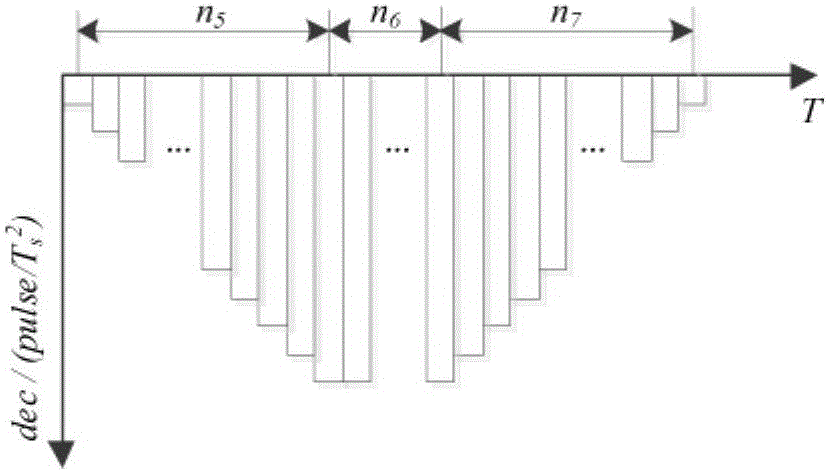

S-shaped acceleration and deceleration control method for changing speed and position of object on line

ActiveCN106168790AAcceleration curve continuousNo mutationNumerical controlDiscretizationPlanning method

The present invention provides an S-shaped acceleration and deceleration control method for changing speed and position of an object on line. The method comprises the acceleration phase speed planning, the deceleration phase speed planning, the constant speed phase speed planning, the real speed reduction point predication, the maximum speed processing, the surplus distance compensation, the online object speed changing algorithm and the online object position changing algorithm. An acceleration and deceleration discretization speed planning method is employed and the user input parameters are combined to calculate the operation time of a seven-phase speed planning phase. It is determined whether the maximum acceleration and the maximum speed can reach the criterion or not, the integration problem of a sampling period Ts according to the acceleration / deceleration acceleration, the acceleration / deceleration speed and the final position L after discretization is considered, and the real reachable acceleration / deceleration acceleration, the acceleration / deceleration speed and the feed rate are corrected. The S-shaped acceleration and deceleration control method for changing speed and position of the object on line greatly simplifies an original calculation formula and saves lots of operation time of a computer, and the surplus distance employs a one-time compensation method in the speed reduction process.

Owner:SOUTH CHINA UNIV OF TECH

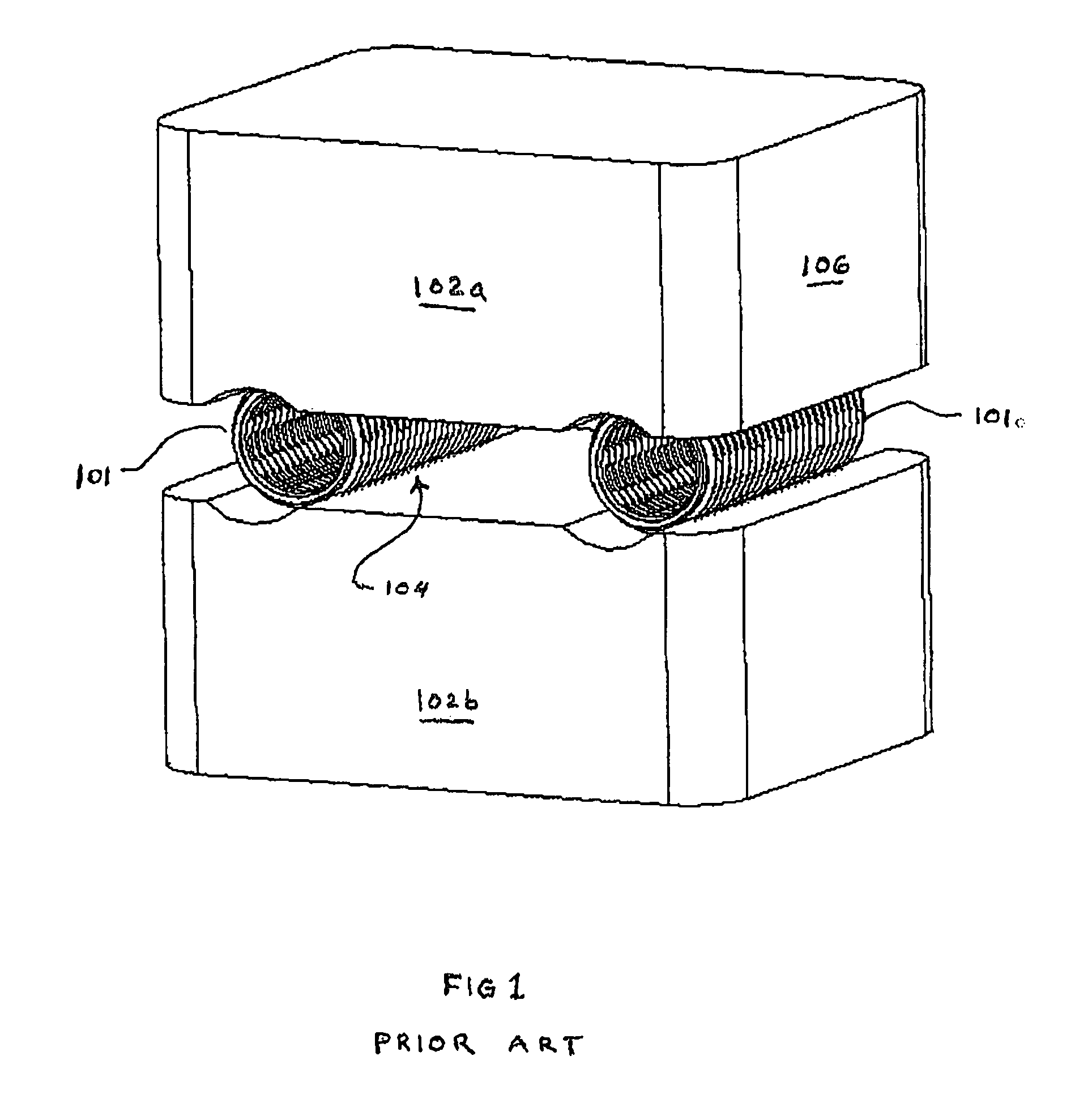

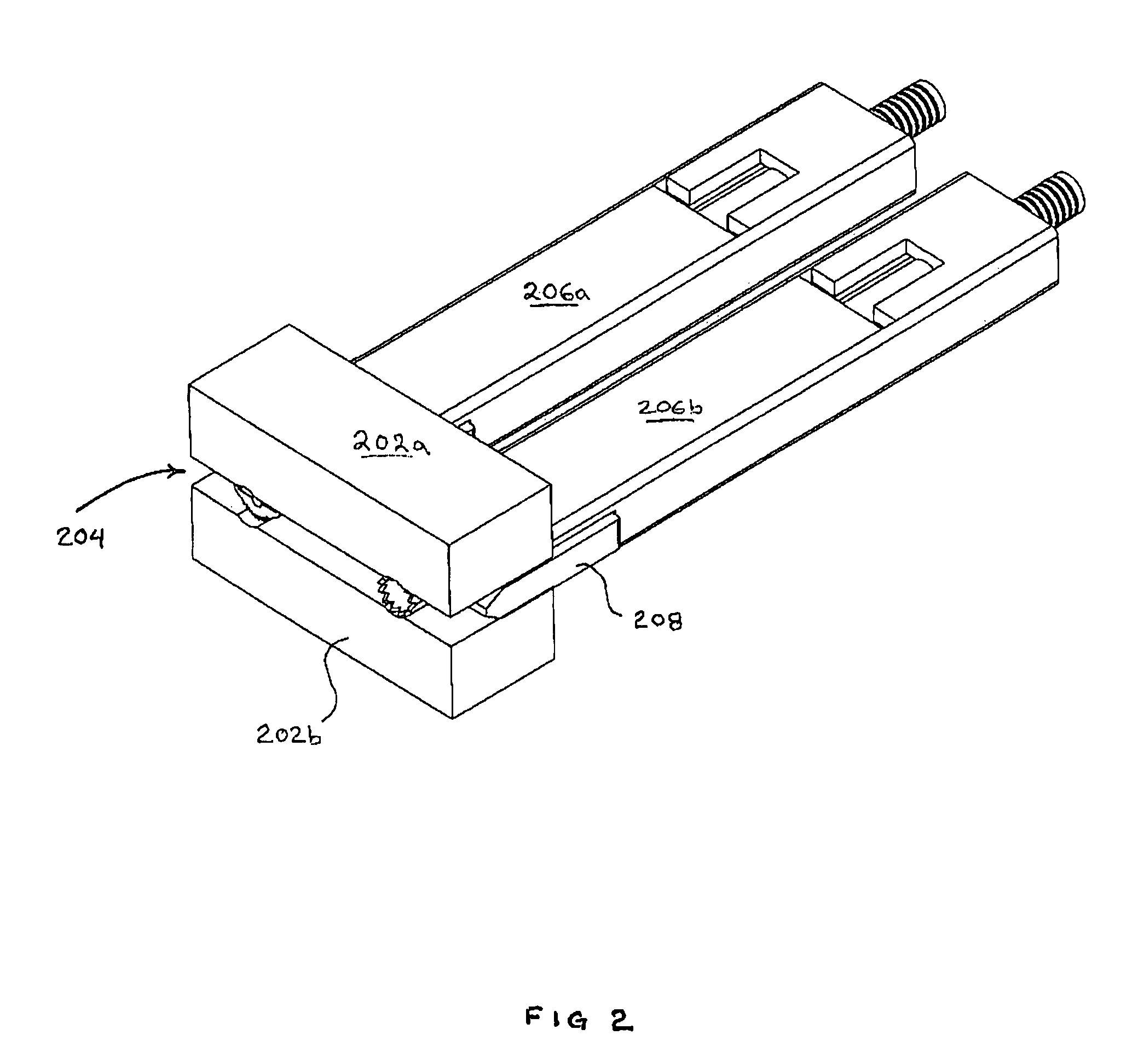

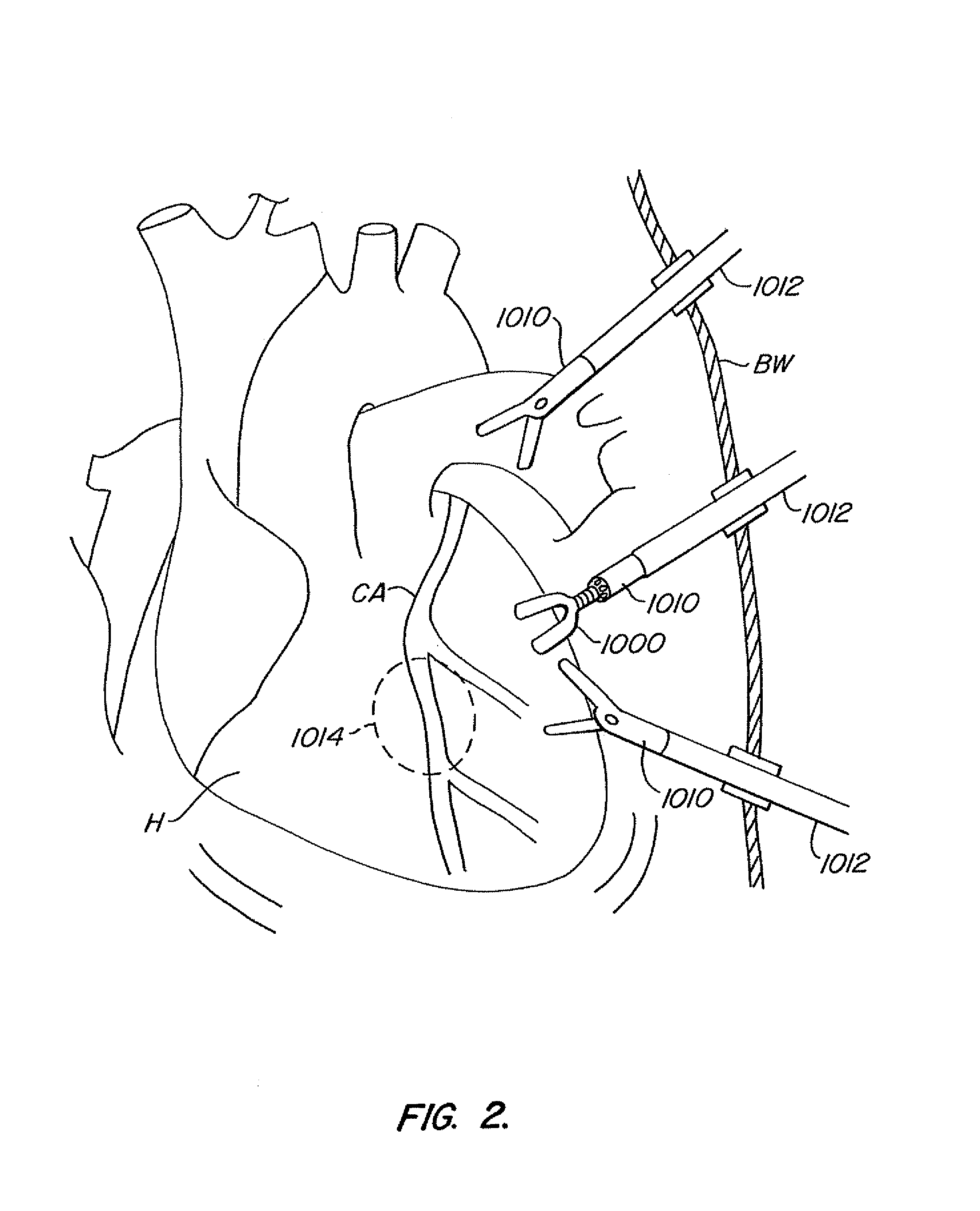

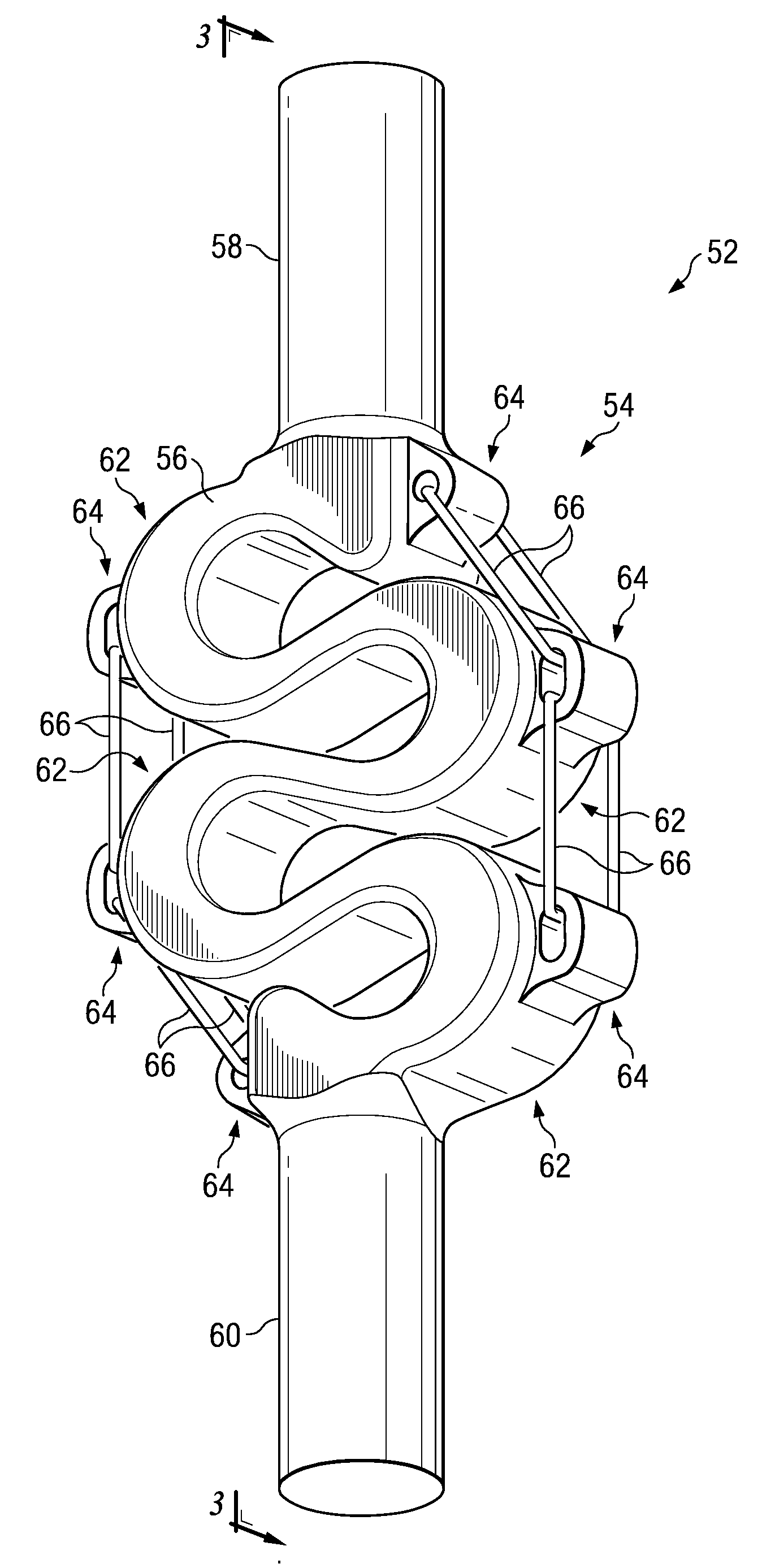

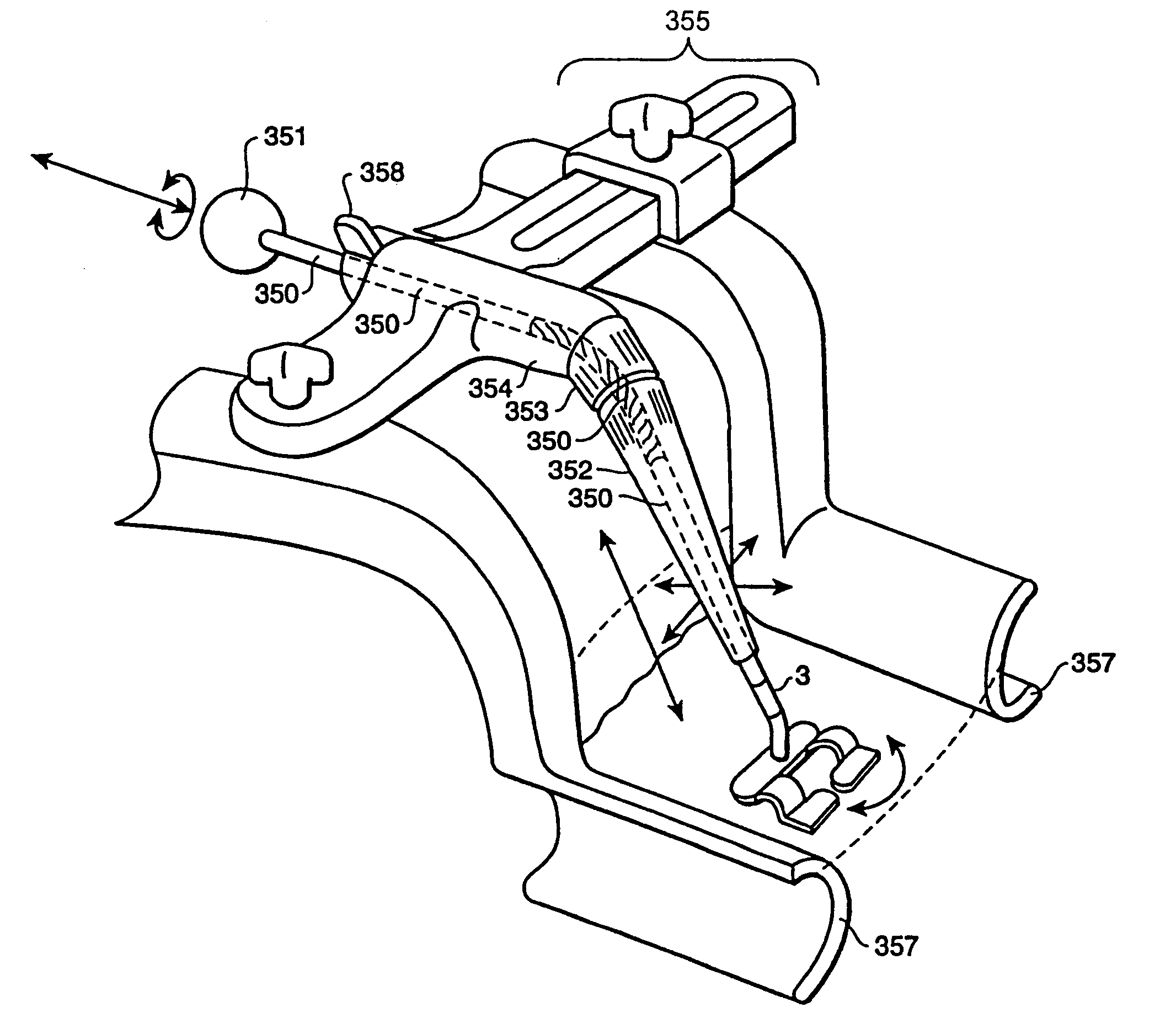

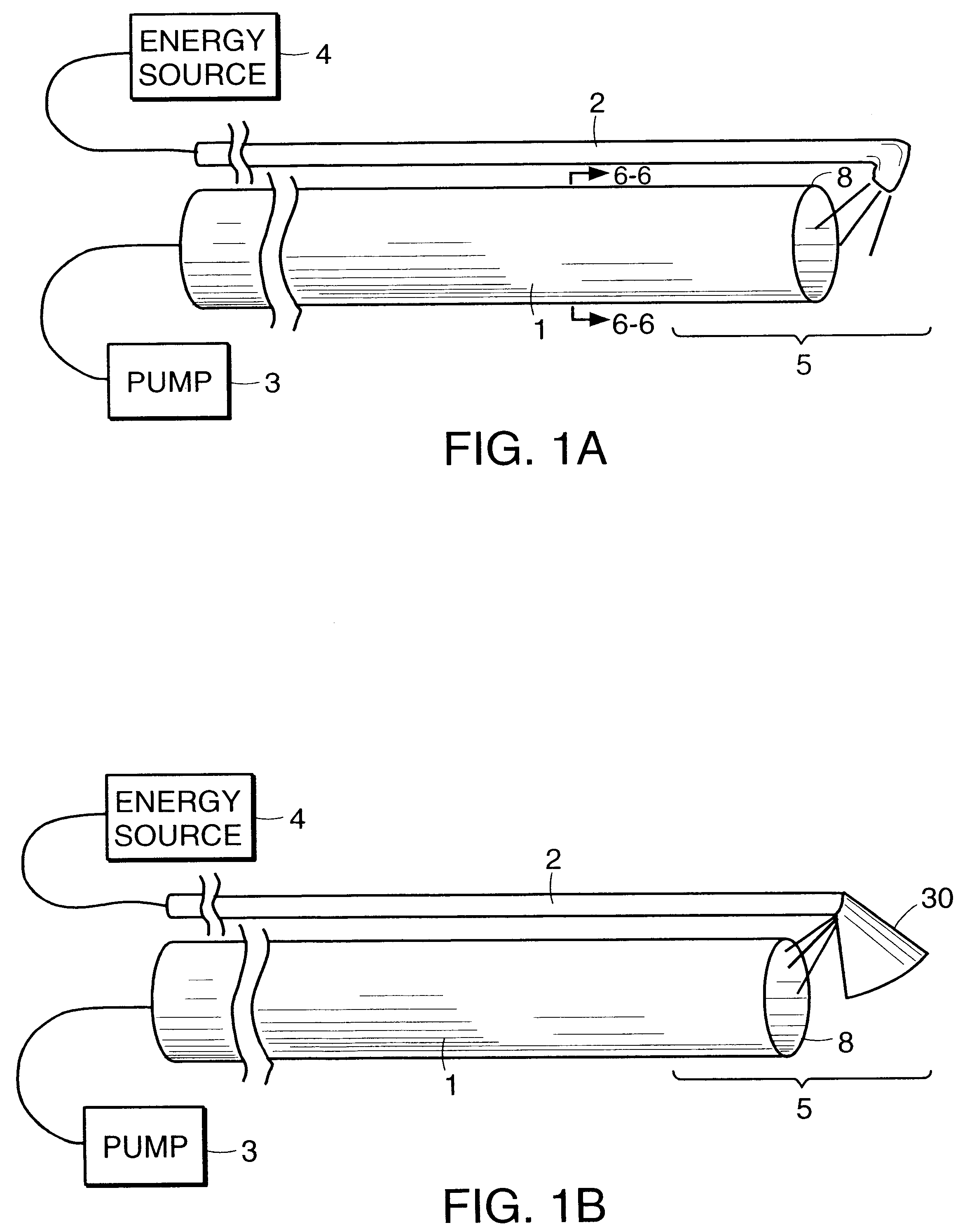

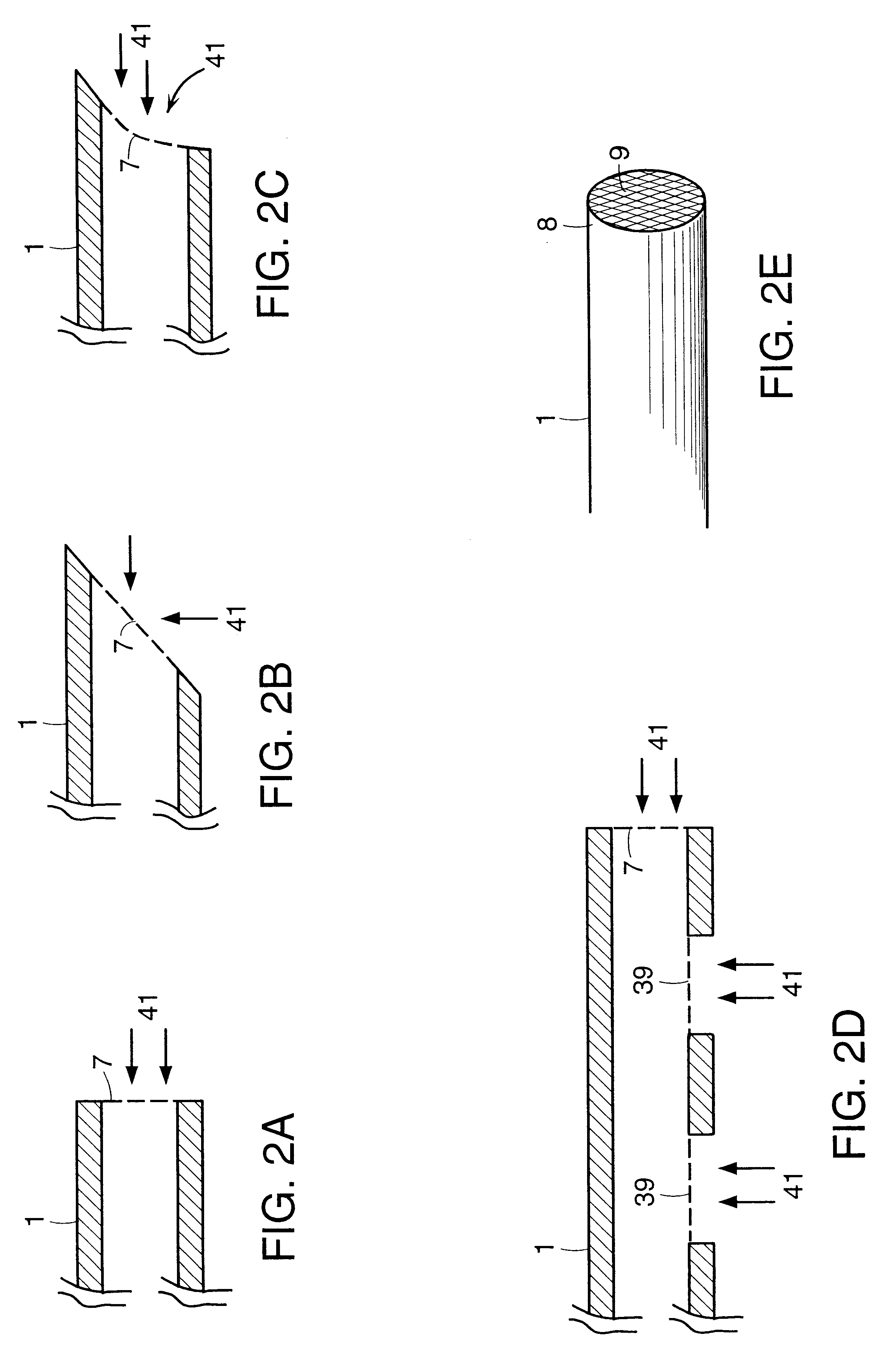

Surgical instruments and procedures for stabilizing the beating heart during coronary artery bypass graft surgery

InactiveUS7056287B2Less traumaMiniaturization exerciseCannulasDiagnosticsSurgical siteCardiac muscle

Devices for stabilizing tissue during a surgical procedure. The beating heart may be stabilized during a surgical procedure on the heart, using a described stabilizing device. In one example, a stabilizing device is introduced through an opening in the chest and brought into contact with the beating heart. By contacting the heart with the device and by exerting a stabilizing force on the device, the motion of the heart caused by the contraction of the heart muscles id effectively eliminated such that the heart is stabilized and the site of the surgery moves only minimally if at all.

Owner:MAQUET CARDIOVASCULAR LLC

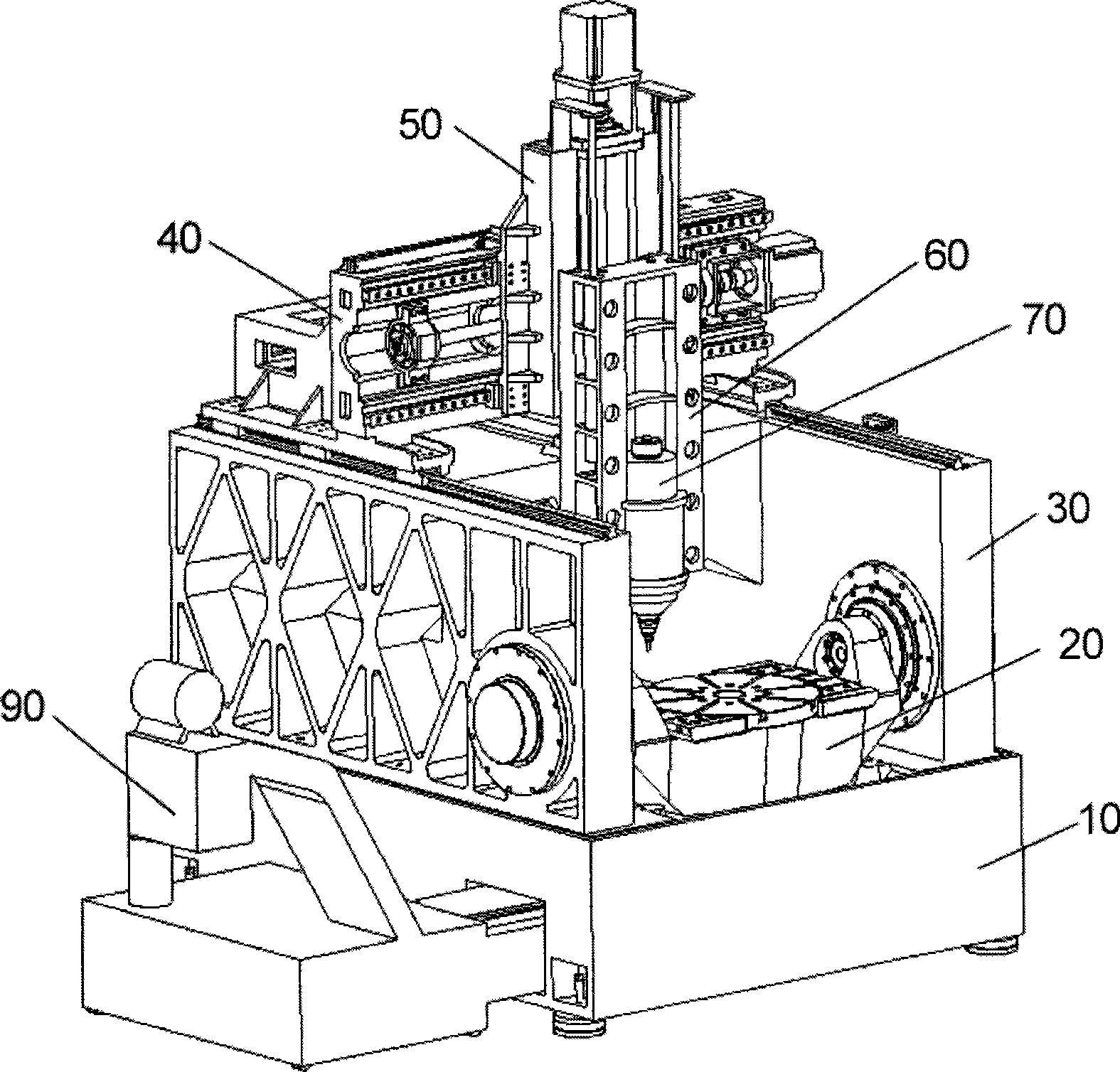

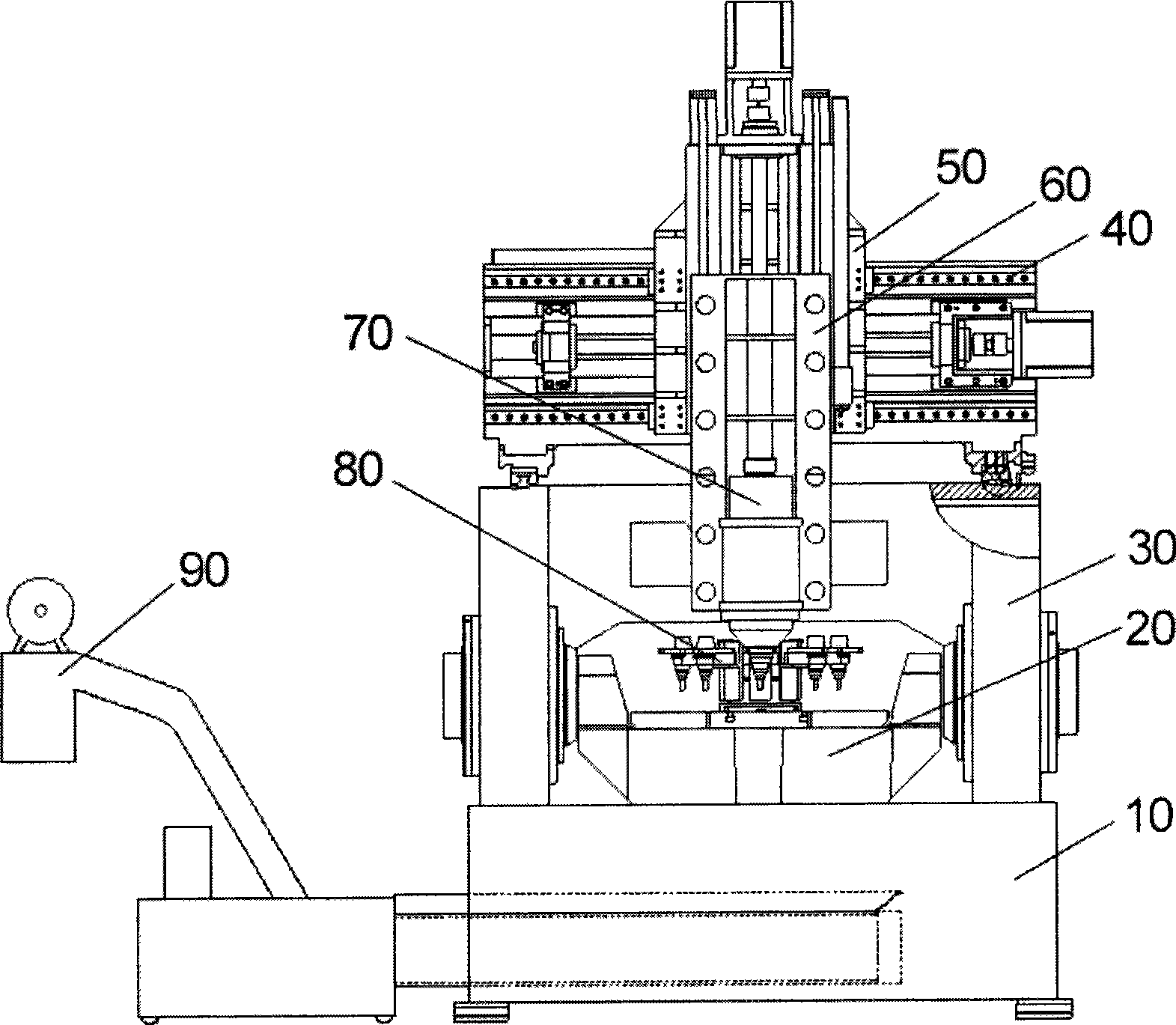

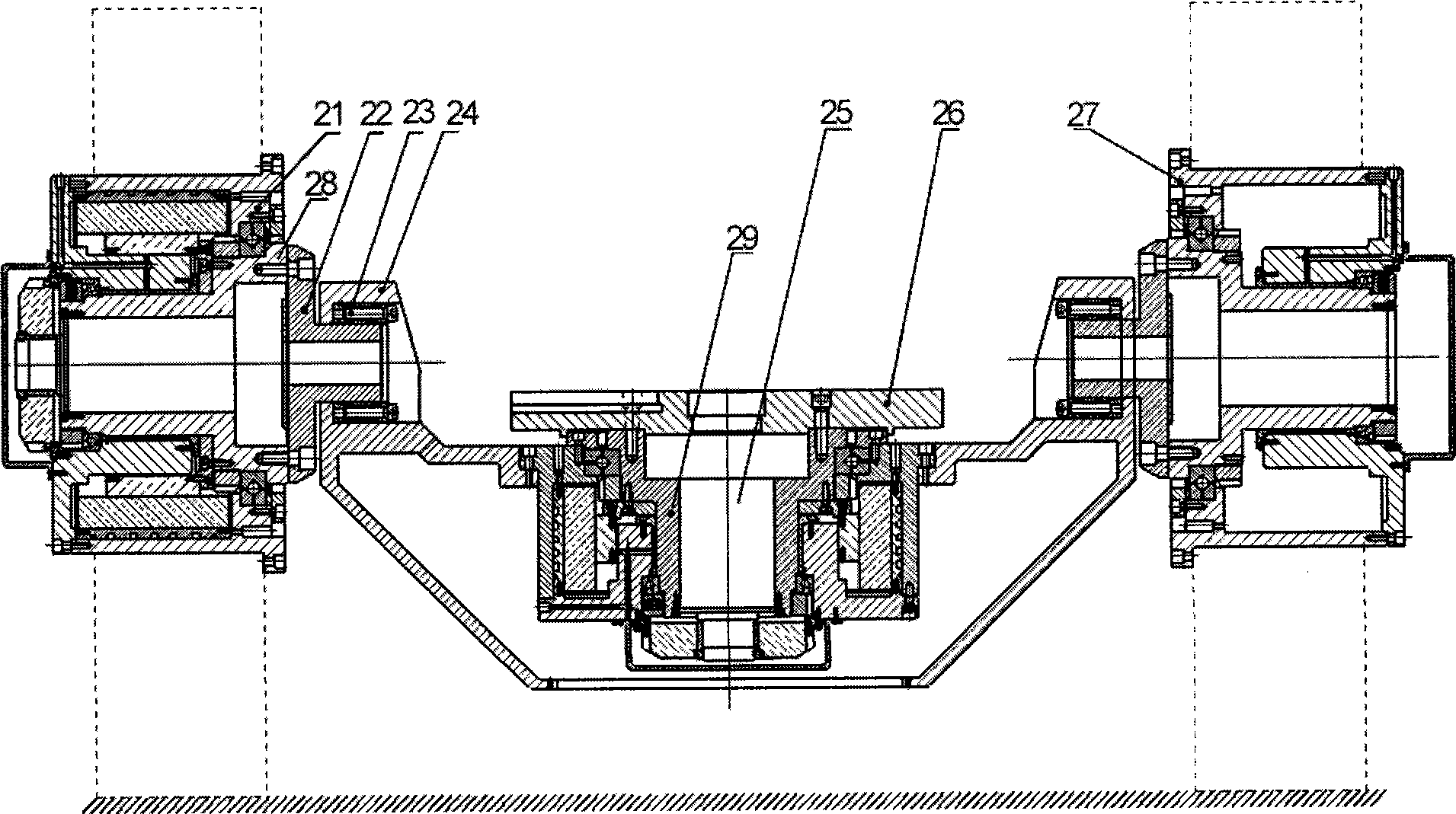

Five-shaft linkage numerical control machining center

InactiveCN101480777ANovel structureSmall footprintLarge fixed membersPositioning apparatusNumerical controlPortal frame

The invention discloses a five-axle linkage digital-control processing centre which comprises a lathe bed (10) and a portal frame (30), wherein the portal frame (30) comprises a left portal upright post (32), a right portal upright post (32) and a fixing portal crossbeam (35), and the front part of each portal upright post (32) is provided with a direct driving type double-shaft precise rotating table (20) which enables a working table (26) to simultaneously rotate round an A shaft and a C shaft. Furthermore, the portal frame (30) is provided with a crossbeam (40) which can move along the Y direction, the front part of the crossbeam (40) is provided with a slide carriage (50) which can move along the X direction, the front part of the slide carriage (50) is provided with a main shaft box (60) which can move along the Z direction, the main shaft box (60) is provided with a main shaft installing hole (66) used for installing a main shaft (70), and a tool magazine (80) is arranged in a cavity positioned between the lathe bed (10) and the portal frame (30). The invention has novel structure, small occupied area, space saving, low cost and stable operation and property. Besides, a motion shaft of a machine tool has high dynamic property, regulating property, positioning precision and repeated positioning precision.

Owner:三六零安全科技股份有限公司 +2

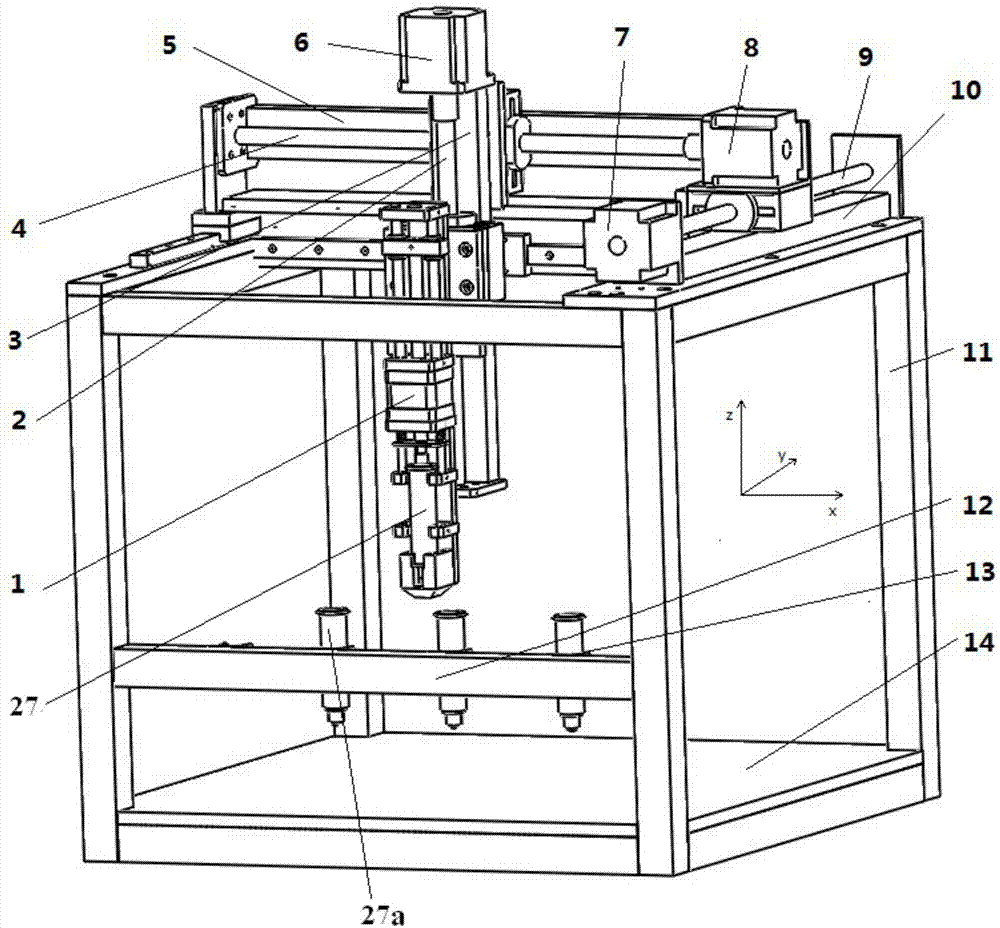

Three-dimensional printer with replaceable nozzle

ActiveCN103878980AAchieve relatively fixedPracticalTool changing apparatusApplying layer meansLiquid foodPiston

The invention discloses a three-dimensional printer with a replaceable nozzle. The three-dimensional printer comprises a three-dimensional adjusting mechanism, and the printing nozzle which performs three-dimensional printing under the adjustment of the three-dimensional adjusting mechanism, wherein the printing nozzle comprises a nozzle bottom plate, a nozzle thermal preservation sleeve which is fixed on the nozzle bottom plate and is provided with a printing through hole and a positioning notch, a material tube which is radially clamped on the nozzle bottom plate, and a linear stepping motor; the material tube is axially clamped in the positioning notch through a material tube pressing plate which is in sliding fit with the nozzle bottom plate; a piston presser used for pushing a piston in a first material tube is fixed at the output end of a lead screw of the motor. When materials in the material tube are used up or the materials are needed to be replaced, the printing nozzle is controlled to automatically replace the material tube, and a three-dimensional object consisting of multiple materials can be printed. The piston is driven to be extruded by adopting the linear stepping motor, thrust is high and can be accurately controlled, and the blockage of the nozzle is avoided. According to the printer, liquid foods and multiple liquid materials such as gel and ceramic powder can be printed.

Owner:ZHEJIANG UNIV

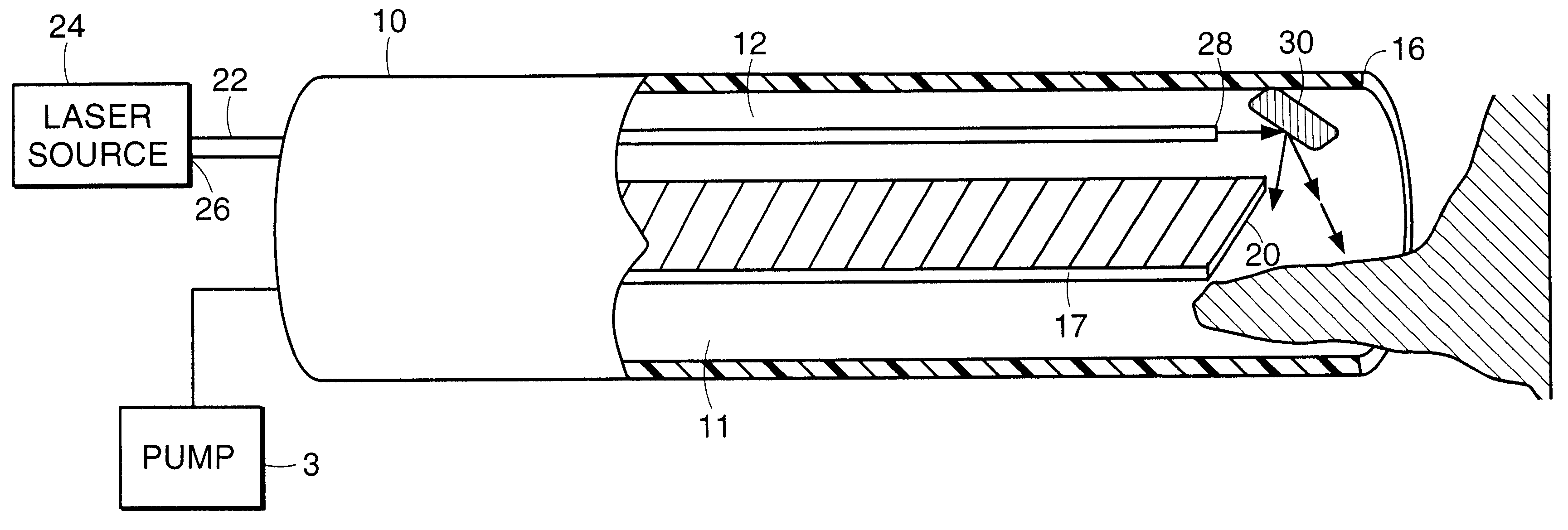

Laser lithotripsy device with suction

A medical device is provided which includes a suction conduit and an energy-transmitting conduit wherein at least some of the transmitted energy is directed to the distal region of the suction conduit. The device may include an optical apparatus for directing the energy. The device has applications in lithotripsy and tissue-removal in a patient.

Owner:BOSTON SCI SCIMED INC

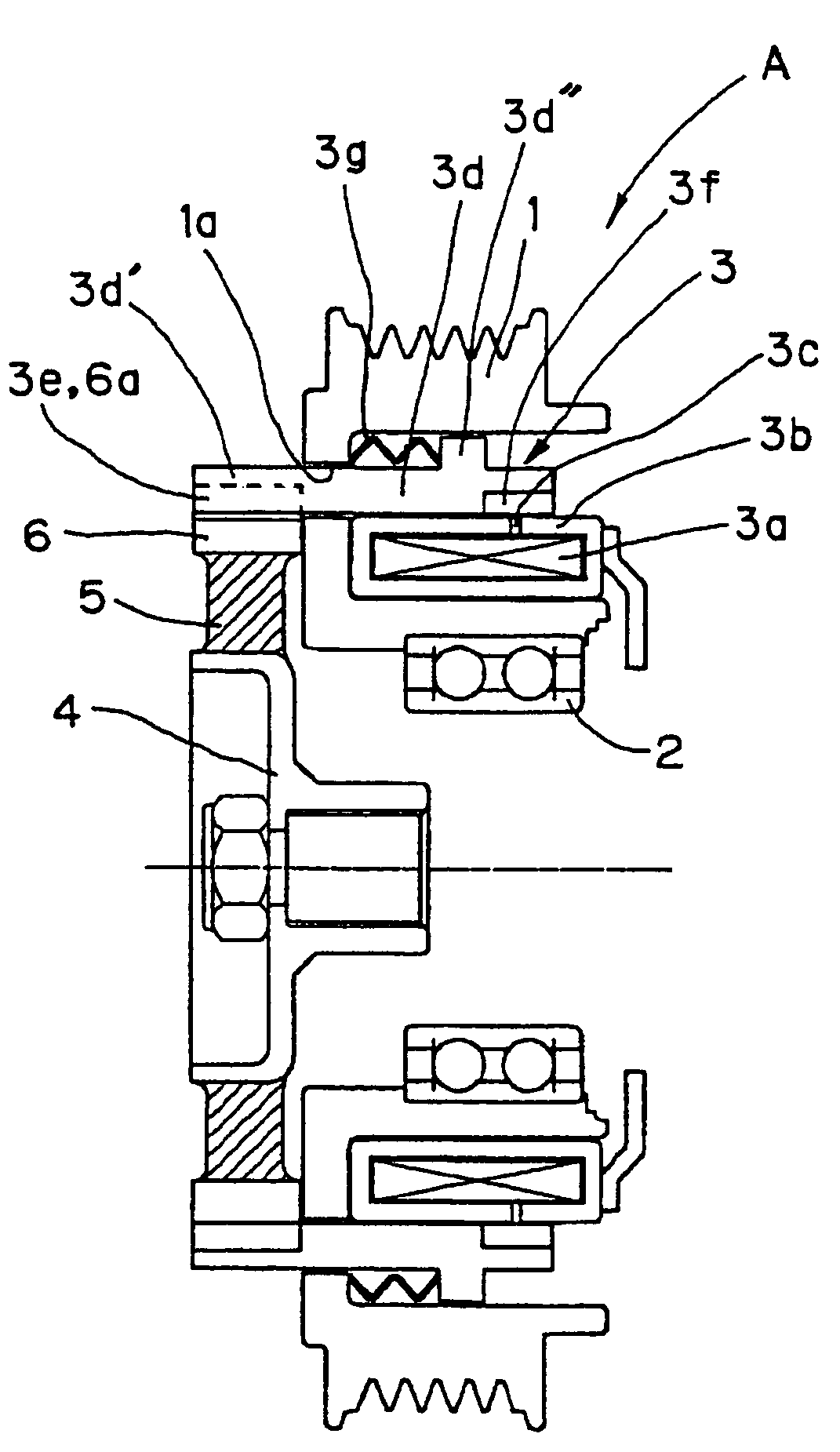

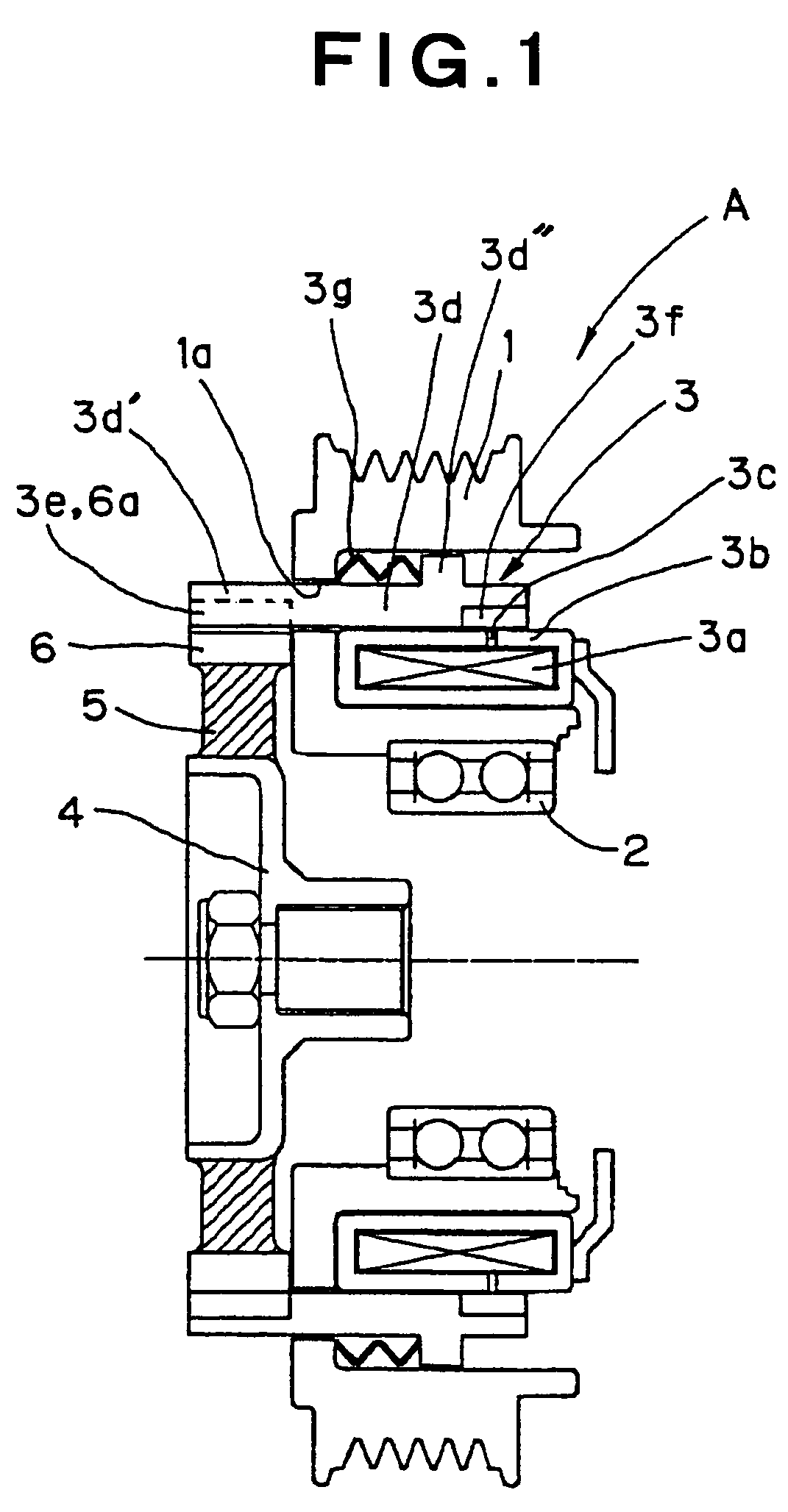

Power transmission

InactiveUS7153228B2Smooth motionReduce and eliminate likelihMechanical actuated clutchesChain/belt transmissionElectric power transmissionTorque transmission

A power transmission includes a first rotating member driven by an external drive source, an electromagnetic solenoid provided to the first rotating member, a second rotating member fixed to a main shaft of a rotary apparatus, and an mechanism for engaging and disengaging a plunger of the electromagnetic solenoid from the second rotating member. When the rotary apparatus is not used, the energy of the external drive source may be prevented from being wasted by interrupting the torque transmission from the first rotating member to the second rotating member by the operation of the mechanism for engaging and disengaging.

Owner:SANDEN CORP

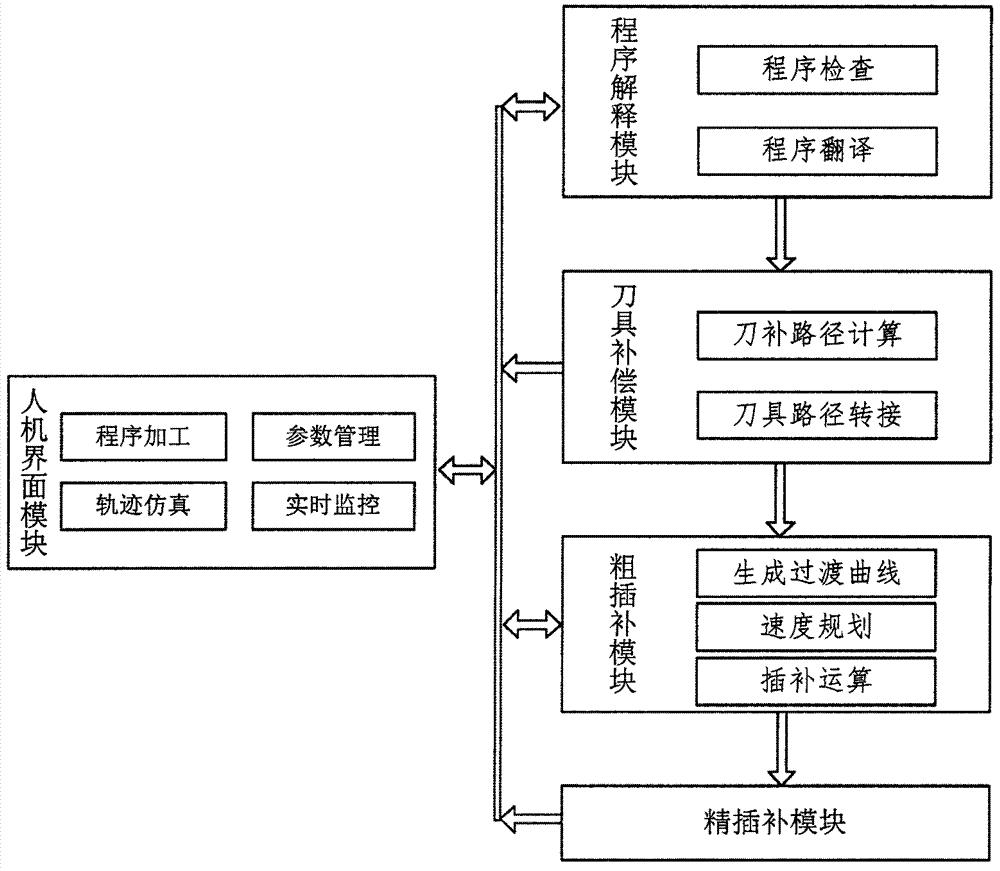

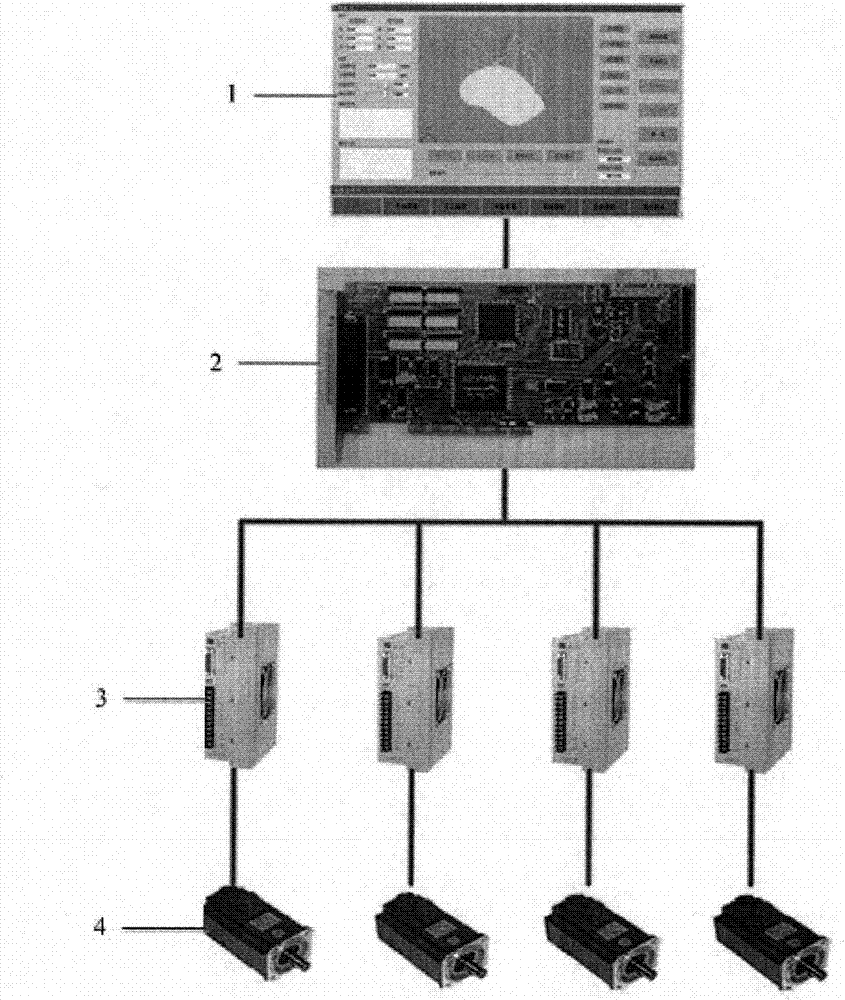

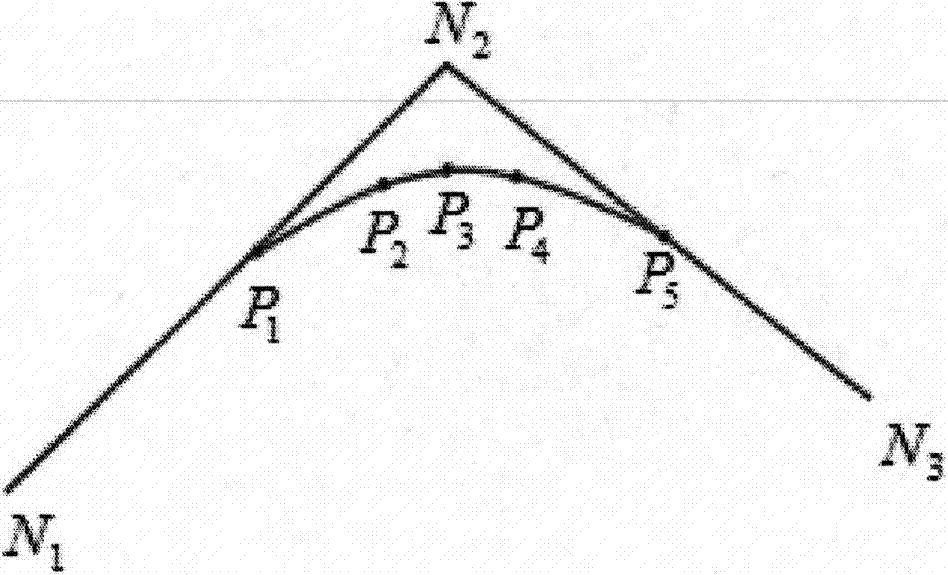

Real-time smooth transition interpolation method of small high-speed and high-accuracy numerical control machining line segment

InactiveCN103699056AStable speedSmooth motionNumerical controlNumerical controlHuman–machine interface

The invention discloses a real-time smooth transition interpolation method of a small high-speed and high-accuracy numerical control machining line segment. The real-time smooth transition interpolation method is characterized by comprising an HMI (Human Machine Interface) module, a program interpretation module, a cutter compensation module, a rough interpolation module and an accurate interpolation module, wherein the HMI module is used for transmitting a numerical control machining program to the program interpretation module, program interpretation can be carried out by the program interpretation module, information of a machining path can be extracted, cutter compensation can be carried out by the cutter compensation module, information of a cutter path can be obtained, the information can be transmitted to the rough interpolation module, smooth transition connection can be carried out on adjacent line segments nearby an adapting point by adopting a cubic B-spline curve passing a control point, a smooth cutter path in continuous curvature can be generated, the smooth cutter path can be subjected to speed planning and interpolation operation, interpolation data can be sent to the accurate interpolation module, and processed data which is subjected to accurate interpolation operation can be sent to a driver so as to drive a numerical control machine tool to move. According to the real-time smooth transition interpolation method disclosed by the invention, the running of the machine tool is more smooth and stable, the computation efficiency is high, the algorithm is simple, and the real-time smooth transition interpolation method is suitable for a high-speed and high-accuracy machining numerical control machine tool.

Owner:JIAXING UNIV

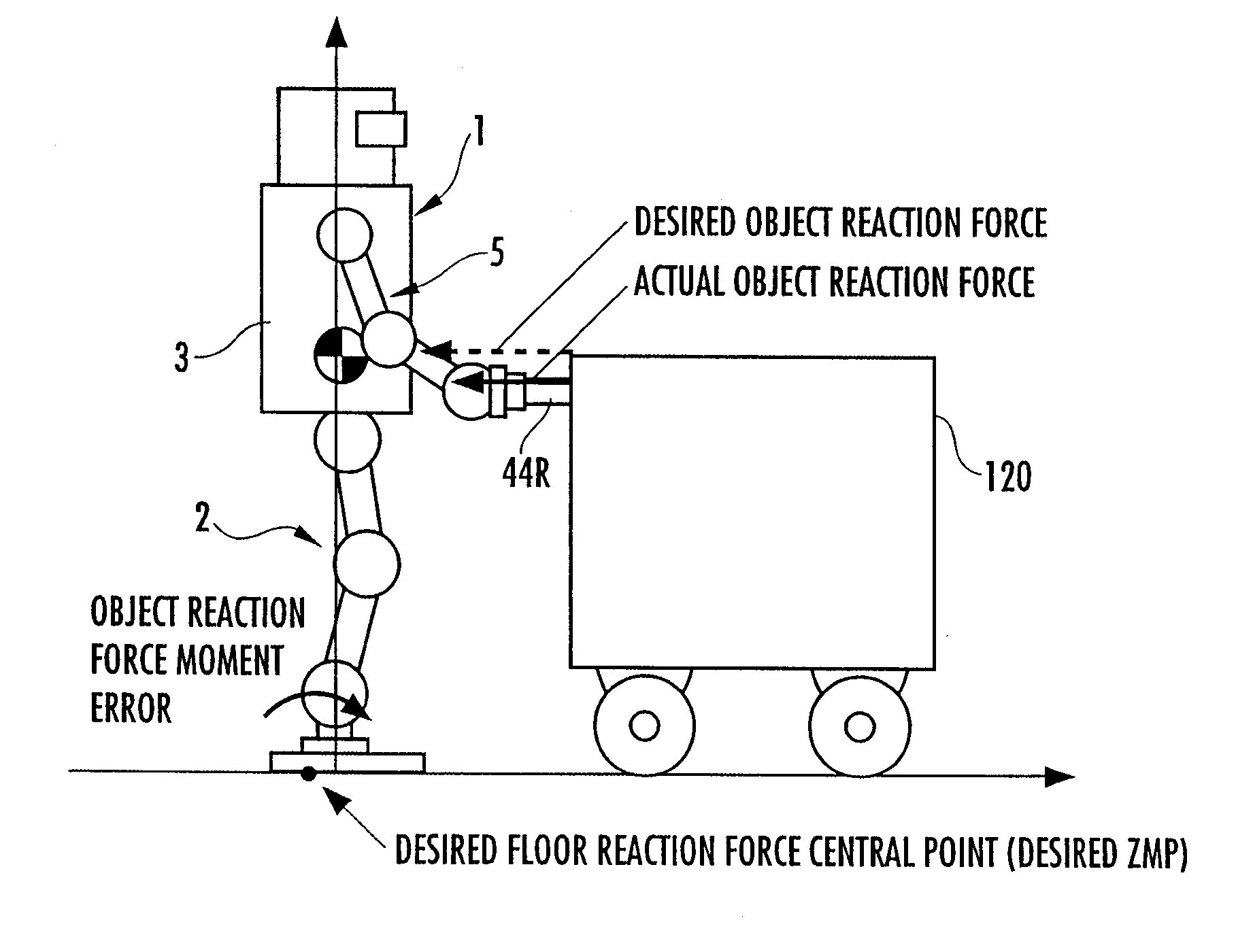

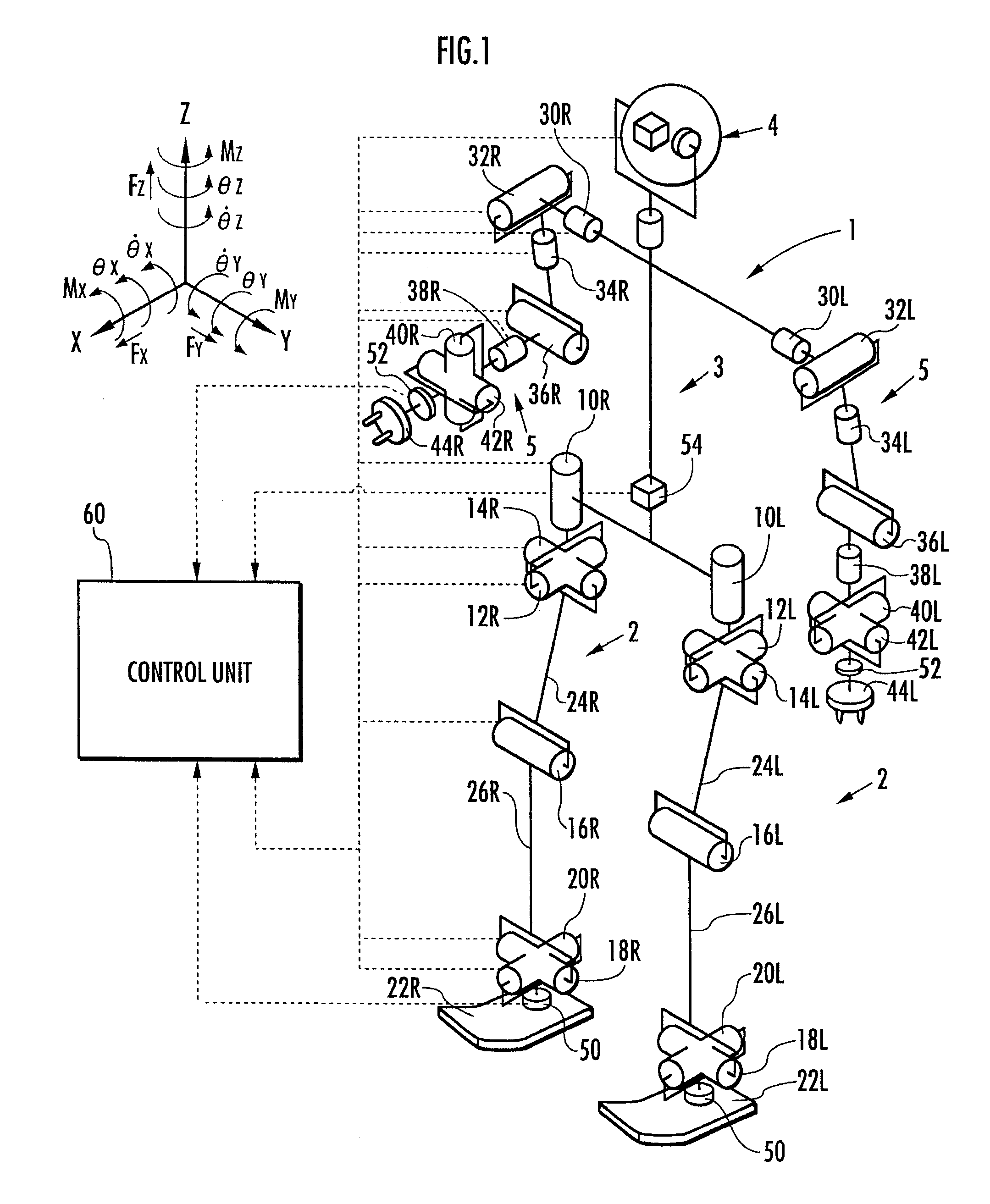

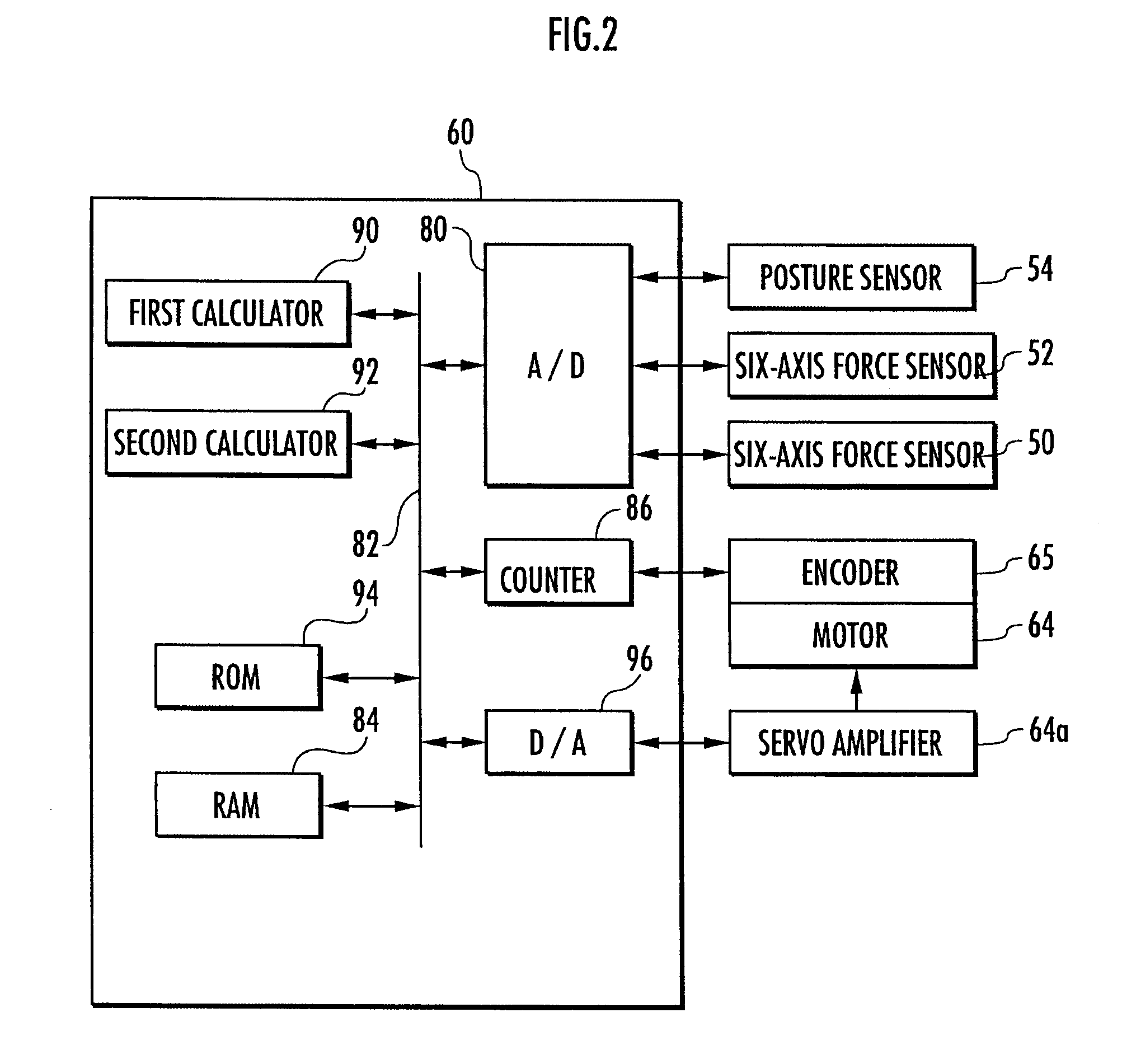

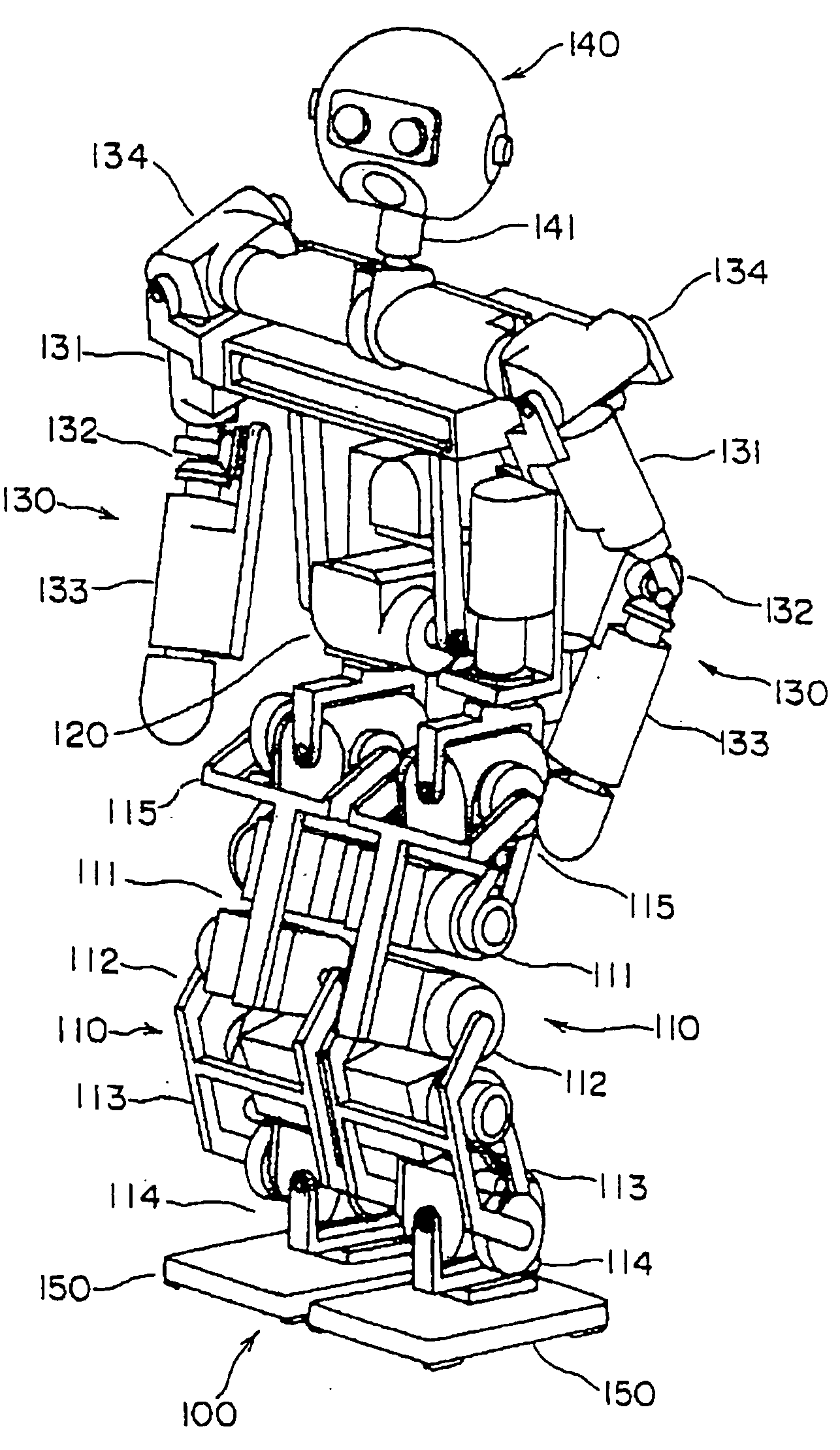

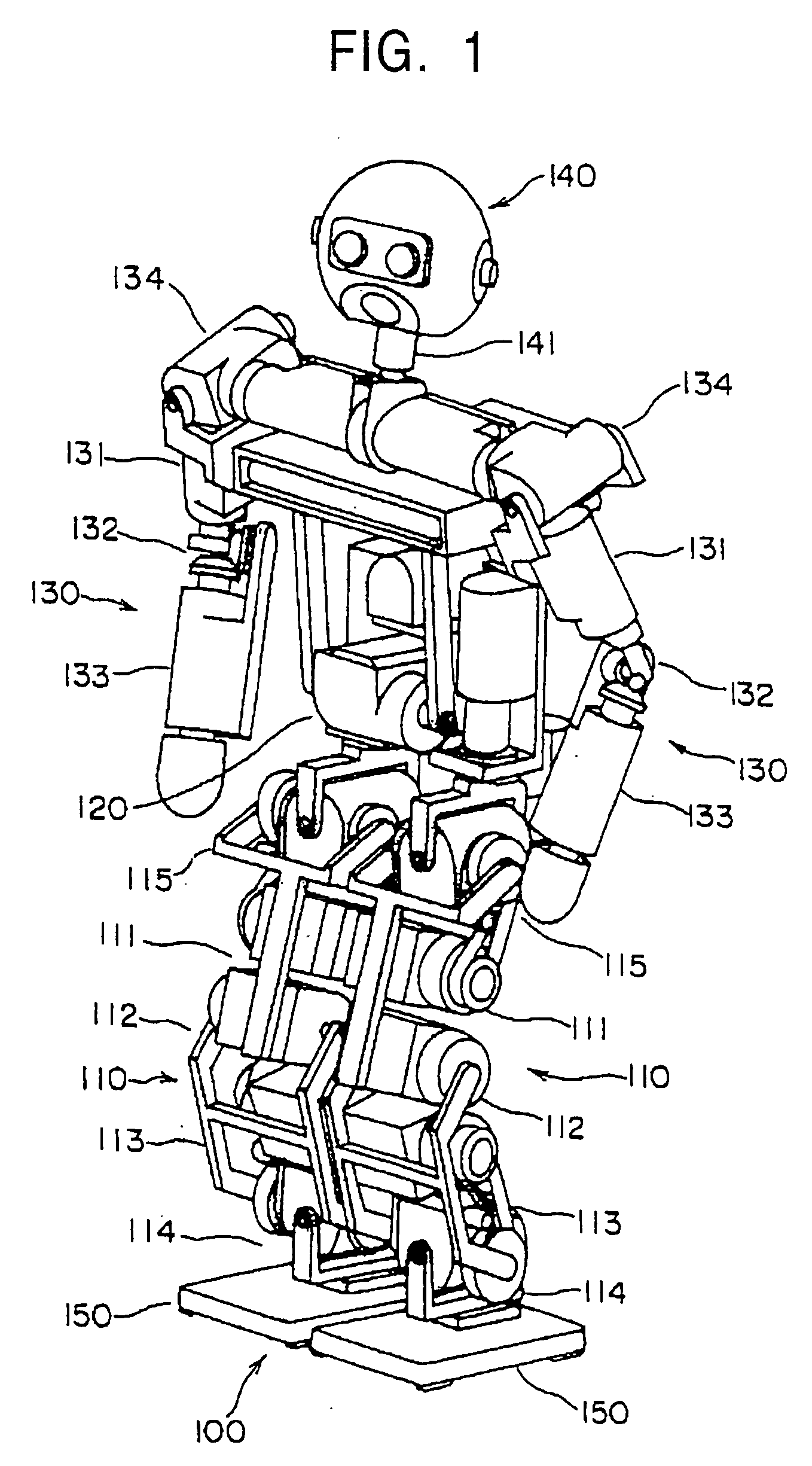

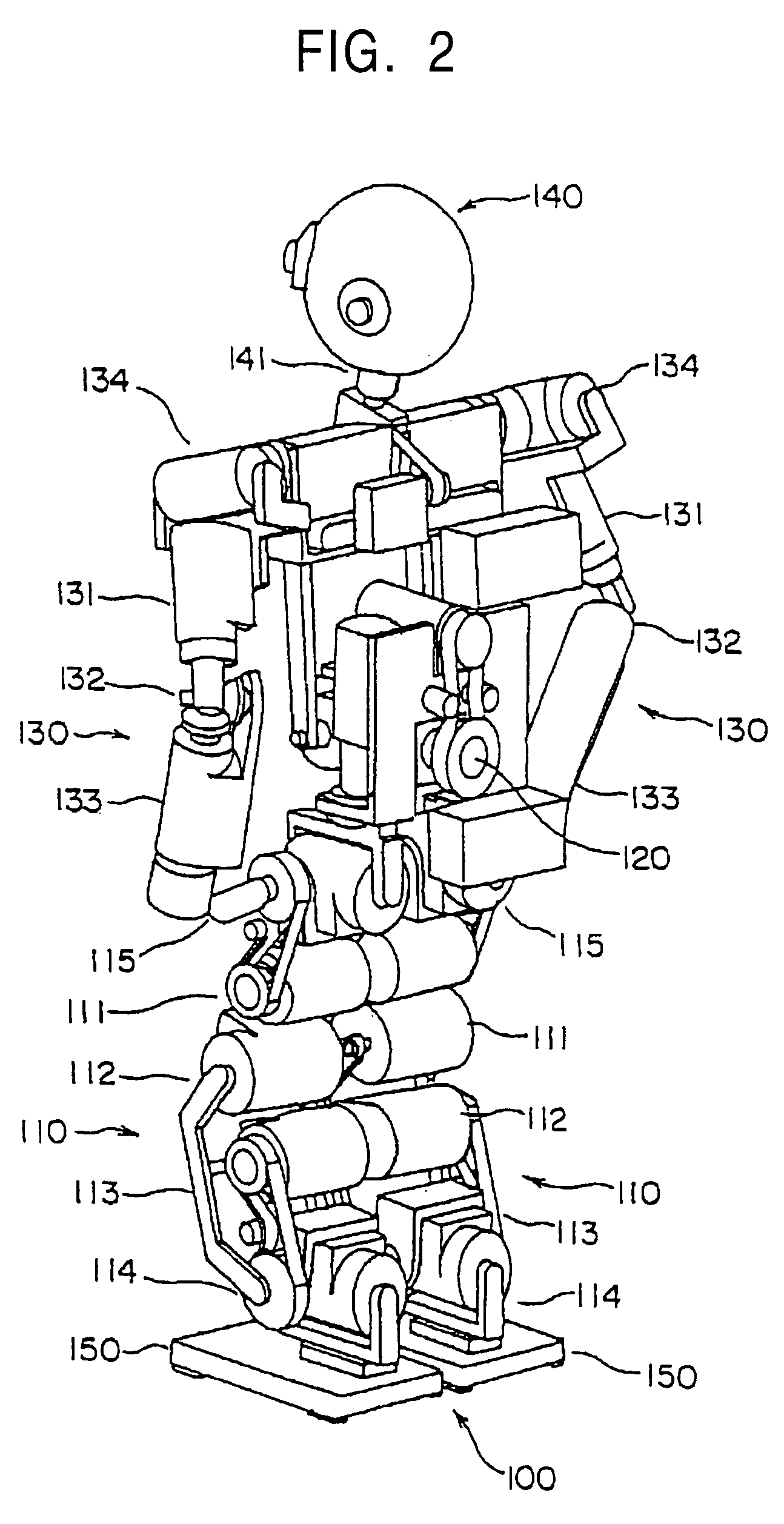

Gait Pattern Generating Device and Controller of Legged Mobile Robot

ActiveUS20080208391A1Maintain stabilityEnhance stabilityComputer controlSimulator controlGait patternMobile robot

A gait generating system of a legged mobile robot is provided with a device for determining a desired trajectory of an external force to be applied to a robot 1, a device for determining a parameter of a desired gait (current time gait) for a predetermined period on the basis of a desired trajectory of an external force or the like, a device for determining a parameter of a virtual cyclic gait that follows the current time gait on the basis of the desired trajectory of the external force or the like, a device for correcting the current time gait parameter such that a body motion trajectory of the robot 1 of the current time gait converges to a body motion trajectory of the cyclic gait, and a device for sequentially determining an instantaneous value of the current time gait on the basis of the corrected current time gait parameter. With this arrangement, in an environment wherein an external force acts on a robot as necessary, a desired gait that allows continual stability of the robot to be secured can be generated even if the external force suddenly changes.

Owner:HONDA MOTOR CO LTD

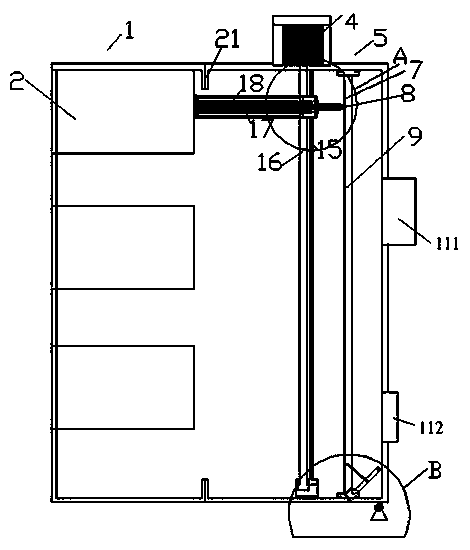

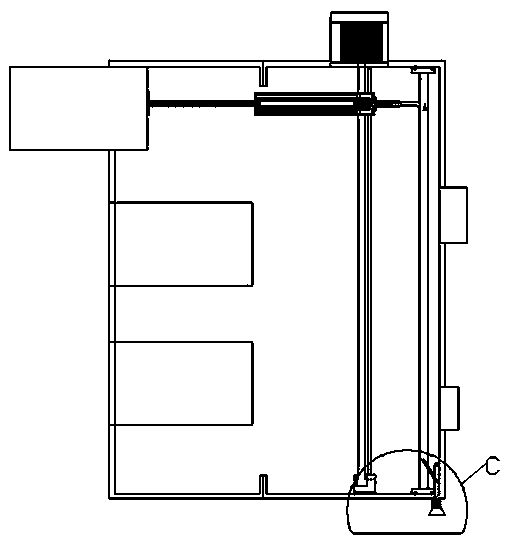

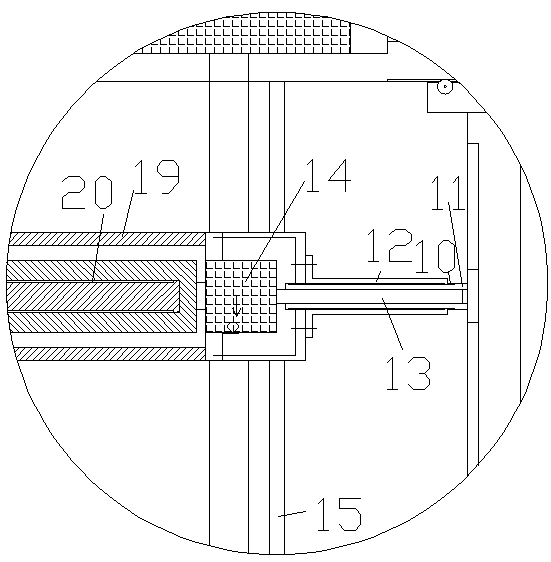

Drawer-type power control cabinet assembly capable of dehumidifying

ActiveCN104300414ASmooth motionGuaranteed driving motion accuracySwitchgear with withdrawable carriageElectric powerPower control

The invention relates to a drawer-type power control cabinet assembly capable of dehumidifying, which comprises a control cabinet part (1), a drawer push-out part (5) and foot margins (25) fixed on a floor. The control cabinet part (1) and the drawer push-out part (5) are fixedly connected together; a plurality of power control drawer boxes (2) are arranged up and down in the control cabinet part (1); the drawer push-out part (5) are used for pushing out the power control drawer boxes (2) in the control cabinet part (1); the drawer push-out part (5) comprises a supporting body, a lifting driving part, a push-out driving part and a latch driving part; the lifting driving part comprises a lifting motor (4), a lifting driving screw (16) and a guide rod (15); and the lifting motor (4) is connected with the upper end of the lifting driving screw (16) so as to drive the lifting driving screw (16) to rotate.

Owner:泰兴市赛尔新能源科技有限公司

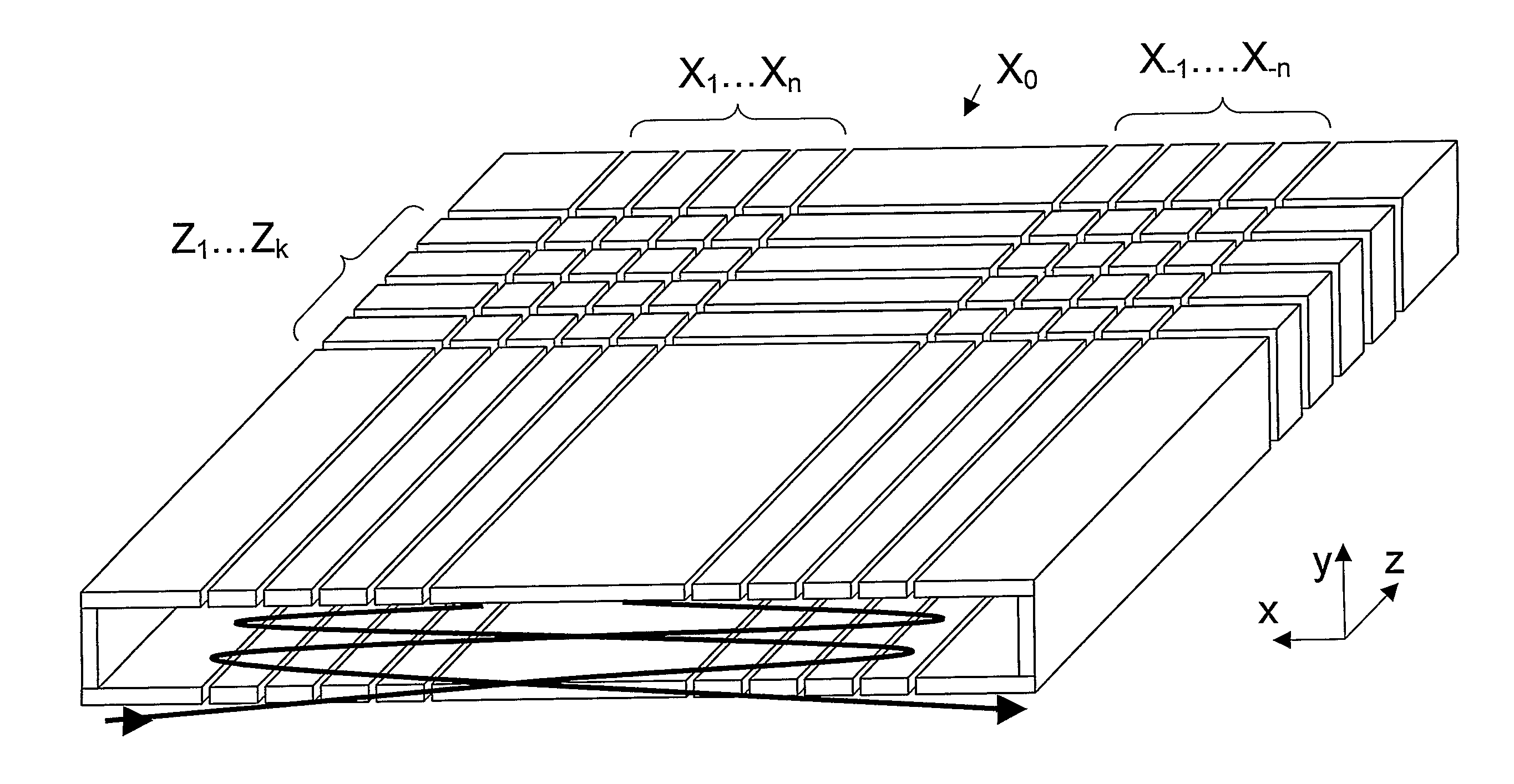

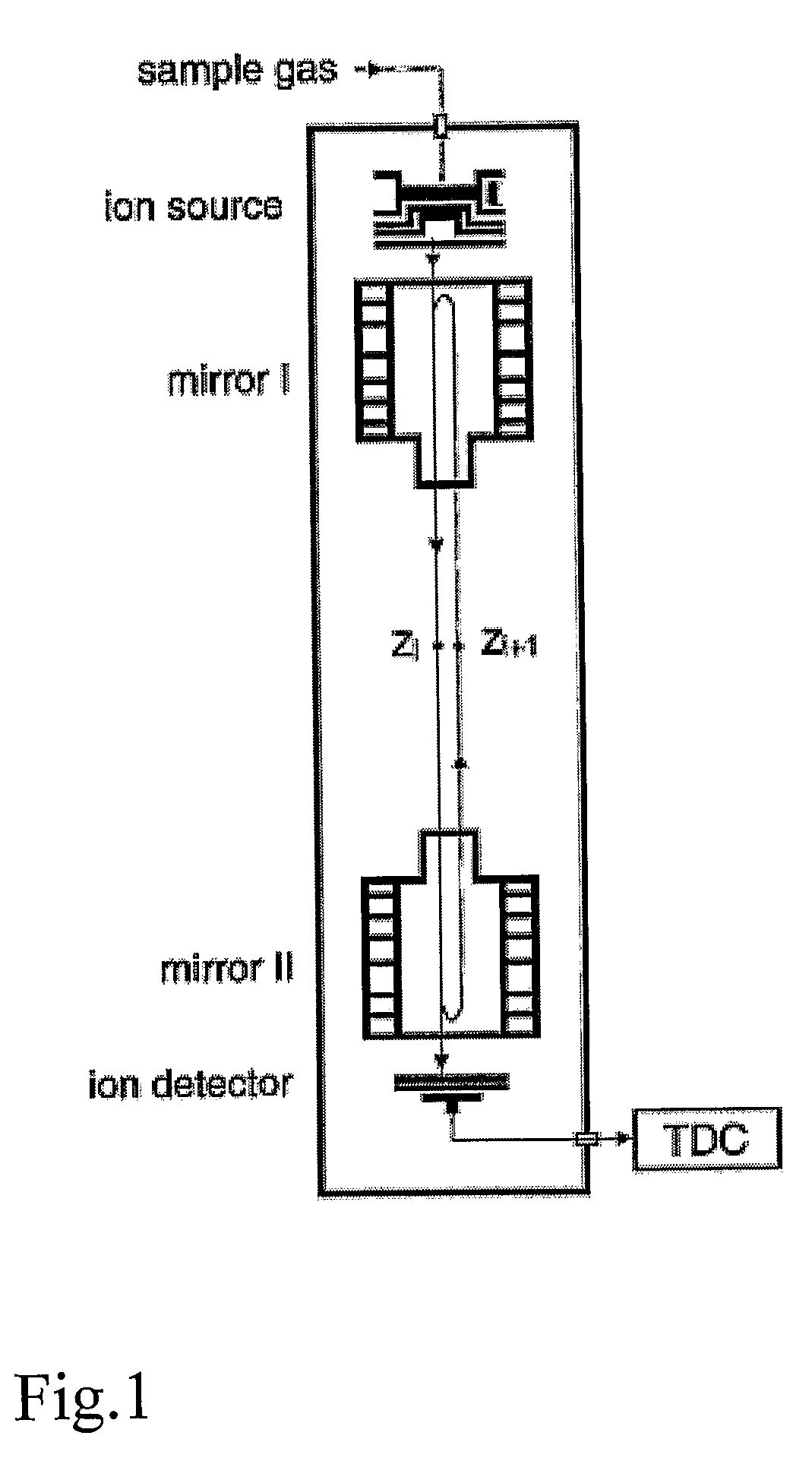

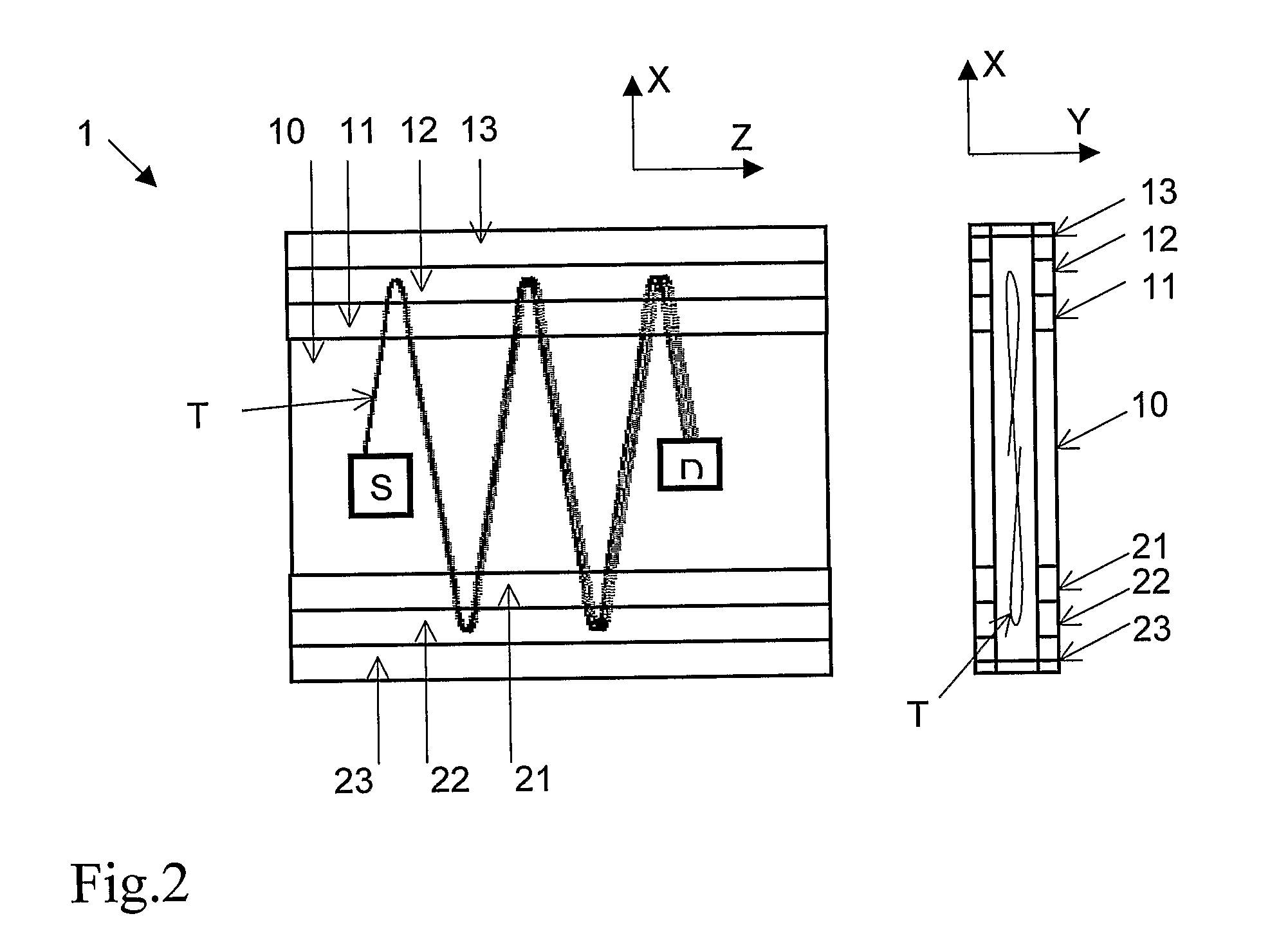

Multi-reflecting time-of-flight mass analyser and a time-of-flight mass spectrometer including the mass analyser

ActiveUS20100044558A1Minimizing beam spreadReducing angular spreadIsotope separationMass spectrometersTime-of-flight mass spectrometryFlight direction

A multi-reflecting TOF mass analyser has two parallel, gridless ion mirrors each having an elongated structure in a drift direction (Z). These ion mirrors provide a folded ion path formed by multiple reflections of ions in a flight direction (X), orthogonal to the drift direction (Z). The analyser also has a further gridless ion mirror for reflecting ions in the drift direction (Z). In operation ions are spatially separated according to mass-to-charge ratio due to their different flight times along the folded ion path and ions having substantially the same mass-to-charge ratio are subjected to energy focusing with respect to the flight and drift directions.

Owner:SHIMADZU CORP

Perpendicular rope climbing patrolling robot in ultra-deep vertical shaft steel-rope guide

ActiveCN105035200APrevent slippingMeet explosion-proof requirementsAssociation with control/drive circuitsElectric locomotivesIntrinsic safetyDrive wheel

The invention discloses a perpendicular rope climbing patrolling robot in ultra-deep vertical shaft steel-rope guide. The perpendicular rope climbing patrolling robot comprises an explosion-proof shell, a driving mechanism, a wheel mechanism, a clamping mechanism, a carrying mechanism and an electric control device. The explosion-proof shell comprises an upper driving shell body, a lower driving shell body, a driver shell body, an electric control device shell body and a carrying mechanism shell body. The driving mechanism comprises an upper driving part, a lower driving part and a motor driver. The wheel mechanism comprises an upper driving wheel part, an upper left side driven wheel part, an upper right side driven wheel part, a lower driving wheel part, a lower left side driven wheel part and a lower right side driven wheel part. The clamping mechanism comprises a left side clamping part and a right side clamping part. The carrying mechanism comprises a movable trolley, an intrinsic safety camera and a cloud deck. The rope climbing patrolling robot can meet the explosion-proof requirement of a coal mine, can climb on the ultra-deep vertical shaft steel-rope guide and can monitor the strain of the shaft wall and the derrick structure situation.

Owner:陕西延长石油矿业有限责任公司 +1

Leg device for leg type movable robot, and method of controlling leg type movable robot

InactiveUS20050067993A1Improve stabilityReduce variationProgramme-controlled manipulatorComputer controlGround contactLeg type

In a foot of a legged mobile robot, deformation of the foot is absorbed by a first concavity and the position and shape of a ground-contact portion hardly change. Accordingly, variation in a resistive force against the moment about the yaw axis can be reduced and a spinning motion can be prevented. In addition, when the foot is placed on a bump or a step, a flexible portion deforms and receives it, and a frictional retaining force is generated between the flexible portion and the bump. Thus, the foot is flexibly adapted to the road surface, and sliding caused by the bump and excessively fast motion are prevented. Accordingly, the foot can be adapted to various kinds of road surfaces such as surfaces having bumps and depressions, and the attitude stability can be increased.

Owner:SONY CORP +1

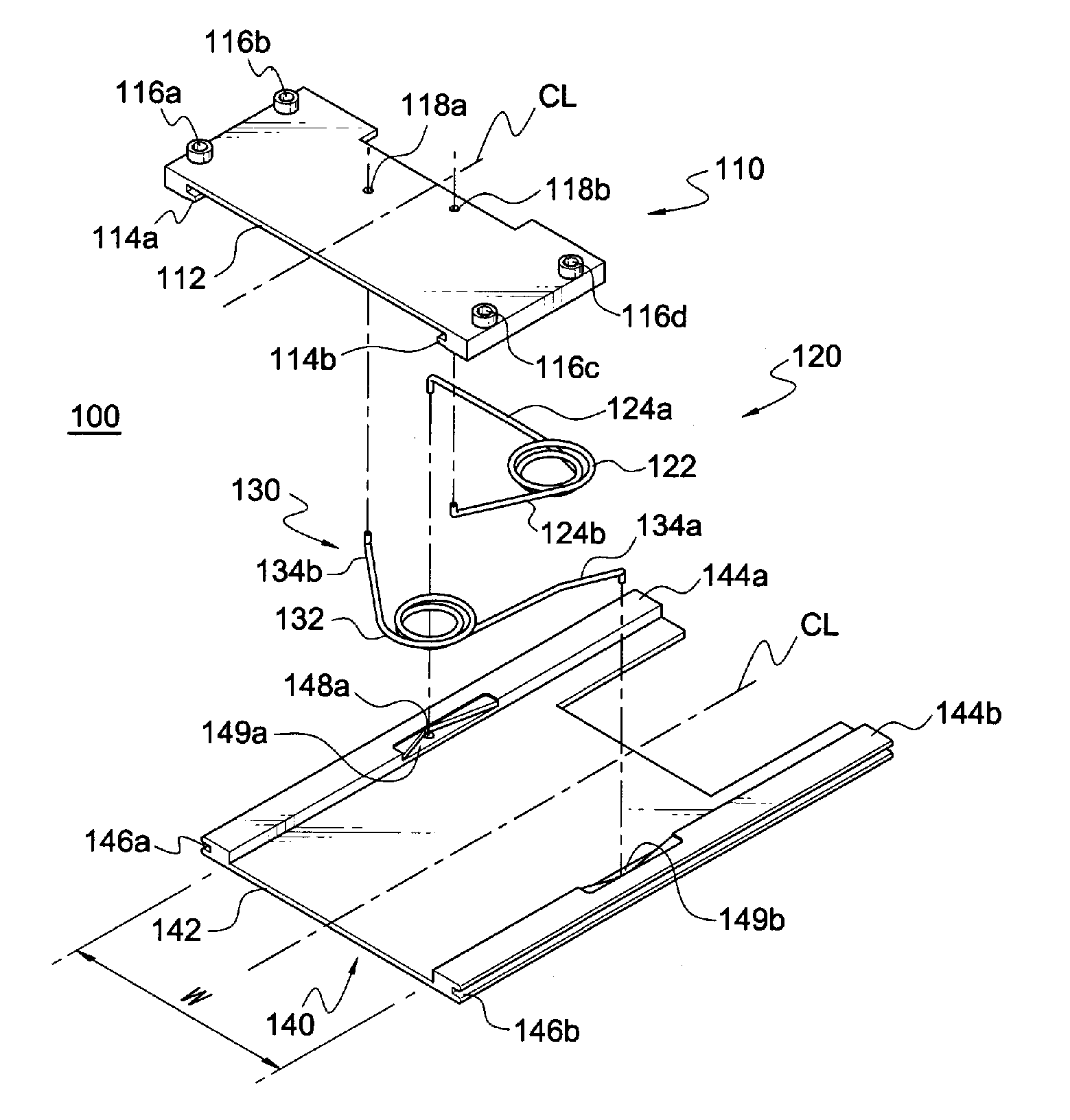

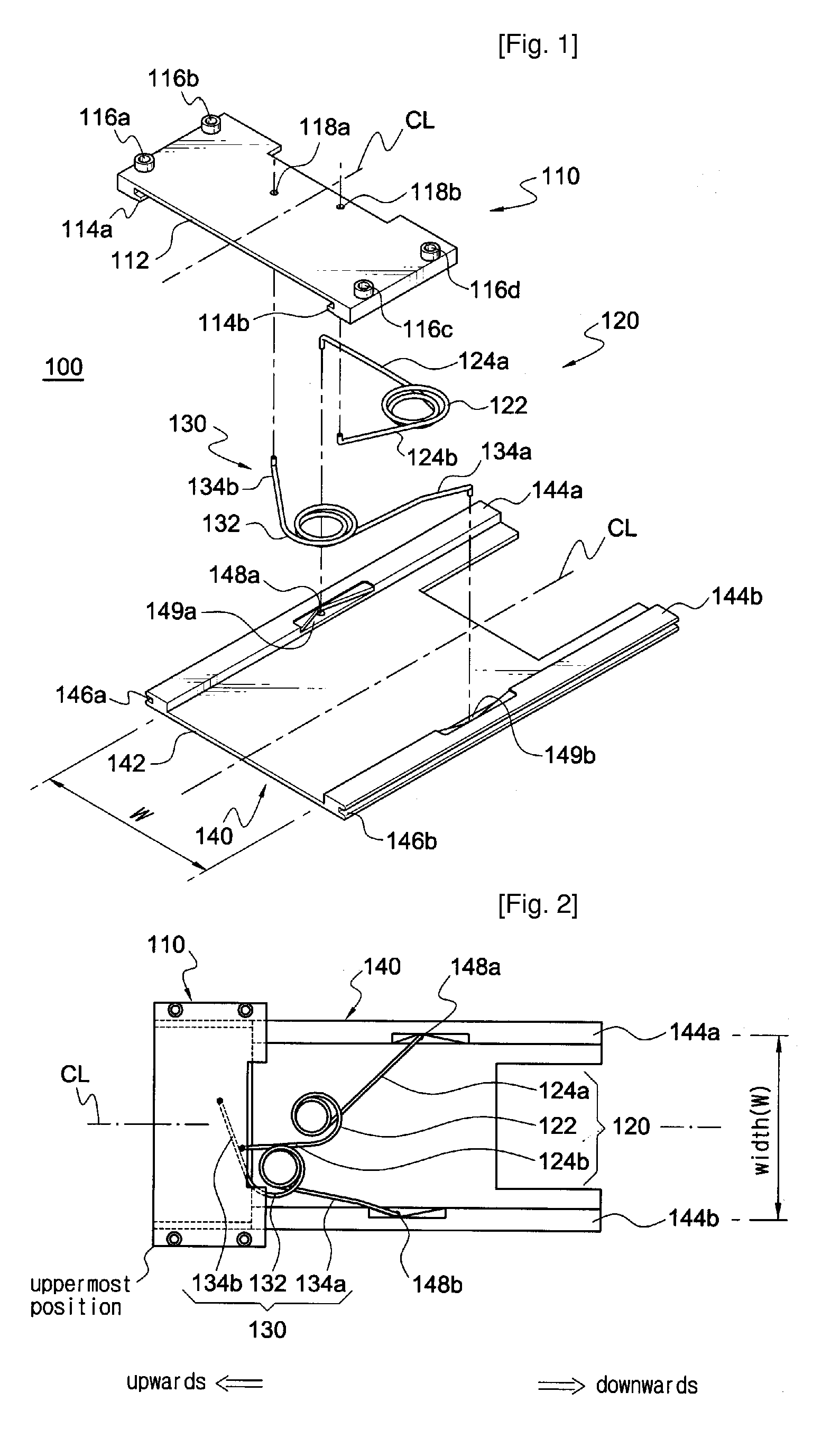

Sliding mechanism apparatus and appliance integrated with the same

InactiveUS20070091555A1Small widthLarge sliding distanceDigital data processing detailsElectrical apparatus contructional detailsAcute angleEngineering

Disclosed is a sliding mechanism apparatus used for slidably opening and closing a slider-type cellular phone. A guide member and a slider member are engaged with each other so as to enable to slide relative to each other. The end of one arm of a first torsion spring is connected to the slider member near the left edge thereof. The end of the other arm thereof is coupled to the right half area of the guide member. The end of one arm of a second torsion spring is connected to the slider member near the right edge thereof. The end of the other arm thereof is coupled to the left half area of the guide member. From the expanded original state of the first and second torsion springs, if an external force is exerted on the slider member or the guide member, the torsion springs are compressed into an acute angle and then spread again by means of the elastic force thereof. In this way, the slider member can move to the lowermost position or the lowermost position. In the first and second torsion springs, the distance between the ends of two arms is larger than at least half of the width of the slider member. Therefore, the first and second torsion springs can maximally utilize the width of the guide member while turning, thereby extending the maximum travel distance of the slider member.

Owner:LEE HAN SANG +1

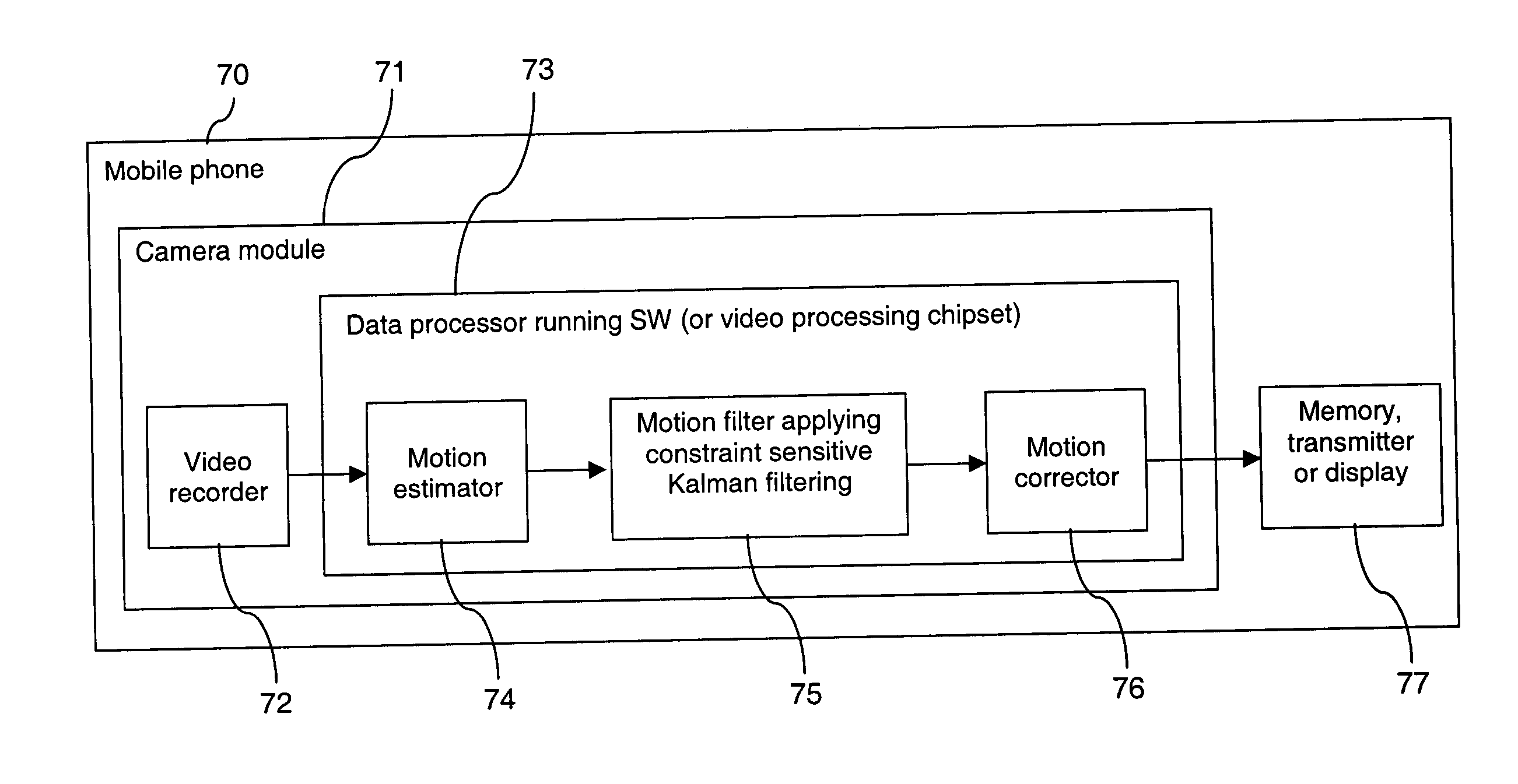

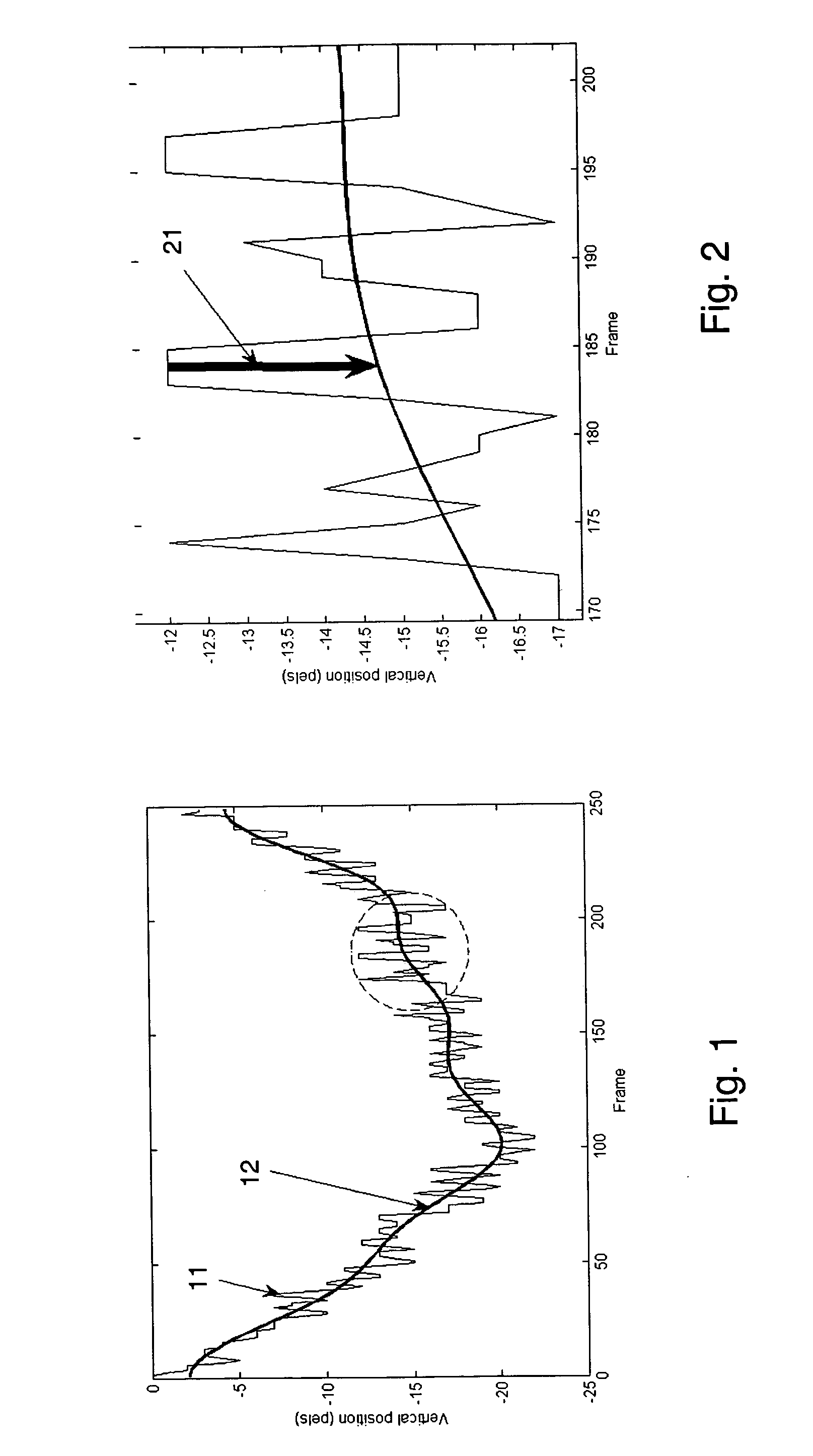

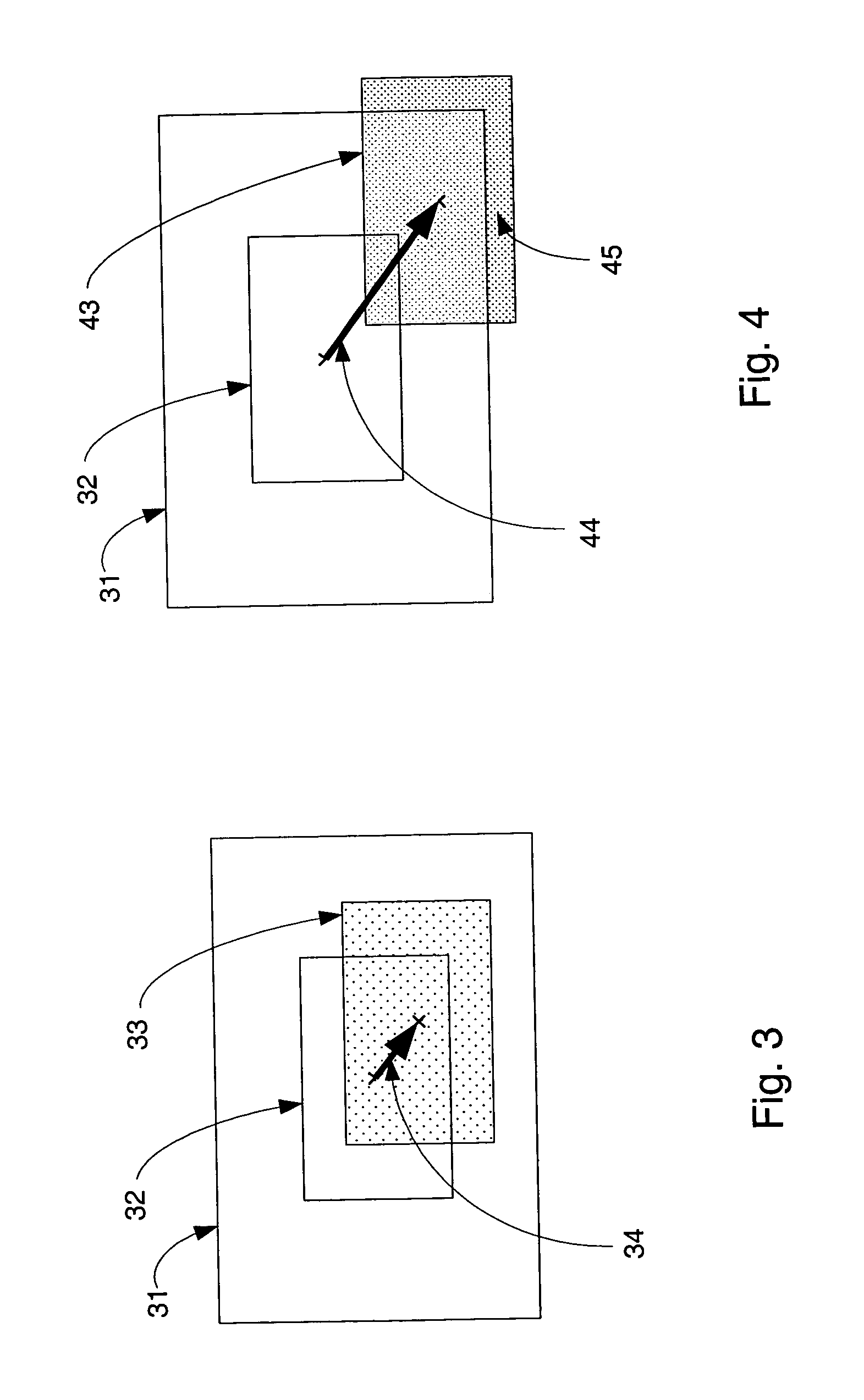

Motion filtering for video stabilization

ActiveUS20070002146A1Smooth stabilized motion trajectoryLarge image resolutionImage enhancementTelevision system detailsState variableComputer vision

For applying a motion filter of a video stabilization system to a sequence of video frames, an estimate of a motion in the current video frame compared to a first video frame of the sequence of video frames is received. Based on the received motion estimate and on at least one state variable of the motion filter, a correction value for the motion in the current video frame is computed. The at least one state variable is updated in the computation. In case the computed correction value exceeds a system constraint of the video stabilization system, the at least one state variable is adjusted in accordance with an extent by which the system constraint is exceeded. The correction value is then recomputed based on the motion estimate and on the adjusted state variable.

Owner:NOKIA TECHNOLOGLES OY

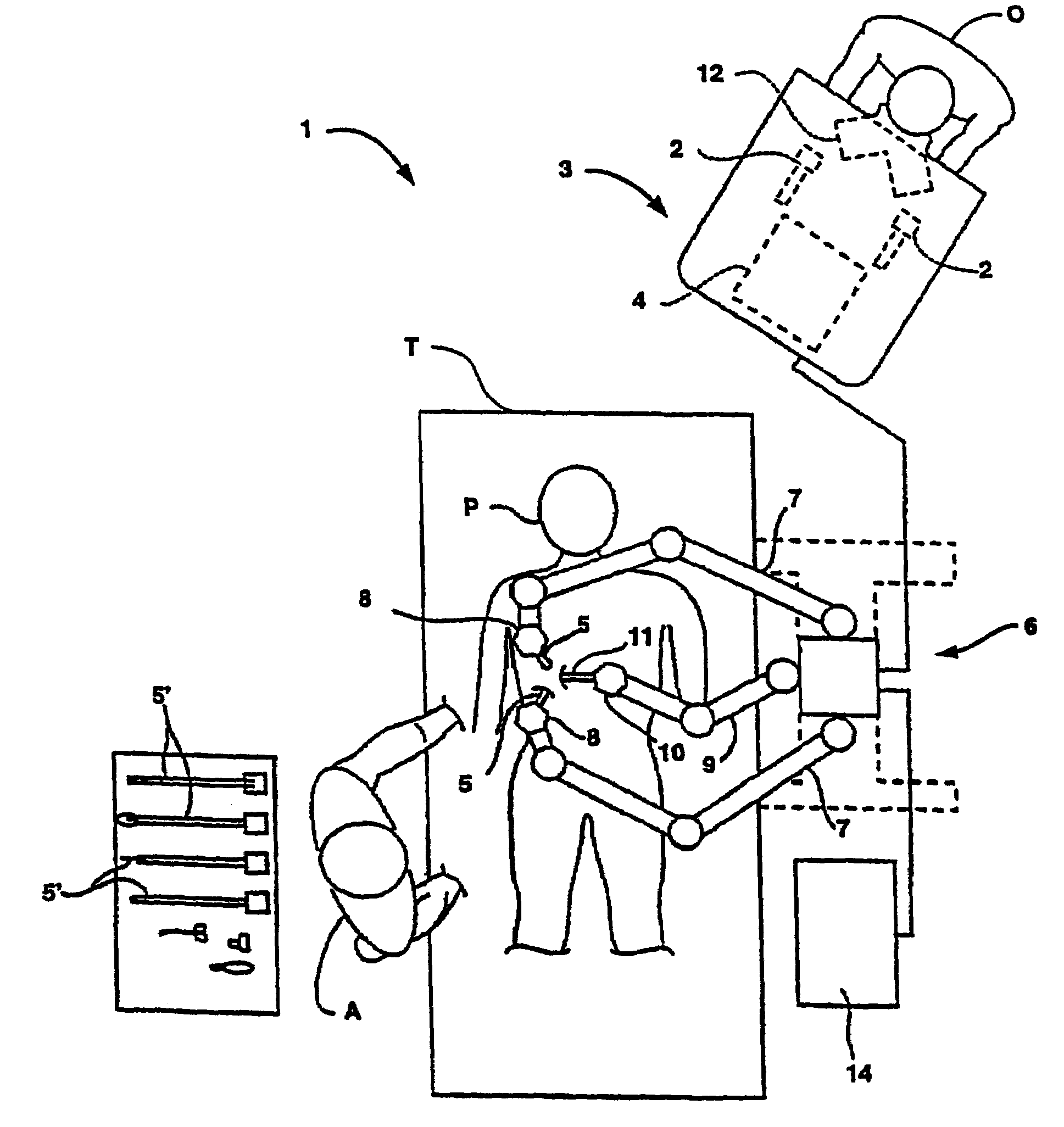

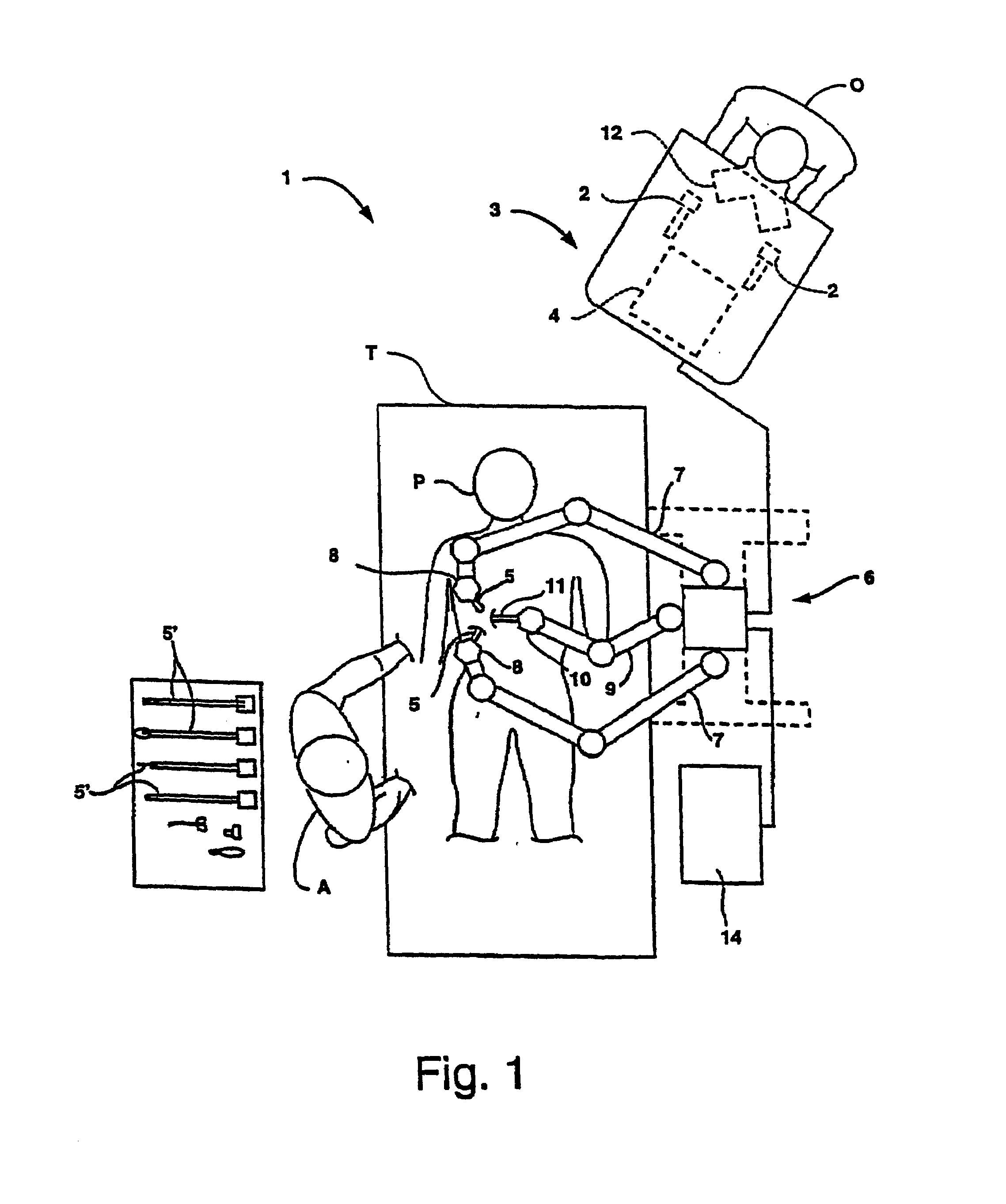

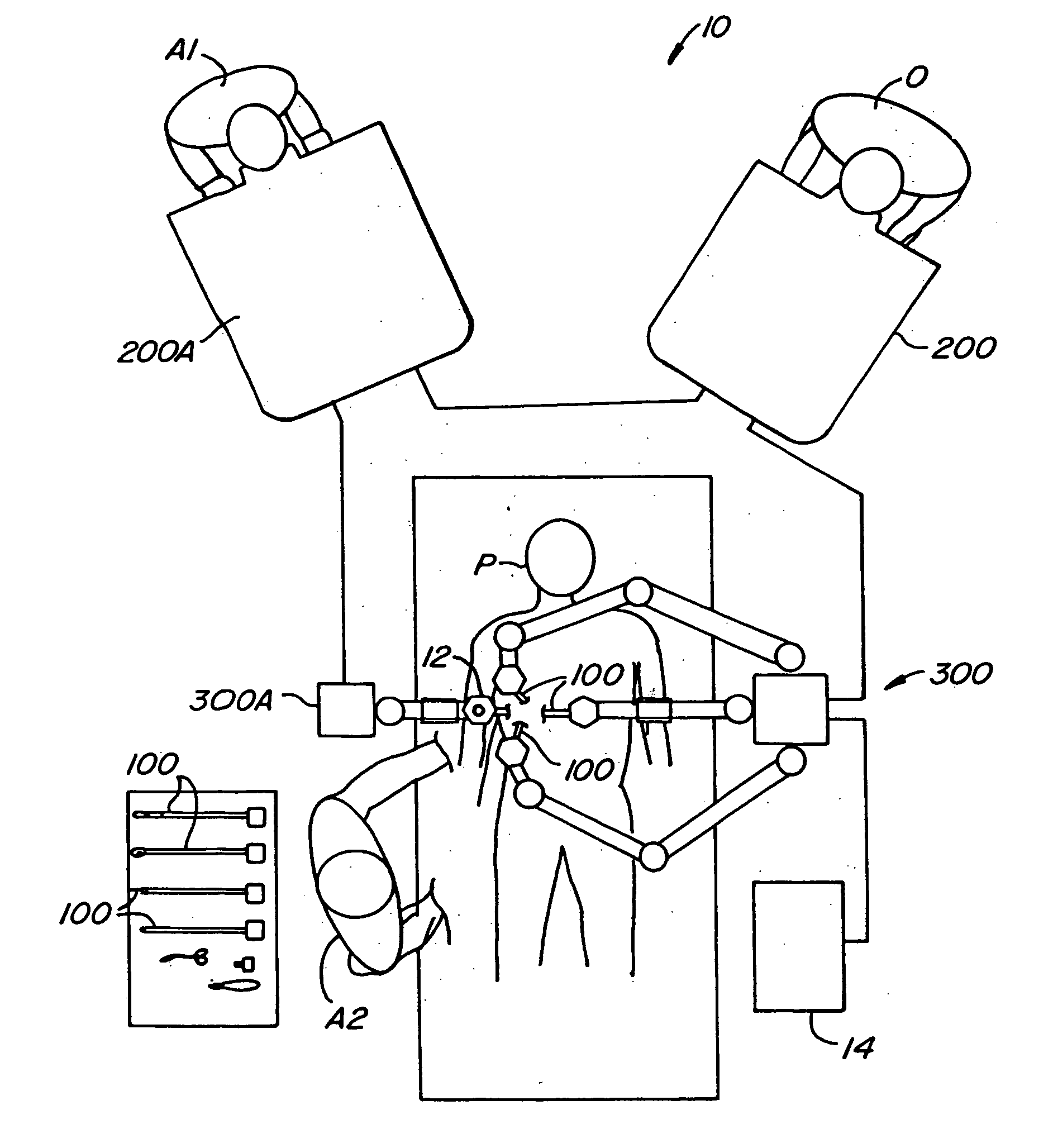

Stabilizer for robotic beating-heart surgery

InactiveUS20050033270A1Physiological motion of stabilizedAvoid relative motionSuture equipmentsDiagnosticsRobotic systemsChest surgery

Surgical methods and devices allow closed-chest surgery to be performed on a heart of a patient while the heart is beating. A region of the heart is stabilized by engaging a surface of the heart with a stabilizer without having to stop the heart. Motion of the target tissues is inhibited sufficiently to treat the target tissues with robotic surgical tools which move in response to inputs of a robotic system operator. A stabilizing surface of the stabilizer is coupled to a drive system to position the surface from outside the patient, preferably by actuators of the robotic servomechanism. Exemplary stabilizers includes a suture or other flexible tension member spanning between a pair of jointed bodies, allowing the member to occlude a coronary blood vessel and / or help stabilize the target region between the stabilizing surfaces.

Owner:INTUITIVE SURGICAL OPERATIONS INC

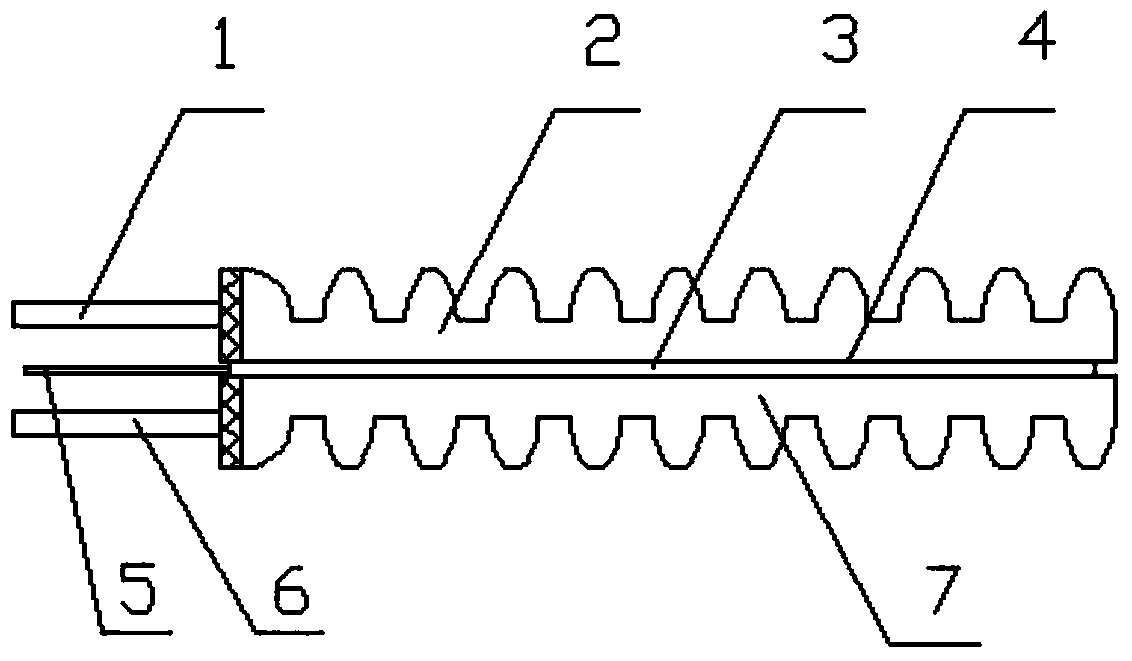

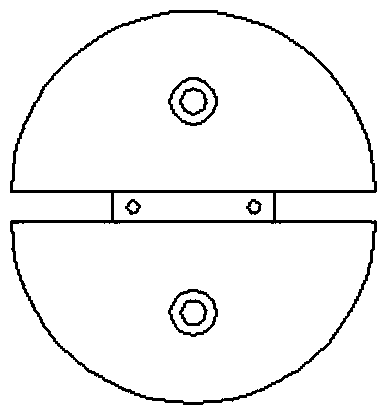

Corrugated double-inner-cavity gas-powered flexible micro finger, control method and grabbing system

The invention discloses a corrugated double-inner-cavity gas-powered flexible micro finger, a control method and a grabbing system. The corrugated double-inner-cavity gas-powered flexible micro finger comprises a double-inner-cavity gas-powered flexible micro finger body composed of two independent pneumatic half-corrugated hollow rubber tube half-fingers I and II which are symmetrically arranged. A thin sheet type bending tilt angle sensor making contact with the two half-fingers is arranged between the two half-fingers. The two half-fingers are provided with a gas inlet and outlet I and a gas inlet and outlet II respectively. The outer side of the top face of each independent pneumatic half-corrugated hollow rubber tube half-finger is a corrugated surface, the bottom face of each independent pneumatic half-corrugated hollow rubber tube half-finger is a horizontal plane, and the top face and the bottom face of each independent pneumatic half-corrugated hollow rubber tube half-finger are connected into a whole to form a hollow sealing cavity. The bottom faces of the two independent pneumatic half-corrugated hollow rubber tube half-fingers I and II are aligned with each other and then are pasted on the thin sheet type bending tilt angle sensor. The corrugated double-inner-cavity gas-powered flexible micro finger has the advantages of being low in cost, safe in cleaning, easy and convenient to install, good in flexibility, smooth in motion, low in noise and free of pollution, having mechanical performance similar to that of biological muscles, and the like.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

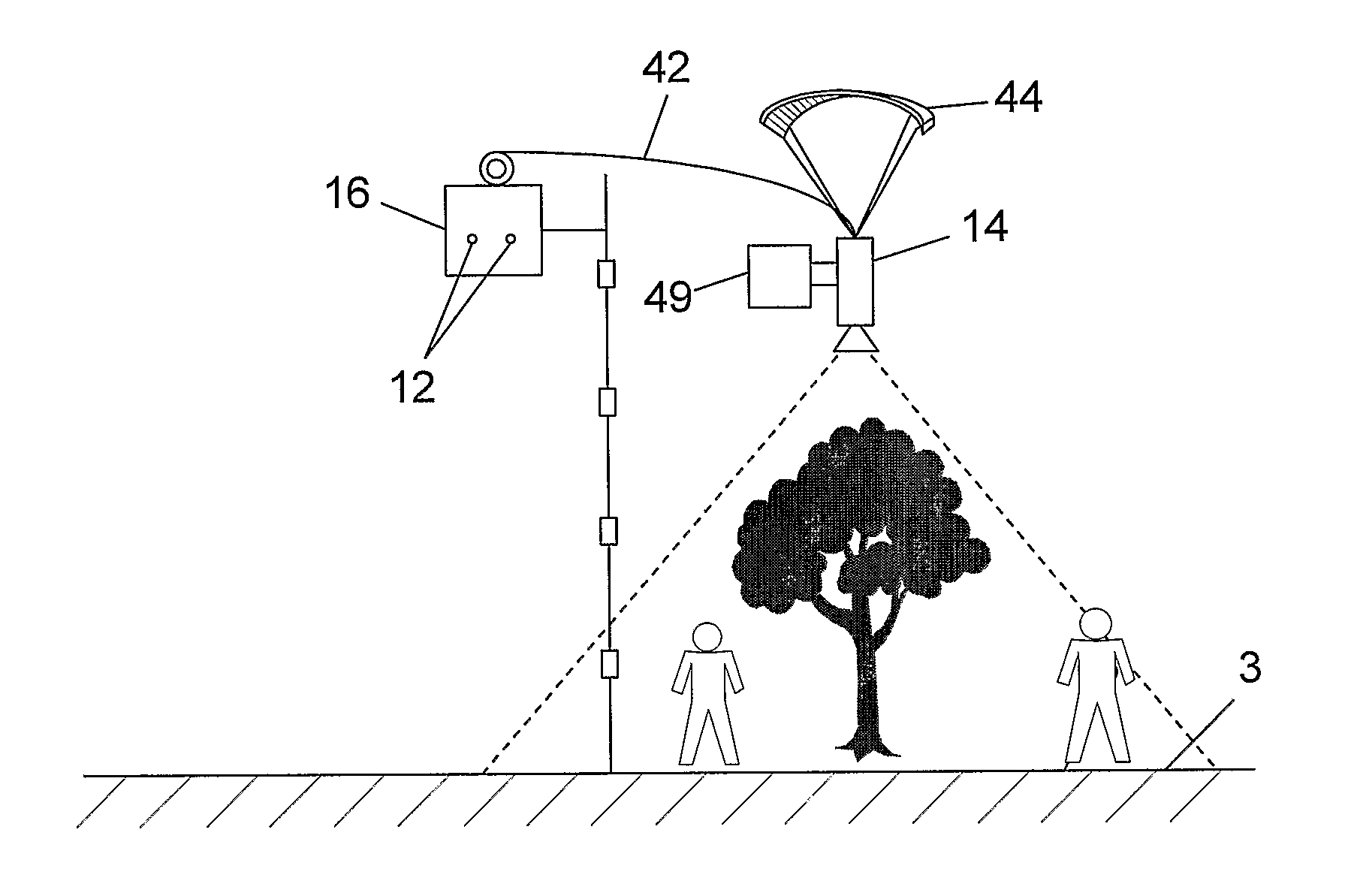

Surveillance System and Method for Detecting Forbidden Movement along a Predetermined Path

InactiveUS20090040307A1Smooth motionClosed circuit television systemsVehicle componentsMonitoring systemEngineering

The present invention relates to a surveillance system for detecting forbidden movement in any direction at one or more locations along a road. The system comprises cameras that are in data communication with a control station for detecting the forbidden movement; mobile platforms that are movable along a desired path along the road; mechanical connectors for connecting the cameras to the mobile platforms, that create an adjustable projection of the spatial distance between the camera and the mobile platform; and a control station for receiving and processing data from and transferring data the cameras.

Owner:PLANUM VISION

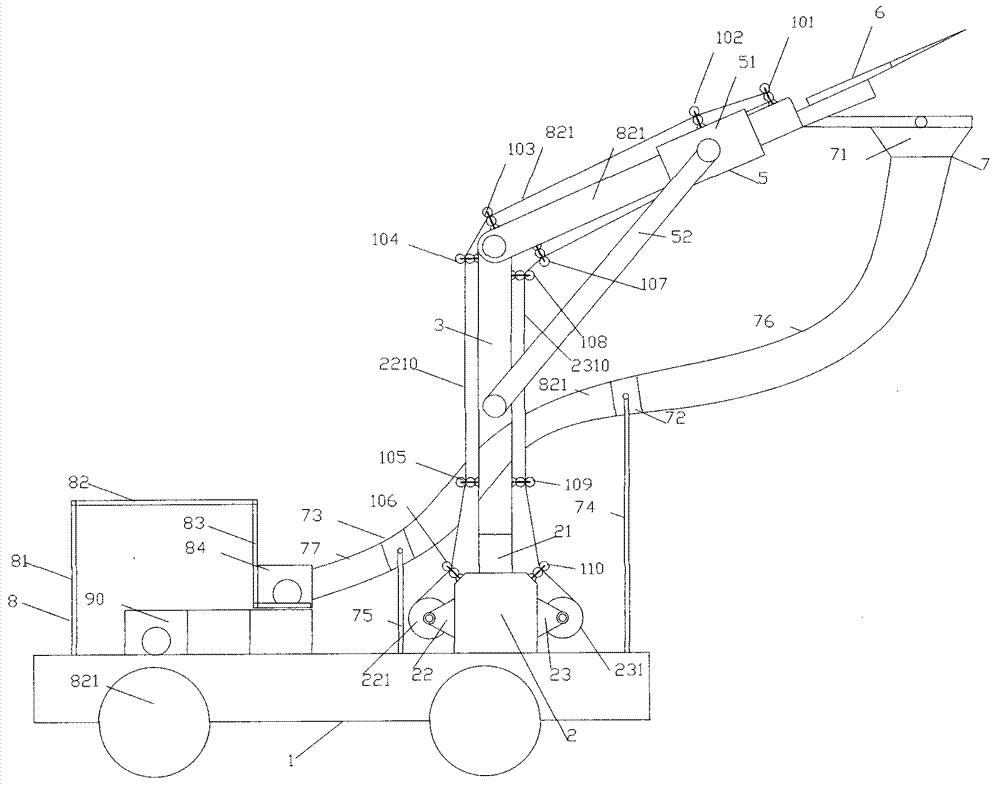

Apple picking machine and method for operating same

ActiveCN104255193AOptimization pathEasy to collectPicking devicesPulp and paper industryUltimate tensile strength

The invention discloses an apple picking machine and a method for operating the same. The apple picking machine comprises a framework, a shearing mechanism, an adjusting mechanism, a collecting channel, an accommodating mechanism and an apple box. The adjusting mechanism comprises a support column, a rotary column and a crank-slider mechanism; the bottom of the support column sleeves a base, and the top of the support column is hinged to an end of the rotary column; the crank-slider mechanism comprises a slider and a connecting rod, the slider sleeves the rotary column, one end of the connecting rod is hinged to the rotary column, and the other end of the connecting rod is hinged to the support column; the shearing mechanism is arranged on the top of the rotary column. The apple picking machine and the method have the advantages that the height of shears can be conveniently controlled via the crank-slider mechanism, and the apple picking machine can be controlled via motors and is simple in operation and low in labor intensity; an electromagnet is arranged at the tail of a handle of the shears, so that the apple picking machine can be conveniently manually operated, and the labor intensity can be reduced; the apple picking machine is provided with the collecting channel, so that apples can be conveniently collected while bruise due to an accommodating machine can be effectively prevented; the apples can be automatically placed by the accommodating mechanism which is matched with the apple box, and accordingly the labor time can be saved.

Owner:刘宝帅 +1

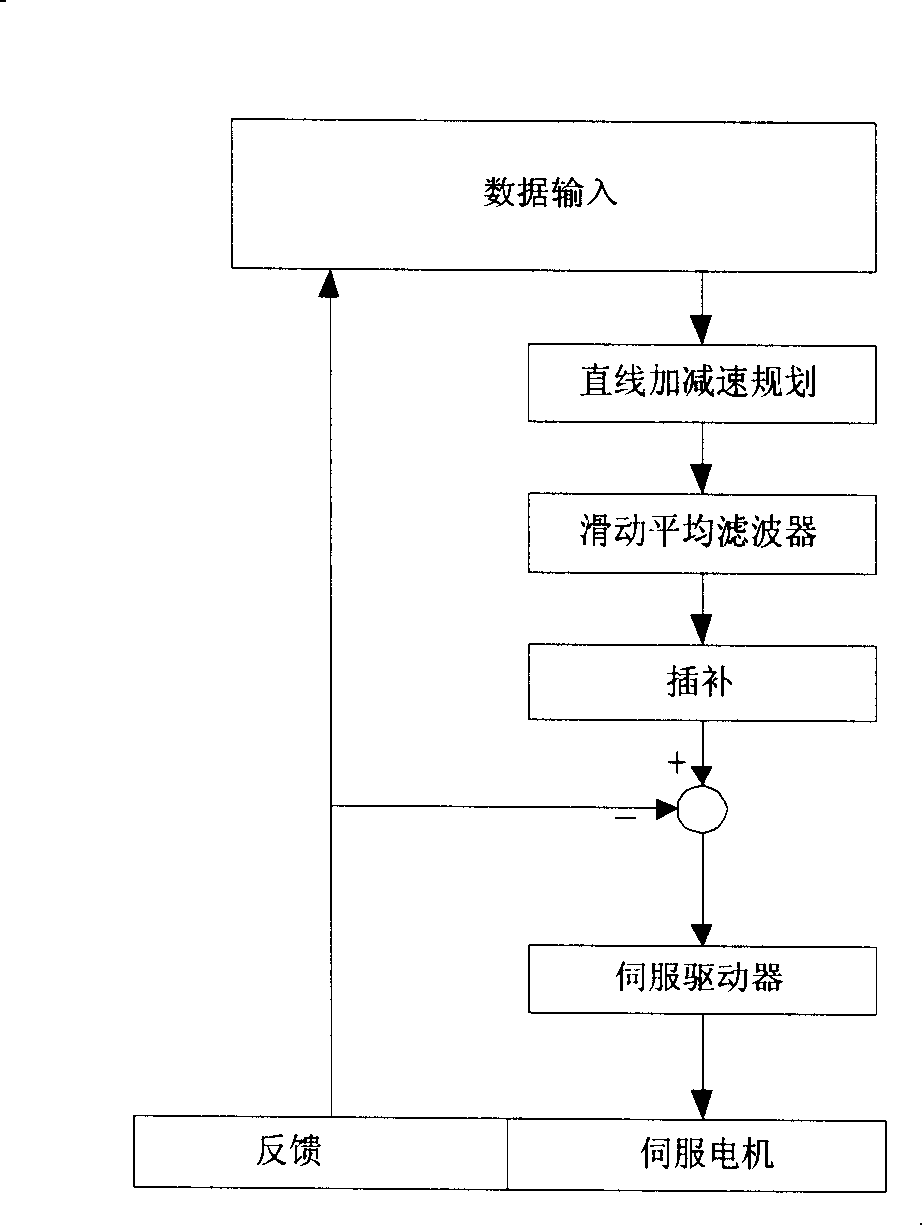

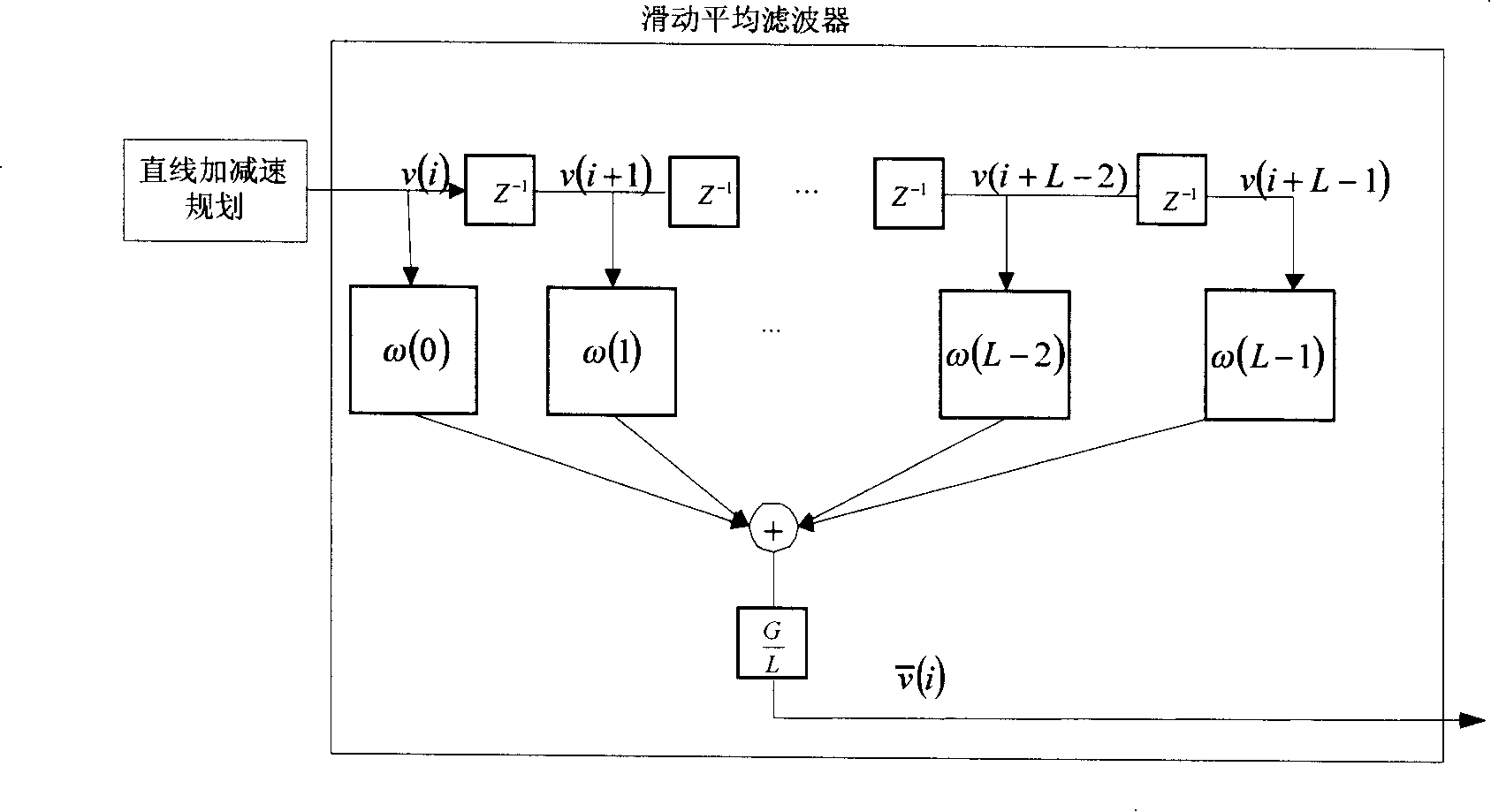

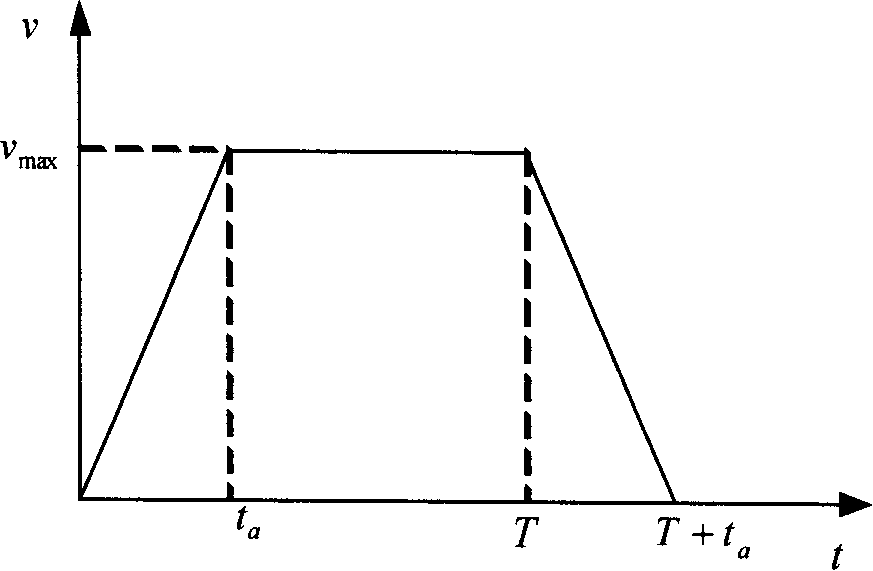

Filter technique based numerical control system acceleration and deceleration control method

ActiveCN101211177ASolve Vibration ProblemsReduce vibrationDigital technique networkNumerical controlMoving averageAverage filter

The invention relates to an acceleration or deceleration control method of numerical control system based on filter technique, which comprises the following steps: planning straight acceleration or deceleration by using the inputted workpiece program data; performing moving average filtering and filter compensation on the planned speed of the straight acceleration or deceleration to obtain a new planned speed value and a position value; performing interpolation on the position value; transmitting the interpolated position value to a servo driver in order to control a servomotor; wherein the moving average filtering of the planned speed of the straight acceleration or deceleration is implemented by adding a moving average filter after planning the straight acceleration or deceleration to control sudden changes of an accelerated speed, particularly comprising the following steps: calculating the speed with a method of planning the moving average filtering speed; changing the smooth degree of the straight acceleration or deceleration by selecting filter length (i.e. controlling the magnitude and the shape of the accelerated speed); and calculating a planned position according to the speed after filtering. The invention solves the vibration problem of a numerically-controlled machine tool during movement, and has the advantages of easy implementation, good compatibility and good flexibility.

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com