Patents

Literature

227 results about "Tail structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinal implants and methods

InactiveUS20090149959A1Reduce relative motionSmooth motionDiagnosticsBone implantPosterior regionIntervertebral disk

Owner:MAGELLAN SPINE TECH

Spinal implants and methods

InactiveUS20090138015A1Reduce relative motionSmooth motionBone implantDiagnosticsPosterior regionIntervertebral disk

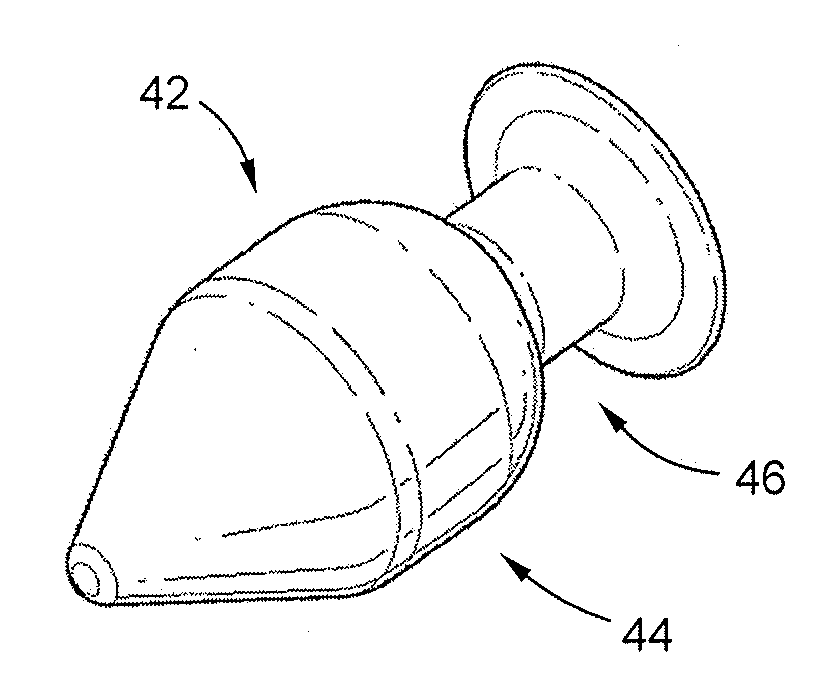

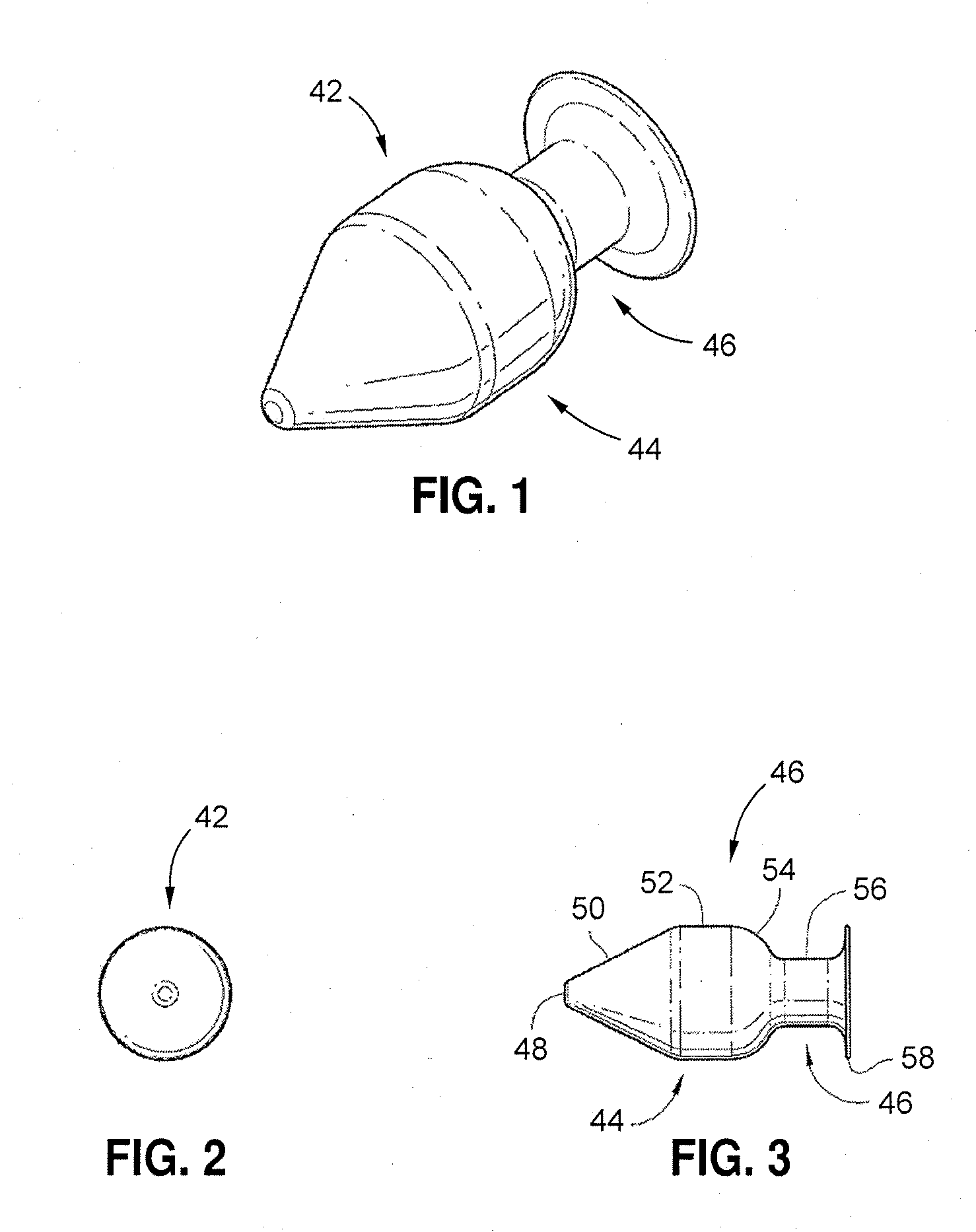

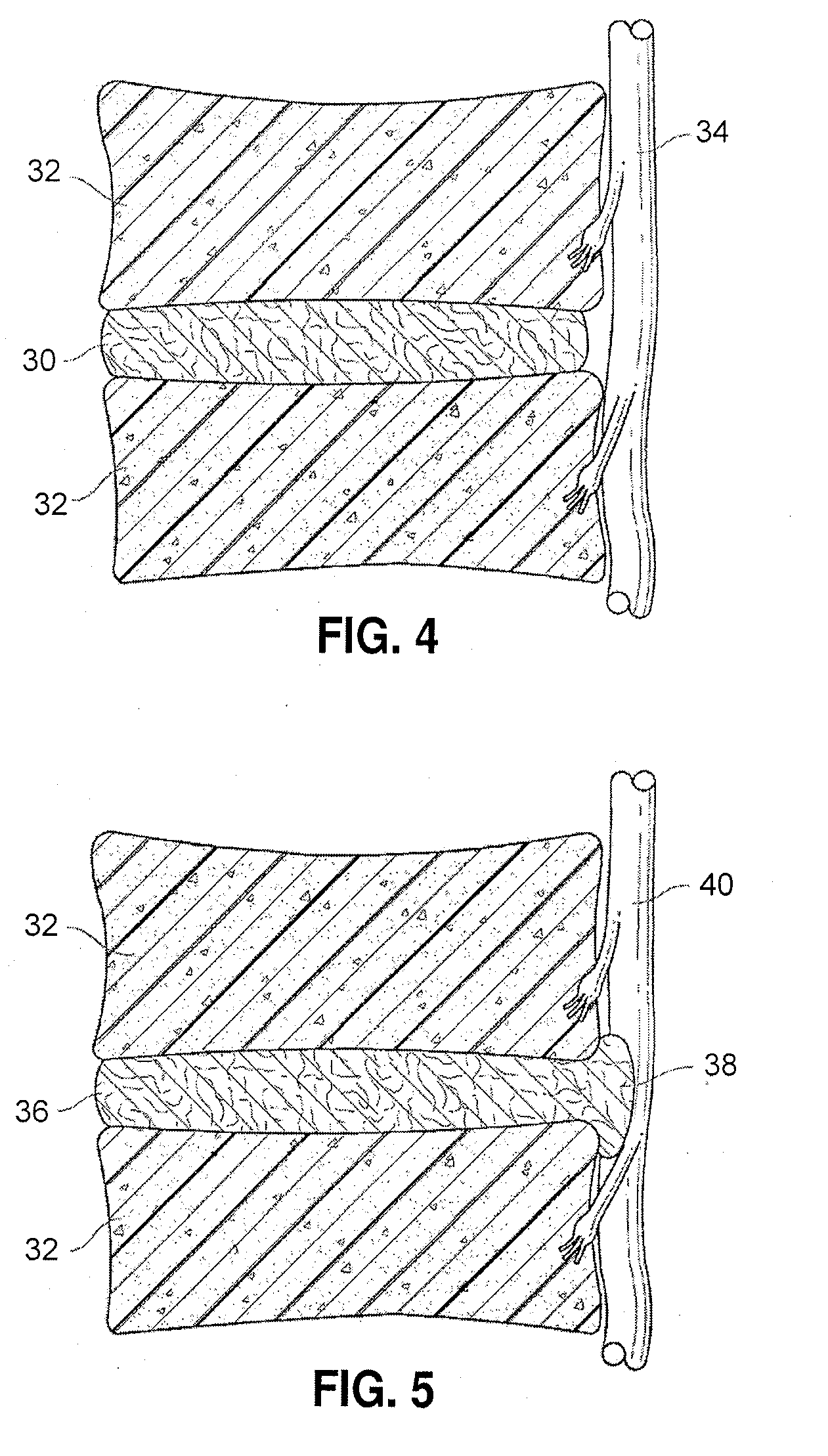

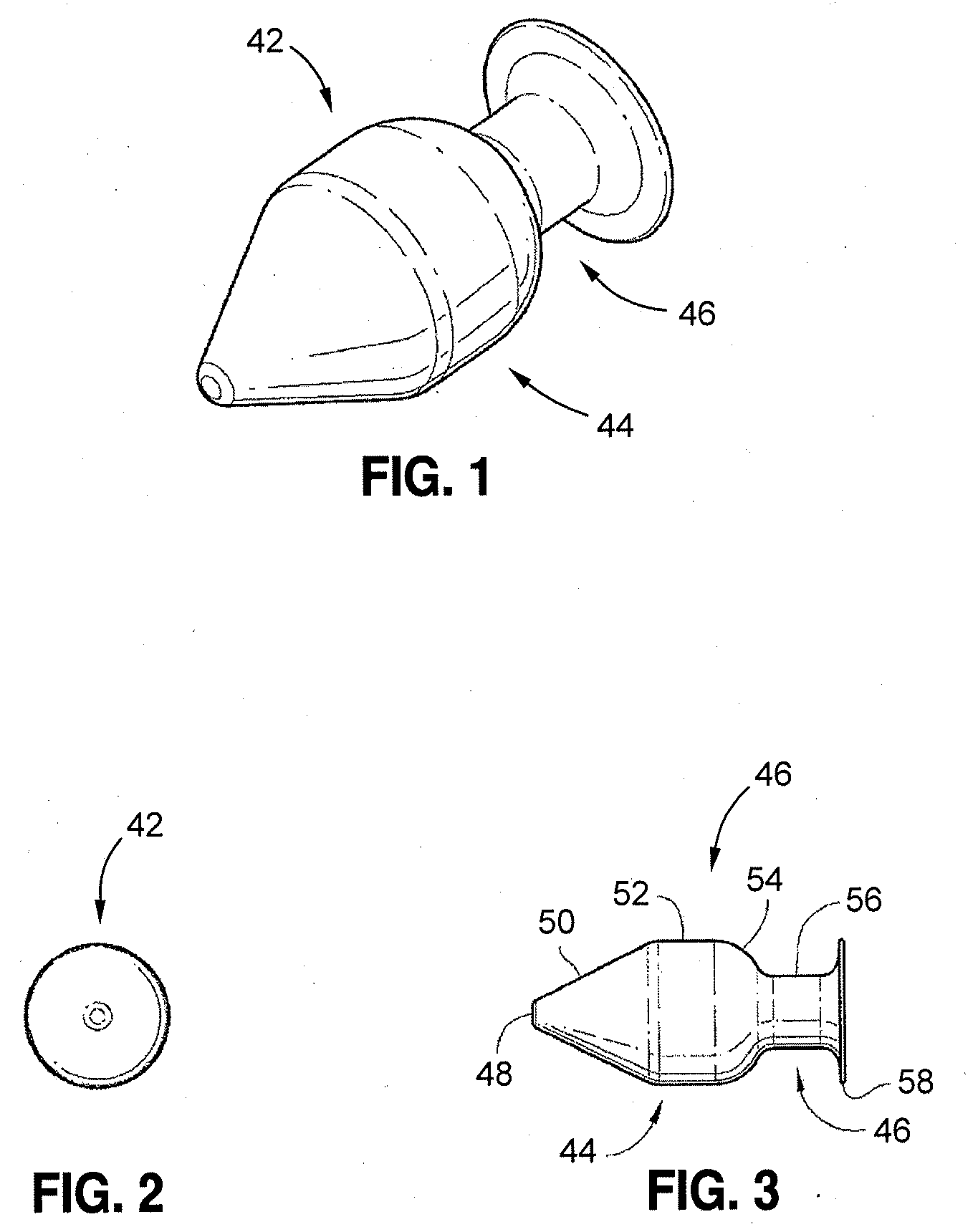

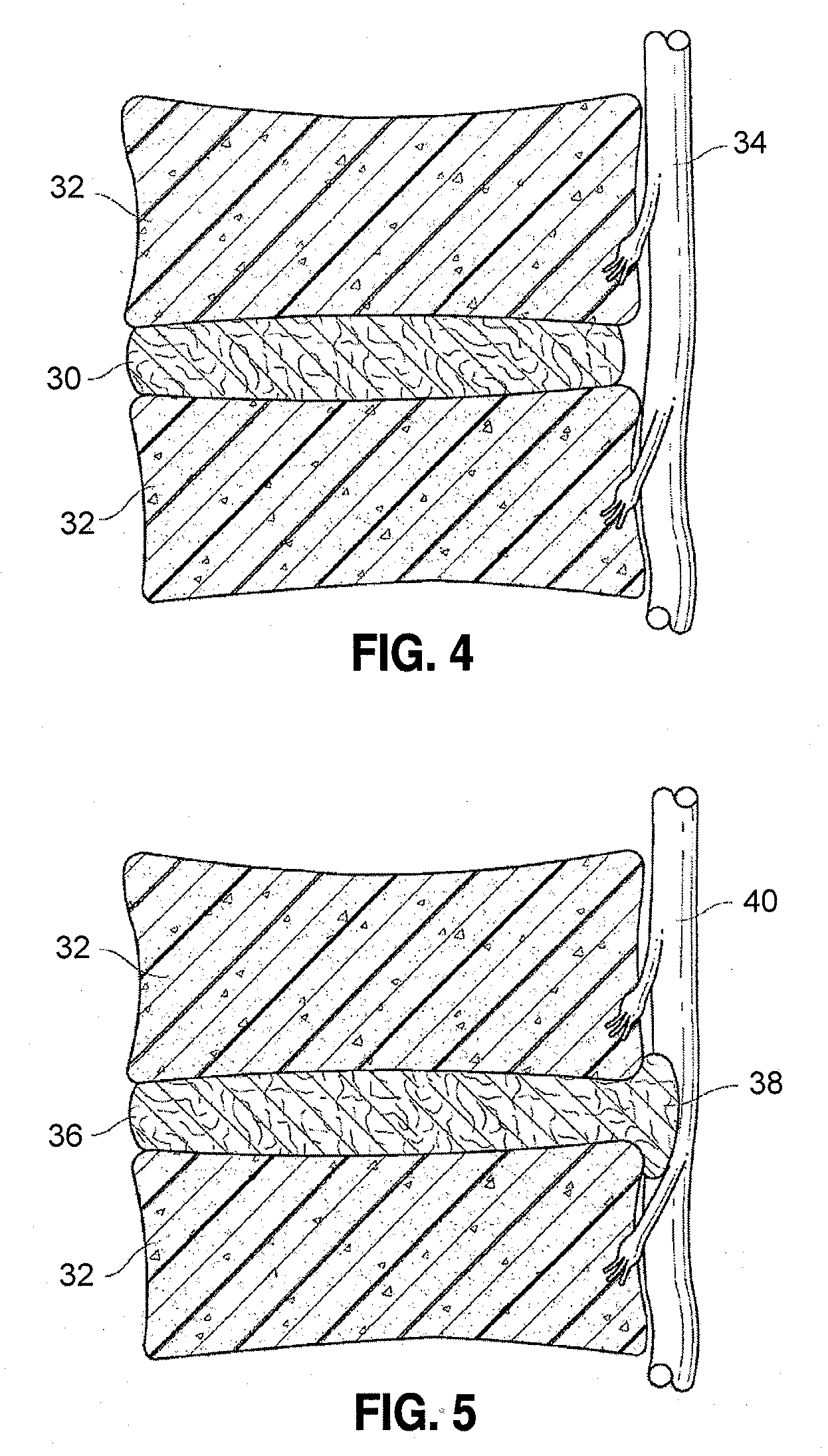

Spinal implants are disclosed that can be used for annular repair, facet unloading, disc height preservation, disc decompression, or for sealing a portal through which an intervertebral implant was placed. In some embodiments, an implant is placed within the intervertebral disc space, primarily within the region of the annulus fibrosus. In some embodiments, the implant is expandable. In some embodiments, the implant has a sealing tail structure comprising a tail flange and a linkage. In some embodiments, the sealing tail structure limits the extrusion or expulsion of disc material, either annulus fibrosus or nucleus, into the posterior region of the spine where it could impinge on nerves. In some embodiments, the tail structure is retained in place within the annulus fibrosus by means of an anchor. In some embodiments, the anchor is constructed from multiple components.

Owner:CONNER E SCOTT DR

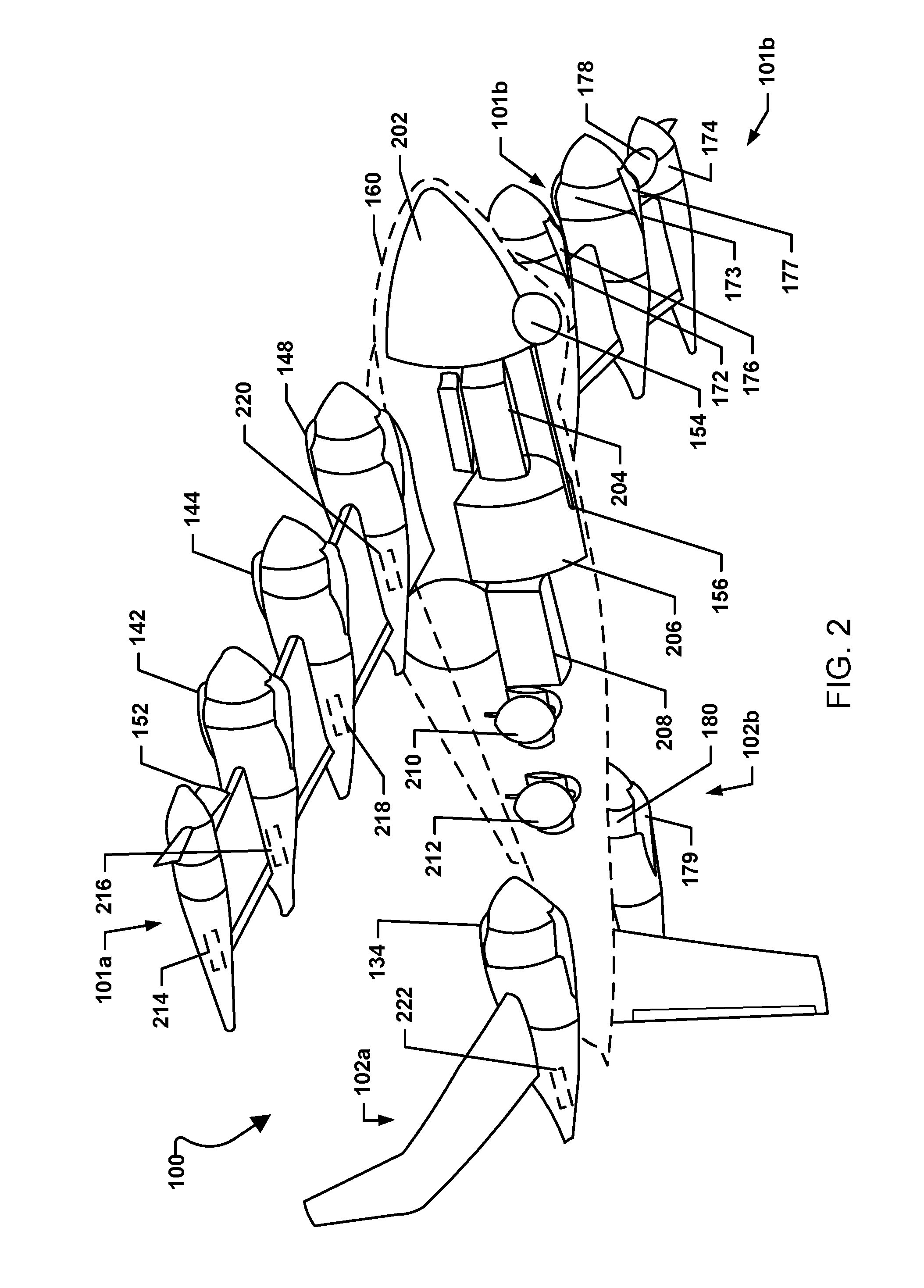

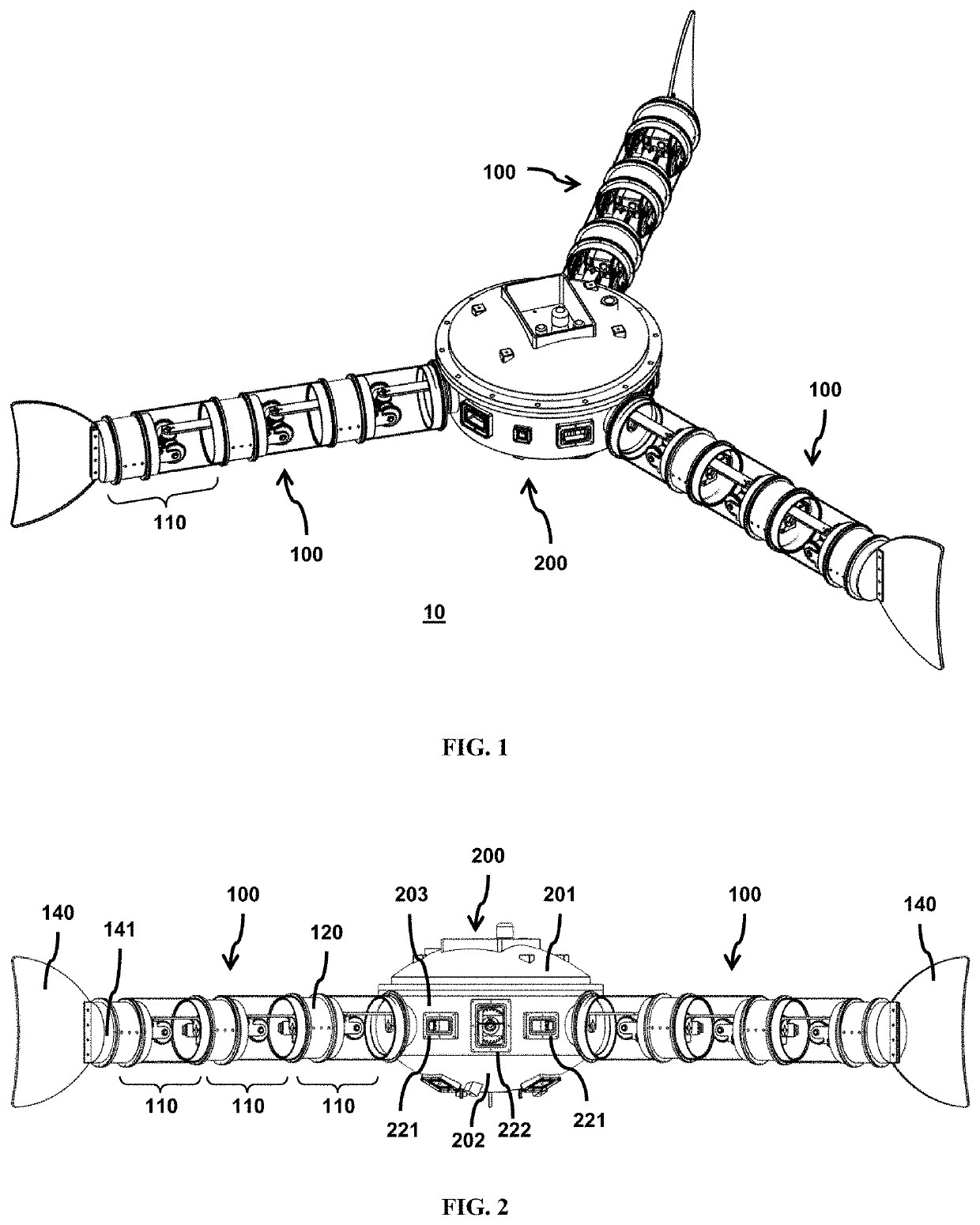

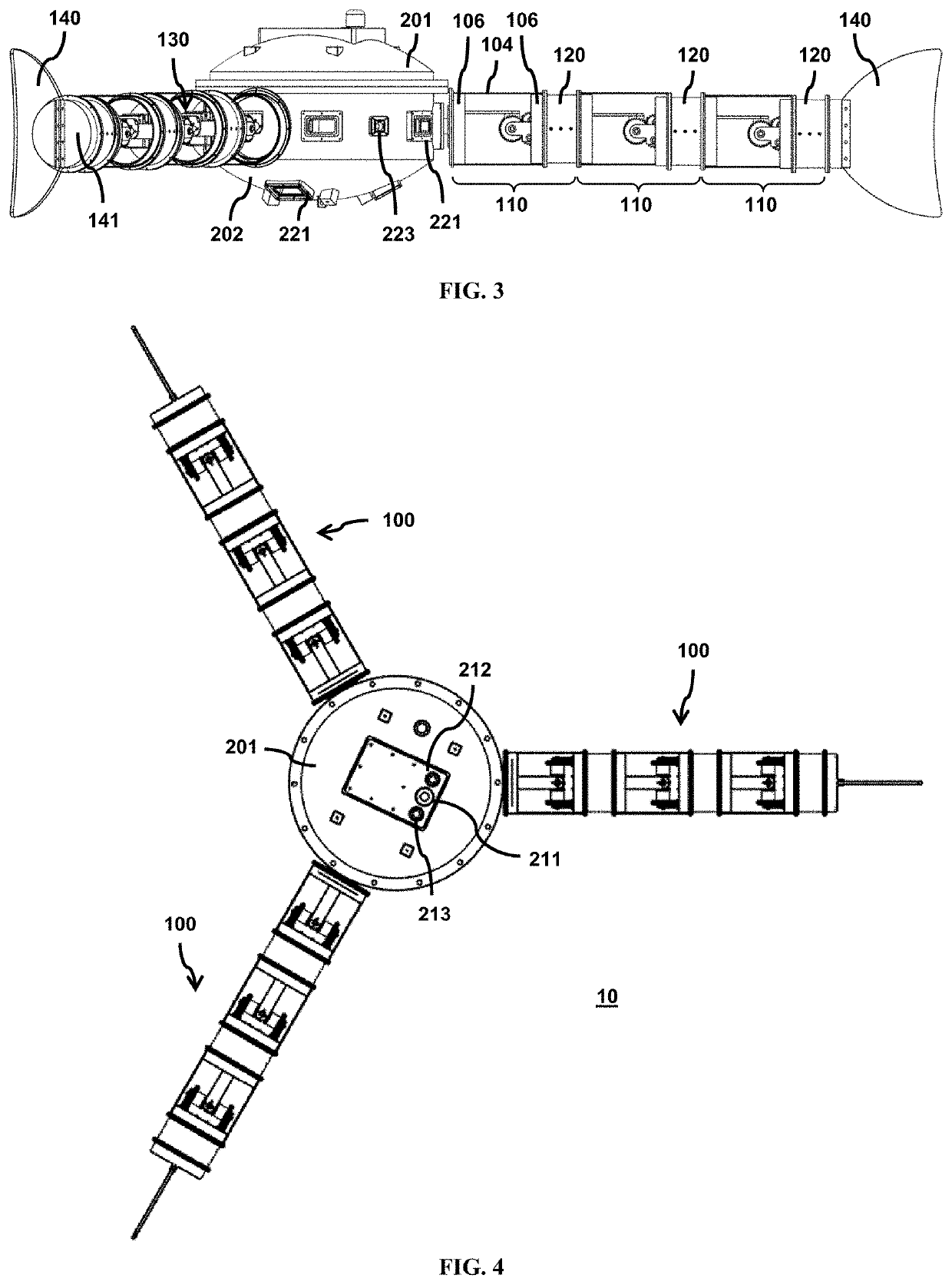

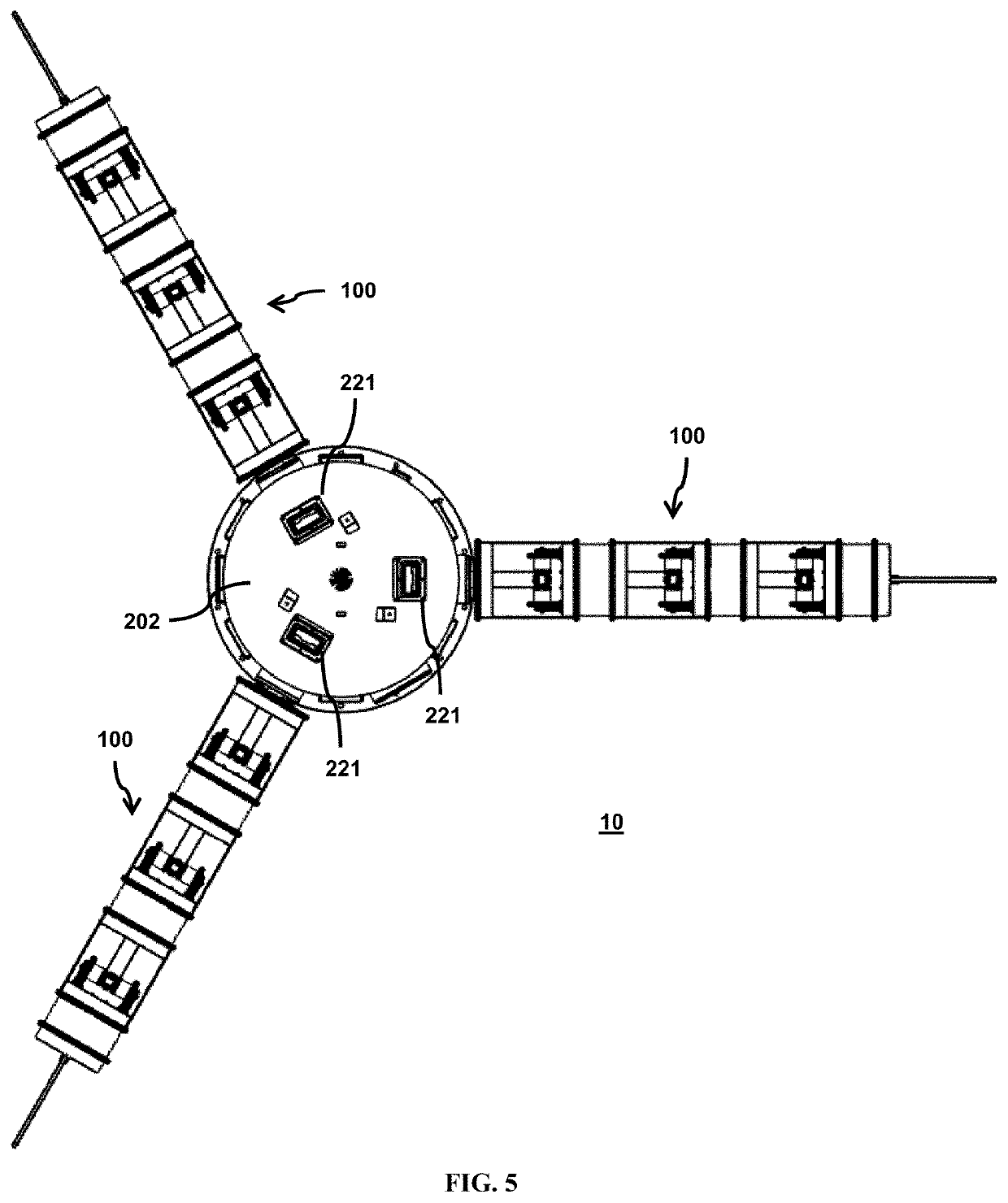

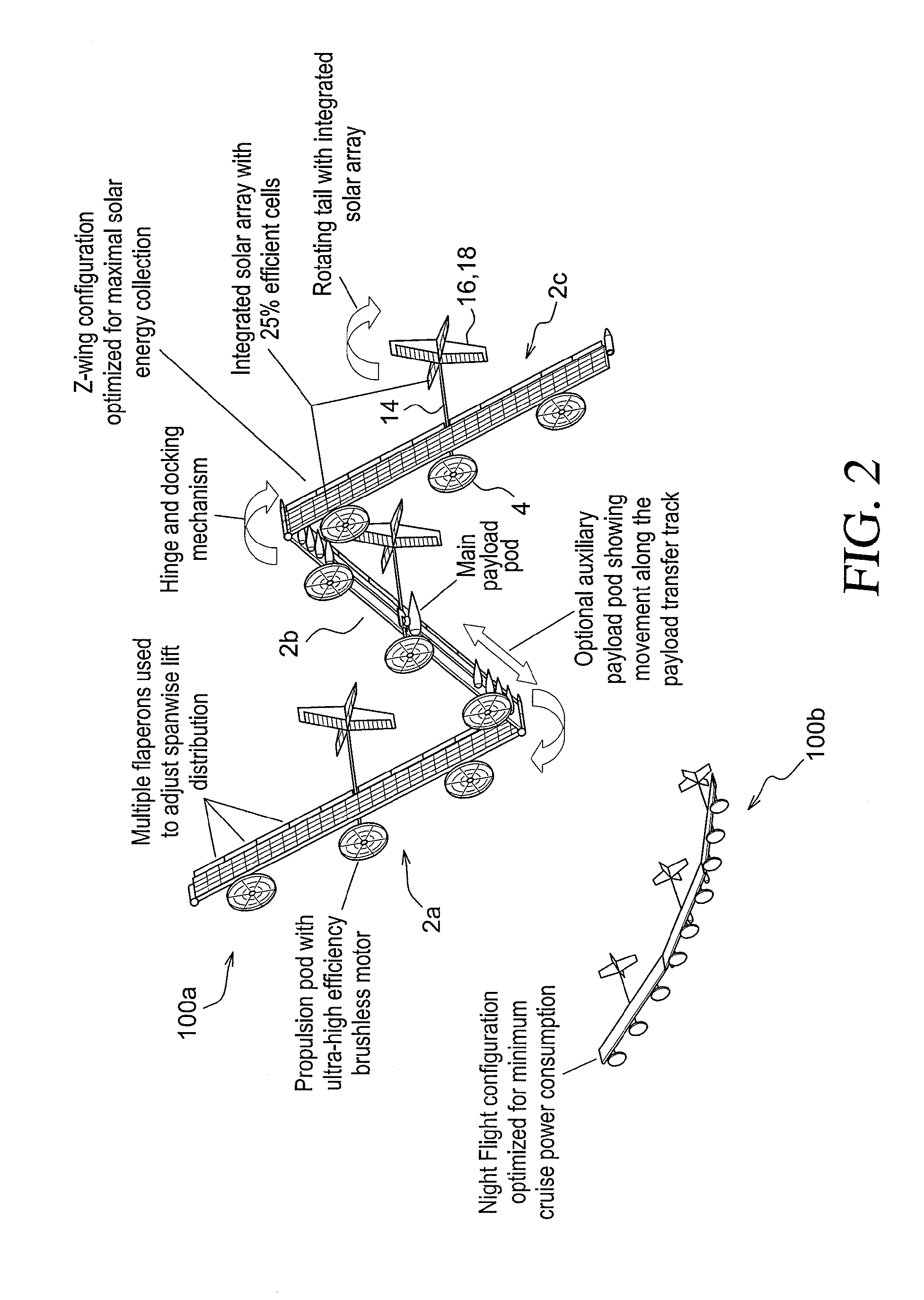

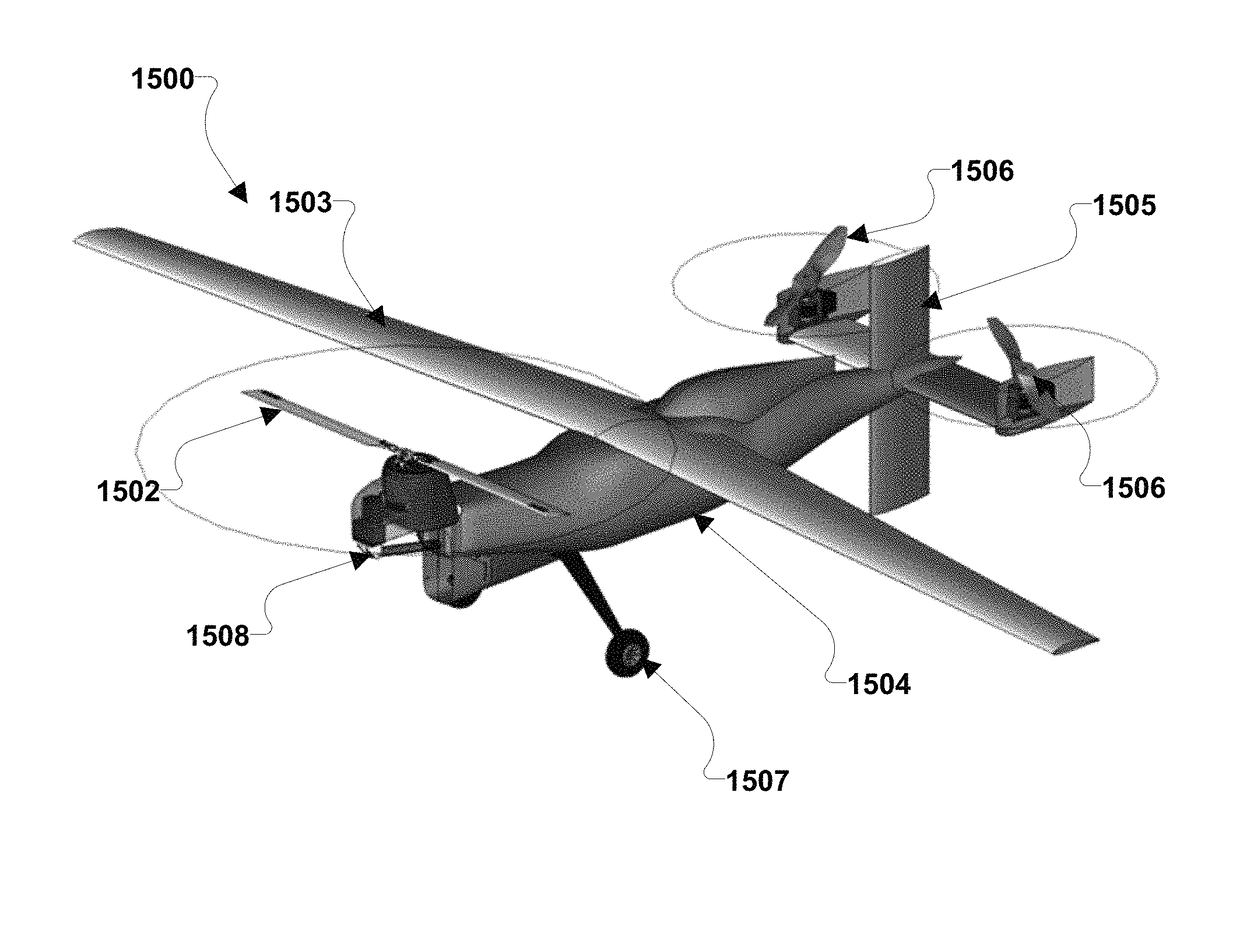

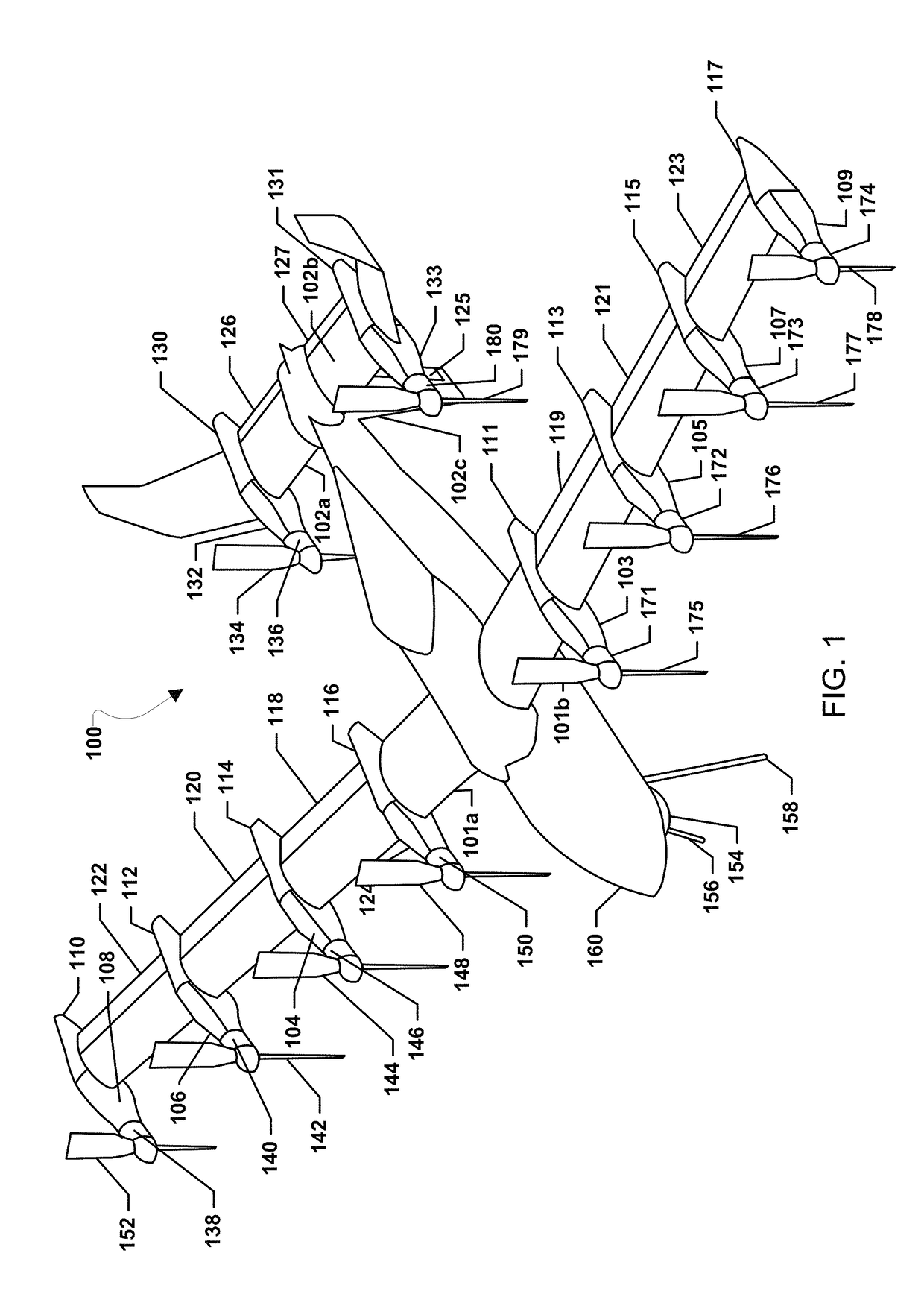

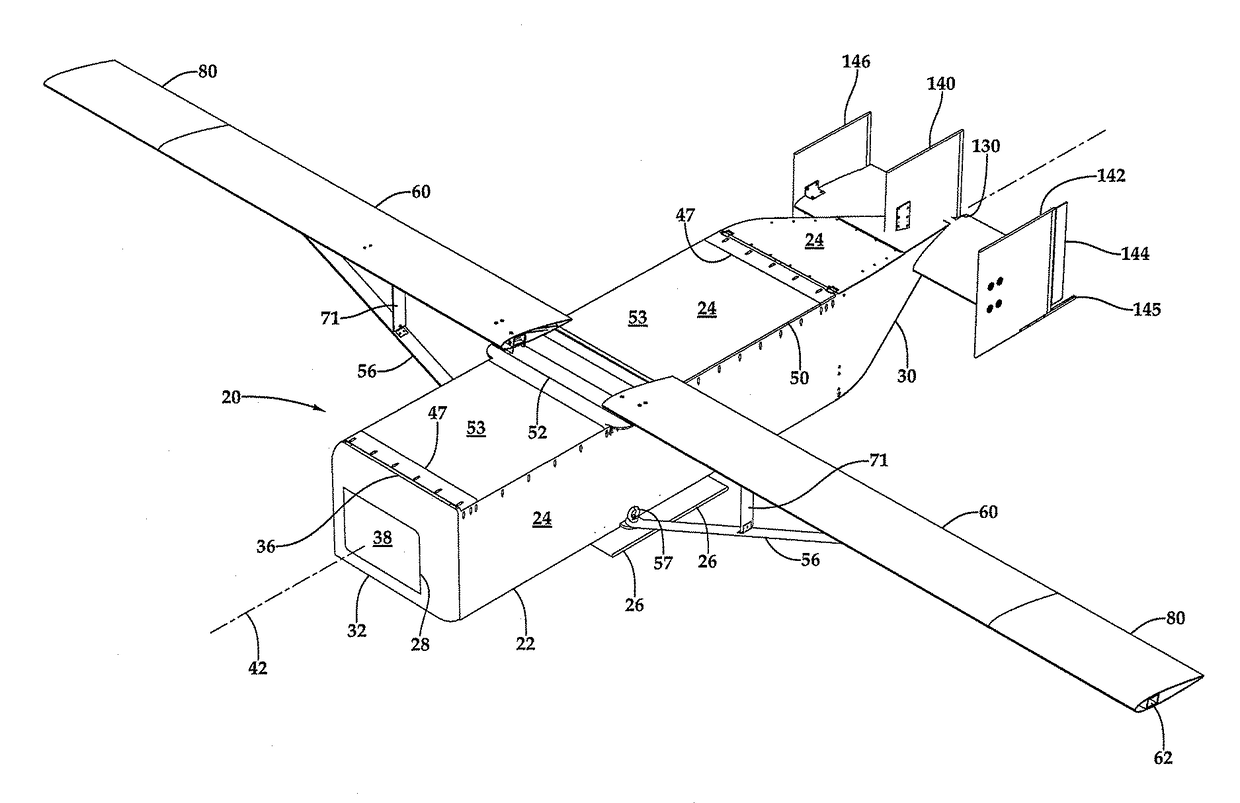

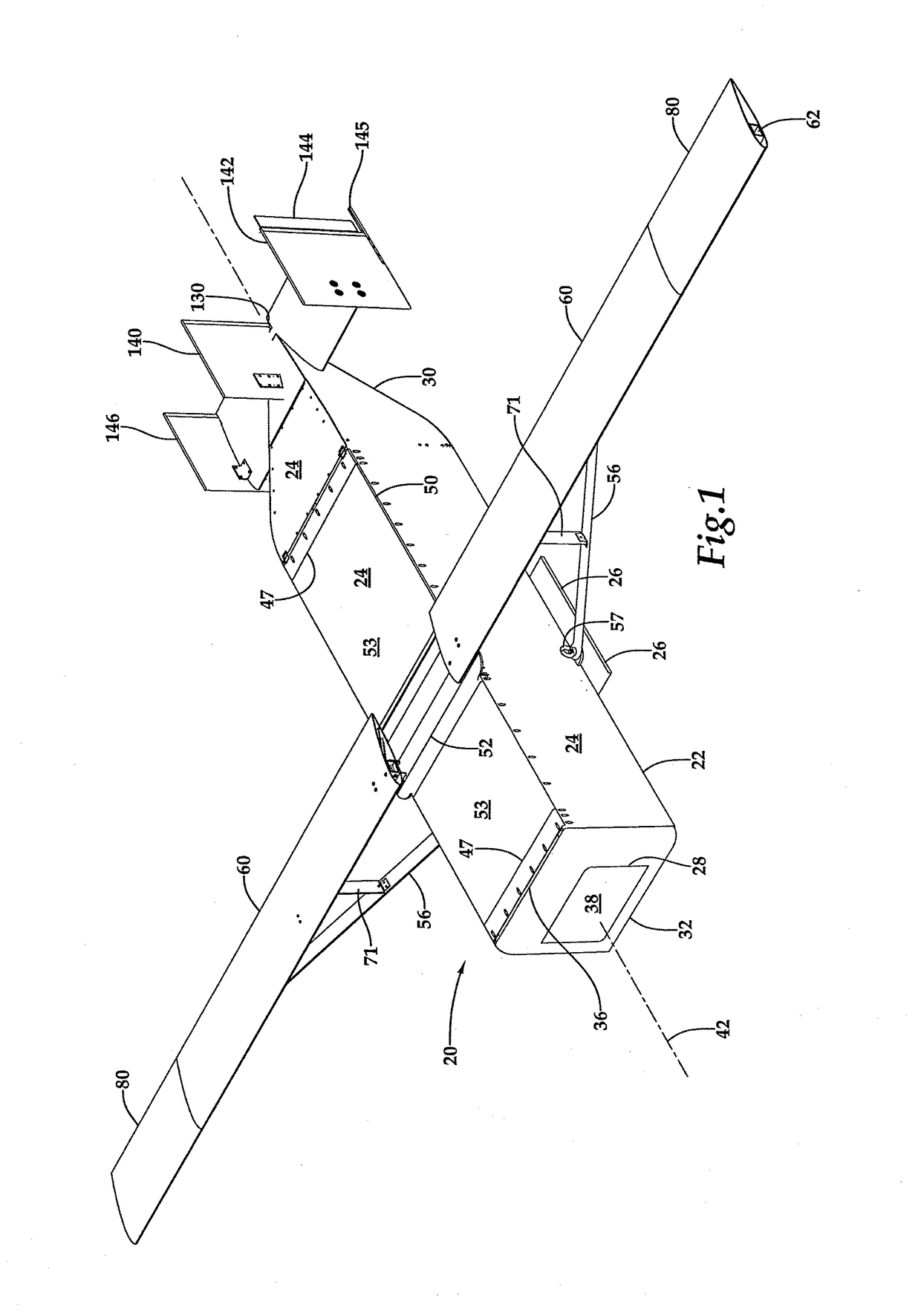

Tri-Rotor Aircraft Capable of Vertical Takeoff and Landing and Transitioning to Forward Flight

ActiveUS20160200436A1Increase rangeImprove enduranceAircraft stabilisationUnmanned aerial vehiclesJet aeroplanePropeller

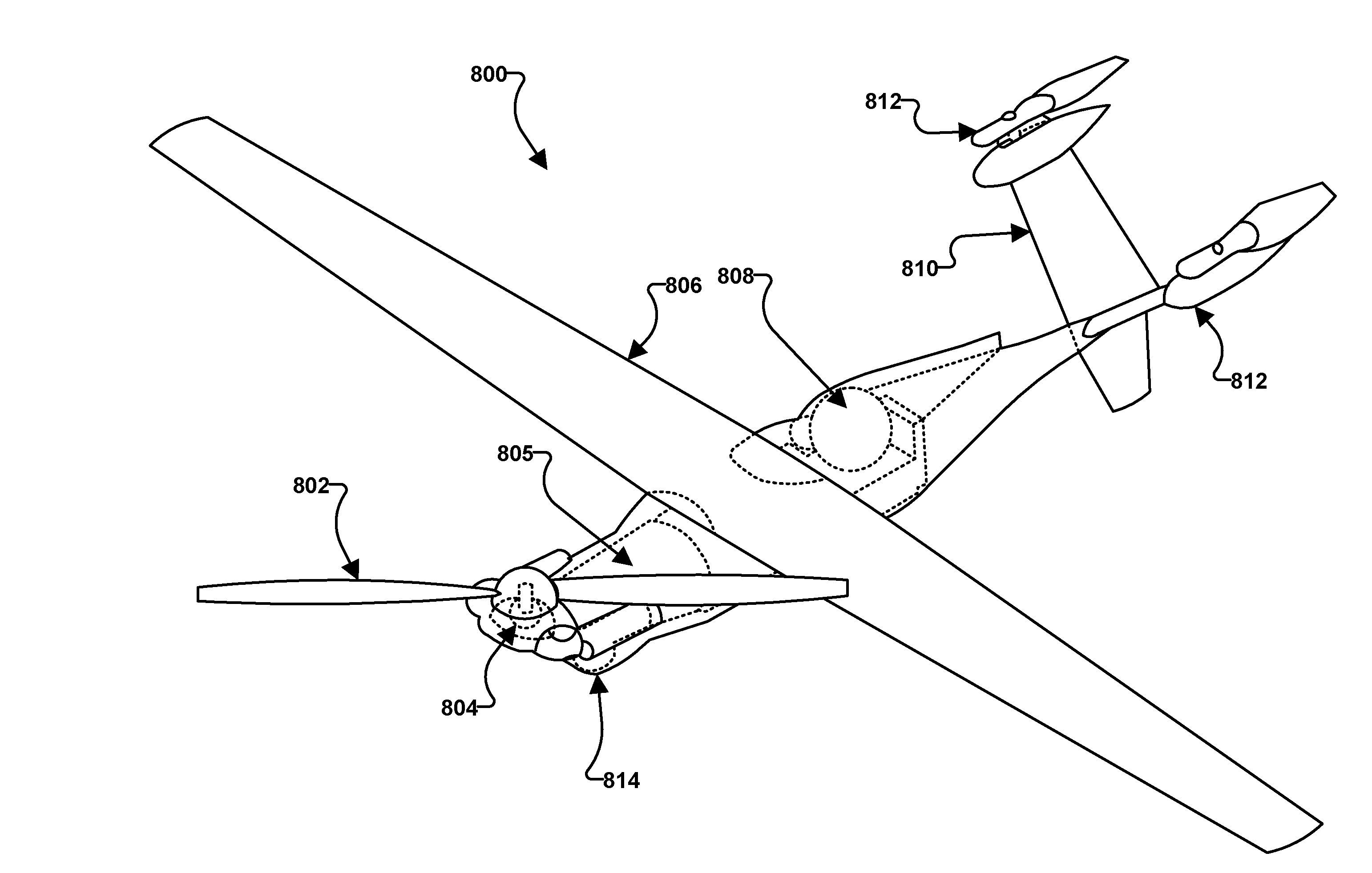

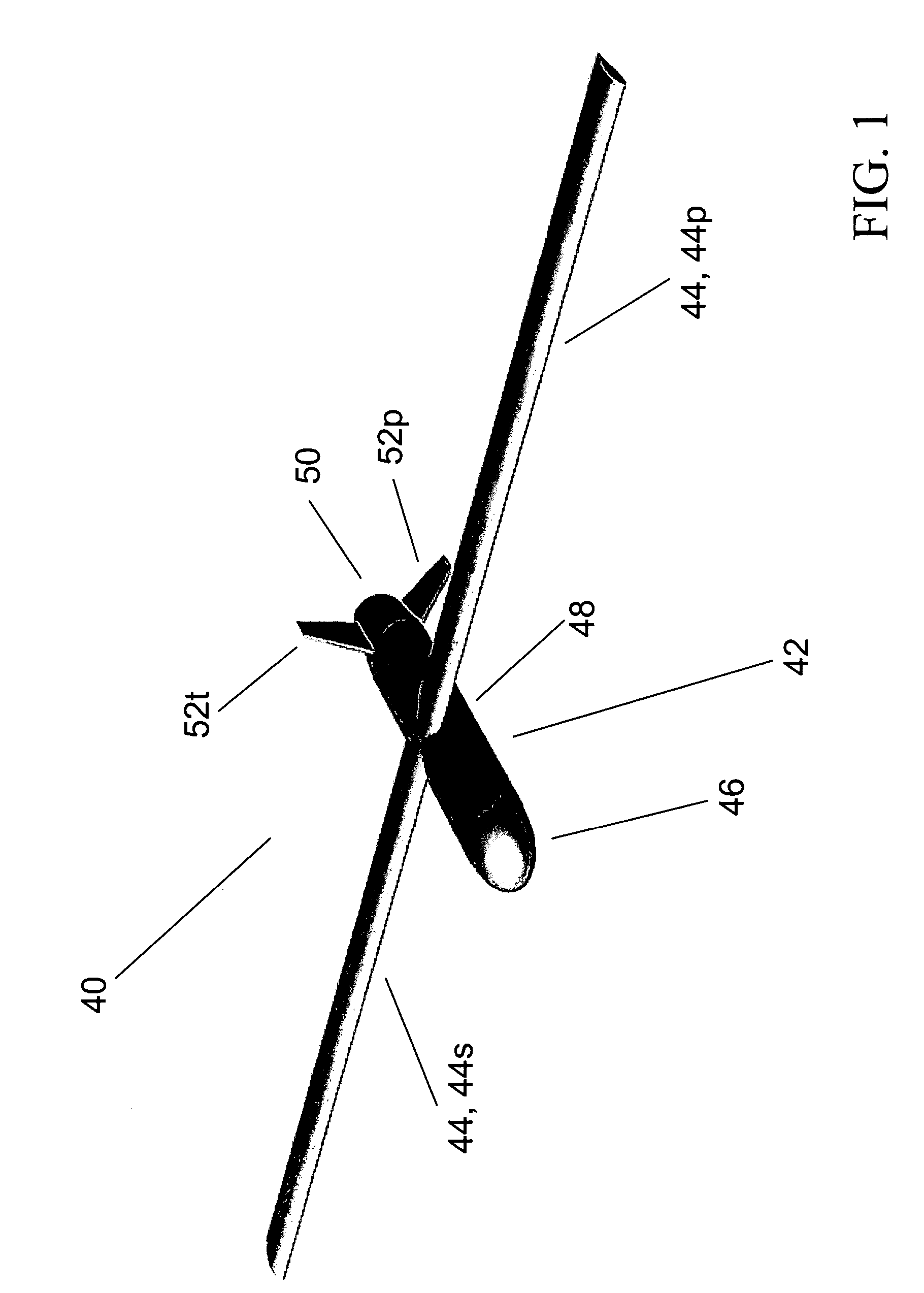

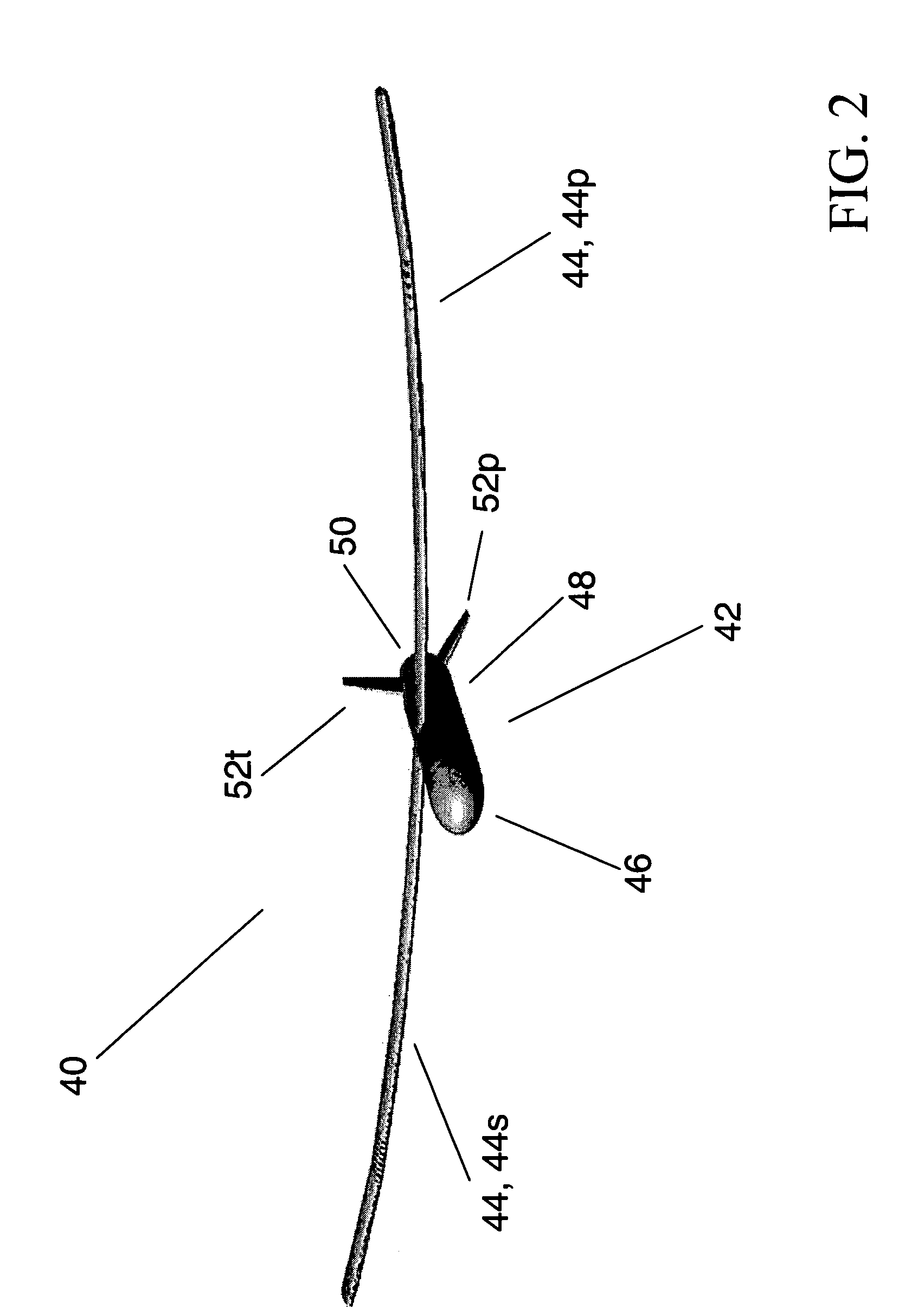

Systems, methods, and devices provide a vehicle, such as an aircraft, with rotors configured to function as a tri-copter for vertical takeoff and landing (“VTOL”) and a fixed-wing vehicle for forward flight. One rotor may be mounted at a front of the vehicle fuselage on a hinged structure controlled by an actuator to tilt from horizontal to vertical positions. Two additional rotors may be mounted on the horizontal surface of the vehicle tail structure with rotor axes oriented vertically to the fuselage. For forward flight of the vehicle, the front rotor may be rotated down such that the front rotor axis may be oriented horizontally along the fuselage and the front rotor may act as a propeller. For vertical flight, the front rotor may be rotated up such that the front rotor axis may be oriented vertically to the fuselage, while the tail rotors may be activated.

Owner:NASA

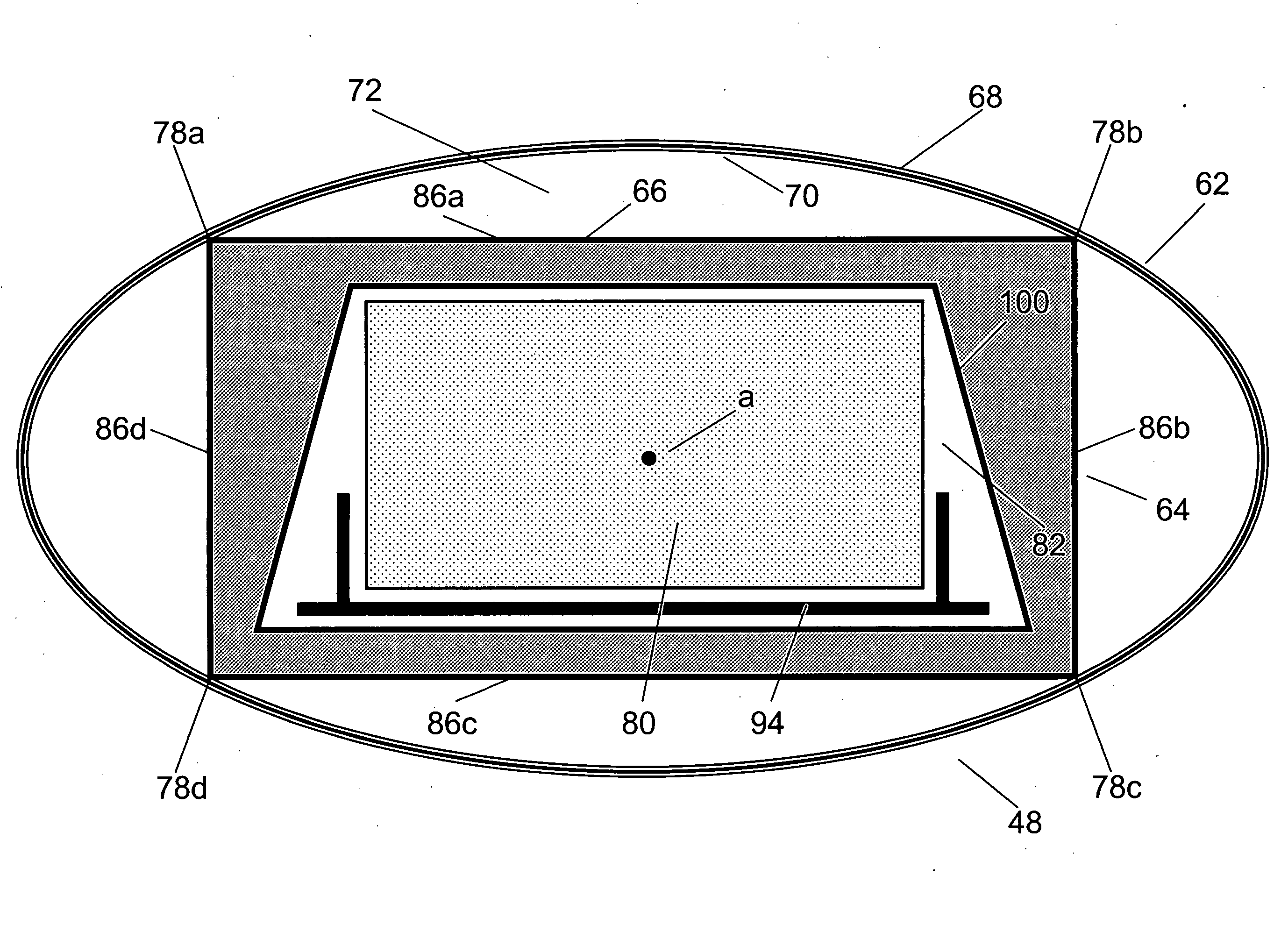

Unmanned aerial vehicle for logistical delivery

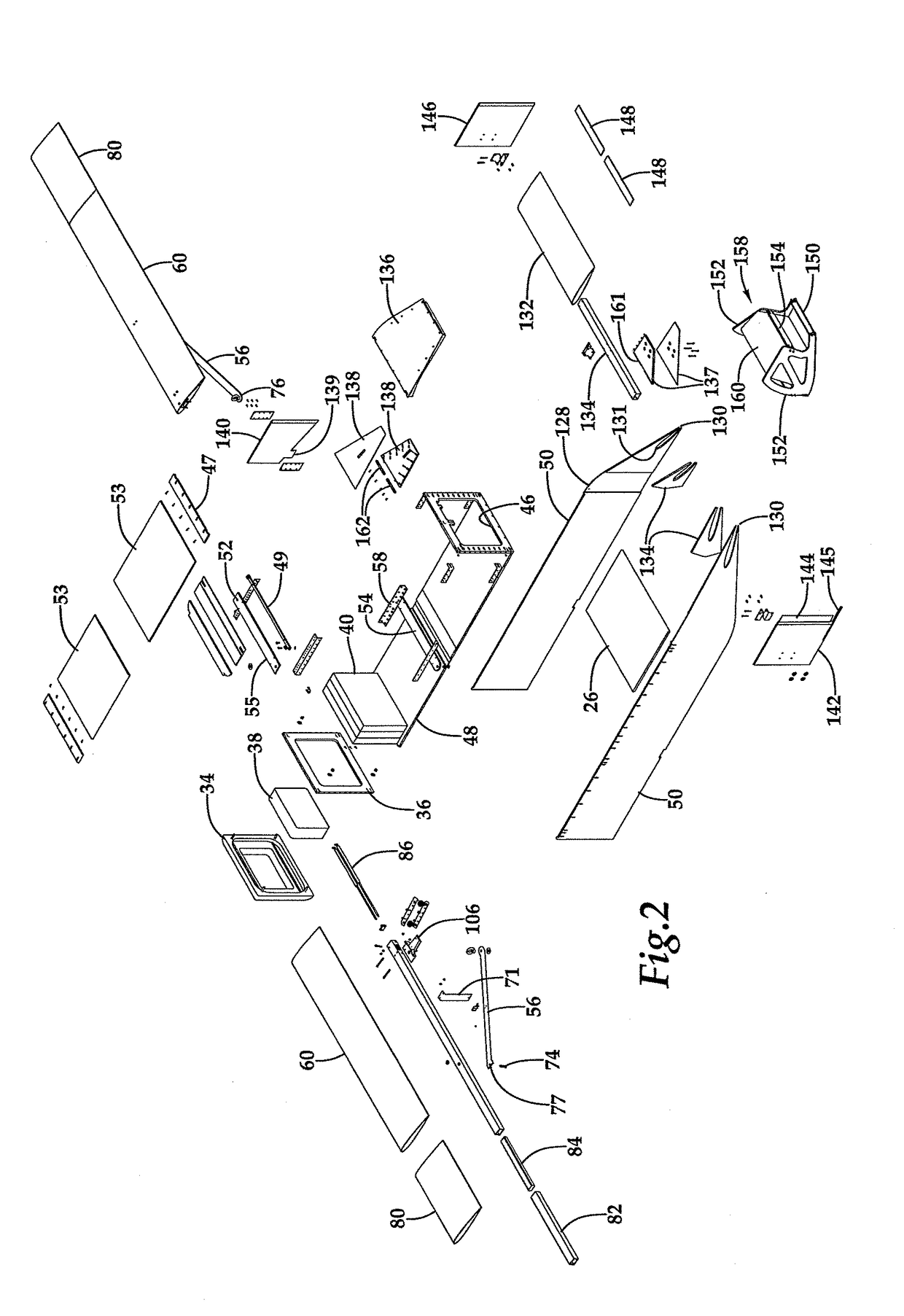

InactiveUS20050006525A1Safe and reliable and effective and economicalLow costFuselage framesGlidersNacelleRocket

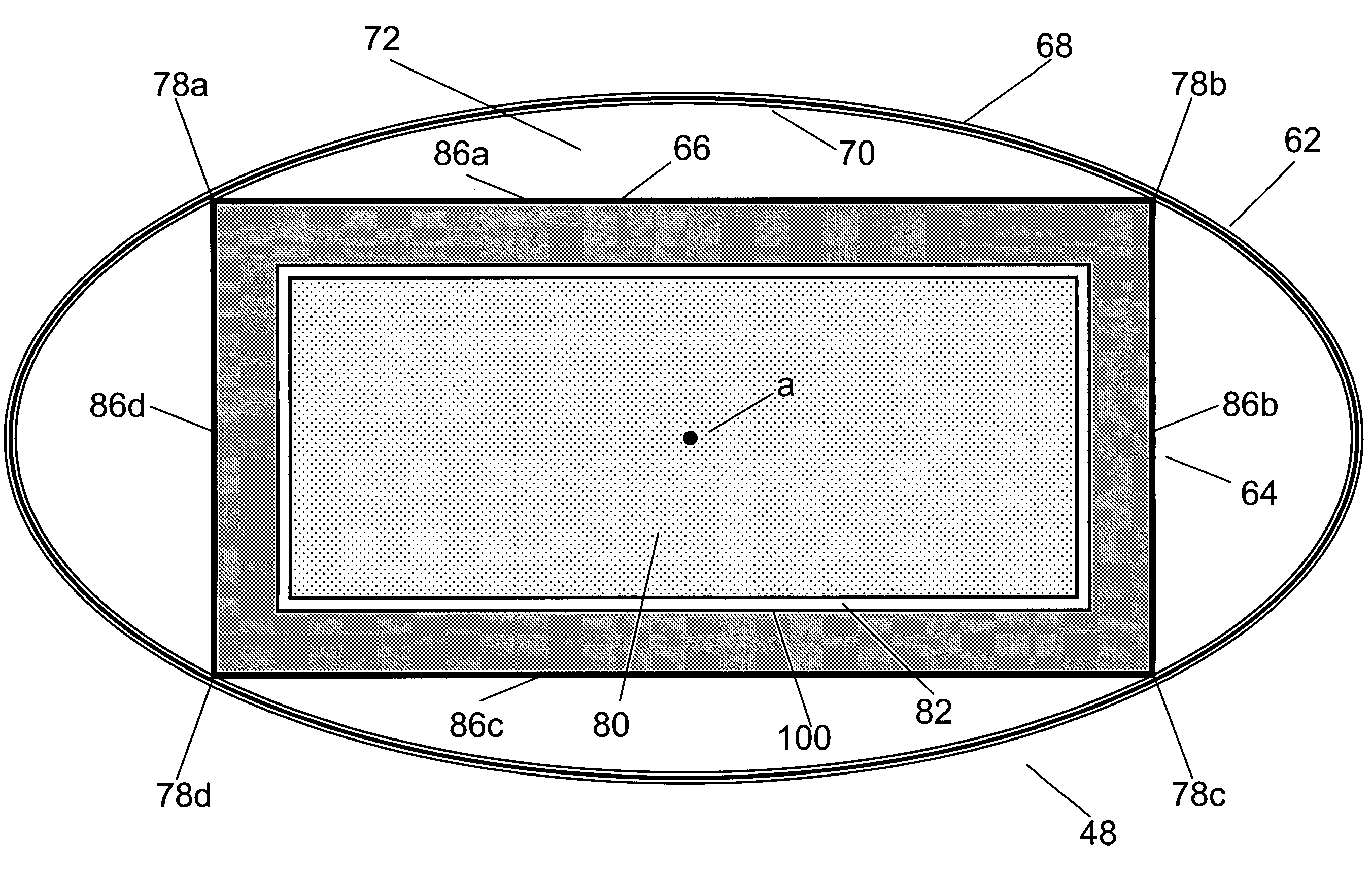

A hollow elliptical-cylindrical hull conformingly houses a hollow rectangular-prismatic cabin whereby the four longitudinal parallel outside edges of the latter make contact with the inside surface of the former. The fully constructed aircraft (either non-powered or powered) includes the integral hull-plus-cabin structure along with nose, tail and airfoil structures that are coupled therewith. The cabin conformingly accommodates hollow rectangular-prismatic modules useful for cargo storage. While the nose and / or tail structure is uncoupled from the integral hull-plus-cabin structure, the modules are inserted into the cabin and the cabin is sealed. The aircraft is lifted (e.g., via airplane, helicopter, rocket or balloon) to a particular elevation and released, whereupon the two wings fully emerge and the aircraft effects controlled flight until reaching its destination. After landing, the nose and / or tail structure is uncoupled from the integral hull-plus-cabin structure, the cabin is unsealed, and the modules are removed from the cabin.

Owner:US SEC THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCIP

Unmanned aerial vehicle for logistical delivery

InactiveUS7059566B2Safe and reliable and effective and economicalLow costFuselage framesGlidersNacelleRocket

A hollow elliptical-cylindrical hull conformingly houses a hollow rectangular-prismatic cabin whereby the four longitudinal parallel outside edges of the latter make contact with the inside surface of the former. The fully constructed aircraft (either non-powered or powered) includes the integral hull-plus-cabin structure along with nose, tail and airfoil structures that are coupled therewith. The cabin conformingly accommodates hollow rectangular-prismatic modules useful for cargo storage. While the nose and / or tail structure is uncoupled from the integral hull-plus-cabin structure, the modules are inserted into the cabin and the cabin is sealed. The aircraft is lifted (e.g., via airplane, helicopter, rocket or balloon) to a particular elevation and released, whereupon the two wings fully emerge and the aircraft effects controlled flight until reaching its destination. After landing, the nose and / or tail structure is uncoupled from the integral hull-plus-cabin structure, the cabin is unsealed, and the modules are removed from the cabin.

Owner:US SEC THE NAVY CHIEF OF NAVAL RES OFFICE OF COUNSEL ATTN CODE OOCIP

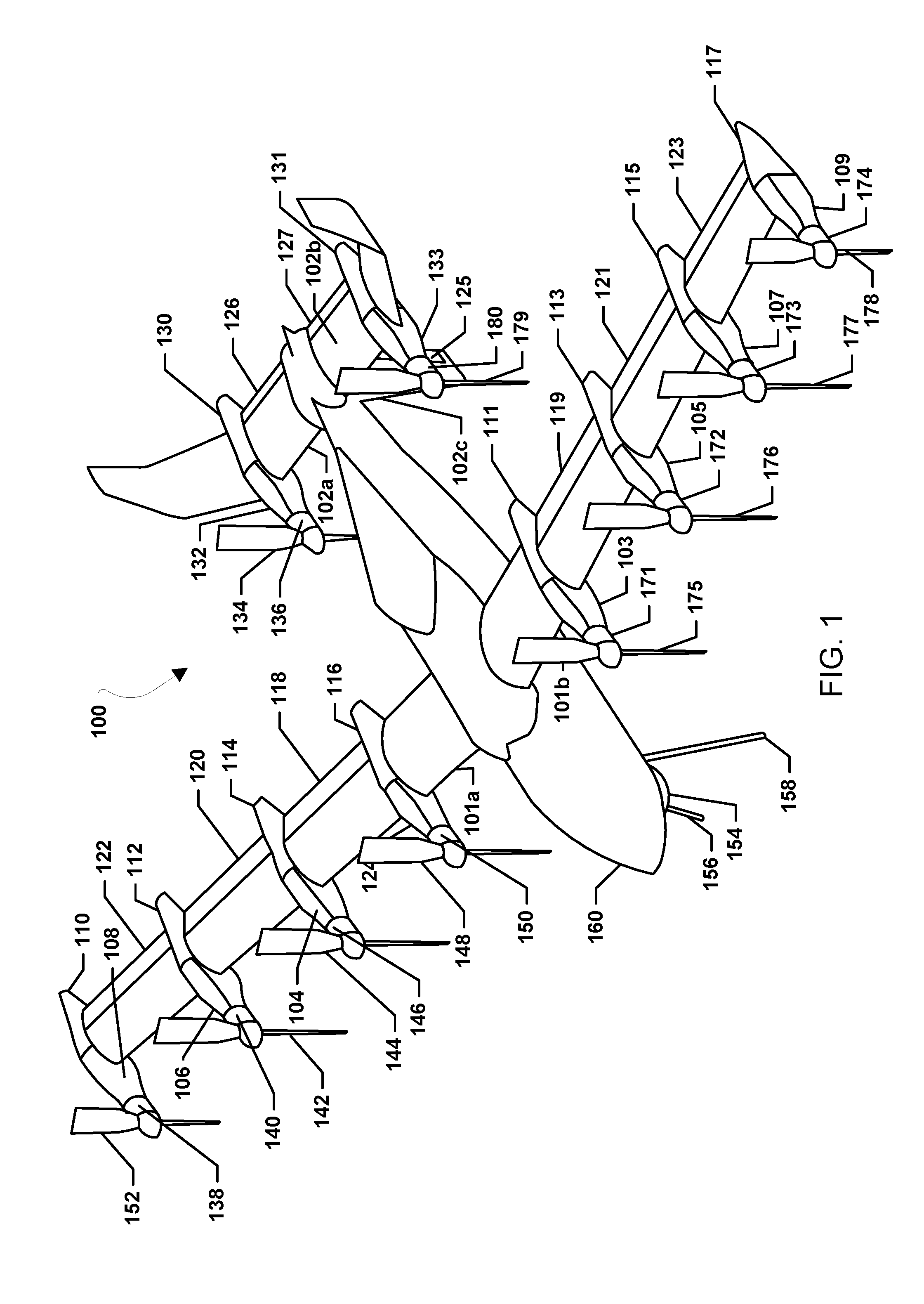

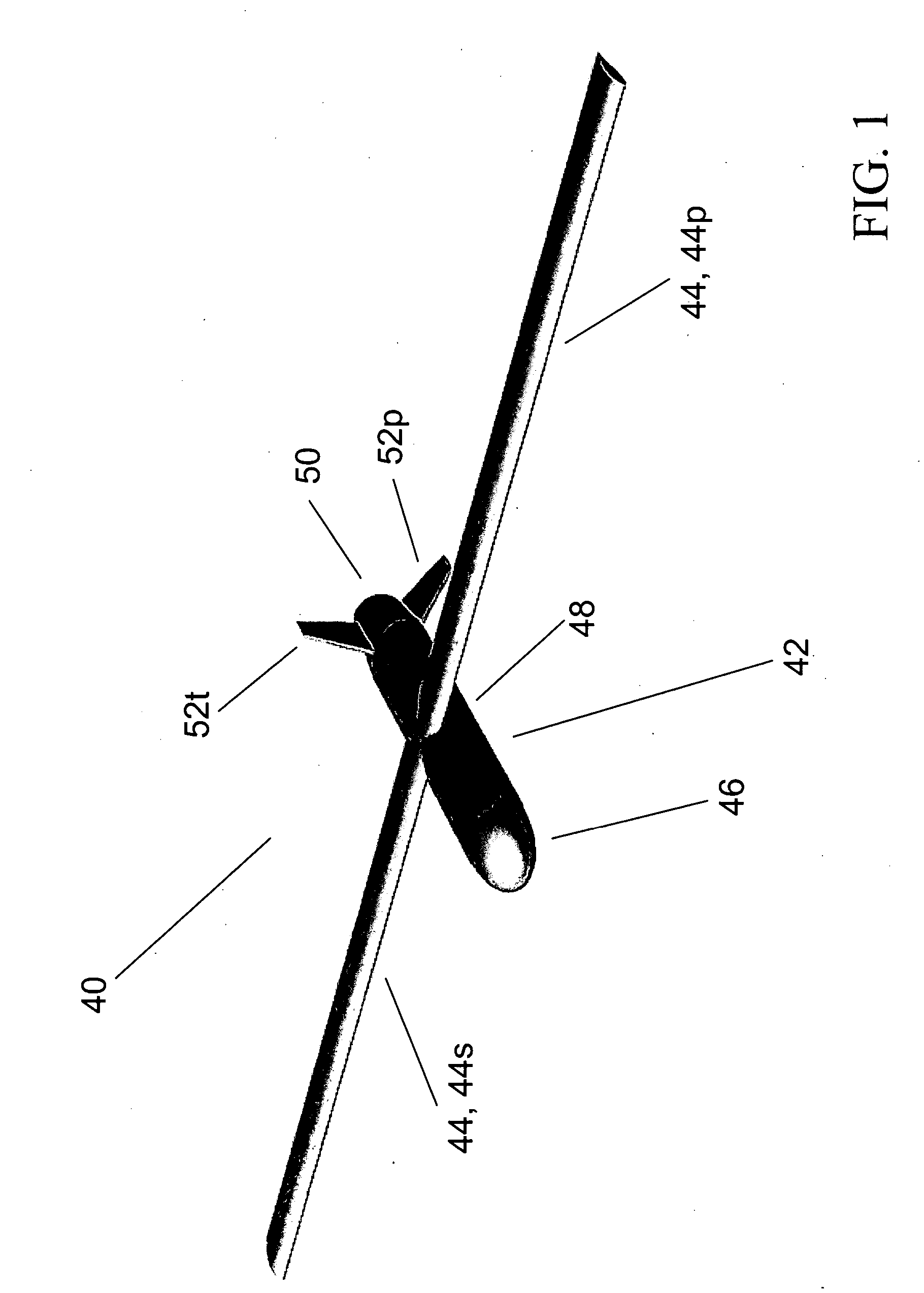

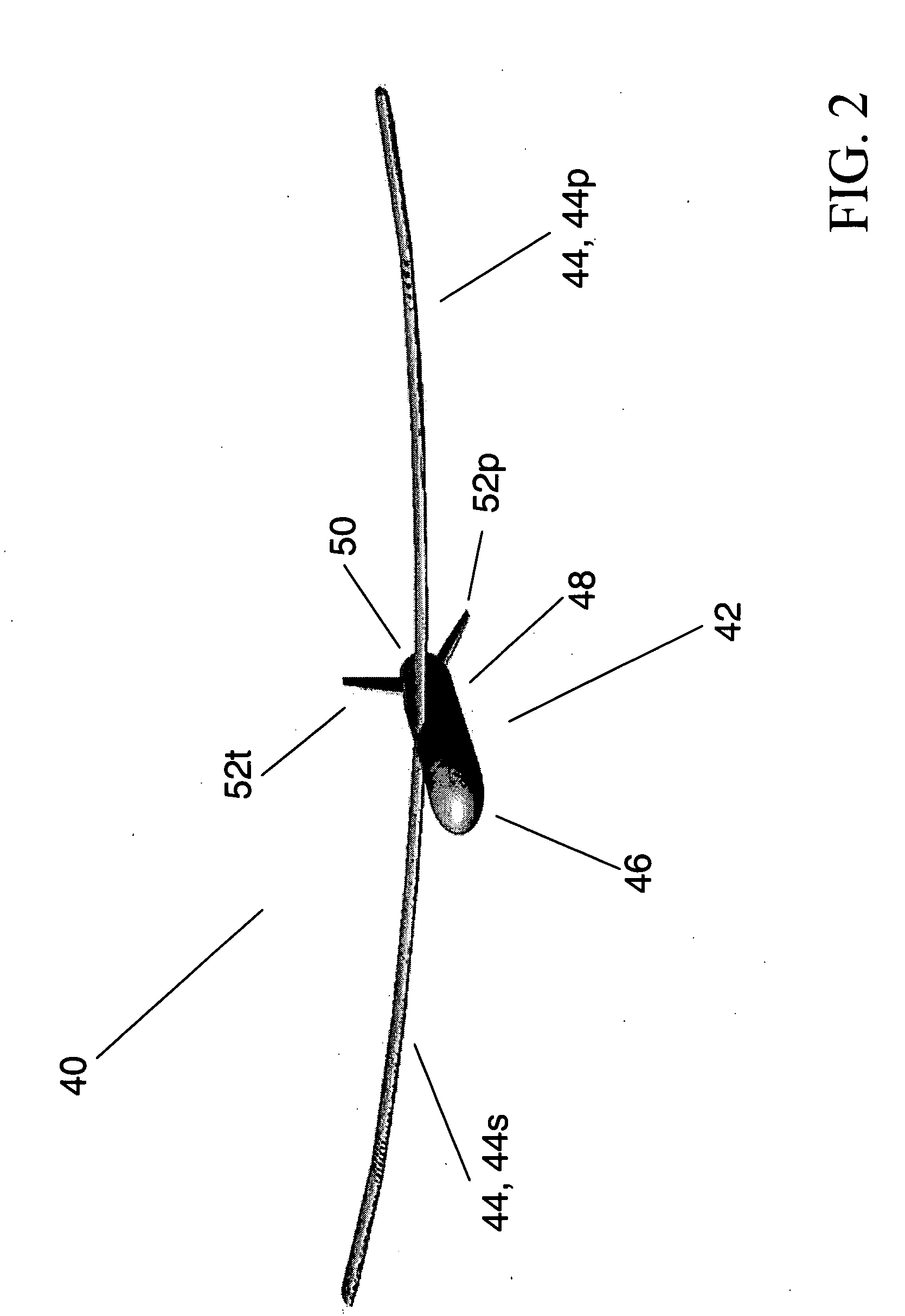

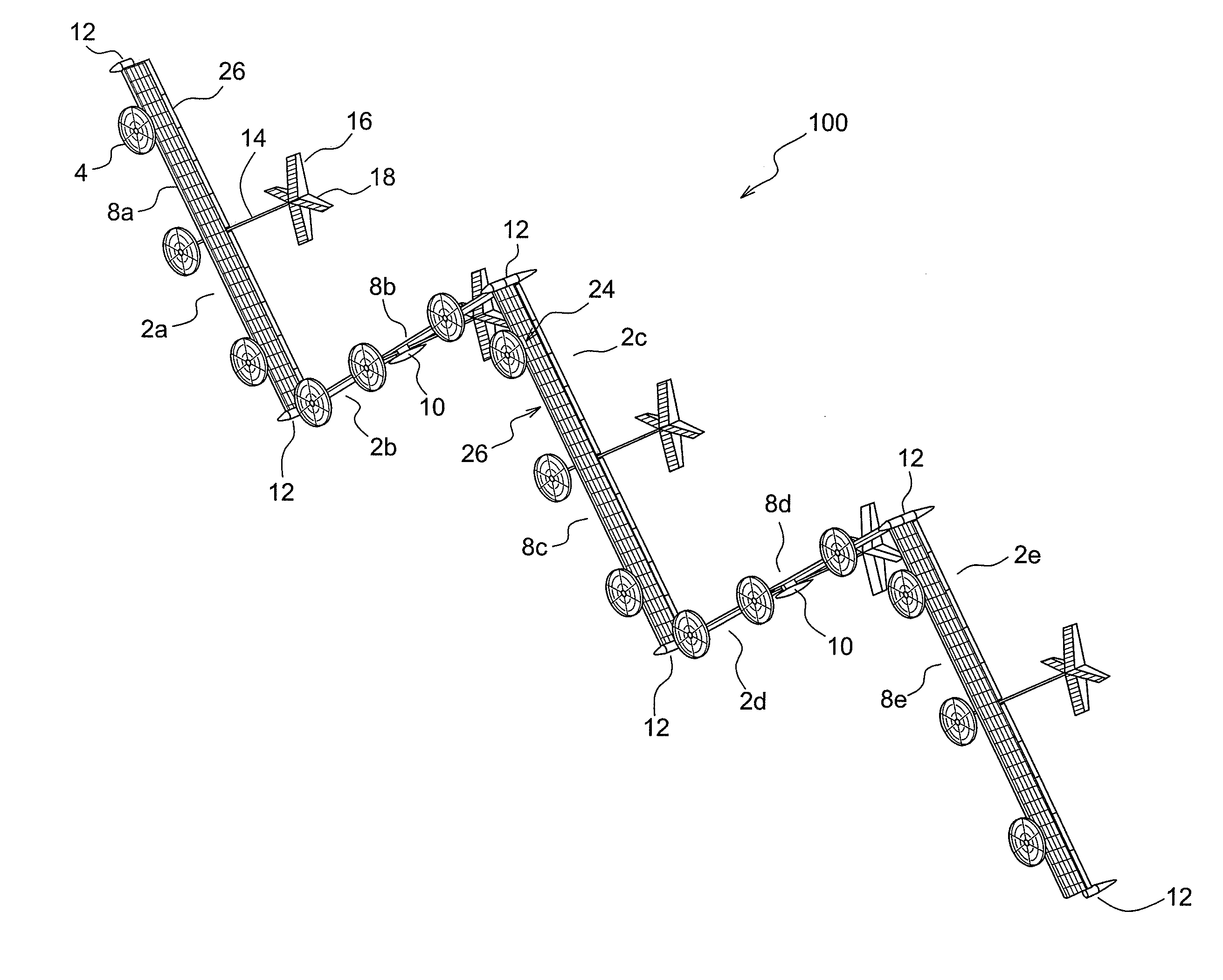

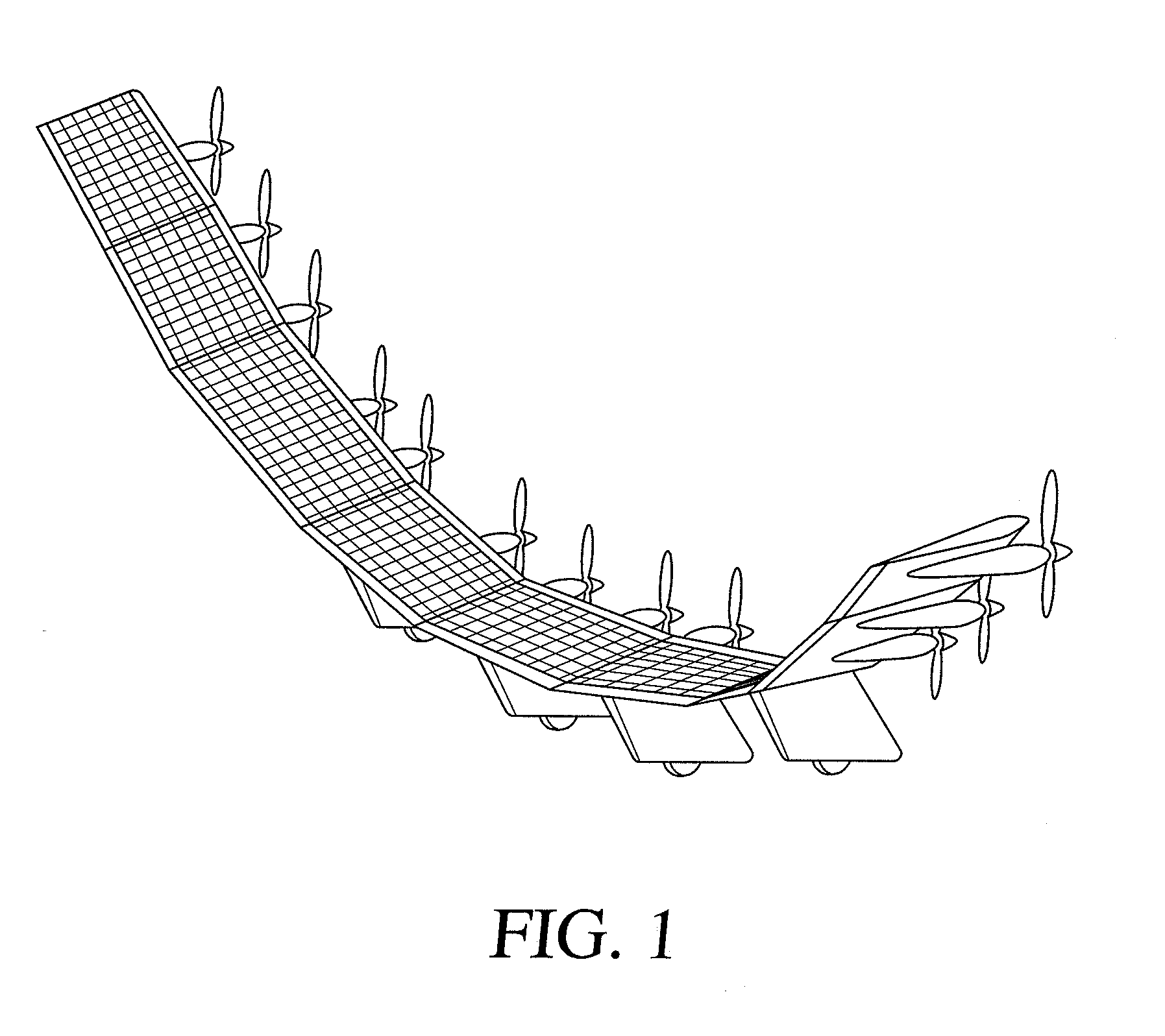

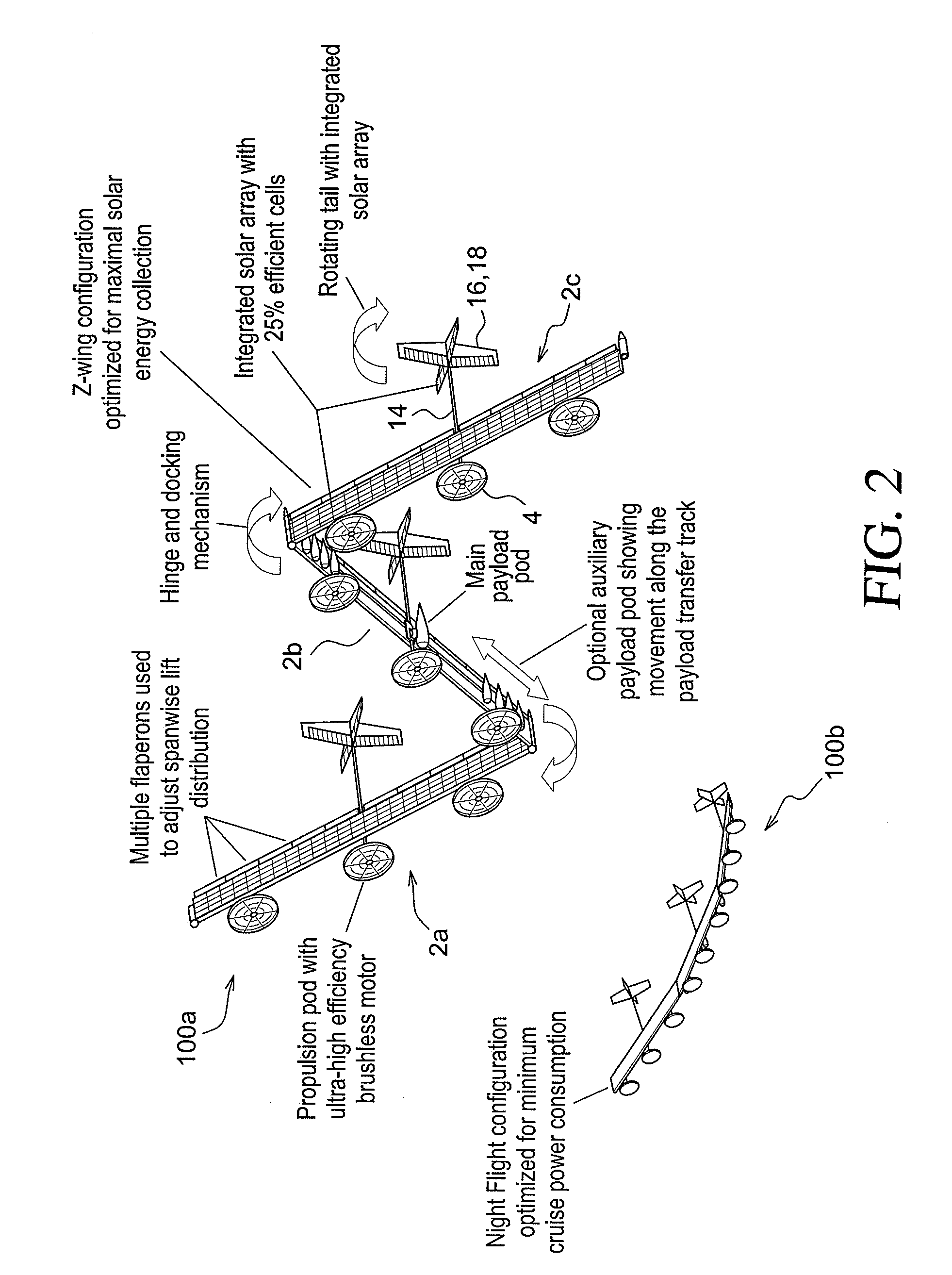

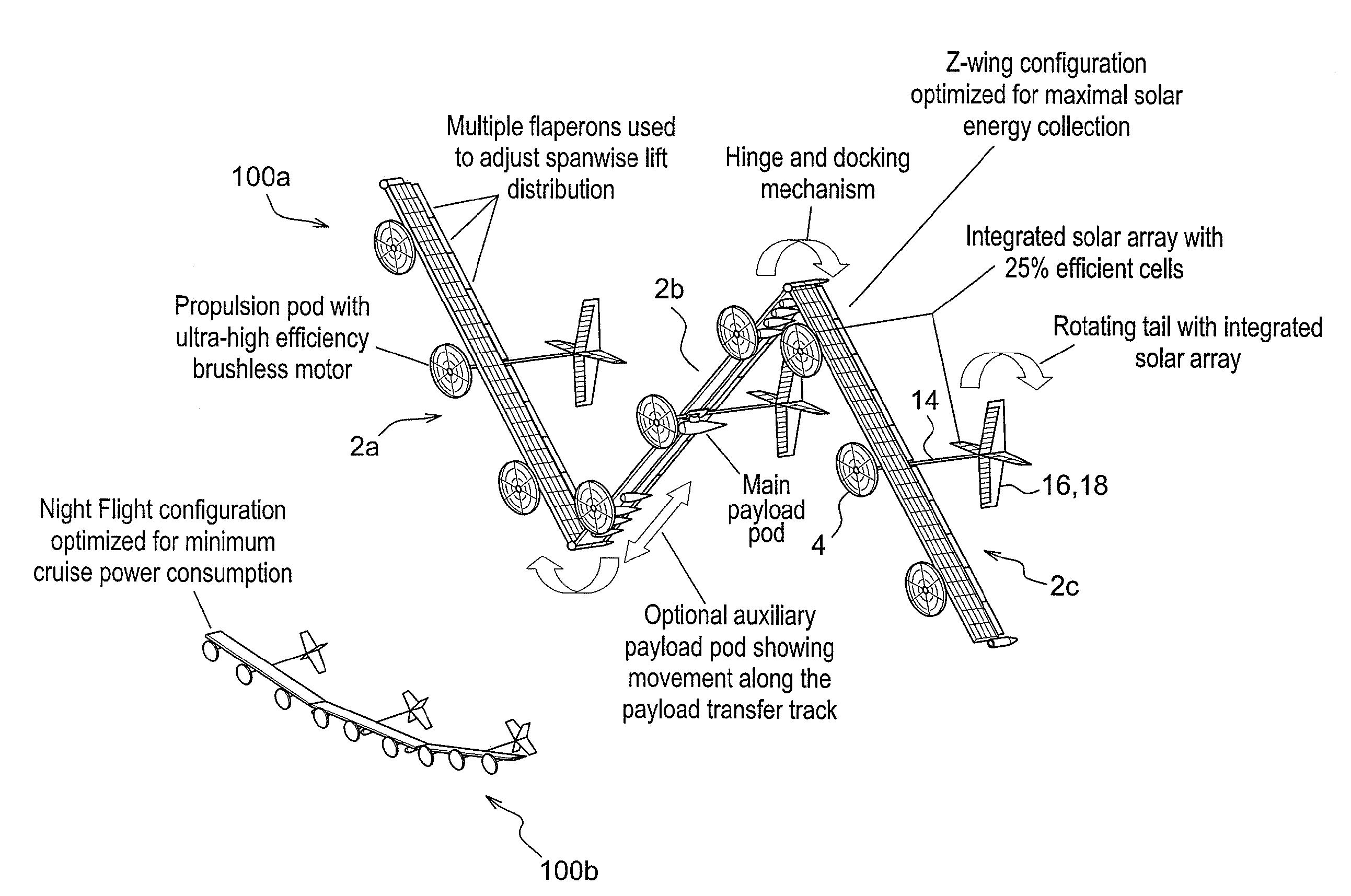

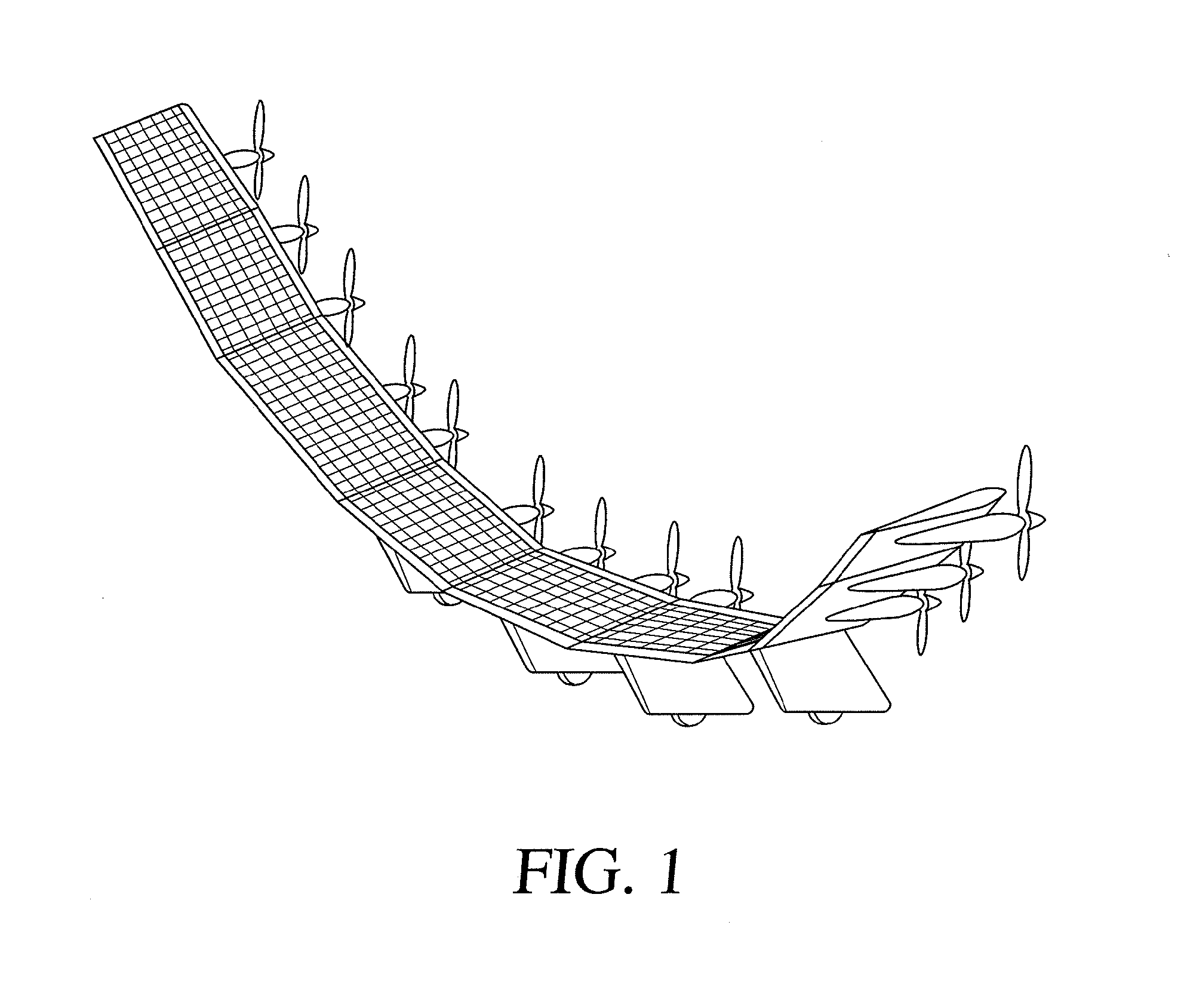

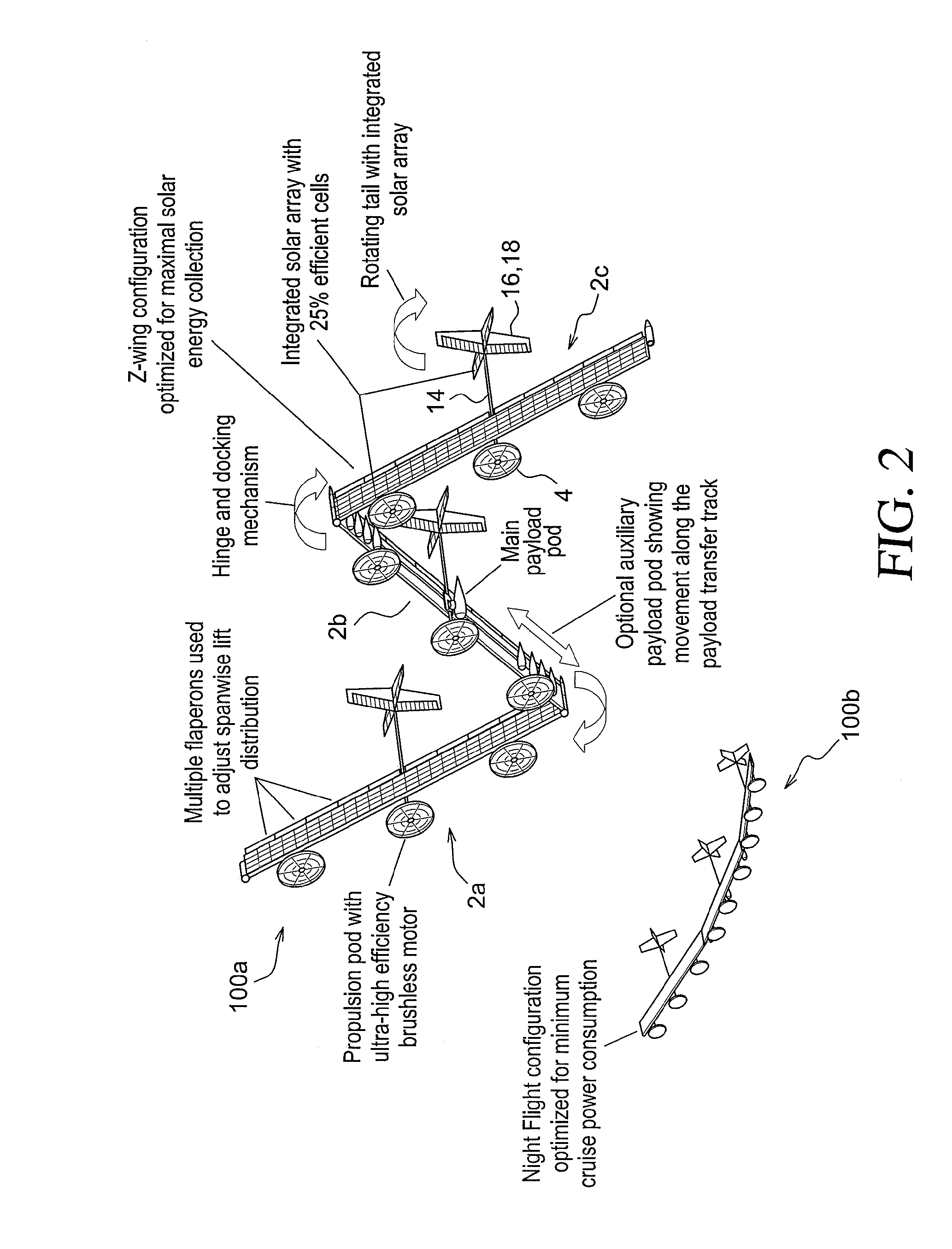

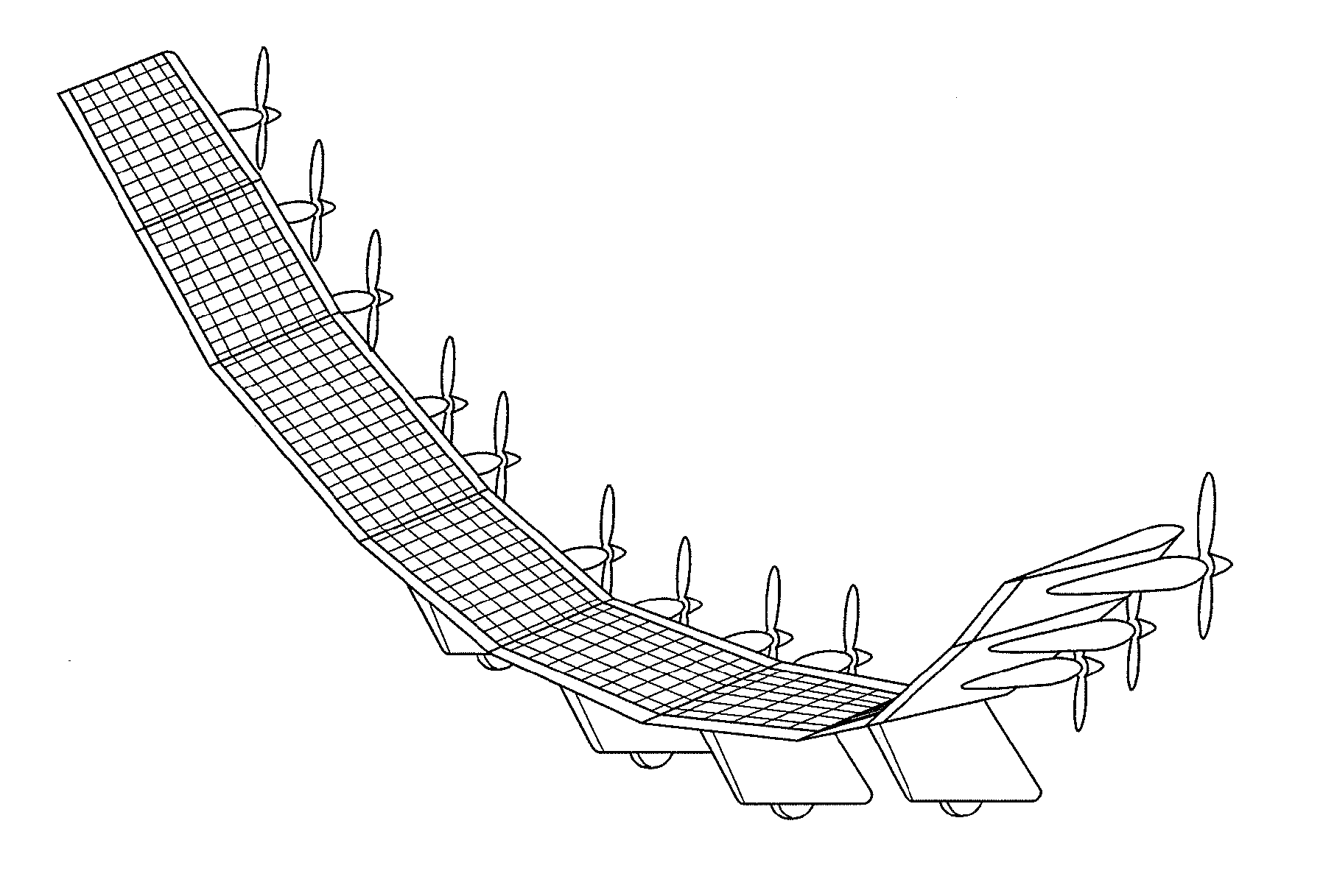

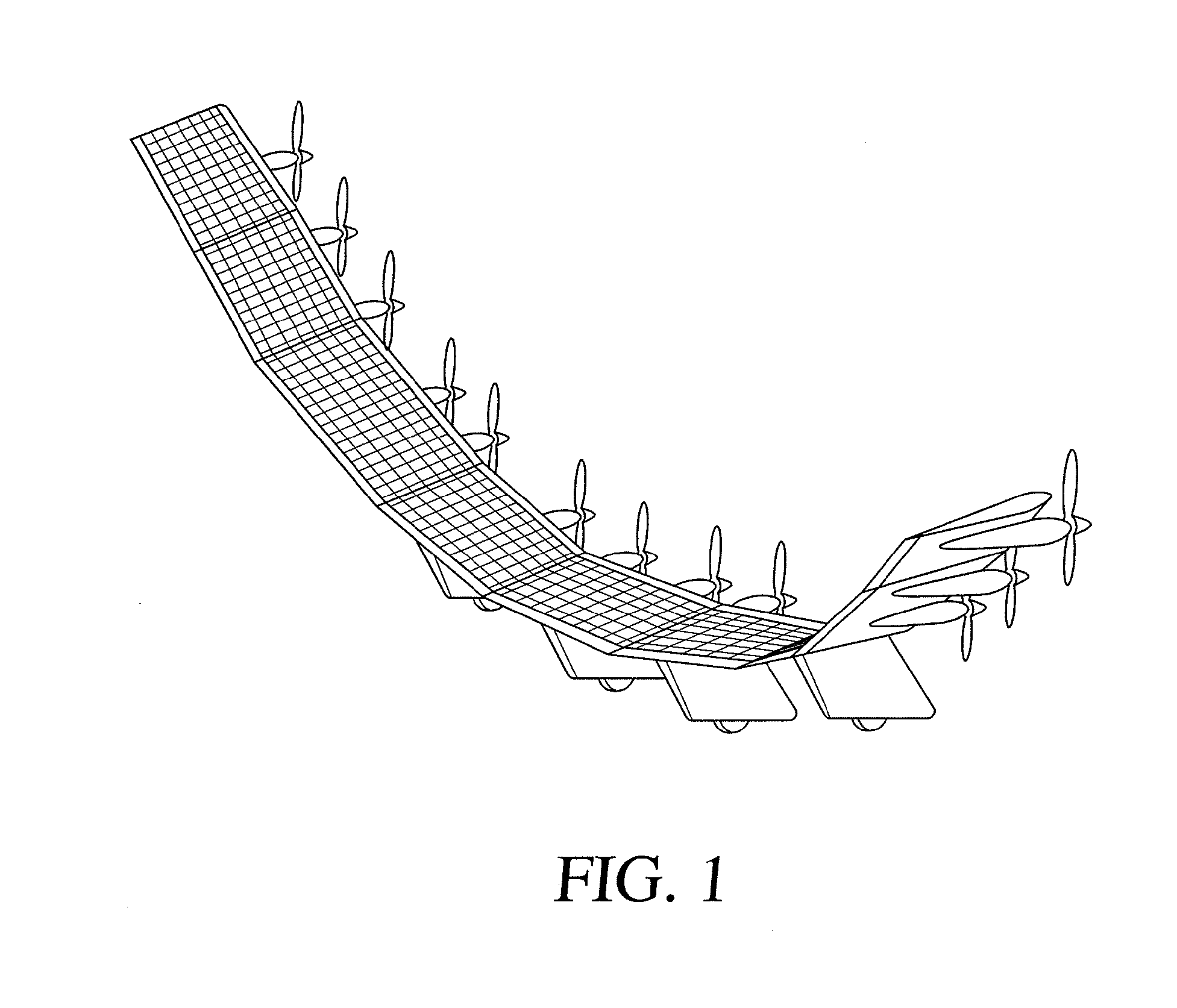

Non-planar adaptive wing solar aircraft

InactiveUS20100213309A1Maximize collectionAircraft controlAircraft power plant componentsThermal energyHorizon

A system and method for assembling and operating a solar powered aircraft, composed of one or more modular constituent wing panels. Each wing panel includes at least one hinge interface that is configured to rotationally interface with a complementary hinge interface on another wing panel. When a first and second wing panel are coupled together via the rotational interface, they can rotate with respect to each other within a predetermined angular range. The aircraft further comprises a control system that is configured to acquire aircraft operating information and atmospheric information and use the same alter the angle between the wing panels, even if there are multiple wing panels. One or more of the wing panels can include photovoltaic cells and / or solar thermal cells to convert solar radiation energy or solar heat energy into electricity, that can be used to power electric motors. Further, the control system is configured to alter an angle between a wing panel and the horizon, or the angle between wing panels, to maximize solar radiation energy and solar thermal energy collection. A tail assembly for the aircraft includes a rotational pivot that allows the flight control surfaces to rotate to different orientations to avoid or reduce flutter loads and to increase solar radiation energy and / or solar thermal energy collection from photovoltaic cells and / or solar thermal cells the can be located on the tail structure associated with the flight control surfaces.

Owner:AURORA FLIGHT SCI CORP

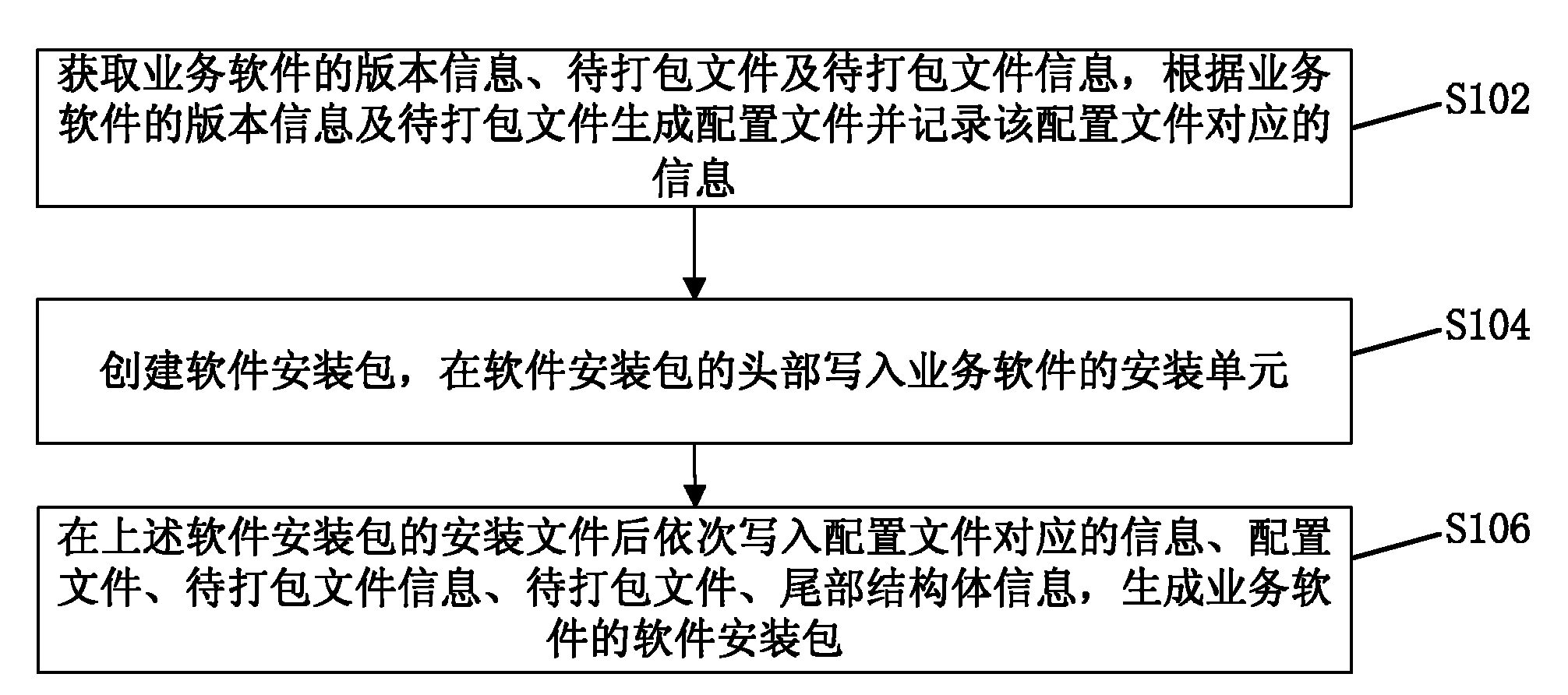

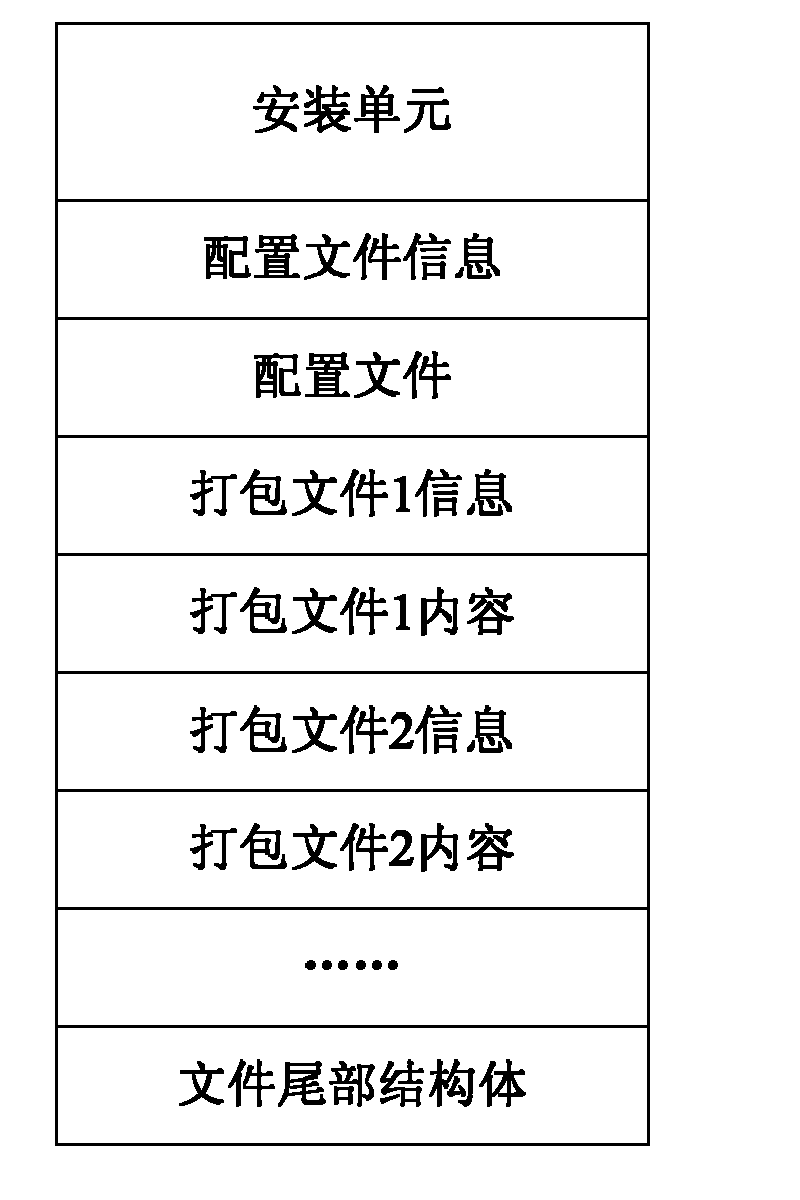

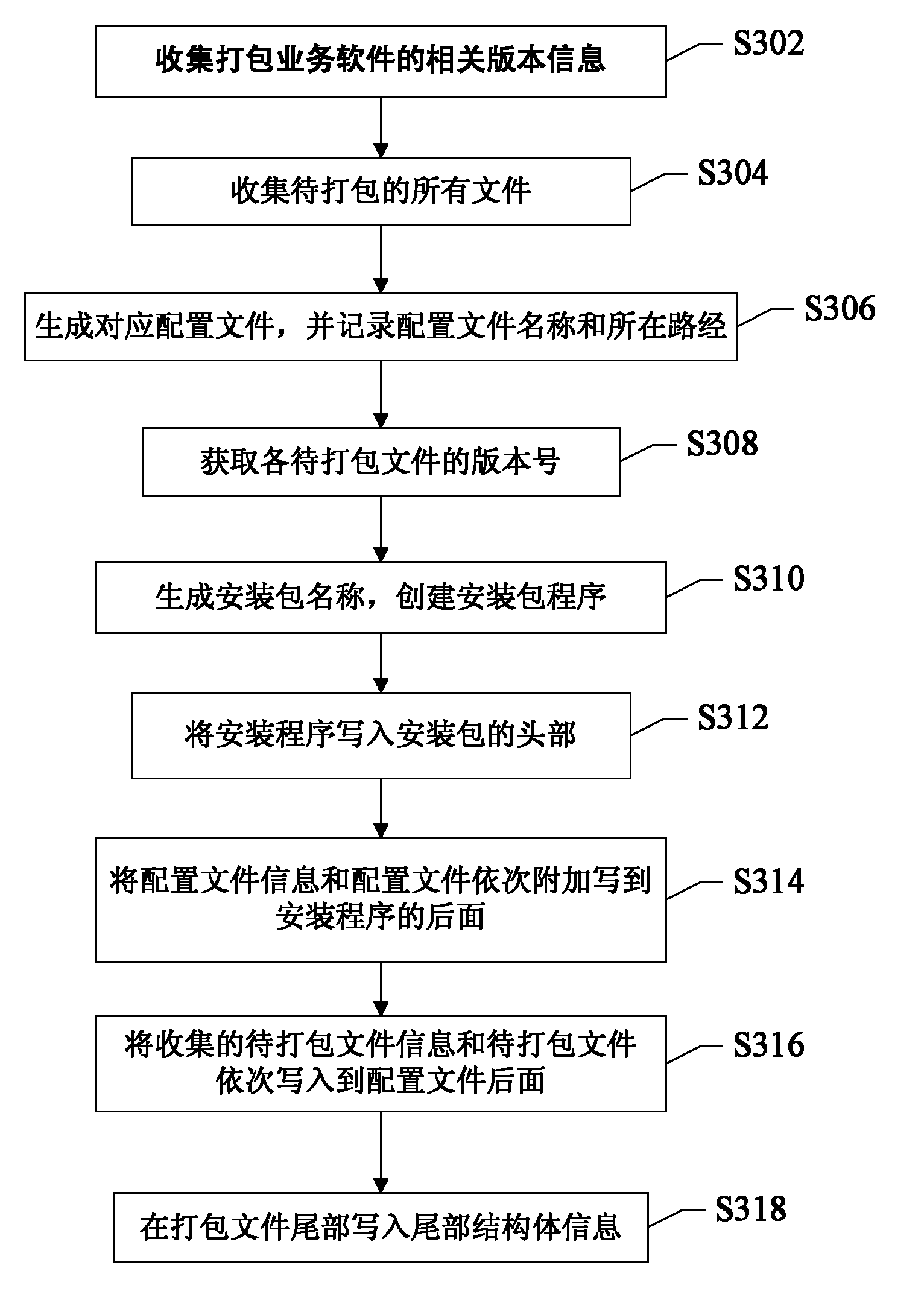

Method and device for generating and unloading software installation package

ActiveCN101984410AIncrease flexibilityGuaranteed CompatibilityProgram loading/initiatingSoftware deploymentSoftware engineeringComputer compatibility

The invention discloses a method and device for generating and unloading a software installation package. The method comprises the following steps: acquiring the version information of business software, a file to be packed and information of the file to be packed, generating a configuration file according to the version information of the business software and the file to be packed and recording information corresponding to the configuration file; creating a software installation package and writing a business software installation unit into the header of the software installation package; and writing the information corresponding to the configuration file, the configuration file, the information of the file to be packed, the file to be packed and the tail structure information into the installation file of the software installation package in turn, and generating the software installation package of the business software. Through the technical scheme of the invention, the entire installation process can be automatically processed by the installation unit; therefore, the invention ensures normal use of all installed business software and can realize matching between the platform software and the business software and guarantee the compatibility of all installed business software and the switch flexibility among various versions of the business software.

Owner:南京浦口科创投资集团有限公司

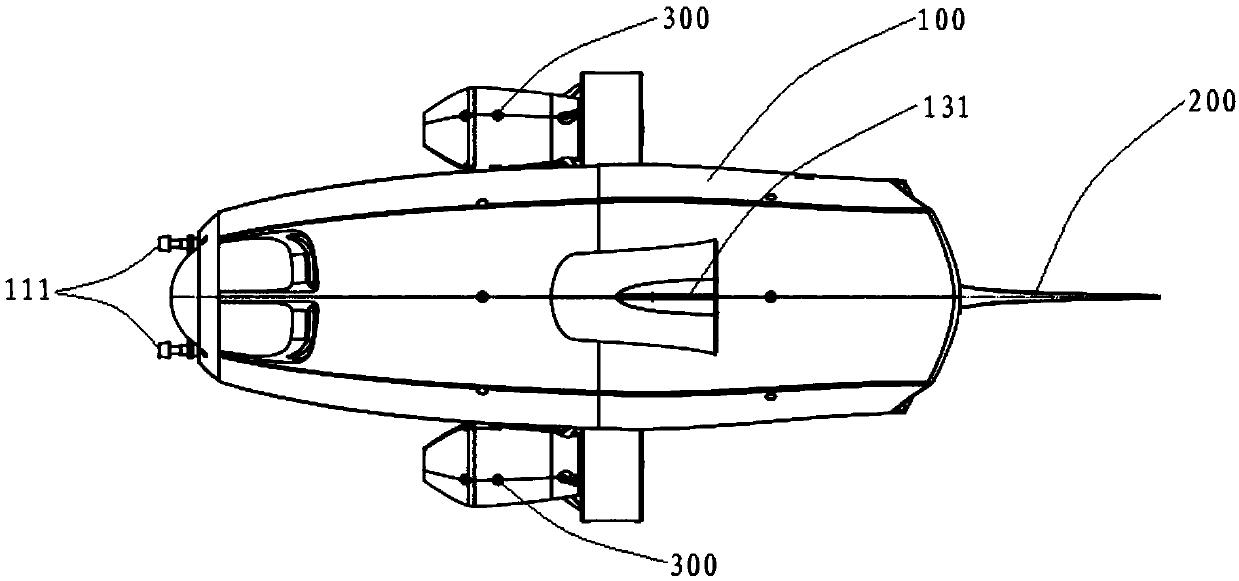

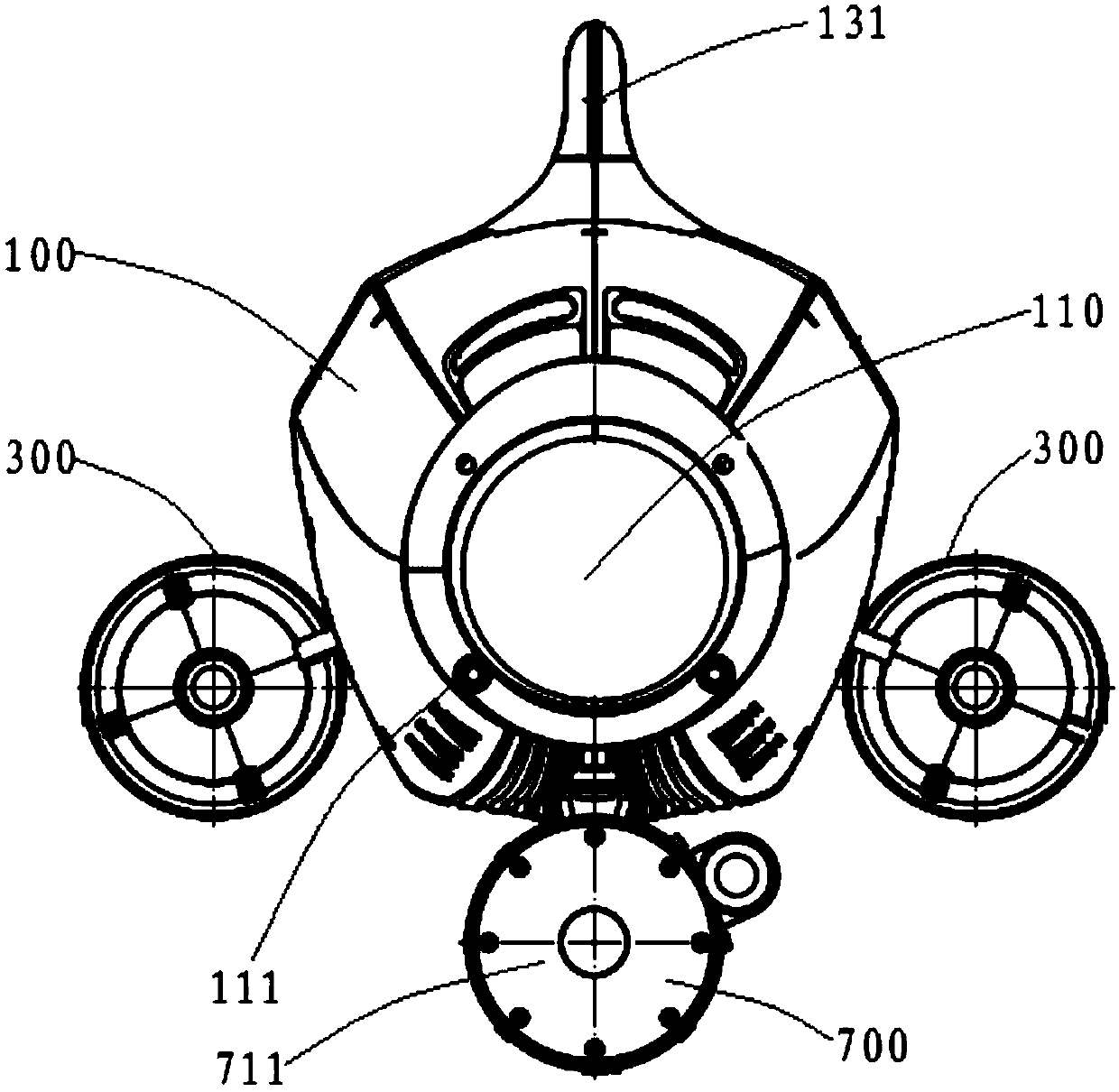

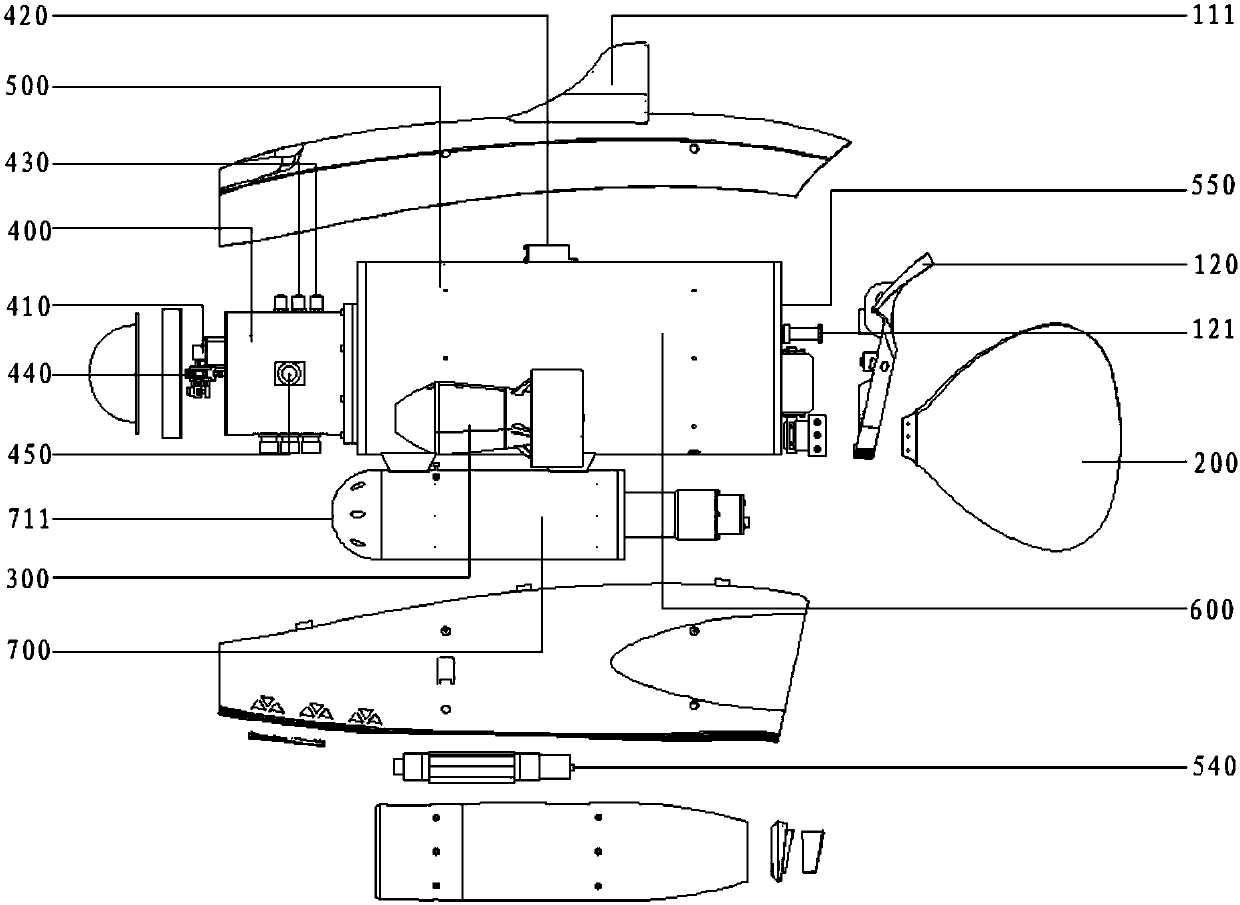

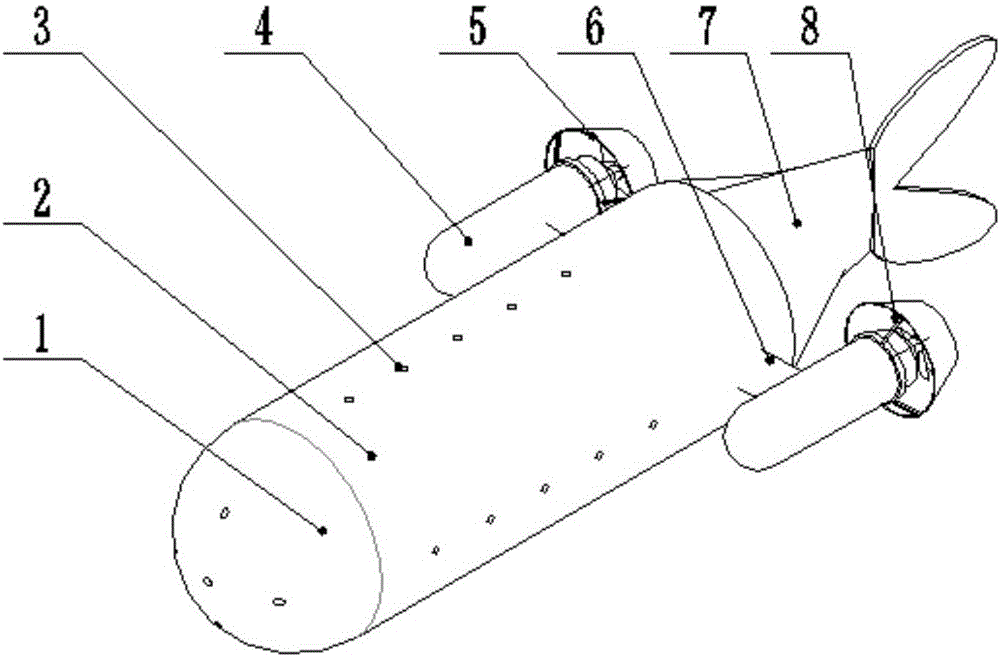

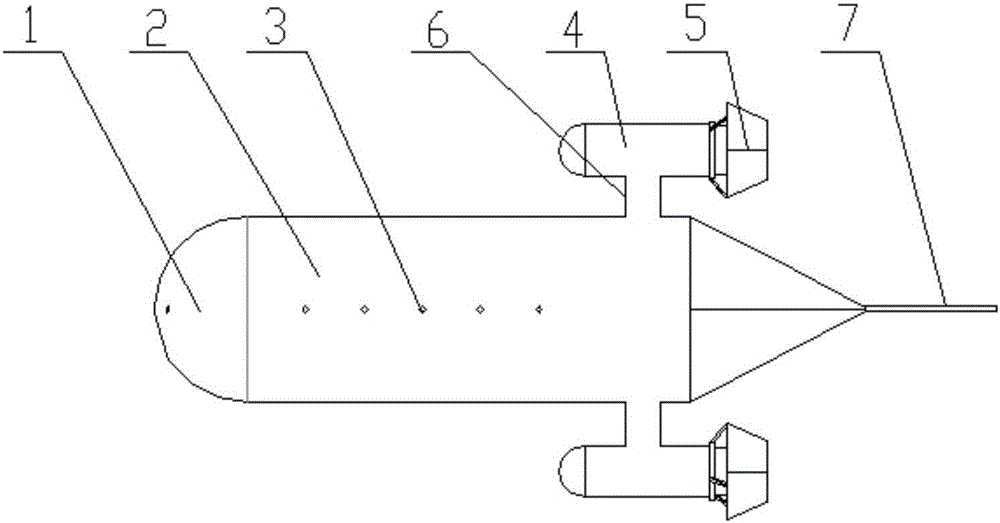

Underwater hybrid-power robot platform

InactiveCN107804443AImprove workabilityMeet complex mission requirementsWithdrawing sample devicesPropulsive elements of non-rotary typeWater qualityEngineering

The invention relates to an underwater hybrid-power robot platform which comprises a housing, a mainframe cabin and a motion control cabin. The outer contour of the housing is in shape of bionic fish,one end of the housing is connected with a bionic fish tail structure, and propellers are arranged on two sides of the housing. The side, close to the front end of the housing, of the mainframe cabinis connected with a camera, and an electronic compass and a controller are arranged in the mainframe cabin. A pitching gravity center adjusting mechanism is installed in the motion control cabin. Thepropellers, the electronic compass and the pitching gravity center adjusting mechanism are electrically connected with a battery cabin. The underwater hybrid-power robot platform adopts the hybrid-power driving design of the propellers and the bionic fish tail structure, and the operating capability of a robot in a complicated ocean current environment is greatly improved. The underwater hybrid-power robot platform can carry multiple types of detection devices, can meet complicated task demands, can performs operations such as water quality extraction, detection and photography, can sample and detect water at different depths through a water pumping cabin and has a wide application prospect.

Owner:BOYA GONGDAO BEIJING ROBOT TECH CO LTD

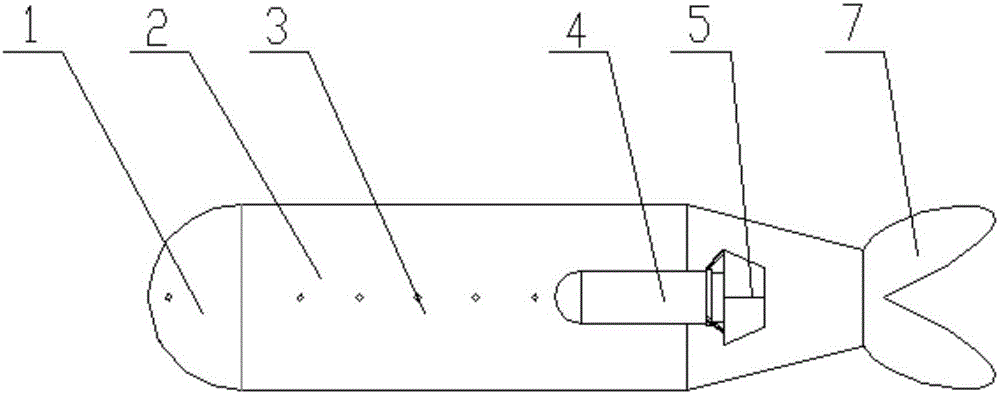

Multifunctional AUV based on bionic lateral line

ActiveCN106564577ANovel structureVersatilePosition/course control in two dimensionsPosition/direction controlPropellerObstacle avoidance

The invention discloses a multifunctional AUV based on a bionic lateral line, sensors are welded on a PCB circuit board and embedded in a carrier casing, a front head cabin, a main body cabin and a tail part are in streamlined head-tail sequential connection, sensor holes showing as the bionic lateral line are evenly distributed on the front head cabin and the main body cabin, the rear ends of both sides of the main body cabin are provided with steering engines, the end parts of the steering engines are connected with propellers, the end parts, far away from the front head cabin, of the propellers are provided with guiding covers, the terminal end of the main body cabin is provided with the tail part, and the tail part is a streamlined fish tail structure. Pressure data is obtained by the sensors which are arranged like the bionic lateral line, and during velocity measurement, a carrier directly faces the flow direction, and can correctly estimate local velocity. The AUV can determine direction and a path of a vibration source by sensing pressure gradients and changes so as to realize underwater positioning or obstacle avoidance. The multifunctional AUV has the advantages of small size and low cost, improves efficiency of identification and intelligentization of underwater equipment, and provides theoretical and data support for flow velocity measurement, underwater positioning and obstacle avoidance.

Owner:OCEAN UNIV OF CHINA +1

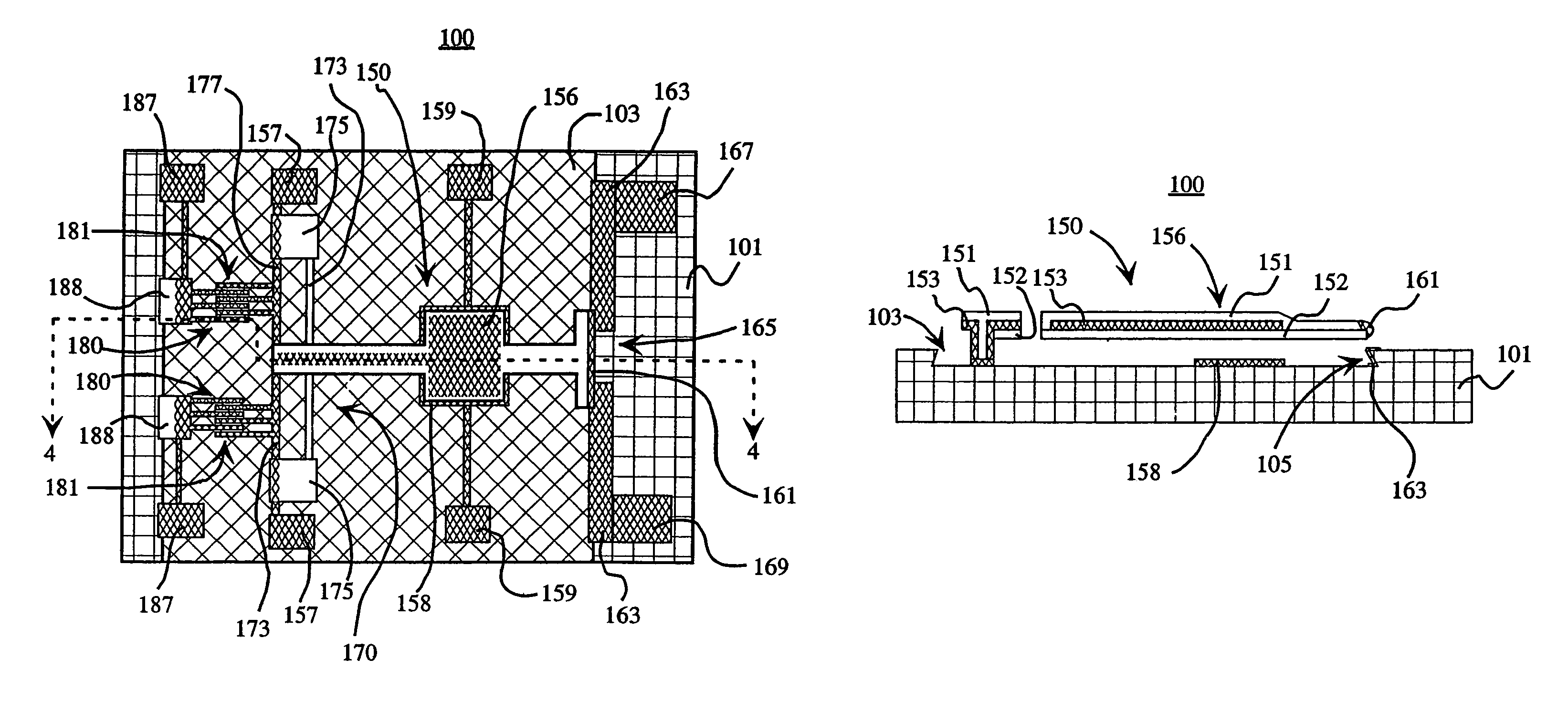

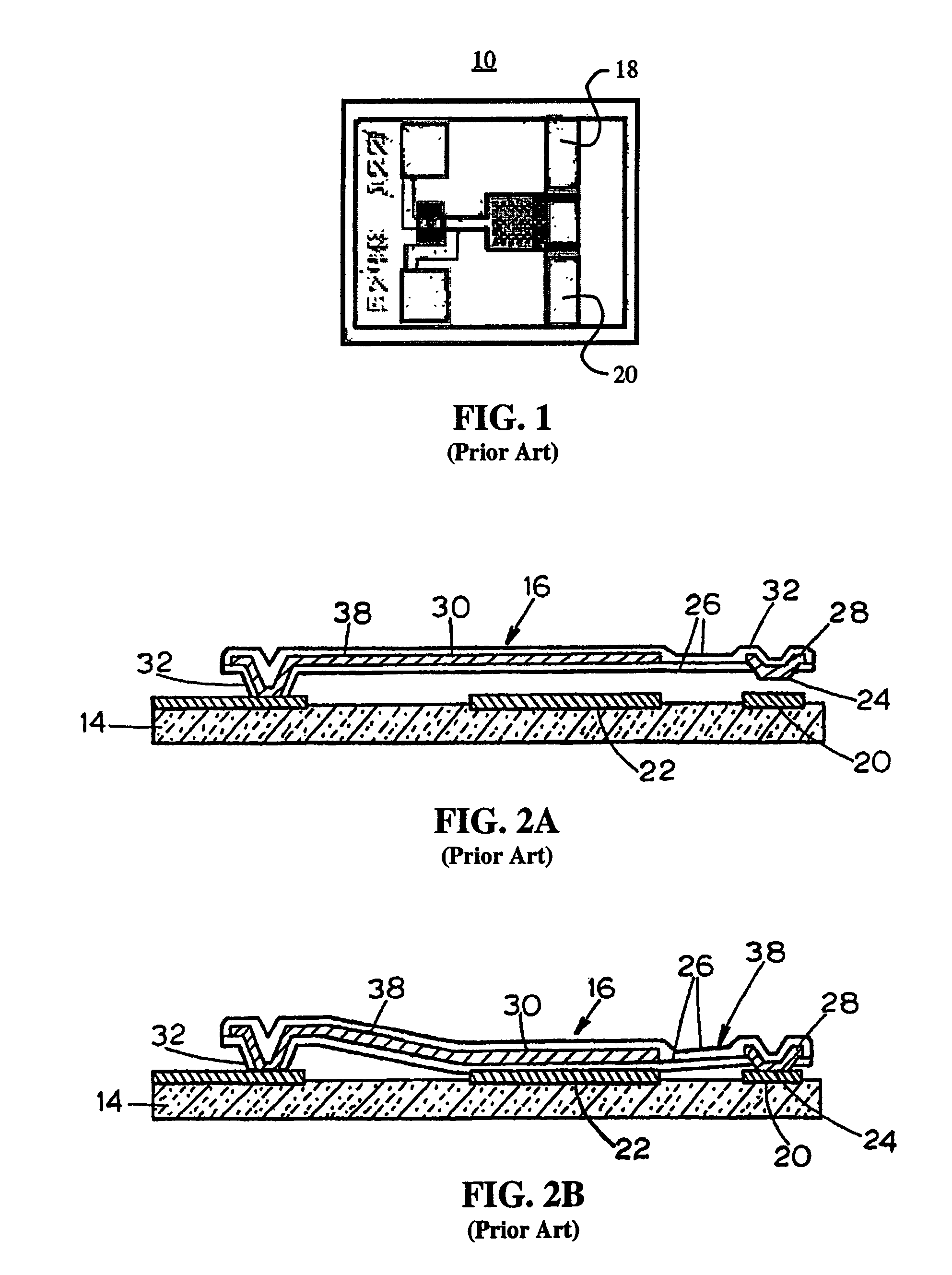

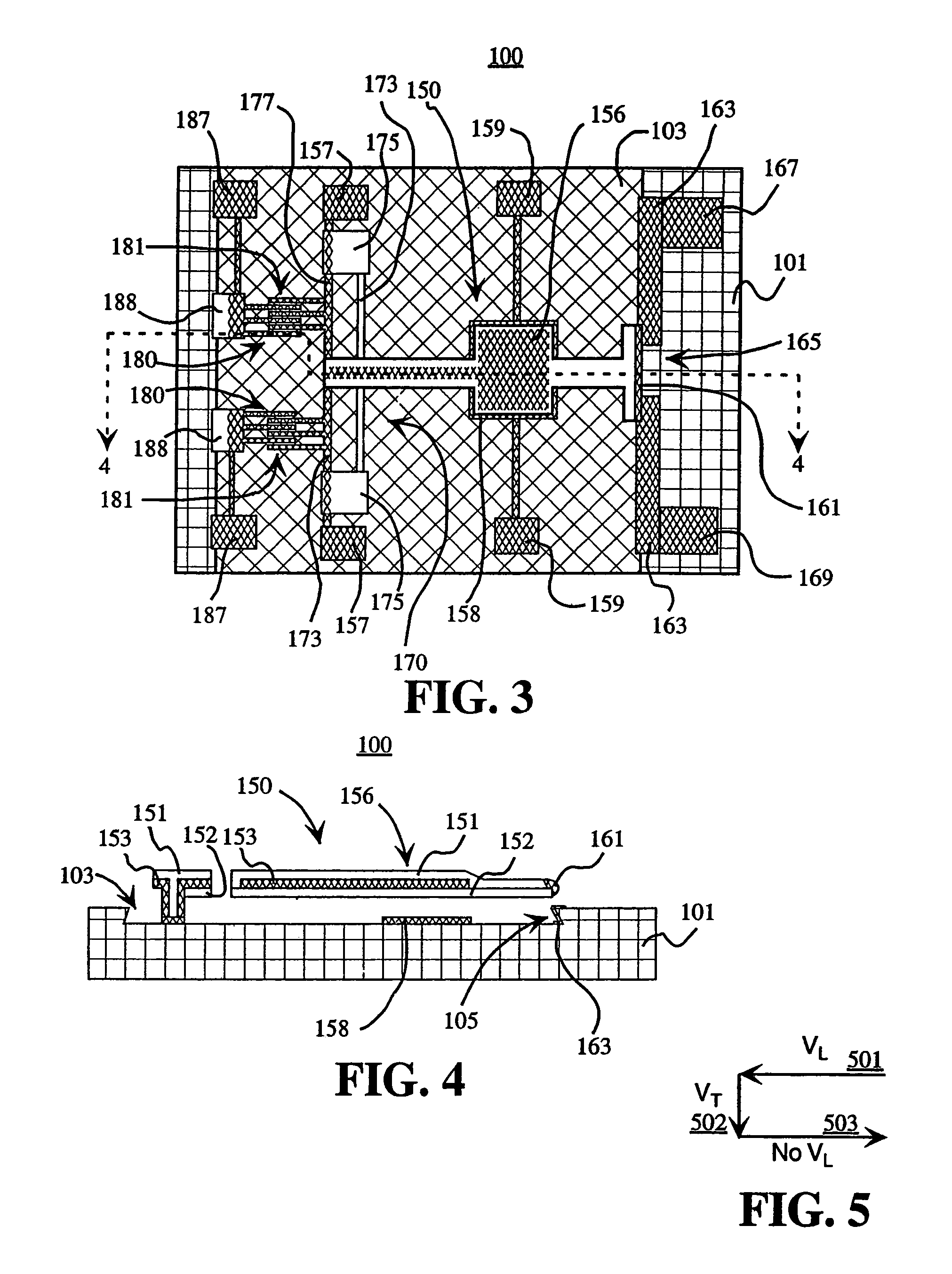

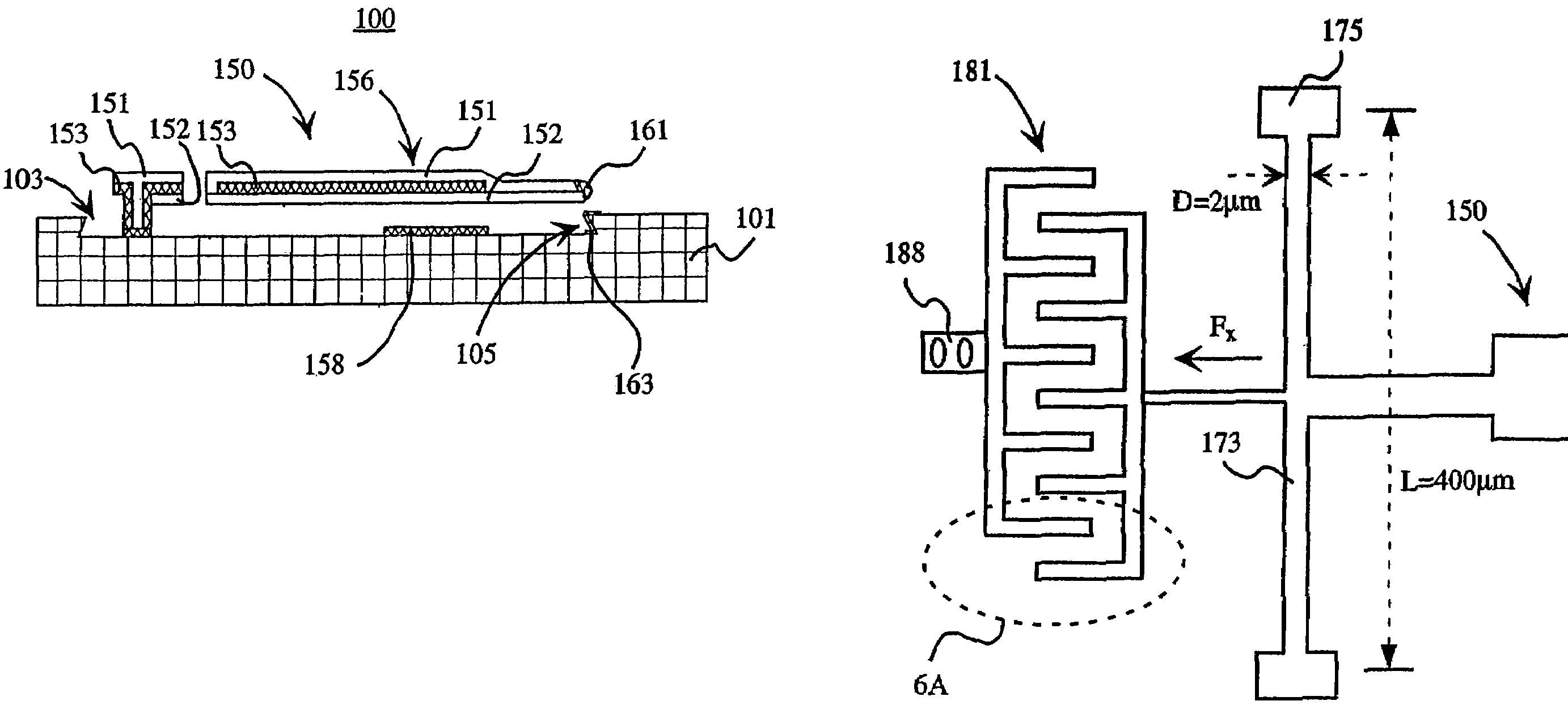

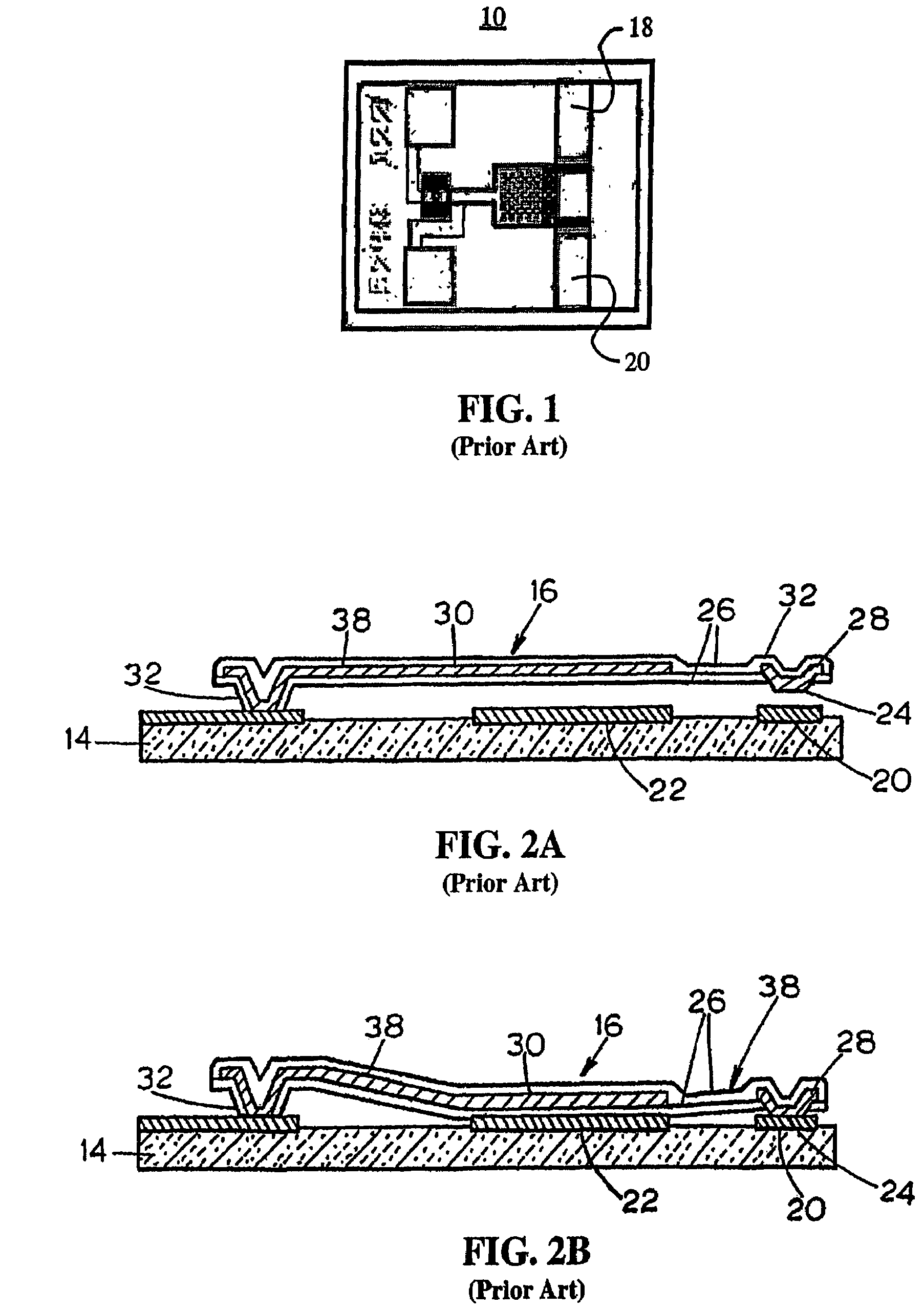

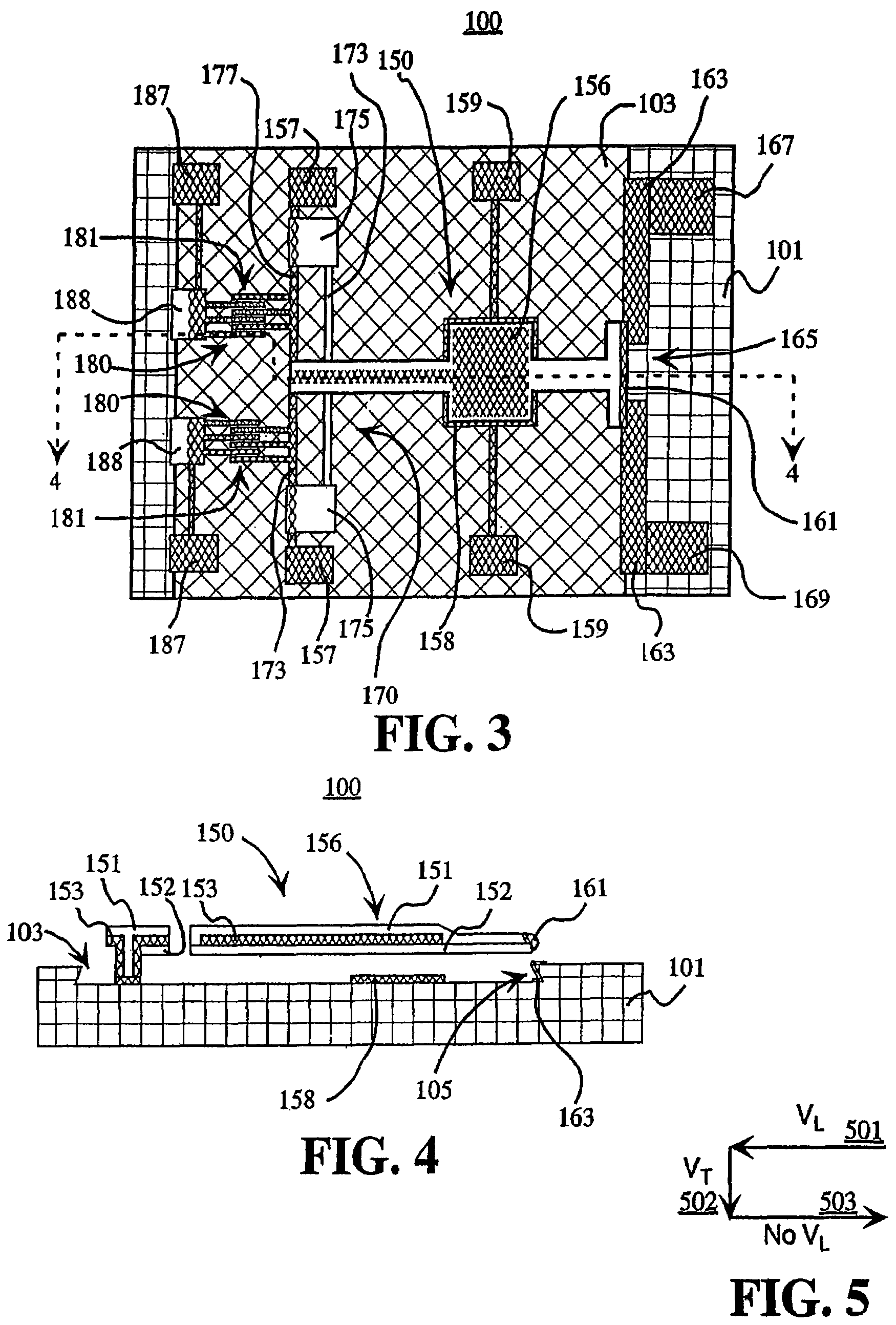

RF MEMS switch with spring-loaded latching mechanism

Apparatus for a micro-electro-mechanical switch that provides for latching switching action. The switch has a cantilever arm disposed on a substrate that can be moved in orthogonal directions for latching and unlatching. To latch the switch, the cantilever arm is moved back by a comb-drive actuator and then pulled down by electrodes disposed on the substrate and the cantilever arm. The comb-drive actuator switch is then released and the cantilever arm moves forward to be captured by a dove-tail structure on the substrate. When the voltage to the electrodes on the substrate and the cantilever arm is removed, the cantilever arm is held in place by the dove-tail structure. The switch is unlatched by actuating the comb-drive actuator to move the cantilever arm away from the dove-tail structure. The cantilever arm will then pop up once it is released from the dove-tail structure.

Owner:HRL LAB

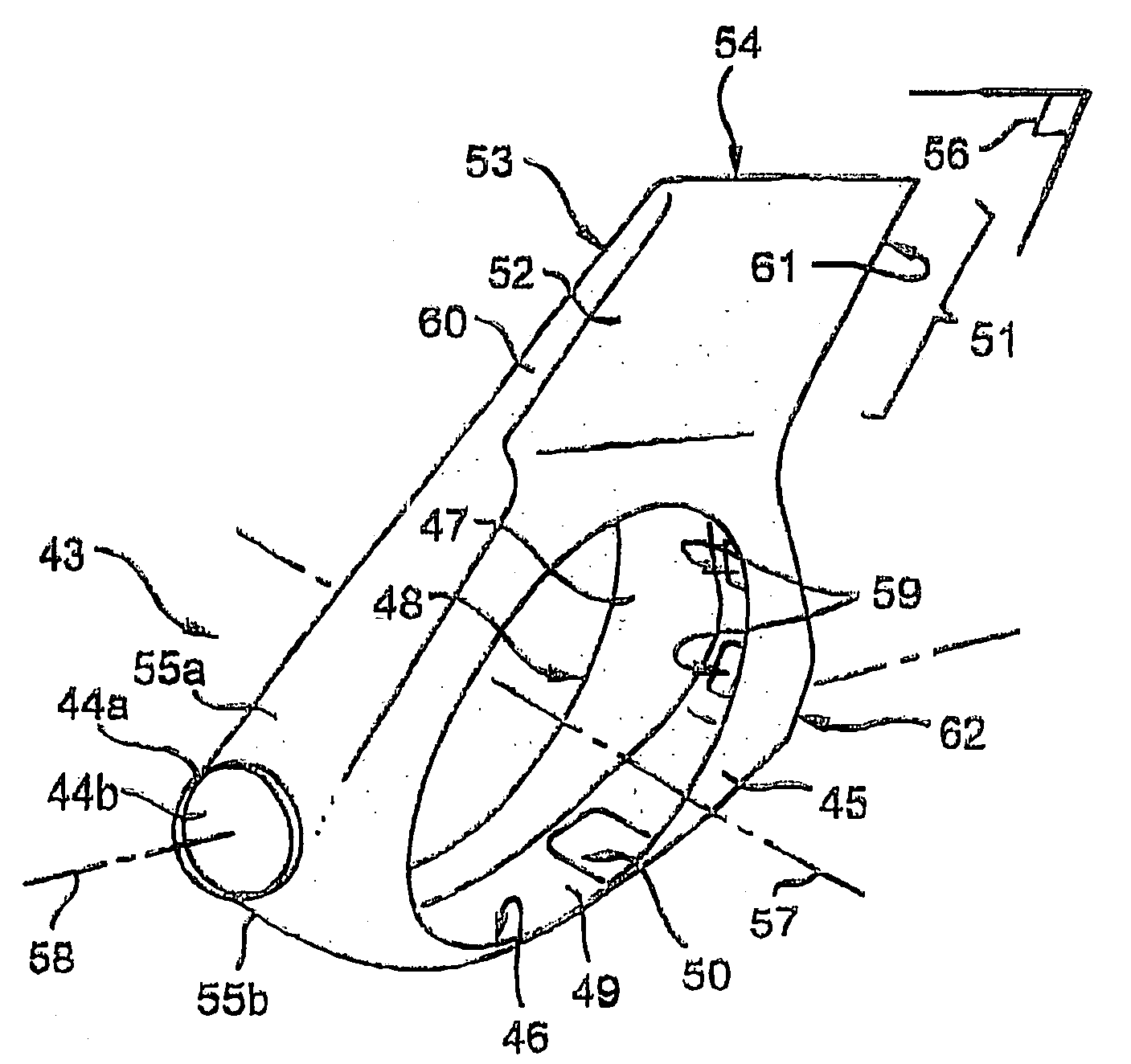

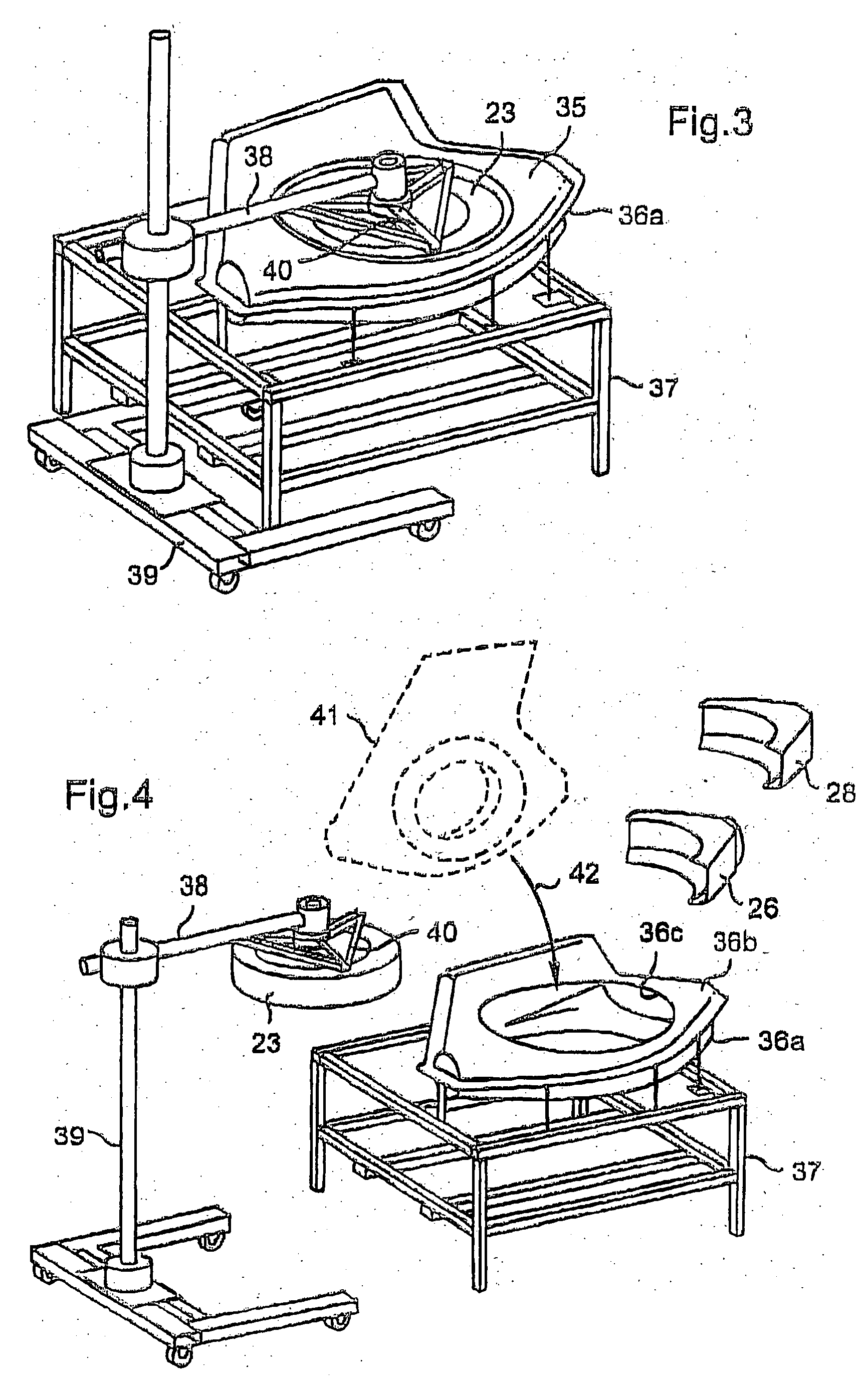

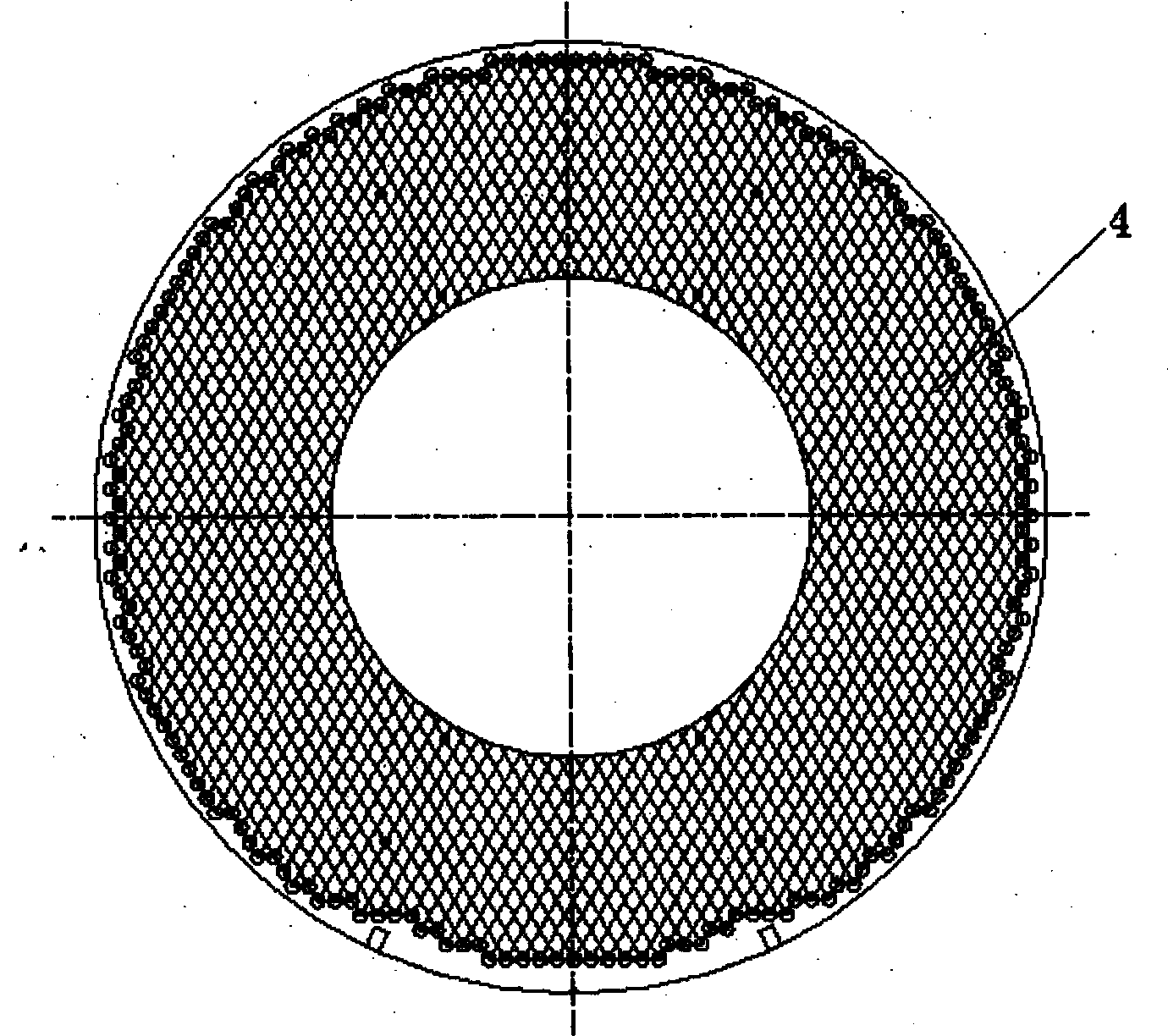

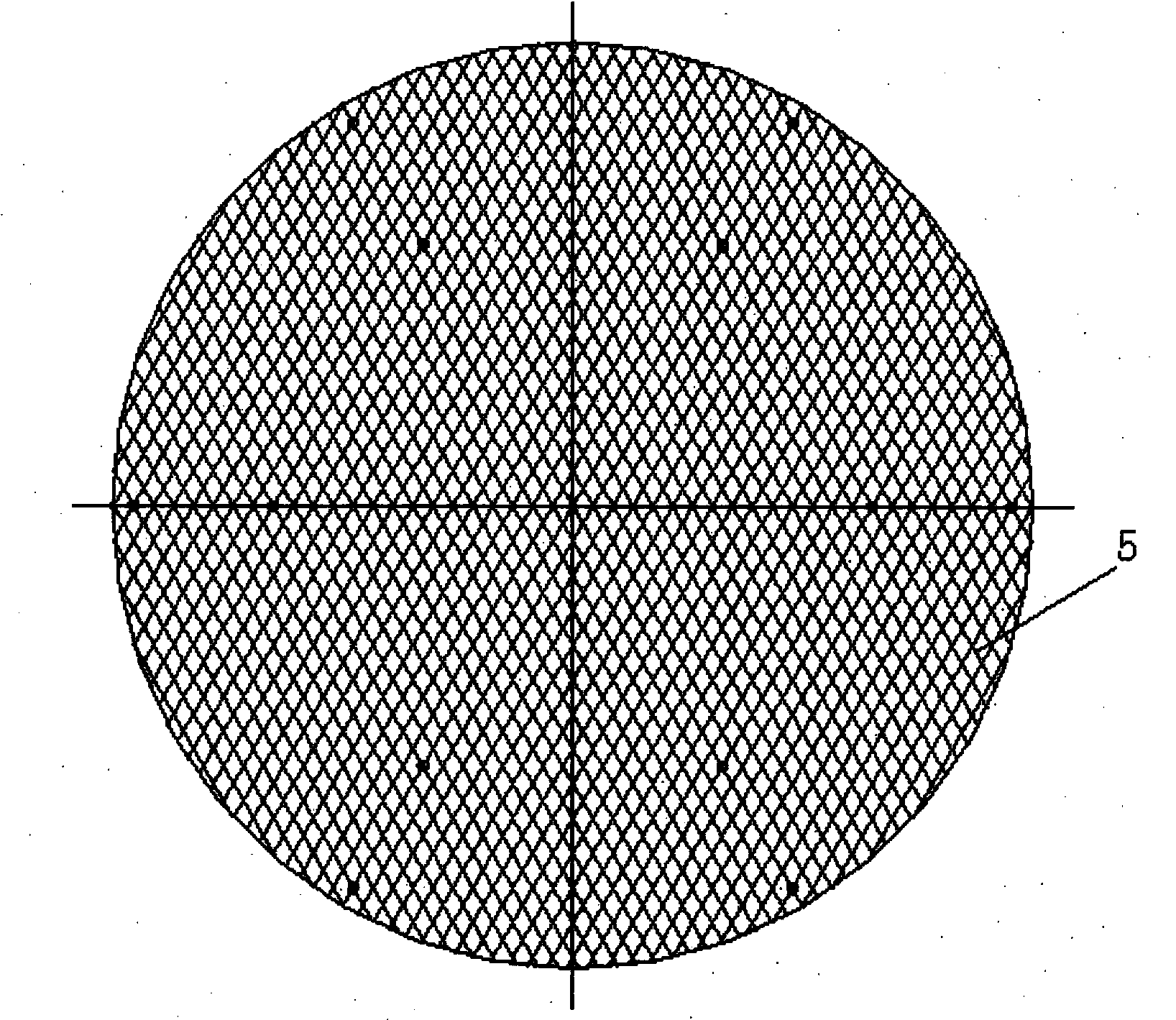

Method and apparatus for manufacturing a helicopter rotor fairing, and a fairing obtained thereby

ActiveUS20060169835A1Improve surface conditionAvoid foldingAircraft assemblyDomestic articlesEngineeringShaft collar

The invention relates to a method of manufacturing a tail structure for a rotary wing aircraft, the structure comprising: a tubular portion or duct (63) presenting two ends and including two collars or flanges (66, 70) extending respectively from each of said two ends; and two curved fairing side walls (45, 47) extending respectively around the two collars or flanges; said two side walls being made of a composite material comprising an organic matrix and reinforcement; in a method of the invention, the side walls are united by solidifying the matrix.

Owner:EUROCOPTER

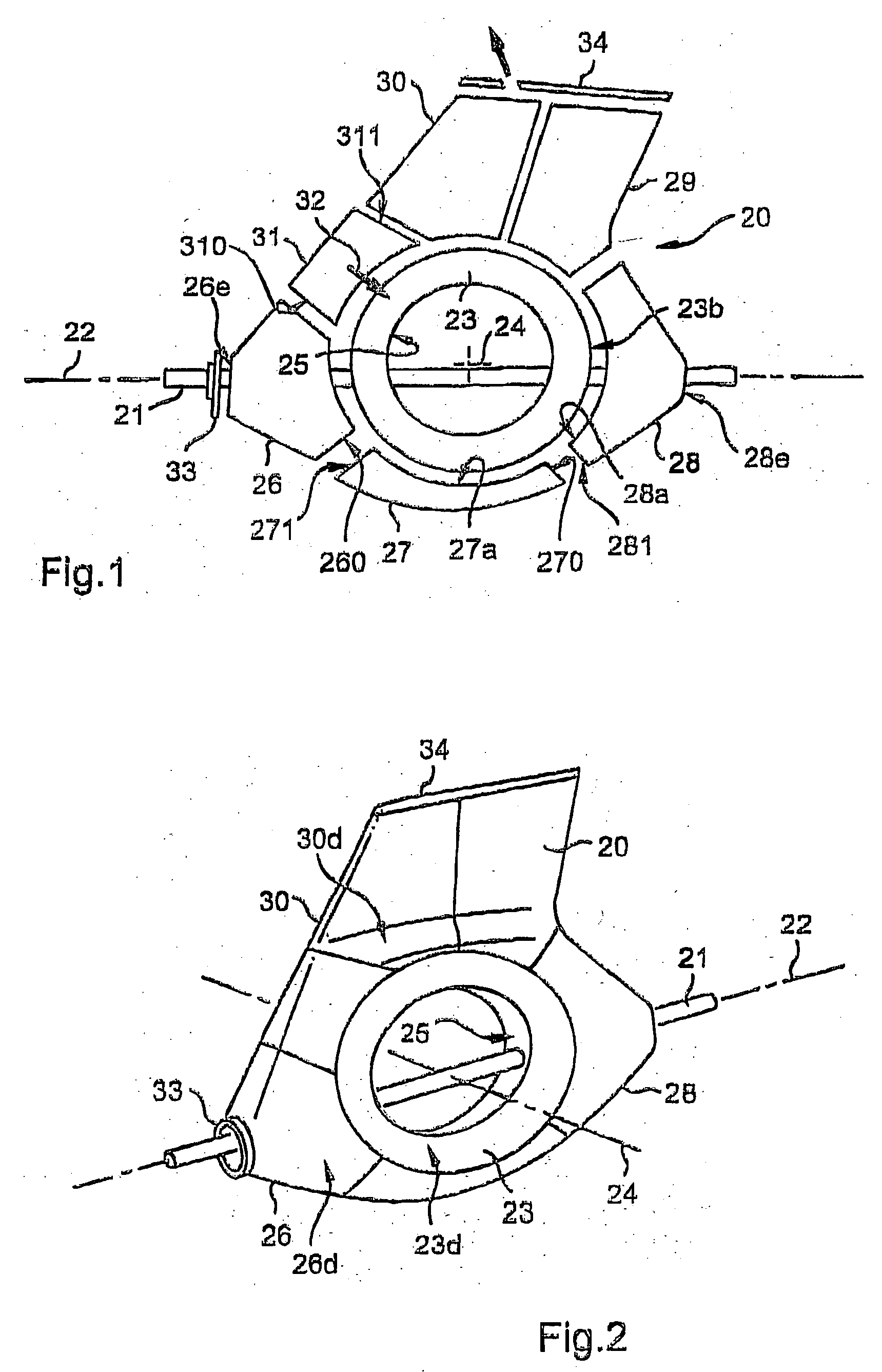

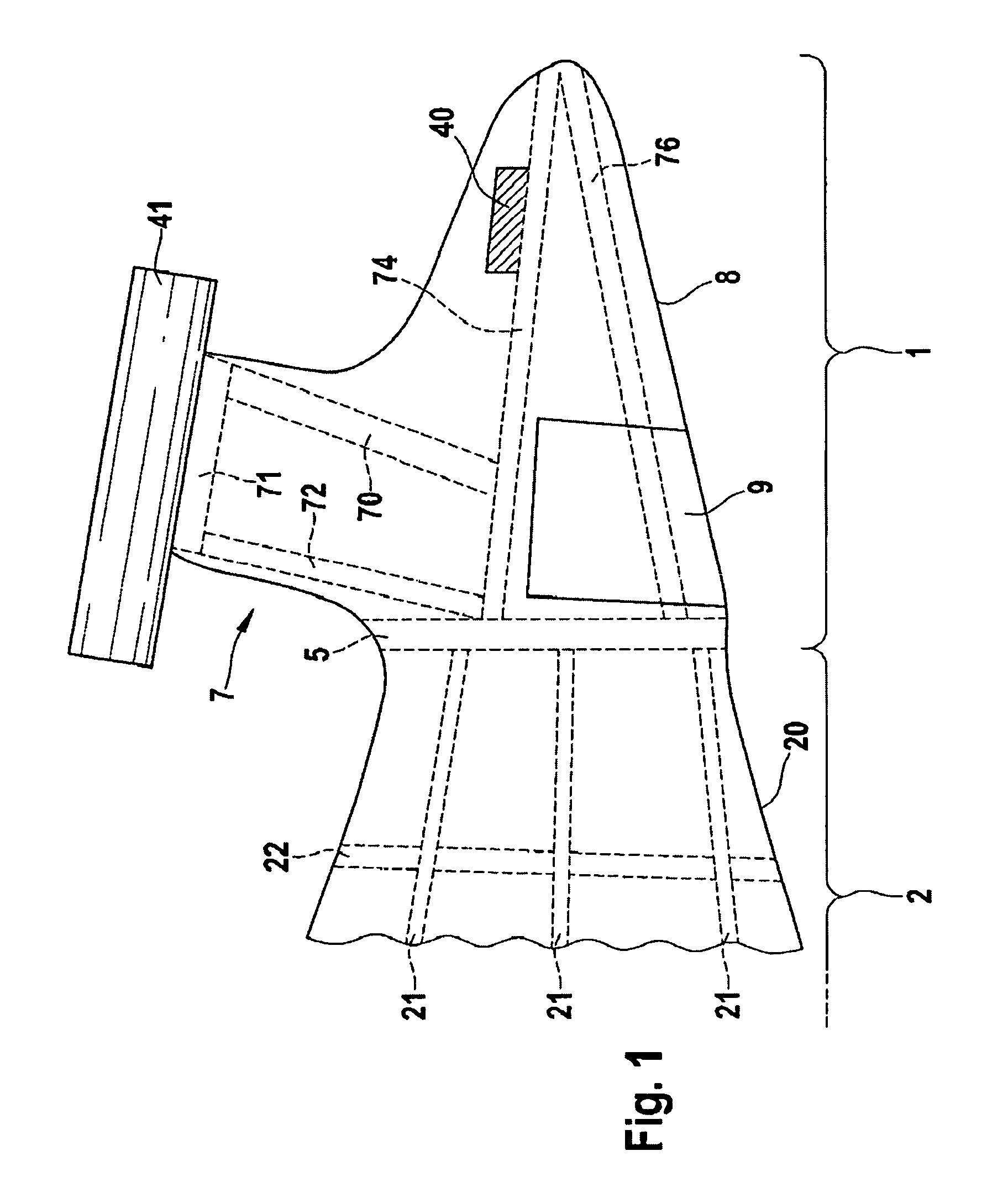

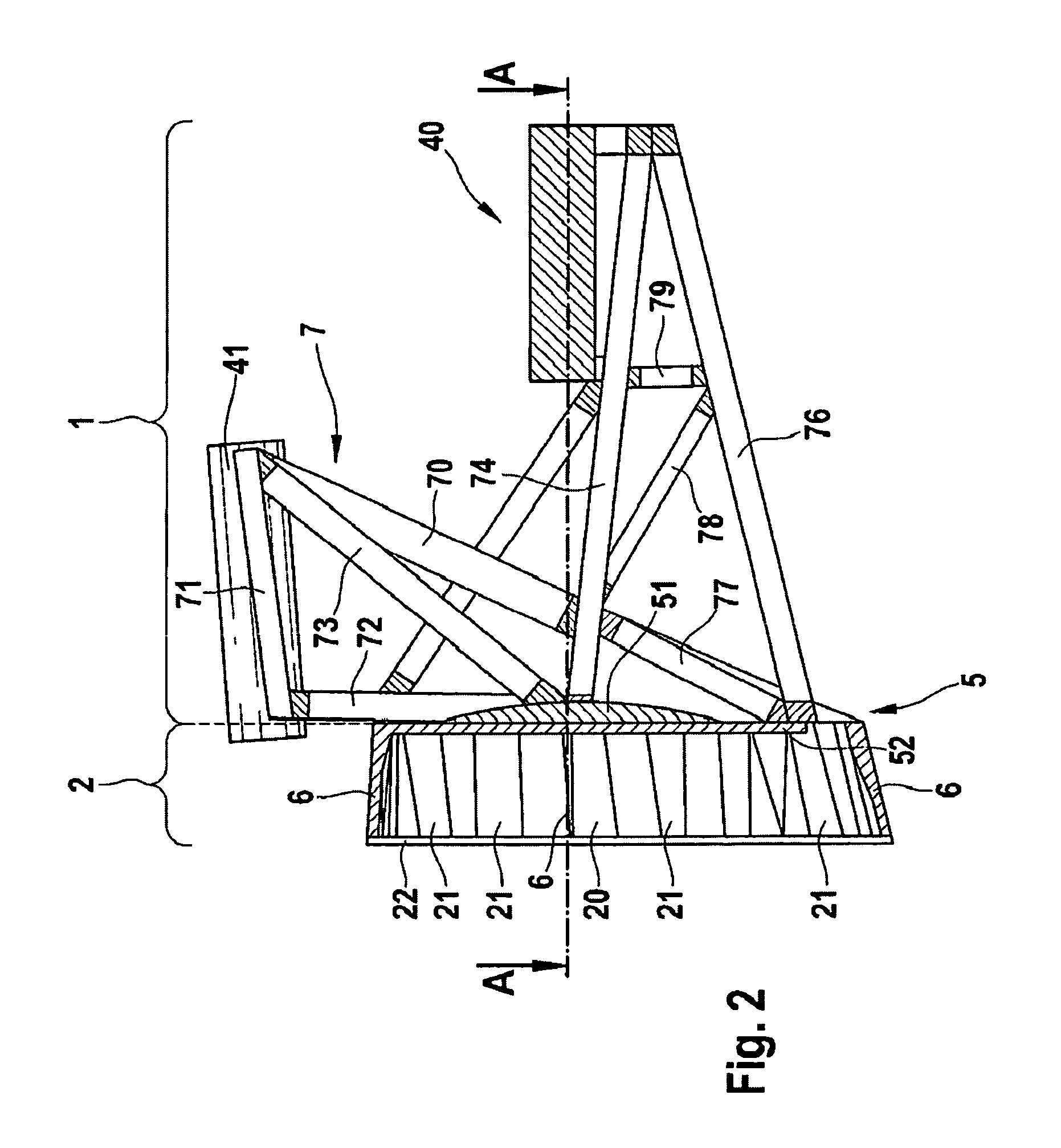

Adaptive tail assembly for solar aircraft

An adaptive aircraft tail assembly includes a tail boom, and a tail structure. The tail structure has a plurality of control surfaces configured to alter or maintain flight characteristics of the aircraft. The tail structure also has at least (i) one or more photovoltaic cells, or (ii) at least one or more solar thermal collection cells, or (iii) both photovoltaic cells and solar thermal collection cells. The tail structure also includes a rotational pivot configured to rotationally attach the tail structure to the tail boom. Preferably, the plurality of control surfaces are configured so as to be manipulatable to rotate the tail structure about a central axis of the tail boom via the rotational pivot.

Owner:AURORA FLIGHT SCI CORP

Bio-inspired underwater robot

ActiveUS20200307750A1Improve agilityStability loading capabilityProgramme-controlled manipulatorPropulsive elements of non-rotary typeControl engineeringBevel gear

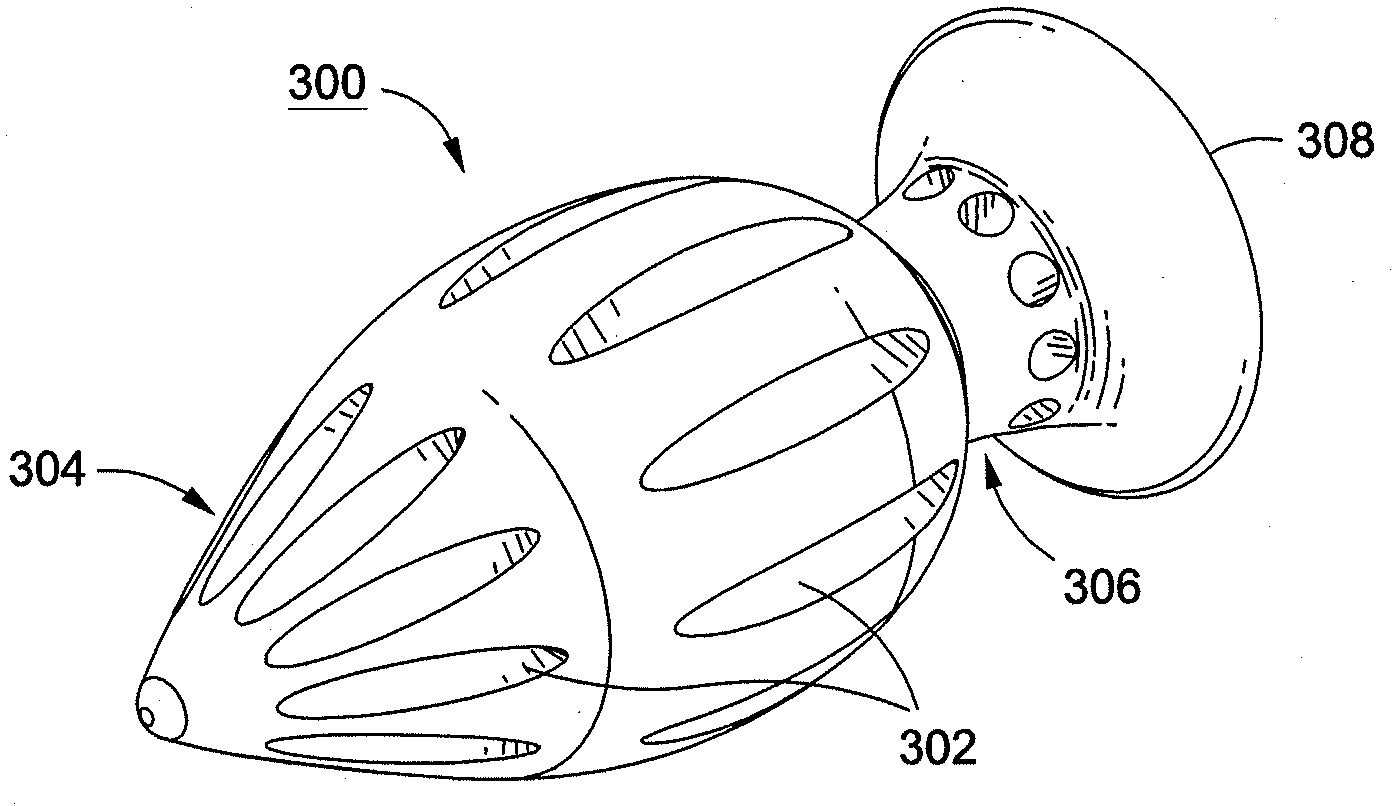

A bionic underwater robot for achieving a variety of motions is disclosed. The bionic underwater robot includes a head and one or more tail structures. Each of the one or more tail structures includes one or more joint structures. Each of the one or more joint structures includes a connection plate, and a modular assembly, comprising an upper servo motor, a lower servo motor, and a bevel gear mechanism, is motorized for performing various movement motions of the joint structure. The bevel gear mechanism is integrally formed by an intermediate bevel gear, a first bevel gear, and a second bevel gear. The upper servo motor drives the first bevel gear from a first side of the modular assembly, while the lower servo motor drives the second bevel gear from a second side.

Owner:THE HONG KONG POLYTECHNIC UNIV

Method of fabricating an RF MEMS switch with spring-loaded latching mechanism

ActiveUS7653985B1Contact member manufacturingElectrostatic/electro-adhesion relaysComb driveEngineering

Disclosed are methods for fabricating a micro-electro-mechanical switch. The switch has a cantilever arm disposed on a substrate that can be moved in orthogonal directions for latching and unlatching. For latching, the cantilever arm is moved back by a comb-drive actuator and then pulled down by electrodes disposed on the substrate and the cantilever arm. The comb-drive actuator switch is then released and the cantilever arm moves forward to be captured by a dove-tail structure on the substrate. When the voltage is removed, the cantilever arm is held in place by the dove-tail structure. The switch is unlatched by actuating the comb-drive actuator to move the cantilever arm away from the dove-tail structure. The cantilever arm will then pop up once it is released from the dove-tail structure.

Owner:HRL LAB

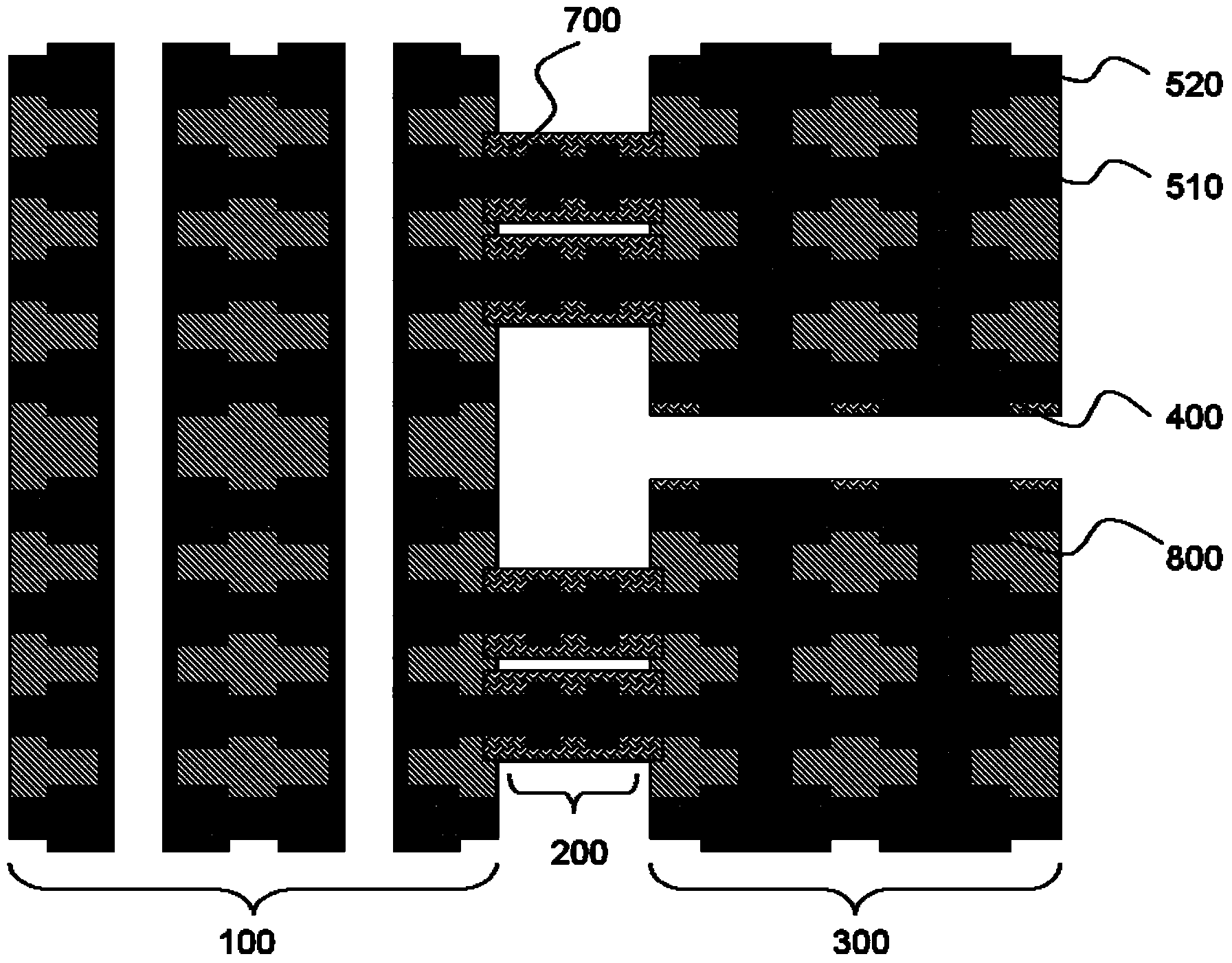

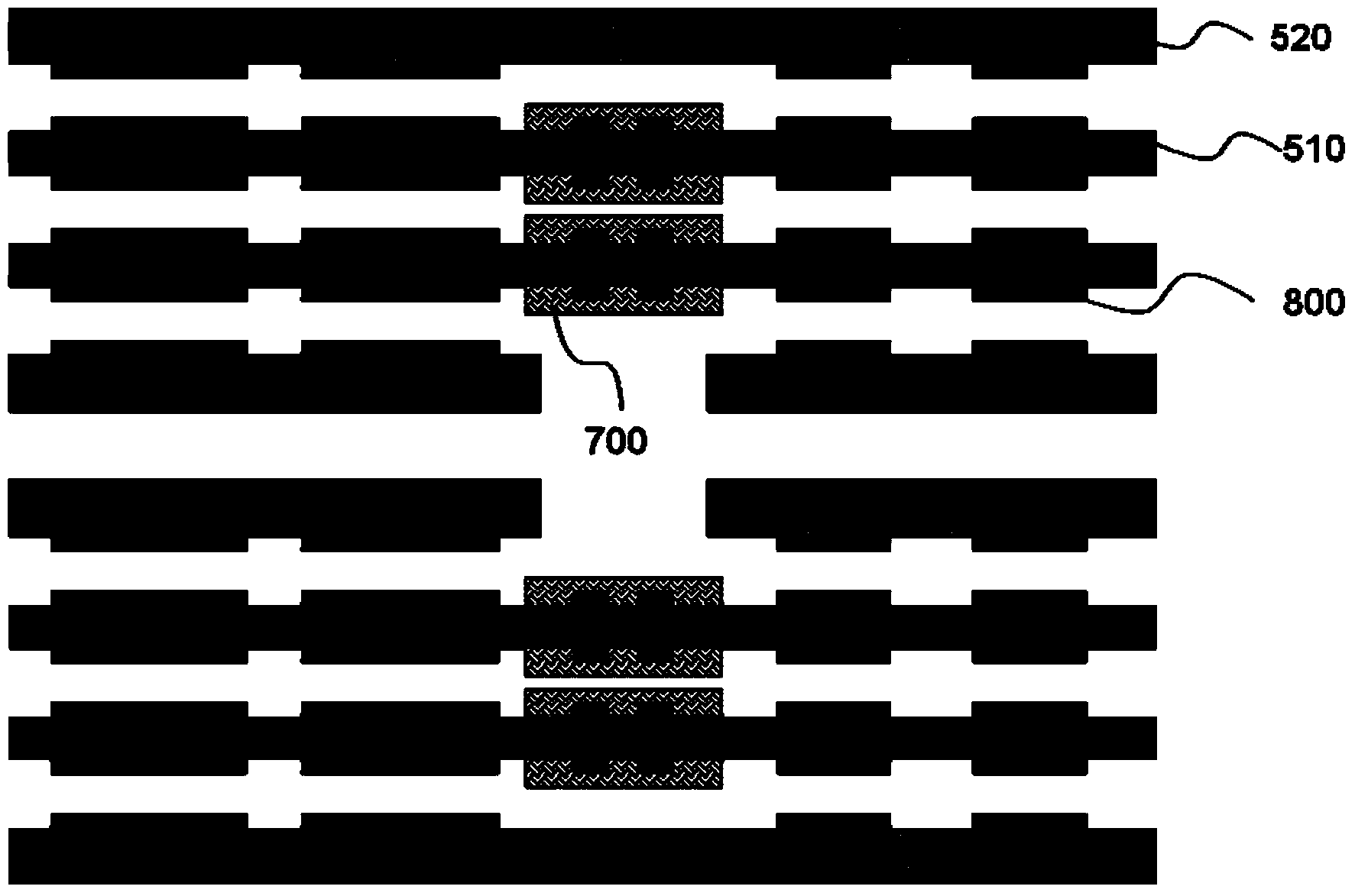

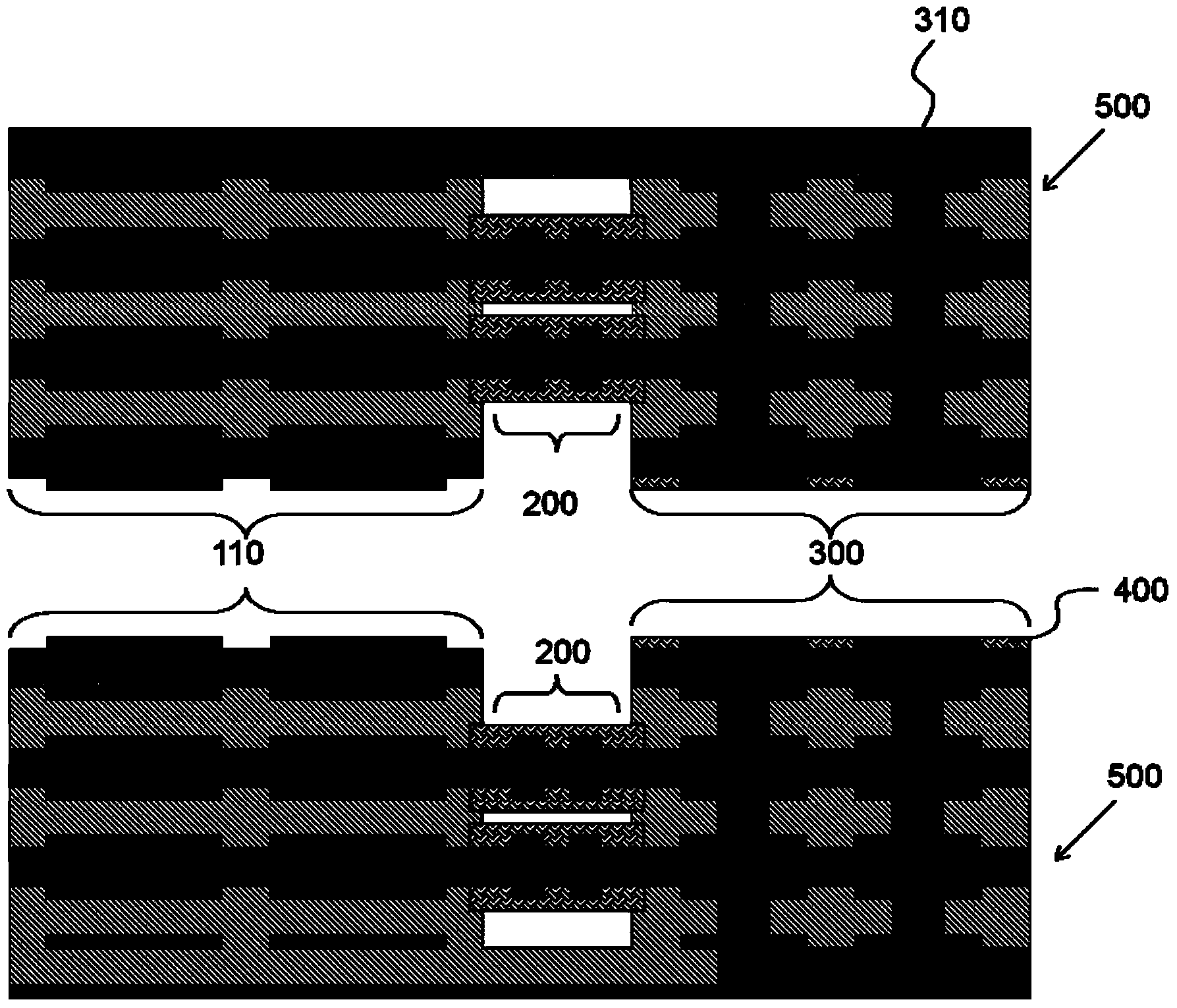

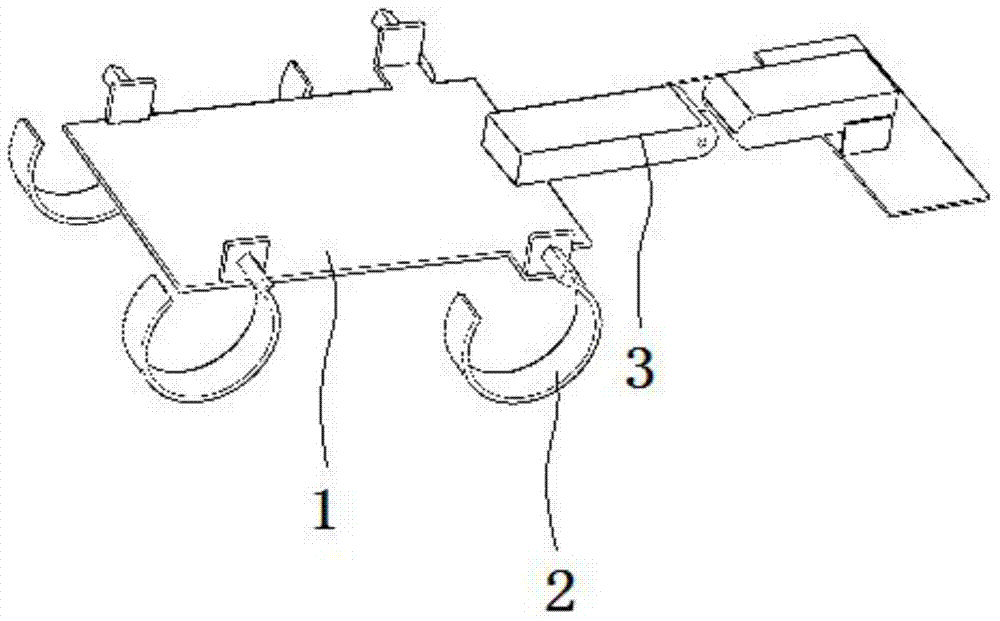

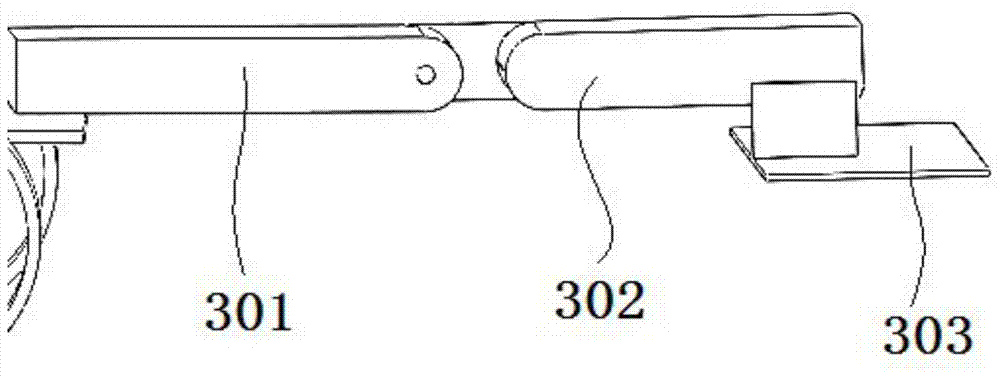

Rigidity-flexibility combined circuit board of flying-tail structure and manufacturing method thereof

ActiveCN103687284AImprove pass rateHigh compressive strengthPrinted circuit assemblingPrinted circuits structural associationsPolyetherimideEngineering

The invention discloses a manufacturing method of a rigidity-flexibility combined circuit board of a flying-tail structure. The manufacturing method includes the following steps that step1, core boards needed by all daughter boards are manufactured, and each daughter board comprises at least one flexibility core board and at least one rigidity core board, all the core boards are stacked and laminated to manufacture the daughter boards equal to second rigidity areas in number, and each daughter board comprises a part of a first rigidity area, a flexibility area and a second rigidity area; step2, all the daughter boards obtained in the step1 are stacked, and polyetherimide covering films are pasted on anti-welding areas of adjacent end faces of all the second rigidity areas; step3, PTFE gaskets are padded between the adjacent flexibility areas and the adjacent rigidity areas, all the daughter boards processed in the step2 are laminated, and the parts of the first rigidity areas of all the daughter plates are laminated together to form the first rigidity areas. The invention further discloses the rigidity-flexibility combined circuit board of the flying-tail structure. The manufacturing method of the rigidity-flexibility combined circuit board of the flying-tail structure can effectively prevent an anti-welding layer from being damaged.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

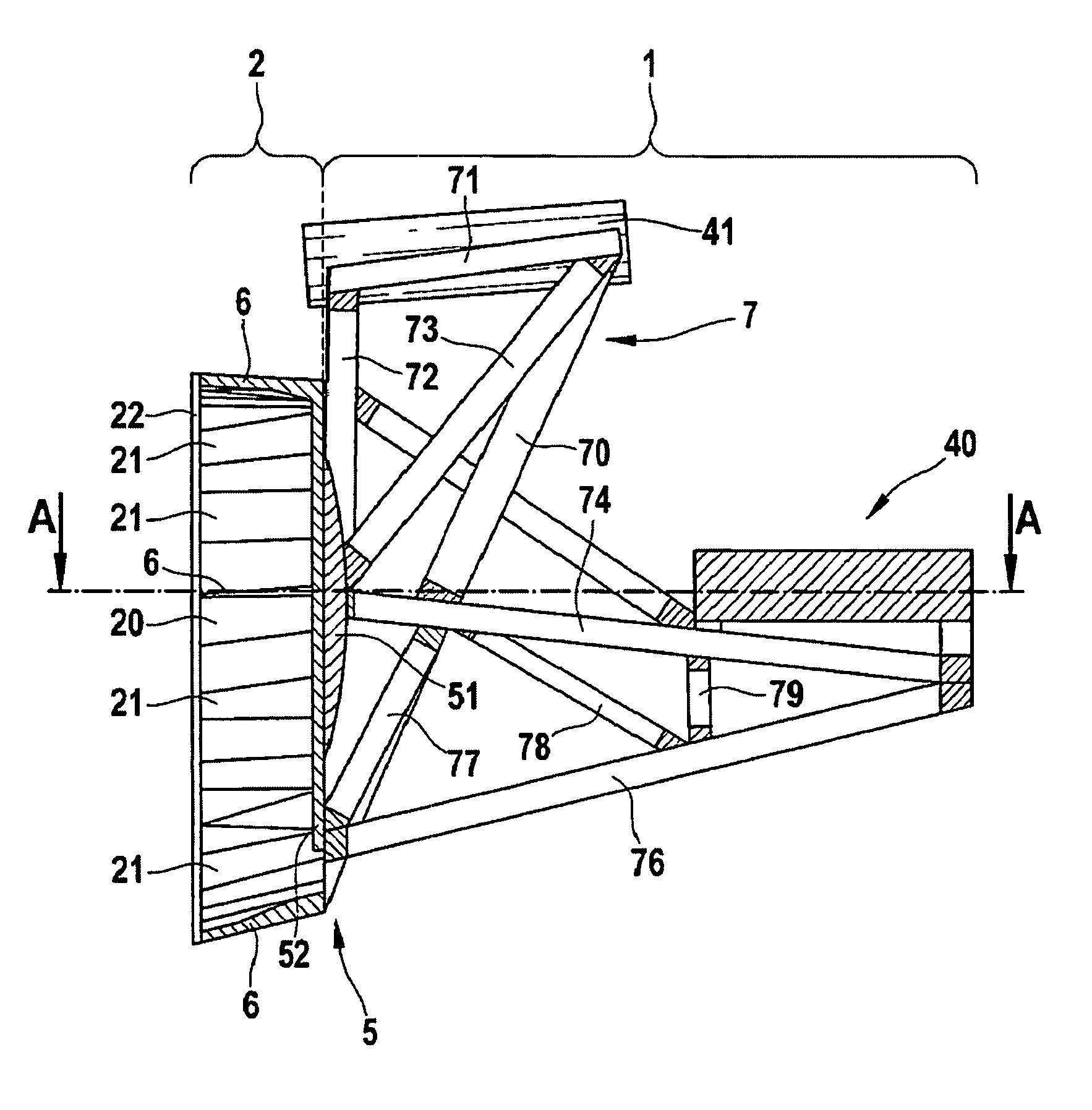

Tail structure for an aircraft or spacecraft

ActiveUS8177166B2Reduce weightImprove mechanical rigidityCosmonautic vehiclesPower plant arrangements/mountingJet aeroplaneTail structure

A tail structure for an aircraft or spacecraft, which adjoins a fuselage section of the aircraft or spacecraft, includes a support construction for supporting at least one craft component, and a bulkhead unit intended for the pressure-tight sealing of the fuselage section and able to be coupled both to the support construction and to the fuselage section so as to form a force flow path between the at least one craft component and the fuselage section.

Owner:AIRBUS OPERATIONS GMBH

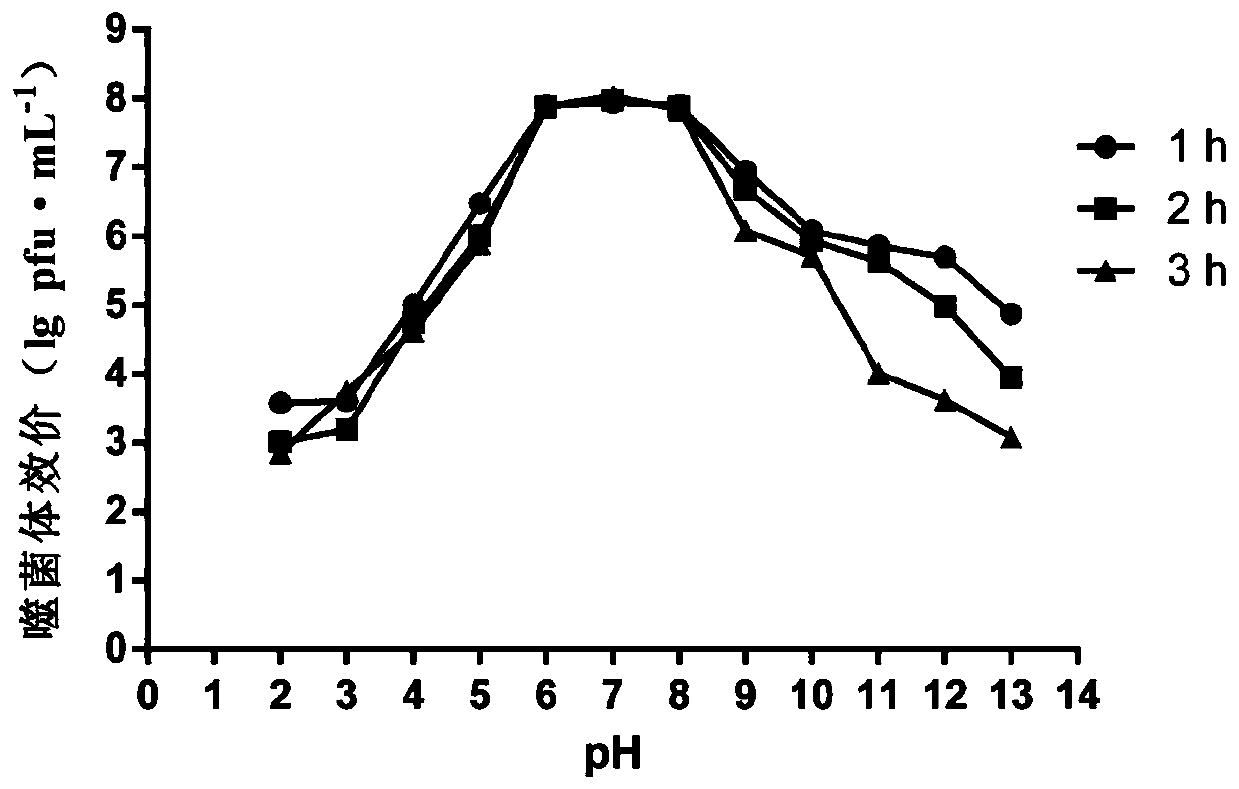

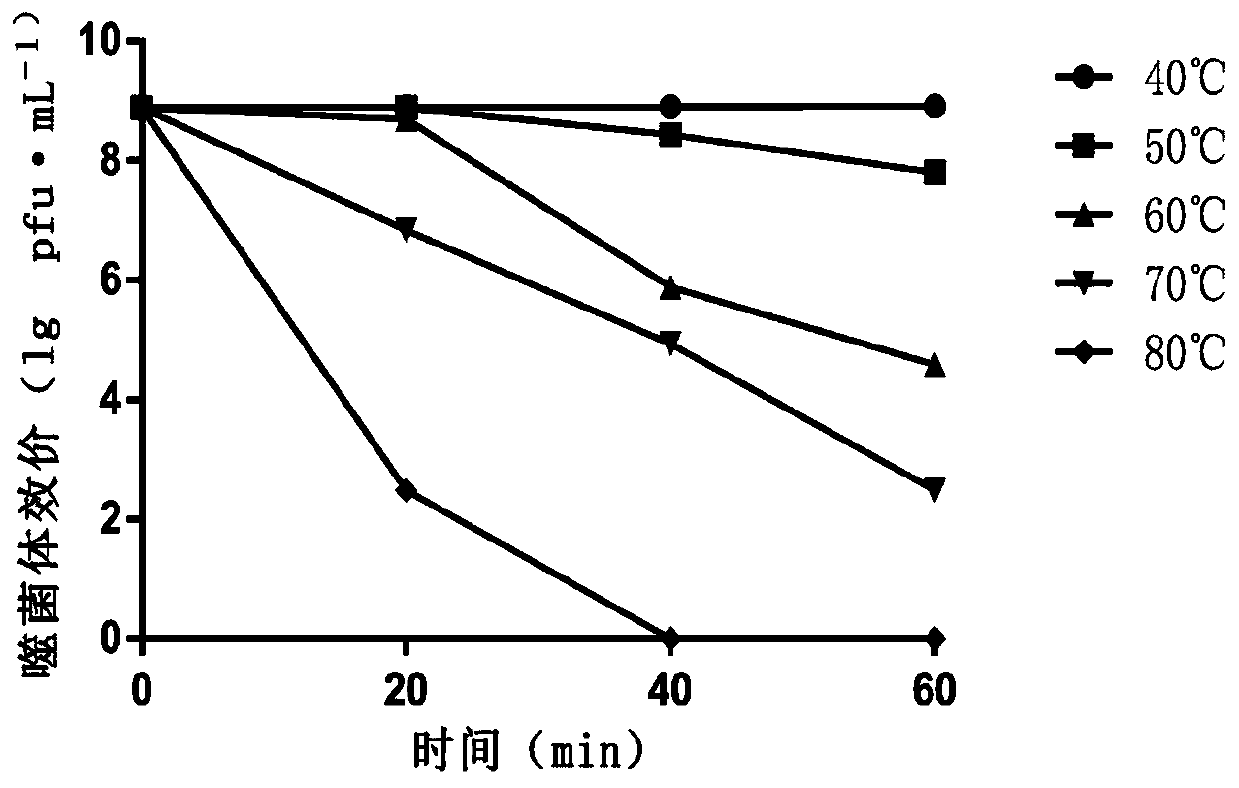

Escherichia coli bacteriophage vB_EcoM_swi3 and application thereof

InactiveCN110607284AImprove securityPhysical and chemical factors are well toleratedAntibacterial agentsViral/bacteriophage medical ingredientsESCHERICHIA COLI ANTIGENAnaplasma phagocytophilum

The invention discloses escherichia coli bacteriophage vB_EcoM_swi3 of which the preservation number is CCTCC M 2019467. The bacteriophage belongs to myoviridae, and is provided with a polyhedral headand a telescopic tail structure, wherein the diameter of the head is about 80nm, and the length of the tail is about 120nm. Bright plaque can be formed on a solid culture medium, an aureole does notexist on the periphery of the plaque, the edge is clear and regular, and the diameter is about 1-1.5mm. The bacteriophage has favorable splitting effects on pig-derived escherichia coli and chicken-derived escherichia coli, especially pig-derived pathogenic escherichia coli and chicken-derived pathogenic escherichia coli, and has quite great application prospects in a plurality of respects of medicinal preparations for preventing and treating pig-derived colibacillosis and chicken-derived colibacillosis, feed additives and the like.

Owner:QINGDAO AGRI UNIV

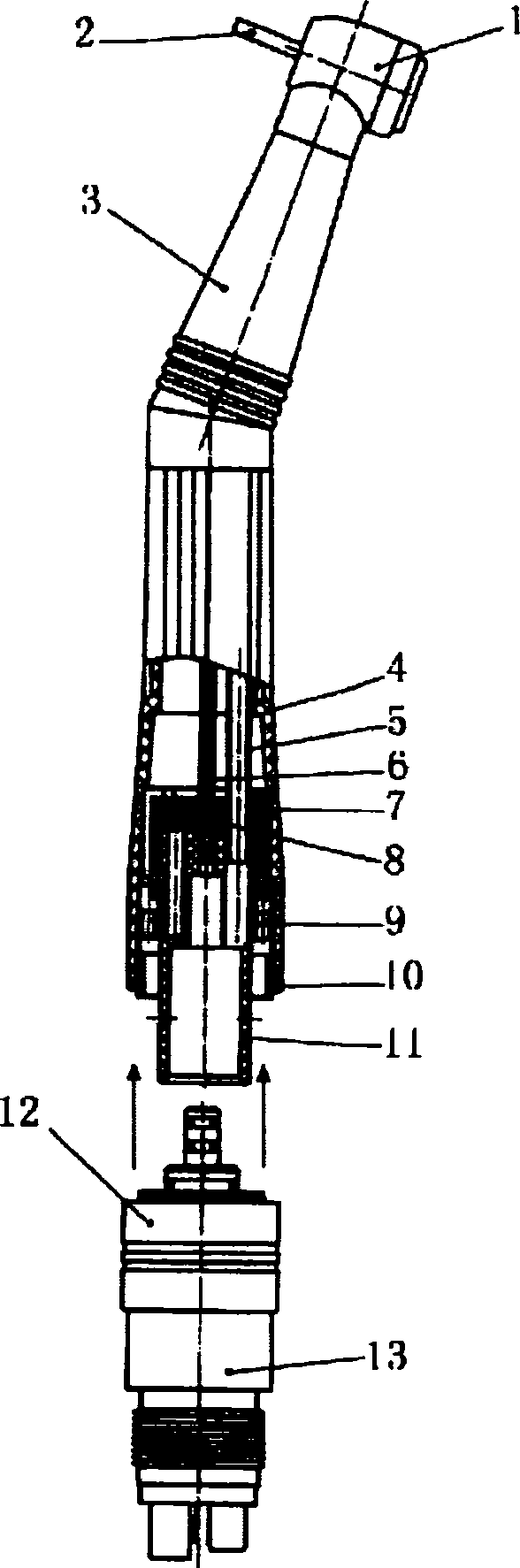

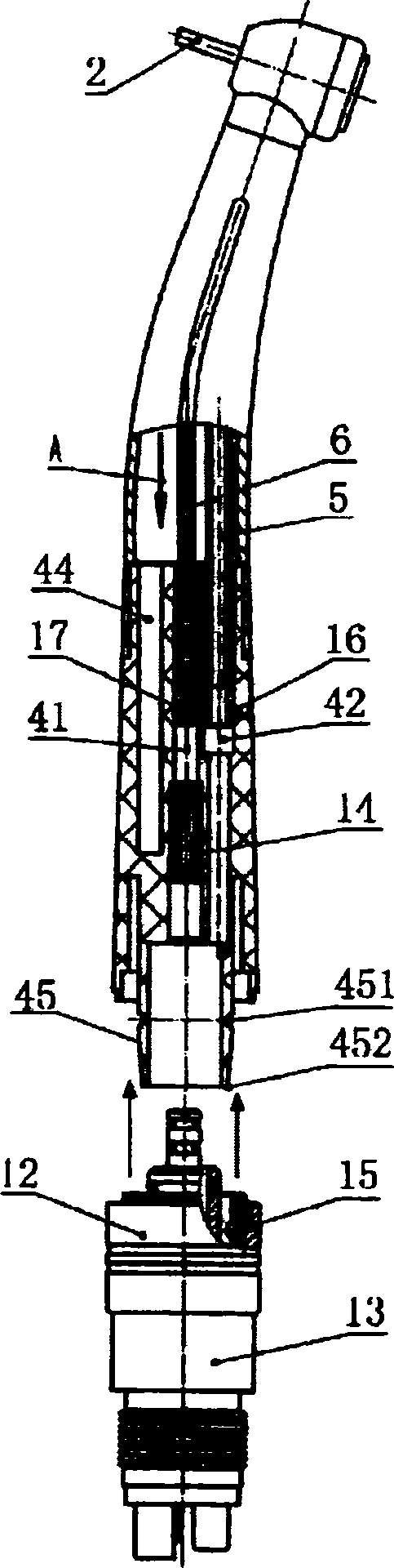

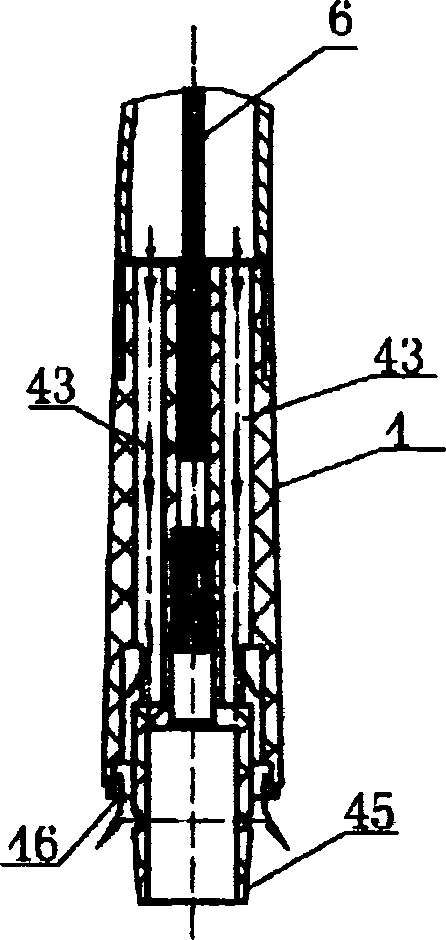

Disposable high speed turbine dental drill hand piece

InactiveCN1887236ASolve the trouble of assemblySimple structureDental toolsBoring toolsO-ringEngineering plastic

The disposable high speed turbine dental drill hand piece has one handle made of molded engineering plastic, and the handle has one integrated back part for connection to the dental drill hand piece and the other end made into tail structure suitable for connecting with water pipe and air pipe easily. The handle features its front part in inserting structure with O-ring for sealing the air pipe and water pipe union. The back part of the handle may be in different sizes for fast connection to water pipe and air pipe of different sizes. The handle may have one non-return valve installed to avoid back flow of water. The handle has light weight, high strength, easy manufacture and installation and low cost and is suitable for use in disposable high speed turbine dental drill hand piece.

Owner:BEIJING NORTH POLE DENTAL HANDPIECE

Desert quadruped robot imitating lizard

ActiveCN104118490APrevent slipping and other problemsGuaranteed travel speedVehiclesLizardEngineering

The invention provides a desert quadruped robot imitating a lizard. The desert quadruped robot imitating the lizard comprises a robot body, a C-type leg structure and a tail structure, the C-type leg structure comprises 2N C-type legs which are symmetrically arranged on the two sides of the robot body through drive motors respectively, the tail structure has two degrees of freedom through a horizontal swinging steering engine and a vertical swinging steering engine and is arranged in the middle of the rear end of the robot body through the horizontal swinging steering engine, and the drive motors of the C-type legs and the horizontal swinging steering engine and the vertical swinging steering engine of the tail structure are connected with a controller through wires. The desert quadruped robot imitating the lizard can ensure a stable and rapid walking state in the desert environment, and is high in adaptability to the desert environment. Meanwhile, intensity of pressure on sand grains from the legs is reduced, and small sinkage of the robot is ensured. The flexible tail structure not only can keep balance of the robot body in the walking process of the robot, but also can help the robot better escape from danger after the robot sinks into the sand.

Owner:SHANGHAI JIAO TONG UNIV

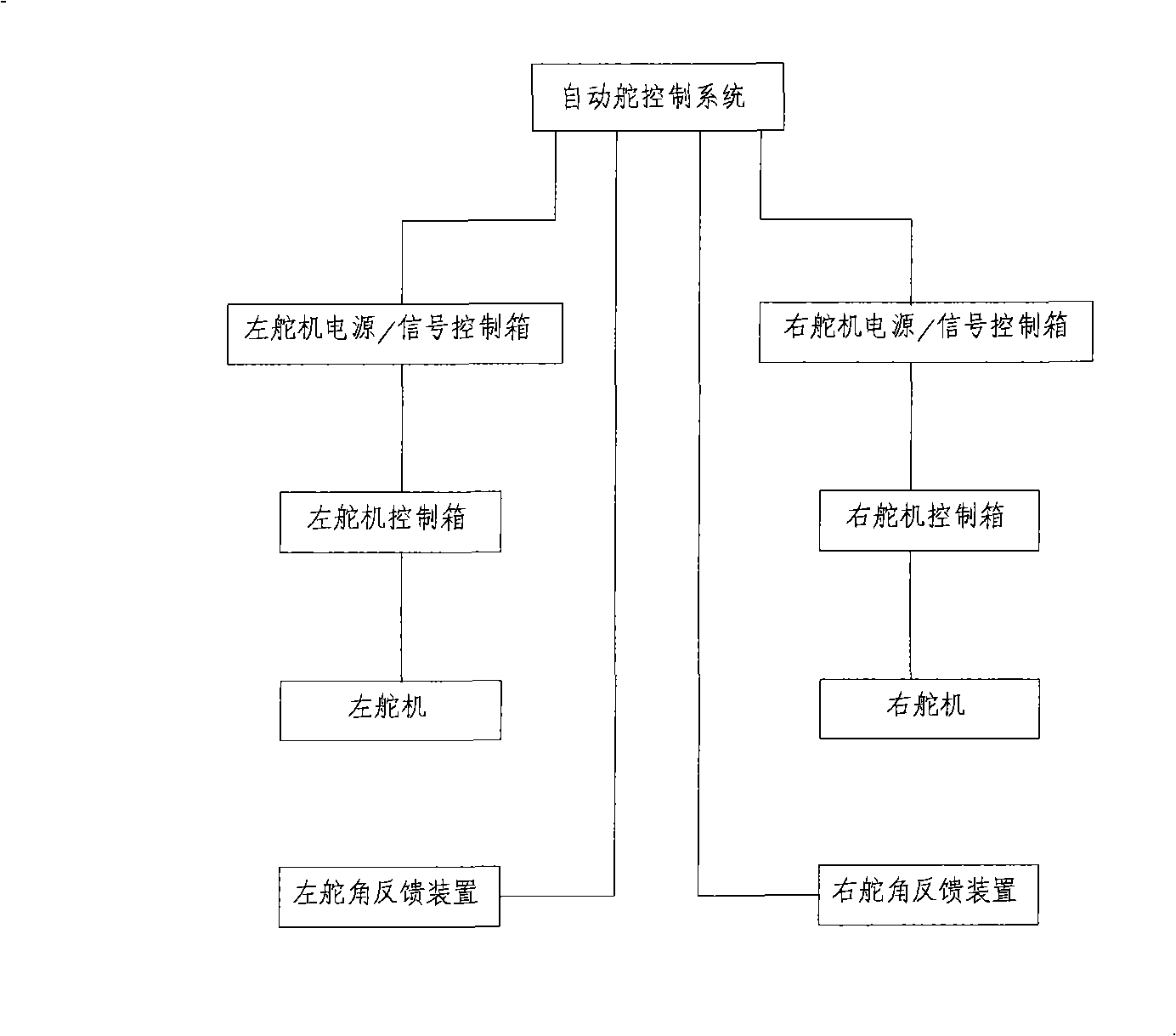

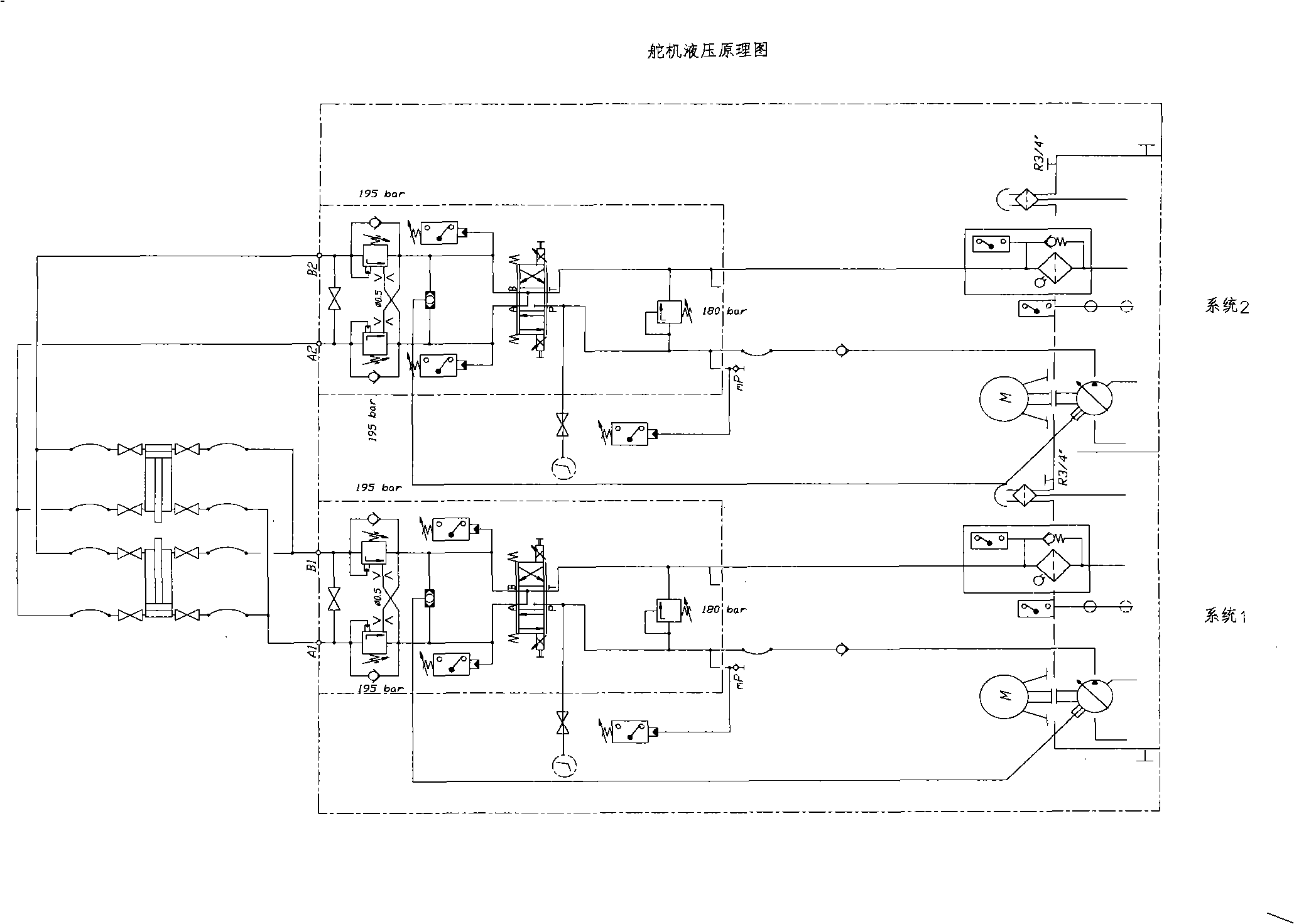

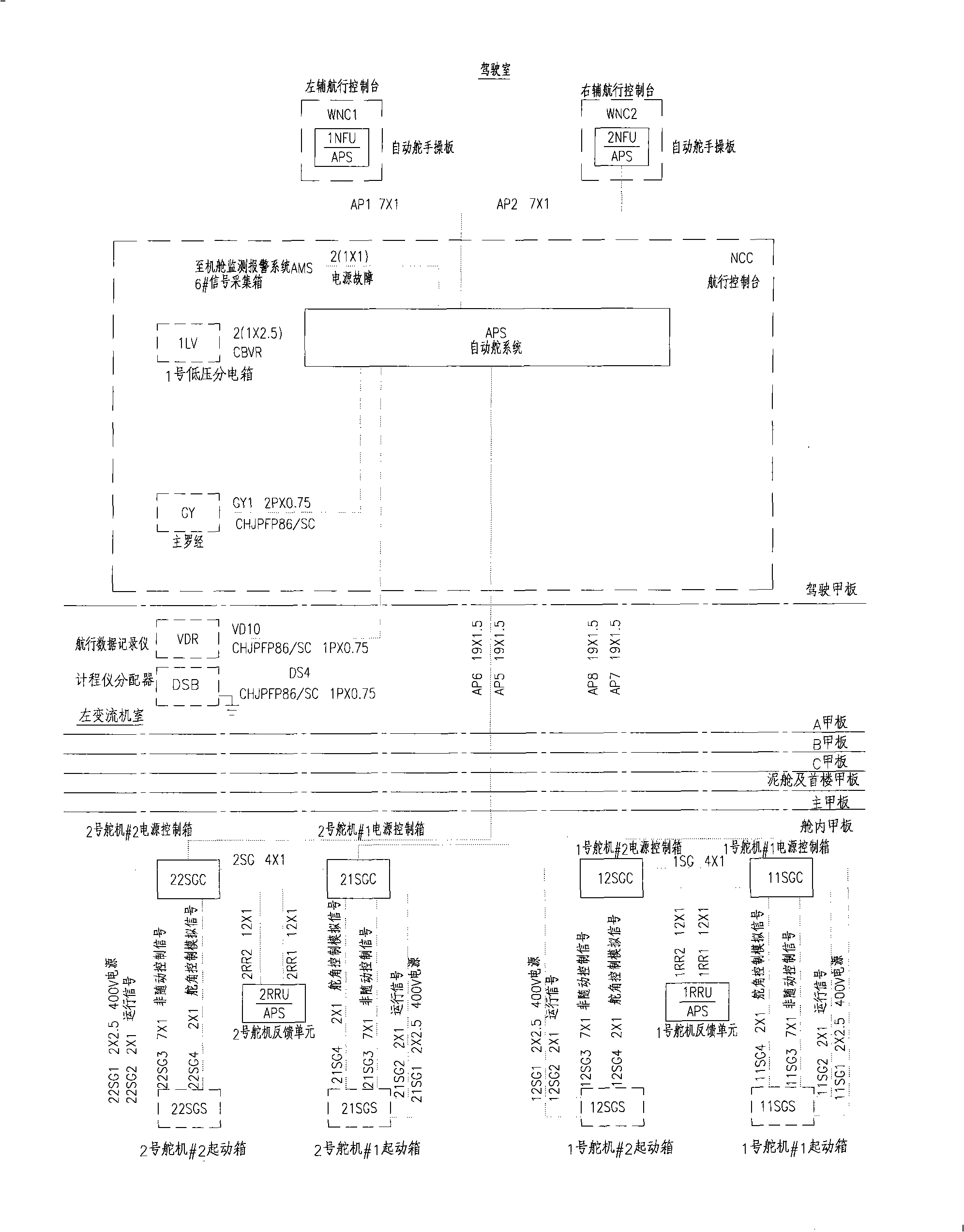

Electro-hydraulic proportional twin rudders follow-up synchronization operation controlled system

InactiveCN101289114AReduce mechanical vibrationProtect mechanical systemsSteering ruddersSolenoid valveHydraulic pump

The invention discloses an electric hydraulic proportion twin rudder following and synchronous operation control system, which comprises an autopilot control system, a left rudder machine power / signal control box, a left rudder machine control box, a left rudder machine system, a left rudder angle signal feedback device as well as a right rudder machine power / signal control box, a right rudder machine control box, a right rudder machine system and a right rudder angle signal feedback device. The left rudder machine system and the right rudder machine system adopt a hydraulic rudder machine control system which uses a variable hydraulic pump and a proportional electromagnetic valve as a control core. In the left rudder machine system and the right rudder machine system, two hydraulic pumps drive two sets of oscillating oil cylinders to drive a tiller; the autopilot control system is a self-adaptive autopilot control system. The control system has the advantages that as the proportional valve and a variable pump are adopted for control, the mechanical shock of the device is reduced so as to be convenient for maintenance; since the use of the proportional valve and steering signals are continuously variable, the continuously stable startup and stop of the whole system are realized to effectively reduce the mechanical shock, thus not only protecting the mechanical system of the rudder machine, but also being beneficial to reducing the mechanical shock of the tail structure; furthermore, the use of the variable hydraulic pump and the proportional valve meets the requirements of various single-control indexes and the synchronous operation for steering the twin rudders.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD +2

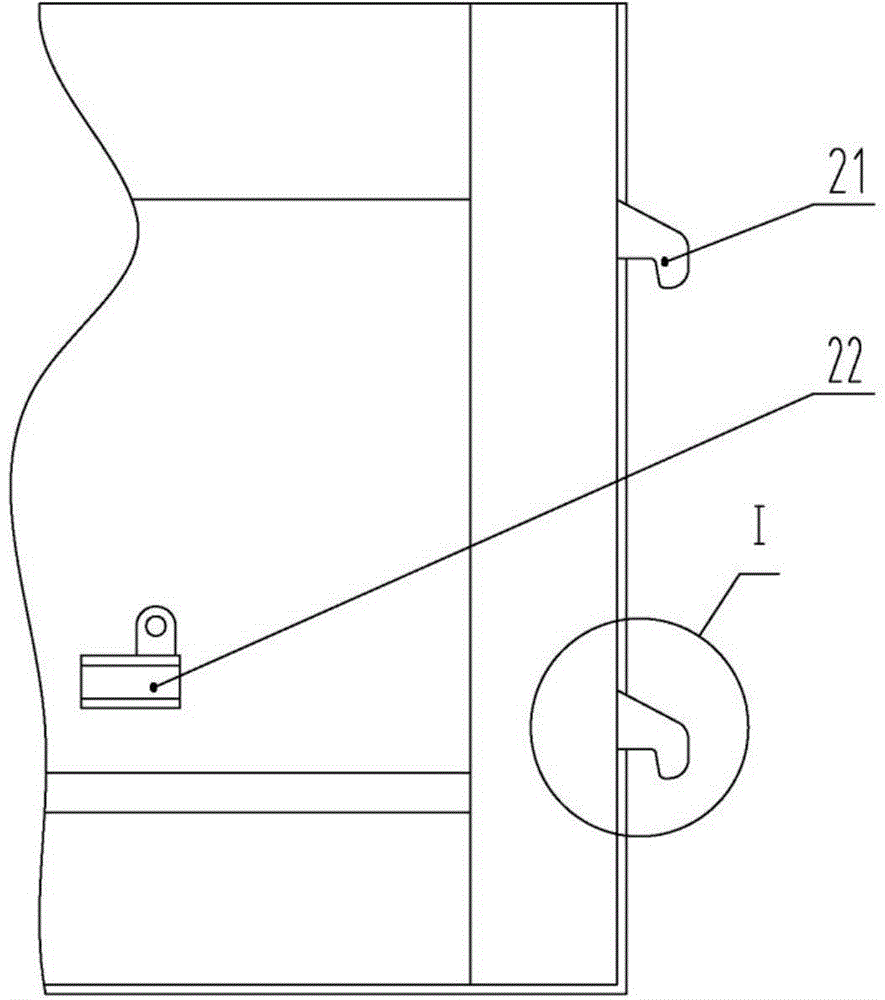

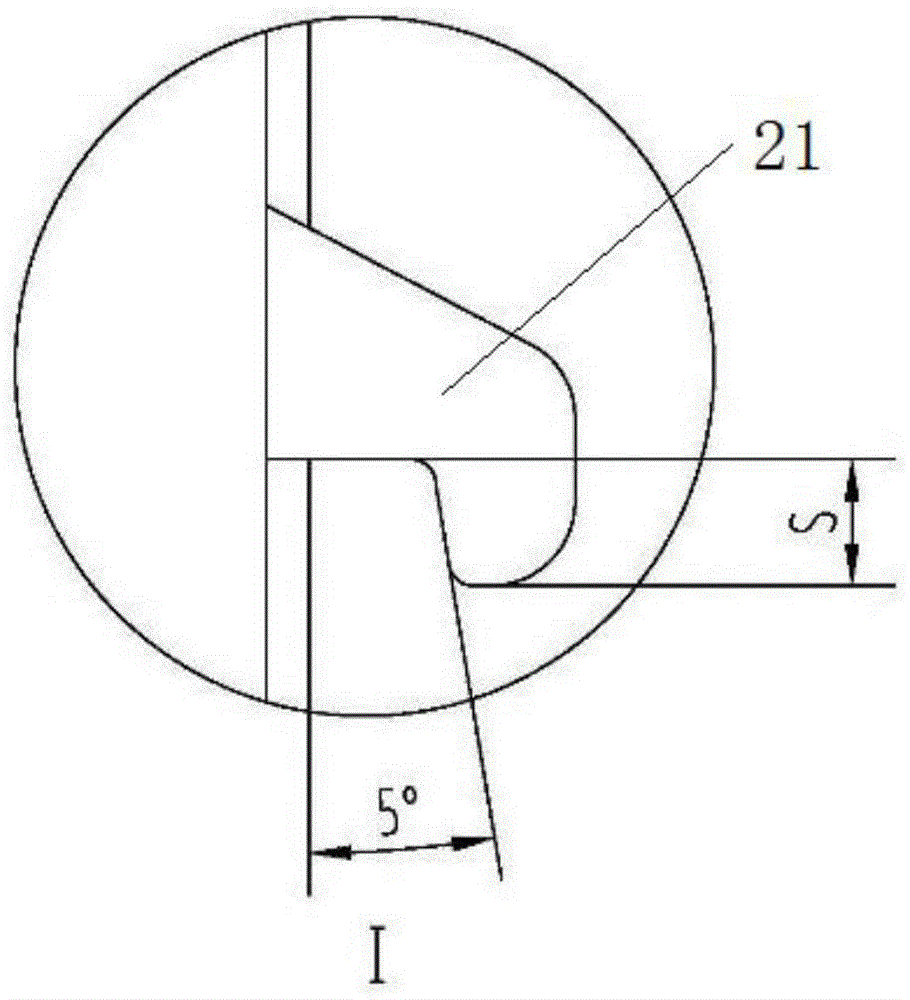

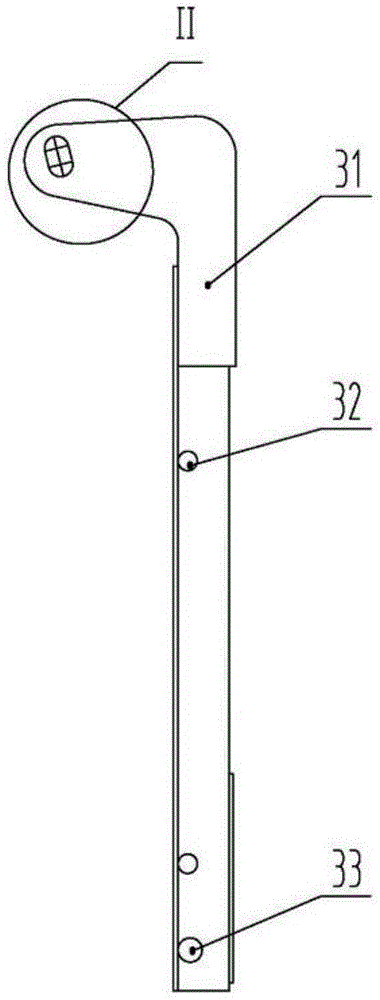

Dumper tail structure with hydraulic locking device

ActiveCN104691392AImprove fitPrevent leakageVehicle with tipping movementLoading-carrying vehicle superstructuresHydraulic cylinderEngineering

The invention discloses a dumper tail structure with a hydraulic locking device. The upper part of a back door body is a hinge plate which is hinged with a hinge seat, the hinge seat is arranged at the upper end of a dumper box body, an oblong hole is formed in a connection part between the hinge plate and the hinge seat and is matched with a connecting shaft on the hinge seat, and the connecting shaft and the oblong hole can generate relative movement; a latch hook clamping shaft is arranged at the lower part of the back door body, and a hook clamping shaft is arranged between the hinge plate and the latch hook clamping shaft on the back door body and is clamped with a hook on the side wall of the dumper box body. According to the dumper tail structure with the hydraulic locking device, a back door and the hydraulic locking device use cooperatively, the locking effect is excellent, the fitting degree of the back door and the box body can be improved, and material leakage can be effectively prevented; the hydraulic locking device can further prevent the back door from jumping up, and ensure the safety and the reliability of a vehicle during using; the hydraulic locking device can further increase the pushing force of a hydraulic cylinder, and provides a larger locking force; the dumper tail structure with the hydraulic locking device has the advantages of being simple in operation, safe, reliable and high in controllability.

Owner:SINO TRUK JINAN POWER

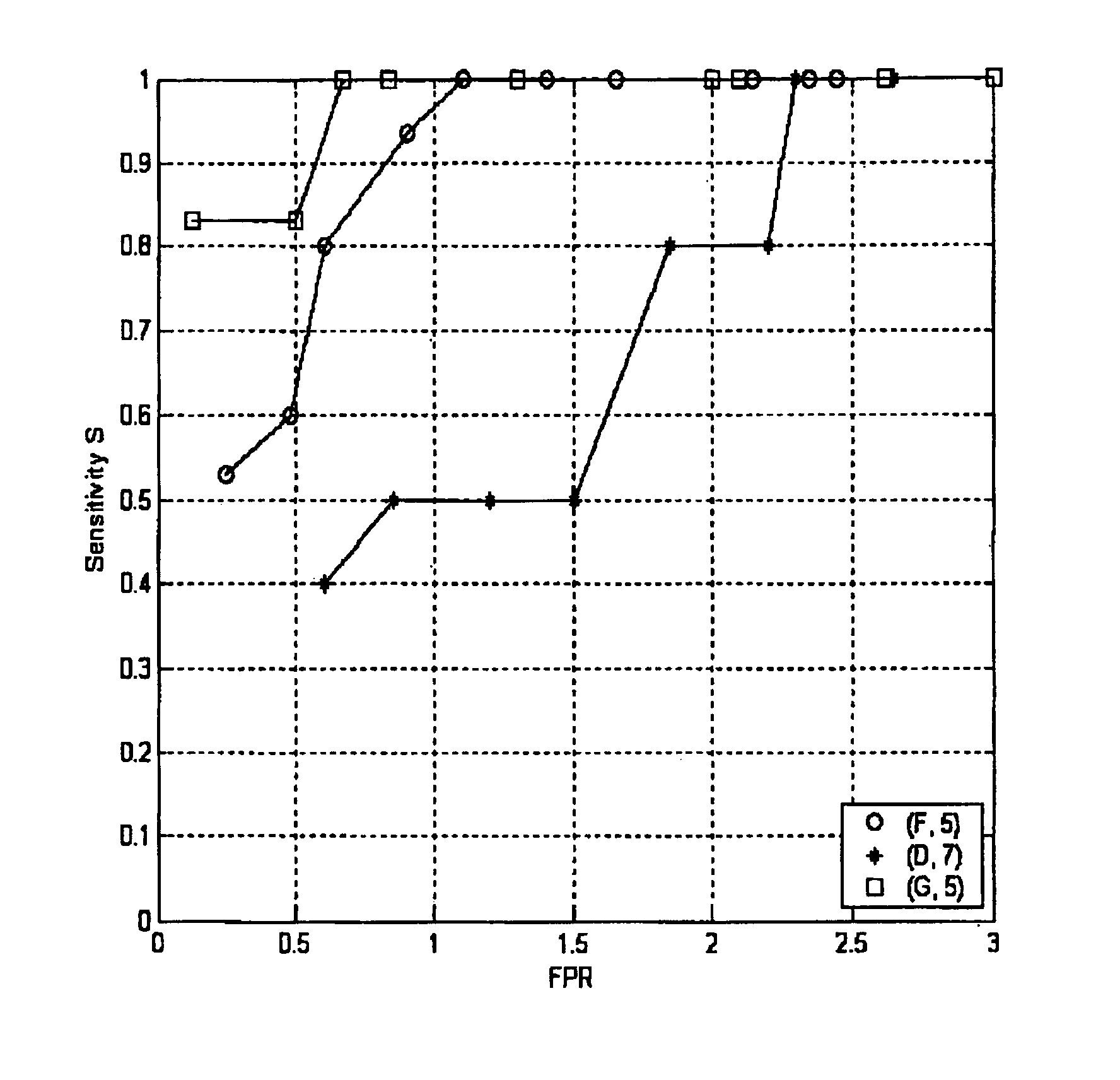

Nonparametric method for detection and identification of regions of concern in multidimensional intensity images

A method for detection and identification of regions of concern in multidimensional intensity images using a template and a nonparametric test is presented. Data corresponding to background intensity is extracted from the outer region of the template while data for mass detection is extracted from the inner region. The statistical nature of the background intensity, specifically the tail structure of the unknown distribution, is estimated via tolerance intervals. Mass detection is based on the fraction of test data within the tail structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

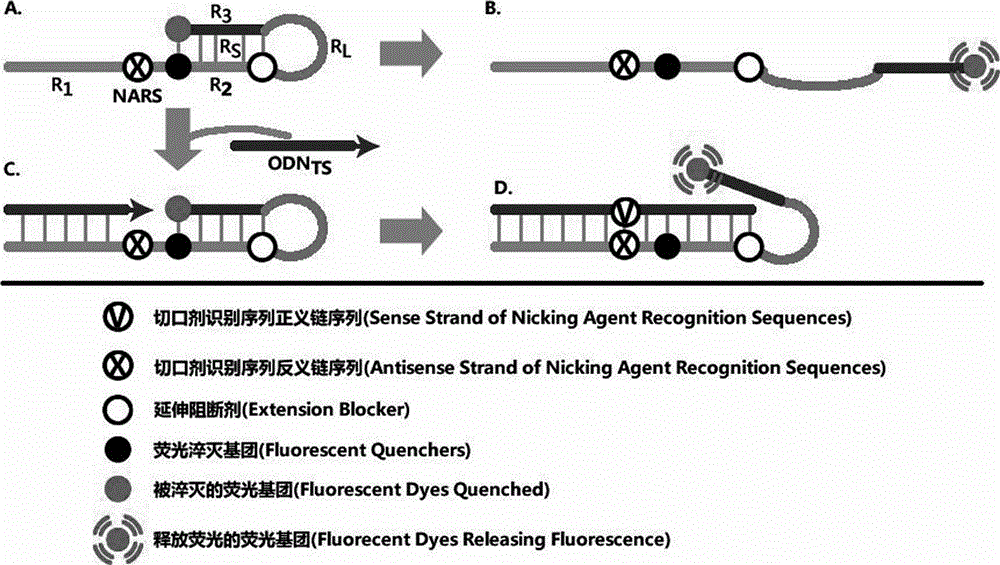

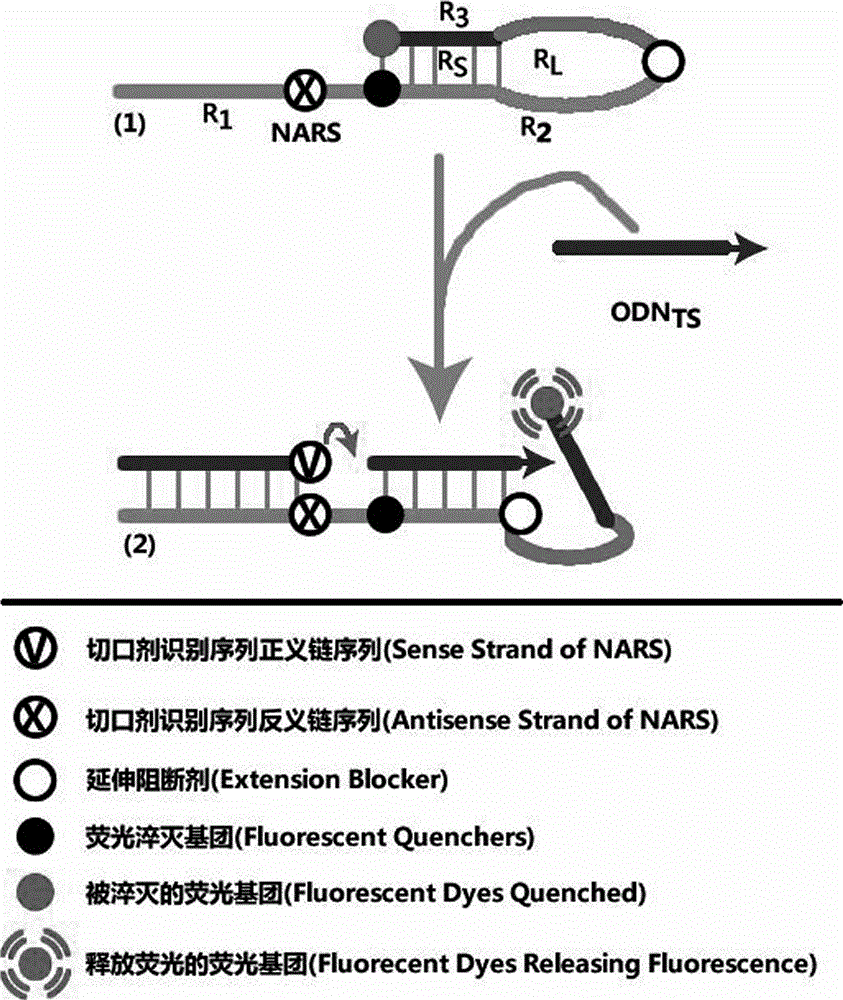

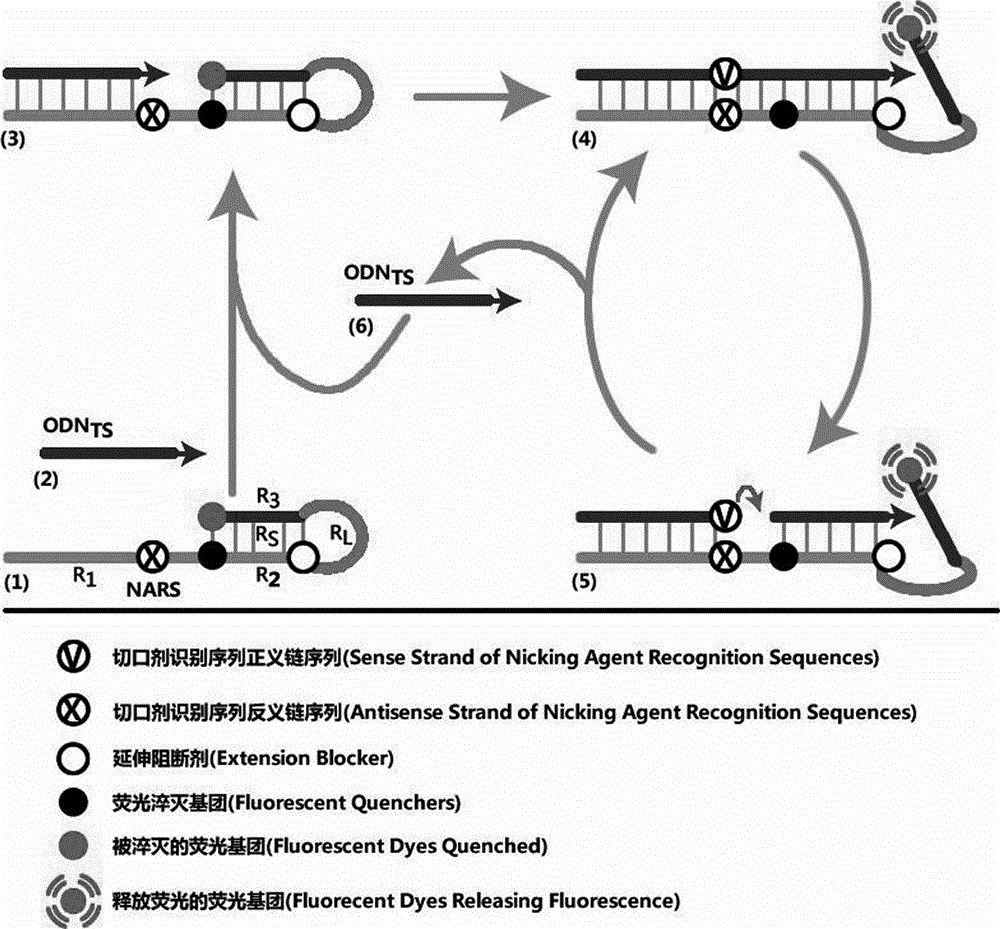

Real-time fluorescence constant temperature index amplification method

InactiveCN105154556AIncrease distanceAchieve qualitativeMicrobiological testing/measurementPolymerase LA-DNA

The invention provides a real-time fluorescence constant temperature index amplification method. According to the method, an oligonucleotide signal amplification template of a stem-ring-tail structure and marked with fluorescence or an oligonucleotide signal amplification template of a pure linear structure and marked with fluorescence are used, the process of cutting, extending and chain replacing can be executed repeatedly at the constant temperature under the combined action of a nicking agent with one chain of a cut double-chain nucleic acid molecule and a DNA polymerase with chain replacing activity, so that target molecule specific oligonucleotides are amplified in an index form, and fluorescence signals can be released. By means of varieties and abundance of the fluorescence signals released by the signal amplification templates corresponding to the different target molecule specific oligonucleotides, multiple target molecules can be detected in parallel in a single reaction tube, a detection tank or a detection hole, the target molecule specific oligonucleotides can be amplified by 106 times or more, and the technical problem that by means of an existing constant temperature amplification technology, multiple target molecules cannot be detected at the same time in one detecting system can be effectively solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

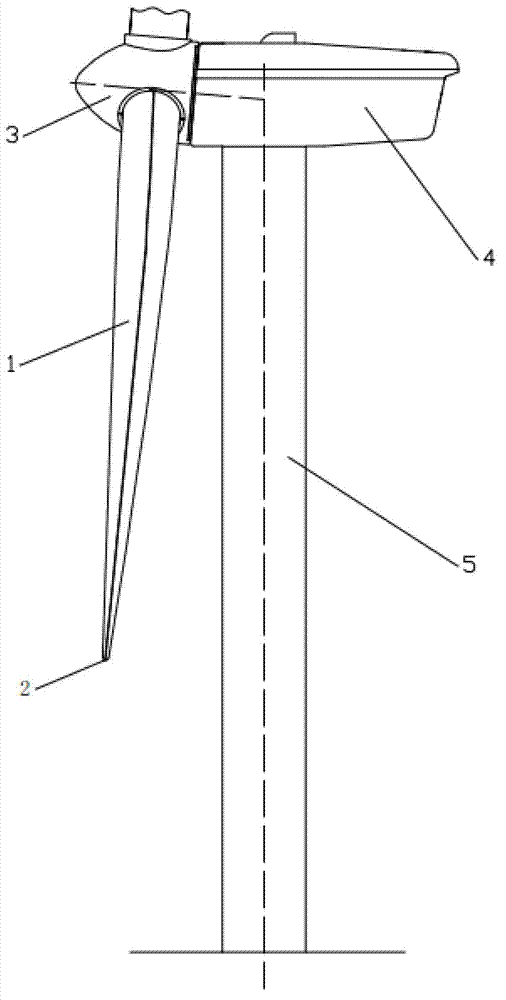

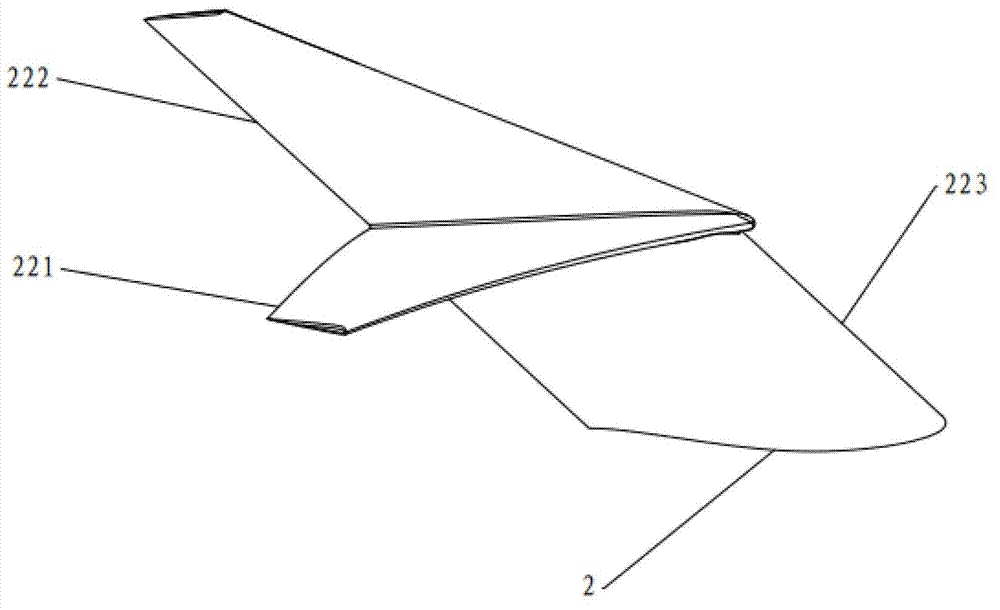

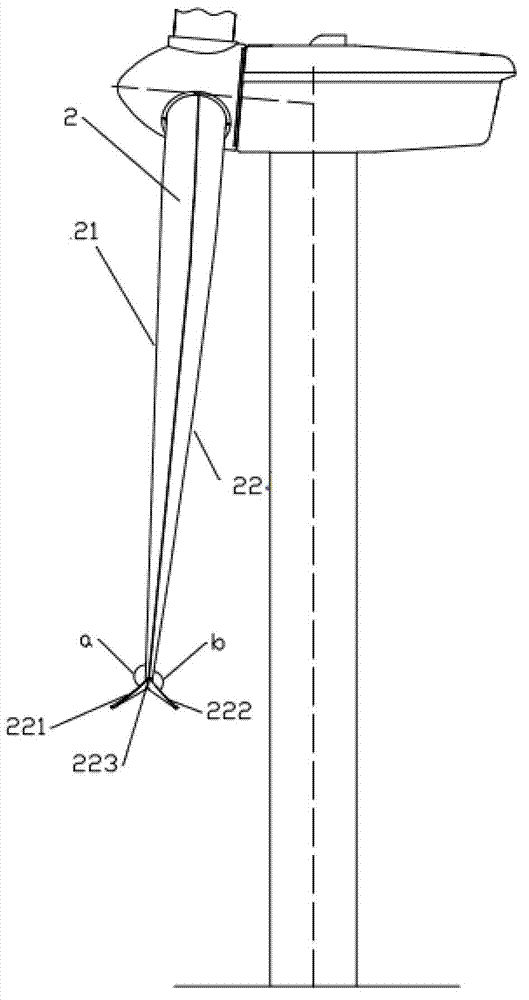

Wind turbine blade with tip vane

InactiveCN103485973ASuitable for different applicationsAchieve aerodynamic performanceMachines/enginesEngine componentsTurbine bladeTail structure

The invention provides a wind turbine blade with a tip vane. The wind turbine blade with the tip vane comprises a tip and a tip vane, wherein the tip vane further comprises an empennage connection component, a first empennage and a second empennage; the first empennage and the second empennage are simultaneously connected with one end of the empennage connection component to form a forked tail structure; the other end of the empennage connection component is sheathed and fixedly arranged on the tip; therefore an included angle is respectively formed between the first empennage and the wind turbine blade as well as between the second empennage and the wind turbine blade; the first empennage is positioned on the windward side of the wind turbine blade; the second empennage is positioned on the lee side of the wind turbine blade; and the first empennage and the second empennage are both of the flat structure and tangentially extend along the rotation track of the wind turbine blade. According to the wind turbine blade with the tip vane, which is disclosed by the invention, the aerodynamic characteristics and the surface load of the wind turbine are effectively improved, and the tip loss and the aerodynamic noise are reduced.

Owner:中国大唐集团科学技术研究总院有限公司 +2

Method of operating a solar aircraft

InactiveUS20120091263A1Maximize collectionWing shapesEfficient propulsion technologiesThermal energyHorizon

A system and method for assembling and operating a solar powered aircraft, composed of one or more modular constituent wing panels. Each wing panel includes at least one hinge interface that is configured to rotationally interface with a complementary hinge interface on another wing panel. When a first and second wing panel are coupled together via the rotational interface, they can rotate with respect to each other within a predetermined angular range. The aircraft further comprises a control system that is configured to acquire aircraft operating information and atmospheric information and use the same alter the angle between the wing panels, even if there are multiple wing panels. One or more of the wing panels can include photovoltaic cells and / or solar thermal cells to convert solar radiation energy or solar heat energy into electricity, that can be used to power electric motors. Further, the control system is configured to alter an angle between a wing panel and the horizon, or the angle between wing panels, to maximize solar radiation energy and solar thermal energy collection. A tail assembly for the aircraft includes a rotational pivot that allows the flight control surfaces to rotate to different orientations to avoid or reduce flutter loads and to increase solar radiation energy and / or solar thermal energy collection from photovoltaic cells and / or solar thermal cells the can be located on the tail structure associated with the flight control surfaces.

Owner:AURORA FLIGHT SCI CORP

Tri-rotor aircraft capable of vertical takeoff and landing and transitioning to forward flight

Systems, methods, and devices provide a vehicle, such as an aircraft, with rotors configured to function as a tri-copter for vertical takeoff and landing (“VTOL”) and a fixed-wing vehicle for forward flight. One rotor may be mounted at a front of the vehicle fuselage on a hinged structure controlled by an actuator to tilt from horizontal to vertical positions. Two additional rotors may be mounted on the horizontal surface of the vehicle tail structure with rotor axes oriented vertically to the fuselage. For forward flight of the vehicle, the front rotor may be rotated down such that the front rotor axis may be oriented horizontally along the fuselage and the front rotor may act as a propeller. For vertical flight, the front rotor may be rotated up such that the front rotor axis may be oriented vertically to the fuselage, while the tail rotors may be activated.

Owner:NASA

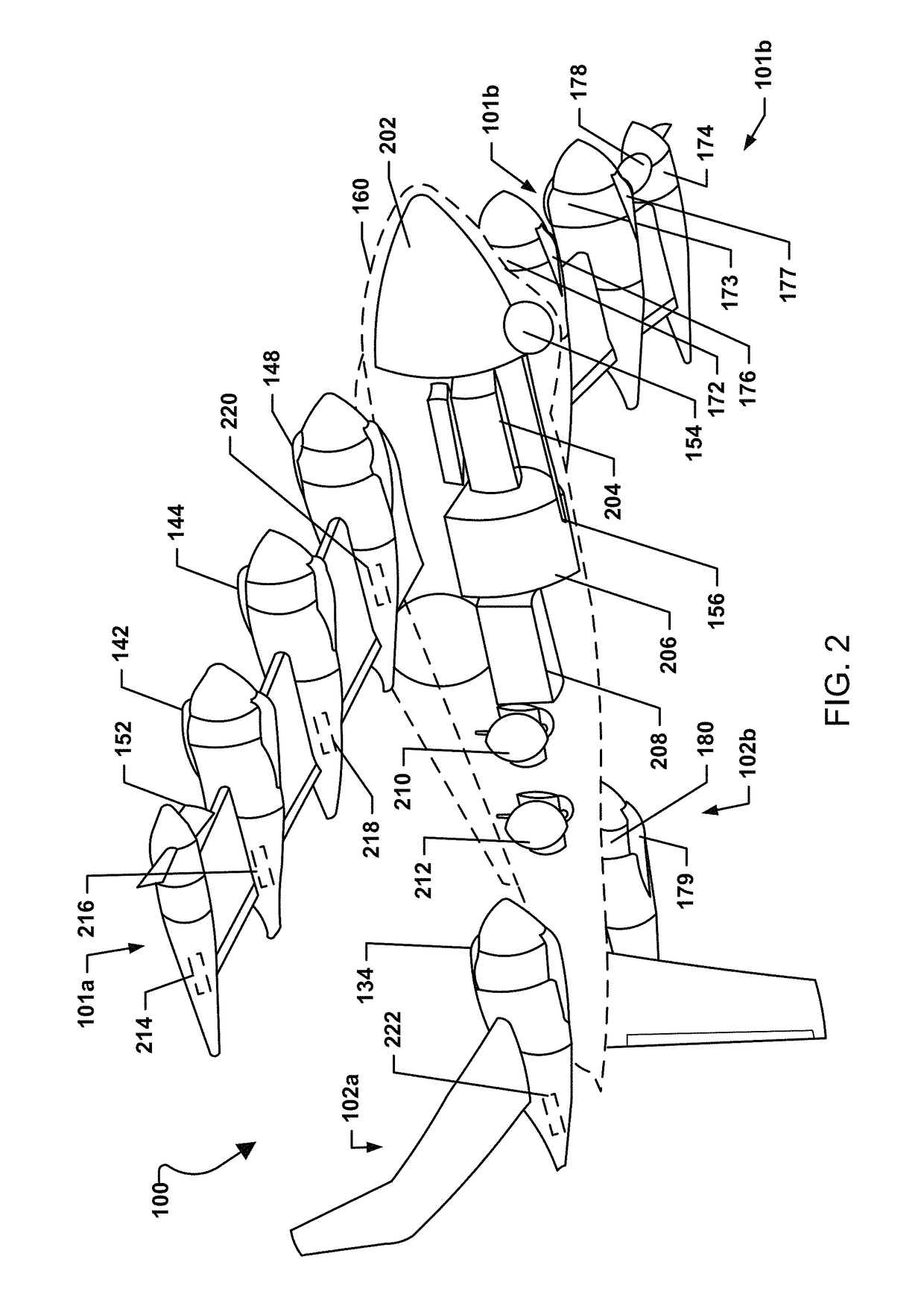

Annealing process of aluminum alloy coiled material

ActiveCN104087879AEffective monitoring of annealing temperatureMonitor annealing temperatureHeating furnaceToughness

The invention provides an annealing process of an aluminum alloy coiled material. According to the annealing process provided by the invention, the annealing time is greatly shortened,the problem of poor finished material coil head-tail structure property difference generated when annealing treatment is carried out on an aluminum-magnesium alloy coiled material is solved by adopting an existing aluminum alloy annealing process, the size of a crystal grain can be effectively controlled and the plasticity and toughness of a finished product state coiled material are improved. The annealing process is characterized by comprising the following steps: placing the aluminum alloy coiled material into an annealing heating furnace; fast heating the aluminum alloy coiled material by setting the furnace gas temperature of the annealing heating furnace as T+delta T, and monitoring the temperature of the aluminum alloy coiled material; when the outer side temperature of the aluminum alloy coiled material, namely the high-point temperature of the aluminum alloy coiled material, reaches T-delta t, reducing the furnace gas temperature of the annealing heating furnace to T, wherein the temperature reduction time is 60-90 minutes; and when the inner side temperature of the aluminum alloy coiled material, namely the low-point temperature of the aluminum alloy coiled material, is monitored to reach T-(5-30 DEG C), preserving heat for 60-120 minutes, and then taking out of the furnace for air-cooling, wherein the temperature T is the predetermined target temperature of the annealing of the aluminum alloy material, the delta T is 20-150 DEG C, and the delta t is 10-70 DEG C.

Owner:YINBANG CLAD MATERIAL

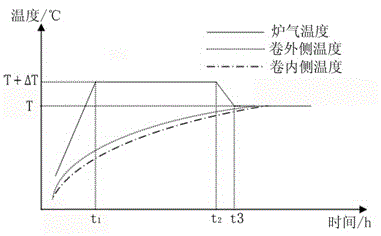

Fixed tube-sheet heat exchanger with temperature control function

InactiveCN103471431AImprove heat transfer coefficientReduce heat transfer areaHeat exchanger casingsStationary tubular conduit assembliesCircular discTemperature control

The invention relates to a fixed tube-sheet heat exchanger with a temperature control function. A head structure and a tail structure are respectively arranged at two ends of a shell, at least one heat exchange pipe is arranged in the shell, tube pass fluid flows out from a head cavity and flows in a tail cavity from the heat exchange pipe, a shell pass inlet and a shell pass outlet are arranged on the shell, the fixed tube-sheet heat exchanger with the temperature control function is characterized in that a central channel is also arranged in the shell, a heat-insulating layer is arranged on the inner wall of the central channel, the tube pass fluid flows out of the head cavity and flows in the tail cavity also by the central channel, the heat exchange between the tube pass fluid in the central channel and shell pass fluid can be isolated by the heat-insulating layer, at least one annular baffle plate and at least disc type baffle plate are also simultaneously arranged in the shell, and the tail cavity at least comprises one mixed cavity. The fixed tube-sheet heat exchanger with the temperature control function has the following beneficial effects that the heat exchange coefficient of the heat exchanger is effectively increased, the heat exchange area can be reduced, and the manufacturing cost of equipment can be lowered; the temperature control structure can ensure the running stability of the heat exchanger under variable working conditions, and guarantee the steady-state operation of downstream equipment of the heat exchanger.

Owner:SHANGHAI BOILER WORKS

Single Use Logistic Glider

A disposable airdropped glider. The glider body is constructed from precut panels cut from (MDO) or (HDO) plywood and assembled with pocket-screw joinery or piano hinges. A skid board forms a landing surface and a cargo deck roll-off surface. The glider has pivoting wings and struts. The glider has a triple-tail, a flat nose and honeycomb paperboard panels between the nose and the cargo. Wings are pivoted from a position overlying the fuselage to a flying position by gas springs in wing spars which are compressed by a chain attached to the fuselage through a rotating bracket such that the gas springs are compressed when the wings are folded. The airfoils are plastic extrusions with openings that hold the wing spars and co-formed jury spars which attach the upper and lower surface of the wing. A parachute uses a part of the tail structure to form a deployment drogue.

Owner:LOGISTIC GLIDERS INC

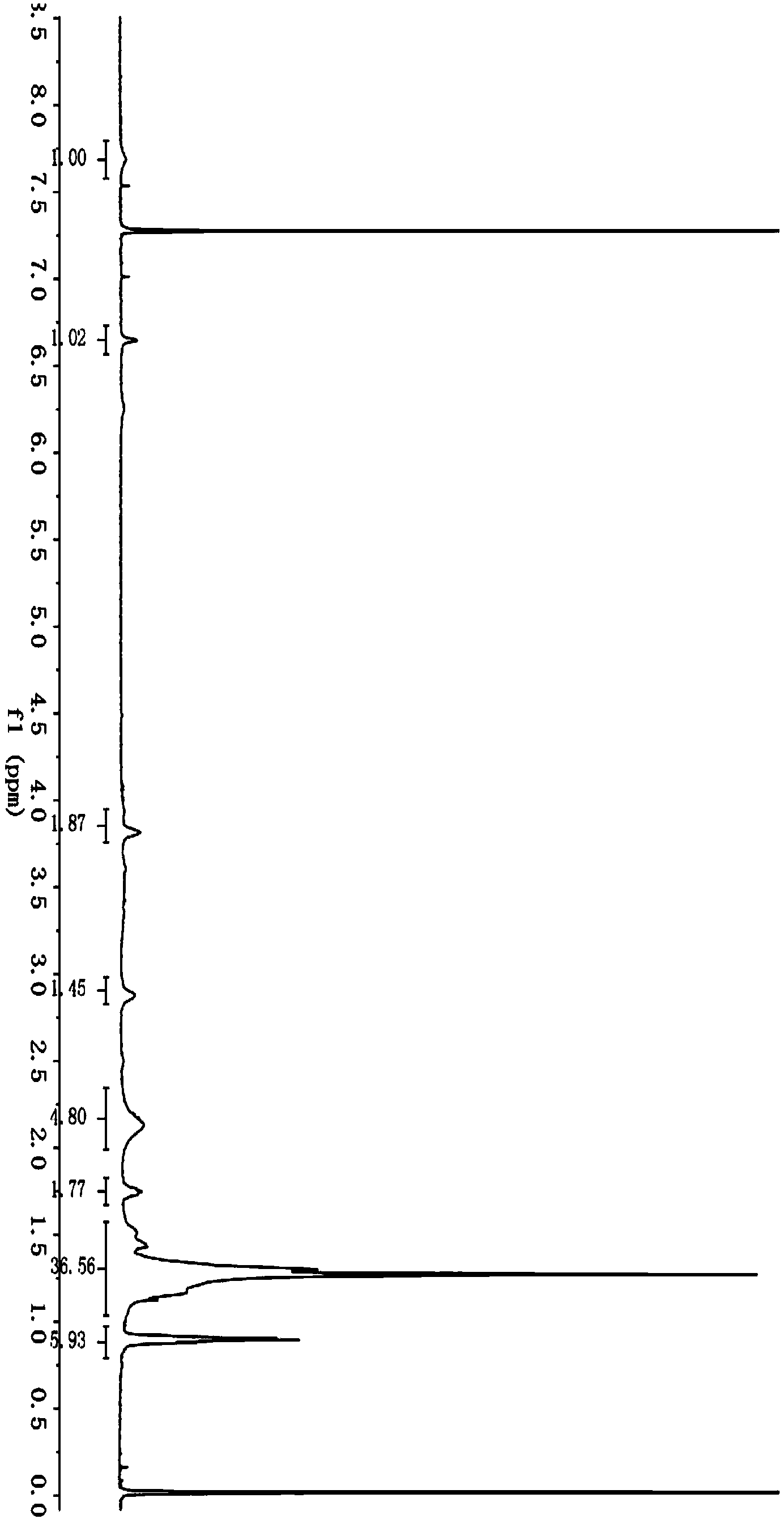

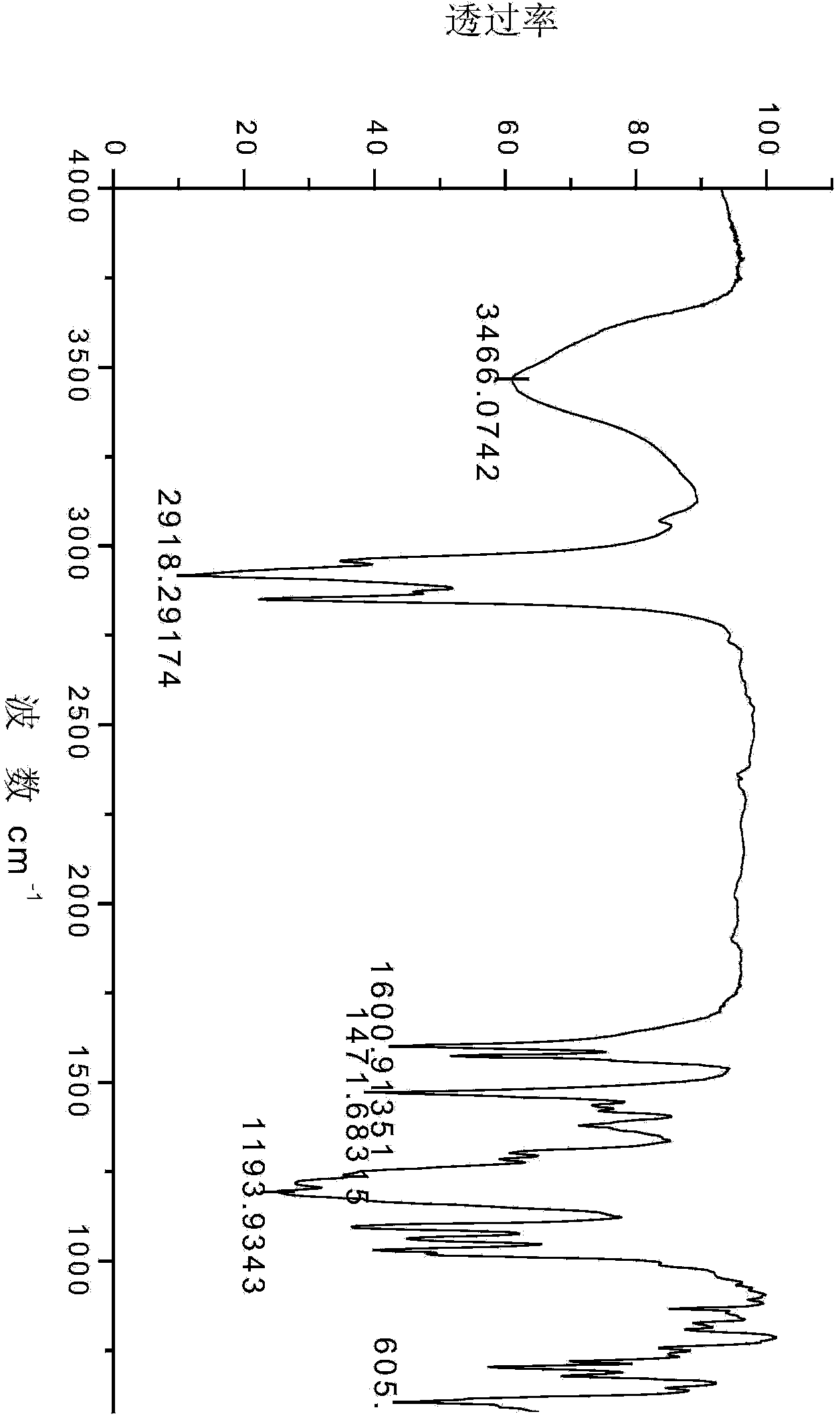

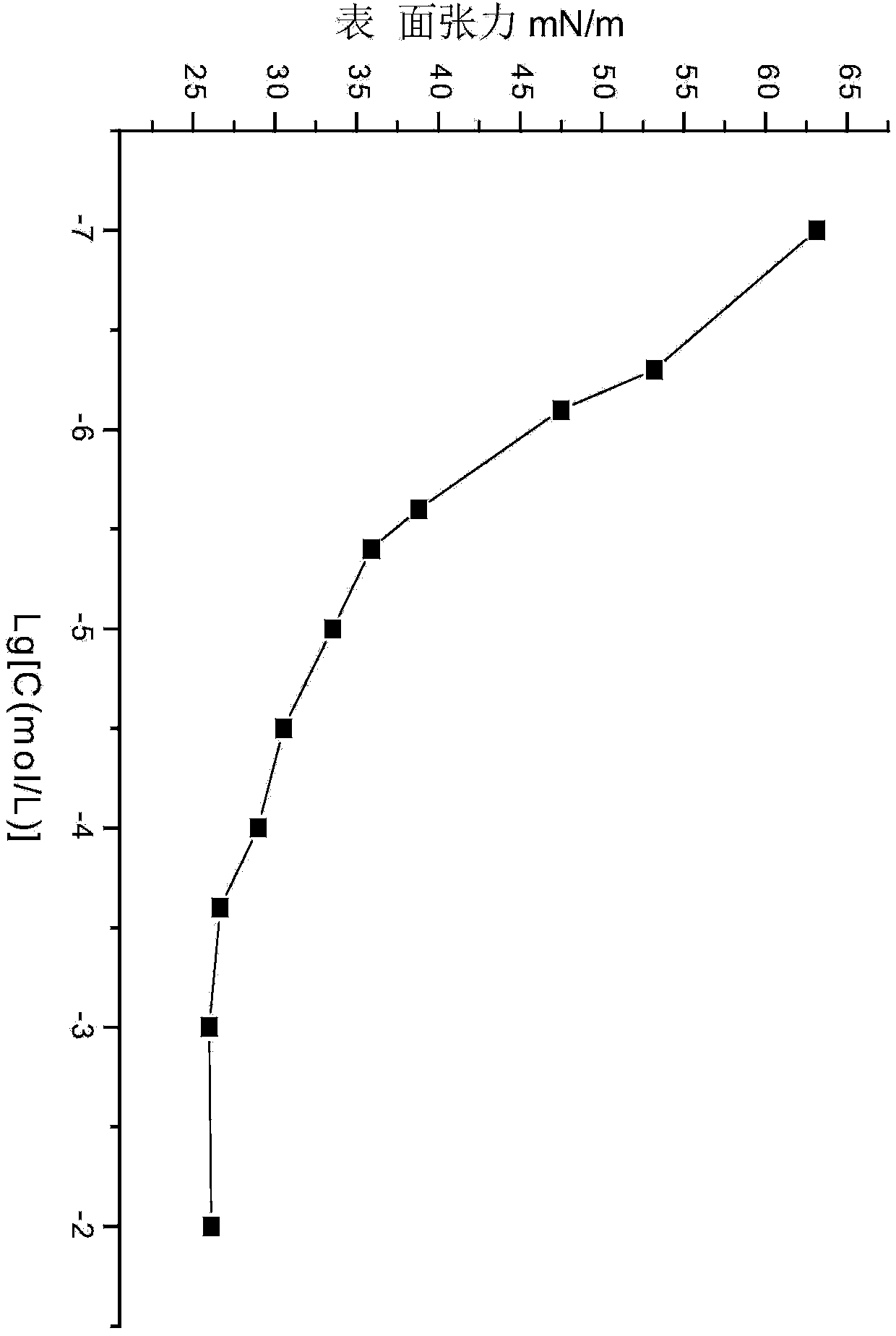

Saturated anacardol ether sulfonate surfactant as well as preparation method and application thereof

The invention belongs to the field of surfactants and particularly relates to a saturated anacardol ether sulfonate surfactant as well as a preparation method and application of the saturated anacardol ether sulfonate surfactant. According to the preparation method, saturated anacardol is taken as a starting material to be subjected to serial reactions to generate an anionic surfactant with a double-tail structure, namely saturated anacardol ether sulfonate; the surface (interface) performance of the anionic surfactant is good due to the unique double-tail structure, the anionic surfactant can form low (or ultralow) interfacial tension with simulated oil alkane or crude oil when being independently used or compounded with other auxiliary agents, has good application prospects in numerous fields including mineral floatation, industrial washing, tertiary oil recovery and the like and can be taken as an efficient oil displacement agent to be applied to the tertiary oil recovery. The saturated anacardol ether sulfonate surfactant has a following structure shown in the specification.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com