Saturated anacardol ether sulfonate surfactant as well as preparation method and application thereof

A technology of cardanol ether sulfonate and surfactant, applied in the field of saturated cardanol ether sulfonate surfactant and its preparation, capable of solving unmentioned problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

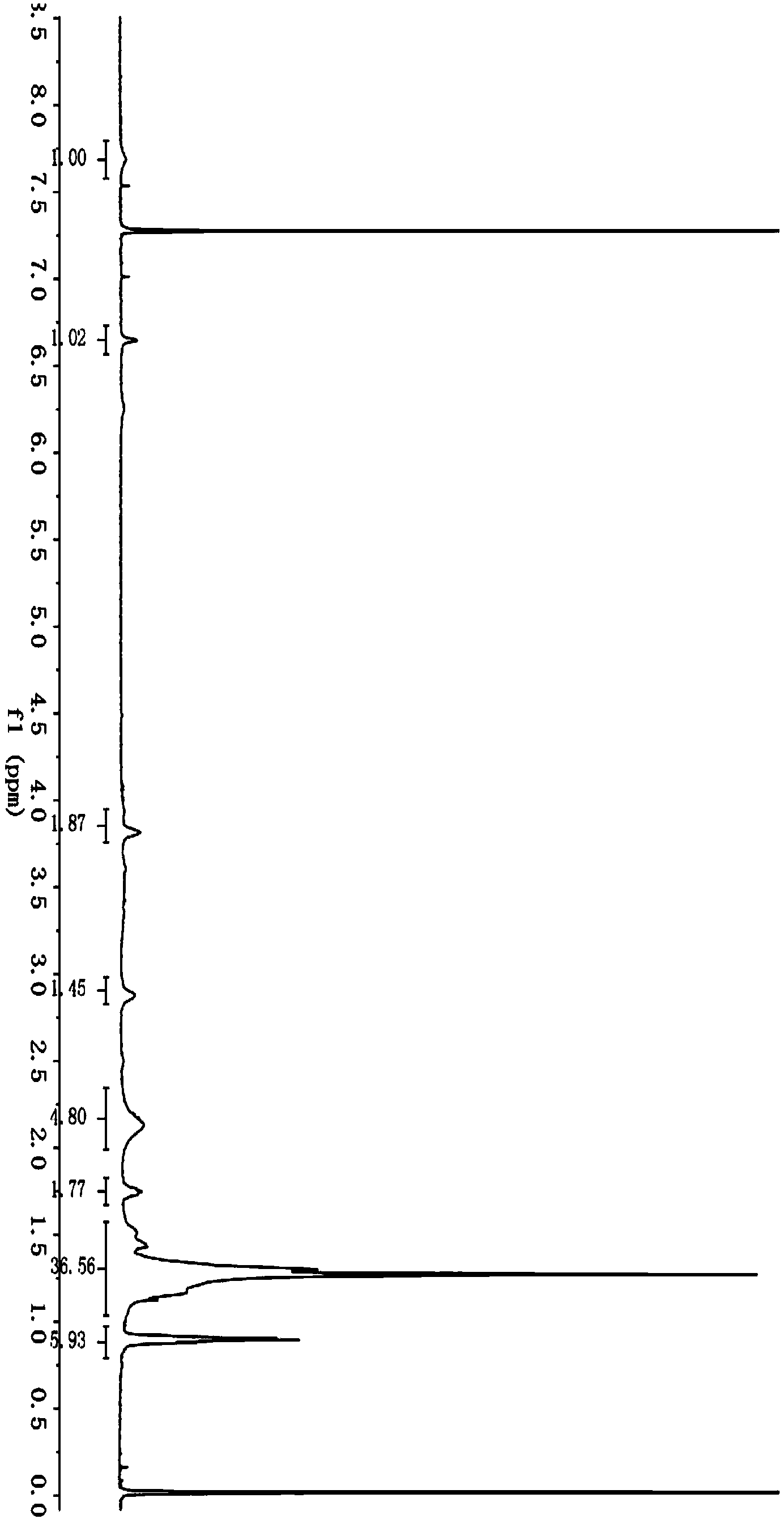

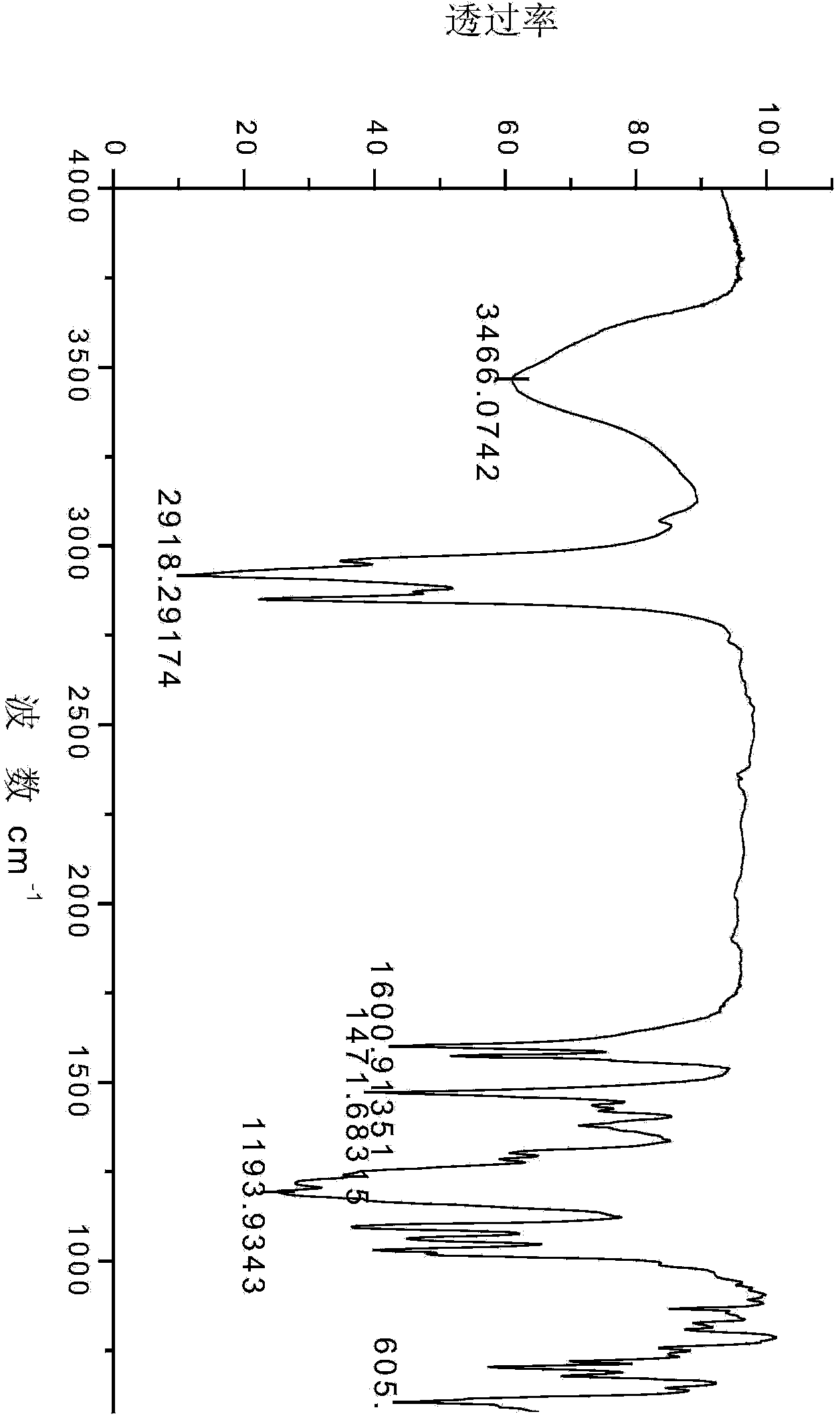

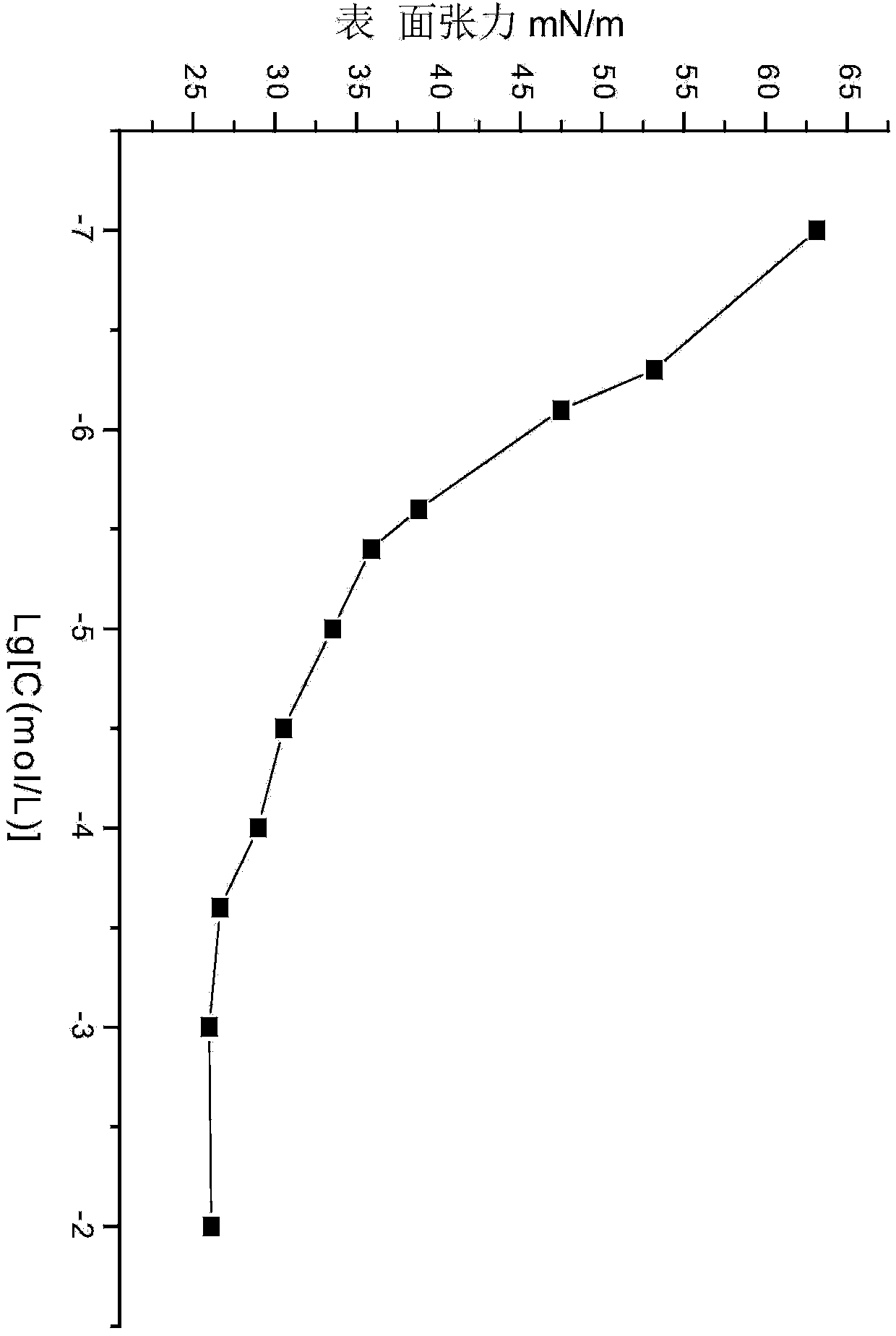

[0042] The preparation and application of embodiment 1 saturated cardanol butyl ether sulfonic acid sodium salt

[0043] (1). Synthesis of saturated cardanol butyl ether

[0044]At room temperature, add 0.025mol (7.61g) of saturated cardanol, 0.030mol (4.11g) of bromobutane and 0.2g of phase to a 50mL three-necked flask equipped with electromagnetic stirring, a thermometer, and a constant pressure dropping funnel. Transfer catalyst tetrabutylammonium bromide, heat at 80°C, add dropwise 6.25g of sodium hydroxide aqueous solution with a concentration of 40wt%, after the dropwise addition of the sodium hydroxide aqueous solution, carry out a reflux reaction for 6 hours, after the reflux reaction is completed, add 60mL of water , extracted 3 times with 80 mL of petroleum ether, combined the petroleum ether extracts, and carried out back-extraction with 50 mL of water for 3 times; dry the petroleum ether phase after back-extraction with water with anhydrous sodium sulfate, filter, ...

Embodiment 2

[0048] The preparation of embodiment 2 saturated cardanol decyl ether sulfonic acid sodium salt and its application

[0049] (1). Synthesis of saturated cardanol decyl ether

[0050] At room temperature, 0.025mol (7.61g) of saturated cardanol, 0.036mol (7.96g) of bromodecane and 0.15g phase transfer were added to a 50mL three-necked flask equipped with electromagnetic stirring, a thermometer and a constant pressure dropping funnel. The catalyst, tetrabutylammonium bromide, was heated at 85°C, and 6.5 g of sodium hydroxide aqueous solution with a concentration of 40 wt% was added dropwise. After the sodium hydroxide aqueous solution was added dropwise, a reflux reaction was carried out for 7 hours. After the reflux reaction was completed, 60 mL of water was added. Extract 3 times with 80 mL of petroleum ether, combine the petroleum ether extracts, and carry out back-extraction with 50 mL of water for 3 times; dry the petroleum ether phase after back-extraction with water with a...

Embodiment 3

[0054] The preparation of embodiment 3 saturated cardanol cetyl ether sulfonic acid sodium salt

[0055] (1). Synthesis of saturated cardanol cetyl ether

[0056] At room temperature, add 0.025mol (7.61g) of saturated cardanol, 0.032mol (9.76g) of bromohexadecane and 0.2g to a 50mL three-necked flask equipped with electromagnetic stirring, a thermometer and a constant pressure dropping funnel. The phase transfer catalyst tetrabutylammonium chloride was heated at 80°C, and 6.0 g of sodium hydroxide aqueous solution with a concentration of 40 wt % was added dropwise. After the sodium hydroxide aqueous solution was added dropwise, a reflux reaction was carried out for 7 hours. After the reflux reaction was completed, 60 mL of Water, extracted 3 times with 80 mL of petroleum ether, combined the petroleum ether extracts, and carried out back-extraction with 50 mL of water for 3 times; dry the petroleum ether phase after back-extraction with water over anhydrous sodium sulfate, filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com