Patents

Literature

42results about How to "Effective fixed load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Olefin two-phase hydroformylation method

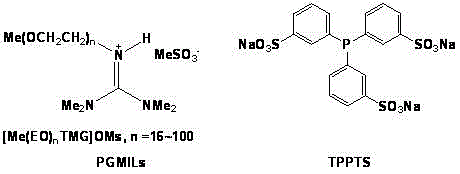

ActiveCN102617308AEffective fixed loadSeparation and easy handlingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by carbon monoxide reactionTPPTSPolymer science

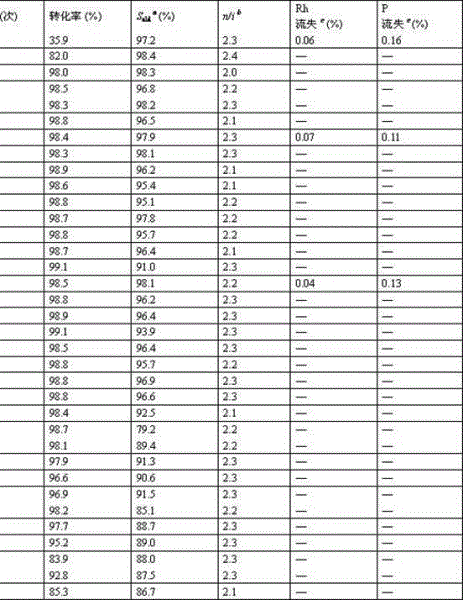

The invention relates to an olefin two-phase hydroformylation method, which consists of three parts: polyether guanidine mesylate ionic liquid (PGMILs) with room temperature solidifiable characteristics, complex catalysts (Rh-TPPTS) formed by RhCl3.3H2O or dicarbonylacetylacetonato rhodium and triphenylphosphine sodium trithionate (TPPTS), and reactants of C6-C14 straight chain 1-olefin, wherein the Rh-TPPTS is dissolved in the PGMILs to form a lower layer catalyst phase, the C6-C14 straight chain 1-olefin or product aldehyde forms an upper layer organic phase, the selectivity of high-carbon aldehyde is 85 to 99 percent, the mol ratio of normal aldehyde to isomerism aldehyde is 2.0 to 2.4, the PGMILs phase containing Rh-TPPTS can be cyclically used for 35 times, the activity and the selectivity are unchanged, the accumulated conversion number (TON) reaches higher than 30000, rhodium flowing to the product phase is 0.04 percent to 0.07 percent, and ultra-long-period catalysis activity and selectivity can be realized.

Owner:山东聚强绿洲生物科技有限公司

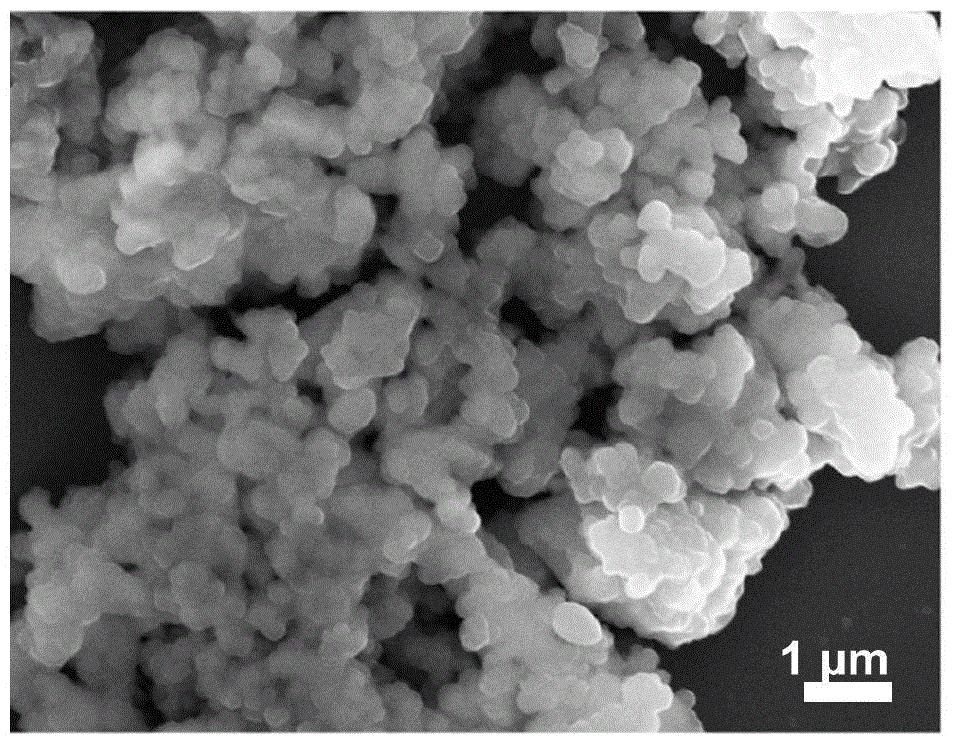

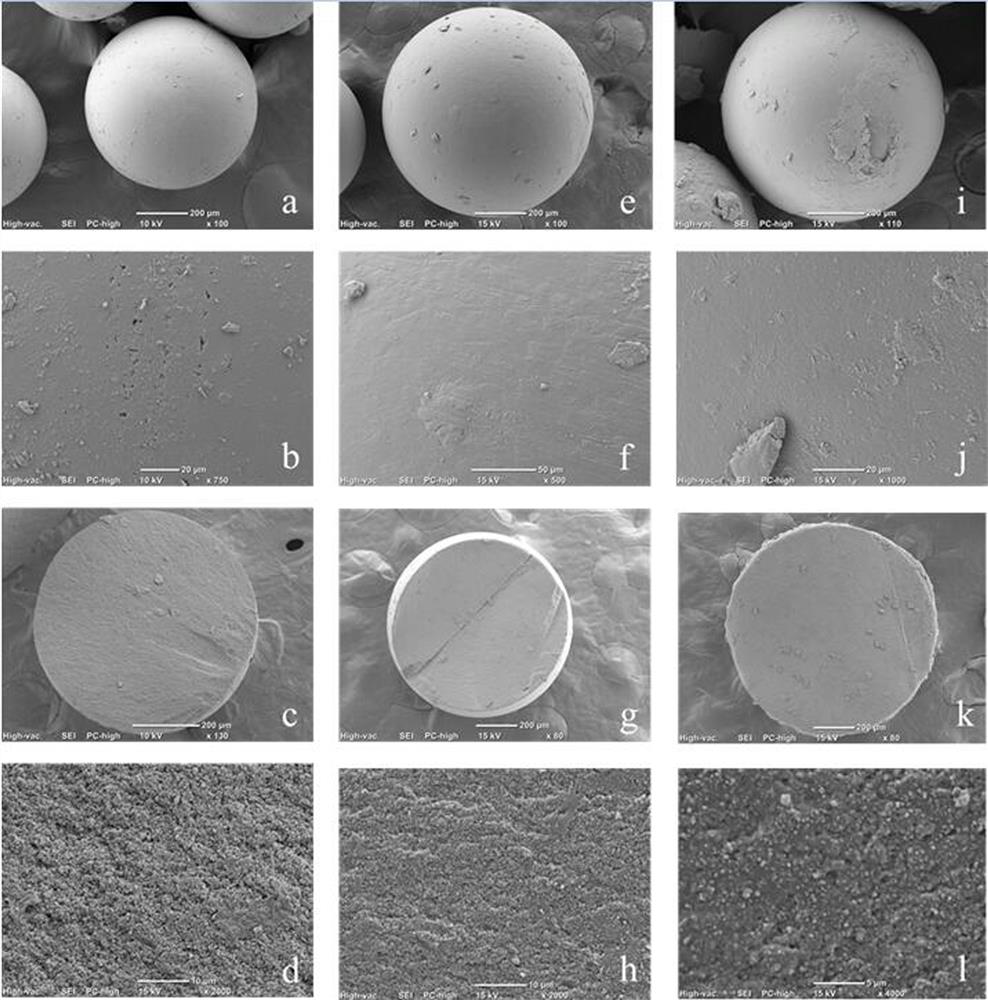

Preparation method of porous matrix composite phase change materials for recycling wide-temperature range afterheat

The invention belongs to the technical field of preparation of composite phase change materials, and particularly relates to a preparation method of porous matrix composite phase change materials for recycling wide-temperature range afterheat. The preparation method comprises the following steps: selecting porous materials (gamma-Al2O3, kaolin, laminated hydrotalcite, montmorillonoid and the like), which are good in heat stability, large in specific surface area, and easy to organically modify as matrix materials; and selecting different types of inorganic salts and multiple organic phase change materials as phase change core materials, and preparing a series of novel porous matrix composite phase change materials through a dispersion dipping method. The method has the advantages that 1) a simple and convenient method is developed to obtain a series of porous matrix composite phase change materials of which the phase change temperature changes in an echelon manner; 2) the prepared porous matrix composite phase change materials are capable of effectively immobilizing a phase change core material, the problems of leakage, corrosion and the like can be prevented, and the cost for secondary packaging is reduced; and 3) the method provided by the invention is simple in process, mild in reaction condition and suitable for large-scale industrial production.

Owner:UNIV OF SCI & TECH BEIJING

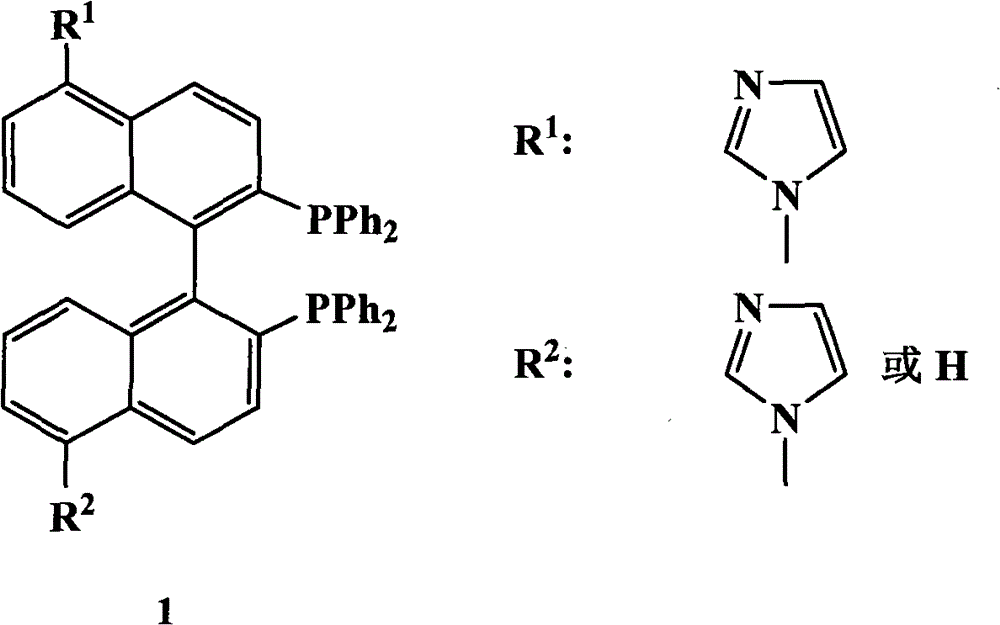

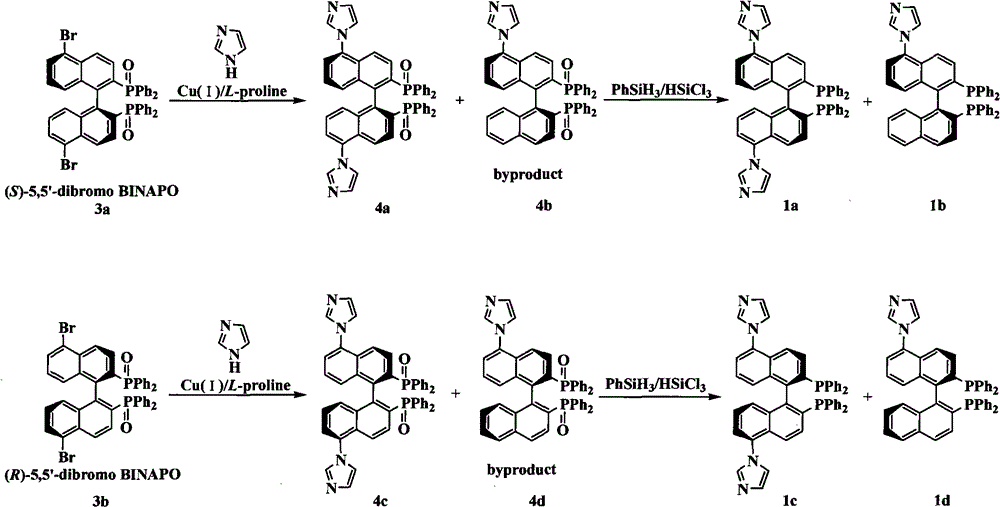

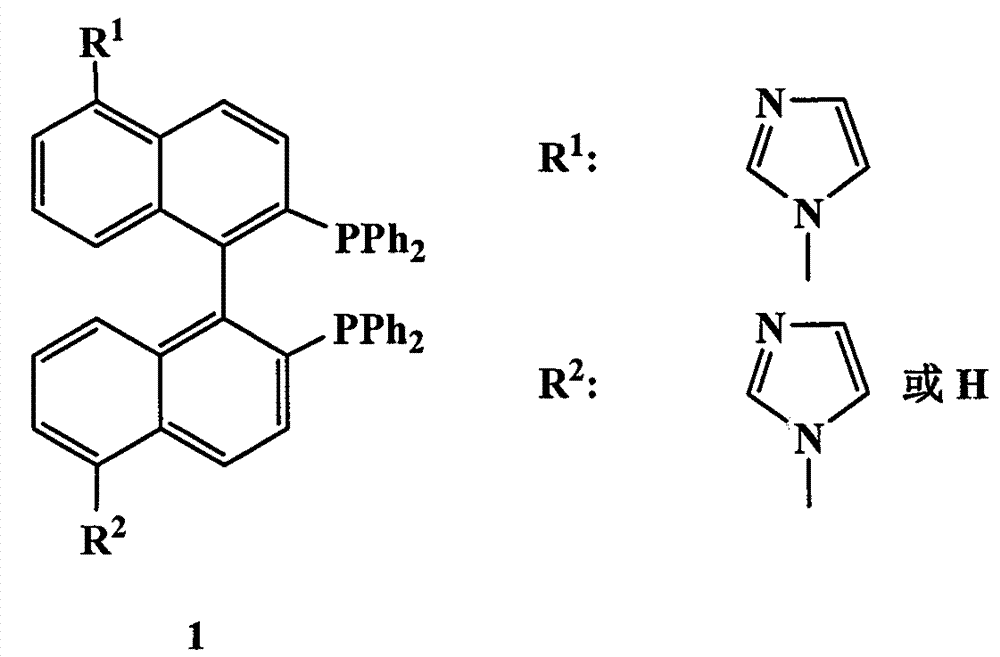

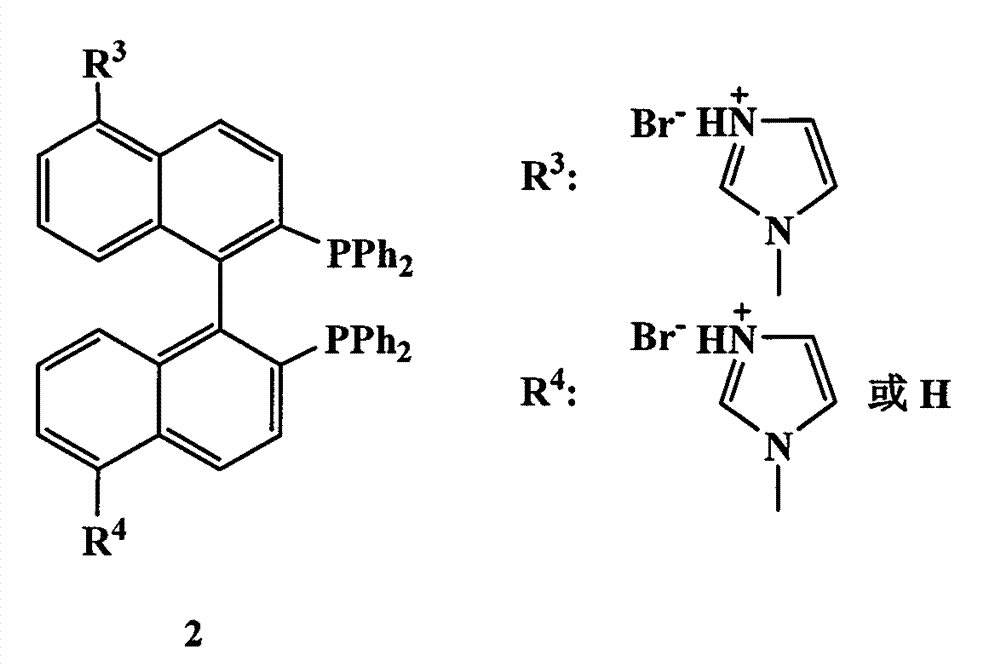

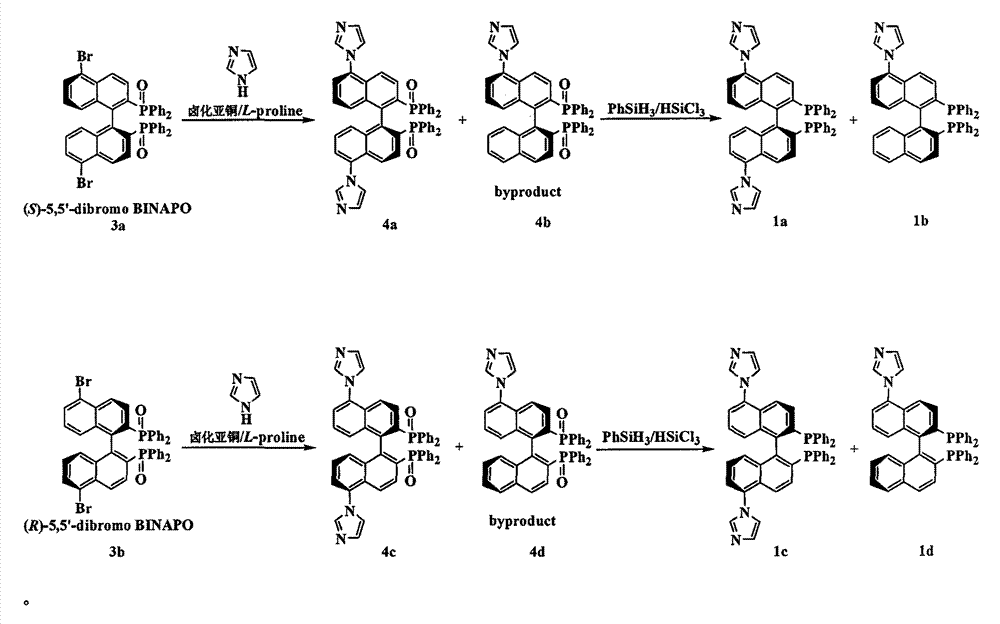

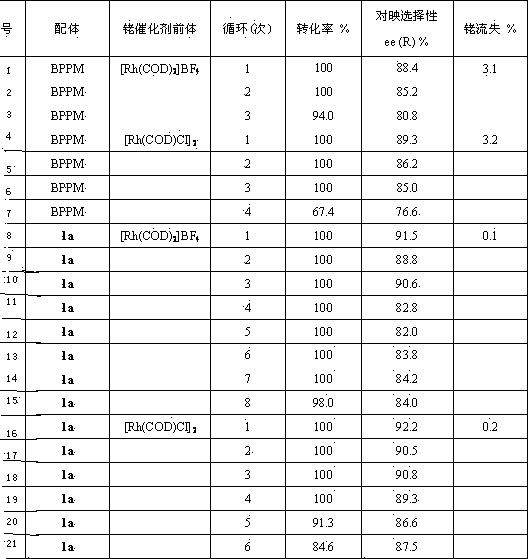

Chiral diphosphine ligand and chiral catalyst, and preparation and application method thereof

ActiveCN103059064AHigh affinityReduced activityOrganic compound preparationGroup 5/15 element organic compoundsCyclic processDiphosphines

The invention relates to a chiral diphosphine ligand and a chiral catalyst, and a preparation and application method thereof. The preparation method of a BINAP (2,2'-bis(diphenylphosphino)-1,1'-binaphthyl) chiral diphosphine ligand based on novel imidazole and imidazole cation modification. Imidazole and imidazole cation are introduced to the 5,5'- position of the BINAP molecule framework to synthesize the chiral diphosphine ligand. The assembly of the imidazole and imidazole cation into the chiral diphosphine ligand molecule can effectively enhance the stability of the chiral catalyst in an ionic liquid and the affinity with the imidazole ionic liquid, and avoids loss of the catalyst in the cyclic process. The imidazole-modified chiral diphosphine ligand has the following chemical structural formula, wherein the spatial configuration of the imidazole-modified chiral diphosphine ligand is S type or R type.

Owner:山东聚强绿洲生物科技有限公司

Preparation method of supermolecule gel-based composite phase change material

The invention discloses a preparation method of a supermolecule gel-based composite phase change material and belongs to the fields of composite materials and composite phase change materials. The preparation method comprises the following steps: preparing a supermolecule gel substrate with a three-dimensional network structure, and regulating the ratio of added raw materials and the three-dimensional network structure of the substrate, so as to well match different types of phase change core materials; dissolving the phase change core materials into water / alcohol to prepare a solution, dispersing the prepared supermolecule gel substrate into the water / alcohol solution of the phase change materials, and drying, so as to obtain the supermolecule gel-based composite phase change material with the shaping superiority. According to the supermolecule gel-based composite phase change material prepared by virtue of the preparation method, the phase change core materials can be effectively immobilized by virtue of a specific network mutual transmission structure of the supermolecule gel substrate, and the leakage problem of the phase change core materials is solved; the developed composite phase change material has relatively good compatibility with the phase change core materials and can be adaptable to different types of the phase change core materials. The preparation method is simple, convenient, feasible, beneficial to large-scale production and wide in application prospect, the process is simple, and conditions are mild.

Owner:UNIV OF SCI & TECH BEIJING

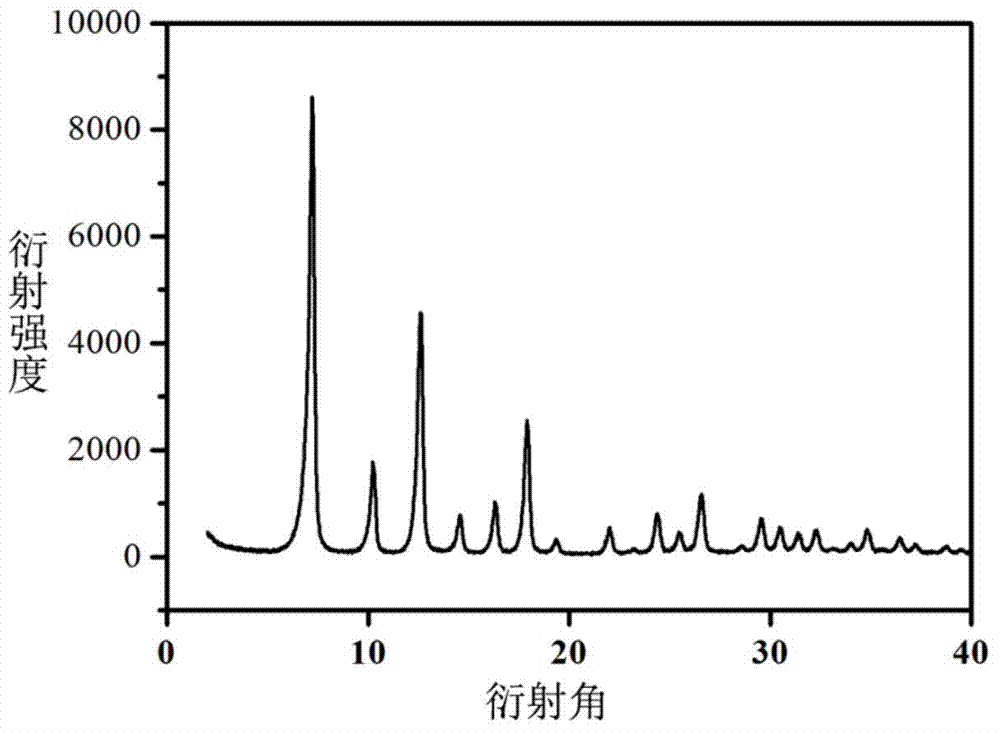

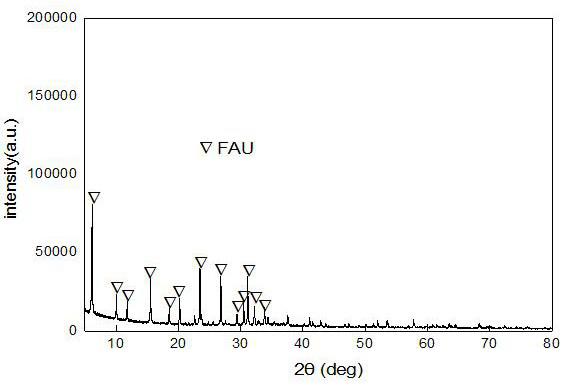

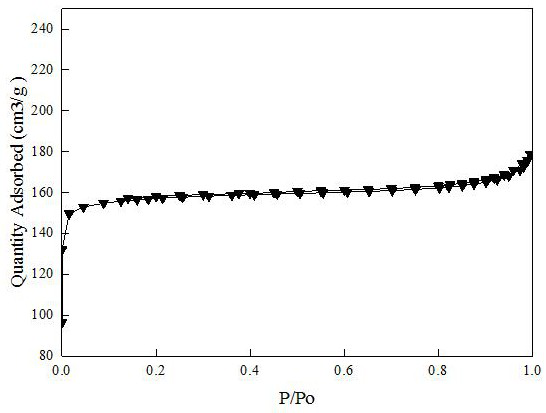

Microporous material loaded ion liquid composite material or film, and preparation thereof

InactiveCN104722284AEffective fixed loadRestricted mobilityOther chemical processesAlkali metal oxides/hydroxidesComposite filmIonic liquid

The invention relates to a microporous material loaded ion liquid composite material or film, and preparation thereof. According to the present invention, the hole cage of a crystallized or amorphous microporous material is adopted as an ion liquid support carrier to prepare the corresponding novel microporous material-ion liquid composite material or microporous material-ion liquid composite film; in-situ synthesis and post-treatment are performed to obtain the novel microporous material loaded ion liquid composite material and the film thereof; and the novel microporous material loaded ion liquid composite material and the film thereof provide special selective adsorption and good separation and purification on small molecule gas.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

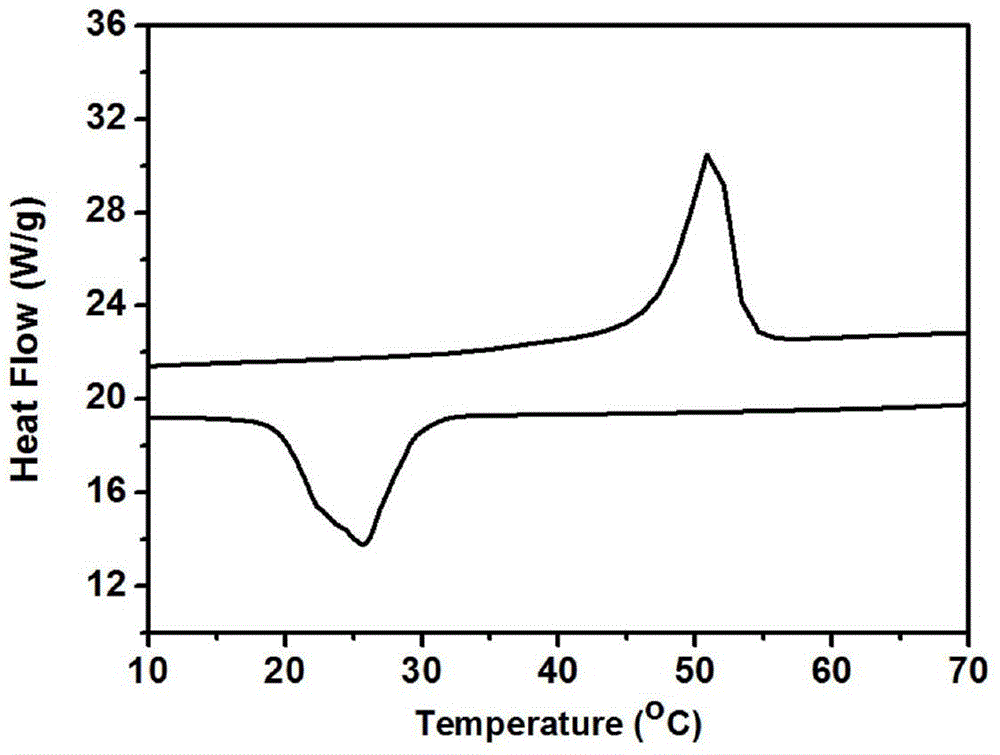

High-performance composite phase-change material and preparation method thereof

ActiveCN108251063AShape stableUniform structureHeat-exchange elementsIndustrial wasteHigh power lasers

The invention discloses a high-performance composite phase-change material, belonging to the technical field of composite materials. The high-performance composite phase-change material comprises liquid alloy with high latent heat of phase change and a modified carbon nanotube sponge skeleton, wherein the modified carbon nanotube sponge skeleton is filled with the liquid alloy with high latent heat of phase change. The high-performance composite phase-change material comprises the liquid alloy with high latent heat of phase change and a melting point adjustable in a range of 20 to 130 DEG C and the modified carbon nanotube sponge skeleton with high thermal conductivity, wherein the liquid alloy uses InSnBi alloy as a substrate and one or more selected from a group consisting of high-enthalpy elements Ga, Cd, Zn and Sb as additives. The high-performance composite phase-change material has high latent heat of volume phase change, high thermal conductivity, low expansion and a melting point adjustable in a range of 20 to 130 DEG C; and the material has excellent and stable thermophysical characteristics and shows good application prospects in fields with high requirements for high-grade heat dissipation, e.g., heat dissipation of high-power lasers, the utilization of industrial waste heat, solar power generation, cooling of fuel cells, photoelectric devices, micro-nano-electronicmechanical systems.

Owner:GRIMAT ENG INST CO LTD

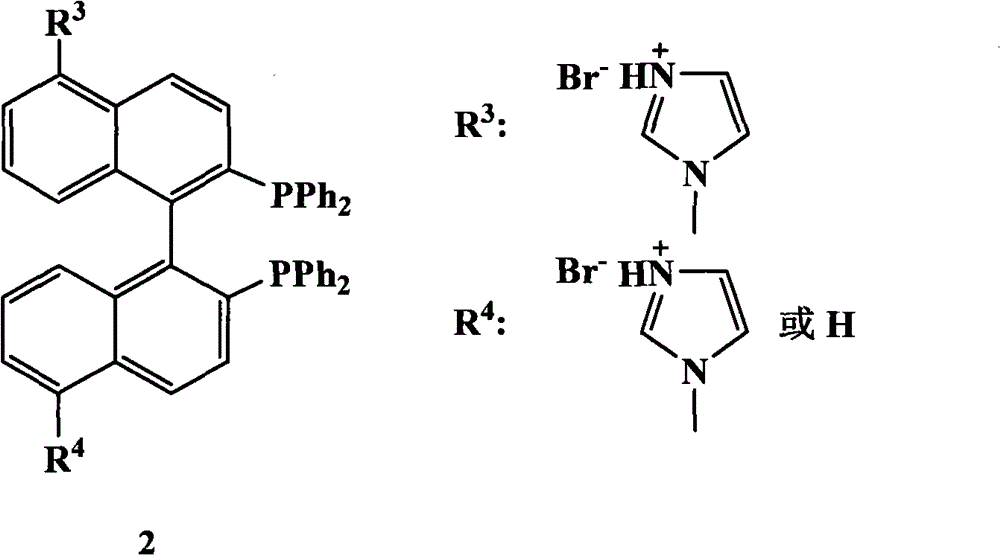

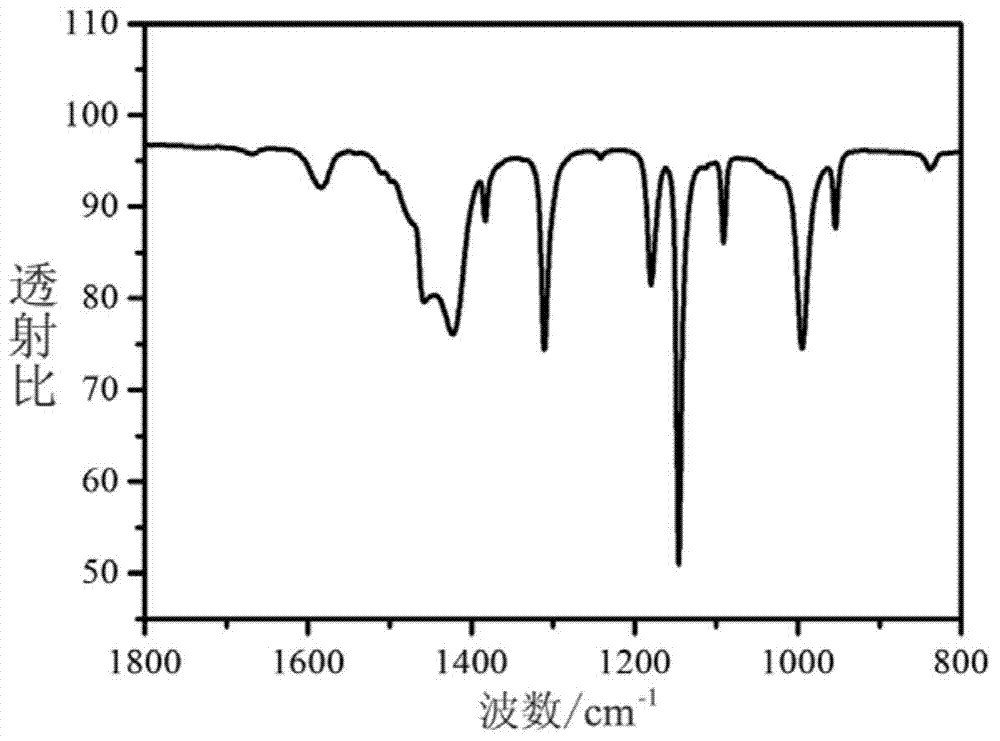

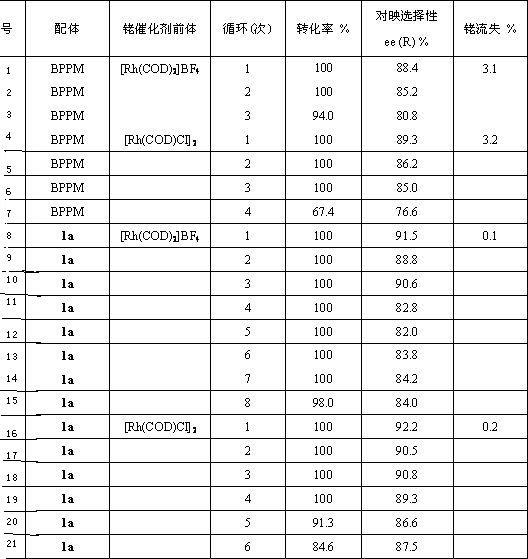

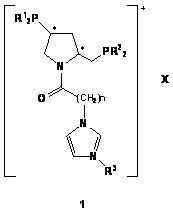

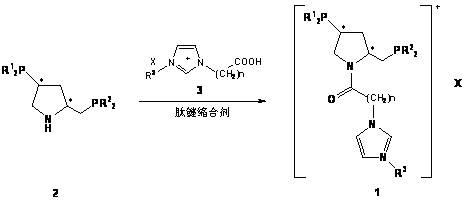

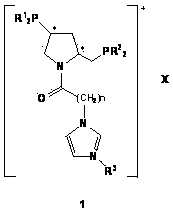

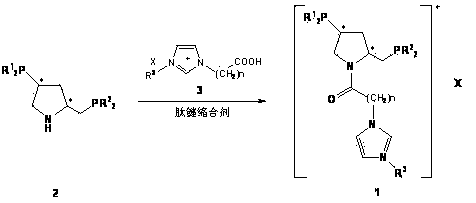

Imidazole ionic liquid supported chiral phosphine ligands and preparation method thereof

ActiveCN102690291AHigh stereoselectivityEffective fixed loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCombinatorial chemistry

The invention relates to imidazole ionic liquid supported chiral phosphine ligands and a preparation method thereof, and application of rhodium complex of the chiral phosphine ligand in asymmetric catalytic hydrogenation of alpha-dehydroamino acid and derivatives thereof. The imidazole ionic liquid supported chiral phosphine ligands are synthesized by introducing cations of an imidazole ionic liquid into proline-derived chiral diphosphine ligand molecules, thereby effectively enhancing the activity, stereoselectivity and affinity with the imidazole ionic liquid of the catalyst. When being used for asymmetric catalytic hydrogenation of alpha-dehydroamino acid and derivatives thereof, the rhodium complex of the phosphine ligands has high enantioselectivity (ee=95.2%) and high conversion frequency (TOF=24000h<-1>), and can effectively inhibit rhodium loss; and after several cycles, the activity and stereoselectivity of the catalyst are not obviously lowered, and the rhodium loss is only 0.1-0.2%.

Owner:山东格新精工有限公司

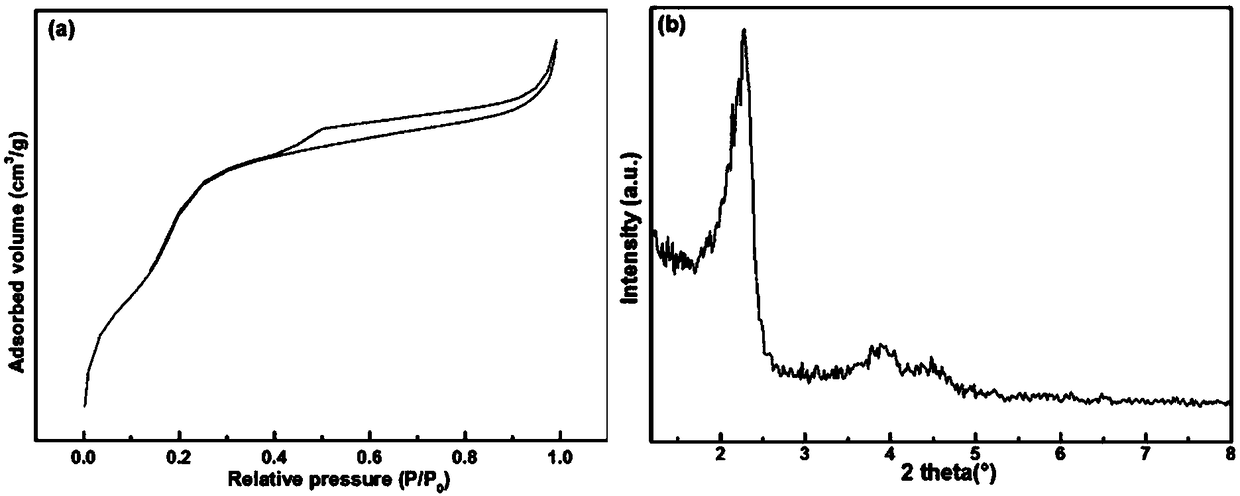

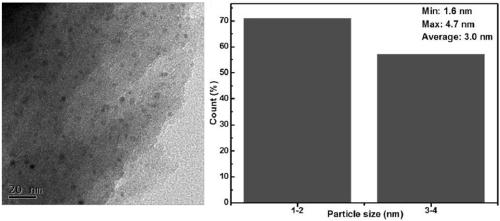

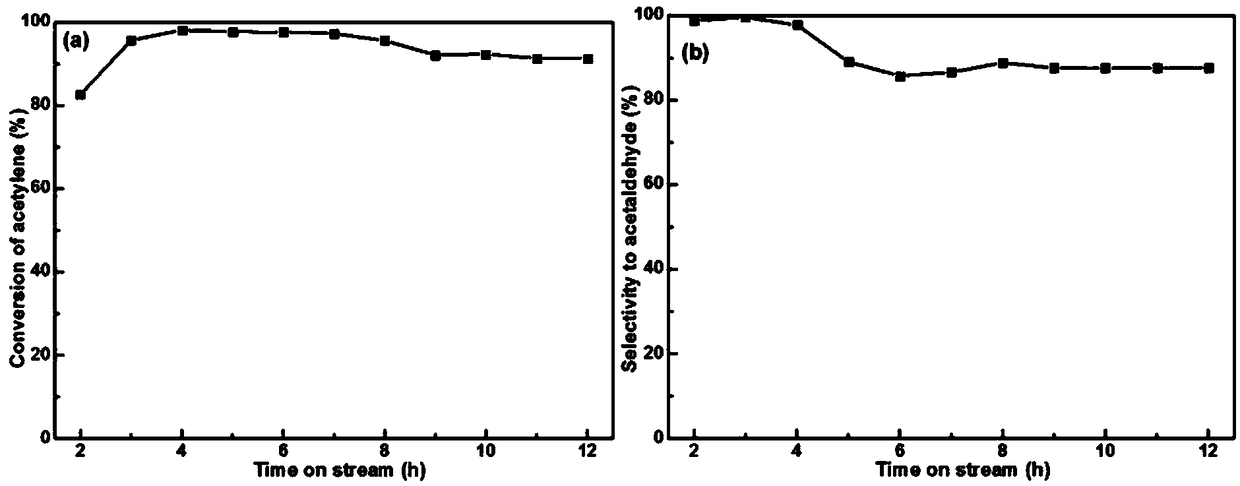

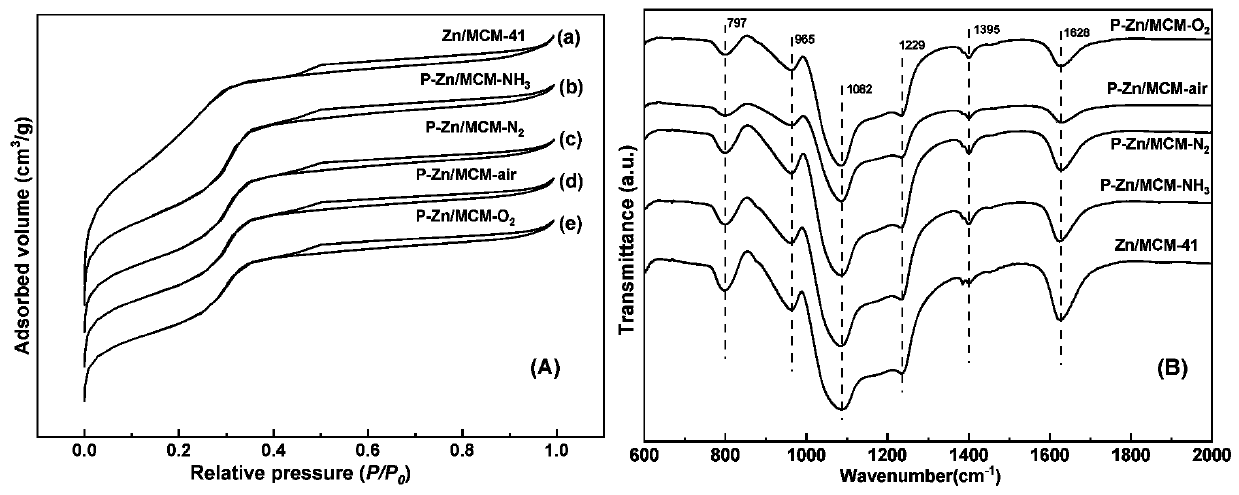

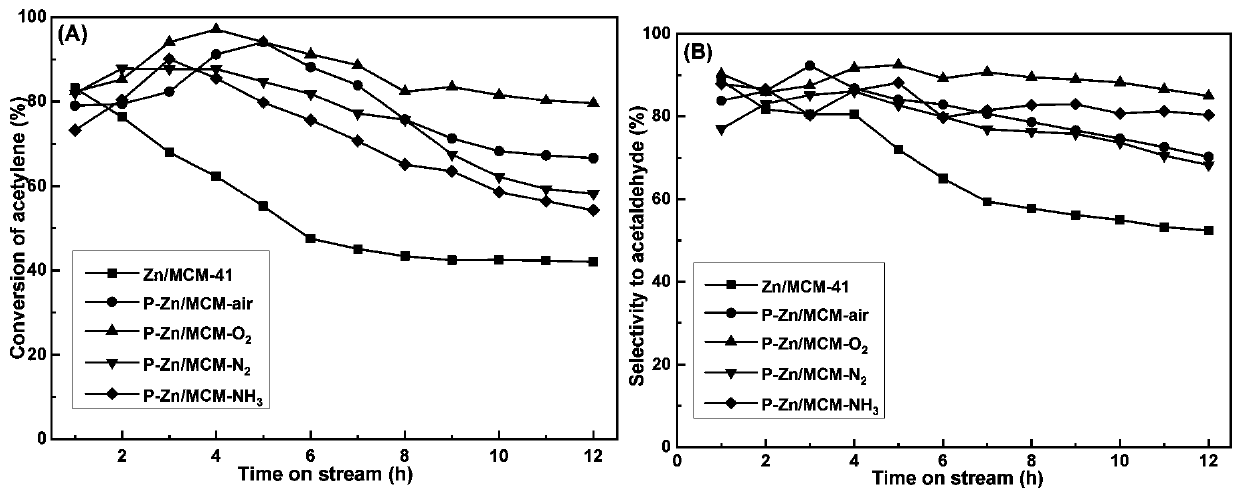

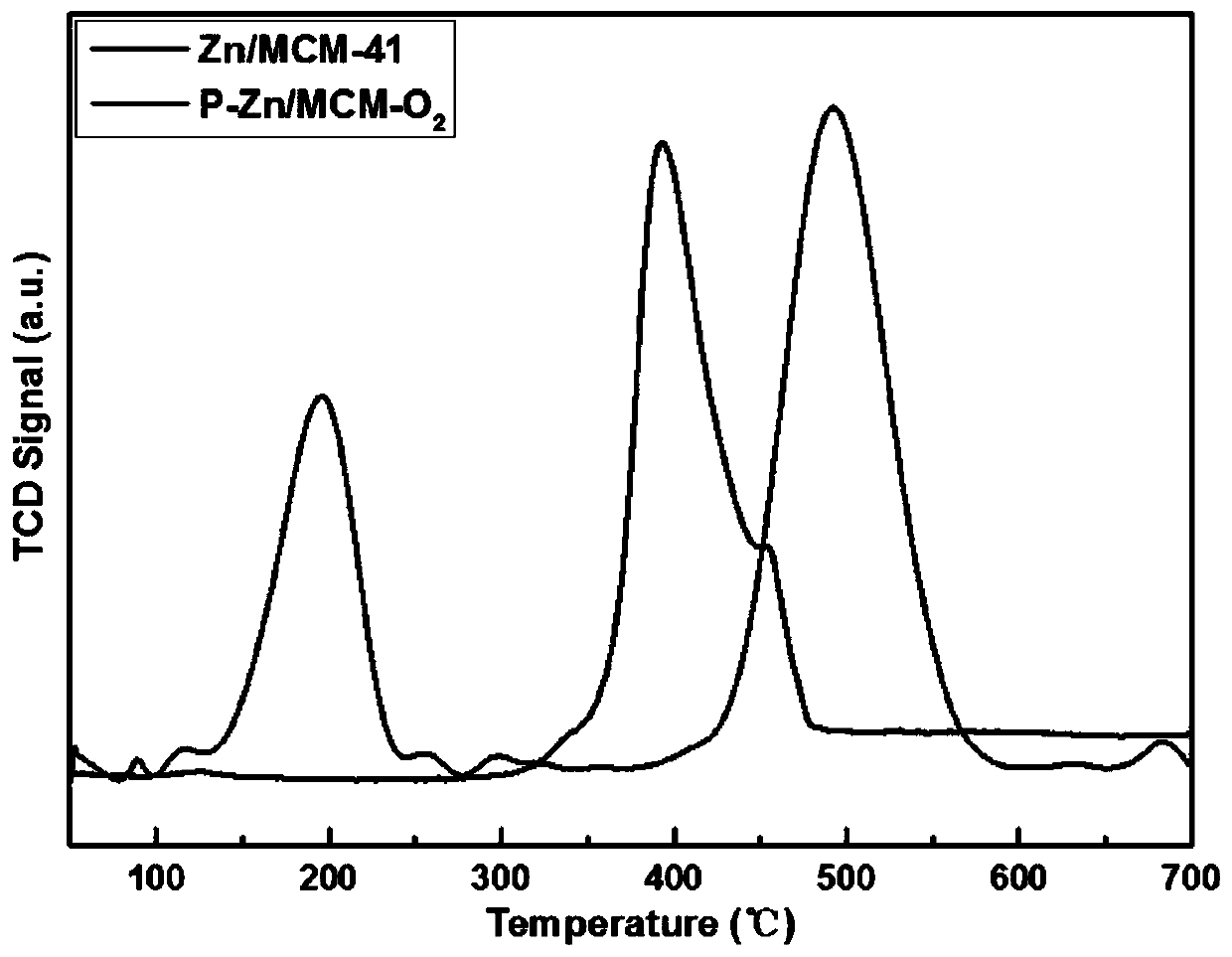

Zinc catalyst for catalyzing acetylene hydration reaction and preparation method of zinc catalyst

PendingCN108993576AEvenly distributedSmall particlesMolecular sieve catalystsPreparation by C-C triple bond hydrationMolecular sieveHydration reaction

The invention relates to a zinc catalyst for catalyzing an acetylene hydration reaction and a preparation method of the zinc catalyst. The method for preparing the zinc catalyst for catalyzing an acetylene hydration reaction comprises the following steps of (1) preparing a modified carrier: adding a modifying agent to a molecular sieve precursor liquid, performing uniform mixing, performing filtering, performing drying, performing calcining and performing roasting to obtain the modified carrier; (2) preparing the catalyst precursor salt liquid: enabling zinc salt to completely dissolve in water to obtain the catalyst precursor salt liquid; and (3) preparing the catalyst: dropwise adding the catalyst precursor salt liquid to the modified carrier, performing immersing for 12h, and performingdrying to obtain the zinc catalyst. According to the zinc catalyst for catalyzing an acetylene hydration reaction and the preparation method of the zinc catalyst, the preparation cycle is short, andthe operation is simple; and the prepared zinc catalyst is a non-mercury catalyst for the acetylene hydration reaction, so that mercury pollution to environment can be avoided. The prepared zinc catalyst is high in activity and high in selectivity in the acetylene hydration reaction.

Owner:SHIHEZI UNIVERSITY

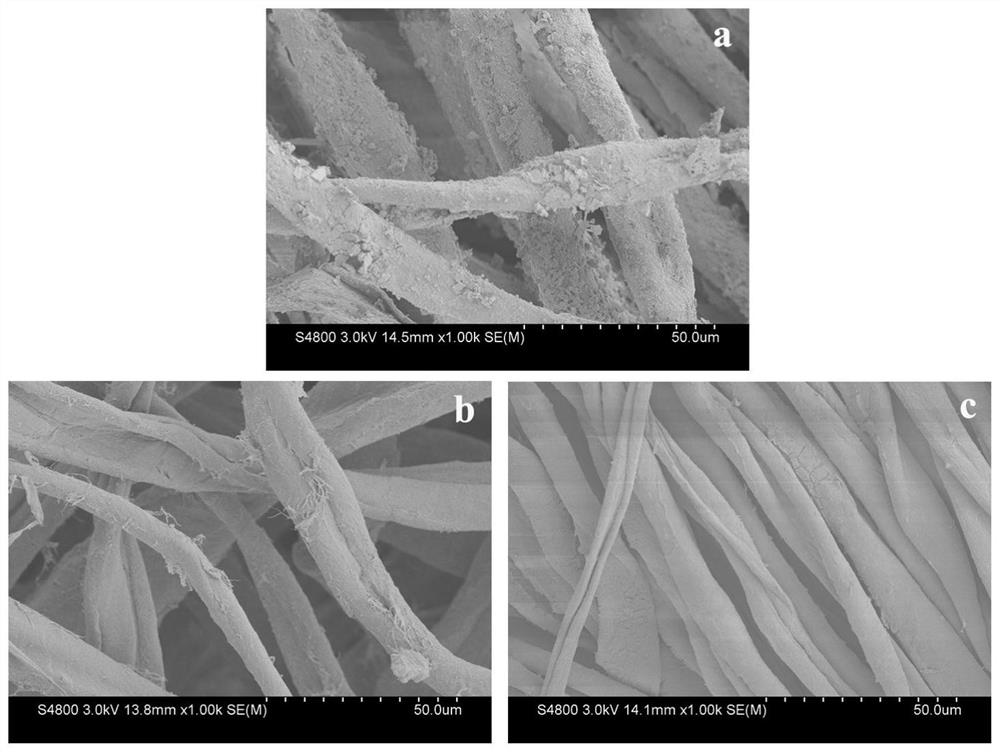

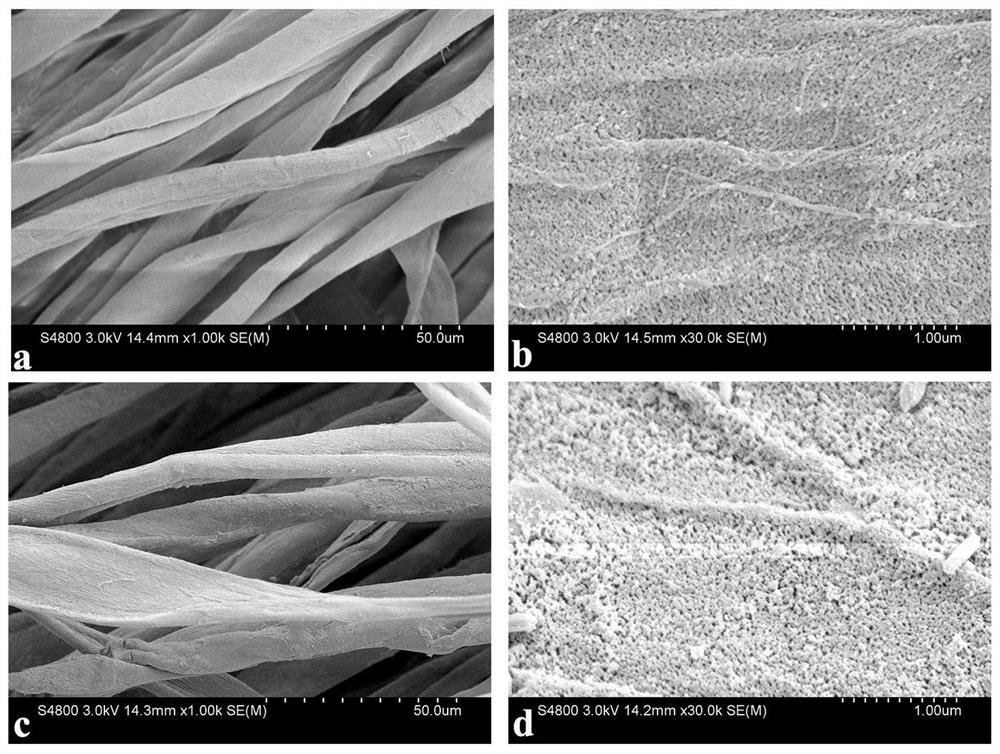

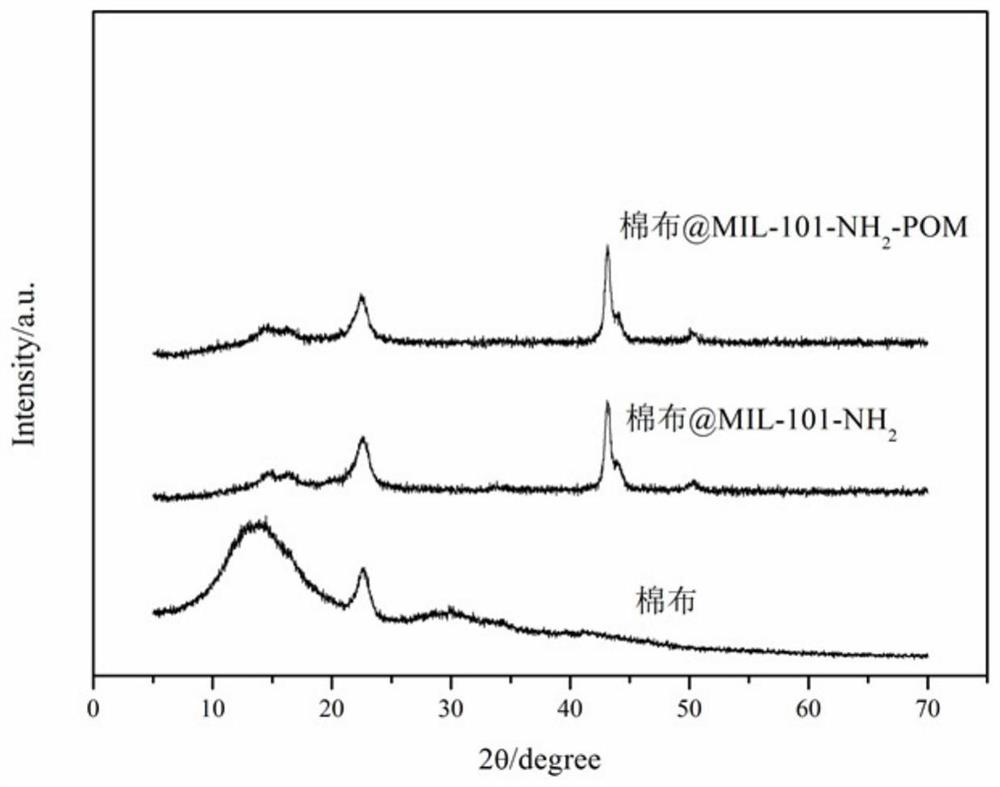

MOF-based cotton cloth immobilized polyacid catalytic material as well as preparation method and application thereof

PendingCN112517078AEffective fixed loadSolve difficult moldingOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsPolymer scienceCotton cloth

The invention relates to the technical field of desulfurization catalytic materials, in particular to an MOF-based cotton cloth immobilized polyacid catalytic material and a preparation method and application thereof.The MOF-based cotton cloth immobilized polyacid catalytic material is prepared from MOF-based cotton cloth and Keggin type phosphorus molybdenum tungsten type polyacid immobilized onthe MOF-based cotton cloth; the MOF-based cotton cloth is cotton cloth and an MOF material growing on the cotton cloth. According to the prepared MOF-based cotton cloth polyacid catalytic material, the problem that the MOF-based polyacid catalytic material is not easy to form can be solved, the preparation process is simple, the prepared MOF-based cotton cloth polyacid desulfurization catalytic material has a good desulfurization effect when used in a gasoline and diesel oil simulation system, and the desulfurization rate of the prepared cotton cloth @MIL-101-NH2-POM can reach up to 100%. Whenthe cotton cloth-coated @MIL-101-NH2-POM is repeatedly used for 12 times, the desulfurization rate of the cotton cloth-coated @MIL-101-NH2-POM can still reach 96%.

Owner:CHANGAN UNIV

Zinc-based catalyst used for catalyzing acetylene hydration reaction and preparation method thereof

PendingCN111185222ASimple processImprove efficiencyMolecular sieve catalystsCatalyst activation/preparationHydration reactionPtru catalyst

The invention relates to a zinc-based catalyst used for catalyzing an acetylene hydration reaction and a preparation method thereof. The preparation method for the zinc-based catalyst used for catalyzing the acetylene hydration reaction comprises the following steps: (1) completely dissolving zinc salt into deionized water so as to obtain a precursor solution; (2) soaking a carrier into the precursor solution, carrying out stirring for 10-14 hours, then carrying out standing for 10-14 hours, and carrying out drying so as to obtain a catalyst; and (3) performing plasma treatment, i.e., carryingout plasma treatment on the catalyst in different plasma atmospheres so as to obtain the zinc-based catalyst used for catalyzing the acetylene hydration reaction. The zinc-based catalyst used for catalyzing the acetylene hydration reaction and the preparation method thereof provided by the invention have the following advantages: the preparation process is simple and short in time; the preparation process is clean and free of pollution; the obtained catalyst is high in efficiency, good in activity in the acetylene hydration reaction and high in selectivity; and the prepared catalyst is a non-mercury catalyst, is used for the acetylene hydration reaction, and can solve the problems of environmental pollution and harm to the human health due to a volatile mercury catalyst.

Owner:SHIHEZI UNIVERSITY

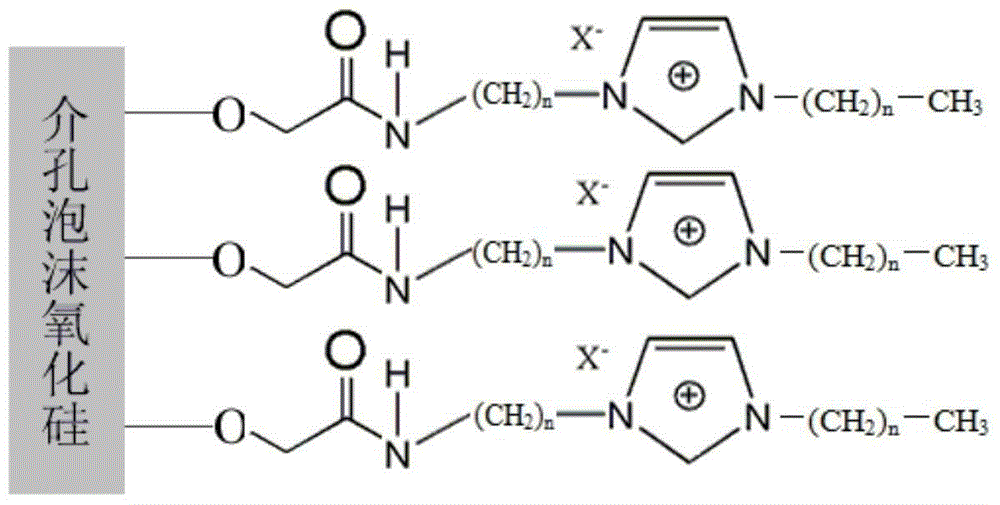

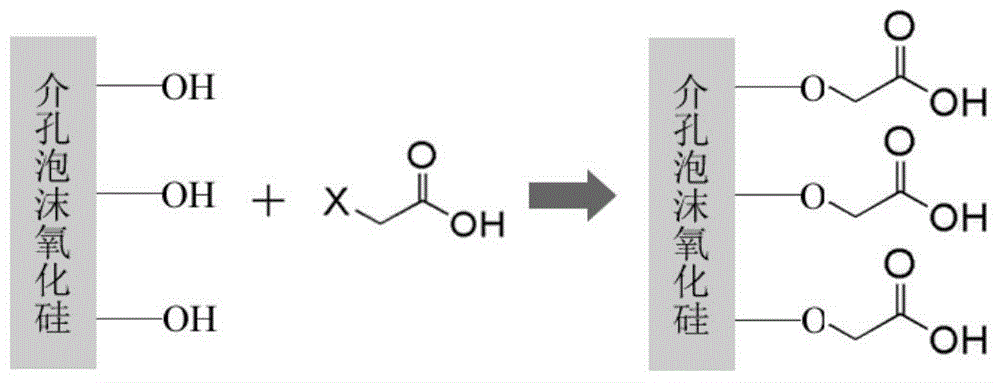

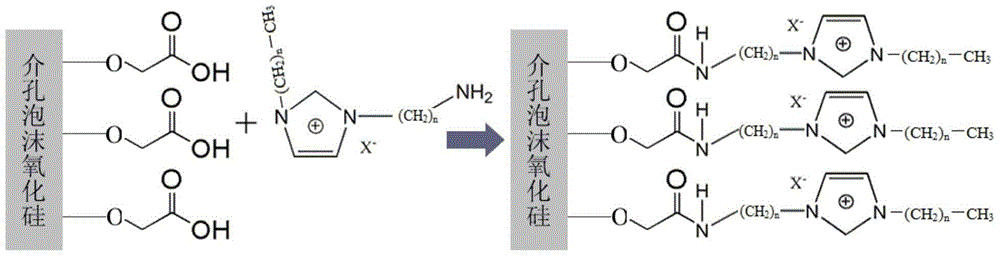

A kind of solid catalyst for synthesizing cyclic carbonate and preparation method thereof

ActiveCN103521262BEffective fixed loadIncrease the number ofCatalyst carriersOrganic chemistryBromoacetic acidSilicon oxide

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

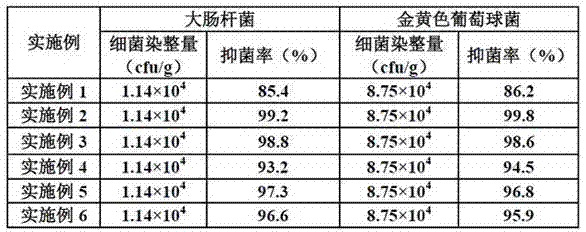

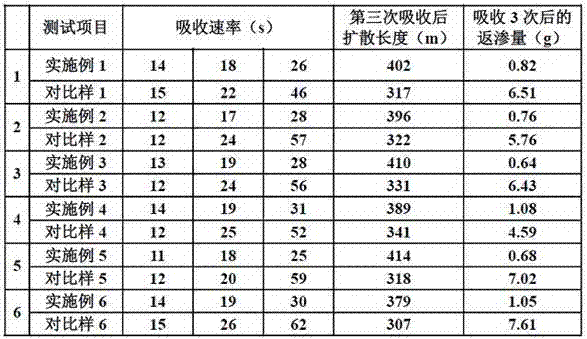

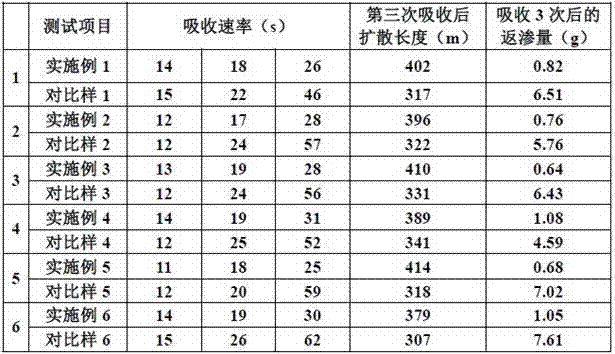

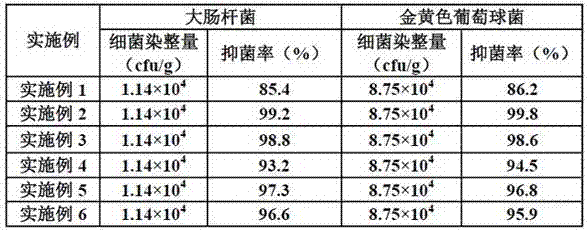

Non-woven fabric for absorbing core wrapping layer

PendingCN108004674AGood antibacterial propertiesSuppresses odor problemsAbsorbent padsNon-woven fabricsGraphene coatingActivated carbon

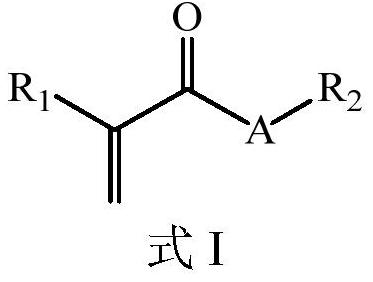

The invention relates to a non-woven fabric for absorbing a core wrapping layer. The non-woven fabric comprises a non-woven base material, wherein the non-woven base material is subjected to hydrophilic finish treatment, the surface layer of the non-woven base material is further coated with a graphene coating, the graphene coating is of a three-dimensional network-like cross-linking structure; the three-dimensional network-like cross-linking structure comprises a cross-linked structure porous polymer continuous phase and graphene which is uniformly dispersed and immobilized in the cross-linked structure porous polymer continuous phase; the three-dimensional network-like cross-linking structure comprises, by weight, 10-50 parts of graphene, 5-47 parts of cross-linking structure porous polymer and activated carbon; through holes which are communicated with one another and penetrate into the non-woven base material are formed in the cross-linked structure porous polymer; the cross-linkedstructure porous polymer is formed by initiating polymerization through polymerization monomers, a pore forming agent and an initiator and conducting cross-linking through a cross-linking agent, at the same time, the through holes are formed, and the size, density and the like of the through holes can be adjusted through the pore-forming agent for ordinary technicists in the field.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

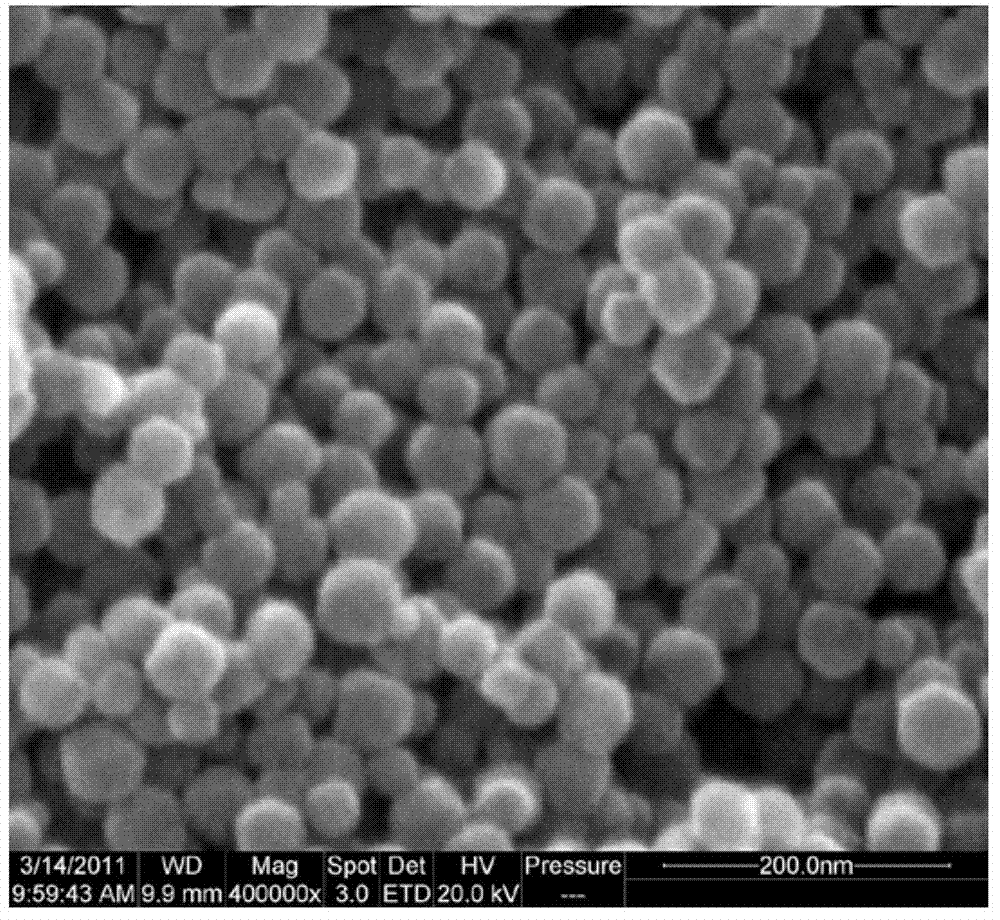

Immobilized rhodium-based catalyst as well as preparation method and application thereof

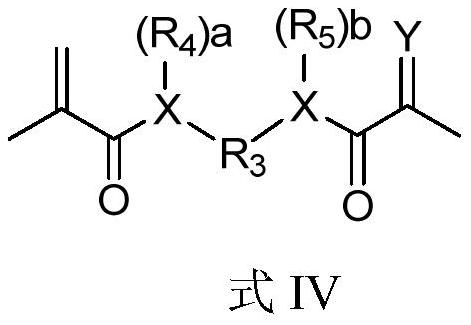

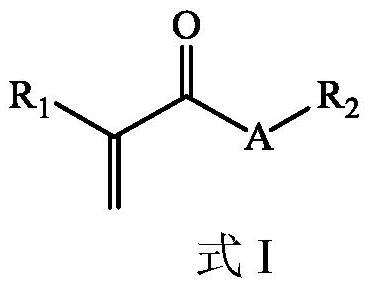

ActiveCN112439460AHigh activityEffective fixed loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRegioselectivityHigh activity

The invention provides an immobilized rhodium-based catalyst. The immobilized rhodium-based catalyst comprises a rhodium complex and an organic ligand polymer; and the organic ligand polymer is a polymer of an organic phosphine ligand and a comonomer. The invention also provides a preparation method of the immobilized rhodium-based catalyst. The method comprises the following steps: complexing theorganic phosphine ligand with the rhodium complex, and polymerizing with the comonomer to obtain the immobilized rhodium-based catalyst. The rhodium-based catalyst disclosed by the invention is of acompact structure that metal rhodium is wrapped by netty macromolecules, and the metal rhodium can be immobilized on microgel very effectively, so that the catalyst is prevented from being lost. The catalyst has the advantages of high activity, high regioselectivity, easiness in separation, recyclability and the like, and can be used for hydroformylation reaction of olefin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for synthesizing ethylene carbonate process solid catalyst

ActiveCN108579789ALarge specific surface areaMany active sitesOrganic chemistryPhysical/chemical process catalystsMethyl carbonateOxide composite

The invention relates to a preparation method for synthesizing an ethylene carbonate process solid catalyst. The catalyst is prepared from raw materials, namely graphene oxide and dicyandiamide, through simple procedures of soaking, drying and roasting, then preparation of a carbon nitride / graphene oxide composite material is achieved, and a novel solid catalyst used in an ethylene carbonate synthesis process is prepared. The method is simple to operate, and the obtained solid catalyst can be continuously recycled after being filtered after reactions, and is high in recycling property and lowin preparation cost. When the solid catalyst prepared by using the preparation method is used in a process that ethylene carbonate is prepared from dimethyl carbonate and gylcol ester through exchangesynthesis, a very good catalysis effect can be achieved.

Owner:辽阳安里其科技发展有限公司

A kind of preparation method of hierarchical porous heterogeneous composite phase change material

InactiveCN103194182BFix the leakImprove thermal conductivityProductsReagentsMolecular sieveWorking temperature

The invention discloses thinking for preparing a series of porous heterogeneous composite phase-change materials of which the temperature changes in a gradient manner. Porous materials (such as expanded graphite, mesoporous molecular sieve, diatomite and the like) which is high-temperature resisting, high in stability and large in specific surface area are used as phase-change base materials, different inorganic fused salt phase-change materials are used as core materials, and a series of porous heterogeneous composite phase-change materials are prepared by using a steeping method; the phase-change temperature of the material has the gradient characteristic, and the potential heat value is more than 100J.g<-1> with slight difference. The porous high-temperature composite phase-change material can be used for both effectively immobilizing a phase-change core material, preventing leakage, saving packaging investment in later period, and increasing the heat conduction of the material and improving the phase-change heat conduction efficiency. The series of porous heterogeneous composite phase-change materials are applicable to working temperature region process with non-stability characteristic, difference and large span, and have significance in effectively recycling industrial intermittent waste heat.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of graphene nonwoven fabric

PendingCN108004793AEffective fixed loadImprove antibacterial propertiesPersonal careCoatingsSurface layerNonwoven fabric

The invention relates to a preparation method of a graphene nonwoven fabric, wherein the preparation method includes the steps: step 1, preparing a solution with a concentration of 25%-65% from a polymeric monomer with deionized water, adding a dispersant and a pore-forming agent, and stirring for 5-30 min; step 2, adding a graphene powder into the solution of the step 1, carrying out ultrasonic dispersion to obtain a graphene suspension mixed liquid A; step 3, heating the graphene suspension mixed liquid up to 42-85 DEG C, then adding a crosslinking agent, and carrying out ultrasonic dispersion to form a graphene suspension mixed liquid B; step 4, evenly spraying a surface layer of a nonwoven fabric base material with the graphene suspension B in turn by a sprayer; step 5, making an initiator into a solution, evenly spraying the surface layer of the nonwoven fabric base material with the initiator by a double-atomizing device, initiating crosslinking polymerization and pore-forming, and thus obtaining a graphene nonwoven fabric; and step 6, placing the graphene nonwoven fabric in a baking oven, and carrying out drying treatment to obtain the graphene nonwoven fabric.

Owner:XIAMEN YUANCHUANGLI TECH SERVICE CO LTD

MnO2/PPS composite material and preparation method and application thereof

PendingCN111359673ADoes not affect filtration efficiencyEfficient dust removalDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystDust control

The invention discloses a preparation method of a MnO2 / PPS composite material, which comprises the following steps: attaching steam atomized by a potassium permanganate solution to an activated PPS fabric, and carrying out an in-situ reaction process on the surface of the PPS fabric to generate MnO2. The invention also discloses the MnO2 / PPS composite material and an application of the MnO2 / PPS composite material in dust removal and denitration. The method is based on the high-efficiency dust removal performance of a PPS filter material and the high-efficiency low-temperature denitration performance of MnO2. According to the invention, effective immobilization of MnO2 on the surface of the PPS filter material is realized through a specific process, meanwhile, the denitration efficiency ofMnO2 and the filter efficiency of the filter material are not influenced, the prepared MnO2 / PPS dedusting and denitration integrated composite filter material is high in dedusting efficiency, good inlow-temperature denitration performance, uniform in dispersion of MnO2 on the surface of the filter material and low in catalyst loading capacity, and the method is simple, low in cost and capable ofrealizing large-scale production.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

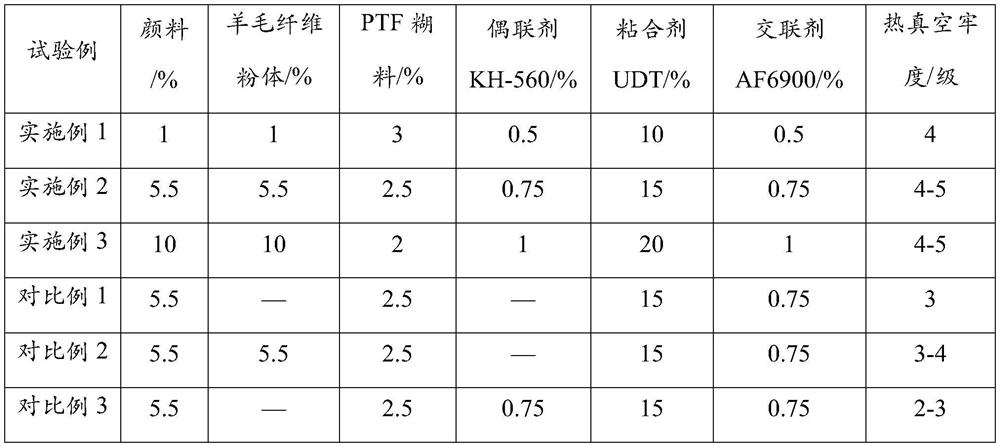

High-thermal-vacuum-fastness pigment printing process

ActiveCN113529441AHigh heat vacuum fastness improvementImproved thermal vacuum fastnessDyeing processTextile printerColour fastness

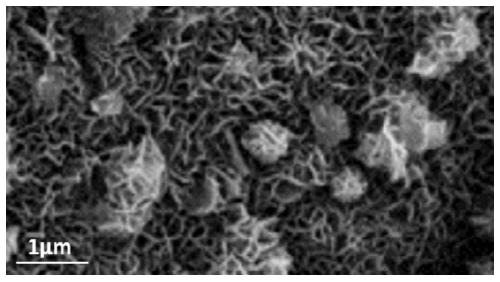

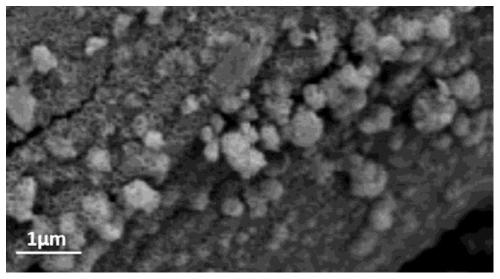

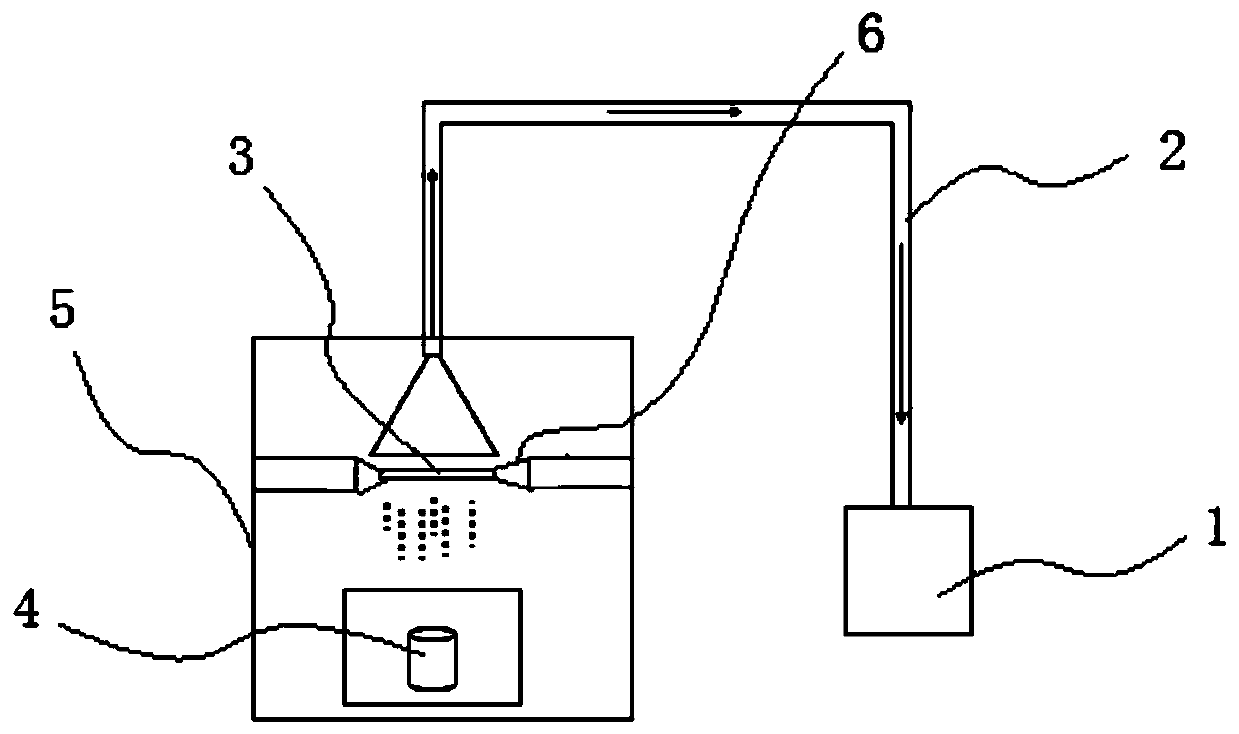

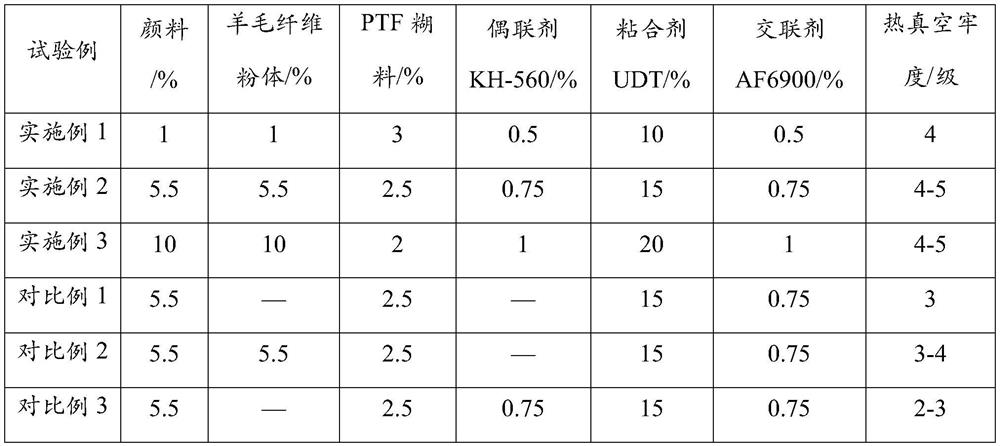

The invention provides a high-thermal-vacuum-fastness pigment printing process. The pigment printing process comprises printing treatment of pigment printing paste and padding treatment of waterborne polyurethane emulsion. The pigment printing paste comprises the following components in percentage by mass of 1%-10% of pigment, 1%-10% of wool fiber powder, 0.5%-1% of a silane coupling agent KH-560, 10%-20% of an adhesive, 2%-3% of a thickening agent, 0.5%-1% of a cross-linking agent and the balance of a solvent. According to the invention, the wool fiber powder with a special structure and the coupling agent are added into the color paste, and a layer of waterborne polyurethane coating film is padded after printing, so that the high thermal vacuum fastness of pigment molecules is remarkably improved, and the problems of pigment sublimation and color fastness migration caused by thermal vacuum suction of pigment molecules of a colored textile under the conditions of high vacuum degree and high-temperature environment are solved.

Owner:WUHAN TEXTILE UNIV

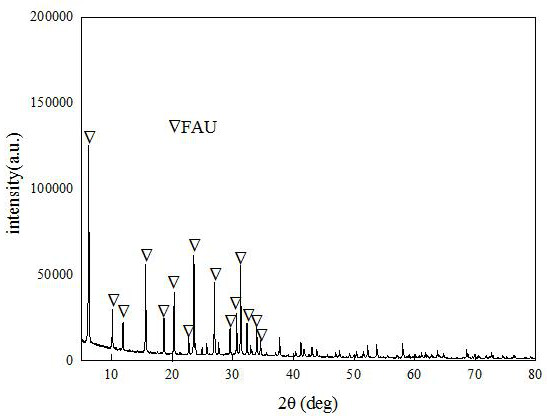

Molecular sieve confinement metal oxide catalyst, and preparation method and application of molecular sieve confinement metal oxide catalyst in catalytic synthesis of pentamethylene diamine

ActiveCN113600227ASimple structureEffective fixed loadMolecular sieve catalystsAmino preparation from aminesMolecular sievePtru catalyst

The invention provides a molecular sieve confinement metal oxide catalyst, and a preparation method and application of the molecular sieve confinement metal oxide catalyst in catalytic synthesis of pentamethylene diamine. The molecular sieve confinement metal oxide catalyst with good lysine decarboxylation catalysis performance is prepared by adopting an in-situ synthesis and dynamic synthesis combined method. The method comprises the steps: putting lysine or lysine salt, water and a molecular sieve confinement metal oxide catalyst into a high-pressure reaction kettle, and reacting to obtain an aqueous solution containing pentamethylene diamine; the molecular sieve confinement metal catalyst is prepared by adopting the in-situ synthesis method, metal active components of the catalyst are effectively immobilized, agglomeration of the active components is avoided, and the structure of the catalyst is well kept; and when the catalyst is used for lysine decarboxylation reaction, the production rate of pentamethylene diamine is effectively improved, the selectivity of pentamethylene diamine reaches 49% after 15 minutes of reaction, the reaction time is greatly shortened, the reaction cost is remarkably reduced, and the industrial application prospect is quite wide.

Owner:郑州中科新兴产业技术研究院

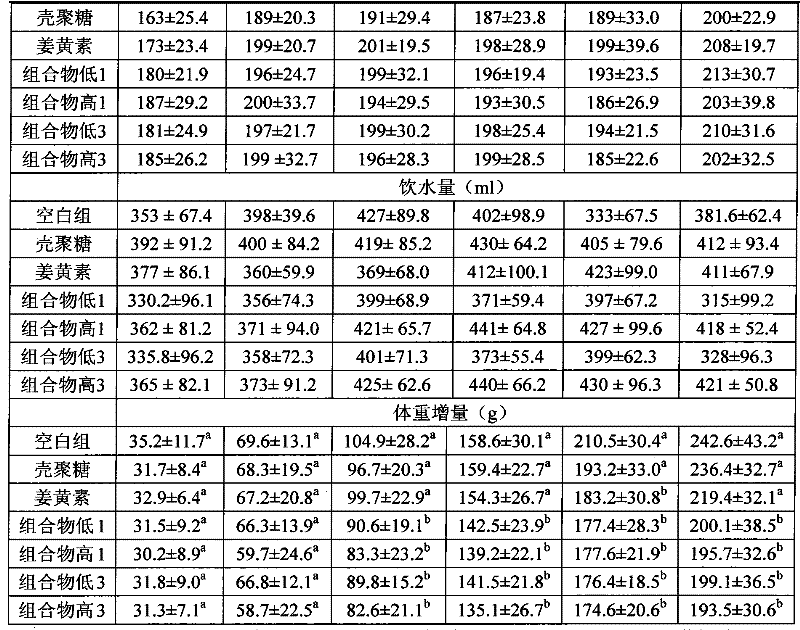

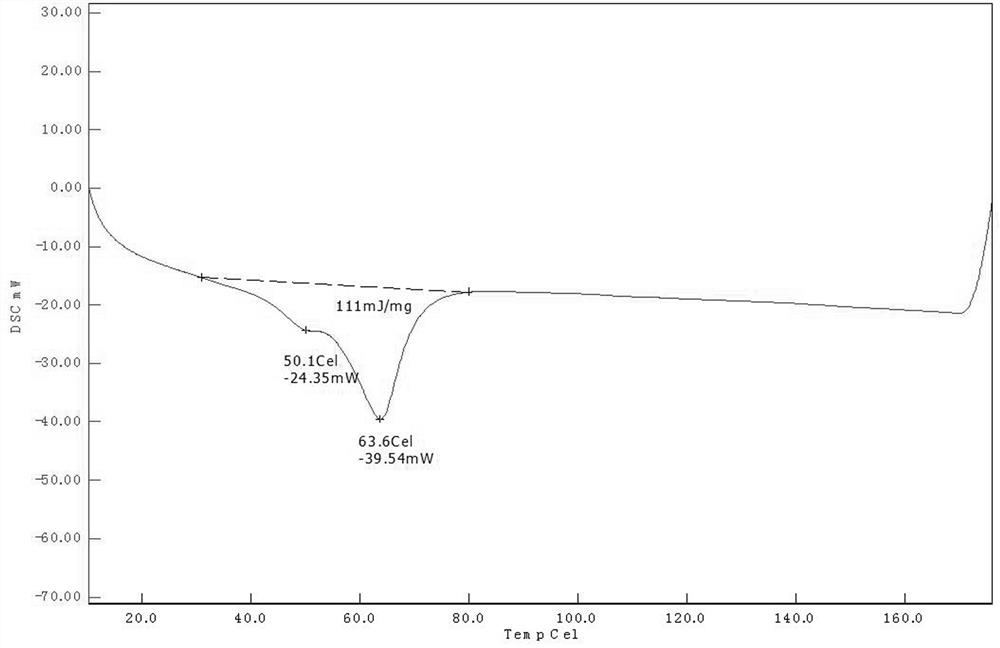

Weight-reducing and lipid-lowering composition

InactiveCN101912407BImprove bioavailabilityEffective fixed loadMetabolism disorderKetone active ingredientsSolubilityLipid formation

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

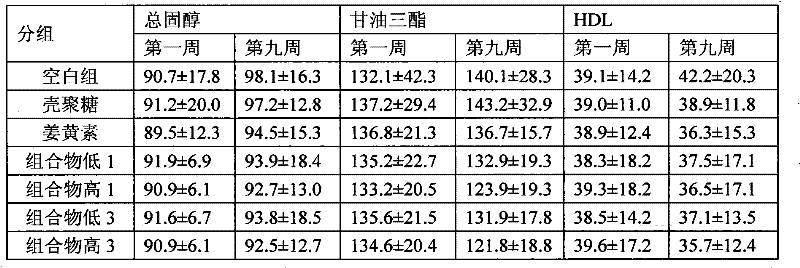

Beeswax/polystyrene composite phase-change energy storage material and preparation method and application thereof

ActiveCN112266770AGood modification effectEasy to separateProductsReagentsResin microspherePolystyrene

The invention belongs to the technical field of phase-change energy storage materials, relates to a beewax and polystyrene composite phase-change energy storage material, in particular relates to a beewax / polystyrene composite phase-change energy storage material and a preparation method and application thereof, and solves the technical problems in the background art. The beewax / polystyrene composite phase-change energy storage material comprises a base material and a phase-change material, the base material is polystyrene macroporous resin microspheres, and the phase-change material is beewax. The beewax / polystyrene composite phase-change energy storage material capable of being used for food is prepared by virtue of the capillary adsorption effect of the polystyrene macroporous resin microspheres; the beewax / polystyrene composite phase-change energy storage material can effectively immobilize the phase-change core material, prevent leakage, save later packaging investment and realizecigarette filter temperature control; the base material polystyrene macroporous resin microspheres of the composite phase-change material are easy to modify, and harmful components in cigarette smokecan be selectively removed while the temperature is controlled by functionally modifying the base material polystyrene macroporous resin microspheres.

Owner:GANSU TOBACCO IND

A kind of preparation method and application of dipentene dehydrogenation catalyst

ActiveCN108404986BSynthetic catalytic activity is highHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsActivated carbonPtru catalyst

The invention discloses a reparation method and an application of a dipentene dehydrogenation catalyst. The preparation method includes the steps: preparing [Rh(COD)Cl]2 by a co-heat backflow method of RhCl3*3H2O ethanol solution and 1, 5-cyclooctadiene (COD); mixing the [Rh(COD)Cl]2 and functionalized activated carbon; adding methanol solution; ultrasonically treating, filtering and drying mixture to prepare a [Rh(COD)Cl]2 / C catalyst; applying the prepared catalyst into dipentene dehydrogenation reaction to obtain p-cymene with high yield. The method is simple to operate, low in device condition requirement, mild in condition and high in dipentene conversion rate and p-cymene selectivity.

Owner:KUNMING UNIV OF SCI & TECH

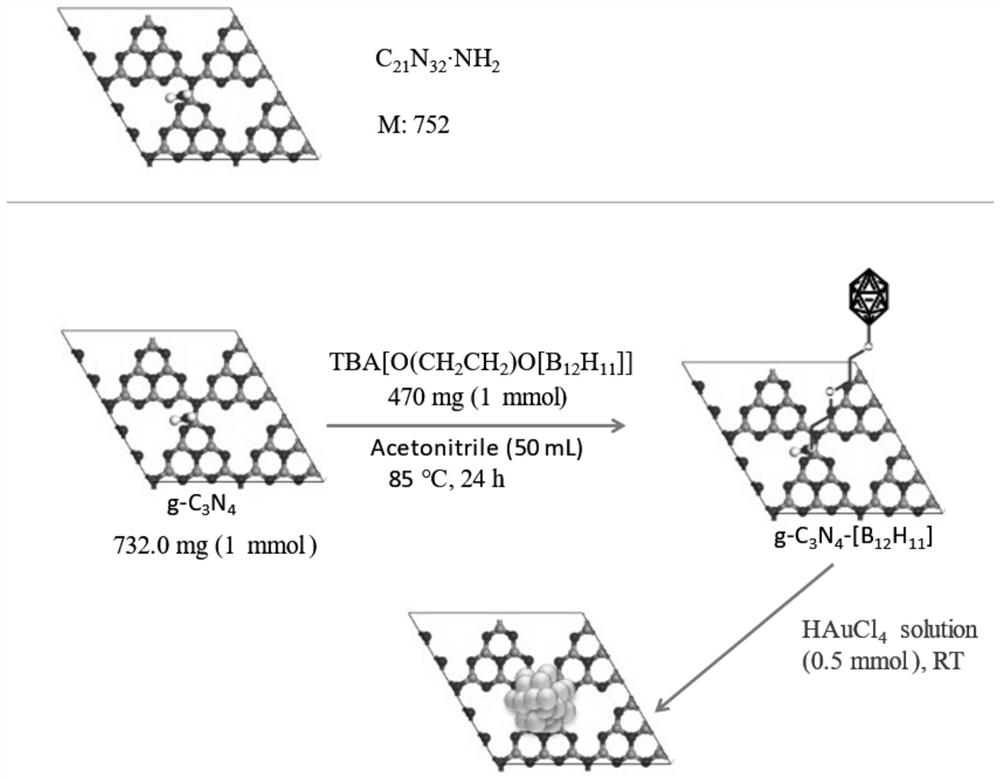

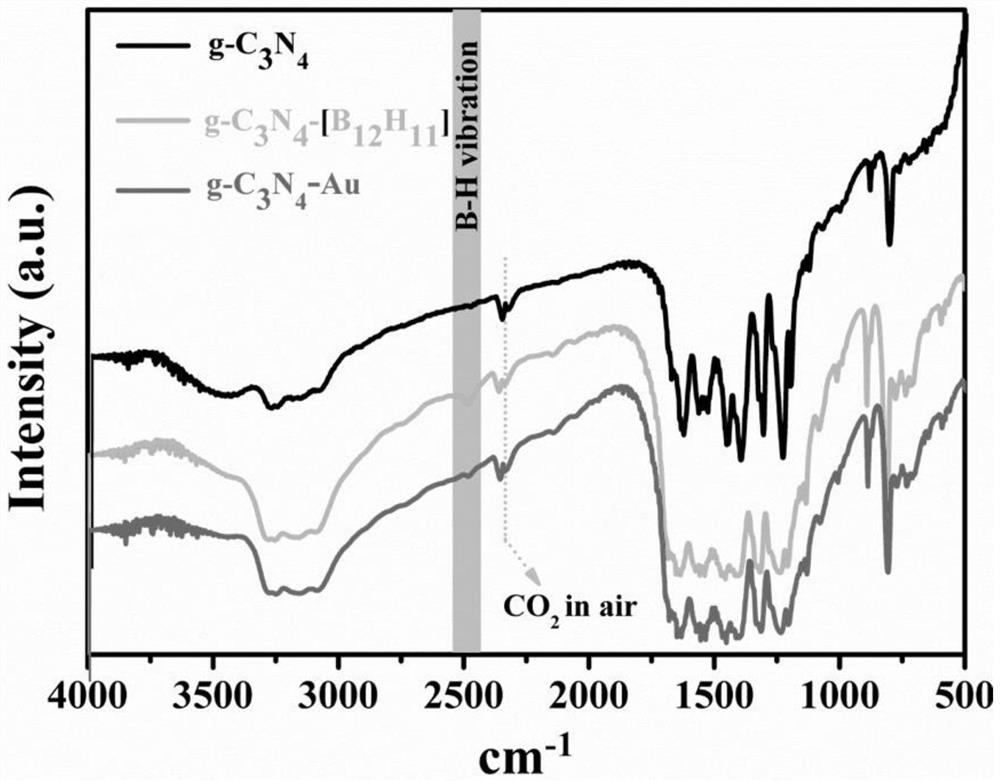

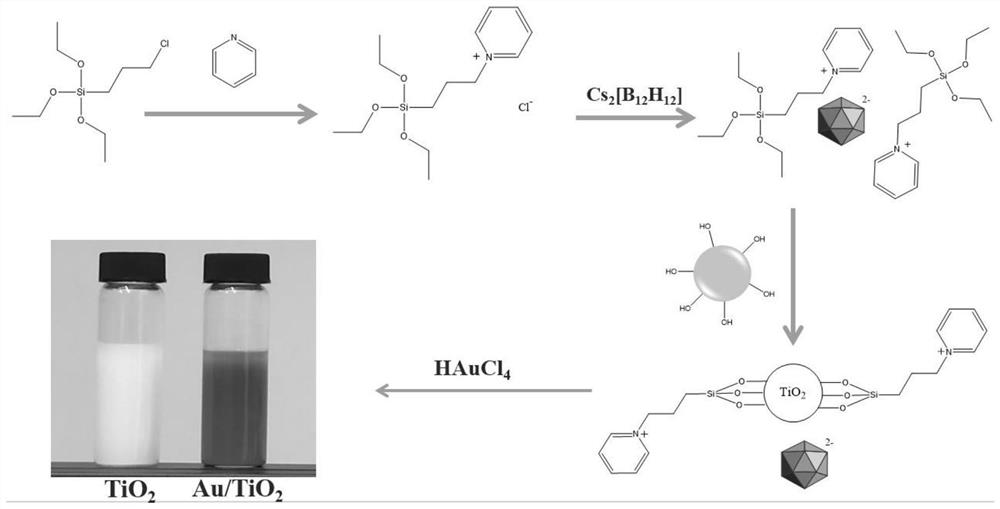

Closed boron group composite nano noble metal catalyst as well as preparation method and application thereof

ActiveCN113289684ASimple preparation processLower production thresholdMaterial nanotechnologyPreparation by oxidation reactionsMethanolNoble metal

The invention discloses a closed boron group composite nano noble metal catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) fully dispersing a layered substrate in water, adding a closed boron cluster M2BxHx, heating and stirring to react completely to obtain a crude product, and washing, carrying out suction filtration and drying to obtain a layered substrate-boron cluster M2BxHx; and (2) dispersing the layered substrate-boron cluster M2BxHx in water, adding noble metal acid or salt, reacting under ultraviolet light, and filtering, washing and drying a product to obtain the layered substrate-boron cluster M2BxHx composite nano noble metal catalyst. The preparation method provided by the invention is simple, easy to operate and mild in reaction condition. The prepared catalyst can be used for catalyzing methane to generate methanol and ethanol. The repeated utilization rate of the catalyst reaches up to 10 times or above, and the catalyst has the advantages of high activity, reproducible carrier, high yield and good selectivity, can be used for industrially catalyzing methane to produce methanol and ethanol, and has great application value.

Owner:WUHAN UNIV

A kind of high performance composite phase change material and preparation method thereof

ActiveCN108251063BShape stableUniform structureHeat-exchange elementsHigh power lasersModified carbon

The invention discloses a high-performance composite phase-change material, which belongs to the technical field of composite materials. The material comprises a high phase change latent heat liquid alloy and a modified carbon nanotube sponge skeleton; the high phase change latent heat liquid alloy is filled in the modified carbon nanotube sponge skeleton. High-performance composite phase-change materials include liquid alloys with high phase-change latent heat and high thermal conductivity carbon nanotube sponge skeleton materials with adjustable melting points in the range of 20°C to 130°C; liquid alloys are based on InSnBi alloys, with high heat One or more of elements Ga, Cd, Zn, and Sb are additives. The material has high volume phase change latent heat, high thermal conductivity, low expansion, and the melting point can be adjusted in the range of 20°C to 130°C; it has excellent and stable thermophysical properties, and is suitable for high-power laser heat dissipation, industrial waste heat utilization, solar power generation, fuel There are broad applications in fields such as battery cooling, optoelectronic devices, and micro-nano electro-mechanical systems that have extremely high requirements for high-end heat dissipation.

Owner:GRIMAT ENG INST CO LTD

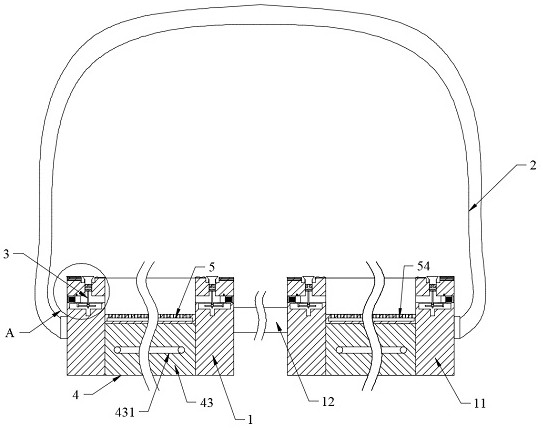

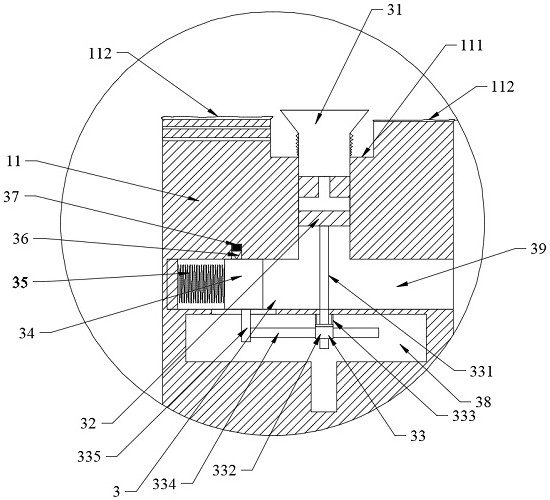

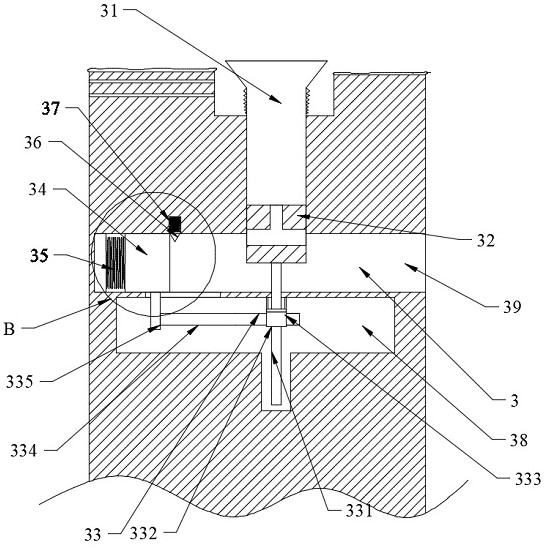

Multifunctional steam eyeshade with heat circulation function

The invention discloses a multifunctional steam eyeshade with thermal circulation, which comprises a glasses frame, an adjusting belt, a stretching assembly, a heating assembly and a steam assembly, the glasses frame comprises two annular sleeves and a nose pad, the two annular sleeves are respectively positioned on two sides of the nose pad, the annular sleeves are fixedly connected with the nose pad, one side, far away from the nose pad, of each annular sleeve is fixedly connected with the adjusting belt, and the stretching assembly is connected with the heating assembly. The stretching assembly is installed in the inner wall of the annular sleeve, the heating assembly and the steam assembly are installed in the inner ring of the annular sleeve and fixedly connected with the side wall of the inner ring of the annular sleeve, and the top of the heating assembly is fixedly connected with the bottom of the steam assembly. According to the steam eyeshade, heat generated by combustion of the moxa sticks serves as a heat source of steam, beneficial substances in the moxa sticks are mixed with the steam to conduct hot compress on the eyes of a user, cyclic utilization of the heat is achieved, and the using effect of the steam eyeshade is enhanced.

Owner:广州三森健康产业科技有限公司

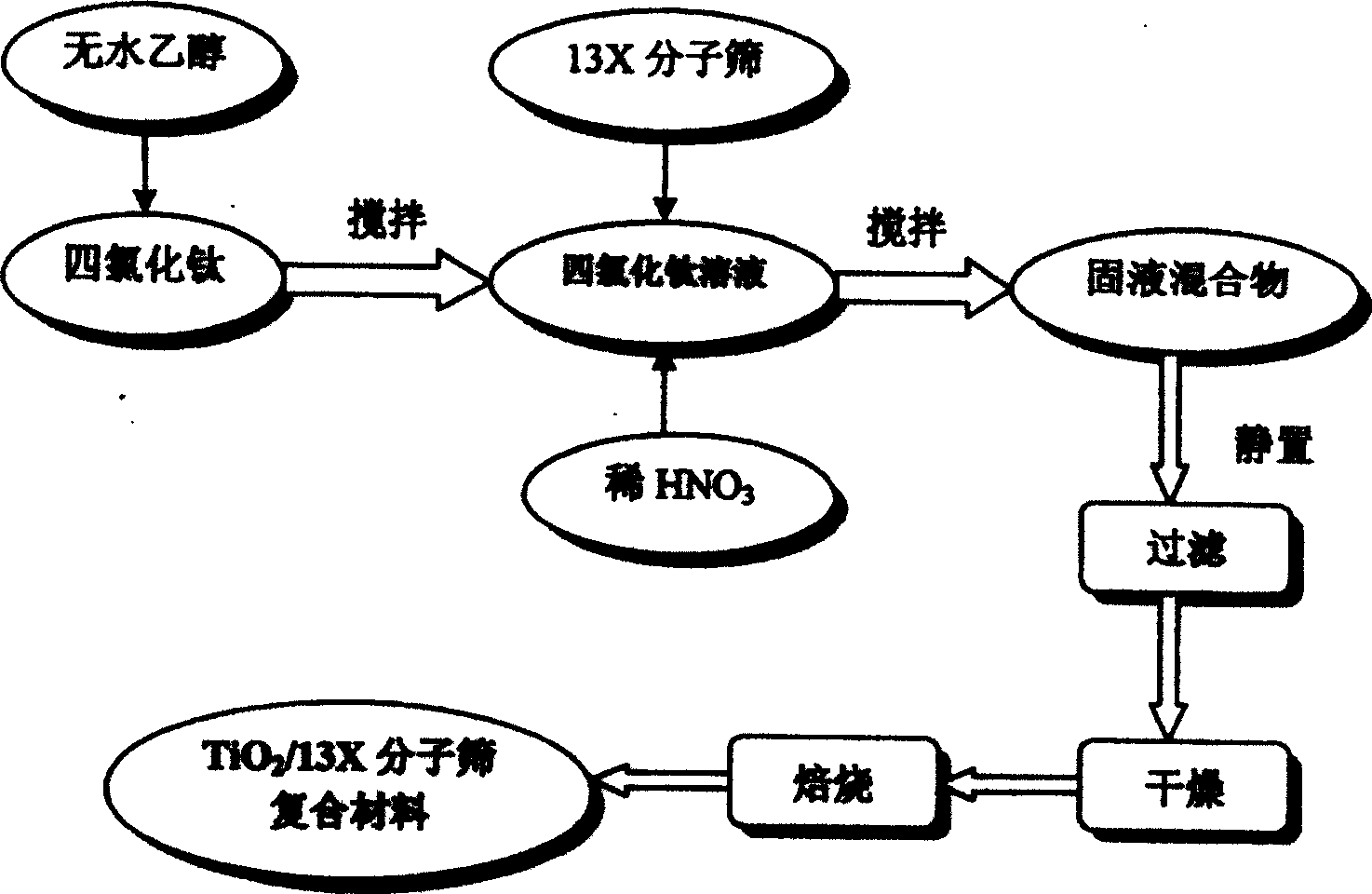

A preparation method of titanium dioxide/13X molecular sieves compound materials used for treating dyestuff waste water

InactiveCN100464848CImprove catalytic performanceEffective fixed loadMolecular sieve catalystsWater/sewage treatment by irradiationVacuum extractionIon exchange

Owner:UNIV OF SHANGHAI FOR SCI & TECH

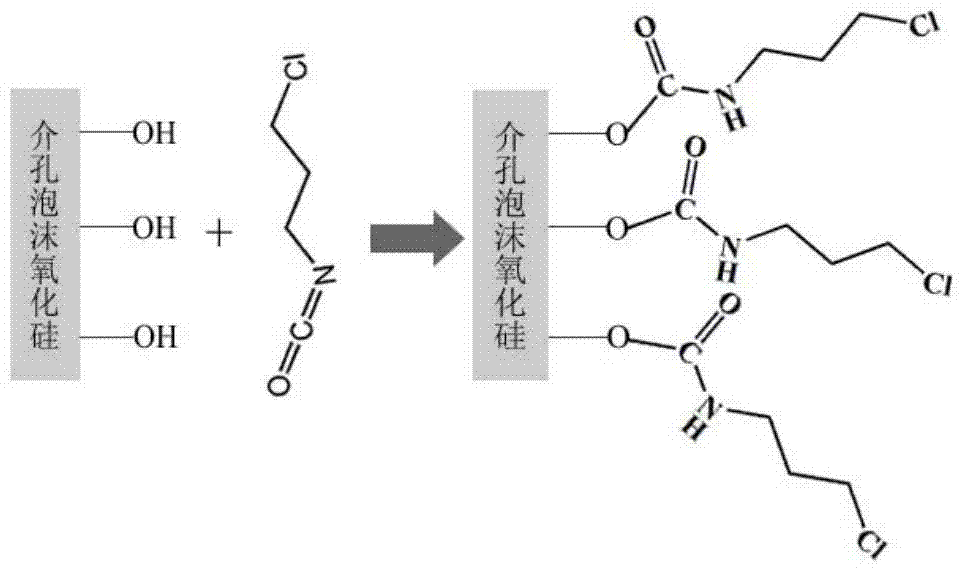

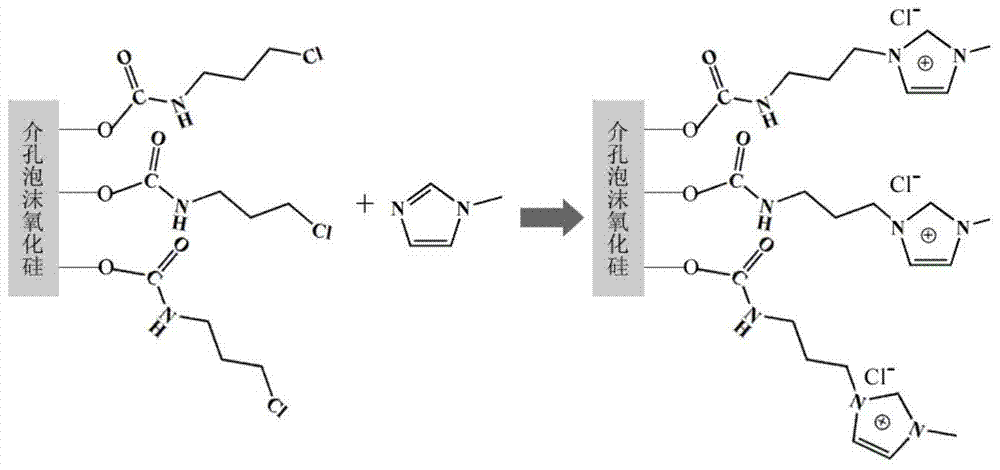

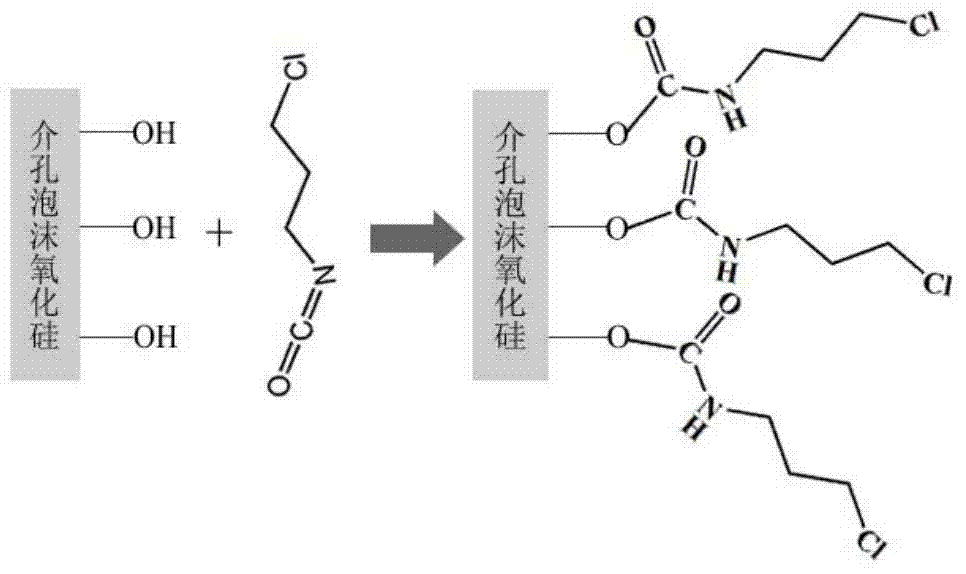

Solid catalyst for process of preparing ethylene glycol by hydrolyzing ethylene carbonate and preparation method thereof

ActiveCN103537318BEffective fixed loadIncrease the number ofOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingCatalytic effect1-Methylimidazole

The invention relates to a solid catalyst for a process of preparing ethylene glycol by hydrolyzing ethylene carbonate and a preparation method thereof. According to the preparation method, the solid catalyst for the process of preparing ethylene glycol by hydrolyzing ethylene carbonate is prepared by using mesoporous foam silicon oxide as a carrier, 3-chloropropyl isocyanate and 1-methylimidazole as raw materials through a two-step reaction. The method is simple in operation, the prepared solid catalyst can be recycled through simple treatment after the catalyst reacts, is long in service life and does not have pollution, and the production cost can be greatly reduced. The catalyst prepared by the method is used in an ethylene carbonate hydrolysis reaction and obtains a good catalytic effect, the conversion rate of ethylene carbonate is over 95 percent, and the ethylene glycol selectivity is 100 percent.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES

Pigment printing process with high heat vacuum fastness

ActiveCN113529441BHigh heat vacuum fastness improvementImproved thermal vacuum fastnessDyeing processTextile printerColour fastness

Owner:WUHAN TEXTILE UNIV

Chiral bisphosphine ligand and chiral catalyst and preparation and application methods

ActiveCN103059064BHigh stereoselectivityHigh reactivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical structurePtru catalyst

The invention relates to a chiral diphosphine ligand and a chiral catalyst, and a preparation and application method thereof. The preparation method of a BINAP (2,2'-bis(diphenylphosphino)-1,1'-binaphthyl) chiral diphosphine ligand based on novel imidazole and imidazole cation modification. Imidazole and imidazole cation are introduced to the 5,5'- position of the BINAP molecule framework to synthesize the chiral diphosphine ligand. The assembly of the imidazole and imidazole cation into the chiral diphosphine ligand molecule can effectively enhance the stability of the chiral catalyst in an ionic liquid and the affinity with the imidazole ionic liquid, and avoids loss of the catalyst in the cyclic process. The imidazole-modified chiral diphosphine ligand has the following chemical structural formula, wherein the spatial configuration of the imidazole-modified chiral diphosphine ligand is S type or R type.

Owner:山东聚强绿洲生物科技有限公司

Imidazole ionic liquid supported chiral phosphine ligands and preparation method thereof

ActiveCN102690291BHigh stereoselectivityEffective fixed loadOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCombinatorial chemistry

The invention relates to a chiral phosphine ligand supported by a class of imidazolium ionic liquid and a preparation method thereof, and also relates to the application of the rhodium complex in the asymmetric catalytic hydrogenation of α-dehydroamino acid and its derivatives. The chiral phosphine ligand supported by the imidazolium ionic liquid of the present invention is synthesized by introducing the cation of the imidazolium-type ionic liquid into the proline-derived chiral bisphosphine ligand molecule, which effectively enhances the activity and stereoselectivity of the catalyst And its affinity with imidazole-type ionic liquids. When the rhodium complex of the phosphine ligand of the present invention is applied to the asymmetric catalytic hydrogenation of α-dehydroamino acids and derivatives thereof, it has higher enantioselectivity (ee=95.2%) and very high conversion frequency ( TOF=24000h-1), at the same time, it can effectively suppress the loss of rhodium. The activity and stereoselectivity of the catalyst did not decrease significantly after several cycles, and the loss of rhodium was 0.1~0.2%.

Owner:山东格新精工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com