Beeswax/polystyrene composite phase-change energy storage material and preparation method and application thereof

A composite phase-change material and polystyrene technology, applied in application, heat exchange materials, chemical instruments and methods, etc., can solve the problems of unfavorable morphological characteristics of beeswax, difficult material control, adding cigarette filters, etc., and achieve the regulation of cigarettes The suction temperature and operating environment requirements are low, and the effect of reducing harmful components in the flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

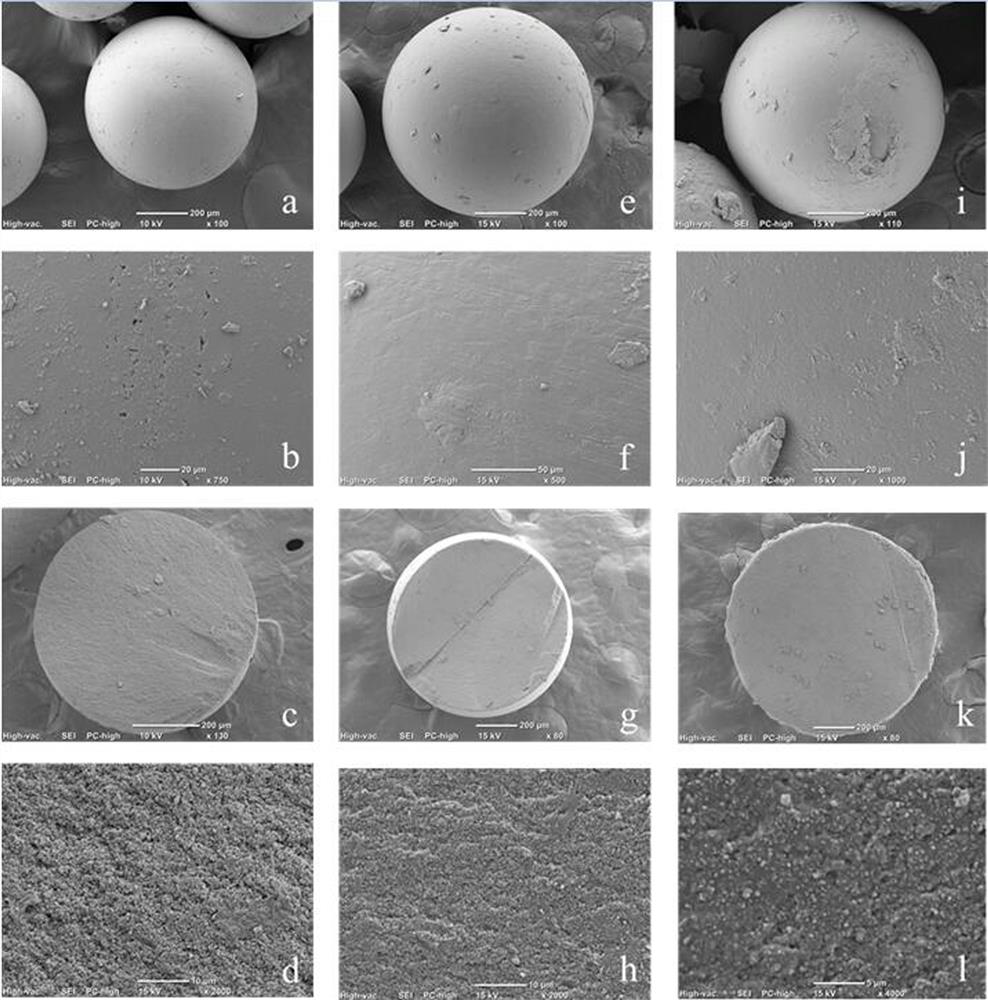

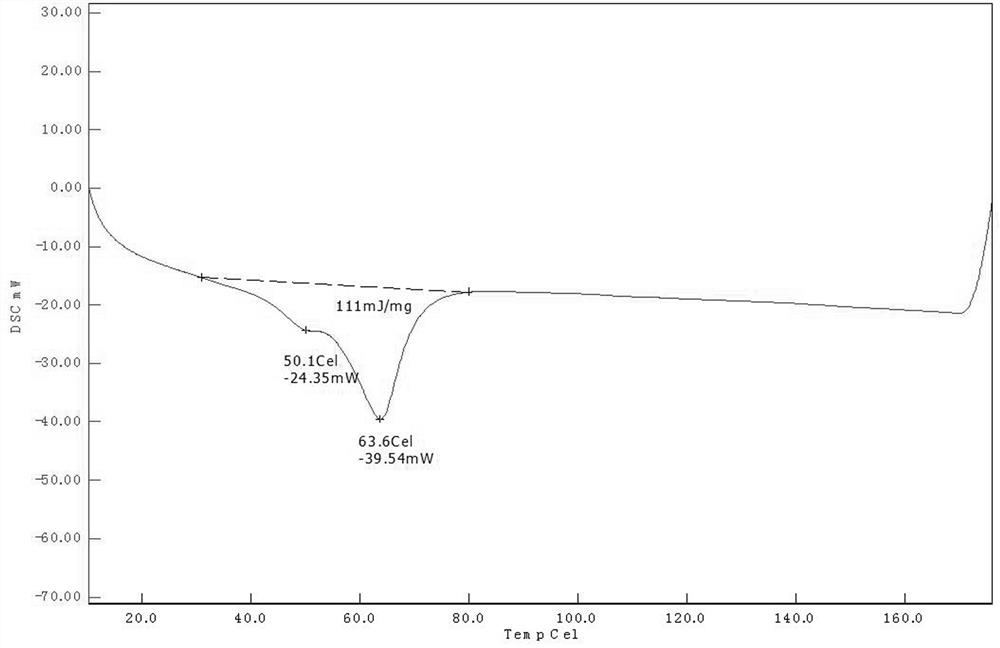

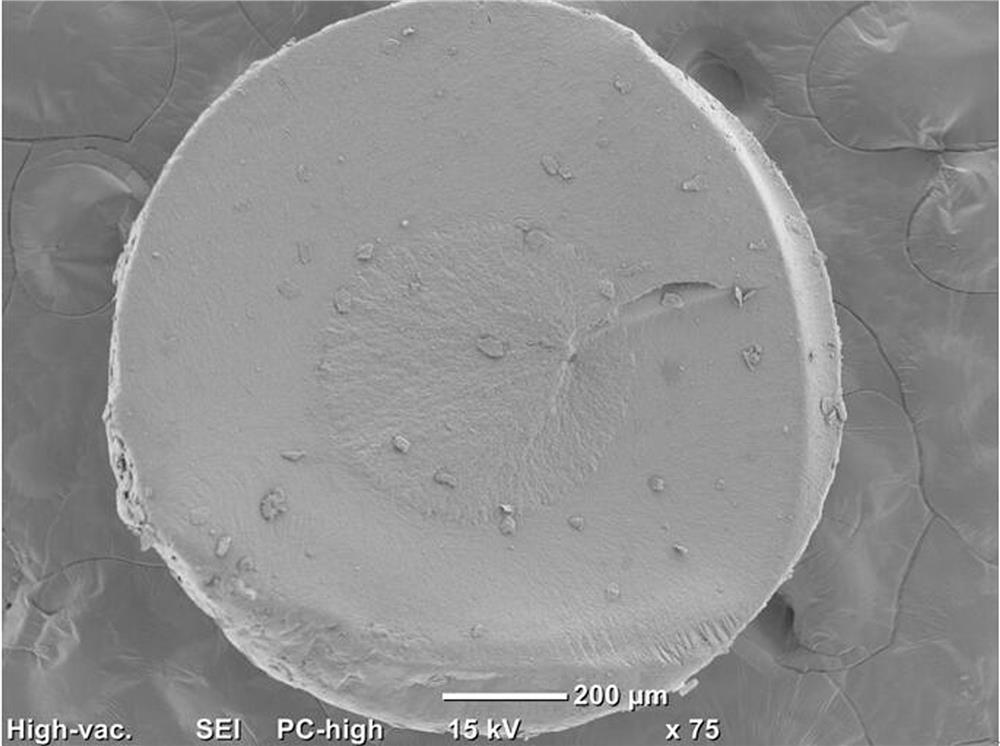

[0028]Example 1: A beeswax / polystyrene composite phase change energy storage material, the mass ratio of beeswax to polystyrene macroporous resin microspheres is 1:2.

[0029]A preparation method of beeswax / polystyrene composite phase change energy storage material includes the following steps:

[0030]First prepare polystyrene macroporous resin microspheres: Place 8g of chloromethylated polystyrene macroporous resin microspheres in 40mL of diethylene oxide to swell for 4h, transfer to a three-necked flask, and add concentration of 0.12 under stirring g / mL sodium hydroxide and 0.005g / mL tetrabutylammonium bromide mixed solution 40mL, quickly add 50mL ethylenediamine dropwise, react at 85℃ for 8-9h, the prepared products are respectively used Wash with ethanol and distilled water to finally obtain polar-modified polystyrene macroporous resin microspheres, which are stored in a wet state at room temperature; then, the polystyrene macroporous resin microspheres obtained above are shaken at 8...

Embodiment 2

[0042]Example 2: A beeswax / polystyrene composite phase change energy storage material, the mass ratio of beeswax to polystyrene macroporous resin microspheres is 1:3.

[0043]A preparation method of beeswax / polystyrene composite phase change energy storage material includes the following steps:

[0044]First prepare polystyrene macroporous resin microspheres: Place 8g of chloromethylated polystyrene macroporous resin microspheres in 40mL of diethylene oxide to swell for 4h, transfer to a three-necked flask, and add concentration of 0.12 under stirring g / mL sodium hydroxide and 0.005g / mL tetrabutylammonium bromide mixed solution 40mL, quickly add 50mL ethylenediamine dropwise, react at 85℃ for 8-9h, the prepared products are respectively used Wash with ethanol and distilled water to finally obtain polar-modified polystyrene macroporous resin microspheres, which are stored in a wet state at room temperature; then, the polystyrene macroporous resin microspheres obtained above are shaken at 8...

Embodiment 3

[0047]Example 3: A beeswax / polystyrene composite phase change energy storage material, the mass ratio of beeswax to polystyrene macroporous resin microspheres is 1:5.

[0048]A preparation method of beeswax / polystyrene composite phase change energy storage material includes the following steps:

[0049]First prepare polystyrene macroporous resin microspheres: Place 8g of chloromethylated polystyrene macroporous resin microspheres in 40mL of diethylene oxide to swell for 4h, transfer to a three-necked flask, and add concentration of 0.12 under stirring g / mL sodium hydroxide and 0.005g / mL tetrabutylammonium bromide mixed solution 40mL, quickly add 50mL ethylenediamine dropwise, react at 85℃ for 8-9h, the prepared products are respectively used Wash with ethanol and distilled water to finally obtain polar-modified polystyrene macroporous resin microspheres, which are stored in a wet state at room temperature; then, the polystyrene macroporous resin microspheres obtained above are shaken at 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com