Patents

Literature

1108results about How to "Improve processing fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bamboo powder filling biodegradable compound material and preparation method thereof

The invention relates to a bamboo powder filling biodegradable compound material and a preparation method thereof. The bamboo powder filling biodegradable compound material comprises the following raw materials in part by mass: 30 to 80 parts of biodegradable resin, 20 to 70 parts of bamboo powder, 1 to 19 parts of plasticizer, 0.6 to 6 parts of interface modifier and 4 to 12 parts of aids. The preparation method comprises the following steps of: uniformly mixing the biodegradable resin, bamboo powder, plasticizer, interface modifier and auxiliary agent by using a mixer according to formula proportion; performing melt blending and granulation of the obtained mixture by using a screw extruder to obtain particles; and processing the particles by using an injection molding machine, a sheet extrusion forming machine, a blow molding machine or a film blowing machine, and molding in molds of different shapes to obtain the bamboo powder filling biodegradable compound materials of different shapes. The method has the advantages of high production efficiency and low cost; and the powder filling biodegradable compound material prepared by the method has the advantages of high environmentally-friendly property and economy and excellent usability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

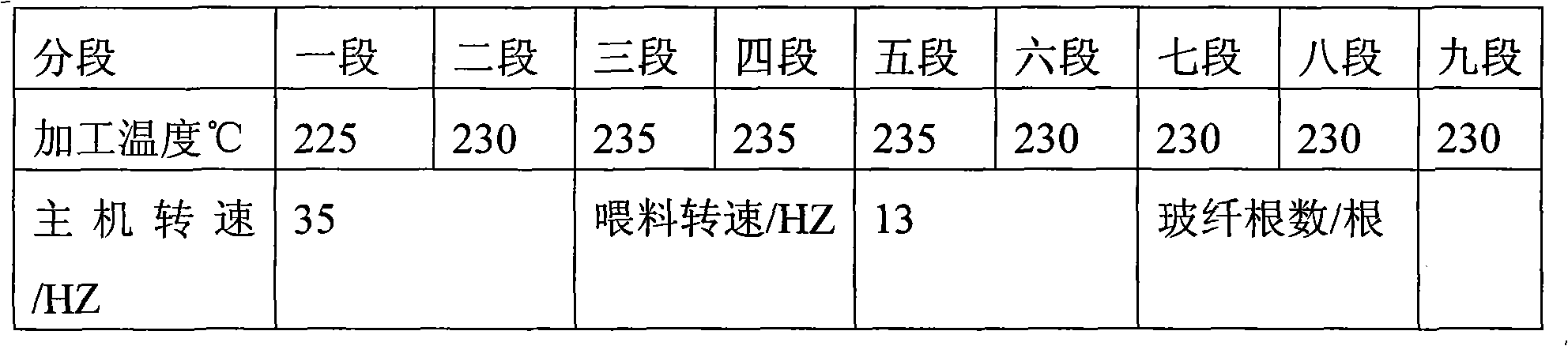

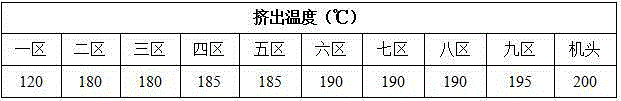

High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

InactiveCN102108187AAvoid decompositionImprove impact performanceGlass fiberPolyethylene terephthalate

The invention relates to a high glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT) / acrylonitrile butadiene styrene (ABS) alloy material. The material comprises the following components in percentage by weight: 22.5-41% of PBT, 22.5-41% of ABS, 6-20% of complexing inflaming retardant, 3-15% of antimonous oxide, 20-30% of glass fiber, 2-10% of flexibilizer, 0.1-1% of antioxidant and 0.1-1% of lubrication dispersing agent. The preparation method comprises the following steps: putting raw materials weighed based on the weight proportion into a high mixer, mixing for 2-5 minutes, and then discharging; and then extruding and granulating by using an extruding machine at the processing temperature of 230-240 DEG C at the screw rotating speed of 30-40Hz. Compared with the alloy material prepared by the prior art, the high glowing filament environment-friendly inflaming retarding reinforced PBT / ABS alloy material has the advantages of high glowing filament temperature, environmental friendliness, balanced comprehensive performance and the like.

Owner:SHANGHAI SUNNY

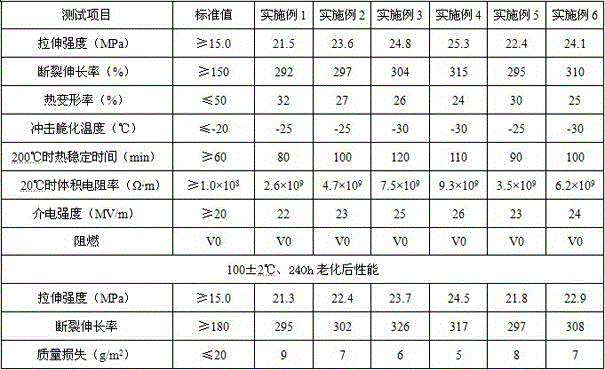

Insulating and environment-friendly PVC modified material and preparation method thereof

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

High-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and preparation method thereof

ActiveCN103059470AImprove wear resistanceImprove wet skid resistancePolymer sciencePolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high-abrasion-resistant and environment-friendly polyvinyl chloride (PVC) modified materials and a preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials. The modified materials comprise following raw materials, by weight, 80-120 parts of PVC resin, 5-15 parts of stuffing bulking agents, 31-70 parts of plasticizer, 1-10 parts of abrasion resistant modifying agents, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 10-20 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to the weight and are blended, after the raw materials are stirred, the stirred raw materials are extruded to be granulated into particles through a double-screw extruder to produce the modified materials. The prepared modified materials are good in abrasion resistant property, environment-friendly, high in strength, good in flame retardant efficiency, strong in compression property and toughness, good in processing property, and good in comprehensive property. The preparation method of the high-abrasion-resistant and environment-friendly PVC modified materials is simple in craft, convenient to operate and control, stable in quality and high in production efficiency and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

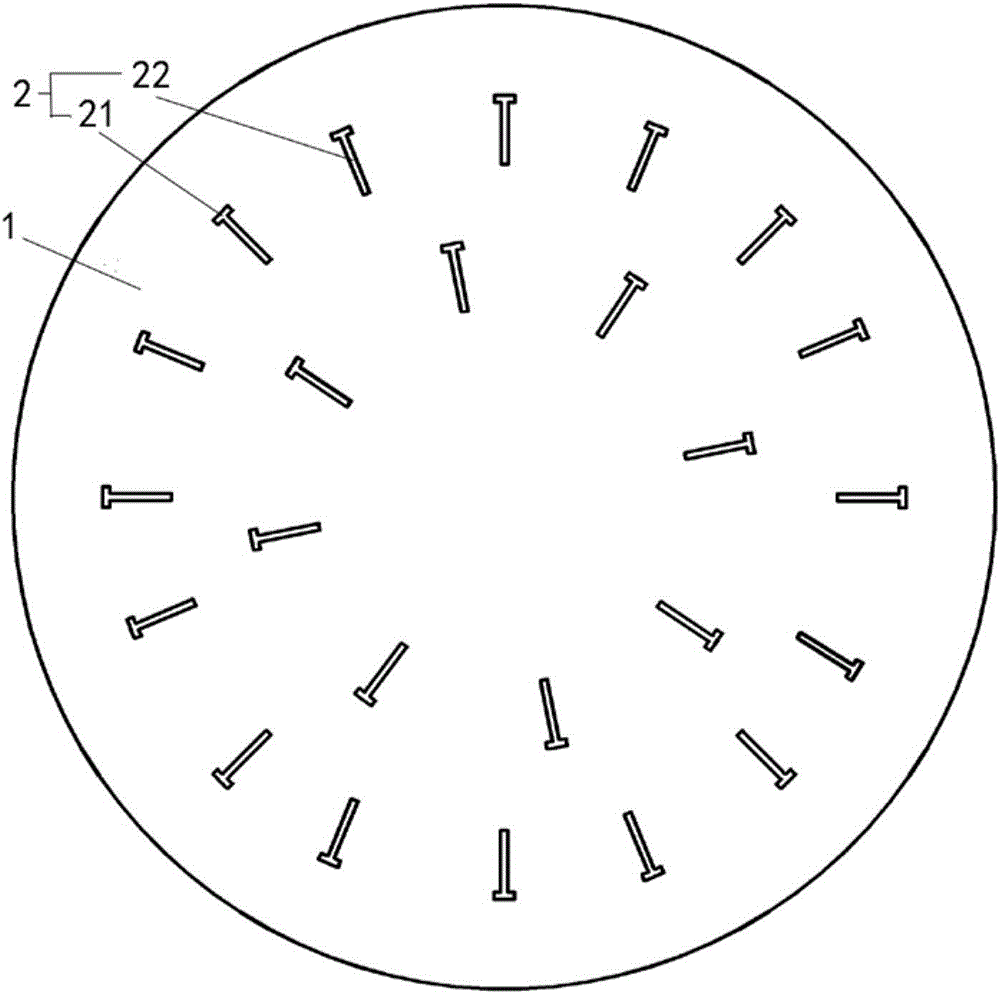

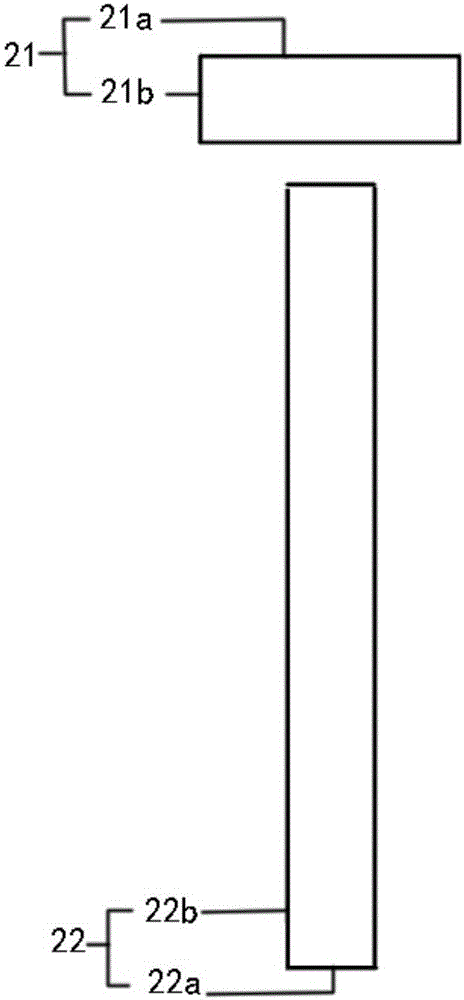

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

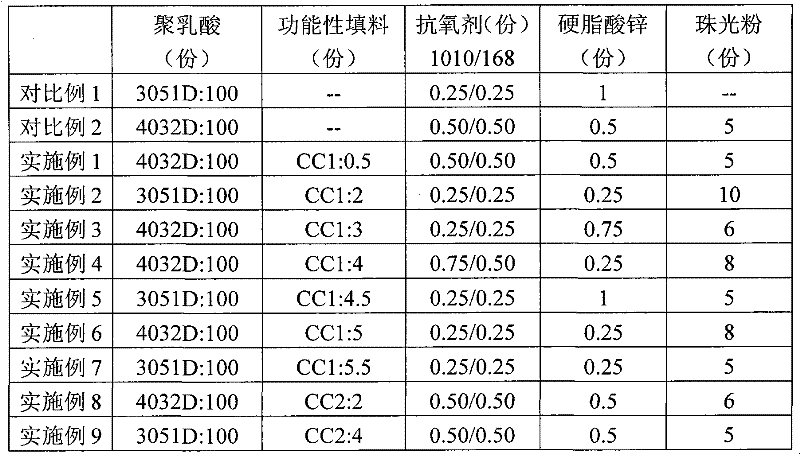

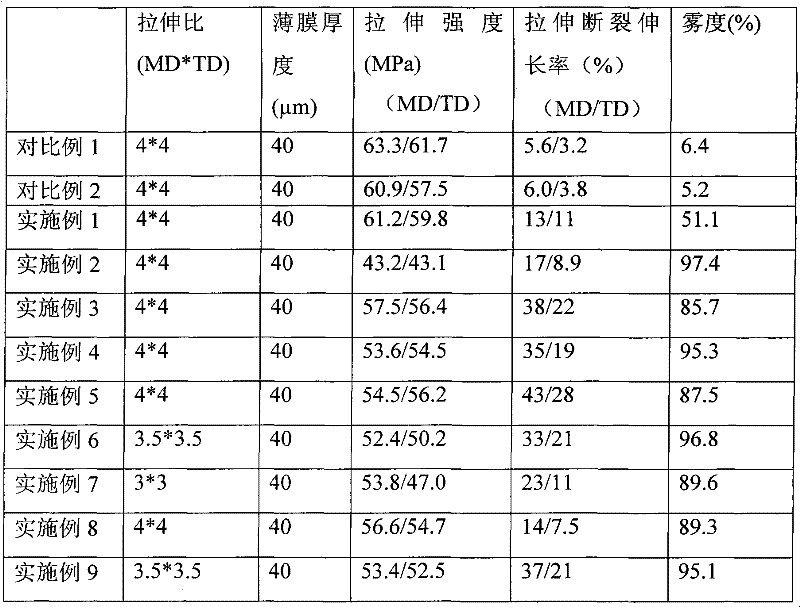

Polylactic resin composition film and preparation method thereof

The invention provides a polylactic resin composition film and a preparation method thereof, and relates to the field of plastic processing. The polylactic resin composition film comprises the following components: 100 weight parts of polylactic resin and 0.5 to 5.5 weight parts of functional filler which are blended, wherein the polylactic resin has the weight-average molecular weight of 80,000-300,000 and the molecular weight dispersibility of 1.5-2.2; and the functional filler is at least one of the following inorganic fillers: calcium carbonate, clay, silica, alumina, barium sulfate, calcium sulfate, talc, magnesium sulfate, titanium dioxide, zeolite, aluminum sulfate, kieselguhr, kaolin, calcium oxide and magnesium oxide. The preparation method comprises the following steps of: melting, blending and granulating the components in the proportion, casting and pressing, and biaxially tensioning to obtain the polylactic resin composition film. The film is completely biodegradable, has balanced rigidity and toughness, maintains the tensile strength, has the elongation at break improved by 3 to 7 times compared with the original elongation at break, and has uniform texture, high decorative property, high printing property and unidirectional tearing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

Low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

ActiveCN103059468AGood flexibility and electrical insulation propertiesImprove low temperature resistancePelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 20-45 parts of filling agent, 41-80 parts of plasticizer, 1-10 parts of cold-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed, after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The low temperature resistant performance of the modified material manufactured by the preparing method is fine; the minimum usage temperature can reach below 65 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in technology, convenient to control and operate, stable in quality, high in production efficiency. In addition, the preparation method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large scale industrial production.

Owner:广东祺龙科技有限公司

Weatherable irradiation crosslinking cable material

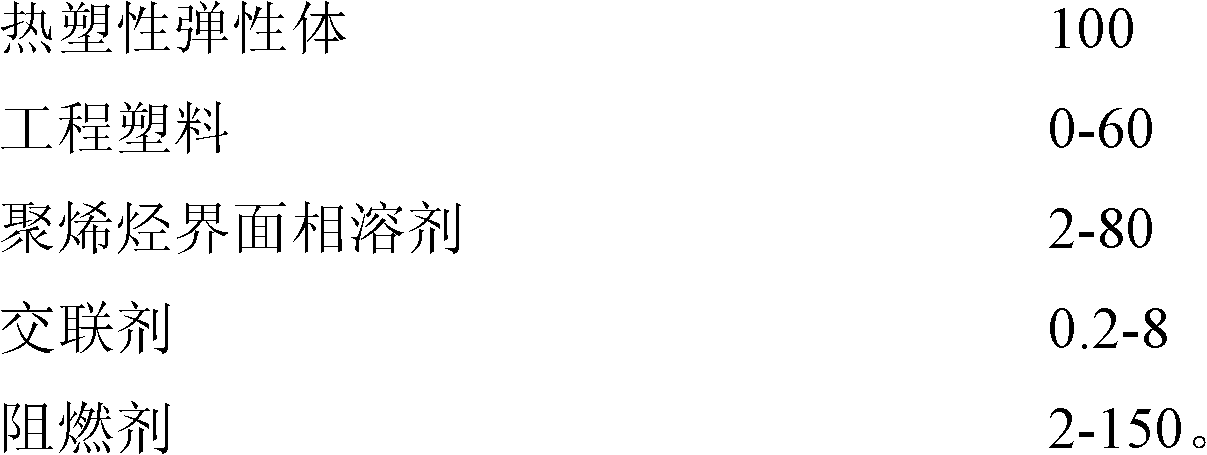

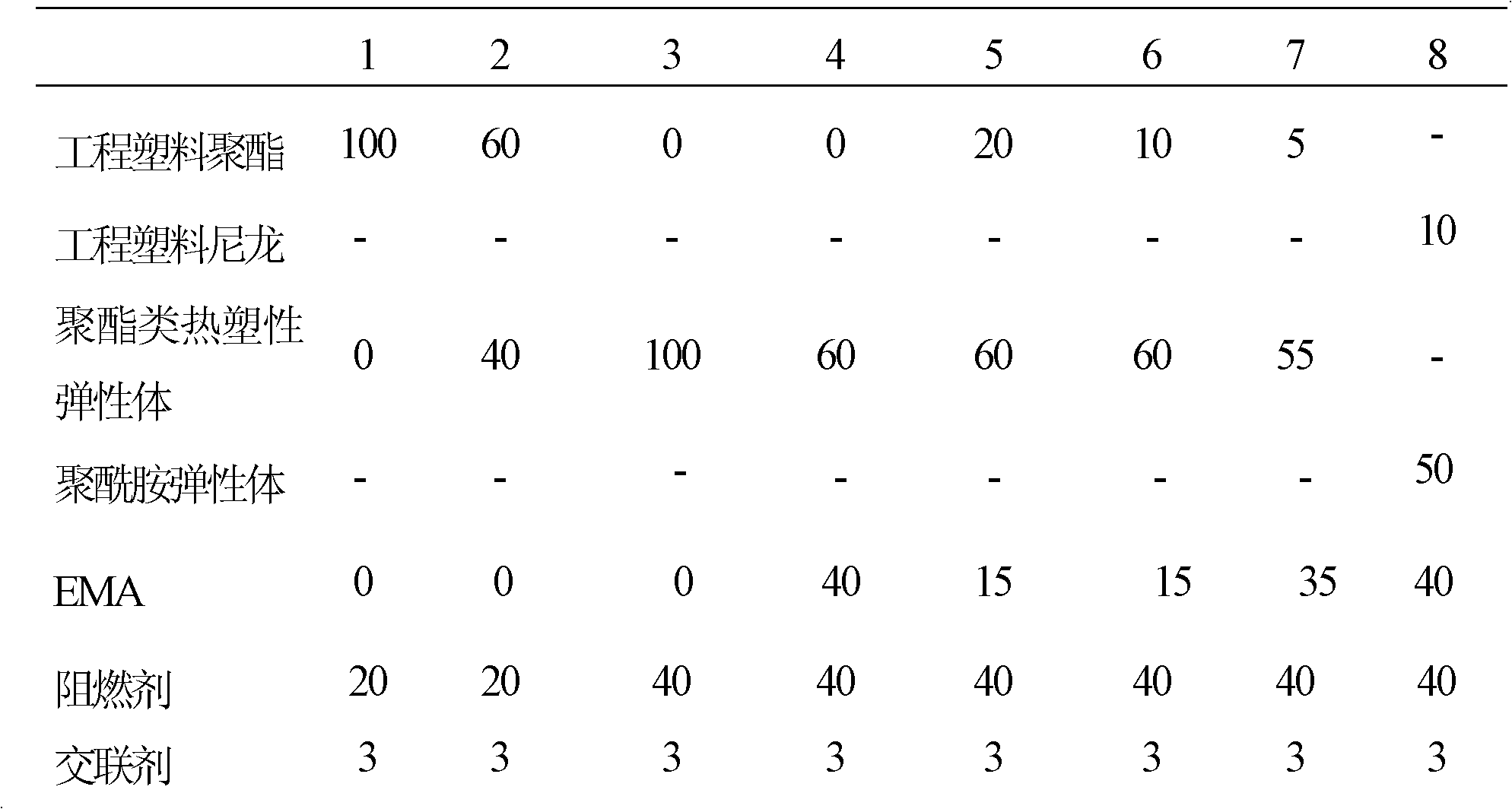

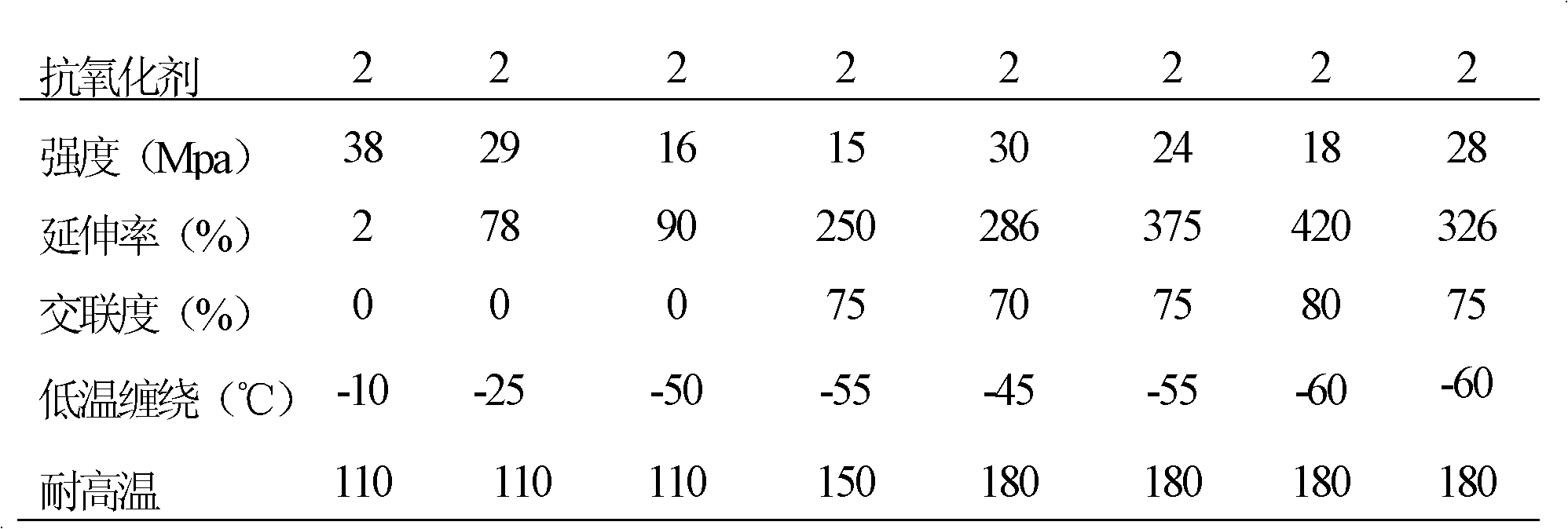

InactiveCN102660108AImprove processing fluidityImprove mechanical propertiesOrganic insulatorsPolyesterExtensibility

The invention discloses a weatherable irradiation crosslinking cable material. Raw materials of the cable material comprise the following components, by weight, 100 parts of a thermoplastic elastomer, 0-35 parts of an engineering plastic, 2-80 parts of a polyolefin, 0.2-8 parts of a crosslinking agent, and 2-150 parts of a fire retardant. According to the invention, problems existing in manufacturing of cable materials from polyester copolymers are solved through reasonably designing the components and the ratio of the components, and utilizing the interaction of the components; and the prepared cable sheath material has the advantages of good processing fluidity, good mechanical properties, oil resistance, high temperature resistance, excellent hot extensibility and superior low temperature resistance after irradiation crosslinking, and substantial reduction of the material cost through the addition of the polyolefin interface phase solvent.

Owner:SUZHOU MEIGUAN PLASTIC MATERIALS

Polyphenylene oxide composition used for photovoltaic junction box

ActiveCN102399433AImprove liquidityGuaranteed toughnessHazardous substanceComparative Tracking Index

The invention provides a polyphenylene oxide composition used for a photovoltaic junction box. The composition comprises the following components by weight: 55-95 parts of polyphenylene oxide, 45-5 parts of styrene resin, 2-10 parts of a flexibilizer, 5-20 parts of a phosphate fire retardant, 0.5-2.5 parts of an acid absorbent, 0.2-0.6 part of a hindered phenol main antioxidant, 0.2-0.6 part of a phosphite auxiliary antioxidant, 0.3-1.5 parts of an ultraviolet absorbent, 0.3-1.5 parts of a hindered amine light stabilizer, 0.1-0.5 part of a lubricating agent, and 0.1-1.0 part of toner. With the characteristics of good flame resistance, thermo-oxidative aging resistance, UV (ultraviolet) resistance, excellent electrical performances, the composition of the invention has flame retardancy up to grade UL945VA, RTI (relative temperature index)=110DEG C, CTI (comparative tracking index) PLC ( programmable logic controller)=2, and GWIT (glow wire ignition temperature)=750DEG C, thus satisfying the requirements in ROHS (restriction of hazardous substances) standard. Thus, the composition provided in the invention can be used for electronic and electrical component production of solar photovoltaic junction boxes, etc.

Owner:广东瑞能新材料有限公司

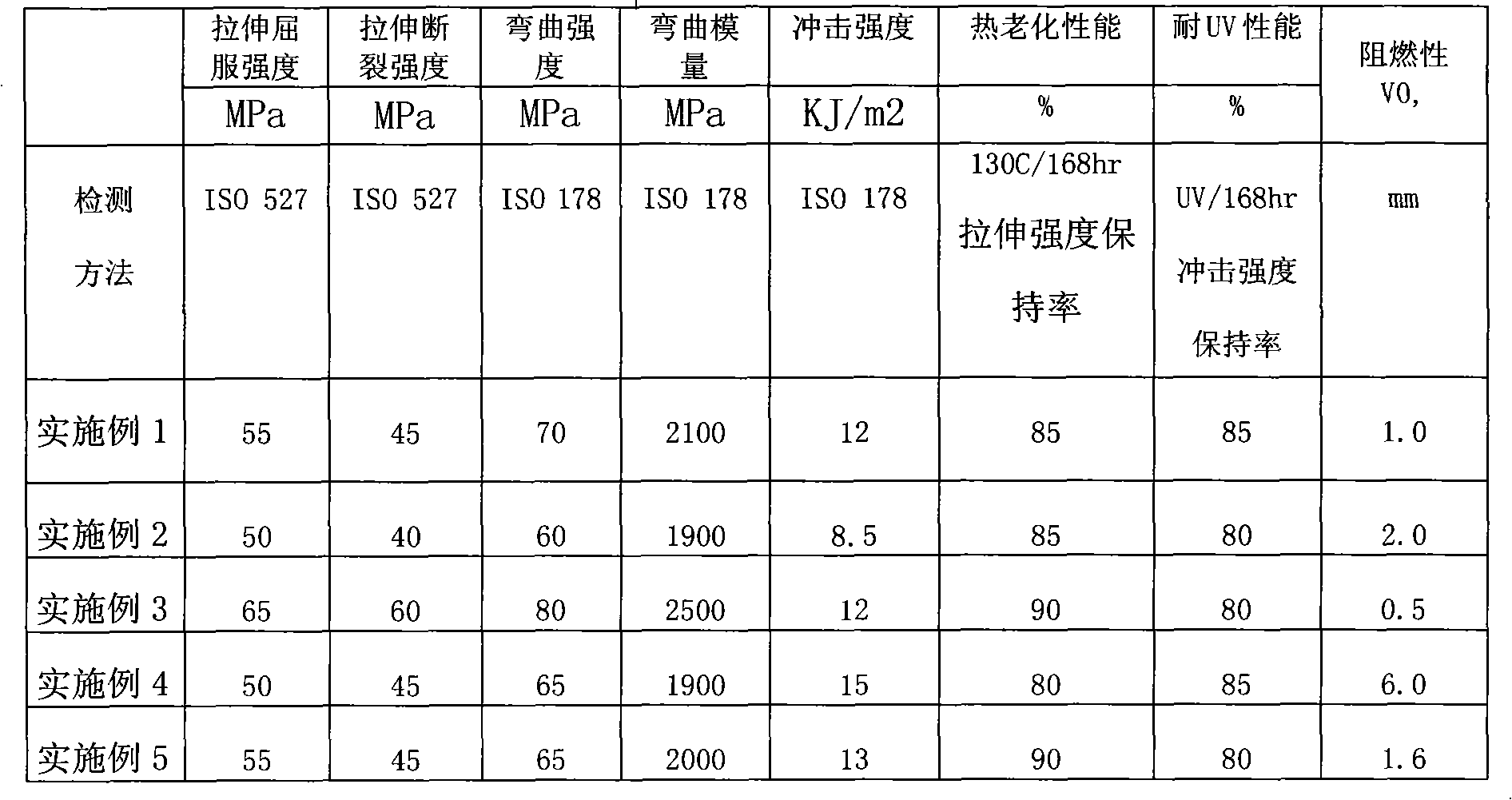

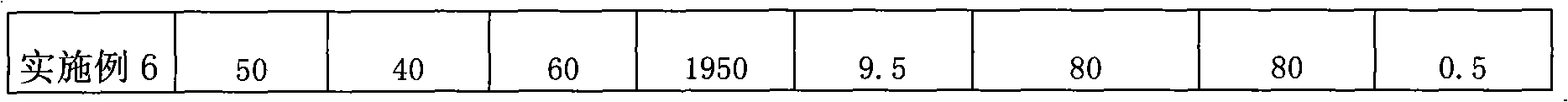

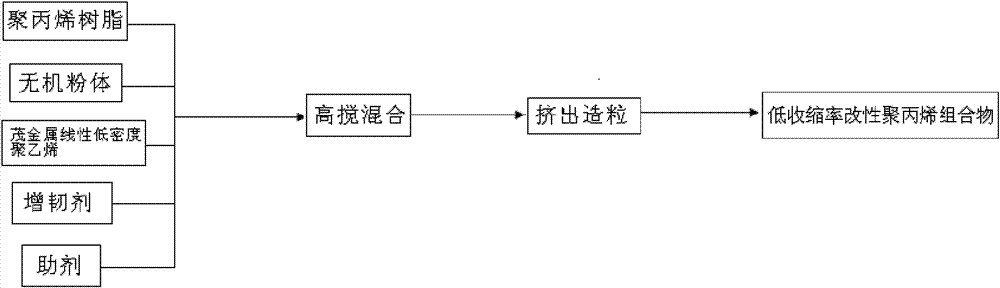

Low-shrinkage polypropylene composition and preparation method thereof

The invention relates to a low-shrinkage polypropylene composition and a preparation method thereof, belonging to the technical field of high polymer materials. The low-shrinkage polypropylene composition is prepared from the following raw materials in parts by mass: 35-87 parts of polypropylene resin, 10-30 parts of inorganic powder, 2-35 parts of metallocene linear low-density polyethylene, 1-5 parts of toughener and 0.05-0.3 part of weather-resistant assistant. According to the invention, the modified polypropylene composition having a low shrinkage is prepared by taking impact polypropylene copolymer as a base resin, adding the inorganic powder, the metallocene linear low-density polyethylene and the toughener and extruding and granulating with a double-screw extruder; the prepared polypropylene composition has low cost, low shrinkage, excellent rigidity-toughness balance, high glossiness and favorable processing flowability; and the preparation method is simple and easy to implement and easy to operate.

Owner:CHINA PETROLEUM & CHEM CORP

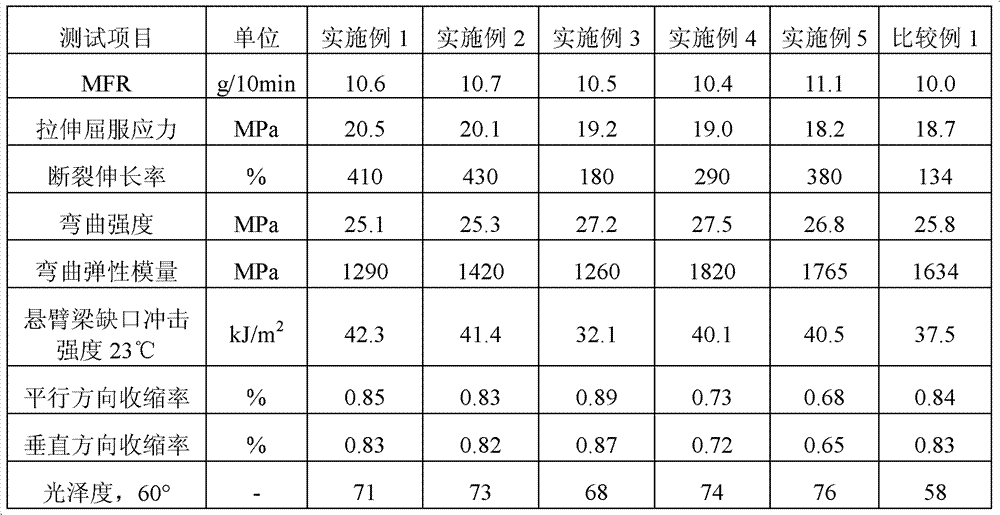

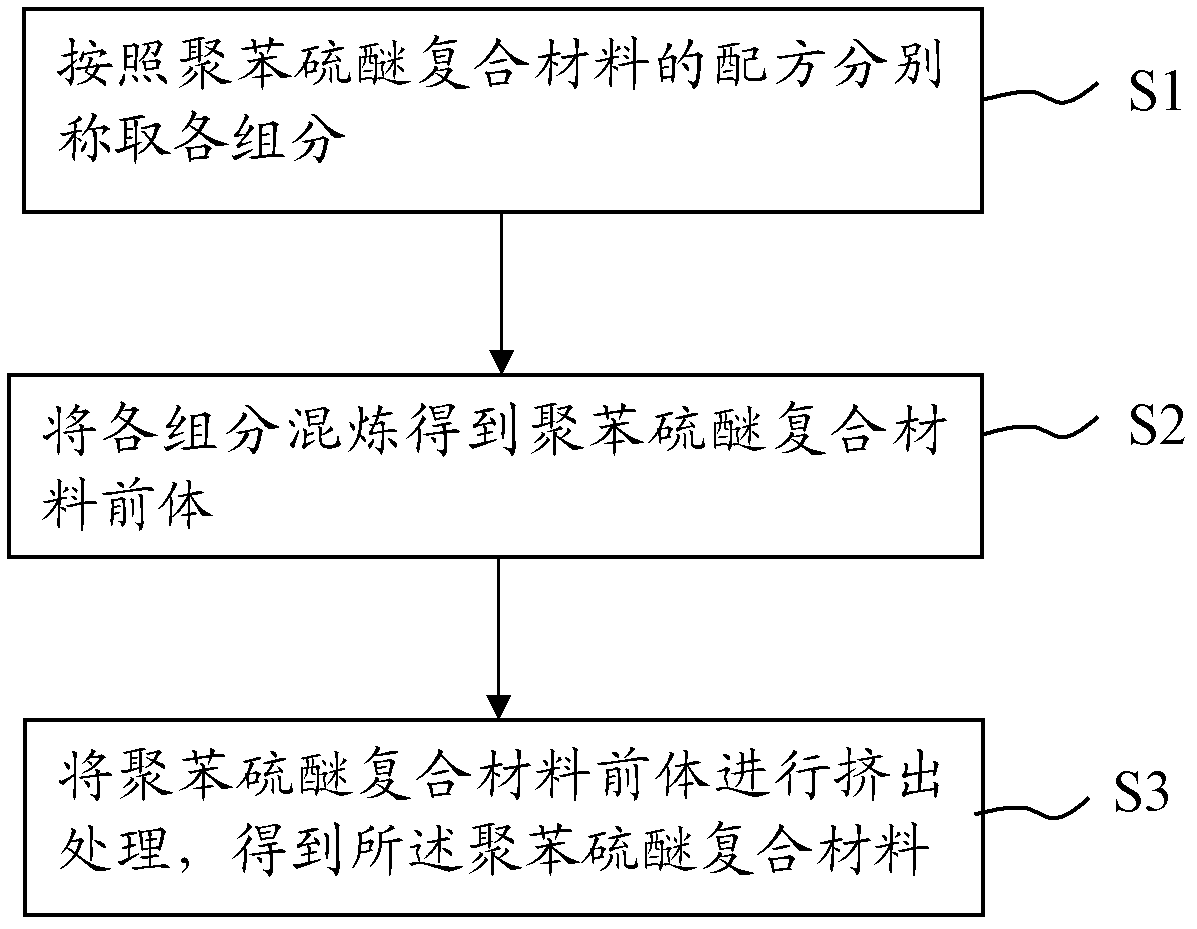

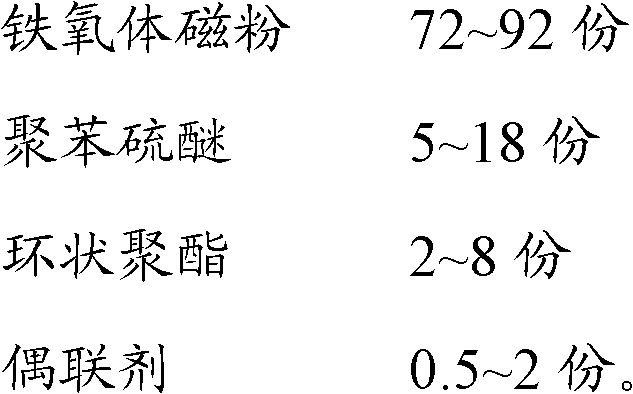

Polyphenylene sulfide composite material and preparation method thereof

InactiveCN102181156AImprove processing fluidityImprove mechanical propertiesPolyesterMechanical property

The invention discloses a polyphenylene sulfide composite material and a preparation method thereof. The polyphenylene sulfide composite material comprises the following formula components in part by weight: 72 to 92 parts of ferrite magnetic powder, 5 to 18 parts of polyphenylene sulfide, 2 to 8 parts of cyclic polyester and 0.5 to 2 parts of coupling agent. By interaction of the components in aproper content range in the extrusion process, the polyphenylene sulfide composite material has good processing flow property and mechanical performance and stable magnetic performance. The product can be obtained by mixing and extruding the components according to the formula in the preparation method of the polyphenylene sulfide composite material; and the preparation method is simple in process, low in cost, low in equipment requirement and suitable for industrialized production.

Owner:SHENZHEN KEJU NEW MATERIAL

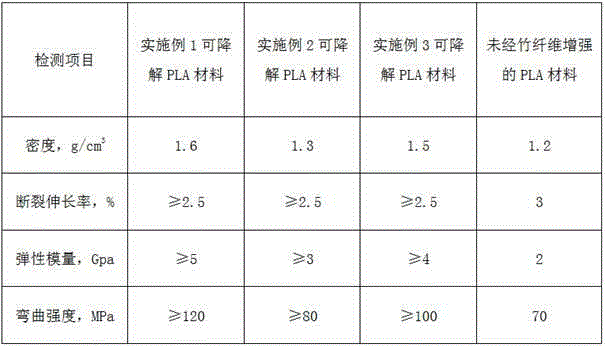

Bamboo fiber reinforced degradable PLA material and preparation method thereof

The invention discloses a bamboo fiber reinforced degradable PLA material and a preparation method thereof. Raw materials for preparing the bamboo fiber reinforced degradable PLA material comprise, by weight, 30-70 parts of polylactic acid resin, 15-40 parts of bamboo fibers, 0.5-2 parts of a coupling agent, 10-30 parts of inorganic powder, 0.5-5 parts of a compatilizer, 0.1-0.5 parts of an antioxidant, 0.5-3 parts of a dispersant and 3-5 parts of a lubricant. The bamboo fiber reinforced degradable PLA material is prepared through blending the bamboo fibers and other assistants with the polylactic acid resin, so the strength of the PLA material is effectively improved, thereby the PLA material can be widely applied in fields of automobile parts, decoration finishing, electric appliance products and packaging; and the material also has the advantages of degradability, environmental protection, and good environmental and social benefits.

Owner:FUZHOU FUSU SCI & TECH RES INST CO LTD

EPDM (ethylene propylene diene monomer) rubber insulated/jacketed cable with high strength, oil resistance and aging resistance

InactiveCN105255019AImprove heat resistanceGood weather resistanceRubber insulatorsInsulated cablesCarbon nanotubeEPDM rubber

The invention discloses an EPDM (ethylene propylene diene monomer) rubber insulated / jacketed cable with high strength, oil resistance and aging resistance. The EPDM rubber insulated / jacketed cable comprises following raw materials: EPDM rubber, nitrile butadiene rubber, maleic anhydride grafted polypropylene, an ethylene-vinyl acetate copolymer, diphenyl hexadiphthalein diamine, stearic acid, zinc oxide, superfine fully vulcanized powder nitrile butadiene rubber, tin(II) chloride dehydrate, bromo-octyl-phenolic curing resin, calcined kaolin, zinc methacrylate, carbon nano tubes, superfine silica, calcium sulfate whiskers, polyacrylonitrile fibers, a silane coupling agent, lanthanum glutamic dithiocarbamate, petroleum wax, naphthenic oil, an anti-aging agent and an accelerator. The EPDM rubber insulated / jacketed cable material with high strength, oil resistance and aging resistance serves as insulation and / or a jacket in a cable and has high strength, good oil resistance, aging resistance and combination properties and long service life.

Owner:ANHUI LAND GRP

Polycarbonate/acrylonitrile-styrene-acrylate copolymer alloy material and preparation method thereof

InactiveCN102399424AImprove processing fluidityImproved stress crack resistanceAcrylonitrileUltraviolet lights

The invention relates to a polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material and a preparation method thereof. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material is prepared mainly from 40 to 70 parts by weight of polycarbonate (PC), 20 to 50 parts by weight of acrylonitrile-styrene-acrylate copolymer (ASA), 2 to 10 parts by weight of a compatilizer, 3 to 15 parts by weight of a flexibilizer, 0.1 to 0.8 parts by weight of anti-oxidants, 0.5 to 5 parts by weight of a lubricant, 0.2 to 1 part by weight of an ultraviolet light absorber and 0.2 to 1.5 parts by weight of teflon through melt blending extrusion. The polycarbonate / acrylonitrile-styrene-acrylate copolymer alloy material obtained by the preparation method has good comprehensive mechanical properties, processing properties and weatherability, and is especially suitable for manufacture of interior and exterior trim parts of automobiles.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Waste PVC (Polyvinyl Chloride) and fly ash composite material and preparation method thereof

The invention relates to the technical field of PVC (Polyvinyl Chloride) composite materials and particularly relates to a waste PVC and fly ash composite material and a preparation method thereof. The waste PVC and fly ash composite material comprises the following raw materials according to parts by weight: 80-120 parts of waste PVC, 35-55 parts of fly ash, 3-10 parts of plasticizer, 1-2 parts of flame retardant, 0.5-2 parts of stabilizer, 0.5-2 parts of impact modifier, 0.3-1 part of lubricant and 0.1-0.5 part of antioxidant. The preparation method comprises the following steps of: weighing all the raw materials according to the parts by weight, mixing, stirring, extruding through a twin-screw extruder for granulation, chopping and air-cooling to obtain the waste PVC and fly ash composite material. The waste PVC and fly ash composite material prepared by the preparation method has excellent heat resistance, high strength, good flame retardant effect, high compression performance and toughness, and excellent processing performance and comprehensive performance; and the additive amount of renewable resources in the waste PVC and fly ash composite material reaches 90%-95%, thus lowering the production cost, reducing the environmental pollution, and bringing good economic benefit and social benefit.

Owner:广东祺龙科技有限公司

Ultra-fine composite modified talc powder body, preparation method and uses thereof

InactiveCN101367962AOvercoming reunion tendenciesFilled tightlyPigmenting treatmentState of artUltra fine

The invention discloses a superfine compound modified talcum powder body, a preparation method and an application thereof. The powder body comprises the following materials by the weight portion: 60-75 portions of talcum powder, 25-35 portions of superfine heavy calcium carbonate powder, 1-2.5 portions of titanium ester coupling agent and 1-1.2 portions of stearic acid. The preparation method includes the following steps: the talc powder is added into a high-speed mixer, then the heavy calcium carbonate is added, the temperature is raised to 100-110 DEG C, the materials are heated for 5-10 minutes; the coupling agent is added, the temperature is raised to 160-165 DEG C, and the materials are heated for 6-10 minutes; the materials are cooled to 95-105 DEG C, and then the stearic acid is added, and mixed evenly to achieve the desired powder body. The powder body can be applied to facia materials and super-tough HIPS materials as well as military packaging materials. Compared with the prior art, the powder body produced by the method has big filling fraction, sound compatibility with other auxiliary materials and strong processing fluidity; in addition to the functions of filling and increment, the powder body can effectively improve the toughness and strength of products.

Owner:芜湖同达新材料科技有限公司

High-flame-retardant polypropylene material and preparation method thereof

InactiveCN105385028AGood flame retardant performanceGood self-extinguishingPolypropyleneBrominated flame retardant

The invention discloses a high-flame-retardant polypropylene material and a preparation method thereof. The material is composed of the following raw materials in parts by mass: 60-75 parts of homo-polypropylene aggregates, 5-15 parts of homo-polypropylene powder, 10-20 parts of a brominated flame retardant, 3-8 parts of an antimony flame retardant, 1-3 parts of a flame retardant synergist, 0-10 parts of a cooling master batch, 0-3 parts of a flexibilizer, 0-1 part of a lubricant, 0-1 part of an ultraviolet light absorber, and 0-1 part of an antioxidant. The preparation method of the material comprises the following steps: 1) uniformly mixing all materials in certain proportion; and 2) adding the obtained mixture into a twin-screw extruder, carrying out high-temperature mixing and shearing, and after the obtained object is subjected to water cooling, sequentially carrying out bracing and grain-sized dicing, so that the high-flame-retardant polypropylene material is obtained. The high-flame-retardant polypropylene material disclosed by the invention is excellent in flame resistance, good in self-extinguishment, excellent in aging resistance, good in insulating property and heat resistance, not easy to deform by heating, excellent in processing fluidity, and easy to shape.

Owner:GUANGDONG JUSHI CHEM CO LTD

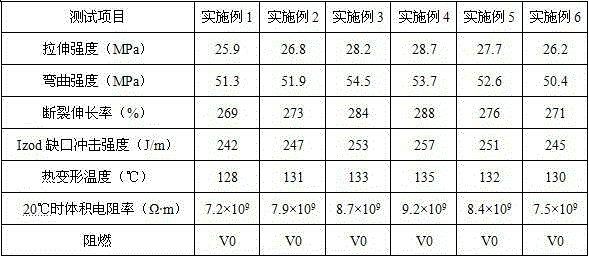

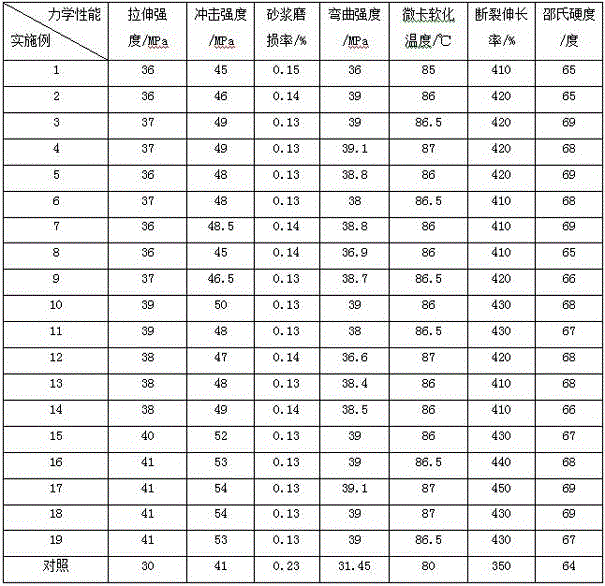

High-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material

The invention relates to a high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material. The blend material comprises the following raw materials by weight: 60 to 100 parts of UHMWPE, 5 to 12 parts of HDPE, 6 to 16 parts of LLDPE, 0.1 to 3 parts of a high-molecular-weight polymer nucleating agent and 1.5 to 3 parts of a flow modifier. The high-molecular-weight polymer nucleating agent has the advantages of no odor, good dispersibility, good compatibility, capacity of realizing heterogeneous crystallization, a high degree of crystallization and a small application amount; the high-molecular-weight polymer nucleating agent-modified ultrahigh-molecular-weight polyethylene blend material retains original characteristics of polyethylene UHMWPE and has obviously improved tensile strength, impact strength, bending strength, Vicat softening temperature, elongation at break and Shore hardness and a reduced mortar wear rate.

Owner:漯河科莱堡科技有限公司

Material for new energy battery cases and preparation method of material

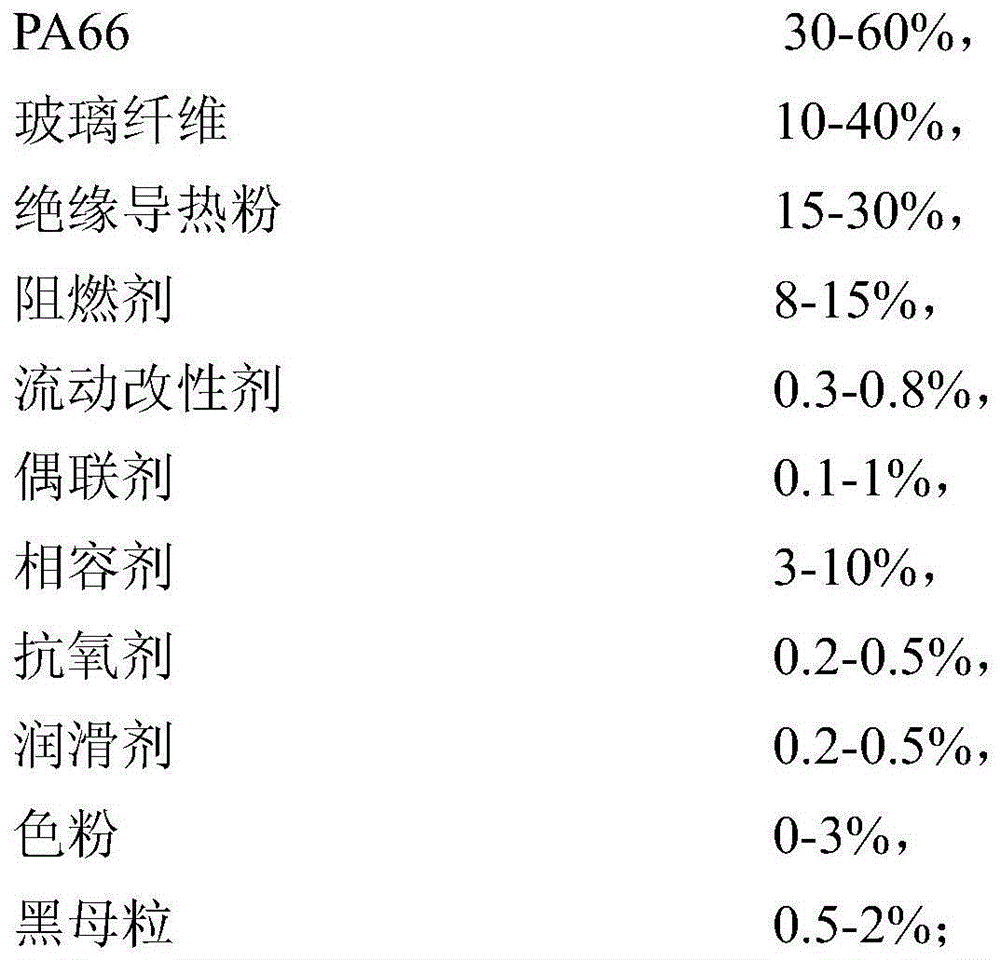

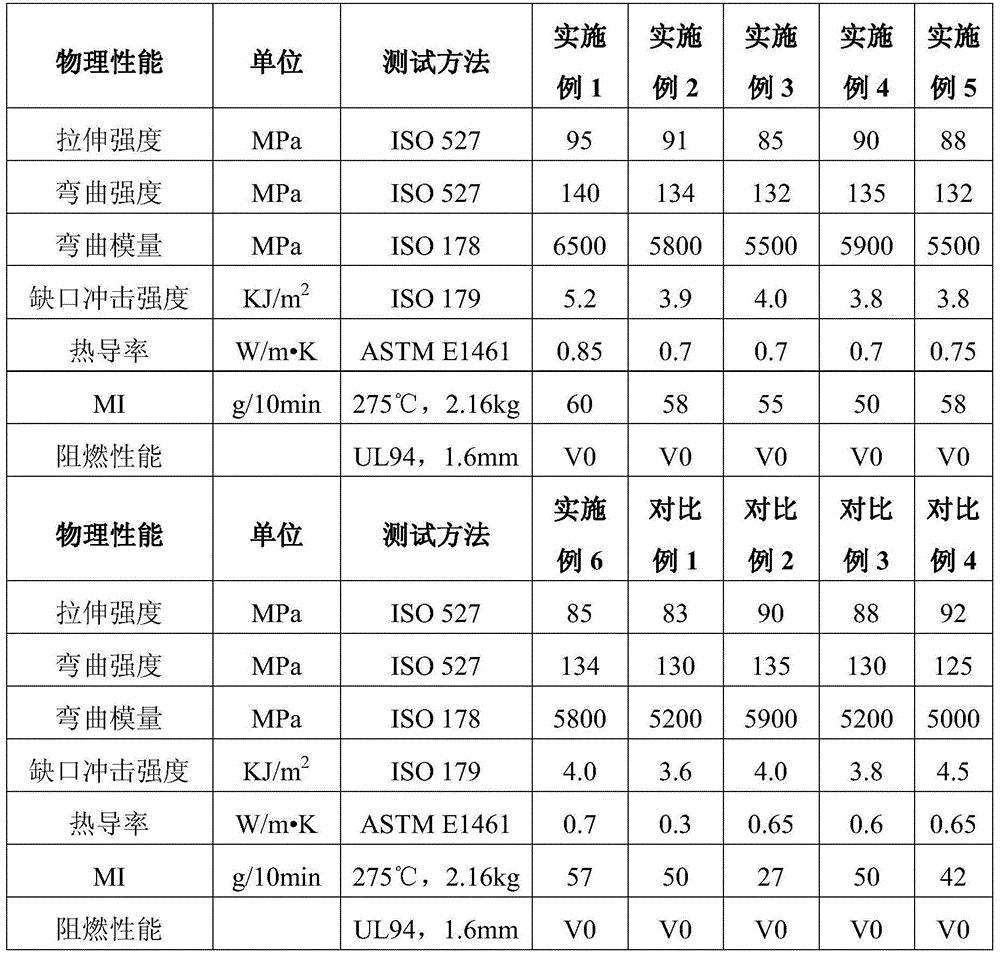

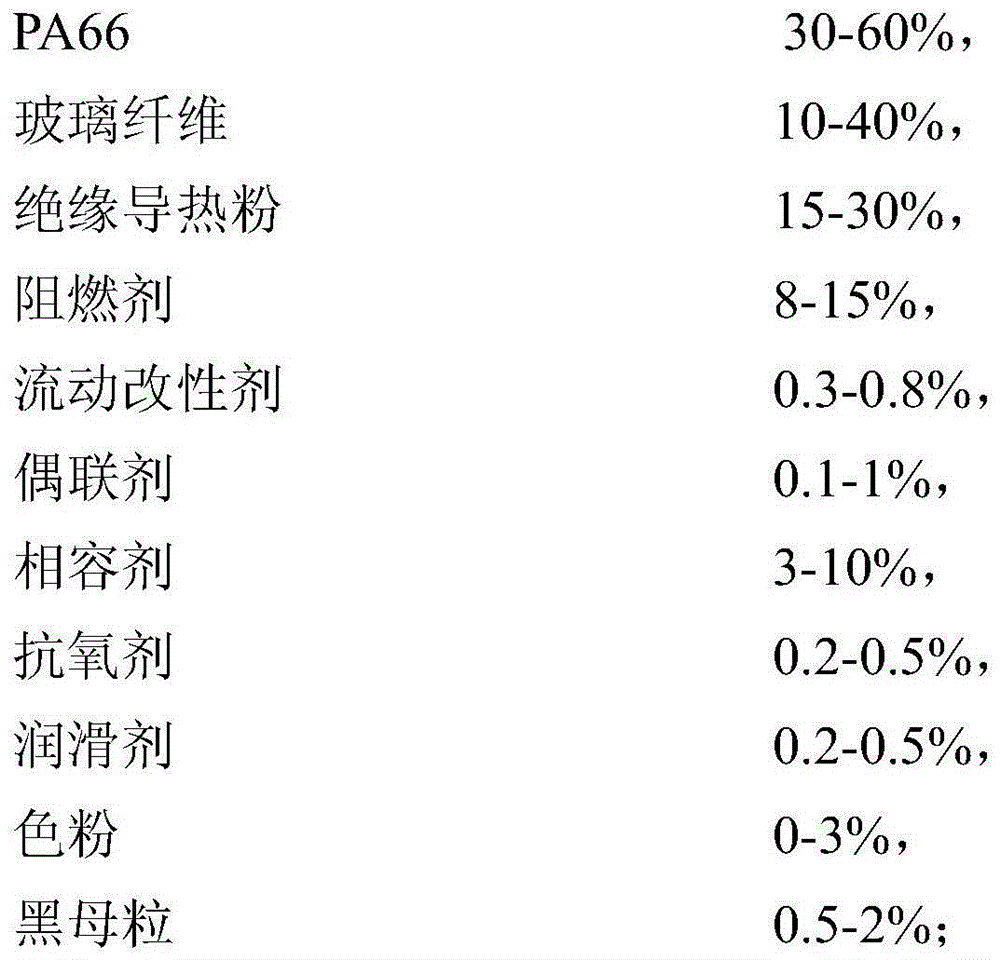

InactiveCN104610740AGood mechanical propertiesExcellent processing fluidityElectrical batteryFire retardant

The invention relates to a material for new energy battery cases and a preparation method of the material. The material is prepared from the following raw materials by mass percent: 30-60% of PA66, 10-14% of glass fiber, 15-30% of insulating heat-conducting powder, 8-15% of a flame retardant, 0.3-0.8% of a high-flow modifier, 0.1-1% of a coupling agent, 3-10% of a compatilizer, 0.2-0.5% of an antioxidant, 0.2-0.5% of a lubricant, 0-3% of toner and 0.5-2% of black master batch. The material provided by the invention not only has excellent mechanical property and flame retardant property, but also has certain heat conducting and cooling capabilities, and has the advantages of greatly improving the working environment of the new energy batteries, prolonging the service life, endowing the material with excellent processing fluidity while not reducing the mechanical property of the material, greatly reducing the processing cost and saving the energy.

Owner:SHANGHAI SUNNY

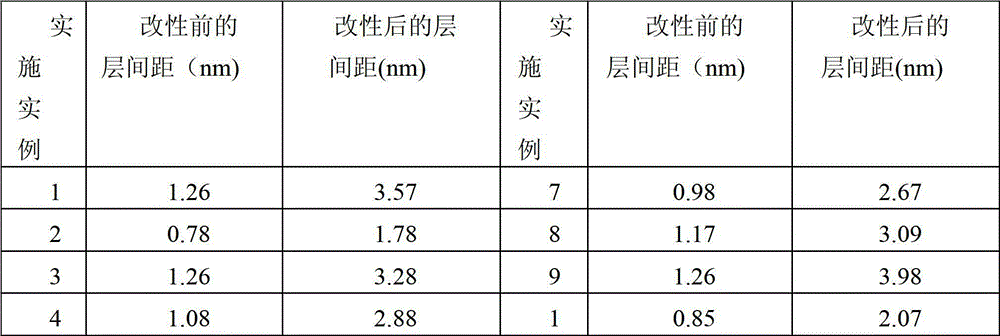

Compound modification method for clay

The invention relates to a compound modification method for clay, which comprises the following steps: dissolving 0.5-2g of silane coupling agent in a certain amount of alcohol-water mixture, and stirring for a certain time on a magnetic stirrer; adding a certain amount of clay into a stirring furnace, performing high-speed stirring at a certain temperature, and meanwhile, adding the alcohol-water mixture into the clay within a certain time; after the alcohol-water mixture is added, continuing to stir for 0.5 hour, pouring out, and performing heat treatment at 80-200 DEG C for 1-3 hours; and mixing the product obtained in the previous step with a certain amount of long-chain alkyl ammonium salt water solution, adding a small amount of acetic acid to regulate the pH value to 2-5, stirring at a certain temperature for a certain time, repeatedly performing vacuum filtration 2-5 times, and performing heat treatment at 80-200 DEG C for 2-5 hours. Secondary modification takes full advantages of the synergic modification effects of the silane coupling agent and the long-chain alkyl ammonium salt, enlarges the molecular layer interval of the clay, increases the affinity of the clay to polymer and widens the application range of the clay.

Owner:南通南京大学材料工程技术研究院

Completely degradable vegetable fiber product and manufacturing method thereof

InactiveCN101525494AImprove use valueReduce pollutionWood working apparatusDomestic articlesMicrowave ovenAdhesive

The invention relates to a completely degradable product and a manufacturing method thereof. The product comprises the compositions in percentage by weight: 40 to 80 percent of vegetable fiber powder, 2 to 40 percent of adhesive, 5 to 15 percent of release agent and 5 to 40 percent of starch. Preferably, the product also contains 1 to 2 percent of toner. The technology can make full use of various natural vegetable fiber materials and increases the using value of raw materials while reducing environmental pollution; the manufactured product is completely biodegradable and nontoxic; moreover, the product has lower manufacturing cost and different types and is suitable for daily use. The manufacturing method essentially and structurally changes the configuration of vegetable fiber and ensures that each composition has excellent processing flowability. Technically, the manufactured product reaches relevant international testing standards (such as American / European food testing standards) and can be tested through dishwasher and microwave oven; therefore, the product is applicable for industrial automatic production.

Owner:艾唐贸易(深圳)有限公司 +1

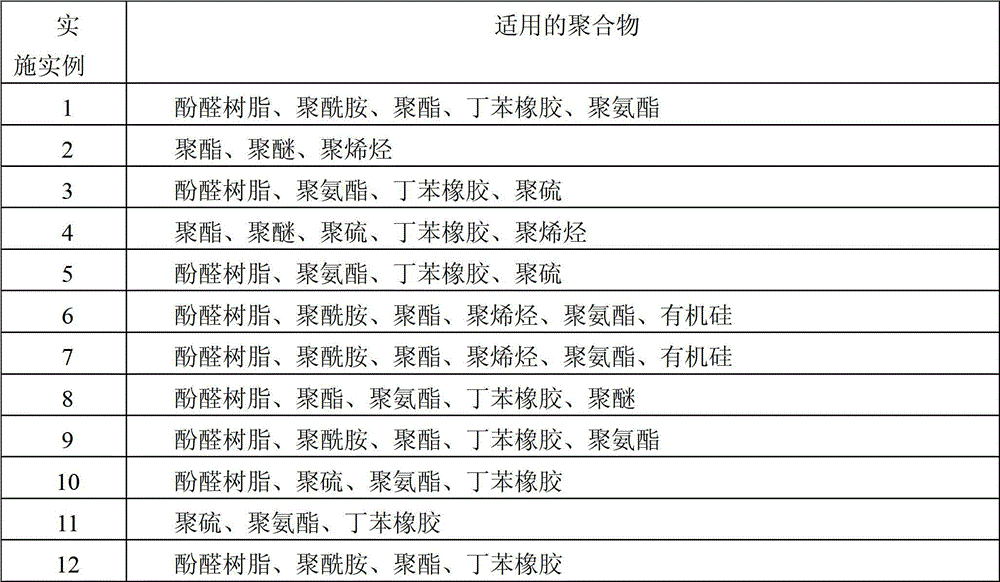

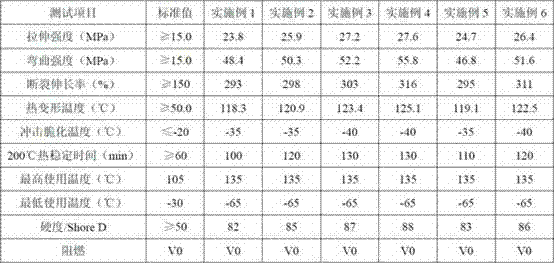

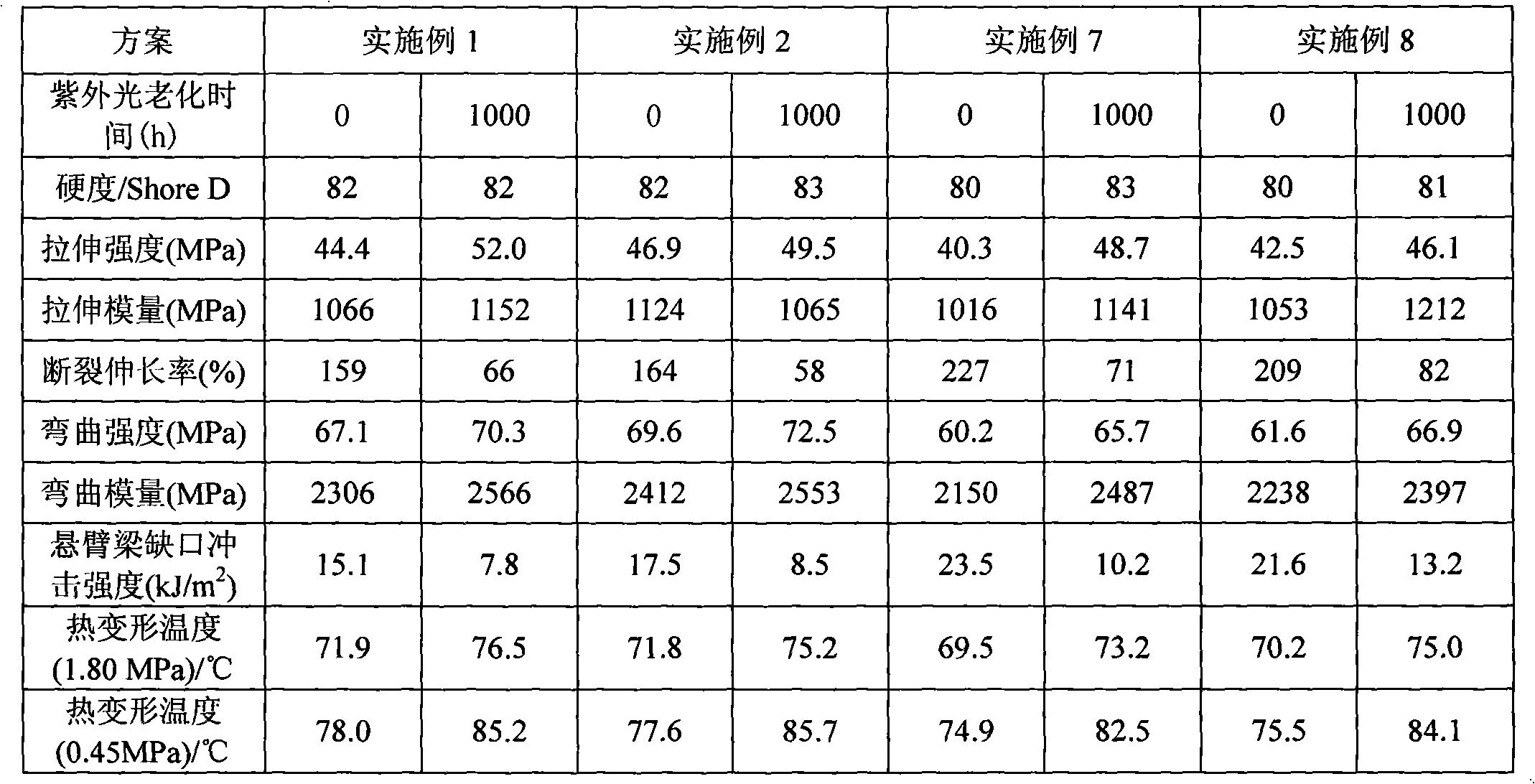

Heat-resisting and cold-resisting environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

ActiveCN103073816AImprove high temperature resistanceImprove low temperature resistancePlasticizerPolyvinyl chloride

The invention relates to the technical field of polyvinyl chloride composite materials, and specifically relates to a heat-resisting and cold-resisting environment-friendly PVC (polyvinyl chloride) modified material and a preparation method thereof. The modified material comprises the raw materials in parts by weight as follows: 80-120 parts of PVC resins, 15-35 parts of a filling agent, 40-80 parts of a plasticizer, 1-10 parts of a fire retardant agent, 1-10 parts of a stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of a lubricating agent. The preparation method comprises the steps that the raw materials are weighed in parts by weight to be mixed, after the stirring, extruding granulation is performed through a double screw extrusion machine, and the modified material is obtained. The prepared modified material has the excellent heat-resisting cold-resisting performance, the highest use temperature reaches 135 DEG C, and the lowest use temperature reaches subzero 65 DEG C; and meanwhile the modified material has the advantages of environmental friendliness, high intensity, good fire retardant effect, strong compression performance and toughness, and excellent processing performance and comprehensive performance. The preparation method is simple in processing, convenient to operate and control, stable in quality and high in production efficiency, so that the large-scale industrial production can be realized.

Owner:广东祺龙科技有限公司

PVC (polyvinyl chloride) foam material for sole and preparation method of PVC foam material

InactiveCN105440505AImprove temperature resistanceGood weather resistanceSolesWeather resistanceFoaming agent

The invention relates to the technical field of PVC materials, in particular to a PVC (polyvinyl chloride) foam material for a sole and a preparation method of the PVC foam material. The PVC foam material for the sole comprises raw materials in parts by weight as follows: 80-120 parts of PVC resin, 40-60 parts of a plasticizer, 20-30 parts of a filling agent, 6-10 parts of a wear-resistant modifier, 4-8 parts of a thermal stabilizer, 2-4 parts of a foaming agent, 0.8-1.2 parts of a lubricant and 1-2 parts of a processing aid. The raw materials are adopted for preparation of the PVC foam material for the sole, the weight proportion of the raw materials is controlled strictly, the performance of the prepared PVC foam material for the sole exceeds the national standards, and the PVC foam material is environment-friendly and has good temperature resistance and weather resistance, high strength, excellent anti-impact performance, good flame-retardant effect, good processing performance and excellent comprehensive performance.

Owner:广东祺龙科技有限公司

Blow molded polyvinyl alcohol membrane and production method thereof

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through blow molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 20 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The method has the advantages of simple process, less device investment, small occupied area, and realization of blow molding of normal-temperature, medium-temperature and high-temperature water soluble membranes. The method is mainly used for producing double-layer membranes, and the membranes can be directly processed to produce various water-soluble bags, and the water-soluble bags are used in the field of medium and low end packaging application, and can be used as a pesticide and chemical engineering product inner packaging liner bag, a hospital washing packaging bag and a refuse bag.

Owner:CHINA PETROCHEMICAL CORP +2

PVC profile outer cover used in base station antenna and preparation method thereof

ActiveCN101635385AImproves UV resistanceImprove impact toughnessRadiating element housingsUltravioletEngineering

The invention discloses a PVC profile outer cover used in a base station antenna and a preparation method thereof, which can not only improve the mechanical property, but also greatly improve high and low temperature resistant ageing property and ultraviolet ray resistant property, and greatly improve the electrical property of the material simultaneously. The PVC profile outer cover used in the base station antenna in the invention is manufactured by the following raw materials according to the mass ratio: 100 parts of PVC, 4-10 parts of inorganic modified padding, 0-10 parts of calcium carbonate, 1-2 parts of organic stannum stabilizing agent; 1-2 parts of metal soap stabilizing agent, 0.5-1.5 parts of lubricating agent, 4-12 parts of impact modifier, 1-3 parts of acrylic ester processing agent and 0-0.6 part of light stabilizer.

Owner:NANJING UNIV OF TECH +1

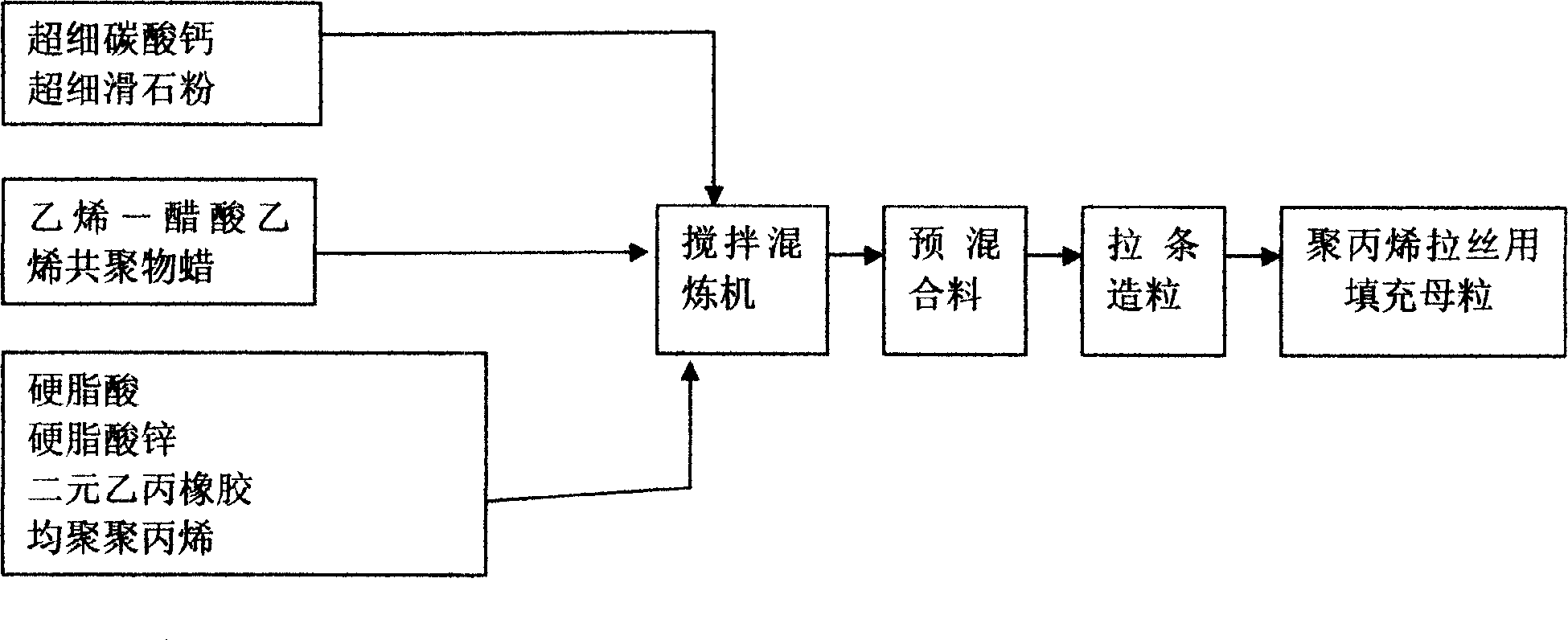

Filling agglomerate for polypropylene wiredrawing and its preparation method

The invention relates to a filling masterbatch used for polypropylene wire-drawing and its preparation method. The said masterbatch includes (weight parts): CaCO3 25~50, and superfine talc (SFT) 5~30, homopolymerized PP 17.5~25, dual EPDM 5~10, ethylene-vinyl acetate copolymer wax 1.5~6, stearic acid 1~4, and zinc stearate 1~2, wherein the average particle size of CaCO3 is 5~10 micron and the average size of SFT is 6-10 micron. The said method comprises: mixing CaCO3 and SFT in a stirring mixer at 100degreeC-130degreeC, adding ethylene-vinyl acetate copolymer wax and mixing 3~5 minutes, respectively adding stearic acid, zinc stearate, dual EPDM, and homopolymerized PP, stirring for 3 min to obtain the pre-mixture, placing the pre-mixture into a cocurrent twin-screw granulation machine, granulating and pelleting, cooling and sifting, separating, and packaging to obtain the final product. The prepared filling masterbatch has good mechanical properties, dispersion, and high economy.

Owner:上海心尔新材料科技股份有限公司

Method for preparing polymer/inorganic nano particle composite material

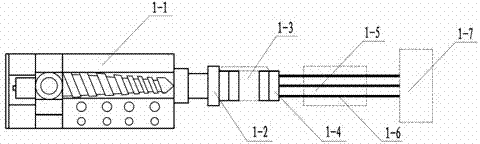

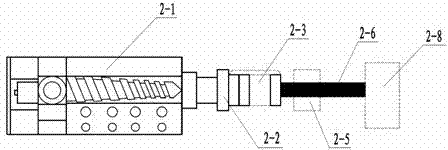

The invention discloses a method for preparing a polymer / inorganic nano particle composite material. The method is characterized by comprising the following steps: after mixing and pelleting a polymer and an inorganic nano particle according to a certain ratio, conveying aggregates through an extruder in a bidirectional stretching melt mixing and forming integrated device, preparing aggregates or a sheet through plasticizing and melting and under a bidirectional stretching-shearing acting force of a bidirectional stretching melt mixer, wherein the aggregates or the sheet is better in inorganic nano particle dispersing property, and excellent in performance. The polymer / inorganic nano particle composite material overcomes the defects of difficulty in dispersing and poor compatibility of the inorganic nano particle in a polymer melt; and the polymer / inorganic nano particle composite material has better mechanical property, barrier property, heat stability performance, and conductive property. The method is simple and easy to operate, simple in equipment, and convenient to produce in large scales.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com