PVC profile outer cover used in base station antenna and preparation method thereof

A technology of base station antennas and profiled materials, which is applied in the direction of the radiation unit cover, etc., can solve the problems of dielectric properties and UV resistance that cannot meet the use conditions of base station antennas, defective products that cannot be processed, and poor quality stability, etc., to achieve UV resistance. Good, good impact toughness, good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

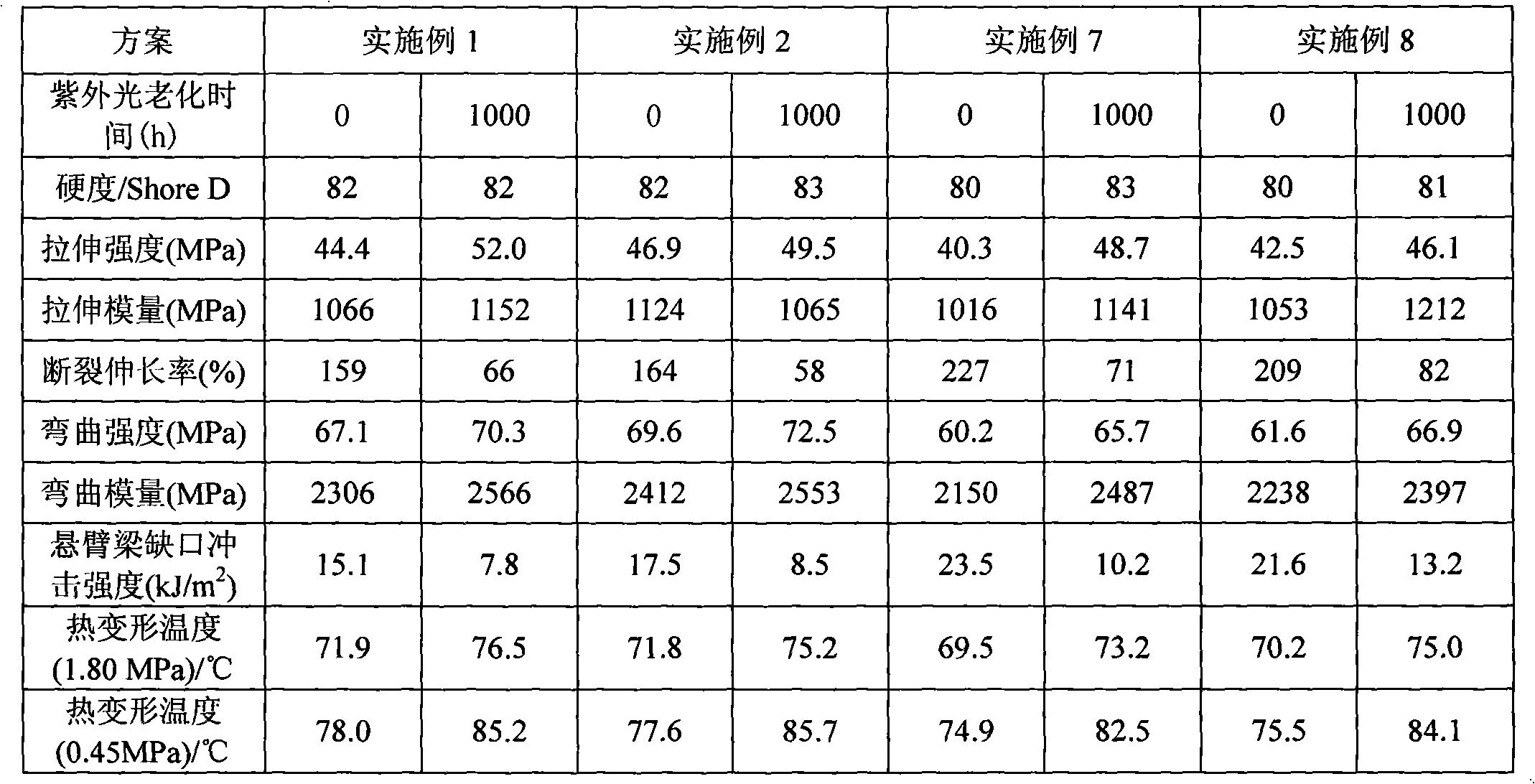

Examples

Embodiment 1

[0034] Raw material formula: 100 parts of PVC, 10 parts of rutile titanium dioxide, 5 parts of calcium carbonate, 1.5 parts of organic tin stabilizer dibutyltin dilaurate, 1.0 parts of calcium stearate, 0.6 parts of paraffin, 0.3 parts of stearic acid, chlorinated polyethylene 6 parts, 2 parts of acrylate processing aid.

[0035] Preparation:

[0036] High-speed powder mixing: put PVC resin, calcium stearate, and organic tin stabilizer into the high-speed mixer, and when the temperature rises to 80°C, add acrylate impact modifiers, processing aids and other additives, and the temperature rises When the temperature reaches 92°C, add inorganic modified fillers such as rutile titanium dioxide and calcium carbonate; when the temperature continues to rise to 115°C, quickly discharge the material into another mixer with jacketed water cooling, and the mixture is in the belt clamp Continue mixing in the water-cooled mixer, and discharge to the silo when the temperature drops to 40°C...

Embodiment 2

[0039] Raw material formula: 100 parts of PVC, 5 parts of rutile titanium dioxide, 5 parts of mica, 1.5 parts of organic tin stabilizer dibutyltin dilaurate, 1.3 parts of calcium stearate, 0.2 parts of zinc stearate, 1.0 parts of polyethylene wax, acrylate 6 parts of impact modifier and 2 parts of acrylate processing aid.

[0040] Preparation:

[0041] High-speed powder mixing: put PVC resin, calcium stearate, zinc stearate, and organotin stabilizer into the high-speed mixer, and when the temperature rises to 85°C, add acrylate impact modifiers, processing aids and other Additives, when the temperature rises to 95°C, add inorganic modified fillers such as rutile titanium dioxide and mica; when the temperature continues to rise to 120°C, quickly discharge the materials into another mixer with jacketed water cooling, and mix The materials are continuously mixed in the jacketed water-cooled mixer, and can be discharged to the silo when the temperature drops to 45°C;

[0042] Tw...

Embodiment 3

[0044]Raw material formula: 100 parts of PVC, 5 parts of rutile titanium dioxide, 5 parts of calcium carbonate, 1 part of organotin stabilizer di-n-octyltin dilaurate, 1.5 parts of calcium stearate, 0.5 parts of polyethylene wax, 0.3 parts of paraffin wax, stearic acid 0.2 parts, 6 parts of acrylate impact modifier, 1.5 parts of acrylate processing aid, 0.3 part of benzophenone ultraviolet light absorber UV-531.

[0045] Preparation:

[0046] High-speed powder mixing: put PVC resin, calcium stearate, and organic tin stabilizer into the high-speed mixer, and when the temperature rises to 83°C, add acrylate impact modifiers, processing aids and other additives, and the temperature rises to 83°C. When the temperature reaches 90°C, add inorganic modified fillers such as rutile titanium dioxide and calcium carbonate; when the temperature continues to rise to 118°C, quickly discharge the material into another mixer with jacketed water cooling, and the mixture is in the belt clamp C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com