Patents

Literature

2728results about How to "Good environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Formula of pure binary super low interface tension composite oil-displacement agent of surfactant and pdymer for triple oil production

The composite oil-displacement agent consists of polymer 0-0.3 wt.%, surfactant 0.05-0.6 wt% and water 99.1-99.95 wt%, and is produced in kettle reactor with coagulated petroleum fraction from raw oil. It has surfactant concentration not higher than available systems, high interface tension reducing effect and stable performance. The ternary composite oil-displacement agent has no alkali and saltwhile reaching superlow interface tension and thus no alkali scale formed, no loss in polymer viscosity and viscolerasticity. In the compounding of the composite oil-displacement agent, common sewagemay be used and this produces certain environment protection effect.

Owner:PETROCHINA CO LTD

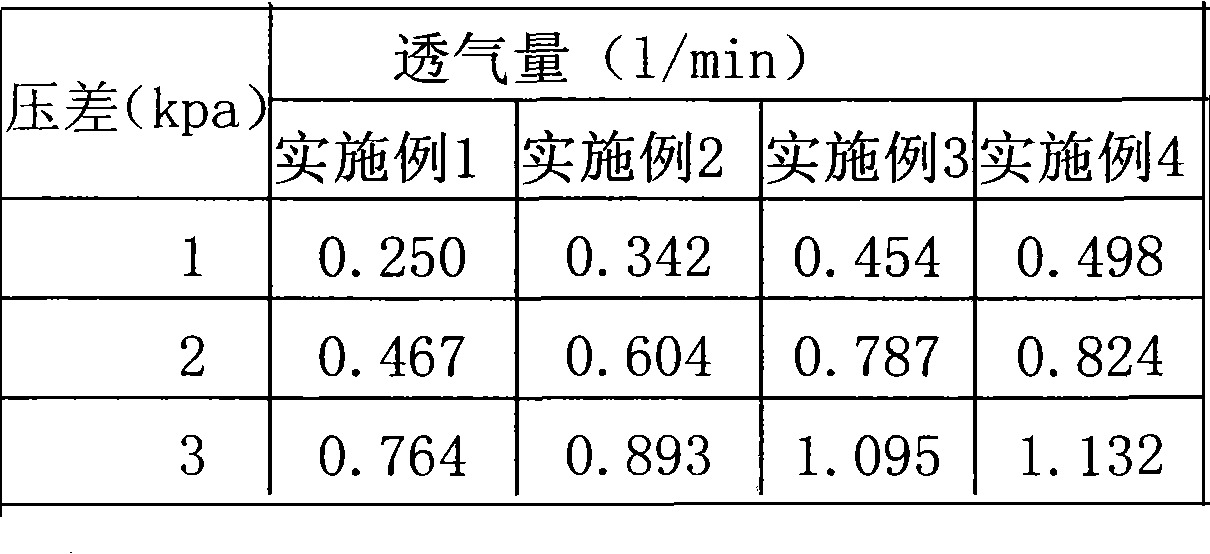

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

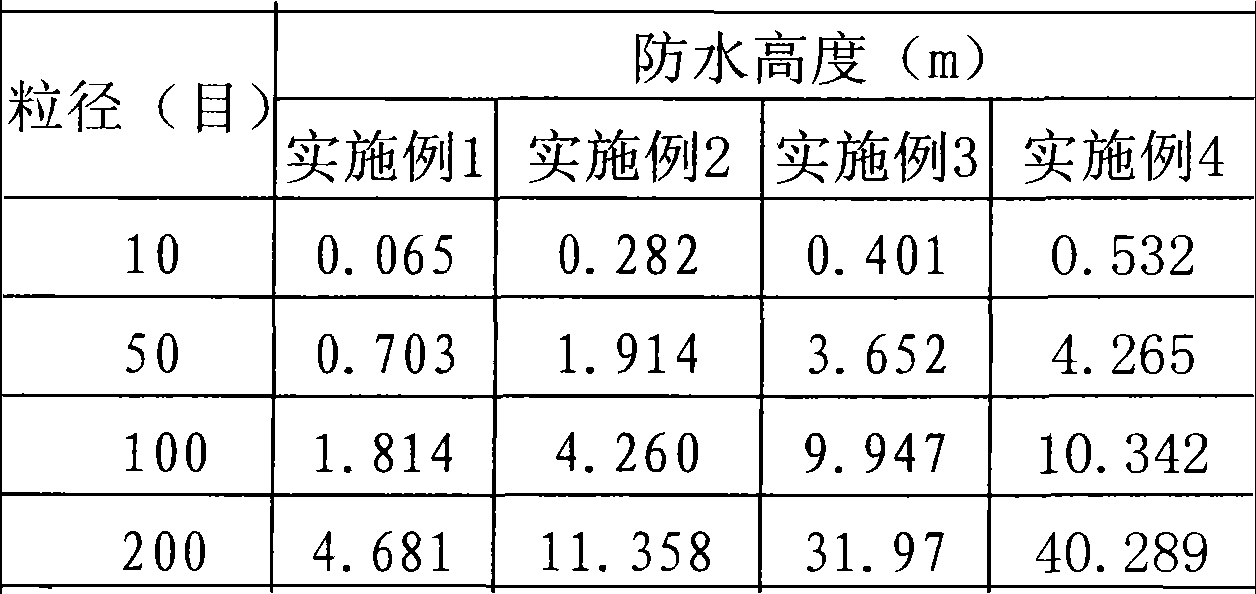

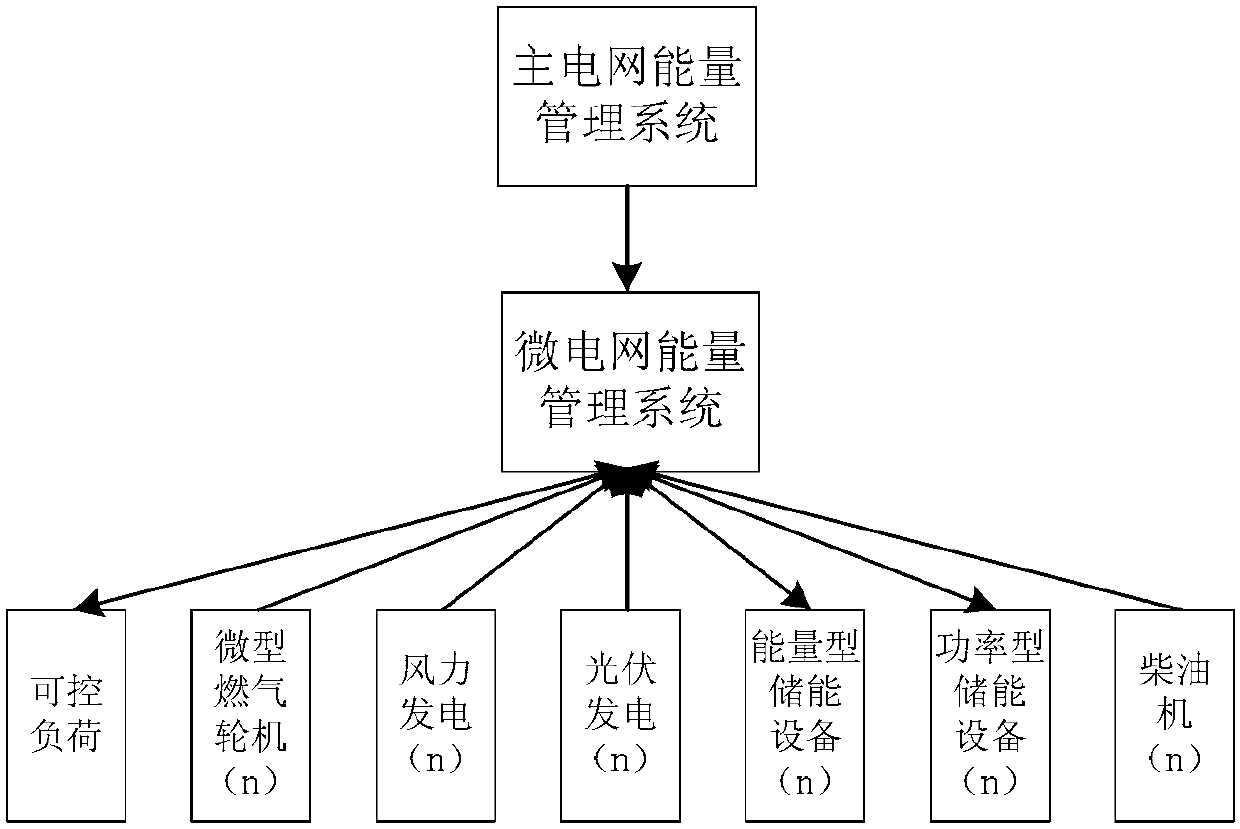

Multi-time scale microgrid energy control method considering demand response

ActiveCN103346562AImprove schedulabilityReduce spare capacitySpecial data processing applicationsAc network circuit arrangementsMicrogridEnergy control

The invention discloses a multi-time scale microgrid energy control method considering demand response. According to the multi-time scale microgrid energy control method considering the demand response, in order to achieve the purpose of lowest operation cost of a microgrid, the electricity generating characteristic of a micro power source and demand response load power utilization property difference are combined to provide a user side load interruptible capacity limiting value, an electricity generating unit power output limiting value, a climbing constraint condition, an energy storage unit storage capacity constraint condition and an interaction maximum capacity constraint condition, an economic combination which can guarantee the optimum environmental benefit is searched under the multi-time scale condition by means of the genetic optimization algorithm, frequency modulation and spare capacity of a main grid are indirectly reduced, and the economical performance of complete-period operation of the grid is improved.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

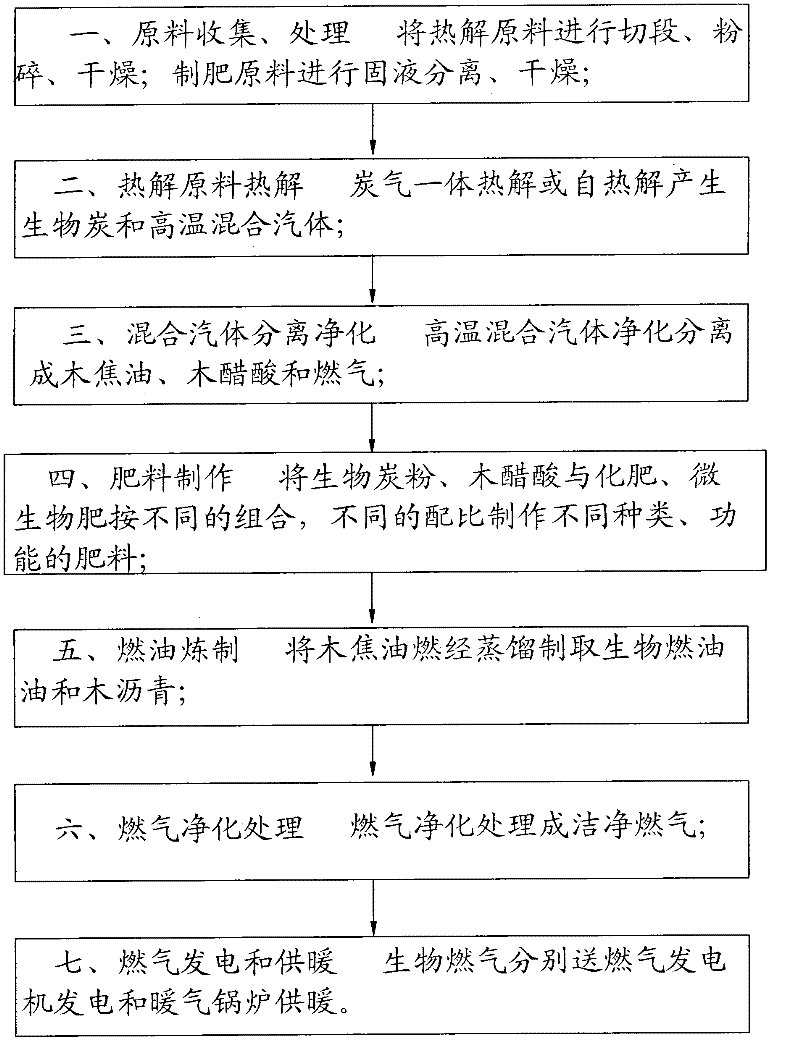

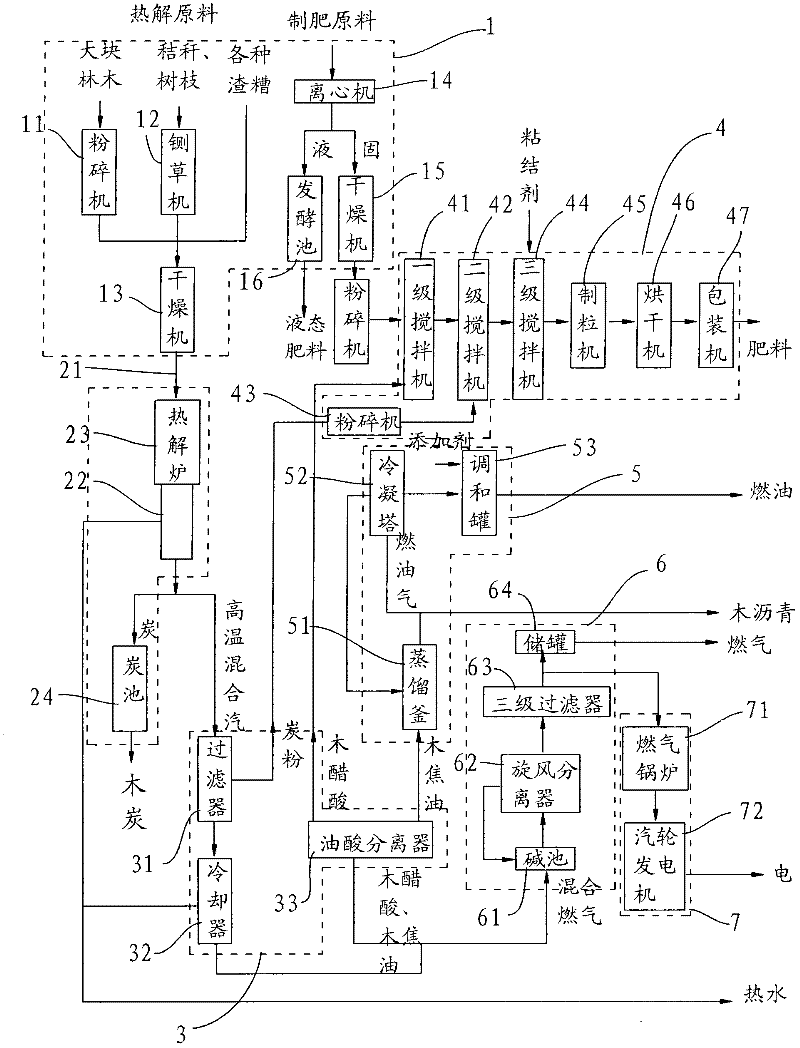

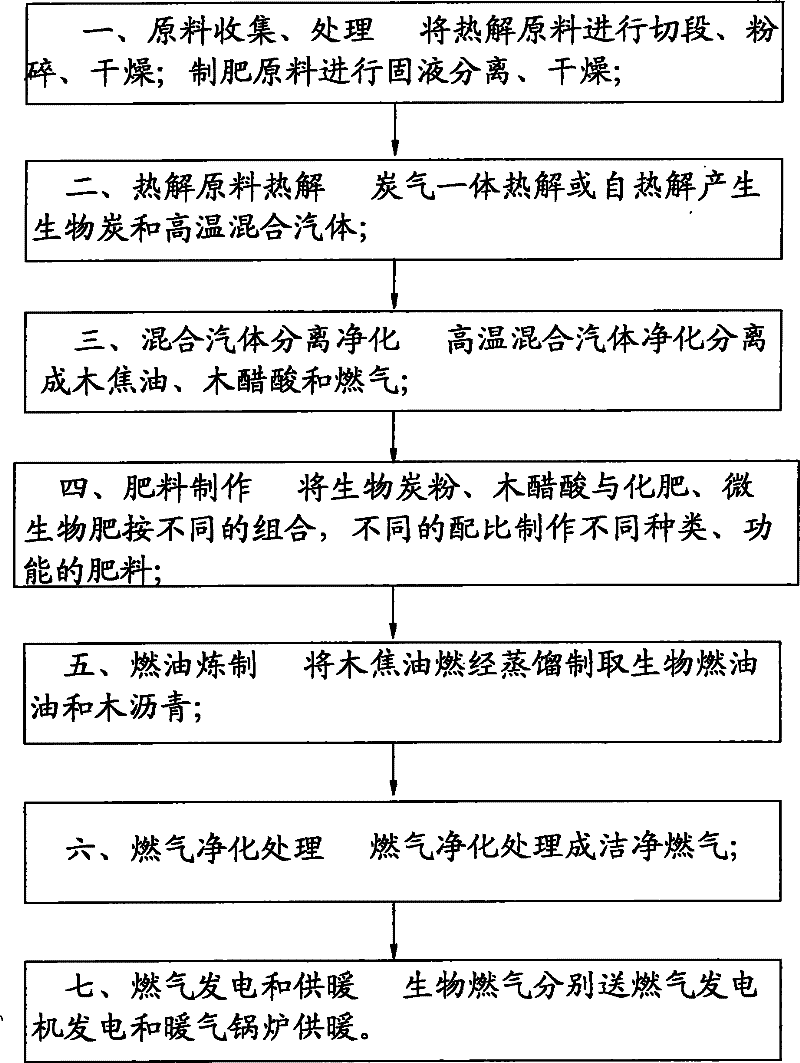

Integrated converting and utilizing co-production method for agricultural waste

InactiveCN102476129AWidely used valueAvoid secondary pollutionSolid waste disposalBiofuelsBiofuelFuel oil

The invention relates to an integrated utilizing technology for agricultural waste and in particular relates to an integrated converting and utilizing co-production method for agricultural waste. The integrated converting and utilizing co-production method comprises the following steps: 1. collecting and processing raw materials; 2. carrying out pyrolysis on the raw materials: generating biochar and high-temperature mixed gas; 3. converting the high-temperature mixed gas: converting the high-temperature mixed gas into wood tar, wood vinegar and fuel gas; 4. manufacturing fertilizers; 5. refining fuel oil: converting the wood tar into biofuel oil and wood pitch; 6. purifying the fuel gas: purifying the fuel gas into clean fuel gas; and 7. converting the fuel gas: respectively sending the biofuel gas into a gas generator, a gas supply pipe network and a heat boiler to covert the biofuel gas into heat energy and electricity energy. The agricultural waste can be converted by multiple levels and are combined to be utilized to obtain straw carbon, fuel gas, heat energy, electricity energy, fertilizers, fuel gas and the like. The use ratio of the agricultural waste reaches 100%. The problem that the agricultural waste is stacked and burnt disorderly can be solved, the pollution problem caused by using chemical fertilizers and pesticides for a long time can be solved, and the problem of utilizing energy, fertilizer and oil in rural areas also can be solved.

Owner:周仁福 +2

Method for recovering alkali and hemicellulose from chemical fibre waste liquid

InactiveCN1450001AEfficient separationEfficient purificationArtificial filament recoveryTextile/flexible product manufactureLiquid wasteFiltration

The method for recovering alkali and hemicellulose from waste liquor produced by producing optical fibre includes the folloiwng steps: making the pressed liquor containing alkali and hemicellulose undergo the processes of prefiltration and fine filtration, and feeding it into membrane separation equipment to obtain the penetrated liquor containing alkali and concentrate containing hemicellulose, and the alkaline liquor concentration in the obtained penetrated liquor can be up to 80-250 g / l, and the final alkali content in the concentrate is 5-30 g / l, and the hemicellulose content is 100-200 g / l. Said technological process is simple, can effectively separate and purify hemicellulose and alkali liquor.

Owner:凯能高科技工程(上海)有限公司

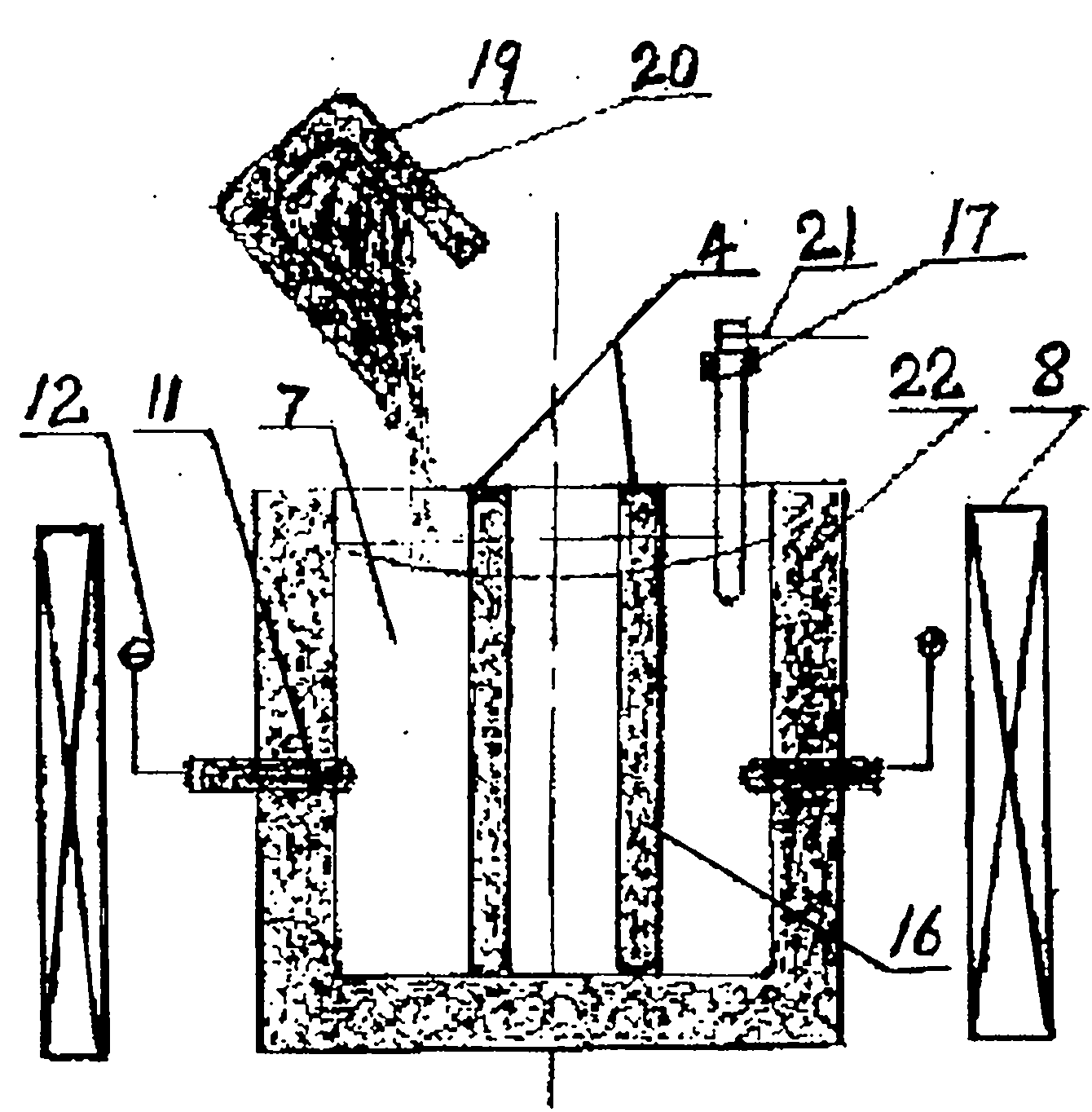

Rapid decomposition method for returning summer maize straws

InactiveCN102020512ANeat emergenceIncrease productionBio-organic fraction processingOrganic fertiliser preparationDecompositionUrea

The invention discloses a rapid decomposition method for returning summer maize straws, which is used for solving the problem of decomposition of the maize straws. The method comprises the following steps of: crushing the maize straws in the fields, and totally and directly returning the crushed maize straws; after the crushed maize straws are returned, broadcasting materials, such as a decomposition agent, accessory ingredients and the like, in a way that 2 to 2.5 kilograms of decomposition agent, 3 to 5 kilograms of accessory ingredients, 0.5 to 1 kilogram of water-retaining agent and 6 to 8 kilograms of urea are broadcast into each acre of land; and timely performing ploughing or rotary tillage and sowing winter wheat after a week. The method has the main advantages that: 1, the summermaize straws are mechanically crushed in situ and then totally and directly returned and utilized, so the problems of difficulties in the collection, transportation and storage of the maize straws are solved; 2, the maize straws are rapidly decomposed, so the straw decomposition rate is increased, soil nutrients are returned, soil conditions are improved, simultaneously seedlings of the followingwinter wheat come out uniformly and the rate of emergence is greatly increased; and 3, farming in the fields is easy to operate and execute, and the method is delightedly accepted by farmers and is convenient to execute.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Organic-inorganic compound fertilizer and preparation method thereof

InactiveCN102153413AAlkali solubleSimple structureBio-organic fraction processingOrganic fertiliser preparationPorositySlag

The invention discloses an organic-inorganic compound fertilizer and a preparation method thereof. The organic-inorganic compound fertilizer comprises the following raw materials in parts by weight: 25-30 parts of green algae, 12-17 parts of humic acid, 7-12 parts of bagasse mortar, 8-12 parts of saw dust, 7-15 parts of vermiculite, 5-10 parts of filtration mud, 5-10 parts of yeast organic waste water concentrated liquid, 5-8 parts of cane slag, 2-5 parts of sugarcane top and 2-5 parts of microbial strain liquid. The amount of the compound fertilizer organic matter is large than or equal to 55 weight parts, the total amount of NPK inorganic matters is large than or equal to 12 weight parts, the amount of the moisture is less than or equal to 25 weight parts, the effective viable count is large than or equal to 2 hundred million / gram, and the pH is 5.0-8.5. The preparation method comprises the following steps: fermenting twice by using microbial strains; adding inorganic porosity vermiculite, evenly mixing, and naturally drying so as to obtain the organic-inorganic compound fertilizer. Biodegradable agricultural and industrial production waste water, waste slag and sugarcane top regeneration organic matters are fully utilized as the raw materials, thereby improving the acidity and basicity of soil, improving the cation exchange capability (CEC) of the soil, improving the utilization of fertilizer, promoting the growth of crop and increasing the yield of the crop. The organic-inorganic compound fertilizer has the advantages of good ecological benefits and circular economy benefits and can be used as an additional fertilizer for crops such as sugarcane, watermelon and the like.

Owner:GUANGXI CHONGZUO XIANGGUI SUGAR

Method for processing dust with zinc of electric furnace

InactiveCN101092664ARealize comprehensive utilizationRealize secondary useProcess efficiency improvementElectric arc furnaceCooling chamber

This invention discloses a method for treating zinc-containing dust generated in electric furnace. The method comprises: mixing zinc-containing dust with carbon, balling, oven-drying to obtain carbon-containing balls, adding into a converter, calcining at a high temperature to reduce into zinc vapor, introducing into an oxidation chamber, introducing air to oxidize zinc vapor into zinc oxide vapor, introducing into a cooling chamber, cooling to obtain zinc oxide powder, introducing into a dust collection chamber, collecting zinc oxide powder, introducing the carbon-containing balls into a cooler, and cooling to obtain semi-metallized balls. The zinc oxide powder has purity above 90%; the semi-metallized balls have metallization rate above 60%, TFe content above 50%, and zinc content below 2%. The method has such advantages as high utility of zinc-containing dust, low cost and no pollution.

Owner:NANJING NANGANG IND DEV CO LTD

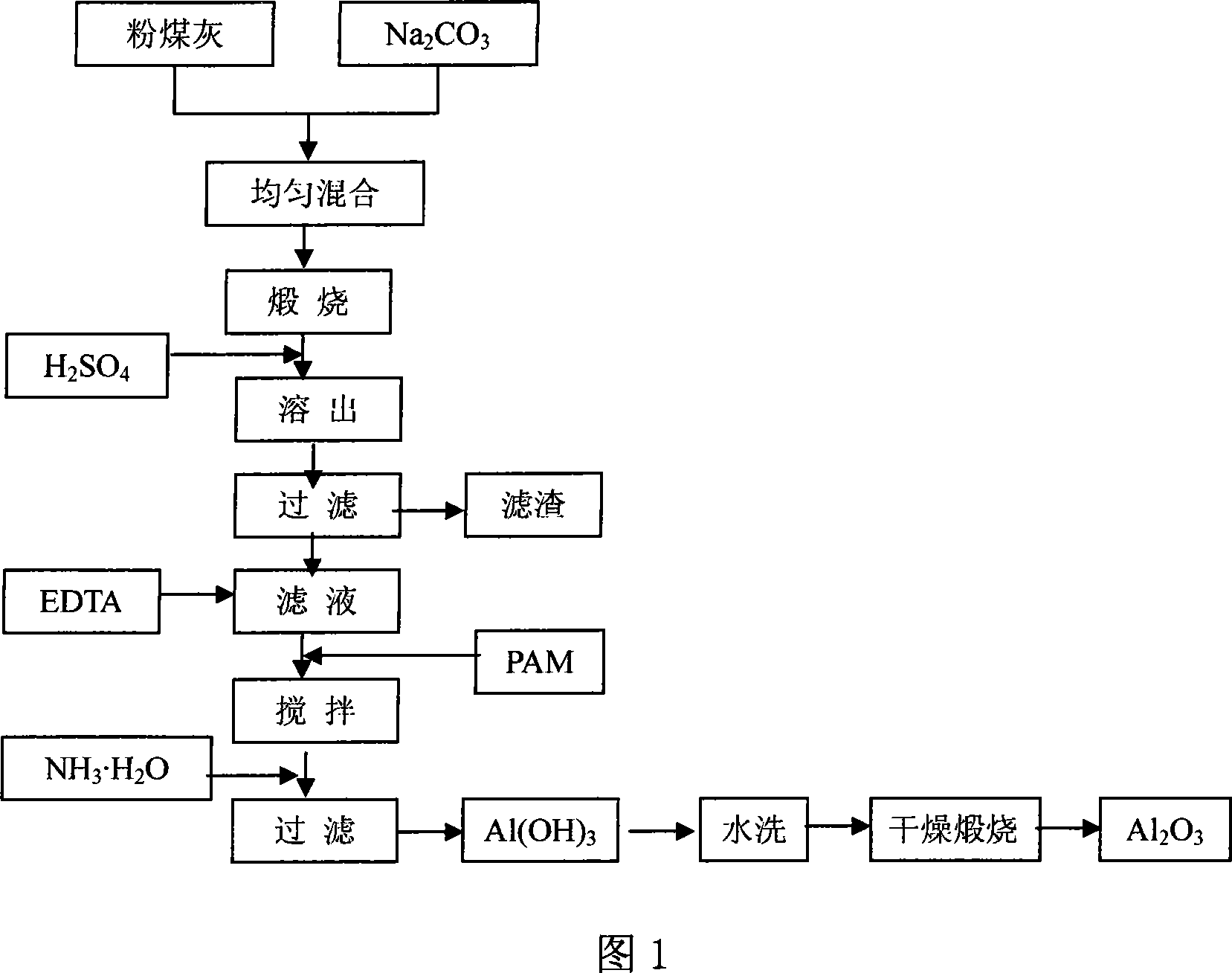

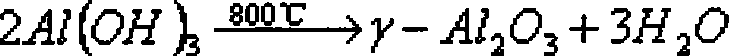

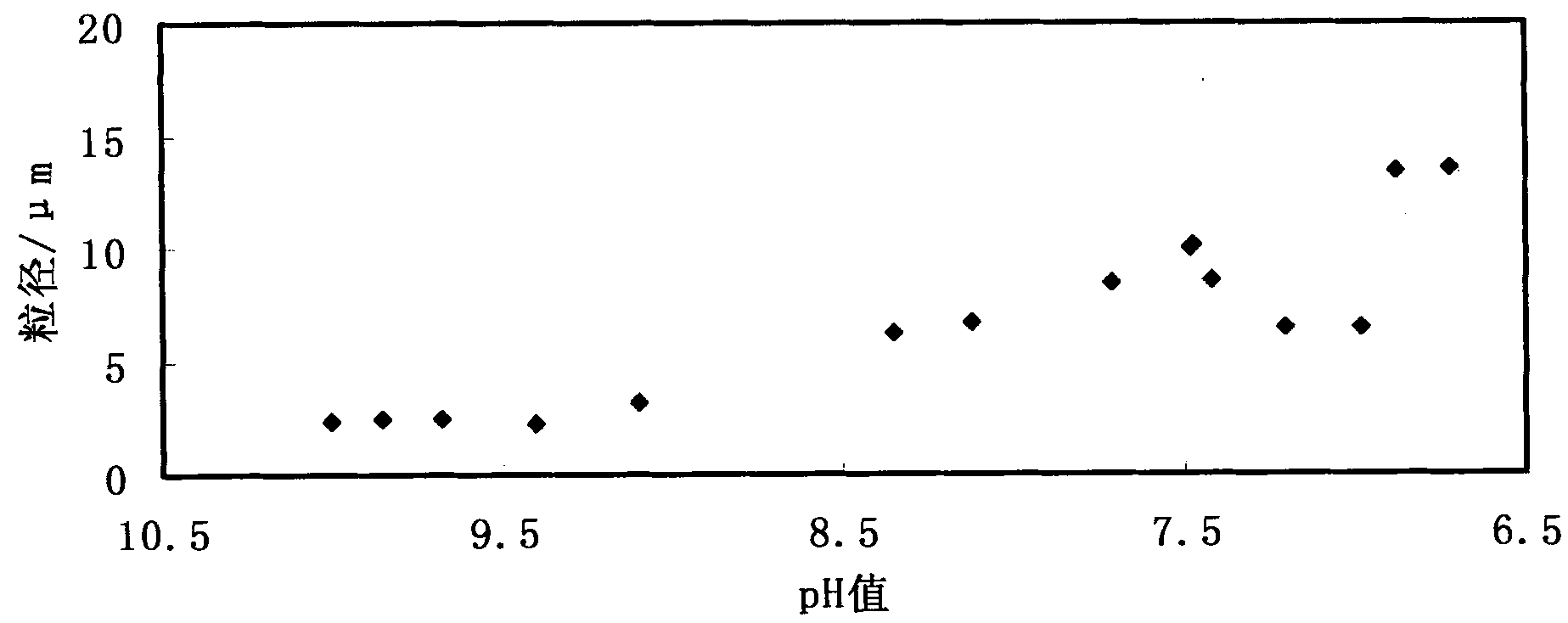

Method for extracting high-purity ultra-fine alumina from coal ash

InactiveCN101200298AGuaranteed dissolution rateWill not polluteAluminium oxides/hydroxidesAluminum IonUltra fine

The invention relates to a method of extracting pure ultrafine alumina from powder coal ash, which comprises the following: 1 sintering and activating process: Na2CO3 is used as activating agent during sintering; 2. aluminum salt extraction process: in the activated power coal, low-concentration sulfuric acid is selected to perform aluminum salt extraction; 3. leaching and sedimentation process: the solution after sulfuric acid is extracted is leached, the aluminum salt filtrate is added with dispersant, ammonia is used as precipitator so that the aluminum ion is separated out in the form of aluminum hydroxide; 4. heat treatment process: the aluminum hydroxide is cleaned with water and then dried, under different temperature, the heat treatment of the aluminum hydroxide is performed so that the aluminum hydroxide is dehydrated, decomposed, and crystallized, so as to obtain different crystal type alumina powder. The invention has the advantages of simple process, good synthetic benefit and high extraction ratio of alumina.

Owner:TIANJIN UNIV

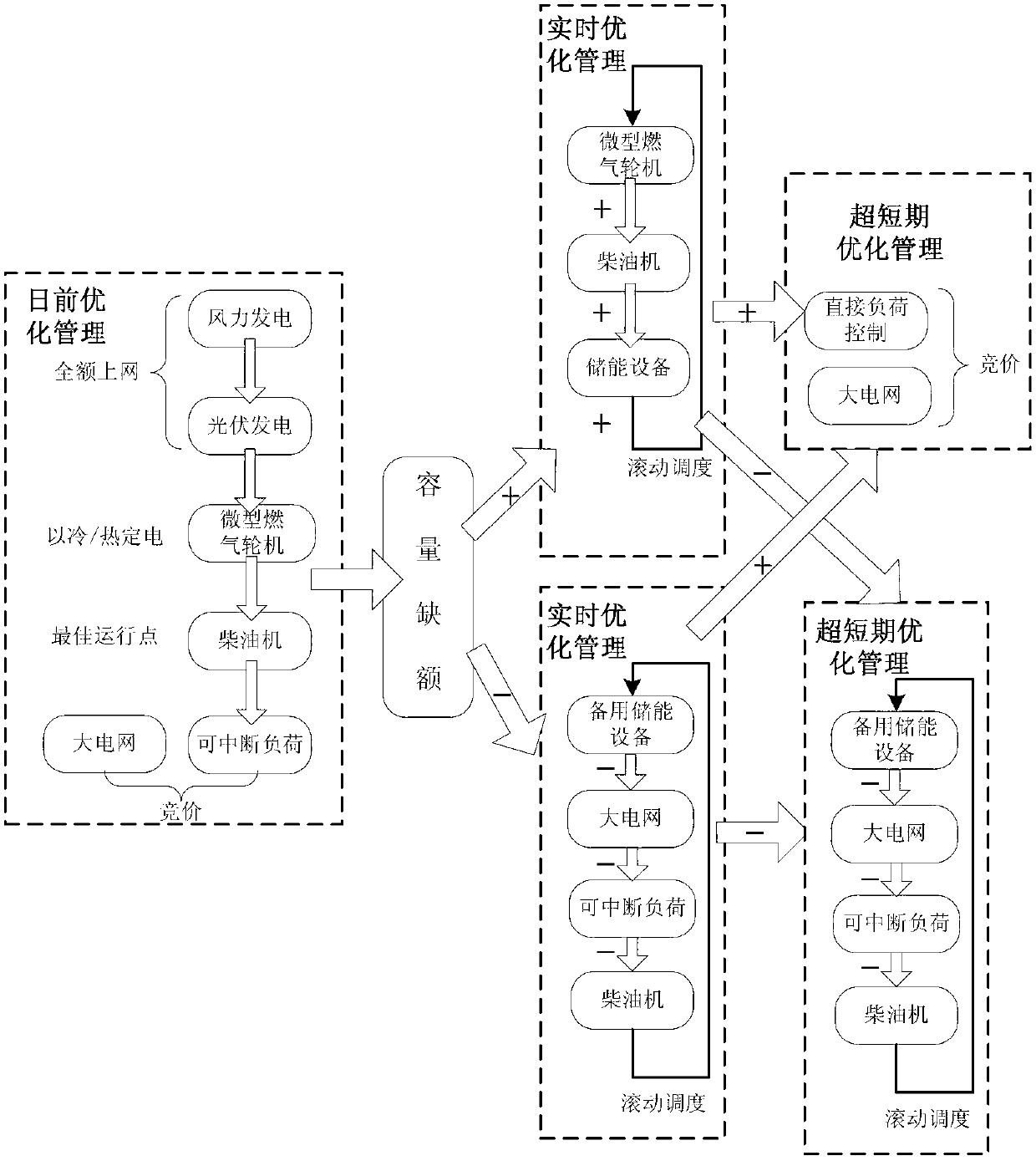

Multi-objective dispatching model-based microgrid energy control method under grid-connected operation mode

ActiveCN103151797AExactly reflect the actual operating statusHigh control precisionSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationPower controllerMicrogrid

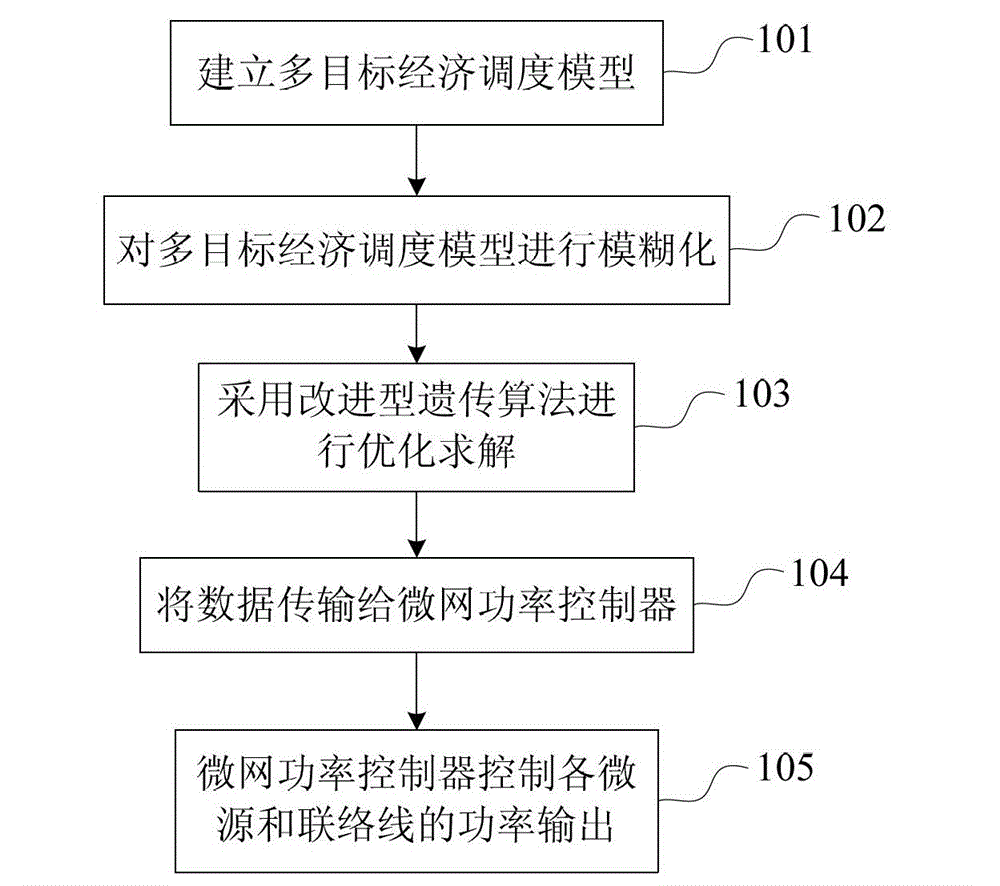

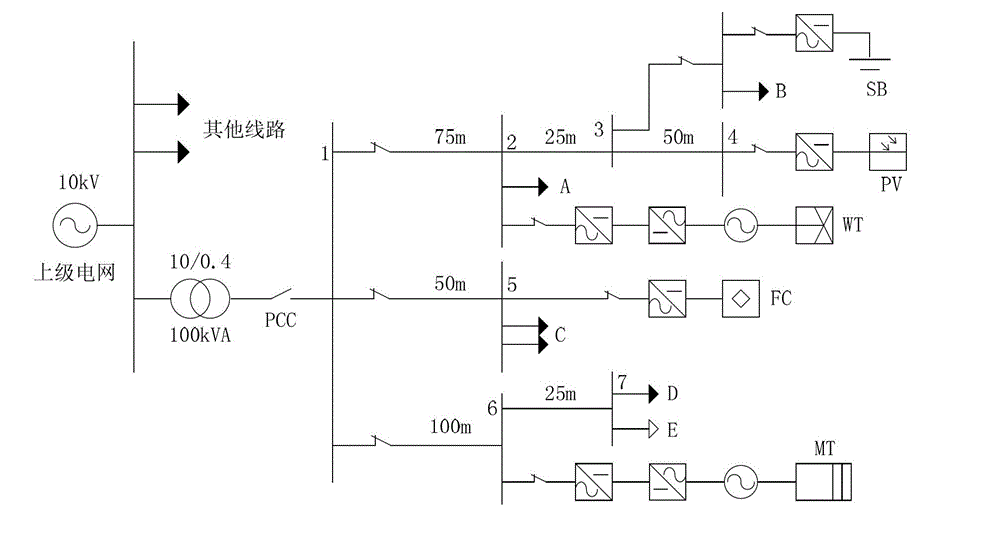

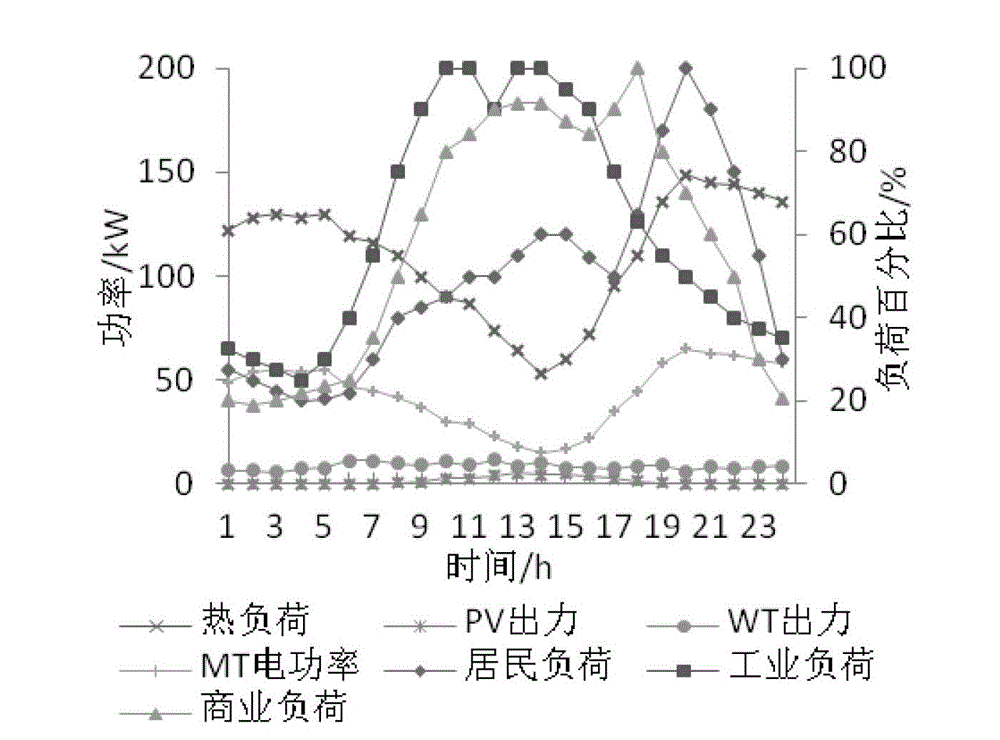

The invention relates to a multi-objective dispatching model-based microgrid energy control method under the grid-connected operation mode. A microgrid comprises a plurality of microsources and a load. The method includes the following specific steps: (1) the information of each microsource and connecting lines in the microgrid is acquired by a processor, and with minimum power generation cost and environmental cost as objectives, a multi-objective economical dispatching model is created; (2) a membership function is created to fuzzify the multi-objective economical dispatching model, so that a non-linear single-objective microgrid economical dispatching model is obtained; (3) an improved genetic algorithm is adopted to optimize the non-linear single-objective microgrid economical dispatching model, so that the optimal active and reactive power data of each microsourcre and the connecting lines are obtained, and the data are transmitted to a microgrid power controller; (4) according to the received optimal active and reactive power data, the microgrid power controller controls the active and reactive power output of each microsoruce and the connecting lines. Compared with the prior art, the method has the advantages of high control precision and the like, and can guarantee the economical operation of the microgrid.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

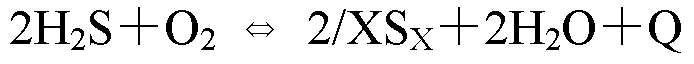

Zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment

InactiveCN102631827ALow temperature methanol washing process has no effectThe process is not affectedDispersed particle separationClosed loopTower

The invention belongs to the technical field of sulfur recovery and particularly relates to a zero-emission sulfur recovery technology combined with low-temperature methanol washing acid gas treatment. In the zero-emission sulfur recovery technology, a low-temperature methanol washing acid gas treatment unit and a Claus sulfur recovery unit are set to a closed loop. The zero-emission sulfur recovery technology comprises the following steps: firstly, acid gas emitted from low-temperature methanol washing is subjected to sulfur production and recovery by the Claus sulfur recovery unit; sulfur production tail gas enters a low-temperature methanol washing unit after being subjected to hydrogenation reduction, cooling and compression; H2S in the tail gas is absorbed by low-temperature methanol and waste gas is exhausted from the top of a tower; methanol at the bottom of a hydrogen sulfide removal tower enters a methanol thermal regeneration tower; concentrated H2S acid gas is obtained at the top of the tower; and the concentrated H2S acid gas together with the H2S-containing acid gas produced in low-temperature methanol washing enters the Claus sulfur recovery unit for sulfur production. The zero-emission sulfur recovery technology is free of limitation by balance absorption of amine-method tail gas treatment, can obtain theoretic 100% sulfur recovery rate and has remarkable economical and environmental benefits; and the process is shortened greatly and the construction investment, operating cost and energy consumption are reduced by over 30%.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

Compound microbial bacterial preparation for degrading crop straw and preparation method and application of compound microbial bacterial preparation

ActiveCN102690755ASolve shipping problemsSolve storage difficultiesBio-organic fraction processingFungiMetabolitePhosphate

The invention relates to a compound microbial bacterial preparation for degrading crop straw and a preparation method and application of the compound microbial bacterial preparation. The compound microbial bacterial preparation is prepared from bacillus subtilis, bacillus cereus, aspergillus niger, aspergillus flavus, trichoderma reesei, trichoderma longibrachiatum, sporotrichum thermophile and phanerochaete chrysosporium through solid fermentation. The compound microbial bacterial preparation can shorten the decomposition time and improve the decomposition efficiency of the crop straw. Microorganisms generate various effective metabolic products with nitrogen fixation and phosphate solubilizing functions and a high disease and pest resistance effect in the fermentation process, so that the compound microbial bacterial preparation is favorable for improving the soil structure and the yield and the quality of crops.

Owner:DEZHOU YUANHE AGRI TECH DEVCO

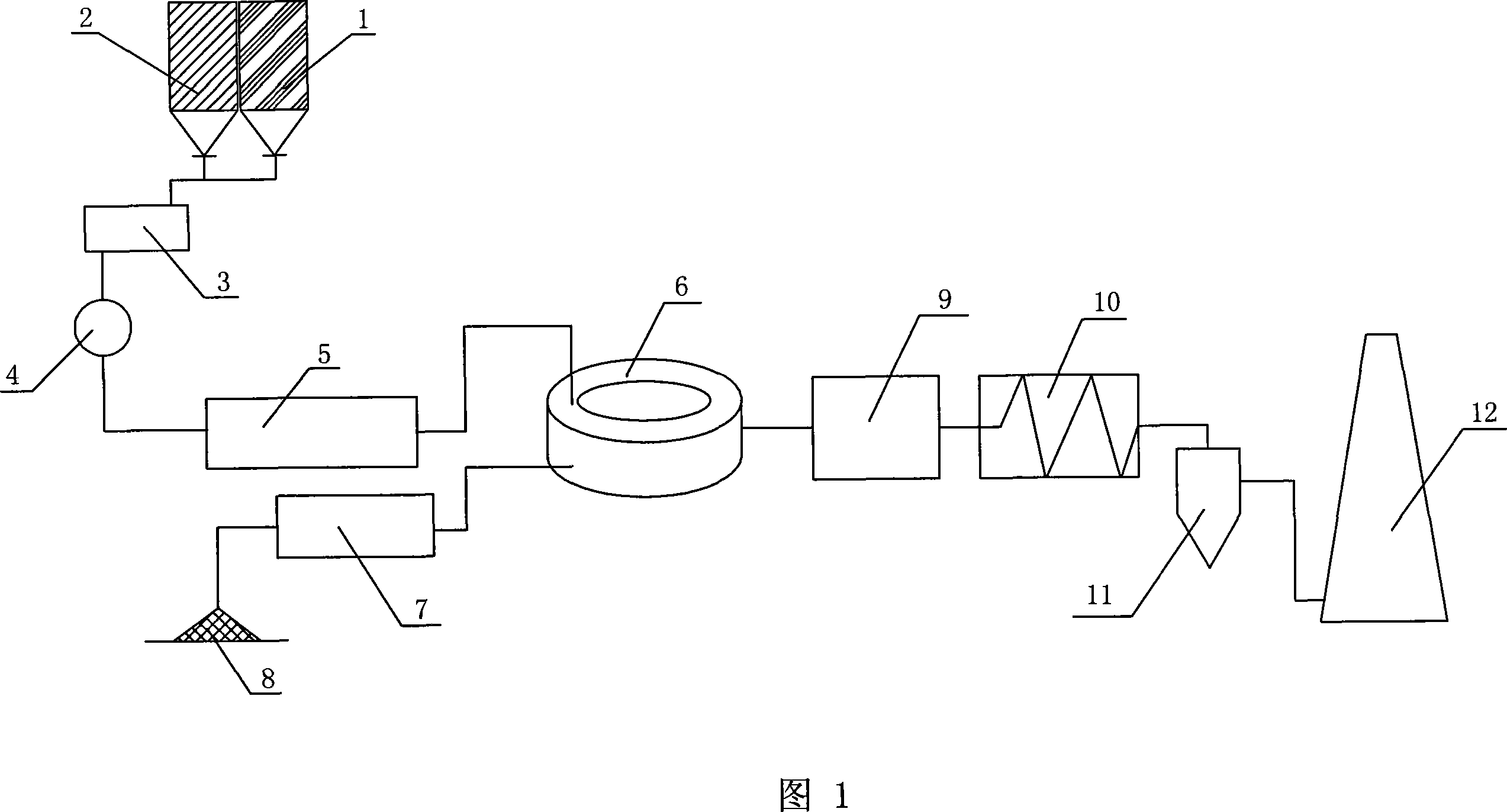

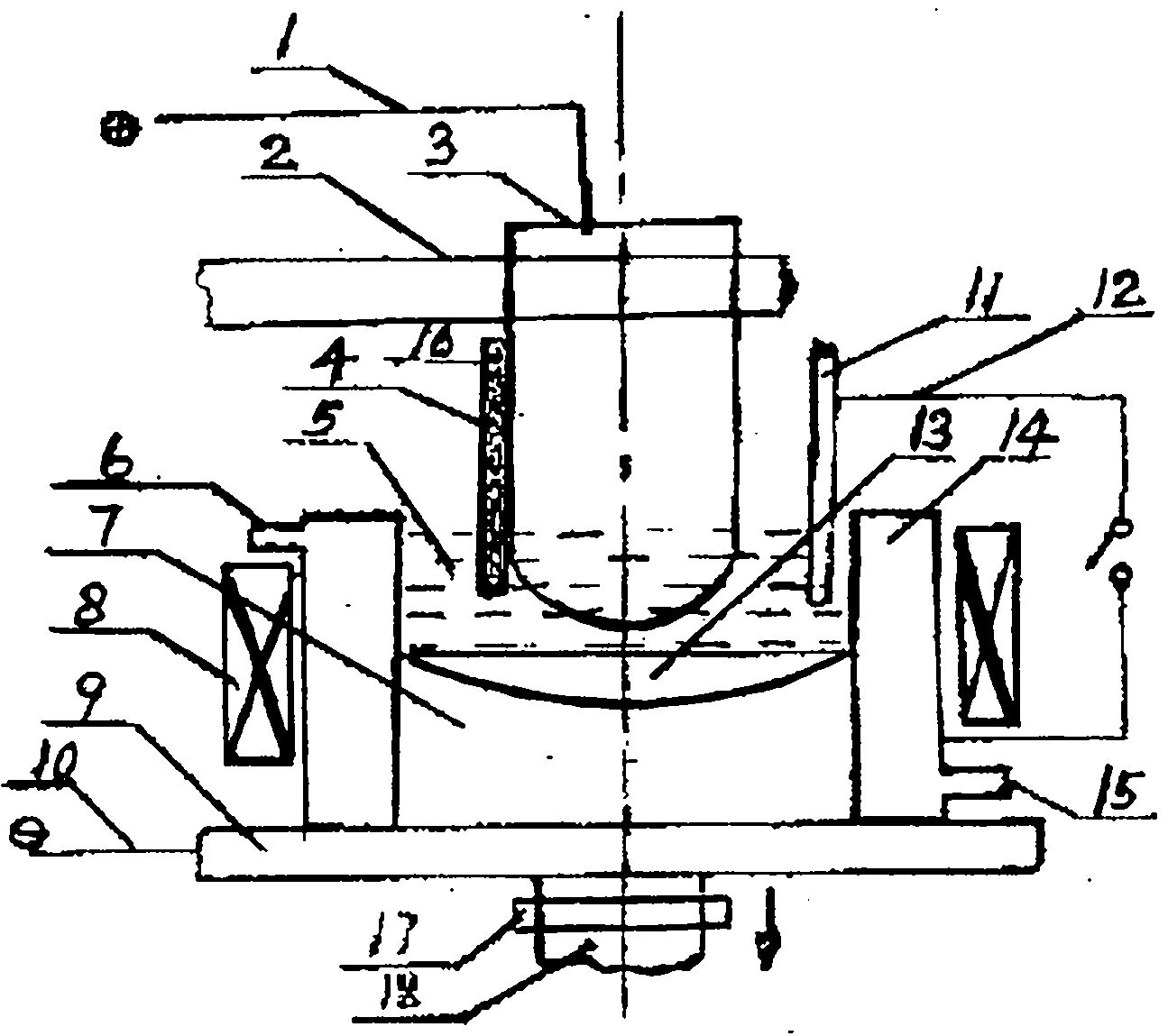

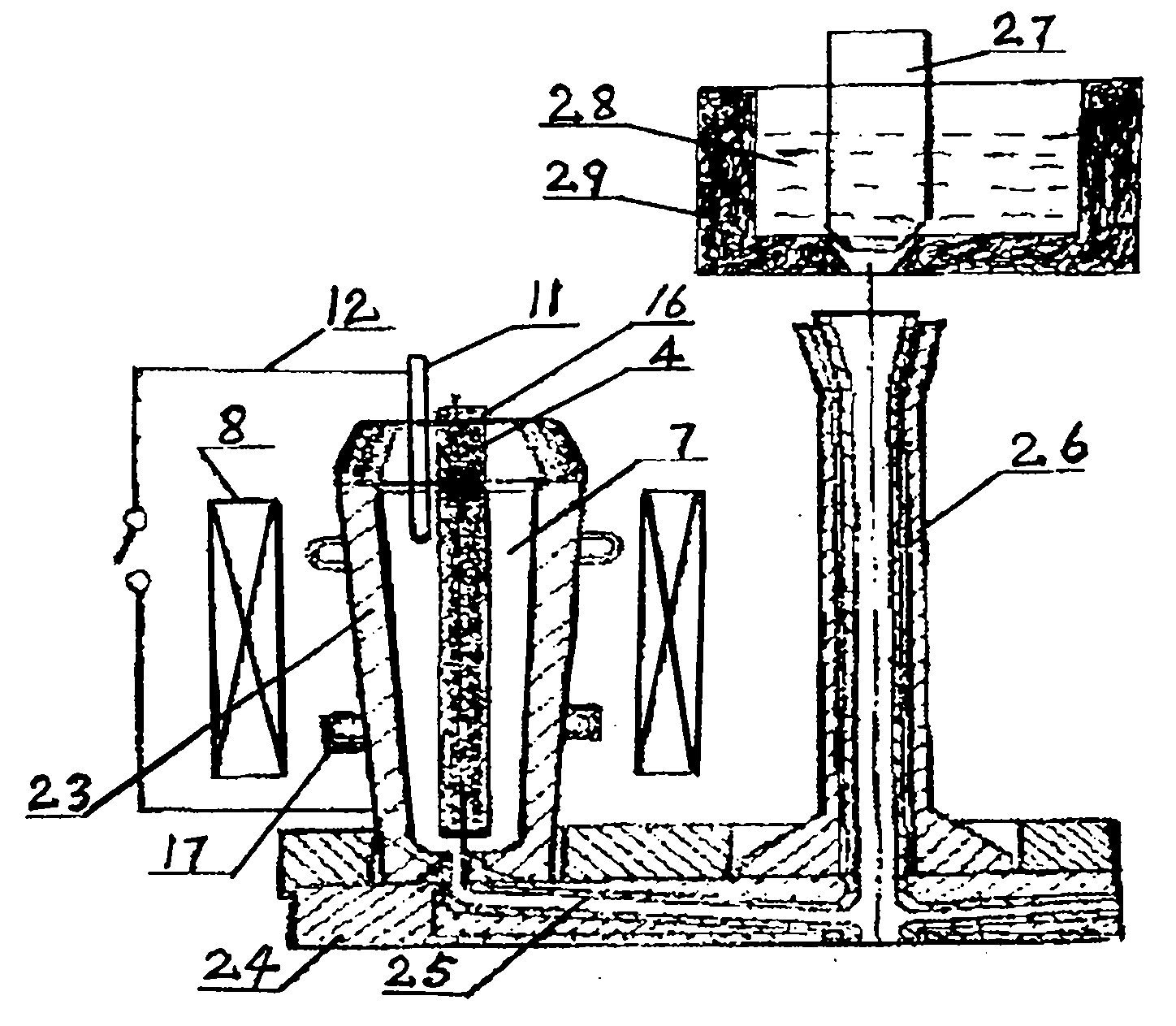

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

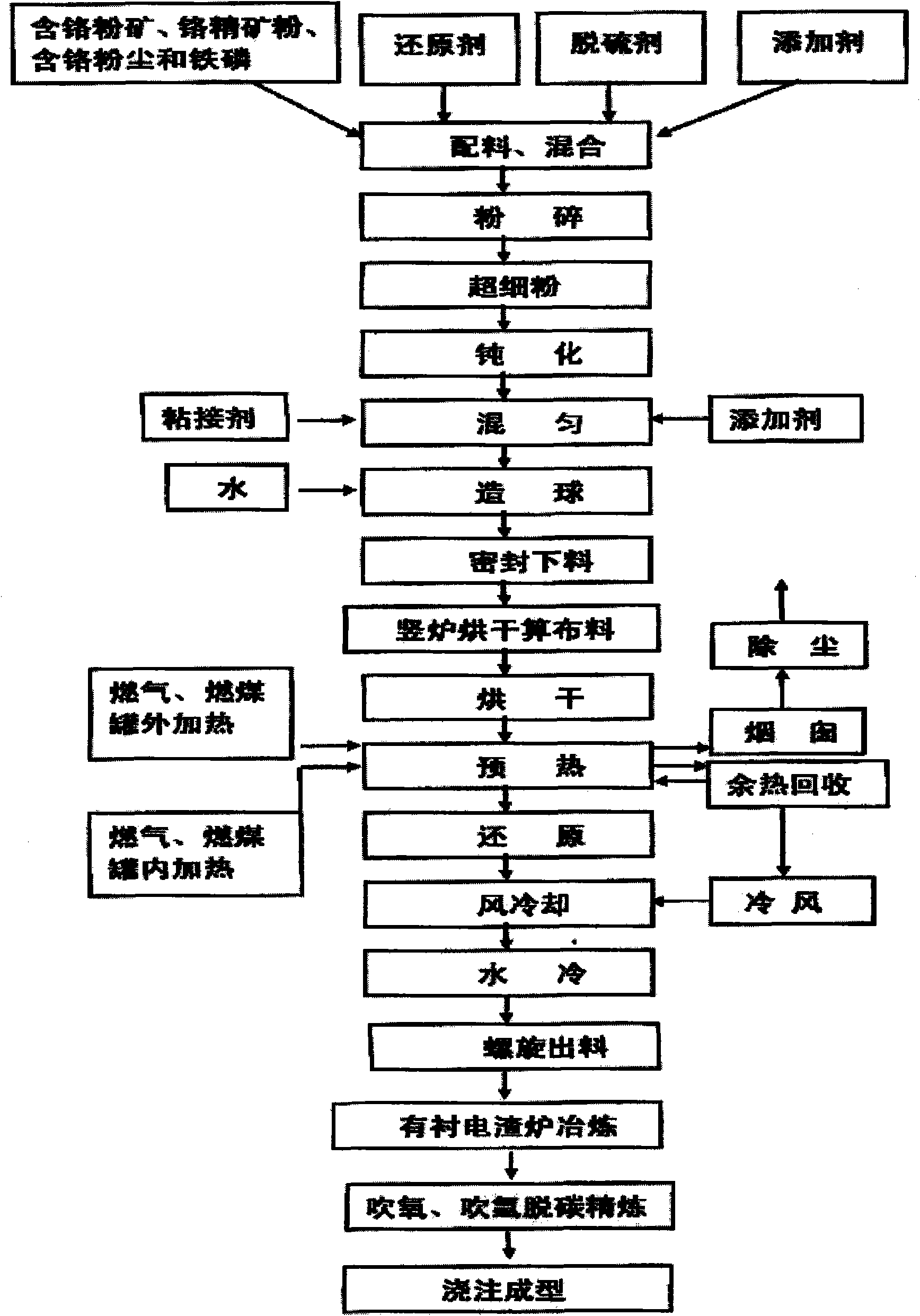

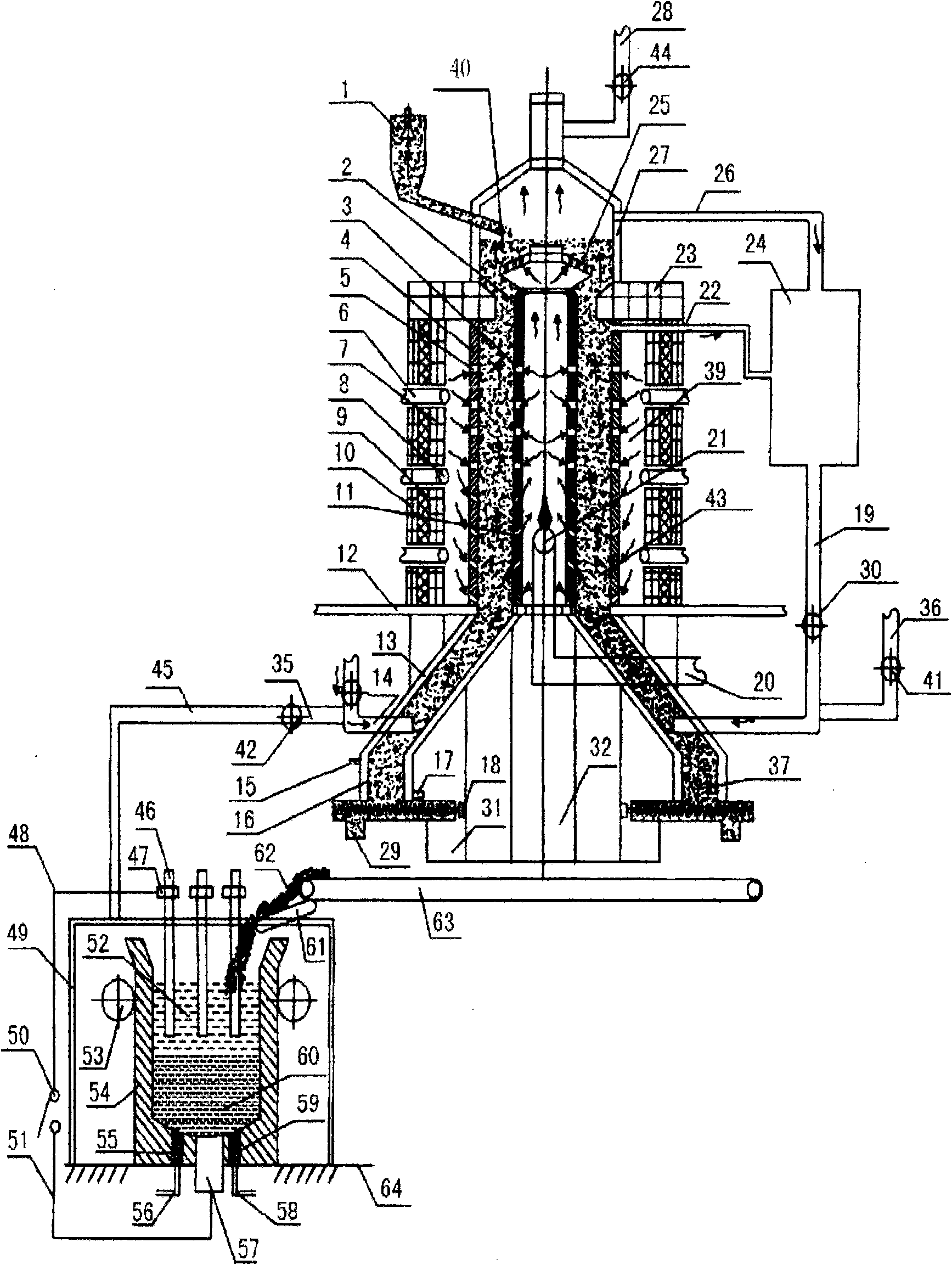

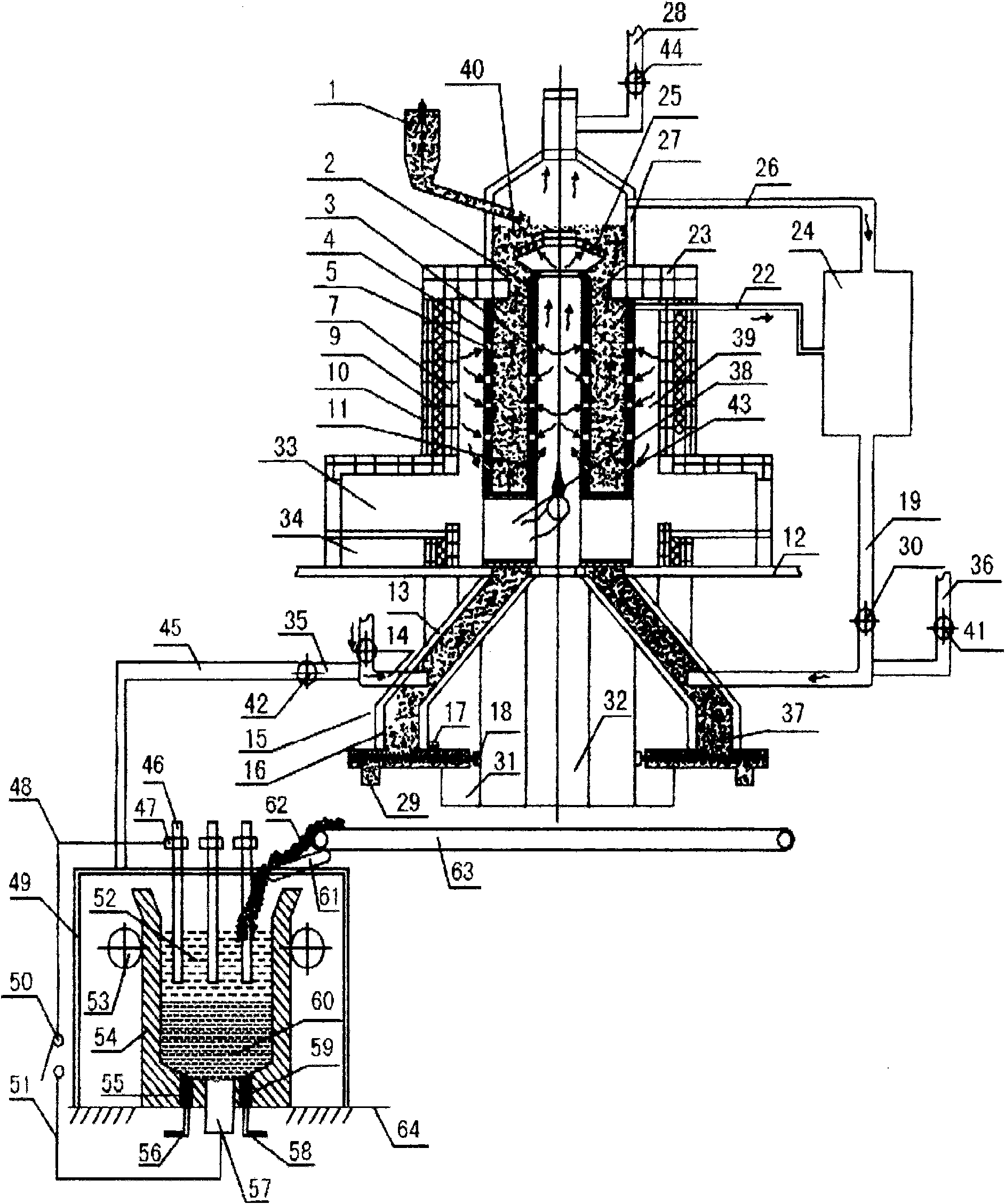

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

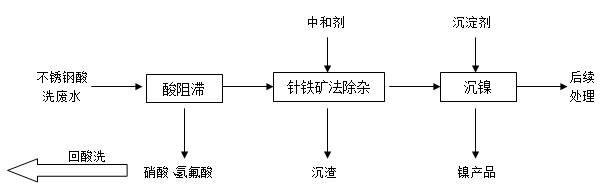

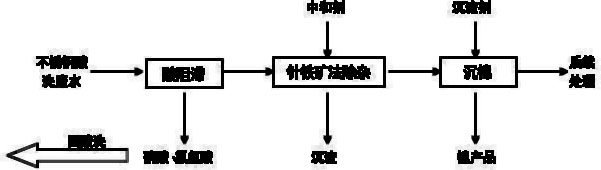

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

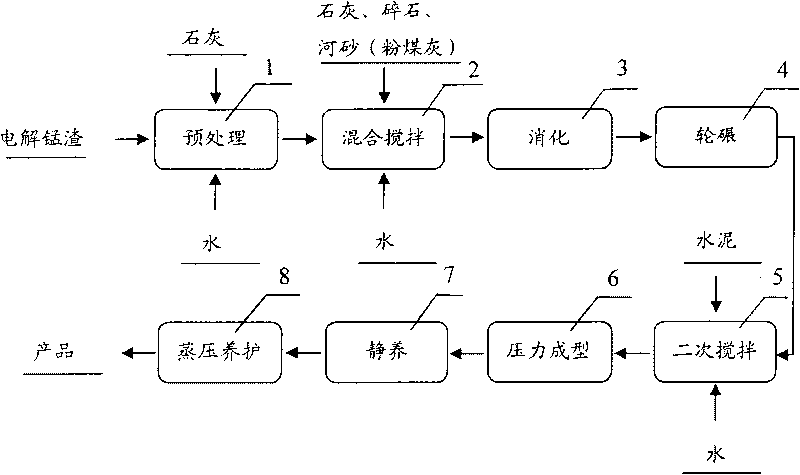

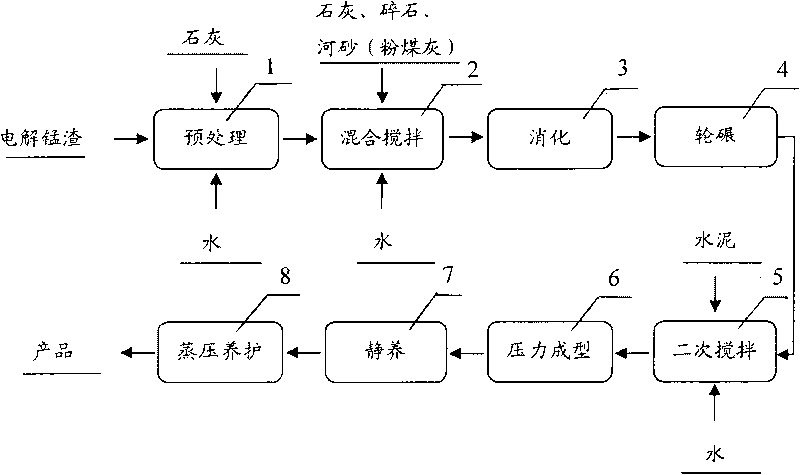

Preparation method of electrolytic manganese slag autoclaved brick

The invention provides a preparation method of an electrolytic manganese slag autoclaved brick. The method comprises the following steps: after preprocessing the electrolytic manganese slag, adding river sand (or fly ash), broken stone and lime in proportion; and stirring, assimilating, rolling, molding, standing, autoclaving and curing, and the like to obtain the electrolytic manganese slag autoclaved brick. The product meets the corresponding index requirements of Autoclaved Sand-lime Brick (GB11945-1999) or Fly Ash Brick (JC239-2001) for a first quality product with the strength level of more than 15MPa. The method has simple technology, high product quality, low production cost and good social, economic and environmental benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Rapid repairing materials for ultrathin layer on the surface of road and airfield runway

InactiveCN1654409AGood value for moneyMinimal disruption to daily traffic operationsWater dispersibleCrushed stone

The super thin fast repair material for highway and airport runway consists of early strengthened hydraulic cementing material 30-90 wt%, polymer resin emulsion or water dispersible polymer powder 0.1-40 wt%, fine sand 8-60 wt% and inorganic modifier 0.1-15 wt%. The repair material is suitable for thin layer and super thin layer repairing of concrete and asphalt road surface, may be also used for repairing damaged part when sand, crushed stone and other aggregate are added. It is also suitable for repairing inner and outer walls of building. The finishing super thin cement mortar layer has the breaking strength reaching 2-4 MPa in 2-3 hr and compression strength up to 20-30 MPa. The present invention can raise the antiwear performance, weather resistance and engine oil and hydraulic oil corrosion resistance.

Owner:桂永全

Novel method for producing superfine calcium carbonate by using carbide slag as raw material

InactiveCN101993104ASolve the possibility of industrializationRealize the possibility of industrializationCalcium/strontium/barium carbonatesCosmetic preparationsSlagCarbide

The invention relates to a method for preparing superfine calcium carbonate by adopting glycine as a dissolving agent, a modifying agent and an acid-binding agent, extracting effective calcium from calcium sources, such as carbide slag or lime, and the like and charging carbon dioxide into a reactor for calcifying, filtering and washing and application of the superfine calcium carbonate to paper making, paint production, and the like.

Owner:BEIJING ZIGUANG YINGLI CHEM TECH CO LTD

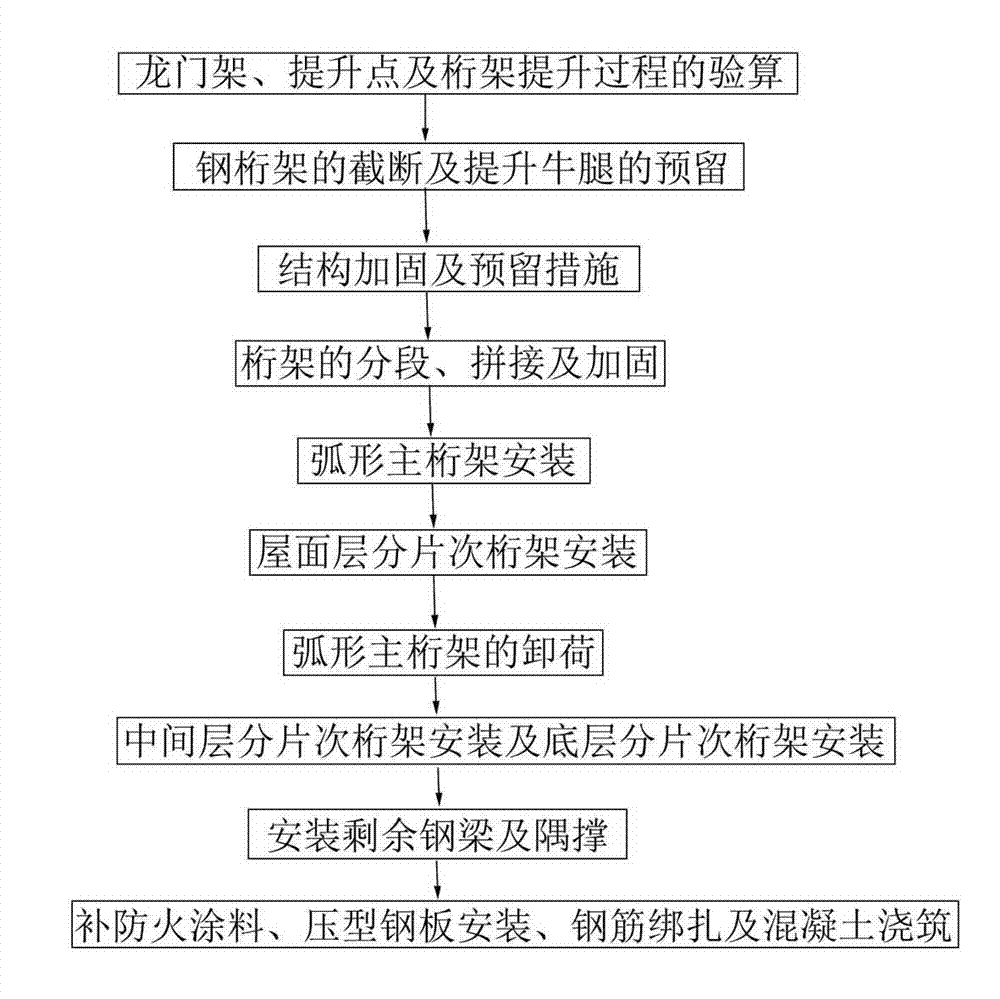

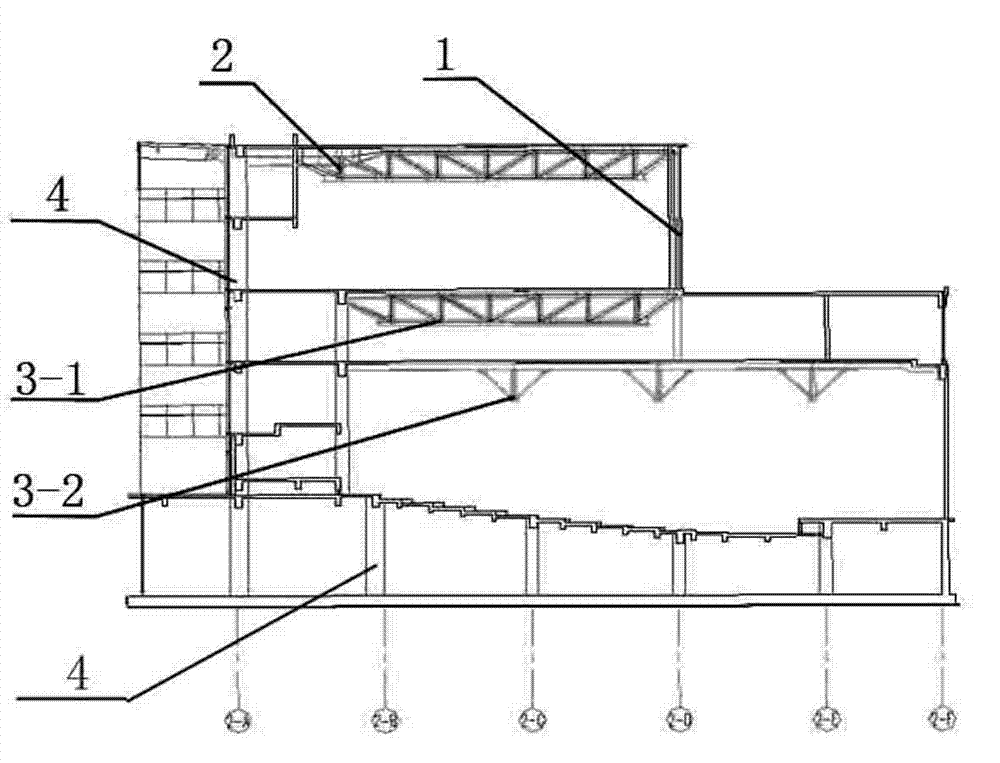

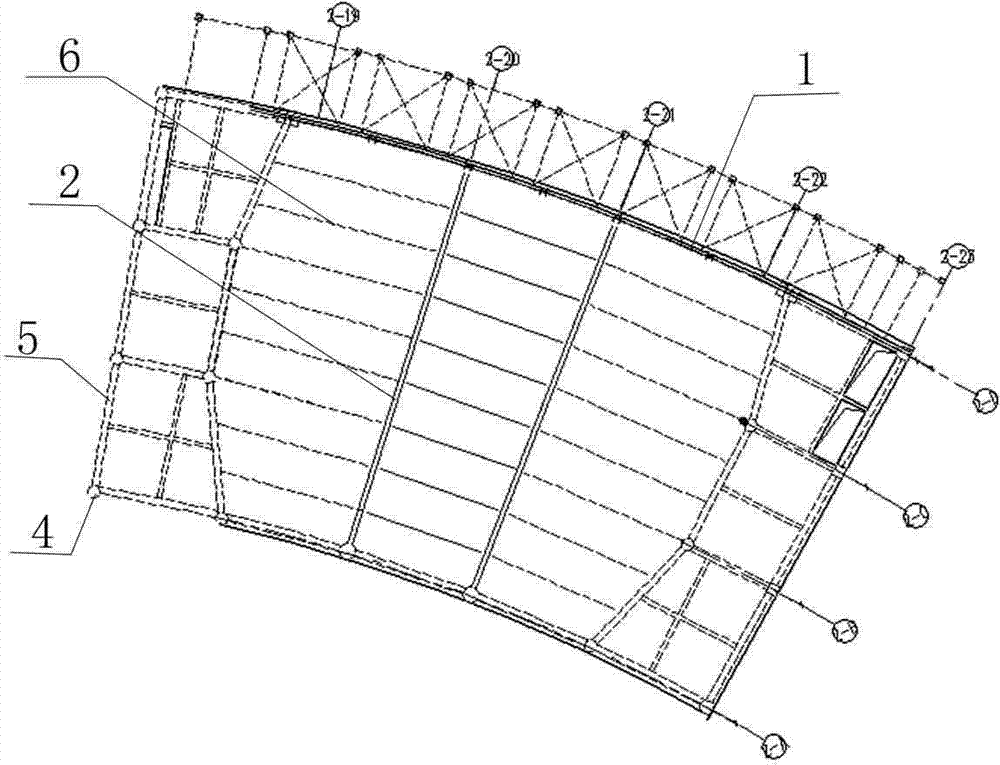

Multilayer steel truss fragmented reverse hoisting construction method in arc-shaped frame

ActiveCN103291076ASolve the problem of difficult control of lateral stabilityReduce high-altitude assemblyBuilding material handlingTower cranePortal frame

The invention relates to a steel truss hoisting construction method, in particular to a multilayer steel truss fragmented reverse hoisting construction method in an arc-shaped frame. The multilayer steel truss fragmented reverse hoisting construction method comprises the steps of firstly performing modeling and checking calculation to all of hoisting conditions, utilizing brackets at two ends and a portal frame in the middle as lifting points of an arc-shaped main truss, hoisting the arc-shaped main truss by combining a hydraulic synchronous hoisting technology, connecting sub trusses above two roof trusses and steel beams to form a trapezoid fragmented truss, utilizing the temporality-fixed main truss hoisted in position and the hydraulic synchronous hoisting technology to install roof layer fragmented trusses, dismounting the lifting point of the portal frame of the arc-shaped main truss after the arc-shaped main truss is stabilized, sequentially and inversely lifting multilayer fragmented sub trusses to a bottom layer downward, and then utilizing the main truss, the sub trusses, a truck-mounted crane, a tower crane and leading chains to install other members and finish hoisting of a multilayer steel structure of the arc-shaped frame. The multilayer steel truss fragmented reverse hoisting construction method in the arc-shaped frame has the advantages of achieving hoisting operation in a narrow field or on a building surface, ensuring quality and safety, saving expenses, shortening a construction period and being free of pollution and good in environmental-protection benefit.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

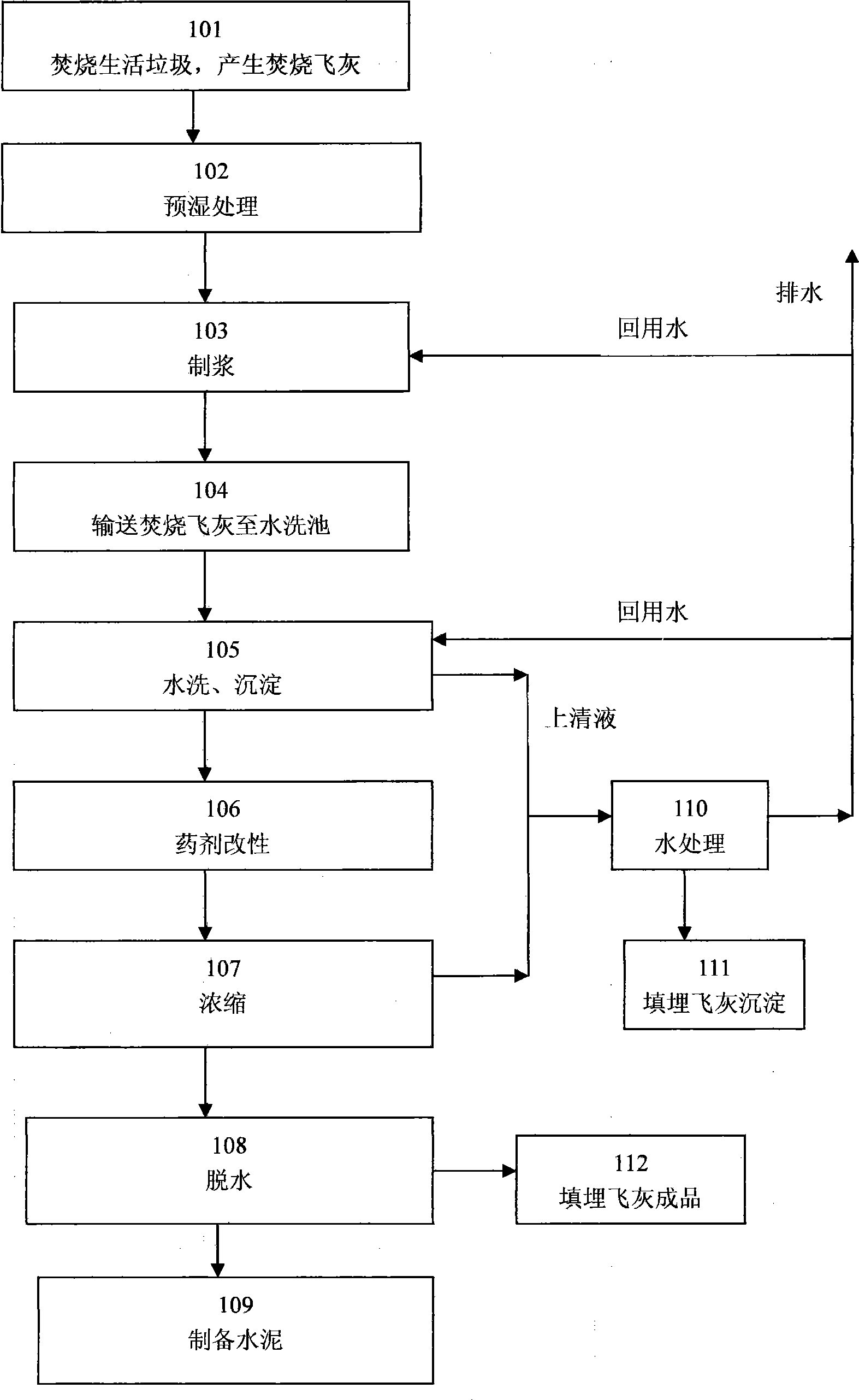

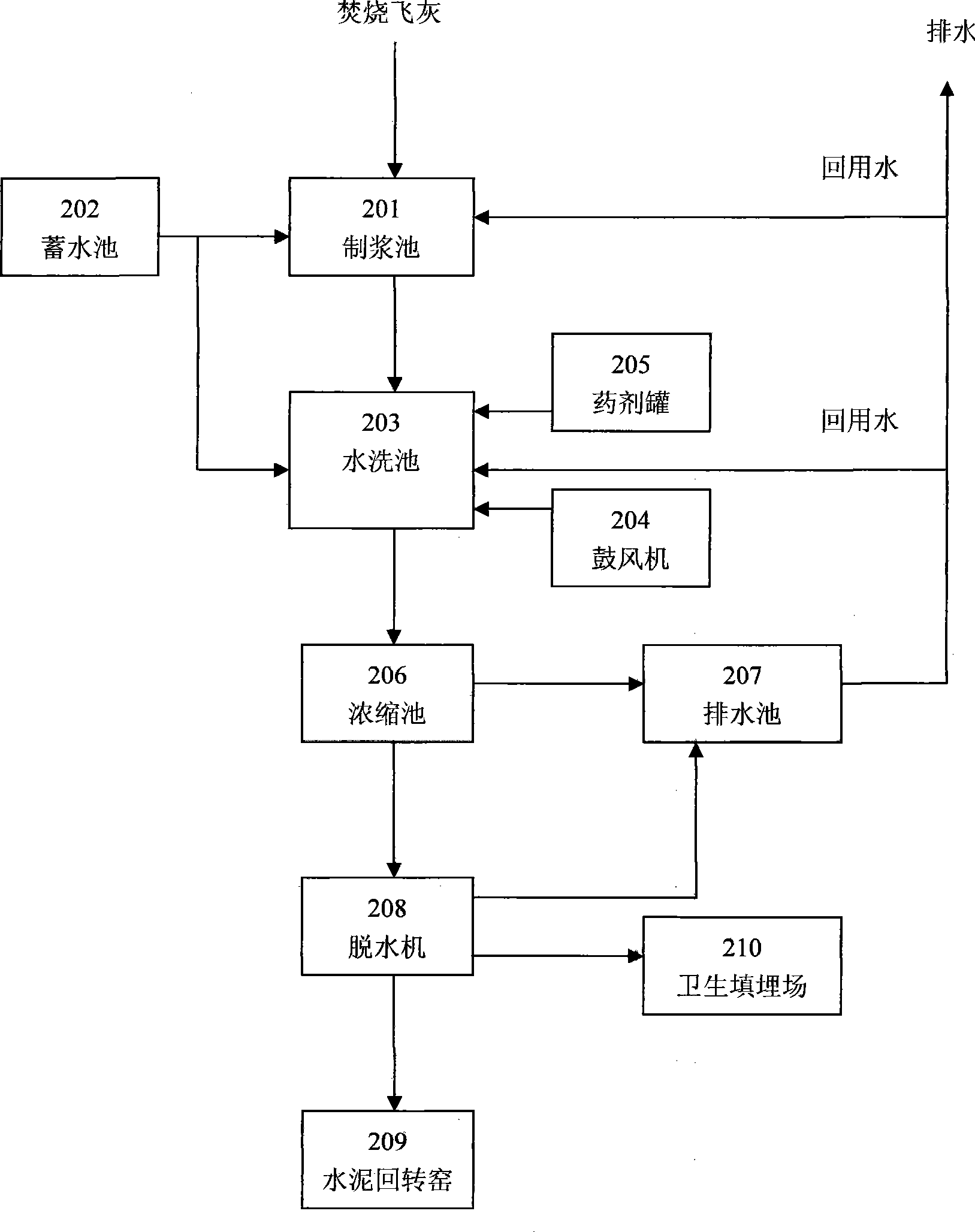

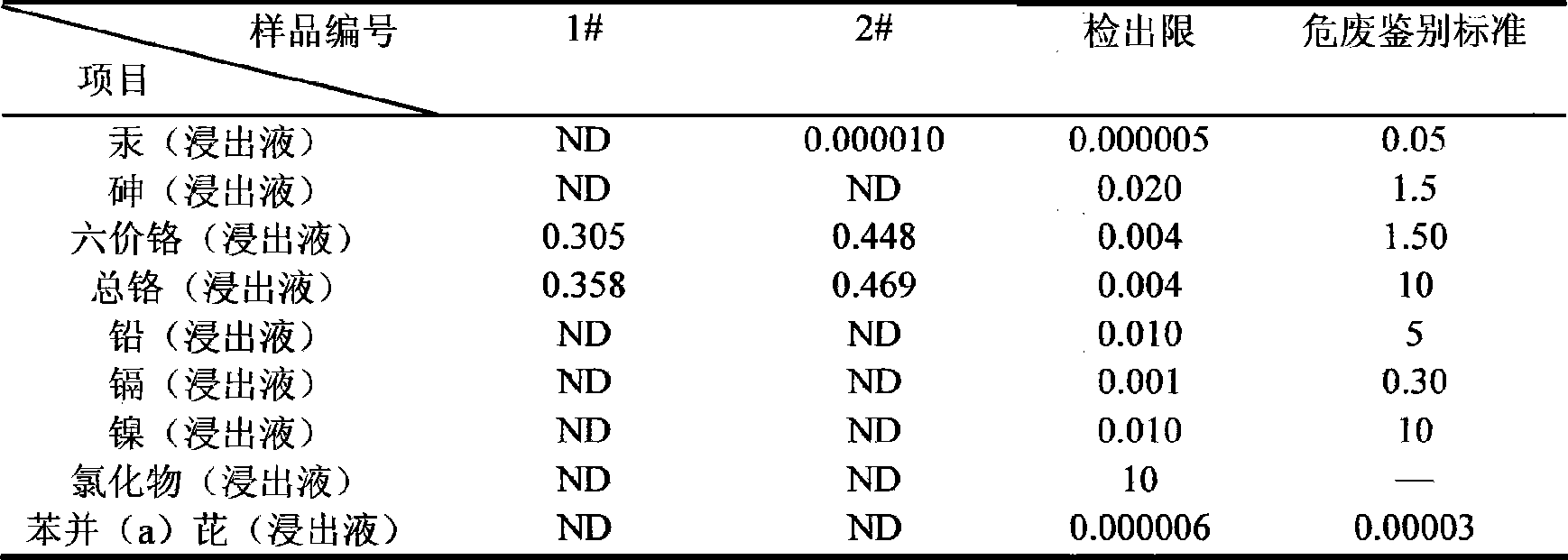

Innocent treatment method and apparatus for refuse burning flyash

ActiveCN101462835AReduce chlorine contentSolve the blockageSolid waste disposalCement productionWater qualitySlurry

The invention proposes a method for the innocent treatment of refuse burning fly ash. The method comprises the following steps: prewetting; pulping: mixing and stirring the fly ash and water in the proportion of 1:2 to 1: 20 to form ash slurry; water washing and precipitation: dissolving the soluble salts in the fly ash; modification through a reagent; concentration for reducing the water content of the ash slurry to 70 to 90 percent; dehydration for reducing the water content of the ash slurry to below 35 percent; water treatment: charging CO2 or acid to make the strongly basic supernatant with the pH value as high as 11 to 12 become the neutral water quality with the pH value of 6.0 to 8.5; flocculant addition for catching tiny particles and speeding up the precipitation process; cement preparation: heating up the fly ash end product in a cement rotary kiln to 1,000 to 1,450 DEG C, and decomposing dioxin and inhibiting the regeneration of the dioxin at the low temperature; and increase of the boiling point of heavy metals for passivating the volatility.

Owner:SHANGHAI SOLID WASTE DISPOSAL CENT +2

Intelligent traffic light controlling method and system

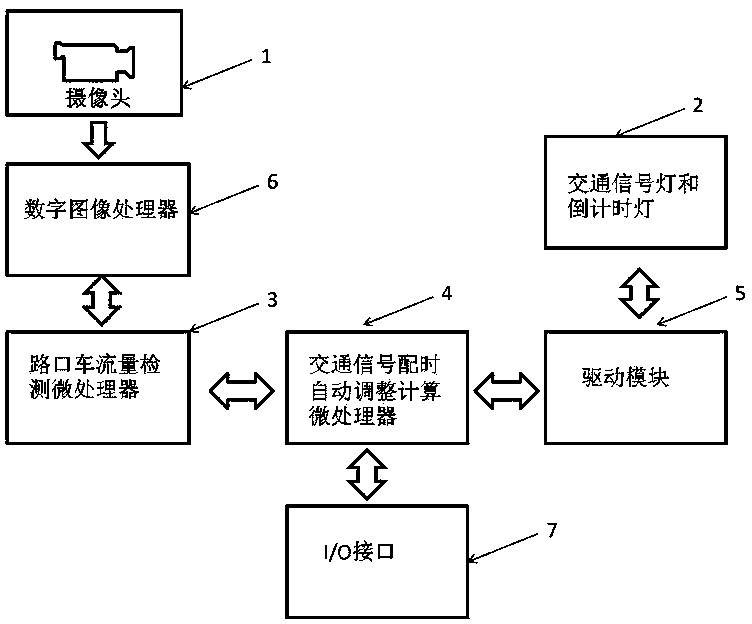

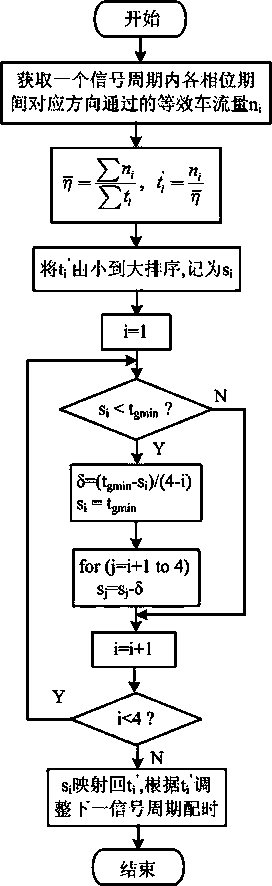

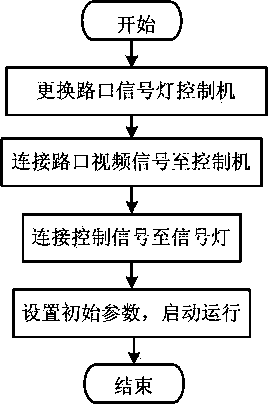

InactiveCN104332058AEmission reductionReduce negative emotionsControlling traffic signalsSurveillance cameraGreen-light

The invention discloses an intelligent traffic light controlling system which comprises a monitoring camera, a traffic signal lamp and countdown lamp, a crossing traffic flow detection microprocessor, a traffic signal timing automatic adjustment and calculation microprocessor, a display driver module, a digital image processor, and an I / O interface. A controller automatically adjusts signal timing of traffic lights to enable utilization rate of green light in each direction of the crossing to increase or decrease along the same trend, compared with the traffic flow, thereby identifying flow state of the crossing in an effective and dynamic manner, adjusting signal timing automatically, and reducing traffic jam.

Owner:NANTONG UNIVERSITY

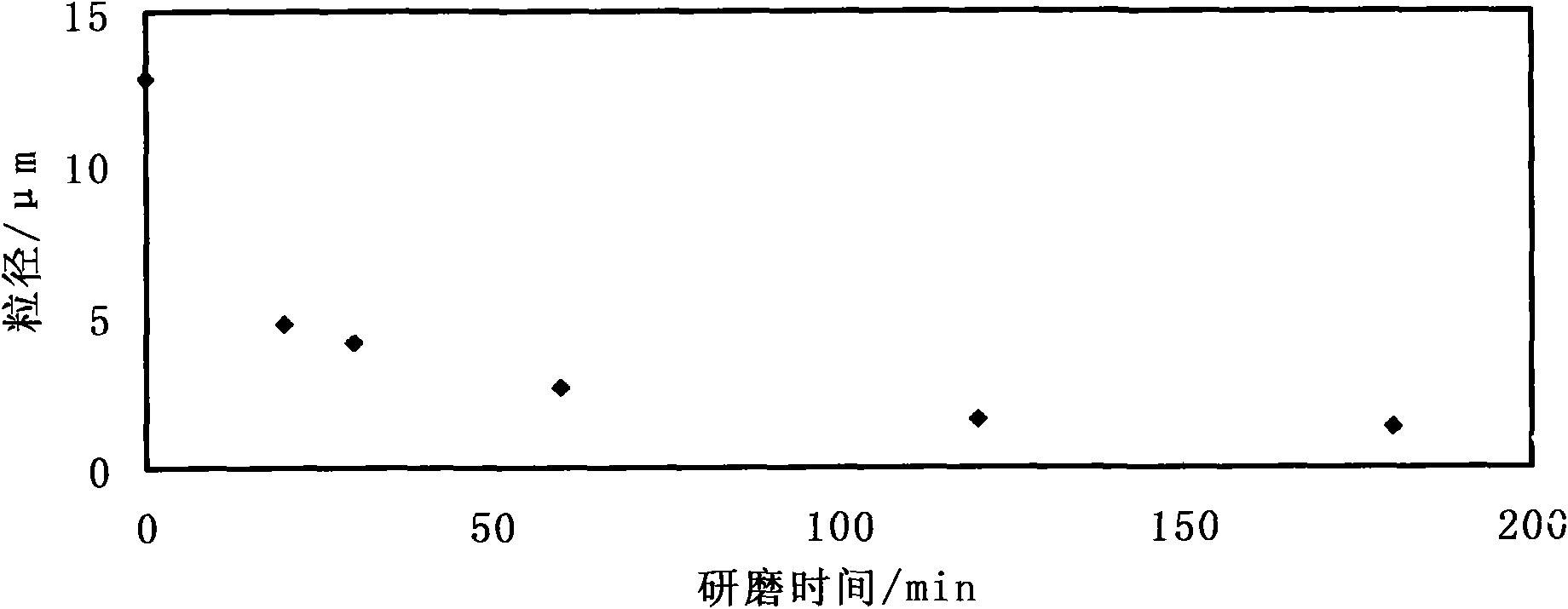

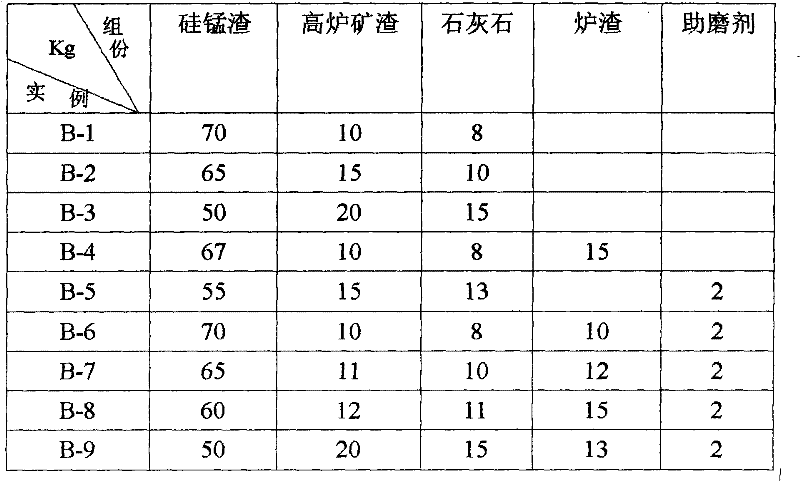

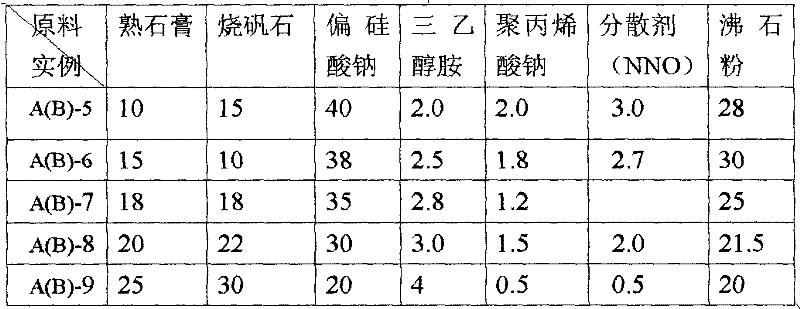

Composite admixture for cement or high-performance concrete and preparation method thereof

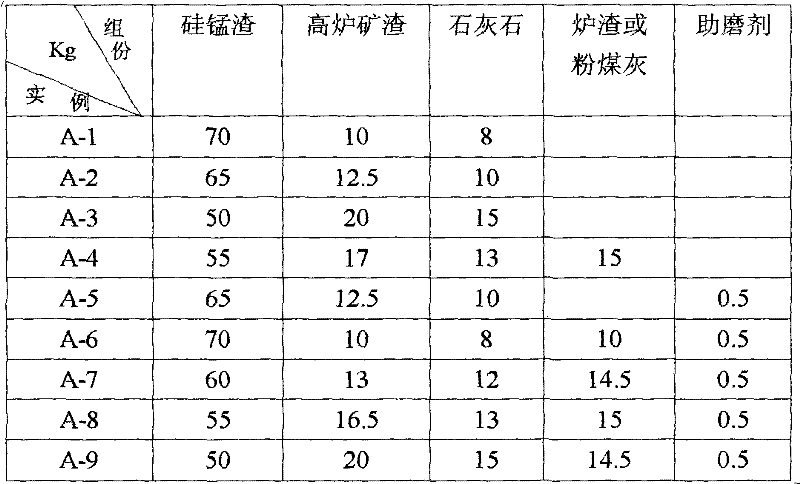

InactiveCN102180612ASave resourcesGood social benefitsSolid waste managementIndustrial wasteHigh performance concrete

A composite admixture for cement or high-performance concrete and a preparation method thereof. The admixture comprises silicon manganese slag, slag, limestone, furnace slag or fly ash, and grinding aids, and the mass ratios are: 50-70 of silicon-manganese slag, 10-20 of slag, 8-15 of limestone, 10-15 of furnace slag or fly ash, and 0.5 or 2 of grinding aids. The preparation method comprises: adding the raw materials according to the ratios into a ball mill, grinding till the grinding fineness meets that the Blaine specific surface area is not less than 400 m2 / kg or 450 m2 / kg so as to obtain the silicon manganese slag-based composite admixture for cement or high-performance concrete. The preparation of the admixture can use a large amount of industrial waste residues - silicon manganese slag discharged from the production of silicomanganese alloy, and the admixture is prepared with a proper amount of slag, limestone, furnace slag or fly ash, and a small amount of grinding aids, which has remarkable economic effect, and outstanding social benefits and environmental benefits.

Owner:葫芦岛市辽西混凝土外加剂有限公司

Loaded mercury-free catalyst for vinyl chloride preparation by hydrochlorination of acetylene and preparation method thereof

InactiveCN102416323ASimple compositionEasy to preparePreparation by halogen halide additionCatalyst activation/preparationHydrogenActive component

The invention discloses a loaded mercury-free catalyst for vinyl chloride preparation by hydrochlorination of acetylene and a preparation method thereof. The catalyst comprises precious metals / active carbon. The load capacity of the active components in the catalyst on a carrier is 0.1-3 wt%. The catalyst is prepared by carrier pretreatment and dipping, and a test for acetylene hydrochlorination activity is performed under a condition with a raw material gas space velocity of 120 h-1, a raw material gas ratio of V(HCl):V(C2H2) of 1.15, a normal pressure, and a reaction temperature of 160 DEG C. The advantages of the invention are that: the catalyst has good environmental benefits; the catalyst has a simple composition, and high catalytic activity; the acetylene conversion rate is more than 96%; the selectivity is high; the vinyl chloride selectivity is up to above 98%.

Owner:XINJIANG UNIVERSITY

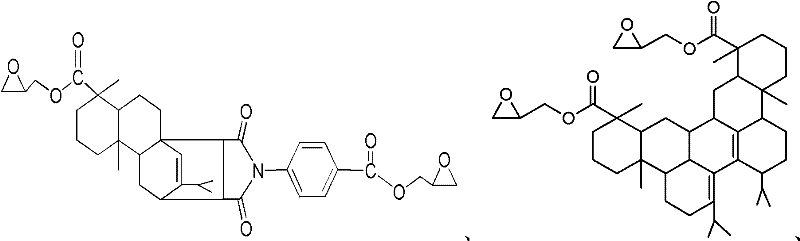

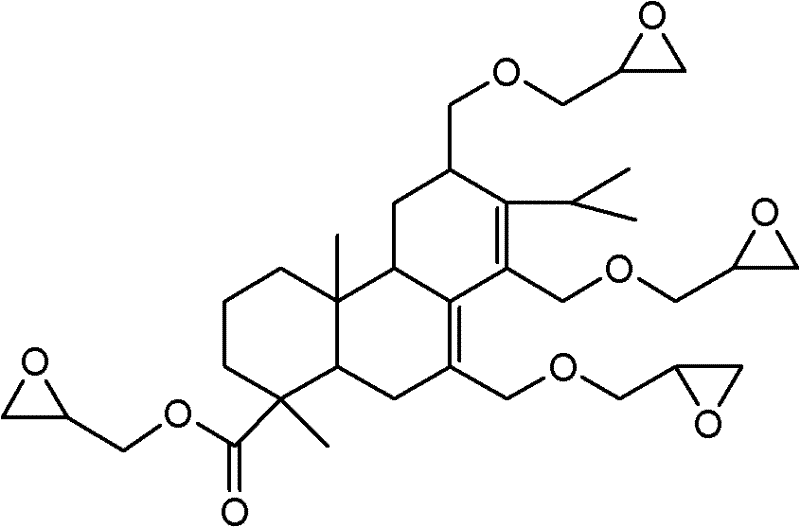

Full-biobased epoxy resin composition and condensate

ActiveCN102206324AGood environmental benefitsImprove flexibilityPlastic/resin/waxes insulatorsEpoxy resin adhesivesAging resistanceResin coating

The invention discloses a full-biobased epoxy resin condensate. The condensate is prepared by the following components in part by weight: 100 parts of abietyl-based epoxy resin base material, 50 to 300 parts of tung oil anhydride and 1 to 15 parts of catalyst, has the characteristics of higher mechanical property, high ultraviolet resistance, high aging resistance and the like and is particularlysuitable for preparing biobased composite material matrix resin and outdoor electric insulation materials. The invention also discloses a preparation method for the full-biobased epoxy resin condensate. The preparation method has a simple preparation process, is high in operability and process controllability and is easy to implement industrially. The invention also discloses a full-biobased epoxy resin composition and application thereof. The full-biobased epoxy resin composition is suitable for preparing a weather resistant epoxy adhesive, epoxy resin paint and an epoxy resin coating and has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

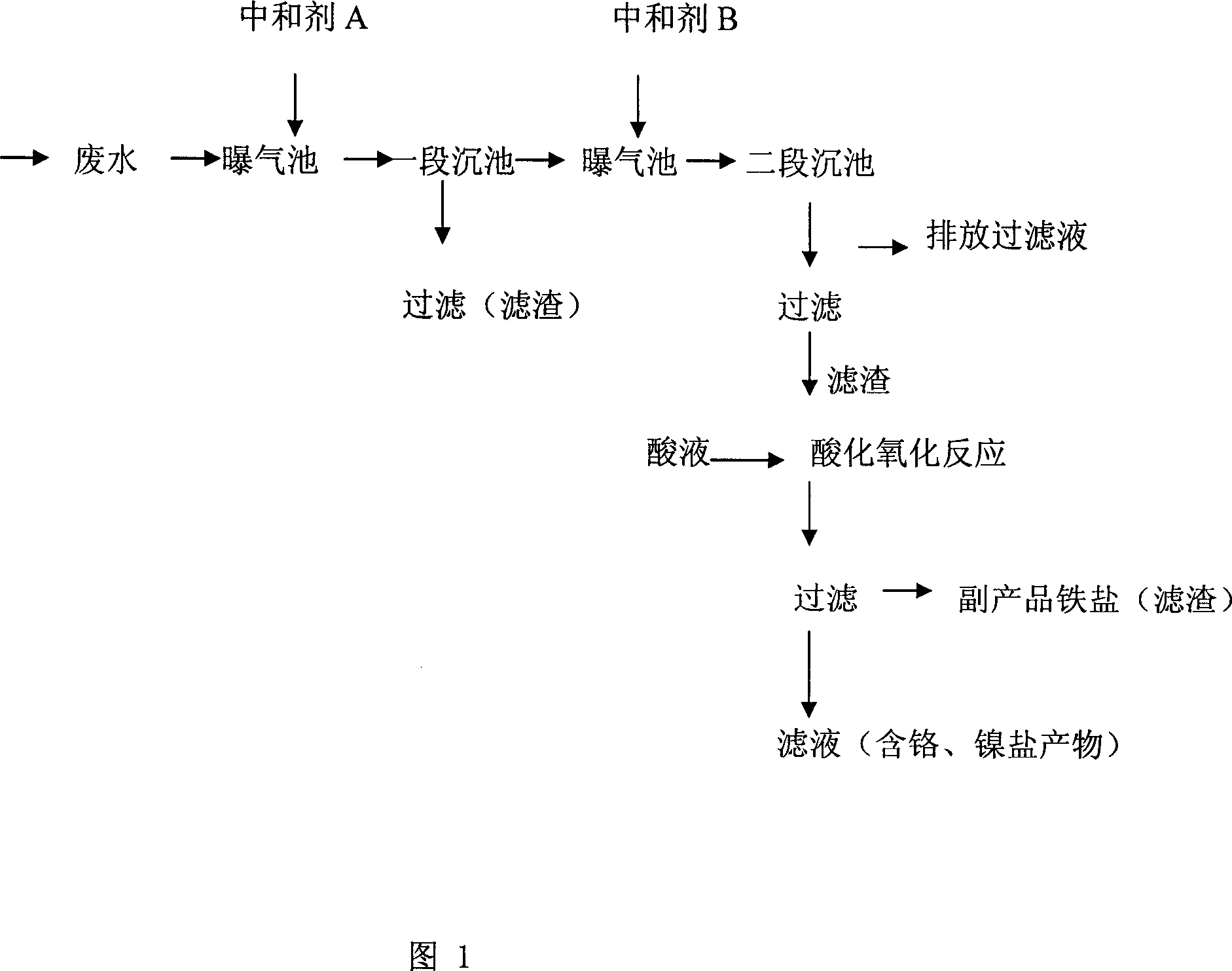

Method for abstracting chromium and nickel salt for stainless steel acid-washing wastewater

ActiveCN101096276AGood environmental benefitsEasy to operateWater contaminantsMultistage water/sewage treatmentIonHeavy metals

The invention discloses a disposing method of acid waste water, in particular to an extracting method of chromium and nickel salt in the stainless steel acid waste water, which comprises the following steps: removing harmful material in the acid waste water step by step; adding calcium salt; controlling the pH value at 2.0-4.0; removing fluorine ion; adding strong base or pure alkaline; controlling the pH value between 7.0 and 8.0; filtering; realizing the discharge standard effectively; acidifying and oxidizing the filter slag; controlling the pH value at 1.0-4.0; removing the iron ion; obtaining the residual filtrate as the extracted precious metal chromium and nickel salt. The invention improves the economic benefit, which is fit for disposing kinds of waste water for stainless steel manufacturing enterprise and similar enterprises.

Owner:SONGYANG COUNTY ZHONGQI ENVIRONMENTAL ENGCO

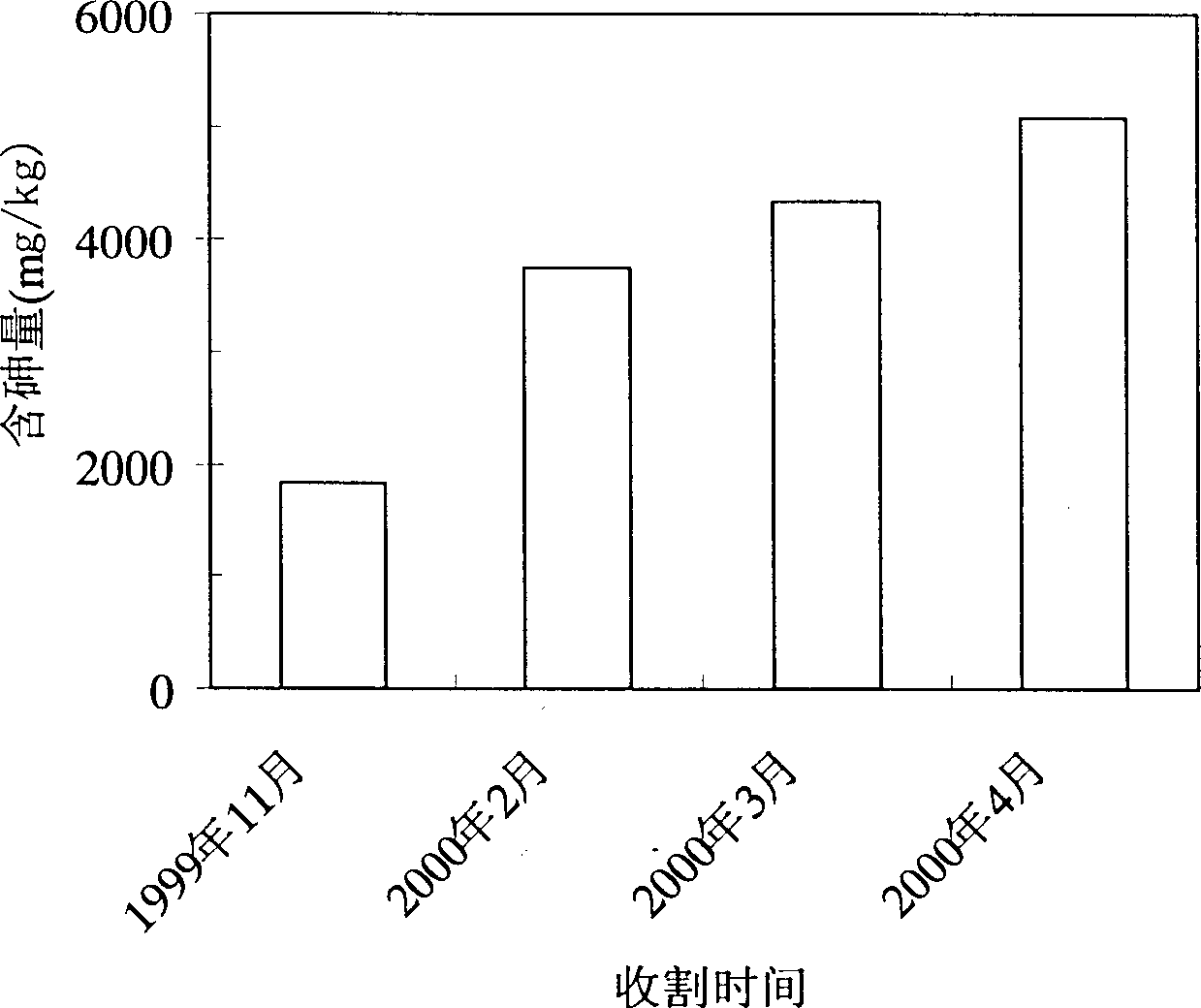

Method for treating As polluted soil

InactiveCN1397390ADoes not destroy physical and chemical propertiesFix fixesContaminated soil reclamationPollution soilBiology

A method for treating the As-polluted soil features that the Chinese brake herbs are planted in said soil for absorbing the As from the soil and the their leaves are removed periodically (5-6 months). For acid soil, the lime or alkaline fertilizer can be applied to increase its pH value.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

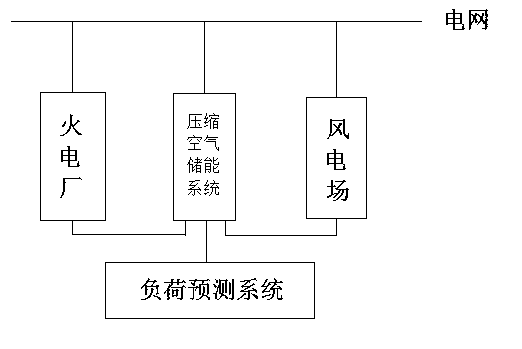

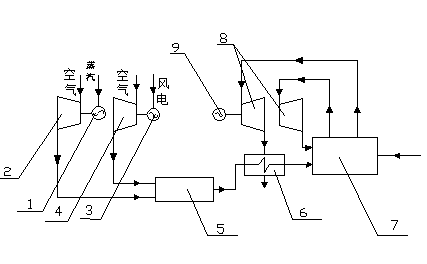

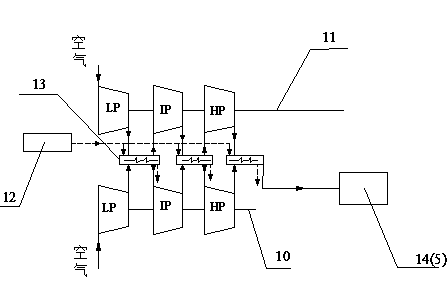

Wind power generation, thermal power generation and compressed air energy storage integrated power generation system

InactiveCN103644081AGood environmental benefitsRotary/oscillating piston combinations for elastic fluidsWind motor combinationsThermal energy storageEngineering

The invention discloses a wind power generation, thermal power generation and compressed air energy storage integrated power generation system. The integrated system is mainly composed of a wind power plant, a thermal power plant and a compressed air energy storage power station. The wind power plant and the thermal power plant are connected through a compressed air system to form a wind power, thermal power and energy storage integrated power generation system. The compressed air energy storage system adjusts power output according to a grid load requirement and the output condition of the wind power plant and the thermal power plant to achieve linkage of the wind power plant and the thermal power plant and improve grid load response capability. Under the condition that grid safety is ensured, more clean energies can be connected into a grid. The compressed air energy storage system utilizes high temperature slag generated by the thermal power plant to generate power and replaces the traditional way that a traditional compressed air energy storage system utilizes natural gas to generate power. Therefore, the system has high environment benefit. Meanwhile, the system is high in peak load adjustment capability. By means of the system, the grid can receive wind power in a large scale, and the peak adjustment capability can be improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

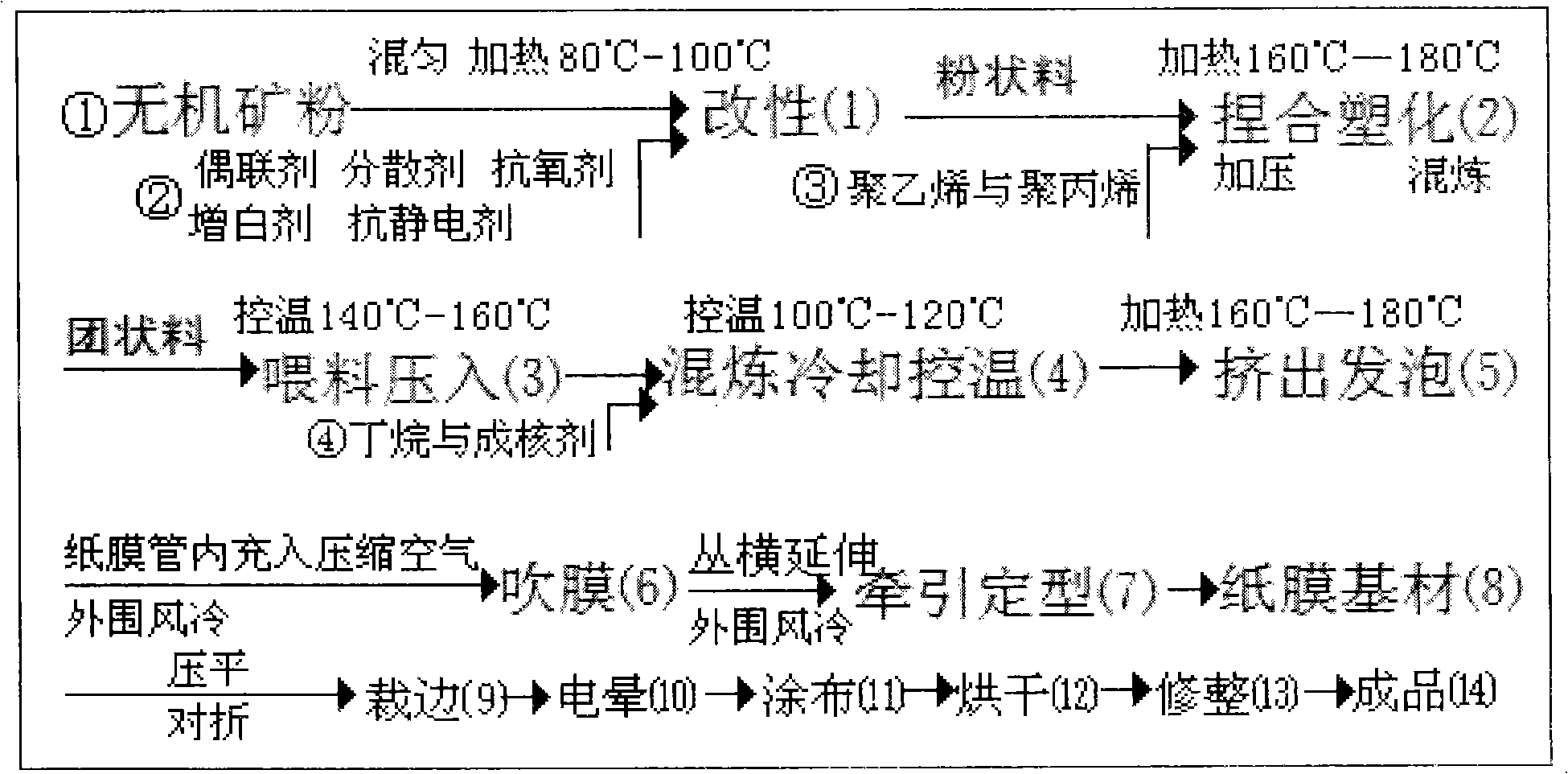

Stone papermaking method

InactiveCN101831835AControl the amount of inflationLight weightInorganic fibres/flakesSpecial paperFilm baseWhite powder

The invention discloses a stone papermaking method, which is characterized by comprising the following steps: adding 2 to 2.5 weight percent of auxiliary agent such as stearic acid and the like into 70 to 80 percent of natural inorganic ore powder such as heavy calcium, light calcium, talcpowder, titanium white powder and the like serving as main raw materials to modify the raw materials, adding 18 to 11.5 weight percent of polyethylene and 9 to 5 weight percent of polypropylene into the raw materials, and mixing, plasticizing and kneading the mixture to form a bulk material; and performing double-fold feed on the bulk material, pressing the bulk material into a paper film extruder, injecting 0.5 weight percent of butane and 0.5 weight percent of nucleating agent into the extruder, mixing and heating the mixture, extruding a paper film, then foaming, blowing, drawing, cooling and shaping the paper film to form a paper film base material, and forming a stone paper finished product through corona, coating, drying and finishing. The gram weight of stone paper is reduced by physical micro-foaming technology. The method has the advantages of simple manufacturing process, low cost, dry production, use of few water circulating cooling machines, no three-waste discharge and pollution avoidance.

Owner:山西典石晨晶科技有限公司

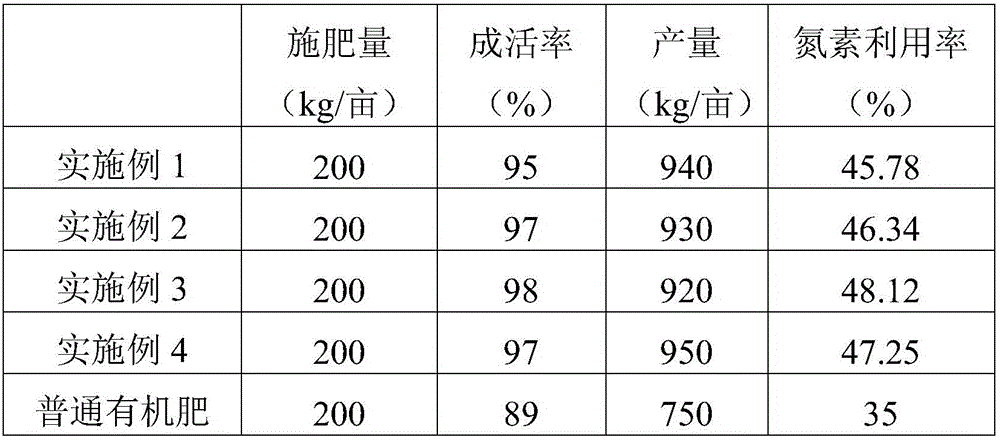

Chicken manure fermentation organic fertilizer

InactiveCN106431599AAvoid pollutionSave resourcesSuperphosphatesAlkali orthophosphate fertiliserPhosphateMonopotassium phosphate

The invention discloses a chicken manure fermentation organic fertilizer, which is prepared from the following raw materials: chicken manure, straw powders, konjak flour, corn flour, cellulose, zeolite, humic acid, potassium dihydrogen phosphate, urea, peat soil, a leavening agent, a soil improvement agent, a film coating agent, potassium sulfate, borax and calcium superphosphate. The above raw materials are subjected to the integrated treatment of anaerobic fermentation and aerobic fermentation, so that the organic fertilizer is prepared through the fermentation of the chicken manure. The chicken manure fermentation organic fertilizer is complete in fermentation effect, and is capable of killing plant pathogenic bacteria, eggs, weed seeds and other harmful microorganisms in the chicken manure, and generating a large amount of nutrients beneficial to the plant growth and the plant absorption. The process is simple and easy to implement. The raw materials of the prepared organic fertilizer are rich in nutrition. Meanwhile, the prepared organic fertilizer is high in fertilizer efficiency and rich in nutrition, and can coordinate the soil nutrient balance, improve the soil nutrient, promote the plant growth, increase the plant yield and improve the plant quality.

Owner:盐亭县佳贝特禽业发展有限公司

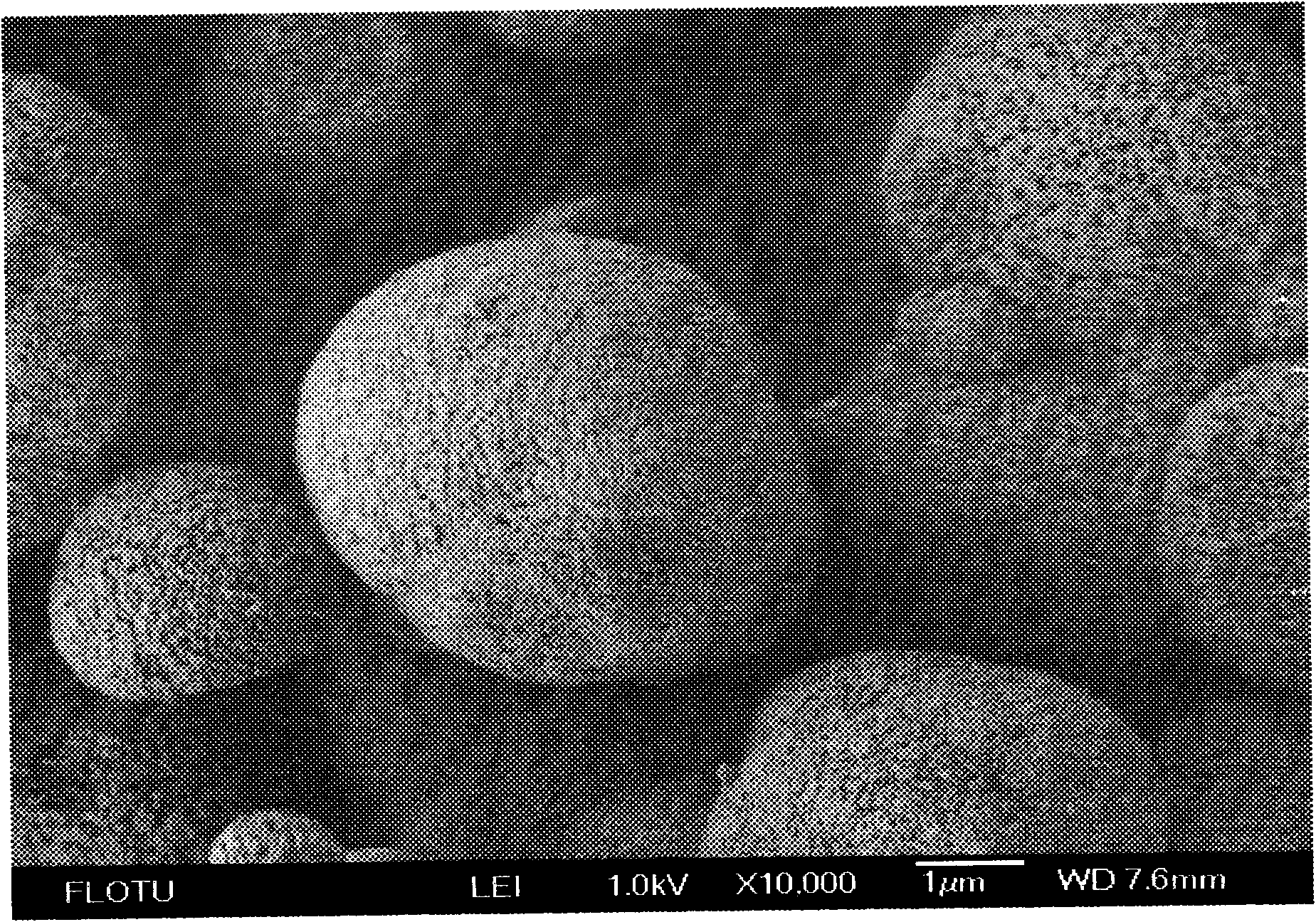

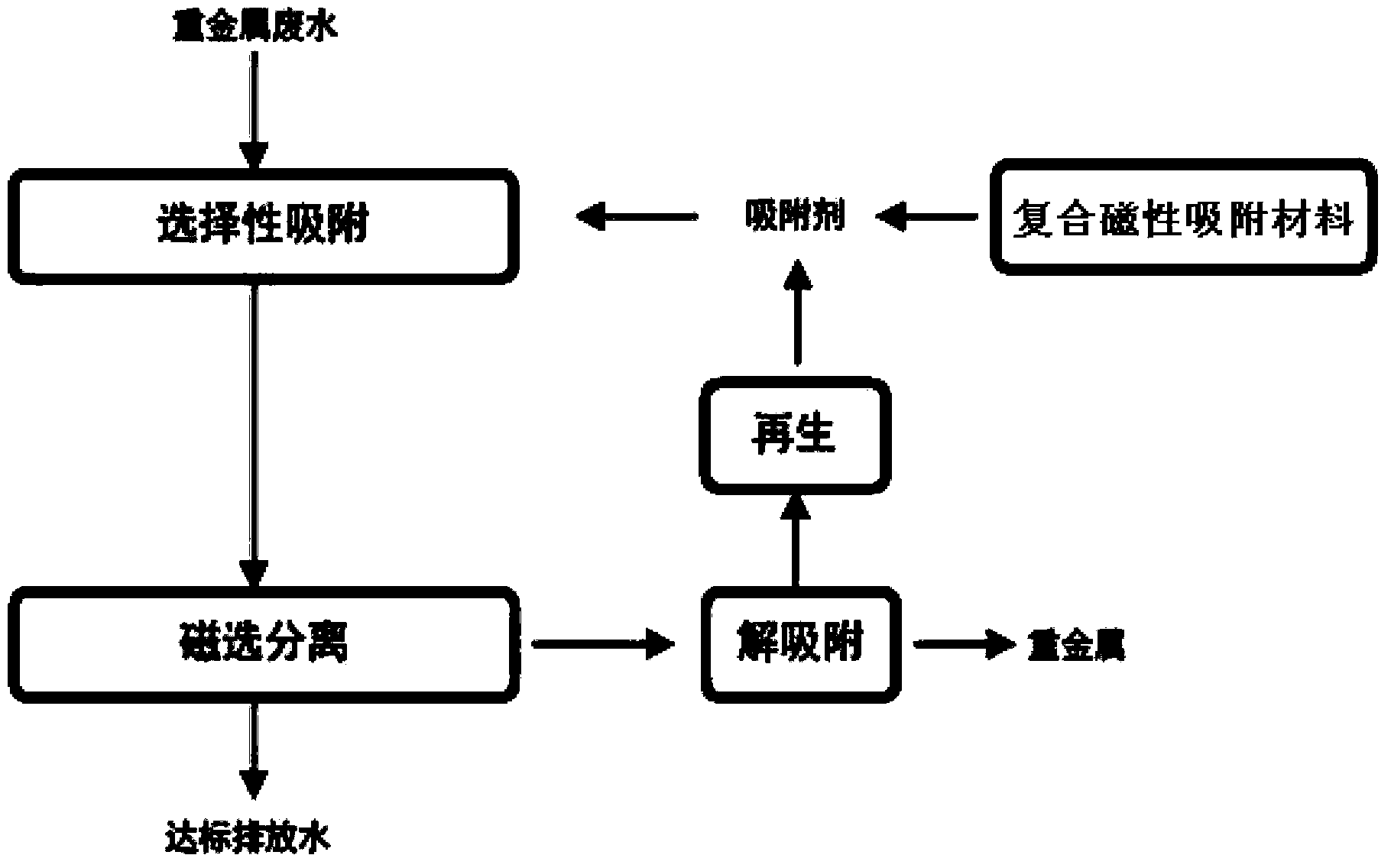

Preparation method for composite magnetic adsorption material and method for removing heavy metal ions in waste water

InactiveCN103623782ALarge adsorption capacityFast adsorptionOther chemical processesWater/sewage treatment by sorptionWastewaterSolvent

The invention relates to a preparation method for a composite magnetic adsorption material and a method for removing heavy metal ions in waste water. The preparation method comprises the following steps: (1) putting a magnetic seed in a grinding machine for fine grinding so as to obtain a submicron magnetic particle; (2) mixing the magnetic particle and a high-molecular natural material capable of absorbing heavy metals with a solvent, adding a flocculating agent and carrying out uniform mixing and a reaction so as to obtain a spherical composite magnetic product; and (3) subjecting the composite magnetic product to magnetic separation, washing and drying so as to obtain the composite magnetic adsorption material. The magnetic adsorption material is added into waste water containing heavy metal ions, then stirring, adsorption and a reaction are carried out, a magnet separator is used for magnetic separation and adsorption of magnetic material containing heavy metal ions, and heavy metals are recovered. According to the invention, the adsorption material is easy to prepare; the removal rate of the heavy metals is high; the advantages of simple process, low cost and environment friendliness are obtained; and the methods are suitable for industrial application.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com