Method for processing dust with zinc of electric furnace

A treatment method and electric furnace technology, applied in the field of metallurgy, can solve the problems of no recovery of valuable metal resources, poor economic benefits, and secondary pollution of the environment, so as to achieve no environmental pollution of valuable metal resources, realize secondary utilization, and be economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

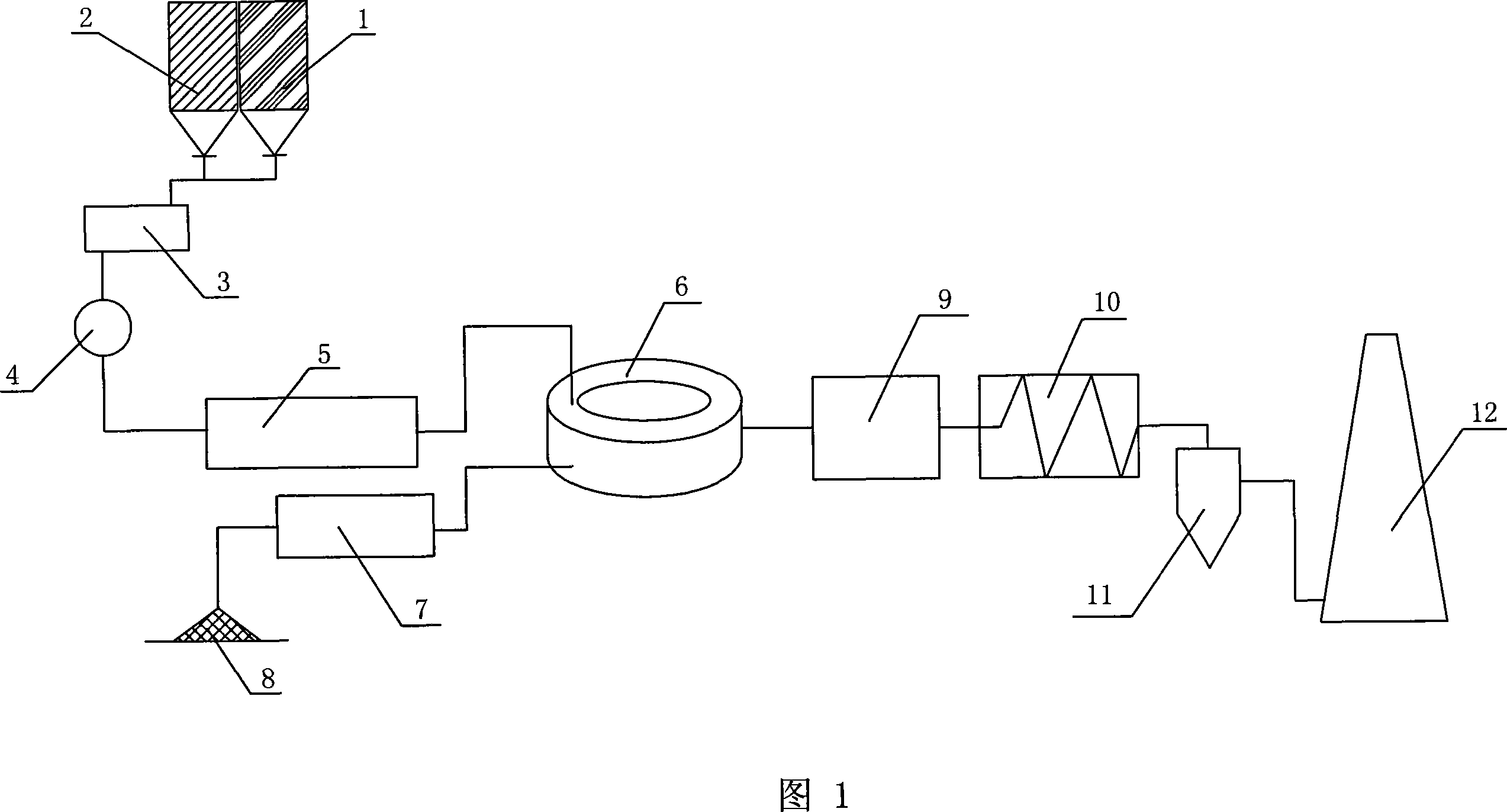

[0049] The flow process of this embodiment is shown in Figure 1, a kind of method that adopts the method for processing zinc-containing electric furnace dust by the direct reduction roasting method of carbon pellets, according to the following steps:

[0050] ① Mix the zinc-containing electric furnace dust in silo 1 and the coke in batching silo 2 into pellets in the mixer 3. The particle size of the coke is 40 mesh, and the pelleting time is 25 minutes. Quantity C / O was 1.1. The zinc-containing electric furnace dust is made into carbon-containing pellets 4 with a pellet diameter of 12 mm. The carbon-containing pellets 4 are introduced into a dryer 5 for drying, and the dried carbon-containing pellets 4 are introduced into a rotary hearth furnace 6 .

[0051] ②The material layer thickness of the carbon-containing pellets 4 in the rotary hearth furnace 6 is 30 mm. In the rotary hearth furnace 6, the dried carbon-containing pellets 4 are subjected to high-temperature reduction ...

Embodiment 2

[0057] The flow process of this embodiment is shown in Figure 1, a kind of method that adopts the method for processing zinc-containing electric furnace dust by the direct reduction roasting method of carbon pellets, according to the following steps:

[0058] ① Mix the zinc-containing electric furnace dust in silo 1 and the coke in batching silo 2 into pellets in the mixer 3. The particle size of the coke is 60 mesh, and the pelletizing time is 30 minutes. Quantity C / O is 1.2. The zinc-containing electric furnace dust was made into carbon-containing pellets 4 with a pellet diameter of 13 mm. The carbon-containing pellets 4 are introduced into a dryer 5 for drying, and the dried carbon-containing pellets 4 are introduced into a rotary hearth furnace 6 .

[0059] ②The material layer thickness of the carbon-containing pellets 4 in the rotary hearth furnace 6 is 40mm. In the rotary hearth furnace 6, the dried carbon-containing pellets 4 are subjected to high-temperature reduction...

Embodiment 3

[0065] The flow process of this embodiment is shown in Figure 1, a kind of method that adopts the method for processing zinc-containing electric furnace dust by the direct reduction roasting method of carbon pellets, according to the following steps:

[0066] ① Mix the zinc-containing electric furnace dust in silo 1 and the coke in batching silo 2 into pellets in the mixer 3. The particle size of the coke is 100 mesh, and the pelletizing time is 35 minutes. Quantity C / O is 1.3. The zinc-containing electric furnace dust is made into carbon-containing pellets 4 with a pellet diameter of 15 mm. The carbon-containing pellets 4 are introduced into a dryer 5 for drying, and the dried carbon-containing pellets 4 are introduced into a rotary hearth furnace 6 .

[0067] ②The material layer thickness of the carbon-containing pellets 4 in the rotary hearth furnace 6 is 50mm. In the rotary hearth furnace 6, the dried carbon-containing pellets 4 are subjected to high-temperature reduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com