Patents

Literature

148results about How to "Realize deep purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano-compound adsorbent for efficiently removing trace phosphorus, arsenic and antimony from water body

ActiveCN101804333ARealize deep purificationAchieving processing powerOther chemical processesWater/sewage treatment by sorptionDivinylbenzeneSorbent

The invention discloses a nano-compound adsorbent for efficiently removing trace phosphorus, arsenic and antimony from a water body, belonging to the technical field of environment functional materials. The organic framework of the nano-compound adsorbent of the invention is hypercrosslinked styrene-divinylbenzene ion exchange resin, a functional group for surface binding of the organic framework is a quaternary ammonium group or pyridyl, nano-inorganic functional particles are loaded, and the total volume of 1-20nm nano-pores accounts for greater than or equal to 90% of the total volume of all the pores of the organic framework. The nano-inorganic functional particles are nano-hydrated ferric oxide or nano-hydrated manganese oxide. The nano-compound adsorbent of the invention has more obvious nano effect, strong reaction activity, great adsorption capacity and high selectivity, well solves the defects of obvious swelling, weak adsorption reaction activity, small adsorption capacity, lower adsorption selectivity and the like of the existing nano-compound adsorbent, and is more suitable for advanced treatment of micro-pollution of water and waste water.

Owner:NANJING UNIV

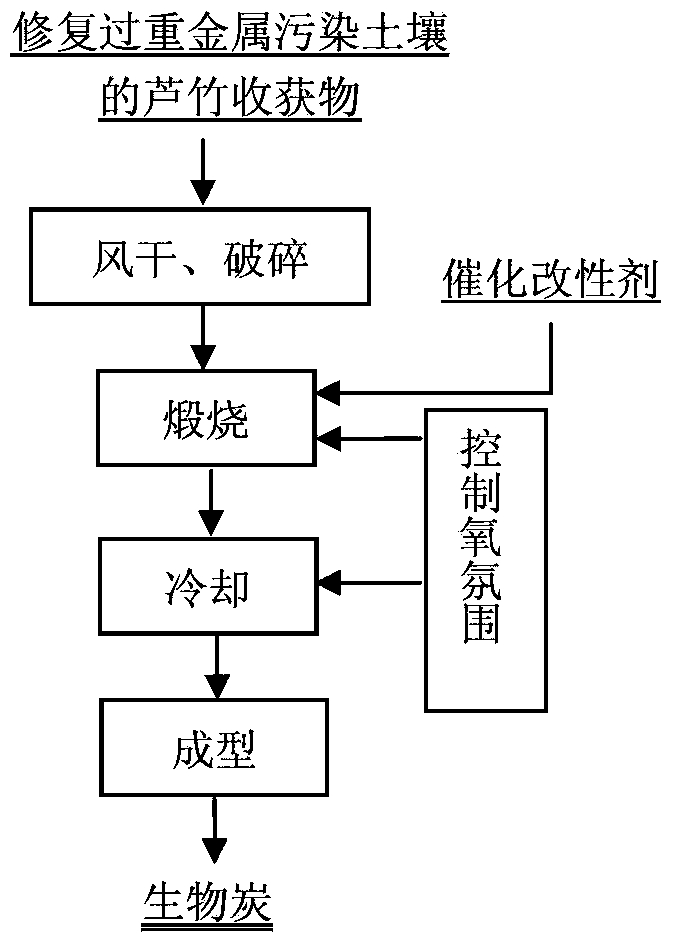

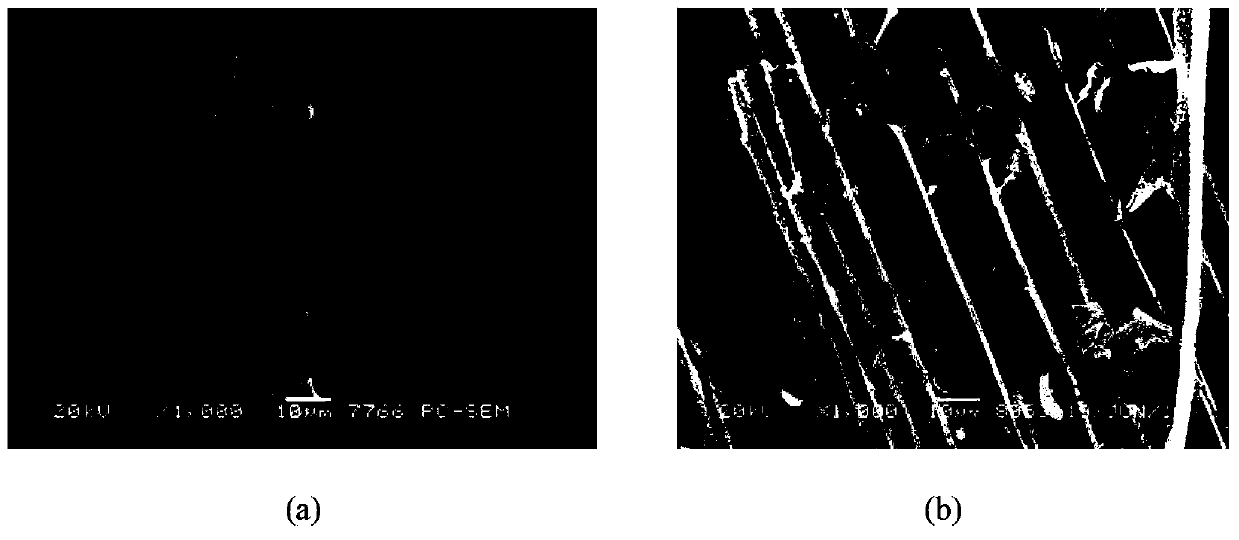

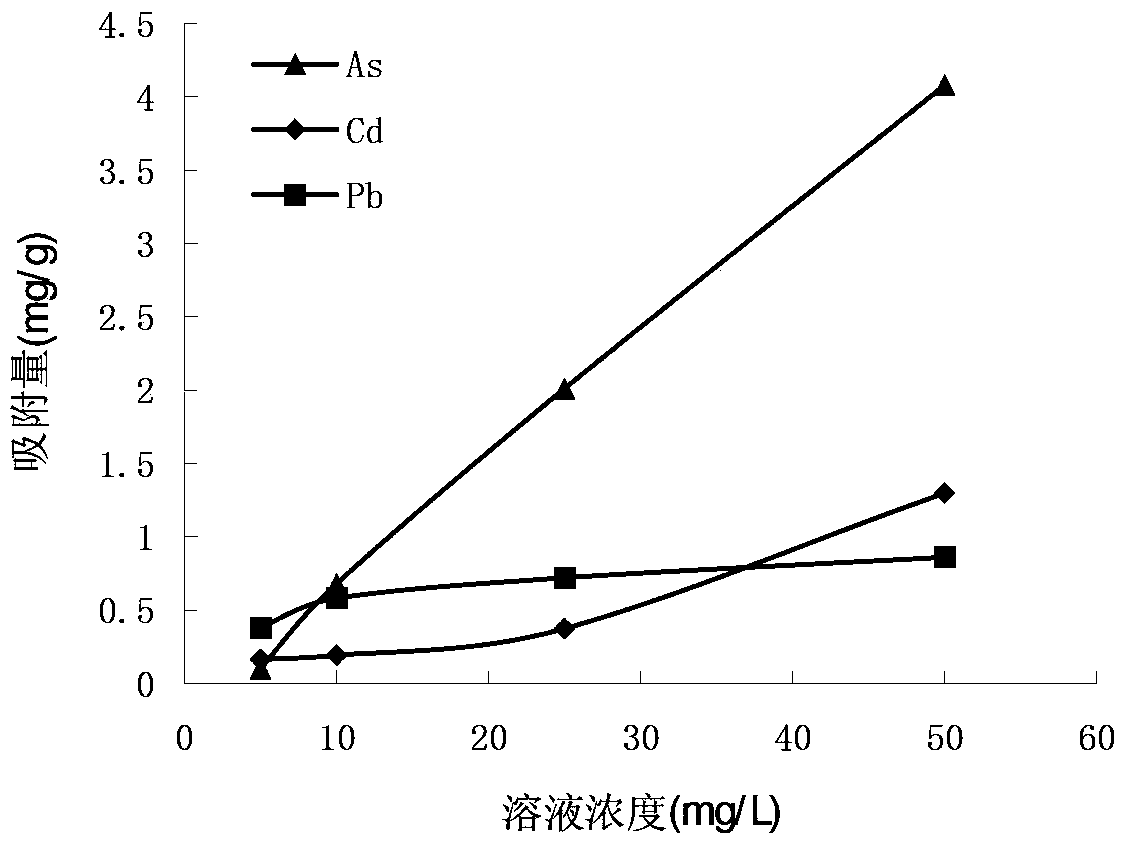

Resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil

ActiveCN103464101APrevent proliferationRealize deep purificationOther chemical processesDispersed particle separationResource utilizationBiochar

The invention discloses a resource utilization method of plant bamboo reed after restoring heavy metal contaminated soil. The method comprises the following steps: air-drying and crushing the harvested plant bamboo reed used for restoring heavy metal contaminated soil, adding a catalytic modifier under a condition of controlling oxygen atmosphere, calcining the plant bamboo reed at 200-800 DEG C for 0.5-4 h, and cooling the plant bamboo reed to obtain charcoal, wherein the yield of the bamboo reed charcoal is 25-75%. When the bamboo reed charcoal is used for adsorbing heavy metals and compounds thereof in contaminated soil, wastewater or waste gases, the adsorption capacity reaches 0.4-6.0 mg / g; meanwhile, the bamboo reed charcoal can be used as an energy source raw material or a reducing agent to be comprehensively utilized by metallurgy enterprises. The invention provides an engineering approach for biomass resource utilization of contaminated soil restoring plants and solving the problem of potential secondary pollution.

Owner:CENT SOUTH UNIV

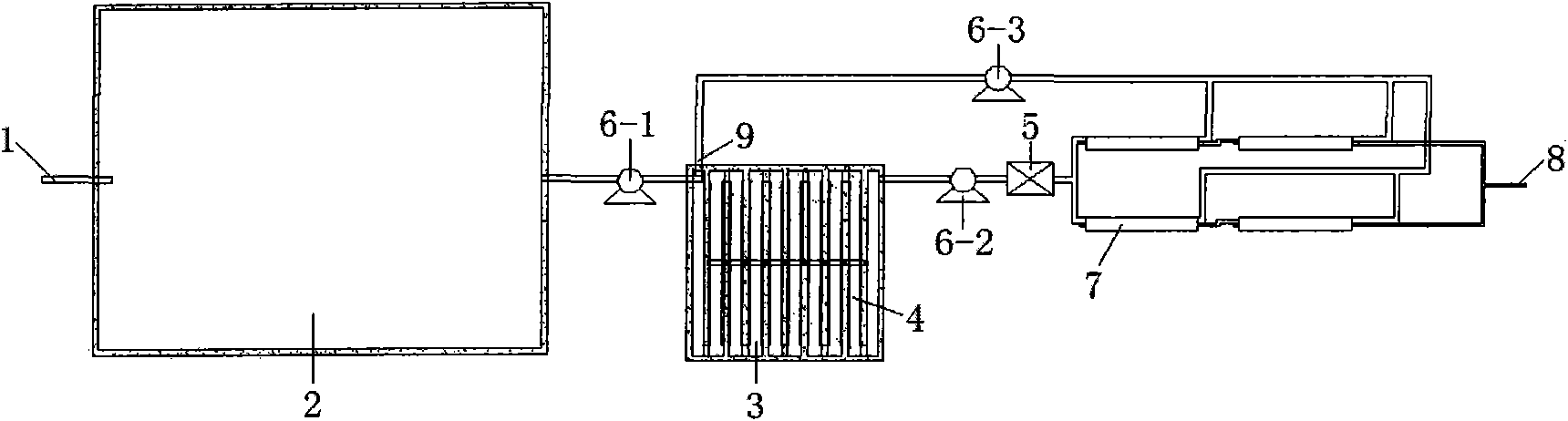

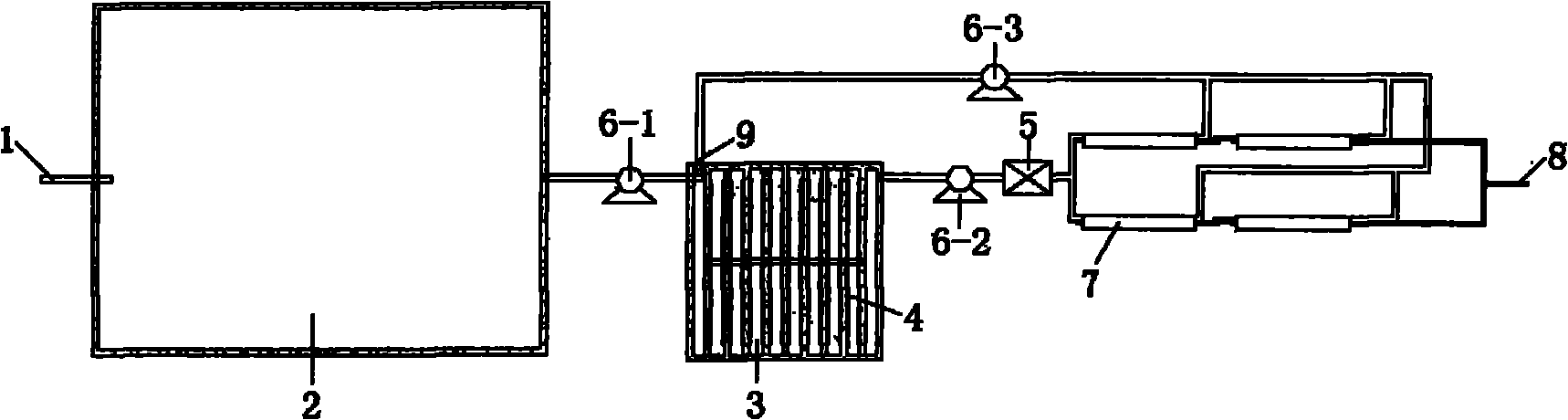

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

InactiveCN101921032AEfficient use ofLess investmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectricityElectrolysis

The invention discloses an electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater, comprising a liquid inlet pipe, an adjusting tank, an electrolytic deposition device, a three-dimensional fixed bed device, a safety filter, three circulating pumps, a membrane assembly, a clear water outlet and a condensed liquid reflex hole, wherein the connection of various components is detailed in the description. The invention has the advantages that: by combining the electrolytic deposition technology with the membrane separation technology, the device has the advantages of less investment, high handle capacity, low energy consumption, high benefit, easy industrialization and easy implementation of the comprehensive utilization of resources; the effluent discharge after reaching standards and the recycling are realized, the heavy metal resources in the wastewater are effectively recycled; and automation degree is high and manual operation is simple and convenient, the complete recovery and zero discharge of heavy metals can be basically realized and water resources are completely recycled and the wastewater is deeply purified.

Owner:PEKING UNIV

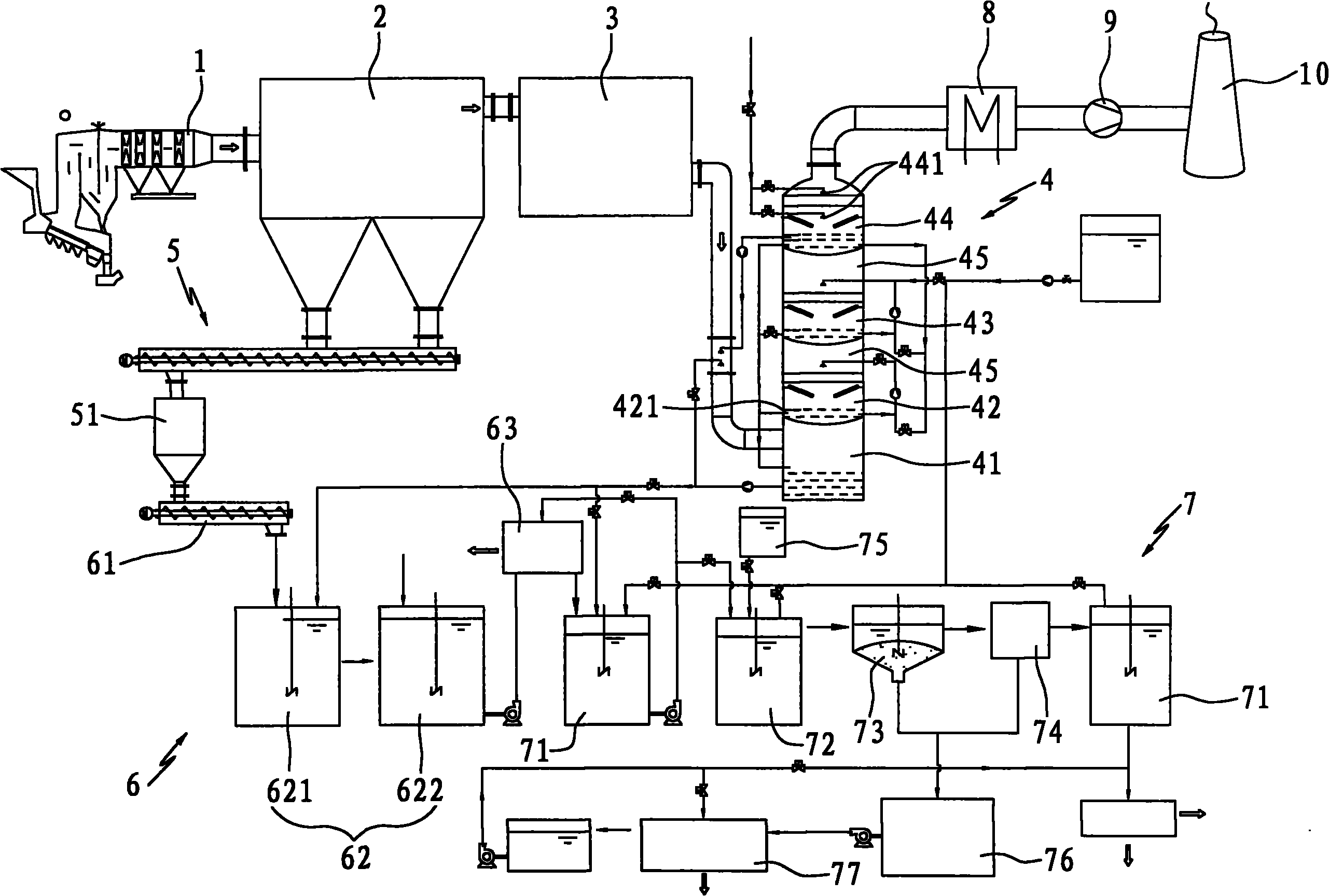

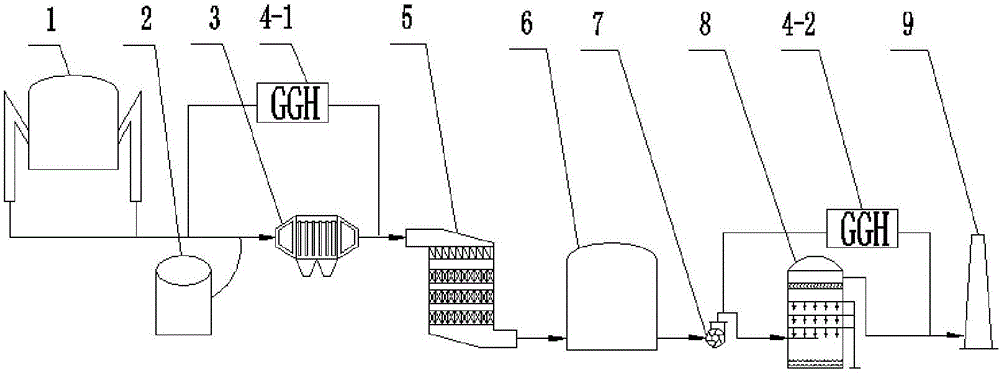

Purification system for flue gas generated by burning wastes and purification process thereof

InactiveCN101810992ASimple purification processEfficient purification processCombination devicesFlue gasSewage

The invention discloses a purification system for flue gas generated by burning wastes and a purification process thereof. The purification system comprises a flue of a refuge incinerator, a dust remover, a device for decomposing and removing dioxins, a flue gas washing tower, a fly ash collecting device, a fly ash washing and dehydrating system, a sewage treatment system, a flue gas heating device and a draught fan; one side of an inlet of the dust remover is connected with the flue, and the other side of the inlet of the dust remover is connected with the device for decomposing and removing dioxins; the fly ash collecting device is connected under the dust remover and the fly ash washing and dehydrating system; the device for decomposing and removing dioxins is connected with the lower part of the flue gas washing tower through a pipeline; an outlet of the flue gas washing tower is connected with the flue gas heating device; meanwhile, a water drain of the flue gas heating device is respectively connected with the fly ash washing and dehydrating system and the sewage treatment system; and purified flue gas is exhausted through the draught fan by using the flue gas heating device. The flue gas can meet the stricter exhaust standard by the purification treatment processes of removing dust, decomposing the dioxins, absorbing and neutralizing acid gases, removing heavy metals, deeply removing dust and the like.

Owner:瀚蓝(厦门)固废处理有限公司 +2

Thallium-containing heavy metal wastewater advanced treatment method

ActiveCN103693819AEliminate secondary pollutionLow costMultistage water/sewage treatmentPretreatment methodFiltration

The invention belongs to a thallium-containing heavy metal wastewater advanced treatment method. The method comprises the following steps: (1) pretreating thallium-containing heavy metal wastewater: adjusting the pH value of wastewater to 9.5-11.5 with alkaline, and adding a chemical thallium removing agent according to the mass ratio of the chemical thallium removing agent to thallium of (0.5-1.5):1; (2) medicating according to the mass ratio of the chemical thallium removing agent to wastewater after the reaction in step (1) for 15-30 minutes, and carrying out mixed reaction for 15-30 minutes; (3) adding liquid alkaline into the solution obtained from the step (2), adjusting the pH value to 11.0-11.5, reacting for 10-20 minutes, adding 5-50g / m<3> of flocculating agents, reacting for 10-20 minutes, carrying out solid-liquid separation by oblique plate deposition or plate frame press filtration, standing for 1-2 hours, and discharging or recycling supernate. The thallium contained heavy metal wastewater treatment method is simple in process, has no secondary pollution, is high in treatment efficiency, runs stably and low in cost, and has very high practicability.

Owner:CENT SOUTH UNIV +1

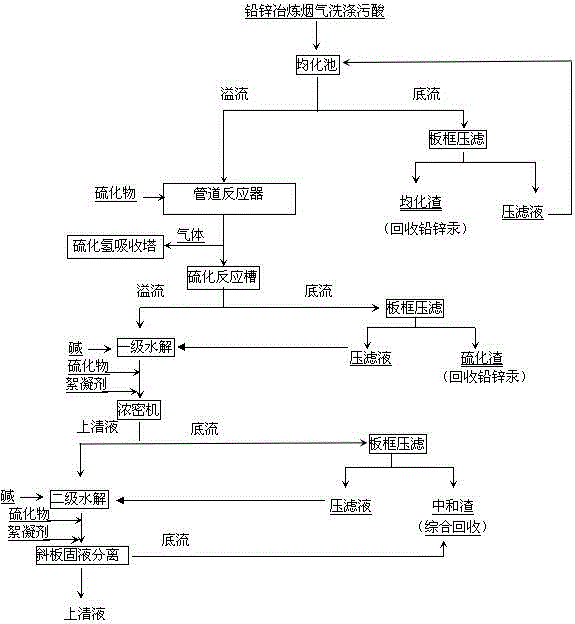

Technology for removing thallium with lead and zinc smelting flue gas washing waste acid water

InactiveCN104445733AGuaranteed deep removalRealize deep purificationWater contaminantsWaste water treatment from gaseous effluentsFiltrationIon

The invention discloses a technology for removing thallium with lead and zinc smelting flue gas washing waste acid water. The technology comprises the steps of settling the flue gas washing waste acid water in an equalizing tank, adding sulfide into the equalized waste acid water to remove most mercury, then carrying out primary treatment, regulating a pH (potential of hydrogen) value of the waste acid water after mercury is removed, adding sulfide and a flocculant in sequence for press filtration, then carrying out secondary treatment, regulating the pH value of primary supernatant purified water to 11, adding sulfide and the flocculant in sequence, and removing thallium and heavy metal ions in depth via inclined plate settling. After the technology is employed, a thallium content in the lead and zinc smelting flue gas washing waste acid water is decreased to be less than or equal to 0.000005g / L, and the technology for removing the thallium is effective and strong in industrial applicability.

Owner:ZHUZHOU SMELTER GRP

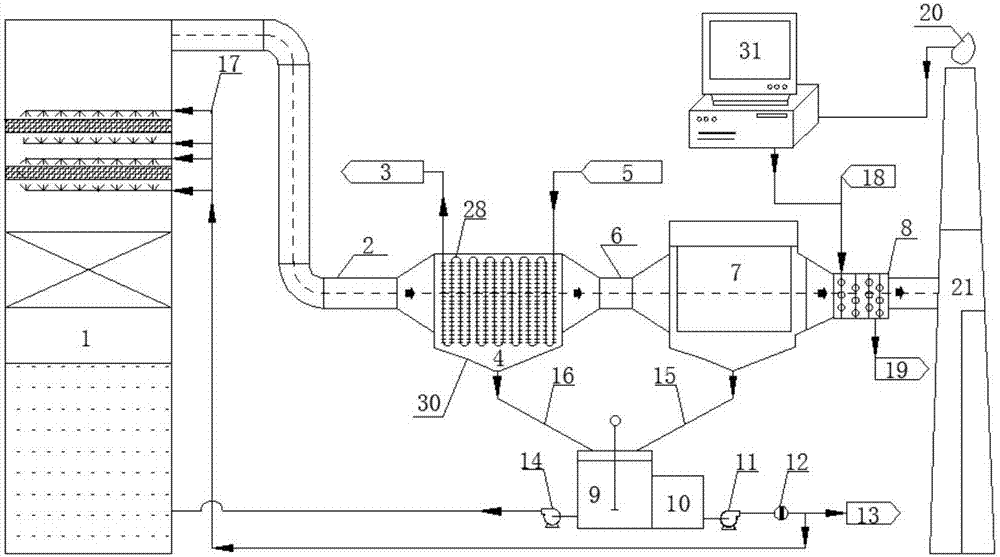

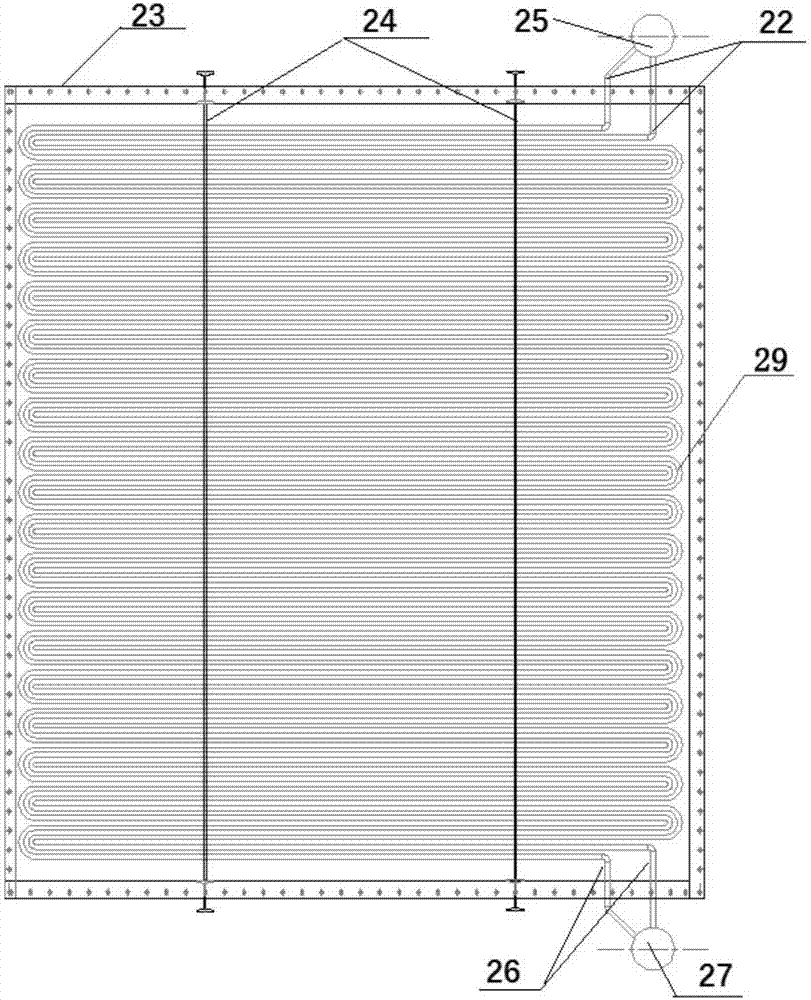

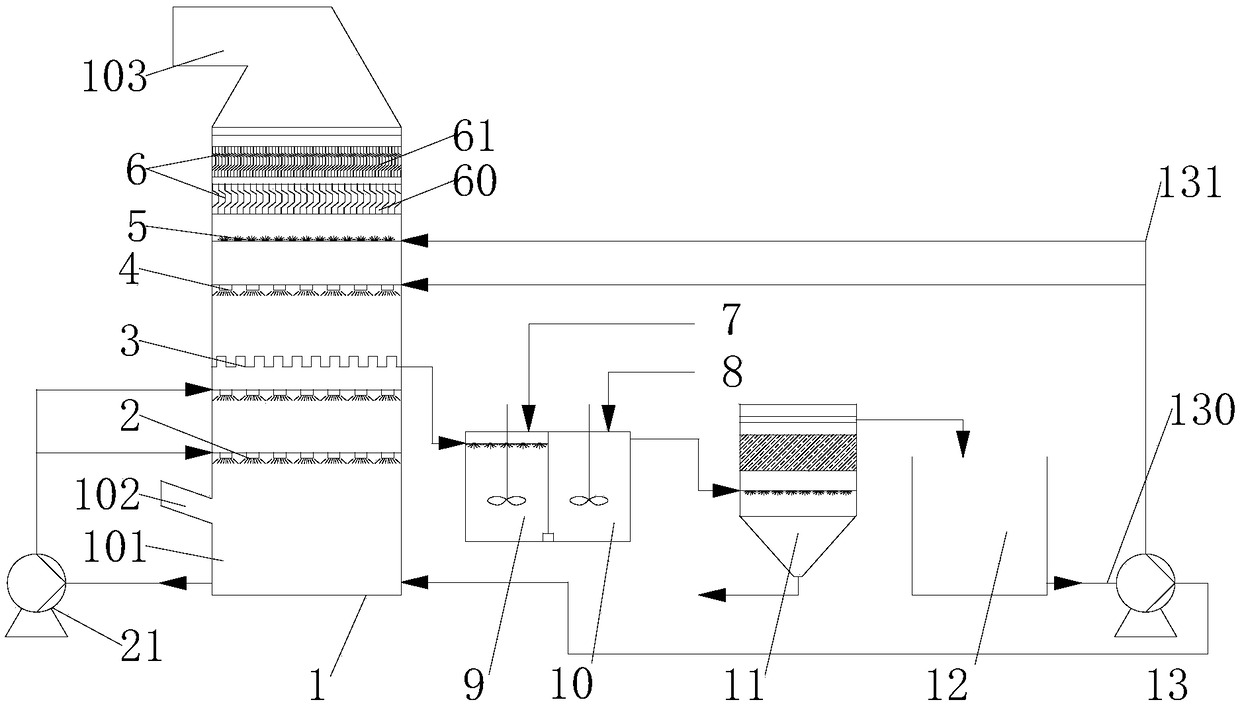

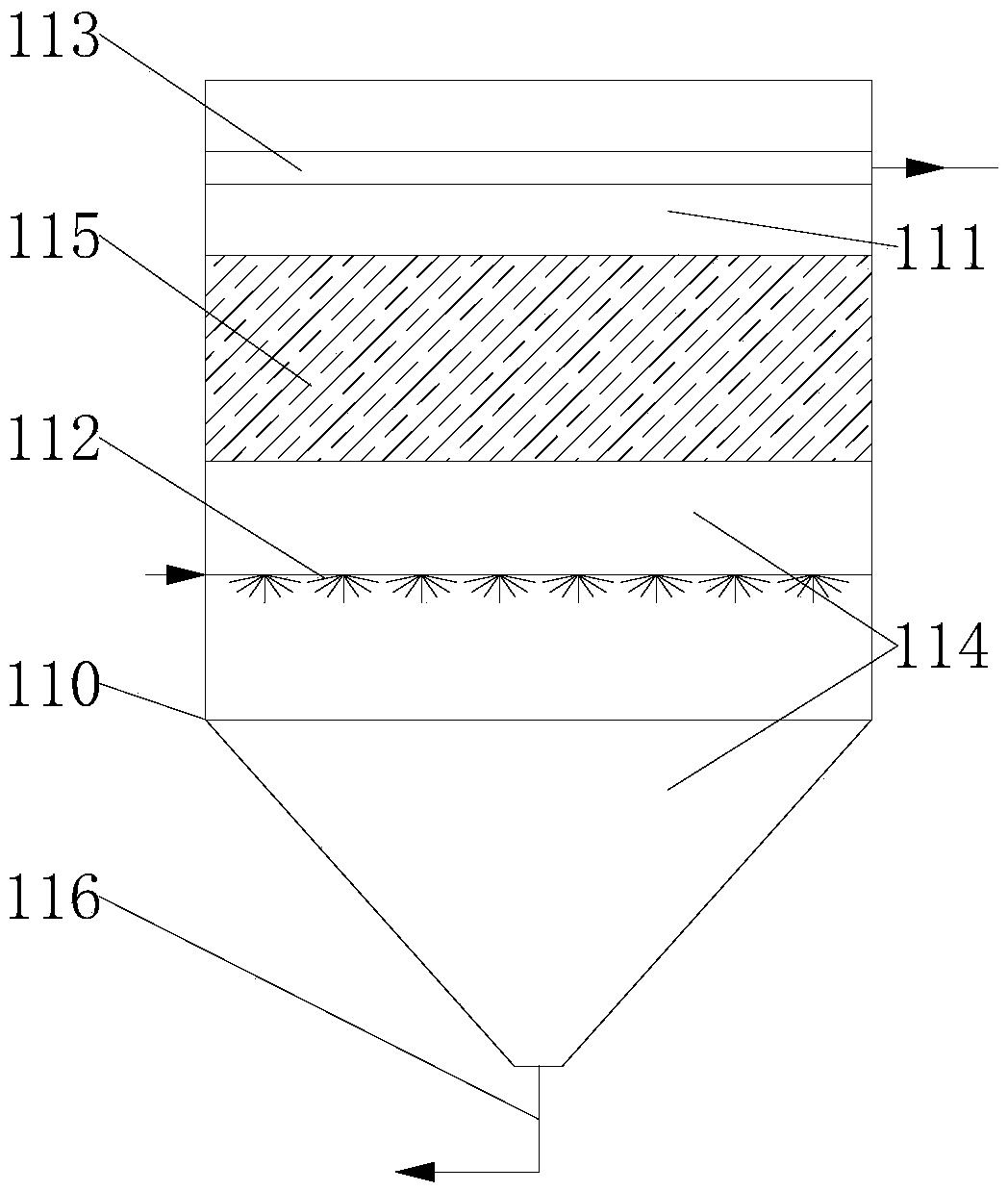

Energy-saving dust removing and intelligent regulation synergetic white smoke removing system and energy-saving dust removing and intelligent regulation synergetic white smoke removing method

ActiveCN107321124AIncrease temperatureRealize "no white" emissionGas treatmentUsing liquid separation agentParticulatesEnergy analysis

The present invention relates to an energy-saving dust removing and intelligent regulation synergetic white smoke removing system and an energy-saving dust removing and intelligent regulation synergetic white smoke removing method. The energy-saving dust removing and intelligent regulation synergetic white smoke removing system comprises a desulfurization tower, a flue gas phase-change condensation device, a wet electrostatic multi-precipitator, a flue gas heating white smoke removing device and an intelligent temperature regulation system, wherein the desulfurization tower, the flue gas phase-change condensation device, the wet electrostatic multi-precipitator, the flue gas heating white smoke removing device and the intelligent temperature regulation system are sequentially communicated, the flue gas phase-change condensation device and the wet electrostatic multi-precipitator are respectively communicated to a water discharging box, the water discharging box is communicated to the desulfurization tower and a circulation water box, and the circulation water box is communicated to a wet electrostatic multi-precipitator spraying water pipe and a demister rinsing water pipe through a self-washing filter. According to the present invention, the system has advantages of high stability, low investment, low operation cost, and simpleness; the smoke discharging temperature is intelligently regulated, such that the flue gas discharging with characteristics of high reliability, low cost and no significant visible white smoke is achieved; the water in the system can be repeatedly utilized so as to reduce the waste of the water resource, and the boiler low-grade steam is used as the heat source so as to reduce the energy consumption by more than 10%; and with the system and the method, the advantages of low energy consumption and no white smoke emission are provided while the particulate matter removing efficiency is comprehensively improved by more than 20%, and the gas-stage SOx synergistic removal efficiency is improved by more than 10%.

Owner:ZHEJIANG UNIV

Preparation method of rare earth-iron intermediate alloy for low-oxygen rare earth steel

The invention discloses a preparation method of a rare earth-iron intermediate alloy for low-oxygen rare earth steel. The preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel comprises the steps that a vacuum smelting furnace is adopted, and rare earth metal and pure iron are placed in a crucible of the vacuum furnace at the mass ratio of 1-5:5-9; vacuumizing is conducted on the vacuum furnace until the pressure of the vacuum furnace is below 20 Pa, inert gas is fed for shielding, and the process of high-temperature melting-refining and electromagnetic stirring alloying is executed, wherein the high-temperature melting temperature is 1000-1500 DEG C, the temperature of the refining process is 1400-1500 DEG C, and the time is 5-15 minutes; molten metal is poured into an ingot mold, and then the rare earth-iron intermediate alloy is obtained. By the adoption of the preparation method of the rare earth-iron intermediate alloy for the low-oxygen rare earth steel, the rare earth yield can be significantly improved, the content of the rare earth in the steel can be accurately controlled, the adding cost of the rare earth is reduced, and the plasticity, the low-temperature impact toughness, the thickness-direction property and the corrosion resistance of the steel are improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

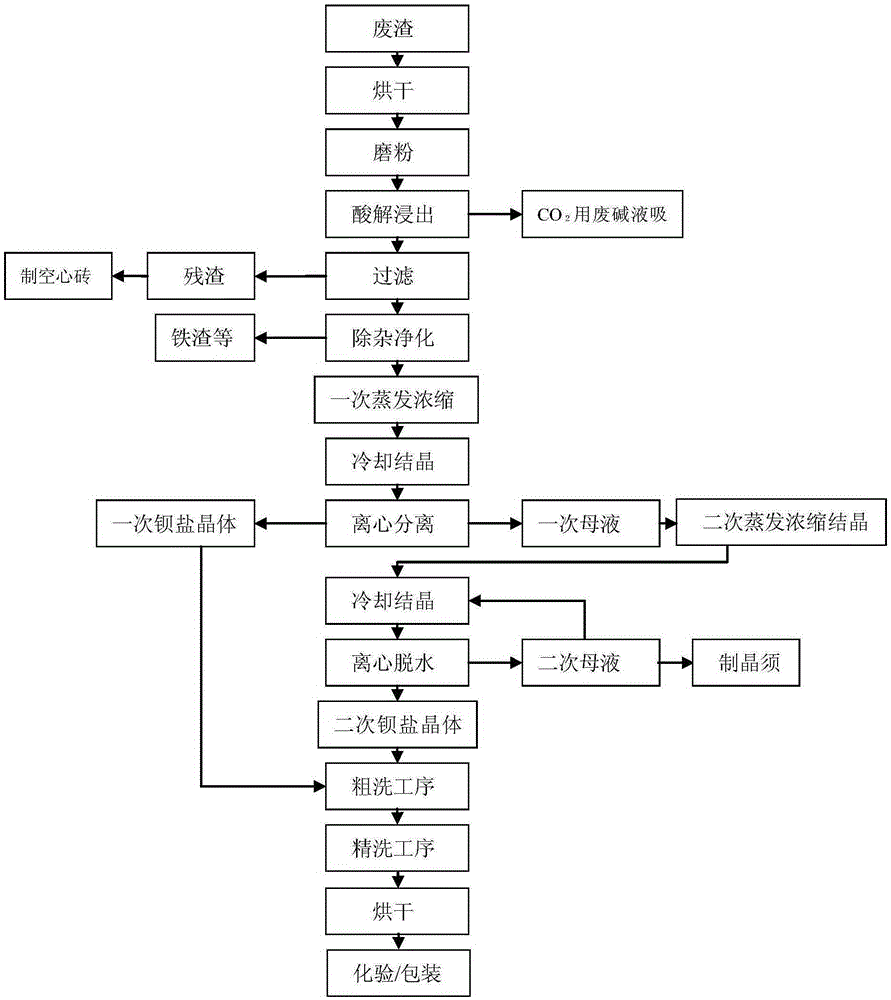

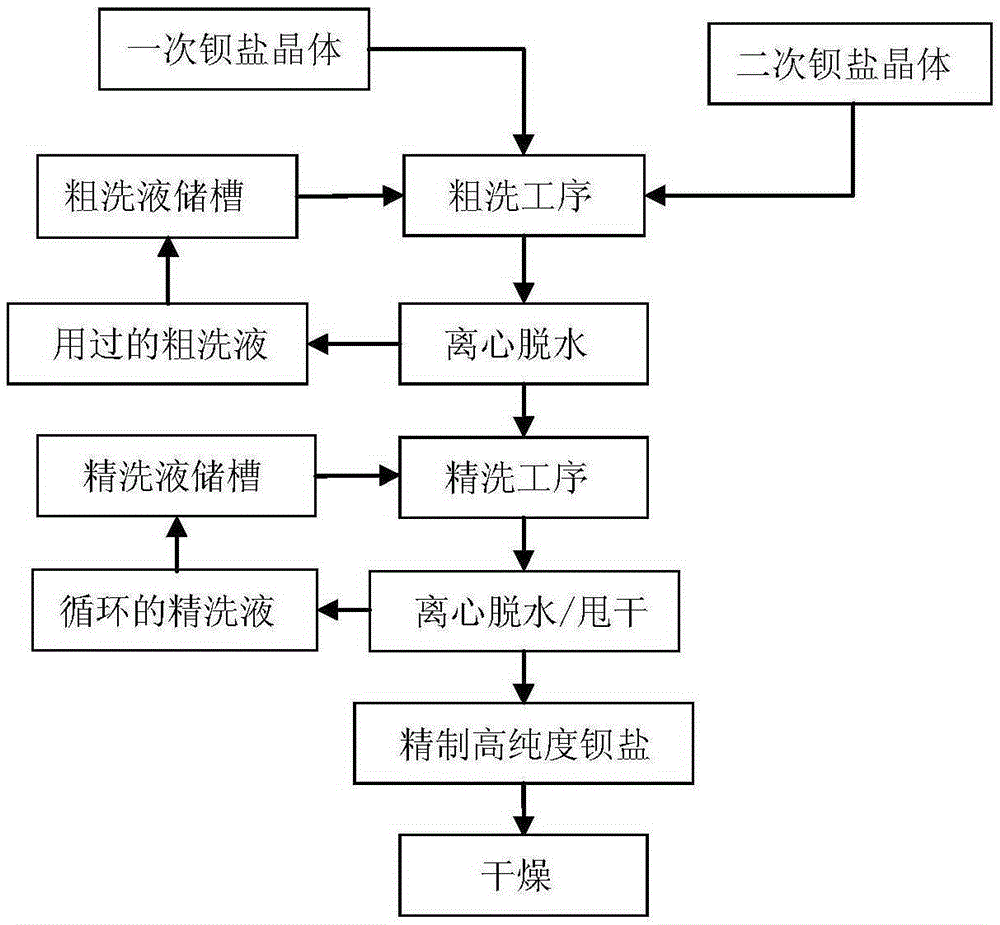

Method for preparing high-purity barium salt by using witherite-barytocalcite industrial waste residues

InactiveCN105271347ARealize deep purificationAchieving a green circular economyCalcium/strontium/barium chloridesSolid waste disposalBarium saltEvaporation

The invention discloses a method for preparing high-purity barium salt by using witherite-barytocalcite industrial waste residues. The method comprises a crushing and grinding procedure, an acid hydrolysis and leaching procedure, an impurity removal and purification procedure, an evaporation, concentration and crystallization procedure, a coarse washing procedure, a fine washing procedure and a drying, testing and packaging procedure. The barium salt with the high product purity and the low impurity content can be prepared with the method, and barium can be recovered efficiently. Meanwhile, high-temperature operation is not required by the whole-wet technology adopted in the method, reaction conditions are mild, the energy consumption is low, three-waste emission is low, thus, clean production and comprehensive utilization in the witherite-barytocalcite industrial waste residue deep-processing field can be further realized, and the economic benefit and the environmental benefit are significant.

Owner:CHONGQING CHUANYU MINING IND CO LTD

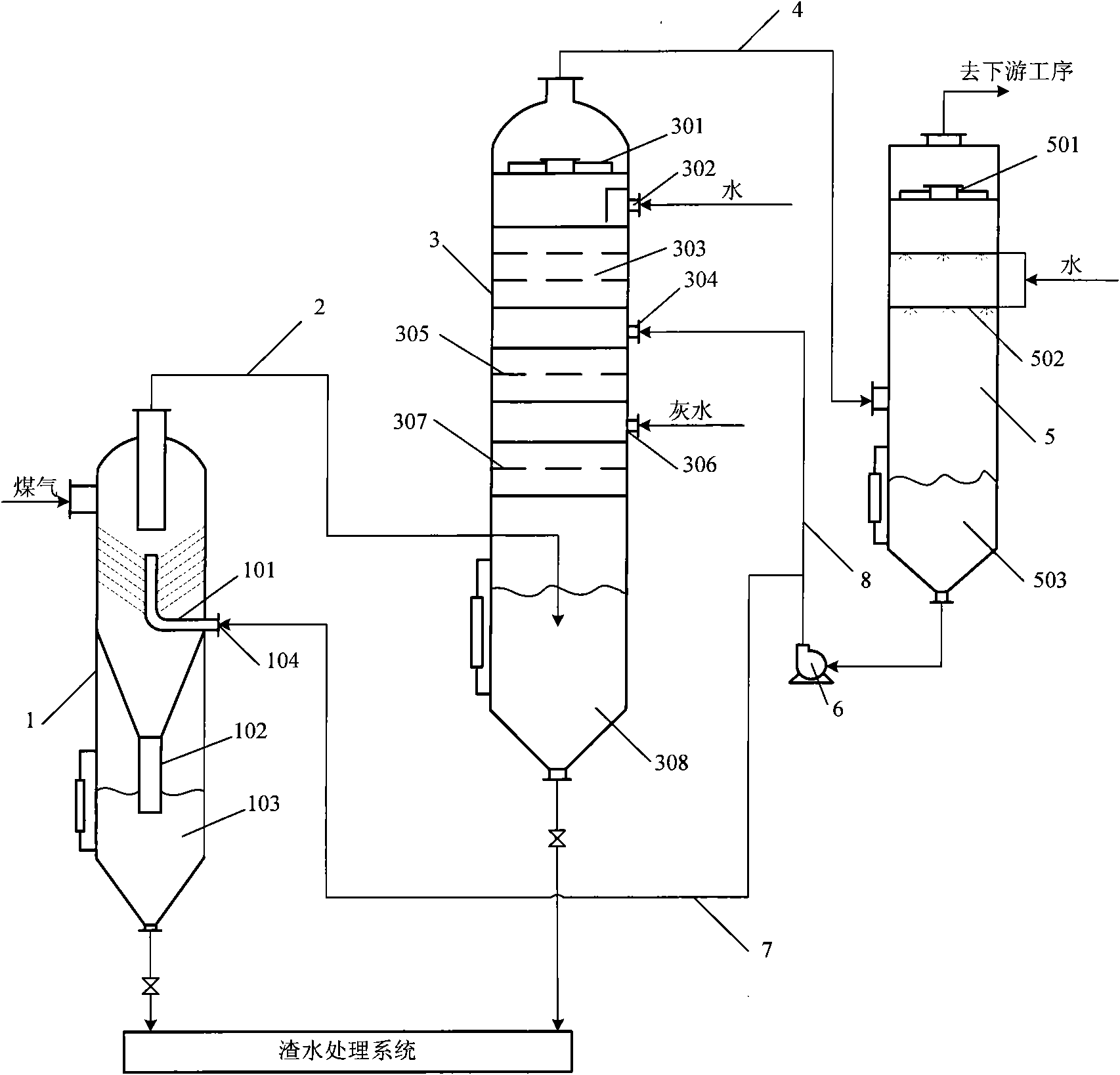

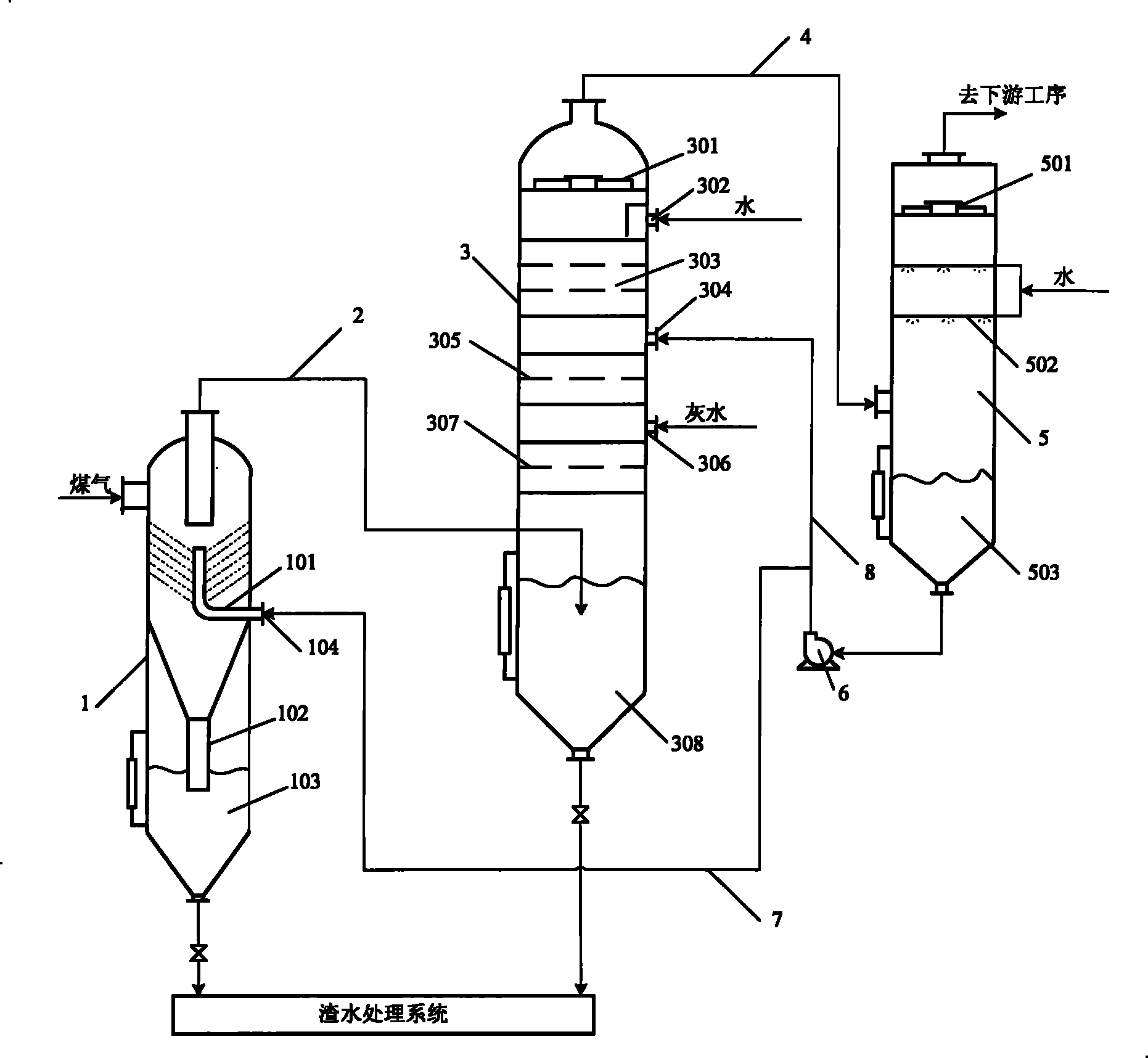

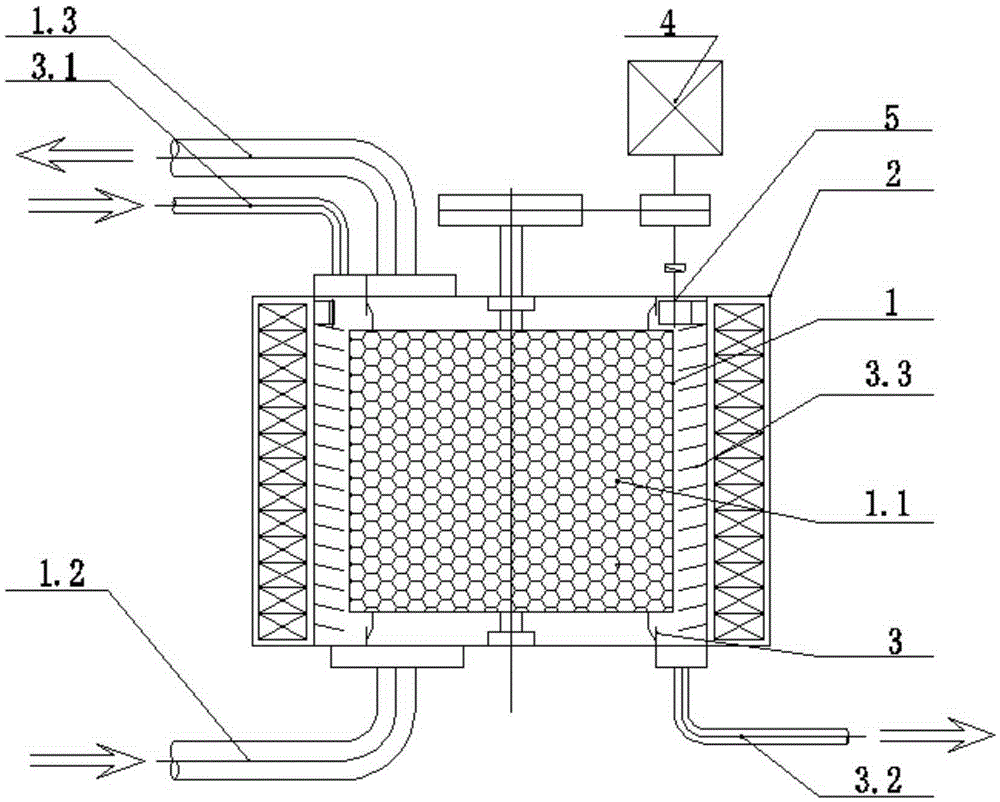

Coal gas purifying device

ActiveCN102031158ASimple structureGreat operating flexibilityCombustible gas purificationCombined combustion mitigationCycloneCyclonic separation

The invention provides a coal gas purifying device, comprising a cyclone scrubber combining cyclone separation and spray washing, a foam scrubber causing a gas outlet at the top of the cyclone scrubber to be communicated with the bottom of the cyclone scrubber by virtue of a first pipeline and a spray tower causing a gas outlet at the top of the foam scrubber to be communicated with the bottom of the foam scrubber by virtue of a second pipeline. The gas purifying device in the invention has the characteristics of simple structure and high operating elasticity, and ensures equipment maintenance to be convenient and long-periodic operation to be stable; the total pressure drop is about 5kPa, thus energy consumption is greatly reduced; and deep purification of gas is realized, so as to ensure the ash content in the purified gas to be less than 1mg / m<3>.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

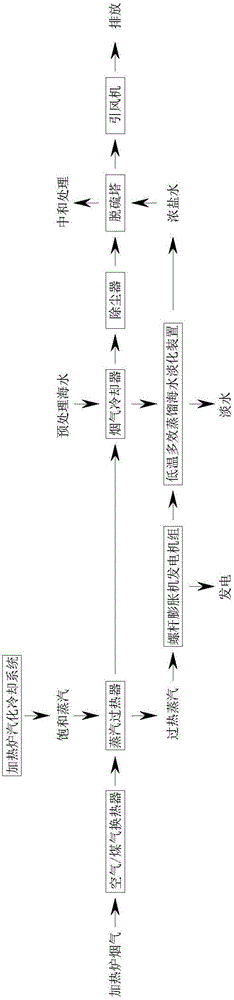

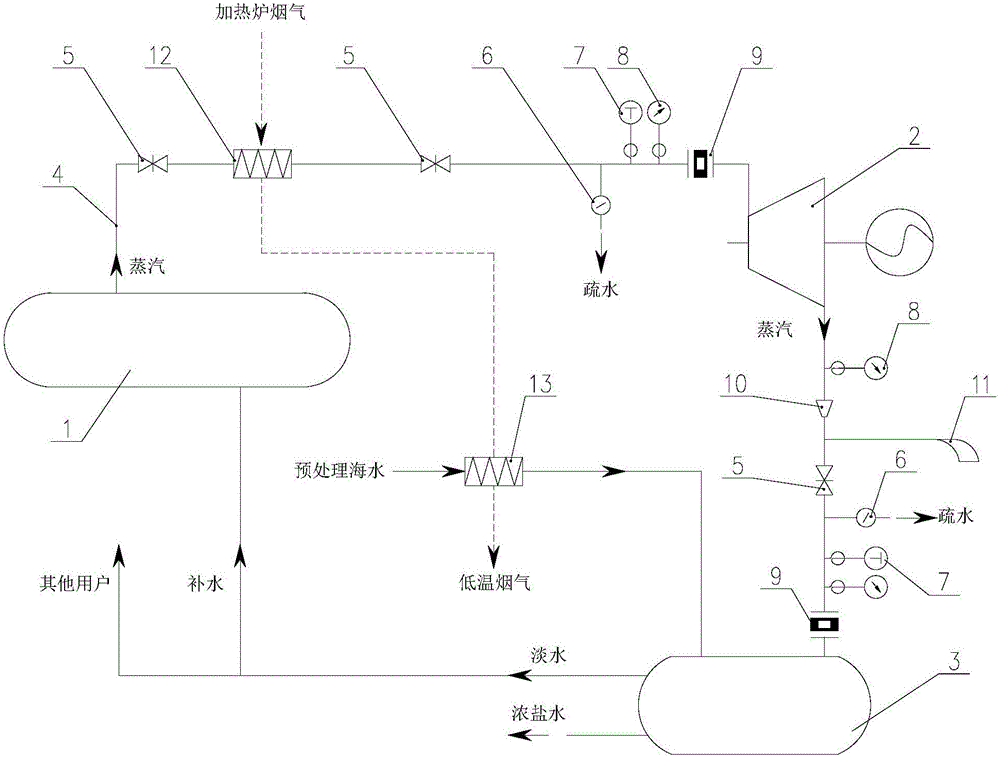

Heating furnace waste heat comprehensive utilization system and method

InactiveCN106052405ARealize cascade utilizationAddressing Adverse Effects of Power GenerationGeneral water supply conservationSeawater treatmentWater desalinationEngineering

The invention discloses a heating furnace waste heat comprehensive utilization system. The heating furnace waste heat comprehensive utilization system comprises a steam superheater, a power generator set and a sea water desalination device. The steam superheater is arranged in a heating furnace flue. Low pressure saturated steam generated by a heating furnace evaporated cooling system flows into the steam superheater and can be heated by heating furnace smoke to form superheated steam. The power generator set communicates with fluid of the steam superheater. The superheated steam generated in the steam superheater flows into the power generator set for power generation. The sea water desalination device communicated with fluid of the power generator set. The steam discharged by the power generator set flows into the sea water desalination device for sea water desalination. The invention further discloses a heating furnace waste heat comprehensive utilization method. Through the heating furnace waste heat comprehensive utilization system and method, gradient utilization of energy of the heating furnace steam is fully achieved, excessive pressure of the steam is used for power generation, and waste heat of the steam is further used for producing fresh water.

Owner:BERIS ENG & RES CORP

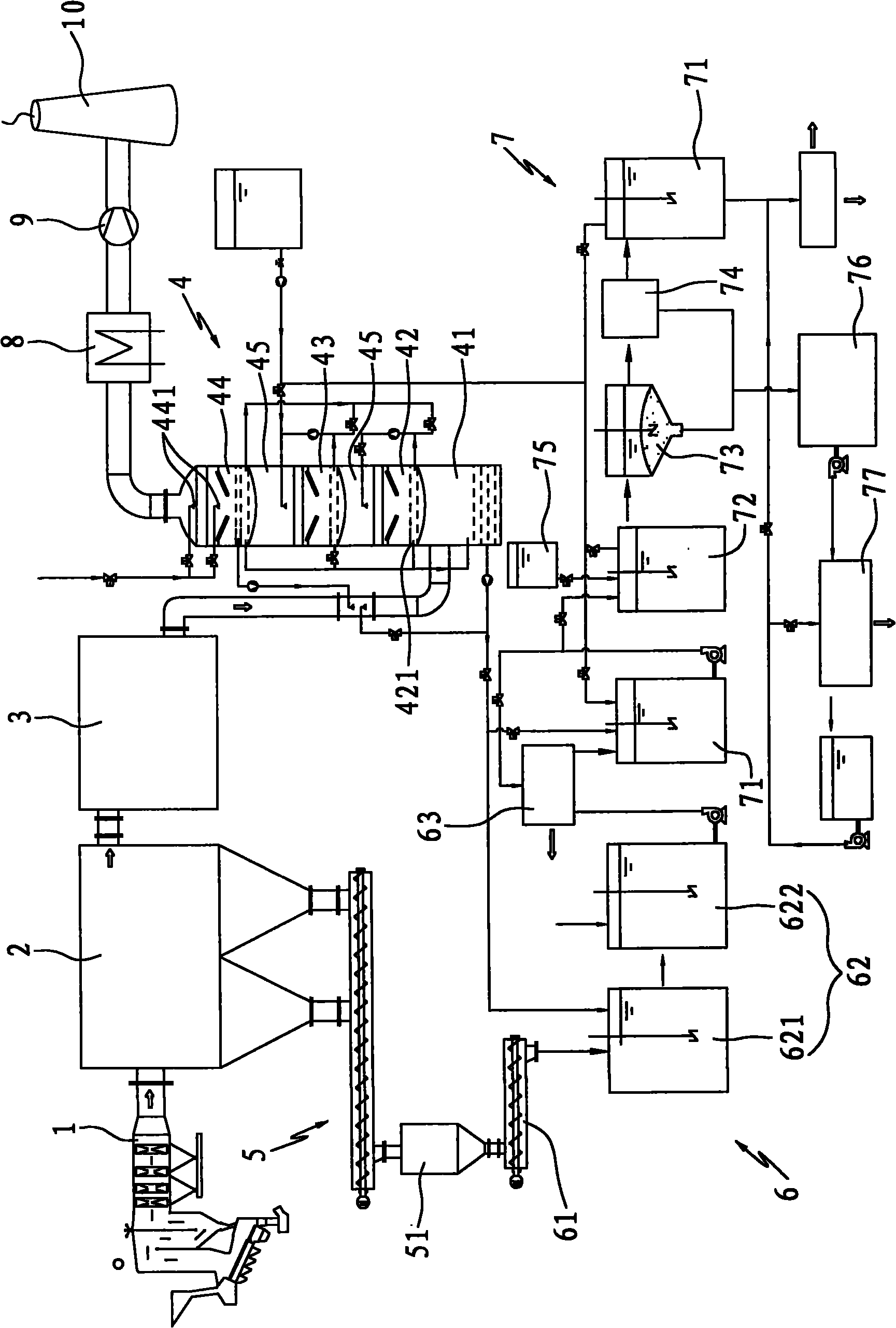

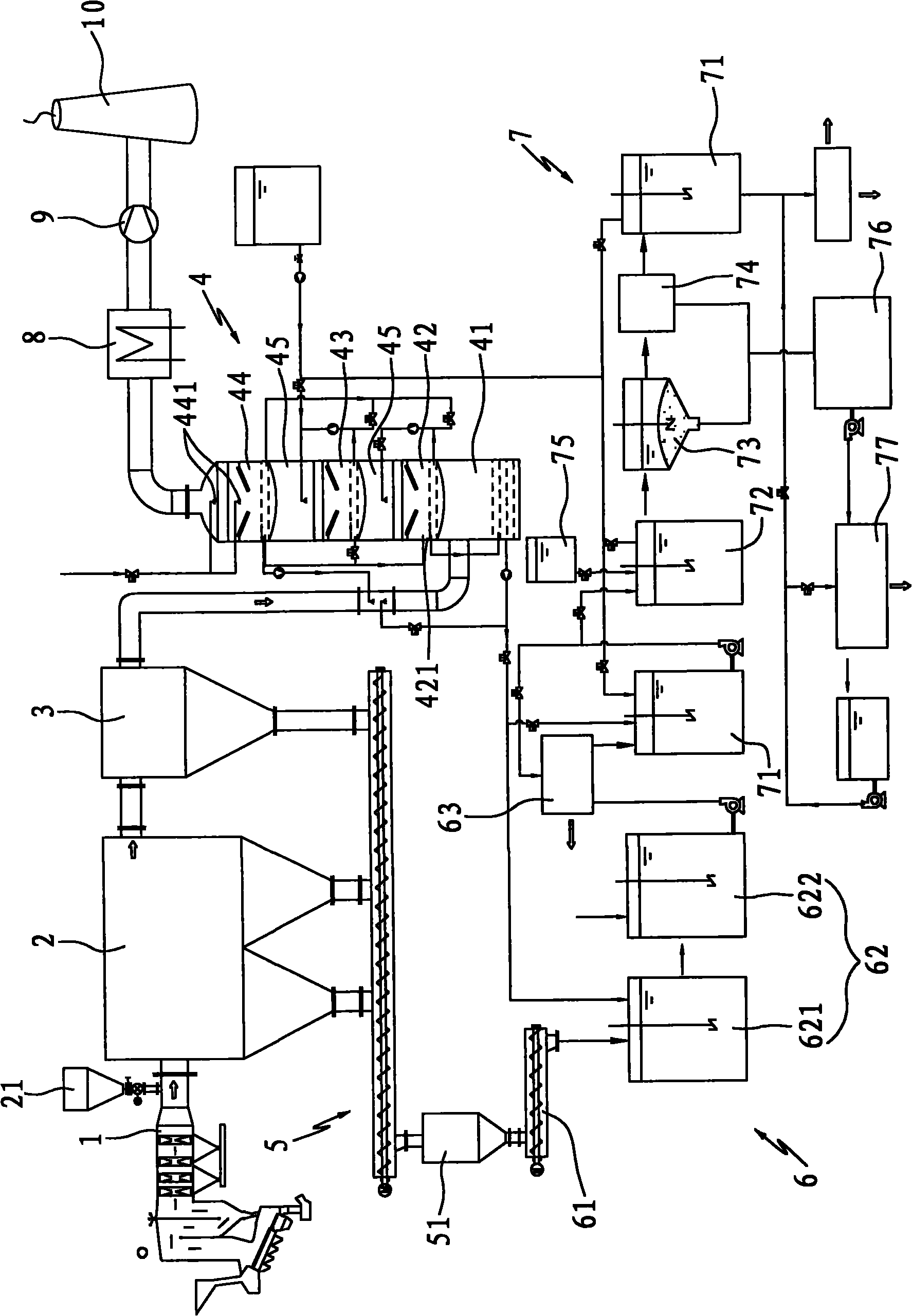

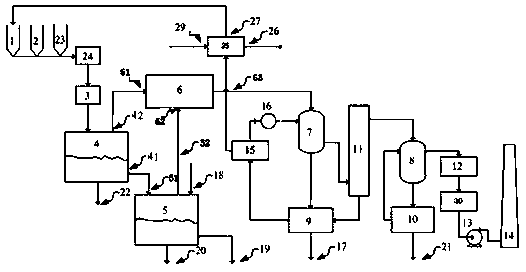

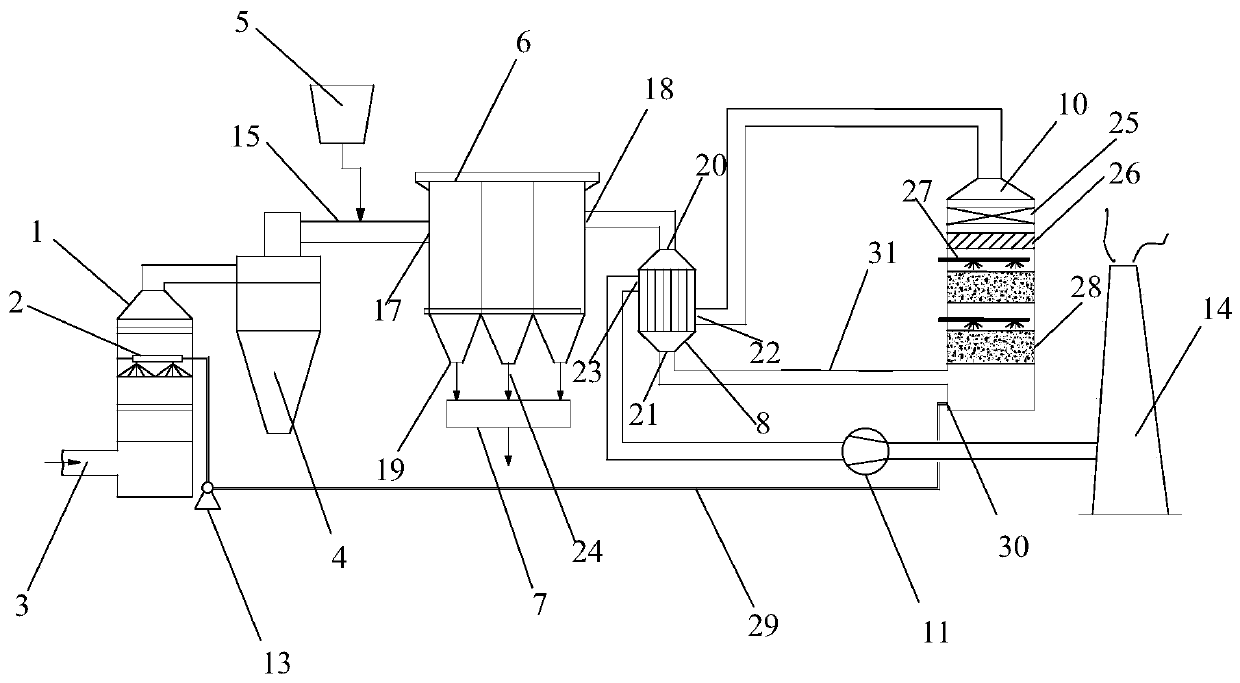

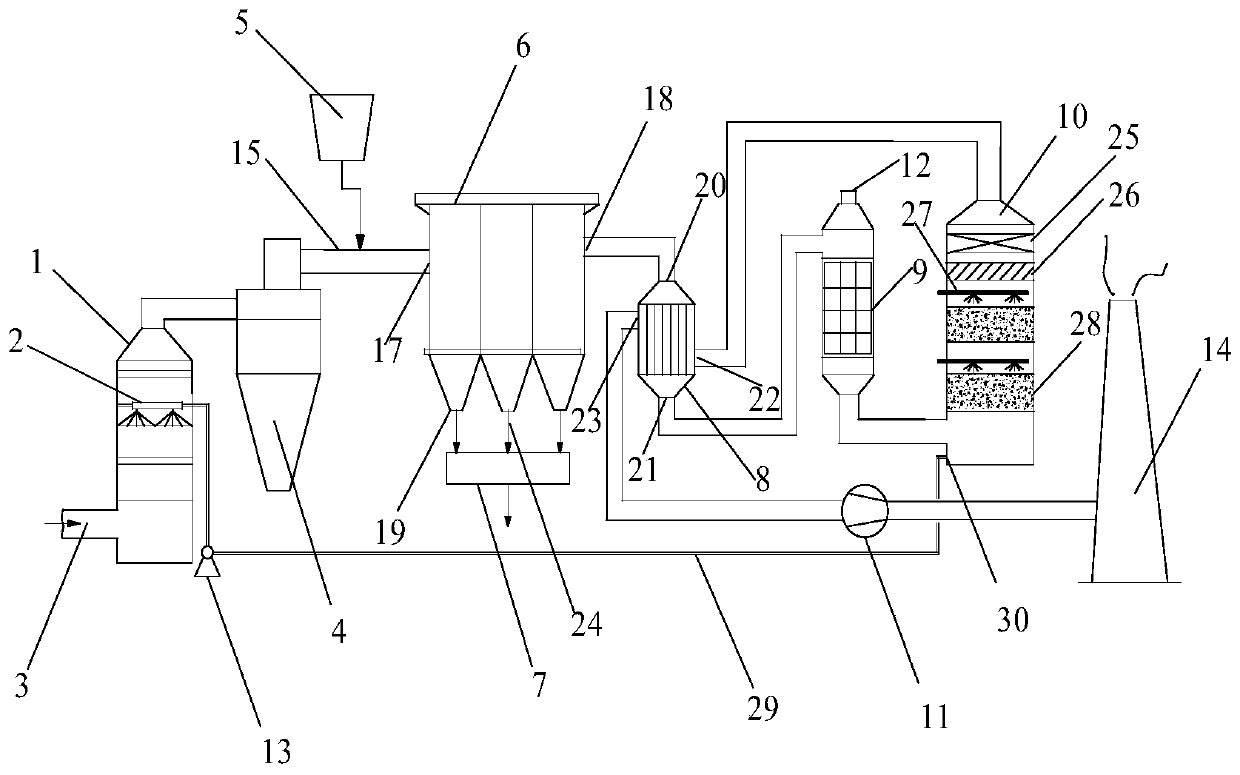

Plasma fly ash fusion treatment and metal recycling system

ActiveCN108704926ARealize deep purificationRealize harmless treatmentElectrostatic separationTransportation and packagingPollutantActivated carbon

The invention discloses a plasma bottom ash and fly ash fusion treatment and metal recycling system. The plasma bottom ash and fly ash fusion treatment and metal recycling system comprises a feeding device, a two-segment type ash fusion device, a combustion chamber, a wet type temperature reduction washing device, a demister, an activated carbon material layer and an induced draft fan. The feedingdevice is connected with the two-segment type ash fusion device. The two-segment type ash fusion device is connected with the combustion chamber. The combustion chamber is connected with the wet typetemperature reduction washing device. The wet type temperature reduction washing device is connected with the demister, and the demister is connected with the activated carbon material layer. The activated carbon material layer is connected with the induced draft fan. The two-segment type ash fusion device is adopted in the plasma bottom ash and fly ash fusion treatment and metal recycling system, harmless treatment of bottom ash and fly ash is achieved, and meanwhile alkali metal and heavy metal in the bottom ash and the fly ash and other metal reduced in a fusion furnace are recycled; through the combustion chamber, it is guaranteed that combustible components in smoke and other pollutants are sufficiently removed; and through the wet type temperature reduction washing device, capturingrecycling of the alkali metal, the heavy metal and other volatile salt substances and deep purification of smoke are achieved.

Owner:加拿大艾浦莱斯有限公司 +1

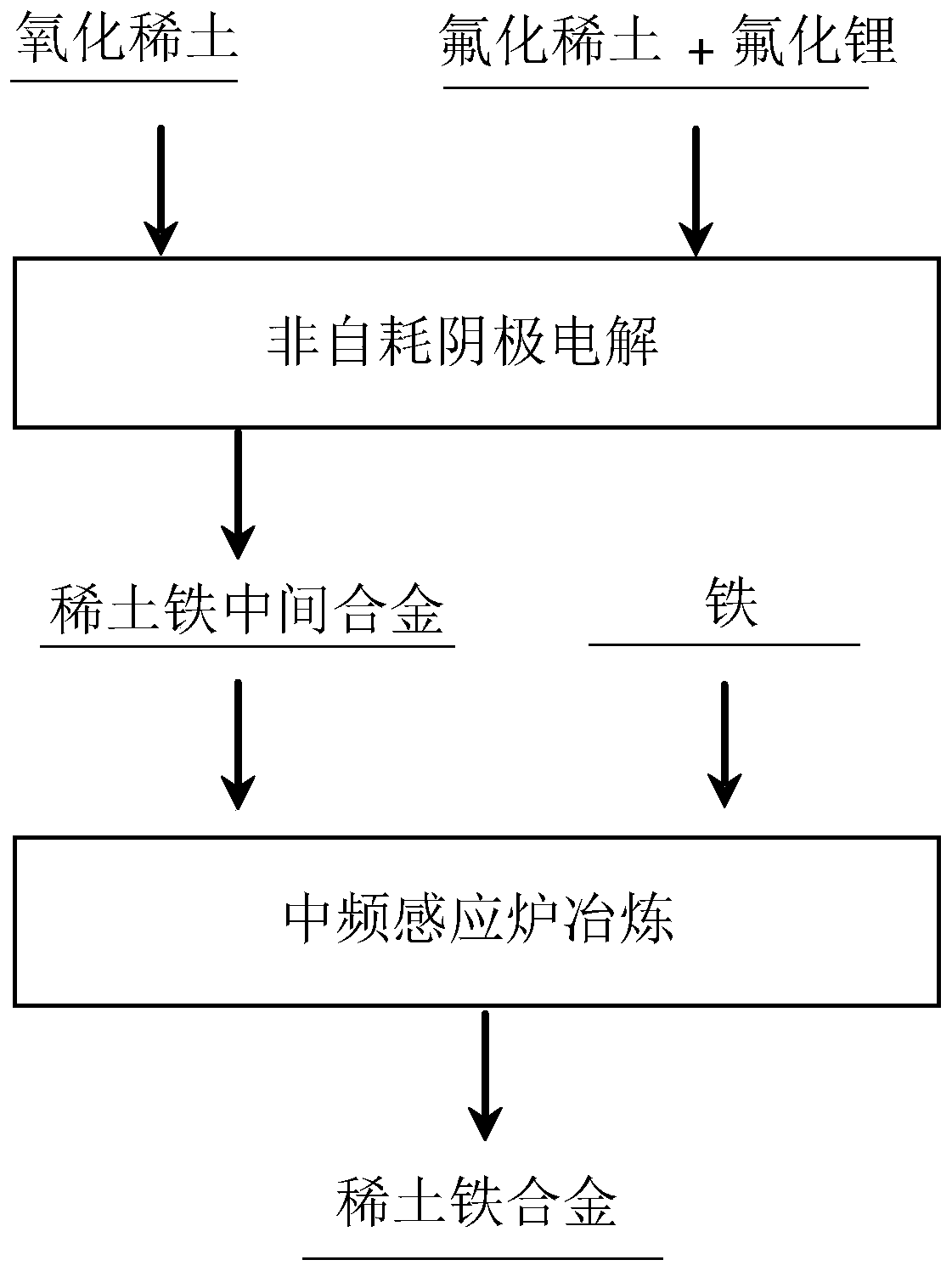

Preparation method of rare earth ferroalloy

ActiveCN111411372AThe composition is uniform and stableReduce segregationInduction furnaceLithium fluoride

The invention discloses a preparation method of a rare earth ferroalloy. The preparation method of the rare earth ferroalloy comprises the steps that a rare earth iron immediate alloy is prepared by non-self-consuming cathode electrolysis; an electrolyte is loaded in an electrolytic cell, a graphite carbon plate is used as an anode, a tungsten or molybdenum material is used as an cathode, and a crucible under the tungsten and molybdenum cathode is used as a receiver; in an electrolyte system of rare earth fluoride and lithium fluoride molten salt, rare earth oxide and iron are used as raw materials, then a direct current is passed for electrolysis, and the rare earth iron immediate alloy is obtained in the receiver; and the rare earth iron immediate alloy and iron are put into the crucibleas the raw materials, and the rare earth iron immediate alloy is further smelted by a melting and mixing method in a medium frequency induction furnace to obtain the rare earth ferroalloy. The rare earth ferroalloy obtained by the preparation method has uniform and stable composition, low impurity element content and close density and melting point to the density and melting point of steel, and the rare earth ferroalloy is easy to be added to the steel; and the rare earth ferroalloy can fundamentally solve the problem of effective addition of rare earth in the steel and can accurately controlthe content of the rare earth in the steel.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Filter core element for electromagnetic filter and purifying method thereof

ActiveCN105396364AClean thoroughlyNo pollution in the processFiltration separationElectromagnetic interferenceDrive motor

The invention provides a filter core element for an electromagnetic filter. The filter element comprises an inner layer and an outer layer, wherein the inner layer is a rotary drum filter core, the outer layer is an outer drum with solenoid coils, two ends of the rotary drum filter core are respectively provided with a technological lubricating fluid inlet and a technological lubricating fluid outlet, one end of the rotary drum filter core is also connected with a driving motor, a sealed collection chamber is located between the inner layer and the outer layer, and the solenoid coils are located out of the collection chamber. The invention also provides a purifying method for the filter core element for the electromagnetic filter. With the filter core element for the electromagnetic filter and the purifying method, the problem of generation of a great amount of waste water in the process of backwashing of the filter core is overcome on the premise that high-efficiency technological performance of the electromagnetic filter is maintained.

Owner:WISDRI ENG & RES INC LTD

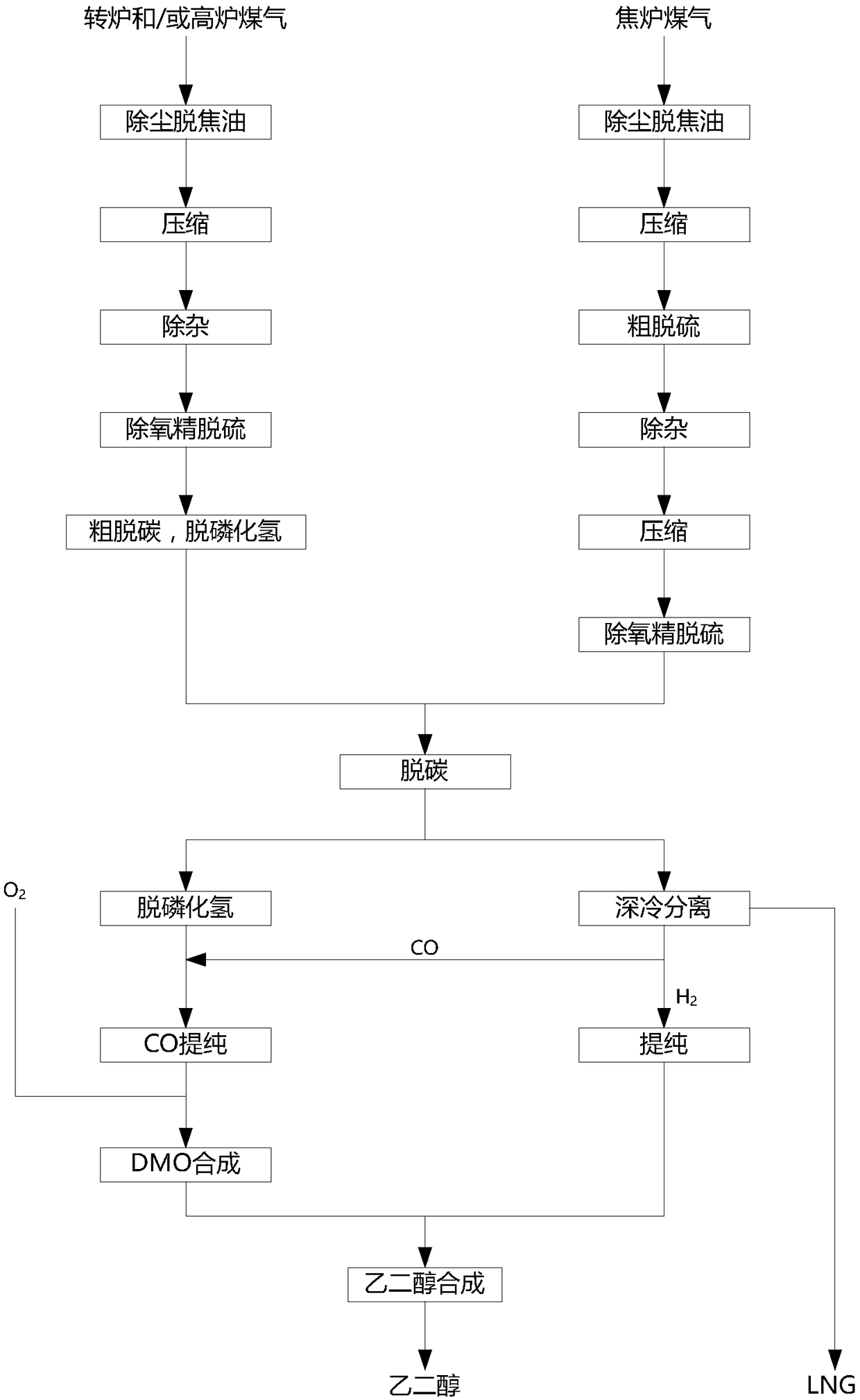

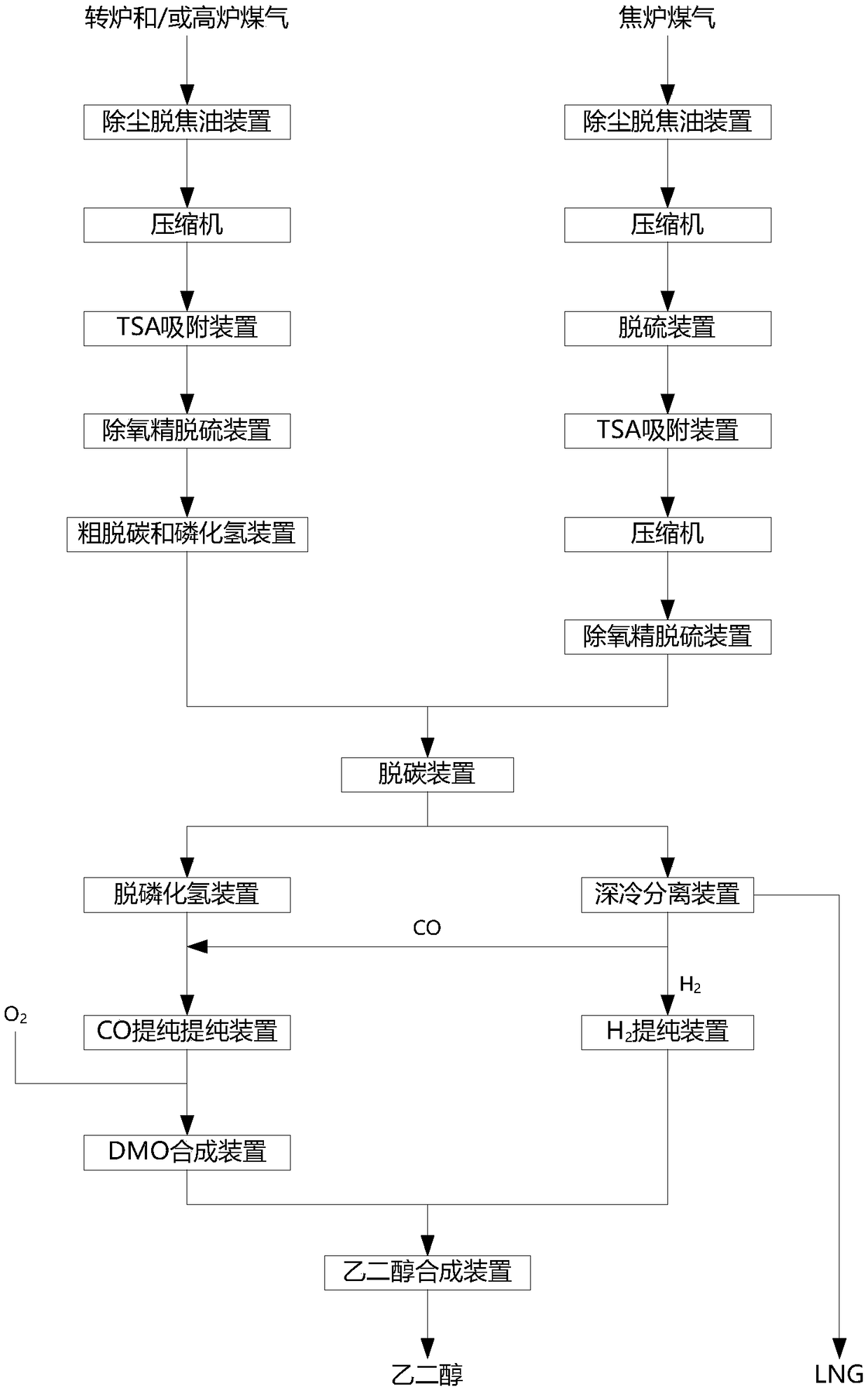

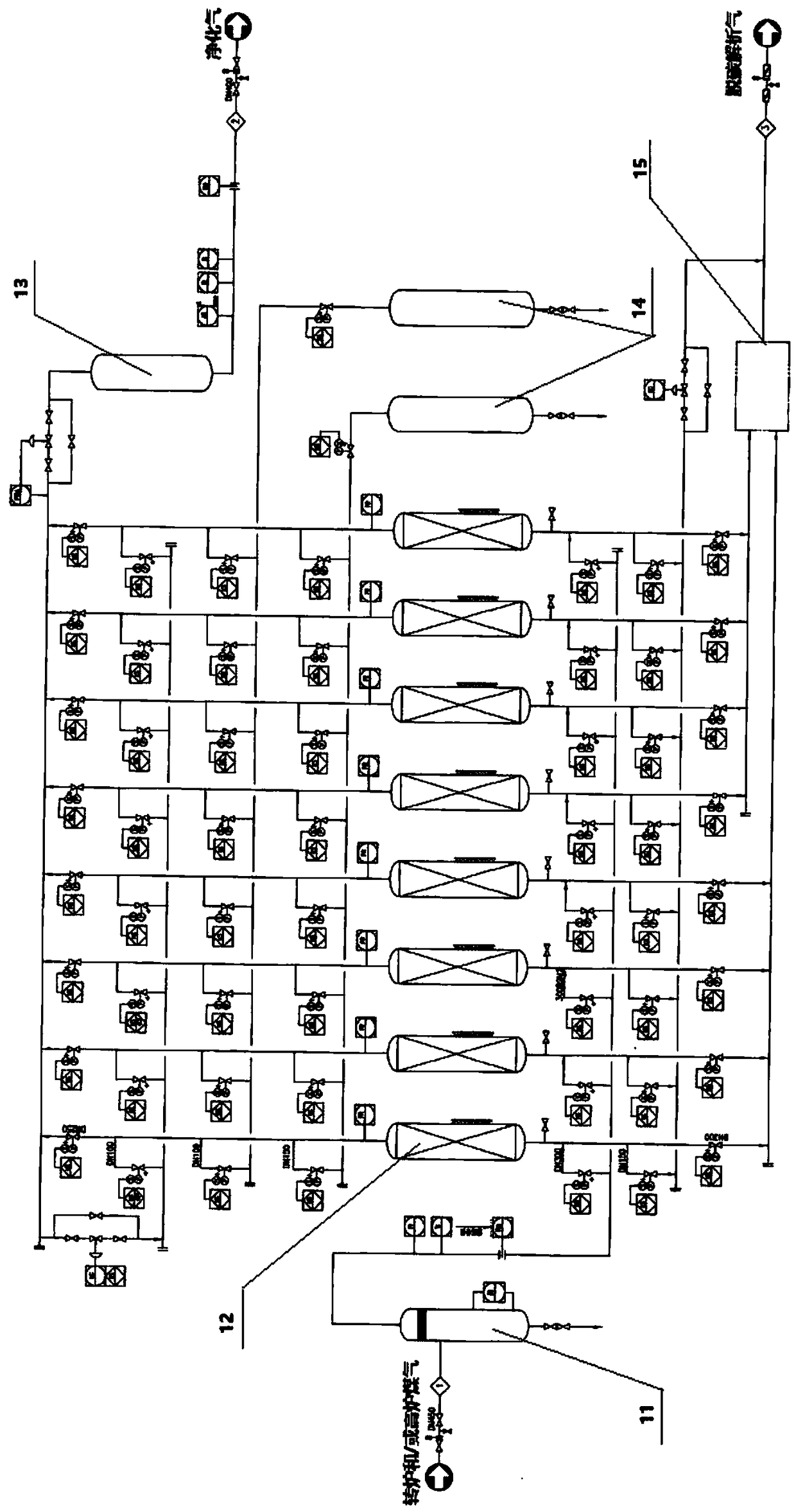

Method for synthesis of glycol and co-production of LNG by using coke oven gas and converter and/or blast-furnace gas

ActiveCN109111341AFull and efficient useReduce wasteOrganic compound preparationGaseous fuelsHydrogenTar

The invention relates to a method for synthesis of glycol and co-production of LNG by using coke oven gas and converter and / or blast-furnace gas, belonging to the technical field of chemical engineering. According to a technical scheme in the invention, the method comprises the following steps: subjecting coke oven gas to dust removal and tar removal treatment, and then performing compression treatment, and then performing crude desulfurization; removing impurities in the coke oven gas having undergone desulfurization treatment; subjecting the gas having undergone impurity removal to compression, fine desulfurization and O2 removal; then removing CO2 gas in the gas by using an amine process; carrying out cryogenic separation to obtain the product LNG, separating H2 and CO-rich gas at the same time, and then purifying H2; then subjecting converter and blast-furnace gas to dust removal and tar removal treatment; then carrying out compression and impurity removal, subjecting the gas having undergone impurity removal to fine desulfurization and O2 removal, and then removing CO2 gas in the gas; and combining the purified gas with the CO-rich gas, purifying the CO gas, subjecting the purified CO to esterification-carbonylation cyclic synthesis to produce DMO, and producing glycol from DMO and purified hydrogen. The method of the invention is applied to the synthesis technology of glycol for the first time.

Owner:戴乐亭 +3

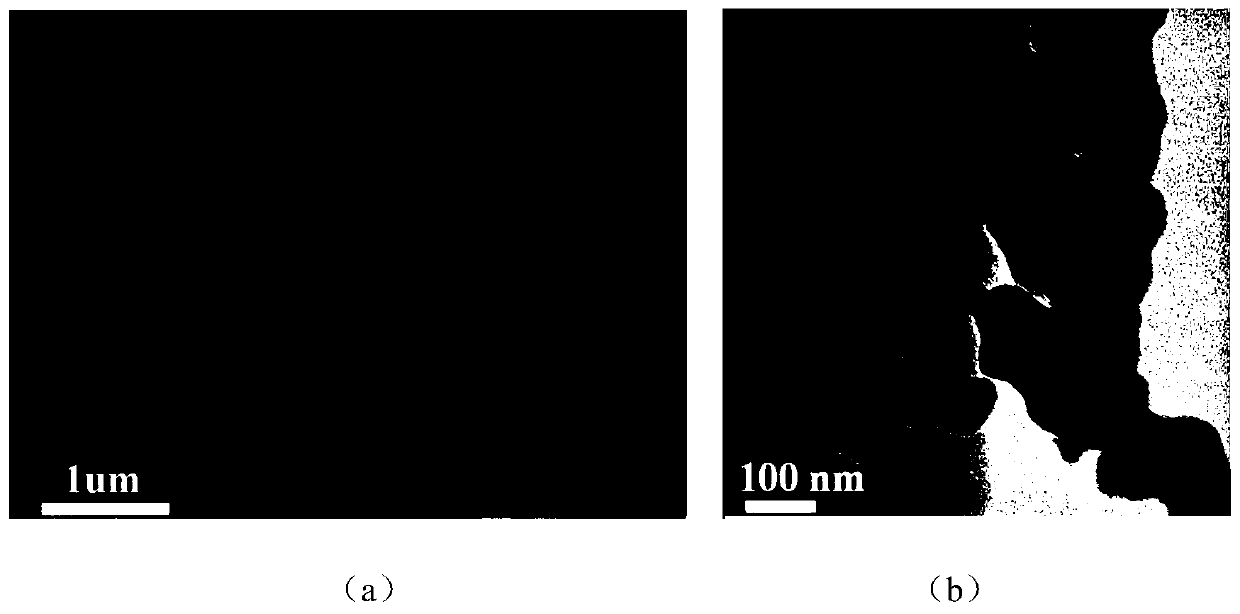

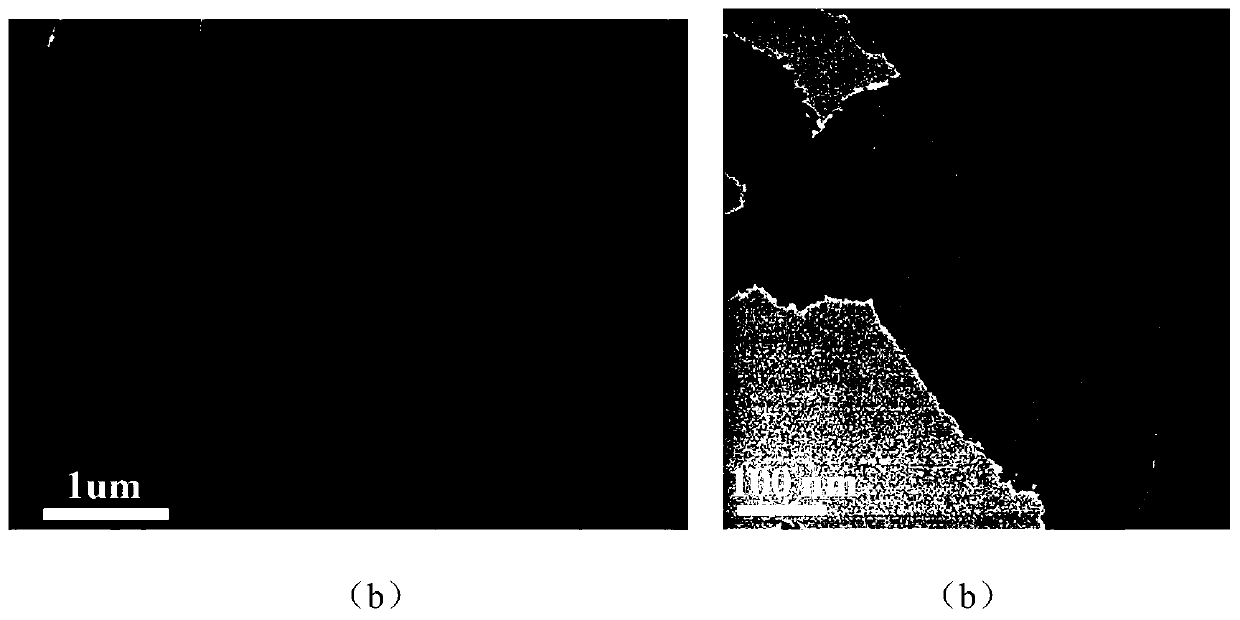

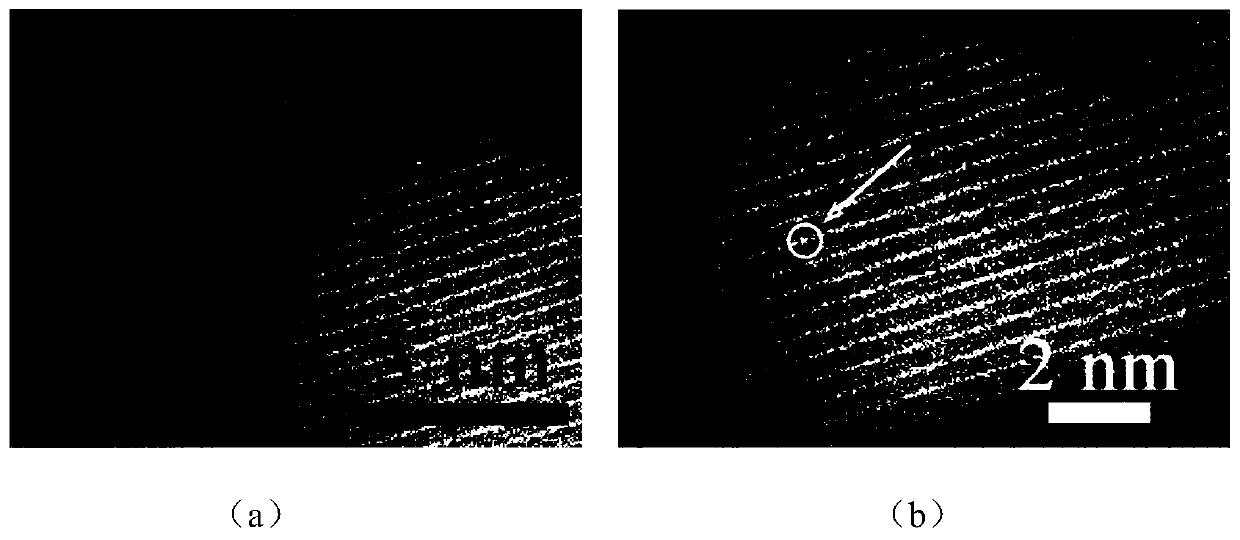

Monodisperse platinum-based two-dimensional metal hydroxide, and in situ synthesis method and application thereof in purification of volatile oxygen-containing hydrocarbons

ActiveCN110090640AStable complexationRich in surface hydroxyl functional groupsGas treatmentDispersed particle separationIonChemistry

The invention discloses a monodisperse platinum-based two-dimensional metal hydroxide, and an in situ synthesis method and an application thereof in the purification of volatile oxygen-containing hydrocarbons. A triblock copolymer poly(ethylene oxide)-polypropylene oxide-poly(ethylene oxide) is dissolved into deionized water, so taht a transparent and clear solution can be formed through stirring;hexamethylene tetramine is added, and then cerium or cobalt salts are added after uniform stirring; glycol is added after uniform stirring; a chloroplatinic acid hexahydrate-glycol solution is addedafter uniform stirring, so that a mixed solution can be obtained after uniform stirring; and heating reflux reaction is performed on the mixed solution in a microwave generator, and centrifugation androasting are performed after complete reaction, so that the monodisperse platinum-based two-dimensional metal hydroxide can be obtained. The prepared catalytic material has atomic-scale dispersed platinum active sites and shows excellent low temperature purifying capabilities of volatile oxygen-containing hydrocarbons; and the related catalyst synthetic method is simple and low in raw material price, and has good industrial application prospects.

Owner:XI AN JIAOTONG UNIV

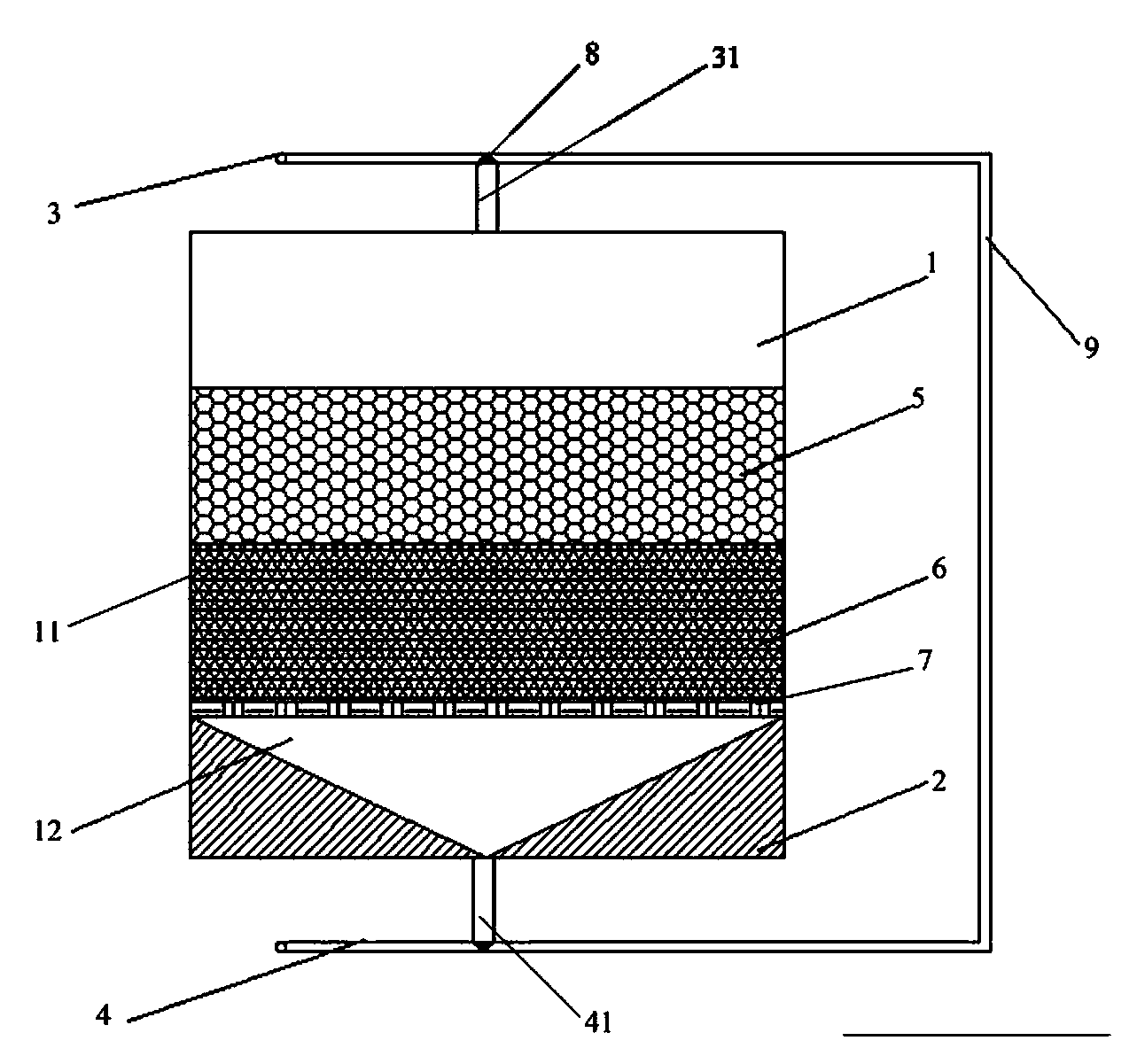

Device for drinking water treatment

InactiveCN104355480ARealize deep purificationDesign scienceTreatment using aerobic processesWater/sewage treatmentFiberActivated carbon

The invention discloses a device for drinking water treatment. The device comprises a water storage tank, a base, a high-density fiber layer, a high-density activated carbon layer and a membrane separation layer, wherein the water storage tank is positioned on the base; the high-density fiber layer, the high-density activated carbon layer and the membrane separation layer are arranged in the water storage tank from top to bottom. The device has the benefits that through integrating a composite filtering technology and a membrane treatment technology, an inseparable organic whole body which is efficiently treated under an synergistic effect is formed; a composite filtering layer is arranged inside the water treatment device in the water flow direction; under the double filtering action, a water purifying process in the water treatment device is divided into a plurality of purifying areas to form multiple stages of filtration; pollutants in water are filtered and removed level by level to realize the deep purification of the drinking water.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

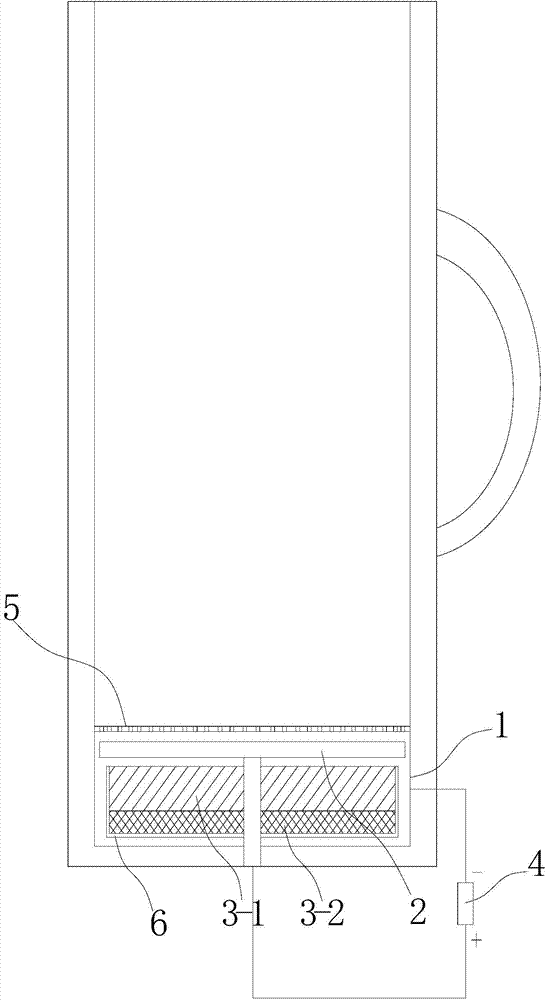

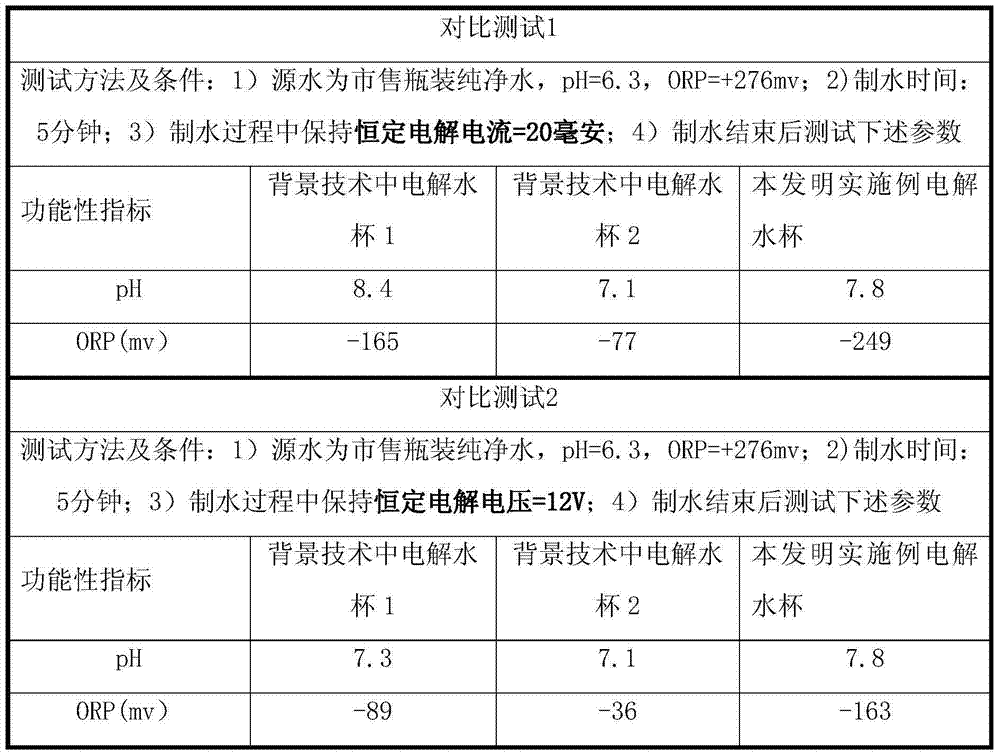

Purification cup

ActiveCN103767465ASave electricityLower redox potentialWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentFiltrationWater flow

The invention relates to a purification cup and belongs to the technical field of electrochemistry and membrane filtration water treatment. The cup comprises an inner container and a power source, wherein the inner container is provided with a negative electrode and a positive electrode, and the positive electrode is arranged at the bottom in the inner container. The positive electrode and the negative electrode are connected with an anode and a cathode of the power source respectively. The portion close to the positive electrode in the inner container is provided with at least two levels of filtering layers with the filter precision from low to high in the water flow direction. The filtering layers have conductivity and are located between the negative electrode and the positive electrode. According to the water cup, electrochemistry water treatment and filtration are integrated to form an organic whole in which electrochemistry treatment and filtration are inseparable and cooperative, and therefore deep purification of source water is achieved.

Owner:DALIAN SHUANGDI TECH

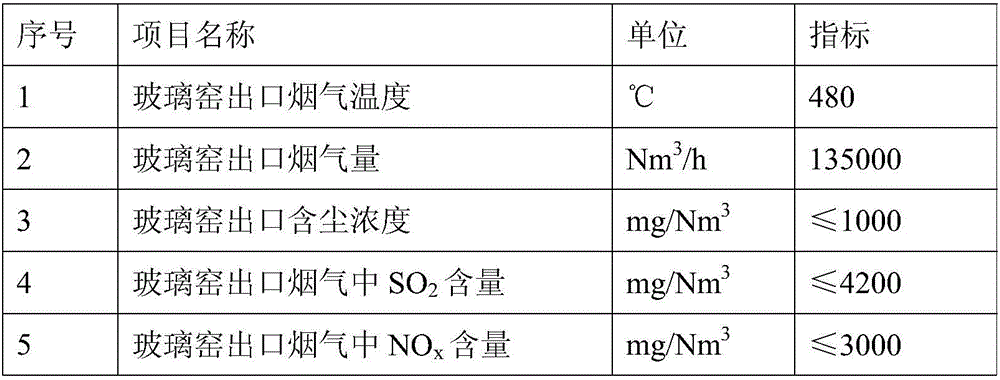

Technique for realizing ultralow emission of glass kiln smoke

ActiveCN105999888ALess corrosiveImprove dust removal efficiencyGas treatmentDispersed particle filtrationFlueElectricity

The invention discloses a technique for realizing ultralow emission of glass kiln smoke. The technique comprises the following steps: purifying the flue smoke generated by the glass kiln by adopting a flue smoke purifying system; after exchanging heat with GGH I and cooling, guiding the flue smoke generated by the glass kiln into a bag-type dust collector for removing dust; after exchanging heat with GGH I and heating, guiding the flue smoke after being de-dusted into a SCR reactor for denitration treatment; recycling the waste heat of the denitrated flue smoke through waste heat boiler and using for generating electricity or preheating air required by kiln; after exchanging heat with GGH II and reducing, guiding the flue smoke from the waste heat boiler into a wet desulfurization tower for desulfurization; after exchanging heat with GGH II and heating, emitting the desulfurized flue smoke through a chimney. The technique has the advantages of high efficiency, stability, low cost and capability of realizing deep purification and ultralow emission of the glass kiln smoke.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

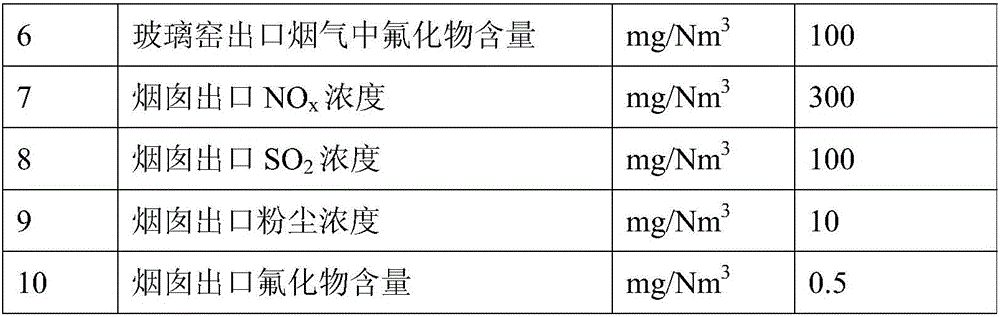

Process for removing thallium through microelectrolysis treatment of thallium-containing heavy metal wastewater

InactiveCN105540946AGood environmental benefitsEasy to operateWater contaminantsMultistage water/sewage treatmentIonPre treatment

The invention relates to a process for removing thallium through microelectrolysis treatment of thallium-containing heavy metal wastewater. The process comprises a microelectrolysis part, a neutralization coagulation part and a sulfuric acid back adjustment part. The microelectrolysis treatment on the thallium-containing wastewater is performed through a high-activity microelectrolysis packing, and pretreatment thallium removal is performed; then the wastewater after microelectrolysis pretreatment thallium removal is subjected to acid-base adjustment and is adjusted to be alkaline, then a thallium removal agent and a flocculant are added successively, solid-liquid separation is performed through an inclined plate sedimentation tank, and thallium and heavy metal ions are removed; and finally sulfuric acid is used for adjusting and purifying water to be neutral, and then the wastewater is directly discharged to the outside. The process can effectively improve the removal rate of thallium and other heavy metal ions in the heavy metal wastewater, and prevents and controls the pollution of thallium and other heavy metal elements to a water environment.

Owner:ZHUZHOU SMELTER GRP

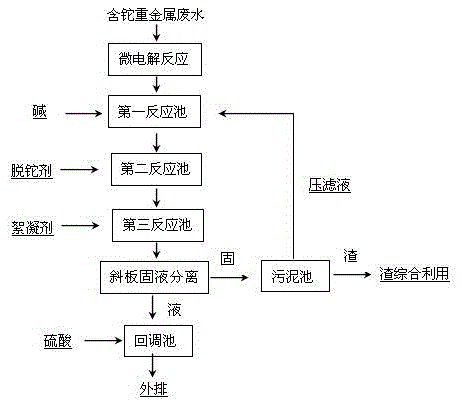

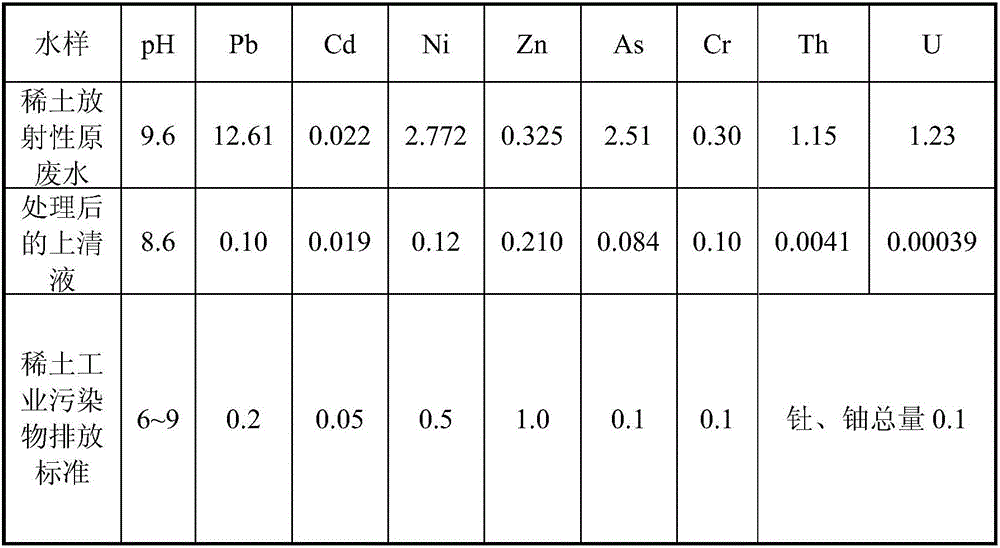

Rapid treating method for rare earth radioactive wastewater

ActiveCN105906099AQuick purificationRealize deep purificationWater contaminantsMultistage water/sewage treatmentRare earthEmission standard

The invention discloses a rapid treating method for rare earth radioactive wastewater. The method comprises the steps that a compound uranium removing agent and an oxidizing agent are added into radioactive wastewater with the pH of 3-7, residual organic extraction agent in rare earth extraction wastewater is efficiently oxidized through the synergistic effect of the compound uranium removing agent and the oxidizing agent, the complexing state of the extraction agent and uranium is damaged, uranium is combined with the compound uranium removing agent to generate a stable compound so as to achieve removal, the compound uranium removing agent can form loose floc in wastewater, and the floc has the strong adsorption ability on residual other radioactive elements such as thorium in water, so that radioactive elements and heavy metal ions in water are rapidly removed, deep removal of radioactive elements is achieved, the drained out can stably reach the limiting value of emission standards of radioactive elements and heavy metal in Rare Earth Industrial Pollutant Emission Standards (GB26451-2011), a new path is developed for rapid deep treatment of radioactive wastewater, and the application prospect is quite good.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH

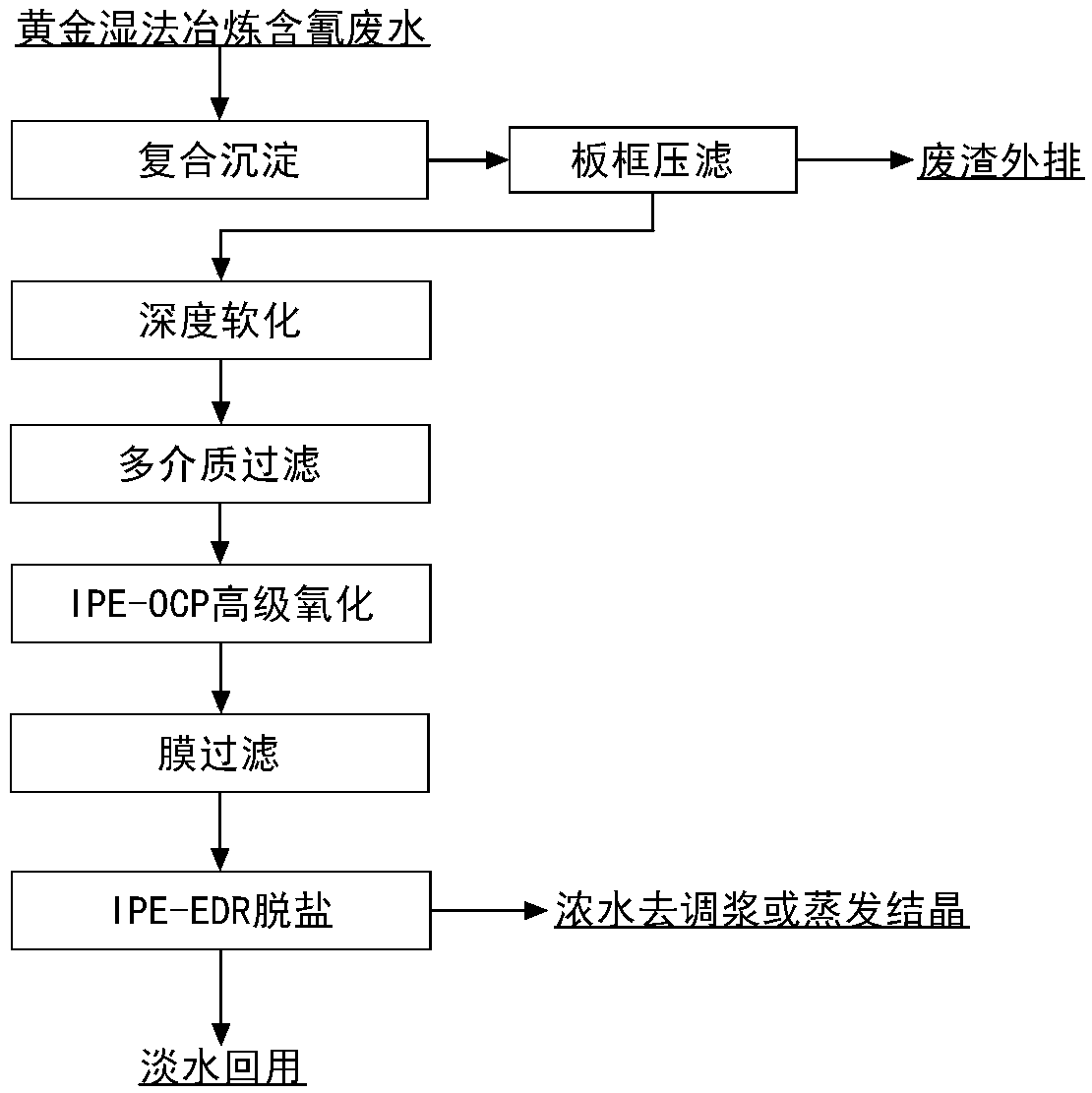

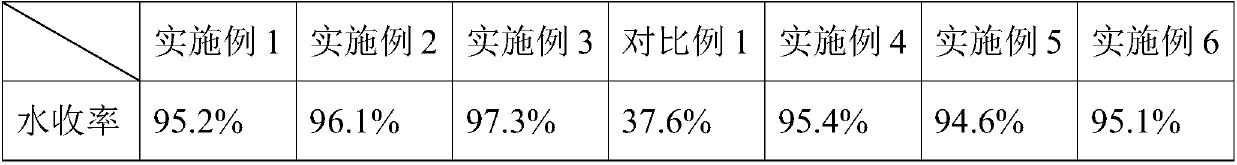

Deep treatment method of gold hydrometallurgy cyanide-containing wastewater

InactiveCN110668613AAchieve reuseIncrease the concentration factorWater treatment compoundsWater contaminantsInorganic saltsAmmoniacal nitrogen

The invention relates to a deep treatment method of gold hydrometallurgy cyanide-containing wastewater. The method comprises: (1) adding a composite precipitant into low-concentration cyanide-containing wastewater obtained after pretreatment of gold hydrometallurgy cyanide-containing wastewater, and filtering out the waste residue after a precipitation reaction to obtain a first filtrate, whereinthe low-concentration cyanide-containing wastewater comprises 40-120 g / L soluble inorganic salt, 10-100 mg / L heavy metal, 100-650 mg / L COD, 0.5-10 mg / L total cyanide and 30-120 mg / L ammonia nitrogen;(2) softening the first filtrate, and then filtering; (3) carrying out heterogeneous catalytic ozonation on the softened filtrate, and then filtering out the waste residue to obtain a second filtrate;and (4) desalting the second filtrate through multi-stage countercurrent electrodialysis, and recycling fresh water. According to the invention, deep purification and fresh water recycling are achieved through the synergistic effect of different processes, the water recycling rate reaches more than 94.6%, and the concentration multiple of the concentrated water reaches more than 3.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

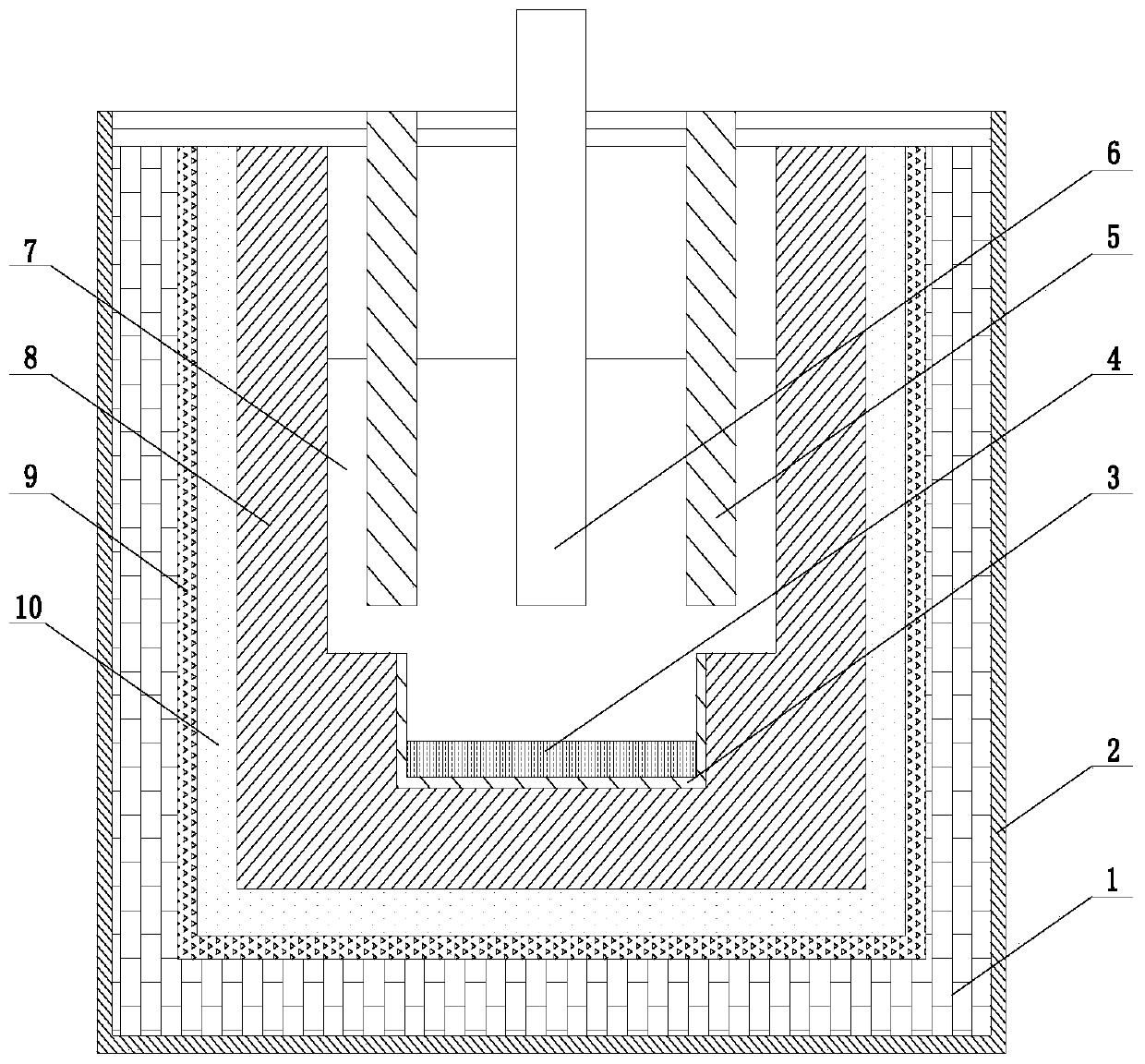

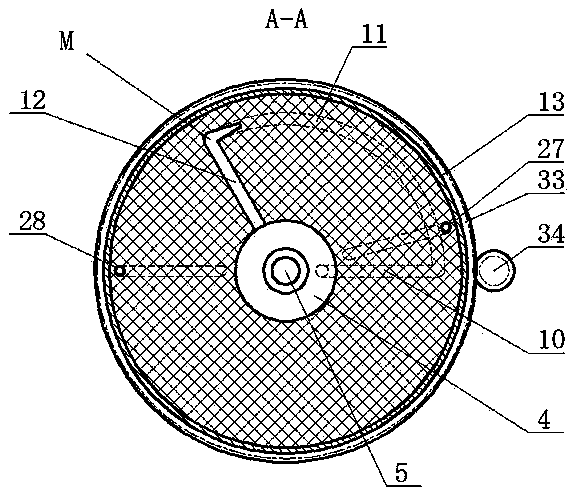

Rotary vacuum degassing device

The invention provides a rotary vacuum degassing device which comprises a rotary machine body, wherein an axial line of the rotary machine body is inclined 15 degrees to 75 degrees relative to a horizontal plane; the rotary machine body is connected with a driving device and rotates around a shaft core of the rotary machine body under the drive of the driving device; the lower end of the rotary machine body is a lower column, the upper end of the rotary machine body is an upper column, and the middle part of the rotary machine body is a middle column; each column is formed by an integral metal shell in a surrounding way; the inner part of the rotary machine body is an integral refractory material lining formed by pouring; a molten metal discharging passage, a refining chamber and a negative pressure passage are respectively formed in the refractory material linings of the upper column, the middle column and the lower column on a shaft core line of the rotary machine body and are communicated mutually; the discharging passage at the lower end of the rotary machine body is communicated with a refining liquid area through a refining liquid conduit; the negative pressure passage at the upper end is communicated with a vacuum bleed-off passage. The rotary vacuum degassing device can overcome defects existing in conventional vacuum refining equipment outside a furnace.

Owner:党浩然

Zero water consumption wet process desulfurization device and desulfurization process thereof

PendingCN108970368ARealize deep purificationZero water consumptionGas treatmentDispersed particle separationHigh humidityEngineering

The invention discloses a zero water consumption wet process desulfurization device and a desulfurization process thereof. The desulfurization device comprises a desulfurization tower, wherein at least one desulfurization spraying layer, a temperature reduction liquid accumulation layer, a temperature lowering spraying layer, a demister flushing layer and a demister dewatering layer are sequentially distributed and arranged in the desulfurization tower from bottom to top; a coagulating pool, a regulating pool, a temperature lowering clarifying pool, a clean water pool and a temperature lowering spraying pump are arranged outside the desulfurization tower; a slurry pool is arranged under the desulfurization spraying layer in the desulfurization tower; a smoke inlet is formed in the tower wall of the desulfurization tower between the slurry pool and the desulfurization spraying layer; a smoke discharge opening is formed in one side of the top of the desulfurization tower. The temperatureof the smoke gas is lowered; the desulfurized smoke gas is subjected to condensation, temperature lowering and water collection, and the recovered water is treated and reused, so that the zero waterconsumption of the desulfurization system is realized; meanwhile, the circulation condensing liquid is subjected to tempering; the treatment volume of the circulation liquid on acidic gas is improved;the multi-contaminant deep purification is realized; the near-zero discharging is reached; the cooperated control level of multiple contaminants of high-humidity smoke gas is greatly improved.

Owner:杭州蕴泽环境科技有限公司

Method for preparing phosphogypsum base cementing material by two-step calcining

The invention discloses a method for preparing a phosphogypsum base cementing material by two-step calcining. The method comprises the following steps: performing washing on the phosphogypsum with water and acid, so as to effectively promote the rate of crystallization transformation of CaSO4.2H2O in phosphogypsum to anhydrous CaSO4, improve the content of anhydrous CaSO4 in the phosphogypsum, realize the deep purification of the phosphogypsum, avoid the influence on calcining by impurity, and reduce calcining temperature, then mixing and grinding the coal ash and activated carbon, and then performing tow-stage calcining including quickly-calcining for dewatering, and sintering under reducing atmosphere and high temperature to obtain the phosphogypsum base cementing material. The inventionhas the advantages that the activated carbon and the coal ash are added, so that the reducing atmosphere is provided for decomposition of the phosphogypsum, the decomposition of the phosphogypsum ispromoted and the decomposition rate of the phosphogypsum is improved.

Owner:MAANSHAN TUORUI METAL SURFACE TECH

Treatment device and method for incineration gas of cremator

PendingCN110180356AReduce the temperatureThrottle low temperature synthesisCombination devicesGas treatmentActivated carbonSulfide

The invention discloses a treatment device and method for incineration gas of a cremator. The method comprises the following steps: conveying the incineration gas of the cremator to a quenching towerfor treatment, quickly reducing the gas temperature and inhibiting low-temperature synthesis of dioxin; introducing the gas into a Mars interceptor to capture combustibles in the gas; mixing the gas with activated carbon to remove dioxin and heavy metals in the gas; introducing the treated gas into a bag dust collector to capture particles and activated carbon mixed in the gas; introducing the treated gas into a heat exchanger for heat exchange; introducing the treated gas into a low-temperature plasma reaction device for generating active particles required for denitration and desulfurization; introducing the gas into an absorption device to capture acidic substances and residual toxic substances in the gas; introducing the purified gas into the heat exchanger and discharging the purifiedgas after heating treatment. Deep purification of the gas with complex composition and more pollutants including malodorous gas, sulfide, nitrogen oxide and dioxin can be realized, and ultra-low emission of the gas is realized.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

Lanthanum-cerium mixed rare earth ferroalloy for rare earth steel production

The invention discloses a lanthanum-cerium mixed rare earth ferroalloy for rare earth steel production. The lanthanum-cerium mixed rare earth ferroalloy comprises the following chemical components in percent by weight: more than or equal to 4.0 percent of lanthanum, more than or equal to 7.5 percent of cerium, less than or equal to 0.05 percent of carbon, less than or equal to 0.010 percent of phosphorus, less than or equal to 0.005 percent of sulfur and the balance of iron and impurities, wherein the content of lanthanum and cerium is less than 20 percent. When the lanthanum-cerium mixed rare earth ferroalloy is used for smelting high-quality rare earth steel, because the specific gravity is close to the specific gravity of steel, the lanthanum-cerium mixed rare earth ferroalloy can be rapidly fused into steel in the refining process, the problem that rare earth is constrained to be added into steel for a long time is solved, and the yield of the rare earth is improved.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Air purifying device

ActiveCN107906642ACompact structureEnsure personal safetyMechanical apparatusLighting and heating apparatusAir cleaningProcessing plants

The invention discloses an air purifying device used for a flour processing plant. The air purifying device comprises a shell, a filtering device, an air extracting device, a fine mist purifying device and a sterilizing and disinfecting device, wherein the filtering device, the air extracting device, the fine mist purifying device and the sterilizing and disinfecting device are sequentially installed in the shell. The filtering device comprises a rough filtering layer and a fine filtering layer. A limiting protruding groove for fixing the rough filtering layer and the fine filtering layer is formed in the inner surface of the shell. A sliding groove is formed in the position, at the positions of the rough filtering layer and the fine filtering layer, of the shell. The sliding groove is further provided with a sliding block. The end, penetrating a sliding plate, of the sliding block is fixedly connected with a cleaning brush. Limiting fixing grooves are formed in the two ends of the sliding groove. First fixing threaded holes are formed in the sliding plate and the shell, and the sliding plate and the shell are fixedly installed together through a first sealing ring. A first impurity outlet is formed in the bottom of the shell, and a first closed round piece is hinged to the first impurity outlet. A second sealing ring is arranged on the edge of the first closed round piece, anda sealing protruding groove is formed in the first impurity outlet. The first closed round piece is further connected with a protruding edge.

Owner:阜阳市国峰伟业粮油有限责任公司

Method for purifying and separating carbon and fluoride from waste carbon material in aluminum electrolysis tank and prolonging service life of equipment

InactiveCN108557814AReduce volatilityReduce corrosionCarbon compoundsAlkali metal fluoridesElectrolysisFluoride

The invention discloses a method for purifying and separating carbon and fluoride from a waste carbon material in an aluminum electrolysis tank and prolonging the service life of equipment. The methodcomprises the following steps: crushing and pulverizing the waste carbon material in the aluminum electrolysis tank till particles of 100 meshes accounts for 50 percent or above; then drying the waste carbon material to reduce the moisture content to 0.1 to 0.8 percent; pre-roasting the dried carbon powder at 700 to 1,200 DEG C for 30 to 150 min; roasting a product obtained by pre-roasting at 1,400 to 1,800 DEG C for 20 to 120 min, and separating the product to obtain a roasted carbon powder A and electrolyte; treating the roasted carbon powder A at the high temperature of 2,200 to 3,000 DEGC for 1 to 60 min, and separating the product to obtain graphitized carbon powder B and ash. According to the method for purifying and separating carbon and fluoride from the waste carbon material inthe aluminum electrolysis tank and prolonging the service life of the equipment, the problems of severe corrosion to the equipment due to the high impurity content of the collected volatilized fluoride during high-temperature graphitization of the waste carbon material in the aluminum electrolysis tank are solved, so that improvement on the purity of a carbon material is implemented.

Owner:CENT SOUTH UNIV

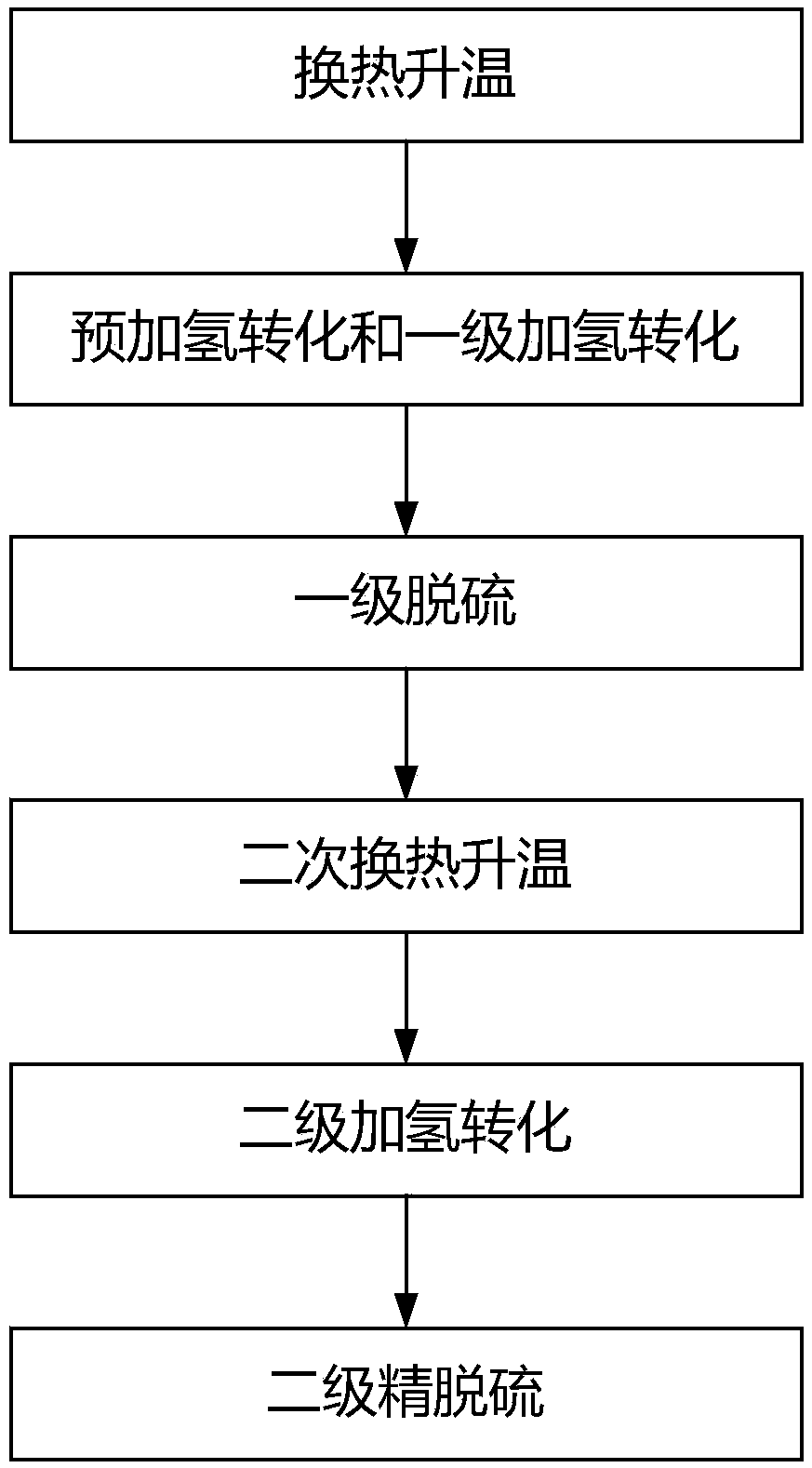

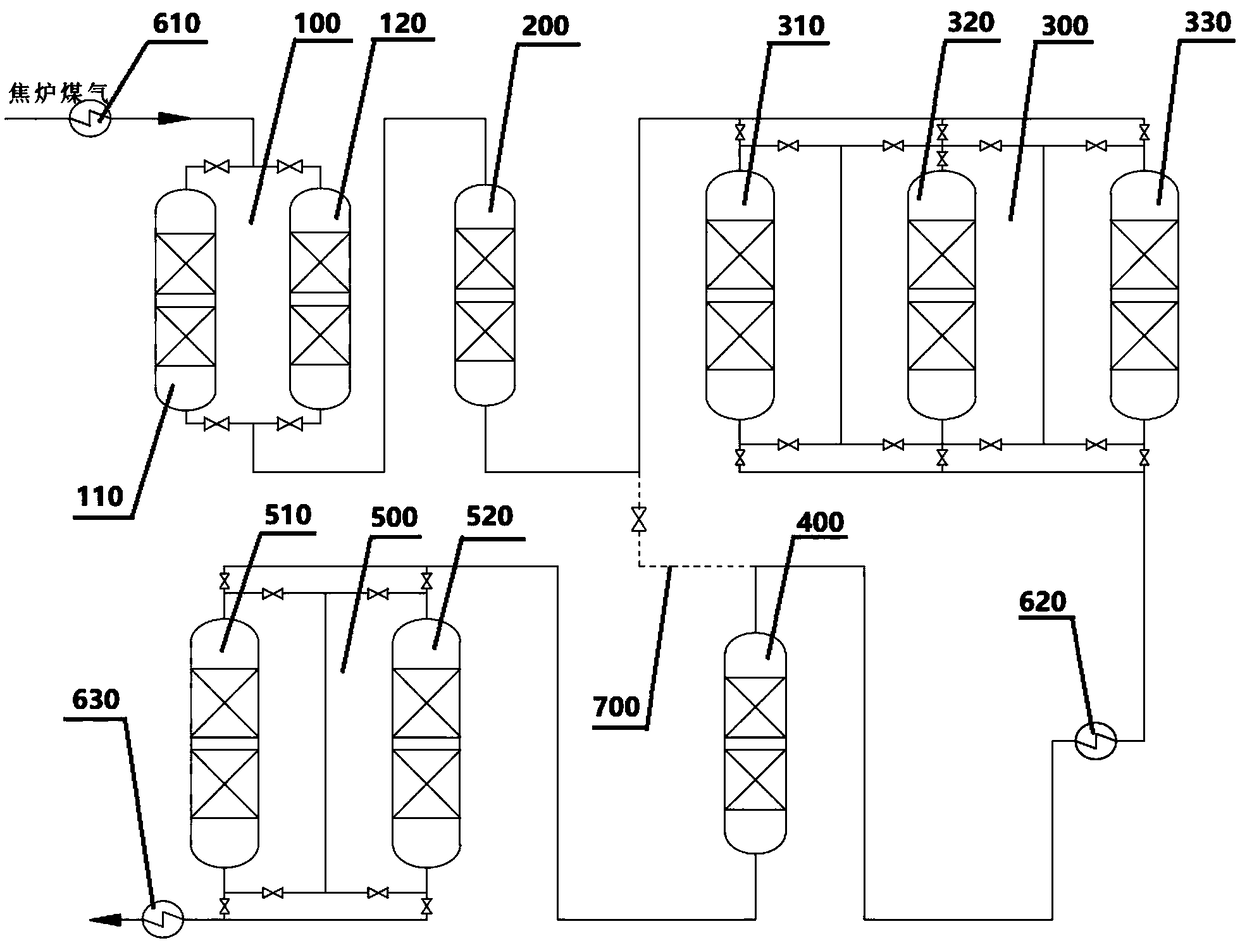

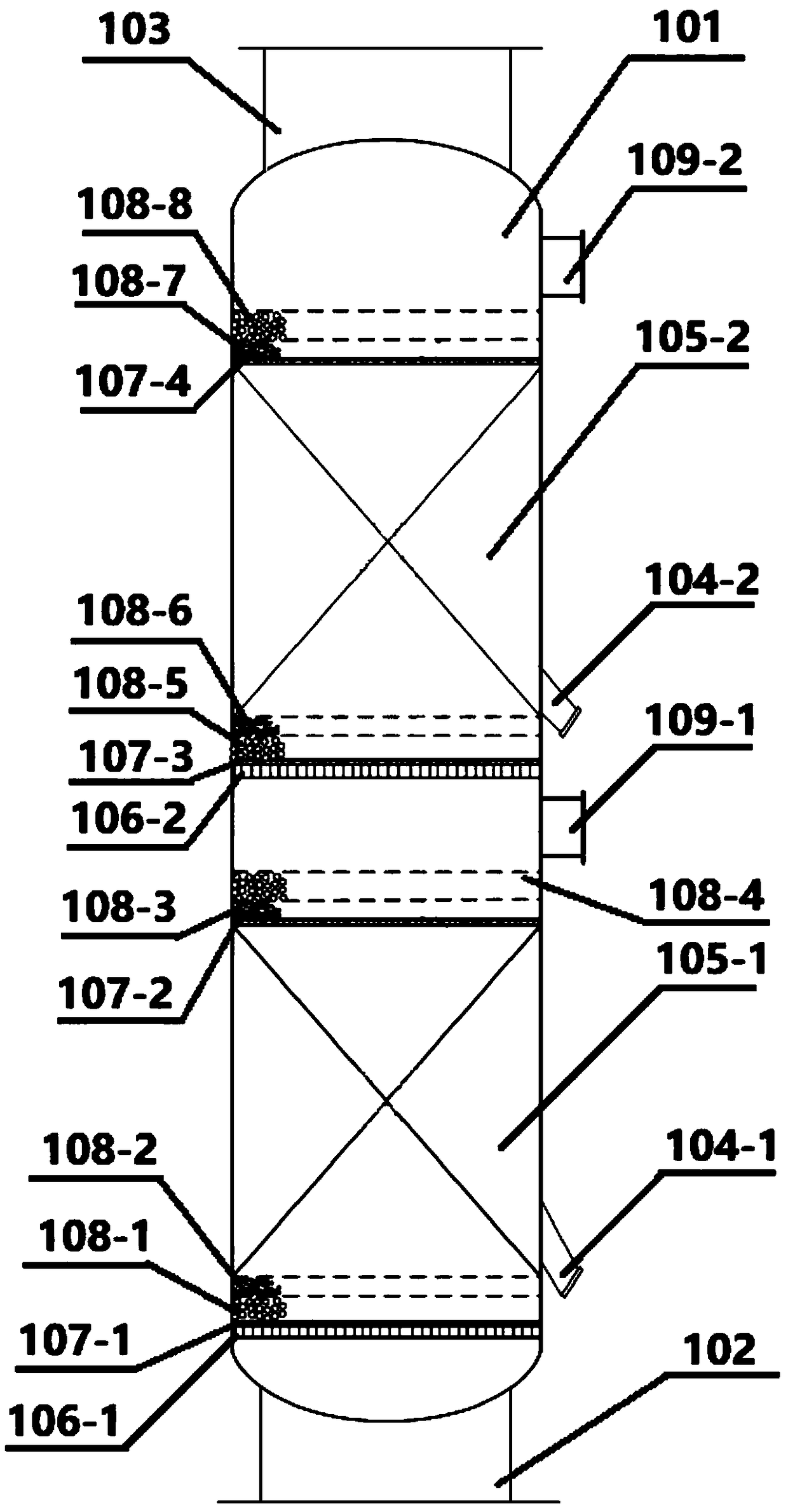

Method for deoxidizing and finely desulfurizing coke oven gas

ActiveCN108977233ARealize deep purificationImprove operational reliabilityDispersed particle separationGas contaminants removalUnsaturated hydrocarbonSulfur

The invention discloses a method for deoxidizing and finely desulfurizing a coke oven gas. The method comprises the following steps: (S1) heat exchanging and temperature rising; (S2) prehydrogenationconversion and first-stage hydrogenation conversion; (S3) first-stage desulfurization; (S4) secondary heat exchanging and temperature rising; (S5) second-stage hydrogenation conversion; (S6) second-stage fine desulfurization. According to the method for deoxidizing and finely desulfurizing the coke oven gas, disclosed by the invention, a two-stage coke oven gas hydrogenation deoxidization and finedesulfurization technology is adopted, most of organic sulfur in the coke oven gas can be converted into H2S by utilizing a first-stage hydrogenation deoxidization and desulfurization section, most of oxygen can be removed through hydrogenation, most of unsaturated hydrocarbon can be saturated through hydrogenation, and meanwhile, other impurities can be treated; the treated coke oven gas entersa second-stage hydrogenation deoxidization and fine desulfurization section, impurities of residual organic sulfur, unsaturated hydrocarbon, trace oxygen and the like can be subjected to secondary deep hydrogenation conversion and treatment, and deep purification of the coke oven gas can be realized.

Owner:太原智领科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com