Zero water consumption wet process desulfurization device and desulfurization process thereof

A technology of wet desulfurization and desulfurization process, applied in separation methods, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as air pollution, misunderstanding of white plume visual effects, etc., to reduce water costs for enterprises and improve coordination Governance level, to achieve the effect of deep purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

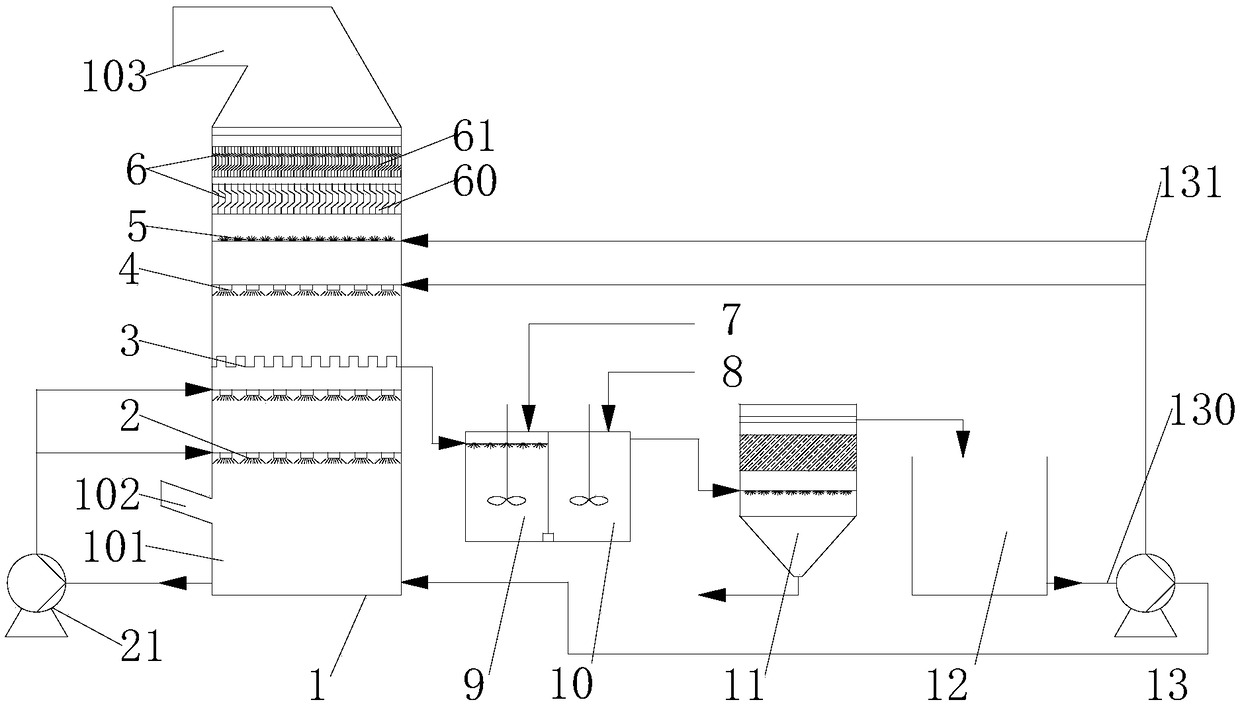

[0035] Embodiment 2: refer to figure 1 . A desulfurization process of a zero-water consumption wet desulfurization device, comprising the following process steps:

[0036] 1) After the original flue gas enters the desulfurization tower 1, it performs a reverse contact reaction with the desulfurization liquid sprayed from the desulfurization spray layer 2, and removes most of the acid gases such as SO2, HF, HCl and dust particles in the original flue gas, and the flue gas cools down. to 50°C-60°C and reach saturation;

[0037] 2) After desulfurization, the high-humidity saturated flue gas passes through the liquid accumulation layer 3 upwards, and conducts reverse contact and heat exchange with the condensate sprayed from the cooling spray layer 4, and the temperature of the flue gas drops to 30°C-45°C. Most of the water vapor and residual acid gas condense into liquid droplets with slurry droplets, soluble salt droplets, and ultrafine dust particles as condensation nuclei; ...

Embodiment 3

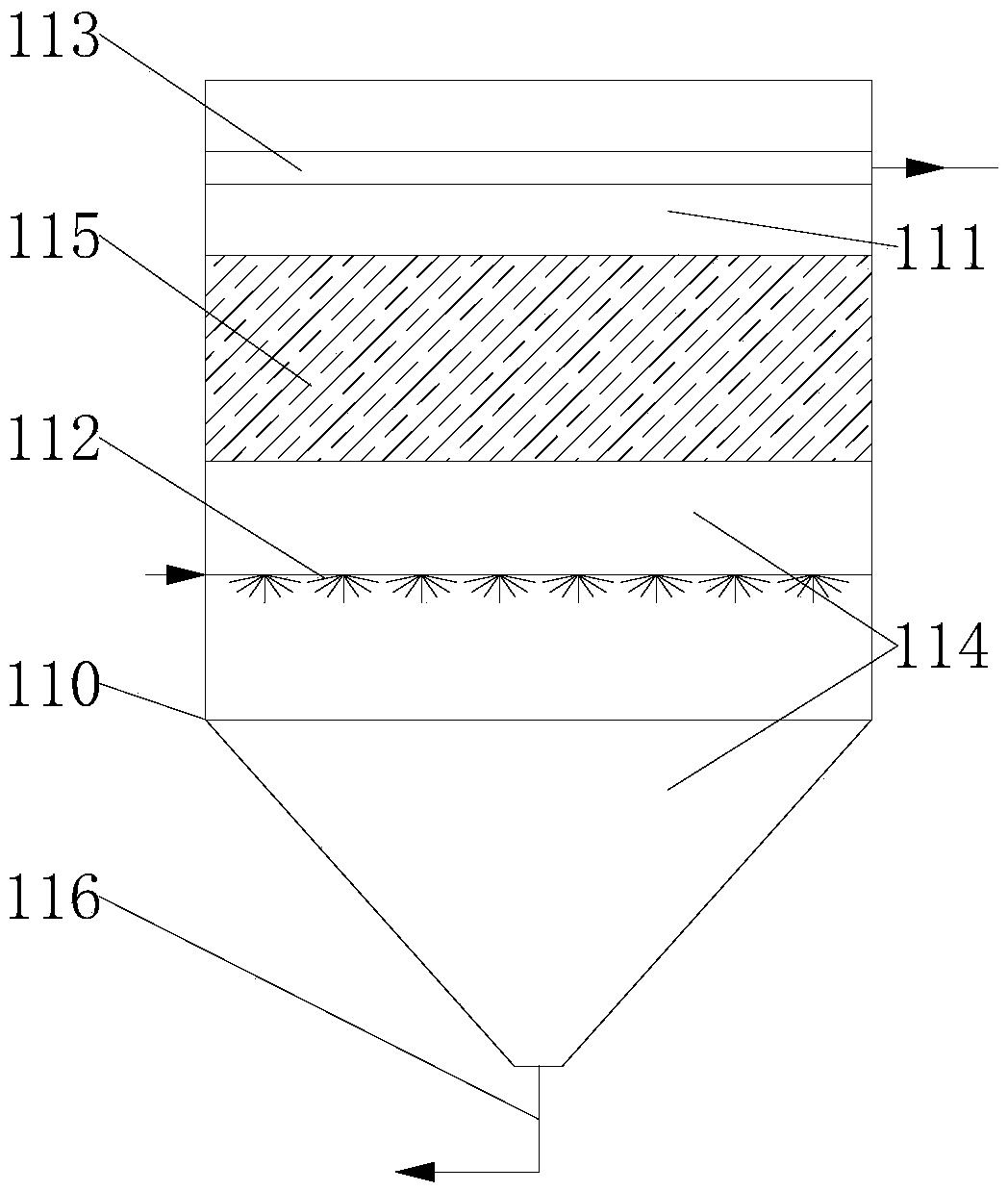

[0044] A thermal power unit, a 300WM flue gas desulfurization renovation project adopts this process, the SO2 concentration in the inlet flue gas is 2338mg / m3, the dust concentration in the inlet flue gas is 28mg / m3, and the liquid-gas ratio of the cooling spray layer circulating fluid is 3L / Nm3, the coverage rate of the spray layer is 300%, the gas-liquid contact time is 1.3s, the flue gas cooling range is 15°C; the preparation pressure of the nozzle of the flushing layer of the demister is 0.20MPa, and the flushing liquid-gas ratio is 0.5L / Nm3, The cooling range of the flue gas is 3.2°C; the pH of the effluent is 8.2; the sedimentation area of the packing layer 5 is an inclined tube packing with a diameter of 35mm, and the flow rate of the inlet water distribution pipe is 0.2m / s. The water pipeline is 1.1m away from the top of the packing layer, and the vertical flow velocity in the sedimentation area is 0.2mm / s. The concentration of SO2 in the outlet flue gas is 3.3mg / m3,...

Embodiment 4

[0046] A thermal power unit, a 135WM unit flue gas desulfurization reconstruction project adopts this process, the SO2 concentration in the inlet flue gas is 1879mg / m3, the dust concentration in the inlet flue gas is 22mg / m3, and the liquid-gas ratio of the cooling spray layer circulating fluid is 2.8L / Nm3, the coverage rate of the spray layer is 300%, the gas-liquid contact time is 1.2s, the temperature drop of the flue gas is 17℃; the preparation pressure of the nozzle of the flushing layer of the demister is 0.20MPa, and the ratio of flushing liquid to gas is 0.6L / Nm3 , the cooling range of the flue gas is 2.7°C; the pH of the effluent is 8.5; the sedimentation area of the packing layer 5 is an inclined tube packing with a diameter of 35mm, the flow rate of the inlet water distribution pipe is 0.2m / s, the distance between the inlet water distribution pipe and the bottom of the packing layer is 0.8m, and the top The outlet pipe is 1.0m away from the top of the packing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com