Patents

Literature

2934results about "Waste water treatment from gaseous effluents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

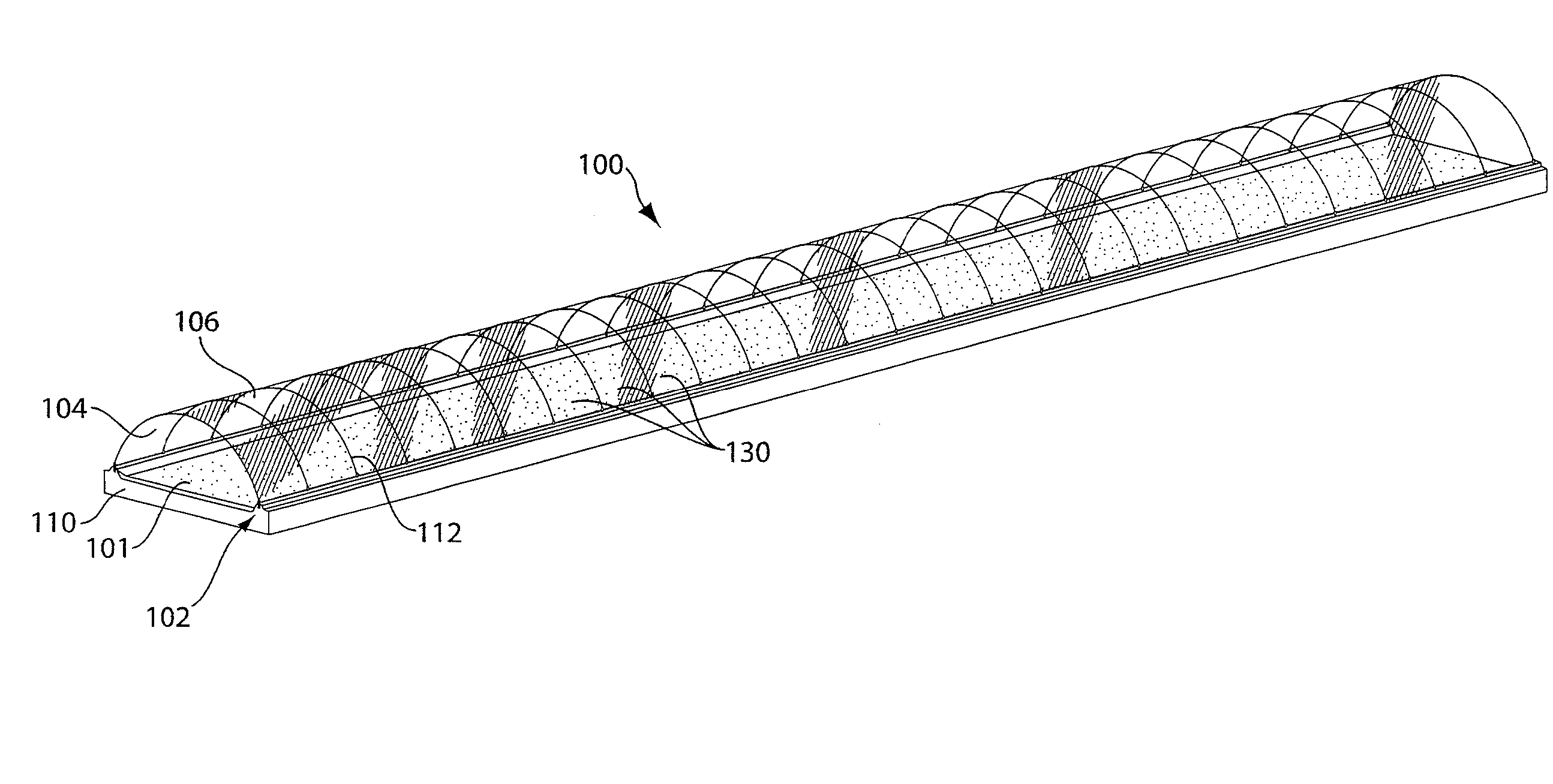

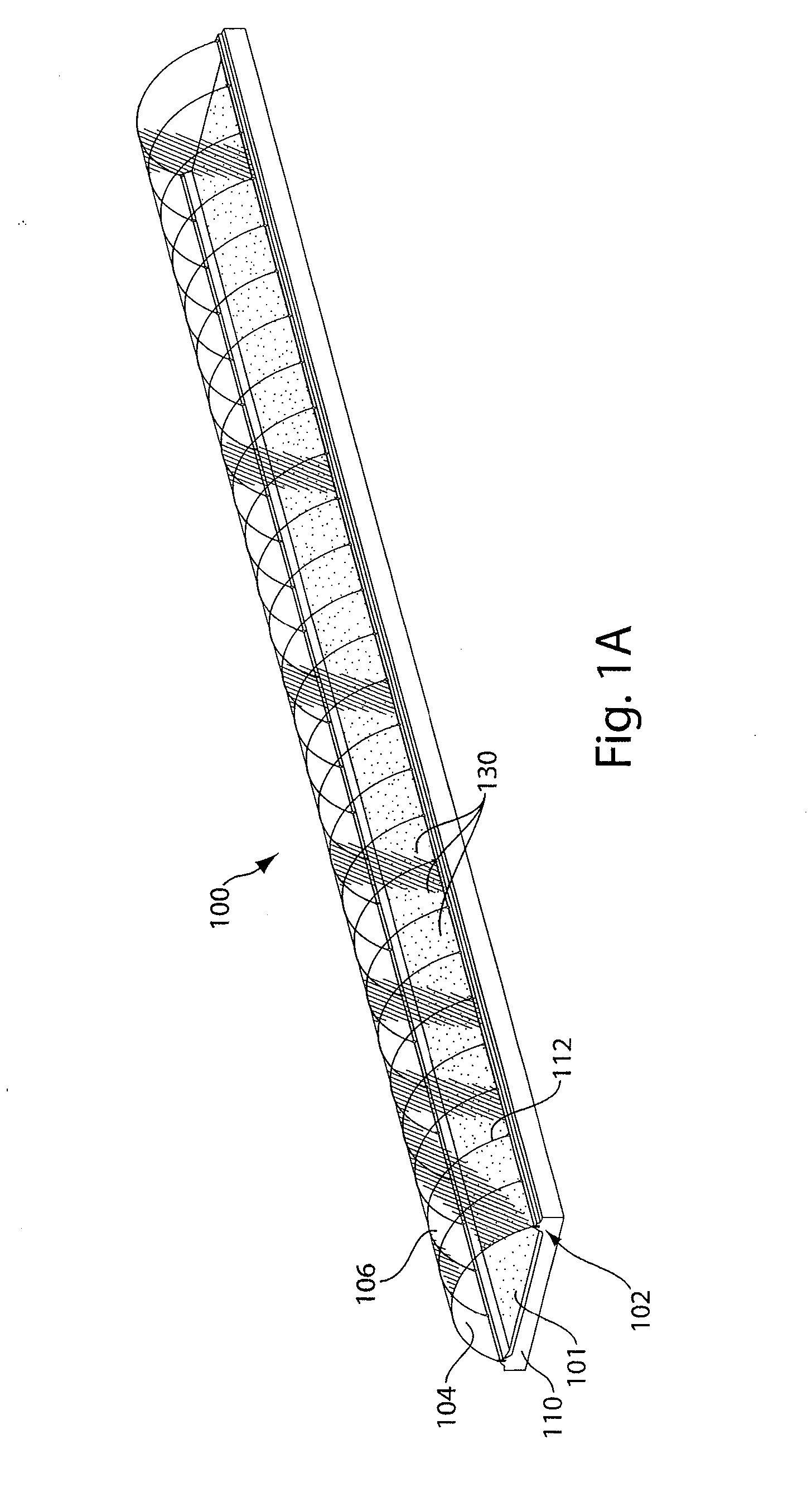

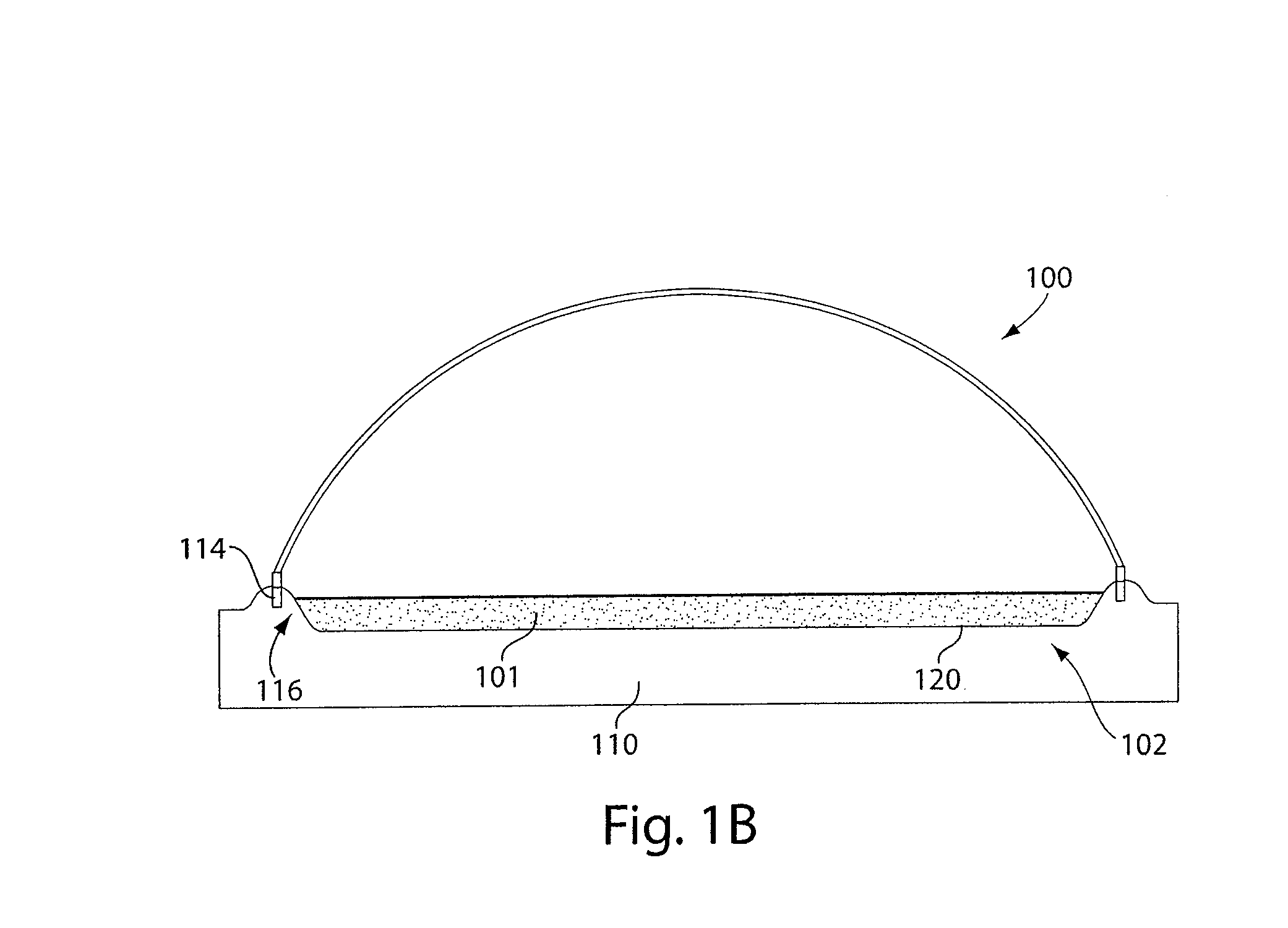

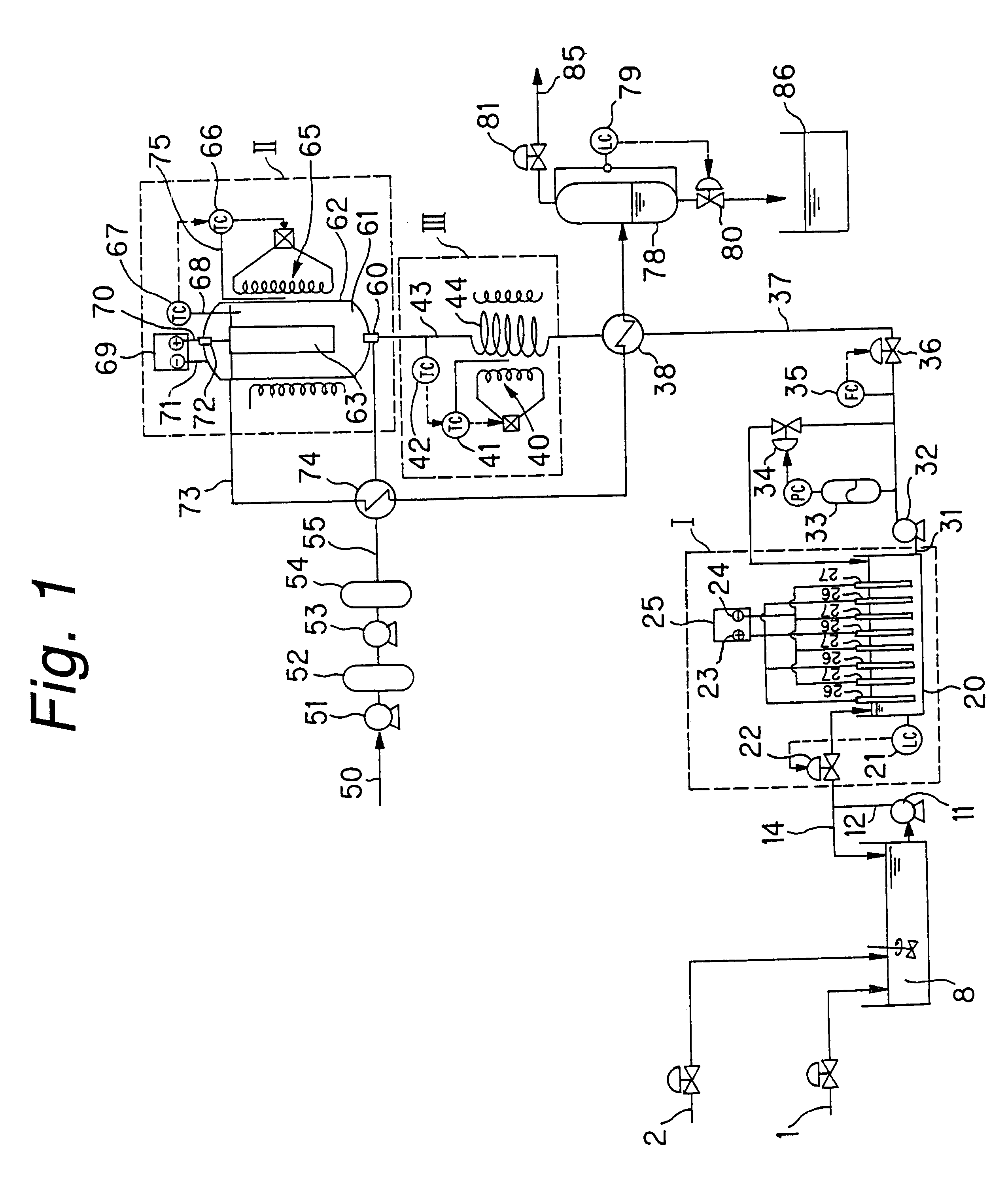

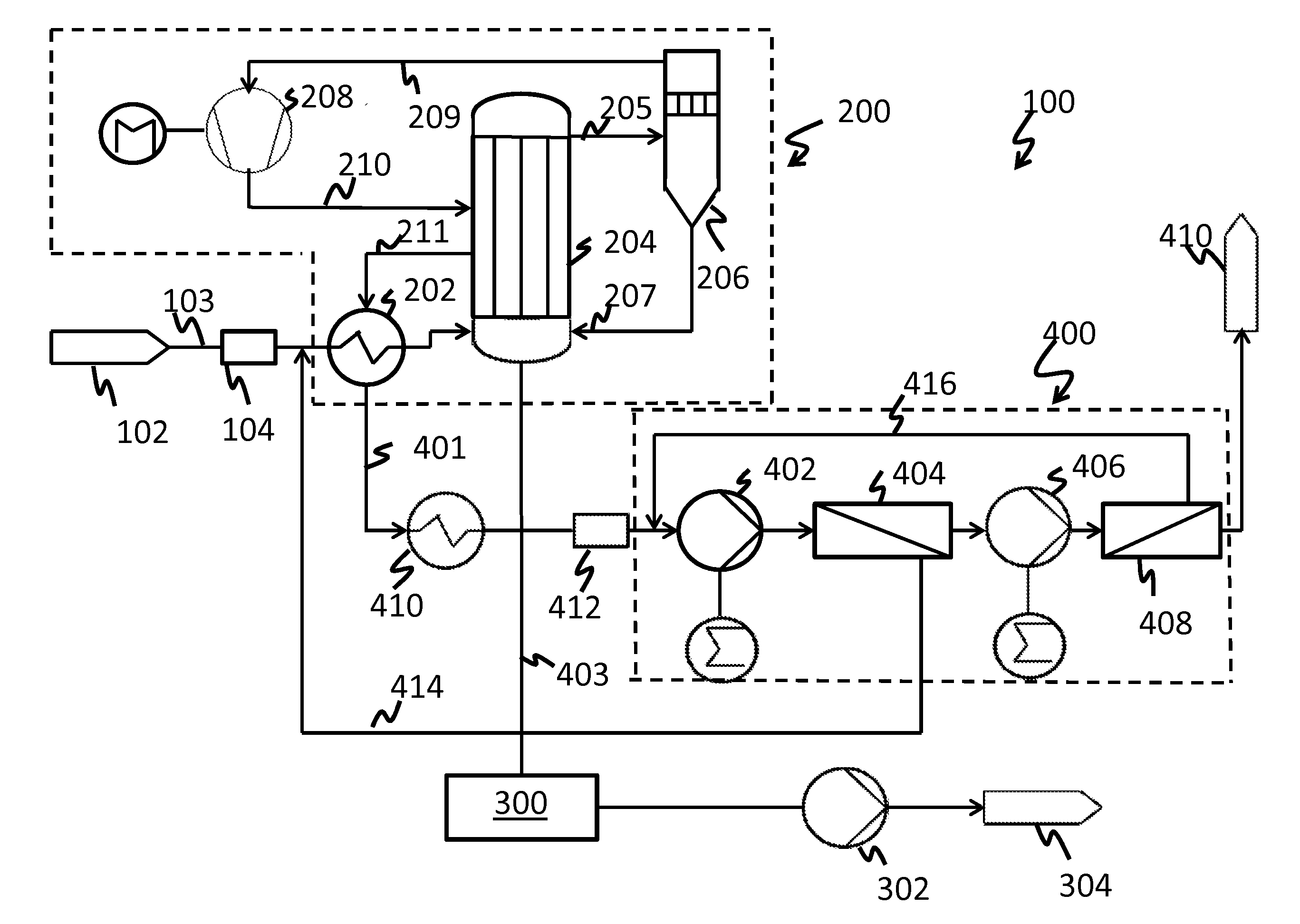

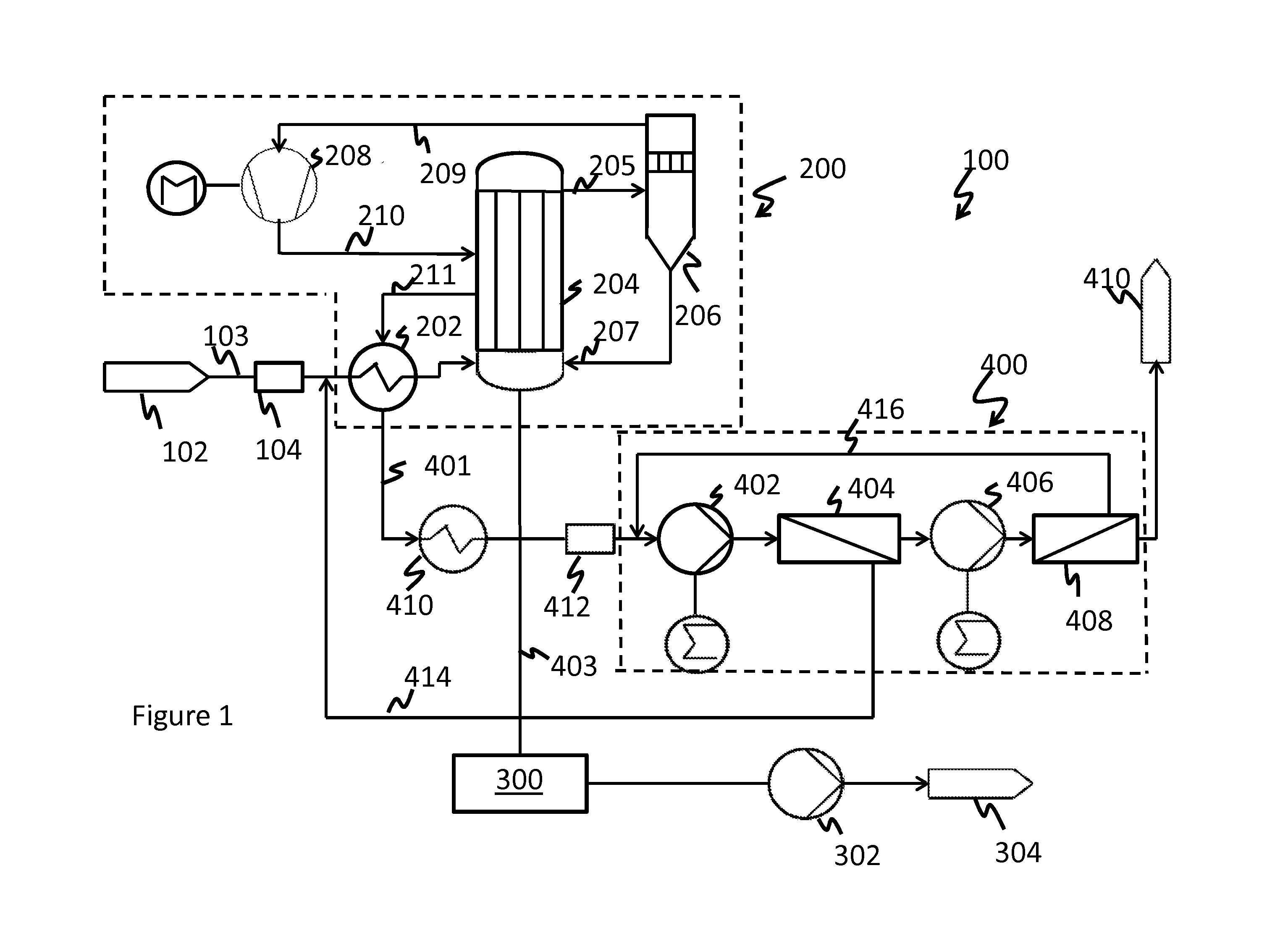

Photobioreactor systems and methods for treating CO2-enriched gas and producing biomass

InactiveUS20080178739A1Facilitate evaporative coolingSupport growthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumStream flow

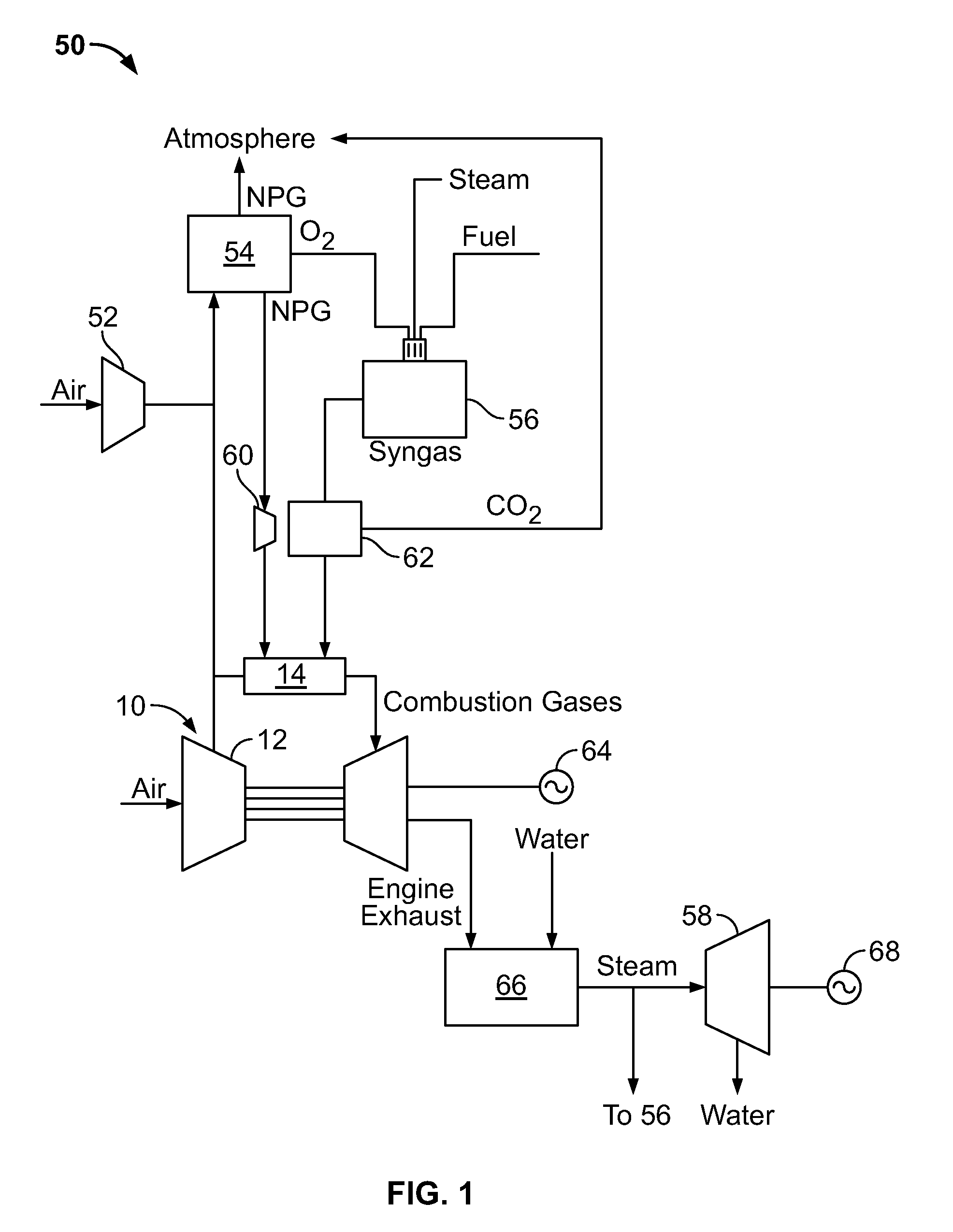

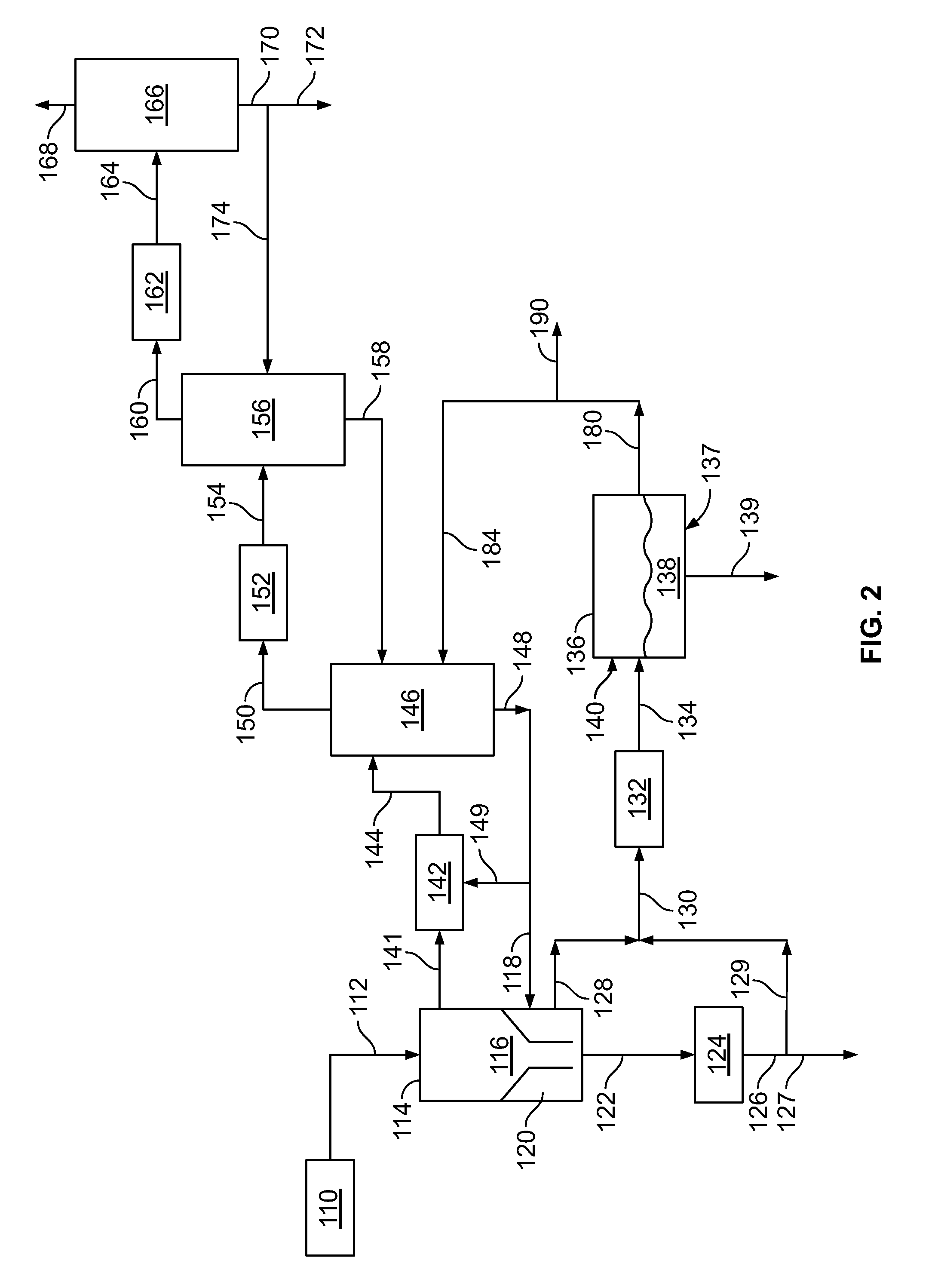

Certain embodiments and aspects of the present invention relate to a photobioreactor including covered photobioreactor units through which a liquid medium stream and a gas stream flow. The liquid medium comprises at least one species of phototrophic organism therein. Certain methods of using the photobioreactor system as part of fuel generation system and / or a gas-treatment process or system at least partially remove certain undesirable pollutants from a gas stream. In certain embodiments, a portion of the liquid medium is diverted from a photobioreactor unit and reintroduced upstream of the diversion position. In certain embodiments, the disclosed photobioreactor system, methods of using such systems, and / or gas treatment apparatus and methods provided herein can be used as part of an integrated combustion method and system, wherein photosynthetic organisms used within the photobioreactor are harvested from the photobioreactor, processed, and used as a fuel source for a combustion system such as an electric power plant.

Owner:THE TRON GRP

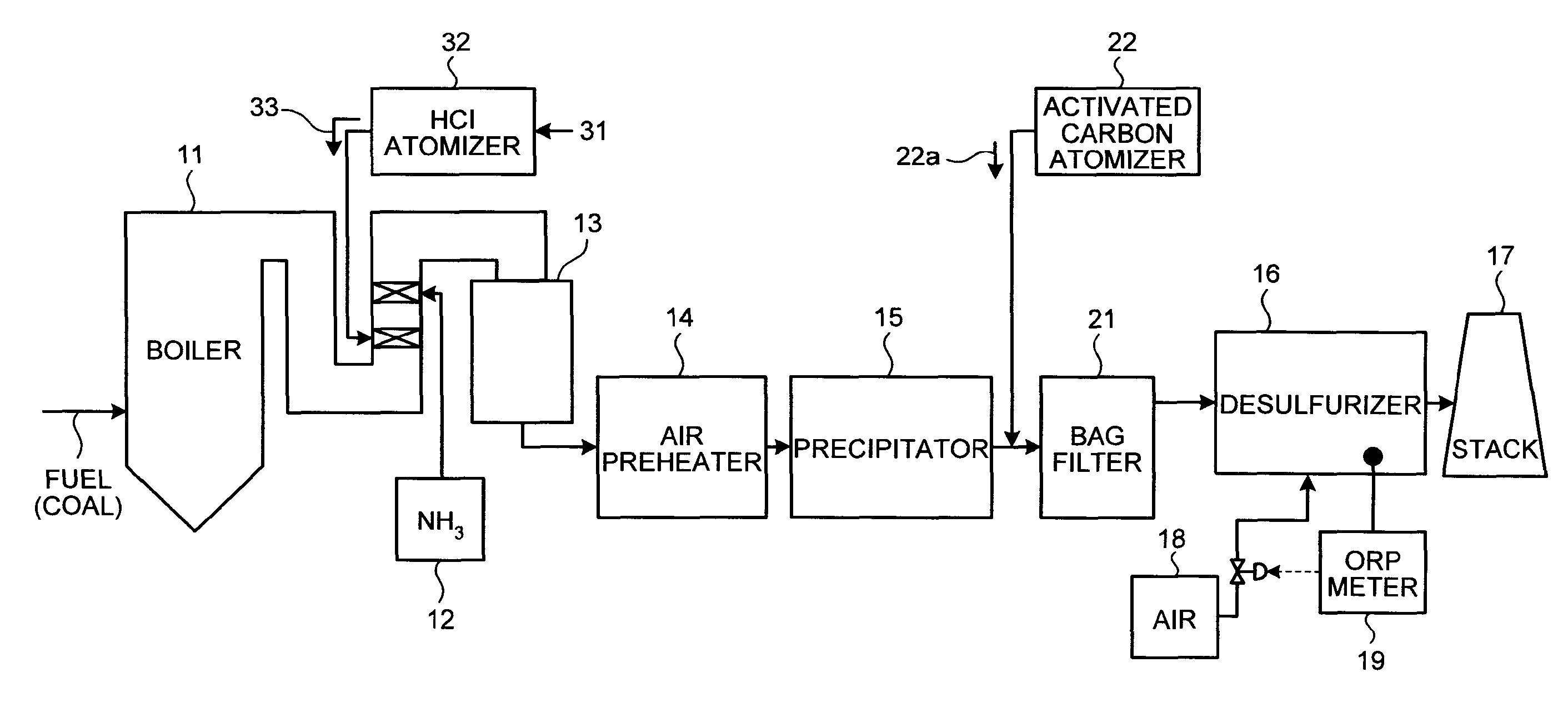

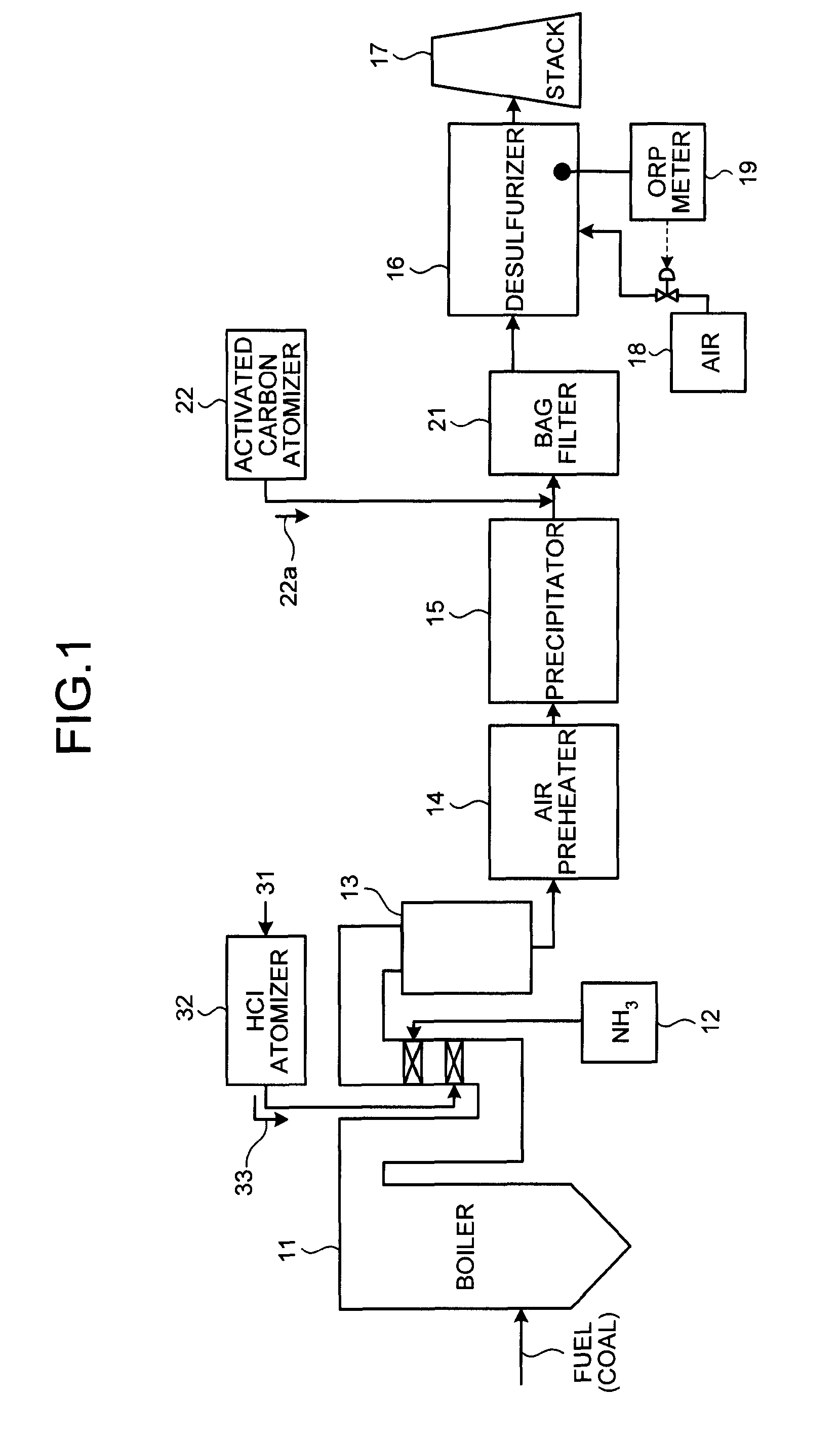

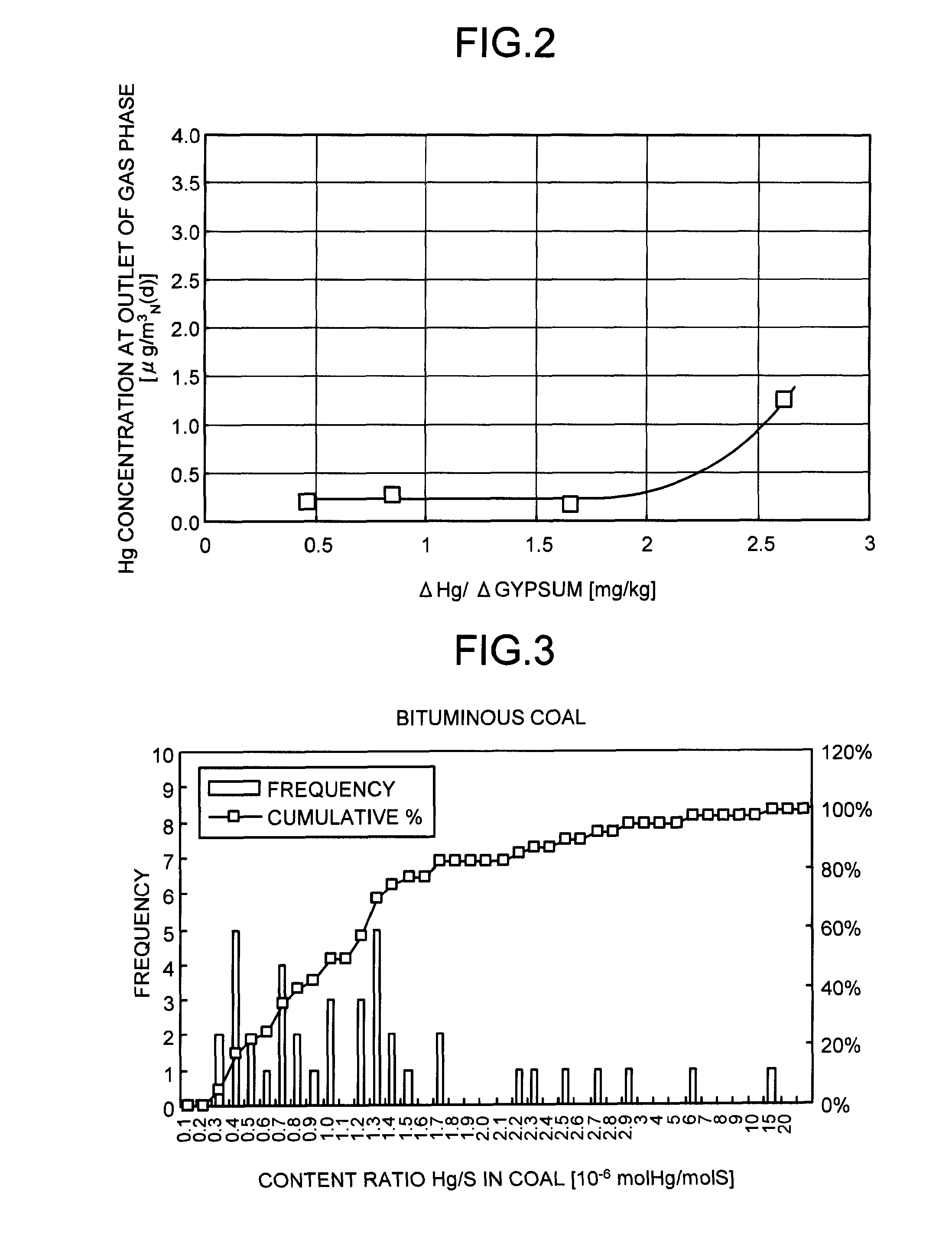

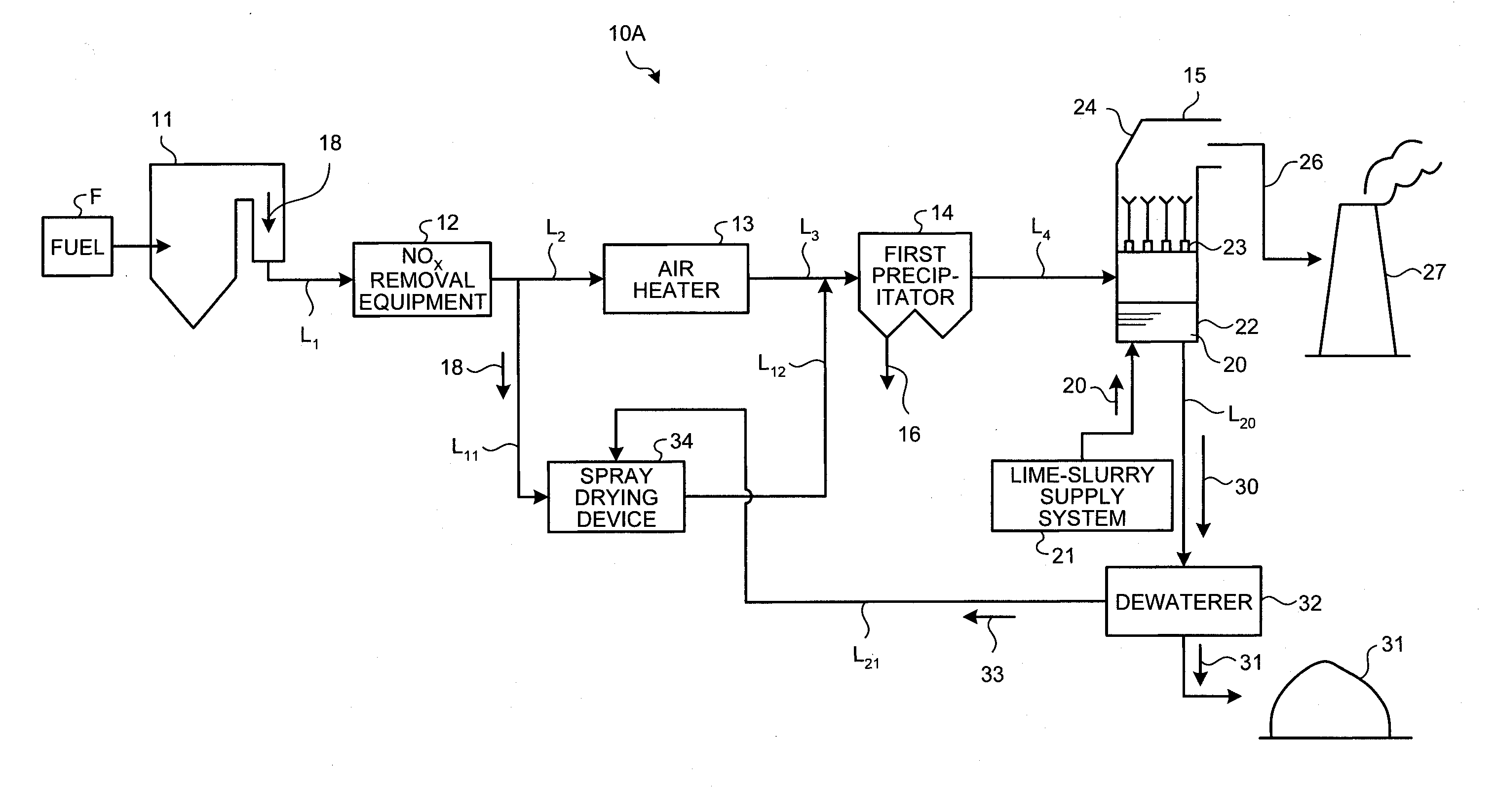

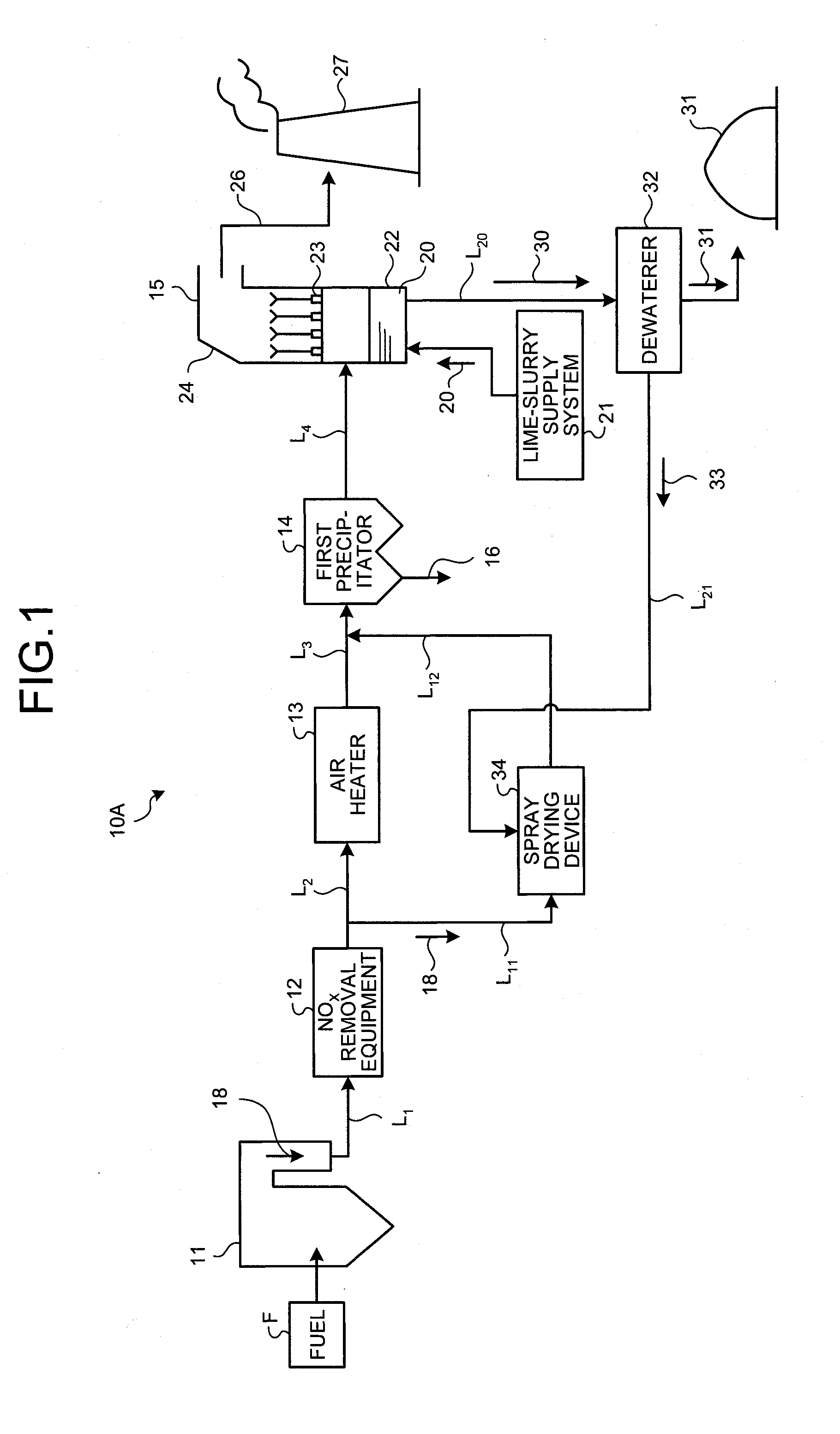

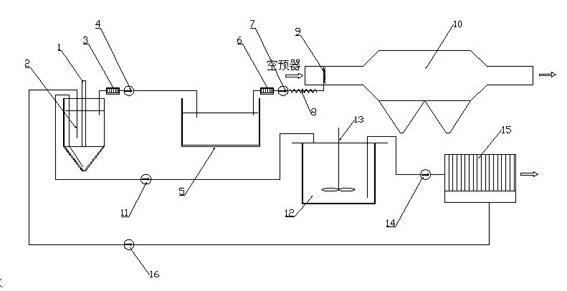

Flue gas control system of coal combustion boiler and operating method thereof

ActiveUS8071060B2Reduce operating costsCombination devicesNitrogen compoundsAir preheaterParticulates

A flue gas control system of a coal combustion boiler comprises an HCl atomizer that sprays hydrogen chloride to flue gas from a coal combustion boiler that uses coal as a fuel; NOx removing apparatus that removes nitrogen oxides by ammonia denitration by adding ammonia to the flue gas after spraying hydrogen chloride and oxidizes mercury; an air preheater that recovers heat in the gas after removal of nitrogen oxides; a precipitator that removes particulates in the gas; an activated carbon atomizer that sprays activated carbon into the gas after particulate collection; a bag filter that collects activated carbon having adsorbed mercury; a desulfurizer that removes sulfur oxides in the flue gas after removal of activated carbon; a stack that discharges the gas which has undergone desulfurization to outside; and an ORP meter that measures an oxidation reduction potential for feeding air to a slurry absorbent in the desulfurizer.

Owner:MITSUBISHI HEAVY IND LTD

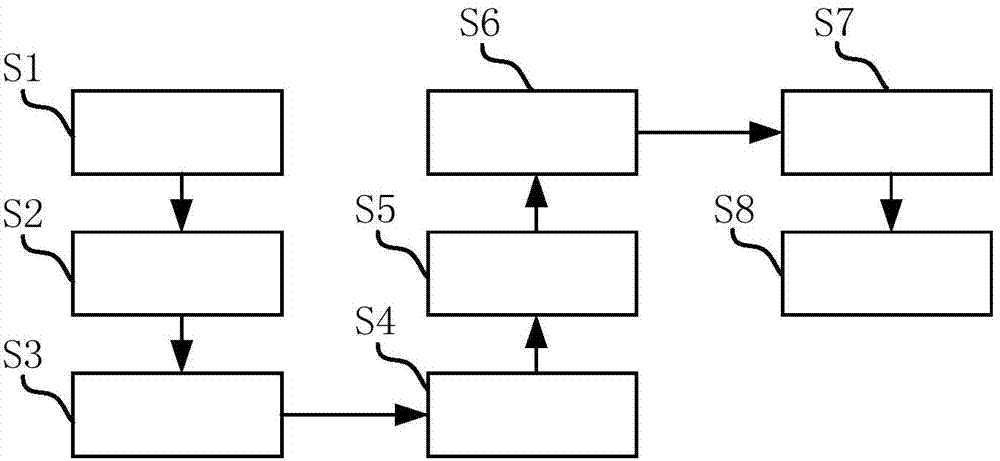

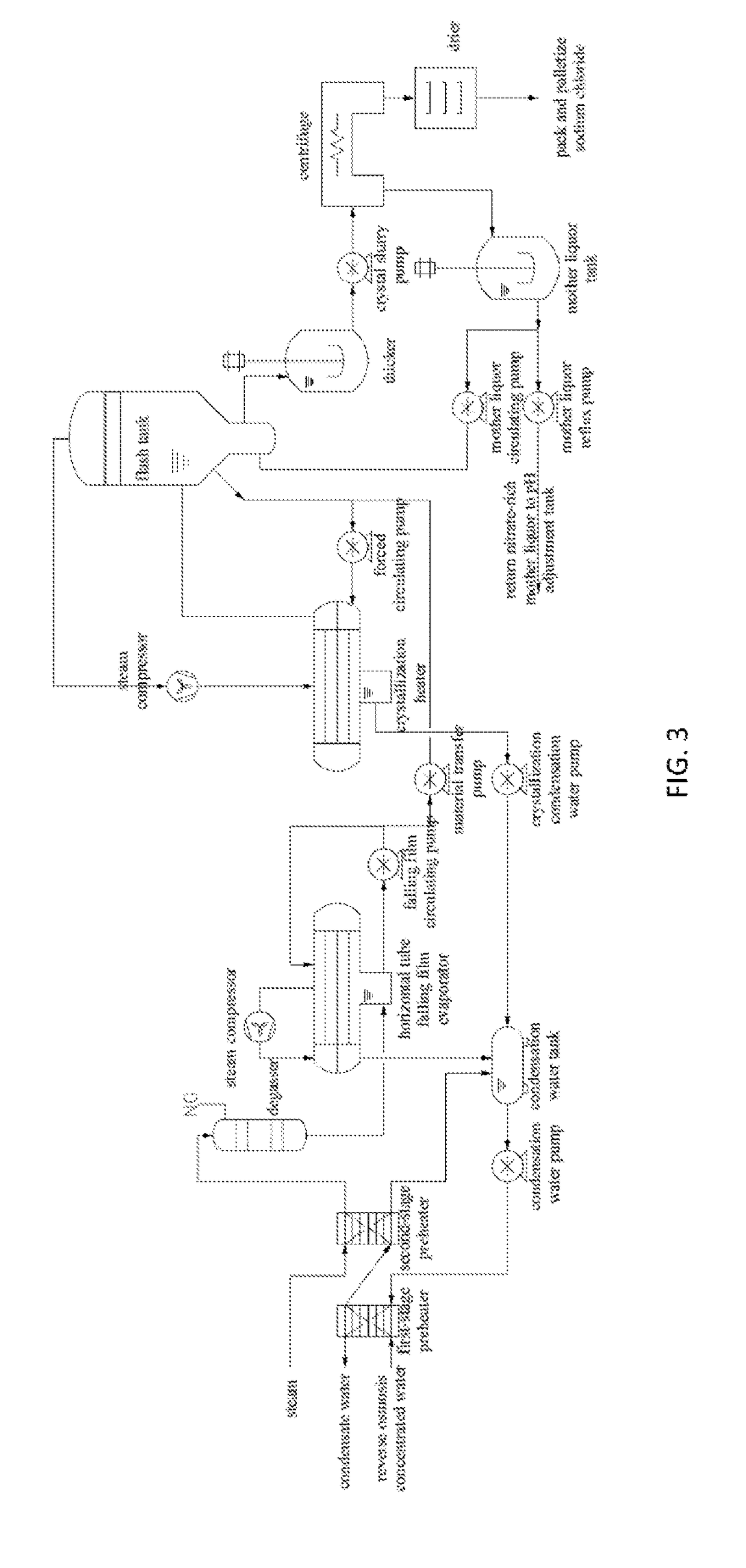

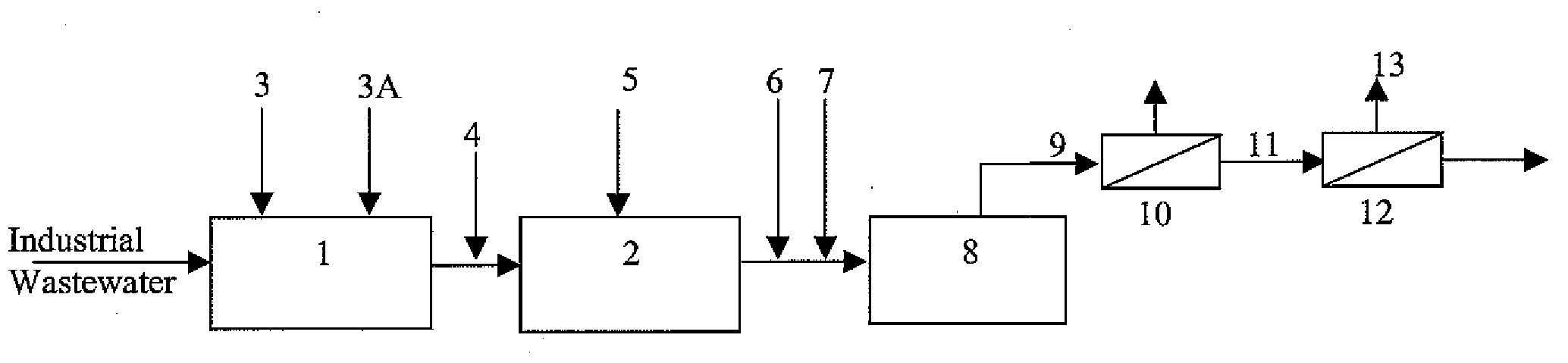

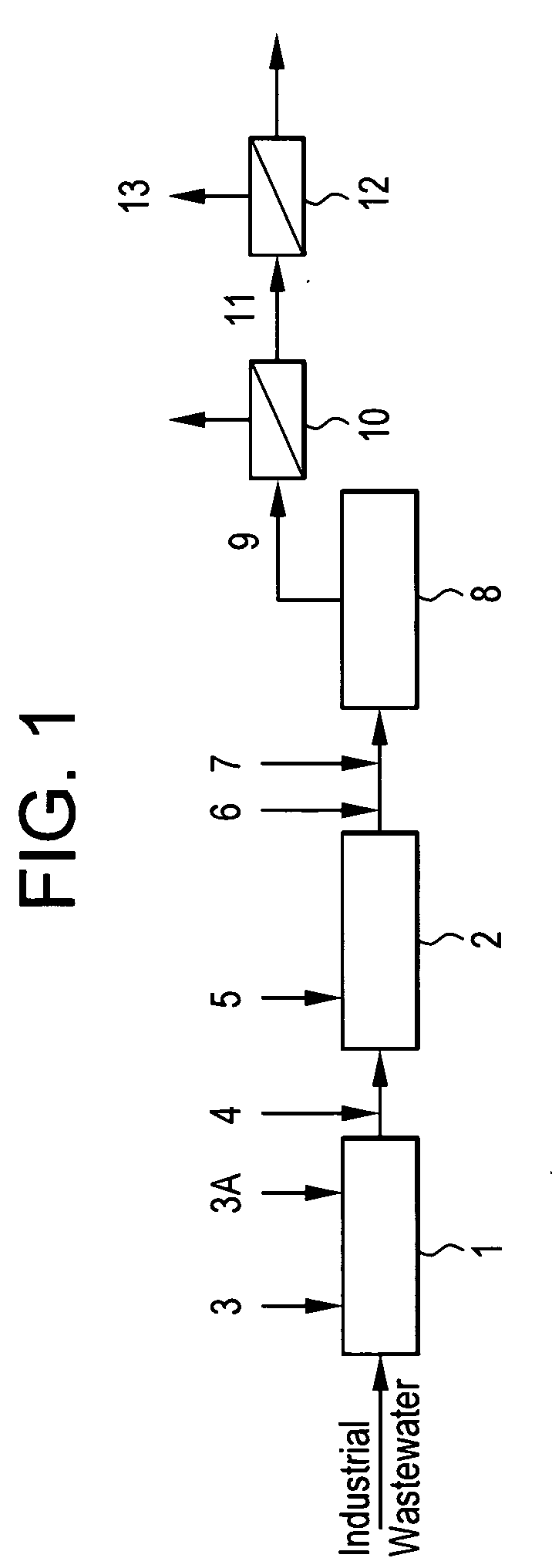

Desulfurization waste water zero discharging process and system

ActiveCN104843927ASolve pollutionWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater useHydration reaction

The invention discloses a desulfurization waste water zero discharging process. The process comprises a chemical dosing softening process and a microfiltration membrane treatment process; after incoming water is subjected to two-stage softening, nanofiltration and reverse osmosis separation are performed; sodium sulfate decahydrate with the purity of more than 99% is separated out by utilizing freezing crystallization; a reverse osmosis concentrated water regeneration sodium ion exchange device is utilized; sodium chloride with the purity of more than 98% is separated out by utilizing evaporative crystallization; solids are comprehensively utilized, and no liquid is discharged outside. The invention further provides a desulfurization waste water zero discharging system. According to the desulfurization waste water zero discharging process and the system, water in desulfurization waste water can be separated to be reutilized as domestic and industrial usable water, and other impurities in the desulfurization waste water are separated in solid form, so that pollutants harmful to the natural environment do not generate, and the problem that the desulfurization waste water pollutes the environment can be completely solved.

Owner:华电水务工程有限公司

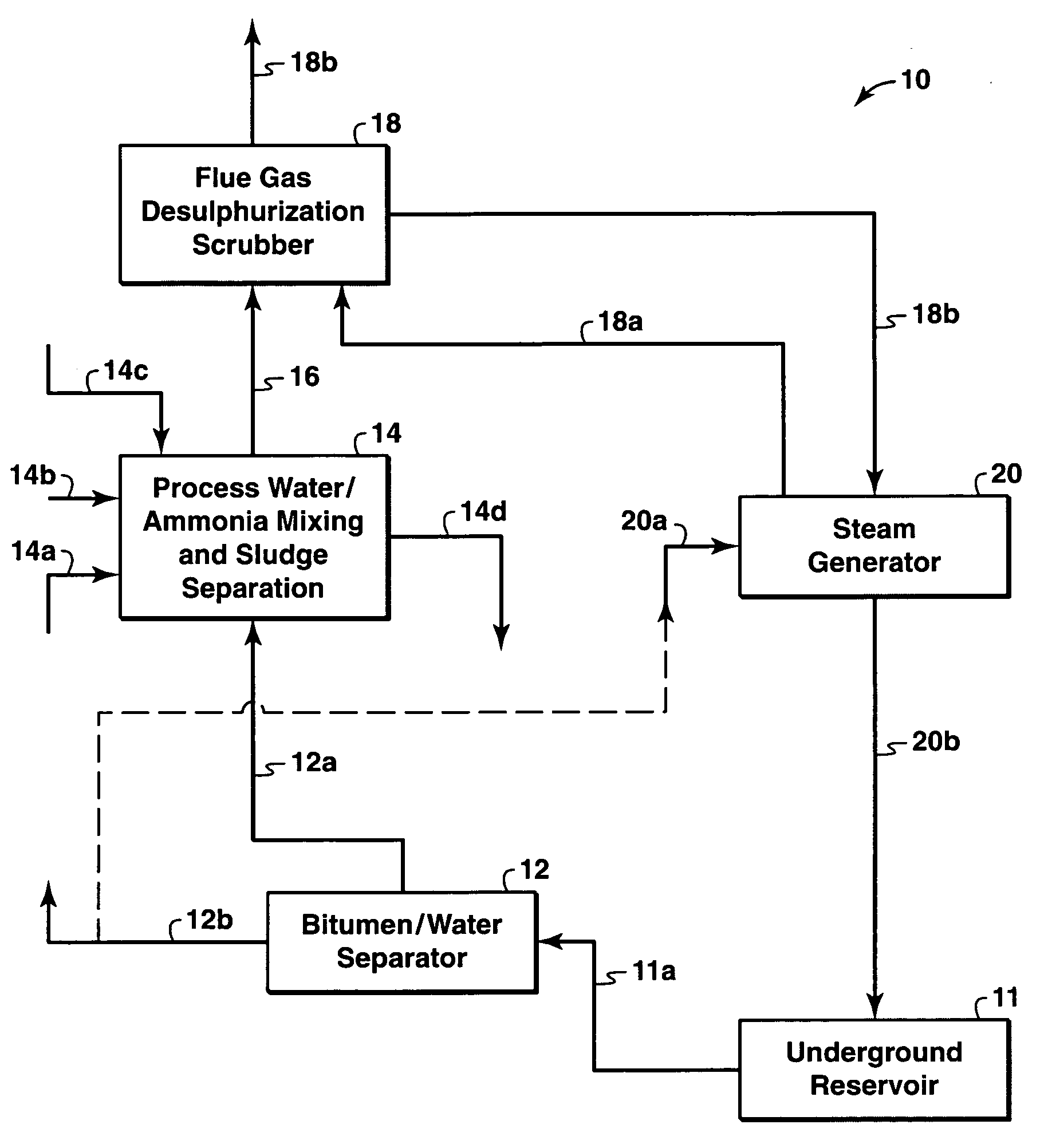

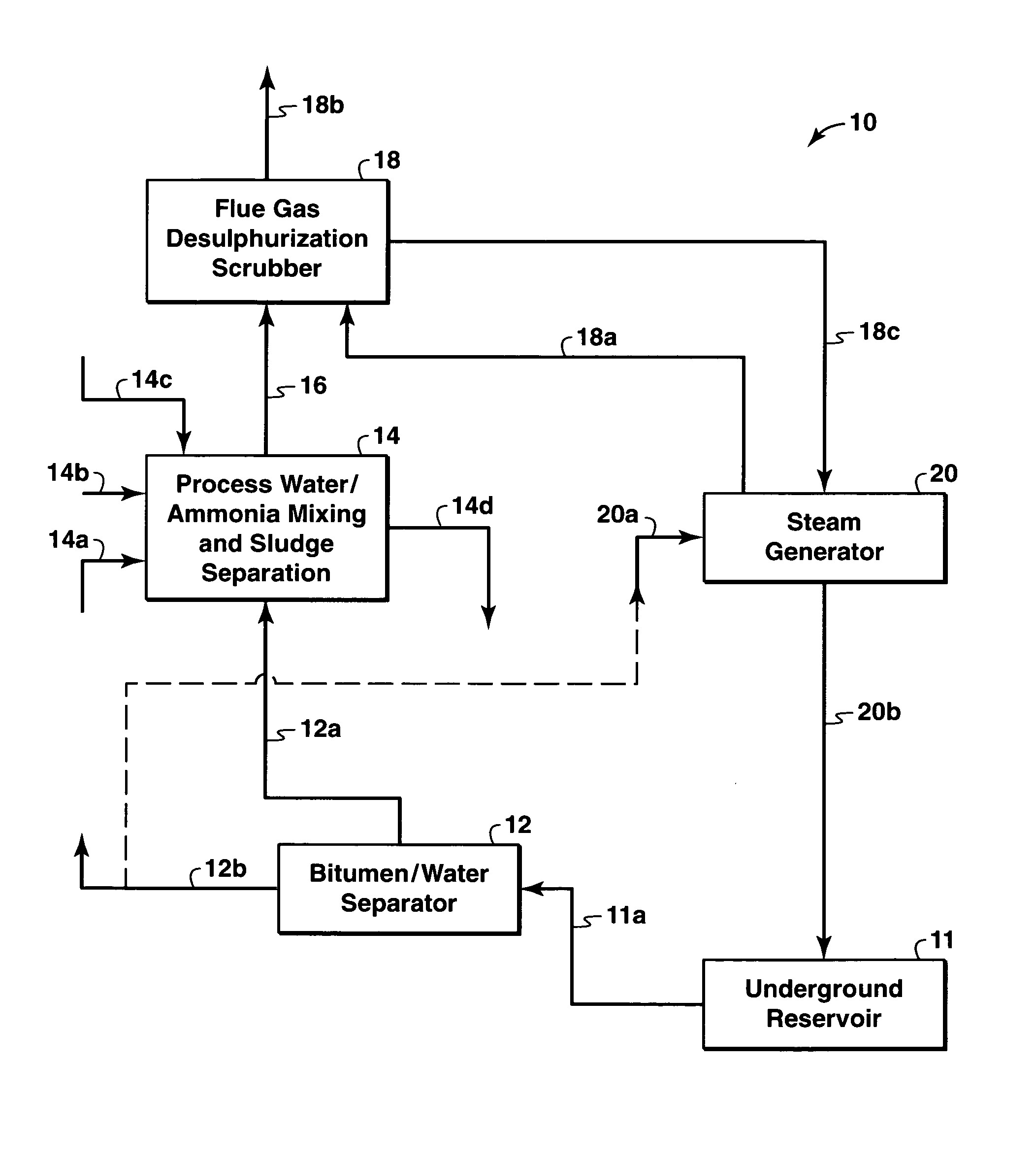

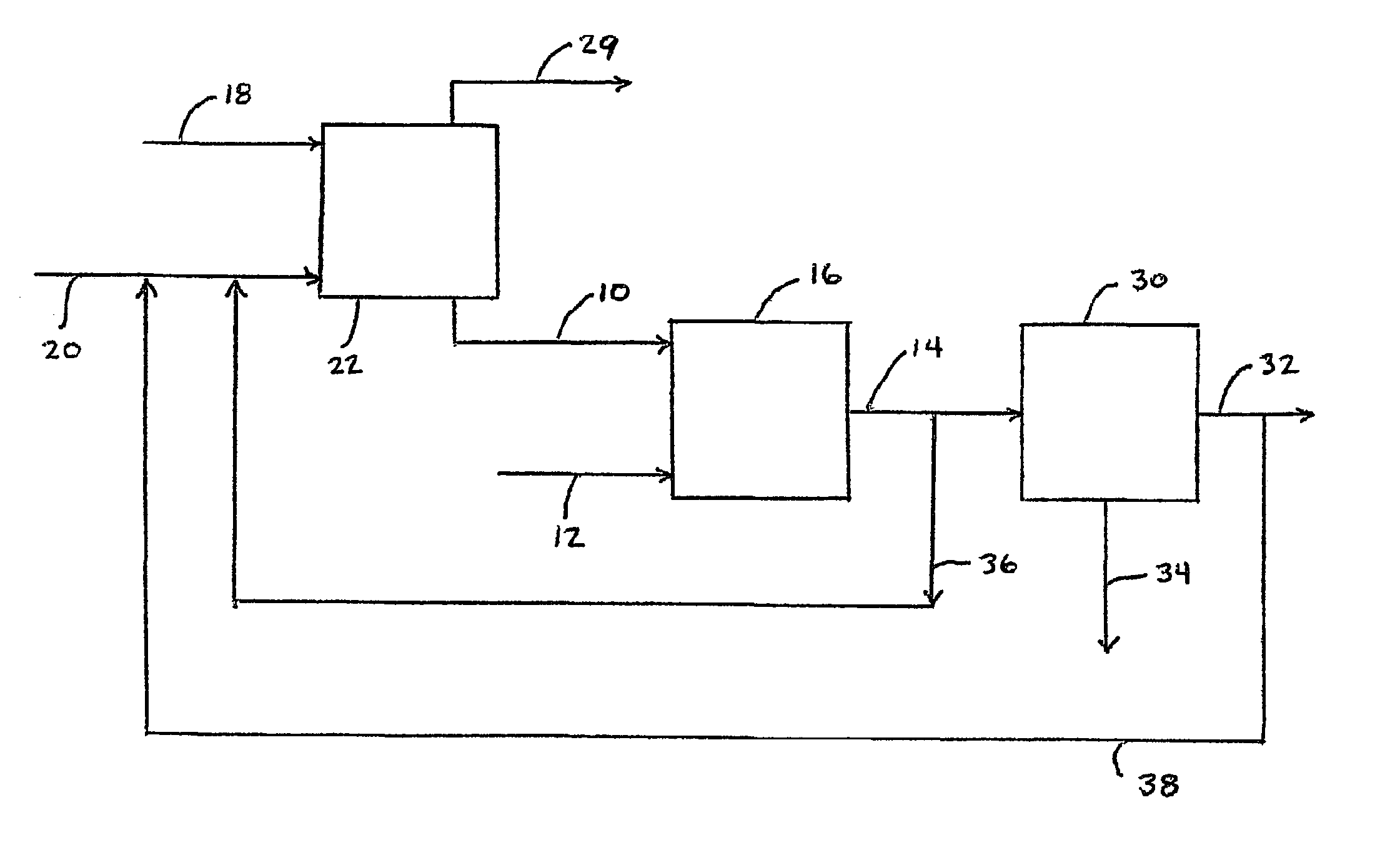

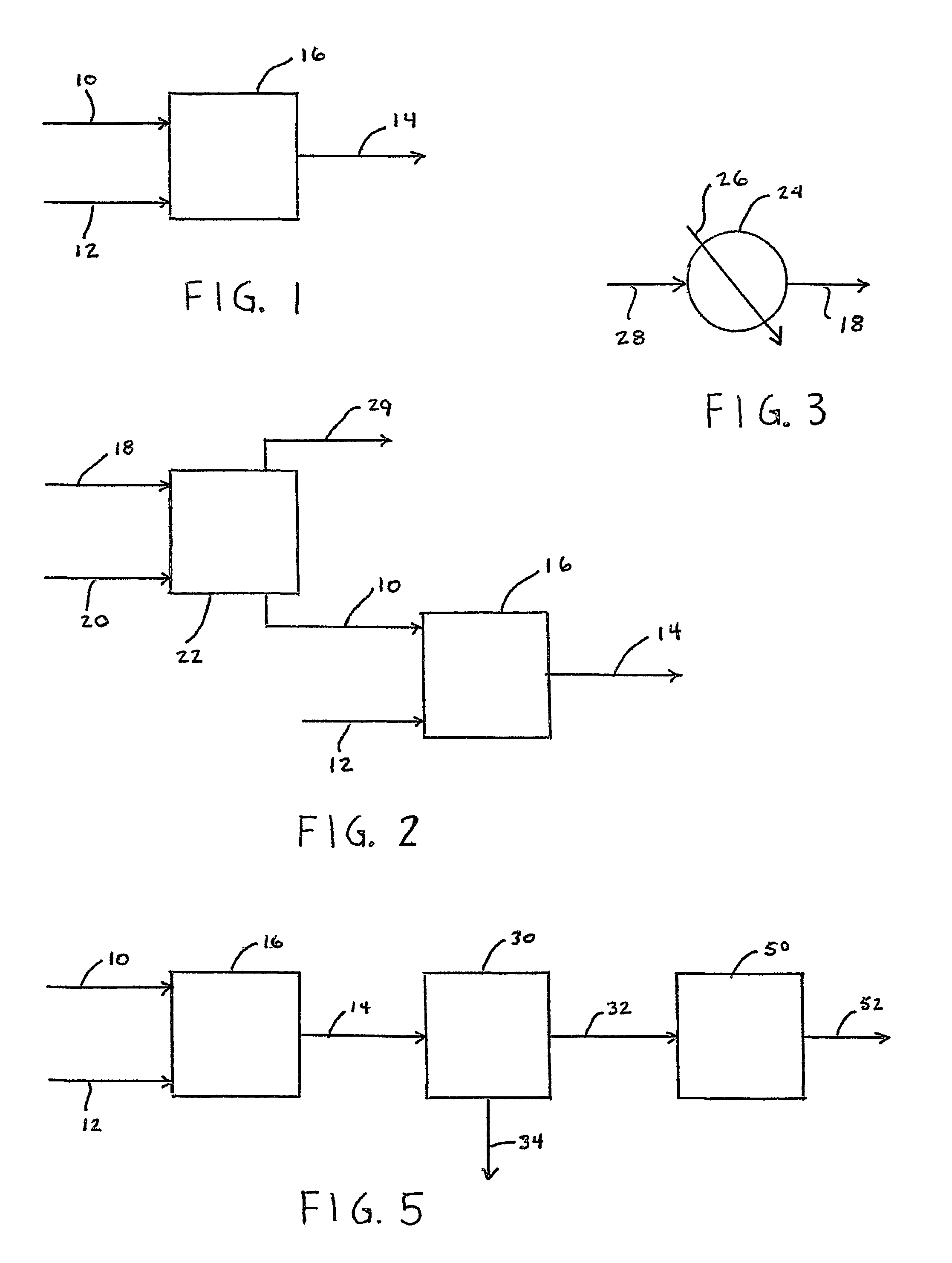

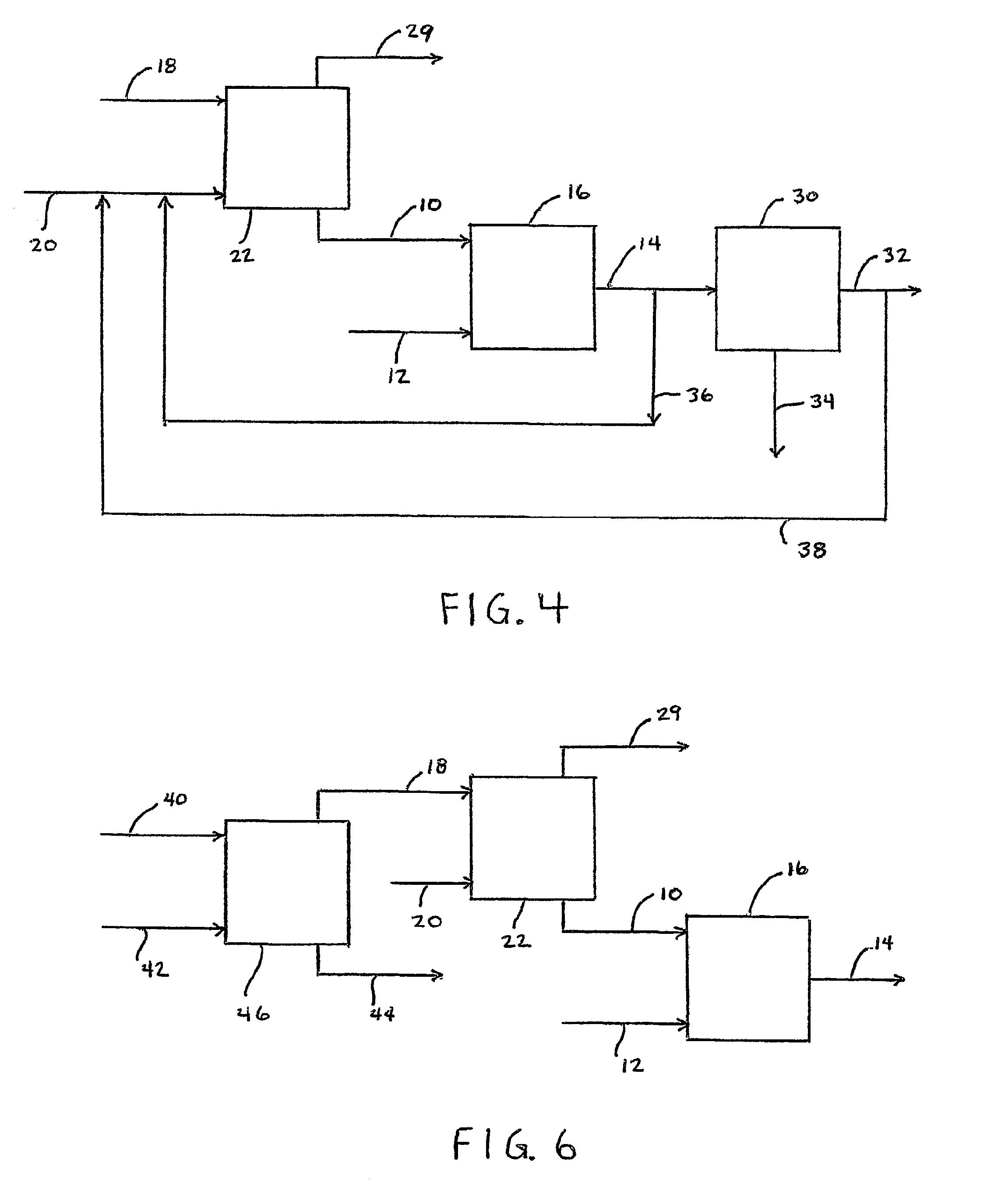

Integrated water treatment and flue gas desulfurization process

A water stream containing hardness minerals is subjected to a water treatment process using an alkali agent to precipitate the hardness minerals and to produce a softened water stream is used to create an integrated water treatment and flue gas desulfurization process. Thereafter, the softened, alkaline water stream is utilized in a scrubber to scrub a flue gas containing sulfur dioxide to produce a sulfur-lean flue gas. The invention may be applied to a steam-based bitumen recovery operation where bitumen, sour produced gas or other sulfur containing fuels are burned for producing steam for bitumen recovery. More specifically, the associated produced water from the bitumen recovery process may be softened for re-use and for utilization as a scrubbing agent for high-sulfur containing flue gas arising from the steam generators. The process provides an economically favorable process while minimizing waste disposal requirements.

Owner:EXXONMOBIL UPSTREAM RES CO

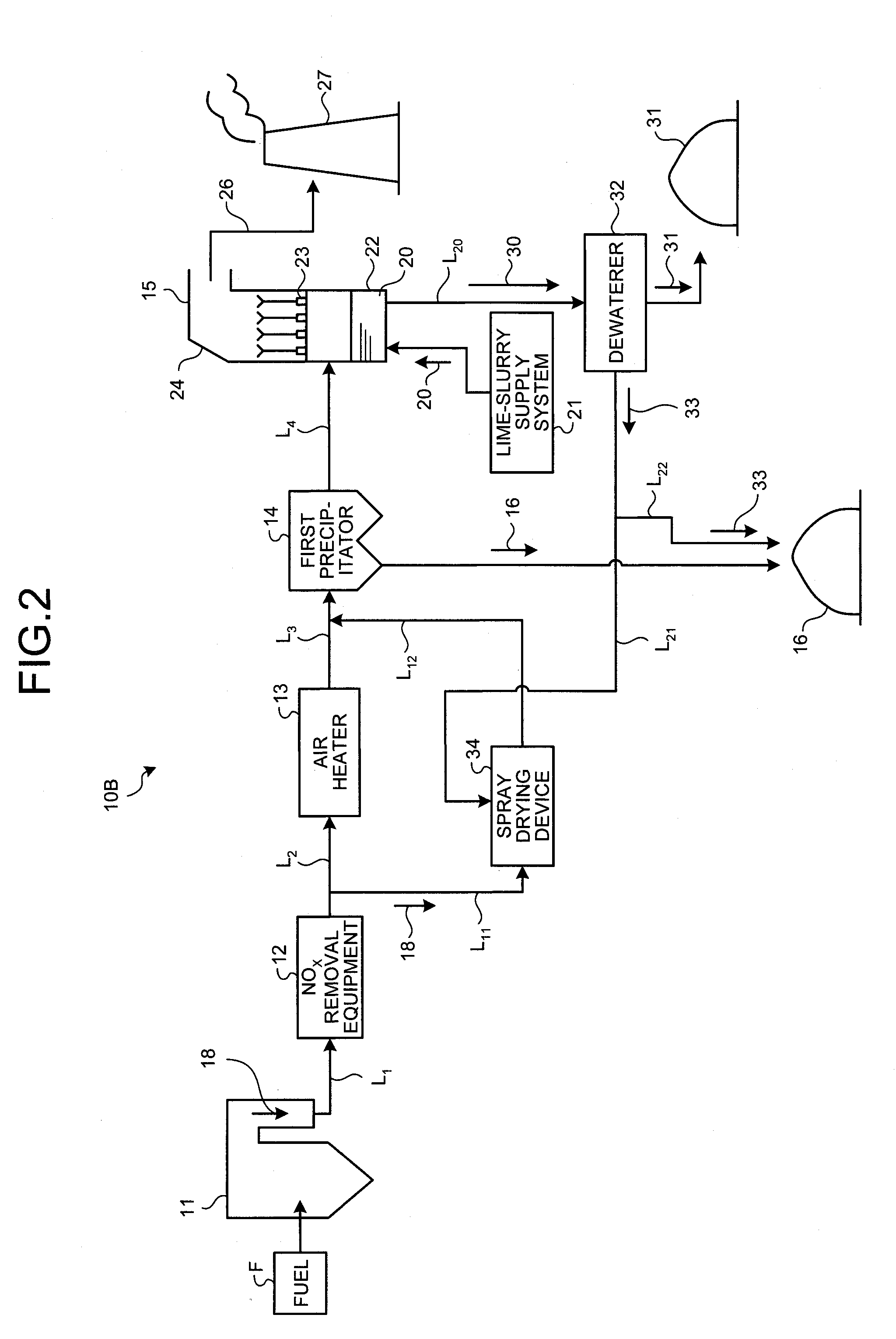

Air pollution control system and air pollution control method, spray drying device of dewatering filtration fluid from desulfurization discharged water, and method thereof

ActiveUS20120240761A1Improve performanceStable atomizationGas treatmentLiquid degasificationControl systemFlue gas

Owner:MITSUBISHI POWER LTD

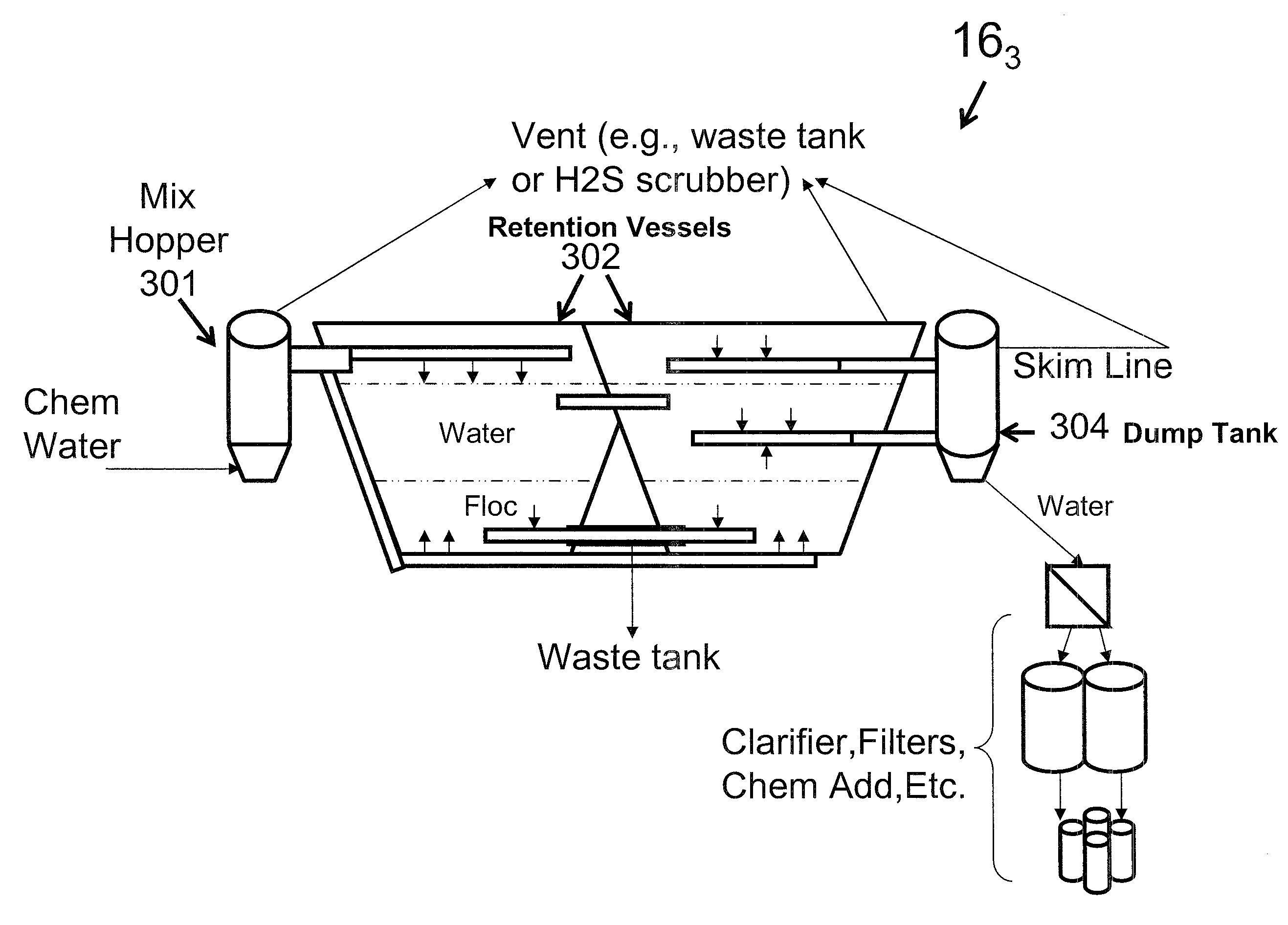

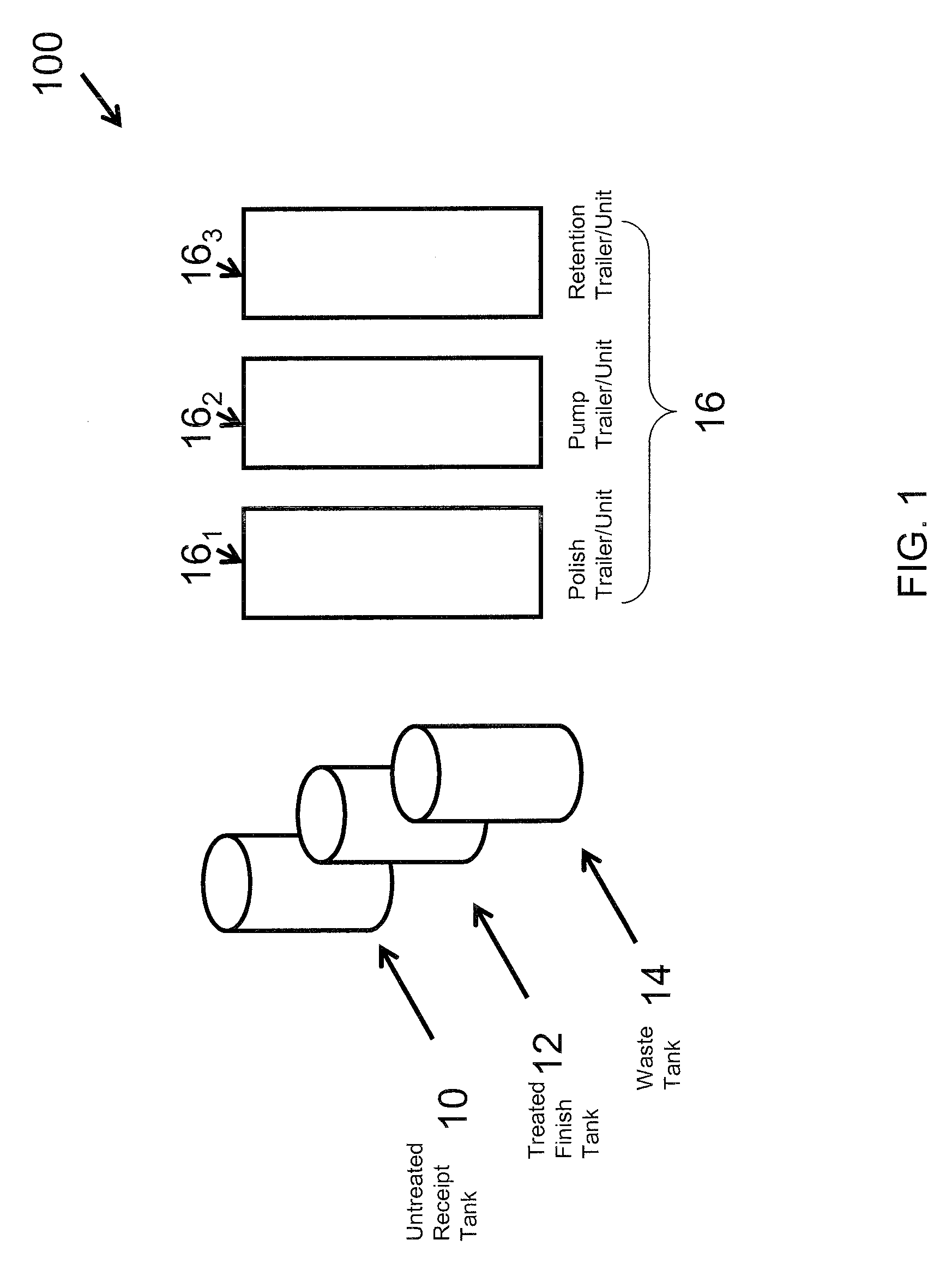

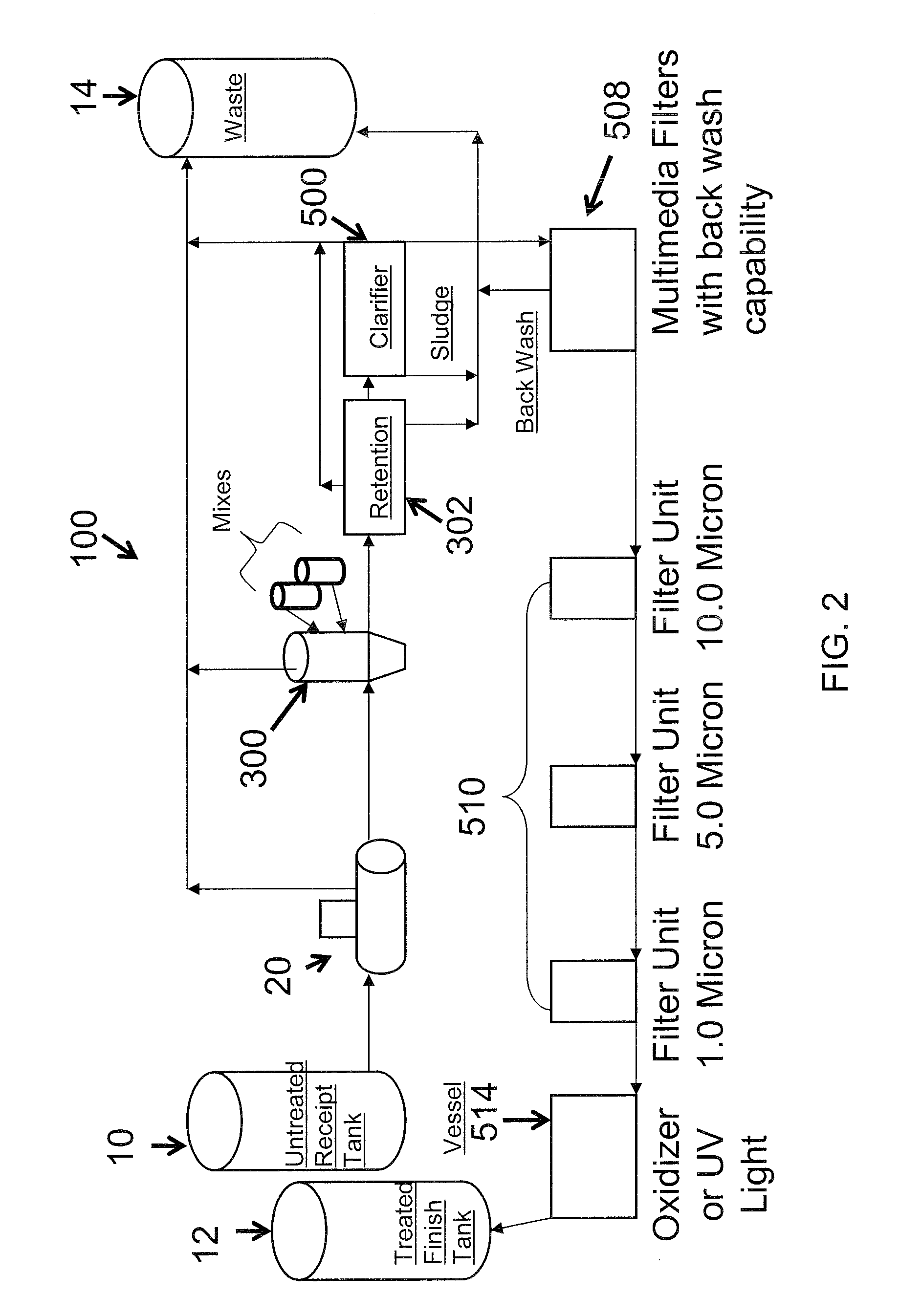

Recycling and treatment process for produced and used flowback fracturing water

ActiveUS20110005999A1Easy to assembleWater cleaningWater/sewage treatment by irradiationSedimentTreatment system

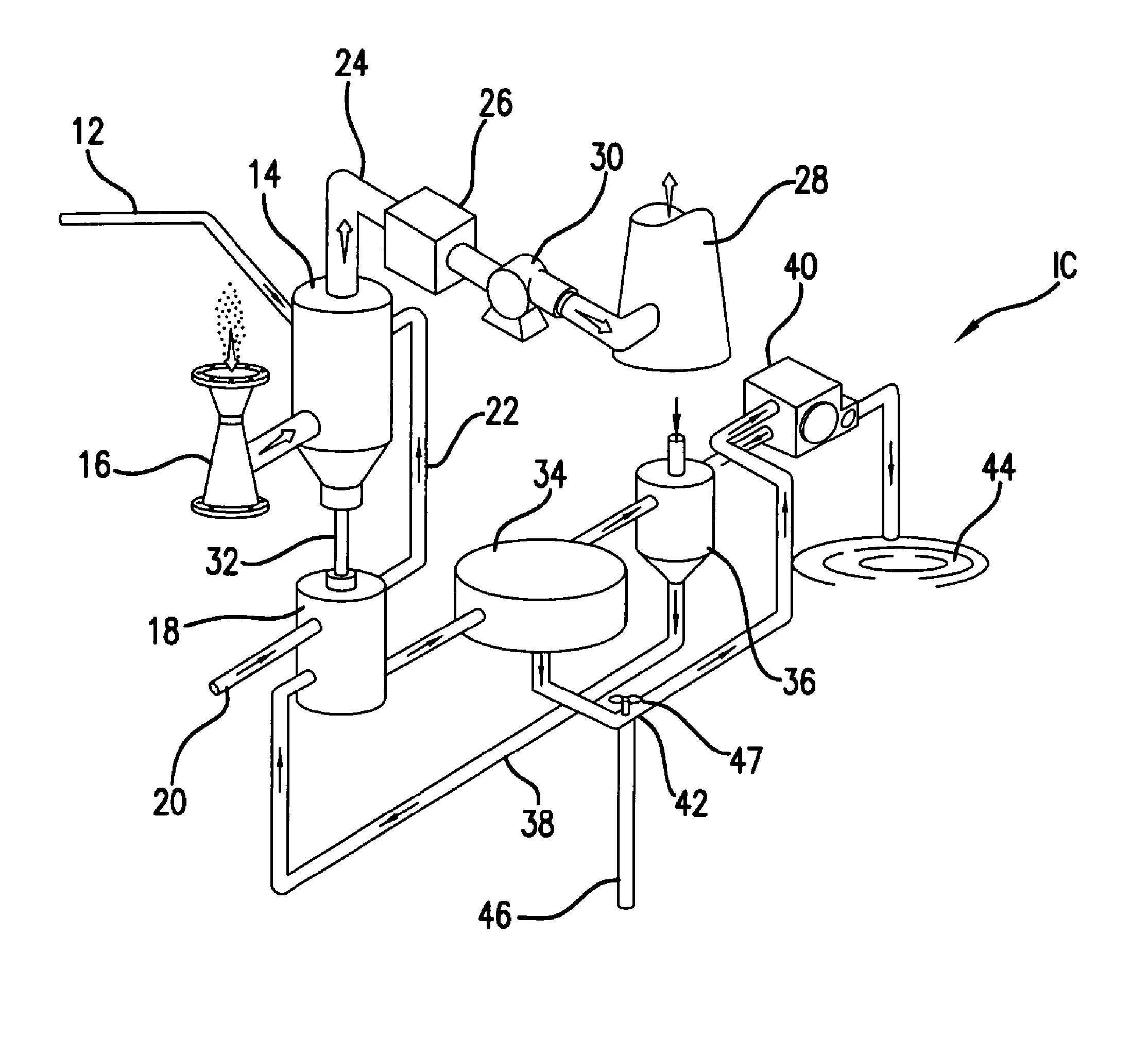

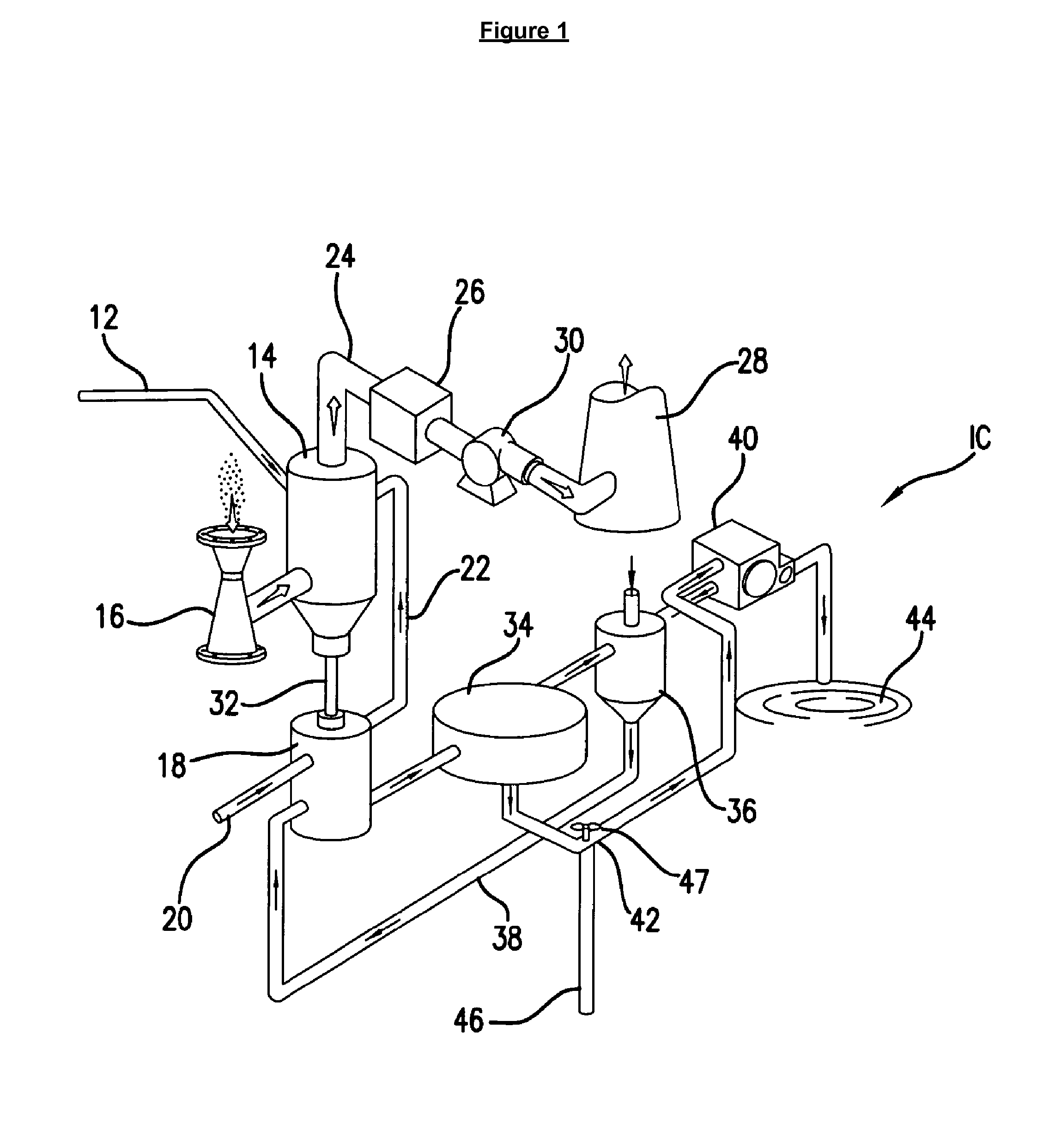

A portable water recycling and treatment system and process for used and produced flowback frac water pumps the water from a collection tank through a series of dedicated hydration, retention and filtering tanks and vessels that provide treatment for the removal of chemicals, sediments and other containments. The system, which is enclosed, can be readily assembled on-site by interconnecting the dedicated tanks, vessels and pumps. The tanks and vessels may be situated in a plurality of trailers / units that are transported separately to the site.

Owner:AUREUS ENERGY SERVICES INC

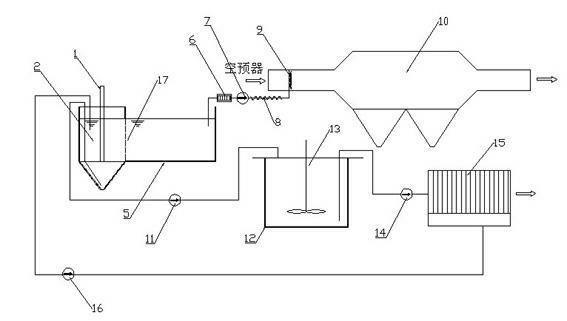

Hybrid copolymers

ActiveUS20070021577A1MiniaturizationLow costSeawater treatmentTransportation and packagingCopolymerMonomer

Hybrid copolymers for use as anti-scalant and dispersant. The polymers are useful in compositions used in aqueous systems. The polymers include at least one synthetic monomeric constituent that is chain terminated by a naturally occurring hydroxyl containing moiety. A process for preparing these hybrid copolymers is also provided.

Owner:AKZO NOBEL CHEM INT BV

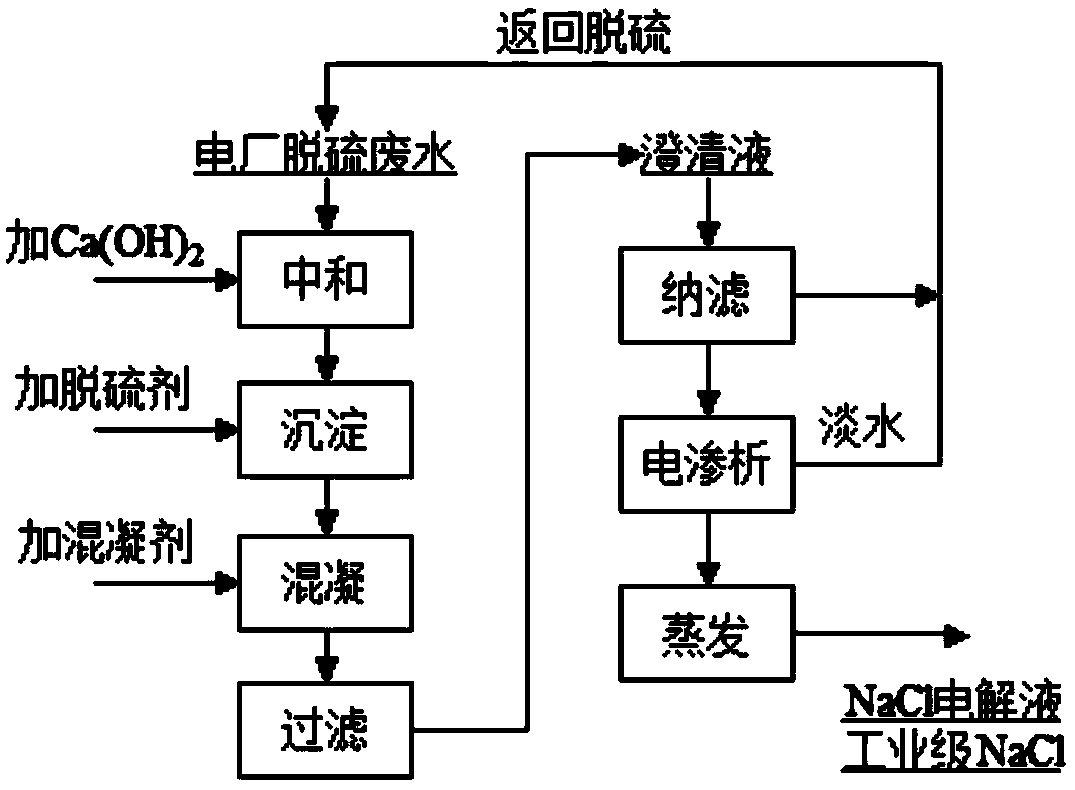

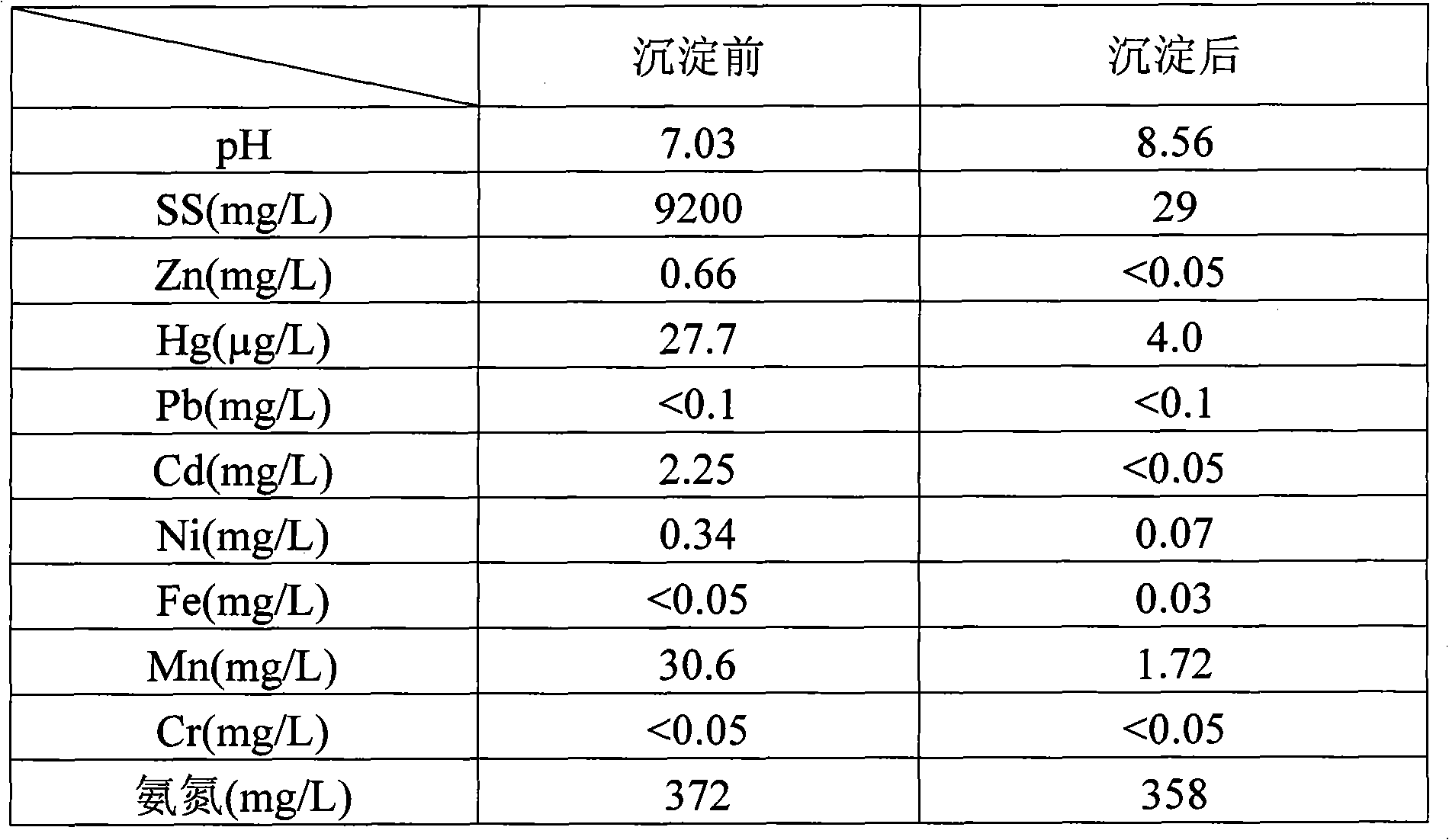

Method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting electrodialysis technology

ActiveCN104355473AMeet water requirementsImprove running stabilityGeneral water supply conservationDispersed particle separationChemical oxygen demandResource utilization

The invention relates to a method for carrying out desalination and zero-discharge processing of power plant desulphurization wastewater by adopting an electrodialysis technology. The method comprises the following steps: neutralizing, precipitating, coagulating and filtering the power plant desulphurization wastewater and removing CODs (Chemical Oxygen Demands), heavy metals, F-ions, gypsum, silicon dioxide, hydroxide of iron and aluminum and other insoluble particles in waste water; separating C1-ions and other monovalent ions in clear liquid from SO3<2->, SO4<2-> and other divalent ions through nanofiltration; desalinating and concentrating water produced by the nanofiltration by adopting a multistage countercurrent reverse electrodialysis method. The method has the advantages that the concentration of the Cl-ions in nanofiltration concentrated water and electrodialysis freshwater generated by the method is lower, and the nanofiltration concentrated water and the electrodialysis freshwater can be returned for flue gas desulfurization; the content of NaCl in a small amount of electrodialysis concentrated water produced reaches above 12 percent, the bivalent ions and other impurities are removed by nanofiltration, and the electrodialysis concentrated water is further evaporated and concentrated, so that chlorine-alkali industry electrolytes and NaCl salt can be obtained. Through the method, the zero-discharge treatment and the resource utilization of the desulfurization wastewater can be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

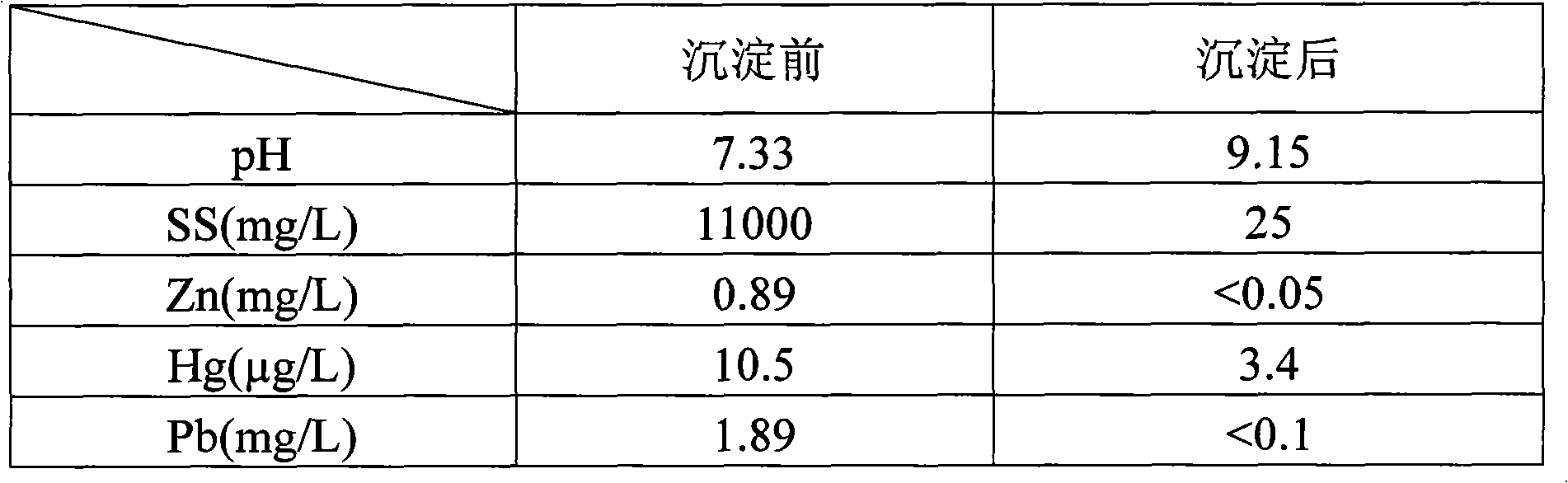

Treatment method of sintering flue gas desulphurization wastewater

ActiveCN101993169AReduce processing costsReduce the amount of waterTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisFlocculationFlue gas

The invention discloses a treatment method of sintering flue gas desulphurization wastewater, which completes the treatment on the sintering flue gas desulphurization wastewater through the following five steps of: 1. neutralization and coagulation: regulating the pH value of the sintering flue gas desulphurization wastewater to 8.5 to 9.5 by lye, and adding 0 to 200ppm of coagulating agents; 2. flocculation: adding 0 to 10ppm of coagulant aids for forming flocs; 3. precipitation and filter liquor separation; 4. biochemical treatment on filter liquor; and 5. deep treatment. The treatment method can be used for reducing the treatment cost of the desulphurization wastewater without generating influence on other treatment systems, thereby having good application and popularization prospects.

Owner:BAOSHAN IRON & STEEL CO LTD

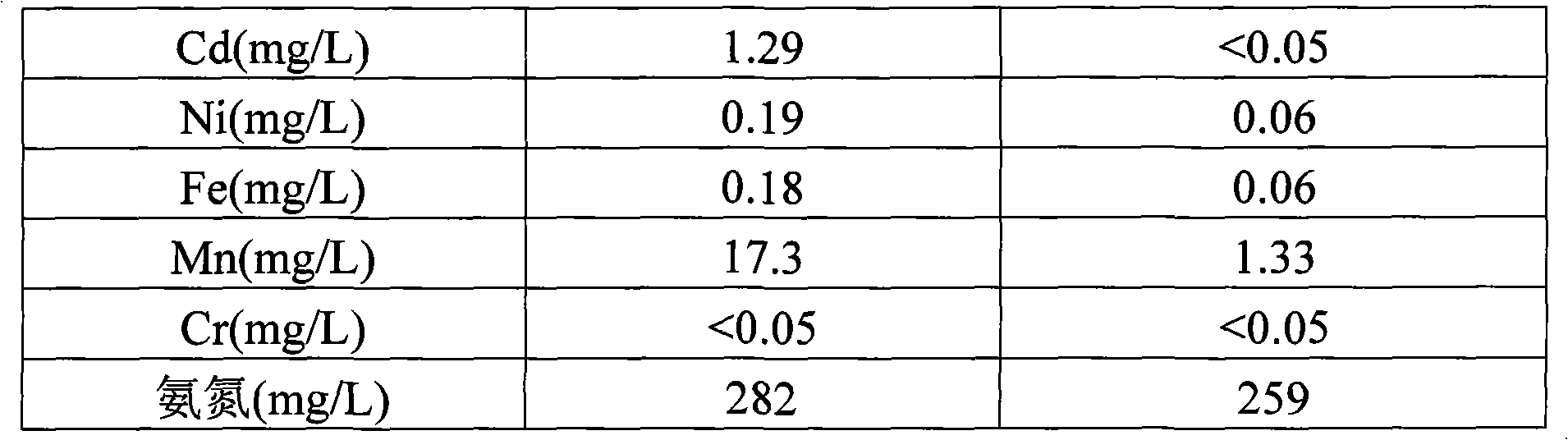

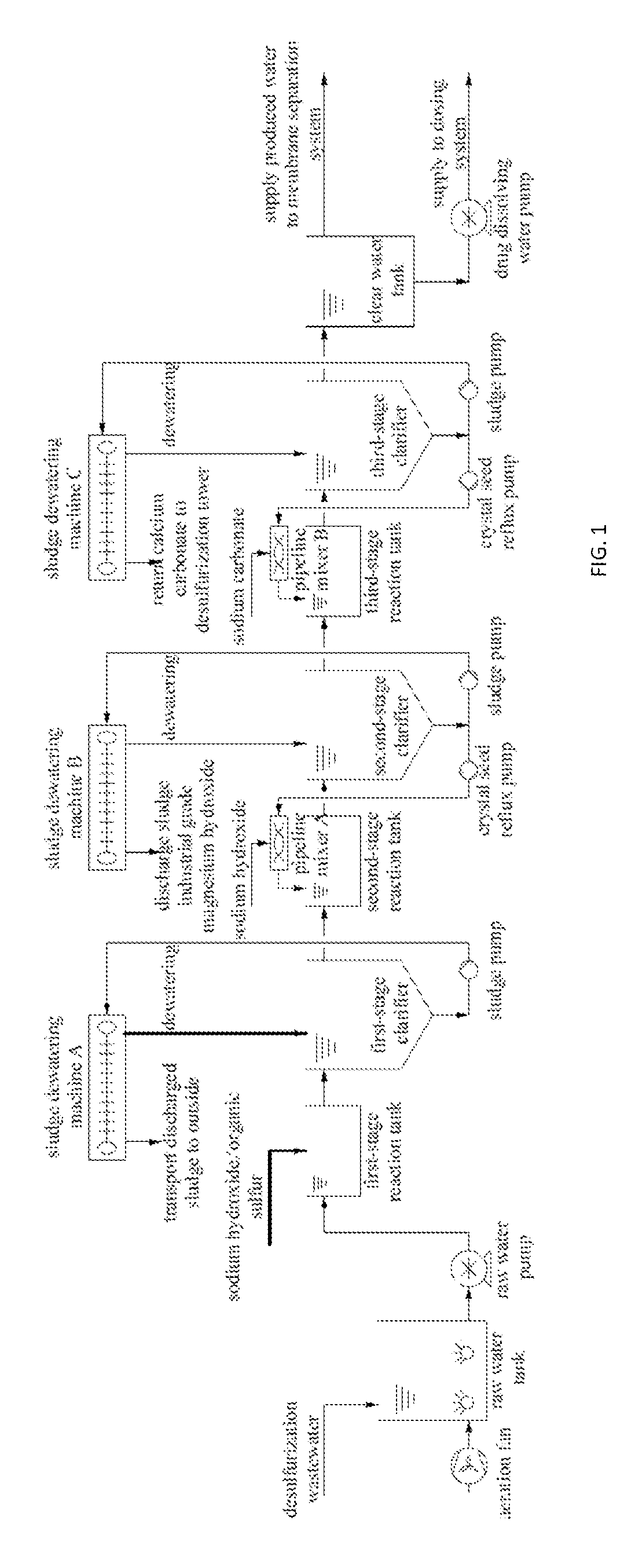

Zero-discharge technique for separating sludge and salt from desulfurization wastewater

ActiveUS20190077686A1Reduce disposal costsReduce project operating costsWaste water treatment from gaseous effluentsWater/sewage treatment by neutralisationSludgeUltrafiltration

A zero discharge process for separating sludge and salt from desulfurization wastewater includes a pretreatment process, a membrane treatment process and an evaporative crystallization process; in the pretreatment process, the desulfurization wastewater enters a raw water tank, an aeration fan introduces compressed air into the raw water tank, and the wastewater is lifted to first-stage reaction and clarification by a raw water pump; in the membrane treatment process, the incoming wastewater is first filtered by ultrafiltration, then enters a pH adjustment tank, and is pumped into a nanofiltration membrane separation system and a reverse osmosis membrane separation system; in the evaporative crystallization process, the incoming wastewater is first subjected to two-stage preheating, then enters a degasser, and finally enters an evaporative concentration system and a crystallization system.

Owner:JIANGSU JINGYUAN ENVIRONMENTAL PROTECTION

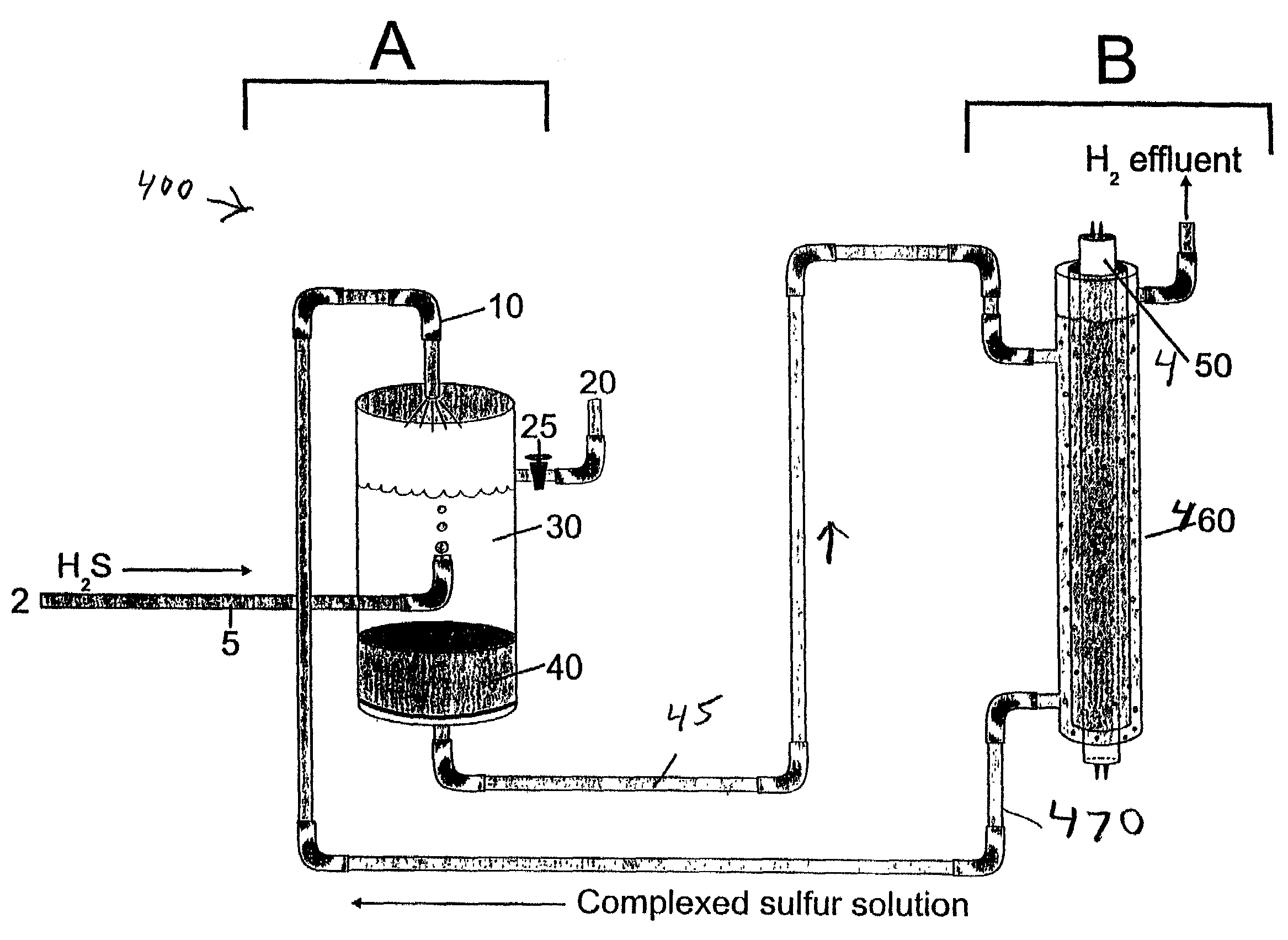

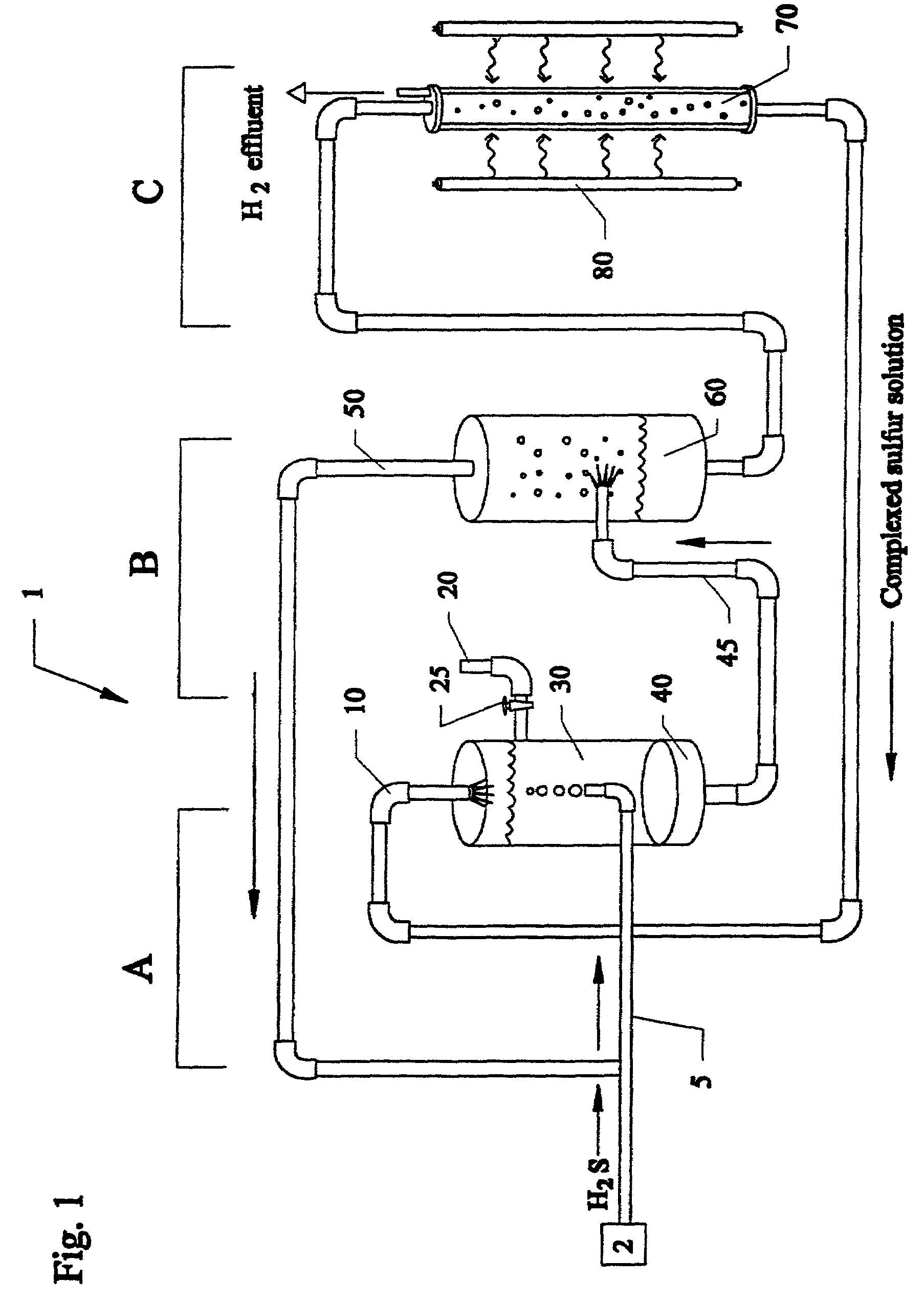

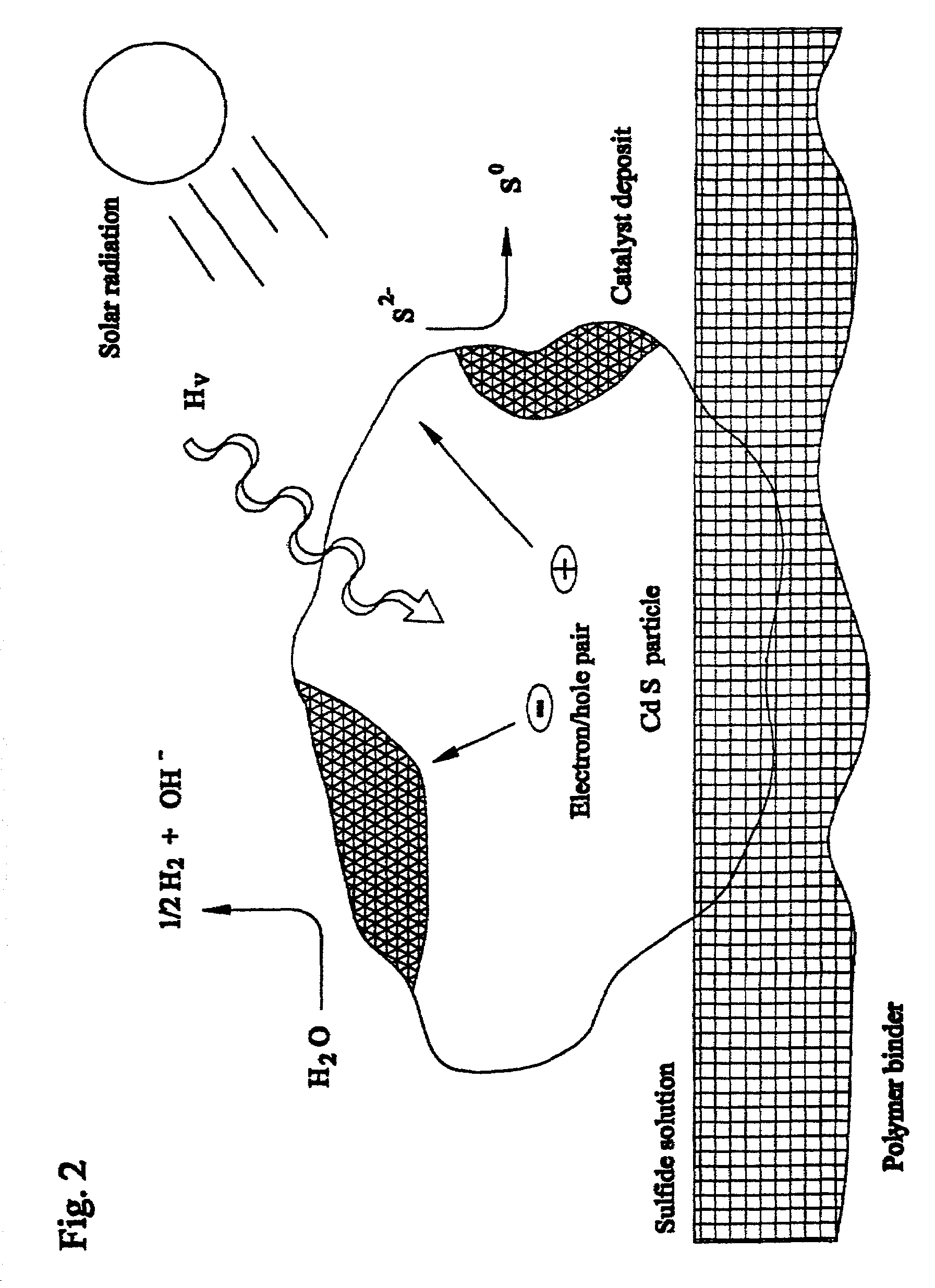

UV photochemical option for closed cycle decomposition of hydrogen sulfide

Methods and systems for separating hydrogen and sulfur from hydrogen sulfide(H2S) gas. Hydrogen sulfide(H2S) gas is passed into a scrubber and filtration unit with polysulfide solution. Interaction frees elemental sulfur which is filtered, excess continues to a stripper unit where the excess H2S is removed. The excess H2S returns to the scrubber and filtration unit, while the sulfide solution passes into a photoreactor containing a photocatalyst and a light source. The sulfide solution is oxidatively converted to elemental sulfur and complexed with excess sulfide ion to make polysulfide ion, while water is reduced to hydrogen. Hydrogen is released, while the polysulfide solution is fed back to the scrubber unit where the system operation repeats. In a second embodiment, the photocatalyst is eliminated, and the hydrogen sulfide solution is directly illuminated with ultraviolet radiation with a light source such as a low pressure mercury lamp operating at approximately 254 nm.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

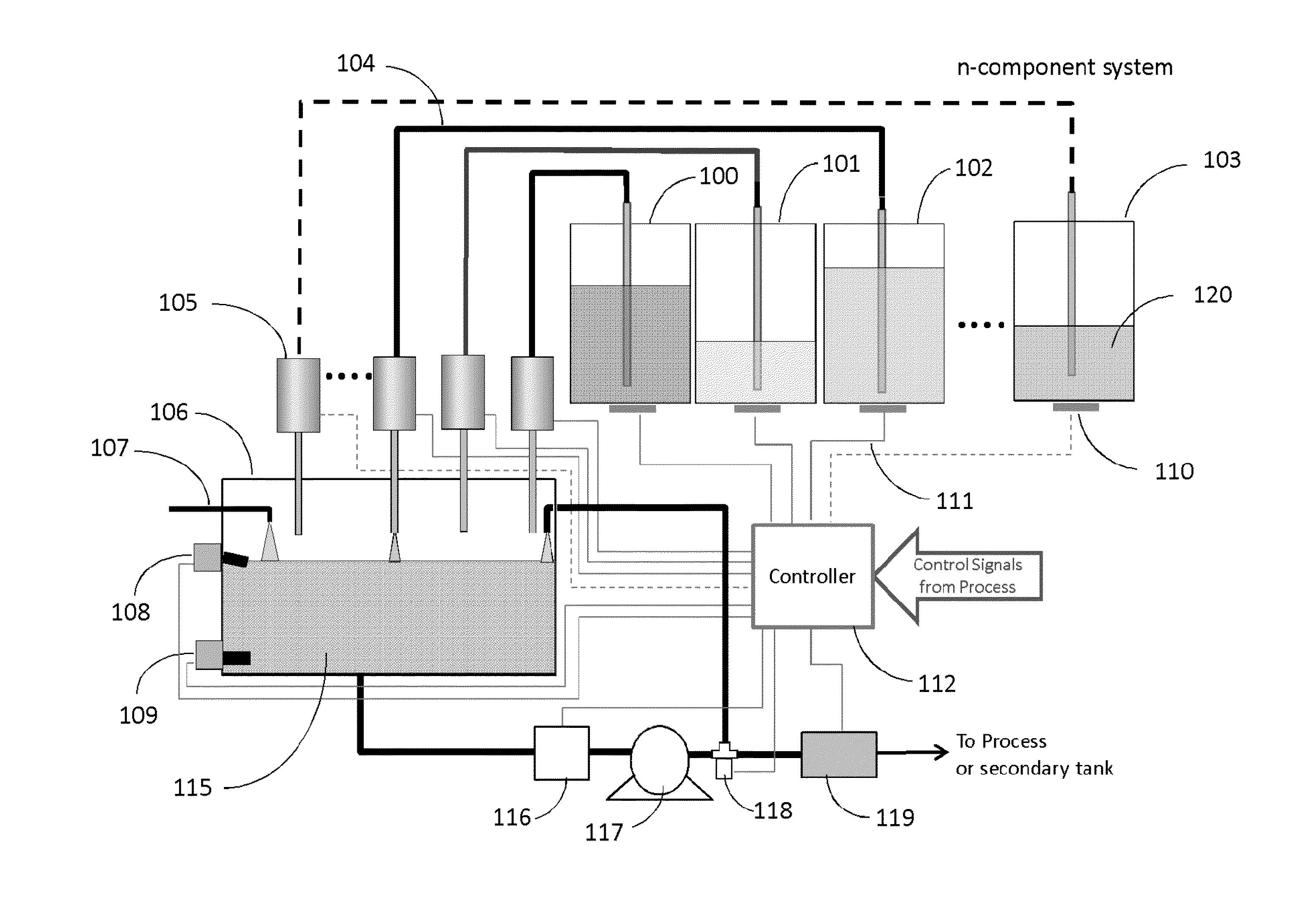

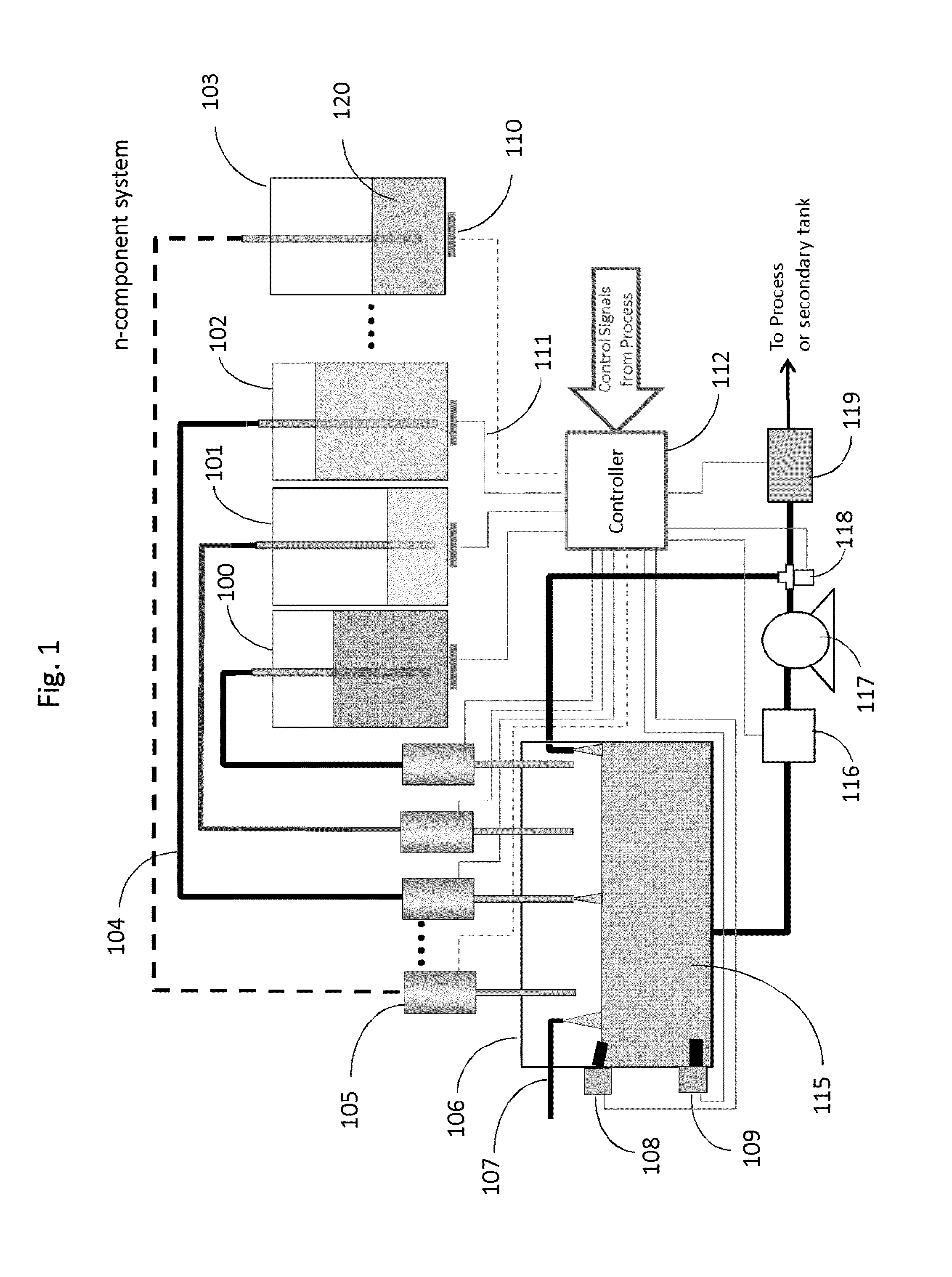

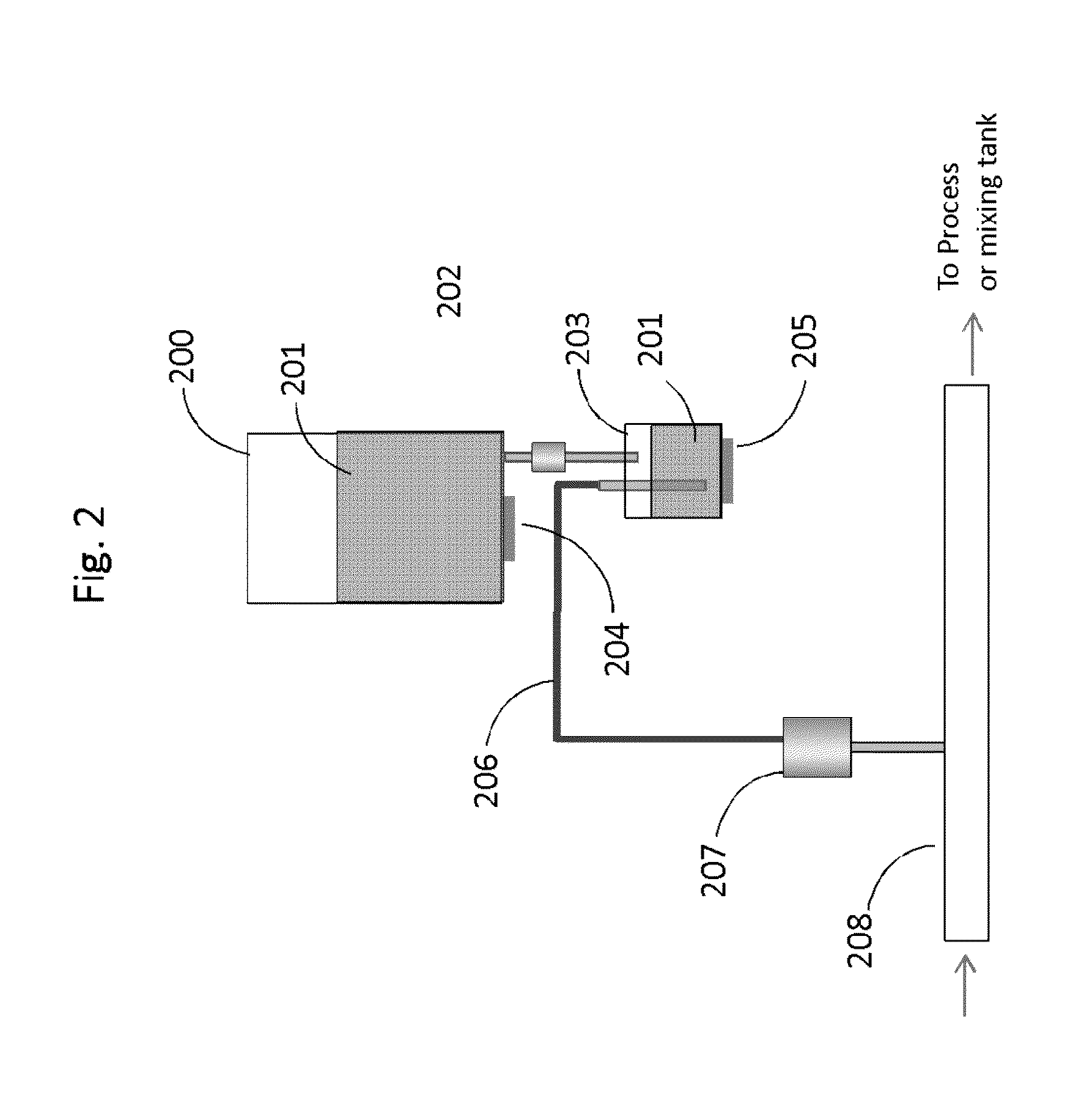

Treatment of industrial water systems

InactiveUS20130233796A1Easy to controlProgramme controlSemi-permeable membranesEnvironmental engineeringBULK ACTIVE INGREDIENT

A method for controlling treatment of an industrial water system is disclosed. The method comprises the steps of providing an apparatus for controlling delivery of at least one treatment chemical, the apparatus comprising at least one sensor and an electronic input / output device carrying out a protocol; measuring a parameter of the industrial water system using the at least one sensor; relaying the measured parameter to the electronic device; adjusting the protocol based on the measured parameter; delivering a concentrated treatment chemical into a stream of the industrial water system according to the adjusted protocol, the concentrated treatment chemical comprising an active ingredient, the active ingredient traced as necessary, the active ingredient having a concentration; repeating the measuring, the adjusting, and the delivering; and optionally repeating the steps for n-number of parameters, n-number of active ingredients, and / or n-number of concentrated treatment chemicals.

Owner:ECOLAB USA INC

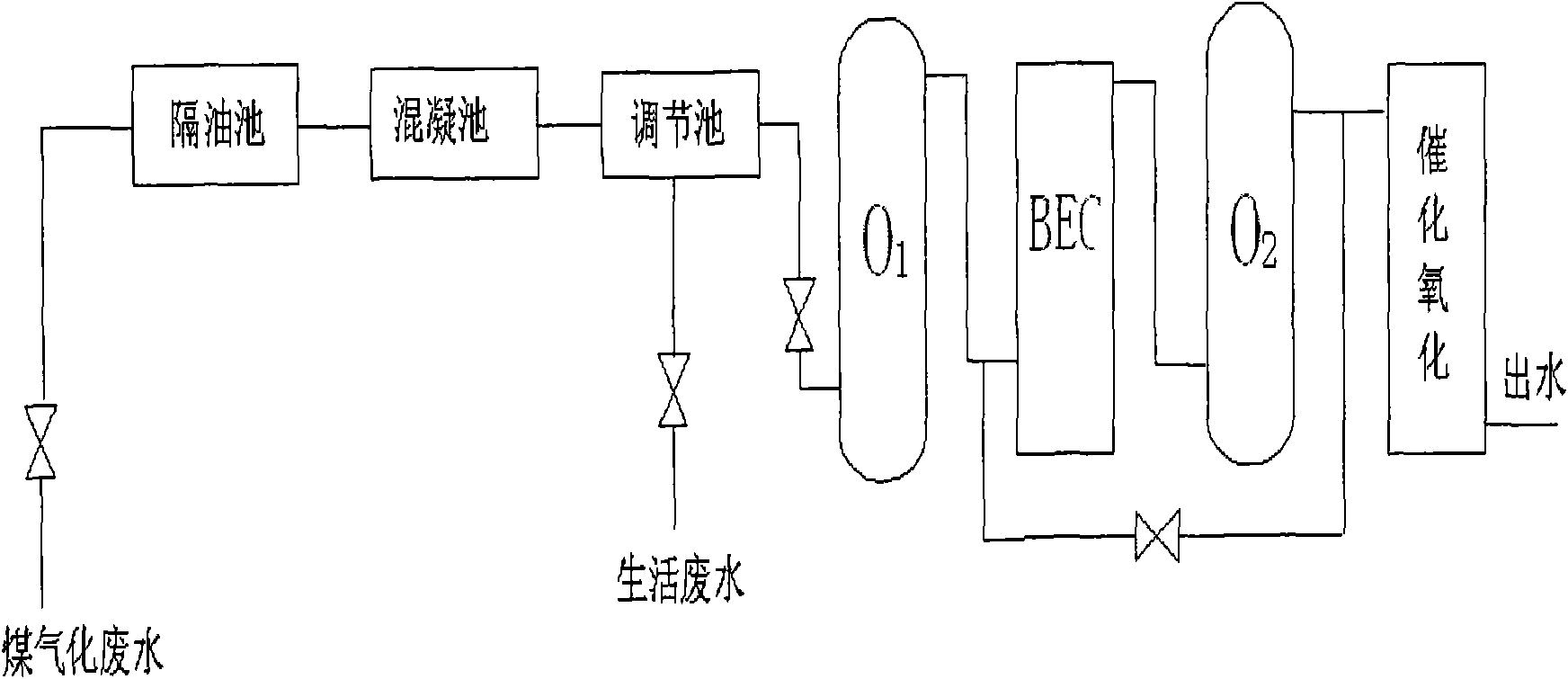

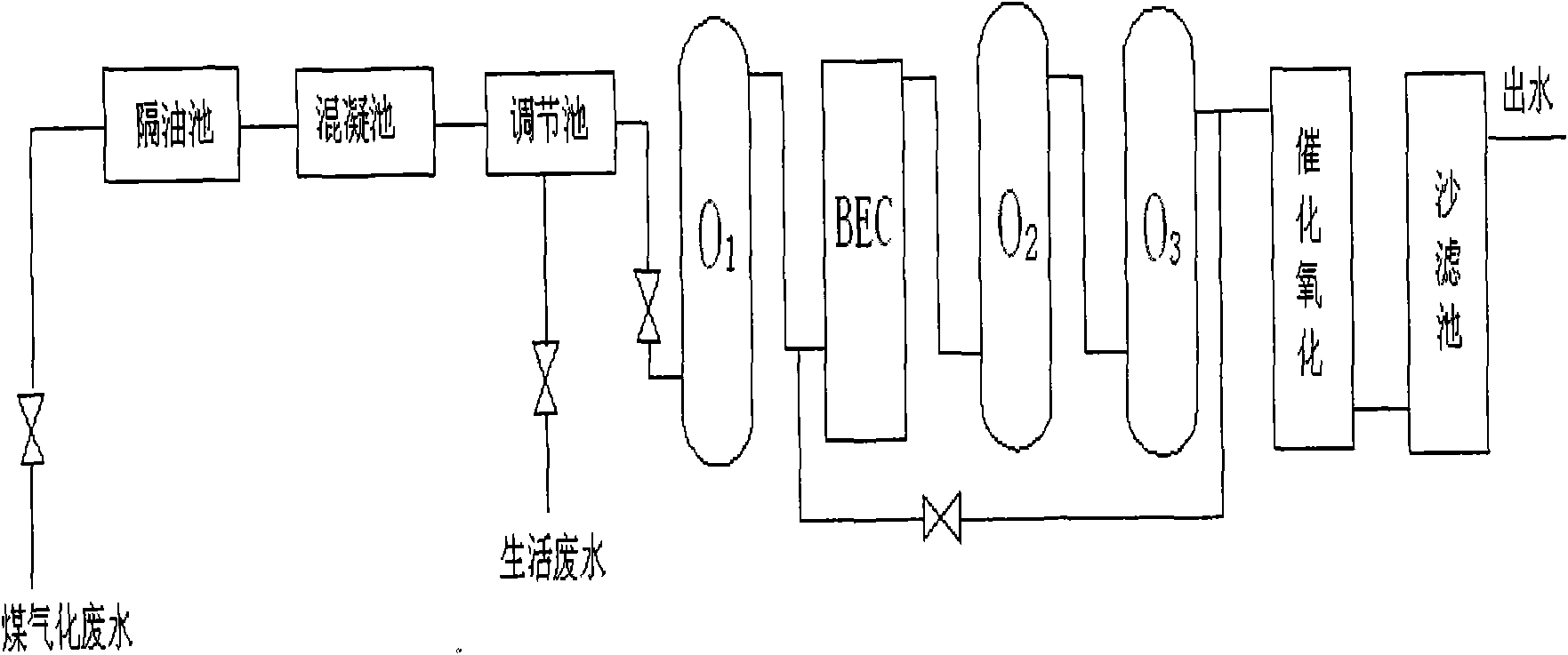

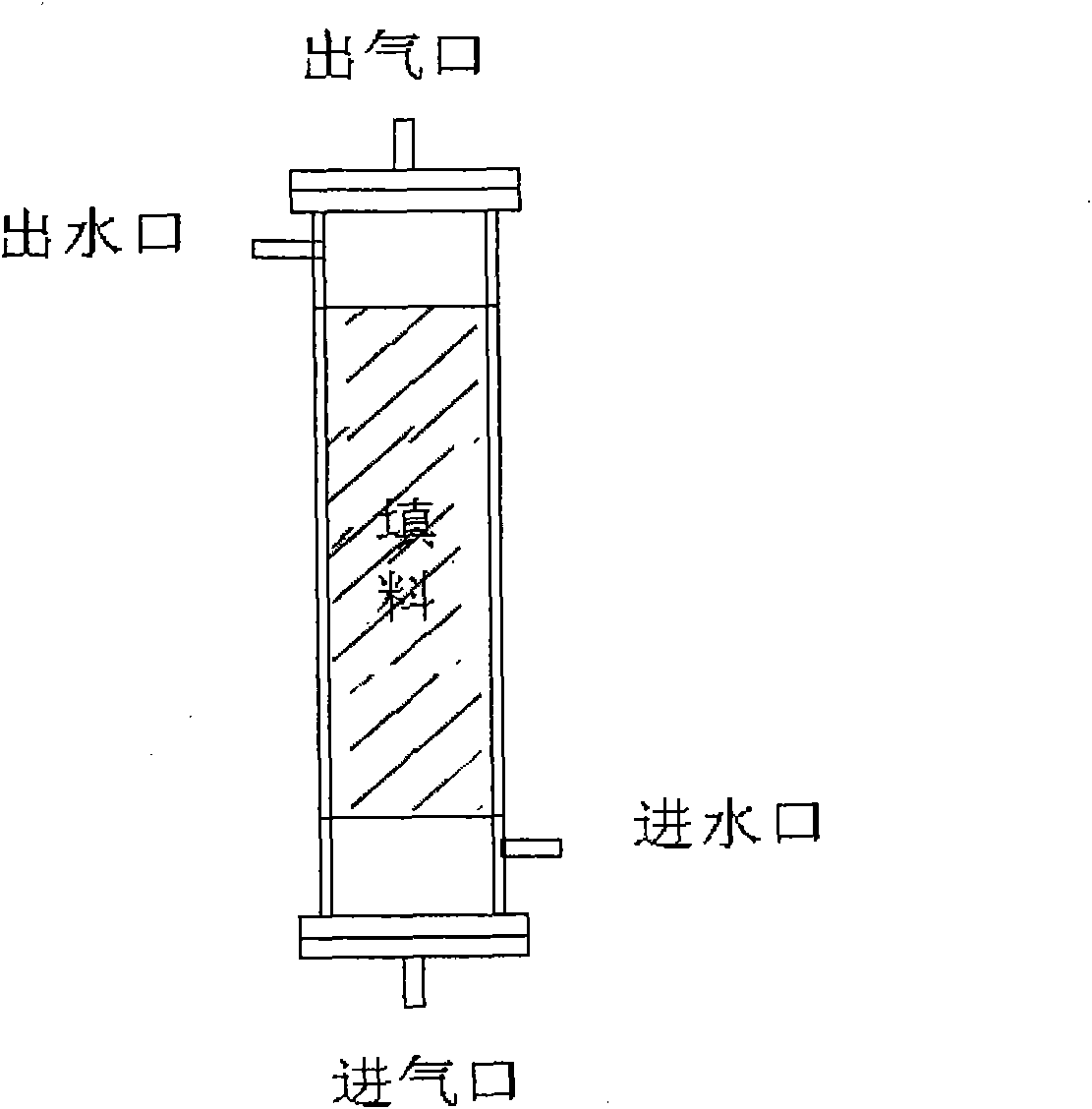

Method for processing coal gasification wastewater

ActiveCN101654316APromote degradationImprove nitrogen removal efficiencyWaste water treatment from gaseous effluentsMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention discloses a method for processing coal gasification wastewater. The method sequentially comprises the following steps: a. carrying out preprocessing on the coal gasification wastewater in a preprocessing step comprising oil removal processing, coagulation processing and optional adjustment processing; then b. leading the preprocessed coal gasification wastewater to sequentially flowthrough a first-class bio-contact oxidation reactor, a biological electrochemical reactor, a second-class bio-contact oxidation reactor and an optional third-class or multi-class bio-contact reactor to carry out biological processing; and c. leading the biologically processed coal gasification wastewater to carry out catalytic oxidation processing in a catalytic oxidation reactor.

Owner:ENN ENVIROTECH CO LTD

Universal method and apparatus for conversion of volatile compounds

InactiveUS7029589B2Increase usageAvoid oversaturationPaint waste treatmentUsing liquid separation agentCompound aOxidizing agent

Owner:MCGINNESS MICHAEL P

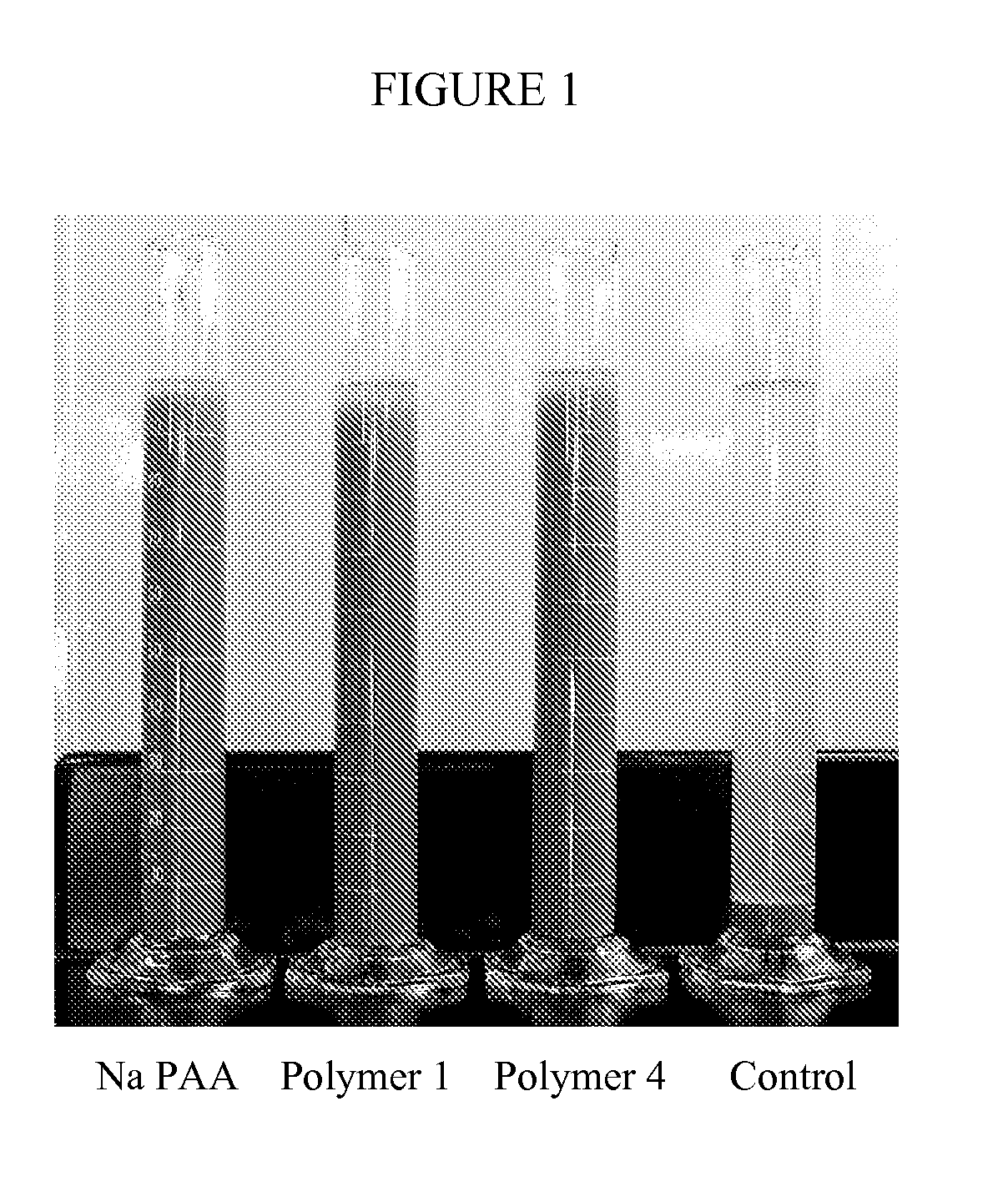

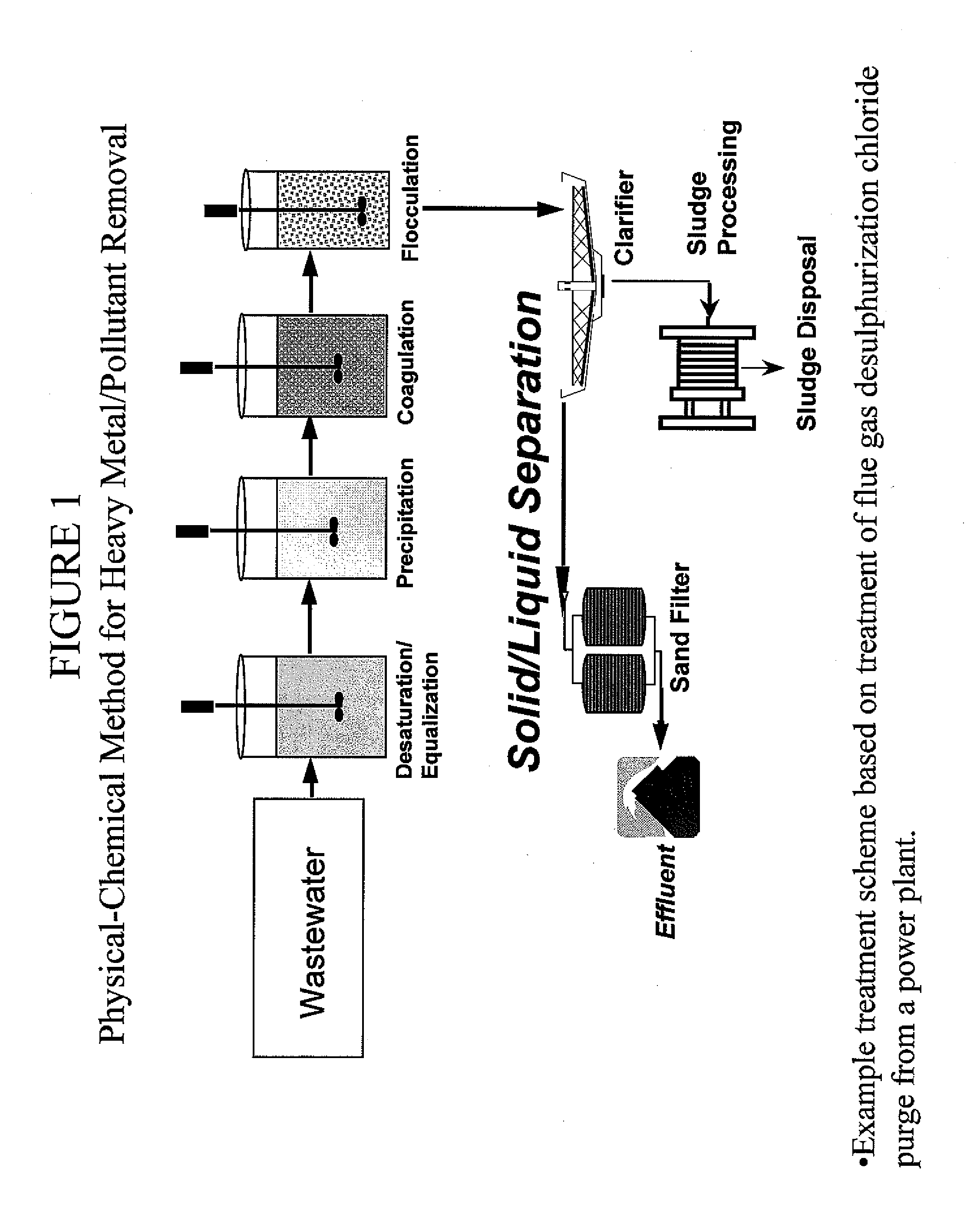

Removing mercury and other heavy metals from industrial wastewater

InactiveUS20080197075A1Sludge treatment by de-watering/drying/thickeningMembranesIndustrial effluentFiltration

A method of removing one or more heavy metals including mercury from industrial wastewater by use of a filtration and / or a solid-liquid separation system by use of a water soluble ethylene dichloride ammonia polymer.

Owner:ECOLAB USA INC

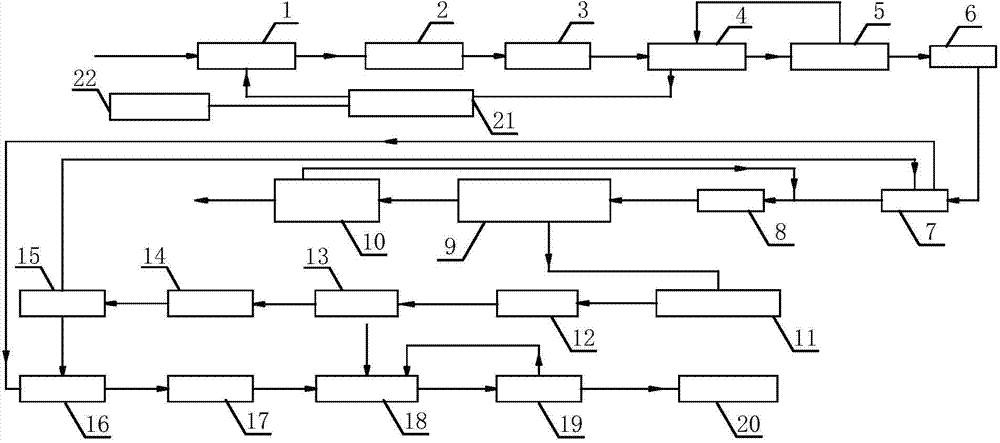

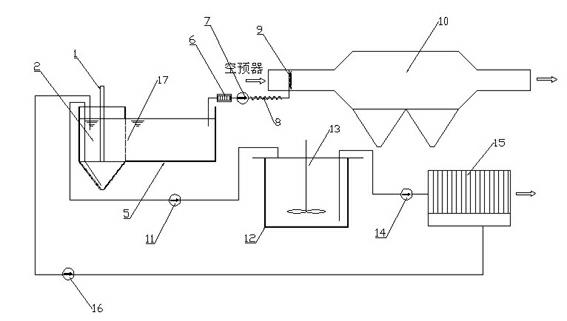

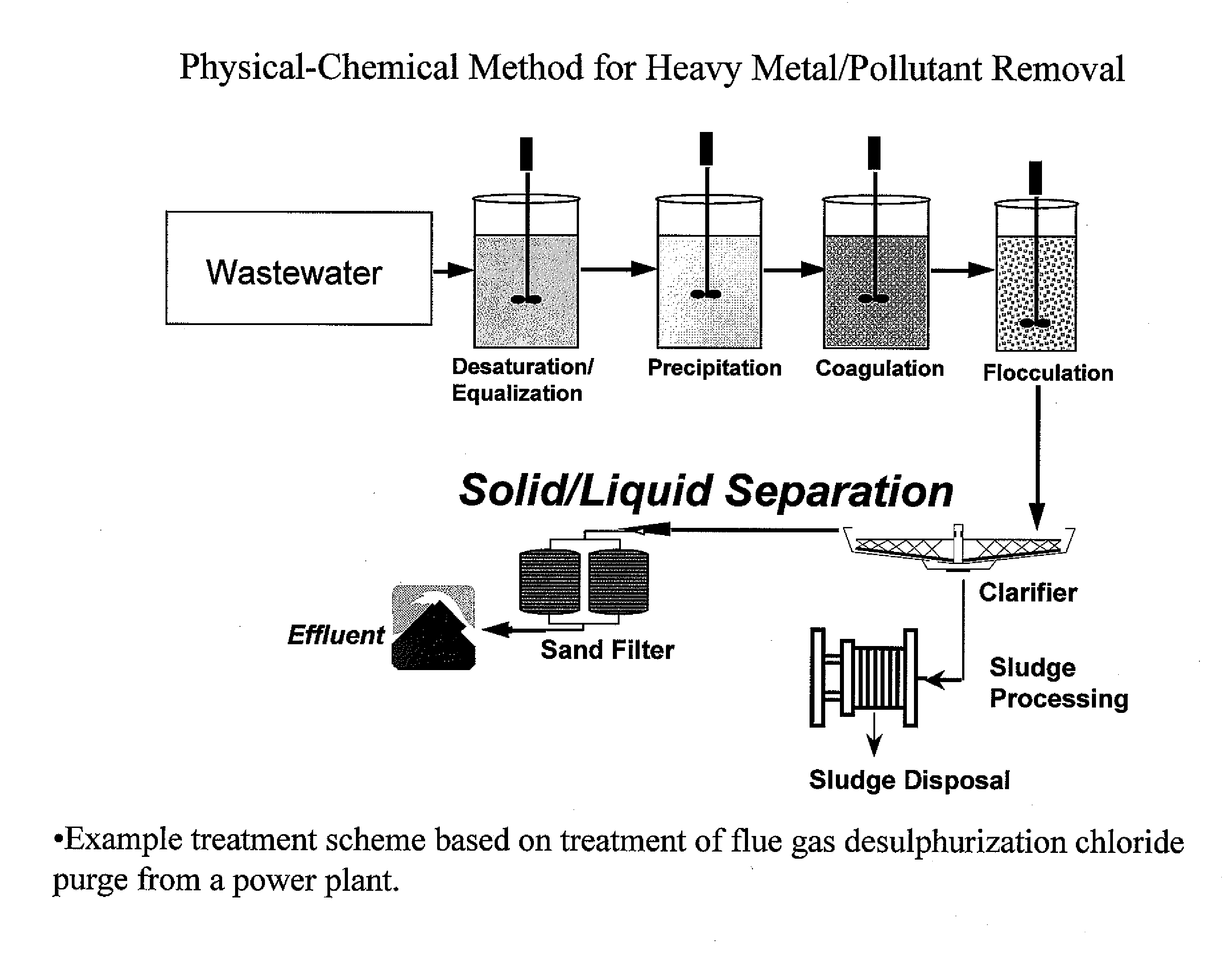

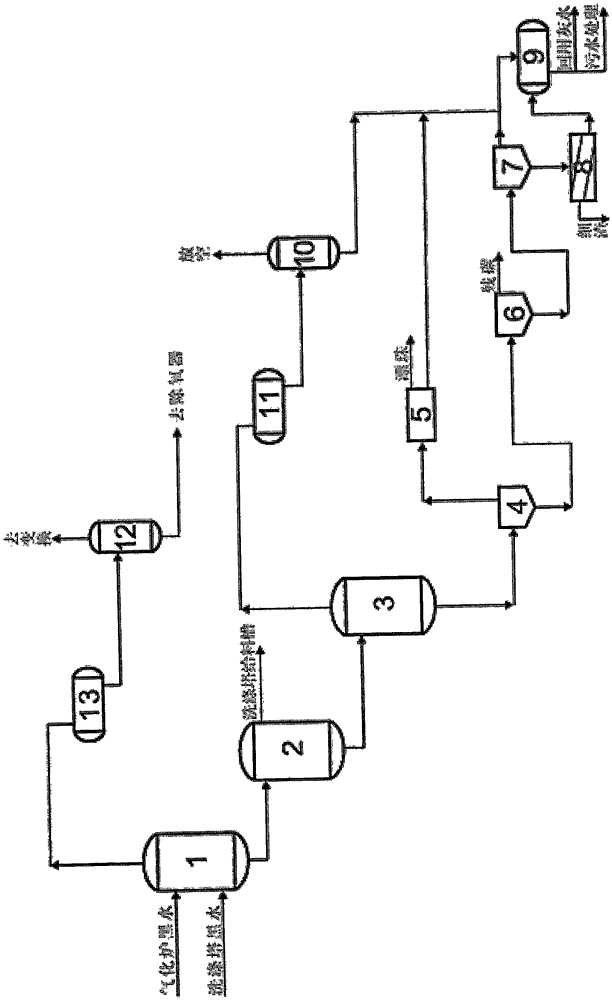

Method and system for zero emission treatment of desulfured waste water

ActiveCN102180549AConvenient zero-emission disposalSimple processWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeWater filter

The invention discloses a method for zero emission treatment of desulfured waste water. The method comprises the following steps: 1) discharging the desulfured waste water obtained after desulfuration in a desulfuration tower into a preliminary sedimentation tank, carrying out primary separation in the preliminary sedimentation tank, and transporting an upper clear liquid separated out to a buffer pool through a slurry pump; 2) successively passing the desulfured waste water in the buffer pool through an atomization plant and a static dust catcher; 3) transporting the waste water which is from the lower part of the preliminary sedimentation tank and has large solid content to a filter press through an another sludge pump; and 4) feeding the waste water filtered back to the preliminary sedimentation tank through the slurry pump. Simultaneously, the invention also discloses a system for zero emission treatment of desulfured waste water. The zero emission treatment is conveniently carried out on the desulfured waste water through the method, the process is simple and labor is saved; and the system has a compact structure, the method is simple to implement, energy is saved, the quality of smoke at the inlet of the dust catcher is improved, the zero emission of the desulfured waste water can be really achieved, thus the system has the advantage of popularization value.

Owner:CHENGDU SHUKE TECH

Hybrid copolymers

ActiveUS7666963B2MiniaturizationLow costSeawater treatmentTransportation and packagingCopolymerMonomer

Hybrid copolymers for use as anti-scalant and dispersant. The polymers are useful in compositions used in aqueous systems. The polymers include at least one synthetic monomeric constituent that is chain terminated by a naturally occurring hydroxyl containing moiety. A process for preparing these hybrid copolymers is also provided.

Owner:NOURYON CHEM INT BV

Metal scavenging polymers and uses thereof

ActiveUS20110243819A1Dispersed particle filtrationSelenium/tellurium compundsWastewater systemsMonomer

Uses for a composition comprising a polymer derived from at least two monomers: acrylic-x and an alkylamine, wherein said polymer is modified to contain a functional group capable of scavenging one or more compositions containing one or more metals are disclosed. These polymers have many uses in various mediums, including wastewater systems.

Owner:ECOLAB USA INC

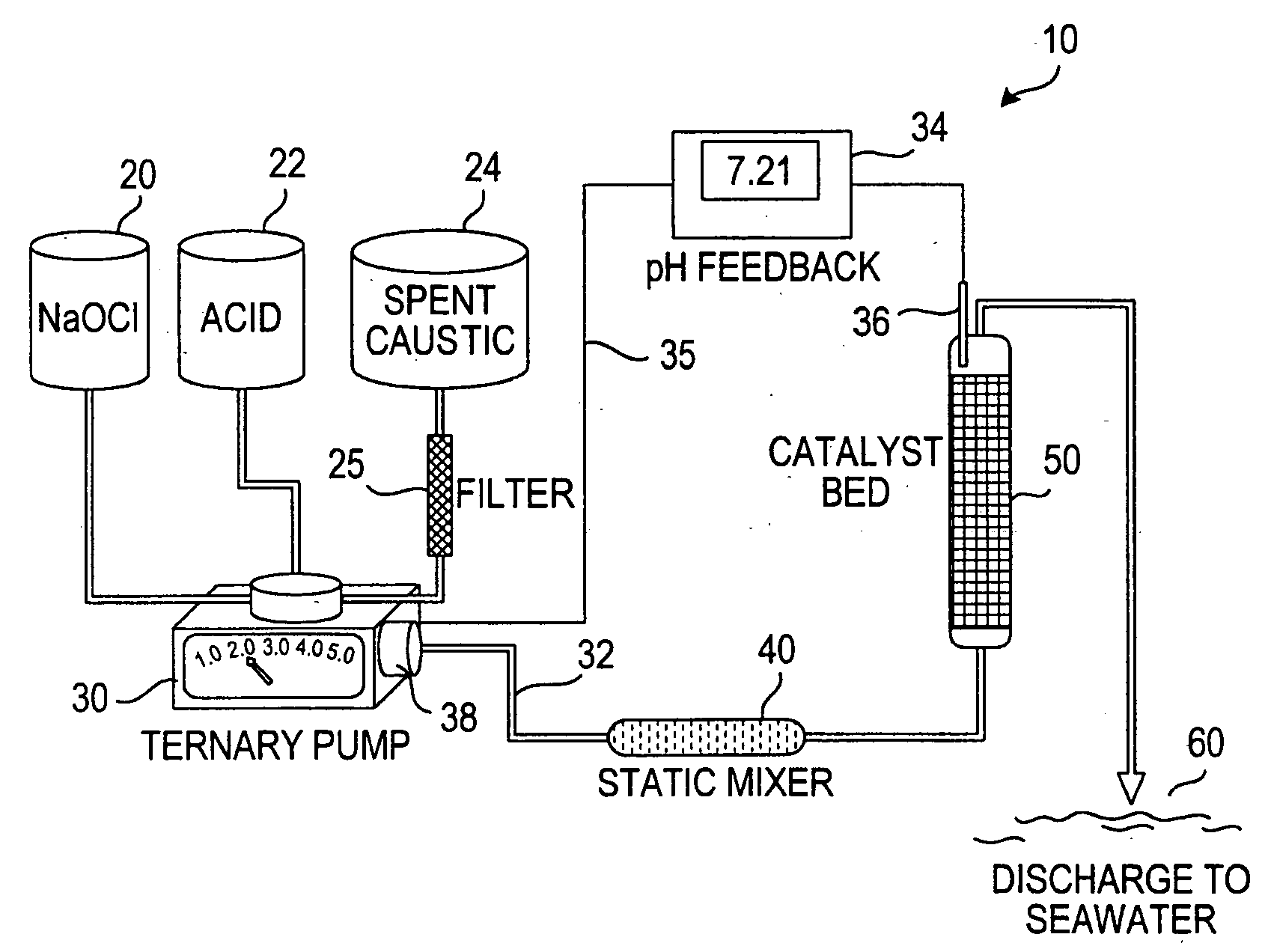

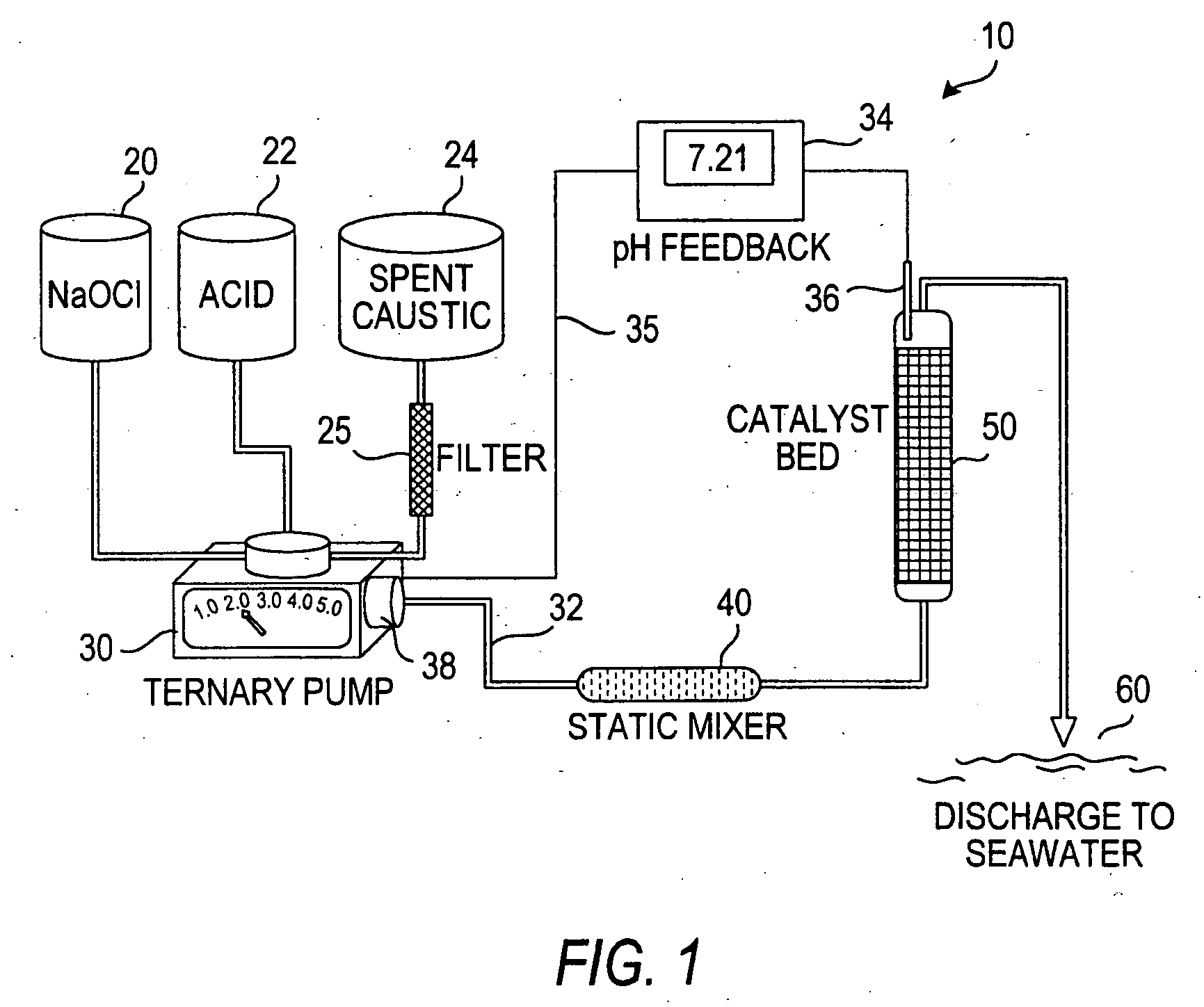

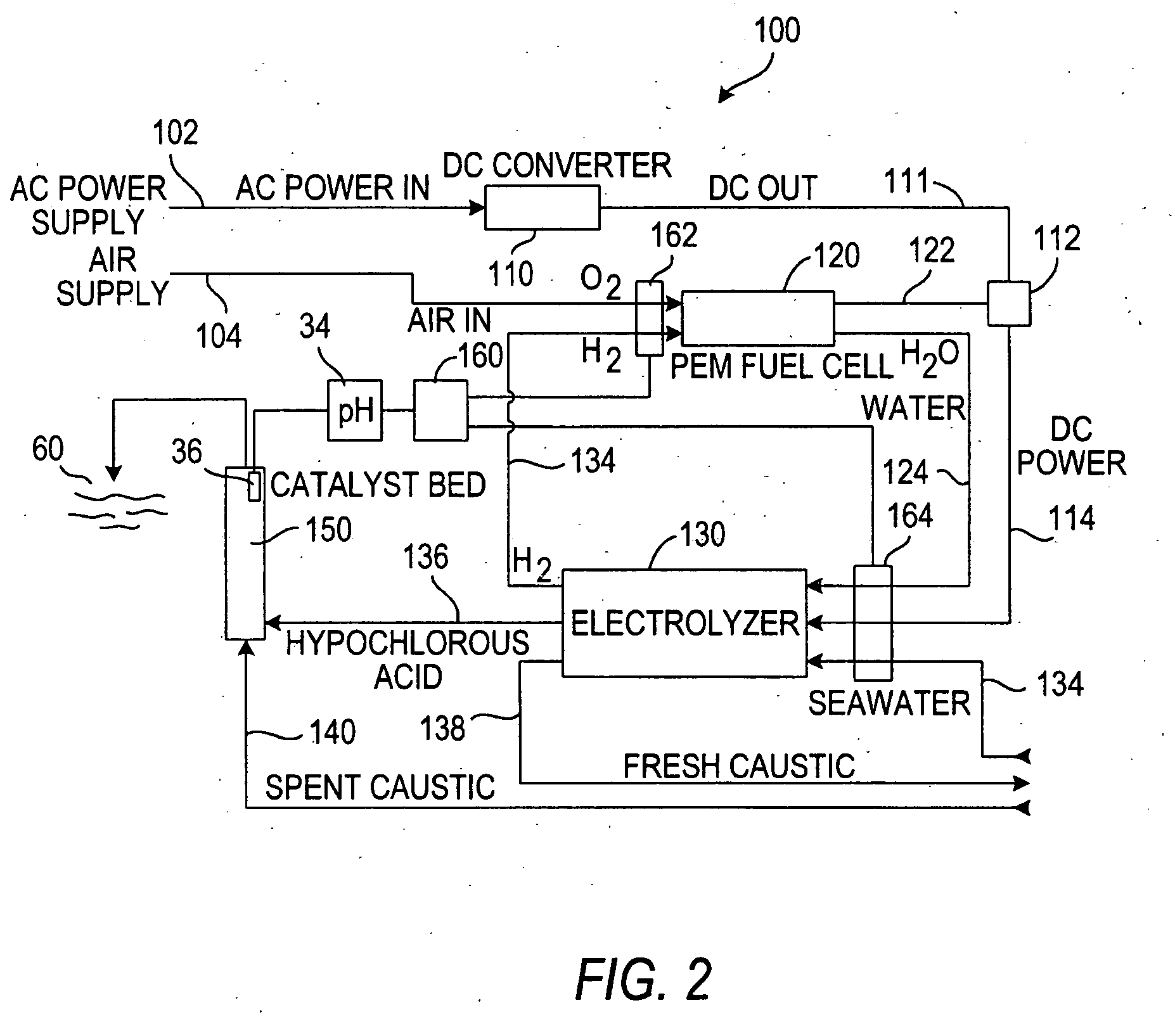

Process for treating a sulfur-containing spent caustic refinery stream using a membrane electrolyzer powered by a fuel cell

ActiveUS20060254930A1Simple and inexpensive and effectiveReduce investmentPhotography auxillary processesElectrolysis componentsSodium sulfateSulfur containing

A continuous method for the treatment of a spent aqueous caustic stream used to scrub a hydrocarbon process stream to remove oxidizable sulfur-containing compounds includes: a. mixing an oxidizing hypochlorous acid stream produced from an aqueous brine solution with the aqueous caustic stream to form a reactive mixed feedstream; b. contacting the reactive mixed feedstream with at least one catalyst to promote the oxidation of the sulfur-containing compounds and the neutralization of the sodium hydroxide; and c. recovering a neutral treated product stream comprising aqueous sodium sulfate, sodium carbonate and sodium chloride that is odorless, non-toxic and environmentally acceptable for discharge into the sea or into a conventional sewage treatment system. Preferably, the hypochlorous acid is produced by an electrolyzer that also produces a (1) hydrogen stream that is directed to a PEM fuel cell to generate at least a portion of the electrical power requirement of the electrolyzer, and (2) water that is combined with fresh sodium hydroxide from the electrolyzer to form a fresh caustic stream for use in scrubbing the hydrocarbon process stream.

Owner:SAUDI ARABIAN OIL CO

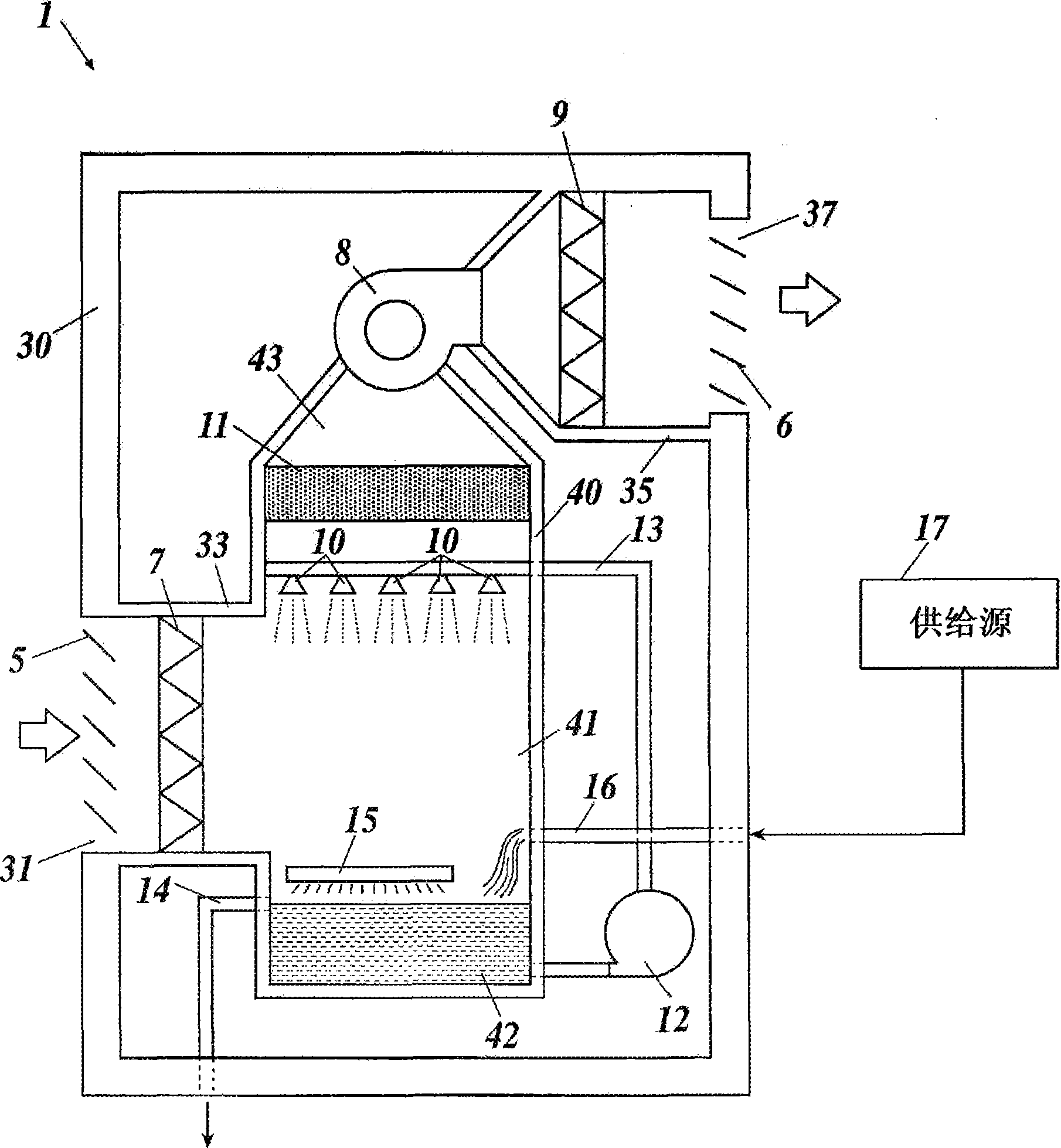

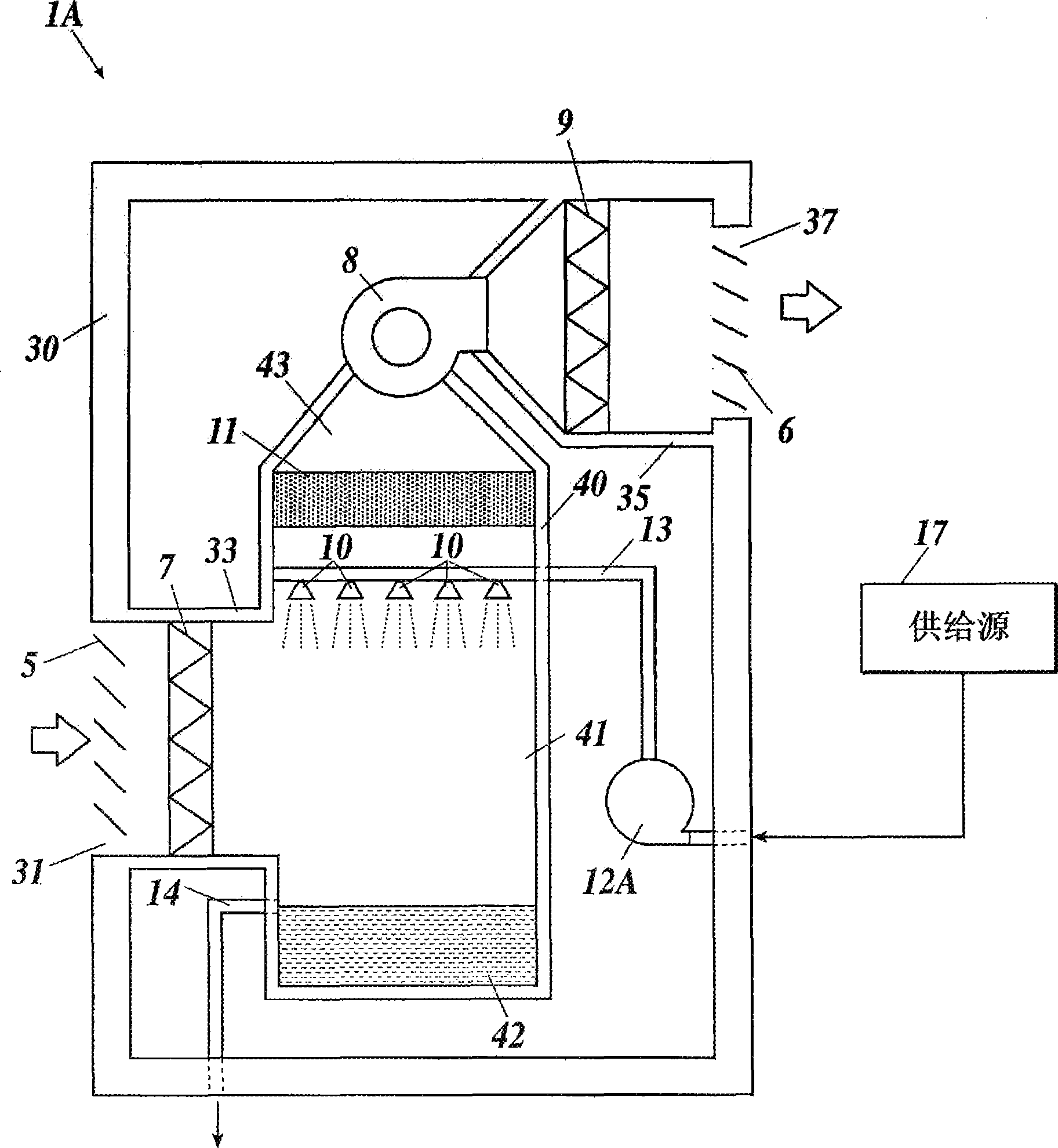

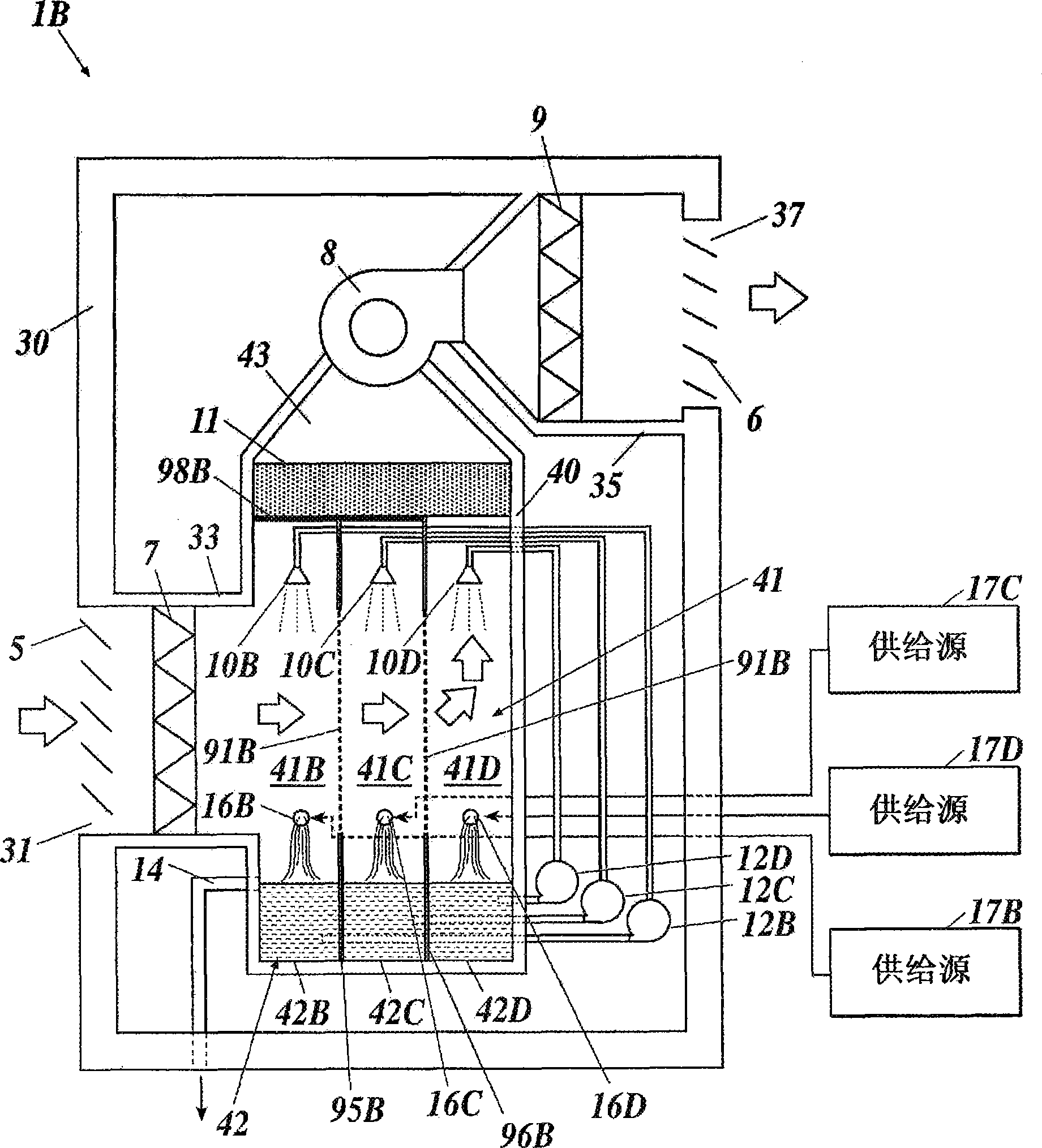

Air purifier

An air purifier comprises a cleaning tower having an internal space communicating with a suction port and a discharge port, a blower for taking air from the suction port into the internal space of the cleaning tower and send it from the discharge port to the outside of the cleaning tower, and nozzles disposed in the internal space of the cleaning tower and spraying water in the internal space of the cleaning tower. The water sprayed from the nozzles is brought into contact with the air supplied by the blower in the cleaning tower.

Owner:MISAWA HOMES CO LTD +1

Desulphurization waste-water zero discharge processing system and technology

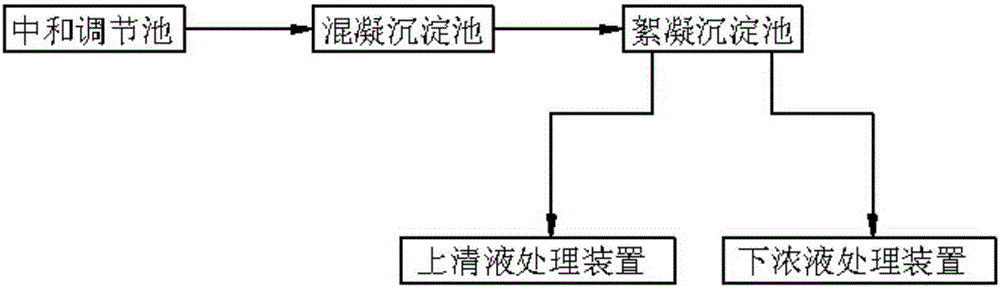

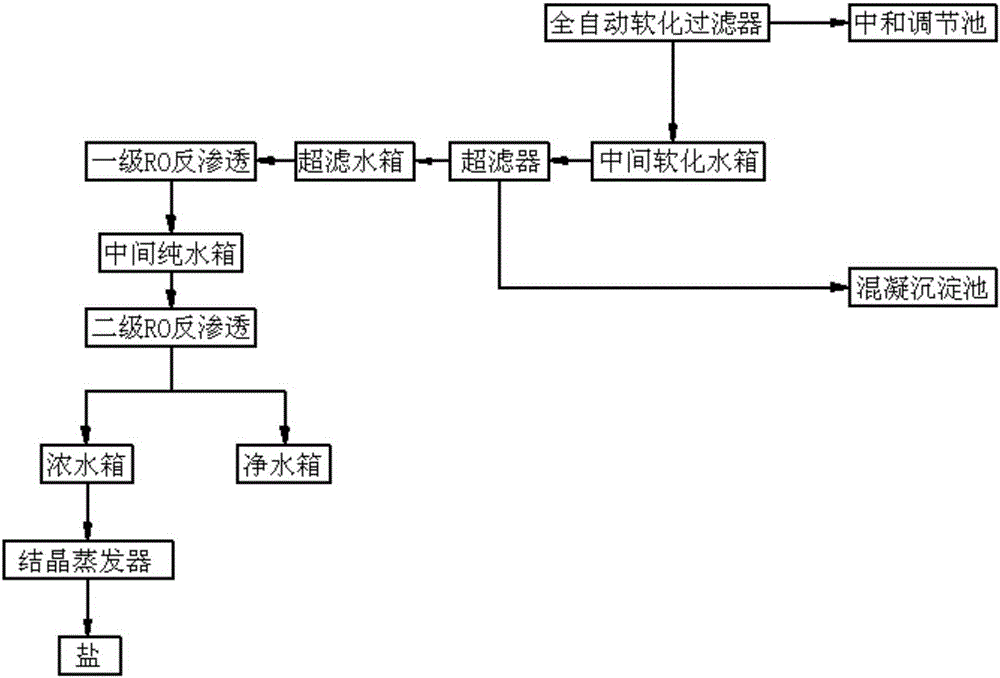

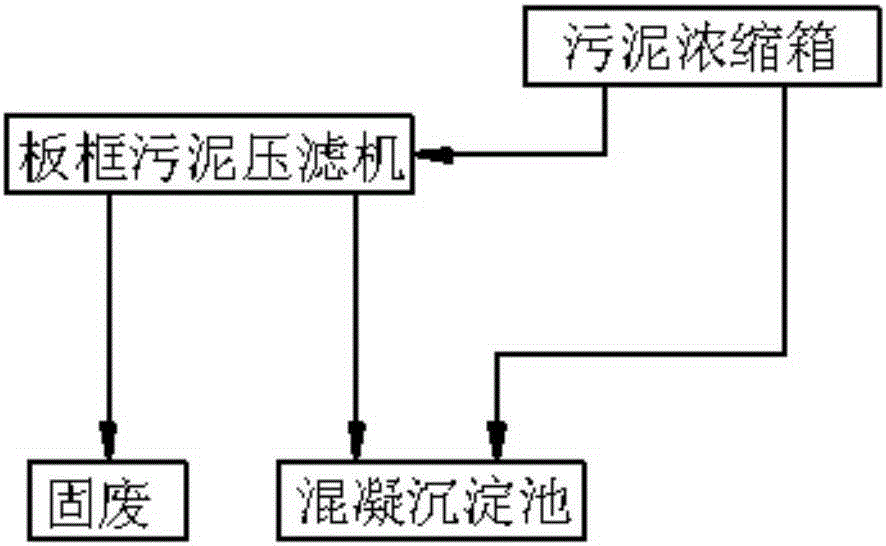

InactiveCN105174580AHigh removal rateReduce foulingSludge treatment by de-watering/drying/thickeningWaste water treatment from gaseous effluentsReverse osmosisSedimentation

A related desulphurization waste-water zero discharge processing system comprises a neutralization adjusting basin, a coagulation sedimentation basin and a flocculation sedimentation basin which are in successive connection. In the flocculation sedimentation basin, a supernatant formed in a specially-produced metering water channel flows into a supernatant processing device, and the lower dense liquid flows into a lower-dense-liquid processing device. The supernatant processing device comprises a full-automatic softening filter, an ultrafilter, a first-grade RO (reverse osmosis) device and a second-grade RO device; the outlet of the second-grade RO device is connected with a dense liquid tank and a pure water tank, pure water in the pure water tank is reusable, and a dense liquid in the dense liquid tank enters a crystallization evaporator for generating a salt. The lower-dense-liquid processing device discharges solid waste. Wastewater separated from a sewage concentration tank is discharged into the neutralization adjusting basin via a pipe for cyclic once-more processing. The technical scheme is combined with an advanced membrane technology, the technological flow is simple, energy-saving and environment-friendly, environment protection benefit is obviously increased, a new zero-discharge technology is realized, and the technical scheme possesses significant meaning on water pollution treatment.

Owner:天津市华通寰昊水务科技有限公司

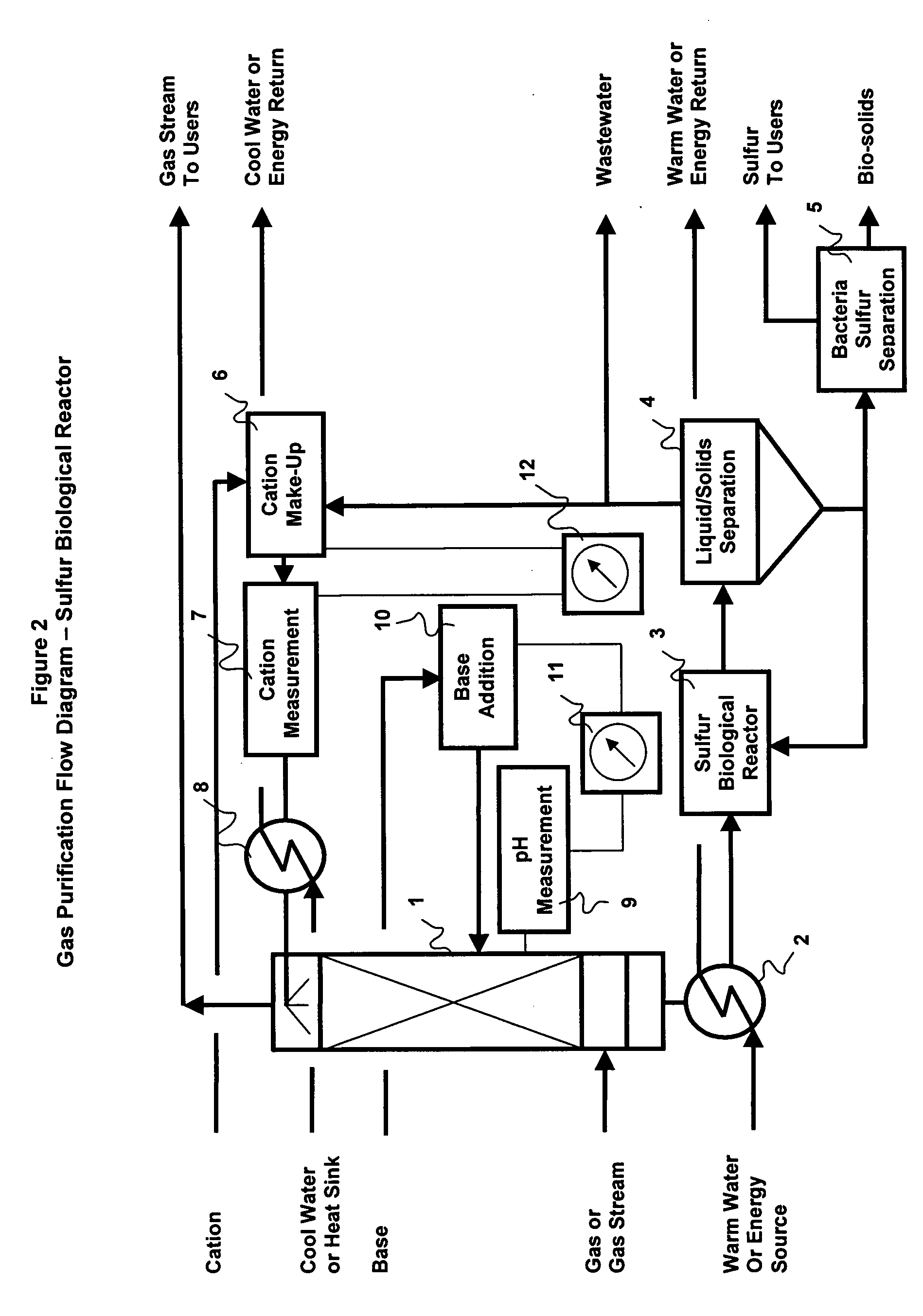

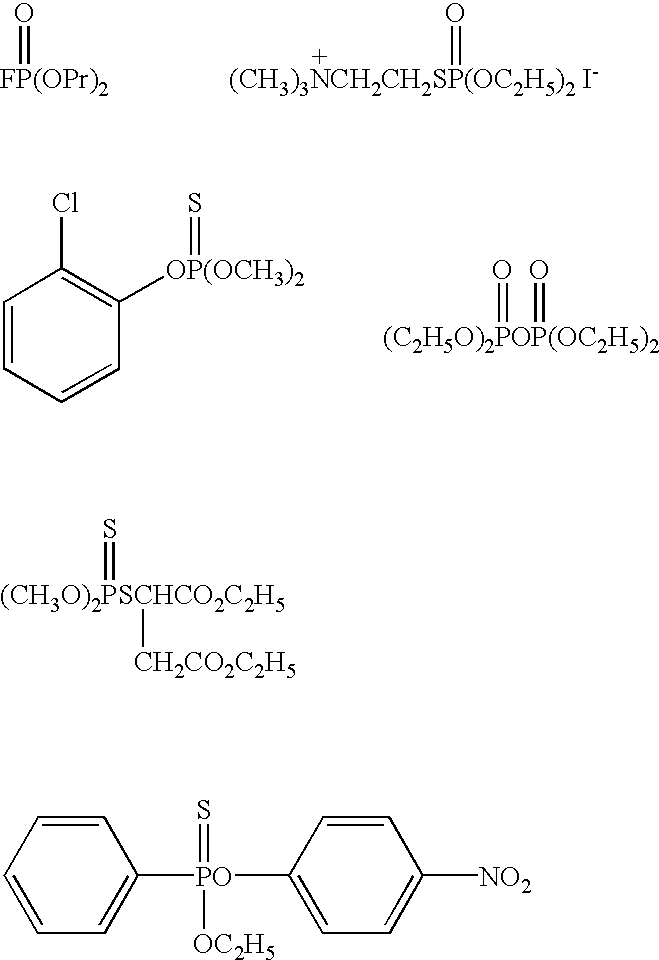

Methods, processes and apparatus for biological purification of a gas, liquid or solid; and hydrocarbon fuel from said processes

InactiveUS20080190844A1Effective and efficient and economically feasibleTreatment using aerobic processesWaste water treatment from gaseous effluentsPresent methodThiobacillus

This invention relates to improved methods, processes and apparatus for the removal of sulfides from a gas, liquid or solid (substance) wherein the substance is contacted with an aqueous solution. The instant invention presents methods and processes wherein at least one of H2S, SO2 and CS2 is chemically converted in an aqueous media to a salt and / or compound comprising sulfur and a cationic moiety. Said salt and / or compound comprising sulfur and a cationic moiety is herein termed a “Sulfur Salt”. After formation of the Sulfur Salt, the Sulfur Salt is converted to elemental sulfur with a bacterium capable of metabolizing sulfur. The preferred bacterium for metabolizing sulfur is a strain from the genus Thiobacillus. The most preferred strain from the genus Thiobacillus is Thiobacillus denitrificans. The instant invention prefers an aqueous operating pH of between 6.0 and 8.0, while the most preferred aqueous pH is between 6.0 and 7.0.

Owner:CLEARVALUE TECH

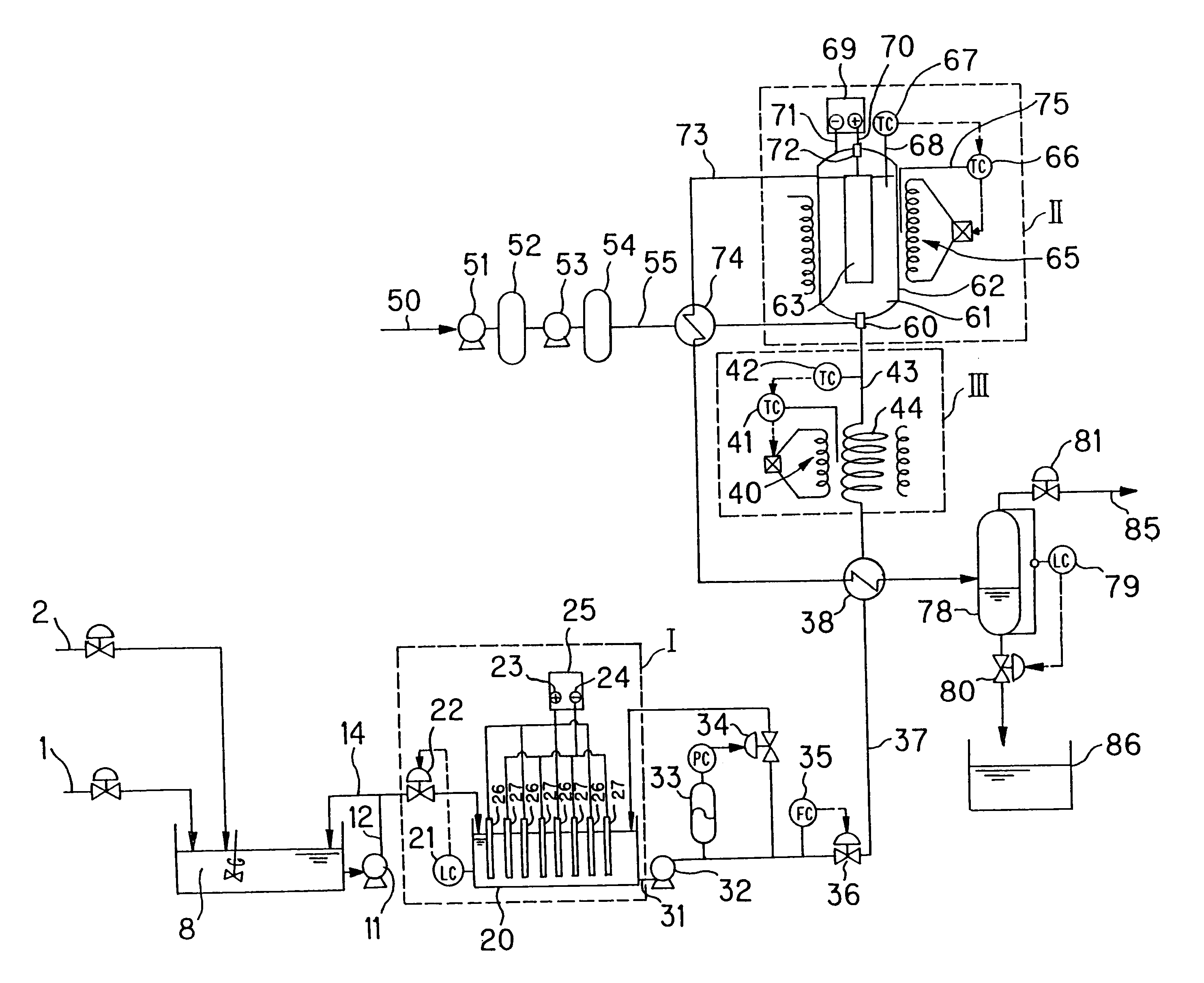

Method and apparatus for treating aqueous medium

InactiveUS6572759B1From normal temperature solutionsLiquid separation by electricityElectricityElectrolysis

An object of the present invention is to provide a process and an apparatus for treating an aqueous medium at low running costs with a decreased electricity required for hydrothermal electrolytic reaction. The present invention proposes a two-step process comprising a first step of performing a conventional hydrothermal reaction or a conventional electrolytic reaction prior to hydrothermal electrolytic reaction to degrade readily degradable substances or ammonia or various electrolytically degradable organics and then a second step of performing hydrothermal electrolytic reaction to degrade the remaining organics, whereby the electricity consumed by hydrothermal electrolytic reaction in the second step can be greatly reduced.

Owner:EBARA CORP

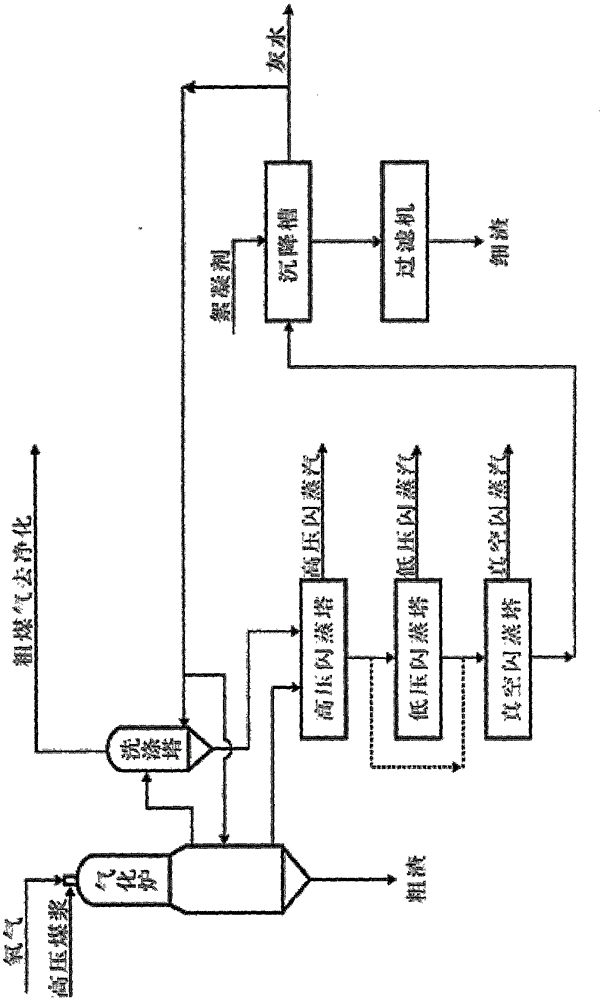

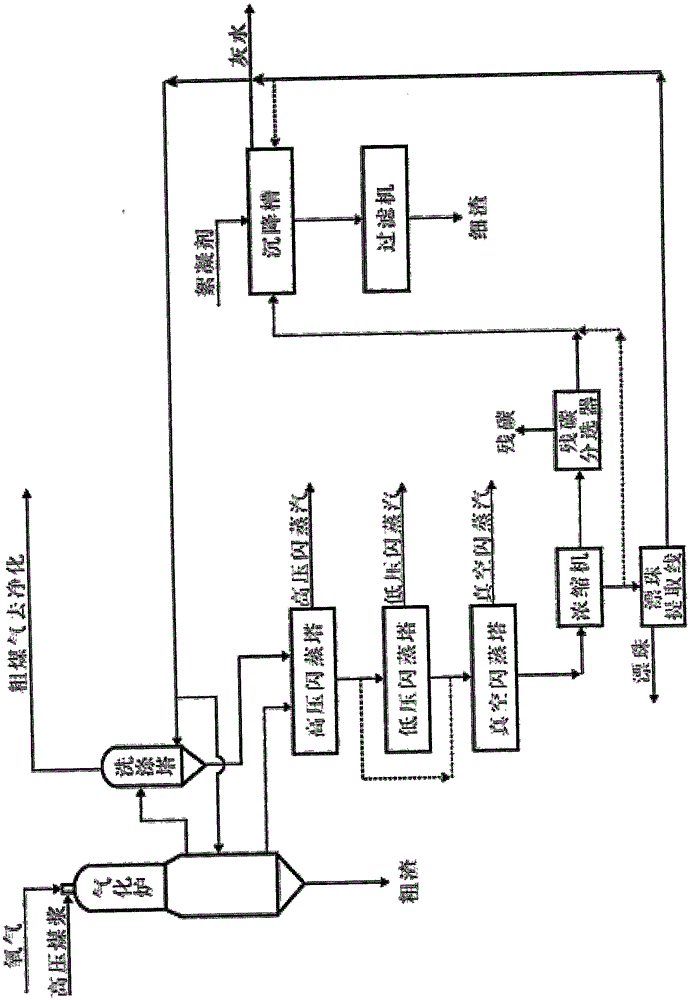

Coal gasification ash water treatment method

InactiveCN105293804AReduce carbon residueReduce suspended particlesWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSuspended particlesThree stage

The invention relates to a coal gasification ash water treatment method. The problem that in the prior art, gasified fine residue is too high in carbon residue and reused ash water contains plenty of suspended particles is solved mainly. The ash water treatment method comprises the steps that black water coming from a gasification furnace and a washing tower undergoes two-stage or three-stage flash evaporation and concentration and then enters a thickener; under the stirring effect, the black water coming from the thickener is divided into two layers, floating bead slurry of the upper layer overflows and enters an ash water circulation system or a sedimentation tank after floating beads are separated; the concentrated black water of the lower layer enters a carbon residue classifier, carbon residue undergoes floatation, tailing slurry of a lower layer of a floatator; supernatant of a settling tank enters the ash water circulation system, and lower layer turbidity solution of the settling tank enters a filter to be dehydrated to obtain filter cake (gasified fine residue). By adopting the ash water treatment method, the carbon residue content of the coal gasified fine residue can be reduced, the utilization of the gasified fine residue is facilitated, and the suspended particles in reused ash water can be reduced.

Owner:张晓峰

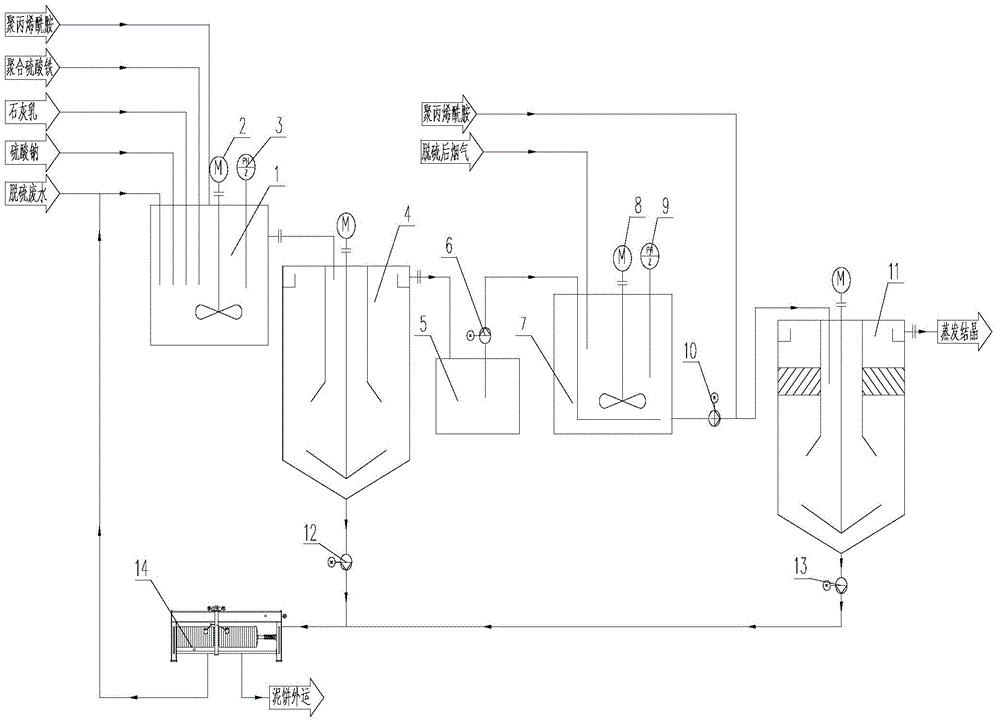

System and method for softening treatment of desulfurization wastewater of coal-fired power plant

ActiveCN105060545AReduce ammonia nitrogenReduce ammonia nitrogen contentWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSulfateEconomic benefits

The invention discloses a system and a method for softening treatment of desulfurization wastewater of a coal-fired power plant. A primary reaction tank, a primary clarification tank, a secondary reaction tank and a secondary clarification tank are arranged, lime milk, sodium sulfate, polymeric ferric sulfate and polyacrylamide are added to the primary reaction tank for a primary reaction and clarified through the primary clarification tank, Mg(OH)2 and CaSO4*2H2O in the wastewater after the primary reaction are removed, the mixture has a secondary reaction in the secondary reaction tank, smoke is fed into the secondary reaction tank and is settled in the secondary clarification tank, CaCO3 is settled, and softening treatment of the desulfurization wastewater of the coal-fired power plant is completed. The system is simple in structure and easy to implement and facilitates industrial production; when the softening treatment effect is met, that is, the content of Mg<2+> is smaller than or equal to 5 mg / L and the content of Ca<2+> is smaller than or equal to 5 mg / L, the adding amount of chemical is reduced, and the chemical operation cost is reduced, so that the operation cost of a zero discharging system for the desulfurization wastewater of the coal-fired power plant is reduced, and the system has important economic benefits and environmental benefits.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

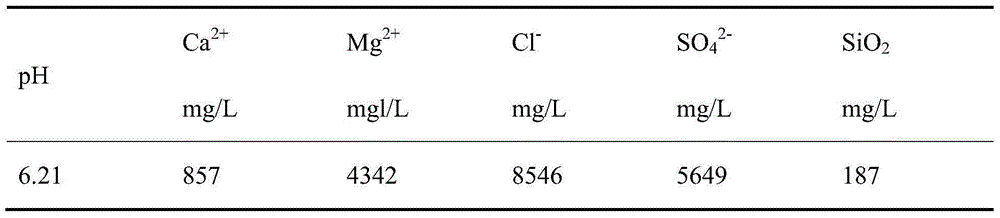

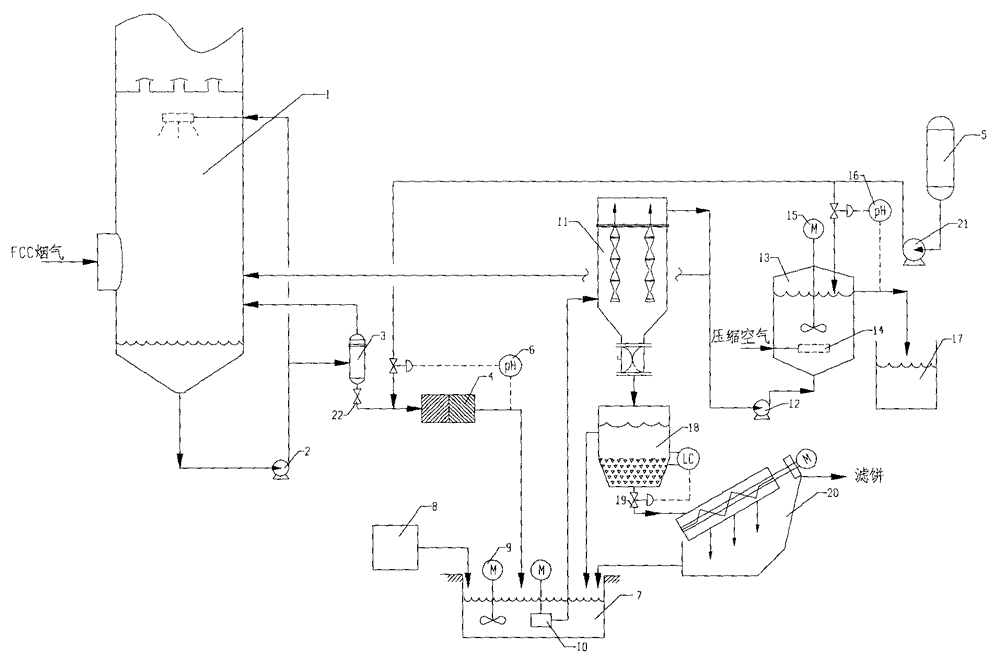

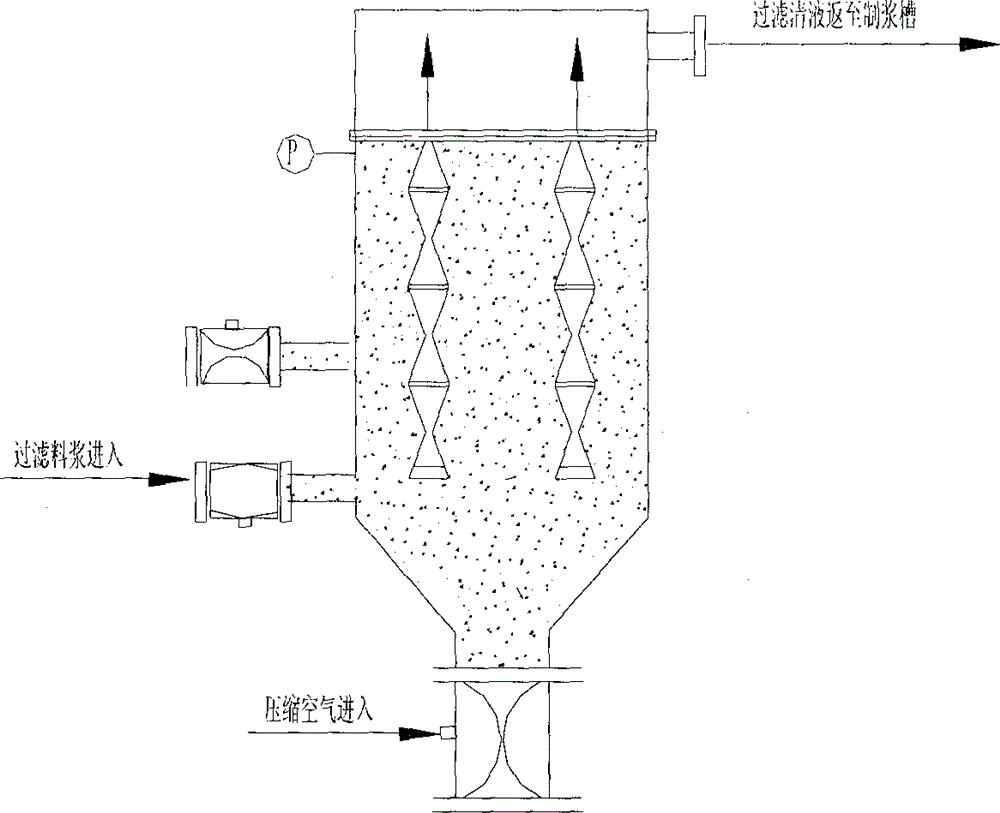

Process for treating waste liquid from catalytic cracking flue gas desulfurization

InactiveCN104418447AReduce dust concentrationReduce wearWater/sewage treatment by centrifugal separationSludge treatmentLiquid wasteSlurry

The invention provides a process for treating waste liquids from catalytic cracking flue gas desulfurization. The process comprises the following steps: enabling a part of waste liquids from a quenching washing tower to enter a hydraulic cyclone separator so as to be subjected to solid-liquid separation, returning the thin liquids to the quenching washing tower so as to be recycled, enabling the thick liquids to enter a neutralization reactor so as to be subjected to neutralization reaction, enabling the neutralized waste liquids to enter a slurry pond so as to be mixed with a flocculating agent uniformly, and enabling the mixture to enter an expansion-drum type filter so as to be subjected to solid-liquid separation with a thick slurry and a supernatant being obtained; returning part of the supernatant to the quenching washing tower so as to be recycled, discharging the remaining supernatant into an oxidation tank, removing the pseudo-COD containing sulfite roots and bisulfite roots by oxidizing, and directly discharging the qualified sewage; enabling the thick slurry to enter a settling pond from the bottom of the expansion-drum type filter so as to be further settled, feeding the thick slurry subjected to settlement into a dewatering machine so as to be concentrated and dewatered, directly transporting the filter cakes obtained by dewatering the thick slurry, returning the filtrate from the dewatering of the thick slurry to the slurry pond, and mixing the filtrate with the waste liquids so as to be retreated. The process provided by the invention has the advantages of a stable and efficient treatment effect, strong shock resistance, low investment and small floor area occupation and convenience of operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of treatment of amine waste water and a system for accomplishing the same

Disclosed herein is a system comprising an evaporation unit comprising a first heat exchanger in fluid communication with a second heat exchanger; where the first heat exchanger is operative to heat an effluent stream comprising an amine solvent and / or amine byproducts and water and to discharge the effluent stream to the second heat exchanger; where the second heat exchanger is operative to convert the effluent stream into a distillate stream and a concentrate stream; and a reverse osmosis unit in fluid communication with the evaporation unit; where the reverse osmosis unit comprises a first reverse osmosis unit that is operative to receive the distillate stream and to separate water from byproducts of the amine solvent such that the water has a purity of greater than 95%, based on the weight of the distillate stream.

Owner:GENERAL ELECTRIC TECH GMBH

Methods for removing suspended solids from a gasification process stream

A method of removing suspended solids from a gasification process water stream includes, in an exemplary embodiment, providing a gasification process water stream containing process derived suspended solids, settling at least a portion of the suspended solids from the process water stream in a settling apparatus, providing a filter apparatus having a plurality of filter elements, and removing a portion of the settled solids from the settling apparatus. The method also includes precoating the filter elements with the settled solids removed from the settling apparatus, directing a portion of the process water stream from the settling apparatus to the filter apparatus, and filtering the portion of the process water stream directed from the settling apparatus through the precoated filter elements to remove suspended solids particles to form a filtrate.

Owner:AIR PROD & CHEM INC

S/m for biological treatment of wastewater with selenium removal

The present invention is directed to systems and methods of treating wastewater. The present invention may include a method of treating such wastewater comprising selenium in the form of water soluble selenates, selenites, and / or selenides, the method including: a chemical / biological treatment process, causing the water soluble selenates, selenites, and / or selenides in the wastewater to be converted into insoluble elemental selenium; and a physical treatment process, trapping the insoluble elemental selenium in a filtration device. Systems and methods in accordance with the present invention may also include a system for including: one or more chemical / biological treatment reactors, the one or more chemical / biological treatment reactors configured to cause the water soluble selenates, selenites, and / or selenides in the wastewater to be converted into insoluble elemental selenium; and one or more physical treatment devices, the one more physical treatment devices configured to trap the insoluble elemental selenium in a filtration device.

Owner:INFILCO DEGREMONT INC

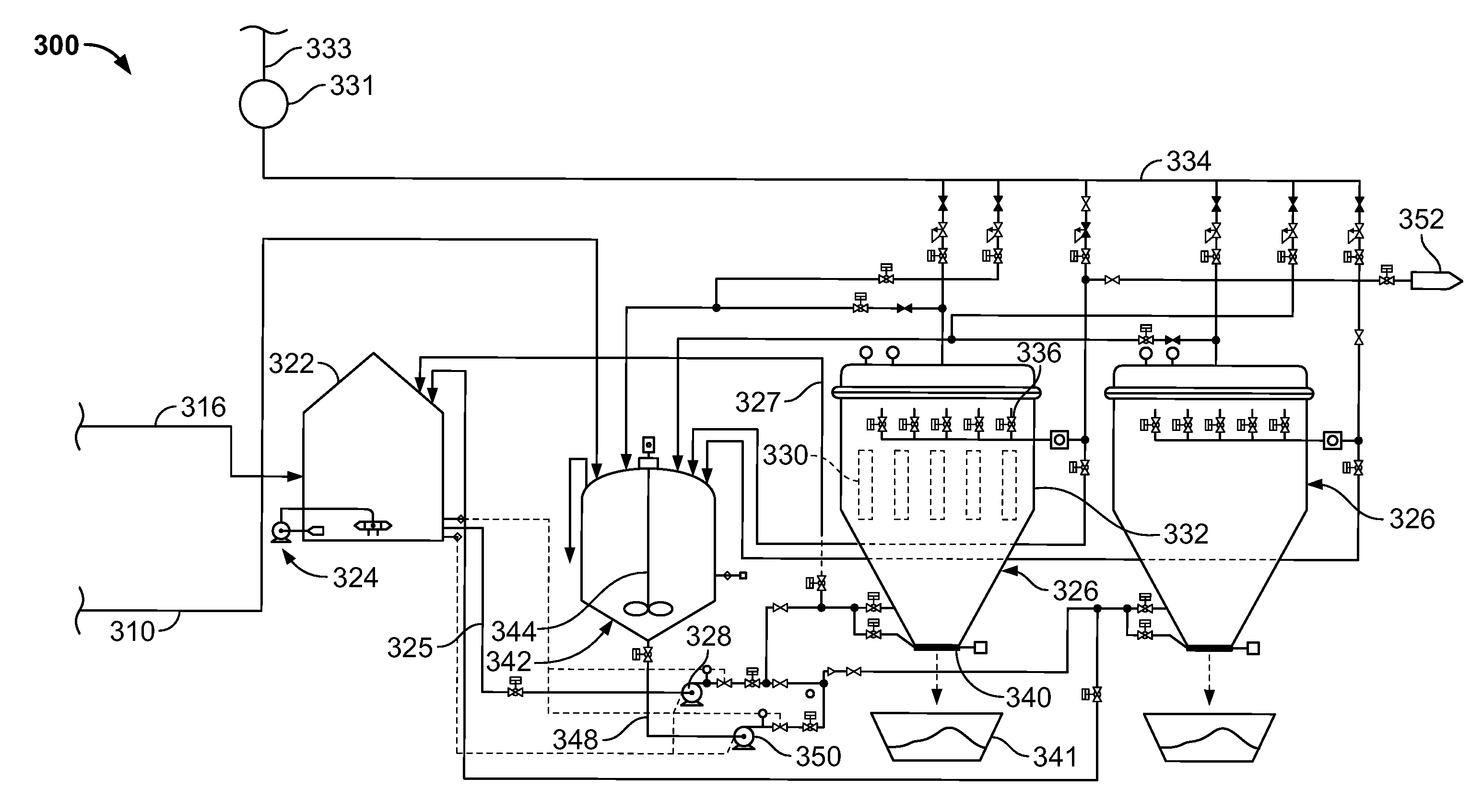

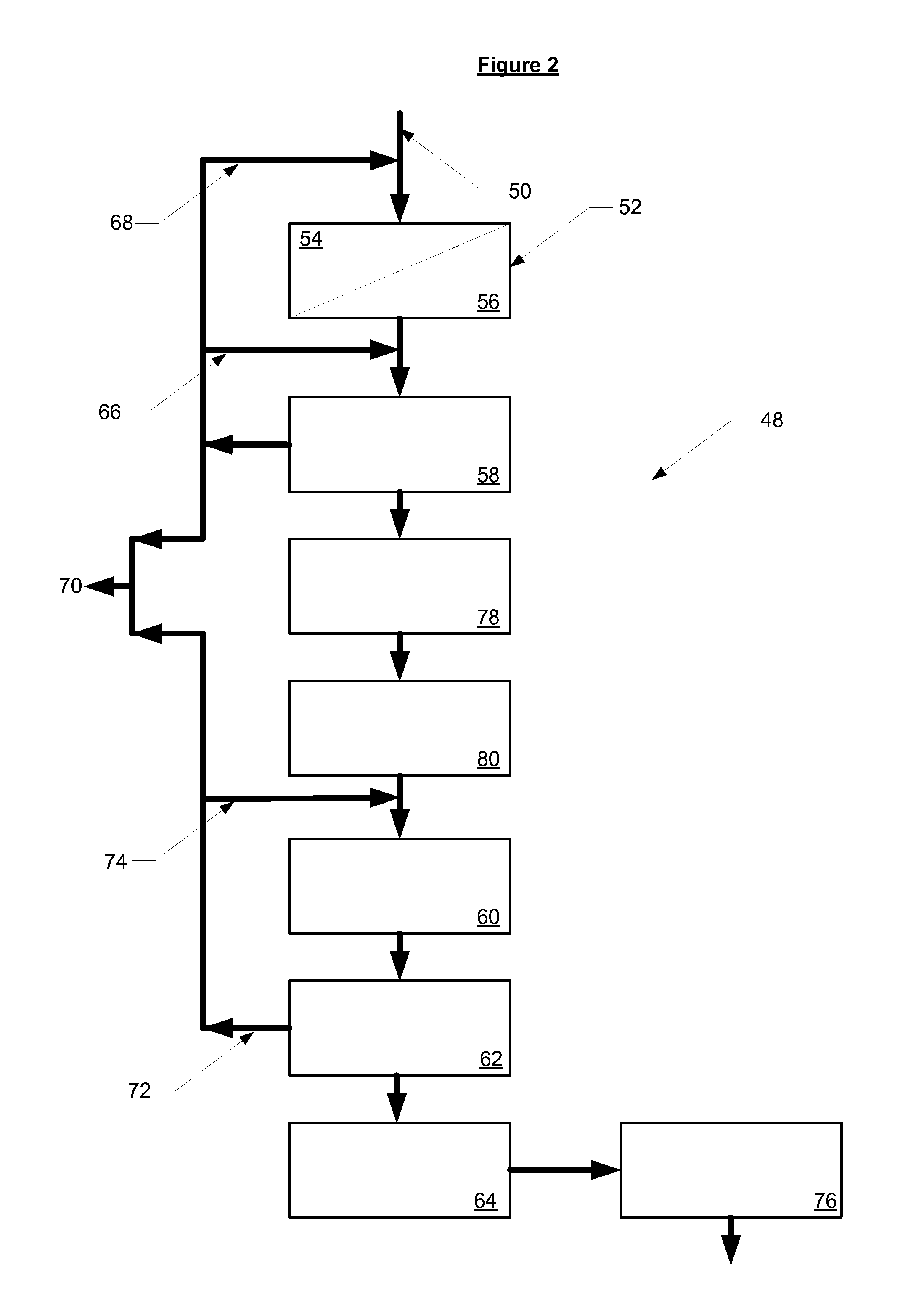

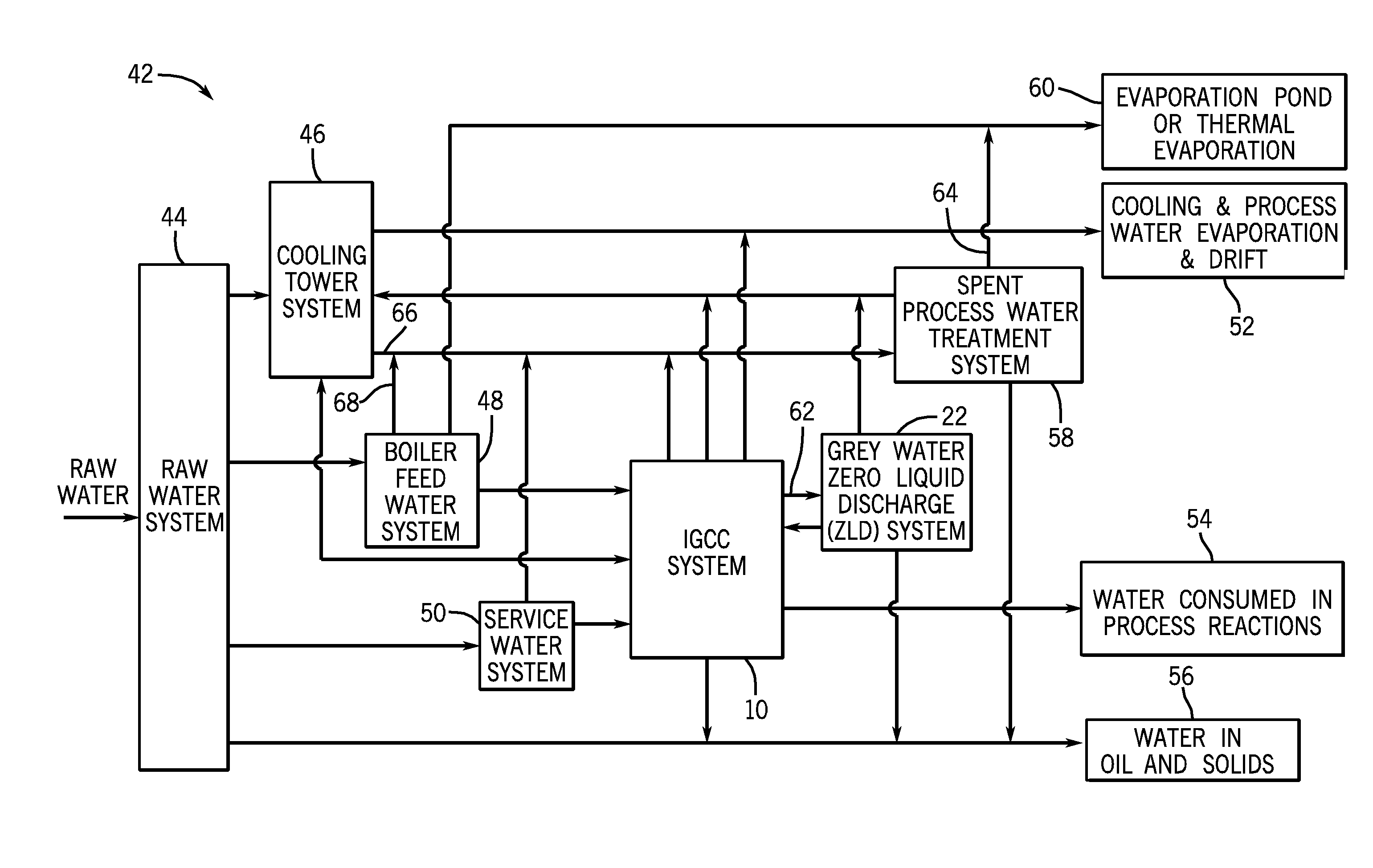

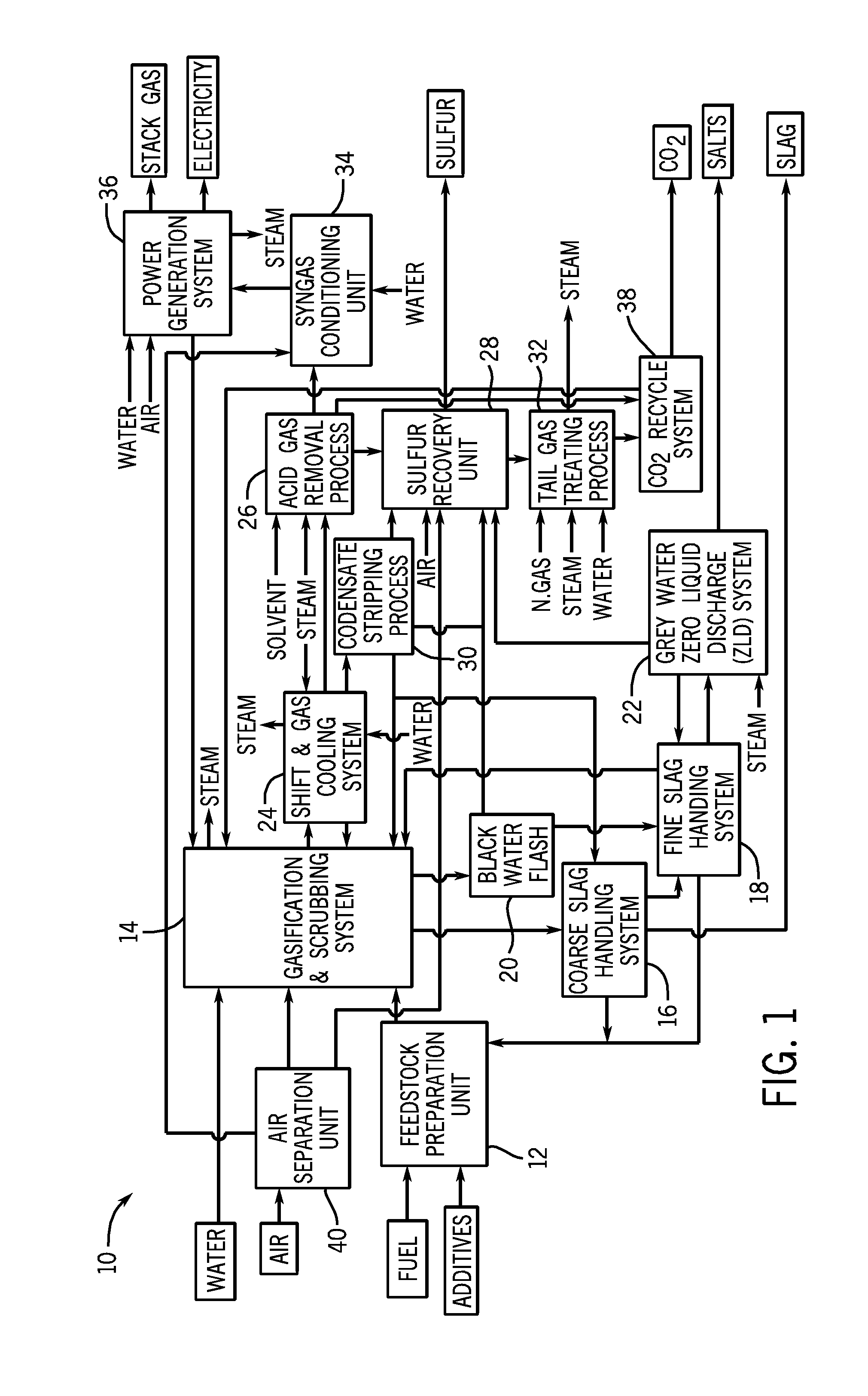

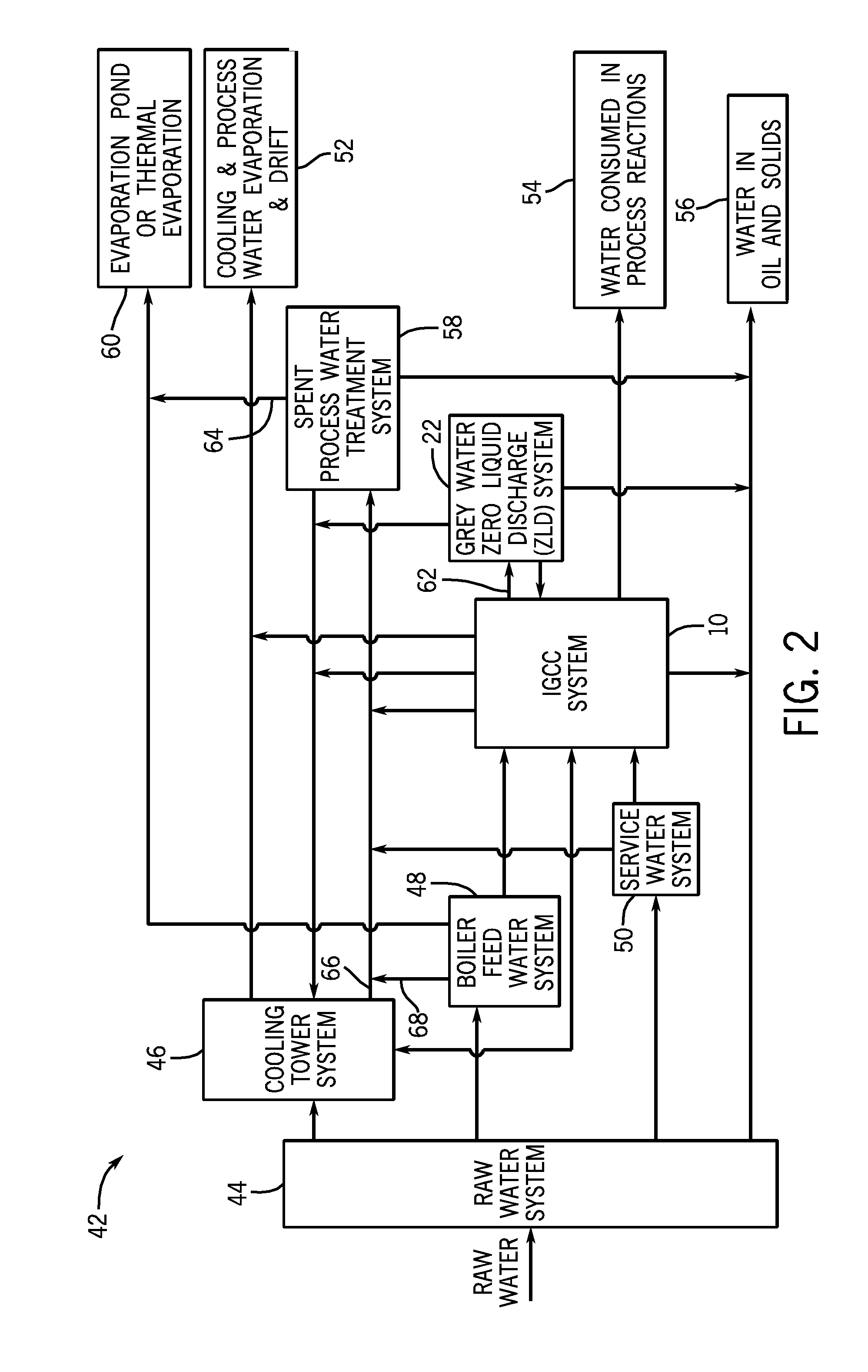

Gasification plant with total zero discharge of plant process waters

ActiveUS20110108405A1Scale removal and water softeningTreatment involving filtrationEngineeringAmmonia

In certain embodiments, a system includes a gasification system configured to output grey water. The system also includes a grey water zero liquid discharge (ZLD) system configured to receive the grey water and to generate a first stream of distillate. The grey water ZLD system comprises an ammonia stripping system. An amount of water into and out of the grey water ZLD system is approximately equal.

Owner:AIR PROD & CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com