Patents

Literature

149results about How to "Reduce carbon residue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

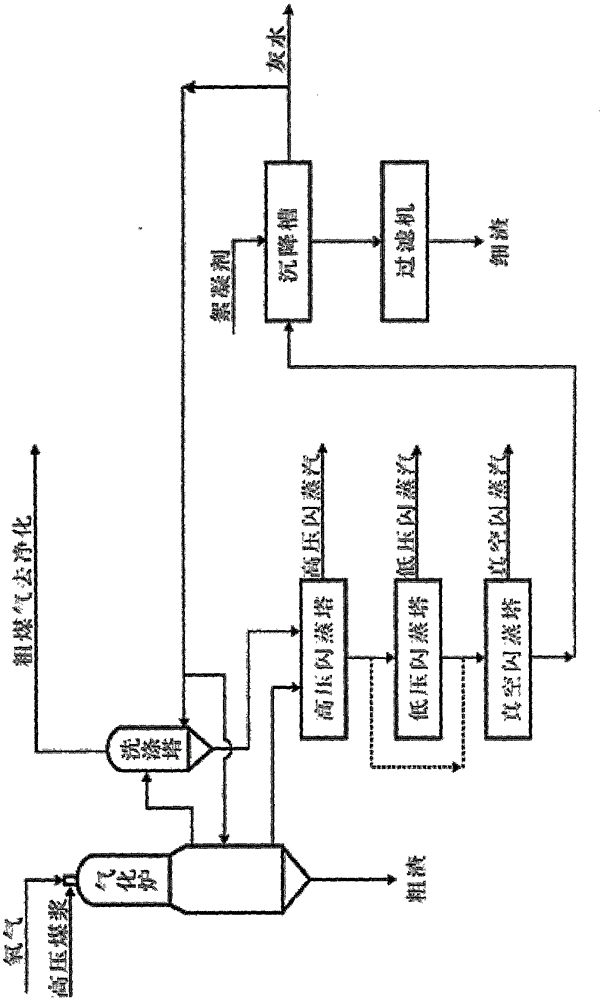

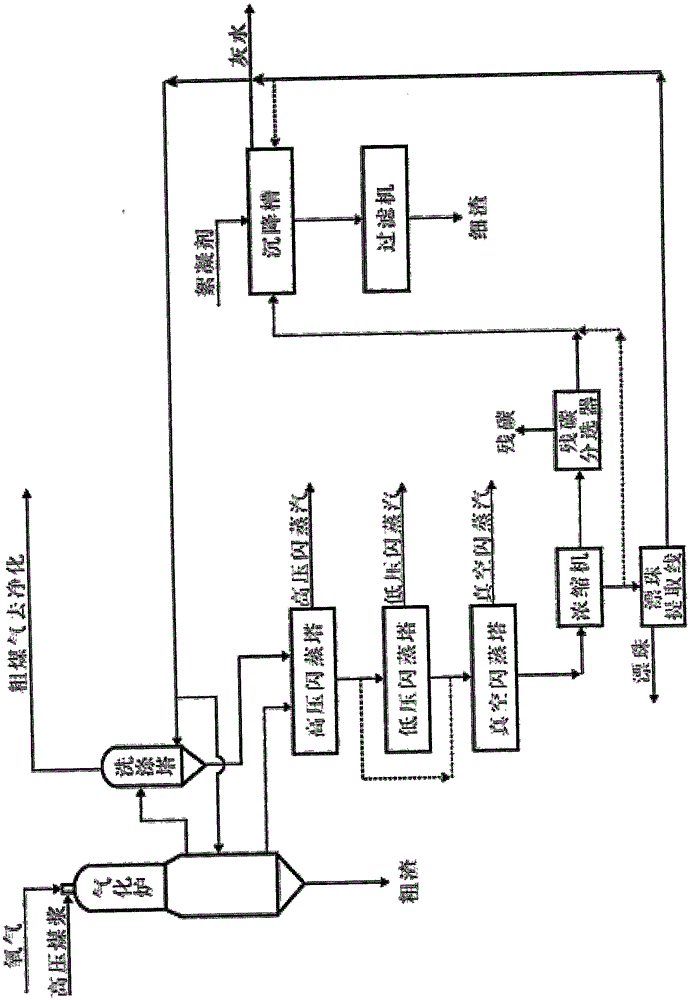

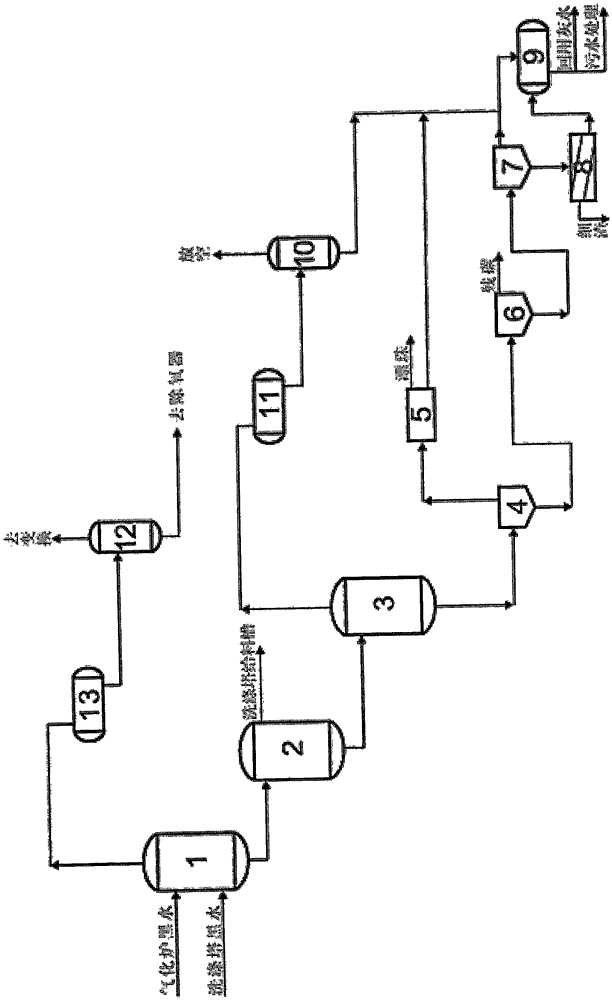

Coal gasification ash water treatment method

InactiveCN105293804AReduce carbon residueReduce suspended particlesWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSuspended particlesThree stage

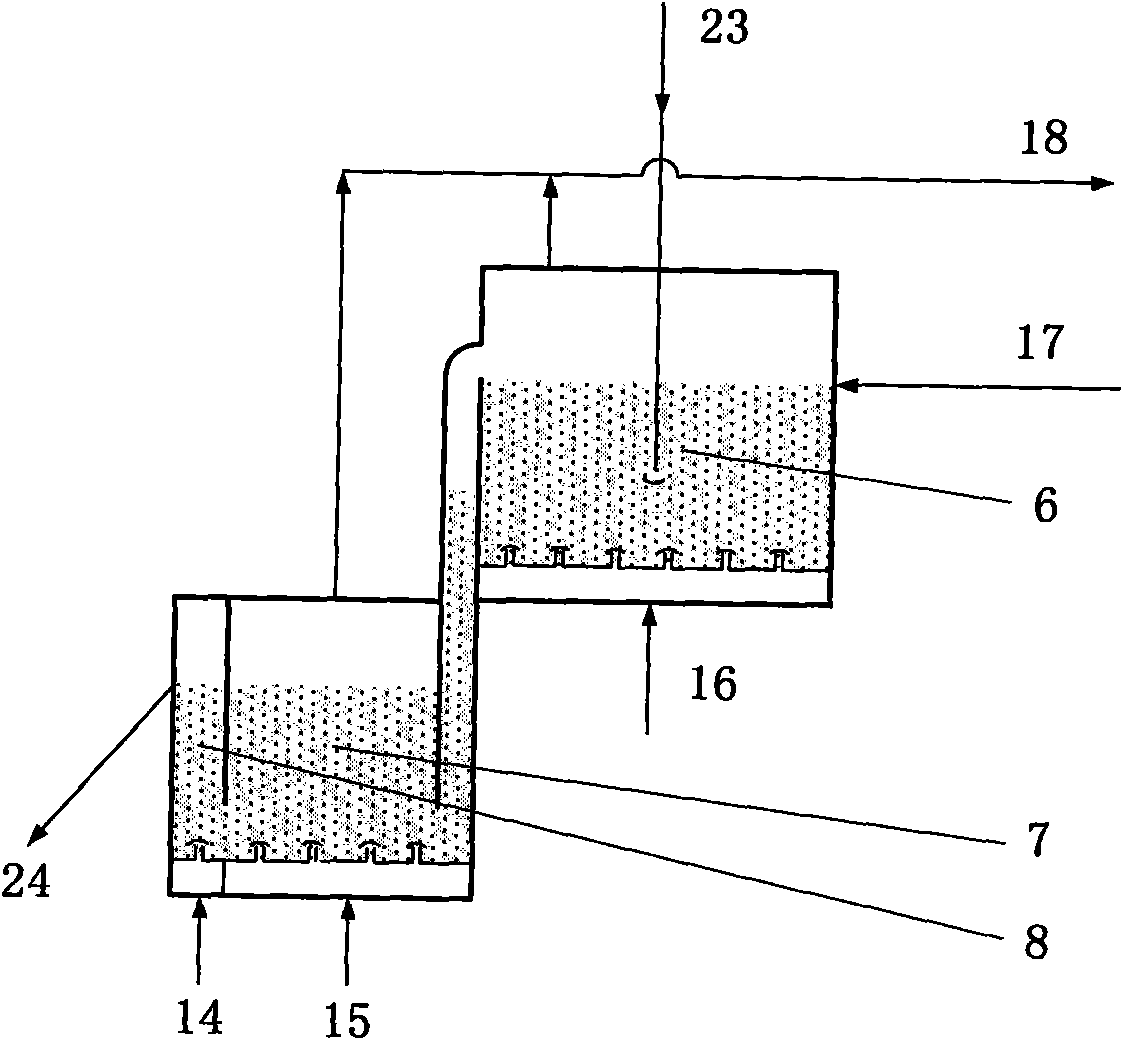

The invention relates to a coal gasification ash water treatment method. The problem that in the prior art, gasified fine residue is too high in carbon residue and reused ash water contains plenty of suspended particles is solved mainly. The ash water treatment method comprises the steps that black water coming from a gasification furnace and a washing tower undergoes two-stage or three-stage flash evaporation and concentration and then enters a thickener; under the stirring effect, the black water coming from the thickener is divided into two layers, floating bead slurry of the upper layer overflows and enters an ash water circulation system or a sedimentation tank after floating beads are separated; the concentrated black water of the lower layer enters a carbon residue classifier, carbon residue undergoes floatation, tailing slurry of a lower layer of a floatator; supernatant of a settling tank enters the ash water circulation system, and lower layer turbidity solution of the settling tank enters a filter to be dehydrated to obtain filter cake (gasified fine residue). By adopting the ash water treatment method, the carbon residue content of the coal gasified fine residue can be reduced, the utilization of the gasified fine residue is facilitated, and the suspended particles in reused ash water can be reduced.

Owner:张晓峰

Process for preparing silicon carbide crystal whisker

InactiveCN1721583AReduce carbon residueImprove Straight Crystal Rate and PurityPolycrystalline material growthFrom solid stateVacuum furnaceCarbon source

The present invention discloses silicon carbide crystal whisker preparing process and aims at preparing silicon carbide crystal whisker separated from residual carbon powder. The technological scheme is to use carbonized rice hull as both silicon source and carbon source to prepare silicon carbide crystal whisker via carbon fiber induction. The preparation process includes crushing rice hull, carbonizing rice hull at 650-700 deg.c in one first-opening-then-closing process, mixing with catalyst in certain weight ratio, loading the mixed material inside graphite crucible, arranging carbon fiber on the upper part of the mixed material, covering the crucible, setting the crucible inside vertical vacuum furnace with graphite heater, and growing silicon carbide crystal whisker on the carbon fiber white introducing argon for protection. The said process realizes the automatic separation of crystal whisker from residual carbon powder to obtain crystal whisker with high straight crystal rate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Coal composite sulfur fixing agent

The invention relates to a coal composite sulfur fixing agent, belonging to the technical field of boiler combustion desulphurization. The composite sulfur fixing agent is made of the following raw materials in parts by weight: 40-70 parts of CaO, 5-10 parts of SiO2, 5-15 parts of Al2O3, 3-5 parts of Fe2O3, 0.5-1 parts of BaS, 0.5-1 parts of BaCO3, 0.1-1.5 parts of Zn, 0.02-0.05 parts of Cu, 0.05-0.1 parts of As, 0.01-0.05 parts of Pb, 1-5 parts of CaF2, 0.05-0.2 parts of MgO, 0.5-1.0 parts of TiO2, 0.5-1.0 parts of K2O, 0.1-1.0 parts of Na2O and 0.04-0.06 parts of Ag. The coal composite sulfur fixing agent of the invention can reduce the emission of SO2, the atmospheric pollution and the formation conditions for acid rain. Since pulverized fuel ash and coal cinder are converted to modified ash and can be used in cement production technology, the clinker production of common cement can be reduced generally, the mine resources and the energy consumed during cement production are reduced, and the emission of CO2 is reduced.

Owner:河南中上环保科技有限公司

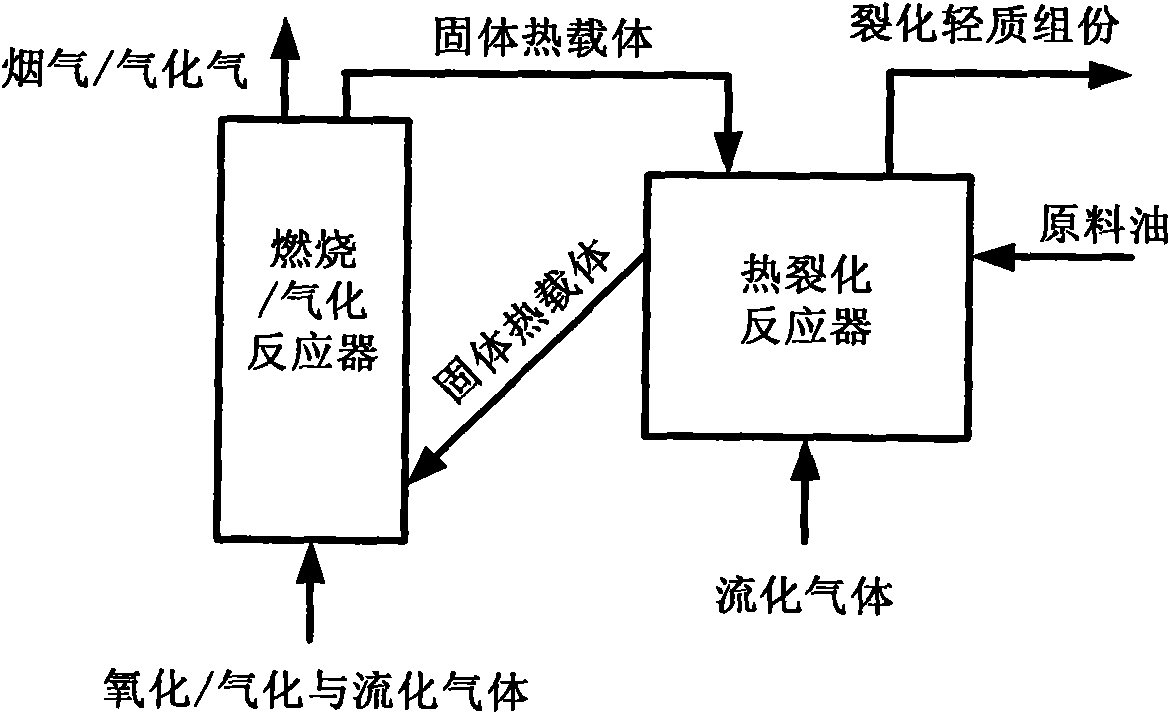

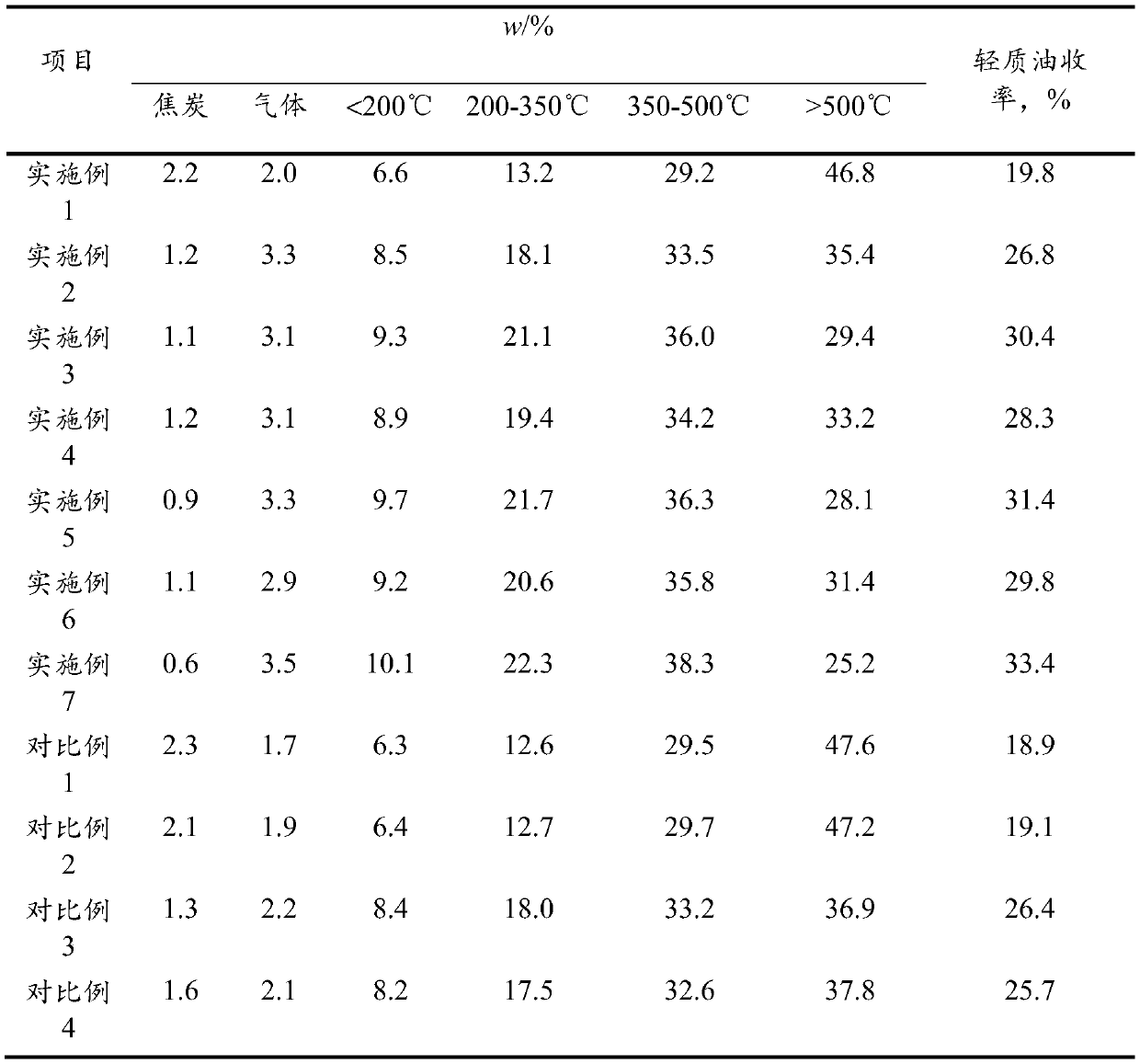

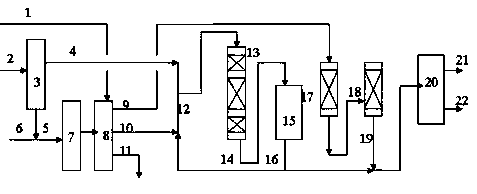

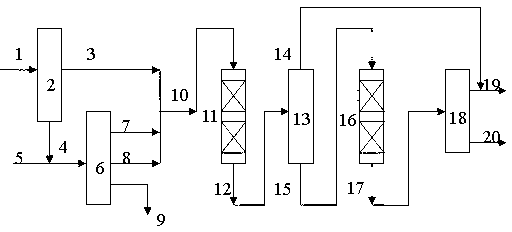

Processing method and apparatus for converting heavy oil to light fractions

InactiveCN102234522AAchieve conversionReduce carbon residueThermal non-catalytic crackingEnergy inputHeat carrierFuel oil

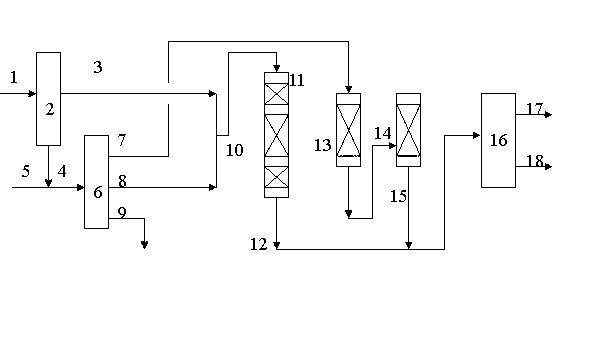

The invention relates to a processing method and an apparatus for converting heavy oil to light fractions. The processing method comprises the following steps: introducing raw oil to a thermal cracking reaction chamber through a material supply system, mixing the raw oil with a high-temperature solid heat carrier from a combustion / gasification reactor for fluidized heat transfer and carrying out thermal cracking reaction on the surface of the solid heat carrier; stripping the cracked gas and light component products generated during thermal cracking reaction with a fluidized medium gas and then introducing to a product outlet, feeding the solid heat carrier attached on petroleum coke into the combustion / gasification reactor through a material return valve, and introducing oxidation / gasification fluidized gas to carry out combustion / gasification reaction on the petroleum coke during fluidized elevating process; and separating the reaction products and the solid heat carrier by a gas-solid separator, feeding the flue gas / gasified gas into a heat exchanger to recover waste heat, then introducing to the product outlet, distributing the solid heat carrier by a distribution valve, separately introducing into the thermal cracking reactor and combustion / gasification reactor for recycling, further processing and utilizing the collected fly ash and thus achieving complete high-value conversion and utilization of heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing clean fuel oil from ethylene tar

ActiveCN103102974AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesTarFuel oil

The invention discloses a method for producing clean fuel oil from ethylene tar. The method consists of: fractionating ethylene tar into light fraction and heavy fraction, mixing the heavy fraction with a conventional coking raw material, conducting delayed coking to obtain coker gasoline and coker diesel oil, performing hydrofining on the coker gasoline, mixing the coker diesel oil with the ethylene tar light fraction, subjecting the mixture to hydrotreating, and leaving the reaction effluent and the coker gasoline hydrofining product together to undergo separation by a fractionating tower, thus obtaining clean gasoline and diesel oil products. Directed at the characteristics of high content of aromatic hydrocarbon, colloid, carbon residue and asphaltene in ethylene tar, the method provided in the invention fractionates the ethylene tar into light fraction and heavy fraction, and adopts different processing processes according to the composition characteristics of each fraction, thus not only enhancing the utilization rate of ethylene tar, increasing the yield of light fuel oil, but also improving the product quality of light fuel oil, and enabling the equipment to run smoothly for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

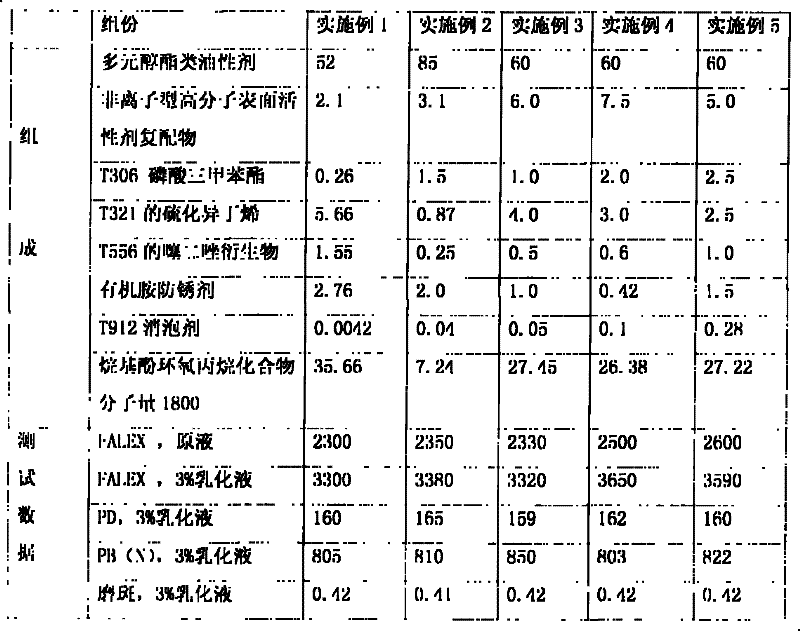

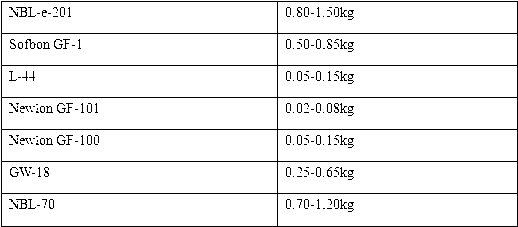

A kind of cold rolling extremely thin plate rolling oil composition

The invention discloses a novel cold rolling extreme thin plate rolling oil composition. Synthesized ester and an alkylphenol epoxypropane compound are compounded to be used as an oily agent and can form a layer of quite dense protective film on the surface of metal to form favorable annealing detergency and heat stability. A nonionic compounded emulsifying agent can increase the diameter of the elaioplast of emulsion and shows better lubricity by matching with the interaction of a metal passivator, a sulfur-containing extreme pressure antiwear agent, and the like.

Owner:石家庄新泰特种油有限公司

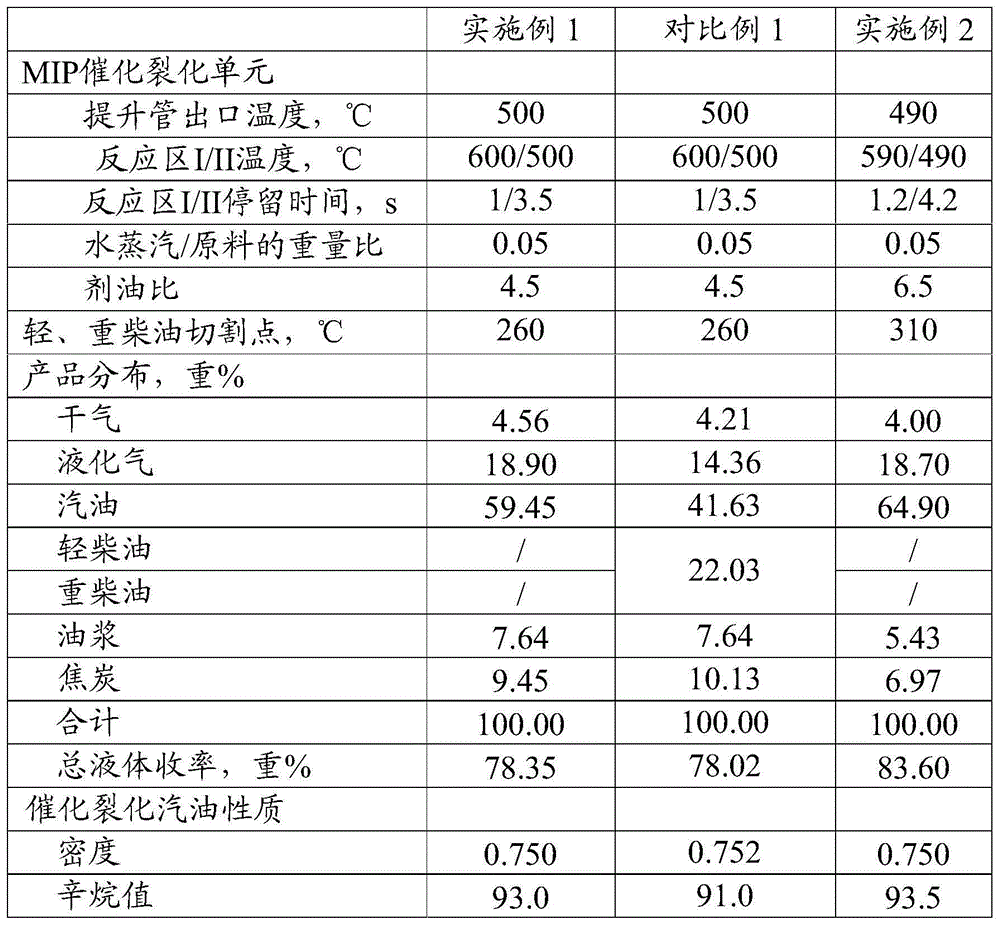

A method of producing gasoline with a high octane number from residual oil

ActiveCN104593068ALow viscosityReduce contentTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonGasoline

A method of producing gasoline with a high octane number from residual oil is provided. According to the method, catalytic cracking heavy diesel is doped into a residual oil hydrogenation raw material and subjected to hydrogenation processing together, thus reducing viscosity of the residual oil, improving intermiscibility of a residual oil system, promoting hydrogenation of the residual oil to remove impurities, and reducing coking of a residual oil hydrogenation catalyst. Hydrogenated diesel rich in mononuclear aromatics is obtained from the catalytic cracking heavy diesel rich in polycyclic aromatic hydrocarbons after the hydrogenation processing. The hydrogenated diesel is mixed with catalytic cracking light diesel rich in mononuclear aromatics, and then the mixture is circulated and returned to a catalytic cracking unit to obtain the gasoline with a high octane number and rich in mononuclear aromatics.

Owner:CHINA PETROLEUM & CHEM CORP +1

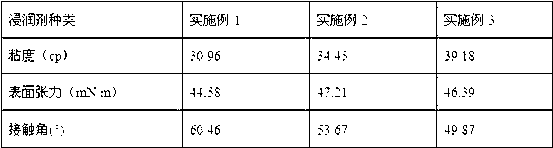

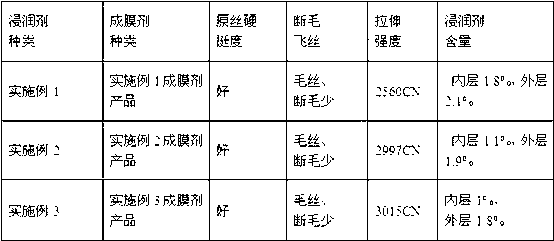

A method for preparing an esterified starch film former for glass fiber wetting

The present invention discloses a method for preparing an esterified starch film former for glass fiber wetting, and the method is characterized in that the product of the esterified starch film former for glass fiber wetting is obtained by: placing corn starch into a reactor, adding water, heating to a temperature of 70-90 DEG C under stirring, reacting for 0.5- 2h, and cooling to 30-60 DEG C; adjusting a pH value to 4-7, adding isoamylase, after reacting for 0.5-6h, heating to a temperature of 80-90 DEG C for 20 min for enzyme deactivation, and filtering to remove the enzyme and obtain a reaction solution; and cooling the reaction solution to a temperature of 25-55 DEG C, adding an acid anhydride, adding an alkaline catalyst, maintaining the pH value being 7-10, reacting for 2-10h, adjusting the pH value to be 6-7, cooling to the room temperature, suction filtering, and drying a solid. The product of the film former has the advantages of a good film forming property and an easy post-treatment process, and has excellent effects of bundling and protecting the glass fiber in the production process of the glass fiber.

Owner:SOUTHWEAT UNIV OF SCI & TECH

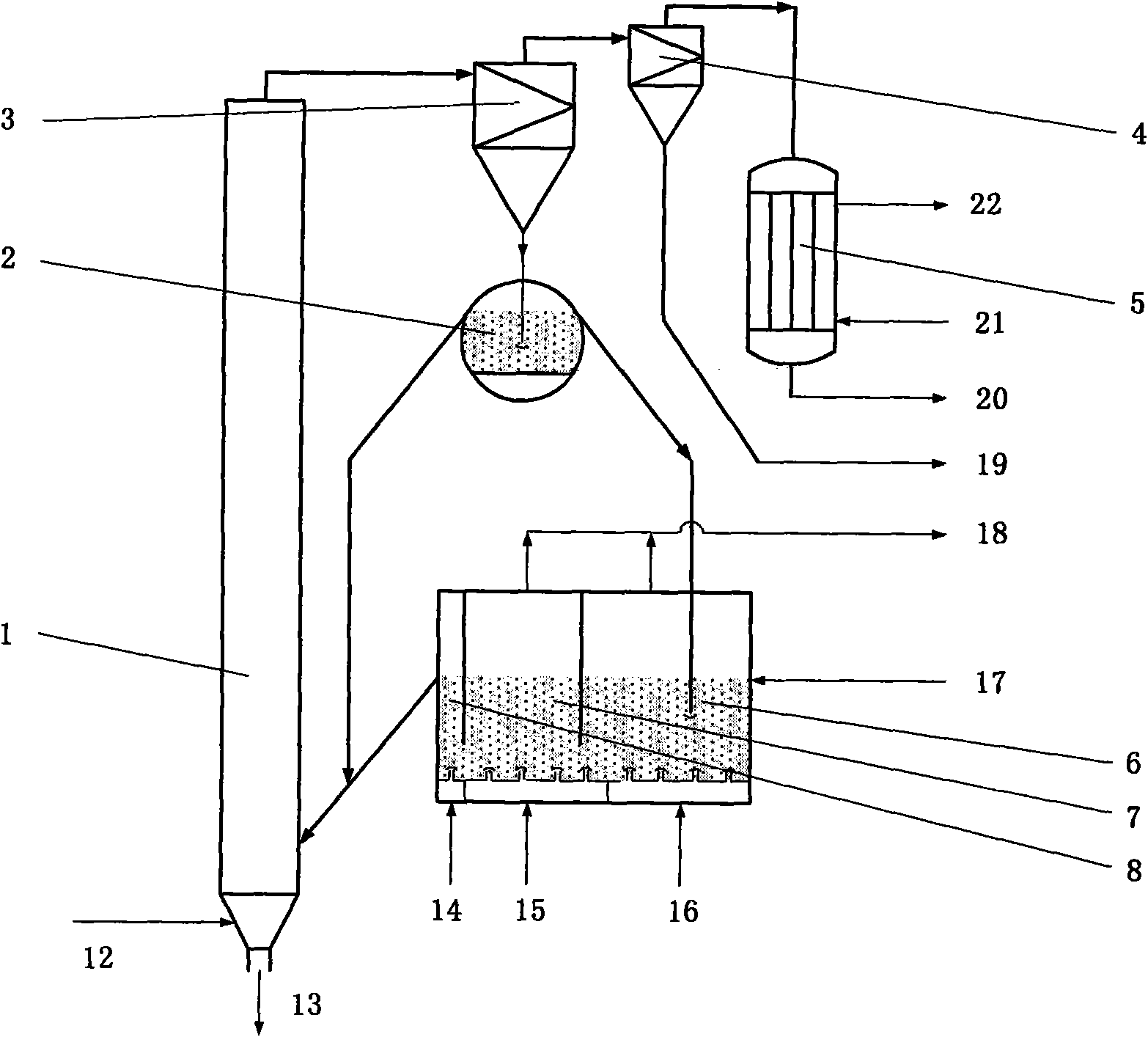

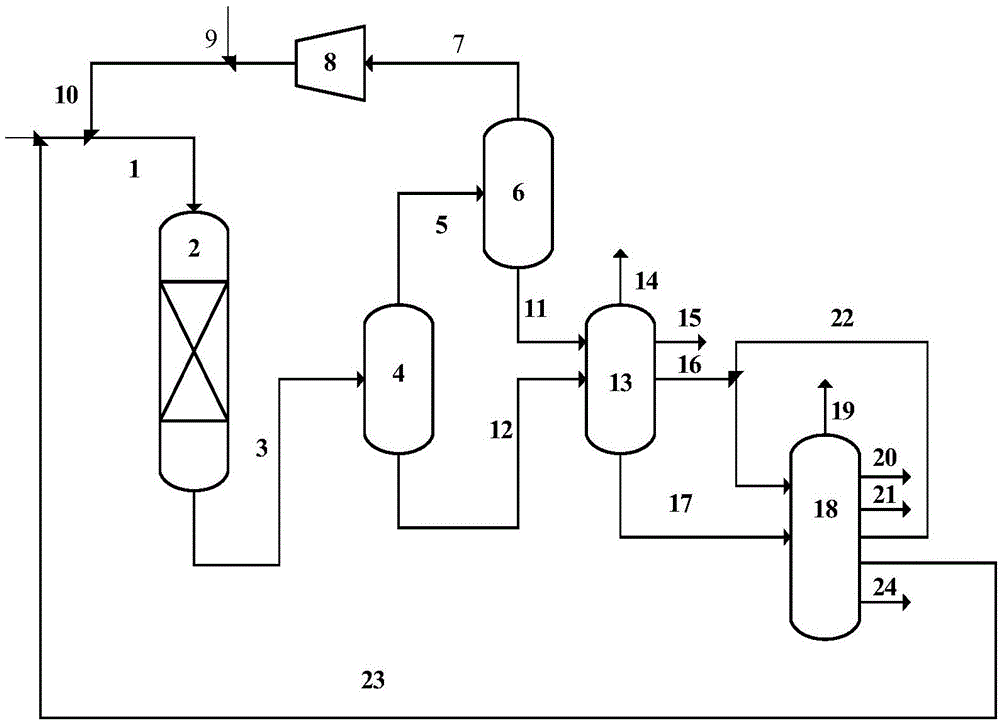

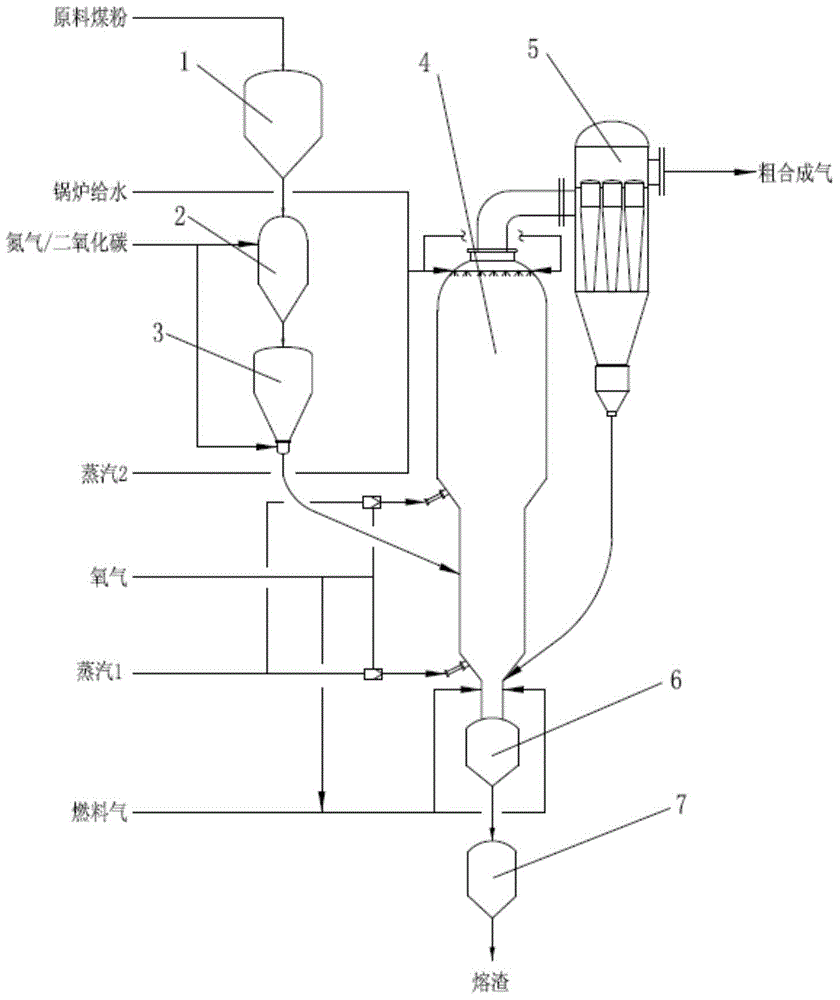

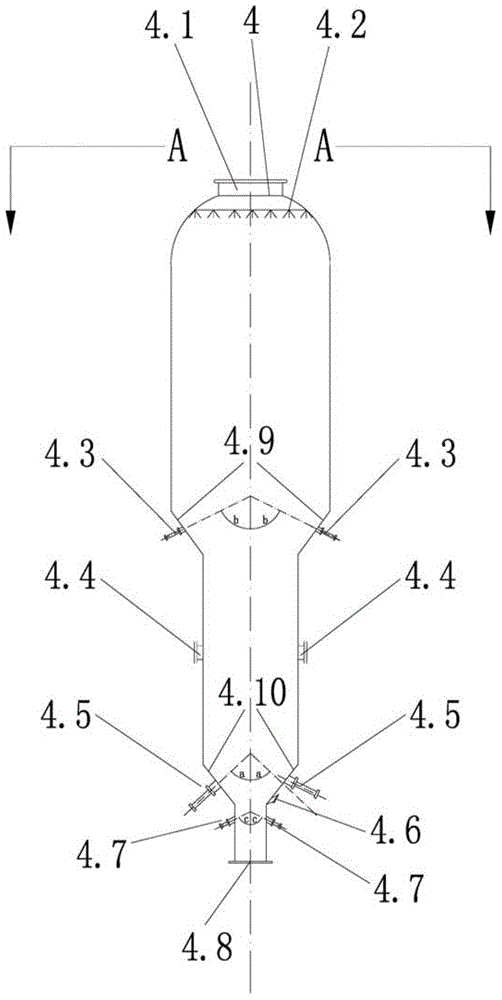

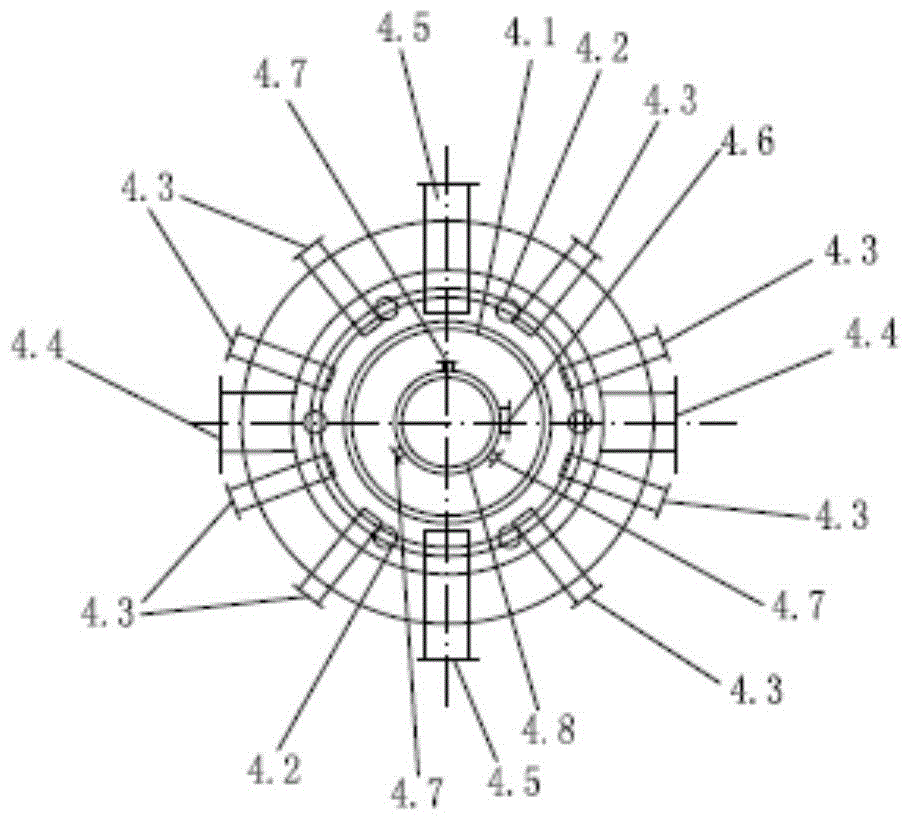

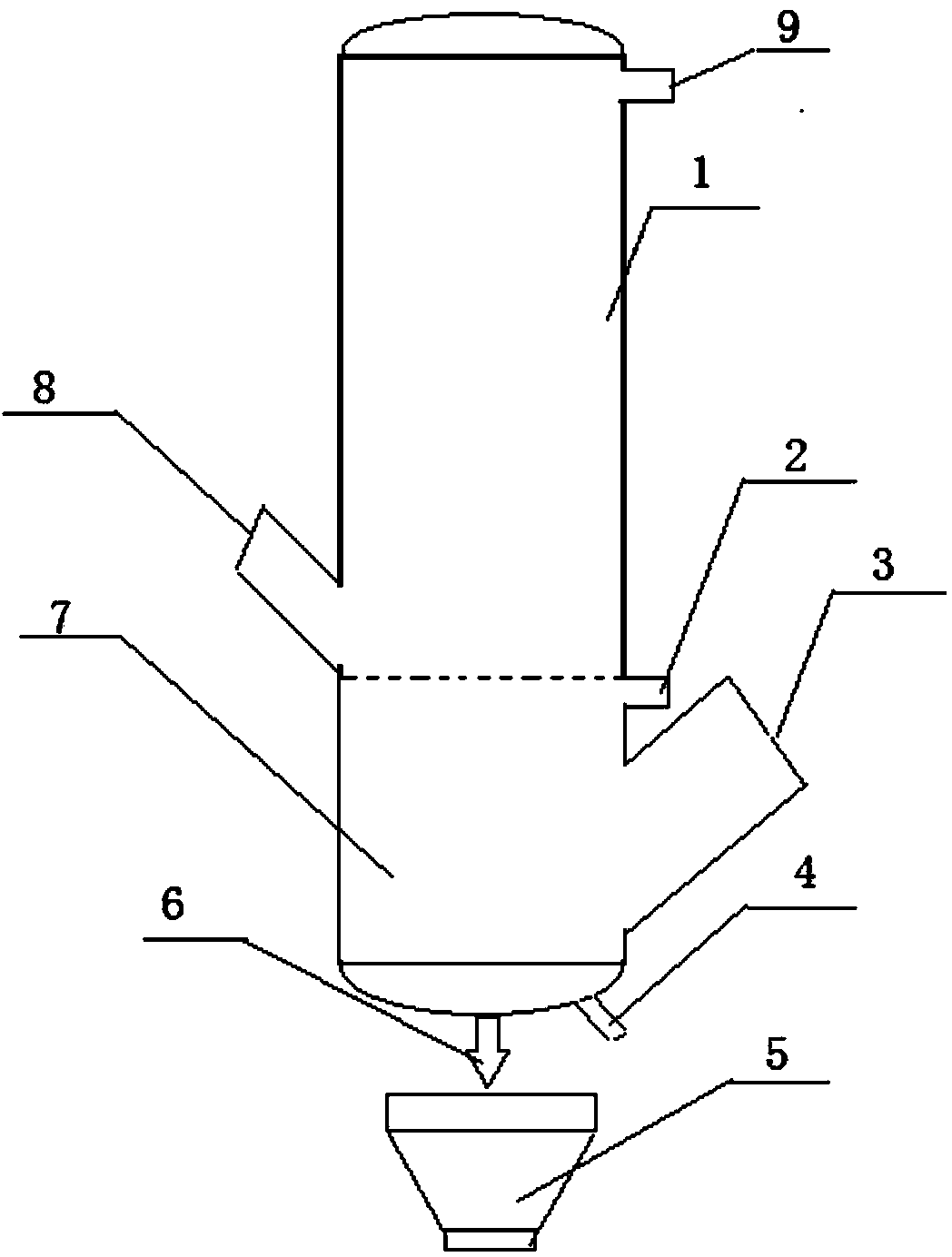

Clean coal pressurized fluidized bed slag gasification process and system

ActiveCN104531224AEffective coagulationEffective returnGasification processes detailsGasification apparatus detailsCycloneFluidized bed gasifier

The invention discloses a clean coal pressurized fluidized bed slag gasification process and system. By means of the gasification process and system, the problems that an existing pressurized fluidized bed industrial gasification process is complex, poor in coal applicability, low in gasification pressure, small in production capacity and low in gasification efficiency, the environment is polluted are solved. According to the technical scheme, the process includes the steps that raw material coal powder is pressurized and sent to a fluidized bed gasification furnace through a material inlet to react with a gasifying agent in a gasification mode, and crude synthesis gas and coal powder ash slag are obtained; the crude synthesis gad rises and is sent to a multi-pipe type cyclone separator through a top outlet of the fluidized bed gasification furnace to be dedusted, fluidizing agents are sprayed twice through a gasification spray nozzle to improve gasification efficiency, the coal powder ash slag is melt through a slag melting device, forms melt slag and then enters a slag quenching tank through a bottom outlet of the fluidized bed gasification furnace to be quenched and discharged through a slag locking hopper. The clean coal pressurized fluidized bed slag gasification process and system are simple in process, easy and convenient to operate, wide in coal applicability, high in gasification pressure, large in production capacity, high in gasification efficiency and environmentally friendly.

Owner:WUHUAN ENG +1

Photocuring resin for investment casting in laser fast molding

The invention discloses a photocuring resin for investment casting in laser fast molding. The resin comprises the following materials in percentage by mass: 30 to 55 percent of unsaturated polyester, 20 to 35 percent of epoxy resin, 20 to 40 percent of active diluent and 1 to 6 percent of light initiator. A preparation process for the resin comprises the following steps of: adding the light initiator into the active diluent, dissolving in a water bath of 40 to 60 DEG C until the light initiator is transparent, adding the unsaturated polyester and the epoxy resin, and stirring and mixing for 1 to 2 hours. The resin has low viscosity, a mold shell does not crack during roasting, the thermogravimetric curve is flat in a roasting process, the gas evolution is uniform and the carbon residue is low.

Owner:湖南西交智造科技有限公司

Method for preparing environmentally-friendly rubber oil through solvent refining and hydrofining combination technology

ActiveCN102952582AReduce carbon residueTreatment with hydrotreatment processesReaction temperatureHigh pressure

The invention relates to a method for preparing environmentally-friendly rubber oil through a solvent refining and hydrofining combination technology. Aromatic hydrocarbon extract oil in a vacuum fraction is adopted as a raw material, a ternary composite solvent comprising 60-75% by volume of furfural, 20-35% by volume of a polyhydroxy alcohol or a polyhydroxy alcohol ester, and the balance an aqueous NaCl solution is adopted as a solvent in a solvent extraction segment, and extraction oil is obtained under operation conditions comprising that the top temperature of an extraction tower is 50-100DEG C, wherein the oil-solvent volume ratio is 0.5-3.0:1; and then the extraction oil is hydrofined under a high pressure, wherein the high-pressure hydrogenation treatment conditions comprise that the reaction pressure is 15.0Mpa, the reaction temperature is 330-350DEG C, the reaction air speed is 0.3-1.0h<-1> and the hydrogen-oil ratio is 500-1000:1, and a catalyst is a non-precious metal sulfide hydrogenation treatment catalyst treating Ni-W as a hydrogenation active component. Environmentally-friendly rubber oil with the CA percentage characterizing the aromatic hydrocarbon content of above 16 can be prepared through the method, the content of the polycyclic aromatic hydrocarbons (PCAs) in the rubber oil is less than 3%, and the sum of eight PAHs is less than 10mg / kg.

Owner:PETROCHINA CO LTD +1

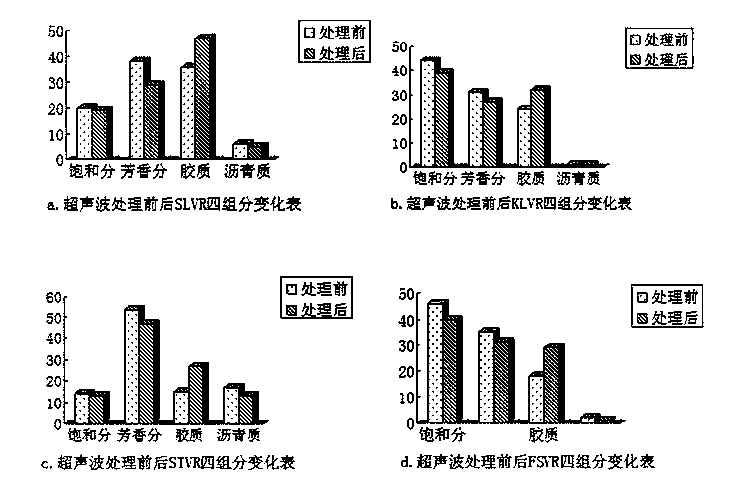

Raw material pretreatment method for improving light performance of residual oil

InactiveCN103805229ASimple methodOperational securityHydrocarbon oils refiningPretreatment methodFeed conversion ratio

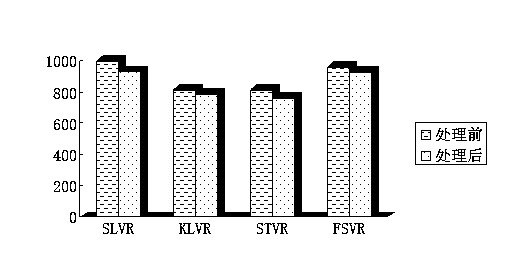

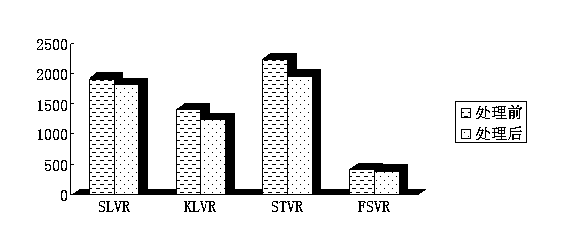

The invention provides a raw material pretreatment method for improving the light performance of residual oil. By means of the cavatition and recombination effects of ultrasonic waves, the colloid structure of the residual oil is changed, the structural composition of the residual oil is optimized, the distribution uniformity of four components is promoted, the stability of a colloid system is improved, and the quality of the residual oil is totally improved, so that the hydrogenation effect of the residual oil is remarkably improved. Residual oil from different sources has relatively large difference in ultrasonic treatment effect. Known from hydrotreated data, the method can be used for reducing the average relative molecular weight of the vacuum residual oil by 3-6%, reducing the viscosity by 5-12%, reducing the carbon residue value by about 21-40%, increasing the hydrogenated residual oil conversion ratio by 8-10%, increasing the light oil yield by 7-11% and the like. The method has the advantages of simplicity in treatment, convenience in operation, low cost and capabilities of more remarkably improving the quality of the residual oil, greatly increasing the conversion ratio of the residual oil and ensuring that the treated residual oil is easier to process and treat in processes such as residual oil hydrogenation and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

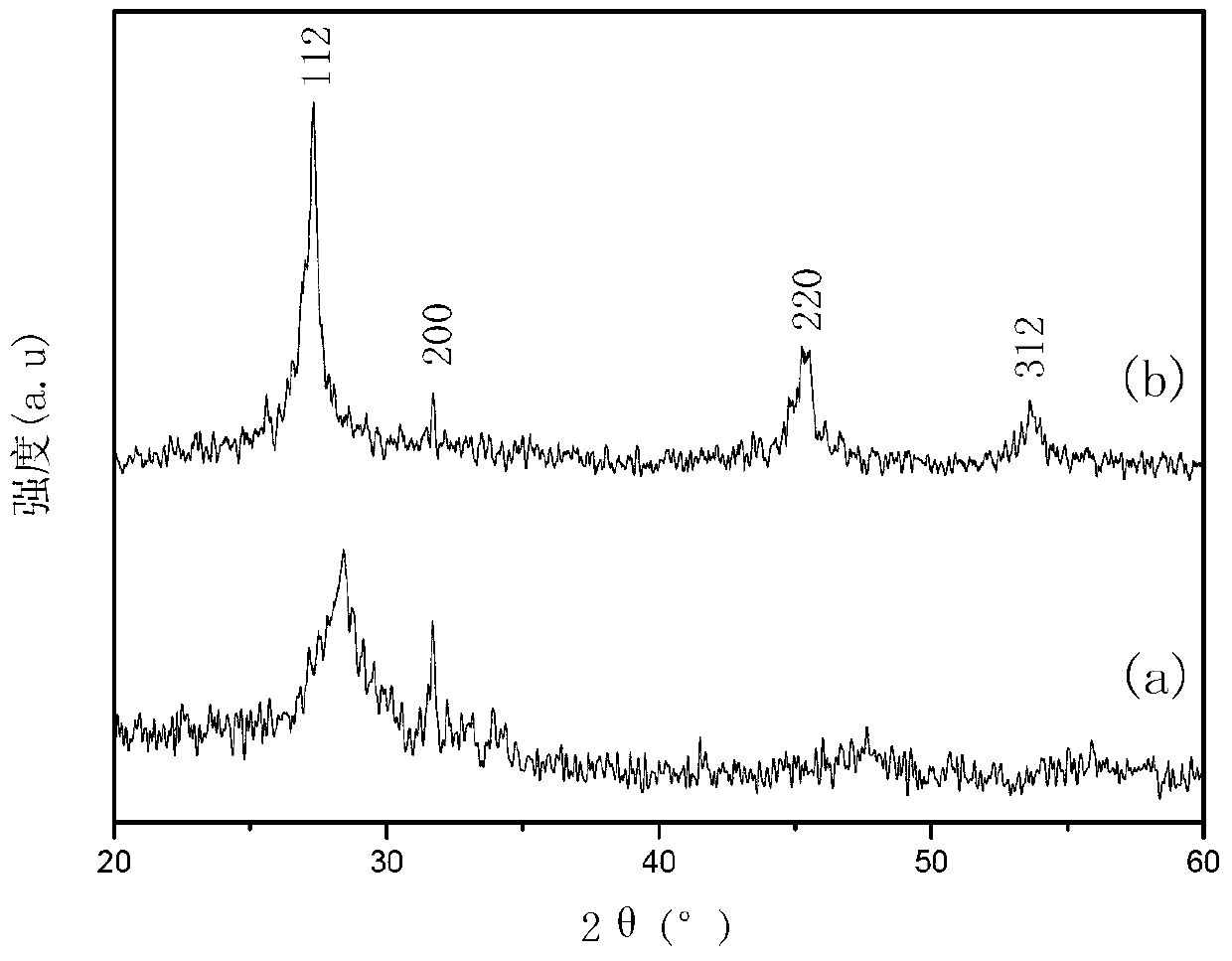

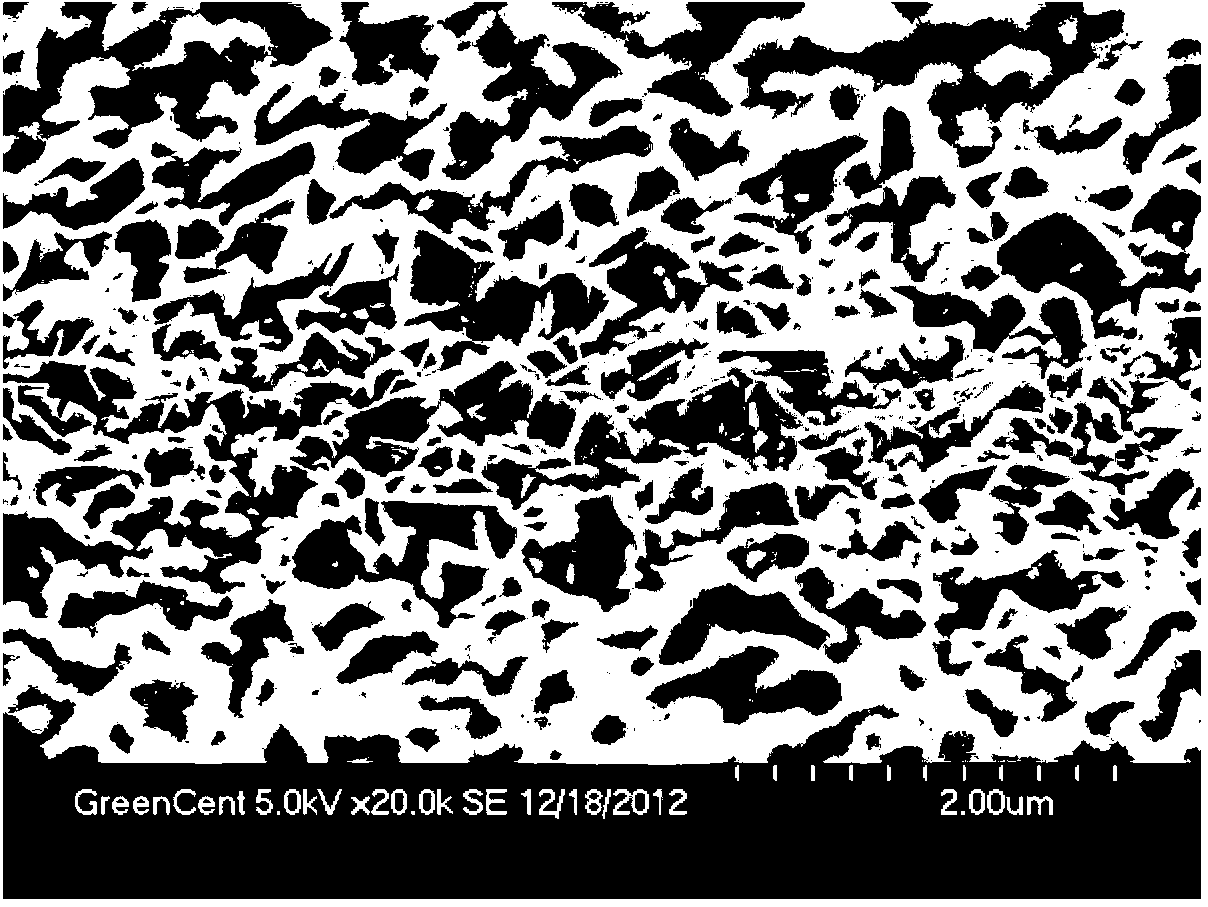

Method for preparing copper-zinc-tin-sulfide solar cell absorbing layer with homogeneous solution method

InactiveCN103346215AIncrease profitReduce carbon residueFinal product manufactureSemiconductor devicesTechnology developmentSulfur

The invention discloses a method for preparing a copper-zinc-tin-sulfide solar cell absorbing layer with a homogeneous solution method and belongs to the field of functional materials. The method comprises the following steps that (a) a substrate is washed, (b) front-body solution is prepared, (c) a front-body thin film is prepared, and (d) annealing processing is carried out. According to the method for preparing the copper-zinc-tin-sulfide solar thin film, expensive raw materials and equipment are of no need, each technology step can be well controlled, toxic macromolecule solvent is of no need, a large amount of residual carbon in the copper-zinc-tin-sulfide solar thin film preparing process is avoided, large-grained and compact copper-zinc-tin-sulfide solar cell absorbing layer thin film preparing is facilitated, the technology is simple, cost is low, repeatability is high, a new idea is provided for environment-protection low-cost high-conversion-efficiency copper-zinc-tin-sulfide thin-film solar cell technology development, and the potential of large-scale industrial production is achieved.

Owner:BEIJING UNIV OF TECH

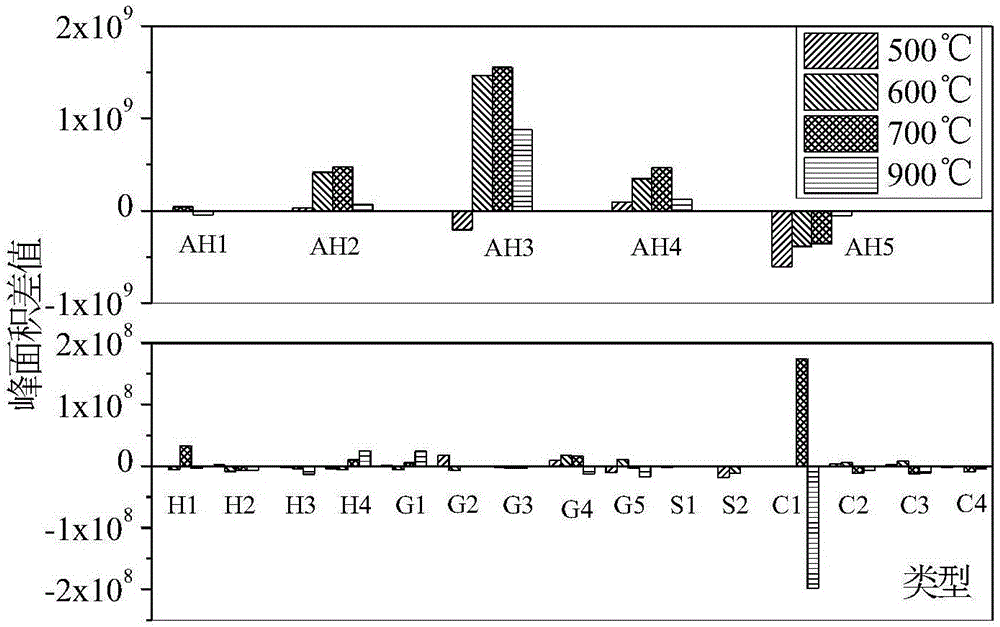

High-temperature chain oil composition and preparation method thereof

ActiveCN105838484AImprove high temperature performanceImprove wear resistanceAdditivesBase-materialsPentaerythritolPhosphate

The invention provides a high-temperature chain oil composition and a preparation method thereof. The high-temperature chain oil composition includes: (a) synthetic ester base oil; (b) alkoxy phosphate anti-wear reagent at extreme pressure; (c) oiliness agent; (d) viscosity index improver; (e) antioxygen; and (f) anticorrosive, wherein the (a) synthetic ester base oil is a mixture of dipentaerythritol ester and aromatic ester. The high-temperature chain oil composition is adapted to using at high temperature, has good high-temperature performance, has no carbon deposition residual working at high temperature for a long time, is without dripping, has good wear-resisting anti-attrition and corrosion resistant performances, and has low friction coefficient and small chain abrasion. Moreover, the high-temperature chain oil composition has low toxicity, is easy to decompose, and is environmentally friendly.

Owner:埃优诺特种新材料科技(山东)有限公司

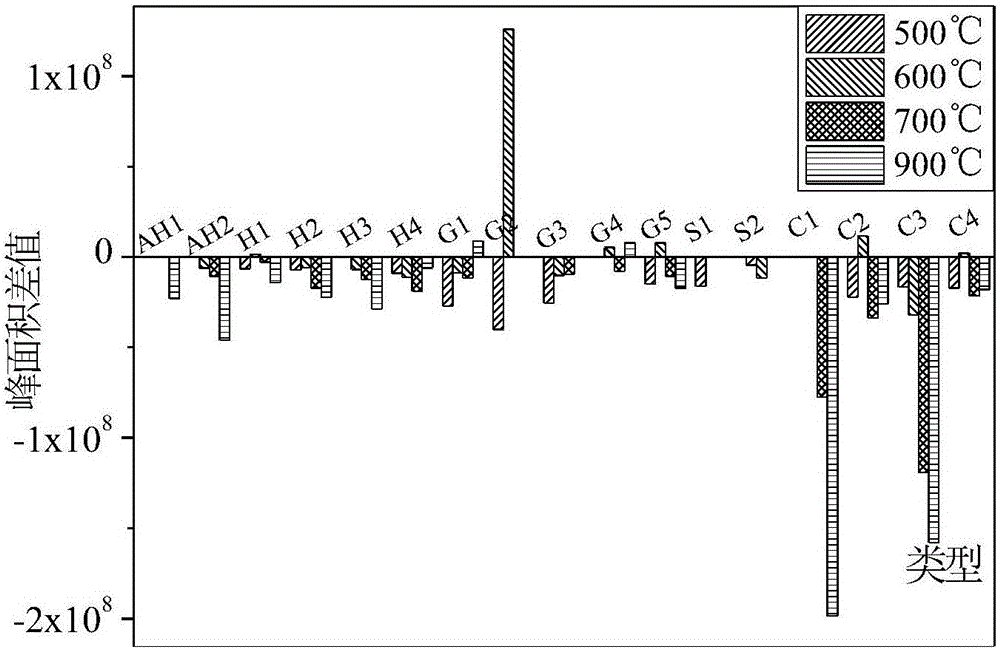

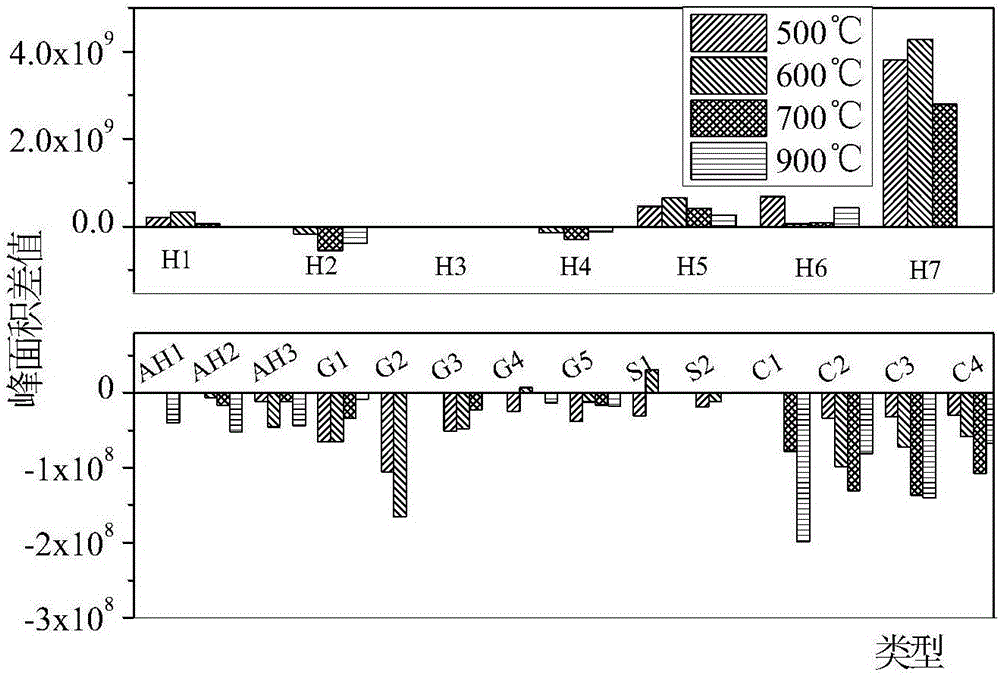

Method for preparing aromatic hydrocarbon compound through blending pyrolysis of lignin and low-density polyethylene or polycarbonate or polystyrene

InactiveCN106431802ARealize resource utilizationPromote generationOrganic compound preparationHydrocarbonsLow-density polyethyleneResource utilization

The invention discloses a method for preparing an aromatic hydrocarbon compound through blending pyrolysis of lignin and low-density polyethylene or polycarbonate or polystyrene. After the lignin and a high-molecular polymer is mixed according to a certain mass ratio, the distribution condition of blending pyrolysis products is inspected by adopting a Py-GCMS analytical means, wherein the temperature is set at 500 DEG C to 900 DEG C, and the temperature increasing rate is set at 20 DEG C / ms; the yield of aromatic hydrocarbon in the blending pyrolysis products of the lignin and polystyrene is obviously increased. Further, the weight loss condition and the small molecule escaping condition in the blending pyrolysis process of the lignin and polystyrene is inspected by adopting a TG-FTIR analytical means, wherein the temperature increasing range is set at to range from 20 DEG C to 900 DEG C, and then the blending pyrolysis mechanism is analyzed. The mode that the lignin is subjected to blending pyrolysis with low-density polyethylene or polycarbonate or polystyrene is low in cost and clean in process; meanwhile, by means of blending pyrolysis of the lignin and polystyrene, the generation amount of monomeric aromatic hydrocarbon can be effectively promoted, and directive guidance is provided for resource utilization of papermaking waste liquid and waste plastic.

Owner:SOUTHEAST UNIV

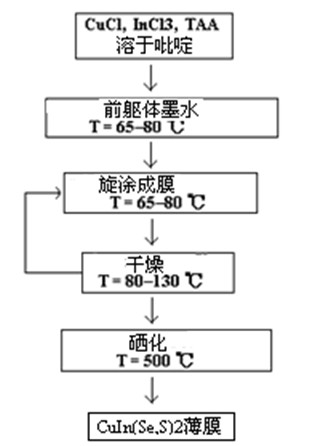

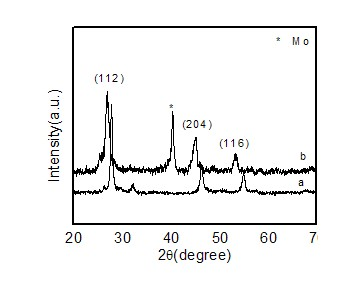

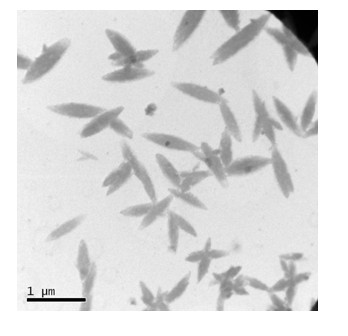

Preparation method of copper indium selenium sulfide thin film for solar cell

InactiveCN102683497APrecise control of stoichiometric ratioReduce carbon residueFinal product manufactureSemiconductor devicesIndiumGas phase

The invention relates to a method for preparing a Culn (Se, S)2 thin film by using a non-vacuum wet chemical method, which comprises the following steps of: (a) precursor ink preparation; (b) precursor thin film preparation; (c) drying; and (d) annealing. Compared a traditional high vacuum-gas phase method, the preparation method of the copper indium selenium sulfide thin film provided by the invention has the advantages of simple process, low cost, strong repeatability, easiness in realization of large-scale production, stable raw material physicochemical property, good safety and high raw material utilization rate, and the rapid development of the copper indium selenium sulfur thin film solar cell industry can be promoted.

Owner:TIANJIN NORMAL UNIVERSITY

Non-preheat composite structure long nozzle liner material

InactiveCN103480833APlay a role in burningReduce carbon residueMelt-holding vesselsThermal dilatationMullite

Disclosed si a non-preheat composite structure long nozzle liner material, and relates to the field of functional refractories for continuous steel casting. The ingredients include 20-50wt% of corundum, 10-50wt% of electric-melted zirconia mullite, 15-40wt% of fused silica, 5-20wt% of light burned alumina and 5-15wt% of zinc oxide, and 5-10% of phenolic resin of the total weight of the liner material is added as a binder. The liner material has high porosity, low thermal expansion coefficient and thermal conductivity, and is capable of resisting scour and erosion of molten steel well.

Owner:LUOYANG INST OF SCI & TECH

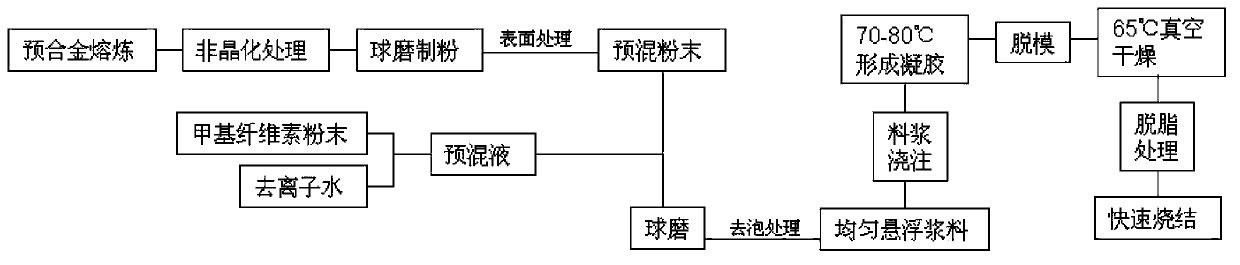

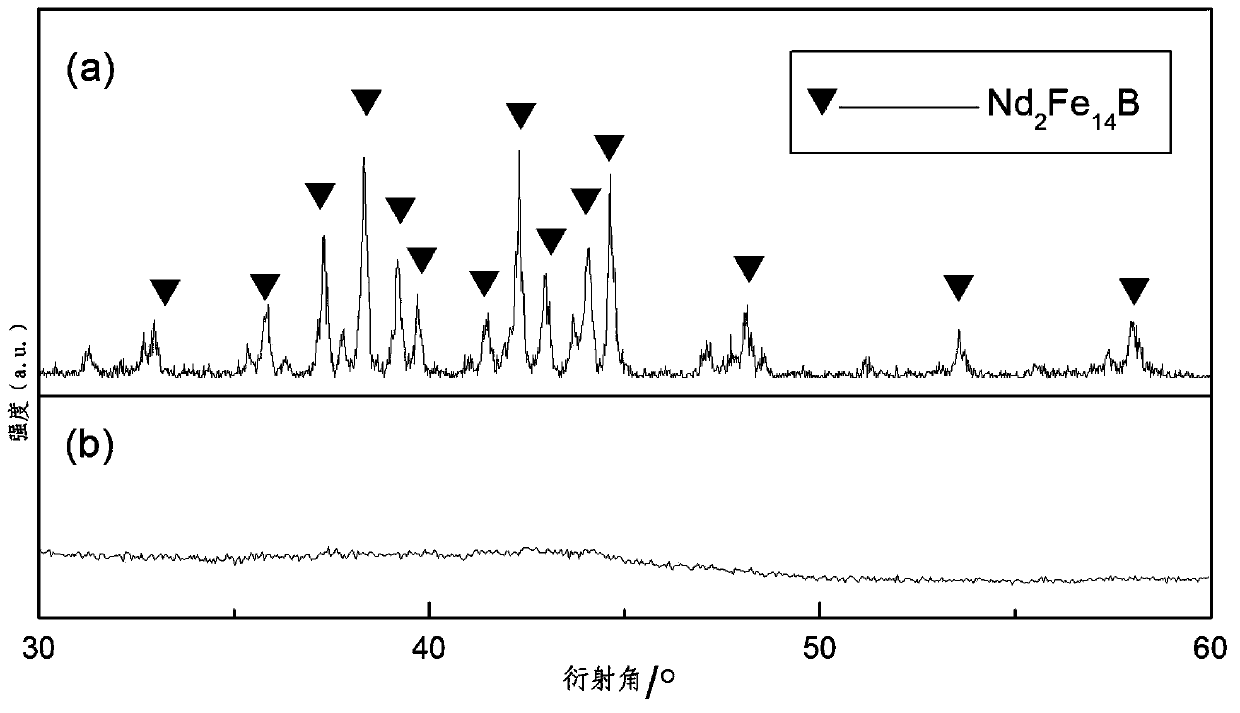

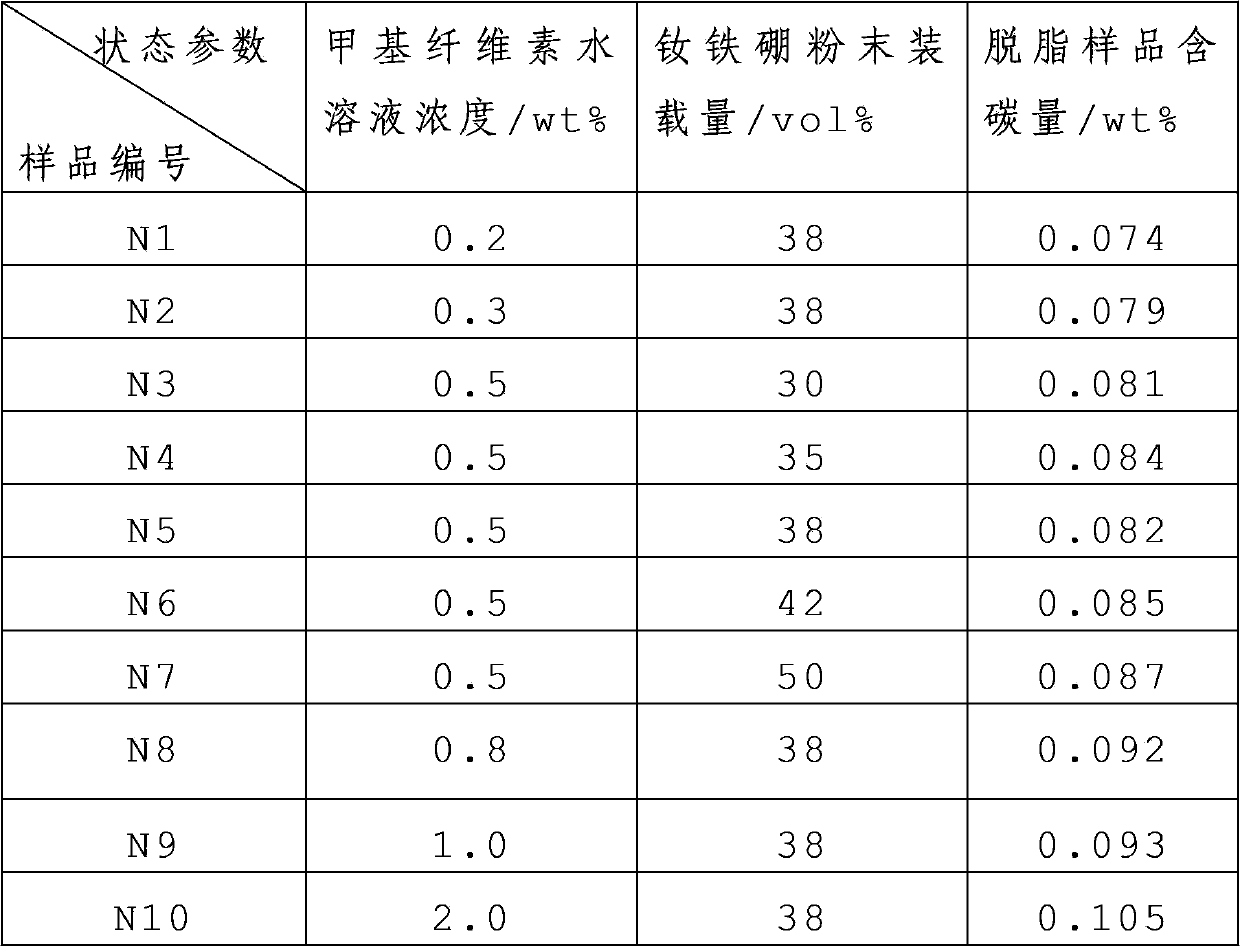

Method for forming isotropic neodymium-iron-boron magnet

The invention provides a method for forming an isotropic neodymium-iron-boron magnet. The method comprises the step of smelting an alloy raw material into a prealloyed cast ingot, the step of performing non-crystallizing treatment on the prealloyed cast ingot to obtain a fast-quenched alloy, the step of performing ball milling on the fast-quenched alloy to obtain a powder, the step of mixing the powder with a binder to obtain a slurry, and the step of forming the slurry into the magnet. The binder is a water-based binder, preferably a methylcellulose aqueous solution, and the solid content in the slurry ranges from 30vol% to 60vol%. The method is capable of realizing the formation of the isotropic neodymium-iron-boron magnet large in dimension and complex in shape, and therefore, the purpose of reducing the oxygen content is achieved, and simultaneously, the carbon residue in a degreasing process can be greatly reduced.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

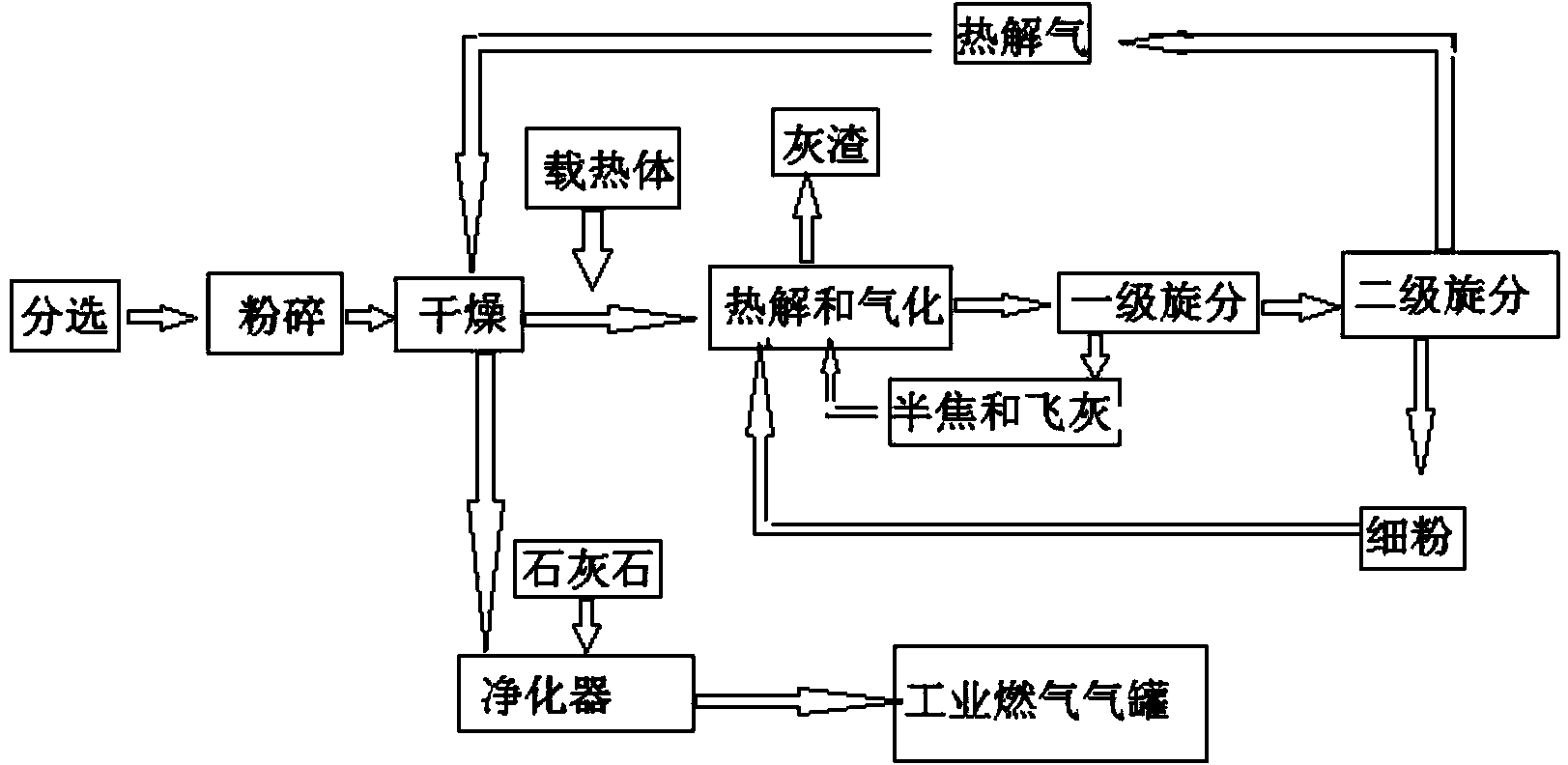

Method for preparing industrial fuel gas through pyrolysis treatment of garbage

ActiveCN104109560AImprove overall utilizationAvoid the formation of dioxinsGas dust removalGranular/pulverulent flues gasificationMagnetic separatorPyrolysis

The invention relates to garbage disposal, specifically to a method for preparing industrial fuel gas through pyrolysis treatment of garbage. The method comprises the following steps: sorting; crushing; drying; pyrolysis; and gasification. Sorting refers to sorting of garbage by using a magnet separator. Crushing refers to crushing of the garbage sorted by the magnet separator. Drying refers to heat exchange between the crushed garbage and pyrolysis gas in a roller dryer. In the steps of pyrolysis and gasification, fly ash is subjected to melting. Pyrolysis gas and the garbage are subjected to heat exchange in the dryer at the same time, so energy consumption of garbage disposal is reduced; through arrangement of an entrained-flow bed and a circulating fluidized bed in one pyrolyzing furnace equipment, hierarchical pyrolysis and gasification of the garbage are realized; through arrangement of a hierarchical separator, entrained semi-coke with different granularity enters different bed layers, so different chemical reactions in different environments are carried out, and thus, the garbage is fully decomposed into industrial fuel gas and the comprehensive utilization rate of the garbage is increased.

Owner:六盘水钟山区民富砖厂

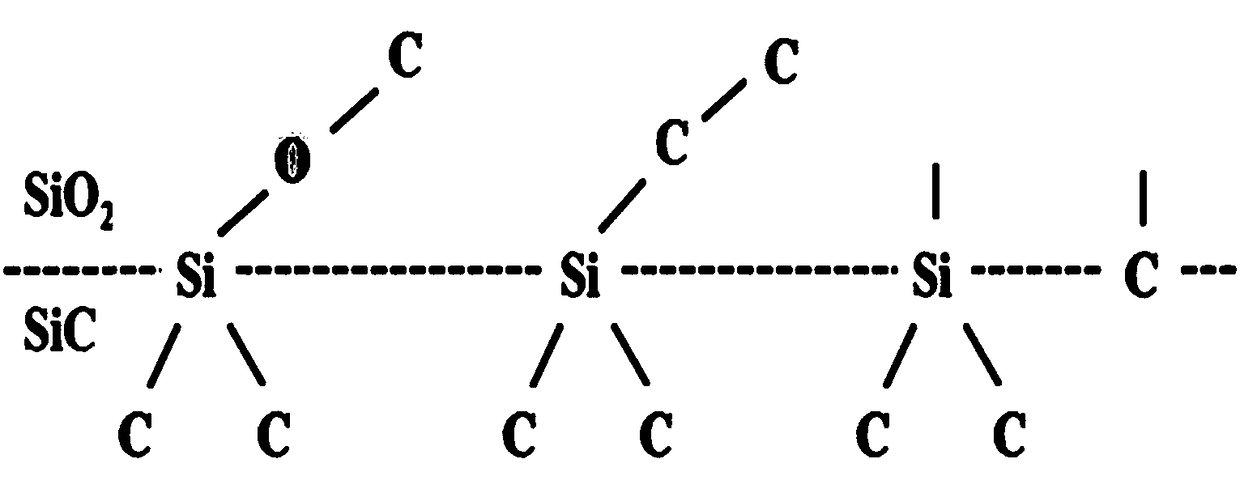

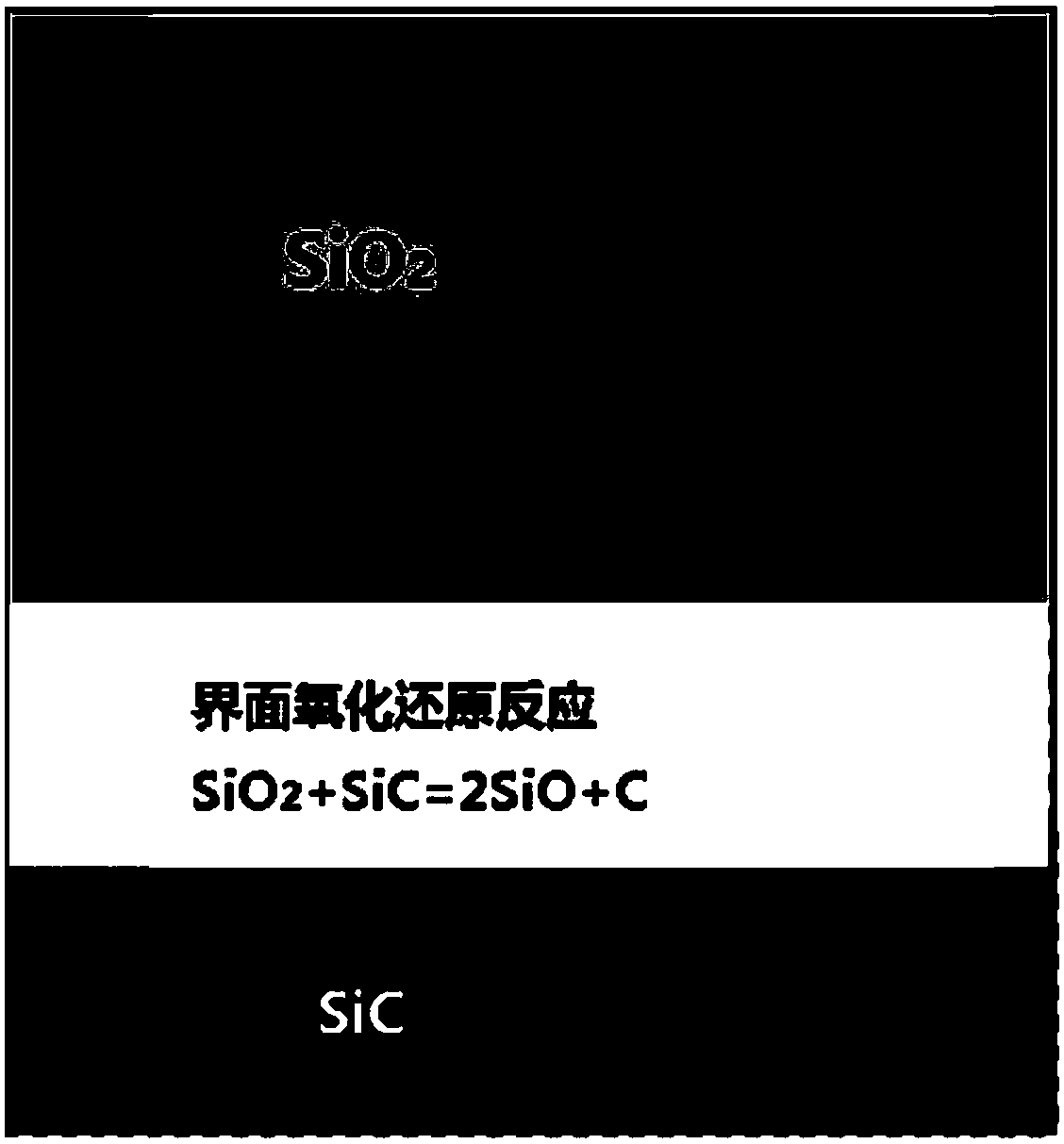

Silicon carbide oxidation method based on microwave plasma

InactiveCN108584963AImprove oxidation efficiencyImprove interface qualitySilicaMicrowaveOxygen plasma

Provided is a silicon carbide oxidation method based on a microwave plasma. The silicon carbide oxidation method comprises the steps that a silicon carbide substrate is provided; the silicon carbide substrate is placed in a microwave plasma generation device; oxygen-containing gas is introduced to generate an oxygen plasma; the oxygen plasma reacts with silicon carbide to generate silicon dioxidewith a preset thickness; the introducing of the oxygen-containing gas is stopped, and reaction is completed; the reaction temperature of the oxygen plasma and silicon carbide is 500-900 DEG C, and thereaction pressure of the oxygen plasma and silicon carbide is 400-1000 millitorrs. The silicon carbide oxidation method based on the microwave plasmas has the advantages that the oxidation efficiencyof the silicon carbide can be significantly improved, the thermodynamic non-equilibrium state can be achieved on interfaces of the silicon carbide and silicon dioxide, and the interface quality is greatly improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

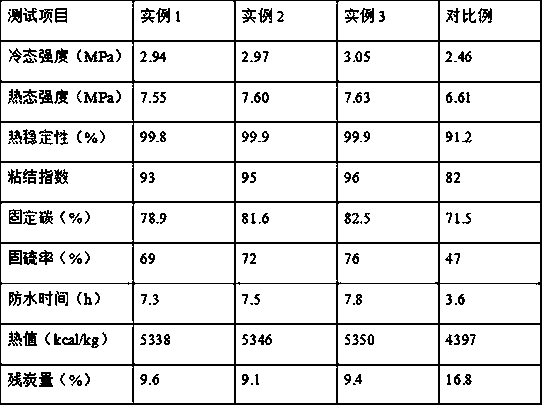

Preparation method of waterproof biomass molded coal binder

ActiveCN108559564AHas a bonding effectImprove adhesionSolid fuelsWaste based fuelFiberActivated sludge

The invention relates to the technical field of coal molding, and concretely relates to a preparation method of a waterproof biomass molded coal binder. The method comprises the following steps: extracting soybean oil used as a raw material by an ethanol solution to obtain a concentrate rich in soybean phospholipids, performing mixing and sealing fermentation on the soybean oil and activated sludge to obtain a fermentation product, cooking rice husks used as a raw material to obtain a cooked product, reacting the cooked product with phenol to obtain a reaction product, and mixing and reactingthe reaction product, the fermentation product and the concentrate to obtain the waterproof biomass molded coal binder. Microorganisms in the activated sludge are used to degrade the soybean oil, parts of fibers play a role in the connection and stretching of molded coal, furfural produced by the hydrolysis of rice husks reacts with phenol to improve the bonding performance of the binder and improve the water resistance, and the activated sludge added to the molded coal binder is rich in volatile groups in order to improve the gasification reactivity of the molded coal, reduce residual carbonin ash residues and improve the conversion rate of carbon, so the waterproof biomass molded coal binder has broad application prospects.

Owner:唐山市古冶区阳辰环保科技型煤厂

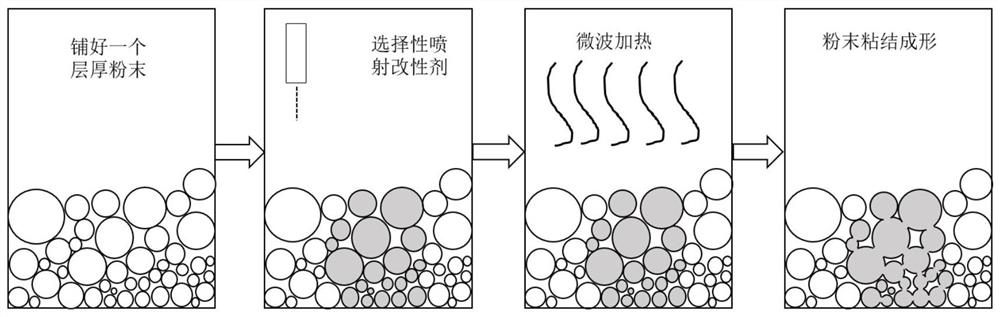

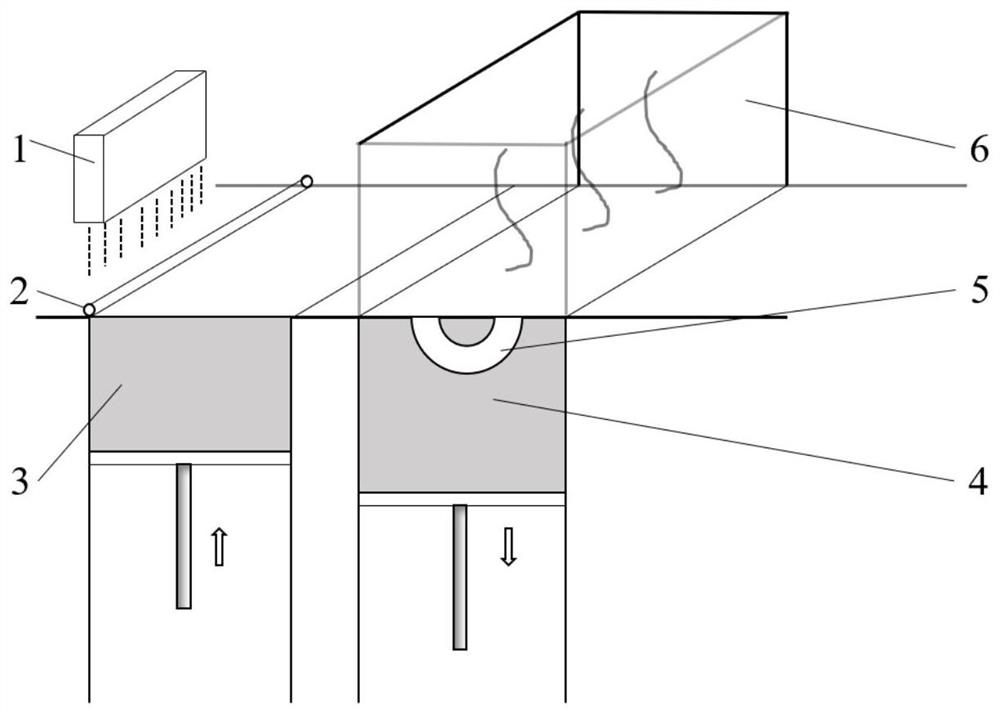

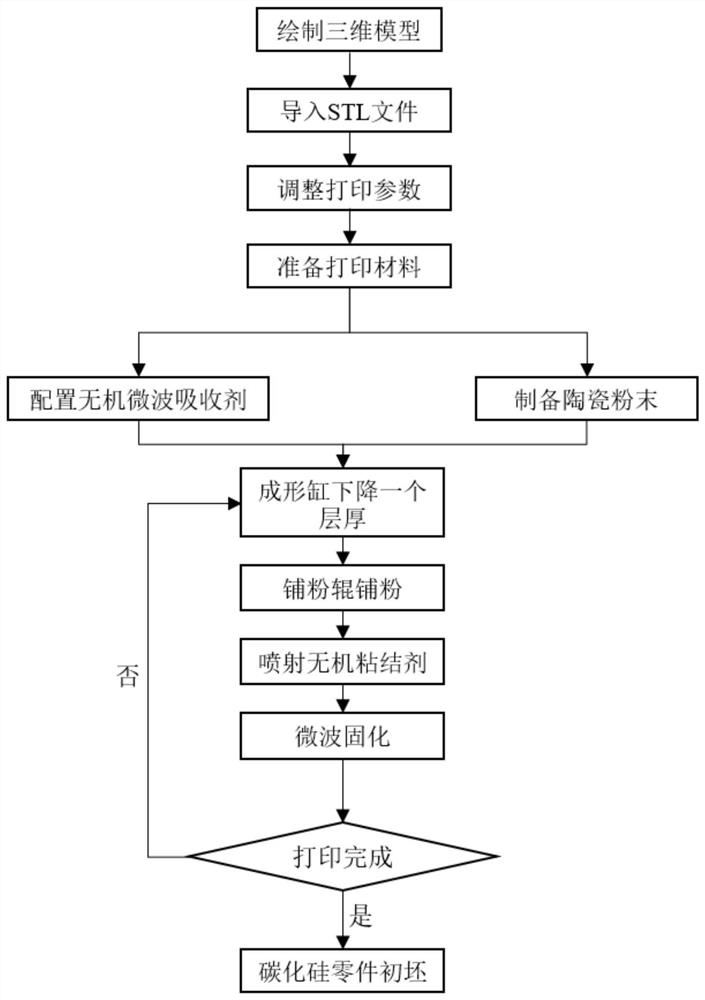

Ceramic initial blank forming method based on microwave in-situ sintering and product

PendingCN113135757ASolve corrosiveSolve problems such as blocked ink channelsAdditive manufacturing apparatusCeramic shaping apparatusAdditive layer manufacturingHeat treating

The invention belongs to the related technical field of additive manufacturing, and discloses a ceramic initial blank forming method based on microwave in-situ sintering and a product. The method comprises the following steps that a microwave absorbent and SiC powder are prepared; and the SiC powder is used for three-dimensional jet printing, in the three-dimensional jet printing process, after a slice layer is formed through jet printing, the microwave absorbent is sprayed to the surface of the slice layer, and then the slice layer is subjected to microwave heating, so that the slice layer is subjected to in-situ heating sintering forming, each slice layer is formed layer by layer, and a required ceramic initial blank is obtained. The invention also discloses a product prepared by the method. By means of the method, the problems that an organic binder is prone to blocking an ink path and corroding a spray head, and the initial blank is low in strength are solved, subsequent curing and degreasing heat treatment procedures are omitted through in-situ sintering forming, and the manufacturing process is simplified.

Owner:HUAZHONG UNIV OF SCI & TECH

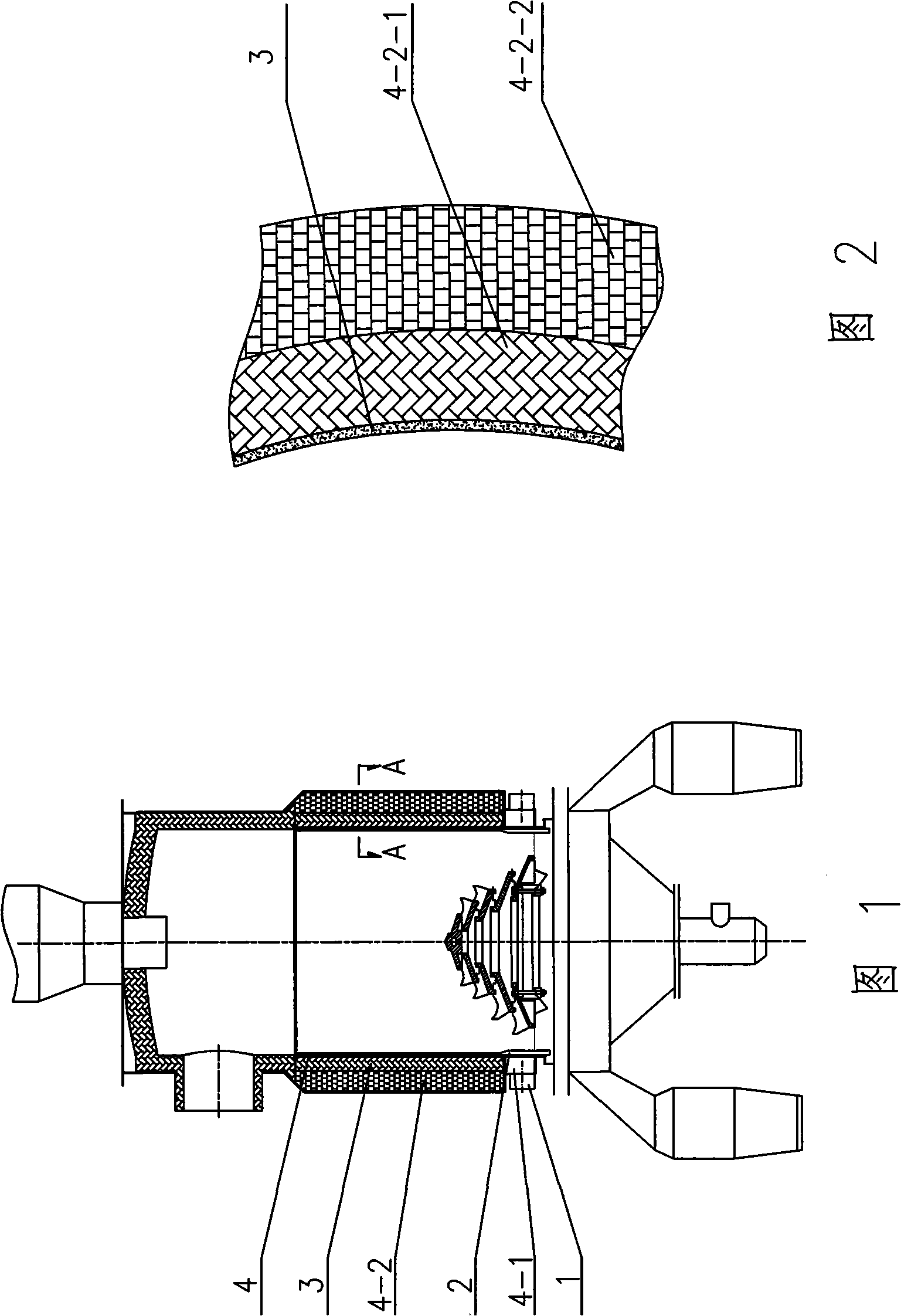

Novel gas generator

InactiveCN101275088AUniform temperatureIncrease gasification strengthCombustible gas productionWear resistantSlag

The present invention provides a new type gas producer, including a furnace body and a disintegrating slag strip, characterized in that the middle wall of the furnace body is poured by a high temperature resistant, heat insulating non-metal material brick masonry or high temperature resistant, heat insulating castable, the inner wall of the furnace wall is covered with a high temperature resistant, wear resistant porcelain plate or coated with high temperature and wear resistant coating layer; the lower of the furnace body is a metal ring cylinder which inner is ring steam channel, the disintegrating slag strip is mounted on the inside of the ring cylinder, the inner wall of the ring cylinder is provided with a steam pylome, the outer wall is provided with an air inlet joint. The invention has no water line jacket, having no water wall effect, the temperature of the furnace inside is evenly, having gasification intensity, adequate coal carbon burn, lower quantity of slag discharge and carbon residue, having high utilization ratio of gasified coal; the invention also has a simple structure, lower investment, convenient operation, lower safety evaluation grade standard, gasified raw material coal having high quality is saved at the same time.

Owner:彭思尧

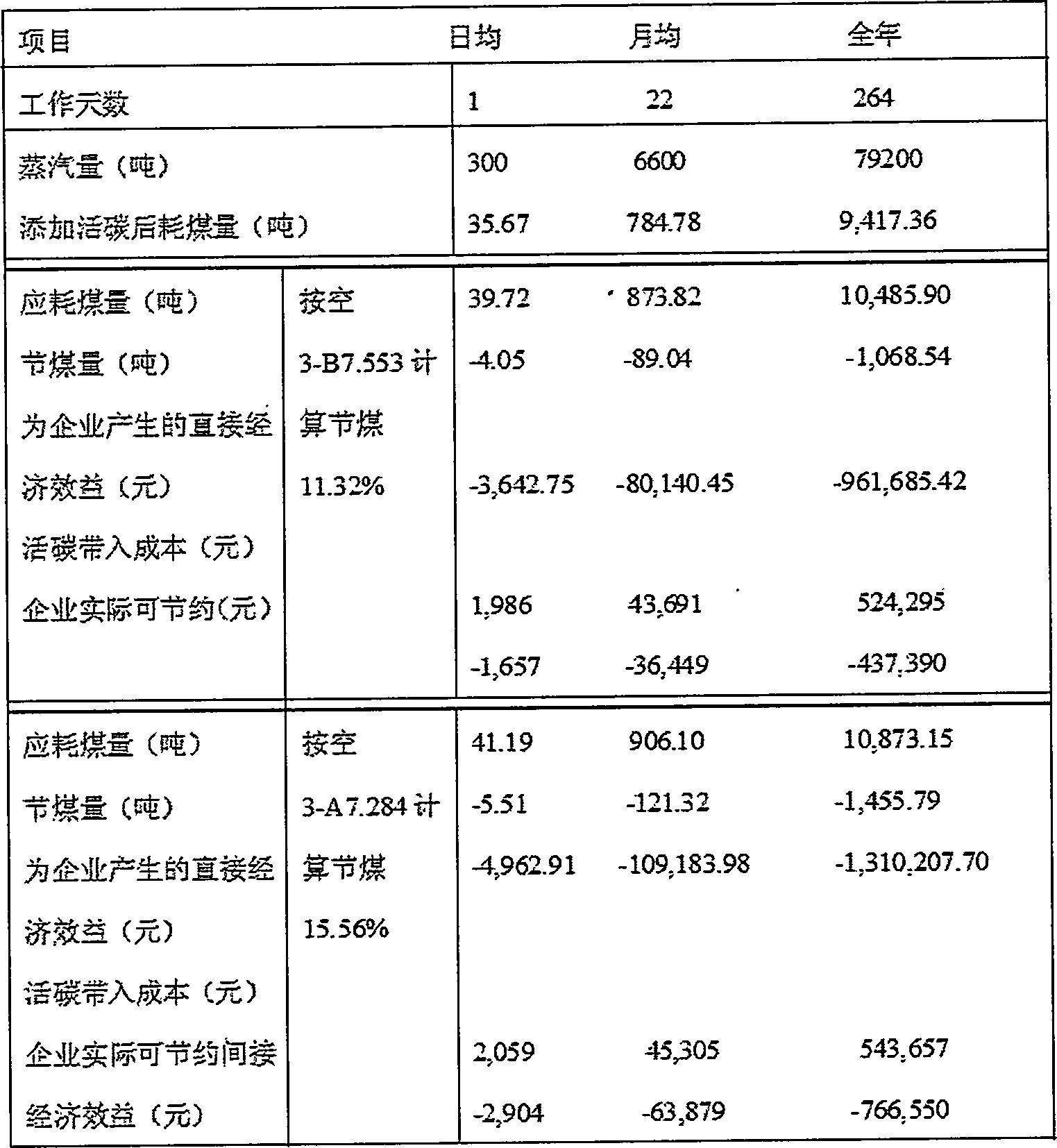

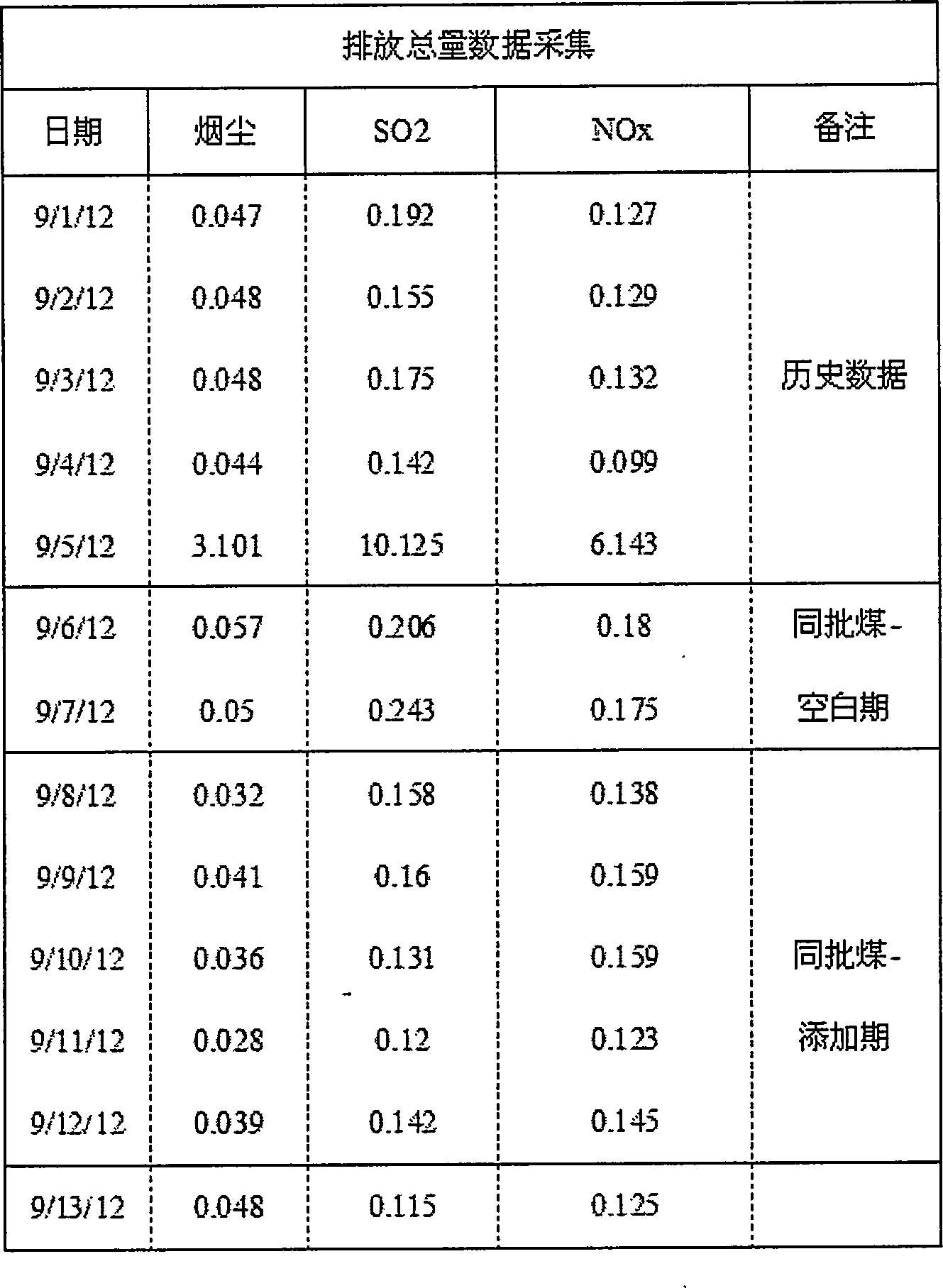

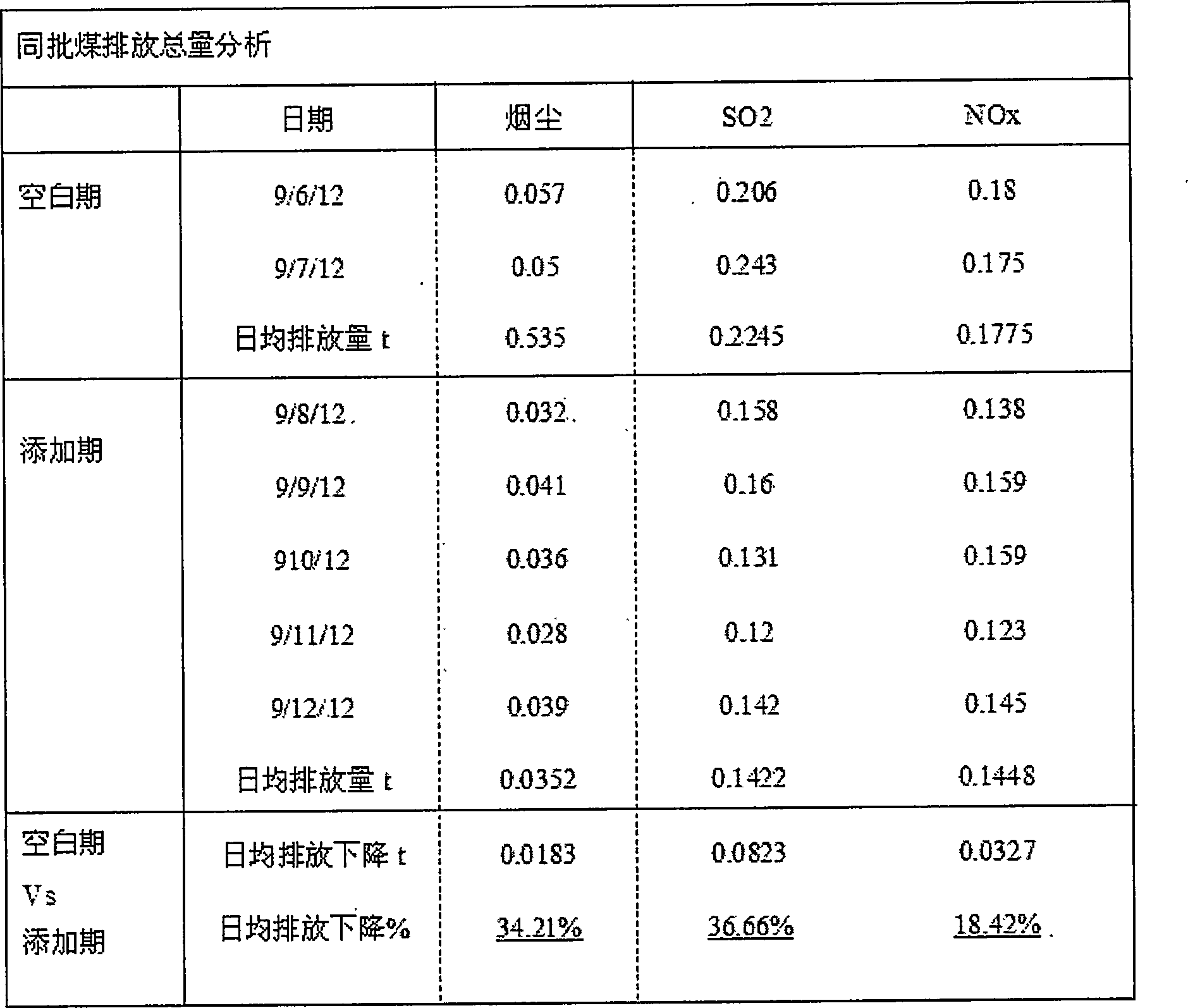

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

Pretreatment method of residual oil hydrogenation raw material and residual oil hydrogenation method

ActiveCN110591758AImprove dispersionImprove stabilityTreatment with hydrotreatment processesChemistryPre treatment

The invention relates to the technical field of residual oil hydrogenation process, in particular to a pretreatment method of a residual oil hydrogenation raw material and a residual oil hydrogenationmethod. The pretreatment method of a residual oil hydrogenation raw material includes the steps of: carrying out cavitation treatment on residual oil subjected to mild hydrotreatment; and the mild hydrotreatment method includes: treating the residual oil raw material at a temperature of 300-350DEG C and under a pressure of 2-5MPa; the cavitation treatment is carried out at a temperature of 90-150DEG C and under a pressure of 2-20MPa. The method provided by the invention performs mild hydrotreatment and cavitation treatment on the residue oil to improve the composition structure and distribution state of the residual oil components, the obtained residual oil has reduced average relative molecular mass and significantly reduced carbon residue and viscosity, also the residual oil can be further subjected to hydrogenation reaction, the light oil yield can be substantially improved, and the coke yield is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for increasing yield of clean fuel oil

ActiveCN103773497AIncrease profitBroaden sources of raw materialsTreatment with hydrotreatment processesProcess engineeringFuel oil

The invention discloses a method for increasing the yield of clean fuel oil. The method comprises the following steps: subjecting ethylene tar to fractionation so as to obtain a light fraction and a heavy fraction, mixing the heavy fraction with a conventional coking raw material, then subjecting the mixture to a delay coking treatment so as to obtain a coking product, transporting the coking product and a C9 component from an ethylene device into a coking distillation tower, carrying out a distillation treatment so as to obtain a coking gasoline fraction and a coking diesel oil fraction, carrying out a hydro-refining treatment on the obtained coking gasoline fraction, mixing the coking diesel oil fraction with the ethylene tar light fraction, then subjecting the mixture to a hydro-treatment, and separating the products so as to obtain a gasoline product and a diesel oil product. The method fully utilizes the ethylene tar and C9 fraction, improves the utilization rate of by-products of ethylene device, prominently improves the yield and quality of lightweight fuel oil, and is beneficial for yield increasing of high quality clean fuel oil for refineries.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing light fuel oil from ethylene tar

ActiveCN103102979AImprove product qualityBroaden sources of raw materialsTreatment with hydrotreatment processesLighter fuelGasoline

The invention discloses a method for producing light fuel oil from ethylene tar. The method is as below: fractionating ethylene tar into a light fraction and a heavy fraction; mixing the heavy fraction with a conventional coking raw material, and subjecting the mixture to delayed coking to obtain coker gasoline, coker diesel and coker gas oil; mixing the coker gasoline and the coker diesel with the light fraction of the ethylene tar, and subjecting the mixture to a hydrofining reaction; distilling the product to obtain a gasoline fraction I and a fraction heavier than the gasoline; subjecting the fraction heavier than the gasoline to a hydrogenation treatment to obtain light fuel oil, and distilling to obtain a gasoline fraction II and a diesel product; and mixing the gasoline fraction I and the gasoline fraction II to obtain a final gasoline product. The method provided by the invention utilizes the characteristics of high contents of ethylene tar aromatic hydrocarbons, colloid, carbon residue and glial and asphaltene of ethylene tar to fractionate the ethylene tar into the light fraction and the heavy fraction; different processing methods are employed to improve the added value of ethylene tar, increase yield of gasoline and diesel, improve product quality of light fuel oil and realize long-period stable operation of devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Photocurable resin material used for casting

The invention provides a photocurable resin material used for casting. The photocurable resin material comprises alicyclic epoxy resin, a butoxy ring derivative, hydrogenated bisphenol A epoxy resin, an acrylate monomer without a benzene ring structure, a thermoplastic polymer and an initiator. The photocurable resin material has less carbon residue after calcination, and is applicable to preparing a precise three-dimensional workpiece prototype through a three-dimensional printing manner, thereby being used for replacing a wax mold for precision casting.

Owner:HUNAN FARSOON HIGH TECH CO LTD

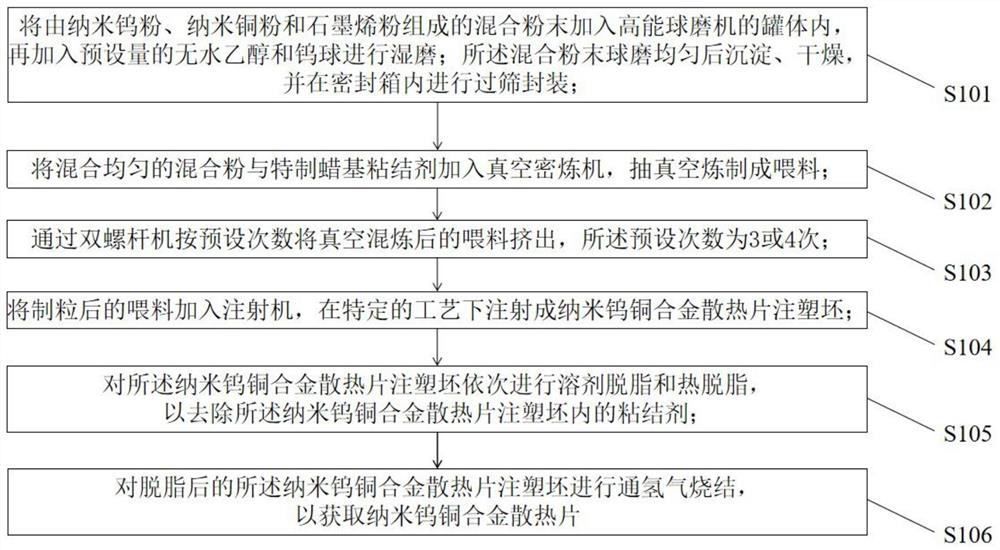

Preparation forming method of nano tungsten-copper alloy cooling fin

PendingCN113070474AHigh densityHigh dimensional accuracyTransportation and packagingMetal-working apparatusPowder metallurgyHeat sink

The invention relates to the technical field of powder metallurgy injection molding, and discloses a preparation forming method of a nano tungsten-copper alloy cooling fin. The preparation forming method comprises the following steps: adding mixed powder consisting of nano tungsten powder, nano copper powder and graphene powder into a tank body of a high-energy ball mill, and then adding a preset amount of absolute ethyl alcohol and tungsten balls for wet milling; adding the mixed powder which is uniformly mixed and a special wax-based binder into a vacuum internal mixer, vacuumizing and refining to obtain feedstock; extruding the feedstock subjected to vacuum mixing according to a preset number of times by using a double-screw machine; adding the granulated feedstock into an injection machine, and injecting into a nano tungsten-copper alloy cooling fin injection-molded blank under a specific process; sequentially performing solvent degreasing and thermal degreasing on the nano tungsten-copper alloy cooling fin injection molding blank; and feeding hydrogen into the degreased nano tungsten-copper alloy cooling fin injection molding blank for sintering to obtain nano tungsten-copper alloy cooling fin. According to the method, the nano tungsten-copper alloy cooling fin which is uniform in structure, high in density and low in carbon residue amount can be prepared.

Owner:深圳市注成科技股份有限公司

Preparation method of FD evaporative pattern plate and evaporative pattern plate prepared by preparation method

InactiveCN107650395ASolve carbon blackSolve the defect of easy slag inclusion in castingsFoundry moulding apparatusFlat articlesUltimate tensile strengthBonding strength

The invention discloses a preparation method of a FD evaporative pattern plate and an evaporative pattern plate prepared by the preparation method. The preparation method comprises the processing steps of selecting of beads, pre-foaming, drying and curing, compression moulding forming, cooling, demoulding, plate drying and the like. According to the preparation method of the FD evaporative patternplate and the evaporative pattern plate prepared by the preparation method, the detects of carbon black on the surface of a nodular iron casting after the nodular iron casting is casted and the likecan be overcome, the gas forming amount can be effectively reduced and reverse spraying in the pouring process can be avoided, the appearance of a manufactured and produced FD evaporative pattern is prevented from deforming, the bonding strength of the beads is improved, sufficient integration of the beads is ensured, and the structural strength of the casting is improved; and the effects of saving raw materials, reducing the cost, and being environmentally friendly are achieved, the yield of castings is greatly increased, and the comprehensive production cost of the casting is further reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com