Silicon carbide oxidation method based on microwave plasma

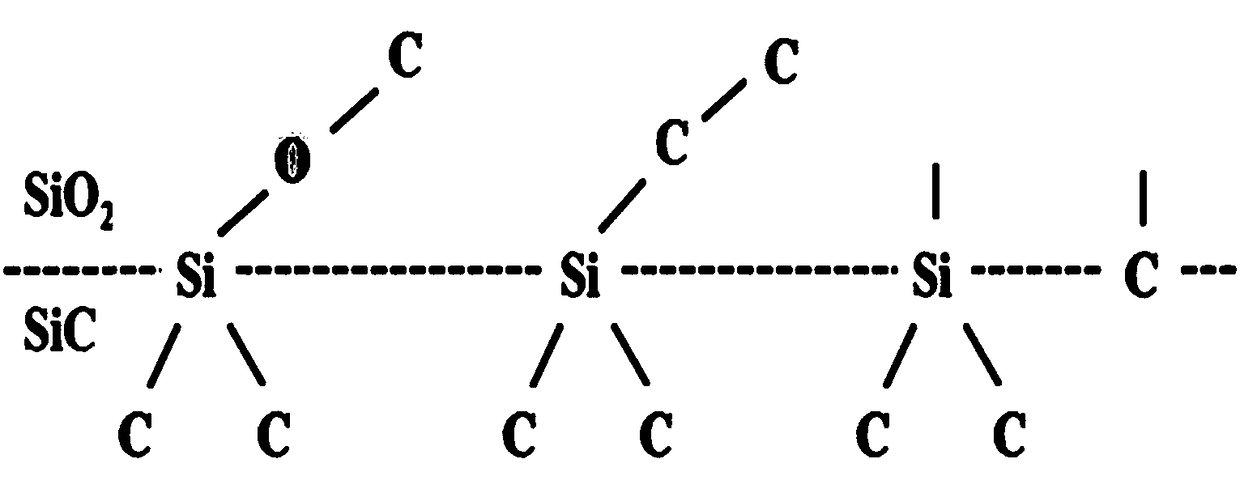

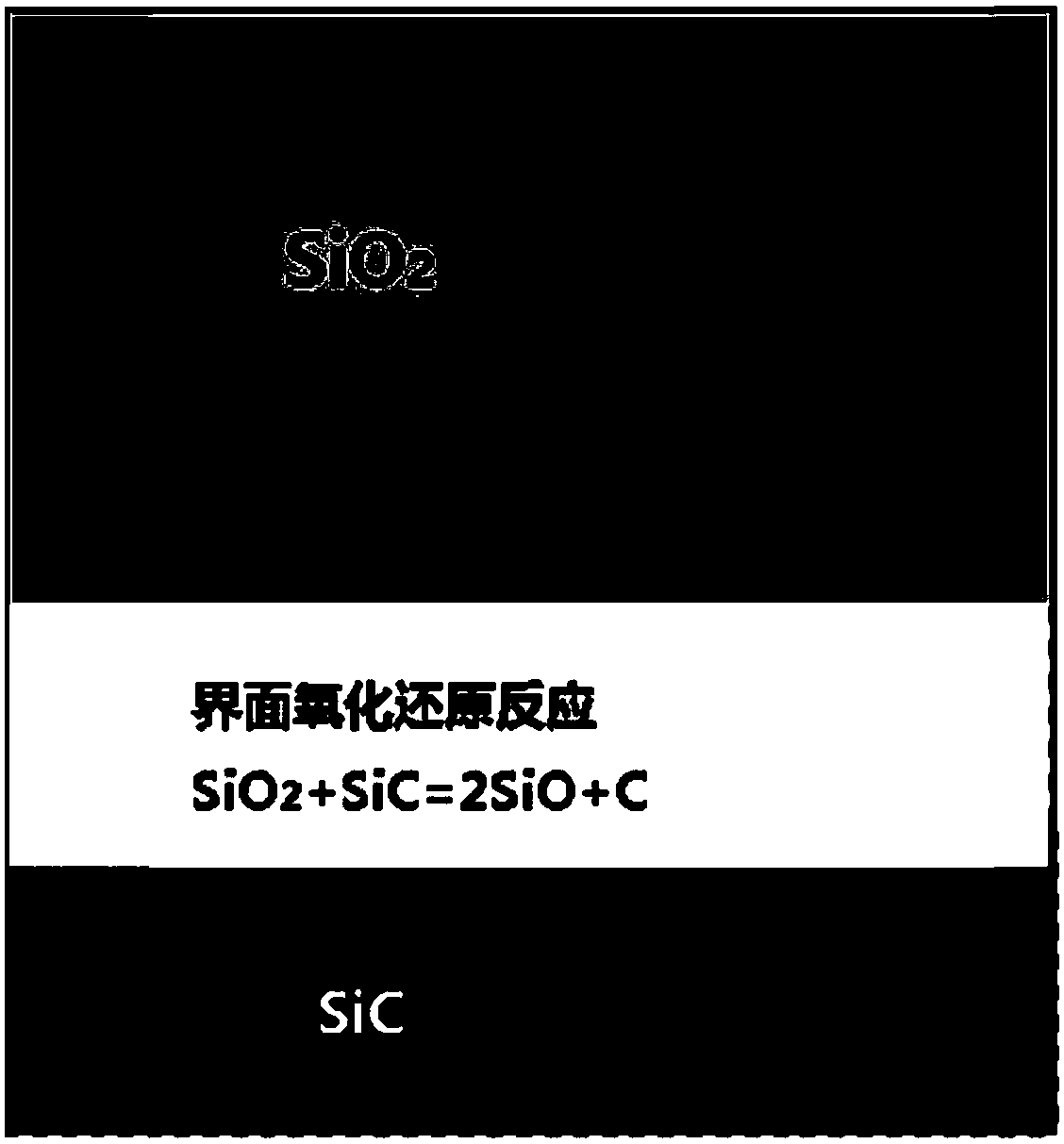

A technology of microwave plasma and oxygen plasma, which is applied in the direction of silicon oxide and silicon dioxide, can solve the problems of low oxidation efficiency, unsatisfactory interface quality, and long oxidation time, so as to reduce carbon residues, reduce electronic defects, and improve Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The microwave input power of the microwave plasma generating device is set to 1000w, and the adjustable range of the microwave frequency for exciting the microwave plasma is 2.4-2.5GHz. Under the atmosphere of 800mTorr and pure oxygen, the initial temperature of the sample stage is set to 100°C, and the plasma is heated up at a rate of 1.5°C / s until the set microwave plasma oxidation temperature is 800°C, and the plasma discharge time is 800s , carry out plasma oxidation, the thickness of the oxide layer is about 40nm, after the oxidation is completed, change the pure oxygen to pure nitrogen, and cool down in the nitrogen atmosphere.

Embodiment 2

[0056] The microwave input power of the microwave plasma generating device is set to 1500w, and the adjustable range of the microwave frequency for exciting the microwave plasma is 2.4-2.5GHz. In an environment with a pressure of 600mTorr and a volume ratio of oxygen to inert gas of 2:1, set the initial temperature of the sample stage to 200°C, and the plasma will heat up at a rate of 1°C / s until the set microwave plasma oxidation The temperature is 600°C, the plasma discharge time is 600s, and the plasma oxidation is performed. The thickness of the oxide layer is about 20nm. After the oxidation is completed, the pure oxygen is changed to pure nitrogen, and the temperature is cooled in a nitrogen atmosphere.

[0057] Depend on Figure 5 It can be seen that adopting the plasma oxidation process of the present invention forms SiC / SiO 2 The interface is relatively clear, the surface roughness is low, the oxide layer is less damaged, the surface is flat, the oxidation rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com