Patents

Literature

888results about How to "Improve oxidation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

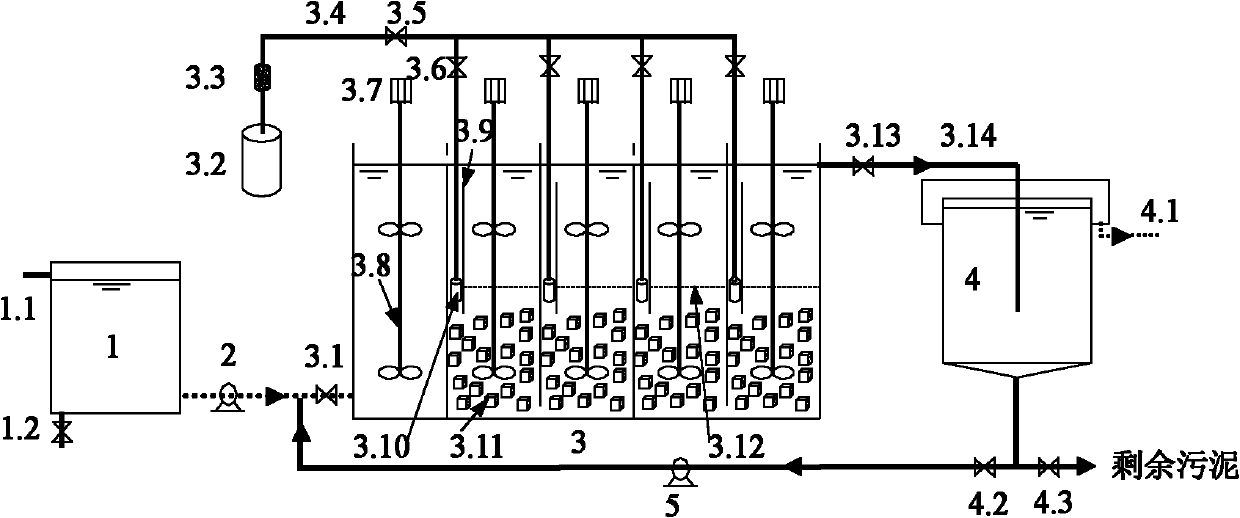

Device and method for denitrification of single stage autotroph in low-cellulose nitrate (CN) high-ammonia nitrogen waste water

ActiveCN102101720AAchieve separationEasy to controlTreatment with aerobic and anaerobic processesCelluloseSludge

The invention discloses a device and a method for denitrification of single stage autotroph in low-cellulose nitrate (CN) high-ammonia nitrogen waste water. The device comprises a raw water tank, a water inlet pump, a reactor, a secondary sedimentation tank and a sludge reflux pump, wherein overcurrent holes are arranged in the water flow direction of the reactor in an up-and-down alternative form and connected with various grid chambers, an anoxic zone grid chamber is arranged at the front end of the reactor, and an aerobic zone grid chamber is arranged at the back end of the reactor; the anoxic zone grid chamber is provided with a stirrer and an agitator blade; the aerobic zone grid chamber is provided with the stirrer, the agitator blade, an aeration riser pipe and an intermediate perforated clapboard; and the aeration riser pipe is internally provided with an aeration head, and sponge filling material is filled below the intermediate perforated clapboard, wherein filling ratio is 30-50%. In the method, shortcut nitrification is achieved above the aerobic zone through low dissolved oxygen (DO is 0.5 <-1>mg / L) and free ammonia (FA) inhibition so that ammonia nitrogen is converted to nitrite nitrogen; and anoxicammoxidation biomembrane acts on the lower part of the aerobic zone, the nitrite nitrogen and ammonia nitrogen are converted to nitrogen, thereby achieving denitrification of autotroph. The method has the advantages of low oxygen consumption, less sludge output and no extra carbon source.

Owner:彭永臻

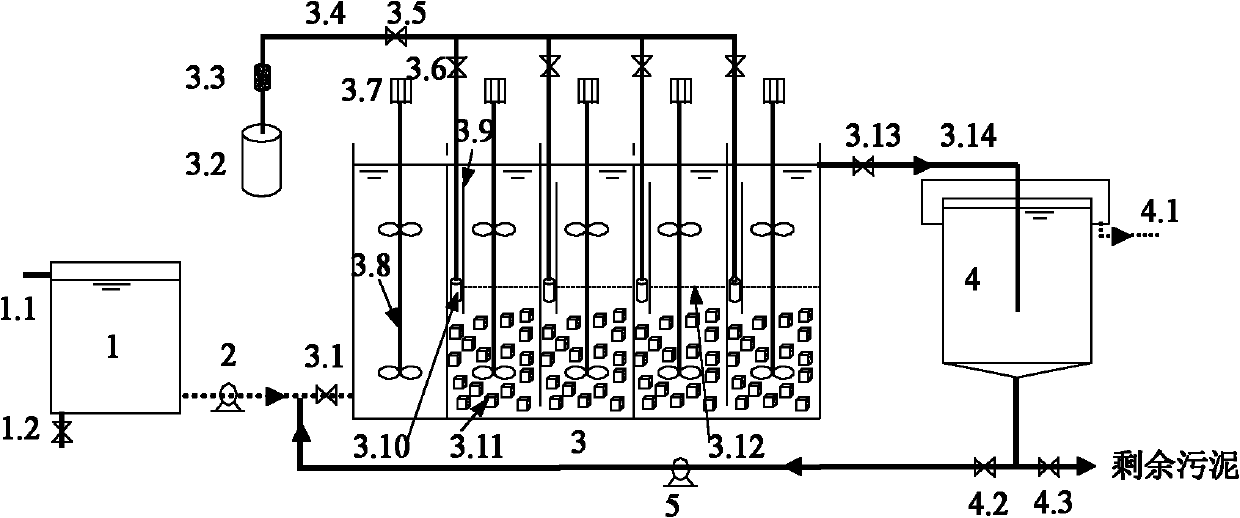

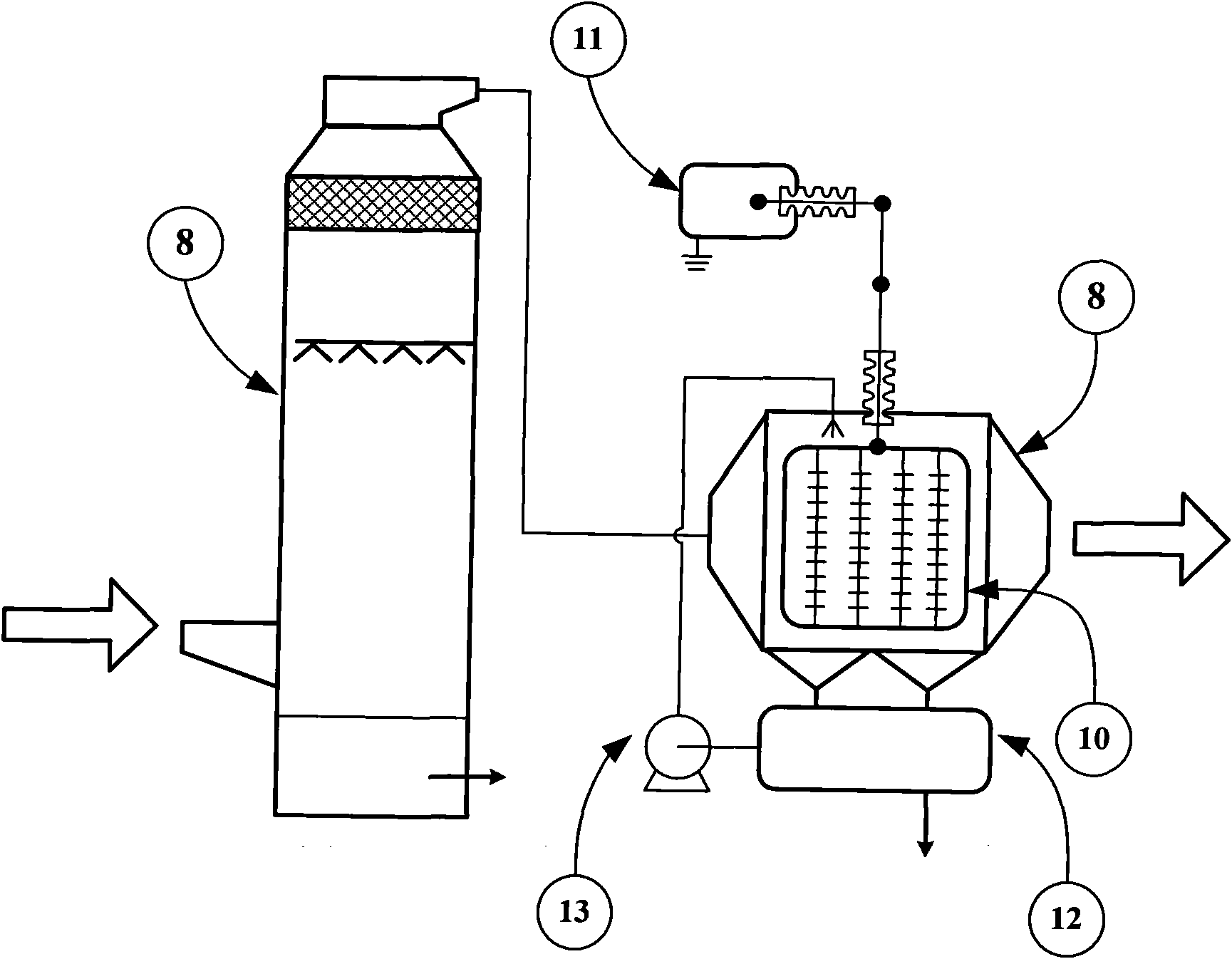

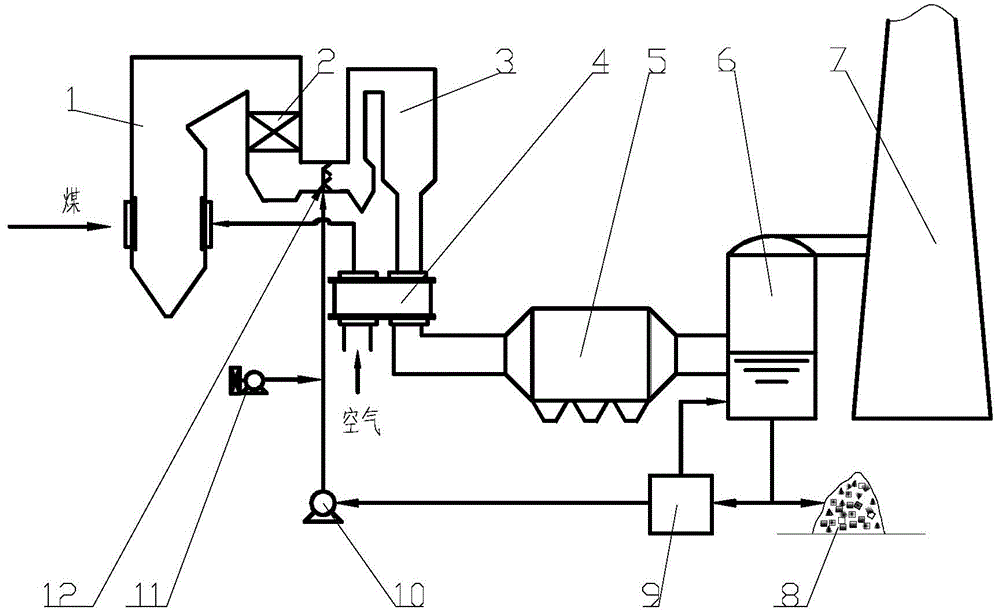

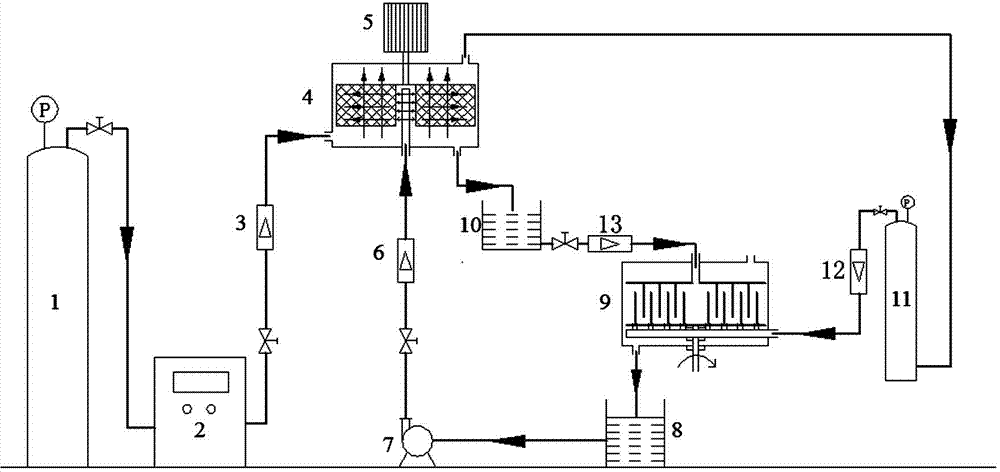

Device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation

ActiveCN103463978AHigh removal rateImprove oxidation efficiencyDispersed particle separationAir quality improvementPtru catalystCatalytic decomposition

The invention provides a device and method for smoke simultaneous desulfurization and denitrification based on hydrogen peroxide catalytic oxidation (H2O2). The H2O2 is sprayed into an H2O2 catalytic decomposition device through an injection pump and reacts with catalysts, a large amount of active matter is generated, the active matter is injected into a smoke channel along with a bypass air flow from an air blower in a blowing mode and reacts with sulfur dioxide (SO2) and oxynitride (NOX) in smoke to generate sulfuric acid and nitric acid. The sulfuric acid, the nitric acid and pollutants left in the smoke enter an ammonia absorption tower, and finally two kinds of important chemical fertilizer, namely ammonium sulfate and ammonium nitrate are generated. The device and method are suitable for smoke simultaneous desulfurization and denitrification in large, medium and small size boiler and reconstruction application of built combustion equipment, and the NOX and SO2 can be removed at the same time.

Owner:NANJING UNIV OF SCI & TECH

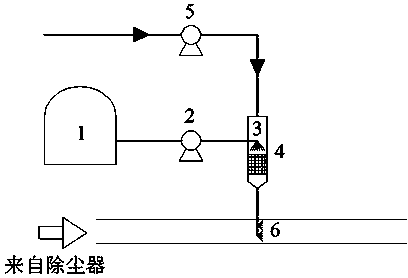

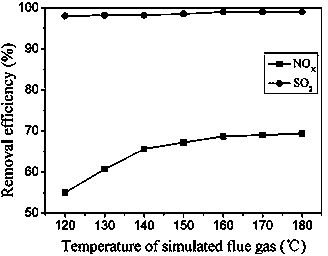

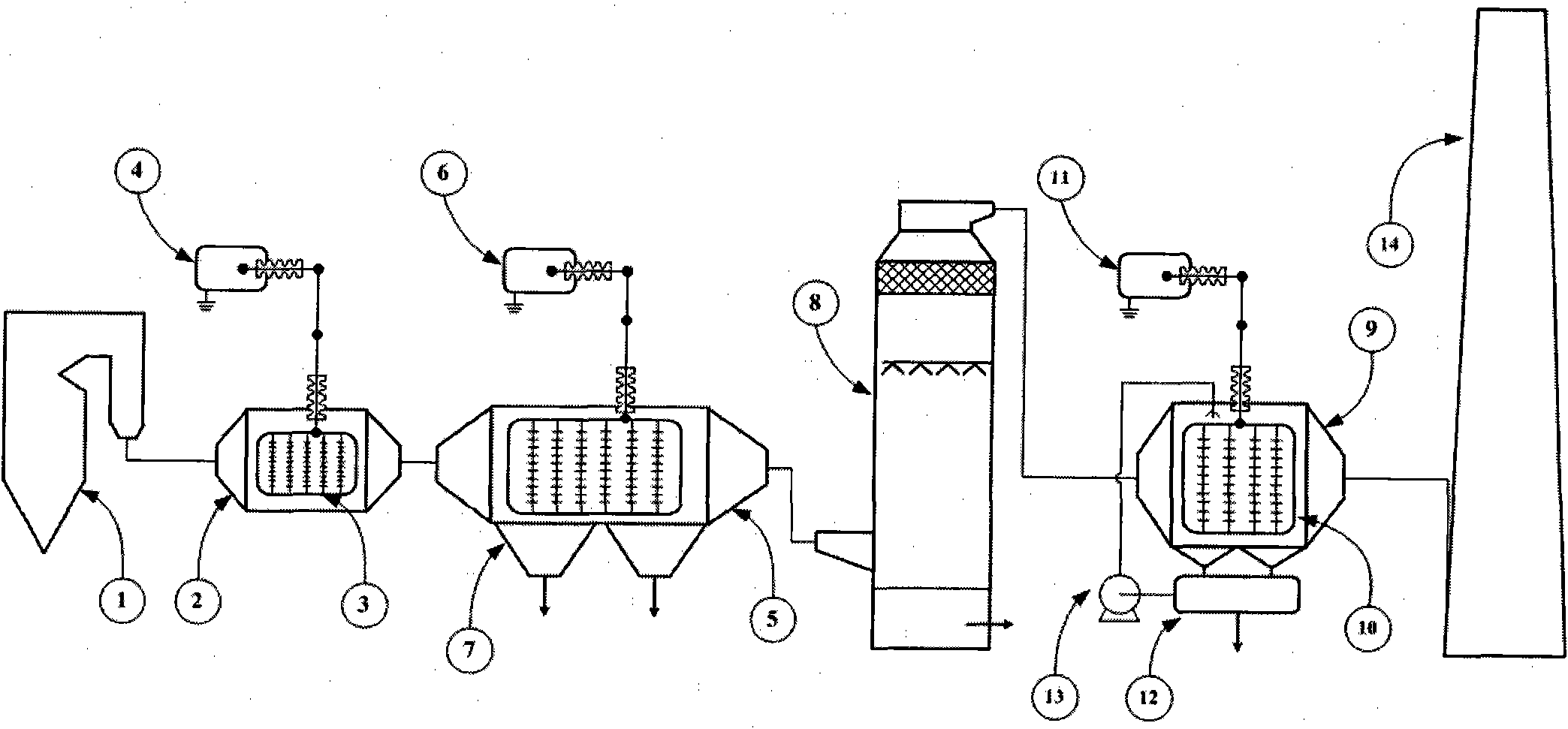

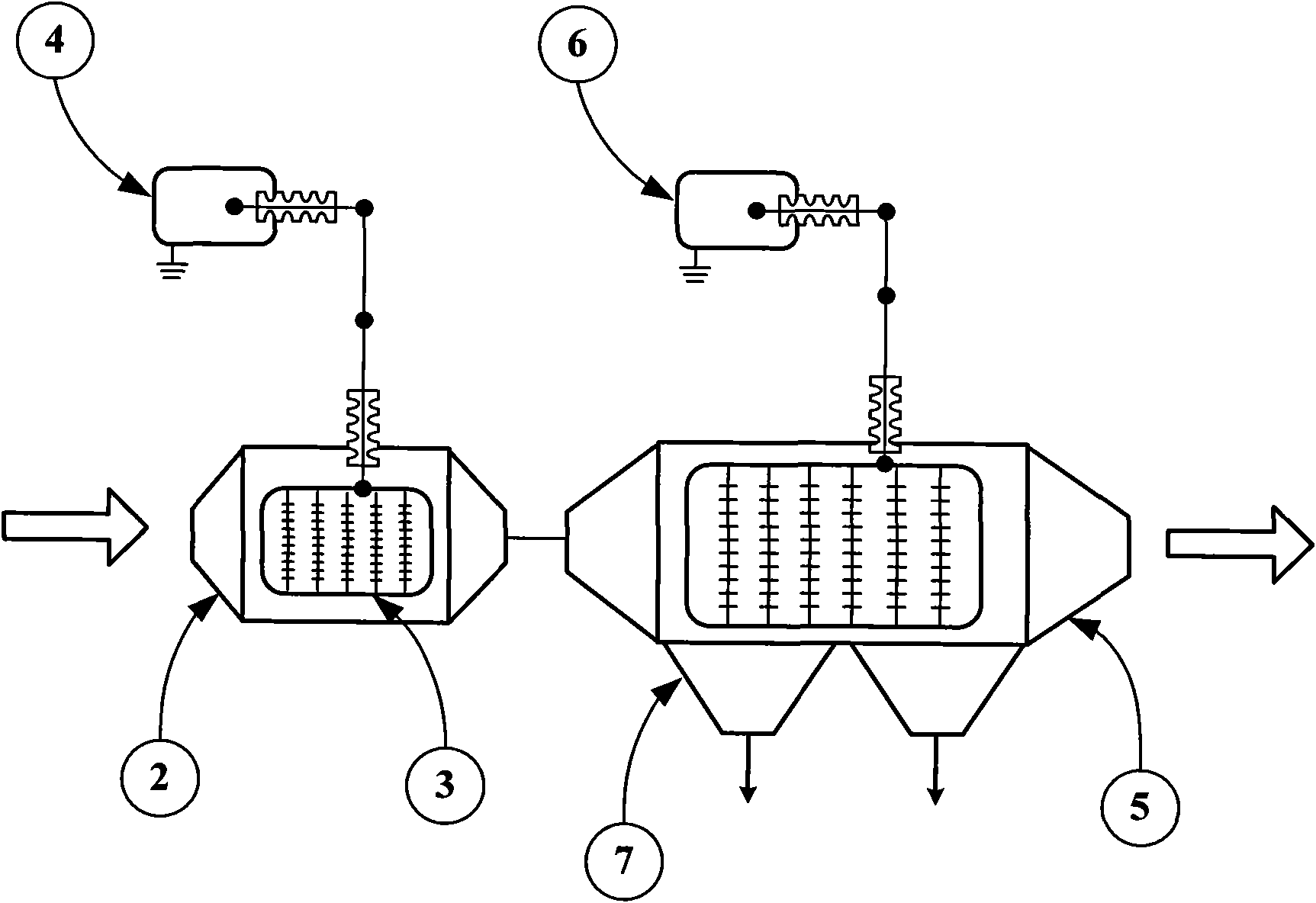

Low-temperature plasma smoke compound pollutant control method

InactiveCN102059050ALow costImprove space utilizationCombination devicesAir quality improvementNitric oxideHigh pressure

The invention discloses a low-temperature plasma smoke compound pollutant control method. By discharging at a high voltage to generate low-temperature plasmas in a dry reactor and a wet reactor, the method controls pollutants and oxidized by-products in the smoke, such as smoke dusts, sulfur dioxide, oxynitride, hydrogen sulfide, hydrogen chloride, heavy metal and the like, by combination with the conventional dedusting method, the ammonia method desulfuration, the limestone / gypsum wet method, the rotary atomization drying method and the like, wherein the dry plasma reactor is used together with a dedusting device to improve the dedusting efficiency and oxidize the nitric oxide; and an absorbing device is used together with the wet plasma reactor to remove gaseous pollutants, oxidize ammonium sulfite, namely a desulfurized product of an ammonia absorber, demist and purify the tail gas. The method can be used for controlling smoke compound pollutants of boilers or incinerators.

Owner:ZHEJIANG UNIV

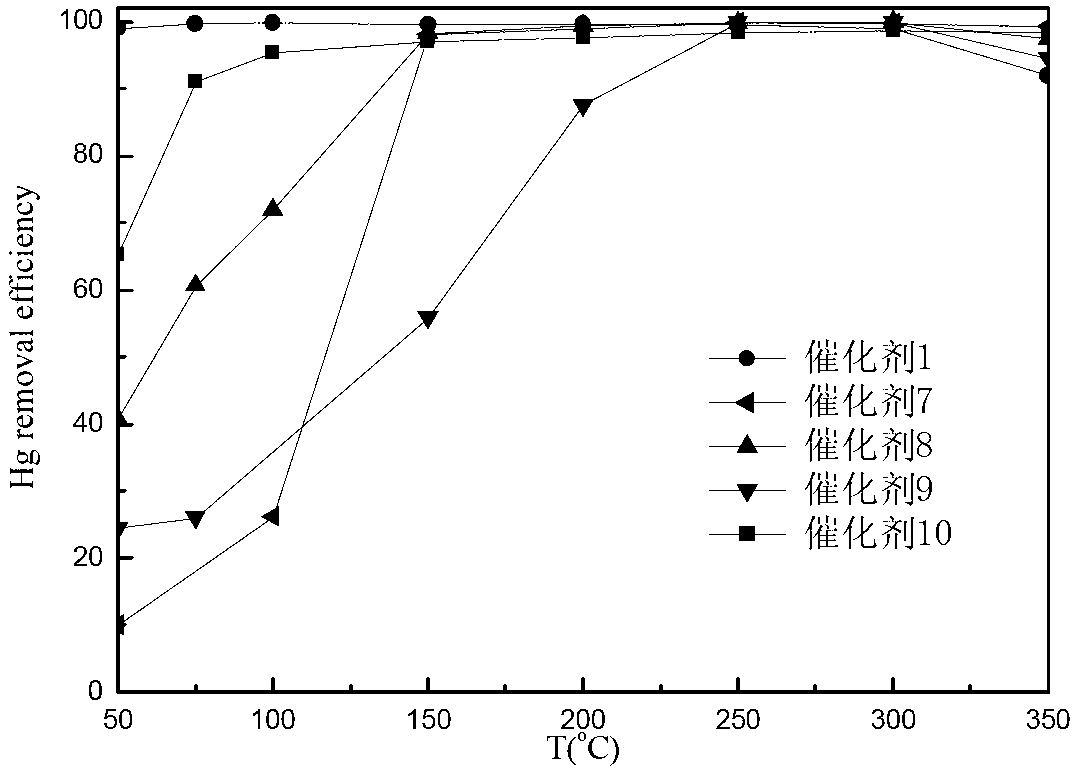

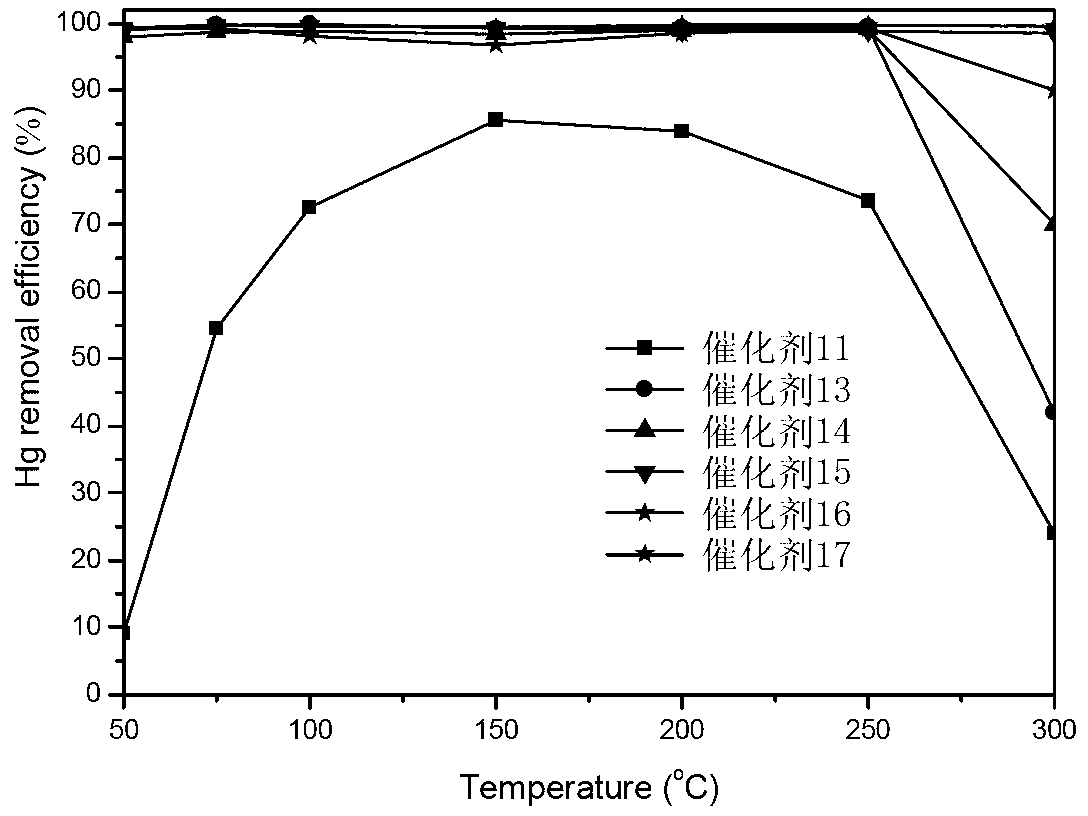

Catalyst for mercury oxidation and preparation method and purpose thereof

ActiveCN102698753AReduce dependenceImprove oxidation efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPower stationCatalytic oxidation

The invention discloses a copper-based composite catalyst for gas-state zero valent mercury oxidation in the field of smoke control and a preparation method and the purpose thereof. The copper-based catalyst is a copper-based composite oxide catalyst and / or a copper-based composite halide catalyst. The catalyst can utilize oxygen and trace HCI existing in smoke to achieve high efficiency conversion of zero valent mercury (HgO) and divalent mercury (Hg2+) under low temperature in a wider temperature range (500-300 DEG C) and can even achieve high efficiency oxidation of simple substance mercury in smoke free of HCI. The catalyst is suitable for catalytic oxidation of mercury in fire coal smoke, and the product Hg2+ of oxidation can be easily dissolved in water and can be removed by other pollutant control devices. The catalyst is simple in preparation method, wide in suitable temperature range, high in oxidation efficiency, weak in dependency on CI in the smoke, good in stability and high in SO2 poisoning resistance and has good application prospects and economical benefits in the fire coal smoke mercury discharge control fields including power station boilers, industrial boilers, industrial kilns and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

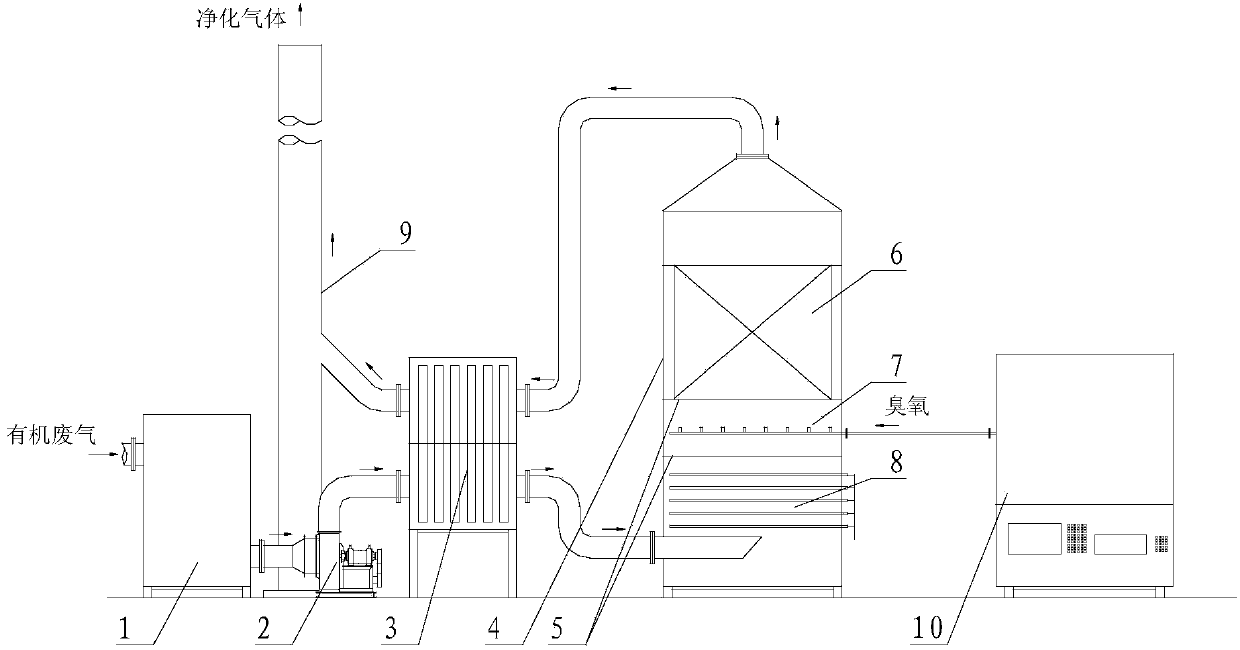

Device and method for treating organic waste gas by catalysis and ozonation

ActiveCN103721563AReduce energy consumptionWith processing efficiencyDispersed particle separationCatalytic oxidationPre treatment

The invention discloses a device and a method for treating organic waste gas by catalysis and ozonation. The method comprises the following steps: (1) the organic waste gas is collected and enters a pretreater, the waste gas is pretreated and oil drops, particulate matter, acid etchant gas and fog drops in the waste gas are intercepted; (2) after the pretreated organic waste gas is pressurized by an induced draft fan, the organic waste gas enters the cold end of a heat exchanger to be preheated; (3) the preheated organic waste gas enters a catalytic oxidation device, the organic waste gas entering the catalytic oxidation device is warmed up and then is mixed with ozone fed into the catalytic oxidation device, and the mixed gas enters a catalytic oxidation reaction region of the catalytic oxidation device to be subjected to the catalytic oxidation reaction so as to remove organic pollutants; (4) the purified gas serving as a heat source enters the hot end of the heat exchanger in the step (2) to be subjected to heat exchange and the gas subjected to heat exchange is discharged by an exhaust pipeline. When being combined with the treatment device disclosed by the invention, the treatment method disclosed by the invention has a better purifying effect on the waste gas and not only ensures purifying efficiency of the waste gas, but also is energy-saving and environment-friendly.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

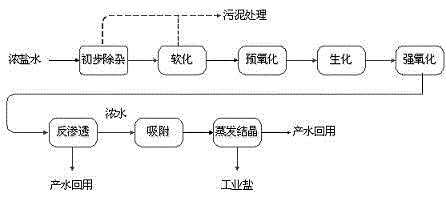

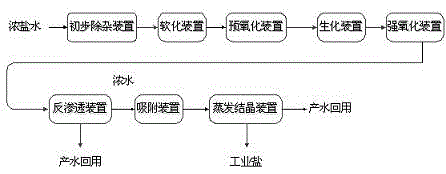

Method and device for realizing zero emission of strong brine

ActiveCN105541017ATake advantage ofEase of useGeneral water supply conservationWater treatment compoundsLoad resistanceEvaporation

The invention provides a method and a device for realizing zero emission of strong brine, overcoming the defects that the existing strong brine treatment technology is high in crystallized impurity salt treatment cost and severe in harm. The impurity removal, softening, pre-oxidation, biochemical and strong oxidation techniques are used for purifying the strong brine, the strong brine after being treated is pre-concentrated by adopting a reverse osmosis way, the reverse osmosis concentrated water is further purified by adopting an adsorption method, and finally the evaporation and quality-divided crystallization technology is used for separating the water to obtain industrial salt. By adopting the method and device, the zero emission of the strong brine is realized, the emission of dangerous waste is reduced, and the recycling is realized. Meanwhile, the general process is mature, the design is reasonable, the impact load resistance is relatively high, the chemical source is convenient, and the cost is low.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

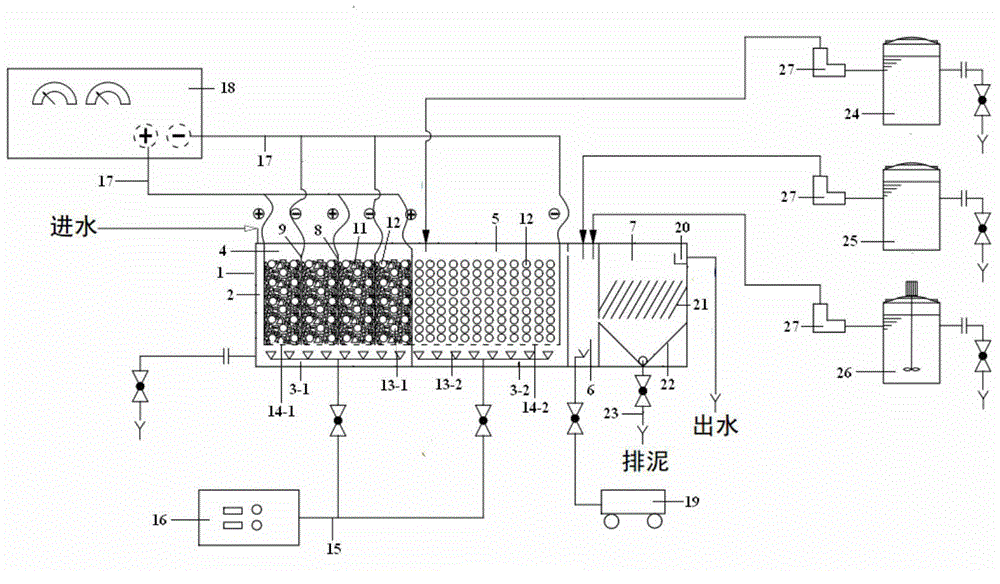

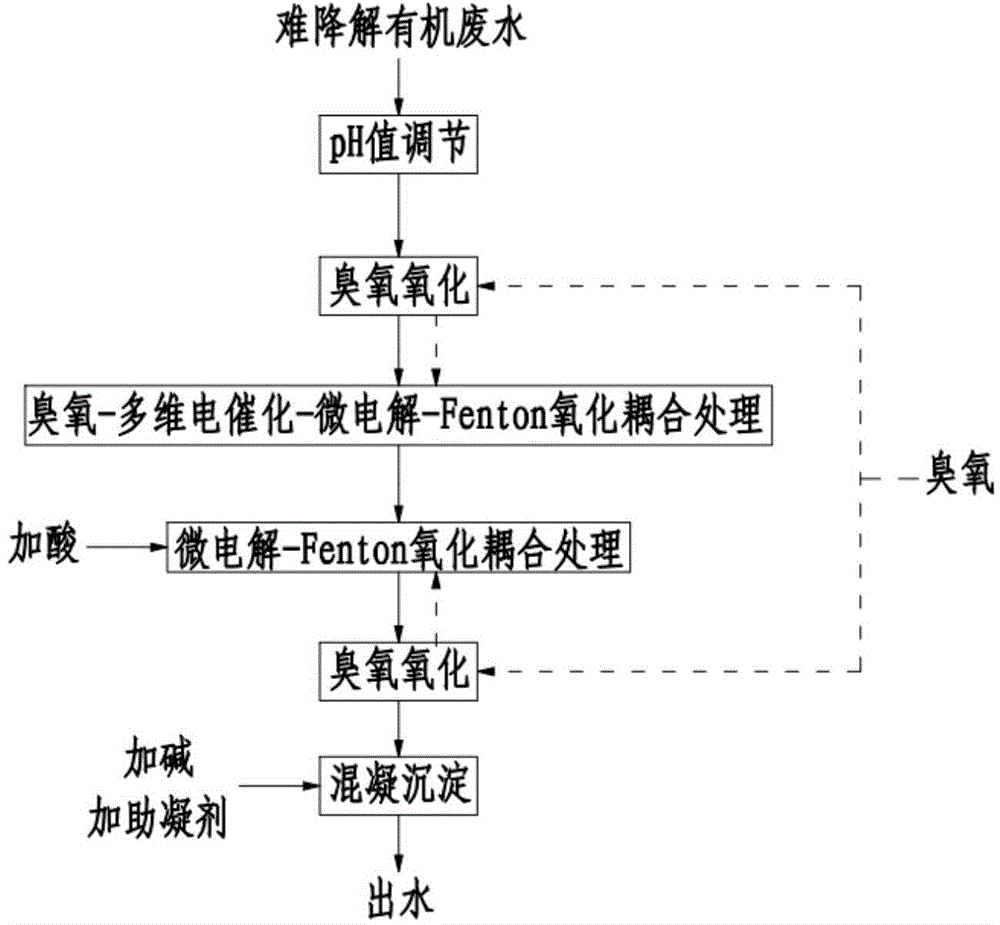

Advanced oxidative coupling device and process for treating organic wastewater difficult to degrade

ActiveCN104787941AImprove removal efficiencyLow running costWater contaminantsWater/sewage treatment by electrochemical methodsElectrolysisMulti dimensional

The invention discloses an advanced oxidative coupling device and process for treating organic wastewater difficult to degrade. A main device body comprises an ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area, an ozone oxidation-microelectrolysis / Fenton area, a coagulation area and an inclined plate sedimentation area, wherein the ozone oxidation-multi-dimensional electro-catalysis / microelectrolysis area comprises a multi-dimensional electrolysis / microelectrolysis area at the upper part and an ozone oxidation area at the lower part; the ozone oxidation-microelectrolysis / Fenton area comprises a microelectrolysis / Fenton area at the upper part and an ozone oxidation area at the lower part. The device combines four levels of advanced oxidation systems, and electrocatalytic oxidation, ozone oxidation, Fenton oxidation and a microelectrolysis reaction are mutually coupled in function, so that an organic matter difficult to degrade is subjected to multi-level oxidation to realize complete oxidative cracking; when the device is used for treating the organic wastewater difficult to degrade, the yield and the production rate of *OH are increased, the liquid phase transfer process is accelerated, the overall current efficiency of the device is increased, operation expenses are saved, flexible regulation and control of a process unit are realized, and the device can be used for treating various kinds of organic wastewater difficult to degrade.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD +1

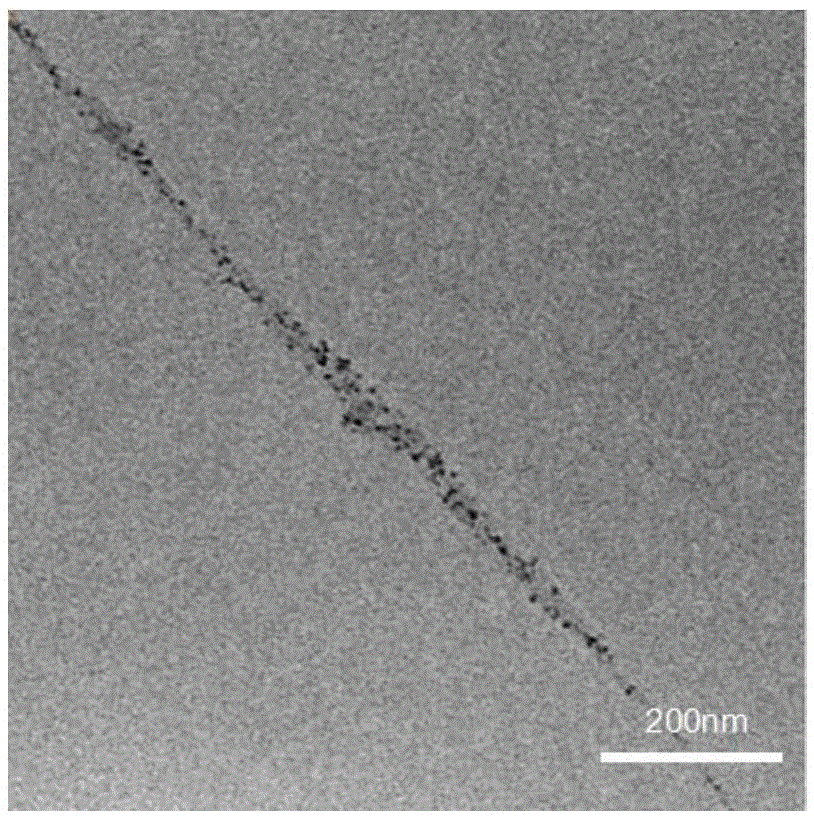

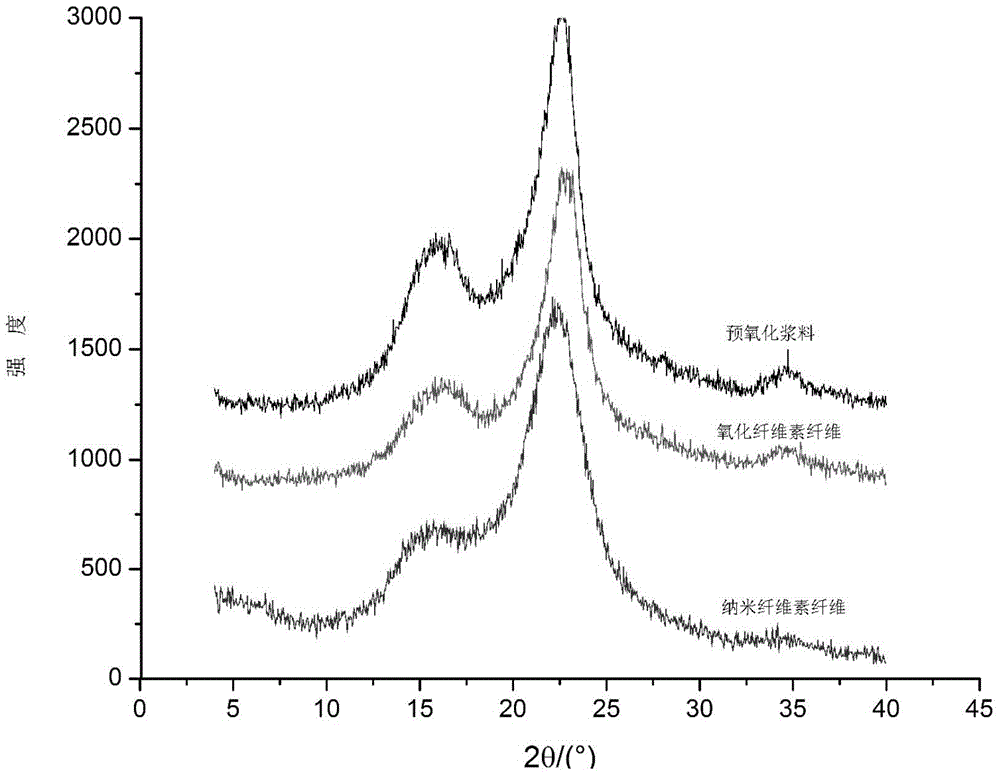

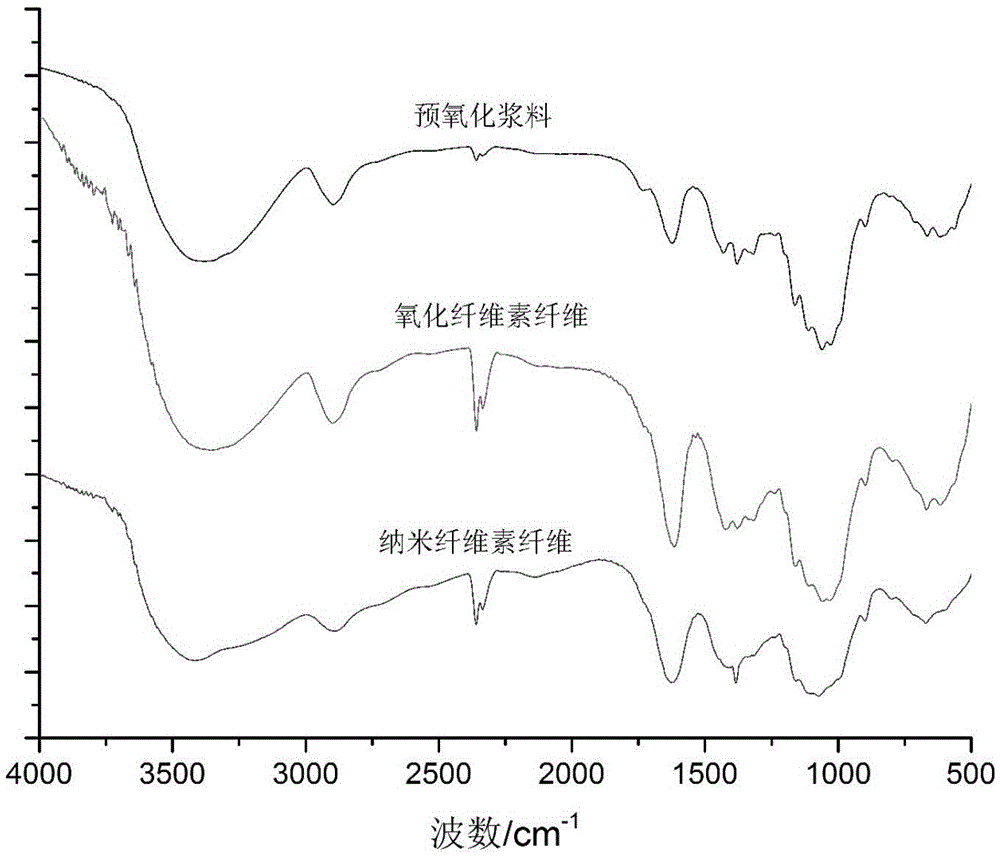

Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

InactiveCN105463606AIncrease the total carboxyl contentGuaranteed crystallinityOther chemical processesArtificial filaments from cellulose derivativesPolymer scienceFreeze-drying

The invention belongs to the technical field of biomass nanometer materials and discloses a nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof. A preparation method comprises the steps of preheating fiber slurry for 0.5-1.5h with sodium periodate at the temperature of 50-60 DEG C; adding a sodium chlorite solution and acetum into the slurry to be reacted for 1-3h at the temperature of 30-50 DEG C, adding TEMPO, NaClO2 and NaClO, and performing microwave heating to the temperature of 55-65 DEG C to enable the mixture to be reacted for 1-3h; performing ultrasonic dispersion and freeze drying to obtain the nano-crystalline cellulose fiber high in carboxyl group content. According to the nano-crystalline cellulose fiber, hydroxyl at the positions of C2 and C3 of cellulose is oxidized into a formyl group which is oxidized into carboxyl by sodium chlorite, hydroxyl at the position of C6 is selectively oxidized into carboxyl through a TEMPO neutral oxidation system, and accordingly the total carboxyl group content of the fiber is greatly increased, and obtained products can be used for advanced treatment of waste water at the middle section of paper making.

Owner:SOUTH CHINA UNIV OF TECH

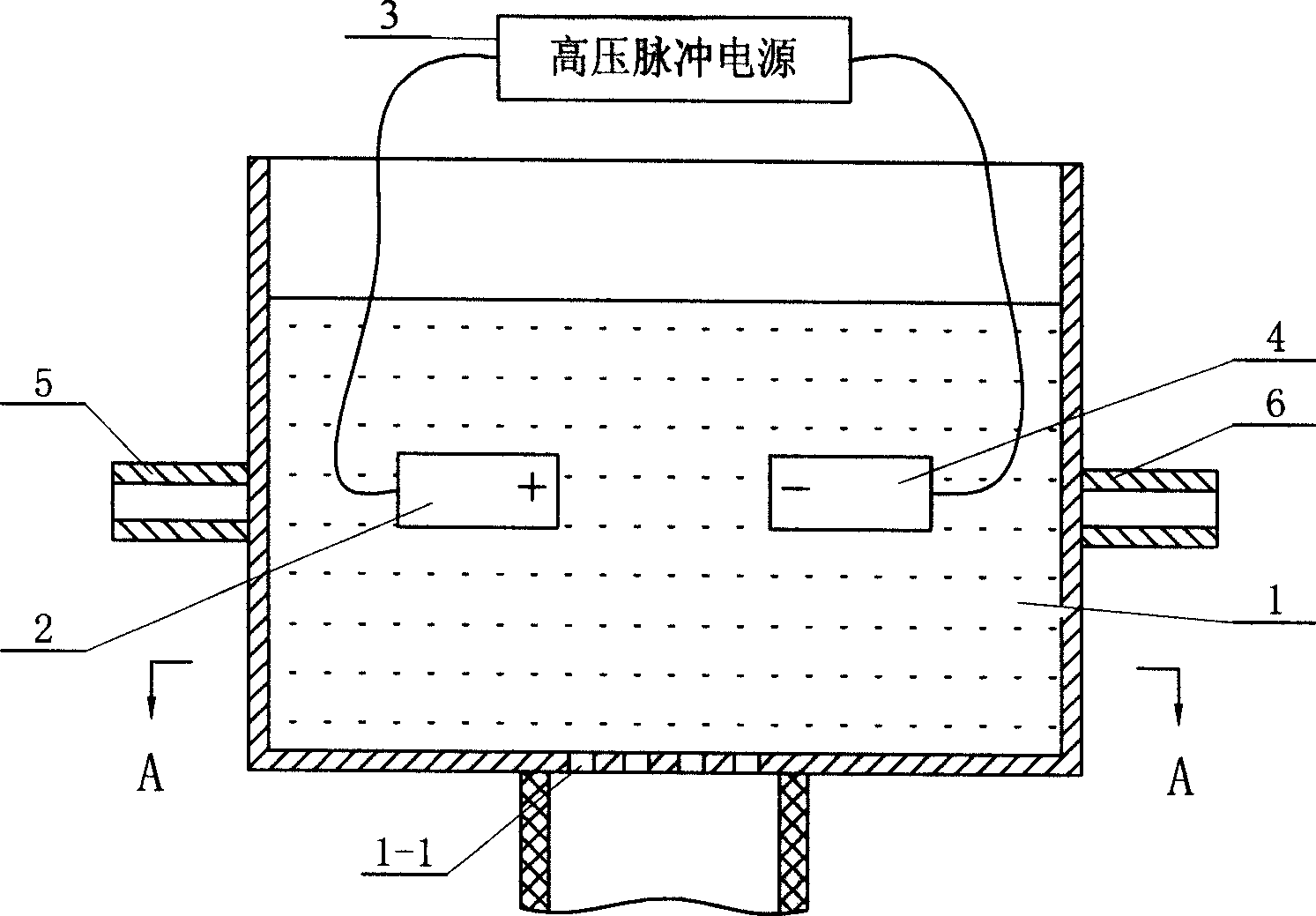

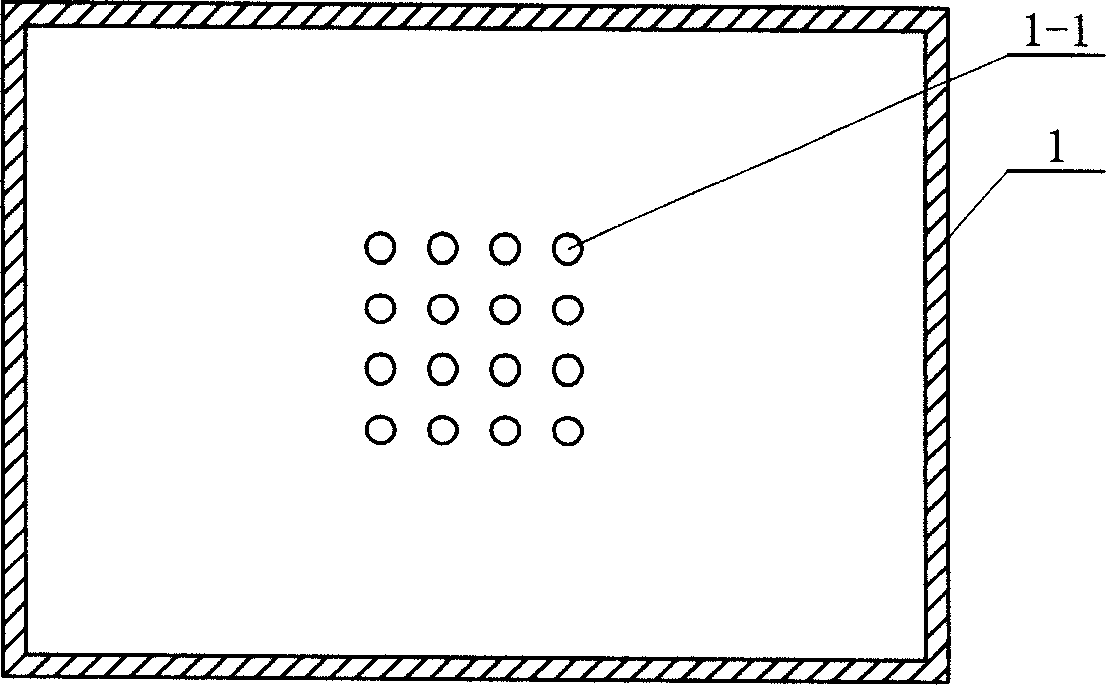

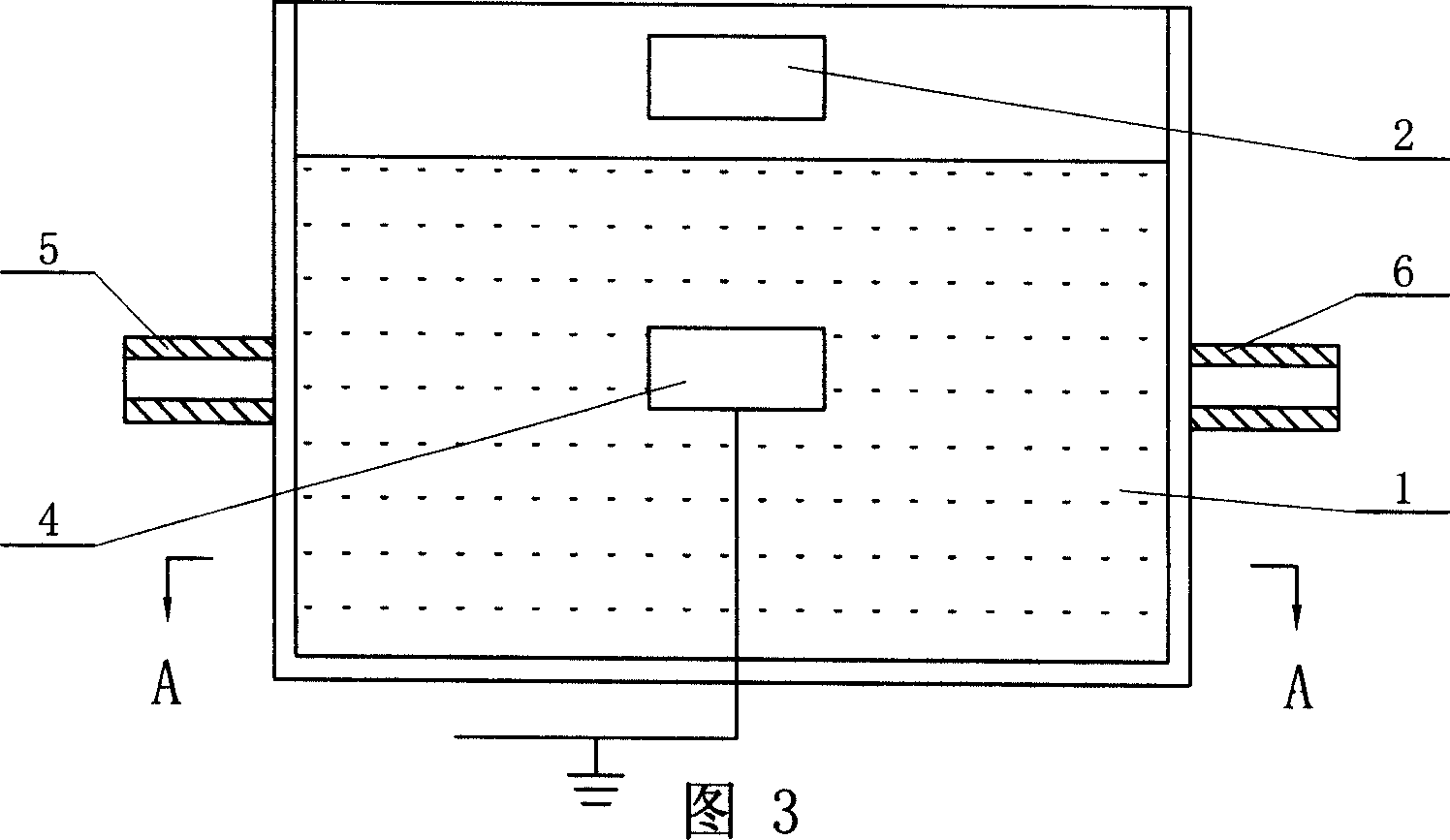

High-pressure pulse discharge catalytic oxidation method for removal of undegradable organic substances in water

InactiveCN1663916AImprove oxidation efficiencyImprove processing efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by magnetic/electric fieldsCatalytic oxidationOxygen

The invention discloses a method of removing the non-degradable organic substance in the water by catalyzed oxidation with high-voltage discharging, comprising applying the high-voltage pulse between the high voltage electrode 2 and earth electrode 4 in the reaction container with water by high voltage impulse power source 3, and at the same time adding oxygen, ozone, powdered activated carbon, transition metal oxide, hydrogen dioxide or transition metal ion to catalyze and oxygenize the organics. The process of removal of non-degradable organic is reinforced because of the existing of diverse catalyst and the efficiency of removal is greatly improved.

Owner:HARBIN INST OF TECH

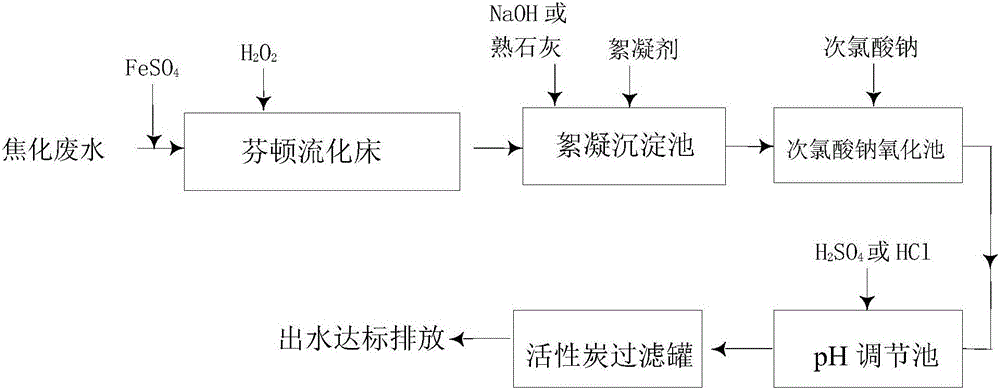

Method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide

ActiveCN106745961AGood effectImprove reaction efficiencyWater treatment compoundsWater contaminantsActivated carbon filtrationWater quality

The invention provides a method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide. The method comprises the following steps: 1) introducing the coking wastewater into a Fenton fluidized bed, and adding a mixed solution of ferrous sulfate, sulfuric acid and water into a solution; 2) adding hydrogen peroxide into the solution of the Fenton fluidized bed and sufficiently reacting; 3) leading out a reaction solution in the Fenton fluidized bed, adjusting the pH (Potential of Hydrogen) value of the reaction solution, adding a flocculating agent, and after precipitating, taking supernatant; 4) mixing the supernatant with sodium hypochlorite, and carrying out an oxidization reaction; and 5) adjusting the pH of the reaction solution, and carrying out adsorption treatment by active carbon to obtain a deeply treated water body. According to the method and the system, the Fenton fluidized bed, flocculation and sedimentation, sodium hypochlorite oxidization, and active carbon filtering and adsorption are effectively combined; the Fenton fluidized bed and the flocculation and sedimentation are carried out, residual cyanide in output water mainly exists in a CN<-> form, the oxidization efficiency of the sodium hypochlorite is higher, and the cyanide can be removed; and the adsorption effect of the active carbon is combined, so that the water concentration of the output water is lower.

Owner:CISDI ENG CO LTD

Method for chemically synthesizing high-dielectric constant electrode foil

InactiveCN101030483AIncrease profitImprove oxidation efficiencyAnodisationElectrolytic capacitorsDielectricO-Phosphoric Acid

The invention is concerned with the converting technique of the high dielectric constant electrode foil, it is: infuses the high dielectric constant electrode foil into the phosphoric acid or phosphate liquor, cleans with pure water, processes the first level anodic oxidation; processes the infusion and the cleaning again; then processes the anodic oxidation; processes heat treatment in high temperature; progresses the anodic oxidation, infuses into the phosphoric acid or phosphate liquor; finally, cleans with pure water and drying. The invention is high producing efficiency, and stable production quality.

Owner:DONGGUAN HEC CONDENSER CO LTD

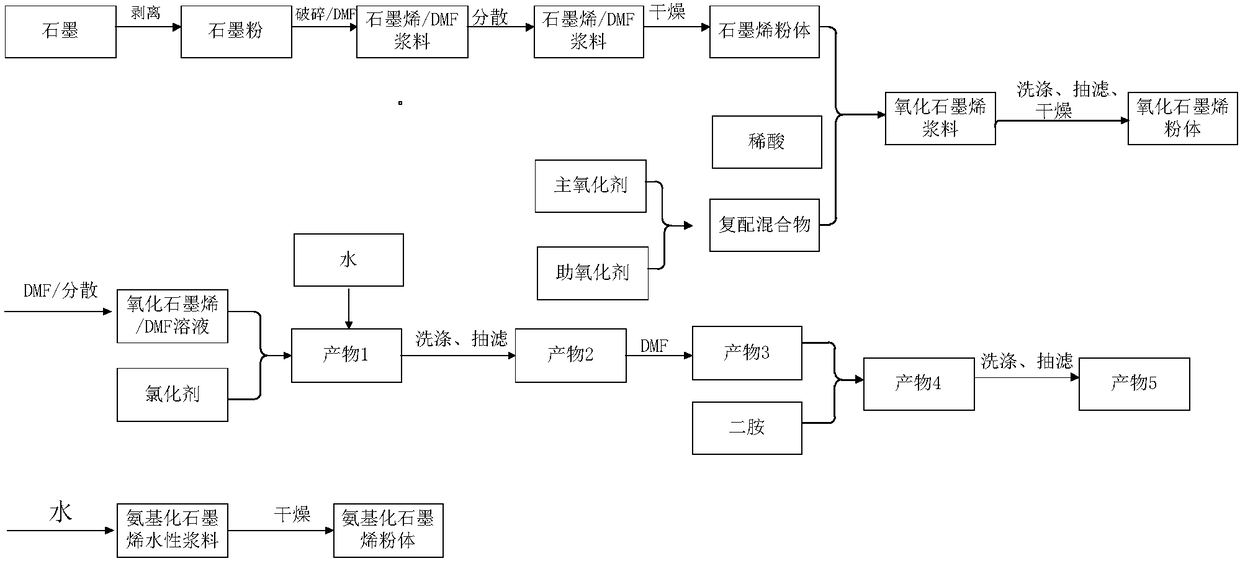

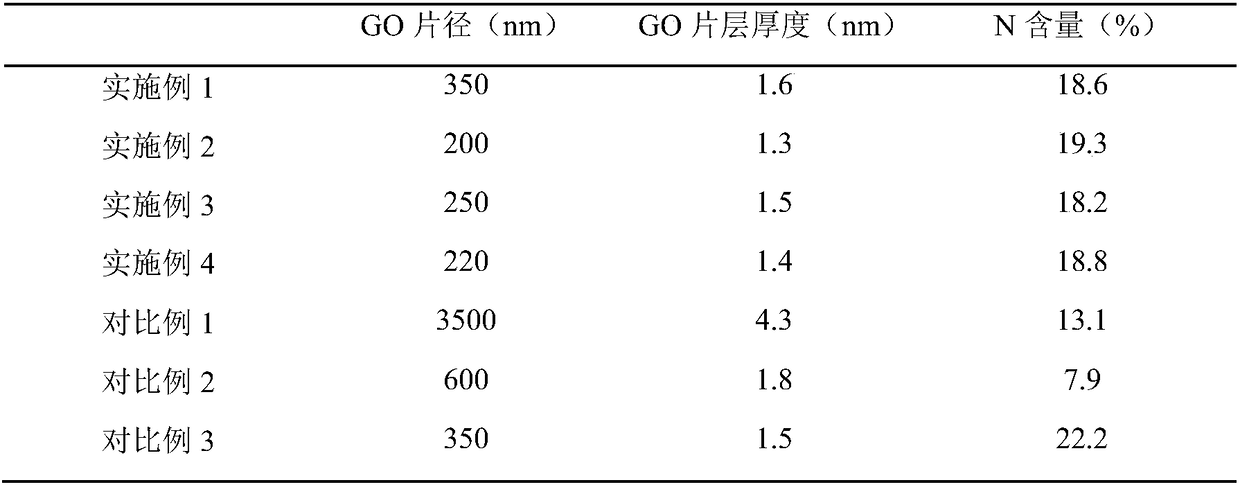

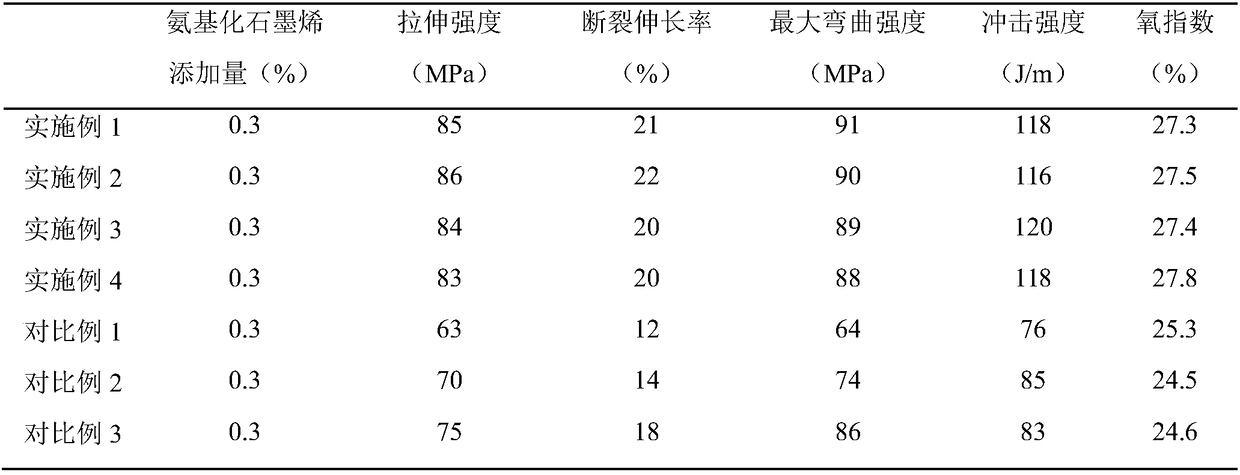

Preparation method of industrial aminated graphene

ActiveCN108373149AReduce dosageLittle damage to the lamellar structureGrapheneBulk chemical productionCvd grapheneDiamine

The invention discloses a preparation method of industrial aminated graphene. The preparation method of the industrial aminated graphene belongs to the technical field of graphene preparation, and comprises the steps of firstly stripping graphite through a mechanical stripping method, oxidizing through adjusting the matching ratio of a main oxidizing agent and an auxiliary oxidizing agent, then activating hydroxyl and carboxyl on the surface of graphene oxide through a chlorinating agent, and finally selecting appropriate diamine for carrying out amination reaction. According to the preparation method of the industrial aminated graphene provided by the invention, through adopting a stripping manner at first, the dosage of the oxidizing agents can be reduced, an ideal effect is achieved atthe same time, and the problem of poor modification effect caused by high oxygen content and severe destructiveness on a graphene slice layer due to large dosage of the oxidizing agents is solved.

Owner:CHANGZHOU HIGHBERY NEW NANO MATERIALS TECH CO LTD +1

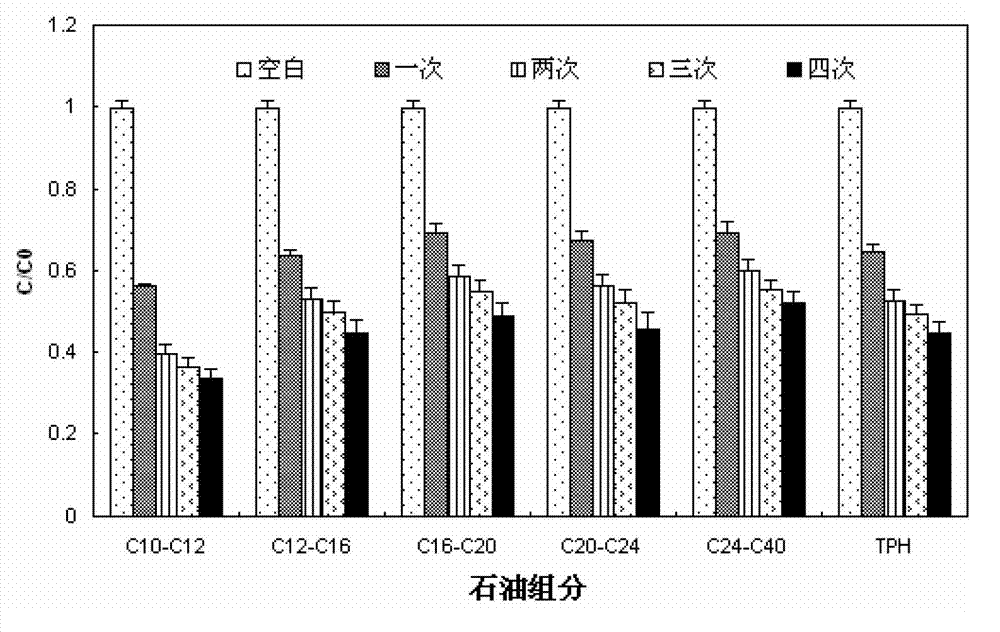

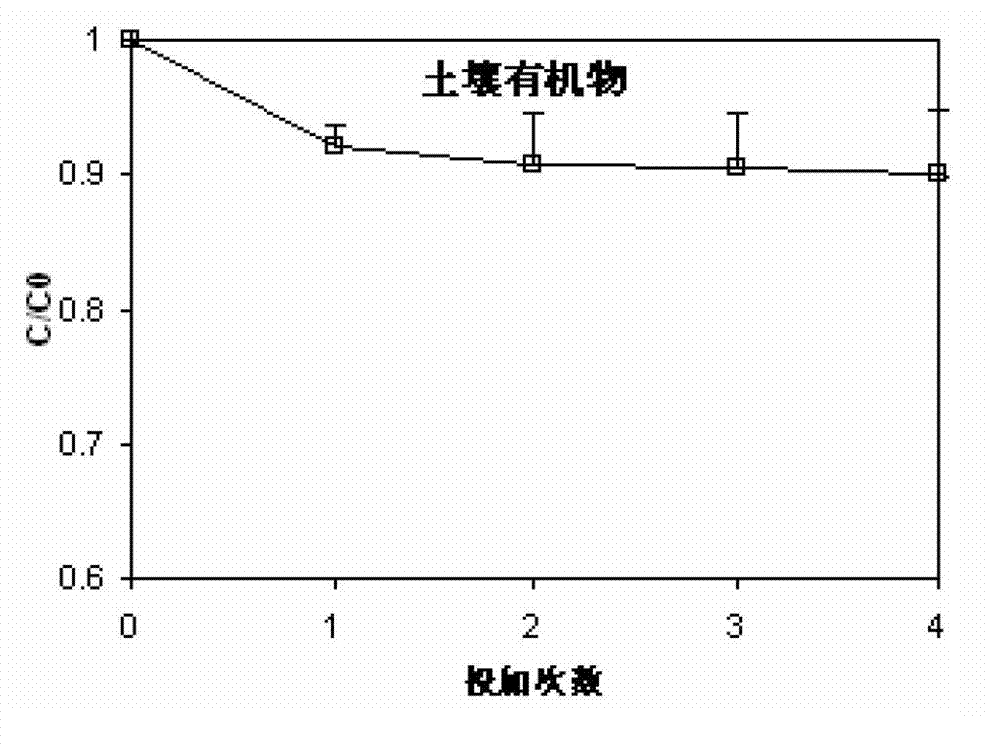

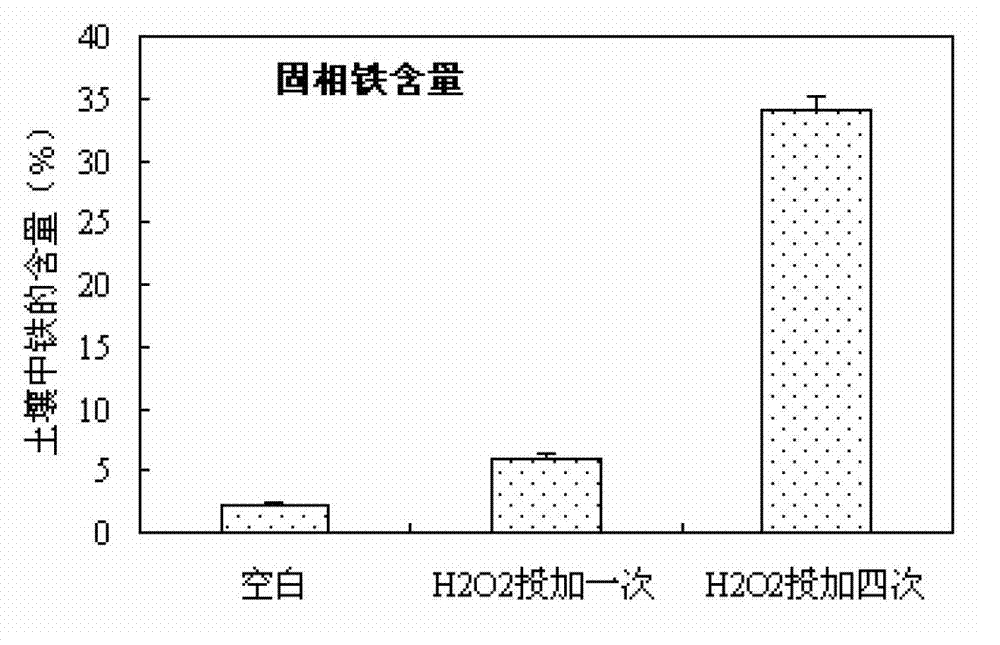

Method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil

ActiveCN102886378AImprove oxidation efficiencyReduce dosageContaminated soil reclamationFenton reagentBioremediation

The invention aims to provide a method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil. According to the method, the preparation concentration of a Fenton reagent is determined by detecting the concentration of petroleum hydrocarbon in the petroleum contaminated soil, different amounts of hydrogen peroxide in the Fenton reagent are fed for multiple times, and the concentration and the dosage of hydrogen peroxide at the next time are adjusted by the concentration of petroleum hydrocarbon after every addition for a certain time, wherein the concentration of hydrogen peroxide is 150mmol / L to 350mmol / L, and the feeding time of H2O2 is 3 to 6 times. According to the invention, a solid phase prepared iron catalyst is utilized to absorb high-activity hydroxide radicals adjacent to the petroleum hydrocarbon, and an absorption state petroleum hydrocarbon is directly oxidized, so that the oxidation efficiency is high; furthermore, the dose of H2O2 is greatly saved, and the use ratio of H2O2 is high; and the method for degrading solid phase adsorbed state petroleum hydrocarbon in petroleum contaminated soil is temperate in reaction condition, little in the heat production, low in degree of damage on the soil organic matters and the microbes, free from secondary pollution, and beneficial for subsequent biological repair.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

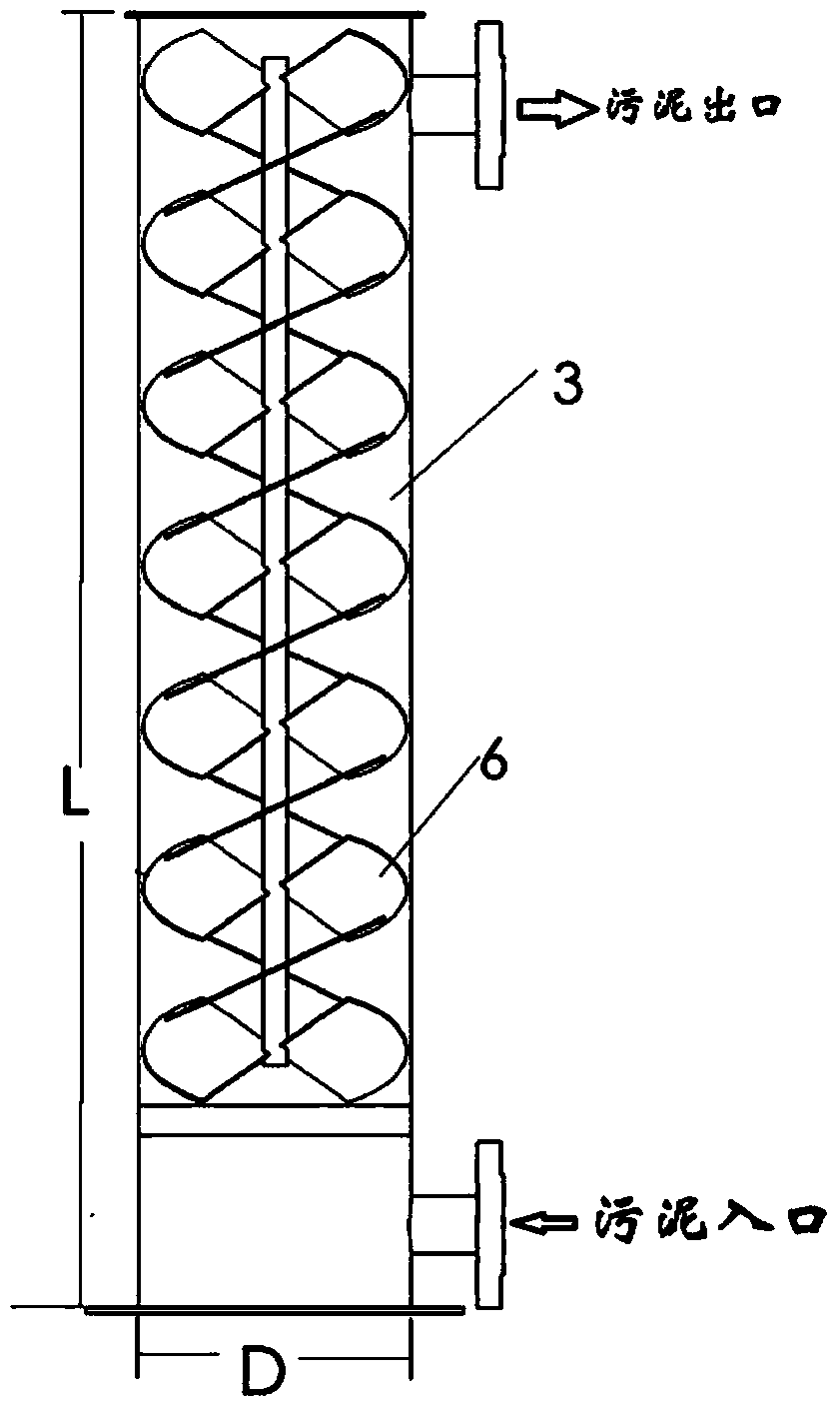

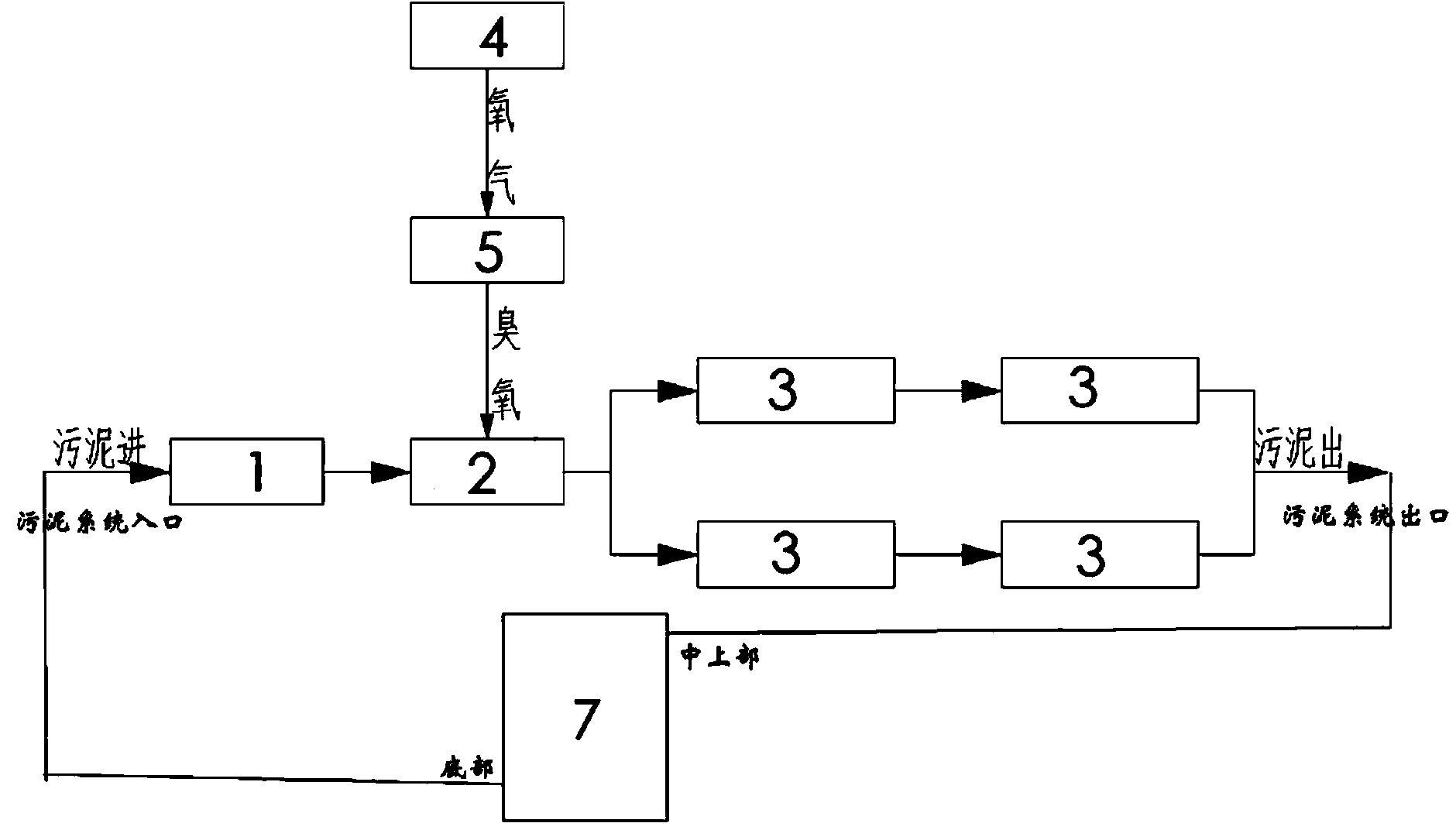

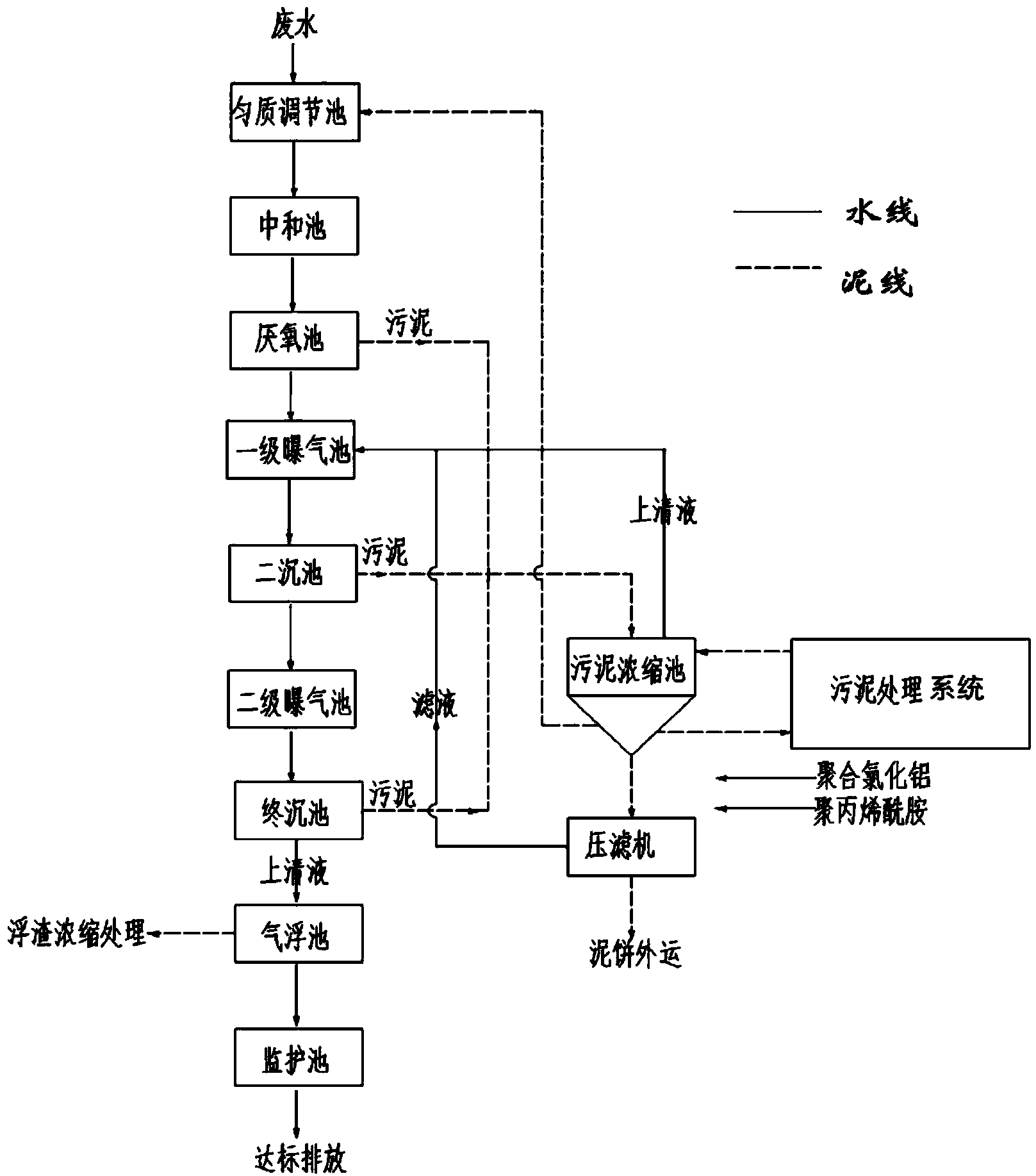

Sludge treatment system and method thereof

InactiveCN103663895AAchieve reductionGuaranteed uptimeSludge treatment by de-watering/drying/thickeningWater treatment parameter controlRedoxEnergy consumption

The invention discloses a sludge treatment system and a method thereof, wherein the sludge treatment system comprises a pump, an ozone generation device, an ejector and a pipeline reactor which are orderly connected by pipes. The sludge treatment system comprises the following steps of: (1) when sludge water to be treated is conveyed to the ejector by the pump in a certain speed, a side inlet of the ejector generates negative pressure to suck ozone generated by the ozone generation device, the sludge water and the ozone are mixed to form a mixture; and (2) the mixture enters a pipe reactor by a pipe, and the mixture is fully contacted with a catalyst layer in the pipeline reactor, to carry out oxidation reduction reaction under catalysis of the catalyst. The sludge treatment system implements modularization production of a sludge deweighting treatment system, does not need to reconstruct a current sludge system, eliminates offensive odor of the sludge treatment system and an outward mud cake, reduces energy consumption in a production process, and reduces a sludge discharge total amount of the system.

Owner:NANJING DELEI SCI & TECH

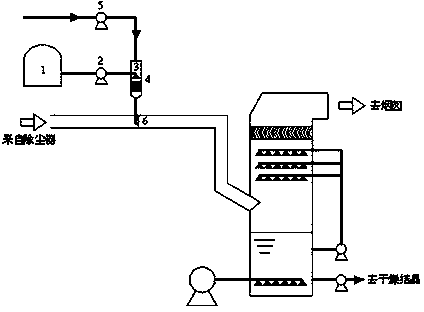

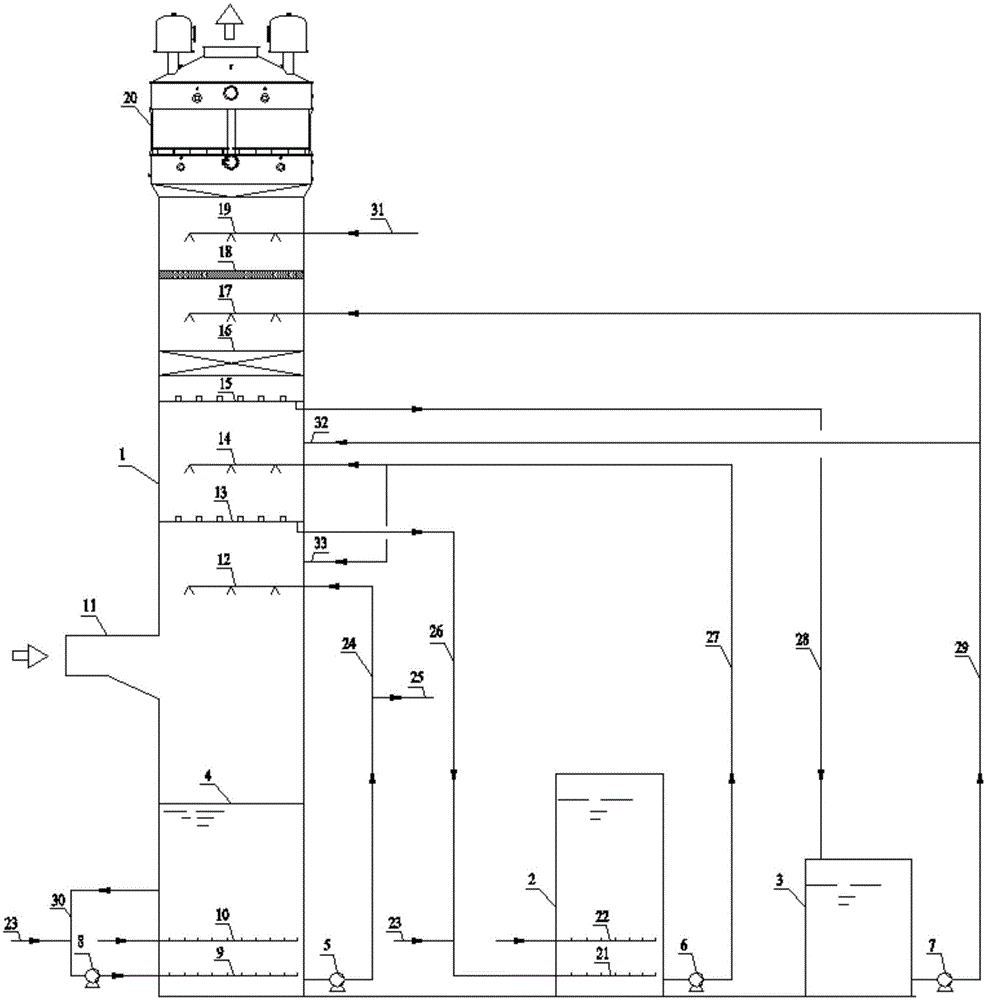

Multi-stage absorbing desulfurizing device by adopting ammonia-ammonium sulfate method

ActiveCN105148712AImprove ammonia utilizationImprove oxidation efficiencyCombination devicesCycloneFlue gas

The invention discloses a multi-stage absorbing desulfurizing device by adopting an ammonia-ammonium sulfate method. The absorbing desulfurizing device comprises a flue gas desulfurizing absorption tower, an absorption liquid circulating tank, a thin slurry circulating tank and a wet-type electric dust remover, wherein the flue gas desulfurizing absorption tower comprises a concentrated slurry circulating tank, a concentration pre-absorption section, an absorption section, a thin slurry washing section and a defogging section that are arranged in a vertical manner; the concentration pre-absorption section comprises at least a layer of concentrated slurry spraying layer; the absorption section comprises an absorption liquid cyclone defogging liquid collector and at least a layer of absorption liquid spraying layer; the thin slurry washing section comprises a thin slurry cyclone defogging liquid collector and a thin slurry spraying layer; the defogging section comprises a defogger and a defogger washing spraying layer. According to the multi-stage absorbing desulfurizing device by adopting the ammonia-ammonium sulfate method, provided by the invention, flue gas cooling, multi-stage defogging absorption and multi-section oxidization are completed in the desulfurizing absorption tower, the utilization rate of ammonia is increased by regulating the ammonia adding positions, and the problems that the concentration of slurry in multiple sections is controlled unsatisfactorily, and the content of aerosol in flue gas after desulfurization is too high are solved, wherein the problems are caused due to the fact that although the conventional desulfurizing absorption tower is divided into multiple sections, slurry in the multiple sections are carried with gases heavily.

Owner:SINOPEC NANJING ENG & CONSTR +1

Deep treatment method for industrial wastewater through natural pyrite catalyzed H2O2 oxidation

ActiveCN103708647ASimple and fast operationHigh implementabilityMultistage water/sewage treatmentWater/sewage treatment by oxidationTreated water sampleWater quality

The invention relates to a deep treatment method for industrial wastewater through natural pyrite catalyzed H2O2 oxidation. The deep treatment method specifically comprises the following steps: pretreating natural pyrite, adding wastewater into a reactor, adjusting the pH value to be 8-10, adding the pretreated natural pyrite, adding nitrilotriacetic acid, fast stirring, adding a hydrogen peroxide solution, after reaction under stirring, adding a FeCl3 solution to control the mass ratio of pyrite and Fe (III) to be 10:1, adding hydrogen peroxide, continuing the reaction, and standing for precipitation, wherein residual mineral can be recycled; introducing air into supernatant separated through precipitation for secondary oxidation while keeping dissolved oxygen in the water to be above 3ppm, after sufficient aeration, adding polyacrylamide for coagulation treatment, and after standing for precipitation, discharging effluent; carrying out water quality analysis on a treated water sample to assess the treatment effect. By a simple way and various synergistic effects, the deep treatment method provided by the invention changes the generation way of Fenton reaction, significantly increases the reaction reactivity, expands the applicable pH range of the wastewater, improves the utilization efficiency of H2O2, and reduces the cost of technology, thus being an economical and efficient wastewater deep treatment technology.

Owner:TONGJI UNIV

Bottom mud repair and treatment material for urban black and odorous river channel and preparing method of bottom mud repair and treatment material

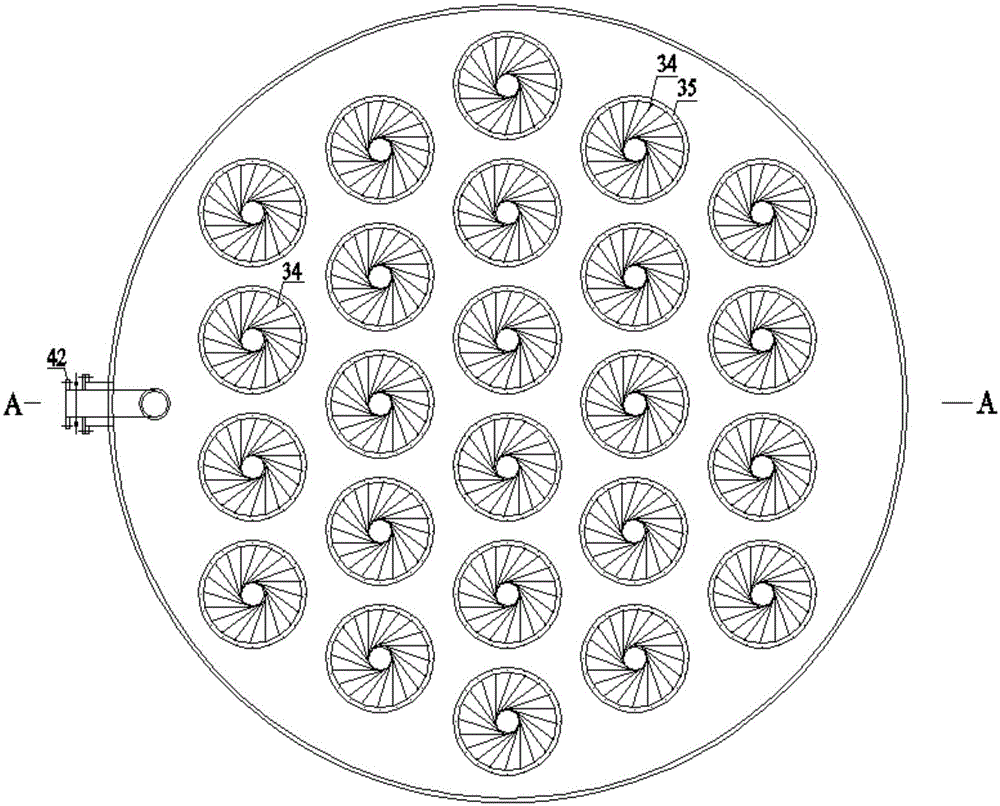

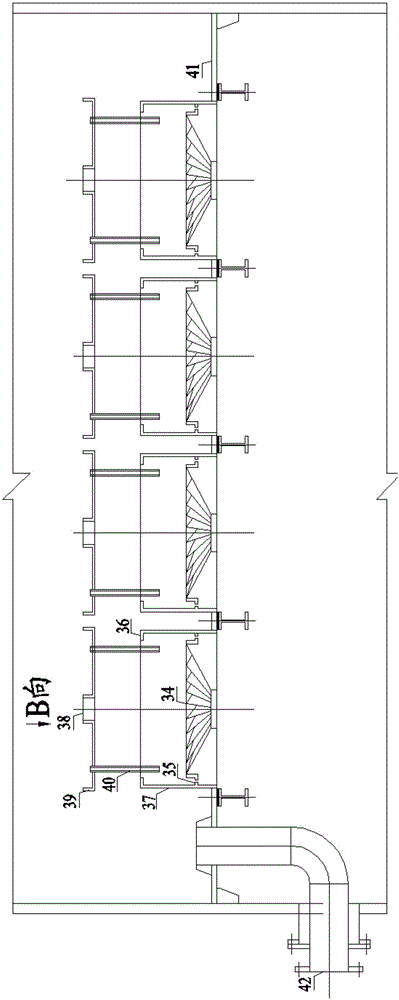

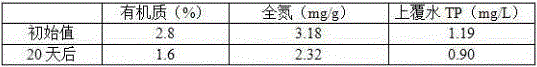

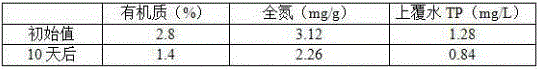

ActiveCN105923961AIncrease oxidation rateImprove oxidation efficiencyBiological sludge treatmentPhosphateNitrogen

The invention relates to a bottom mud repair and treatment material for an urban black and odorous river channel and a preparing method of the bottom mud repair and treatment material. The bottom mud repair and treatment material for the urban black and odorous river channel and the preparing method of the bottom mud repair and treatment material can be applied to the technical field of bottom mud repair of urban black and odorous river channels. Raw materials for preparing the filler include CaO2, MgO2, attapulgite clay, dry EM powder and nanometer titanium dioxide. All the raw materials are pretreated with specific steps respectively and then evenly mixed according to a specific proportion, and the powder material is formed. The repair material is evenly mixed with the bottom mud of the urban black and odorous river channel in situ, nitrogen, phosphate and organic matter in the bottom mud can be effectively removed, stinks can be eliminated, and the effect of controlling source pollution in the river channel can be achieved.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Hydrogen peroxide working solution and its application in preparation of hydrogen peroxide

ActiveCN103588177AReduce solubilityImprove solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesOrganic solventPhosphate

The invention belongs to the technical field of hydrogen peroxide, and especially relates to a hydrogen peroxide working solution and its application in the preparation of hydrogen peroxide. The hydrogen peroxide working solution comprises 2-ethylanthraquinone having a mass concentration of 120-200g / L and an organic solvent, and the organic solvent comprises, by volume, 70-80% of a C9-C10 aromatic hydrocarbon, 14-20% of trioctyl phosphate, 4-10% of 2-methylcyclohexyl acetate and 0.4-0.9% of tertiary amine When the hydrogen peroxide working solution is used in the preparation of hydrogen peroxide, the hydrogen peroxide working solution can greatly improve the hydrogenation efficiency and the oxidation efficiency of 2-ethylanthraquinone, and has the advantages of low production cost, no peculiar smell and product yield improvement.

Owner:WEIFANG MENJIE CHEM

Method for quickly removing organic pollutants in water based on intermediate-state iron

ActiveCN105600911AEasy to transportLow priceWater treatment compoundsMultistage water/sewage treatmentWater basedWastewater

The invention discloses a method for quickly removing organic pollutants in water by utilizing pyrosulfite to activate ferrate and relates to a method for utilizing the pyrosulfite to activate the ferrate and produce intermediate-state iron (Fe (V) and Fe (IV)) so as to quickly oxidize and remove the pollutants in water. The method can be used for deep treatment of domestic sewage and can be also used for deep treatment of high-concentration organic wastewater. The method has the following advantages that 1, a green and safe solid agent is adopted, is convenient to transport and low in price, is applied to an existing process and does not need process transformation; 2, the conditions required by reaction are mild and facilitate actual application; 3, reactants are ferric iron and sulfate radicals, wherein the ferric iron has adsorption and coagulation enhancement effects and can promote removal of the pollutants, a coagulant can be subsequently added to further remove organic pollutants in water when needed, and the sulfate radicals are non-toxic and harmless and are background ions in the water; 4, the method has the higher oxidation efficiency, oxidation speed and oxidation capability to the pollutants.

Owner:TONGJI UNIV

Microwave electro-Fenton method for processing organic wastewater and device thereof

InactiveCN102765783APromote degradationHigh removal rateWater/sewage treatment by irradiationWater contaminantsReaction rateElectrochemical degradation

The invention relates to a microwave electro-Fenton method for processing organic wastewater and a device thereof. Under the action of microwave, a boron-doped diamond film electrode is used as an anode material for electrochemical degradation processing, and organic pollutant containing wastewater is processed efficiently by an electrochemical method. According to the invention, the boron-doped diamond film electrode is utilized to continuously generate hydroxyl radical with strong oxidation capacity in a wastewater system containing divalent iron ions, and in-situ activation of the boron-doped diamond film electrode is carried out by means of thermal effect and non-thermal effect of microwave so as to increase activity of the electrode and promote mass transfer process during the degradation process of organic pollutants. Therefore, the oxidation capacity of the electro-Fenton reaction is enhanced, and mineralization reaction rate is effectively accelerated. In comparison with traditional Fenton and electro-Fenton methods, the processing effect of the microwave electro-Fenton method provided by the invention is effectively enhanced. The method provided by the invention is simple to operate, has a good effect of processing organic wastewater, and has a wide application prospect as well as development potential.

Owner:TONGJI UNIV

Wet desulphurization method for coal-fired power plant and additive used by same

The invention discloses a wet desulphurization method for a coal-fired power plant and an additive used by the same. The additive comprises the following components in percentage by weight: 70 to 80 percent of alkyl carboxylates, 5 to 10 percent of limestone active agent, 2 to 10 percent of metallic oxide and 5 to 15 percent of surfactant. The additive of the invention can improve the desulfurization effect of an absorption tower and adapt to high-sulfur coal, so that the outlet concentration of SO2 reaches the standard, and a slurry circulating pump also can be stopped in varying degrees to fulfill the aim of energy conservation; and the additive is dissolved in water easily, and the pH value is neutral, so the additive has the characteristic that the additive is easy and convenient to use, does not have air bubbles in the using process and corrode equipment. By the desulphurization method using the additive, the use amount of limestone can be reduced, the oxidization efficiency and gypsum purity of CaSO3 can be improved, the dehydration efficiency of gypsum can be improved, and NO content and Hg content in smoke also can be reduced to achieve the effects of desulfuration, denitration, demercuration and smoke purifying.

Owner:HUADIAN ENVIRONMENTAL PROTECTION ENG & TECH +1

Treatment method for reverse osmosis concentrated water

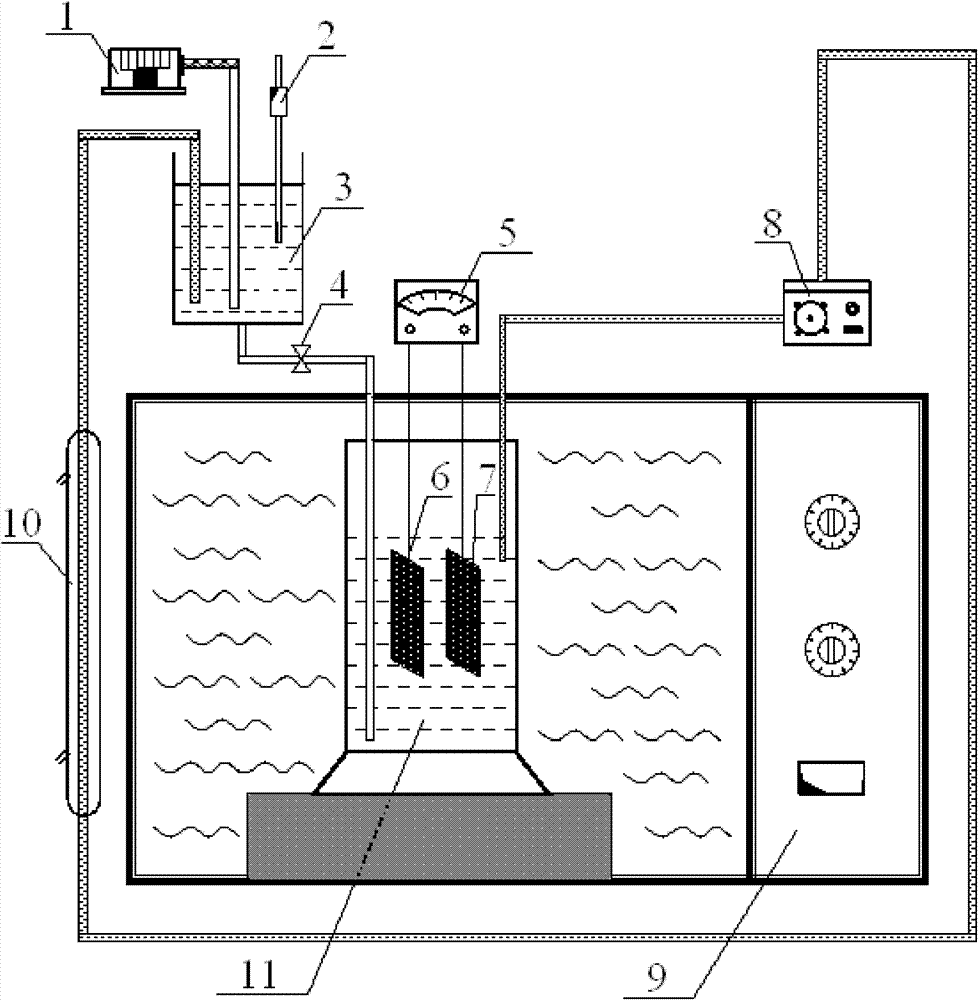

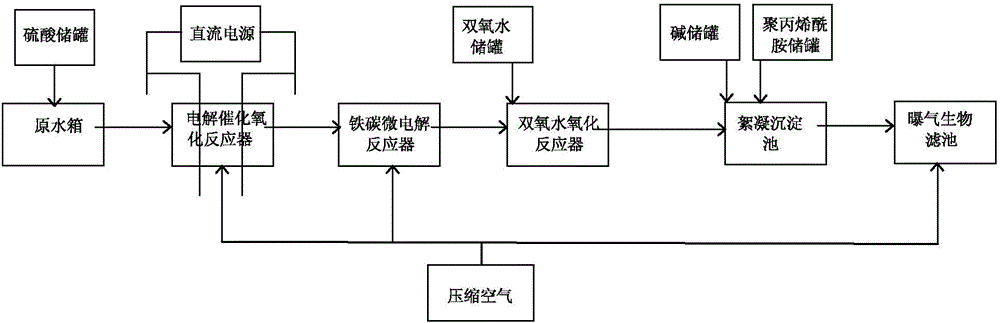

ActiveCN104556533AImprove oxidation efficiencyLarge specific surface areaTreatment using aerobic processesMultistage water/sewage treatmentElectrolysisReverse osmosis

The invention relates to a treatment method for reverse osmosis concentrated water, in particular to a standard treatment method for the reverse osmosis concentrated water which is produced during sewage reusing. The treatment method comprises the following steps: the pH value of the reverse osmosis concentrated water is regulated to be 2.0-4.0, and electrolytic catalysis oxidation is carried out; water produced from the electrolytic catalysis oxidation is subjected to redox reaction in an electrolytic reactor, which is filled with iron-carbon fillers obtained through sintering of iron and carbon; hydrogen peroxide is then added, so that oxygenolysis is further achieved; the pH value is regulated to be 6.0-8.0, and a flocculant is added for flocculent settling; a supernate obtained from the flocculent settling enters an aeration biological tank, and a co-substrate is added for biological degradation. The COD of the reverse osmosis concentrated water with lower biodegradability, which is obtained through reverse osmosis reusing treatment after standard biochemical treatment, is reduced from 70-200 milligrams per liter to below 50 milligrams per liter, so that the strictest local emission standards can be met.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing oxidation catalyst from gold ore tailing slag, and prepared oxidation catalyst and application thereof

InactiveCN102580743AEasy to operateSignificant progressMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical oxygen demandIndustrial waste water

The invention provides a method for preparing an oxidation catalyst from gold ore tailing slag, and a prepared oxidation catalyst and application thereof. The method comprises the following steps of: crushing the slag into particles of 50-200 meshes, and performing acid washing treatment; mixing the treated slag with a ferrous slat solution in an inert gas protection atmosphere, performing ion exchange adsorption, and then filtering and washing a filter cake; impregnating the obtained filter cake in water, and adding an alkali liquor to adjust the pH to alkalinity so that iron ions react in situ on the surface of the filter cake to obtain the filter cake loaded with hydroxyl iron; activating the filter cake loaded with the hydroxyl iron to obtain the oxidation catalyst loaded with nano-ferric oxide. The method provided by the invention is simple and convenient, moderate in reaction conditions, low in cost and friendly to the environment; the catalyst prepared by the method disclosed by the invention contains components which are not easy to loss and is high in oxidation; and therefore, the catalyst is suitable for treating various kinds of industrial waste water, especially dye waste water mother liquor which is high in COD (Chemical Oxygen Demand), low in pH value, high in salinity, and difficult to degrade and oxidize.

Owner:ZHEJIANG UNIV +1

Joint structure of copper wire and aluminum wire, and joint method

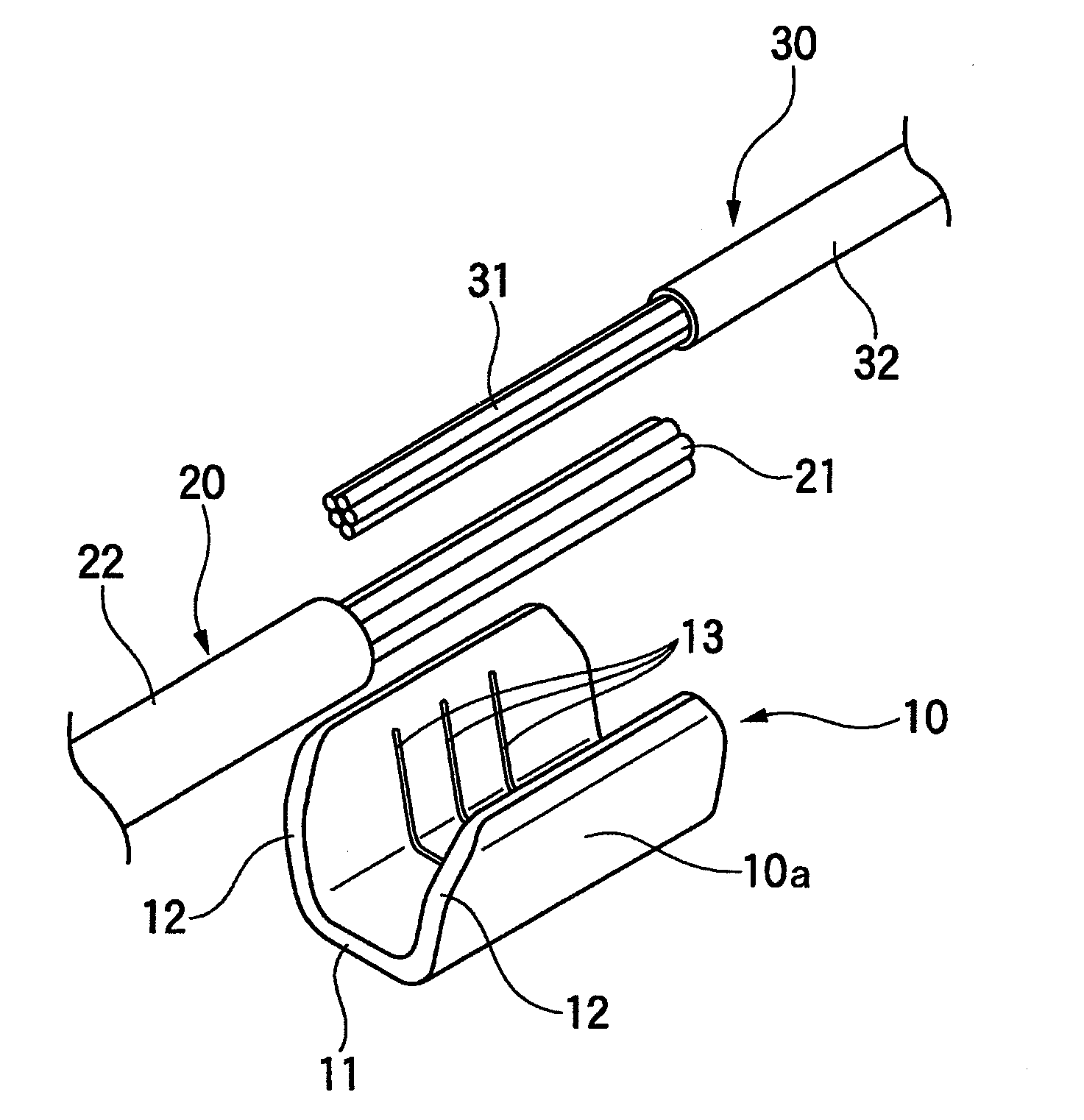

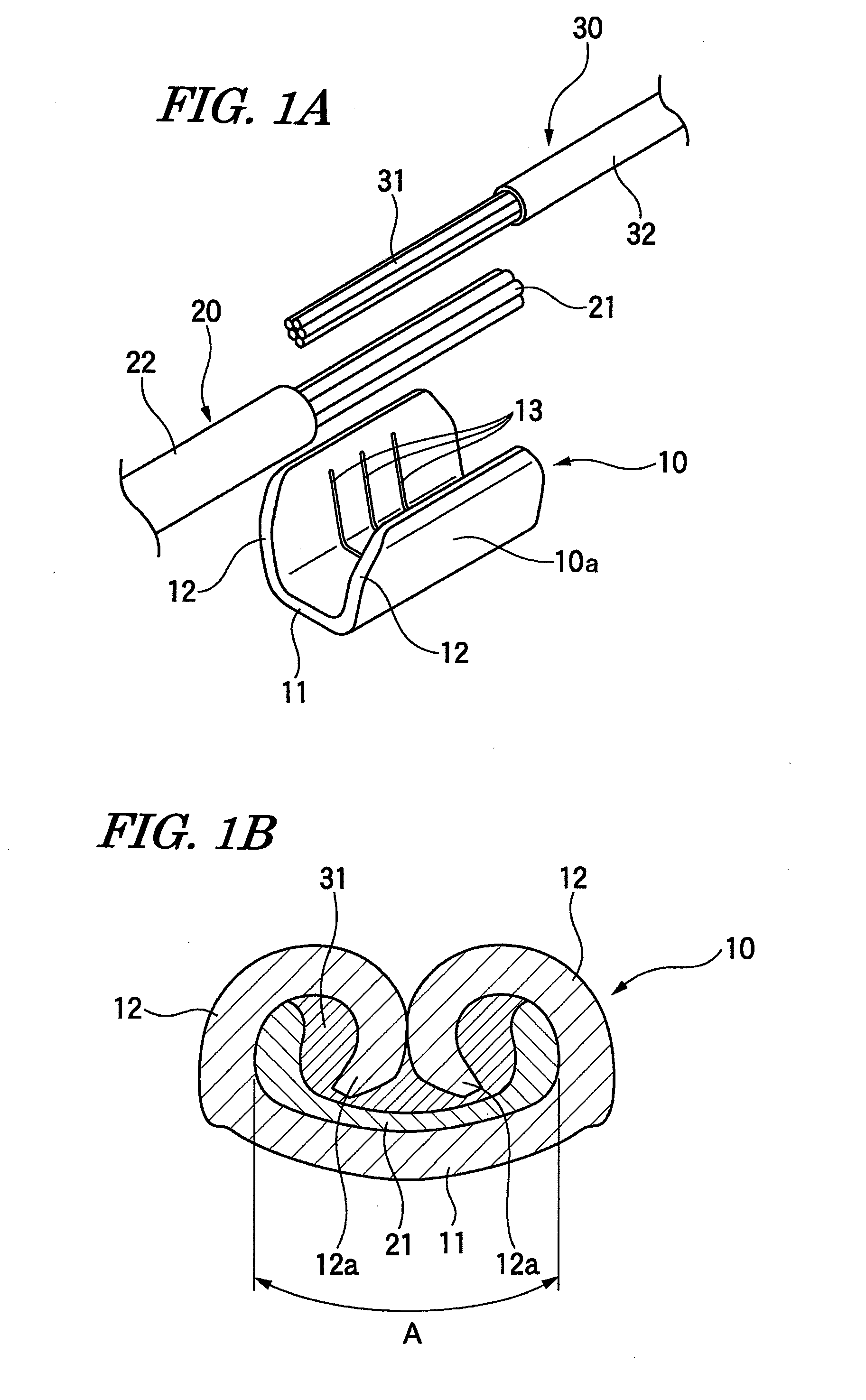

InactiveUS20090133927A1Low fuel costGood removal effectLine/current collector detailsCoupling contact membersCopper wireEngineering

A joint structure of electric wires includes: a copper wire which includes a conductor formed of copper; an aluminum wire which includes a conductor formed of aluminum or aluminum alloy; and a joint terminal provided with a conductor press-fitting part having a U-shape in cross section. The conductor press-fitting part includes a bottom plate and a pair of conductor caulking pieces which are upwardly extended from both side edges of the bottom plate, and is inwardly folded to caulk the conductors of the copper wires and the aluminum wires so as to enclose the conductors. The conductor press-fitting part is press-fitted to the conductors of the aluminum wire and the copper wire in a state that the conductor of the aluminum wire is disposed on the upper face of the bottom plate, and the conductor of the copper wire is disposed on the conductor of the aluminum wire.

Owner:YAZAKI CORP

Device and method for oxidizing and removing elemental mercury by using wet flue gas desulfurization wastewater

InactiveCN104084028APromote catalysisAvoid dependenceDispersed particle separationAir preheaterAir compressor

The invention relates to a device and a method for oxidizing and removing elemental mercury by using wet flue gas desulfurization wastewater. The device comprises a boiler, wherein the boiler is connected with a SCR (Selective Catalytic Reduction) denitration device through a coal economizer; the SCR denitration device is connected with a limestone-gypsum wet desulphurization tower through an air pre-heater and a dust remover; a chimney is arranged on the limestone-gypsum wet desulphurization tower; atomizing nozzles are distributed in a flue between the coal economizer and the SCR denitration device; the atomizing nozzles are connected with a desulfurization wastewater tank through a slurry pump; an air compressor is connected with the atomizing nozzles and used for supplying compressed air for the atomizing nozzles in the atomizing process. By virtue of the device and the method, the problem that combustion low-chloride coal elemental mercury is difficultly discharged is solved, and the problem of treatment of the desulfurization wastewater is solved.

Owner:SHANDONG UNIV

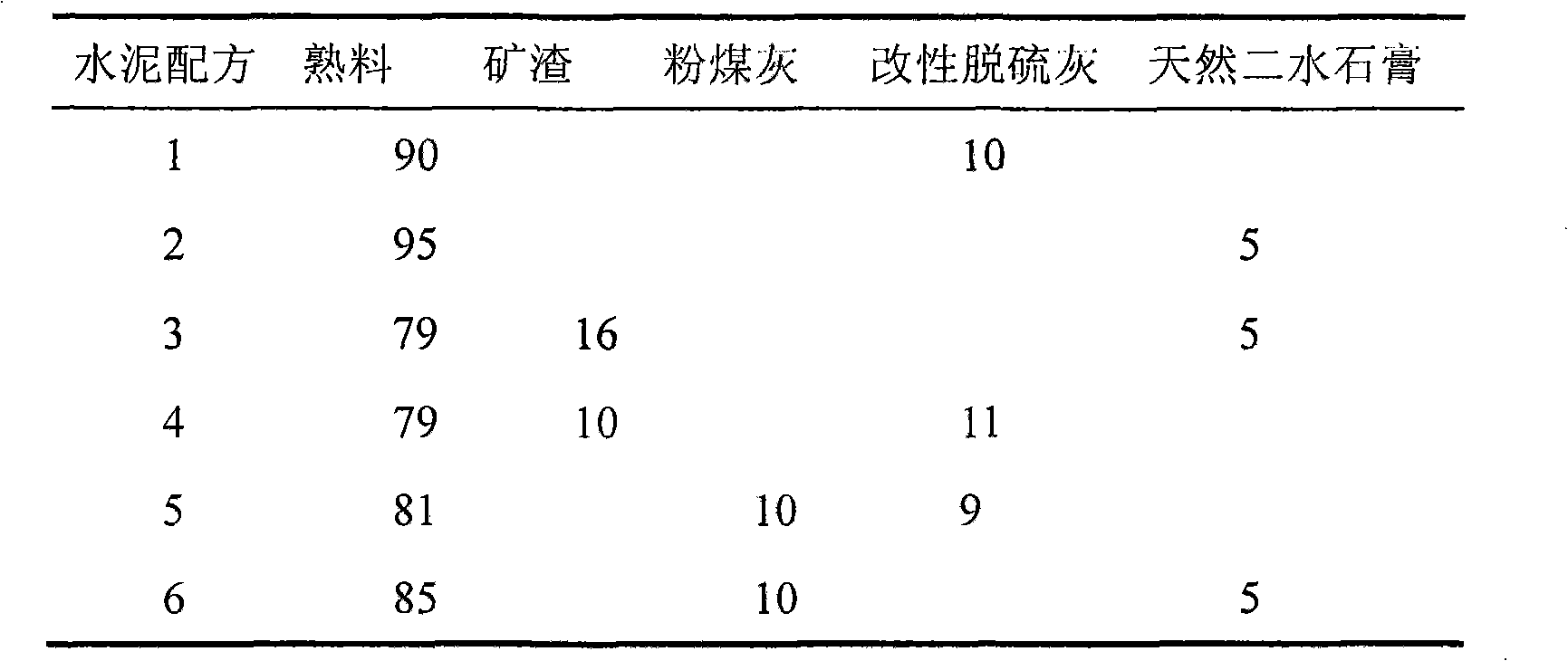

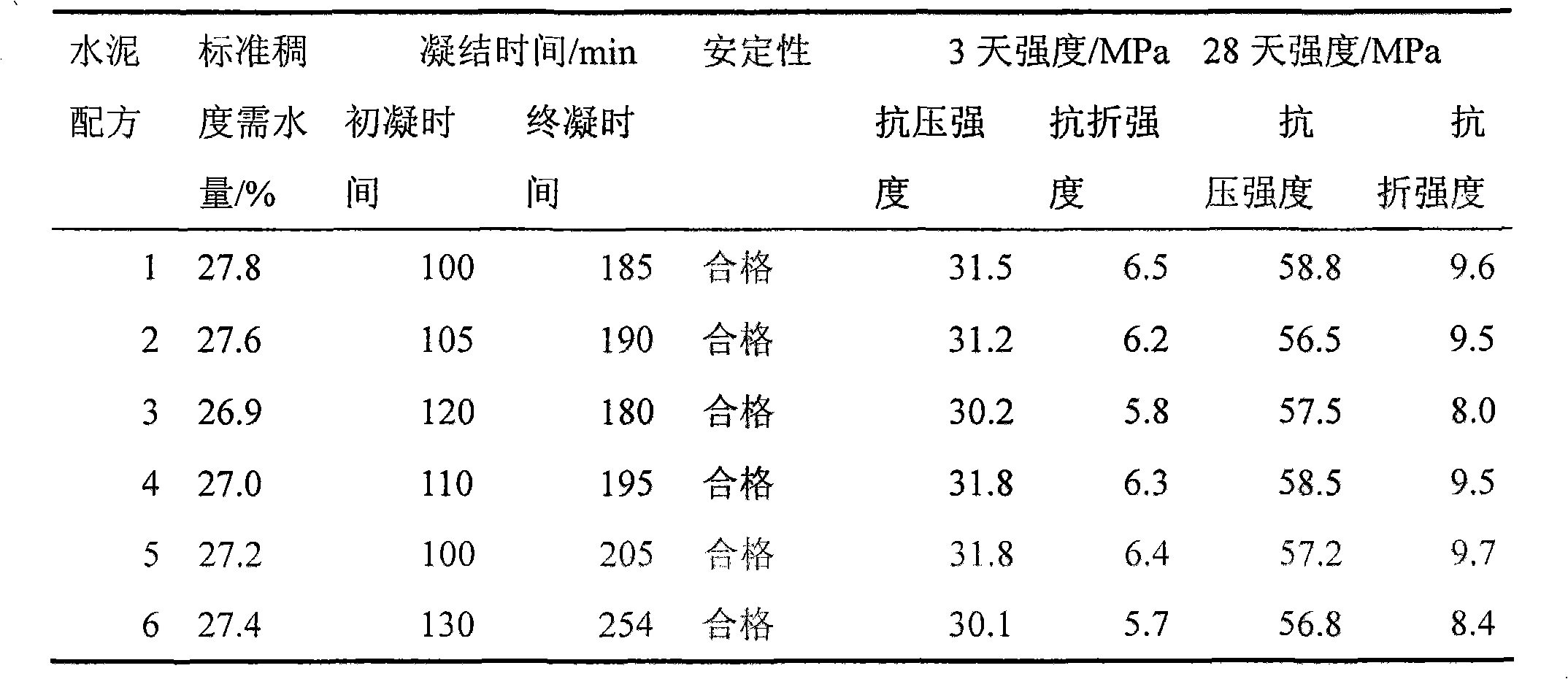

Method for modifying desulfuration ash for cement retarder

InactiveCN102010146ALarge specific surface areaSolve environmental problemsSocial benefitsEconomic benefits

The invention relates to a method for modifying desulfuration ash produced by a steel enterprise sintering process or a power plant smoke drying method or semidry method smoke desulfuration for cement retarder. The method is characterized by comprising the following steps of: A, performing micro thinning treatment on the desulfuration ash by adopting a ball milling or airflow crushing mode so that the specific surface area of the desulfuration ash grain diameter is 300 to 1,000 m<2> / kg; and B, putting the desulfuration ash subjected to the micro thinning treatment into a closed container of 450 to 700 DEG C, blowing oxygen or air into the closed container, and reacting for 20 to 60 minutes to obtain the modified desulfuration ash for the cement retarder. The method for modifying the desulfuration ash for the cement retarder not only can solve a series of environment problems caused by long-term stacking of the desulfuration ash, but also can produce certain economic benefit and social benefit.

Owner:中钢集团武汉安全环保研究院有限公司

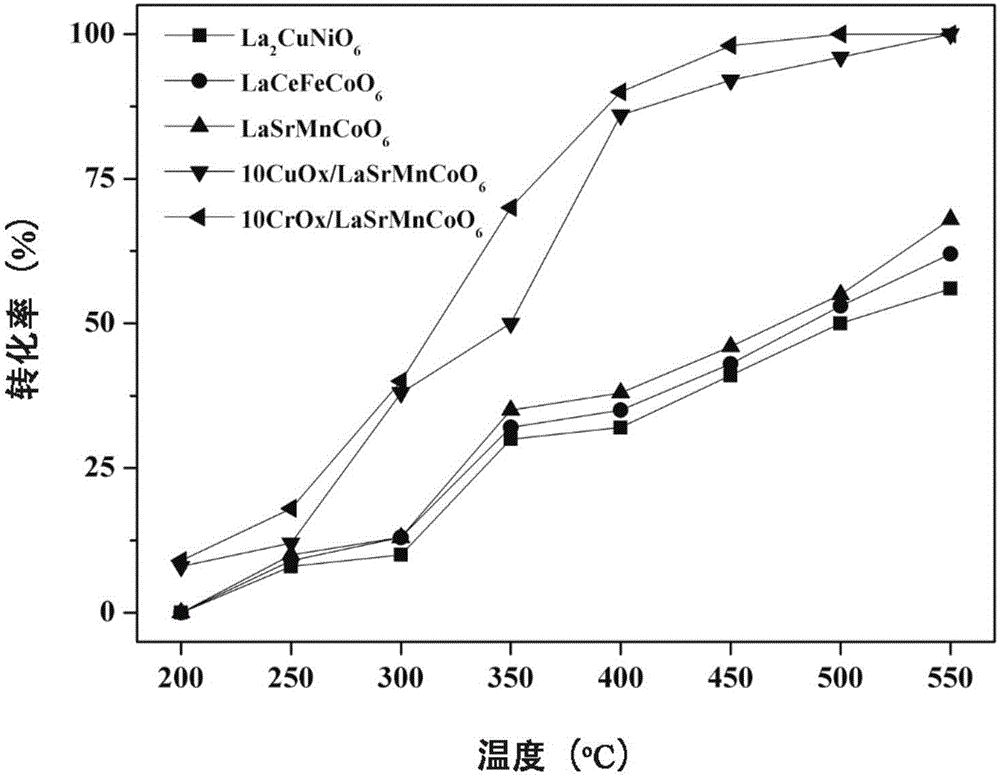

Double-perovskite composite metal oxide catalyst and preparation method and application thereof

ActiveCN106475105AThe synthesis method is simpleLow priceGas treatmentHeterogenous catalyst chemical elementsReaction temperatureTemperature resistance

The invention discloses a double-perovskite composite metal oxide catalyst and a preparation method and application thereof and belongs to the technical field of atmospheric pollution treatment. The condensed structural formula of the double-perovskite composite metal oxide catalyst is A2B2O6, wherein A is La, Sr or Ce, and B is Mn, Fe, Co, Cu or Ni. The double-perovskite composite metal oxide catalyst has the advantages that the catalyst is excellent in high temperature resistance, water resistance and chlorine resistance and applicable to effective degradation of CVOCs under an industrial high-temperature environment; the catalyst can achieve complete oxidization of industrial typical CVOCs (1,2-dichloroethane) under reaction temperature of 500-550 DEG C, reaction air speed of 20000-30000h<-1> and oxygen concentration of 10-20%; meanwhile, by regulating the loading capacity of transition metal oxide, the oxidizing efficiency of the catalyst can be increased effectively, and the selectivity of the reaction product CO2 can be increased greatly. The preparation method of the catalyst is simple, cheap in raw material and promising in industrial application prospect.

Owner:XI AN JIAOTONG UNIV

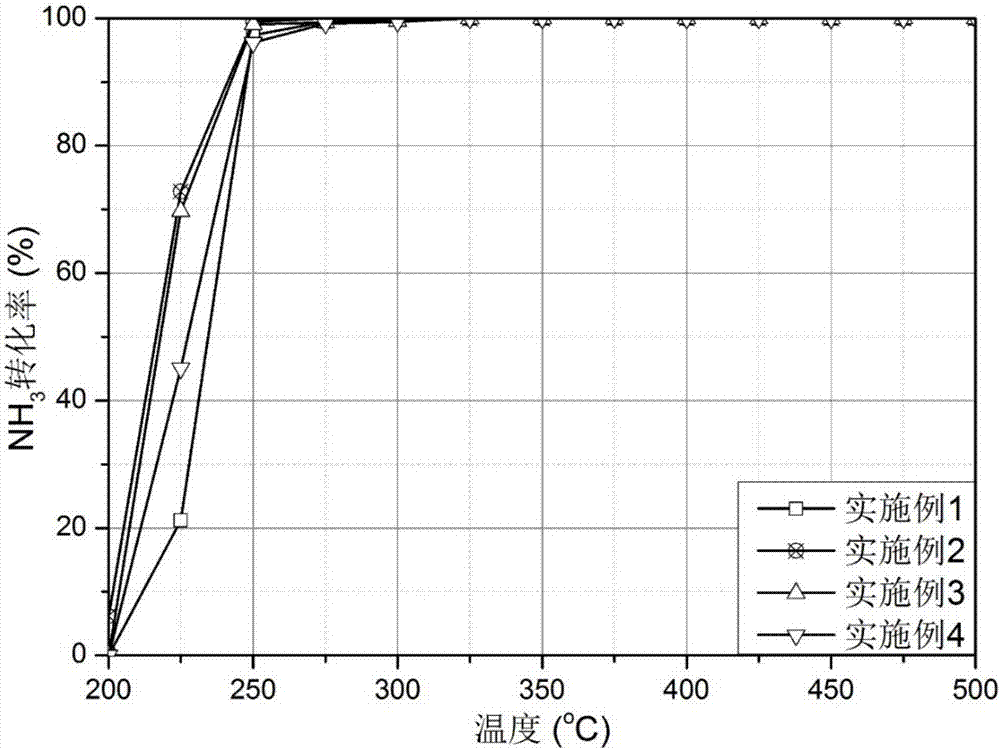

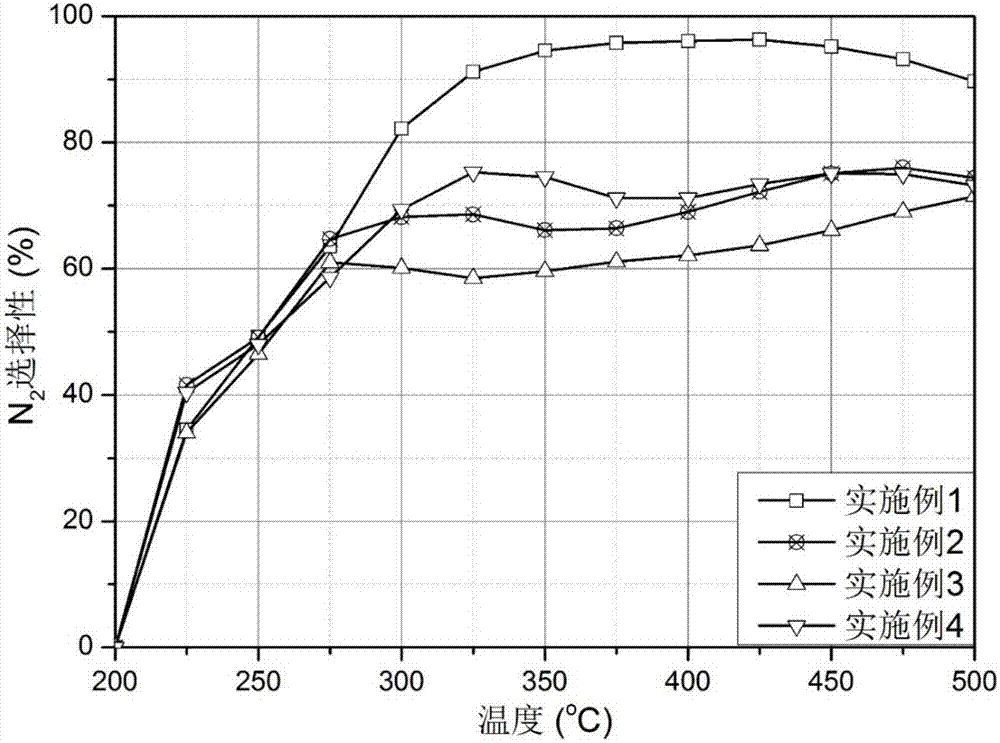

Ammoxidation catalyst for diesel engine exhaust gas purification system and preparation method thereof

InactiveCN106902864AEasy to prepareSteps are easy to followGas treatmentMolecular sieve catalystsExhaust gasComposite oxide

The invention relates to an ammoxidation catalyst and a preparation method thereof, and belongs to the technical field of catalyst preparation. The catalyst comprises a carrier and a coating for coating the carrier. Precious metal platinum is loaded in the coating and the loading capacity of platinum is 0.01 to 1 g / L. The coating comprises composite oxides and molecular sieves. The composite oxides account for 60 to 99% of the quality of the coating. The molecular sieves account for 1 to 40% of the quality of the coating. The coated weight of the coating is 80 to 150 g / L. The preparation method is simple and the steps are easy to operate. The catalyst obtained through preparation is used for downstream usage of SCR method and is capable of effectively reducing the escape of ammonia.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

Method and device for strengthened ozone treatment of nitrobenzene waste water in high gravity filed

InactiveCN104710053AIncrease update rateSpeed up entryMultistage water/sewage treatmentOrganic matter mineralizationElectrolysis

The invention aims to provide a method and device for strengthened ozone treatment of nitrobenzene waste water in a high gravity filed, belongs to the field of nitrobenzene organic waste water treatment, and solves the problem of low ozone utilization ratio of a conventional rotating packed bed in the ozonation technology application. The method comprises the following steps: exhaust gas generated by ozonidation-oxidation reaction in the rotating packed bed and waste water are introduced into a hypergravity-electrolysis unit reactor, ozone and oxygen in the exhaust gas in the hypergravity-electrolysis unit reactor are reduced into hydrogen peroxide through electrocatalytical reduction; the generated hydrogen peroxide, along with the waste water, enters the rotating packed bed again in a circulation manner to be subjected to ozonidation-oxidation reaction; ozone is catalyzed to generate hydroxyl free radicals due to the fact that the content of the generated hydrogen peroxide is in the ozone decomposition acceleration concentration range, therefore organic matters in the waste water are decomposed through mineralization; the problem of exhaust gas treatment is solved, the recycle of the exhaust gas resources can be realized, the ozone can be catalyzed, the oxydative degradation efficiency is improved, when the method is compared with a process with a treatment process without hypergravity electrolysis stage, the oxidation efficiency is improved by 50%, the water treatment cost is reduced by 30%.

Owner:ZHONGBEI UNIV

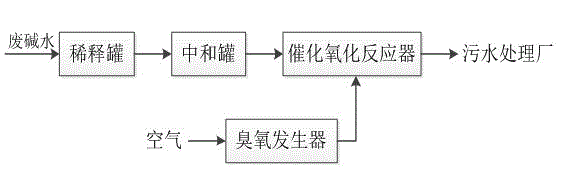

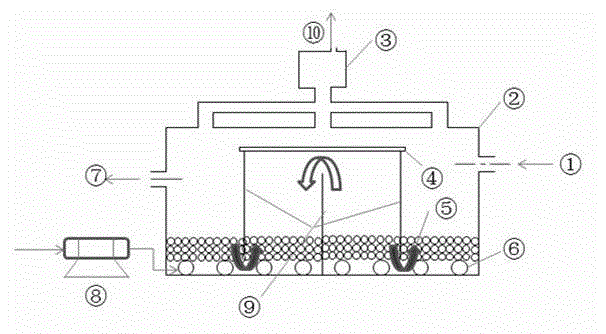

Method for degrading waste alkaline residues through ozone-light wave catalytic oxidation

InactiveCN104692569AEasy to degradeGuaranteed uptimeMultistage water/sewage treatmentAlkaline waterCatalytic oxidation

The invention aims to provide a method for treating waste alkaline residues of a refinery plant. The method includes the steps that waste alkaline water of the refinery plant is delivered into a dilution tank and diluted with water according to the ratio of 7-15:1, the diluted waste alkaline water is delivered into a neutralization tank, the pH value is adjusted to 7-9 with a neutralization agent, then the waste alkaline water is delivered into an ozone-light wave catalytic oxidation reactor which is provided with a solid catalyst and an ultraviolet light generator inside, ozone is led into the ozone-light wave catalytic oxidation reactor, the waste alkaline water makes even and full contact with the ozone, the catalyst and ultraviolet light with catalytic oxidation reaction generated, foam generated in the reaction is led into a demister at the top of the ozone-light wave catalytic oxidation reactor, the demister performs foam killing, waste gas generated in the reaction is led into an incinerator through an exhaust pipe at the top of the demister, and the waste alkaline water treated through ozone-light wave catalytic oxidation is delivered into a waste water treatment plant to be further treated. By treating the waste alkaline residues through the method, the removal rate of various components of the waste alkaline residues is high, and the difficulty of further treatment of the waste water is greatly lowered.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com