Preparation method of industrial aminated graphene

A technology of aminated graphene and graphene powder, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problem that surface groups cannot be fully utilized, the amount of various groups on the surface cannot be determined, and graphene sheets cannot be fully utilized. The problem of large damage to the layer is achieved, and the effect of reducing oxygen content, high nitrogen content and high interfacial bonding force is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

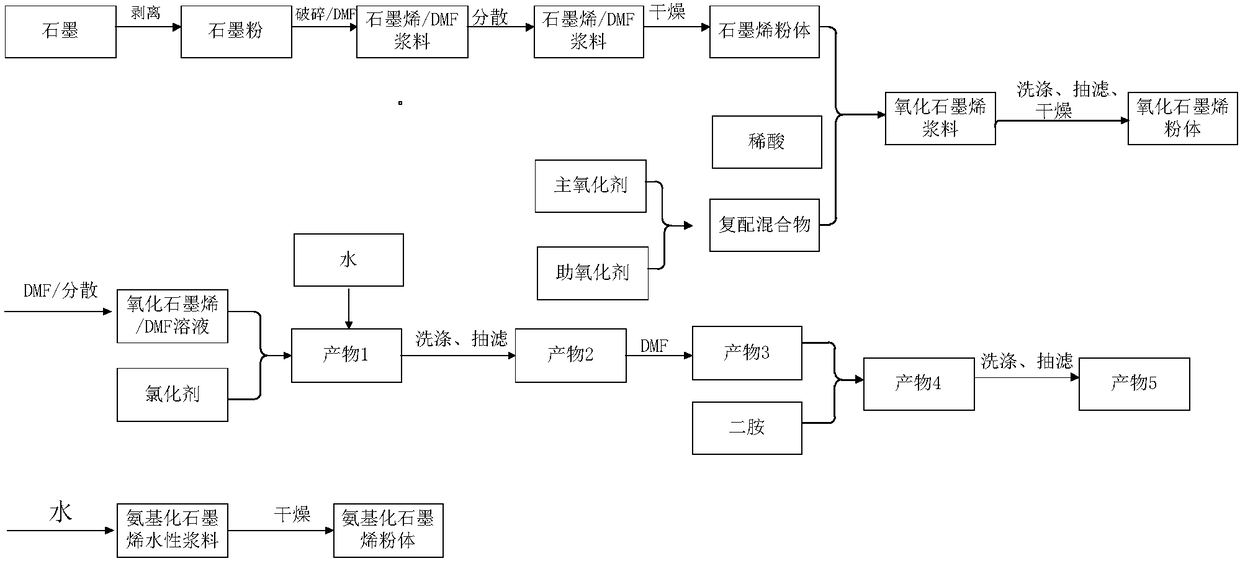

[0035] Such as figure 1 The method for preparing industrial aminated graphene according to the present invention adopts the following steps:

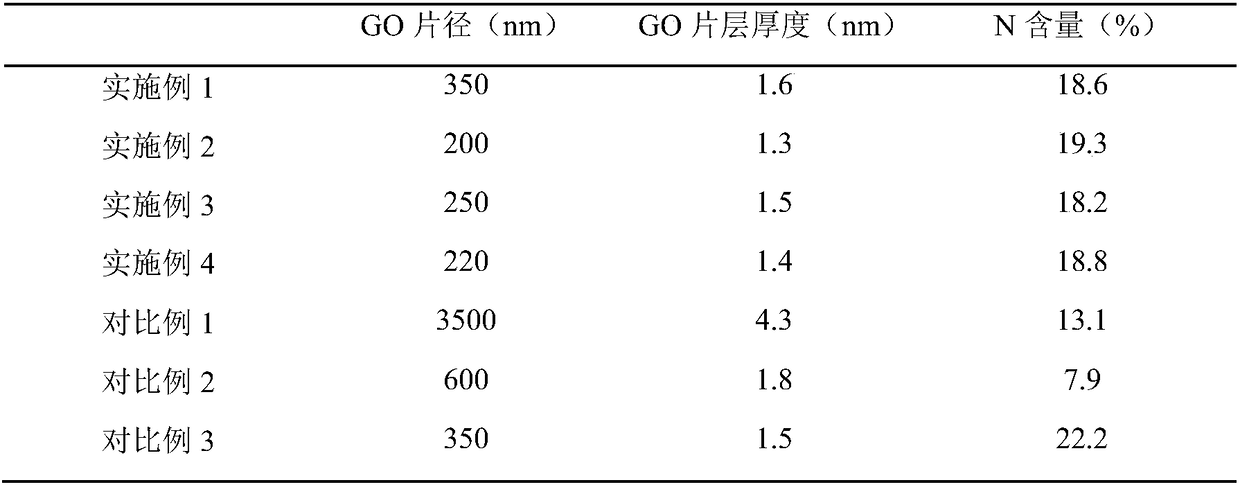

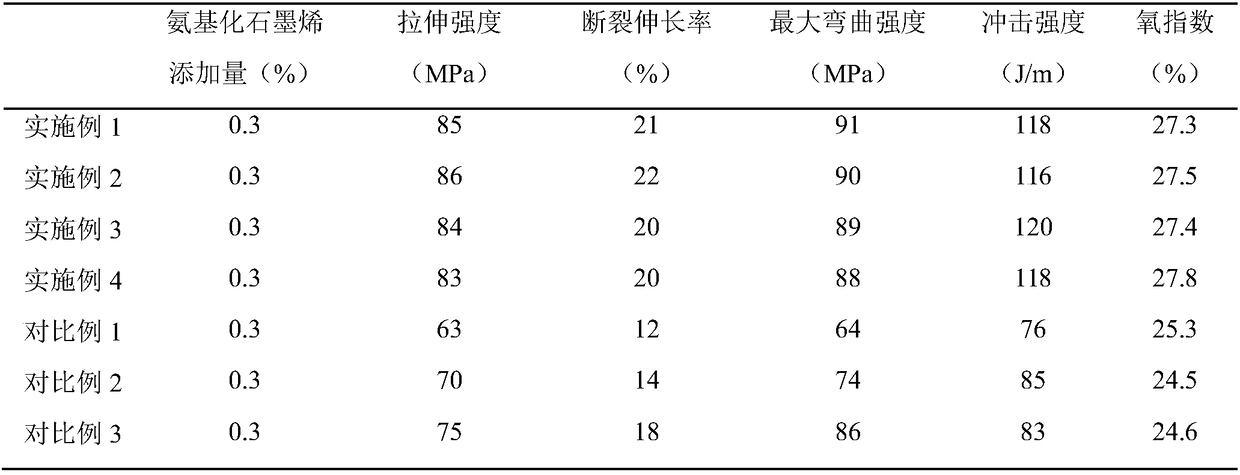

[0036] Step 1. Strip 100kg of graphite powder by supercritical carbon dioxide method, add 500kg of water to the obtained graphite powder, and crush the resulting slurry through a homogenizer. The pressure of the homogenizer is 80MPa. After the crushing is completed, ultrasonic and shearing , The emulsified compound dispersion method is used for processing. After the dispersion is completed, it is dried. The drying temperature is 150℃. Add the dried product to 100kg dilute hydrochloric acid for soaking at -10℃, and then add potassium permanganate and hydrogen peroxide compound after 4h. The mass of potassium permanganate is 10kg, the mass of hydrogen peroxide is 10kg, the temperature is controlled at 10℃, 400kg of deionized water is added after 2h reaction, suction filtration, washing, and finally drying to obtain graphene oxide powder, the...

Embodiment 2

[0044] The method for preparing industrial aminated graphene in Example 2 adopts the following steps:

[0045] Step 1. Exfoliate 100kg of vermicular graphite with supercritical carbon dioxide, add 500kg of water to the obtained graphite powder, and crush the resulting slurry through a homogenizer. The pressure of the homogenizer is 150MPa. After the crushing is completed, ultrasonic, shear, The emulsified compound dispersion method is used for processing. After the dispersion is completed, air-flow spray drying is used for drying. The drying temperature is 230 ℃, and the dried product is added to 300 kg of dilute sulfuric acid for soaking at 20 ℃. After 0.5h, potassium perchlorate and benzene peroxide are added. The compound mixture of formyl, in which potassium perchlorate is 100kg, the mass of benzoyl peroxide is 1kg, the temperature is controlled at 90℃, 400kg of deionized water is added after 6 hours of reaction, filtered, washed, and finally obtained by airflow spray drying ...

Embodiment 3

[0051] The method for preparing industrial aminated graphene in Example 3 adopts the following steps:

[0052] Step 1. Strip 100kg of flake graphite through supercritical carbon dioxide, add 500kg of water to the obtained graphite powder, and crush the resulting slurry through a homogenizer. The pressure of the homogenizer is 110MPa. After the crushing is completed, ultrasonic, shear, The emulsified compound dispersion method is used for processing. After the dispersion is completed, it is dried by airflow spray drying. The drying temperature is 170 ℃, and the dried product is added to 120 kg of dilute nitric acid for soaking at -1 ℃. After 1.5 hours, potassium dichromate and potassium dichromate are added. The compound mixture of hydrogen peroxide, 40kg potassium dichromate, 9kg hydrogen peroxide, control the temperature at 55℃, add 300kg deionized water after 3 hours of reaction, suction filter, wash, and finally obtain graphene oxide powder by airflow spray drying , Drying tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com