Patents

Literature

453 results about "Potassium perchlorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium perchlorate is the inorganic salt with the chemical formula KClO₄. Like other perchlorates, this salt is a strong oxidizer although it usually reacts very slowly with organic substances. This, usually obtained as a colorless, crystalline solid, is a common oxidizer used in fireworks, ammunition percussion caps, explosive primers, and is used variously in propellants, flash compositions, stars, and sparklers. It has been used as a solid rocket propellant, although in that application it has mostly been replaced by the higher performance ammonium perchlorate. KClO₄ has the lowest solubility of the alkali metal perchlorates (1.5 g in 100 mL of water at 25 °C).

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1386554AAvoid corrosionWon't happenFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, alot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Fire-extinguishing aerosol without toxicity and corrosion for electric appliance

InactiveCN1150952CStrong fire extinguishing functionRealize total flooding fire extinguishingFire extinguisherHazardous substancePotassium ferrocyanide

A fire-extinguishing aerosol not generating harmful substance for electric equipment (computer, communication equipment, electric generator, etc) is prepared from oxidant (strontium nitrate or strontium nitrate / potassium nitrate), reducer (guanidine nitrate or dicyandiamide) and modifier (potassium ferrocyanide, aluminium powder, carbon powder and phenolic resin). After it is ignited by sensor, a lot of fire-extinguishing particles are generated to cover on the object to be protected while the inert gas is generated for extinguishing fire.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Electrolyte

InactiveCN102185156AThe group ratio is reasonableReasonable ratioSecondary cellsHigh energyMethyl carbonate

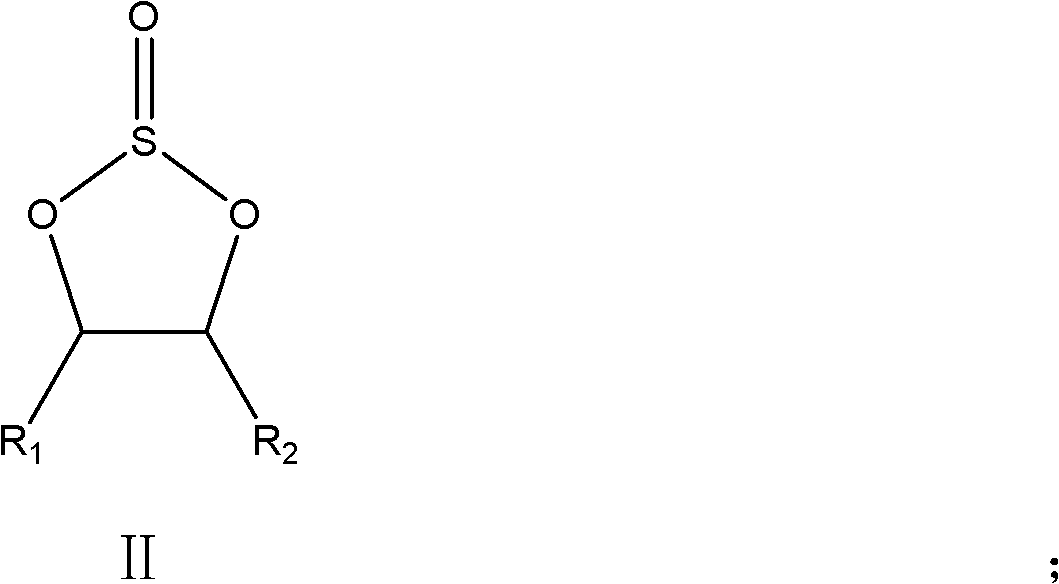

The invention relates to electrolyte, belonging to the technical field of material chemistry and high energy batteries. The electrolyte consists of an organic solvent, an additive and lithium salt, wherein the organic solvent is one or a mixture of ethylene carbonate, ethyl methyl carbonate, methyl-carbonate or diethyl carbonate; the additive is sulfurous ester; and the lithium salt is selected from lithium perchlorate, lithium hexafluorophosphate, lithium tetrafluoroborate, perfluoroalkyl lithium sulfonate, perfluoroalkyl sulfoacid imide lithium, annular perfluoroalkyl di(sulfonyl)lithium imide, perfluoroalkyl acyl sulfonate lithium methide, organic boric acid ester lithium, organic lithium phosphate or organic aluminic acid ester lithium. Due to the adoption of the electrolyte, a layer of stable solid electrolyte phase boundary face film can be formed on the surface of a graphite electrode, the compatibility between the electrolyte and an electrode material is improved, the temperature suitability of the electrolyte material is expanded through proportion optimization, and the cycle performance, rate capability and temperature suitability of a lithium secondary battery using the electrolyte can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Fire suppressing gas generator composition

InactiveUS20020137875A1Increase volumeReduce the temperatureOther chemical processesFire extinguisherElastomerParticulates

A fire suppressing gas generator composition which has a low burn temperature which provides an adjustable mass flow rate, which provides high inert gas yields upon combustion, which generates flame suppressing gasses during composition, which provides exhaust gas with low particulate content, and which is suitable for use in pellet form. The gas generator composition of the invention generally comprises a high nitrogen content solid, preferably 5-amino tetrazole, and potassium perchlorate or other oxidizer salt in an amount sufficient to allow flameless deflagration of the high nitrogen contant solid. The composition of the invention also preferably comprises a flame inhibitor precursor such as perbrominated aromatic compound, an elastomeric binder, a powder pressing modifier or enhancer such as mica, and an electrostatic charge suppressant such as graphite.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

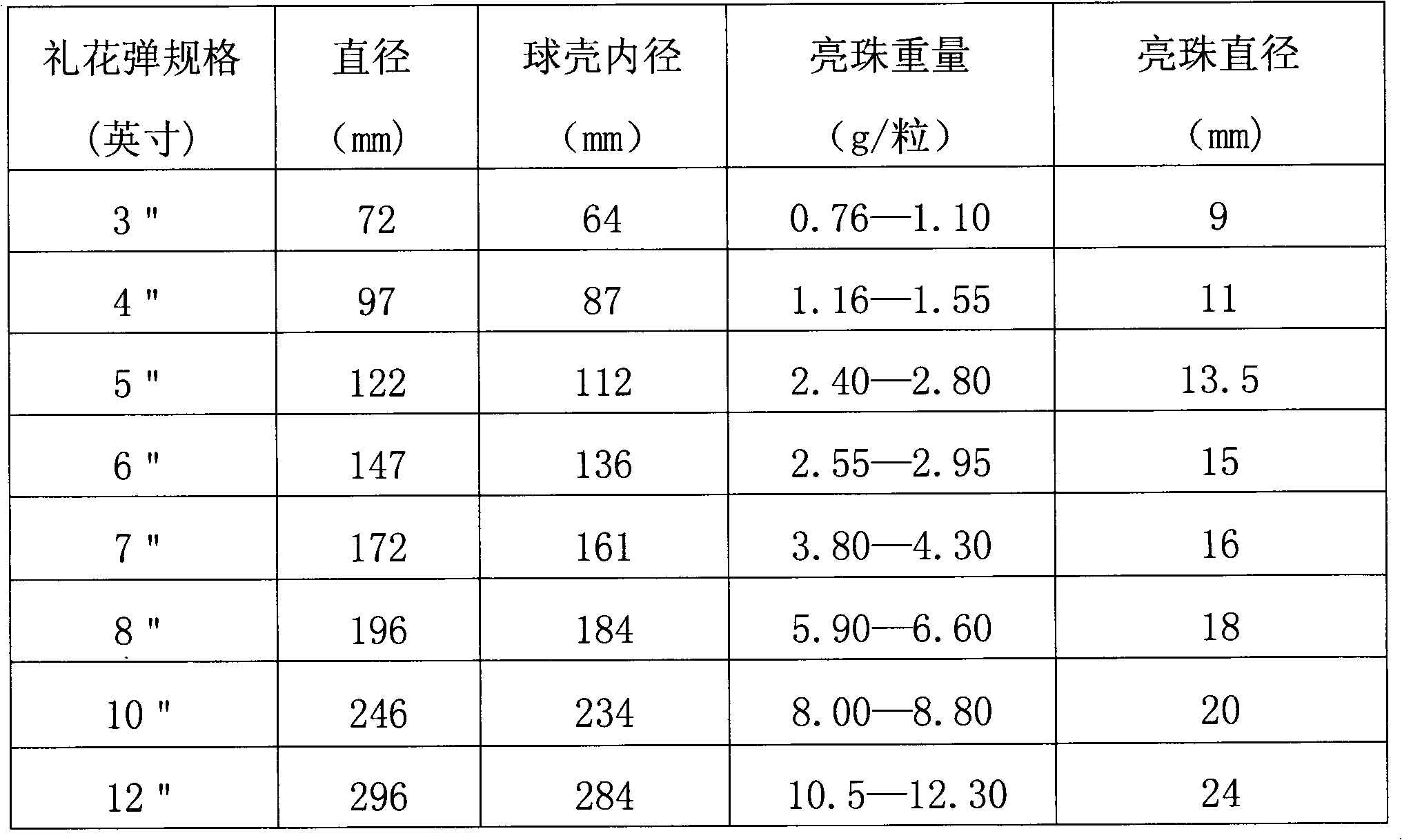

Sparkle beads producing cardamon green firework effect, and manufacturing method thereof

The invention relates to firework effect sparkle beads and a manufacturing method thereof, and specifically relates to sparkle beads producing a cardamon green firework effect, and a manufacturing method thereof. The sparkle beads comprises main components of, by weight: 50-60 parts of barium nitrate, 6-8 parts of phenolic resin, 18-22 parts of aluminum-magnesium alloy, 6-8 parts of polrvinyl chloride, 13-17 parts of potassium perchlorate, and 1-3 parts of cryolite. The manufacturing method of the sparkle beads comprises the steps of: agent weighing; raw material crushing; mixing and stirring; molding; drying; and packaging. With the sparkle beads provided by the invention, a novel firework color variety is provided. A light duration is 3.5 seconds, and a sparkle bead combustion residue rate is lower than 0.3%.

Owner:浏阳市五环烟花厂

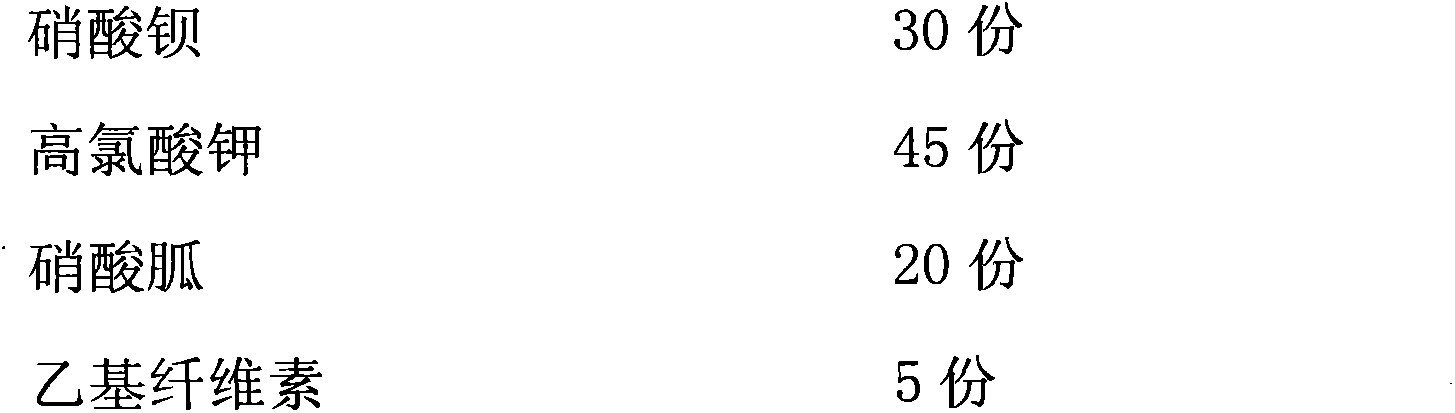

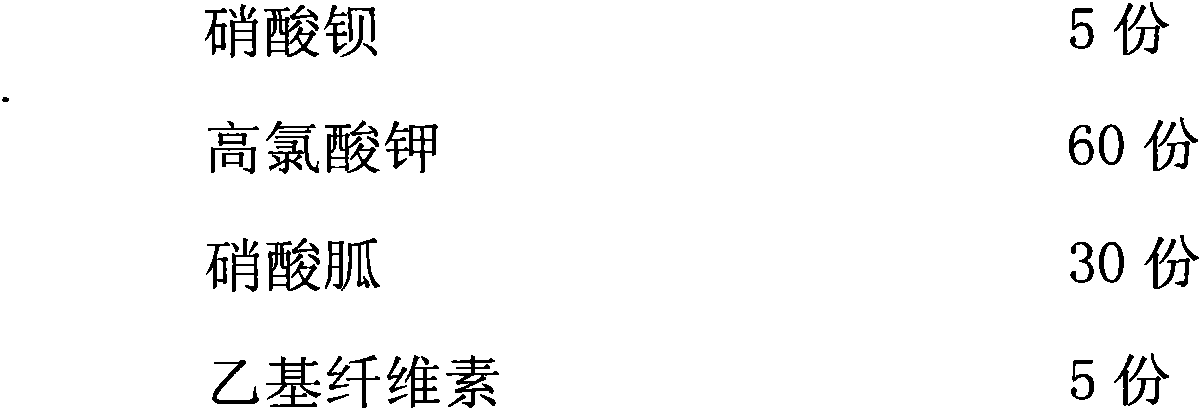

Sulfur-free ring stabilizing agent propellant powder

The invention discloses sulfur-free ring stabilizing agent propellant powder which consists of the following components in parts by weight: 70 parts of an oxidant, 34 parts of a burnable agent, 6 parts of an adhesive, 2 parts of a stabilizing agent, 2 parts of an anti-aging agent, 1 part of a catalyst and 2 parts of an antismoke agent which are uniformly mixed according to a general method, wherein the oxidant is a mixture consisting of potassium perchlorate, amine perchlorate and barium nitrate; the burnable agent is a mixture consisting of potassium hydrogen terephthalate, potassium acid phthalate, nitrocellulose, purified terephthalic acid and hemp stem carbon powder; the stabilizing agent adopts calcium stearate; the anti-aging agent adopts calcium phthalate; the catalyst adopts copper oxide; the antismoke agent adopts aluminum hydroxide; the adhesive is selected from one or a mixture of multiple of phenolic resin, strong adhesive powder, glutinous rice flour and polyvinyl alcohol according to any ratio. The sulfur-free ring stabilizing agent propellant powder is high in power capability and excellent in safety performance indexes and has excellent storage stability, and the environment-friendly performance is greatly improved.

Owner:HUNAN FEIYU NEW MATERIAL CO LTD

Mixing fireworks and producing method thereof

A mixed 'firecracker-fireworks' having the effects of firecracker and fireworks and generating 5 colors is prepared from potassium perchlorate, Mg-Al alloy powder, strontium carbonate, phenolic resin, polyvinyl chloride, strontium nitrate, sulfur, glutinous rice flour, etc. Its advantages are simple preparing process, dual effect, multiple color and long perdurability.

Owner:黄远清 +1

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

Environment protection coal-saving agent for cement vertical kiln

The invention provides an environmental-friendly coal-saving agent for a cement shaft kiln, comprising the following raw materials by weight portion: 3-7 portions of a coal combusting low-temperature modifying agent, 2-6 portions of a compound sulphur-fixing agent, 0.5-0.96 portion of a combusting inductive agent, 3-7 portions of a raising agent, 56-96 portions of a combusting poising agent, and 5-15 portions of a highly-efficient sulphur-fixing agent. The coal combusting low-temperature modifying agent can be potassium permanganate, potassium chlorate, potassium perchlorate, sodium chlorate, sodium nitrate and the like; the compound sulphur-fixing agent can be sodium carbonate, calcium oxide and the like; the raising agent can be waste liquor of paper mill containing Na or / and Ca sulphonate and the like; and the combusting poising agent can be a chemical waste reducing substance containing sodium chloride and the like. The method solves the problems of environmental pollution and resource waste in the prior art, uses compatibility of multiple chemical raw material of 6-10 percent and chemical waste to prepare the coal-saving agent with small dosage and fast effect to be added to the production of the cement shaft kiln in trace quantity, and has the advantages of resource conservation by using waste, coal conservation and consumption reduction, and reduction of dust and SO2 discharge and environmental pollution.

Owner:陶小勇

Sulfur-free and pearlite-free firecracker reagent and preparation method thereof

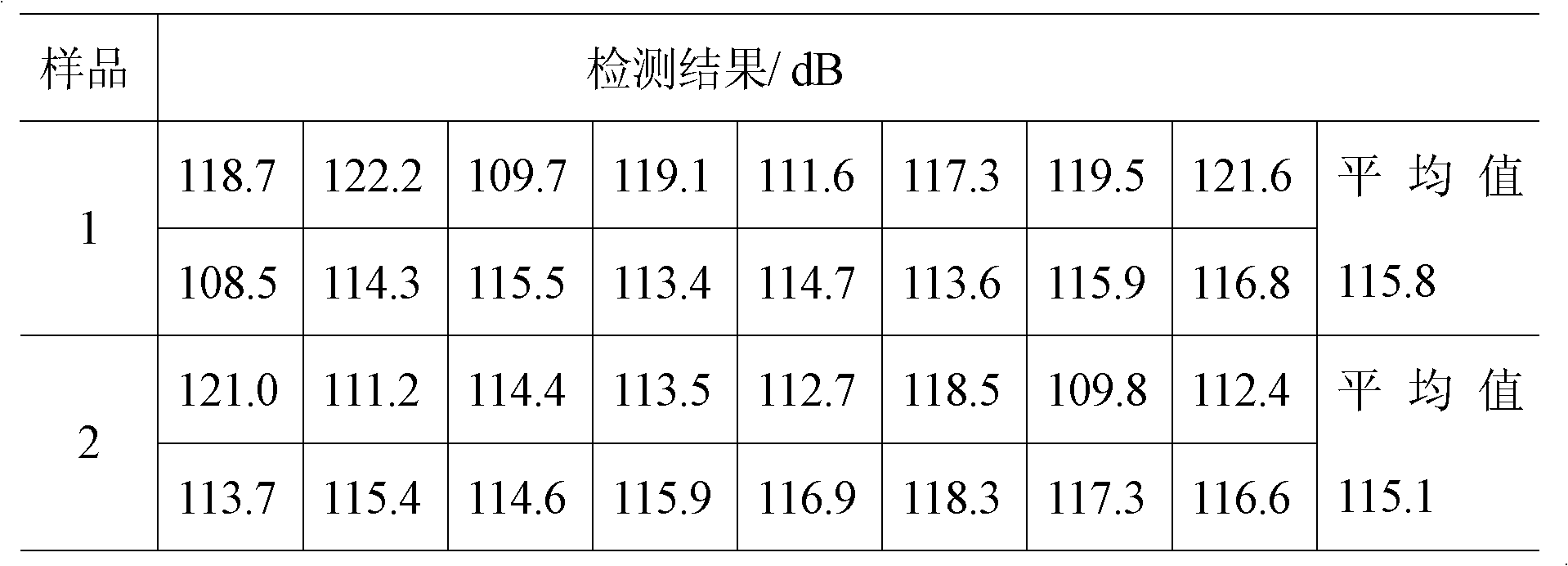

The invention discloses a sulfur-free and pearlite-free firecracker reagent and a preparation method thereof. The reagent comprises the following mass components: 35-65 percent of A component and 35-65 percent of B component, wherein the A component comprises the mass compositions: a mixture formed by 20-50 percent of potassium perchlorate, 0-30 percent of potassium nitrate and 30-50 percent of barium nitrate and a complexing agent occupying 1-5 percent of the mixture, and the B component comprises the mass compositions: 50-80 percent of aluminum powder, 10-25 percent of charcoal powder and 10-25 percent of organic foaming powder. The burning rate of a firecracker prepared from the reagent is more than 98 percent, the sound level value is no less than 100dB and is no more than 140dB, the time the gas product pressure rises from 0.69MPa to 2.07MPa is 1.74ms, a pH value of the pyrotechnic composition is 5-9, the moisture is no more than 1.5 percent, the hygroscopicity is no more than 2.0 percent, the thermal stability is 75 DEG C plus / minus 2 DEG C, the firecracker has no decomposition phenomenon under the condition of 48h, the friction sensitivity is no more than 40 percent, and the impact sensitivity of the pyrotechnic composition is no more than 0 percent. The key is that the reagent reduces the environmental pollution without harm to human bodies and has great application prospect.

Owner:HUNAN VOCATIONAL INST OF SAFETY TECH +1

Novel preparation method of netaglinide oxazolone

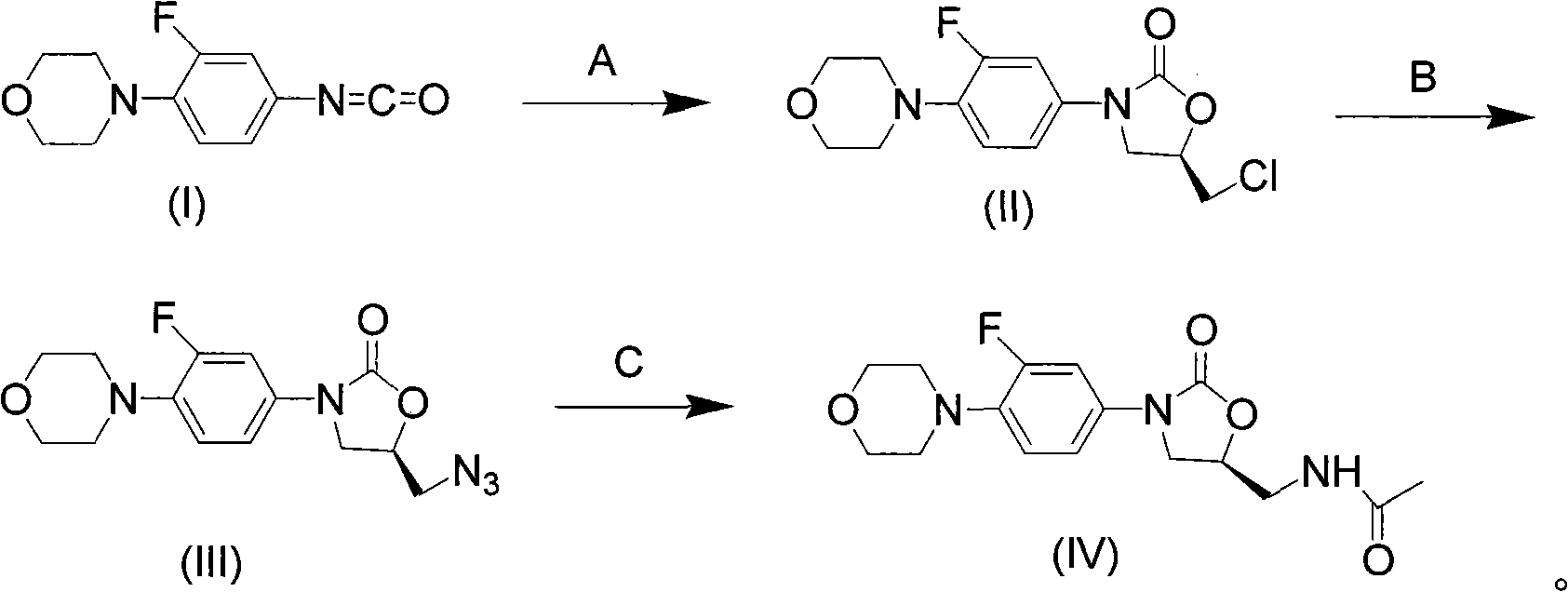

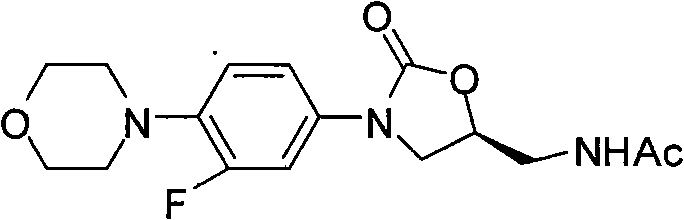

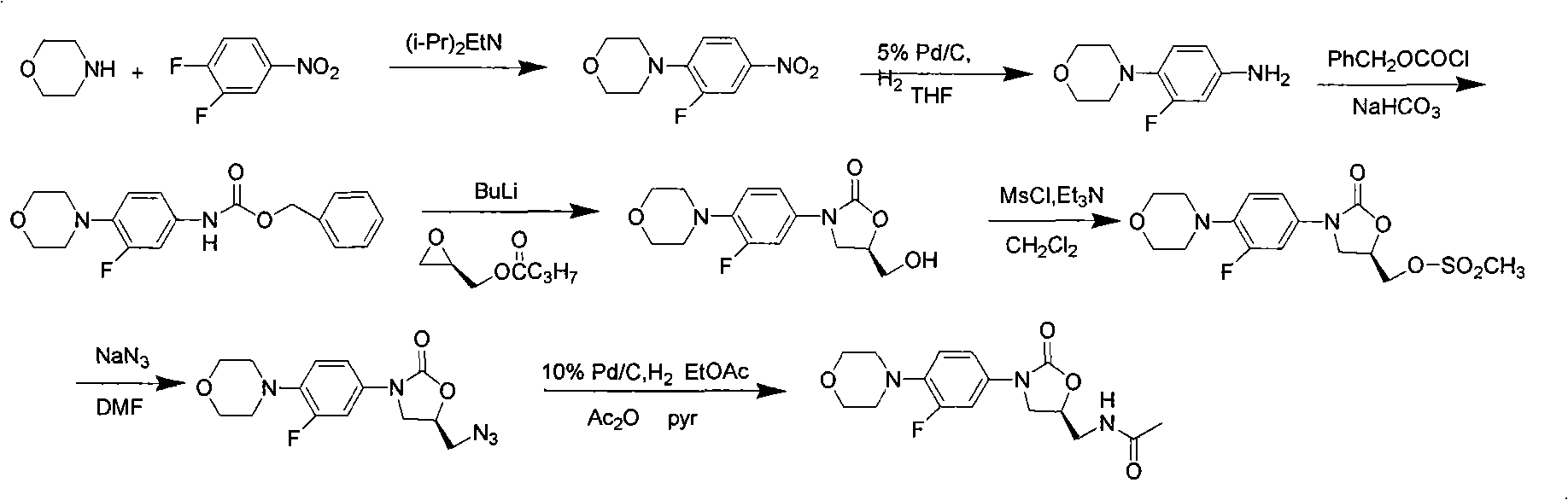

InactiveCN101638392AAtom utilization is highHigh stereoselectivityAntibacterial agentsOrganic chemistryEpoxyMorpholine

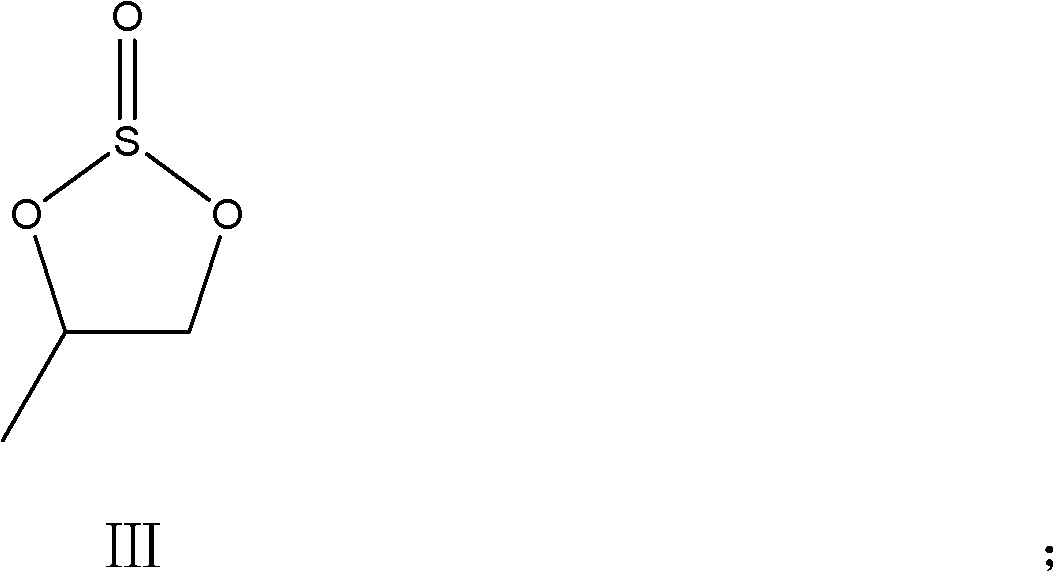

The invention discloses a novel preparation method of netaglinide oxazolone shown in the formula (IV), which comprises the following steps: under the action of a catalyst A, enabling 3-fluorine-4-morpholine phenyl isocyanate shown in the formula (I) to react with (R)-epoxy chloropropane to obtain a compound (II), wherein the catalyst A is magnesium diiodide, magnesium dibromide, magnesium dichloride, magnesium perchlorate or magnesium trifluoromethanesulfonic acid; enabling the compound (II) to react with sodium azide to obtain a compound (III); reducing the compound (III) by hydrogenation, and then, acetylating the reduced compound (III) to obtain the compound (IV). In the invention, the low-cost and environment-friendly catalyst (Lewis acid magnesium) is used for catalyzing the cycloaddition reaction of the (R)-epoxy compound and the isocyanate to establish a mother nucleus structure of the netaglinide oxazolone by one step, thus the prepared netaglinide oxazolone has high stereoselectivity, does not need rigorous operation conditions, such as low temperature, no water, no oxygen and the like, has the advantages of moderate reaction conditions, simple and convenient operation, high utilization ratio of atoms, environment protection, low production cost and the like, and is suitable for industrialized production.

Owner:ZHEJIANG UNIV OF TECH

High efficiency biomass fuel and preparation method thereof

InactiveCN105238480ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsDry weightAdhesive

The invention discloses a high efficiency biomass fuel and a preparation method thereof. The high efficiency biomass fuel comprises the following components by dry weight: 60-80 parts of agricultural and forestry waste, 5-15 parts of sludge, 25-35 parts of organosilicon waste, 1-15 parts of an adhesive, and 5-15 parts of a combustion supporting agent. The combustion supporting agent comprises the following components by weight: 80-100 parts of attapulgite clay, 10-20 parts of dolomite powder, 5-10 parts of heavy calcium carbonate powder, 1-8 parts of carbonyl diamine, 5-15 parts of potassium perchlorate, 2-8 parts of manganese oxide, 6-12 parts of potassium permanganate, and 1-8 parts of carboxymethyl cellulose. The biomass fuel has a high combustion temperature up to 1350-1400DEG C and combustion efficiency enhanced by about 32% compared to ordinary biomass fuels; the calorific value can reach 5100-5300kcal / kg, and per ton of biomass fuel is equivalent to 0.75 ton of standard coal; the combustion tail gas is accord with relevant provisions of the state, also the sulfur removal rate can reach 97.4%, and the nitrate removal rate is up to 93.2%.

Owner:DONGZHI COUNTY XINGNONG MUSHROOM PROCESSING

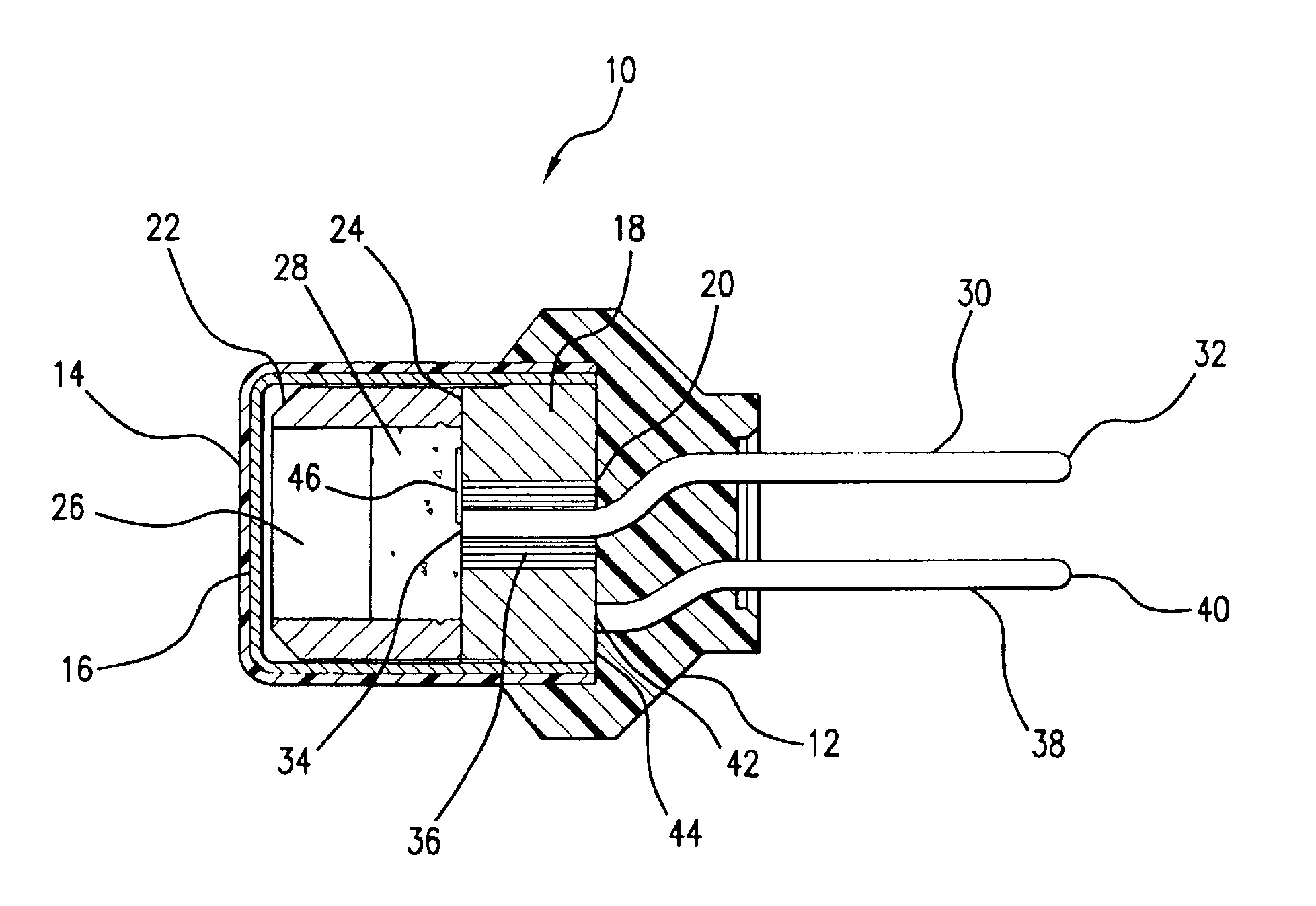

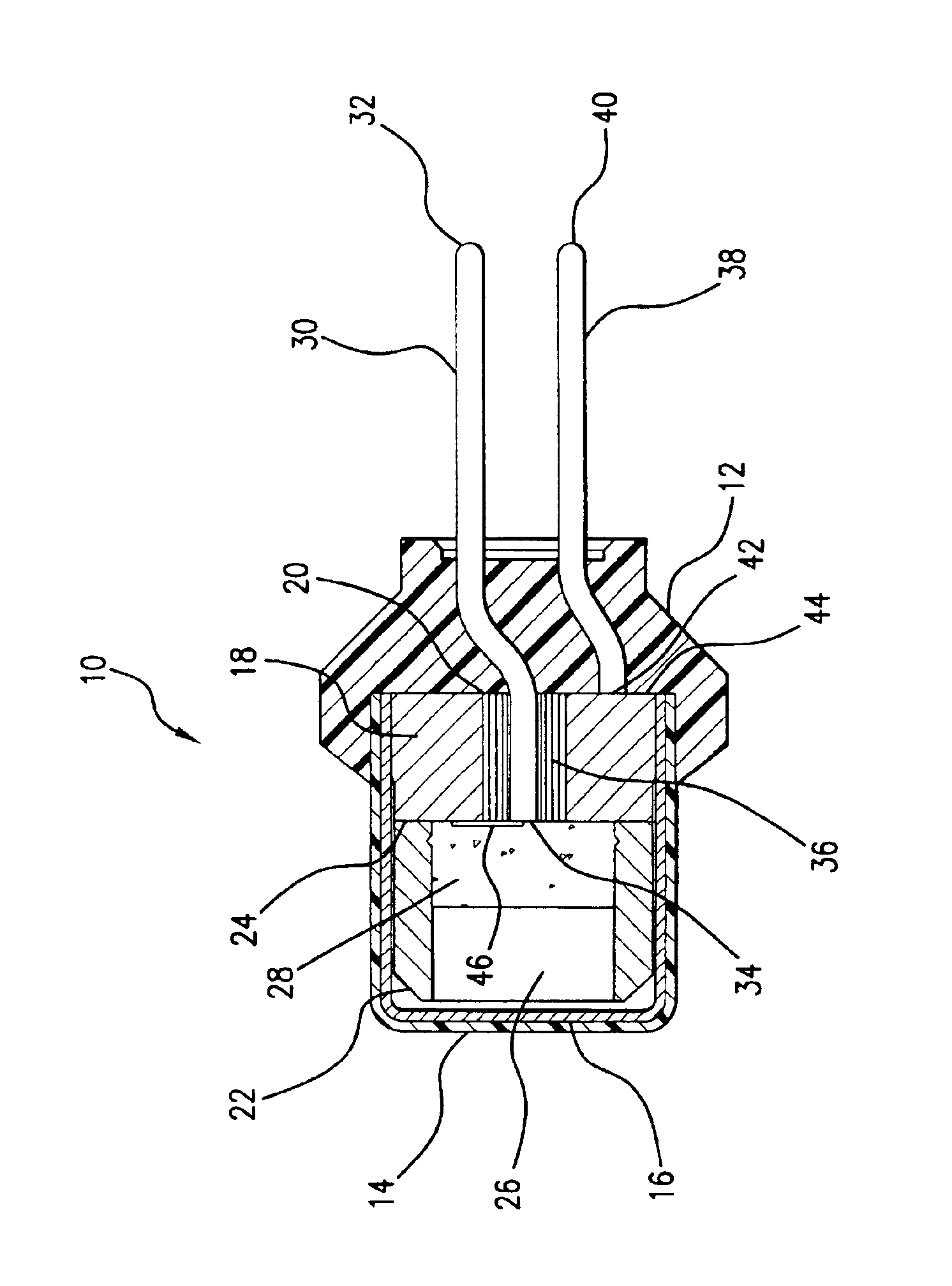

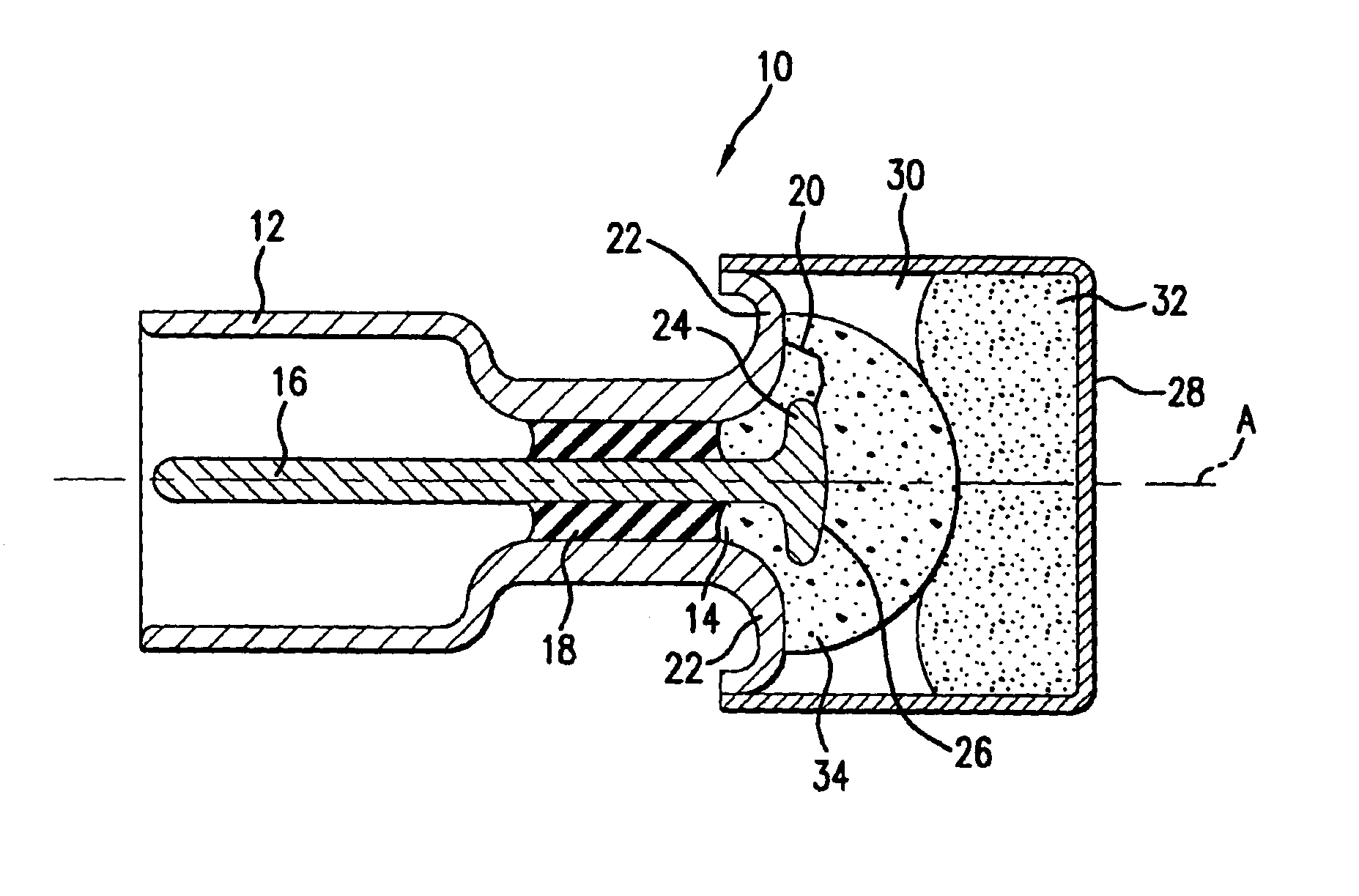

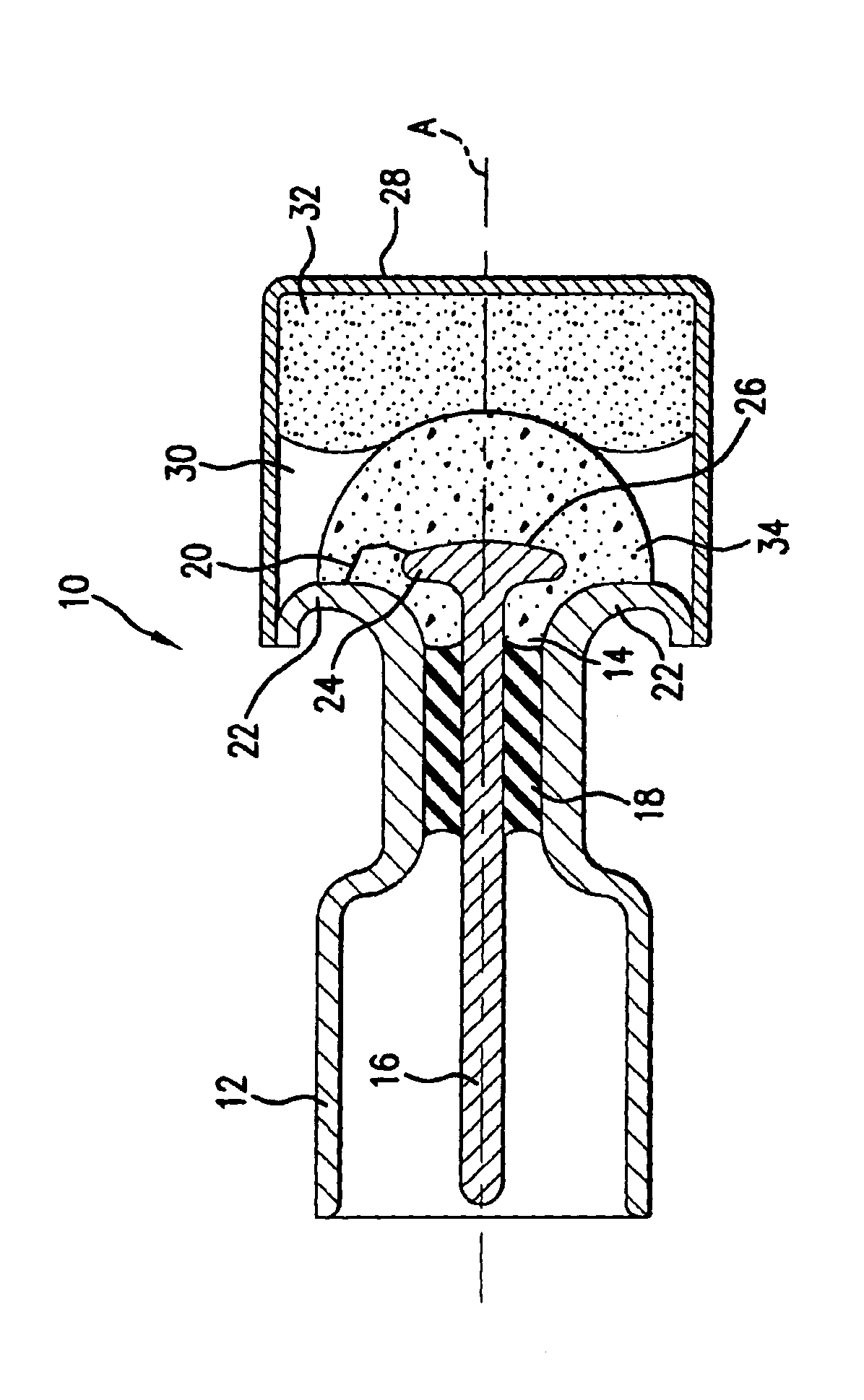

Single increment initiator charge

A single increment initiator charge for use in an inflatable restraint system and a method of preparing the single increment initiator charge are provided. The single increment initiator charge includes a homogeneous blend of zirconium, an oxidizer such as potassium perchlorate, and a combustion enhancer such as titanium hydride in an amount effective to result in the single increment initiator charge being effective to ignite an associated pyrotechnic charge. The single increment initiator charge may be formed by preparing a homogeneous blend such as by dry-blending the constituents or by mixing the constituents with a solvent such as an alcohol to form a slurry, loading the homogeneous blend into a charge holder and compressing the homogeneous blend.

Owner:AUTOLIV ASP INC

Combustion assisting agent with aeration combustion-supporting and coal saving function

The invention offer strong oxygen combustion supporting synergy coal saving combustion adjuvant. Its main technique feature is proportioning the following each preparation by weight part ratio according to coal quality: strong oxidant: potassium permanganate, potassium chlorate, potassium nitrate, hydrogen peroxide, hexamethylene tetramine, potassium perchlorate; strong catalyst: manganese dioxide, magnesia; scale remover: calcium oxide dolomite fines, calcium carbonate; fume clearing agent: sodium carbonate, active magnesia, light magnesium oxide; desulfurizer: alumina, magnesium silicate, barium nitrate; leavening agent: industry using sodium chloride; diatomite: pumice, boric sludge; ferric oxide is very fit for low grade coal. The advantages of the invention are that it can make low grade coal burn fully, increase thermal efficiency, save energy, no pollution; and it can save fund for corporation; it can save 100-250 thousand yuan per ten thousand ton coal; and the coal saving rate can reach 15-25%.

Owner:迟万斌

Non-sulphur firecracker components and preparation thereof

The invention discloses a sulfur-free firecracker medicament and a method for the production thereof, and the medicament constituents are 50 to 70 parts of potassium perchlorate, 20 to 45 parts of aluminum powder, 5 to 20 parts of pearl powder, 10 to 30 parts of modified wood flour, and 0 to 5 parts of a mixture of ferroferric oxide and manganese dioxide or one material thereof. The preparation of the sulfur-free firecracker medicament is mainly characterized in that the wood flour undergoes the imbibitions treatment and the surface treatment by adopting a potassium nitrate and a micro-crystalline wax respectively. The sulfur-free environment-friendly firecracker produced by the sulfur-free firecracker medicament system of the invention has advantages of sonorous sound when setting off the firecracker, high rate of sonority, non discharge of noxious gas of sulfur dioxide, easy obtaining of constituents and materials, rather low cost, not containing prohibited articles such as potassium chlorate and being fully fit to replace the current sulfur-bearing firecracker.

Owner:湖南省浏阳金生花炮有限公司

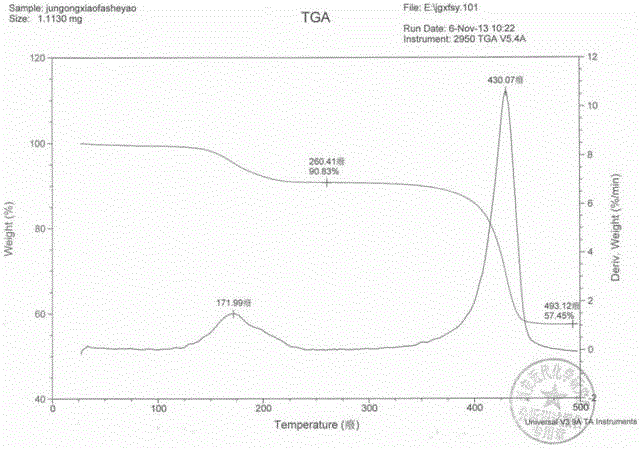

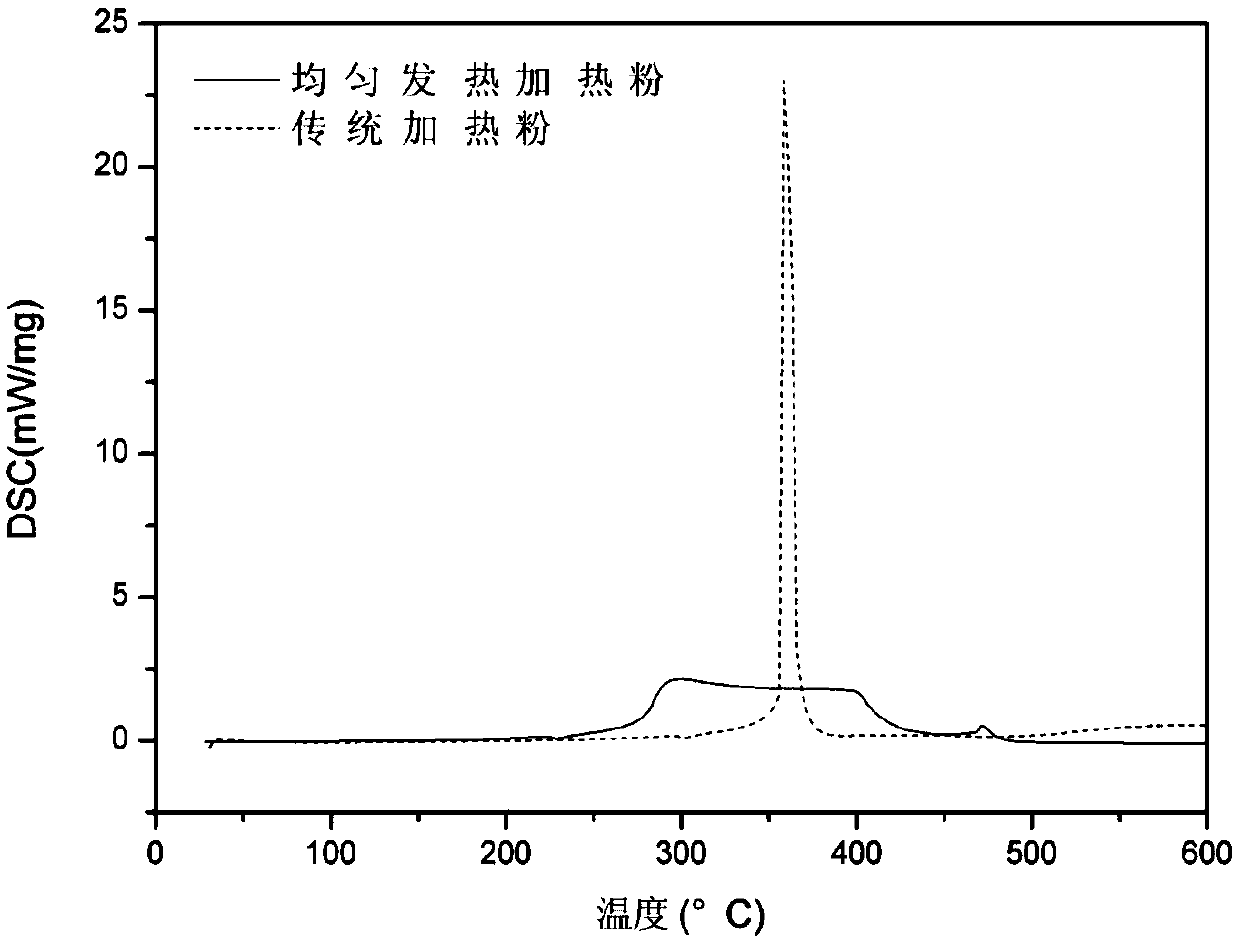

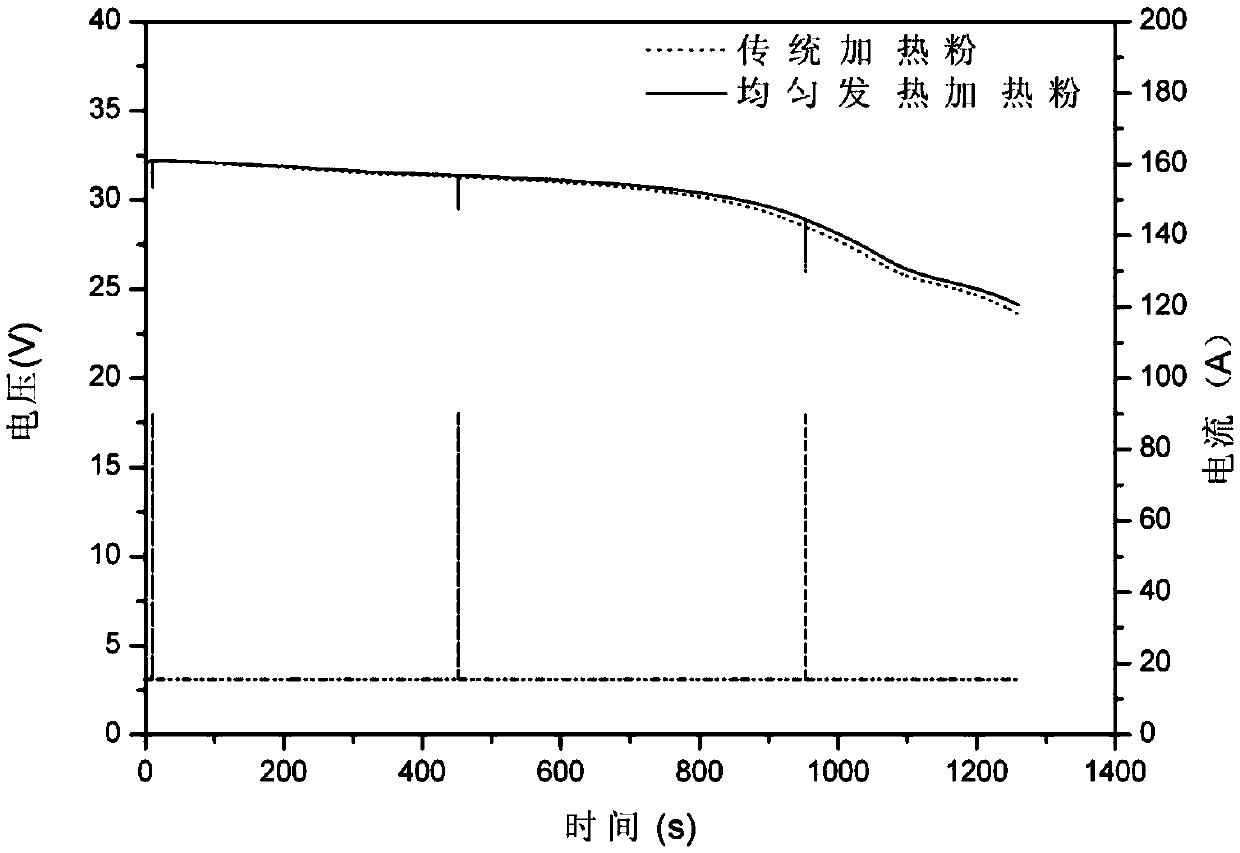

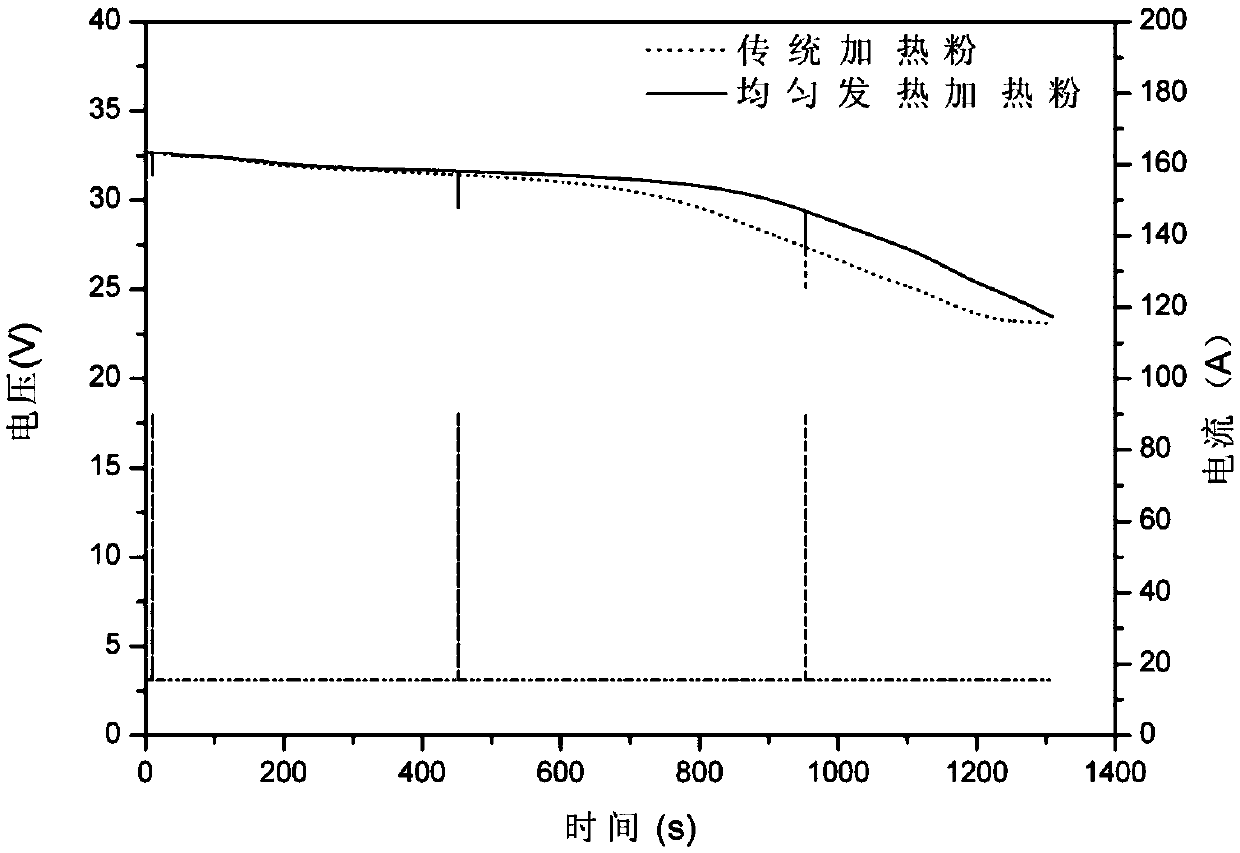

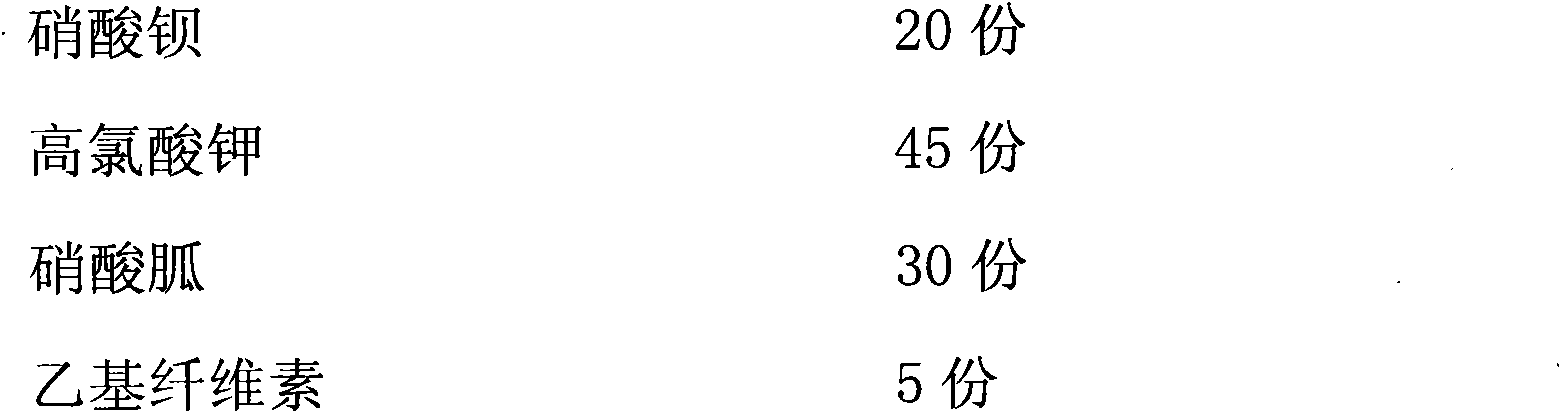

Manufacturing method for heating material uniformly heating used for thermal battery and application thereof

ActiveCN109546173AGood dispersionThe initial redox temperature value advancesDeferred-action cellsPrimary cell maintainance/servicingHigh energyFreeze-drying

The invention relates to a manufacturing method for a heating material uniformly heating used for a thermal battery and application thereof. The method comprises: pouring analytical pure grade potassium perchlorate into a high-energy ball-milling cup, adding appropriate water to prepare a slurry, placing a zirconia ball, performing high-energy ball milling, and then putting ball-milled powders into a freeze dryer to dehydrate, and then crushing using a pulverizer to obtain ultrafine potassium perchlorate, pouring active iron powders into an inert atmosphere glove box, adding an inorganic potassium salt, and then mixing the active iron powders and the inorganic potassium salt using a physical or chemical method, to form potassium-containing iron powders; finally, mixing the ultrafine potassium perchlorate and the potassium-containing iron powders according to a certain ratio. The method is beneficial to widening a heating region of a heating material, to release heat more uniformly, thereby weakening thermal shock amount on a positive electrode material of a thermal battery in an initial working phase of the material, and improving utilization rate of the positive electrode materialof the battery.

Owner:航天江南集团有限公司 +1

Micro smoke ignition agent for fireworks

The invention discloses a micro smoke ignition agent for fireworks, which consists of potassium perchlorate, carbon powder, nitro-cotton and / or nitroguanidine, a high-energy reducing agent and a detonation agent. The invention has the advantages that: an oxidant adopts a high-oxygen content and high-stability substance, so that the using amount can be controlled and smoke can be reduced; combustibles can release a large amount of heat during combustion, so that a high-temperature substance is generated; therefore, the using amount can be controlled and the smoke can be reduced; and main combustibles adopt high-oxygen content substances, so that the using amount of smoke oxidants can be reduced to the greatest extent. Therefore, only micro smoke is generated during combustion of the ignition agent. Due to the detection result of light transmittance, compared with that of the conventional same-class corresponding products, the produced smoke is reduced by 70 percent. Meanwhile, the configuration of the whole medicament system guarantees ignition performance and stability of the ignition agent, and the safety performance meets the requirement of the national standard.

Owner:浏阳市达浒花炮艺术焰火燃放集团有限公司

Low density slurry bridge mix

InactiveUS6905562B2Blasting cartridgesAlkali metal salt explosive compositionsSlurryVolumetric Mass Density

A low density slurry bridge mix for use in an inflatable restraint system is provided. The low density slurry bridge mix includes zirconium metal, a thermal conductivity enhancer such as aluminum metal, potassium perchlorate oxidant, and a binder material and has a dry density of about 45 to about 65 percent of theoretical density. The low density slurry bridge mix may be used in an initiator including an unground header attached to a raised bridgewire wherein the low density slurry bridge mix surrounds and adheres to the bridgewire.

Owner:AUTOLIV ASP INC

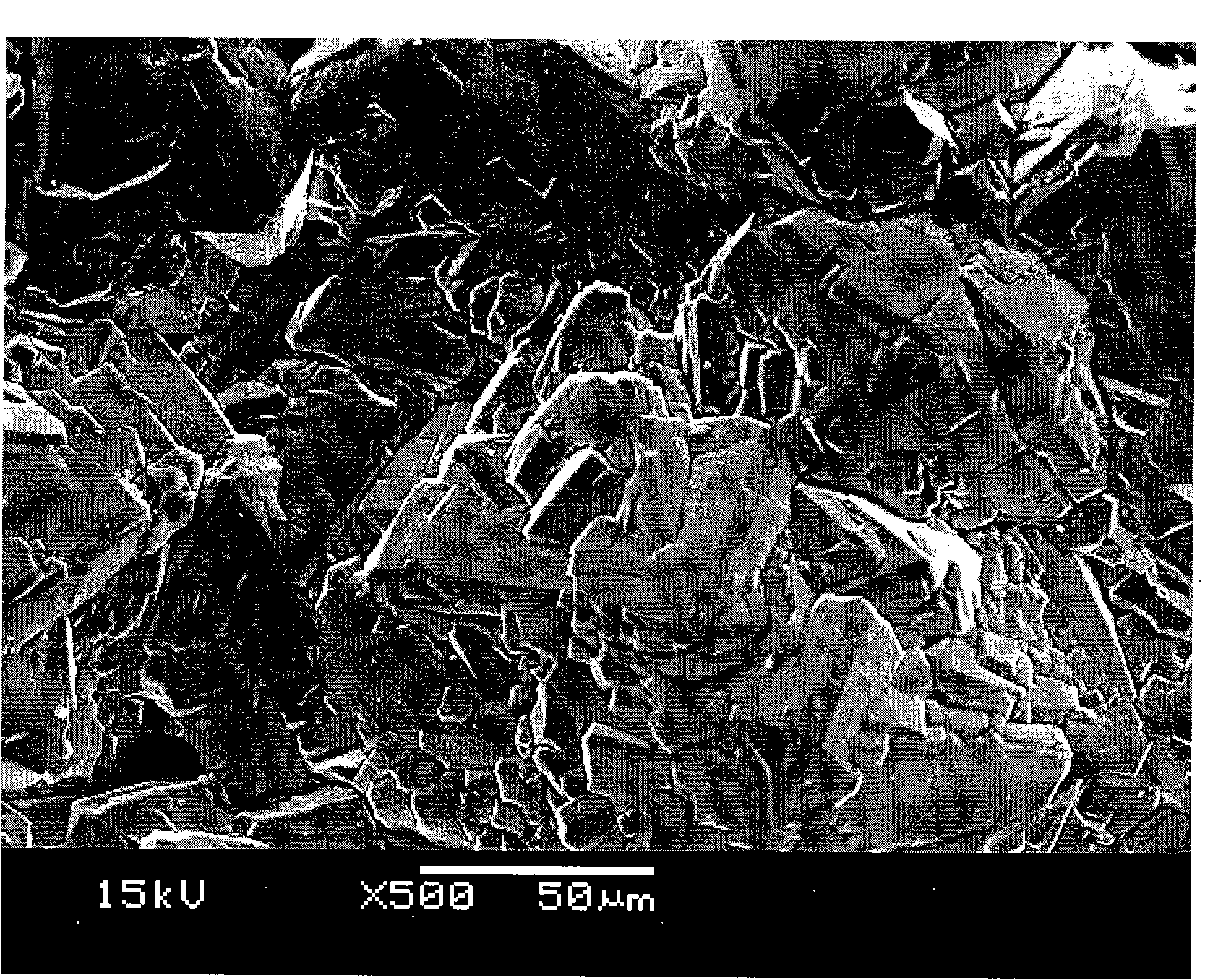

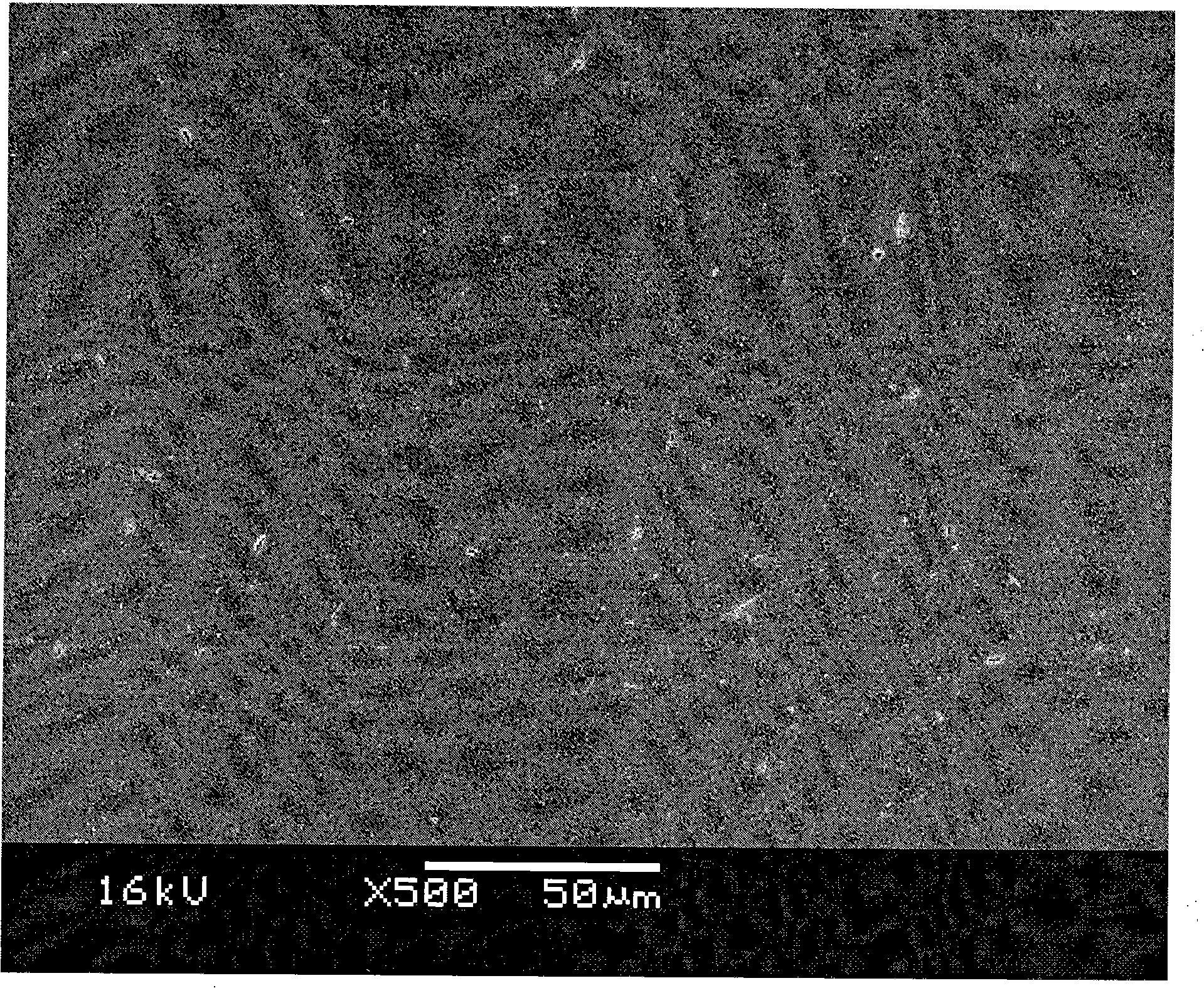

Sulfur-smoke-free powder composition and preparation method thereof

InactiveCN103214322ADisadvantages of Avoiding Cryogenic DecompositionSolve the disadvantage of easy moisture absorptionExplosivesNitro compoundBarium nitrate

The invention discloses a sulfur-smoke-free firework powder composition and a preparation method thereof. According to the powder composition, potassium perchlorate and barium nitrate are used as oxidants, and a nitro-compound is used as a flammable agent, so that the safety and environment-friendliness of the firework production are greatly improved, the production cost of the firework powder is lowered, and various indexes are excellent through the detection. The preparation method of the sulfur-smoke-free firework powder composition is simple and mainly comprises the simple processes of mixing, pelletizing, drying and screening. According to the sulfur-smoke-free firework powder composition and the preparation method thereof disclosed by the invention, the problems that the conventional black powder is poor in safety, easy to absorb moisture, large in production risk and the like are solved. The sulfur-smoke-free firework powder composition has the advantages of having an emission effect better than that of black powder, achieving zero-exhaustion of sulfur dioxide and the like. The sulfur-smoke-free firework powder composition is extensively applicable to preparing firework propellant powder and 3-8-inch powder of large festive fireworks.

Owner:LIUYANG HELI HIGH TECH DEV CO LTD

Fire extinguishing agent

InactiveCN102772877AReduce manufacturing costRaw materials are easy to getFire extinguisherSilicone oilPollution

The invention discloses a fire extinguishing agent. The fire extinguishing agent consists of the following raw material components in parts by weight: 0.1-0.2 parts of organic silicon oil, 2-3 parts of carbamide, 3.5-4.5 parts of ammonium phosphate, 6.1-6.2 parts of potassium perchlorate, 32-35 parts of concentrated latex and 11-12 parts of water. The fire extinguishing agent has the advantages of capability of overcoming the defects of an ordinary fire extinguishing agent, low manufacturing cost, readily available raw materials, harmlessness of raw materials for making the fire distinguishing agent on human bodies, no pollution, safety and reliability.

Owner:启东市中勇机电工具有限公司

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Blasting fuse of high-safety firecracker and preparation method thereof

InactiveCN101270015AStable chemical propertiesLow mechanical sensitivityInorganic oxygen-halogen salt explosive compositionsFuse detonationYarnDecomposition

The present invention relates to a preparation method of a safe firing cable of firecrackers. In the method, yarn is used as a carrier to infuse the following medicines, which are used raw materials, according to the following steps. The medicines comprise potassium perchlorate, potassium terephthalic acid, ammonium dichromate, polyethylene alcohol, moisture resistant agent, charcoal and sulfur. The method has the following steps: the potassium perchlorate, the potassium terephthalic acid, the ammonium dichromate, the charcoal, the sulfur and the polyethylene alcohol are arranged in a container according to the weight ratio; water with a certain proportion is added into the container; the mixture is stirred so that the medicines can be dissolved in the water; then the moisture resistant agent is added; and the mixture is mixed well; the yarn is infused in the container, taken out and then sent to a drying device to be dried; thus the safe firing cable can be prepared. In the method, the yarn is used as the carrier to infuse the medicines of the firing cable; the production is simple; the amount of the medicines is reduced; the method is safe; and the cost is reduced. The application of the potassium perchlorate has the advantages of low oxygen content, low decomposition temperature, excellent stability and low sensitivity. Thus the application of the potassium perchlorate is superior to the application of potassium chlorate. The firing cable solves the problems of storage, transportation and insecurity in use.

Owner:醴陵神马花炮有限公司

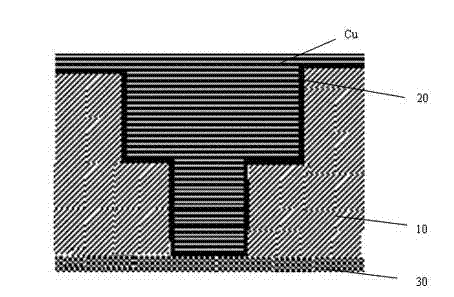

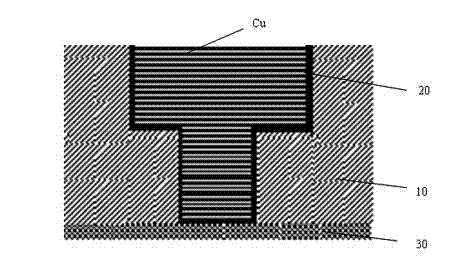

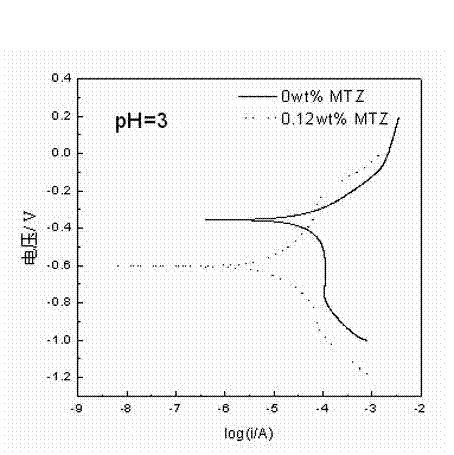

Polishing solution based on polishing process of metal Co and application thereof

InactiveCN102516875AInhibit Static CorrosionReduce polishing rateOther chemical processesSemiconductor/solid-state device manufacturingCeriumSilicon dioxide

The invention discloses a polishing solution based on a polishing process of metal Co and application thereof. The polishing solution comprises the following raw material components in percentage by weight: 0.01-2% of inhibitor, 0-5% of oxidant, 0.1-10% of grinding granules, 0.001-10% of chelating agent and the balance of water, wherein the pH value of the polishing solution is adjusted to 3-5 by a pH value adjusting agent; the inhibitor is selected one or more of five-membered heterocyclic ring derivatives containing S and / or N; the oxidant is selected from one or more of hydrogen peroxide, ammonium persulfate, potassium periodate and potassium perchlorate; the grinding granules are selected from one or more of silicon dioxide, cerium dioxide and alumina; and the chelating agent is selected from amino acid or citric acid or a mixture thereof. The polishing solution disclosed by the invention can effectively inhibit the static corrosion of cobalt, reduce the polishing rate of cobalt and prevent the over-corrosion of cobalt in the polishing process.

Owner:FUDAN UNIV

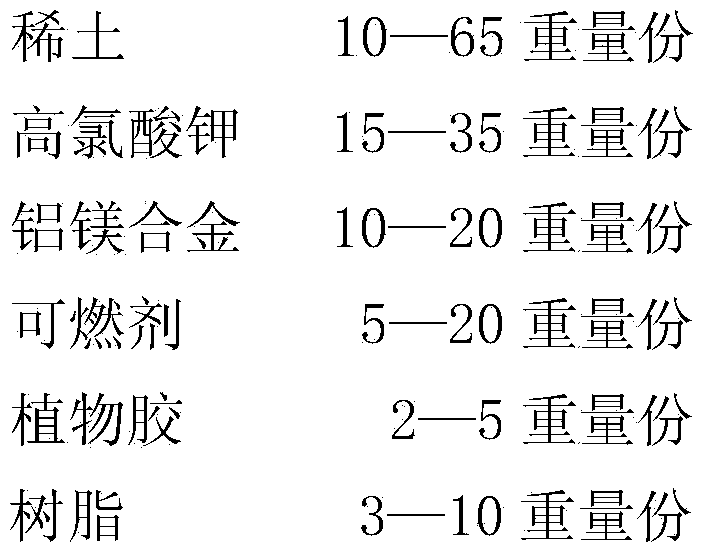

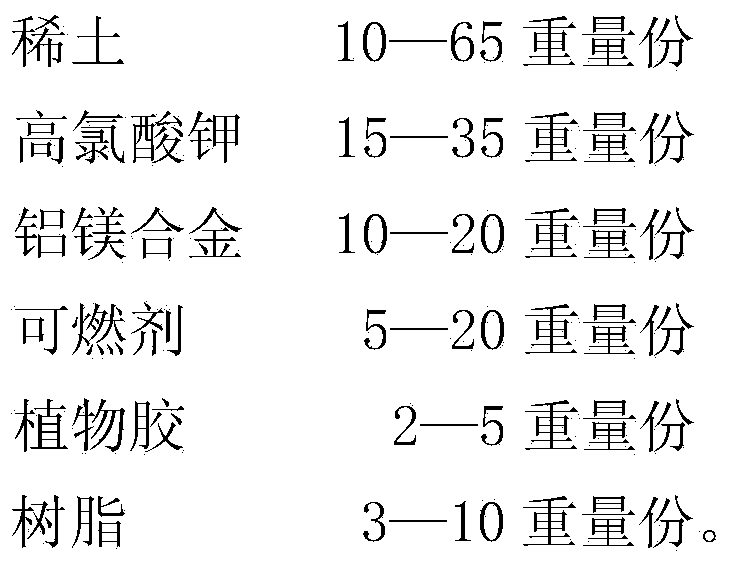

Environment-friendly firework propellant

The invention discloses an environment-friendly firework propellant which is characterized by being composed of the following components in parts by weight: 10-65 parts of rare earth, 15-35 parts of potassium perchlorate, 10-20 parts of aluminum magnesium alloy, 5-20 parts of combustible agent, 2-5 parts of plant gum and 3-10 parts of resin, wherein the combustible agent is selected from any one or combined by any two from hemp xyloid stem carbon powder and Chinese fir carbon powder at any proportion, and the plant gum is a rice flour adhesive. The environment-friendly firework propellant is free of chlorate, small in horizontal launching force, low in moisture absorption property, low in impact and friction sensitivity, small in dosage of charges for preparing fireworks, slight in smoke, long in shelf life and displaying time, free of residues after displaying, good in physical and chemical stability, simple in processing technology and suitable for various firework propellants.

Owner:喻自达

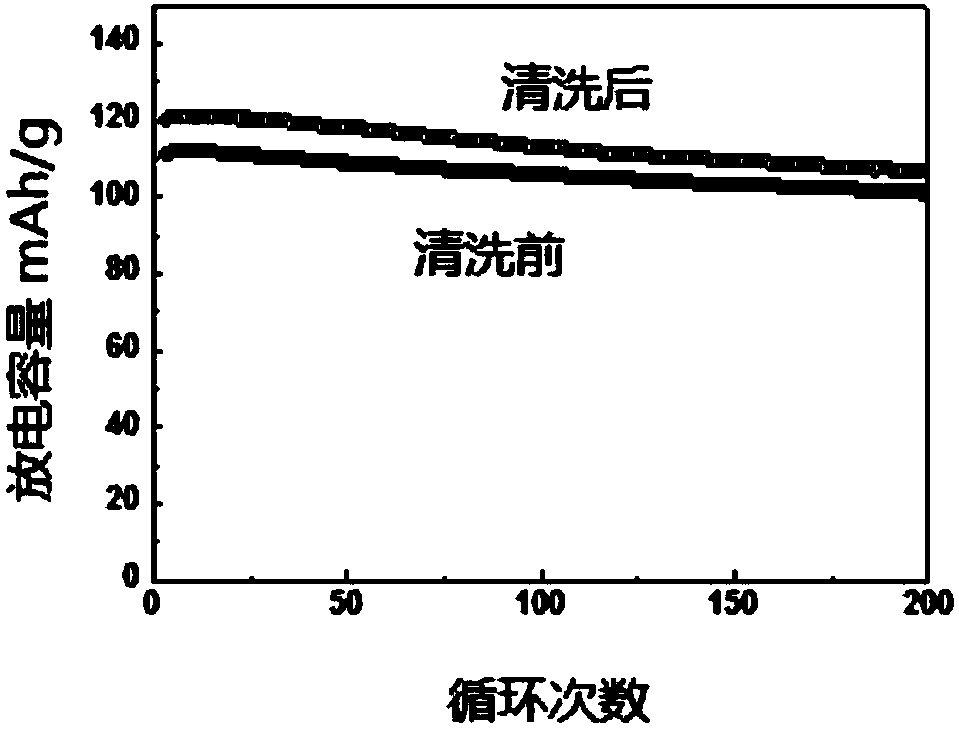

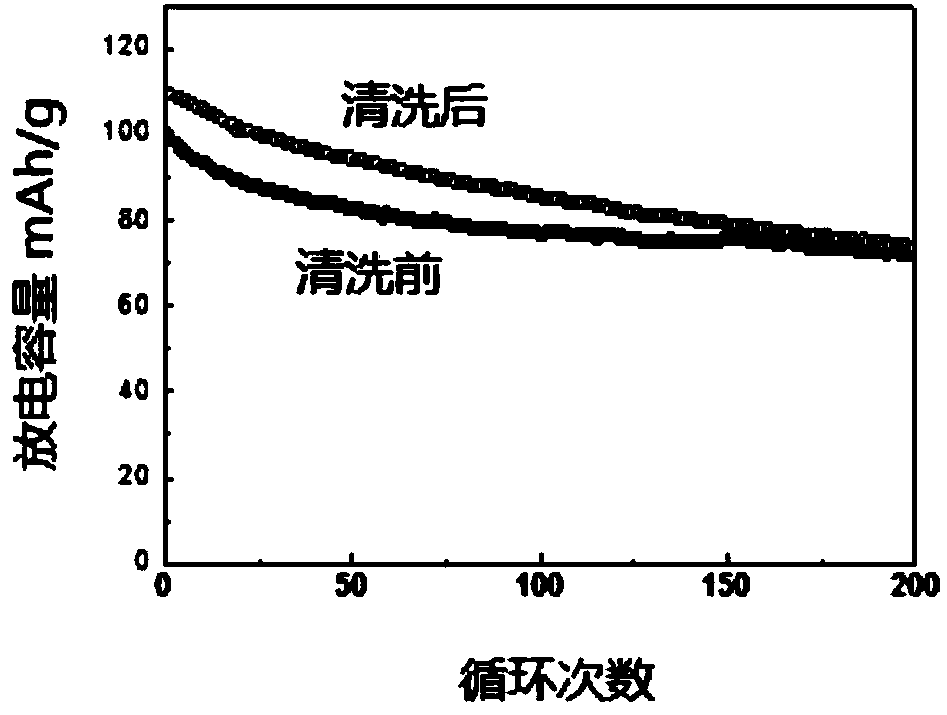

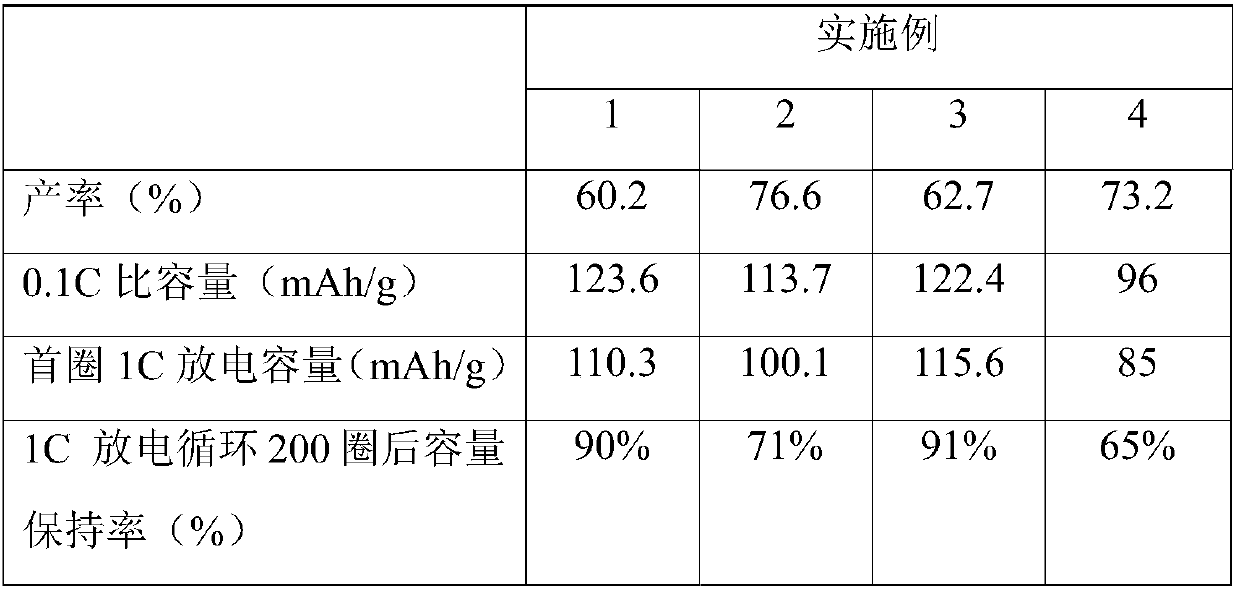

Preparation method of prussian blue type energy storage material

ActiveCN107634220ASimple production processAvoid lossIron cyanidesCell electrodesAmmonium perchlorateSodium-ion battery

The invention provides a preparation method of a prussian blue type energy storage material, and specifically relates to a preparation method of a prussian blue type sodium-ion battery electrode material with high yield. The preparation method comprises the following steps: S1, dissolving divalent transition metal perchlorate and sodium ferrocyanide into water respectively to obtain a divalent transition metal perchlorate solution and a sodium ferrocyanide solution; S2, dissolving sodium perchlorate into water to obtain a sodium perchlorate solution; and S3, mixing the divalent transition metal perchlorate solution and the sodium ferrocyanide solution with the sodium perchlorate solution to obtain a mixed solution, and stirring and standing the mixed solution to obtain a sediment product;and separating and drying the sediment product to obtain the prussian blue type energy storage material. According to the preparation method, a great deal of loss of the prussian blue type material inthe cleaning process is avoided, and high-yield production can be realized. The preparation method is simple and high in yield, and is easy for industrial large-scale production.

Owner:浙江钠创新能源有限公司

Fireworks spraying pyrotechnic compound composition with composite effect

InactiveCN101386558AImprove performanceSuitable for industrial mass productionExplosivesComposite effectFireworks

The invention discloses a flower-spraying pyrotechnic composition with composite effects. The flower-spraying pyrotechnic composition comprises the following components in weight portion: 30 to 60 portions of potassium perchlorate, 8 to 20 portions of magnalium, 5 to 25 portions of strontium carbonate, 5 to 15 portions of polyvinyl chloride, hexachlorobenzene or chlorinated paraffin, 2 to 15 portions of phenolic resin and 10 to 20 portions of 40 to 60 mesh aluminum dross. A flower-spraying product manufactured according to the formulation of the invention can simultaneously and compositely reveal the effects of slowly burning, landing, flowering and showing red light, and is stable in performance and suitable for industrialized batch production.

Owner:王贤凤

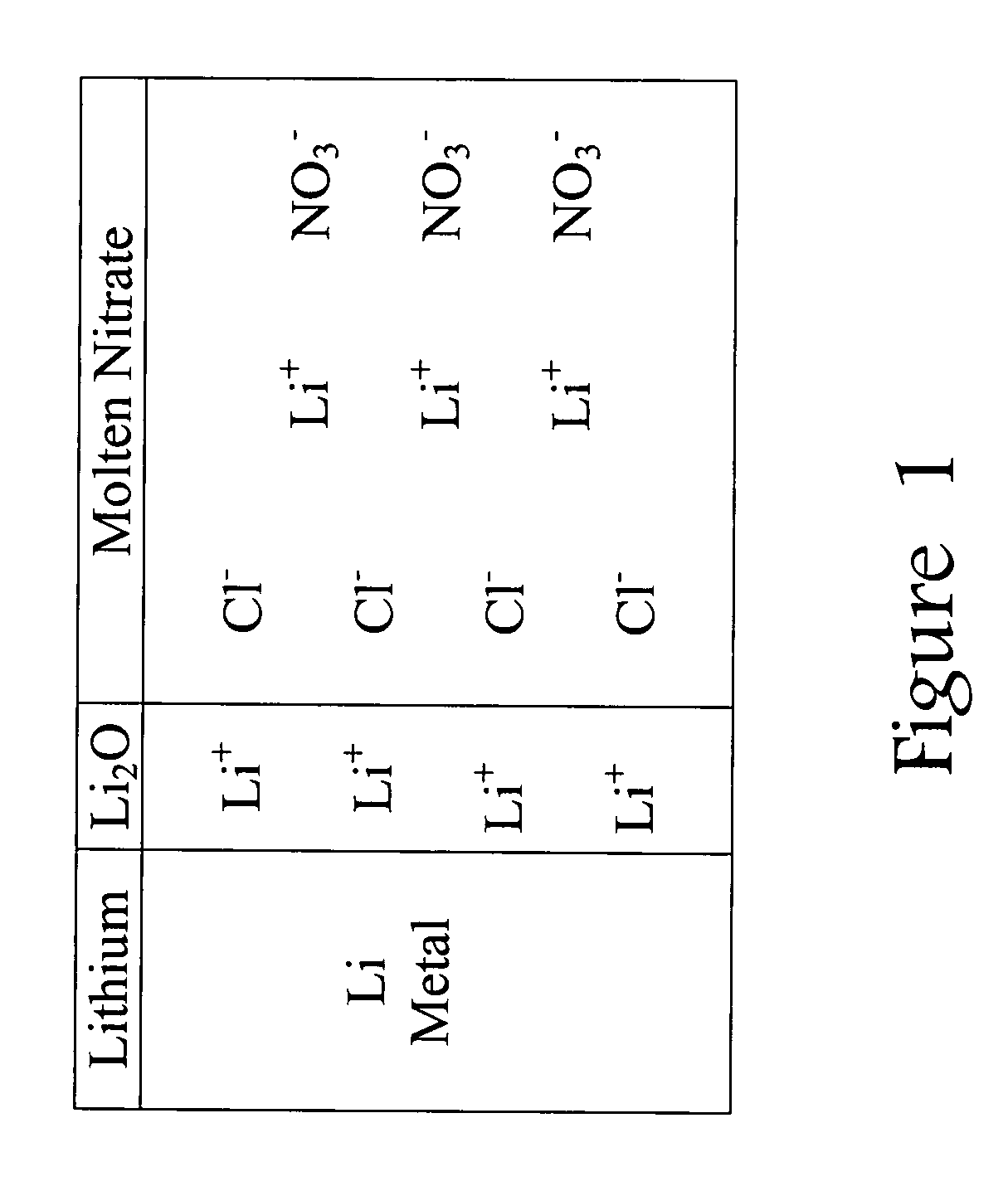

Chloride-free thermal batteries using molten nitrate electrolytes

ActiveUS20090047573A1Shorten activation timeReduce weightDeferred-action cellsCell electrodesHigh cellDecomposition

Thermal batteries using molten nitrate electrolytes offer significantly higher cell voltages and marked improvements in energy and power densities over present thermal batteries. However, a major problem is gas-evolution reactions involving the molten nitrate electrolytes. This gassing problem has blocked the advantages offered by thermal batteries using molten nitrates. The solution to this problem is the use of chloride-free molten nitrate electrolytes. Most important is the avoidance of potassium perchlorate (KClO4) or any other chlorine-containing substances that can decompose to produce chloride ions in any thermal battery component. The Fe+KClO4 pyrotechnic used to activate thermal batteries is a key example. The decomposition of such substances into chloride ions (Cl−) results in passivating-film breakdown and gas-producing reactions with the molten nitrate electrolyte. These reactions largely involve the lithium-component of the anode used in thermal batteries such as Li—Fe (LAN), Li—Si, and Li—Al. The introduction of chloride ions into the nitrate melt via the pyrotechnic materials produces a rapid breakdown of the protective oxide film on lithium-based anodes and leads to gas-producing reactions.

Owner:AXIENT LLC

Formula of gunpowder for timing firing cable of display shell

InactiveCN102249824ASafe storagePromote safe productionInorganic oxygen-halogen salt explosive compositionsNon-explosive/non-thermic compositionsPotassium nitrateCombustion

The invention relates to a formula of gunpowder for a timing firing cable of a display shell. According to the invention, because in the formula provided by the invention, potassium perchlorate is used as a main component, thereby completely avoiding the use of a high-risk potassium nitrate product and effectively reducing the generation of risk accidents caused by a firing cable; barium nitrate in the components has combustion and speed regulation effects, so that the combustion speed of the firing cable meets the timing ignition requirement of the display shell, thereby effectively achieving the timing effect; and the combustion color of the firing cable is golden or silvery through using larch carbon powder, a yellow light agent or titanium sponge in the components.

Owner:徐敏

Efficient and environment-friendly coal additive and preparation method thereof

The invention discloses an efficient and environment-friendly coal additive, comprising the following components in parts by weight: 2-15 parts of tea seed cake or rapeseed dregs, 5-33 parts of slag, 0.5-2 parts of sodium percarbonate, 0.8-4 parts of potassium chlorate, 1-8 parts of potassium perchlorate, 2-8 parts of sodium chloride, 4-12 parts of barium hydroxide, 1-5 parts of light magnesium oxide, 0.1-1.7 parts of manganese dioxide, 0.5-2.5 parts of nano-titania and 1-21 parts of humic acid. A preparation method comprises the following steps of: mixing the raw materials in weight ratio, crushing to 40-60 meshes, and placing into a stirrer to be stirred for 5-10 minutes. The coal additive provided by the invention is efficient and environment-friendly. The preparation method is simple and convenient and low in cost.

Owner:HUNAN XINWANG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Fireworks product

The invention relates to a fireworks product, which comprises an outer cylinder with a sealed end, and an inner cylinder arranged in the outer cylinder, wherein the sealed end of the outer cylinder is provided with a small hole for an outer igniter cord; the inside of the outer cylinder is provided with propellant powder; the inner cylinder is provided with a small hole for an inner igniter cord; the inner igniter cord is contacted with the propellant powder; and the inside of the inner cylinder is provided with propellant powder. The fireworks product contains effective powder comprising red light powder, unpacking powder, igniting powder, sounding powder and black powder, wherein the red light powder comprises 43 percent of potassium perchlorate, 30 percent of powered alloy, 20 percent of strontium carbonate, 7 percent of hexachlorobenzene and 7 percent of phenolic resin; the unpacking powder comprises 50 percent of potassium perchlorate, 30 percent of powered alloy and 20 percent of aluminum powder; the igniting powder comprises 18 percent of potassium perchlorate, 7 percent of powered alloy, 12 percent of brimstone, 47 percent of potassium nitrate and 16 percent of charcoal; the sounding powder comprises 18 percent of powered alloy, 3 percent of brimstone, 5 percent of potassium nitrate, 52 percent of minium and 22 percent of copper oxide; and the black powder comprises 7 percent of potassium perchlorate, 6 percent of powered alloy, 9 percent of brimstone, 60 percent of potassium nitrate and 18 percent of charcoal. The fireworks product can generate flowery red light when set off, and simultaneously has high safety.

Owner:王生宝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com