Patents

Literature

37results about How to "Reduce polishing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110081780A1Reduce polishing rateHigh polishing rateOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidSilica particle

A chemical mechanical polishing aqueous dispersion includes (A) silica particles, and (B1) an organic acid, the number of silanol groups included in the silica particles (A) calculated from a signal area of a 29Si-NMR spectrum being 2.0 to 3.0×1021 / g.

Owner:JSR CORPORATIOON

Aqueous dispersion for chemical mechanical polishing and chemical mechanical polishing method

InactiveUS20110053462A1Reduce polishing rateHigh polishing rateOther chemical processesDecorative surface effectsIon contentIon chromatography

A chemical mechanical polishing aqueous dispersion including (A) silica particles, and (B1) an organic acid, the sodium content, the potassium content, and the ammonium ion content of the silica particles (A) determined by ICP atomic emission spectrometry, ICP mass spectrometry, or ammonium ion quantitative analysis using ion chromatography having a relationship in which the sodium content is 5 to 500 ppm and at least one of the potassium content and the ammonium ion content is 100 to 20,000 ppm.

Owner:JSR CORPORATIOON

Mixed rare earth oxide, mixed rare earth fluoride, cerium-based abrasive using the materials and production processes thereof

InactiveCN101010402AReduce polishing rateRare earth metal oxides/hydroxidesOther chemical processesCeriumFluoride

Owner:SHOWA DENKO KK

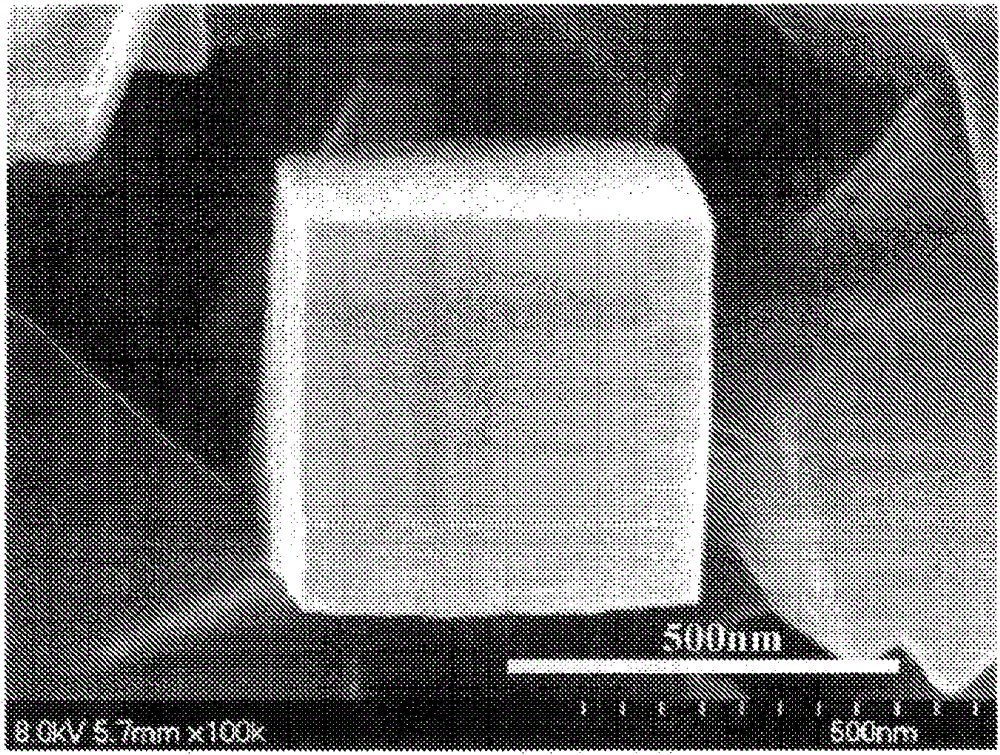

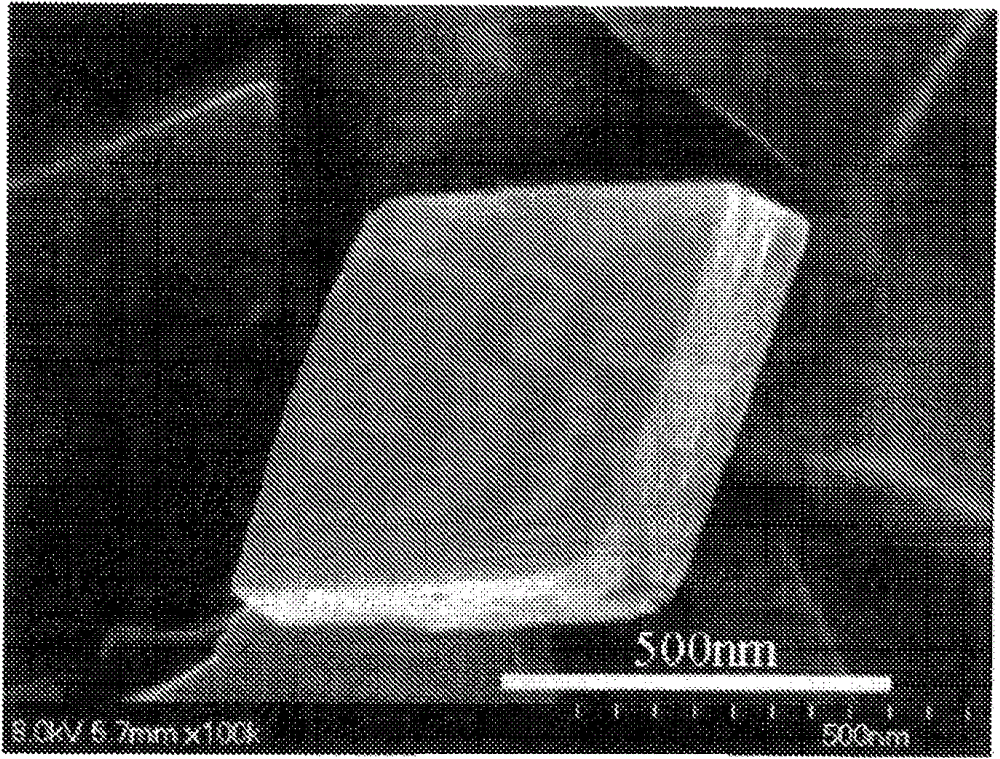

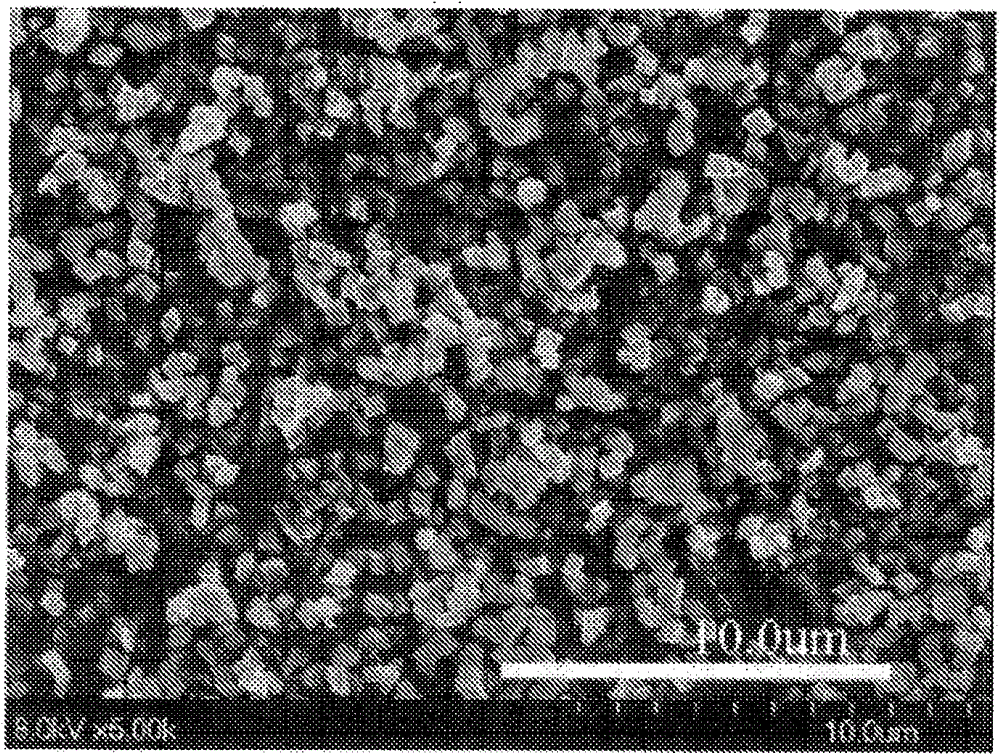

Aluminum oxide particle and polishing composition containing the same

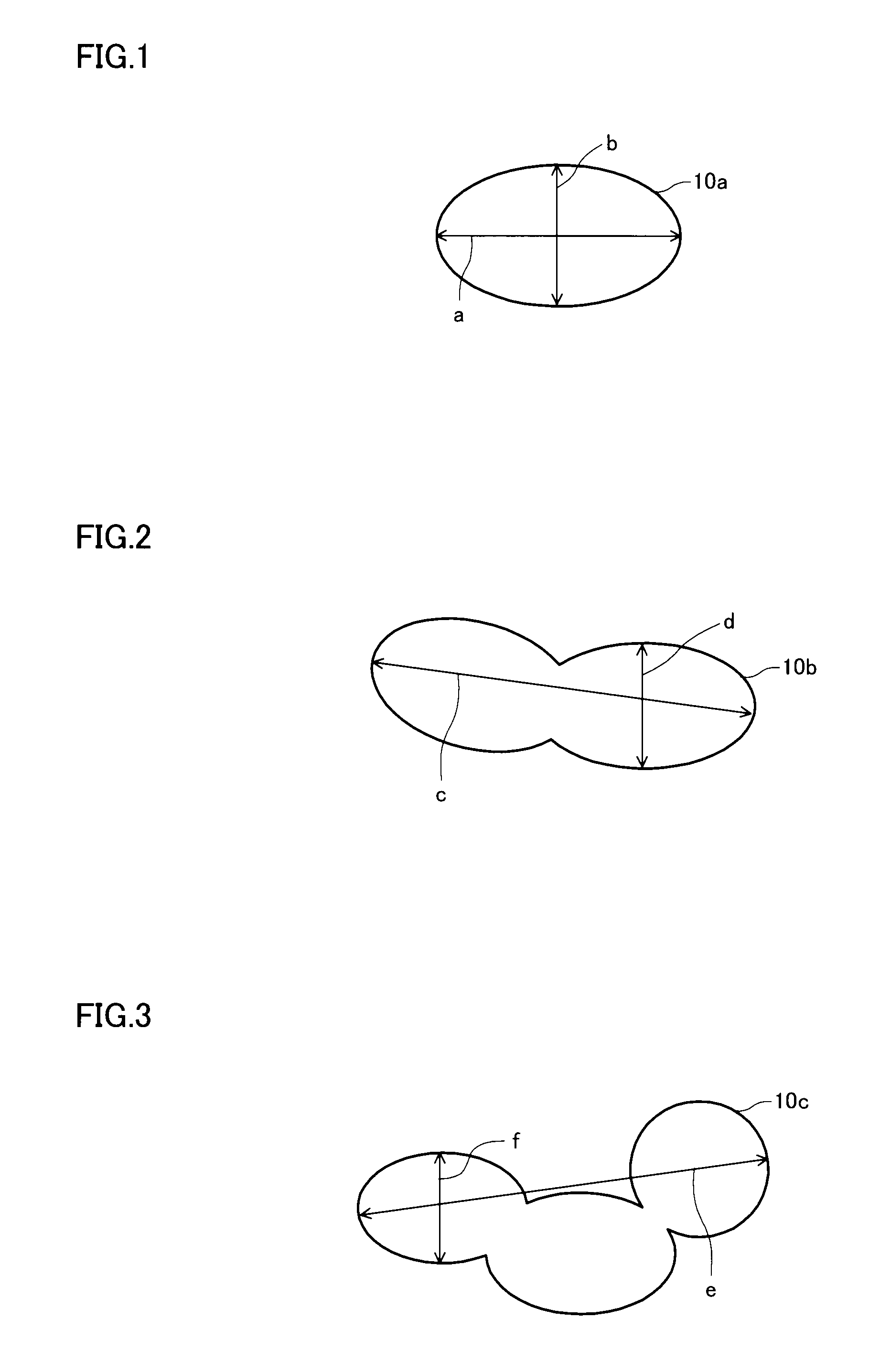

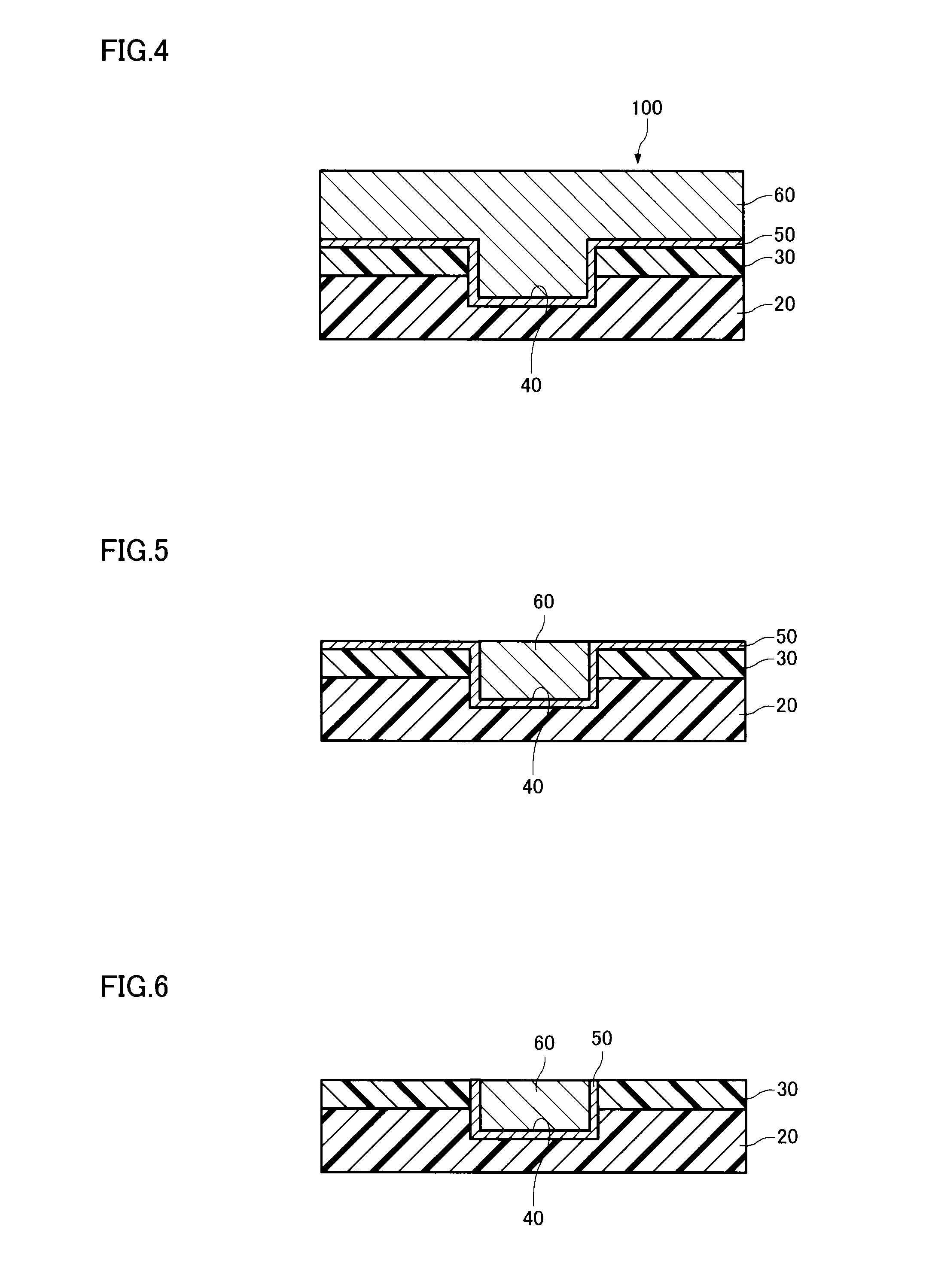

ActiveCN102105266AReduce polishing rateReduced wash-off easeOther chemical processesAbrasion apparatusSemiconductorSemiconductor device

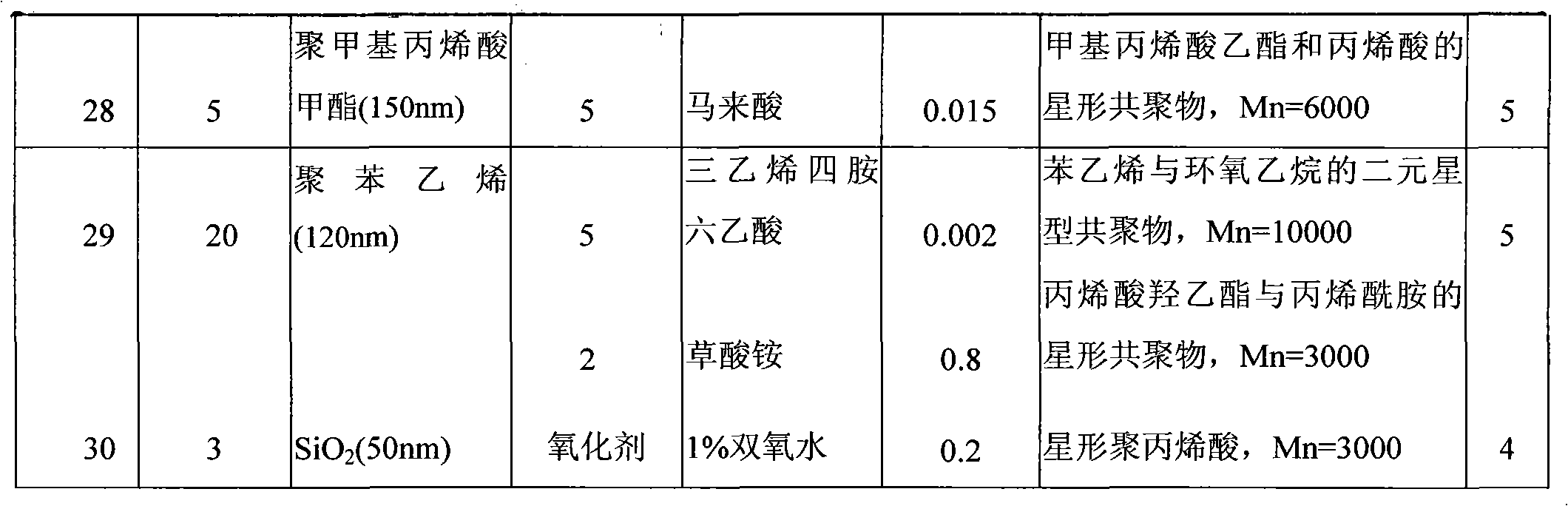

Disclosed are aluminum oxide particles wherein primary particles have a hexahedral shape and an aspect ratio of 1-5. The average primary particle diameter of the aluminum oxide particles is preferably 0.01-0.6 [mu]m. The a-particle ratio in the aluminum oxide particles is preferably 5-70%. The average secondary particle diameter of the aluminum oxide particles is preferably 0.01-2 [mu]m, and the value obtained by dividing the 90% particle diameter of the aluminum oxide particles by the 10% particle diameter is preferably 3 or less. The aluminum oxide particles are used as abrasive grains for polishing semiconductor device substrates, hard disk substrates or display substrates.

Owner:FUJIMI INCORPORATED

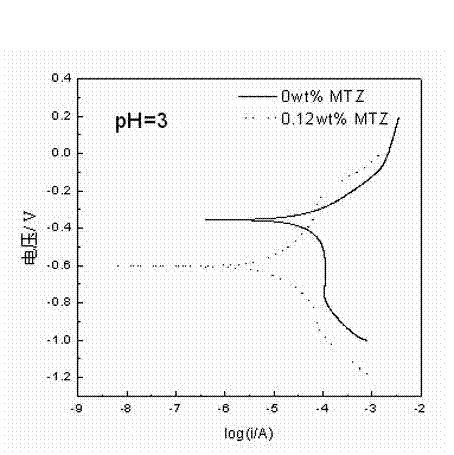

Polishing solution based on polishing process of metal Co and application thereof

InactiveCN102516875AInhibit Static CorrosionReduce polishing rateOther chemical processesSemiconductor/solid-state device manufacturingCeriumSilicon dioxide

The invention discloses a polishing solution based on a polishing process of metal Co and application thereof. The polishing solution comprises the following raw material components in percentage by weight: 0.01-2% of inhibitor, 0-5% of oxidant, 0.1-10% of grinding granules, 0.001-10% of chelating agent and the balance of water, wherein the pH value of the polishing solution is adjusted to 3-5 by a pH value adjusting agent; the inhibitor is selected one or more of five-membered heterocyclic ring derivatives containing S and / or N; the oxidant is selected from one or more of hydrogen peroxide, ammonium persulfate, potassium periodate and potassium perchlorate; the grinding granules are selected from one or more of silicon dioxide, cerium dioxide and alumina; and the chelating agent is selected from amino acid or citric acid or a mixture thereof. The polishing solution disclosed by the invention can effectively inhibit the static corrosion of cobalt, reduce the polishing rate of cobalt and prevent the over-corrosion of cobalt in the polishing process.

Owner:FUDAN UNIV

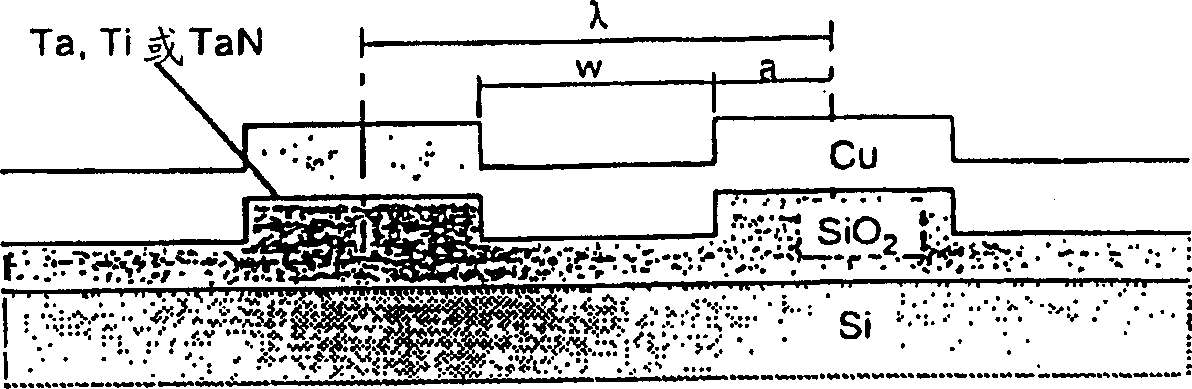

Chemico-mechanical polishing liquid for copper process

ActiveCN101457122AMeet polishing requirementsReduce pollutantsSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCopper platingNitrogen

The present invention discloses a chemical machinery polishing solution used in copper plating, which contains seat grinding granule, organanic phosphonic acid compounds, azole nitrogen compounds, oxidizer and carrier. The polishing solution provided in the invention can guaranty polishing rate of speed with little seat grinding granule dosage, and deduce defect, cullet cut, sticky dirt and otherresidue obviously at the same time, hence reduce infectant on substrate surface; appropriate copper / tantalum remove rate selection ratio is provided to satisfy copper plating polishing requirement; can prevent local and whole corrosion that generated in metal polishing process and improve product yield rate.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

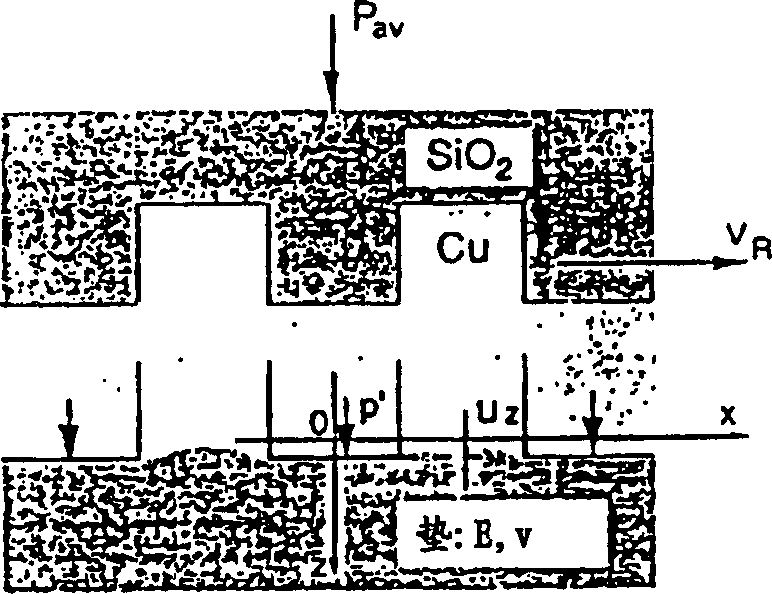

Electropolishing liquid and process for planarization of metal layer

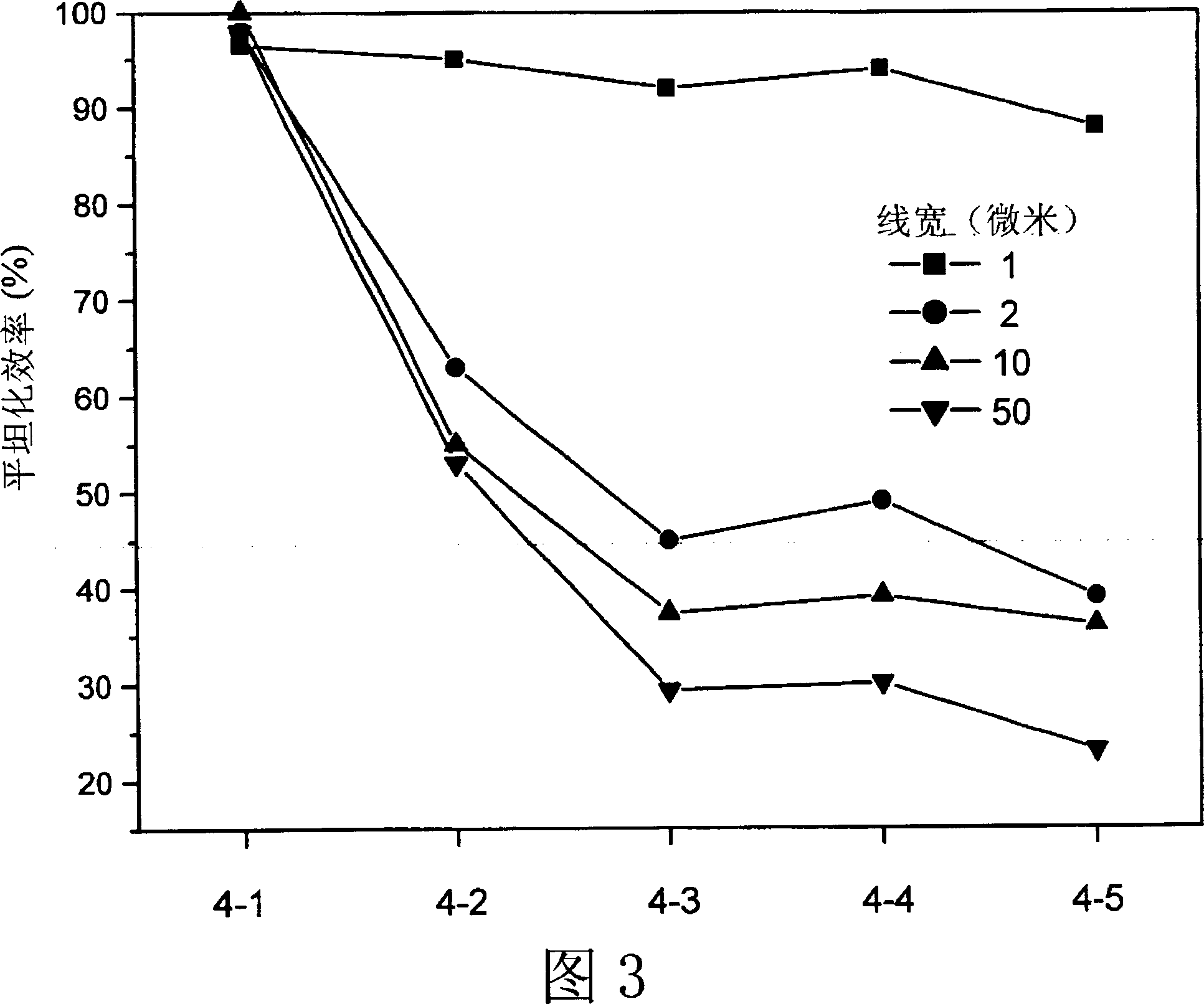

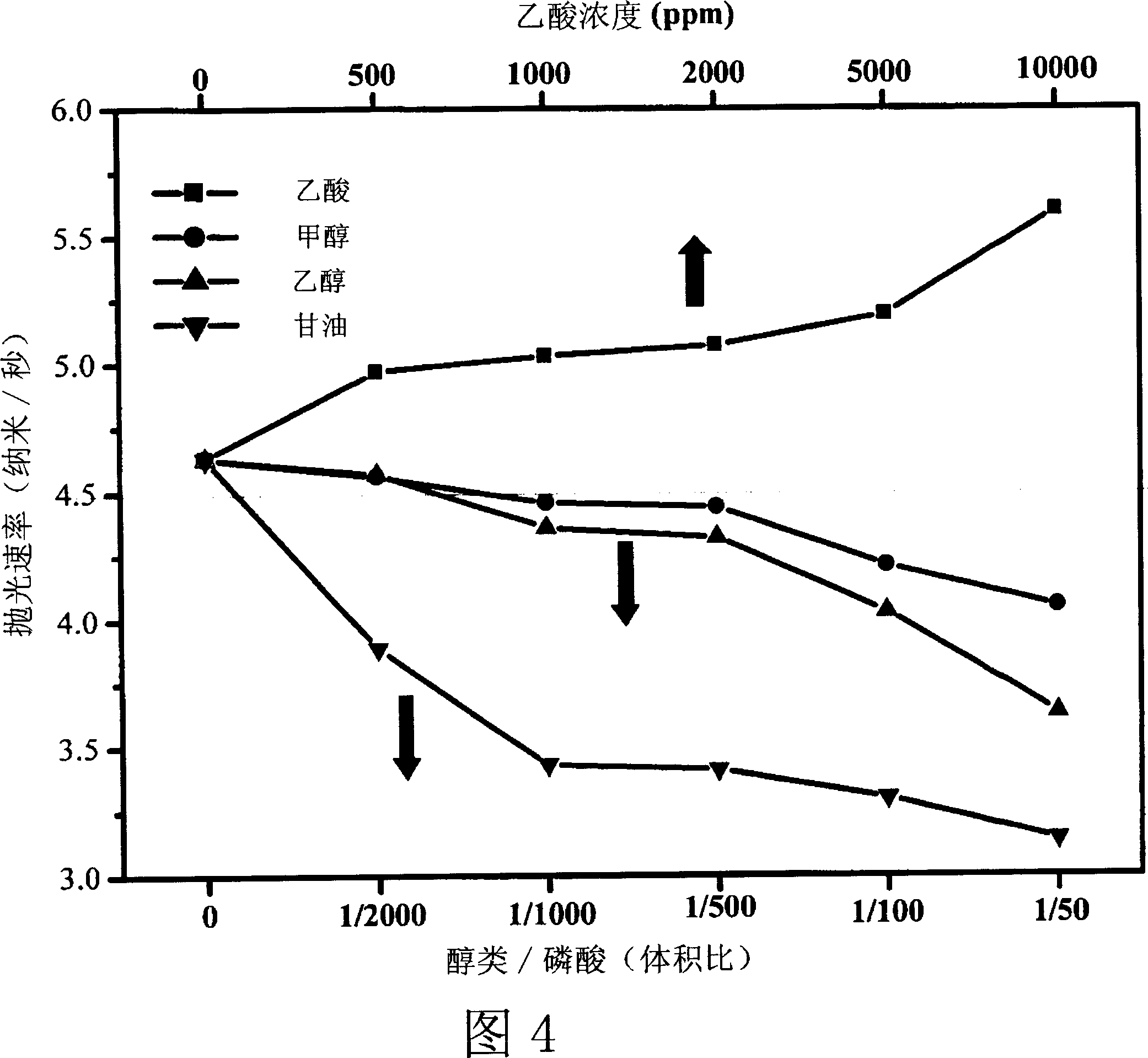

InactiveCN1952221AReduce polishing rateSemiconductor/solid-state device manufacturingAcetic acidOrganic acid

The invention reveals an electrolytic polishing fluid containing alcohol-based additives and its smoothened metal layer method. The said electrolytic polishing fluid contains an alcohol-based additives and acid solution. Optimization, the said alcohol-based additives can be glycerol, methanol or ethanol, the said acid solution contains phosphoric acid and organic acid additives, the organic acid additives can be acetic acid or citric acid. The invention degrades the burnishing rate of the said metal layer surface through the said alcohol-based additives forming the diffusion restraint layer on the said metal layer surface, but the rabbet and prominence of the said metal layer show the same degree of polishing inhibition in some certain concentration. Adding organic acid additive in the electrolytic polishing liquid leads to the difference of organic acid concentration of the convex and concave metal layer thereby causes greater difference of polishing rate of the convex and concave.

Owner:BASF CORP

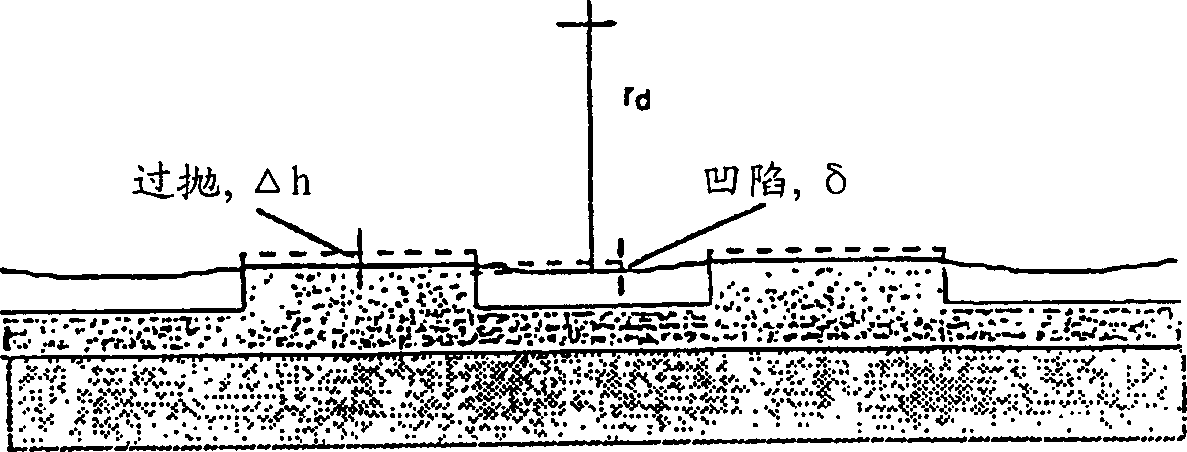

Method for Chemical Mechanical Planarization of A Metal-containing Substrate

InactiveUS20090061630A1Reduce saggingSmall to negligible effect on polishing rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesMetallic substrateMetal substrate

A method using an associated composition for chemical mechanical planarization of a metal-containing substrate (e.g., a copper substrate) is described. This method affords low dishing and local erosion levels on the metal during CMP processing of the metal-containing substrate.

Owner:VERSUM MATERIALS US LLC +1

Chemically mechanical polishing slurry

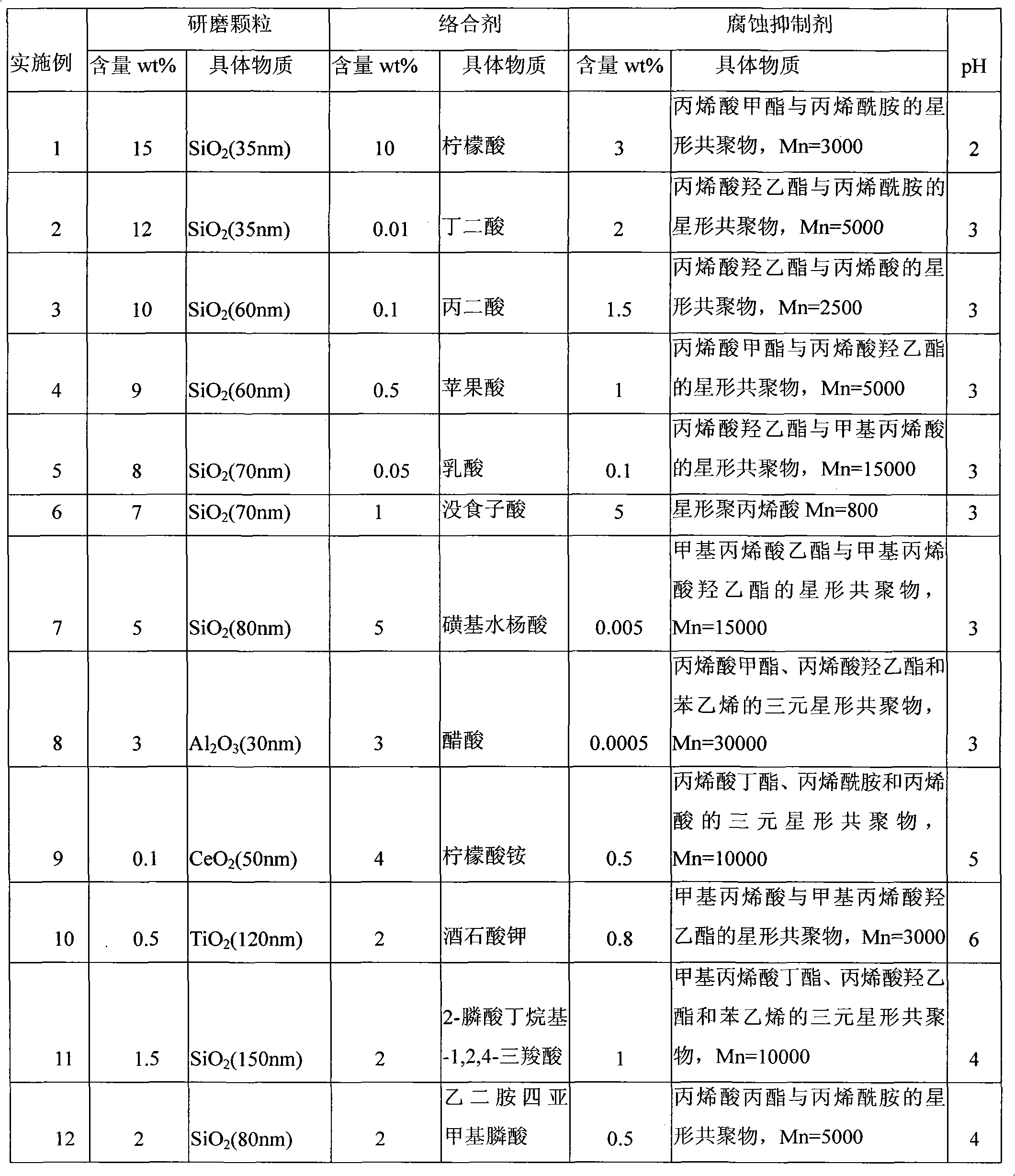

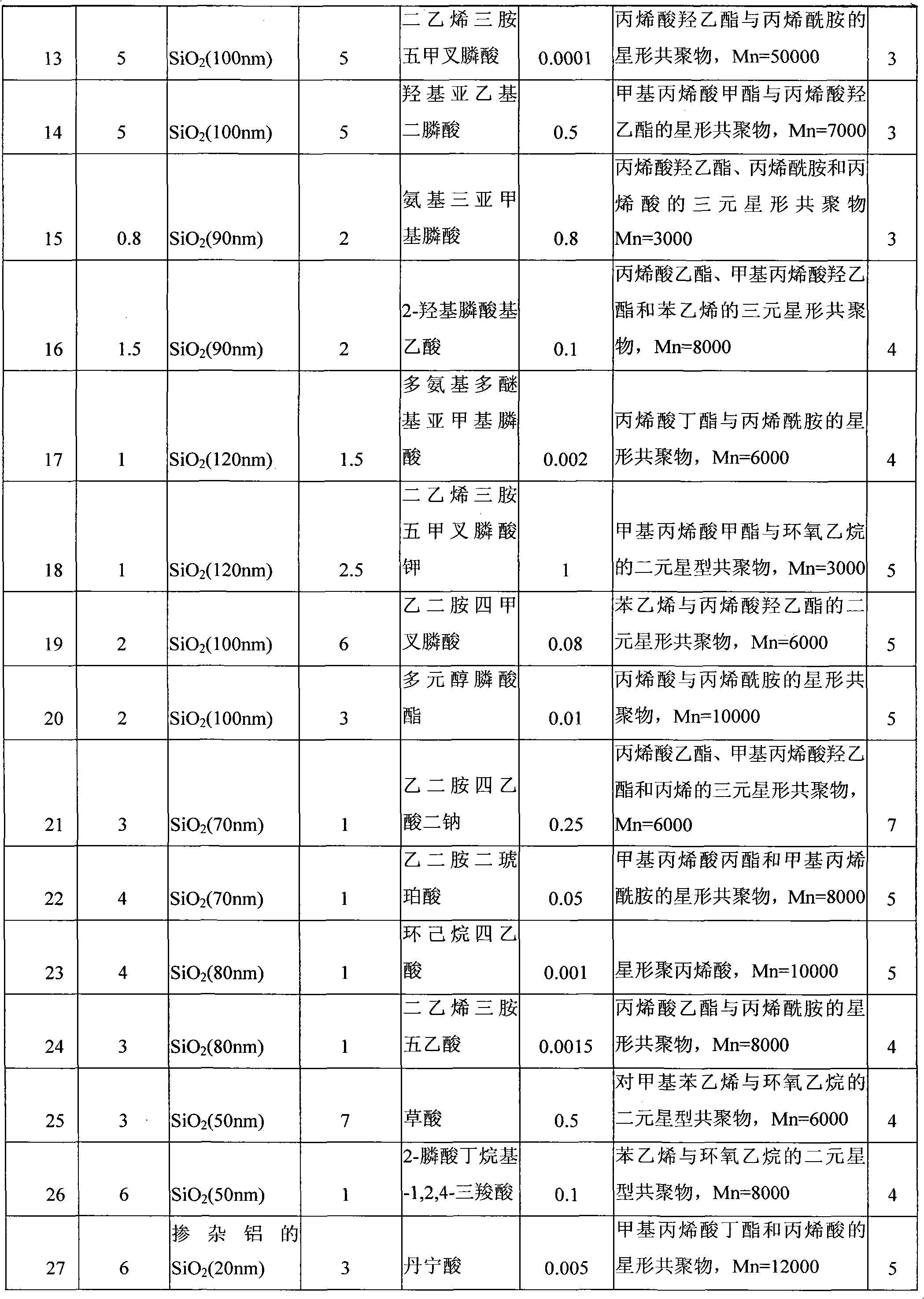

ActiveCN102101977AReduce defective rateReduce polishing rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesMetallic materialsSlurry

The invention discloses new chemically mechanical polishing slurry for polishing metals. The polishing slurry is prepared by combining the following substances: abrasive particles, complexing agents and corrosion inhibitors. The slurry has the following positive effects: the removal rate of metals can be reduced, the metal materials can be prevented from whole and local corrosion, the defects can be obviously decreased and the surface quality can be improved.

Owner:ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Polishing solution and polishing method of silicon carbide crystals

ActiveCN108949036ASmall scratchSmall roughnessPolishing compositions with abrasivesSoft layerOrganic matter

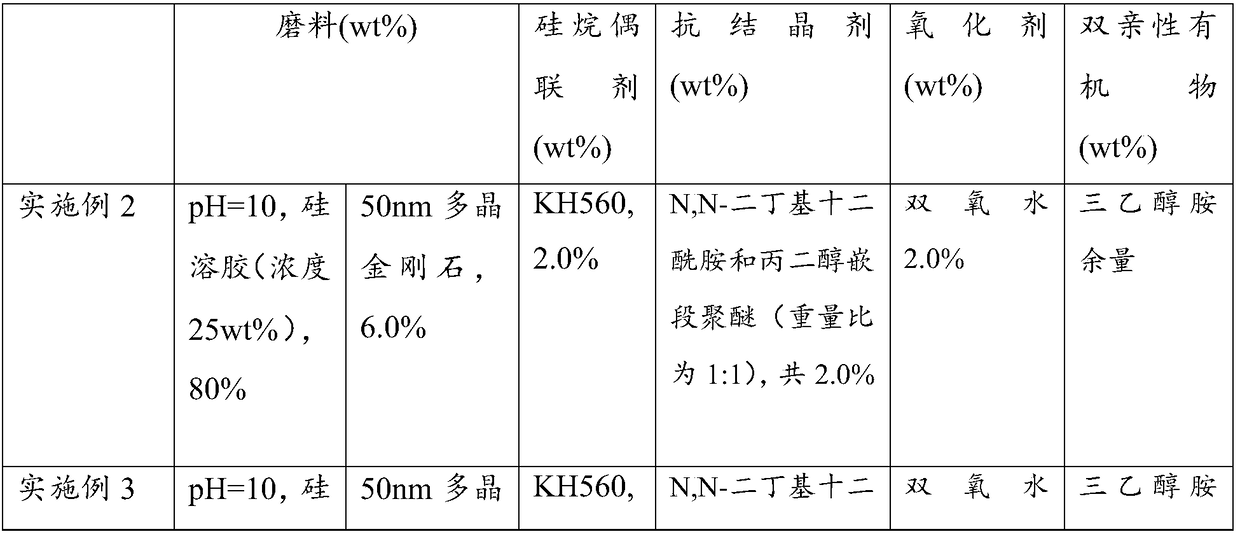

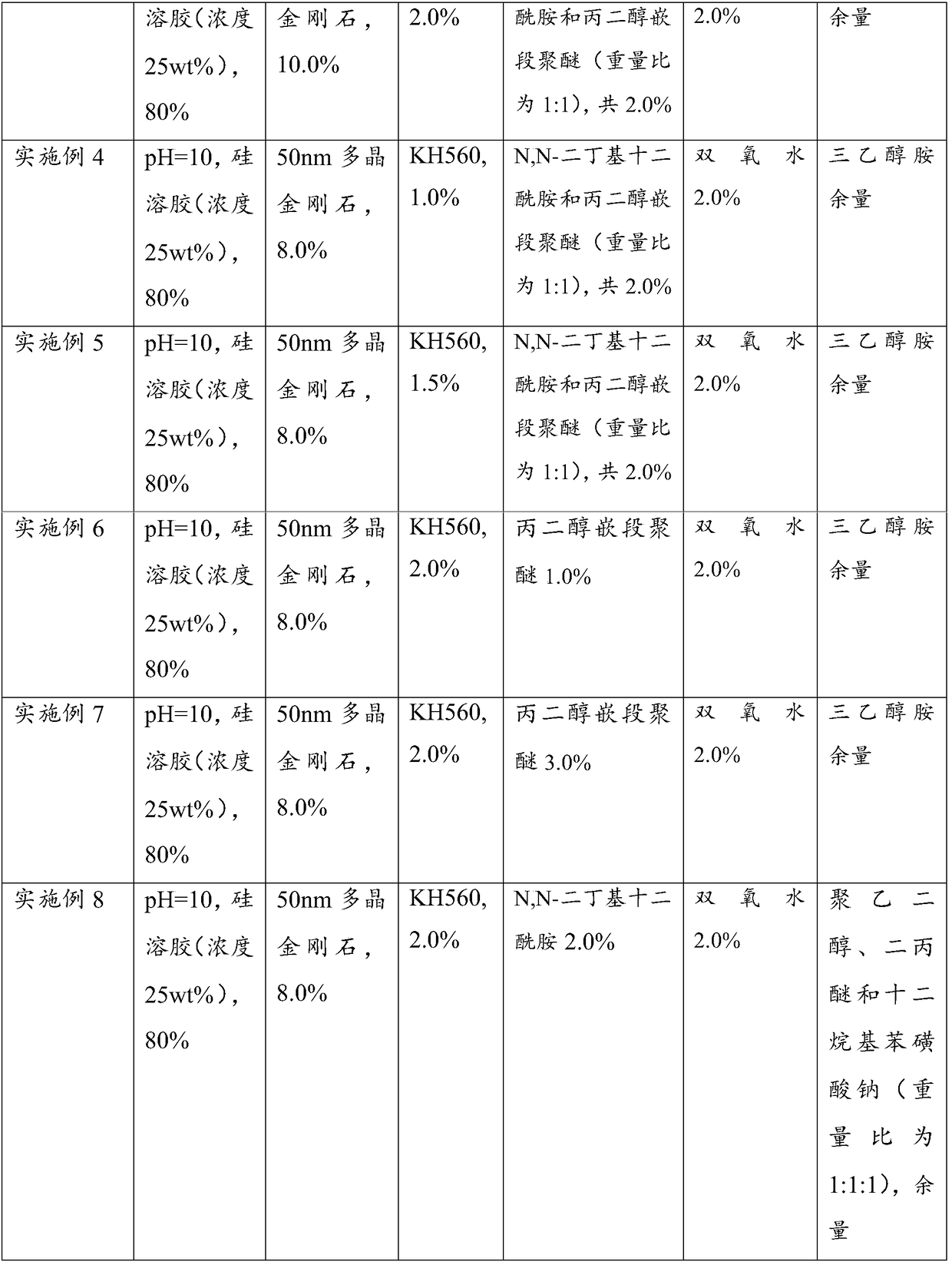

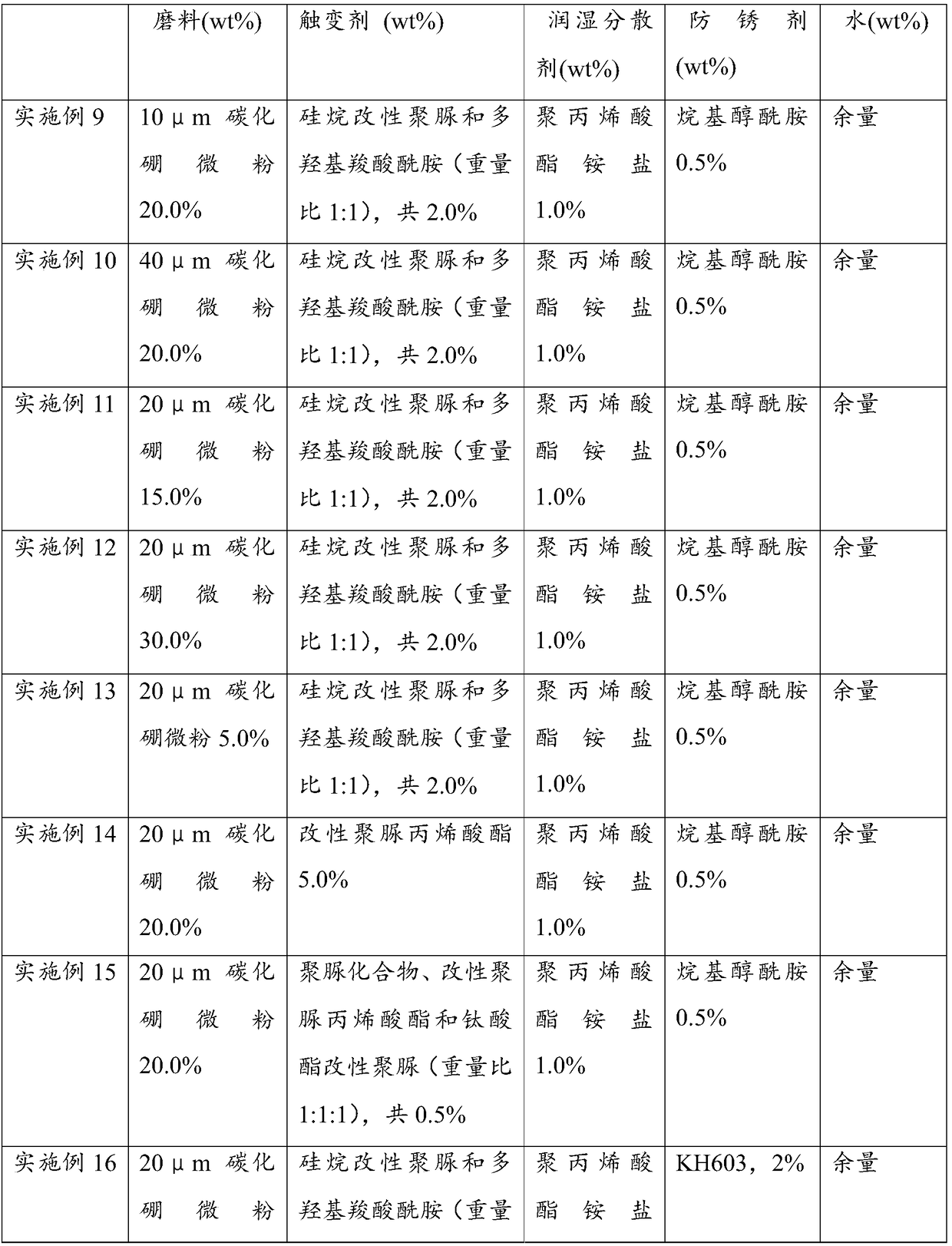

The invention relates to a polishing solution and a polishing method of silicon carbide crystals. The polishing solution comprises the following components in percentage by weight: 6-10% of nanoscalepolycrystalline diamond, 75-87% of alkaline silica sol, 1-2% of a silane coupling agent, 1-3% of an anti-crystallization agent, 1-2% of an oxidant, and the balance of amphiphilic organic matter. The polishing solution of the invention has the advantages of good wet spreading performance, high soft layer removal rate, being not prone to crystallization, and the like, and therefore polishing for silicon carbide solves the problems of low polishing rate and poor polishing effect. In addition, as the polishing solution is used in combination with a coarse grinding fluid and a fine grinding fluid,a high-speed, high-flatness, high-gloss, low-roughness polishing effect can be achieved.

Owner:BEIJING POLYSTAR HITECH CO LTD

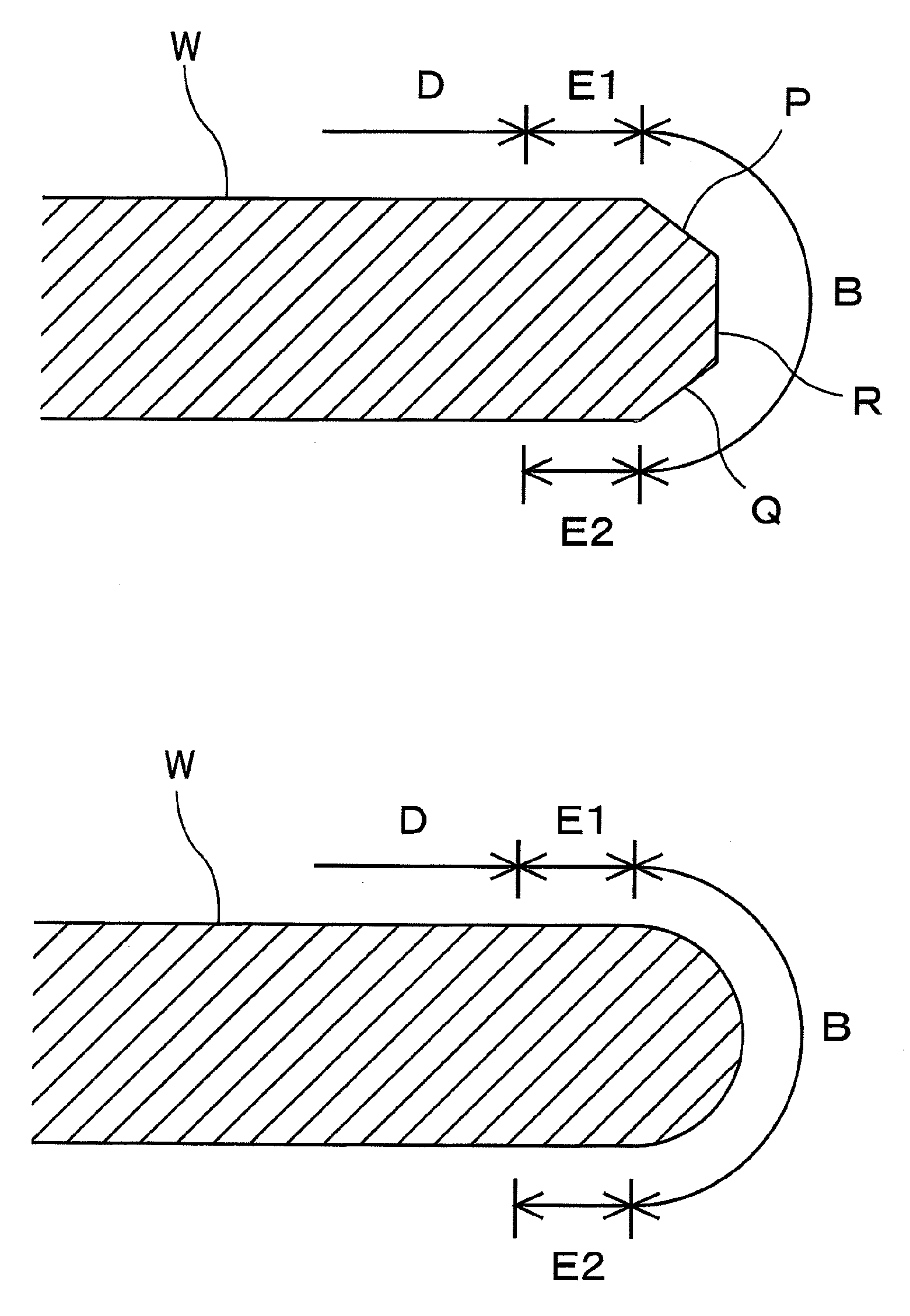

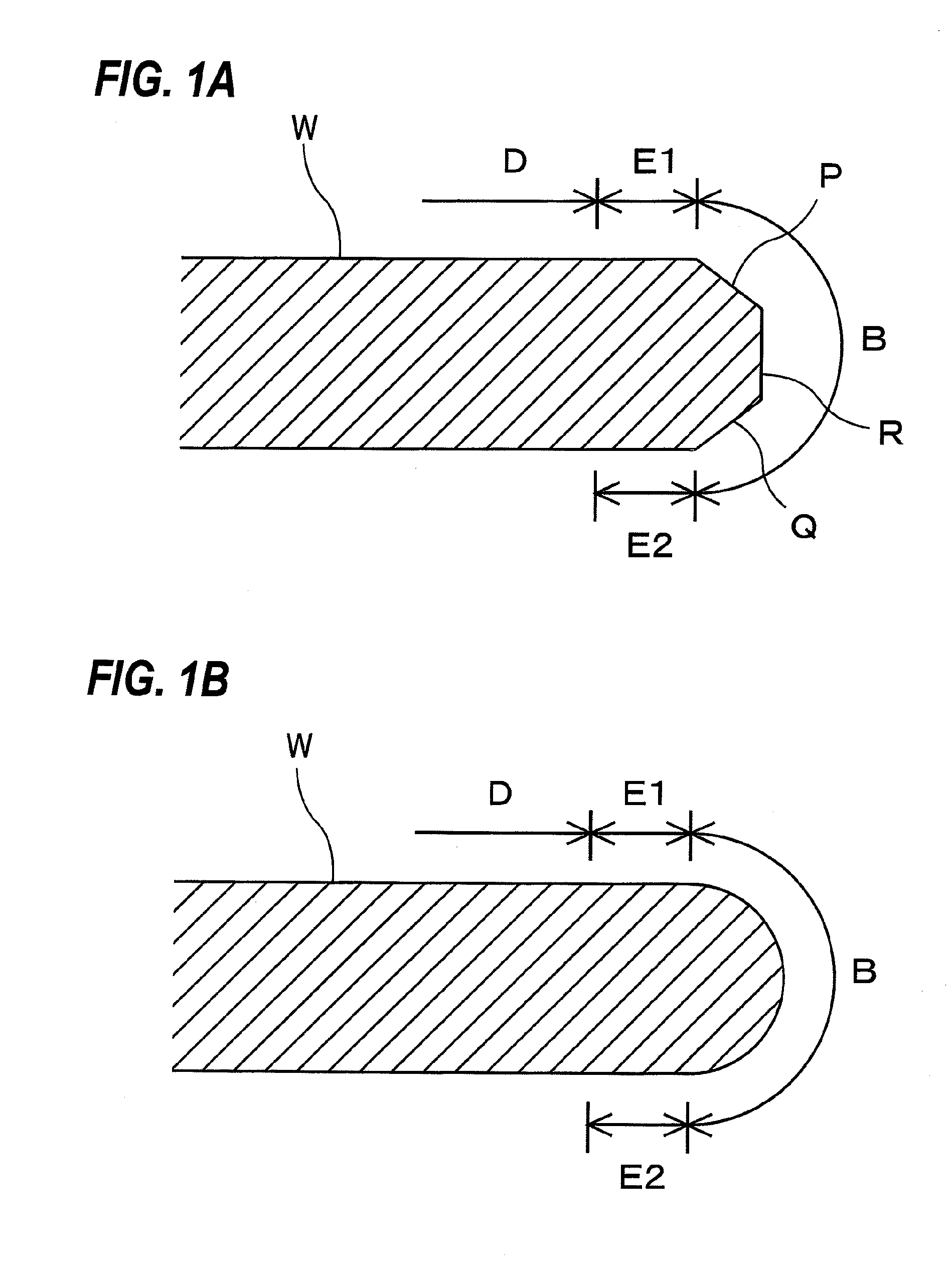

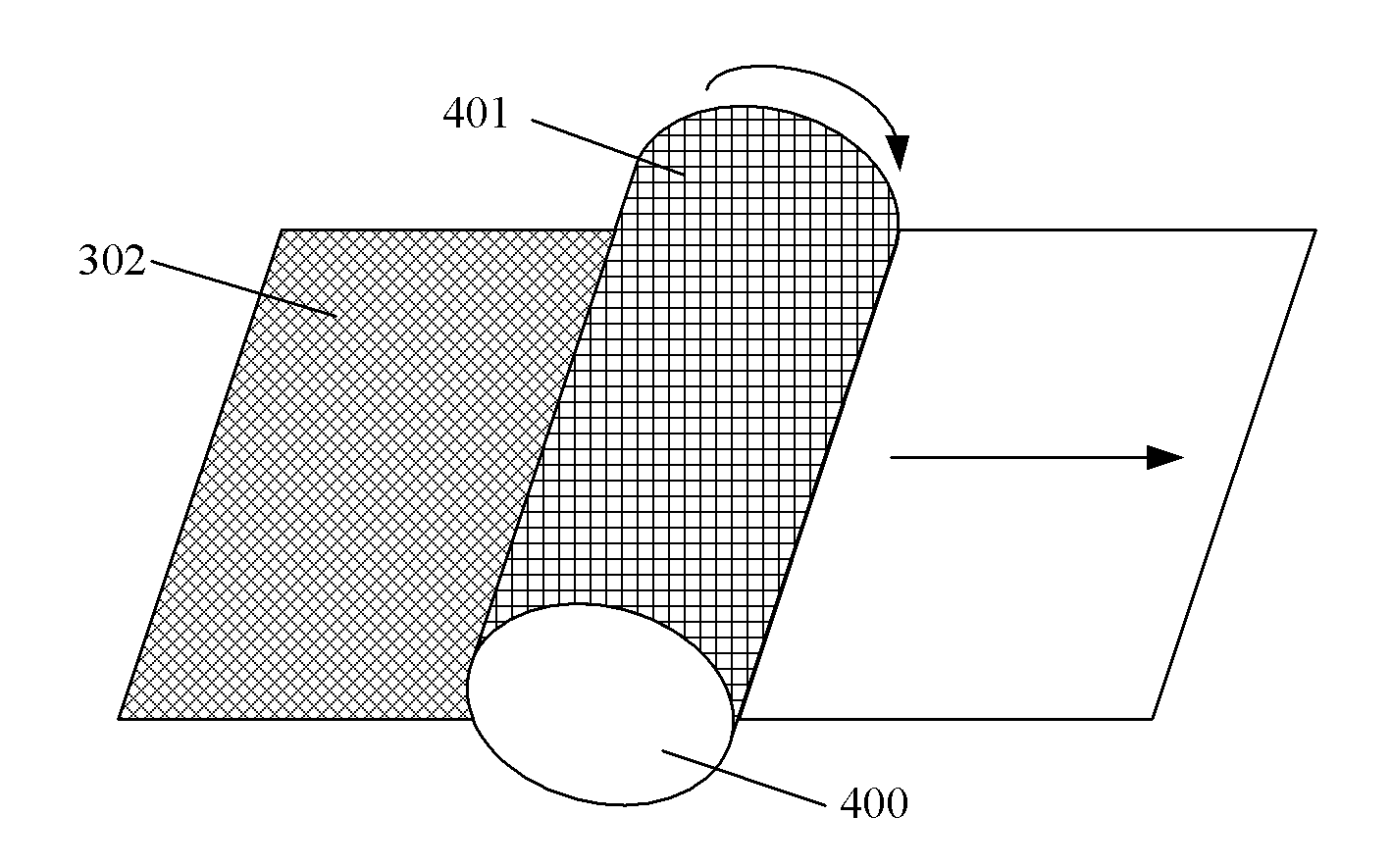

Method of polishing a substrate using a polishing tape having fixed abrasive

ActiveUS20120135668A1Reduce polishing rateAvoid adverse influenceEdge grinding machinesPolishing machinesEngineeringAbrasive

A method of polishing a peripheral portion of a substrate is provided. This method includes: causing sliding contact between the peripheral portion of the substrate and a polishing tape; and supplying a polishing liquid onto the polishing tape contacting the peripheral portion of the substrate. The polishing tape includes a base tape and a fixed abrasive formed on the base tape, and the polishing liquid is an alkaline polishing liquid containing an alkaline chemical and an additive including molecules that cause steric hindrance.

Owner:EBARA CORP

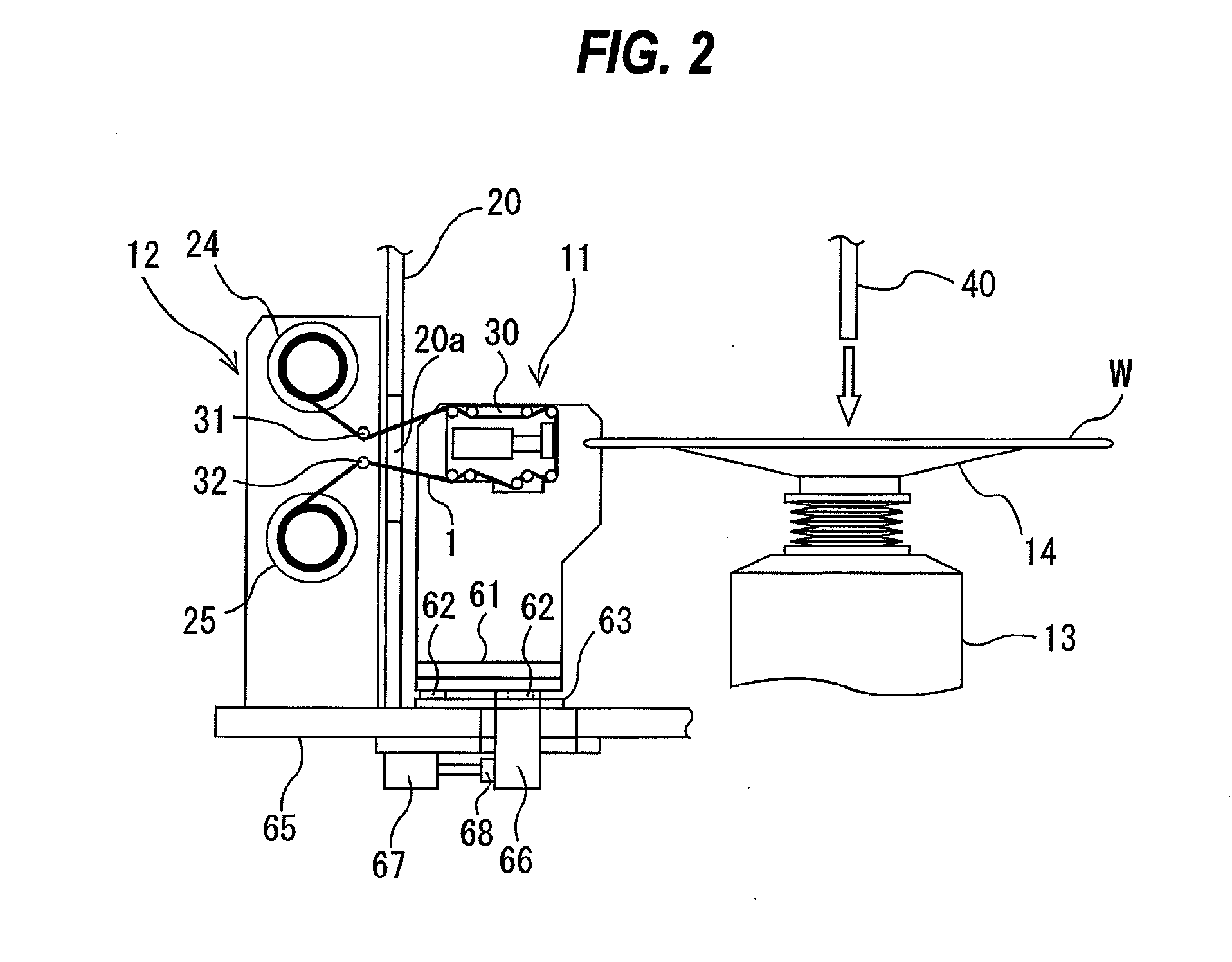

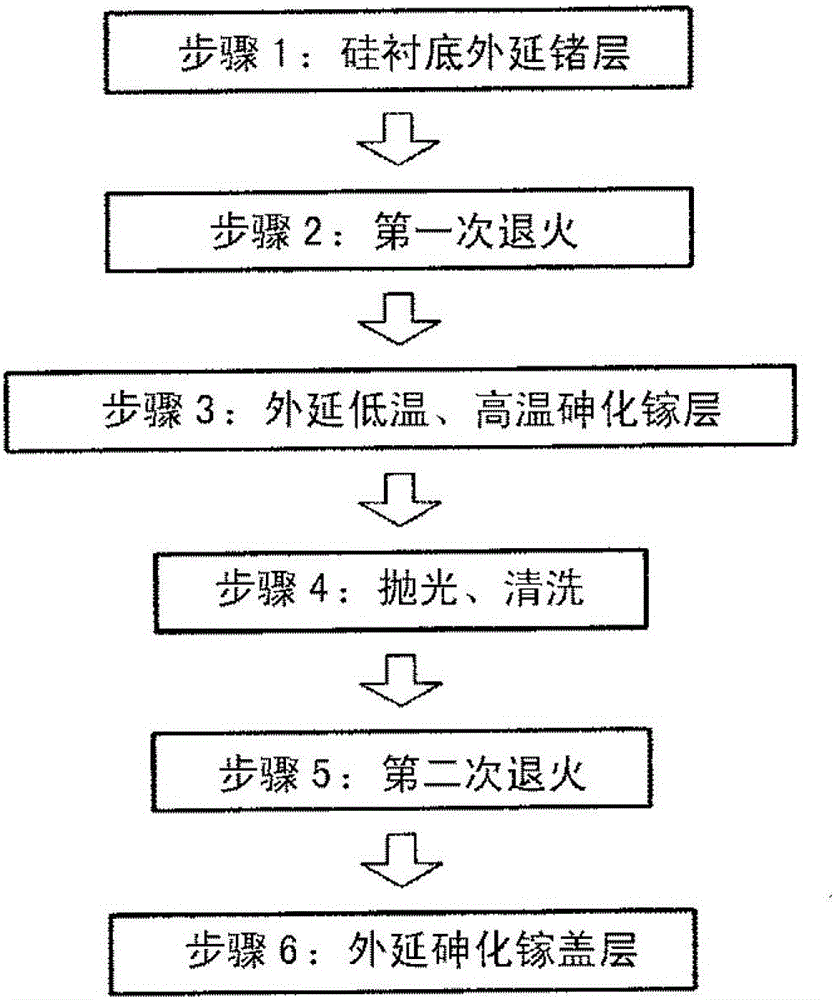

Preparation method for silica-based gallium arsenide material with high quality and low surface roughness

ActiveCN103311106AReduce polishing rateSemiconductor/solid-state device manufacturingFrom chemically reactive gasesOrganic chemicalsGermanium

The invention discloses a preparation method for silica-based gallium arsenide material with high quality and low surface roughness. The preparation method comprises the following steps: step 1, a germanium layer is grown on a silicon substrate; step 2, the silicon substrate on which the germanium layer is grown is placed in an MOCVD (metal-organic chemical vapor deposition) reaction chamber to be subjected to annealing for the first time; step 3, a low-temperature gallium arsenide nucleating layer and a high-temperature gallium arsenide layer are grown on the germanium layer in sequence to form a sample; step 4, the sample is polished and rinsed; step 5, the sample is put in the MOCVD reaction chamber to be subjected to annealing for the second time; and step 6, a gallium arsenide cover layer is grown on the surface of the sample, and the preparation of the silica-based gallium arsenide material is finished. The preparation method for the silica-based gallium arsenide material with high quality and low surface roughness can solve the transition problem of the silicon substrate to III-V material and establishes the basis of substrate for silica-based gallium arsenide photoelectric and microelectronic devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

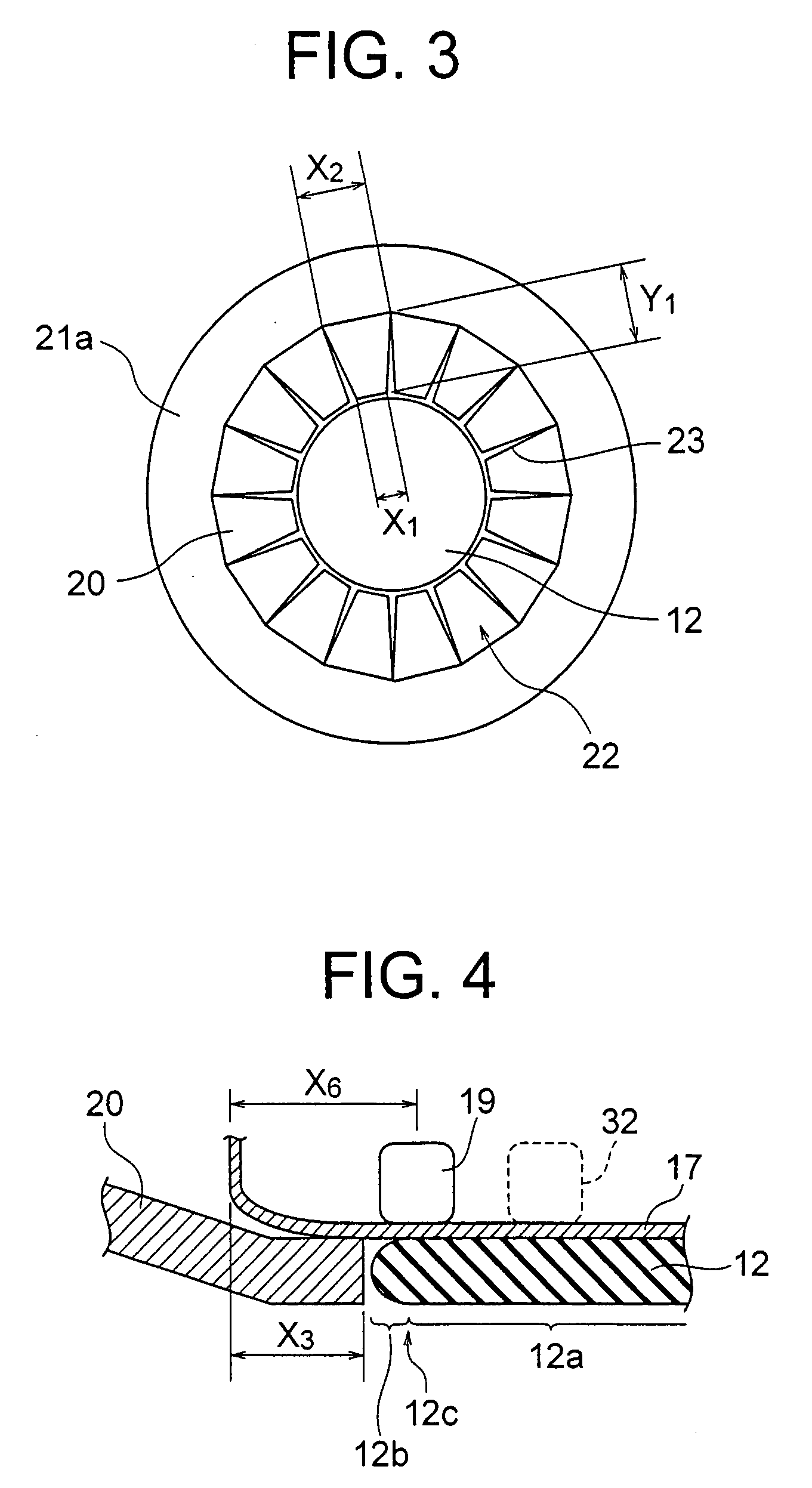

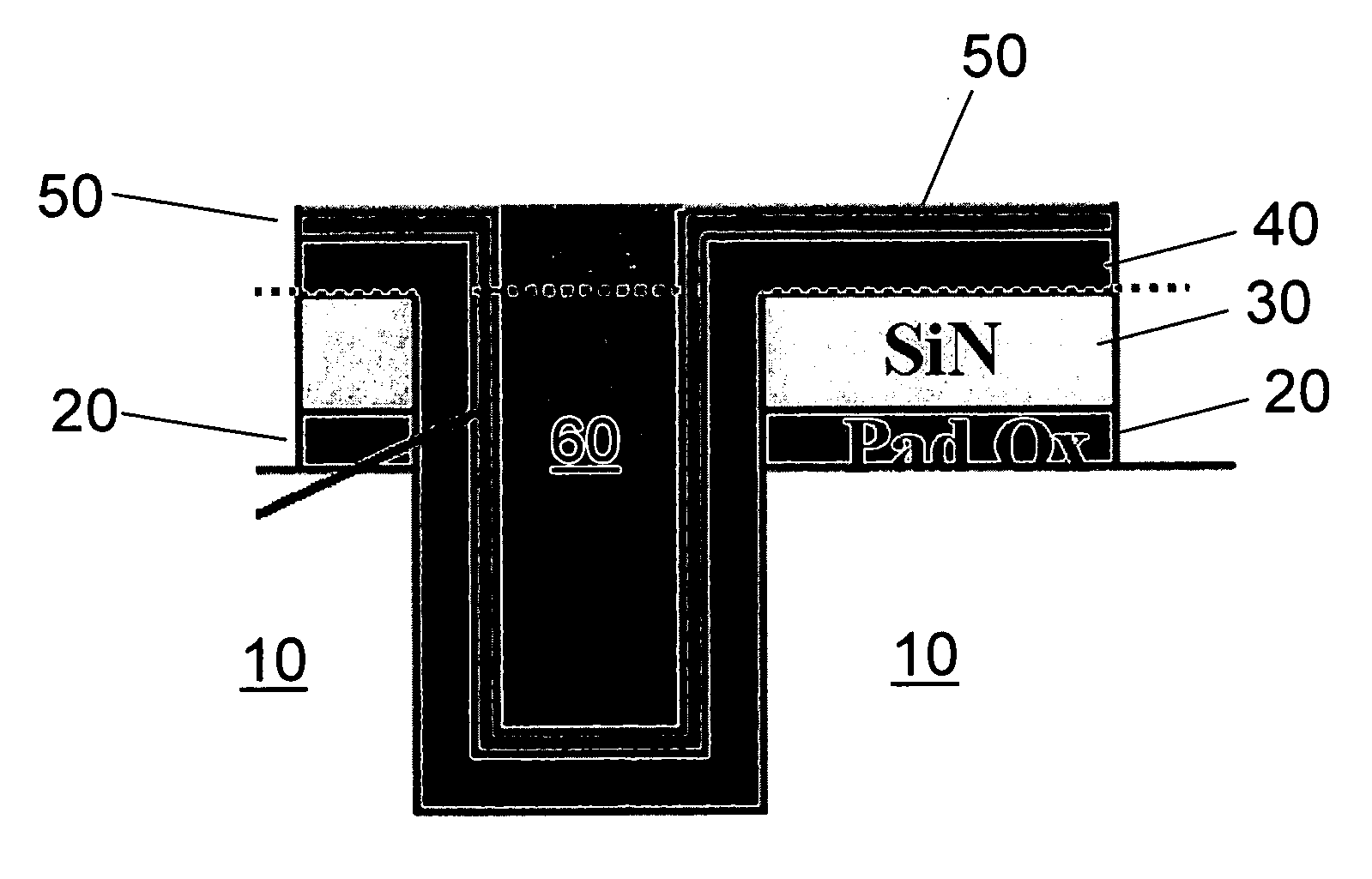

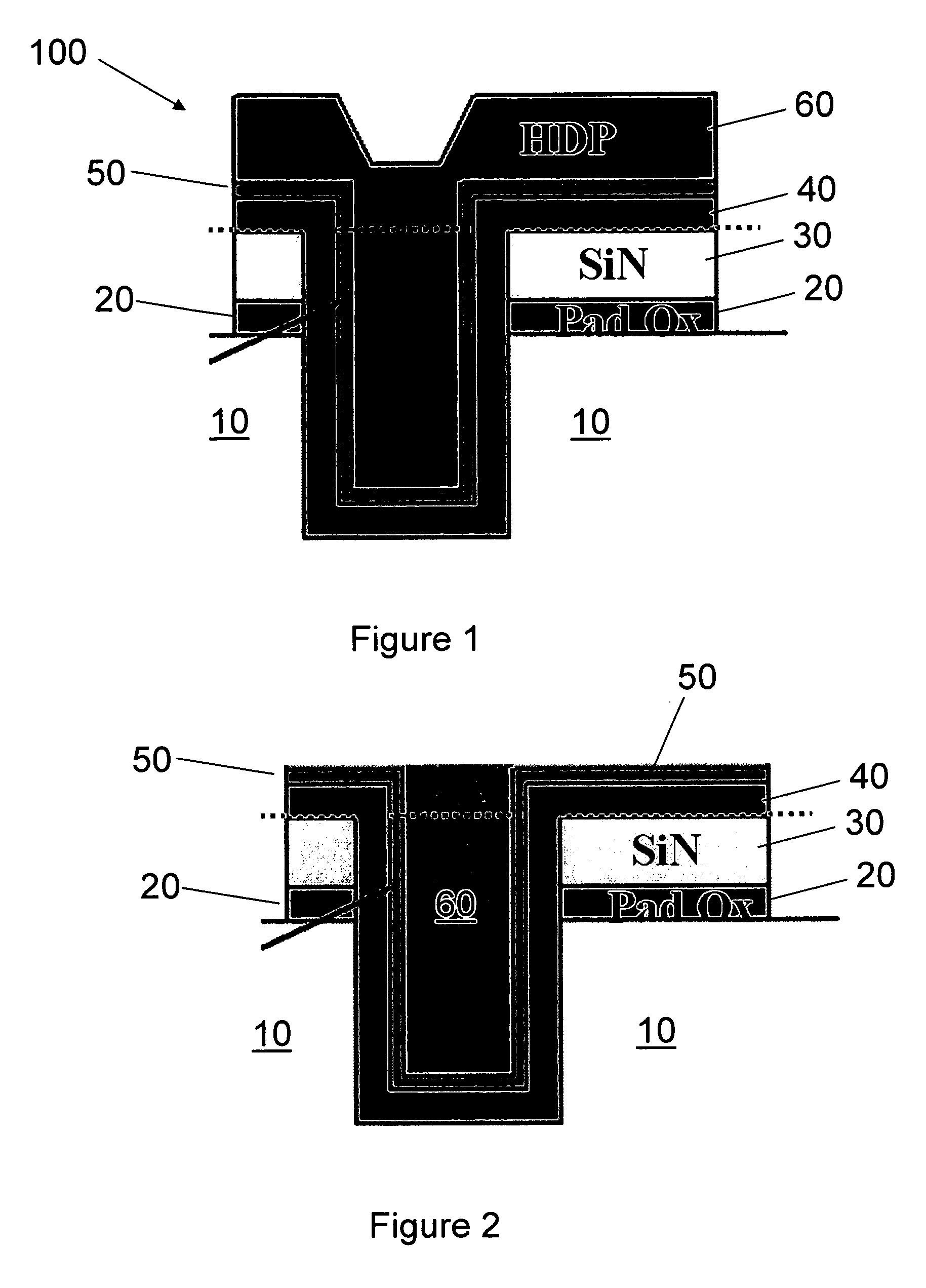

Chemically mechanical polishing solution

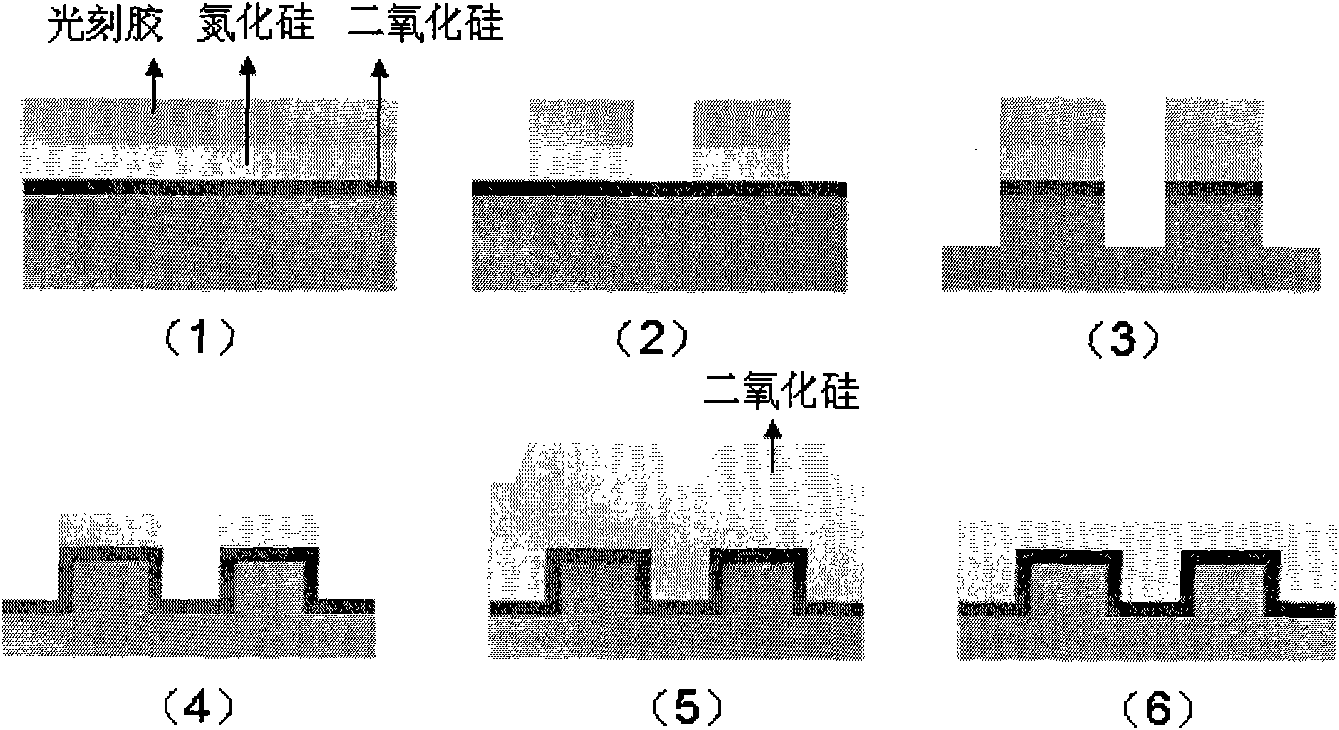

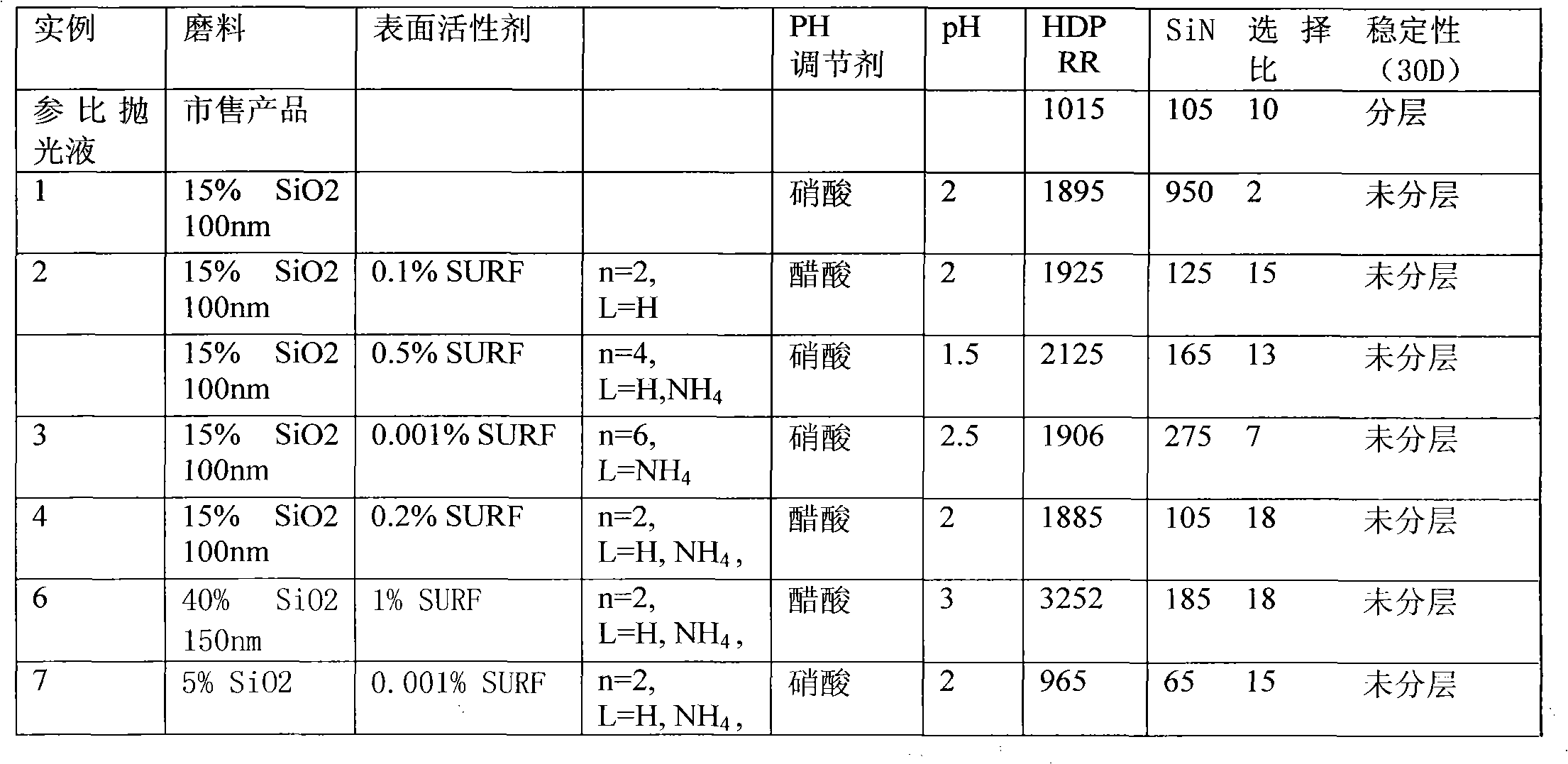

InactiveCN102464945AHigh HDP removal rateProlong settling timePolishing compositions with abrasivesWater solubleHigh silica

The invention discloses a chemically mechanical polishing solution used for shallow-trench isolation. The polishing solution at least contains one silicon-based abrasive material, one water-soluble anionic surfactant and one pH regulator, and has higher silica removal rate and lower silicon nitride removal rate, a polished surface is smooth and clean, and the chemically mechanical polishing solution has good stability and is suitable for the chemical-mechanical planarization for the shallow-trench isolation.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

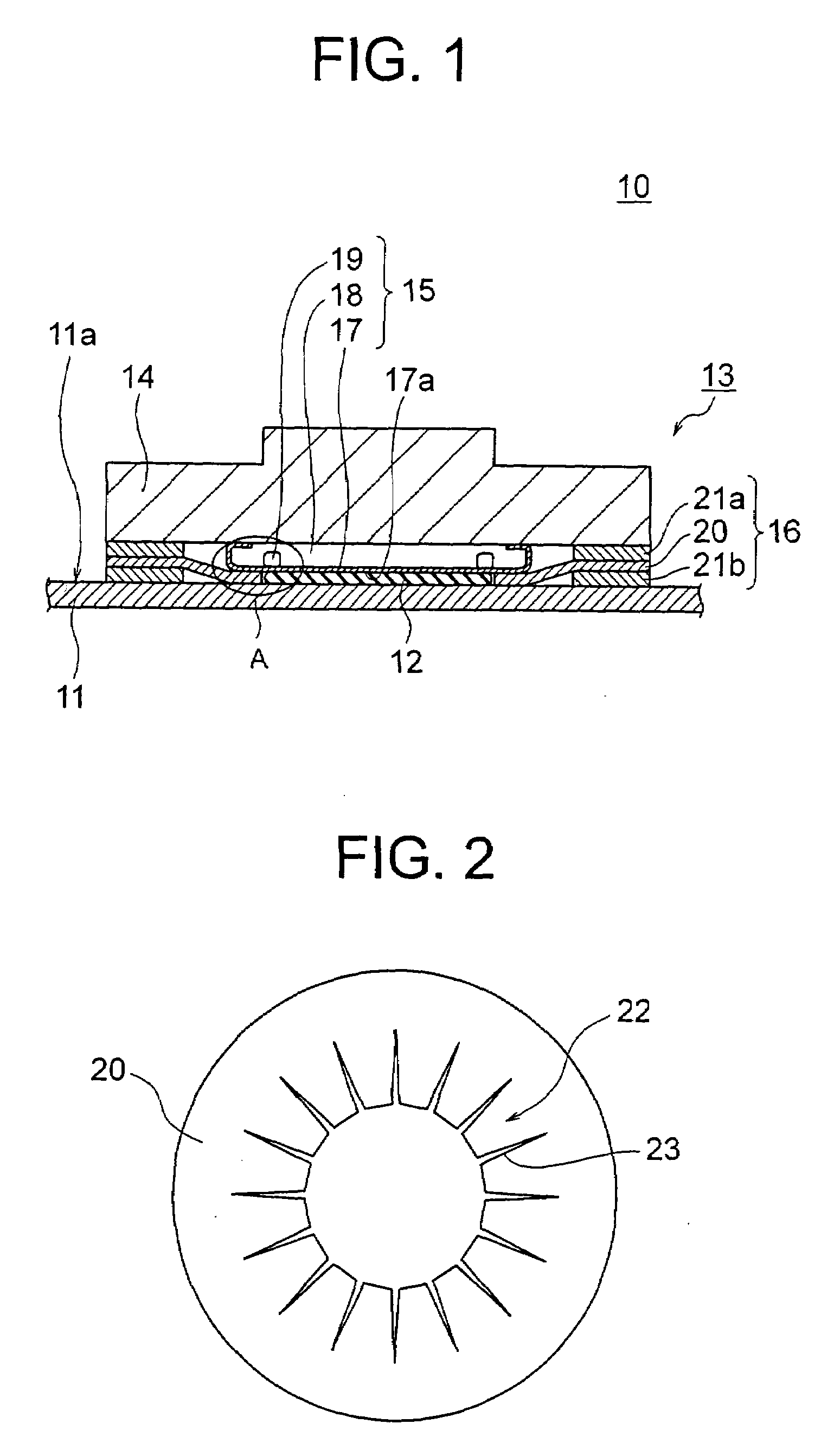

Polishing device

ActiveUS20070270089A1Reduce polishing rateImprove within-wafer uniformityPolishing machinesRevolution surface grinding machinesIn planeBiomedical engineering

A polishing device includes a polishing pad for polishing a wafer and a polishing head for holding the wafer. The polishing head has a retainer ring for retaining the wafer in the in-plane direction of the wafer, a membrane sheet for pressing the wafer against the polishing pad, and a head body for supporting the retainer ring and the membrane sheet. The retainer ring has a subordinate retainer member having a ring portion and a plurality of fins extending from the ring portion to retain the peripheral surface of the wafer. The subordinate retainer member has a thickness equal to the thickness of the wafer. The membrane sheet has a diameter larger than the wafer, and presses the wafer and the vicinity of the inner edge of the subordinate retainer member.

Owner:MICRON TECH INC

Chemical mechanical polishing process

ActiveUS20070202702A1Reduce polishing rateDecorative surface effectsSemiconductor/solid-state device manufacturingCompound (substance)Chemo mechanical

A chemical mechanical polishing method is disclosed. The method includes forming a film on a wafer having at least one trench structure thereon; polishing the surface of the film by providing a polishing composition to provide a first polished surface; rinsing the first polished surface with a rinse composition to provide a rinsed surface; and polishing the rinsed surface by providing a second polishing composition to provide a second polished surface.

Owner:MACRONIX INT CO LTD

Chemo-mechanical polishing solution

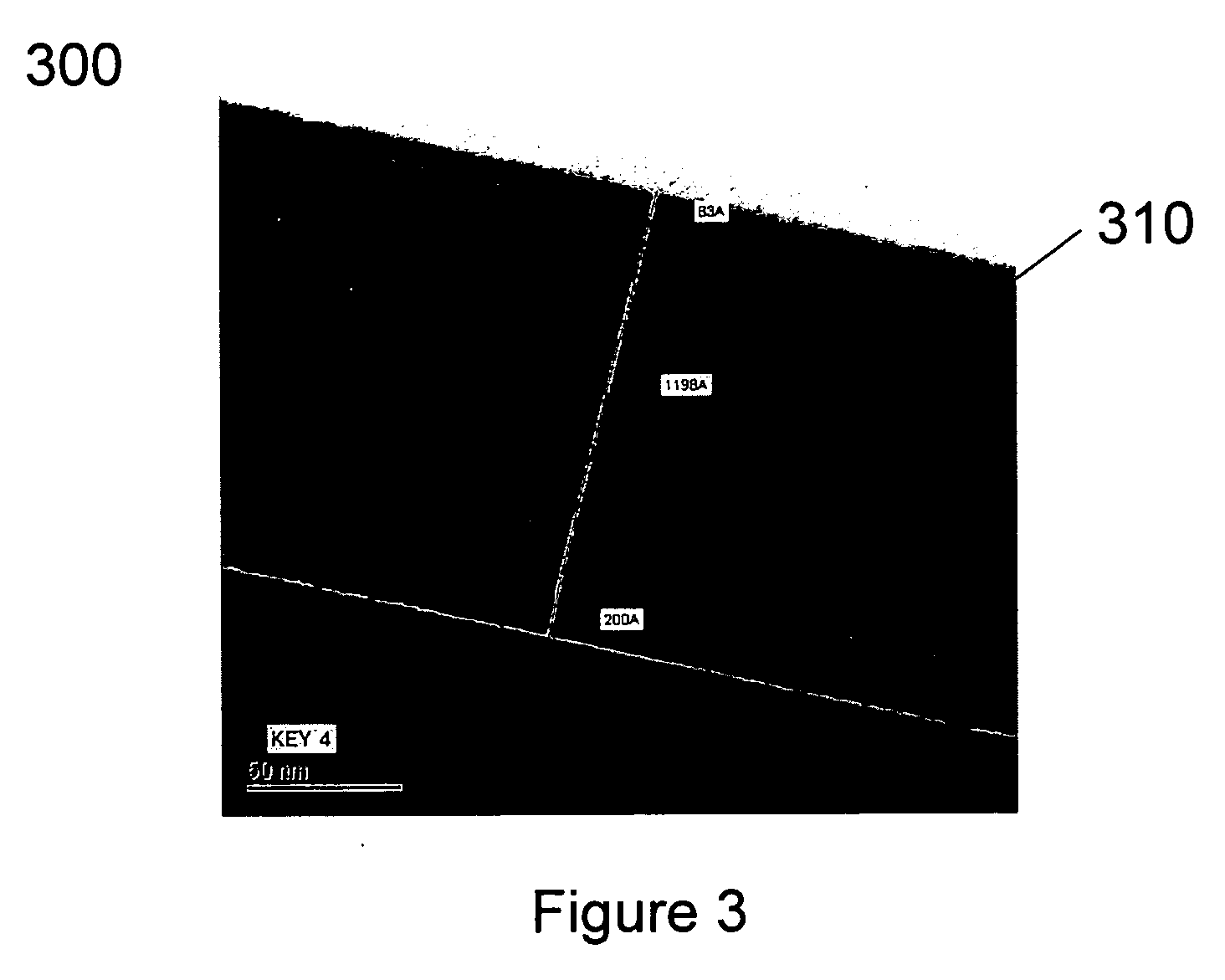

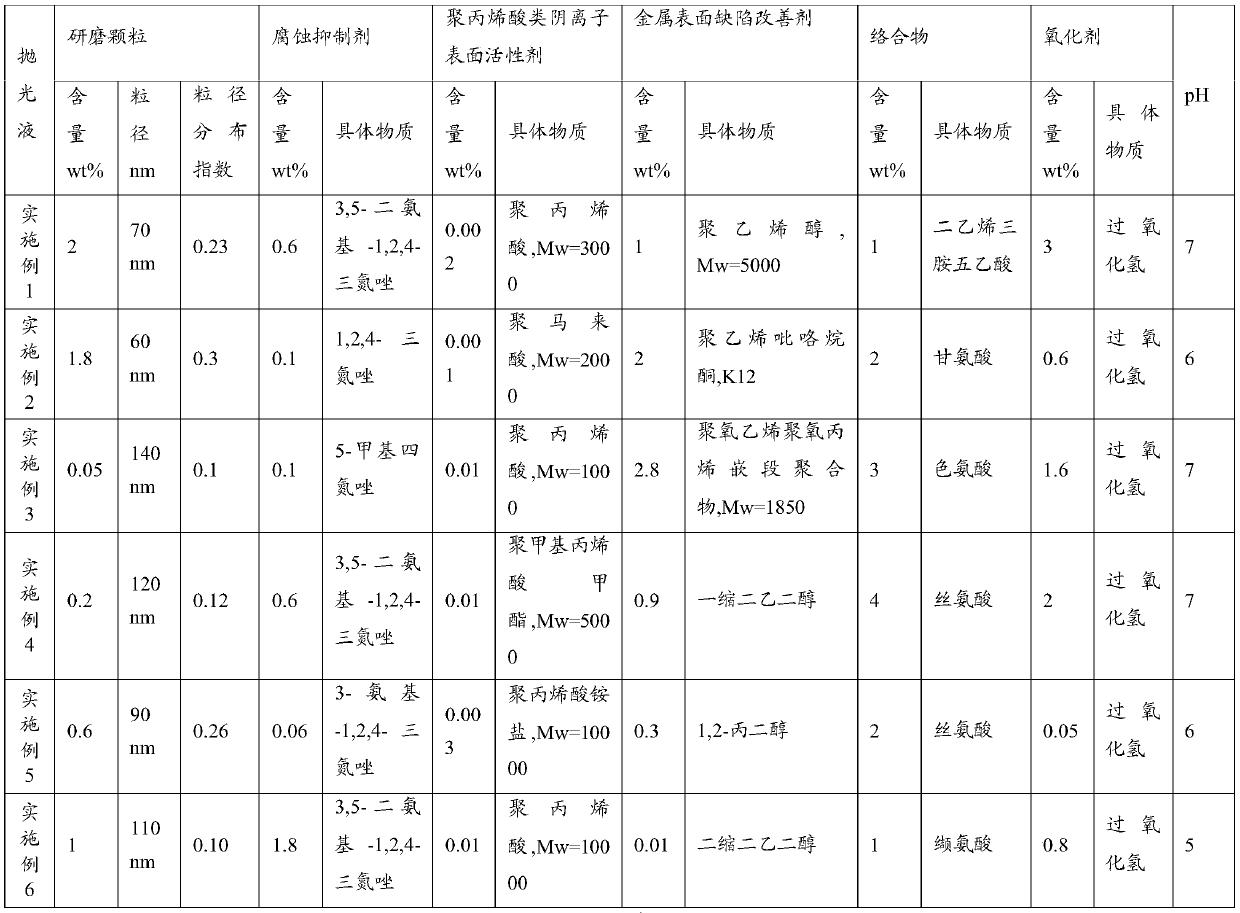

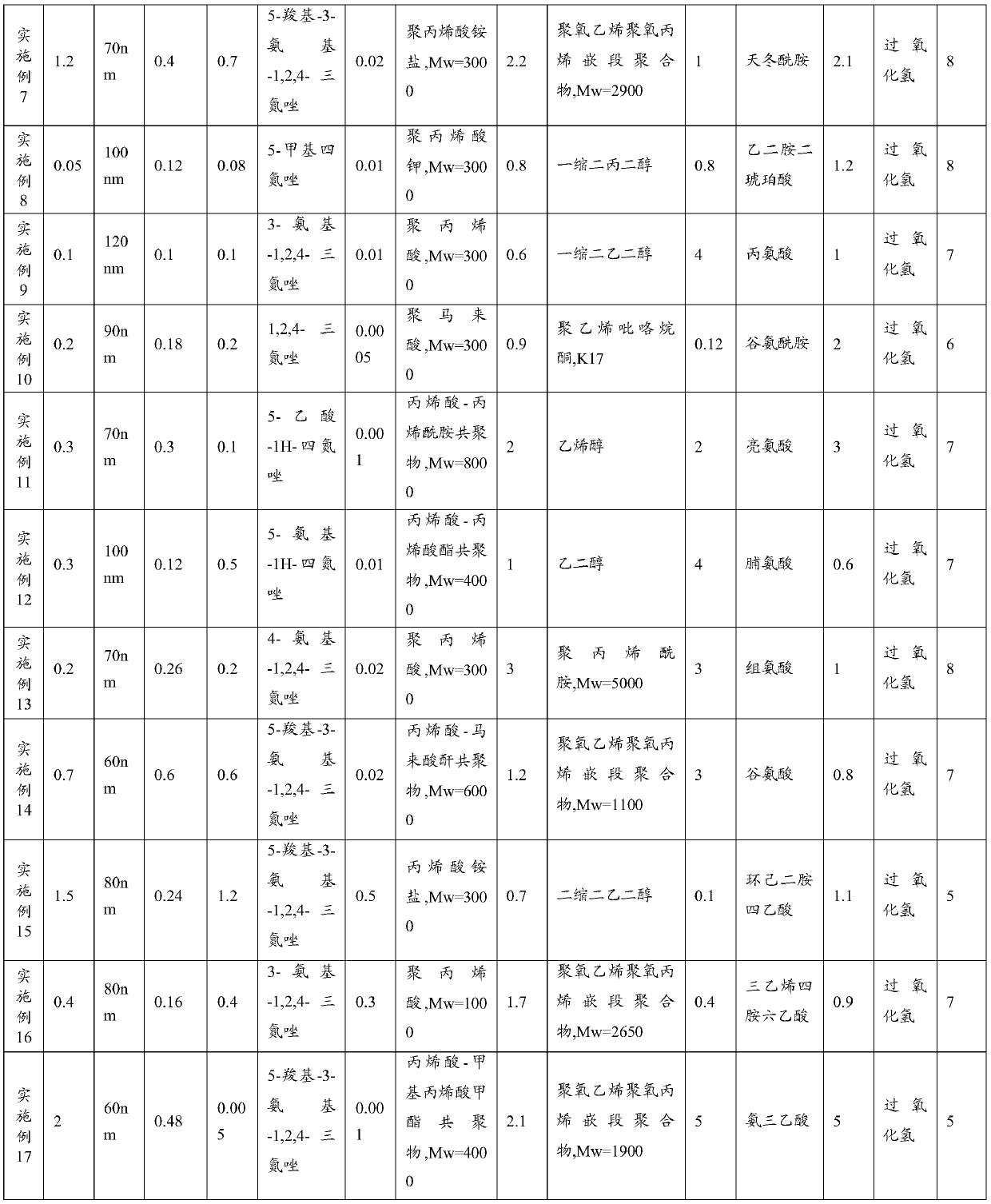

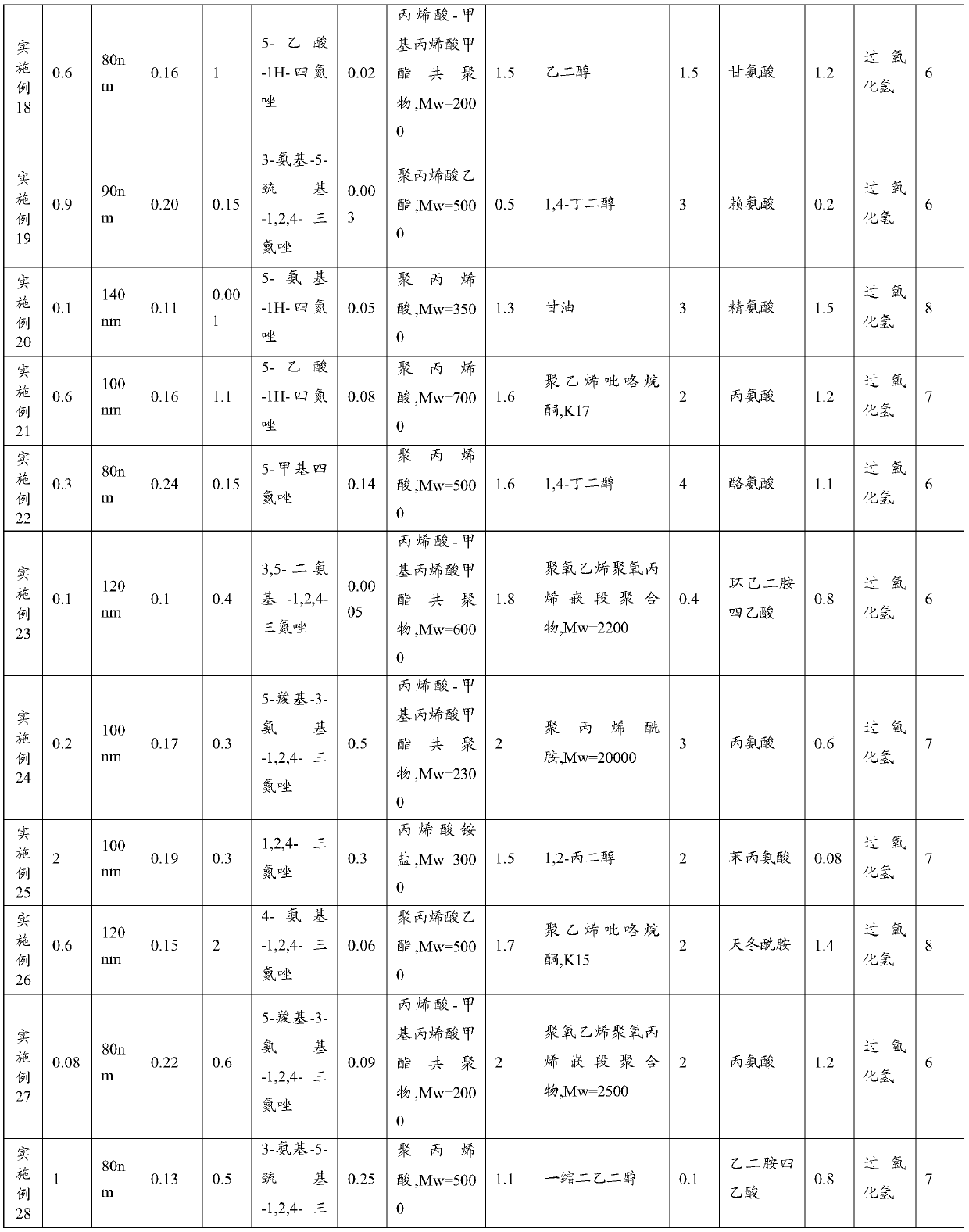

The invention provides a chemo-mechanical polishing solution which comprises silicon dioxide grinding particles, a corrosion inhibitor, a complexing agent, an oxidant, at least one polyacrylic acid anionic surfactant and a metal surface defect improver. The polishing solution has the advantages that 1) the polishing solution is high in polishing rate to copper and low in polishing rate to tantalum, so that the polishing solution has a relatively high copper / tantalum polishing rate selection ratio; 2) the polishing solution can improve disc sinking and medium layer erosion of a polished copperwire; and 3) the polishing solution can improve the surface roughness of the polished copper, so that defects are reduced.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

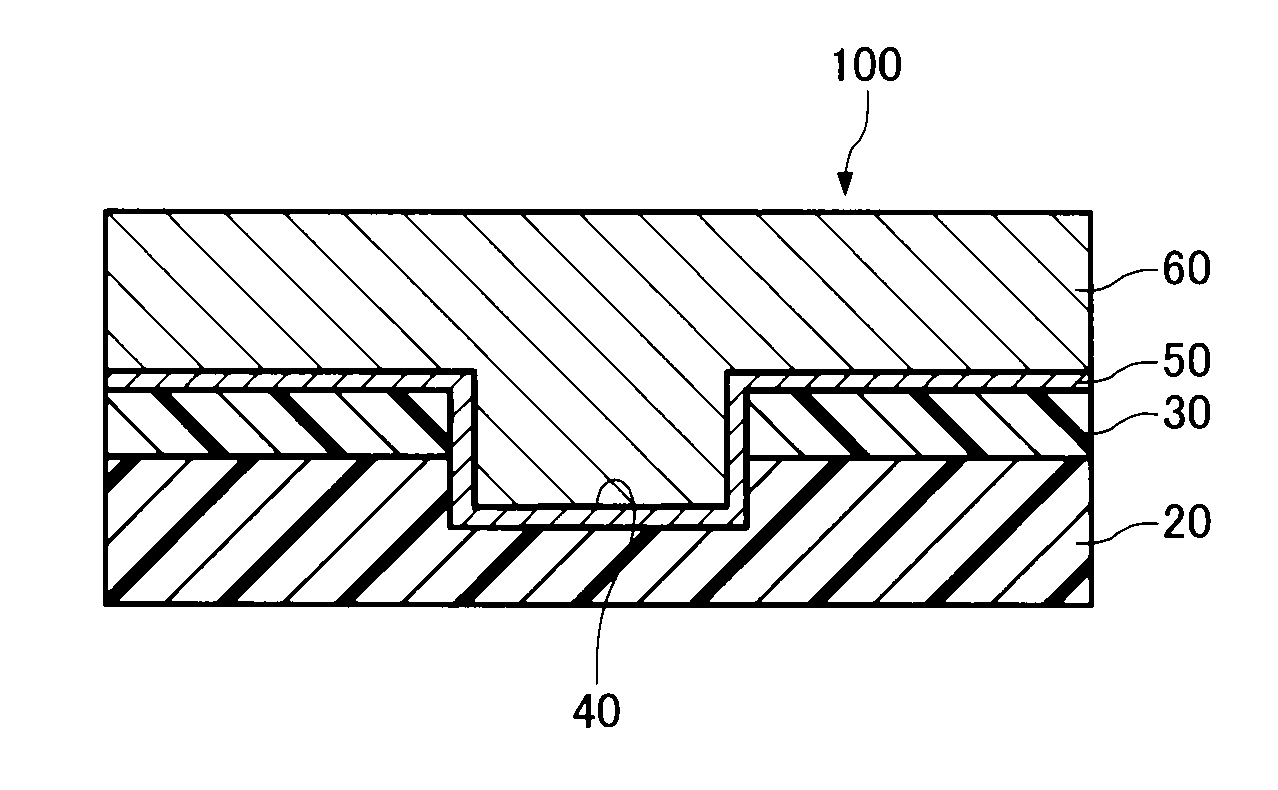

Polishing pad and methods for manufacturing and using the same

InactiveUS20120190276A1Reduce polishing rateComplement polishing efficacyOther chemical processesAbrasion apparatusEngineeringWafering

This invention provides a polishing pad, which includes a substrate and a plurality of discrete abrasive blocks fixed on the substrate, wherein the abrasive blocks are of at least two kinds of heights. This invention would not reduce the polishing rate dramatically during the process for polishing a wafer by using the polishing pad in the long run. Therefore a thickness of the wafer to be polished is able to be controlled accurately, thereby improving the effect and yield of polishing the wafer. The present invention further provides a method for manufacturing the polishing pad. The polishing pad according to this invention is manufactured conveniently by using this method. Correspondingly, a method for using the polishing pad is also provided in this invention.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Silicone modified acrylic resin and application

ActiveCN111533854AReduce polishing rateReduce contentAntifouling/underwater paintsPaints with biocidesPolymer chemistryAcrylic resin

Owner:上海亿祺化工技术有限公司 +1

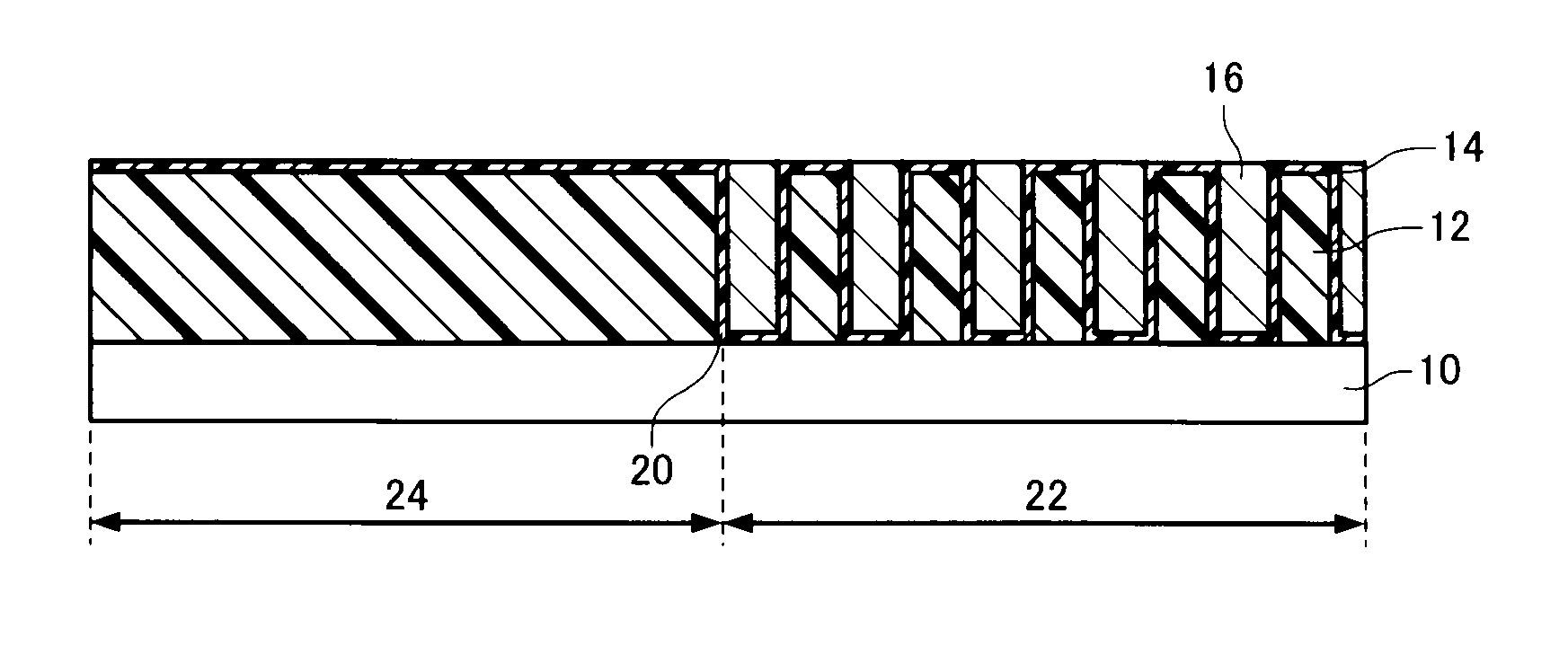

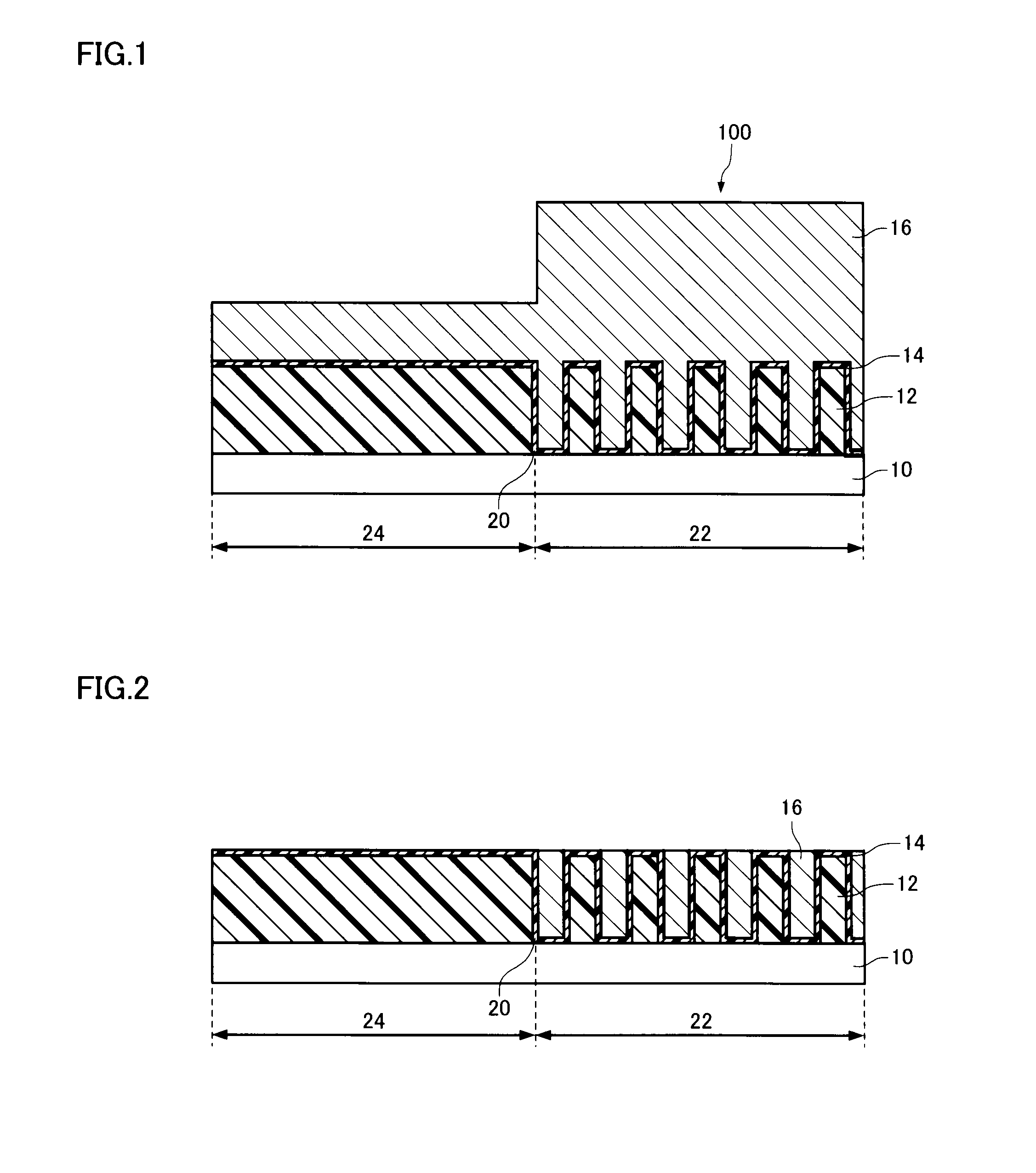

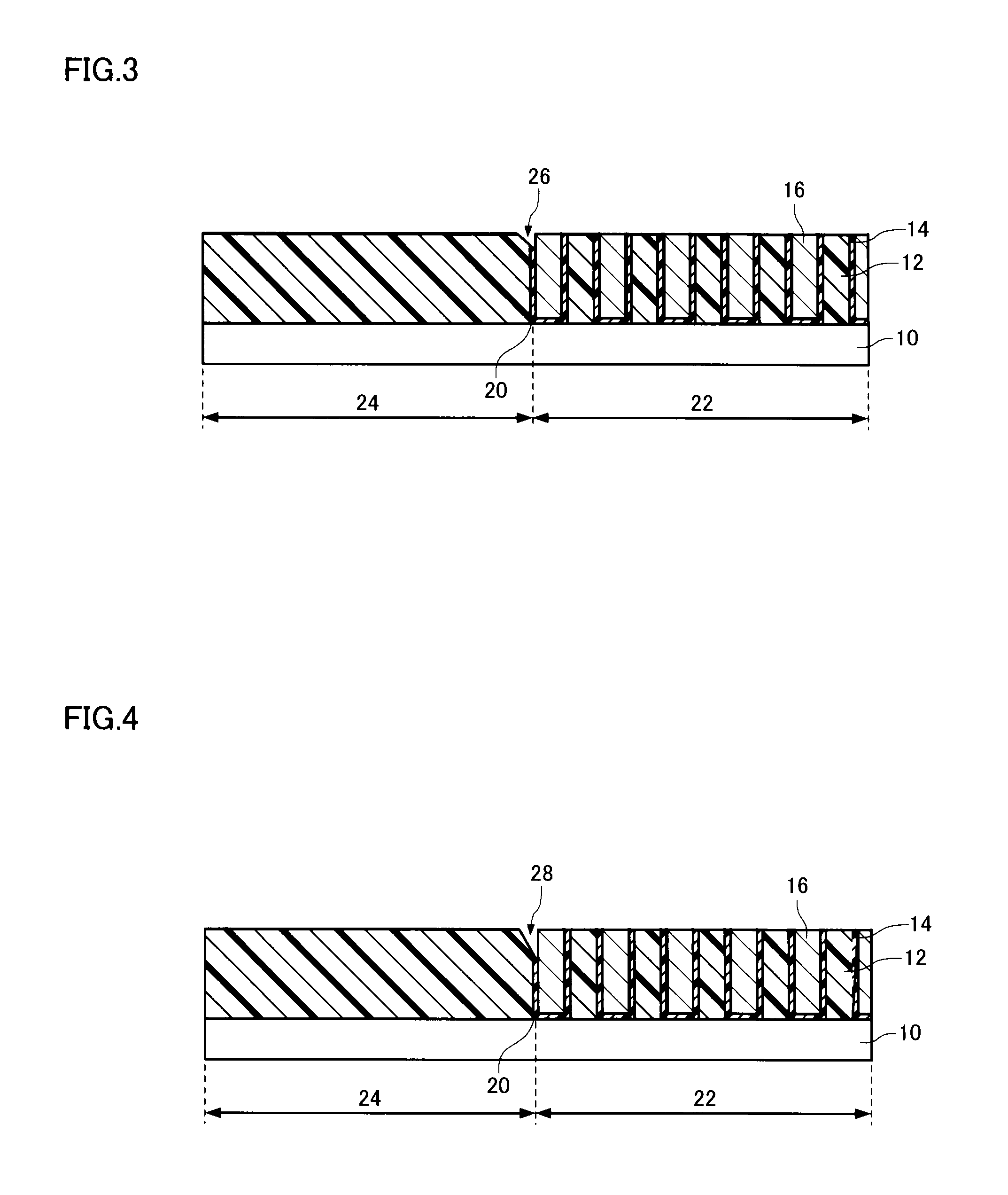

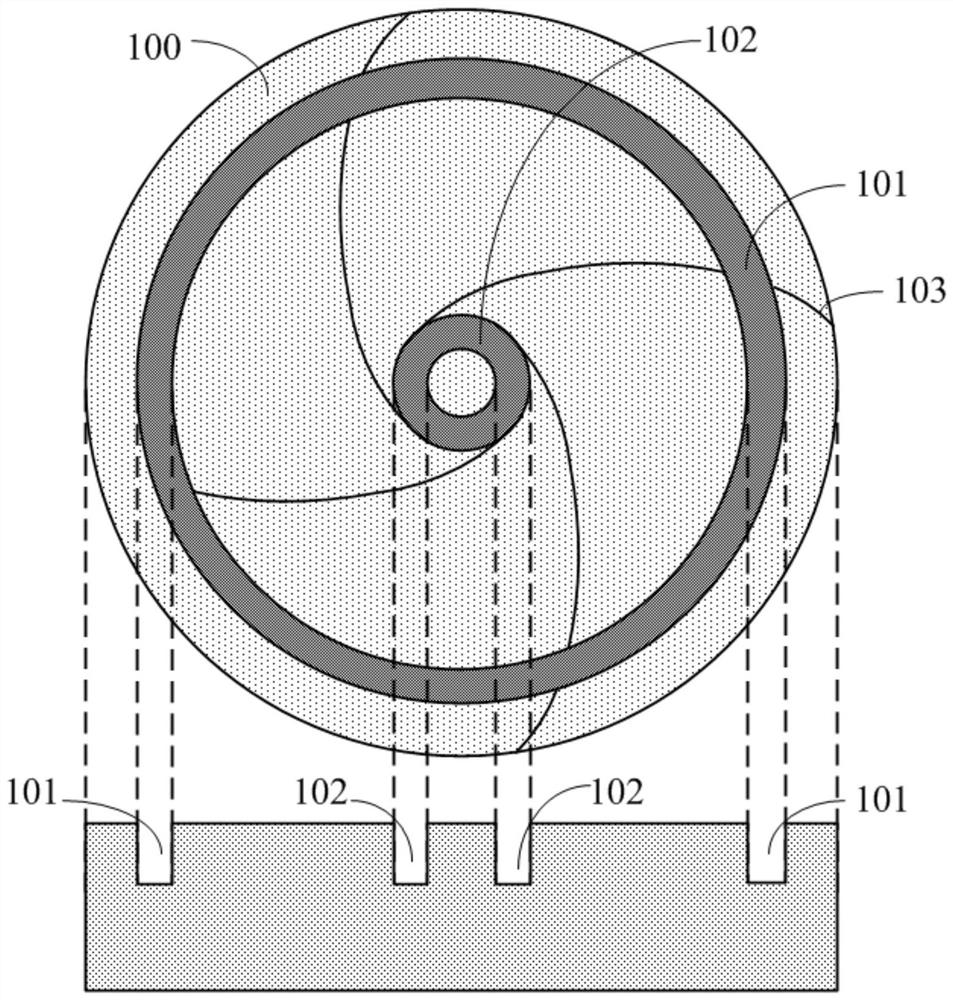

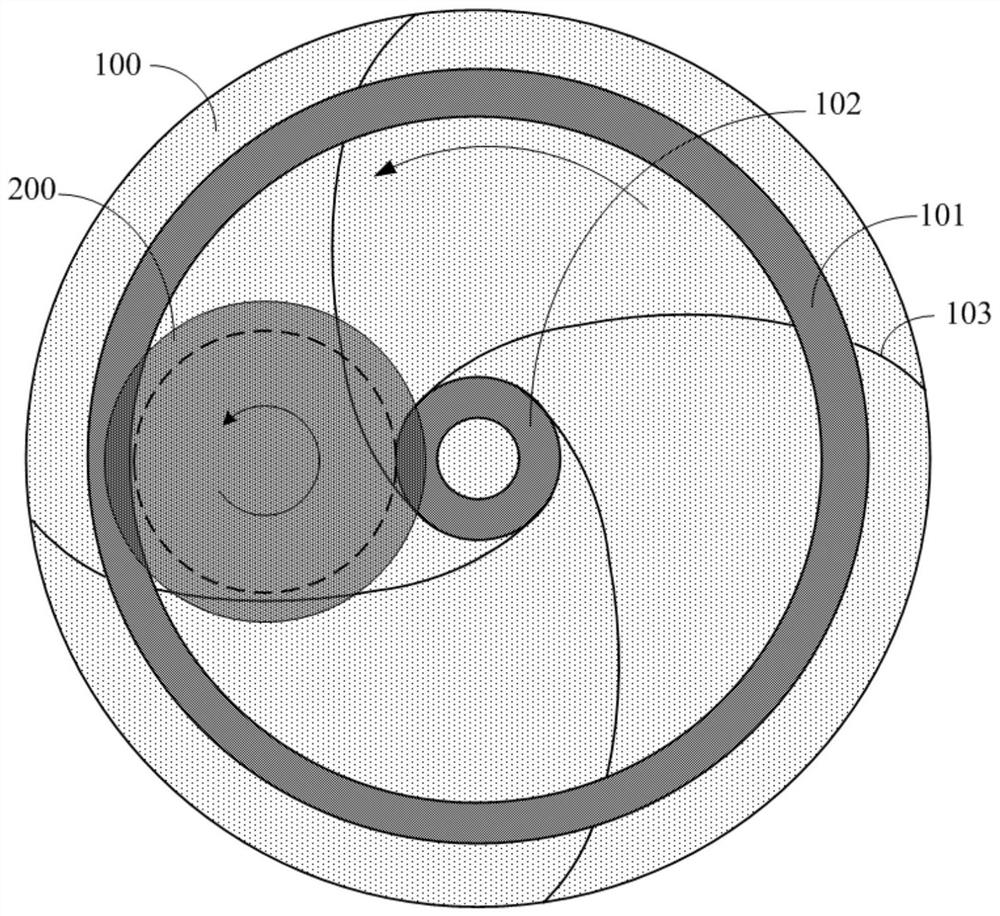

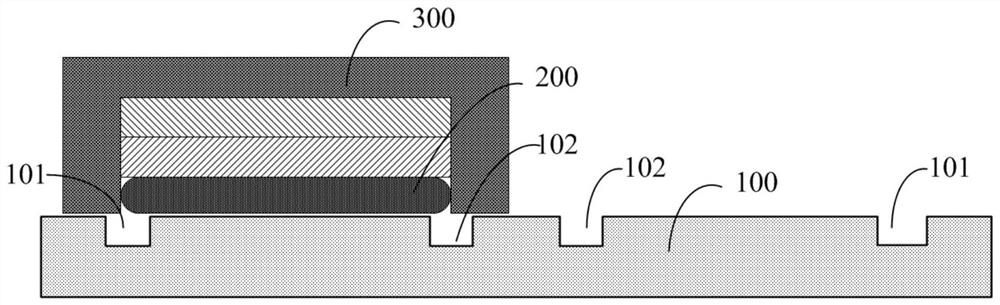

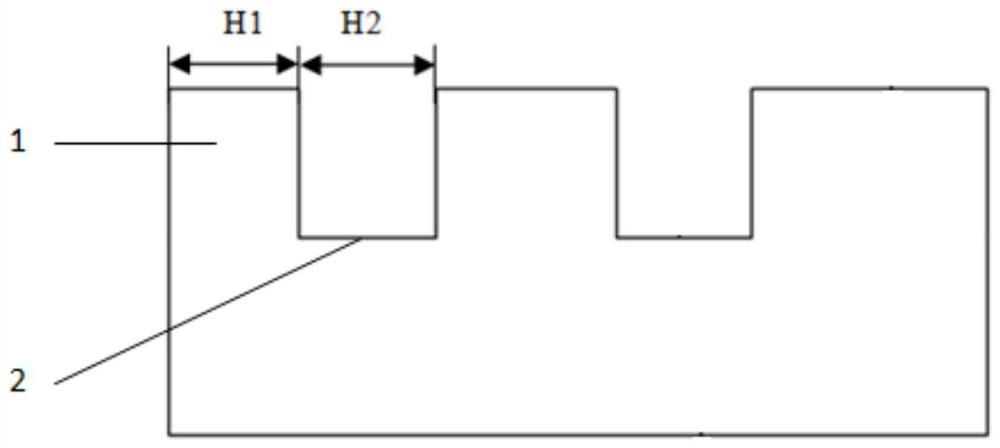

Polishing pad, polishing equipment and polishing method of silicon wafer

PendingCN111941251AReduce polishing rateImprove flatnessPolishing machinesSemiconductor/solid-state device manufacturingPolishingSilicon chip

The invention provides a polishing pad, polishing equipment and a polishing method of a silicon wafer. The polishing pad comprises a polishing surface in contact with the silicon wafer, the polishingsurface is provided with at least one groove, the grooving positions of the grooves enable the edge of the silicon wafer to be at least partially suspended above the grooves when the silicon wafer ispolished. According to the polishing pad, the polishing equipment and the polishing method of the silicon wafer, only the polishing rate of the edge position of the silicon wafer is reduced under thecondition that the polishing rate of the whole wafer is kept basically unchanged, so that the flatness of the edge thickness of the silicon wafer is improved, and the product yield is increased.

Owner:ZING SEMICON CORP

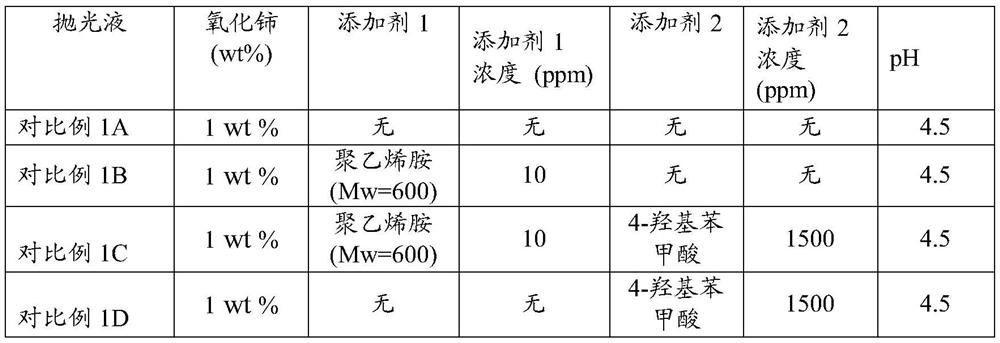

Chemical mechanical polishing solution

PendingCN113004797AImprove polishing rateReduce polishing rateOther chemical processesSemiconductor/solid-state device manufacturingPhysical chemistryCerium

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises water, cerium oxide, polyquaternium salt, carboxylic acid containing a benzene ring and polyvinylamine. Only when the polyquaternium salt, the carboxylic acid containing the benzene ring and the polyvinylamine are used together, the real automatic stopping function can be achieved, a blank wafer has the low polishing rate, the high polishing rate is kept when the step height of the patterned silicon wafer is high, the lower the step height is, the better the polishing speed is restrained, and the better the polishing effect is achieved. Therefore, the automatic stop function is realized.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemical mechanical polishing solution

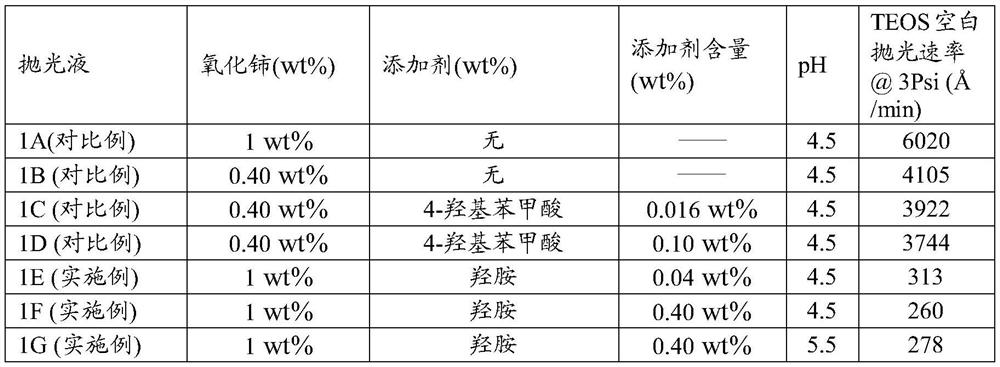

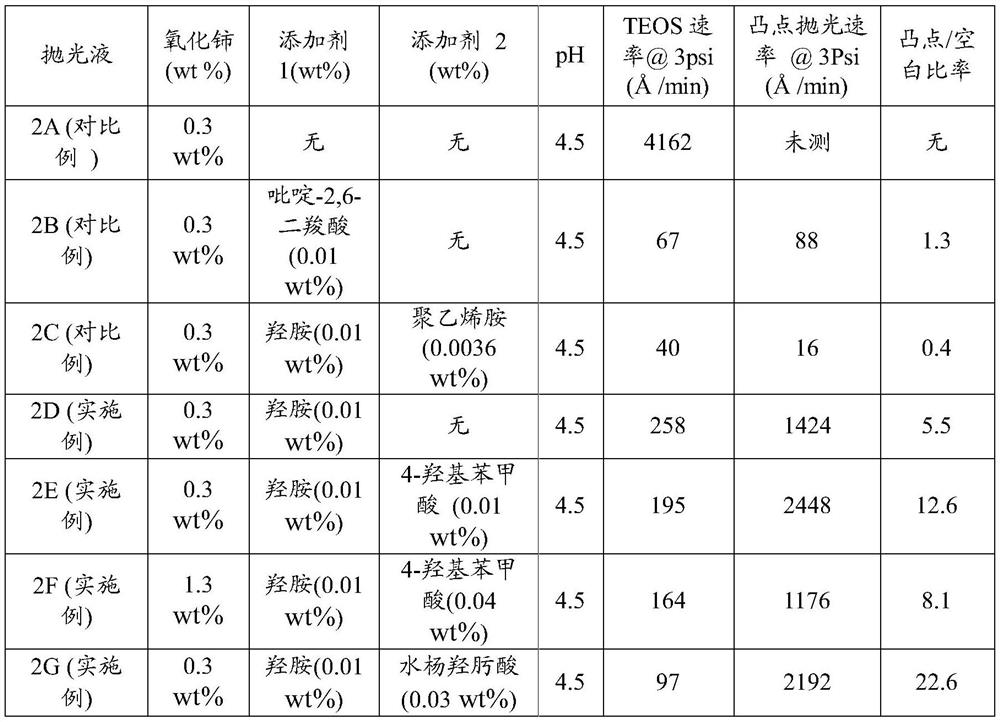

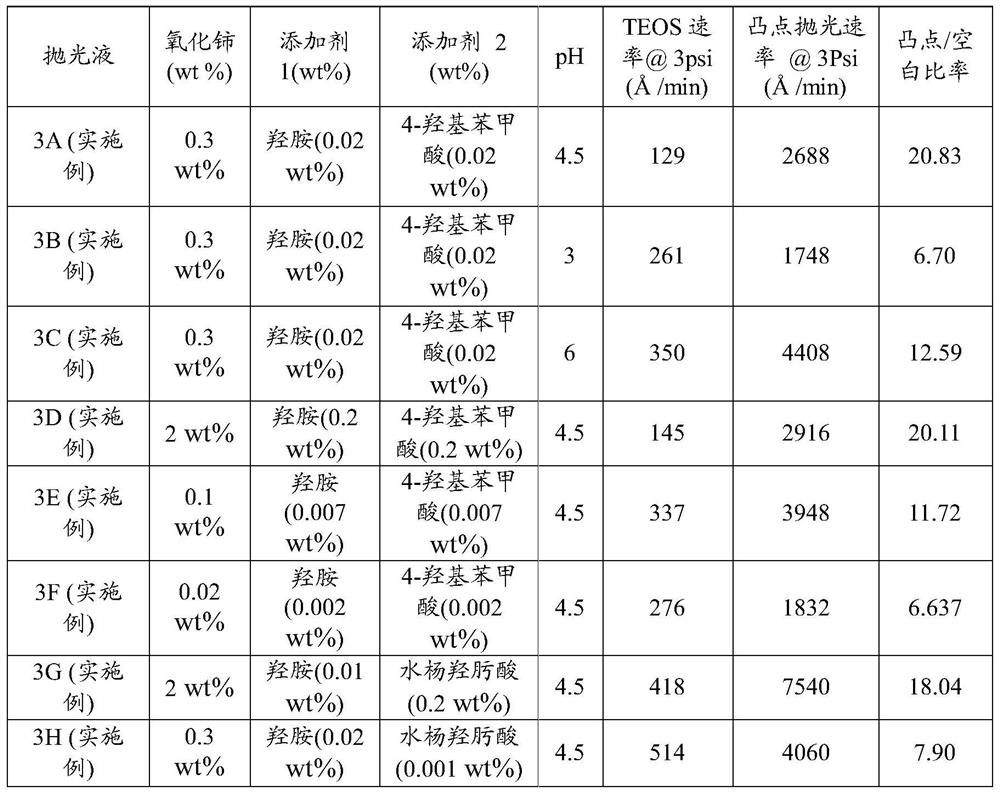

PendingCN113004798AReduce low point lossesSimple stepsSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesCerium oxideCerium

The invention provides a chemical mechanical polishing solution. The chemical mechanical polishing solution comprises water, cerium oxide grinding particles and hydroxylamine. 4-hydroxybenzoic acid or salicylhydroxamic acid can be further added into the chemical mechanical polishing solution, so that the removal rate of the patterned silicon dioxide sheet can be increased.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Chemical mechanical polishing of copper-oxide damascene structures

InactiveCN1620355AImprove removal rateSmall surface unevennessSemiconductor/solid-state device manufacturingLapping machinesCopper oxideMetal

The present invention provides a method for chemical mechanical polishing of a metallic damascene structure comprising: an insulating layer having grooves on a wafer; and a metal layer having a lower portion and a metal layer positioned within the grooves of the insulating layer Covering the lower part and the upper part of the insulating layer. The method includes: a first step of planarizing the upper portion of the metal layer; and a second step of polishing the insulating layer and the lower portion of the metal layer. In a first step, the wafer and the polishing pad are loaded together in contact mode by applying a pressure p between the wafer and the polishing pad and creating a relative velocity v to increase the metal removal rate. In a second step, in a steady state mode, the lower portions of the insulating and metal layers are polished to form individual metal lines in the grooves with minimal dishing of the metal lines and overpolishing of the insulating layer.

Owner:ASML US LLC +1

Preparation method of silicon-based gallium arsenide material with low surface roughness

ActiveCN103311106BReduce polishing rateSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSurface roughnessGallium arsenide

The invention discloses a preparation method for silica-based gallium arsenide material with high quality and low surface roughness. The preparation method comprises the following steps: step 1, a germanium layer is grown on a silicon substrate; step 2, the silicon substrate on which the germanium layer is grown is placed in an MOCVD (metal-organic chemical vapor deposition) reaction chamber to be subjected to annealing for the first time; step 3, a low-temperature gallium arsenide nucleating layer and a high-temperature gallium arsenide layer are grown on the germanium layer in sequence to form a sample; step 4, the sample is polished and rinsed; step 5, the sample is put in the MOCVD reaction chamber to be subjected to annealing for the second time; and step 6, a gallium arsenide cover layer is grown on the surface of the sample, and the preparation of the silica-based gallium arsenide material is finished. The preparation method for the silica-based gallium arsenide material with high quality and low surface roughness can solve the transition problem of the silicon substrate to III-V material and establishes the basis of substrate for silica-based gallium arsenide photoelectric and microelectronic devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

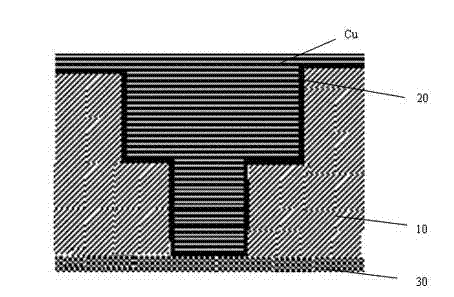

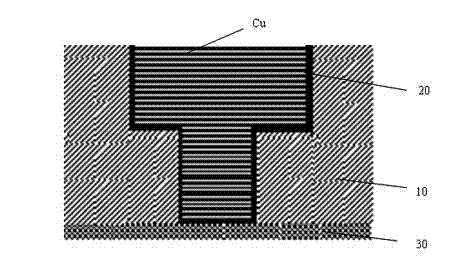

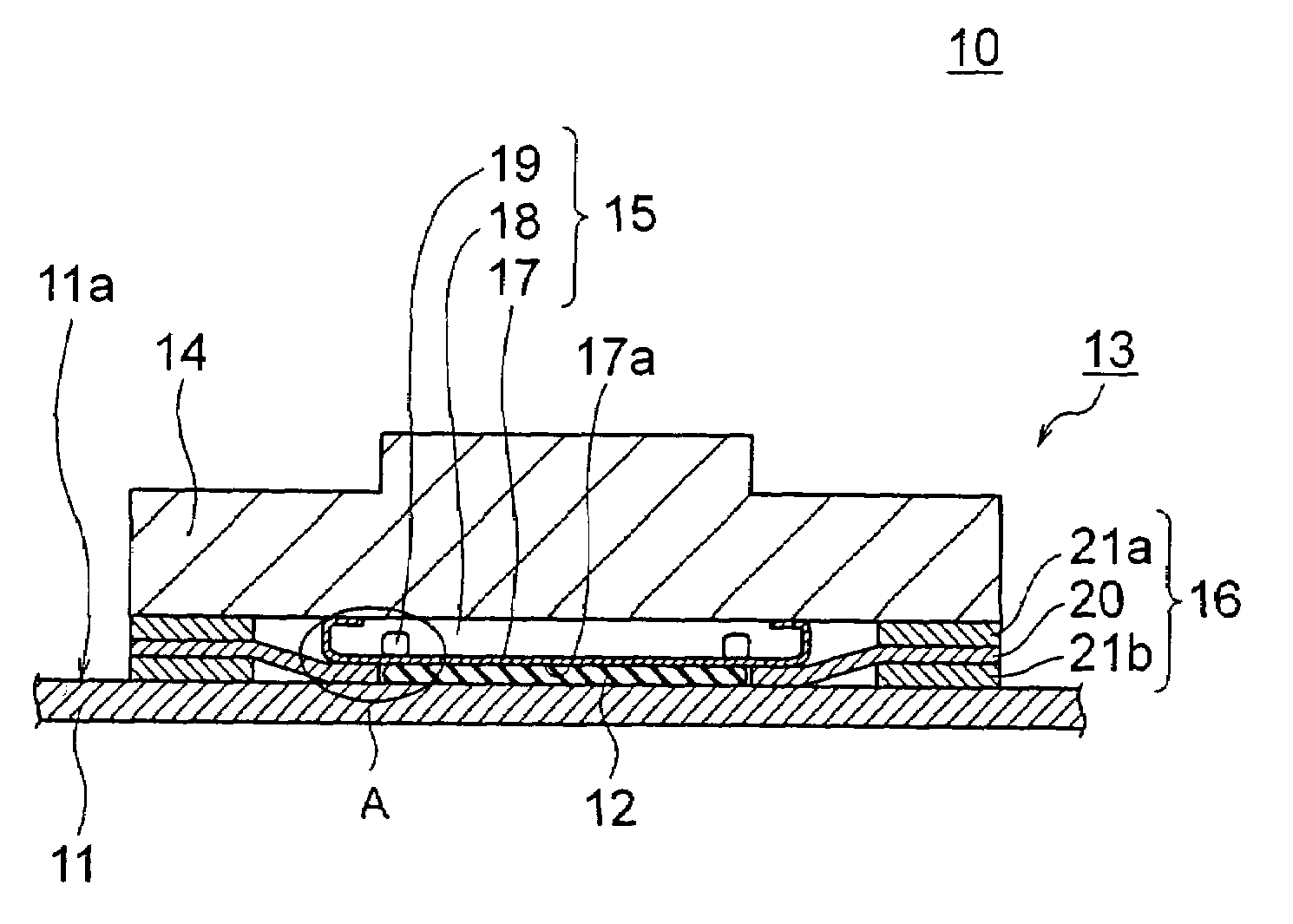

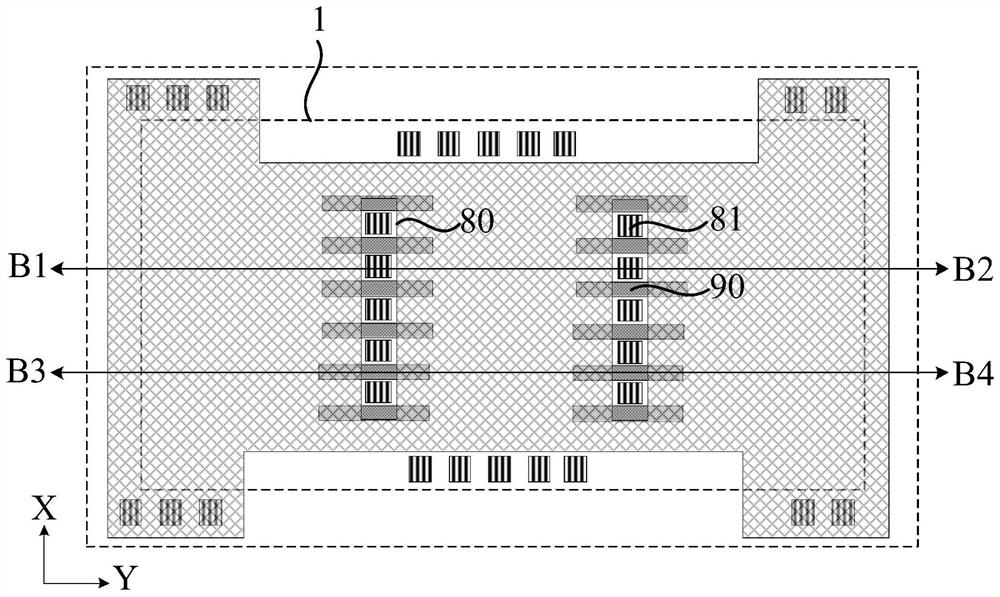

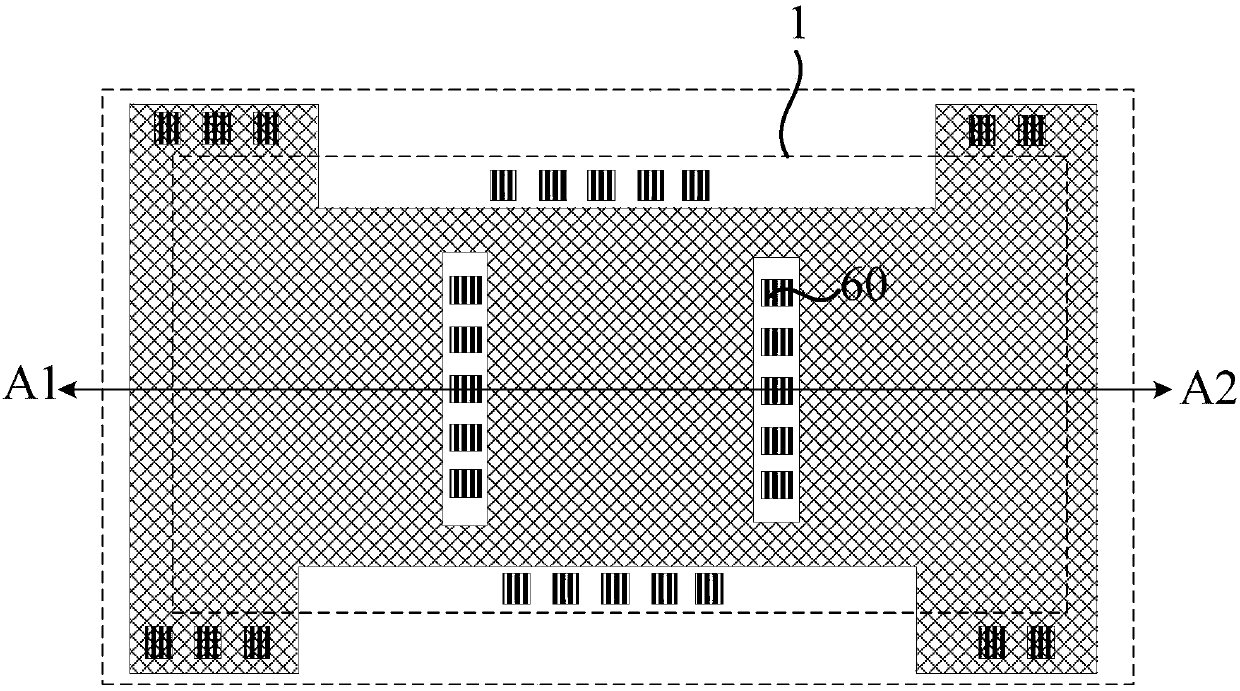

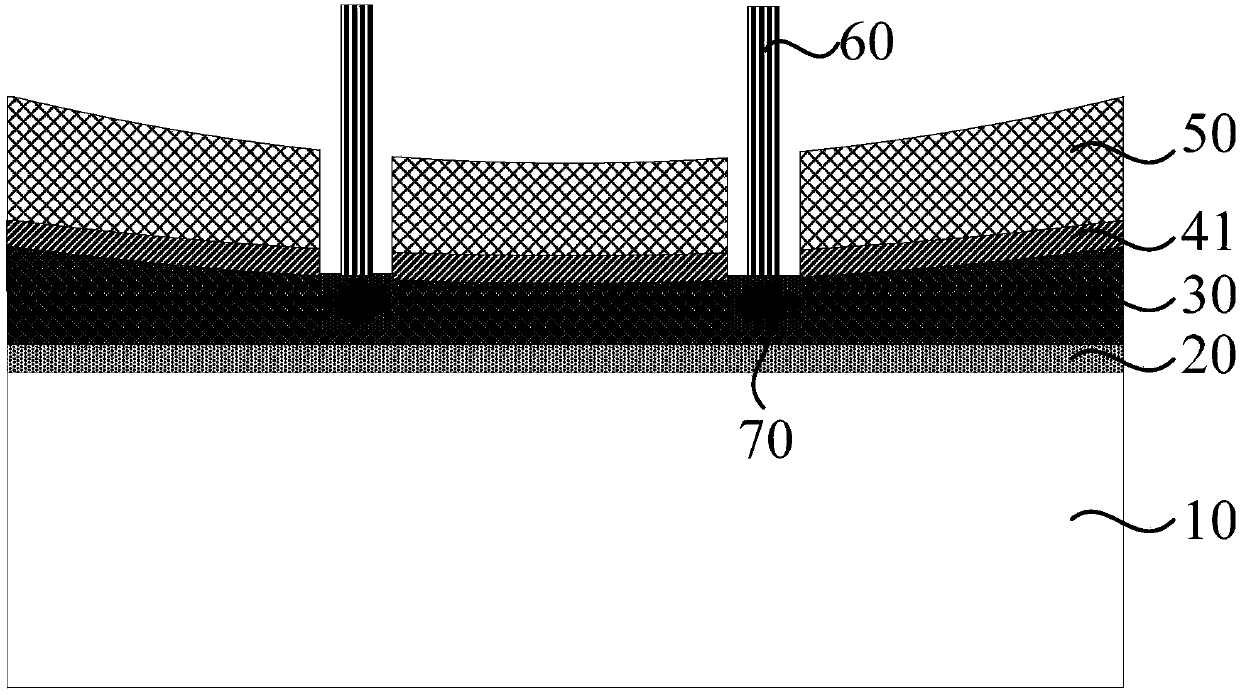

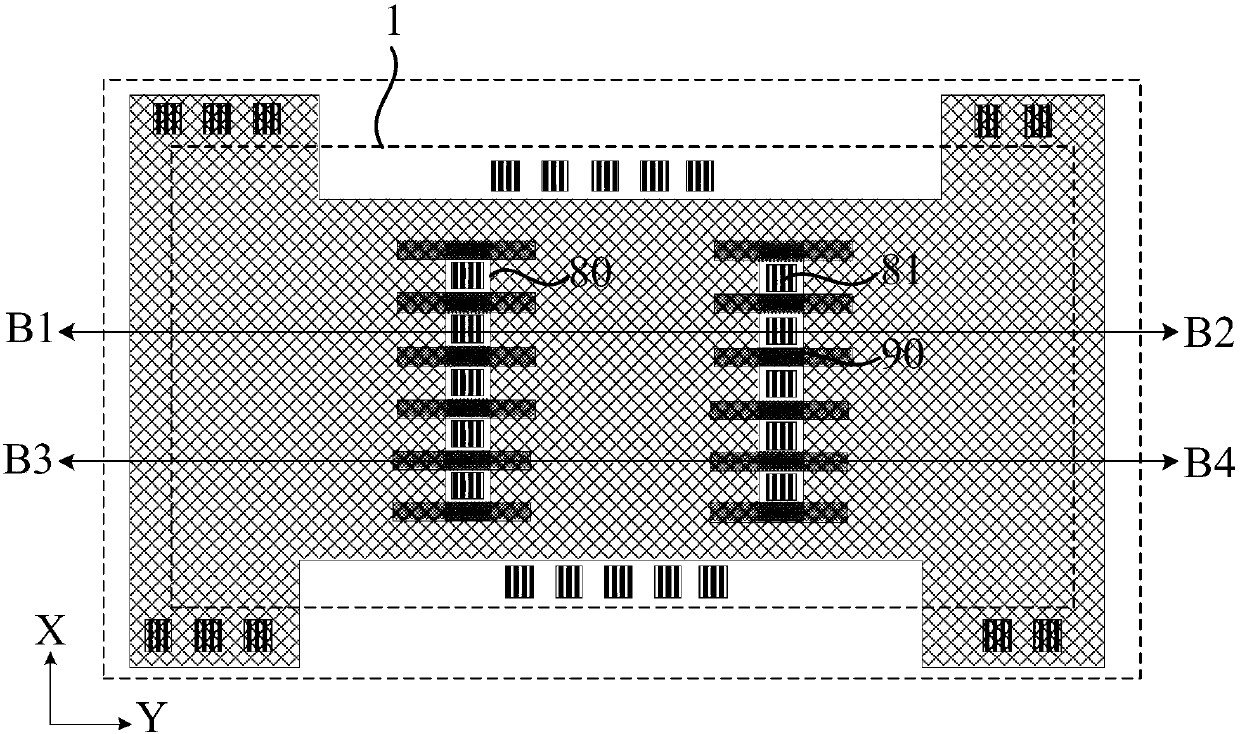

A kind of NOR flash memory device and preparation method thereof

ActiveCN110335867BPrevent leakageImprove reliabilitySolid-state devicesSemiconductor devicesEngineeringDielectric layer

The invention discloses a NOR flash memory device and a preparation method thereof, wherein the NOR flash memory device comprises a sequentially stacked substrate, a tunnel oxide layer, a floating gate layer, a dielectric layer and a control gate layer; at least one through the control gate layer and the floating gate via hole of the dielectric layer, the floating gate via hole is located in the active area, and is used to expose the floating gate layer to lead out the floating gate electrode; at least one active area blocking structure, the active area blocking structure is arranged on the substrate Between the dielectric layer and the chemical mechanical polishing process on the floating gate layer, it is used to reduce the wear of the floating gate layer exposed by the floating gate via hole. The technical scheme of the present invention can effectively reduce the polishing rate of the floating gate layer around it by the chemical mechanical polishing process by adding a barrier structure in the active region, increase the thickness of the floating gate layer around it, and avoid damage caused by the floating gate layer being too thin. This leads to leakage or breakdown of the NOR flash memory device, which improves the reliability of the NOR flash memory device.

Owner:GIGADEVICE SEMICON SHANGHAI INC +1

Nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating and preparation method thereof

ActiveCN102618165BLower surface energyImprove corrosion resistanceAntifouling/underwater paintsPaints with biocidesGas phaseSlurry

The invention relates to the field ship antifouling coatings, in particular to a nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating for sea ships and a preparation method thereof, which are used for solving the problem of long-term nontoxicity, antifouling and corrosion on the outer bottom surface of a ship. The nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating comprises the following components in parts by weight: 50-55 parts of polysiloxane resin, 1-5 parts of nanometer slurry, 5-8 parts of dimethylbenzene, 6-10 parts of butyl ester; 2.0-3.0 parts of ethylene glycol diethyl ether acetic ester, 0.3-0.5 part of a dispersing agent, 0.3-0.5 part of an antifoaming agent, 0.1-0.3 part of a flatting agent, 0.5-0.8 part of an anti-settling agent, 0.4-0.7 part of gas phase white carbon black, 15-22 parts of a pigment and 3-6 parts of a filler. The preparation method comprises the following steps of: proportionally preparing, dispersing, and grinding till the fineness is below 30 micros to obtain a component A; and mixing the component A and the component B for curing to obtain the nontoxic long-term ship sea antifouling coating. The nanometer polysiloxane nontoxic low-surface-energy ship antifouling coating is a surface protection material with extreme low surface energy, and plays roles in preventing fouling and scaling, and marine organisms are prevented from being adhered to the antifouling coating easily.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

NOR flash memory device and preparation method thereof

ActiveCN110335867APrevent leakageImprove reliabilitySolid-state devicesSemiconductor devicesCompound (substance)Engineering

The invention discloses an NOR flash memory device and a preparation method thereof. The NOR flash memory device comprises a substrate, a tunneling oxide layer, a floating gate layer, a dielectric layer and a control gate layer, which are stacked up in sequence; at least one floating gate via hole running through the control gate layer and the dielectric layer, wherein the floating gate via hole is arranged in an active region and is used for exposing the floating gate layer to lead out a floating gate electrode; and at least one active region blocking structure, which is arranged between thesubstrate and the dielectric layer and is used for reducing wear of the floating gate layer exposed by the floating gate via hole in the chemical mechanical polishing process of the floating gate layer. According to the technical scheme, by adding the active region blocking structure, polishing rate of the chemical mechanical polishing process for the floating gate layer around can be effectivelyreduced, the thickness of the floating gate layer around is increased, the phenomenon leakage or breakdown of the NOR flash memory device due to too thin floating gate layer can be prevented, and reliability of the NOR flash memory device is improved.

Owner:GIGADEVICE SEMICON SHANGHAI INC +1

A chemical mechanical polishing liquid for regenerated wafer and preparation method thereof

ActiveCN113861848BPlay a protective effectReduce roughnessPolishing compositions with abrasivesBetaineActive agent

The invention provides a chemical mechanical polishing liquid for regenerated wafers and a preparation method thereof. The mass percentage composition comprises 5% to 50% of abrasive particles, 0.1% to 10% of a rate accelerator, and 0.5% to 5% of a complexing agent. , 0.1% to 2% of pH regulator, 0.001% to 1% of nonionic surfactant and 0.001% to 1% of betaine type zwitterionic surfactant, and the balance is water. The polishing liquid can effectively repair the surface damage of the regenerated wafer, remove the residual film on the surface, and maintain a high removal rate of the silicon wafer. The surface quality of the regenerated wafer after polishing is excellent, and the number of cycles is increased.

Owner:万华化学集团电子材料有限公司 +1

Alumina particles and polishing composition containing the same

ActiveCN102105266BReduce polishing rateReduced wash-off easeOther chemical processesAbrasion apparatusSemiconductorSemiconductor device

The present invention provides alumina particles including primary particles each having a hexahedral shape and an aspect ratio of 1 to 5. The alumina particles preferably have an average primary particle diameter of 0.01 to 0.6 μm. The alumina particles preferably have an α-conversion of 5% to 70%. In addition, the alumina particles preferably have an average secondary particle diameter of 0.01 to 2 μm, and the value obtained by dividing the 90% particle diameter of the alumina particles by the 10% particle diameter of the alumina particles is preferably 3 or less. The alumina particles are useful, for example, as abrasive grains in applications for polishing semiconductor device substrates, hard disk substrates, or display substrates.

Owner:FUJIMI INCORPORATED

Chemical and mechanical polishing liquid

ActiveCN1900146BReduce defective rateReduce polishing rateEdge grinding machinesSemiconductor/solid-state device manufacturingPolishingChemical compound

The present invention discloses a kind of chemical and mechanical polishing fluid, which includes at least one kind of grinding grain, one kind of chemical additive and one kind of carrier, where the chemical additive is polycarboxylic acid and / or its salt. The chemical and mechanical polishing fluid can raise the flatness of the polished metal surface, lower the metal polishing rate obviously, optimize the dielectric polishing rate and expand technological parameter window.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Polishing composition, polishing method, and method for producing substrate

ActiveUS10106704B2Reduce polishing rateOther chemical processesSemiconductor/solid-state device manufacturingZeta potentialMetallurgy

To provide a polishing composition that can be used as an alternative of a polishing composition containing cerium oxide abrasive grains in STI and other such CMP applications, and to provide a polishing method and a method for producing a substrate using this polishing composition.A polishing composition being used in applications for polishing a layer that contains a substance having a pH range presenting a positive zeta potential in an aqueous solution of pH 6 or lower, wherein the polishing composition contains abrasive grains (A), abrasive grains (B), and a pH adjusting agent, and the abrasive grains (B) has a negative zeta potential in an aqueous solution of pH 6 or lower, and the value of the average secondary particle diameter of the abrasive grains (B) is less than the value of the average secondary particle diameter of the abrasive grains (A) and is 15 nm or less and the polishing composition has a pH of 6 or lower.

Owner:FUJIMI INCORPORATED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com