Polishing solution based on polishing process of metal Co and application thereof

一种抛光液、工艺的技术,应用在微电子工艺领域,能够解决钴铜脱附、抛光速率快、铜蝶形坑等问题,达到降低缺陷的产生、降低抛光速率、抑制静态腐蚀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

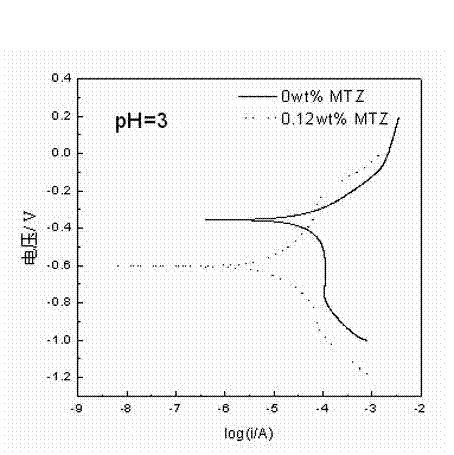

[0035] Polishing solution configuration: 1wt% silica sol; 0.75wt% glycine; 0.12wt% dimercaptothiazoline (MTZ); and the rest of water, adjusted to pH 3.0 with diluted nitric acid and potassium hydroxide.

[0036] Polishing equipment and mechanical parameter setting: The polishing machine used in this embodiment is the CP-4 desktop polishing machine produced by CETR Company; The rotational speed of the polishing table was 150 rpm.

Embodiment 2

[0045] Polishing liquid configuration: 5wt% silica sol; 0.5wt% hydrogen peroxide; 0.75wt% glycine; 0-0.24wt% benzotriazole; The weight percentage of benzotriazole (BTA) in the polishing liquid is 0.06, 0.12, 0.18 and 0.24 respectively to configure the polishing liquid.

[0046] Polishing equipment and mechanical parameter setting: The polishing machine used in this embodiment is the CP-4 desktop polishing machine produced by CETR Company; The rotational speed of the polishing table was 150 rpm.

[0047] As shown in Table 2, it is the self-corrosion rate data in the polishing solution obtained when cobalt is contained in different percentages of benzotriazole in Example 2.

[0048] Table two: the self-corrosion rate of cobalt in the polishing solution gained in embodiment 2

[0049]

[0050] From the data in Table 2, it can be seen that with the increase of the concentration of benzotriazole, the self-corrosion rate of cobalt gradually decreases. After adding 0.24wt% benzo...

Embodiment 3~8

[0053] The polishing liquid formulations of Examples 3-8 (the balance is water) and the test data of the obtained polishing liquid are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com