Chemical mechanical polishing liquid for polishing alloy phase change materials

A technology of chemical mechanics and polishing fluid, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the static corrosion rate of phase change material substrates, unsatisfactory effects, and low polishing rate, so as to inhibit GST Static corrosion, increase GST removal rate, low static corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

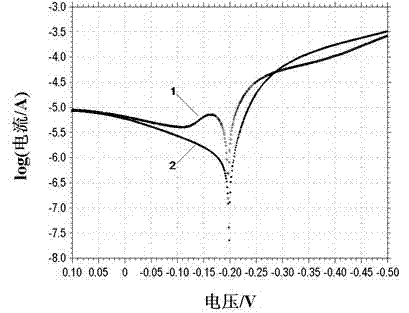

Image

Examples

Embodiment 1~3

[0032] Table 1 is a comparison table of the removal rate when using the chemical mechanical polishing liquid embodiment 1~3 containing the removal rate accelerator of the present invention and the chemical mechanical polishing liquid comparative example not containing the removal rate accelerator for phase change material polishing , wherein embodiments 1 to 3 include different abrasive particles, and different removal rate accelerators.

[0033] It can be seen from Table 1 that the GST polishing rate of the polishing liquid examples 1 to 3 by adding removal rate accelerators such as phosphotungstic acid, silicotungstic acid, and potassium tungstate is significantly higher than that of the polishing liquid comparison example without adding removal rate accelerators.

Embodiment 4~6

[0035] Table 2 shows the GST removal rate of Examples 4-6 of the present invention when using 2.0wt% hydrogen peroxide as the oxidizing agent and using different abrasive grains, and a comparison table with the GST removal rate of the comparative example.

[0036] From Table 2, through the comparison of the above-mentioned Examples 4-6 and the comparative examples, it can be seen that after the present invention adds a small amount of removal rate accelerator, it still has a higher GST removal rate compared with the comparative examples. And the removal rate of GST can be effectively adjusted by changing the abrasive particles or adjusting the content of additives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com